Patents

Literature

59results about How to "Good low temperature heat sealability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite membrane for sauce and preparation method thereof

ActiveCN101624112AGood fragrance retentionGood low temperature heat sealabilityFlexible coversWrappersLow-density polyethylenePolyethylene terephthalate

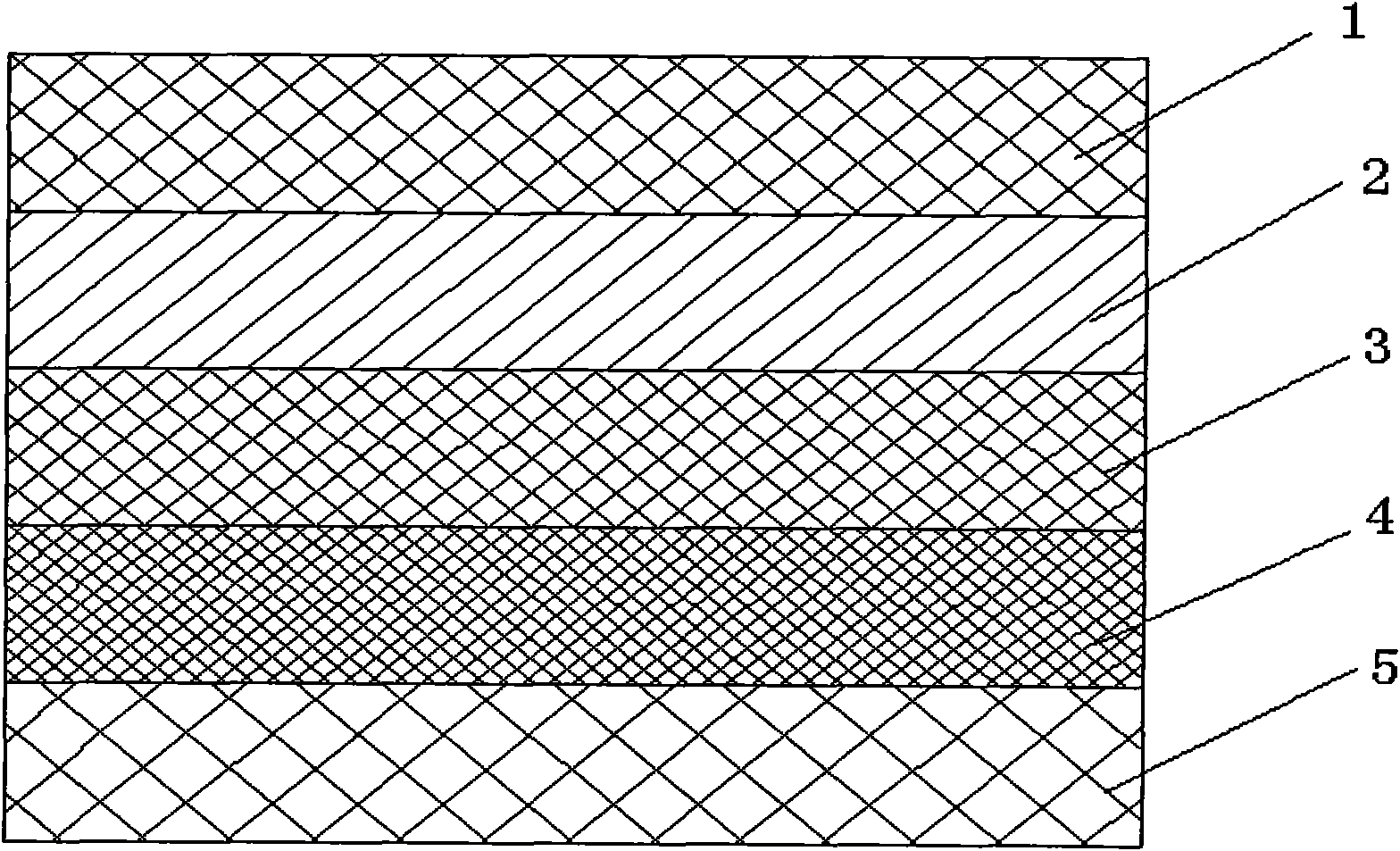

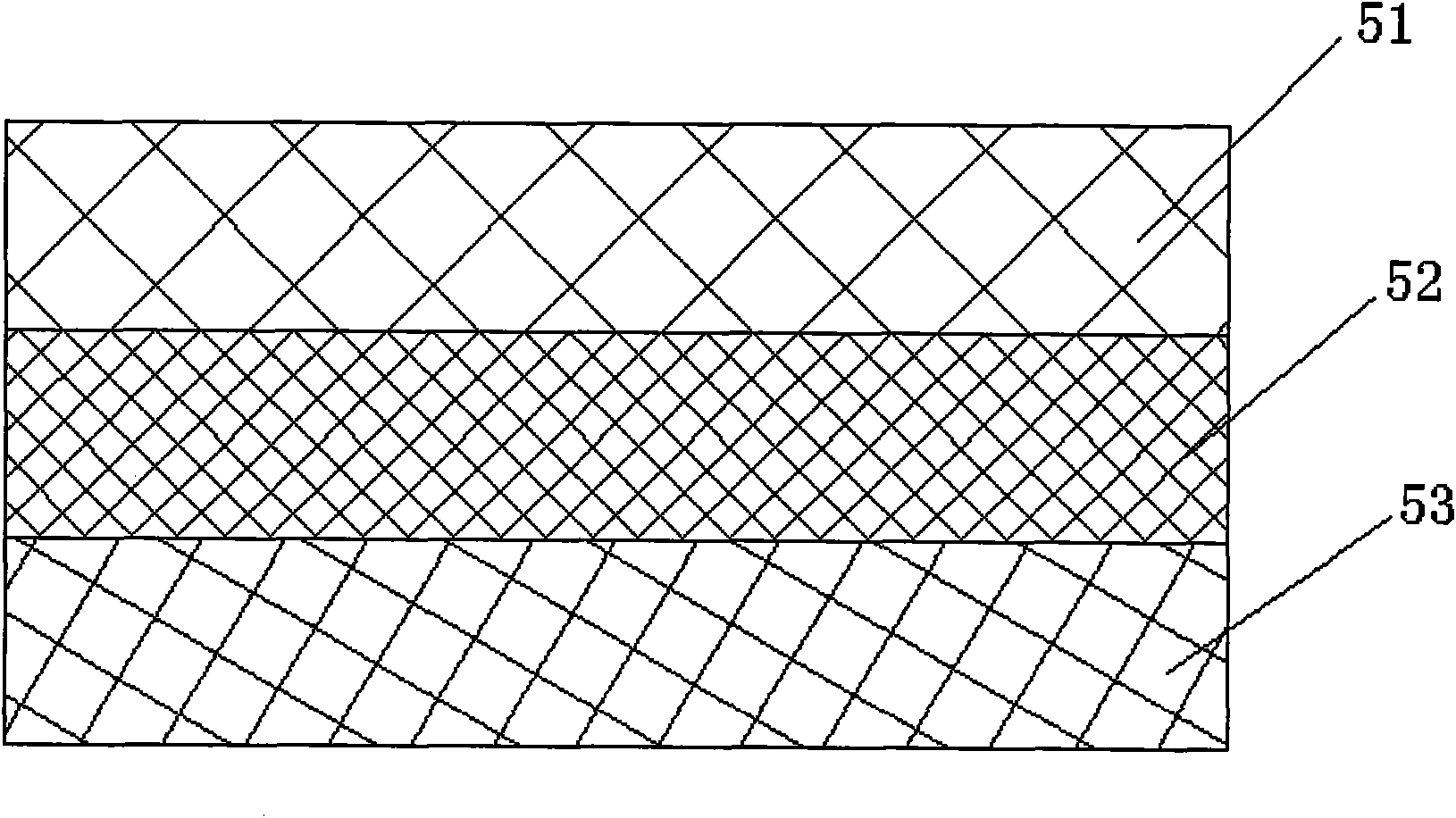

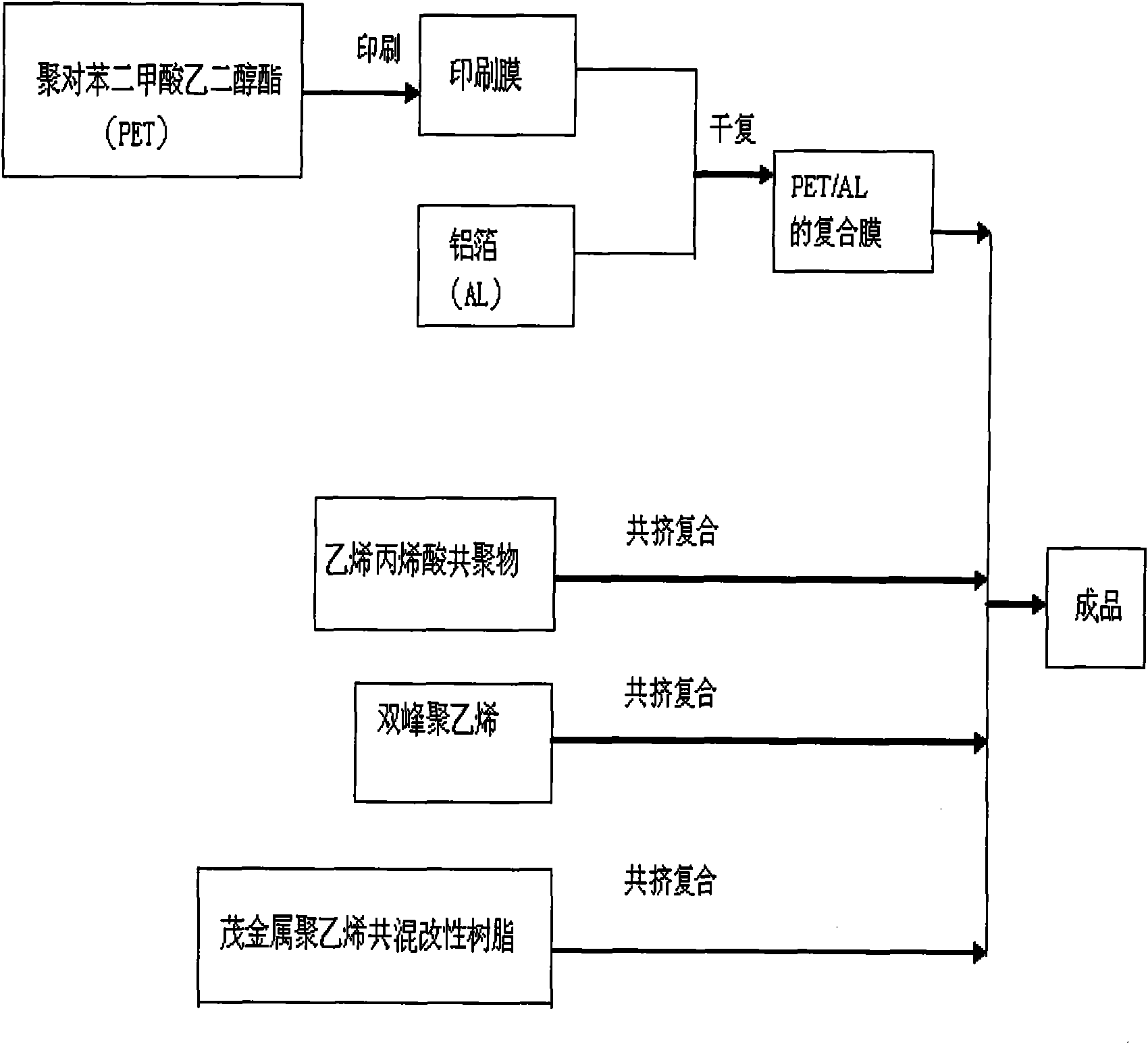

The invention discloses a composite membrane for sauce and a preparation method thereof. The composite membrane sequentially comprises a polyethylene glycol terephthalate layer, an aluminum foil layer, an ethylene acrylic multipolymer layer, a double-peak low-density polyethylene layer and a metallocene polyethylene blending and modifying resin layer. The preparation method is characterized by comprising the following steps: dry compounding, preparing the metallocene polyethylene blending and modifying resin layer and blending and compounding. Compared with the prior art, the composite membrane for sauce has high sealing strength, short hot seal time, good sealing effect, good sealing planeness, good pollution resistance, medium resistance, low cost, no delamination, and the like.

Owner:HUANGSHAN NOVEL

Acrylic acid coating film and its manufacturing method

ActiveCN1686712AGood low temperature heat sealabilityHigh heat sealing strengthLayered productsEmulsionSoftened water

An acrylic acid coated film is composed of a substrate layer, a coated acrylic paint layer and a sandwich layer between the first two layers. Its preparing process includes such steps as preparing acrylic paint from acrylic emulsion, softened water, smoothing agent and detackifier, coating it on the substrate and baking.

Owner:HAINAN SHINER IND

Low-temperature heat sealing aluminium-plated polyethylene blown film and vacuum aluminium-plated film

ActiveCN103434241AImprove stiffnessImprove barrier propertiesSynthetic resin layered productsMetal layered productsDyneVolumetric Mass Density

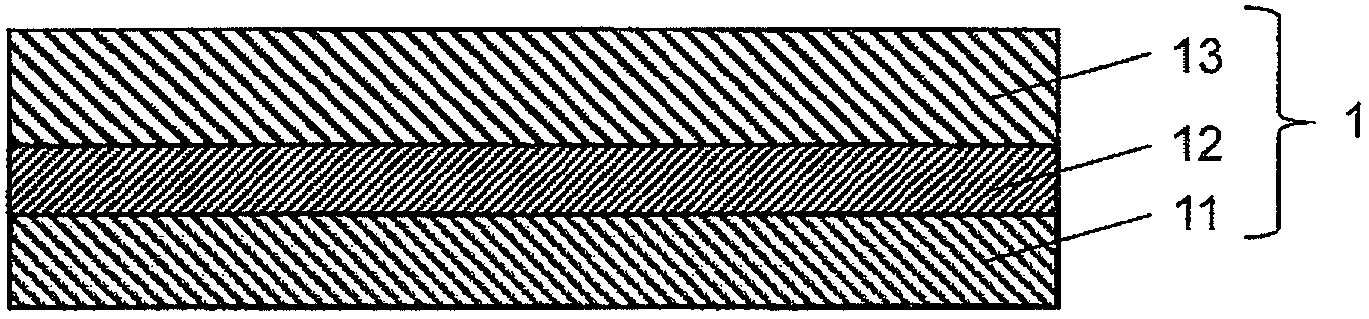

The invention relates to a low-temperature heat sealing aluminium-plated polyethylene blown film. The blown film comprises a body, wherein the body is provided with a composite layer, a base layer and a heat sealing layer from outside to inside in sequence; the ratio of the thickness of the composite layer to the thickness difference between the body and the heat sealing layer is (2:5)-(3:5); the surface tension of the outer side wall of the composite layer is 36-40 dynes. The blown film has the advantages that the film prepared by mixing double-peak linear medium density polyethylene with high density polyethylene has high sealing strength and heat viscosity; the low temperature heat sealability of the film is improved via low density polyethylene; the film has good bonding fastness via ethylene-acrylic acid copolymer resins.

