Patents

Literature

937 results about "Isooctyl acrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method for halogen-free flame retardant polyester labeled paper

ActiveCN102518003AImprove flame retardant performanceImprove stabilityStampsNon-fibrous pulp additionMethacrylatePolyester

The invention discloses a preparation method for halogen-free flame retardant polyester labeled paper. The method is characterized in that the method comprises the following steps: adopting butyl acrylate, ethylhexyl acrylate, acrylic acid, hydroxyethyl acrylate, ethyl methacrylate, a phosphorus-containing flame retardant monomer, a solvent, an initiator, and the like as raw materials to prepare a phosphorus-containing flame retardant acrylic acid pre-polymerization resin; preparing a phosphorus-containing flame retardant acrylic acid pressure sensitive adhesive; uniformly coating the phosphorus-containing flame retardant acrylic acid pressure sensitive adhesive on a halogen-free flame retardant polyester thin film; compounding the polyacrylate pressure sensitive adhesive-coated halogen-free flame retardant polyester thin film and a polyester release film; and carrying out ripening to prepare the halogen-free flame retardant polyester label product. With the present invention, the flame retardant and pressure sensitive adhesion property, the appearance and the environmental protection quality of the whole label product can be effectively improved, and the halogen-free flame retardant polyester labeled paper can meet the performance requirement of VTM-0 grade flame retardation.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Waterborne acrylate resin emulsion and synthetic method and application thereof

InactiveCN101565484AImprove performanceGood film formingFibre treatmentEster polymer adhesivesIsooctyl acrylateEmulsion

The invention pertains to the technical field of polymer materials and particularly relates to a waterborne resin emulsion for car cleaning cloth or common cleaning cloth and a textile finishing adhesive agent, a synthetic method and application of the waterborne resin emulsion. The resin emulsion consists of a waterborne resin polymer, an emulsifier, an evocating agent, a pH value modulator and water; the waterborne resin polymer is obtained by polymerization of 3-5 monomers such as butyl acrylate, ethyl hexyl acrylate and methyl methacrylate and the like. The synthesis comprises two steps of monomer pre-emulsion and polymerization by the evocating agent. The product of the invention has stable performance and good film formation performance, as well as soft hand feeling, good moisture permeability, long-term moisture and environment protection by absorbing fine dusts when used as cleaning cloth, and when used as a textile adhesive agent, the product can not only realize the characteristics and requirements above, but also decrease electrostatic interaction of the textile, thus having good and wide application in the textile field.

Owner:JILIN UNIV

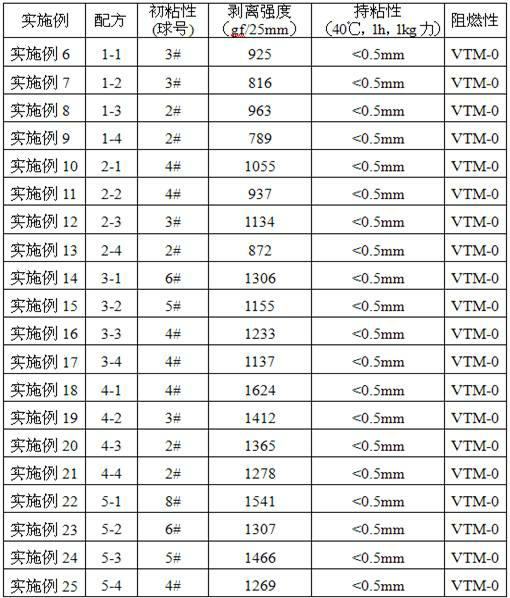

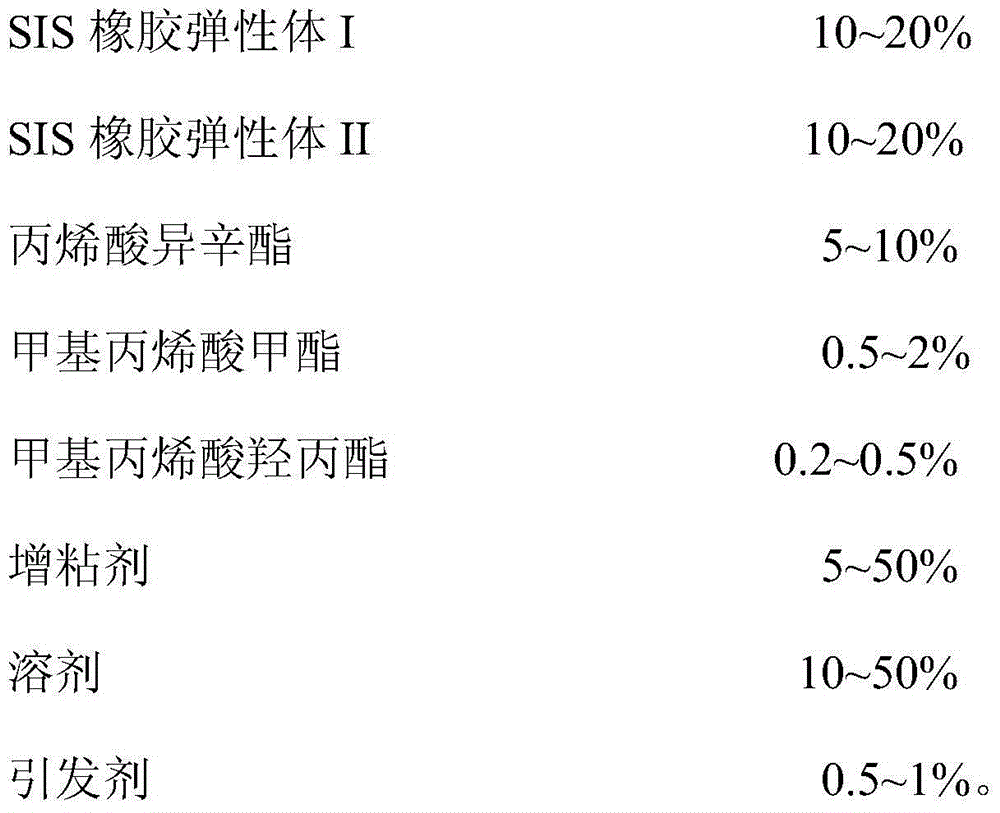

Acrylic acid modified hot-melt pressure-sensitive adhesive for bearing adhesive tape and preparation method of acrylic acid modified hot-melt pressure-sensitive adhesive

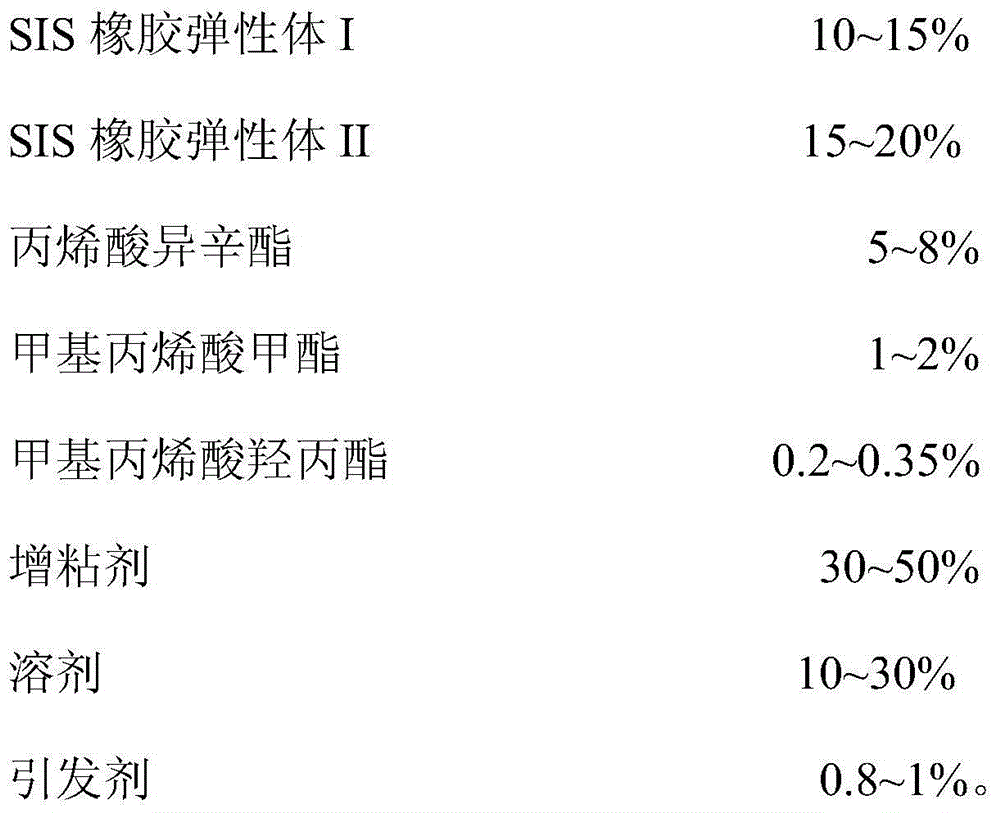

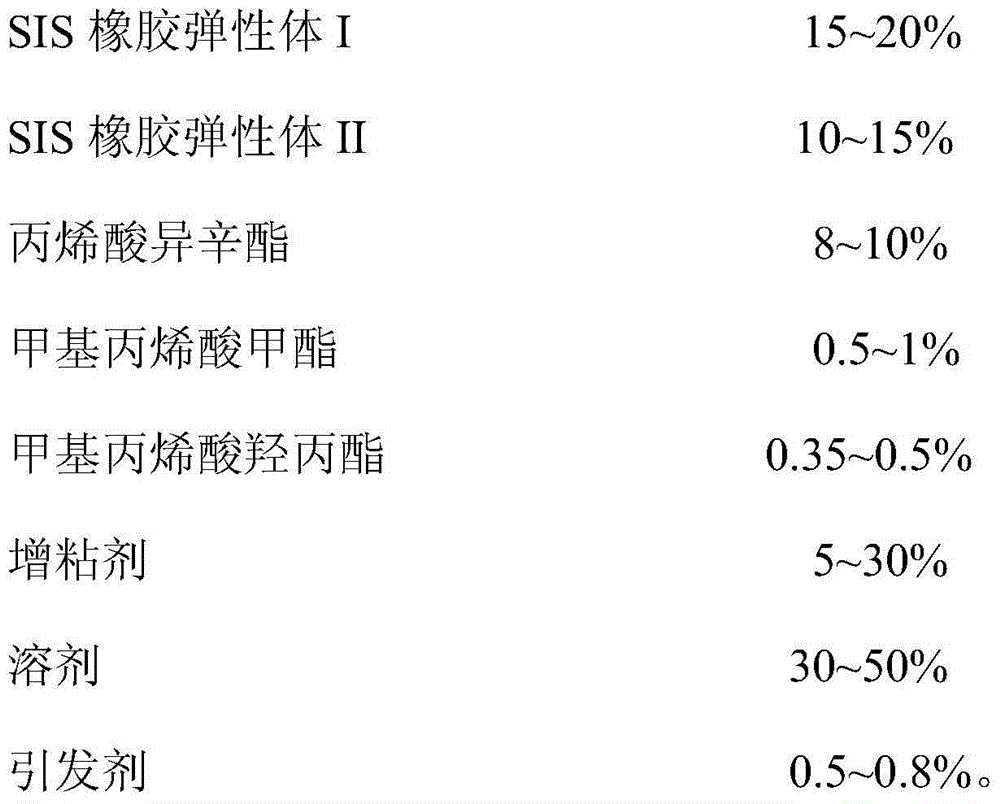

The invention relates to an acrylic acid modified hot-melt pressure-sensitive adhesive for a bearing adhesive tape. The acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following raw materials in percentage by weight: 10-20 percent of an SIS rubber elastomer I, 10-20 percent of an SIS rubber elastomer II, 5-10 percent of 2-ethylhexyl acrylate, 0.5-2 percent of methyl methacrylate, 0.2-0.5 percent of hydroxypropyl methacrylate, 5-50 percent of a tackifier, 10-50 percent of a solvent, and 0.5-1 percent of an initiator. The acrylic acid modified hot-melt pressure-sensitive adhesive is high in cohesion, high in adhesion stress, high in ageing resistance, strong in adhesive force on a substrate, and wide in application range. A preparation method of the acrylic acid modified hot-melt pressure-sensitive adhesive comprises the following steps: the materials are weighed: the SIS rubber elastomer I, the SIS rubber elastomer II and a solvent account for the total amount of the solvent are added in a first reaction kettle, and 2-ethylhexyl acrylate, methyl methacrylate, hydroxypropyl methacrylate, the initiator and the rest of the solvent are added in a second reaction kettle to form a mixed solution; the mixed solution is slowly added in the first reaction kettle; the tackifier is added in the first reaction kettle, and the solvent is distilled out; the materials are discharged in heating, and the finished product is obtained. The preparation method is simple in process, and high in the production efficiency and yield.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

