Ultraviolet cross-linked organosilicone modified acrylate copolymer emulsion

A technology of acrylate and ultraviolet light, applied in the direction of coating, etc., can solve the problems of low slipperiness and anti-adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

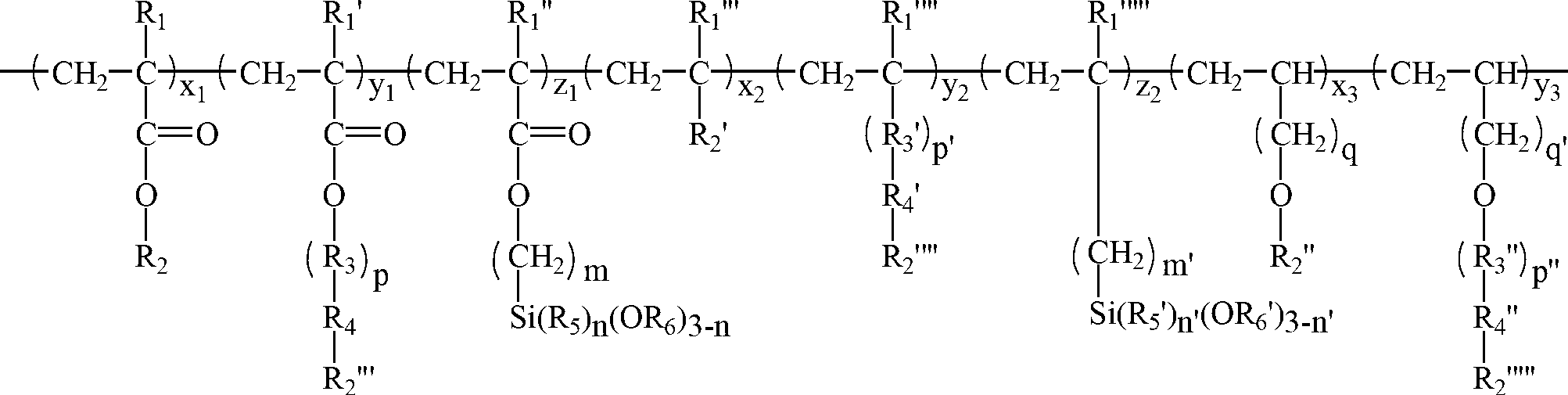

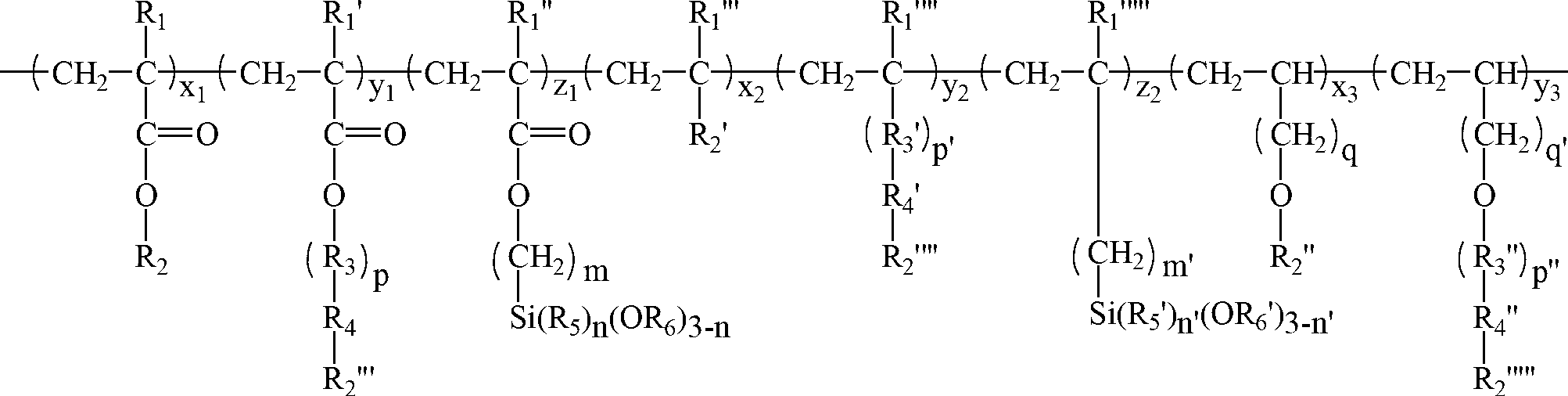

Image

Examples

Embodiment 1

[0046] 10 parts of 4-(2-hydroxy-3-allyloxy-propoxy)benzophenone, 10 parts of vinyltriethoxysilane, 19 parts of methyl methacrylate, 5 parts of methyl acrylate, acrylic acid 25 parts of butyl ester, 17 parts of isobutyl methacrylate, 8 parts of isobornyl acrylate, 3 parts of isooctyl methacrylate, 1 part of maleic acid and 2 parts of acrylic acid were used as a monomer composition. Among them, 4-(2-hydroxy-3-allyloxy-propoxy)benzophenone is a UV active monofunctional monomer, and vinyltriethoxysilane is alkoxysiloxane monofunctional Degree monomers, others are the third monofunctional monomers.

[0047] A preparation method of an ultraviolet-light crosslinked silicone-modified acrylate copolymer emulsion, the steps of which are:

[0048] (1) Put 100 parts of the above-mentioned monomer composition, 2 parts of nonylphenol polyoxyethylene ether ammonium sulfate, 1.5 parts of octylphenol polyoxyethylene ether and 20 parts of primary distilled water into the 123.5 parts of the pr...

Embodiment 2

[0056]5 parts of 4-acryloxybenzophenone, 10 parts of methacryloxypropyl trimethoxysilane, 10 parts of methyl acrylate, 15 parts of methyl methacrylate, 5 parts of styrene, methacrylic acid 5 parts of isobutyl ester, 30 parts of n-butyl acrylate, 10 parts of isooctyl acrylate, 5 parts of octadecyl acrylate, 3 parts of 