Patents

Literature

227results about How to "Good anti-pollution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

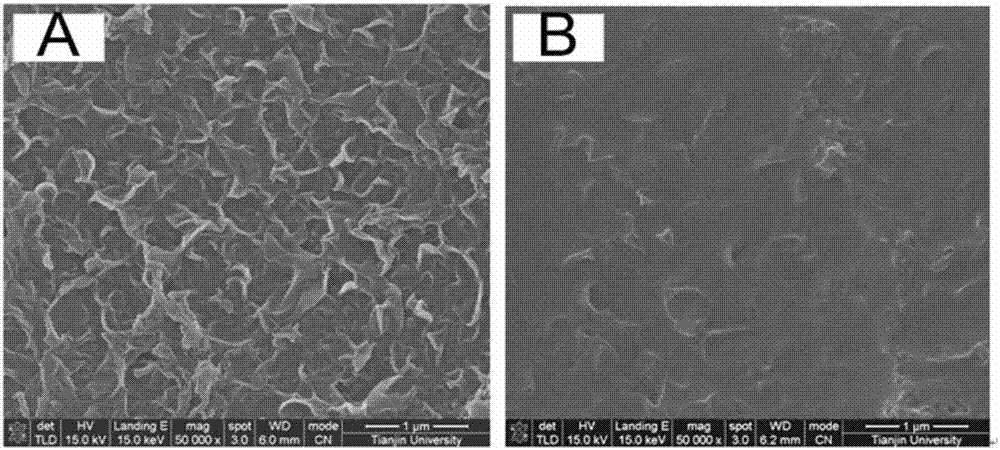

Preparation method for organic-inorganic composite separation membrane with hydrophilicity and function of photocatalytic degradation of pollutants

InactiveCN104383821AExcellent photocatalytic degradation performanceGood resistance to protein contaminationSemi-permeable membranesMetal/metal-oxides/metal-hydroxide catalystsPhotocatalytic degradationSolvent

The invention relates to a preparation method for an organic-inorganic composite separation membrane with hydrophilicity and the function of photocatalytic degradation of pollutants. The steps include: (1) blending a magnetic composite photocatalytic material composed of the magnetic particle @TiO2 with a graphene oxide loaded core-shell structure, polymer resin, a solvent and an additive to prepare a membrane casting solution; (2) placing the obtained membrane casting solution in a 100-20000 Gauss magnetic field to prepare a membrane, after 10-200sec, immersing the membrane into a coagulation bath for 30-120sec coagulation, taking the membrane out of the coagulation bath, carrying out washing, soaking and drying, thus obtaining the composite separation membrane with the function. By applying the action of a magnetic field in the evaporation and coagulation process of membrane formation, migration of the magnetic composite photocatalytic material in the membrane casting solution to the surface of a separation membrane can be realized, thus solving the problem that during inorganic nano-material blending modification of the separation membrane, nano-materials are mostly embedded in a membrane matrix, and the modification effect of the nano-materials cannot be brought into full play. The surface of the polymer separation membrane is endowed with good hydrophilicity and the property of photocatalytic degradation of pollutants.

Owner:TIANJIN POLYTECHNIC UNIV

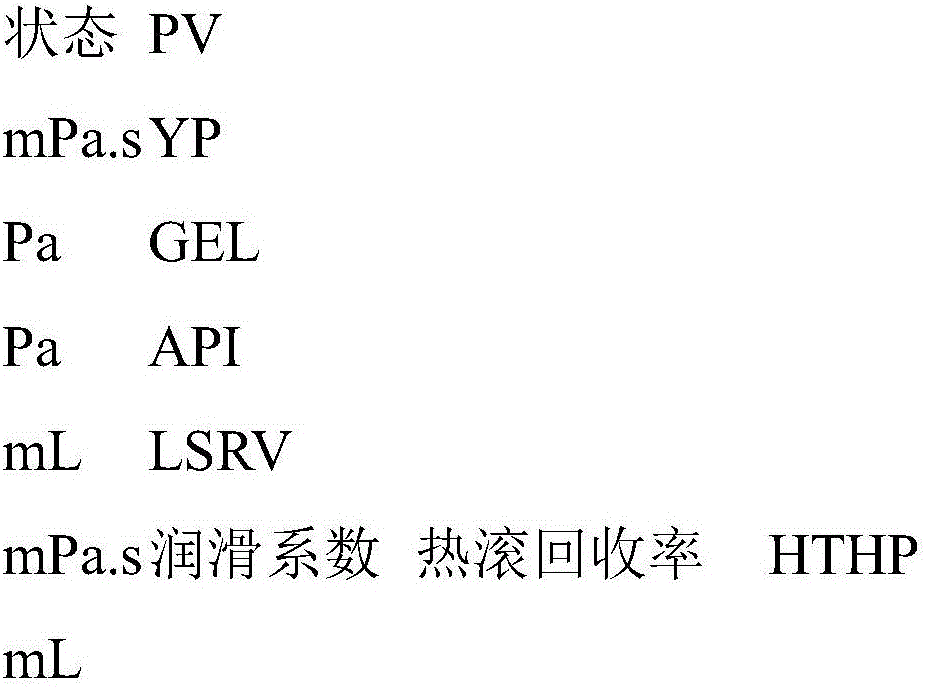

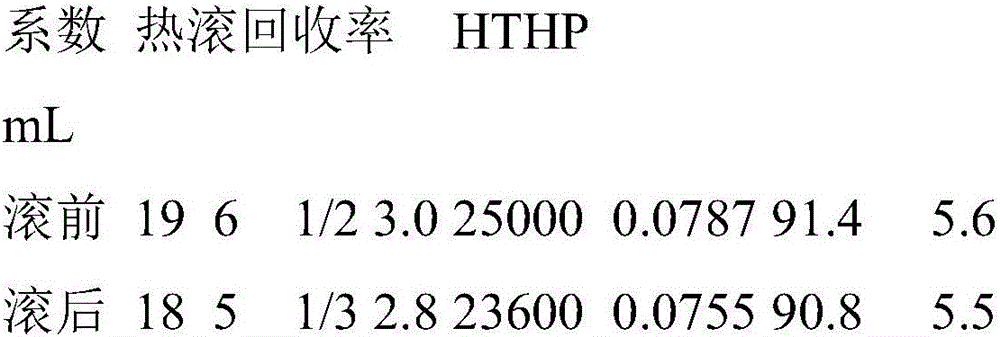

Oil-based drilling fluid for development drilling of shale gas

ActiveCN103614122AGood application effectHigh ratio of dynamic plasticDrilling compositionOil phasePetroleum

The invention relates to an oil-based drilling fluid for development drilling of a shale gas, and belongs to the technical field of drilling fluids for petroleum drilling engineering. The oil-based drilling fluid is characterized by being prepared from the following components by weight percent: 0.2% to 2% of main emulsifier, 0.1% to 1% of auxiliary emulsifier, 0% to 1.5% of wetting agent, 0.2% to 1.5% of alkalinity regulating agent, 0% to 1.5% of organic soil, 0% to 1.5% of tackifier, 0.2% to 2% of filtrate reducer, 0% to 80% of weighting agent, 0% to 20% of water phase and the balance of oil phase. The oil-based drilling fluid can be used for meeting a special requirement of the shale gas drilling to the drilling fluid, and is good in stability, inhibitory capability and lubricity even under low and high temperatures. The oil-based drilling fluid has the characteristics of high dynamic plastic ratio, low plastic viscosity, wide application range and good economic benefit.

Owner:JINGZHOU JIAHUA TECH

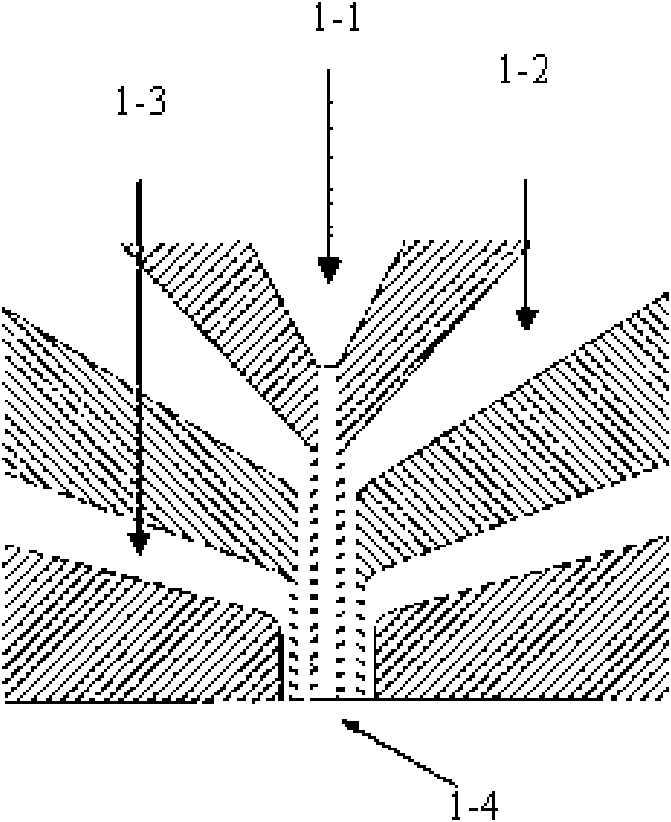

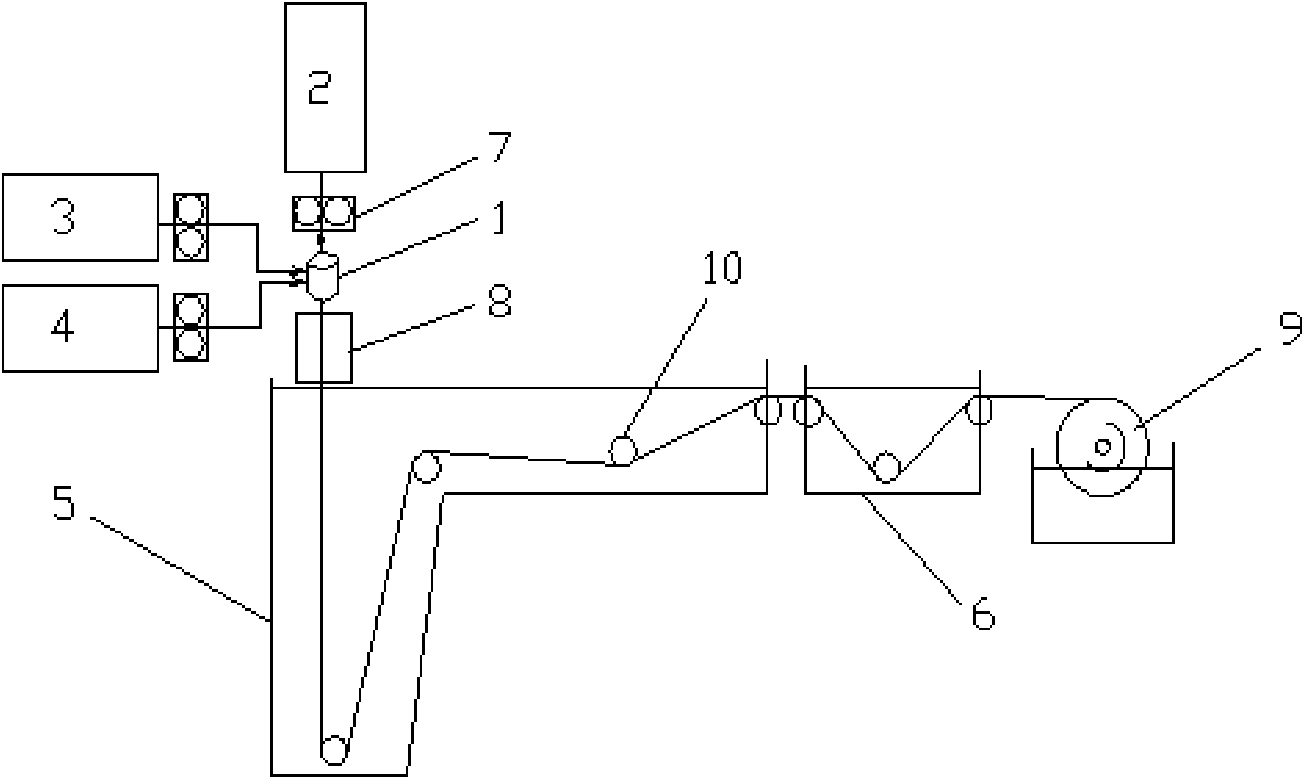

Double-layer composite hollow fiber nano-filtration membrane and preparation method and special tool thereof

ActiveCN101642683ADoes not impair mechanical strengthReduce manufacturing costSemi-permeable membranesFiberHollow fibre

The invention discloses a double-layer composite hollow fiber nano-filtration membrane and preparation method and special tool thereof, wherein the nano-filtration membrane comprises a selective separating outer sheath layer and a mechanical inner supporting layer; the selective separating outer sheath layer with the thickness of 10-10000 nm is provided with the membrane holes with the hole diameter of 0.5-2 nm, wherein the thickness of the mechanical inner supporting layer is 1-3mm; the selective separating outer sheath layer and the mechanical inner supporting layer of the double-layer composite hollow fiber nano-filtration membrane are respectively dissolved into the solvent through the high polymer of the selective separating outer sheath layer and the high polymer of the mechanical inner supporting layer. The invention can control the thickness of the selective separating outer sheath layer to be 10-100 nm, thereby greatly reducing the materials of the selective separating outer sheath layer and greatly lowering the cost. The invention effectively controls the internal / external diameter of the membrane, the effective hole diameter of the membrane, the hole rate and the hole diameter distribution by controlling the components of the liquid materials, the spinning condition, the condensing bath and the post processes so as to obtain the high effective separating membrane provided with the good hydrophilic performance, pollution proof and large water flux.

