Patents

Literature

2040 results about "Hydrogen atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

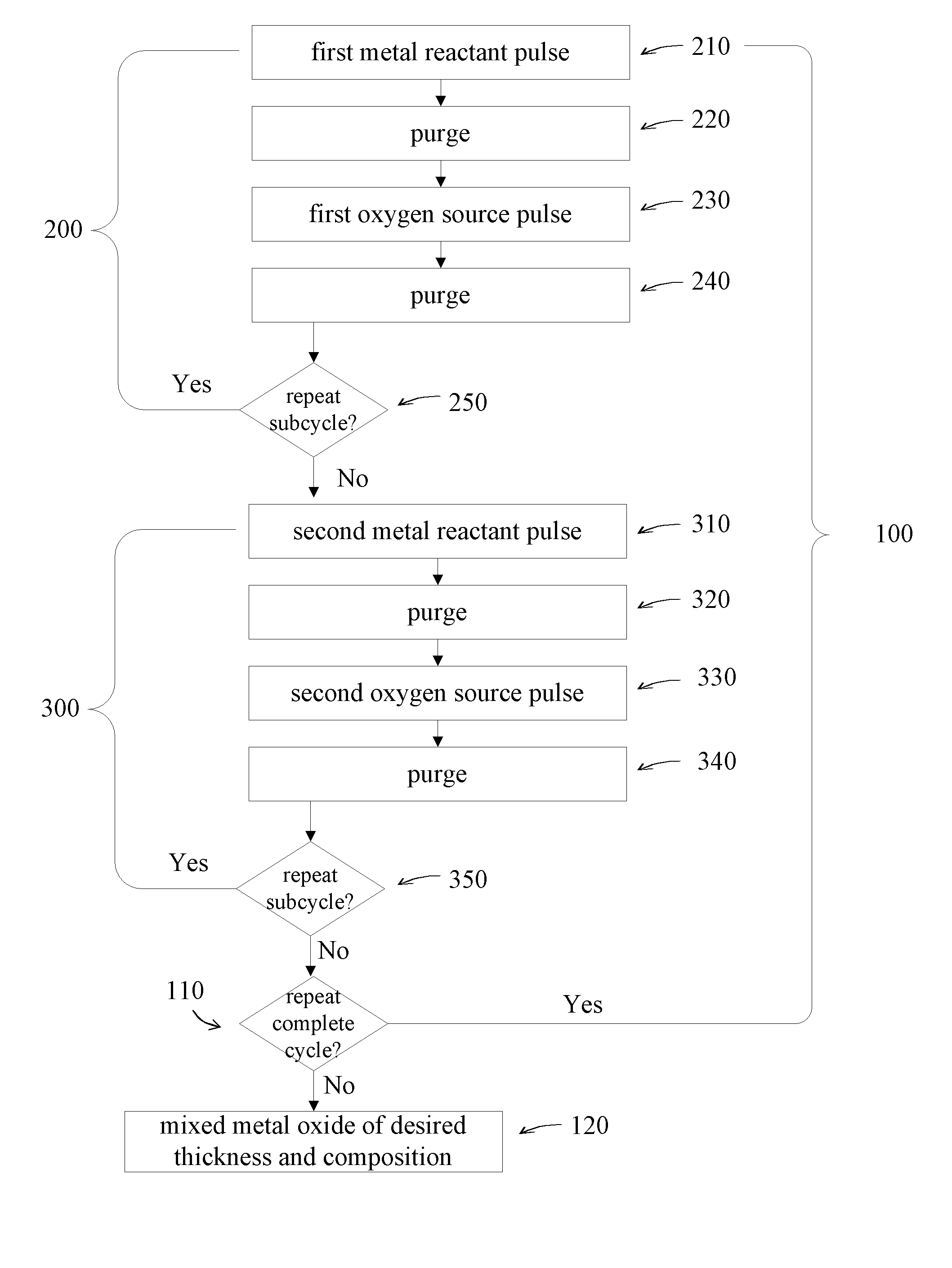

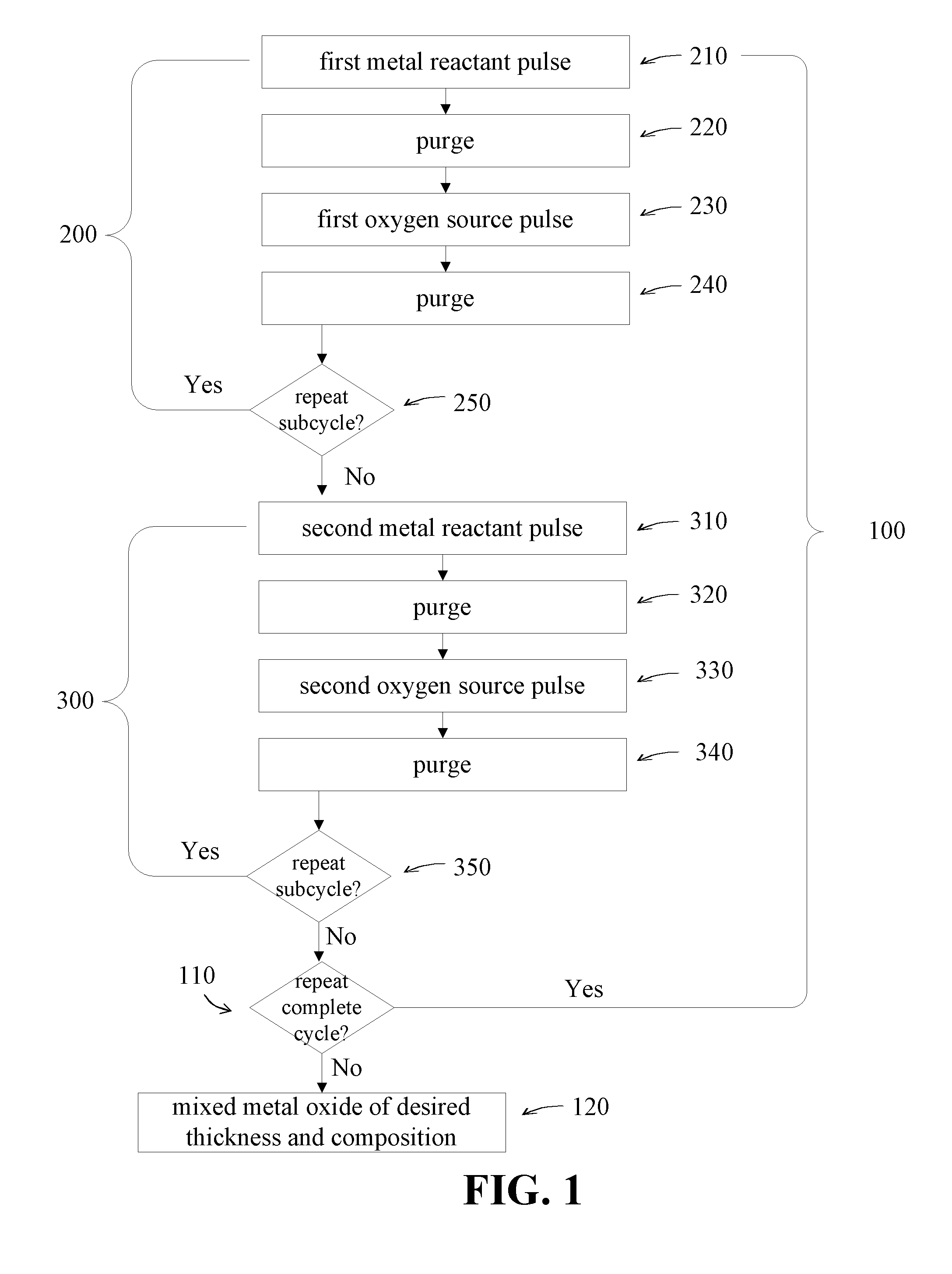

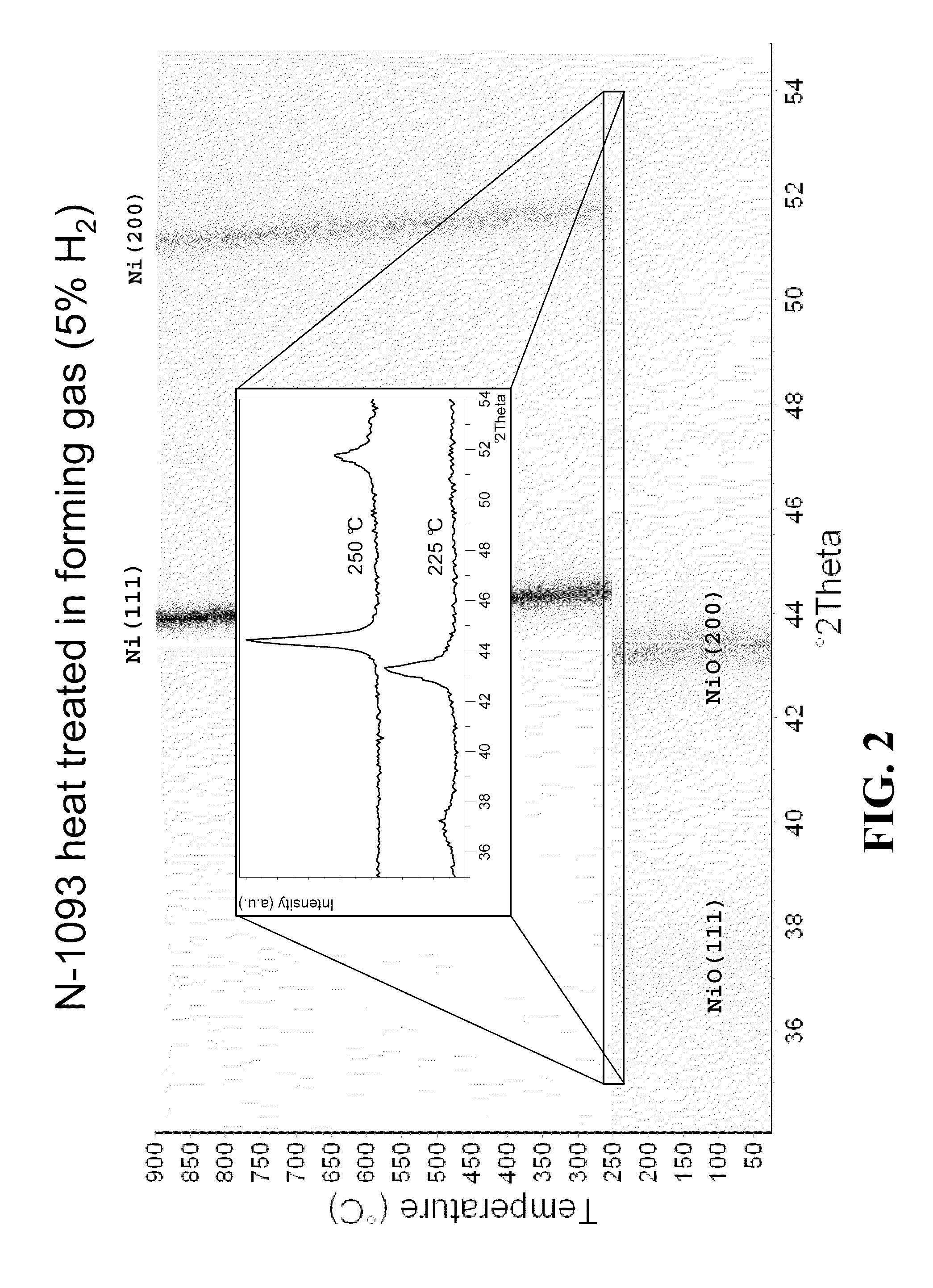

Deposition and reduction of mixed metal oxide thin films

ActiveUS20120302055A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingHydrogen atmospherePhysical chemistry

