Patents

Literature

168results about How to "Reduce conveying resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

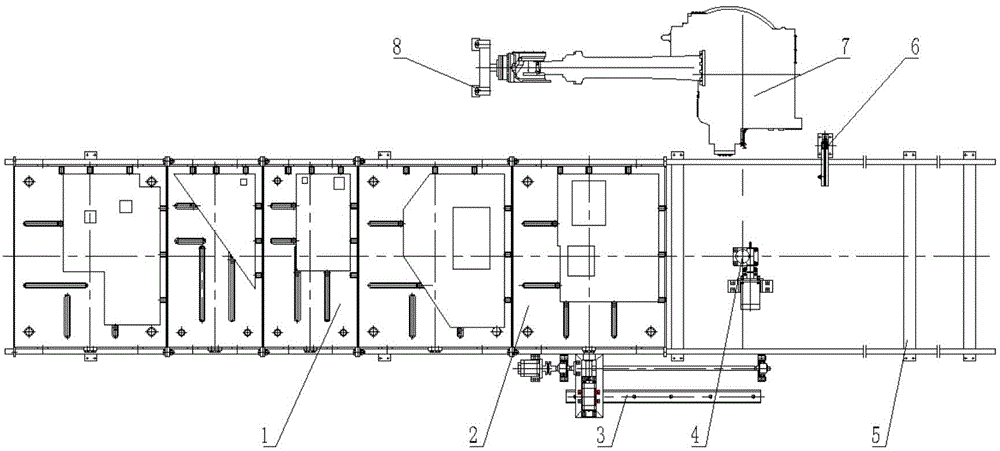

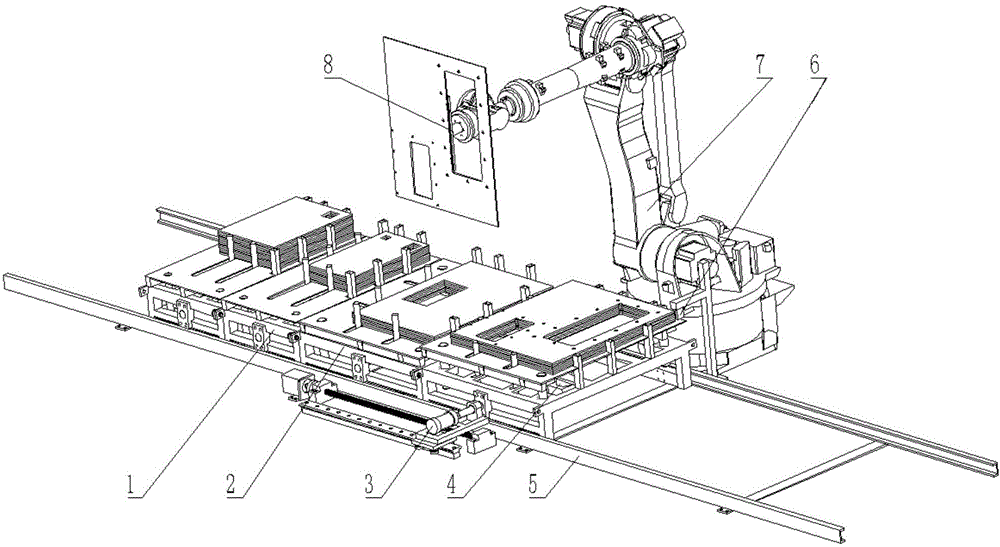

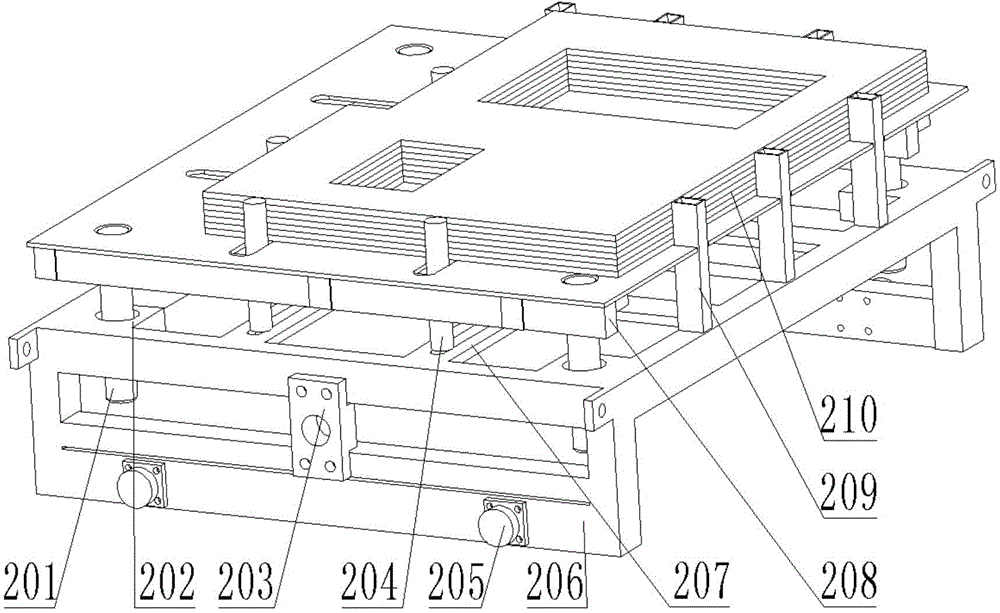

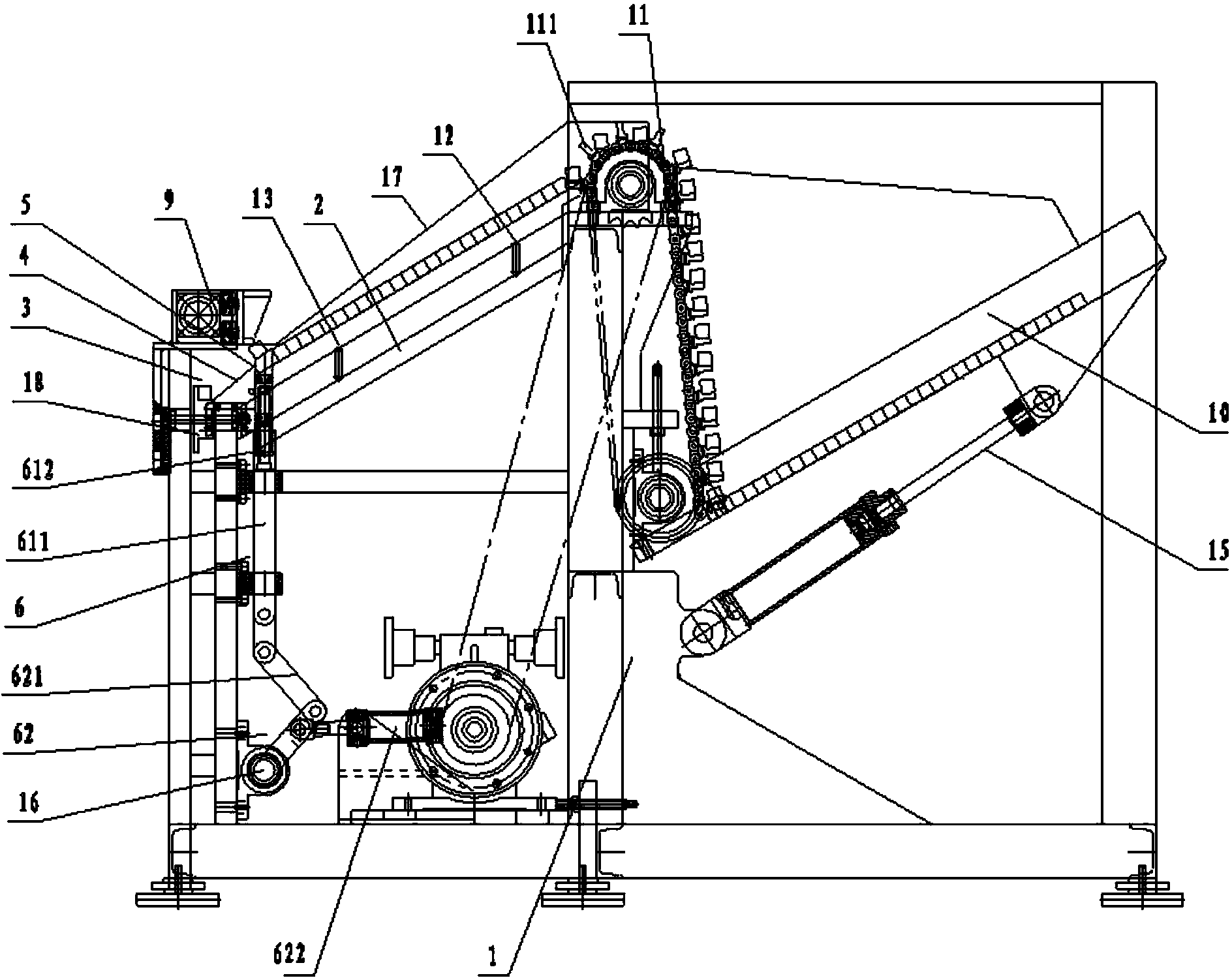

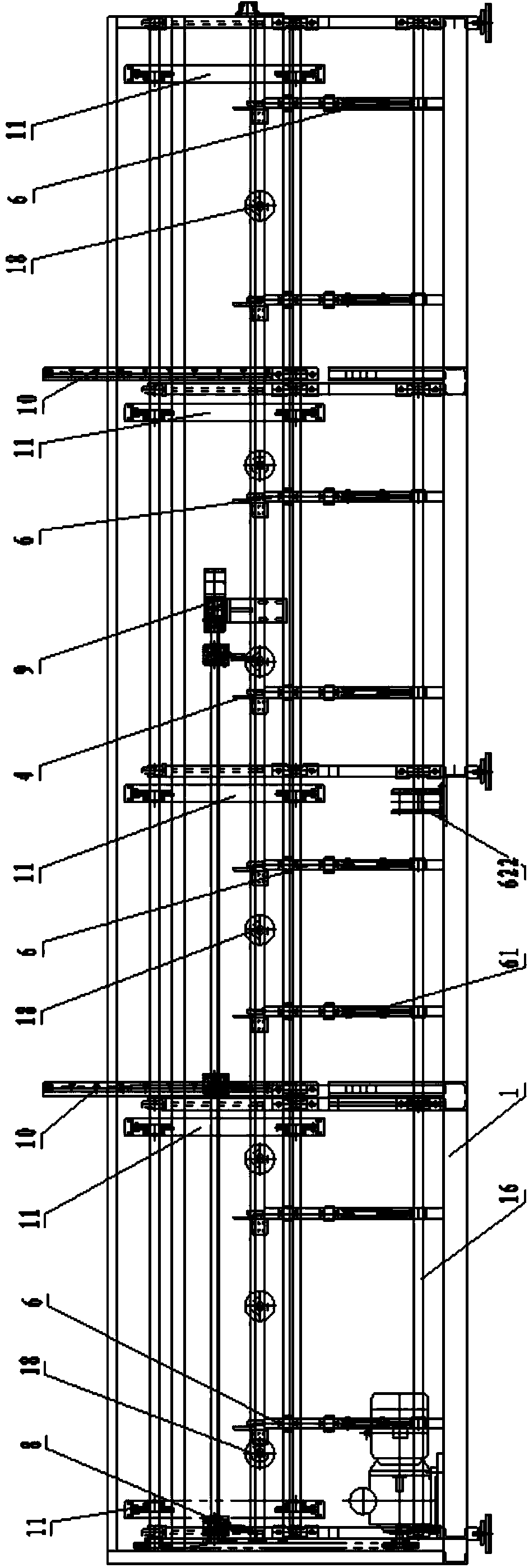

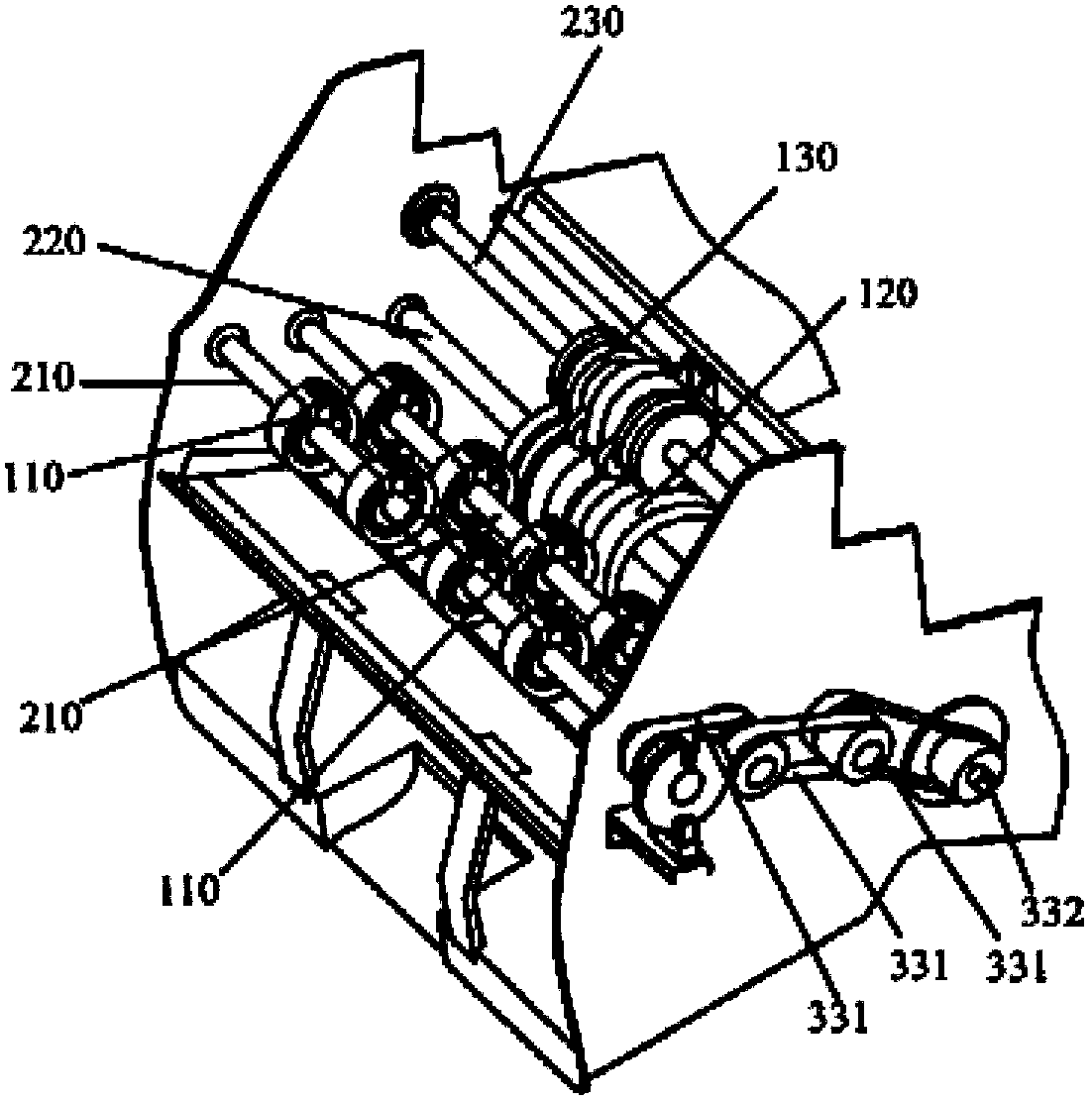

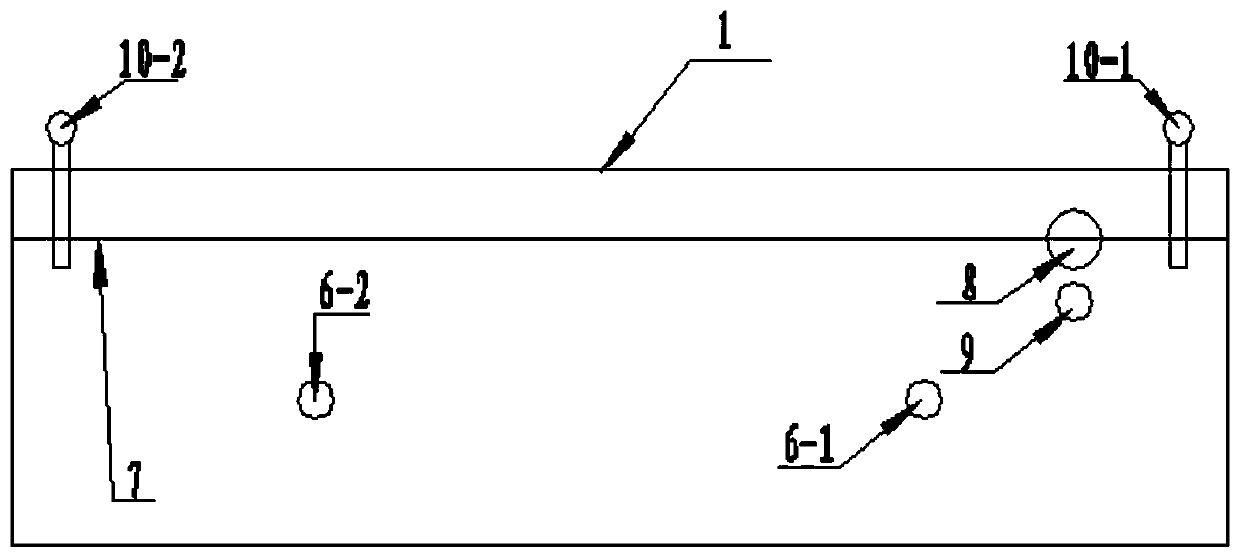

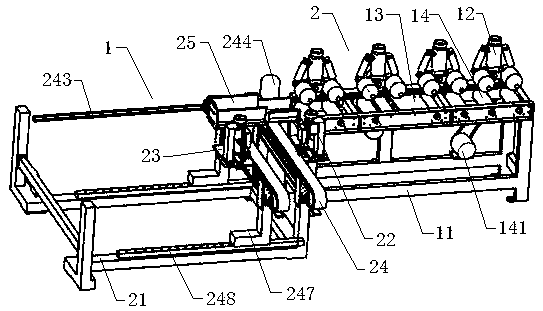

Feeding device for boards of various specifications

InactiveCN104551461ARealize flexible feedingFeeding is satisfiedWelding/cutting auxillary devicesAuxillary welding devicesManipulatorContinuous feeding

The invention discloses a continuous feeding device which can be used for sequentially providing boards of various specifications to a board welding automatic line. The feeding device comprises two conveying guide rails which are arranged in parallel, wherein material racks which are as many as specifications of the boards are arranged on the conveying guide rails in a sliding manner; the material racks are sequentially connected, and jacking holes are formed in the middle of the material racks; material carrying plates capable of moving up and down are arranged on the material racks; a jacking device for jacking the material carrying plates is arranged on a position, at a feeding station, between the conveying guide rails; a sensor for confirming whether the boards reach material getting height or not is arranged above the feeding station; feeding mechanical hands are arranged on positions, corresponding to the jacking device, at sides of the conveying guide rails; step mechanisms for driving the material racks to move are arranged at the other sides of the conveying guide rails; each step mechanism comprises a lead screw which is parallel to the guide rails and a step motor for driving the lead screw to rotate, wherein a slide base is arranged on each lead screw in a sleeving mode, and a drive rod which moves in a direction vertical to the conveying guide rails and a positioning drive device for driving the drive rod are arranged on the slide base; connecting sleeves which are matched with the drive rods are arranged on the material racks.

Owner:JIANGSU UNIV OF SCI & TECH IND TECH RES INST OF ZHANGJIAGANG +1

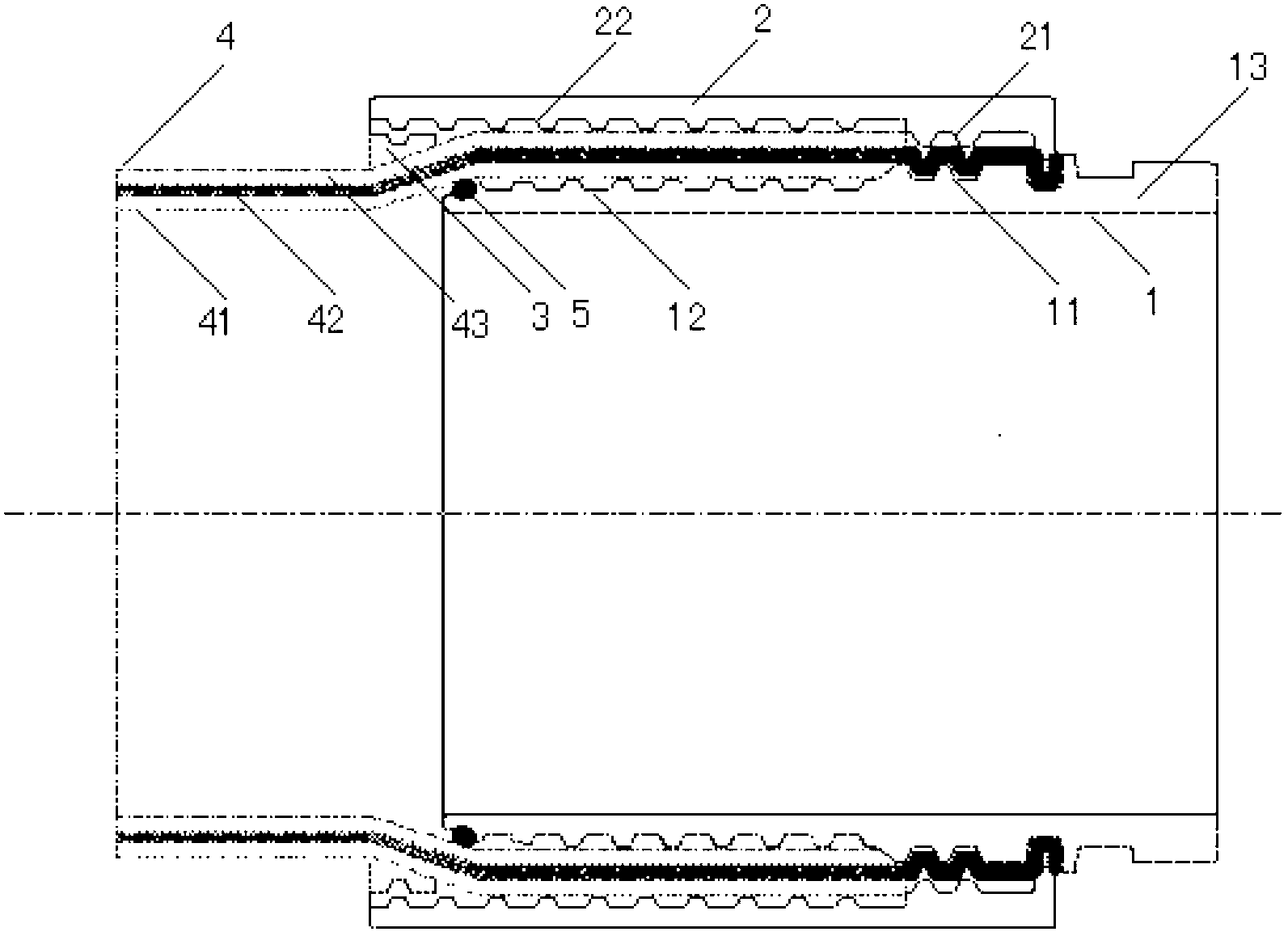

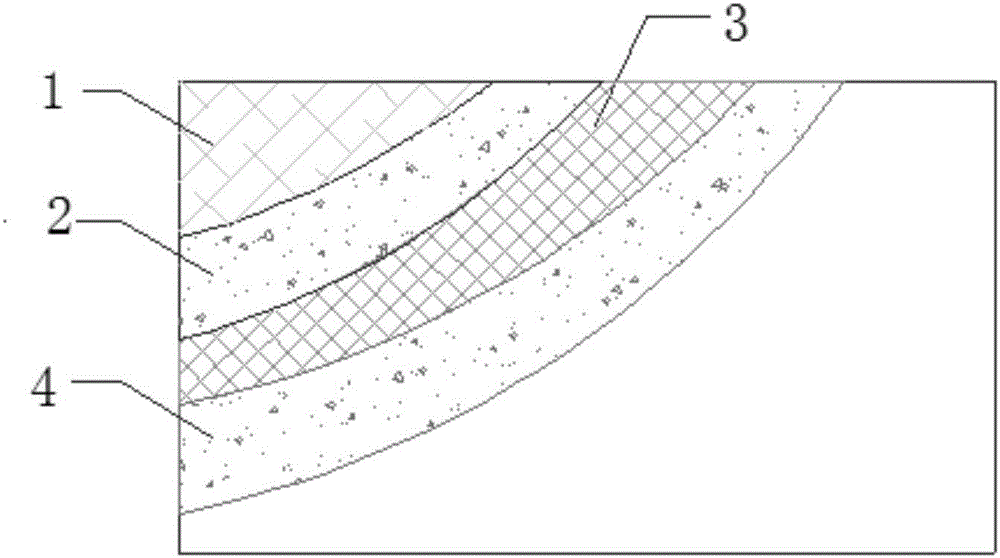

Thermoplastic plastic composite tube

ActiveCN102853176AFirmly connectedGuarantee the safety of useFlexible pipesRigid pipesThermoplasticEngineering

The invention relates to a thermoplastic plastic composite tube, which comprises a thermoplastic plastic composite tube body and a joint. The joint comprises a core tube and a jacket, which are buckled on both ends of the tube body; the end of a tube body of the thermoplastic plastic composite tube is expanded in a radial direction, so that the inner diameter of the core tube is equal to the inner diameter of the tube body, an inner layer and an outer layer of the tail end of the end of the tube body are stripped, the expanded end of the tube body is buckled between a trapezoidal tooth groove outside the core tube and a trapezoidal tooth groove of the jacket; and the end of the core tube is a joint connecting part. The thermoplastic plastic composite tube has the advantages of firm joint buckling, good sealing property, high pressure resistance and drawing resistance, the inner diameter of the joint is equal to the inner diameter of the pipeline, and the fluid conveying resistance is reduced.