Owner:SUZHOU FAITH HOPE MEMBRANE TECH

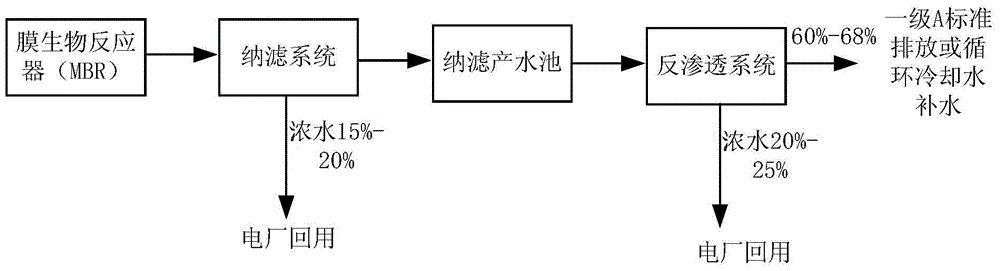

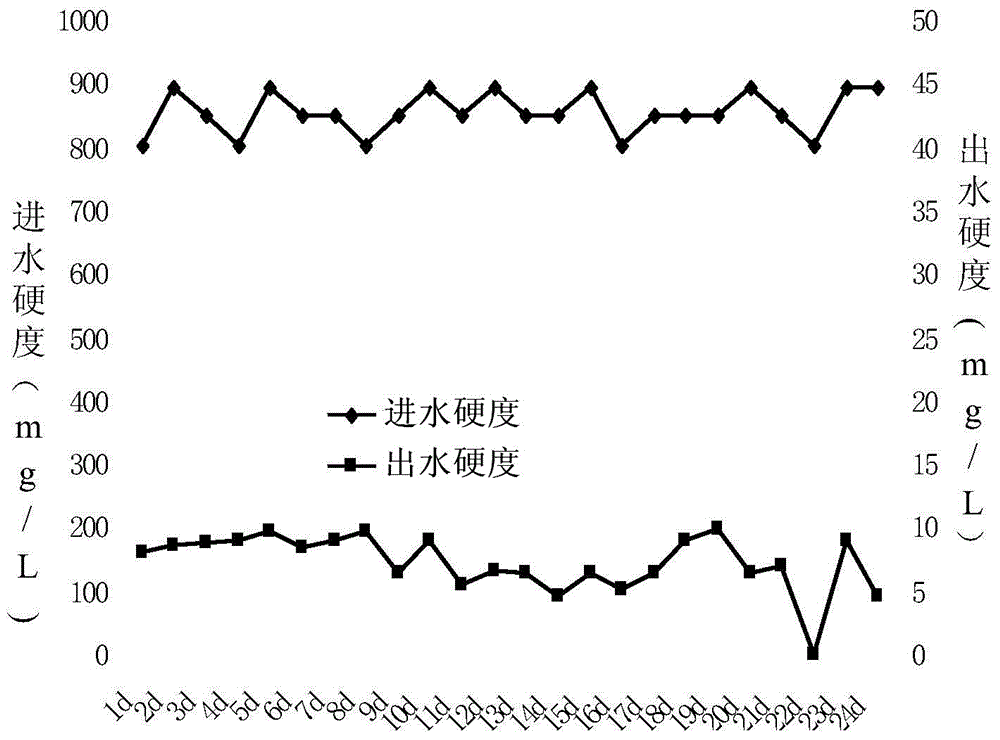

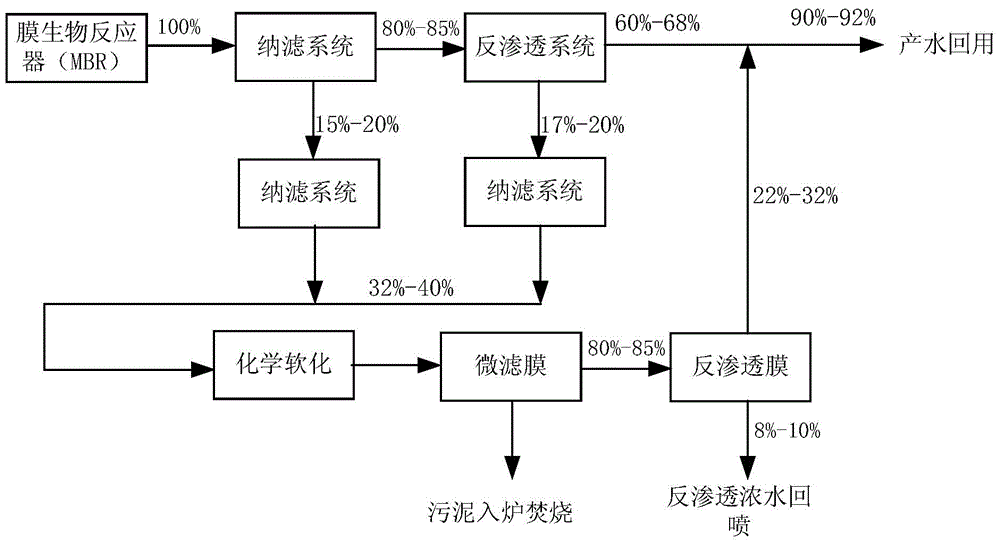

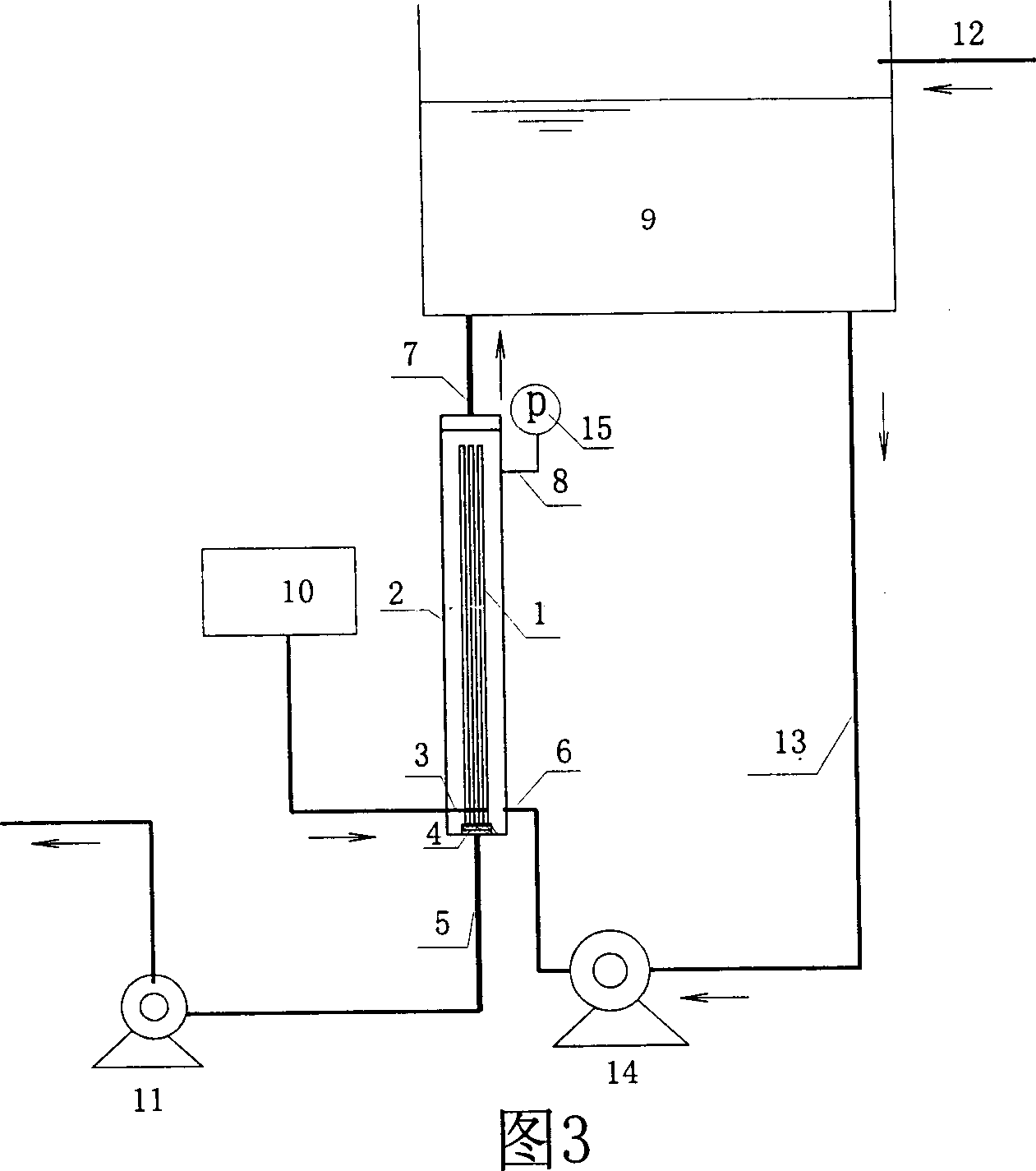

Treatment method and device of landfill leachate concentrate

InactiveCN104787929AIncrease productionAchieve recyclingUltrafiltrationMultistage water/sewage treatmentReverse osmosisWater resources

The invention relates to a treatment method and a device of landfill leachate concentrate. The method comprises the following steps: Step S1: carrying out chemical softening treatment on the concentrate to reduce hardness of the concentrate, Step S2: filtering effluent of Step S1 with a microfiltration membrane to remove suspended solids from the concentrate, and Step S3: carrying out reverse osmosis treatment on effluent of Step S2 with a disc tubular reverse osmosis membrane to form recycled effluent. The method and the device have the following advantages: 1, a 'chemical softening, microfiltration membrane and DTRO (Disk Tubular Reverse Osmosis)' technology is employed for treating the nanofiltration and reverse osmosis concentrate, the fresh water yield of a whole system is increased, the recycling of water resources is achieved, and operating cost of a power plant is saved; and 2, the 'chemical softening, microfiltration membrane and DTRO' technology is employed for treating the nanofiltration and reverse osmosis concentrate, so that the concentrate is reduced, and the predicament that the yield of the concentrate is high, and the power plant cannot eliminate the concentrate is solved.

