Patents

Literature

3069 results about "Packing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

METHOD 1. Volume packing: Container dimensions ( volume ) will be used to pack your products ( products dimensional volume ) into your containers. Products will be packed together for shipment. This packing method will take into consideration dimensional weight, cubic weight, if your shipping company uses this rule.

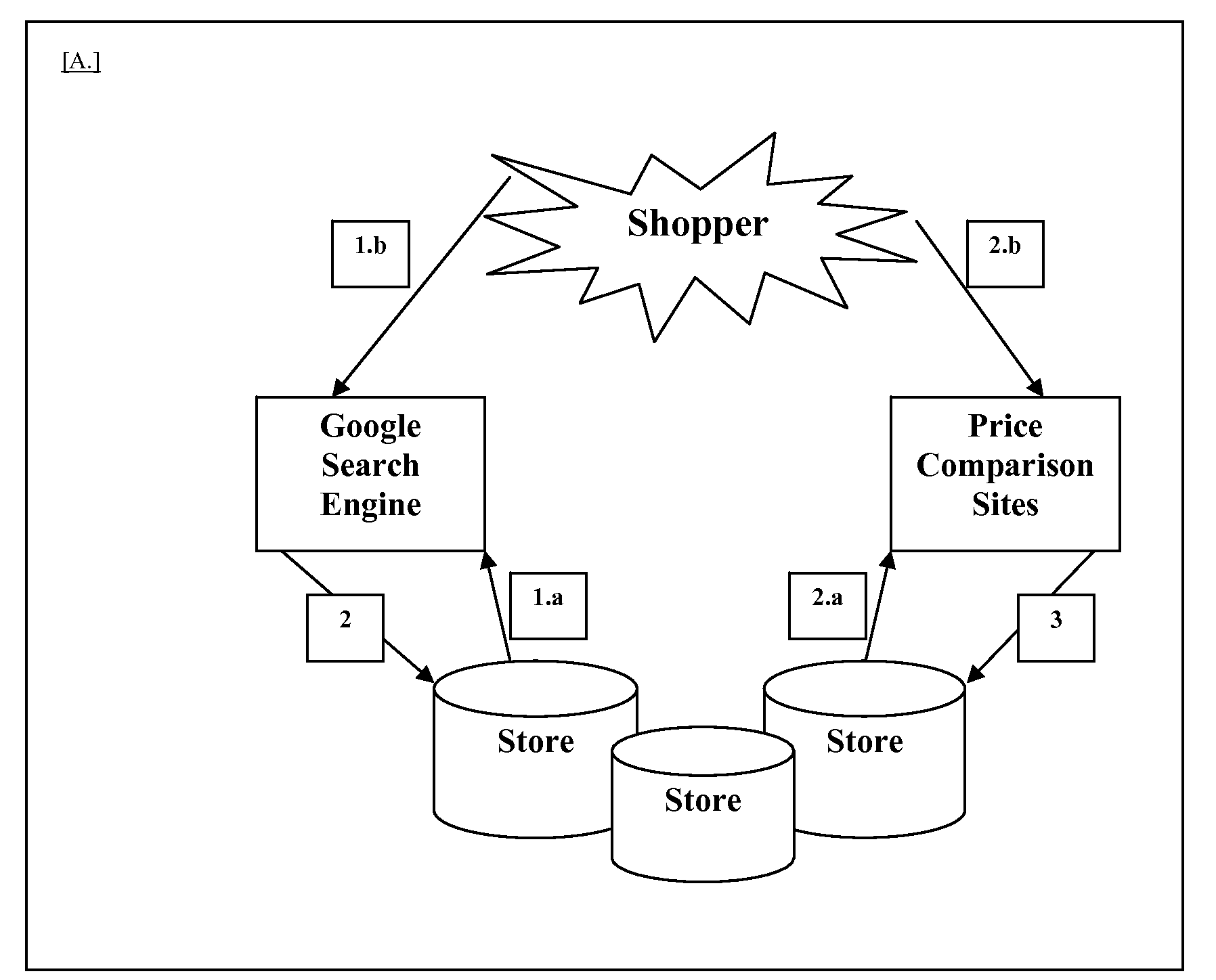

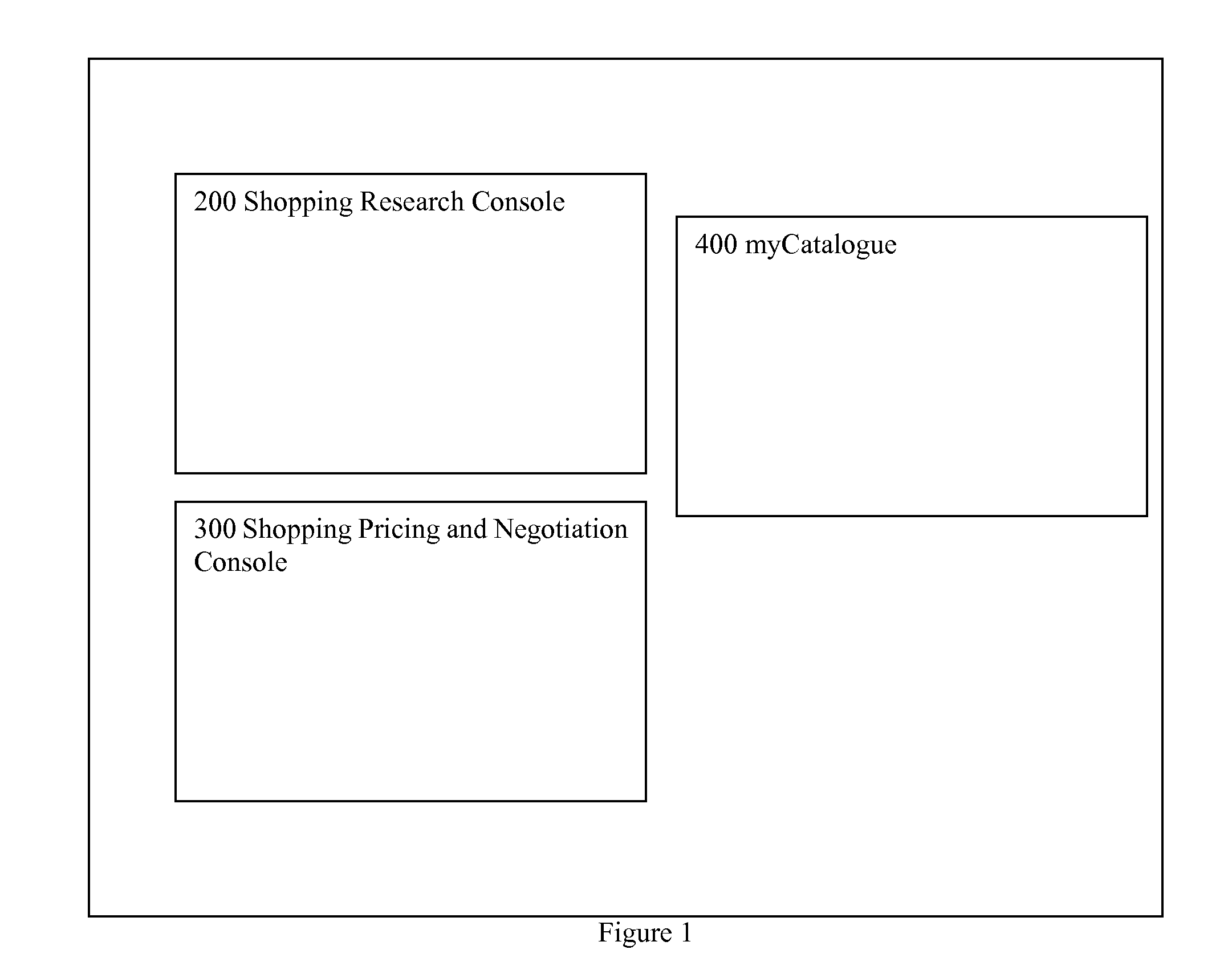

Pricing and auctioning of bundled items among multiple sellers and buyers

InactiveUS7840447B2Buying/selling/leasing transactionsElectric/magnetic computingGroup buyingComputer science

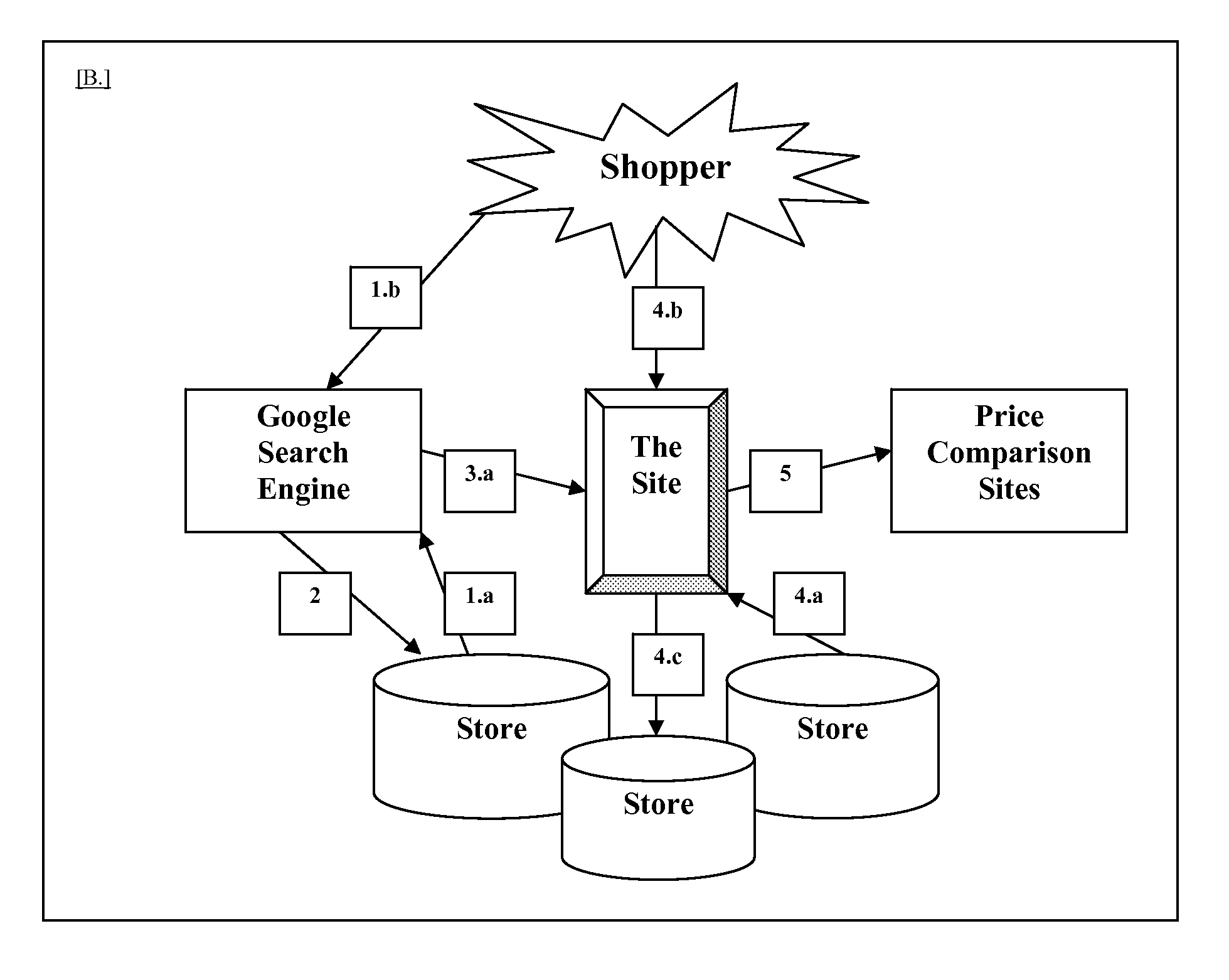

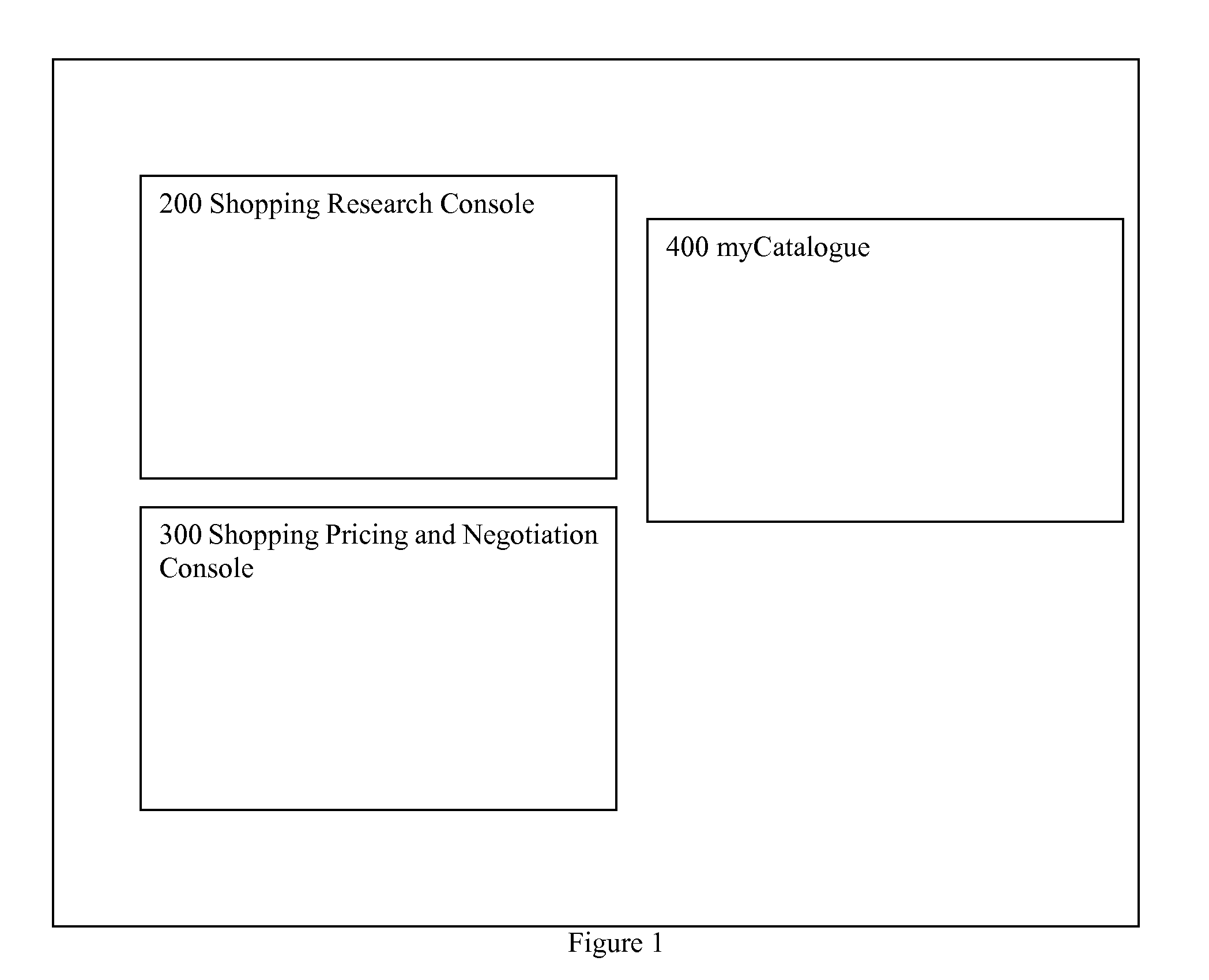

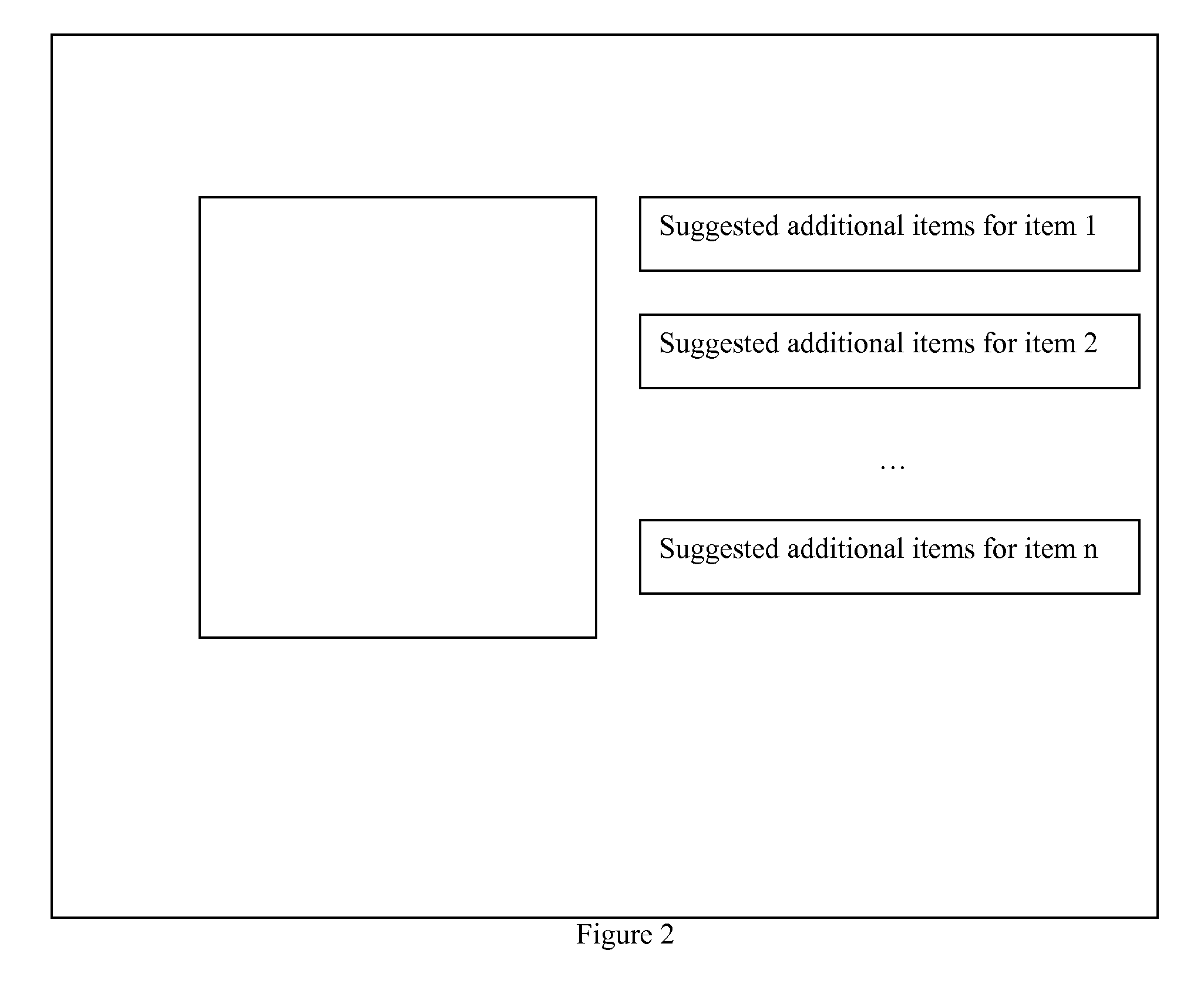

A number of sets of methods and apparatuses applicable to online shopping are disclosed. One set, “Bin Packing Methods with Approximate Membership”, includes methods in pricing and auctioning a bundle of items, some of which could belong to another bundle. Significantly, the membership of a bundle, during pricing and auction, could change. Another set, the “Shopping Console”, puts a structure into the online shopping experience, so that through one interface various shopping activities can be facilitated, including but not limited to researching, pricing, negotiation, group buying, and tracking of purchases. Still another set, “Flash Mob Shopping”, allows sellers and a (spontaneous) group of shoppers to connect on prices without requiring shoppers' hard commitments, and with sellers revealing only necessary price information.

Owner:TAMIRAS PER PTE LTD LLC

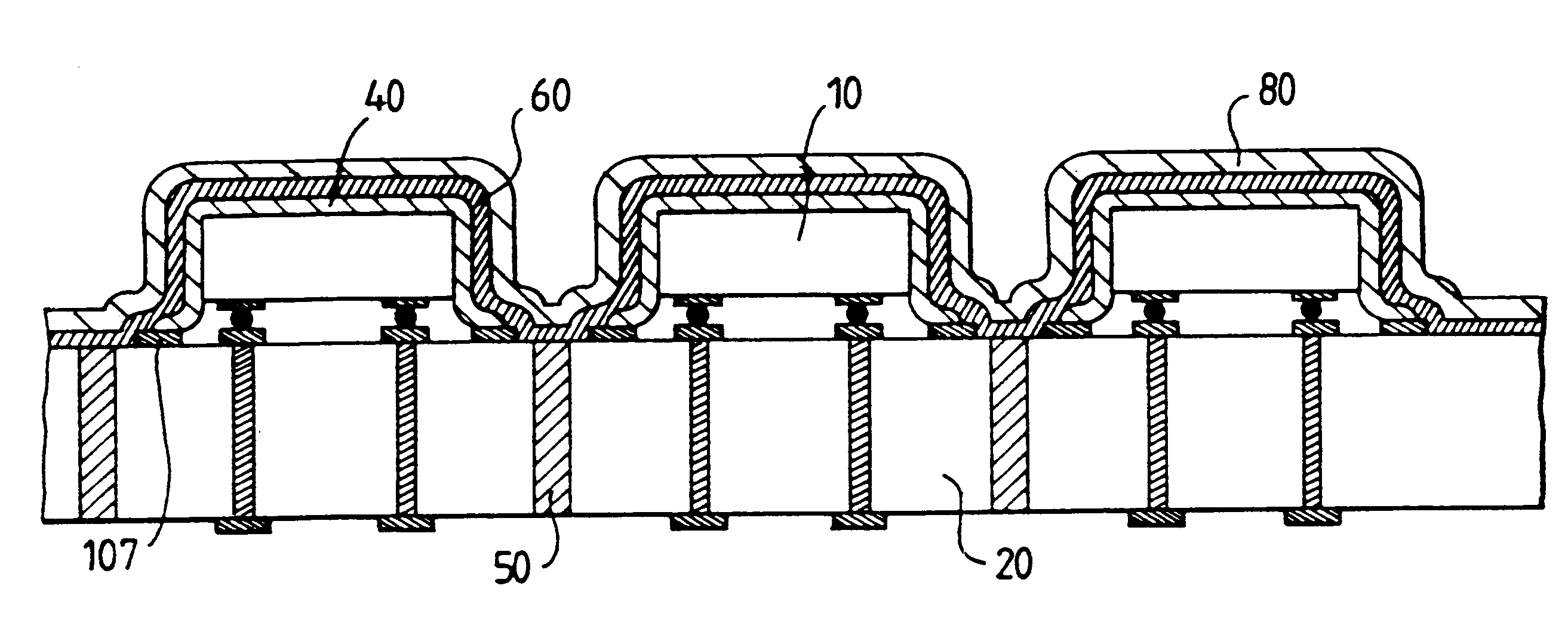

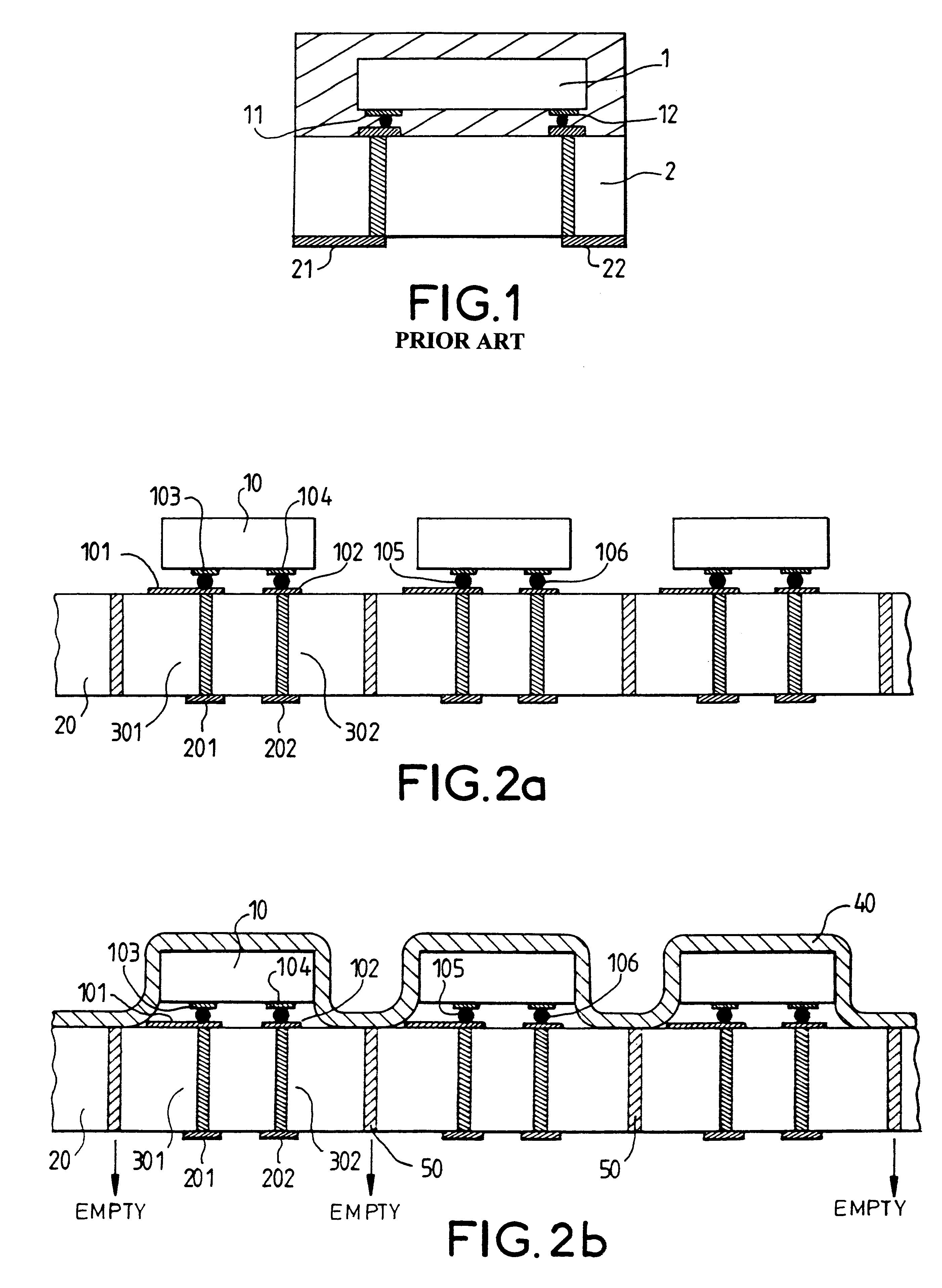

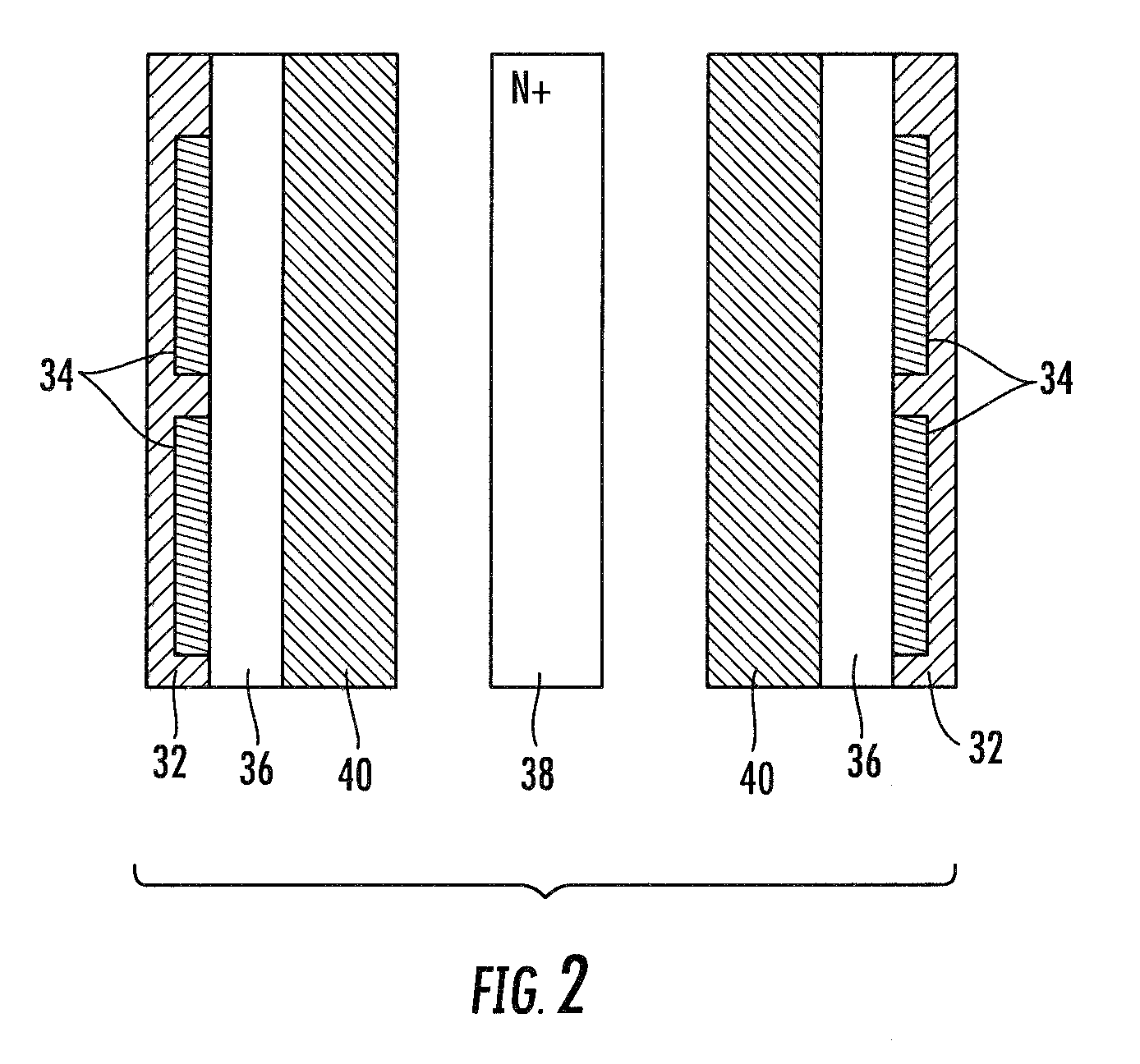

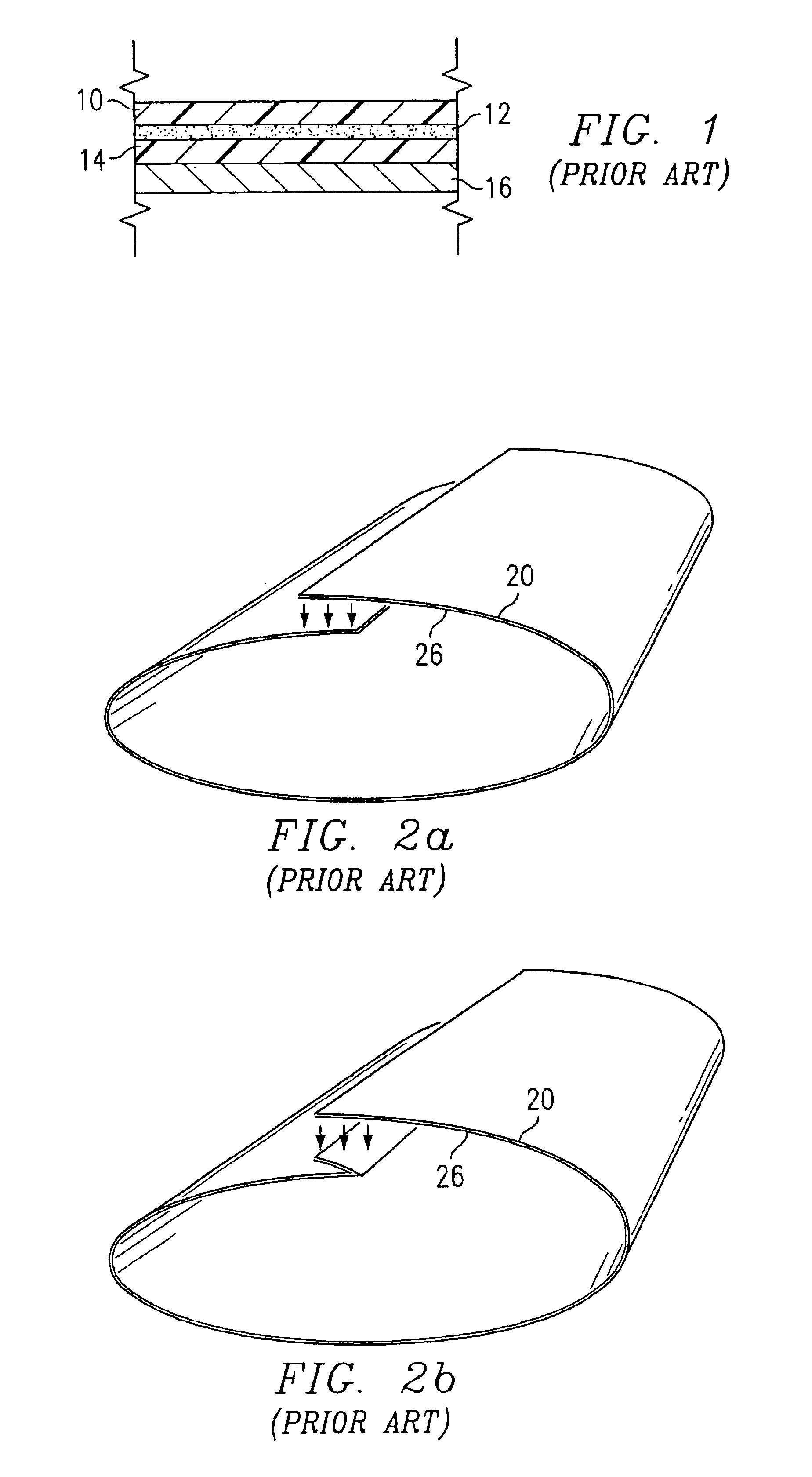

Method for the packaging of electronic components

InactiveUS6492194B1Improve seal qualityEfficient electromagnetic shieldingImpedence networksSemiconductor/solid-state device detailsHermetic sealElectronic component

A method for the packaging of electronic components, including the mounting of at least one electronic component on its active face side to a base, the base including electrical contacts on an external face and connection pads on a face opposite the external face, and including a first series of via holes connecting the electrical contacts and the connection pads and a second series of holes for use in aspiration. A deformable film is deposited on the face opposite to the active face of the electronic component or components. The deformable film is aspirated through the second series of holes from the face opposite the external face of the base, so as to sheath the electronic component or components. The method may furthermore include, on top of the deformable film, a mineral deposition to provide for the hermetic sealing of the components and a conductive deposition to provide for the shielding. Such an application may find particular application to surface wave filters.

