Patents

Literature

337 results about "Methylaluminoxane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

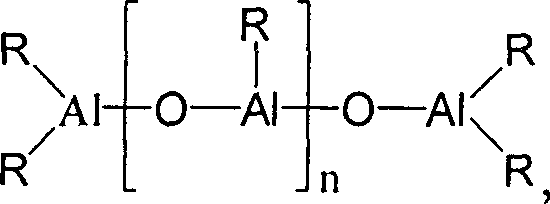

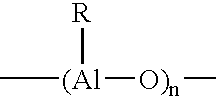

Methylaluminoxane, commonly called MAO, is an organoaluminium compound with the approximate formula (Al(CH₃)O)ₙ. Although it is usually encountered as a solution in (aromatic) solvents, commonly toluene but also xylene, cumene, or mesitylene, it can be isolated as a white pyrophoric solid. It is used to activate precatalysts for alkene polymerization.

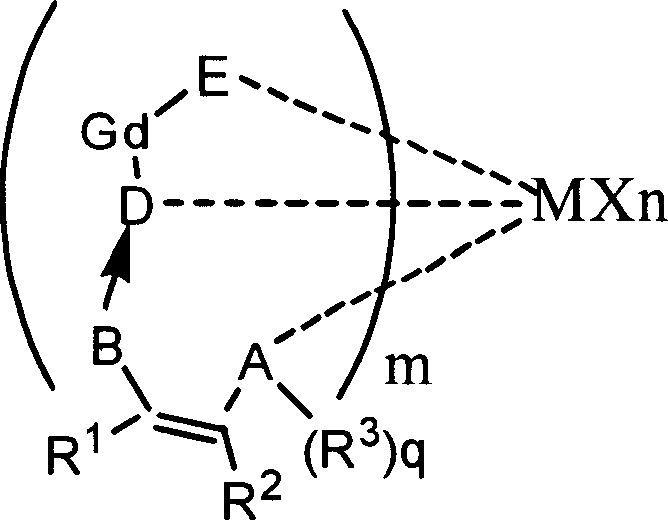

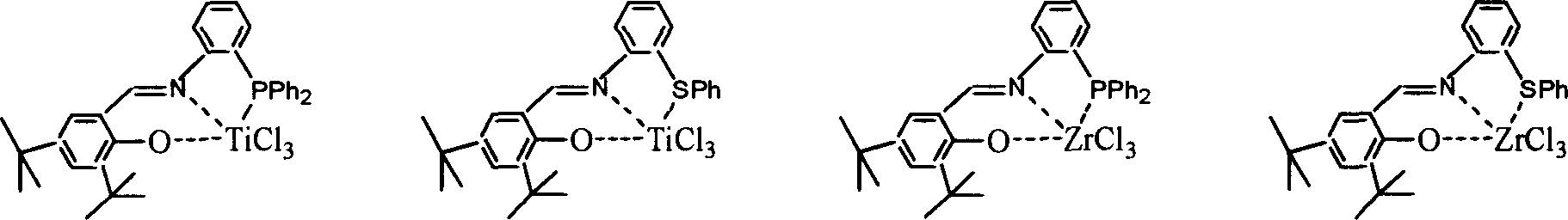

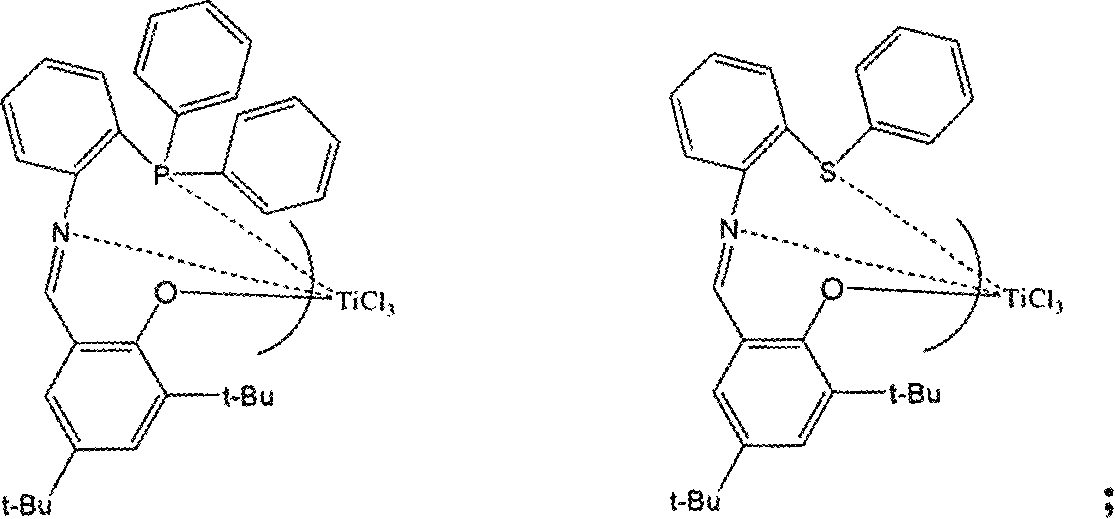

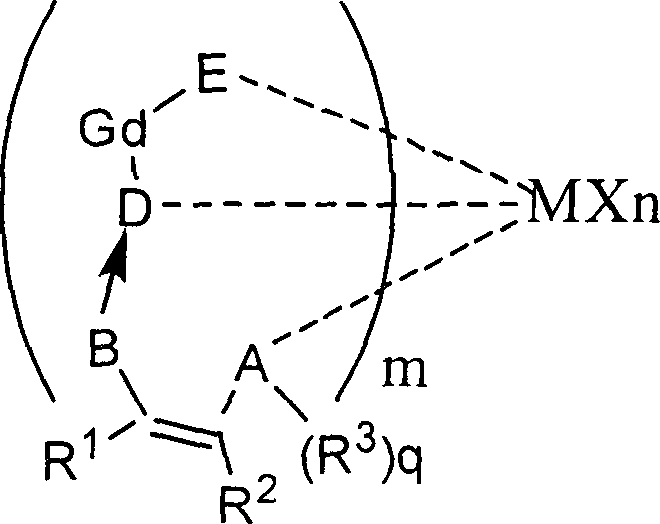

Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

The invention discloses an equivoluminal dipping loading method of non-metallocene olefin polymeric catalyst as well as application of copolymerizing course within two or more different olefins, which comprises the following steps: dissolving non-metallocene olefin polymeric catalyst in the solvent; mixing solution and carrier; stirring wet solid material evenly; drying; obtaining the load-typed non-metallocene olefin polymeric catalyst; making the solvent and carrier satisfy specific relationship.

Owner:SINOPEC YANGZI PETROCHEM

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

Highly active supporting method of non-metallocene catalyst

A method of non- metallocene catalyst loading with high active: the carrier and chemical activating agent reacting with each other to get the modification carrier; dissolving the magnesium compounds into the tetrahydrofuran-alcohol mixing system to form solution, adding the modification carrier into the solution for reaction, filtering, washing, drying and sucting to get the composite carrier; dissolving the non- metallocene catalyst for lkene polymerization into the dissolvent, then reacting with the composite carrier and through process of washing, filtering and drying to get the load non- metallocene catalyst. It can also be: proceeding heating activating treatment before the reaction of carrier with the chemical activating agent; the composite carrier reacting with chemical additive before reacting with catalyst to get the modification composite carrier, the modification composite carrier reacting with catalyst to get the load non- metallocene catalyst. The load catalyst produced in this invention is high active; the load catalyst of high property can be produced with less methylaluoxane; the polyolefine produced with the catalyst prepared in this invention possesses sound granual shape.

Owner:SINOPEC YANGZI PETROCHEM

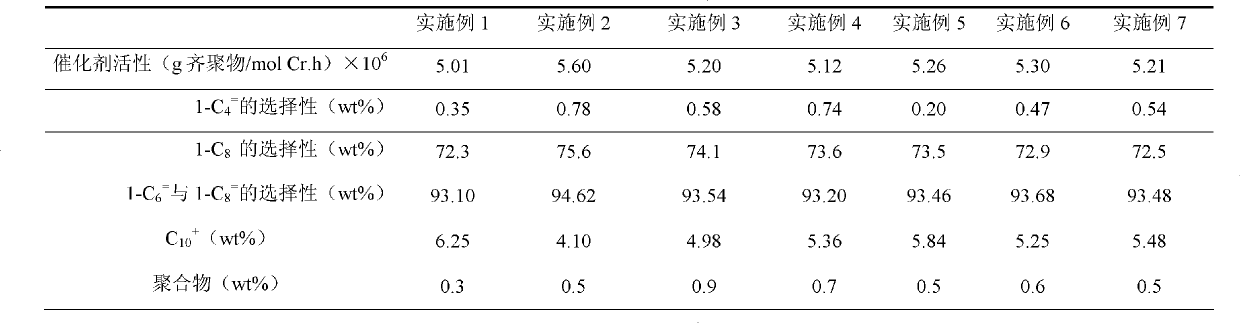

Catalyst composition of ethylene oligomerization and the application

ActiveCN101032695AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAryl1-Octene

The present invention relates to catalyst composition for oligomerizing ethylene and its application. The catalyst composition includes complex of acetylacetone chromium, tetrahydrofuran chromium chloride and / or chromium isooctanate; ligand containing P and N; activator of methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; and promoter of X1R6X2, where, each of X1 and X2 is F, Cl, Br, I or alkoxyl, and R6 is alkyl or aryl group; with the molar ratio of the complex, the ligand, the activator and the promoter being 1 to 0.5-10 to 50-3000 to 0.5-10. The catalyst composition is used in oligomerizing reaction of ethylene to prepare 1-octene, and has high catalytic activity and high 1-octene selectivity.