Owner:PETRO OIL & LUBRICANT RES INST OF THE GENERAL LOGISITIC DEPT OF PLA +1

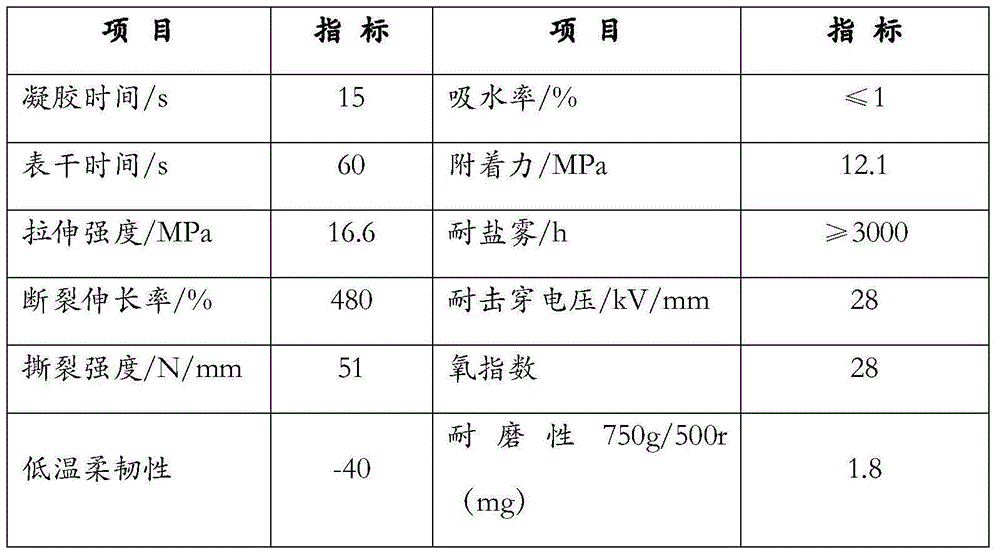

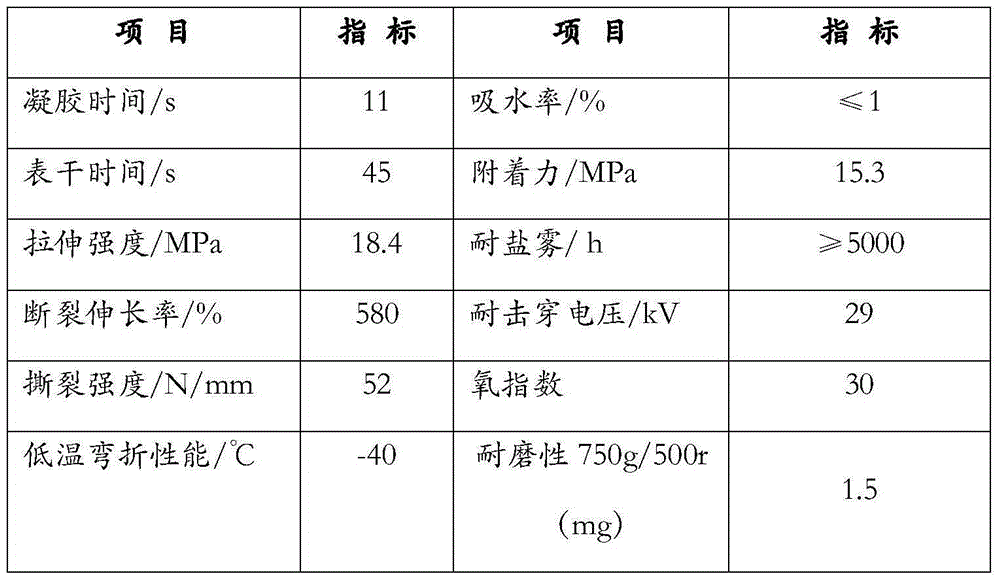

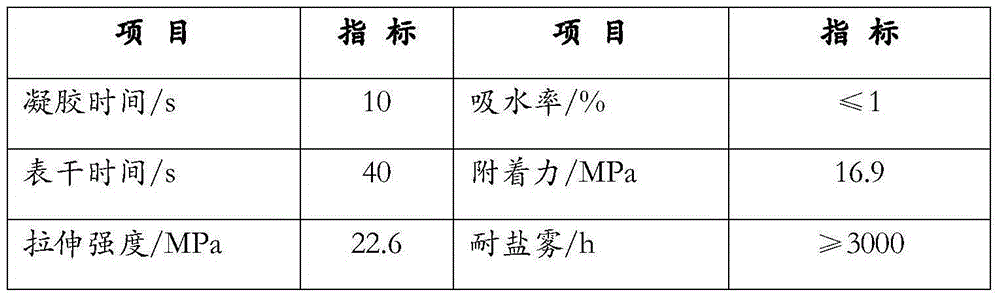

Spray polyurea elastomer and preparation method thereof

ActiveCN105038546AImprove corrosion resistanceMeet anti-corrosion requirementsPolyurea/polyurethane coatingsElastomerPolyol

The invention discloses a spray polyurea elastomer and a preparation method thereof. The spray polyurea elastomer comprises a component A and a component B, wherein the volume ratio of the component A to the component B is 1: 1; the component A is isocyanate prepolymer compounded through the reaction of polyether polyol, fluorine-containing polyol, and isocyanate, and the -NCO content is 12%-20%; the component B comprises the followings in parts by weight: 30-50 parts of amine-terminated polyether, 30-45 parts of a chain extender, 0.5-1.0 part of fumed silica, 0.1-0.5 part of a dispersing agent, 0.5-1.0 part of a defoaming agent and 1.0-5.0 parts of color paste. The polyurea elastomer provided by the invention is excellent in weather resistance, resistance to chemical reagents and fire resistance and good in abrasion resistance.

Owner:QINGDAO AIR NEW MATERIALS

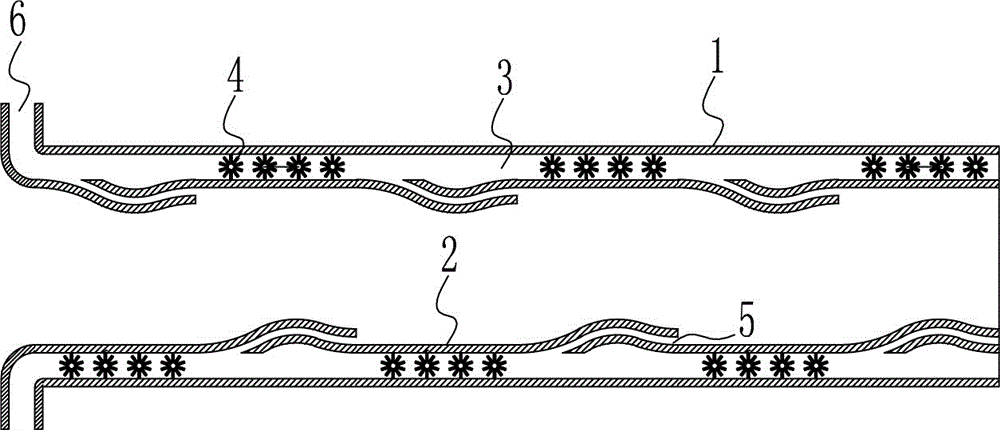

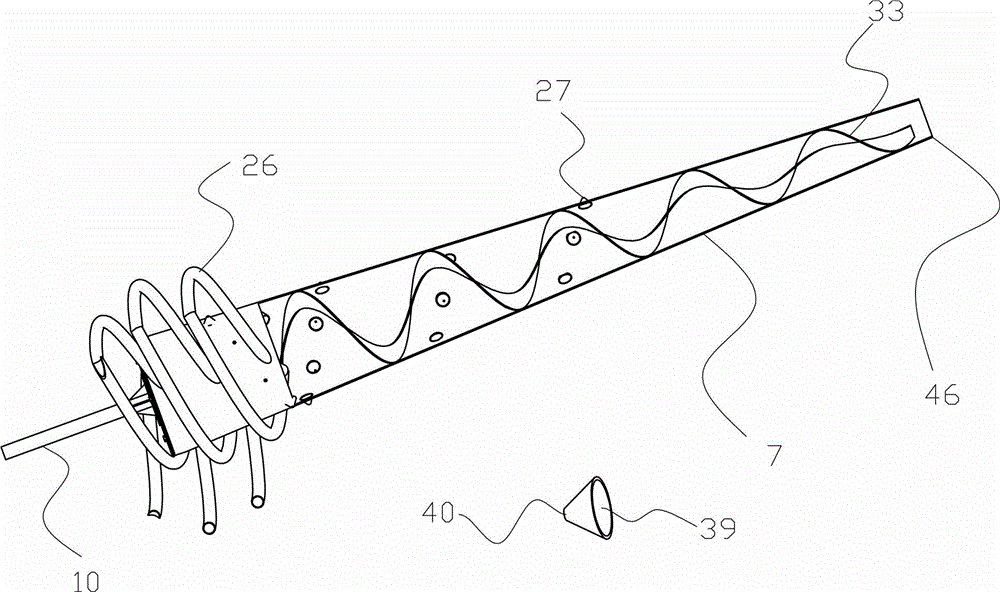

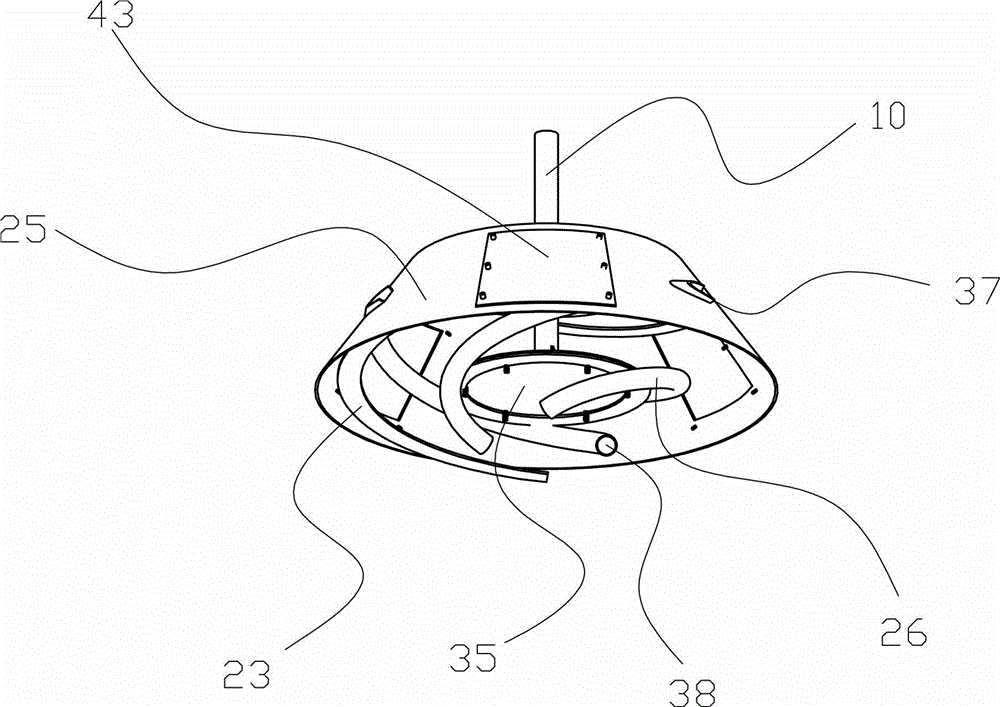

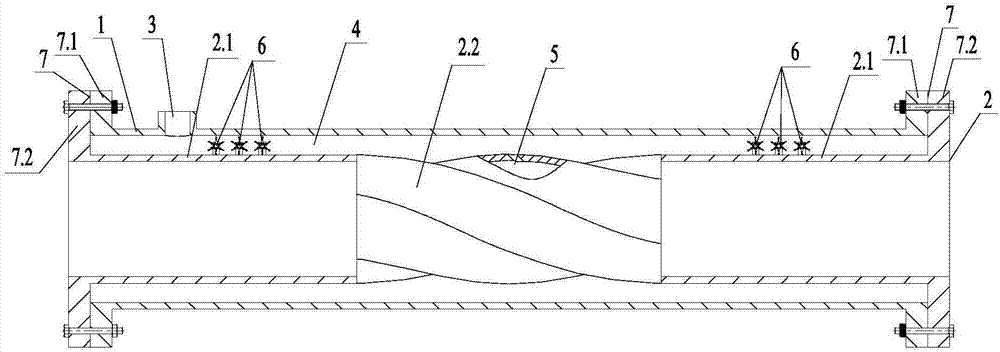

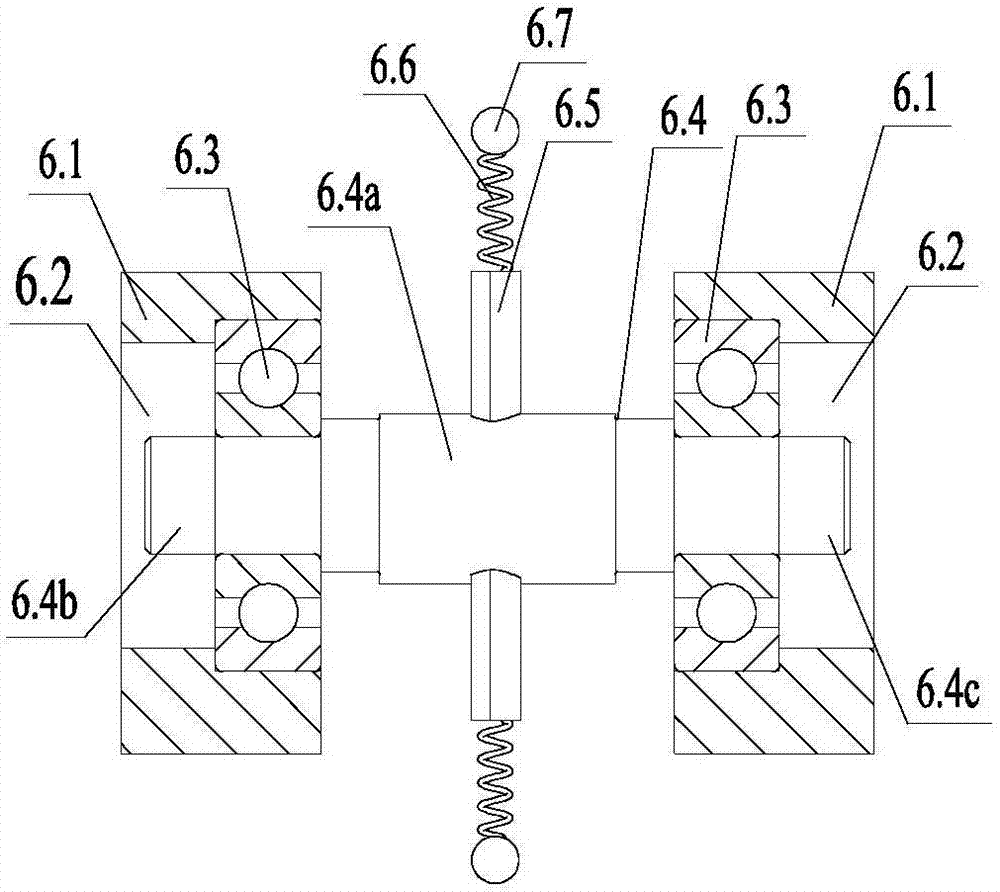

Pipeline gas adding resistance reduction slurry conveying device

ActiveCN106697953AReduce conveying resistanceLow viscosityBulk conveyorsSlurryTransportation technology

The invention belongs to the technical field of pipeline slurry conveying, and relates to a pipeline gas adding resistance reduction slurry conveying device. The pipeline gas adding resistance reduction slurry conveying device achieves the technical aims that flowing resistance of slurry in the pipeline is reduced, and hydraulic losses of the slurry along the way are reduced; in order to achieve the aims, the pipeline gas adding resistance reduction slurry conveying device comprises an outer pipe wall, an inner pipe wall, a high-pressure gas way, a high-frequency vibrator, a gas film generation way and a high-pressure air inlet; the high-pressure gas way is arranged between the outer pipe wall and the inner pipe wall, the high-frequency vibrator is arranged in the high-pressure gas way, the gas film generation way is arranged on the inner pipe wall, and the high-pressure air inlet is connected with the high-pressure gas way; the defects that the flowing resistance of the slurry in the pipeline is large, and hydraulic lowering along the way is rapid are overcome, and the effects that the flowing resistance of the slurry in the pipeline is reduced, and the hydraulic losses of the slurry along the way are reduced are achieved.

Owner:绍兴市城投再生资源有限公司

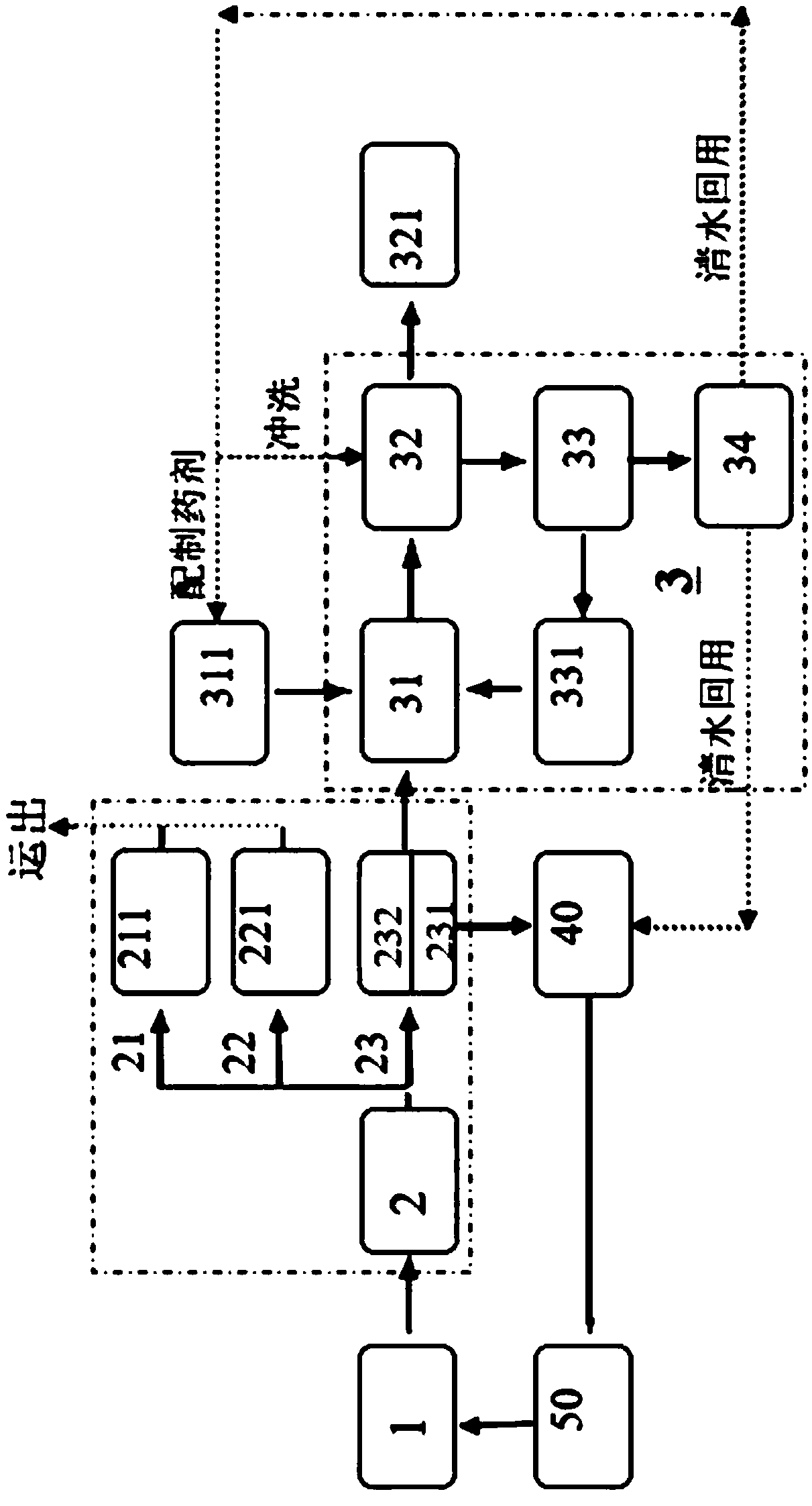

Purifying treatment method and system for cuttings-carrying slurry of bentonite

PendingCN107842330AReduce wear and tearAchieve the goal of energy saving and emission reductionFlushingFlocculationSlurry

The invention provides a purifying treatment method for cuttings-carrying slurry of bentonite. The purifying treatment method for the cuttings-carrying slurry of the bentonite comprises the steps thatmud-water separating treatment is conducted, specifically, a multistage sieving device is used for conducting separating treatment on the input cuttings-carrying slurry, sandstone which does not conform to a slurry system is sorted out, then the slurry is subjected to concentrating and dewatering, and concentrated slurry and a mud-containing water body are obtained; and purifying and recovery ofthe mud-containing water body are conducted and comprise the steps of flocculation filter pressing and flocculation sedimentation, specifically, according to the flocculation filter pressing step, first the mud-containing water body is adjusted to a predetermined solid content, a flocculant is added, then a mixture enters a filter press for filter pressing, a mud cake and filter water are obtained, and according to the flocculation sedimentation step, the filter water generated in the flocculation filter pressing step is sent into a sedimentation tank and is subjected to sedimentation and layering in the sedimentation tank, and the upper layer of clear water is sent into a clear water tank for storage. According to the purifying treatment method for the cuttings-carrying slurry of the bentonite, the cuttings-carrying slurry can be subjected to full purifying treatment, zero discharge of water is realized, and a large amount of bentonite and the cost for dumping the waste slurry are saved.

Owner:河南小威环境科技有限公司

Preparation and application of ultrahigh wear-resisting hydrogen sulfide-proof polyether-ether-ketone aqueous suspension specially used for oil-well tube

InactiveCN101665621ALow VOC contentGood self-lubricating performanceDrilling rodsPretreated surfacesHigh pressureLubrication

The invention provides an ultrahigh wear-resisting hydrogen sulfide-proof polyether-ether-ketone aqueous suspension specially used for oil-well tubes, which has extremely low VOC content. After beingcoated on the internal wall of the oil-well tube by a high-speed rotating airless spraying process, the suspension provides a coating layer with the performances of high wear resistance, self-lubrication, high-temperature and high-pressure resistance, hydrogen sulfide resistance and corrosion protection. The aqueous suspension can be sprayed by air and can be applied to various nut threads and various impellers so as to improve the chemical resistance and wear resistance of the equipment. The PEEK aqueous suspension has excellent self-lubrication, provides less surface resistance for the equipment and has excellent effect in reducing conveying resistance and saving energy.