Owner:THOMSON CSF SA

Gravel packing method

Owner:SCHLUMBERGER TECH CORP

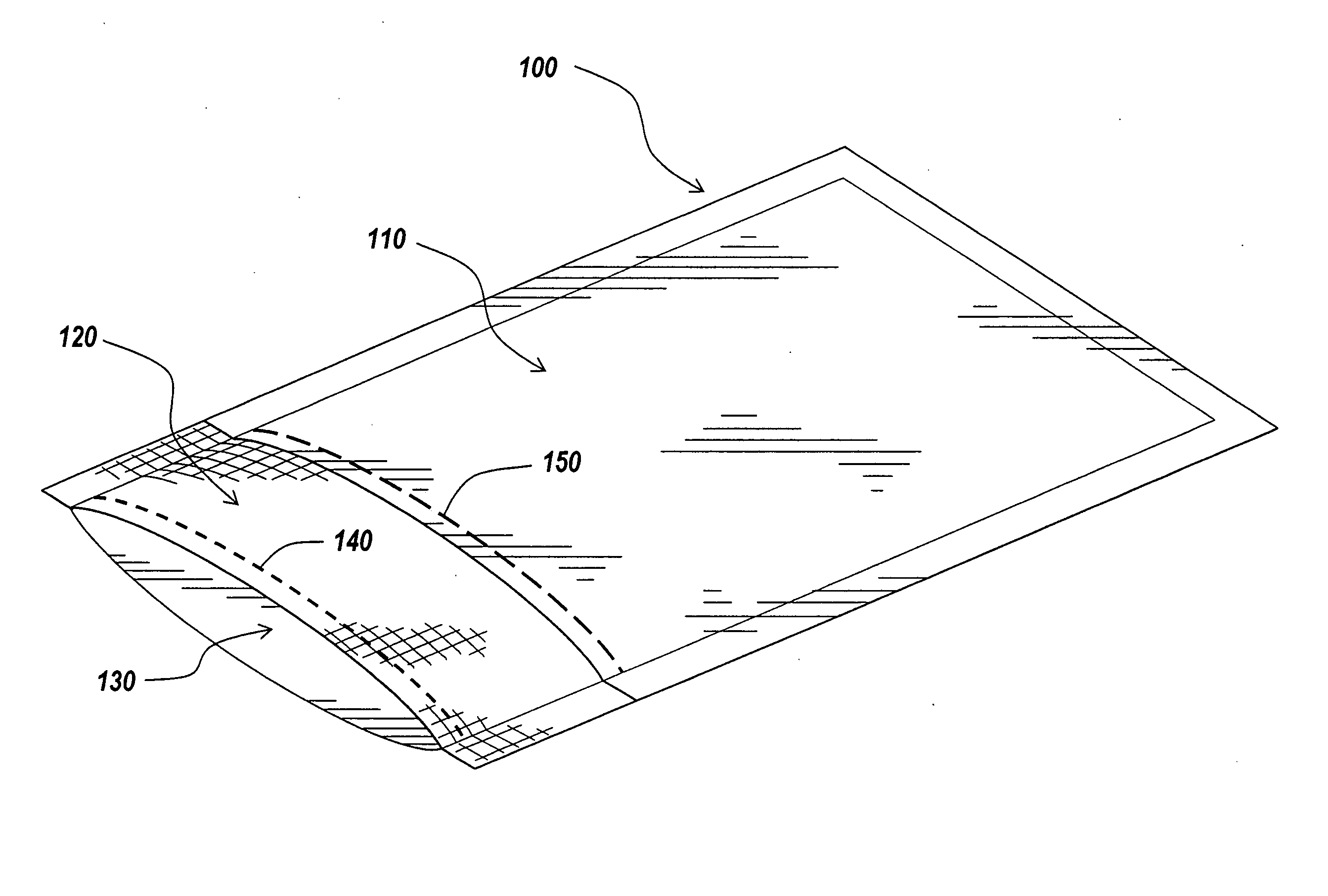

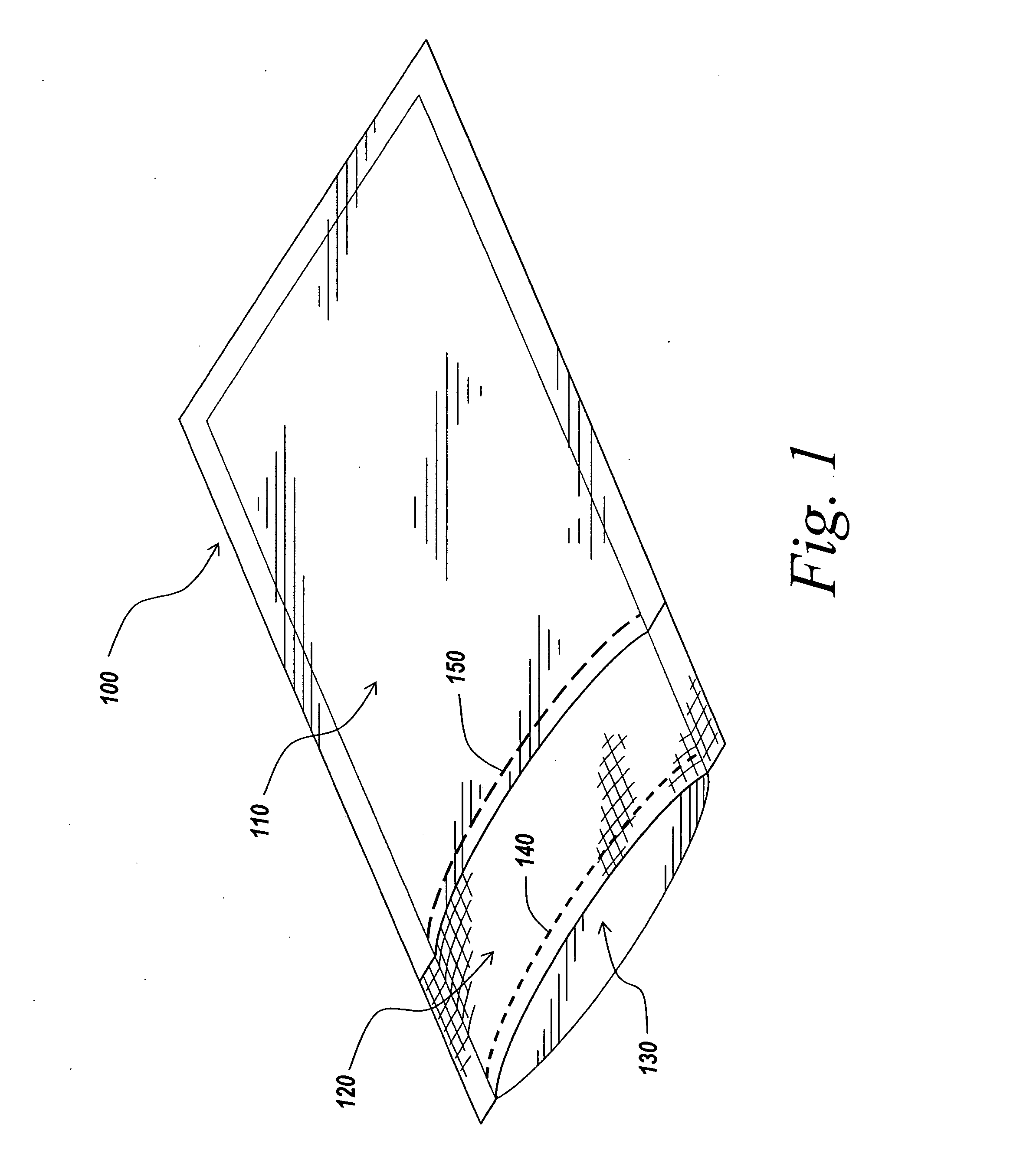

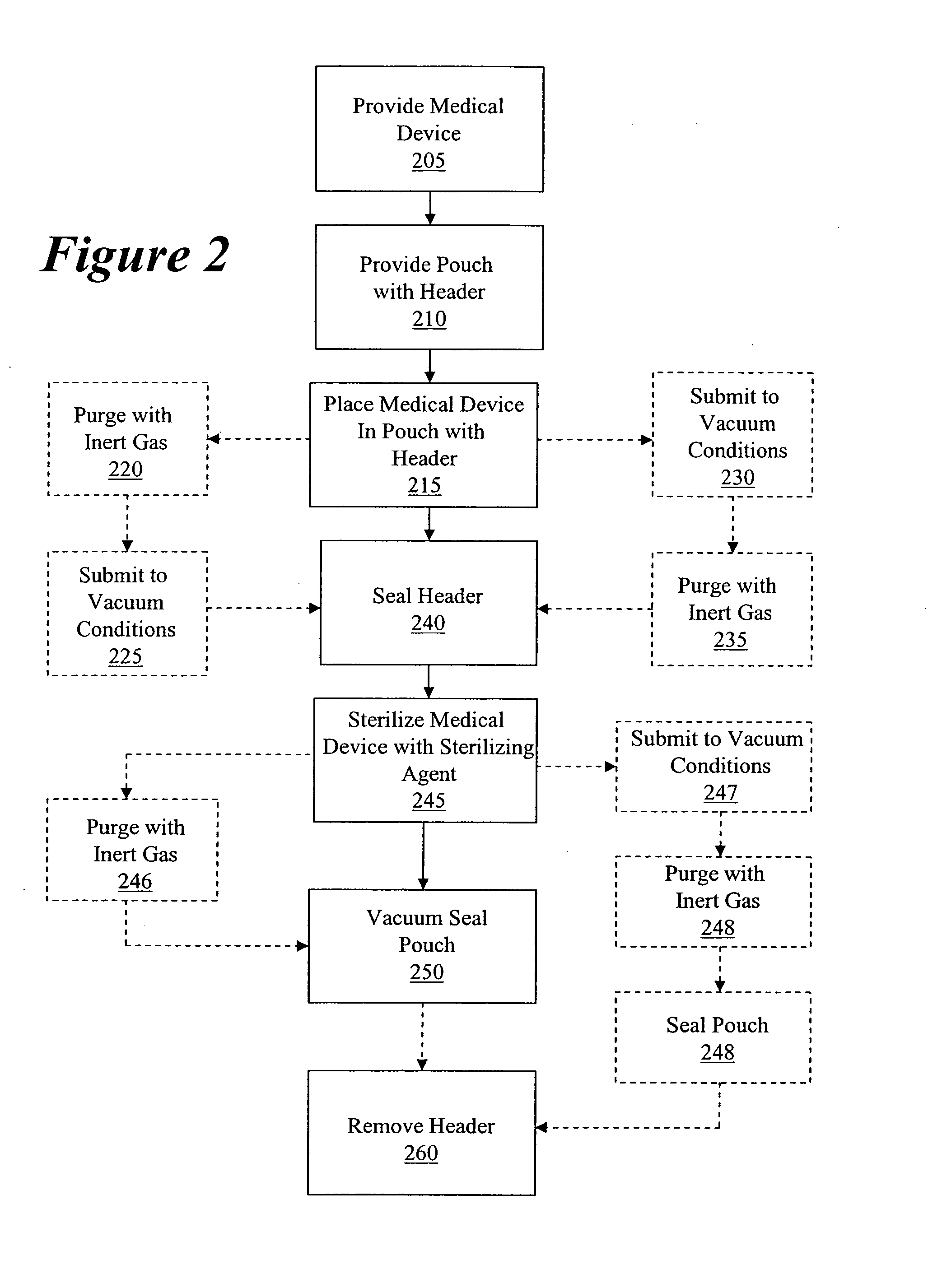

Packaging and sterilization of medical devices

InactiveUS20070084144A1Minimize timeExtended shelf lifeStentsSurgical furnitureCompound (substance)Fish oil

A method for the sterilization and packaging of a chemically sensitive medical device is provided. The chemically sensitive medical device has a coating derived from fish oil, a vitamin E compound or a combination thereof. The packaging pouch for the chemically sensitive medical device comprises a non-permeable chamber and a gas-permeable header. The sterilizing agent is administered to the packaged chemically sensitive medical device at a temperature of between about 20° C. and 40° C.

Owner:ATRIUM MEDICAL

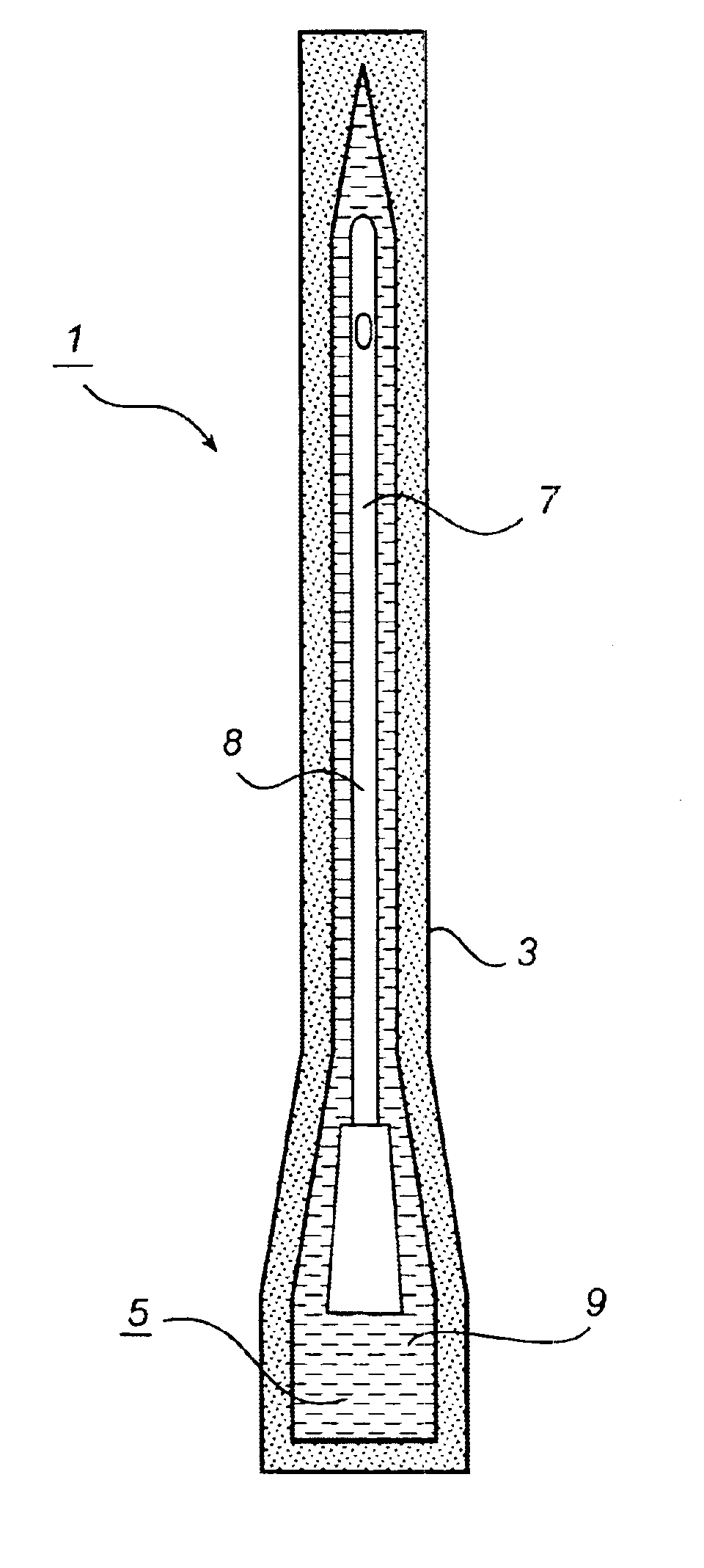

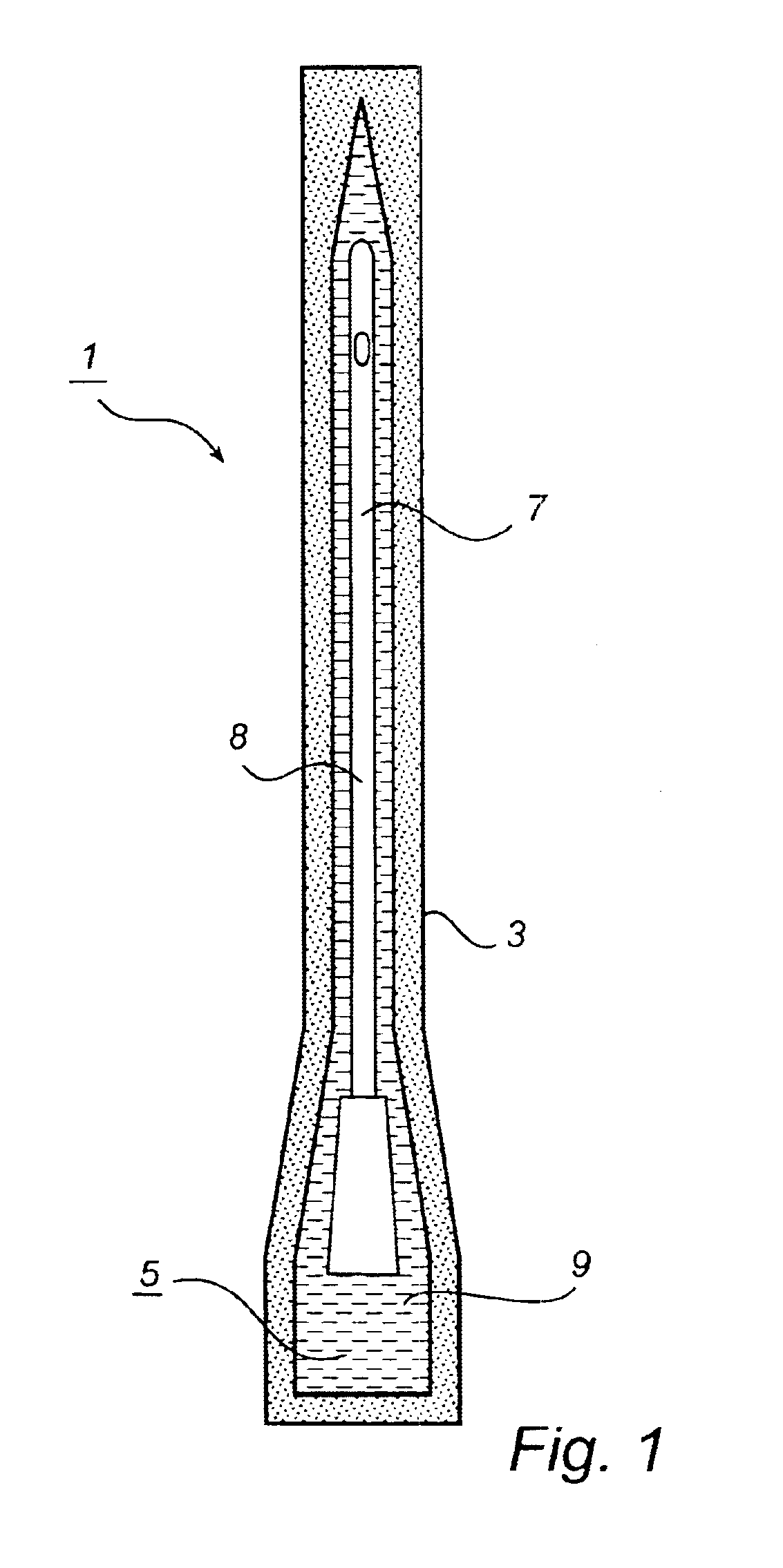

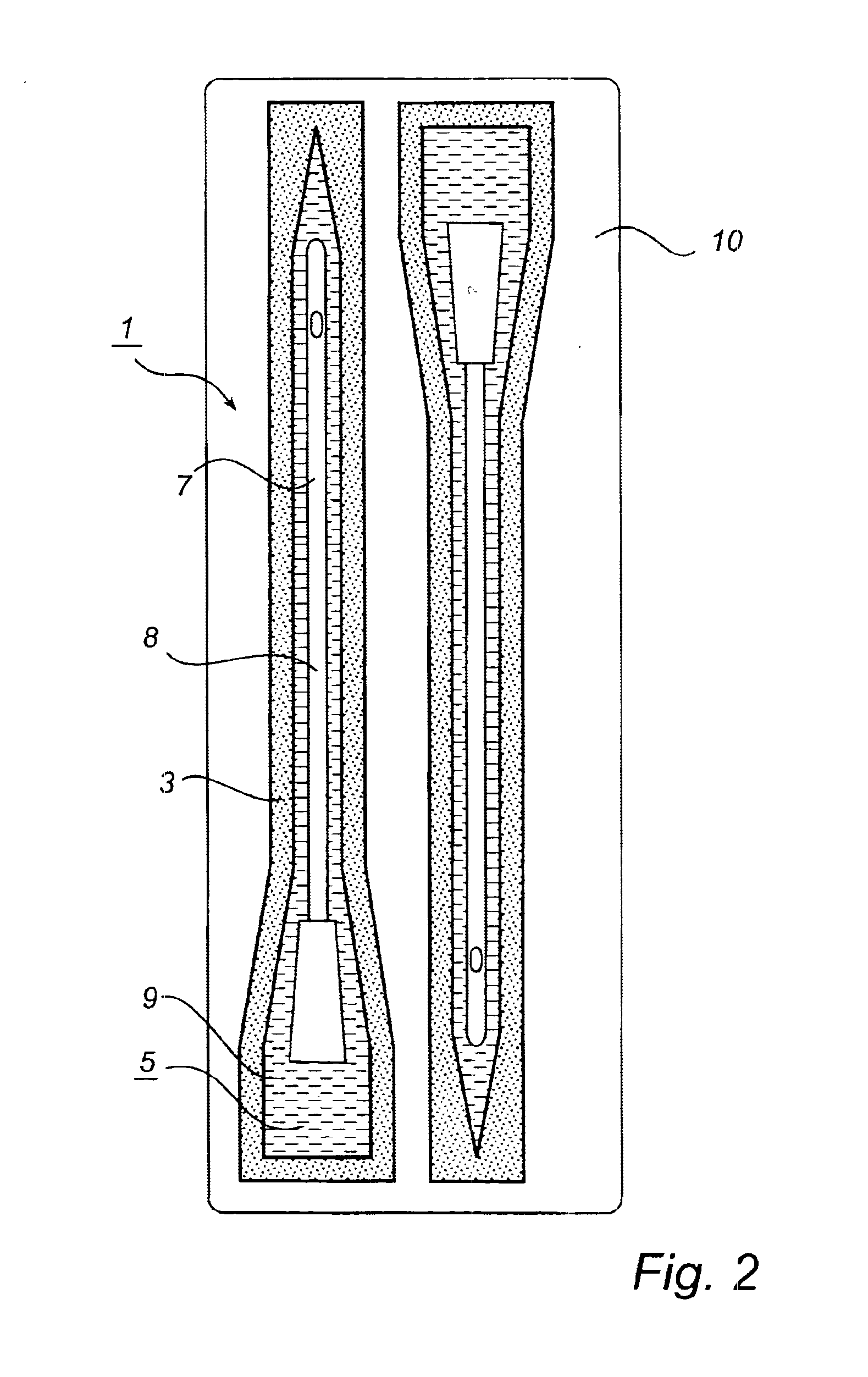

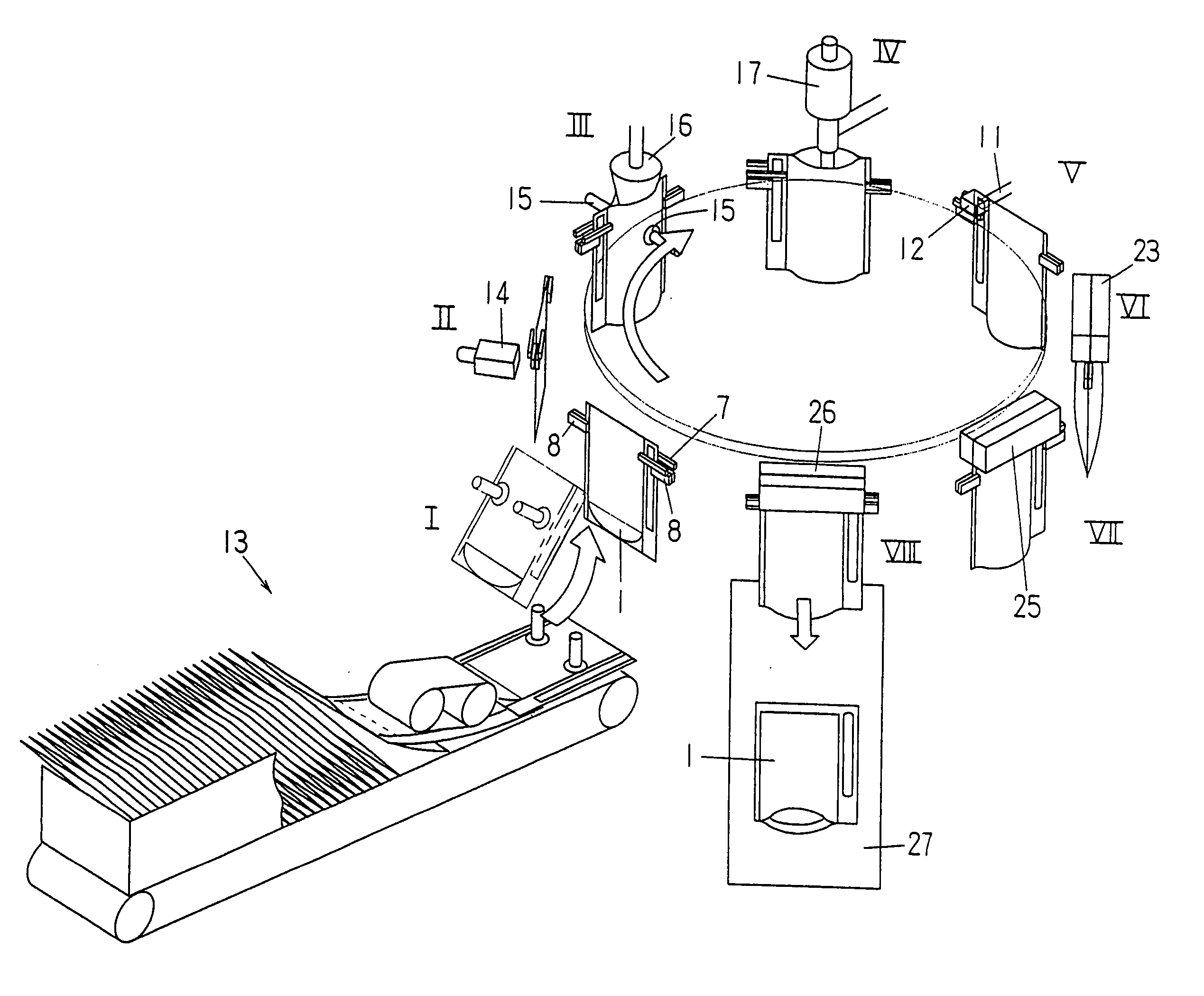

Storage package and a method for packaging

InactiveUS6848574B1Long shelf lifeExtended shelf lifeWrappersDispensing apparatusCoated surfaceUrethral catheter

A storage package (1) contains a medical device (7) having a coated surface (8 ) which exhibits a reduced friction when wetted with a wetting liquid and a supply of the wetting liquid (9). The package is adapted such that the coated surface of the medical device is maintained contact with the supply of wetting liquid during storage. A good shelf-life for the medical device is achieved an where the medical device is a urethral catheter the catheter is immediately “ready-for-use” after the package has been opened.