PE (polyurethane) protective film glue and preparation method thereof

InactiveCN102206476AStrong adhesionHigh bonding strengthFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateWater based

The invention discloses PE (polyurethane) protective film glue and a preparation method thereof. The PE protective film glue consists of the following components in parts by weight: monomers: 20-60 parts of butyl acrylate, 25-45 parts of methyl methacrylate, 12-32 parts of methyl acrylate, 5-15 parts of acrylic acid, 10-24 parts of hydroxyethyl acrylate, 120-140 parts of enthyl hexyl acrylate; emulsifying agents: 0.5-1.5 parts of polyoxyethylene octyl phenyl ether, 0.5-1.5 parts of sodium dodecyl sulphate, 0.5-1.5 parts of sodium dodecyl benzene sulfonate; a solvent: 280-350 parts of deionized water; and an initiating agent: 0.6-1.5 parts of ammonium persulfate. The PE protective film glue provided by the invention is the water-based adhesive and has the advantages of environment friendliness, no pollution, strong adhesive force and adhesive strength, and short drying time. A PE protective film coated with the PE protective film glue provided by the invention can be used for a vehicleprotective film, the protective films of all home appliances and so on. The effects of non-degumming and no residue glue can be realized.

Owner:BOLEX SHENZHEN ADHESIVE PROD

Water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and preparation method of matt-leather-membrane aqueous coating adhesive

ActiveCN104831540AAssociative functionCombined with styleFibre treatmentIsooctyl acrylatePolymer science

The invention relates to a water-repellent, oil-repellent, sun-proof, anti-bend torsion and cold-resistant matt-leather-membrane aqueous coating adhesive for textiles and a preparation method of the matt-leather-membrane aqueous coating adhesive. The preparation method comprises the steps of emulsifying isooctyl acrylate, isobornyl methacrylate, glycidyl methacrylate, trifluoroethyl methacrylate, vinyl trimethoxysilane, hydroxypropyl acrylate, fatty alcohol ethoxylate XL90 and dodecyl benzene sulfonate to trigger polymerization, and compounding a thickening agent, namely an associated polyurethane flatting rheological agent, a cross-linking agent, namely terminated isocyanate, a flatting agent, namely polymethyl urea resin and silicon dioxide with the particle size of 2-7 microns, so as to obtain the matt-leather-membrane aqueous coating adhesive.

Owner:DANDONG UNIK TEXTILE

Aqueous adhesive for non-woven fabric composite membrane and preparation method of aqueous adhesive

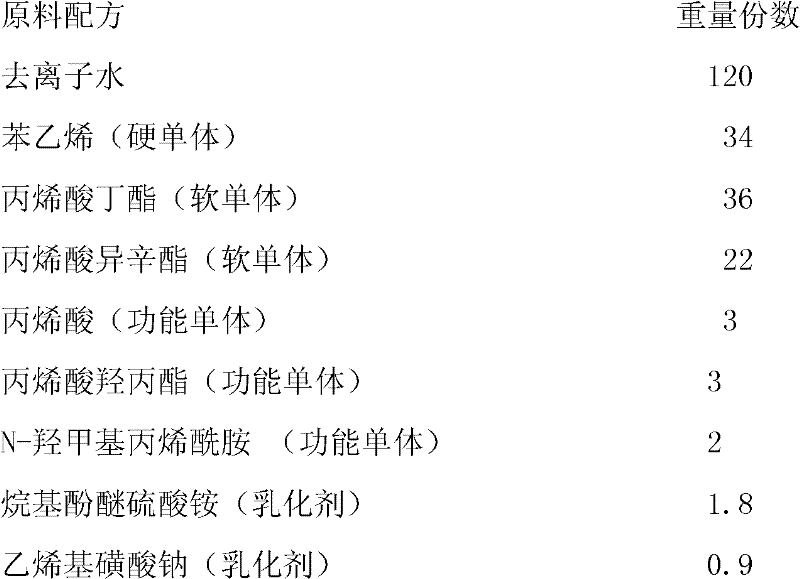

InactiveCN102443367AImprove stabilityGood adhesionEster polymer adhesivesHydrocarbon polymer adhesivesIsooctyl acrylateFunctional monomer

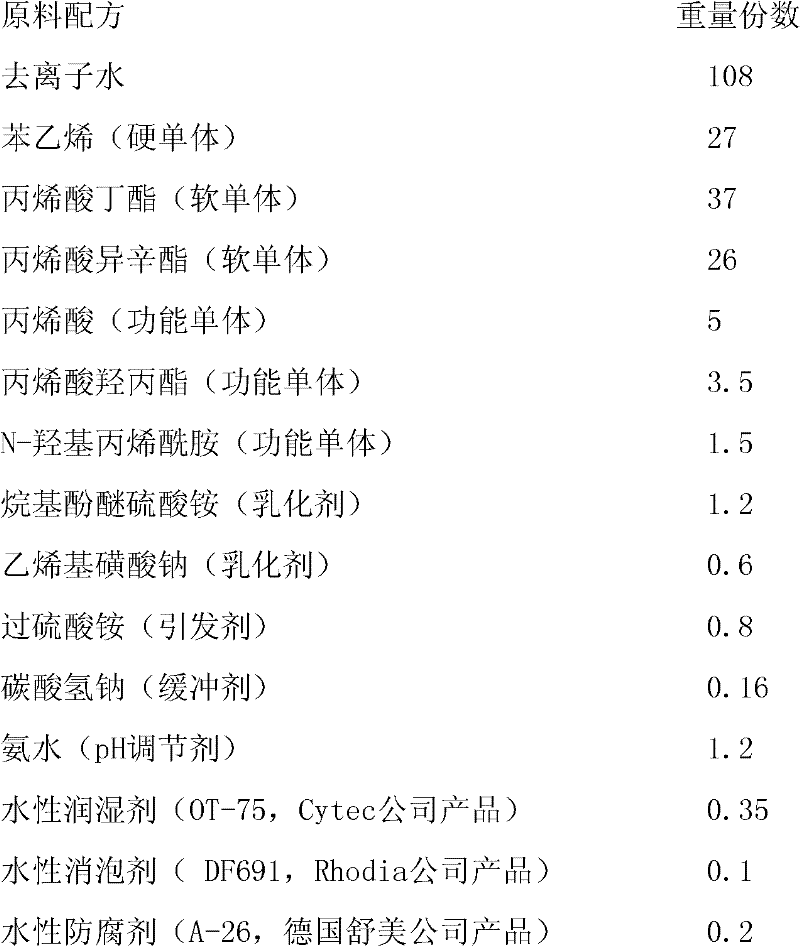

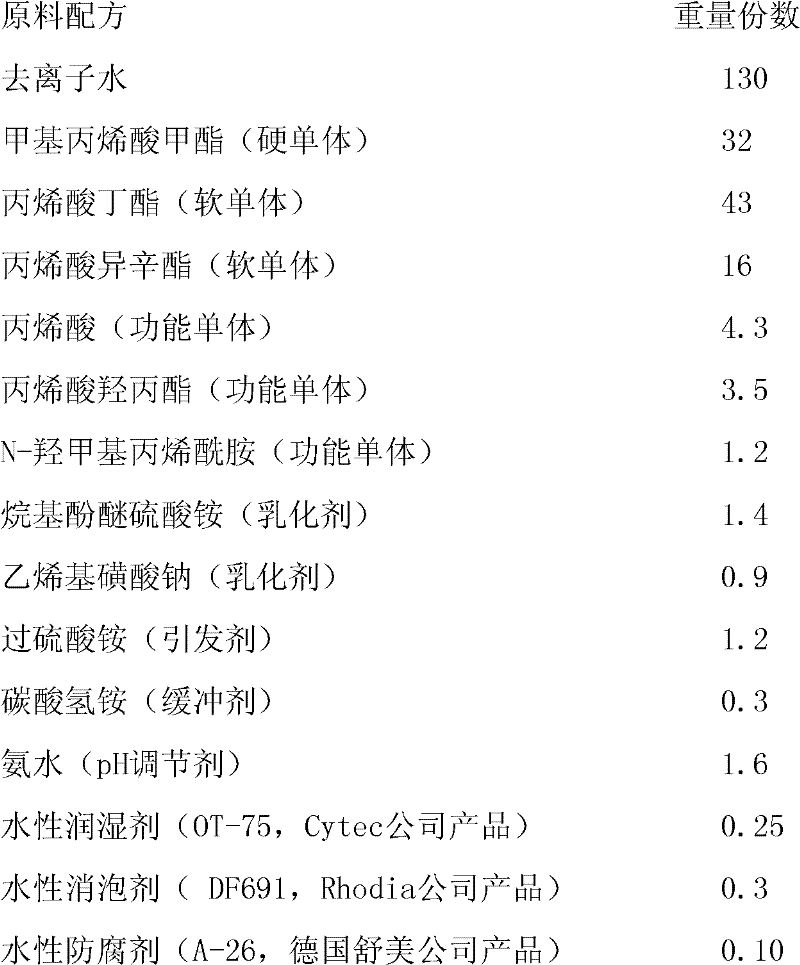

The invention discloses an aqueous adhesive for a non-woven fabric composite membrane and a preparation method of the aqueous adhesive, belonging to the field of manufacturing of adhesives. The adhesive comprises the following components of: deionized water, monomers, a composite emulsifier, an initiator, a buffering agent, a pH regulator and an aqueous addition agent, and the solid content of the adhesive is 40-50%. The monomers in the components of the adhesive comprise a hard monomer, soft monomers and functional monomers, wherein the hard monomer is styrene or methyl methacrylate, the soft monomers are butyl acrylate and iso-octyl acrylate, and the functional monomers are composed of crylic acid, hydroxy-propyl acrylate and N-methylol acrylamide. The monomers comprise the following components in percentage by mass: 20-40% of styrene or methyl methacrylate, 10-30% of iso-octyl acrylate, 30-50% of butyl acrylate, 1-5% of crylic acid, 1-5% of hydroxy-propyl acrylate and 1-5% of N-methylol acrylamide. The aqueous adhesive has the advantages of effectively improving wetting and flatting properties on the surface of a plastic film, ensuring that the plastic film has a better wettingproperty with the non-woven fabric, and enhancing the peeling strength.