Owner:SHANGHAI HILONG ANTI CORROSION TECH ENG

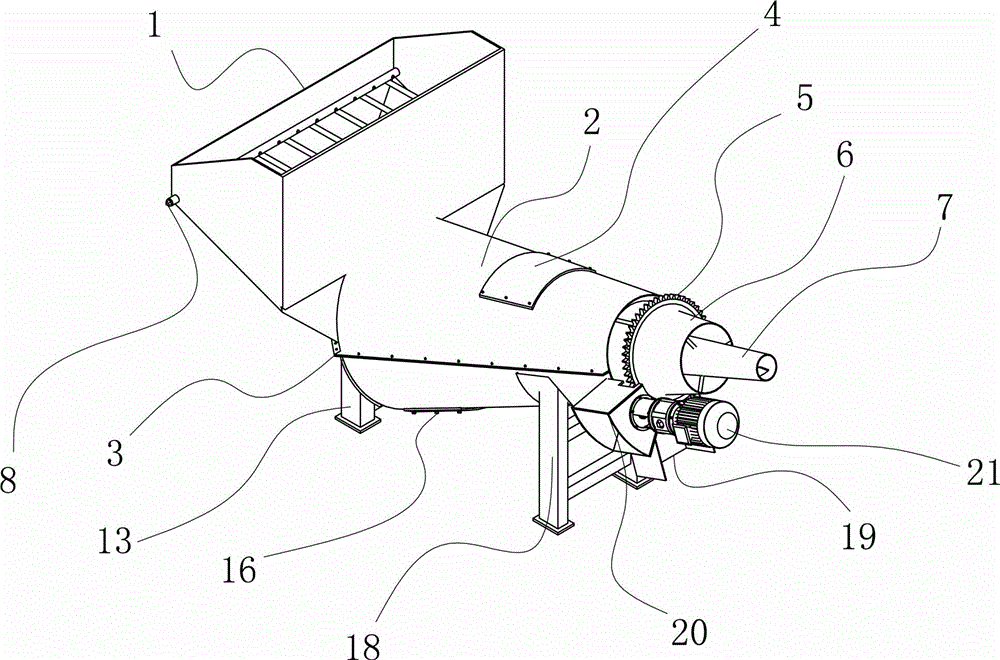

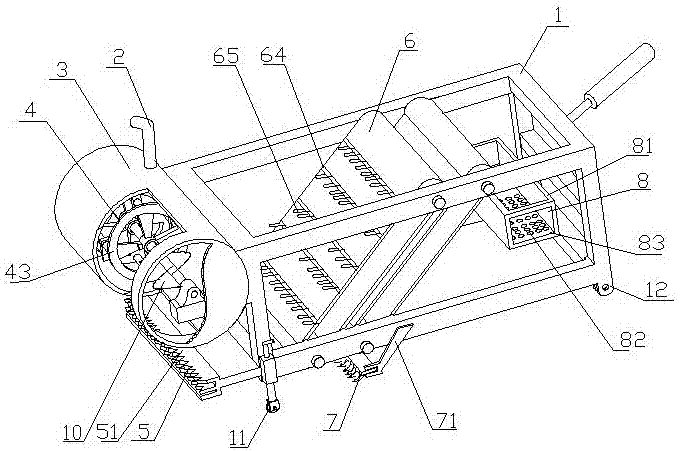

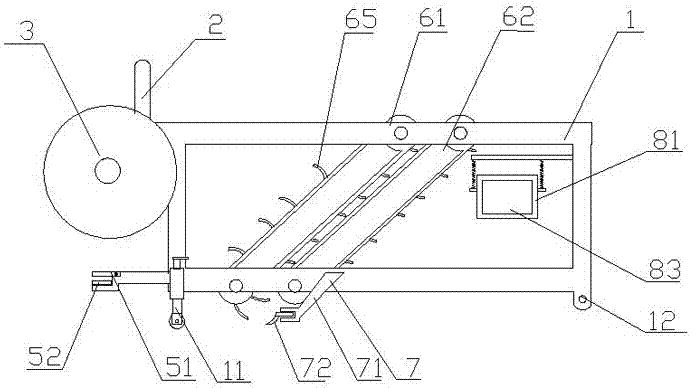

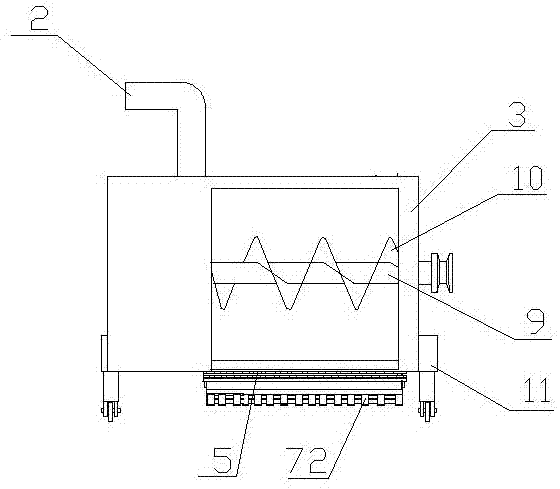

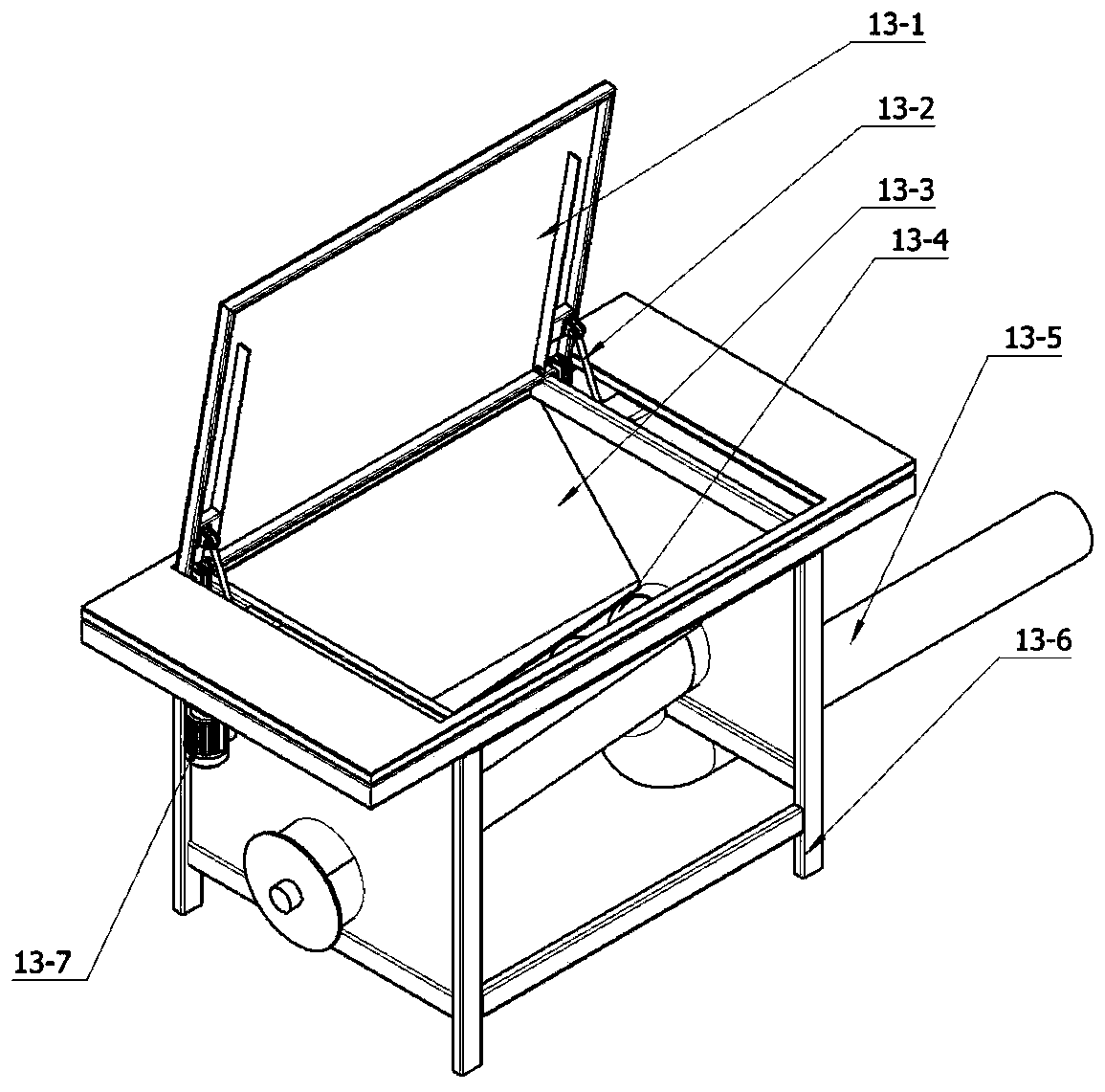

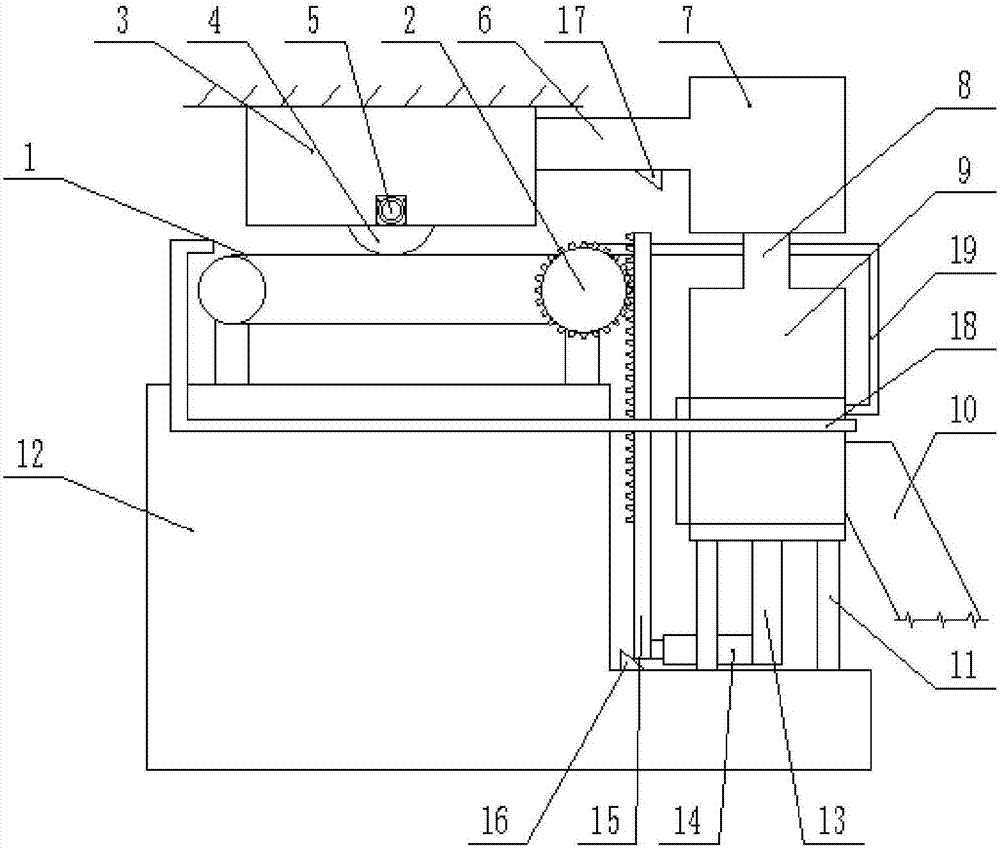

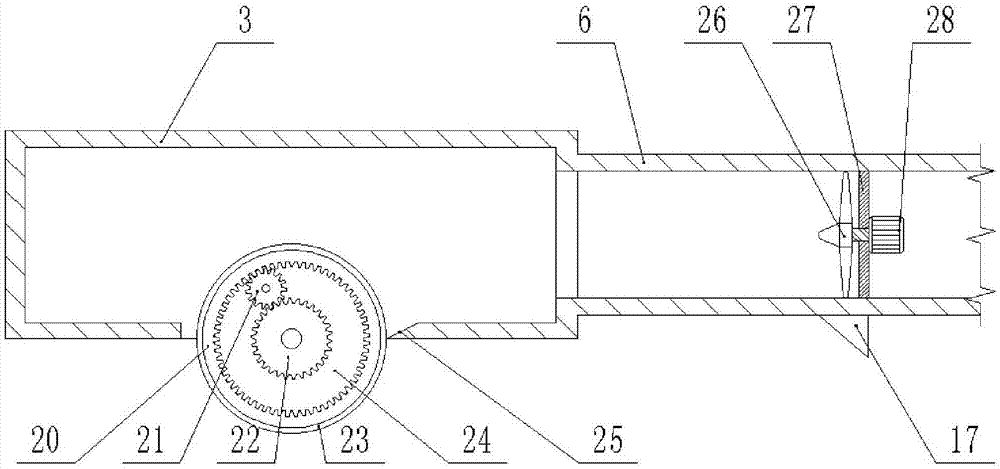

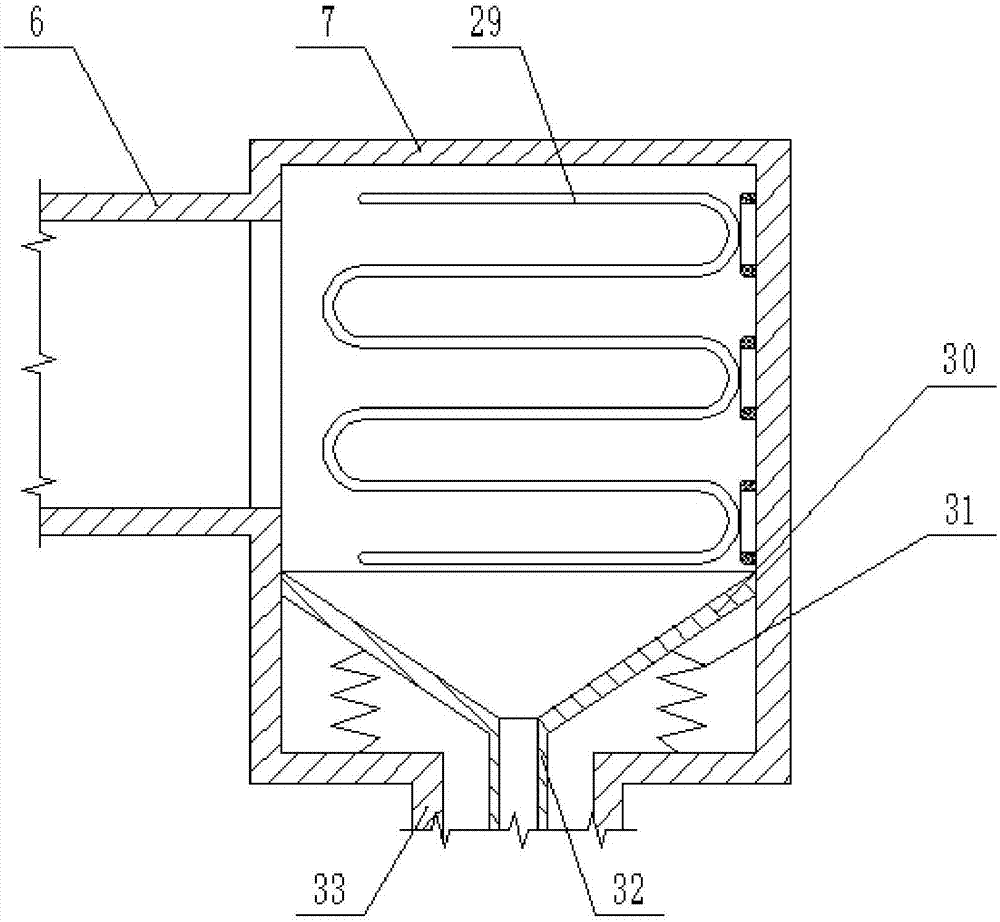

Wet concrete recycling and screening machine with automatic sewage pumping and transporting function and application method thereof

The invention belongs to the technical field of wet concrete recycling, and relates to a wet concrete recycling and screening machine and an application method thereof. The machine has an automatic sewage pumping and transporting function and an automatic fine sand filtration function. The provided screening machine has the advantages of small material transportation resistant force, controllable sewage flow, easy separation between fine sand from sewage, and reduction on energy and water. The screening machine comprises screening and transporting devices for sewage, stones, and sand materials. The application method comprises steps of pre-mixing, transportation, screening on stones and sand materials, and transportation of stones and sand materials. The recycling and screening machine has the following advantages: (1) the material is fed in a higher place and discharged in a lower position, and thus the transportation resistant force is greatly reduced; (2) the sewage in the recycling and screening machine is pumped and transported, and changed is the conventional sewage recycling method through a sewage overflowing opening; (3) the filtration of sewage containing fine sand and automatic screen net cleaning are realized; (4) the vehicle washing tank is clean without washing, the fine sand in sewage can be completely filtered and removed without a swirl separation system, and the screen net can be maintained a clean state without washing during vehicle cleaning.

Owner:铜陵亚摩管业有限公司

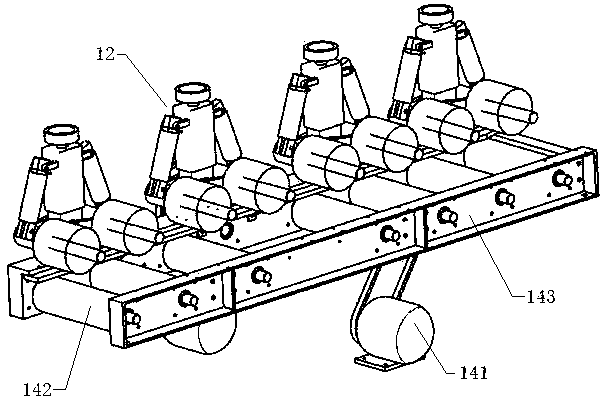

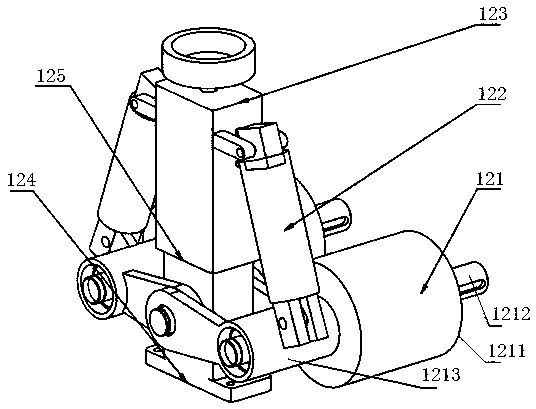

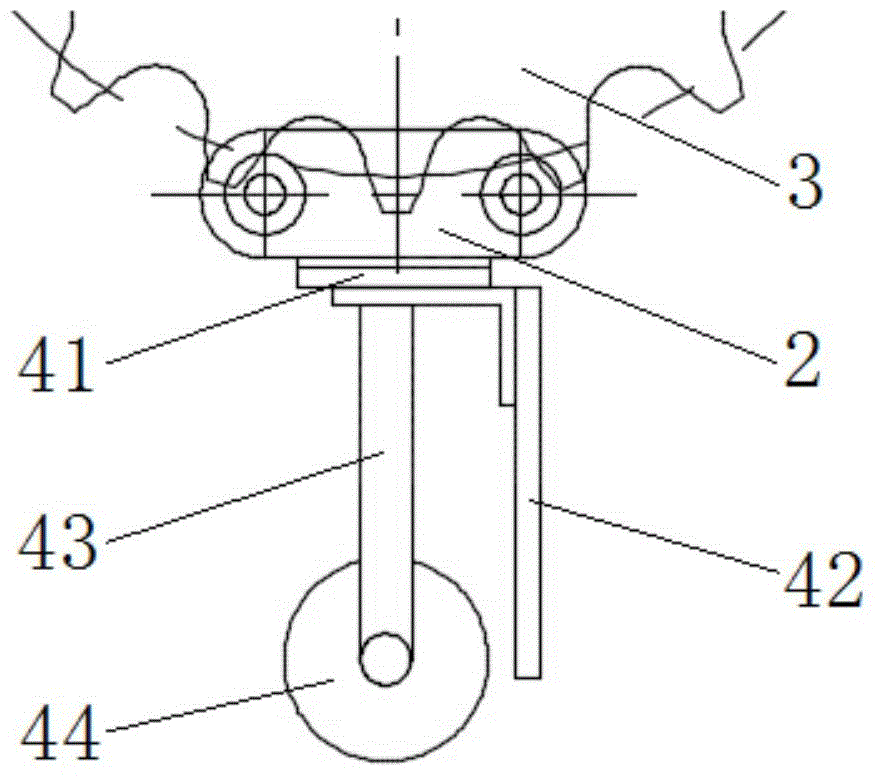

Pipe conveying machine matched with pipe processing equipment

ActiveCN104016091ARealize automatic feedingSimple structureMechanical conveyorsEngineeringMechanical engineering

The invention discloses a full-automatic pipe conveying machine matched with pipe processing equipment. The full-automatic pipe conveying machine matched with the pipe processing equipment comprises a machine frame, wherein the machine frame is provided with a feeding inclined surface and a feeding groove, a guide plate is arranged on the machine frame and between the feeding inclined surface and the feeding groove, and a material blocking pillar is arranged at the bottom of the feeding inclined surface. The machine frame is provided with an ejection mechanism conveying pipe materials from the feeding inclined surface to the guide plate. The ejection mechanism comprises at least two ejection rods movably arranged on the machine frame in the vertical direction and a driving mechanism driving the ejection rods to move vertically, the top surface of each ejection rod is an inclined surface in the same inclining direction as the feeding inclined surface, a material sensor is arranged in the feeding groove, and a pushing part and a pushing oil cylinder for driving the pushing part are arranged at the tail end of the feeding groove.

Owner:ZHANGJIAGANG DONGDA IND TECH RES INST

Rare earth metal catalyst system and method for preparing high cis-conjugated diene polymer

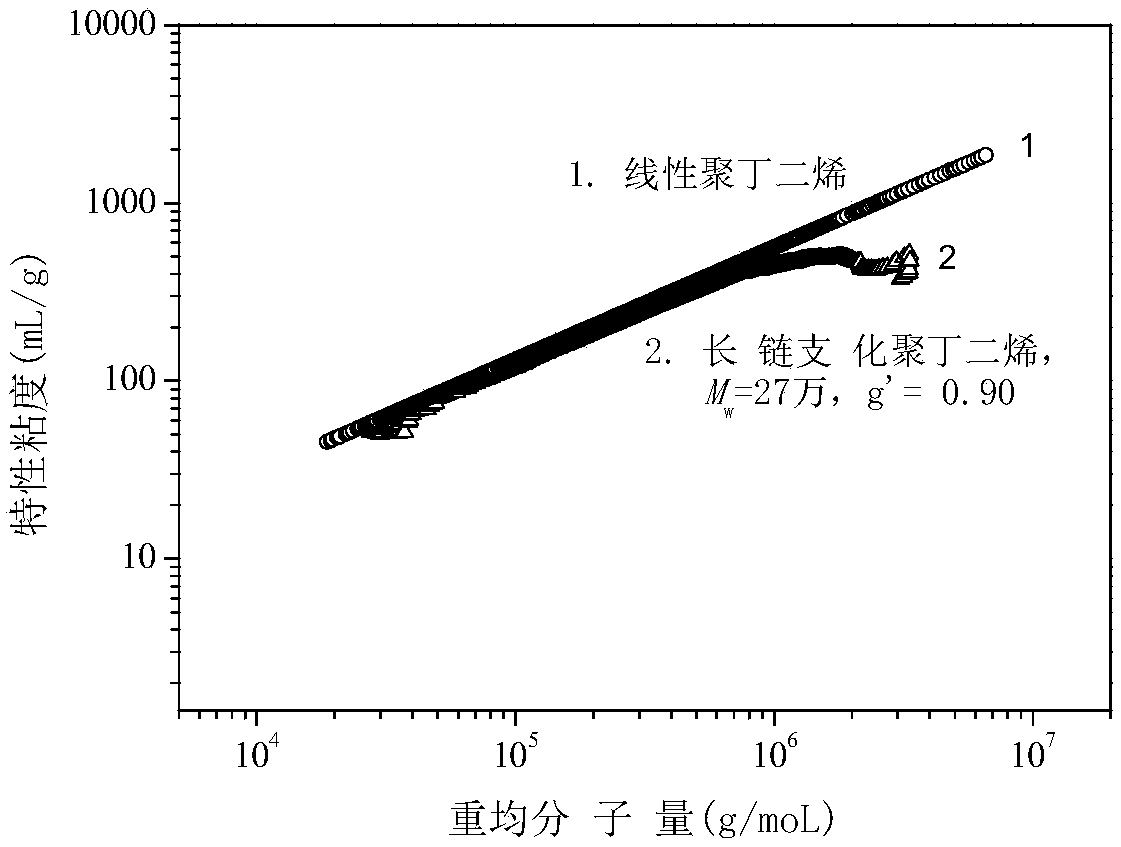

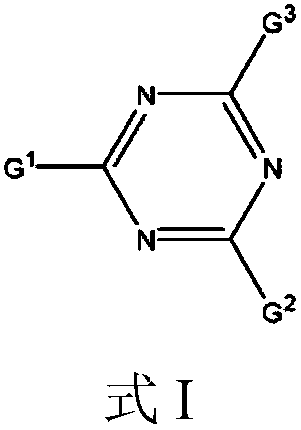

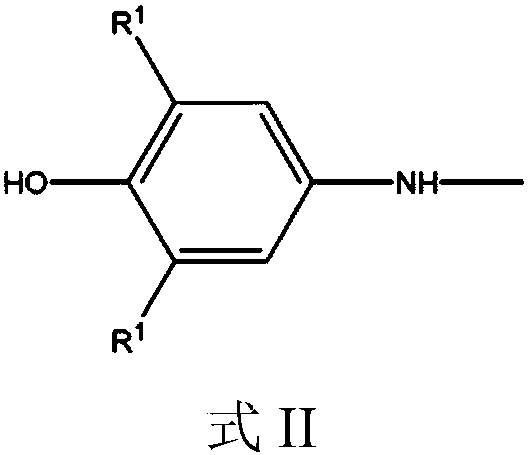

ActiveCN108929396AEliminate the process of cross-linking reactionEasy to preparePolymer scienceHalogen

The invention relates to the field of rare earth metal catalysts, and provides a rare earth metal catalyst system and a method for preparing a high cis-conjugated diene polymer. The catalyst includes:(A) rare earth salts, (B) organic aluminum compounds, (C) at least one of halogen-containing hydrocarbon compounds and halogen-containing carboxylic ester compounds, (D) C6-C20 carboxylic acids, (E)compounds with phenolic hydroxyl groups, and (F) conjugated olefin compounds, wherein the molar ratio of all the components is A:B:C:D:E:F=1:(7-30):(0.8-20):(0.1-4.5):(1.0*10<-6>-8.0*10<-4>):(0-700).The method includes the steps: under the protection of inert gas, the catalyst makes contact with conjugated olefin monomers, and the conjugated olefin monomers are initiated to carry out coordinationpolymerization reaction to prepare the linear or long-chain branched high cis-conjugated diene polymer. The branching degree of the obtained polymer can be adjusted in a wide range. The method is simple and high in efficiency.

