Energy-saving environment-friendly dedusting equipment

A technology of dust removal equipment, energy saving and environmental protection, which is applied in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve the problems of high maintenance and repair costs, damage to the production environment, and unfavorable health of production workers. Low cost, convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The detailed description and technical content of the present invention are described below with the accompanying drawings, but the accompanying drawings are only provided for reference and description, and are not intended to limit the present invention.

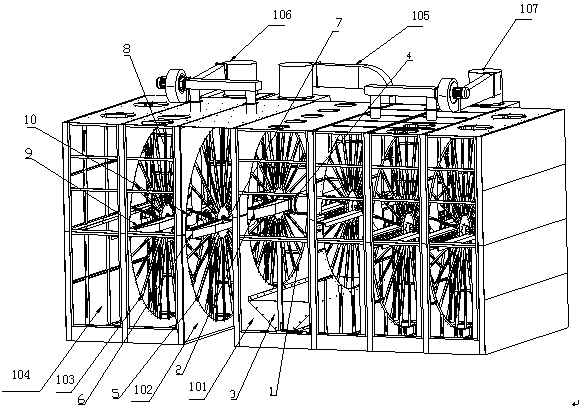

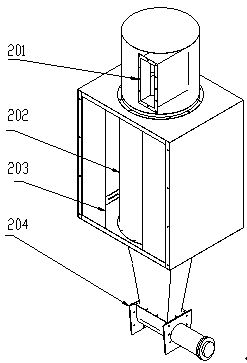

[0019] Such as Figure 1-2 As shown, an energy-saving and environment-friendly dust removal equipment includes a main dust removal room in the middle and two secondary dust removal rooms symmetrically arranged on the left and right sides of the main dust removal room. The upper ends of the chamber and the secondary dust removal chamber are connected to the air inlets of the compactors of the respective compactors through their respective exhaust fans and pipes, and the air outlets of the compactors are at the rear of the main dust removal chamber and the secondary dust removal chamber The side communicates with the inside of the main dust removal chamber and the secondary dust removal chamber.

[0020] The main dust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com