Owner:EVERBRIGHT ENVIRONMENTAL PROTECTION TECH RES INST SHENZHEN CO LTD

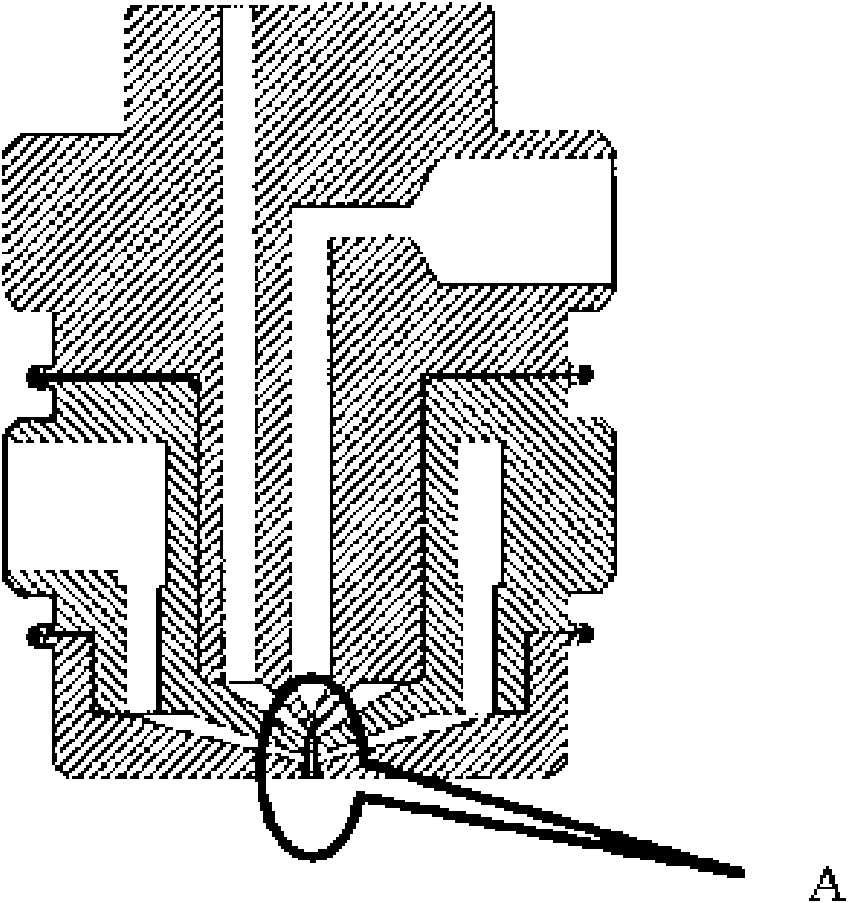

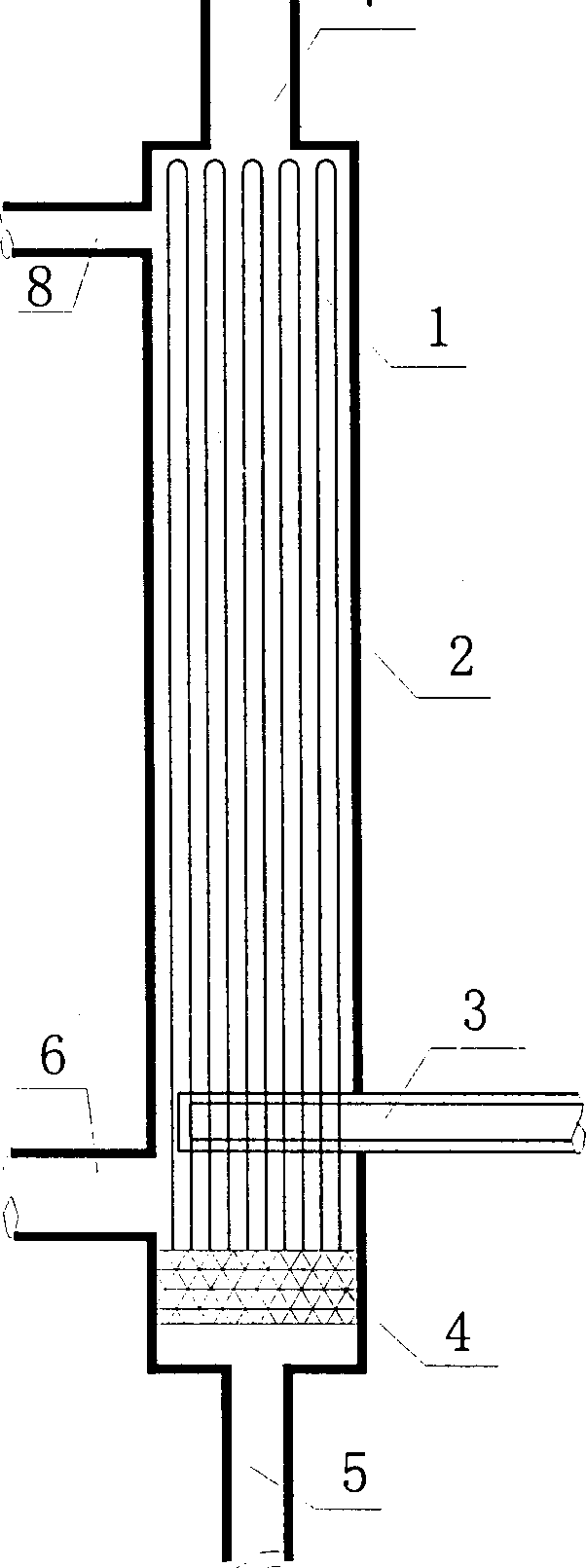

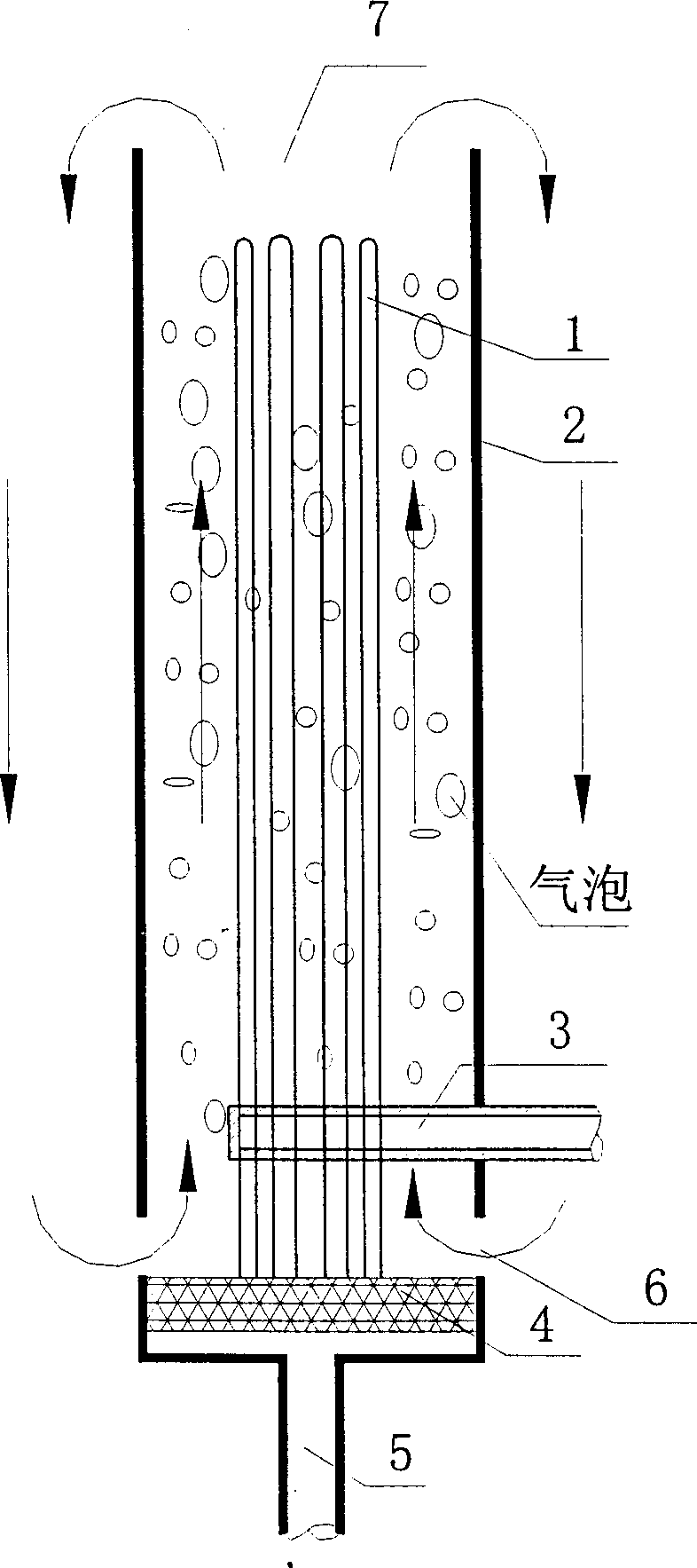

External pressure pillar type hollow fiber films subassemblies capable of air blast

InactiveCN1446618AGood anti-pollutionImprove anti-pollution performanceSemi-permeable membranesTreatment using aerobic processesFiberHollow fibre membrane

An external-pressure column type hollow fibre membrane assembly able to be flushed by gas features that the dedicated glass flushing part is arranged among membran fibres at bottom, and the height / diameter ratio of column, the length / diameter ratio of membrane fibre, and the filling density of membrane assembly are reasonably set up for normalizing the moving tracing of gas and water and the flowing state of two-phase stream and making the membrane assembly work in subcritical throughput region. Its advantages are high membrane throughput and less pollution to membrane.

Owner:TSINGHUA UNIV

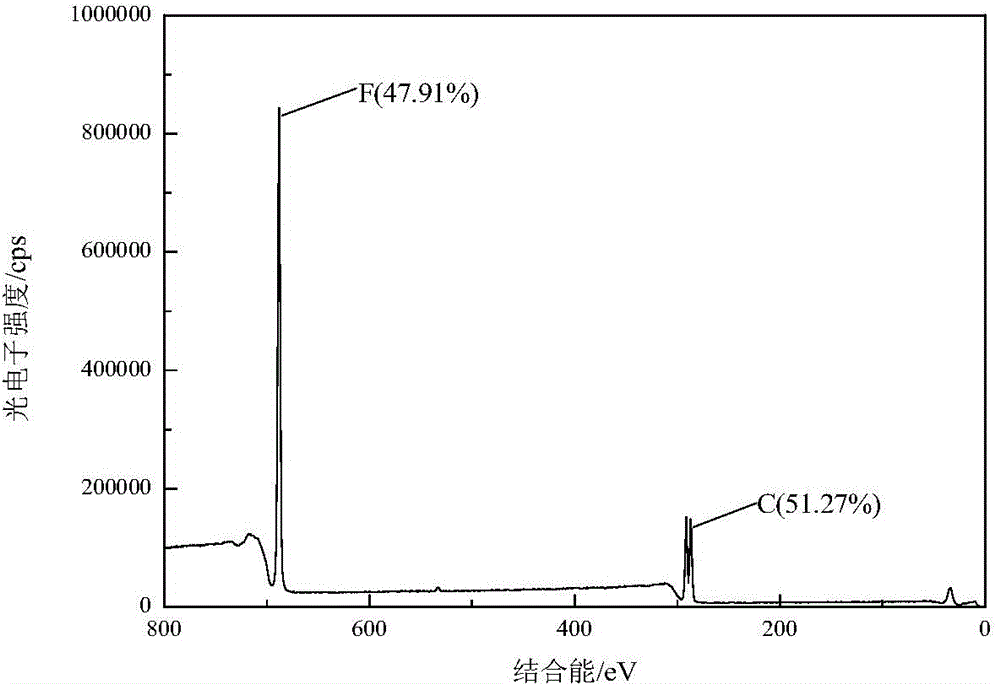

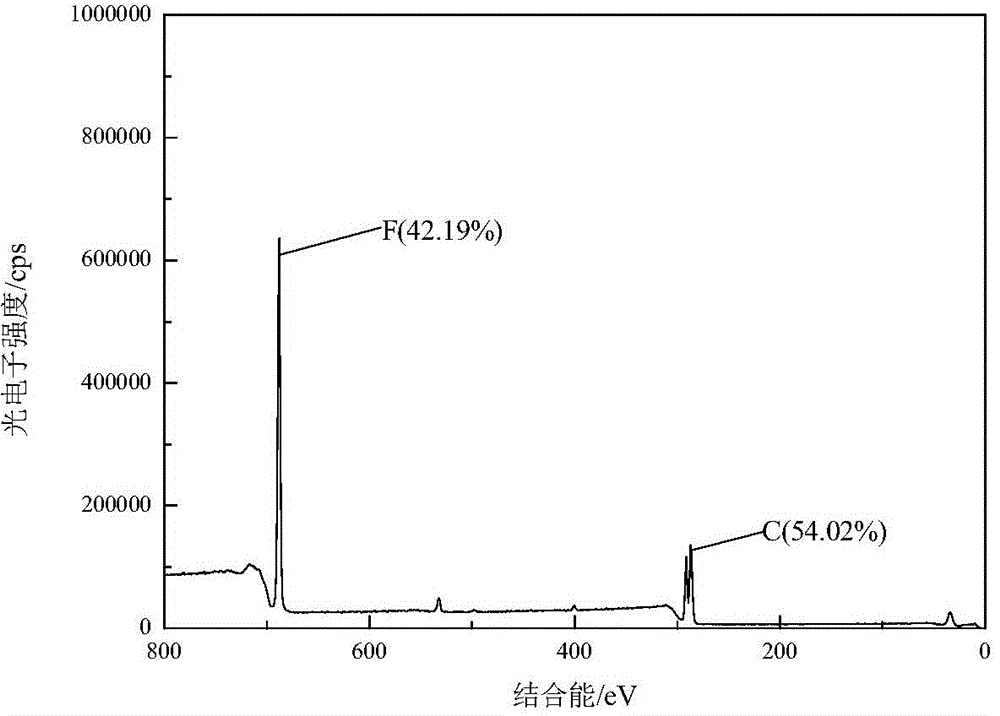

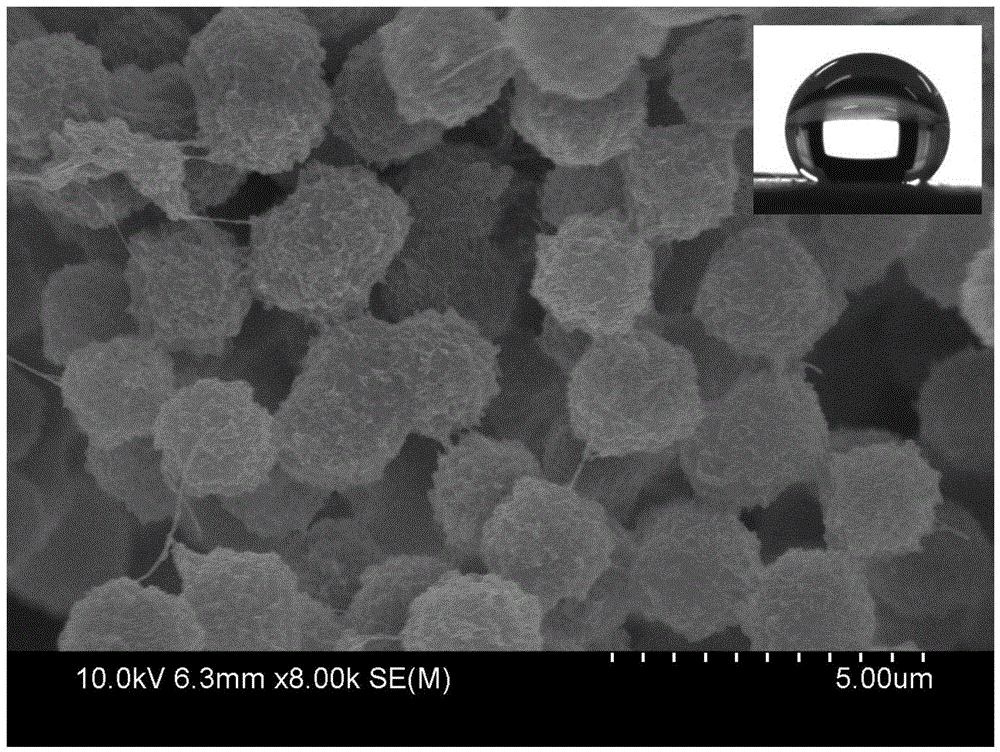

Production formula and method of PVDF (polyvinylidene fluoride)/carbon nano-tube super-hydrophobic film

InactiveCN104826503AImprove and modify pore structureImprove and modify distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a production formula and method of a PVDF (polyvinylidene fluoride) / carbon nano-tube super-hydrophobic membrane. The formula includes, by weight, 5% to 30% of PVDF, 0.005% to 5% of carbon nano-tubes, and 67% to 91% of solvent. The production method includes: evenly dispersing the carbon nano-tubes in the solvent, adding the PVDF, and performing high-speed stirring at 50 DEG C to 100 DEG C to obtain casting solution; producing a flat membrane by scraping, or producing hollow fibers to obtain a primary membrane via a hollow spinneret; solidifying the primary membrane in the non-polar steam environment, and removing solvent residue by deionizing soaking so as to obtain the PVDF / carbon nano-tube super-hydrophobic membrane. The membrane produced by the formula and the method is rich in CNTs on surface and has super-hydrophobic surface and excellent permeability; the method is simple, and operability is high.

Owner:TIANJIN POLYTECHNIC UNIV

Method for manufacturing easy-to-clean artificial leather

ActiveCN102851994AGood anti-pollutionAchieve cleaning effectPattern makingSynthetic resin layered productsPolyvinyl chlorideSolvent

The invention discloses a method for manufacturing easy-to-clean artificial leather. The method comprises stirring 100 parts of a polyvinyl chloride resin, 30-50 parts of a plasticizer, 30-50 parts of a filler, 0.5-1 part of a lubricant, 2-5 parts of a heat-resistant stabilizer, 3-5 parts of a pigment, 30-50 parts of a modifying agent and 1 part of an anti-contamination processing auxiliary agent, or 100 parts of a polyurethane resin, 10-50 parts of a solvent, 10-50 parts of a filler, 3-5 parts of a pigment, 1-5 parts of a modifying agent and 1 part of an anti-contamination processing auxiliary agent in a high-speed dispersing mixer at 120-130 DEG C for 150-250 s, mixing, milling, calendering, base bonding or coating to form a semifinished product, and performing surface treatment and hot pressing on the semifinished product. The surface of the product manufactured by the inventive method has excellent anti-contamination effects, and contaminants on the surface of the manufactured product can be cleaned by wiping through common base cloth, without destroying the surface effects of the product.

Owner:KUSN ACHILLES ARTIFICIAL LEATHER

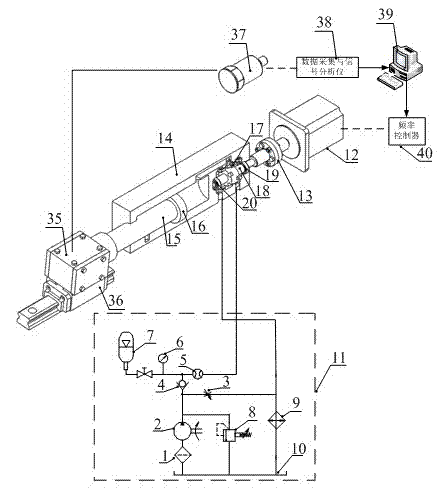

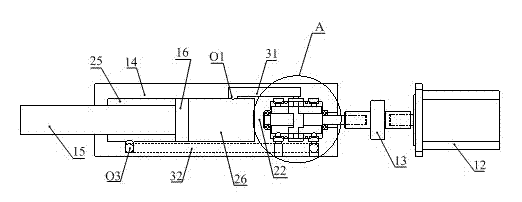

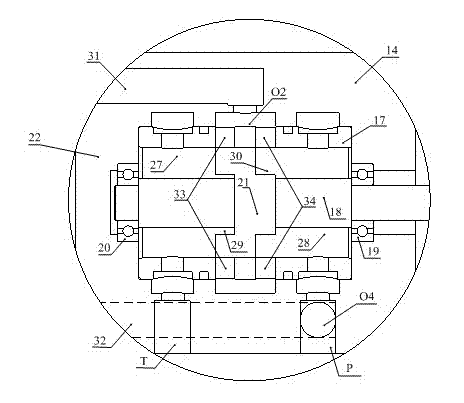

Electrohydraulic vibration exciter

InactiveCN102734279ARealize high frequency commutationHigh control precisionFluid-pressure actuator componentsCouplingEngineering

The invention discloses an electrohydraulic vibration exciter which comprises a step motor and a vibration excitation device. An accommodation cavity inside a case of the vibration excitation device is divided into a first chamber and a second chamber by a clapboard. The first chamber is divided into a rod cavity and a rodless cavity by a piston with a single-acting piston rod. A single-shoulder valve plug provided with a valve sleeve is arranged inside the second chamber and is connected with a main shaft of the step motor through a coupling. The second chamber is divided into a third cavity and a fourth cavity by the shoulder of the single-shoulder valve plug, an oil return port is arranged on the wall of the third cavity, and an oil inlet port is arranged on the wall of the fourth cavity. A first flow channel and a second flow channel are arranged on the wall of the accommodation cavity; the rodless cavity is communicated with the second chamber through the first flow channel, and the rod cavity is communicated with the oil inlet port through the second flow channel. First and second grooves which can be communicated with the first flow channel are arranged on the two sides of the shoulder of the single-shoulder valve plug along the circumferential direction at intervals. Along with the rotation of the single-shoulder valve plug, an opening at the other end of the first flow channel is communicated with either of the first and second grooves all the time.

