PVC and PP hard board die

A mold and hard board technology, applied in the field of PVC and PP hard board molds, can solve the problems of short continuous startup time, easy accumulation of material at the seams, mechanical traces on the board surface, etc., so as to solve the mechanical traces and achieve high production quality. , the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

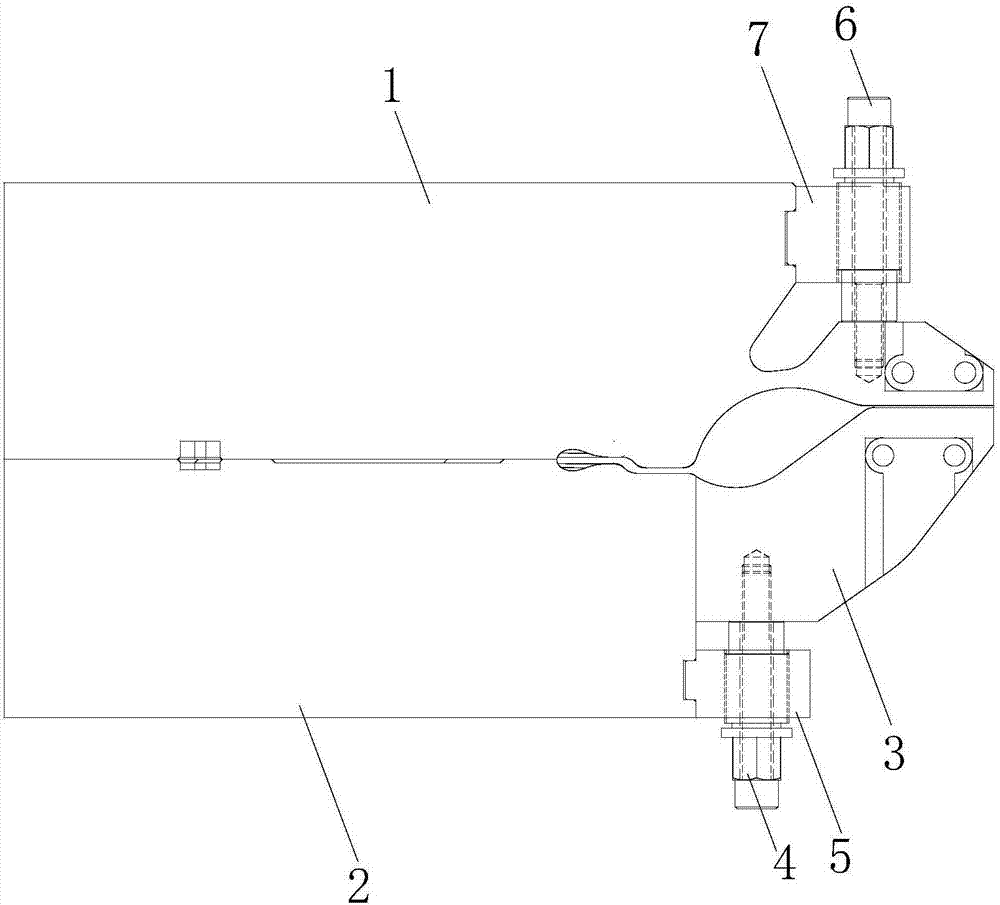

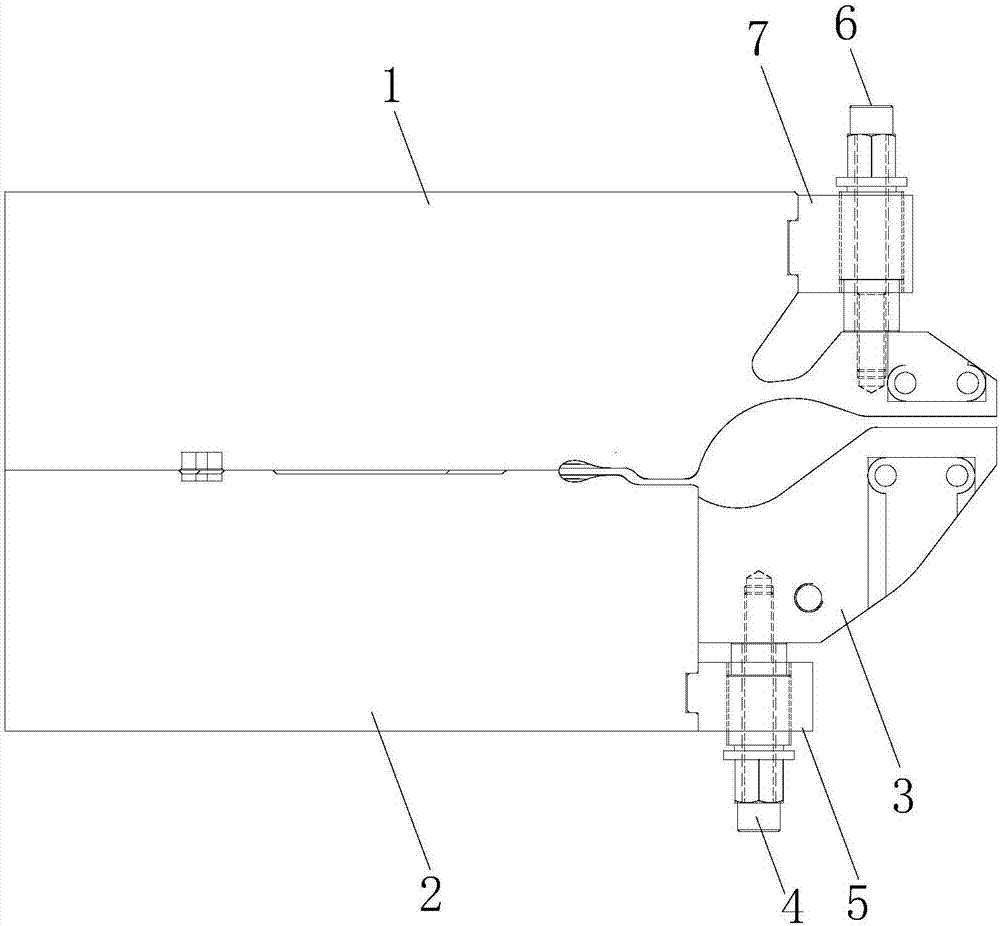

[0016] see Figure 1-2 , in an embodiment of the present invention, a PVC and PP hard board mold, including fine-tuning die mouth elasticity 1 without joints in the flow channel, a lower mold body 2 and a lower movable die lip 3, and a mold without joints in the flow channel in the mold Mouth elasticity fine-tuning 1 There is no splicing seam, the upper mold is not easy to accumulate material and hang material, and there is no mechanical trace on the produced board surface, which can achieve mirror quality effect and high production quality. On the basis of the original old-fashioned mold, 50% of the problem has been solved. At the same time, the probability of downtime caused by accumulated material is also reduced by 50%, which improves the quality and reduces the production cost. There is no splicing seam in the runner. The lower mold body 2 is located below the elastic fine-tuning 1 of the non-joint die mouth in the flow channel. A lower movable die lip 3 is arranged on on...