Owner:ASM IP HLDG BV

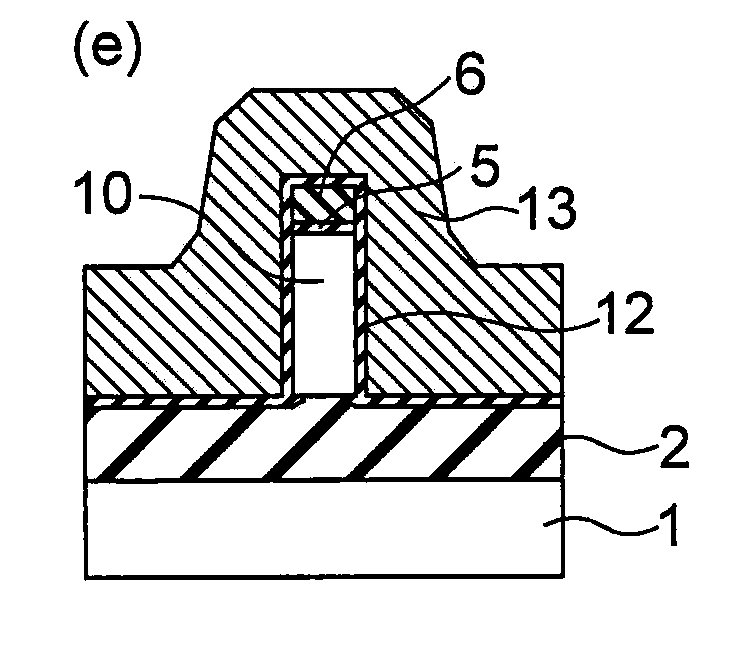

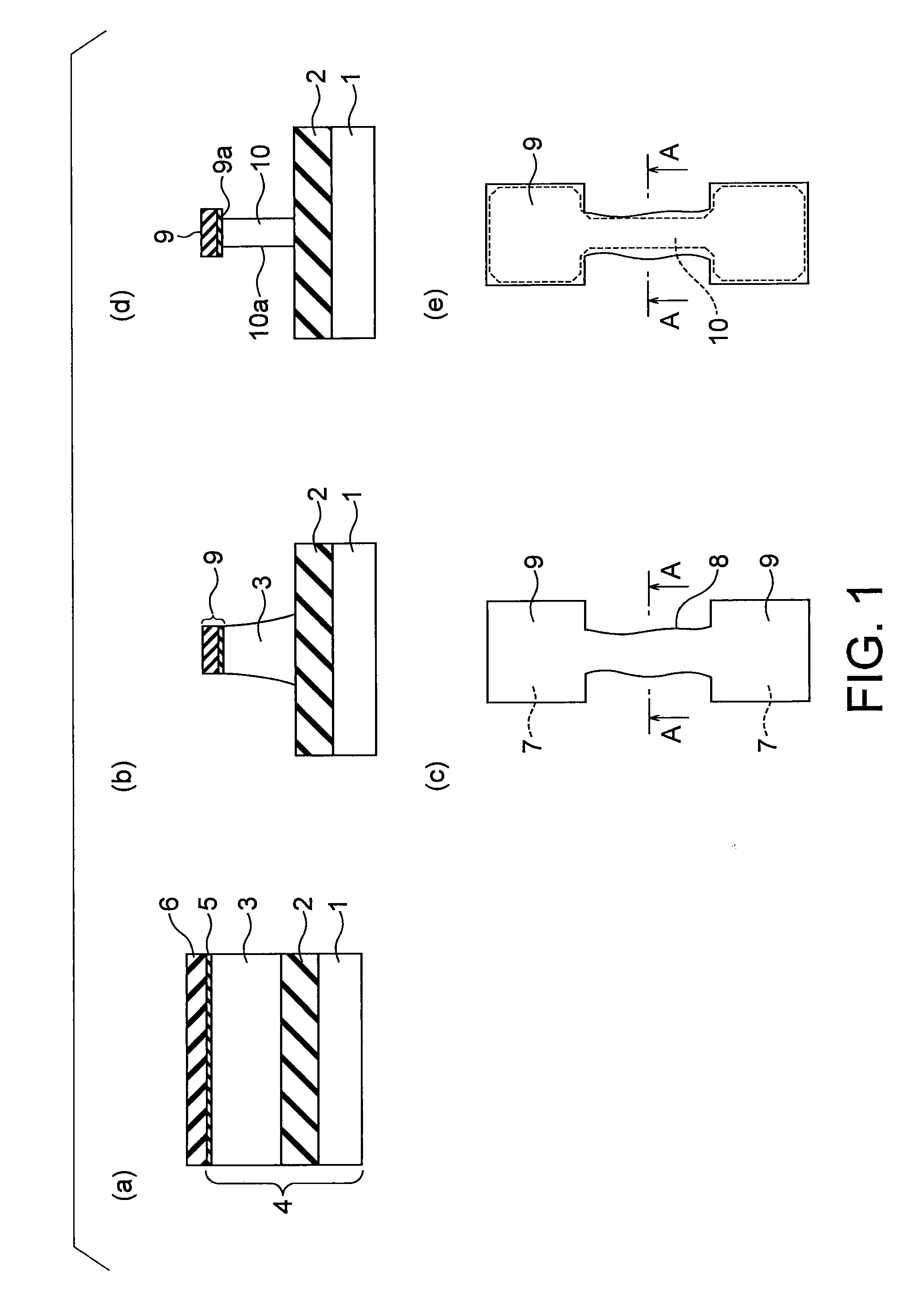

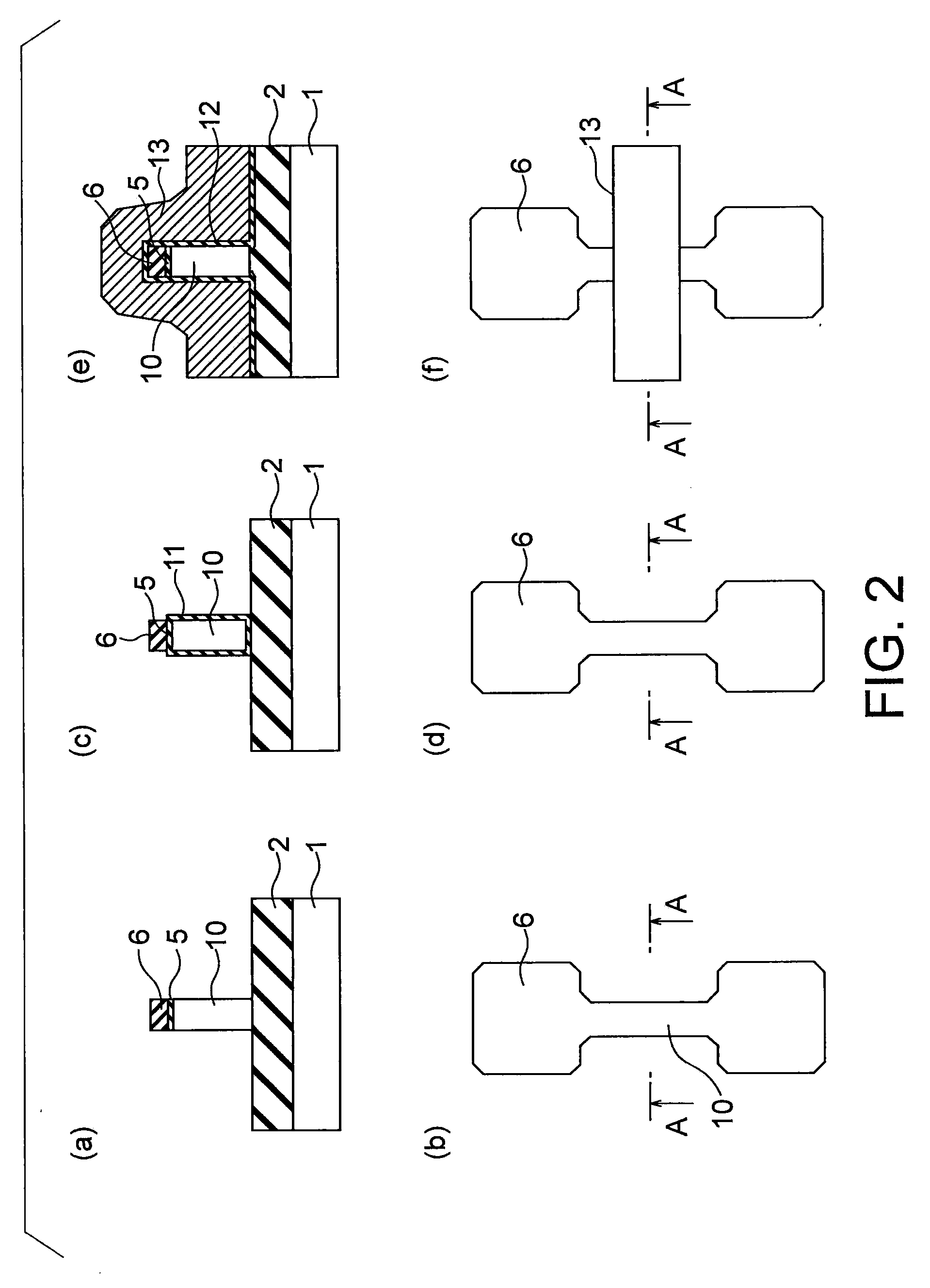

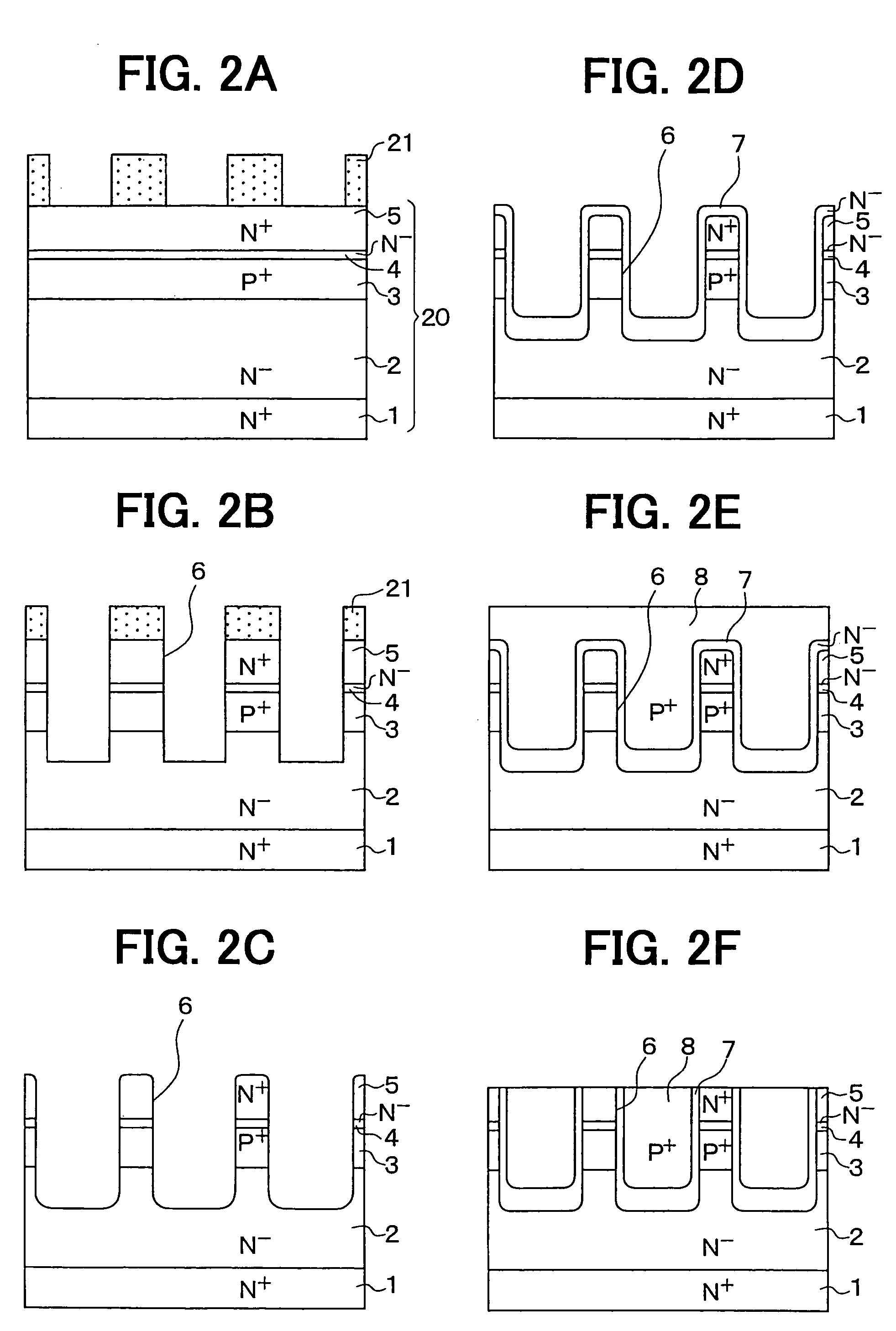

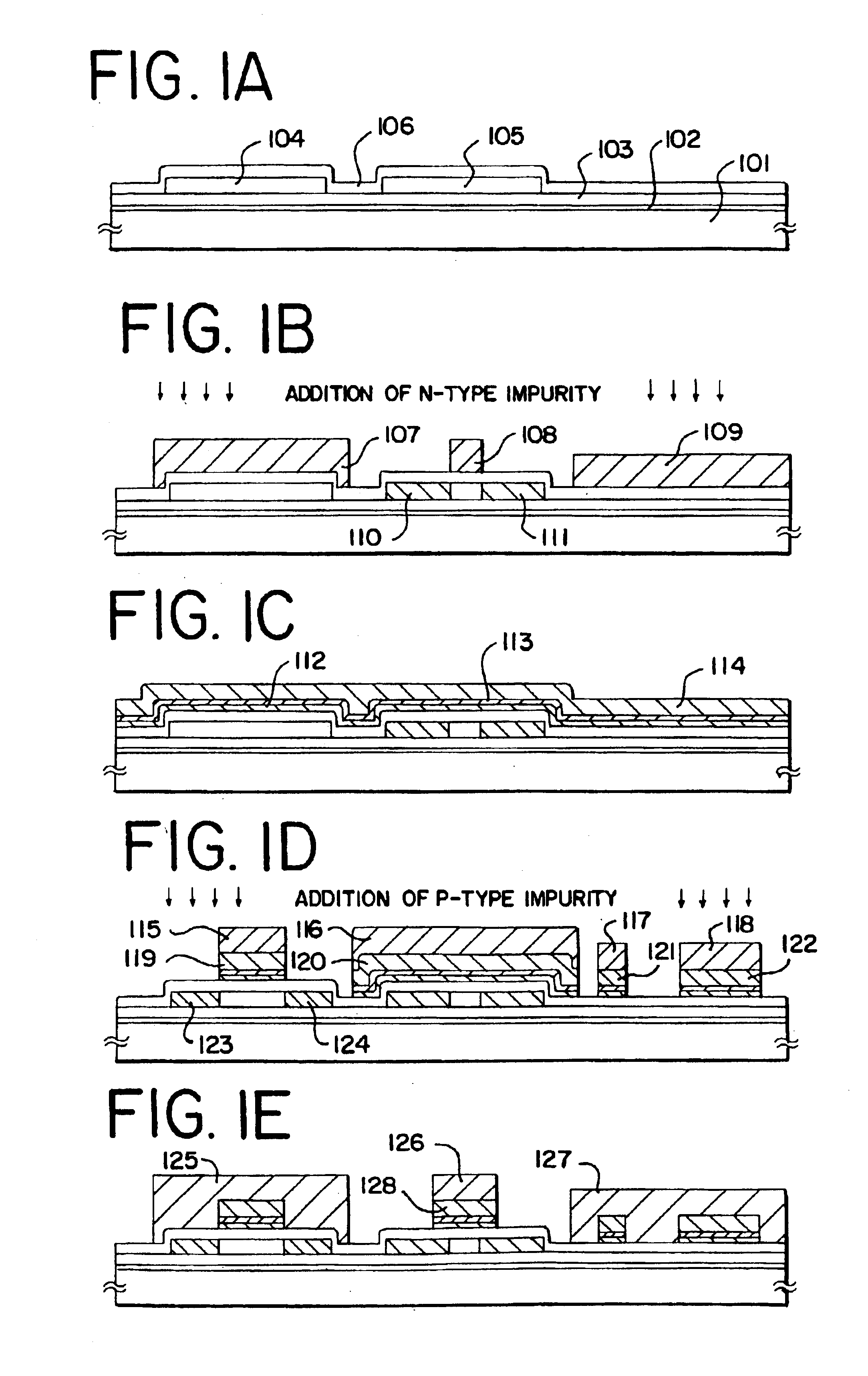

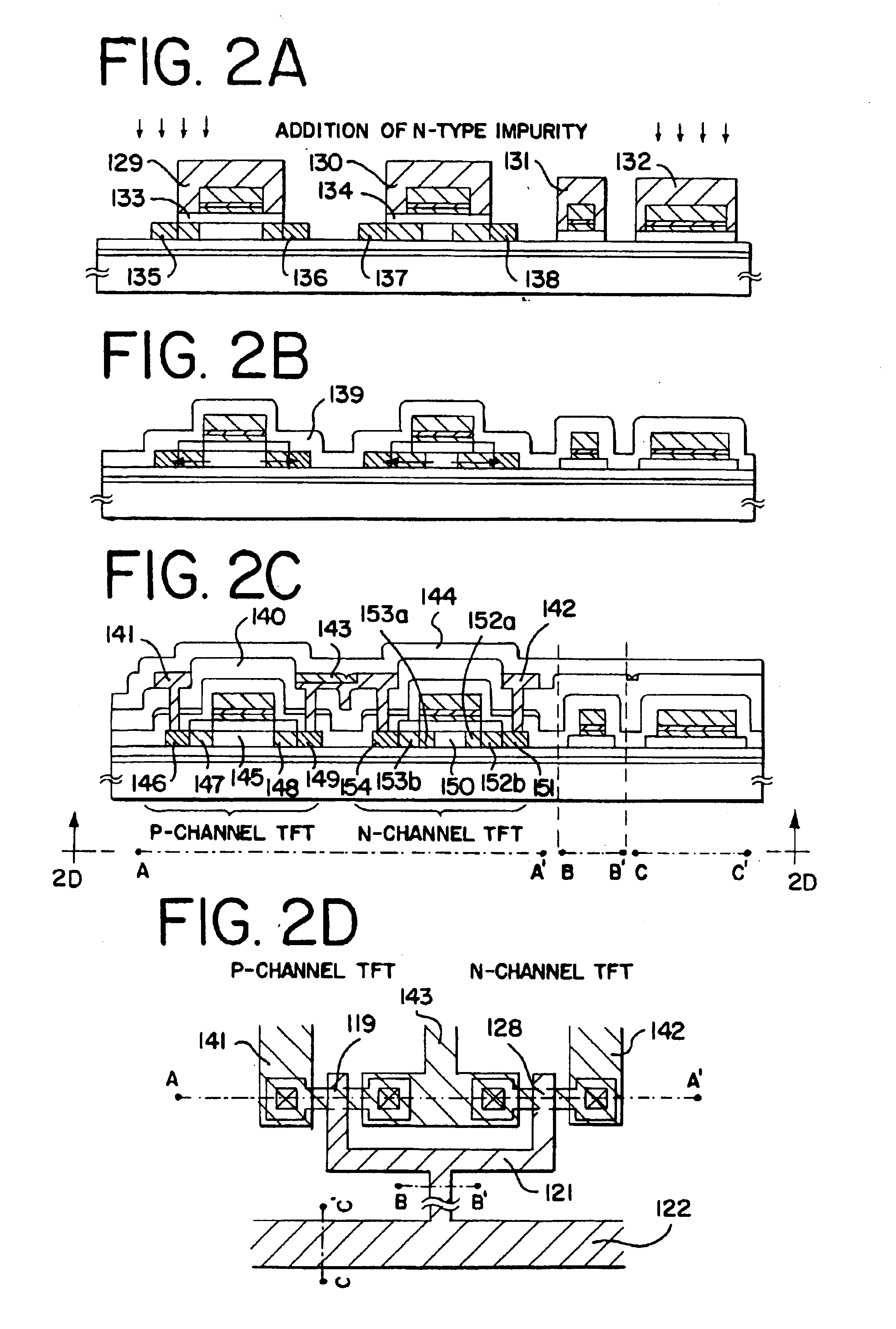

Field Effect Transistor and Method for Manufacturing the Same

ActiveUS20090090934A1Small shape variationSmall sizeSolid-state devicesSemiconductor/solid-state device manufacturingHydrogen atmosphereEngineering

A method for manufacturing a field effect transistor, includes: forming a mask of an insulating film on a semiconductor layer containing Si formed on a semiconductor substrate; forming the semiconductor layer into a mesa structure by performing etching with the use of the mask, the mesa structure extending in a direction parallel to an upper face of the semiconductor substrate; narrowing a distance between two sidewalls of the mesa structure and flattening the sidewalls by performing a heat treatment in a hydrogen atmosphere, the two sidewalls extending in the direction and facing each other; forming a gate insulating film covering the mesa structure having the sidewalls flattened; forming a gate electrode covering the gate insulating film; and forming source and drain regions at portions of the mesa structure, the portions being located on two sides of the gate electrode.

Owner:KK TOSHIBA

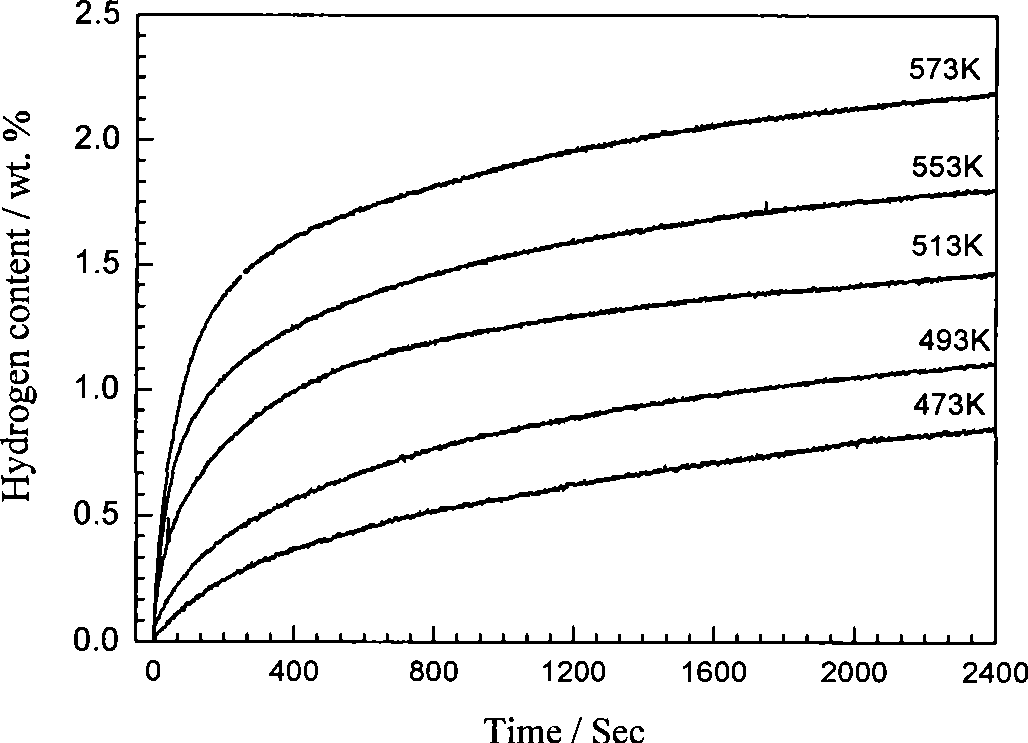

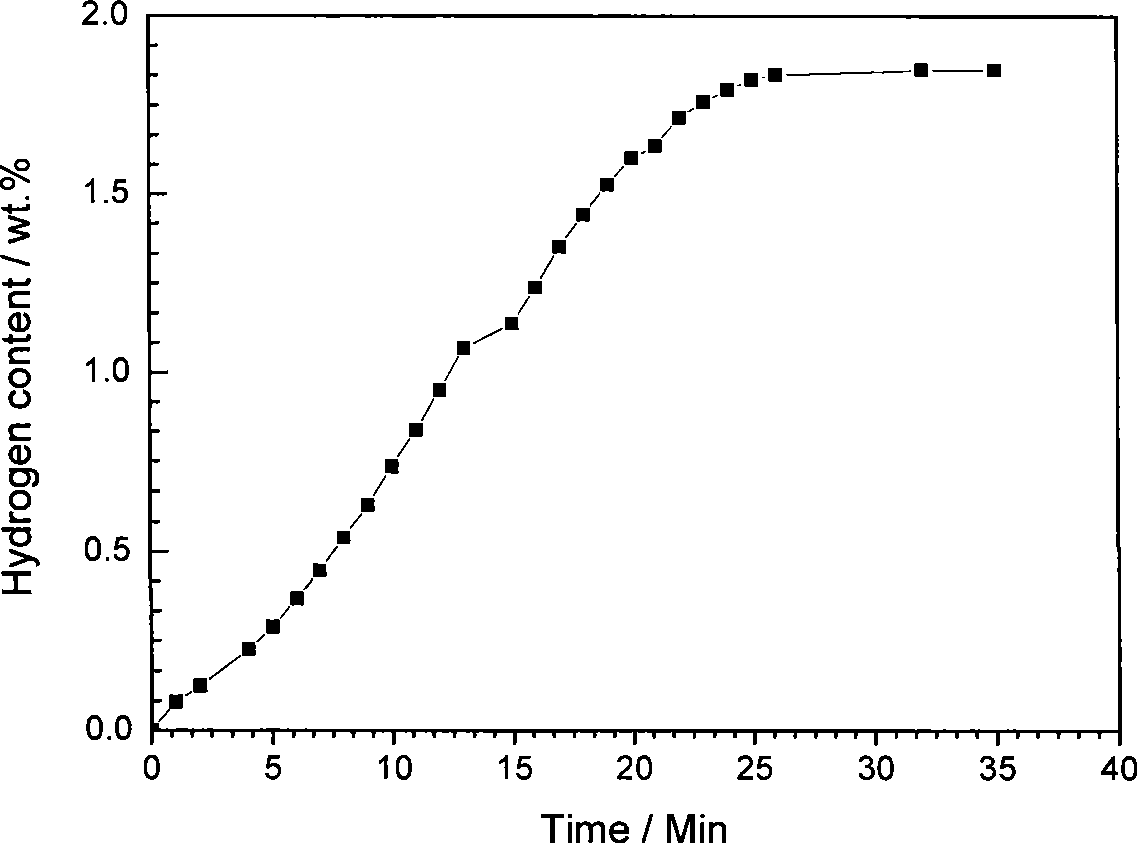

Magnesium base composite hydrogen storage material and preparation method

The invention discloses a magnesium-based composite hydrogen storage material comprising the following compositions by weight percent: 1.0-10.0% of Al, 1.0-5.0% of Ni, and the balance of Mg. A preparation method thereof comprising the following steps: at first, smelting block-shaped metal Mg and Al by a medium frequency induction to prepare Mg17Al12 alloy which is crushed to 300 meshes; hydrogenising Mg powder at 340 DEG C under a hydrogen atmosphere of 4.0MPa to prepare MgH2; then blending Mg17Al12, MgH2, Ni powder in accordance with contents by weight percent for ball-grinding for 60 to 100 hours under an atmosphere of argon. The magnesium-based composite hydrogen storage material can reversely absorb and release hydrogen at low temperature, and has high hydrogen storage capacity, excellent activation performance and superior hydrogen absorbing and releasing kinetics property. The magnesium-based composite hydrogen storage material can be used for manufacturing hydrogen source to facilitate purification and storage and transportation of hydrogen, and can also used for hydrogen storage material for fuel cells.

