Patents

Literature

126 results about "Triethylaluminium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Triethylaluminium is an organoaluminium compound. It is actually a dimer, so despite its name, the formula for this compound is Al₂(C₂H₅)₆, shortened to Al₂Et₆ (Et, ethyl). This volatile, colorless liquid is highly pyrophoric, igniting immediately upon exposure to air. It is normally stored in stainless steel containers either as a pure liquid or as a solution in hydrocarbon solvents such as hexane, heptane, or toluene. Triethylaluminium is mainly used as a co-catalyst in the industrial production of polyethylene, polypropylene and for the production of medium chain alcohols.

Carry type non-metallocene calalyst for polymerization of olefine, its preparation method and uses

The invention discloses an equivoluminal dipping loading method of non-metallocene olefin polymeric catalyst as well as application of copolymerizing course within two or more different olefins, which comprises the following steps: dissolving non-metallocene olefin polymeric catalyst in the solvent; mixing solution and carrier; stirring wet solid material evenly; drying; obtaining the load-typed non-metallocene olefin polymeric catalyst; making the solvent and carrier satisfy specific relationship.

Owner:SINOPEC YANGZI PETROCHEM

Application of supported non-metallocene catalyst in ethene polymerization process by slurry method

The invention discloses an application of load non- metallocene catalyst in the slurry process for vinyl polymerying, the load non- metallocene catalyst and catalyst promoter forming the catalytic system, the alkene polymerization comprising: vinyl homopolymerization, combined polymerization of vinyl with propylene, butylenes, hexane, octane or norbornene; the catalyst carrier being chosen from: inorganic oxide of metallic oxide from IIA, IIIA, IVA, and IVB groups, or oxided mixture and mixing oxide; the catalyst promoter being chosen from: methylaluoxane, ethylaluoxane, isobutylaluoxane, trimethylaluminum,triethylaluminum,triisobutylaluminum,methylaluoxane-trimethylaluminum or methylaluoxane-triethylaluminum; the mole proportion between the catalyst promoter and catalyst being Al / Ti= 1:1-500. The inventioin is characterized by the less methylaluoxane consumption, stable reaction, easy-to-control polymerization temperature and non still-sticking phenomenon. The produced polyolefine possesses perfect granual shape, and the maximum polymer clamp density can reach 0.385 g / ml.