Owner:NANTONG GAOMENG NEW MATERIAL

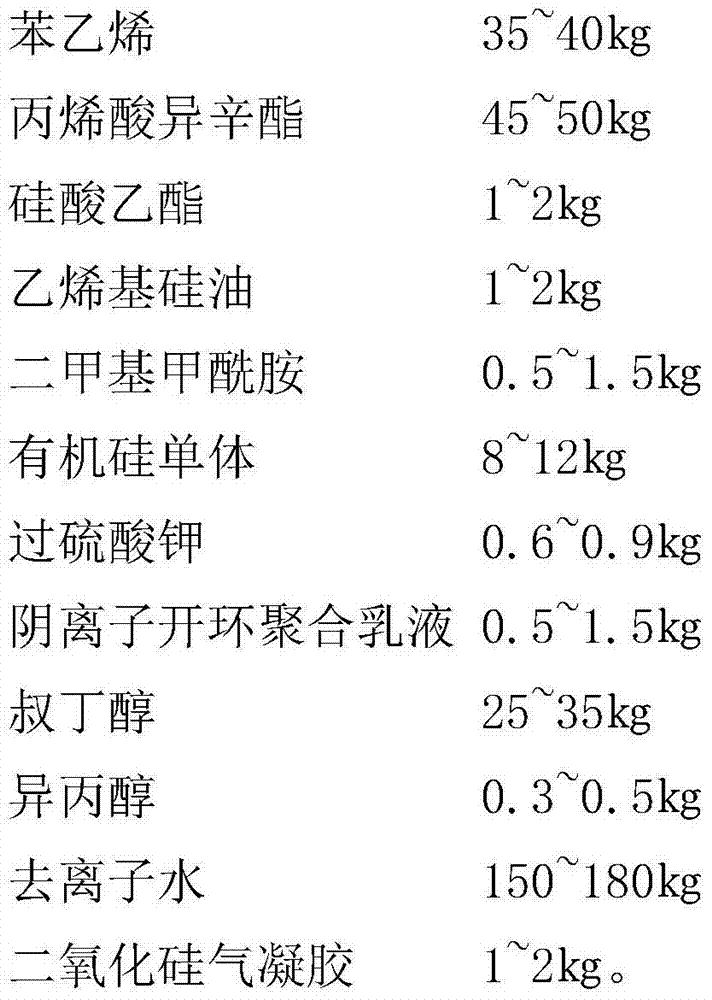

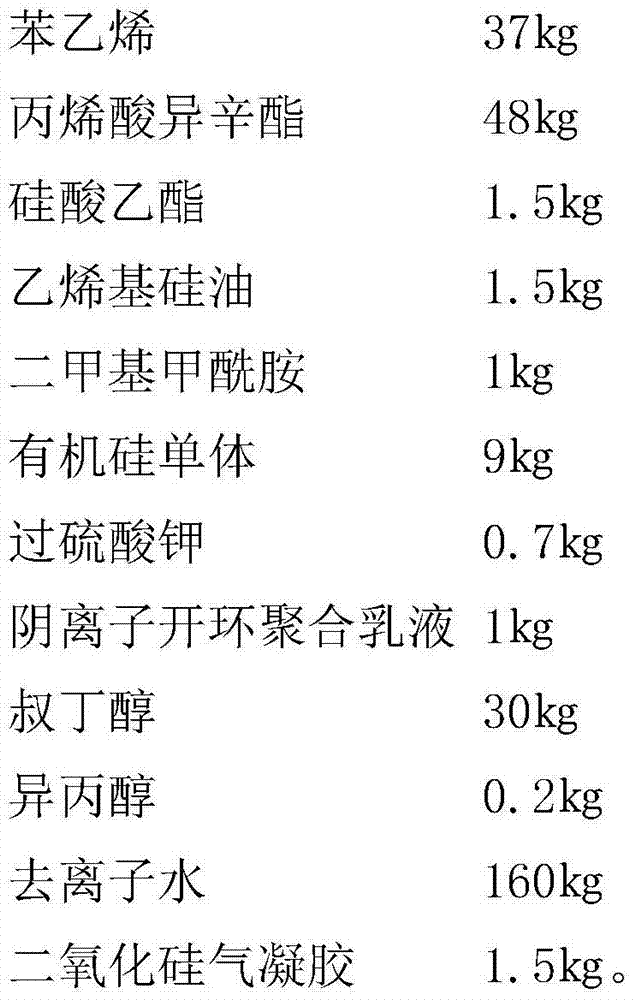

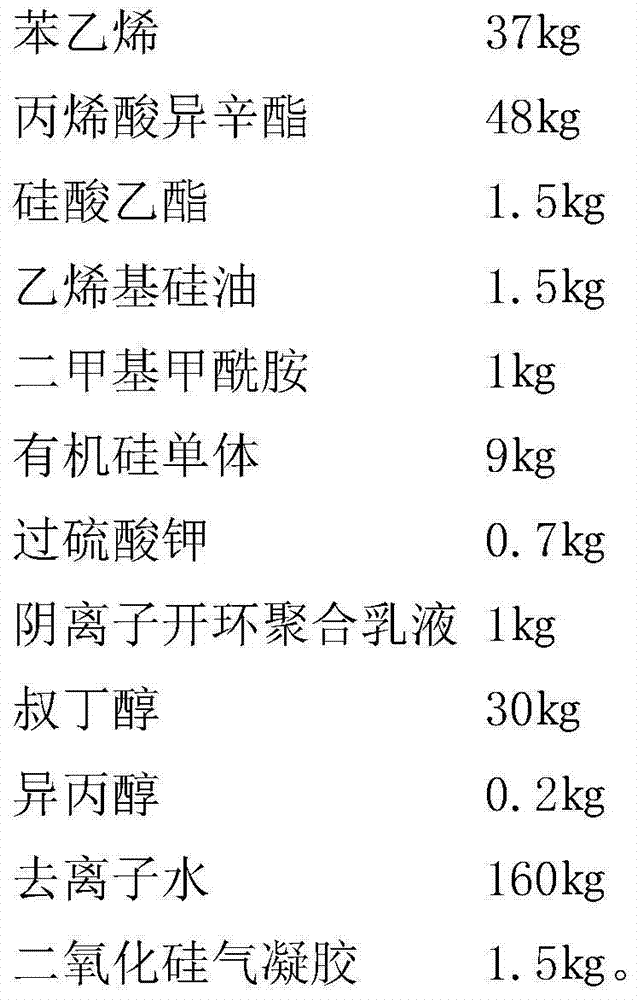

Method for modifying styrene-acrylic emulsion through organic silicon

ActiveCN103923271AHigh degree of polymerizationImprove water resistanceIsooctyl acrylatePotassium peroxodisulfate

The invention provides a method for modifying styrene-acrylic emulsion through organic silicon, relating to the field of chemical engineering technologies. The method comprises steps of (1) firstly putting deionized water, tertiary butanol and isopropanol into a reaction kettle and mixing uniformly through stirring, and heating up to 60-70DEG C, so as to prepare a solution a; (2) dissolving styrene, 2-ethylhexyl acrylate, ethyl silicate, organosilicone monomer and anion ring opening polymerization emulsion into the solution a, fully mixing through stirring till the temperature rises up to 80-90DEG C, and preserving heat for 2 hours, so as to prepare a solution b; (3) putting vinyl silicone oil, silicon dioxide aerogel and dimethyl formamide into the solution b, stirring for 30 minutes to be mixed uniformly to prepare a solution c; (4) controlling the temperature of the solution c at 60-65 DEG C, then dripping potassium peroxodisulfate for 0.5 hour, and cooling to room temperature, so as to prepare a solution d; (5) regulating the pH value of the solution d to be neutral with ammonia water, filtering the discharged material so as to prepare the styrene-acrylic emulsion. Due to the addition of organic silicon monomer, ethyl silicate and the like, the degree of crosslinking of a latex film is improved, and the weather fastness of the styrene-acrylic emulsion is greatly improved.

Owner:DONGZHI OASIS ENVIRONMENTAL PROTECTION CHEM

Elastic raindrop impression resisting styrene-acrylic emulsion and preparation method thereof

The invention discloses an elastic raindrop impression resisting styrene-acrylic emulsion. The elastic raindrop impression resisting styrene-acrylic emulsion is prepared from, by mass, 80-130 parts of water, 38-60 parts of styrene, 22-45 parts of methyl methacrylate, 12-18 parts of 2-ethylhexyl acrylate, 22-73 parts of butyl acrylate, 0.5-5 parts of acrylic acid, 0.5-5 parts of methacrylic acid, 1-5 parts of acrylamide, 7-18 parts of an anionic emulsifier, 0.5-2 parts of a reactive emulsifier, 1-5 parts of a crosslinking monomer, 0.2-0.9 part of an initiator, 0.1-0.5 part of an oxidant and 0.1-0.5 part of a reducing agent. The elastic raindrop impression resisting styrene-acrylic emulsion has excellent mechanical strength and higher weather resistance.