Owner:ZHEJIANG UNIV

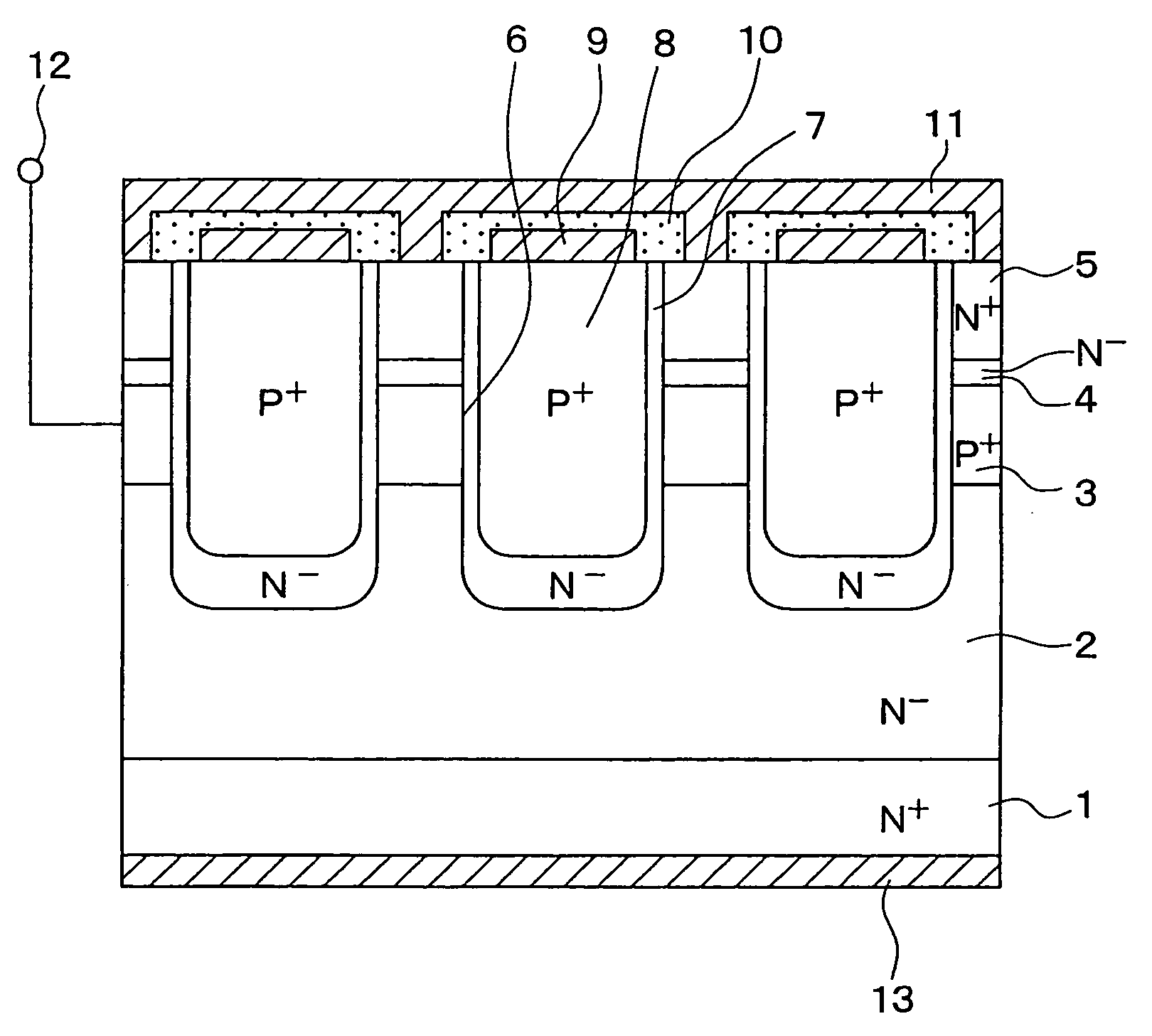

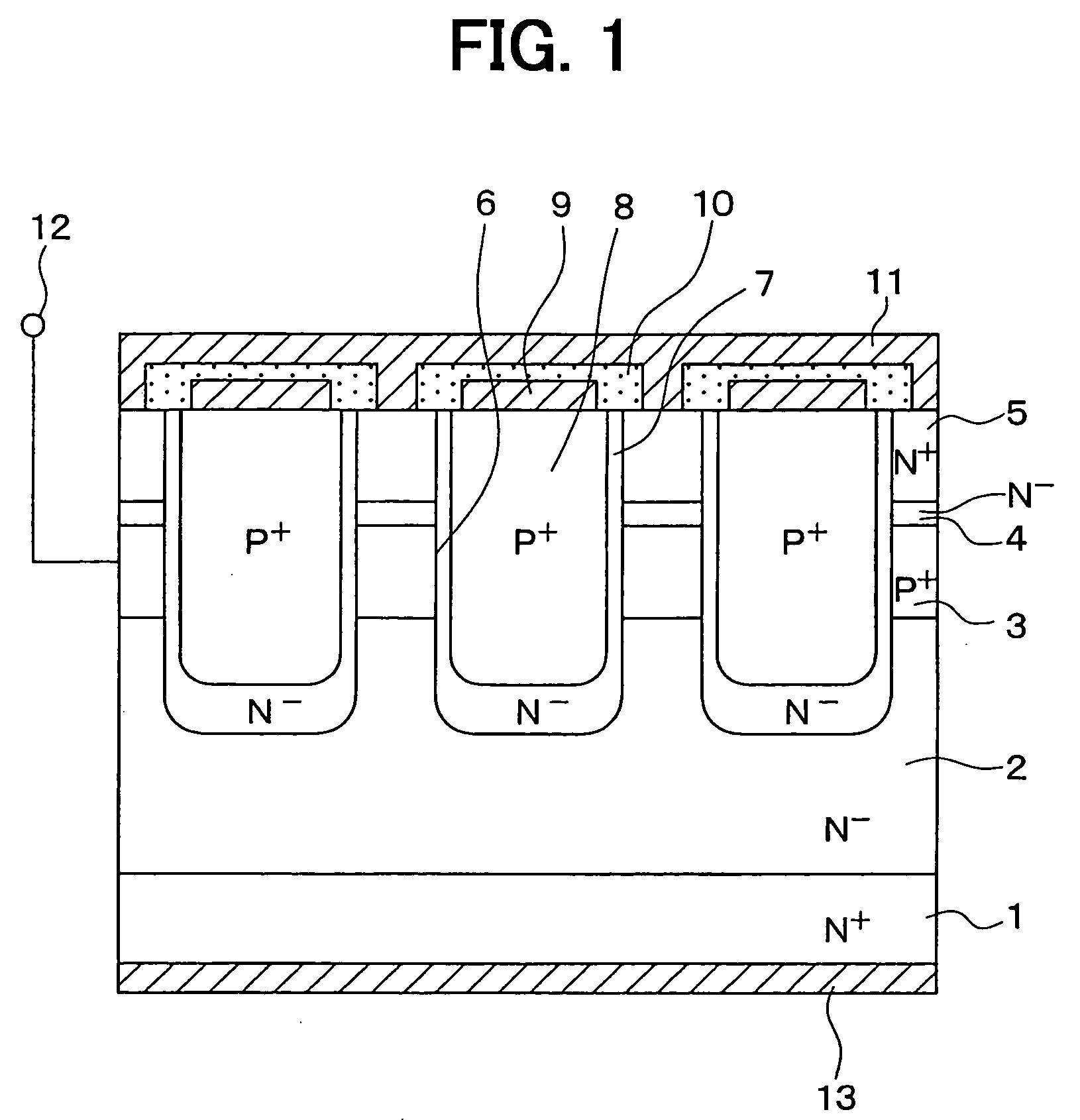

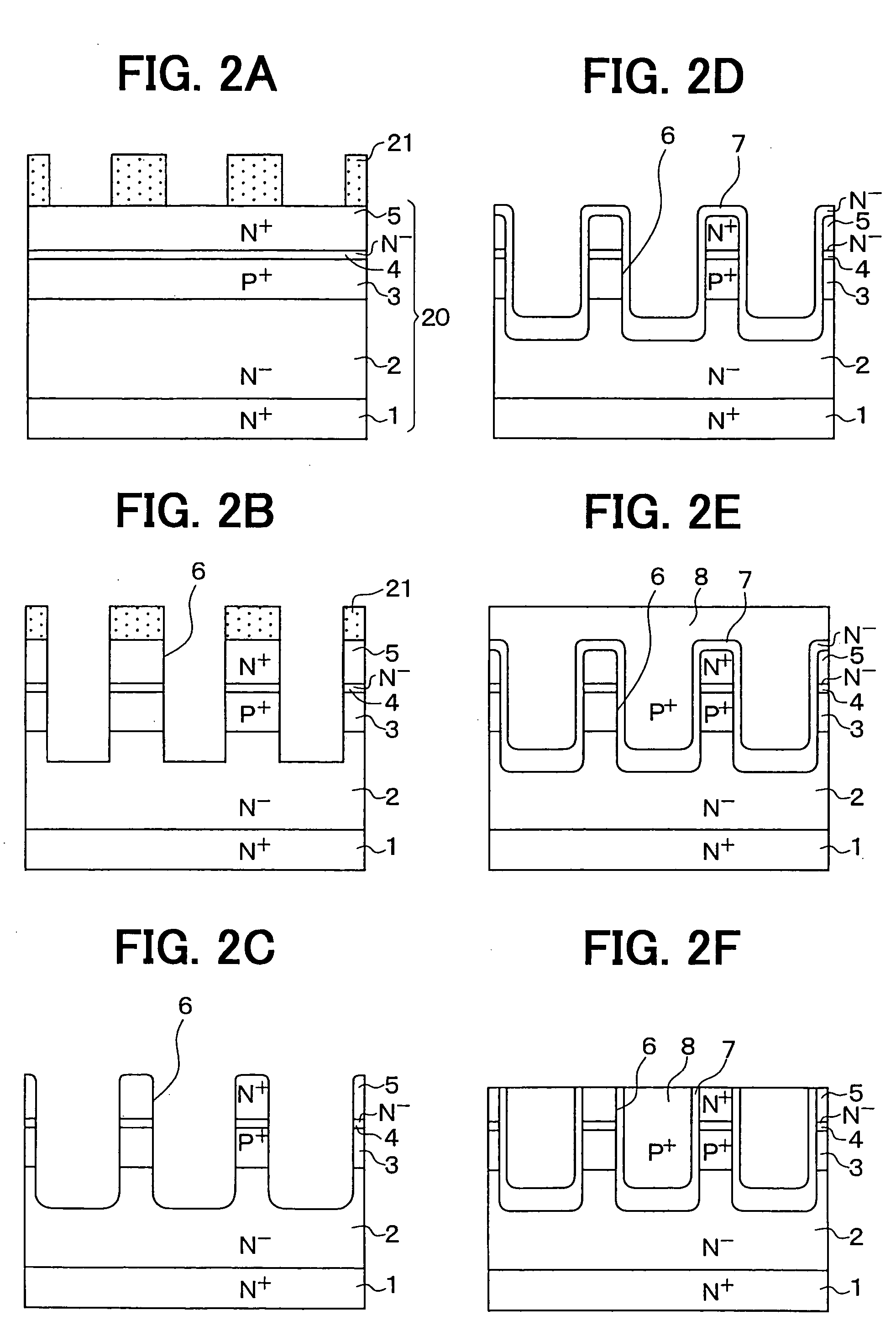

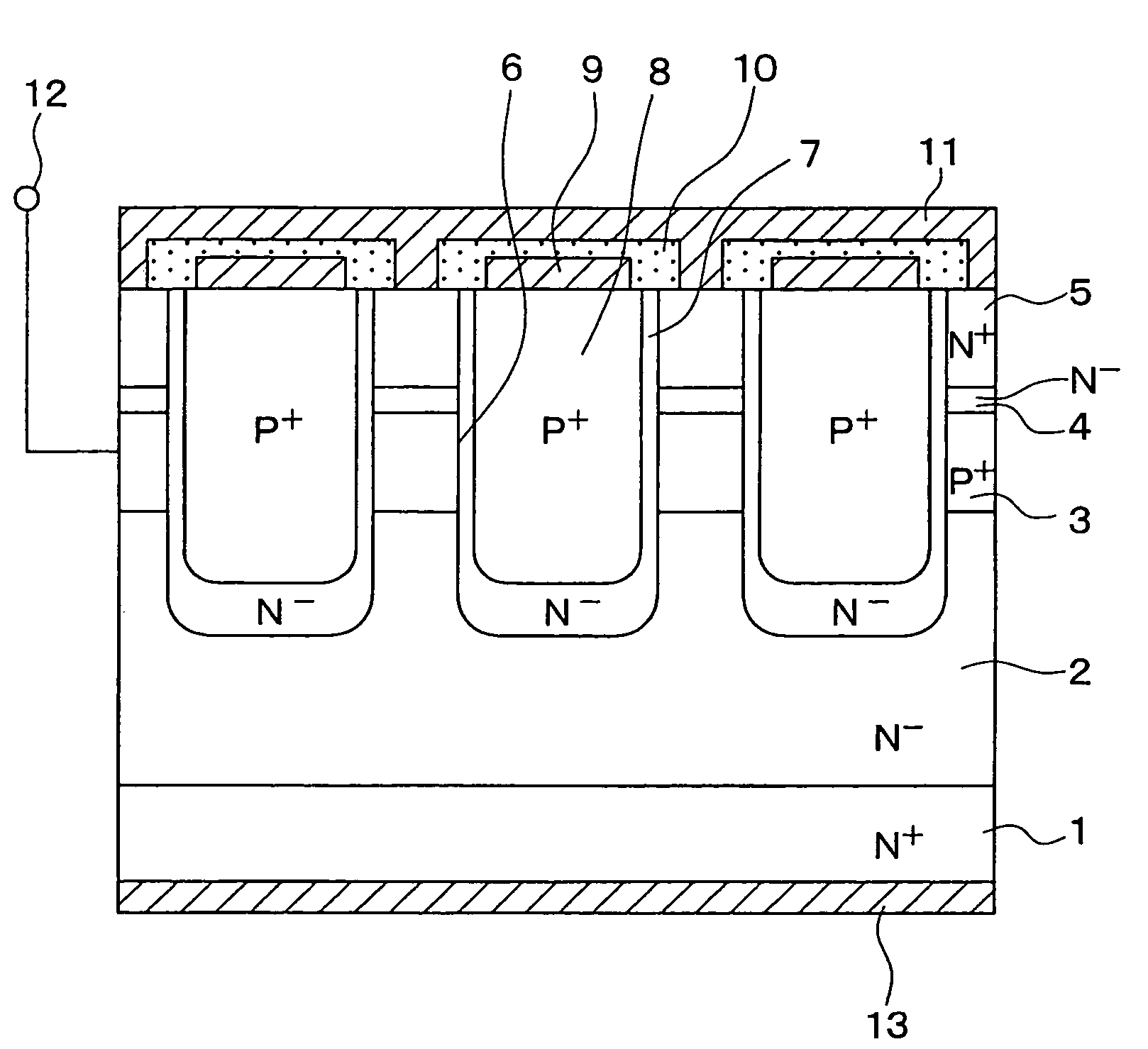

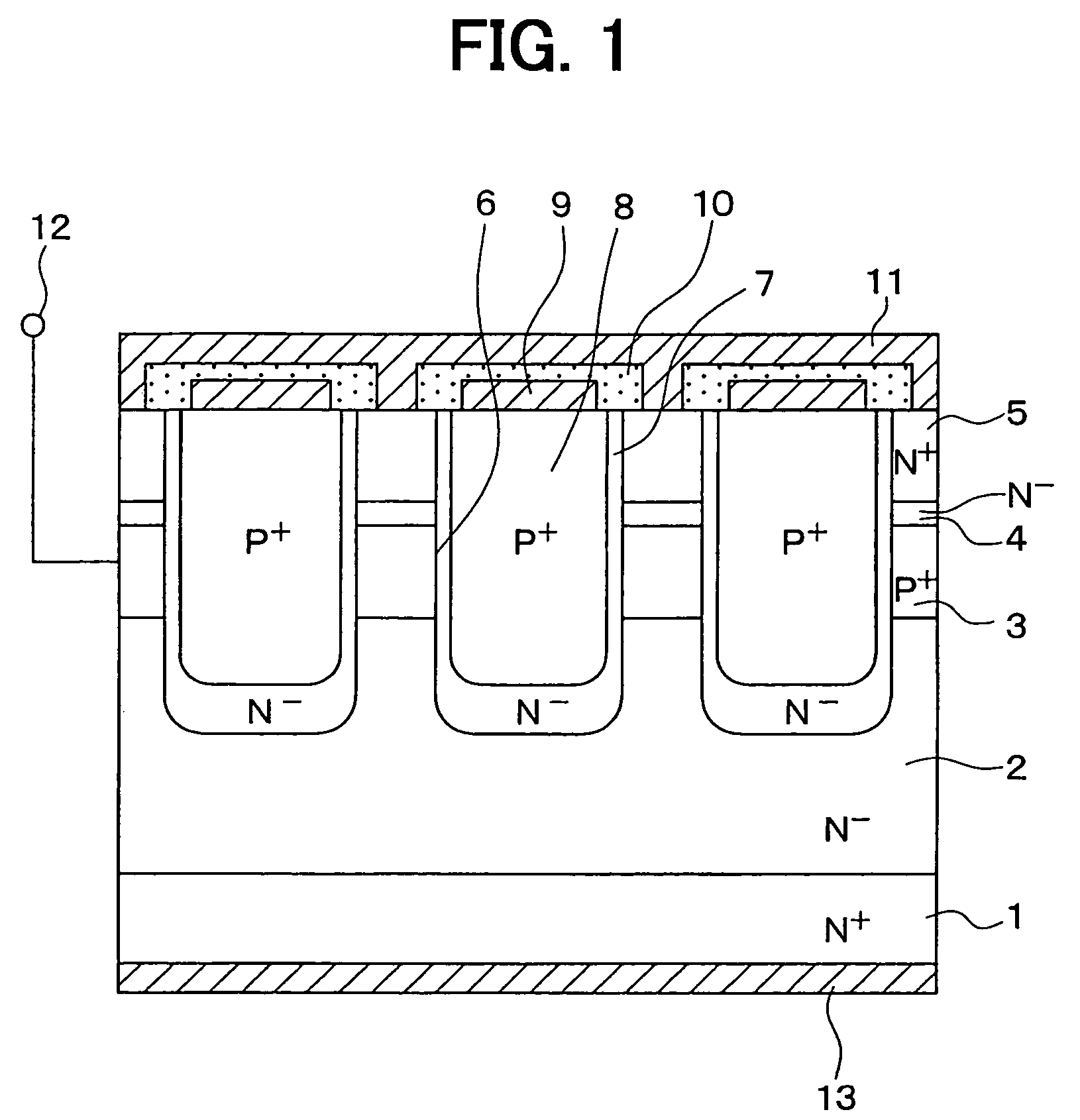

Method for manufacturing semiconductor device having trench in silicon carbide semiconductor substrate

ActiveUS20050233539A1Uniform shapeGood on-off performanceSemiconductor/solid-state device manufacturingFrom condensed vaporsSlant angleHydrogen atmosphere

A method for manufacturing a silicon carbide semiconductor device includes the steps of: forming a trench mask on an upper surface of a semiconductor substrate; forming the trench such that the trench having an aspect ratio equal to or larger than 2 and having a trench slanting angle equal to or larger than 80 degrees is formed; and removing a damage portion in such a manner that the damage portion disposed on an inner surface of the trench formed in the semiconductor substrate in the step of forming the trench is etched and removed in hydrogen atmosphere under decompression pressure at a temperature equal to or higher than 1600° C.

Owner:DENSO CORP

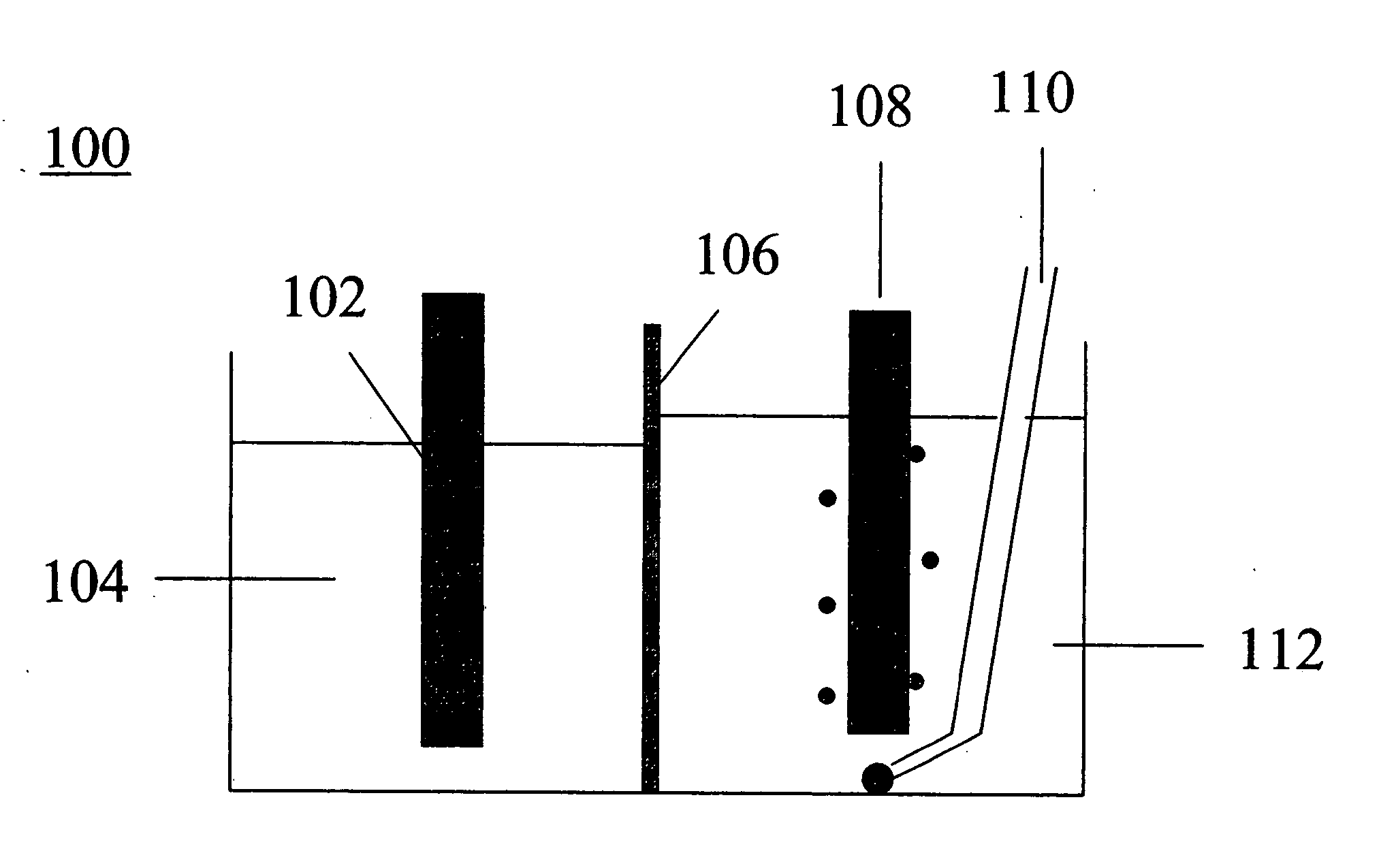

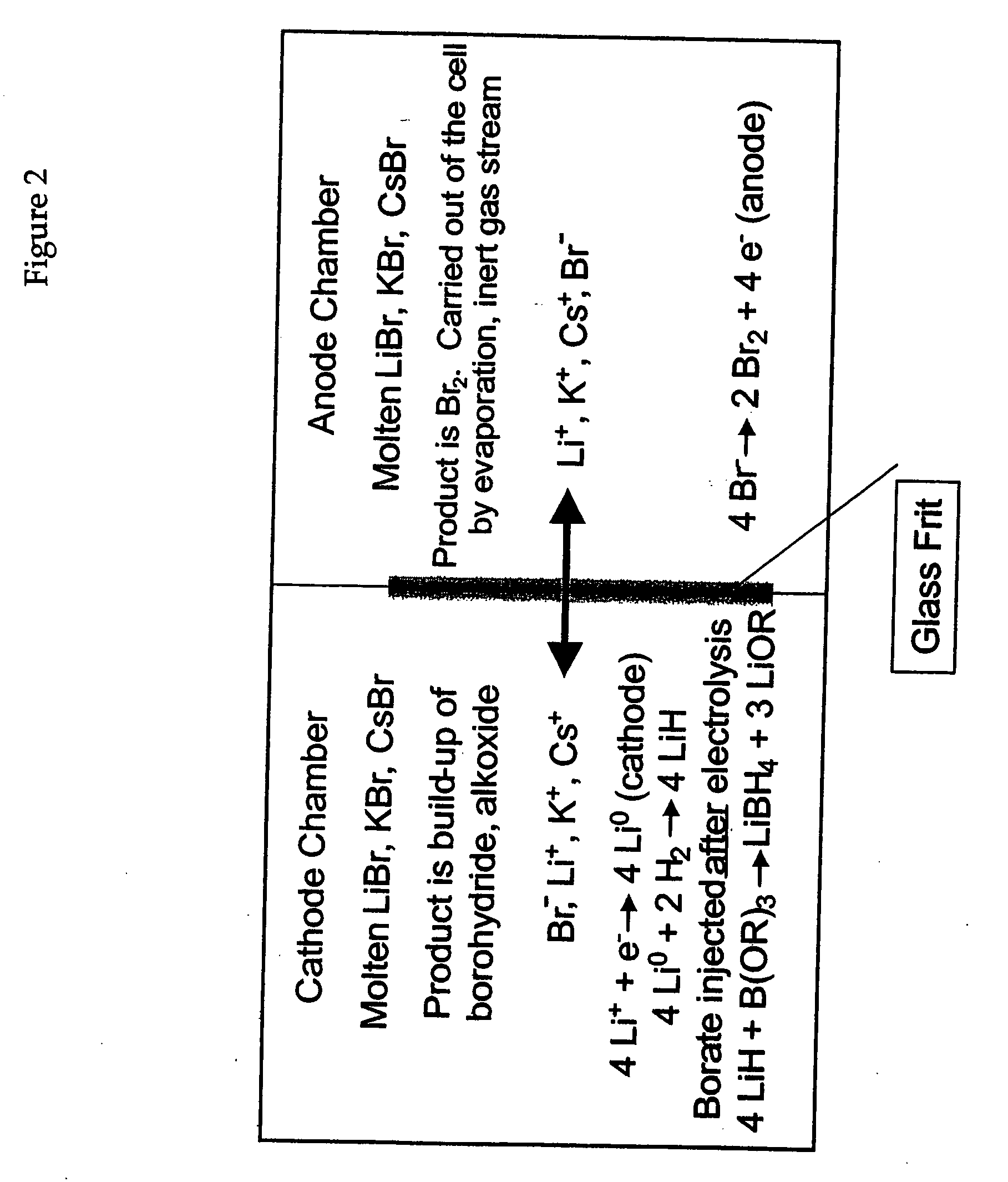

Methods and apparatus for synthesis of metal hydrides

An electrochemical process and apparatus for preparing metal hydride compounds from metal salts under a hydrogen atmosphere are disclosed. The electrochemical process may be integrated with chemical reaction of a boron compound to produce borohydride compounds. A metal salt and a borate are charged to the cathode of an electrolytic cell wherein the borate reacts with the hydride, to produce the borohydride compound.