Owner:SINOPEC YANGZI PETROCHEM

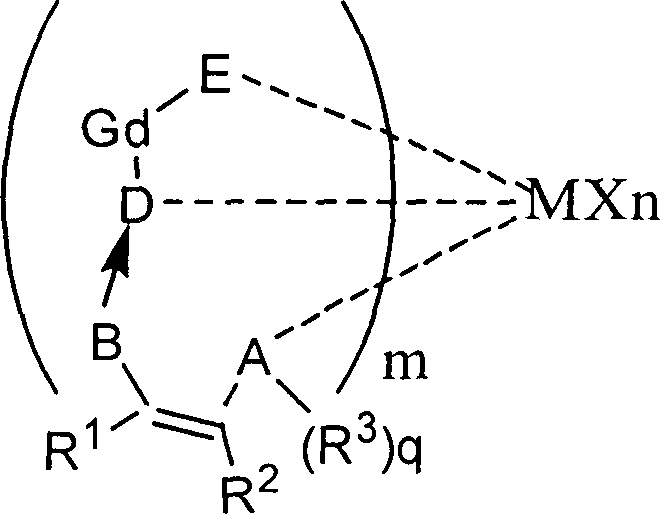

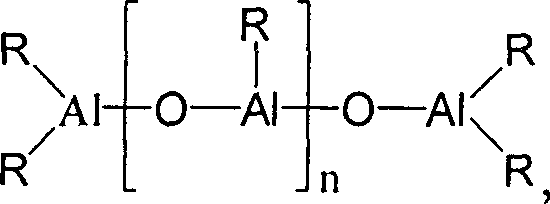

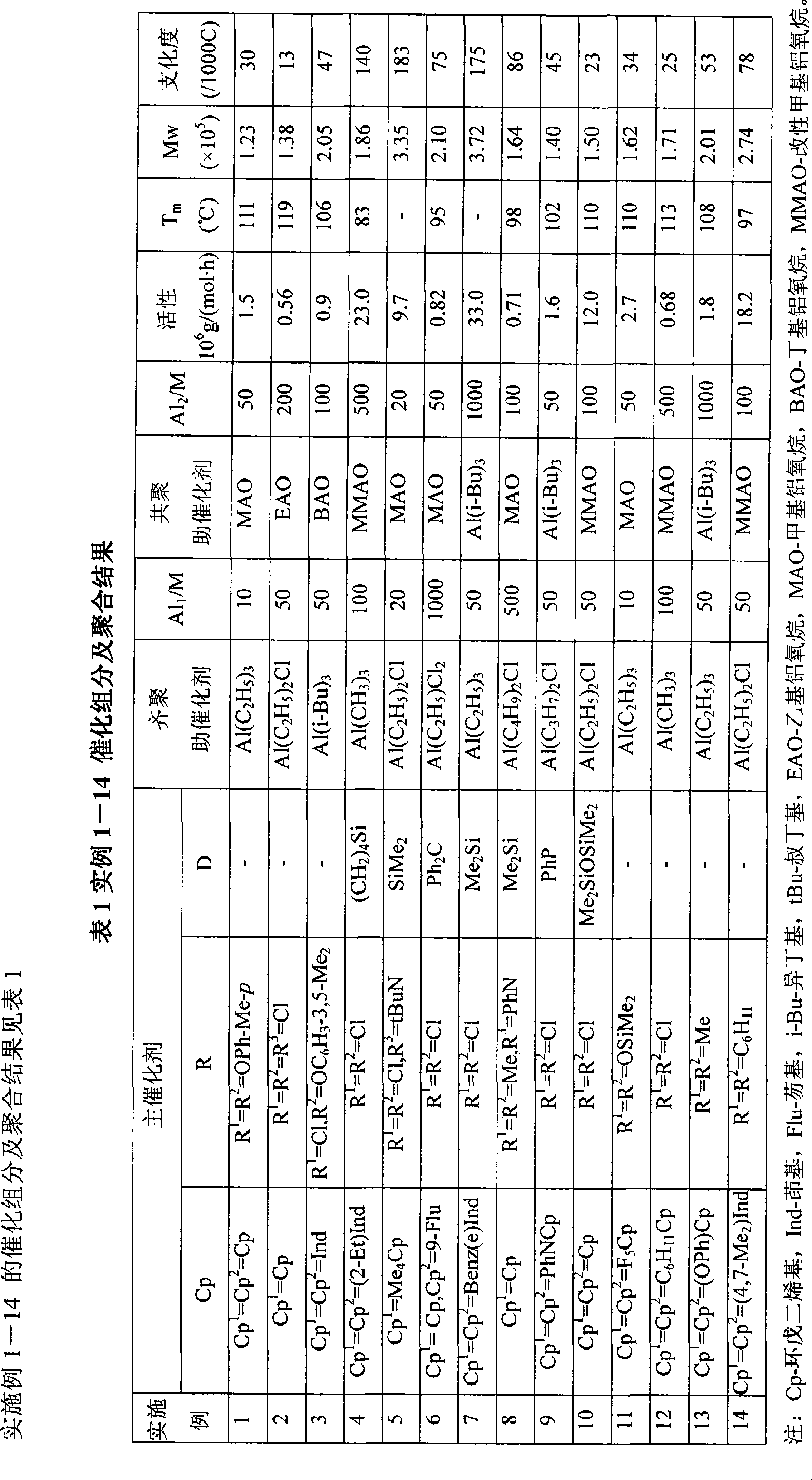

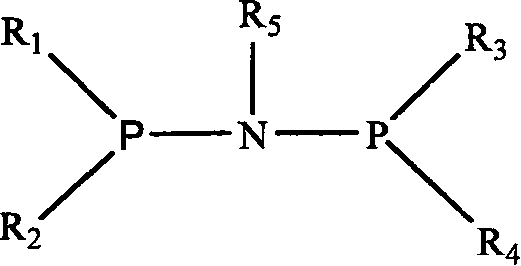

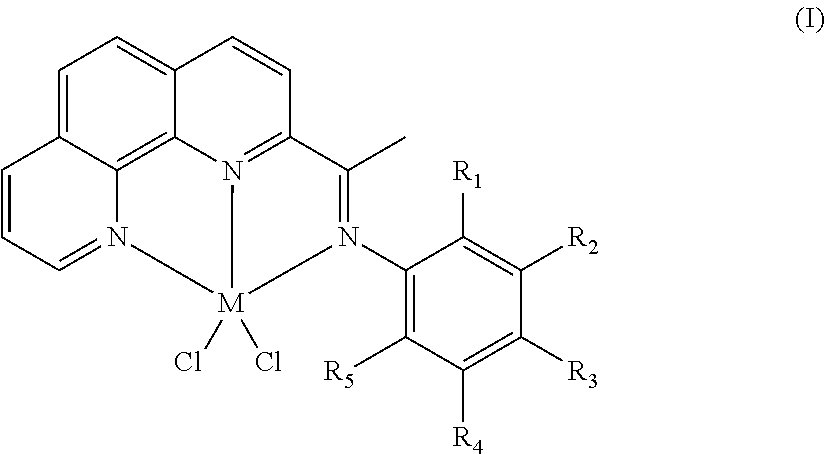

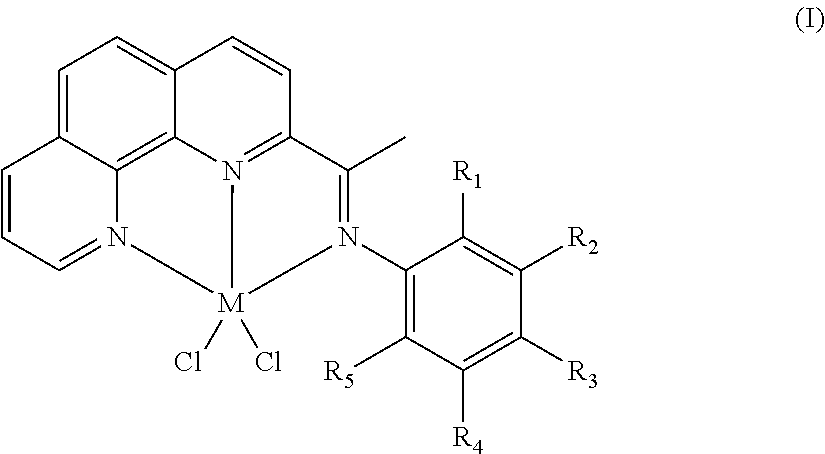

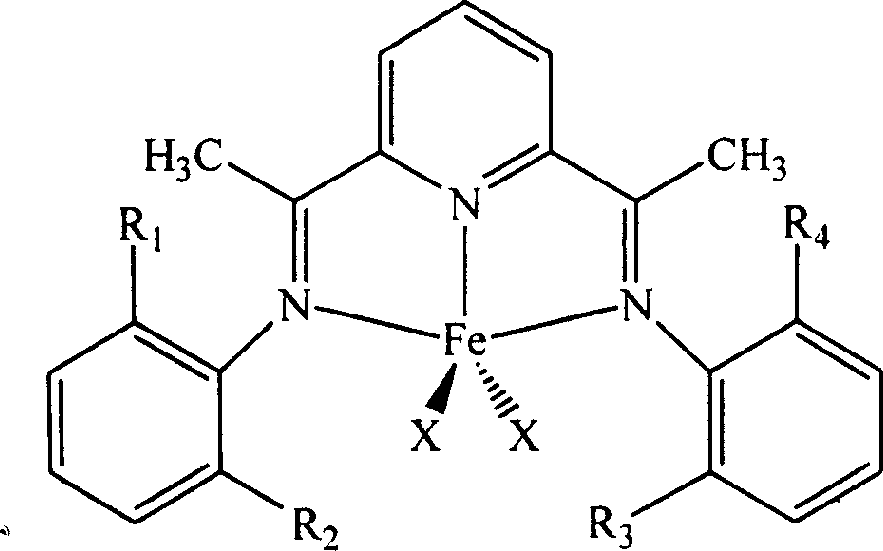

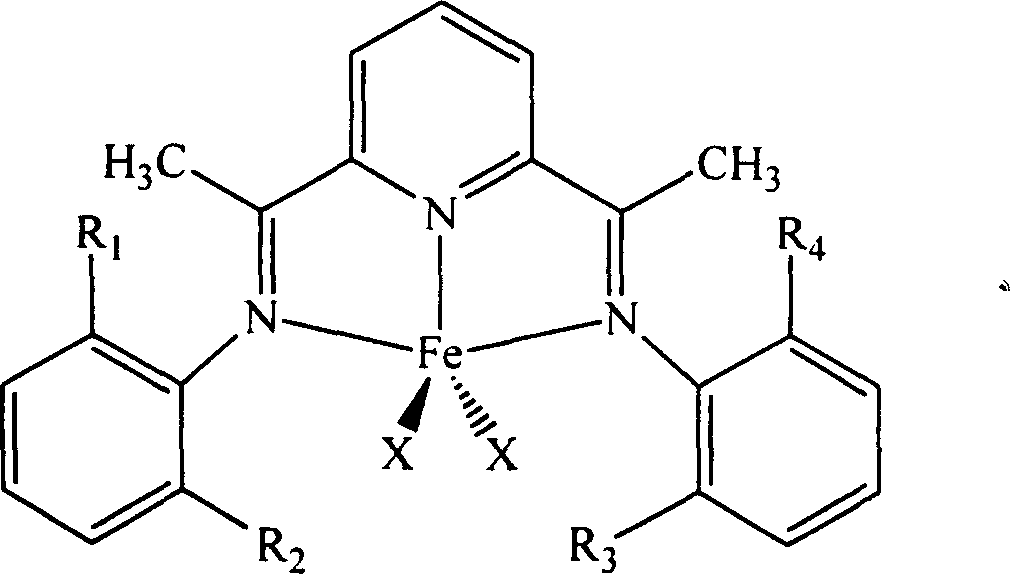

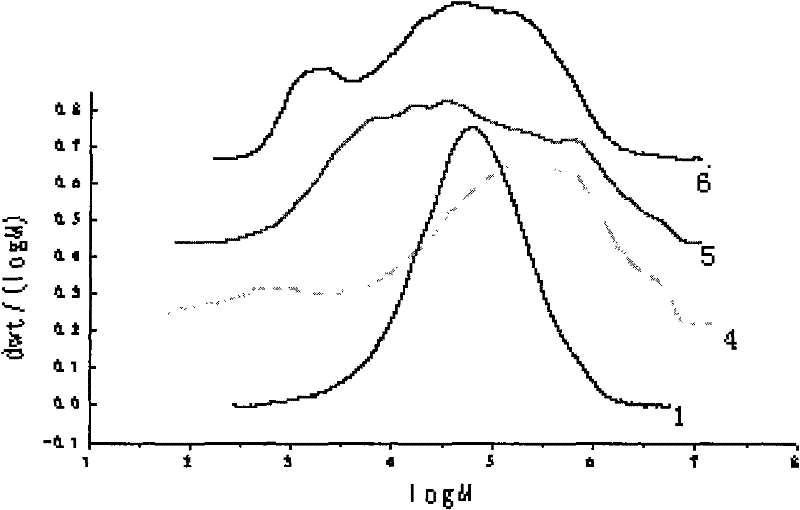

Metallocene domino catalytic system for preparing branched polyethylene using ethylene as only monomer and use thereof

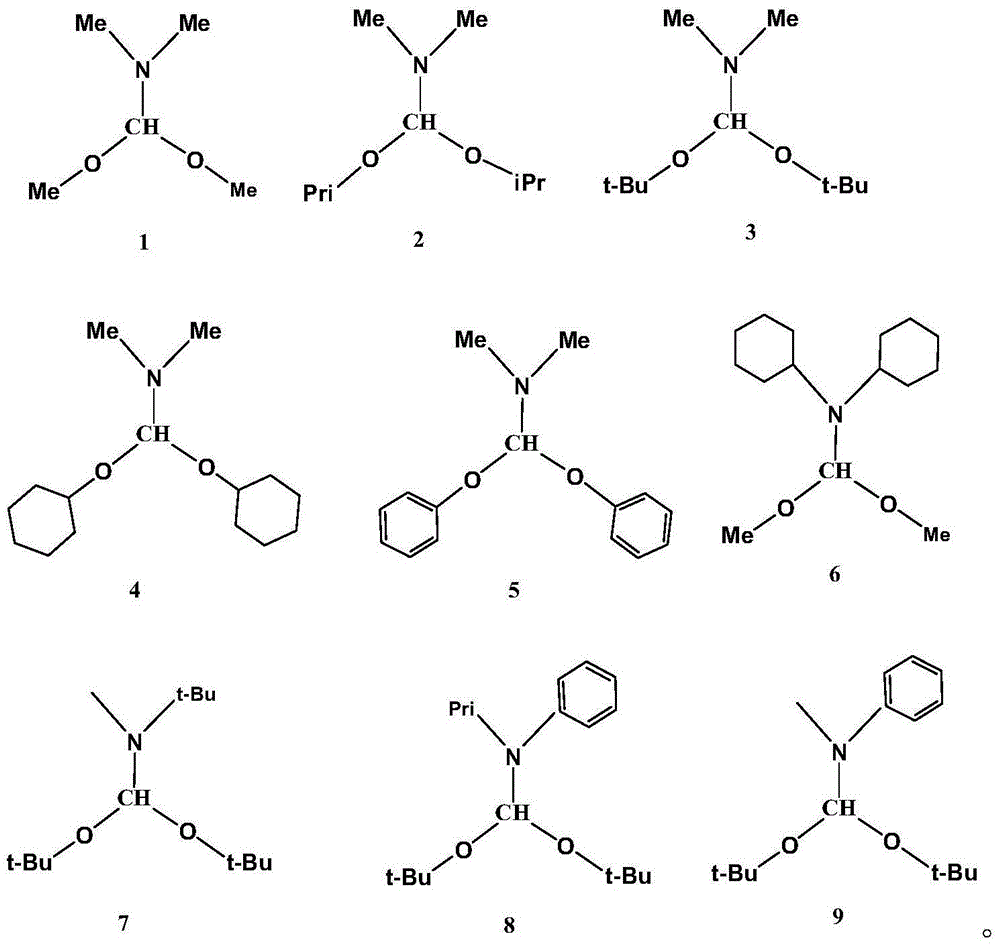

InactiveCN101392036ALower synthesis costAchieve the effect of molecular tailoringTriisobutylaluminiumStructural formula

The invention discloses a domino catalyzing system of a primary metallocene catalyst, which takes ethane as a sole monomer to prepare branched polyethylene, and the application thereof, which relates to vinyl copolymer. the catalyzing system is a compound catalyzing system consisting of the single primary metallocene catalyst and two different catalyst promoters, wherein, the primary catalyst is a metallocene catalyst with a structural formula of Cp<1>MR<1>R<2>R<3>, Cp<1>Cp<2>MR<1>R<2> or Cp<1>-D-Cp<2>MR<1>R<2>; alkyl aluminium acts as an oligomerization catalyst promoter; methylaluminoxane or triisobutyl aluminium or triethyl aluminum that is not used together with the oligomerization catalyst promoter acts as a copolymerization catalyst promoter; the mole ratio between the oligomerization catalyst promoter and the primary catalyst is 10-1000 to 1, and the mole ratio between the copolymerization catalyst promoter and the primary catalyst is 20-1000 to 1. The catalytic activity of the metallocene domino catalyzing system for preparing the branched polyethylene is 5 multiplied by 10<5> to 5 multiplied by 10<7>gPE / (molM per hour), the degree of branching is 10-200 / 1000C, the molecular weight of the branched polyethylene prepared under the effect of the catalyzing system ranges from 1 multiplied by 10<5> to 4 multiplied by 10<5> and the melting point is below 120 DEG C or even no melting point exists.

Owner:HEBEI UNIV OF TECH

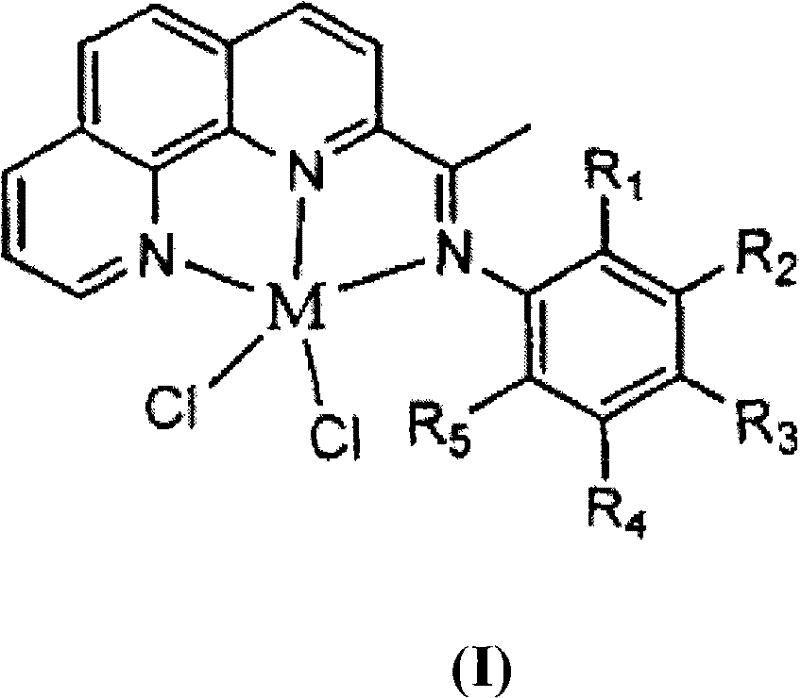

Ethylene oligomerization method

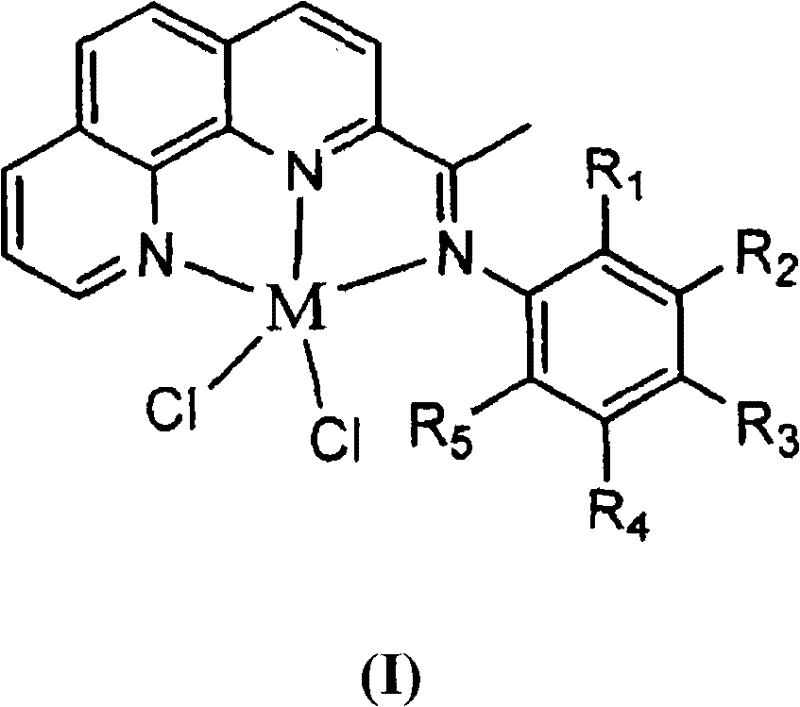

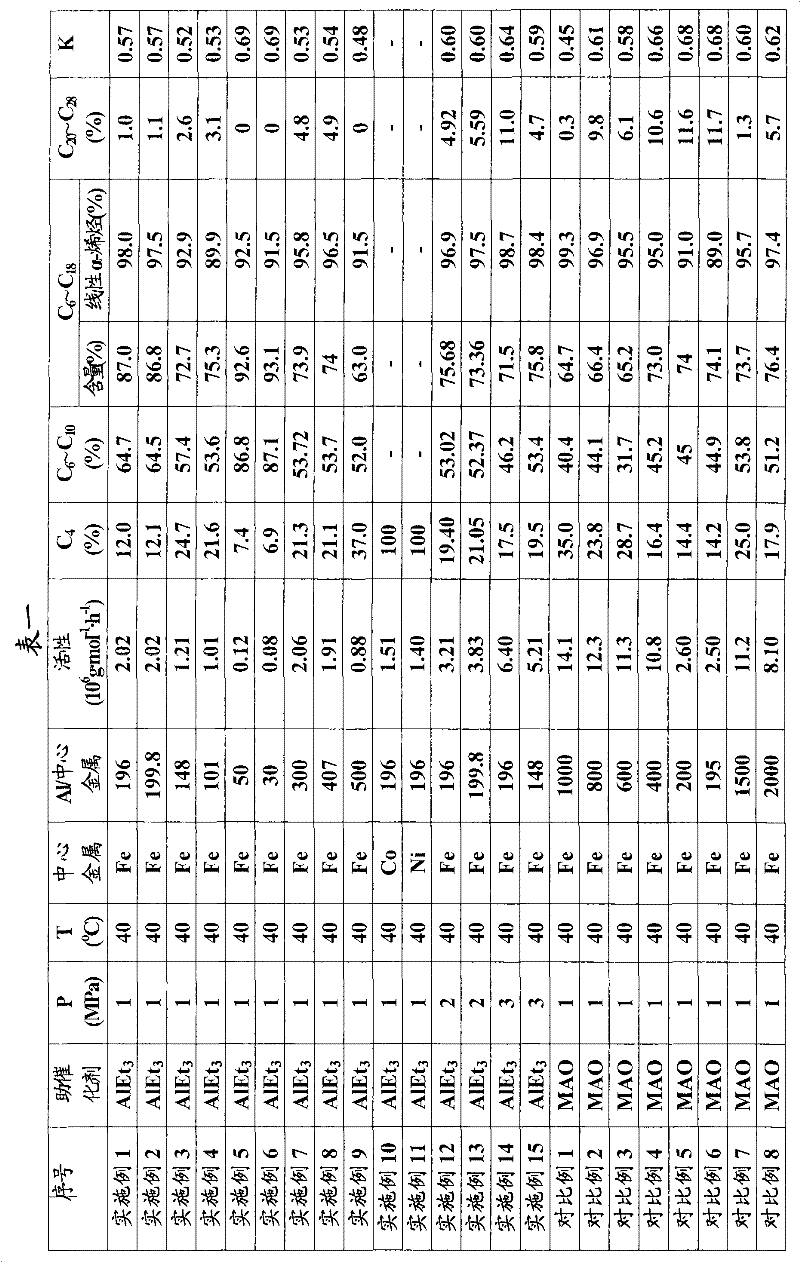

InactiveCN102206127ALow molar ratioMolar ratio (Al/M) decreasedHydrocarbonsHydrocarbon preparationPhenanthrolineChloride

The invention provides an ethylene oligomerization method. Chloride of Fe<2+>, Co<2+> and Ni<2+> with 2-imino-1, 10-phenanthroline coordinated is taken as a main catalyst, Triethylaluminium is taken as a cocatalyst for replacing a high-price methylaluminoxane and the like, and the mol ratio of aluminum in the cocatalyst of triethylaluminium to central metal in the main catalyst is more than 30 and less than 200 or more than 200 and less than 500, The amount of the cocatalyst is greatly reduced, therefore the cost of the ethene oligomerization reaction is greatly reduced, the invention has a broad industrialization prospect.