Owner:BEIJING UNIV OF CHEM TECH

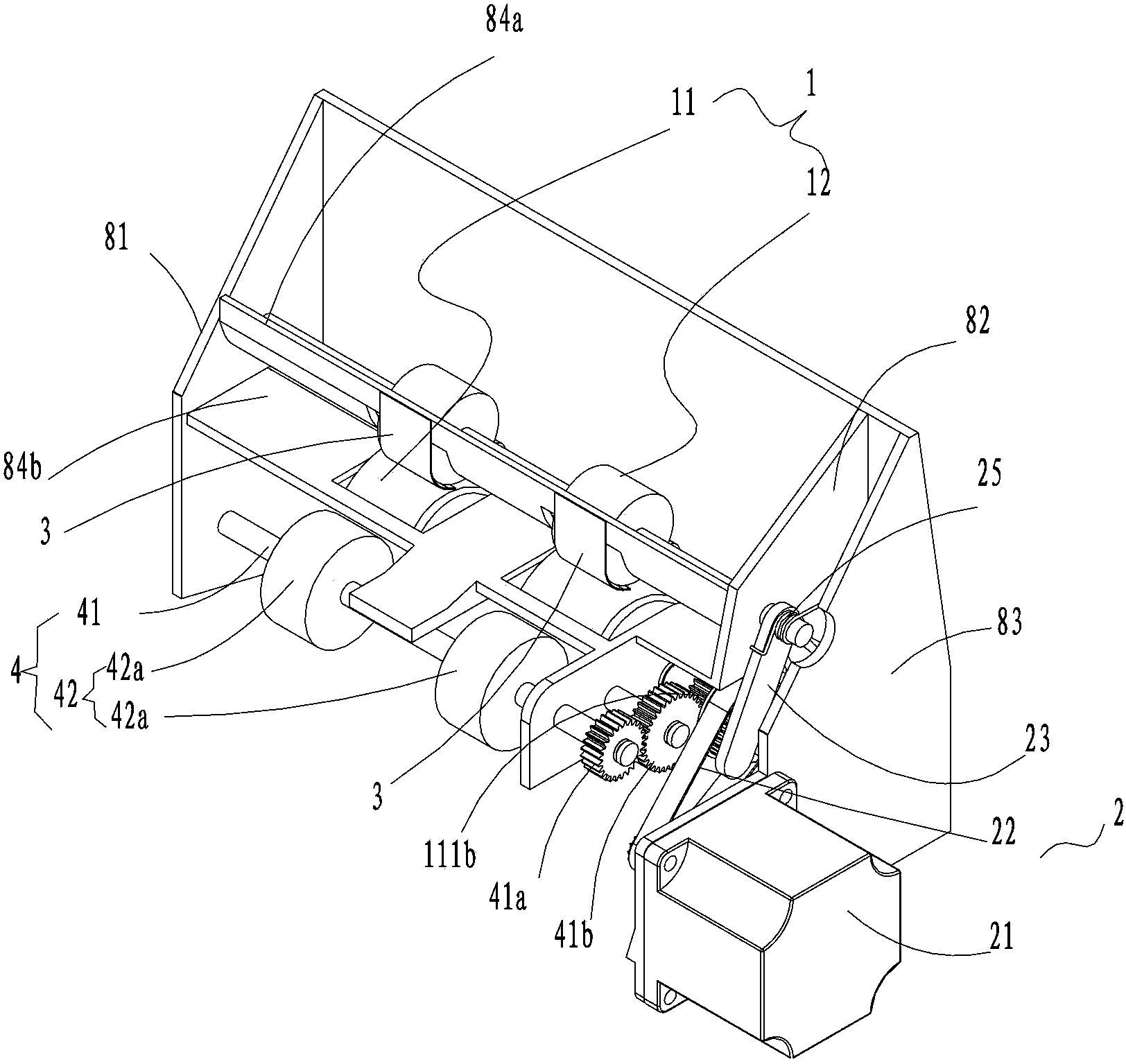

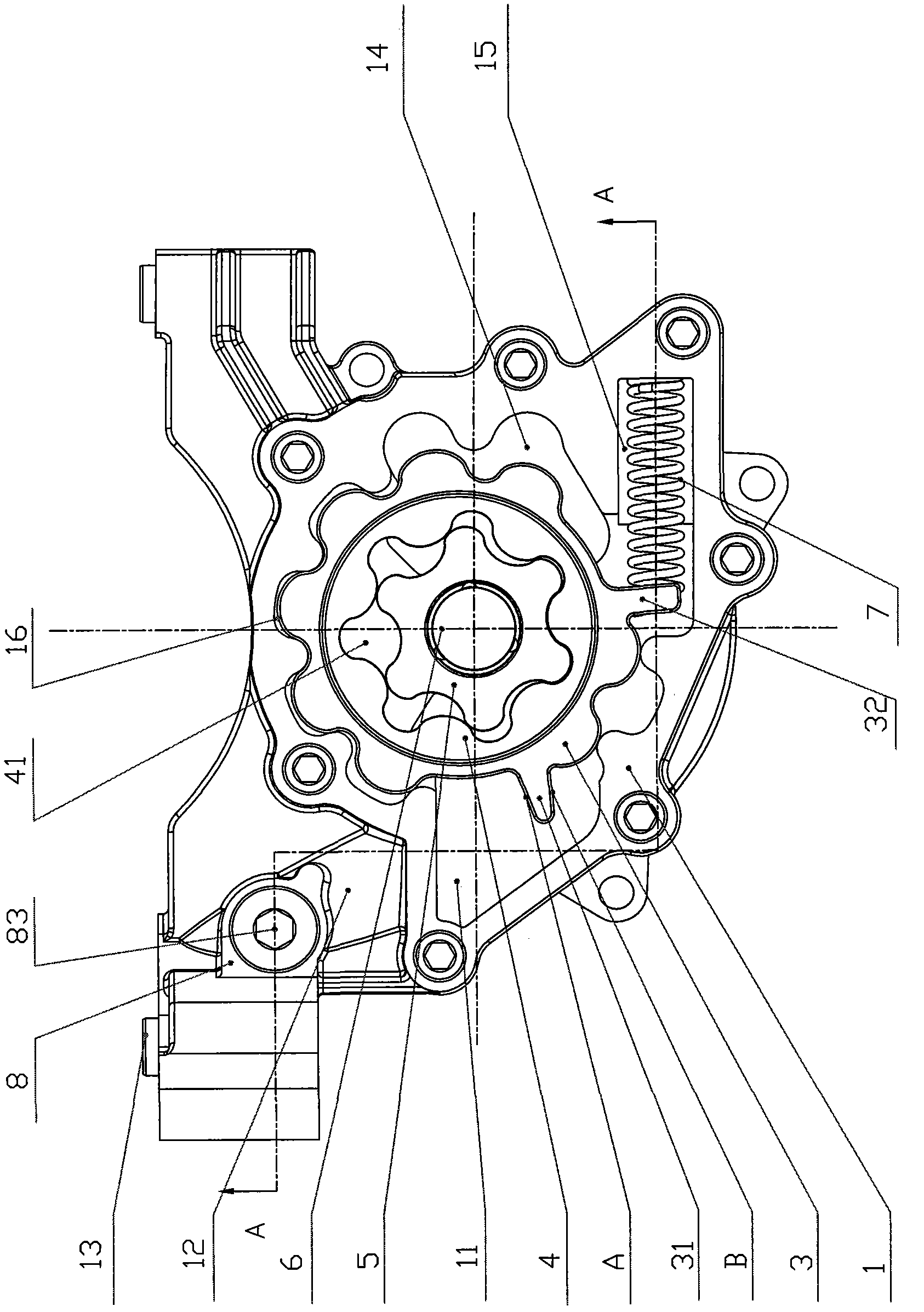

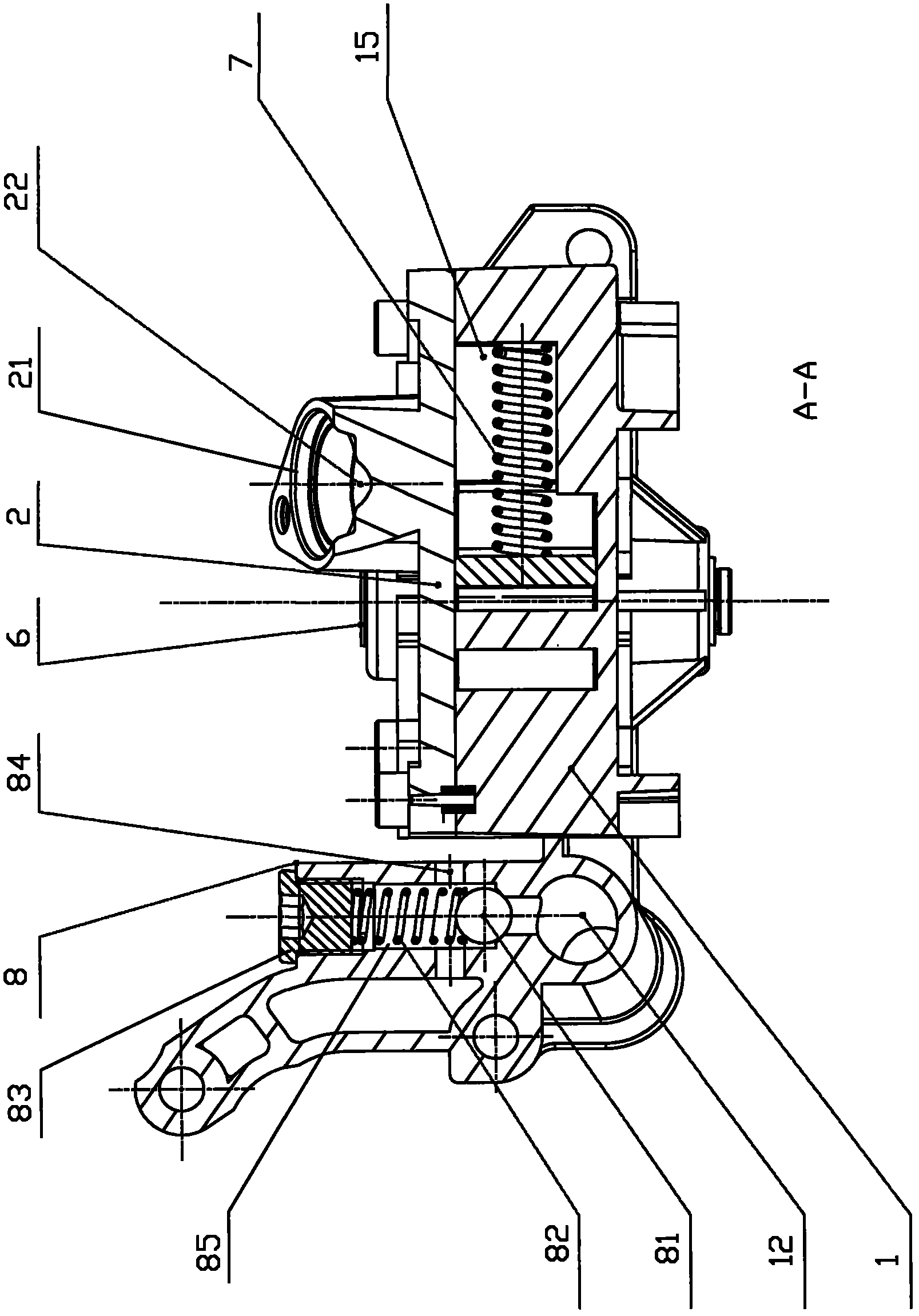

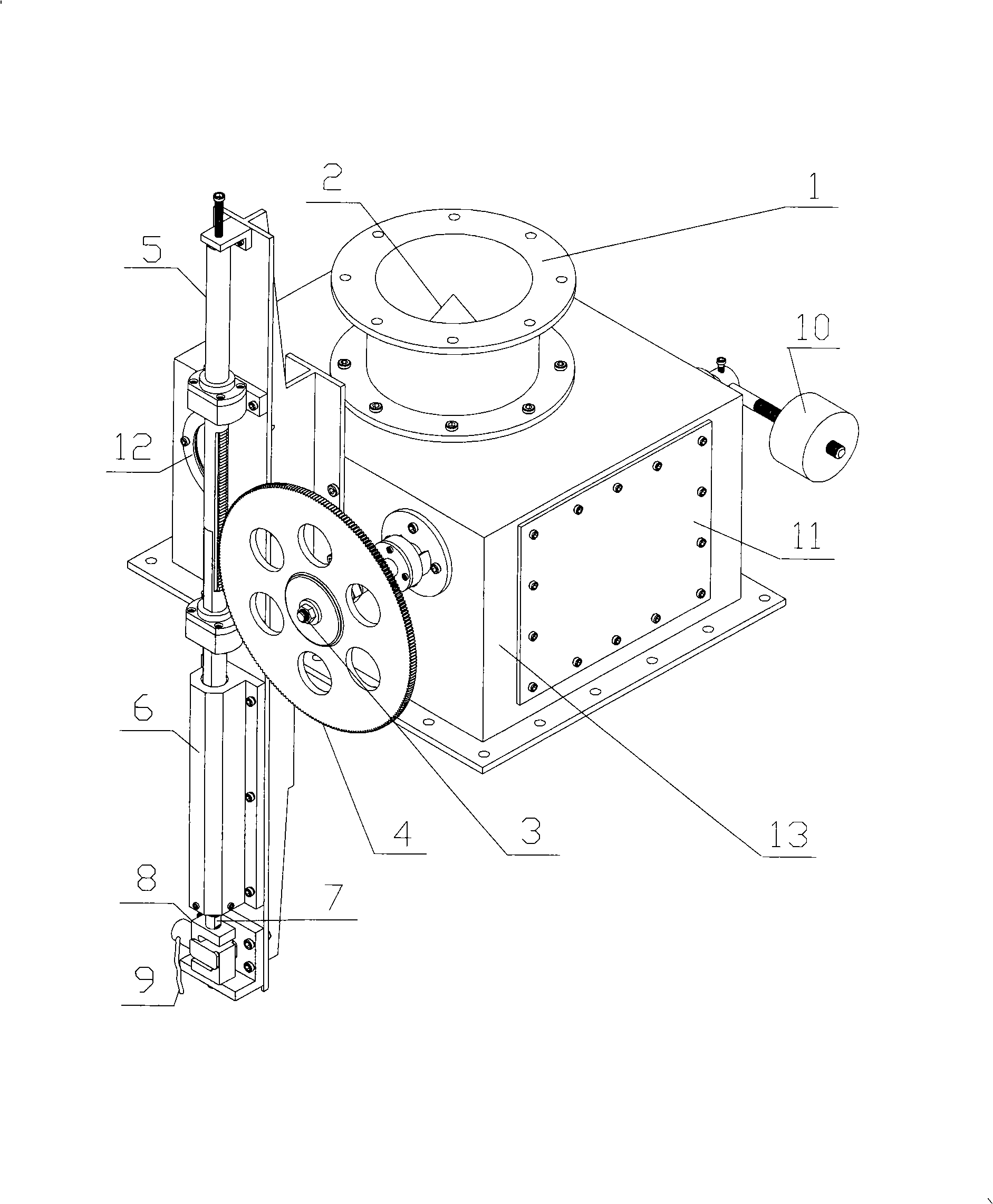

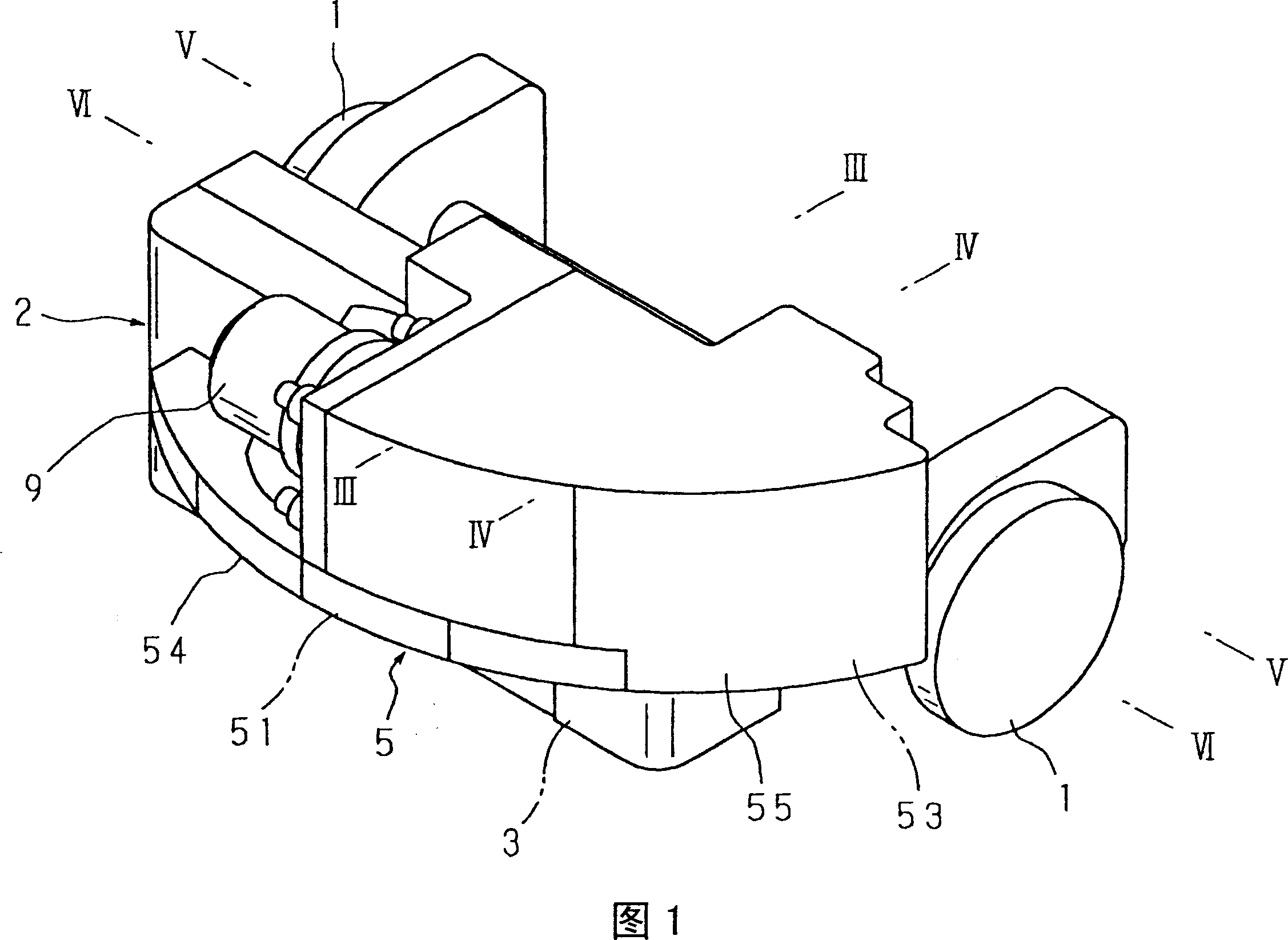

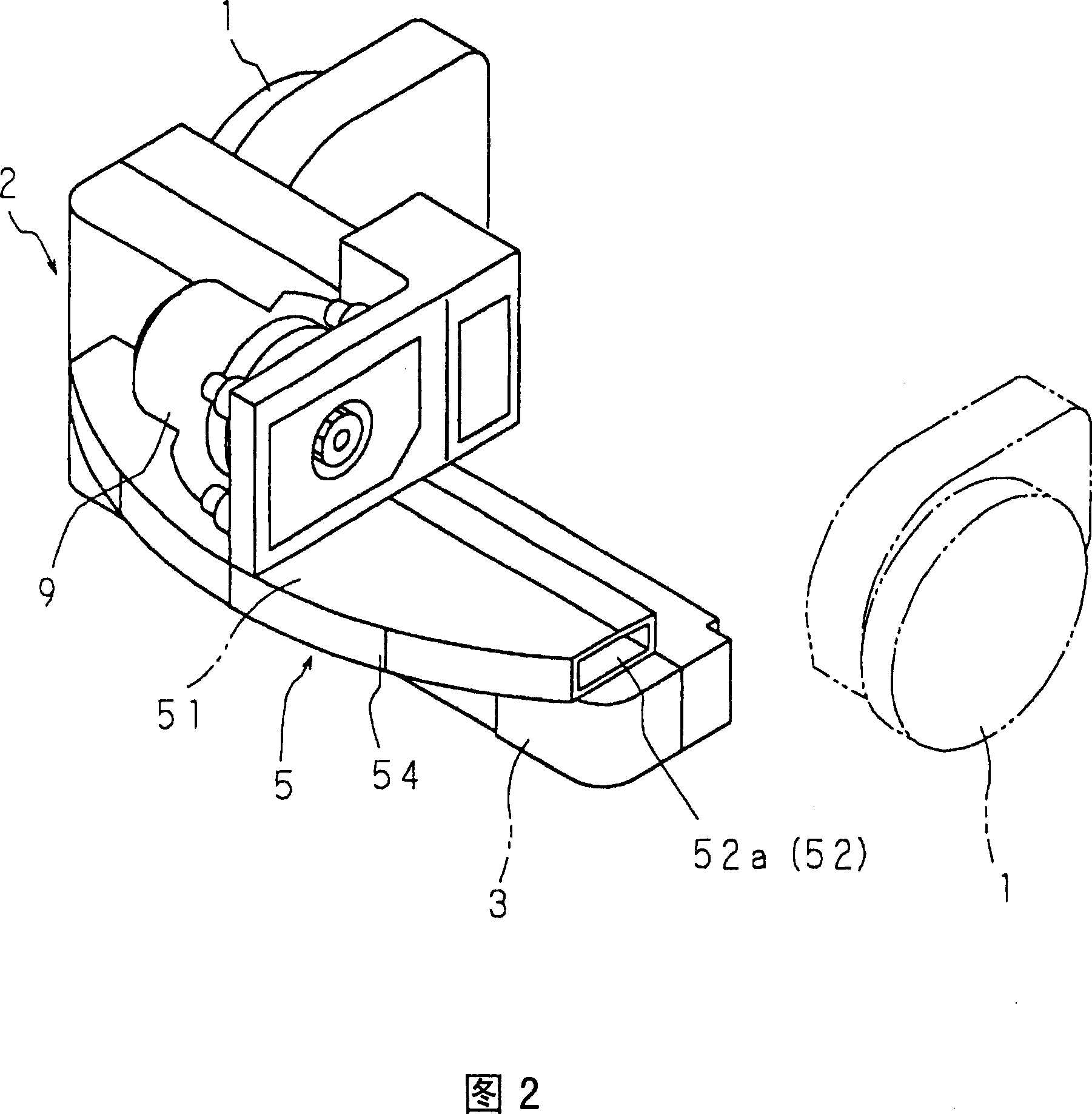

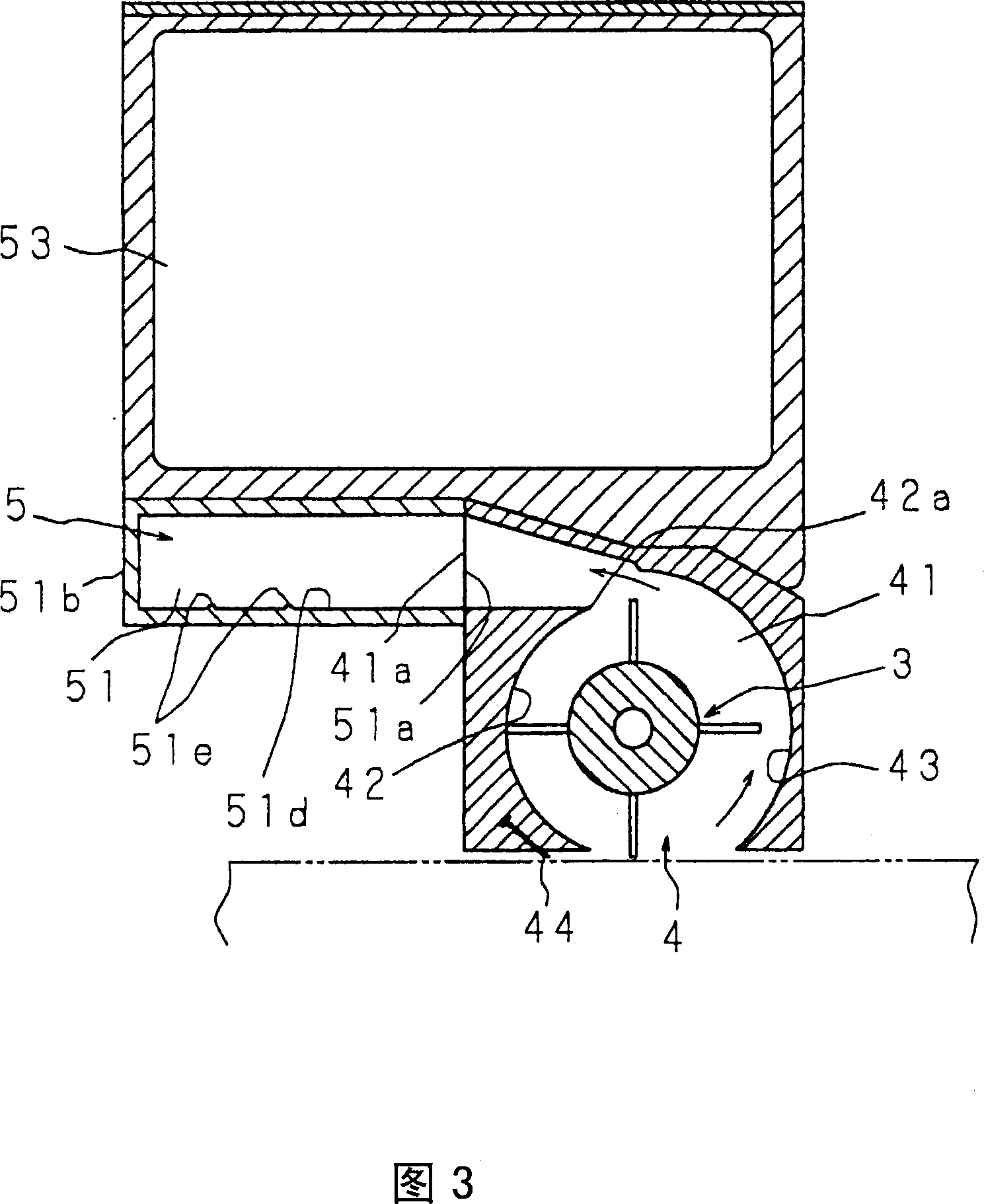

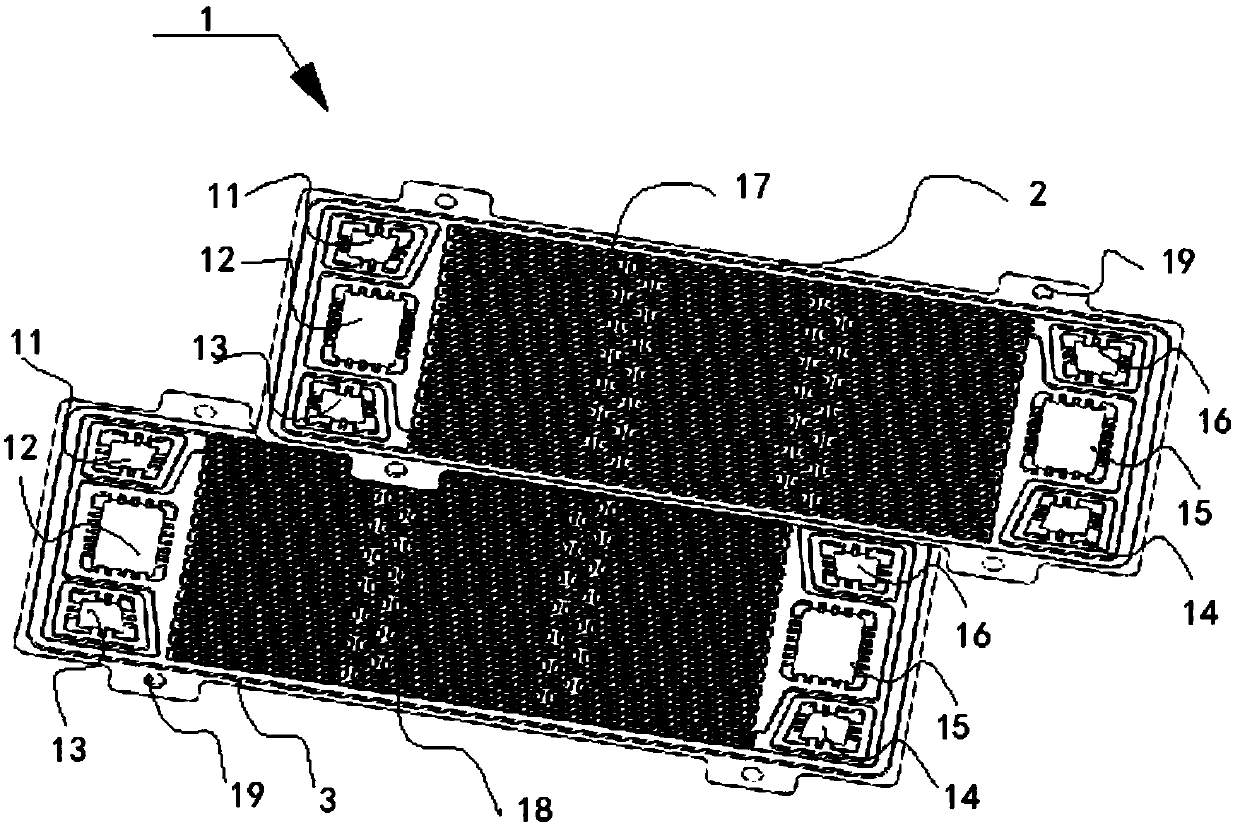

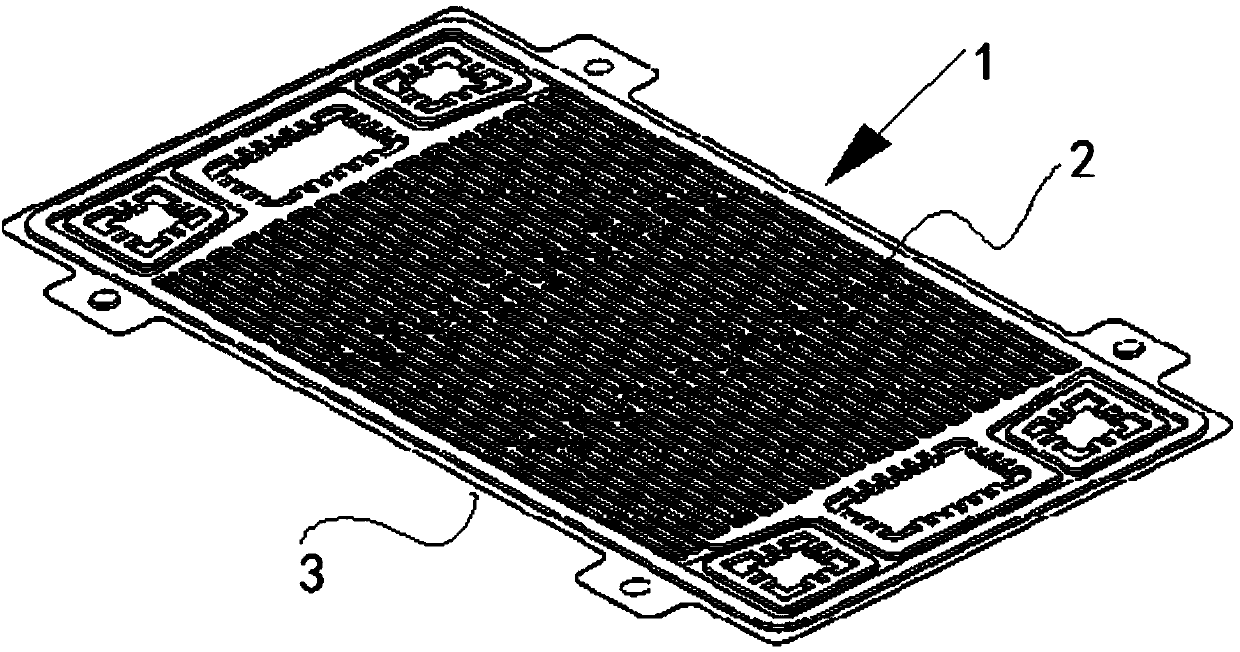

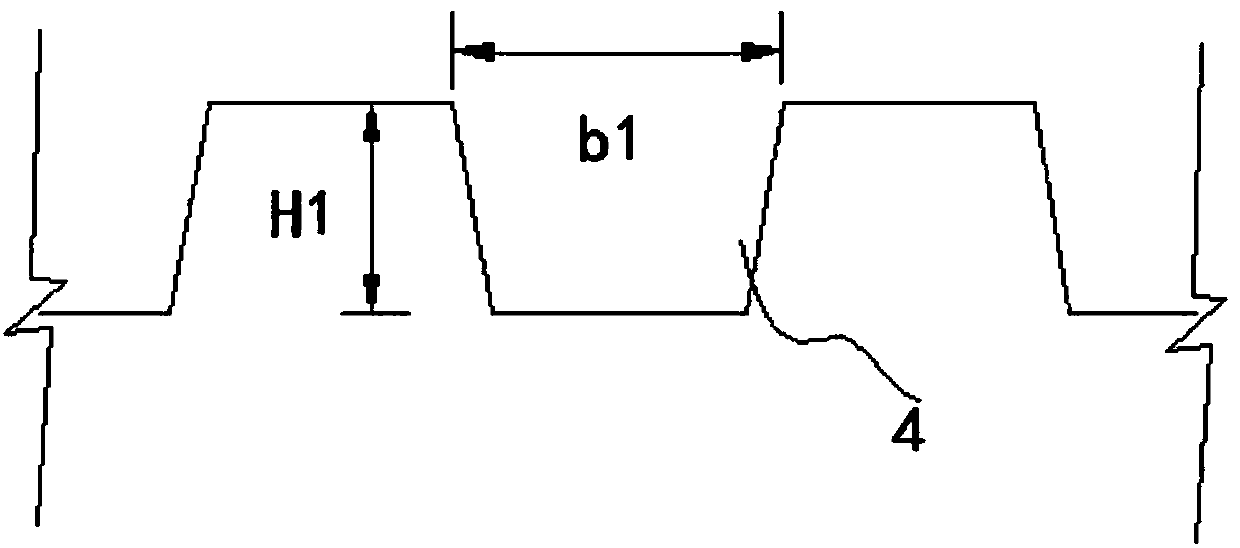

Separation method and separation mechanism for slice medium

ActiveCN103803318AReduce conveying resistanceStable deliveryArticle separationPulp and paper industrySeparation method

The invention discloses a separation method and a separation mechanism for a slice medium. The separation method comprises the steps that a separation roller drives the slice medium to move in the paper feed direction and a paper unwinding roller arranged opposite to the separation roller rotates intermittently in the paper unwinding direction, so that separation of the slice medium is achieved. The separation mechanism comprises a machine frame, the separation roller, the paper unwinding roller, a driving mechanism, an eccentric part, a one-way bearing and a thumbing rod, wherein the separation roller and the paper unwinding roller are oppositely arranged on the machine frame, the driving mechanism driving the separation roller to rotate, the eccentric part is arranged on the separation roller in a sleeved mode, the one-way bearing is arranged on the paper unwinding roller and can rotate in the paper unwinding direction, and the thumbing rod is arranged on the one-way bearing and can be thumbed by the eccentric part. The separation roller drives the slice medium to move in the paper feed direction and the paper unwinding roller rotates intermittently in the paper unwinding direction. According to the separation mechanism and the separation method, the paper unwinding roller rotates intermittently and stops rotating at other times, and therefore conveying resistance to the single slice medium is reduced, and smooth conveying of the single slice medium is achieved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD

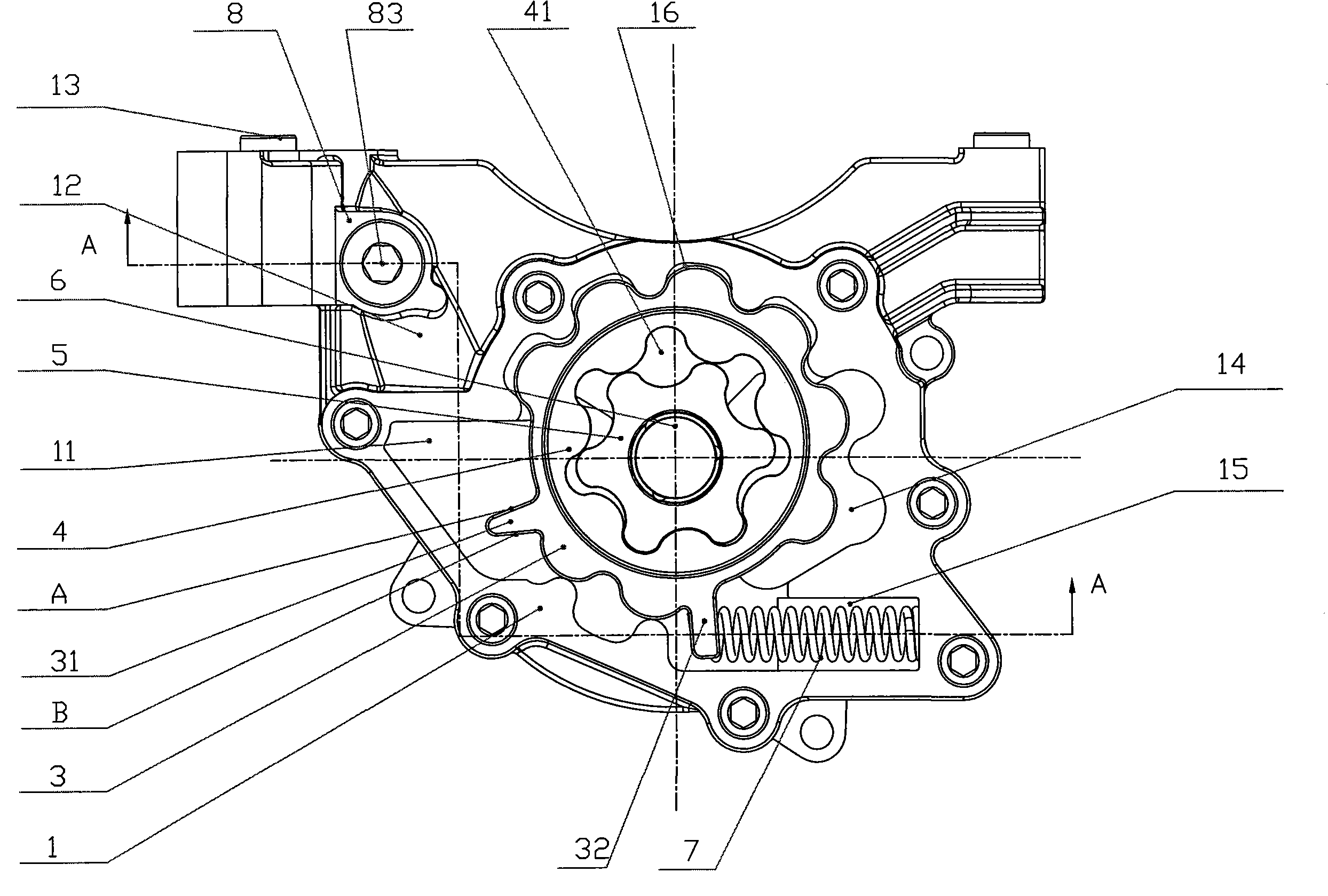

Variable rotor oil pump regulated and controlled by wave wheel

InactiveCN102095068AGuaranteed fuel supplyEffective protectionLubricating pumpsLubrication check valvesInterference fitDrive shaft

The invention discloses a variable rotor oil pump regulated and controlled by a wave wheel. The variable rotor oil pump is composed of a pump body, a pump cover, a wave wheel regulating and controlling ring, an outer rotor, an inner rotor, a transmission shaft, a spring and a safety valve component, wherein the pump body and the pump cover are connected through a bolt; the wave wheel regulating and controlling ring and the spring are installed in a wave wheel ring hole and a spring groove hole which are positioned on the pump body, the middle part of the transmission shaft is in interference fit with the inner rotor, and the transmission shaft, the inner rotor and the outer rotor are installed in an intermediate hole on the wave wheel regulating and controlling ring and the shaft holes of the pump body and the pump cover; two sides and bottom surface of the wave wheel ring hole of in the pump body are provided with an oil inlet chamber, an oil outlet chamber, an oil outlet duct and an oil outlet, and the oil outlet is communicated