Owner:PETROCHINA CO LTD

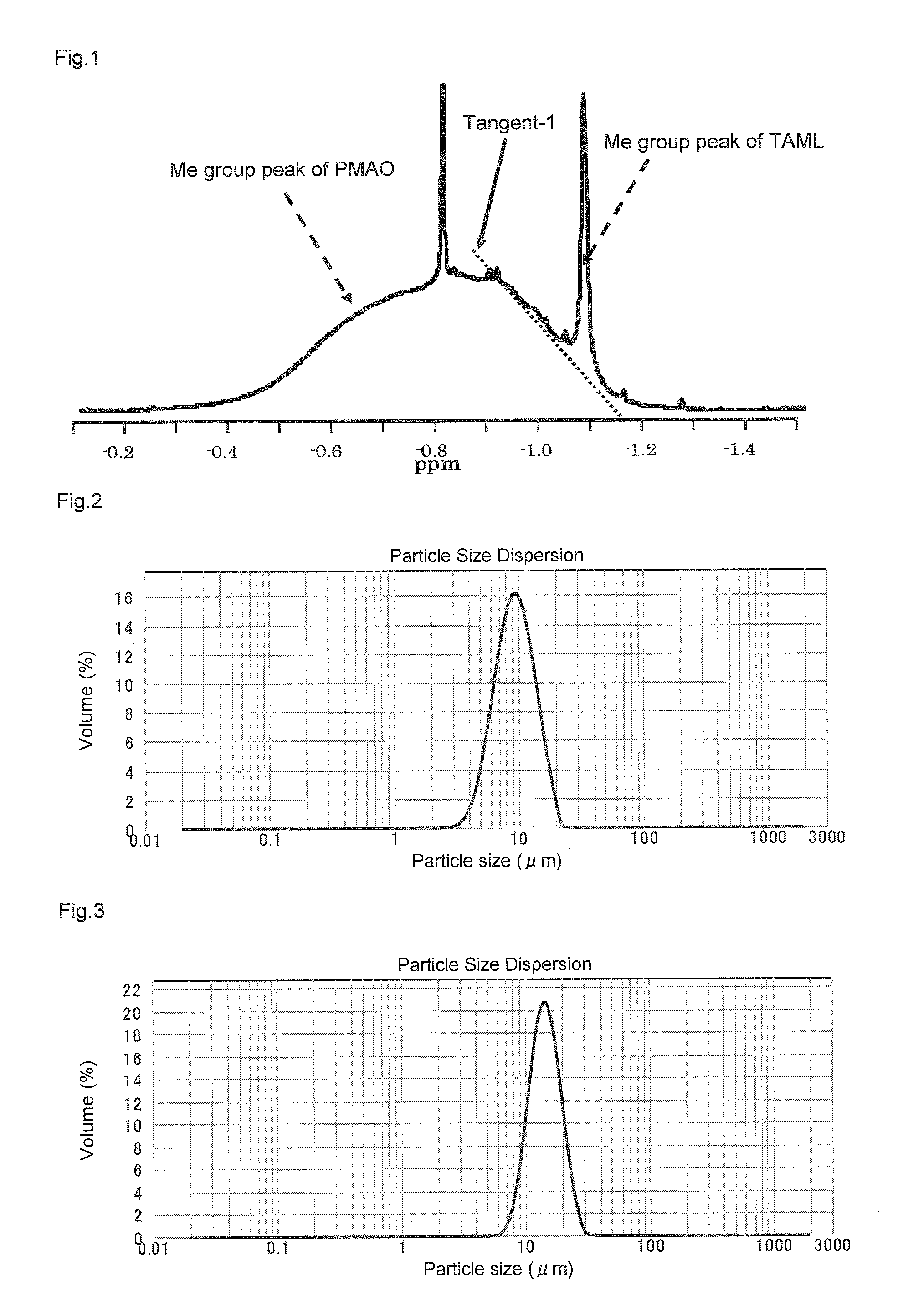

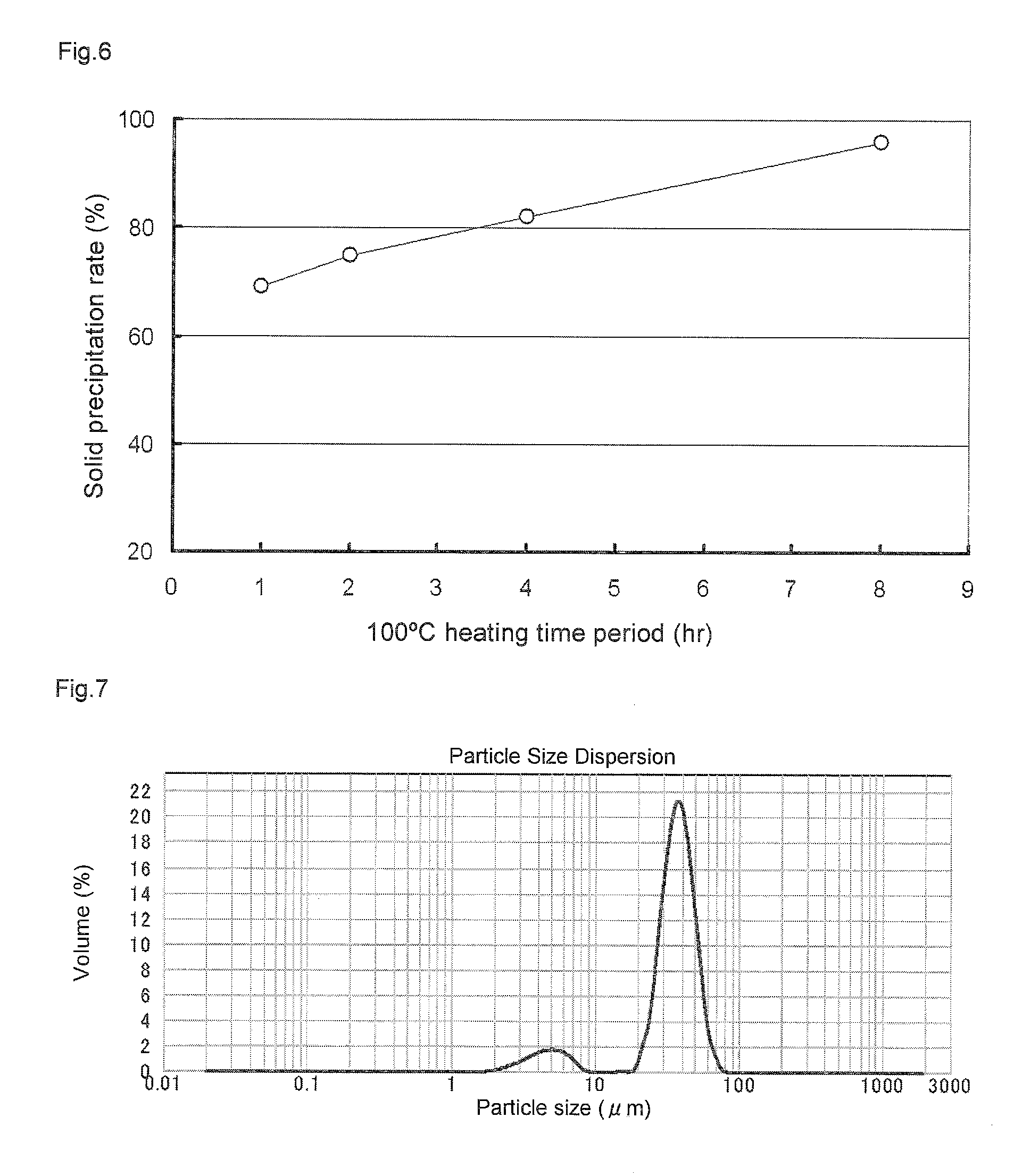

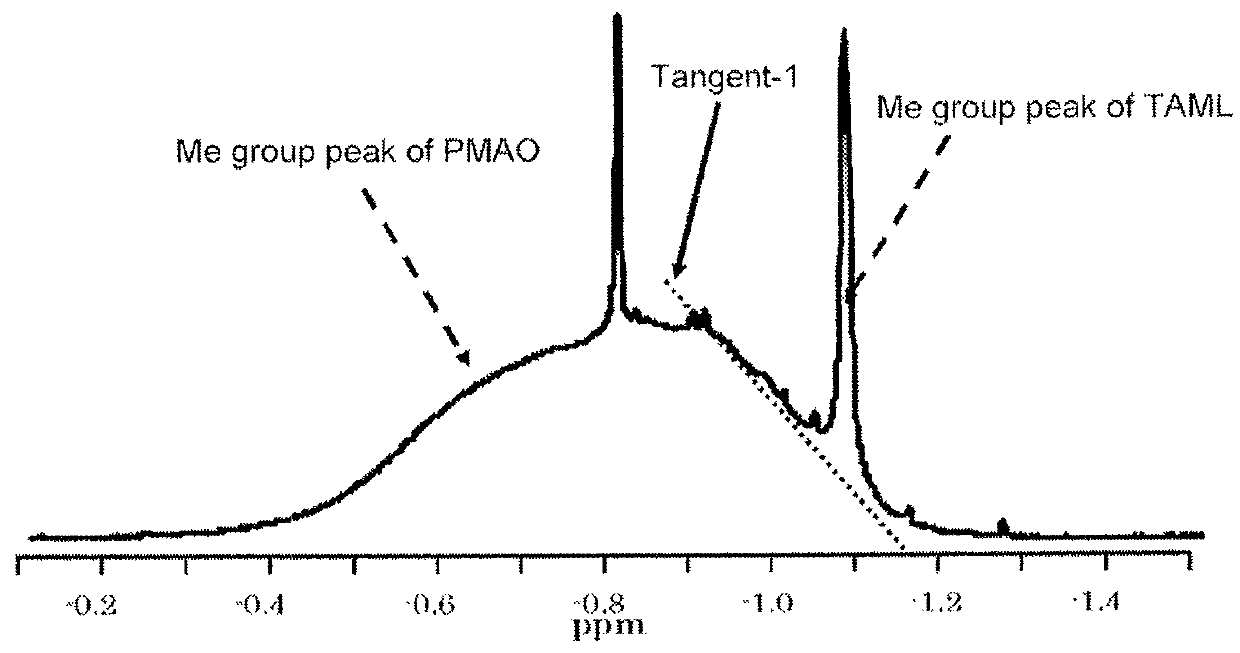

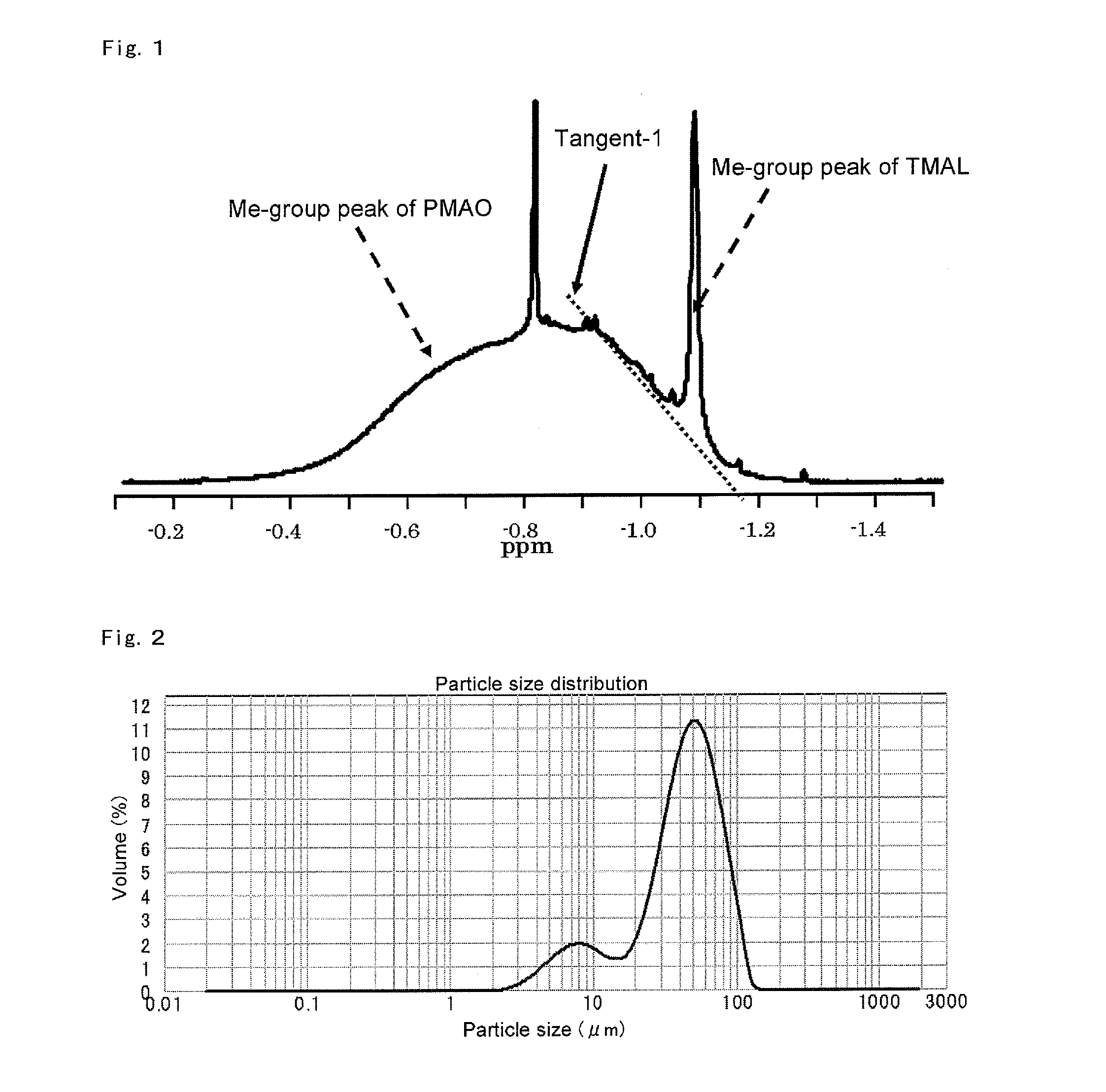

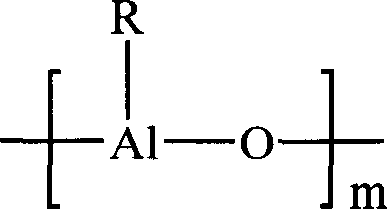

Solid polymethylaluminoxane composition and method for manufacturing same

ActiveUS8404880B2High polymerization activityReduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationMethyl group

Owner:TOSOH FINECHEM CORP

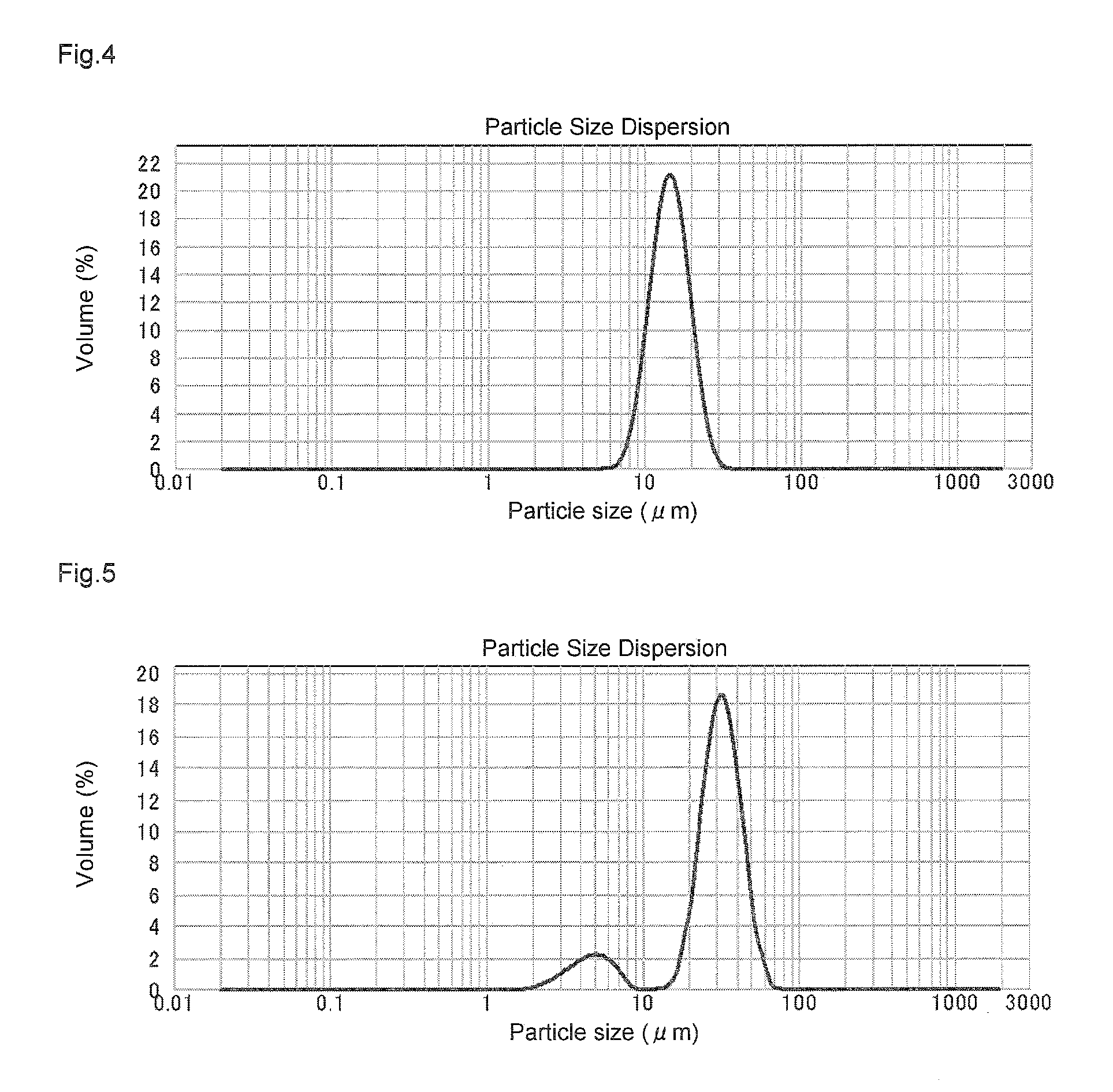

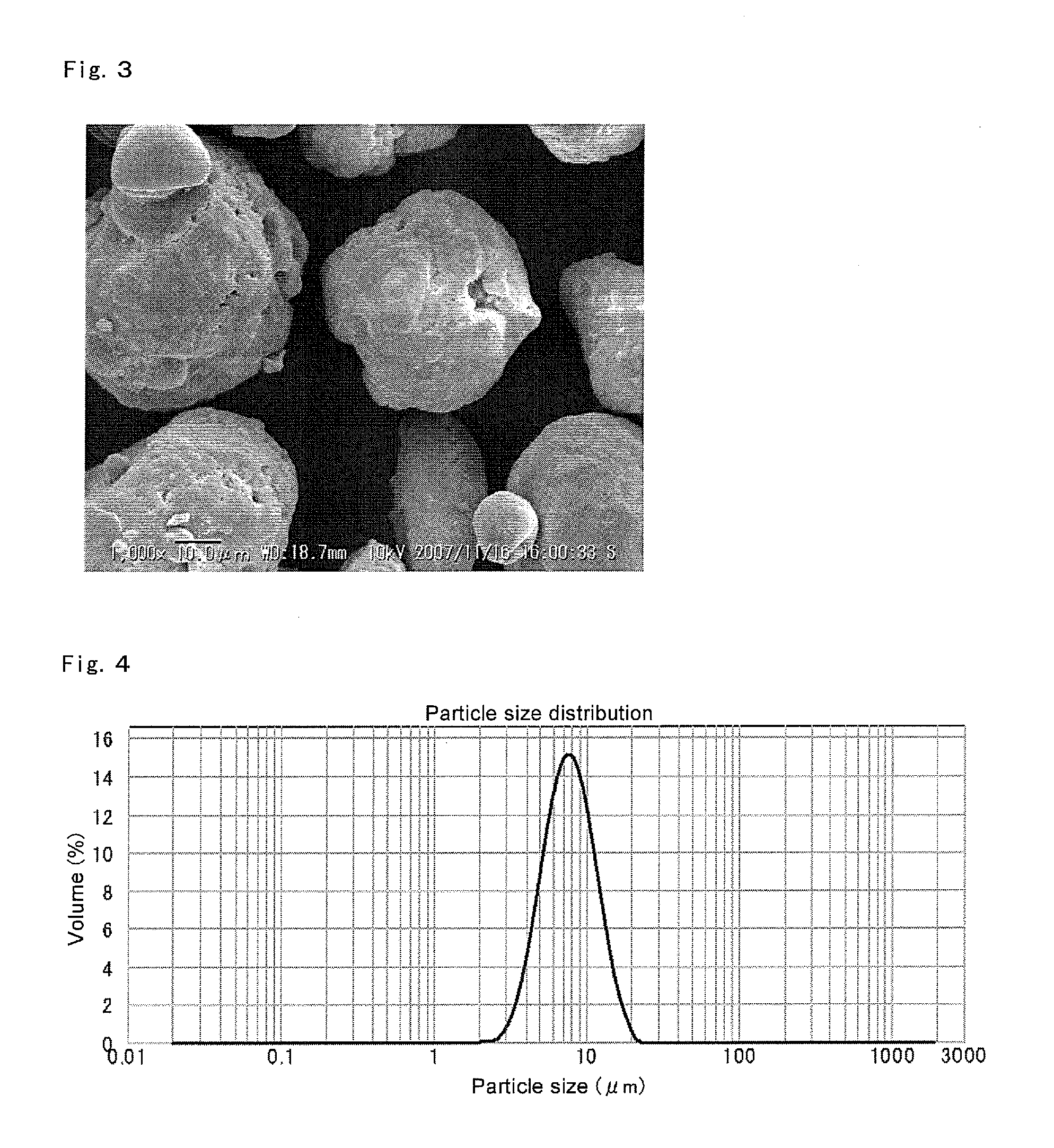

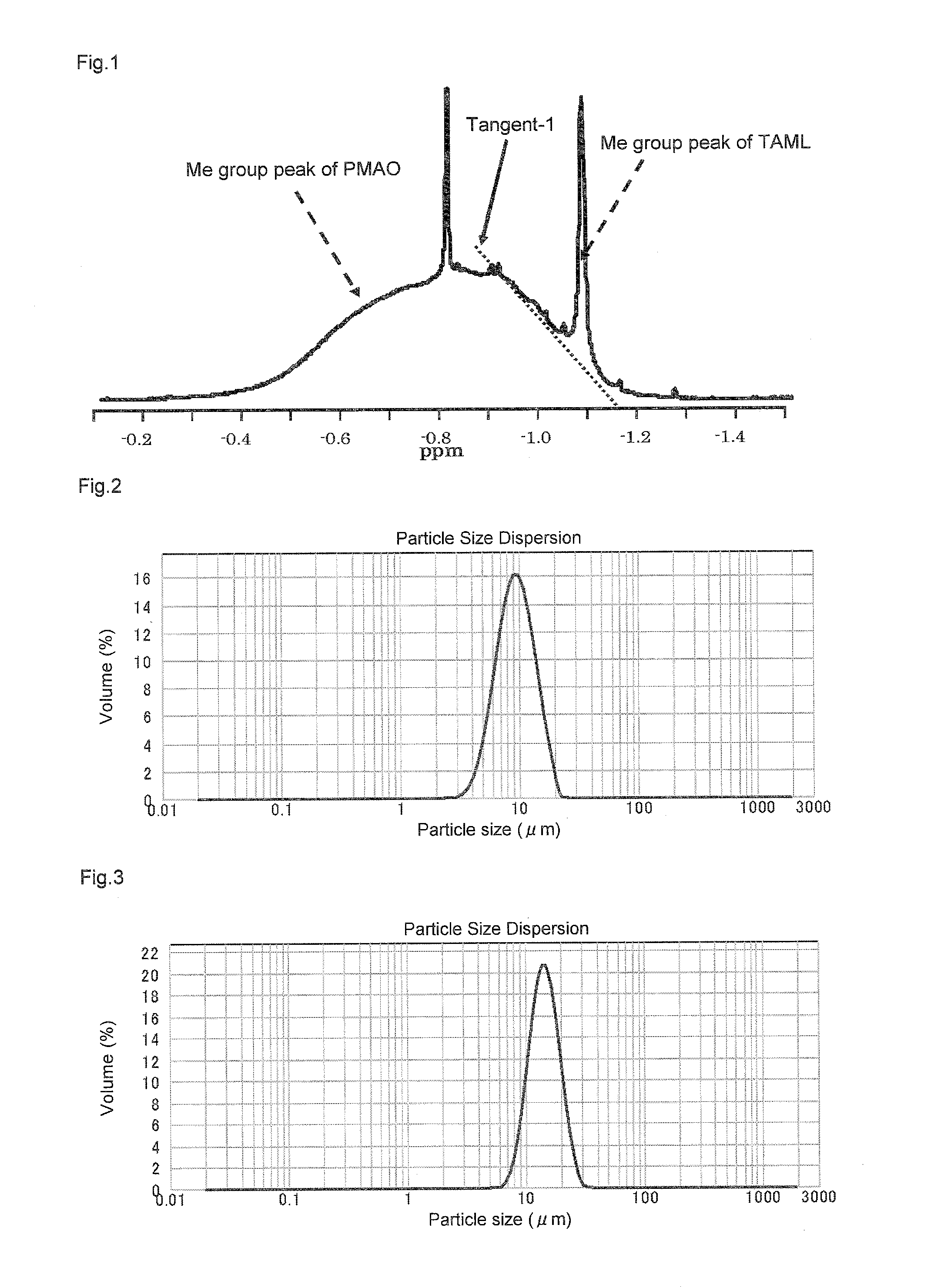

Method for manufacturing a small particle diameter product of solid polymethylaluminoxane composition

