Patents

Literature

1025 results about "Granular activated carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

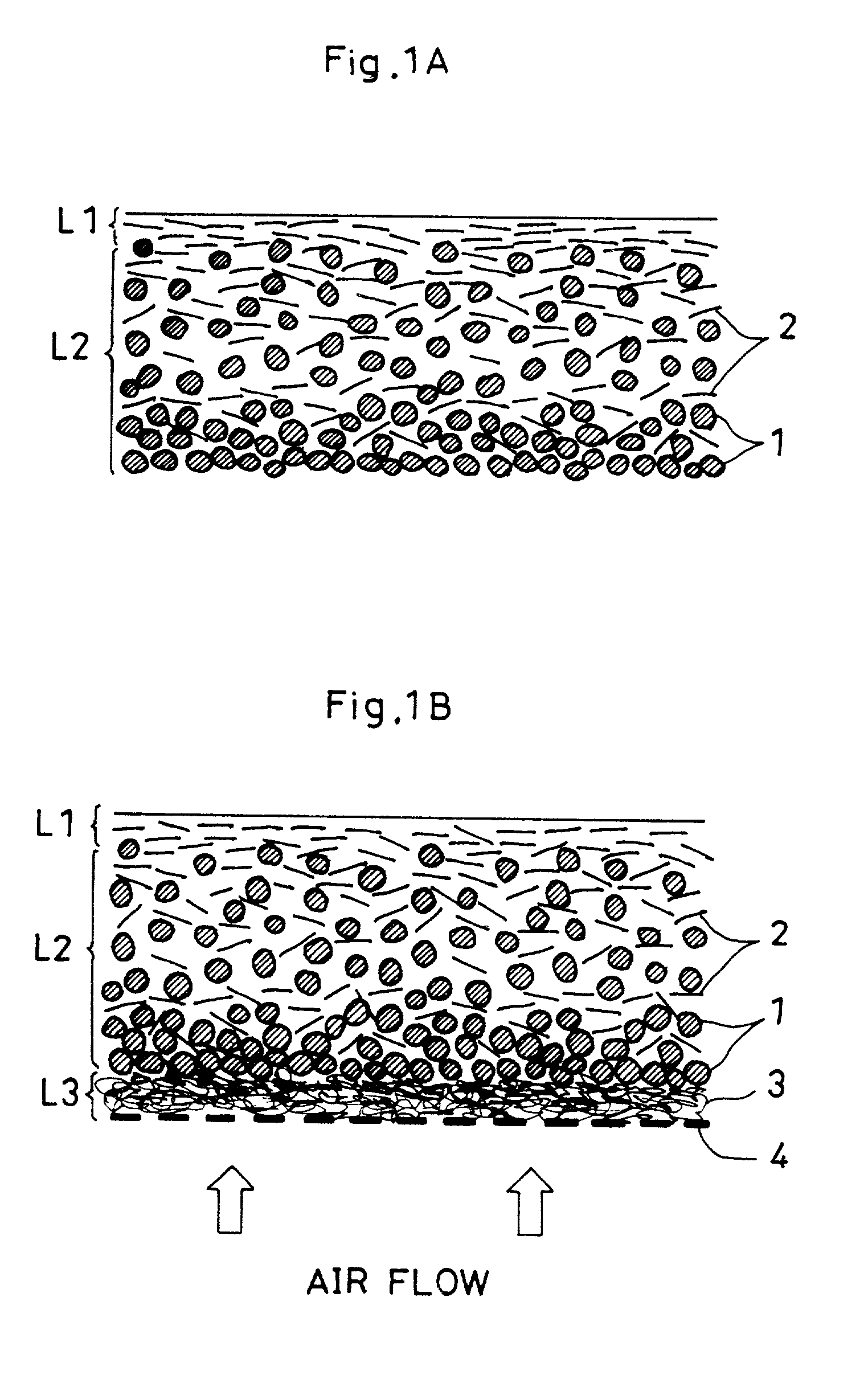

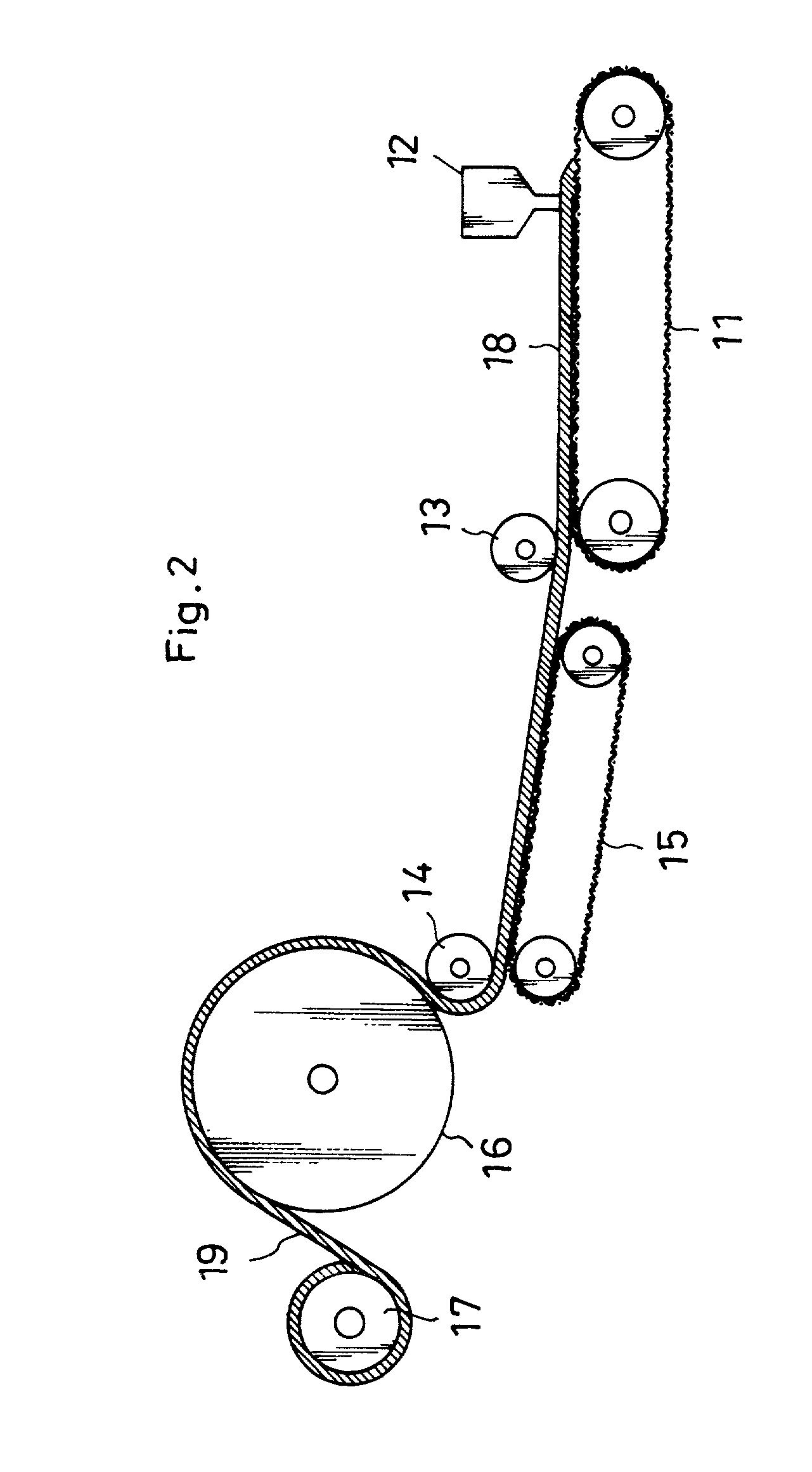

Gas adsorption sheet and air-purifying filter

InactiveUS20030207635A1Improve breathabilityImprove dust removal effectWarp knittingPaper/cardboardFiberSlurry

The gas adsorption sheet of the present invention has a granular activated carbon-containing sheet comprising a granular activated carbon having an average particle diameter of 60 to 600 mum, a supporting fiber for fixing the granular activated carbon in contact with it, and an adhesive fiber which mainly contributes to shape retention. An air-purifying filter of the present invention is obtained by forming the gas adsorption sheet into a shape of pleats or wave. A method for producing a gas adsorption sheet of the present invention comprises a step of forming a granular activated carbon-containing sheet by using an aqueous slurry containing a granular activated carbon, a supporting fiber and a water-swelling adhesive fiber.

Owner:TOYO TOYOBO CO LTD

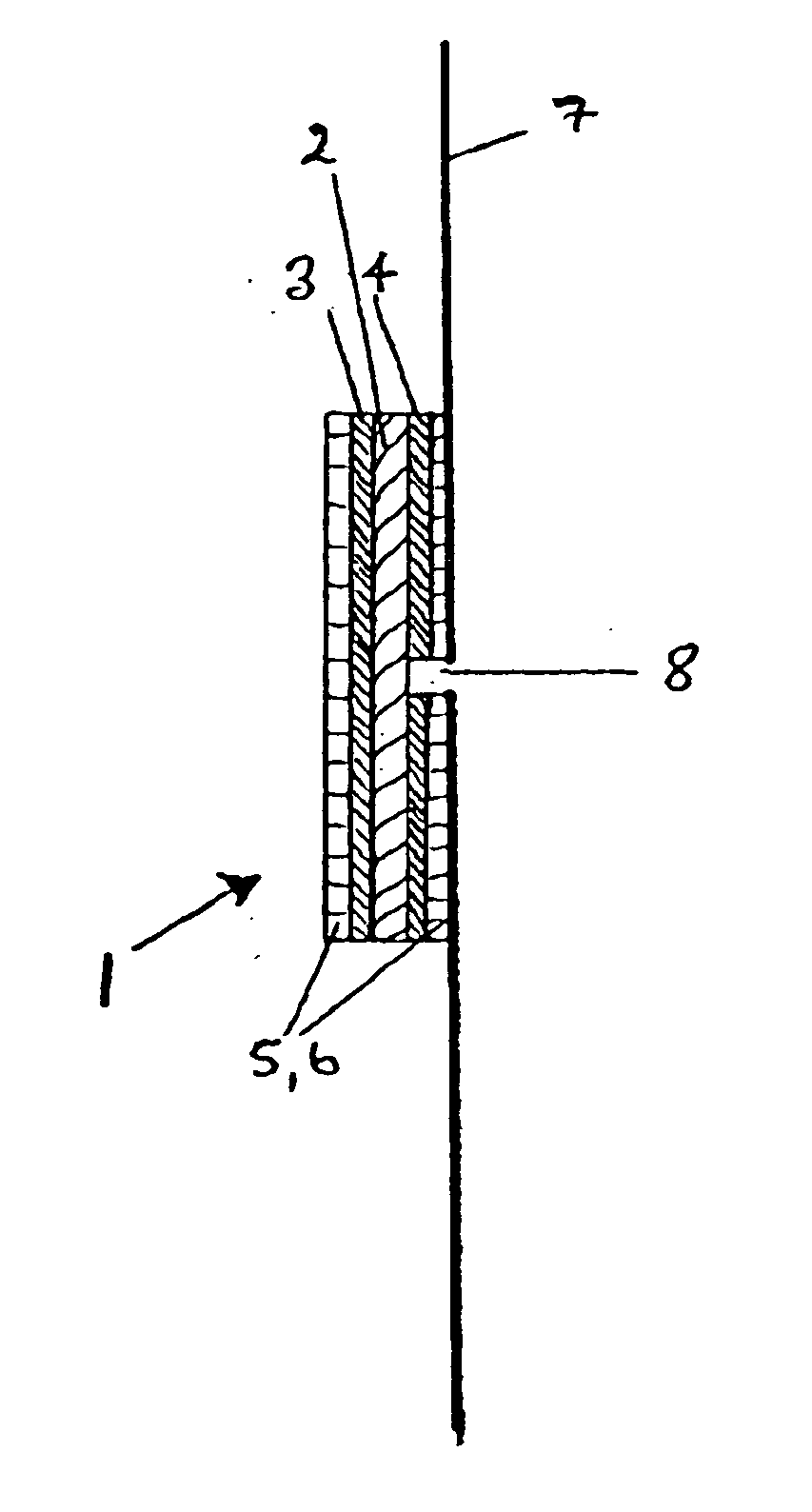

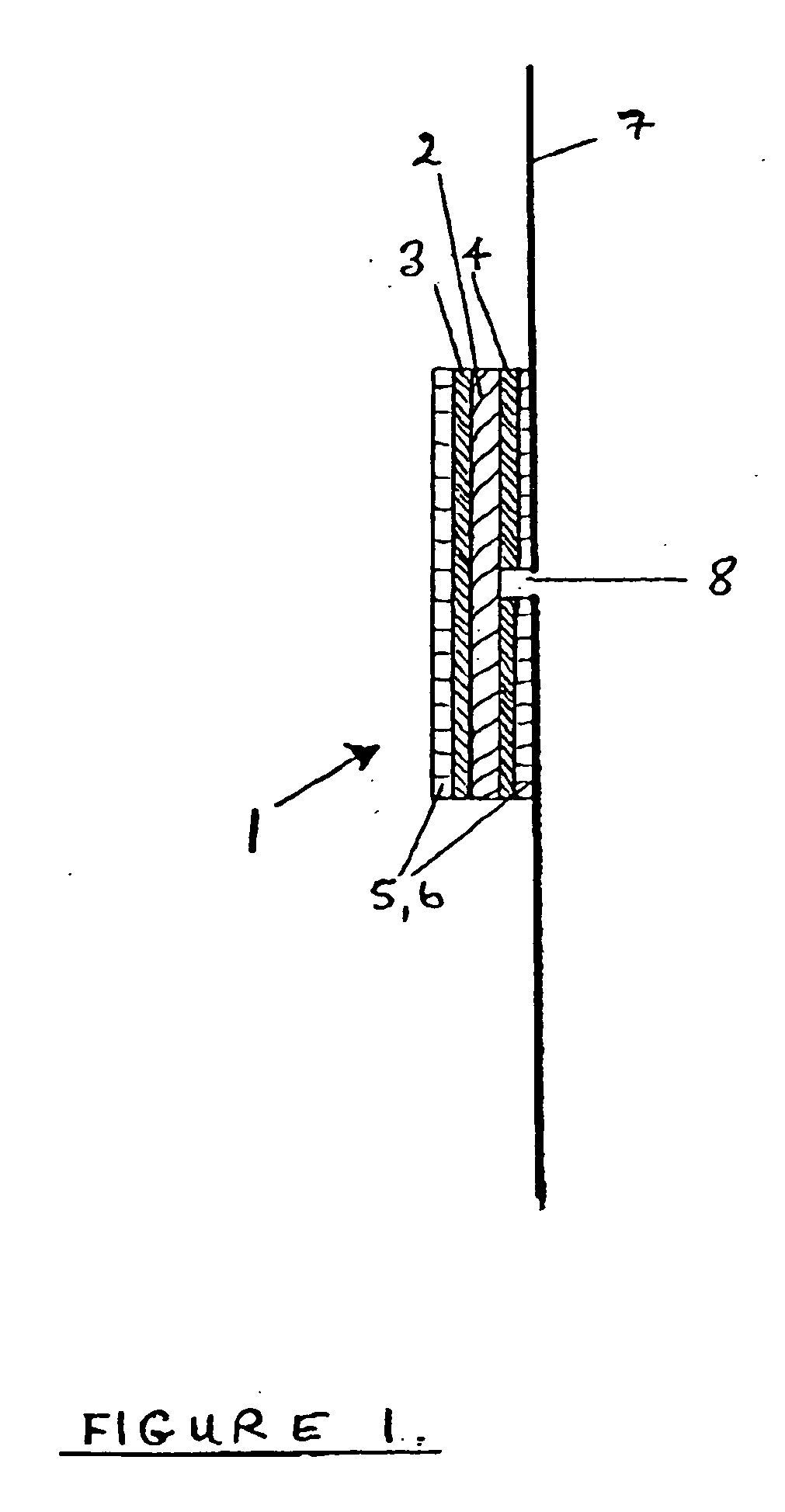

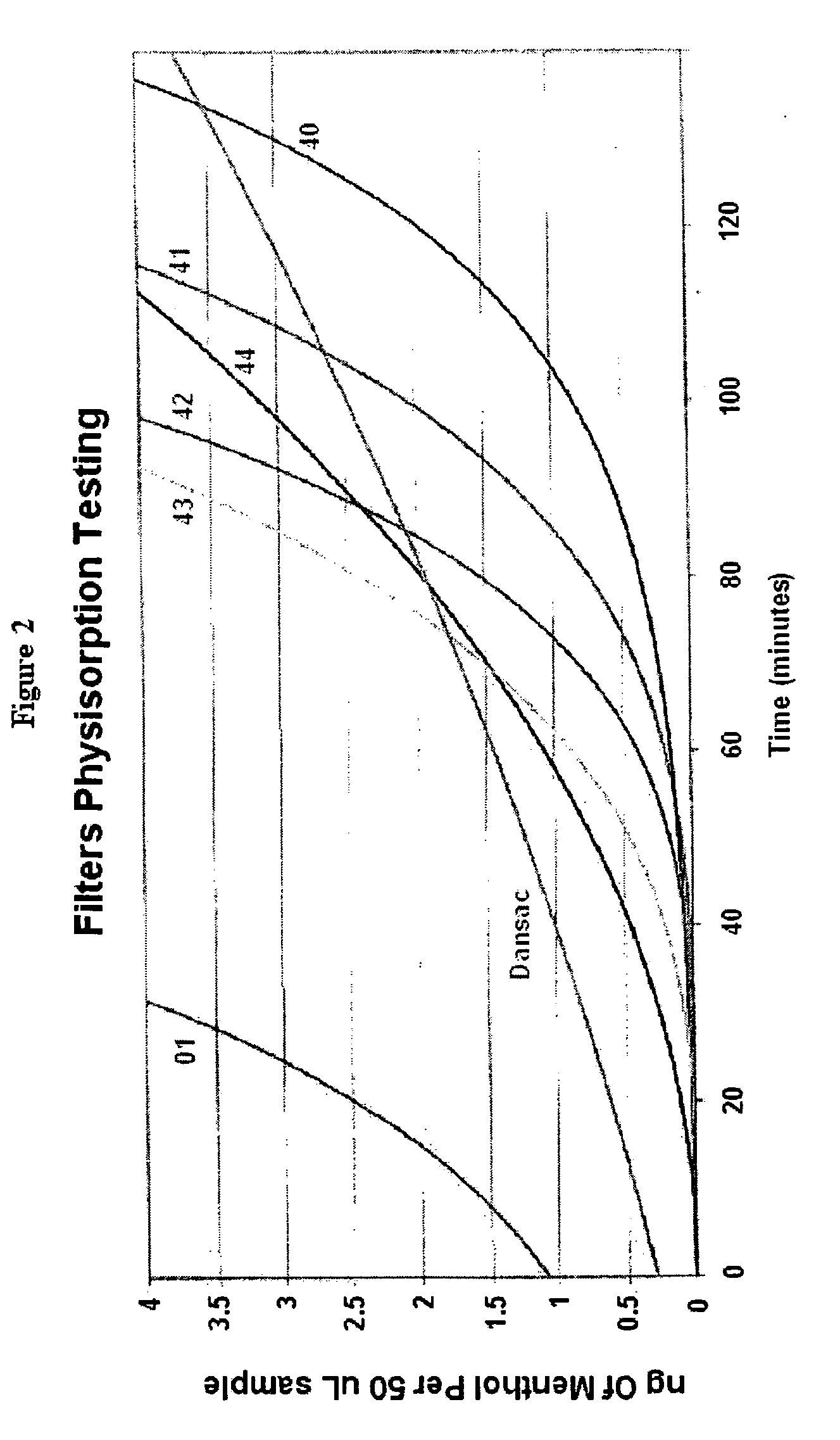

Odour absorbing filters

An odour adsorbing or deodorizing filter which comprises a matrix or substrate impregnated with a mixture of particulate chemically modified activated carbon and particulate activated carbon, together with a binder. The filter may be incorporated into an ostomy collection bag, wound dressing, respirator, air conditioning unit or the like.

Owner:CLINIMED

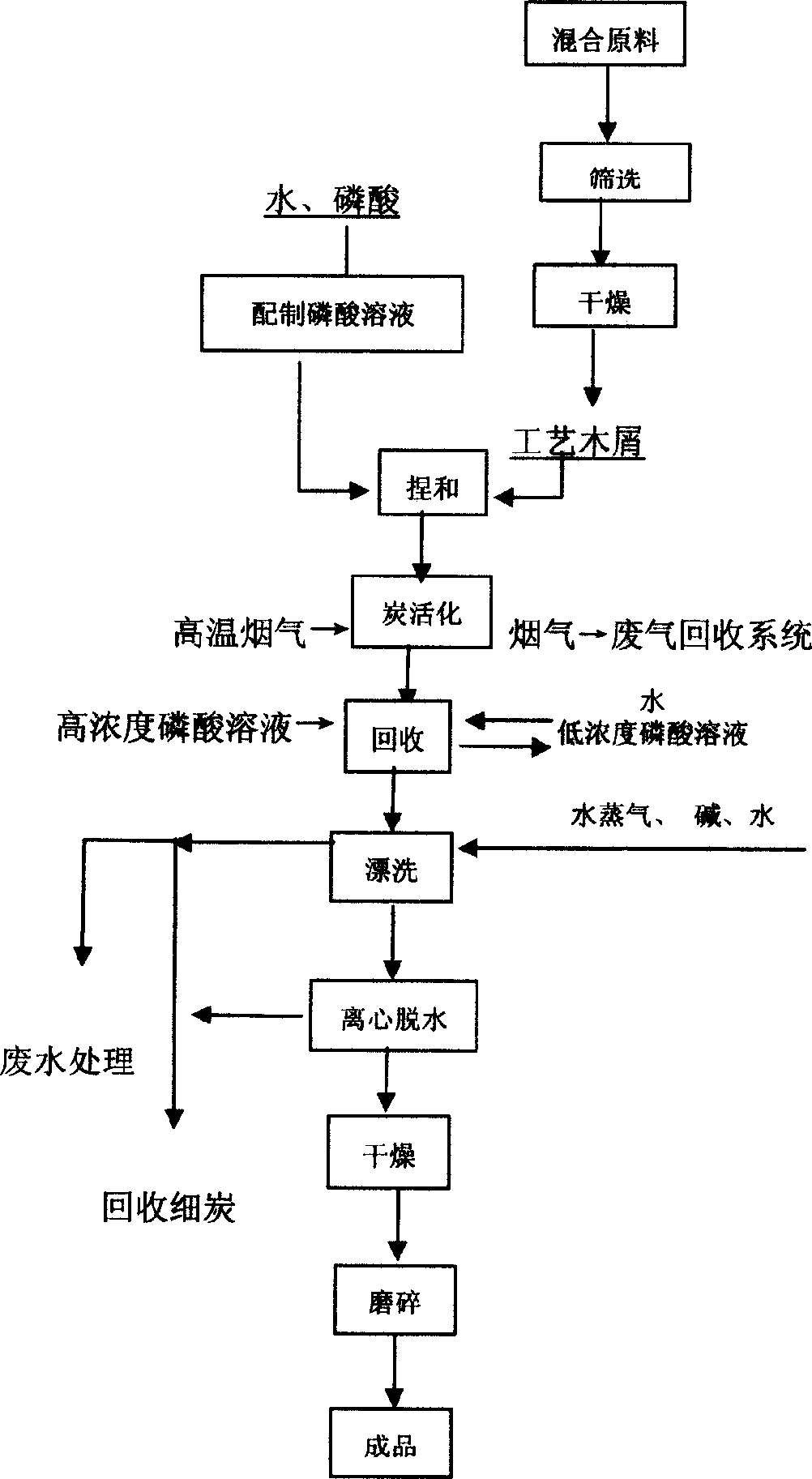

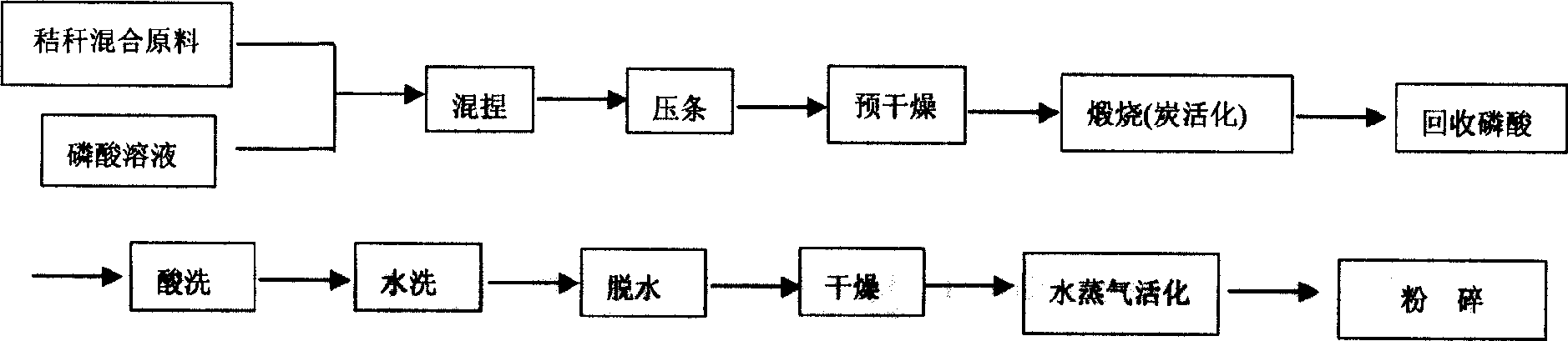

Active carbon producing process with mixed stalk material

The present invention discloses the active carbon producing process with mixed stalk material. The mixed stalk material of crop stalk, waste fruit branch and sawdust is produced into powdered or granular active carbon via phosphoric acid process and combined physical process. Or, the mixed stalk material is produced into powdered or granular active carbon in a chemical physical process with potassium hydroxide as activating agent and perchloric acid for pre-treatment of the material. The present invention has small investment scale, low cost, high utility and simple operation, and the product may be used widely.

