Patents

Literature

234results about How to "Avoid sliding friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

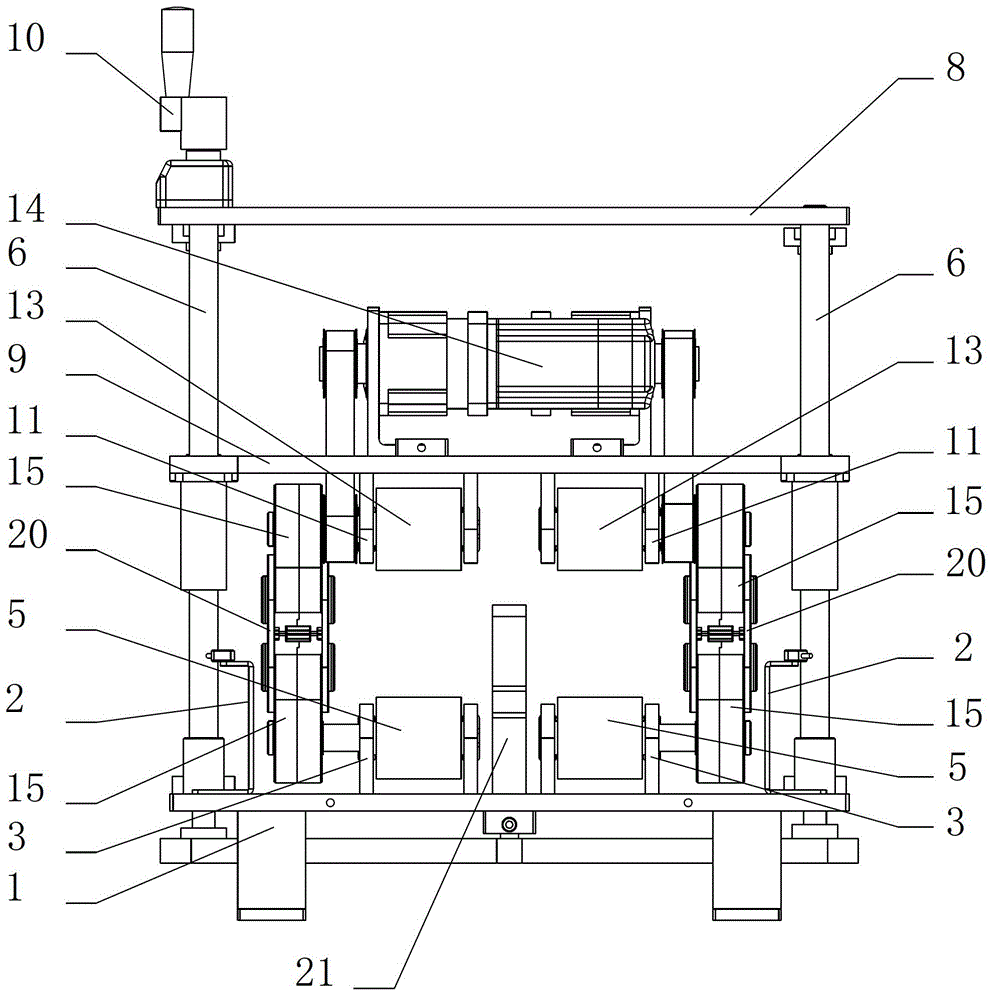

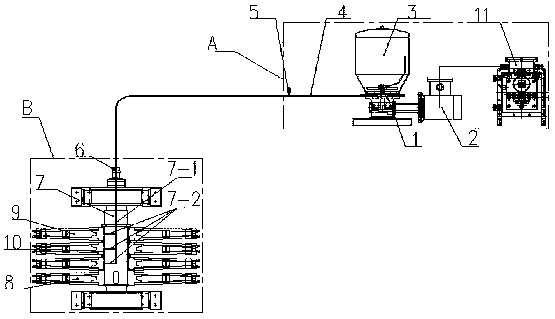

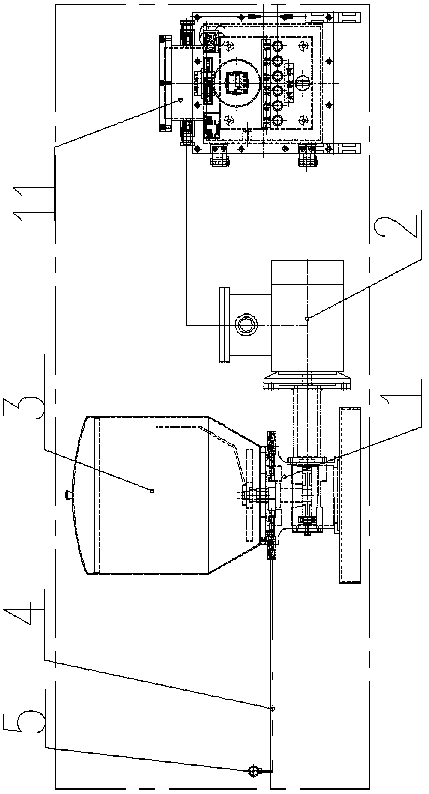

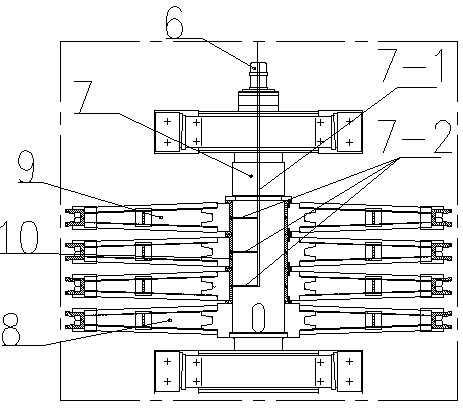

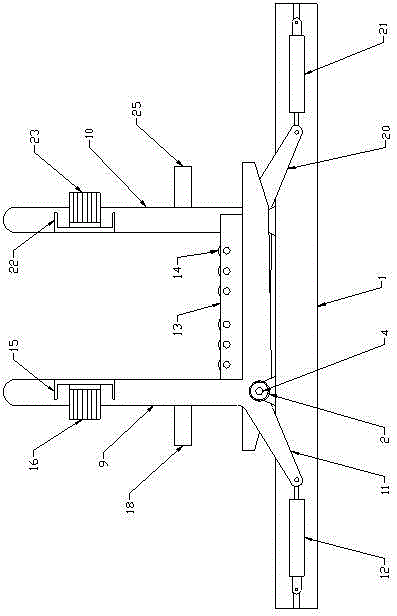

Material packaging method and device for laterally transferring full material bags

ActiveCN102275654AAvoid sliding frictionShorten the transfer distanceSolid materialFilling materialsEngineering

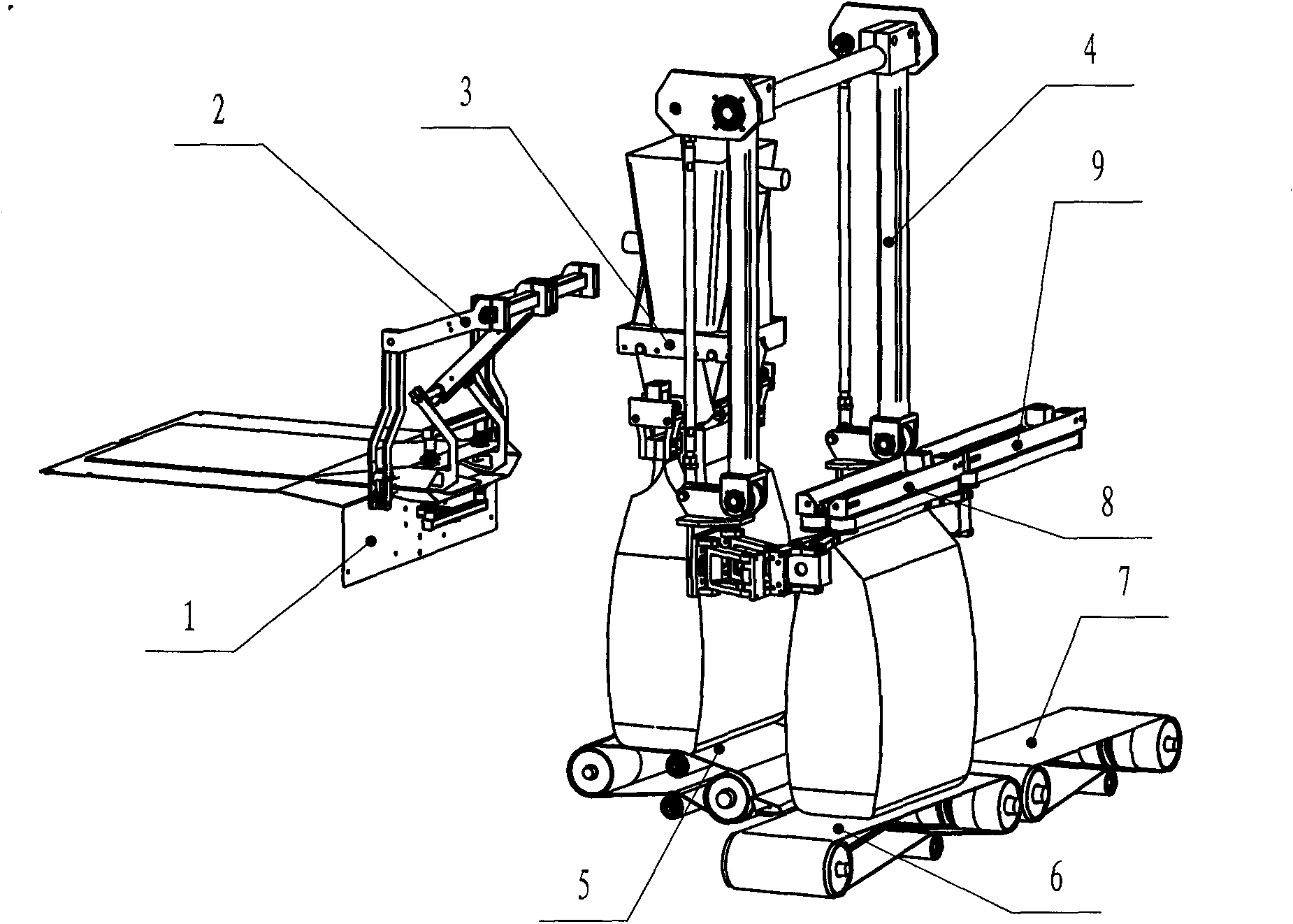

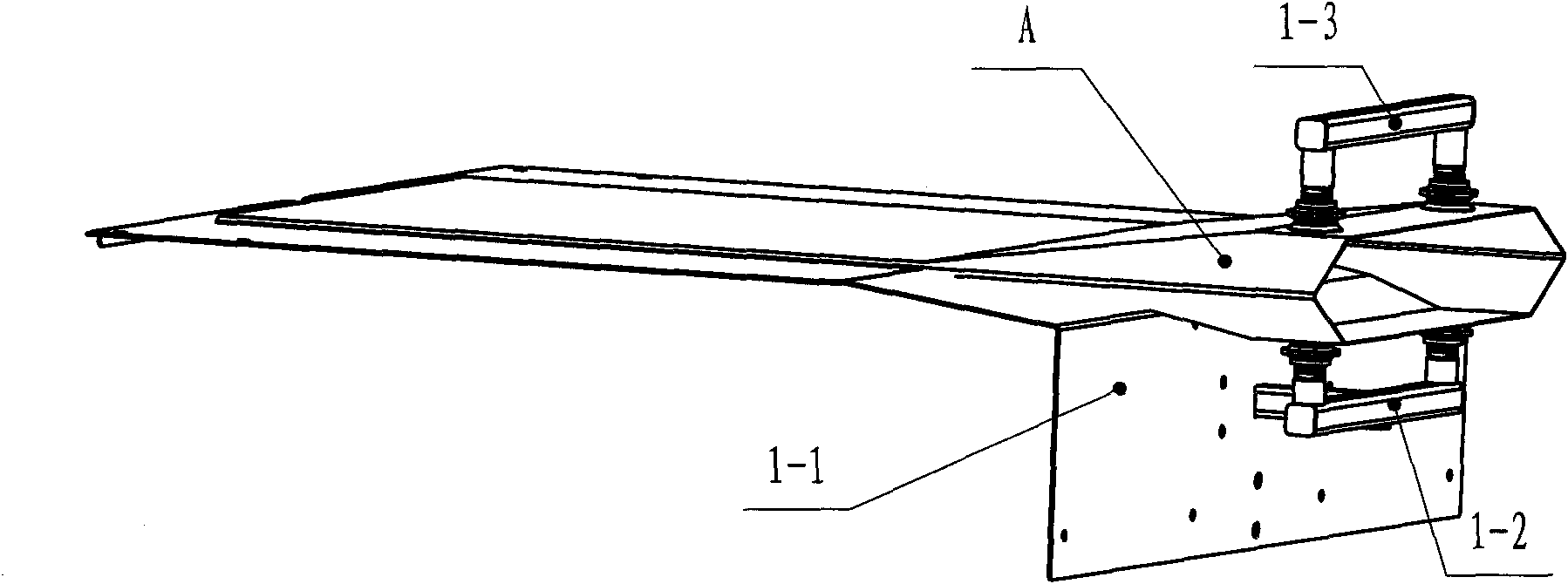

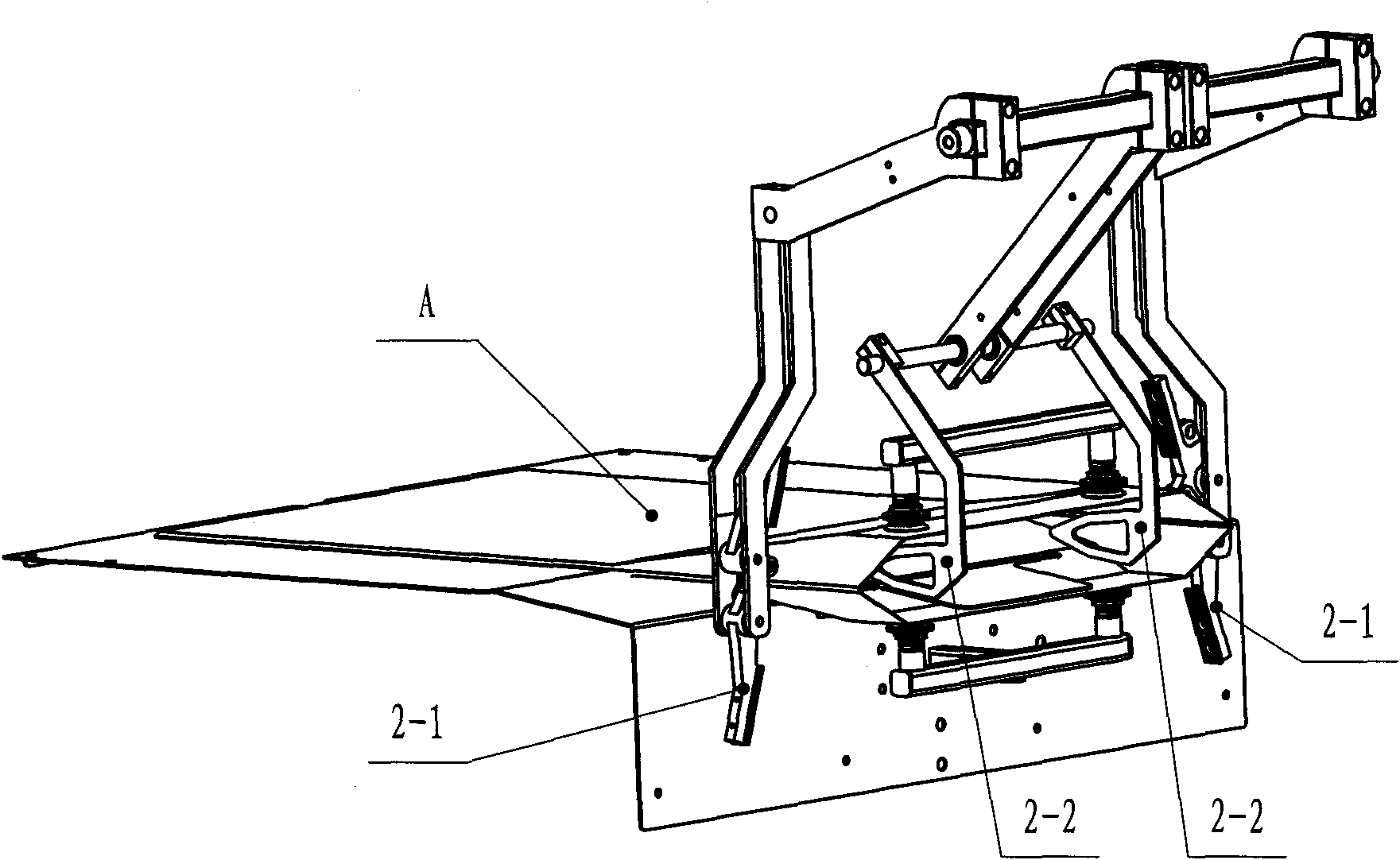

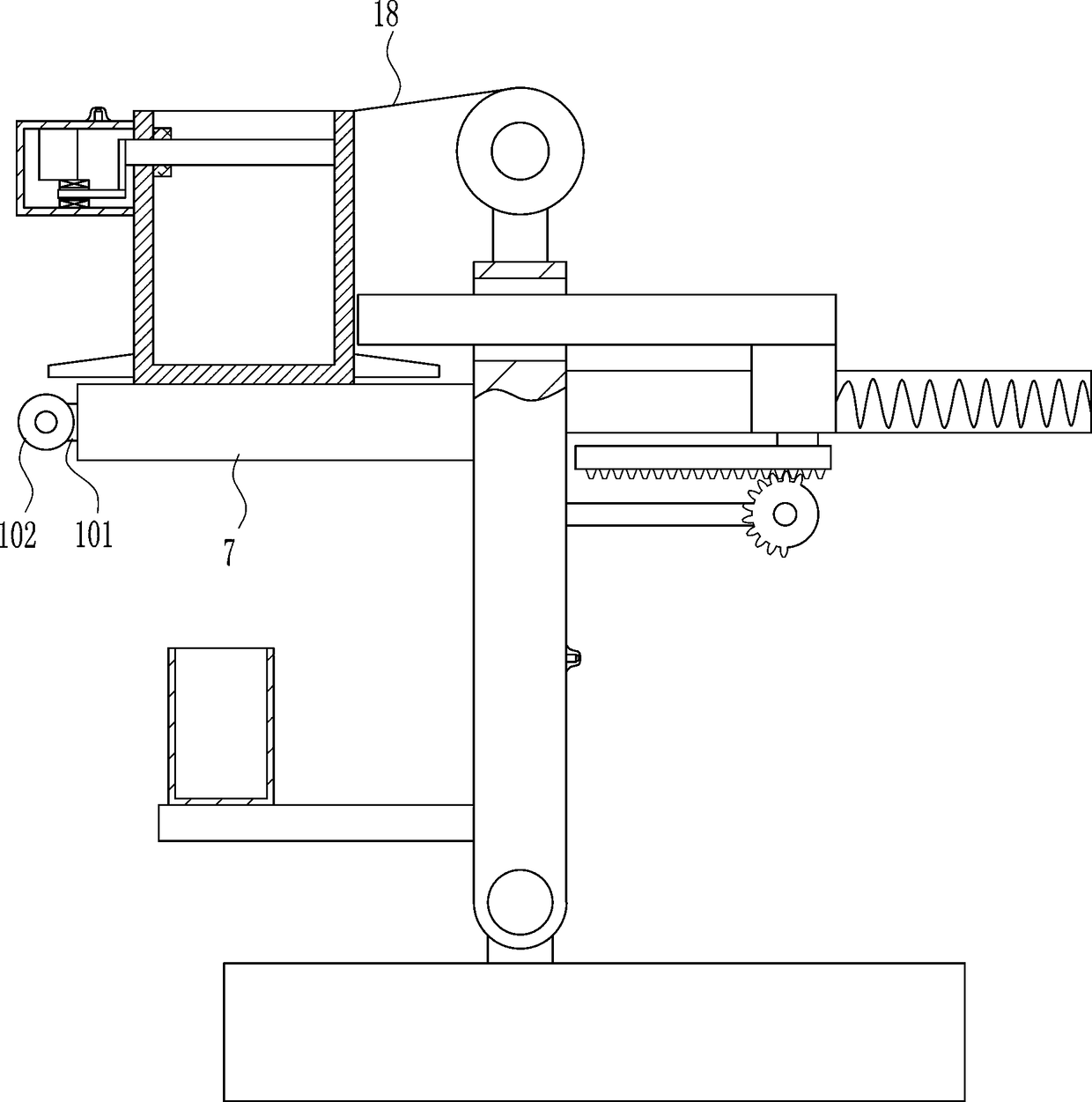

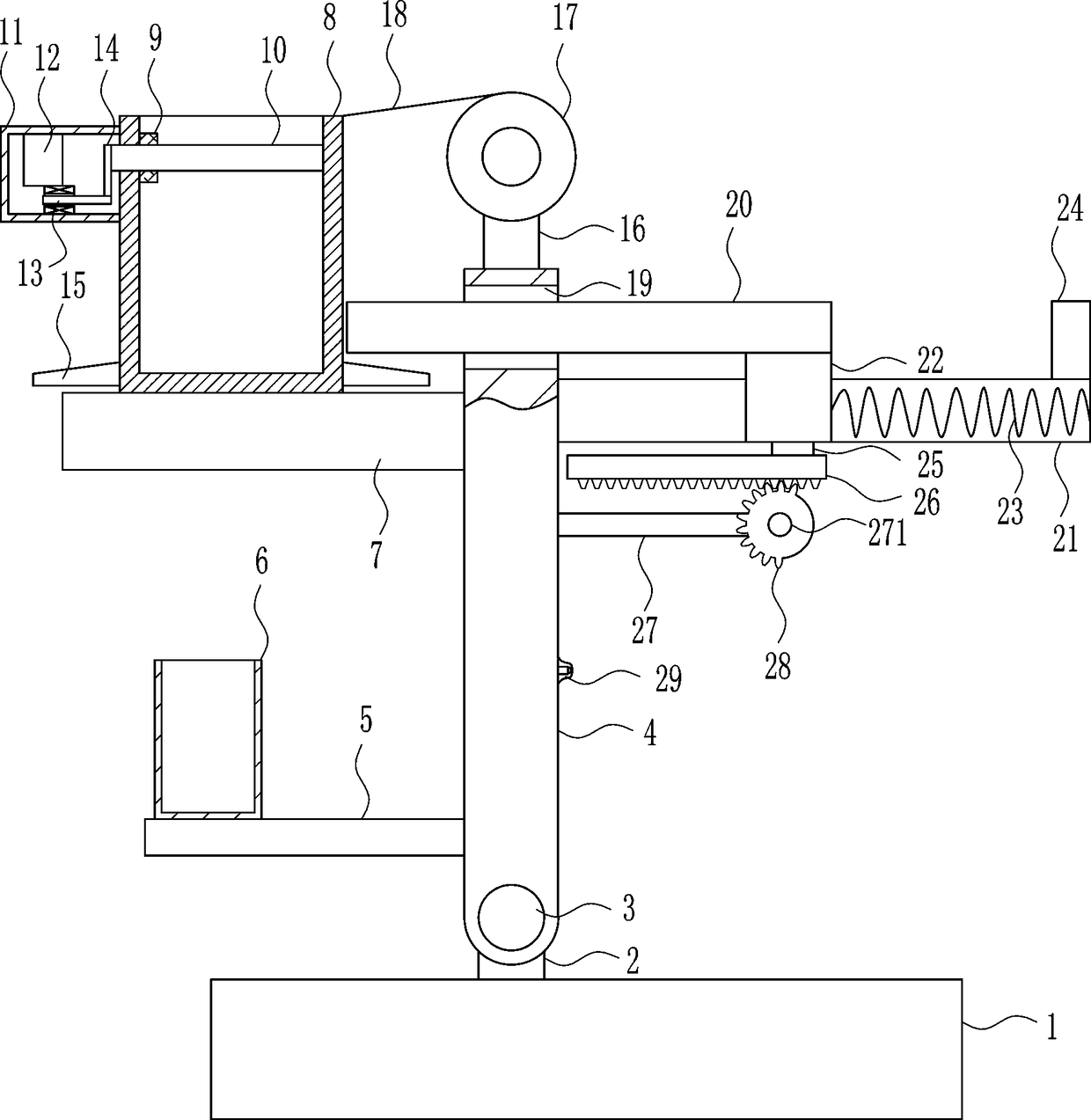

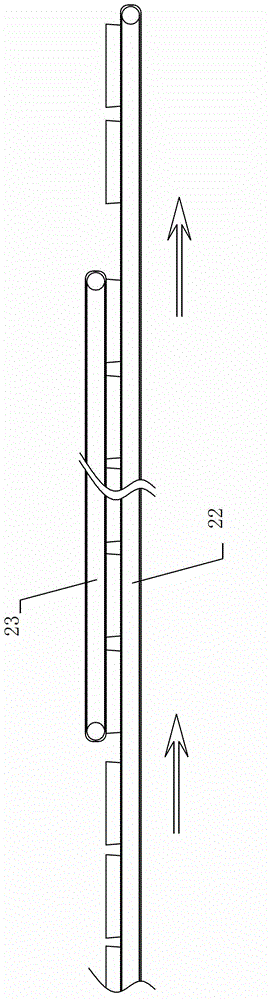

The invention discloses a material packing method for transversely conveying full bags, and aims to solve the problems that a full bag conveying distance is long and sliding friction exists at the bottoms of the full bags in the conventional packing method for longitudinally conveying the full bags. The packing method comprises the following steps of: (1) opening bag mouths; (2) taking empty bags; (3) sleeving the empty bags; (4) clamping the empty bags; (5) propping up contracted bag mouths; (6) filling materials in the bags; (7) grasping the full bags; (8) transversely conveying the full bags; (9) clamping the full bags; (10) outputting the full bags; and (11) conveying the full bags. By the material packing method, the material packing speed can be improved to more than 1,600 bags per hour.