with the oil duct of an engine; the oil outlet duct of the pump body is provided with the safety valve hole, the safety valve hole is communicated with the oil outlet duct, the passageway of the safety valve hole is provided with an oil drainage hole, and the safety valve hole is internally provided with the safety valve component; and the combination surface of the pump cover and the pump body is provided with an oil inlet duct and an oil inlet, the oil inlet is communicated with an oil absorption device, and the oil inlet duct is communicated with the oil inlet chamber of the pump body.

Owner:HUNAN OIL PUMP

Novel coal ash grouting material

The invention discloses a novel coal ash grouting material, which is composed of specific components by mass: 1 part of coal ash, 2 parts of water, liquid water glass occupying 5% to 10% of the coal ash and sepiolite occupying 2%. to 5%.of the coal ash. Improved coal ash grout has strong adhesion performance on firing articles, can evenly and effectively cover the surfaces of the firing articles, is strong in water-retaining performance and good in fire resistance, can effectively block leakage insulate oxygen to prevent grout from losing, and is low in price, environmental-friendly, good in stability and suitable for pipeline transportation.

Owner:CHINA COAL RES INST

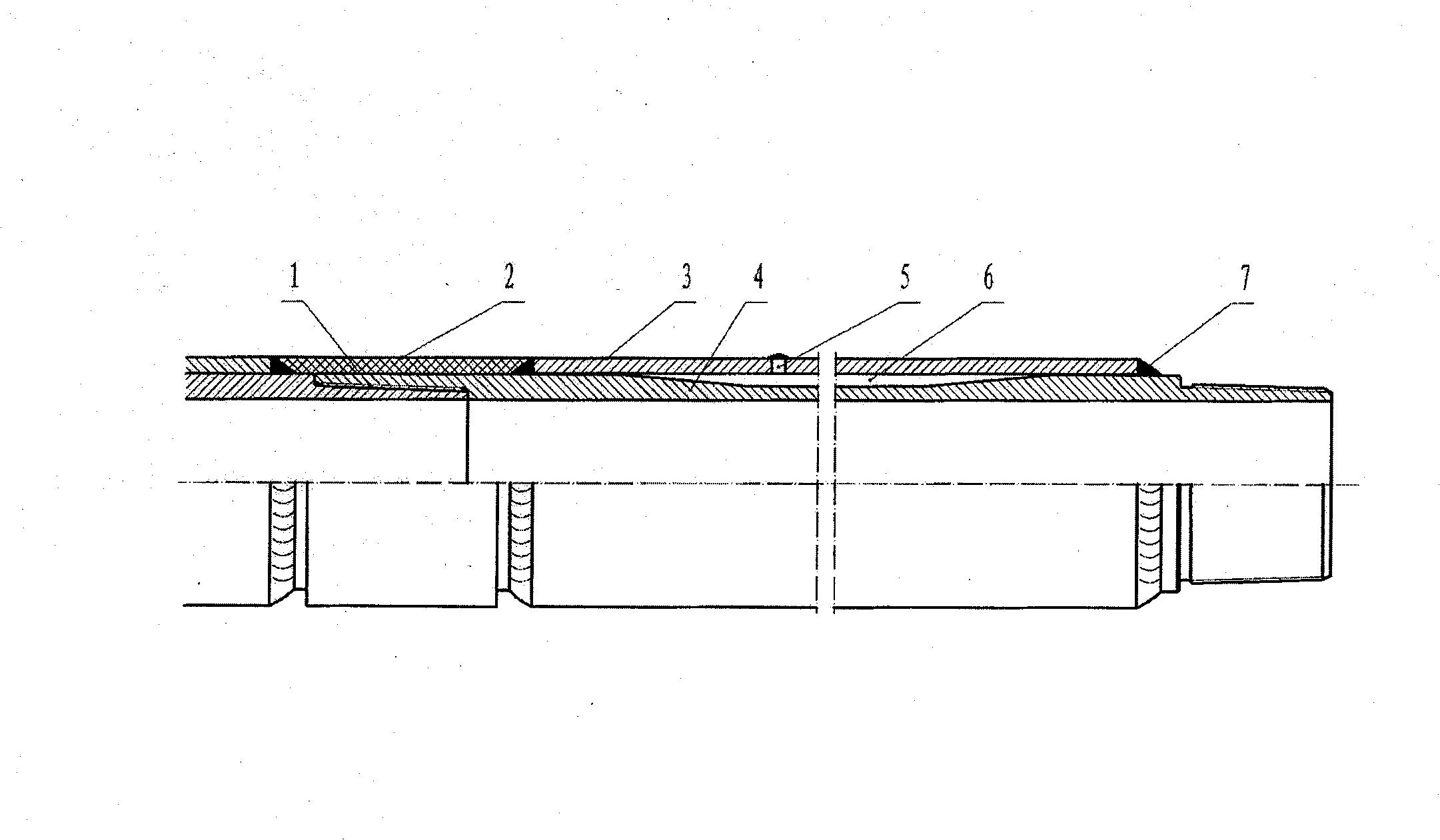

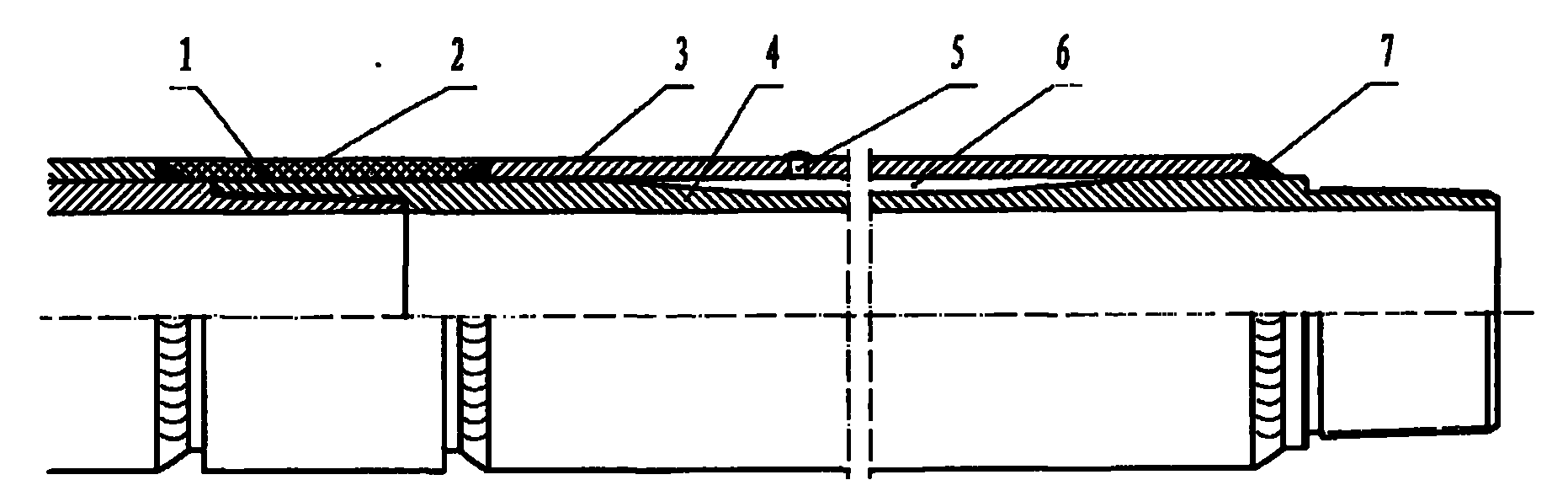

Straight-joint type insulated tubing and processing technology thereof

InactiveCN102102492ASmall outer diameterImprove insulation performanceDrilling rodsThermal insulationInsulation layerMiddle frequency

The invention discloses a straight-joint type insulated tubing and a processing technology thereof, wherein the effects of steam injection and oil extraction are improved through improving the structure of the product of the existing insulated tubing. The straight-joint type insulated tubing comprises an external pipe and an internal pipe; an internal insulation layer is arranged between the external pipe and the internal pipe; the external diameters of the two ends of the internal pipe are larger than that of the middle part; one end of the internal pipe is provided with internal threads and the other end of the internal pipe is provided with external threads; and an external insulation layer is arranged at the joint of the internal pipe. The processing technology of the straight-joint type insulated tubing comprises the following steps of: processing the external pipe, processing the internal pipe, and assembling the internal pipe and the external pipe. In the step of processing the internal pipe, the continuous upsetting is carried out on the external cycles of the both ends of the internal pipe through an upsetter after both ends of the internal pipe are heated through middle frequency, and then the internal threads at one end of the internal pipe and the external threads at the other end of the internal pipe are processed. Through directly processing the threads at both ends of the internal pipe for connection, the hoop connection of the existing insulated tubing is prevented, and the external diameter of the pile of the insulated tubing is effectively reduced. At the joint of the internal pipe, the diameter of the internal hole is not changed so that the turbulent flow can be prevented while steam injecting, the flow resistance is reduced, and the work tools can be conveniently put upside down.