Owner:ZHEJIANG UNIV

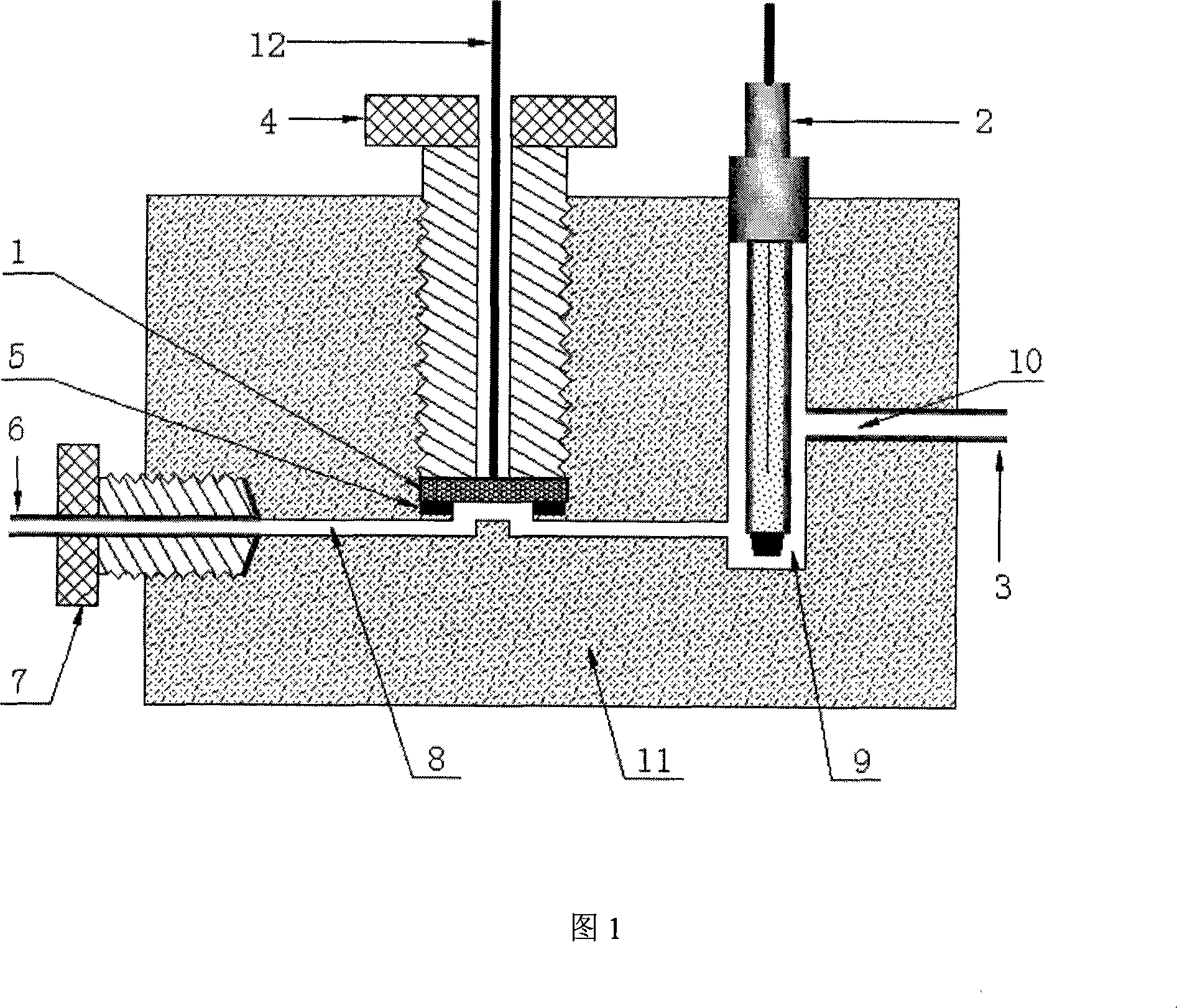

Subaqueous chemical oxygen demand measuring apparatus and method and method based on flow injection sampling

ActiveCN101221145ANo secondary pollutionHigh mechanical strengthMaterial analysis by electric/magnetic meansWater basedMeasurement device

The invention relates to a device and a method for measuring the chemical oxygen demand in water based on flowing injection sampling feeding, which belongs to the technical field of environment monitoring. The measuring device is composed of a flowing injection sampler feeder, a three-electrode system electrochemical circulation detecting pool and an electrochemical working station. The invention is characterized in that a working electrode of the electrochemical circulation detecting pool is a boron-doped diamond film electrode and is fixed on an inlet channel by a fastening bolt and is lined with a lock ring. The inlet channel, a reference electrode mounting channel and an outlet channel enlightened on an insulating, hard and corrosion-resistant pool body are mutually communicated. When in measurement, the pH value of a carrier liquid is 3 to 10 with a concentration of 0.05 to 0.5 mol / l. When the reference electrode adopts a saturated calomel electrode or an Ag / AgCl electrode, a positive voltage applied on the working electrode of the boron-doped diamond film electrode is 2.2 to 3.2V. The invention realizes the fast and accurate measurement of COD with no pollution.

Owner:DALIAN UNIV OF TECH

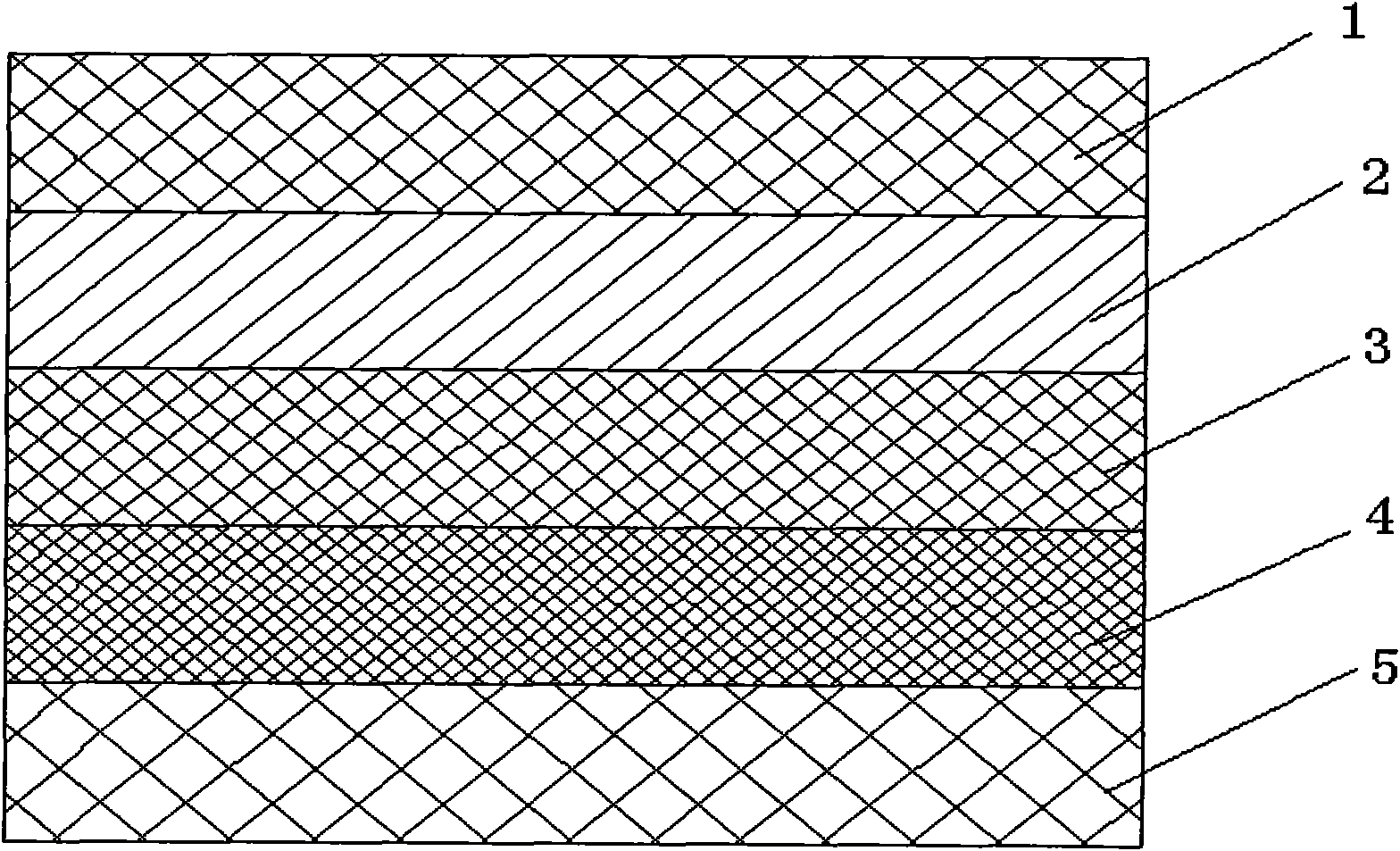

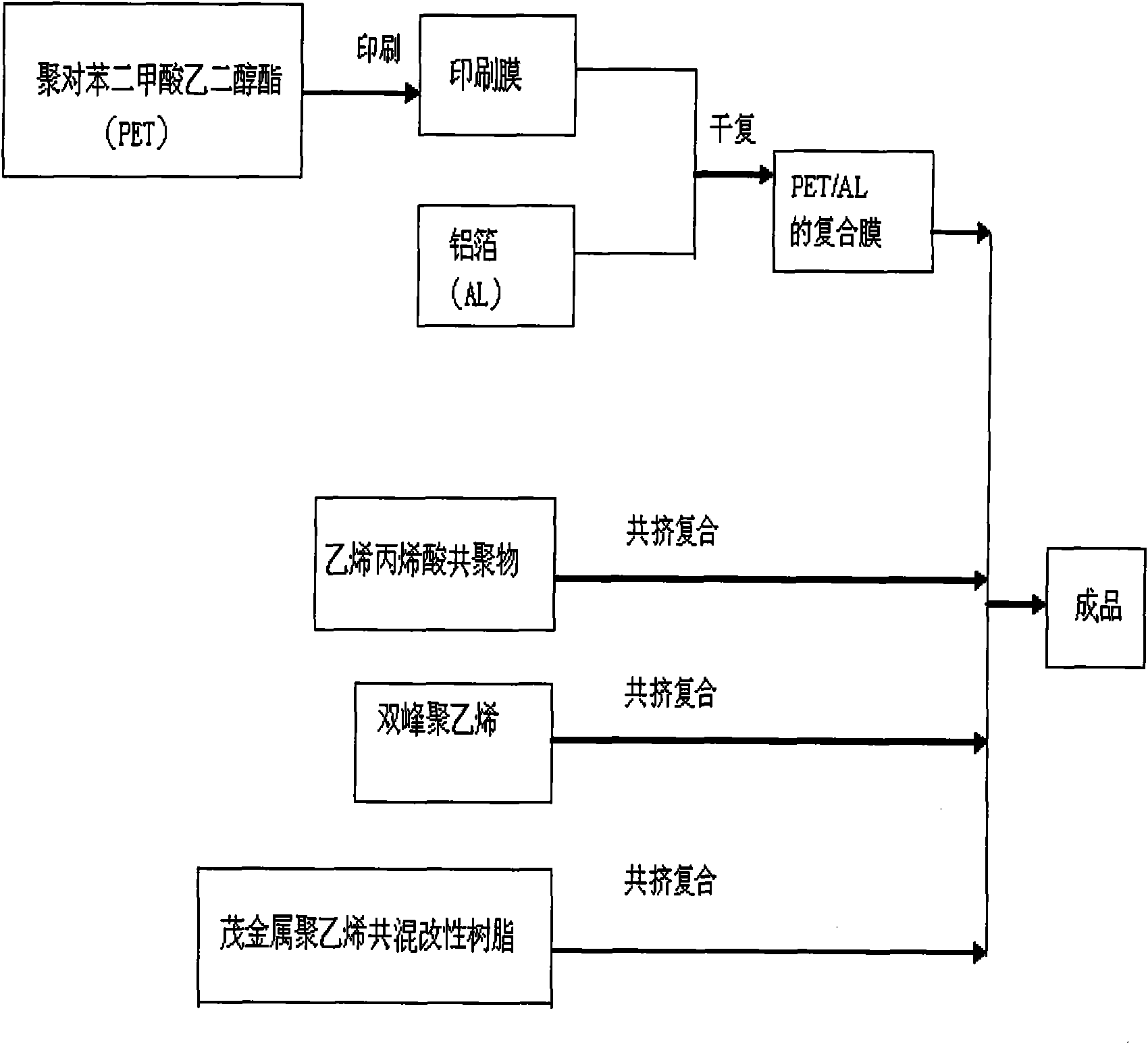

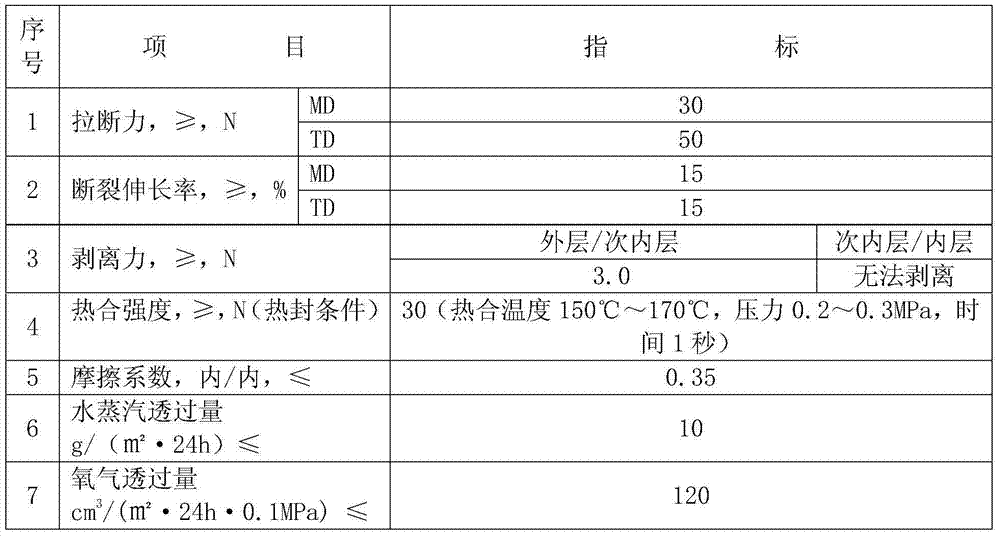

Composite membrane for sauce and preparation method thereof

ActiveCN101624112AGood fragrance retentionGood low temperature heat sealabilityFlexible coversWrappersLow-density polyethylenePolyethylene terephthalate

The invention discloses a composite membrane for sauce and a preparation method thereof. The composite membrane sequentially comprises a polyethylene glycol terephthalate layer, an aluminum foil layer, an ethylene acrylic multipolymer layer, a double-peak low-density polyethylene layer and a metallocene polyethylene blending and modifying resin layer. The preparation method is characterized by comprising the following steps: dry compounding, preparing the metallocene polyethylene blending and modifying resin layer and blending and compounding. Compared with the prior art, the composite membrane for sauce has high sealing strength, short hot seal time, good sealing effect, good sealing planeness, good pollution resistance, medium resistance, low cost, no delamination, and the like.