Owner:HARBIN BOSHI AUTOMATION

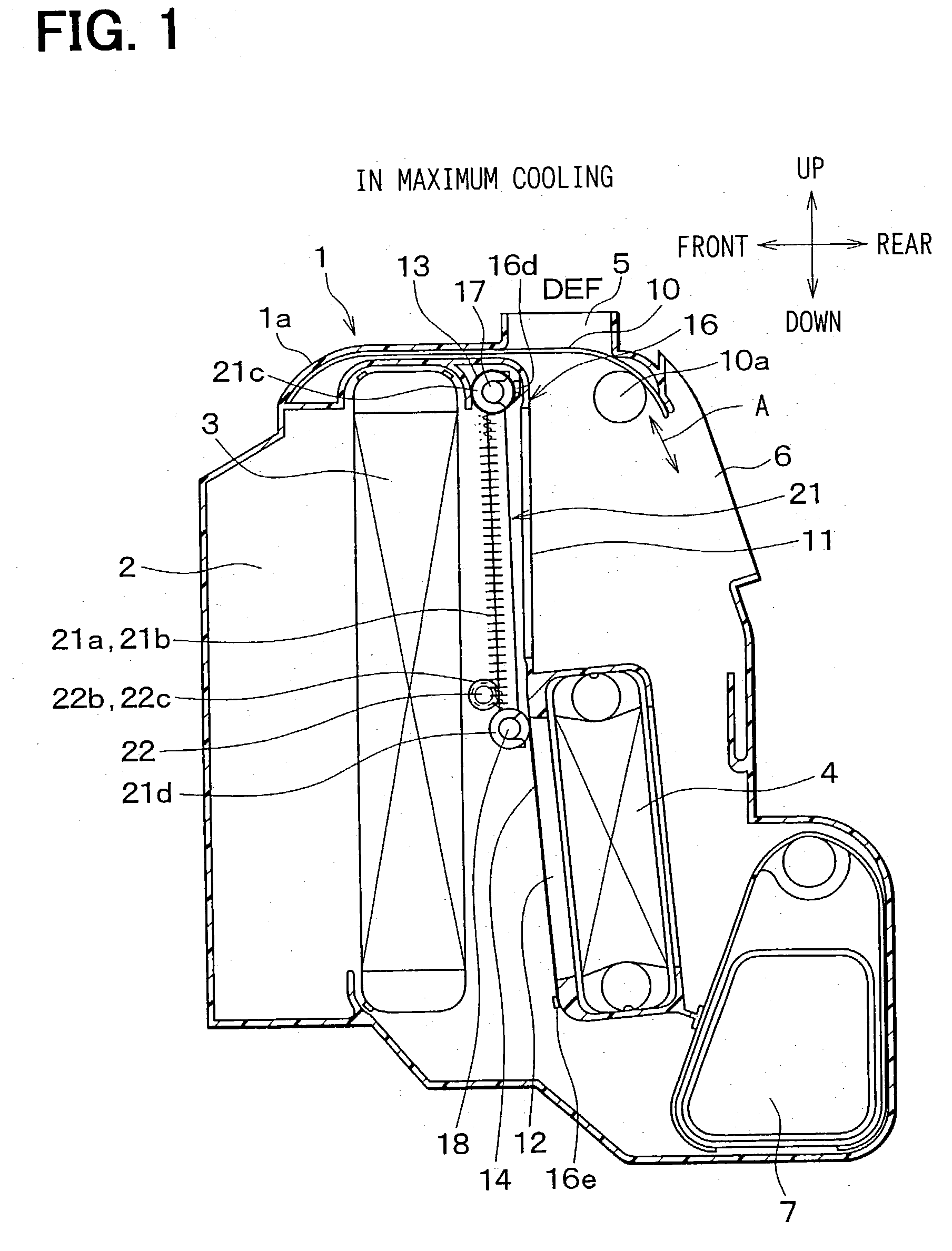

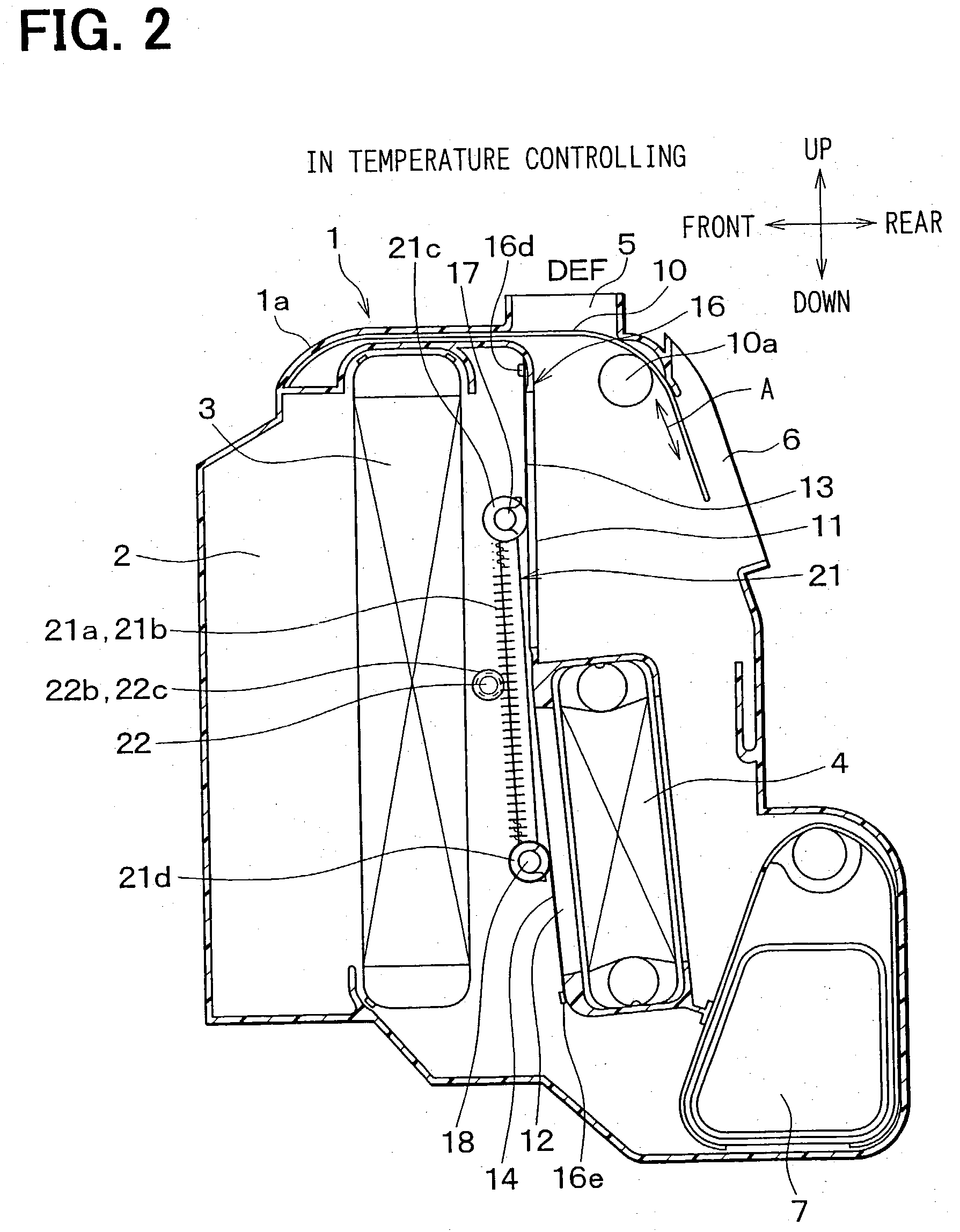

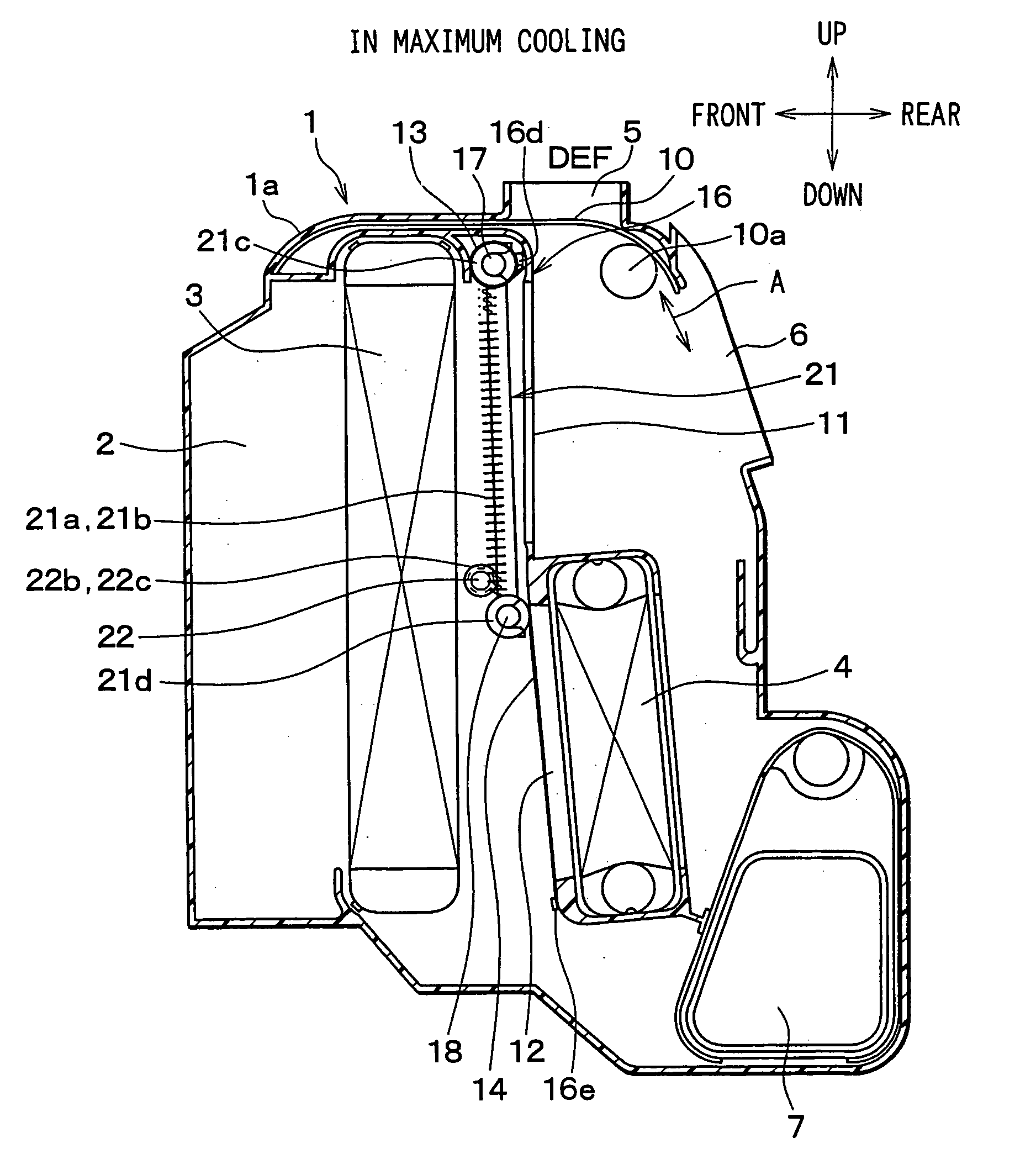

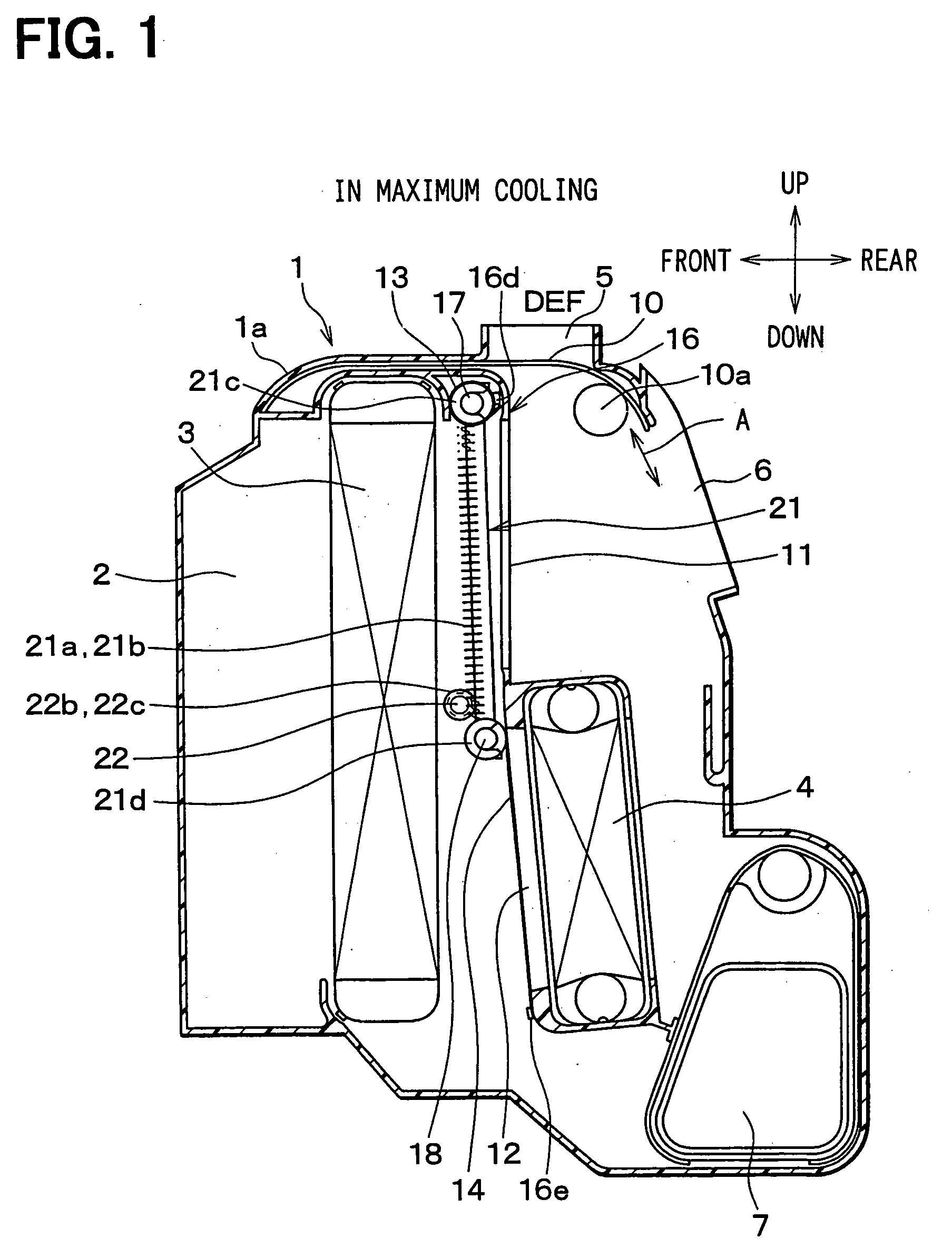

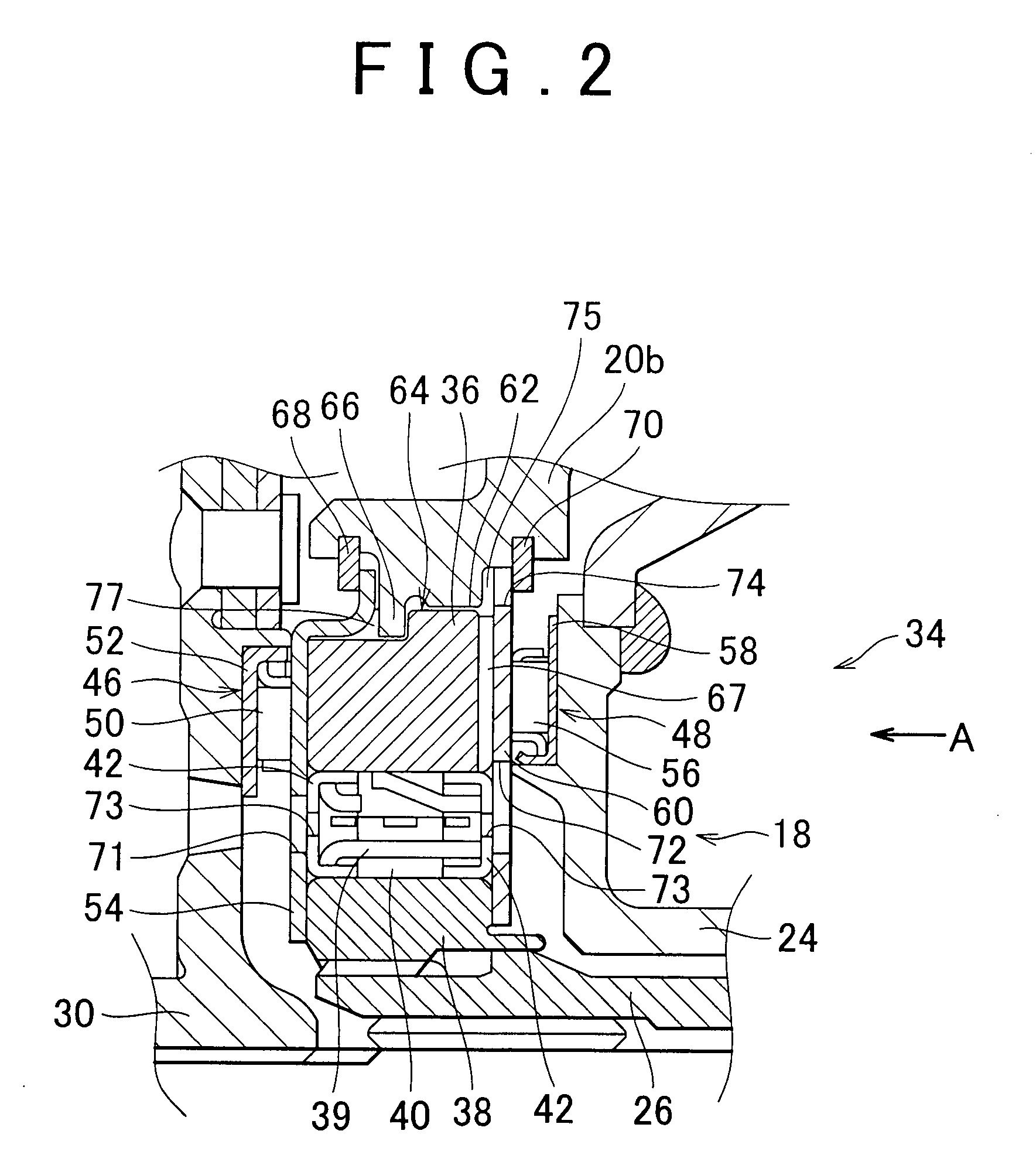

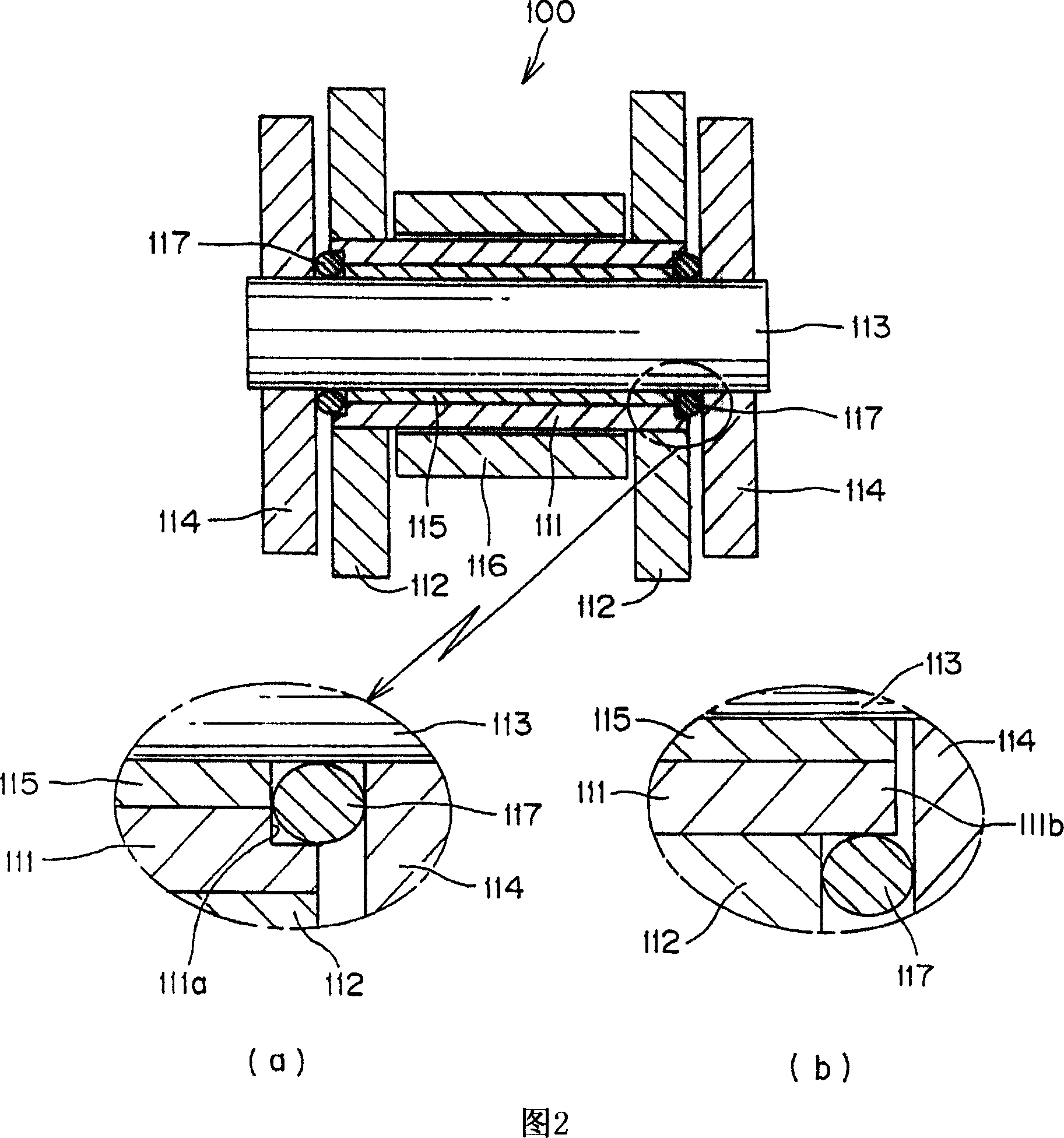

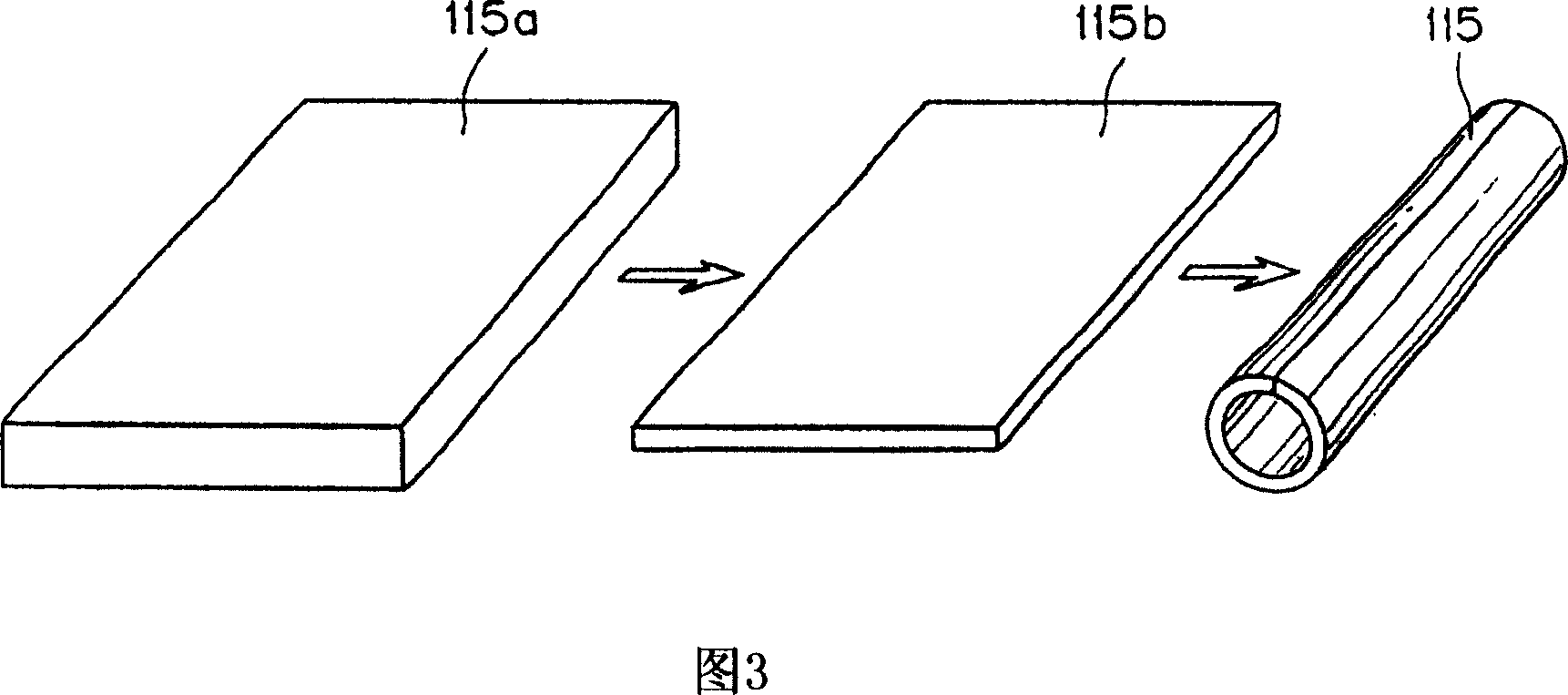

Air-passage opening/closing device

ActiveUS20030232590A1Avoid sliding frictionLow costAir-treating devicesOperating means/releasing devices for valvesDrive shaftEngineering

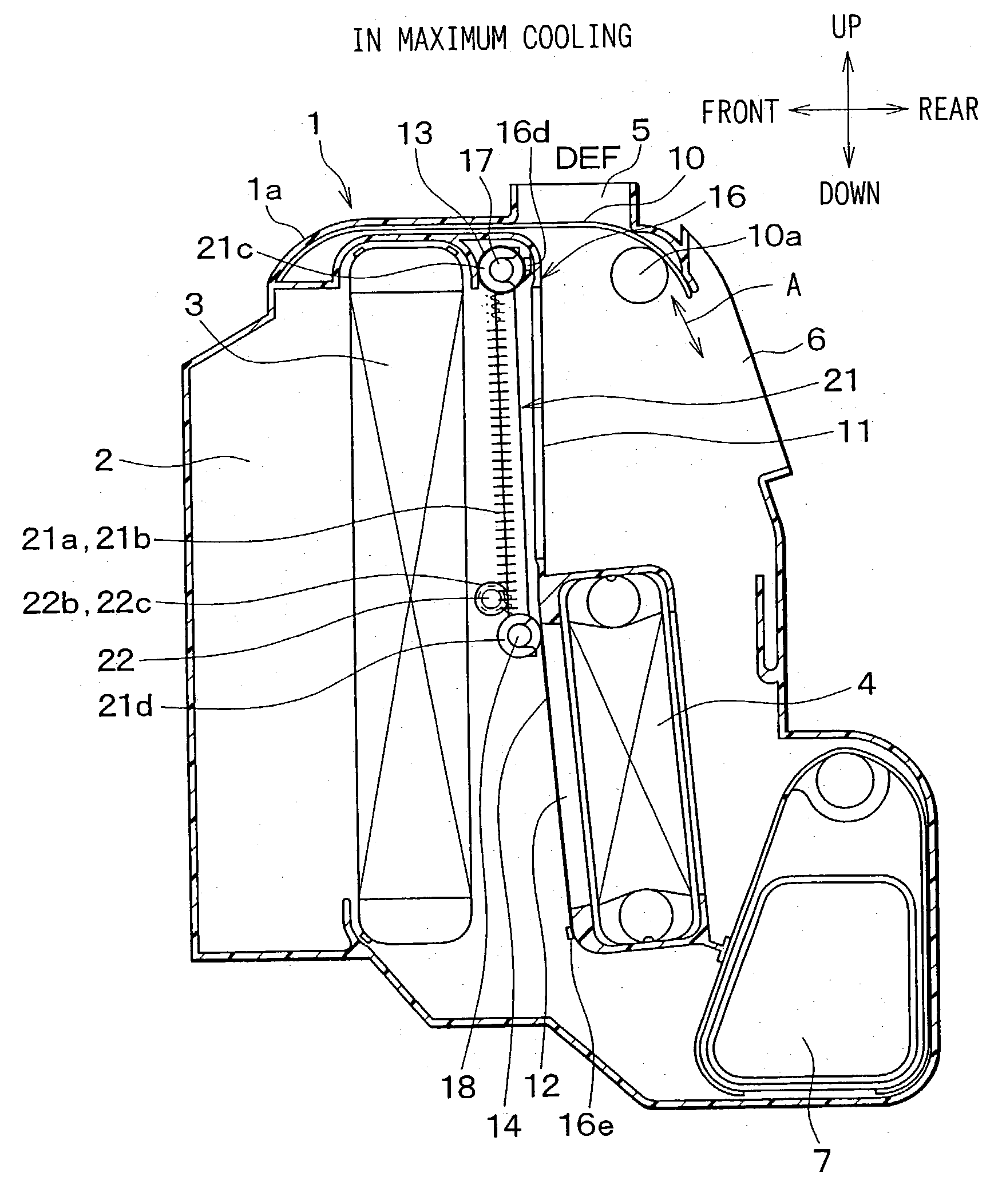

An air passage opening / closing device includes a film member for opening and closing an opening of an air passage of a case. One end of the film member is fixed to a fixing portion on an outer periphery of the opening of the air passage, and the other end thereof is connected to a film winding shaft. A moving member movable by rotation of a drive shaft is provided on the opening, and the film winding shaft is moved while being rotated by the movement of the moving member, so that the film member at the other end side is wound around and unwound from the film winding shaft. Accordingly, when the air passage is opened and closed by the film member, sliding friction can be prevented from being generated between the film member and the case.

Owner:DENSO CORP

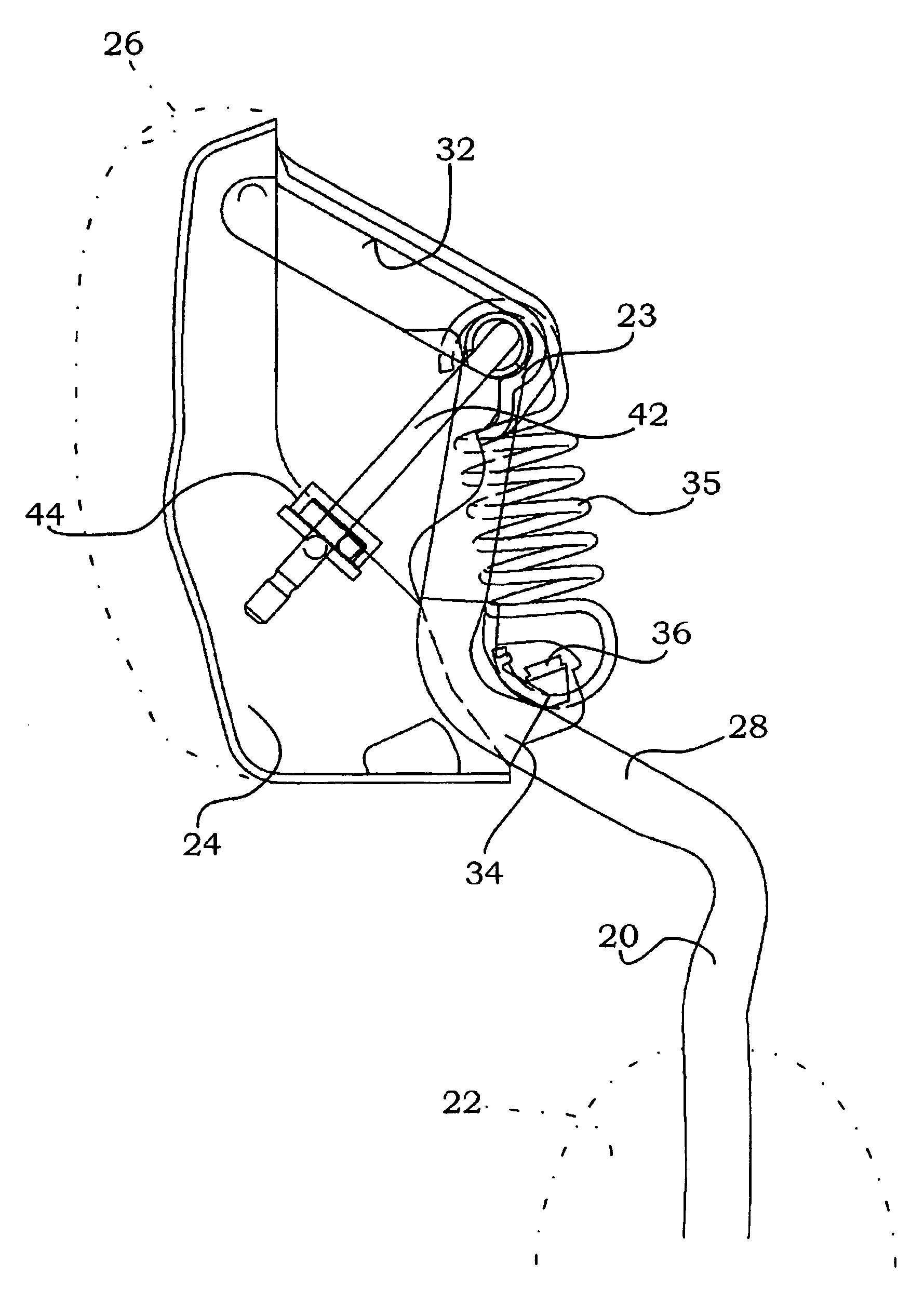

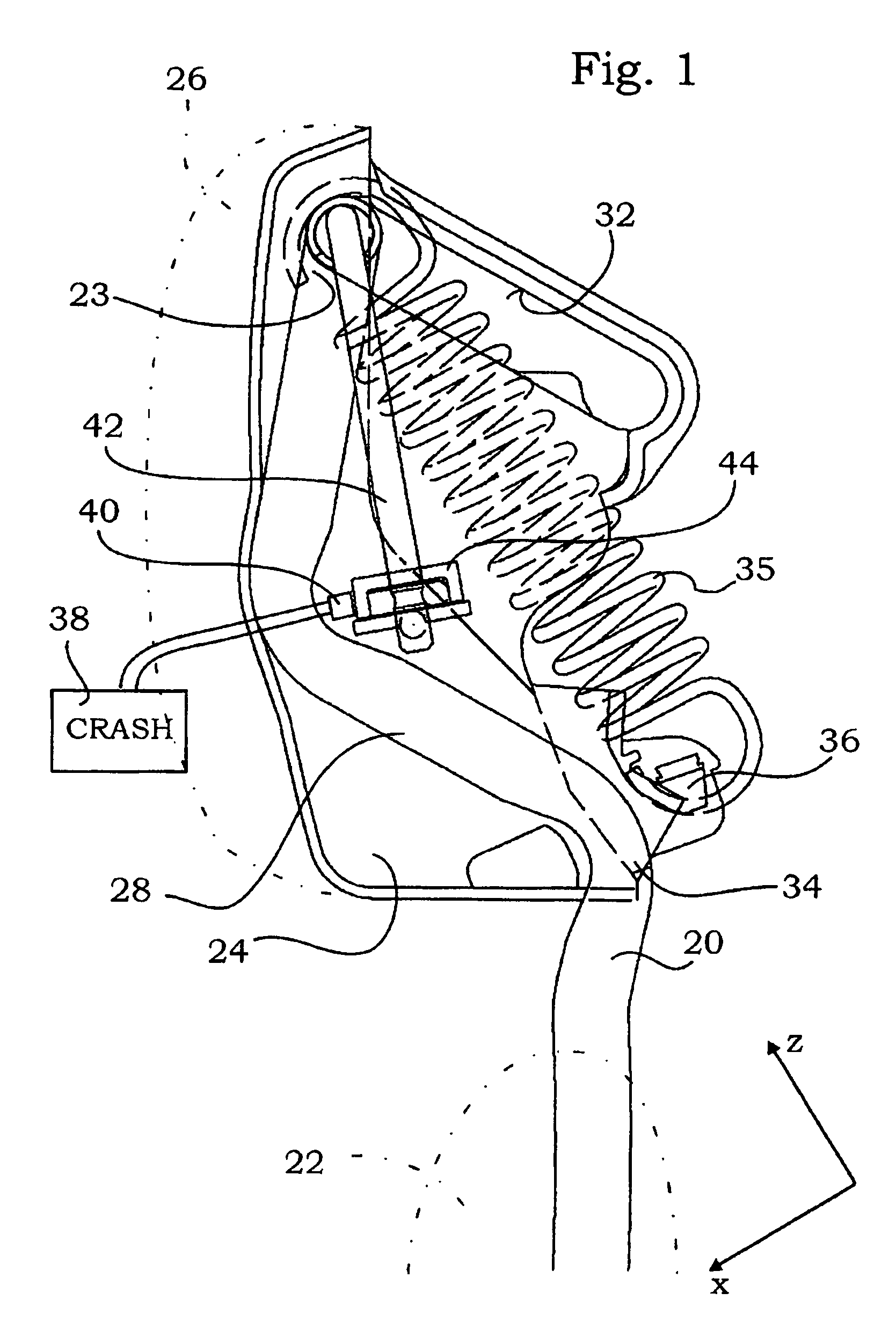

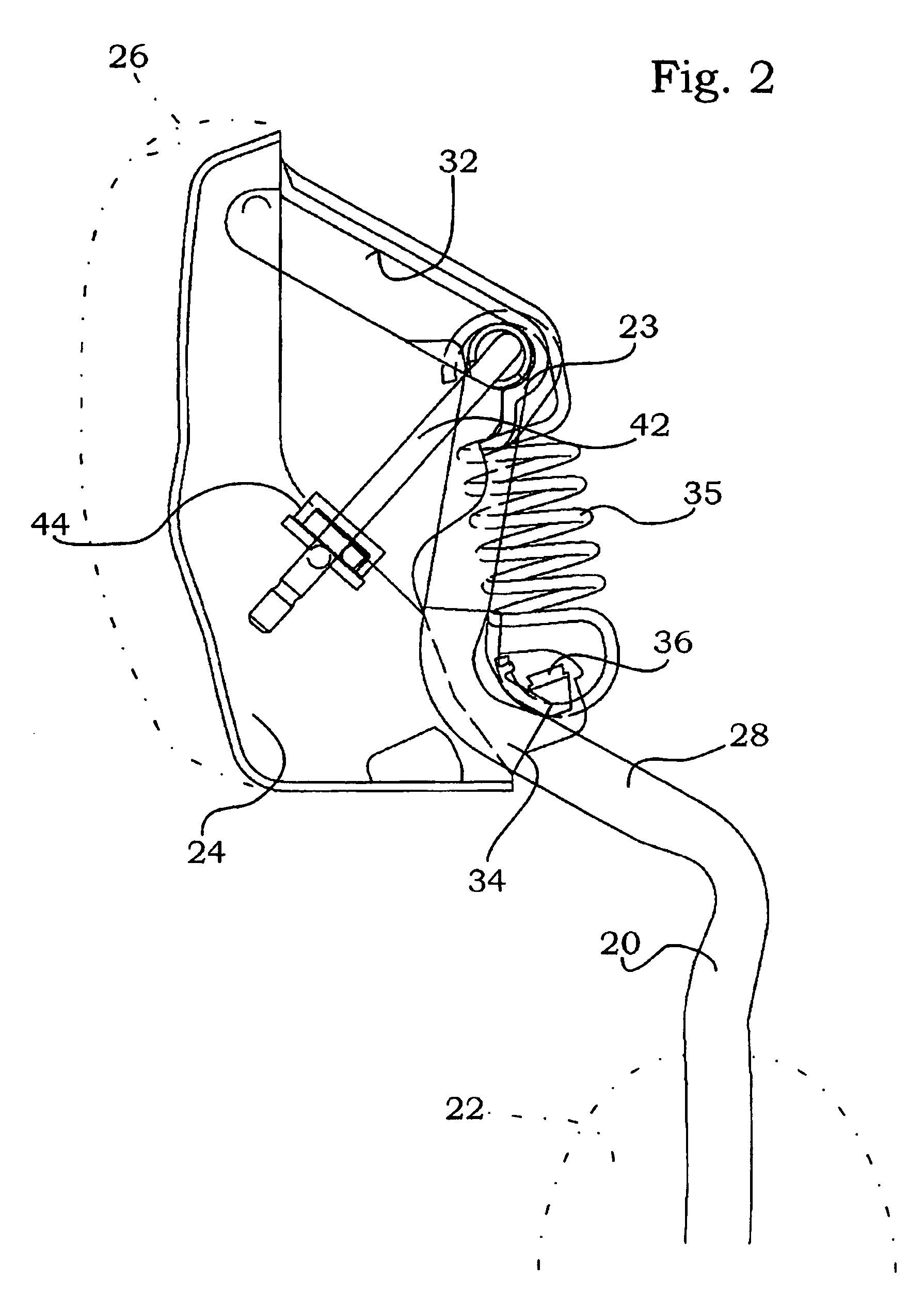

Headrest for motor vehicle

InactiveUS7293829B2Reduce frictionForce is smallVehicle seatsPedestrian/occupant safety arrangementMobile vehicleNormal case

The headrest has a first structural component for fastening the headrest to a seat back of a motor vehicle seat and a second structural component that is movable with respect to said first structural component in the event of a crash. A drive unit is disposed between the first structural component and the second structural component and comprises a locking unit, which is locked in the normal case, and a crash sensor connected to the locking unit which it controls. The locking unit comprises a disengagement drive with an electromagnet or a piezoelectric drive. The locking unit has one retainer member associated with the first structural component and one movable disengagement member associated with the second structural component. Retainer member and disengagement member are connected together via a hinge or via balls. The disengagement drive is capable of causing said disengagement member to move.

