Ethylene polymer, thermoplastic resin composition comprising the polymer, and molded article

A thermoplastic resin and polymer technology, applied in the field of moldings formed from thermoplastic resin compositions, can solve problems such as poor anti-blocking properties, wide composition distribution, low-temperature heat-sealability or deterioration of softness, etc., and achieve excellent low-temperature heat-sealability, The effect of excellent mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0228] Preparation of catalyst solution

[0229] Add bis(p-tolyl)methylene(cyclopentadienyl)(octamethyloctahydrodibenzofluorenyl)zirconium dichloride 0.0005 to a glass flask fully replaced with nitrogen. mmol, and a catalyst solution was obtained by adding thereto a hexane solution of MMAO manufactured by Tosoh Fine Chemicals Co., Ltd. so that the amount of aluminum was 0.125 mmol.

[0230] polymerization

[0231] 800 ml of dehydrated hexane and 200 ml of dehydrated 1-octene were placed in a stainless steel autoclave with an internal volume of 2 L that was fully replaced with nitrogen, and after the temperature in the system was raised to 145°C, 1500 ml of hydrogen was charged, and the total was dehydrated by supplying ethylene. The pressure becomes 3MPa-G. Next, 1.0 mmol of triisobutylaluminum and the above-prepared catalyst solution were injected with nitrogen pressure, and polymerization was started by making the stirring rotation number 400 rpm. Thereafter, polymerizati...

Embodiment 2

[0234] Preparation of catalyst solution

[0235] Add bis(p-tolyl)methylene(cyclopentadienyl)(octamethyloctahydrodibenzofluorenyl)zirconium dichloride 0.00025 to a glass flask fully replaced with nitrogen. mmol, a catalyst solution was obtained by adding thereto a hexane solution of TMAO-341 manufactured by Tosoh Fine Chemicals Co., Ltd. so that the amount of aluminum was 0.0625 mmol.

[0236] polymerization

[0237] 800 ml of dehydrated hexane and 200 ml of dehydrated 1-octene were placed in a stainless steel autoclave with an internal volume of 2 L that was fully replaced with nitrogen, and after the temperature in the system was raised to 145°C, 1500 ml of hydrogen was charged, and the total was dehydrated by supplying ethylene. The pressure is 3MPa-G. Next, 1.0 mmol of triisobutylaluminum and the above-prepared catalyst solution were injected with nitrogen pressure, and polymerization was started by making the stirring rotation number 400 rpm. Thereafter, polymerization ...

Embodiment 3

[0239] Preparation of catalyst solution

[0240] Add bis(p-tolyl)methylene(cyclopentadienyl)(octamethyloctahydrodibenzofluorenyl)zirconium dichloride 0.00025 to a glass flask fully replaced with nitrogen. mmol, a catalyst solution was obtained by adding thereto a hexane solution of TMAO-341 manufactured by Tosoh Fine Chemicals Co., Ltd. so that the amount of aluminum was 0.0625 mmol.

[0241] polymerization

[0242] 700 ml of dehydrated hexane and 350 ml of dehydrated 1-octene were placed in a stainless steel autoclave with an internal volume of 2 L that had been fully replaced with nitrogen, and after the temperature in the system was raised to 145°C, 1200 ml of hydrogen was charged, and the total was dehydrated by supplying ethylene. The pressure is 3MPa-G. Next, 1.0 mmol of triisobutylaluminum and the above-prepared catalyst solution were injected with nitrogen pressure, and polymerization was started by making the stirring rotation number 400 rpm. Thereafter, polymeriza...

PUM

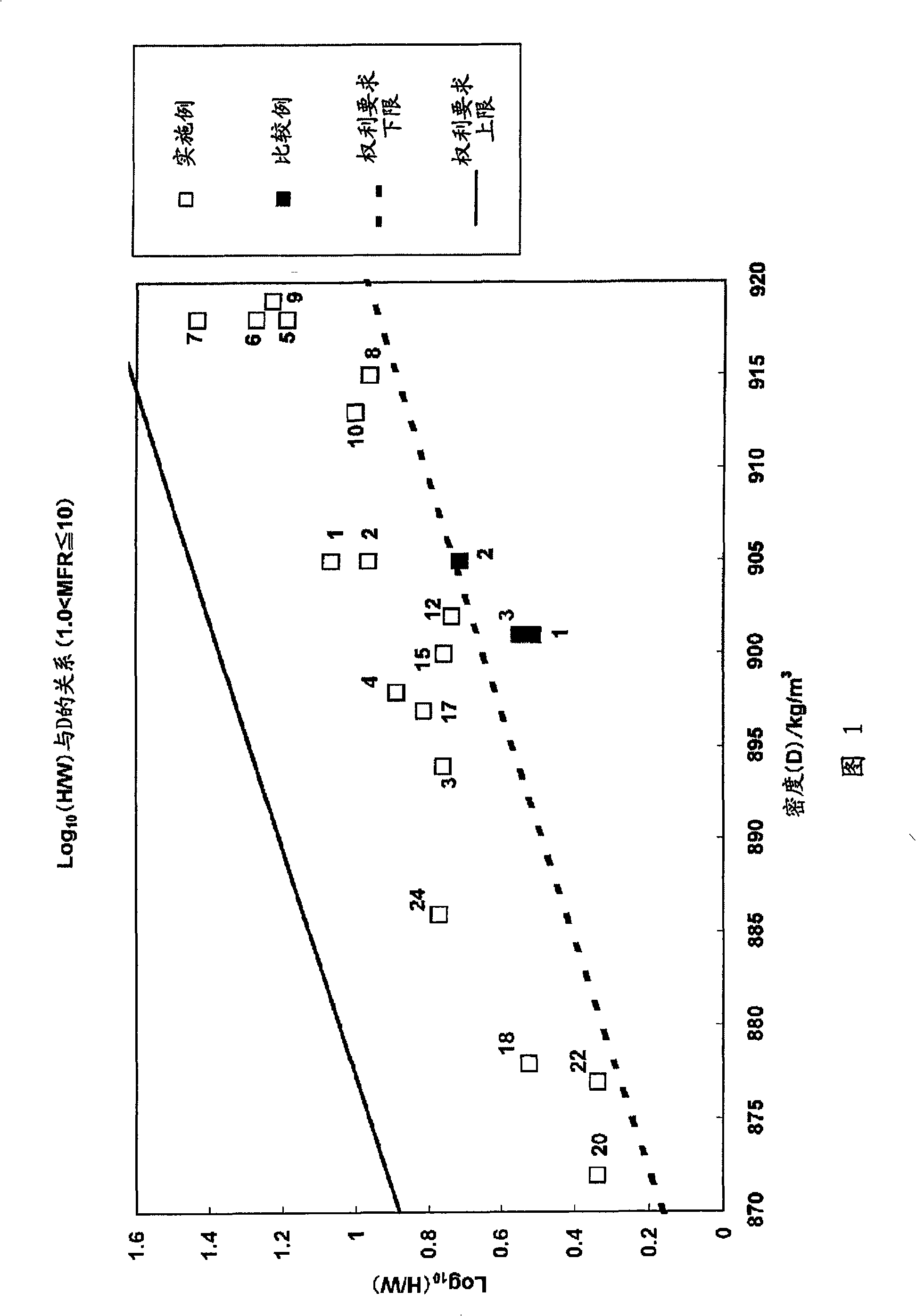

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com