Owner:CHINA PETROLEUM & CHEM CORP

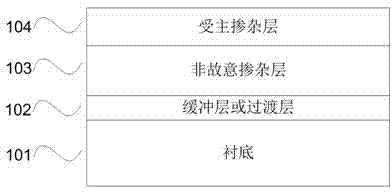

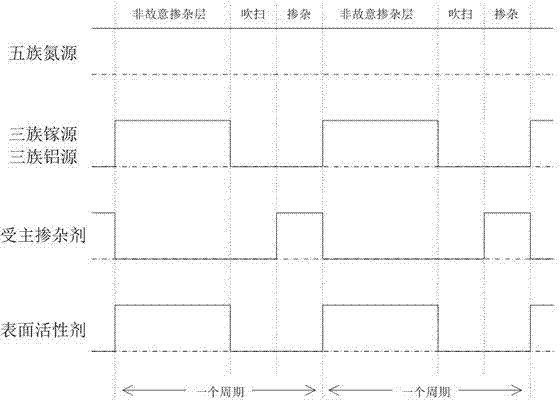

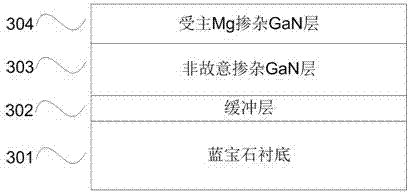

Preparation method of p type GaN and AlGaN semiconductor material

ActiveCN102903615AEasy to desorbImprove bindingSemiconductor/solid-state device manufacturingDimethylhydrazineSemiconductor materials

The invention discloses a preparation method of a p type GaN and AlGaN semiconductor material. A substrate, and a buffer layer or a transition layer, an unintended doped layer and an acceptor doped layer grown on the substrate from bottom to top are contained; in a growth process of the structure, ammonia or nitrogen dimethylhydrazine is used as a five-group nitrogen source; trimethyl gallium or TEGa used as a three-group gallium source, trimethylaluminium or triethyl aluminum used as a three-group aluminium source, and trimethylindium or TEIn used as a three-group indium source are collectively called three-group metal sources; and the trimethylindium or the TEIn is also used as a surface active agent and used in the acceptor doped layer. According to the method, the trimethylindium or the TEIn is used as the surface active agent to assist growth, and simultaneously, the acceptor doped layer is prepared by adopting a delta doping method. According to the method, the doping efficiency of acceptor doped magnesium atoms is increased, and simultaneously, the self-compensation effect is suppressed, so that the p type GaN and AlGaN semiconductor material with favorable crystalline quality and high hole concentration is obtained.

Owner:SUN YAT SEN UNIV

Catalyst of ethylene trimerization, and application

ActiveCN1872416AHigh activityGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsChromium(III) acetylacetonateTriisobutylaluminium

A catalyst for the self-polymerization of the ethene with three molecule to selectively generate 1-hexene is prepared from the Cr compound, the ligand containing P and / or N, aluminum alkylide, and promoter in the mole ratio of 1: (0.5-100): (50-5000): (0.5-100).

Owner:PETROCHINA CO LTD +1

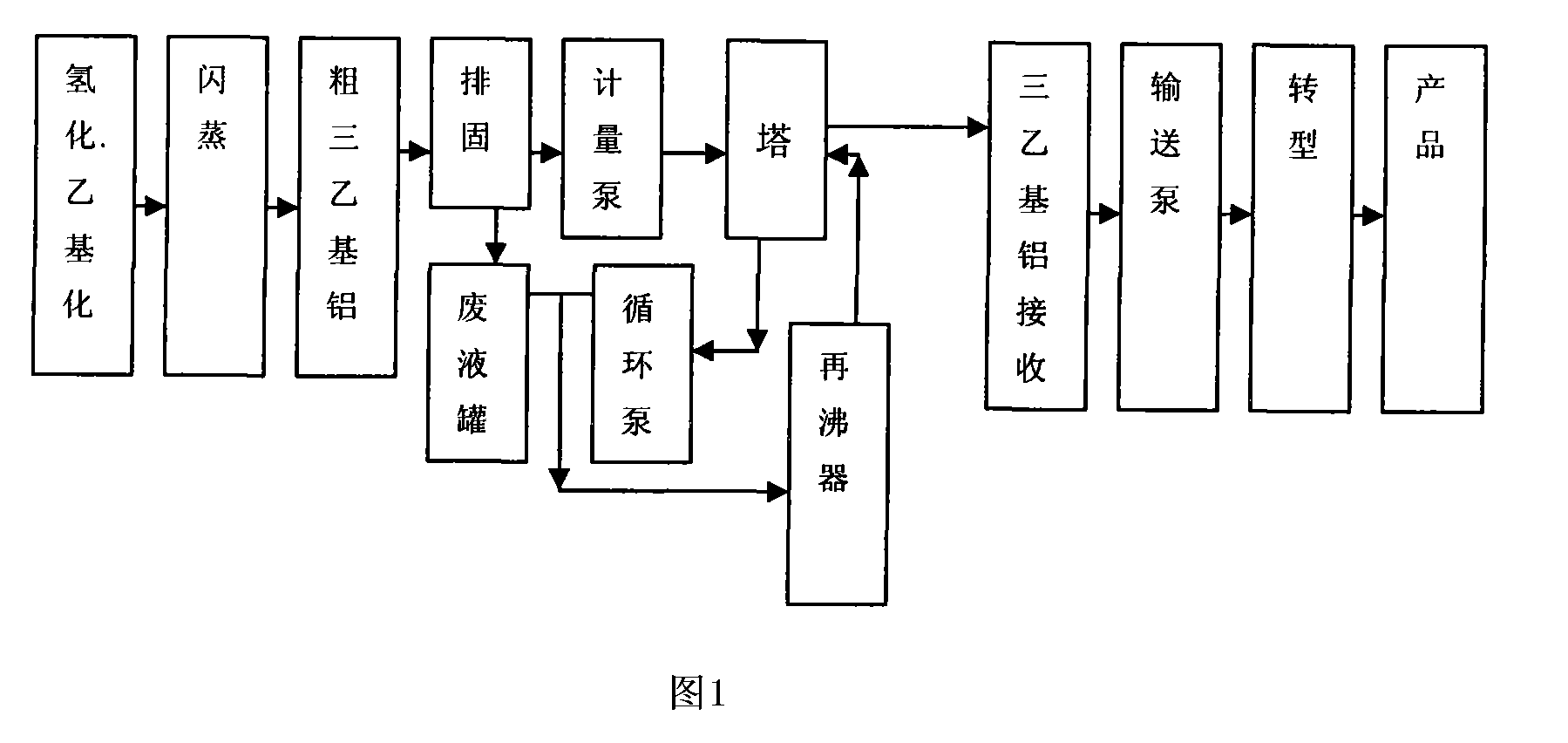

Technique for synthesizing triethylaluminum

InactiveCN101220049ALow hydrogenation pressureLow costGroup 3/13 element organic compoundsDistillationTitanium

The invention relates to a synthesizing process of aluminum triethide. The process contains the following procedures: continuous hydrogenation in a hydrogenation reactor for hydrogenation of titanium-containing aluminum powder for six to seven hours under the protection of inert gas and a pressure of 10-12MPa with aluminum triethide as the seed; continuous ethylene introduction under 0.5-3 pressure to acquire crude aluminum triethide after reaction completion within five to six hours; vaporizing distillation to separate impurities and ethylene transformation reaction to get aluminum triethide; dilution of residual impurity solution after distillation with hexane; hydrolization; and hexane recovery. The hydrogenation pressure of the invention is low, decreased from 28MPa to 10MPa. Adopting the body catalysis with aluminum triethide seed to disperse aluminum powder, the invention has simple process flow, All the equipment are localized. No pollution is caused. The cost is low while the yield is over 85-90 percent and the product quality is high.

Owner:王学力

Bulk ethylene oligomerization using a low concentration of chromium catalyst and three-part activator

InactiveUS20140142360A1Organic-compounds/hydrides/coordination-complexes catalystsCatalystsOligomerAluminoxane

This invention enables the “bulk” oligomerization of ethylene (i.e. the oligomerization of ethylene in the presence of the oligomer product) using a catalyst system comprising 1) a very low concentration of a chromium catalyst and 2) a three part activator. The chromium catalyst contains a diphosphine ligand, preferably a so called P—N—P ligand. The activator includes an aluminoxane, trimethyl aluminum, and triethyl aluminum.