Owner:MILLENNIUM CELL

Process for producing high-purity ruthenium

InactiveUS6036741AReduce Particle GenerationVacuum evaporation coatingSolid-state devicesAlkaline earth metalHydrogen atmosphere

A process comprises forming ruthenium tetroxide by blowing ozone-containing gas into crude ruthenium powder while hypochlorous acid is being added to the powder, allowing a hydrochloric acid solution to absorb the ruthenium tetroxide, evaporating the solution to dryness, and roasting the RuOCl3 crystals thus obtained in a hydrogen atmosphere. Thus a high-purity ruthenium material for thin film deposition, typically sputtering targey, is obtained which contains less than 1 ppm each of alkali metal elements, less than 1 ppm each of alkaline earth metal elements, less than 1 ppm each of transition metal elements, less than 10 ppb each of radioactive elements, a total of less than 500 ppm of carbon and gaseous ingredient elements, the material having a purity of ruthenium of at least 99.995% excluding the gaseous ingredient elements.

Owner:JAPAN ENERGY CORP

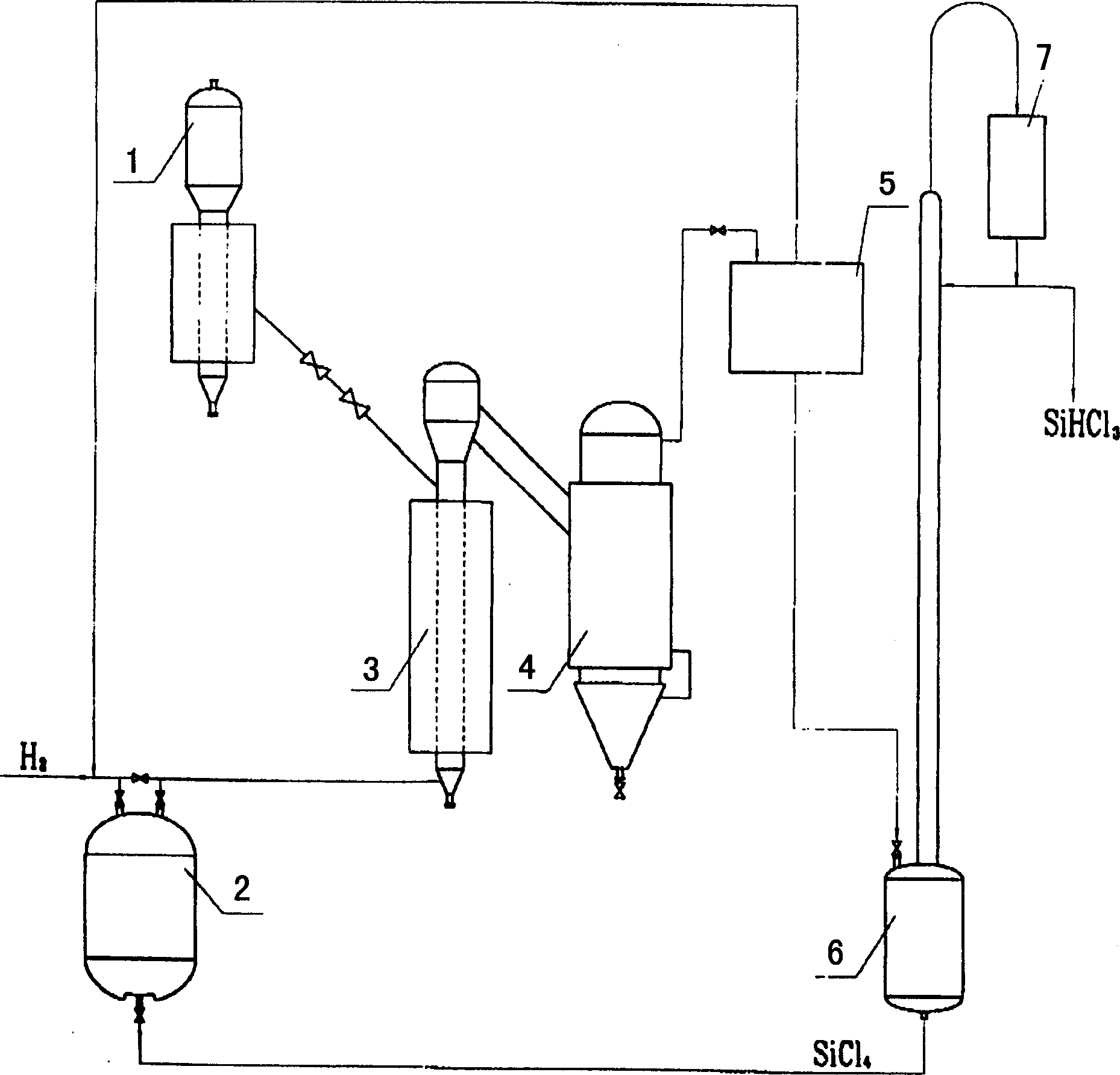

Silicon tetrachloride hydrogenating process of producing trichloro hydrosilicon

InactiveCN1436725ANo pollution in the processEasy to controlSilicon hydridesHalogenated silanesNickel catalystHydrogen atmosphere

The silicon tetrachloride hydrogenating process of producing trichloro-hydrosilicon includes: mixing powdered nickel catalyst and silicon powder in the mass ratio of 1-10 and activating the mixture in hydrogen atmosphere and at the temperature of continuously change from 20 deg.C to 420 deg.c; and making mixed gas of hydrogen and SiCl4 in the molar ratio of 1-10 pass through the activated catalyst and silicon powder layer for hydrogenating SiCl4 continuously at 400-500 deg.c temperature and 1.2-1.5 MPa pressure. The equipment, system and operation of the present invention has high once SiCl4 converting rate and low power consumption and may be used in large-scale production.

Owner:CHINA ENFI ENG CO LTD

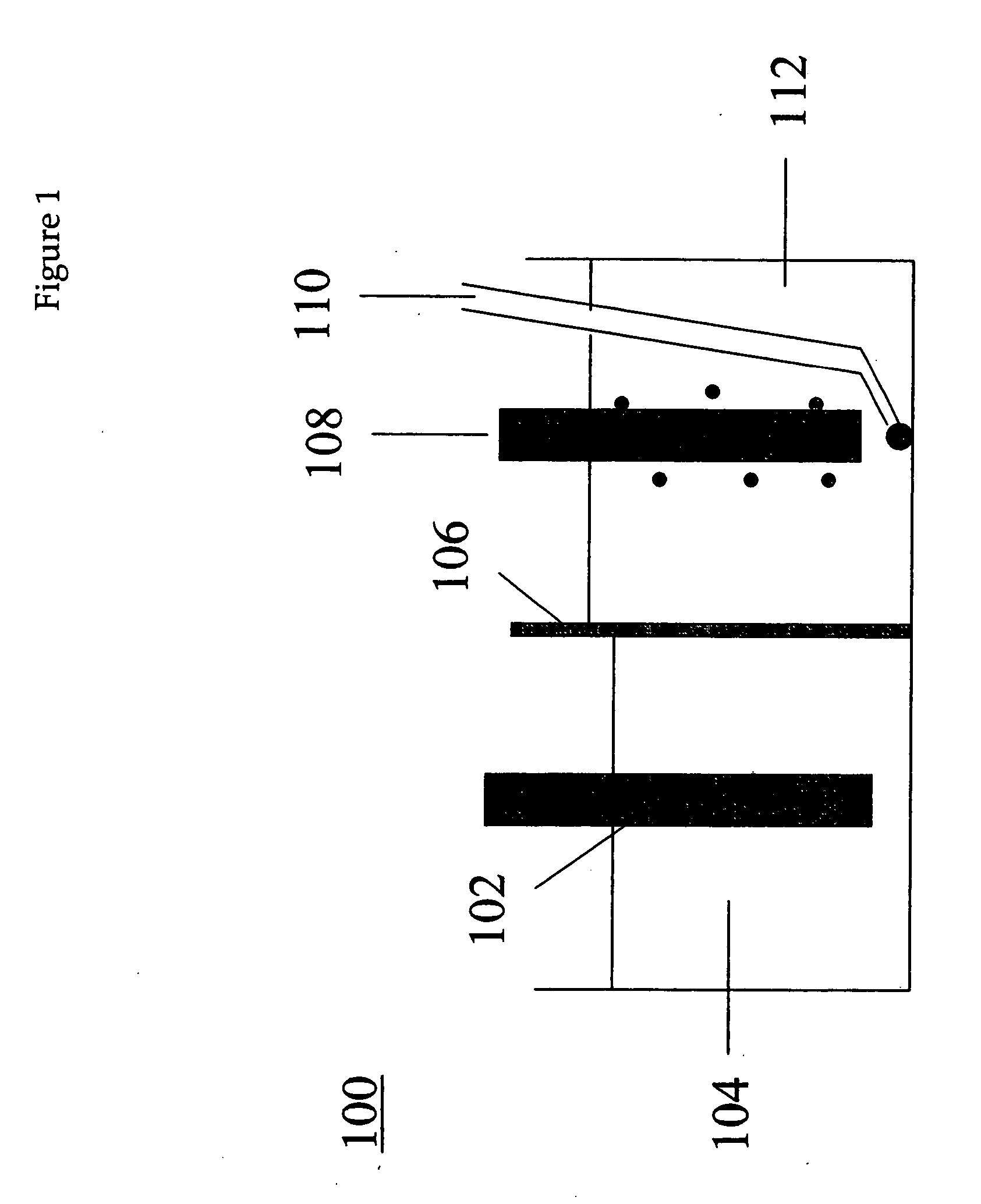

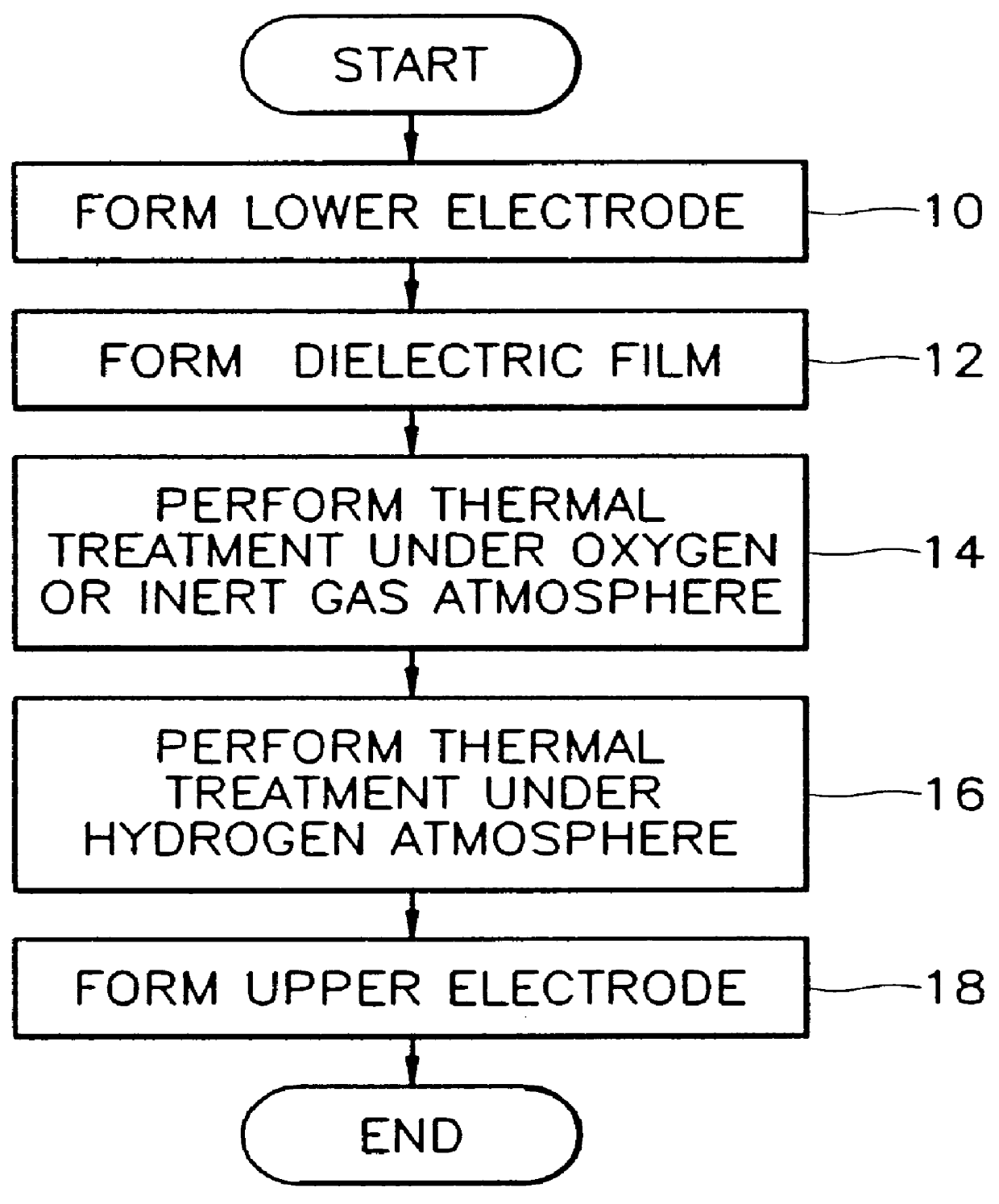

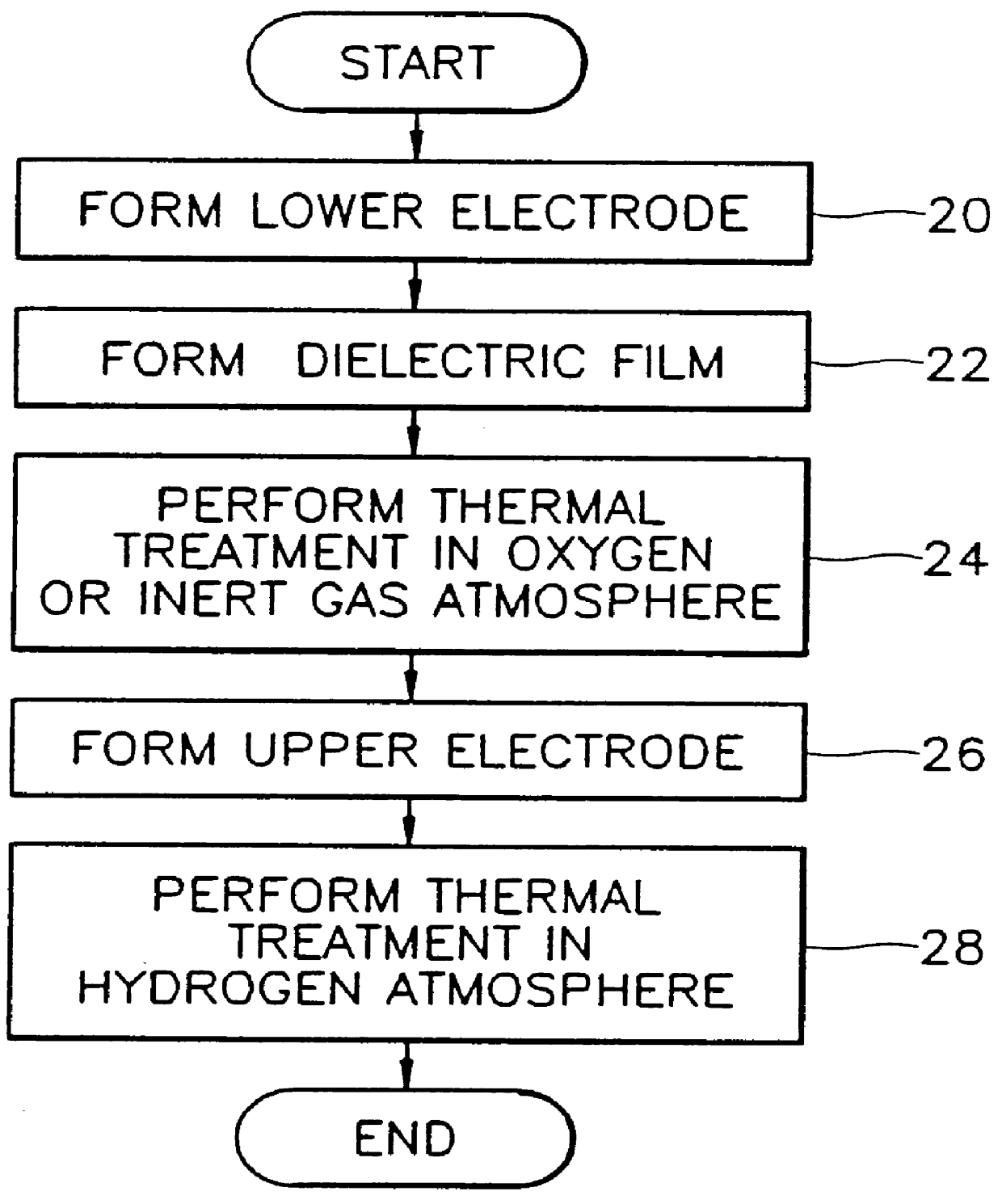

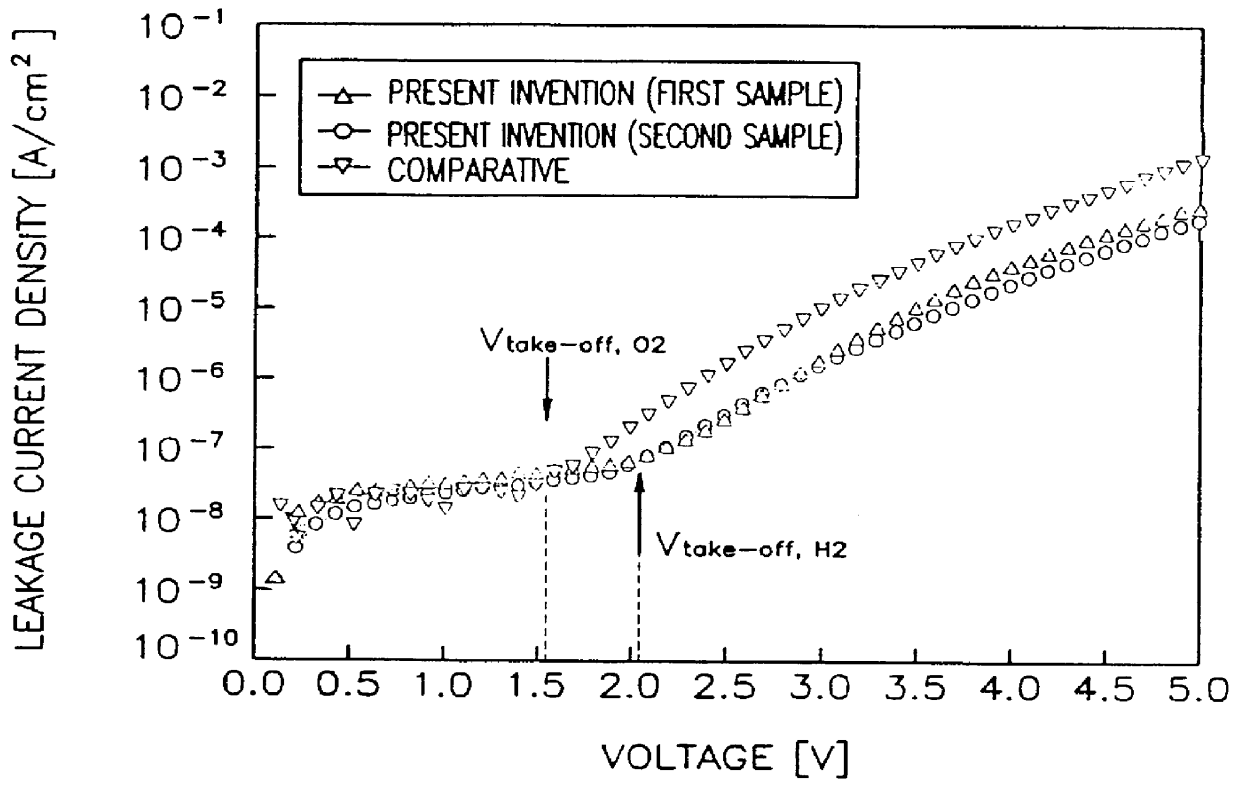

Method for manufacturing capacitor of semiconductor device including thermal treatment to dielectric film under hydrogen atmosphere

InactiveUS6136641AReduce leakage currentImprove the state of the interfaceSemiconductor/solid-state device manufacturingCapacitorsDielectricDevice material

A capacitor fabricating method for a semiconductor device where a dielectric film is thermally treated under hydrogen atmosphere to improve interface characteristics between the dielectric film and an electrode. In the method, a lower electrode is formed on a semiconductor substrate. A dielectric film is formed on the lower electrode. The dielectric film is thermally treated under hydrogen atmosphere. An upper electrode is formed on the dielectric film, thereby completing formation of the capacitor. The thermal treatment under the hydrogen atmosphere is performed at a temperature of 300 to 600 DEG C. using H2 gas or H2 plasma for 5 to 60 minutes. Thus, the density of an interface trap between the electrode and the dielectric film of the capacitor is reduced.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for preparing high-purity ruthenium sputtering target and high-purity ruthenium sputtering target

InactiveUS6284013B1Minimize formation of particleSolve the large leakage currentTransportation and packagingRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsHydrogen atmosphereImpurity

There is provided a high-purity ruthenium sputtering target with a low impurity content, in particular producing extremely few particles, which is suitable for applications such as the formation of semiconductor thin films. The high-purity ruthenium sputtering target is manufactured by feeding crude ruthenium powder into a sodium hydroxide solution; blowing an ozone-containing gas while or after blowing chlorine gas into the solution to form ruthenium tetroxide; absorbing the ruthenium tetroxide in a hydrochloric acid solution or a mixed solution of hydrochloric acid and ammonium chloride, and evaporating the solution to dryness; sintering the resultant ruthenium salt in a hydrogen atmosphere to form high-purity ruthenium powder; and hot-pressing the ruthenium powder into a sputtering target.