Owner:CHANGSHU BATF TECH CO LTD

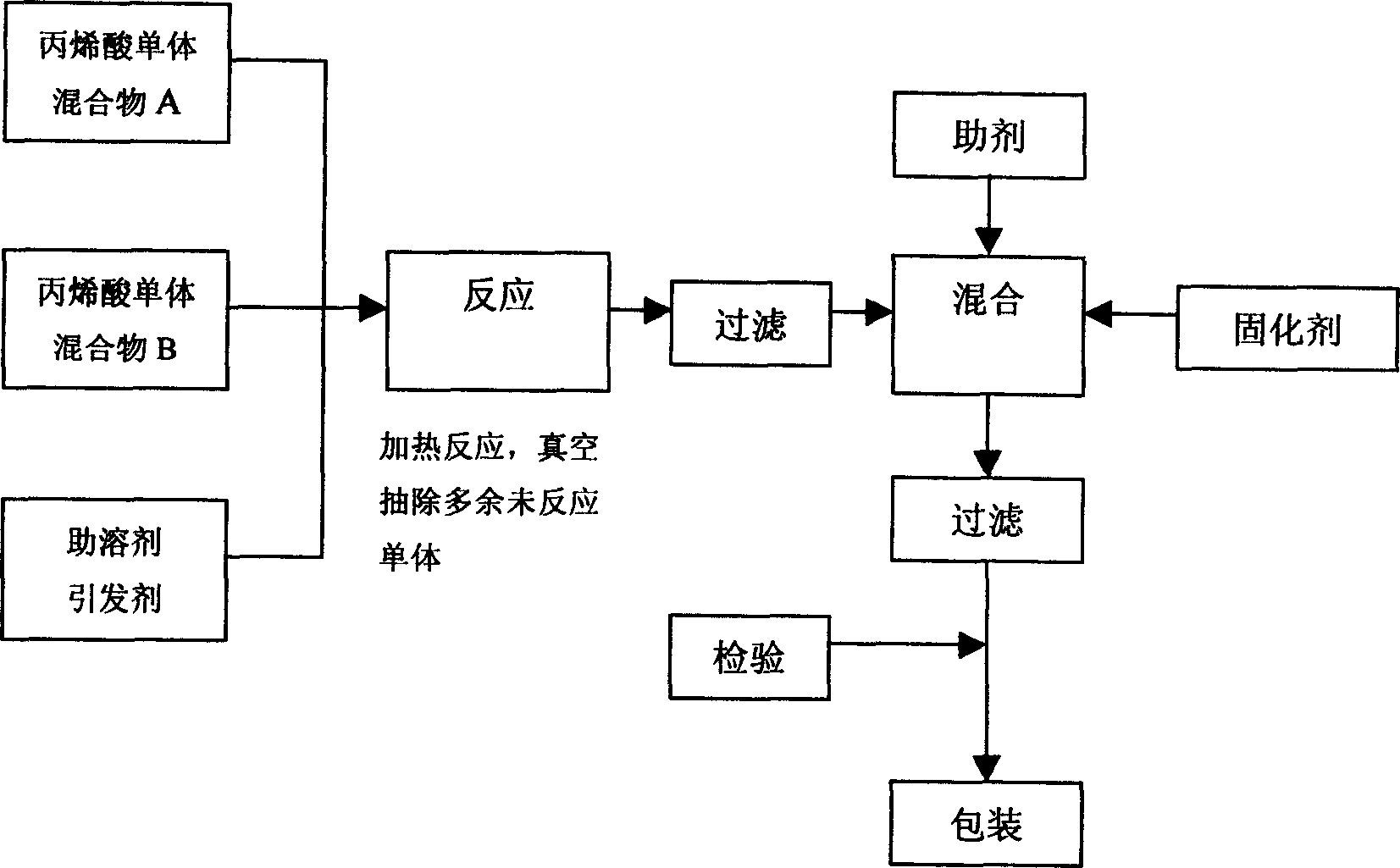

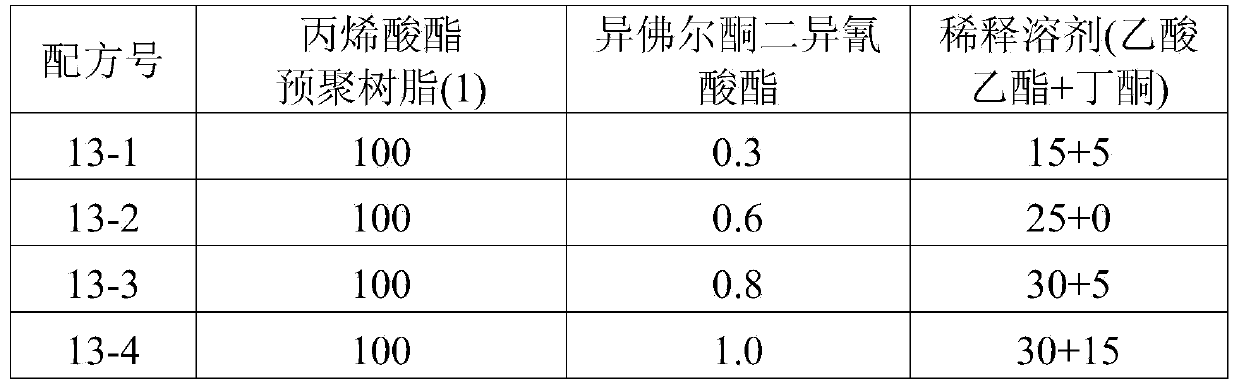

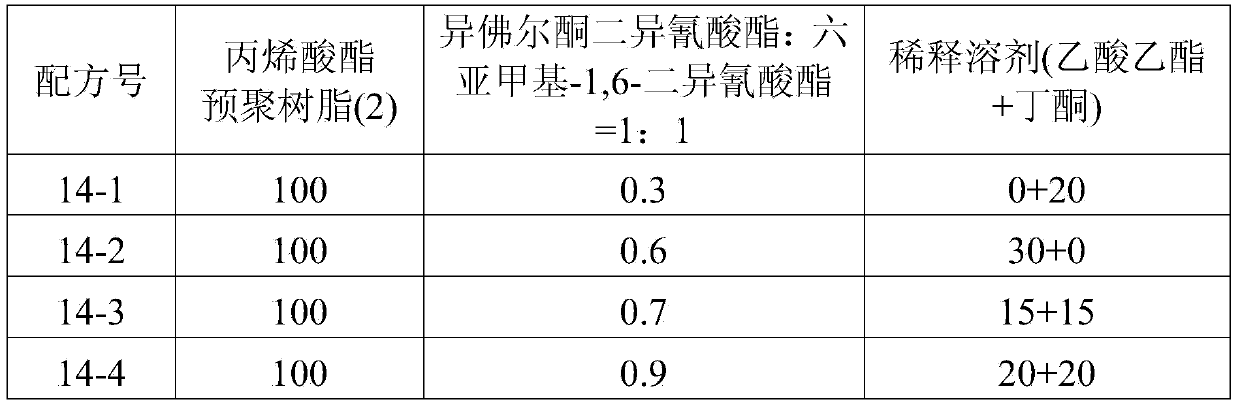

Preparation method of single-component solvent-type high-stripping acrylic acid pressure-sensitive adhesive

InactiveCN104817986AHigh peel strengthGood first stickMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesIsooctyl acrylateEthyl acetate

The invention discloses a preparation method of a single-component solvent-type high-stripping acrylic acid pressure-sensitive adhesive, wherein the preparation method comprises: 1) preparing raw materials of the high-stripping acrylic acid pressure-sensitive adhesive, comprising, by weight: (A) an internal-polymerization monomer (hard monomer): 10 parts of methyl methacrylate, 12 parts of styrene and 10 parts of vinyl acetate, (B) a viscous monomer (soft monomer): 45 parts of butyl acrylate and 40 parts of 2-ethylhexyl acrylate, (C) a modified monomer: 6 parts of methyl acrylic acid and 2 parts of hydroxyethyl acrylate, (D) a solvent: 40 parts of ethyl acetate and 15 parts of ethanol, (E) a curing (crosslinking) agent: 0.5 parts of triacetylacetone; (F) a residual monomer eliminating agent and a crosslinking agent: 0.2 parts of triethanolamine; (G) 1 part of an initiator (of which the use amount accounts for 0.8% of the total mass of the monomers); and (H) 0.02 parts of a chain transfer agent. The preparation method can be used for preparing the acrylic acid pressure-sensitive adhesive being good in original adhesion, high in stripping strength, good in adhesion permanence and excellent in coating processing performance, thereby greatly developing the available range of the acrylic acid pressure-sensitive adhesive.

Owner:江苏耐斯数码科技股份有限公司

Double-sided pressure sensitive adhesive tape for computer embroidery and preparation method thereof

ActiveCN101602919AHigh peel strengthGood peeling effectFilm/foil adhesivesEster polymer adhesivesIsooctyl acrylateBenzoyl peroxide

The invention relates a double sided pressure-sensitive adhesive tape for computer embroidery and a preparation method thereof. The double-sided pressure sensitive adhesive tape comprises base material, a pressure-sensitive adhesive layer coated on the two sides of the base material and a release paper layer; wherein, the pressure sensitive adhesive layer is prepared by being coated with pressure sensitive adhesive which is prepared by the following components according to the parts by weight: 80.0-100.0 parts of 2-ethylhexyl acrylate, 8.0-15.0 parts of butyl acrylate, 3.0-7.5 parts of acrylic acid, 8.0-15.0 parts of vinyl acetate, 1.0-7.5 parts of hydroxy-ethyl acrylate, 0.20-1.0 part of benzoyl peroxide, 120.0-200.0 parts of main solvent, 5.0-30.0 parts of auxiliary solvent and 2.0-6.0 parts of crosslinking and curing agent solution. In the formula design of the invention, the molecular weight design dispersion coefficient is designed to be a little smaller, the molecular weight is not too large and the soft monomer is increased so as to improve the peeling strength, thus reaching the aim that the adhesive tape has high peeling performance and can be pasted repeatedly.

Owner:永大(中山)有限公司

Wood lacquer water-borne flat self-crosslinking acrylic emulsion and synthesizing method thereof

ActiveCN109439124AReduce manufacturing costReduce energy consumptionCoatingsIsooctyl acrylateSodium bicarbonate

The invention discloses a wood lacquer water-borne flat self-crosslinking acrylic emulsion and a synthesizing method thereof. The wood lacquer water-borne flat self-crosslinking acrylic emulsion is composed of raw materials of monomers, functional monomers, solvent, neutralizer, buffer agent, initiator, emulsifier and flatting agent, wherein the monomers are composed of, by weight part, 3-12 partsof methacrylic acid, 120-300 parts of methyl methacrylate, 2-20 parts of butyl acrylate, 10-50 parts of styrene and 40-120 parts of ethylhexyl acrylate; the functional monomers are composed of 4-14 parts of diacetone acrylamide, 3-10 parts of adipic dihydrazide and 1-10 parts of vinyl trimethoxysilane; the solvent is 500-800 parts of deionized water; the neutralizer is 2-10 parts of ammonia hydroxide; the buffer agent is 0.2-1 part of sodium bicarbonate; the initiator is composed of 0.5-3 parts of ammonium persulfate, 0.1-2 parts of tert-butyl hydroperoxide and 0.1-2 parts of ascorbic acid; the emulsifier is 0.5-8rts of lauryl sodium sulfate; the flatting agent is 5-35 parts of fumed silica. The wood lacquer water-borne flat self-crosslinking acrylic emulsion has the advantages of excellent transparency, excellent water resistance, excellent alcohol resistance and flatness and can be combined to manufacture water-borne wood lacquers of different glossiness.

Owner:HUBEI JIADE PUAN PAINT

Polyacrylate, pressure-sensitive adhesive and preparation method

ActiveCN109762097AThe polymerization process is simpleHigh temperature resistance and good adhesionEster polymer adhesivesPressure sensitive film/foil adhesivesIsooctyl acrylateGlycidyl methacrylate