Embodiment 2

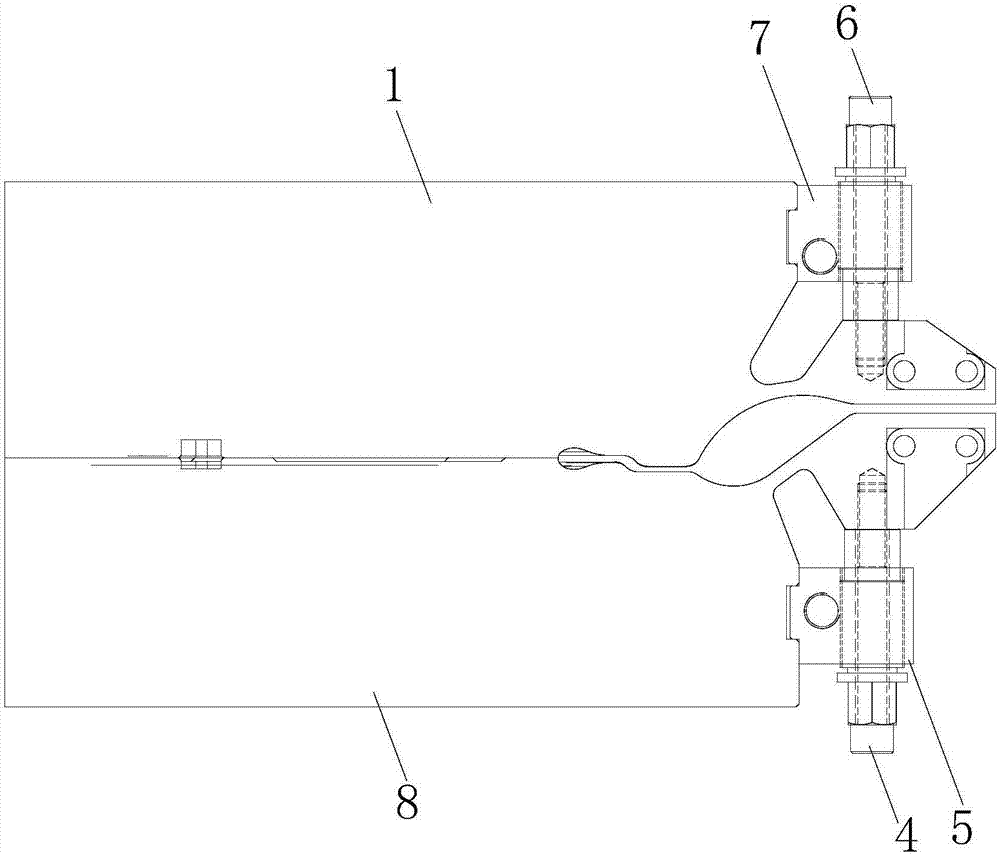

[0019] see image 3 , in the embodiment of the present invention, a PVC and PP hard board mold, including the fine-tuning of die mouth elasticity 1 without joints in the flow channel and the integral die mouth elasticity fine-tuning 8 of the lower mold, to produce boards of different thicknesses, which can be replaced by different openings For molds of different sizes, the upper and lower die openings of each set of molds can be adjusted respectively to increase or decrease the opening to produce plates within the allowable thickness range. The elastic fine-tuning die opening is used to fine-tune the uneven discharge speed of the runner, and there is no splicing in the runner. One side of the slot die opening elastic fine adjustment 1 is provided with a lower mold integral die opening elastic fine adjustment 8, and the lower mold integral die opening elastic fine adjustment 8 is located directly below the die opening elastic fine adjustment 1 without jointing seams in the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com