Energy-saving scraper blade conveying device for dust removal

A conveying device and scraper technology, which is applied in the field of energy-saving scraper conveying devices for dust removal, can solve the problems of increasing conveying resistance, reducing conveying efficiency, and increasing energy consumption, so as to reduce equipment occupation space, improve conveying efficiency, and reduce operating noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

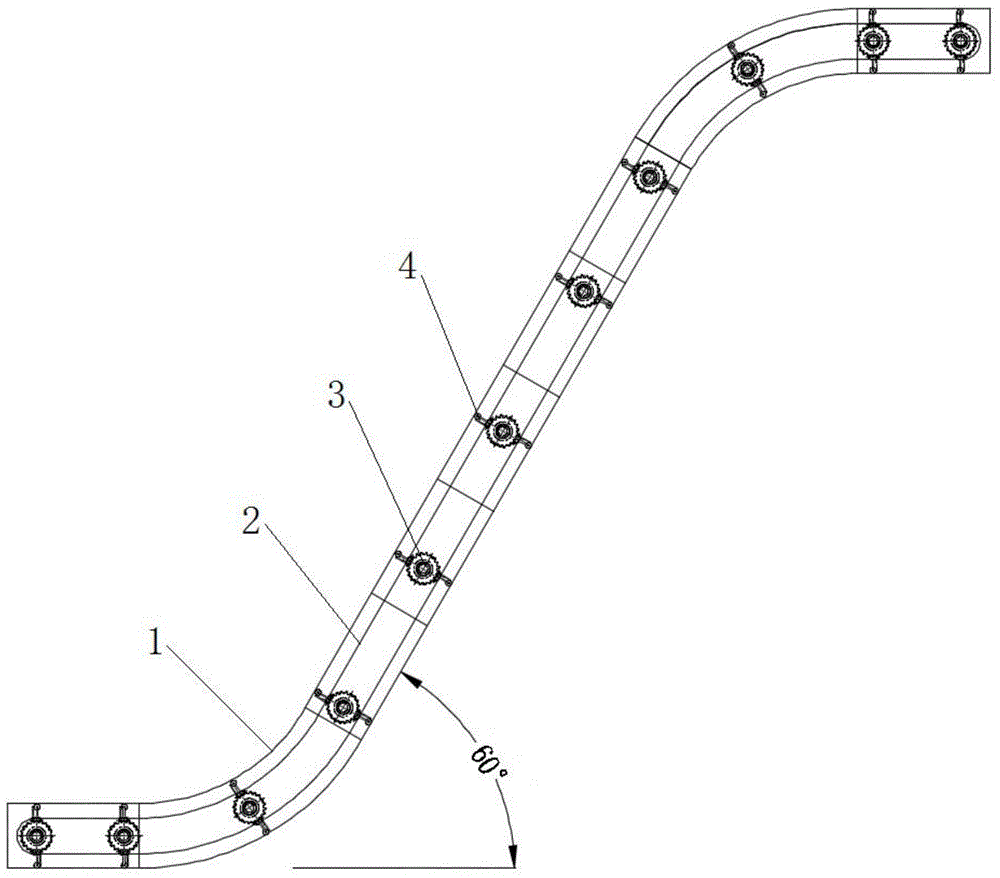

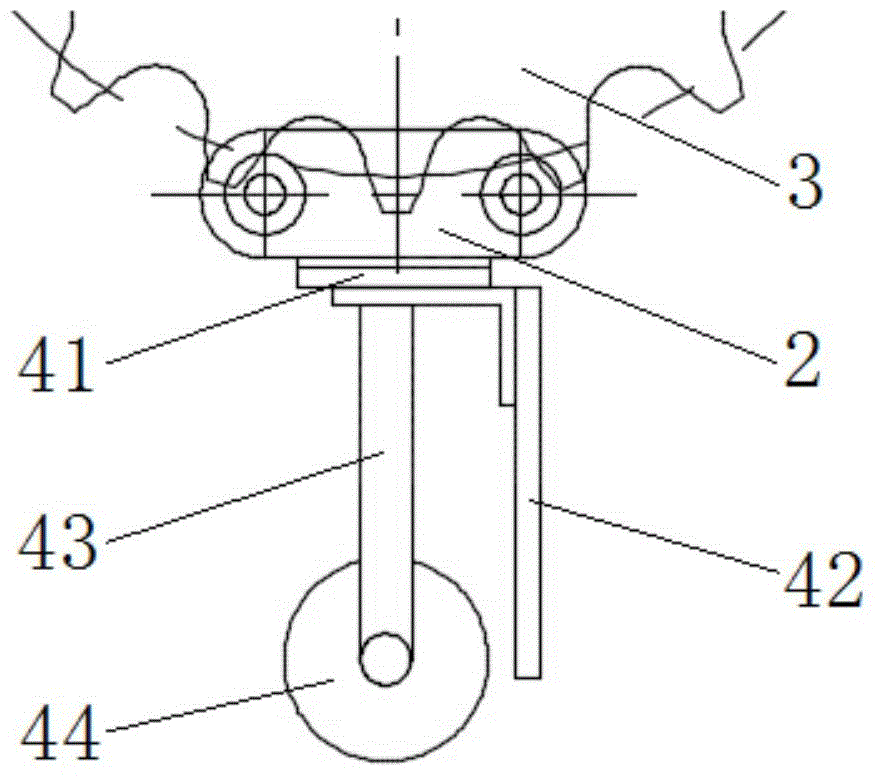

[0030] combine figure 1 and figure 2As shown, an energy-saving scraper conveying device for dust removal in this embodiment includes a conveying box 1, a chain transmission mechanism installed in the conveying box 1, and several scrapers 42 arranged at intervals on the chain transmission mechanism. The mechanism is used to drive the scraper 42 to rotate circularly in the conveying box 1, so as to transport the dust collected by the dust collector from the bottom of the conveying box 1 to the top of the conveying box 1, so as to realize efficient dust conveying. Different from the prior art, there is an inclination α between the conveying box 1 and the horizontal plane in this embodiment, and the inclination α can reach 60°, and the turning part of the conveying box 1 is a circular arc transition, adopting a large inclination angle The structure of the conveying box 1 reduces the conveying distance, reduces the space occupied by the equipment, and improves the conveying effic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com