Owner:ASTRA TECH SE

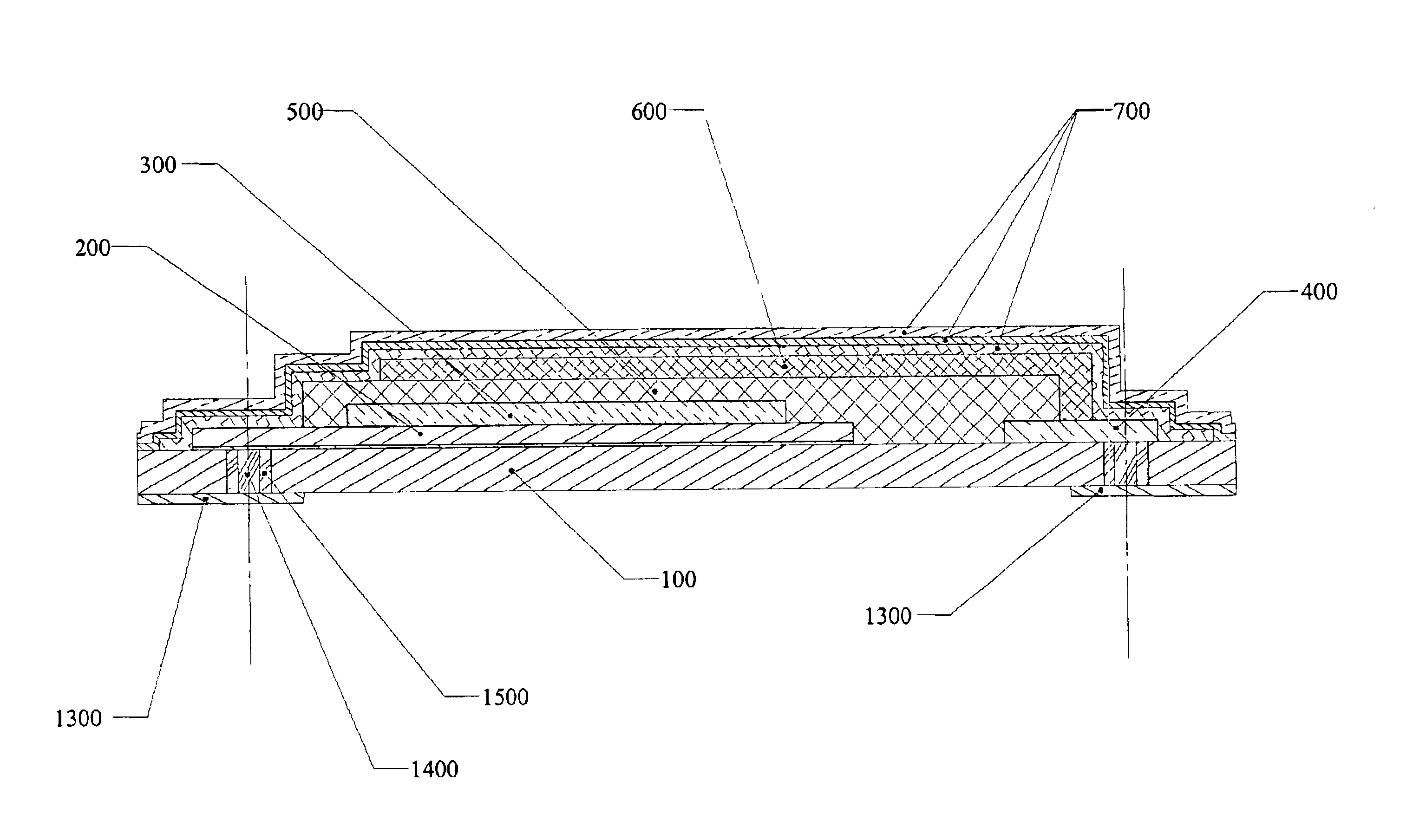

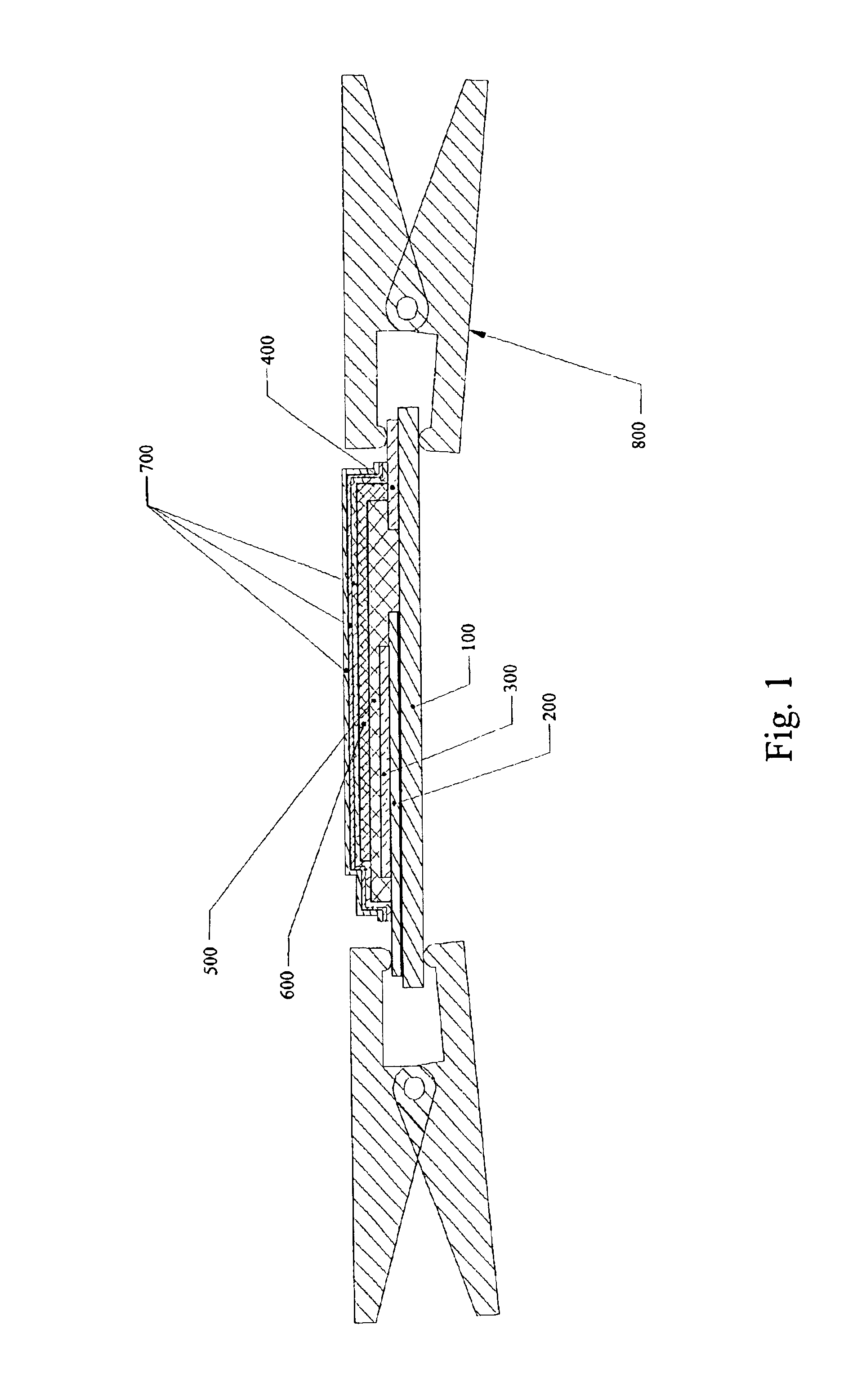

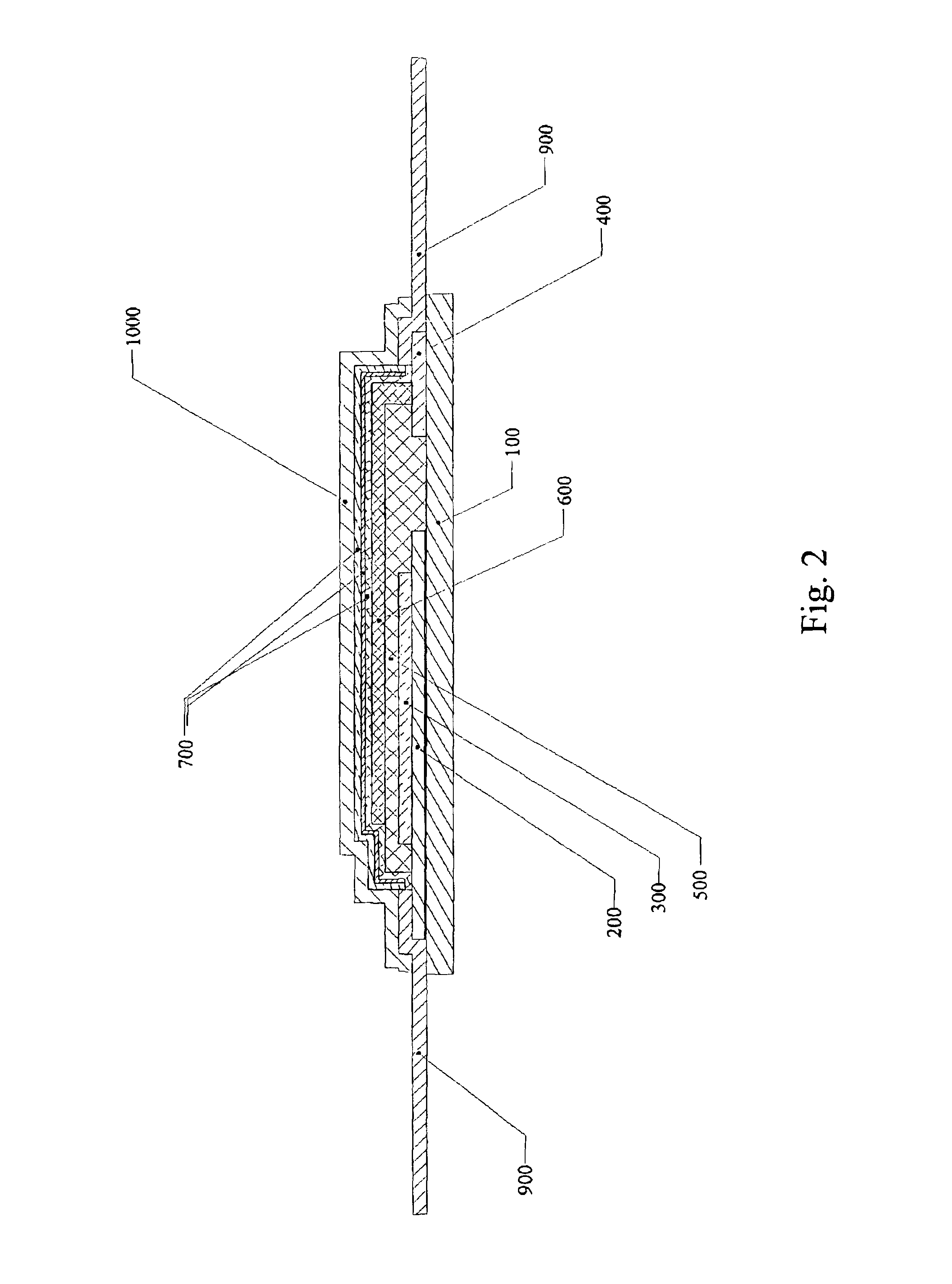

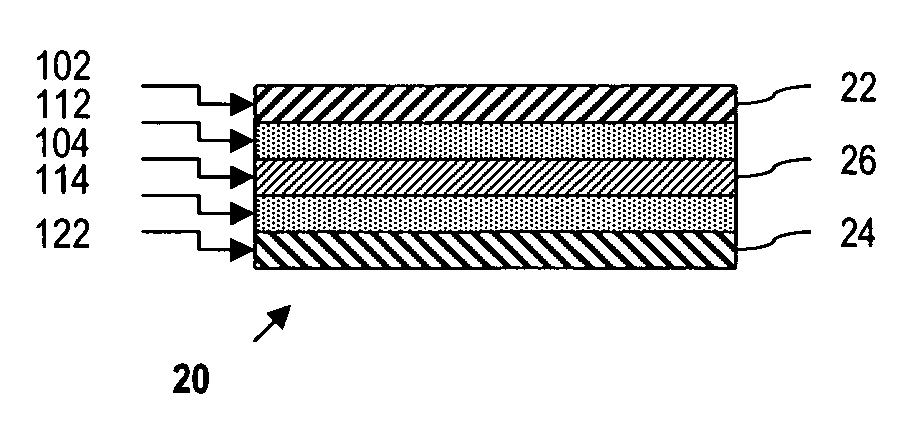

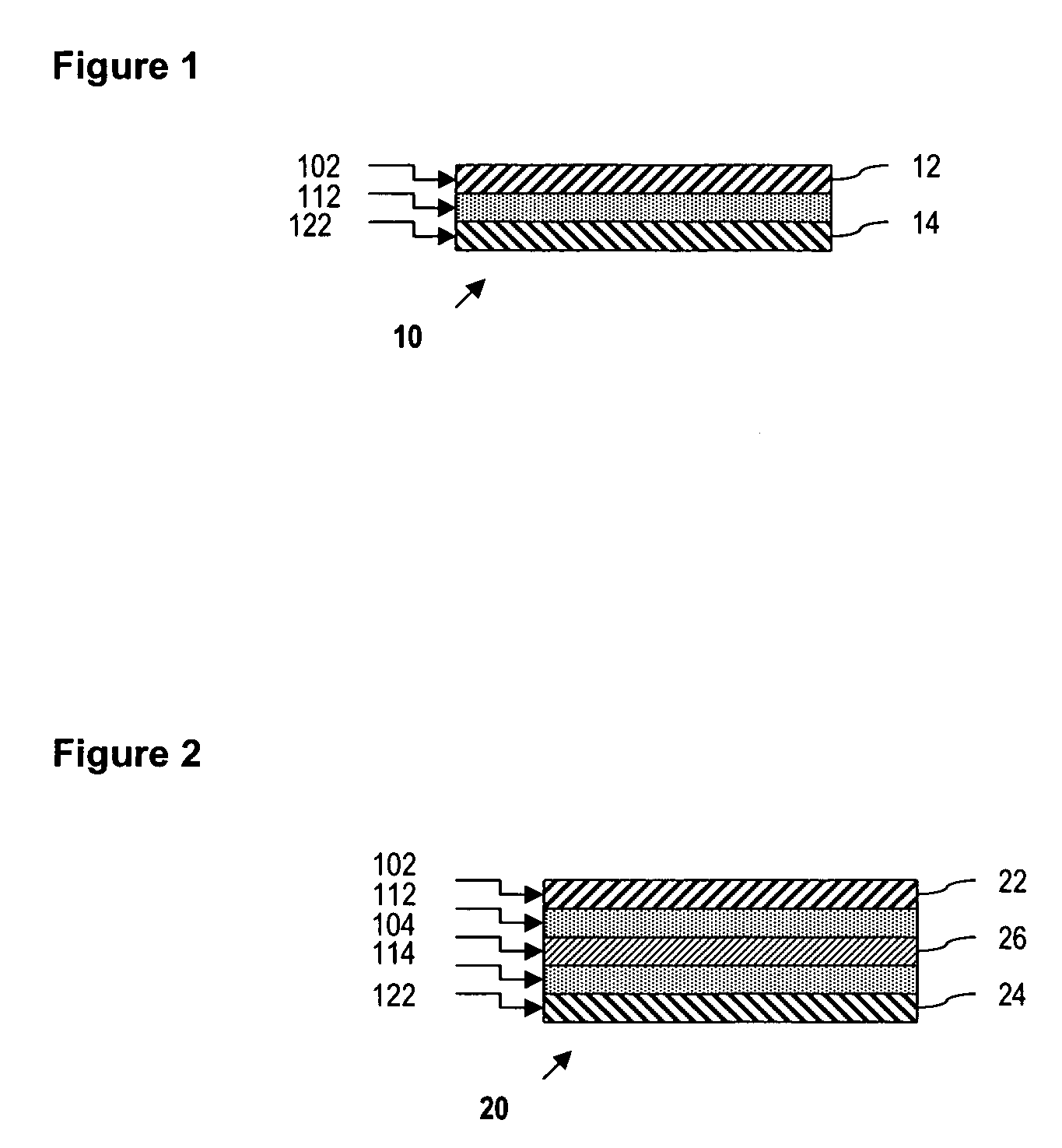

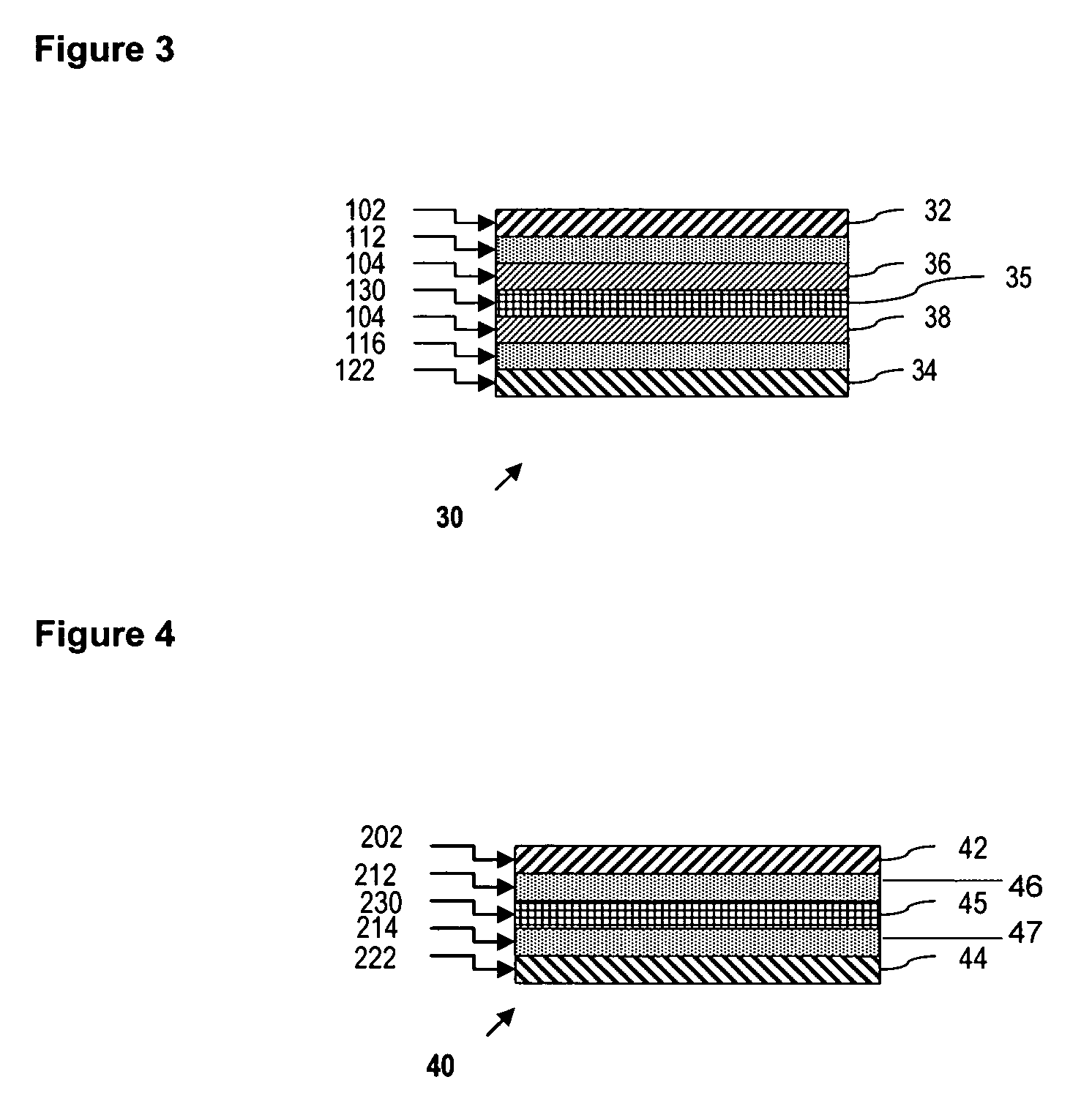

Methods of and device for encapsulation and termination of electronic devices

InactiveUS6916679B2Improve sealingPrevent buildupPV power plantsFinal product manufactureElectricityElectrical devices

A novel method for production of and an apparatus for an encapsulated solid-state electrochemical device is disclosed. The present invention provides for electrical devices, such as, for example, thin-film batteries with sensitive chemistries that can survive environmental exposure while providing external electrical contact to the internal cell chemistry. The method of packaging of the present invention may include bonding one or more protective multi-layer laminates to the environmentally sensitive surfaces of an electronic device. The present invention may provide the advantage of avoiding entrapped air beneath the laminates.

Owner:SAPURAST RES

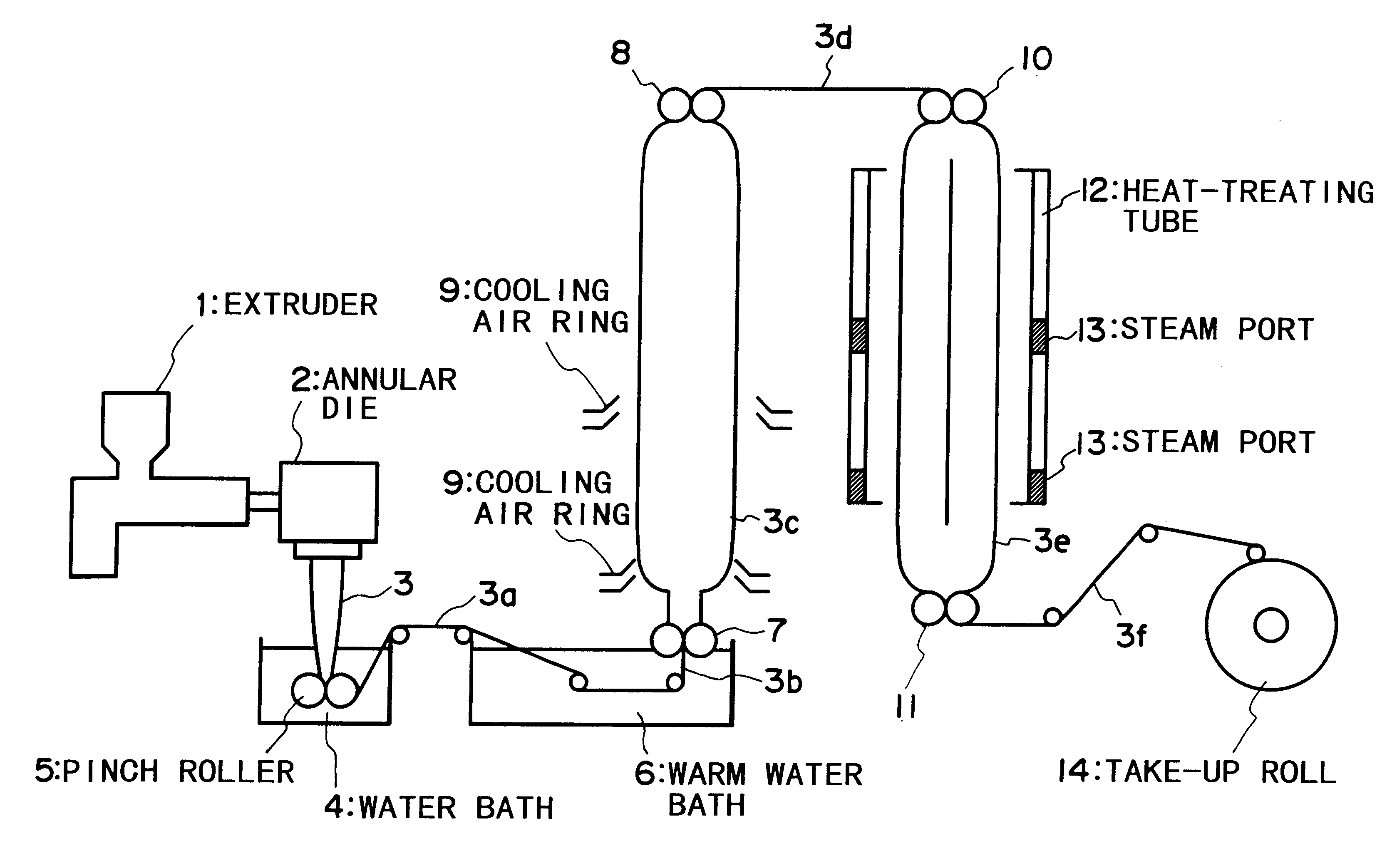

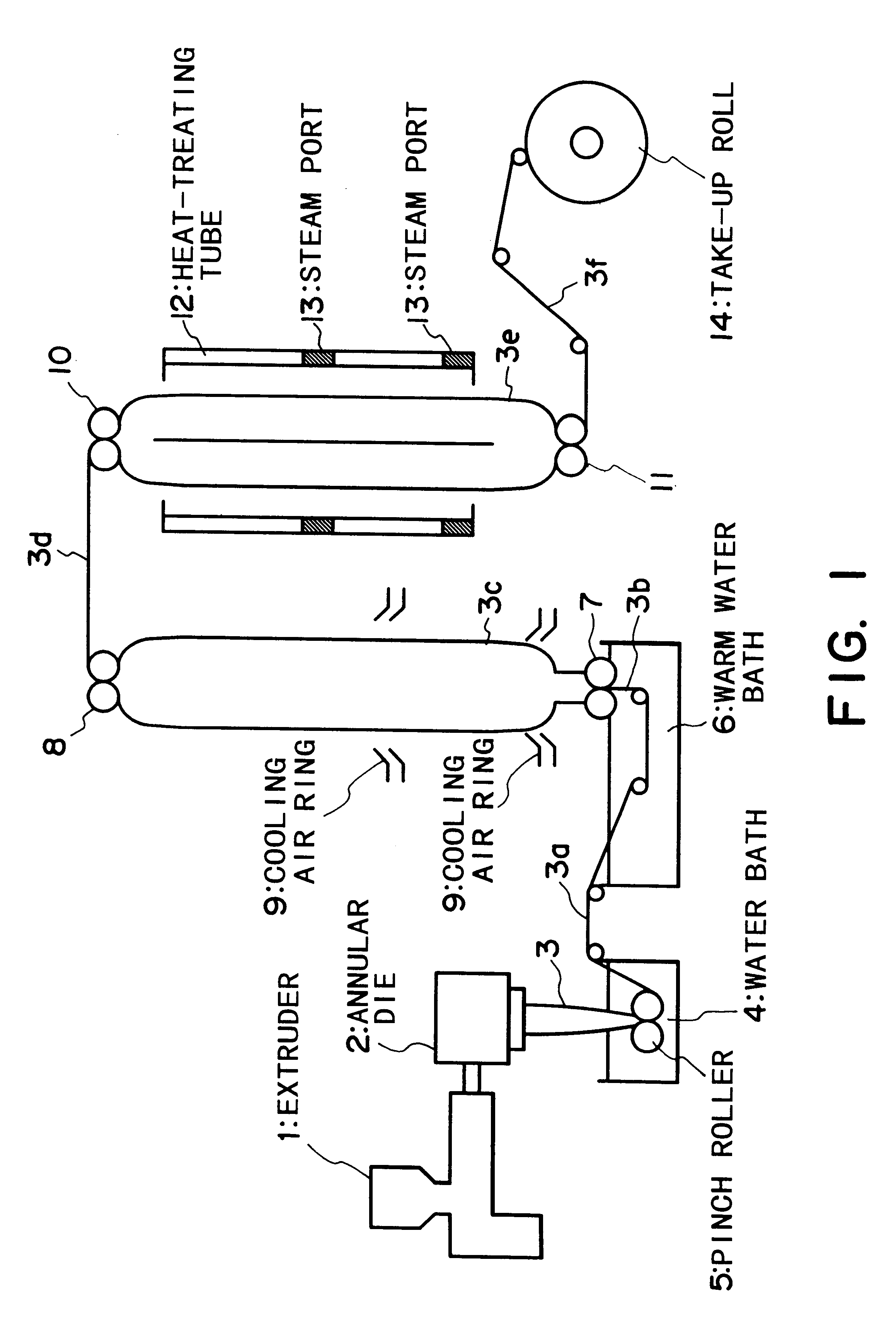

Heat-shrinkable multilayer film

A polyester-surfaced heat-shrinkable multilayer film exhibiting good printability and adaptability to various automatic packaging processes is provided, including an outer surface layer (a) comprising a polyester resin, an intermediate layer (b) comprising a polyamide resin and an inner surface layer (c) comprising a sealable resin. The film exhibits a heat-shrinkable stress at 50° C. of at most 3 MPa both in longitudinal direction and in transverse direction, and a hot water shrinkability at 90° C. of at least 20%.

Owner:KUREHA KAGAKU KOGYO KK

Gravel pack crossover tool with single position multi-function capability

Owner:BAKER HUGHES INC

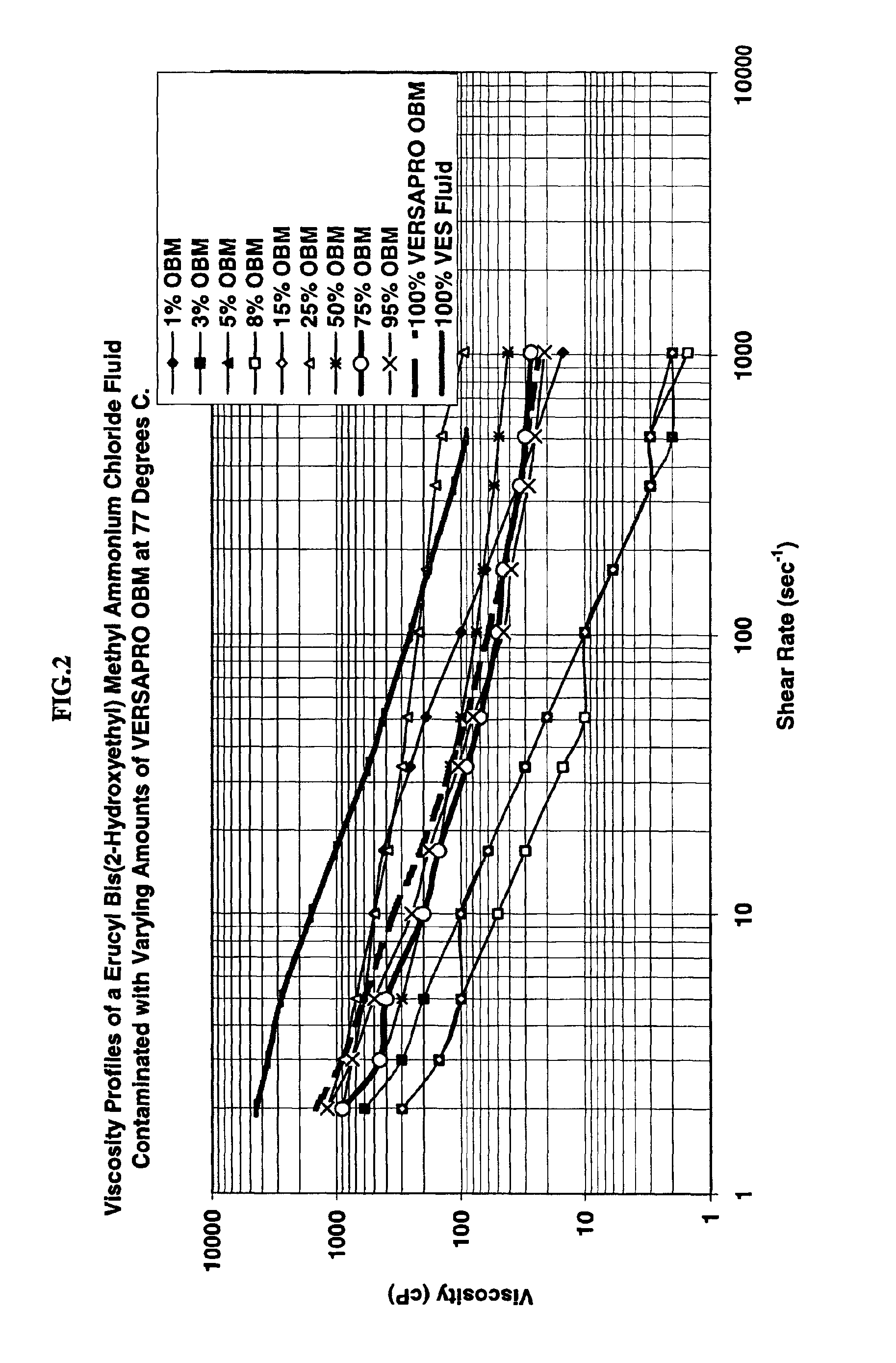

Orthoester compositions and methods for reducing the viscosified treatment fluids

InactiveUS7168489B2Low viscosityReduced pHOrganic compound preparationFluid removalOrthoesterViscosity

In one embodiment, the present invention provides a method of reducing the viscosity of a viscosified treatment fluid comprising contacting the viscosified treatment fluid with an acid generated from an orthoester composition that comprises an orthoester. In another embodiment, the present invention provides a method of reducing the pH of a viscosified treatment fluid comprising providing an orthoester composition that comprises an orthoester; contacting the viscosified treatment fluid with the orthoester composition; allowing the orthoester to generate a generated acid; and allowing the generated acid to at least partially reduce the pH of the viscosified treatment fluid. Embodiments of fracturing and gravel packing methods also are disclosed.

Owner:HALLIBURTON ENERGY SERVICES INC

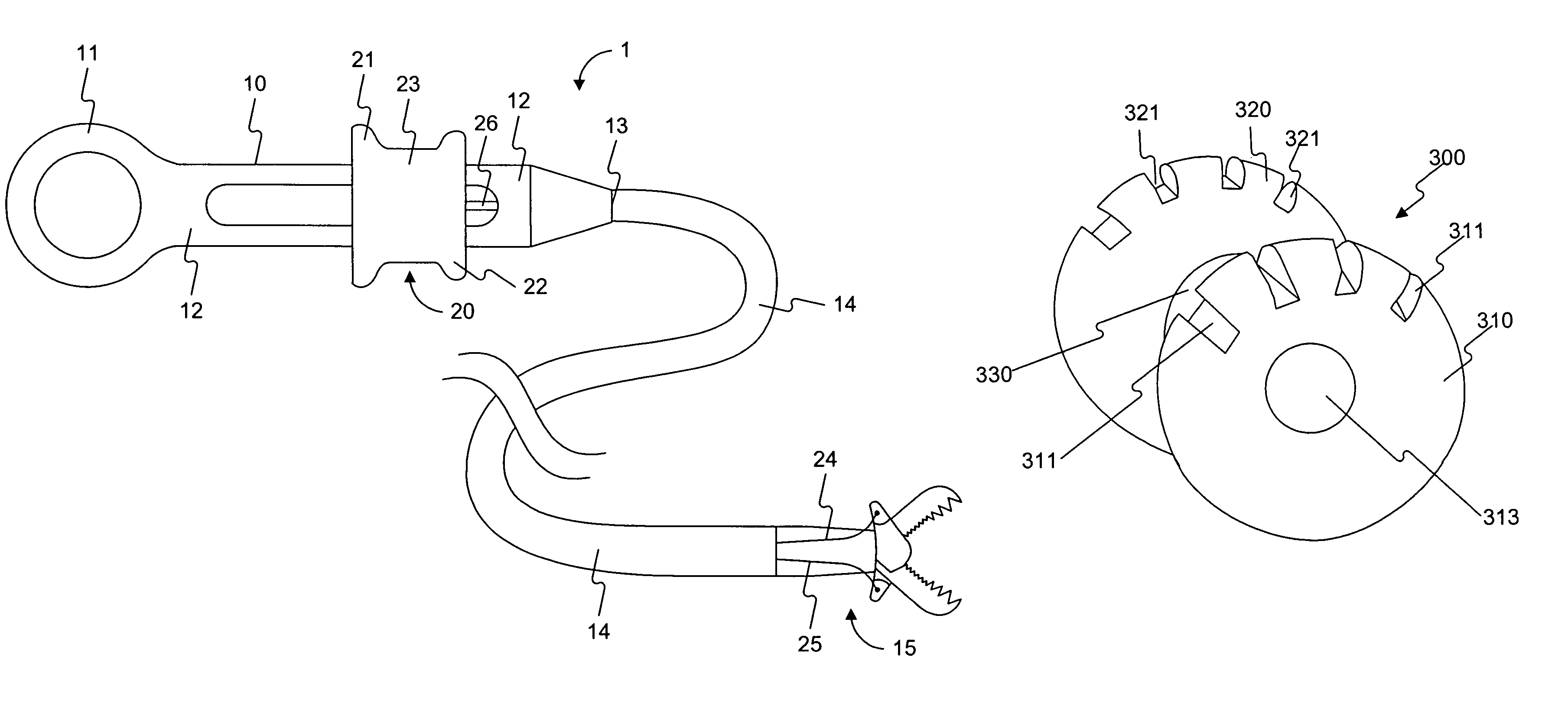

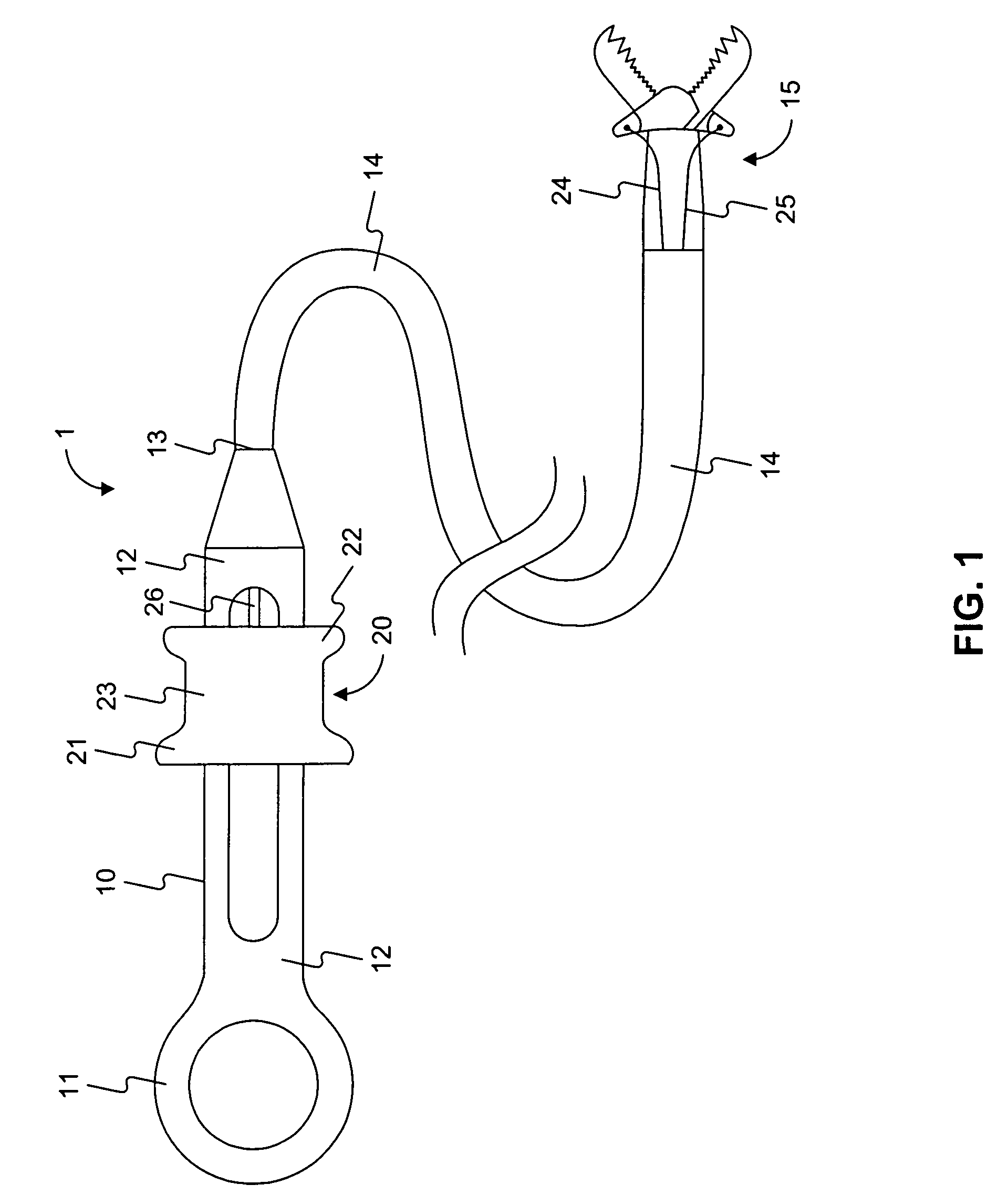

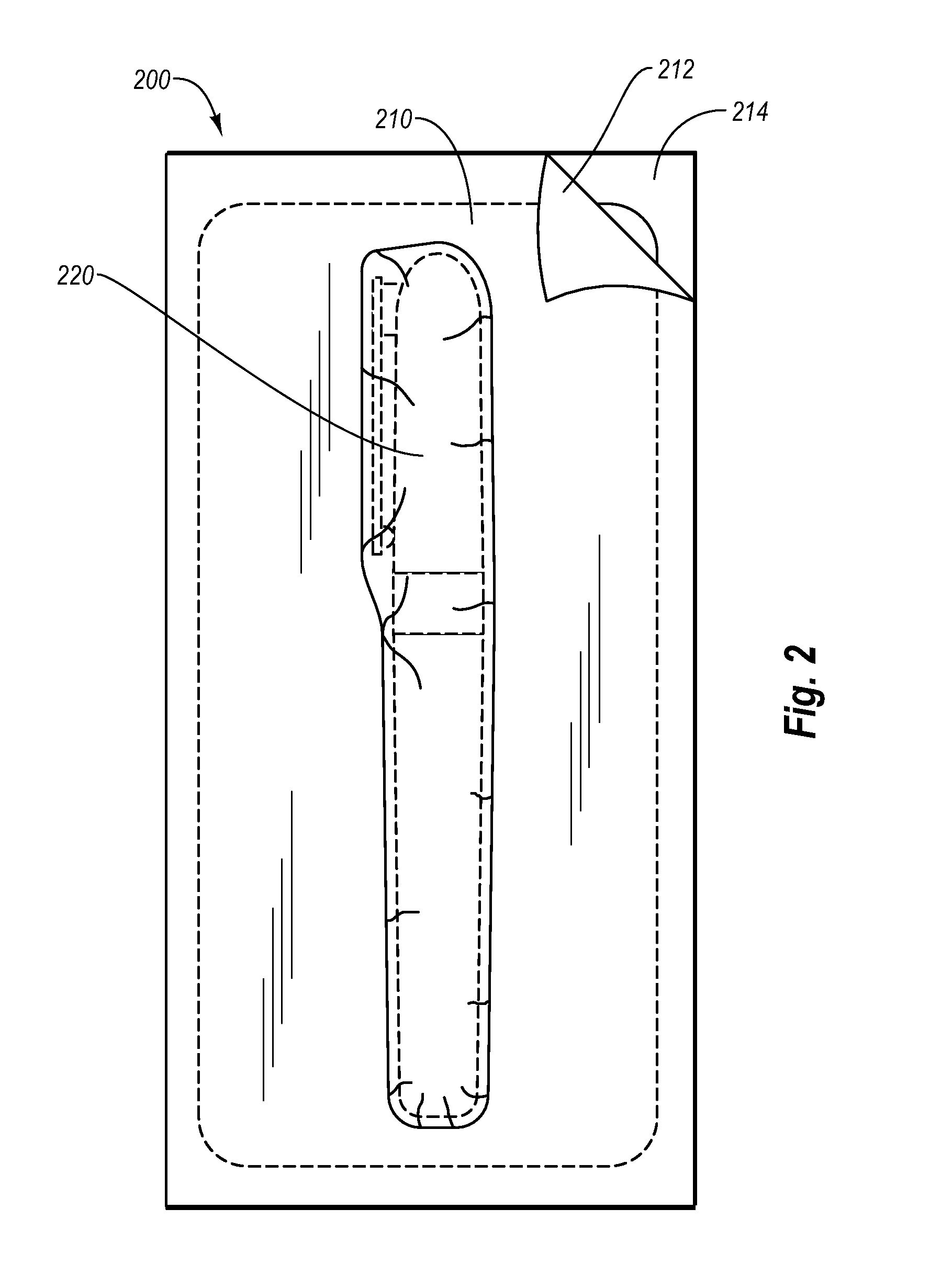

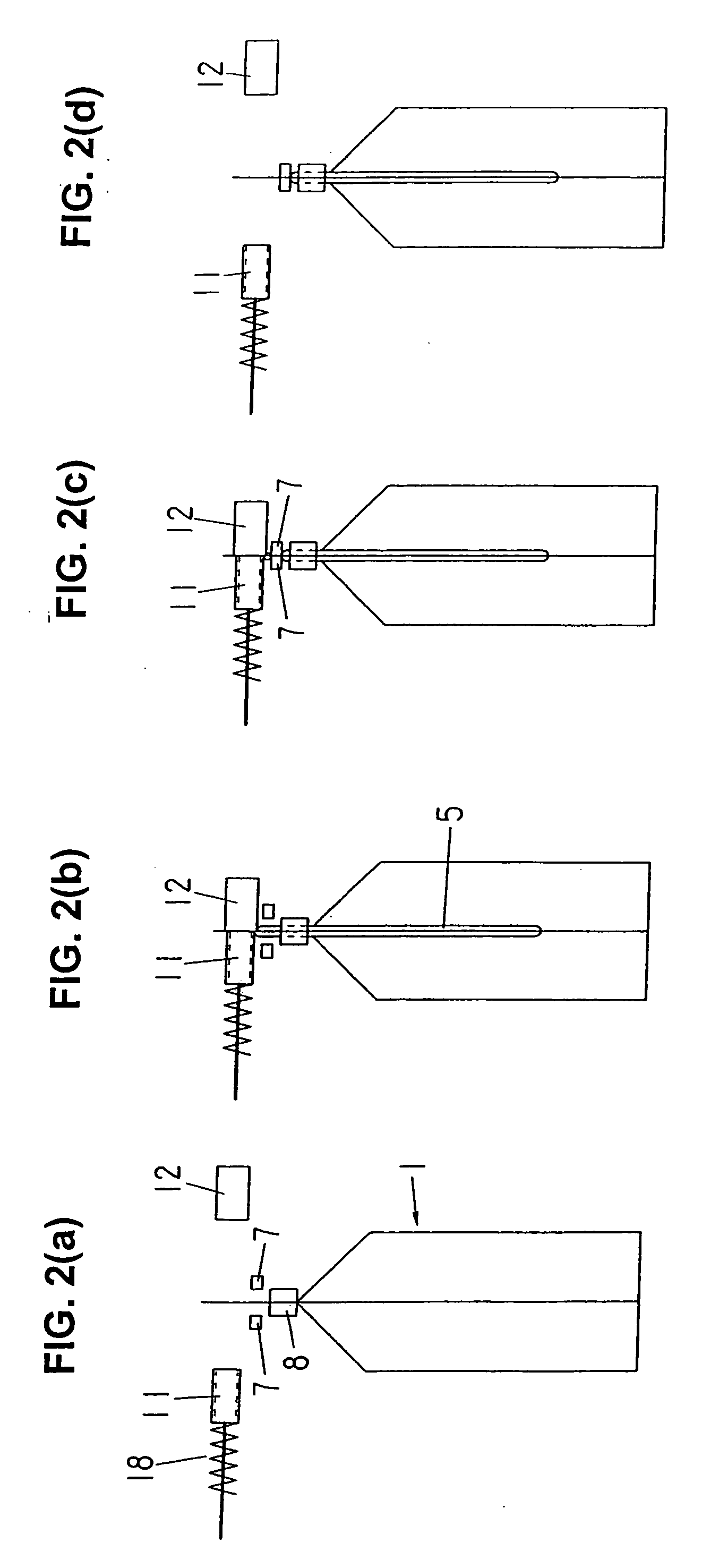

Medical device and related methods of packaging

Embodiments of the invention relate to a medical device having a proximal portion that can selectively receive other portions of the device. More specifically, embodiments of the invention relate to an endoscopic instrument with a handle portion configured to accommodate an elongate, flexible member and an end effector assembly of the endoscopic instrument for protection, coiling, looping, containment, packaging and for disposal. The device may have a variety of configurations.