Owner:NOVA CHEM (INT) SA

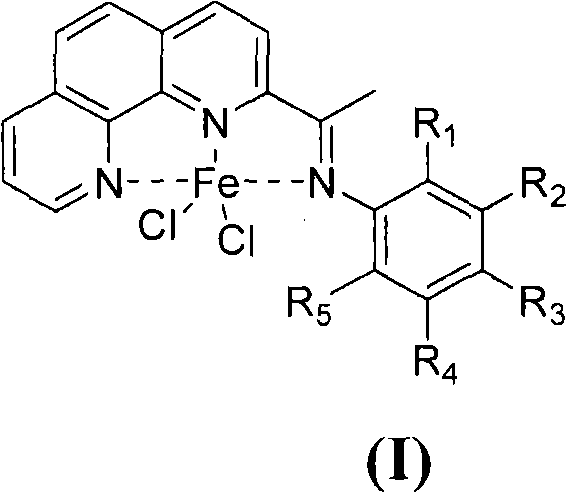

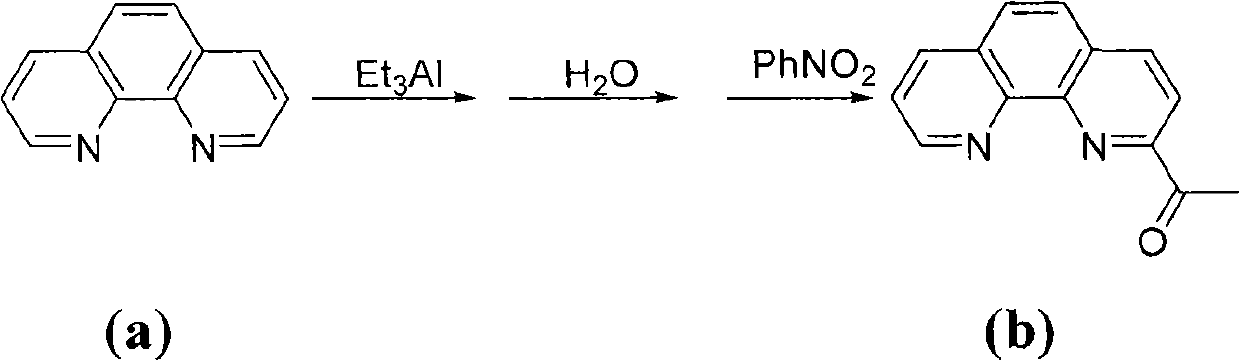

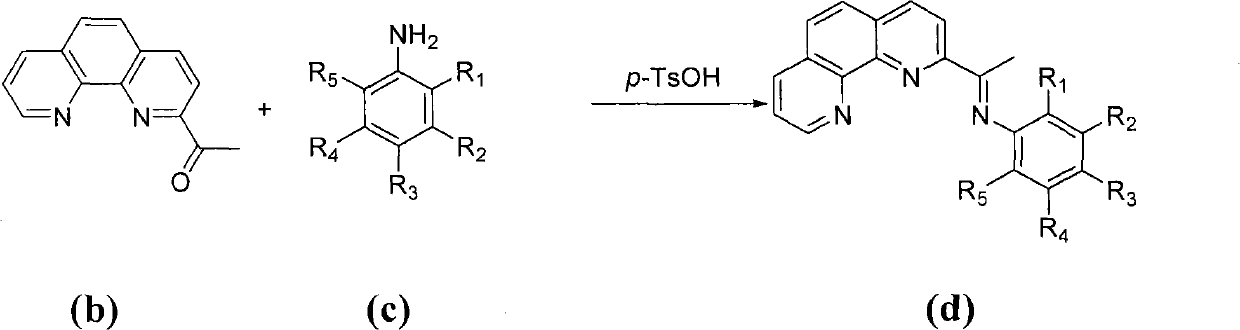

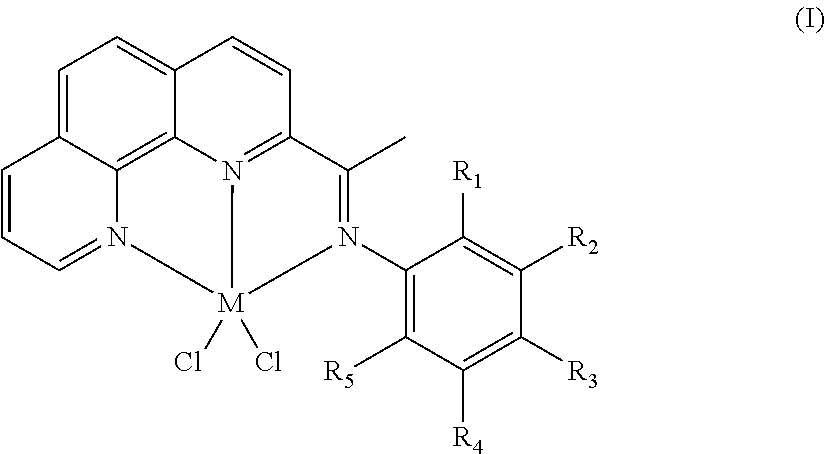

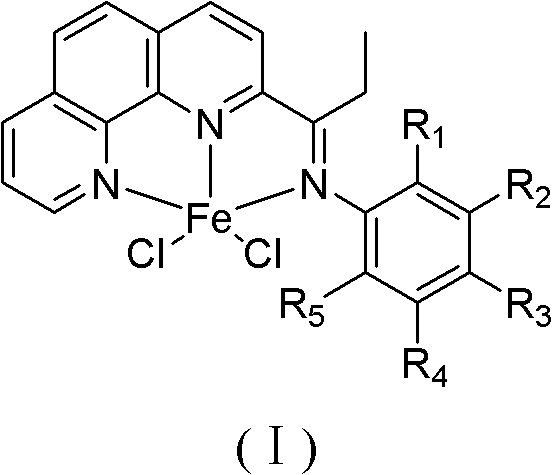

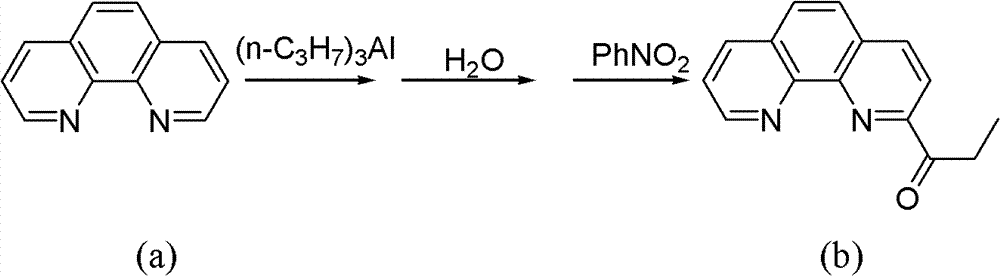

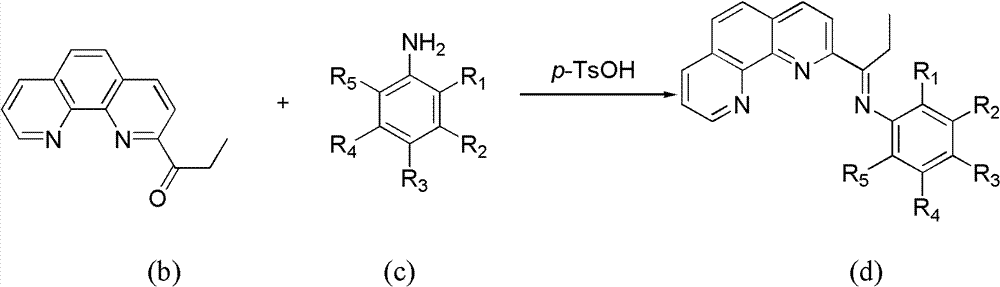

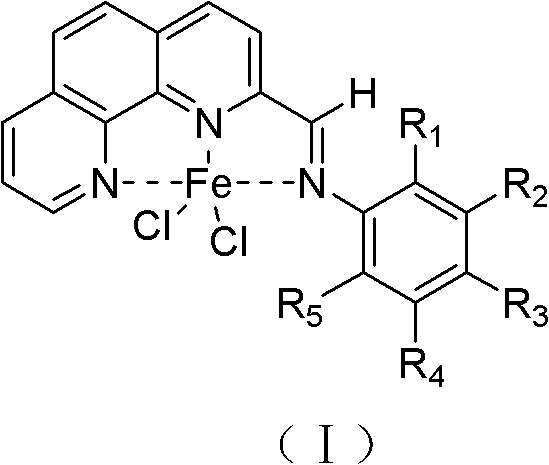

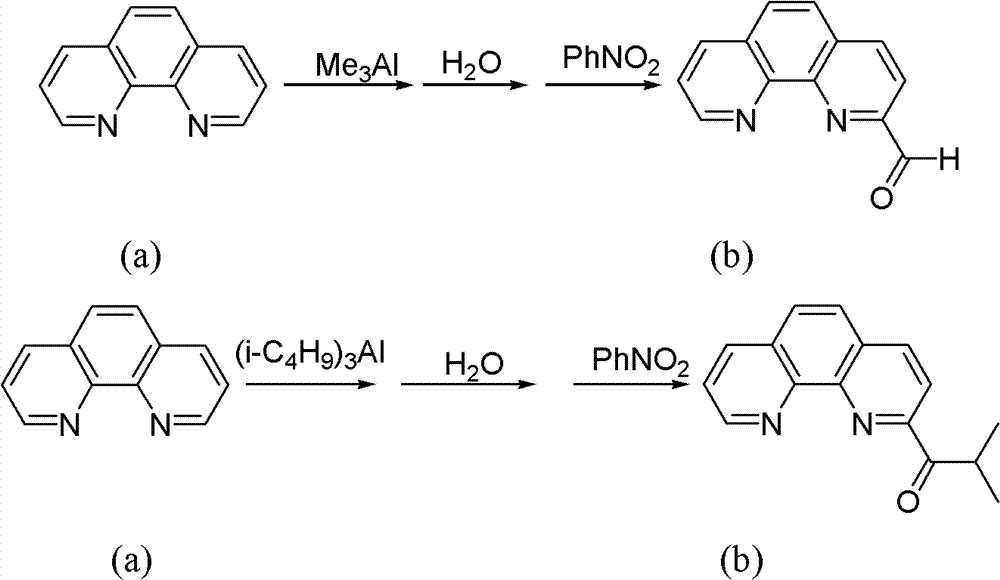

Preparation of acetyl-substituted-1,10-phenanthroline complex and application of prepared complex as catalyst

ActiveCN102485733AReduce manufacturing costLess varietyOrganic-compounds/hydrides/coordination-complexes catalystsIron organic compoundsPotassium cyanidePhenanthroline

The invention provides a method for preparing chlorinated-2-acetyl-1,10-phenanthroline amine iron (II) complex with the structural formula of formula (I) and an application of the obtained complex as an ethylene oligomerization catalyst, wherein variables in the formula (I) are defined in the specification. According to the method, triethyl aluminum which is adopted as an initial raw material in the process of the preparation of 2-acetyl-1,10-phenanthroline from 1,10-phenanthroline is hydrolyzed and undergoes an oxidation reaction with nitrobenzene to obtain 2-acetyl-1,10-phenanthroline, 2-acetyl-1,10-phenanthroline is condensed with substituted aniline to obtain a 2-acetyl-1,10-phenanthroline amine ligand, and the ligand is reacted with iron dichloride to obtain the complex. The synthetic method of the invention, which has the advantages of less step, simple technology, and catalyst preparation cost reduction, and adopts nontoxic triethyl aluminum to replace potassium cyanide used in routine preparation methods, has a wide industrialization prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