ActiveUS9340630B2Easy to optimizeHigh yieldGroup 3/13 element organic compoundsThin material handlingParticulatesDiameter product

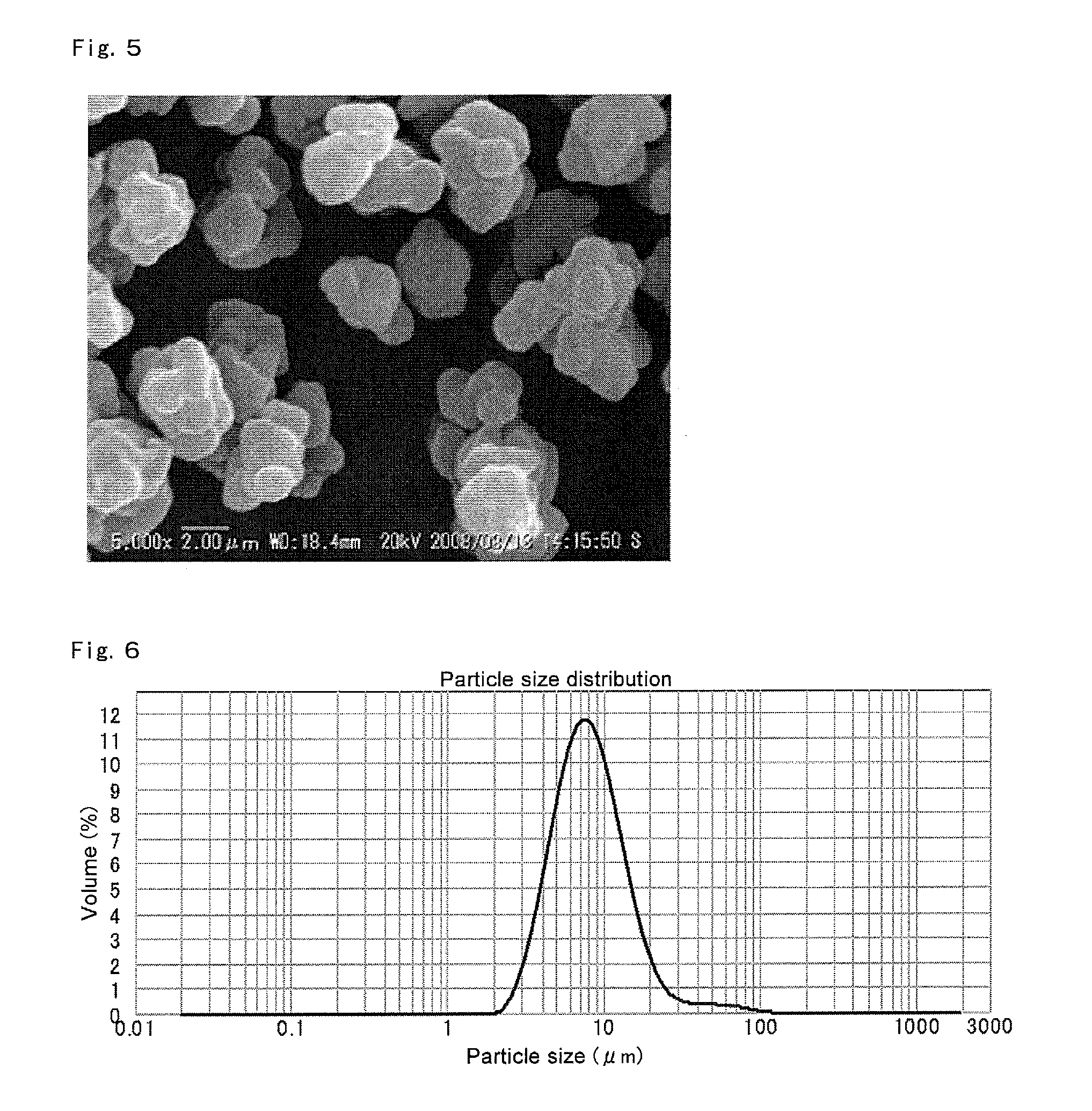

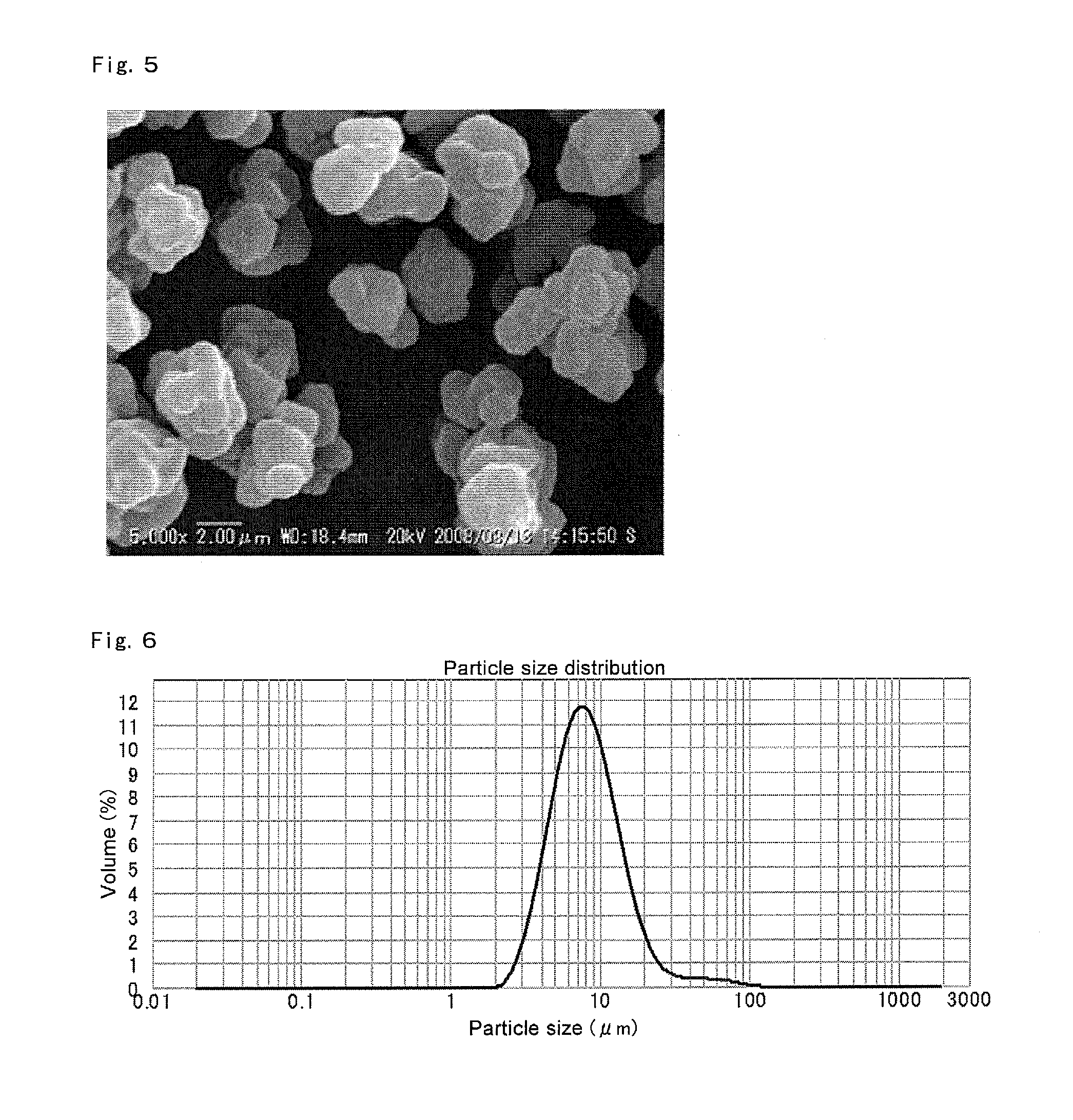

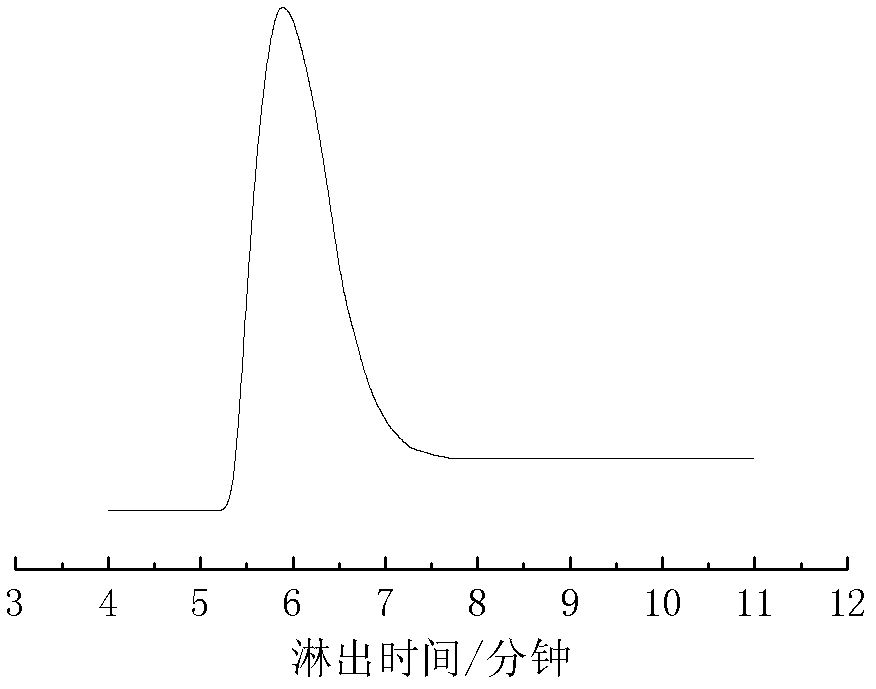

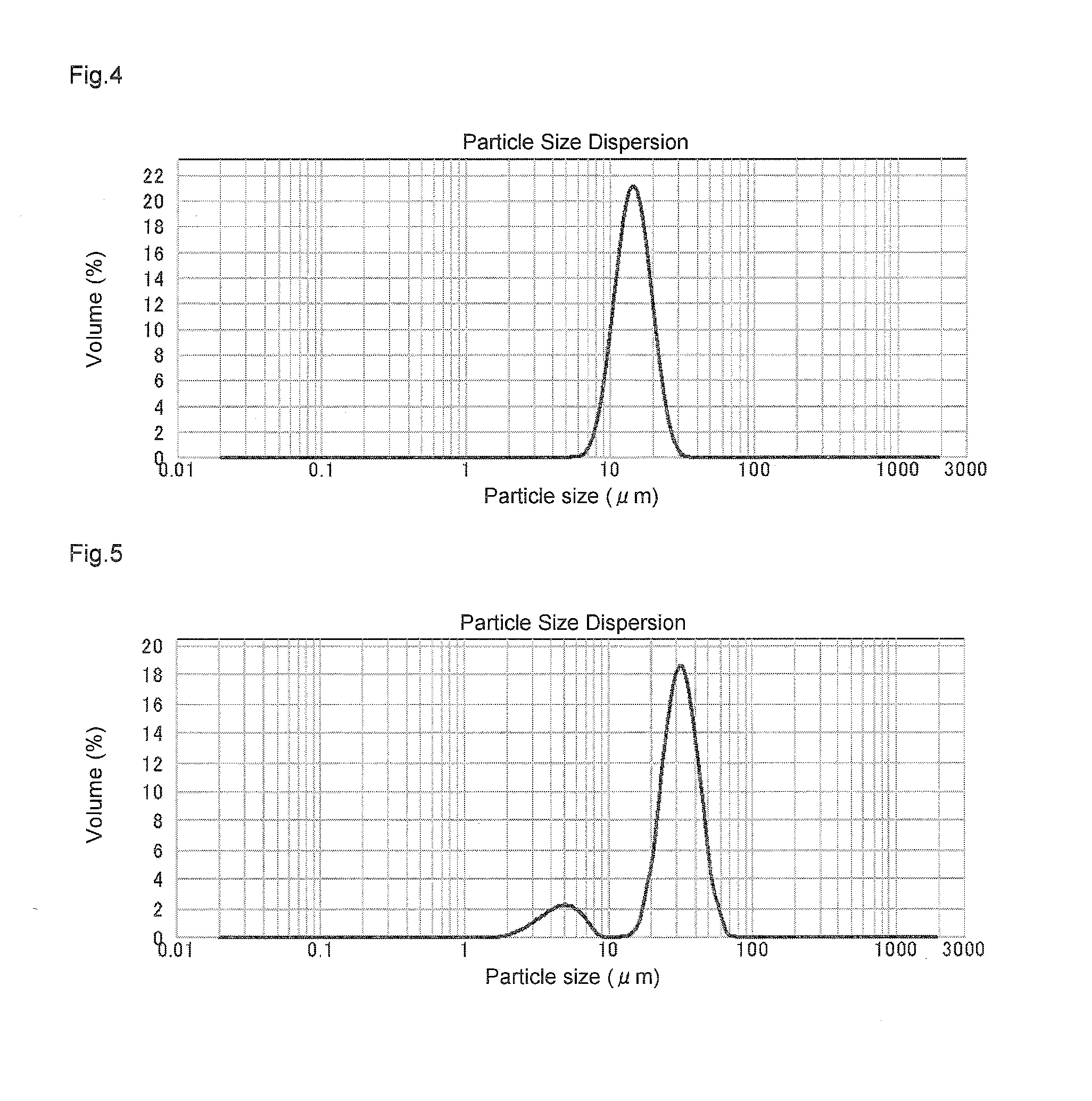

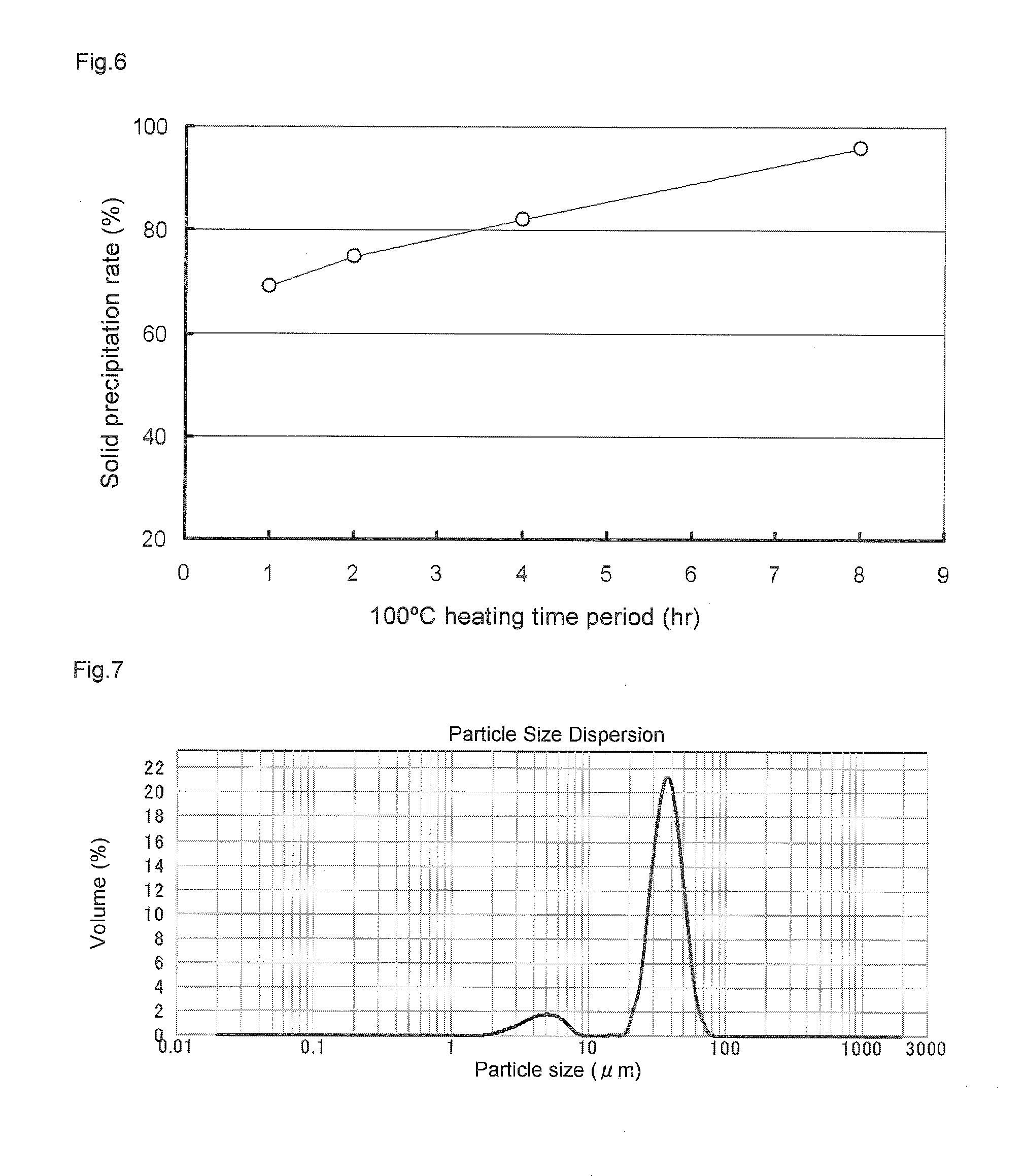

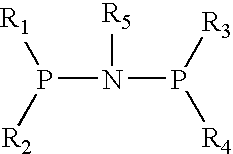

A solid polymethylaluminoxane composition is provided having uniform particle diameter in the form of fine particles of less than 5 μm employed to polymerize olefins with high polymerization activity without silica. A method for manufacturing thereof, a polymerization catalyst, and a method for manufacturing a polyolefin are also provided. The solid polymethylaluminoxane composition: has an aluminum content within a range of 36 mass % to 43 mass %; has a mole fraction of methyl groups derived from trimethylaluminum moieties relative to the total number of mols of methyl groups of 12 mol % or less; and is particulate having a median diameter based on volume within a range of 0.1 μm to less than 5 μm. In a step of heating an aromatic hydrocarbon solution containing trimethylaluminum and the polymethylaluminoxane to cause solid polymethylaluminoxane composition to precipitate, prior to or during the heat treating step, a dry, inert gas is bubbled through.