Owner:GRAMMER AUTOMOTIVE CZ

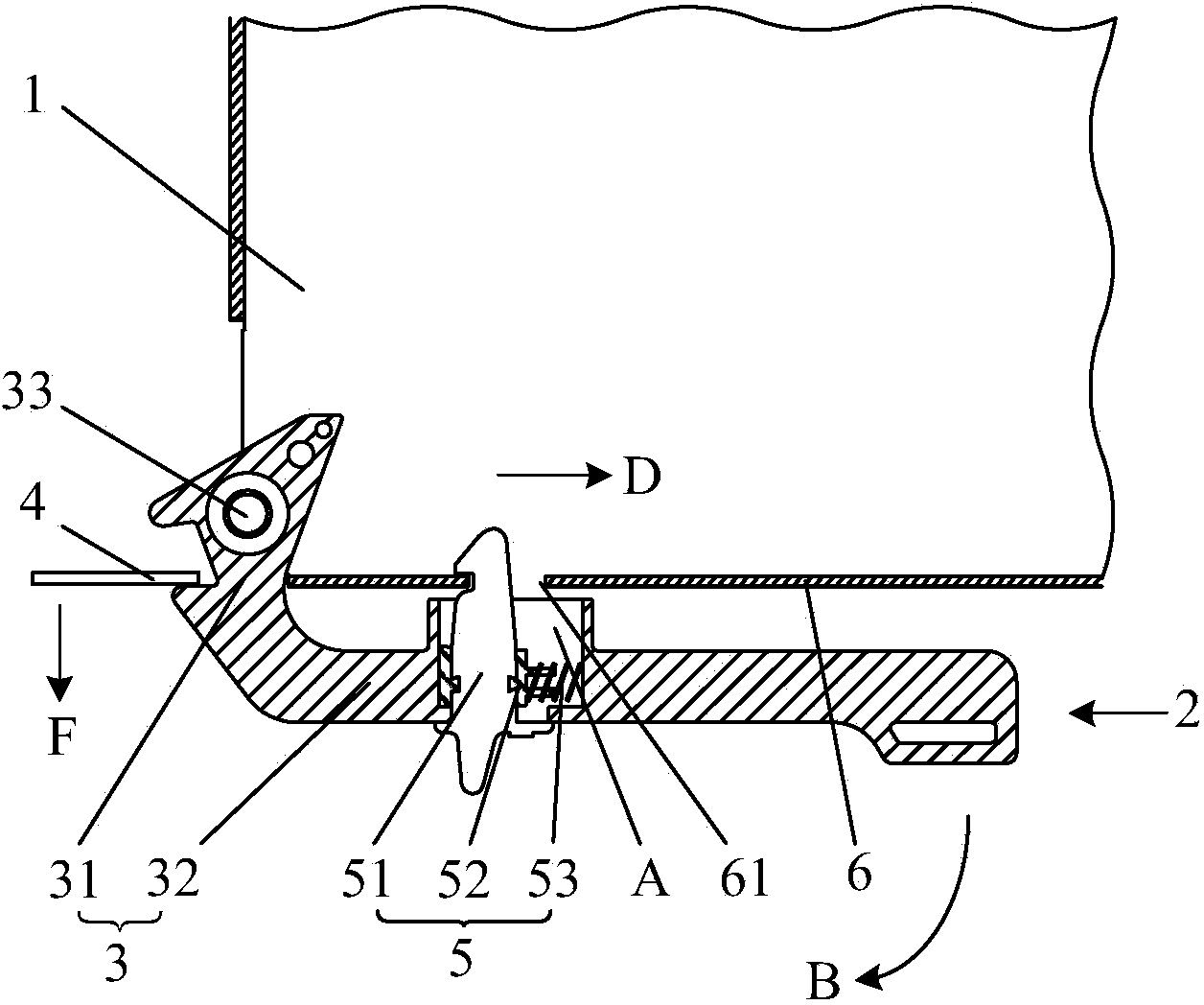

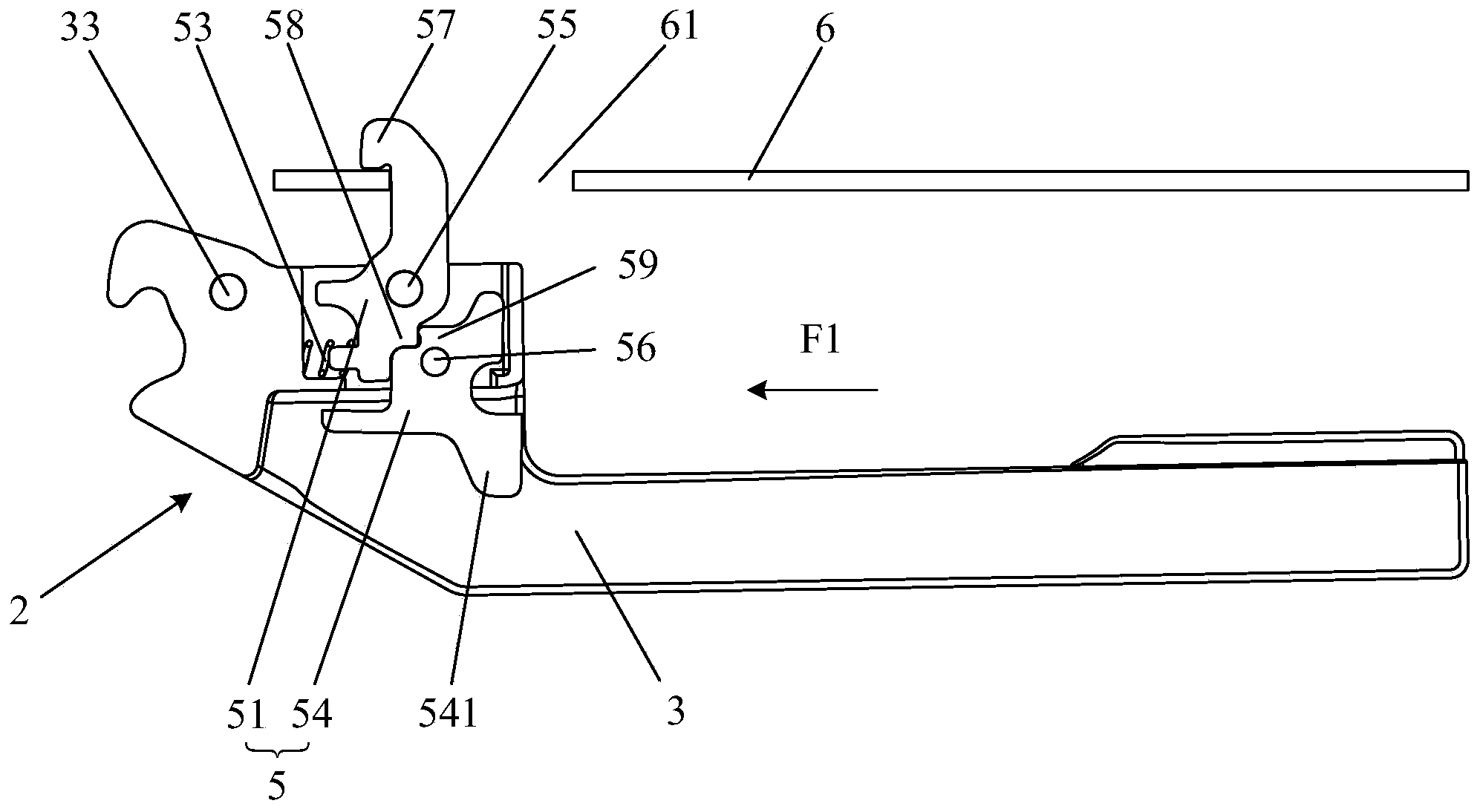

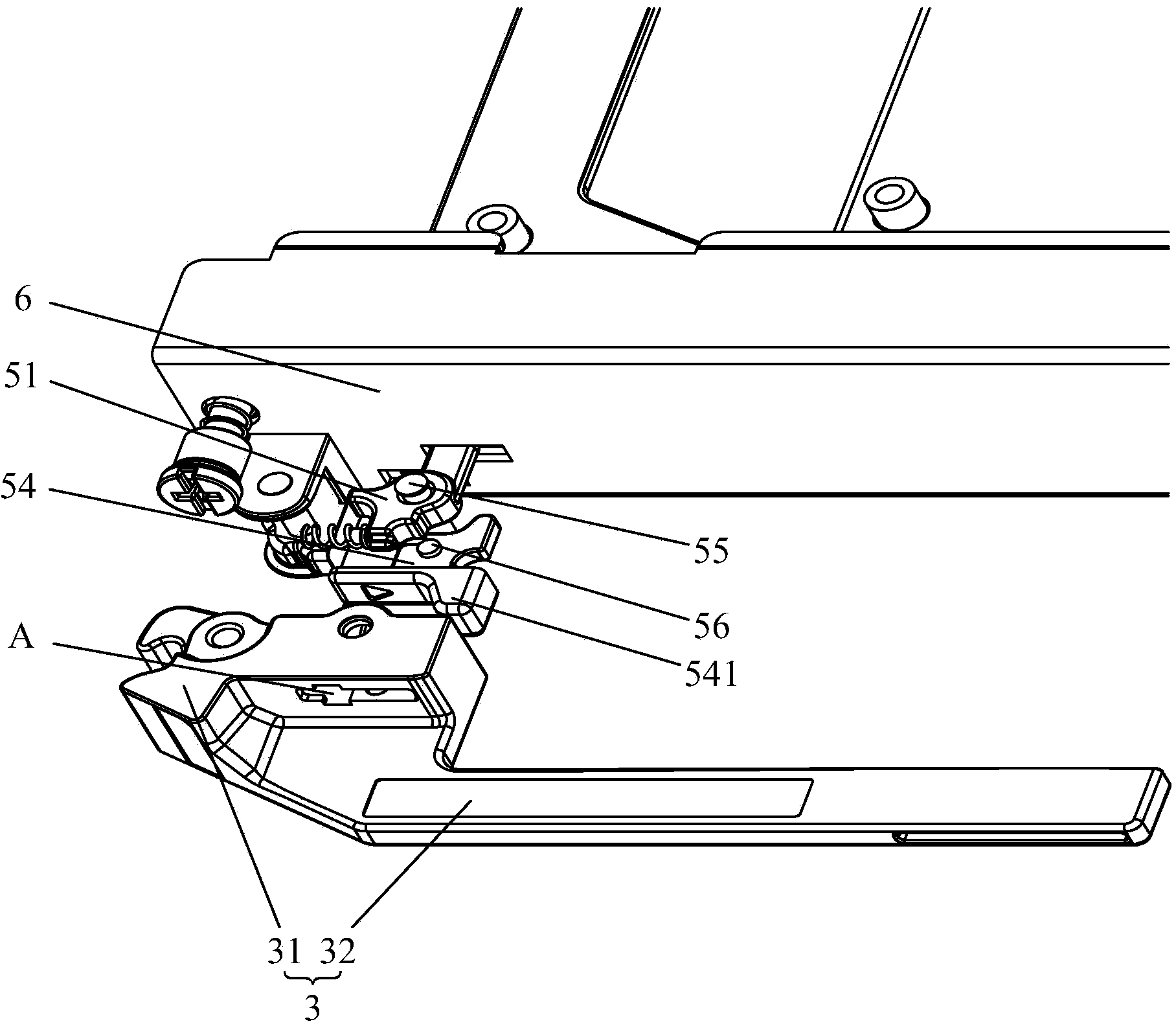

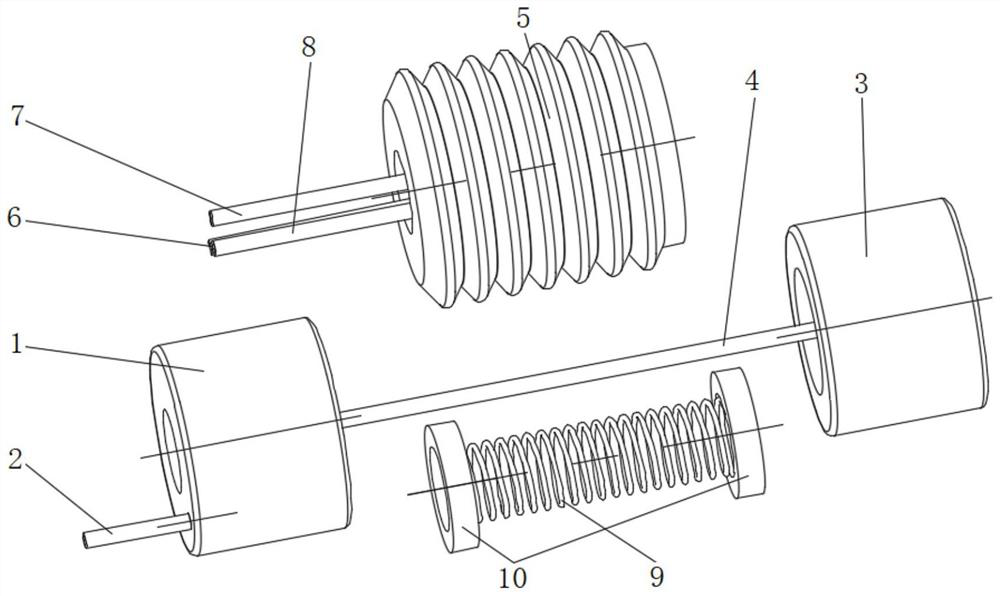

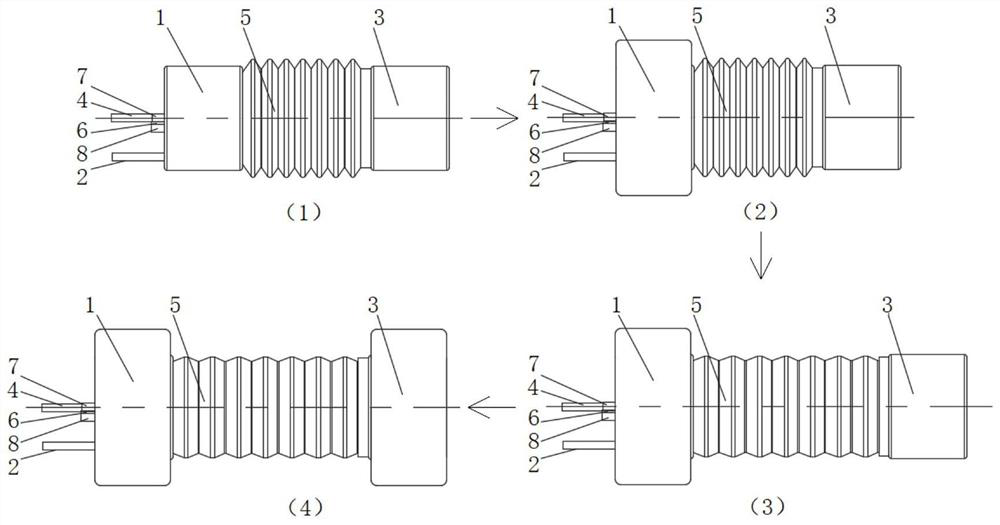

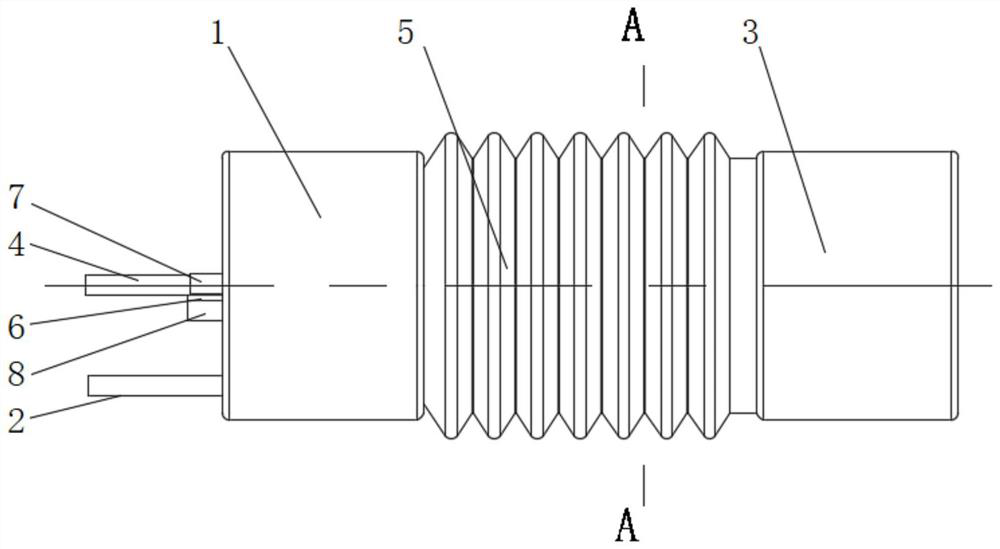

Single-board assembly, communication system, handle bar wrench and unlocking method of handle bar wrench

ActiveCN103841789AEasy to unlockAvoid sliding frictionDigital data processing detailsConstruction fastening devicesCommunications systemSingle plate

The invention discloses a single-board assembly, a communication system, a handle bar wrench and an unlocking method of the handle bar wrench, and relates to the technical field of communications. Slide friction force between an unlocking hook and a panel in the unlocking process of a traditional handle bar wrench is avoided, so that unlocking is easier. The handle bar wrench comprises a wrench body and an unlocking mechanism, wherein the unlocking mechanism comprises an unlocking hook and a trigger; the unlocking hook is connected to the wrench body through a first rotary shaft in a rotary mode; the trigger is connected to the wrench body through a second rotary shaft in a rotary mode; the unlocking hook is provided with a first end and a second end; the first end is opposite to the second end, and the first rotary shaft is arranged between the first end and the second end; the first end is provided with a hook; the second end is provided with a first abutting portion; the trigger is provided with a second abutting portion; the first abutting portion makes contact with the second abutting portion; the second abutting portion is used for exerting first force on the first abutting portion when the trigger rotates around the second rotary shaft so that the unlocking hook can rotate around the first rotary shaft.

Owner:HUAWEI TECH CO LTD

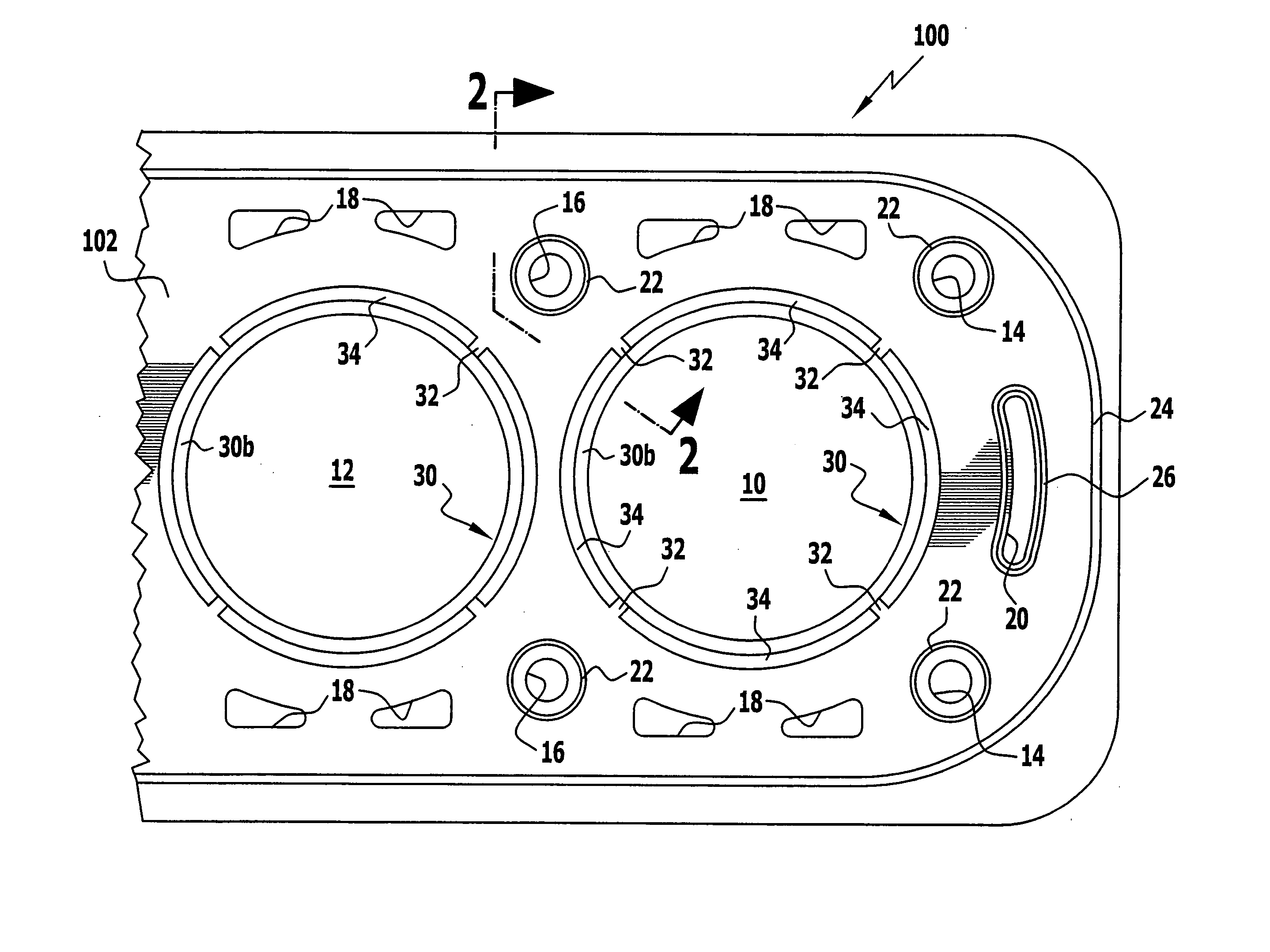

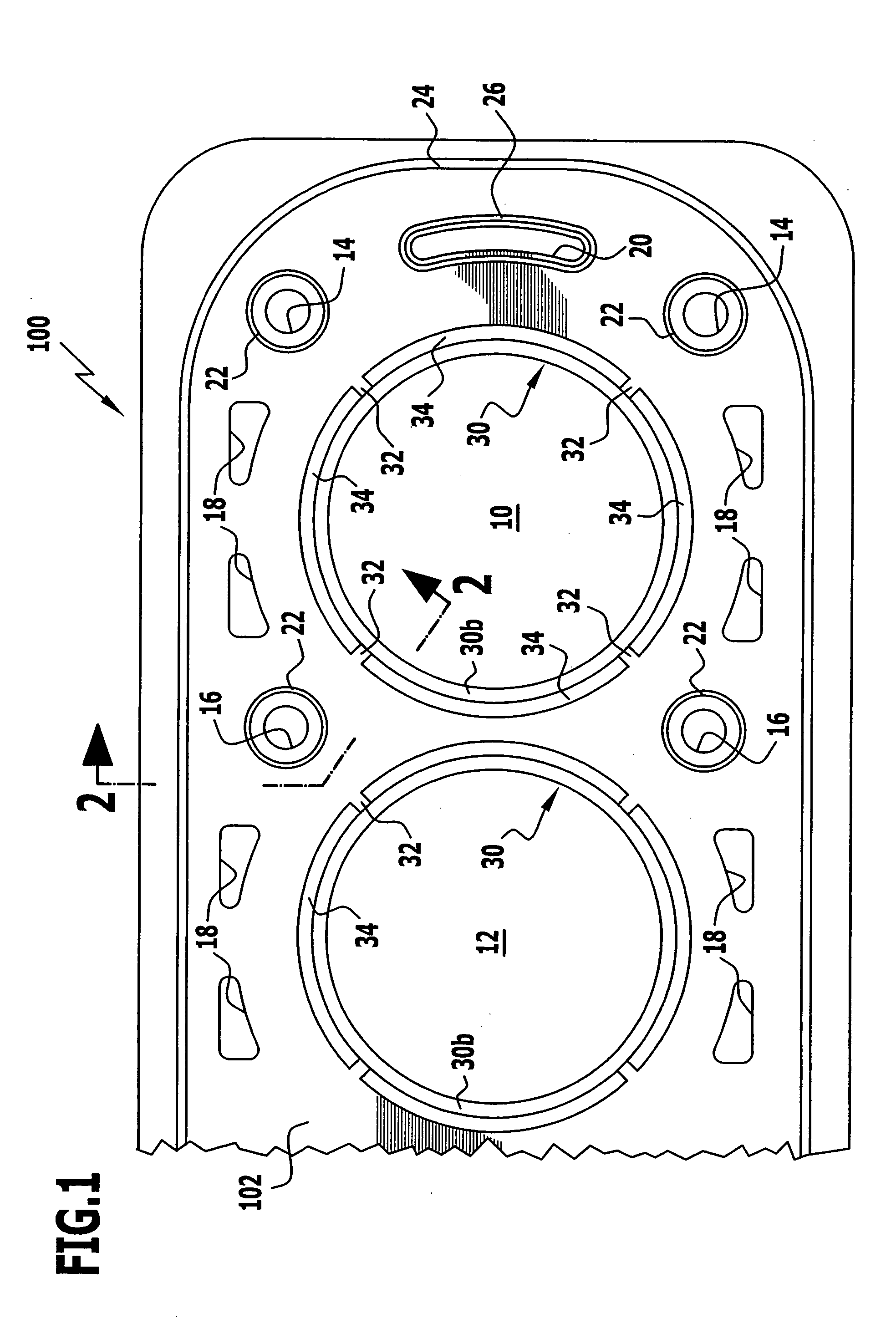

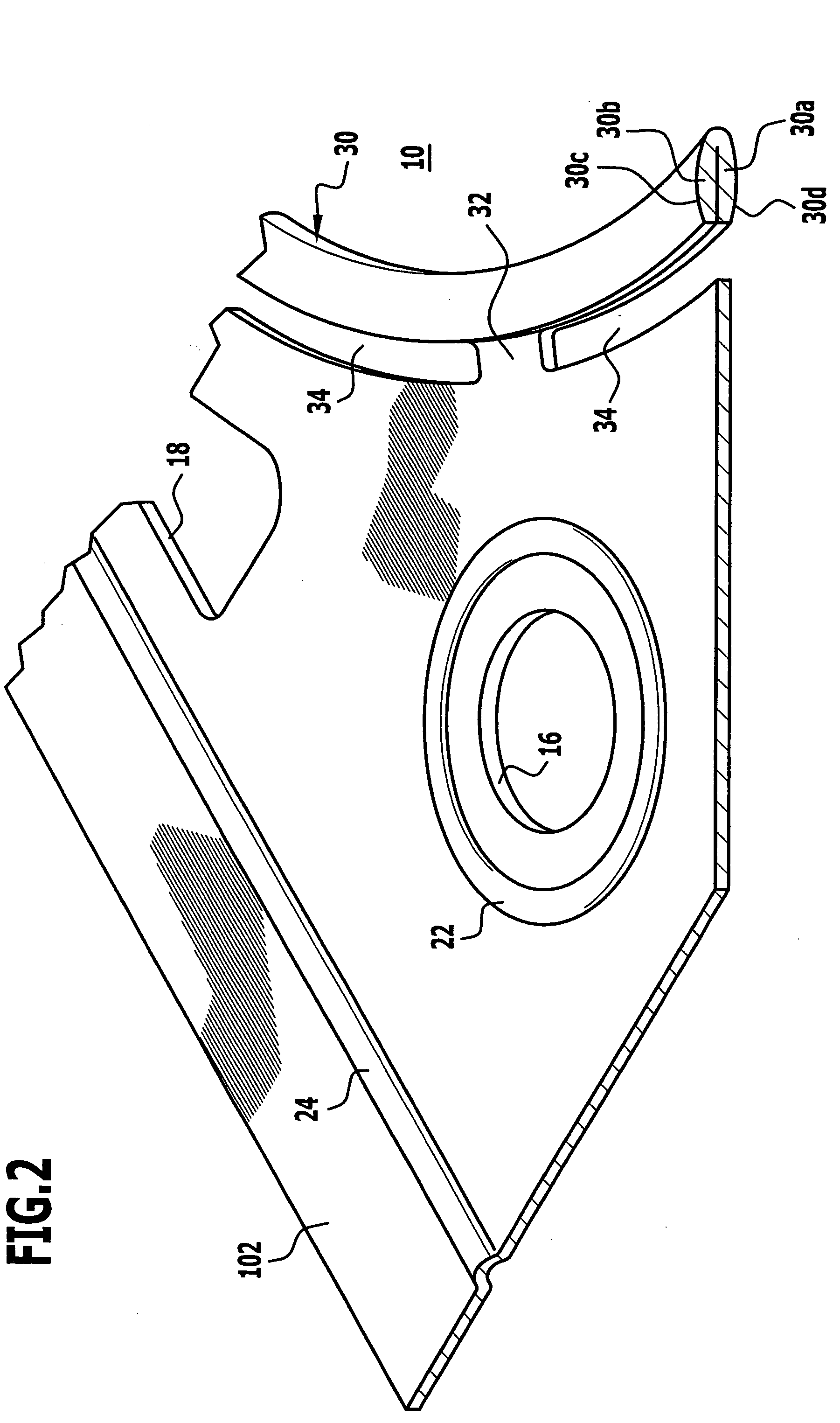

Cylinder head gasket

InactiveUS20060103079A1Avoid sliding frictionPrevent excessive flatteningEngine sealsSealing arrangements for enginesCylinder headGasket

Cylinder head gasket with a ring-shaped metallic sealing element extending around a through-opening of the gasket, wherein, for automatic adaptation to changes in the width of the sealing gap to be sealed by the cylinder head gasket, the sealing element is of such spherical shape in cross section at its sides facing the two main surfaces of the gasket as to result in convex surfaces of the sealing element that face the main surfaces of the gasket and each have a crest, and, in the unpressed state of the gasket, these crests, in cross section perpendicular to the longitudinal center axis of a metallic sealing strand forming the sealing element, are laterally offset from one another in the direction of a gasket plane defined by the gasket so that the spacing of planes running parallel to the gasket plane and tangentially to the convex surfaces of the sealing element varies when these convex surfaces tilt about the longitudinal center axis of the sealing strand.

Owner:ELRINGKLINGER AG

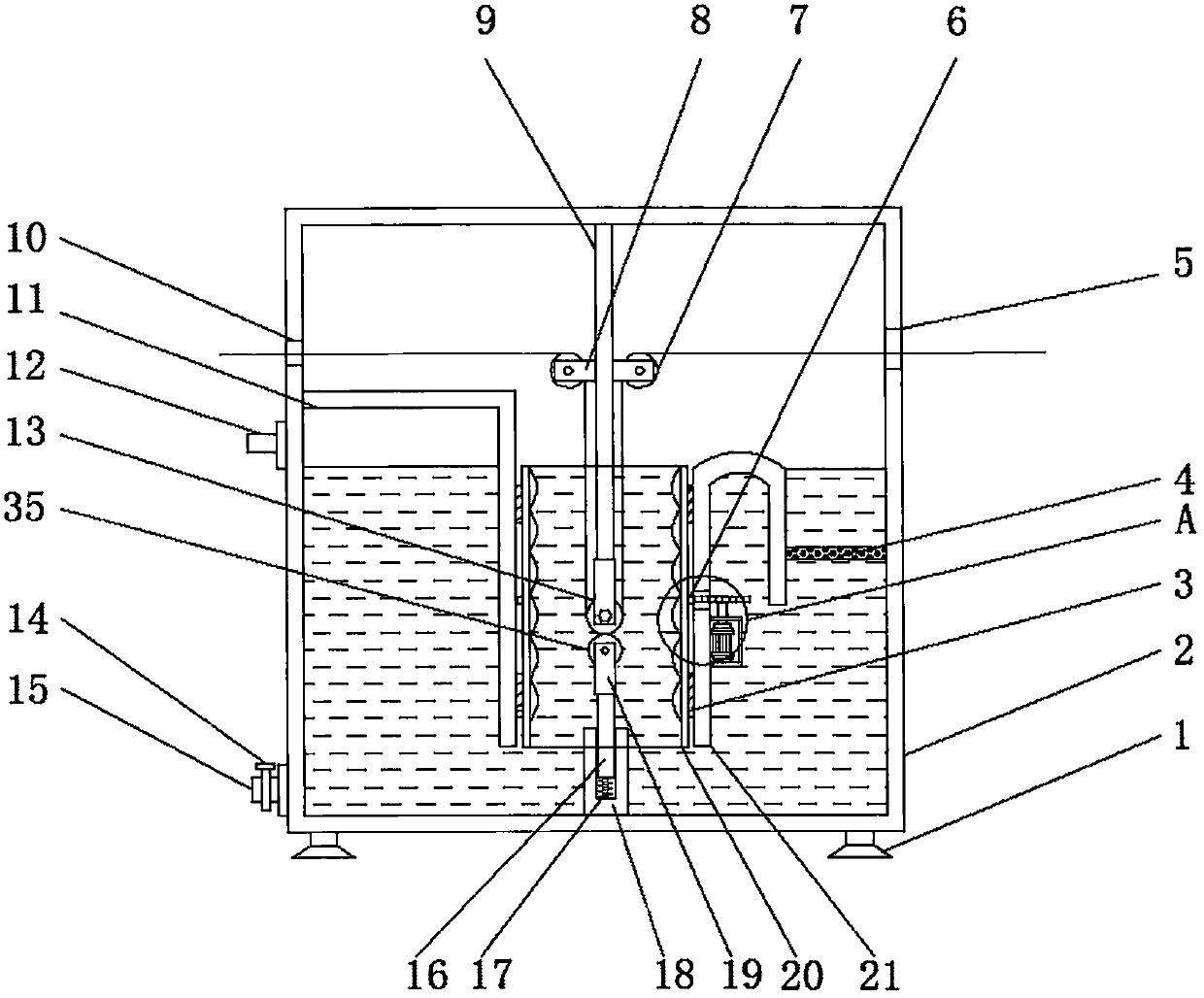

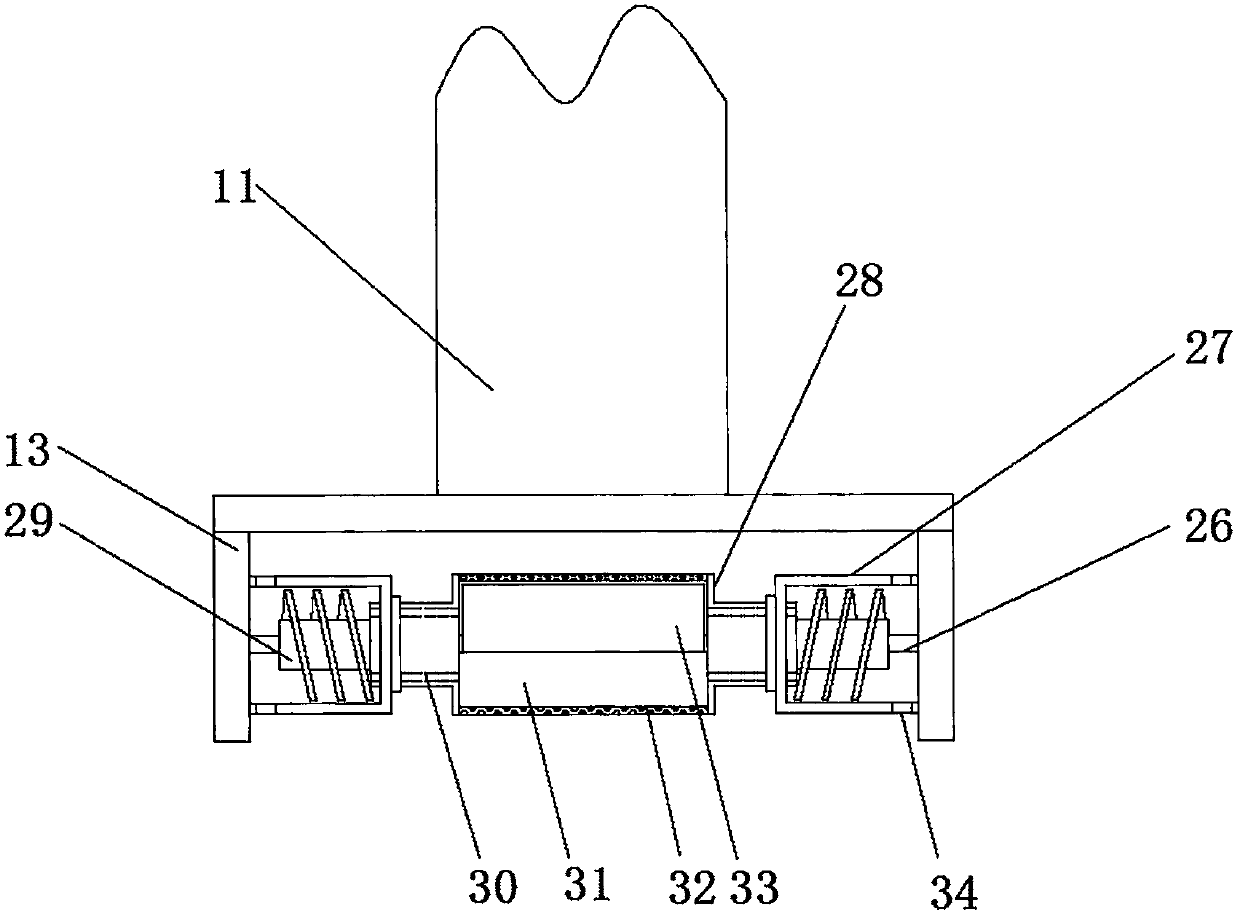

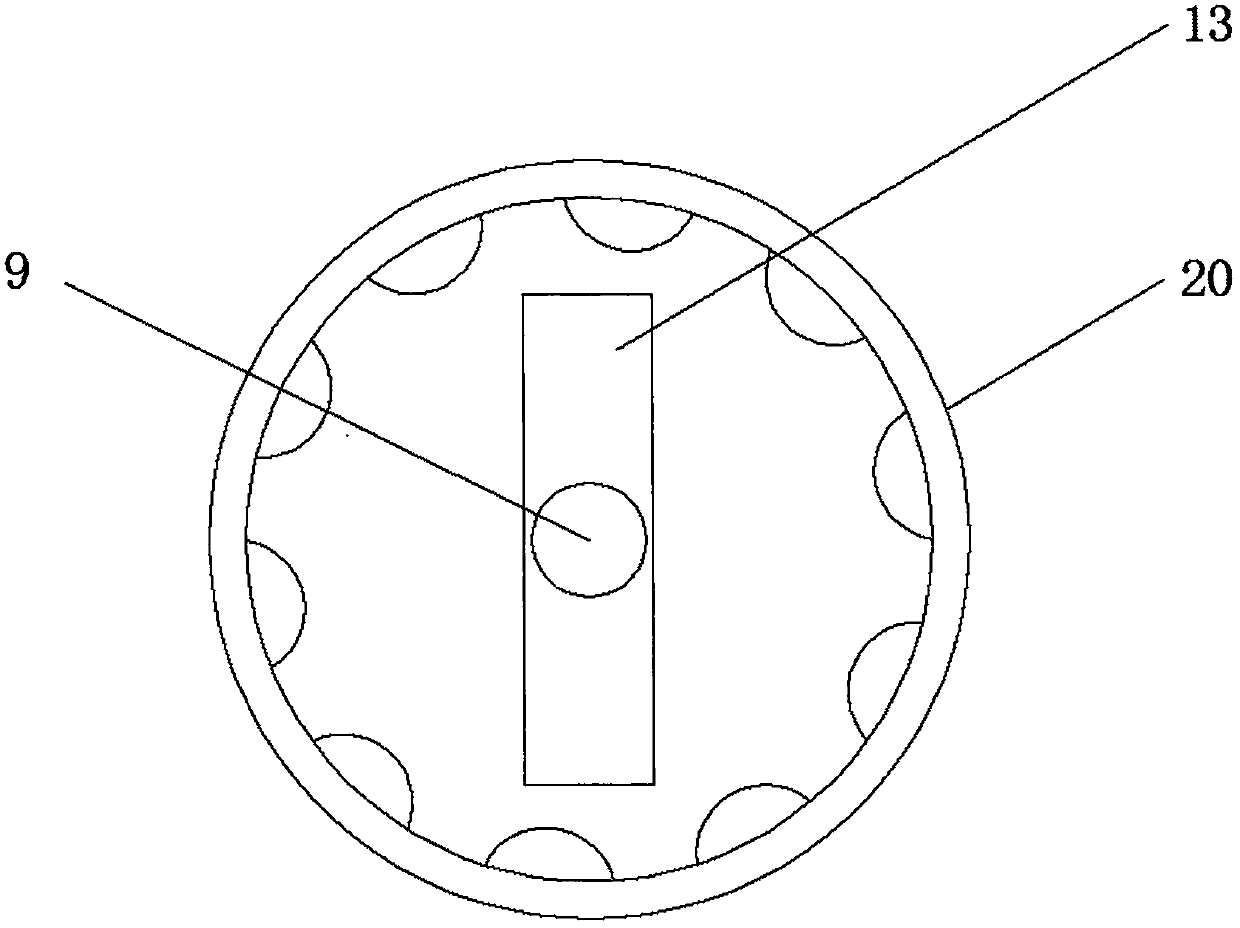

Lake water quality detection and sampling device for water conservancy

ActiveCN108709769AAvoid wear and tearReduce labor intensityWithdrawing sample devicesWireless controlComputer module

The invention relates to a water quality detection device, in particular to a lake water quality detection and sampling device for water conservancy. The invention aims at providing a lake water quality detection and sampling device which can collect the water at different positions and at different depths, can alleviate the labor intensity and can improve the safety. The lake water quality detection and sampling device for the water conservancy is characterized by being comprising a bottom plate, an installation block, a first rotating shaft, a supporting plate, a placement plate, a collection box, a connecting plate, a water collection box, a sealing ring, a baffle plate, an installation box, a wireless control module and a power supply; and the upper-middle portion of the bottom plate is connected with the installation block, and the front side of the installation block is connected with a first rotating shaft in a rotating manner. The water collection box is submerged in the waterdue to the balancing weight, so that the water at different positions and at different depths in a lake can be sampled, the water in the lake does not need to be manually sampled by virtue of a boat,the labor intensity can be alleviated, and the safety can be improved.