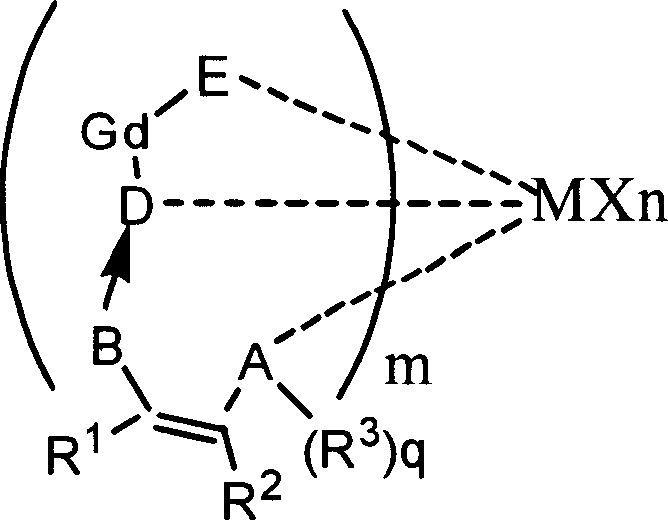

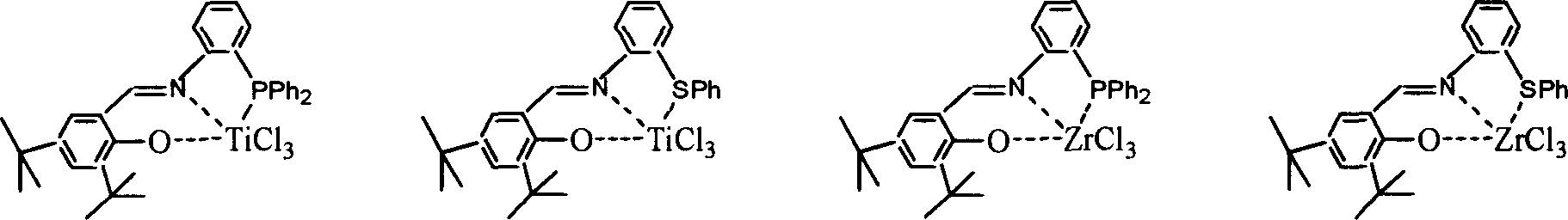

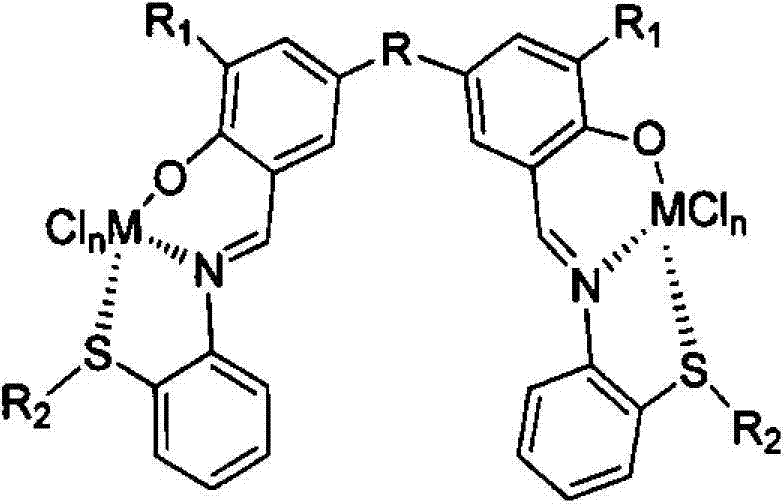

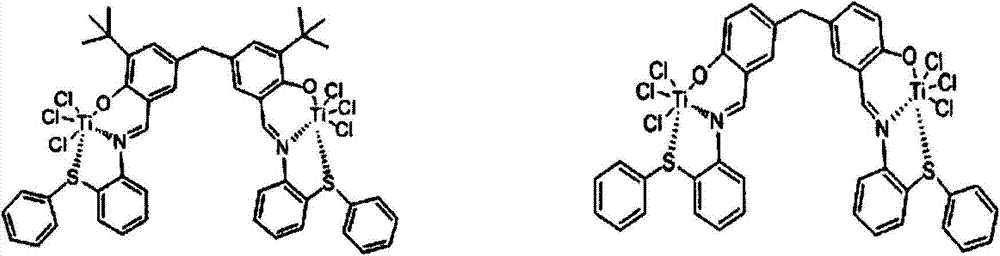

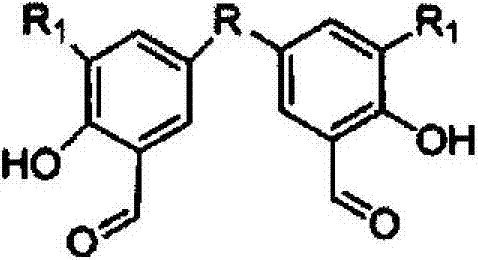

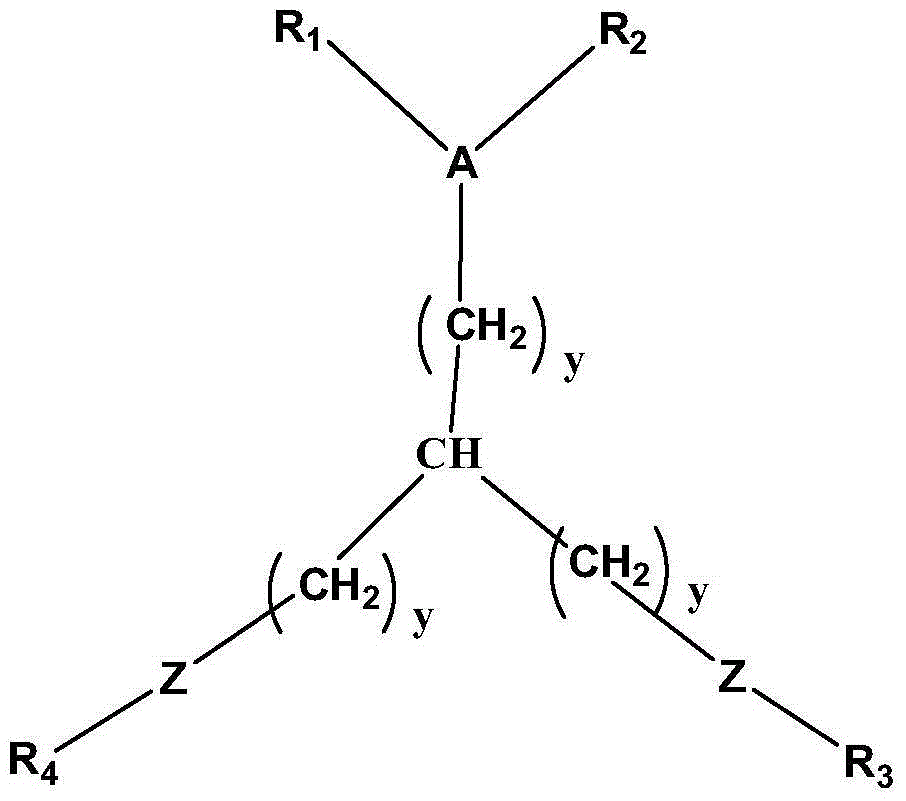

ONS (Organometallics) type salicylaldimine binuclear metallic alkene catalyst and preparation method thereof

The invention relates to an ONS (Organometallics) type salicylaldimine binuclear metallic alkene catalyst as well as a preparation method thereof and the application thereof. Under an effect of p-toluenesulfonic acid, bisalicylaldehyde or a bisalicylaldehyde derivative performs condensation reaction with amines containing sulfur atoms in an alcohol solution so as to obtain Schiff base; and the obtained Schiff base has complexing reaction with IVB group transition metal under water-free and oxygen-free conditions so as to obtain the ONS type salicylaldimine binuclear metallic alkene catalyst. Compared with a mononuclear metal alkene catalyst, the ONS type salicylaldimine binuclear metallic alkene catalyst provided by the invention has the advantages of higher catalytic activity and better thermal stability due to binuclear metallic synergistic effect during catalyzing ethylene homopolymerisation or ethylene and 1-hexene copolymerization. Under the pressure of a methylaluminoxane (MAO) or triethylaluminium assisted catalyst and 1 atm ethylene, the ethylene homopolymerisation is catalyzed and the activity can reach 1.6*10<6> gPE / molTi.h; and during catalyzing the ethylene and 1-hexene copolymerization, the activity reaches 3.8*10<5> gPE / molTi.h.

Owner:SHANGHAI RES INST OF CHEM IND

Catalyst composition for oligomerization of ethylene and processes of oligomerization

InactiveUS20130018214A1Low costReduce the amount requiredOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPhenanthrolineChloride

The present invention provides a catalyst composition for the ethylene oligomerization, which comprises 2-imino-1,10-phenanthroline coordinated iron (II), cobalt (II) or nickel (II) chloride as main catalyst and triethylaluminum as cocatalyst. The present invention also provides a process for oligomerization of ethylene is provided, wherein a catalyst composition comprising 2-imino-1,10-phenanthroline coordinated iron (II), cobalt (II) or nickel (II) chloride as main catalyst and triethylaluminum as cocatalyst is used, and the molar ratio of aluminum in the cocatalyst to central metal in the main catalyst ranges from 30 to less than 200. According to the present invention, another process for oligomerization of ethylene is also provided, wherein a catalyst composition comprising 2-imino-1,10-phenanthroline coordinated iron (II), cobalt (II) or nickel (II) chloride as main catalyst and triethylaluminum as cocatalyst is used, and the temperature of ethylene oligomerization ranges from −10 to 19° C. According to the present invention, the price of cocatalyst i.e. triethylaluminum, is low, just a fraction of that of methylaluminoxane, the amount of cocatalyst is therefore significantly reduced, with the catalytic activity is still acceptable, thus the cost of ethylene oligomerization is significantly reduced. In view of both the catalytic activity and the cost, the present invention is highly applicable in industry.

Owner:CHINA PETROCHEMICAL CORP +1

Adjustment method for molecular weight distribution of rare-earth isoprene rubber

The invention relates to an adjustment method for the molecular weight distribution of a rare-earth isoprene rubber; an isoprene monomer comprises 5-20g / 100mL of hexane in concentration; a ratio of the mole number of Nd of a rare-earth catalyst to the gram of the isoprene monomer is 1*10<-7>-1*10<-6>:1, wherein the rare-earth catalyst contains a component A, i.e. neodymium naphthenate or neodymium neodecanoic acid, a component B, i.e. one or a mixture of diethyl aluminium hydride and aluminium ethyl and a component C, i.e. one of aluminium diisobutyl monochloride or aluminium diethyl monochloride; the molar ratio of A to B to C is 1:5-20:1-5; different polymer molecular weight distribution indexes MW / MN in the range of 1.90-7.80 are obtained by respectively selecting feeding modes of (A+B)+C, (A+C)+B or (C+B)+A; and according to the adjustment method, the content of a cis-1,4 structure is larger than 96.5%, and the Moony viscosity is 80+ / -5 (ML+4100 DEG C).

Owner:PETROCHINA CO LTD

Polypropylene alloy and preparation method thereof

The present invention relates to one kind of polypropylene alloy and its preparation process. The polypropylene alloy is prepared with propylene monomer, Ti, Cl, Mg, diester or diether in certain weight proportion, and through bulk polymerization after adding supported spherical catalyst and composite co-catalyst at 40-80 deg.c and 1.0-4.0 MPa for 1-2hr; and further polymerization after adding monocyclopentadiene Ti or Zr homogeneous catalyst and composite co-catalyst for other 1-3 hr to obtain spherical granular product. The polypropylene alloy has high bending modulus and high impact strength.

Owner:PETROCHINA CO LTD

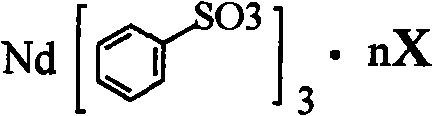

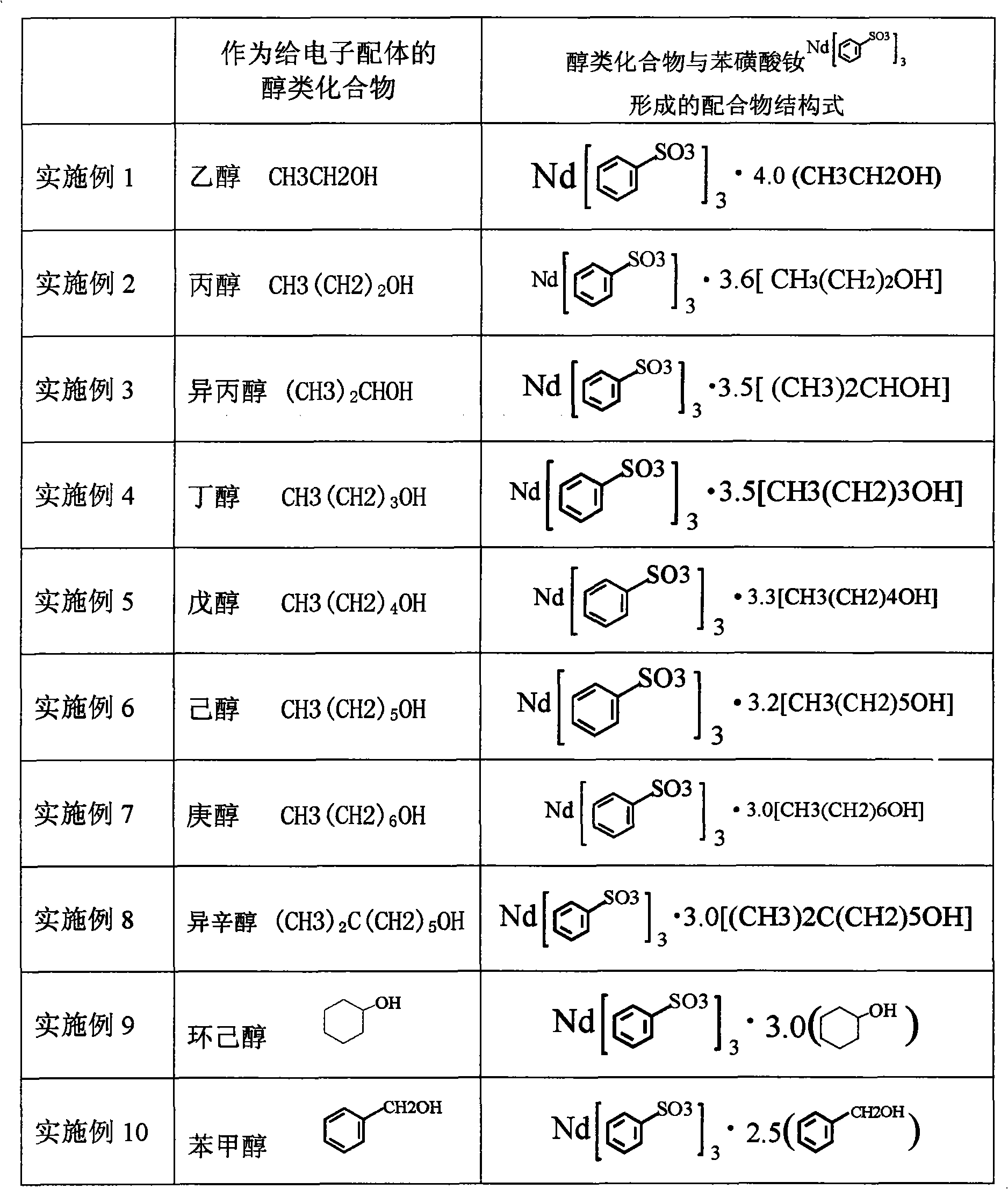

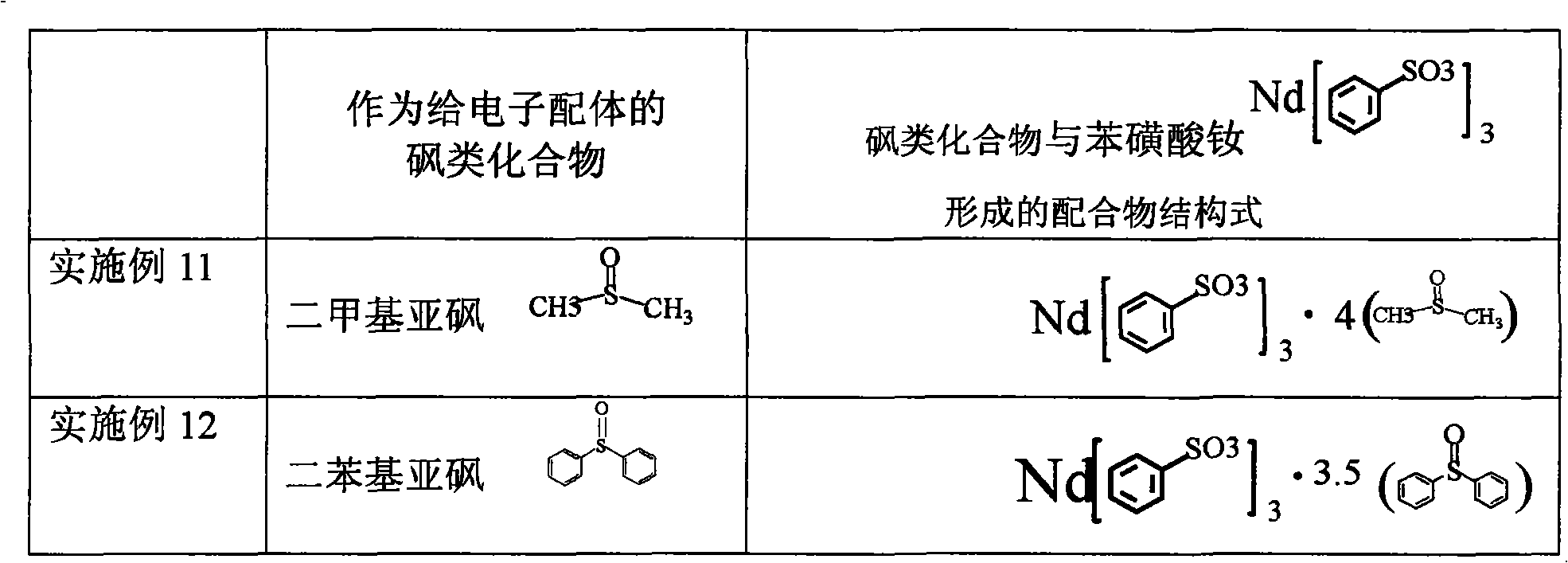

Sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and preparation method thereof