Owner:NORTHWEST A & F UNIV

Granular activated carbon filler for paper mill sludge and preparation method thereof

InactiveCN102205964AWell-developed pore structureHigh strengthOther chemical processesSolid waste disposalSodium BentoniteFluidized bed

The invention relates to a granular activated carbon filler for paper mill sludge and a preparation method thereof. The preparation method comprises the following steps: mixing 70-90 parts by weight of anhydrated paper mill sludge and 10-30 parts by weight of bentonite, performing granulation in a granulator, drying at room temperature, performing carbonization of the raw balls at a low temperature, modifying the carbonized material balls with hydrochloric acid, and activating the balls in an activation furnace. The sludge granular activated carbon filler prepared by the invention has the characteristics of large specific surface area, developed pores, high intensity, and the like. Fillers sintered at different process conditions can be respectively used as reactor fillers for sewage treatment, biological aerated filters, fluidized beds, and the like, have wide application range and low cost.

Owner:SHANDONG UNIV

Water purification cartridge

InactiveUS20050072729A1More energyEqually distributedTreatment involving filtrationSettling tanks feed/dischargeCeramic water filterHalogen

The water purification cartridge treats water with a halogen liberated from halogenated hydantoinyl resins and polymers, resulting in the safe, complete, and economical purification of non-potable water at low flow rates typically found in gravity feed filtration systems and at water pressures of less than 1 psig. The cartridge of the invention purifies non-potable water of bacteria, viruses, and some protozons without the need for additional power sources or risk to the consumer for exposure to chemicals that have been identified to have harmful, long-term effects. The cartridge described herein enables a gravity fed water purification system by combining the cartridge with conventional filters, such as porous diatomaceous earthen ceramic water filters or activated carbon filters packed either with granular activated carbon or block.

Owner:HALOSOURCE INC

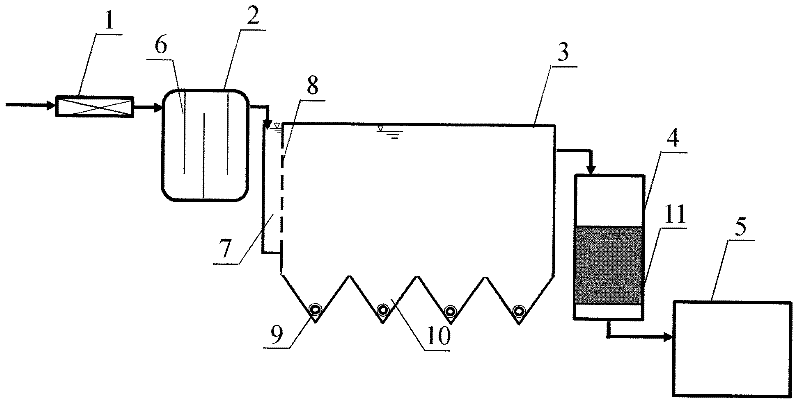

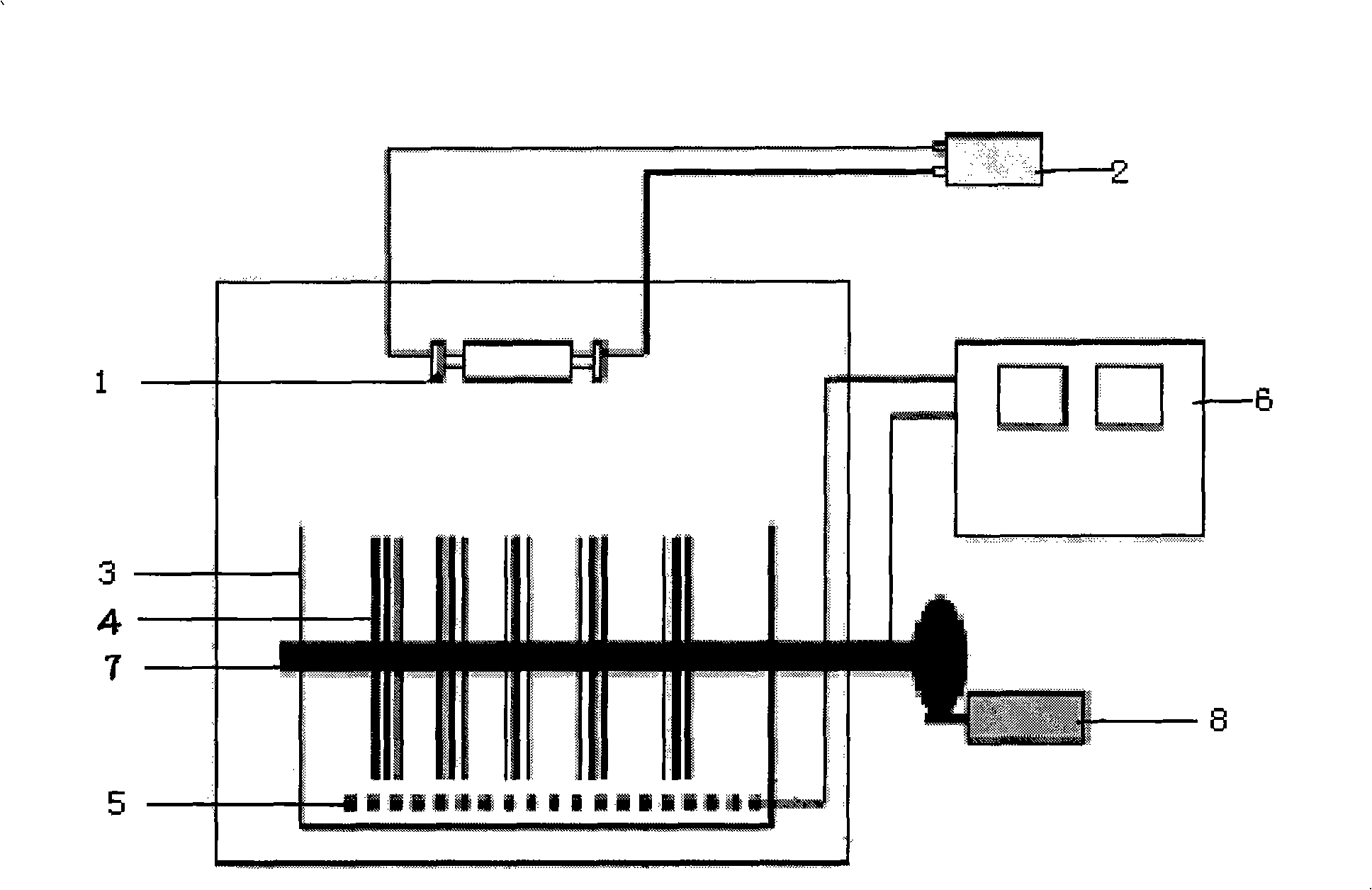

Method and apparatus for treating oil refining sewerage

ActiveCN101434443AReduce shockFacilitate deep processing and reuseWater/sewage treatmentMultistage water/sewage treatmentHigh concentrationActivated sludge

The invention relates to a treatment method and a device for refinery sewage. The refinery sewage is sent into an electrolytic catalysis oxidation reactor which is provided with an anode, a cathode and solid catalyst particles, wherein, the lower part of the reactor is provided with an oxygenation aeration device, the solid catalyst particles are filled between the anode and the cathode, and the solid catalyst particles adopts particle activated carbon loaded with metals having catalytic and oxidation function. The effluent of the electrolytic catalysis oxidation can be further treated by adopting an activated sludge process. The method is used for treating high-concentration salt-containing mixed wastewater such as the draining water of a refinery electrical desalting unit, the alkali washing waste alkali liquid of oils, liquefied petroleum gas and dry gas, and cutting water in an oils tank farm, and the like, the wastewater after treatment satisfies the requirement of direct discharging, thus alleviating impact on a wastewater treatment plant. The method put forward by the invention has the advantages that high-concentration wastewater can reach disposable treatment standard and does not need any dilution biochemical treatment, treatment effluent is not polluted secondarily by metal ions, and investment and running cost are lower, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

