Catalyst for preparing 1,4-cyclohexanedicarboxylic acid through selective hydrogenation of terephthalic acid, preparation method and use method thereof

A technology of cyclohexanedicarboxylic acid and terephthalic acid, which can be used in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, preparation of carboxylic acid by ozone oxidation, etc., can solve the problems of poor selectivity and activity, The catalyst activity is not very good, the cost is reduced, etc., to achieve the effects of short reaction time, good catalytic activity and target product selectivity, and mild hydrogenation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

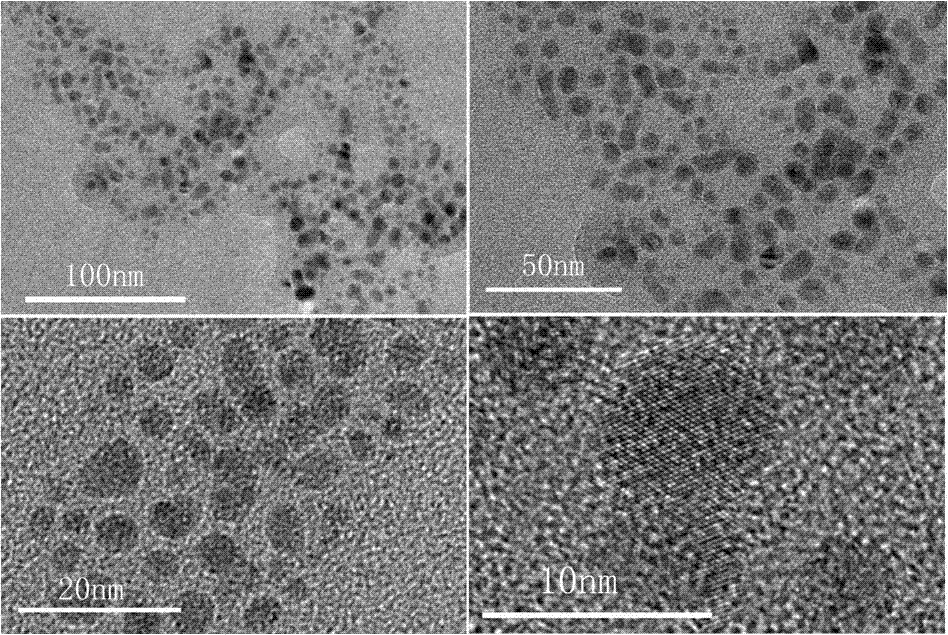

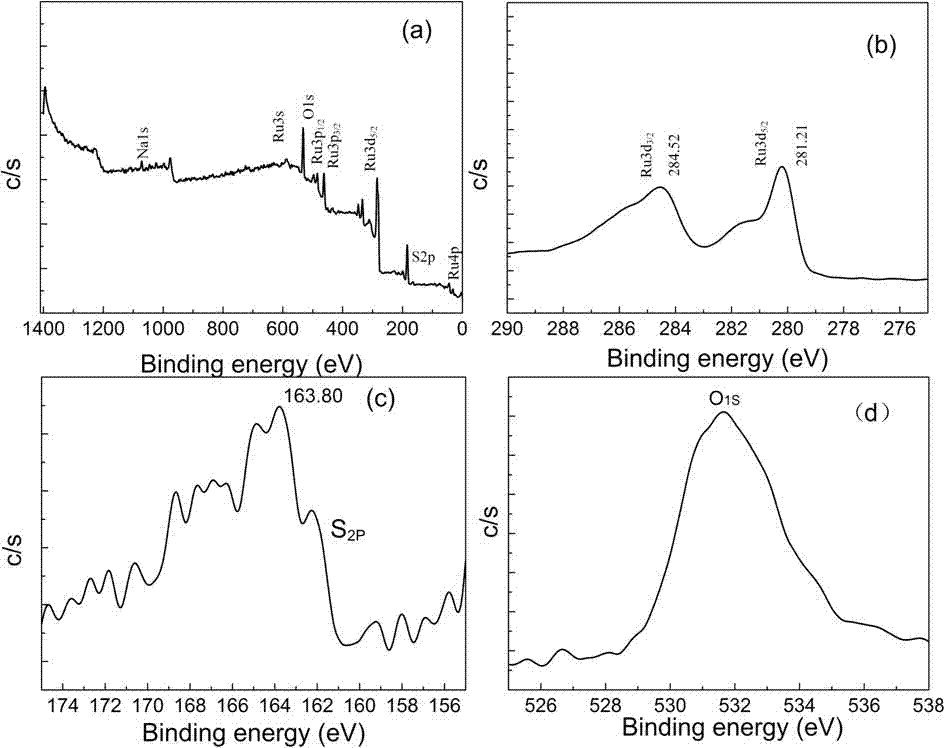

[0025] A method for preparing a catalyst for selective hydrogenation of terephthalic acid to prepare 1,4-cyclohexanedicarboxylic acid, the specific steps are as follows:

[0026] ① Solution preparation: first, 1.0 g RuCl 3 ·3H 2 O was dissolved in 200 ml of deionized water, stirred for 20 min; then, 50 g of PEG-2000 and 200 ml of deionized water were added to the above solution, and stirred for 20 min;

[0027] ② Reduction reaction: transfer the above solution to a 1L lined C276 Hastelloy autoclave, and perform the reduction reaction for 3 hours at 140°C, 4.5MPa hydrogen pressure, and 800r / min stirring speed;

[0028] ③ Precipitation washing: After the reduction reaction is completed, remove the supernatant, and wash the precipitate (ie Ru particles) with deionized water until it is neutral and free of chloride ions;

[0029] ④Molecular modification: add 0.1g thiophene dicarboxylic acid and 0.05g NaOH to 100ml deionized water, after the dissolution is complete, add 0.3g of t...