The invention relates to a sulfoacid rare earth catalyst for polymerizing high-cis-isoprene rubber and a preparation method thereof. The catalyst comprises benzenesulfonic acid neodymium rare earth complex and alkyl aluminum; the molar ratio of the alkyl aluminum to the rare earth neodymium in the benzenesulfonic acid neodymium rare earth complex is 15 to 40:1, wherein the benzenesulfonic acid neodymium rare earth complex comprises benzenesulfonic acid neodymium alcohol complex, benzenesulfonic acid neodymium sulphoxide complex, benzenesulfonic acid neodymium furan complex, benzenesulfonic acid neodymium amine complex, benzenesulfonic acid neodymium ether complex and benzenesulfonic acid neodymium ester complex; ligand comprises: alcohol compound, sulfoxide compound, furan compound, amine compound, ether compound and ester compound; and the alkyl aluminum comprises: 3-isobutyl aluminum, triethyl aluminum, diisobutyl aluminum hydride, or diethyl aluminum hydride. The sulfoacid rare earth complex catalyst is used for polymerizing isoprene, and can obtain the high-cis rare earth polyisoprene rubber with the cis 1,4 structure content more than 96.0 percent and the weight-average molecular weight more than 2.2 million.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Ethylene oligomerization catalyst composition containing 1, 10-phenanthroline amino-iron (II) complex substituted by propionyl

InactiveCN103008010AReduce dosageHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsPhenanthrolineEthyl group

The invention provides an ethylene oligomerization catalyst composition. The ethylene oligomerization catalyst composition comprises a main catalyst of a 1, 10-phenanthroline amino-iron (II) complex which is substituted by propionyl in a formula (I) and a catalyst promoter of triethyl aluminum, wherein the molar ratio of the metallic aluminium of the catalyst promoter to the central metallic aluminium of the main catalyst is between 30 and 900. According to the ethylene oligomerization catalyst composition, the triethyl aluminum which is used as the catalyst promoter is low in price and only accounts for a small percentage of the price of methylaluminoxane, and the usage of the catalyst promoter is greatly reduced, the catalyst has good catalytic activity of catalyzing ethylene oligomerization, so that the ethylene oligomerization reaction cost is greatly lowered; the selectivity of linear alpha-olefin in an oligomerization product is high; the oligomerization product is distributed reasonably; polyvinyl cannot be generated; and thus, the ethylene oligomerization catalyst composition has a wide industrial prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carried catalyzer for olefinic polymerization and preparation method

A carried metallocene catalyst or post-transition metal catalyst for the catalytic polymerization of ethylene and propylene contains Zr or Fe (0.05-1.00 wt. portions), aluminium alkylide chosen from trimethyl aluminium, triethyl aluminum and triisobutyl aluminum (1-50) and molecular sieve-like calcium silicon compound (100). Its preparing process is also disclosed. Its advantages are high catalytic activity and no adhesion to reactor.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Antibacterial formaldehyde-removing coating and preparation method thereof

InactiveCN110343460AImprove performanceImprove water resistanceAntifouling/underwater paintsPaints with biocidesPtru catalystAnti bacteria

The invention relates to the technical field of coatings, and provides an antibacterial formaldehyde-removing coating. The coating comprises the following raw materials: polyether polyol, polyisocyanate, an acrylate monomer, a first chain extender, a second chain extender, a neutralizer, a catalyst, an initiator, butanone, acetone, water, an emulsifier, an antibacterial agent, a silane coupling agent, a formaldehyde removal acting substance, activated bamboo charcoal powder and ethylene glycol. According to the invention, titanium trichloride and triethyl aluminum are used as catalysts, and asemi-interpenetrating network polymer is prepared by using complementary properties of polyurethane and polyacrylate, so that water resistance of a coating film is improved, and storage stability is good. A diatom purificant, the activated bamboo charcoal powder and the antibacterial agent are adopted as antibacterial and formaldehyde removal functional materials of the coating, so that the coating has a good antibacterial property and high formaldehyde removal capability.

Owner:HUNAN INSTITUTE OF ENGINEERING

Production method of lithium ion battery barrier membrane homo-polypropylene special material

ActiveCN103540020ASatisfied with the weightMeet needsCell component detailsBulk chemical productionPolymer sciencePtru catalyst

The invention discloses a production method of a lithium ion battery barrier membrane homo-polypropylene special material. According to the production method, a propylene polymerization catalyst with high activity and moderate hydrogen regulation sensitivity is used; a propylene polymerization activator is used as triethyl aluminium and the addition amount is controlled to be below 7.0L / hours; and an external electron donor is prepared from bicyclo-amyl dimethoxy silane and tetraethoxysilane in the molar rate of 1:1 and 1:8. In the pelleting workshop section of the special material, a stabilizing agent system consisting of main antioxygen, auxiliary antioxygen, disacidifying agent and the like is added; and a biaxially-oriented polypropylene (BOPP) membrane special material used for producing the lithium ion battery barrier membrane is finally produced, wherein the biaxially-oriented polypropylene (BOPP) membrane special material has the characteristics that the isotacticity is more than 98 percent, the melting flow rate (MFR) is controlled to be 2.8+ / -0.2g / 10min, the ash content is controlled to be 50-100ppm, the volatile matter is less than 100ppm, the oxidation induction time is more than 15min and the molecular weight distribution is controlled to be 7.0-10.0.

Owner:CHINA PETROLEUM & CHEM CORP

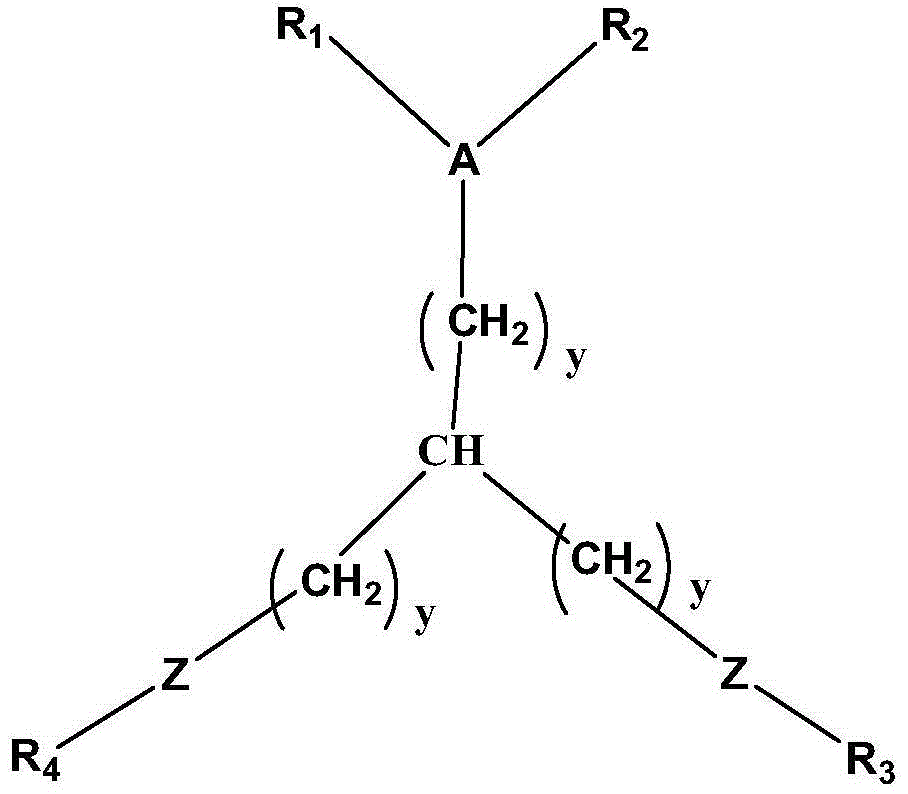

Main catalyst of olefin polymerization catalyst, preparation method thereof, and olefin polymerization catalyst

A main catalyst of an olefin polymerization catalyst comprises the following components: a magnesium compound carrier, transition metal halides, C2-C15 alcohols, and asteroid organic aza-ether compounds. The preparation method of the main catalyst comprises the following steps: (1) dispersing a magnesium compound carrier into an inert organic solvent, adding C2-C15 alcohols into the solvent, and stirring to dissolve the alcohols; (2) cooling the solution obtained in the step (1), and adding asteroid organic aza-ether compounds to carry out reactions; and (3) contacting the system obtained in the step (2) with transition metal halides at a temperature of -25 to 30 DEG C, after reactions, washing the reaction products by toluene or n-hexane, filtering to remove unreacted substances, and carrying out vacuum drying to obtain the main catalyst. An olefin polymerization catalyst comprises the abovementioned main catalyst and an auxiliary catalyst, which is one of trimethyl aluminum, triisobutyl aluminum, tri-n-hexyl aluminum, aluminum diethyl mono-chloride, and methyl aluminoxane (MAO).

Owner:PETROCHINA CO LTD

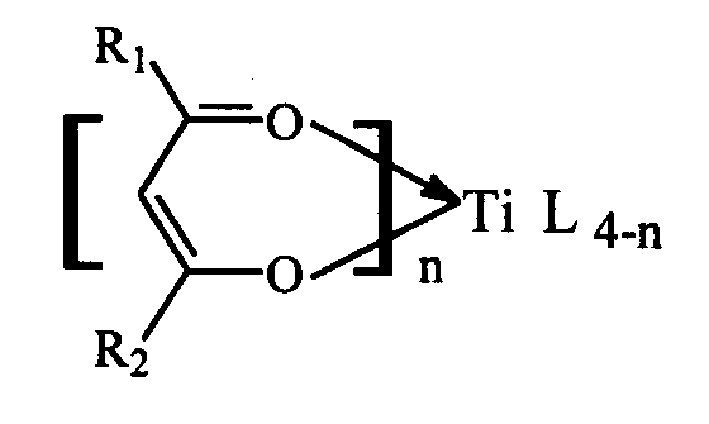

Technical method of preparing polynorbornene using beta diketone titanium non cyclopentadienyl catalyst

A process for preparing polynorbornene with non-cyclopentadiene beta-diketone titanium catalyst includes, adding beta-diketone titanium as primary catalyst, then adding norbornene monomer solution, further adding toluene or o-dichlorobenzene as solvent for dissolving the catalyst, then further adding methyl aloxyane, triethyl aluminium, or triisobutyl aluminium as secondary catalyst, and reaction at 0-90 deg.C. Its product has high-temp. resistance (more than 400 deg.C) and high-vitrification temp. (300-400 deg.C).