Owner:TOSOH FINECHEM CORP

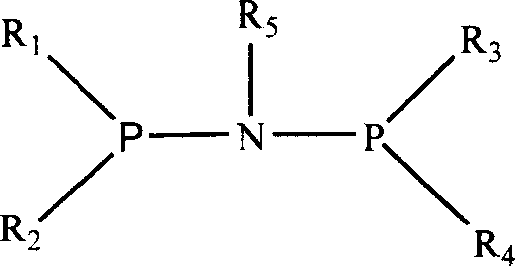

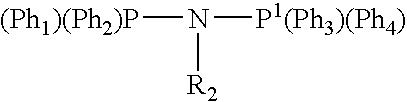

Tetramerization

ActiveUS7829749B2Organic-compounds/hydrides/coordination-complexes catalystsGroup 8/9/10/18 element organic compoundsAluminoxaneOligomer

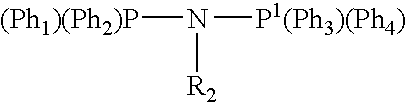

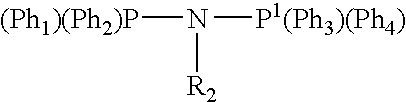

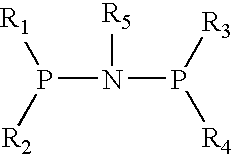

A new P-N-P ligand is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methylalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

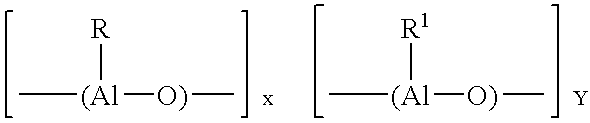

Solid support-polymethylaluminoxane complex, method for producing same, olefin polymerization catalyst, and method for producing polyolefin

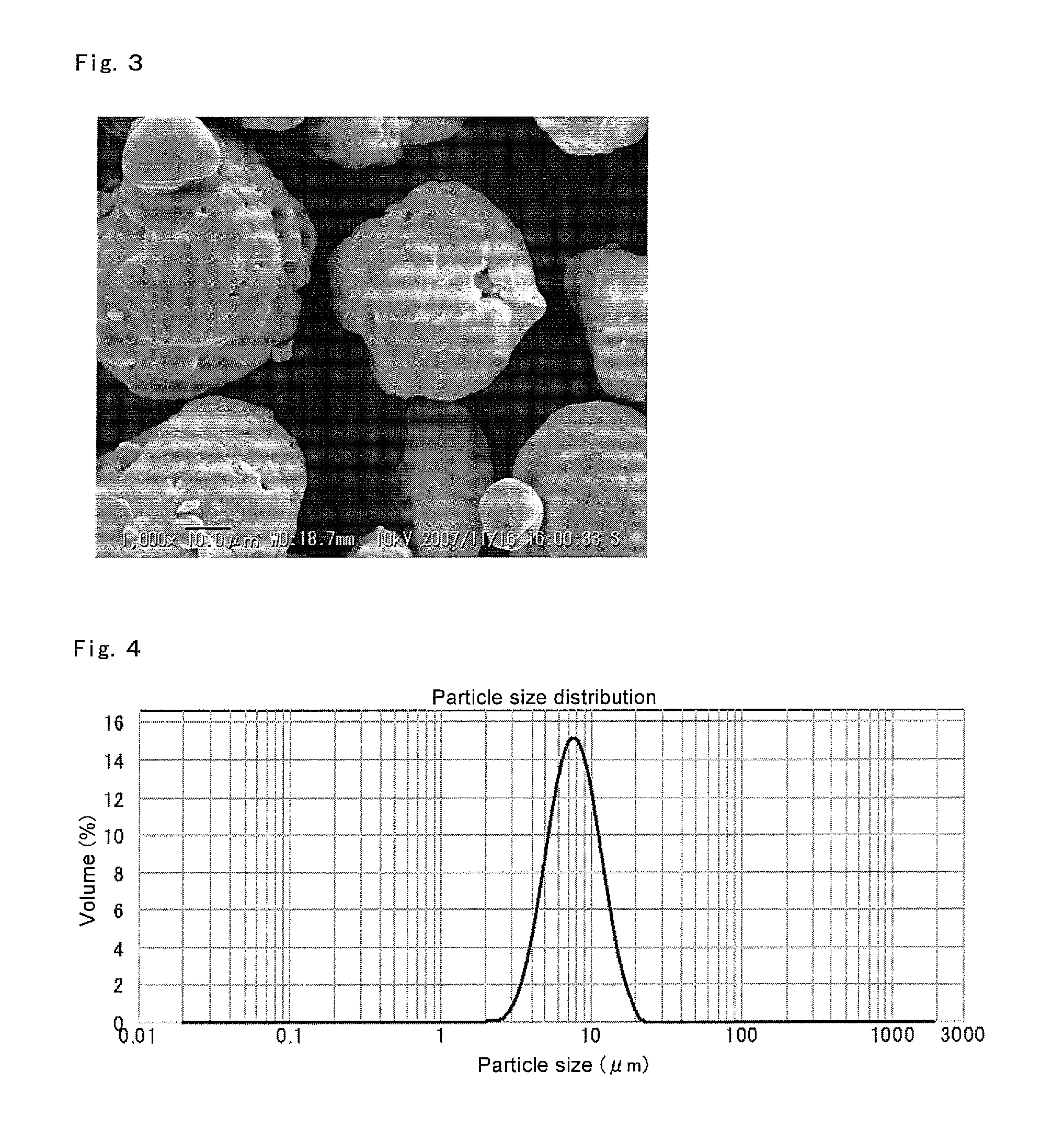

ActiveUS8975209B2Conveniently obtainHigh polymerization activityOrganic-compounds/hydrides/coordination-complexes catalystsOrganic chemistry methodsPolyolefinOlefin polymerization

Disclosed is a solid support-polymethylaluminoxane complex exhibiting a higher polymerization activity than a conventional substance and being homogeneous. Also disclosed is a method for producing an olefin-based polymer having a favorable quality using the complex and a transition metal compound. The complex comprises a coating layer containing polymethylaluminoxane and trimethylaluminum on the surface of a solid support. The coating layer comprises a solid polymethylaluminoxane composition in which (i) the content of aluminum is in a range of 36 to 41 mass % and (ii) the molar fraction of methyl groups derived from a trimethylaluminum moiety to the total number of moles of methyl groups is 12 mol % or less. Also disclosed is an olefin polymerization catalyst comprising the complex and a transition metal compound represented by general formula (III): MR5R6R7R8 as catalyst components, and a method for producing a polyolefin comprising polymerizing an olefin using the catalyst.

Owner:TOSOH FINECHEM CORP

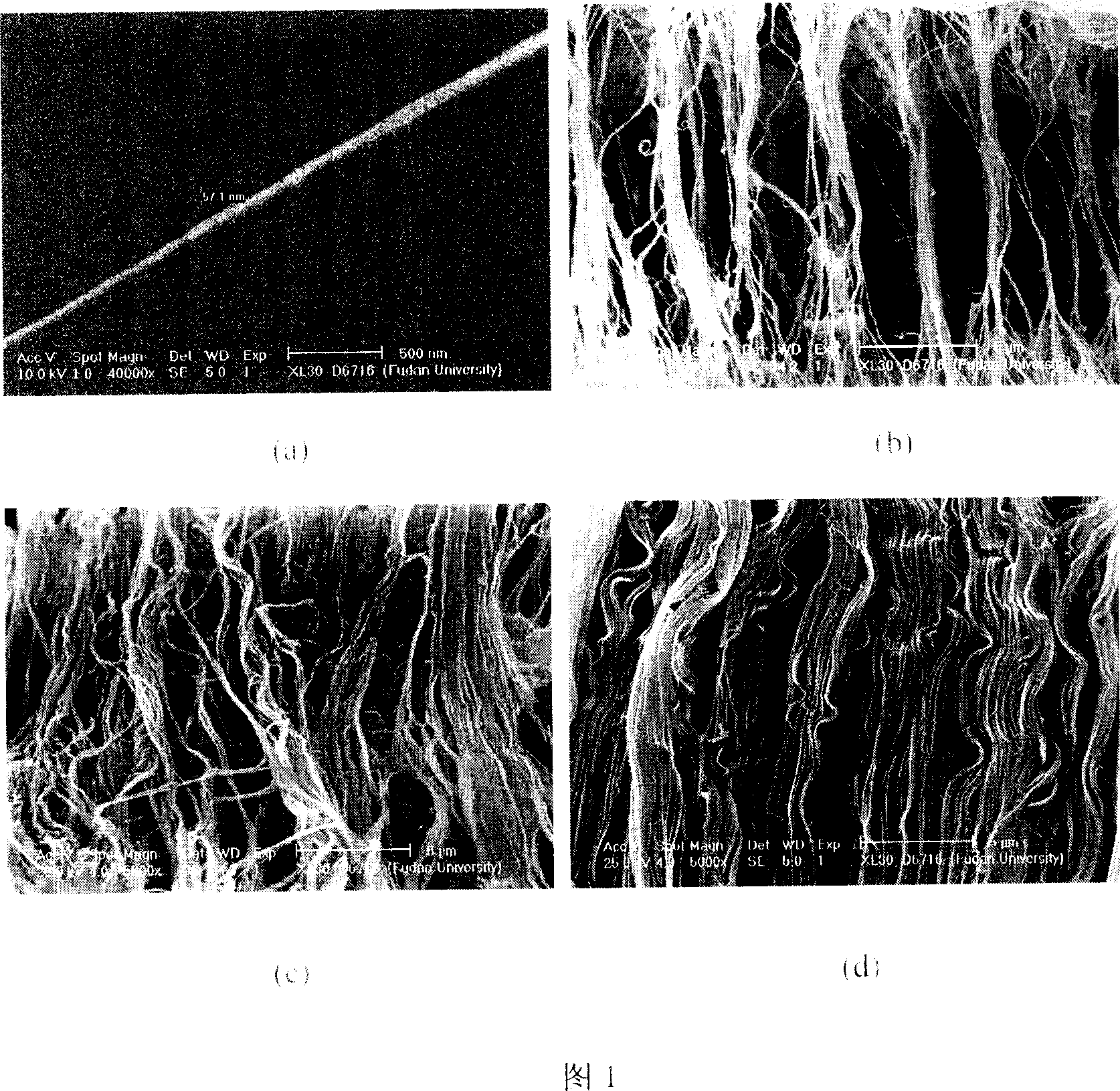

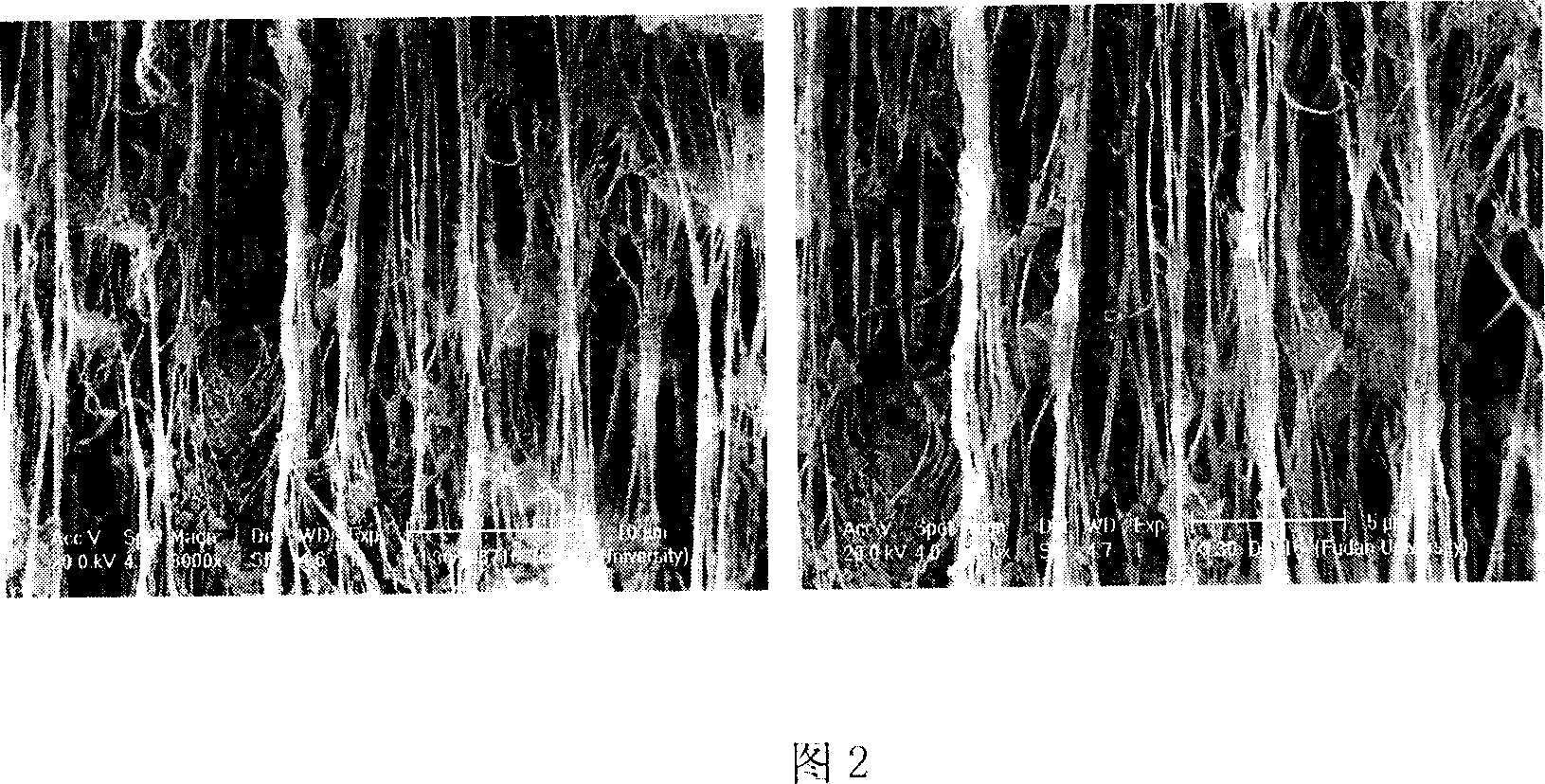

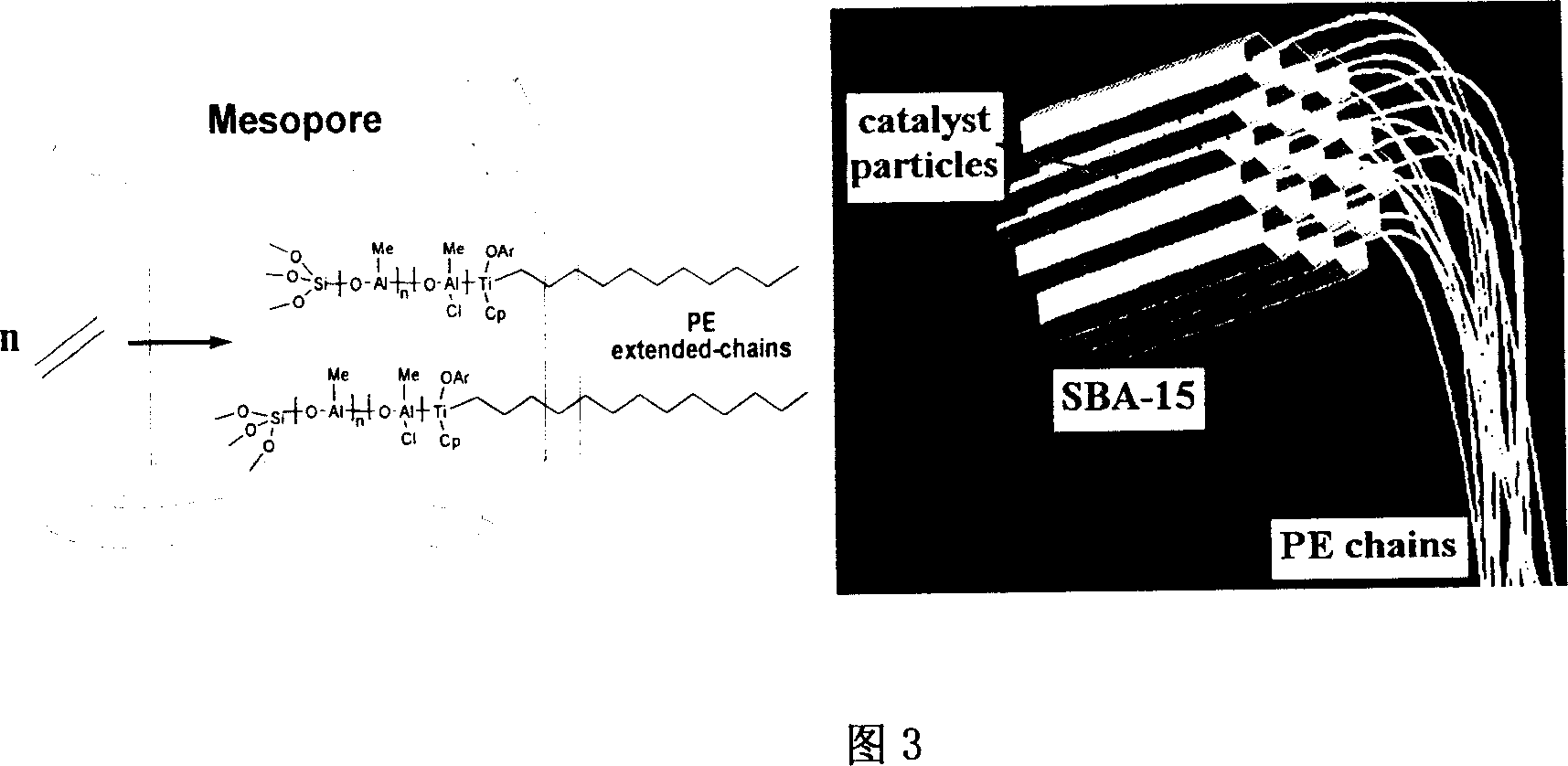

Mesoporous molecular sieve carried olefin polymerization catalyst, preparation method and application thereof