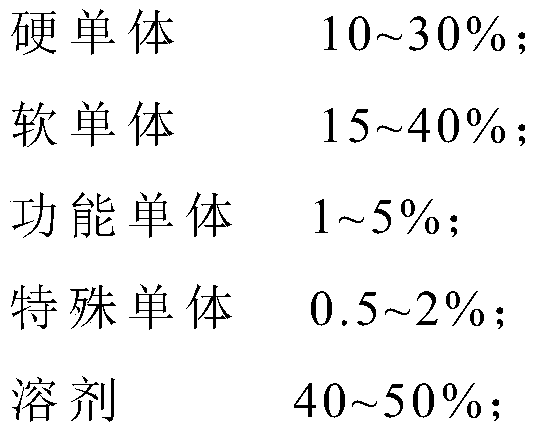

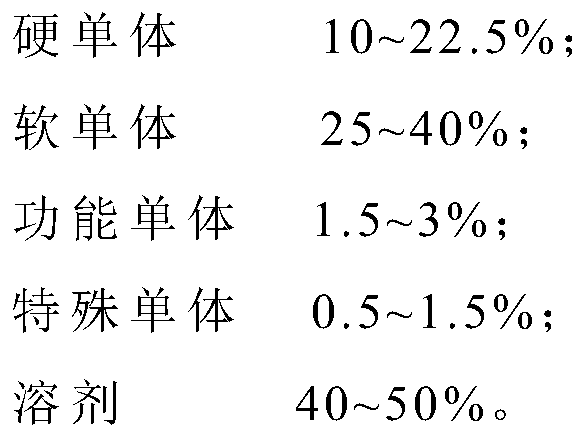

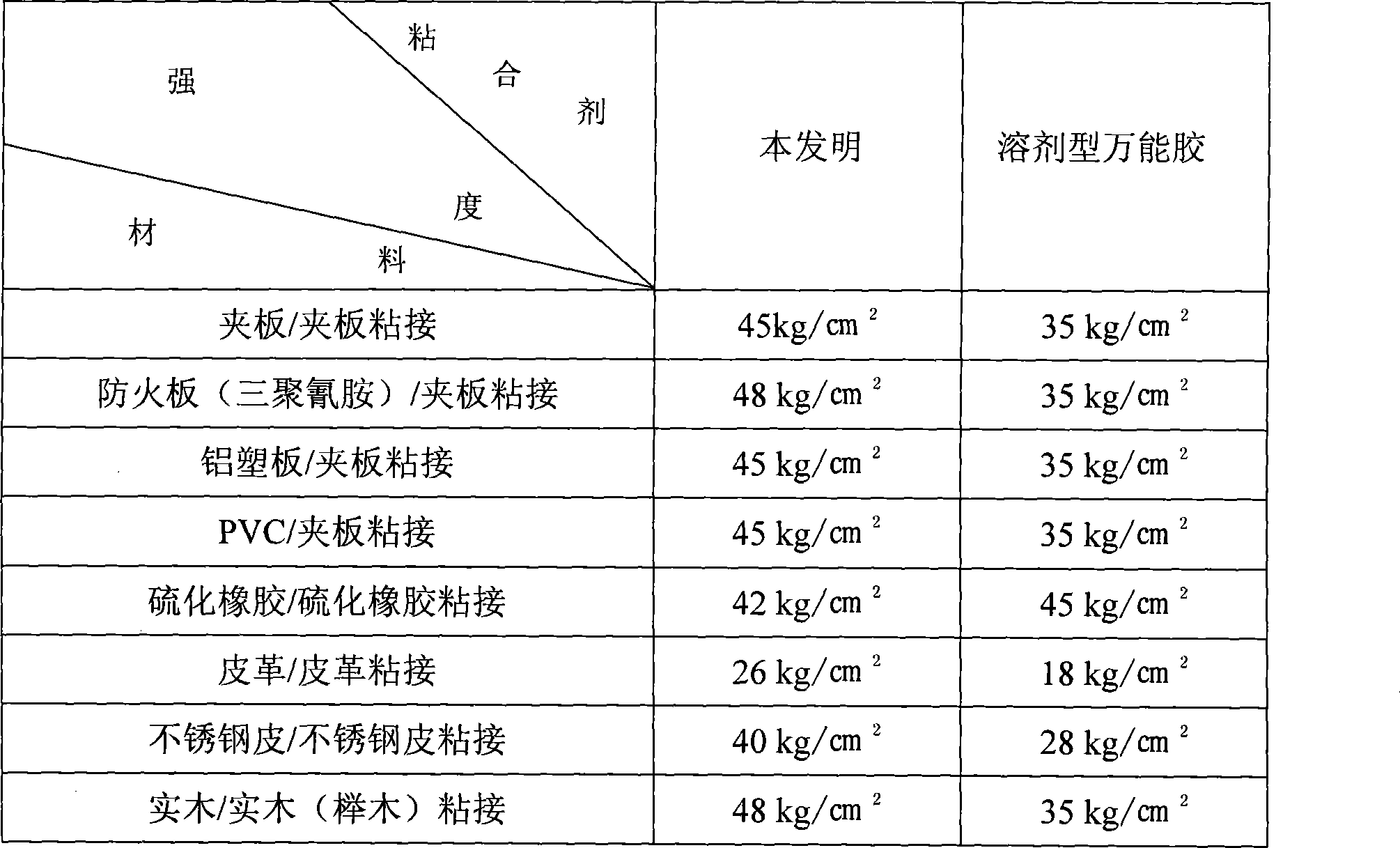

The invention relates to polyacrylate. Polyacrylate is synthesized from raw materials in percentage by mass as follows: 10%-30% of a hard monomer, 15%-40% of a soft monomer, 1%-5% of a functional monomer, 0.5%-2% of a special monomer and 40%-50% of a solvent, wherein the hard monomer comprises one or more of methyl acrylate, methyl methacrylate, vinyl acetate, acrylonitrile and isobornyl methacrylate; the soft monomer comprises one or more of ethyl acrylate, n-butyl acrylate, 2-ethylhexyl acrylate and n-propyl acrylate; the functional monomer comprises one or more of hydroxyethyl acrylate, acrylic acid, methacrylic acid, hydroxypropyl acrylate and 2-hydroxyethyl methacrylate; the special monomer comprises one or more of methacrylamido ethyl ethylene urea, hydroxyethyl methacrylate phosphate and glycidyl methacrylate. A pressure-sensitive adhesive has good high-temperature-resistant adhesive property, does no squeeze out, has no residue, has low cost and can be applied to masking tapesused in capacitor taping in the electronics industry as well as certain high-temperature-resistant adhesive tapes.

Owner:CYBRID TECHNOLOGIES INC

High gloss high abrasion resistance ultra-violet curing overprinting varnish of mobile phone and preparation method thereof

InactiveCN101967338AImprove wear resistanceHigh gloss and high wear resistancePolyurea/polyurethane coatingsPolyester coatingsIsooctyl acrylatePolyester

The invention discloses a high gloss high abrasion resistance ultra-violet (UV) curing overprinting varnish of mobile phone and a preparation method thereof. The method of the invention uses low-viscosity polyester acrylate and aliphatic polyurethane acrylate as base resin which combines with ethoxylated pentaerythritol tetraacrylate, Trimethylolpropane triacrylate, Tri(propylene glycol) diacrylate, 1,6-hexanediol diacrylate and 2-ethylhexyl acrylate which are used as active diluent, alcohol and ethyl acetate which are used as diluent, benzophenone and 1-hydroxycyclohexyl phenyl ketone which are used as photoinitiator, reactive amine coinitiator, defoaming agent, flatting agent, slip agent and other agents to mix evenly and prepare the UV overprinting varnish. The overprinting varnish of the invention adopts the special raw material formula and has good lustrousness, adhesive force and mechanical stability; as some polyfunctional resins and resins with special functional groups are added, the crosslink density of the UV varnish is increased in the curing process and the hardness of the product is up to 5-7H; and as solid wax powder used as the slip agent is added, the coefficients of friction can be reduced and the product can have extremely high wear resistance.

Owner:苏州凯康化工科技有限公司

Preparation method and application of thermal-peeling acrylic ester pressure-sensitive adhesive

InactiveCN104371610AWill not cause separationSmall particlesNon-macromolecular adhesive additivesFilm/foil adhesivesMethacrylateIsooctyl acrylate

The invention relates to a thermal-peeling acrylic ester pressure-sensitive adhesive. The thermal-peeling acrylic ester pressure-sensitive adhesive comprises, by weight, 60-140 parts of 2-ethylhexyl acrylate, 60-140 parts of vinyl acetate, 3-10 parts of acrylic acid, 5-15 parts of hydroxyethyl acrylate, 3-10 parts of methyl methacrylate, 0.1-2 parts of N-hydroxymethyl acrylamide, 0.5-2 parts of azodiisobutyronitrile and 200-300 parts of ethyl acetate by polymerization. The polyacrylate pressure-sensitive adhesive is synthesized by (methyl) acrylic monomers through polymerization, and stickiness of an adhesive tape is changed via a temperature variation range. The thermal-peeling acrylic ester pressure-sensitive adhesive has excellent adhesiveness and thermal peeling property, the adhesiveness is larger than 900gf at the temperature lower than 90 DEG C, and the peel strength to a steel plate is smaller than or equal to 1N / m after foaming expansion at the temperature of 130 DEG C. When the pressure-sensitive adhesive tape is sufficiently foamed at the temperature of 130 DEG C, the foaming adhesive layer cannot be separated from a base material. After the pressure-sensitive adhesive tape is sufficiently foamed at 130 DEG C, the foaming agent is small in particles after foaming and the adhesive side is good in flatness.

Owner:新丰杰力电工材料有限公司

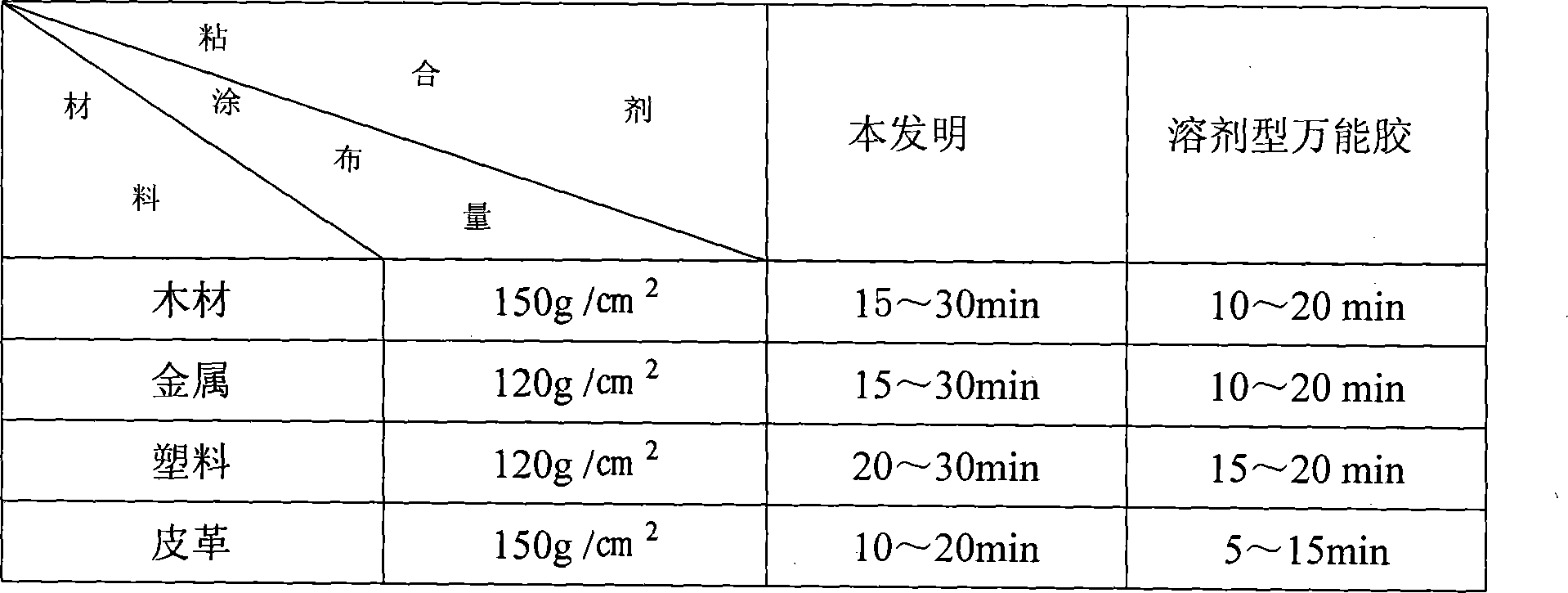

Water-based all-purpose adhesive and method for preparing same

InactiveCN101225271AWith adhesive strengthImprove stabilityInksCoatingsIsooctyl acrylatePolymer science

The invention discloses a water-based all purpose adhesive and the preparation method, which belongs to the field of water-based adhesive, the technical proposal is a copolymer emulsion of 120 to 300 portions of vinyl acetate, 15 to 50 portions of organic silicon monomer with unsaturated double bond, 60 to 150 portions of ethylene tertiary carbonate, 80 to 120 portions of butyl acrylate, 90 to 150 portions of iso-octyl acrylate, 5 to 15 portions of acrylic acid; the emulsion also comprises 20 to 80 portions of tackifying resin, 3 to 8 portions of sodium salt decocting mixture, 50 to 150 portions of plasticizer, 15 to 50 portions of polyvinyl alcohol, 2 to 8 portions of silane coupling agent, 8 to 12 portions of hydrochloric acid, 3 to 15 portions of anionic emulsifier and 3 to 12 portions of nonionic emulsifier. The preparation method is that the mixed monomer is dropped by the manner of emulsion polymerization, and should be completed in three to five hours; warming up to 85 to 95 DEG C to cure for 40 to 60 minutes; then discharging and filtering and packaging after cooling down to 45 to 35 DEG C. The water-based all purpose adhesive has the advantages of convenient use, wide applicability, and can be used for the manufacturing of furniture, luggage and construction decoration.

Owner:唐浩

Medicinal hydrophilic polyacrylic ester pressure-sensitive adhesive and preparation method

InactiveCN101875828ANo allergic reactionImprove water absorptionSurgical adhesivesEster polymer adhesivesIsooctyl acrylateGlycidyl methacrylate

The invention discloses medicinal hydrophilic polyacrylic ester pressure-sensitive adhesive, which consists of ethylhexyl acrylate, hydroxyethyl acrylate, methyl acrylate, glycidyl methacrylate, peroxide initiator and acetic ether solvent, wherein the initiator is benzoyl peroxide or azodiisobutyronitrile. A preparation method comprises the following steps of: dividing the components into two parts, and mixing the two parts to form first and second mixed solution respectively; putting the first mixed solution into a reactor, introducing nitrogen into the reactor to remove oxygen, heating the solution to a reflux temperature, starting continuously dripping the second mixed solution into the reactor, reacting the solution at the temperature of between 70 and 80 DEG C, and dripping all the second mixed solution within 1.5 to 2.5 hours; and continuously reacting the solution for 4 to 6 hours after the dripping is finished, stopping heating the solution, cooling the reaction product to between 30 and 40 DEG C, and pouring and sieving the reaction product to obtain the medicinal hydrophilic polyacrylic ester pressure-sensitive adhesive. The preparation method is simple and feasible; and the adhesive has good water absorption property and water vapor penetrability after coating, can be repeatedly adhered for use, has good skin compatibility, can be used as medicinal pressure-sensitive adhesive, and overcomes the defect of hydrophobic pressure-sensitive adhesive.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Water-based acrylic emulsion and preparation method and application thereof

InactiveCN101974184ATransparent appearanceImprove wettability and dispersibilityNon-fibrous pulp additionInksIsooctyl acrylateWater based

The invention discloses water-based acrylic emulsion and a preparation method and application thereof. The water-based acrylic emulsion is prepared by the following steps of: performing radical polymerization on methyl methacrylate, styrene, ethyl hexyl acrylate, glycidyl methacrylate, ammonia water, an emulsifier, an initiator and deionized water to form a macromolecular substance so as to form a main body of the water-based acrylic emulsion; and matching the main body with a film forming substance, an aid and a defoaming agent. The water-based acrylic emulsion has a transparent, fine and smooth appearance, fine grain size, high wetting dispersability and stable quality, is not broken when dispersed by a high-shear dispersing machine for 24 hours, is not broken and generates particles in color paste grinding, is not sensitive to calcium and magnesium ions, and has high lustre equivalent to that of similar products abroad; and because the consumption of the emulsifier in the system is low, a dry film has good water resistance, the applied product has high mechanical stability, wear resistance, adhesion and excellent picking resistance, and paper printed and polished has the characteristics of no scratch and the like.