Owner:INST OF CHEM CHINESE ACAD OF SCI

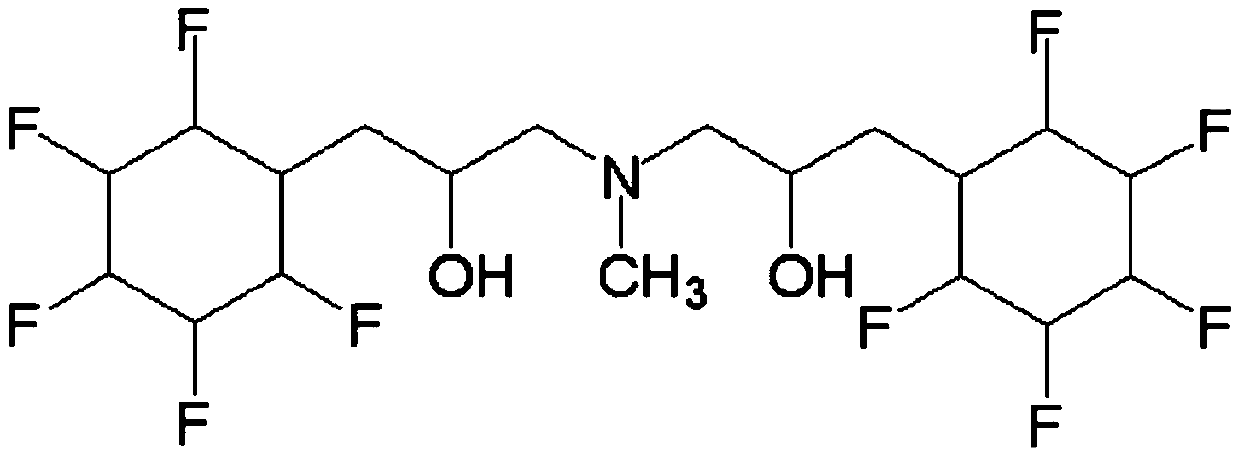

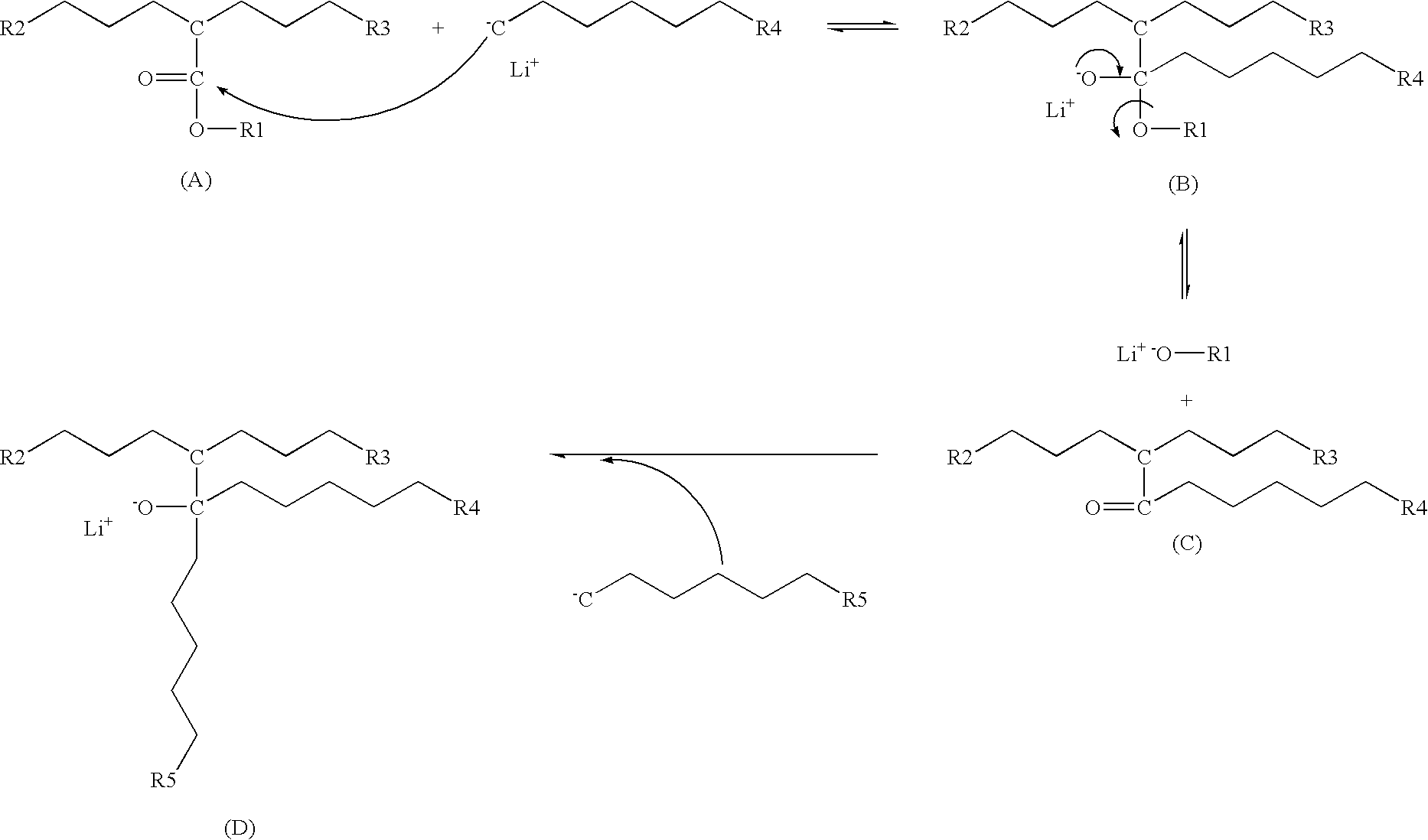

Radial multi-block copolymers

ActiveUS20090137704A1Avoid yellowingCoupling efficiency is improvedIn situ pavingsFilm/foil adhesivesCarbanionPolymer modified

A radial multi-block copolymer composition comprising a polystyrene block A1, a hard block A2 comprising another type of monovinylarene monomer, two soft blocks B, and B2 of conjugated diene monomer and a coupling agent, the composition of the radial multi-block copolymer having the structure (B1A1A2B2)nZ, where the weight percent of n=5+ is greater than about 40 and Z is a residue of the coupling agent. A process comprising (a) anionically polymerizing styrene monomer Al, at least one monovinylarene monomer A2 other than styrene, and at least one conjugated diene monomer B1 to form multi-block copolymer chains having the structure (B1A1A2), wherein the amount of monovinylarene monomer A2 is from about 0.5 wt % to about 80 wt % of the total amount to form a hard block A1A2; (b) anionically polymerizing at least one conjugated diene monomer to form copolymer chains having a soft block B2 and a polydienyllithium carbanion at the end of the copolymer chains; (c) adding a metal alkyl coupling promoter, preferably triethylaluminum, after initiating anionic polymerization and before reaching a peak reaction temperature; and (d) mixing in a coupling agent to form a copolymer having a residue (Z) of the coupling agent, wherein the copolymer is a radial multi-block copolymer having the structure (B1A1A2B2)nZ, and wherein the weight percent of n=5+ is greater than about 40. The radial multi-block copolymer has application in pressure-sensitive adhesives, engineering plastics, and polymer-modified asphalts with good control of viscosity and without yellowness.

Owner:DYNASOL ELASTOMEROS S A DE

Method for preparing wear-resistant sole

InactiveCN102504416ADoes not affect elasticityWithout compromising comfortSolesPolyvinyl alcoholPolystyrene

The invention discloses a method for preparing a wear-resistant sole, which comprises the following steps of weighing the following materials in weight parts: 70-78 parts of ethylene propylene diene rubber, 11-13 parts of carbon black, 5-7 parts of aluminum triethyl, 10-12 parts of p-nitrophenol, 10-12 parts of polystyrene, 30-35 parts of natural 3L rubber, 5-8 parts of polyvinyl alcohol and 11 parts of talcum powder; mixing the weighed raw materials together and then putting the materials into an internal mixer for banburying; pouring out the mixture after all the raw materials are evenly mixed when the temperature reaches 110-113 DEG C; then pelletizing the banburied mixture via a pelletizer to obtain granules, and then putting the granules into a water tank for cooling and then drying the granules under room temperature; finally injection molding the dried granules so as to obtain the sole. The sole prepared by the invention is greatly improved in wear resistance on the premise of not influencing the elasticity, comfort and other properties, and the sole has no toxic or polluting effects and also guarantees safety and environmental friendliness.

Owner:WUJIANG TIANYUAN PLASTIC

Catalyst containing load odd tianocene complexes and method for preparing polyethylene thereby

The invention discloses a catalyst containing and loading titanocene complex and a method of using the catalyst to prepare for polyethylene. The catalyst consists of a main catalyst and an assistant catalyst. The titanocene is loaded at a carrier of modified magnesium chloride to form the main catalyst; Et2AlCl is used as the assistant catalyst. A structural general formula of the titanocene complex is RTiL3. The carrier of modified magnesium chloride is magnesium chloride alcohol complex compound modified from triethylaluminum. The novel catalyst of the invention ensures that ethylene polymerization reaction can be processed when ordinary alkylaluminium is used as the assistant catalyst, which saves expensive MAO or boron polyfluoride compound and reduces the cost of the catalyst greatly; the catalyst has high catalytic activity, simple preparation and good stability, and at the same time the invention can obtain the polyethylene with the high molecular weight and the good form.

Owner:SUN YAT SEN UNIV

Synthesis of fused liquid crystal of chitosan grafted polylactic acid

The synthesis of fused liquid crystal of chitosan grafted polylactic acid includes vacuum deairing of chitosan for 1 hr, charging nitrogen, adding toluene as dispersant, dripping toluene solution of aluminium ethide as catalyst in 1-3 molar times of chitosan, ring opening polymerization of lactide inside solution to produce grafted copolymer of chitosan and polylactic acid. The grafted copolymer of the present invention has special performance, and may be used as interface coupling agent for polymer blend of chitin, chitosan and polylactic acid as well as medicine delayed releasing material and other human body implanting biological material. In addition, it has the performance of fused liquid crystal and thus may be produced into various biological material.

Owner:SHANGHAI JIAO TONG UNIV

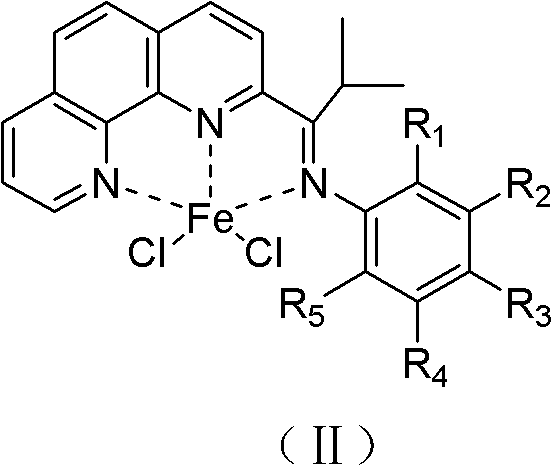

Ethylene oligomerization catalyst composition containing 1, 10-phenanthroline amino-iron (II) complex substituted by formyl or isobutyryl

ActiveCN103008011AReduce dosageHigh selectivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbonsEthyl groupPhenanthroline

The invention provides an ethylene oligomerization catalyst composition. The ethylene oligomerization catalyst composition comprises a main catalyst of a 1, 10-phenanthroline amino-iron (II) complex which is substituted by formyl in a formula (I) or a 1, 10-phenanthroline amino-iron (II) complex which is substituted by isobutyryl in a formula (II) and a catalyst promoter of triethyl aluminum, wherein the molar ratio of the metallic aluminium of the catalyst promoter to the central metallic aluminium of the main catalyst (I) is between 30 and 500, and the molar ratio of the metallic aluminium of the catalyst promoter to the central metallic aluminium of the main catalyst (II) is between 30 and 900. According to the ethylene oligomerization catalyst composition, the triethyl aluminum which is used as the catalyst promoter is low in price, and the usage of the catalyst promoter is greatly reduced, the catalyst has good catalytic activity of catalyzing ethylene oligomerization, so that the ethylene oligomerization reaction cost is greatly lowered; the selectivity of linear alpha-olefin in an oligomerization product is high; the oligomerization product is distributed reasonably; polyvinyl cannot be generated; and thus, the ethylene oligomerization catalyst composition has a wide industrial prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Prepn of dissolved liquid crystal of chitosan grafted polylactic acid

The preparation of dissolved liquid crystal of chitosan grafted polylactic acid includes vacuum deairing of chitosan for 1 hr, charging nitrogen, adding toluene as dispersant, dripping toluene solution of aluminium ethide as catalyst in 1-3 molar times of chitosan, ring opening polymerization of lactide inside solution to produce grafted copolymer of chitosan and polylactic acid. The copolymer is dissolved in trifluoro acetic acid, acetic acid, dichluoro acetic acid or water, and when the solution concentration is greater than 1%, the liquid crystal behavior may be observed in polarizing microscope. The grafted copolymer of the present invention has special performance, and may be used as interface coupling agent for polymer blend of chitin, chitosan and polylactic acid as well as medicine delayed releasing material and other human body implanting biological material and various biological fibrous material.

Owner:SHANGHAI JIAO TONG UNIV

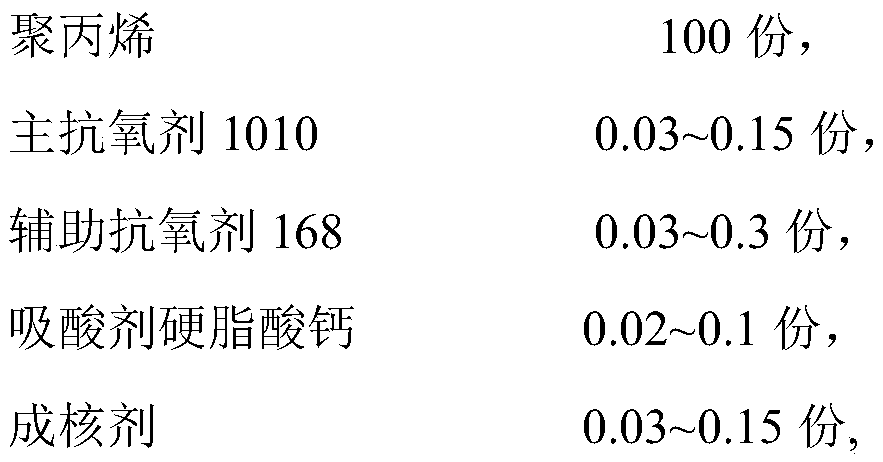

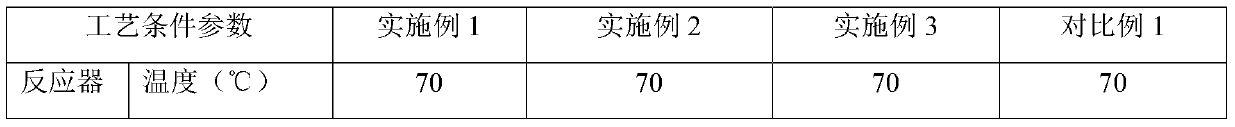

Transparent rigidity-and-toughness balanced thermoforming homo-polypropylene resin, and preparation method and application thereof

The invention discloses a transparent rigidity and toughness balanced thermoforming homo-polypropylene resin. The resin comprises polypropylene, a main antioxidant 1010, an auxiliary antioxidant 168,an acid acceptor calcium stearate and a nucleating agent. The invention also discloses a preparation method of the transparent rigidity and toughness balanced thermoforming homo-polypropylene resin. The method comprises the following steps: adding propylene and hydrogen into a Unipol gas phase fluidization reactor, carrying out a polymerization reaction in the presence of a main catalyst SHACTM 201, a cocatalyst triethyl aluminum and an external electron donor n-propyltrimethoxysilane, and adjusting the content of xylene-soluble substances in the obtained powder to obtain a polypropylene powder; and adding the main antioxidant 1010, the auxiliary antioxidant 168, the acid acceptor calcium stearate and the nucleating agent, performing mixing, and carrying out double-screw melt extrusion andgranulation to obtain the resin. The resin prepared in the invention has the advantages of excellent transparency, well balanced modulus and impact strength, specific content range of xylene-solublematters, high heat resistance and good processability.