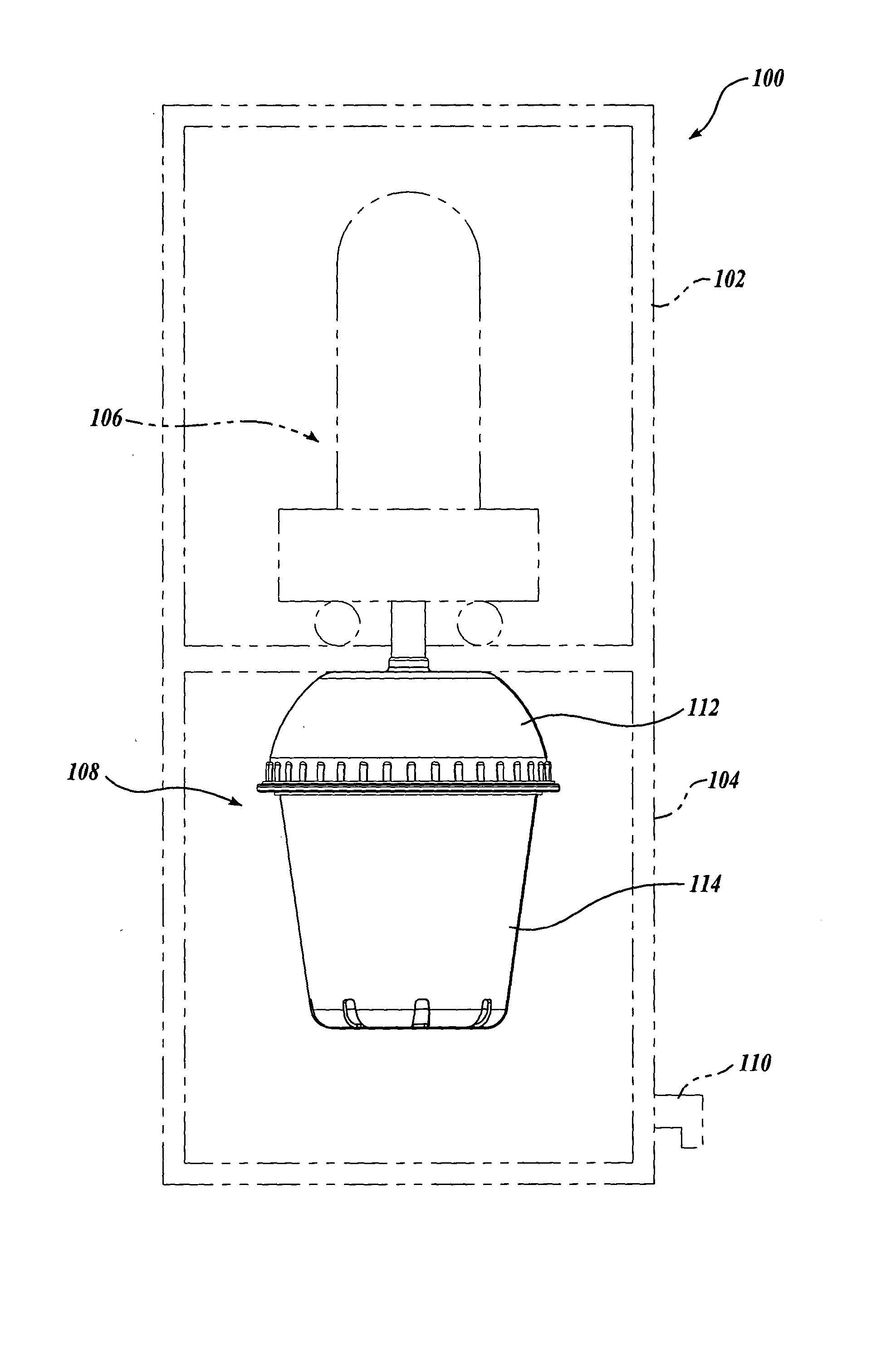

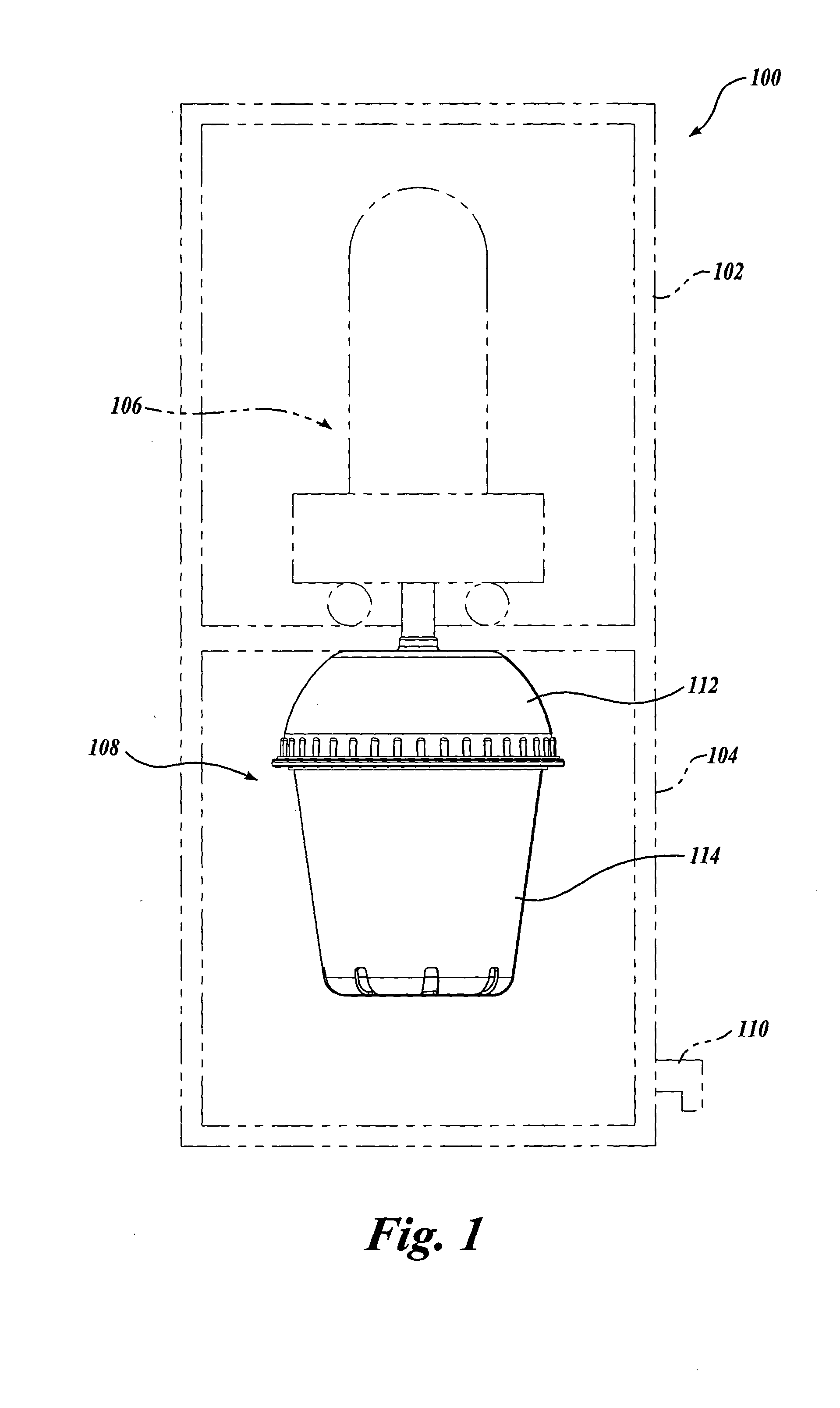

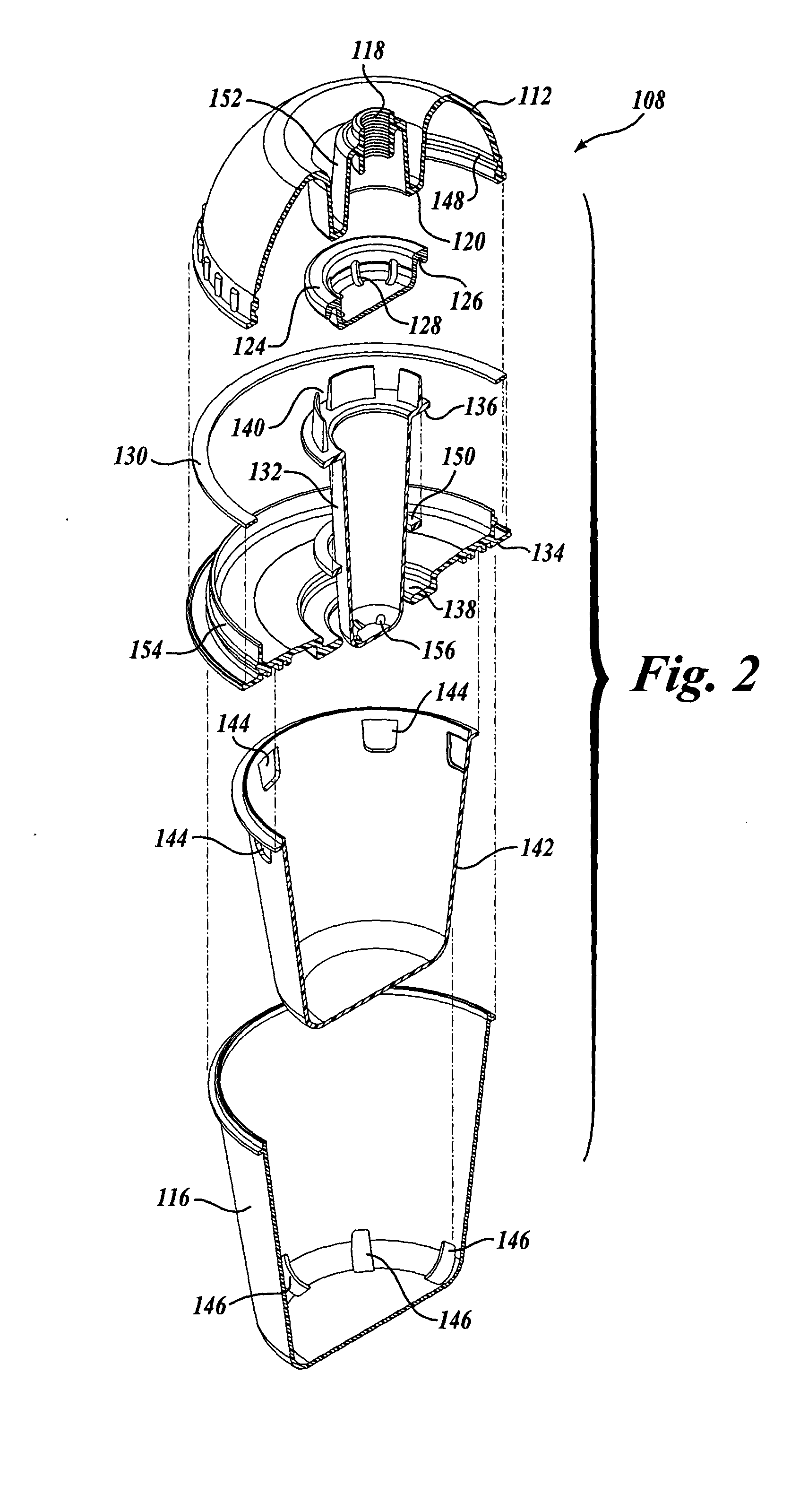

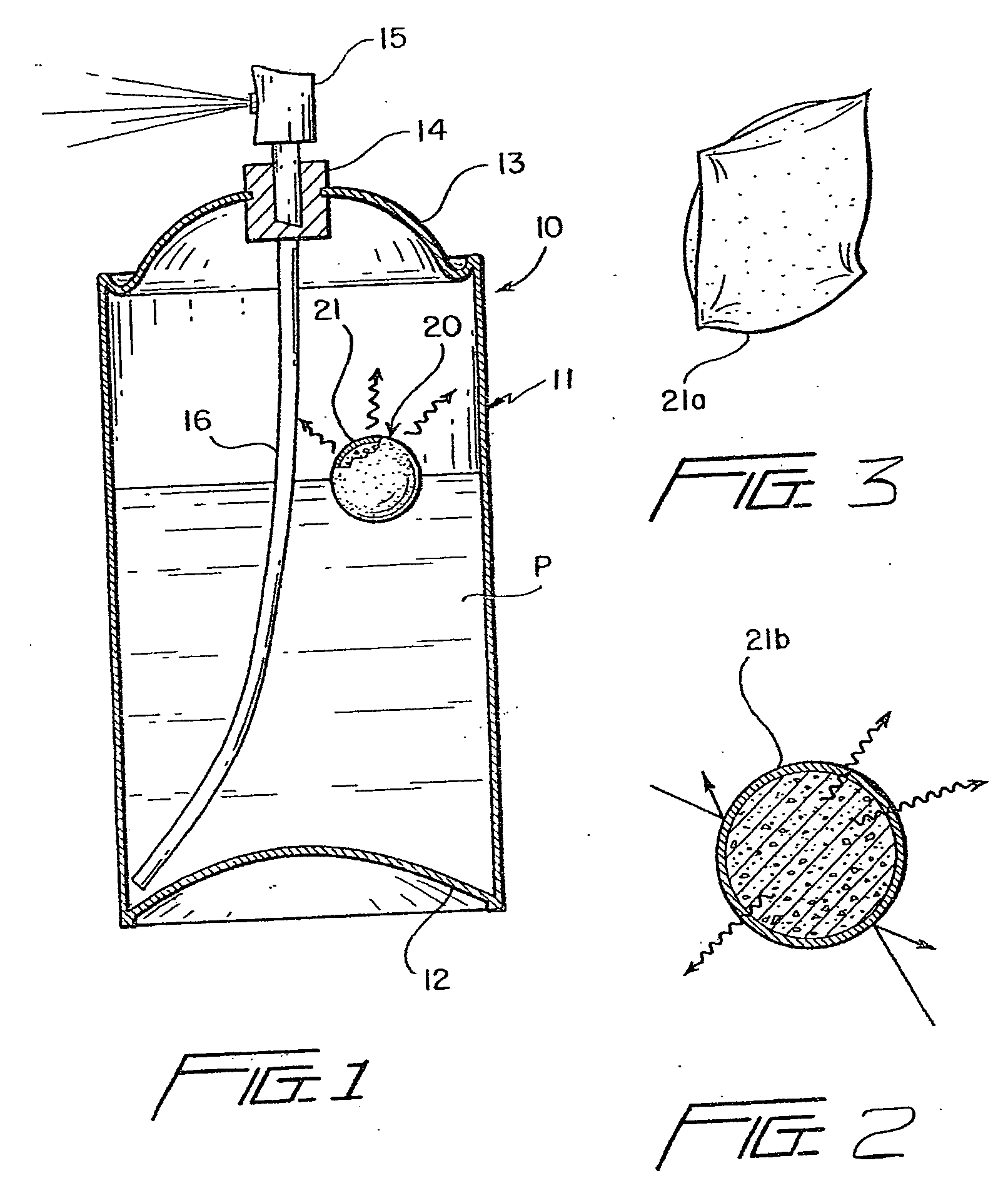

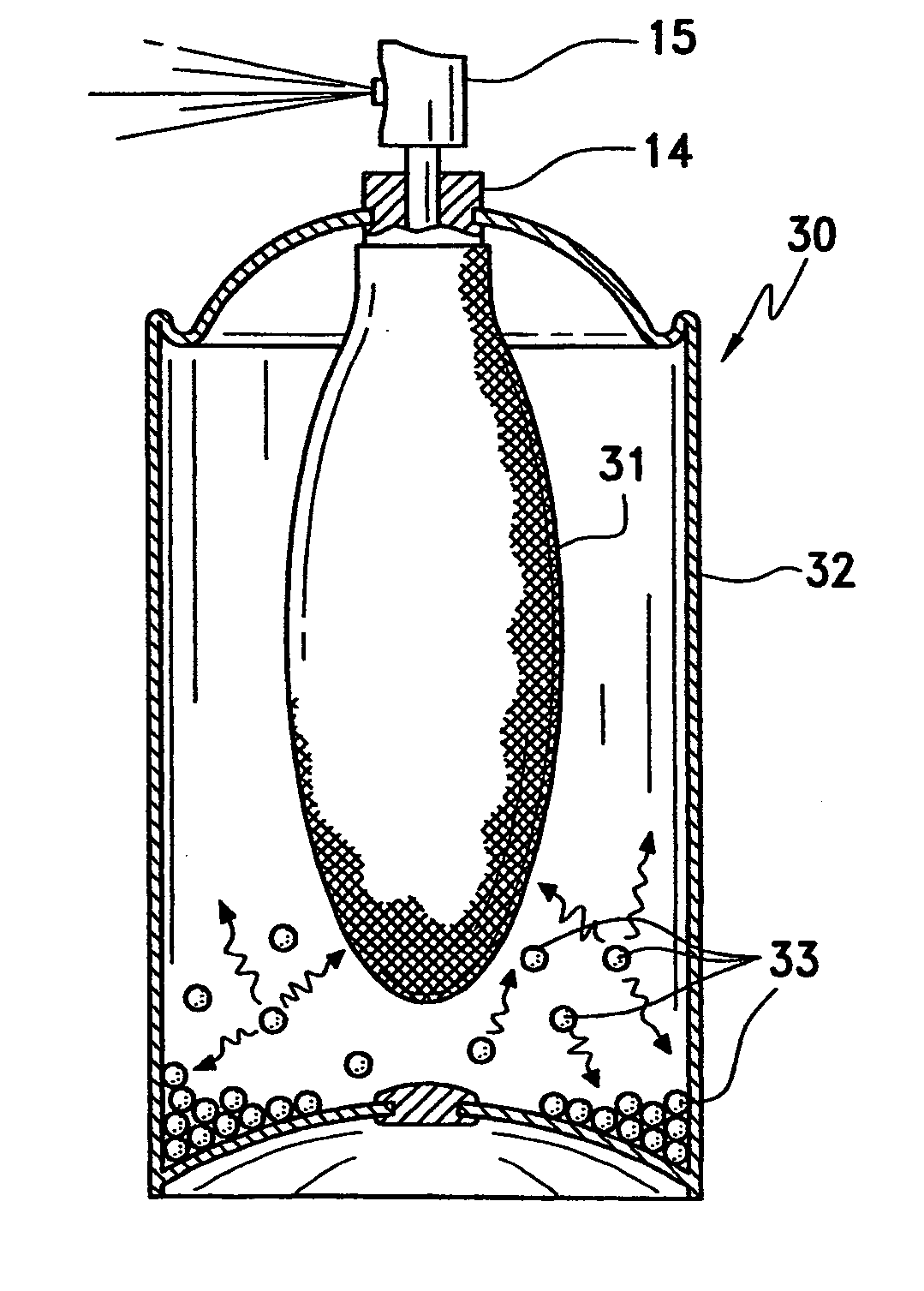

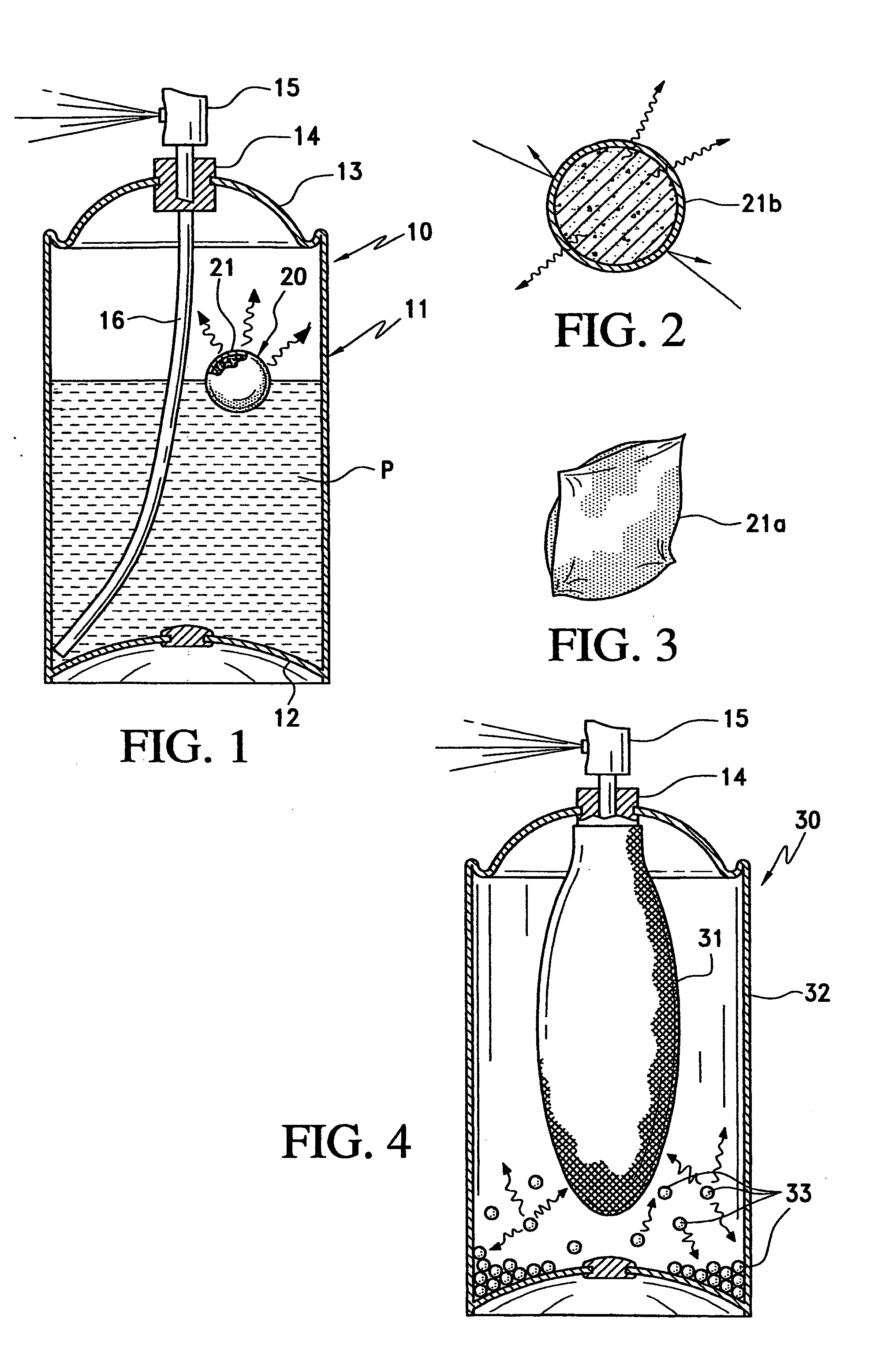

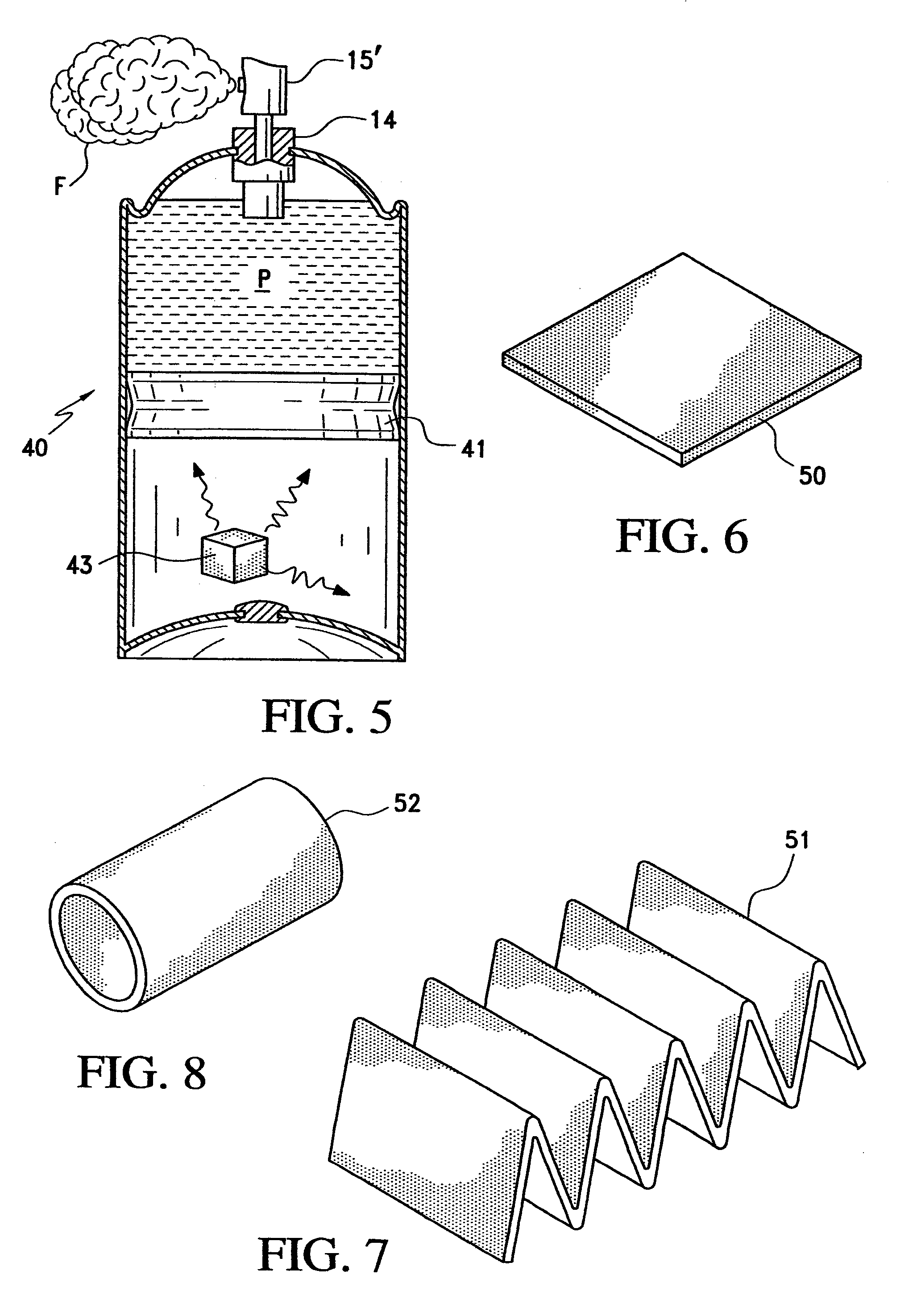

Gas storage and delivery system for pressurized containers

InactiveUS20050274737A1Consistent and uniform and acceptable spray patternFine foamOpening closed containersBottle/container closureSodium bicarbonateDesorption

A gas adsorption material containing a desired quantity of gas is placed in a pressurized container along with a product to be dispensed, and as pressure in the container is depleted during use, stored gas is released into the container to maintain pressure in the container within a predetermined range. The material may be in contact with the product, or it may be isolated from the product, and is known as a pressure swing adsorption (PSA) system, wherein adsorption of gas into the material occurs at a high pressure, and desorption of gas from the material occurs at a low pressure. Such devices are capable of storing under pressure a volume of gas 18 to 20 times the volume of the material. A preferred adsorbent gas storage material is granular activated carbon, or a carbon fiber composite molecular sieve (CFCMS). Other materials, such as zeolite, starch-based polymers, activated alumina, silica gel, and sodium bicarbonate, or mixtures thereof, may be used, although they generally are not as effective as activated carbon. The adsorbent material may be in granular, powdered, or pellet form, or a mass of the material may be formed into variously shaped cohesive bodies, such as balls, tubes, cubes or rods, or sheets or screens which may be flat or curved or folded into various shapes, such as, for example, an accordion-like fold.

Owner:LIM WALTER K

Method for preparing bioactive filler through immobilization of anaerobic ammonia oxidizing bacterium

ActiveCN103193315AReduce churnWell-developed poresTreatment with anaerobic digestion processesDrug biological activityLiquid culture

The invention discloses a method for preparing a bioactive filler through immobilization of an anaerobic ammonia oxidizing bacterium, and belongs to the field of water treatment. The active filler is prepared by the following steps of: grinding active carbon, soaking in an anaerobic ammonia oxidizing bacterium liquid culture medium, and preparing an embedding solution from polyvinyl alcohol, calcium carbonate and condensed anaerobic ammonia oxidizing bacterium liquor in proportion; mixing and uniformly stirring the prepared embedding solution with soaked granular active carbon, and implementing immobilization through boric acid to finish cross-linking immobilization, thereby obtaining the active filler. The bioactive filler, after being cultured for 2 weeks, can recover anaerobic ammonia oxidizing activity. The bioactive filler disclosed by the invention is good in settlement performance and high in mechanical strength, and can achieve a micro-expansive state in an upflow biofilter.

Owner:BEIJING UNIV OF TECH

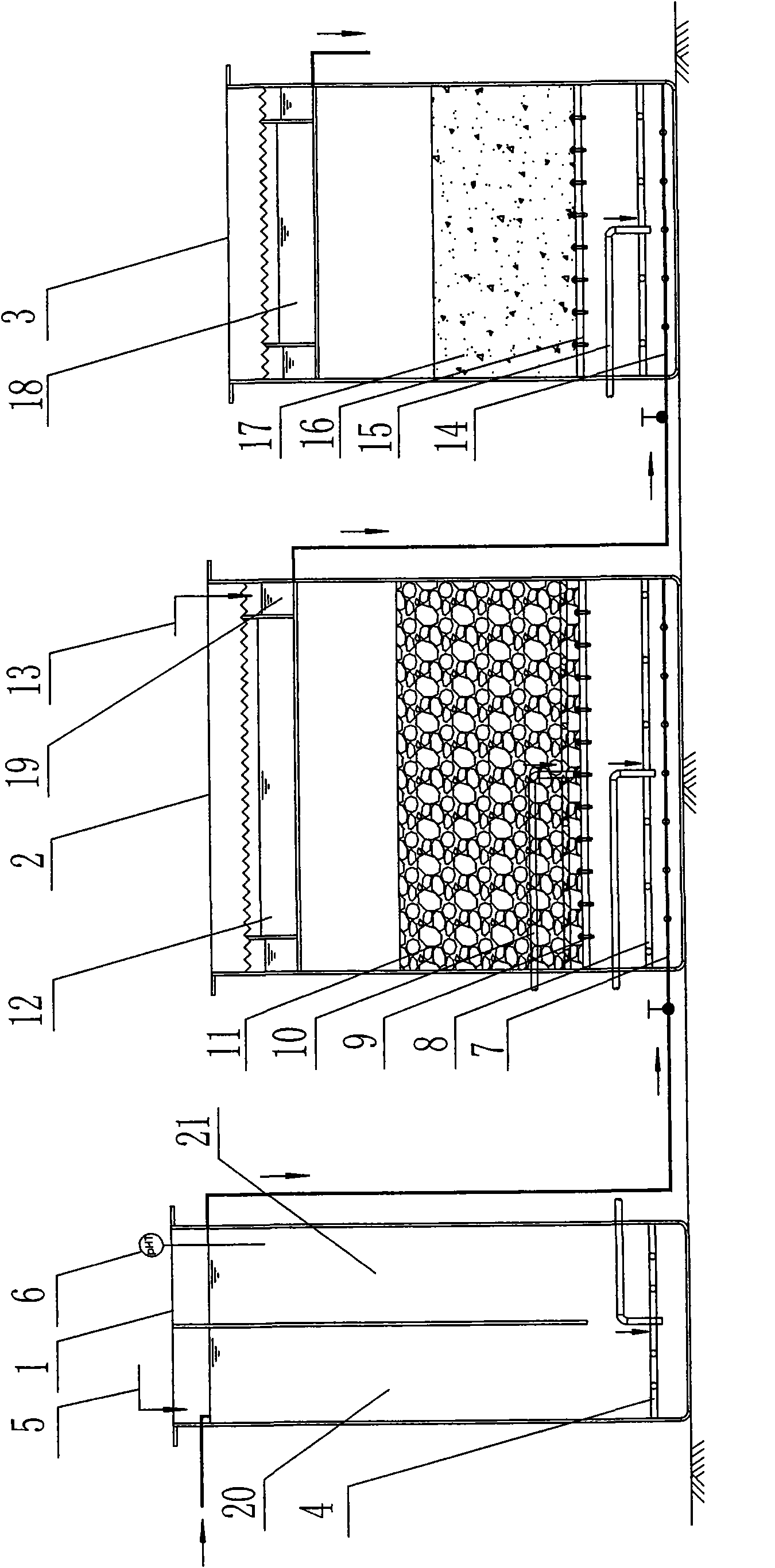

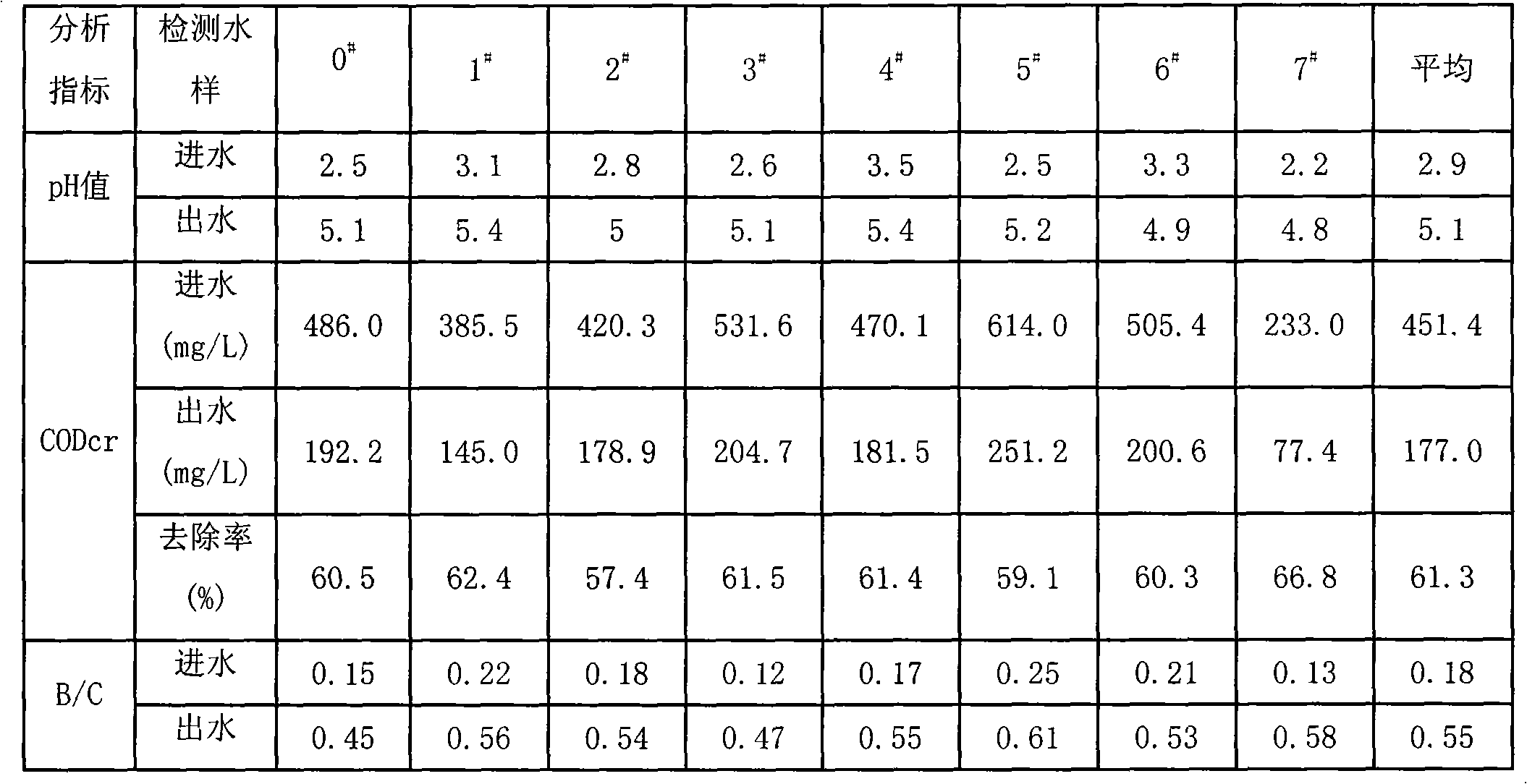

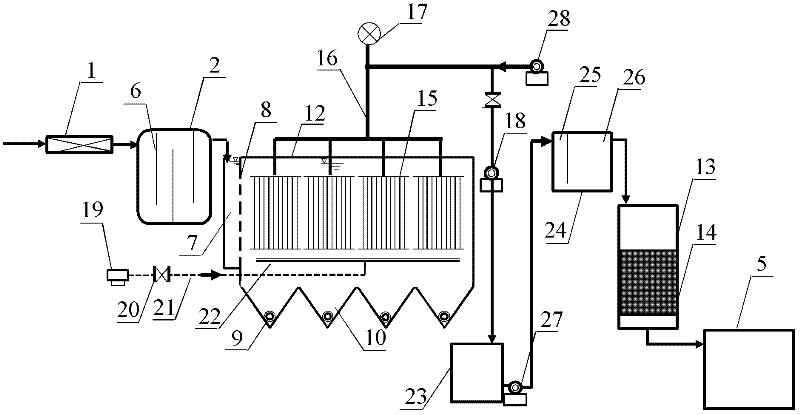

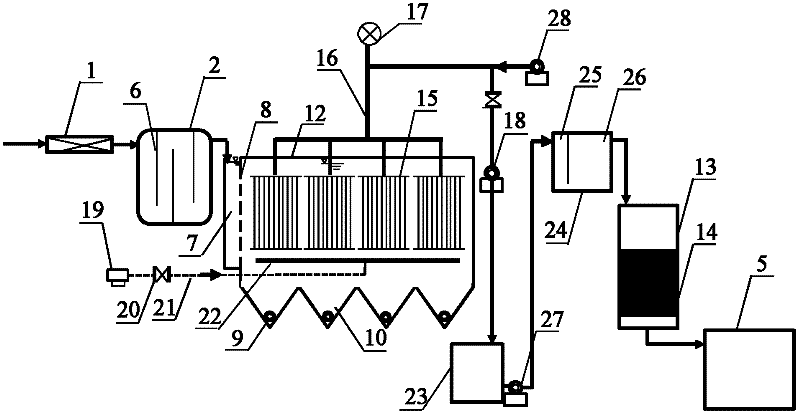

Method and device for multicomponent oxide pretreatment of organic electroplating waste water

InactiveCN101591082AImprove biodegradabilityGood water conditionsWaste water treatment from metallurgical processMultistage water/sewage treatmentPretreatment methodElectrolysis

The invention relates to a method and a device for multicomponent oxide pretreatment of organic electroplating waste water, which belong to the technical filed of electroplating waste water treatment in the environment engineering. The pretreatment method is characterized in that organic electroplating waste water is sequentially subjected to acidity adjustment, ferrum-carbon micro-electrolysis reaction and Fenton oxidation reaction. The corresponding device comprises a pH adjusting tank, a ferrum-carbon micro-electrolysis bath and a Fenton oxidation pond; an acid-alkali feeding device and a pH controller which are in link control are arranged above the pH adjusting tank; the middle low part of the ferrum-carbon micro-electrolysis bath is paved with a ferrum-carbon filler layer, while the bottom is provided with a micro-electrolysis bath perforation water distribution pipe; a hydrogen peroxide feeding device is arranged above the ferrum-carbon micro-electrolysis bath; the bottom of the Fenton oxidation pond is provided with a Fenton oxidation pond perforation water distribution pipe; and the middle lower part of the Fenton oxidation pond is provided with a granular active carbon catalytic carrier layer. The method and the device obviously improve the capability of biochemistry, simultaneously perform oxidation reaction to remove mostly organic pollutants and create favorable water inlet condition for subsequent coagulating sedimentation, air flotation and biochemical treatment.

Owner:CHINA COAL TECH & ENG GRP HANGZHOU ENVIRONMENTAL PROTECTION INST

Method for treating salt-containing sewage

ActiveCN101898844AEasy to handleTo achieve the effect of deep processingMultistage water/sewage treatmentWater/sewage treatment by neutralisationActivated sludgeCatalytic oxidation

The invention relates to a method for treating salt-containing sewage. The pH value of the salt-containing sewage is adjusted to between 8 and 12, the salt-containing sewage is biochemically treated by an activated sludge process, the effluent after the activated sludge process treatment is treated by an ozone-catalytic oxidation process adopting a solid catalyst, and the effluent after the ozone-catalytic oxidation process treatment is discharged through a biofilter; and in the ozone-catalytic oxidation process adopting the solid catalyst, the solid catalyst is granular activated carbon loaded with an active component which is one or more of tin, copper, manganese, titanium, cobalt, vanadium and nickel. The method can effectively purify the sewage which has high salt content and is refractory to biodegrade, and the effluent after treatment has the COD of less than or equal to 50 mg / L and the NH3-N of less than or equal to 8 mg / L, so that the strict sewage discharge standard of developed regions is met. The method has the advantages of simple treatment process, no need of sewage dilution, clean and clear effluent after treatment and realization of direct standard discharge.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing high specific surface area granular activated carbon by physical activation process

The invention provides a method for preparing grain active carbon with high specific surface area by a physical activation method, comprising the steps as follows: firstly, coconut shell is carbonized under high temperature; subsequently, the crushed and screened carbonization material is arranged in a microwave radiation device; by controlling activation temperature and adjusting activation time and activation gas flux, the raw material is activated so as to gain the grain active carbon product with the specific surface area more than 2200m<2> / g. The method utilizes high-temperature carbonization to improve the micro-pore structure of the carbonization material of the coconut shell, is beneficial for improving the orderly structure of the carbonization material of the coconut shell, reduces the burning of the carbon during the carbonization process and improves the yield of the active carbon product; the prepared active carbon is the grain active carbon, and the applicable range is improved.

