Pipeline gas adding resistance reduction slurry conveying device

A mud and pipeline technology, which is applied in the field of pipeline gas filling and drag reduction mud transportation equipment, can solve the problems of short transportation distance, pipeline wear, high energy consumption, etc., and achieve the effect of reducing flow resistance and reducing hydraulic loss along the way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

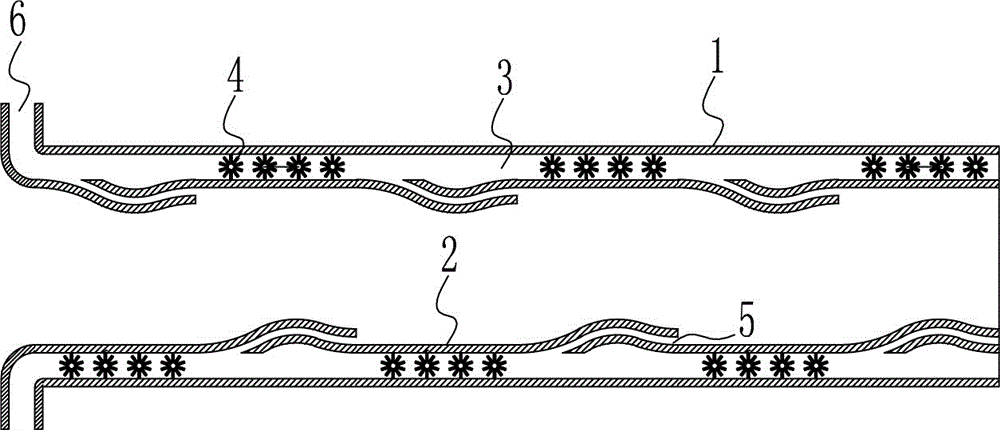

[0031] A pipeline gas filling and drag reduction transporting mud device, such as Figure 1-2 As shown, it includes an outer pipe wall 1, an inner pipe wall 2, a high-pressure air passage 3, a high-frequency vibrator 4, an air film generation passage 5 and a high-pressure air inlet 6, and the space between the outer pipe wall 1 and the inner pipe wall 2 is a high pressure The air channel 3 is provided with a high-frequency vibrator 4 inside the high-pressure air channel 3 , an air film generating channel 5 is provided on the inner pipe wall 2 , and the high-pressure air inlet 6 is connected with the high-pressure air channel 3 .