Owner:苏州凯康化工科技有限公司

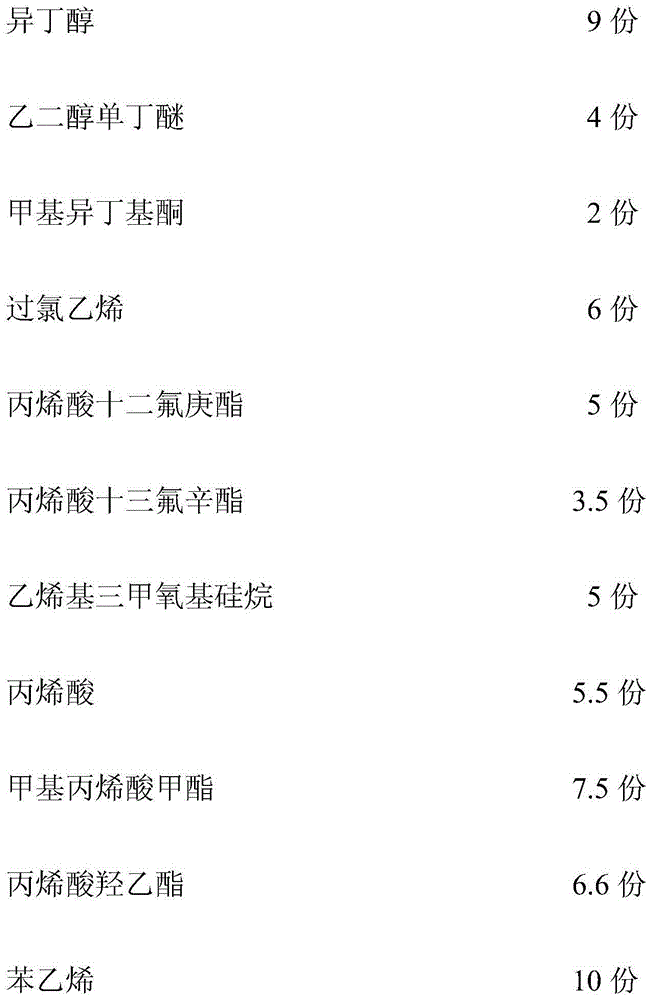

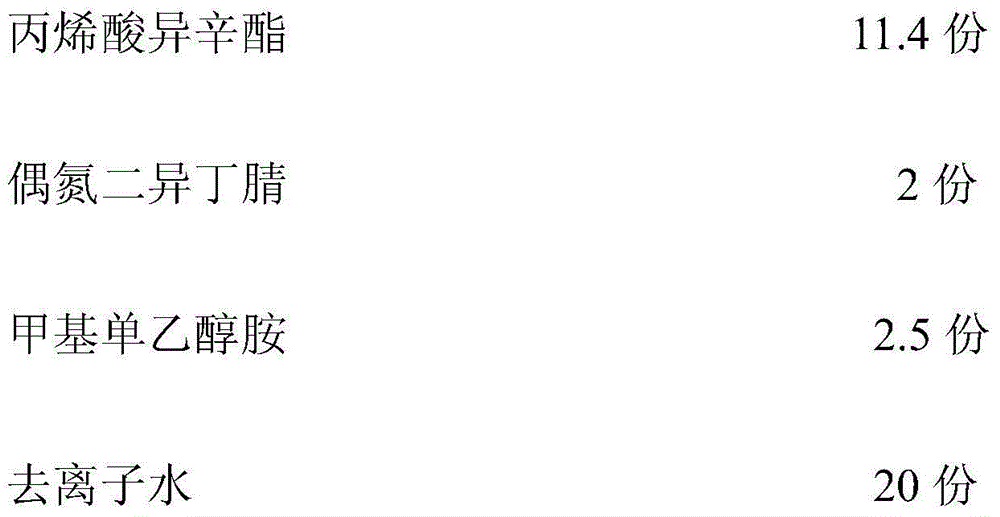

High-salt-mist high-weather-proof water paint and preparing method thereof

ActiveCN104140732AFlat and bright appearanceImprove the level ofAnti-corrosive paintsMethacrylateIsooctyl acrylate

The invention relates to high-salt-mist high-weather-proof water paint and a preparing method of the high-salt-mist high-weather-proof water paint. The high-salt-mist high-weather-proof water paint mainly comprises acrylic acid modified emulsion. The acrylic acid modified emulsion is composed of isobutyl alcohol, ethylene glycol monobutyl ether, methyl isobutyl ketone, vinylidene chloride, dodecafluoroheptyl methacrylate, perluorooctyl acrylate, vinyl trimethoxy silane, acrylic acid, methyl methacrylate, hydroxyethyl acrylate, phenylethylene, 2-ethylhexyl acrylate, azodiisobutyronitrile, N-methyl monoethanolamine and deionized water. The paint is quite excellent primer-topcoat coating and suitable for metal workpieces, the paint is dried at normal temperature after being sprayed, the appearance of a coating is smooth and bright, the leveling property is good, the mechanical property is good, the weather-proof property is excellent, after 2500 hours of QUV aging tests, the dulling rate is smaller than or equal to 15%, and delta E is smaller than or equal to 1.5, meanwhile, corrosion resistance is good, salt mist resistance reaches 1000 hours, and the one-way corrosion width is smaller than or equal to 2 mm.

Owner:HAOLISEN COATING SHANGHAI +1

Multipolymer type waterproof sealant for construction

InactiveCN102994016ANon-toxic and environmentally friendlyExtended service lifeMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesIsooctyl acrylatePolyester

The invention discloses a multipolymer type waterproof sealant for construction, wherein raw materials in a prescription based on ratio of part by weight are as follows: vinyl acetate, organic silicone monomer containing unsaturated double bonds, vinyl versatate, butyl acrylate, 2-ethylhexyl acrylate, acrylic acid and de-ionized water. The multipolymer type waterproof sealant has the advantages that the sealant can be used for coating surfaces of substances such as cement components, ceramics, glass, plywoods, shaving boards, palm fiber boards, bamboo slag boards, paper slag boards, composite boards, aluminum-plastic panels, polyvinyl chloride (PVC) boards, fireproof plates, metal, plastics, leather, rubber and the like and has the bonding strength that other waterproof materials cannot reach; the sealant has good stability and the shelf life at 5-35 DEG C. is more than 12 months; and the multipolymer type waterproof sealant for the construction has the advantages of no toxicity, no odor, no pollution, no corrosion, no combustion, no wiredrawing during coating and the like; and the problems of easy combustion, short shelf life, wiredrawing during coating, serious air pollution and the like during applications of solvent type materials, polyester type materials and the like are solved.

Owner:GUANGDONG BADESE CHEM

Adhesive for wrapping paper material

ActiveCN102876241AImprove adhesionHigh mechanical strengthNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveIsooctyl acrylateEpoxy

The invention provides adhesive for a wrapping paper material, and belongs to the technical field of adhesives. The adhesive for the wrapping paper materialcomprises the following raw materials in part by weight: 5-10 parts of polyol, 6-12 parts of acrylic acid, 3-5 parts of pigment and filler, 20-40 parts of plant starch, 1 part of coupling agent, 2-3 parts of ethylene-vinyl acetate copolymer, 1 part of trimeric aluminum phosphate, 1 part of ferric chloride, 2-4 parts of alum, 4-6 parts of cellulose, 2-4 parts of polyolefin resin, 1-6 parts of polylactic acid, 2-4 parts of epoxy resin, 1-3 parts of isooctyl acrylate, 2-4 parts of acrylamide, 1-2 parts of pH adjusting agent, 1 part of 2,6-di-tert-butyl p-cresol, 1 part of surfactant and 50-80 parts of water. The adhesive for the wrapping paper material has excellent adhesion property, has good mechanical strength after being applied to a paper wrapping box, and still has good adhesion property after a destructive test.

Owner:DONGGUAN HOPEWAY PACKING CO LTD

Preparation method of epoxy acrylate antirust emulsion

ActiveCN104152009ASolve the problem of poor compatibility and difficult emulsification of epoxy resinImprove adhesionAnti-corrosive paintsEpoxy resin coatingsIsooctyl acrylateSolubility

The invention relates to a preparation method of an epoxy acrylate antirust emulsion. The method includes following steps: (1) preparing an emulsifying agent I, an emulsifying agent II and emulsifying agent III; (2) preparing an epoxy ester pre-emulsion from the emulsifying agent I, nonylphenol polyoxyethylene ether, sodium lauryl diphenyl ether disulfonate, isooctyl acrylate and epoxy resin; (3) prepaing an acrylic acid pre-emulsion from the emulsifying agent II, the nonylphenol polyoxyethylene ether, the sodium lauryl diphenyl ether disulfonate, the isooctyl acrylate and methacrylic acid; and (4) carrying out a reaction to the emulsifying agent III, the acrylic acid pre-emulsion and the epoxy ester pre-emulsion to prepare the epoxy acrylate antirust emulsion. Through the method, problems that an emulsifying agent is instable and poor in water solubility in a preparation method of the epoxy acrylate antirust emulsion in the prior art and is compounded with an anionic emulsifier and a nonionic emulsifier are solved. A production which is excellent in performances is prepared.

Owner:上海科罗纳精细化工有限公司

High-viscosity yellowing-resistant explosion-proof film adhesive, adhesive tape and preparation method of adhesive tape

ActiveCN110527464ALight colorImprove antioxidant capacityNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateEthyl acetate

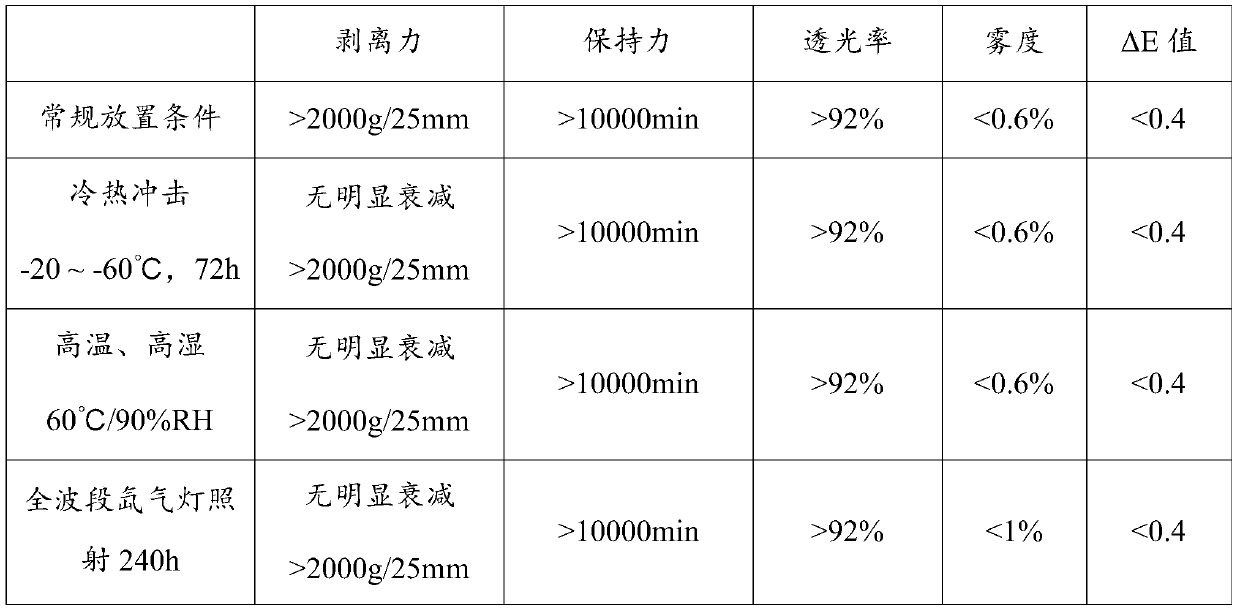

The invention discloses a high-viscosity yellowing-resistant explosion-proof film adhesive. The explosion-proof film adhesive comprises the following components in parts by weight: 100 parts of acrylic acid adhesive, 5-10 parts of tackifying resin, 0.15-0.6 part of a curing agent and 50-90 parts of a solvent, wherein the acrylic acid adhesive is prepared by reacting the following components in parts by weight: 26-30 parts of isooctyl acrylate, 3-5 parts of acrylic acid, 0.5-1 part of hydroxyethyl acrylate, 5-10 parts of methyl acrylate, 53-65 parts of ethyl acetate and 0.5-1 part of azobisisobutyronitrile; the solvent is one or more selected from ethyl acetate, toluene and butanone; and the tackifying resin is hydrogenated resin. The invention also provides a high-viscosity yellowing-resistant adhesive tape prepared from the adhesive. The high-viscosity yellowing-resistant explosion-proof film adhesive has colorless transparent appearance, and can still ensure sufficient peeling forceaccording to different coating thicknesses. Under the condition of high-temperature aging, the explosion-proof film adhesive is not yellowing in appearance, and peeling force is basically not attenuated.