Owner:福建谦一建设发展有限公司

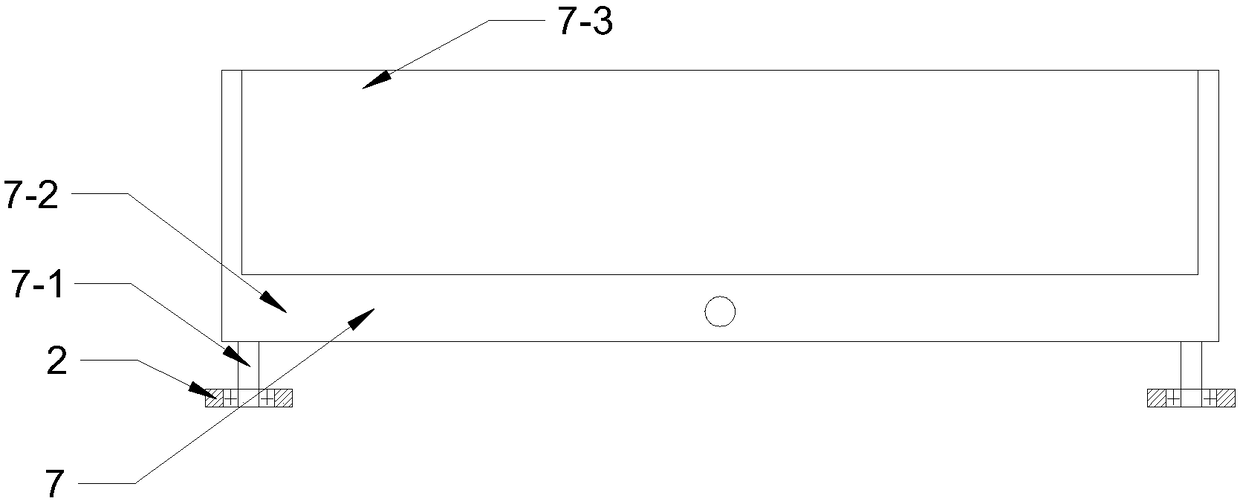

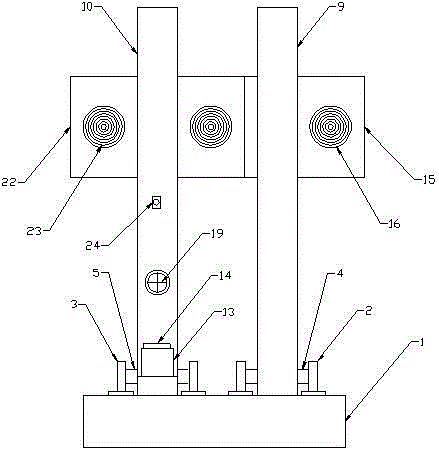

Conveying device

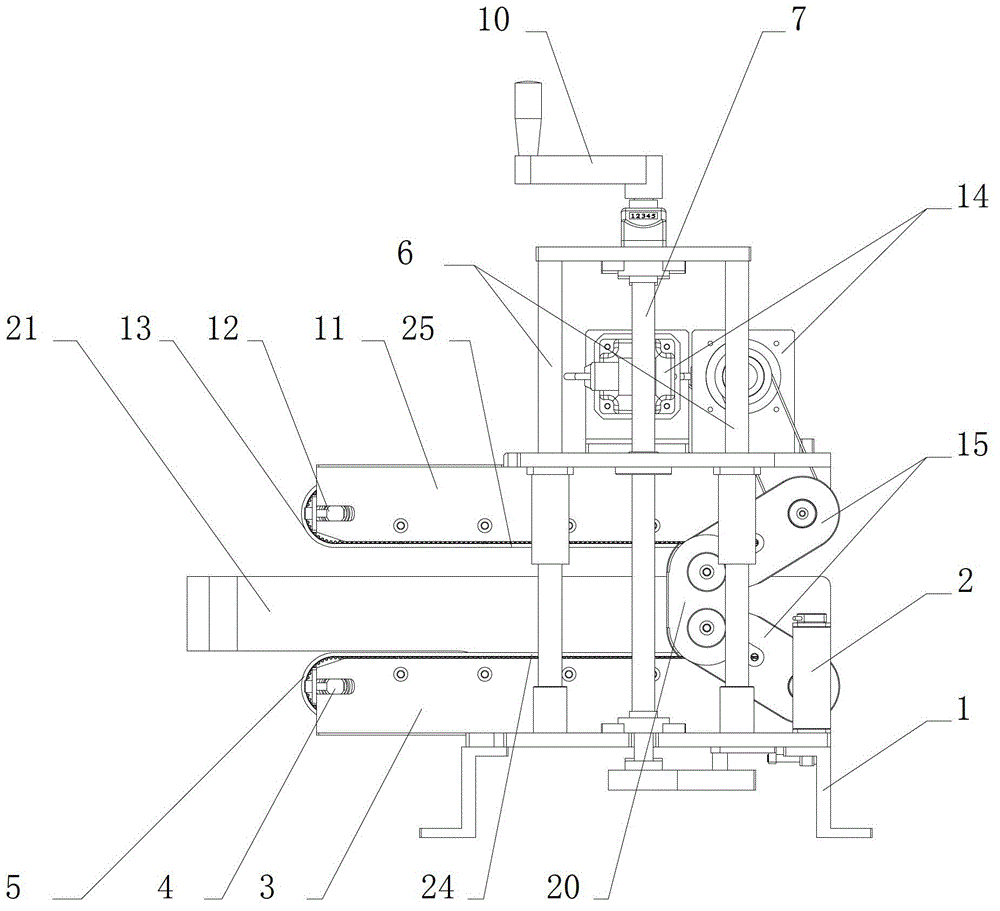

The invention discloses a conveying device. The conveying device comprises a rack and a clamping and conveying mechanism, wherein the clamping and conveying mechanism comprises a conveying part I, a conveying part II, a transmission part and a power part, the conveying part I is fixedly arranged on the rack, the conveying part II is movably connected to the rack through a lifting part, the conveying part I and the conveying part II are parallelly and oppositely arranged and are movably connected through the transmission part, and the power part is connected with the transmission part. The conveying device is provided with the clamping and conveying mechanism in synchronous reverse rotation with the same speed, the surfaces of goods and the conveying device are always in a stationary state when the goods are arranged at the inner part of the conveying device, and the goods can be prevented from suffering from sliding friction; the conveying device is provided with an independent power component, the conveying operation of the goods runs independently and cannot be affected by other devices, and the working stability is high; and the conveying device is enabled to be applied to goods conveying in various heights due to the regulation function of the clamping and conveying mechanism, and thus the conveying device also has the characteristic of wide application range.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

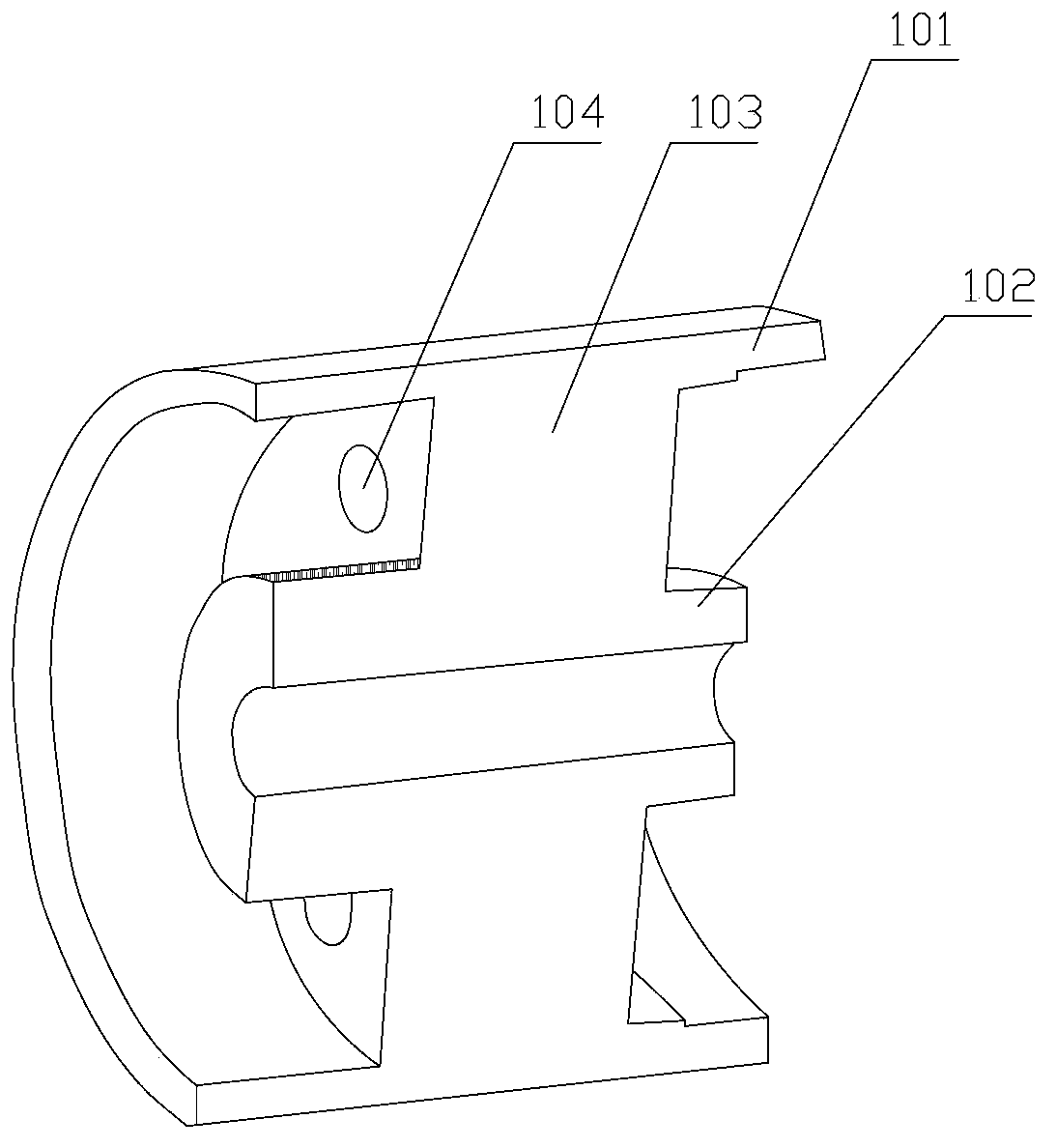

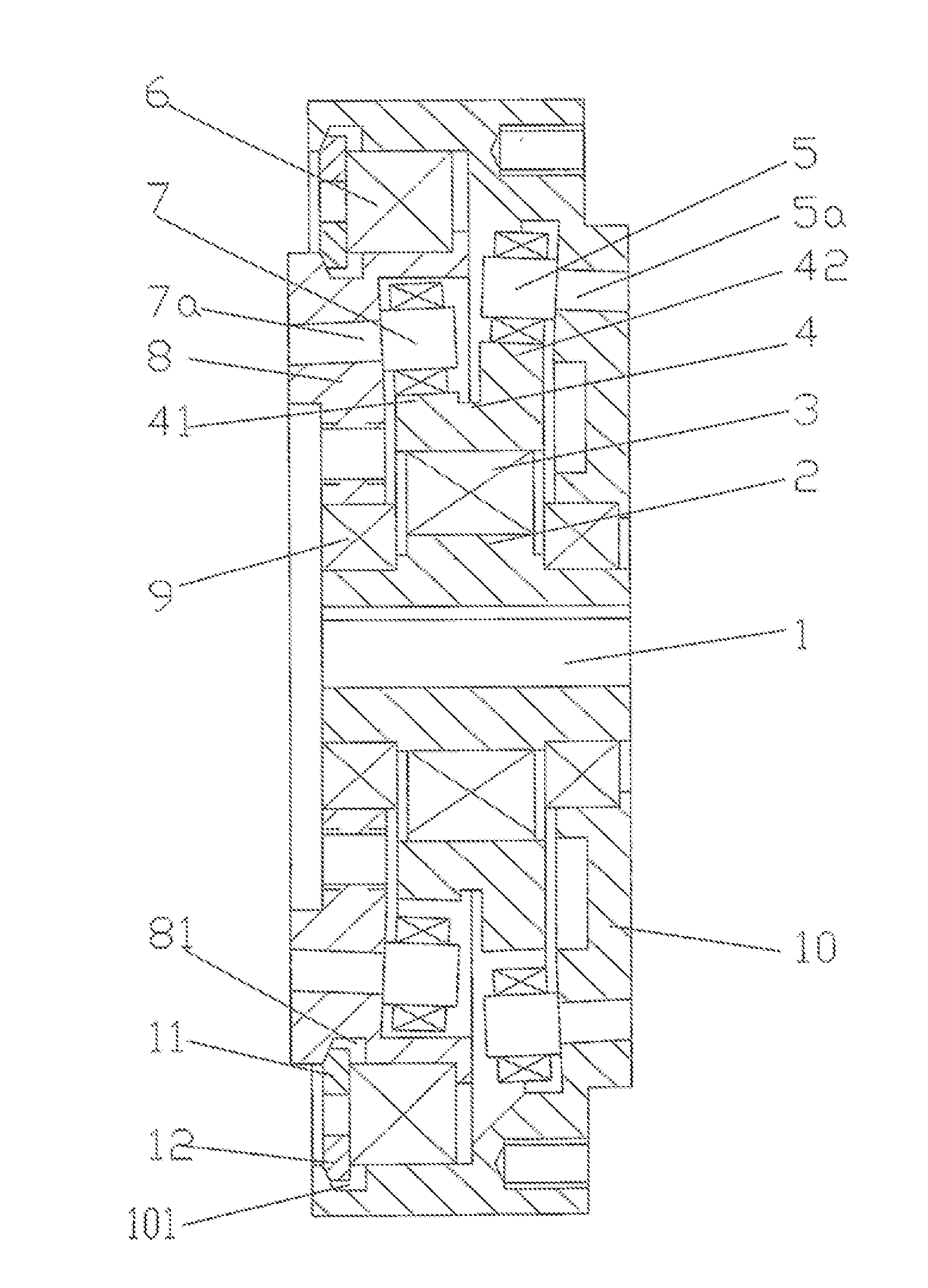

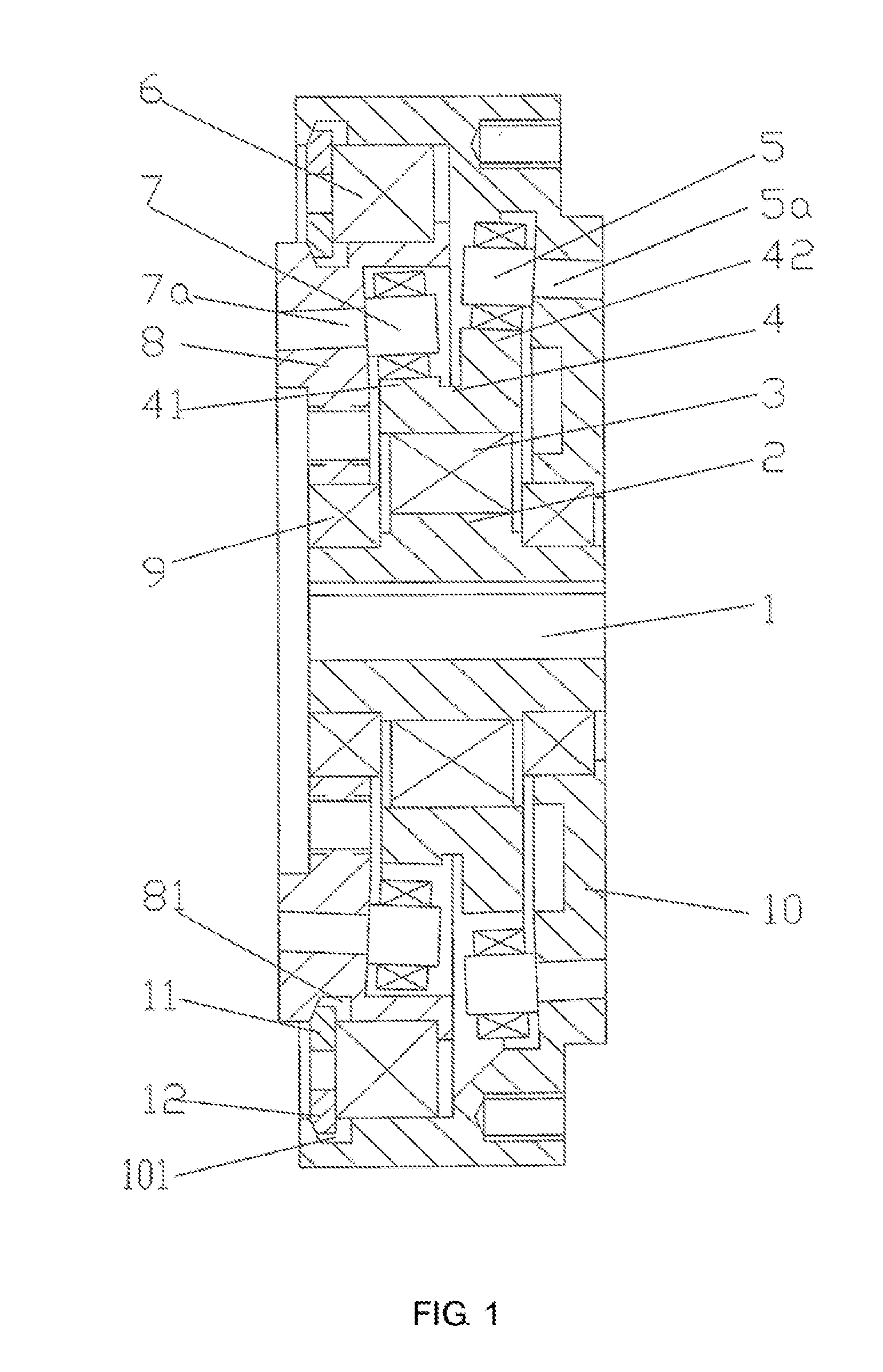

Robot joint with power-off protection function and adjustable rigidity

ActiveCN103358317AEfficient deliveryFacilitate structural reconstructionJointsElectrical connectionSteel ball

The invention discloses a robot joint with a power-off protection function and adjustable rigidity. A spring press plate and a steel ball are arranged in the support structure, the steel ball elastically moves in the axial direction of the mechanical support structure, a shallow pit matched with the circular arc surface of the steel ball is arranged on a steel ball press plate, the steel ball press plate is in rotating connection with the mechanical support structure through a bearing connecting device, when the external input torque acts on the mechanical support structure, the steel ball drives the steel ball press plate to rotate, and when the torque is oversize, the steel ball is disconnected from the shallow pit of the steel ball press plate. An annular clamp groove with a groove is formed in the connecting plate and is clamped and connected with a convex strip arranged on the side wall of the steel ball press plate, and the double protection effects are realized on the robot joint. A convex block matched with a magnetic slide block is arranged on the side wall in an outer casing, a spring pushes a friction layer of the magnetic slide block to be pasted with the convex block, and the braking is realized. The robot joint has the advantages that under the condition of not influencing the normal mechanical and electrical connection, the overload protection function on the joint is realized, after the overload disappears, the initial state can be conveniently and fast recovered, and in addition, the power-off protection function is realized.

Owner:ANHUI TATSU PRECISION ALLOY

Air-passage opening/closing device

InactiveUS20050215190A1Avoid sliding frictionControl air leakageAir-treating devicesOperating means/releasing devices for valvesDrive shaftEngineering

An air passage opening / closing device includes a film member for opening and closing an opening of an air passage of a case. One end of the film member is fixed to a fixing portion on an outer periphery of the opening of the air passage, and the other end thereof is connected to a film winding shaft. A moving member movable by rotation of a drive shaft is provided on the opening, and the film winding shaft is moved while being rotated by the movement of the moving member, so that the film member at the other end side is wound around and unwound from the film winding shaft. Accordingly, when the air passage is opened and closed by the film member, sliding friction can be prevented from being generated between the film member and the case.

Owner:DENSO CORP

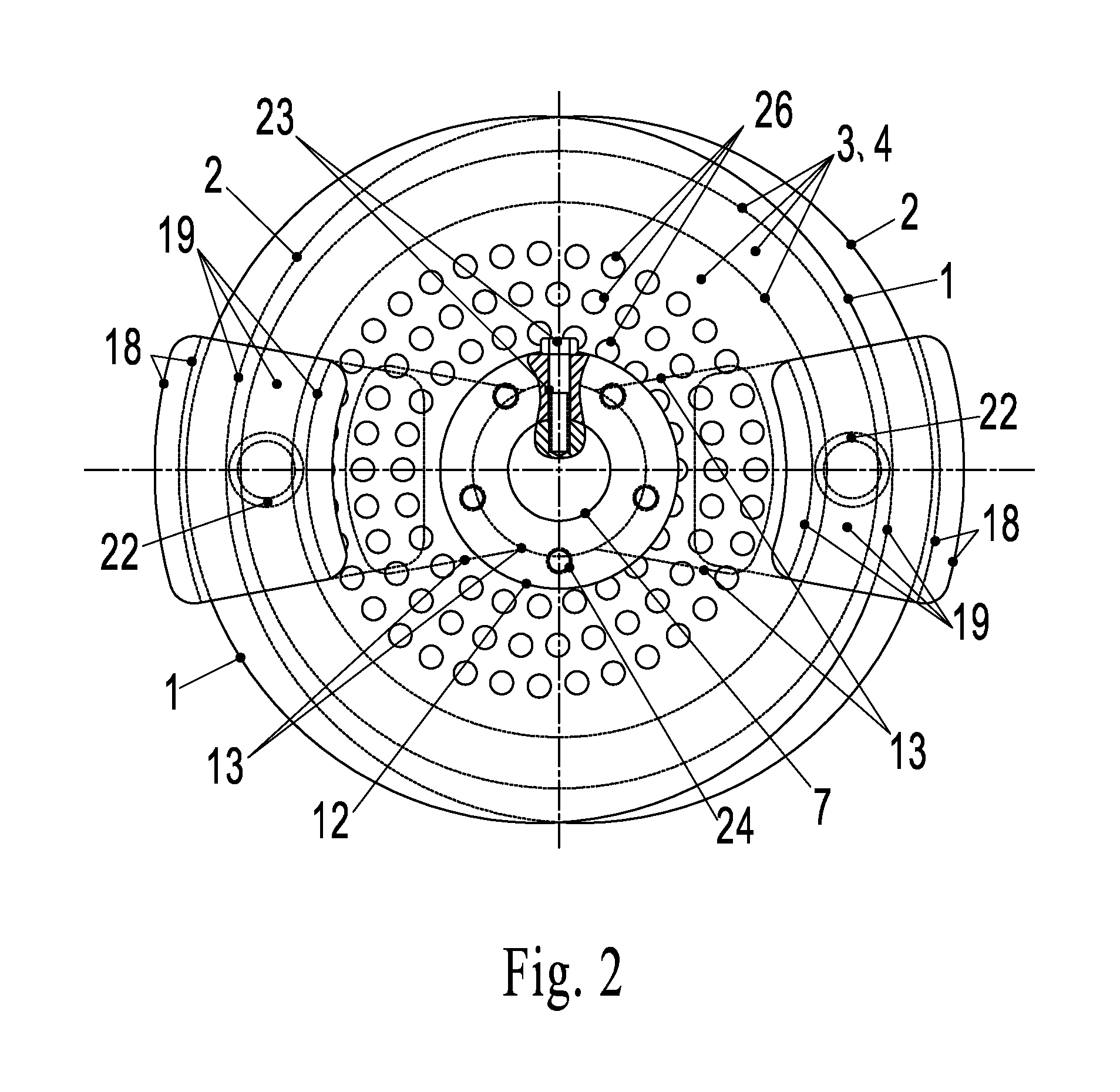

Dual-directions braking method of disc brake, braking mechanism and application thereof

InactiveUS20150204398A1Improve safety braking performanceHigh rateFluid actuated brakesAircraft braking arrangementsSafety controlEngineering

A dual-directions braking method of a disc brake, a braking mechanism and applications thereof are applied in fields of automobiles, trains and aircrafts. The dual-directions braking mechanism includes a crankshaft having three concentric sections and two eccentric sections, two friction discs, a friction disc ring and at least a pair of brake calipers and friction pads, wherein the two eccentric sections are respectively provided between each neighboring two of the three concentric sections and mutually disposed at 180°; the two friction discs are respectively provided on the two eccentric sections; the friction disc ring is provided on the main section between the two eccentric sections. Through a translationally rotating friction by the two friction discs respectively with the friction disc ring and with the friction pads of each pair of brake calipers, a backward braking moment and a forward braking moment are simultaneously generated on the main sections, so as to enhance a braking performance twice while keeping a wheel friction load unchanged, compared to conventional backward brakes. An automobile dual-directions braking system including the dual-direction braking mechanism is able to accomplish electronic safety control functions of DABS, DEBD and DESP, and greatly improve transportation safety.