Owner:GLODSTONE PACKAGING JIAXING

Transparent packaging film and preparation method thereof

PendingCN108790352AHigh solid contentLow viscosityFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

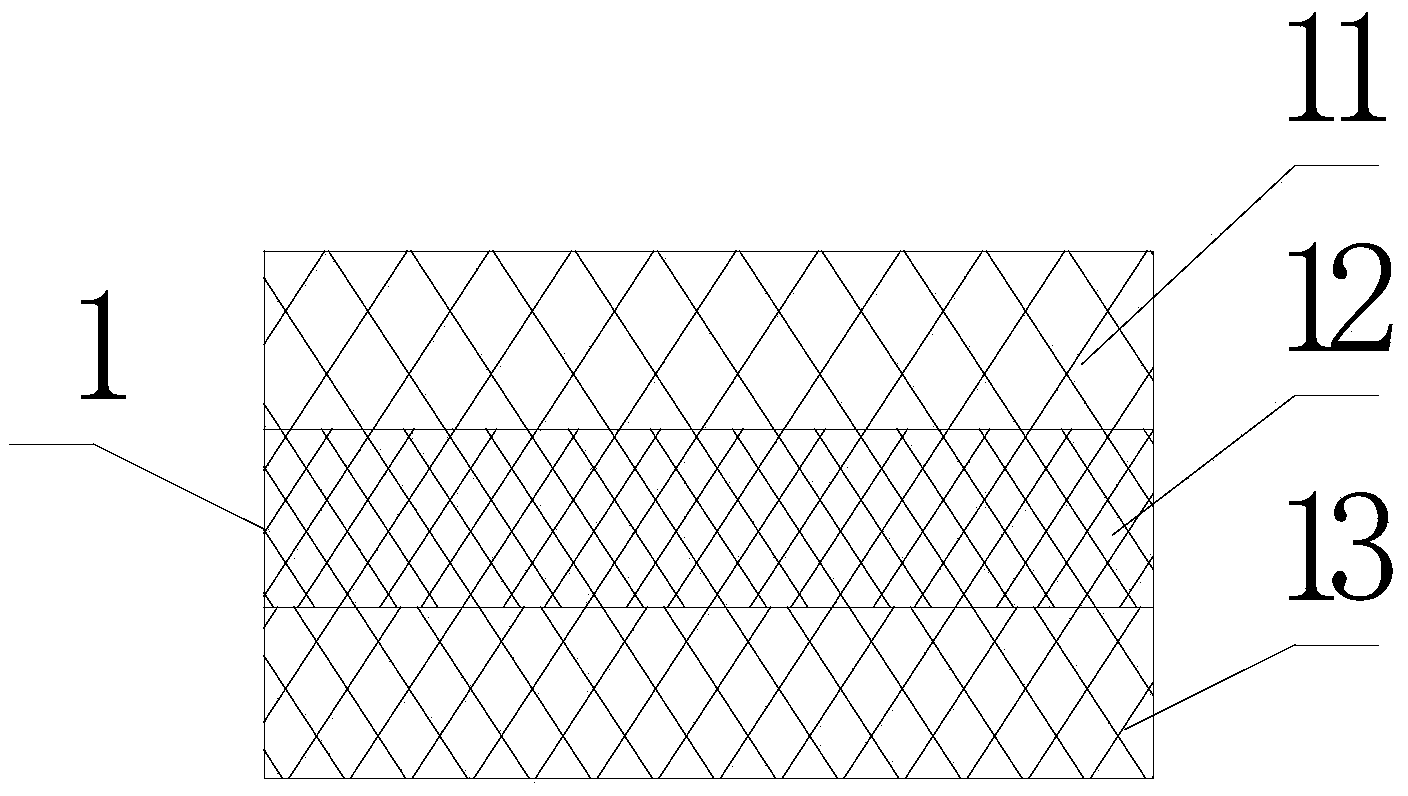

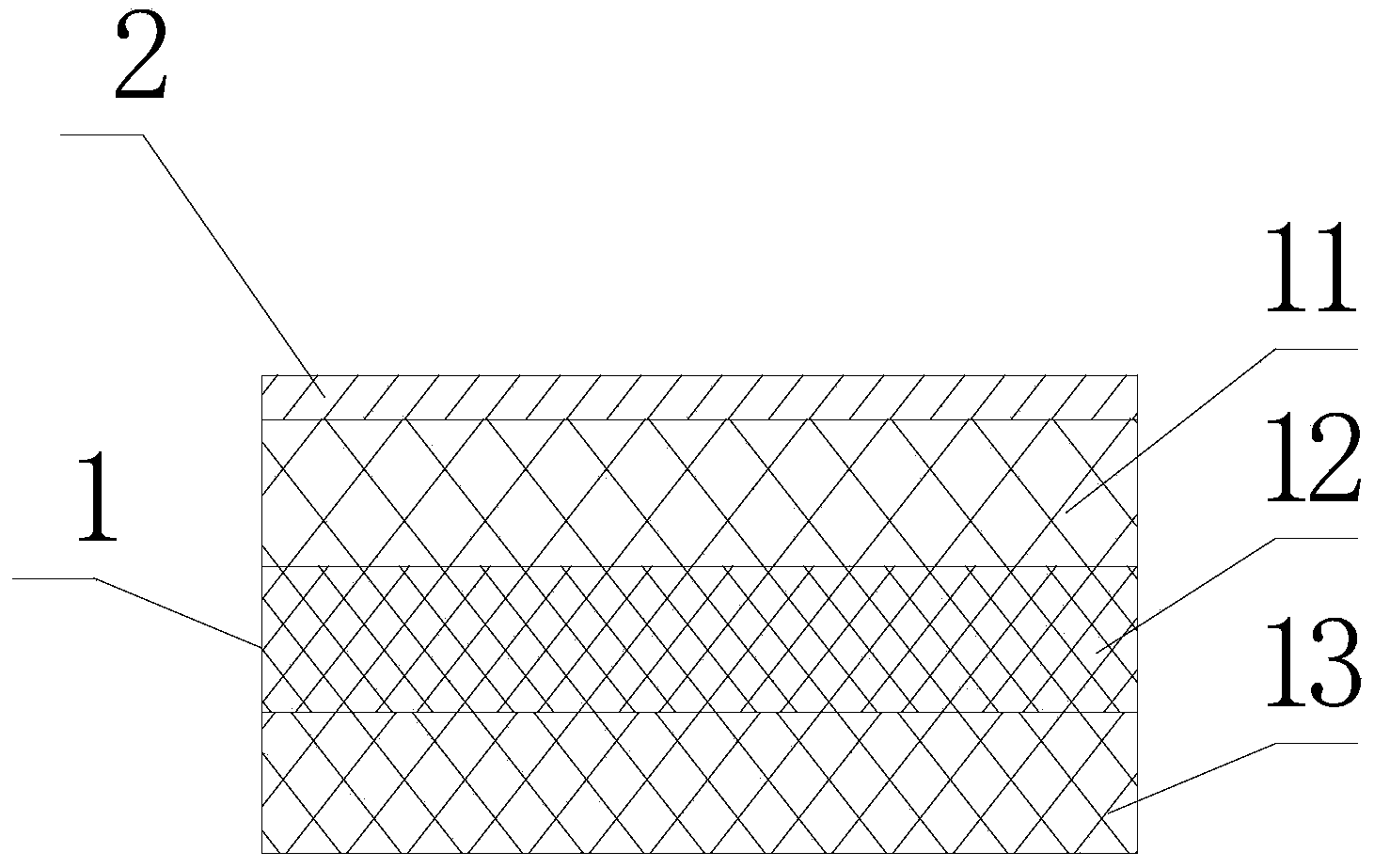

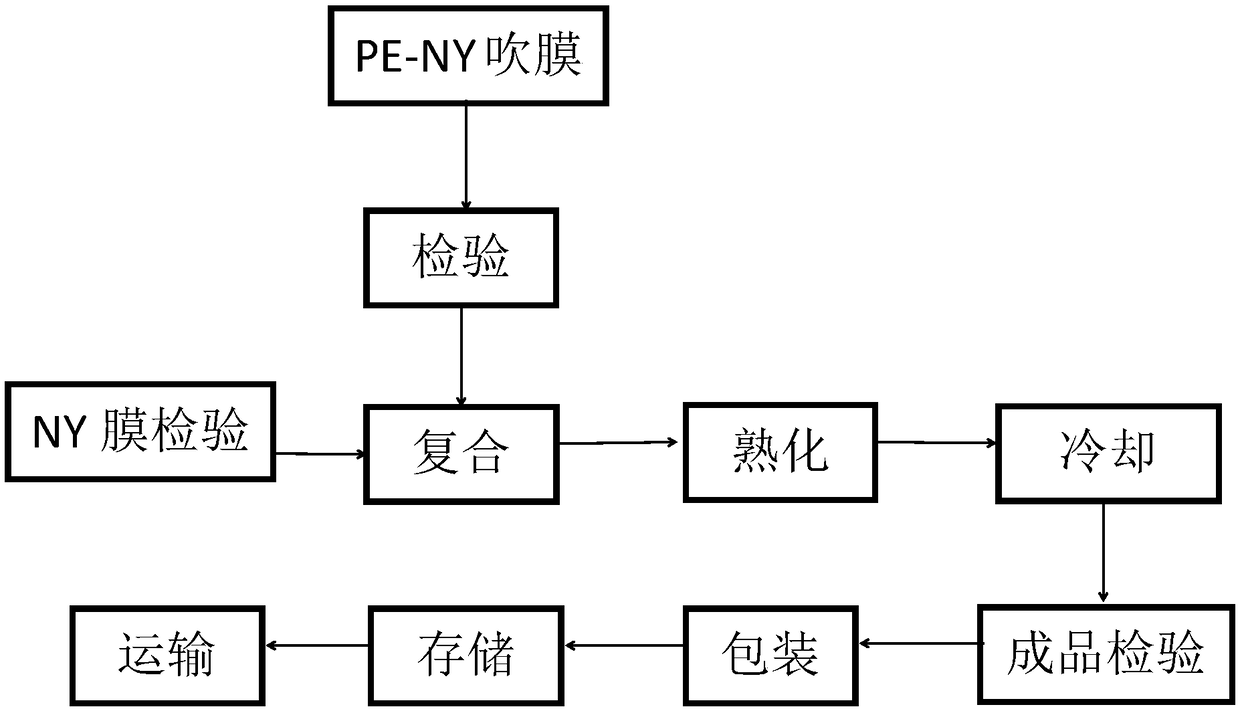

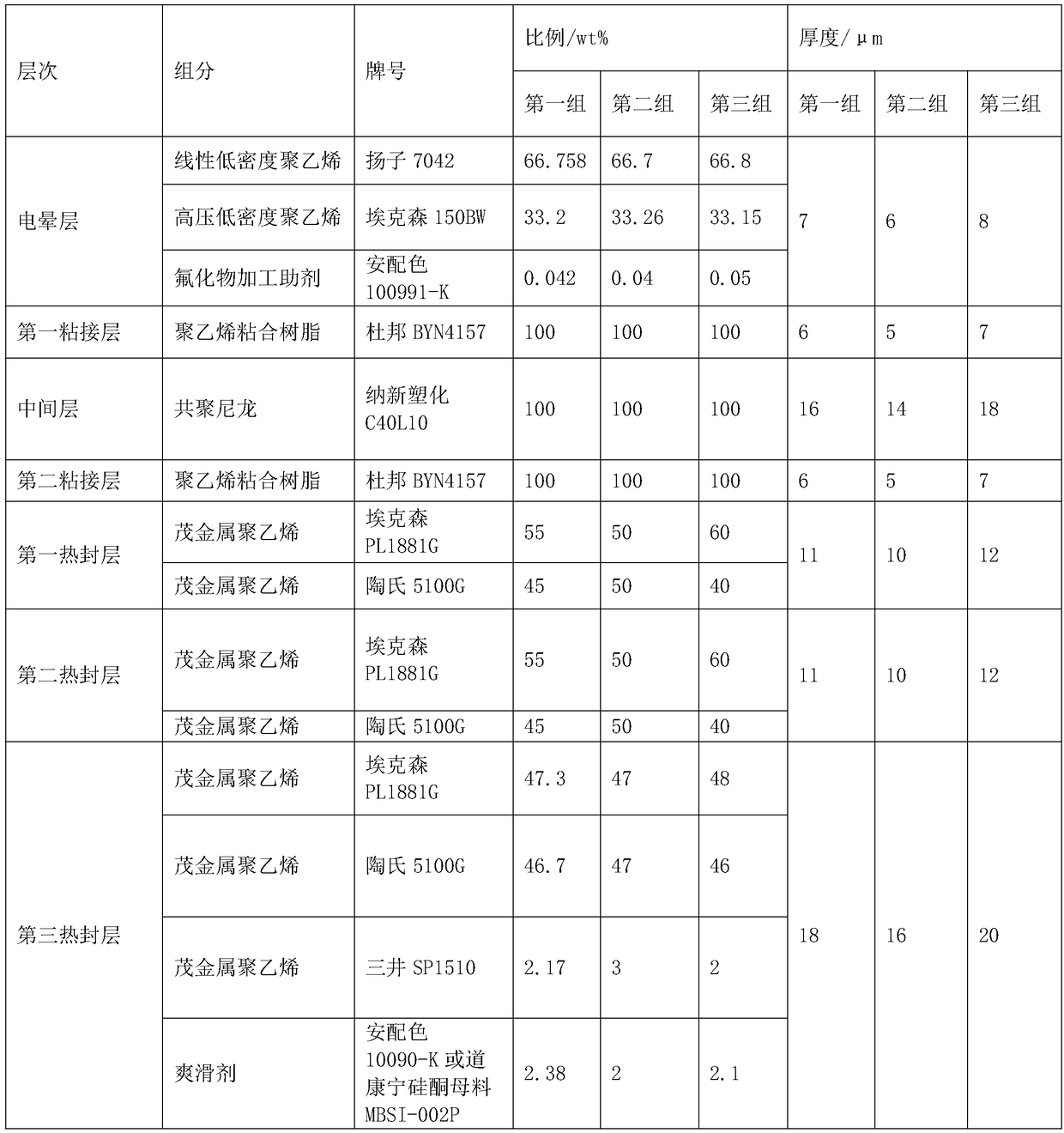

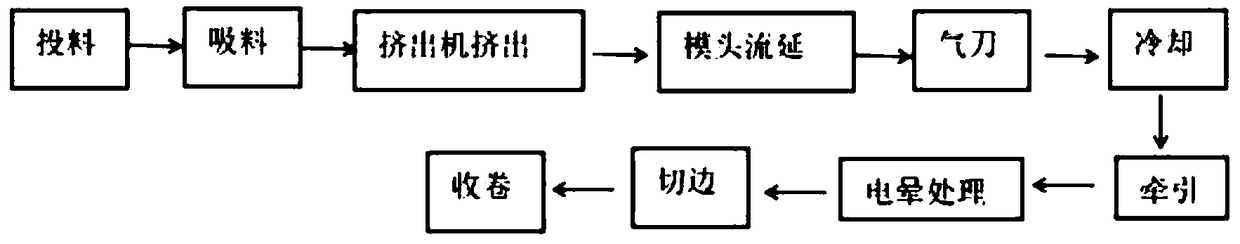

The invention relates to a transparent packaging film and a preparation method thereof. The transparent packaging film comprises an NY (nylon) film layer, an adhesive layer and a PE-NY (polyethylene-nylon) co-extrusion film which are tightly bonded, wherein the PE-NY co-extrusion film layer consists of a corona layer, a first adhesive layer, a middle layer, a second adhesive layer, a first heat sealing layer, a second heat sealing layer and a third heat sealing layer which are sequentially adhered together; the corona layer comprises 66.7 to 66.8wt% of linear low density polyethylene, 33.1 to33.3wt% of high-pressure low density polyethylene and 0.04 to 0.05wt% of fluoride processing additive; the first adhesive layer and the second adhesive layer comprise polyethylene bonding resin; the middle layer comprises copolymerizing nylon; the first heat sealing layer and the second heat sealing layer comprise metallocene polyethylene; the third heat sealing layer comprises 95 to 97wt% of metallocene polyethylene, 2 to 3wt% of smoothing agent and 1 to 2wt% of opening agent. The transparent packaging film is a composite film with good heat sealing and packaging adaptability.

Owner:HUANGSHAN NOVEL

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

Plastic film preventing cultivated crabs from escaping and preparation thereof

InactiveCN101353455ALow costAvoid truncationPisciculture and aquariaFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a plastic membrane for preventing cultured crabs escaping and a preparation method thereof. The plastic membrane comprises the components with the following weight portions: 70 to 90 portions of polyolefin base material, 2.5 to 3.5 portions of antioxidant 2, 6 di-butyl-p-cresol, 0.01 to 0.03 portions of isocyanuric three(3,3- di-butyl-4-hydroxy benzyl) ester, 5 to 10 portions of reinforcing agent nano-montmorilonite and 15 to 20 portions of the mixture of terpineol / rough dipentene with the weight ratio of 50:50. The polyolefin base material is preferably 55 to 65 weight portions of liner low density polyethylene and 15 to 25 weight portions of low density polyethylene. As the improvement of the invention, the raw material of the plastic membrane also comprises 10 to 25 weight portions of metallocene catalyst for liner low density polyethylene. With the invention, the plastic membrane has good aging inhibiting effect and better solves the problem that the plastic membrane is easy to age and deteriorate due to sun burning and watering outside for a long time.