Owner:胜利油田孚瑞特石油装备有限责任公司

Hot-rolled and hot-forged steel ball waste heat quenching device and process

InactiveCN109777941AAvoid it happening againReduce conveying resistanceFurnace typesHeat treatment furnacesHardnessSteel ball

The invention provides a hot-rolled and hot-forged steel ball waste heat quenching device and process. The quenching device comprises a quenching water tank, and a screw push-rising mechanism obliquely arranged in the quenching water tank. A quenching medium is put in the quenching water tank, and the quenching water tank is divided into a quenching region and a slow cooling region through a supporting plate arranged below the screw push-rising mechanism. The screw push-rising mechanism pushes a steel ball to move through the quenching region and the slow cooling region from bottom to top. Thequenching process is based on the device, the quenched steel ball is uniform in hardness and free of cracking, and the mechanical performance is improved.

Owner:沈阳国谷新材料有限公司

Flow monitoring type non-return flap apparatus

InactiveCN101298298AReduce heat lossIncrease temperatureHuman health protectionCheck valvesPositive pressureTransportation technology

The invention relates to a transportation technology of the pulverized fuel ash of coal-fired power plants. The pulverized fuel ash from the coal-fired power plant needs to be transported to an ash storage for later use. According to the existing transportation technology, the coal-fired power plant usually adopts the positive pressure dense phase pneumatic ash transportation system. However, facts have proven that the positive pressure transportation system has some defects, the ash content of the coal used by the coal-fired power plant coal-fired power plant increases greatly, which leads the pulverized fuel ash transportation system to be inadaptable, so the pipe is often blocked or an ask bucket has to been discharged immediately when too much ash is blocked in the ash bucket of the electrostatic precipitator, and the environment is seriously polluted. The invention adopts a flow-monitoring non-return device, which changes the intermittent transportation into continuous transportation, solves the emergent ash discharge problem of the positive pressure dense phase pneumatic ash transportation system; the technology also has the air lock and flow-monitoring functions.

Owner:集成国际能源科技集团有限公司

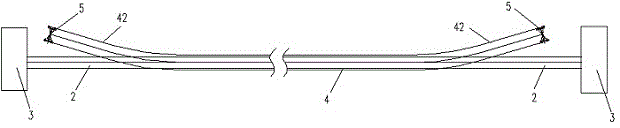

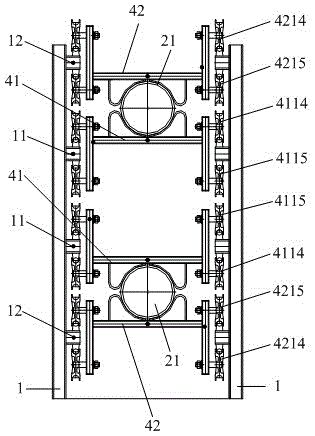

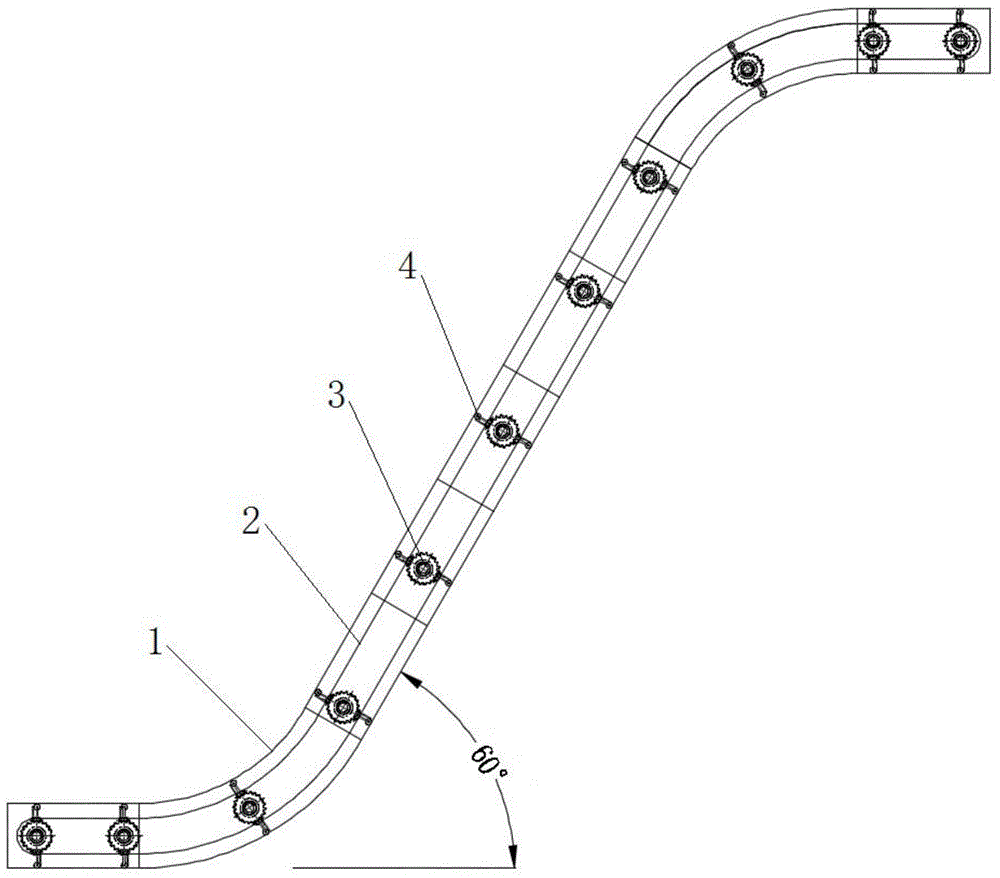

Sidesway separation movable bracket type tubular belt conveyor

The invention relates to a sidesway separation movable bracket type tubular belt conveyor. The sidesway separation movable bracket type tubular belt conveyor comprises machine frames, annular adhesive tapes, driving components, annular supporting and clamping components and guide rail bend wheels, wherein the annular adhesive tapes can bear materials; the driving components of the adhesive tapes are respectively arranged at machine heads and machine tails; the annular supporting and clamping components can support and clamp the adhesive tapes; the annular adhesive taps are hung and wound on the driving components in a sleeving manner; the supporting and clamping components are movably supported and clamped between the adhesive tapes and the machine frames; the support clamping components near the machine heads and the machine tails are separated from the adhesive tapes. The sidesway separation movable bracket type belt conveyor disclosed by the invention has the beneficial effects that the support components are used to replace carrier rollers in the prior art, and resistance between the carrier rollers and the adhesive tapes is changed into rigid rolling friction between the support components and guide rails; through the change of a mechanical structure, transport resistance is obviously reduced, and the dissipation power of the conveyor is greatly reduced.

Owner:NINGXIA TIANDI NORTHWEST COAL MACHINERY

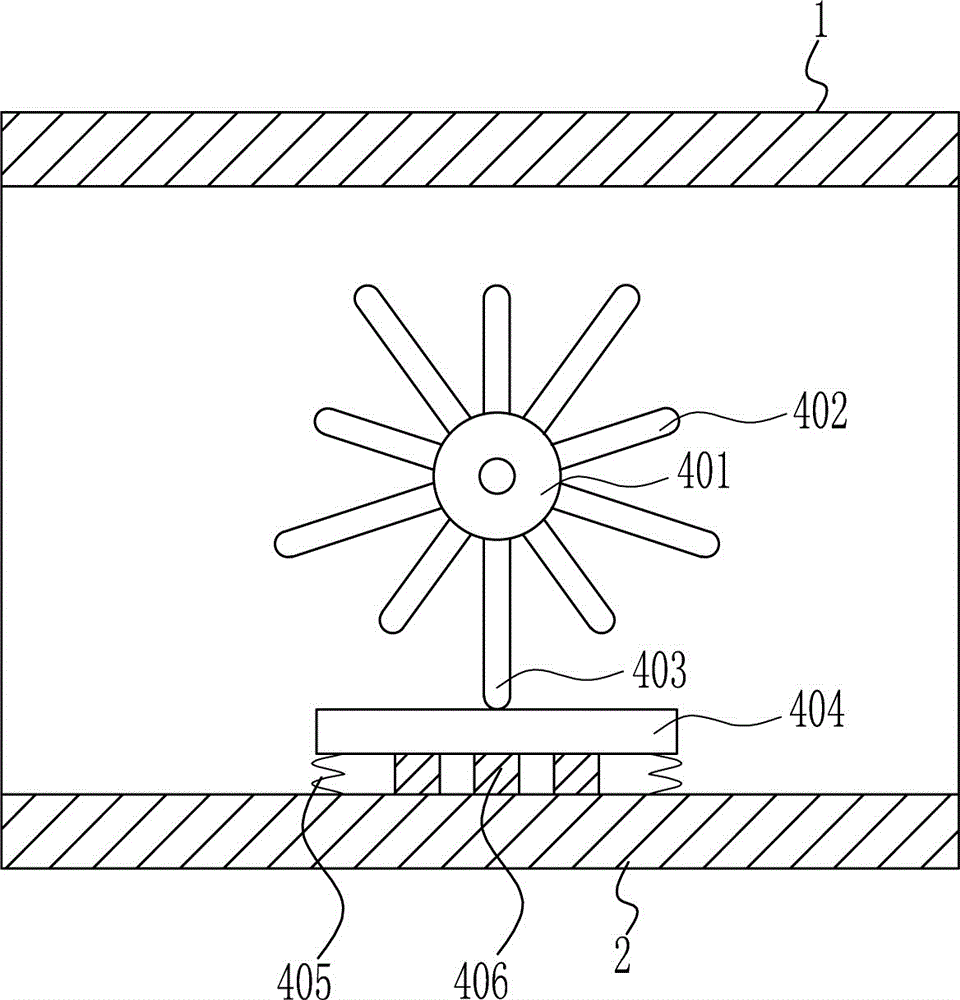

Pipeline mud conveying device

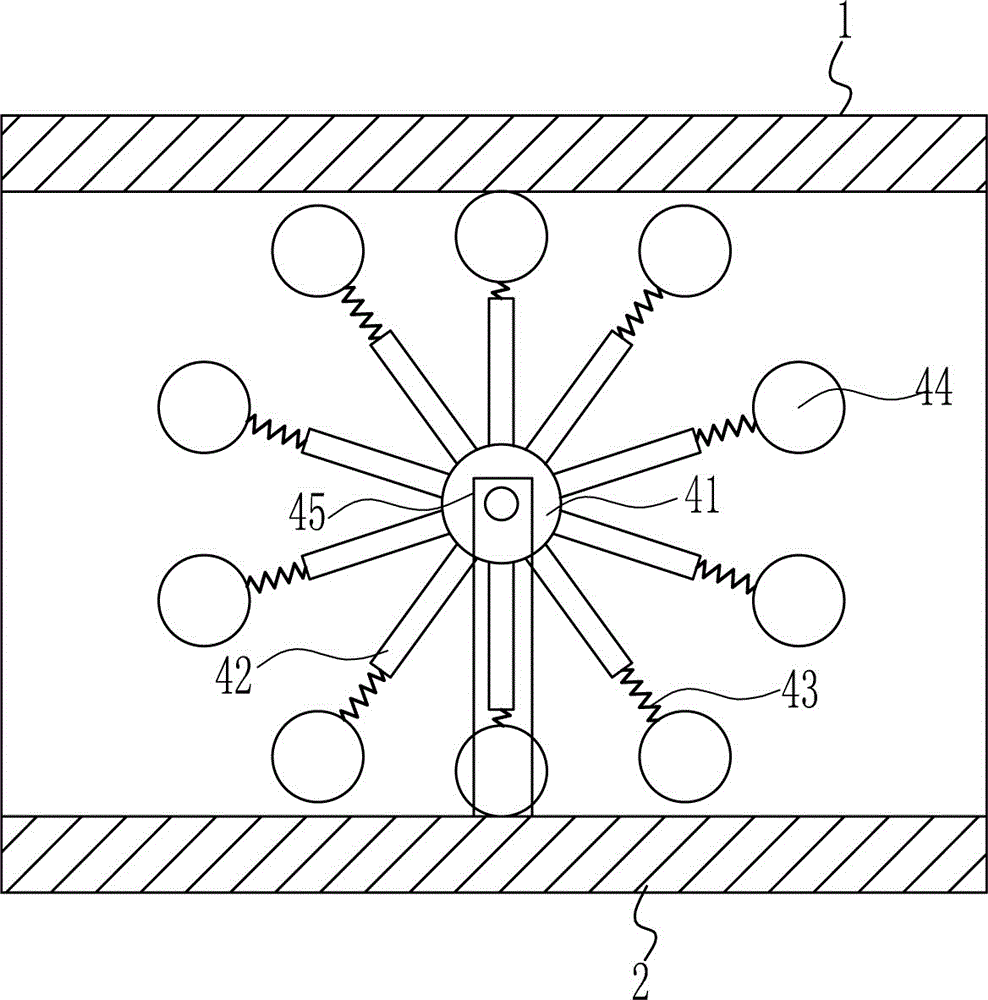

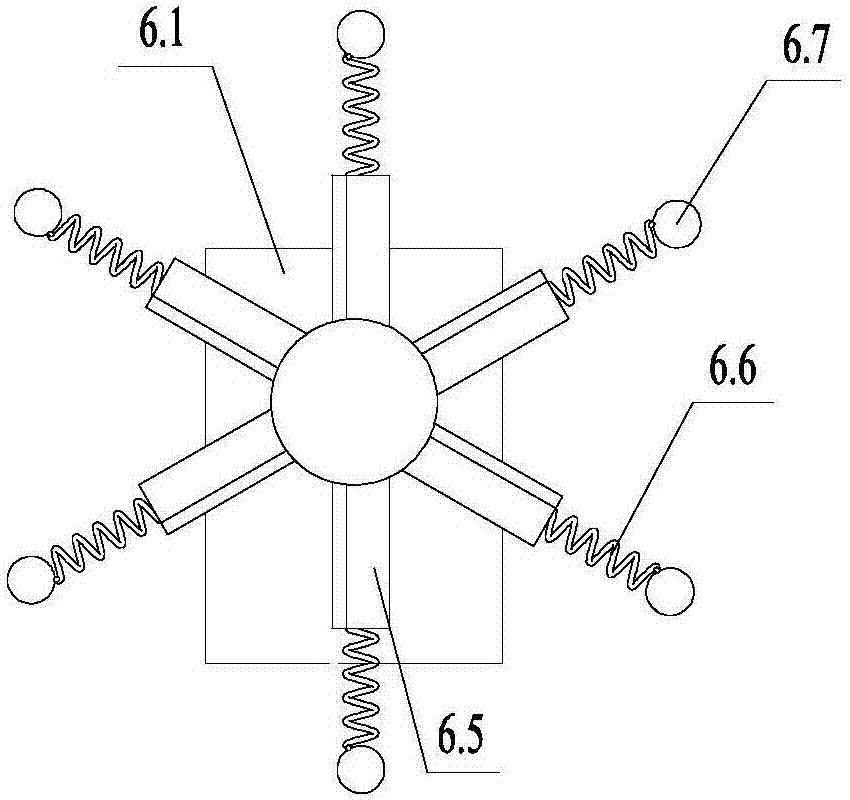

InactiveCN107044146AReduce resistanceSpeed up the flowSoil-shifting machines/dredgersSteel ballHigh pressure

The invention discloses a pipeline mud conveying device. The pipeline mud conveying device comprises an outer pipeline, an inner pipeline concentric with the outer pipeline, and an air inlet formed in the outer pipeline, and a high-pressure air way is formed by a gap between the outer pipeline and the inner pipeline. A plurality of high-frequency vibrators are arranged in the high-pressure air way and located on the air inlet side. A high-pressure air hole communicating with the high-pressure air way is formed in the inner pipeline and located in the air inlet side. Each high-frequency vibrator comprises a pair of vibration supports, a vibrator shaft, a plurality of blades and a vibration steel ball arranged on the top of each blade through a vibration spring. The defects that during channel dredging work, the flowing resistance of mud in the pipelines is large, hydraulic power along the way is reduced rapidly, consequently, a dredger mud conveying system pipeline is abraded and blocked, the conveying distance is short and energy consumption is high are overcome, and therefore the flowing resistance of the mud in the pipelines is reduced, and hydraulic losses of mud along the way are reduced.