Owner:KUNMING UNIV OF SCI & TECH

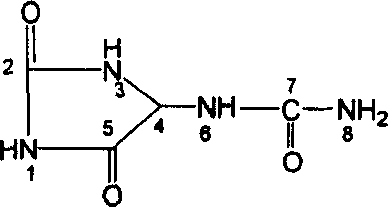

Preparation of allantoin and allantoin extract from cistanche salsa and their use thereof

An allantoin and the component containing said allantoin are extracted from cistanche through separation with macroreticular adsorption resin and granular activated carbon. Said allantoin can be used to decrease blood fat.

Owner:XINJIANG MEDICAL UNIV

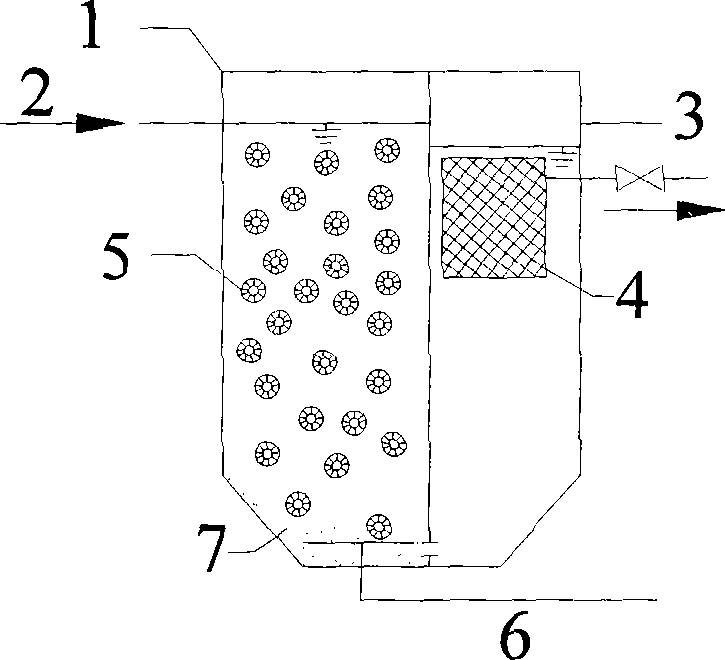

Reaction device for deep treatment of drinking water and method for deep treatment of drinking water by water factory

ActiveCN102336493ALarge amount of workIncrease the areaWater aerationWater/sewage treatment bu osmosis/dialysisUltrafiltrationWater treatment

The invention relates to the field of drinking water treatment, in particular to a reaction device for deep treatment of drinking water and a method for deep treatment of the drinking water by a water factory. In order to realize the goal of transforming the conventional drinking water treatment process into the deep treatment process, the reaction device and the method adopt the scheme that (1) a static mixer and a coagulation reaction pool are not changed; (2) a sedimentation pool is transformed into an ultrafiltration membrane pool; (3) a medium water pool and a lifting pump used for waterlifting are additionally arranged at the back end of the ultrafiltration membrane pool; (4) a main ozone oxidization pool is in additional arrangement; and (5) an original sand filter pool is transformed into a particular active carbon filter pool. The coagulation and the ultrafiltration are combined, particular colloid and macromolecular organic matters in the water are removed, difficult-to-degrade pollutants are damaged through ozone oxidization, in addition, the macromolecular organic matters are converted into middle and small molecular weight organic matters, and organic matters and pollutants such as ammonia nitrogen and the like in the water are further reduced through the absorption of particular active carbon and the biological degradation of microbes grown on the surface.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

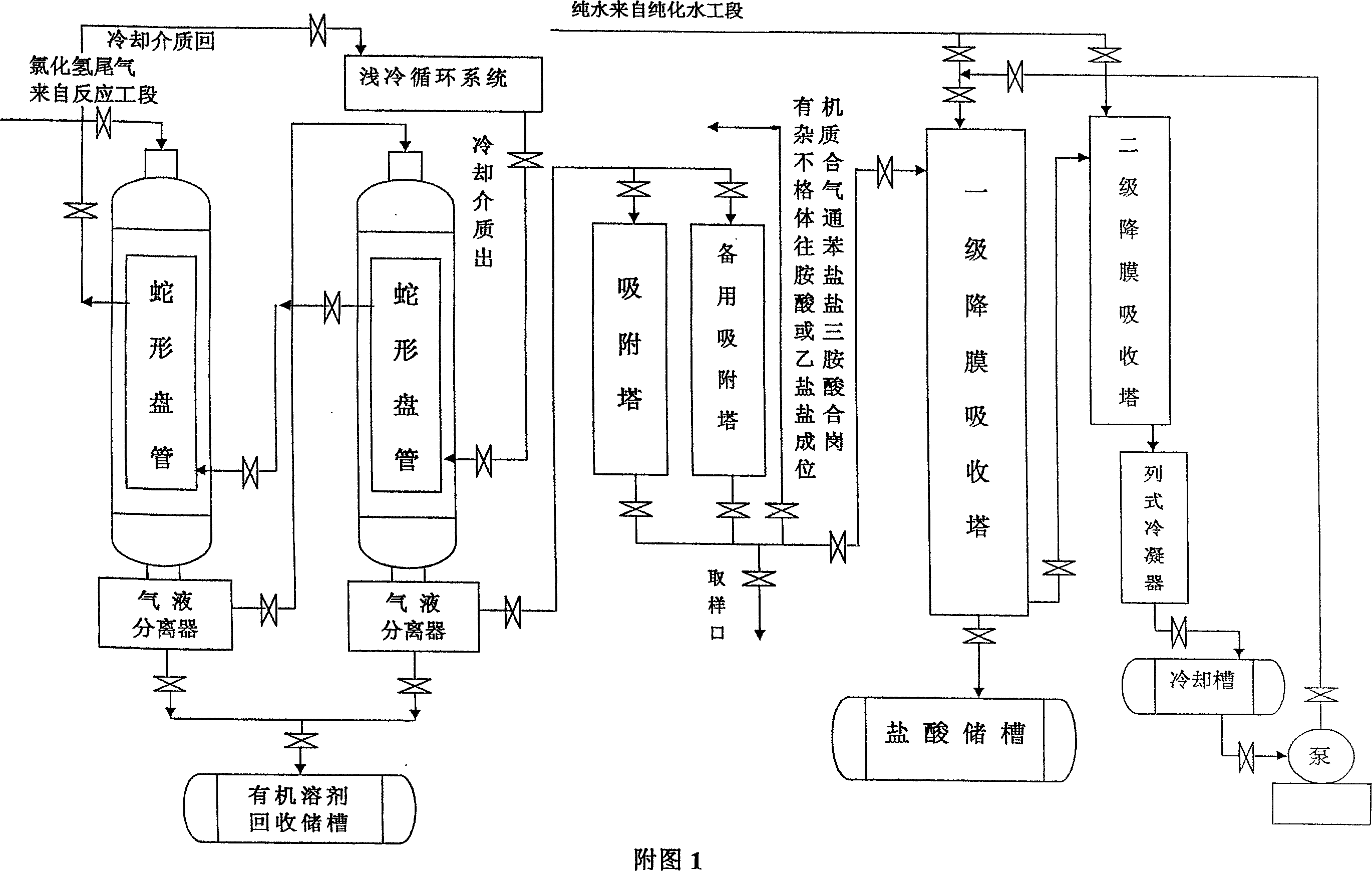

Process for preparing high purity hydrochloric acid by circularly absorbing hydrogen chloride by-product

InactiveCN1951801ASatisfied with the resultExpand the range of industrial applicationsChlorine/hydrogen-chloride purificationActive particlesPolypropylene

The invention discloses a preparing method of high-purity alcaine technology through circulating and adsorbing by-product of hydrogen chloride, which comprises the following steps: aerating hydrogen chloride gas with organic impurity in the condenser at -10- -40 deg.c and gas-liquid separator; adsorbing gas with little impurity through active particle charcoal; aerating adsorbed gas into one-grade and two-grade graphite falling-film; adsorbing through pure water to obtain the high-purity alcaine; adsorbing non-adsorbed hydrogen chloride through cold water; putting hydrogen chloride and diluted acid in the graphite polypropylene falling-film adsorbing tower into cooling groove; utilizing circulating pump to transmit the inlet of one-grade falling-film adsorbing tower; circulating the adsorption.

Owner:ZHEJIANG UNIV OF TECH

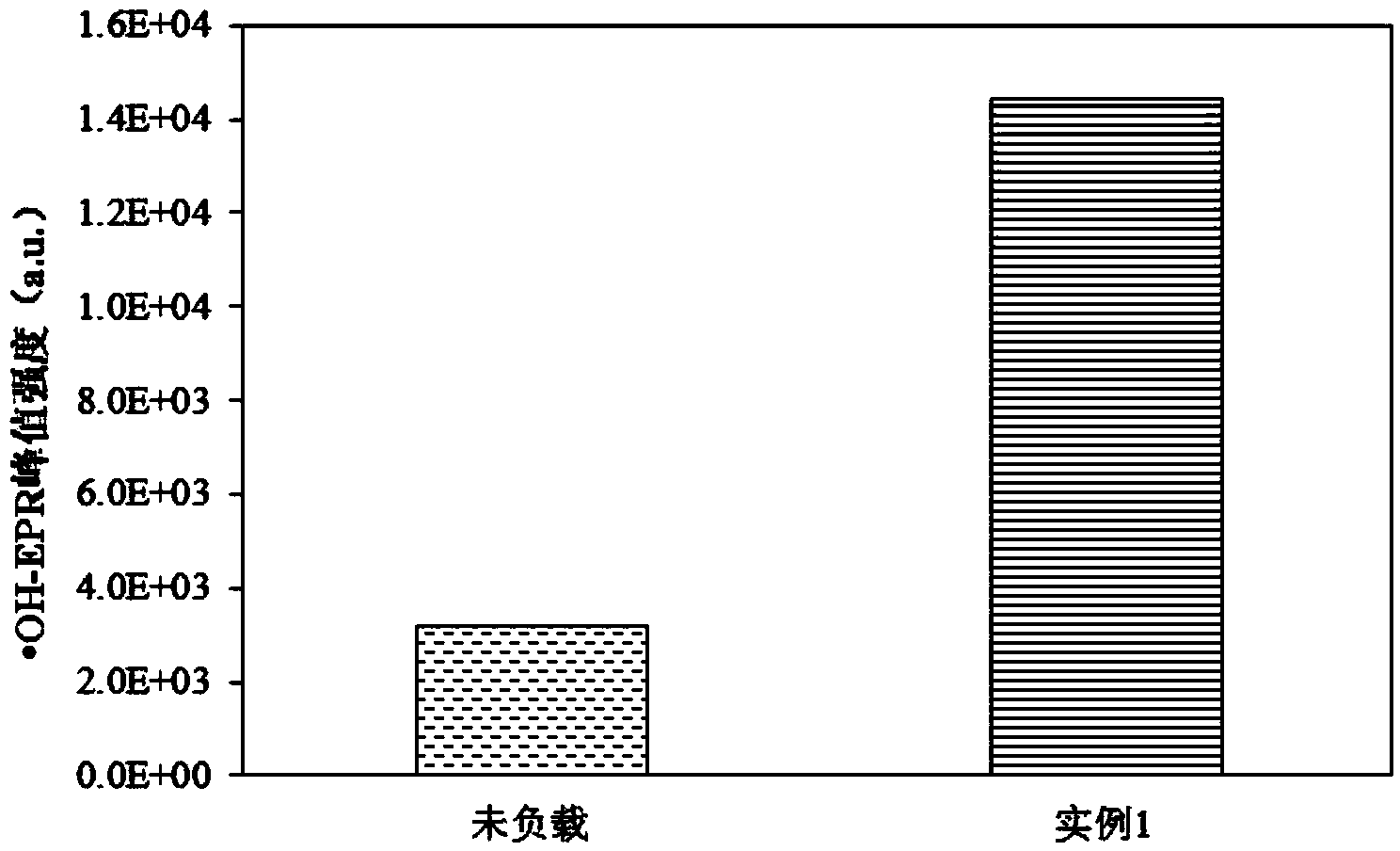

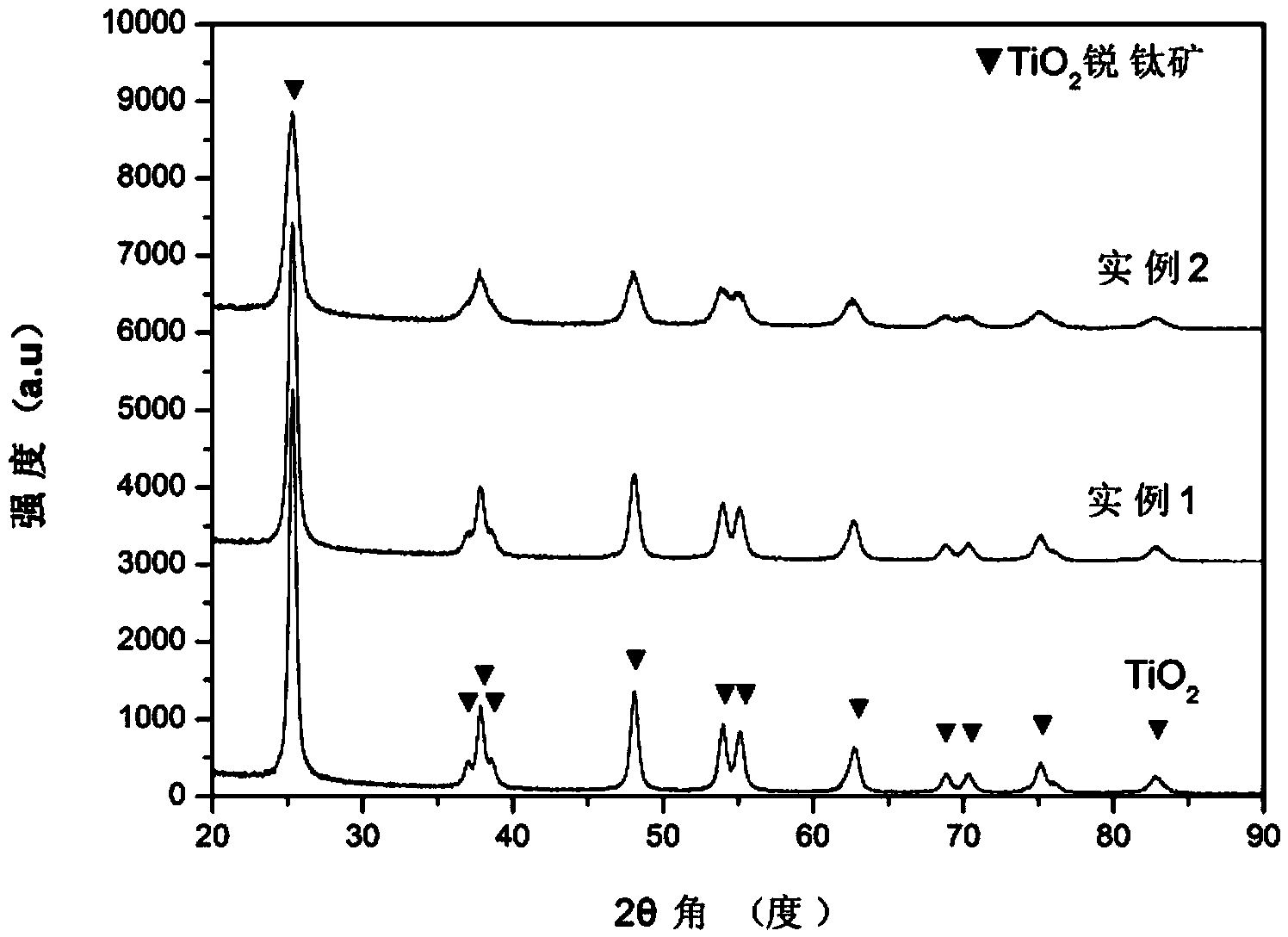

Three-dimensional particle electrode loaded with catalyst active carbon and preparation method thereof

ActiveCN103663631AIncrease productionImprove structural stabilityWater contaminantsWater/sewage treatmentThree dimensional electrodeSolid solution

The invention discloses a three-dimensional particle electrode loaded with catalyst active carbon and a preparation method thereof. The electrode consists of particle active carbon and a TiO2 solid solution compound catalyst which is loaded on the particle active carbon and is doped with Sn and Sb elements. The method comprises the steps of particle active carbon pretreatment, catalyst preparation, soaking for aging, drying and roasting for activating. The three-dimensional particle electrode loaded with the catalyst active carbon prepared with the method has the characteristics of high pollutant removing rate, high electrocatalytic activity, high yield of hydroxyl radicals, little loss of a catalyst and the like; moreover, the preparation method is simple, noble metal catalysts are not used, used raw materials are widely available, the manufacturing cost is low, and secondary pollution is avoided. When the three-dimensional particle electrode loaded with the catalyst active carbon prepared with the method is applied to a three-dimensional electrode reactor, non-biodegradable organic waste water can be treated efficiently.

Owner:TSINGHUA UNIV

Photoelectric catalysis degrading organic reactor with swivel disc loaded with catalyst and degrading method

InactiveCN101327968AKeep aliveInhibitory complexWater/sewage treatment by irradiationWater/sewage treatment by electrochemical methodsUltravioletOxygen

The invention discloses a reactor for photoelectrocatalysis degradation of organic compounds using a rotary table supported with a catalyst, and a method for degrading the organic compounds by the reactor. The reactor comprises a rotary table supported with a photo-electro catalytic activity catalyst as the anode of the reactor, a motor driving the rotary table to rotate, a conductive granular activated carbon which can electrically catalyze the oxygen to generate hydrogen peroxide as the cathode, an ultraviolet or visible light source arranged in the reactor. The hydrogen peroxide generated from the activated carbon cathode forms hydroxyl radical under the action of the ultraviolet and degrades the organic compounds around both the anode region and the cathode region; the application of the rotary table avoids the light adsorption of the solution and accelerates the transfer of oxygen in the solution, which obviously improves the catalysis degradation efficiency of the refractory organic compounds.

Owner:GUANGDONG UNIV OF TECH

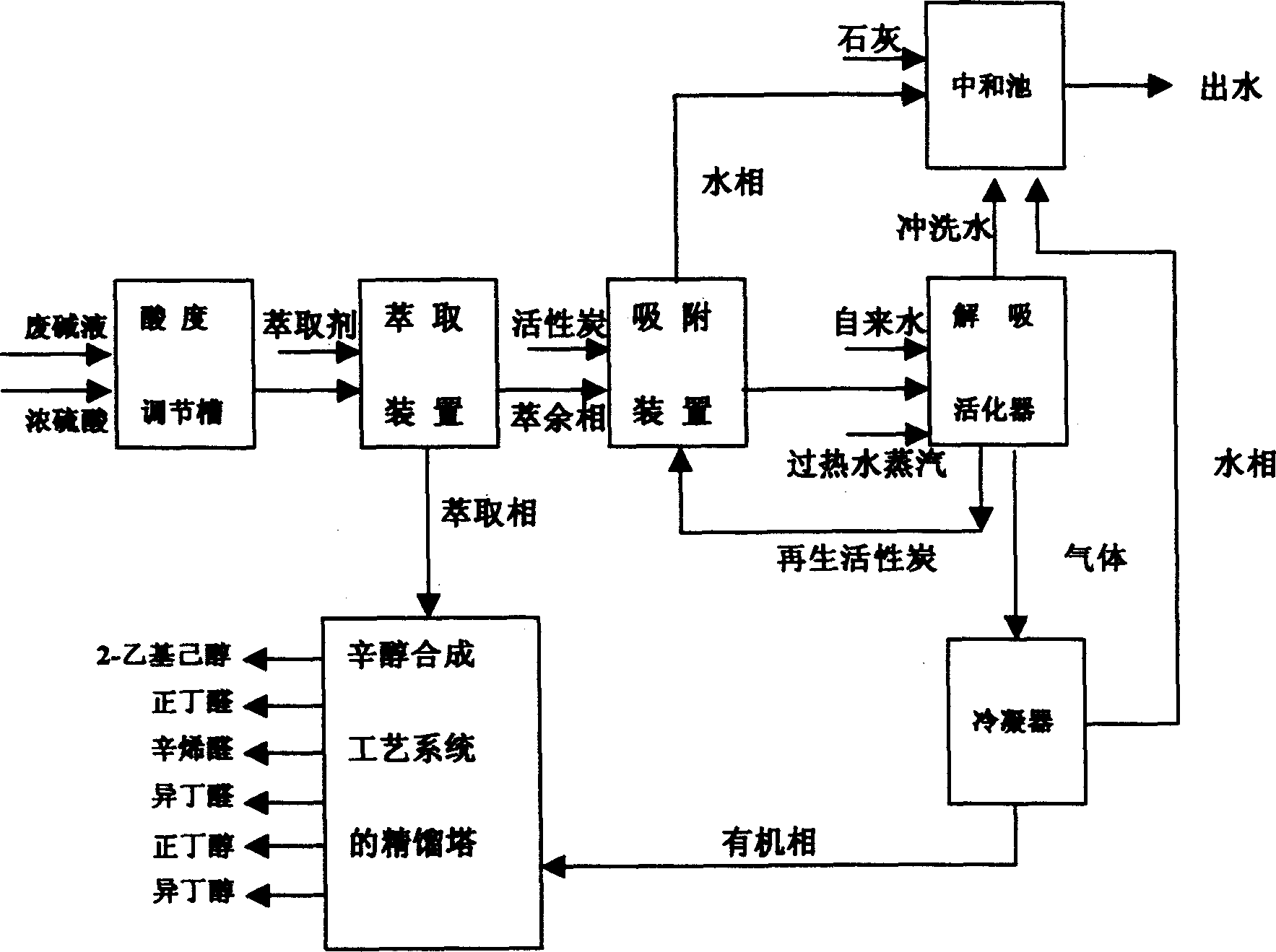

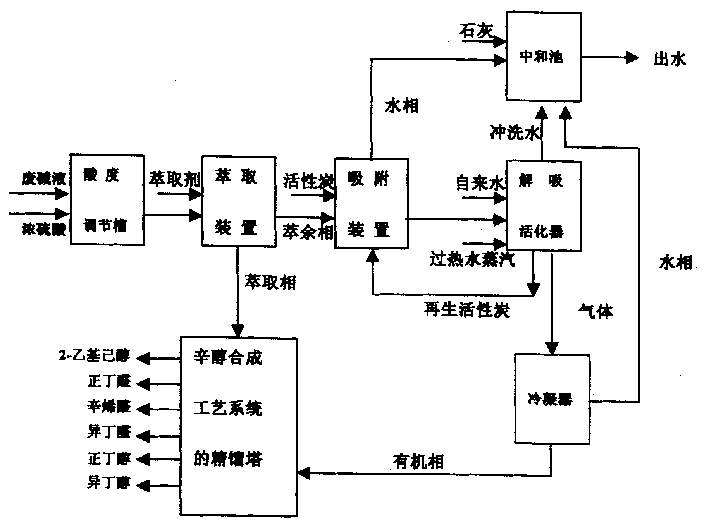

Treatment process for two stage recycling alkali waste liquid drained off by process system of synthesizing octanol

InactiveCN1462729AReduce liquiditySave investment costMultistage water/sewage treatmentWater/sewage treatment by neutralisationProcess systemsWastewater

A two-stage process for reclaiming the waste alkaline solution discharged by octanol synthesizing system includes "after-heat self-extracting" and "activated carbon adsorption" stages, that is, usingthe afterheat and inorganic acid to acidify the waste alkaline solution, extracting the organic components from waste solution by 2-ethylhexanol as the product of said octanol synthesizing system, adsorbing the residual phase by granular activated carbon, neutralizing by alkali, biochemical treating, and regenerating the used activated carbon. Its advantagesa re high effect etc.