InactiveCN1923862AHigh molecular weightHigh melting pointBulk chemical productionGas phaseHomogeneous catalysis

The invention discloses an olefin polymeric catalyst and preparing method and reacting technology, which is characterized by the following: the expression formula of catalyst is [SiO2-Cat], wherein Cat represents semi-sandwich homogeneous phase catalyst of transient element metallic titanium (IV) or zirconium (IV); SiO2 represents dielectric molecular sieve SBA-15 decorated by methyl alundum alkyl, which can synthesize polyethylene; the catalyst possesses high ethylene polymeric activity, which displays ultrahigh molecule with different patterns.

Owner:FUDAN UNIV

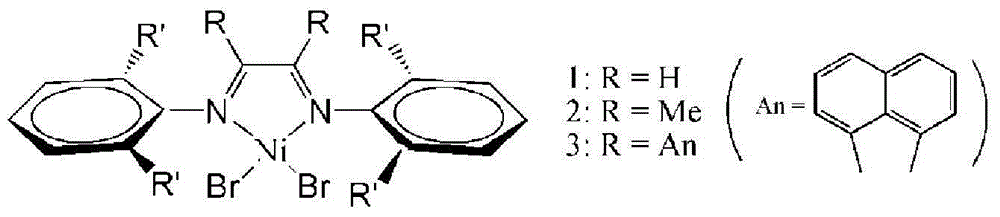

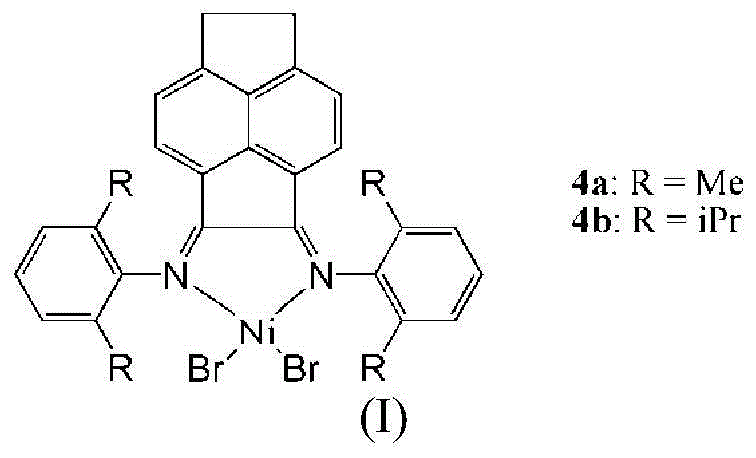

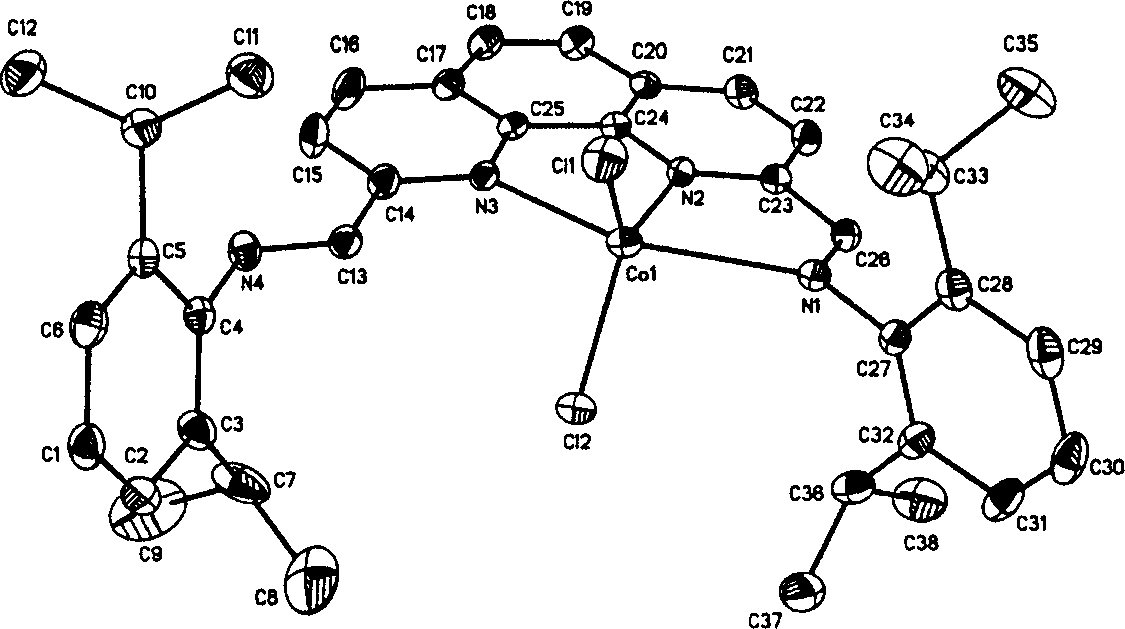

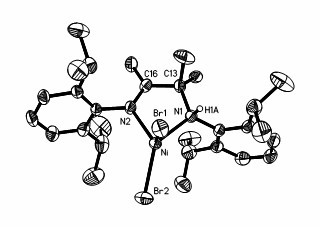

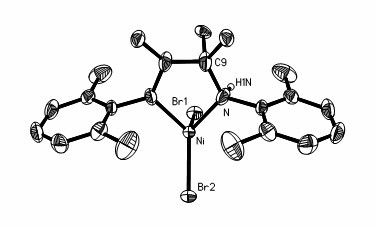

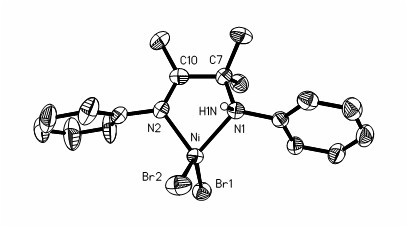

Ethylene acenaphthylene (alpha-diimine) nickel complex/alkyl aluminum chloride combined catalyst

The invention relates to the field of catalytic polymerization of olefins, aiming at providing an ethylene acenaphthylene (alpha-diimine) nickel complex / alkyl aluminum chloride combined catalyst. The combined catalyst consists of an ethylene acenaphthylene (alpha-diimine) nickel complex and alkyl aluminum chloride, wherein the molar ratio of aluminum in alkyl aluminum chloride to nickel in the ethylene acenaphthylene (alpha-diimine) nickel complex is 20-800:1. Compared with the prior art, the combined catalyst provided by the invention has higher activity and better stability in catalyzing polymerization of ethylene and propene. According to the invention, alkyl aluminum chloride is used as a cocatalyst. Compared with that of using methylaluminoxane or modified methyl aluminoxane, cost is significantly reduced, and in addition, localization of alkyl aluminum chloride is realized, saving the need of importing.

Owner:ZHEJIANG UNIV

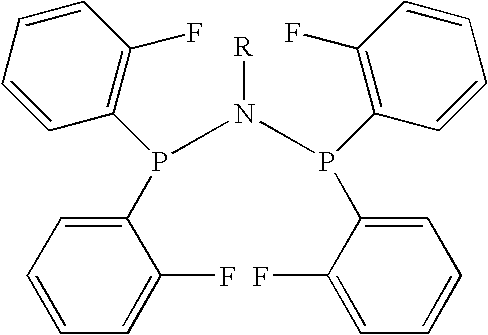

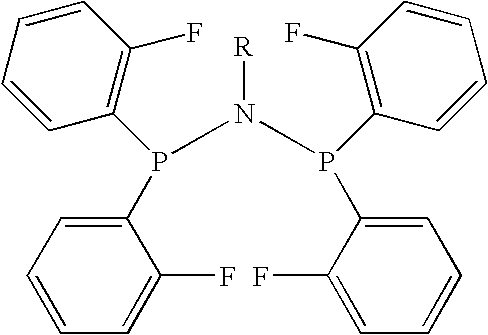

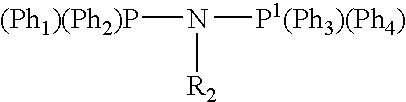

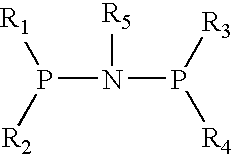

Amino phosphine

ActiveUS7994363B2Organic-compounds/hydrides/coordination-complexes catalystsCatalystsAluminoxaneOctene

A new P-N-P ligand in which each phosphorus atom is bonded to two ortho-fluorine substituted phenyl groups is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

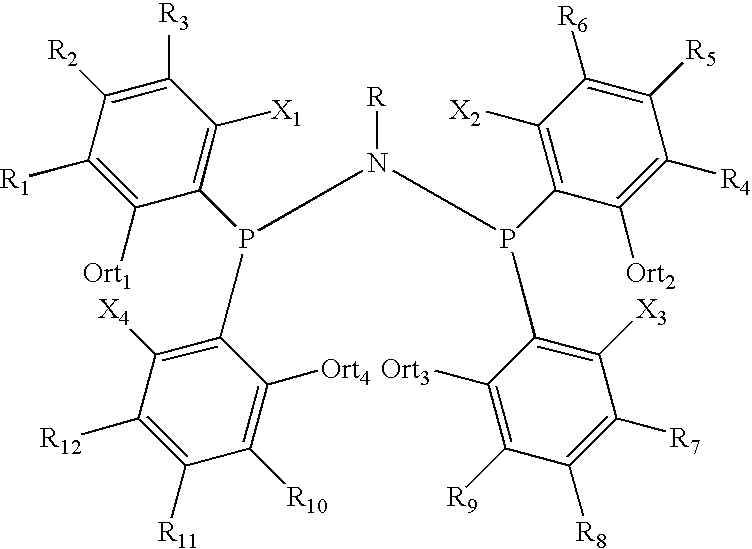

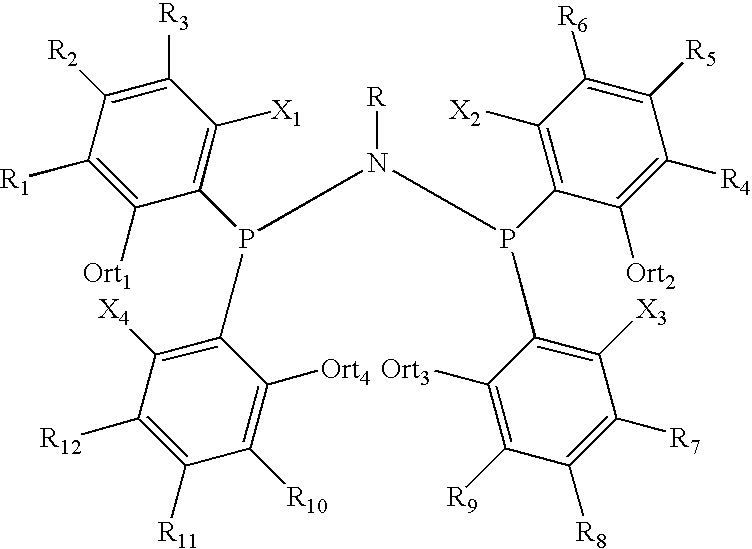

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS20070232481A1High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionChromium Compounds1-Octene

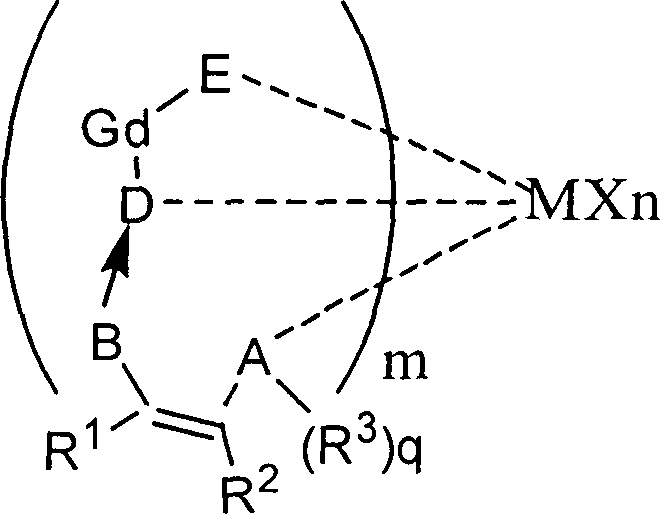

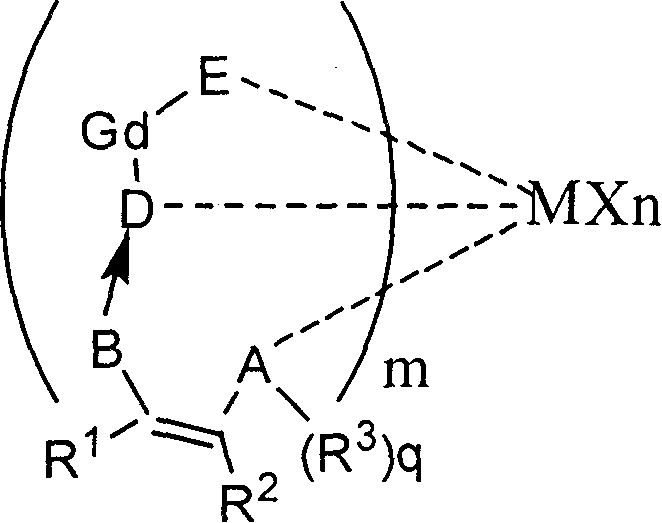

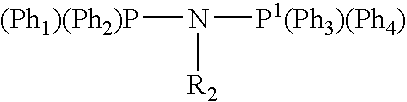

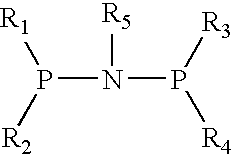

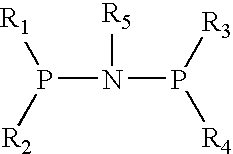

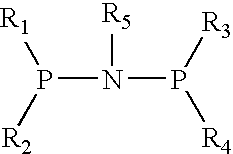

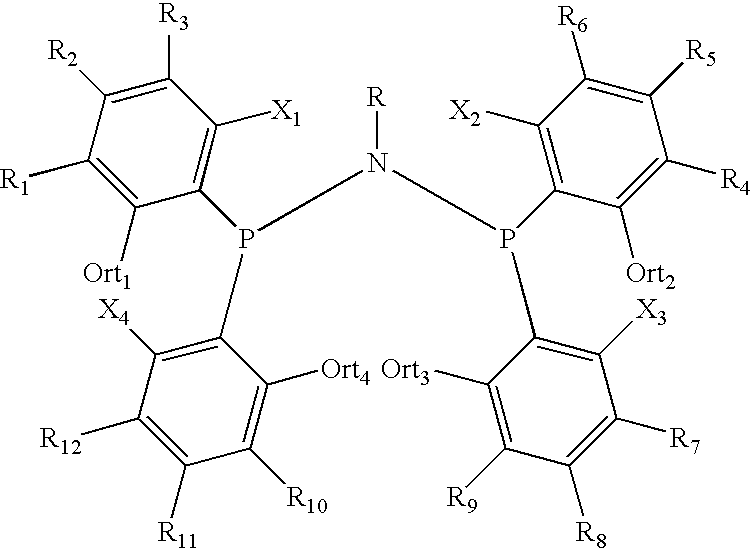

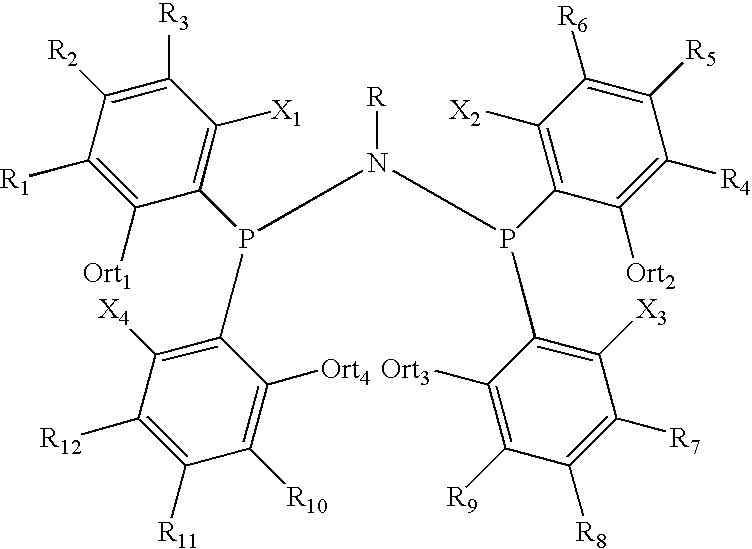

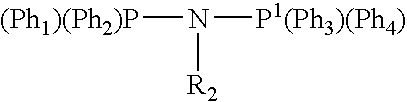

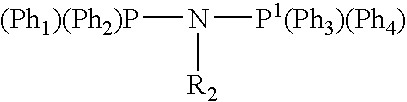

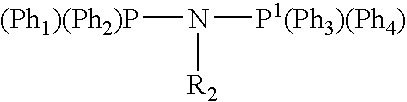

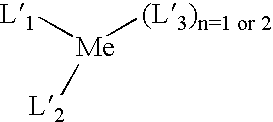

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and / or Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as: in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; general formula of the accelerator is X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkyl or aryl; the molar ratio of a, b, c and d is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·mol−1 Cr ·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