Owner:NIKKO MATERIALS CO LTD

Silicon carbide ceramic support body and preparation method thereof

InactiveCN102389719AHigh strengthExtended service lifeSemi-permeable membranesHydrogen atmospherePlasticizer

The invention relates to a silicon carbide ceramic support body and a preparation method thereof. The raw material powder of the support body is mixed powder consisting of silicon carbide powder 1 and silicon carbide powder 2, wherein the silicon carbide powder 1 has a median particle diameter D50 of 25-45mu m, the silicon carbide powder 2 has a median particle diameter D50 of less than 5mu m, the ratio of the D50 of the silicon carbide powder 1 to the D50 of the silicon carbide powder 2 is not less than 6, and the consumption of the silicon carbide powder 2 is 0.5-13 percent of the weight of the used silicon carbide powder 1. The raw material powder is mixed with a solvent, an adhering agent, a plasticizer and a pore-forming agent to form pug, the pug is subjected to stamping to form a raw blank, the raw blank is dewatered and degreased to form a calcined product, and the calcined product is sintered in argon or hydrogen atmosphere or vacuum to form the support body of a recrystallized silicon carbide ceramic membrane. The support body of the recrystallized silicon carbide ceramic membrane has filtering flux and strength which are higher than those of the traditional commercial support body of an aluminum oxide ceramic membrane.

Owner:SANDA FILM SCI & TECH XIAMEN

Method for manufacturing semiconductor device having trench in silicon carbide semiconductor substrate

ActiveUS7241694B2High crystallinitySemiconductor/solid-state device manufacturingFrom condensed vaporsSlant angleHydrogen atmosphere

A method for manufacturing a silicon carbide semiconductor device includes the steps of: forming a trench mask on an upper surface of a semiconductor substrate; forming the trench such that the trench having an aspect ratio equal to or larger than 2 and having a trench slanting angle equal to or larger than 80 degrees is formed; and removing a damage portion in such a manner that the damage portion disposed on an inner surface of the trench formed in the semiconductor substrate in the step of forming the trench is etched and removed in hydrogen atmosphere under decompression pressure at a temperature equal to or higher than 1600° C.

Owner:DENSO CORP

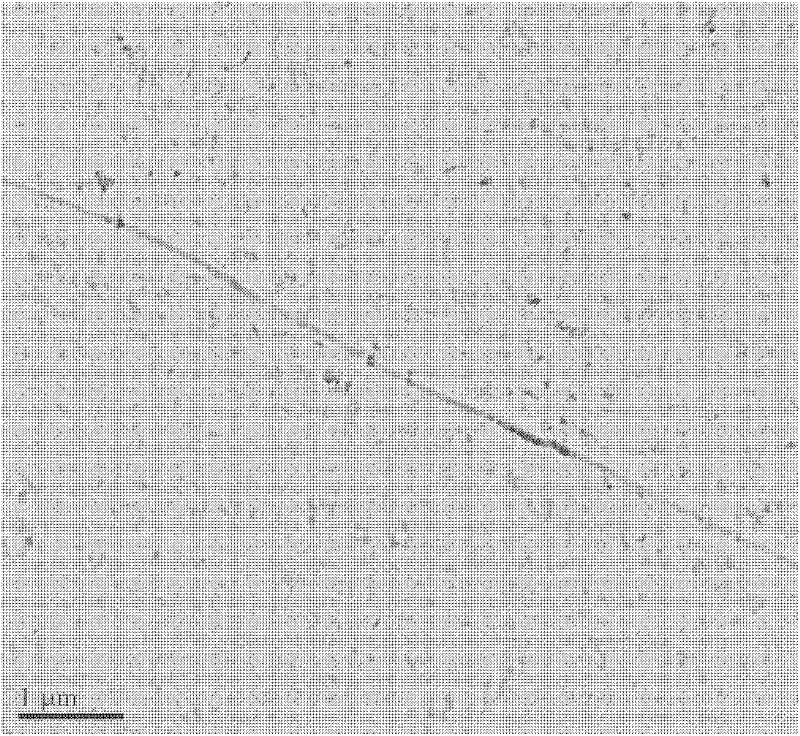

Superfine cobalt powder and its manufacturing technology

The present invention relates to one kind of superfine cobalt powder and its production process. The production process includes the following steps: setting cobalt carbonate or cobalt oxalate powder, grinding dispersant and hard alloy balls in certain weight proportion into high energy ball mill pot; vacuumizing the ball mill pot and introducing protective argon; sealing the ball mill pot, and ball milling at controlled rotation speed to obtain superfine cobalt carbonate or cobalt oxalate powder; and reducing the superfine cobalt carbonate or cobalt oxalate powder in hydrogen atmosphere to obtain superfine cobalt powder in oxygen content not more than 0.5 % and granularity smaller than 0.6 micron. The superfine cobalt powder is applied in producing high quality hard alloy, and has simple production process and low cost.

Owner:GEM CO LTD +1

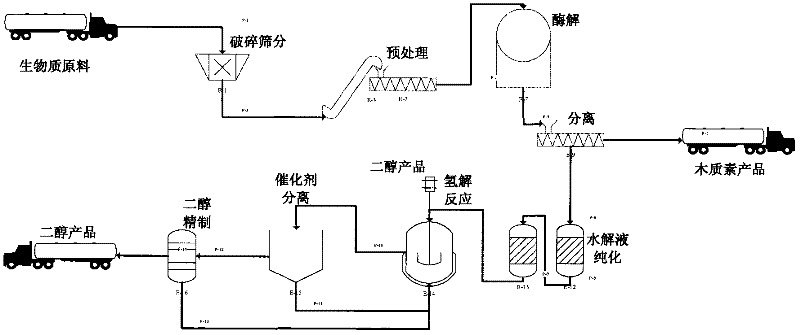

Method for preparing dihydric alcohol from lignocellulosic biomass

ActiveCN102286548AWidely distributedFully distributedOrganic compound preparationHydroxy compound preparationLiquid glucoseFiber

The invention relates to a method for preparing dihydric alcohol from lignocellulosic biomass, which has main steps of: 1, adding alkali liquor, acid liquor or water for pretreatment after lignocellulosic biomass crushing; 2, carrying out enzymolysis and concentrating liquid glucose filtered through enzymolysis after decoloration and ion exchange impurity removal; 3, adding catalysts with hydrogenation hydrogenolysis activity for carrying out hydrogenation hydrogenolysis reaction on the concentrated liquid glucose under the conditions of the pH being 8 to 14, the temperature being 130 to 250 DEG C and hydrogen atmosphere, separating the catalysts, and producing various dibasic alcohol with the carbon number being 2 to 6 after product rectification. The method utilizes the lignocellulosic biomass pretreatment-zymolyting glucose liquid as raw materials, and monosaccharide, soluble polysaccharides and sugar degradation products can respectively react, so both the efficiency and the process controllability can be greatly improved, and products can be independently used through separation and can be directly used for producing unsaturated polyester resin, polyurethane, fuel additives, surface active agents, emulsifying agents, motor vehicle antifreeze fluid and the like without depth separation.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Preparing cyclohexene catalyst and for benzene hydrogenation its manufacturing method

InactiveCN1597099AHas industrial application valueLow costHydrocarbon by hydrogenationMetal/metal-oxides/metal-hydroxide catalystsBenzeneCyclohexene

A catalyst for preparing cyclohexene from benzene by hydrogenating is prepared from metal Ru, one or two transition metals or RE elements, the hydroxide of alkali metal as precipitator, and hydrophilic indifferent oxide. It has high activity and selectivity.

Owner:ZHENGZHOU UNIV

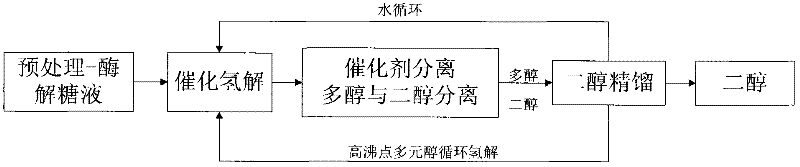

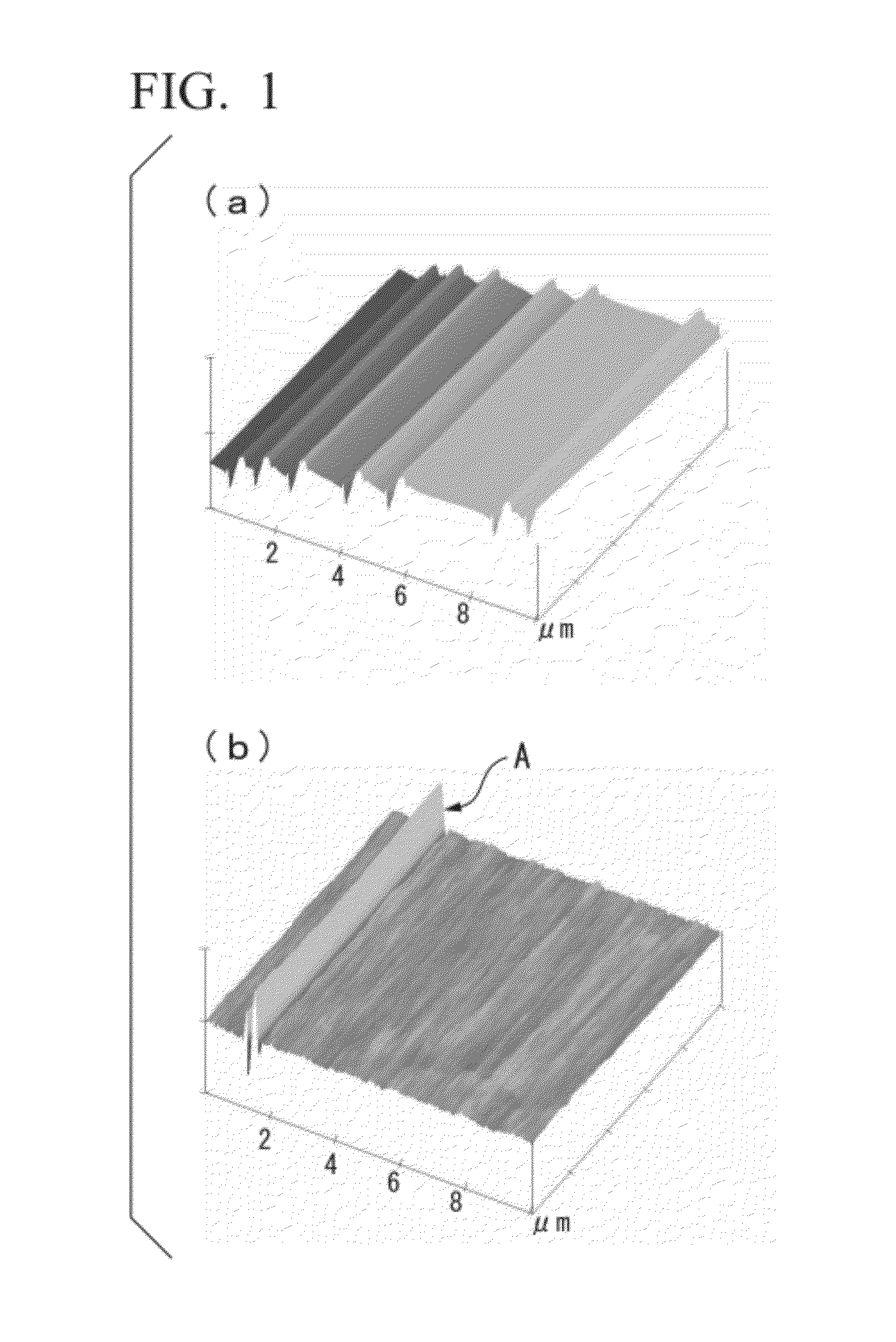

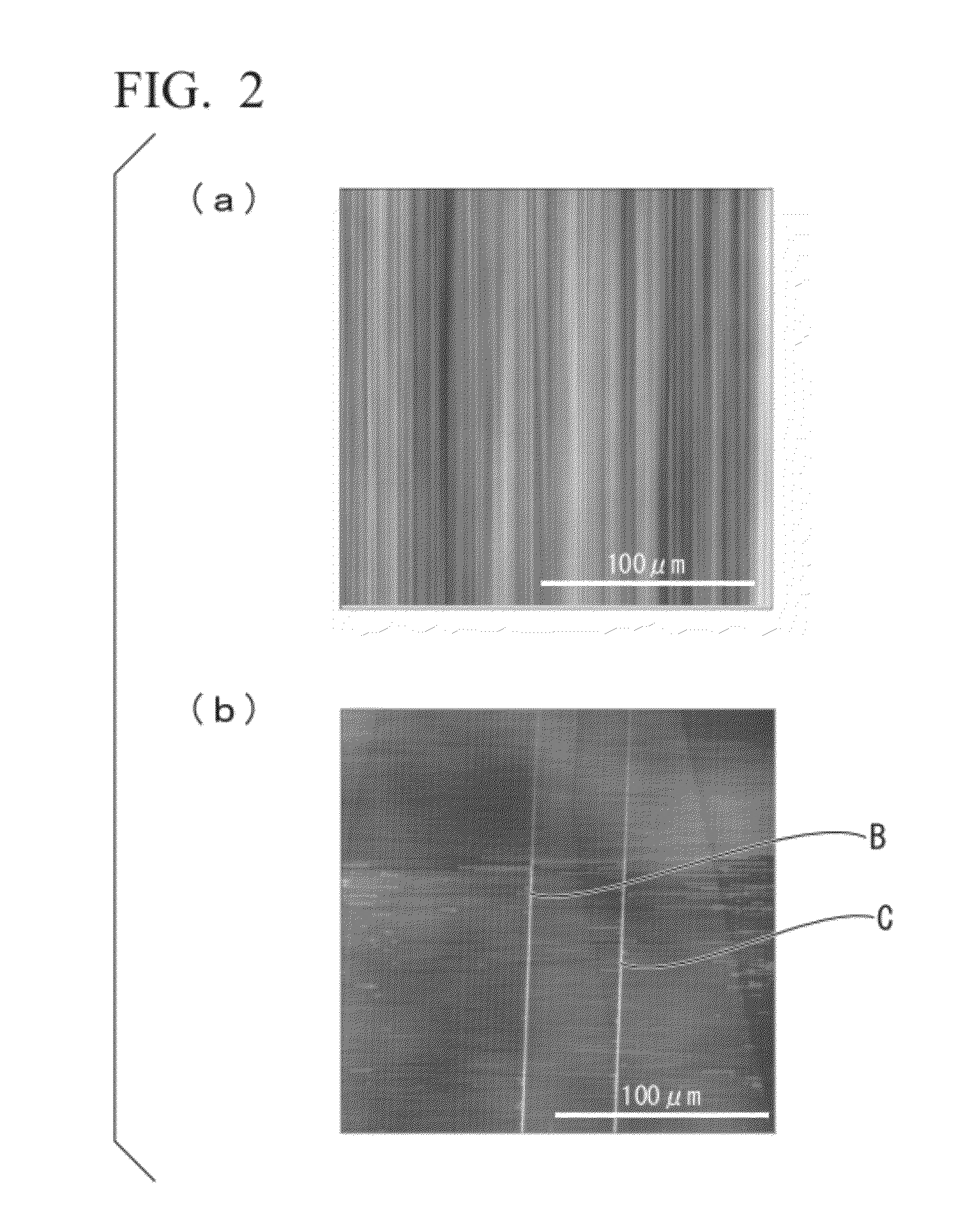

Silicon carbide epitaxial wafer and manufacturing method therefor

ActiveUS20120146056A1Polycrystalline material growthSemiconductor/solid-state device manufacturingHydrogen atmosphereSingle crystal substrate

Provided is a silicon carbide epitaxial wafer, the entire surface of which is free of step bunching. Also provided is a method for manufacturing said silicon carbide epitaxial wafer. The provided method for manufacturing a silicon carbide semiconductor device includes: a step wherein a 4H—SiC single-crystal substrate having an off-axis angle of 5° or less is polished until the lattice disorder layer on the surface of the substrate is 3 nm or less; a step wherein, in a hydrogen atmosphere, the polished substrate is brought to a temperature between 1400° C. and 1600° C. and the surface of the substrate is cleaned; a step wherein silicon carbide is epitaxially grown on the surface of the cleaned substrate as the amounts of SiH4 gas and C3H8 gas considered necessary for epitaxially growing silicon carbide are supplied simultaneously at a carbon-to-silicon concentration ratio between 0.7 and 1.2 to 1; and a step wherein the supply of SiH4 gas and the supply of C3H8 gas are cut off simultaneously, the substrate temperature is maintained until the SiH4 gas and the C3H8 gas are evacuated, and then the temperature is decreased.

Owner:RESONAC CORP

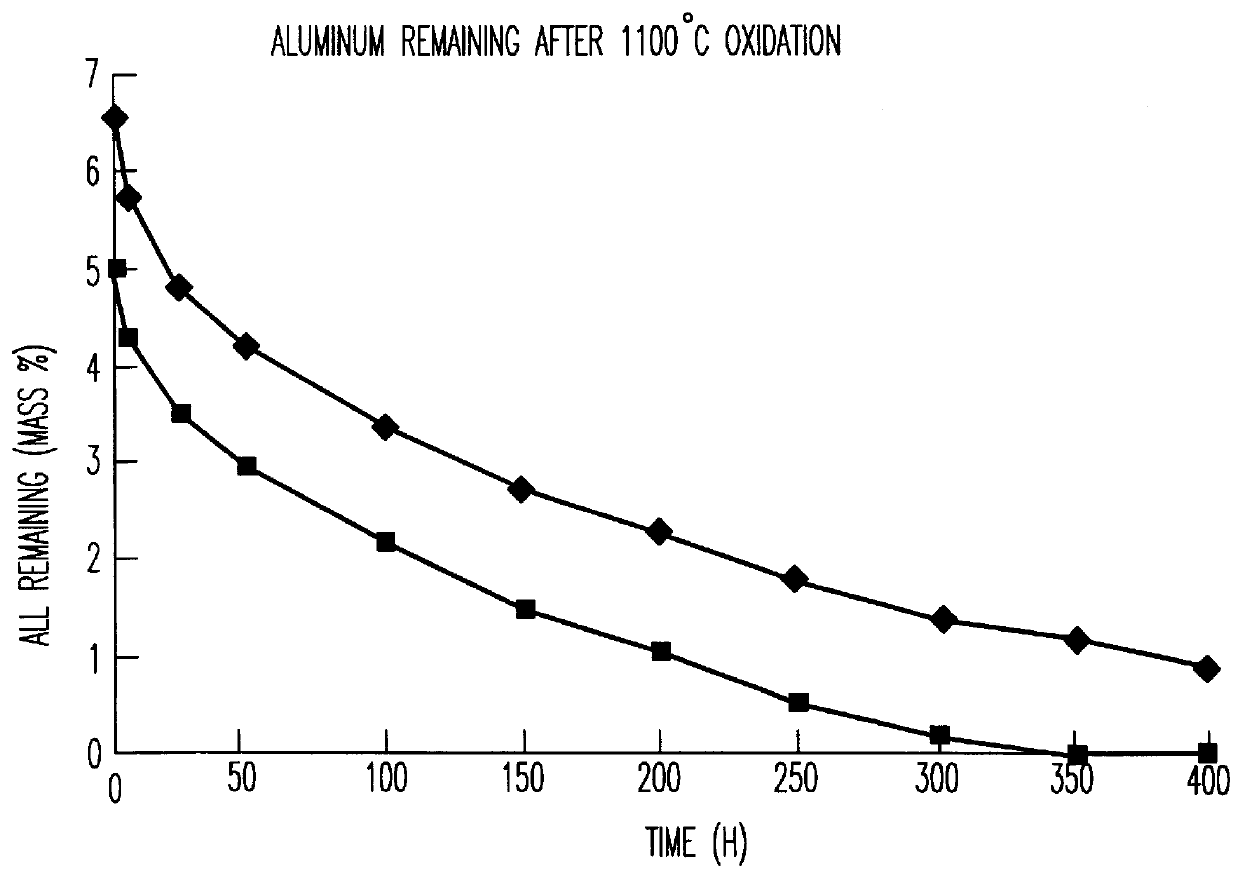

Process for manufacturing a foil of ferritic stainless steel having a high aluminum content, aluminum-containing ferritic stainless steel, and catalyst support useful for a motor-vehicle exhaust

InactiveUS6086689AHot-dipping/immersion processesDispersed particle separationRare-earth elementHydrogen atmosphere

Process for manufacturing a foil of ferritic stainless steel having a high aluminum content, which can be used in particular for a catalyst support in a motor-vehicle exhaust, wherein a ferritic stainless steel sheet of the following composition: 0.005%<carbon<0.060% 10%<chromium<23% 0.1%<aluminum<3% 0.003%<nitrogen<0.030% 0.1%<manganese<2% 0.1%<silicon<2% rare-earth elements in a proportion of between 0.03% and 0.15%, is subjected to: plating between two sheets of aluminum in order to obtain a laminate, rolling the laminate to a thickness of 0.03-0.25 mm to form a foil, static diffusion annealing the foil in a hydrogen atmosphere, and finish rolling greater than 20%.