Owner:HUANGSHAN NOVEL

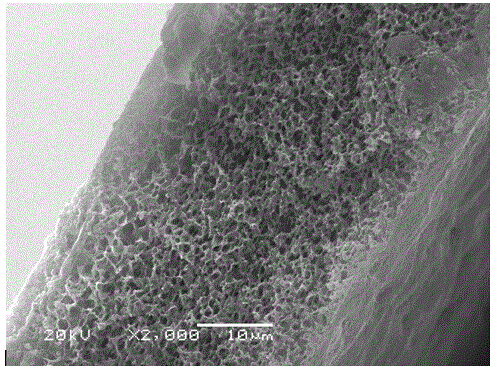

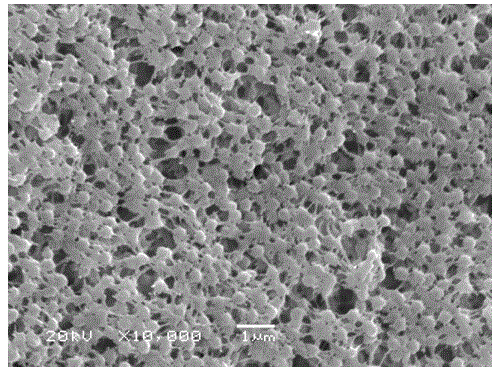

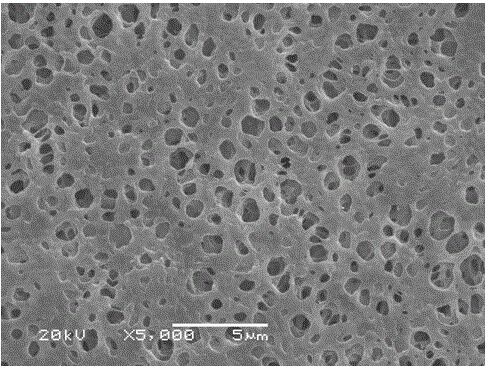

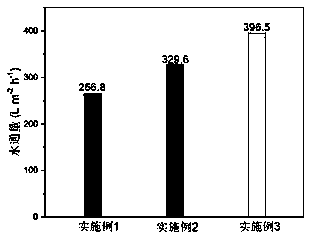

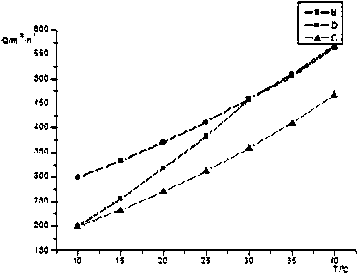

Preparation method of high-flux PVDF (polyvinylidene fluoride) porous membrane

ActiveCN104971631AIncrease water fluxImprove hydrophilicitySemi-permeable membranesEngineeringBovine serum albumin

The invention discloses a preparation method of a high-flux PVDF porous membrane. The method comprises the following steps: mixing PVDF, a highly hydrophilic polymer, a pore-forming additive, deionized water, a solvent and graphene powder, curing, stirring, standing, defoaming so as to obtain membrane casting liquid, and forming a wet membrane from the membrane casting liquid in a scraping manner; pre-evaporating the wet membrane in air, putting the pre-evaporated membrane in a solidification bath, and soaking to obtain a primary membrane in the deionized water; putting the primary membrane in the deionized water, performing heating activation, soaking in absolute ethyl alcohol and n-butyl alcohol, and airing in the air. According to the method, graphene nano-particles with two-dimensional structures are used as additives, the pure water flux can be up to 800L*m<-2>*h<-1> or more, and the rejection rate on bovine serum albumin is 98% or more; the hydrophilic polymer is added for performing the activation on the primary membrane, so that the hydrophilia of the PVDF membrane is greatly improved, and the membrane surface contact angle is up to 59.8 degrees; a porous membrane material is adopted, so that the structure is controllable, and the pore diameter range is controlled to be within 0.1-5 microns.

Owner:CENT SOUTH UNIV

Water-based paint

ActiveCN103614032APhenomena that reduce the apparent effectPhenomena that affect the appearanceAntifouling/underwater paintsPaints with biocidesCoated surfaceEmulsion

The invention provides a water-based paint. The water-based paint comprises potassium methyl silanolate and a wetting agent with an emulsification function. After the water-based paint provided by the invention is coated on a wall surface polluted by greasy dirt, the wetting agent penetrates into the surface of the greasy dirt for emulsifying oil into small liquid drops, the small liquid drops enter into a coating to react with the potassium methyl silanolate in the coating to be cured into the coating as filler of the coating, so that a purpose of beautifying and cleaning is achieved, and pre-treatments for refreshing the wall surfaces can be reduced. Meanwhile, an emulsion with high stain resistance is selected to co-act with organic silicon, so that the formed coating surface is easy to clean, and long-term decorative and protective functions are provided. Besides, as the organic silicon component is contained, the water-based paint provided by the invention has better pollution resistance.

Owner:广州富美奥涂料有限公司

Use of residual active sludge protein as foam drilling liquid and preparing method thereof

This invention involves the surplus activation and pollutes proteins as the application of the foam well drilling liquid and prepares the method, utilize surplus active mud person who foam of protein is it foam the pharmaceutical as foam well drilling to use it for, it is to use active mud the impractical law or alkali law that it prepares the method, yes temperature is 110-148 deg.C hydrolysis one hour under the terms, it is appear impurity win protein liquid, and then go protein liquid after the impurity transfer pH value to filter, to a little becoming used as preparing hydrolysising proteins of foam well drilling liquid alkalinly promptly, and then make and foam pharmaceutical and dispose the foam well drilling liquid with the protein hydrolysats. Invention this utilize surplus active mud characteristic of foaming of protein, hydrolysis active mud protein regard as foam well drilling liquid foam the pharmaceutical, its bubble is of good performance, the foaming amount is big, can produce a large number of foam after contacting the gas.

Owner:HUBEI UNIV

Hydrophilic porous diffusion barrier and its prepn. method

InactiveCN1868573AGood anti-pollutionLow costSemi-permeable membranesPhase conversionPolyvinyl alcohol

A hydrophilic porous separating membrane is prepared by phase conversion method. Its membrane forming liquid contains modified polyvinyl alcohol, which is modified by acetalizing, esterifying or etherifying, solvent and pore-forming agent.

Owner:TIANJIN MOTIAN MEMBRANE ENG & TECH +1

Method for preparing UiO-66 composite membrane material

InactiveCN108786494AIncrease water fluxGood anti-pollutionMembranesUltrafiltrationPhase conversionUltrafiltration

The invention discloses a method for preparing a UiO-66 composite membrane material and belongs to the technical field of composite membrane materials. By adopting the method, UiO-66 is coated with polydopamine, so that high compatibility can be achieved for MOFs (Metal organic Frameworks) and polymers. The method comprises the following steps: coating UiO-66 with polydopamine, dispersing a polydopamine coated MOF material into N,N-dimethylacetamide, carrying out ultrasonic treatment, preparing a casting membraneliquid of polyvinylidene fluoride, centrifuging and defoaming the casting membraneliquid, scraping films on a glass plate, and carrying out phase conversion in an N,N-dimethyl acetamide solution, thereby obtaining membranes. By adopting the method, an ultrafiltration flat membranematerial of polyvinylidene fluoride is prepared from UiO66, and the composite membrane material has the advantages of being high in water flux, high in pollution resistance, high pressure resistance,and the like.

Owner:KUNMING UNIV OF SCI & TECH

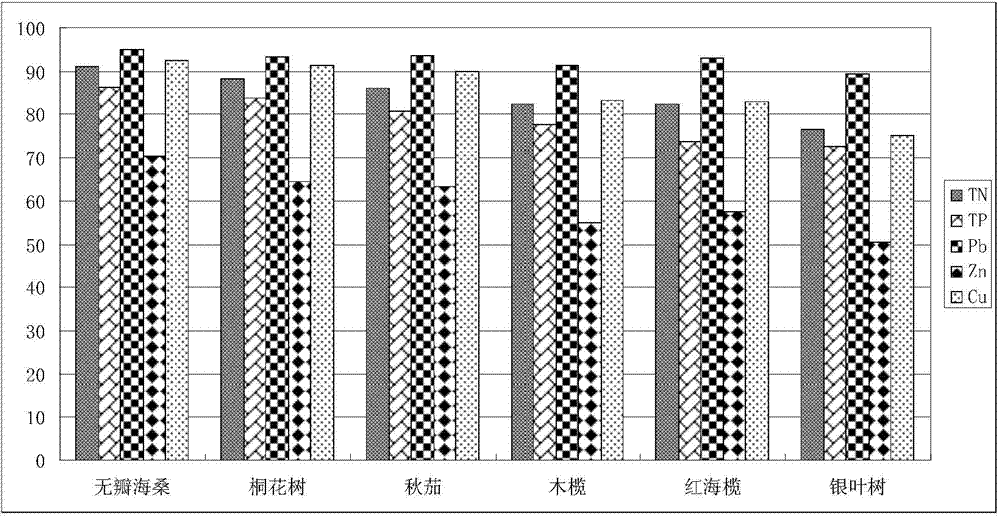

Construction and building method of anti-pollution mangrove forest protection forest

InactiveCN104488656AImprove stain resistanceAvoid influenceClimate change adaptationAfforestationProtection forestSonneratia caseolaris

The invention discloses a construction and building method of an anti-pollution mangrove forest protection forest. The construction and building method comprises the following steps that 1-2-year seedling mangrove plant species with the standard municipal sewage rate being more than 50% are selected according to municipal sewage standards; annular pagatpat annual or laguncularia racemosa biennial seedling forest zone with the width being 15m-20m is planted and constructed on mudflats which have more serious offshore pollution and great storms and are unsuitable for afforestation; after a pagatpat or laguncularia racemosa forest is planted for 2-3 years, the mangrove plant species are planted in a space in an offshore annular zone with the width being 15m-20m; the plant spacing and the row spacing for planting pagatpat or laguncularia racemosa are 1m-2m and 1m-2m respectively; the plant spacing of planting a local mangrove forest is 0.5m-1m and the row spacing is 0.5m-1m. According to the construction and building method, the mangrove forest is built on the mudflats which have more serious offshore pollution and great storms and are unsuitable for afforestation, so that the local mangrove forest can be built while exotic species are planted; the landscape ecology is coordinated and the species are diversified and abundant; the mangrove forest is high in survival rate and has good anti-pollution and anti-storm performances.

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

Hydrophilic polysulfone-type membrane and preparation method thereof

ActiveCN106943899AImprove hydrophilicityGood anti-pollutionMembranesSemi-permeable membranesInorganic saltsFiltration membrane

The invention relates to a hydrophilic polysulfone-type membrane and a preparation method thereof. The polysulfone-type membrane is composed of: a polysulfone polymer, a compound membrane composed of acrylonitrile-maleic anhydride polymer, and a dopamine layer coating the compound membrane. With the polysulfone polymer as a membrane material, a less amount of the acrylonitrile-maleic anhydride polymer is added to a membrane producing liquid; because the polymer contains large amount of carboxyl group, hydrophilicity of the membrane is significantly improved. Then the membrane is coated with the dopamine for several times, so that the hydrophilicity of the membrane is further improved, and pore size of the membrane is further reduced; after modification, the hydrophilicity of the membrane is significantly improved, and the pore size is changed from the range of ultra-filtration to nano-filtration. The nano-filtration membrane allows inorganic salts and small molecules to pass through while dye large molecules are blocked, so that the membrane can be used for desalting dyes. The modified membrane, when being used for desalination of direct red dye, can reach 80-99% in retention rate.