Owner:QIANG HAISHENG

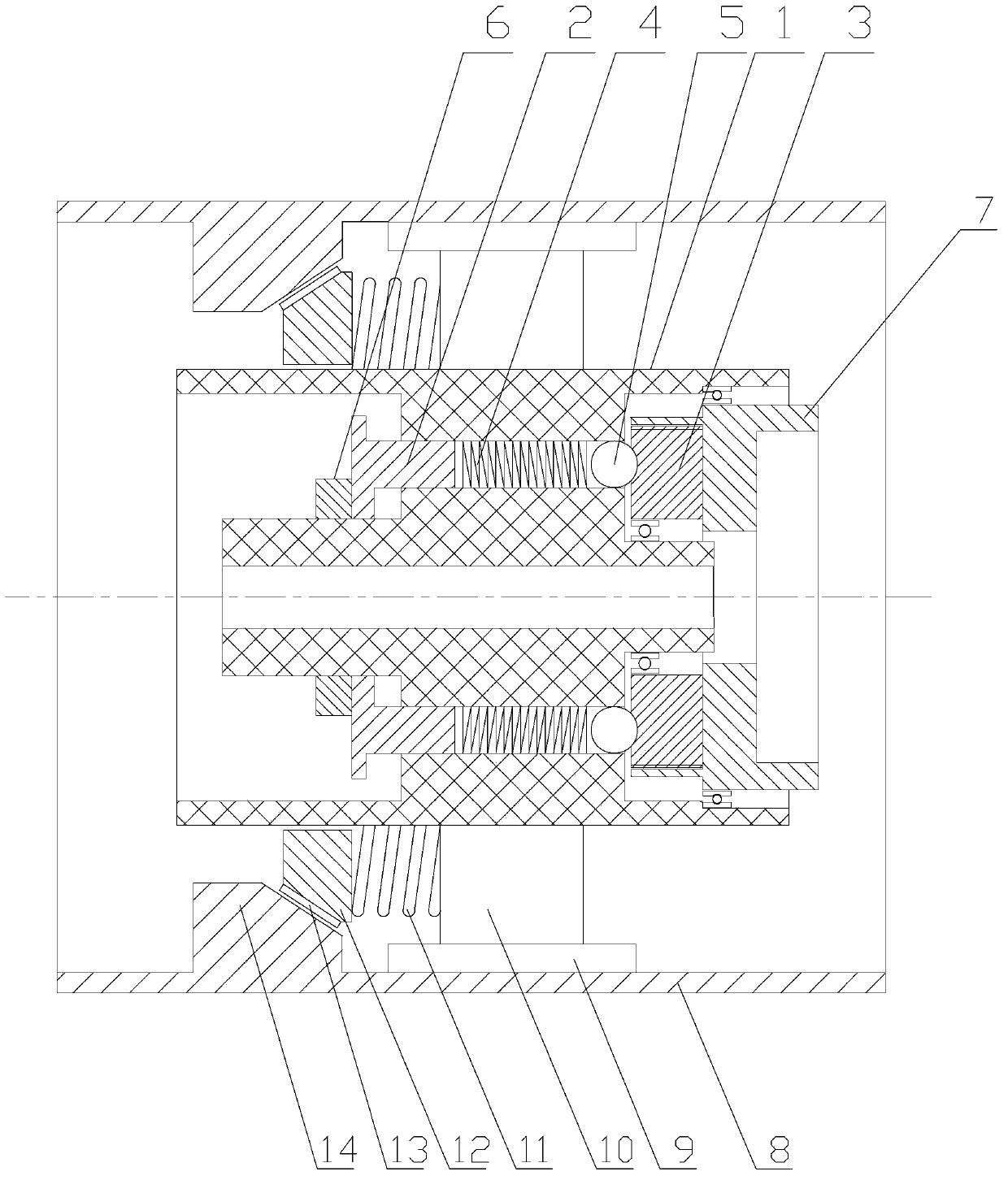

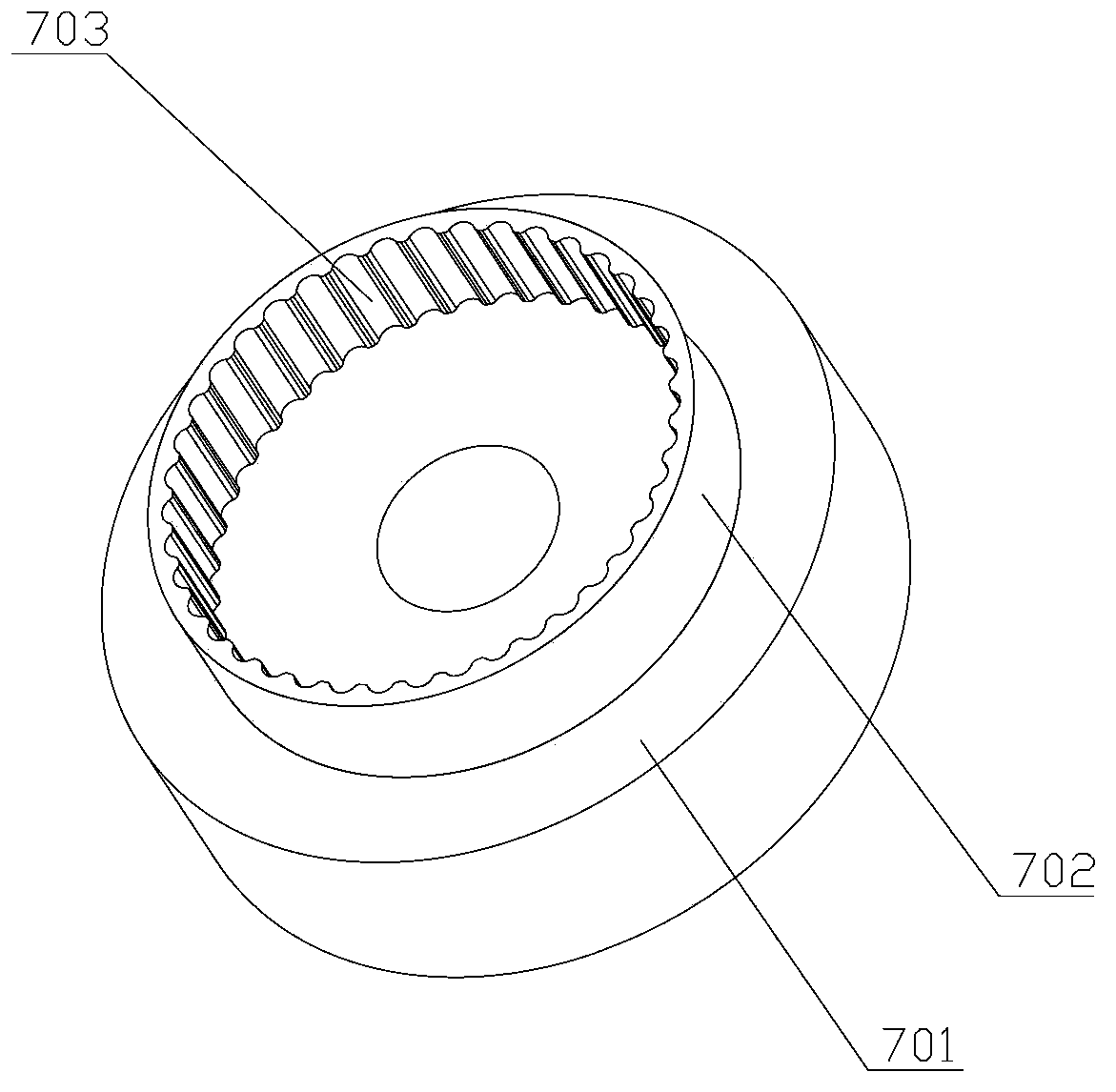

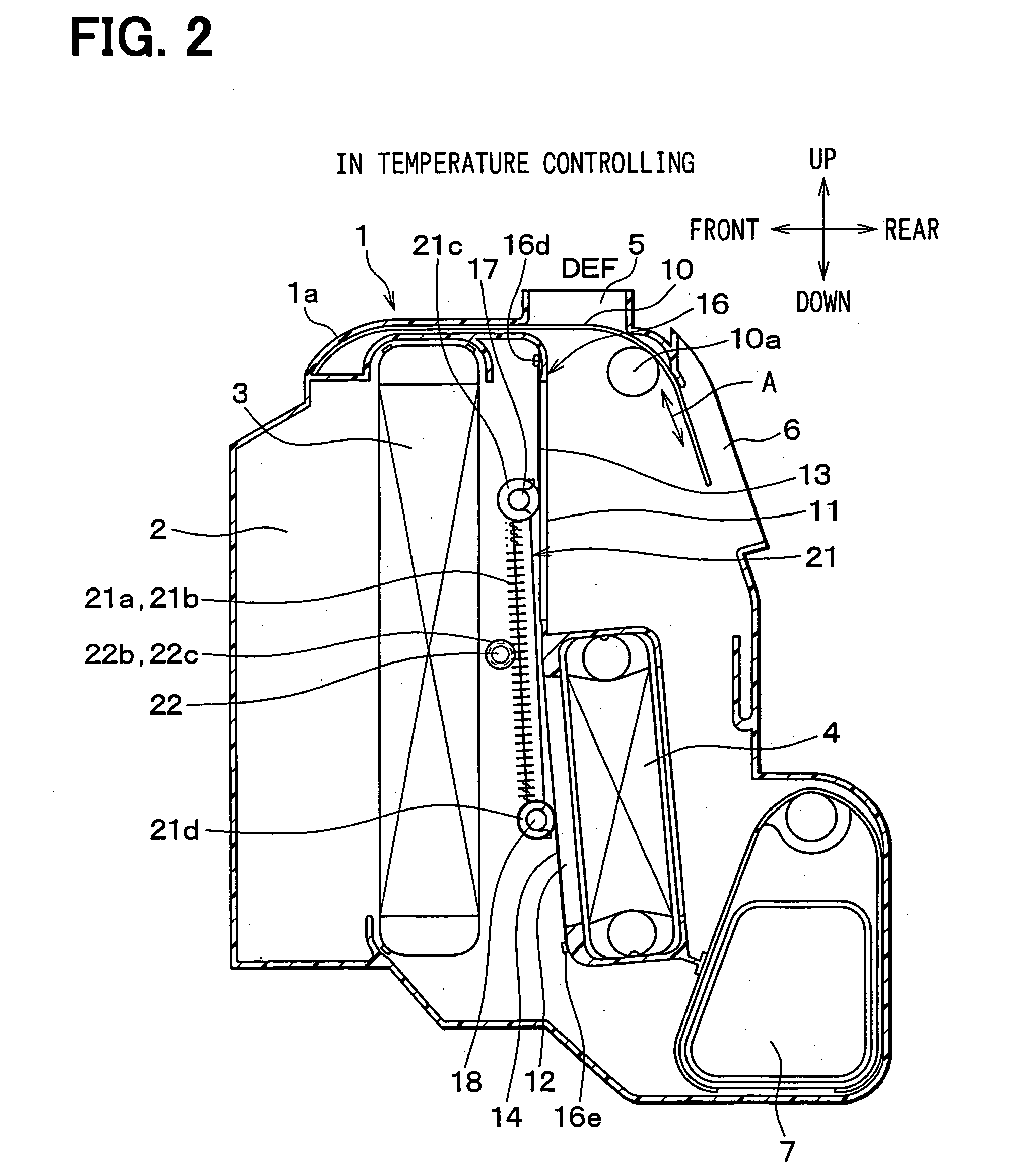

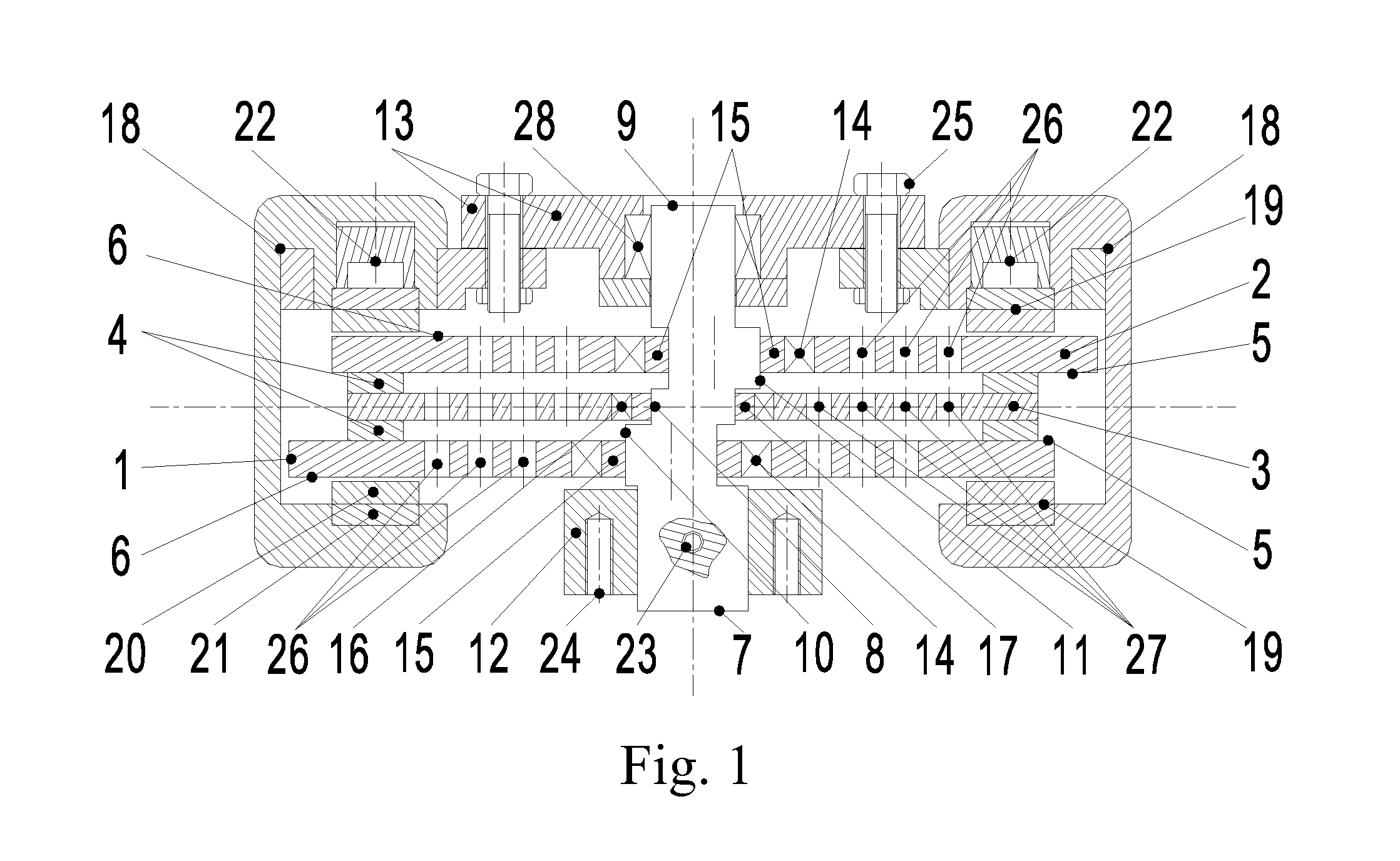

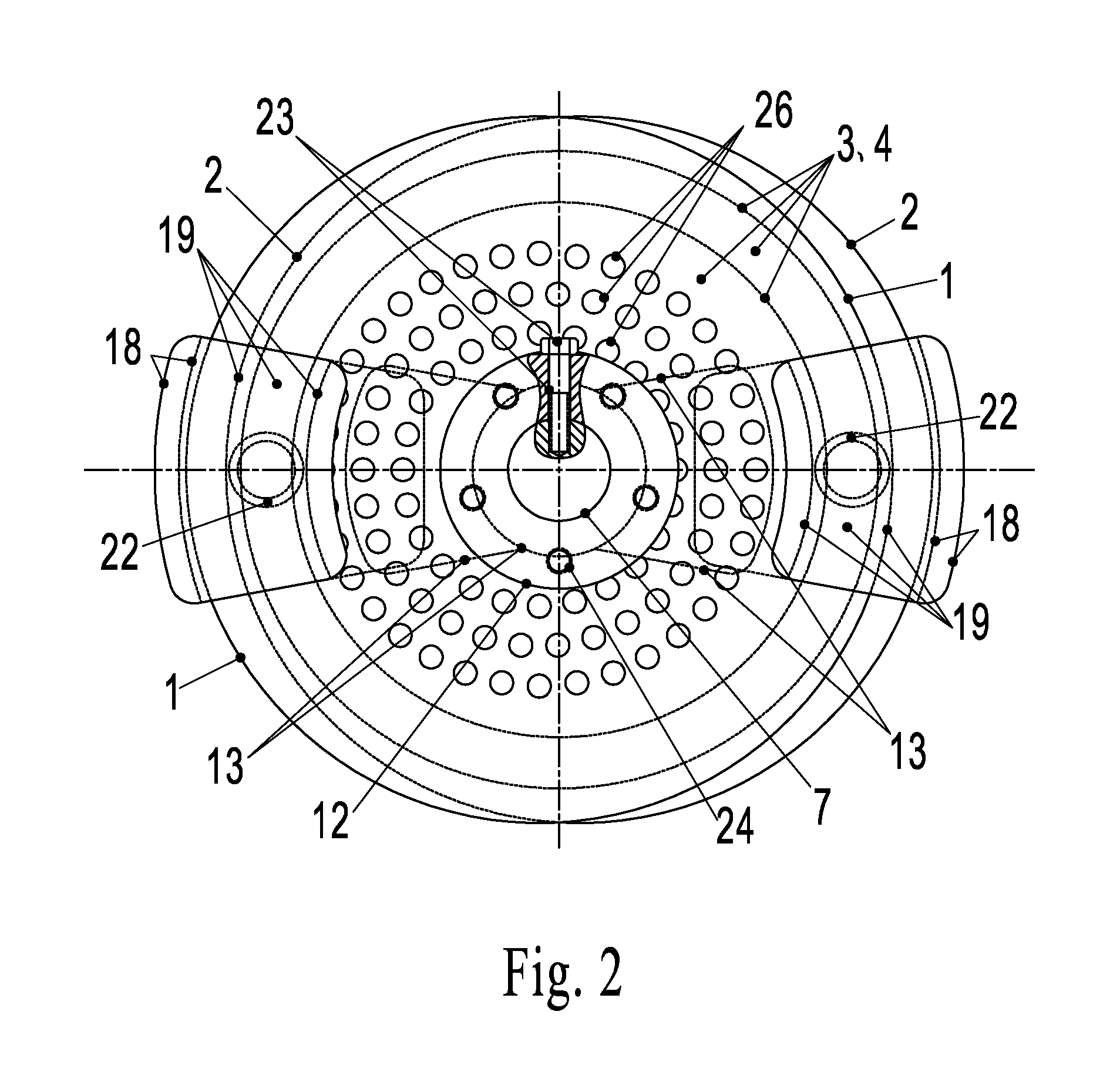

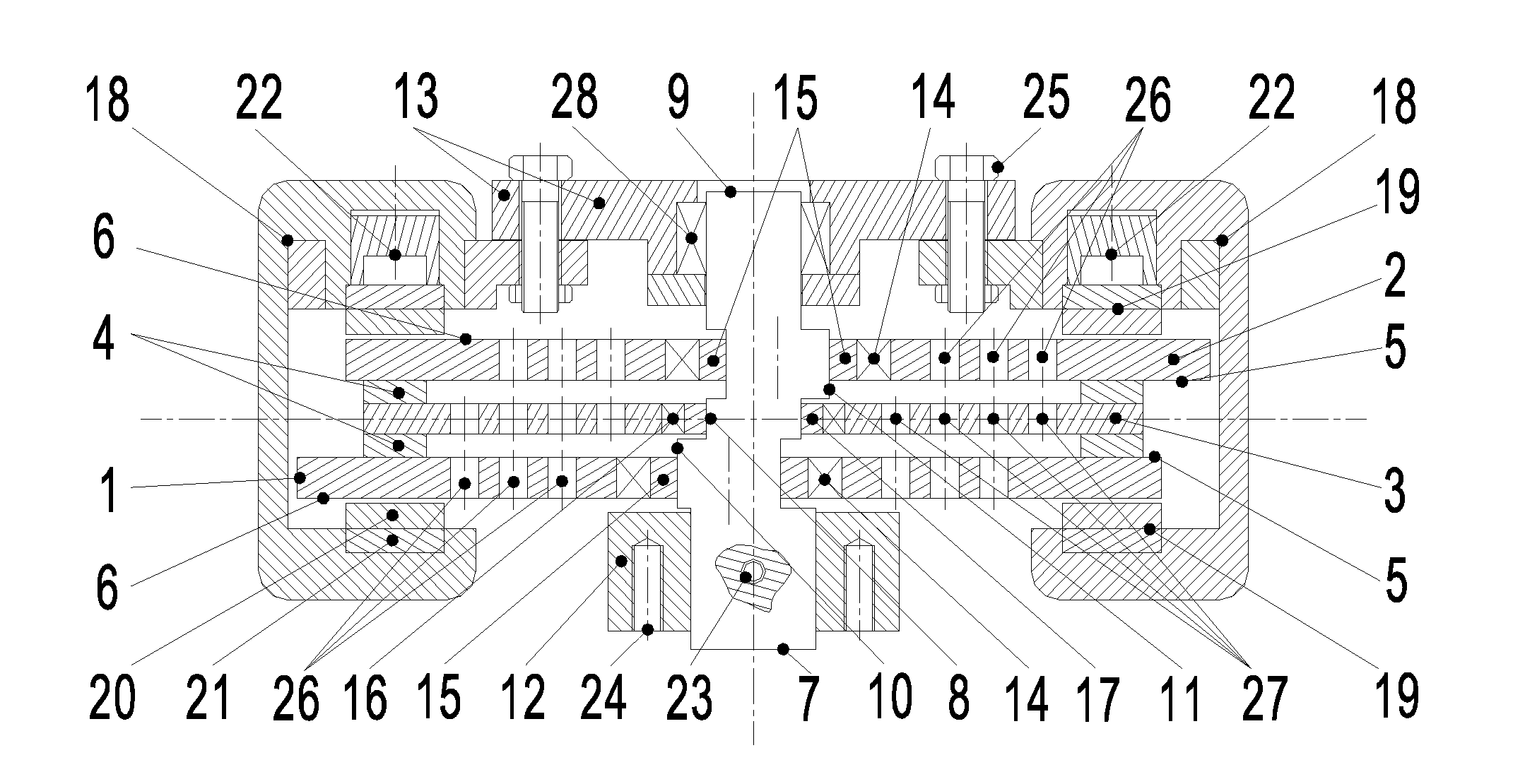

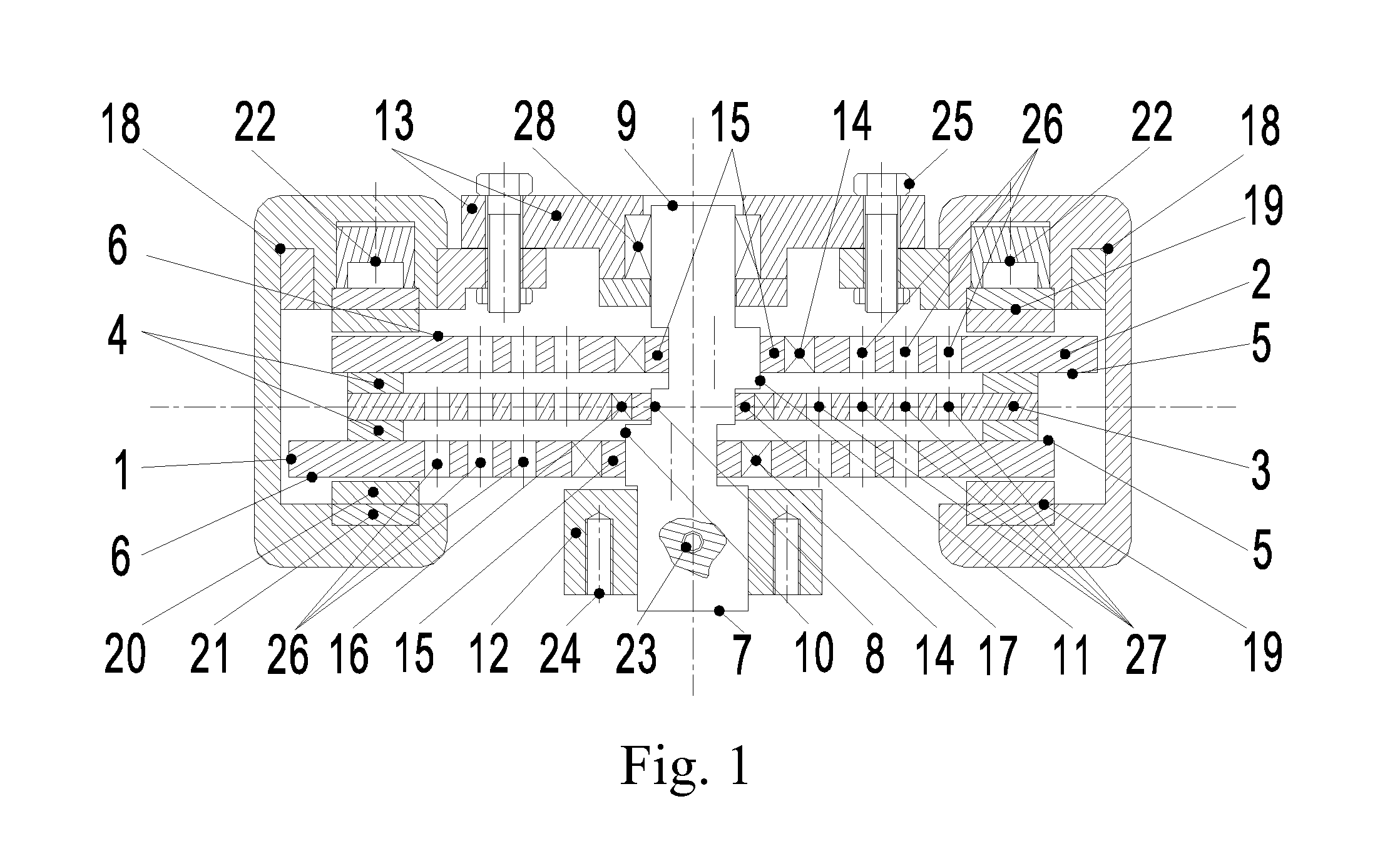

Gapless planetary transmission

ActiveUS20120264563A1Avoid sliding frictionImprove accuracyPortable liftingToothed gearingsLow noiseEngineering

The present invention provides a backlash-free planetary transmission device, comprising a housing (10), a power input shaft (1) and a power output shaft (8). An eccentric sleeve (2) is securely positioned on a circumference of the power input shaft (1). A fixed pin gear (5) is set on the housing (10) that is concentric with the power input shaft (1). A power output pin gear (7) is set on the power output shaft (8) in circumferential transmission fit and concentric with the power input shaft (1). An outer ring of the eccentric sleeve (2) rotatably fits with a dual outer gear (4). An outer gear (42) of the dual outer gear (4) is meshed with the fixed pin gear (5) with small teeth difference, and the other outer gear (41) is meshed with the power output pin gear (7) with small teeth difference. The pin teeth of both the fixed pin gear (5) and the power output pin gear (7) include a roller that can rotate around its own axis. The profiles of teeth of the two outer gears (41, 42) of the dual outer gear (4) are respectively enveloped by profiles of the fixed pin gear (5) and the power output pin gear (7) meshed therewith. The outer gears (41, 42) and roller are pure rolling mesh, to avoid sliding friction between meshed gear teeth. The dual outer gear (4) of the backlash-free planetary gear contacts with teeth of both the fixed pin gear (5) and the power output pin gear (7), having properties of zero transmission error and zero gear backlash. The transmission device has high accuracy, low noise, high transmission efficiency and long service life.

Owner:CHONGQING UNIV

Textile fabric dyeing device with good dyeing uniformity

ActiveCN110878454AIncrease pressureIncrease contact areaTextile treatment machine arrangementsLiquid/gas/vapor treatment of indefinite length materialsPolymer scienceEngineering

The invention discloses a textile cloth dyeing device with good dyeing uniformity, which comprises a housing, a second guide roller support, a sleeve and an inner spiral pipe; a cloth feeding port isarranged at the top of one side of the housing, a cloth discharging port is arranged at the top of the other side of the housing, an L-shaped retainer is arranged on the inner wall of the housing below the cloth feeding port, and an n-shaped retainer is arranged in the housing at one side of the cloth feeding port. The second guide roller is driven to rotate through the transmission of cloth, a dye liquor is pressed into a cavity and is sprayed from a second outlet, the contact area between the cloth and the dye liquor is increased, and the dyeing efficiency is improved; in addition, the dye liquor inside the inner spiral pipe is rotated and surges upward; when the dye liquor rotates, the dye liquor can penetrate the cloth, so that the dyeing efficiency for the cloth is further improved, the cloth is uniformly dyed, and a dye in the dye liquor is prevented from precipitating; when the dye liquor surges upward, impurities floating on the surface of the dye liquor move to the other sideof the n-shaped retainer and are filtered so that the dye liquor is kept clean, the service life of the dye liquor is prolonged, and the cost is reduced.

Owner:JIANGSU SHUANGSHAN GRP

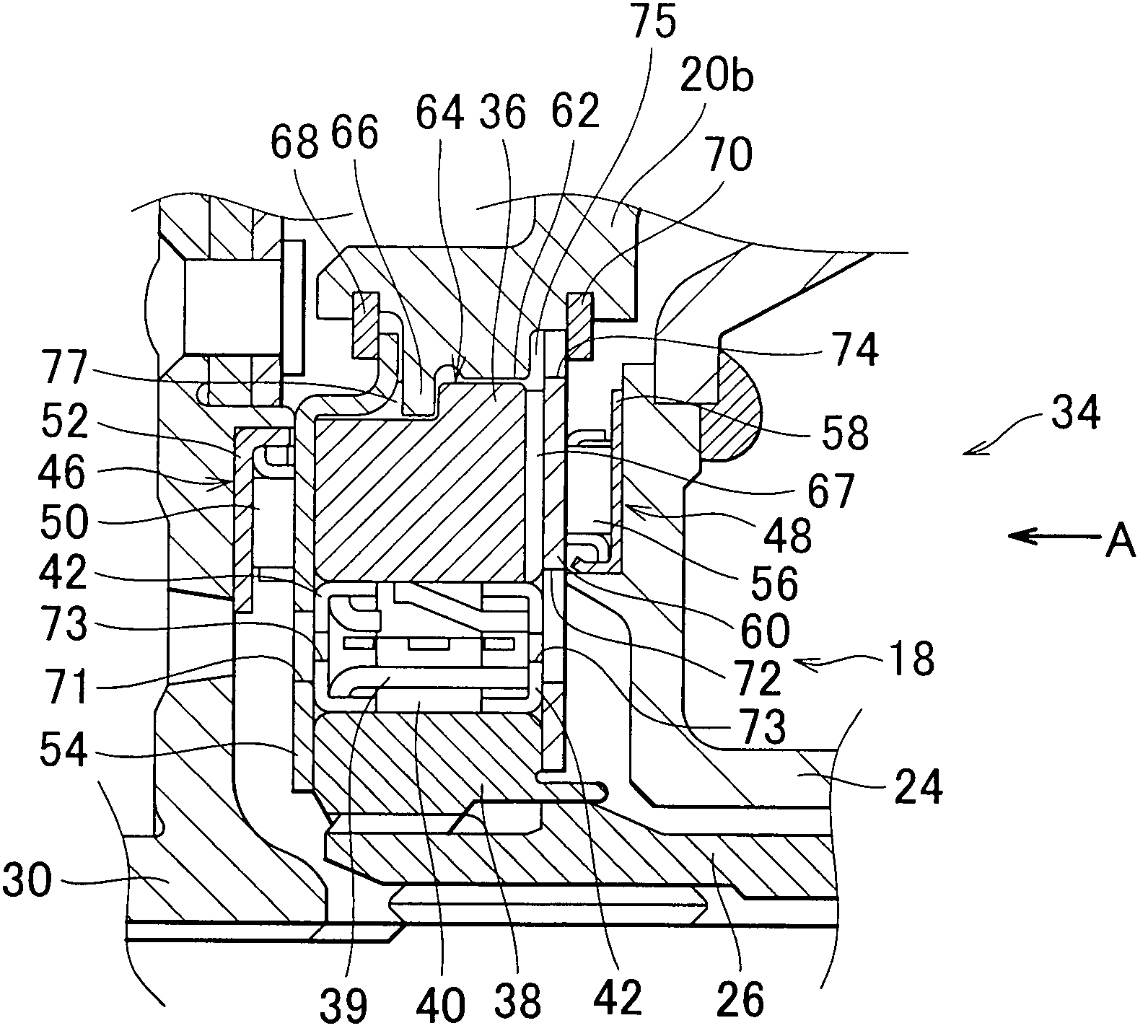

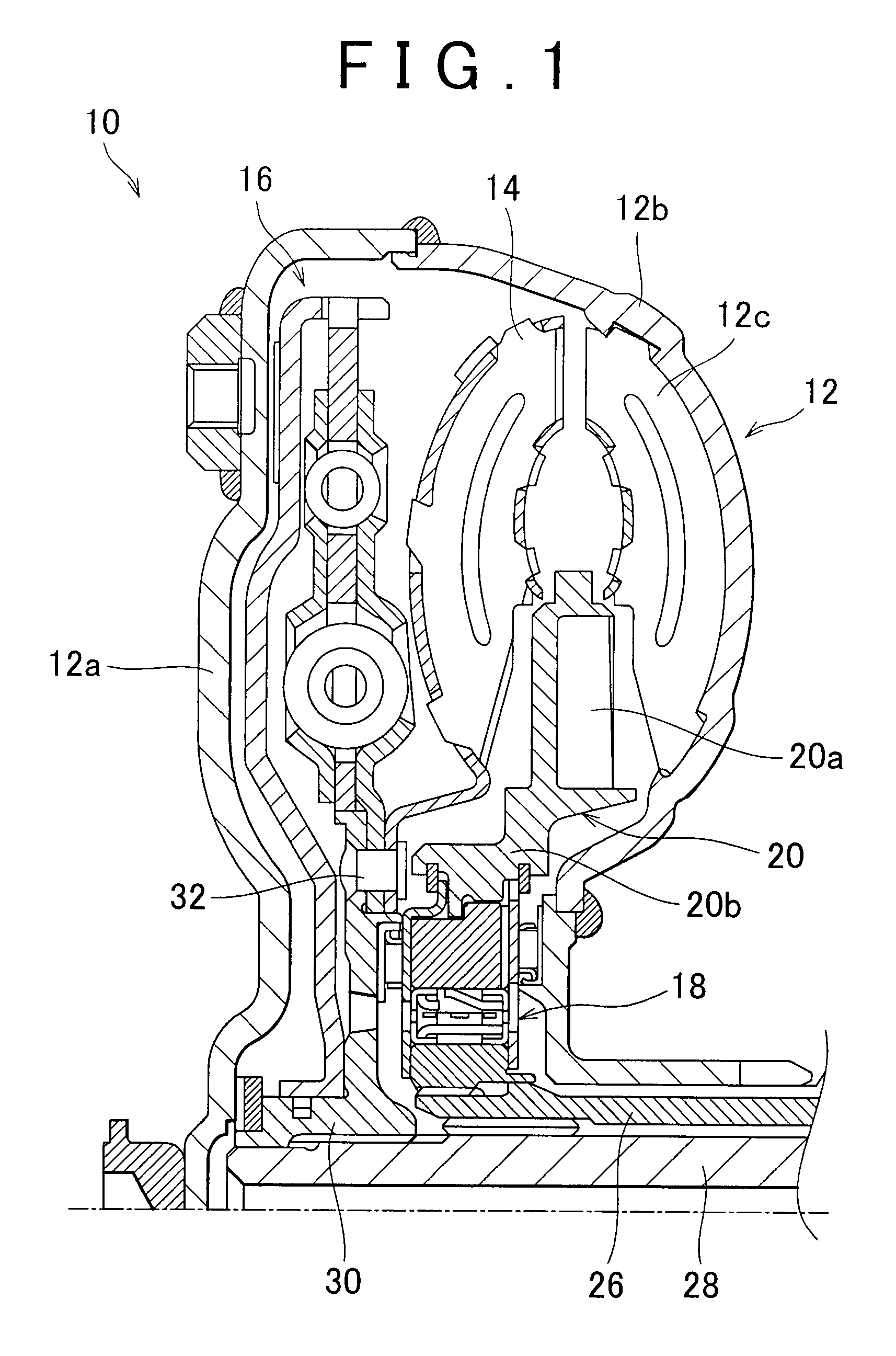

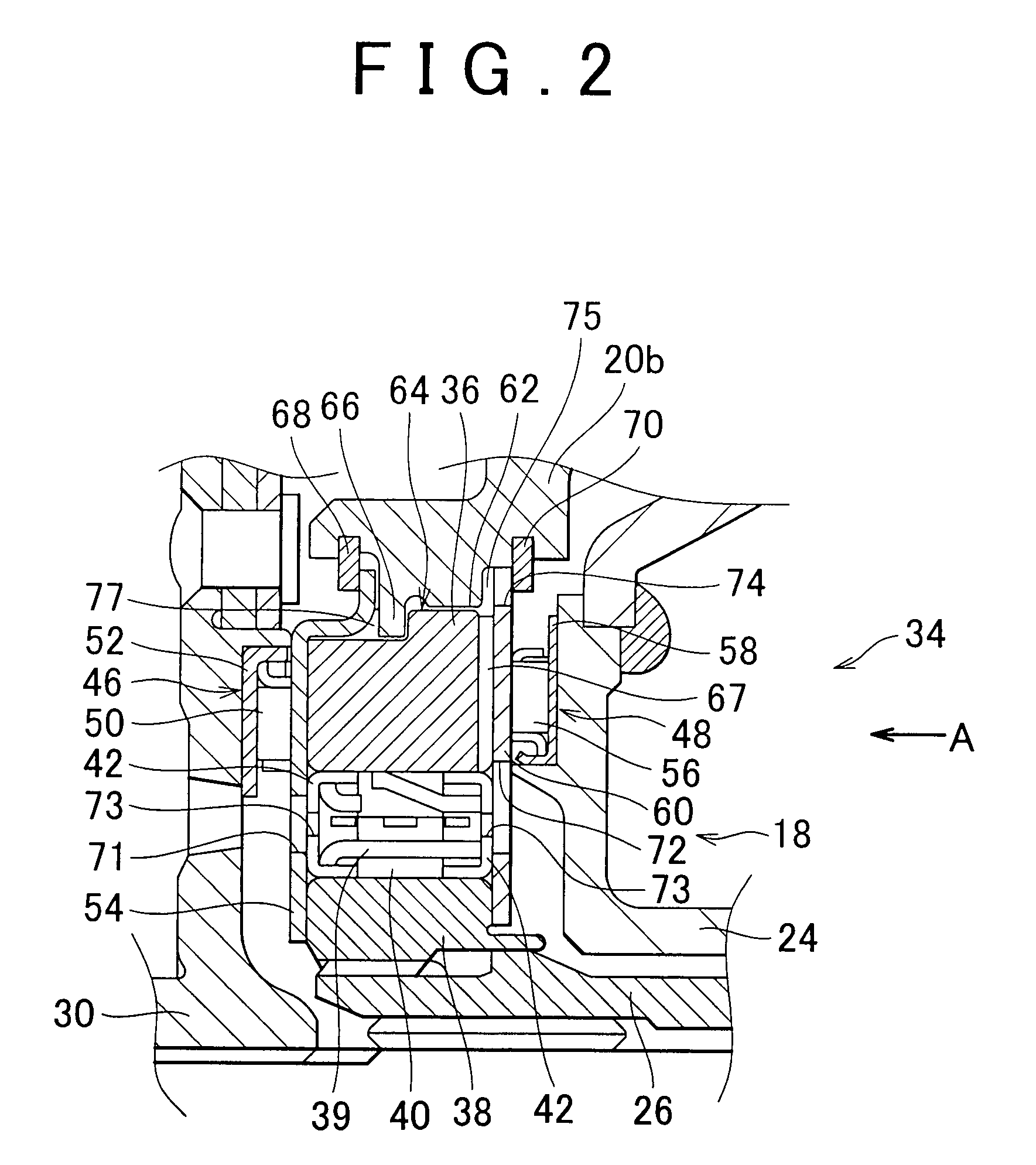

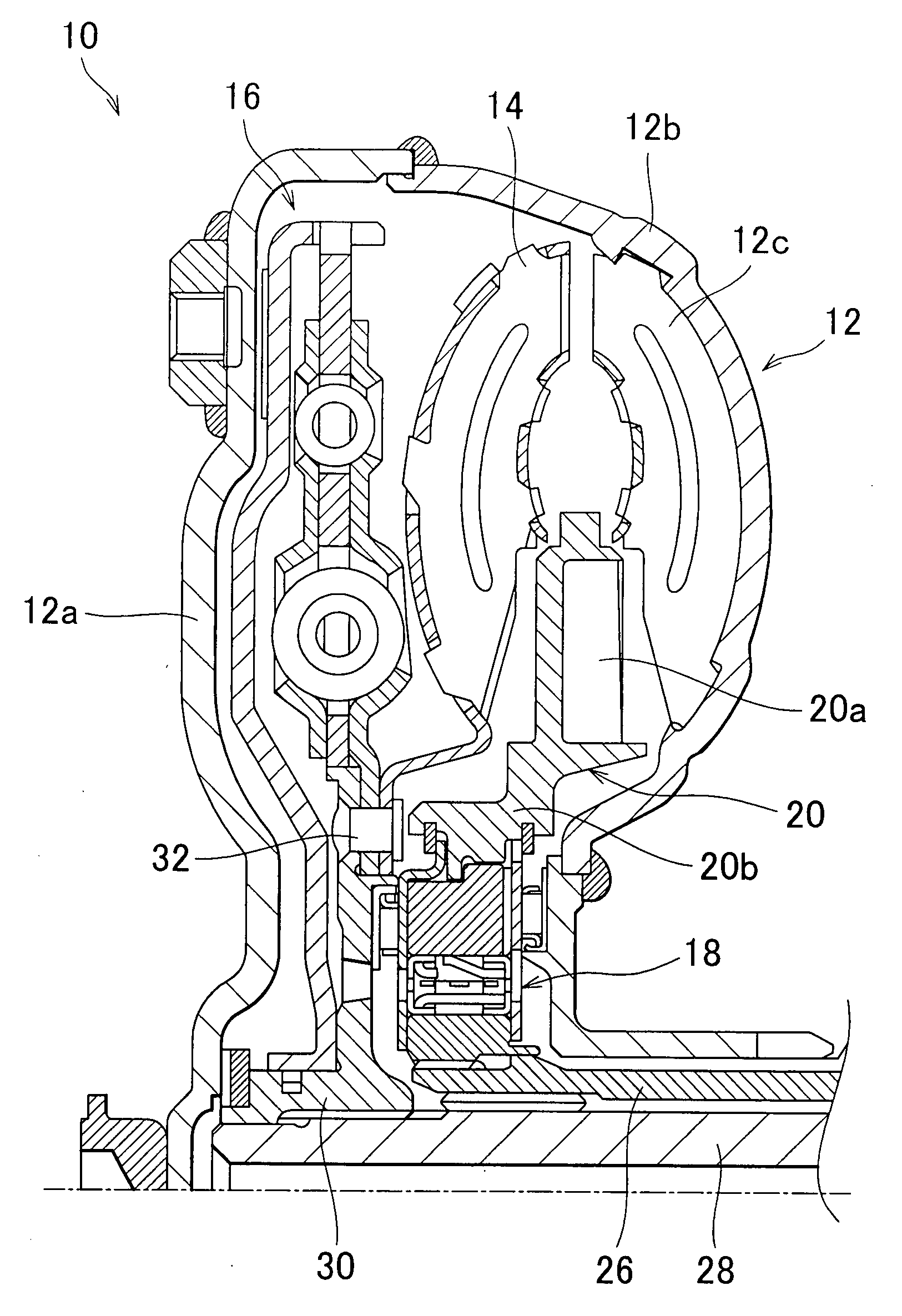

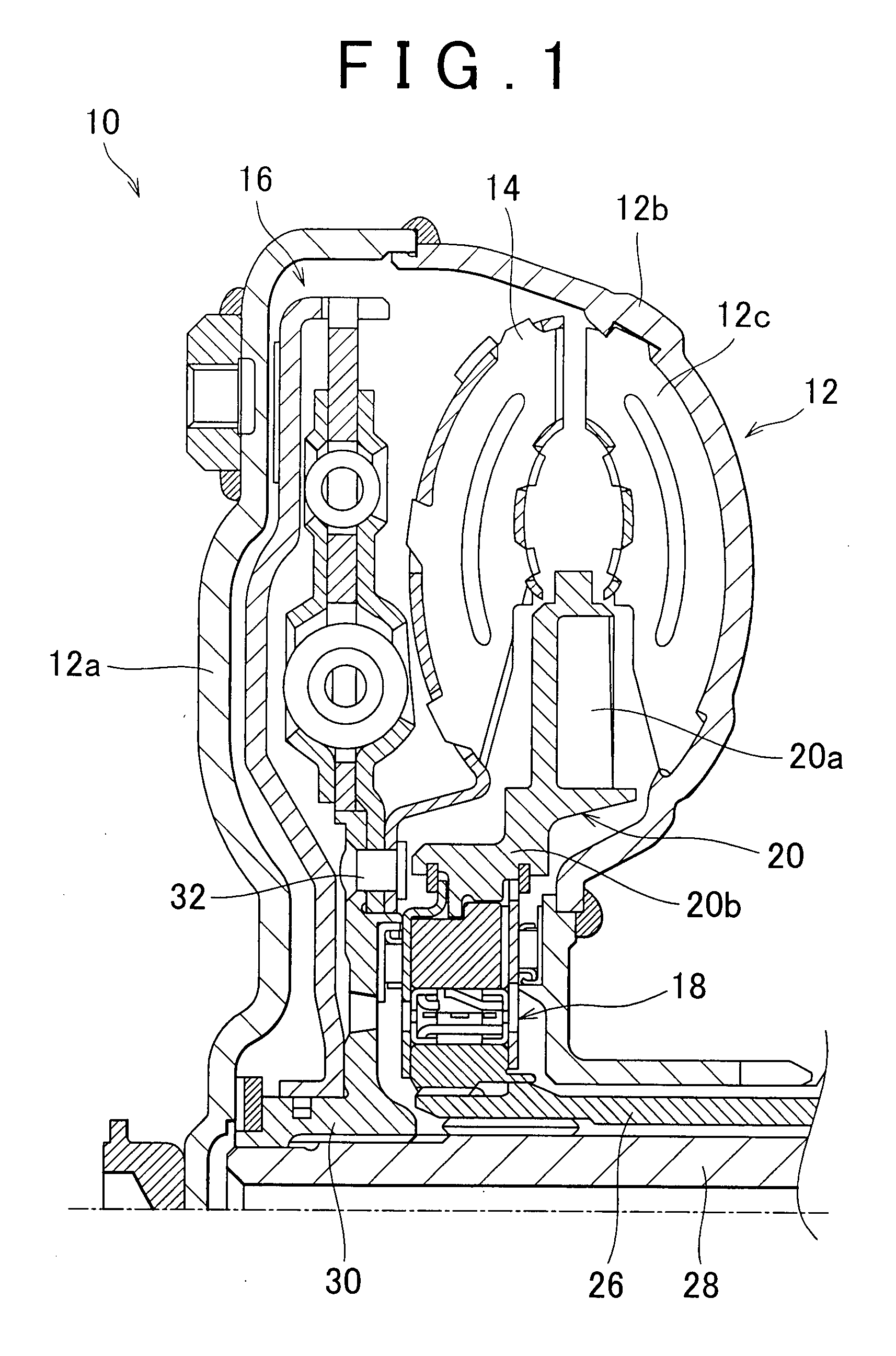

Stator support structure for a torque converter

InactiveUS7762065B2Avoid sliding frictionReduce manufacturing costRotary clutchesDrip or splash lubricationControl theoryTorque converter

A stator support device for a torque converter having a stator wheel and a non-rotating member has a one-way clutch and a bearing race. The one-way clutch includes an outer race disposed along the inner periphery of the stator wheel, an inner race connected to the outer periphery of the non-rotating member to prevent rotation of the inner race relative to the non-rotating member, and an end bearing provided between the outer race and the inner race. The bearing race is disposed at a side face of the outer race. The bearing race is supported so as to be rotatable in the circumferential direction. A gap is formed between the bearing race and the stator wheel.