Owner:UGINE SA

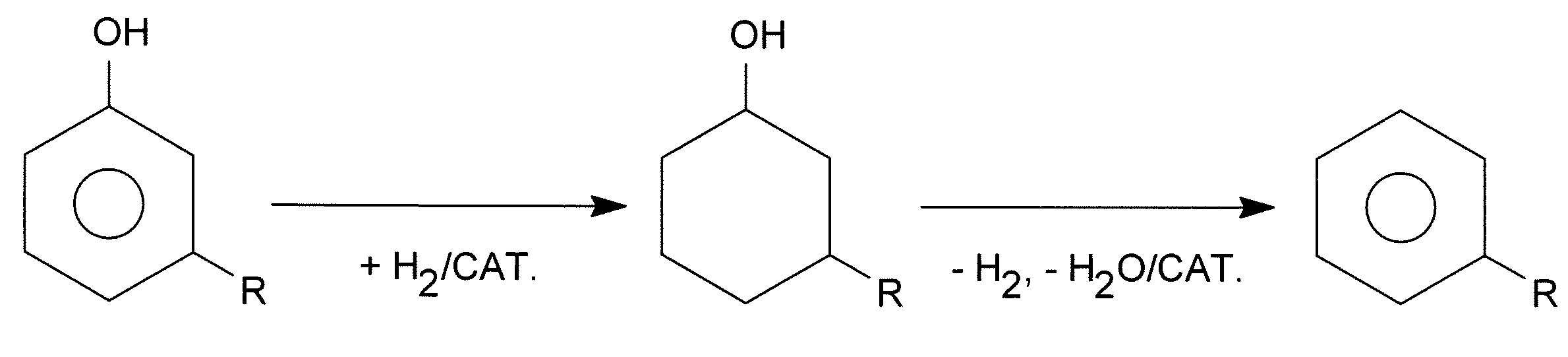

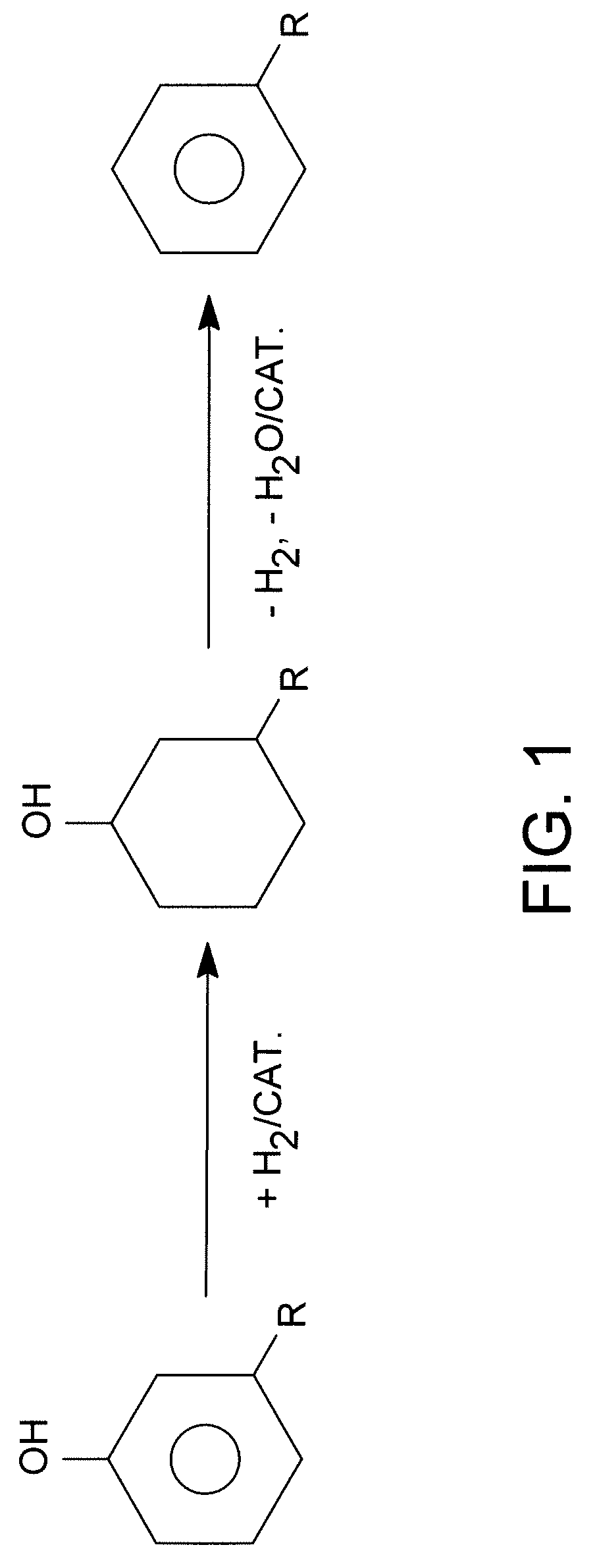

Combination of Hydrogenation and Base Catalyzed Depolymerization for Lignin Conversion

ActiveUS20100137663A1Low oxygenReduce the amount requiredLiquid hydrocarbon mixture productionHydrocarbonsDepolymerizationHydrogen atmosphere

A process for the conversion of lignin to chemical precursors is presented. The process comprises treating the lignin to form less acidic compounds. The process includes reacting lignin with a hydrogenation catalyst under a hydrogen atmosphere to convert acidic oxygenate compounds to less acidic oxygenates or hydrocarbons. The oxygenate compounds are reacted in a dehydrogenation and deoxygenation process to remove the oxygen and to convert the cyclic hydrocarbons back to aromatic compounds.

Owner:UOP LLC

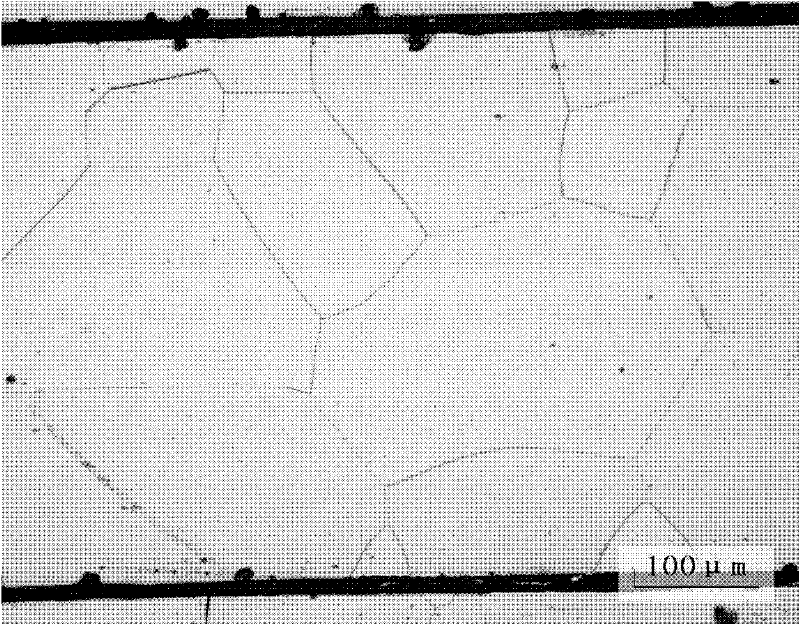

Production method for high-grade non-oriented silicon steel

The invention relates to a manufacturing method for non-oriented electric steel. The method comprises the following steps of: smelting according to a clean steel process and continuously casting into billets; heating the continuous casting billets; performing hot rolling; reeling; naturally cooling to room temperature; normalizing; performing acid washing conventionally; performing cold rolling for the first time; performing intermediate annealing in the total hydrogen atmosphere or the mixed atmosphere of hydrogen and nitrogen; performing cold rolling for the second time; performing final annealing; and cooling conventionally, coating and finishing for later use. The finished product silicon steel with coarse grains and good texture can be obtained by adopting lower process heat treatment temperature; brittleness of the steel is reduced and cold rolling performance of a steel plate is improved by adopting lower normalizing temperature and intermediate annealing temperature; the problems of surface oxidation of the steel plate, nodulation of a furnace bottom roller and the like can be effectively solved by adopting lower finished product annealing temperature; and the high-grade non-oriented silicon steel with lower iron loss can be produced stably.

Owner:武汉钢铁有限公司

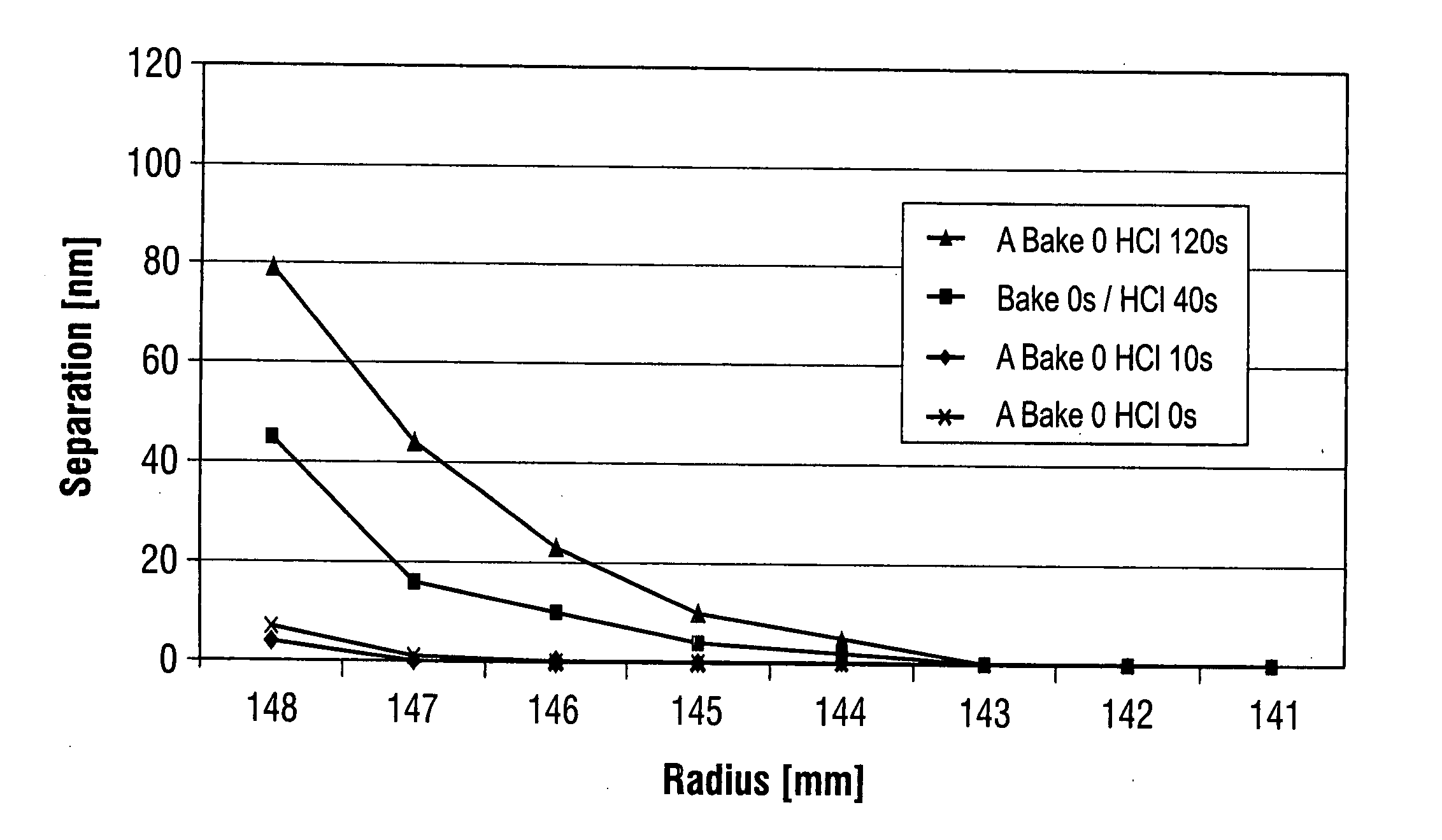

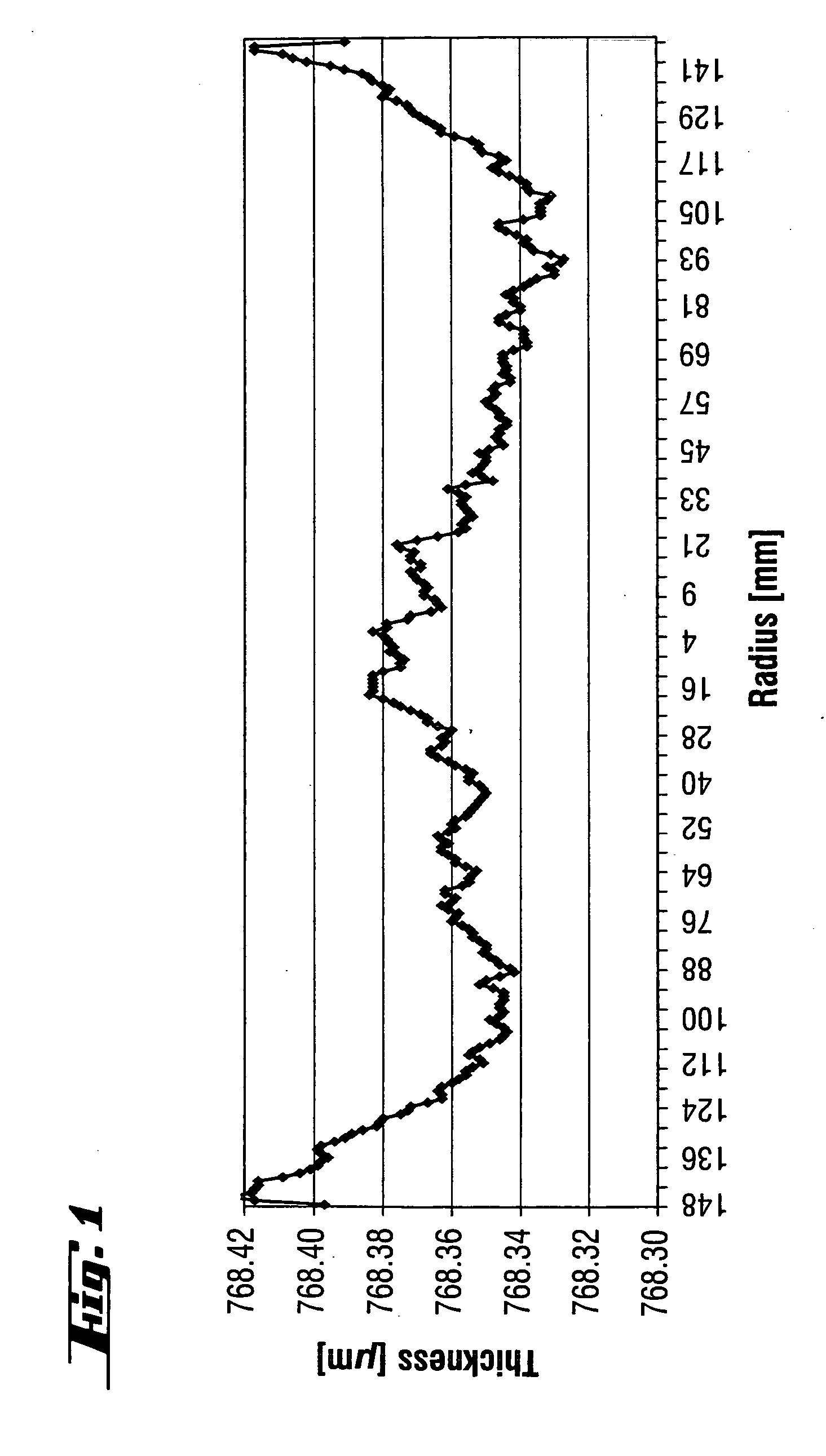

Epitaxially coated silicon wafer and method for producing epitaxially coated silicon wafers

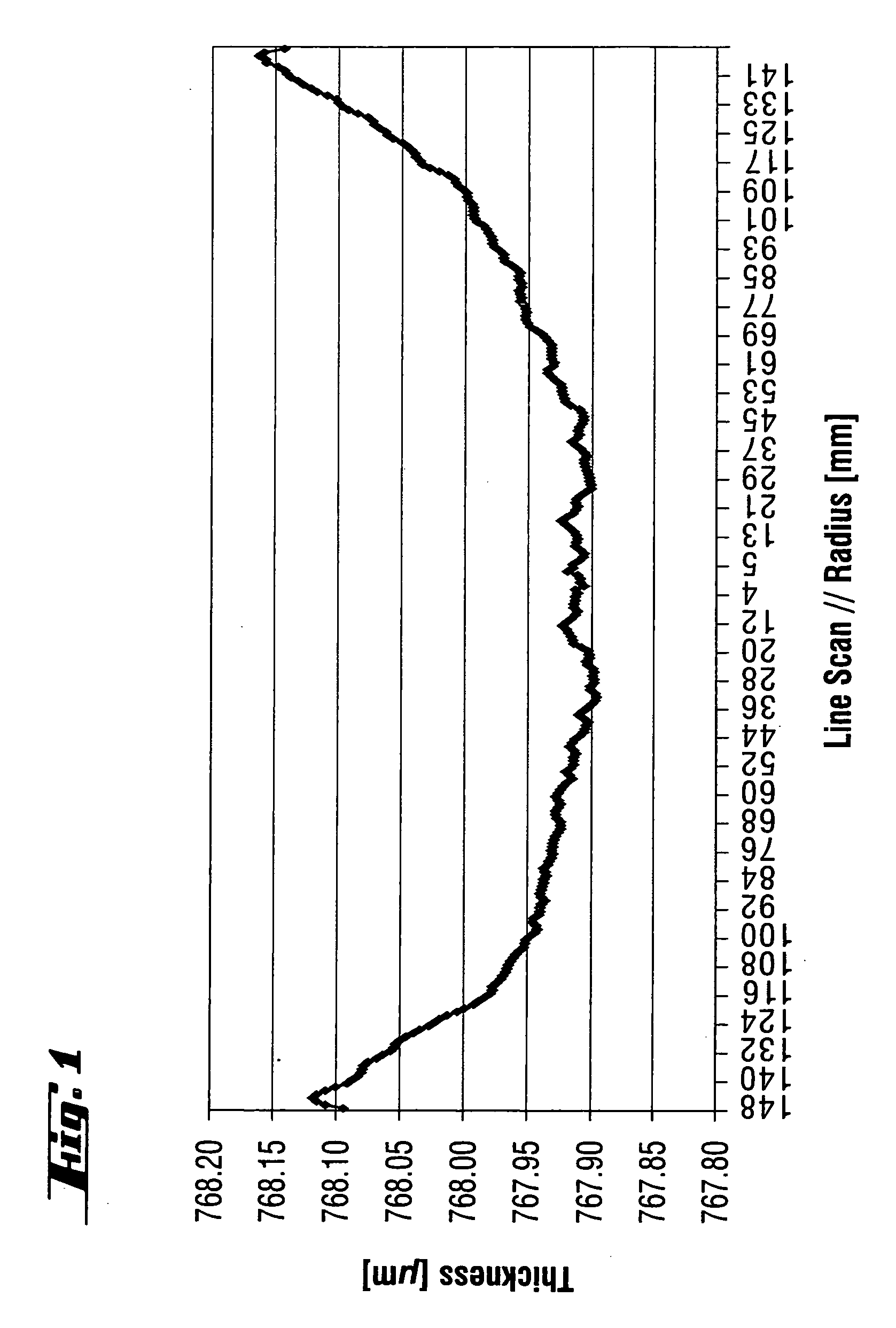

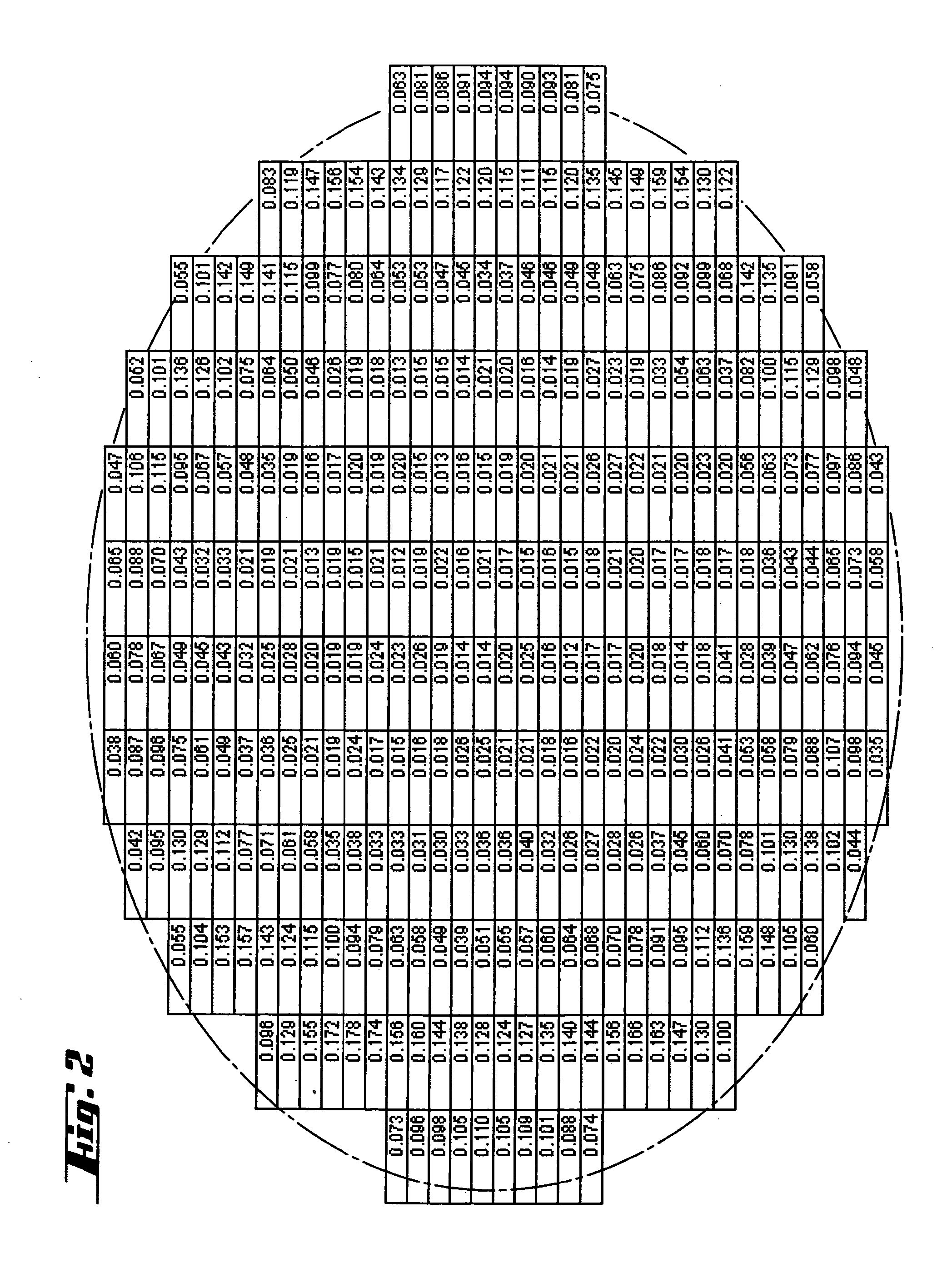

ActiveUS20070066036A1Improve flatnessReduce trafficPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorWafering

A multiplicity of silicon wafers polished at least on their front sides are provided and successively coated individually in an epitaxy reactor by a procedure whereby one of the wafers is placed on a susceptor in the epitaxy reactor, is pretreated under a hydrogen atmosphere at a first hydrogen flow rate, and with addition of an etching medium to the hydrogen atmosphere at a reduced hydrogen flow rate in a second step, is subsequently coated epitaxially on its polished front side, and removed from the reactor. An etching treatment of the susceptor follows a specific number of epitaxial coatings. Silicon wafers produced thereby have a global flatness value GBIR of 0.07-0.3 μm relative to an edge exclusion of 2 mm.

