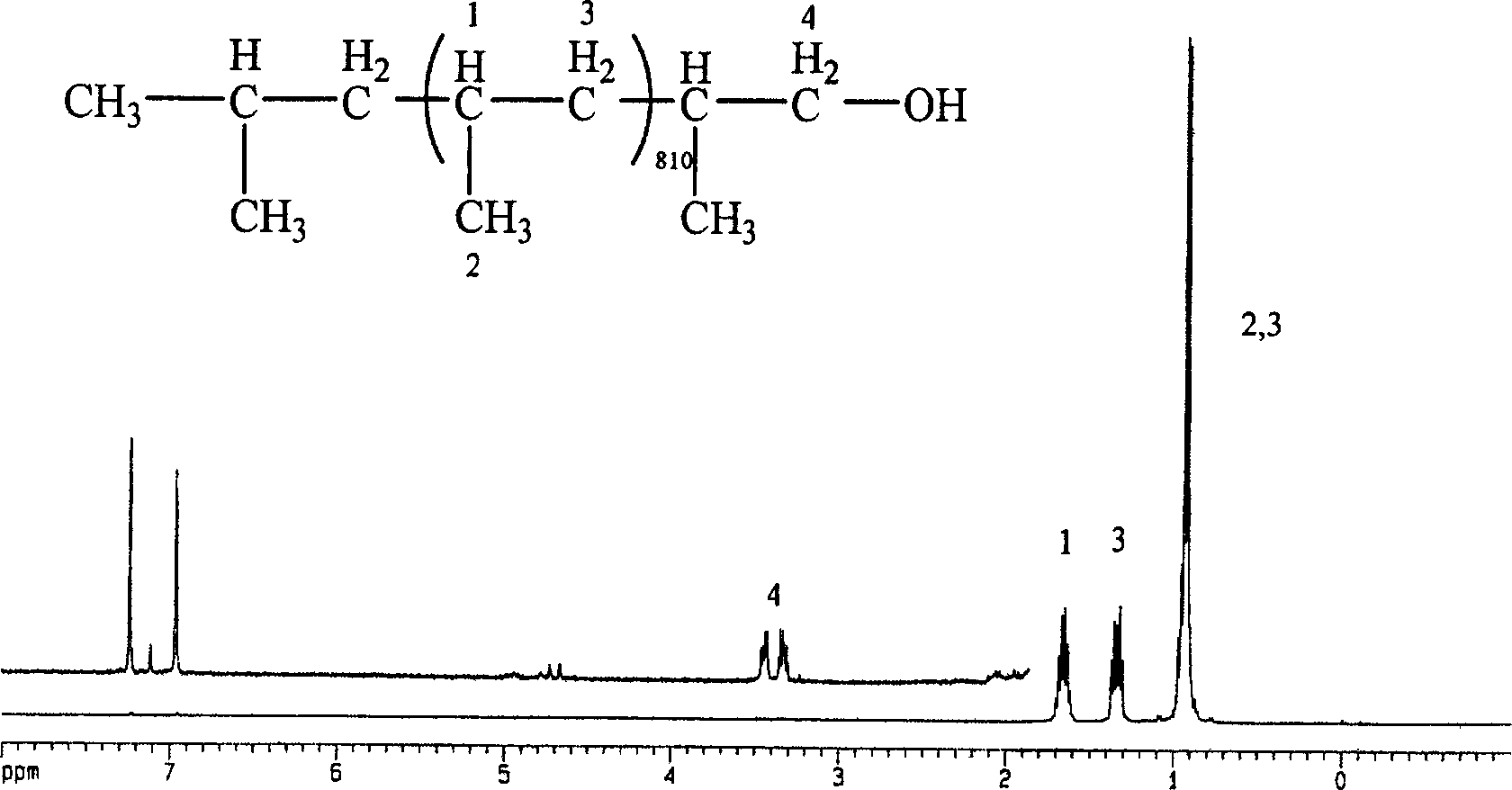

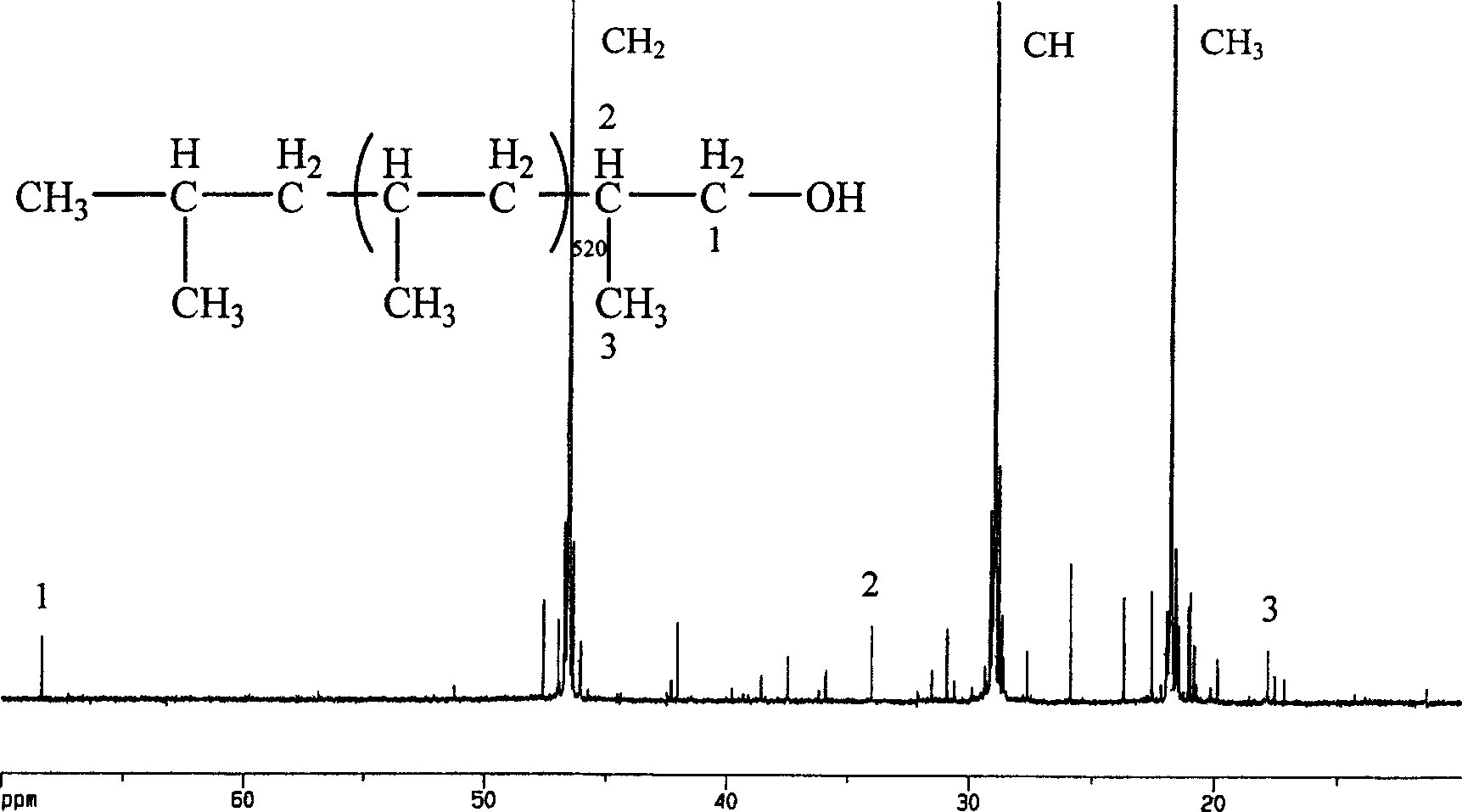

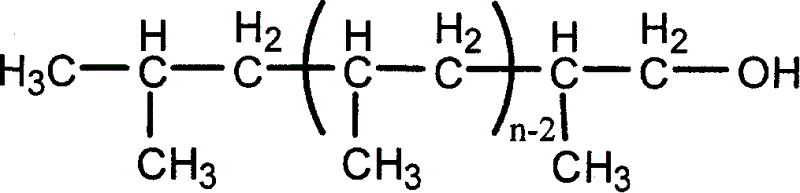

Hydroxy terminated polypropylene and its preparing method

A technology of hydroxyl-terminated polypropylene and polypropylene, which is applied in the field of hydroxyl-terminated polypropylene and its preparation, can solve the problems of complex steps, decreased catalytic polymerization efficiency, and unsuitability for large-scale production and preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Catalyst: Dimethylsilyl bis(2-methyl-4-naphthyl-indenyl)zirconium dichloride

[0074] Cocatalyst: Methylalumoxane

[0075] Under an argon atmosphere, add 50mL of toluene and 1.8mL of 1.4mol / L methylaluminoxane cocatalyst into the polymerization reactor, and stir at 30°C for 10 minutes; then replace the argon with propylene gas three times, and keep the propylene gas The pressure is 0.1Mpa; then at 30°C, add 2.5×10 -6 The metallocene catalyst of mol, the mol ratio=1000:1 of methylaluminoxane cocatalyst and metallocene catalyst, 30 ℃ of stirring 30 minutes, propylene gas pressure is kept on 0.1Mpa in the polymerization process; The product was oxidized with