Owner:TOYOTA JIDOSHA KK

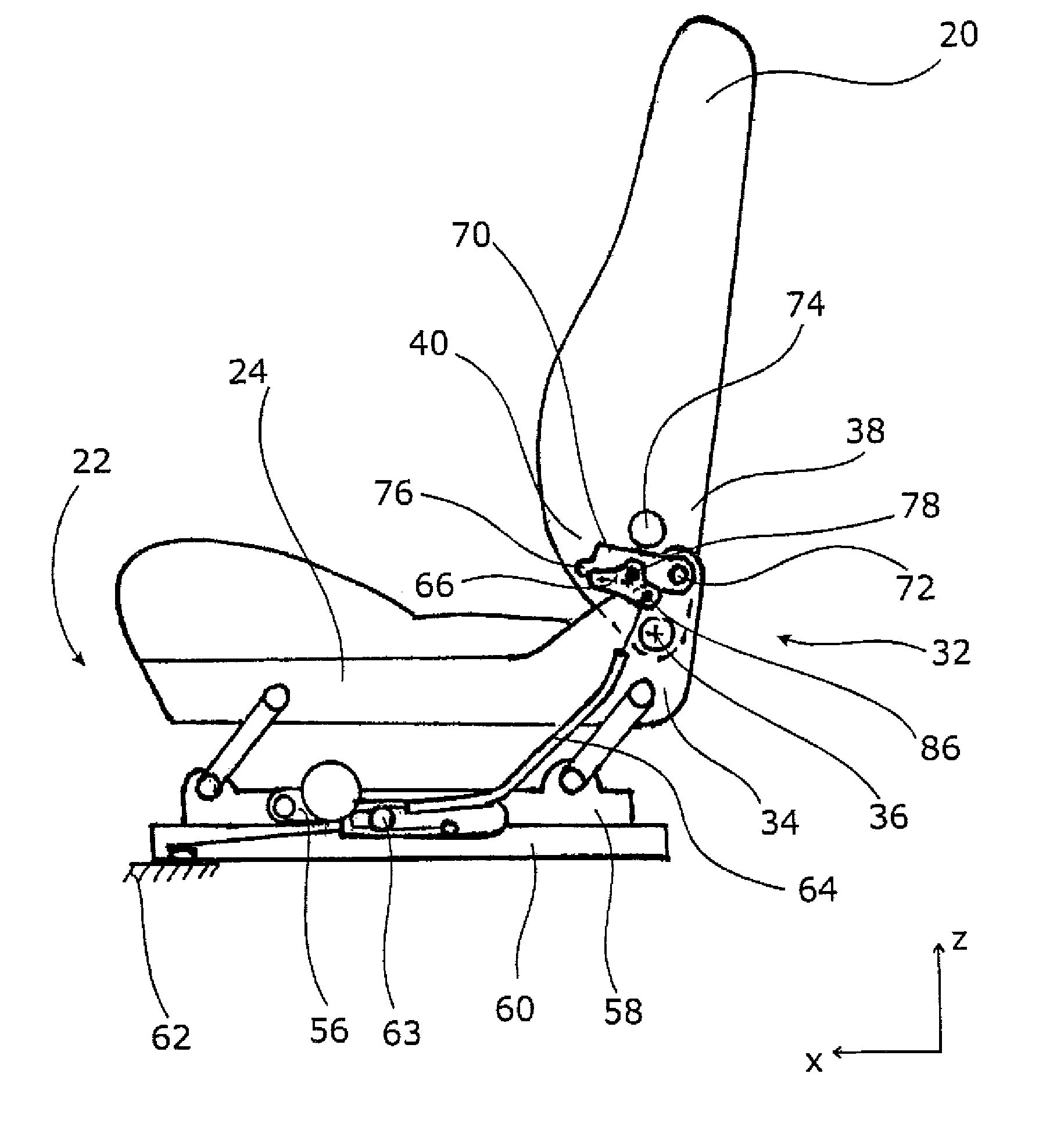

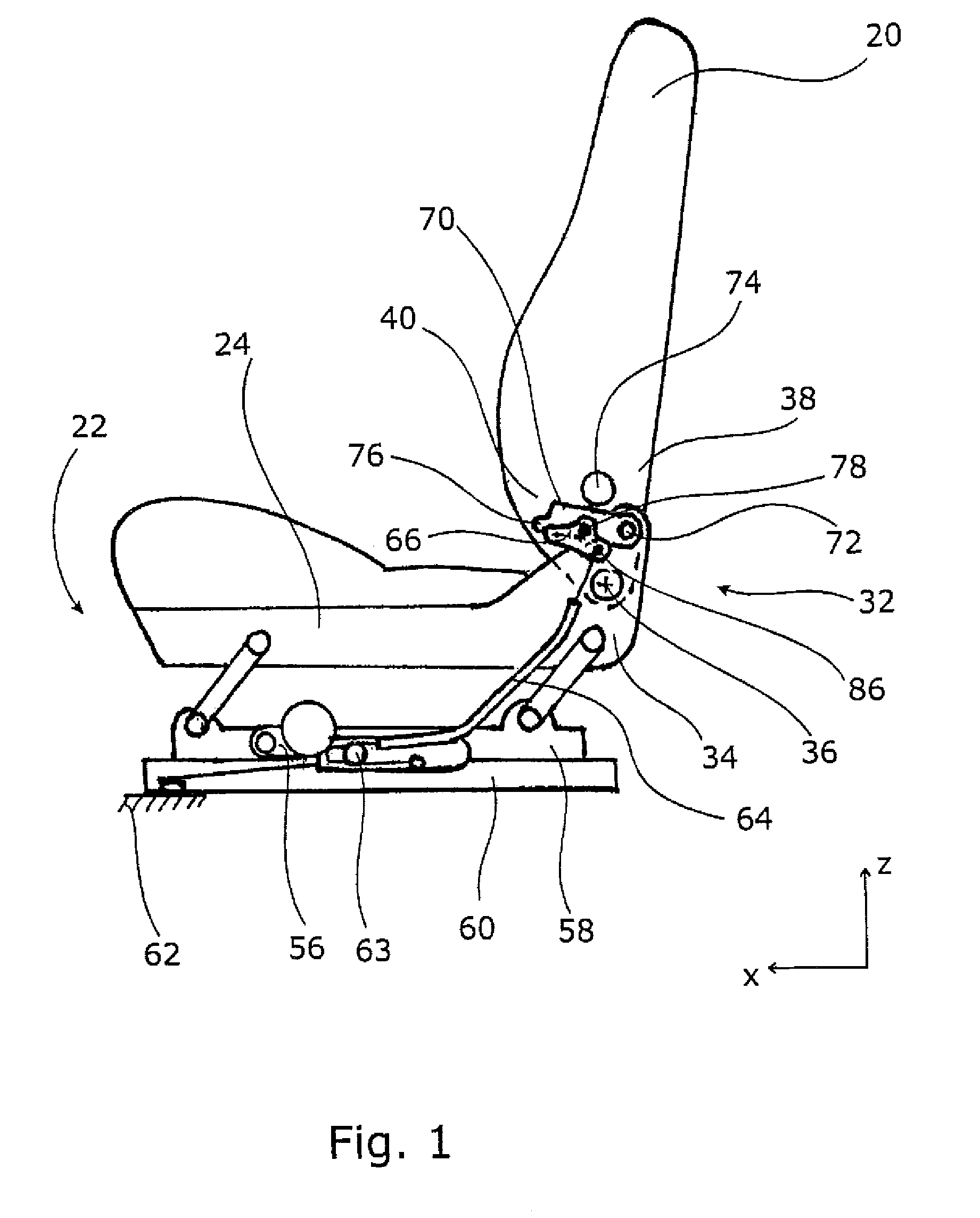

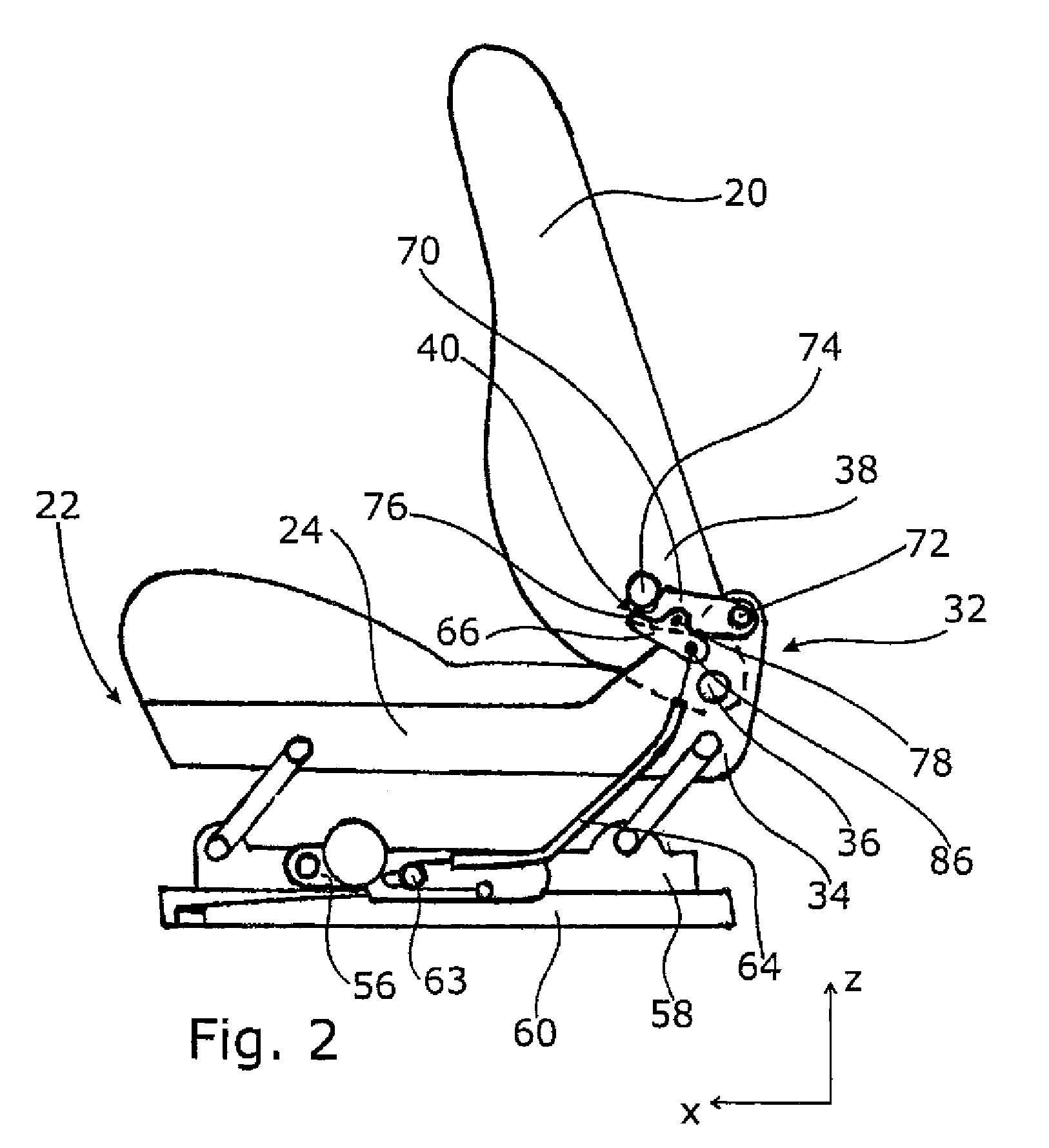

Forwardly movable motor vehicle seat

InactiveUS7963604B2Less tensile forceLower actuation forceOperating chairsDental chairsEngineeringMotorized vehicle

The forwardly movable motor vehicle seat has a seat back (20) and a seat frame with a seat pan. The motor vehicle seat may be moved between a normal position of utilization and a forwardly moved position. An immobilizing device is associated with the seat frame. In particular, the seat back (20) has a seat back hinge (32) and a stopper device (40). The stopper device (40) retains the seat back (20) in the forward tilted position as long as the seat frame is located in a front portion of the travel path. The stopper device (40) enables said seat back to tilt upward into the normal position of utilization when the seat frame is located in a rear portion (74) of the travel path. The stopper device (40) has a first limit stop and a second limit stop, one limit stop being disposed on the seat frame and the other one on the seat back (20).

Owner:C ROB HAMMERSTEIN GMBH & CO KG

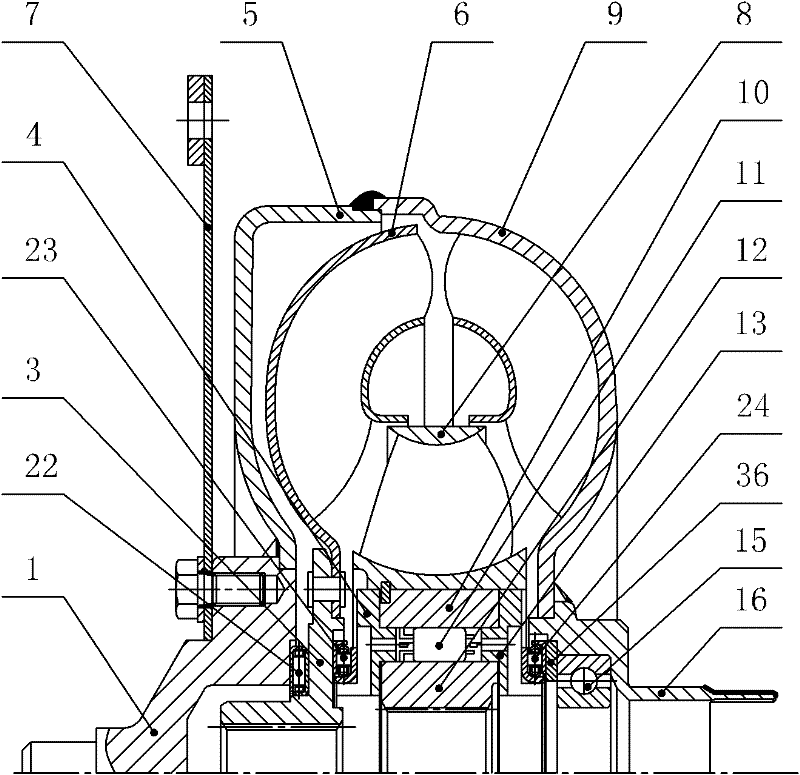

Automatic oil injection system for head sheave of multi-rope friction-type elevator

InactiveCN108266629AImproving the ability to guarantee safe production technologyReduce manual operationsEngine lubricationInjection equipmentRemote control

The invention discloses an automatic oil injection system for a head sheave of a multi-rope friction-type elevator, and belongs to the technical field of oil injection equipment. Fixed wheels are fixedly mounted on a head sheave main shaft. One side of each fixed wheel is provided with a plurality of traveling sheaves. The traveling sheaves are mounted on the head sheave main shaft through bearingbushes. A main oil channel is formed in the axial center position of one end of the head sheave main shaft. Oil separating channels communicating with the main oil channel are formed in the positions, opposite to the bearing bushes, of the outer circumferential surface of the head sheave main shaft. An end opening of the main oil channel is provided with a rotating joint. The rotating joint is rotationally mounted at the end of the head sheave main shaft. A through hole communicating with the end opening of the main oil channel is formed in the axial center of the rotating joint. The other end of the through hole of the rotating joint is connected with an oil pipe. The other end of the oil pipe is connected with an oil injection pump. According to the automatic oil injection system for the head sheave of the multi-rope friction-type elevator, the oil injection time and the oil injection amount can be controlled, and the effects of refined and automated lubrication are achieved; moreover, automatic oil injecting can be achieved under the situation that the multi-rope friction-type traveling head sheave works dynamically; and specific control can be completed on a site, and remote control can further be achieved in a hoist house.

Owner:夏恒报

Stator support structure for a torque converter

InactiveUS20080185257A1Avoid sliding frictionReduce manufacturing costDrip or splash lubricationRotary clutchesControl theoryTorque converter

A stator support device for a torque converter having a stator wheel and a non-rotating member has a one-way clutch and a bearing race. The one-way clutch includes an outer race disposed along the inner periphery of the stator wheel, an inner race connected to the outer periphery of the non-rotating member to prevent rotation of the inner race relative to the non-rotating member, and an end bearing provided between the outer race and the inner race. The bearing race is disposed at a side face of the outer race. The bearing race is supported so as to be rotatable in the circumferential direction. A gap is formed between the bearing race and the stator wheel.

Owner:TOYOTA JIDOSHA KK

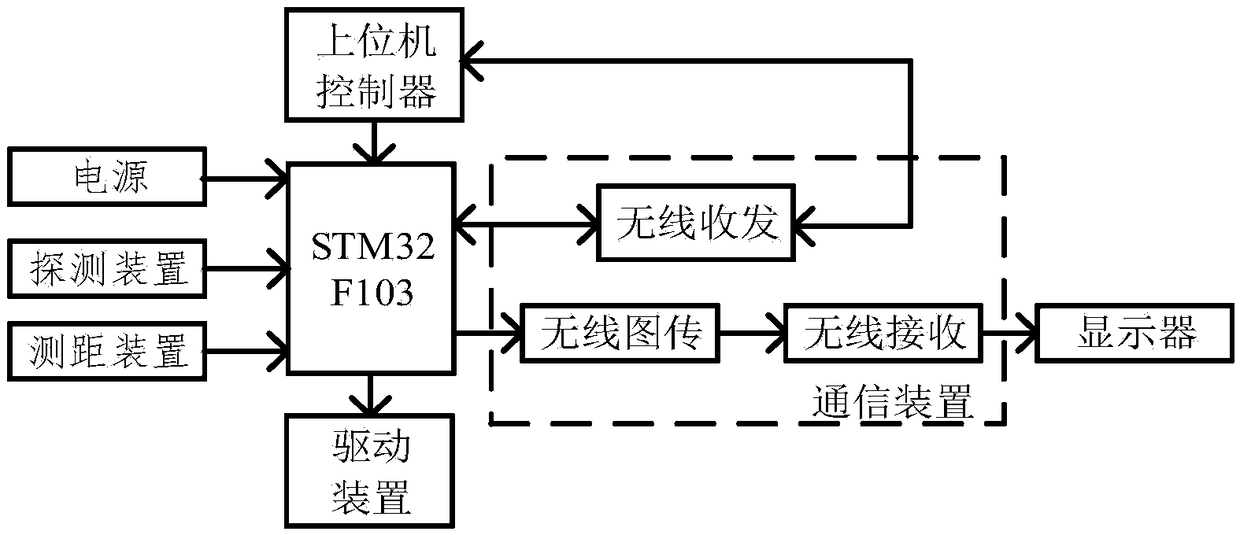

Robot used for electric power pipeline inspection

PendingCN109397306AHigh measurement accuracyAvoid sliding frictionProgramme-controlled manipulatorLine tubingMeasurement precision

The invention relates to a robot used for electric power pipeline inspection. The robot comprises a control device used for receiving and processing video and distance measurement signals, a detectiondevice, a distance measurement device used for carrying out inner wall distance measurement, a communication device and a drive device. The detection device is used for detecting whether cracks, obstacles and the blocking situation exist in electric power pipelines or not in real time. The communication device is used for transmitting the in-pipeline condition detected by the detection device andthe distance signals measured by the distance measurement device, and the robot can be controlled by an upper computer. The drive device is responsible for providing power for the robot. The robot ishigh in measurement precision, the blocking condition in the electric power pipelines can be remotely controlled and accurately measured, and the cost is relatively low.

Owner:STATE GRID ZHEJIANG NINGBO YINZHOU POWER SUPPLY LTD CO +1

Dual-directions braking method of disc brake, braking mechanism and braking system thereof

InactiveUS9476467B2Improve safety braking performanceHigh rateFluid actuated brakesAircraft braking arrangementsEngineeringCalipers

A dual-directions braking method of a disc brake, a braking mechanism and a braking system thereof are applied in fields of automobiles, trains and airplanes. The dual-directions braking mechanism includes a crankshaft having three concentric sections and two eccentric sections, two friction discs, a friction disc ring and at least a pair of brake calipers and friction pads, wherein the two eccentric sections are respectively provided between each neighboring two of the three concentric sections and mutually disposed at 180°; the two friction discs are respectively provided on the two eccentric sections; the friction disc ring is provided on the main section between the two eccentric sections. Through a translationally rotating friction by the two friction discs respectively with the friction disc ring and with the friction pads of each pair of brake calipers, a backward braking moment and a forward braking moment are simultaneously generated on the main sections.

Owner:QIANG HAISHENG

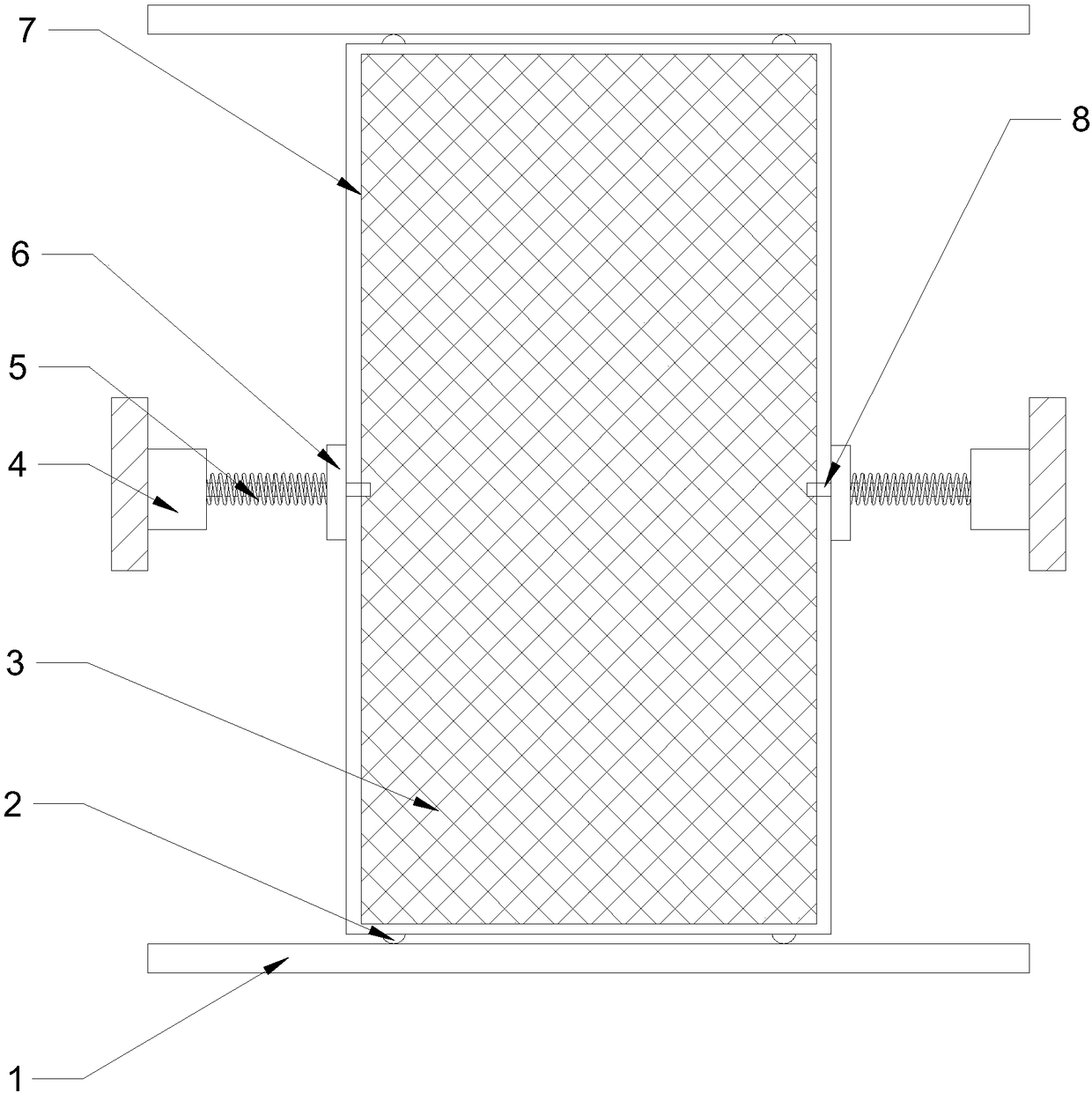

Electromagnetic type grain winnowing device

InactiveCN108202019ARealize the purpose of reciprocating driveAvoid damageSievingScreeningEmbedded systemElectromagnet

The invention relates to the field of grain processing equipment, in particular to an electromagnetic type grain winnowing device. The device comprises a screen net, wherein the screen net is fixed ona screen net frame, the screen net frame is a square frame, the opposite sides of the screen net frame are provided with guiding rails, a sliding slot is formed in one side of each guiding rail opposite to the screen net frame, the screen net frame is embedded into the sliding slots of the guiding rails, the other two sides of the screen net frame are fixedly provided with magnets, and one side,back onto the screen net frame, of each magnet is provided with an electromagnet. The electromagnetic type grain winnowing device has the advantages that an electromagnetic driving method is effectively adopted to repeatedly drive a grading screen, and only acts on the movement in the driving direction, compared with a traditional method of adopting a swinging rod to repeatedly drive the grading screen, the vibration is smaller, damage to the device is less likely to be caused, the service life of the device is prolonged, and less noise is generated during the production process, thereby reducing damage to the auditory system of field men.

Owner:郑州龙威电气安装有限公司

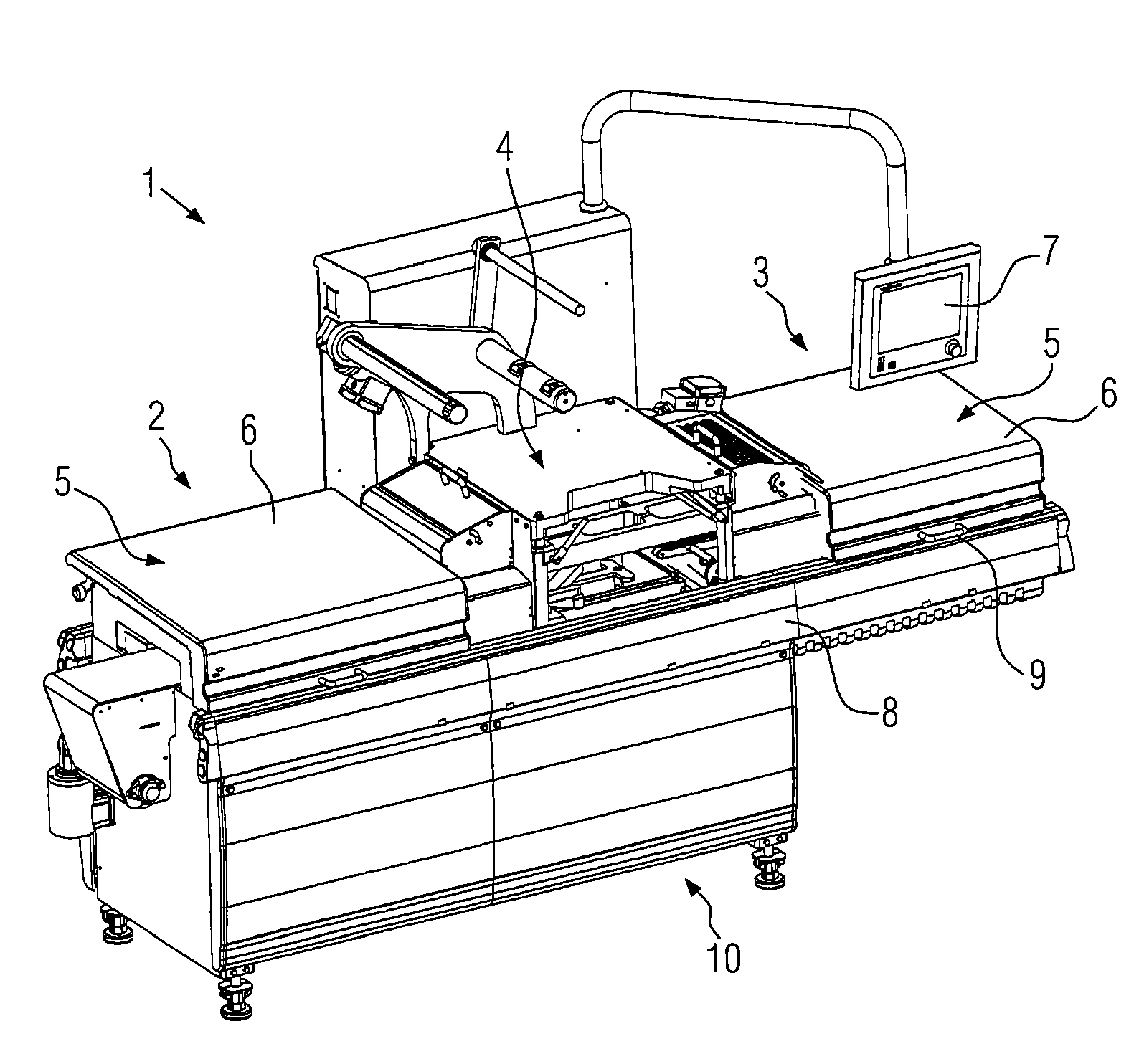

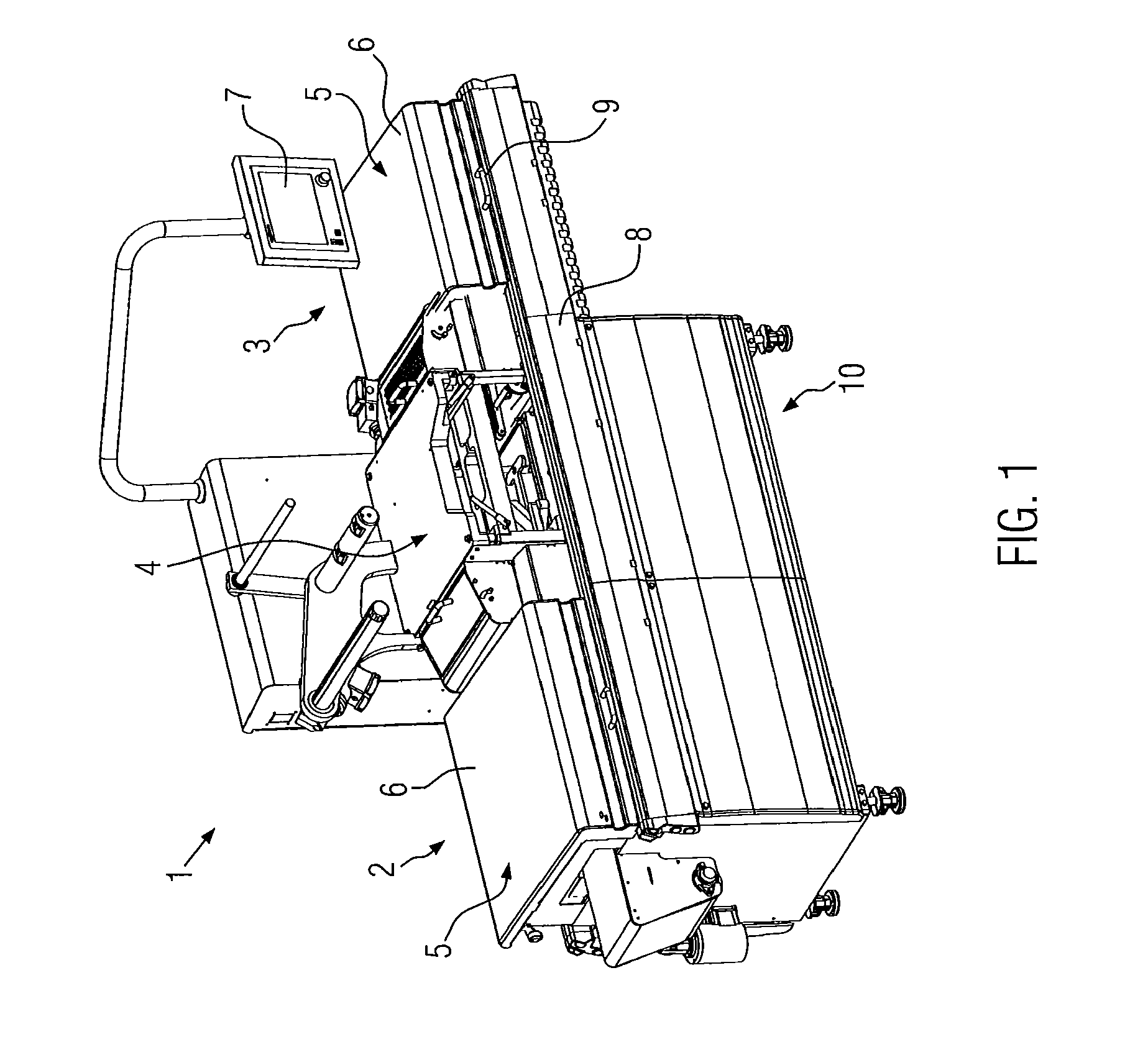

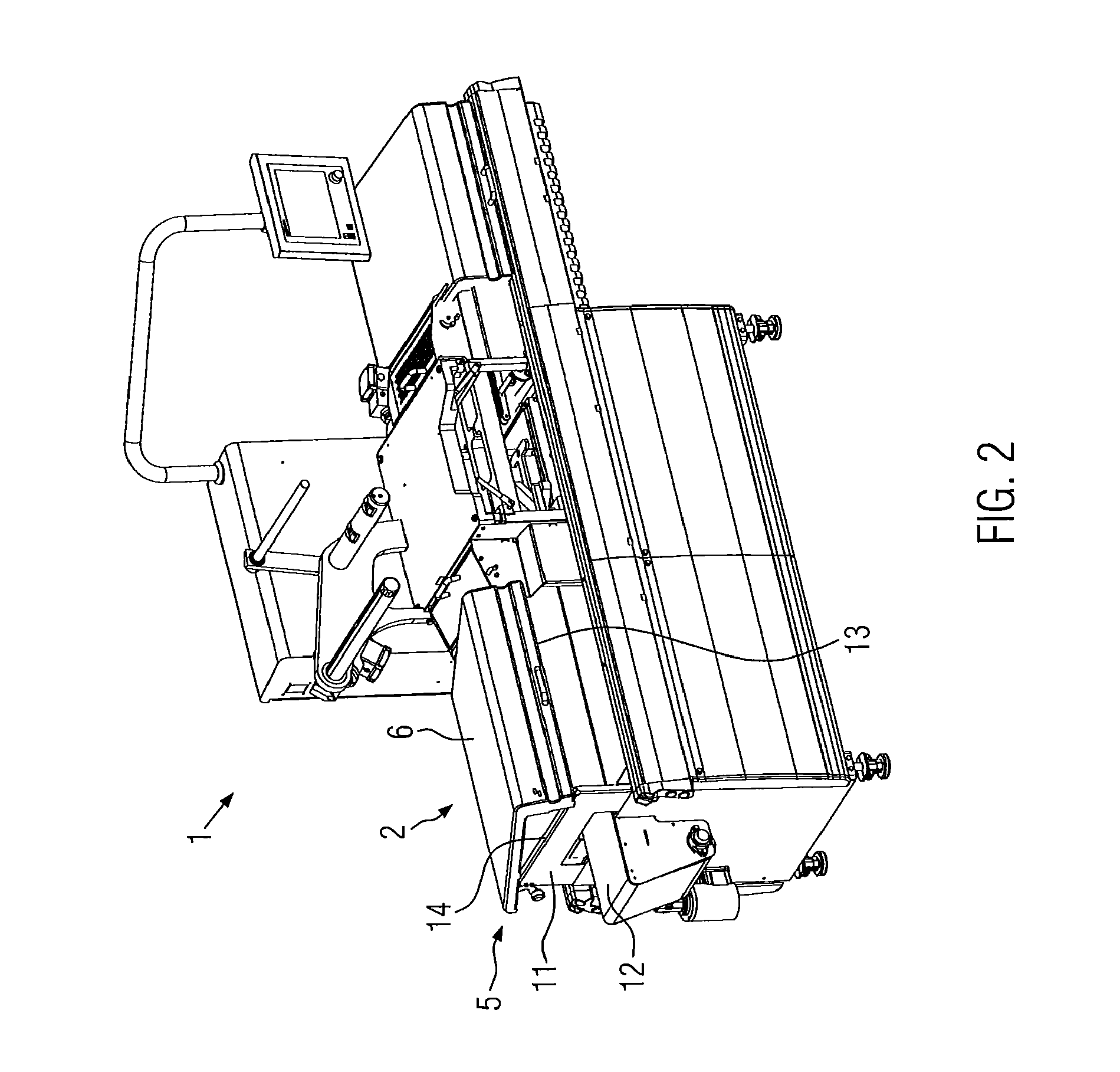

Packaging Machine with a Protective Device and Method

ActiveUS20140182246A1Easy accessSimple configurationWrapping material feeding apparatusEngineering safety devicesEngineeringPackaging machine

The present invention refers to a packaging machine and a method, wherein one embodiment of a protective device comprises a protective hood and the protective hood is lifted around a shaft comprising two rolls, and is shifted by means of guides in the protective hood on the rolls.