Owner:江东头

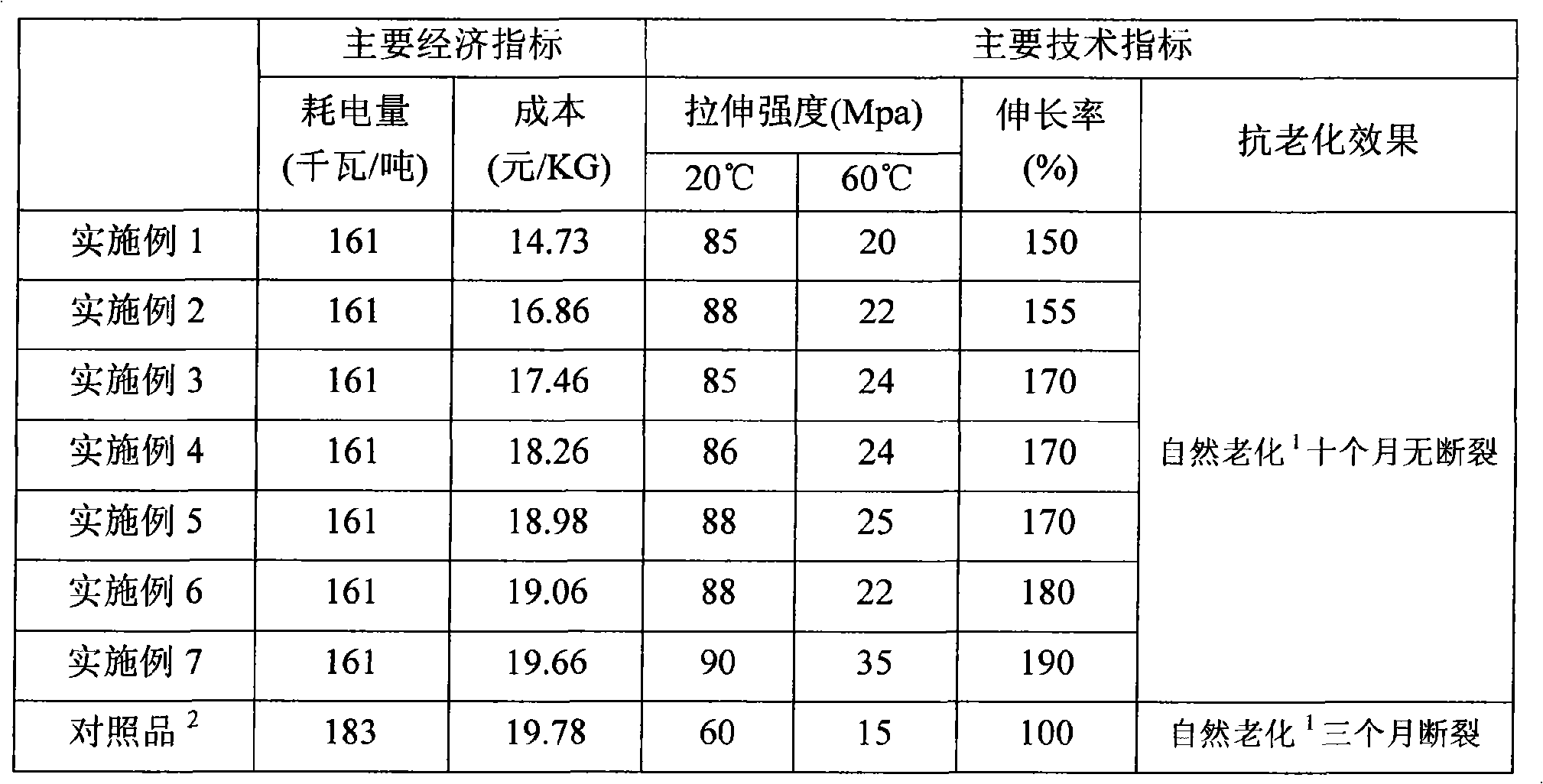

Ethylene/alpha-alefin copolymer, composition thereof, film thereof and uses of these

InactiveCN1305502AHigh mechanical strengthImprove heat resistancePlastic/resin/waxes insulatorsSynthetic resin layered productsElutionAlkene

Owner:JAPAN POLYOLEFINS CO LTD

Heat shrinkable film applicable to automatic quick packaging on production line

ActiveCN107696623AImprove packaging efficiencyEasy to operateSynthetic resin layered productsSacksLinear low-density polyethyleneInter layer

The invention relates to the field of heat shrinkable films, in particular to a heat shrinkable film applicable to automatic quick packaging on a production line. The heat shrinkable film comprises anouter surface layer, a heat seal layer on the inner surface and a barrier layer between the outer surface layer and the heat seal layer. The barrier layer comprises an EVOH (ethylene-vinyl alcohol) barrier interlayer, at least one side of the EVOH barrier interlayer is provided with a barrier layer protecting layer which is a PA (polyamide) layer, the surface layer is a PA layer, and the heat seal layer is a POP (polyether polyol) layer or one of an mLLDPE (metallocene linear low density polyethylene) layer, a ULDPE (ultralow-density polyethylene) layer and a Surlyn resin layer or a POP and mLLDPE mixed layer. The surface layer and the barrier layer as well as the barrier layer and the heat seal layer are connected through adhesive resin. The heat shrinkable film is high in strength, great in barrier and heat seal performance, excellent in machinability and suitable for full-automatic online packaging. By the heat shrinkable film, the shrinkable bag packaging modes and packaging efficiency can be changed.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

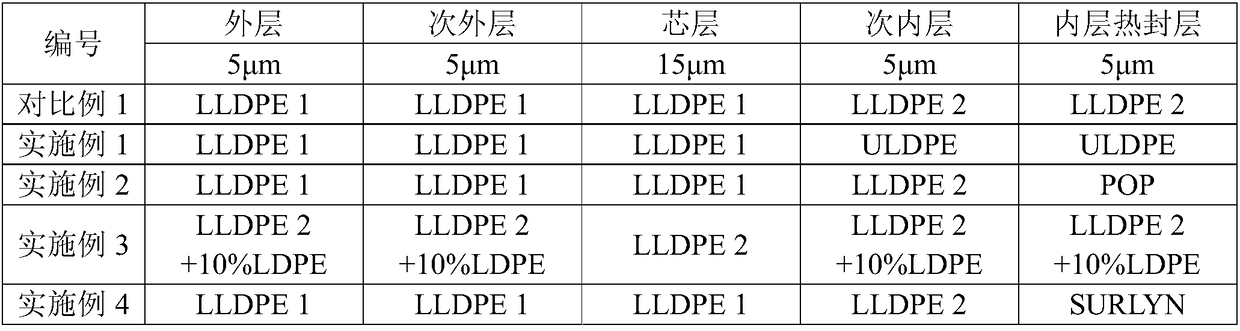

POF shrinkage film applicable to cold fresh chicken packaging

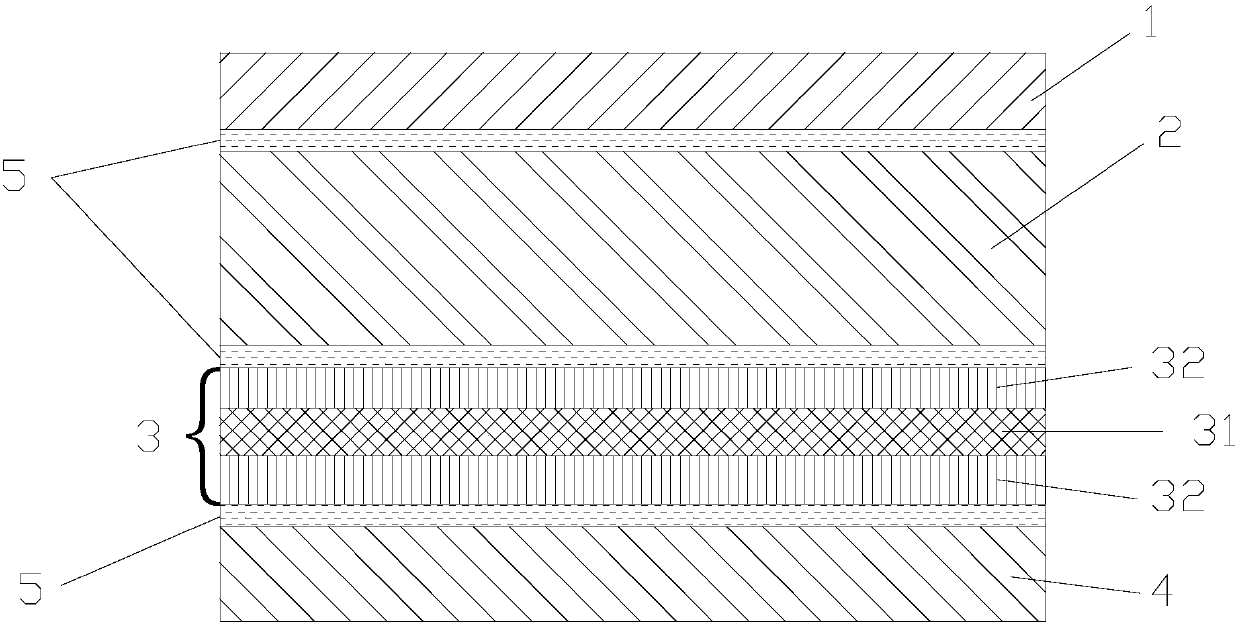

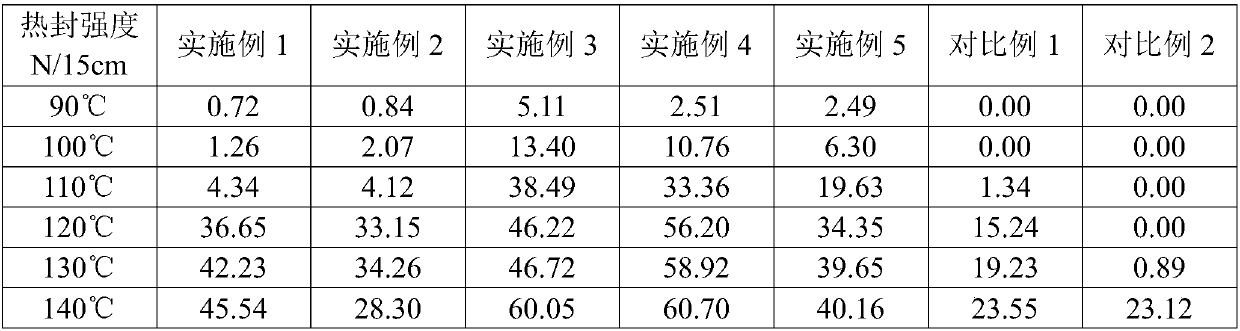

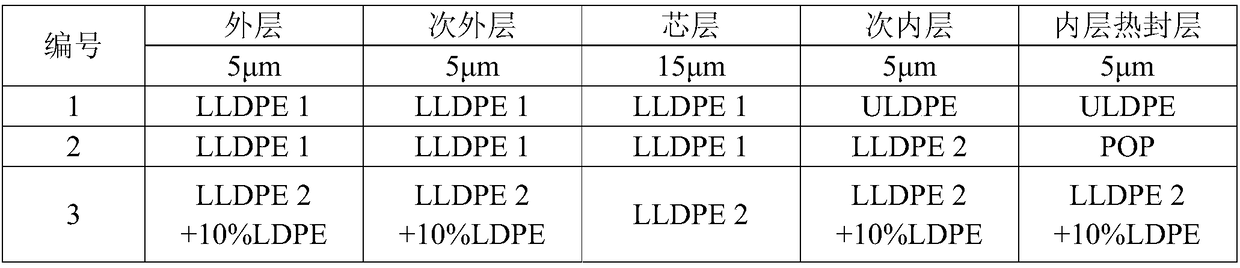

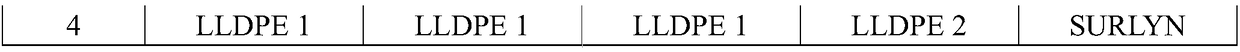

InactiveCN109263212AGood low temperature heat sealabilityEfficient anti-pollution heat sealing performanceSynthetic resin layered productsPolymer scienceTotal thickness

The invention relates to the field of packaging films, in particular to a POF shrinkage film applicable to cold fresh chicken packaging. The film is a five-layer co-extrusion film; the total thicknessis 10 to 100 microns; the film comprises an outer layer, a sub outer layer, a middle core layer, a sub inner layer and an inner layer hot sealing layer, wherein the middle core layer is an LLDPE layer; the outer layer and the sub outer layer is an LLDPE layer or a blending layer of LLDPE and LDPE; the sub inner layer is selected from one of the LLDPE layer, a ULDPE layer and the blending layer ofLLDPE and LDPE; the inner layer hot sealing layer is selected from one of the LLDPE layer, the ULDPE layer, a POP layer, an SURLYN layer and the blending layer of LLDPE and LDPE. The POF shrinkage film has excellent low-temperature hot sealing performance and efficient anti-pollution hot sealing performance.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

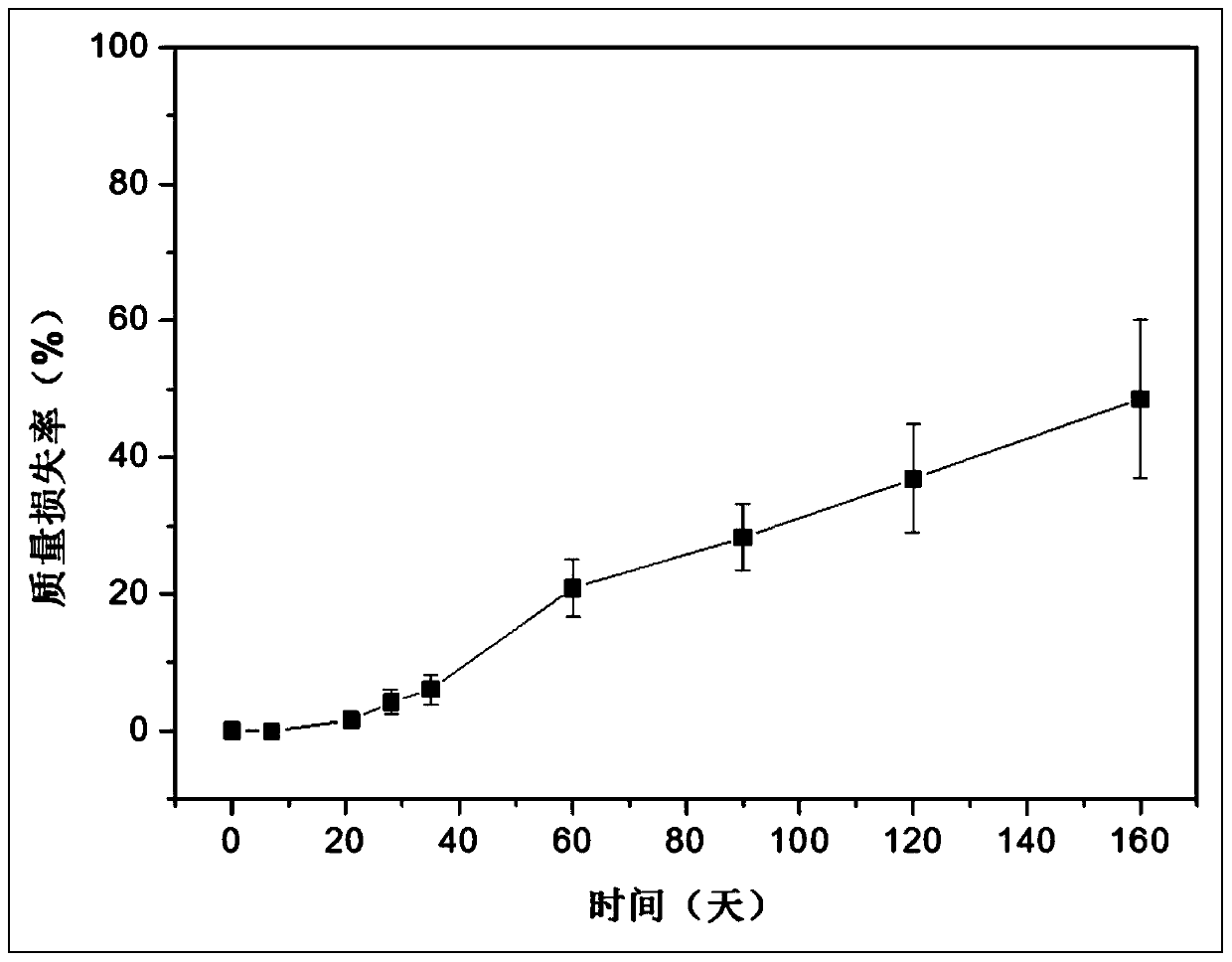

Composite film and preparation method thereof

InactiveCN111516317AGood mechanical propertiesGood low temperature heat sealabilitySynthetic resin layered productsFlat articlesPolyesterPolymer science

The invention discloses a composite film. The composite film has an A / B / A, A / B / A / C or A / B / A / C / A layer structure, the A layer is modified poly epsilon-caprolactone, the B layer is at least one of aluminum or paper, and the C layer is at least one of polyamide, polyester, polyolefin and enol copolymer. The composite film has good heat sealability, good tensile mechanical properties and high peel strength. The composite material comprises biodegradable modified poly epsilon-caprolactone (layer A) as a heat sealing layer, a sealing layer and an outer protective layer. After the use period of the composite flexible package material ends, the modified poly epsilon-caprolactone with excellent biodegradability can be degraded within a certain period of time, so that all layers forming the composite material are separated due to connection loss, the problem that the composite flexible package material is difficult to recycle is solved, and the ecological environment effect is reduced through adegradation, classification and recycling technology.