oxygen for 2 hours, then added 6mL of 30% hydrogen peroxide and 20mL of 0.1g / mL sodium hydroxide aqueous solution, and carried out hydrolysis reaction at 50°C for 4 hours; then the reaction product was precipitated with excess 10wt% hydrochloric acid ethanol, filtered A white solid was obtained, which was thoroughly ...

Embodiment 2

[0077] Catalyst: Dimethylsilyl bis(2-methyl-4-naphthyl-indenyl)zirconium dichloride

[0078] Cocatalyst: Methylalumoxane

[0079] Under an argon atmosphere, add 50mL of toluene and 3.6mL of 1.4mol / L methylaluminoxane cocatalyst into the polymerization reactor, and stir at 30°C for 10 minutes; then replace the argon with propylene gas three times, and keep the propylene gas The pressure is 0.1Mpa; then at 30°C, add 2.5×10 -6 The metallocene catalyst of mol, the mol ratio=2000:1 of methylaluminoxane cocatalyst and metallocene catalyst, 30 ℃ of lower stirring 30 minutes, propylene gas pressure kept on 0.1Mpa in the polymerization process; The product was oxidized with oxygen for 2 hours, then 12mL of 30% hydrogen peroxide and 20mL of 0.2g / mL sodium hydroxide aqueous solution were added, and the hydrolysis reaction was carried out at 50°C for 4 hours; then the reaction product was precipitated with excess 10wt% hydrochloric acid ethanol, filtered A white solid was obtained, whic...

Embodiment 3

[0081] Catalyst: Dimethylsilyl bis(2-methyl-4-naphthyl-indenyl) zirconium dichloride Cocatalyst: Methylalumoxane

[0082] Under an argon atmosphere, add 50mL of toluene and 5.4mL of 1.4mol / L methylaluminoxane cocatalyst into the polymerization reactor, and stir at 30°C for 20 minutes; then replace the argon with propylene gas three times, and keep the propylene gas The pressure is 0.1Mpa; then at 30°C, add 2.5×10 -6 The metallocene catalyst of mol, the mol ratio=3000:1 of methylaluminoxane cocatalyst and metallocene catalyst, 30 ℃ of stirring 30 minutes, propylene gas pressure is kept on 0.1Mpa in the polymerization process; The product was oxidized with oxygen for 2 hours, then 18mL of 30% hydrogen peroxide and 30mL of 0.2g / mL sodium hydroxide aqueous solution were added, and the hydrolysis reaction was carried out at 50°C for 8 hours; then the reaction product was precipitated with excess 10wt% hydrochloric acid ethanol, filtered A white solid was obtained, which was thorou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com