2-hydroxyethyl acrylate and 2 parts of methacrylic acid were used as a monomer composition. Among them, 4-acryloyloxybenzophenone is a UV active monofunctional monomer, methacryloxypropyltrimethoxysilane is an alkoxysiloxane monofunctional monomer, and others are the second Three monofunctional monomers.

[0057] A preparation method of an ultraviolet-light crosslinked silicone-modified acrylate copolymer emulsion, the steps of which are:

[0058] (1) Put 100 parts of the above monomer composition, 1.5 parts of sodium lauryl sulfate, 3.5 parts of octylphenol polyoxyethylene ether and 20 parts of deionized water into the Add device and thermometer in the reactor ...

Embodiment 3

[0066] 2 parts of 4-(2-hydroxy-3-allyloxy-propoxy)benzophenone, 15 parts of methacryloxypropyltrimethoxysilane, 18 parts of styrene, 3 parts of n-propyl acrylate 32 parts of n-butyl acrylate, 5 parts of n-butyl methacrylate, 10 parts of isooctyl methacrylate, 10 parts of isodecyl acrylate, 2 parts of acrylamide and 3 parts of acrylic acid as a monomer composition. Among them, methacryloxypropyltrimethoxysilane is a UV active monofunctional monomer, methacryloxypropyltrimethoxysilane is an alkoxysiloxane monofunctional monomer, and others It is the third monofunctional monomer.

[0067] A preparation method of an ultraviolet-light crosslinked silicone-modified acrylate copolymer emulsion, the steps of which are:

[0068] (1) Put 100 parts of the above-mentioned monomer composition, 2 parts of octylphenol polyoxyethylene ether and 15 parts of deionized water into a reaction kettle equipped with a stirrer, a temperature control device, a condensation device, a dropping device an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com