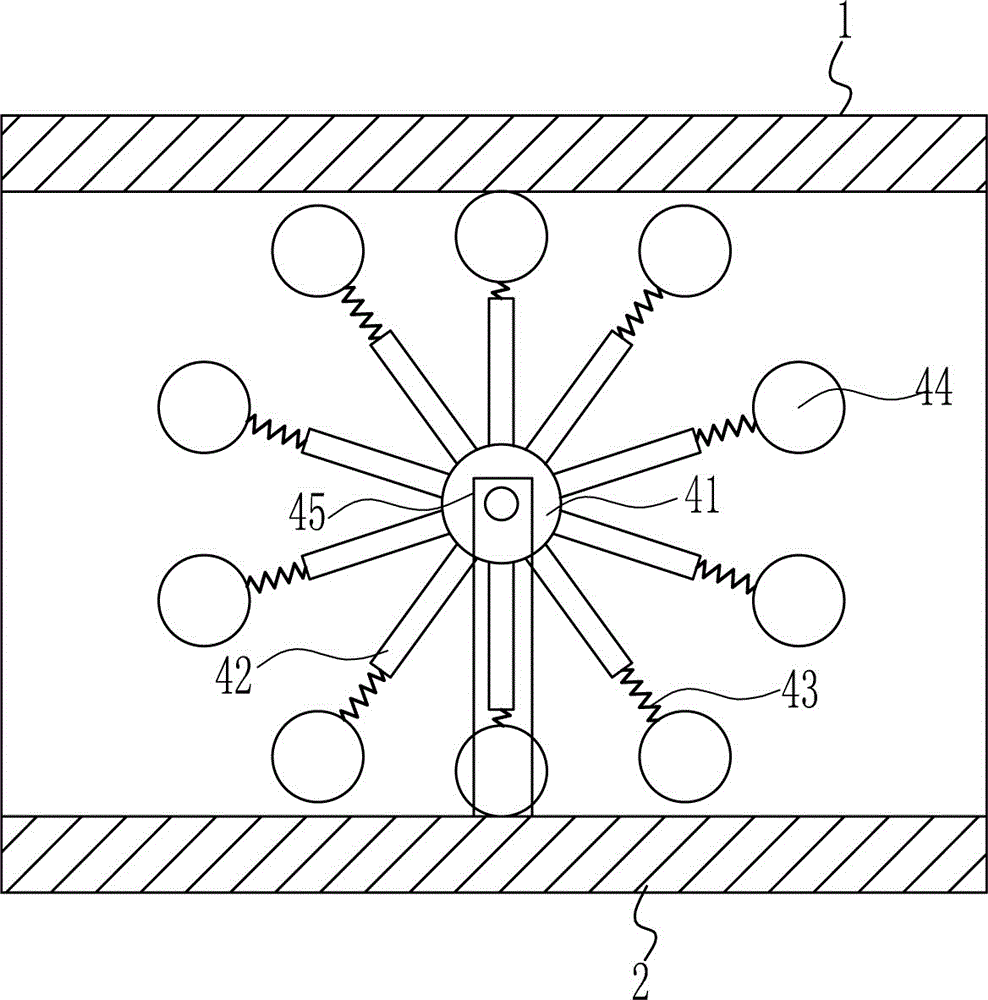

[0032] The high-frequency vibrator 4 includes a vibrating turntable I41, a vibrating blade 42, a vibrating spring I43, a vibrating steel ball 44 and a vibrating support 45, the vibrating support 45 is installed on the inner tube wall 2, and the vibrating turntable I41 is installed on the vibrating support 45 Vibration blades 42 are installed on the v...

Embodiment 2

[0037] A pipeline gas filling and drag reduction transporting mud device, such as Figure 1-6 As shown, it includes an outer pipe wall 1, an inner pipe wall 2, a high-pressure air passage 3, a high-frequency vibrator 4, an air film generation passage 5 and a high-pressure air inlet 6, and the space between the outer pipe wall 1 and the inner pipe wall 2 is a high pressure The air channel 3 is provided with a high-frequency vibrator 4 inside the high-pressure air channel 3 , an air film generating channel 5 is provided on the inner pipe wall 2 , and the high-pressure air inlet 6 is connected with the high-pressure air channel 3 .

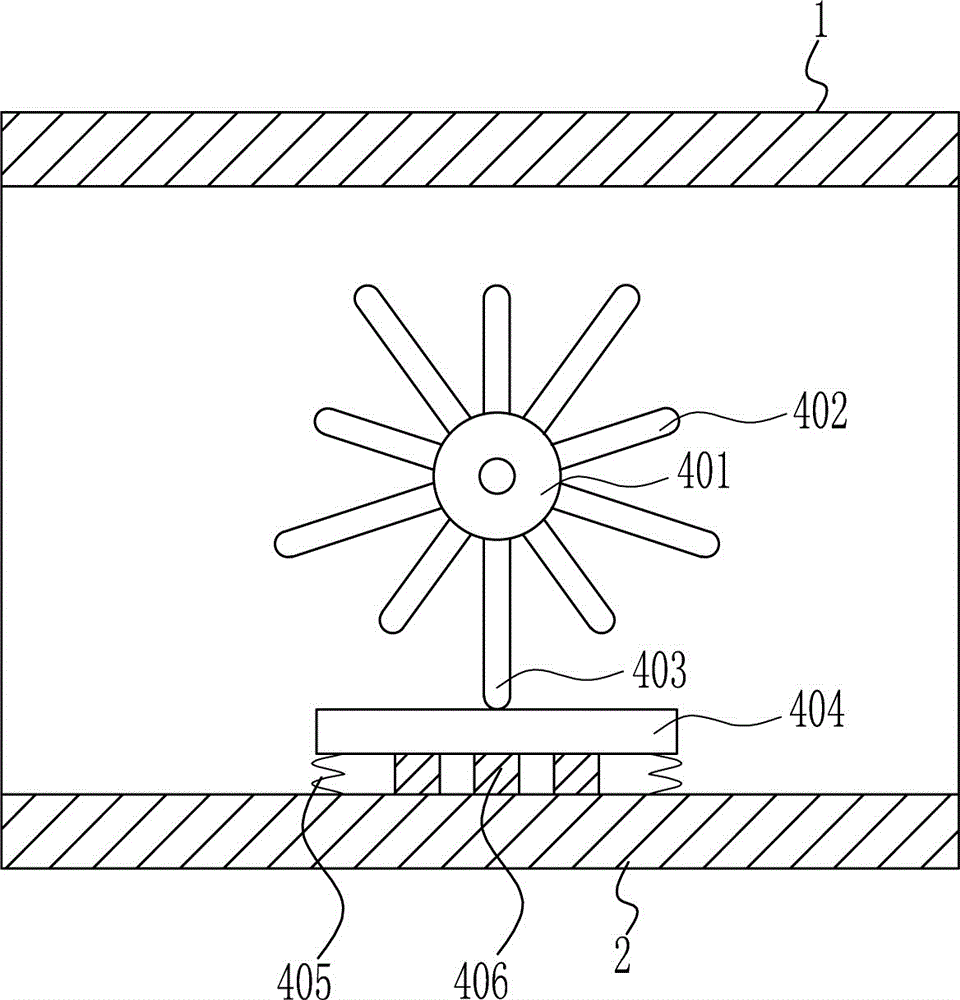

[0038] The high-frequency vibrator 4 includes a vibrating turntable II 401, a vibrating short blade 402, a vibrating long blade 403, a vibrating platform 404, a vibrating spring II 405 and a vibrating block 406. Short vibration blades 402 and long vibration blades 403 are installed. A vibration platform 404 is provided below the vibration turntable I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com