Light fireproof ecological aldehyde purifying cement board

A cement board and ecological technology, applied in the field of building interior decoration, can solve the problems of ineffectiveness, inappropriate use, easy discoloration and yellowing, etc., and achieve the effect of keeping fresh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

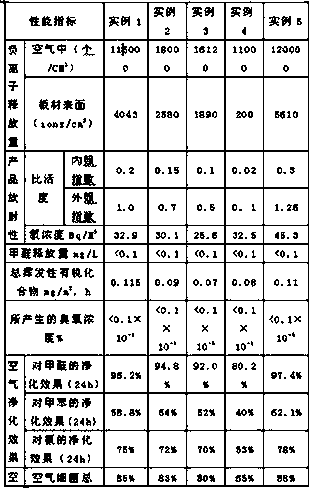

Examples

Embodiment 1

[0067] A light-weight fireproof ecological net aldehyde cement board and its production method and decorative application

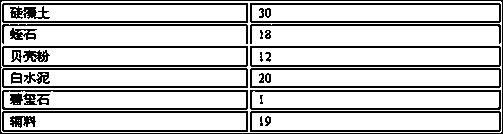

[0068] (1) Click on the content of the volume to prepare the raw materials:

[0069]

[0070] The diatomite is obtained by calcining the diatomite raw material in a kiln at 200°C-400°C for 1 hour, and then through high-fine ball milling to 300-6000 mesh.

[0071] The expanded vermiculite powder raw material is placed in an extruding furnace at 500°C-1100°C, expanded for 10-25 seconds, and then subjected to high-precision jet milling to 100-5000 mesh.

[0072] The raw material of the shell powder is to use natural marine biological solid waste resource shells to be calcined in a kiln at 1100° C. for 150 minutes, and dry-milled and wet-milled to form a powder of 150-2000 mesh.

[0073] The tourmaline powder is a boron-containing aluminum, sodium, iron, lithium ring-shaped silicate substance, which is carefully made from natural materials through...

Embodiment example 2

[0081] A preparation method of lightweight fireproof ecological net aldehyde cement board;

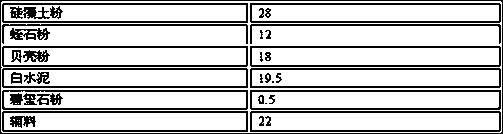

[0082] (1) Click on the content of the volume to prepare the raw materials:

[0083]

[0084] The diatomite is obtained by calcining the diatomite raw material in a kiln at 200°C-400°C for 1 hour, and then through high-fine ball milling to 300-6000 mesh.

[0085] The expanded vermiculite powder raw material is placed in an extruding furnace at 500°C-1100°C, expanded for 10-25 seconds, and then subjected to high-precision jet milling to 100-5000 mesh.

[0086] The raw material of the shell powder is to use natural marine biological solid waste resource shells to be calcined in a kiln at 1100° C. for 150 minutes, and dry-milled and wet-milled to form a powder of 500-2000 mesh.

[0087] The tourmaline powder is a boron-containing aluminum, sodium, iron, lithium ring-shaped silicate substance, which is carefully made from natural materials through nanotechnology, and has a mesh...

example 3

[0094] A light-weight fireproof ecological net aldehyde cement board and its production method and decorative application

[0095] (1) Click on the content of the volume to prepare the raw materials:

[0096]

[0097] The diatomite is obtained by calcining the diatomite raw material in a kiln at 200°C-400°C for 1 hour, and then through high-fine ball milling to 300-6000 mesh.

[0098] The expanded vermiculite powder raw material is placed in an extruding furnace at 500°C-1100°C, expanded for 10-25 seconds, and then subjected to high-precision jet milling to 100-5000 mesh.

[0099] The raw material of the shell powder is to use natural marine biological solid waste resource shells to be calcined in a kiln at 1100° C. for 150 minutes, and dry-milled and wet-milled to form a powder of 500-2000 mesh.

[0100] The tourmaline powder is a boron-containing aluminum, sodium, iron, lithium ring-shaped silicate substance, which is carefully made from natural materials through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com