Owner:SHANGHAI JIAO TONG UNIV

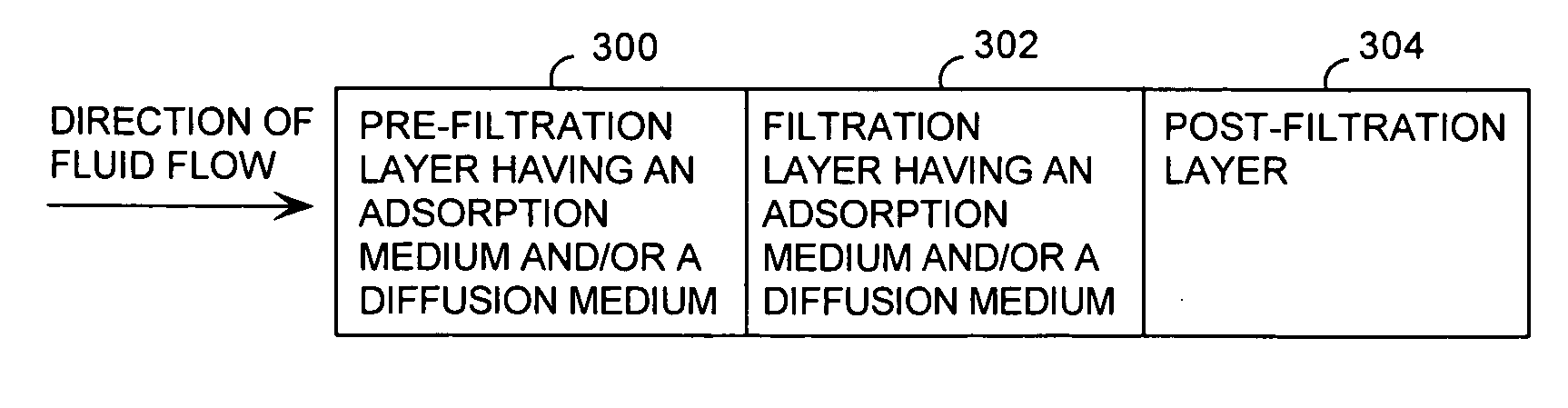

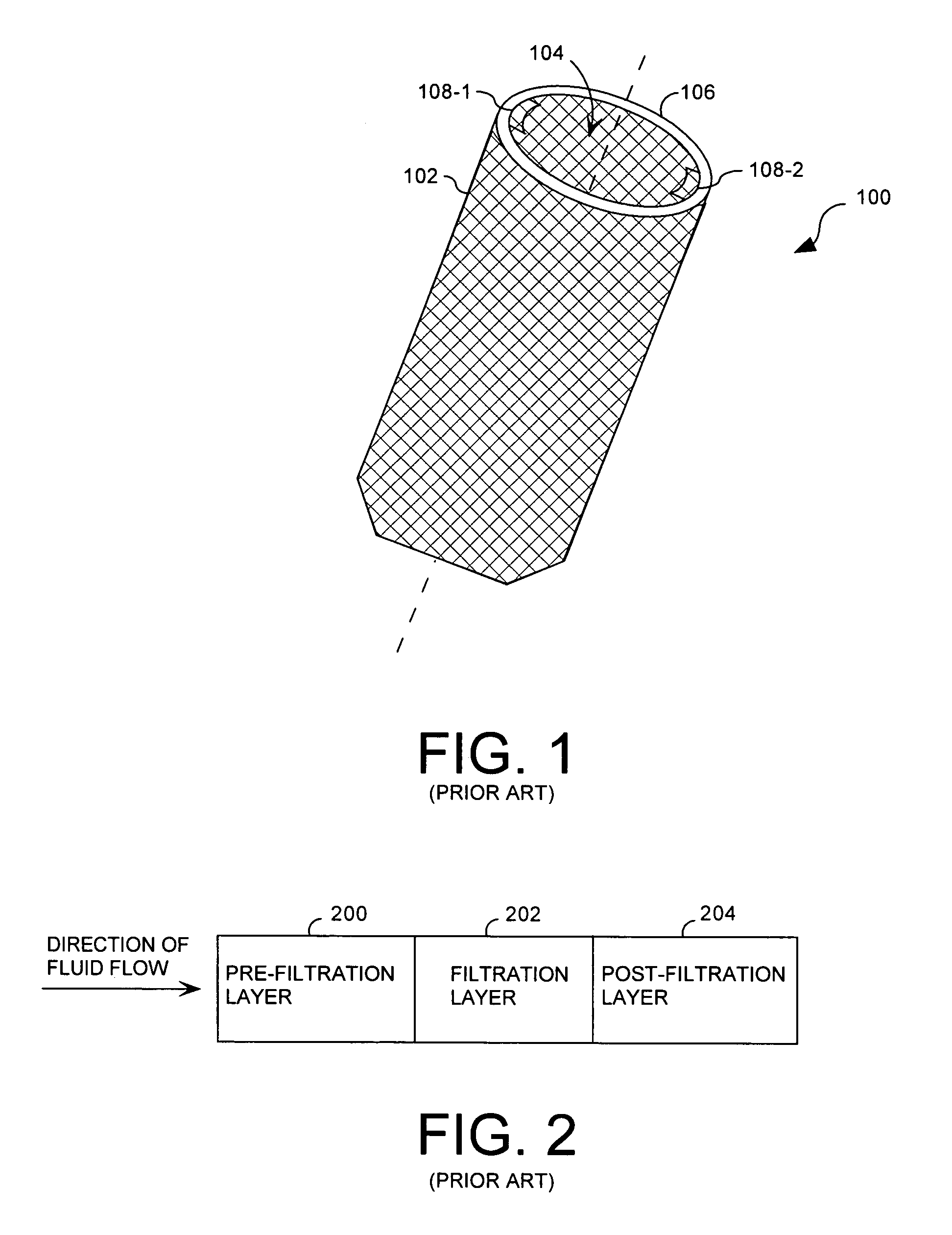

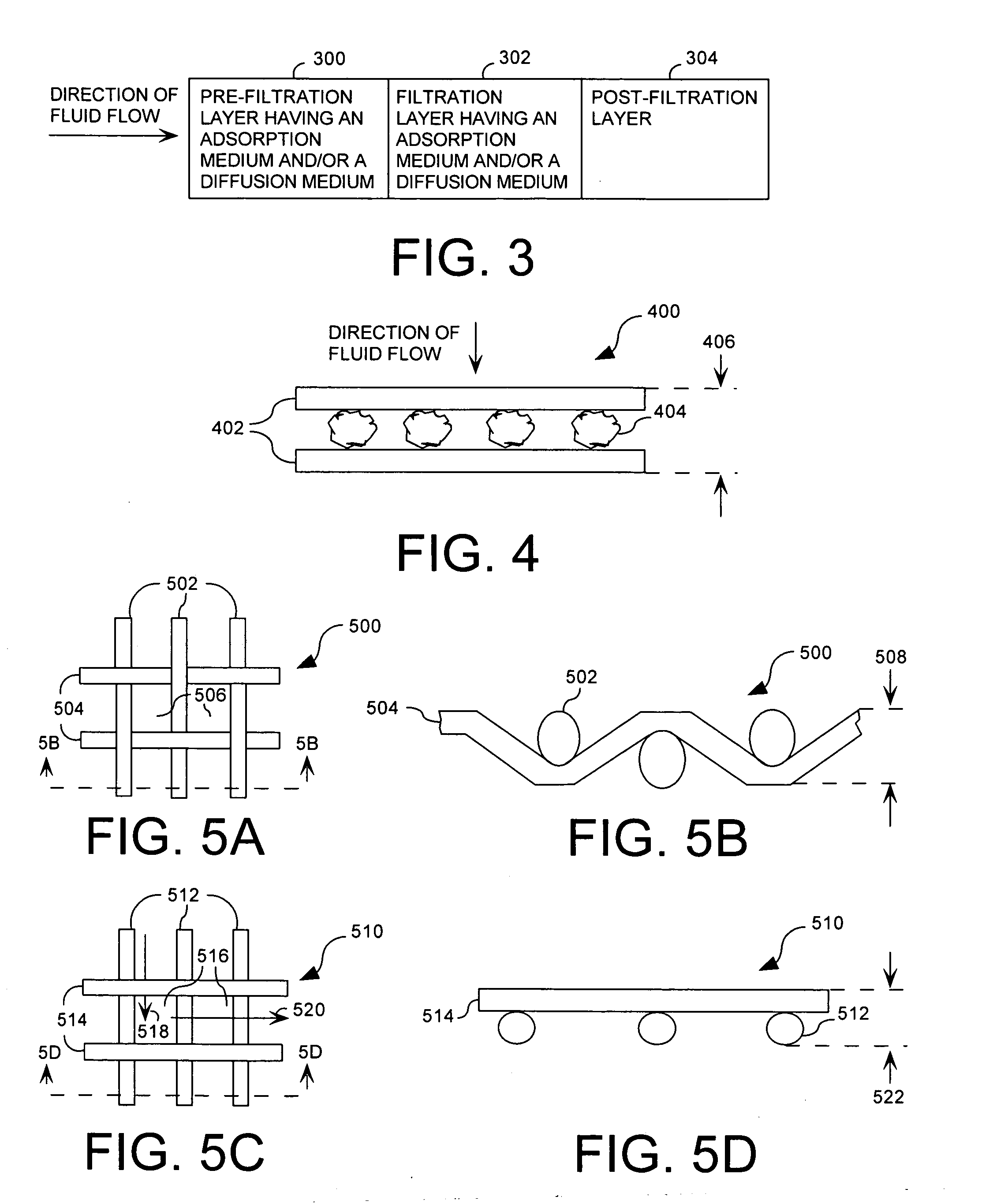

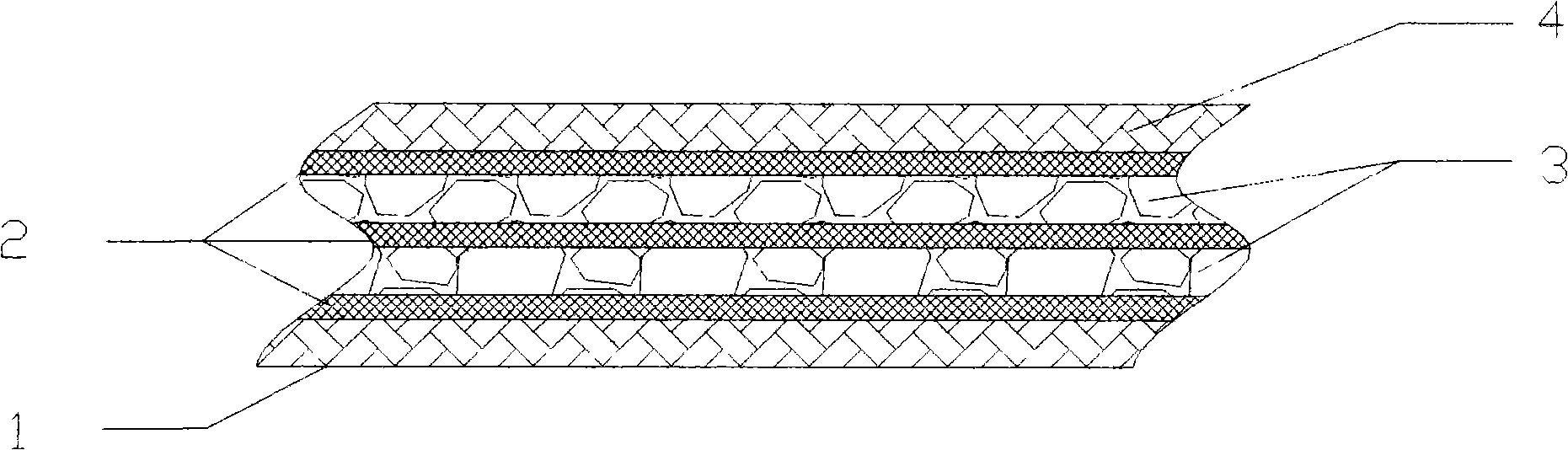

Filtration architecture for optimized performance

A filter bag for use in a liquid filtering system is provided. The filter bag comprises a filtration layer. The filtration layer is defined by one or more filter mediums. The filter mediums can be composed of an adsorbent material disposed between two thin wall substrates. The adsorbent material can be a granular activated carbon. The thin wall substrates can be selected to be highly porous thin wall substrates. The filter bag can further comprise one or more diffusion mediums. The diffusion mediums can be defined by a woven or a non-woven mesh material. The mesh material can be selected from a suitable material that is temperature and fluid compatible with the filtering application to be carried out. The filter bag can include alternating layers of medium having one or more filter mediums and one or more diffusion mediums.

Owner:MECHANICAL MFG

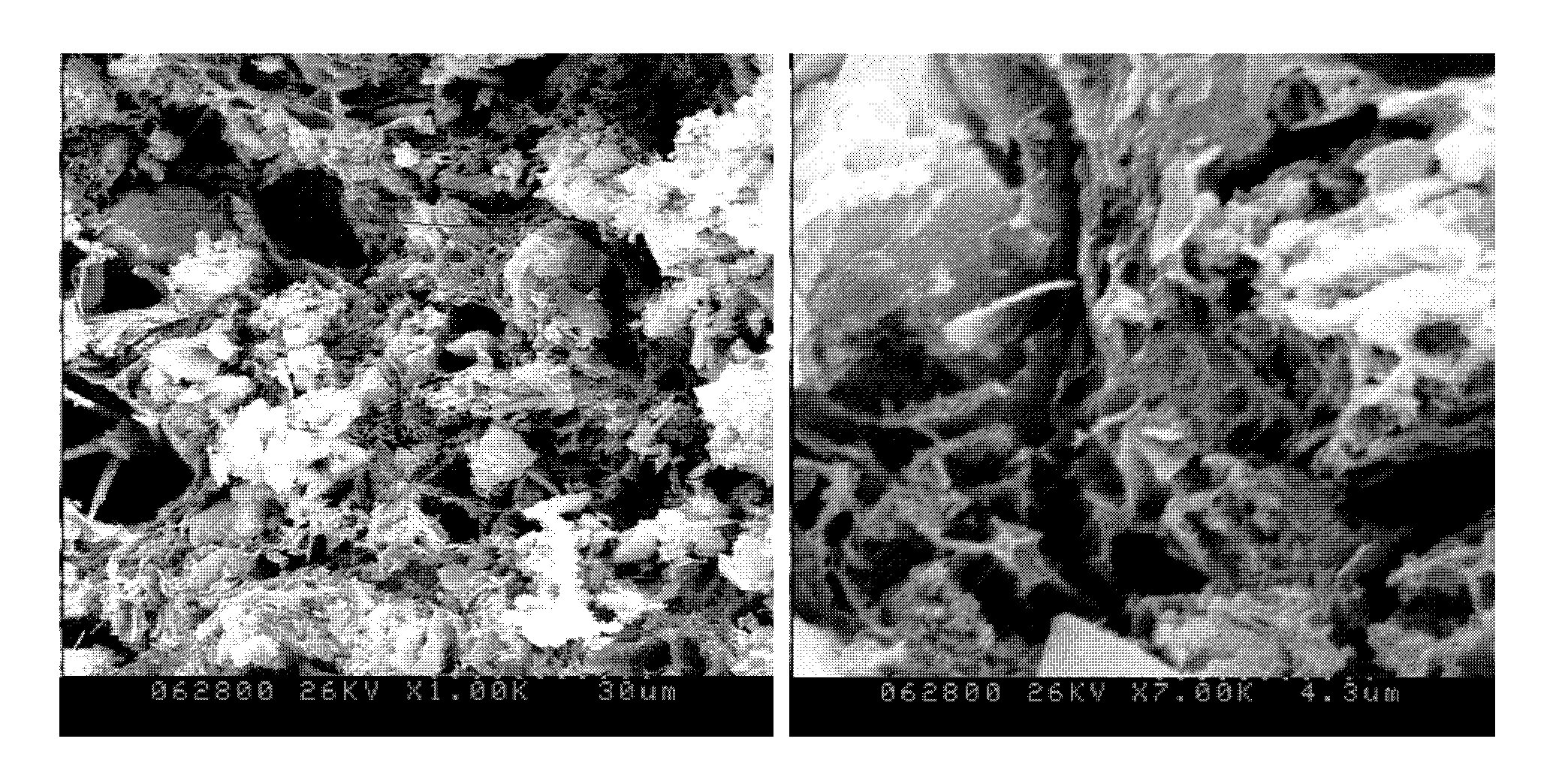

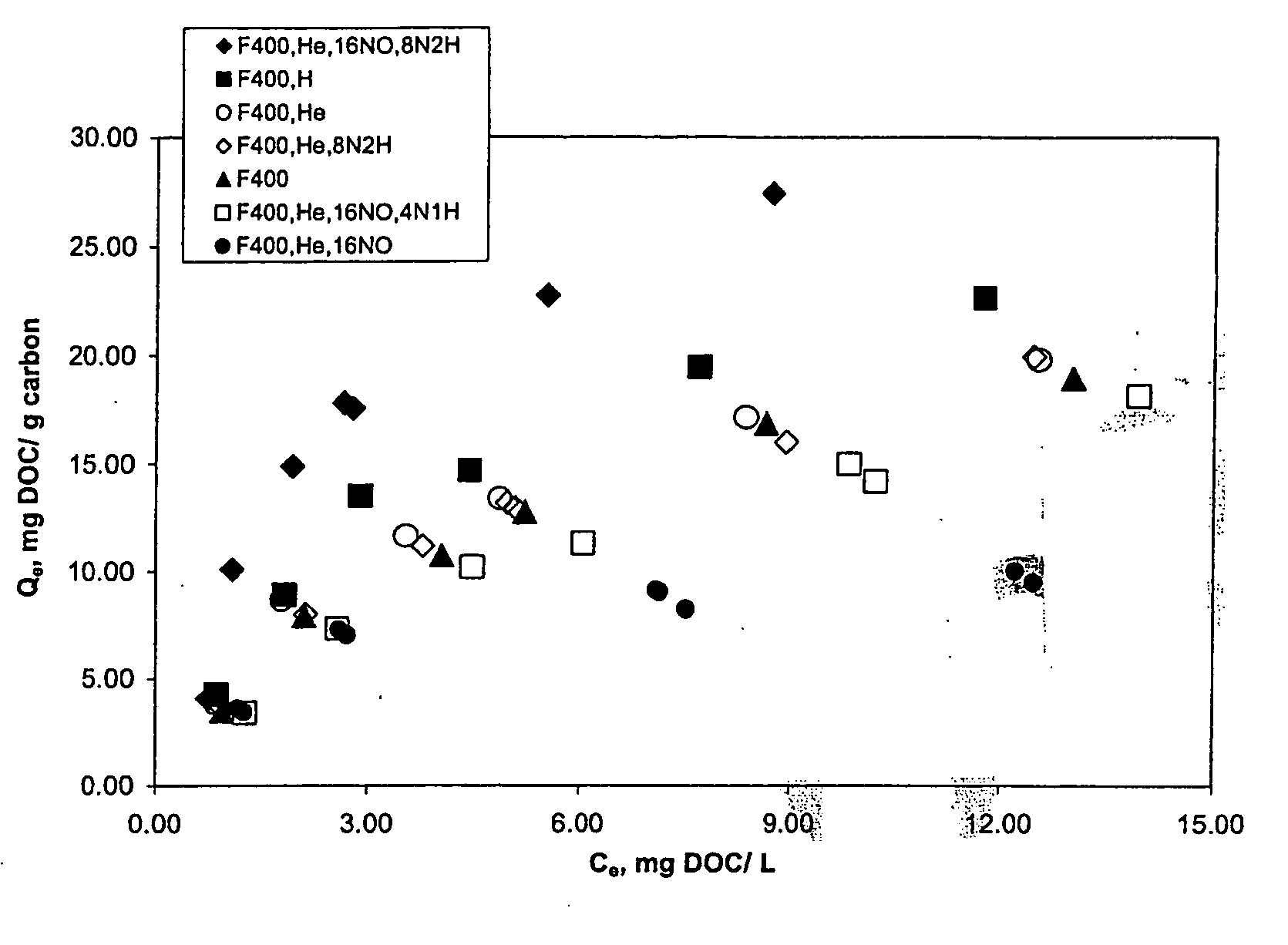

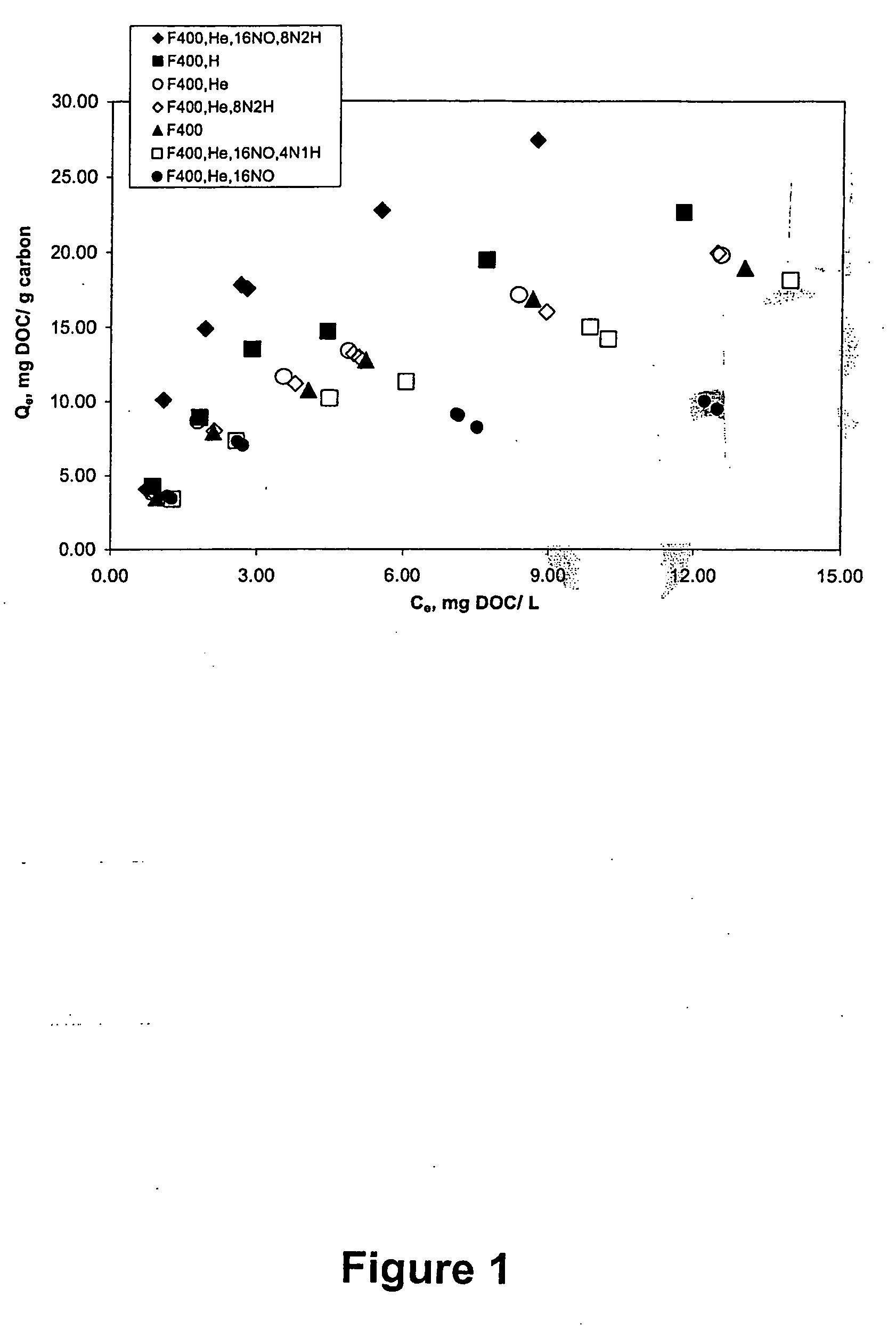

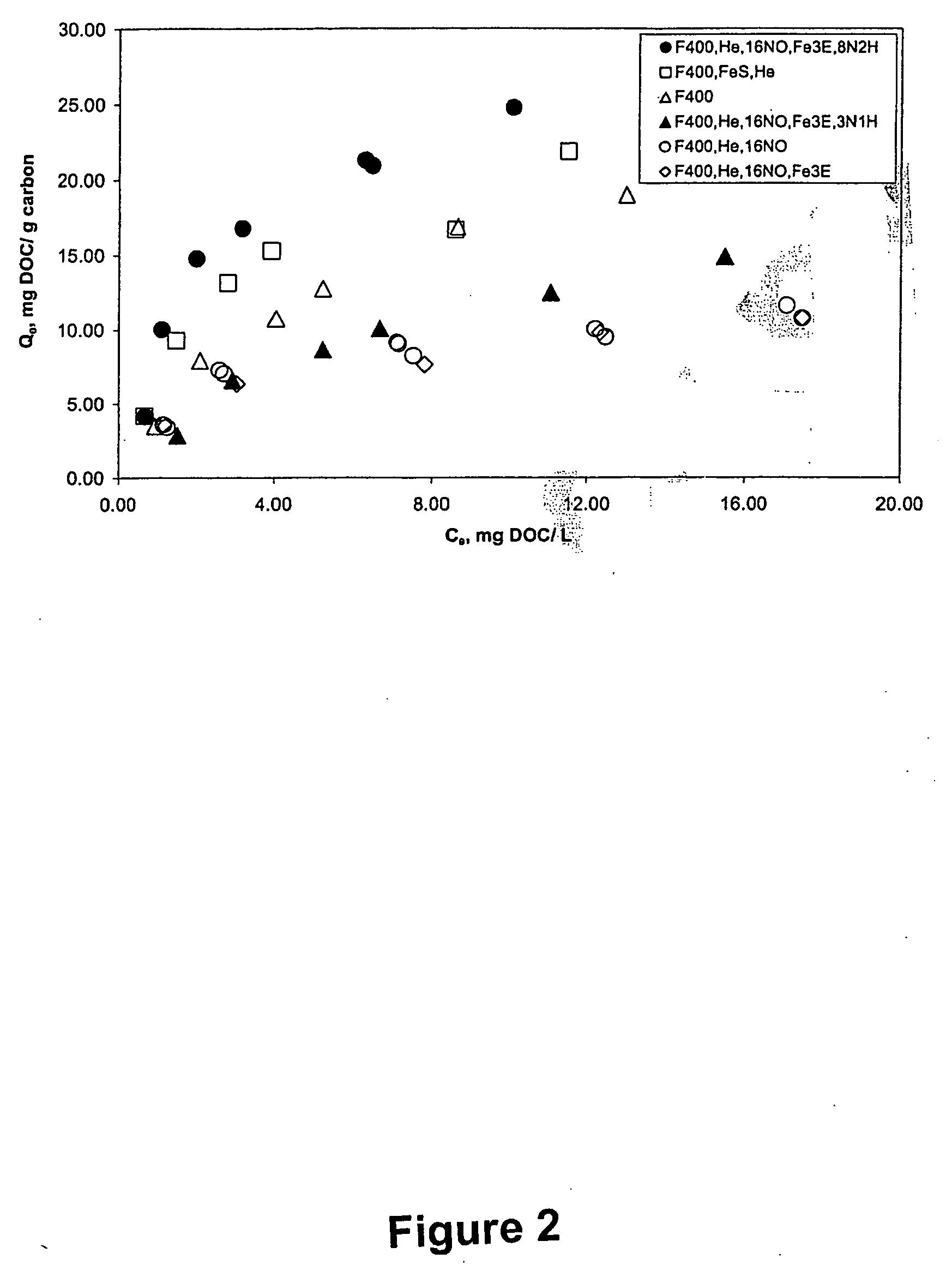

Activated carbon exhibiting enhanced removal of dissolved natural organic matter from water