Owner:BOSTON SCI SCIMED INC

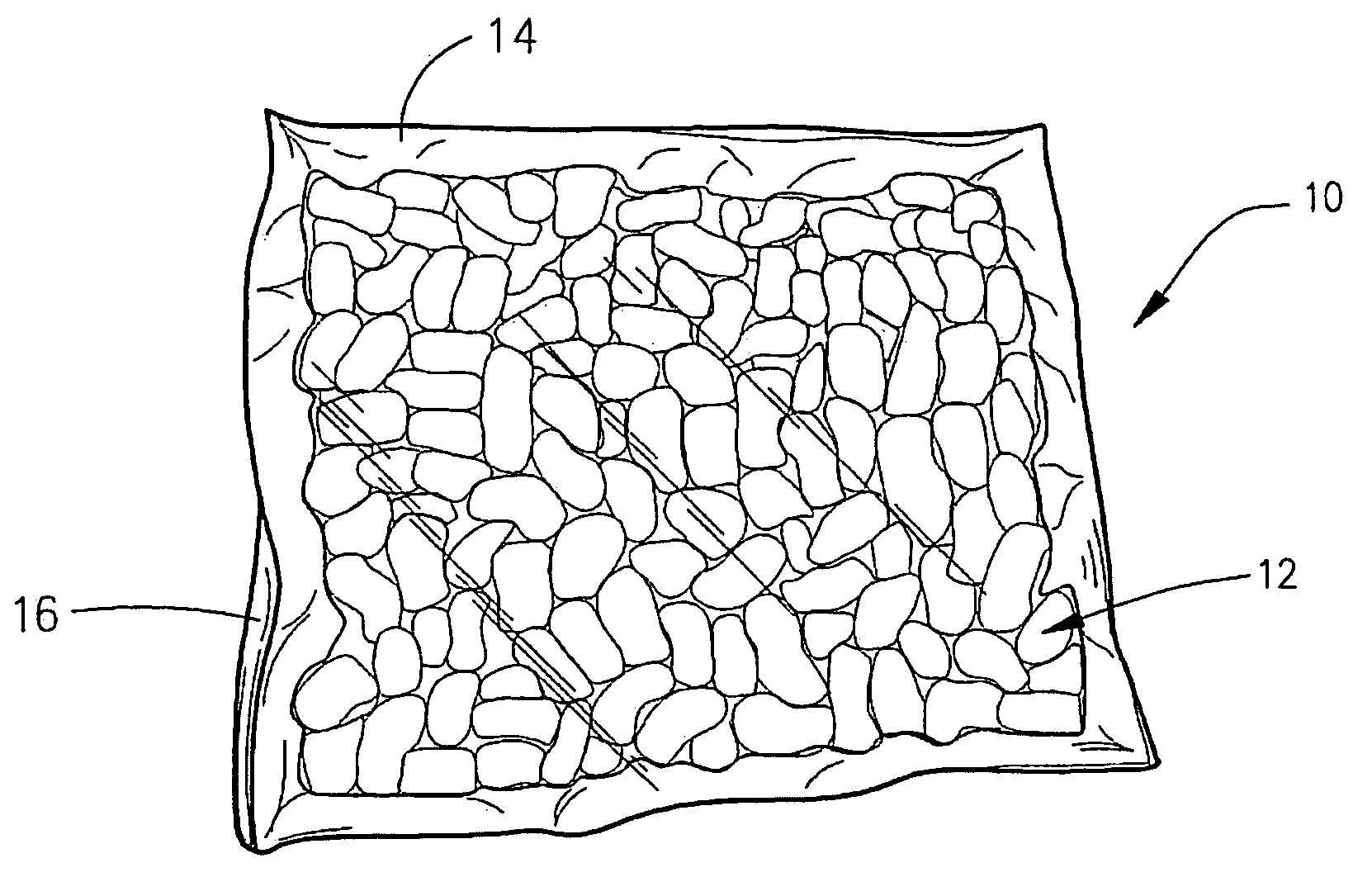

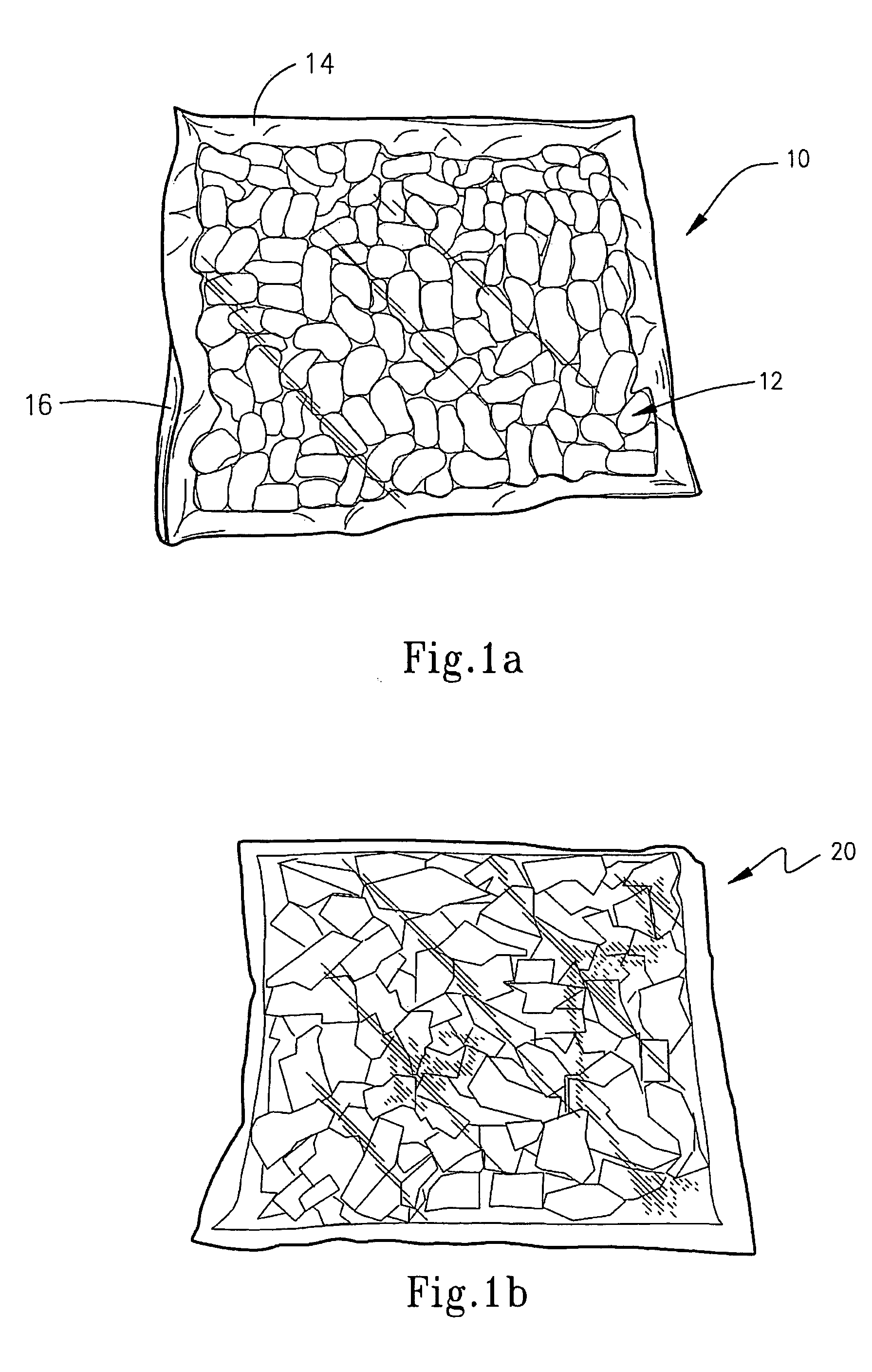

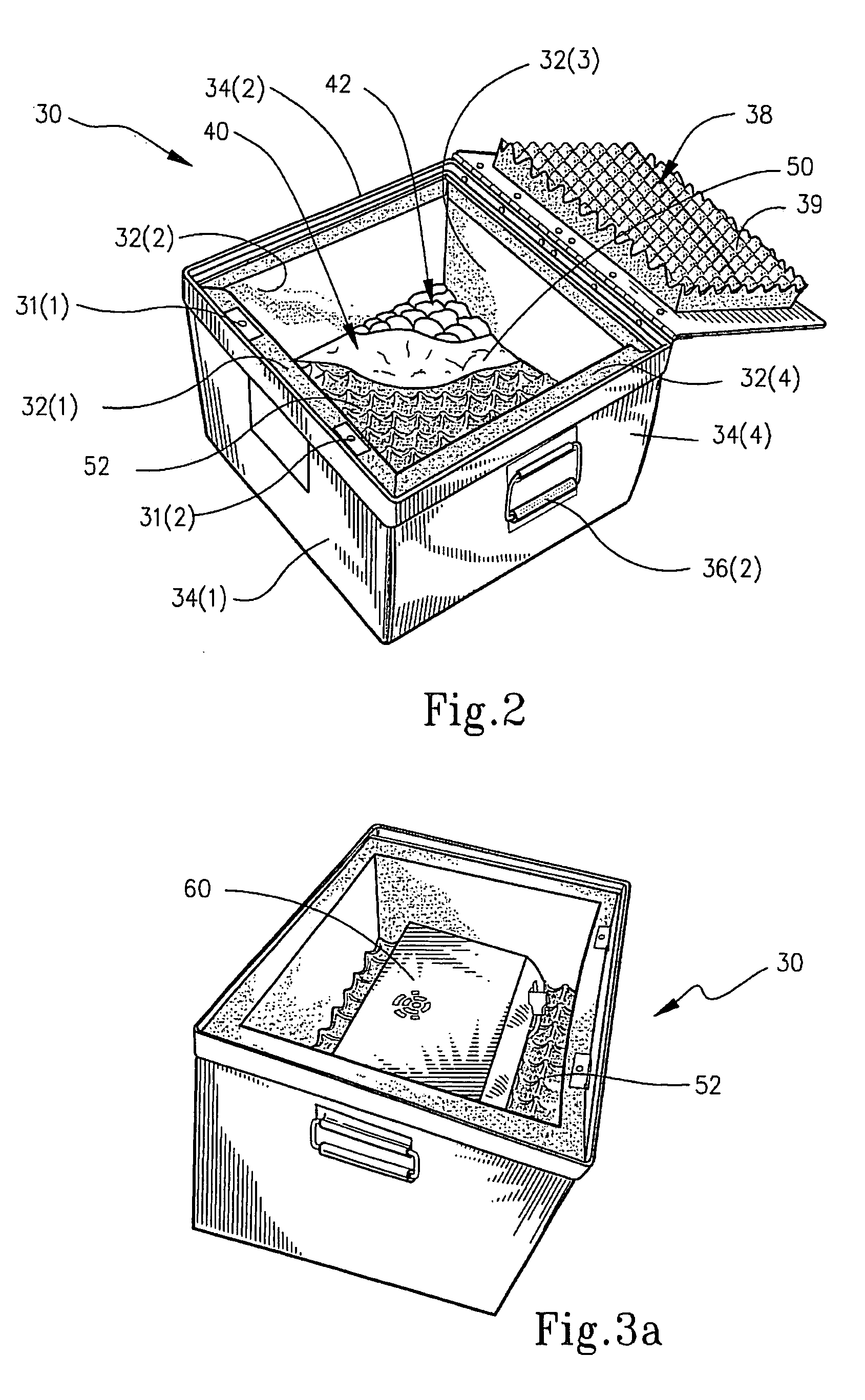

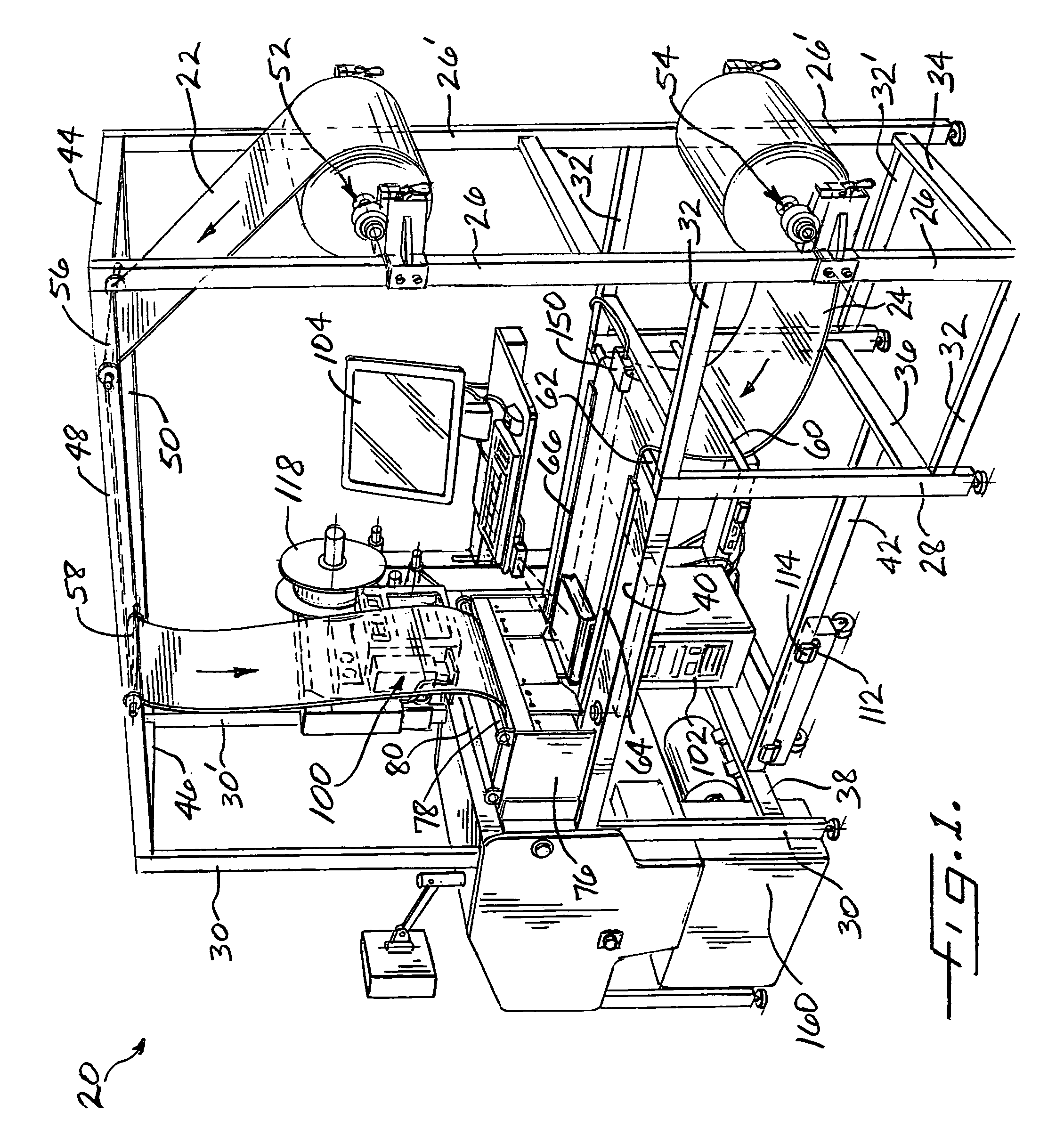

Shipping container, system and packing method, along with reusable packing accessory for use therewith

InactiveUS20080203090A1Reduce risk of damage and lossPackage recyclingLarge containersCushioningAirbag deployment

A reusable shipping system comprises a closable shipping container and a packing ensemble disposed in the container's interior which includes an expandable cushioning assembly and at least one reusable packing accessory. The expandable cushioning assembly may be a layered arrangement having at least one foam layer and an inflatable bladder, while the packing accessory may be one or more cushioned bags or the like. Methods are also described for preparing a shipping container having a padded interior and a layered cushioning assembly. One or more items are inserted into the shipping container, and its cushioning assembly is thereafter expanded, for example by inflating a bladder, to compress the container's padded interior against the item(s).

Owner:EGGS OVERNIGHT

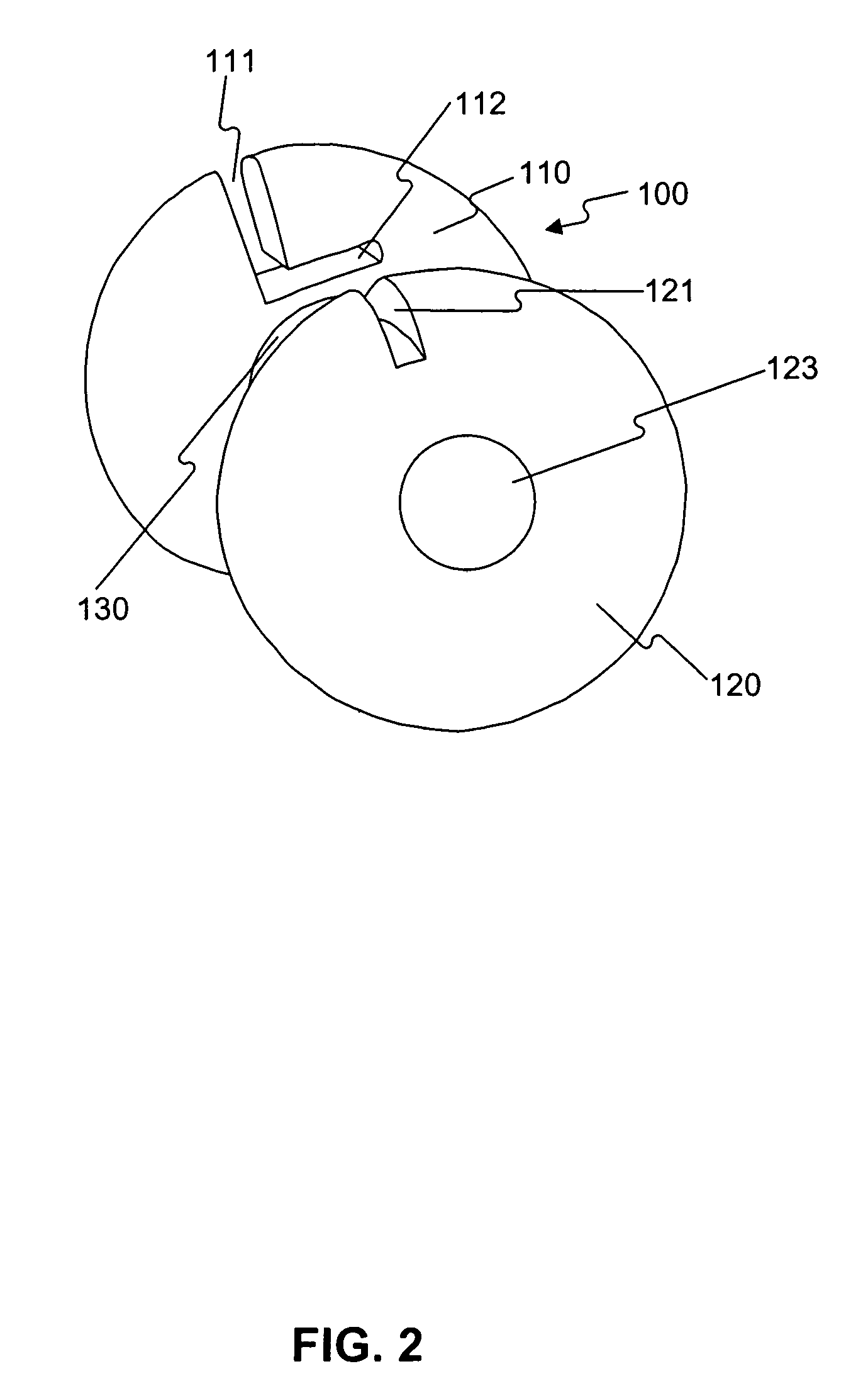

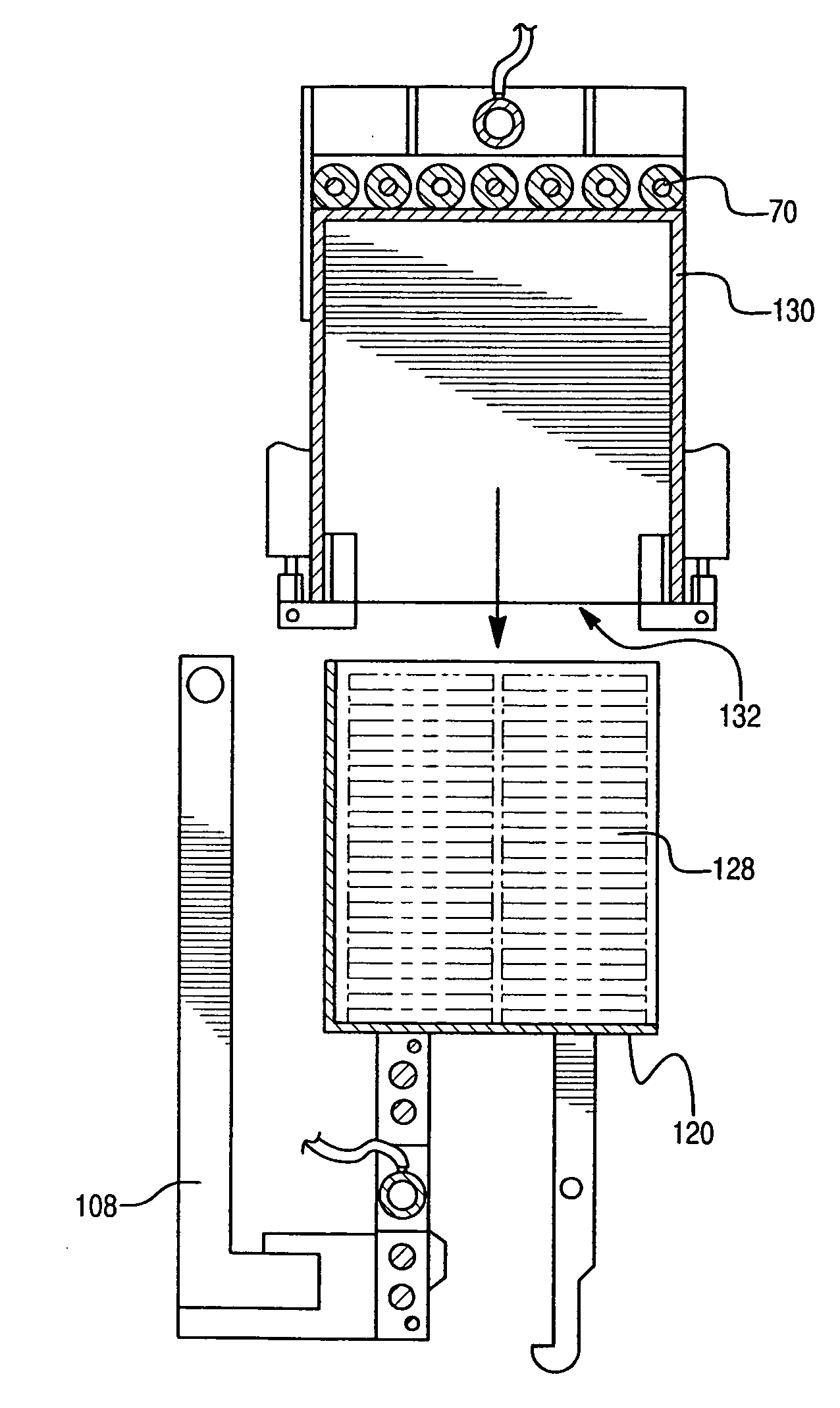

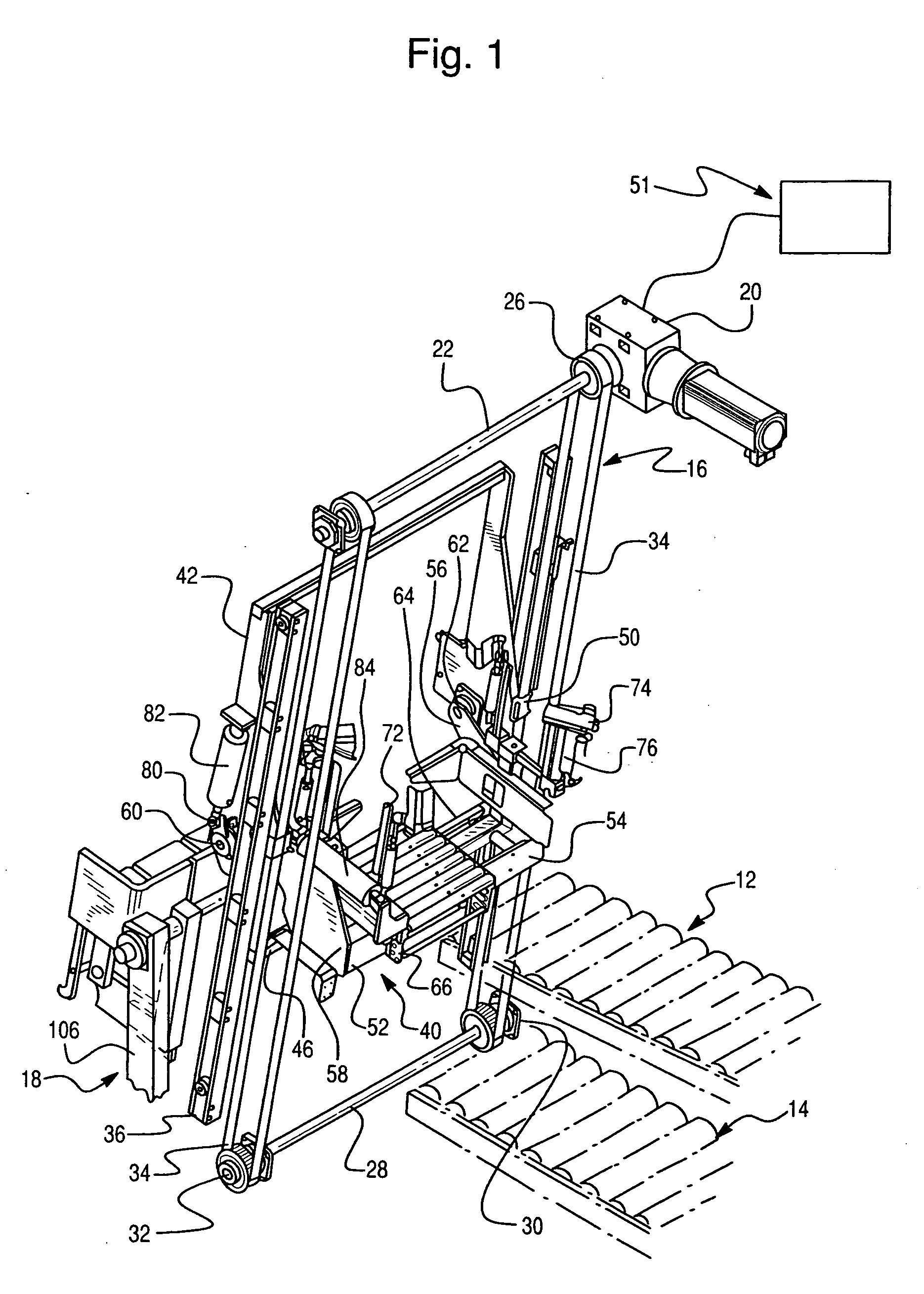

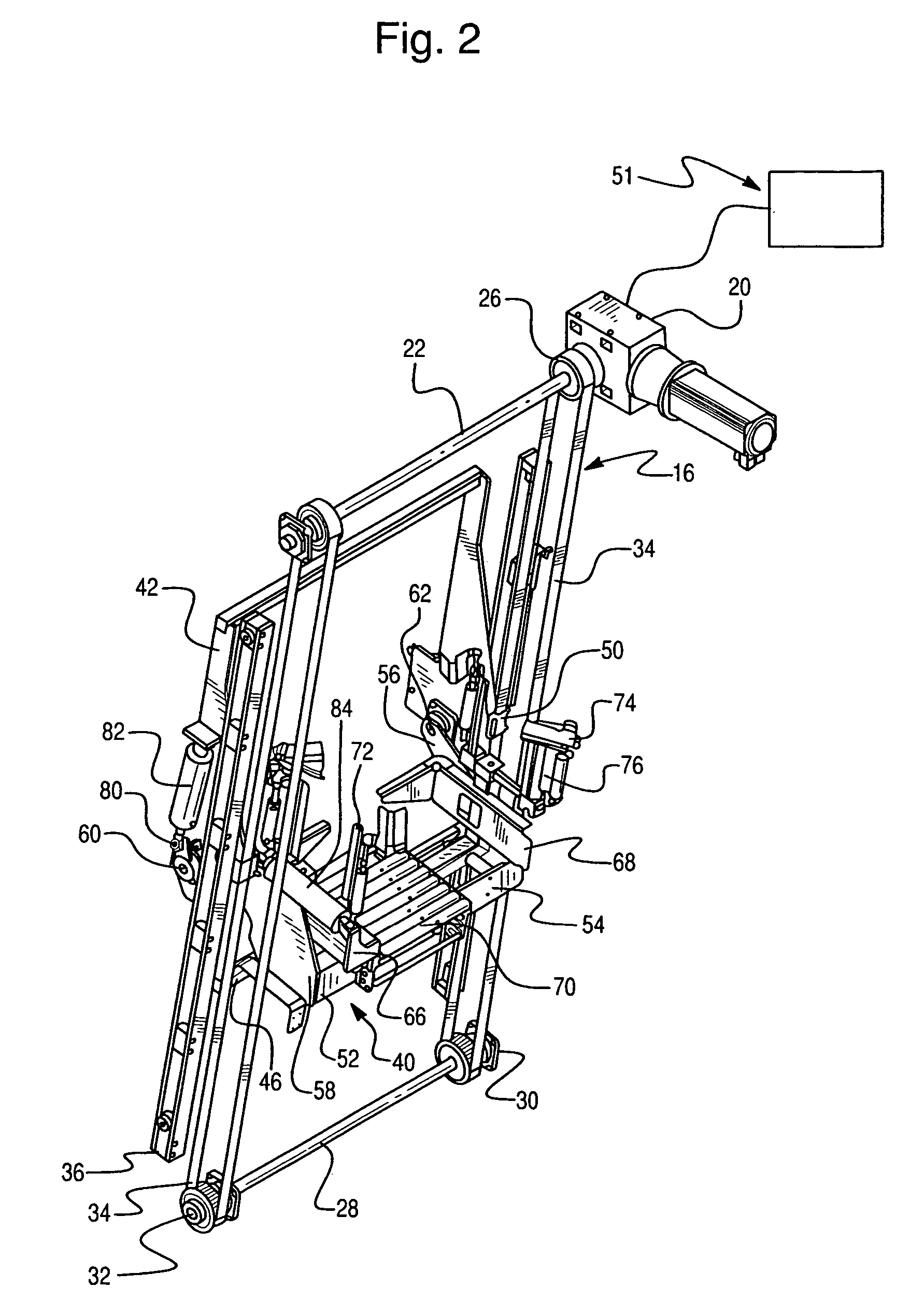

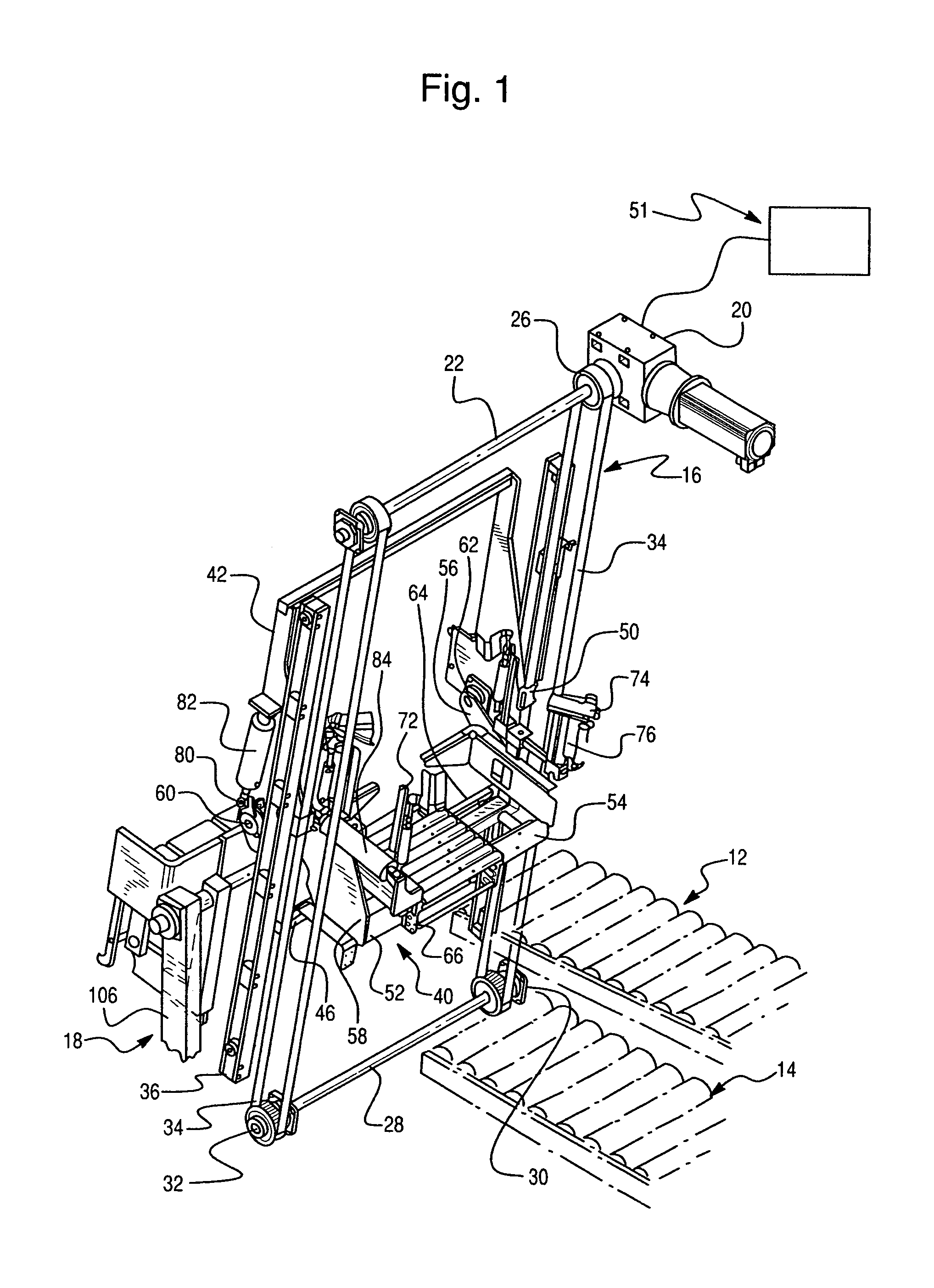

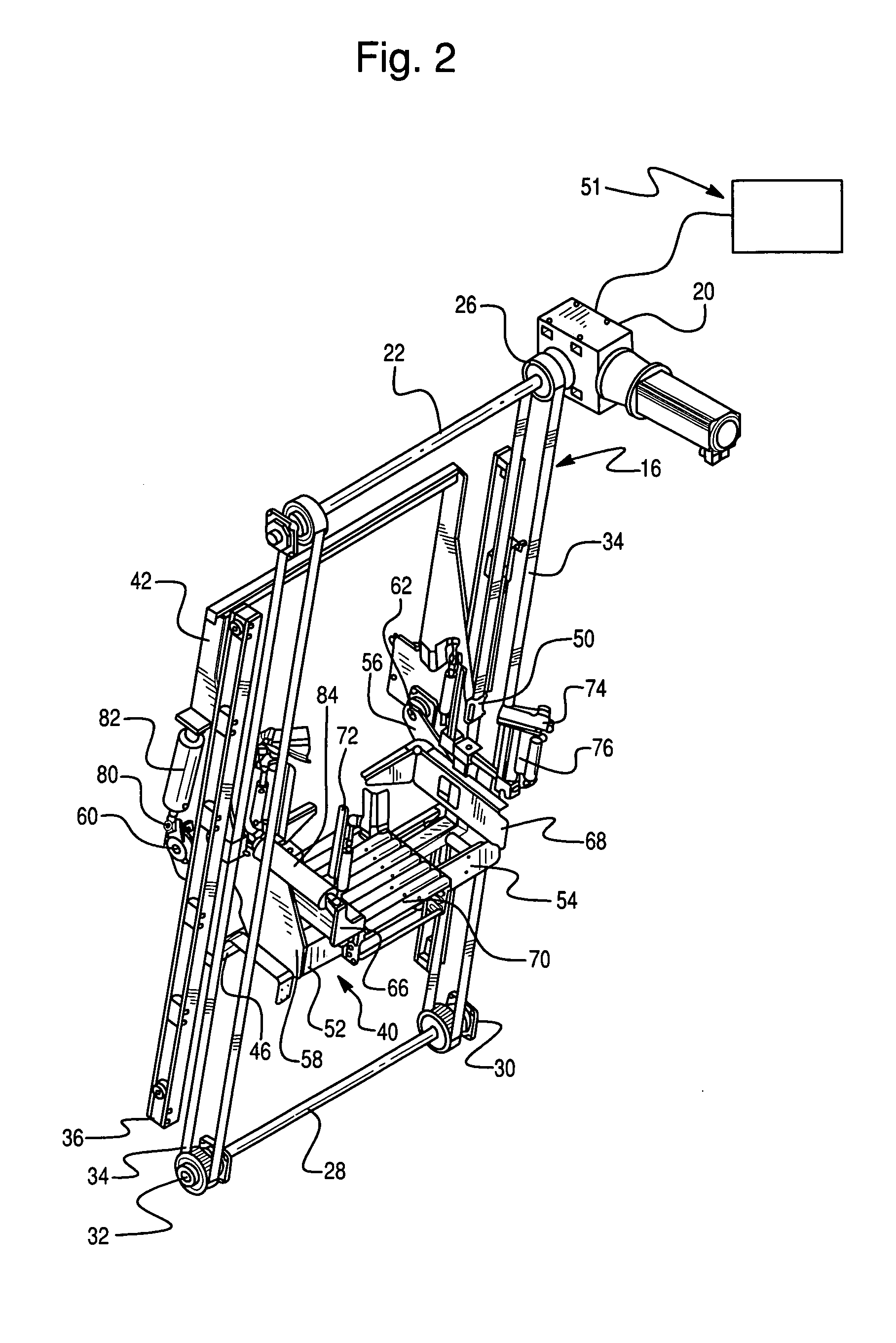

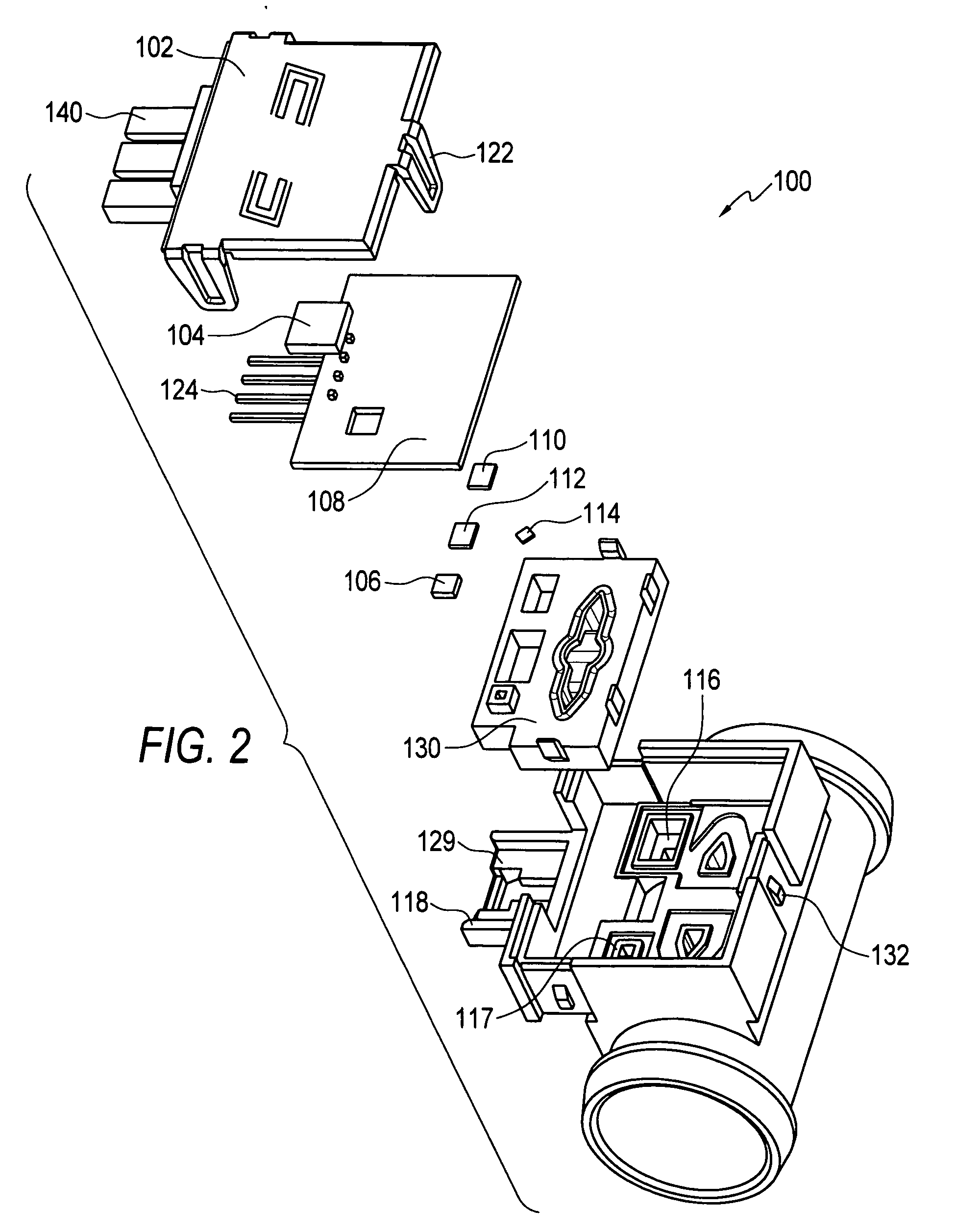

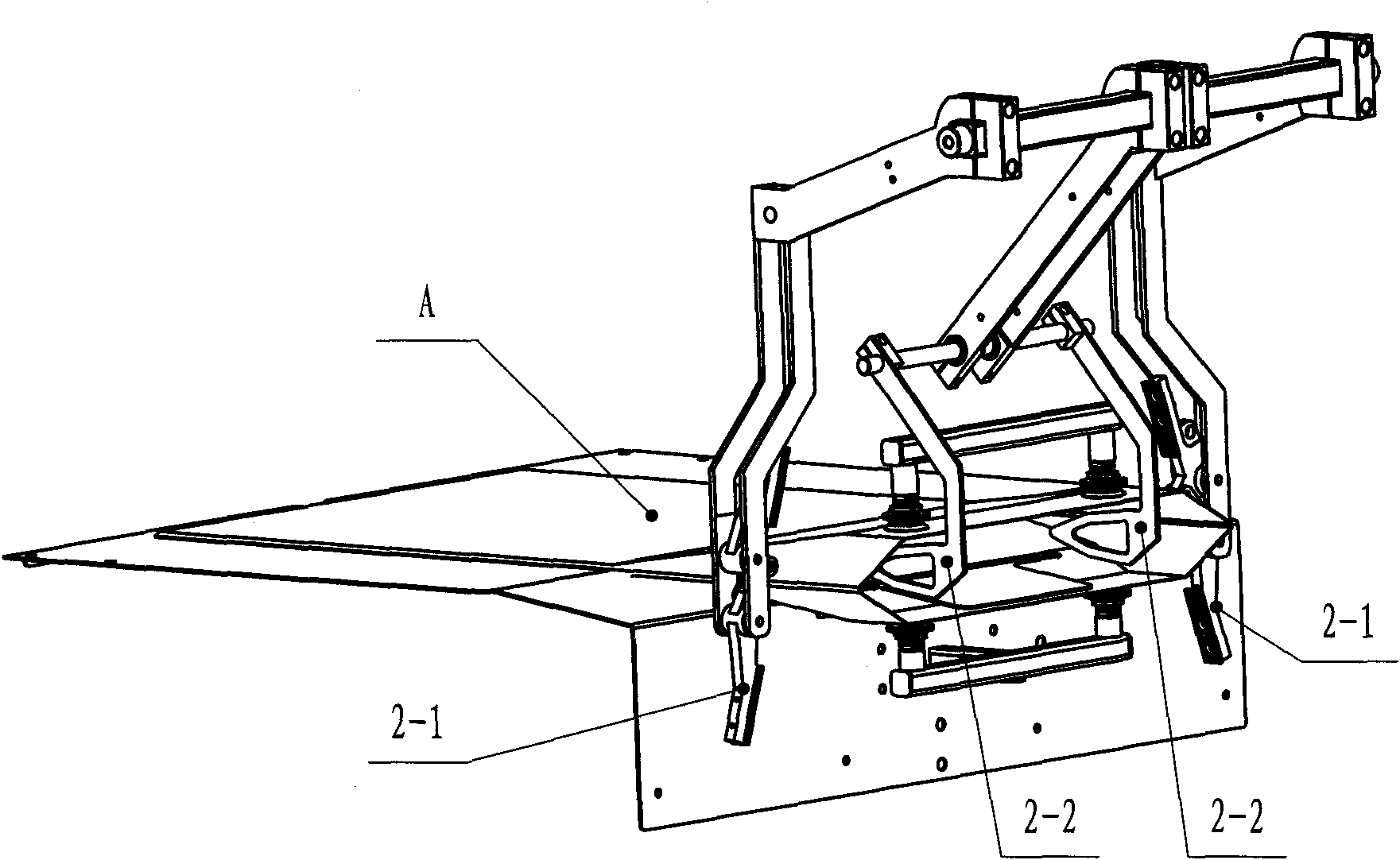

Method and apparatus for packing

A packing method and system are disclosed which system includes a first platform having a product support surface for supporting a product and a second platform for supporting a box into which the product is to be packed. After a box is received on and secured to the second platform, the second platform is rotated so that the open top of the box faces the first platform and moved toward the first platform until the box substantially surrounds the product on the product support surface. The first and second platforms are then rotated simultaneously so that the product is transferred from the product support to the box, and the full box is discharged to a discharge conveyor.