Owner:WUHAN UNIV OF TECH

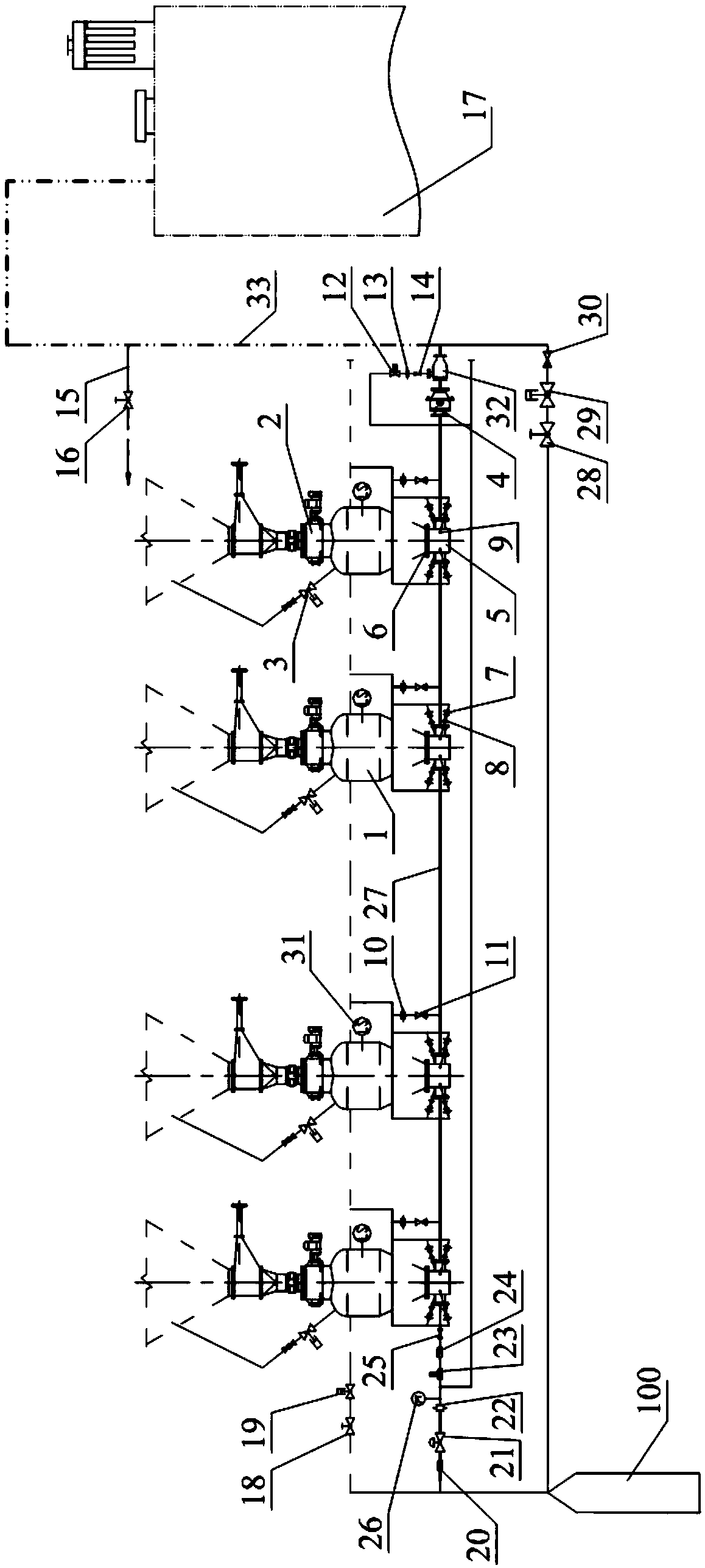

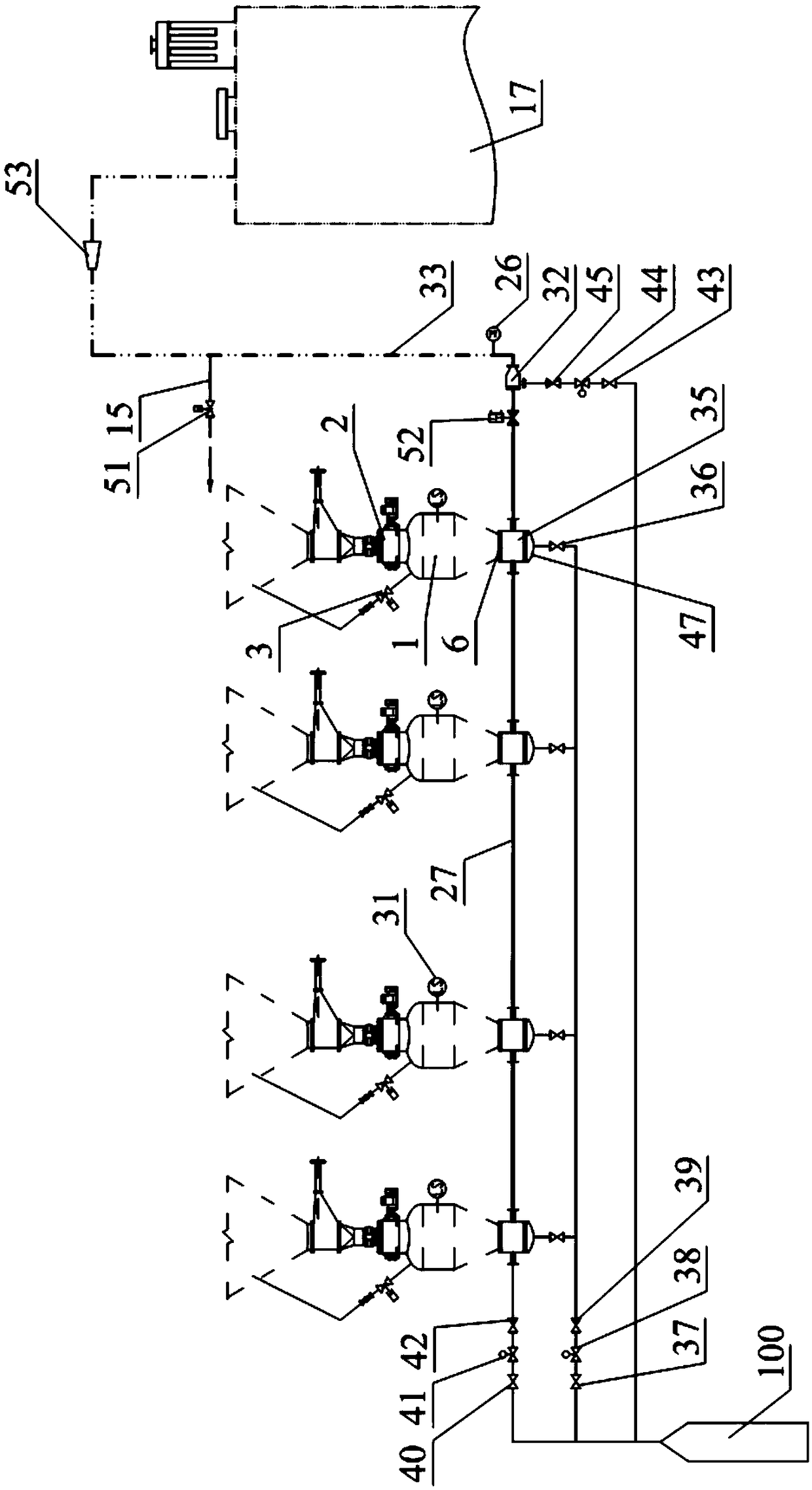

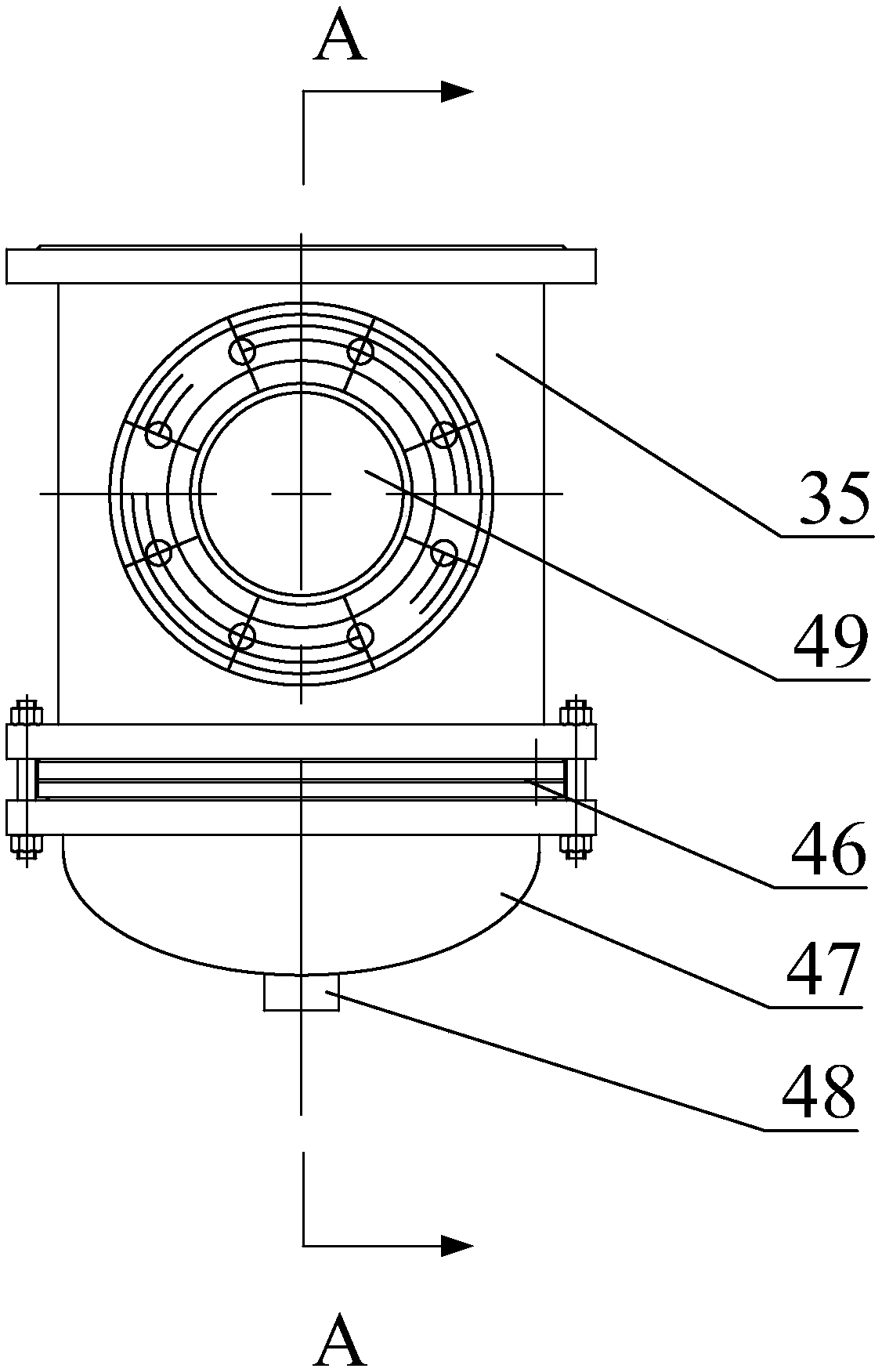

Pneumatic conveying system

The invention discloses a pneumatic conveying system. The pneumatic conveying system comprises a compressed air conveying mother tube, one or more bin pumps which are arranged in series, a discharge valve, a discharge hole gas supplementing machine, a conveying pipeline and a terminal bin, wherein the lower end of each bin pump is connected with a fluidizing device, the fluidizing device comprisesa fluidizing room, a fluidizing disc and a fluidizing room sealing head which are sequentially connected from top to bottom, and further comprises a fluidizing room discharge tube which transverselypenetrates through the fluidizing room, a fluidizing room discharge lifting tube which longitudinally communicates with the lower portion of the fluidizing room discharge tube and is positioned abovethe fluidizing disc is arranged inside the fluidizing room. According to the scheme adopted by the invention, the compressed air conveying mother tube is re-arranged, and is divided into three gas inlet branches, namely a fluidized gas inlet branch which communicates with the fluidizing room sealing head, a conveyed gas inlet branch which is connected to the first fluidizing room discharge tube which is in series connection in a gas flow conveying direction, and an auxiliary gas-blowing gas inlet branch which communicates with the discharge hole gas supplementing machine. According to the scheme adopted by the invention, the pneumatic conveying system is greatly simplified in structure, and also can realize great reduction of comprehensive gas consumption of the system.

Owner:FUJIAN LONGKING

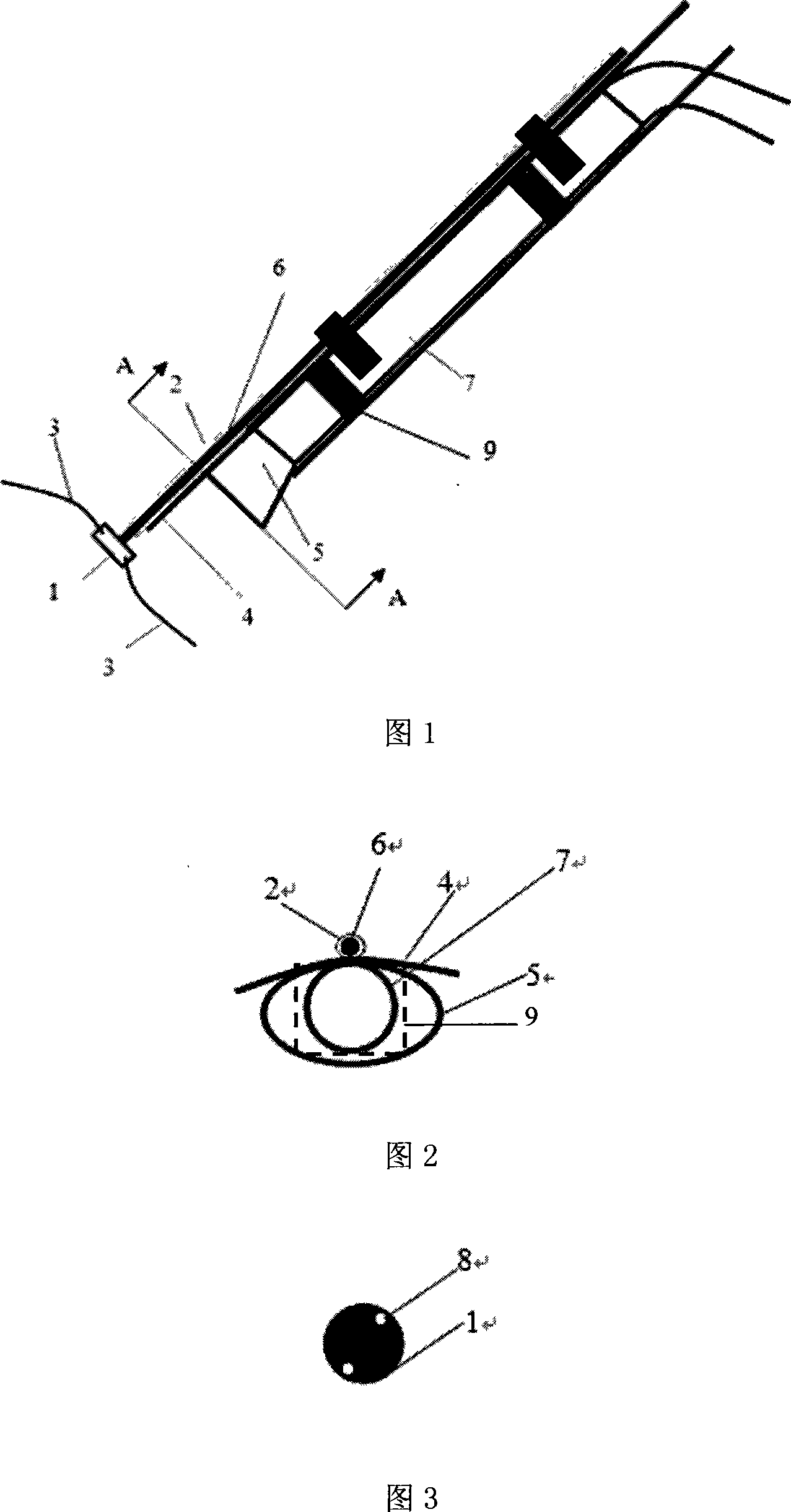

Garlic harvester

PendingCN107371552AImprove work efficiencyReduced Harvest CostsTopping machinesDiggersAnimal feedAgricultural engineering

A garlic harvester comprises a frame, a garlic bulb harvesting device is arranged on the rear side of the frame, and a garlic stem cutting and grinding device is arranged on the front side of the frame and comprises a cover. A stem cutting mechanism is arranged at the lower end of the cover, a rotating shaft is rotationally arranged in the cover, one end of the transmission shaft is provided with a spiral blade, a grinding mechanism is mounted at the other end of the transmission shaft, and the front side of the cover is provided with a feeding port corresponding to the spiral blade. The garlic bulb harvesting device comprises the frame fixedly arranged on the rear side of the cover, a soil loosening and shoveling mechanism is arranged on the lower side of the frame, a vibratory screening mechanism is arranged on the frame and on the rear side of the soil loosening and shoveling mechanism, a garlic bulb conveying mechanism is arranged on one side of the soil loosening and shoveling mechanism, and traveling wheels are arranged on the frame. The garlic harvester has advantages that garlic bulbs and garlic stems can be separated while garlic bulb mud removal and garlic stem grinding operations can be completed, ground garlic stems can be used as animal feed, and accordingly garlic harvesting efficiency is greatly improved, and labor amount is decreased.

Owner:肖杰

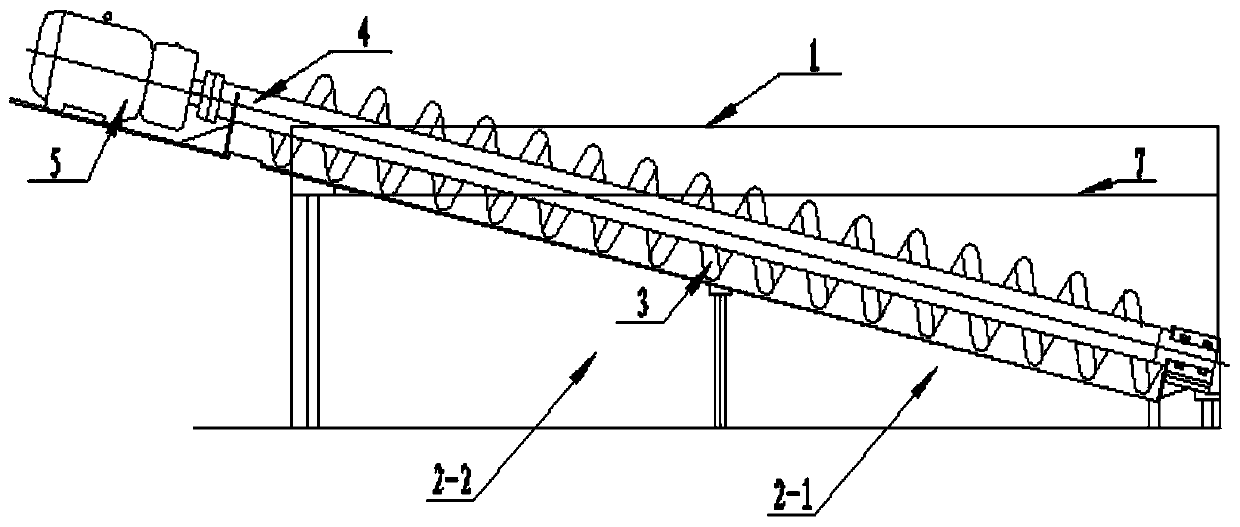

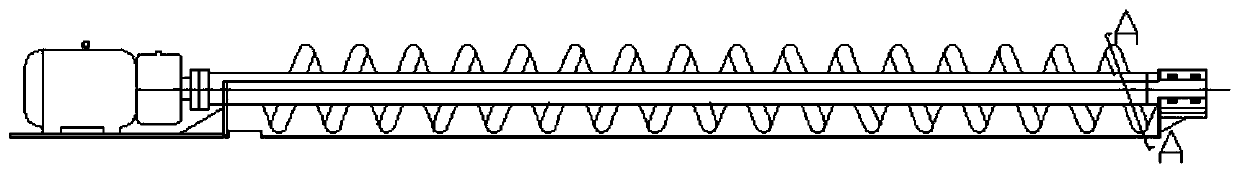

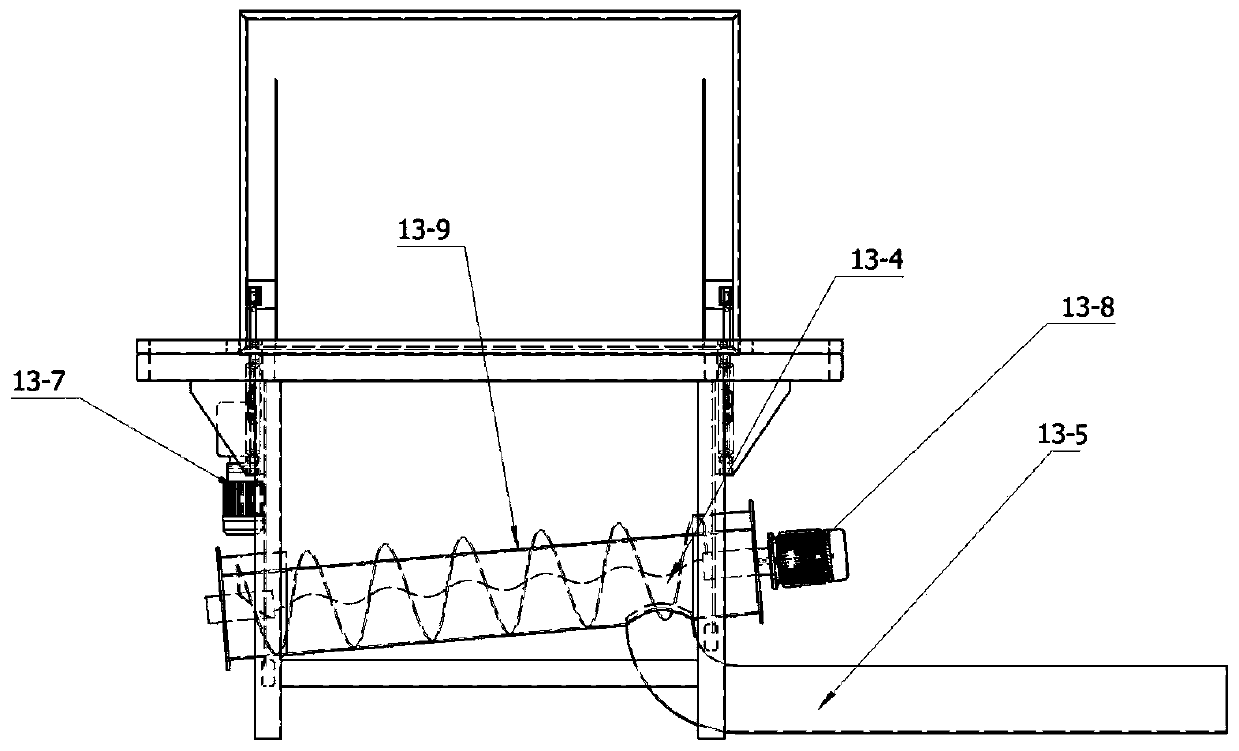

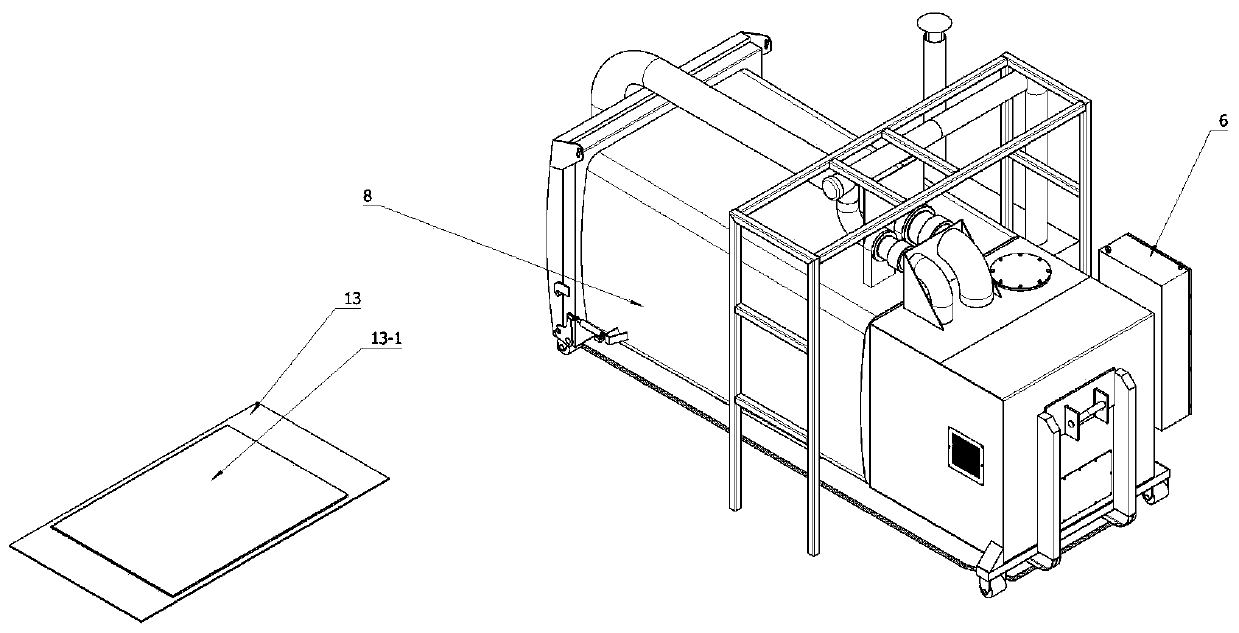

Rubbish moving device in buried box, negative-pressure rubbish collecting and transporting system and negative-pressure rubbish collecting and transporting method

ActiveCN110451141AIncrease potential energyEasy accessRefuse transferringStorage devicesTransport systemButt joint

The invention discloses a rubbish moving device in a buried box, a negative-pressure rubbish collecting and transporting system and a negative-pressure rubbish collecting and transporting method. Therubbish moving device, the negative-pressure rubbish collecting and transporting system and the method have better effects on collecting and transferring rubbish dumped by using a rubbish truck and ahandcart. The rubbish moving device comprises a foundation pit box, wherein a spiral conveyor is obliquely arranged in the foundation pit box; the higher end of the spiral conveyor is a discharging end; a strip-shaped feeding port is formed in the upper part of a shell of the spiral conveyor; the upper end of the strip-shaped feeding port is connected with a feeding hopper; the upper end of the foundation pit box is provided with a feeding door; the lower part of the discharging end of the spiral conveyor is provided with a discharging pipe; the discharging pipe is in a shape of a horizontal L; the vertical pipe section of the discharge pipe is connected with the spiral conveyor; and the horizontal pipe section of the discharge pipe is positioned below the spiral conveyor. The negative-pressure rubbish collecting and transporting system comprises the rubbish moving device in the buried box, a negative-pressure type rubbish collecting and transporting box and a butt joint system. The negative-pressure rubbish collecting and transporting method comprises the steps: a, carrying out butt joint; b, pumping a sealed bin and carrying out waste gas treatment; c, placing the rubbish into the box; and e, transferring the full box.

Owner:重庆宇洁环卫设施有限公司

Panel surface edge scraping machine

PendingCN109352754AEasy to adjust scraping depthVarious scraping effectsProfiling/shaping machinesEngineering

The invention discloses a panel surface edge scraping machine. The panel surface edge scraping machine comprises a longitudinal edge scraping device (1) and a transverse edge scraping device (2) perpendicular to the discharging direction of the longitudinal edge scraping device (1), wherein a feeding port of the transverse edge scraping device (2) is arranged below the end side of a discharging port of the longitudinal edge scraping device (1). The longitudinal edge scraping device (1) is provided with a scraping mechanism (3) capable of performing edge scraping on the long edge side wall of aplate. The transverse edge scraping device (2) is provided with a scraping mechanism (3) capable of performing edge scraping on the short edge side wall of the plate. When the panel surface edge scraping machine is used to perform edge scraping processing on the panel, the panel enters the feeding port of the longitudinal edge scraping device first to be subject to edge scraping processing in thelength direction and then enters the transverse edge scraping device from the discharging port of the longitudinal scraping device to be subject to edge scraping processing in the width direction, sothat panels with different thicknesses and lengths can be adapted to, the edge scraping depths of the panels can be adjusted conveniently, and the edge scraping effects are diversified.