Owner:东华能源(宁波)新材料有限公司 +3

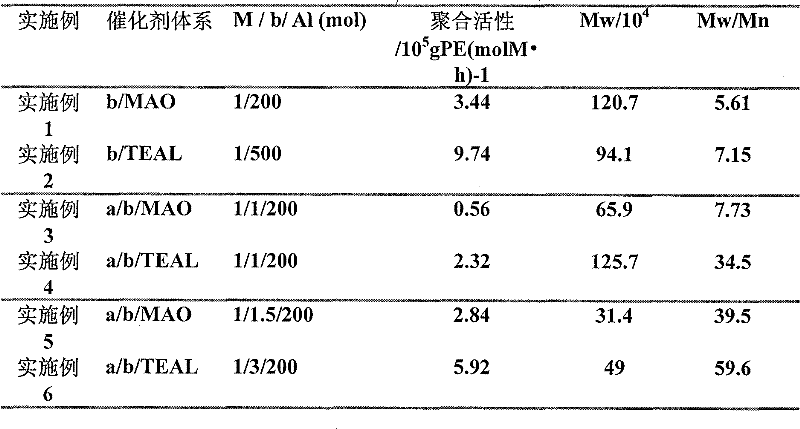

Preparation method of doublet or wide molecular weight distribution polyvinyl

The invention relates to a preparation method of doublet or wide molecular weight distribution polyvinyl. In polymerization, ethylene is used as monomer, butene-1 or hexene-1 as comonomer and hydrogen as molecular weight modifier. Polymerization temperature is 70 DEG C to 110 DEG C, pressure is 0.7 MPa to 2.5 MPa, reaction time is 2 h to 4 h, and catalyst is vanadium catalyst with the structural formula of VMg.nAl, wherein the range of n is 0.1 to 10. Promoter is the mixture of one or two of triisobutyl aluminium and aluminium ethyl, and the molar ratio of aluminum of the promoter and vanadium of the main catalyst is 10 to 10000: 1. The molecular weight and the molecular weight distribution wide of polyethylene products are adjusted through the adjustment of the types and the dosage of the promoter. Polymerized products have the characteristics of high molecular weight and wide molecular weight distribution, and the morphology of the polymerized products is regular spheroidal particles, and has no fine powder and no oligomer. The production of high value-added doublet or wide molecular weight distribution polyvinyl products can be achieved in a single reactor of a slurry process and a gas phase method technology.

Owner:PETROCHINA CO LTD

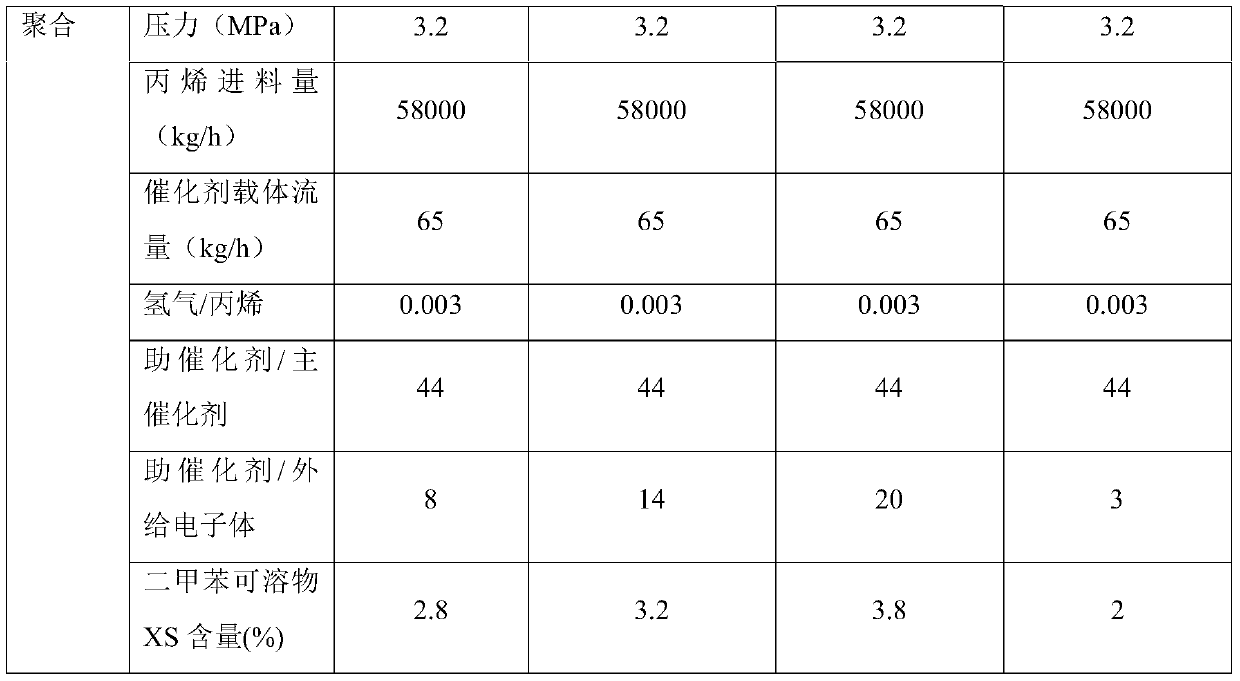

Catalyst system for preparing broad-peak/dimodal polyethylene in single reactor

The invention relates to a catalyst system for preparing broad-peak / dimodal polyethylene in a single reactor, wherein the catalyst system belongs to a polymerization catalyst which is used for the macromolecular compound preparation and is obtained only through a carbon-carbon unsaturated bond reaction. The catalyst system is characterized in that the catalyst comprises a main catalyst and an assistant catalyst, wherein the main catalyst comprises a component a or a component b; the component a is a transition metal-containing complex with the molecular formula of R1R2R3MX, R1 is selected from C1-20 alkyl, R2 is selected from C1-20 alkoxy, R3 is selected from C1-20 aryl or arlyoxy, M is Ti or Zr, and X is a halogen atom; the component b is a transition metal compound with the general formula of MXn or MXn(OR)4-n, M is a transition metal Ti or Zr, X is halogen, and n is between 1 and 4; and the assistant catalyst is methyl siloxane (MAO) or triethyl aluminum (TEAL). The catalyst system for preparing broad-peak / dimodal polyethylene in the single reactor provided in the invention has the advantages of easily controlled production technology, realization of the obtaining of broad-peak / dimodal polyethylene resin products with uniform molecular weight distribution, saved investment of equipment for the polyethylene production, and low production cost.

Owner:CHINA PETROLEUM & CHEM CORP

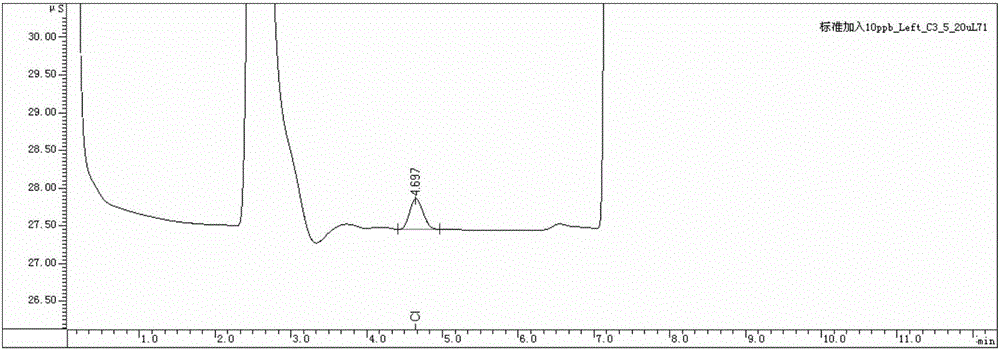

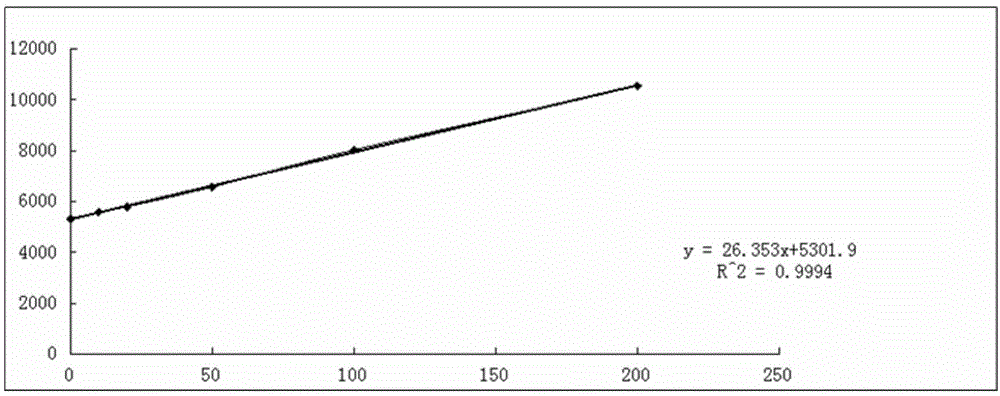

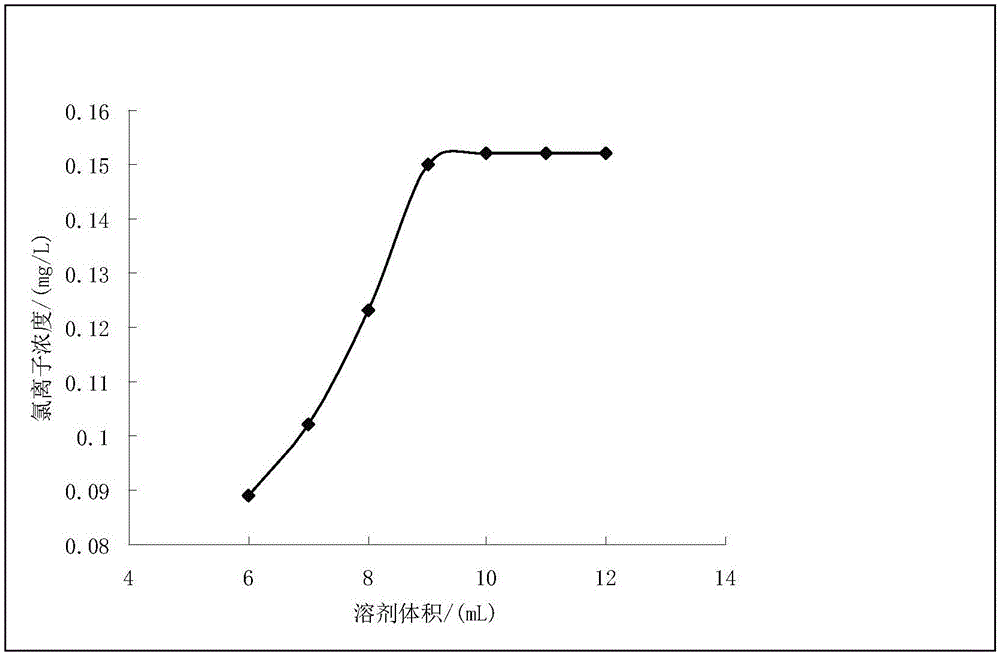

Ion method for measuring trace chloride ions in triethyl aluminum

ActiveCN106526062AEfficient determinationSolve the problem of pollution damageComponent separationIon chromatographySolution analysis

The invention provides an ion chromatography method for measuring trace chloride ions in triethyl aluminum. The method includes the steps of 1, pretreatment of a sample to be measured, wherein the TEAL sample is dissolved with isopropanol, the volume is kept at scales with secondary deionized water, ultrasonic and centrifugal treatment is carried out, and supernatant is taken, passes through a 0.22-micrometer pin type filter and an H-type pretreatment column, and then enters an ion chromatography system for analysis; 2, preparation of a work curve solution; 3, analysis of a standard addition method solution, wherein the repetitive solution is continuously injected 6 times, a chromatogram of Cl- standard addition solution analysis is obtained, the pretreated triethyl aluminum sample solution is subjected to ion chromatography analysis, the peak area of Cl- is obtained, and the content of Cl- in triethyl aluminum is obtained according to a work curve and the peak area of Cl-. The method is easy to operate, good in repeatability and high in sensitivity, the content of chlorine ions in TEAL can be effectively measured, and the problem that in the measuring process, heavy metal aluminum contaminates and damages the chromatographic column and a suppressor is solved.

Owner:中国检验认证集团山东检测有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com