Owner:睿泊(中国)环保科技有限公司

Composite membrane for packing explosive

InactiveCN101633422ALow costMeet safety requirementsFlexible coversWrappersLow-density polyethyleneMasterbatch

A composite membrane for packing explosive is composed of an upper membrane, an intermediate membrane and a lower membrane by coextrusion; wherein the upper membrane is composed of polypropylene and slip strengthening master batch, the intermediate membrane is low-density polyethylene; and the lower membrane is composed of low-density polyethylene, linear low-density polyethylene, metallocene polyethylene and slip strengthening master batch. The invention has the advantages that: 1, cost is low and about 20% of cost can be saved; 2, the composite membrane has excellent low temperature heat sealing performance and meets safety requirement of explosive; and the composite membrane has resistance to low temperature, good tear strengthen and excellent transparency and luster; 3, the product is formed in one step by adopting coextrusion technology, contains no binder and can be completely recycled.

Owner:JINGMEN TIANHUA PACKING

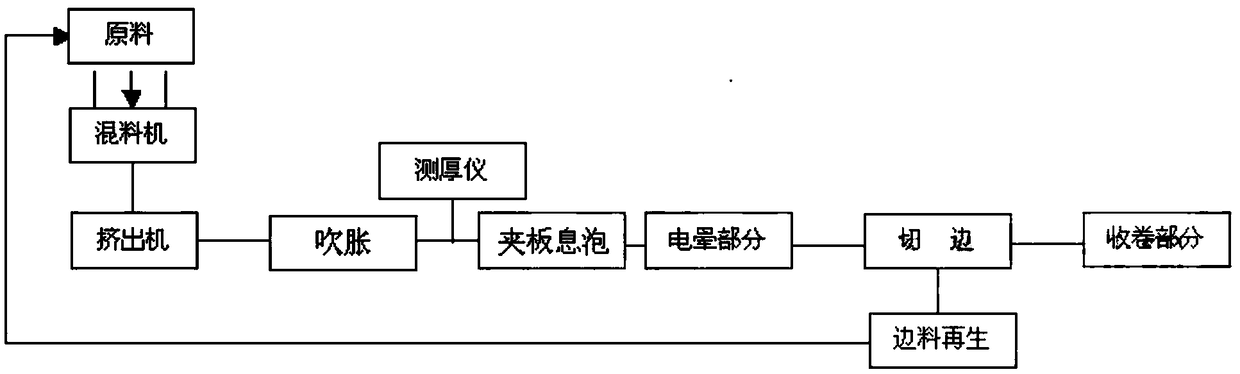

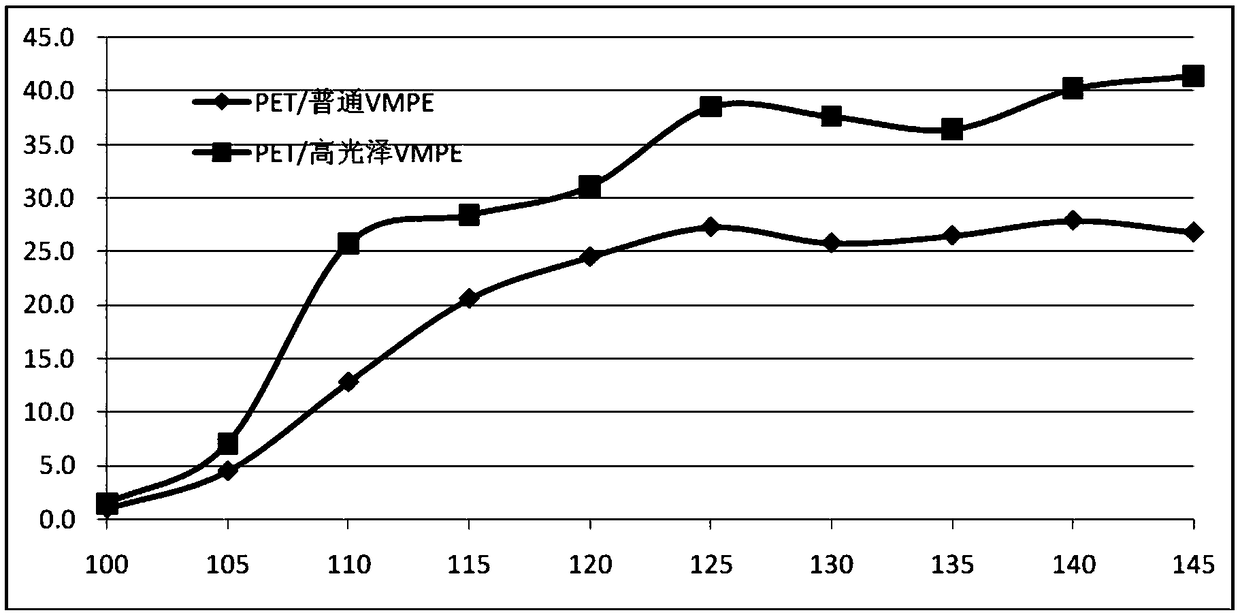

Composite-grade high-gloss aluminized polyethylene blown film and production method thereof

InactiveCN109130413AHigh glossIncreased composite peel strengthSynthetic resin layered productsVacuum evaporation coatingHigh pressureChemistry

The invention relates to a composite-grade high-gloss aluminized polyethylene blown film and a production method thereof. The aluminized polyethylene blown film comprises an aluminum atom accumulationlayer, a corona layer, a middle layer and a heat sealing layer; the corona layer comprises ethylene and methyl methacrylate random copolymer resin, C2-C8 metallocene catalytic copolymer plastic resinand medium-density linear polyethylene resin; the middle layer comprises low-density high-pressure polyethylene resin and medium-density linear polyethylene resin; the heat sealing layer comprises low-density high-pressure polyethylene resin, C2-C8 metallocene catalytic copolymer plastic resin, medium-density linear polyethylene resin and an opening agent master batch; the thickness of the coronalayer is 13-17 micron, the thickness of the middle layer is 18-22 micron, the thickness of the heat sealing layer is 13-17 micron, and the thickness of the aluminum atom accumulation layer is 330-380angstroms. The aluminized polyethylene blown film has high glossiness, the surface tension value can be kept at 35 dyne or above for a long time, and the composite peel strength is greatly improved.

Owner:HUANGSHAN NOVEL

Composite film capable of positioning internally-printed variable codes and preparing method of composite film

ActiveCN106079791AIncrease surface tensionImprove adhesionSynthetic resin layered productsLaminationElectricityComposite film

The invention provides a composite film capable of positioning internally-printed variable codes and a preparing method of the composite film. The method comprises the steps that a printing layer is subjected to corona treatment, printed with oil ink and then subjected to corona removing treatment, then variable code jet printing and hot sealing layer combination are carried out in sequence, curing treatment is carried out, and the composite film can be obtained. According to the preparing method, the printing layer is subjected to corona treatment before a pattern layer is formed, so that the adhesive force of the printing layer to liposoluble intaglio printing oil ink is improved; then, the printing layer is subjected to corona removing treatment before an anti-fake layer is formed, so that the surface tension of the printing layer is reduced, and the adhesive force of the printing layer to UV oil ink is improved; meanwhile, the static amount, increased due to corona treatment, of the printing layer material can be transferred, so that the defect of static deckle edges and even fuzziness caused by directly printing anti-fake codes on an oil ink pattern layer in a jetting mode in the prior art is effectively overcome, and thus the use effect of anti-fake codes is greatly improved.

Owner:浙江博升新材料技术有限公司

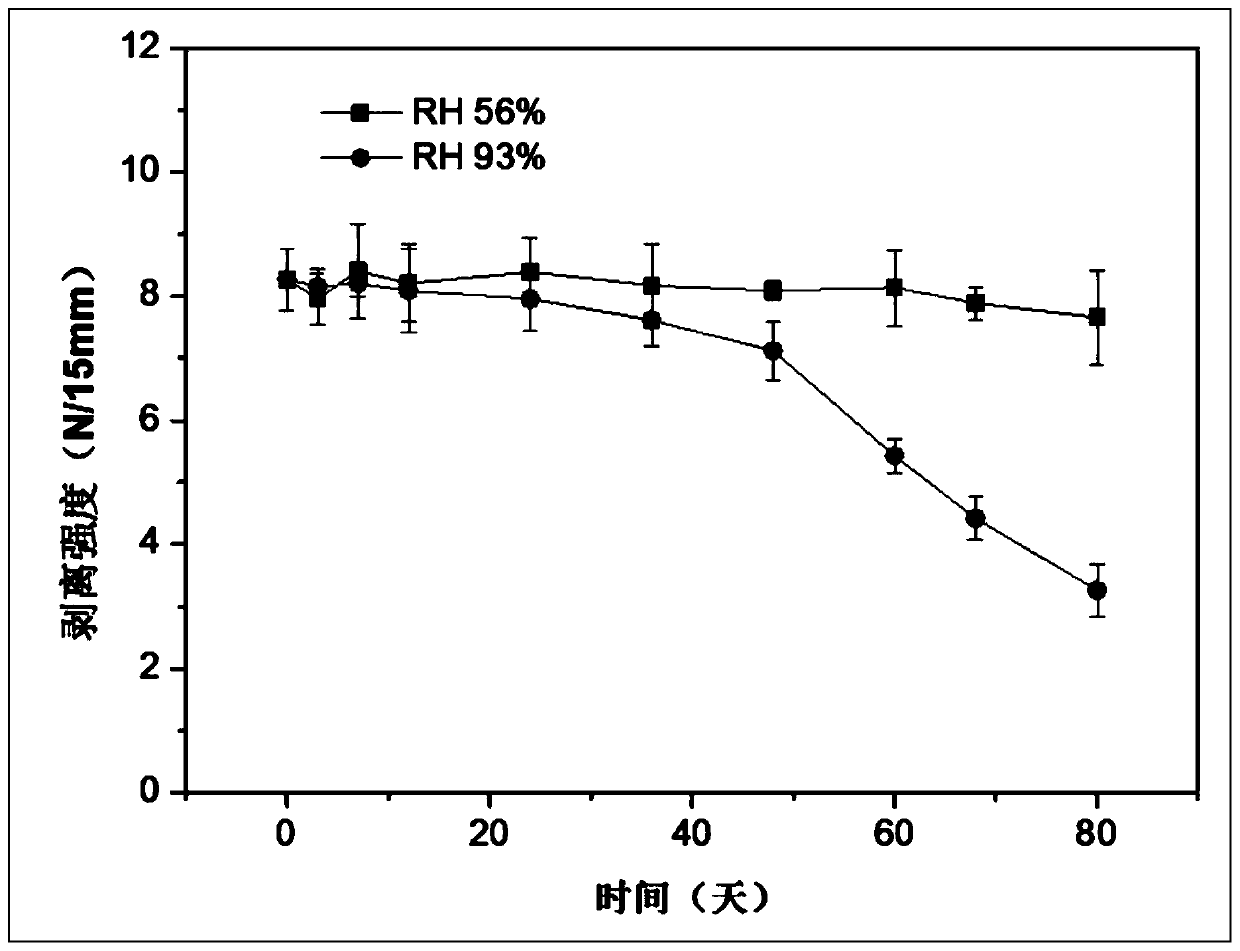

Composite film material for manufacturing liquid package sealing tape and preparation method thereof

InactiveCN106183294ANot easy to stretchNot easy to cutLamination ancillary operationsSynthetic resin layered productsLow-density polyethylenePolyester

The invention belongs to the field of sealing materials, and in particular relates to a composite film material used for making liquid packaging sealing strips. The invention comprises a double-sided corona biaxially stretched polyester film layer, wherein one side of the double-sided corona biaxially stretched polyester film layer is sequentially compounded with a first metallocene polyethylene resin film layer, a first low-density polyethylene resin film layer, the second metallocene polyethylene resin film layer, the other side of the double-sided corona biaxially stretched polyester film layer is sequentially compounded with the third metallocene polyethylene resin film layer, the second low density polyethylene resin film layer , the fourth metallocene polyethylene resin film layer. The strip-shaped sealing strip prepared from the composite film material of the present invention is not easy to stretch and cut off during use, and has strong peel strength, good low-temperature heat-sealability, smoothness and medium resistance. Composite film materials provide domestic manufacturers with more choices about sealing strips for liquid aseptic liquid packaging.

Owner:程淋

Low-temperature heat sealing coating film suitable for lightweight packaging, and manufacturing method thereof

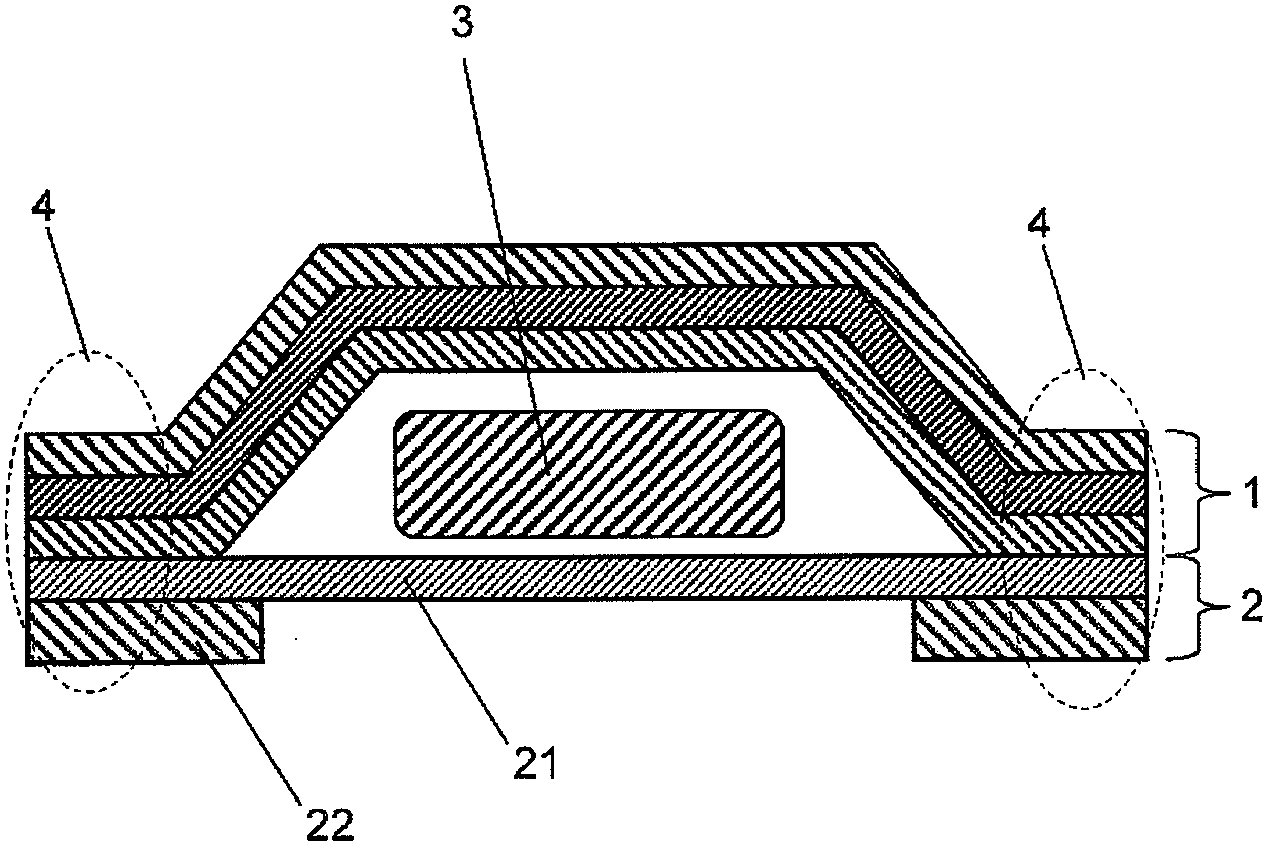

ActiveCN108164729AGood low temperature heat sealabilityImprove film qualityPolyurea/polyurethane coatingsWater basedAcrylic coating

The invention relates to a low-temperature heat sealing coating film suitable for lightweight packaging. The coating film is a double-sided coating structure, and comprises a substrate, an upper coating layer on the upper surface of the substrate, a lower coating layer at the lower surface of the substrate, an upper primer layer between the substrate and the upper coating layer, and a lower primerlayer between the substrate and the lower coating layer, the upper primer layer and the lower primer layer are coatings layers formed by water-based polyurethane in the prior art, the substrate is abiaxially-oriented polypropylene film, the upper coating layer is a low-temperature heat sealing coating layer, and the lower coating layer is an acrylic coating layer; and the acrylic coating layer is a printed layer, the low-temperature heat sealing layer and the low-temperature heat sealing layer are heat-sealed during sealing, and the heat seal strength at 70 DEG C is 1.0-1.5 N / 15 mm. The low-temperature heat sealing coating film has the advantage of good film rolling quality, no sticky phenomenon, good printing performance, implementation of packaging without compounding, and meeting requirements of high-speed packaging, and is especially for lightweight (less than 100 g) packaging of heat-sensitive foods.