Owner:WELBORN KENNETH M +4

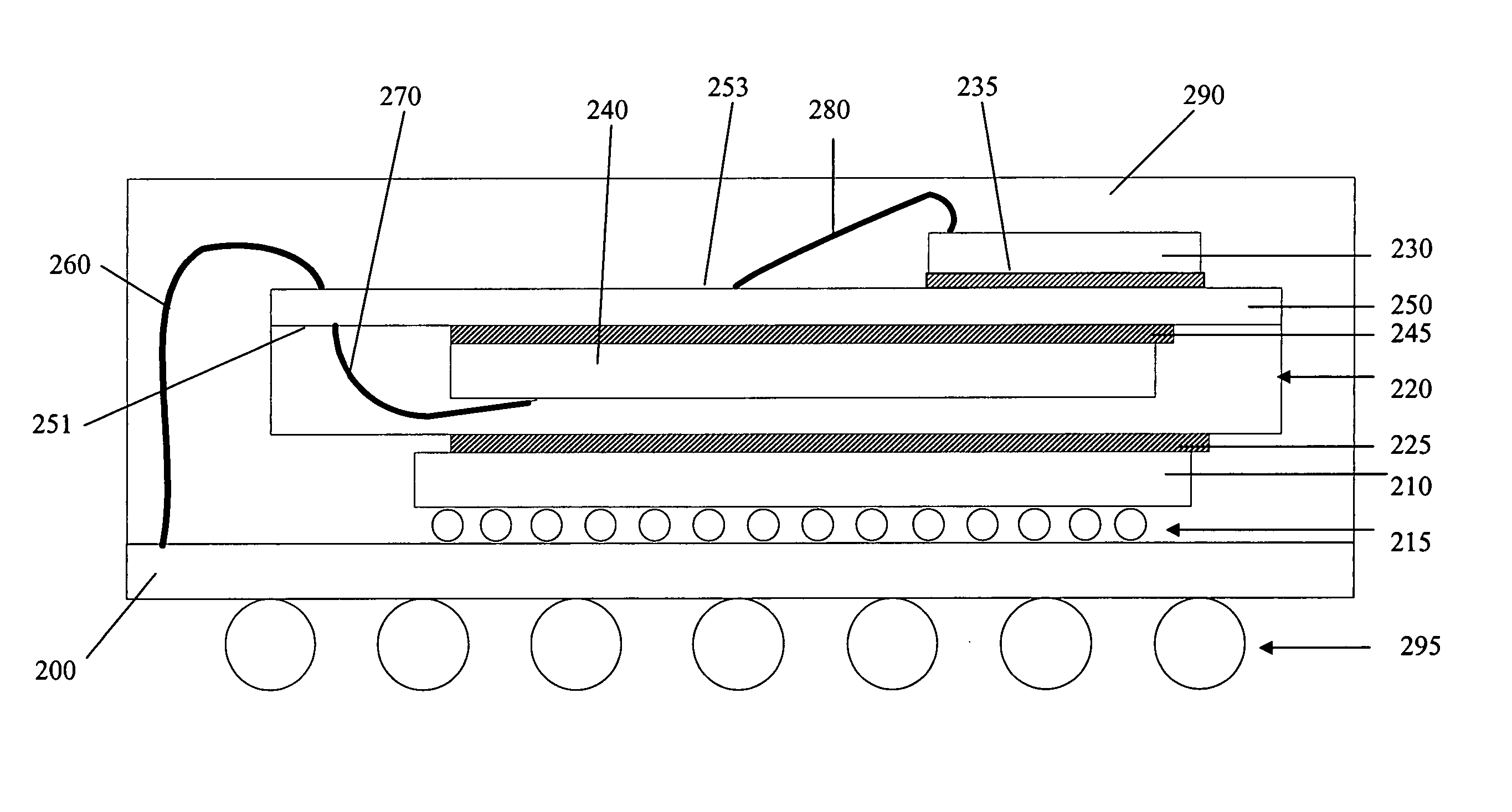

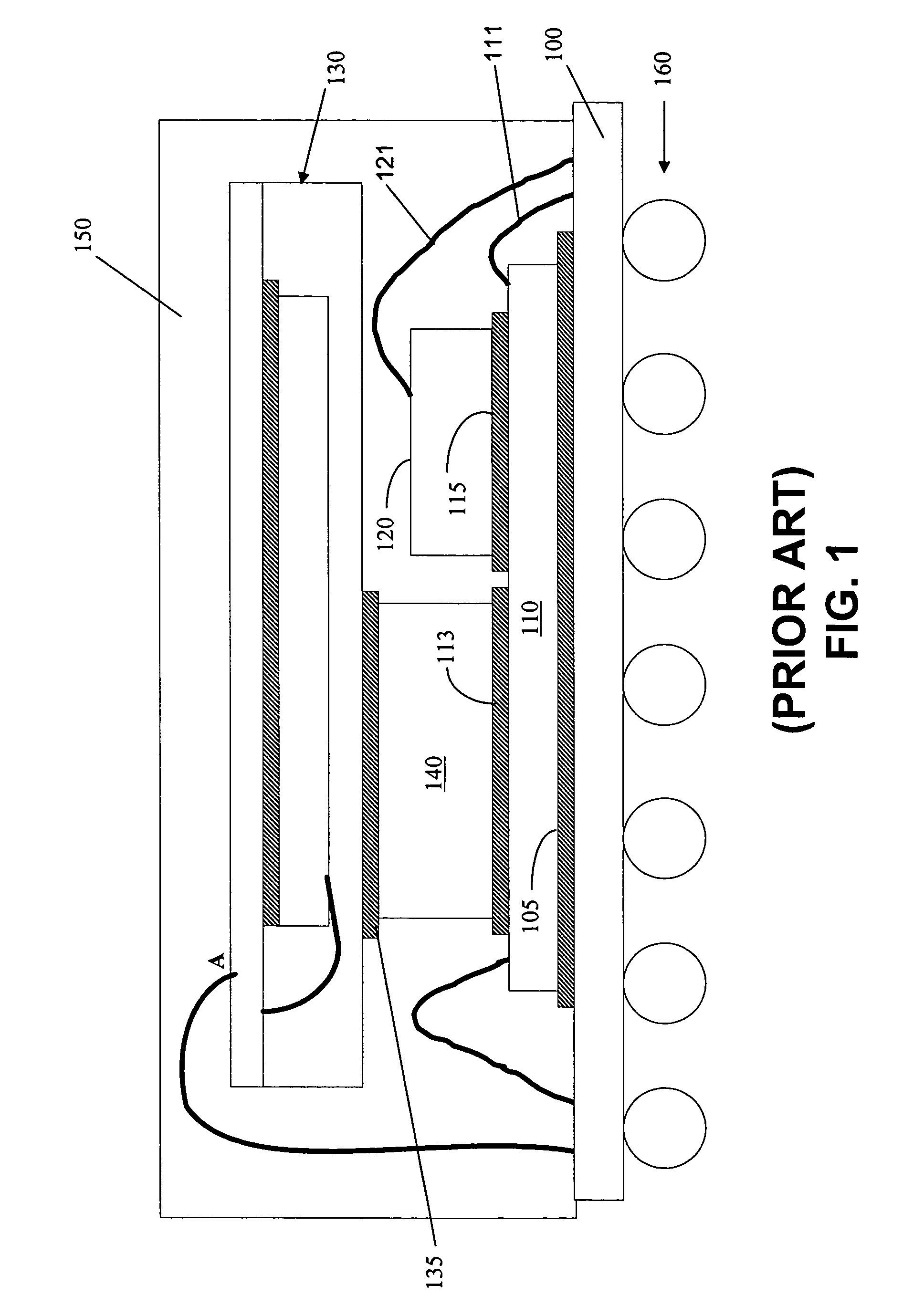

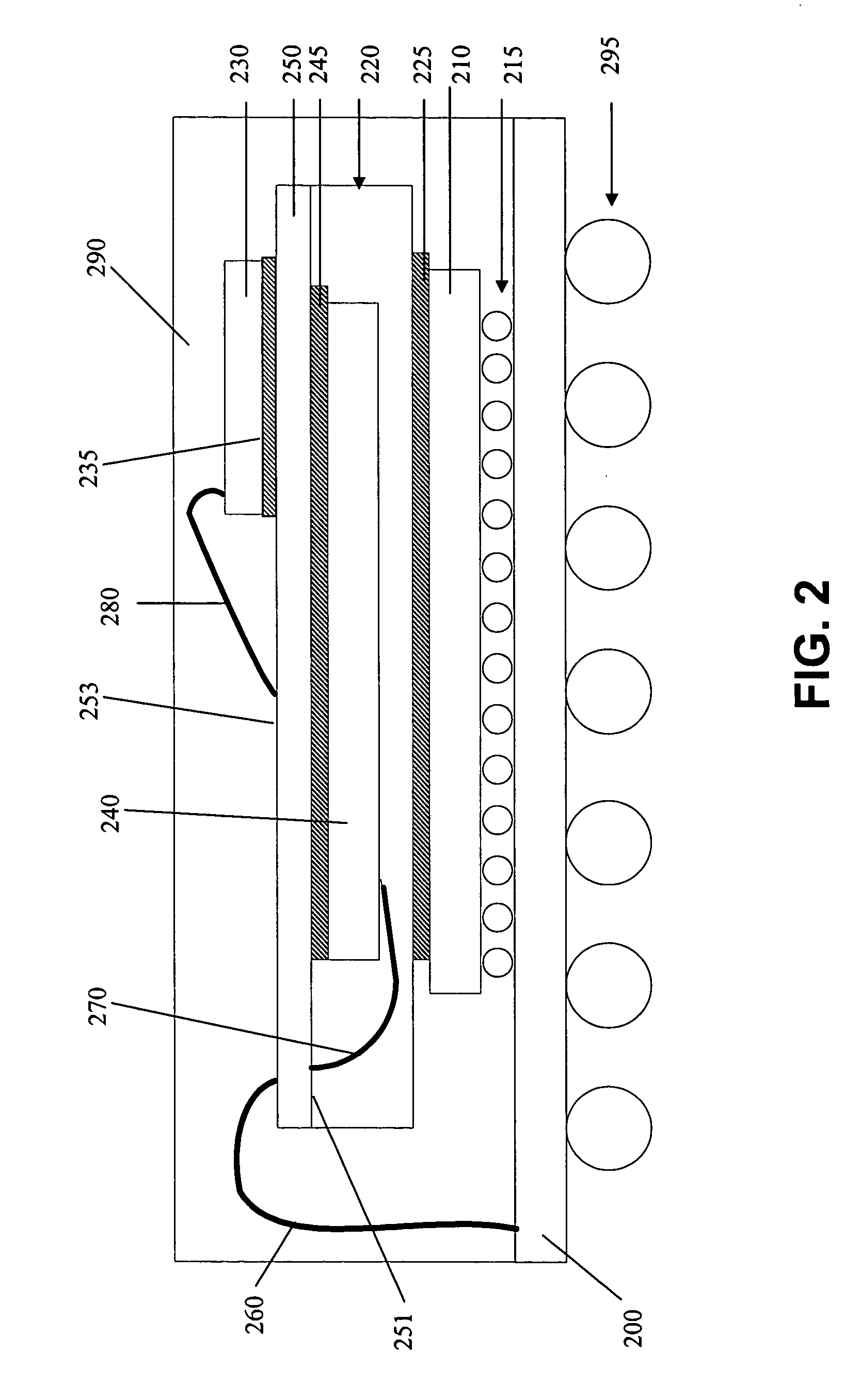

Stacked packaging methods and structures

InactiveUS20060043556A1Semiconductor/solid-state device detailsSolid-state devicesChip-scale packageElectrical and Electronics engineering

A packaging method and structures are disclosed. A first die is mounted on a package substrate. A chip scale package is mounted on the first die. The chip scale package comprises a chip scale package substrate and a second die mounted on a first surface of the chip scale package substrate. A third die is mounted on a second surface of the chip scale package substrate. Accordingly, the height of the stacked package can be reduced.

Owner:TAIWAN SEMICON MFG CO LTD

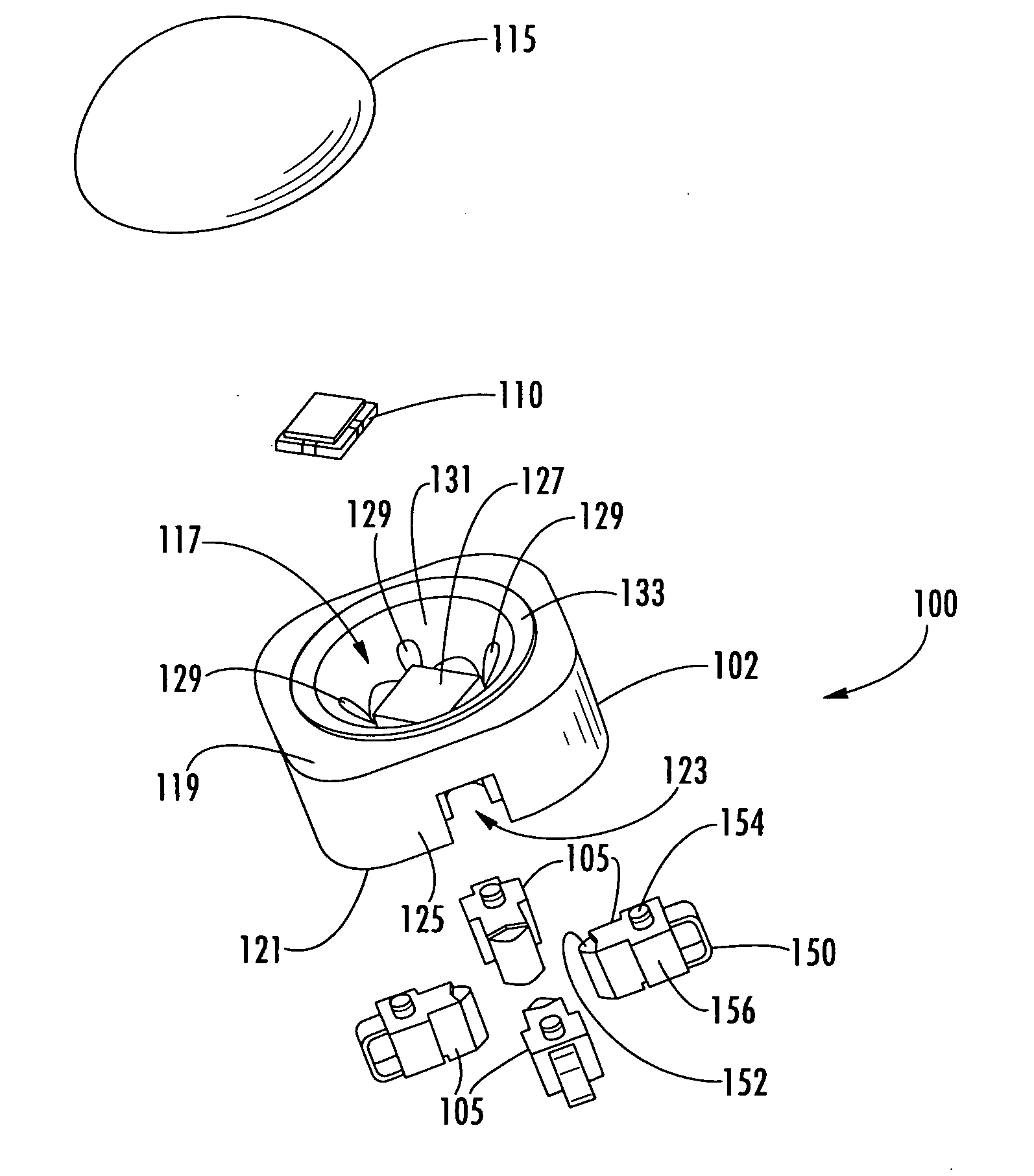

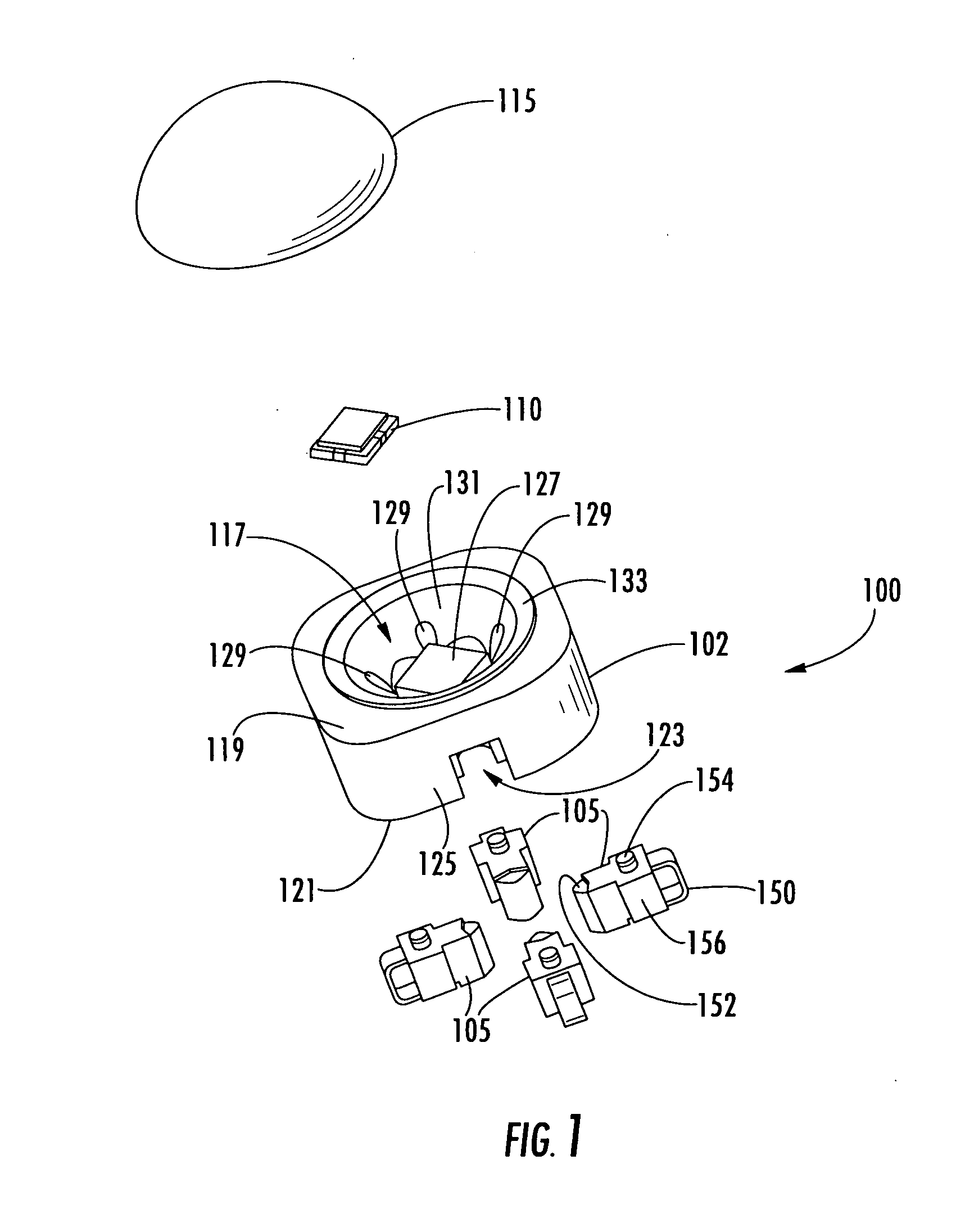

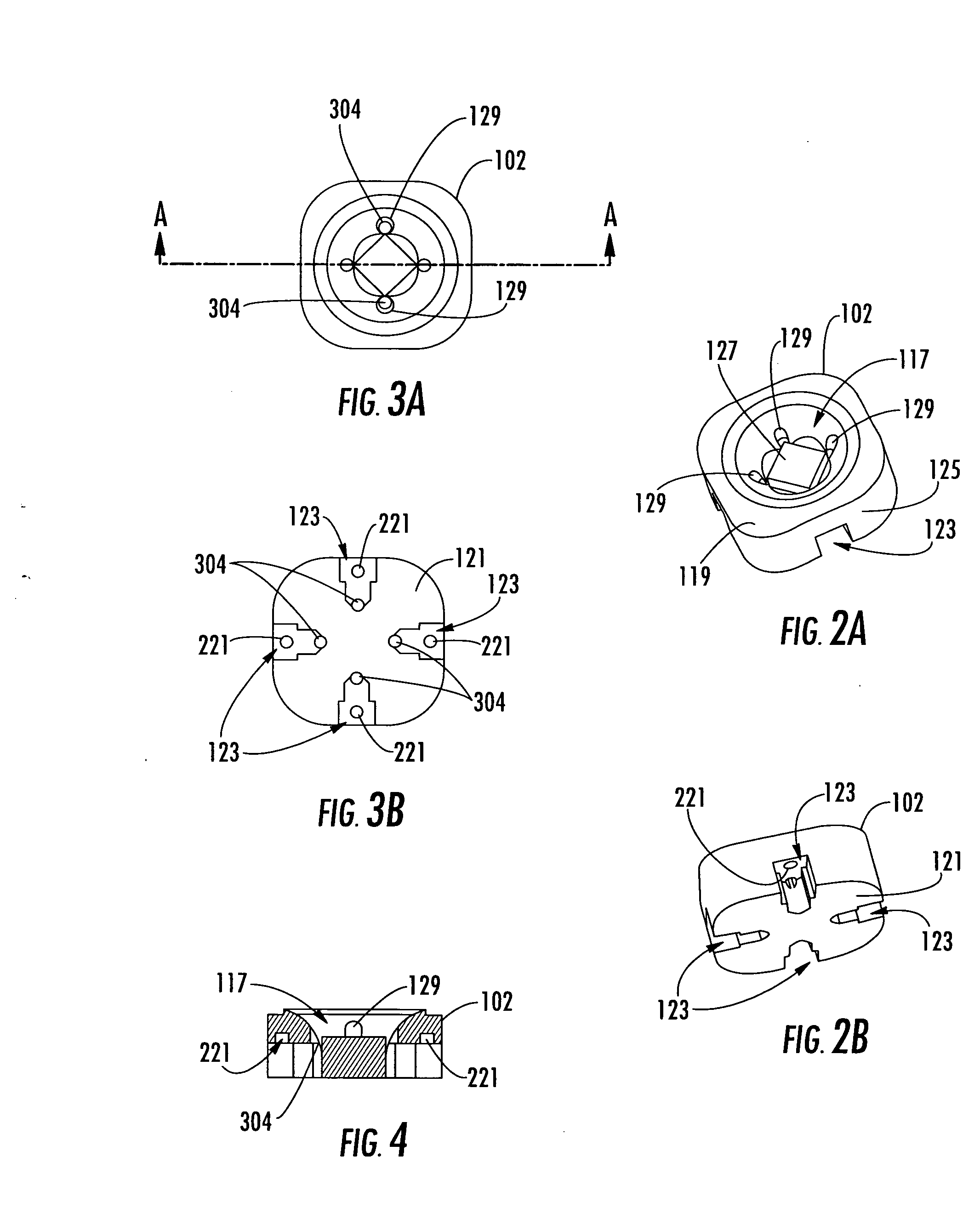

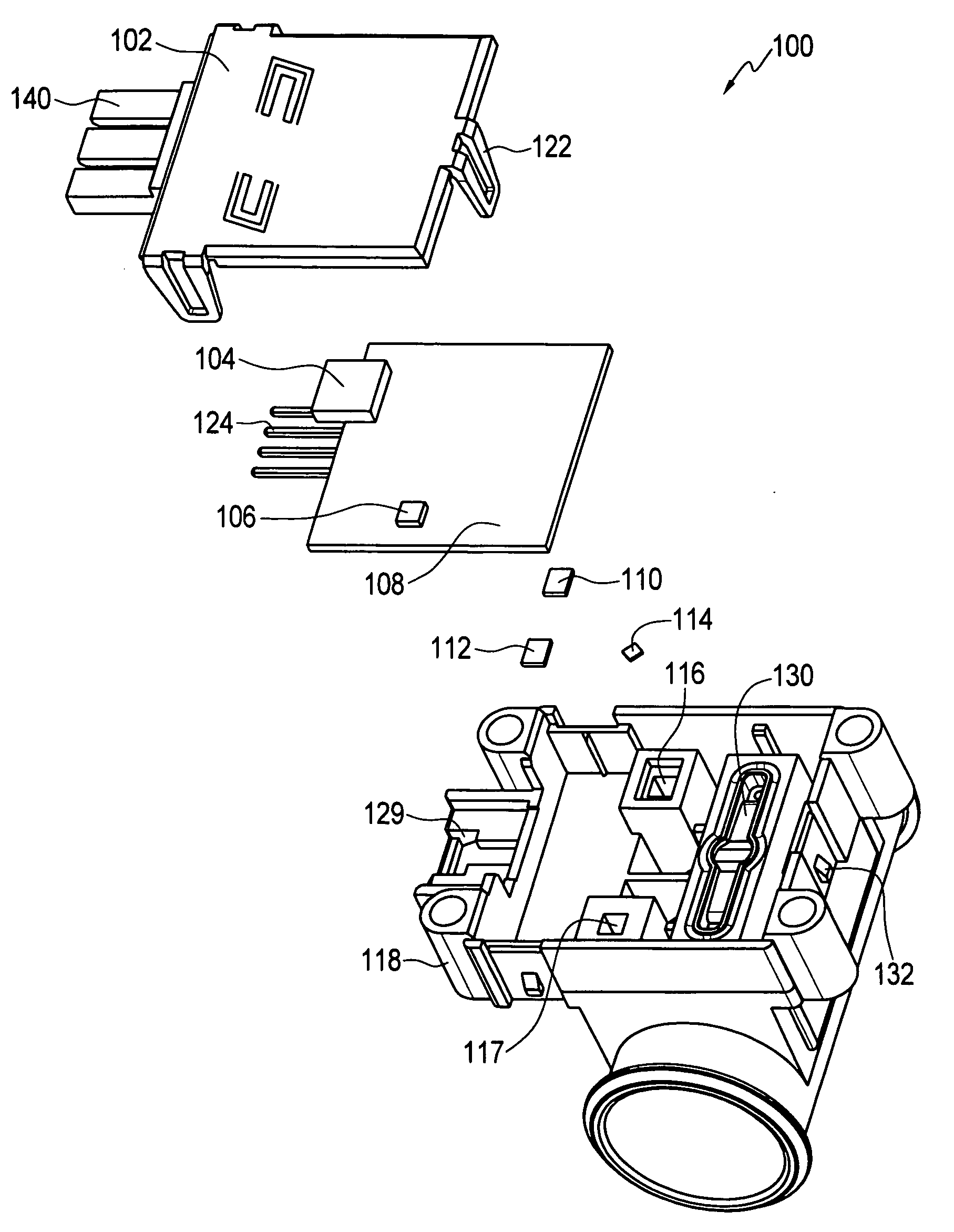

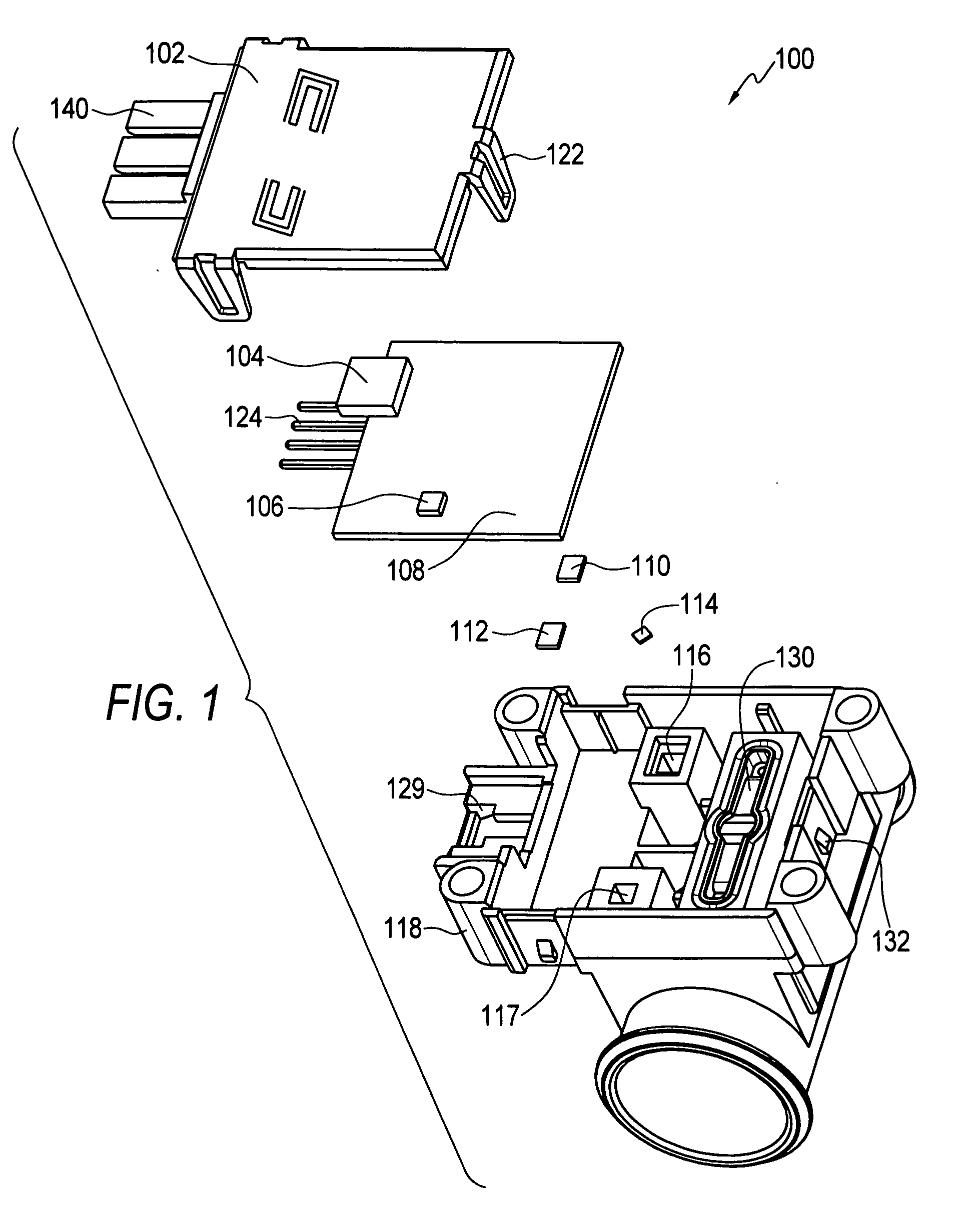

Semiconductor light emitting device mounting substrates including a conductive lead extending therein and methods of packaging same

ActiveUS20060157726A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringPacking method

A mounting substrate for a semiconductor light emitting device includes a thermally conductive mounting block. The mounting block has, in a first face thereof, a cavity that is configured to mount a semiconductor light emitting device therein and to reflect light that is emitted by the semiconductor light emitting device that is mounted therein away from the cavity. A conductive lead inserted into the mounting block extends into the cavity. The conductive lead is electrically isolated from the mounting block and has an exposed contact portion in the cavity. The conductive lead may be a plurality of conductive leads each having an exposed contact portion at different locations in the cavity. Related packaging methods also may be provided.

Owner:CREELED INC

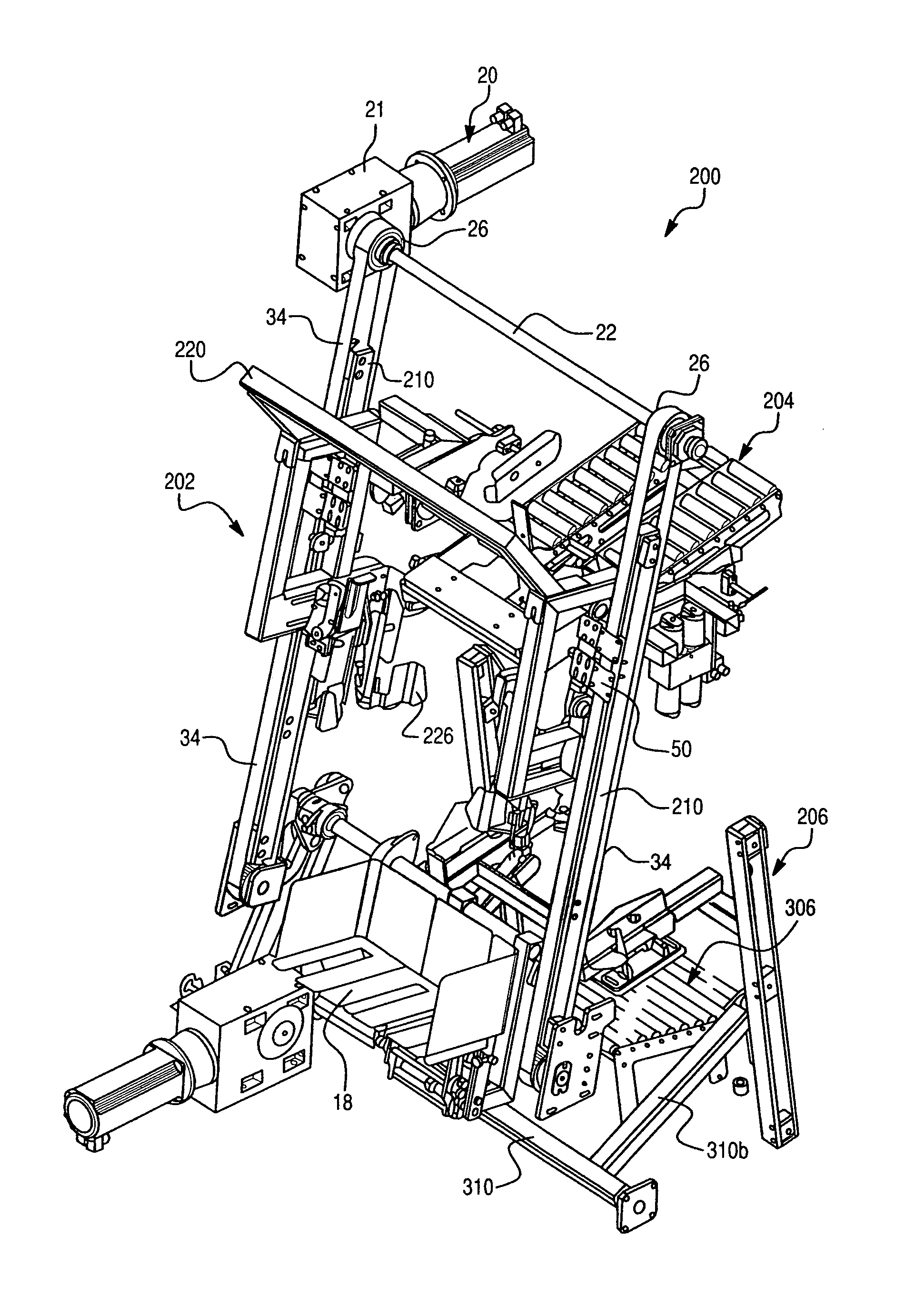

Apparatus for packing

A packing method and system are disclosed which system includes a first platform having a product support surface for supporting a product and a second platform for supporting a box into which the product is to be packed. After a box is received on and secured to the second platform, the second platform is rotated so that the open top of the box faces the first platform and moved toward the first platform until the box substantially surrounds the product on the product support surface. The first and second platforms are then rotated simultaneously so that the product is transferred from the product support to the box, and the full box is discharged to a discharge conveyor.

