Acroleic acid/polyurethane transparent anode electrophoresis coating and its preparation method

A transparent cathode and electrophoretic coating technology, applied in the direction of electrophoretic coatings, coatings, etc., can solve the problems of water resistance, solvent resistance, salt spray resistance, light transmission and transparency, etc., to achieve stable and uniform polymerization reaction and maintain stability , the effect of maintaining the uniformity of co-deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

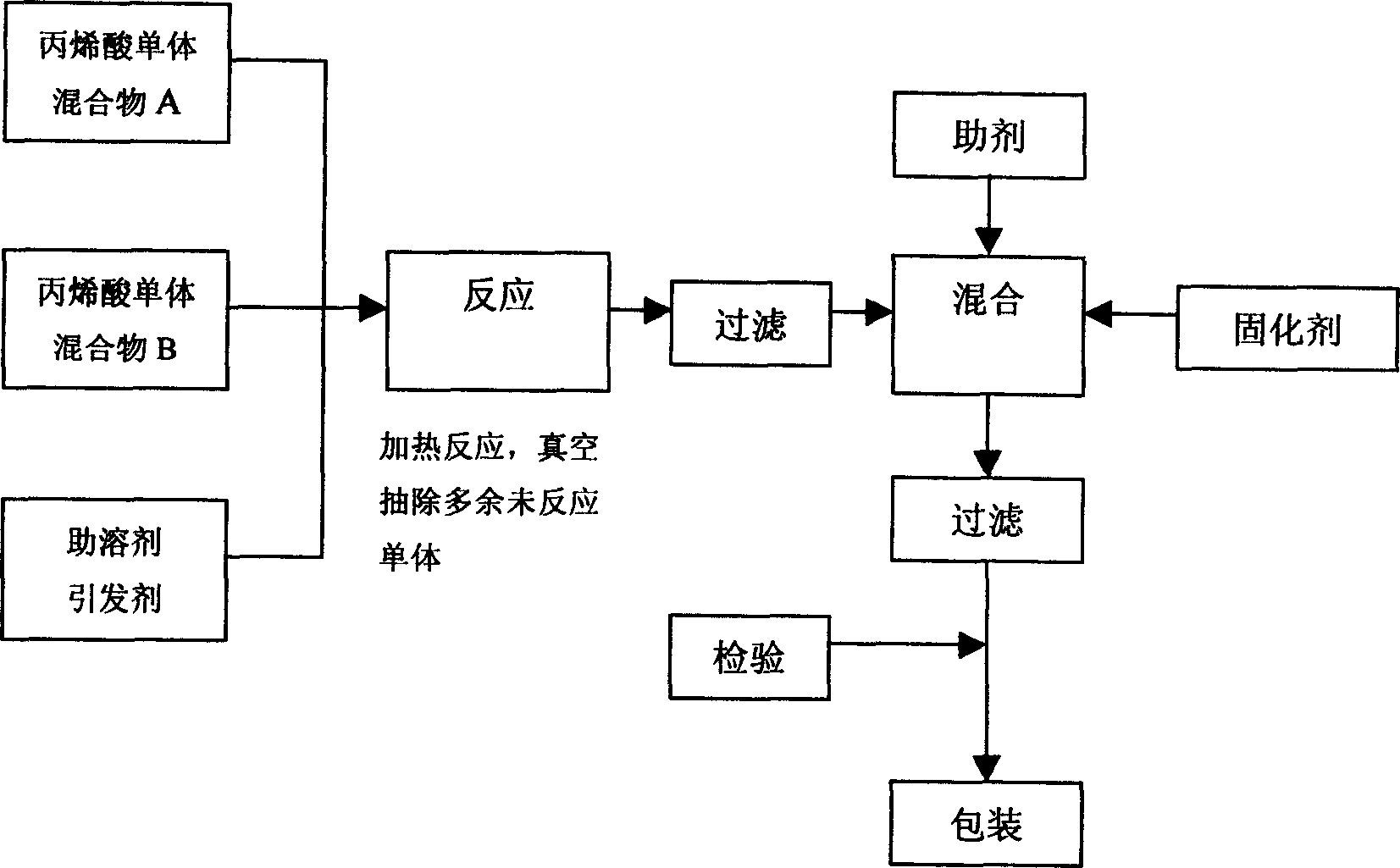

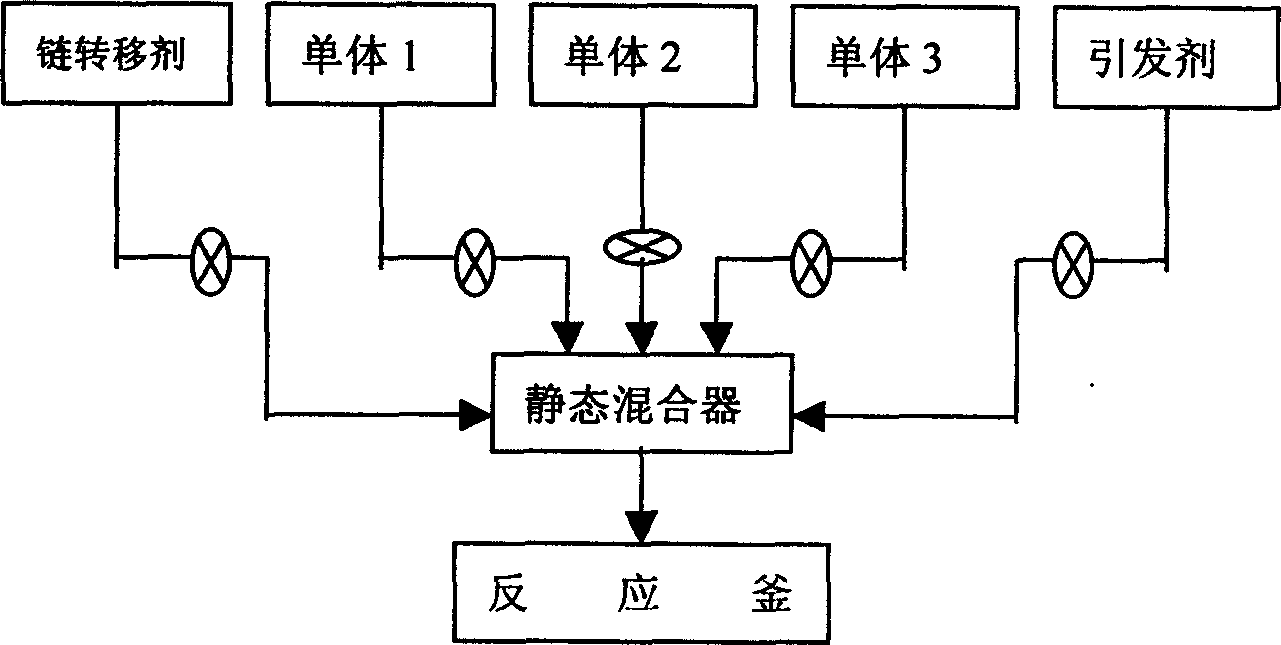

[0052] see figure 1 , 2 38 parts of isopropanol were put into a reaction kettle heated by heat conduction oil and the temperature was raised to 105 degrees, and then the mixed monomer 53 was added dropwise at a constant speed, and the dropping time was 6 hours. After the dropwise addition, keep warm for 2 hours, add 12 parts of isopropanol and initiator at a constant speed for one hour, cool to 45 degrees after the dropwise addition and keep warm for 1.5 hours, put in 27 parts of blocked isocyanate and mix for 1 hour, add 3.5 parts of refined lactic acid part, 1.2 parts of (bismuth) catalyst, and 43 parts of deionized water were mixed for one hour to obtain AC2008 novel acrylic acid / polyurethane transparent cathodic electrophoretic coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com