Owner:HAINAN SHINER IND

Polypropylene resin composition, film or sheet, stretched film obtained from such film or sheet, multilayer body, and stretched film obtained from such multilayer body

InactiveCN101233185AGood formabilityHigh transparencySynthetic resin layered productsThin material handlingPropylene PolymersPolypropylene

Disclosed is a polypropylene resin composition which has good moldability and enables to obtain a film or sheet having excellent transparency and heat sealing property. Specifically disclosed is a polypropylene resin composition composed of 1-50% by weight of a propylene polymer (A) having a melting point Tm as measured by a differential scanning calorimeter (DSC) of not less than 150 DEG C, 10-90% by weight of a propylene copolymer (B) having a melting point Tm of not less than 100 DEG C but less than 150 DEG C, and 1-80% by weight of an olefin copolymer (C) having a melting point of not less than 40 DEG C but less than 100 DEG C. The olefin copolymer (C) is composed of (a) not less than 50% by mole of either of a constitutional unit derived from propylene and a constitutional unit derived from 1-butene, and (b) not more than 50% by mole of one or more constitutional units other than (a) selected from constitutional units derived from a-olefins having 2-20 carbon atoms (with the total of (a) and (b) being 100% by mole). A film obtained from such a resin composition is suitable as a packaging film for foods or the like.

Owner:MITSUI CHEM INC

Lactic acid-based resin composition

InactiveCN1643061AGood physical propertiesImprove moisture resistanceSynthetic resin layered productsLaminationIonomerCombustion

Provided is a lactic acid-based resin composition that comprises a lactic acid-based (component (A)), and an ethylene-unsaturated carboxylic acid copolymer (component (B)) and / or an ethylene-unsaturated carboxylic acid copolymer ionomer (component (C)). The lactic acid-based resin composition has good physical properties in melt and can be efficiently formed into films and laminates through casting or extrusion lamination. The paper laminates obtained through extrusion with the resin composition have good moisture barrier property, and have the advantages of good antibacterial ability, good biodegradability and low combustion heat. And the moldings obtained from the resin composition of the invention have a characteristic which is excellent in impact strengh.

Owner:MITSUI CHEM INC +1

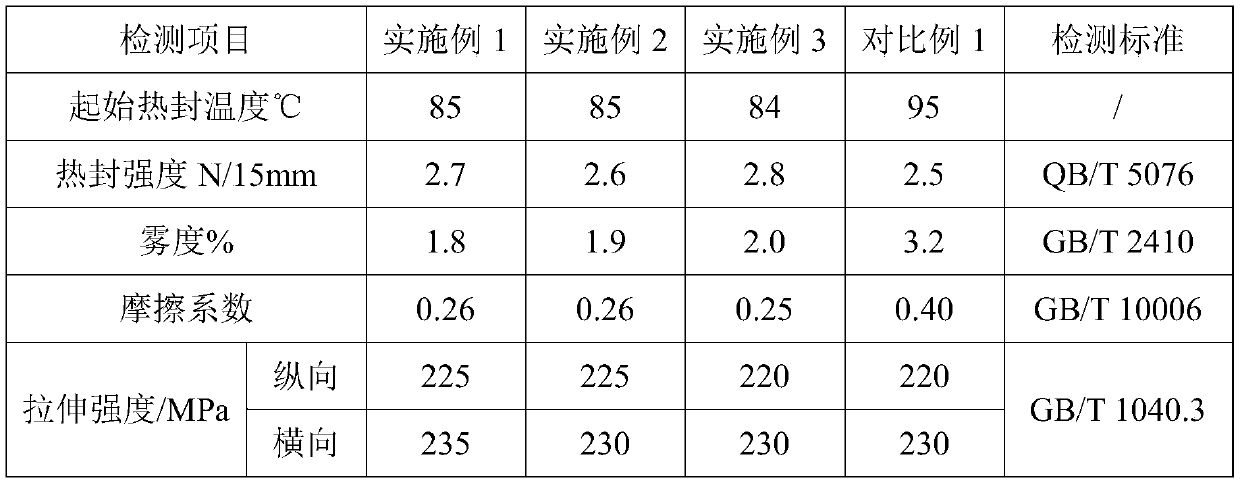

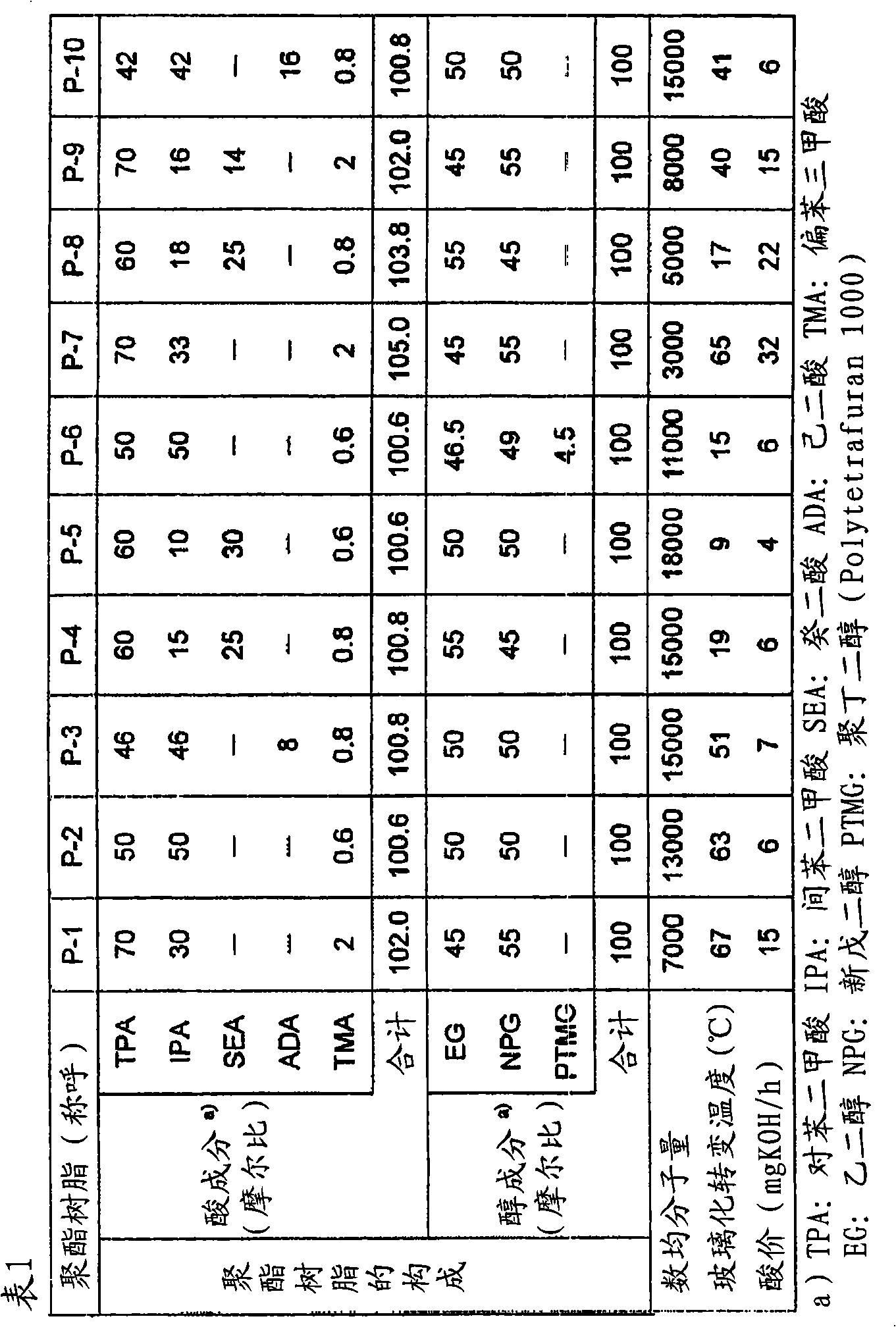

Low-friction low-temperature heat-sealing BOPET film and preparation method thereof

InactiveCN110920187AImprove appearance qualityImprove flatnessSynthetic resin layered productsLaminationOXALIC ACID DIHYDRATEMasterbatch

The invention discloses a low-friction low-temperature heat-sealing BOPET film and a preparation method thereof. The film is composed of an upper surface layer, a core layer and a lower surface layer.The lower surface layer is a low-temperature heat-sealing layer and is made of a copolymerization modified PETG polyester heat-sealing master batch, the copolymerization modified PETG polyester heat-sealing master batch is obtained by copolymerizing terephthalic acid, ethylene glycol, neopentyl glycol and oxalic acid, and the molar ratio of terephthalic acid to ethylene glycol to neopentyl glycolto oxalic acid is (40-45): (40-45): (5-10): (5-10). The upper surface layer is an anti-sticking layer and is prepared from the following raw materials in percentage by weight: 40-50% of super brightpolyester chips, 5-10% of a smooth master batch and 40-50% of an anti-sticking master batch. The core layer is made of super bright polyester chips. The prepared low-friction low-temperature heat-sealing BOPET film is stable in performance and good in low-temperature heat-sealing performance, the application field of the BOPET heat-sealing film is expanded, and heat-sealing energy consumption is reduced.

Owner:ANHUI GUOFENG PLASTIC

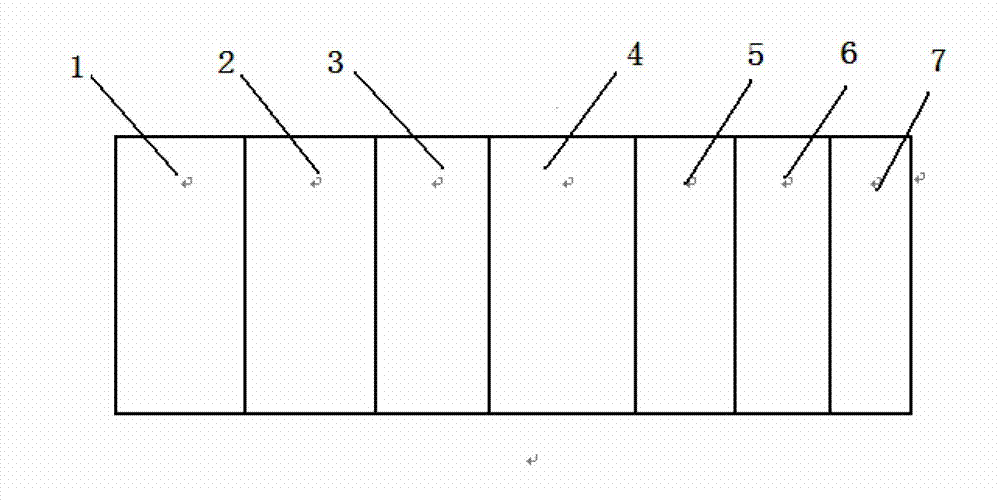

Polypropylene/polyethylene composite medical packaging film

InactiveCN102975451AImprove thermal stabilityGood compatibilityFlexible coversWrappersSterile environmentHeat resistance

The invention relates to a polypropylene / polyethylene composite medical packaging film with a seven-layer structure, which adopts mixed modified resin as a seal coat, and polypropylene / polyethylene mixed resin in various proportions as other layers. In comparison with the prior art, the polypropylene / polyethylene composite medical packaging film has the main advantages that 1) the packaging film is excellent in flexibility and formability; 2) an excellent heat-sealing strength with non-adhesive paper is guaranteed; 3) the packaging film is capable of effectively separating bacteria and resisting puncture, and is applied in a sterile environment; 4) the packaging film can guarantee stable contents, heat resistance, no generation of harmful substance migration and other sanitation performances; and 5) in comparison with the conventional dry-type composite process, the environmental friendliness is better improved.

Owner:NINGBO HUAFENG PACKAGE

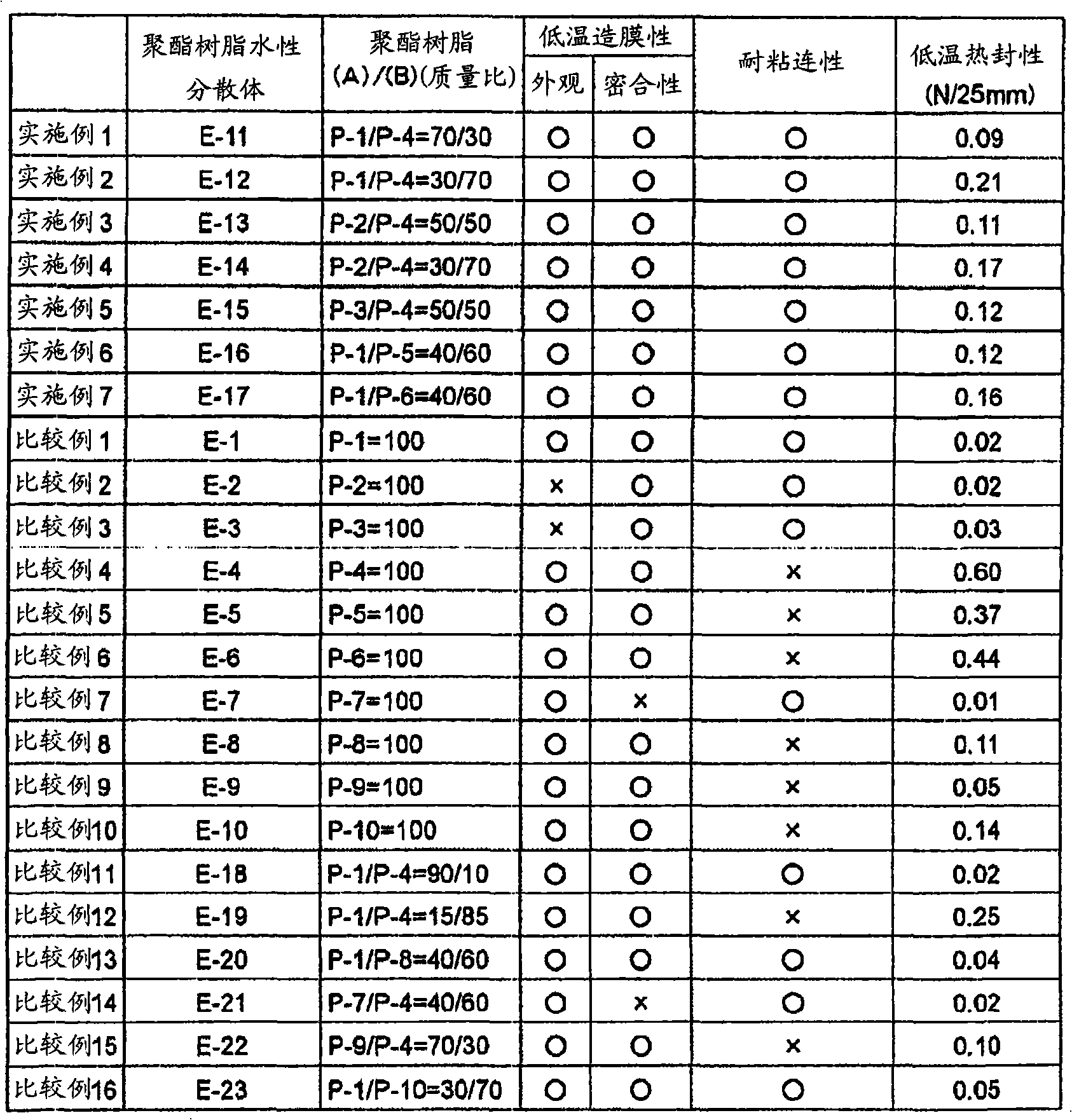

Polyester resin aqueous dispersion, coating film obtained from same, and packaging bag using such coating film