Amino phosphine

ActiveUS20080242811A1Sure easyOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsOligomerOctene

A new P—N—P ligand in which each phosphorus atom is bonded to two ortho-fluorine substituted phenyl groups is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

Trimerization

ActiveUS8252955B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionOligomerAluminoxane

A new P—N—P ligand is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methylalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

Ethylene oligomerization catalyst composition and application thereof

InactiveCN103285926AHigh activityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsArylAluminoxane

The invention relates to an ethylene oligomerization catalyst composition and an application thereof. The composition comprises the following components: a component a contains chromium acetylacetonate, tetrahydrofuran chromium chloride and / or chromium 2-ethylhexanoate; in the formula of a component b, R1, R2, R3 and R4 are phenyl, benzyl or naphthyl; and R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; a component c contains methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; a component d has a formula X1R6X2, wherein X1 and X2 are F, Cl, Br, I or alkoxy, and R6 is alkyl or aryl; in the formula of a component e, R is a linking group and selected from alkyl and derivatives thereof as well as aryl and derivatives thereof; and the molar ratio is 1: (0.5-10): (50-3000): (0.5-10): (0.5-10). The catalyst has the catalytic activity being more than 5.0*10<6>g mol<-1>Cr.h<-1>, and the mass of 1-hexene and 1-octylene is more than 93%.

Owner:PETROCHINA CO LTD

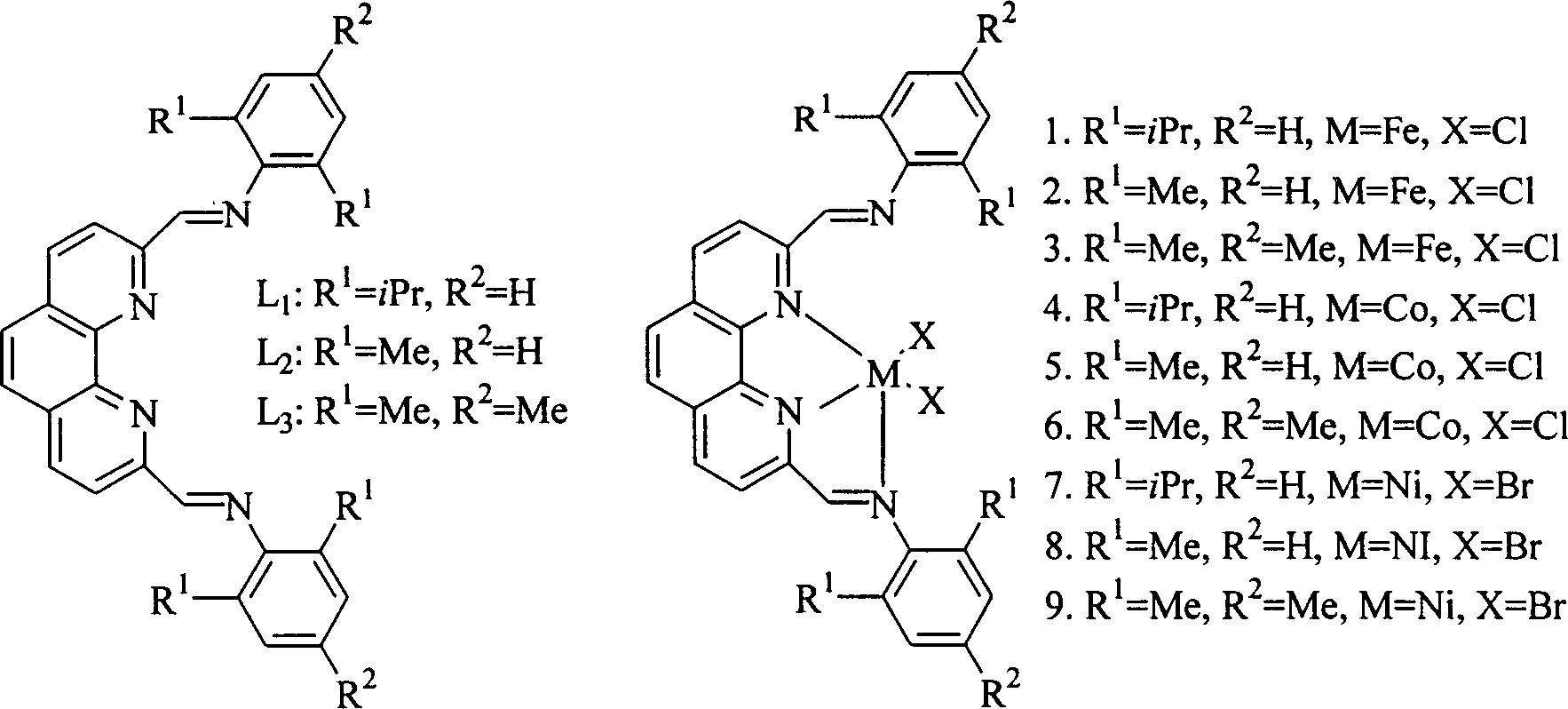

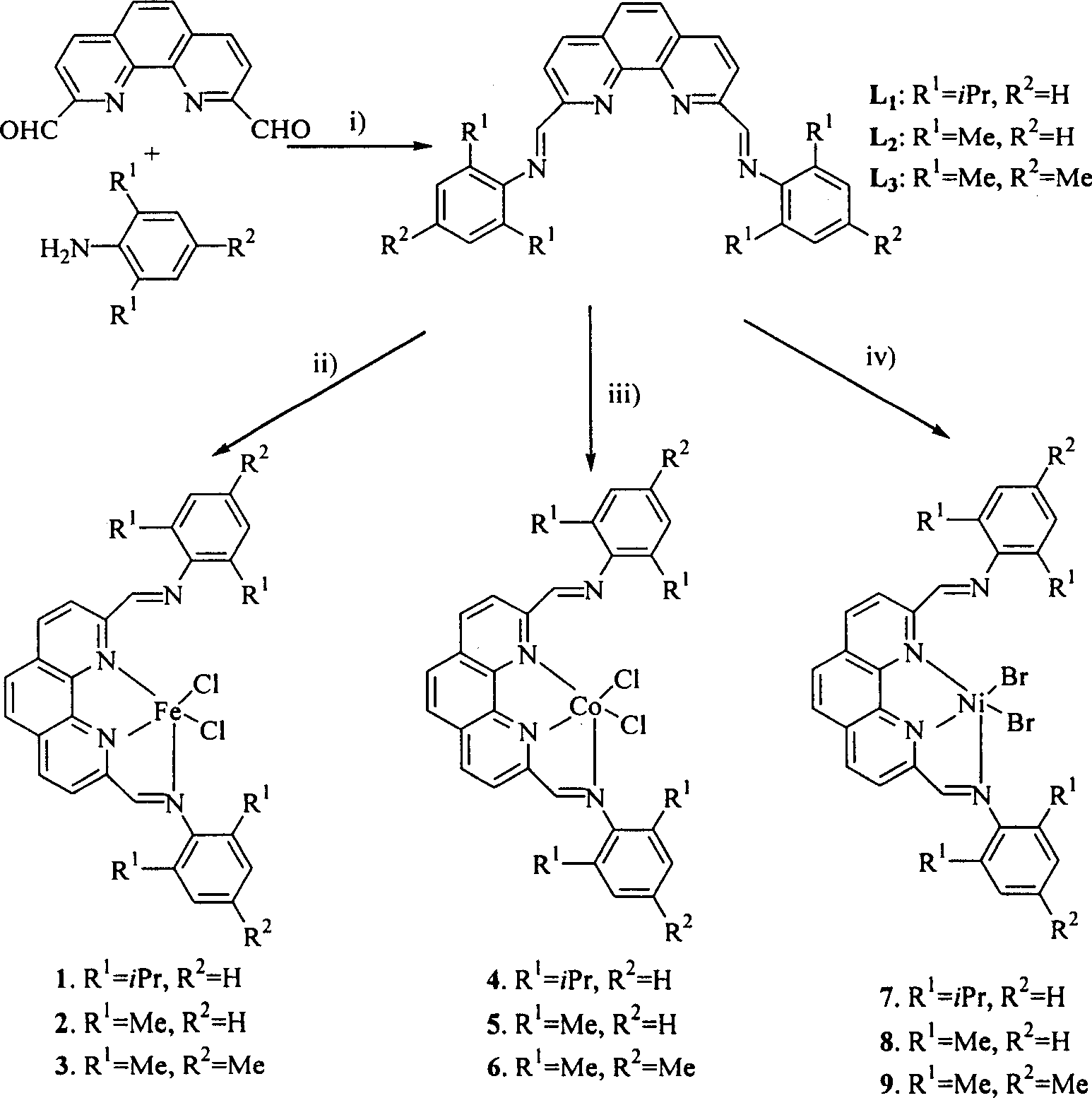

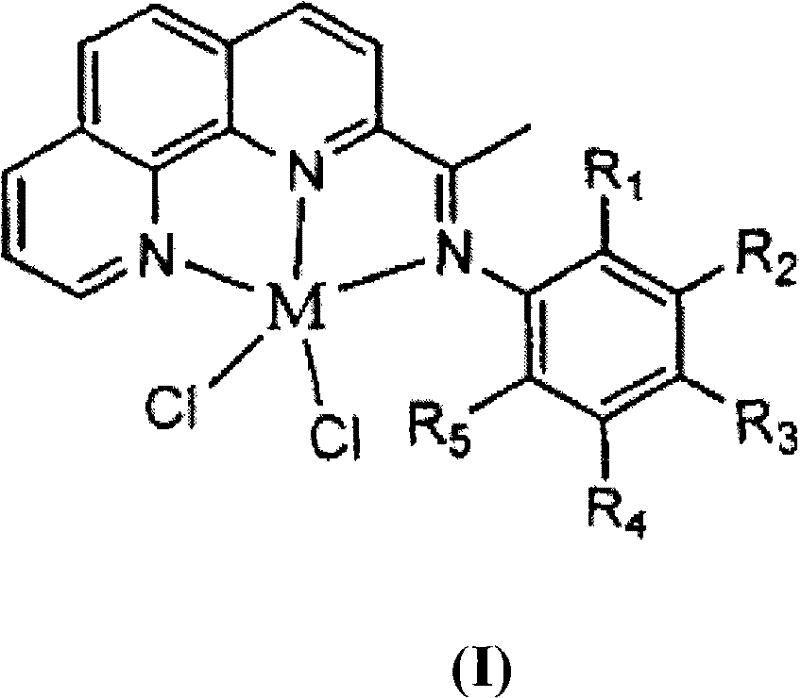

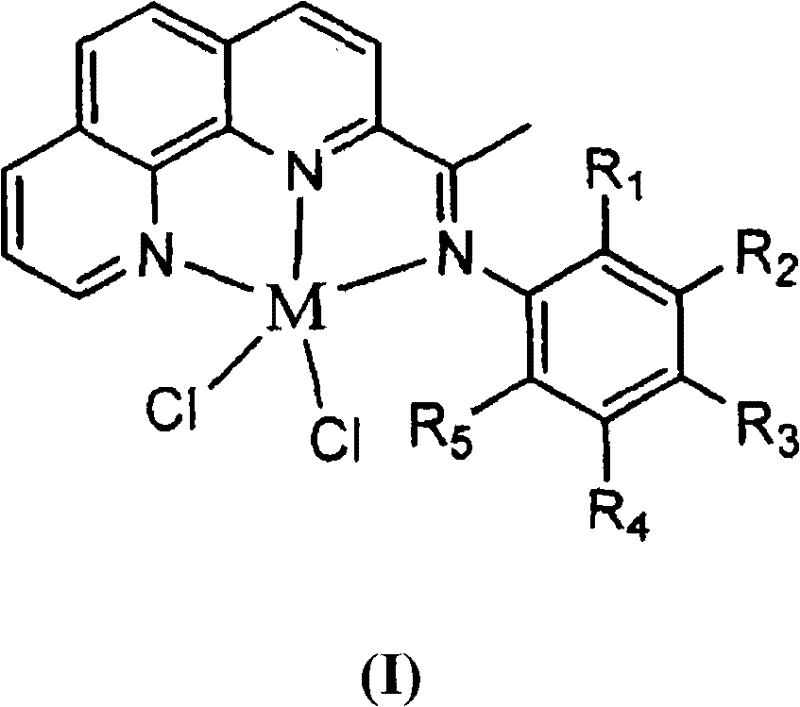

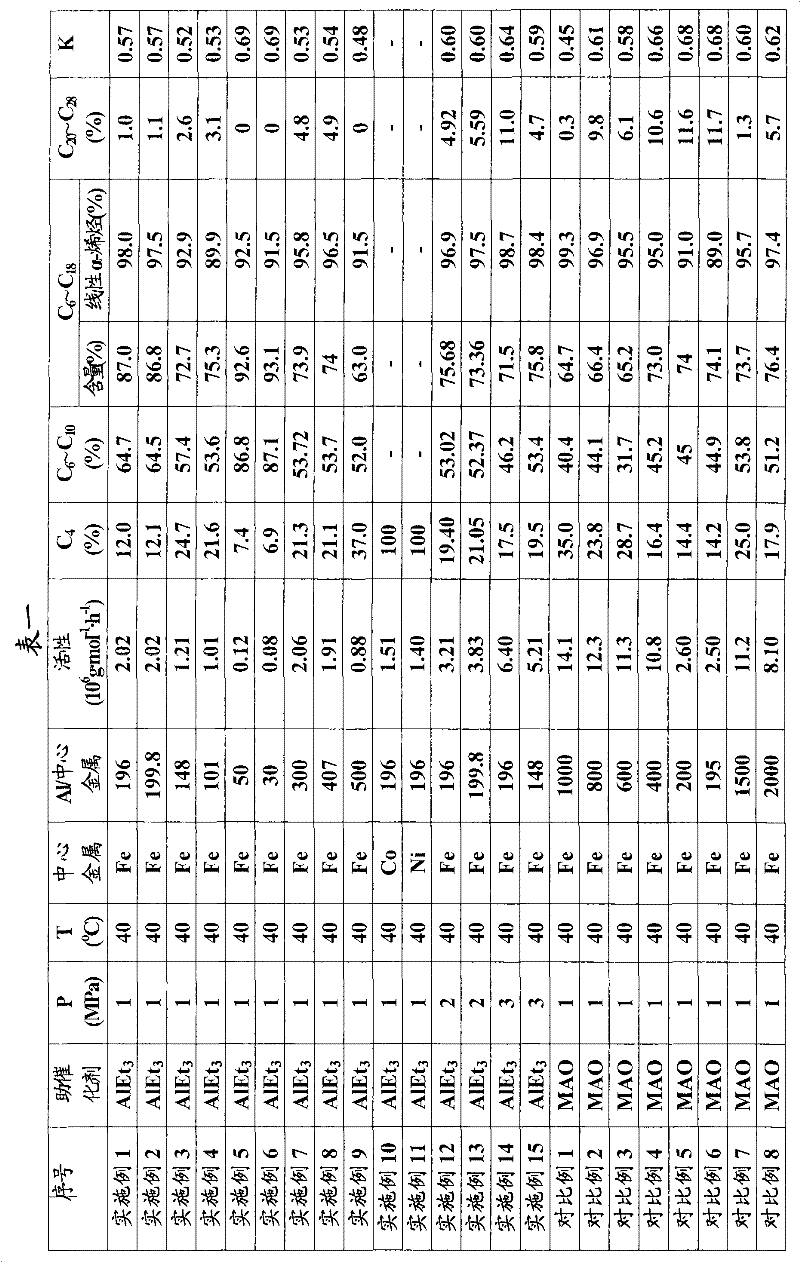

Ethene oligomerization and polymerization post transition metal complex catalyst

InactiveCN1401666AHydrocarbonsHydrocarbon preparationHigh volume manufacturingPolymerization catalysts

A post-transition metal coordination catalyst for ethylene oligomerization and polymerization is disclosed. It is halogenated 2,9-bis(imino)-1,10-orthophenanthralloline Fe, Ni and Co complexes. Its advantages are simple preparing process, easy purification, and high stability.