Owner:SILTRONIC AG

Copper-tungsten/copper-alloy integrated contact and preparation method thereof

The invention relates to a contact material for high-voltage switches and discloses a copper-tungsten / copper-alloy integrated contact and a preparation method thereof. The copper-tungsten / copper-alloy integrated contact comprises a contact part and a conducting rod part, wherein the tungsten content of the contact part gradually decreases from head to tail. The preparation method comprises the following steps: firstly, mechanically mixing powder by a wet method to prepare copper-tungsten particles with different tungsten contents; secondly, putting the tungsten in the die cavity of a compression mold according to the weight contents of tungsten in a descending order to carry out the press forming; thirdly, putting the pressed blank in a graphite boat, and sintering and infiltrating the pressed blank in a sintering furnace in the hydrogen atmosphere to obtain the copper-tungsten alloy of the contact part; and finally, sintering the low-tungsten-content end of the copper-tungsten alloy and the copper conducting rod part or the copper alloy conducting rod part to form an integral body by using a sintering method, an electro-beam welding method or a diffusion welding method, thereby obtaining the copper-tungsten / copper-alloy integrated contact.

Owner:XIAN FULAI ELECTRICAL ALLOY

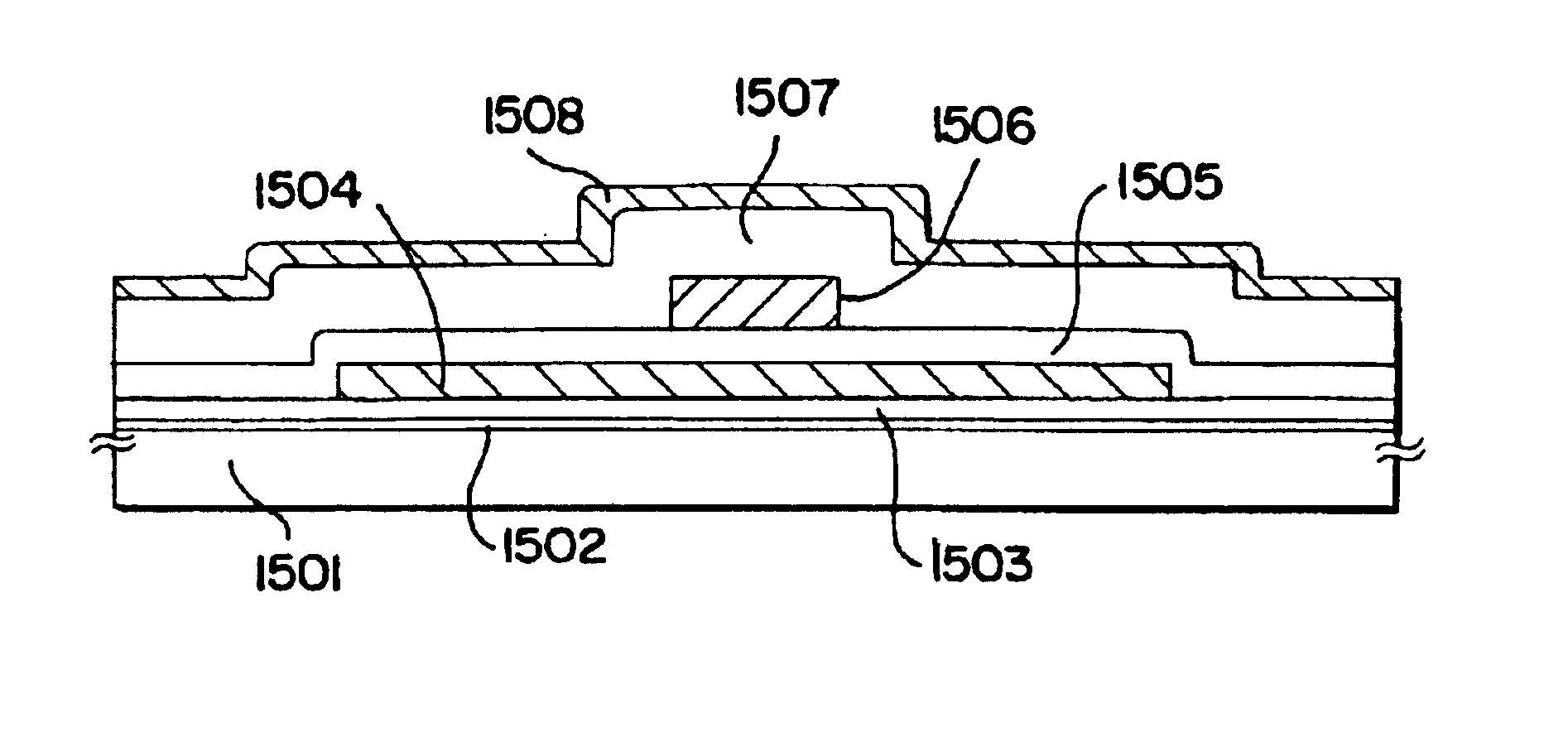

Semiconductor device and fabrication method thereof

InactiveUS6853002B2Efficient processingImprove performanceTransistorSemiconductor/solid-state device detailsHydrogen atmosphereNitrogen

A hydrogenation method that utilizes plasma directly exposes a crystalline semiconductor film to the plasma, and therefore involves the problem that the crystalline semiconductor film is damaged by the ions generated simultaneously in the plasma. If a substrate is heated to 400° C. or above to recover this damage, hydrogen is re-emitted from the crystalline semiconductor film.To solve these problems, a method of fabricating a semiconductor device according to the present invention comprises the steps of forming a hydrogen-containing first insulating film on a semiconductor layer formed into a predetermined shape, conducting heat-treatment in a hydrogen atmosphere or in an atmosphere containing hydrogen formed by plasma generation, forming a second insulating film in contact with the first insulating film, conducting heat-treatment in a hydrogen atmosphere or in an atmosphere containing hydrogen formed by plasma generation, forming a hydrogen-containing third insulating film on the second insulating film and conducting heat-treatment in an atmosphere containing hydrogen or nitrogen.

Owner:SEMICON ENERGY LAB CO LTD

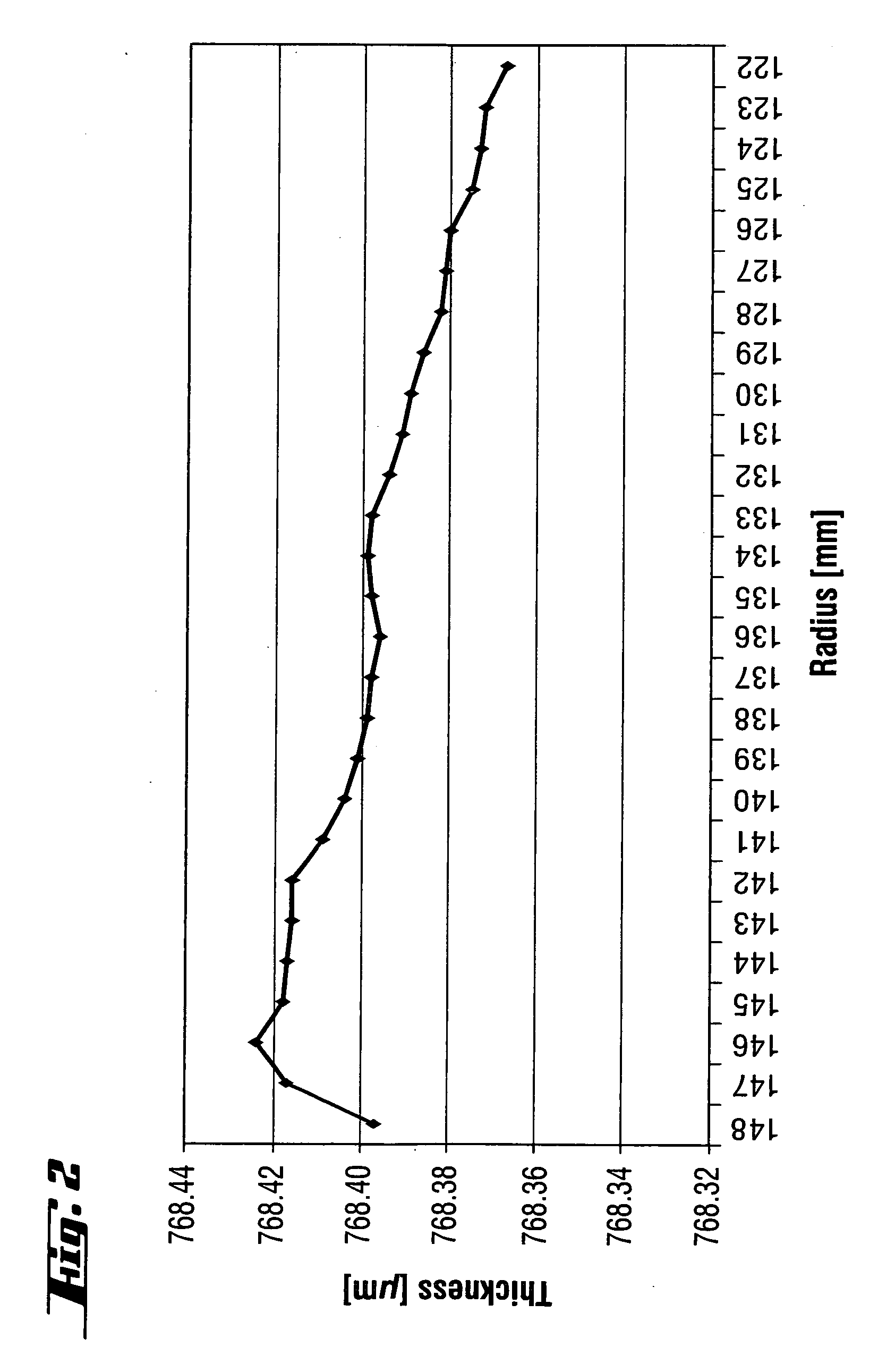

Epitaxially coated silicon wafer and method for producing epitaxially coated silicon wafers

ActiveUS20070062438A1High yieldPolycrystalline material growthSemiconductor/solid-state device manufacturingSusceptorWafering

Epitaxially coated silicon wafers, are produced by epitaxially coating a multiplicity of wafers polished at least on their front sides, successively and individually in an epitaxy reactor, by placing a silicon wafer on a susceptor, pretreating under a hydrogen atmosphere followed by addition of an etching medium to the hydrogen atmosphere, coating epitaxially on the polished front side and removing the water from the epitaxy reactor. The susceptor is then heated, in each case, to a temperature of at least 1000° C. under a hydrogen atmosphere, and furthermore an etching treatment of the susceptor and a momentary coating of the susceptor with silicon are effected after a specific number of epitaxial coatings. Silicon wafers characterized by a parameter R30-1 mm of −10 nm to +10 nm, determined at a distance of 1 mm from the edge of the silicon wafer are produced.

Owner:SILTRONIC AG

Sintering method

InactiveUS6267797B1Active material electrodesMetallic material coating processesSurface layerHydrogen atmosphere

There is disclosed a method of sintering cemented carbide bodies including heating said bodies to the sintering temperature in a suitable atmosphere and cooling. If said cooling at least to below 1200° C. is performed in a hydrogen atmosphere of pressure 0.4-0.9 bar cemented carbide bodies with no surface layer of binder phase are obtained. This is an advantage when said bodies are to be coated with wear resistant layers by the use of CVD-, MTCVD- or PVD-technique.

Owner:SANDVIK INTELLECTUAL PROPERTY AB

Formula and prepn process for epoxidating propylene to prepare epoxy propane catalyst in oxy-hydrogen atmosphere

InactiveCN1387948ANo pollution in the processOrganic chemistryMolecular sieve catalystsPlatinumMolecular sieve

The catalyst for epoxidation propylene to prepare epoxy propane in oxy-hydrogen atmosphere consists of Pd, Pt, transition metal compound and titanium silicone molecular sieve. The preparation of the catalyst includes soaking to make Si-Ti molecular sieve carry compounds of Pd and Pt to prepare double-function Pd-Pt-Si molecular sieve catalyst; mixing nano level transition metal compound with the said Pd-Pt-Si molecular sieve catalyst to obtain Pd-Pt-Si-transition metal molecular sieve catalyst system; and activation in reducing atmosphere. The present invention one green synthesis process andcan result in epoxy propane yield up to 8.3 wt% and selectivity of 70% and no any environmental pollution.

Owner:CHANGJIANG SECURITIES +1

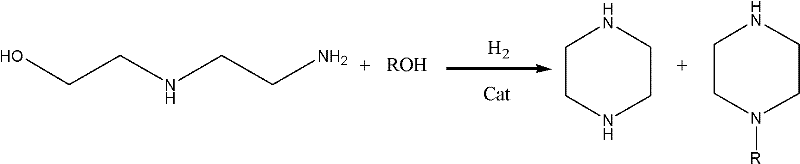

Process for coproducing piperazine and N-alkyl piperazine

The invention discloses a process for coproducing piperazine and N-alkyl piperazine, which comprises the following steps of: dissolving N-beta-hydroxyethyl ethylenediamine in carbinol with carbon atom number of 1-7, and in hydrogen atmosphere, reacting under the catalysis of a catalyst to obtain a mixture of piperazine and N-alkyl piperazine. The process has the advantages that: the piperazine is produced and a corresponding N-alkyl substituted piperazine compound is coproduced; the conversion rate of the N-beta-hydroxyethyl ethylenediamine is over 99 percent; the process is easy and convenient to operate; and synthesized products have high yield.

Owner:SHAOXING XINGXIN CHEM

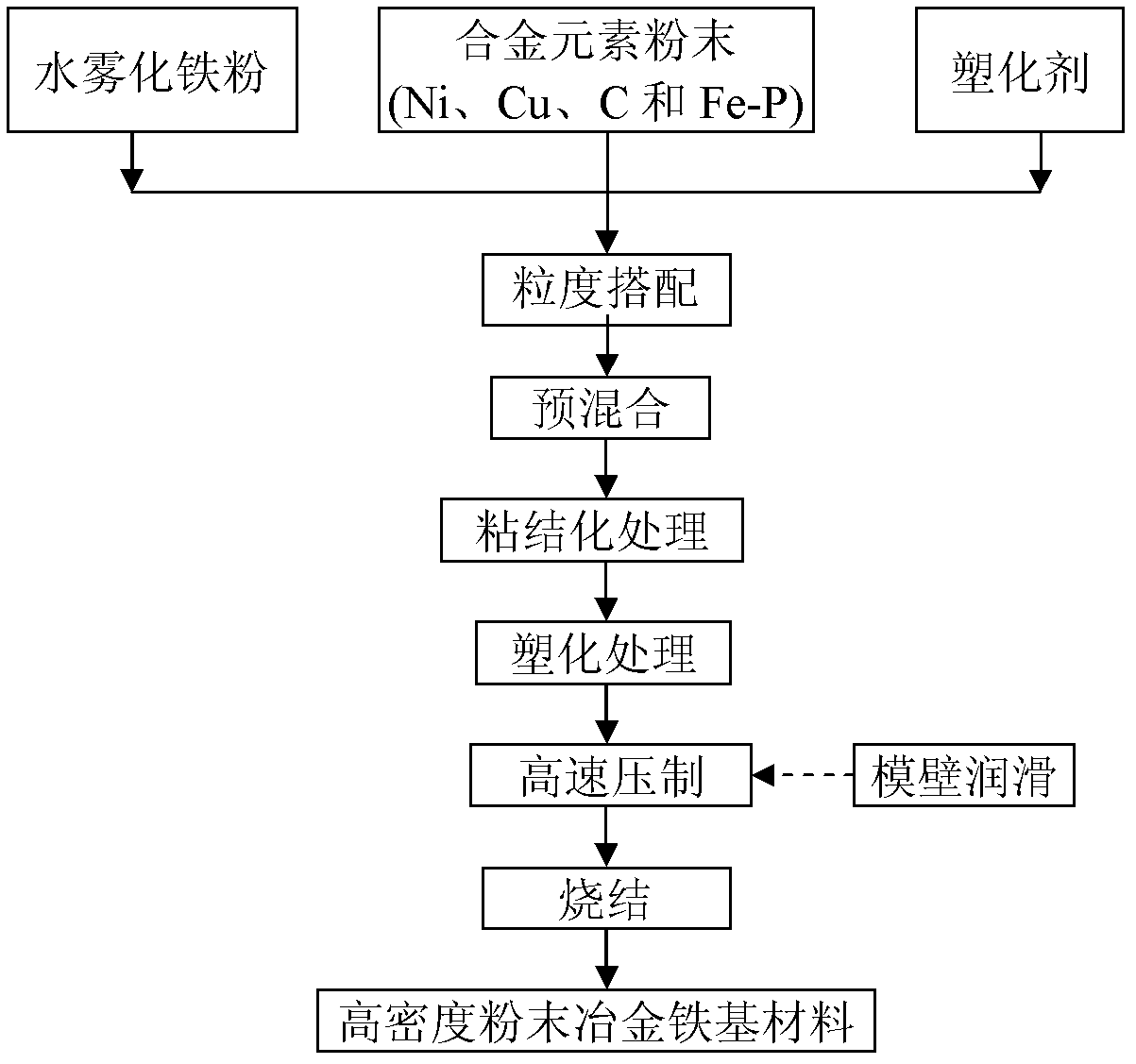

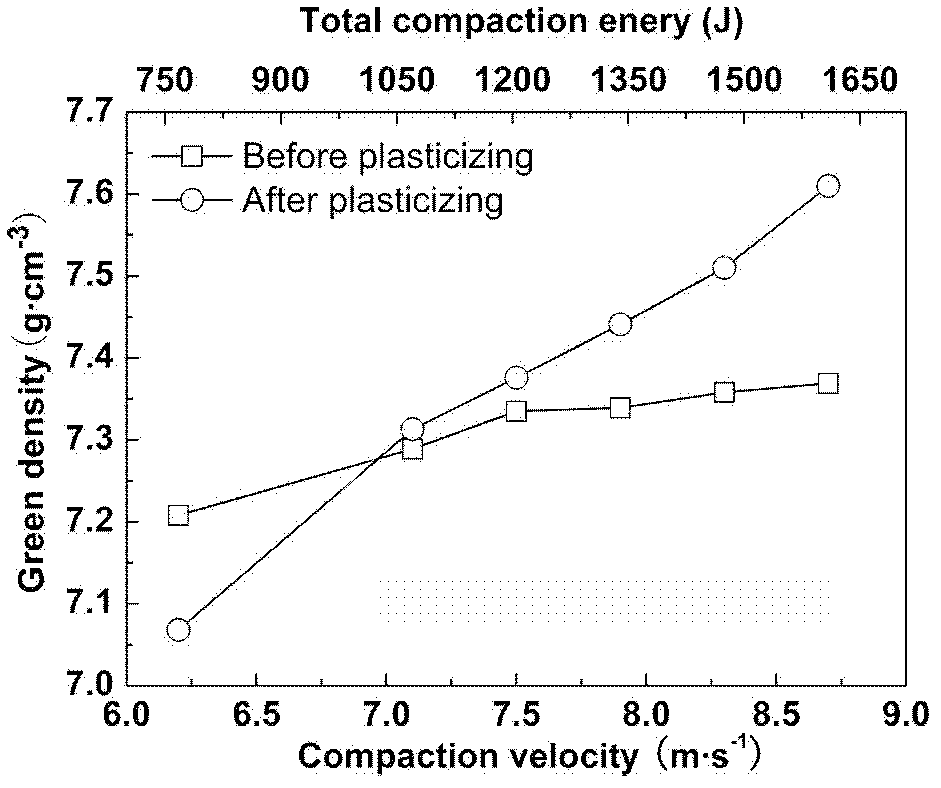

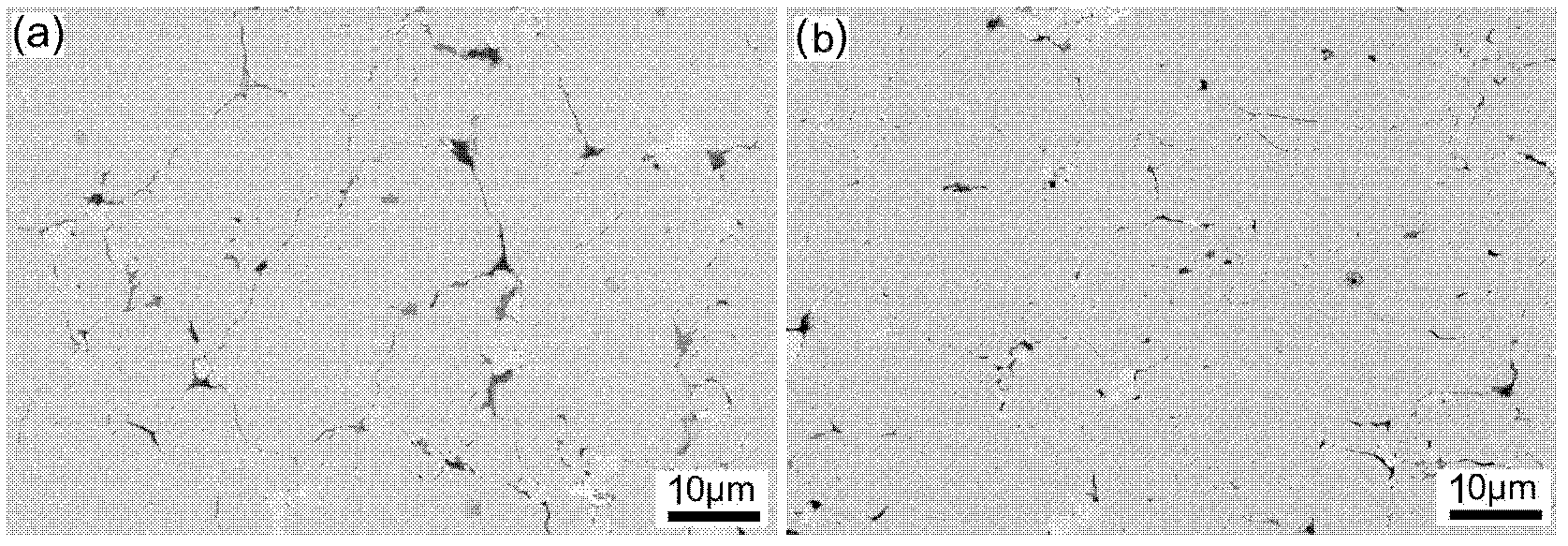

Method for forming bonded iron-based powder by high velocity compaction technology

