Reversible hydrogen storage material and preparation method thereof

A technology of hydrogen storage material and deposition method, which is applied in the direction of metal material coating process, hydrogen production, ion implantation plating, etc., can solve the problem of high temperature and pressure of hydrogenation/dehydrogenation, poor reversibility of complex hydrides, kinetics, etc. Poor performance and other problems, to achieve the effect of low initial dehydrogenation temperature, good thermal stability, and fast dehydrogenation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A method for preparing a reversible hydrogen storage material, specifically comprising the following steps:

[0017] (1) Metal magnesium, zinc, and boron were co-deposited on silicon wafers in a hydrogen environment by physical vapor deposition, and the vacuum degree was 5.2x10 -4 Pa, a deposition rate of 2.5 nm / min yields metal borohydrides, Mg x Zn 1-x (BH 4 ) 2 , where x=0.05~0.95;

[0018] (2) Deposit metal palladium (Pd), platinum (Pt) or cobalt (Co) on the surface of the above-mentioned metal borohydride in a hydrogen-free vacuum environment by vacuum sputtering, and the vacuum degree is 1×10 -8 Pa, the deposition rate is 1.5nm / min, and the deposition thickness is 2-20nm to obtain a reversible hydrogen storage material, Mg x Zn 1-x (BH 4 ) 2 -M, where x=0.05-0.95, and M is one of Pd, Pt and Co.