Owner:盐城鼎恒机械有限公司

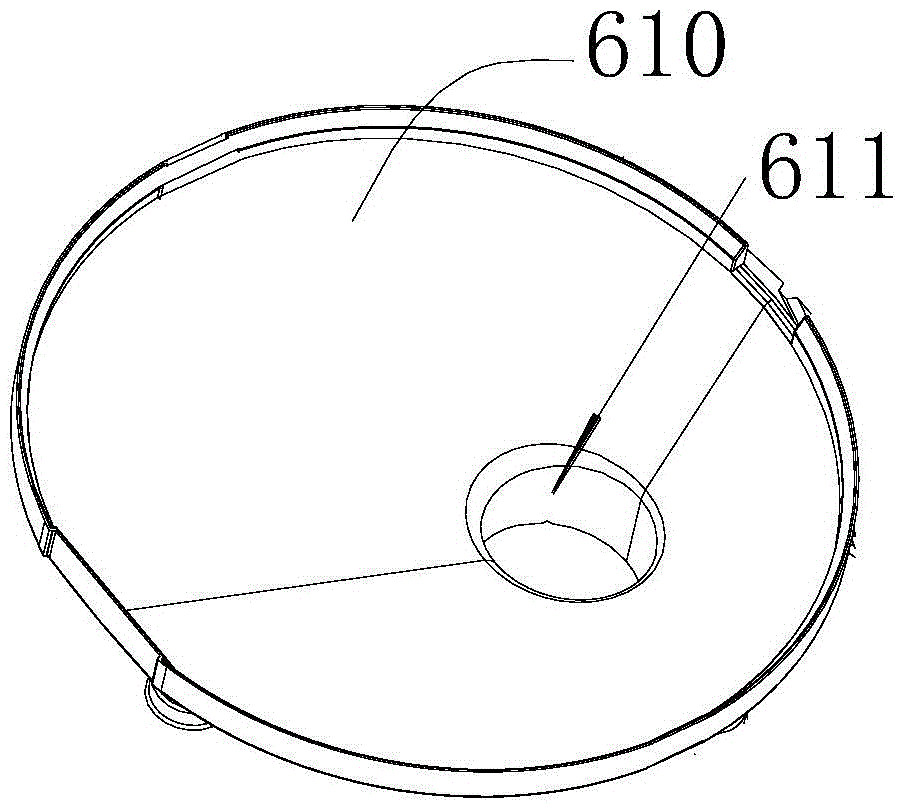

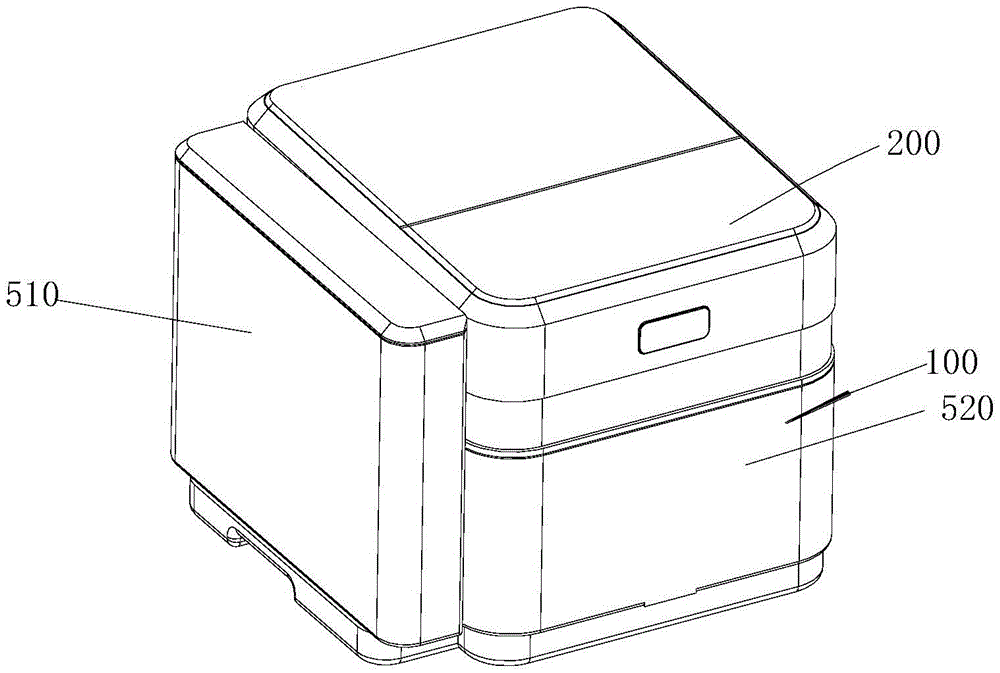

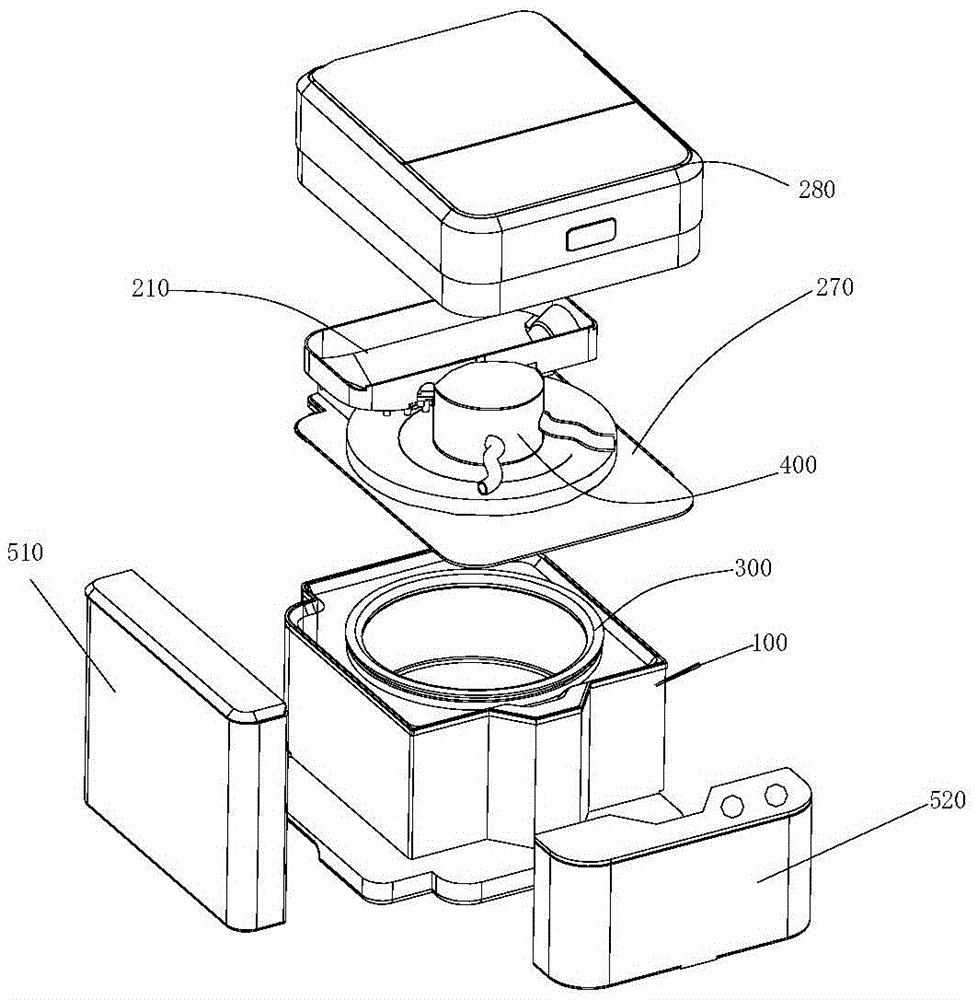

Cooking utensil

The invention provides a cooking utensil which comprises a cooker body and a cooker cover. The cooker cover is provided with a storage bin for storing raw materials, a discharge port is formed in the storage bin, and a first material conveying device is arranged in the storage bin; the cooker cover is further provided with a first driving device, and the first material conveying device is driven by the first driving device to convey the raw materials in the storage bin to the discharge port, wherein the volume of the storage bin is 0.2 L-3.6 L. The volume of the storage bin can be increased to decrease the overall size of the cooker cover, then the size of the cooking utensil is decreased, and therefore usage of a user is promoted.

Owner:JOYOUNG CO LTD

Dust collecting device

InactiveCN1937948AReduce delivery capacityReduce power consumptionSuction filtersCarpet cleanersPower consumptionPower capacity

A dust collecting device capable of reducing the transfer power required to transfer dust, downsizing a transfer means, saving power consumption, and reducing noise from the transfer means. The dust collecting device is provided with a dust take-in section having a rotary brush (3), and a dust collecting section (5) for collecting dust taken in from the dust take-in section. The dust collecting section (5) has a primary chamber (51) for storing dust combed up by the rotation of the rotary brush (3), and a secondary chamber (53) communicating with the primary chamber through a communication passage. An electric fan (9) is installed in order to intermittently transfer dust in the primary chamber (51) into the secondary chamber (53).

Owner:SANYO ELECTRIC CO LTD

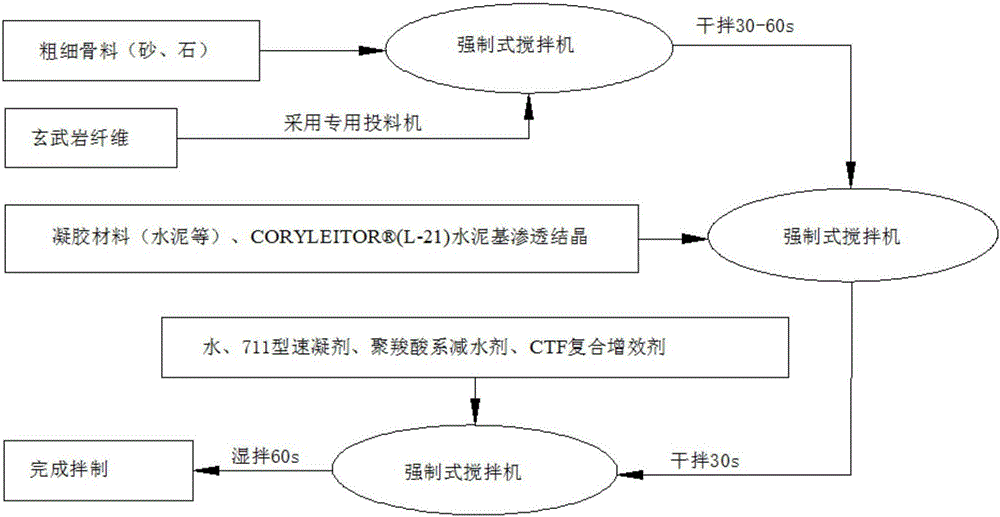

Sprayed basalt fiber concrete and side slope supporting surface layer construction method

The invention discloses sprayed basalt fiber concrete and a side slope supporting surface layer construction method. The sprayed basalt fiber concrete per cubic meter comprises, by weight, 2-4 parts of basalt fibers, 365-410 parts of cement, 73-82 parts of superfine active mineral admixtures, 3-5 parts of cement based permeable crystal, 4-5 parts of concrete compound synergist, 13-19 parts of accelerating agents, 4-5 parts of water reducing agents, 900-925 parts of river sand, 785-815 parts of broken stones and 170-185 parts of water. Compared with the prior art, the sprayed concrete prepared by mixing the basalt fibers is good in consistency and workability, stable in volume and low in spraying rebound loss, tensile strength, crack resistance and frost resistance are remarkably improved, service life is prolonged, and service environments are improved.

Owner:ZHEJIANG HENGDIAN CONSTR ENG CO LTD

Fabric production process

InactiveCN108004601ACause secondary damageQuality improvementFilament forming substance formingFloats removalAdhesivePulp and paper industry

The invention belongs to the technical field of mechanical methods or equipment for production of filament, thread or analogs and particularly discloses a fabric production process. The fabric production process includes the steps of electrostatic adherence, waste filament collection, waste filament transportation, heating and melting, additive adding and spinning. Waste terylene filaments dissociating on terylene fabric are collected and reused, so that problems that chemical reagents remain on the fabric when the waste filaments are adhered through a chemical adhesive and waste and environment pollution are caused due to the fact that the adhered waste filaments are not treated reasonably in the prior art are solved.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

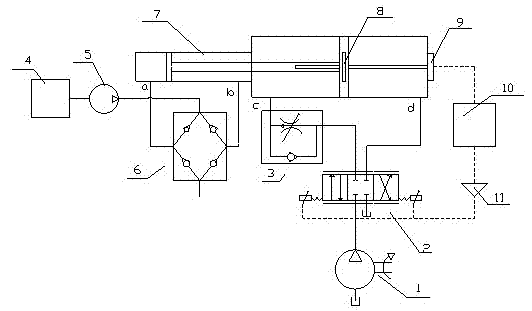

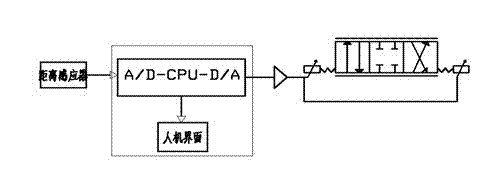

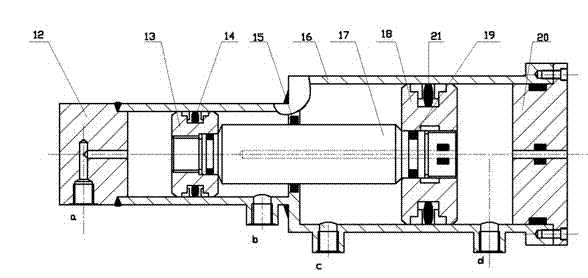

Automatic low-penetration lubricating grease delivery system

InactiveCN103047528AReduce conveying resistanceFulfillment requirementsEngine lubricationHydraulic cylinderHydraulic pump

An automatic low-penetration lubricating grease delivery system comprises a hydraulic pump station, a lubricating grease handler, a grease pump and a composite hydraulic cylinder. An output end of the hydraulic pump station is connected with a three-position four-way electro-hydraulic proportional reversing valve, an access of the three-position four-way electro-hydraulic proportional reversing valve is connected with a hydraulic cavity access on the right side of the composite hydraulic cylinder through a pipeline, a grease pump outlet connected with the lubricating grease handler is connected with a one-way valve bridge through a pipeline, and two side outlets of the one-way valve bridge are respectively connected with a lubricating grease cavity access on the left side of the composite hydraulic cylinder. An electromagnetic ring is arranged on a piston of the composite hydraulic cylinder, signals are transmitted to a distance sensor at the front end of the composite hydraulic cylinder through a measuring rod penetrating the electromagnetic ring, and an output interface of the distance sensor is connected with an electro-hydraulic controller controlling the three-position four-way electro-hydraulic proportional reversing valve. By arranging the lubricating grease handler, low-penetration lubricating grease is stored and heated, delivery resistance of the system is reduced, and automatic delivery of low-penetration lubricating grease is realized. Good lubricating performance of equipment is guaranteed, and labor intensity is reduced.

Owner:CHINA UNIV OF MINING & TECH

Energy-saving scraper blade conveying device for dust removal

The invention discloses an energy-saving scraper blade conveying device for dust removal, and belongs to the field of dust removal equipment. The energy-saving scraper blade conveying device comprises a conveying box body, a chain transmission mechanism mounted in the conveying box body and a plurality of scraper blades which are arranged on the chain transmission mechanism at intervals, wherein an inclined angle alpha is provided between the conveying box body and the horizontal plane; the turning part of the conveying box body is in circular-arc transition; the chain transmission mechanism comprises a plurality of groups of chain wheels which are arranged according to the conveying track of the conveying box body at intervals, a ring-shaped chain which is engaged with the chain wheels and is matched with the conveying track of the conveying box body in shape, and a motor which drives the chain wheels to rotate; the scraper blades are mounted on the chain at intervals; and rollers which are higher than the scraper blades are further arranged on mounting positions of the scraper blades. The energy-saving scraper blade conveying device reduces equipment occupied space, and improves dust conveying efficiency; the scraper blades do not directly generate friction with the conveying box body, so that conveying resistance is reduced, energy consumption is reduced, operation noises are reduced, manufacturing cost is reduced, and the dust conveying stability and safety are improved.

Owner:JIANGSU CHANGJING ENVIRONMENTAL PROTECTION TECH

Metal bipolar plate of miniature fuel battery

The invention discloses a metal bipolar plate of a miniature fuel battery. The metal bipolar plate comprises an anode single-pole plate and a cathode single-pole plate having a same structure, the single-pole plate comprises an inlet end and an outlet end respectively positioned at two sides, and a flow path area positioned at a central section, the inlet end comprises a fuel inlet, a cooling medium inlet and an oxidizing agent inlet, the outlet end comprises a fuel outlet, a cooling medium outlet and an oxidizing agent outlet, a groove at a right side of the single-pole plate and a ridge forma right side channel of the single-pole plate, the right side channel of the anode single-pole plate is a fuel flow channel, the right side channel of the cathode single-pole plate is an oxidizing agent channel, the anode single-pole plate and the cathode single-pole plate are applied to form a cooling channel, and the oxidizing agent channel and the fuel flow channel are the snakelike flow channels. Three snakelike flow channels are arranged on the anode single-pole plate and the cathode single-pole plate, the gas conveying pressure of the bipolar plate is large, the drainage is good, the fuel concentration of the bipolar plate is uniform and consistent, the fuel utilization rate is increased, and the reaction efficiency of the fuel battery is high.

Owner:苏州中氢能源科技有限公司

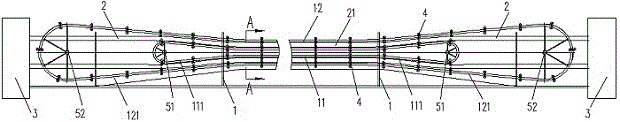

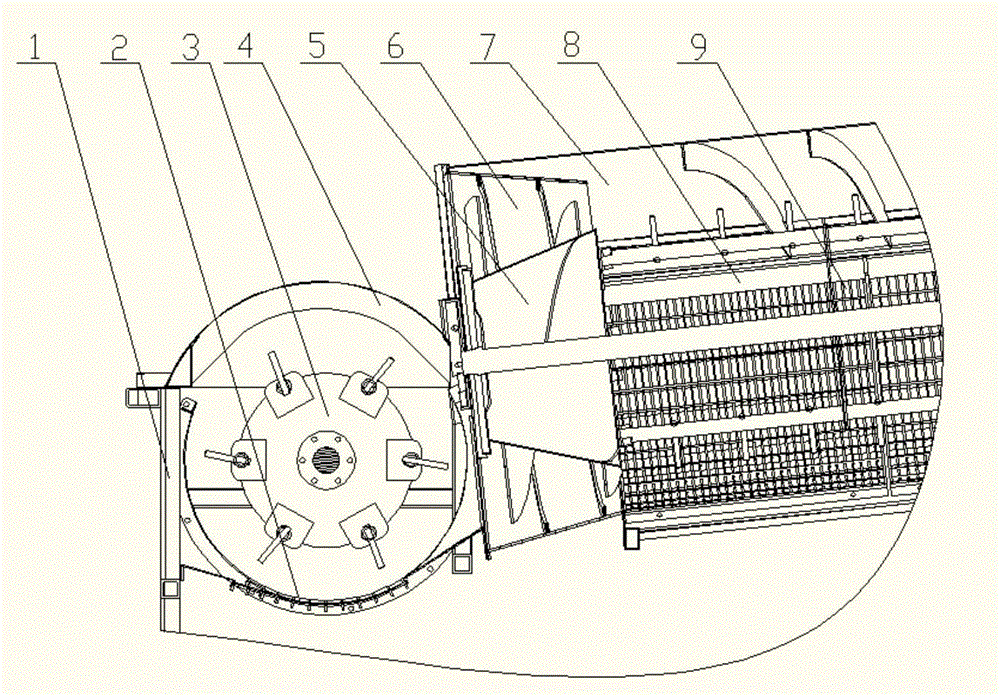

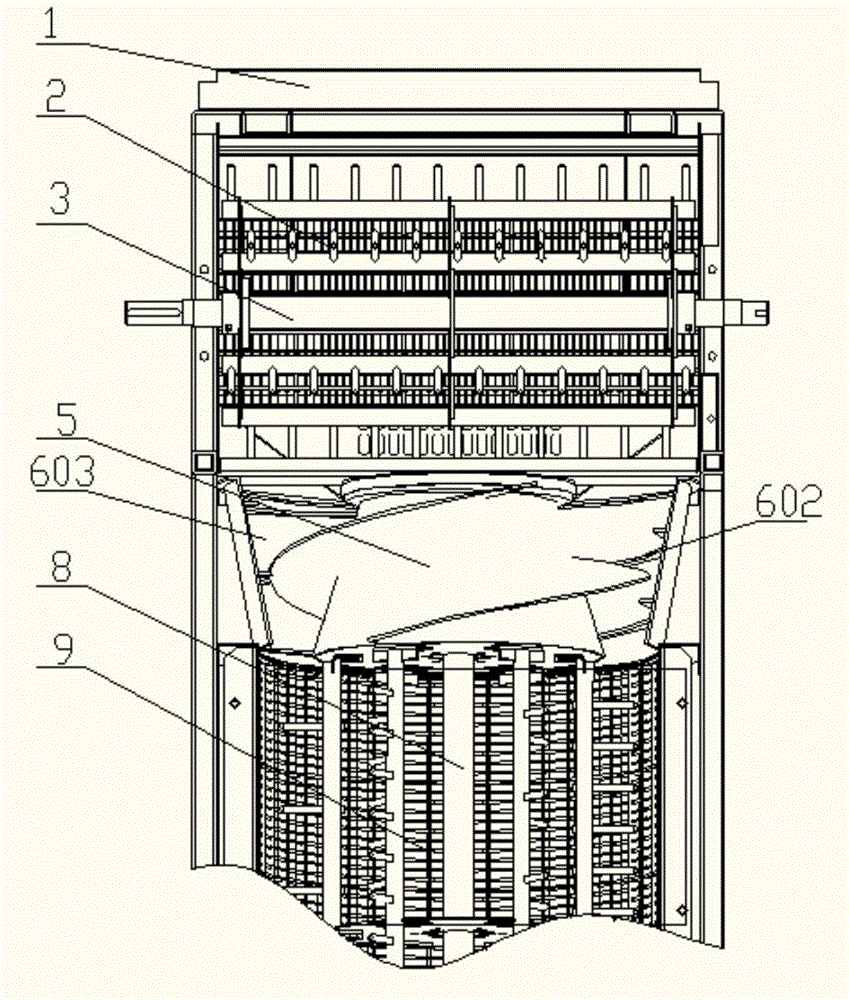

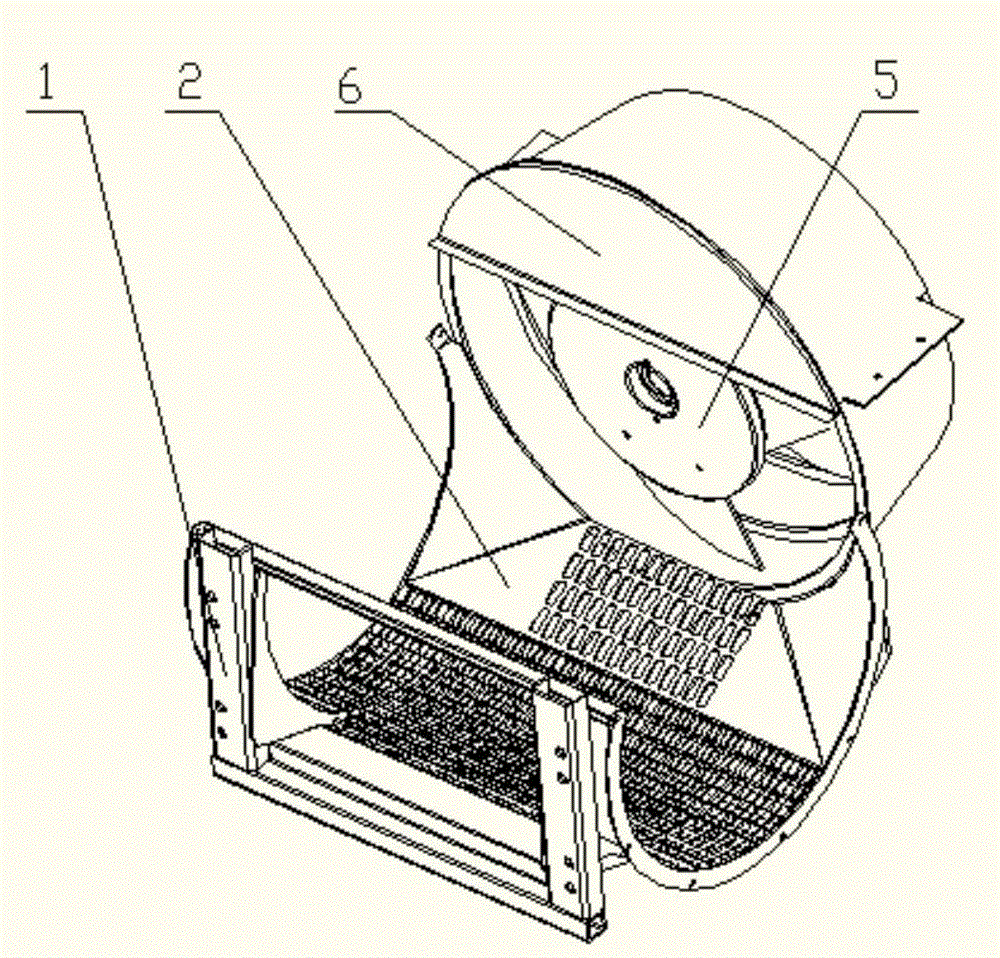

Tangential and longitudinal axial flow roller butt-joint negative pressure airflow feeding device

The invention provides a tangential and longitudinal axial flow roller butt-joint negative pressure airflow feeding device which comprises a tangential flow threshing separation device, a conical spiral feeding device, a conical flow guide cover assembly and a longitudinal axial flow threshing separation device. An area for containing a tangential roller is defined by a tangential flow concave grid assembly and a tangential flow top cover in the tangential flow threshing separation device. The two ends of a concave grid plate in the tangential flow concave grid assembly are each coaxially connected with a fixing arc plate. A feeding flat plate and two supporting arc plates connected with the two ends of the feeding flat plate are welded to the inlet of the concave grid plate along the tangent line. An arc punching cross connecting plate connected with the rear end of the concave grid plate is welded between the two fixing arc plates, is of a concave structure and is provided with a plurality of through holes. A concave grid baffle is welded to the joint between the arc punching cross connecting plate and a lower flow guide cover. The problem that tangential and longitudinal axial flow threshing separation device is prone to blockage at the large- feeding-amount position is avoided, and tangential flow and longitudinal axial flow mechanical conveying and airflow conveying performance is better exploited.

Owner:JIANGSU UNIV

Underwater dredging head in type of twisting flying rope

InactiveCN101092819AReduce manufacturing costImprove flowMechanical machines/dredgersMarine engineeringFlywheel

This invention relates to an underwater dredging head of rope cutter suction including: a flywheel, a drive rod, a rope, a breakwater and a mud-suction orifice, in which said rope passes through the edge of the flywheel, said mud-suction orifice is set on the frame of a suction pipeline of a dredge ship or its device, said drive rod is set on the suction pipeline of the suction orifice or the ship, said flywheel is set on the drive rod, which rotates to drive the flywheel to rotate, which drives the rope to rotate to cut submud underwater to strike out large and hard sundries and reduce soaked volume of them and jam of the orifice and mud cut by the rope forms mud water to enter into the mud-absorption pipeline via the orifice under the suction of the ship and a mud pump.

Owner:SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com