Owner:INST OF CHEM CHINESE ACAD OF SCI

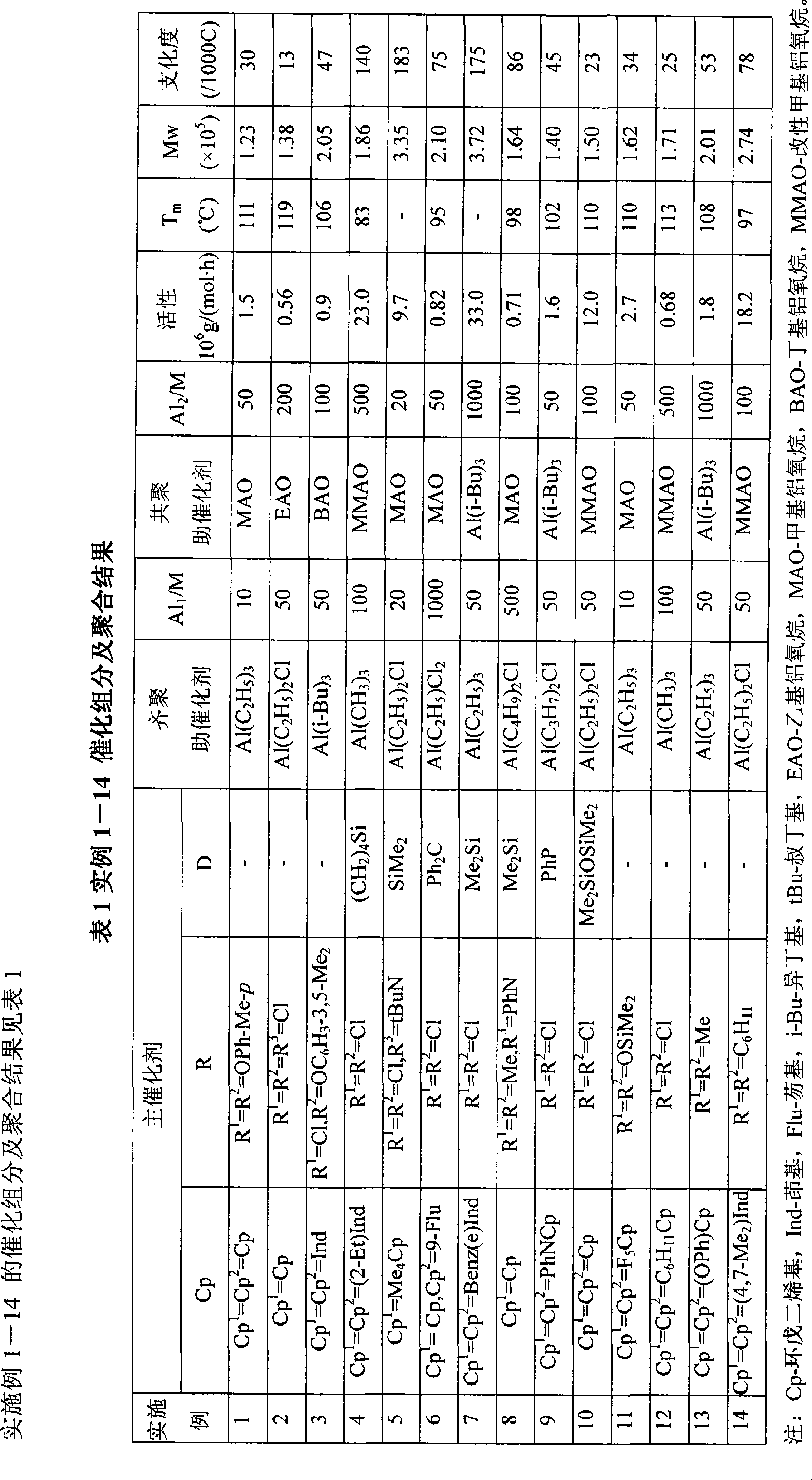

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

Solid support-polymethylaluminoxane complex, method for producing same, olefin polymerization catalyst, and method for producing polyolefin

ActiveUS20130059990A1High yieldHigh polymerization activityOrganic chemistry methodsOrganic-compounds/hydrides/coordination-complexes catalystsPolyolefinOlefin polymerization

Disclosed is a solid support-polymethylaluminoxane complex exhibiting a higher polymerization activity than a conventional substance and being homogeneous. Also disclosed is a method for producing an olefin-based polymer having a favorable quality using the complex and a transition metal compound. The complex comprises a coating layer containing polymethylaluminoxane and trimethylaluminum on the surface of a solid support. The coating layer comprises a solid polymethylaluminoxane composition in which (i) the content of aluminum is in a range of 36 to 41 mass % and (ii) the molar fraction of methyl groups derived from a trimethylaluminum moiety to the total number of moles of methyl groups is 12 mol % or less. Also disclosed is an olefin polymerization catalyst comprising the complex and a transition metal compound represented by general formula (III): MR5R6R7R8 as catalyst components, and a method for producing a polyolefin comprising polymerizing an olefin using the catalyst.

Owner:TOSOH FINECHEM CORP

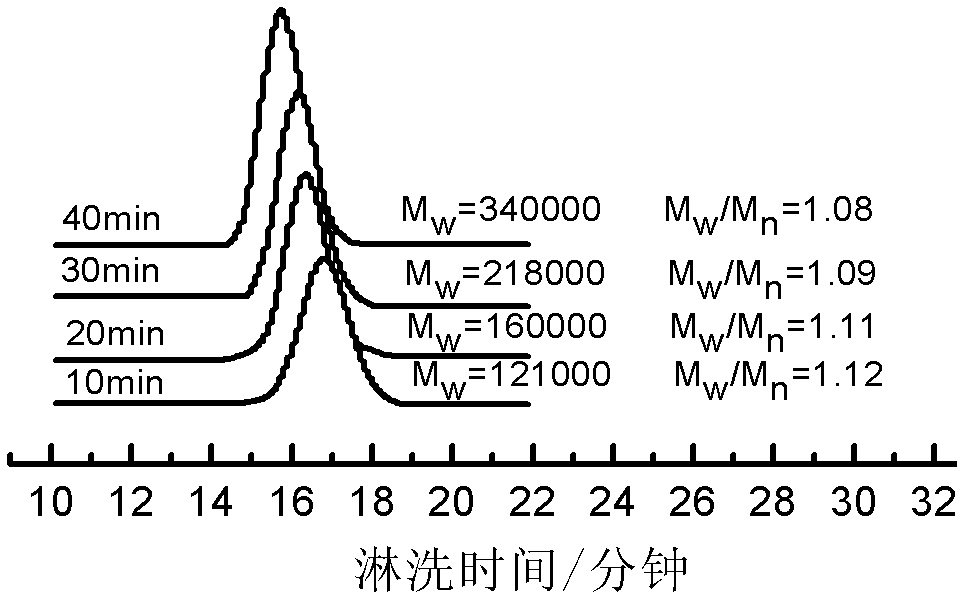

Polymerization method for catalyzing olefin by nickel-diimine catalytic system

The invention provides a polymerization method for catalyzing olefin by a nickel-diimine catalytic system. The system takes[(2,6-i-PrPh)2DABAn]NiBr2 as a main catalyst, methylaluminoxane as an auxiliary catalyst, and C6-C8 chain type saturated hydrocarbon as a solvent to catalyze a homopolymerization reaction of ethylene, propylene and C6-C18 alpha-olefin, or to catalyze a copolymerization reaction of ethylene and C6-C18 alpha-olefin, or to catalyze a copolymerization reaction of propylene and C6-C18 alpha-olefin, wherein the Ai / Ni molar ratio is equal to or less than 1000, and the reaction is carried out at -15-60 DEG C for 30-120 minutes. By adopting the catalyst system, the homopolymerization or the copolymerization of the olefin can be achieved within the polymerization temperature range of -15-60 DEG C, simultaneously, high catalysis efficiency can be kept, and living polymerization can be achieved at -10 DEG C.

Owner:PETROCHINA CO LTD

Polymerization process using metallocene catalyst systems

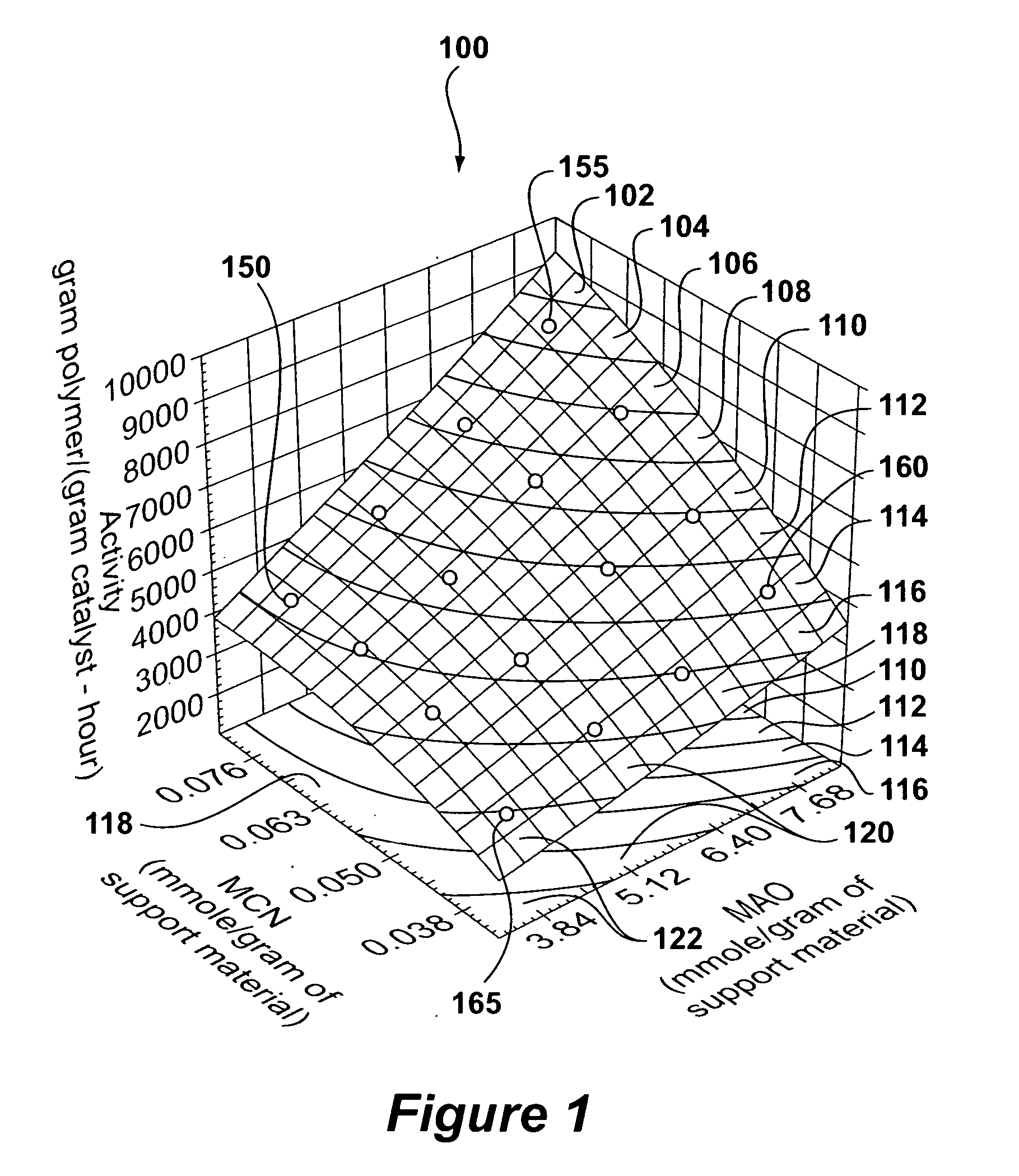

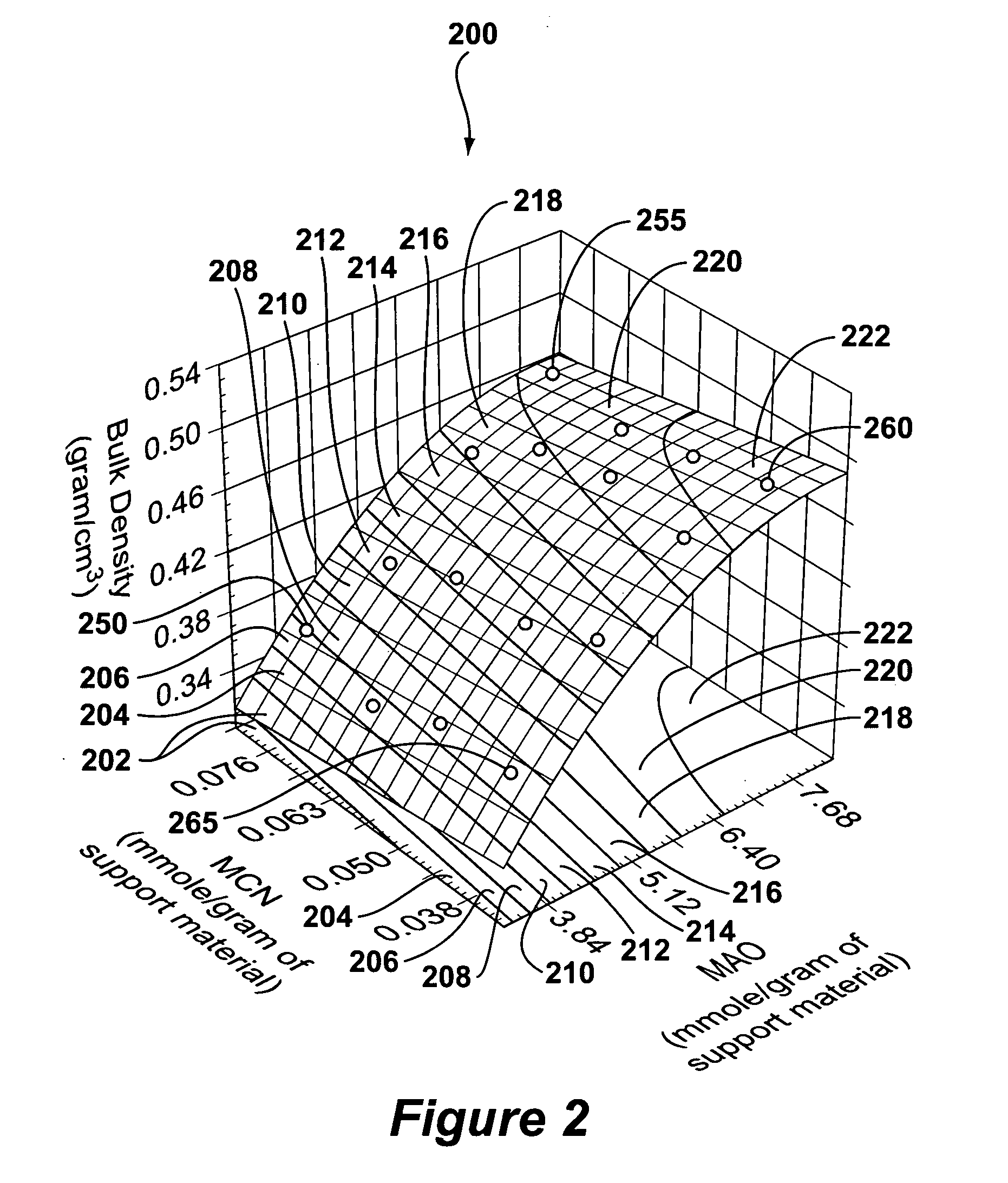

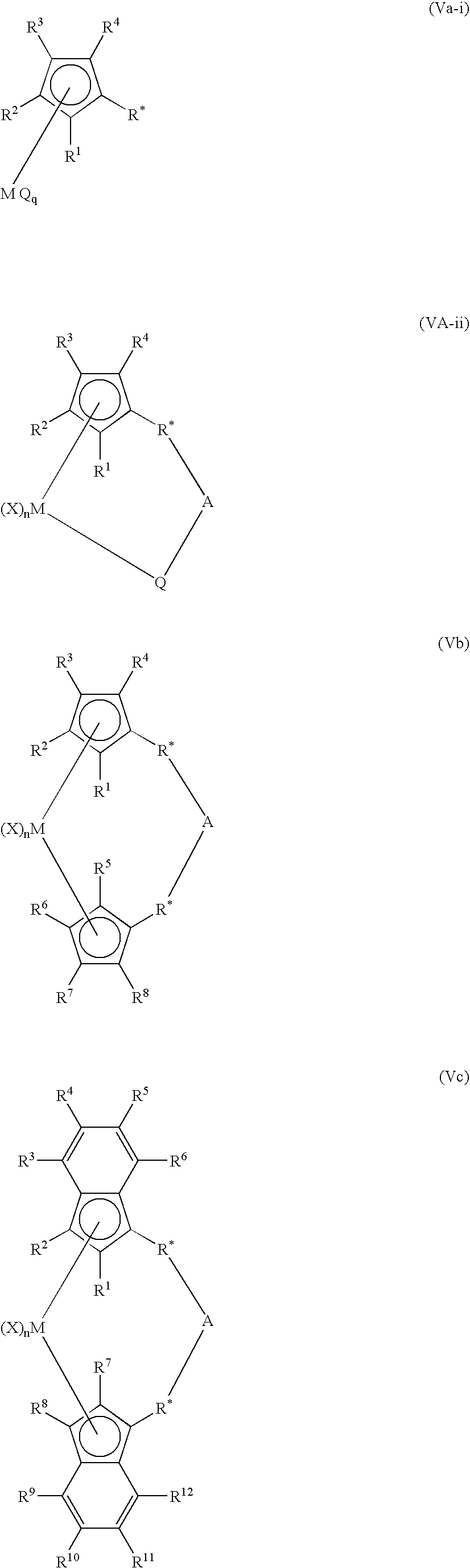

ActiveUS20050124487A1Optimized metal loadingOptimized activator concentrationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationProduction rateAluminoxane

The present invention relates to a polymerization process using improved metallocene catalyst systems. Specifically, the catalyst systems of the present invention relate to a metallocene compound having optimized metals loading and activator concentration, and demonstrate improved operability and productivity. In an exemplary embodiment, the improved metallocene catalyst system of the present invention comprises a metallocene catalyst compound activated by methylaluminoxane, and a support material, the methylaluminoxane being present in the range of from 3 to 9 mmole methylaluminoxane per gram of support material, and the metallocene being present in the range of from 0.01 to 1.0 mmole metallocene per gram of support material.