Owner:F R DRAKE

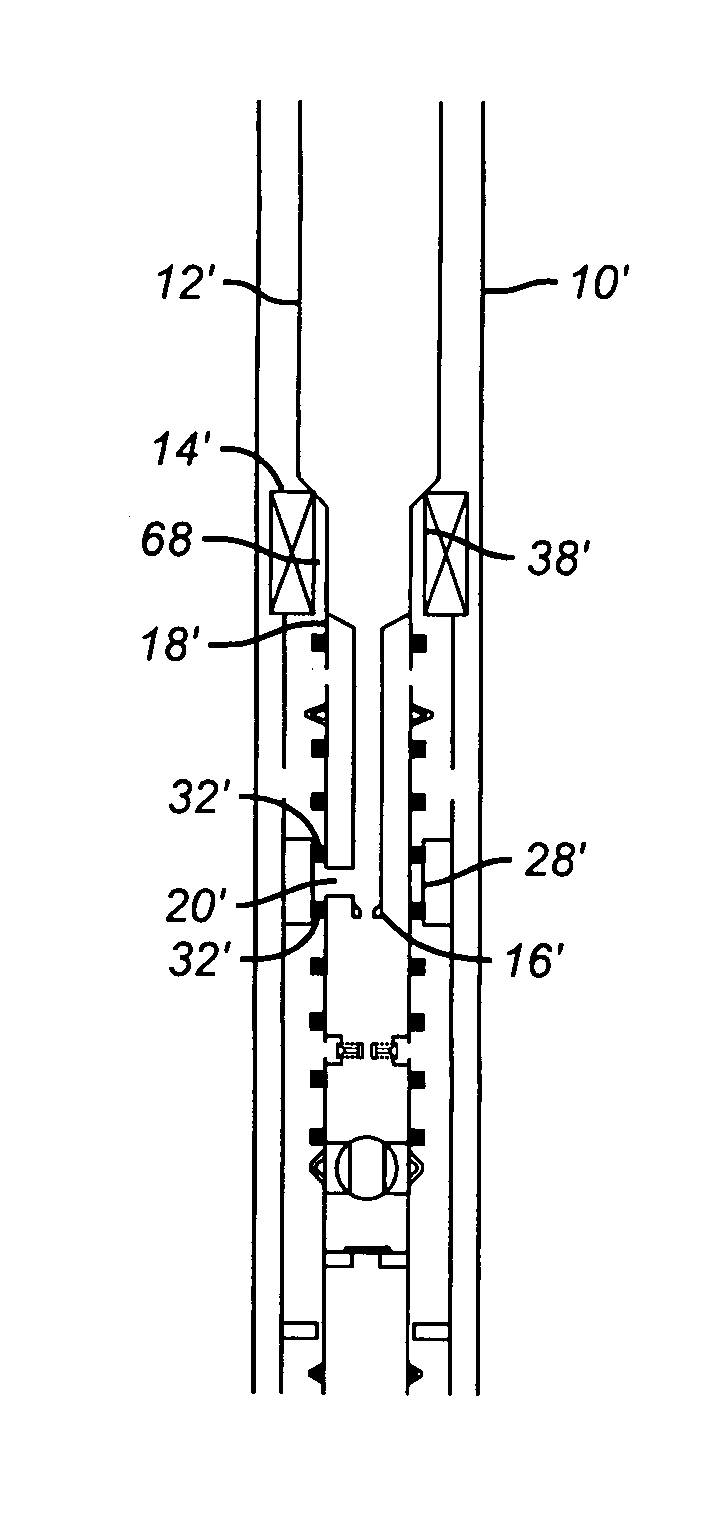

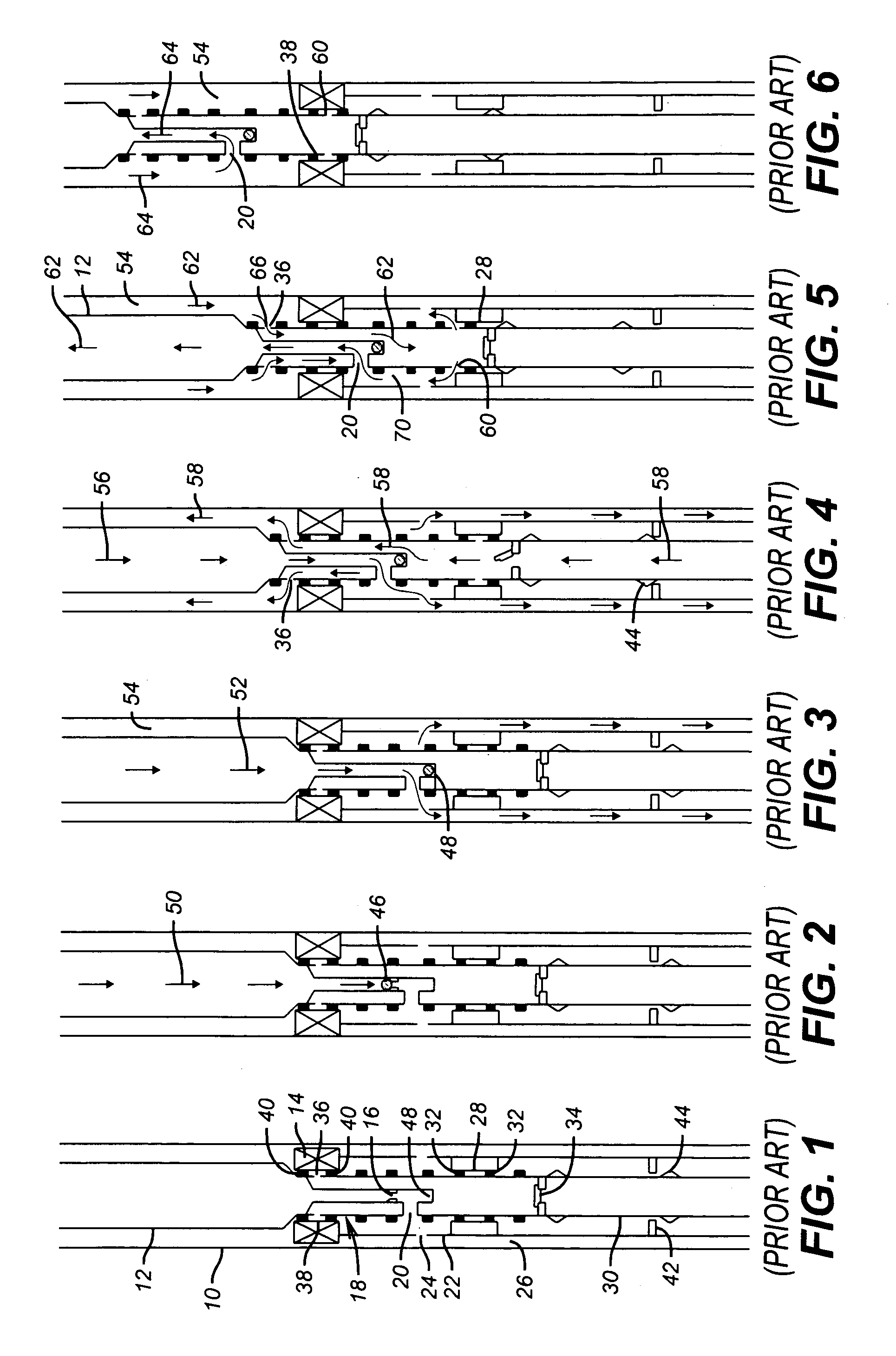

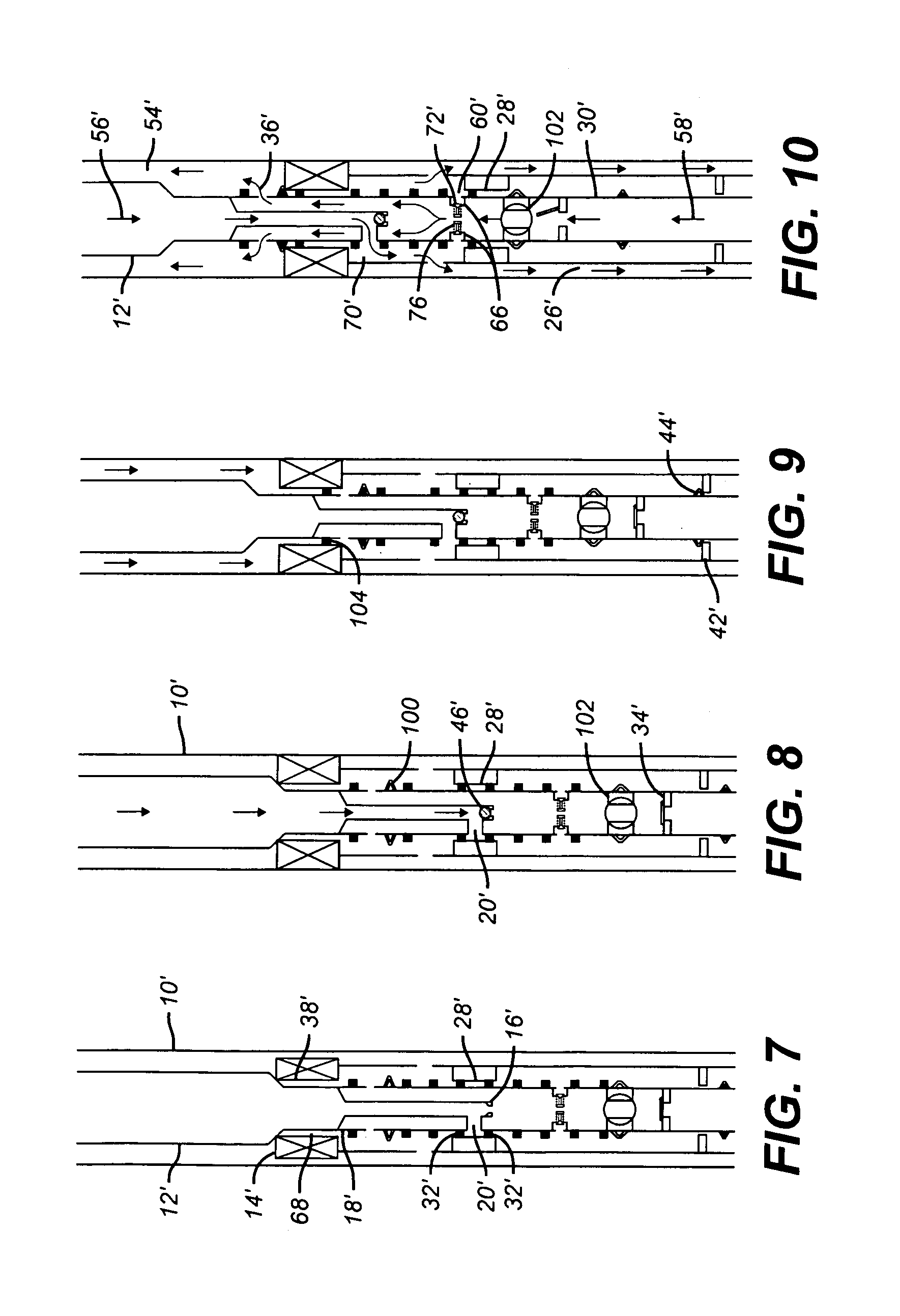

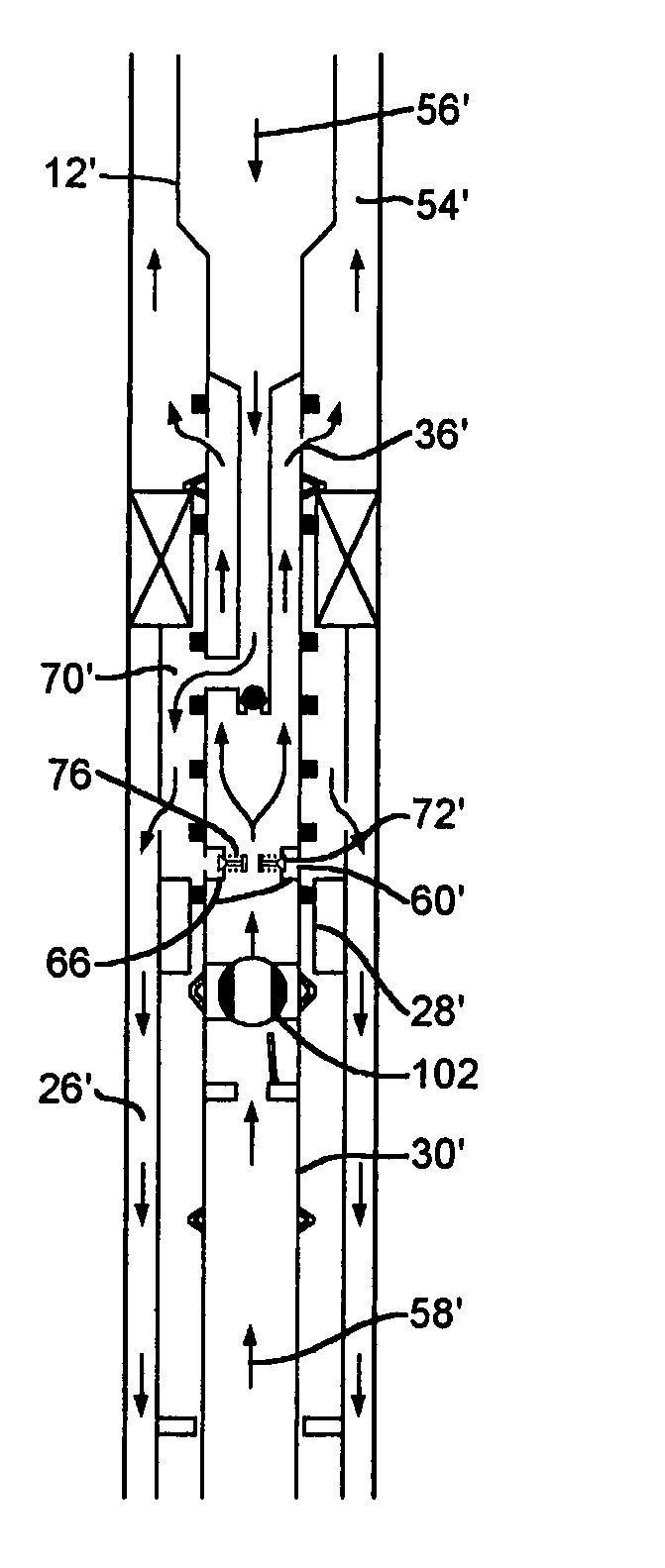

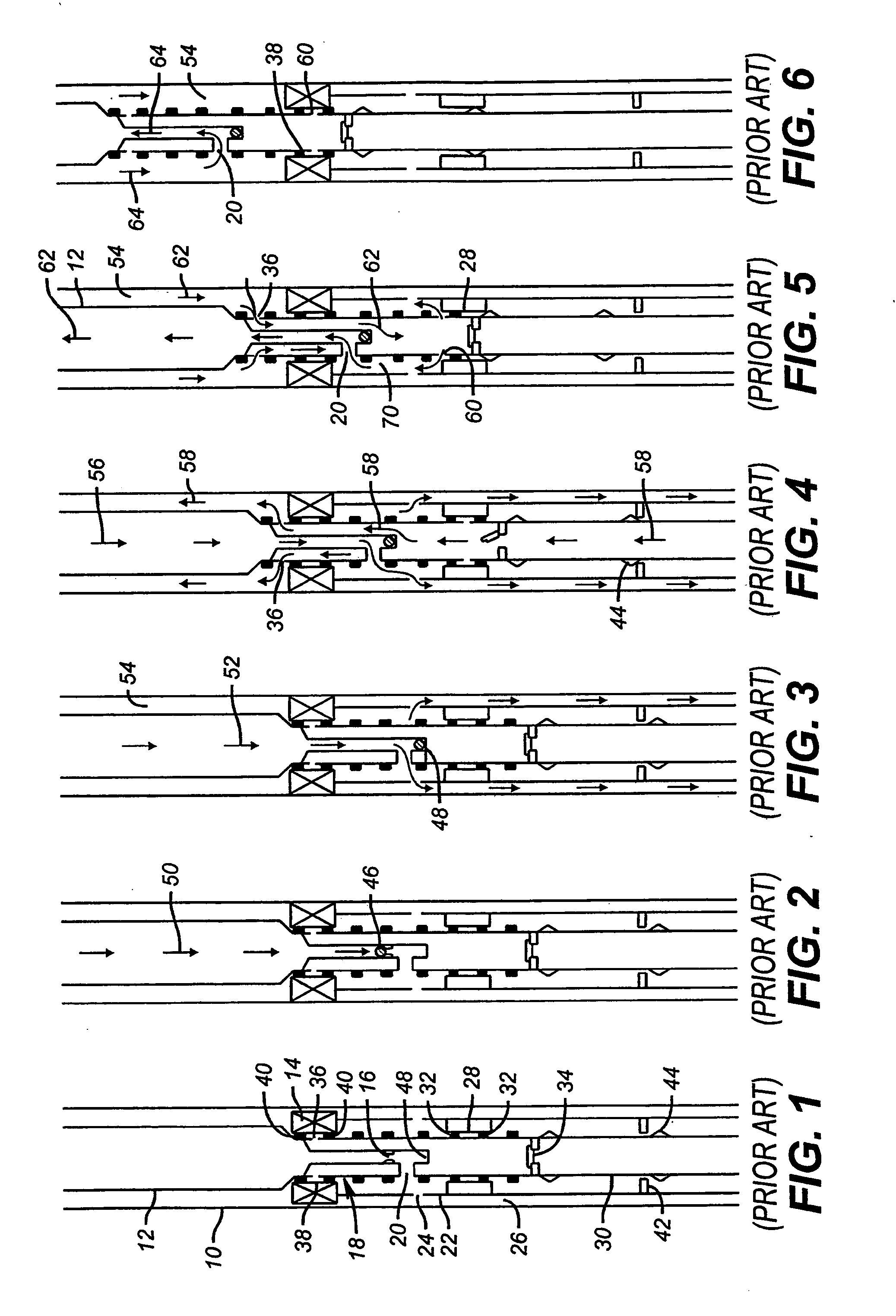

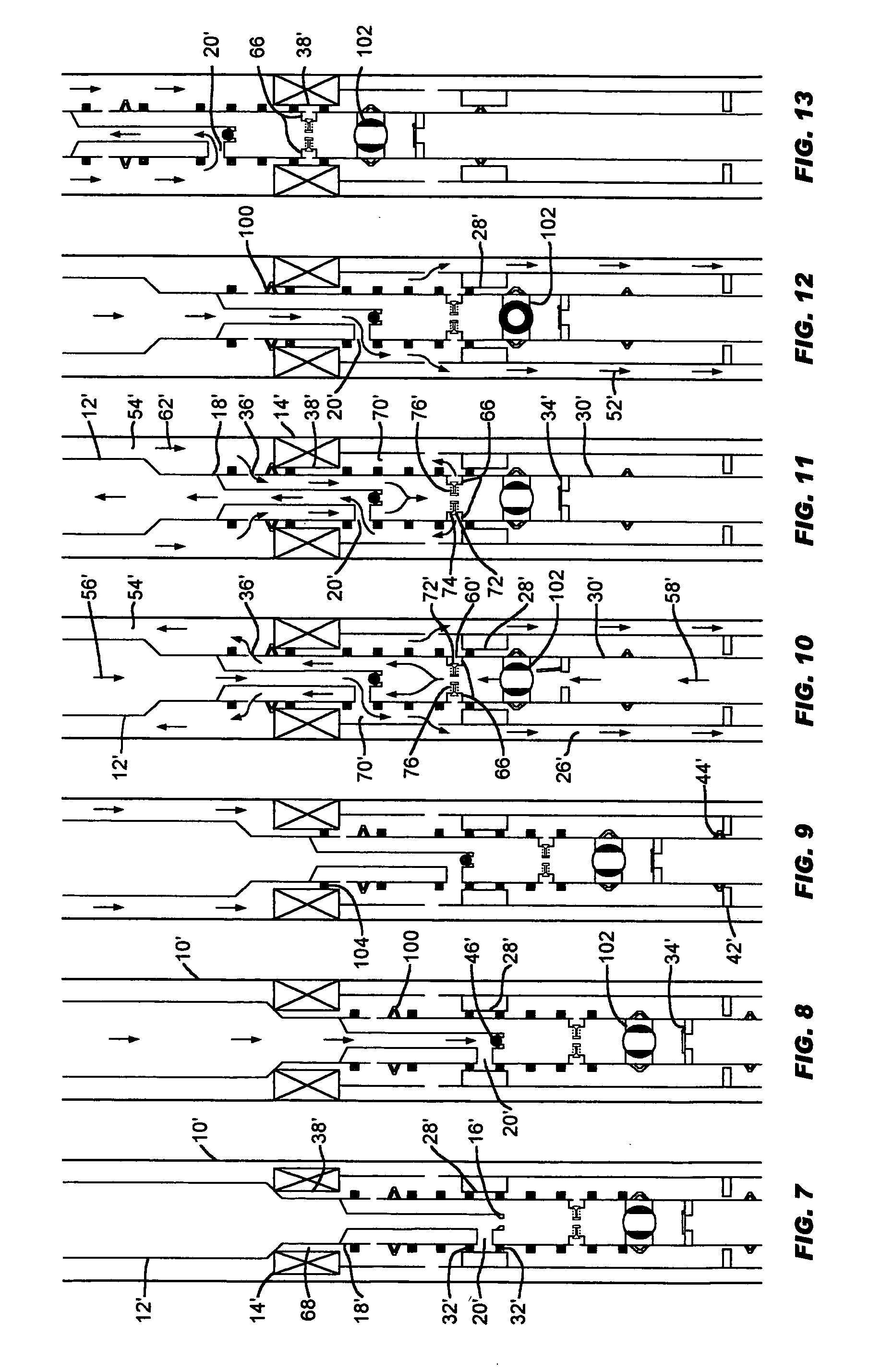

Gravel pack crossover tool with single position multi-function capability

A gravel packing method and apparatus are described where to set the packer; a ball is dropped to a seat that it isolated from the effects of formation pressures when trying to set the packer. This is accomplished by isolation of the gravel pack outlet port when setting the packer and locating the ball seat in a position where the effects of formation pressure are irrelevant. Additionally, by positioning the evacuation ports above a seal bore in the screen extension during circulation or squeeze to deposit gravel and further putting check valves in the evacuation ports, the evacuation step after circulation or squeeze can be accomplished without having to reposition the crossover. The crossover is supported from the packer and movement of the crossover away and back to the support from the packer operates a valve to allow squeezing when the valve is closed and circulating and reversing out when the valve is open. Thus, the gravel pack method and apparatus facilitates circulation, squeeze and reverse circulation in a single supported position.

Owner:BAKER HUGHES INC

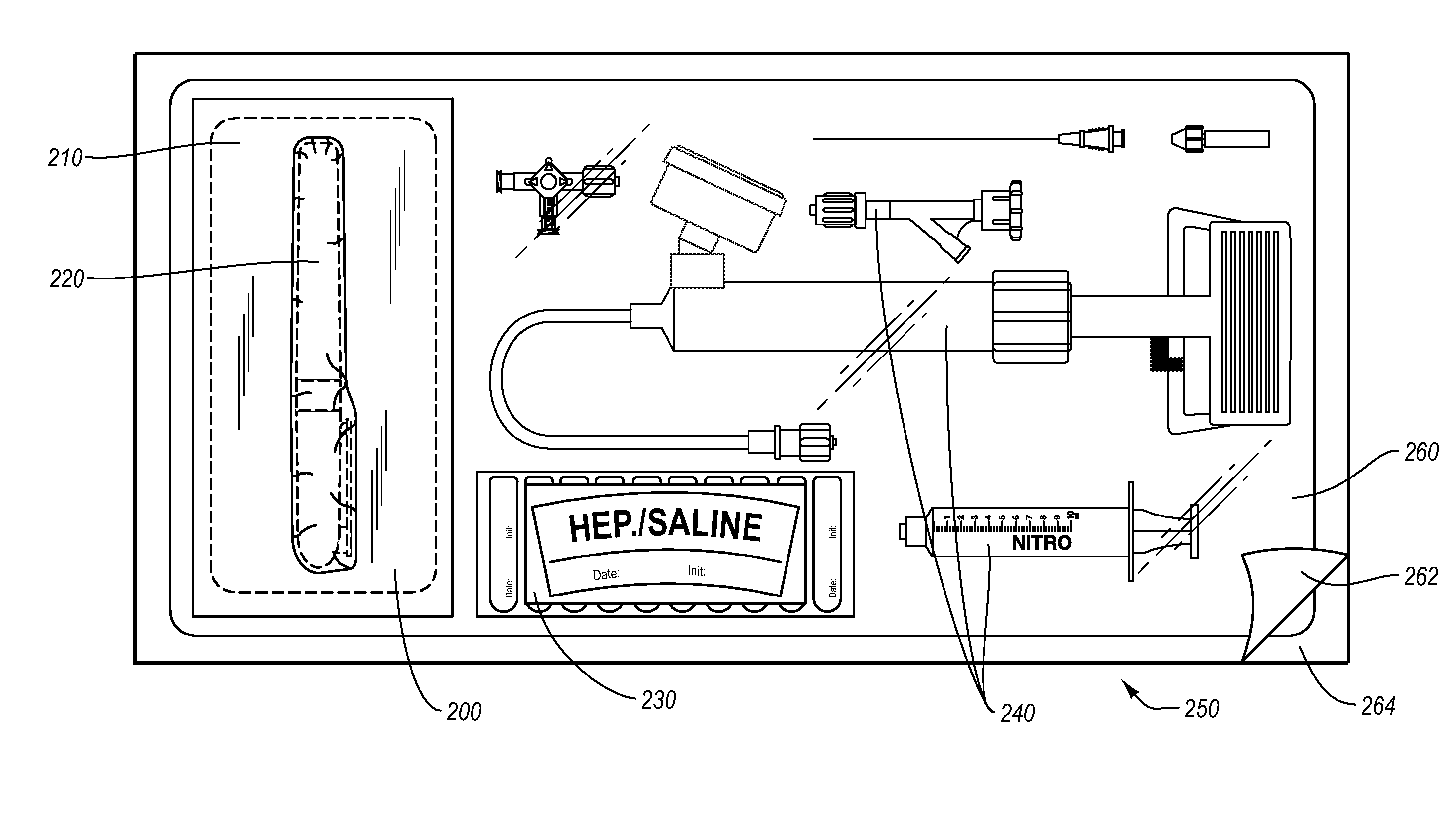

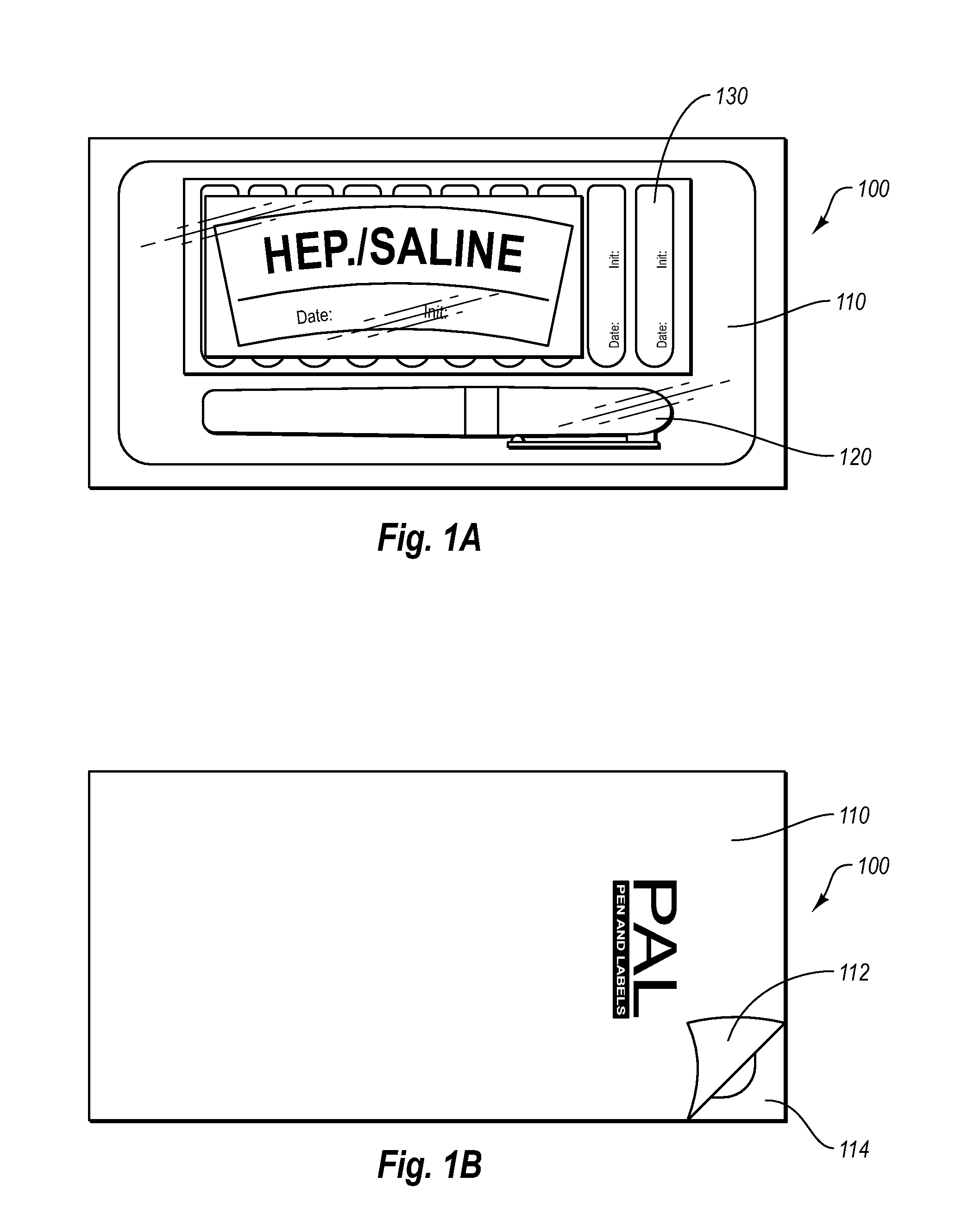

Packing and sterilizing a pen in a kit

InactiveUS20080116106A1Effective sterilizationEnsure sterilizationSurgical furnitureDiagnosticsPALBiomedical engineering

Sterile packaging of pens for use in a medical environment may include labels packaged along with a pen in a pen and label (PAL) kit. The present invention also relates to methods of packaging a pen and / or the PAL kit. In particular, the method of packaging includes the steps of placing a writing instrument into packaging configured to be sealed such that the writing instrument is contained in a sealed portion of the packaging, sealing the package, and sterilizing the writing instrument and the package using gamma sterilization such that all portions of the writing instrument are sterilized.

Owner:MERIT MEDICAL SYST INC

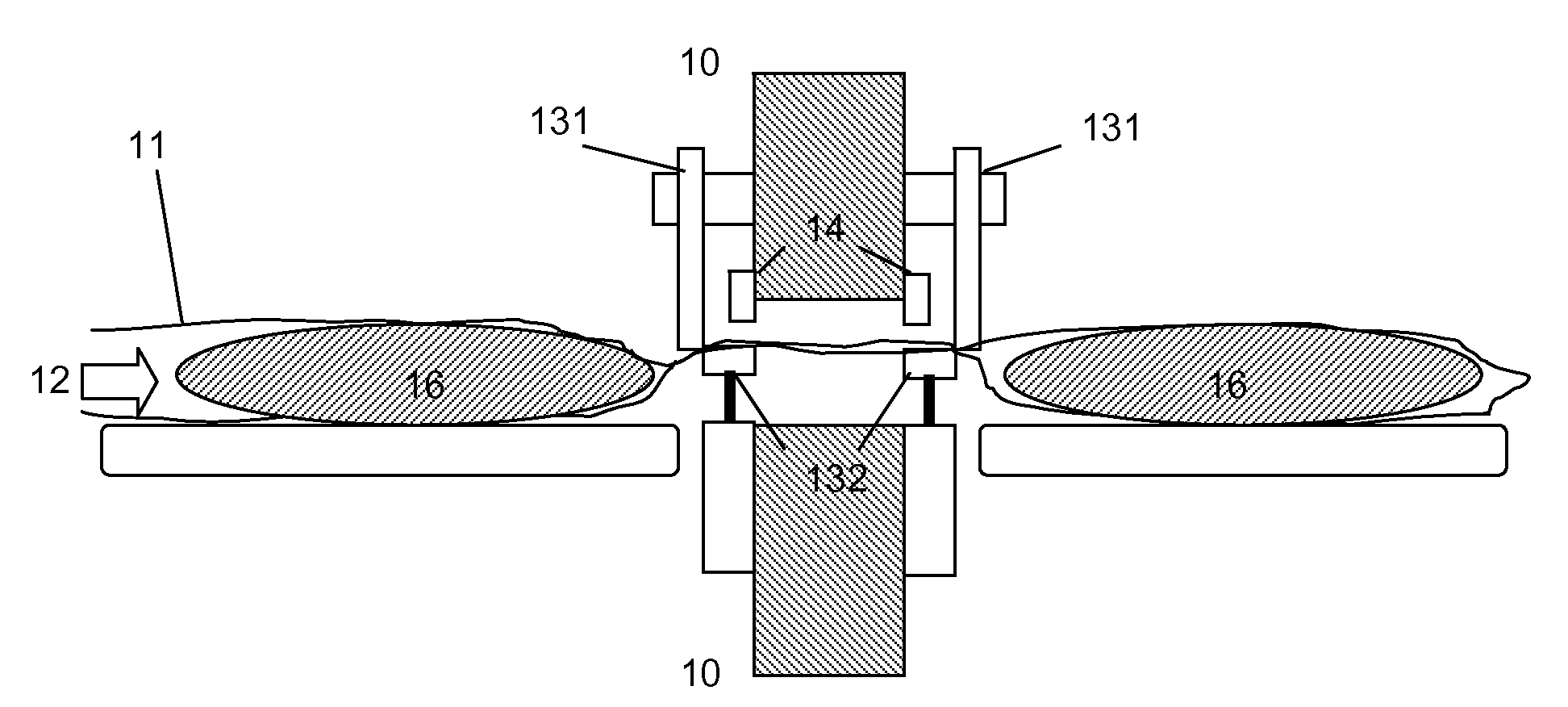

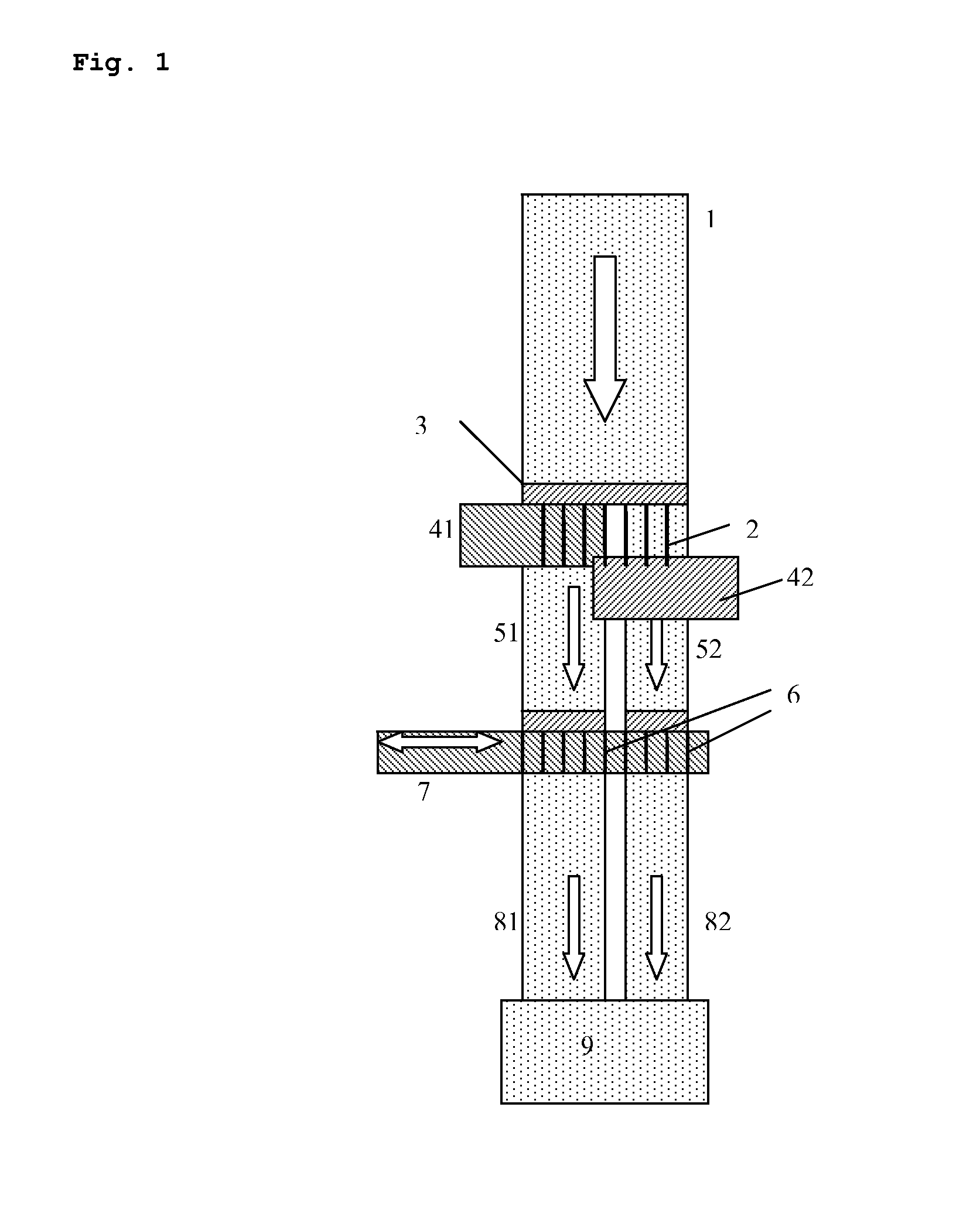

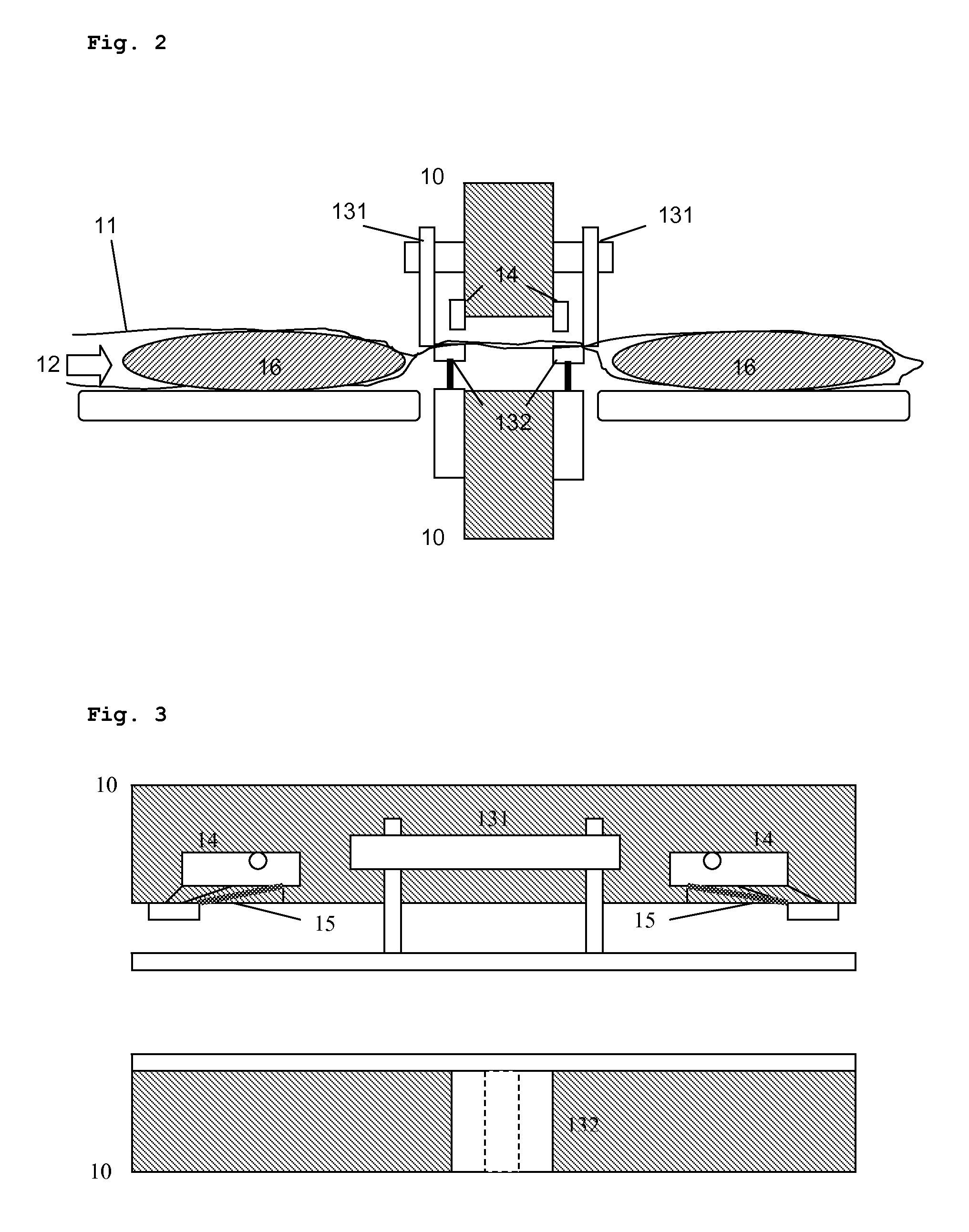

Packaging methods and systems for measuring multiple measurands including bi-directional flow

ActiveUS20080163683A1Quantity minimizationPrinted circuit assemblingLine/current collector detailsEngineeringPacking method

A packing method and system for measuring multiple measurands including bi-directional flow comprises of sampling ports arranged within a flow tube in a symmetrical pattern. The ports are arranged symmetrically with respect to the X and Y centerlines of the flow tube. In addition, the ports are also arranged symmetrical to the restrictor to minimize the amount of turbulent flow within the flow tube.