Owner:NANJING UNIV OF TECH

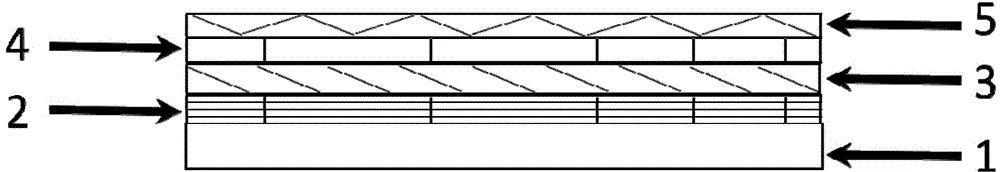

Hyaluronic acid modified surface plasma resonance spectrometer chip and preparation method thereof

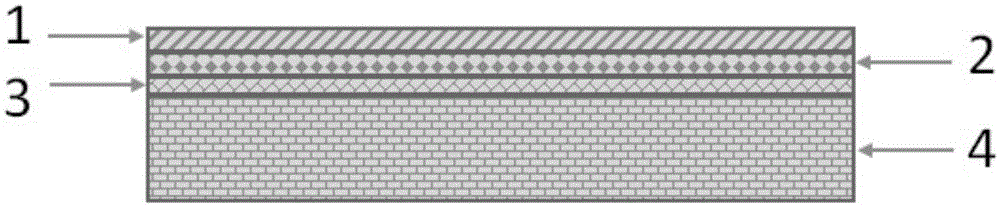

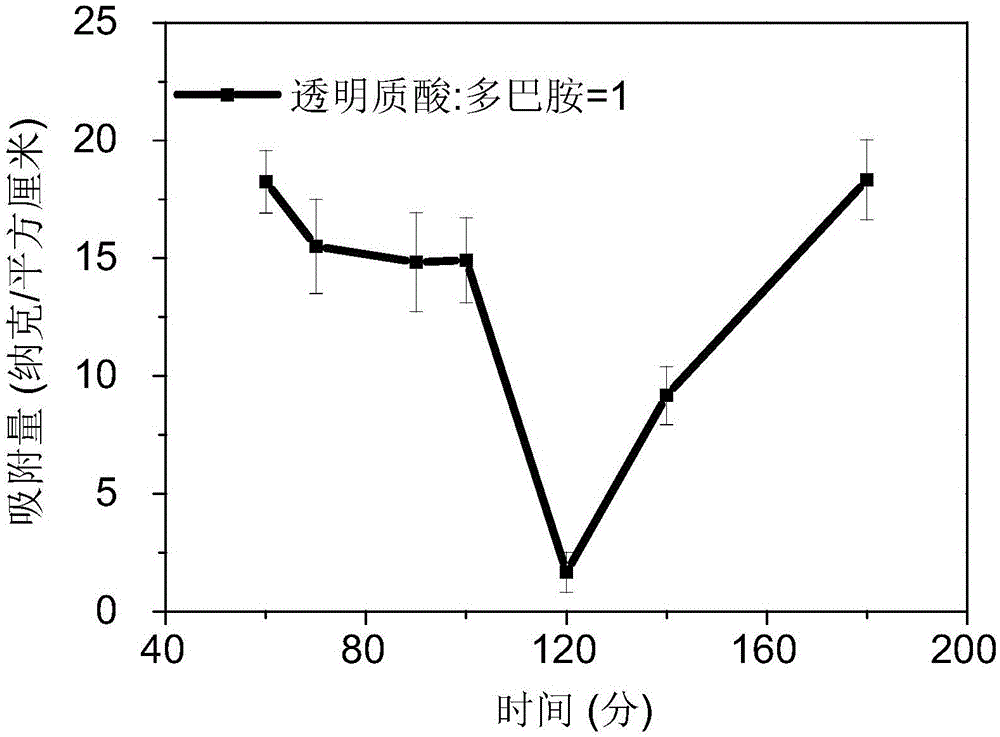

InactiveCN104155453AIncrease the loading capacityImprove biocompatibilityMaterial analysis by optical meansBiological testingCarboxylationChemistry

The invention relates to a hyaluronic acid modified surface plasma resonance spectrometer chip and a preparation method thereof. The structure of the hyaluronic acid modified chip is orderly composed of a glass layer, a chromium layer, a gold film layer, a mercapto-alcohol monomolecular layer and a hyaluronic acid layer. The surface of the gold film is modified by use of mercaptoundecanol and then a self-assembly single layer can be formed; next, the self-assembly single layer is epoxidized by use of epoxy chloropropane and then immersed into a hyaluronic acid solution, covalently modified with a layer of hyaluronic acid and further subjected to carboxylation by use of bromoacetic acid, and finally, the hyaluronic acid-based surface plasma resonance spectrometer chip can be obtained. The chip has excellent antifouling property in a single protein, a natural complex sample and 10% blood serum, and has high immobilization capacity and excellent compatibility for biomacromolecular antibodies, and high-specificity sensitive quick detection on target molecules in a complex protein system is realized. The chip has excellent antifouling property, and is low in raw material cost; the preparation method of the chip is easy to operate; the chip has excellent economic feasibility and practicability.

Owner:TIANJIN UNIV

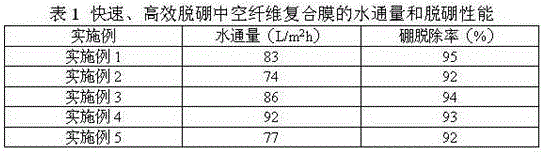

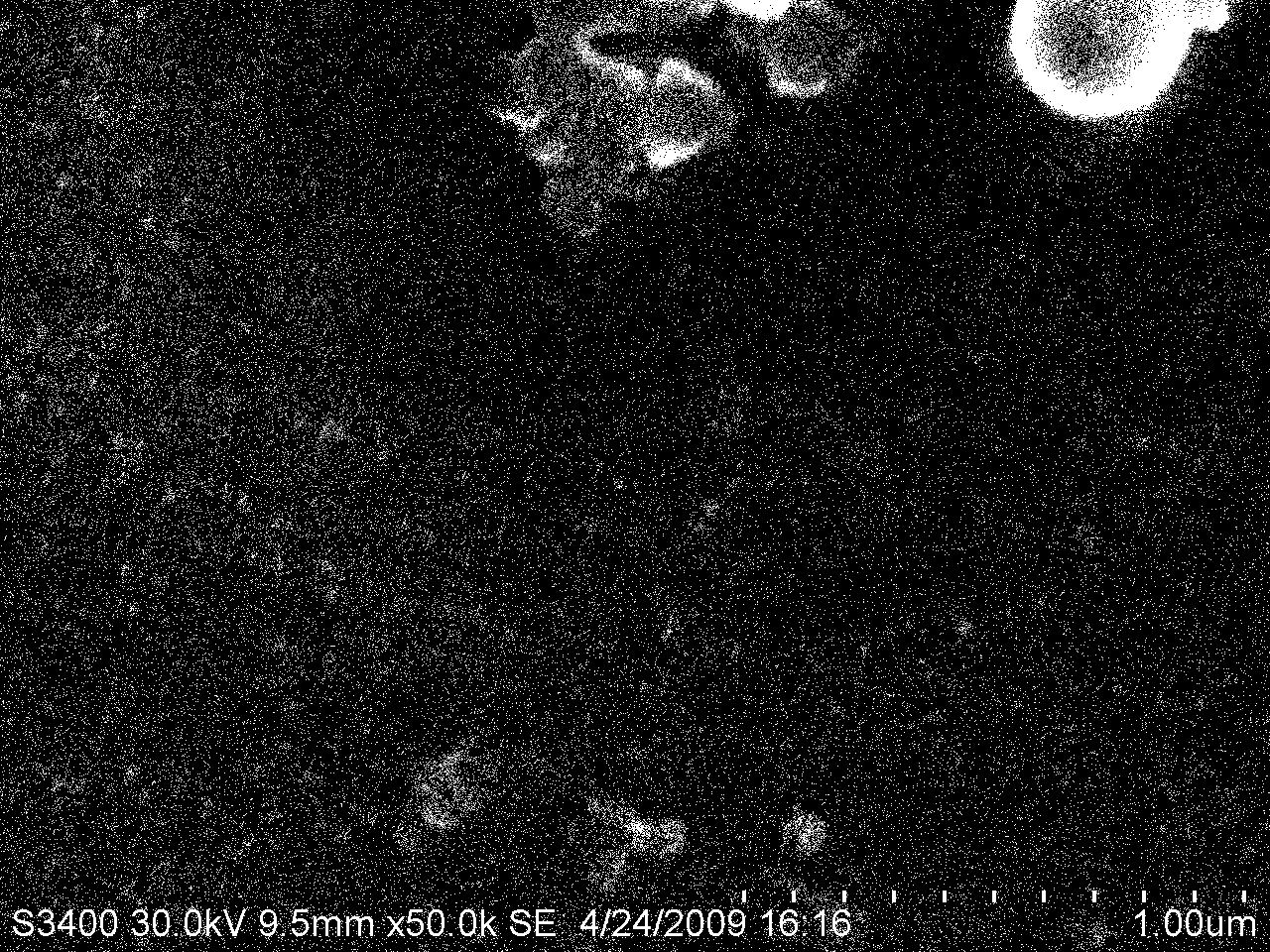

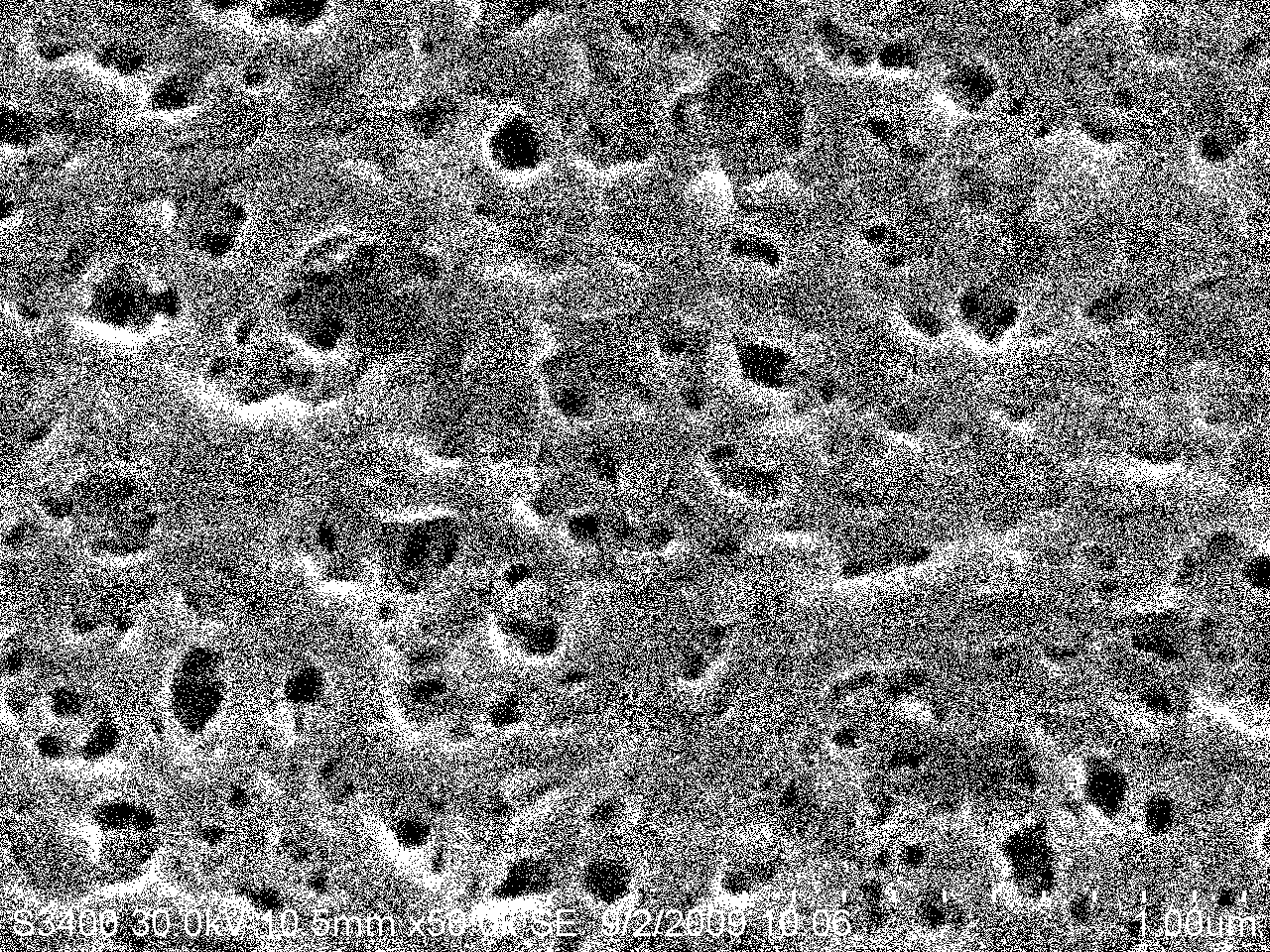

Fast and efficient boron removal hollow fiber composite membrane and preparation method thereof

The invention discloses a fast and efficient boron removal hollow fiber composite membrane and a preparation method thereof. In the invention, DA / PEI is applied to the surface of a hollow fiber membrane by a one-step process, and a polyhydroxyl composite membrane is prepared through a ring-opening reaction with glycidol through the polyamino at the branch end. The method disclosed by the invention is simple and easy to operate while the cost is low; meanwhile, with a relatively large contact area relative to a flat sheet membrane, the hollow fiber membrane is easy to clean and has relatively good application prospect in industrial boron removal; and the prepared hollow fiber composite membrane can fast and efficiently realize a boron removal effect and has a good development prospect in a seawater desalination process targeted at drinking water. Moreover, a hollow fiber composite membrane with high throughput and high pollution resistance can be prepared by selecting polyethyleneimine different in molecular weight and can be widely applied to the industrial fields such as oil-water separation and protein and drug purification.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

Thermo-sensitive type ultrafiltration membrane and preparation method thereof

InactiveCN103418255AImprove hydrophilicityImprove pollutionSemi-permeable membranesWater basedUltrafiltration

The invention relates to a thermo-sensitive type ultrafiltration membrane and a preparation method thereof. The thermo-sensitive type ultrafiltration membrane comprises main components of 85-90 wt% of a polyvinylidene fluoride membrane material and 10-15 wt% of a thermo-sensitive type amphiphilic water-based polymer. The preparation method is as below: first synthesizing the thermo-sensitive type amphiphilic water-based polymer; then mixing well the high-molecular film material and the polymer; mixing the mixture of the high-molecular film material and the polymer, a pore forming agent and a solvent for a film casting liquid to prepare a film casting liquid; and preparing the film casting liquid into a flat sheet membrane, a spiral-wound membrane and a hollow-fiber membrane. The ultrafiltration membrane provided by the invention has large flux, lasting hydrophilicity and anti-pollution performance, and can response to changes of environmental temperature.

