Printing waste water advanced treatment and reusing method adapted for medium and small-sized printing plant

A printing wastewater and advanced treatment technology, which is applied in textile industry wastewater treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor system stability, cumbersome operation, high investment cost, etc., and achieve operating costs Low cost, low investment cost, simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

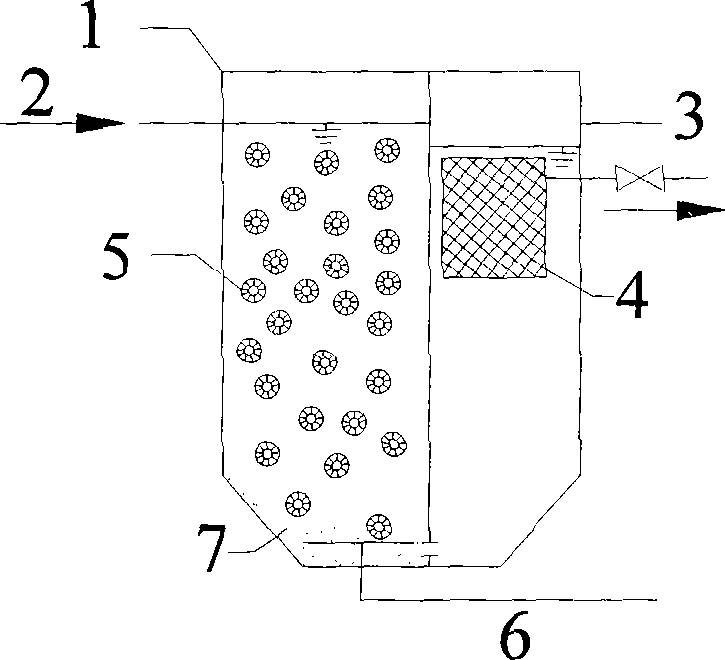

Image

Examples

Embodiment 1

[0031] A printing company in Shaoxing City, Zhejiang Province has a number of composite veneer elastic platens made according to silk printing standards, and is equipped with various wide-format photosensitive, stretching, and drying equipment. The company focuses on cut pieces and supplemented by gray cloth, and mainly prints on fashion, woolen sweaters, headscarves, toys, bags, leather, PVC (polyvinyl chloride), PU (polyurethane) coatings, etc. Printing range: water glue, four-color printing, discharge printing, thick board pulp, foaming, gold and silver onion, hot stamping, hot silver, hot diamond, flocking, luminous powder, pearl powder, glass beads, laser, embossed printing, Printing business such as silicone printing. The water quality indicators of the printing wastewater after being treated by the factory's old-fashioned biochemical facilities are: pH = 8.0-9.0, COD Cr (Expression form of chemical oxygen consumption measured by potassium dichromate as an oxidant)<250m...

Embodiment 2

[0035] A flocking printing Co., Ltd. in Yiwu City, Zhejiang Province is a flocking printing enterprise integrating R&D, production and marketing. It has flocking production lines and finishing equipment, specializing in the production of various high-end flocking fabrics. The company's main products are: printed velvet, printed color velvet, printed flash velvet, douglas velvet, sea lion velvet, deerskin velvet, corduroy, sheep velvet, leather flocking, etc. The products are mainly used in clothing, apparel, furniture textiles, automobiles, etc. Accessories are also widely used in the shoe industry and the toy industry. The water quality indicators of the printing wastewater of the factory after electrolytic air flotation treatment are: pH = 8.5 ~ 9.5, COD Cr <450mg / L, SS<300mg / L, chromaticity<180 times.

[0036] In order to cooperate with production and reuse, the original sedimentation tank was transformed, the height of the tank was twice the depth of the tank, and spheric...

Embodiment 3

[0038] A printing factory in Zhongshan City, Guangdong Province, is mainly engaged in the printing processing business of clothing, bags, shoes and hats, etc. The business scope includes: printing, piece packaging, flocking, bronzing, printing, thermal transfer, burning cotton, three-dimensional printing, etc. Various prints. The wastewater discharged from production is mainly the cleaning wastewater of printing plates, containers and utensils. In addition, some wastewater will also be generated from the floor washing several times a day in the workshop. The total discharge of wastewater averages 11m 3 / d, the water quality index after primary coagulation and sedimentation treatment is: pH=8.0~9.5, COD Cr Cr And higher chroma. Affected by factors such as rising tap water prices, it is urgent to reuse advanced printing wastewater for part of the production process.

[0039] According to the treatment method of this invention, a 2.5m×2m×4m advanced treatment device is built, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Proportion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com