Owner:HONEYWELL INT INC

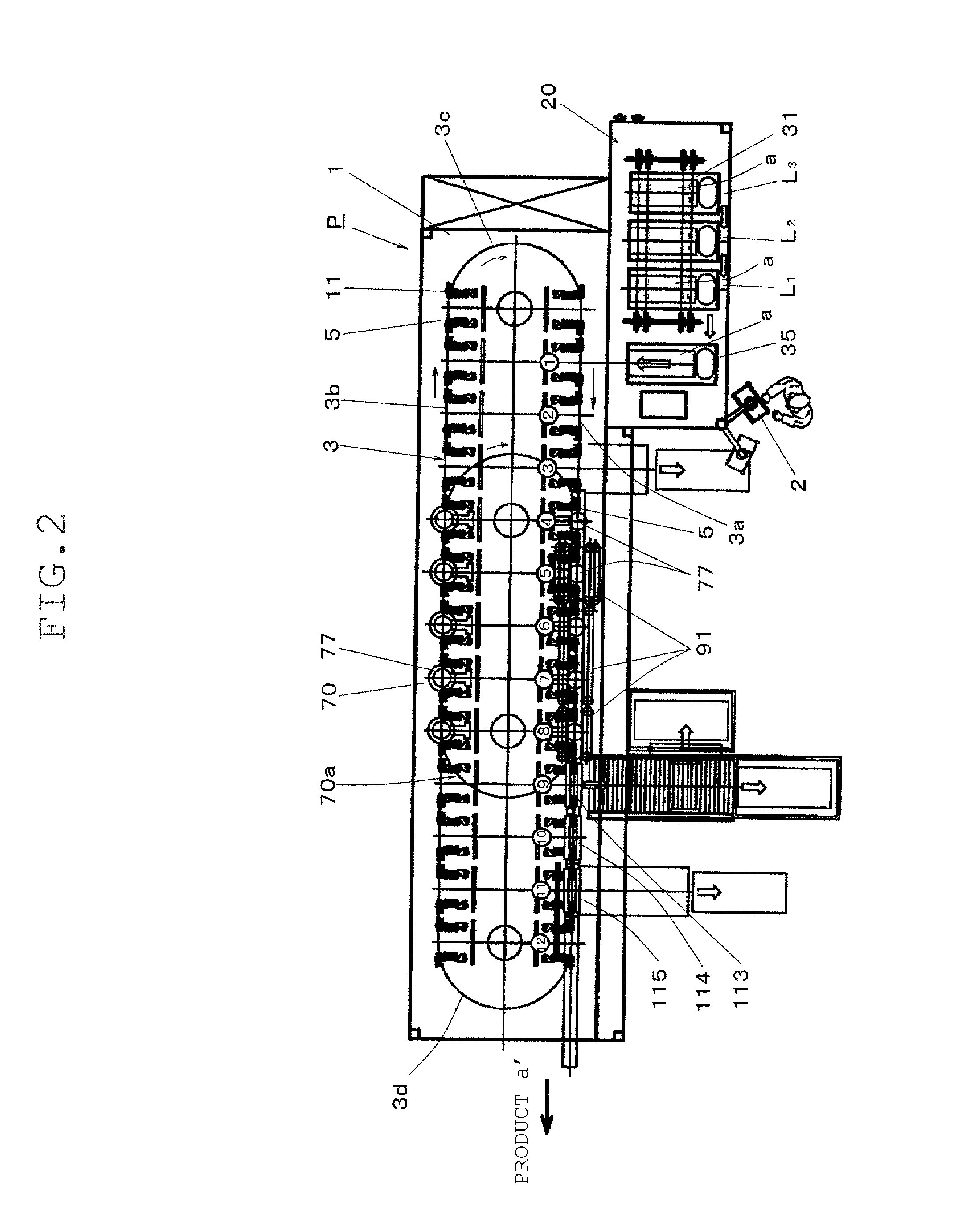

Gas seal-in method for a bag with a gas filling compartment and packaging method for a bag with a gas filling compartment

ActiveUS20070089377A1Automate processingEasy to operateCapsBag making operationsEngineeringPacking method

A method for sealing-in a gas in a gas filling compartment 5 of a bag having a cut-in 6 formed near the upper edge of the gas filling compartment. In the method, two edges of the bag with the contents inserted therein are gripped by grippers and suspended, the blow-in port of a gas (air) blow-in nozzle is brought to contact the cut-in, the back surface side of the bag is supported by a backing member, gas (air) is blown into the gas filling compartment, and the position below the cut-in is held from both sides of the bag by a gas cut-off grippers while the gas blow-in continues, so that the gas inside the gas filling compartment is not allowed to escape from the cut-in, and then the entire bag mouth, including the cut-in, is sealed.

Owner:TOYO JIDOKI CO LTD

Myoglobin blooming agent, films, packages and methods for packaging

InactiveUS20060286323A1Maintain and promote desirable colorationGood colorEnvelopes/bags making machinerySynthetic resin layered productsThermoplasticFood contact

Non-shrink, forming and nonforming thermoplastic webs comprising a myoglobin blooming agent on a food contact surface are useful for packaging fresh meat and other products to fix a desirable color on the surface of the product.

Owner:CURWOOD INC

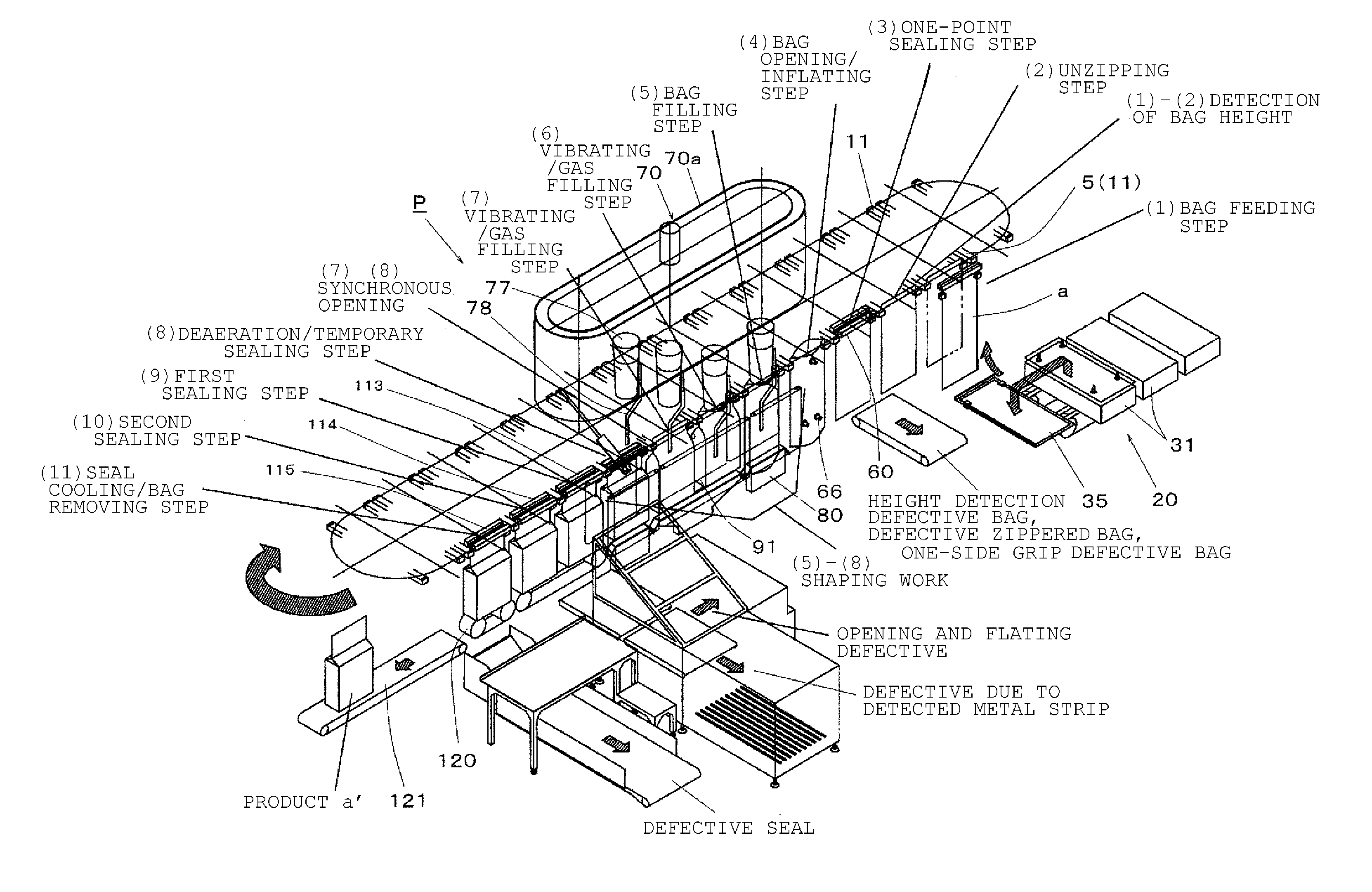

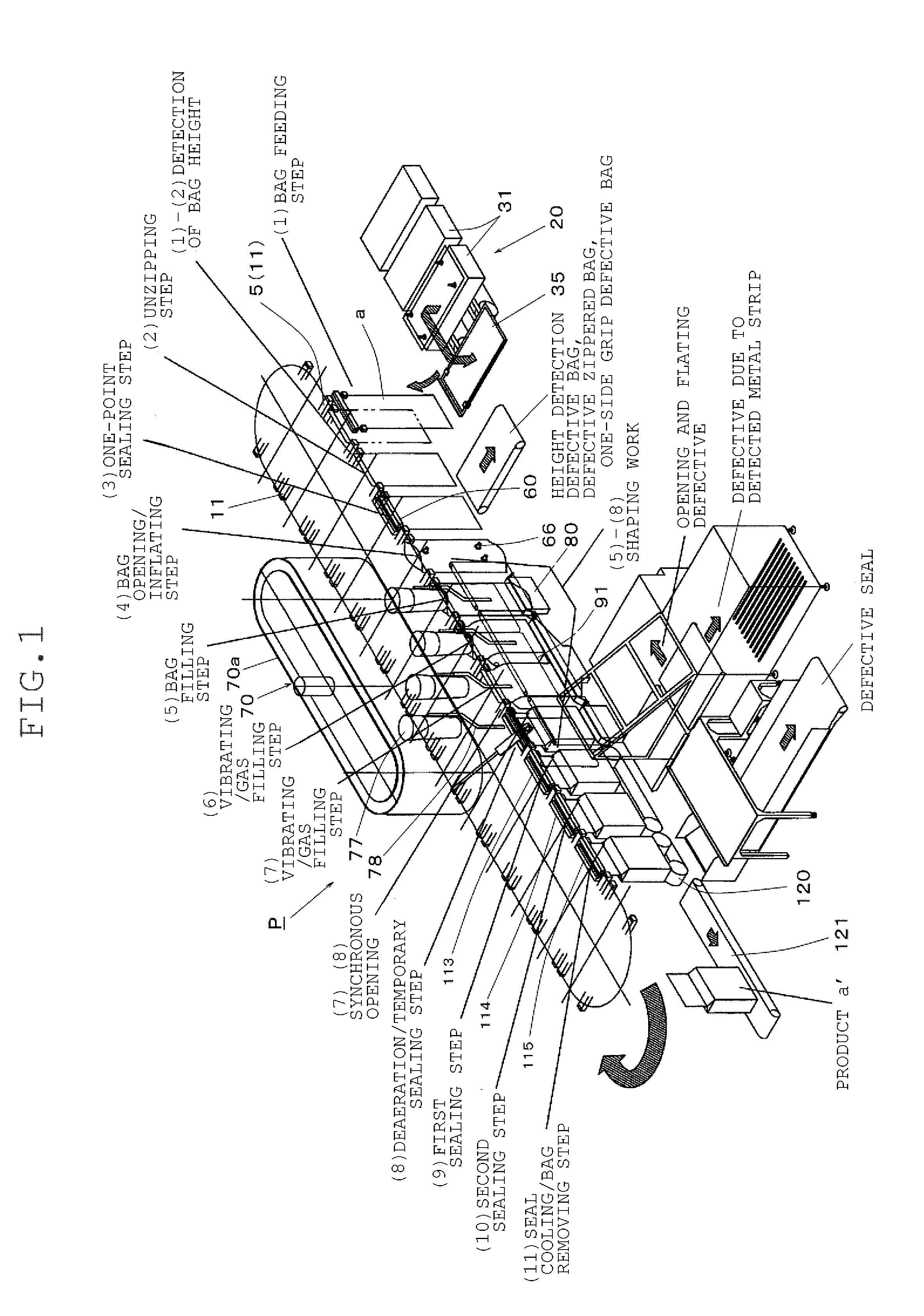

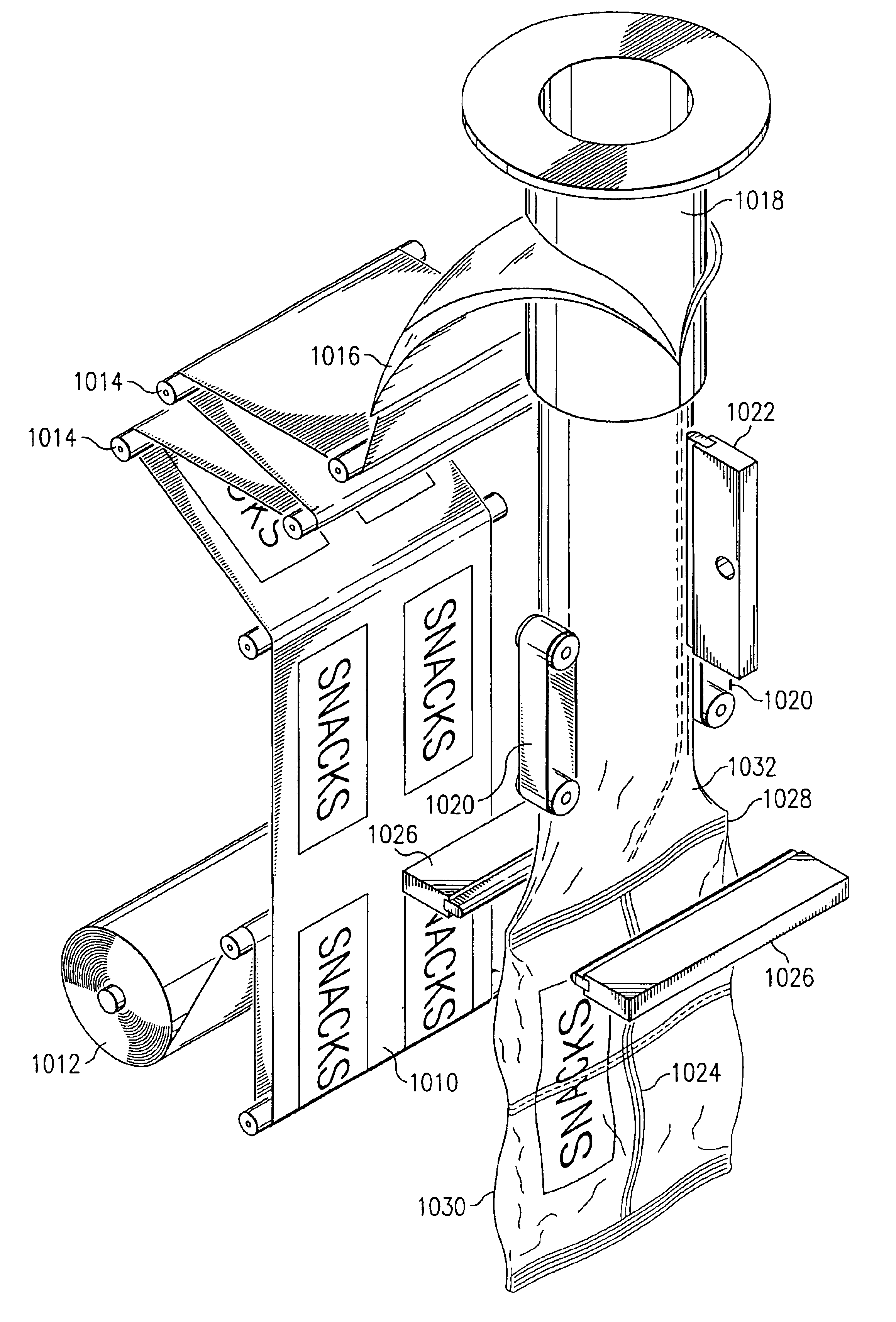

Gas-Filliing Packaging Method and Packaging Machine Therefor

InactiveUS20140331603A1Good quality and stabilityPackaging by pressurising/gasifyingWrapper twisting/gatheringPacking methodPackaging machine

A gas-filling packaging method using a track type gas-filling packaging machine includes a bag placing step in which a number of packaging bags set in a magazine in a stacked state are turned up one by one by a sucker and picking up and then passing the bag to a bag chuck, a bag opening / inflating step of opening the bag mouth and inflating the bottom of the bag by suckers, a bag filling step of lowering a synchronous funnel to be inserted into the bag and applying a receiving member of a bottom tapping unit to the bag, so that the bag is filled with a predetermined amount of article while the bottom is tapped, a deaeration / temporarily sealing step of inserting a deaeration nozzle into the bag to remove air in the bag and holding the bag mouth by a temporary heater.

Owner:GENERAL PACKER

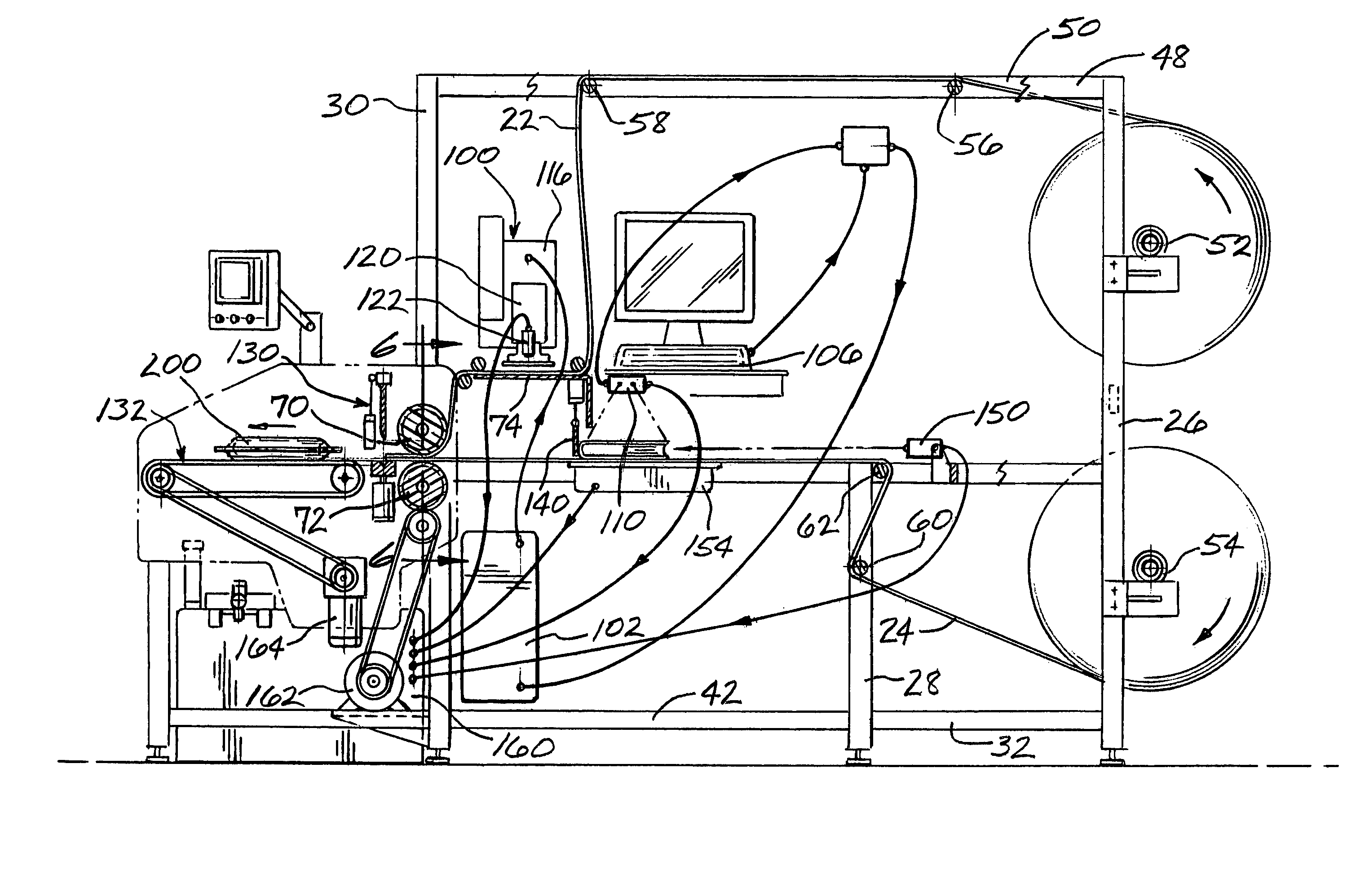

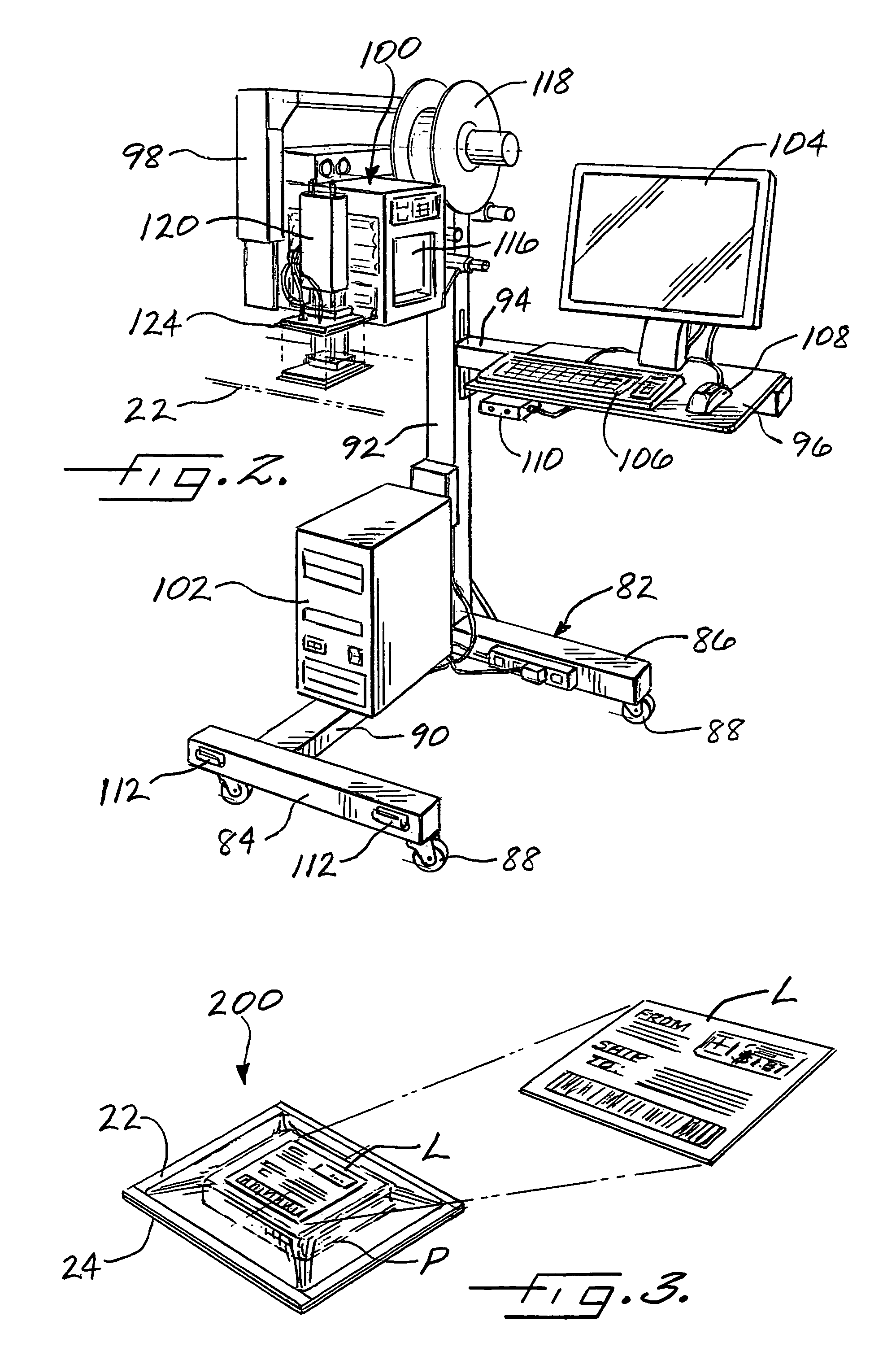

Packaging machine and method

ActiveUS7386968B2Facilitates automatic detectionPackaging cigarettePackaging cigarsProduct baseProcess engineering

A packaging method and apparatus wherein each product is packaged by enveloping the product in flexible packaging material. A programmed microprocessor calculates the length of flexible packaging material needed to package the product based on the physical dimensions of the product, calculates the weight of the flexible packaging material needed, and calculates a total package weight as the sum of the weight of the product and the calculated weight of the flexible packaging material. A printer prints information specific to the product that is being packaged onto a label that is then affixed to the flexible packaging material prior to the product being packaged. The information can be a function of the package weight, and the calculated total package weight can be communicated from the microprocessor to the printer. Finally, the product is packaged in the flexible packaging material having the label already affixed thereto.

Owner:SEALED AIR U S

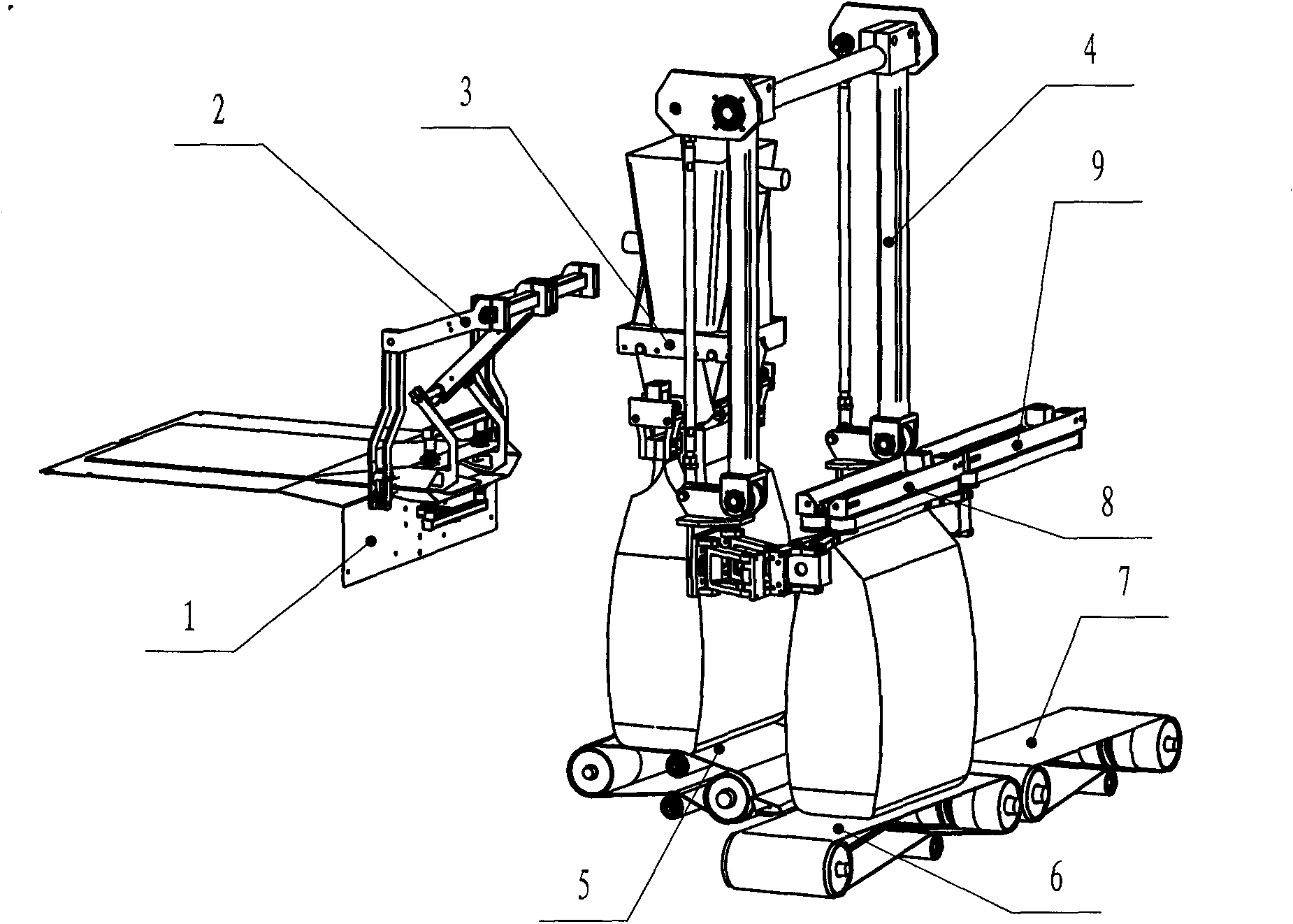

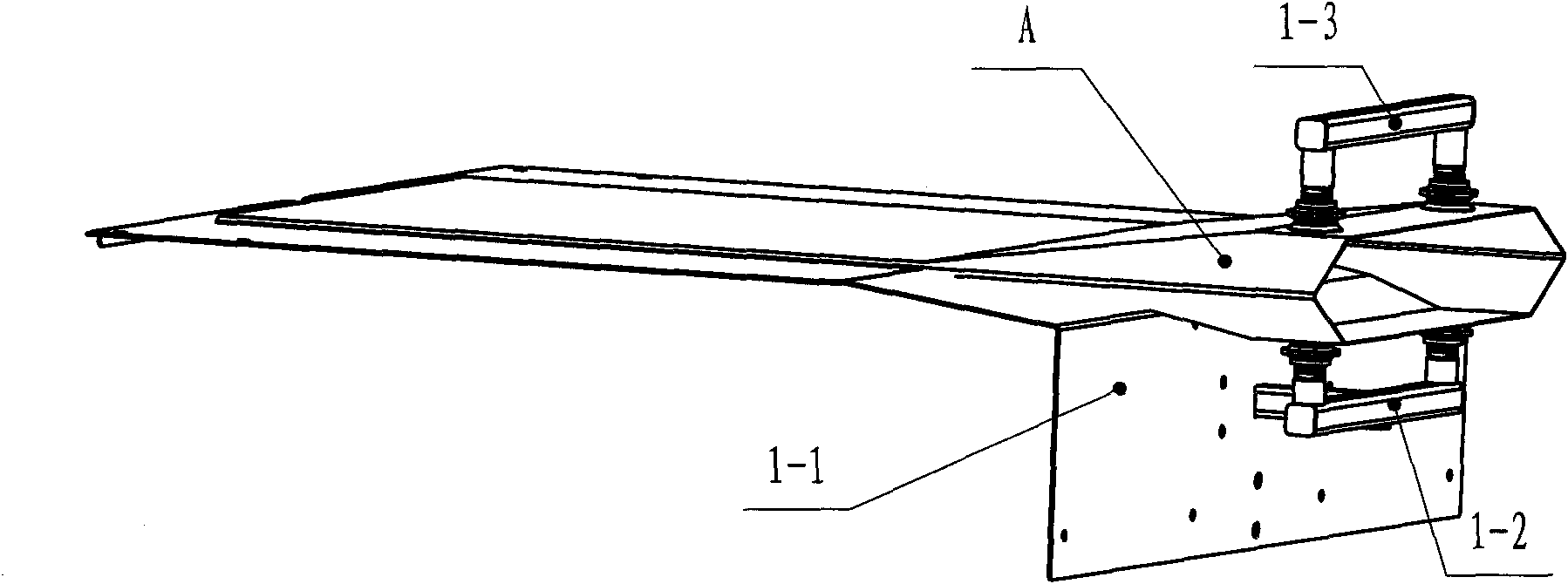

Material packaging method and device for laterally transferring full material bags

ActiveCN102275654AAvoid sliding frictionShorten the transfer distanceSolid materialFilling materialsEngineering

The invention discloses a material packing method for transversely conveying full bags, and aims to solve the problems that a full bag conveying distance is long and sliding friction exists at the bottoms of the full bags in the conventional packing method for longitudinally conveying the full bags. The packing method comprises the following steps of: (1) opening bag mouths; (2) taking empty bags; (3) sleeving the empty bags; (4) clamping the empty bags; (5) propping up contracted bag mouths; (6) filling materials in the bags; (7) grasping the full bags; (8) transversely conveying the full bags; (9) clamping the full bags; (10) outputting the full bags; and (11) conveying the full bags. By the material packing method, the material packing speed can be improved to more than 1,600 bags per hour.

