Technique for synthesizing triethylaluminum

A triethylaluminum, synthesis process technology, applied in the field of triethylaluminum synthesis process, can solve the problems of complex process, small scale, low production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

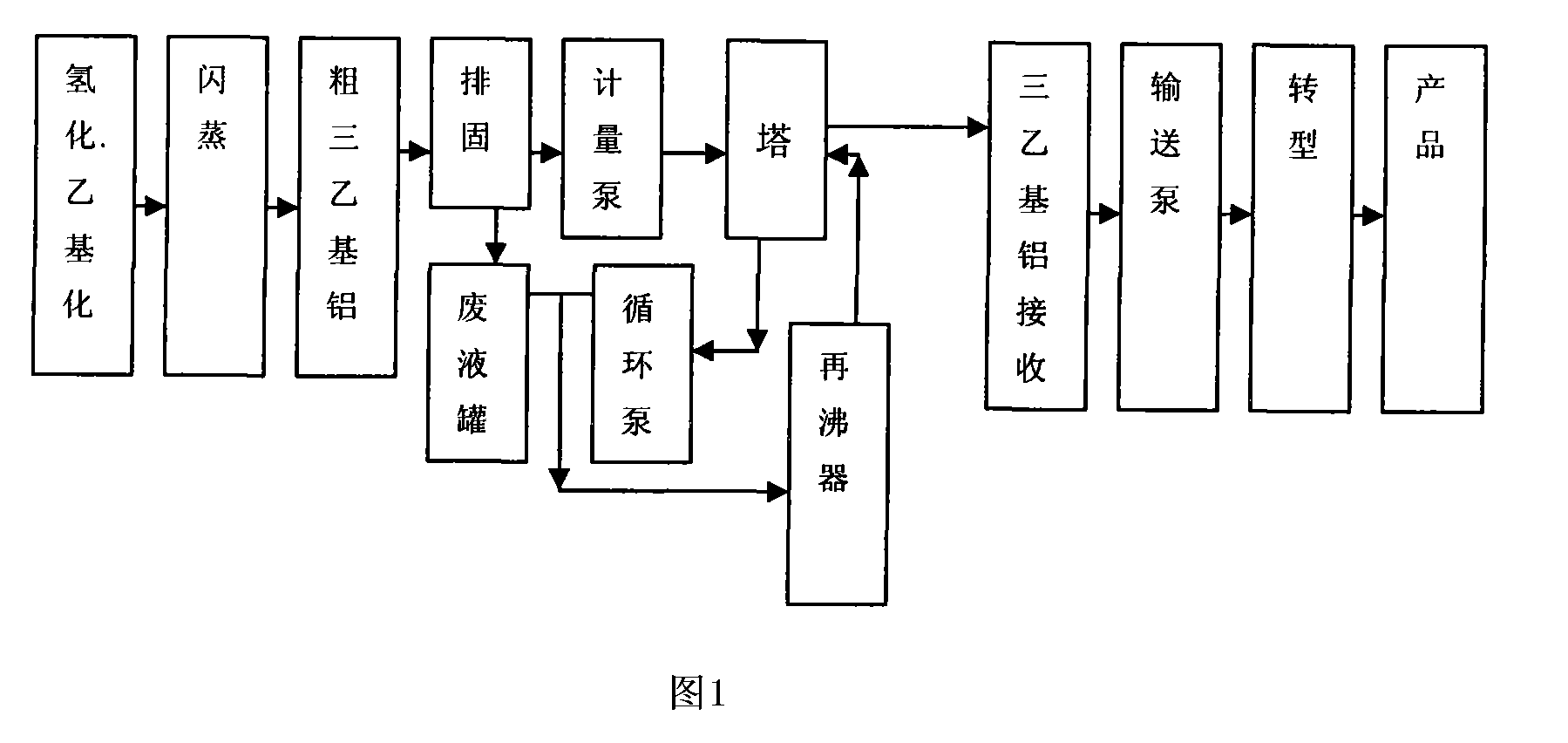

Image

Examples

Embodiment 1

[0020] 1) The titanium powder catalyst is melted in the aluminum powder:

[0021] After dissolving the aluminum ingot in the melting furnace, add titanium powder (below 200 mesh) into the dissolved aluminum and stir to make the titanium evenly dispersed in the dissolved aluminum, atomize and spray the dissolved aluminum to obtain 0.25% titanium-containing ( 0.2-0.3% can be) titanium-containing aluminum powder.

[0022] 2) Hydrogenation reaction is carried out in a magnetically driven reaction hydrogenation kettle: 4 tons of triethylaluminum retention solution is reserved in the kettle as a seed, and the pressure is 12MPa, and 175 kilograms of aluminum powder containing the above-mentioned catalyst is added to the kettle under nitrogen protection, The temperature was raised to 132° C. under stirring, and hydrogenation was continued for 7 hours under a pressure of 10 MPa to complete the reaction.

[0023] 3) Direct ethylation in the hydrogenation kettle: After the hydrogenation...

Embodiment 2

[0035] The reaction of step 3) can be carried out in the ethylation reactor, and others are with embodiment 1.

[0036] A spiral ethylation reactor is used. There is a 100-meter spiral tube with an inner diameter of 200 mm in the shell side (the above-mentioned materials are passed inside). The tube inlet is where the hydrogenated material and ethylene are mixed. The reactants react in the 100-meter tube, and the shell Hexane is housed in the process, and when the reaction temperature rises, the hexane vaporizes in the shell, and returns to the shell after being cooled by the shell-and-tube condenser (water cooling) above the shell, and the vapor pressure of the hexane is controlled to be 0.15MPa. The reaction temperature was 100°C. Get 150 kg / hour of crude triethylaluminum.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com