Owner:UNIVATION TECH LLC

Ethylene oligomerization method

InactiveCN102206127ALow molar ratioMolar ratio (Al/M) decreasedHydrocarbonsHydrocarbon preparationPhenanthrolineChloride

The invention provides an ethylene oligomerization method. Chloride of Fe<2+>, Co<2+> and Ni<2+> with 2-imino-1, 10-phenanthroline coordinated is taken as a main catalyst, Triethylaluminium is taken as a cocatalyst for replacing a high-price methylaluminoxane and the like, and the mol ratio of aluminum in the cocatalyst of triethylaluminium to central metal in the main catalyst is more than 30 and less than 200 or more than 200 and less than 500, The amount of the cocatalyst is greatly reduced, therefore the cost of the ethene oligomerization reaction is greatly reduced, the invention has a broad industrialization prospect.

Owner:CHINA PETROLEUM & CHEM CORP

Rare-earth catalyst for diolefin polymerization and its prepn.

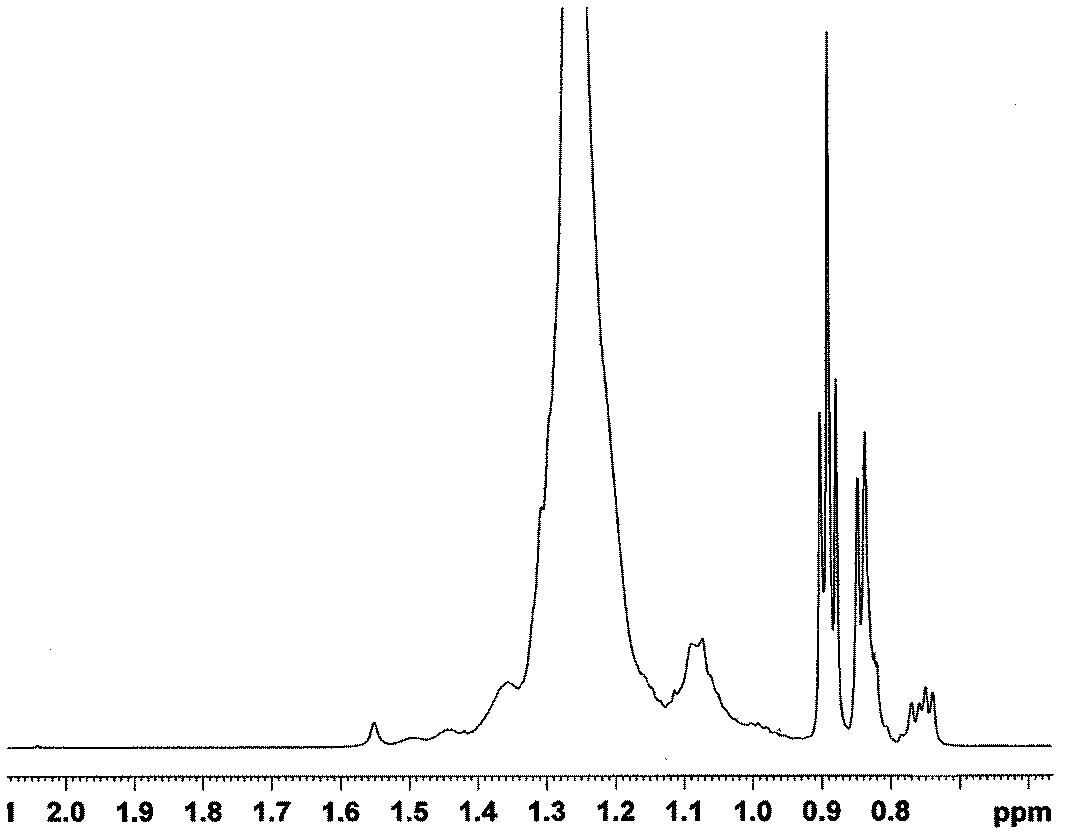

This invention is attributed to the rare earth catalyst for diene polymerization and its preparation method. The catalyst is composed of neodymium chloride electron donor complex and organic methylaluminoxane with a molar ratio of 1:20~200. Monomers can be also added, with a neodymium chloride electron donor complex / monomer molar ratio of 1:5~40. The preparation method is simple and the obtained rare earth catalyst has high catalytic activity. With this catalyst, polybutadiene with a cis-1, 4-butadiene content of over 95%, polyisopentadiene and butadiene / isopentadiene copolymer can be obtained and the polymers uniquely have narrow molecular weight distributions, i.e., the ratio of weight-average molecular weight to number-average molecular weight is not larger than 2.0.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Solid polymethylaluminoxane composition and method for manufacturing same

ActiveUS20110282017A1High yieldReduce solubilityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOlefin polymerizationMethyl group

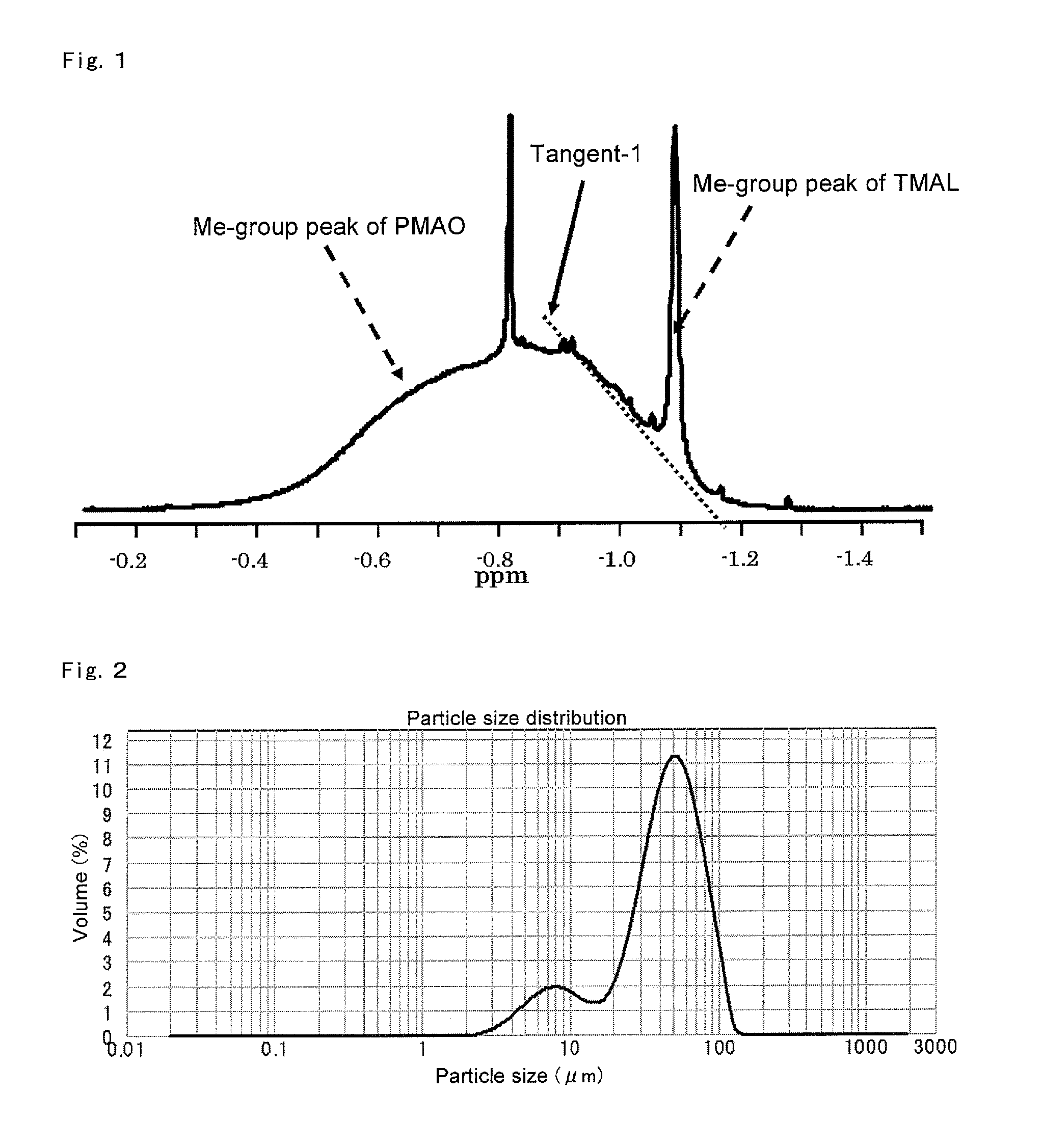

Disclosed are: a solid polymethylaluminoxane composition which does not utilize silica or the like, has the form of relatively fine particles, has more uniform particle sizes, and exhibits a high polymerization activity when used in the preparation of an olefin polymer; a process for producing the solid polymethylaluminoxane composition; a polymerization catalyst; and a process for producing an olefin polymer. Specifically disclosed are: a solid polymethylaluminoxane composition which has an aluminum content of 36 to 41 mass % and contains a methyl group derived from a trimethylaluminum moiety at a molar fraction of 12 mol % or less; a process for producing the solid polymethylaluminoxane composition, which comprises the step of heating an aromatic hydrocarbon solution containing polymethylaluminoxane and trimethylaluminum to cause the precipitation of the solid polymethylaluminoxane composition; a polymerization catalyst for an olefin, which comprises the solid polymethylaluminoxane composition and a transition metal compound as catalyst components; and a process for producing an olefin polymer by using the polymerization catalyst.

Owner:TOSOH FINECHEM CORP

Catalyst composition for ethylene oligomerization and the use thereof

ActiveUS7786336B2High activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon addition1-OcteneAluminoxane

The present invention relates to a catalyst composition for ethylene oligomerization and the use thereof. Such catalyst composition includes chromium compound, ligand containing P and N, activator and accelerator; wherein the chromium compound is selected from the group consisting of acetyl acetone chromium, THF-chromium chloride and Cr(2-ethylhecanoate)3; general formula of the ligand containing P and N is shown as:in which R1, R2, R3 and R4 are phenyl, benzyl, or naphthyl. R5 is isopropyl, butyl, cyclopropyl, cyclopentyl, cyclohexyl or fluorenyl; the activatior is methyl aluminoxane, ethyl aluminoxane, propyl aluminoxane and / or butyl aluminoxane; the accelerator is selected from the group consisting of 1,1,2,2,-tetrachloroethane, 1,1,2,2-tetrabromoethane, 1,1,2,2-tetrafluoroethane, and compounds having a formula of X1R6X2, in which X1 and X2 are F, Cl, Br, I or alkoxyl, R6 is alkylene or arylene group; the molar ratio of chromium compound, ligand containing P and N, activator and accelerator is 1:0.5˜10:50˜3000:0.5˜10. After mixing the four components mentioned previously under nitrogen atmosphere for 10 minutes, they are incorporated to the reactor, or these four components are incorporated directly into the reactor. Then ethylene is introduced for oligomerization. Such catalyst can be used in producing 1-octene through ethylene oligomerization. It is advantageous in high catalysing activity, high 1-octene selectivity, etc. The catalytic activity is more than 1.0×106 g product·ma−1 Cr·h−1, the fraction of C8 linear α-olefin is more than 70% by mass.

Owner:PETROCHINA CO LTD

Catalyst composition having improved comonomer reactivity

A process for producing an olefin polymer, which comprises contacting at least two olefin monomers under polymerization conditions with a catalyst composition comprising A) an aluminoxane-impregnated support prepared by contacting an aluminoxane with an inert carrier material and heating to a temperature of at least about 80 DEG C.; B) a metallocene of the formula: (L)y(L')MY(x-y-1) wherein M is a metal from groups IIIB to VIII of the Periodic Table; each L and L' is independently a cycloalkadienyl group bonded to M; each Y is independently hydrogen, an aryl, alkyl, alkenyl, alkylaryl, or arylalkyl radical having 1-20 carbon atoms, a hydrocarboxy radical having from 1-20 carbon atoms, a halogen, RCO2-, or R2N-, wherein R is a hydrocarbyl group containing 1 to about 20 carbon atoms; y is 0, 1, or 2; x is 1, 2, 3, or 4; and x-y> / =1; C) a bulky aluminum alkyl of the formula: AlR1xR2(3-x) wherein R1 is a hydrocarbyl group having 1 to 12 carbon atoms; x is an integer from 0 to 2; R2 is a hydrocarbyl group of the formula -(CH2)y- R3, wherein y is an integer from 1 to 8; and R3 is a saturated or unsaturated hydrocarbyl group having 3 to 12 carbon atoms containing at least one ring, and D) methylaluminoxane is provided. The catalyst composition may be used to prepare olefin polymers having increased short chain branching frequency.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Iron-based catalyst, preparation method of iron-based catalyst, and application of iron-based catalyst in isoprene polymerization

The invention relates to the technical field of conjugated diene catalytic polymerization, in particular to an iron-based catalyst; the iron-based catalyst comprises a main catalyst and an auxiliary catalyst; the main catalyst is pyridylimine iron complex, the auxiliary catalyst is methylaluminoxane, and a molar ratio of aluminum in the auxiliary catalyst to iron in the main catalyst is 500:1. Application of the iron-based catalyst in isoprene polymerization is also disclosed. The iron-based catalyst of the application has high activity in catalyzing isoprene, the obtained polymer has high molecular weight and narrow molecular weight distribution, the microscopic structure of the polymer may be controlled through cutting the main catalyst structure, the proportion of cis-1,4 structure in isoprene is adjustably in the range of 62.7% to 86.7%, the proportion of trans-1,4 structure is adjustably in the range of 2.8% to 8.2%, and the proportion of 3,4 structure is adjustably in the range of 6.7% to 34.5%. The iron-based catalyst is insensitive to reaction temperature.

Owner:QUFU NORMAL UNIV

Tetramerization

ActiveUS20100081777A1Sure easyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAluminoxaneOligomer

A new P—N—P ligand is useful in ethylene oligomerizations. In combination with i) a source of chromium and ii) an activator such as methylalumoxane; the ligand of this invention may be used to prepare an oligomer product that contains a mixture of hexenes and octenes. The hexenes and octenes produced with this ligand contain very low levels of internal olefins when produced under preferred reaction conditions.

Owner:NOVA CHEM (INT) SA

Preparation method and application of amido-imine nickel vinyl polymerization catalyst

ActiveCN102250152AThe synthesis method is simpleRaw materials are cheap and easy to getNickel organic compoundsAnilineBiological activation

The invention discloses a preparation method of an amido-imine nickel catalyst and application of the amido-imine nickel catalyst to catalyzing vinyl polymerization. The complex has the structures of a formula (I) and a formula (II) shown in the specification, wherein R1 is hydrogen or alkyl, R2 is hydrogen or alkyl, R3 is hydrogen or alkyl, R4 is hydrogen or alkyl, and X is halogen. The preparation method of the complex comprises the following steps of: carrying out condensation reaction on a diketone compound and phenylamine through ketoamine to obtain an diimine compound; then reacting with trimethyl aluminum, and hydrolyzing to obtain an amido-imine ligand; finally carrying out coordination reaction on the amido-imine ligand and (DME)NiX2 under the condition without water and oxygen to obtain a nickel complex. The complex disclosed by the invention has a specific ligand replacement structure and can be used for catalyzing the vinyl polymerization under the activation of modified methyl aluminium oxane or alkyl aluminum, showing the characteristics of living polymerization under specific conditions and obtaining the high-molecular-weight narrowly-distributed branched polyethylene.

Owner:SUN YAT SEN UNIV

Styrene/isoprene/butadiene tri-component random copolymer of rare-earth catalysis system and preparation method thereof

ActiveCN101914183AHigh cis structure contentNarrow molecular weight distributionAluminoxaneCarboxylic salt

Owner:DALIAN UNIV OF TECH

Modified (MAO + aluminum alkyl) activator

A cocatalyst system for olefin polymerization comprises an aluminoxane (especially methylaluminoxane, or “MAO”), an aluminum alkyl and a halogenated phenol. The preferred halogenated phenol is pentafluorophenol. The use of pentafluorophenol permits the substitution of a portion of the MAO cocatalyst (which is expensive) with inexpensive aluminum alkyl. The cocatalyst is most preferably employed in combination with an organometallic catalyst having at lease one pi ligand.

Owner:NOVA CHEM (INT) SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com