InactiveCN101258199AGood low temperature heat sealabilityImprove use valueThin material handlingPolyester resinResin coating

Owner:UNITIKA LTD

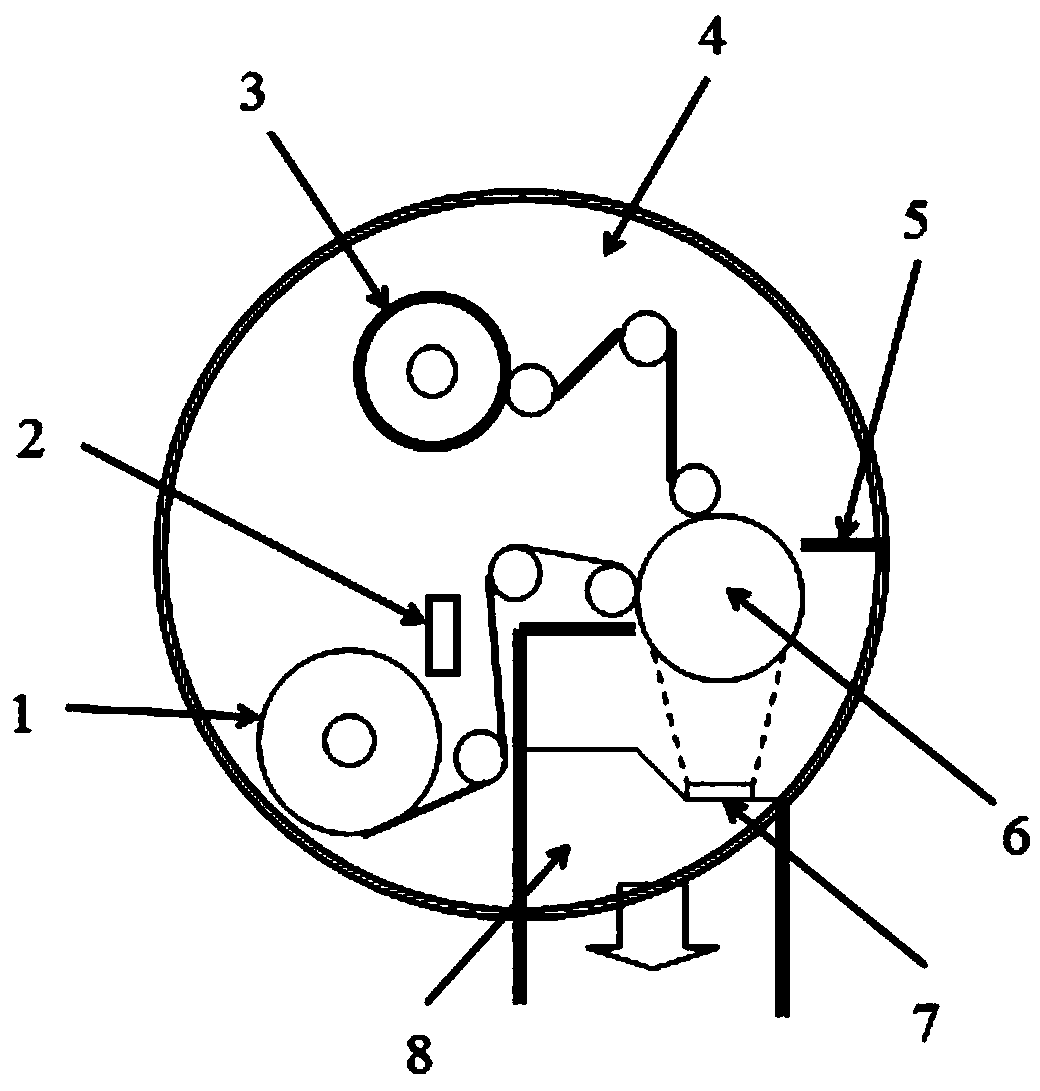

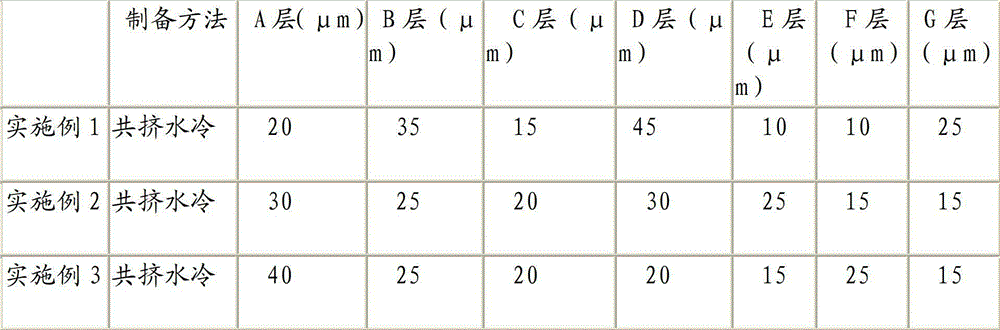

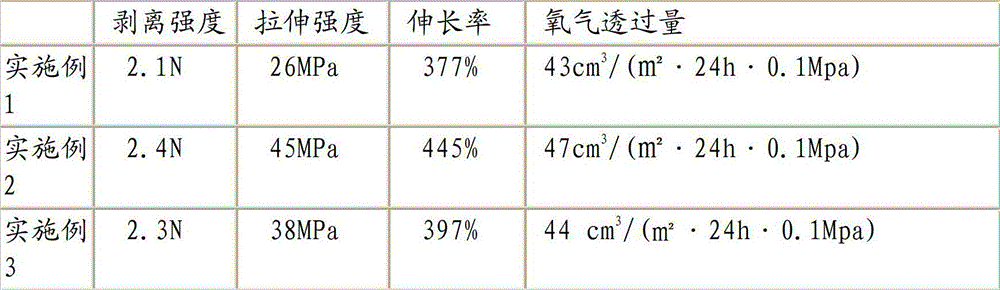

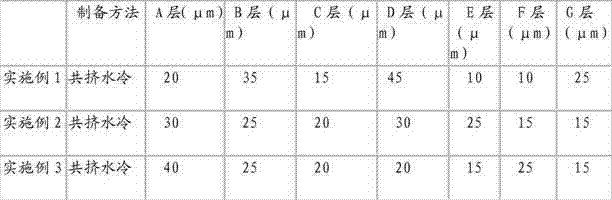

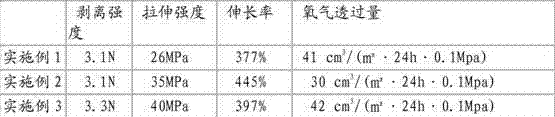

Polyamide/polypropylene composite medical packaging film

InactiveCN102963094AHigh tensile strengthGood printabilityFlexible coversWrappersComposite filmPolyamide

The invention relates to a polyamide / polypropylene composite medical packaging film. The packaging film adopts polyamide as the outer layer to keep heat resistance and puncture resistance, reduce moisture absorption rate, guarantee barrier property and fit for high-temperature high-moisture environments; a heat seal layer adopts metallocene polyethylene (mLLDPE) and ethylene-methyl acrylate (EMA) blend modified resin to guarantee good heat sealing between the film and a non-adhesive breathable paper; the polyamide crystallization speed and polyethylene crystallization speed have larger difference, and in the production technology, the heat seal layer (polyethylene) is put at the utmost outer layer, the polypropylene layer is put in the inner layer, so that the coiling of the film surface is solved and the flat heat sealing with the non-adhesive breathable paper is guaranteed; the film is coextruded and blown by using a bottom blowing water cooling method to guarantee that the transparency of the film surface is not less than that of the dry composite film; and meanwhile, the dew point height, the blow-up ratio and the traction ratio are strictly controlled during production so that optimal formability of the film in the longitudinal and transverse directions is guaranteed. Compared with the prior art, the packaging film has good comprehensive performance and high market competition strength, and is material-saving and competitive in markets.

Owner:NINGBO HUAFENG PACKAGE

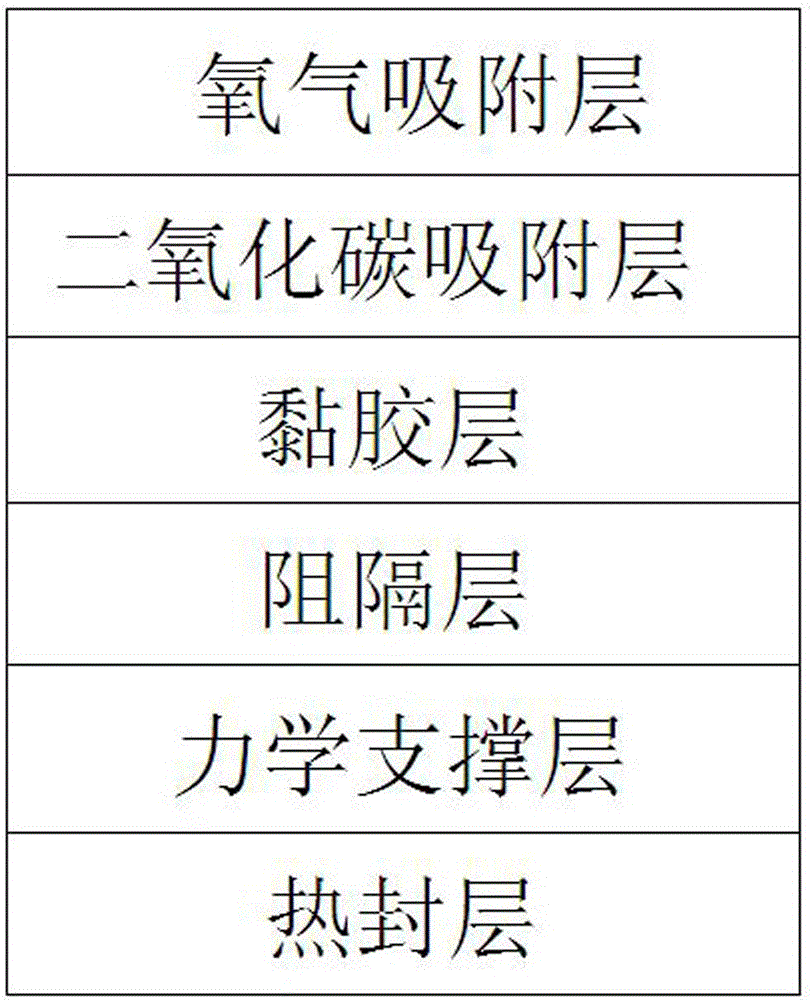

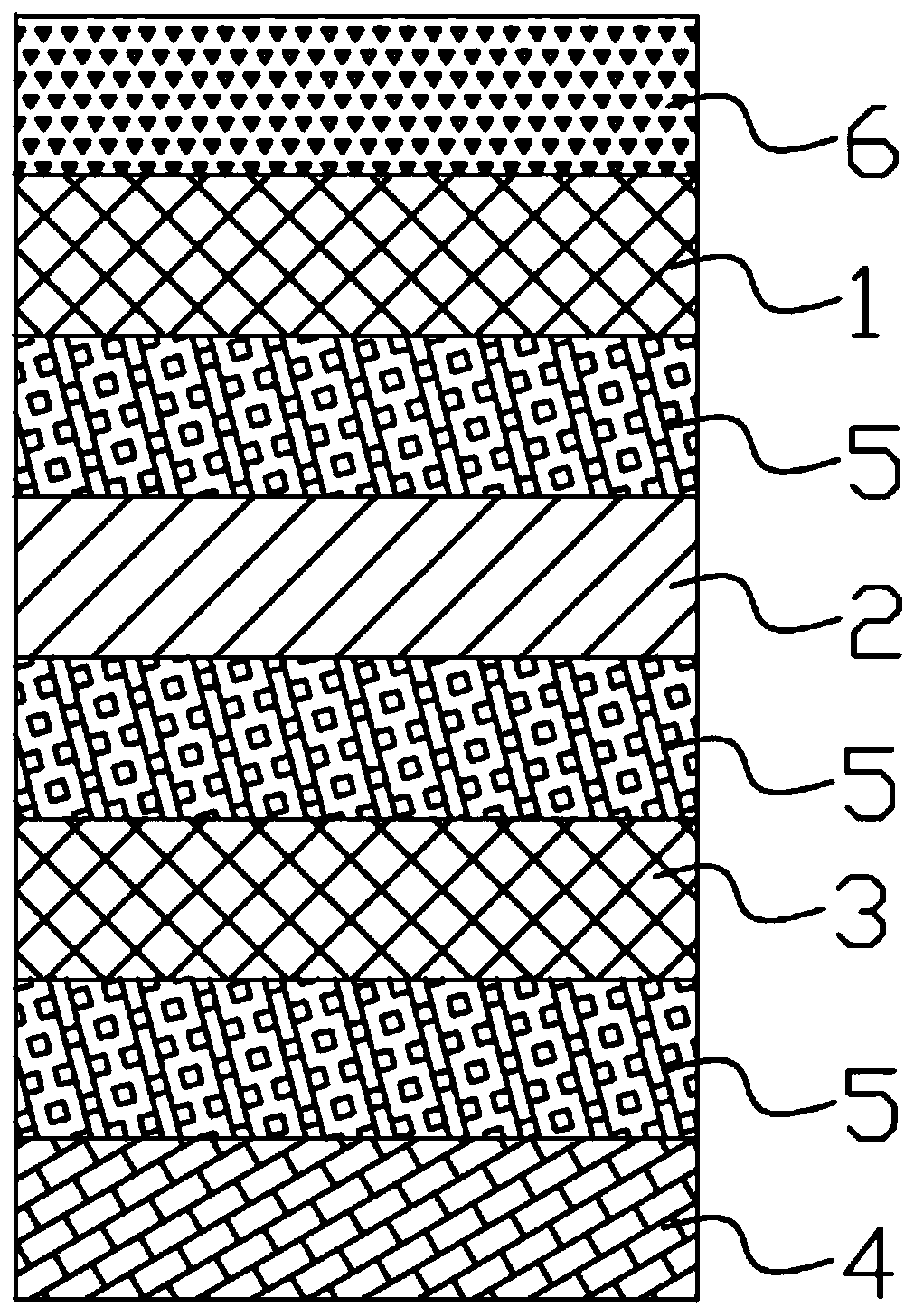

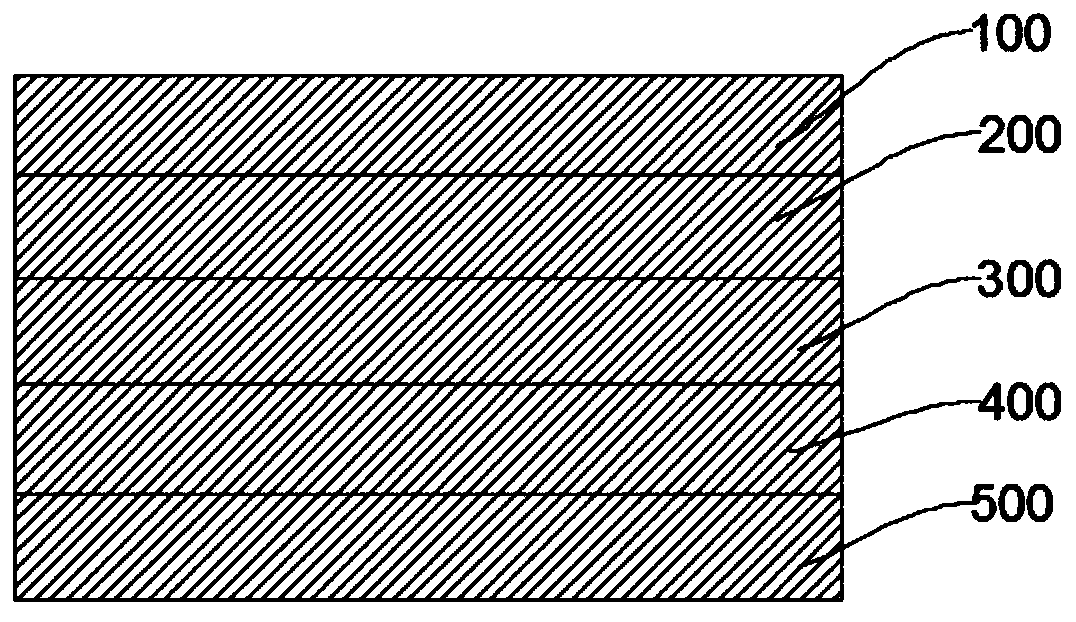

Gas adsorption type inner-layer co-extrusion membrane for flexible packaging of lithium battery and preparation method of gas absorption type inner-layer co-extrusion membrane