Owner:HARBIN BOSHI AUTOMATION

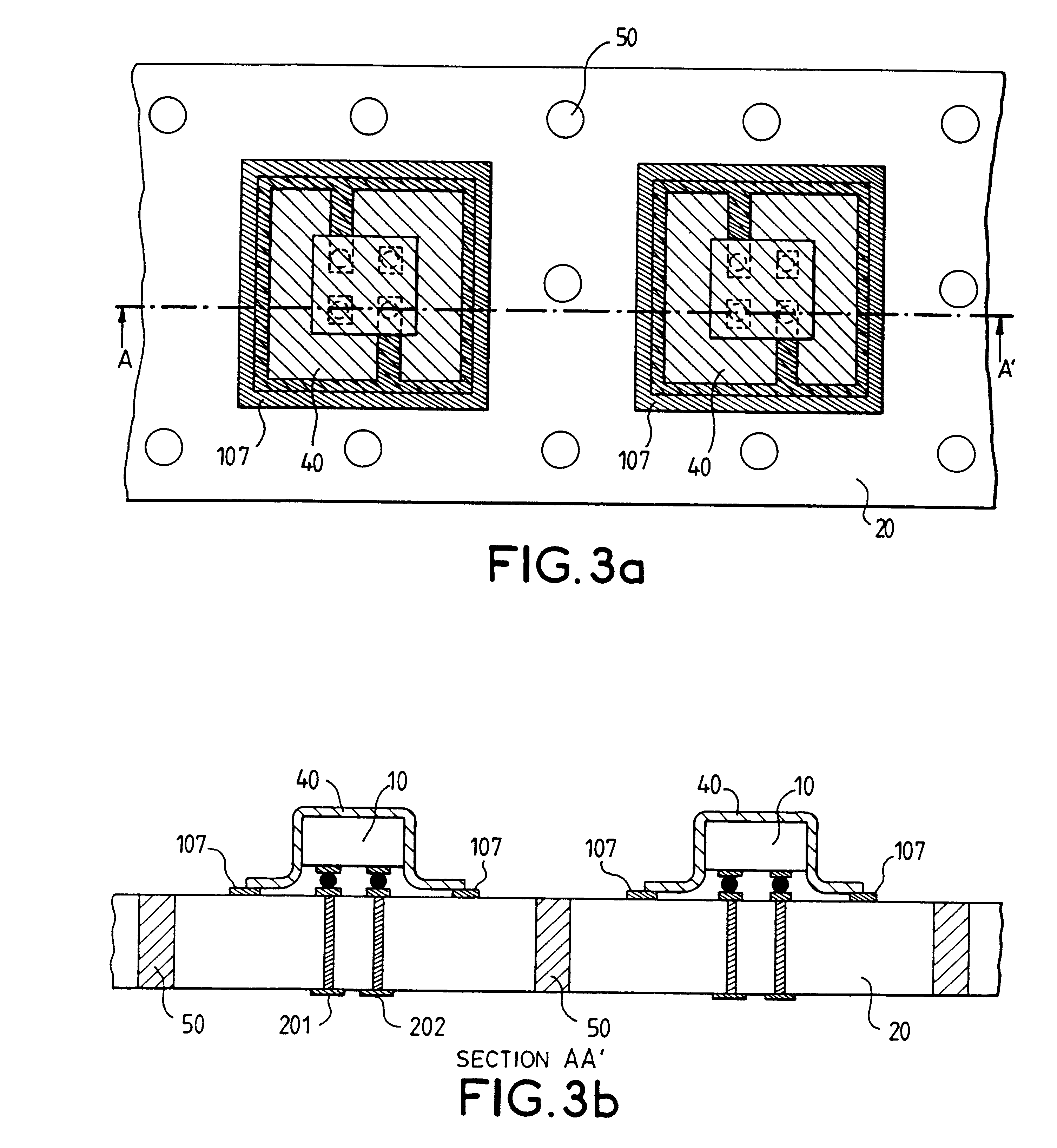

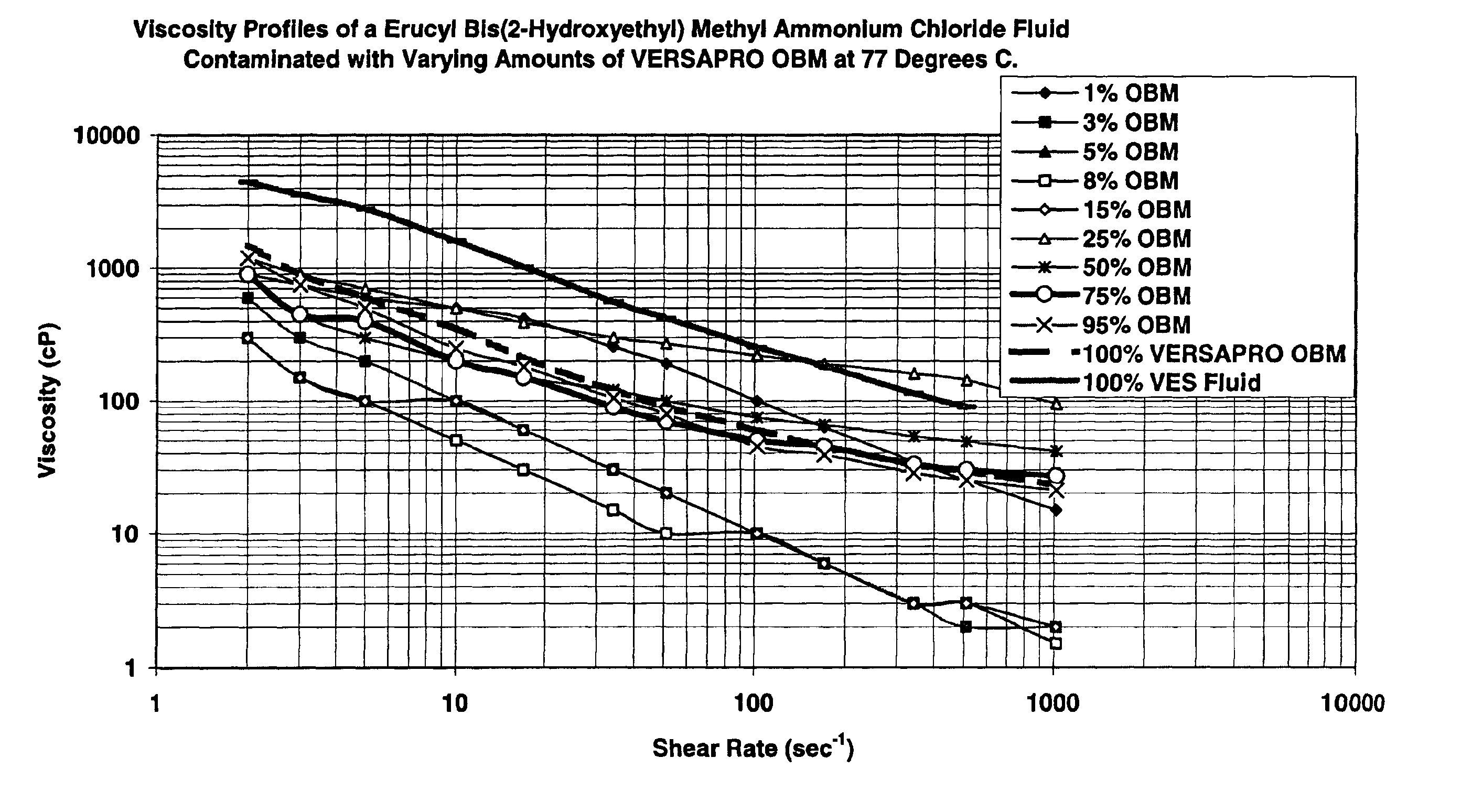

Orthoester compositions and methods for reducing the viscosified treatment fluids

InactiveUS20050045328A1Low viscosityReduced pHOrganic compound preparationFluid removalOrthoesterViscosity

In one embodiment, the present invention provides a method of reducing the viscosity of a viscosified treatment fluid comprising contacting the viscosified treatment fluid with an acid generated from an orthoester composition that comprises an orthoester. In another embodiment, the present invention provides a method of reducing the pH of a viscosified treatment fluid comprising providing an orthoester composition that comprises an orthoester; contacting the viscosified treatment fluid with the orthoester composition; allowing the orthoester to generate a generated acid; and allowing the generated acid to at least partially reduce the pH of the viscosified treatment fluid. Embodiments of fracturing and gravel packing methods also are disclosed.

Owner:HALLIBURTON ENERGY SERVICES INC

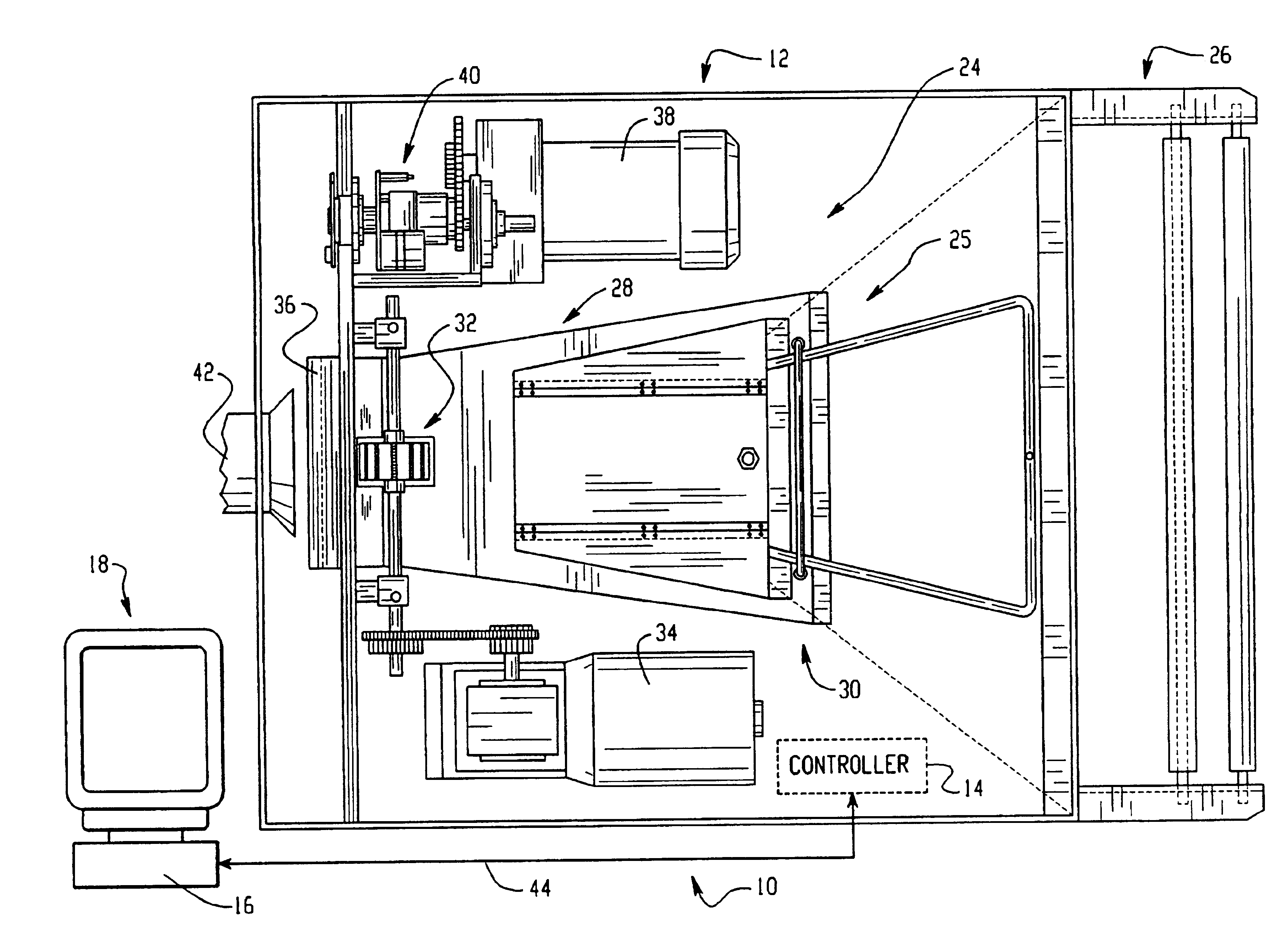

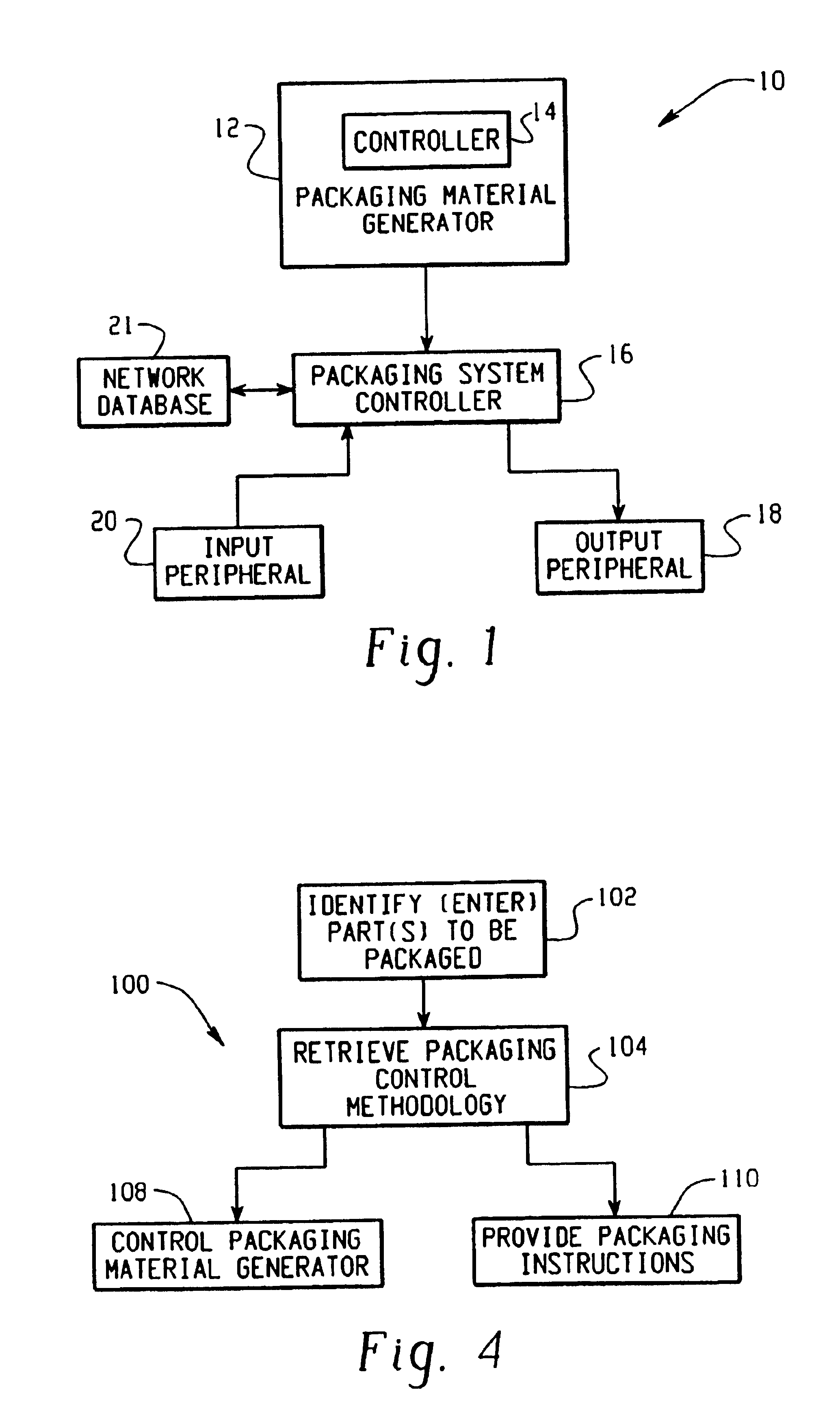

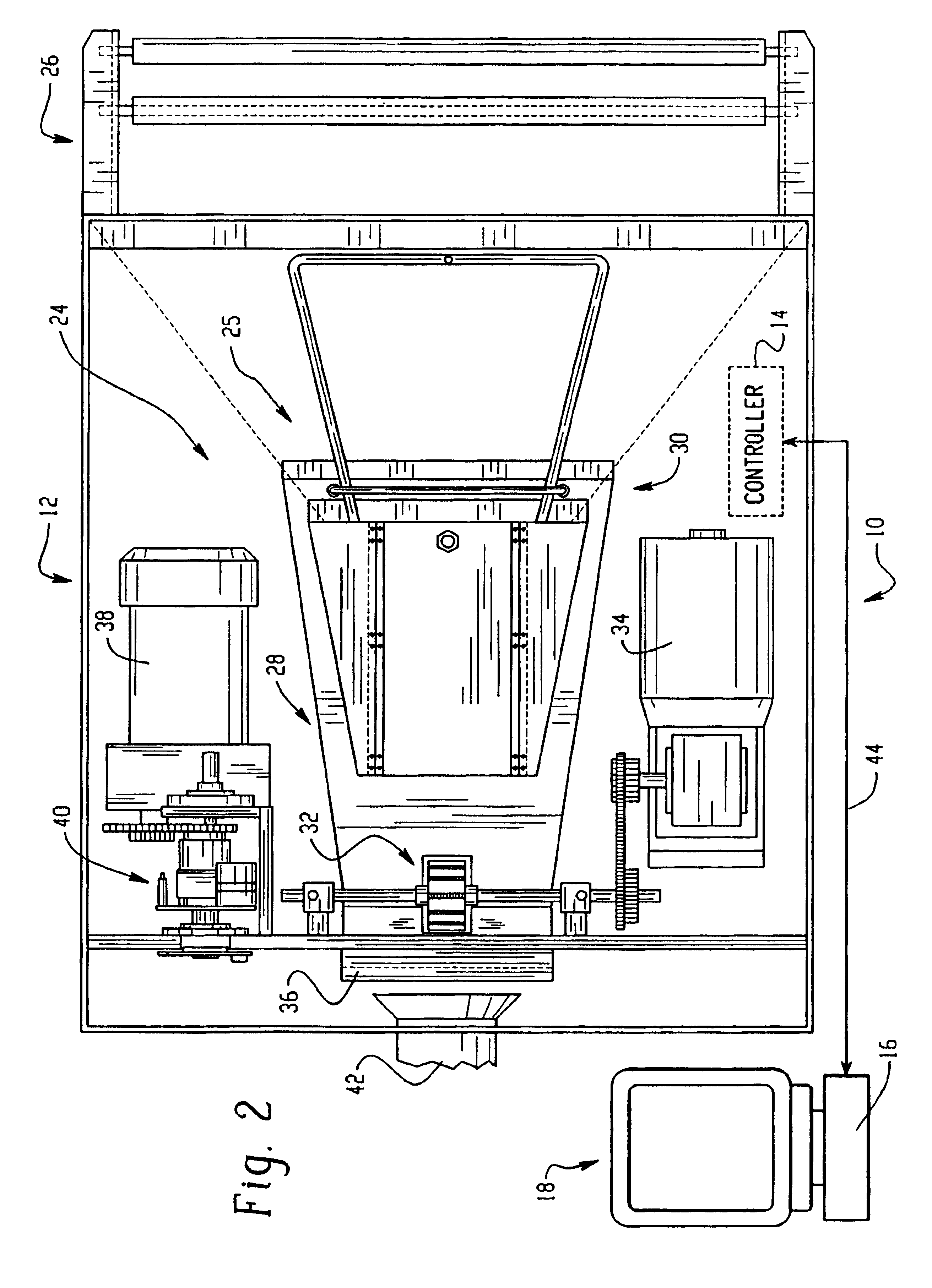

Cushioning conversion system and method

InactiveUS6877297B2Efficient and effective of partMaintained effectively and efficientlyPaper/cardboard articlesOral administration deviceCushioningDunnage

A packaging system includes a cushioning conversion machine for converting stock material into relatively low density cushioning material or dunnage and a packaging system controller. The packaging system controller provides packaging instructions related to a part or parts to be packaged and instructs the cushioning conversion machine to produce the cushioning material. In one aspect of the present invention the packaging system controller provides packaging instructions by retrieving a predetermined set of packaging instructions associated with a particular part. In another aspect of the present invention the packaging system controller provides packaging instructions by determining an optimized packaging methodology using one or more characteristics of the part or parts to be packaged. The packaging system also provides for automated inventory control and productivity monitoring.

Owner:RANPAK CORP

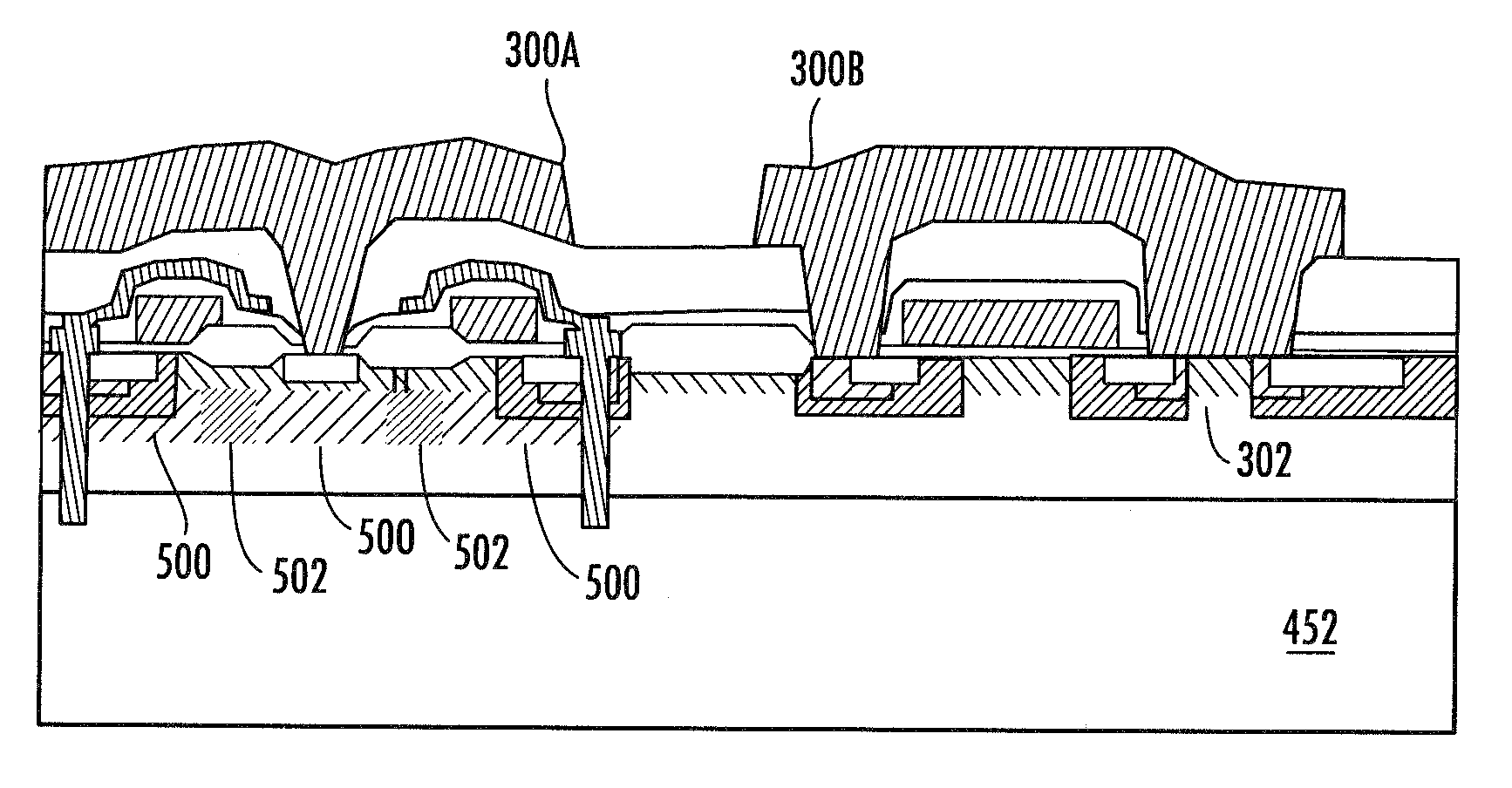

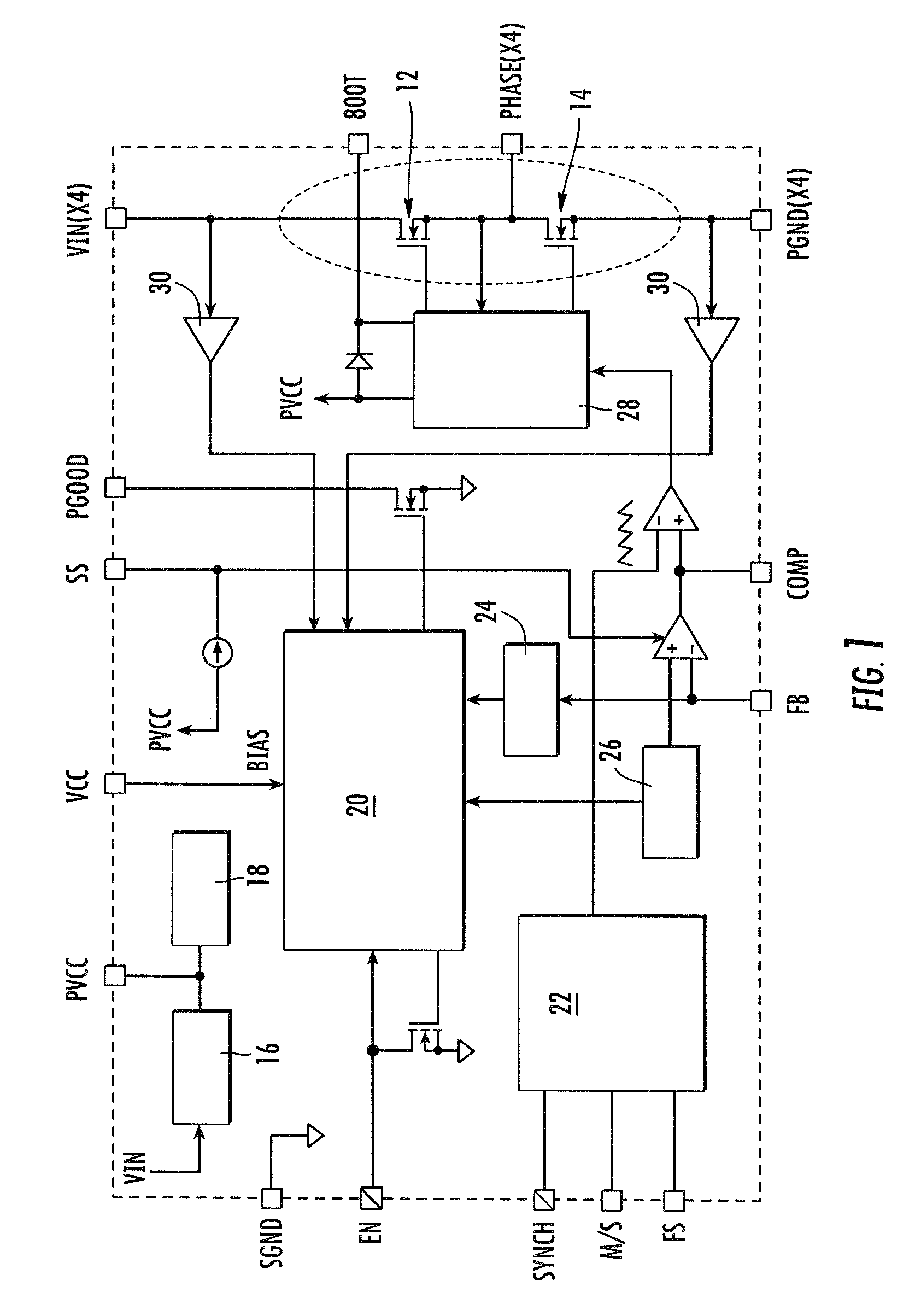

Co-packaging approach for power converters based on planar devices, structure and method

A voltage converter includes an output circuit having a high-side device and a low-side device which can be formed on a single die (a “PowerDie”). The high-side device can include a lateral diffused metal oxide semiconductor (LDMOS) while the low-side device can include a planar vertical diffused metal oxide semiconductor (VDMOS). The voltage converter can further include a controller circuit on a different die which can be electrically coupled to, and co-packaged with, the power die.

Owner:INTERSIL INC

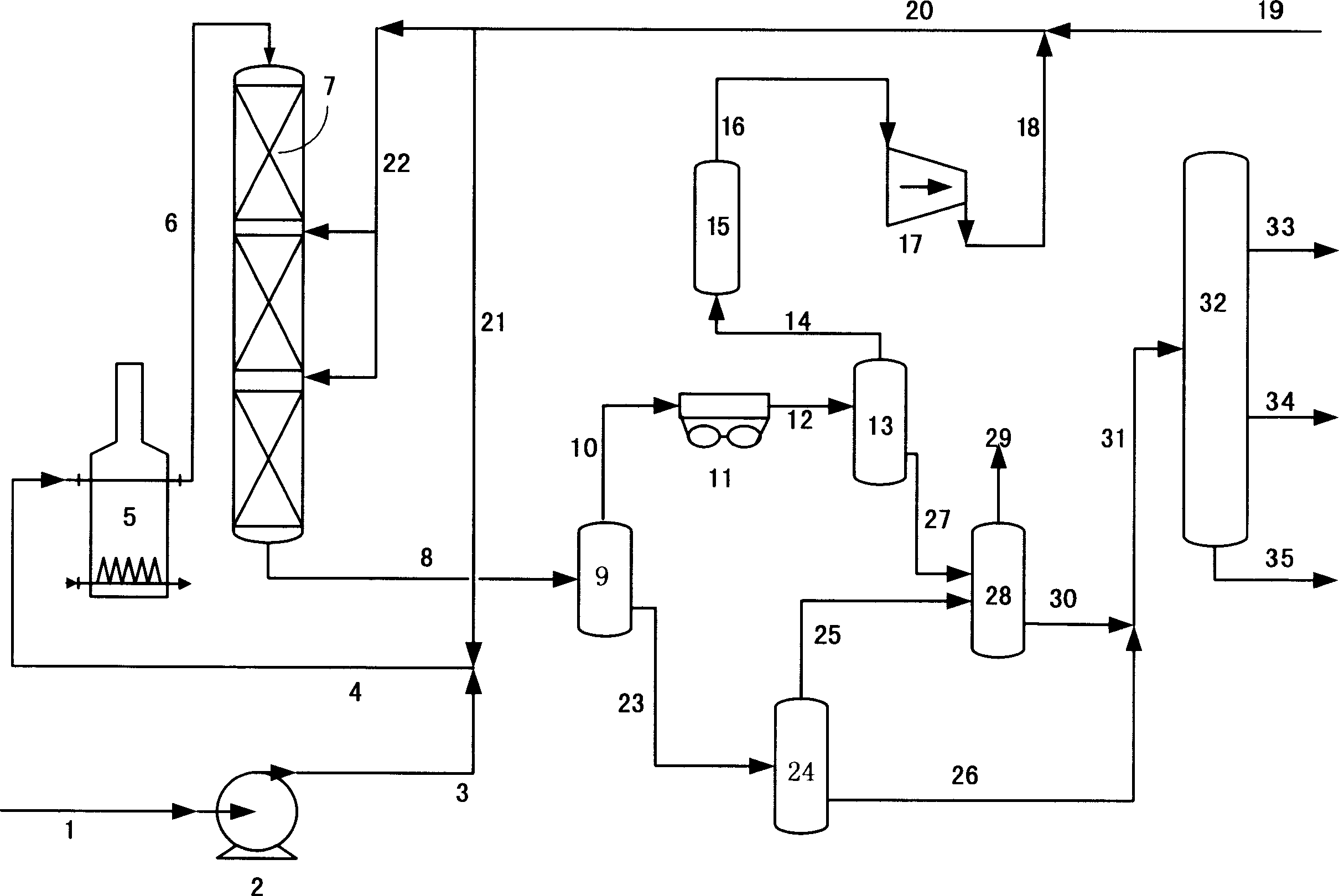

Hydrogenation method for producing good quality catalytic cracking material

ActiveCN101007964AReduced activityDelay pressure drop riseRefining to eliminate hetero atomsHydrogenNaphtha

The invention relates to a hydrogenation method for high- quality catalytic cracking material. It comprises: carrying out hydrogenation and modifying reaction for mixture of raw oil and hydrogen gas in hydrogenation preservative, any hydrogenation demetalation catalyst and hydrogenation treating catalyst in turn; and the filling volumetic percentage of mentioned preservative and catalyst are 2- 15%, 0- 30% and 55-95%, cooling reactant and separating and getting a large amount of refined gas oil fraction, part of low-sulphur diesel fraction and little amount of benzine naphtha fraction, and the refined gas oil fraction is the catalytic cracking material. The invention can prolong the operation cycle for device under high percentage of desulfurization, the activity of employed catalyst is high, and the rational packing method ensures better catalyst activity, and reduces production cost. The invention is characterized by simple process, low operation pressure, low device investment and operation cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for dosing and packaging polysilicon chunks and dosing and packaging unit

ActiveUS20120198793A1Low costAccurate doseWrapper twisting/gatheringSolid materialHard metalProcess engineering

Disclosed is a method for dosing and packaging polysilicon chunks, wherein a product flow of polysilicon chunks is transported via a feed channel, separated by at least one screen into coarse and fine chunks, weighed and dosed to a target weight by a dosing balance, discharged via a discharge channel and transported to a packaging unit where a first plastic bag is filled with the polysilicon chunks and sealed, the plastic bag containing polysilicon chunks being packaged with a further plastic bag which is formed by a shaper and subsequently welded, wherein the at least one screen and the dosing balance at least partially include a hard metal on their surfaces and the shaper for forming the plastic bag includes a wear-resistant coating. Also disclosed are a dosing unit, a packaging unit and a device for dosing and packaging polysilicon chunks, which contains a dosing unit and a packaging unit.

Owner:WACKER CHEM GMBH

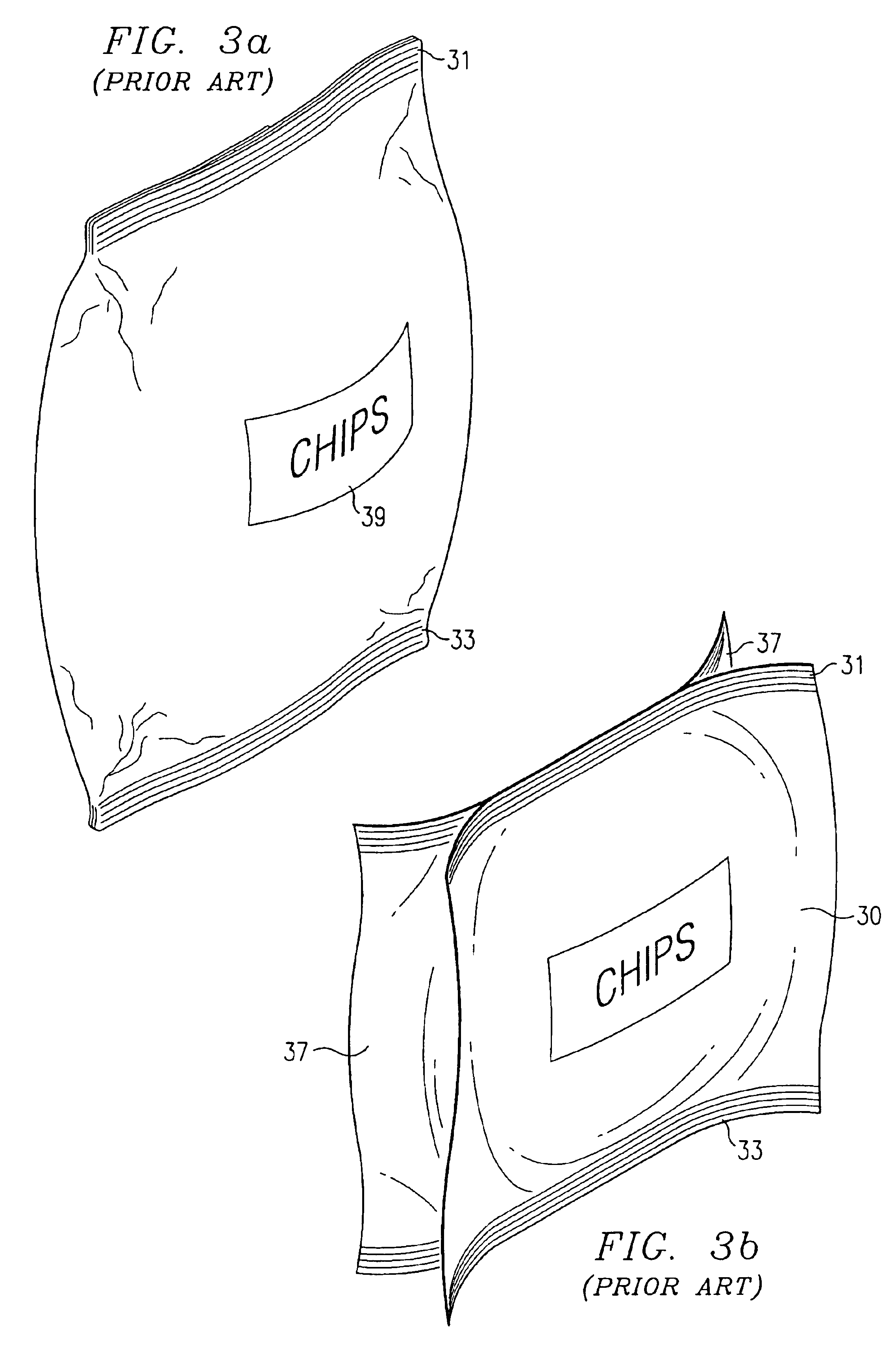

Double-bag package and perforation knife

A double-bag package, and method for manufacturing same, constructed by modification to existing vertical form and fill packaging machines and perforation knives. In a preferred embodiment, the invention involves producing a double-bag package from a single sheet of packaging film by feeding a roll of film having graphics printed sideways rather than vertically into a vertical form, fill and seal packaging machine and using a novel perforating / cutting knife to alternately cut and perforate transverse seals. The perforating / cutting knife has teeth in the shape of oblique triangular pyramids, with each tooth having three cutting edges. The perforating / cutting knife produces self-correcting T-shaped perforation patterns capable of capturing and redirecting errant tears for fail-safe directional separation.

Owner:FRITO LAY NORTH AMERICA INC

Pricing and auctioning of bundled items among multiple sellers and buyers

InactiveUS20090125414A1Buying/selling/leasing transactionsElectric/magnetic computingGroup buyingComputer science

A number of sets of methods and apparatuses applicable to online shopping are disclosed. One set, “Bin Packing Methods with Approximate Membership”, includes methods in pricing and auctioning a bundle of items, some of which could belong to another bundle. Significantly, the membership of a bundle, during pricing and auction, could change. Another set, the “Shopping Console”, puts a structure into the online shopping experience, so that through one interface various shopping activities can be facilitated, including but not limited to researching, pricing, negotiation, group buying, and tracking of purchases. Still another set, “Flash Mob Shopping”, allows sellers and a (spontaneous) group of shoppers to connect on prices without requiring shoppers' hard commitments, and with sellers revealing only necessary price information.

Owner:TAMIRAS PER PTE LTD LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com