Owner:YANGZHOUSSHINE POWDER METALLURGY

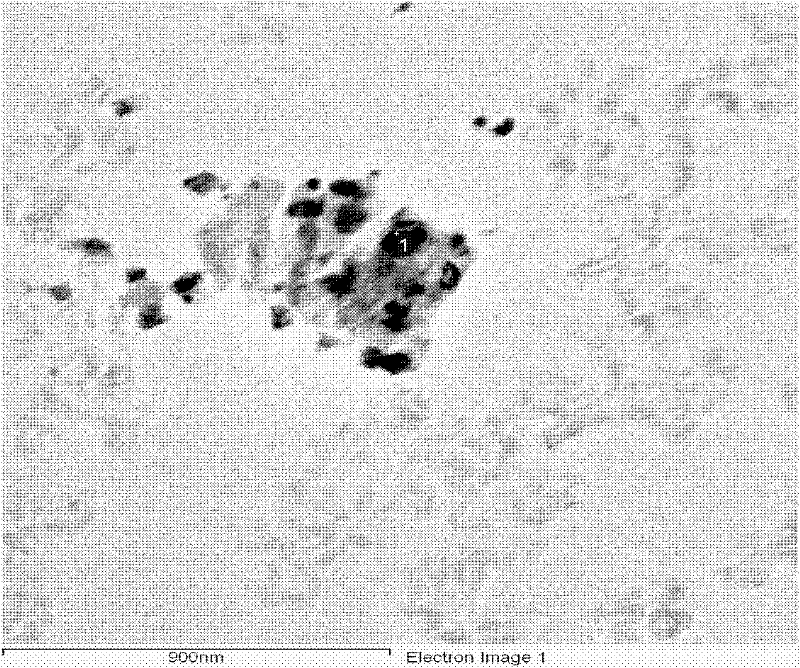

Nano-scale wolfram carbine composite powder and method of manufacturing the same

The invention provides a nanometer carbonized tungsten compound powder, which includes carbonized tungsten, vanadium carbide or / and chrome carbide, and a metallic element without binding phase exists in the compound powder. The preparation method of the nanometer carbonized tungsten compound powder is characterized in that the powdery ammonium tungstate, the carbonaceous reducing agent and the inhibitor are adopted as raw materials, the raw materials are dissolved in deionized water or distilled water and evenly stirred so as to obtain a solution, then the solution is heated and dried, the precursor powder is obtained finally, the precursor powder is put into a high-temperature reaction furnace, under the vacuum, argon or hydrogen atmosphere protection condition and the condition of 1,000 to 1,200 DEG C and 30 to 60 min, the carbonized tungsten compound powder with the average particle diameter less than 100 nm and even particle size distribution is obtained through carbonization. The method has the characteristics of low reaction temperature, short reaction time, low manufacturing cost, simple process and the like, which is suitable for the industrial production and used for the ultrafine hard alloy nanometer carbonized tungsten compound powder.

Owner:SICHUAN UNIV

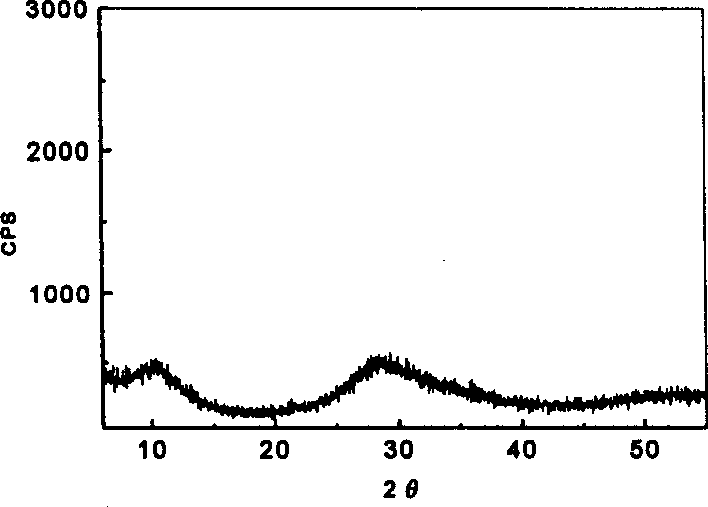

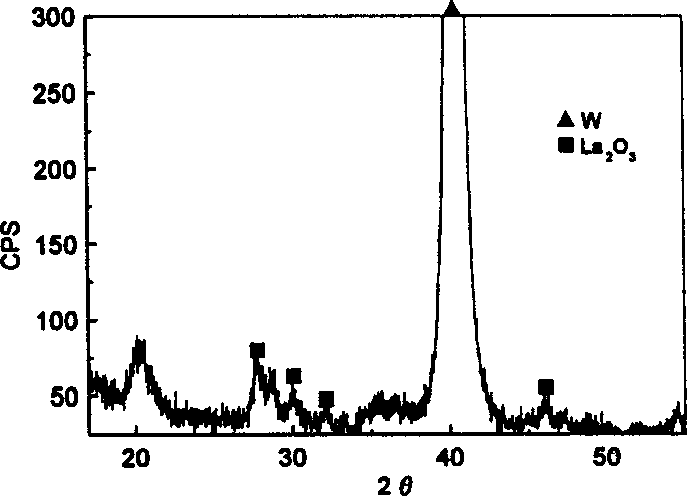

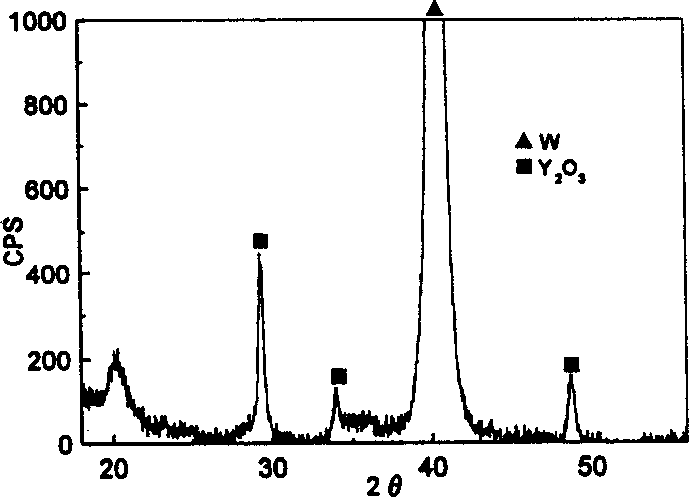

Nano-rare earth tungsten powder and its preparation method

A nano-class RE-W particle contains RE oxide powder (CeO2, La2O3, or Y2O3) (0.5-30 wt%) and W (70-99.5 wt%), and is prepared through dissolving the ammonium metatungstate powder and RE oxide powder in water respectively, mixing, clarifying, dispersing it in liquid nitrogen by nitrogen sprayer for pre-freezing, vacuum freeze drying, and secondary reducing in hydrogen atmosphere. Its advantage is molecule-class mixing uniformly.

Owner:BEIJING UNIV OF TECH

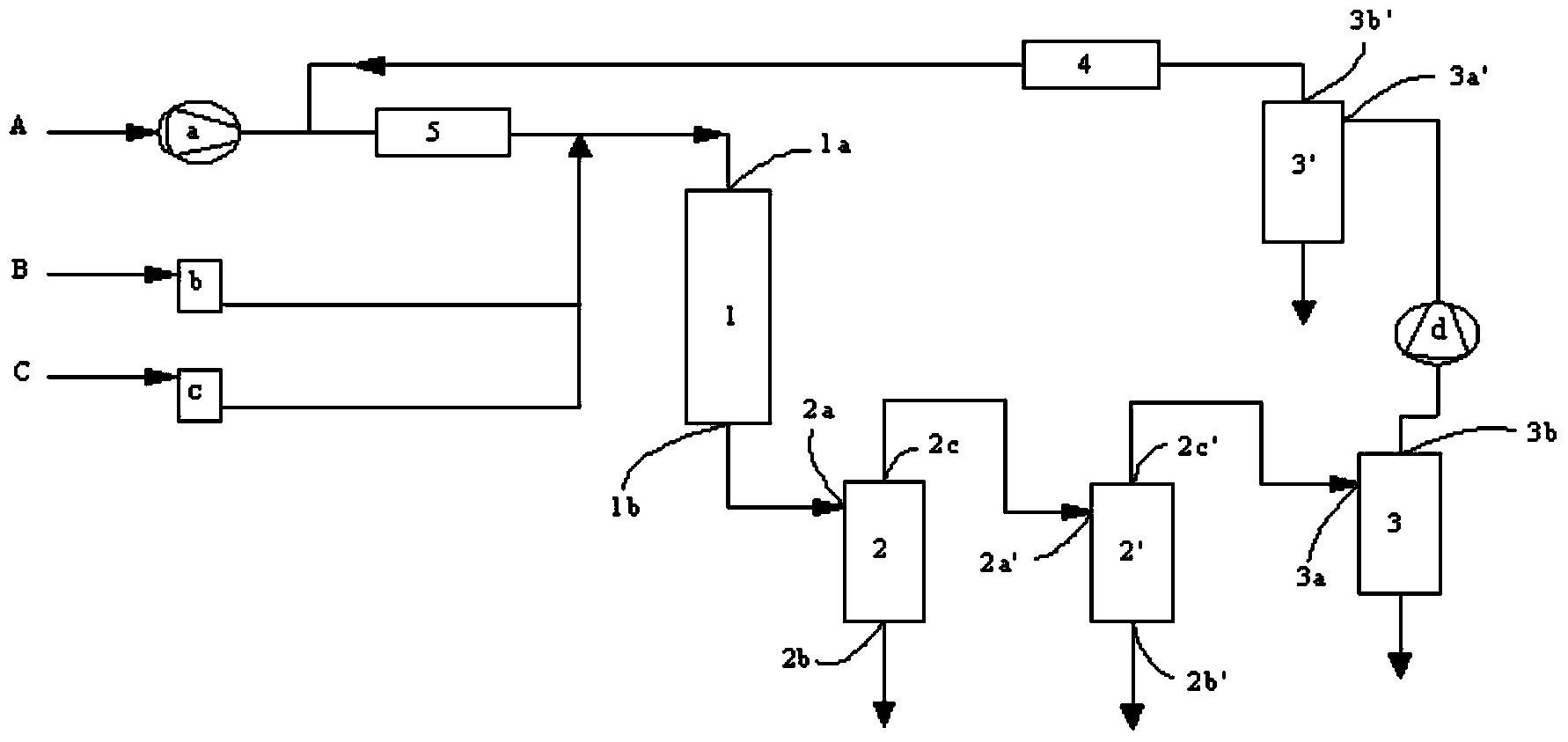

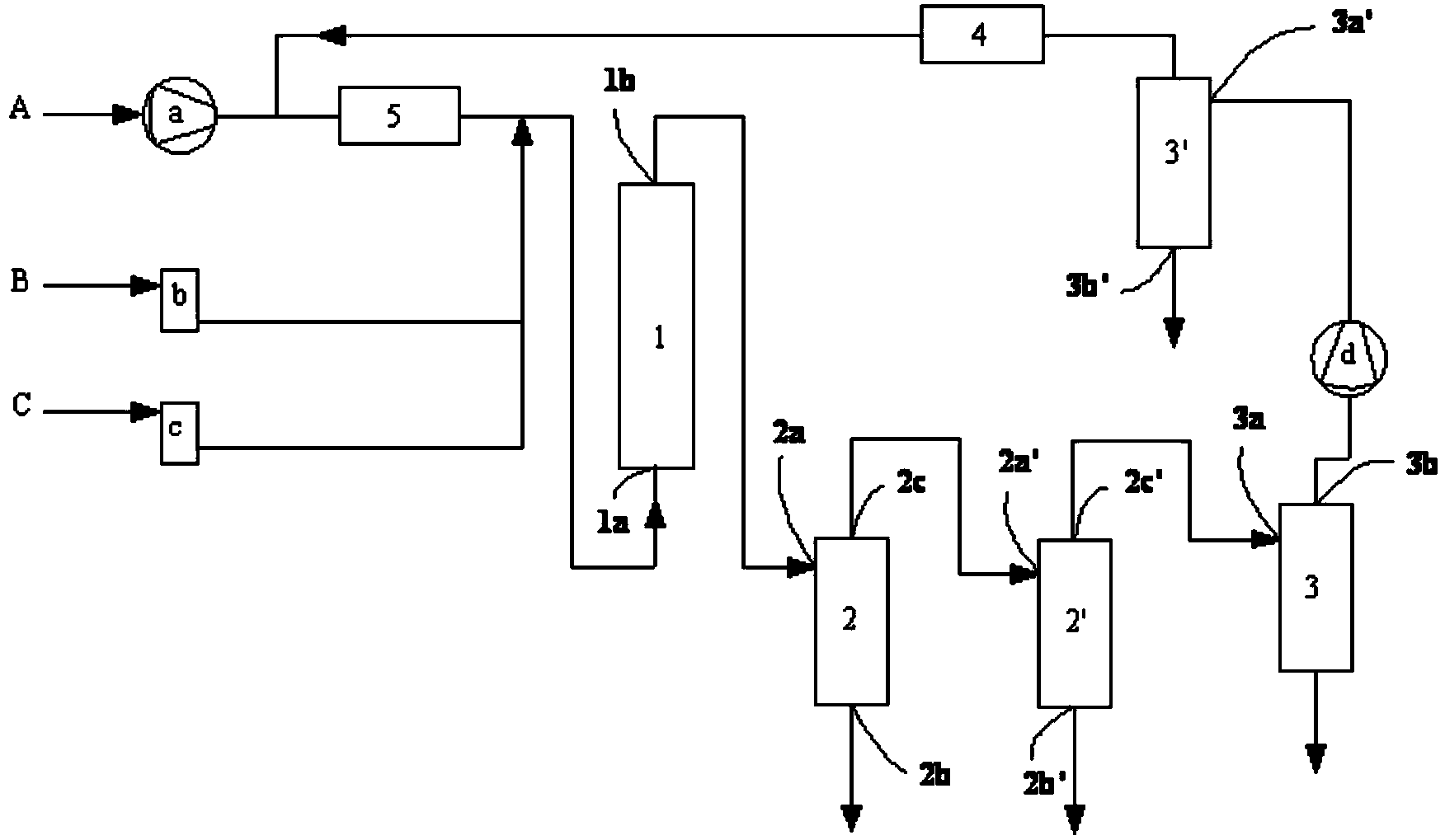

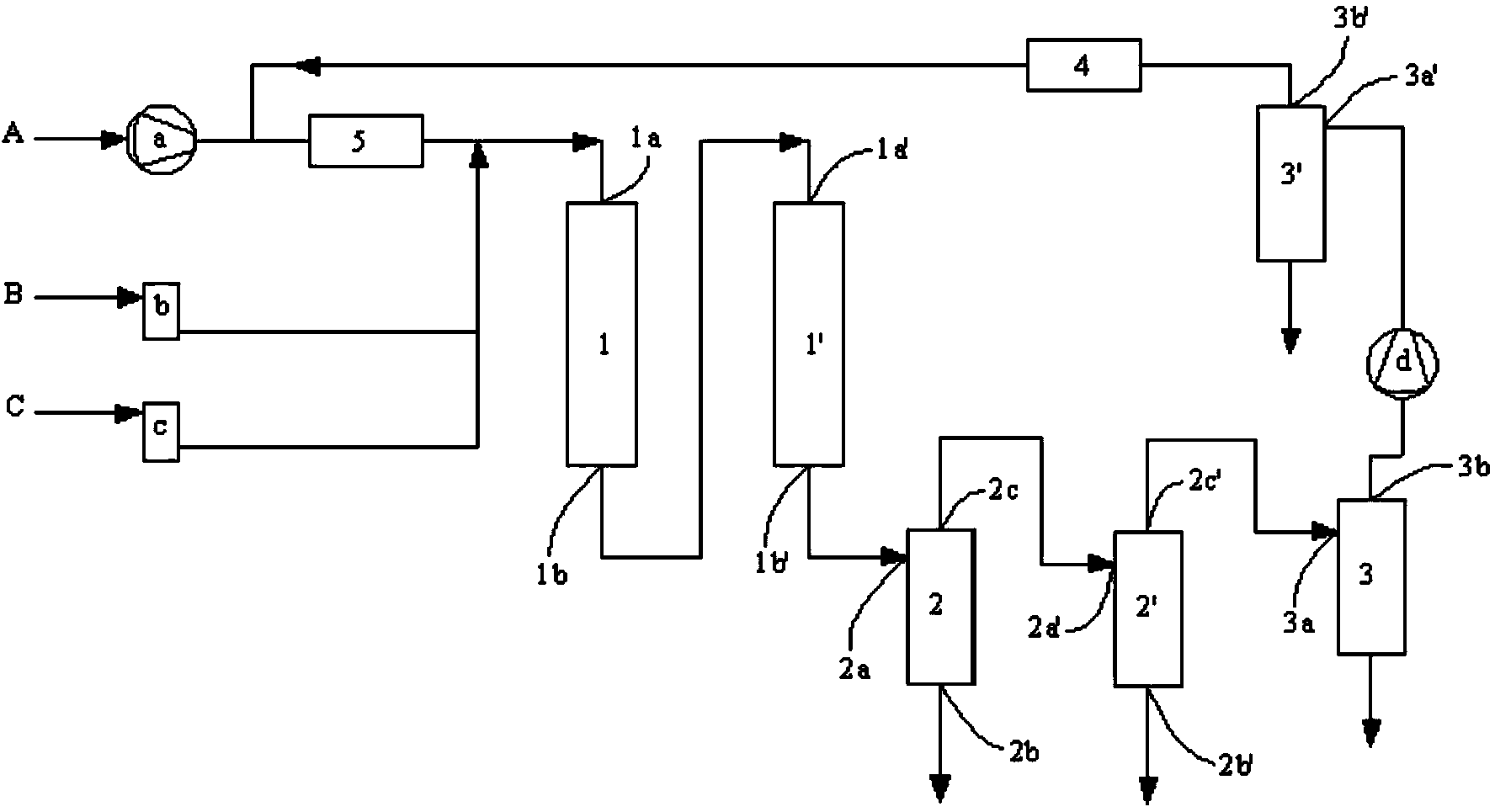

Device and method for continuously synthesizing amine-terminated polyether by utilizing fixed bed

ActiveCN103524725AGood effectContinuous and stable productionChemical recyclingVapor–liquid separatorAlcohol

The invention provides a device and a method for continuously synthesizing amine-terminated polyether by utilizing a fixed bed. The device for continuously synthesizing amine-terminated polyether by utilizing the fixed bed comprises a fixed bed reactor, a preheater, two gas-liquid separators, a compressor, a circulating compressor, a raw material pump, a liquid ammonia pump and two buffer tanks, hydrogen is preheated by virtue of the preheater and is fed into the fixed bed reactor with raw material and liquid ammonia; the amine-terminated polyether is synthesized in a hydrogen atmosphere of the fixed bed; the fixed bed reactor is at the temperature of 150-300 DEG C and the pressure of 1-20MPa, ammonia alcohol ratio is 1-15, and unreacted hydrogen and ammonia are recycled. The device and method for continuously synthesizing amine-terminated polyether by utilizing the fixed bed overcome the defects of tedious operation, unstable product quality, low synthesis efficiency and the like of the existing technology as a batch-type operation is adopted, a continuous reaction technological design is adopted, a technology is simple, performance is stable, yield is high, excessive ammonia and hydrogen are recycled, pollution to the environment is reduced, production cost is reduced, and energy is saved; conversion rate of hydroxyl-terminated polyether or derivative thereof and selectivity of the amine-terminated polyether product are obviously improved, so that production cost of the amine-terminated polyether product is obviously reduced.

Owner:康达新材料(集团)股份有限公司

Carbon nanotube-metal composite enhanced copper-based composite material and preparation method thereof

The invention relates to a carbon nanotube-metal composite enhanced copper-based composite material and a preparation method thereof, and belongs to the field of preparation of composite materials. The preparation method comprises the following steps: preparing colloidal sol by using soluble salts containing metallic elements and copper ions and carbon nanotube as raw materials, carrying out spray granulation by using the colloidal sol through a spray dryer so as to obtain nanoscale mixed powder, calcining the mixed powder in an oxygen-free atmosphere so as to obtain black powder, reducing the black powder in a hydrogen atmosphere so as to obtain carbon nanotube-metallic element composite enhanced copper-based powder, carrying out isostatic press moulding on the mixed powder, and then sintering in the hydrogen atmosphere so as to obtain the carbon nanotube-metallic element composite enhanced copper-based composite material, wherein the content of a metallic element X in the composite material is 0.1-2wt%, and the content of the carbon nanotube in the composite material is 0.1-2wt%. The preparation method has the advantages that corresponding carbides can be formed, the problem of reinforcement agglomeration caused by poor interface bonding between reinforcement and a copper matrix is solved, and the copper-based composite material with excellent combination properties can be obtained.

Owner:NINGBO CPX ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com