Owner:MULTIVAC SEPP HAGGENMULLER GMBH & CO KG

Welding and overturning device for crane beam

InactiveCN105417453AEasy to fixImprove protectionWelding/cutting auxillary devicesLifting devicesHydraulic cylinderEngineering

The invention relates to a welding and overturning device for a crane beam. The welding and overturning device comprises a base. A hydraulic cylinder A and a hydraulic cylinder B are hinged to the two ends in the base. The hydraulic cylinder A and the hydraulic cylinder B are connected with an overturning frame A and an overturning frame B in a hinged manner respectively. Rolling seats are arranged on the upper surfaces of horizontal supports of the overturning frame A and the overturning frame B. A supporting plate A is arranged on the upper portion of a vertical support of the overturning frame A. An electromagnet A is arranged on the rear side face of the supporting plate A. A contact switch A is arranged in the middle of the overturning frame A. One side of the lower portion of the overturning frame A is connected with an electric push rod A. A rolling seat is arranged on the upper surface of a horizontal support of the overturning frame B. A rotating roller is arranged in the rolling seat. A supporting plate B is arranged on the upper portion of a vertical support of the overturning frame B. An electromagnet B is arranged on the rear side face of the supporting plate B. A contact switch B is arranged in the middle of the overturning frame B. An electric push rod B is connected with one side of the lower portion of the overturning frame B. The welding and overturning device has the beneficial effects that the structure is simple, use and operation are convenient, and design is reasonable.

Owner:HENAN SINOKO CRANES

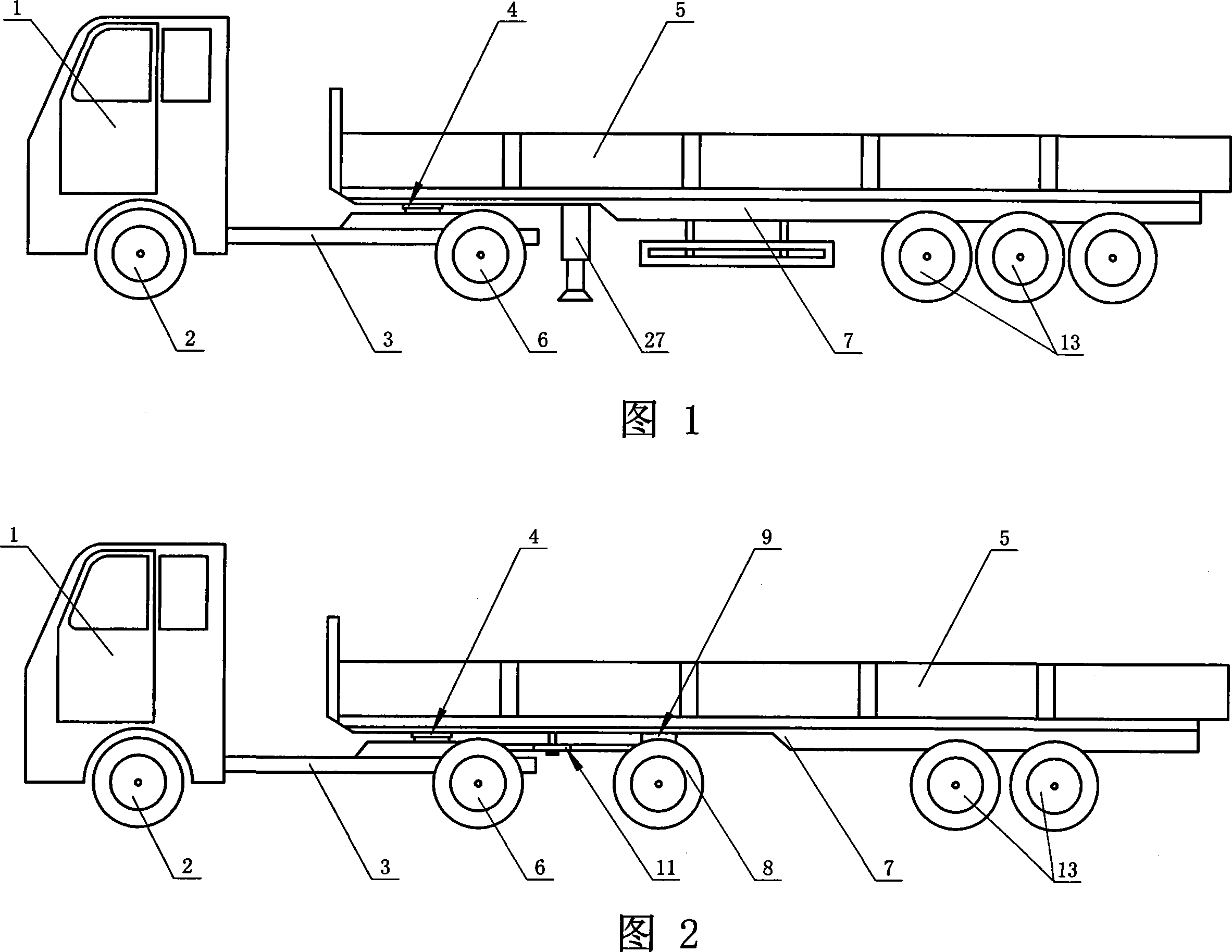

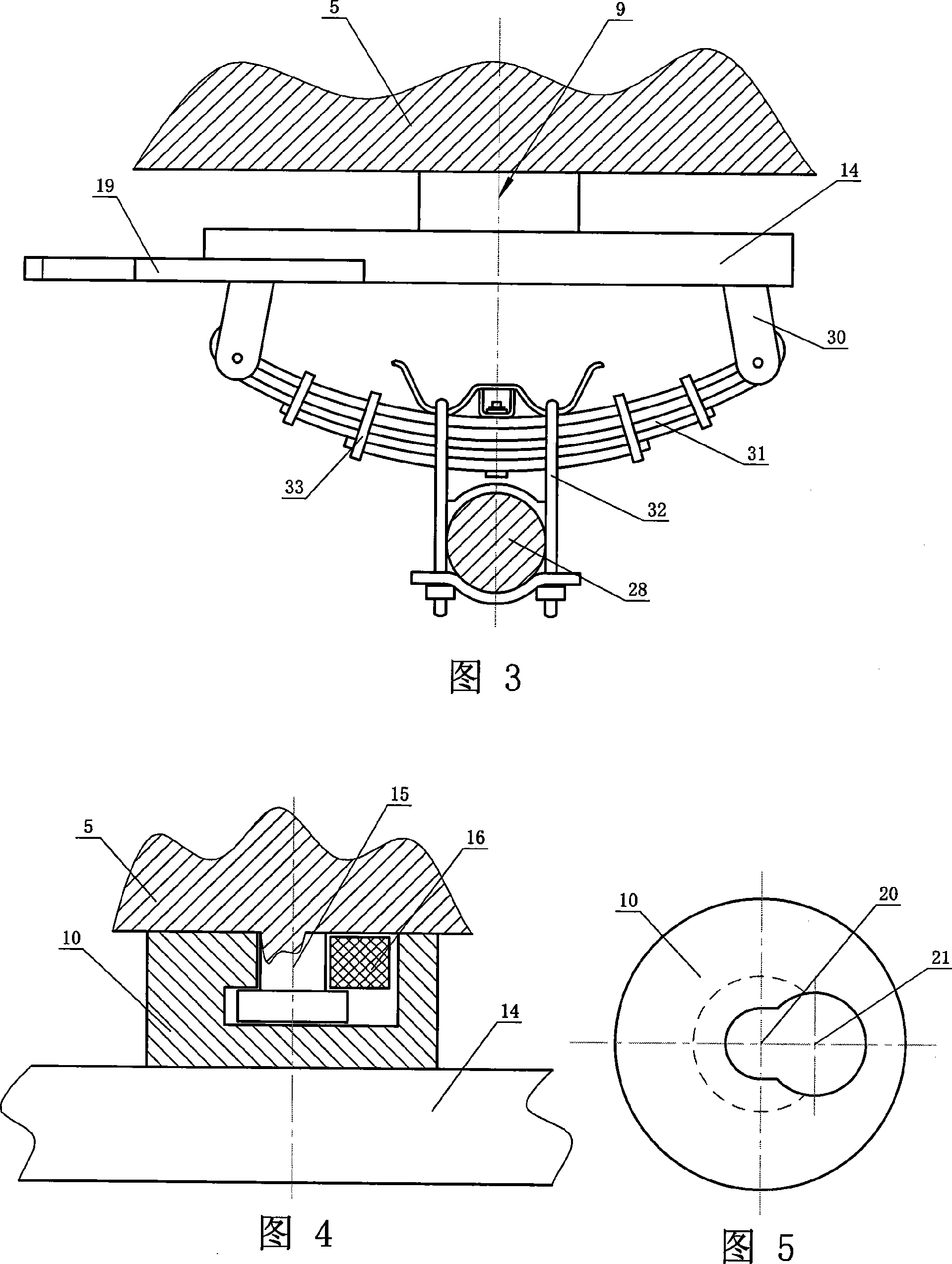

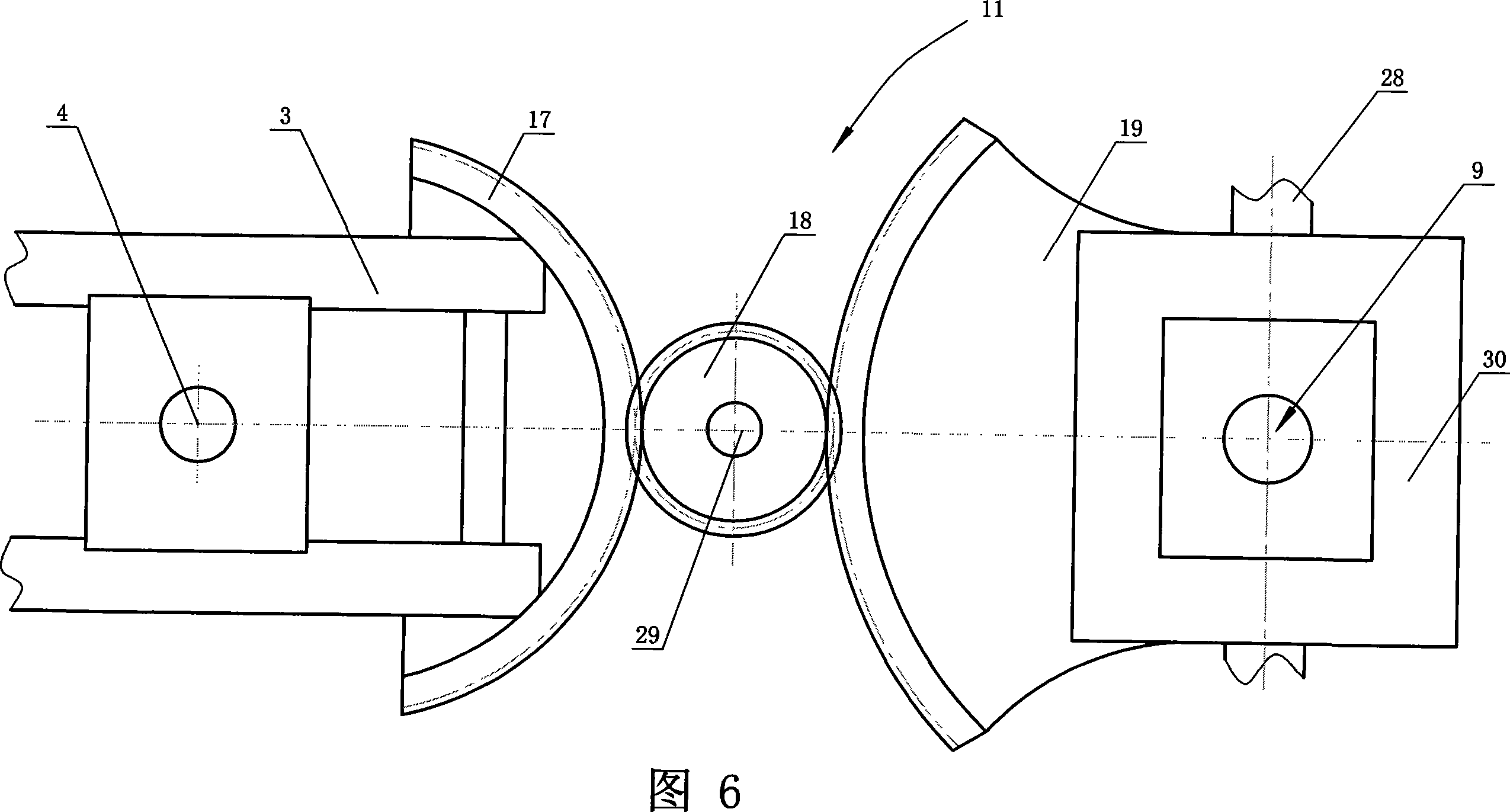

Novel semi-trailer with automatic synchronization steering mechanism

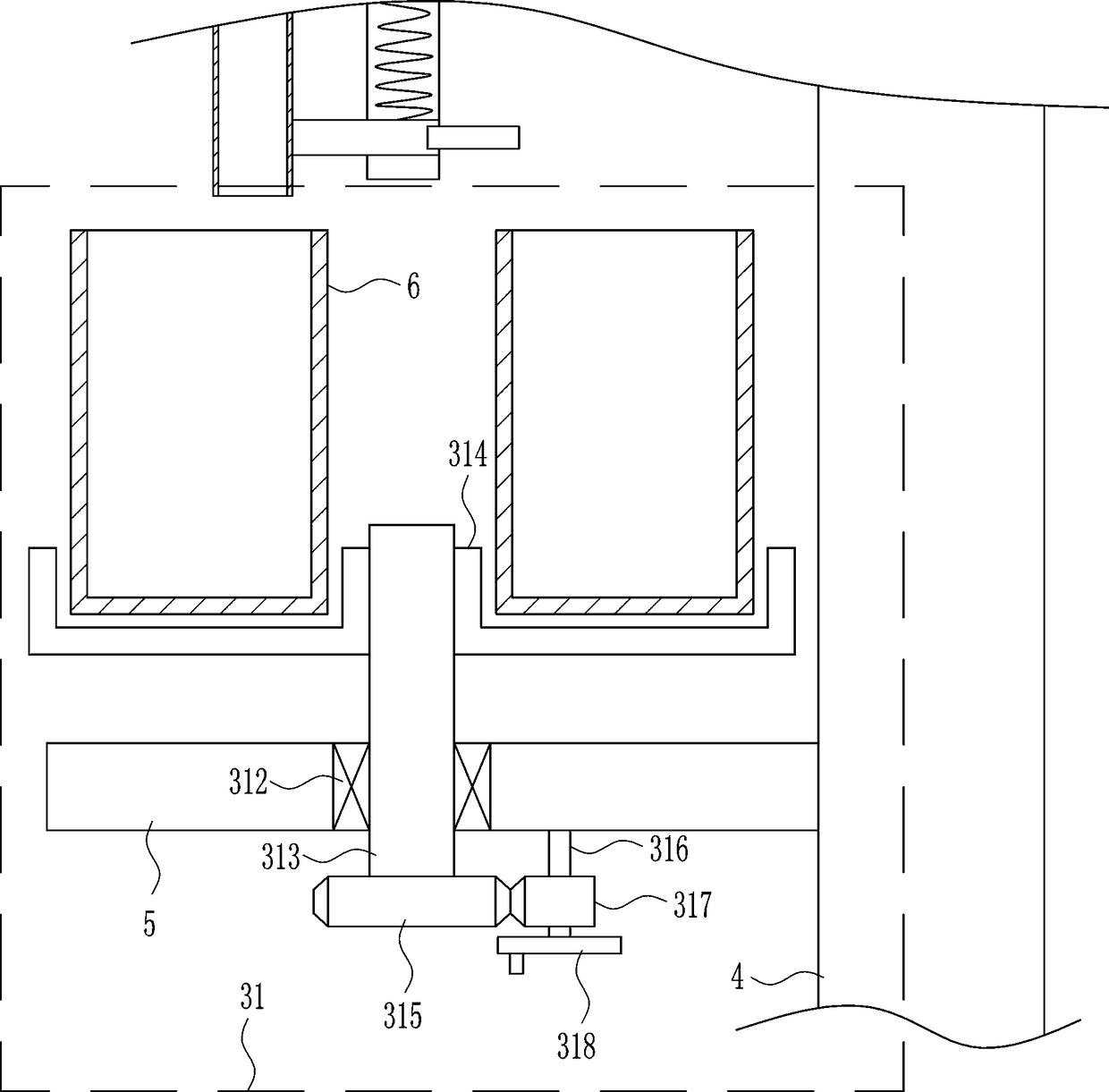

InactiveCN101117132AImprove the forceIncrease bearing pointSteering for vehicles in tandemTrailer steeringDrive wheelStress conditions

The invention relates to a novel semi-trailer with automatic synchronized steering mechanism which comprises a trailer body (1), a tractive girder (3) connected with the trailer body (1) and a driving wheel (6) arranged on the tractive girder (3), wherein the tractive girder (3) is movably connected with the semi-trailer (5) through a rotary connection device (4), a semi-trailer bearing wheel (8) is arranged on the rear end of the bottom of a semi-trailer girder (7), a semi-trailer front bearing wheel (13) is arranged on the front end of the bottom of the semi-trailer girder (7), the semi-trailer front bearing wheel (13) is arranged on the bottom of the semi-trailer girder (7) through a bearing wheel rotation mechanism (9), and the gear-driven synchronized steering mechanism (11) or a guide rod-driven synchronized steering mechanism (12) is arranged between the tractive girder (3) and the front bearing wheel rotation mechanism (9). The novel semi-trailer with automatic synchronized steering mechanism of the invention changes the bearing stress structure of a prior semi-trailer, adds a bearing point to the front part of the semi-trailer, and reduces the length of the suspension part of the semi-trailer, thereby improving the stress condition of the whole trailer, prolonging the service life of the trailer, promoting safety factor, and reducing transportation cost. The invention is very suitable for generalization and application with easy use, easy manufacture or modification.

Owner:薛玉泉

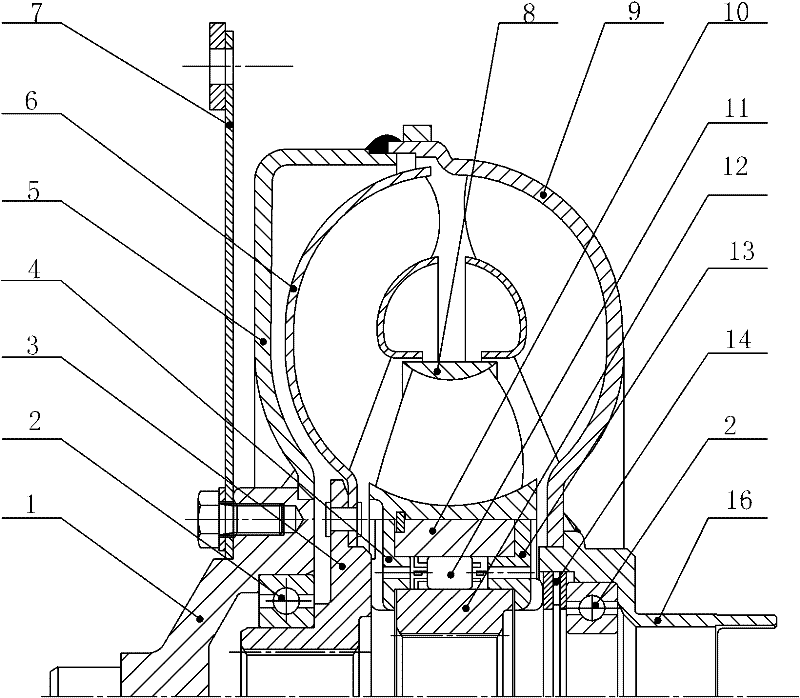

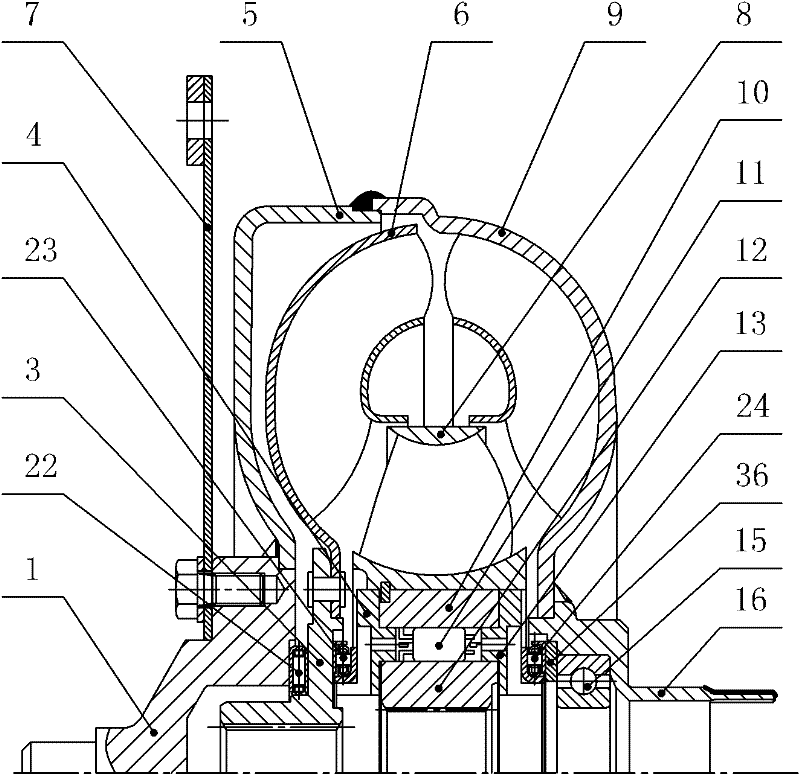

Hydraulic torque converter for fork truck

ActiveCN102537267AReduce fuel consumptionImprove economyLifting devicesFluid gearingsLow noiseImpeller

The invention relates to a hydraulic torque converter for a fork truck. The hydraulic torque converter comprises a cover wheel assembly, a turbine assembly, a pump impeller assembly and a guide wheel assembly, wherein the cover wheel assembly comprises a cover wheel hub and a cover wheel shell; the turbine assembly comprises a turbine hub and a turbine body; the pump impeller assembly comprises a pump impeller hub and a pump impeller body; the guide wheel assembly comprises a front retaining ring, a rear retaining ring and a guide wheel body; a three-coating-sheet bearing, an anti-thrust sheet and a ball bearing are arranged between the cover wheel hub and the turbine hub, between the turbine hub and the front retaining ring as well as between the rear retaining ring and the pump impeller hub; the bearing between the cover wheel hub and the turbine hub is a three-coating-sheet bearing; a three-coating-sheet bearing is arranged between the rear retaining ring and the pump impeller hub; and a three-coating-sheet bearing is arranged between the rear retaining ring and the ball bearing. According to the invention, the technical problems of unreasonable inside positioning, severe wearing, and noise generation of the traditional hydraulic torque converter for the fork truck are solved; and the hydraulic torque converter provided by the invention has low oil consumption, low noise and large torque.

Owner:SHAANXI AEROSPACE POWER HIGH TECH

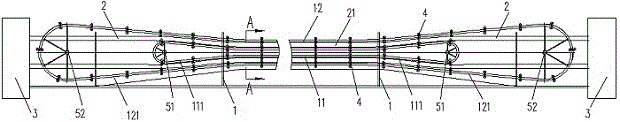

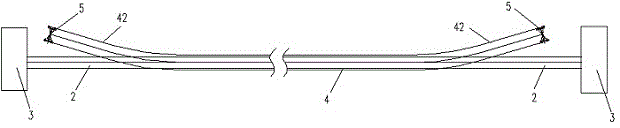

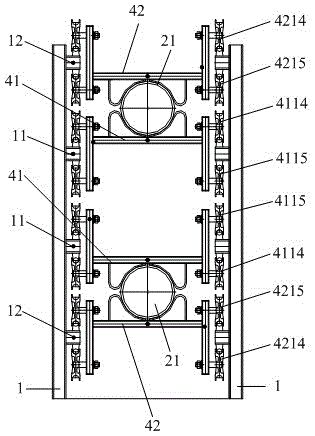

Sidesway separation movable bracket type tubular belt conveyor

The invention relates to a sidesway separation movable bracket type tubular belt conveyor. The sidesway separation movable bracket type tubular belt conveyor comprises machine frames, annular adhesive tapes, driving components, annular supporting and clamping components and guide rail bend wheels, wherein the annular adhesive tapes can bear materials; the driving components of the adhesive tapes are respectively arranged at machine heads and machine tails; the annular supporting and clamping components can support and clamp the adhesive tapes; the annular adhesive taps are hung and wound on the driving components in a sleeving manner; the supporting and clamping components are movably supported and clamped between the adhesive tapes and the machine frames; the support clamping components near the machine heads and the machine tails are separated from the adhesive tapes. The sidesway separation movable bracket type belt conveyor disclosed by the invention has the beneficial effects that the support components are used to replace carrier rollers in the prior art, and resistance between the carrier rollers and the adhesive tapes is changed into rigid rolling friction between the support components and guide rails; through the change of a mechanical structure, transport resistance is obviously reduced, and the dissipation power of the conveyor is greatly reduced.

Owner:NINGXIA TIANDI NORTHWEST COAL MACHINERY

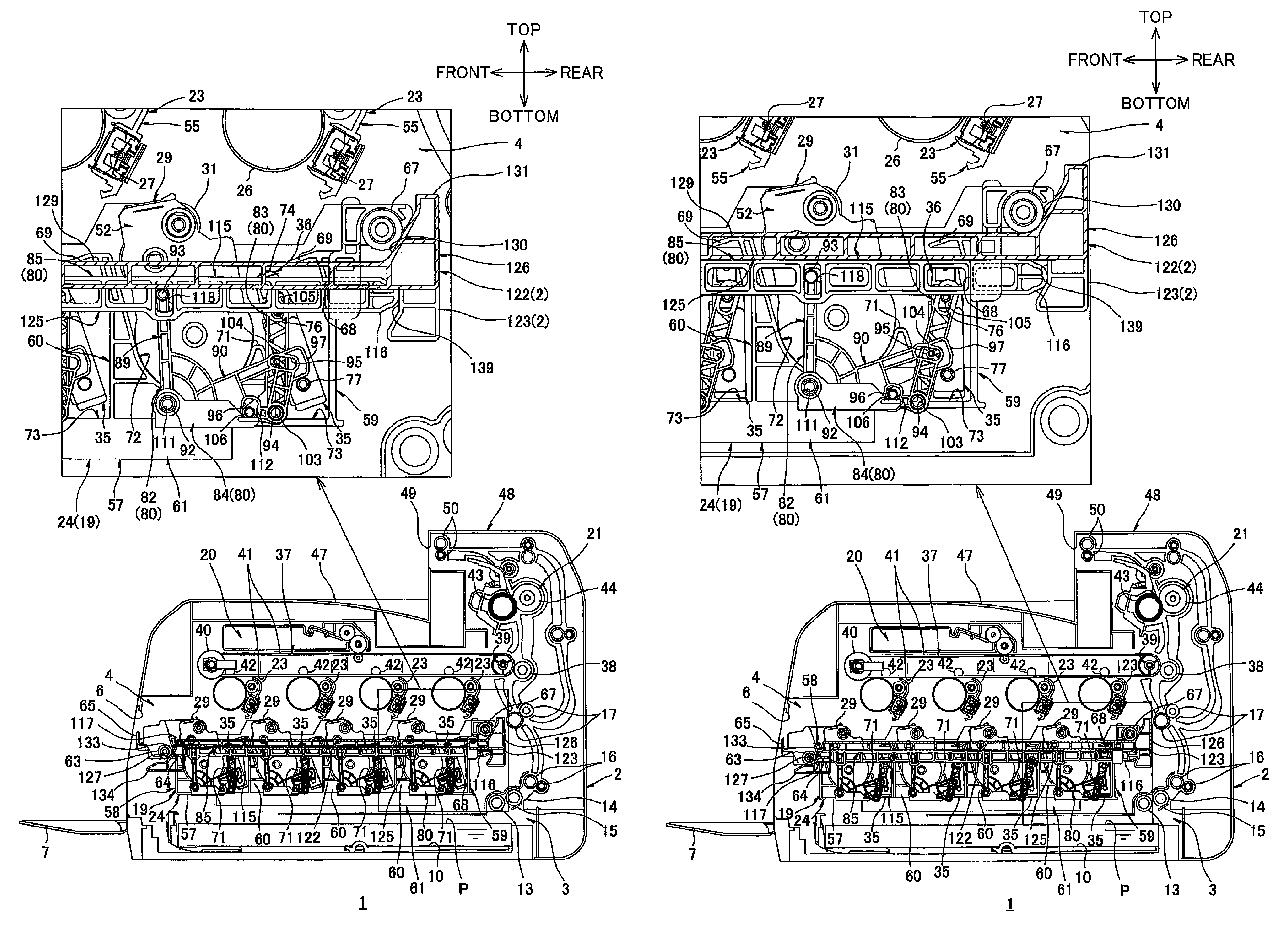

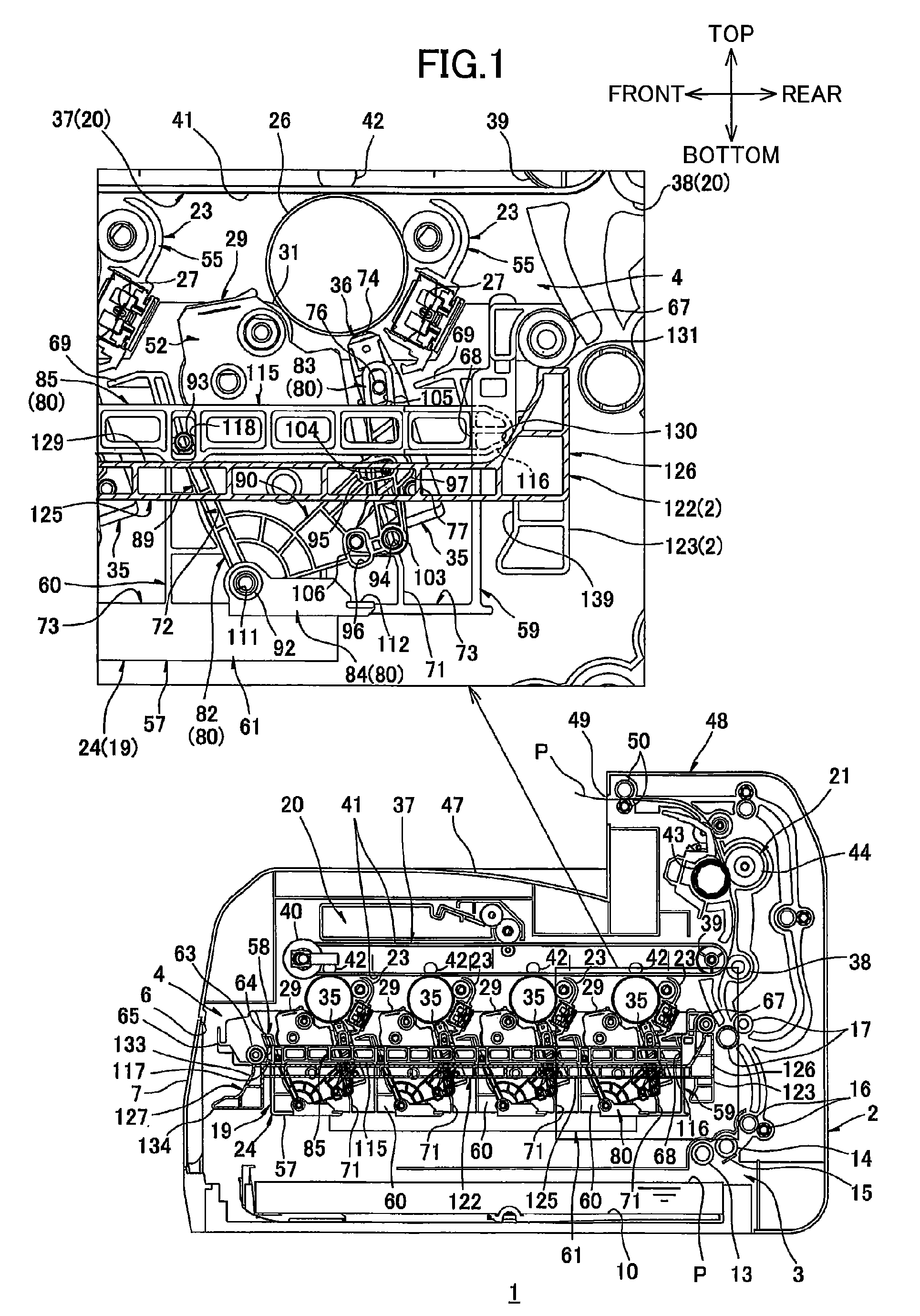

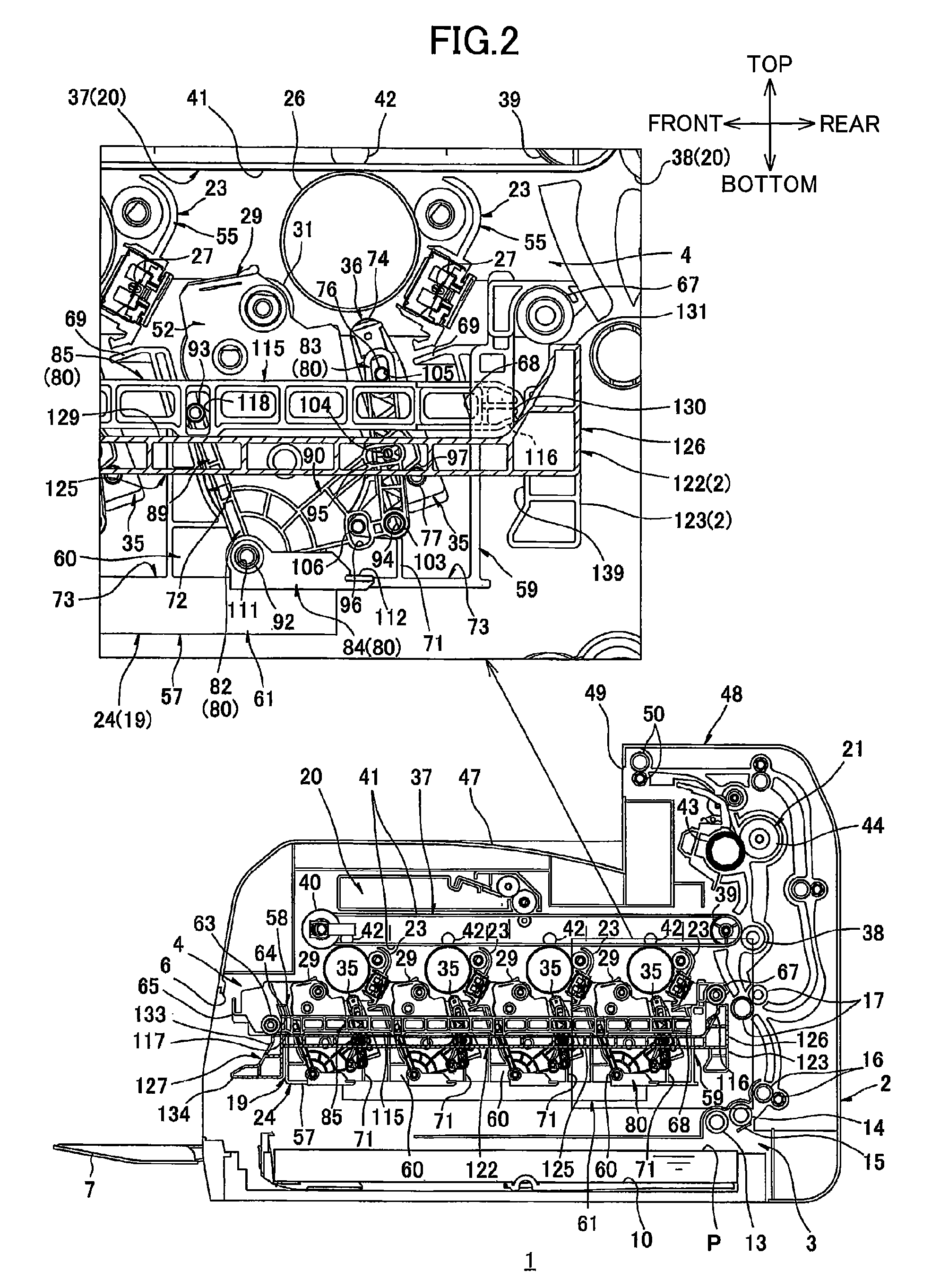

Image forming apparatus capable of reliably protecting exposure member

InactiveUS9134690B2Avoid sliding frictionImprove protectionElectrographic process apparatusImage formationMechanical engineering

An image forming apparatus includes: a main casing; a photosensitive member; a moving mechanism; a movable member; and a cartridge. The photosensitive member is provided in the main casing. The movable member moves between an inside position in which the movable member is inside the main casing and an outside position in which the movable member is at least partly outside the main casing. The movable member includes: a frame; a protection member; and an exposure member. The protection member is fixed to the frame. The moving mechanism moves the exposure member between an exposing position in which the exposure member exposes the photosensitive member to light and a protected position in which the exposure member is protected by the protection member. The cartridge includes a developer bearing member. The cartridge is supported at the movable member.