Owner:CROWN TAICANG ADHESIVE PROD CO LTD

Silicon composite waterborne acrylic emulsion and preparation method thereof

InactiveCN105218736AImprove water resistanceExcellent color developmentCoatingsIsooctyl acrylateFunctional monomer

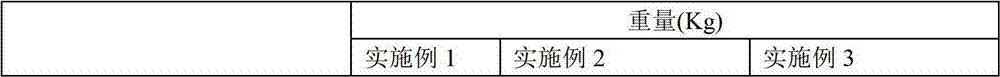

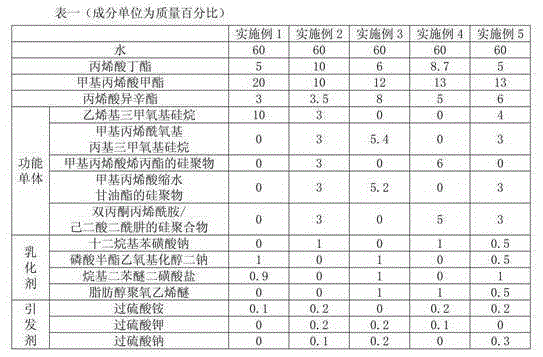

The invention discloses a silicon composite waterborne acrylic emulsion which is characterized by comprising the following components in percentage by mass: 60 percent of water, 5 to 10 percent butyl acrylate, 10 to 20 percent of methyl methacrylate, 3 to 8 percent of ethylhexyl acrylate, 10 to 15 percent of functional monomer, 1 to 3 percent of emulsifying agent and 0.1 to 0.5 percent of initiator. The silicon composite waterborne acrylic emulsion disclosed by the invention has good water resistance and excellent color contrast property.

Owner:佛山市顺德区巴德富实业有限公司

Acroleic acid/polyurethane transparent anode electrophoresis coating and its preparation method

InactiveCN1807528AControl molecular weightIncrease the degree of effective responsePaints for electrolytic applicationsMethacrylateSurface-active agents

The invention relates to an acroleic acid / polyurethane transparent anode electrophoresis coating and its preparation method, comprising the following raw materials (by weight ratio): cationic acrylic polymer 52-85, closed isocyanate cross linking agent 14.5-23.5, non-ionic or / and cationic surface active agent 4.6-8, catalyst 0.6-1.1, chain-transferring agent 0.5-0.8, deionized water 26-51. The cationic acrylic polymer comprises the following raw materials (by weight portions): isobutyl methacrylate 35-55, methyl acrylic ester 23-43, methyl methacrylic hydroxyl propyl ester 15-26, dimethyl amido propyl ester methacrylamide 13.5-23, 2-ethylhexyl methacrylate 13-28, azo-diisobutyronitrile 0.5-1.2, and dimethyl carbinol 35-89.

Owner:冯国贤

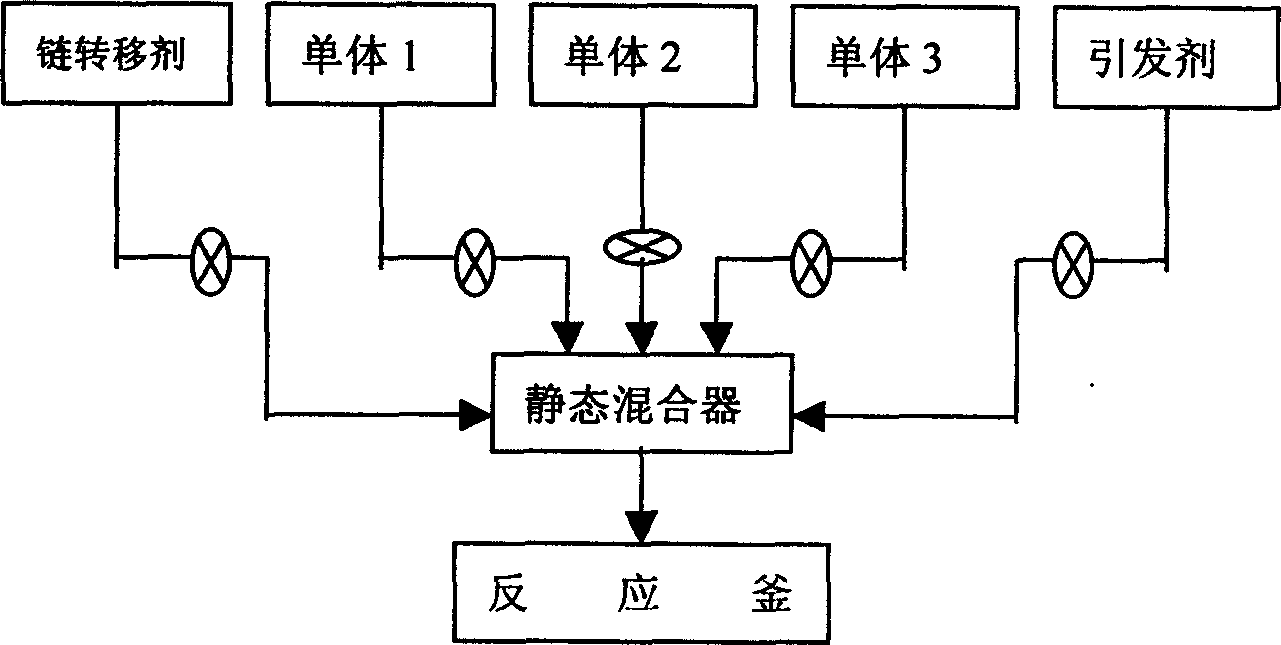

Adhesive material for adhesive tapes and preparation method thereof

ActiveCN103725231AImprove heat resistanceImprove aging resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylateIsooctyl acrylate

The invention discloses an adhesive material for adhesive tapes. The invention is characterized in that the adhesive material is prepared by mixing 1000 parts by mass of acrylate prepolymer resin with the solid content of 40%, 3-10 parts by mass of curing agent and 200-500 parts by mass of diluting solvent. The preparation method of the acrylate prepolymer resin comprises the following steps: adding 350 parts of butyl acrylate, 150-200 parts of 2-ethylhexyl acrylate, 250-350 parts of ethyl methacrylate, 200-300 parts of functional monomer, 100-150 parts of glycidyl methacrylate, 1200 parts of solvent and 8-20 parts of initiator into a reaction kettle, and stirring and mixing; and in a nitrogen protective atmosphere, heating to 70-75 DEG C to react for 4-6 hours, and adding a solvent until the solid content reaches 40%. The adhesive material for adhesive tapes has the advantages of high heat resistance, high aging resistance, high working properties and favorable product performance, is convenient to use, and can be used for manufacturing various single-sided and double-sided pressure-sensitive adhesive tapes and optical clear adhesive tapes.

Owner:SICHUAN DONGFANG INSULATING MATERIAL

Ultraviolet light curing transfer printing glue and preparation method and application thereof

ActiveCN105602515AHigh glass transition temperatureHigh tensile shear strengthDuplicating/marking methodsPolyureas/polyurethane adhesivesIsooctyl acrylateUltraviolet lights

The invention discloses an ultraviolet light curing transfer printing glue composition for a transfer printing film. The ultraviolet light curing transfer printing glue composition comprises the following components in parts by weight: 20-40 parts of modified acrylate, 20-40 parts of epoxy resin, 10-30 parts of reactive diluent, 3-8 parts of photoinitiator, 5-15 parts of adhesion promoter, 2-5 parts of silane coupling agent and 0-1 part of auxiliary, and the modified acrylate is prepared by modifying pentapolymer prepared from methyl methacrylate (MMA), n-butyl acrylate ((i)n( / i)-BA), hydroxypropyl methacrylate (HMPA), acrylic acid (AA) and 2-ethylhexyl acrylate (EHA) through free radical copolymerization by using polyurethane containing isocyanato. The prepared ultraviolet light curing transfer printing glue has good adhesion to a glass base material, and is good in water resistance, high in tensile strength and excellent in transfer printing effect.

Owner:GUANGDONG UNIV OF TECH

Water-based dry-type complex film adhesive and preparation method thereof

ActiveCN102134463AReduce the amount addedReduce contentHydrocarbon polymer adhesivesIsooctyl acrylateWater based