ActiveCN106183312APrevent Inflator FailureComposite goodFlexible coversWrappersPolymer electrolytesCo extrusion

The invention discloses a gas adsorption type inner-layer co-extrusion membrane for packaging of a lithium battery and a preparation method of the gas adsorption type inner-layer co-extrusion membrane, and particularly provides an inner-layer co-extrusion membrane, contacted with a polymer electrolyte solution, of a polymer lithium battery inner layer and a preparation method of the inner-layer co-extrusion membrane. The gas adsorption type inner-layer co-extrusion membrane is characterized by comprising a gas adsorption layer, an adhesion layer, a separation layer, a mechanical support layer and a hot sealing layer from outside to inside sequentially. The gas adsorption type inner-layer co-extrusion membrane is prepared through preparation of raw materials of all layers and co-extrusion of the adjacent layers. With the adoption of the gas adsorption type inner-layer co-extrusion membrane and the preparation method, the conditions of integral damage and liquid leakage of the flexible packaging can be avoided, the safety of the lithium battery is improved, and the service life of the lithium battery is prolonged.

Owner:江苏华谷新材料有限公司

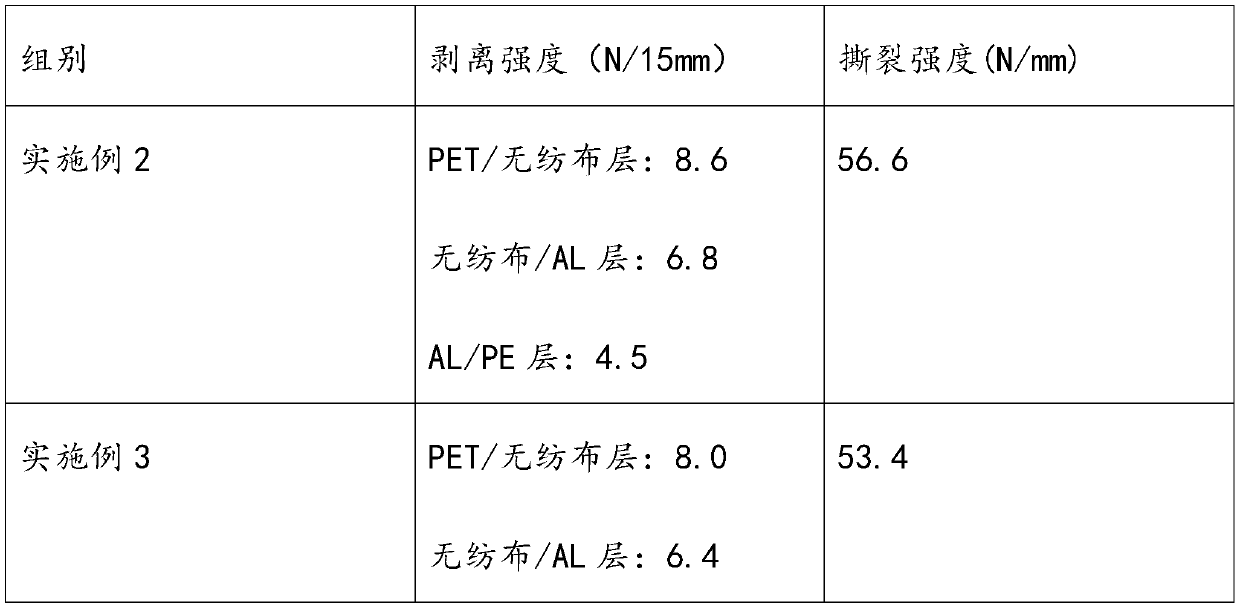

Composite bag made of non-woven fabric material

PendingCN110421916AMoisture-proofBreathablePackage recyclingSynthetic resin layered productsCombustionDecomposition

The invention relates to the field of packaging materials, and in particular relates to a composite bag made of a non-woven fabric material, the composite bag comprises a surface printing layer, a reinforcing layer, a barrier layer and an inner film layer which are sequentially arranged, wherein the reinforcing layer is the non-woven fabric; the reinforcing layer is made of the non-woven fabric, the reinforcing layer is arranged in the composite bag; the non-woven fabric has the advantages of moisture resistance, ventilation, flexibility, light weight, no combustion supporting, easy decomposition, no toxicity, no irritation, rich colors, low price and recyclability; and the non-woven fabric has better tear resistance, so that the tear resistance of the composite bag can be improved.

Owner:ZHEJIANG GOLDSTONE PACKING

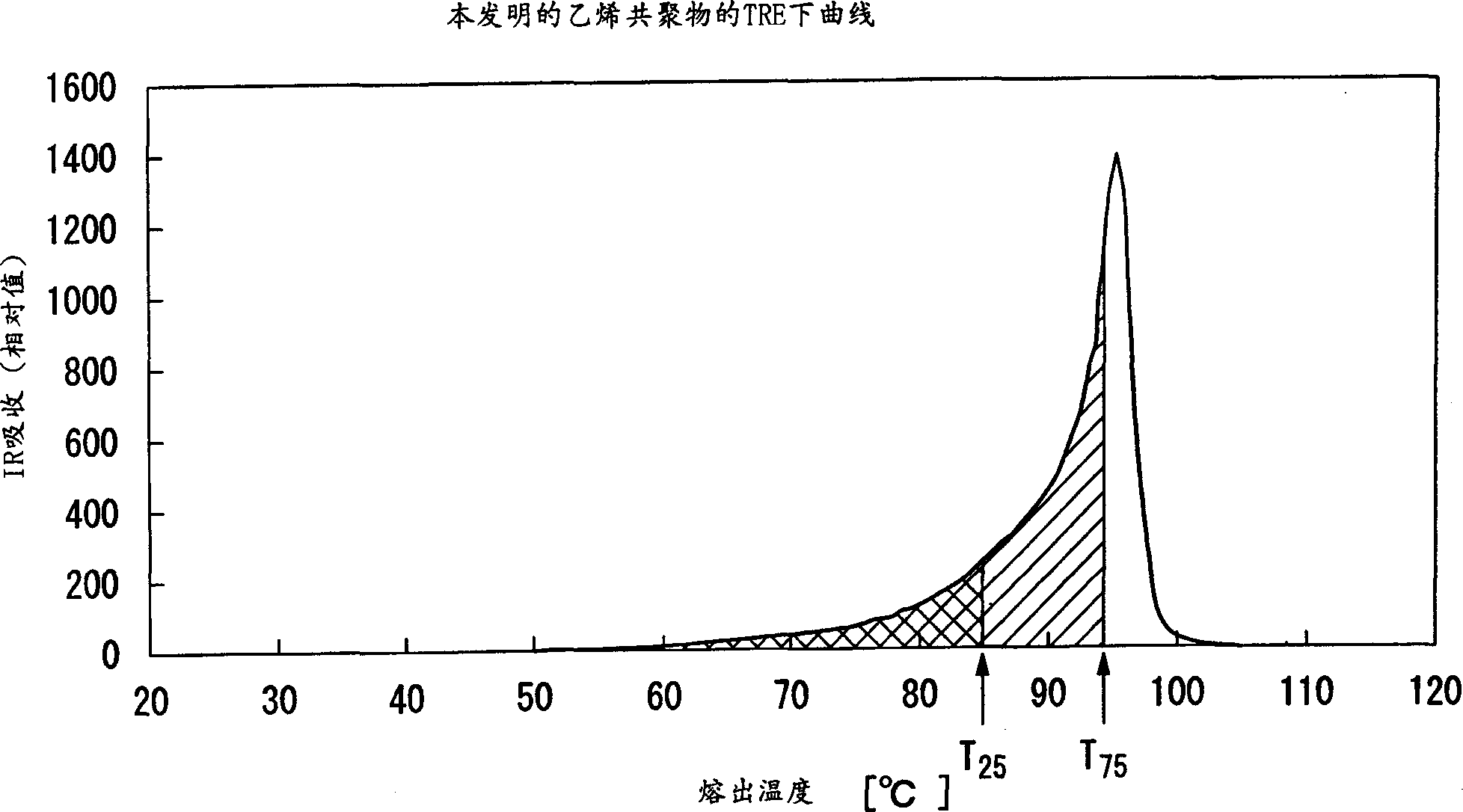

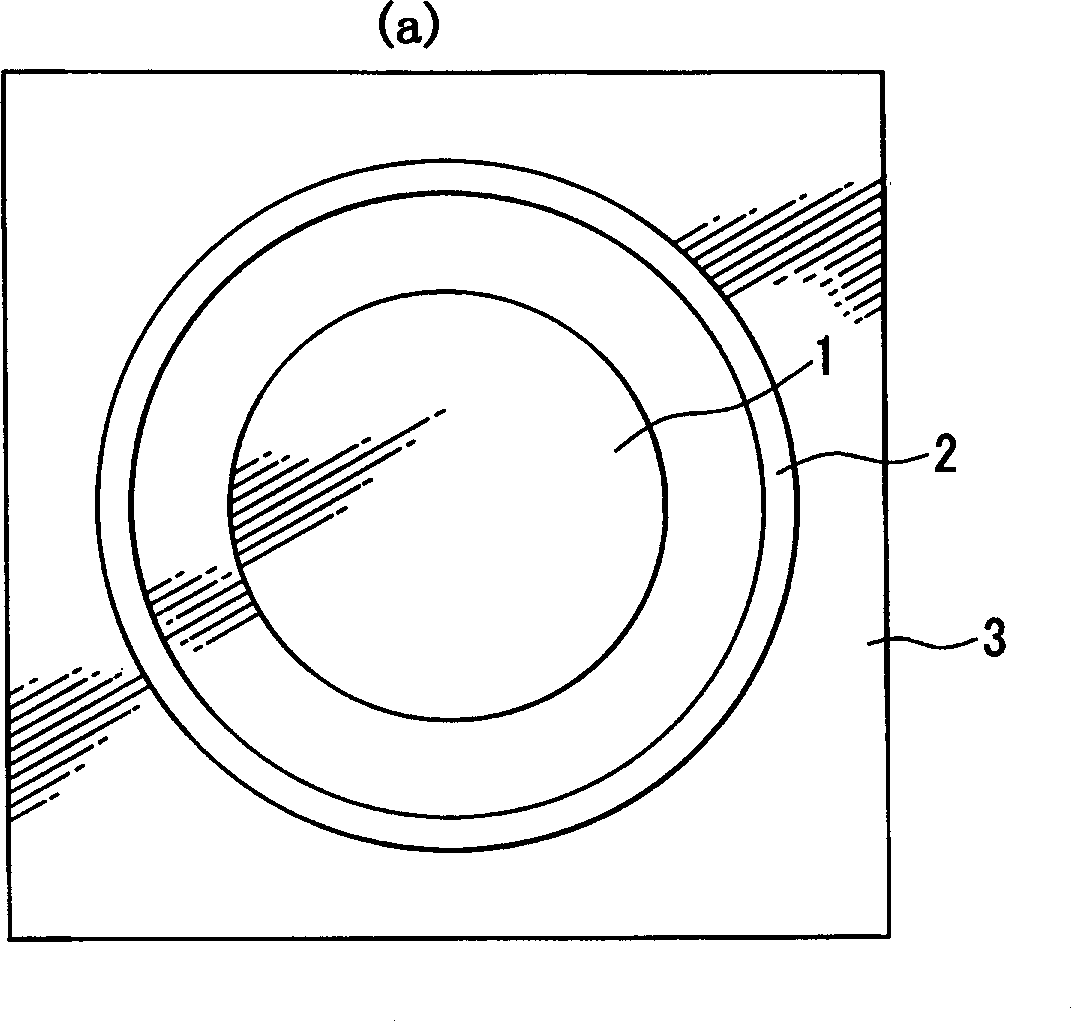

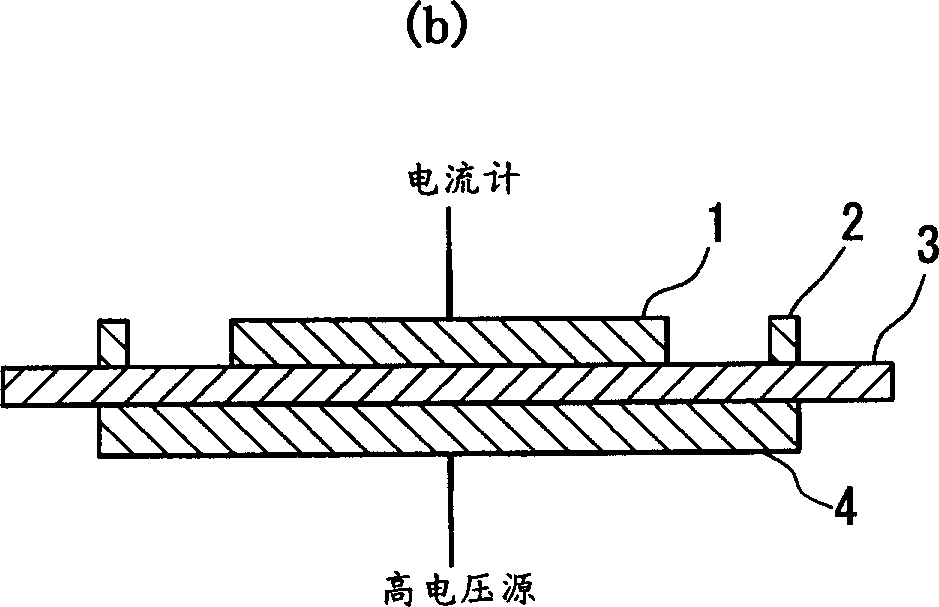

Ethylene polymer, thermoplastic resin composition comprising the polymer, and molded article

InactiveCN101268108AGood anti-adhesionGood low temperature heat sealabilityPolymer scienceVolumetric Mass Density