InactiveUS20060157419A1Increase surface areaIncrease volumeSolid sorbent liquid separationWater/sewage treatment by sorptionNatural organic matterMedicine

Owner:CLEMSON UNIV RES FOUND

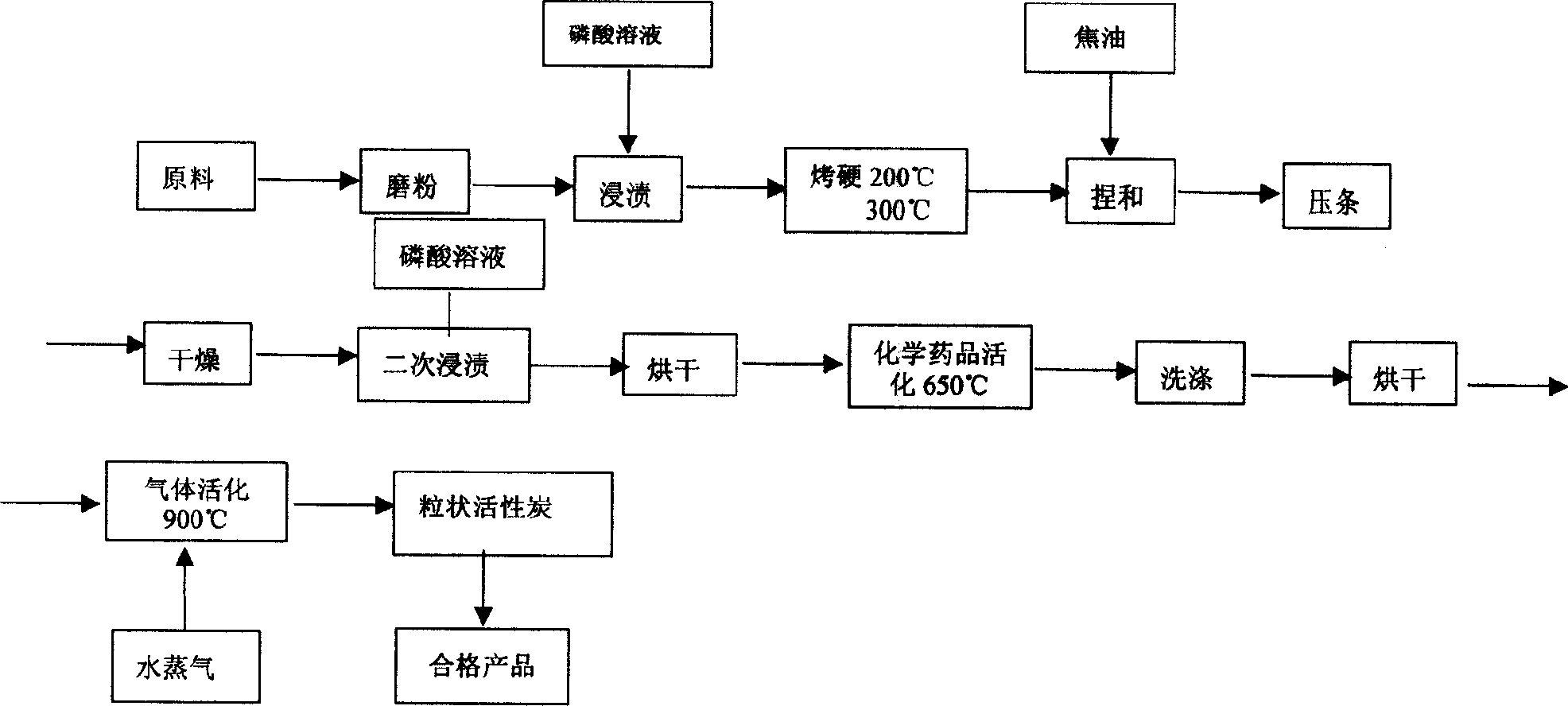

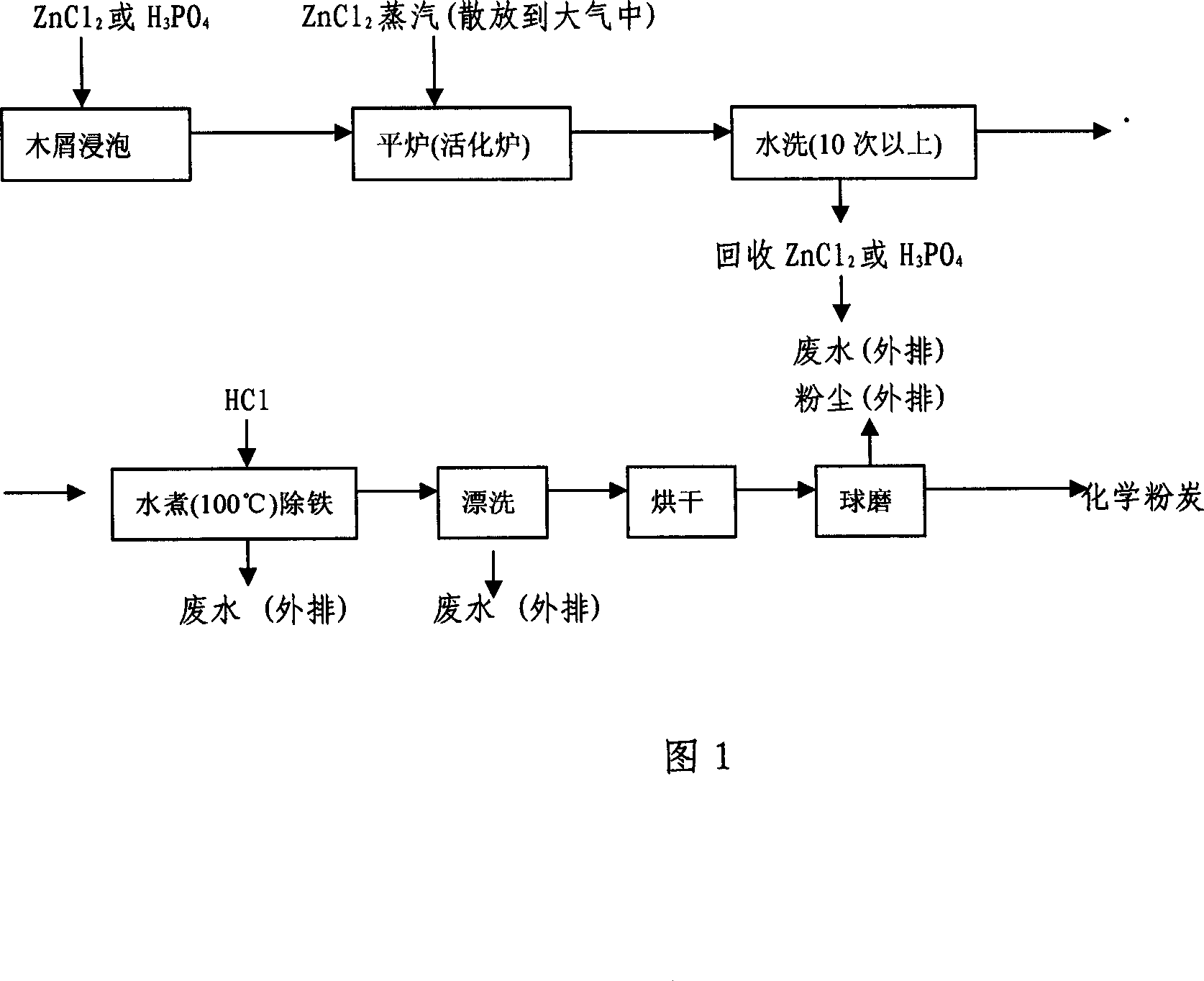

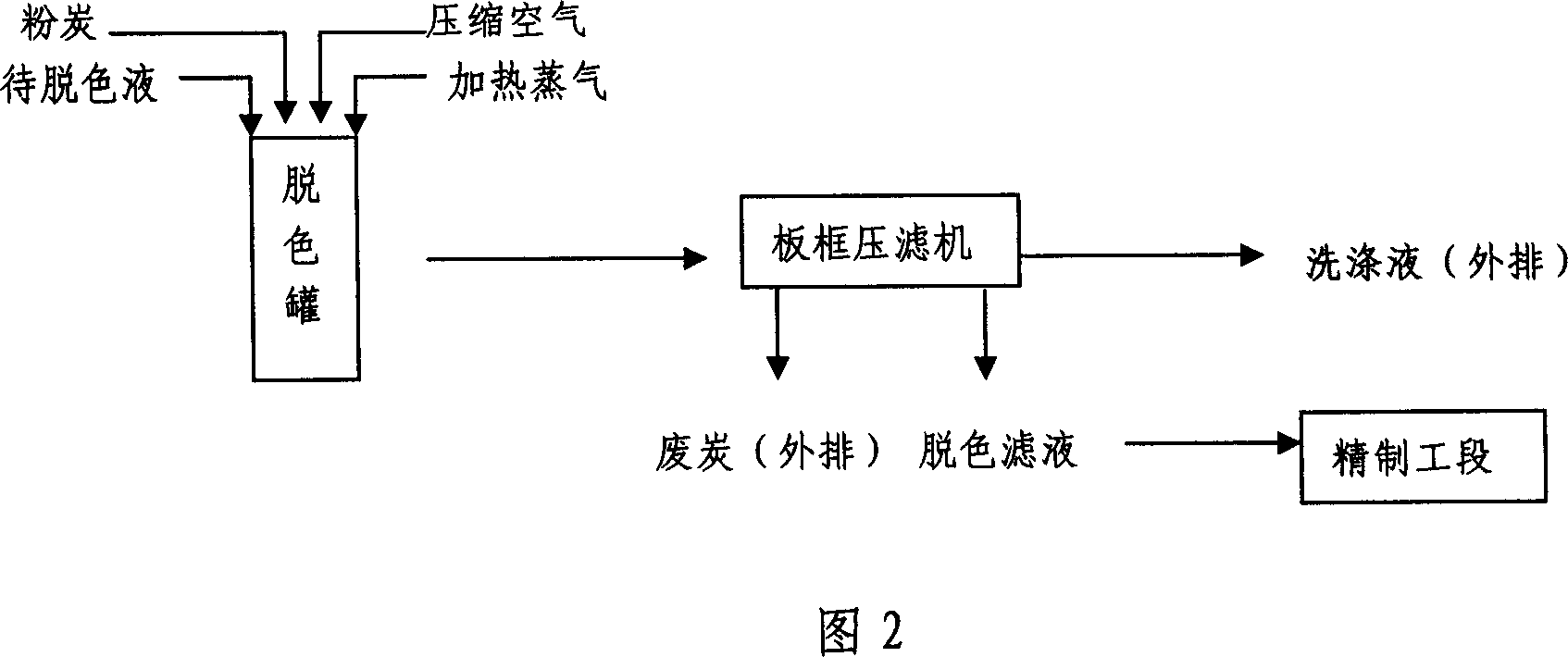

Granule decoloration active carbon and preparation method thereof

ActiveCN101054176AExcellent ability to remove macromolecular pigmentsGood decolorizationOther chemical processesActivation methodPhosphoric acid

The present invention relates to special active carbon for caramel decolorization and the preparation method thereof. The solid nutshell or coal serves as raw material which is processed by a physical chemistry immersion activation method to create active carbon. The immersion liquid is a water solution mainly comprising phosphoric acid, sodium hydroxide, magnesia and zinc chloride, wherein the proportioning by weight of each component is phosphoric acid: sodium hydroxide: magnesia: zinc chloride = 1:0.8~2.0:0.5~1.0:1~1.5. The obtained active carbon has an iodine value of 800~1000 mg / g, a caramel decolorization ratio of 80~100%, and a mechanical strength of 95%. The material is subjected to carbonizing, immersing, drying and activating treatment to create the active carbon product. The active carbon of the present invention has excellent decolorization property for macromolecule pigment, higher mechanical strength as general physical carbon, and wide application range. The traditional powdery carbon is replaced by granular activated carbon, the decolorizing pot is replaced by decolorizing column, the active carbon is changed from the disposable usage to the repeated and regenerated usage, and the decolorizing system can be continuously operated for a long time.

Owner:CHAOYANG SHENYUAN ACTIVE CARBON

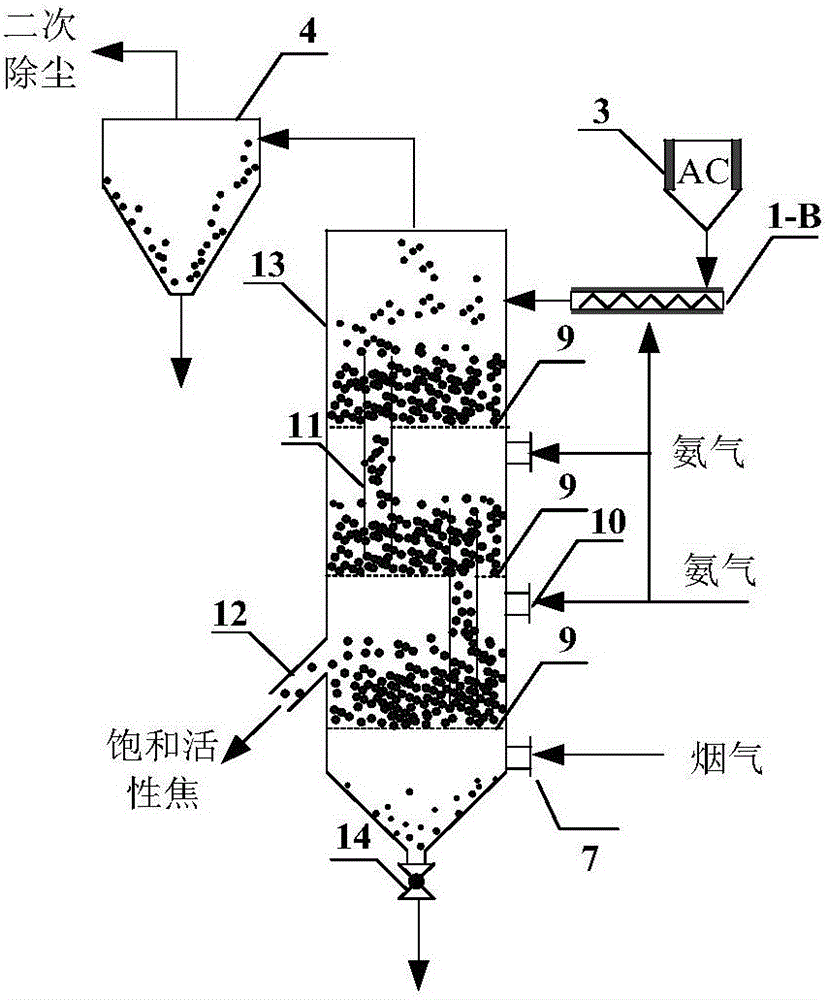

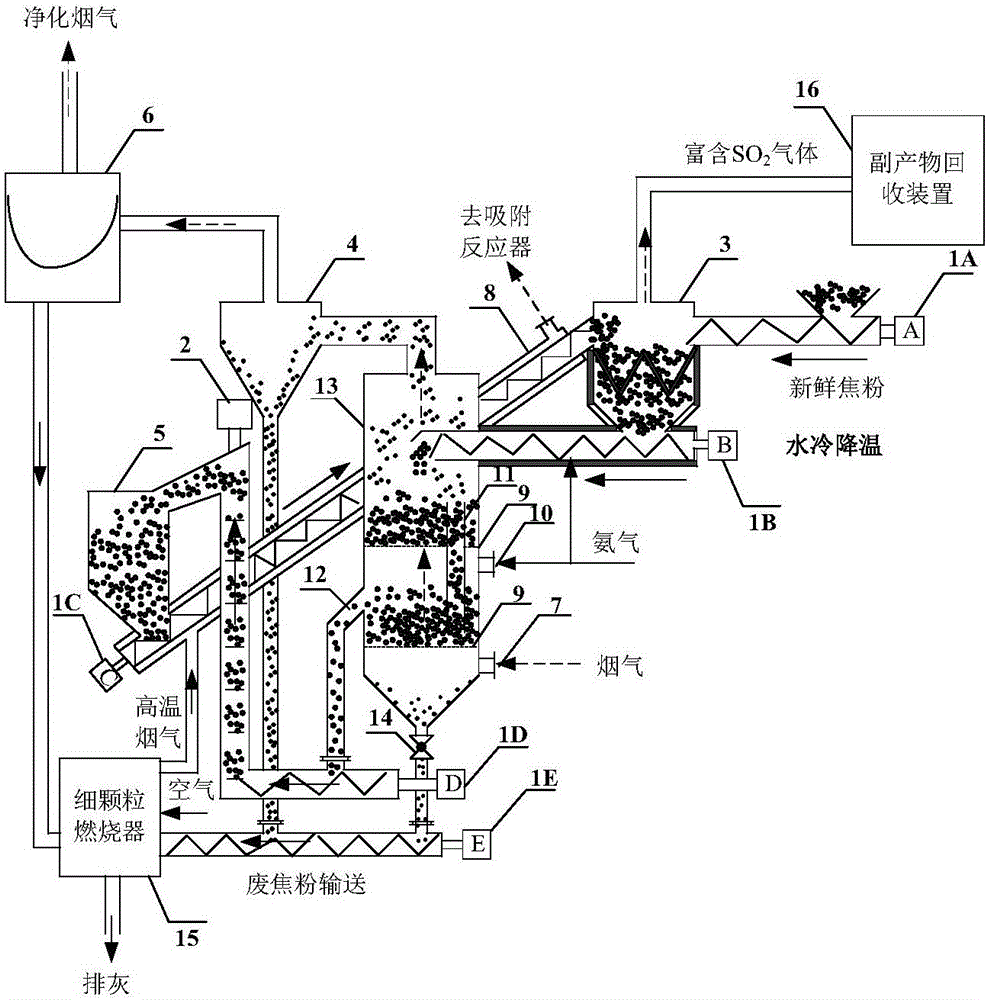

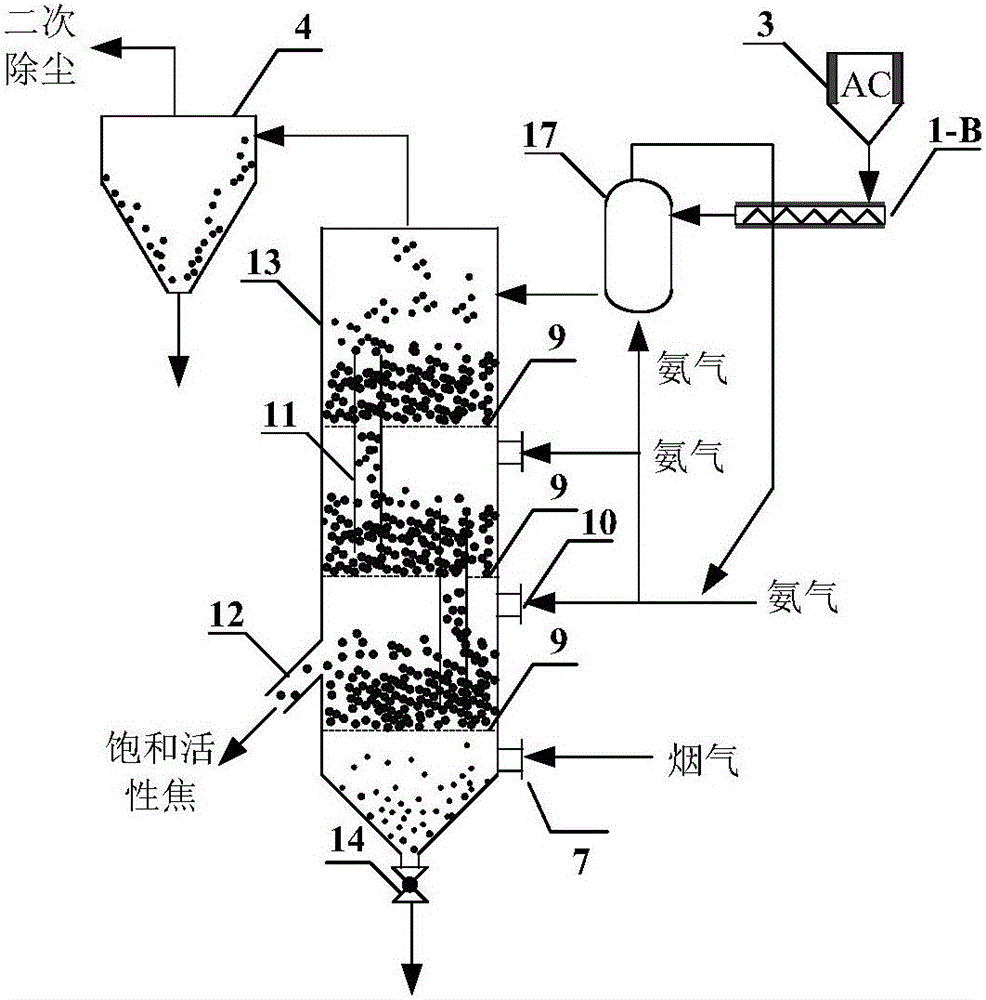

Multi-layer fluidized bed two-stage activated carbon/coke flue gas simultaneous-desulfurization and denitrification system and method

ActiveCN105727708ASave spaceEfficient use ofGas treatmentDispersed particle separationInjection portFluidized bed

The invention relates to the field of industrial flue gas pollution control. A multi-layer fluidized bed two-stage activated carbon / coke flue gas simultaneous-desulfurization and denitrification system of the invention comprises a dust removal device (4) and further comprises a desulfurization and denitrification multi-layer fluidized bed reactor (13), wherein a feed port of the dust removal device (4) is communicated with the top of the desulfurization and denitrification multi-layer fluidized bed reactor (13); the desulfurization and denitrification multi-layer fluidized bed reactor (13) is divided into an upper denitrification section and a lower desulfurization section; the denitrification section comprises several layers of fluidized beds; an ammonia gas injection port (10) is formed in a side wall corresponding to a position below the bottom of each layer of fluidized bed; the desulfurization section comprises several layers of fluidized beds; a flue gas inlet (7) is formed in the side wall corresponding to the position below the bottom of a lowest layer of fluidized bed. The system provided by the invention can enhance the mass transfer and heat transfer, improve the efficiency of desulfurization and denitrification, replace high-cost formed activated carbon / coke with fine granular activated carbon / coke to reduce the costs for desulfurization and denitrification, and is suitable for the flue gas purification of power plant boilers, industrial boilers, heating boilers and coking industry.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

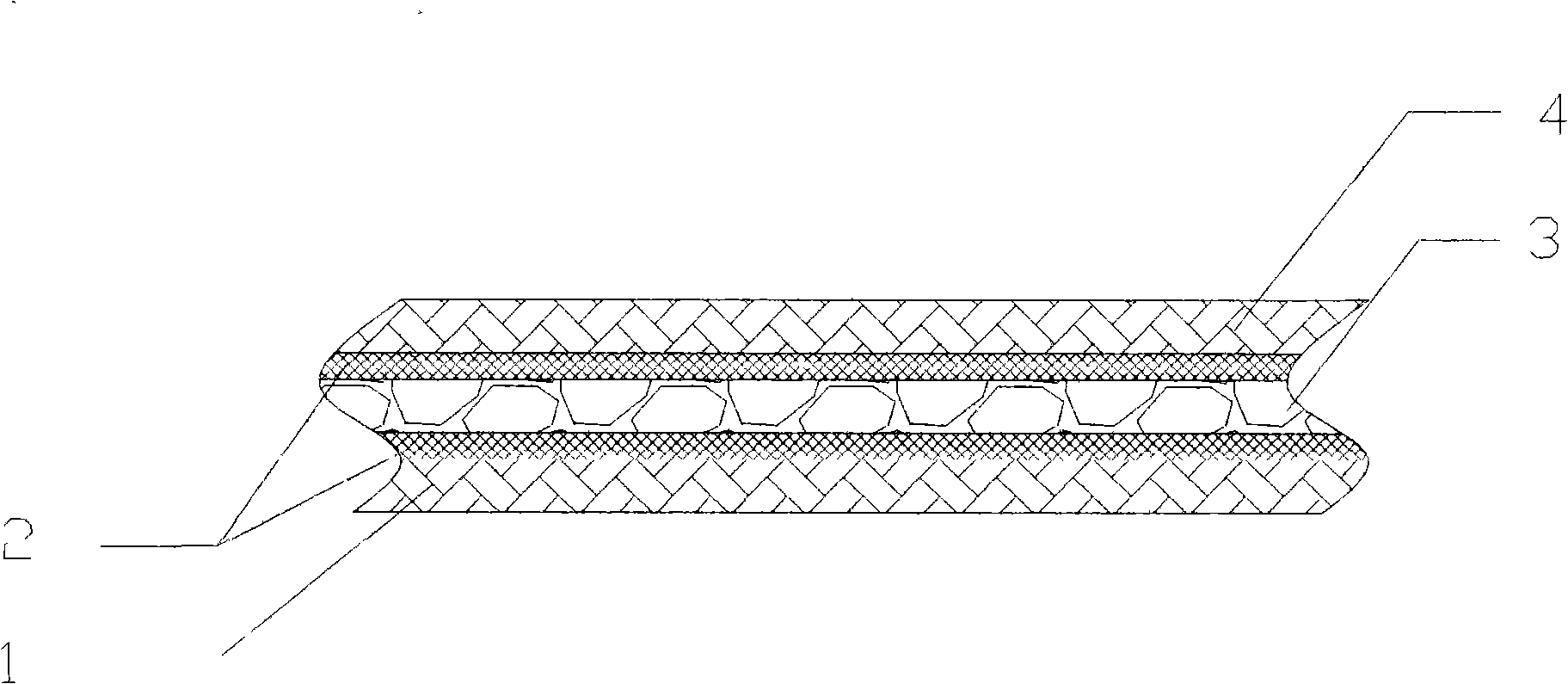

Filter material

InactiveCN101332385AGuaranteed low resistance requirementsImprove adsorption capacityLayered productsFiltration separationAir filterEnvironmental engineering

The invention discloses a filtering material, which more particularly relates to a material of an air filter applied to a central fan system; the material mainly includes an upper layer of non-woven fabrics and a lower layer of non-woven fabrics which are taken as base material as well as one or a plurality of composite layer(s) that is / are compounded between the upper and lower layers of non-woven fabrics; the material is characterized in that the composite layer(s) is / are composed of a granular activated carbon layer which is wrapped between two layers of nemaline cementing compound, and the granular activated carbon layer is formed by spreading independent activated carbon granules; the filtering material not only is not only efficient and has low resistivity, but also maintain the adsorption performance of the original activated carbon; furthermore, the hardness and stiffness of the general filtering material used for ventilation are kept, and the humdrum form of a chemical air filter is changed, so that the filtering material has the form of the general filtering material used for ventilation.