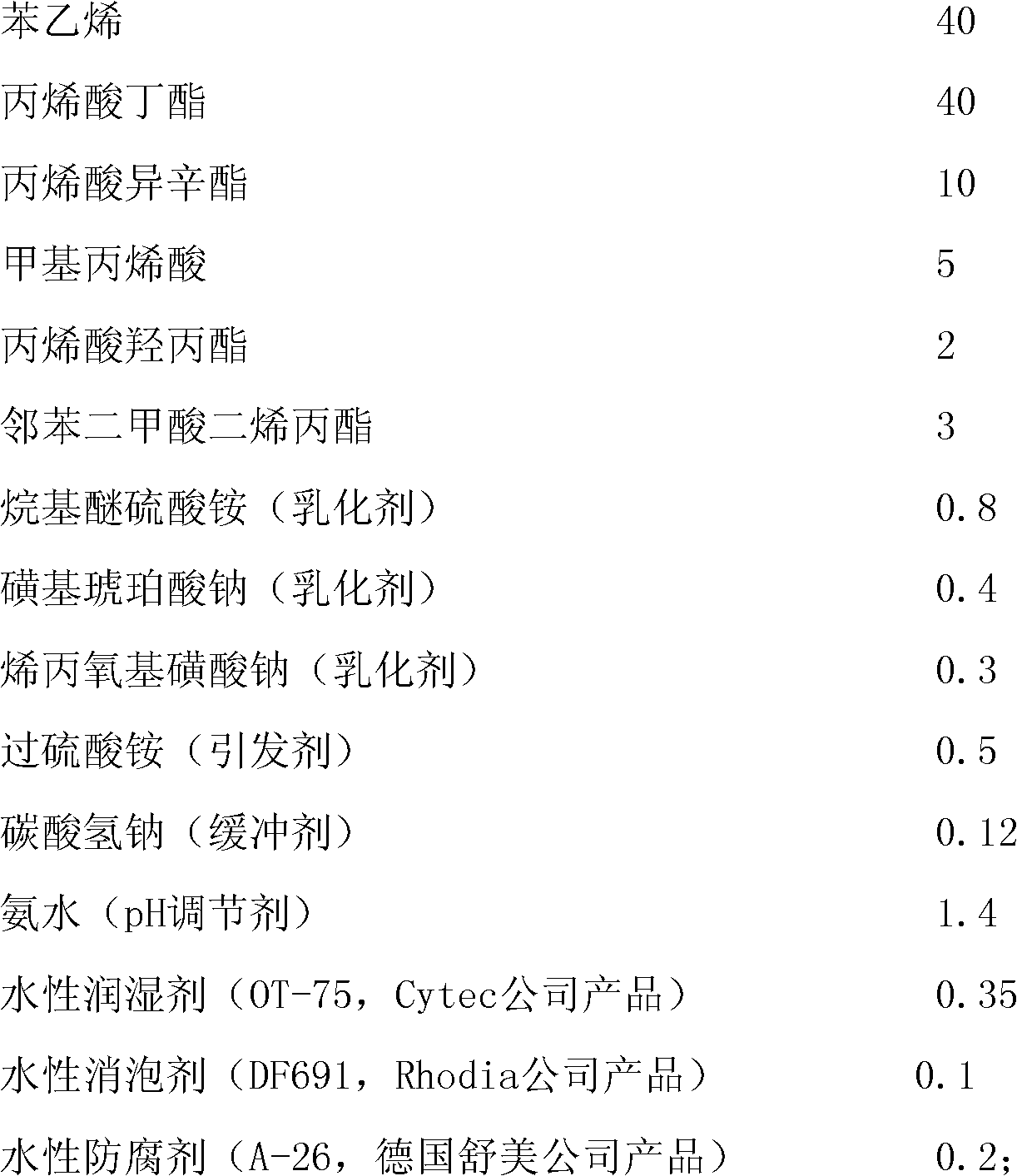

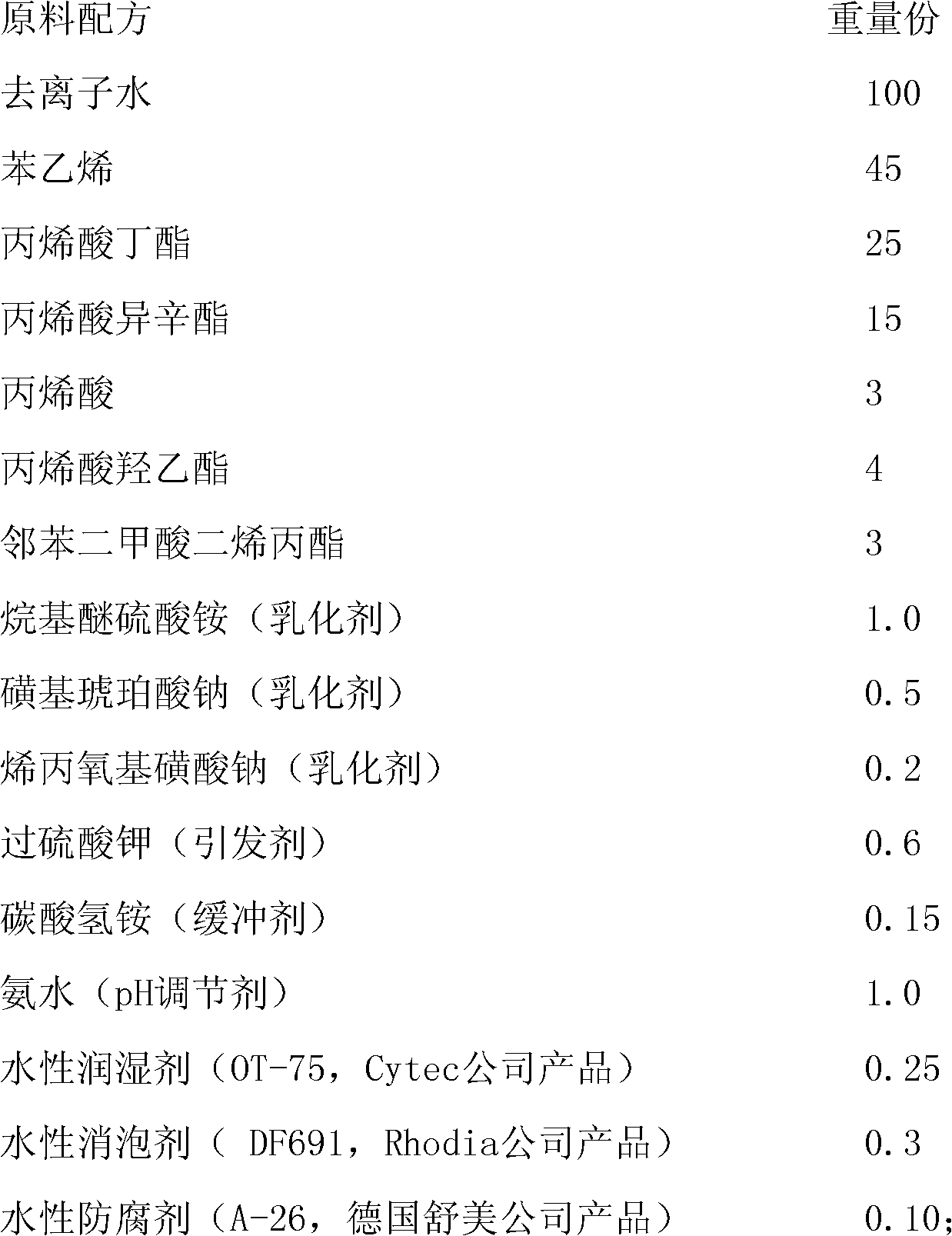

The invention discloses a water-based dry-type complex film adhesive and a preparation method thereof, belonging to the field of preparation of adhesive. The preparation method of the complex film adhesive comprises the following steps: by using monomers, an emulsifier, an initiator, a buffering agent, deionized water, a pH regulator and water-based assistants as raw materials, emulsifying, carrying out seed reaction and polymerization reaction, and compounding to obtain the complex film adhesive of which the solid content is 45-55%, wherein the monomers comprise a hard monomer, soft monomers and functional monomers; the hard monomer is styrene; the soft monomers comprise butyl acrylate and 2-ethylhexyl acrylate; the functional monomers comprise acrylic acid or methacrylic acid, 2-hydroxyethyl acrylate or 2-hydroxypropyl acrylate, and diallyl phthalate; and the emulsifier comprises ammonium alkyl ether sulfate, sodium sulfosuccinate and sodium allyloxysulfonate in a weight ratio of 2:1:(0.4-0.8). The complex film adhesive has the advantages of high bonding strength, favorable affinity and covering performance for ink, and environment protection since the content of VOCs (volatile organic compounds) is lowered.

Owner:NANTONG GAOMENG NEW MATERIAL

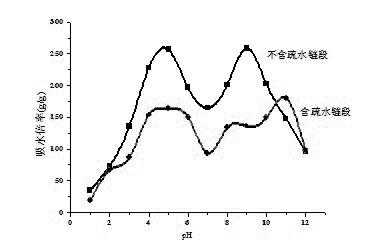

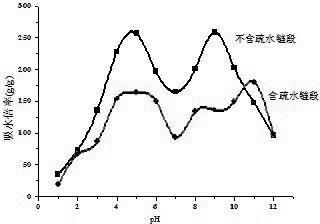

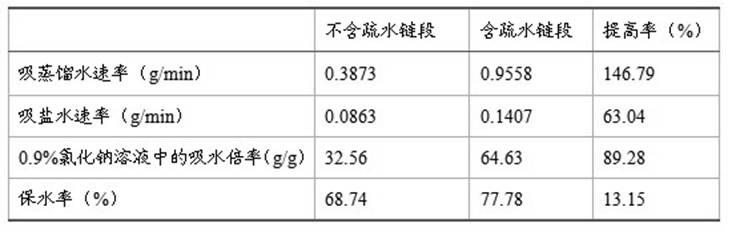

Preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments

InactiveCN102633944ATo achieve the purpose of sustained releaseTo achieve the purpose of salt toleranceIsooctyl acrylateCellulose

The invention relates to a preparation method of salt-tolerance controlled-release high-water-absorption resin with hydrophobic chain segments. At present, acrylic-acid-series high-water-absorption resin has many defects and particularly has the defects that the salt tolerance is poor and the water absorbing capacity is easy to be weakened remarkably and normally is weakened to dozens of times from hundreds of times under the action of metal ions, therefore, the improvement of the salt tolerance of the high-water-absorption resin has significance. According to the invention, the high-water-absorption resin with a three-dimensional cross-linked network is formed through copolymerization of acrylic-acid hydrophobic monomers such as butyl methacrylate, iso-octyl methacrylate, n-decyl methacrylate, lauryl methacrylate, lauryl methacrylate or octadecyl methacrylate with acrylic acid, acrylic amide and carboxymethy cellulose under the existence of initiator and cross-linking agent. Compared with the high-water-absorption resin without the hydrophobic chain segments, the high-water-absorption resin disclosed by the invention has the advantages that the magnification on absorption of 0.9% sodium chloride solution is improved by 89.28%, and the water retention is improved by 13.15%.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method and application of high temperature solvent resistant acrylate pressure sensitive adhesive

ActiveCN104449486AImprove mechanical propertiesImprove high temperature resistanceNon-macromolecular adhesive additivesFilm/foil adhesivesIsooctyl acrylateCarvacryl acetate

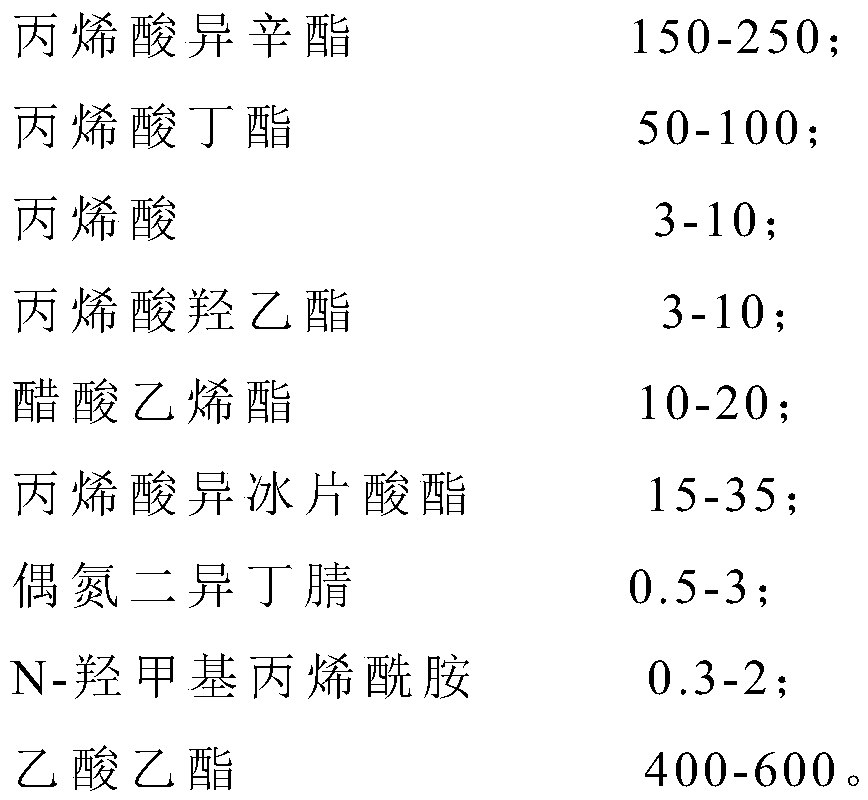

The invention relates to a high temperature solvent resistant acrylate pressure sensitive adhesive which comprises the following components in parts by weight: 150-250 parts of 2-ethylhexyl acrylate, 50-100 parts of butyl acrylate, 3-10 parts of acrylic acid, 3-10 parts of hydroxyethyl acrylate, 10-20 parts of vinyl acetate, 15-35 parts of bornyl isoacrylate, 0.5-3 parts of azobisisobutyronitrile, 0.3-2 parts of N-hydroxymethyl acrylamide and 400-600 parts of ethyl acetate. The mechanical property, high temperature resistance and weather resistance of the emulsion type acrylate pressure sensitive adhesive are improved, so that the application range of the emulsion type acrylate pressure sensitive adhesive is widened, and the pressure sensitive adhesive has the characteristics of high viscidity, high temperature resistance, damp-heat aging resistance and low cost.

Owner:新丰杰力电工材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com