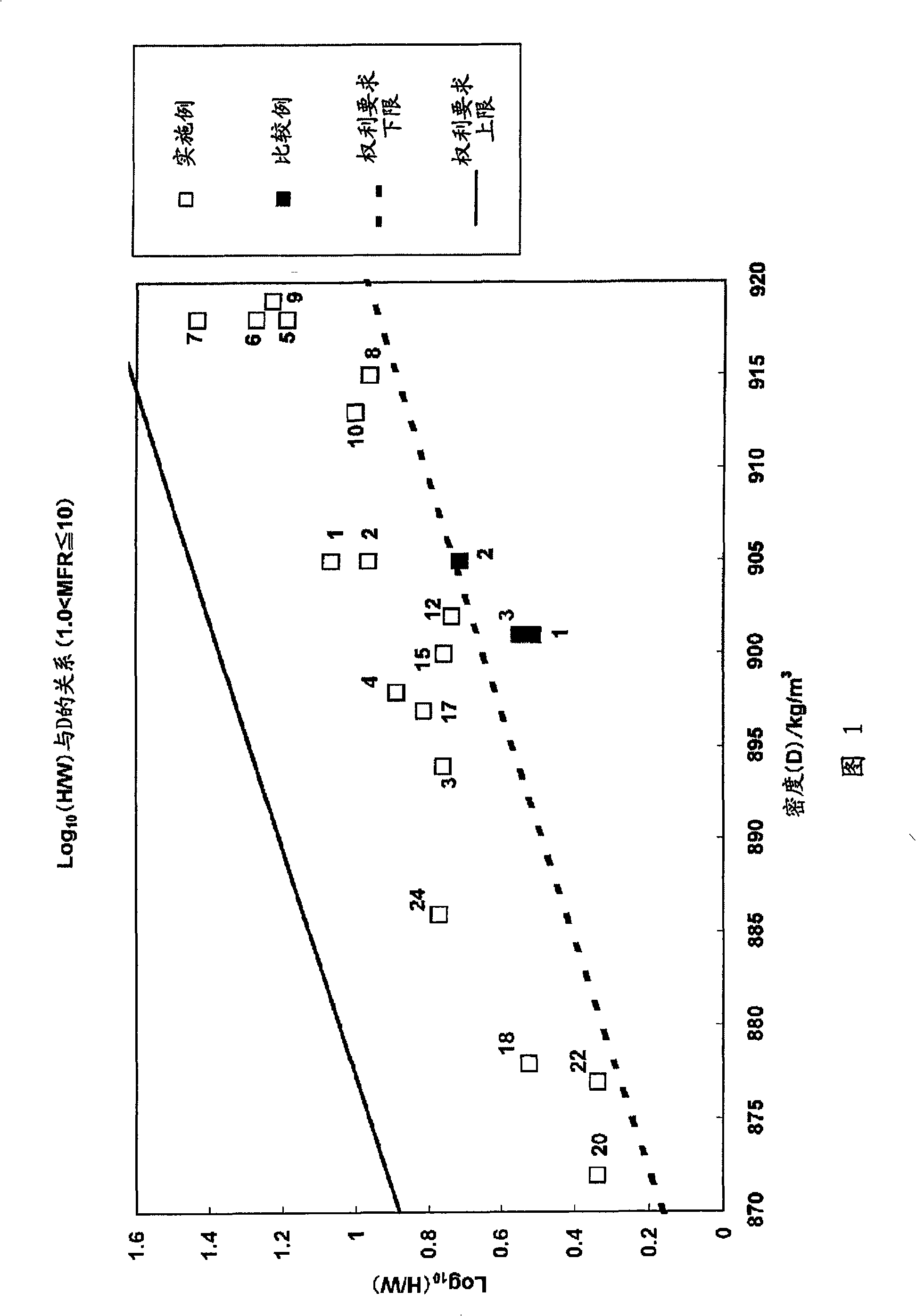

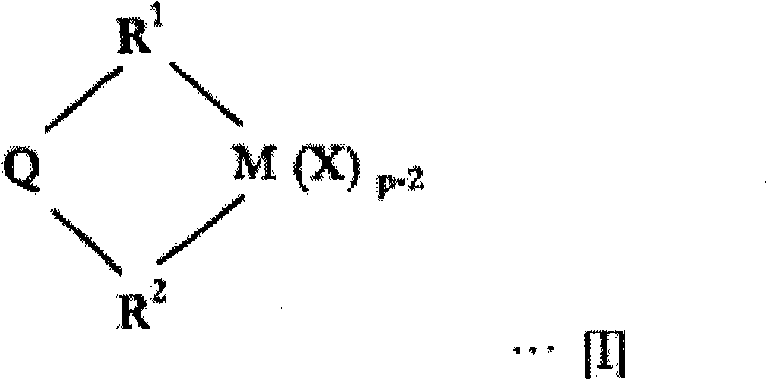

Disclosed is an ethylene polymer which is a copolymer of ethylene and an alpha-olefin having 4 to 10 carbon atoms and satisfies the following requirements [1] to [4]: [1] the MFR value falls within the range from 0.10 to 100 g / 10 min.; [2] the density (D) falls within the range from 860 to 930 kg / m<3>; [3] the ratio (Mw / Mn) of the weight average molecular weight to the number average molecular weight falls within the range from 1.50 to 3.00 inclusive; and [4] both the ratio (H / W) of the height (H) of a peak having the highest peak intensity to the width (W) of the peak at a height which is half of the height (H) in an elution curve given by temperature rising elution fraction and the density (D) satisfy a specified relationship in accordance with the MFR value of the requirement [1]. Also disclosed is a molded article which comprises the ethylene polymer, is excellent in blocking resistance, a low-temperature heatseal property and a mechanical strength, and can be used suitably for a film or the like.

Owner:MITSUI CHEM INC +1

Light conversion film, multilayer light conversion film and preparation method of multilayer light conversion film

InactiveCN111002682APromote absorptionIncreased content of photosynthesis productsClimate change adaptationSynthetic resin layered productsUltraviolet lightsInsect pest

The invention relates to a thin film and a preparation method thereof, in particular to a light conversion film, a multilayer light conversion film and a preparation method of the multilayer light conversion film. The light conversion film comprises a film body and a light conversion film layer, and the light conversion film layer comprises, by weight, 18%-22% of a light conversion agent, 55%-60%of an organic carrier, 13%-15% of a light stabilizer and 9%-12% of an antioxidant, wherein the film body comprises 60%-75% of a film matrix, 12%-20% of a light stabilizer and 10%-20% of an antioxidant; according to the method provided by the invention, by adding the light conversion agent, ultraviolet light in sunlight can be converted into red light, absorption of plants on nutrient elements suchas nitrogen, phosphorus, potassium and zinc is promoted, the content of photosynthesis products in leaves is increased, crop growth is promoted, and meanwhile, the effect of reducing diseases and insect pests is achieved.

Owner:徐蕾

Aluminum-plastic film for packaging lithium battery and preparation method of aluminum-plastic film

PendingCN114388948AImprove corrosion resistanceImprove hydrolysis resistanceMaterial nanotechnologySynthetic resin layered productsPolyolefinUltra-high-molecular-weight polyethylene

The invention discloses an aluminum-plastic film for lithium battery packaging, which comprises an outer nylon composite layer, a polyurethane bonding layer, an aluminum alloy foil layer, a polyolefin bonding layer and a polypropylene composite layer which are arranged in sequence, the polypropylene composite layer is a three-layer co-extrusion composite film, the middle layer of the co-extrusion composite film is ultra-high molecular weight polyethylene toughened polypropylene, and the middle layer of the co-extrusion composite film is an aluminum alloy foil layer. The outer layer is co-polypropylene filled with nano filler, and the inner layer is co-polypropylene. Due to the addition of the nano filler, the mechanical property of polypropylene can be improved, the effect of neutralizing hydrofluoric acid is achieved, the low-temperature heat sealing property of the inner-layer film can be improved, and the corrosion resistance of the aluminum-plastic film is improved. The invention further discloses a preparation method of the aluminum-plastic film, the inner layer film of the aluminum-plastic film is manufactured in a hot compounding mode, plasma cleaning treatment is conducted on the surface of the aluminum foil firstly, then plasma etching is conducted on the cleaned aluminum foil, the bonding performance between the aluminum foil and a bonding agent can be improved, and the service life of the aluminum-plastic film is prolonged. Therefore, the corrosion resistance and humidity and heat resistance of the aluminum-plastic film are improved.

Owner:江阴市申美包装材料有限公司

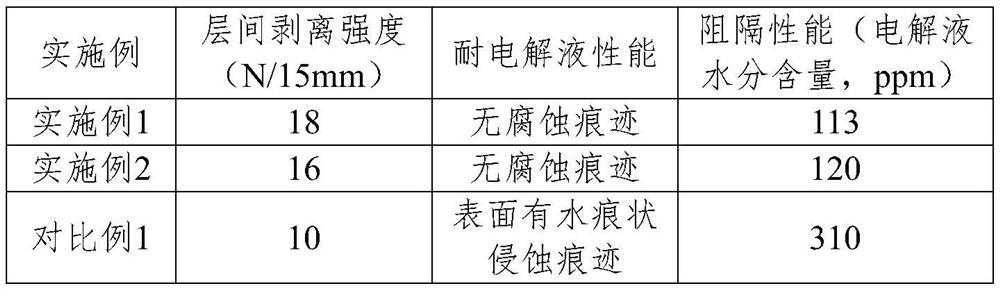

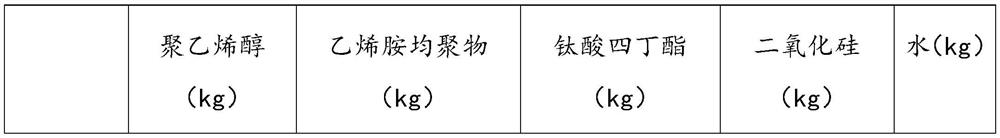

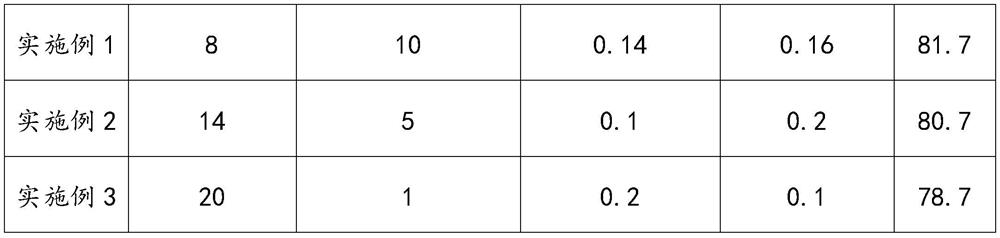

Barrier coating and high-barrier composite material applied in barrier coating

InactiveCN111690300AGood gas barrierStrong adhesionSynthetic resin layered productsPaper/cardboard layered productsPolyvinyl alcoholAluminum foil

The invention relates to the field of packaging materials, in particular to a barrier coating and a high-barrier composite material applied in the barrier coating. The barrier coating is prepared fromthe following raw materials in percentage by mass: 8 to 20 percent of polyvinyl alcohol, 1 to 10 percent of vinylamine homopolymer, 0.1 to 0.2 percent of tetrabutyl titanate, 0.1 to 0.2 percent of silicon dioxide and the balance of water. The polyvinyl alcohol, the vinylamine homopolymer, the tetrabutyl titanate and the silicon dioxide in a specific mass ratio are added into the water for a mixing reaction, the effect of modifying the polyvinyl alcohol is achieved, the polyethylene barrier coating with high barrier performance is finally obtained, and compared with the aluminum foil, the polyethylene barrier coating has the advantage of being easy to recycle and meets the development requirement for environmental protection.

Owner:ZHEJIANG GOLDSTONE PACKING

Transverse-longitudinal linear easy-to-tear film and manufacturing process thereof

InactiveCN111073124AGood physical propertiesGood low temperature heat sealabilityFlat articlesThin membraneMechanical engineering

The invention discloses a transverse-longitudinal linear easy-to-tear film and a manufacturing process thereof. The transverse-longitudinal linear easy-to-tear film comprises COC, LLDPE and DDPE, wherein the mass fraction of COC is 20-50%, the mass fraction of LLDPE is 30-60%, the mass fraction of DDPE is 10-20%, and the manufacturing process of the transverse-longitudinal linear easy-to-tear filmcomprises the steps of feeding, hot melting and filtering, extrusion molding, tape casting and cooling, trimming and recycling, corona treatment and aging treatment. The film prepared from COC, LLDPEand DDPE is prepared from COC of LLDPE with a large mass fraction and a small amount of DDPE, the film is easier to tear while certain strength is provided, and in addition, a torn crack of the filmis a linear crack; by means of the manufacturing process, the product has good physical properties, especially the low-temperature heat sealing performance is excellent, and the heat sealing temperature is 103-105 DEG C; and the product can be used for compounding to form easy-to-tear films with different properties.

Owner:JINHUA HENGYU PACKAGING CO LTD

Porous film for bag-constituting member and bag-constituting member for disposable body warmer

InactiveCN102827415AImprove productivityGood heat sealing performanceFlexible coversWrappersLinear low-density polyethyleneCopolymer

The invention relates to a porous film for a bag-constituting member and a bag-constituting member for a disposable body warmer. The invention aims at providing a porous film for a bag-constituting member which has good low-temperature heat sealability. In addition, the invention aims ar providing a bag-constituting member for a disposable body warmer which uses the porous film for a bag-constituting member. The porous film for a bag-constituting member is characterized in that the porous film is prepared by a linear low-density polyethylene, an olefinic copolymer having a Vicat softening point of from 20 DEG C to 50 DEG C and a density of less than 0.900 g / cm3 and an inorganic filler, and is formed by stretching an unstretched film to be porous.

Owner:日东来福泰株式会社

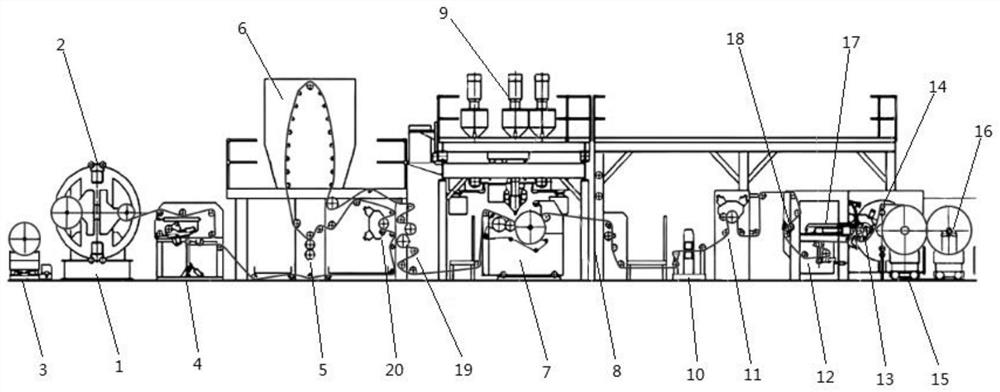

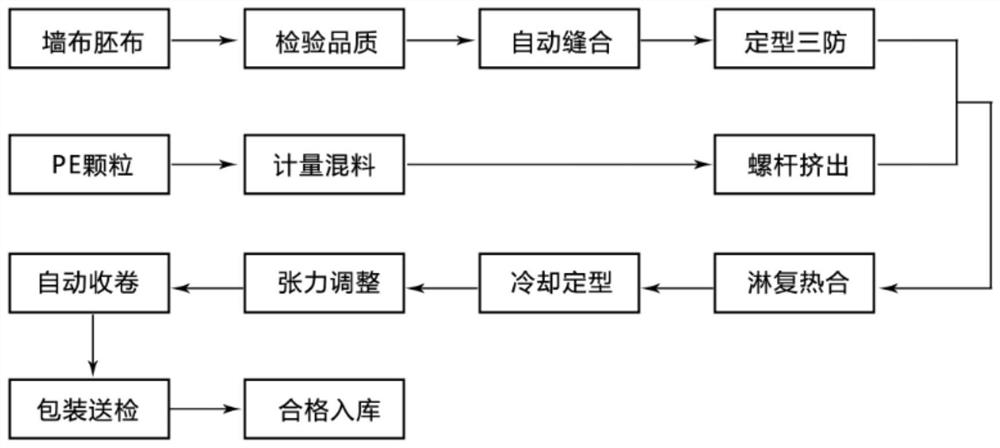

Traceless hot glue wall cloth production device and production process

PendingCN113897795AGuaranteed temperatureReduce consumptionConstructions elementsTextiles and paperElectrical energy consumptionProcess engineering

The invention discloses a traceless hot glue wall cloth production device and production process. The traceless hot glue wall cloth production device comprises a base plate; an unwinding machine is fixedly installed on the upper surface of the base plate; a feeding plate is arranged on one side of the unwinding machine; a tension device is arranged on the other side of the unwinding machine; a coating device is arranged at the rear end of the tension device; a heat preservation device is arranged above the coating device; a drying device is arranged at the tail end of the interior of the coating device; a cooling device is arranged at the rear end of the coating device; a screw extruder installed on a supporting framework is arranged over the cooling device; and a thickness measuring device, a corona device, the tension device, an auxiliary device, a cutter device, a receiving device and a discharging trolley are sequentially arranged at the rear end of the cooling device. According to the production device, the heat preservation device is additionally arranged on an existing hot glue compounding machine, so that the temperature of raw materials is guaranteed when the production device is used, electric energy consumption for heating is reduced, and the processing cost is saved.

Owner:杭州知合纺织有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com