Owner:BROTHER KOGYO KK

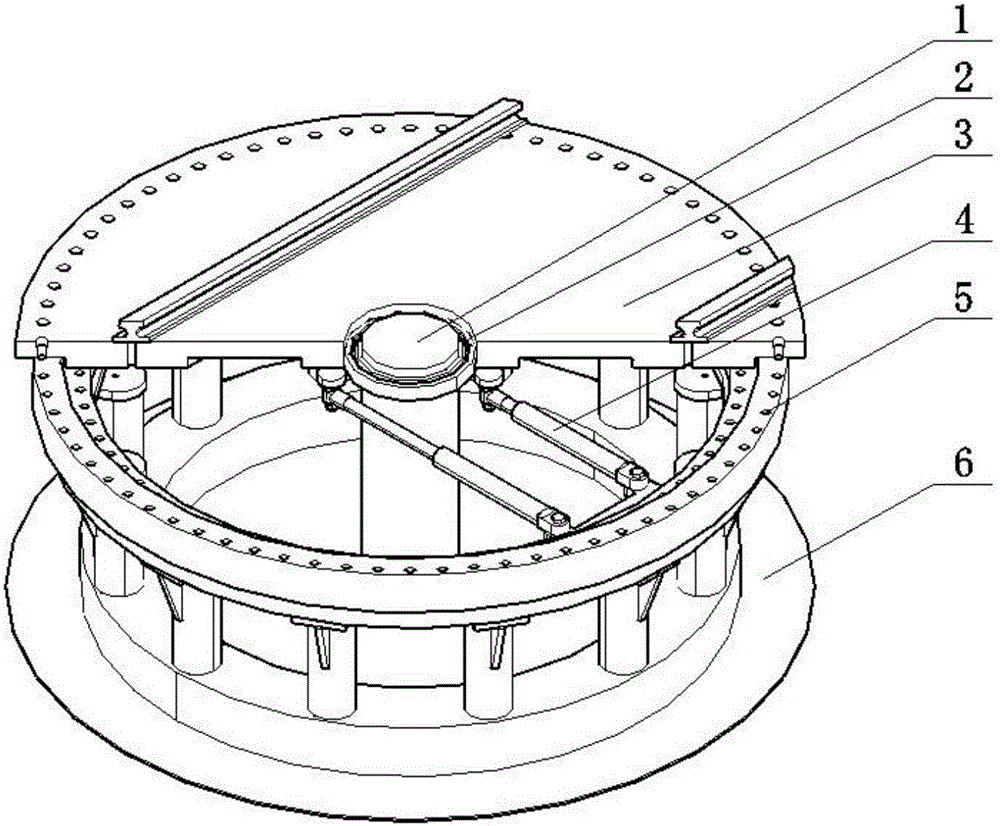

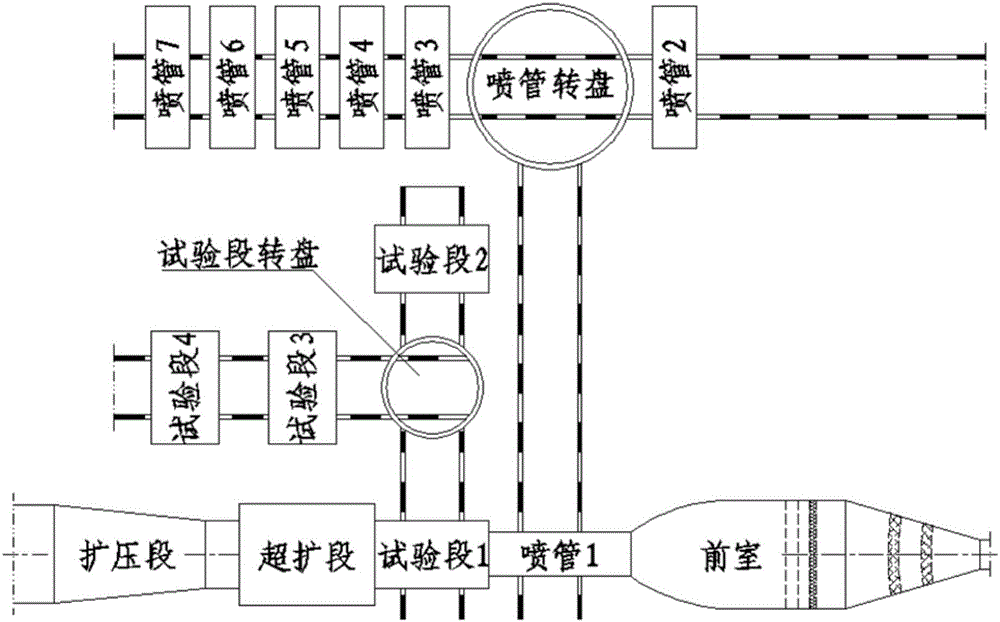

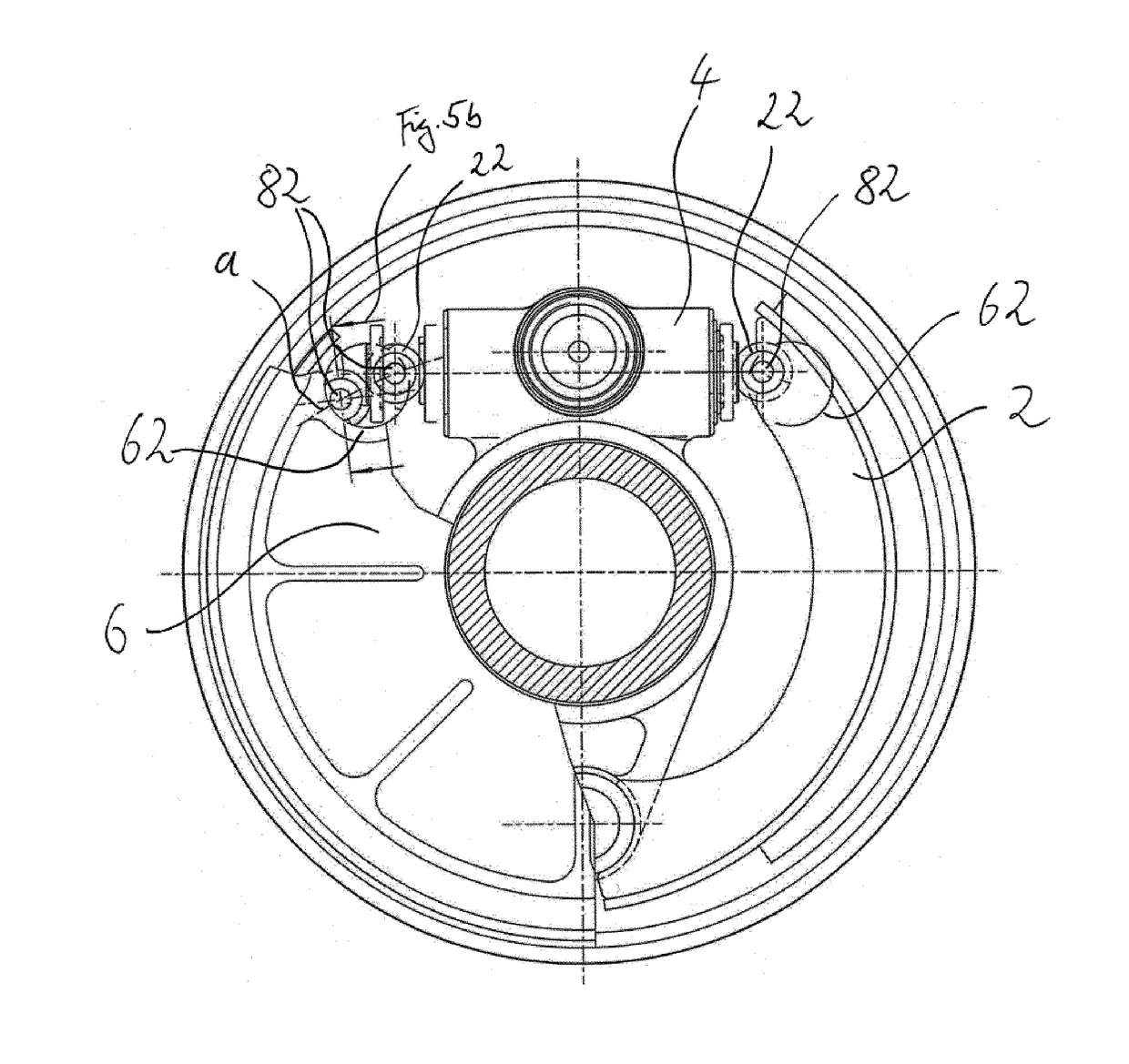

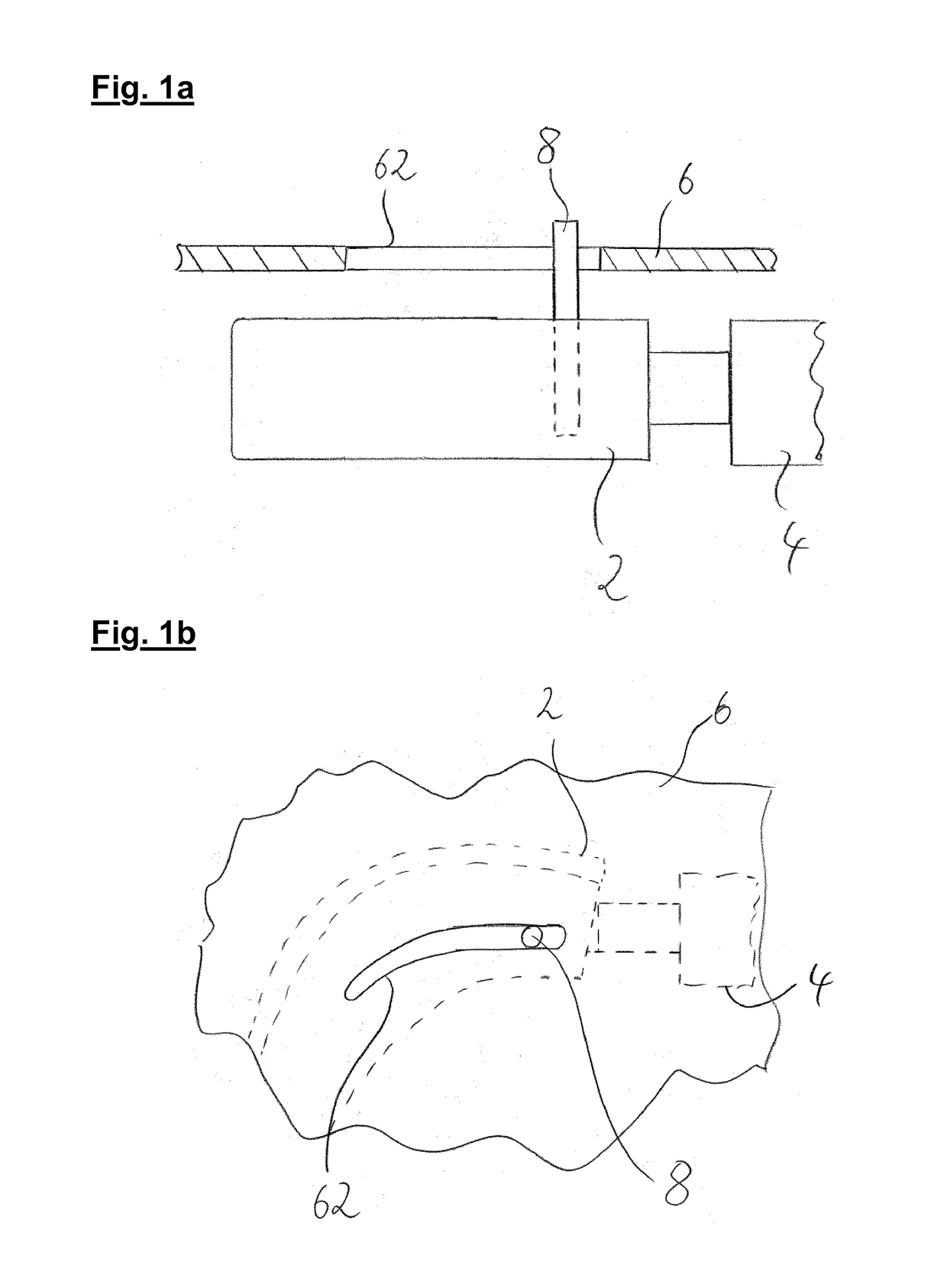

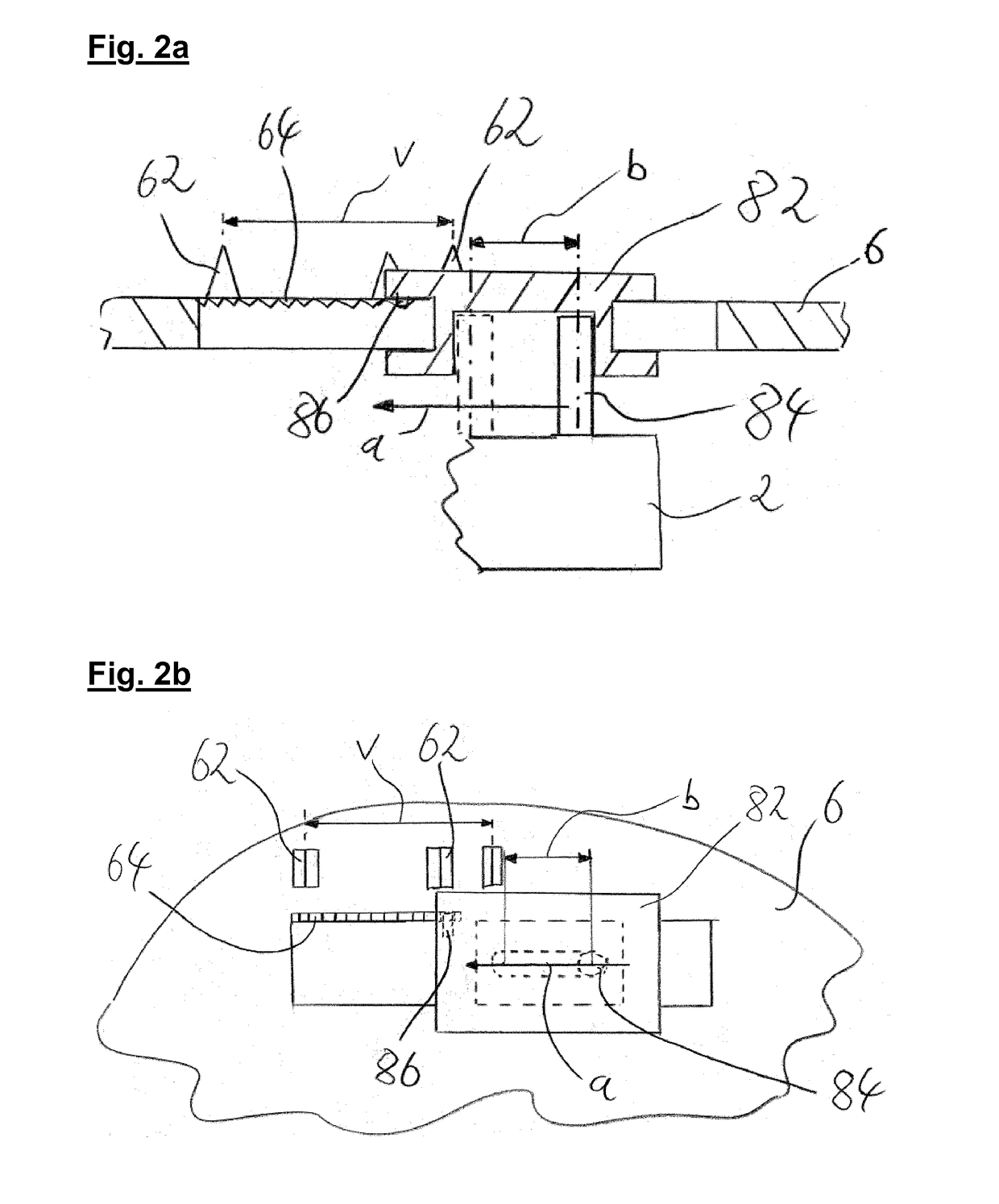

Rotating disk apparatus for wind tunnel jet pipe

InactiveCN106441788AAvoid the phenomenon of lifting the headDense support pointsAerodynamic testingPush and pullHydraulic cylinder

The invention discloses a rotating disk apparatus for a wind tunnel jet pipe. The rotating disk apparatus for a wind tunnel jet pipe includes a center shaft, a center bearing, a pedestal, a rotating disk cover, a slewing back-up bearing, a hydraulic cylinder and the like, wherein the center shaft is fixed on a foundation and does not move; both the center bearing and the slewing back-up bearing rotate by taking the center shaft as a slewing center; the center bearing uses a deep groove ball bearing, and the inner ring of the center bearing sleeves the center shaft, and the outer ring of the center bearing is inlaid in the rotating disk cover; the slewing back-up bearing uses a three-row roller type slewing back-up bearing, and the inner ring of the slewing back-up bearing is connected with the rotating disk cover; and the outer ring of the slewing back-up bearing is connected with the pedestal fixed on the foundation. Therefore, through push-and-pull of the hydraulic cylinder, rotation of the rotating disk cover can be realized, so that a jet pipe at the top of the rotating disk cover is driven to turn by 90DEG. As the rotating disk apparatus for a wind tunnel jet pipe uses the general deep groove ball bearing and the three-row roller type slewing back-up bearing as the slewing members, the rotating disk apparatus for a wind tunnel jet pipe has the advantages of being simple in structure, being convenient in mounting, being high in positioning accuracy, being low in the cost of maintenance, being able to bear the100t load of the top of the rotating disk cover, and being able to satisfy the requirement for 90DEG turning of the wind tunnel jet pipe.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Braking System

The invention relates to a brake system in particular for wedge-actuated drum brakes, comprising a carrier unit, an actuation unit, a reference unit and an indicator unit, wherein the reference unit shields the carrier unit and the actuation unit at least in regions, wherein the actuation unit engages on the carrier unit and displaces the carrier unit into a particular position relative to the reference unit or secures the carrier unit in one position relative to the reference unit, wherein the carrier unit engages on the indicator unit in order to displace the indicator unit into a particular position relative to the reference unit, wherein a state of wear of the brake system can be determined from outside the brake system by way of the position of the indicator unit relative to a reference geometry provided on the reference unit.

Owner:SAF HOLLAND GMBH

Soft pneumatic robot capable of wriggling, and bending method of soft pneumatic robot

InactiveCN112120663ASolve the problem of not being able to do active bendingUnable to realize the problem of active bendingSurgeryEndoscopesEngineeringCapsule Endoscopes

The invention discloses a soft pneumatic robot capable of wriggling, and a bending method of the soft pneumatic robot. The soft pneumatic robot comprises an annular air bag, an air bag, a telescopic pipe and an extension spring, wherein both the annular air bag and the air bag are connected with air pipes, initial shapes of the annular air bag and the air bag are in a wizened shape, the telescopicpipe is arranged between the annular air bag and the air bag, three independent closed cavities are formed inside the telescopic pipe, each closed cavity is connected with one corresponding air pipe,the extension spring is arranged in the telescopic pipe, two ends of the extension spring are fixedly connected with two end faces of the telescopic pipe respectively, meanwhile, two ends of the extension spring are fixedly connected with the annular air bag and the air bag respectively, and the extension spring can help the telescopic pipe to complete the contraction. The soft pneumatic robot isdesigned by imitating the motion state of inchworm, and problems that a traditional capsule endoscope is low in efficiency and high in randomness can be solved. The soft pneumatic robot can realize bending in a specified direction at an intestinal tract bending part.

Owner:TIANJIN UNIV

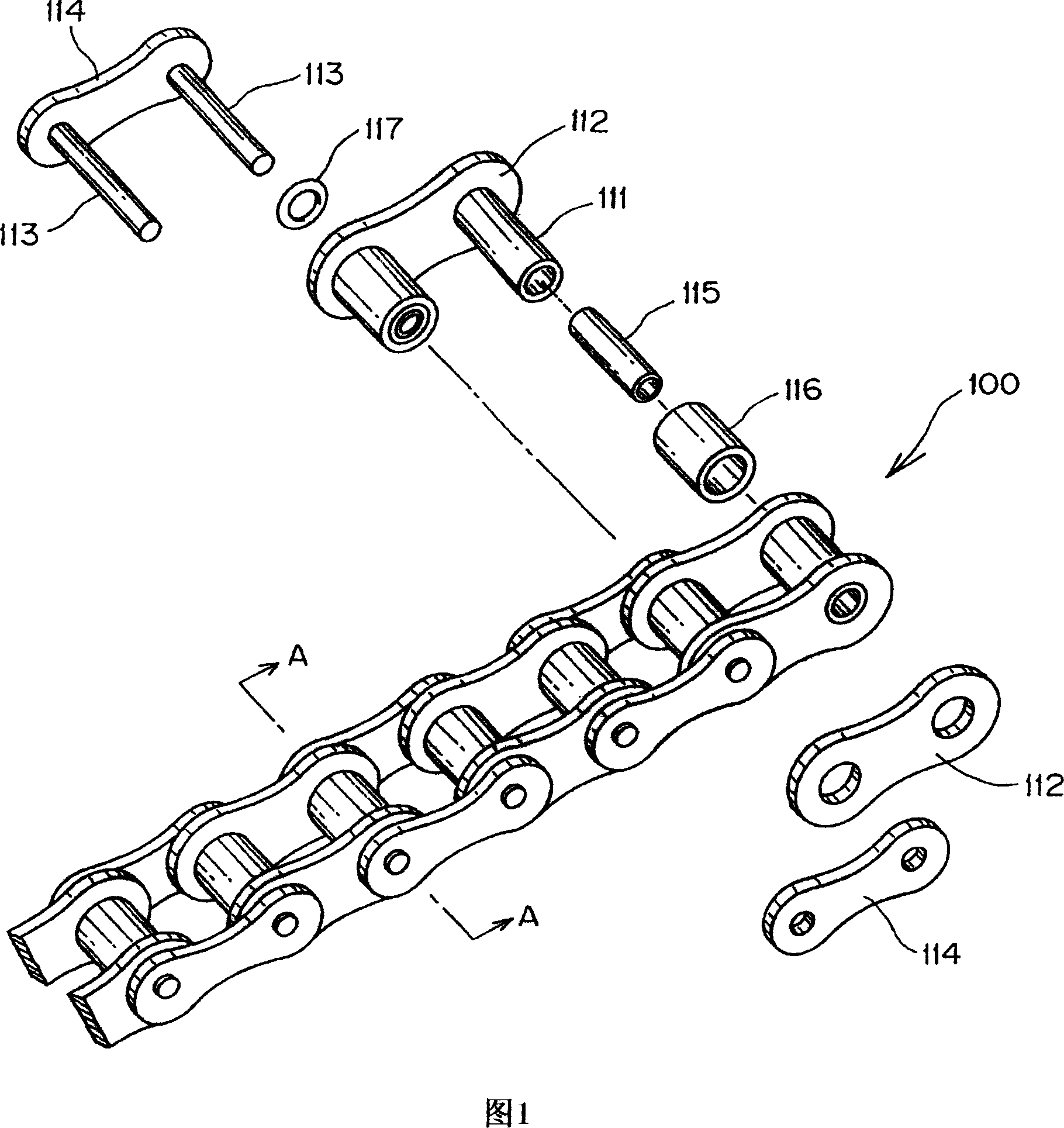

Solid lubrication oil-free chain

InactiveCN1987147AAvoid sliding frictionEfficient lubricating propertiesConveyorsDriving chainsFree rotationOil free

An oil-free chain that includes excellent lubricating properties, and satisfactorily maintains the lubricating properties even in high temperature atmosphere and dust particle atmosphere so that a stable lubrication effect can be maintained for a long period of time. The chain is a bush chain having a pair of inner plates into which the opposite ends of a bush are fitted, and a pair of outer plates which mount the opposite ends of a pair of pins. The pins are rotatably fit-inserted into the bushes of adjoining outer link plates. The inner and outer plates are connected in alternation to form the roller chain in which a roller is rotatably mounted on the outer surface of each bush. A sliding member formed of a 100% graphite sheet is provided between the bush and the pin and / or between the bush and the roller.

Owner:TSUBAKIMOTO CHAIN CO

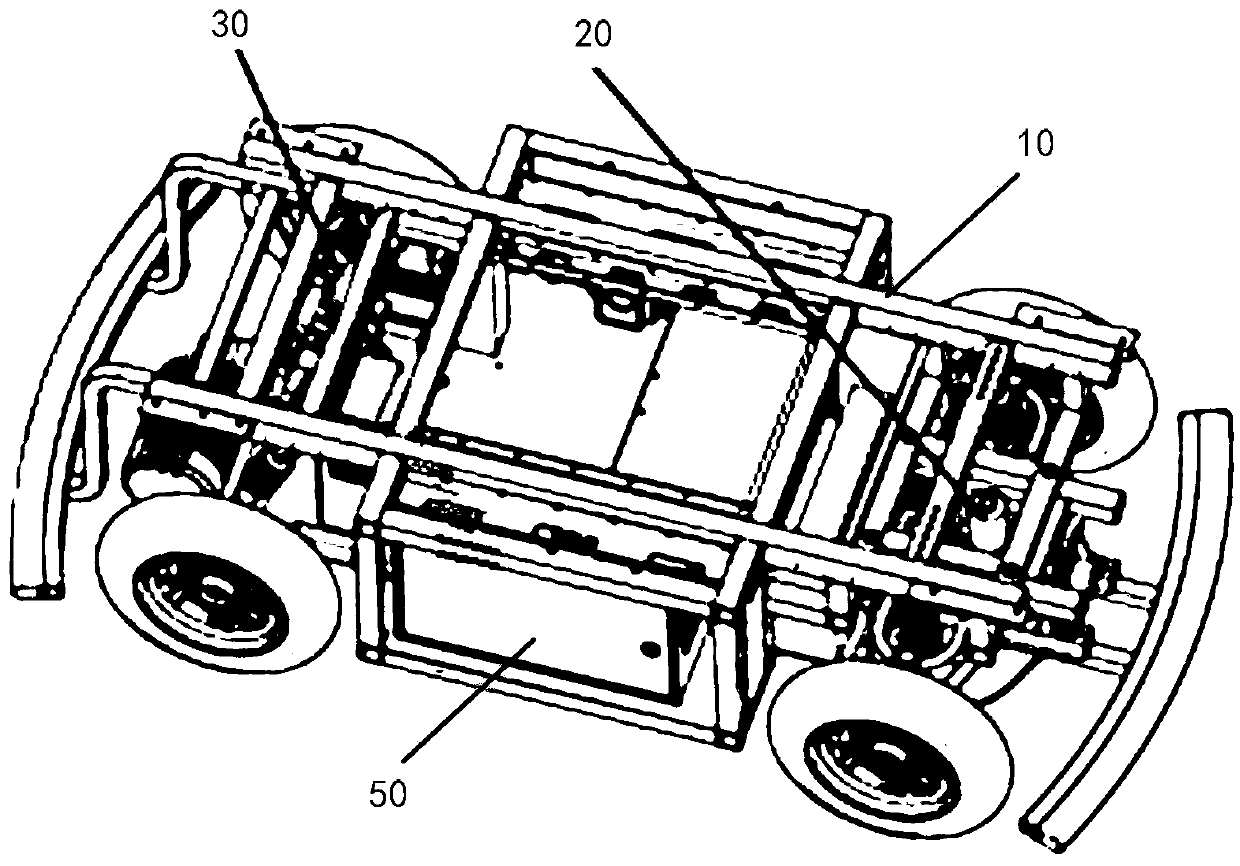

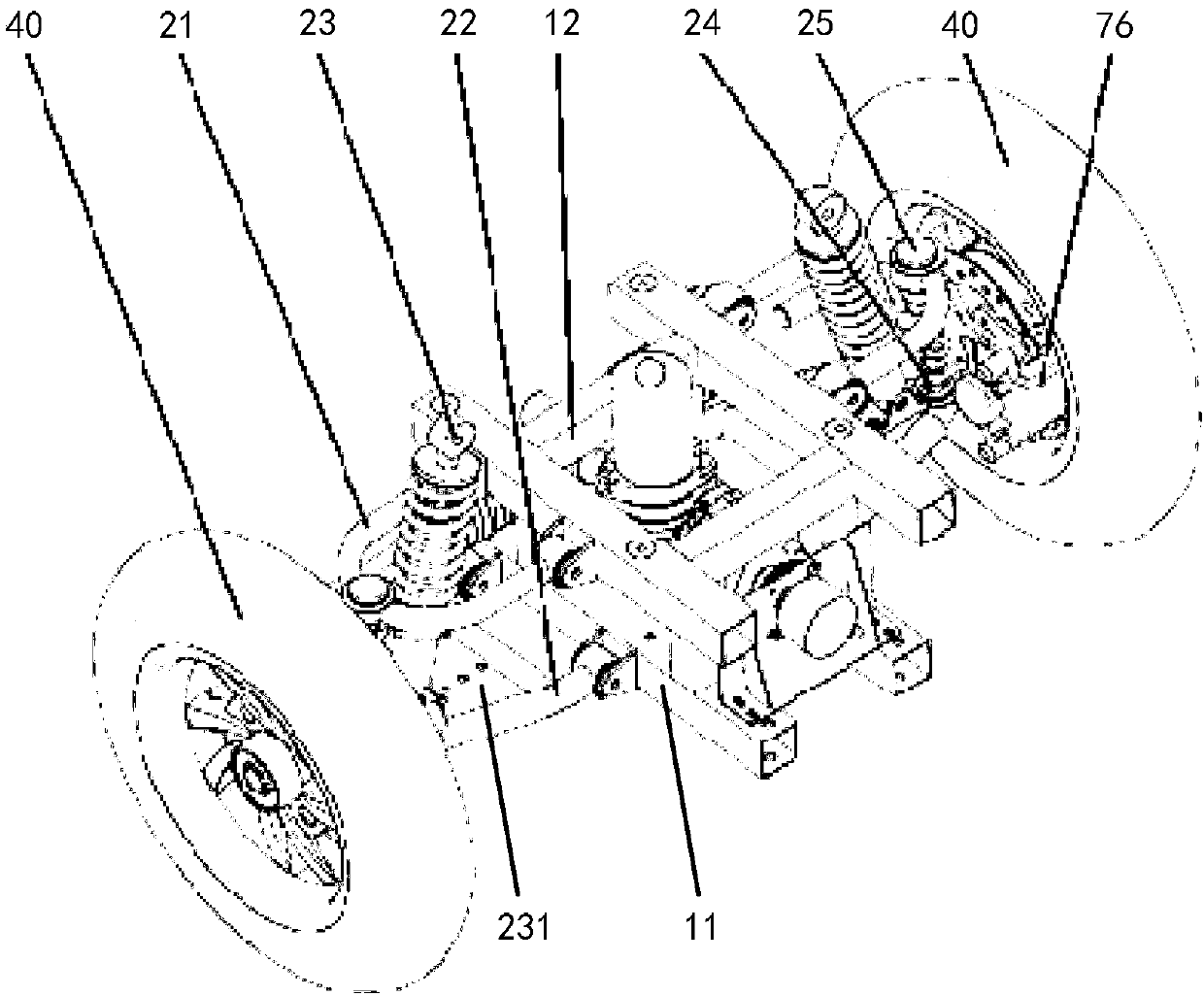

Unmanned distribution robot chassis assembly and unmanned distribution robot

PendingCN110370875AAvoid sliding frictionExtend your lifeElectrical steeringResilient suspensionsVehicle frameIndependent suspension

The invention provides an unmanned distribution robot chassis assembly and an unmanned distribution robot. The unmanned distribution robot chassis assembly comprises a frame, a front axle assembly anda rear axle assembly, wherein the front axle assembly comprises an independent suspension system and a steering system, one end of the independent suspension system is suspended on the frame, the other end of the independent suspension system is rotationally connected with front wheels, so that the front wheels can move in the direction vertical to the ground relative to the frame, the steering system is fixed on the frame, a rack of the steering system is connected with the front wheels through rotatable connecting rods and steering knuckles and is used for driving the rack to move so as todrive the front wheels to turn, the rear axle assembly is connected with rear wheels, a driving part and the frame, and driving force of the driving part is transmitted to the rear wheels through therear axle assembly.

Owner:BEIJING JINGDONG QIANSHITECHNOLOGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com