Embodiment 1

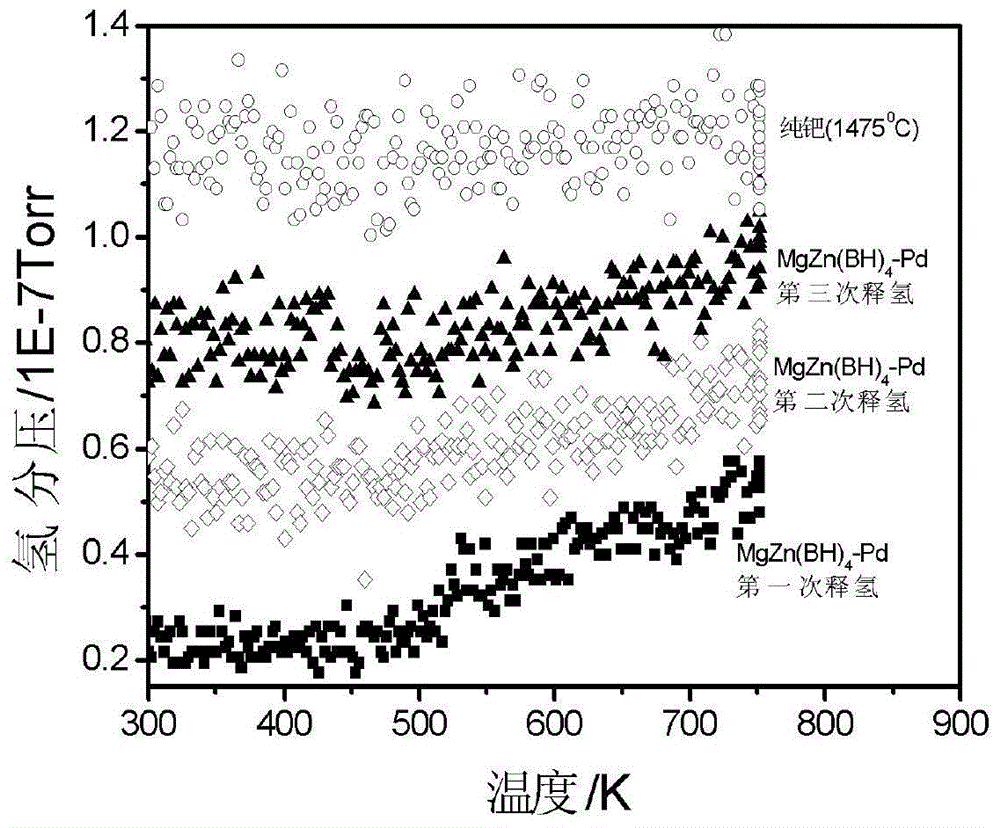

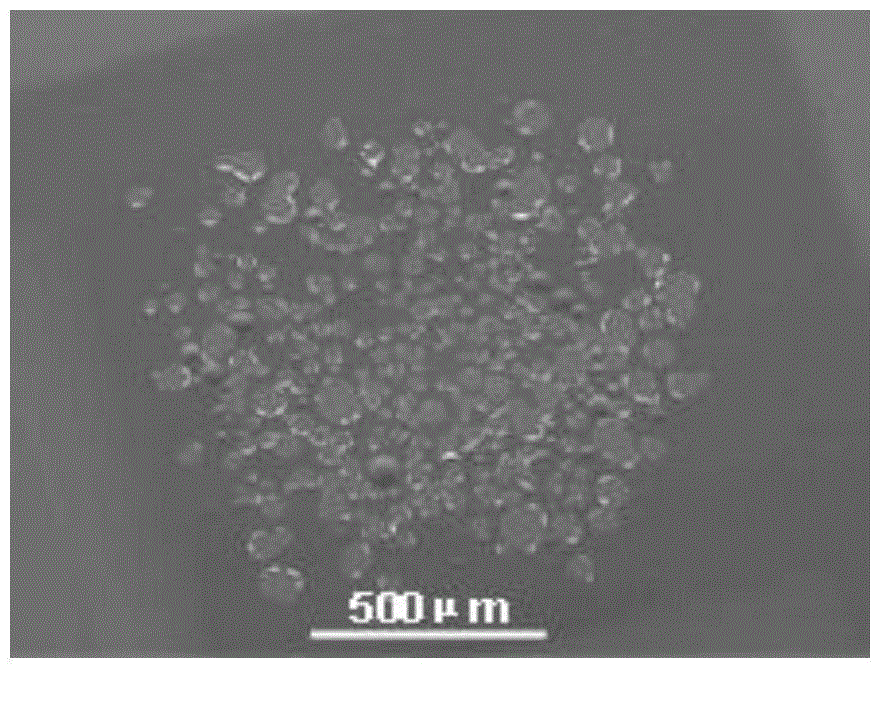

[0020] Mg prepared as above 0.1 Zn 0.9 (BH 4 ) 2 and Mg 0.1 Zn 0.9 (BH 4 ) 2 -Pd (palladium layer thickness is 10nm) for hydrogen absorption and desorption cycle test. The maximum temperature of dehydrogenation is 982K, and the heating rate is 23K / s; the subsequent cycle hydrogenation temperature is normal temperature, the pressure is 1MPa, and the time is 7.5 hours. The results show that the Mg without palladium layer 0.1 Zn 0.9 (BH 4 ) 2 did not show the reversibility of the hydrogen storage performance, and no hydrogen was detected during the dehydrogenation process after subsequent cyclic hydrogenation, while Mg 0.1 Zn 0.9 (BH 4 ) 2 -Pd exhibits good hydrogenation reversibility. Depend on figure 1 The partial pressure of hydrogen during the hydrogen release process is also known. The hydrogen storage material is reversible, and the initial temperature of the three hydrogen releases hardly changes. SEM pictures show that the Mg without palladium layer 0.1 ...

Embodiment 2

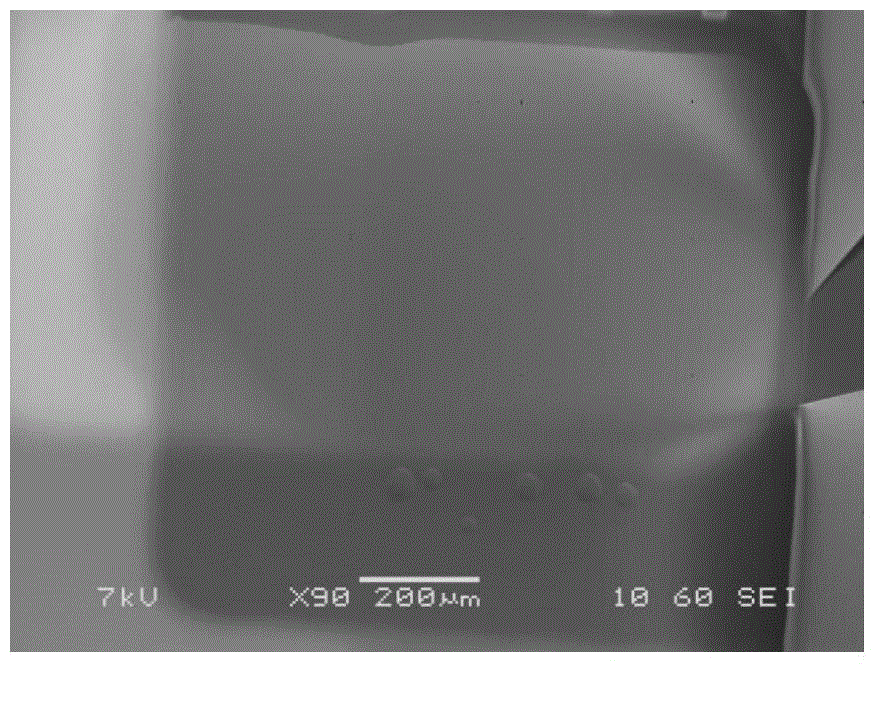

[0022] Mg prepared as above 0.2 Zn 0.8 (BH 4 ) 2 and Mg 0.2 Zn 0.8 (BH 4 ) 2 -Pd (palladium layer thickness is 20nm) for hydrogen absorption and desorption cycle test. The highest temperature for dehydrogenation is 982K, and the heating rate is 23K / s; the temperature for subsequent cycle hydrogenation is normal temperature, the pressure is 1MPa, and the time is 6 hours. The results show that the Mg without palladium layer 0.2 Zn 0.8 (BH 4 ) 2 did not show the reversibility of the hydrogen storage performance, and no hydrogen was detected during the dehydrogenation process after subsequent cyclic hydrogenation, while Mg 0.2 Zn 0.8 (BH 4 ) 2 -Pd exhibits good hydrogenation reversibility. Mg without palladium layer 0.2 Zn 0.8 (BH 4 ) 2 After hydrogenation and dehydrogenation at 982K, most of the material has peeled off from the substrate, while Mg 0.2 Zn 0.8 (BH 4 ) 2 -Pd still exhibits a complete and continuous form. It shows that the presence of the pall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com