Owner:烟台宝源净化有限公司

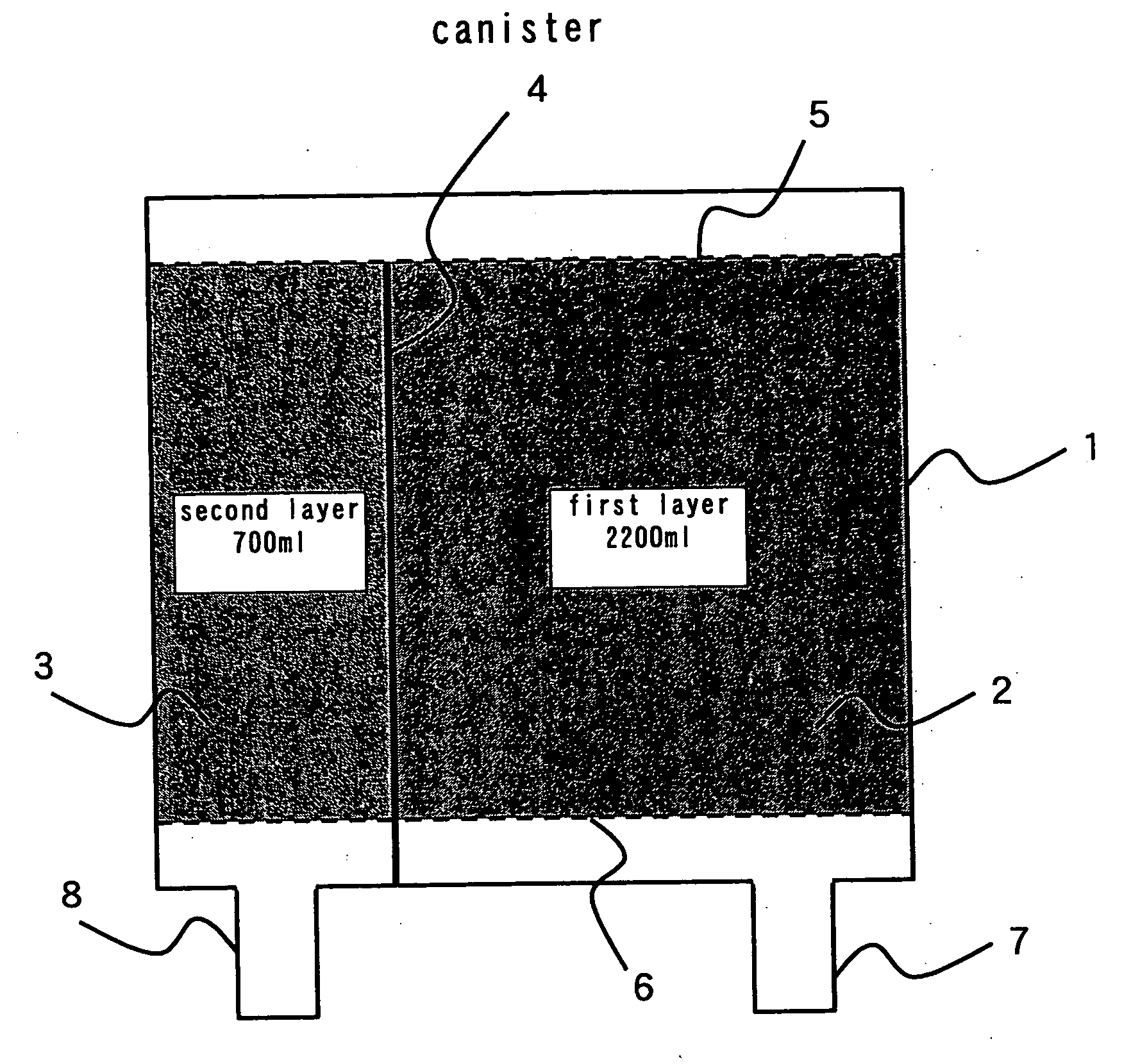

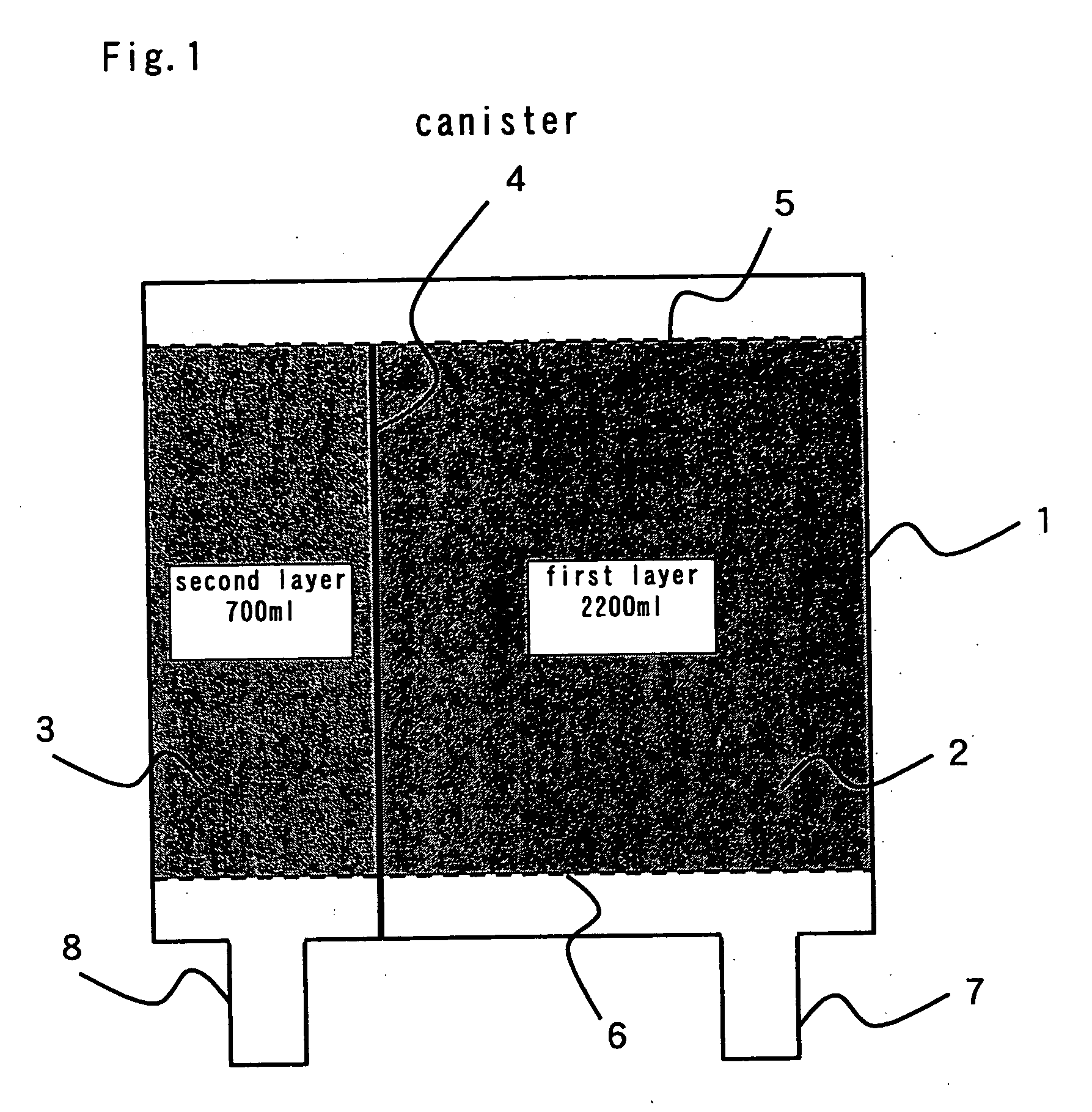

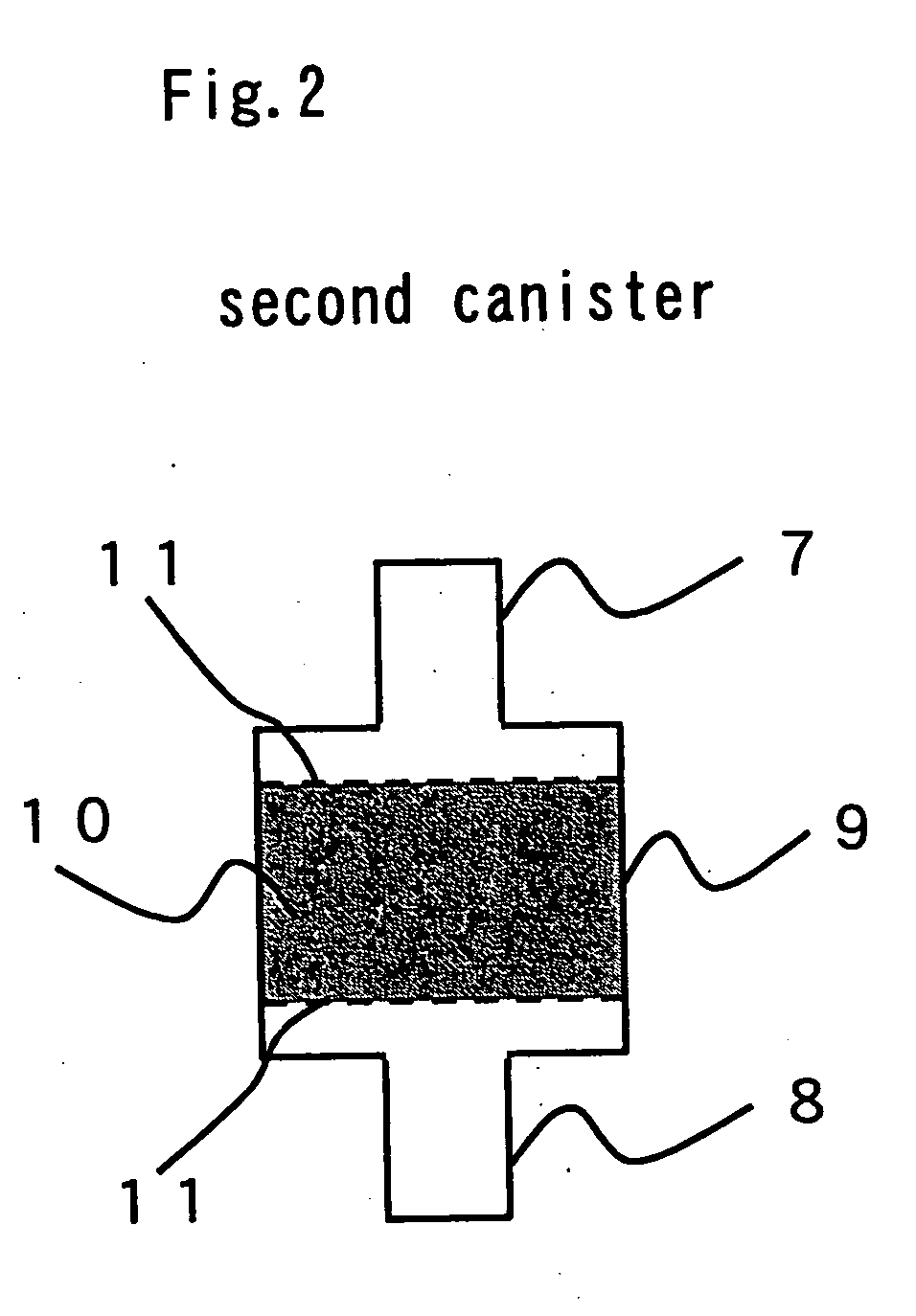

Pelletized activated carbon, method for producing pelletized activated carbon, and canister

InactiveUS20070078056A1Improve adsorption capacityHigh mechanical strengthGas treatmentNon-fuel substance addition to fuelCelluloseSodium Bentonite

A pelletized activated carbon and canister capable of reducing the amount of fuel gases evaporated and emitted into the atmosphere when a vehicle is stopped for a long time. A method for preparing the pelletized activated carbon including adding a binder and water to a powdery or granular activated carbon where the binder includes a cement (A) and at least one of a bentonite-based compound, a cellulose-based compound, and a polyvinyl alcohol-based compound; and the cement (A) is 30% by weight or more of the weight ratio of the solids; further including mixing with water to produce pellets of activated carbon. Pelletized activated carbon can be obtained by further hardening, drying, and cooling.

Owner:KURARAY CHEM CORP

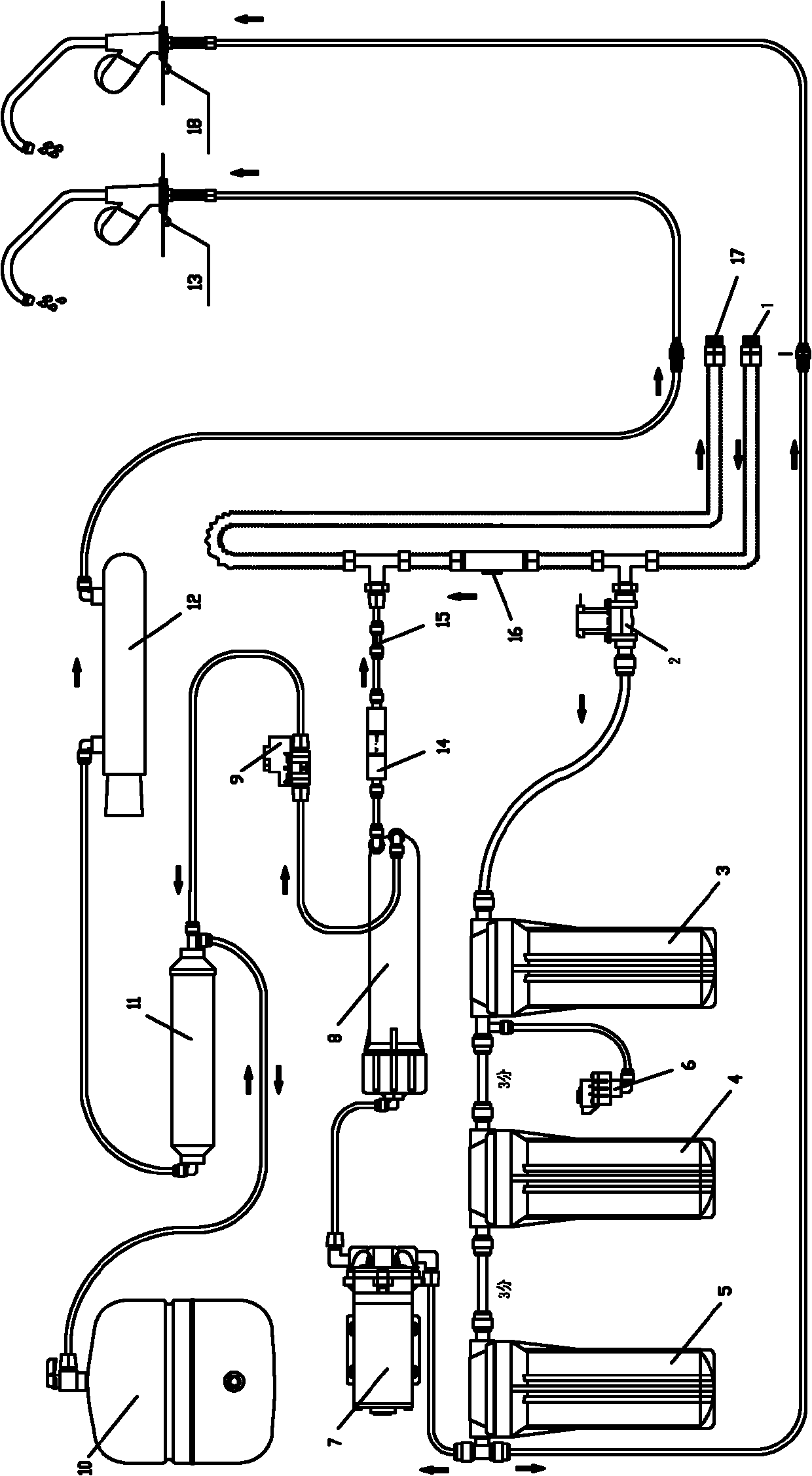

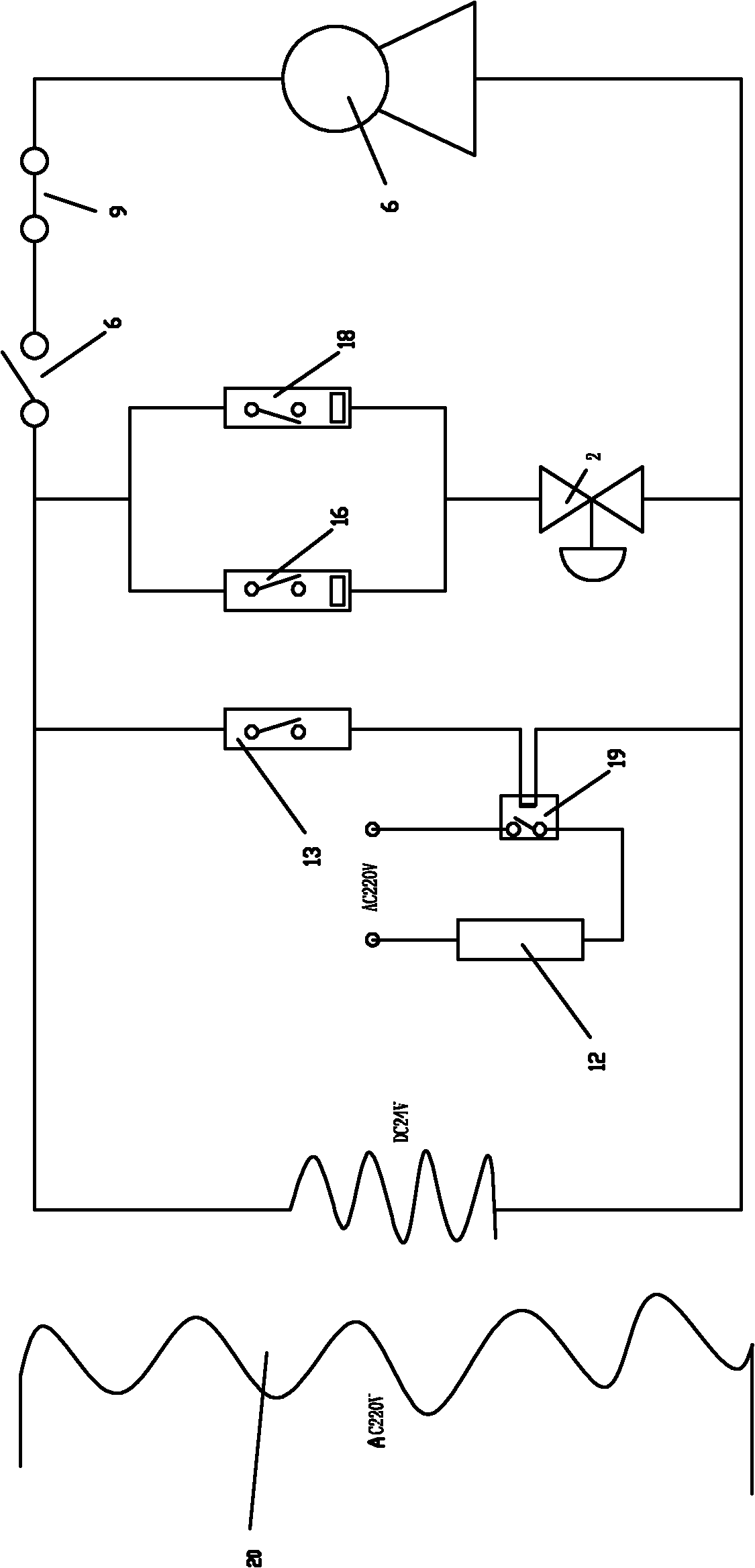

Reverse osmosis water purifier

InactiveCN102198988AConstant pressureAvoid bursting and leakingWater/sewage treatment by irradiationWater/sewage treatment bu osmosis/dialysisWater channelReverse osmosis

The invention discloses a reverse osmosis water purifier. The water purifier comprises a water circuit device and an electric circuit device, wherein the water circuit device comprises a municipal tap water inlet, a first-level filter core, a second-level granular activated carbon filter core, a third-level filter core, a booster pump, a fourth-level reverse osmosis component and a fifth-level post coconut shell activated carbon filter core which are sequentially connected; a water inlet electromagnetic valve is arranged on a pipeline between the municipal tap water inlet and the first-level filter core; a water tap outlet is provided with a magnetic switch; a concentrated water channel is connected to a tap water pipeline through a waste water ratio valve and a one-way valve which are sequentially connected; and a sterilizer is arranged between the coconut shell activated carbon filter core and a purified water outlet. The water purifier has the characteristics of preventing explosion and leakage, avoiding wastewater and ensuring drinking safety.

Owner:厦门市鑫宏鹏电子有限公司

Printing waste water advanced treatment and reusing method adapted for medium and small-sized printing plant

InactiveCN101234814ACompact structureLow investment costSustainable biological treatmentWaste water treatment from textile industrySludgeWastewater

The invention relates to an advanced treatment and reusing method for wastewater from print, which is applicable to middle and small printing plants and comprises the following processes: (1) selecting appropriate biological suspended fillers; (2) laying a filter bed of granular activated carbon; (3) cultivating sludge strains with high efficiency; (4) selecting a support for a dynamic membrane; (5) forming the dynamic membrane, and (6) cleaning and regenerating the dynamic membrane. The advanced treatment and reusing method for wastewater from print has the advantages of simple equipment, compact structure, low investment cost, small operation expenses, large flux, good performance of pollution resistance and easy cleaning and regenerating; therefore, the advanced treatment and reusing method for wastewater from print is particularly applicable to advanced treatment of wastewater from print in middle and small printing plants, which can be reused in the cleaning technology.