Embodiment 2

[0034] A method for preparing a catalyst for selective hydrogenation of terephthalic acid to prepare 1,4-cyclohexanedicarboxylic acid, the specific steps are as follows:

[0035] ① Solution preparation: preparation of RuCl 3 ·5H 2 A mixed aqueous solution with 5% O mass fraction and 5% polyethylene glycol (PEG-10000) mass fraction was stirred and dissolved for 1 hour;

[0036] ② Reduction reaction: At 25°C, normal pressure, and 500r / min stirring speed, use an aqueous solution of sodium borohydride with a mass fraction of 0.5% as the reducing agent, and add drop by drop until the solution becomes colorless;

[0037] ③ Precipitation washing: After the reduction reaction is completed, remove the supernatant, and wash the precipitate (ie Ru particles) with pure water until it is neutral and free of chloride ions;

[0038] ④Molecular modification: Prepare a mixed solution with a mass fraction of thiophenedicarboxylic acid of 0.2% and a mass fraction of sodium hydroxide of 0.09%, ...

Embodiment 3

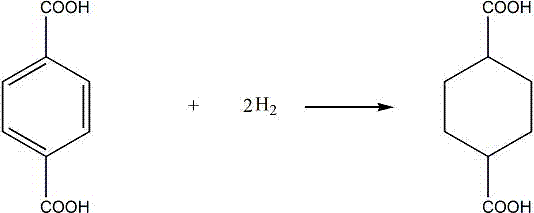

[0042] A method for using a catalyst for preparing 1,4-cyclohexanedicarboxylic acid through selective hydrogenation of terephthalic acid, the specific steps are as follows:

[0043] Using water as solvent, the mass ratio of terephthalic acid (PTA) and water is 1:25, the mass ratio of catalyst (Example 1) and terephthalic acid (PTA) is 1:5, at 110°C and 4 MPa hydrogen pressure , 1000r / min stirring speed, reaction 3h, centrifugation to remove the catalyst, do H NMR spectrum, integral calculation selectivity, 1,4-cyclohexanedicarboxylic acid selectivity 93.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com