Owner:NINGBO UNIV

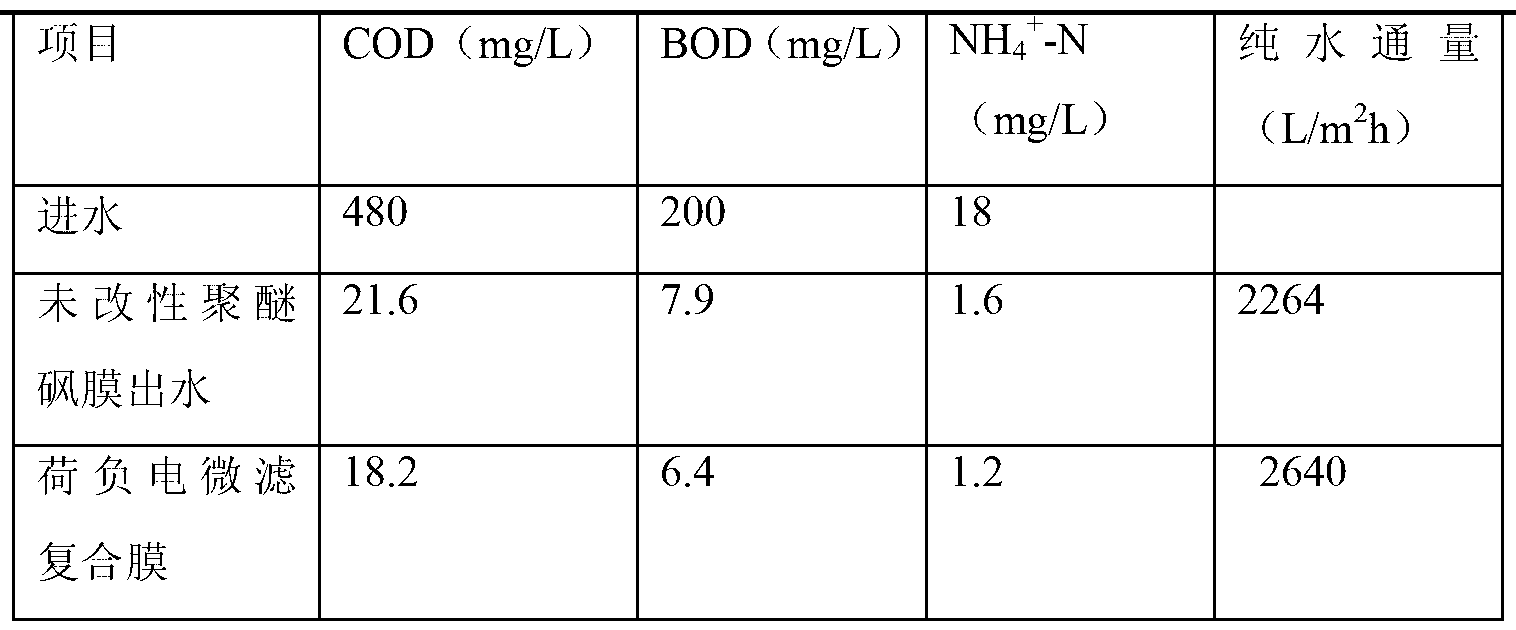

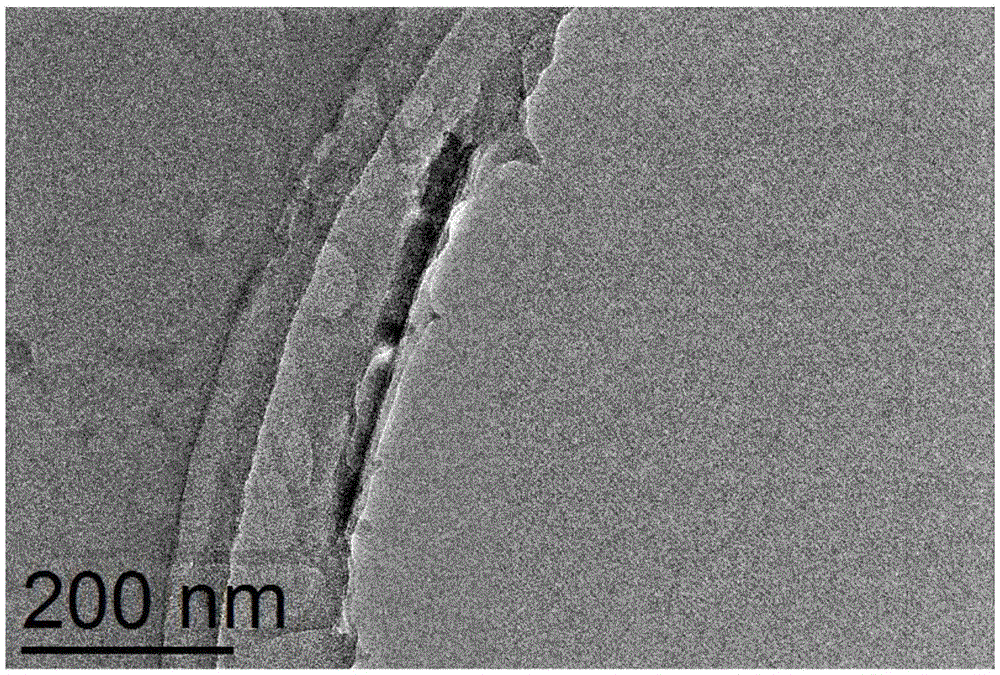

Manufacturing method and application of electronegative composite microfiltration membrane

InactiveCN103272502AGood anti-pollutionShorten the cleaning cycleUltrafiltrationBiological water/sewage treatmentPolyesterOrganic solvent

The invention discloses a manufacturing method of an electronegative composite microfiltration membrane, which comprises the following steps of: (1) dissolving polyether sulfone in an organic solvent, adding an additive and an electronegative reagent, stirring and dissolving sufficiently, filtering an undissolved substance, standing, obtaining membrane casting liquid, (2) casting the memebrane casting liquid onto polyester non-woven cloth, scraping a membrane with a scraper, immersing in a coagulating bath for membrane forming, obtaining a polyether sulfone microfiltration membrane, immersing the polyether sulfone microfiltration membrane in an electronegative reagent solution, taking out for drying, and (3) crosslinking the membrane subjected to electronegative treatment in a crosslinking agent solution, washing to be neutral with deionized water, and obtaining the electronegative composite microfiltration membrane. In addition, the invention provides an application of the electronegative composite microfiltration membrane in a membrane bioreactor. Since bacteria and the surfaces of colloids in the membrane bioreactor are electronegative, the prepared membrane is electronegative, has good hydrophilicity, is not easy to pollute, is not required to be cleaned frequently, has high water flux of stable operation, and lowers the sewage treatment cost.

Owner:NANJING UNIV

Preparation method of polysulfone ultrafiltration membrane

InactiveCN102921317ARaw materials are easy to getEasy to prepareSemi-permeable membranesPolysulfone membraneUltrafiltration

The invention discloses a preparation method of polymeric membrane, in particular to a preparation method of polysulfone ultrafiltration membrane. The preparation method comprises the following steps: a certain concentration of surfactant is dissolved in N-N dimethylacetamide solution at the temperature of 70 DEG C, after the surfactant is completely dissolved, polysulfone with the mass fraction of 18% is added, after the two are completely dissolved, prepared casting membrane solution is used to prepare membrane by a machine membrane scraping method, and the obtained polysulfone membrane is dipped in pure water for a period of time, so that the performance stability of the polysulfone membrane is improved, a hydrophilic modifier is dissolved in water, and the void ratio of the ultrafiltration membrane is improved. The preparation method has the advantages that the selection separation performance is not lower than that of existing ultrafiltration membrane, the materials are easily obtained, the preparation method is simple, and the membrane surface has good hydrophily and good antifouling property.

Owner:HANGZHOU WATER TREATMENT TECH DEV CENT

Cellulose acetate/nano cellulose blended ultrafiltration film

ActiveCN105107390AImprove molecular structureAdd surface functional groupsSemi-permeable membranesN dimethylformamideFiltration

The invention discloses a cellulose acetate / nano cellulose blended ultrafiltration film, belonging to the technical field of films. The blended ultrafiltration film is characterized by being prepared through the steps of firstly, pretreating raw material filter paper by adopting a water solution of alkali system sodium hydroxide / urea, carrying out suction filtration to be neutral, baking, then carrying out acidolysis by using a sulfuric acid solution, and diluting, centrifuging and drying to obtain nano cellulose; and then by adopting cellulose acetate and nano cellulose as film materials, adding an additive, selecting acetone and N,N-dimethylformamide as a mixed solvent, stirring uniformly, then defoaming, and after film scraping, soaking the material into a gel tank with a certain temperature to obtain the blended ultrafiltration film. The blended ultrafiltration film has the effects and benefits that the obtained ultrafiltration film has the good performances of cellulose acetate / nano cellulose, the porosity of the cellulose acetate / nano cellulose ultrafiltration film is improved, the pore diameter is increased, the hydrophilicity is improved, the ultrafiltration film has the advantages of high flux, good pollution resistance, good mechanical performance and the like, the operation is simple, the pretreatment is not needed, and the cost is low.

Owner:DALIAN UNIV OF TECH

Bottom bonding material used in preservative treatment of chimney and flue

ActiveCN101602927AReduce load requirementsStrong weather resistanceNon-macromolecular adhesive additivesWeather resistanceStrong acids

The invention relates to a bottom bonding material used in preservative treatment of a chimney and a flue. The bottom bonding material is modified silicon rubber (M50), and surface modified polytetrafluoroethylene (DS1) of a surface preservative material is bonded to the inner walls of the chimney and the flue; the modified silicon rubber (M50) is formed by modifying room-temperature vulcanized silicon rubber through nano SiOx and TiO2 additives, and the weight ratio of the room-temperature vulcanized silicon rubber to the nano SiOx to the TiO2 is 100:2-6:1-3; and x in the nano SiOx is 1.2 to 1.6. The bottom bonding material can provide effective bonding for DS1 (surface modified polytetrafluoroethylene board) with temperature resistance and strong corrosion resistance in the preservative treatment of the chimney and the flue so that an integral preservative layer has good temperature resistance, strong adhesive force, super-strong acid resistance, good thermal shock resistance, good weather resistance, strong permeability resistance, strong pollution resistance and good scouring resistance.

Owner:重庆大众防腐股份有限公司

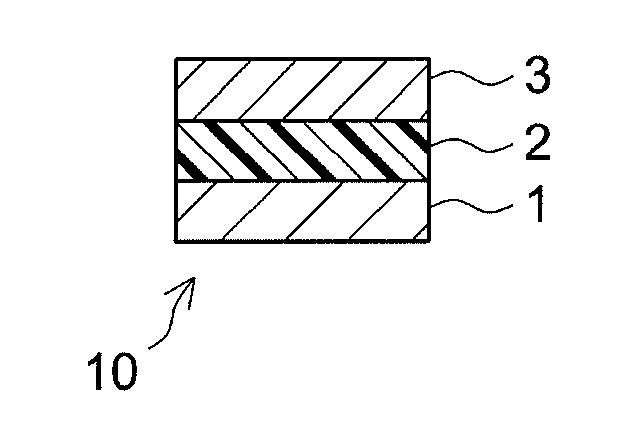

Pressure-sensitive adhesive composition for surface protective films and use thereof

InactiveUS20120064339A1Easy to controlImprove performanceFilm/foil adhesivesEster polymer adhesivesUltimate tensile strengthAcrylic polymer

The present invention provides a surface protective film that exhibits small differences in peel strength on account of the surface state of an adherend and that is excellent in anti-contamination to adherends, and a pressure-sensitive adhesive (PSA) composition for the protective film. The PSA composition provided by the present invention comprises 0.01 to 5 parts by weight of a compound containing an oxypropylene group with respect to 100 parts by weight of an acrylic polymer as a base polymer. A surface protective film 10 provided by the present invention has a PSA layer 2, formed using the above PSA composition, on one or both sides of a support 1.

Owner:NITTO DENKO CORP

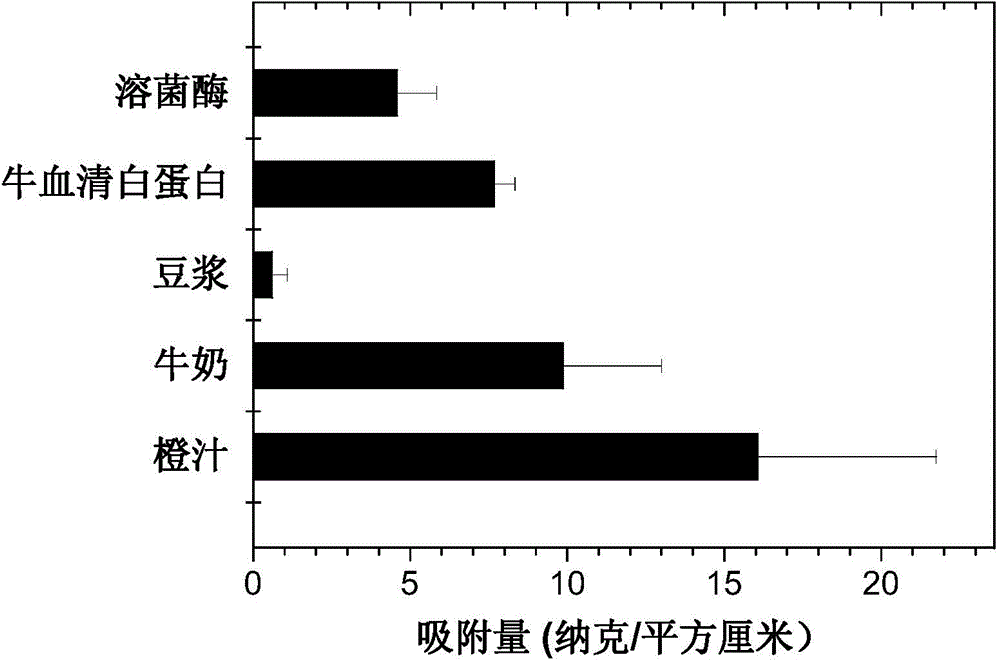

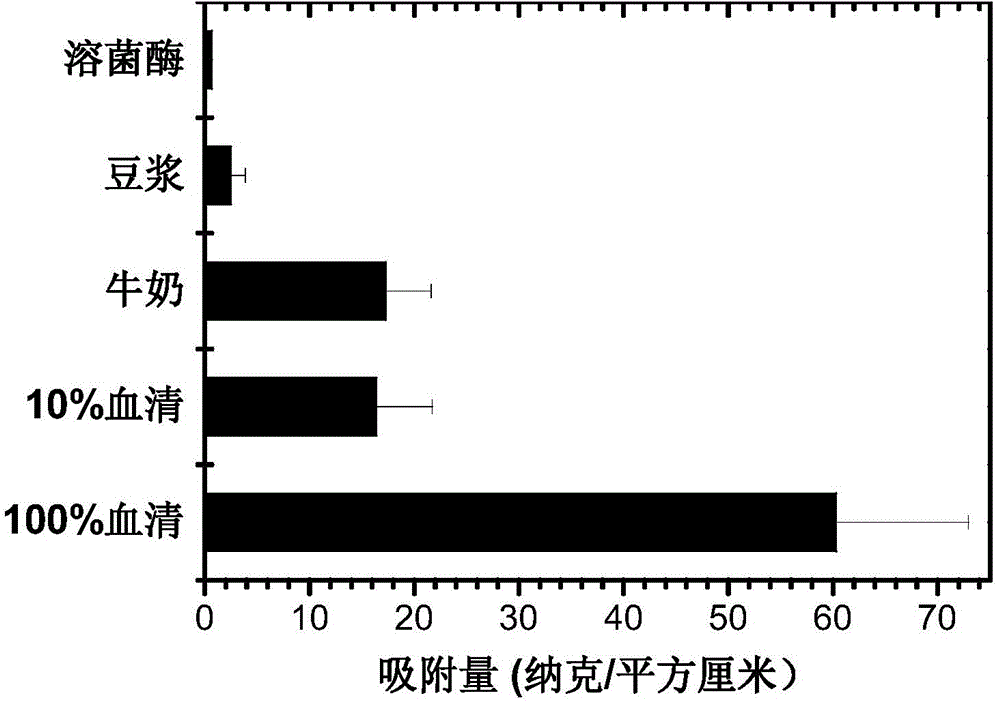

Surface plasma resonator chip based on modification of hyaluronic acid assisted by dopamine and preparation method of chip

ActiveCN105044359AExcellent anti-protein adsorption performanceEasy to recycleMaterial analysis by optical meansBiological testingSputteringDopamine

The invention relates to a surface plasma resonator chip based on modification of hyaluronic acid assisted by dopamine, and a preparation method of the chip. The chip comprises a structure consisting of a glass layer, a chromium layer, a sensing layer, and a dopamine and hyaluronic acid mixed layer in sequence. The preparation method comprises: firstly, coating a BK7 glass substrate with the chromium layer through vacuum sputtering, and then coating the chromium layer with the sensing layer to obtain a sensing chip; immersing the sensing chip in a solution mixed by concentrated sulfuric acid and hydrogen peroxide; and immersing the obtained chip into a hyaluronic acid solution of dopamine to form the dopamine and hyaluronic acid mixed layer. The surface plasma resonator chip based on hyaluronic acid is high in stability, and is unchangeable in pollution resistance after stored for 4 months in a dry state or for 7 days in a phosphate buffer with the pH of 7.4. The chip can be recyclable for reuse, and after ten times recycling, the chip can also keep good pollution resistance. The preparation method is simple in operation and has good economic practicability.