Owner:DONGHUA UNIV

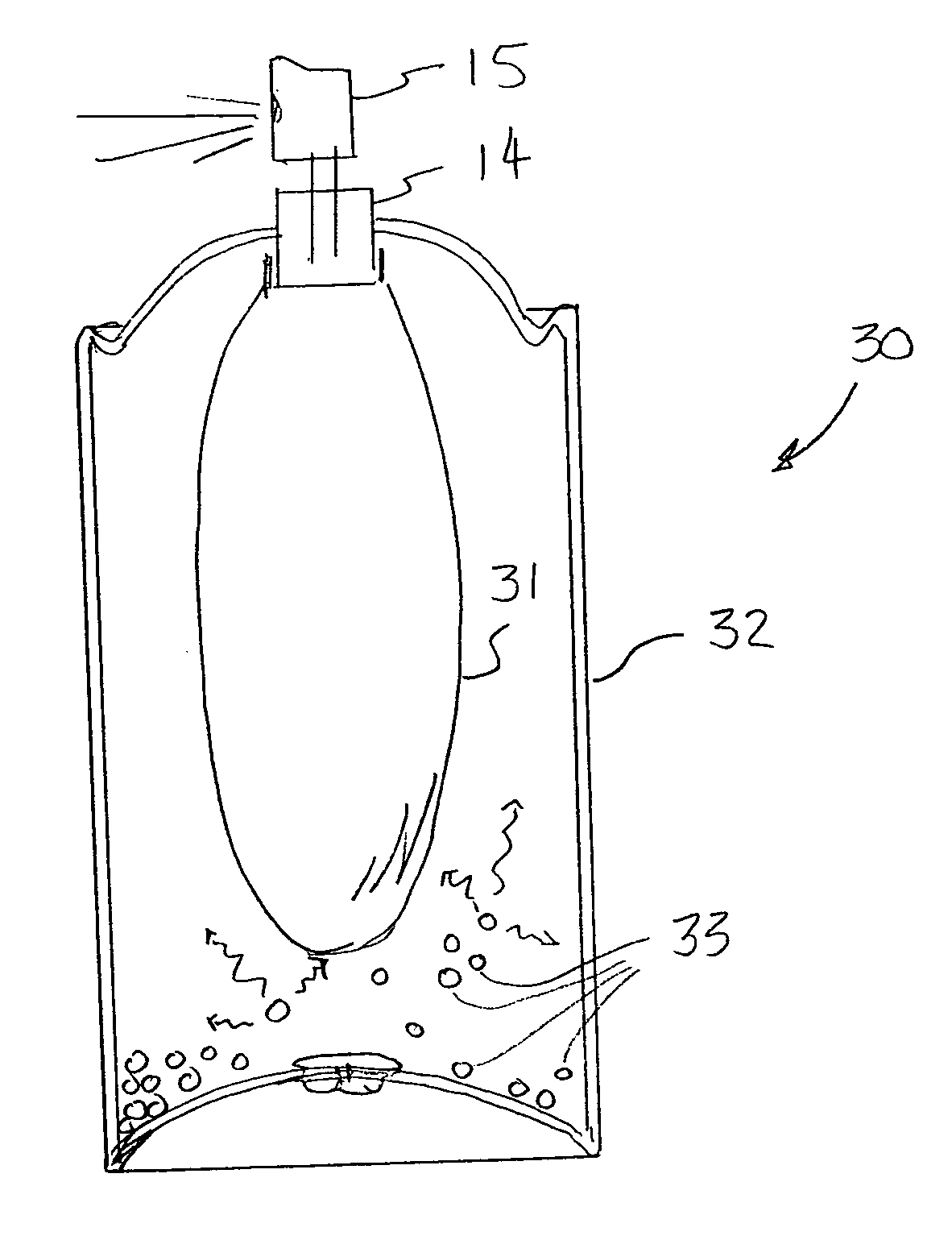

Gas storage and delivery system for pressurized containers

InactiveUS7185786B2Consistent, uniform and acceptable spray patternBetter aerosolize the productOpening closed containersBottle/container closureSodium bicarbonateDesorption

A gas adsorption material containing a desired quantity of gas is placed in a pressurized container along with a product to be dispensed, and as pressure in the container is depleted during use, stored gas is released into the container to maintain pressure in the container within a predetermined range. The material may be in contact with the product, or it may be isolated from the product, and is known as a pressure swing adsorption (PSA) system, wherein adsorption of gas into the material occurs at a high pressure, and desorption of gas from the material occurs at a low pressure. Such devices are capable of storing under pressure a volume of gas 18 to 20 times the volume of the material. A preferred adsorbent gas storage material is granular activated carbon, or a carbon fiber composite molecular sieve (CFCMS). Other materials, such as zeolite, starch-based polymers, activated alumina, silica gel, and sodium bicarbonate, or mixtures thereof, may be used, although they generally are not as effective as activated carbon. The adsorbent material may be in granular, powdered, or pellet form, or a mass of the material may be formed into variously shaped cohesive bodies, such as balls, tubes, cubes or rods, or sheets or screens which may be flat or curved or folded into various shapes, such as, for example, an accordion-like fold.

Owner:LIM WALTER K

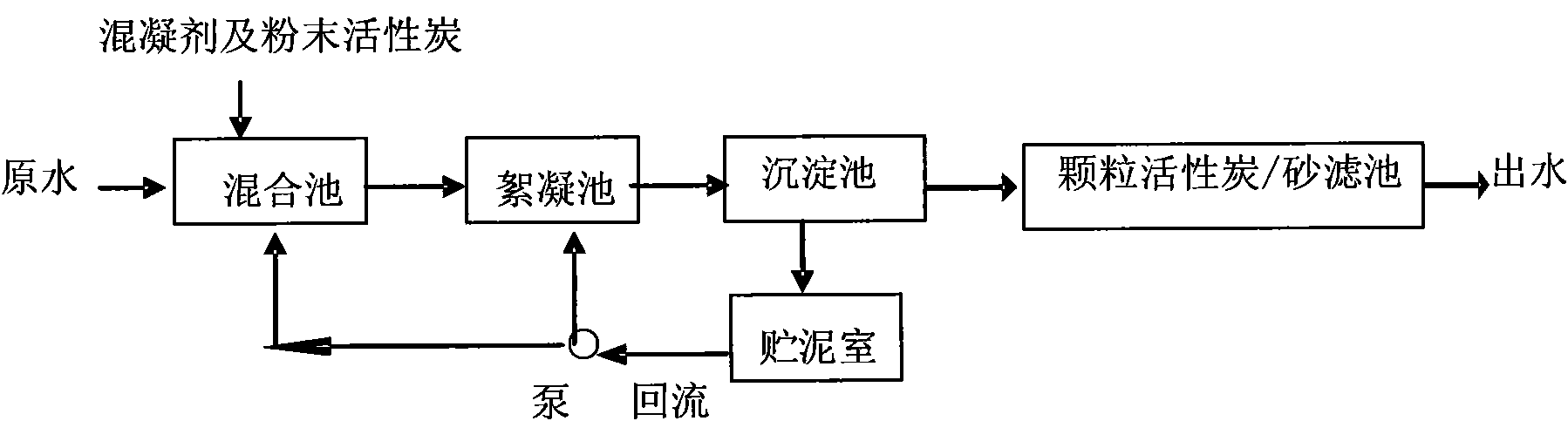

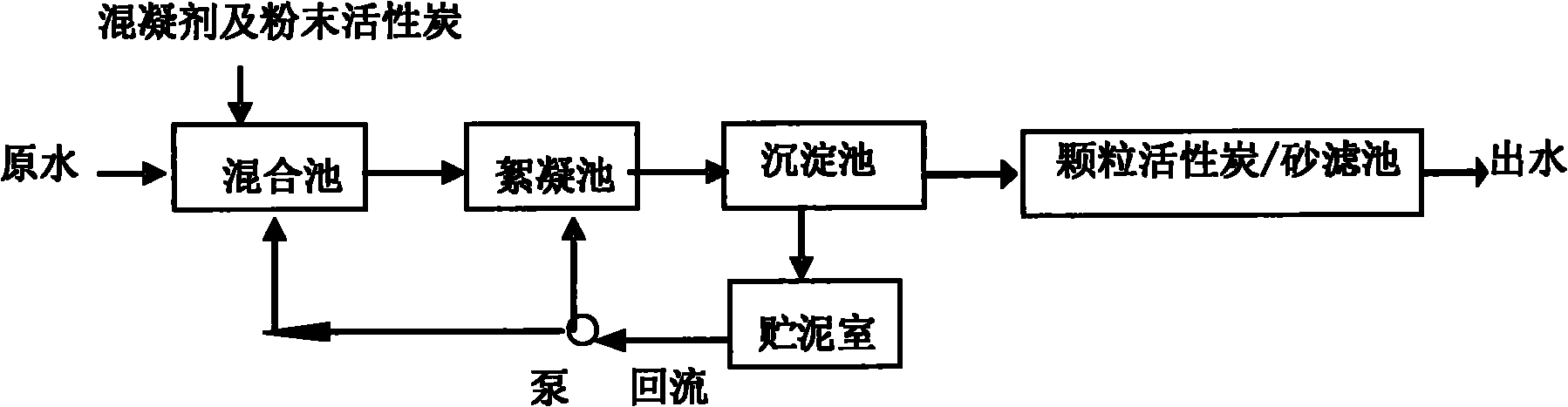

Powdered carbon backflow and carbon/sand filter combined process for treating polluted water

InactiveCN101962251AMake full use of the adsorption capacityEfficient removalMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSand filter

The invention discloses a powdered carbon backflow and carbon / sand filter combined process for treating polluted water, which belongs to the field of water treatment. A device comprises a mixing tank, a flocculating tank, a settling pond and a carbon / sand filter which are connected in series in turn, wherein powdered active carbon and a coagulant are added in raw water to be treated, and the raw water is mixed with the coagulant in the mixing tank; the mixed raw water enters the flocculating tank to undergo a flocculation reaction and then enters the settling pond to undergo solid-liquid separation, active carbon mud settled in the settling pond is concentrated in a mud storage chamber and flows back to the mixing tank or flocculating tank by a reflux pump, the concentrated active carbon mud flows back to the mixing tank when the coagulant is added and flows back to the flocculating tank when the coagulant is not added; and water after the settlement enters the carbon / sand filter, the granular active carbon is filled on the upper layer of the carbon / sand filter, and quartz sand is filled in the lower layer. In the invention, a powdered carbon backflow process is adopted, so that over 50 percent of medicinal preparation can be saved; and the physical absorption effect, biological degradation effect and strengthening coagulation effect of the active carbon act in coordination, and the carbon / sand dual-layer filter has the physical absorption and biological degradation effects at the same time.

Owner:BEIJING UNIV OF TECH +1

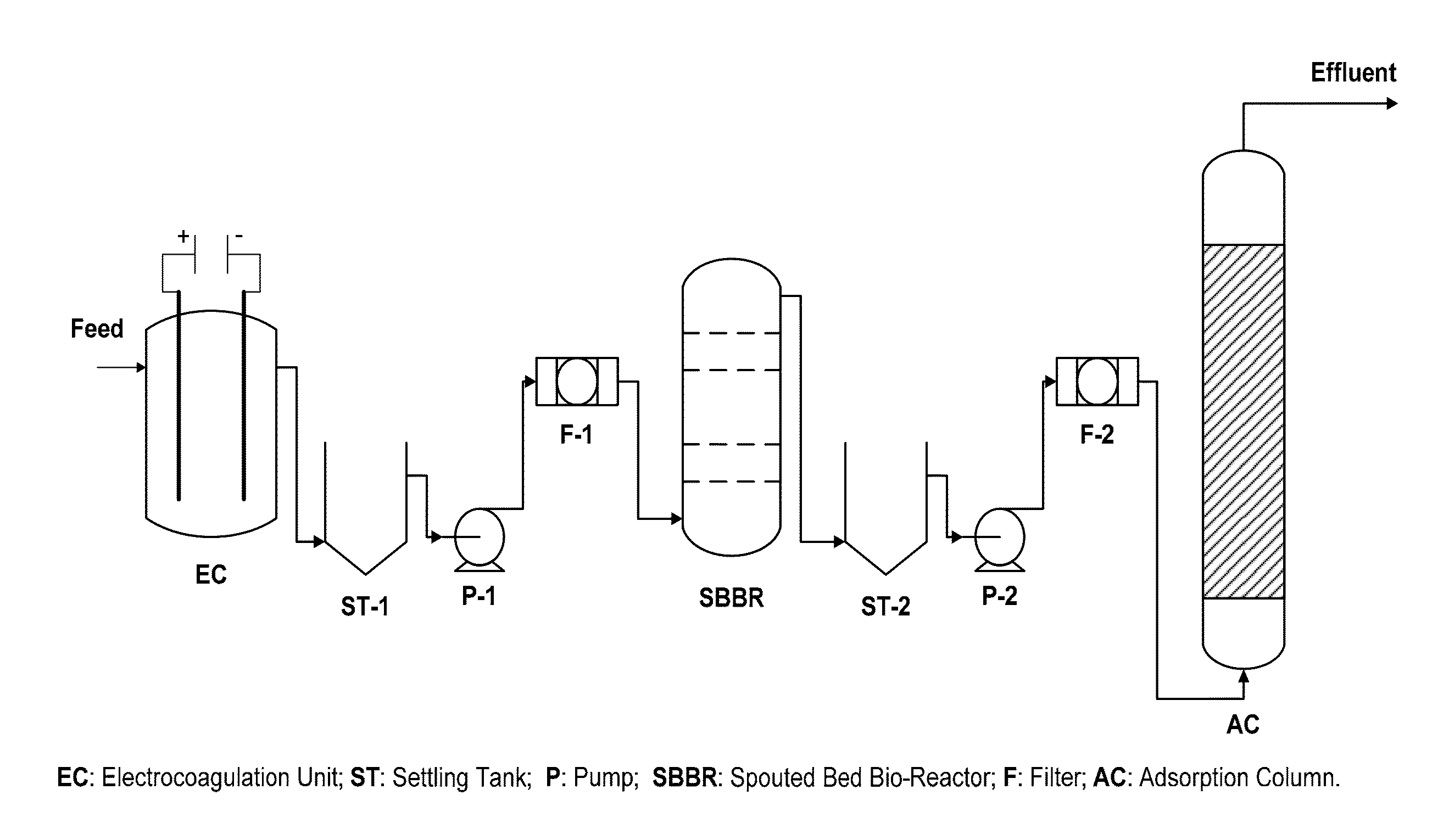

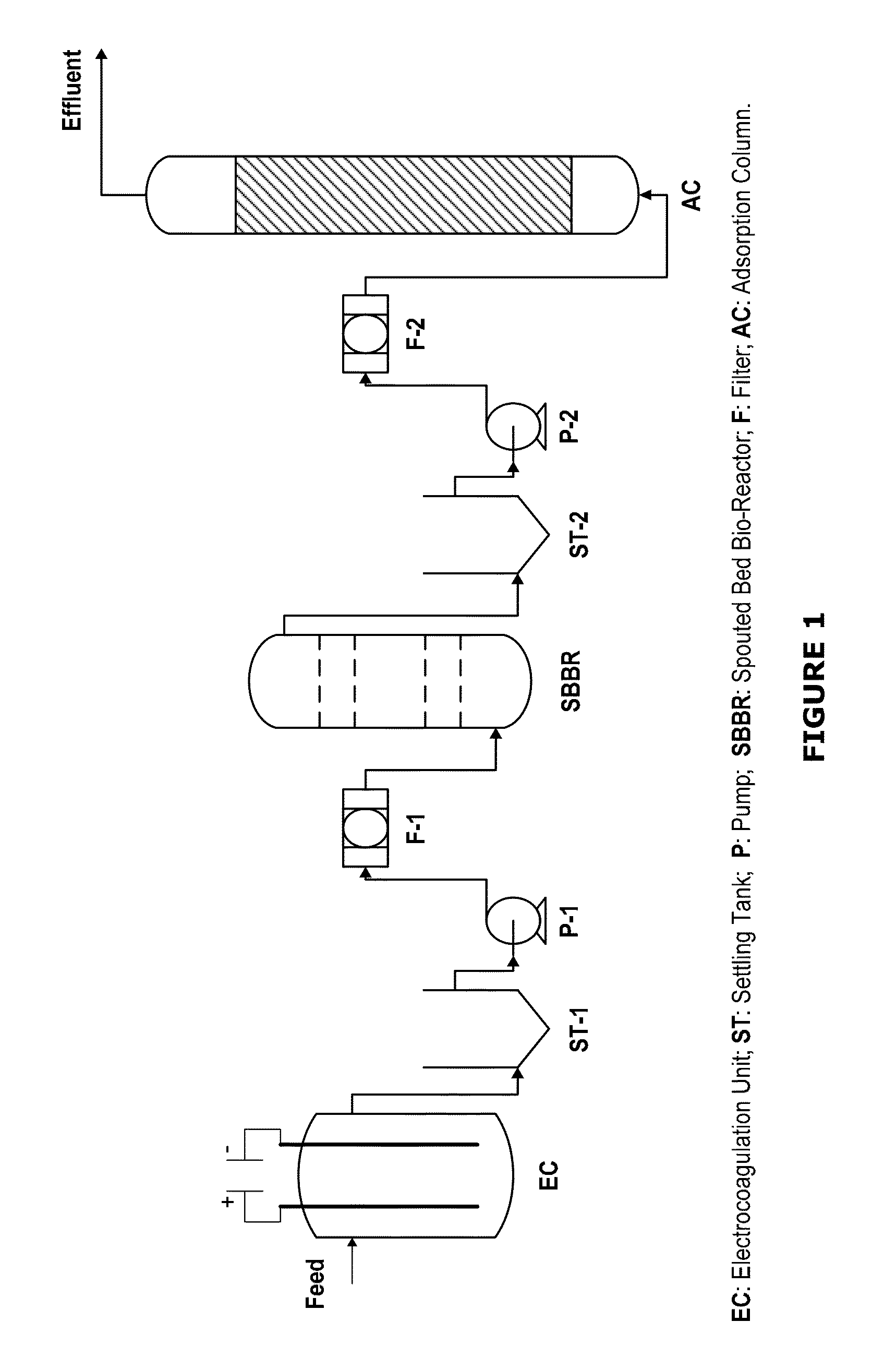

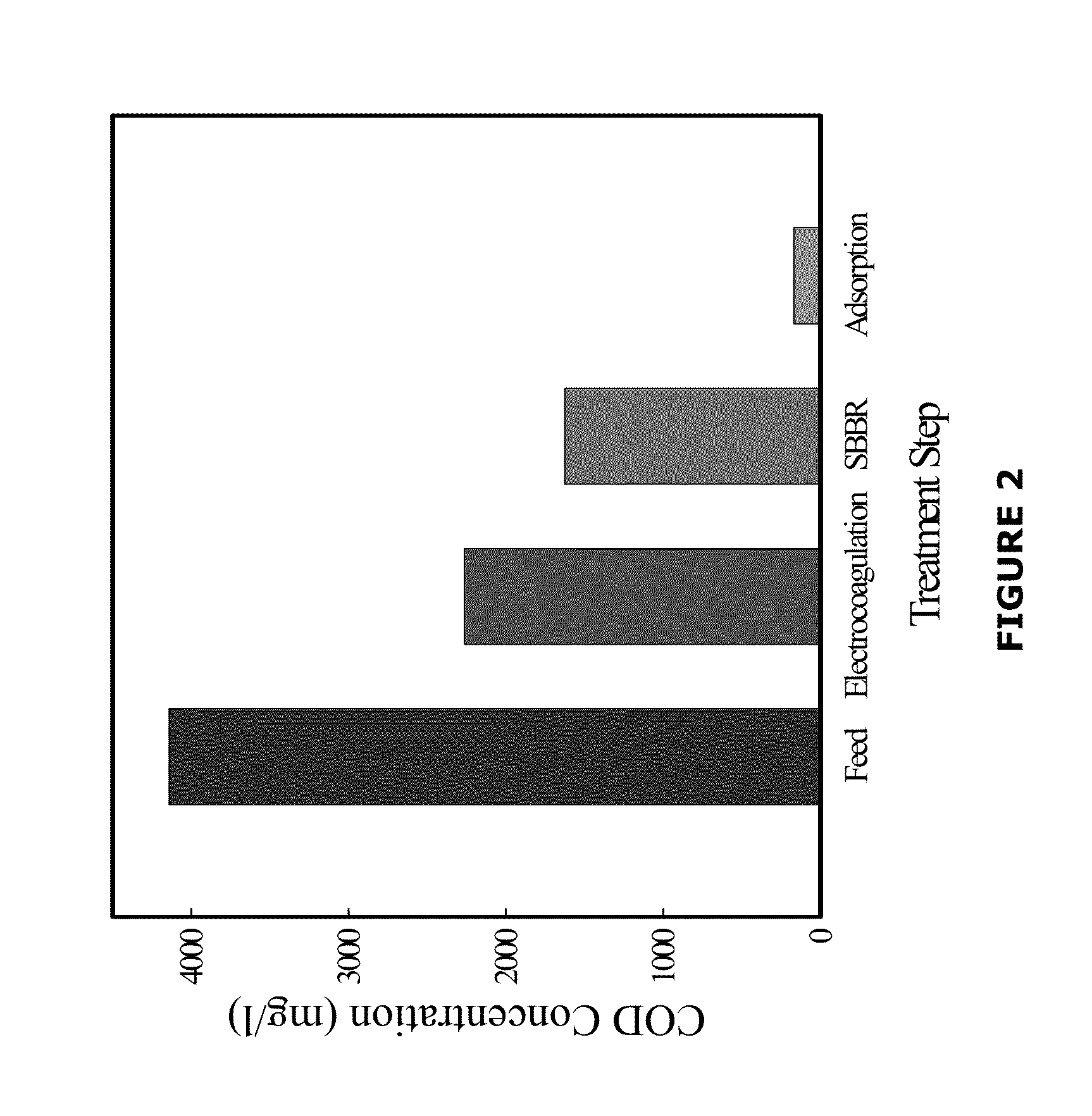

Process And System For The Treatment Of Industrial And Petroleum Refinery Wastewater

InactiveUS20130206688A1Reduce concentrationReduce replacement costsTreatment using aerobic processesWater contaminantsElectrocoagulationAfter treatment

There is provided a process of reducing concentration of contaminants in a contaminated wastewater stream, such as contaminated wastewater output from a refinery, such as an oil-refinery; the process comprising: first, passing the contaminated wastewater stream into an electrocoagulation reactor for coagulating dispersed particles, filtering the wastewater stream after electrocoagulation for removing the coagulated dispersed particles, and providing a first stream of treated wastewater after the first filtration; second, passing the first stream of treated wastewater into a Spouted Bed Bio-Reactor (SBBR) containing a micro-organism or bacterium immobilized in polyvinyl alcohol (PVA) gel, filtering the first stream after treatment by the SBBR and providing a second stream of treated wastewater after the second filtration; and third, passing the second stream of treated wastewater into an adsorption column containing granular activated carbon (GAC) and providing a third stream of treated wastewater. There is also provided a system for doing the same.

Owner:UNITED ARAB EMIRATES UNIVERSITY +1

Preparation for catalyst of Nano titanium dioxide, and method for treating ozonized water of catalysis

InactiveCN1695796AEasy reunionEasy to recycleCatalyst activation/preparationWater/sewage treatment by oxidationHYDROSOLSilica gel

A process for preparing the nano-TiO2 catalyst includes slowly dissolving tetrabutyl titanate in absolute alcohol, immersing the granular activated carbon or active Al2O3 or white silica gel or molecular sieve or zeolite in it, oscillating for 5-48 hrs, filtering, and drying or ageing. It can be used to treat water by making it, ozone and water to be treated in contact for 1-50 min.

Owner:HARBIN INST OF TECH

Method for restraining generation of manganous dithionate in process of leaching sulfur dioxide gas out of pyrolusite

The invention discloses a method for restraining the generation of manganous dithionate in the process of leaching sulfur dioxide gas out of pyrolusite, which comprises the following main technical measures: (1) pyrolusite pulp is prepared by stirring and mixing in the proportion that 100-500g of pyrolusite and 0.2-100g of granular active carbon are added into 1L of water; (2) in a synchronous reaction process of absorbing the sulfur dioxide gas by the pyrolusite pulp, desulphurizing and leaching manganese, the pH value of the pyrolusite pulp is controlled to be lower than 3.5 by blowing oxygen or air into the pyrolusite pulp. The method restraining the generation of the manganous dithionate does not need to extra consume sulphuric acid and guarantee an oxido-reduction potential by extra adjusting the concentration of Fe<3+> / Fe<2+>, is easy to meet the requirement of industrial process production and can guarantee the concentration of a manganese sulfate mother liquor.

Owner:成都合众新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com