Owner:TIANJIN UNIV

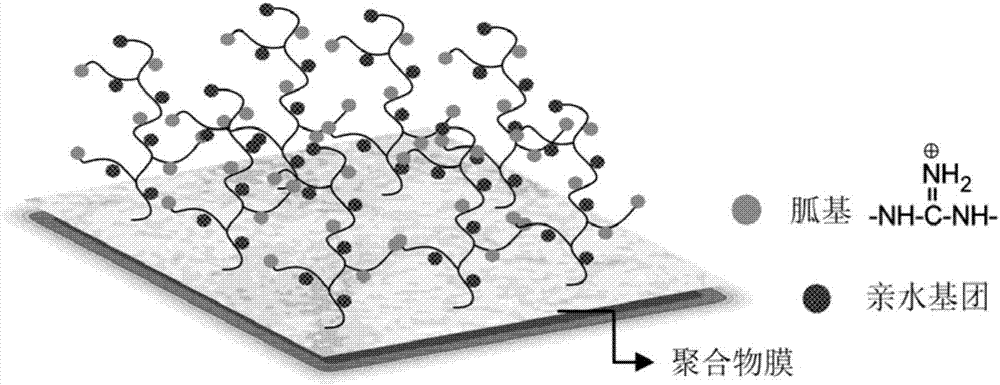

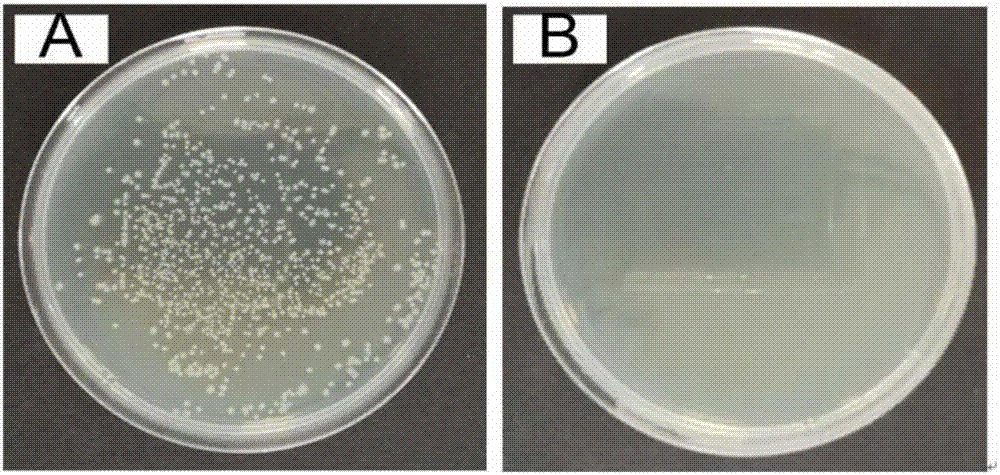

Method for preparing antibacterial and antifouling separation membrane through surface grafting modification

ActiveCN107243261AMaintain permeate fluxGood choiceMembranesSemi-permeable membranesPermeationPolyamine

The invention discloses a method for preparing an antibacterial and antifouling separation membrane through surface grafting, and grafting a functional guanidyl macromolecular antimicrobial material to a surface of the separation membrane. The method comprises the following steps: firstly, mixing guanidine salt, polyamine micromolecule and polyamine polymer uniformly; performing heating reflux reaction under the protection of nitrogen to prepare the functional guanidyl macromolecular antimicrobial material; then, contacting the separation membrane with a mixed aqueous solution of dopamine hydrochloride and tris(hydroxymethyl)aminomethane to obtain a polydopamine-modified separation membrane; grafting the guanidyl macromolecular antimicrobial material to the surface of the membrane to obtain the guanidyl macromolecular grafted polymer separation membrane. The method provided by the invention is simple in preparation process, mild in preparation condition, easy in amplification, and suitable for surface modification of a plurality of separation membranes; the prepared separation membrane can maintain original permeation selectivity of the polymer separation membrane basically, and maintain excellent antibacterial performance and anti-pollution performance durably and efficiently in a use process.

Owner:TIANJIN UNIV

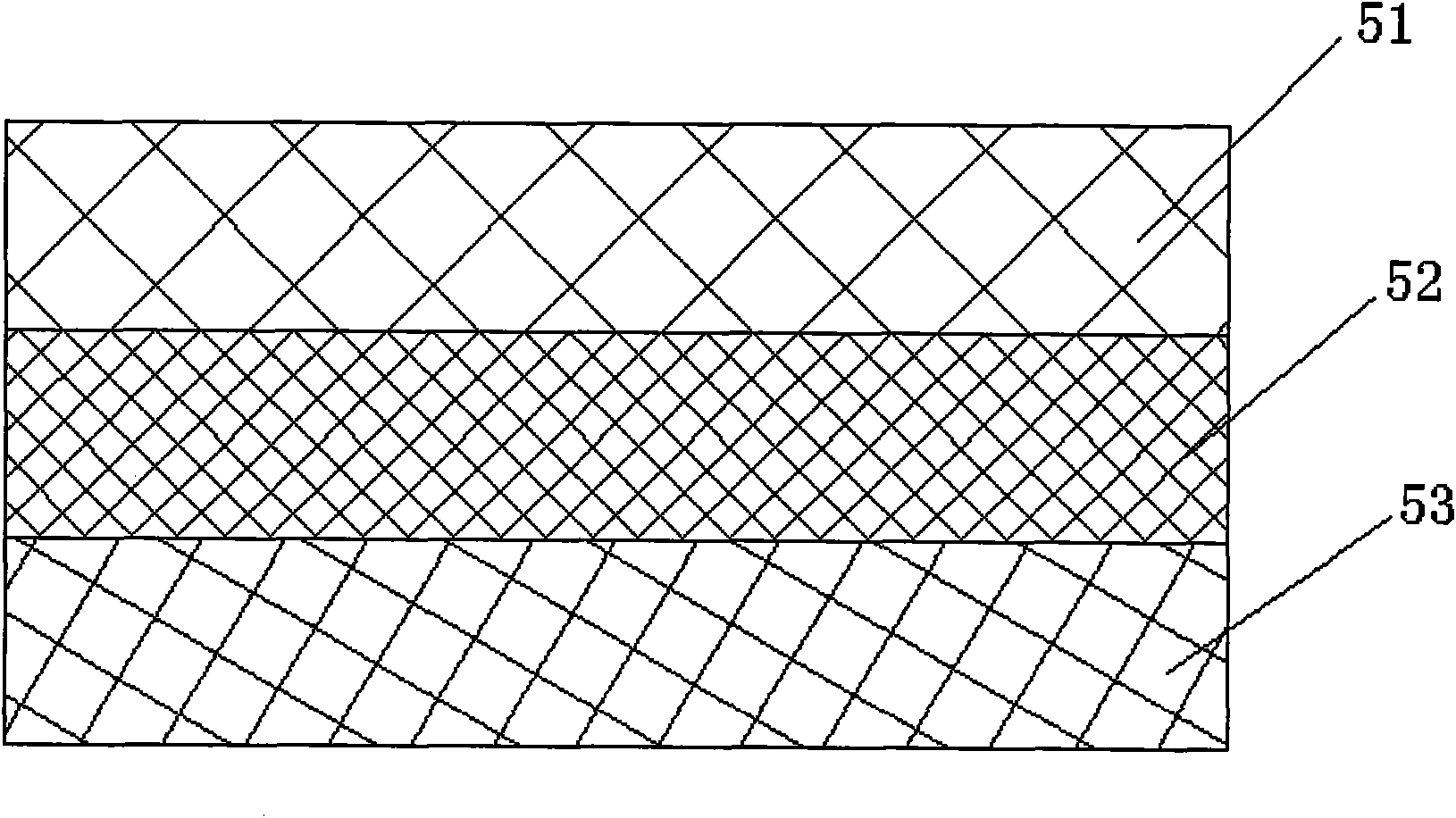

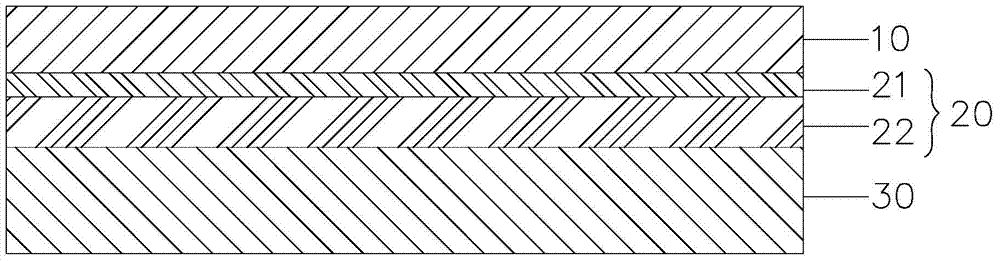

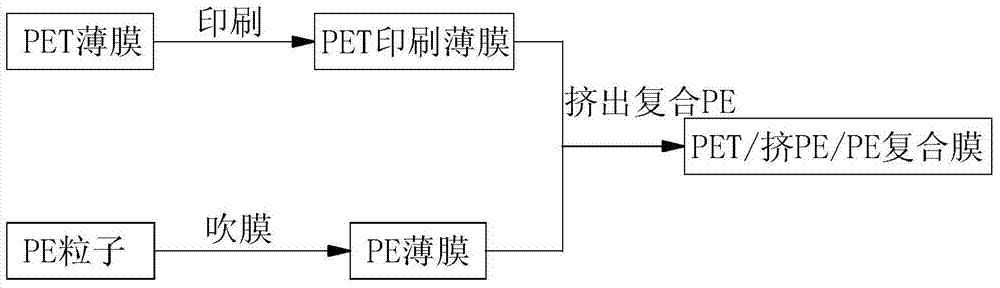

Chilli sauce packaging composite film and preparation method thereof

ActiveCN104260520AHigh sealing strengthLow costFlexible coversWrappersComposite structureLow-density polyethylene

The invention specifically relates to a chilli sauce packaging composite film and a preparation method thereof. The packaging composite film is formed by tightly attaching a PET printing thin film layer which is 12 microns thick, a functional polyethylene thin film layer which is 15-20 microns thick and a PE thin film layer which is 60-80 microns thick, wherein the PET printing thin film layer, the functional polyethylene thin film layer and the PE thin film layer are connected in sequence; the functional polyethylene thin film layer is of a double-layer co-extrusion composite structure, and one side, which is adhered to the PET printing thin film layer, of the functional polyethylene thin film layer is provided with an ethylene acrylic acid copolymer layer; one side, which is adhered to the PE thin film layer, of the functional polyethylene thin film layer is provided with a low-density polyethylene and white master batch blending layer; the weight ratio of low-density polyethylene to white master batches is 20 to 3; the thickness ratio of the ethylene acrylic acid copolymer layer to the low-density polyethylene and white master batch blending layer is 2 to 3. The composite film has high performance such as high sealing intensity, low cost, good sealing effect, high sealing flatness and high pollution resistance and also has the advantages of good anti-medium effect, low cost, difficulty in layering and the like.

Owner:HUANGSHAN NOVEL

Double-membrane pressure-bearing water-based drilling fluid

The invention discloses a double-membrane pressure-bearing water-based drilling fluid comprising the following materials by mass: 1000 parts of water, 10-30 parts of bentonite, 5-10 parts of soda ash, 20-30 parts of a plugging agent, 30-50 parts of a film-forming agent, 2-5 parts of a coating agent, 30-50 parts of a mud shale inhibitor, 5-10 parts of a pH adjusting agent, 5-20 parts of a flow type regulator, 10-40 parts of a filtration loss reducing agent and 20-30 parts of a borehole wall stabilizer; salt and barite can be appropriately adjusted according to needs, and the double-membrane pressure-bearing water-based drilling fluid solves the special requirements of shale gas well drilling for drilling fluids, especially solves the problems of well leakage and borehole wall stability, and is suitable for well drilling requirements of a two-opening large borehole of a shale gas well.

Owner:中石化石油工程技术服务有限公司 +1

Permeation resisting composite film

ActiveCN105922690AImprove penetration resistanceImprove sealingSynthetic resin layered productsDomestic containersLow-density polyethylenePolyester

The invention discloses a permeation resisting composite film. The permeation resisting composite film comprises a polyester layer, a first polyethylene layer, a polyester aluminum coated layer and a second polyethylene layer from outside to inside in sequence. The second polyethylene layer is composed of a composite layer, a middle layer and a heat sealing layer, wherein the composite layer is composed of low-density polyethylene and linear low-density polyethylene according to the weight ratio of 1:3, the middle layer is composed of low-density polyethylene, linear low-density polyethylene and high-density polyethylene according to the weight ratio of 1:1:1, and the heat sealing layer is composed of low-density polyethylene and metallocene polyethylene according to the weight ratio of 2:1. By improving the formula of the second polyethylene layer and using 2050 glue between the polyester aluminum coated layer and the second polyethylene layer, barrier property and medium resistance of the product are improved greatly while the requirement for heat sealing strength is met; meanwhile, pollution resistance is high, and the permeation resisting composite film is especially suitable for packaging oily substances such as gluten.

Owner:永新股份(黄山)包装有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com