Patents

Literature

413results about How to "Fully distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

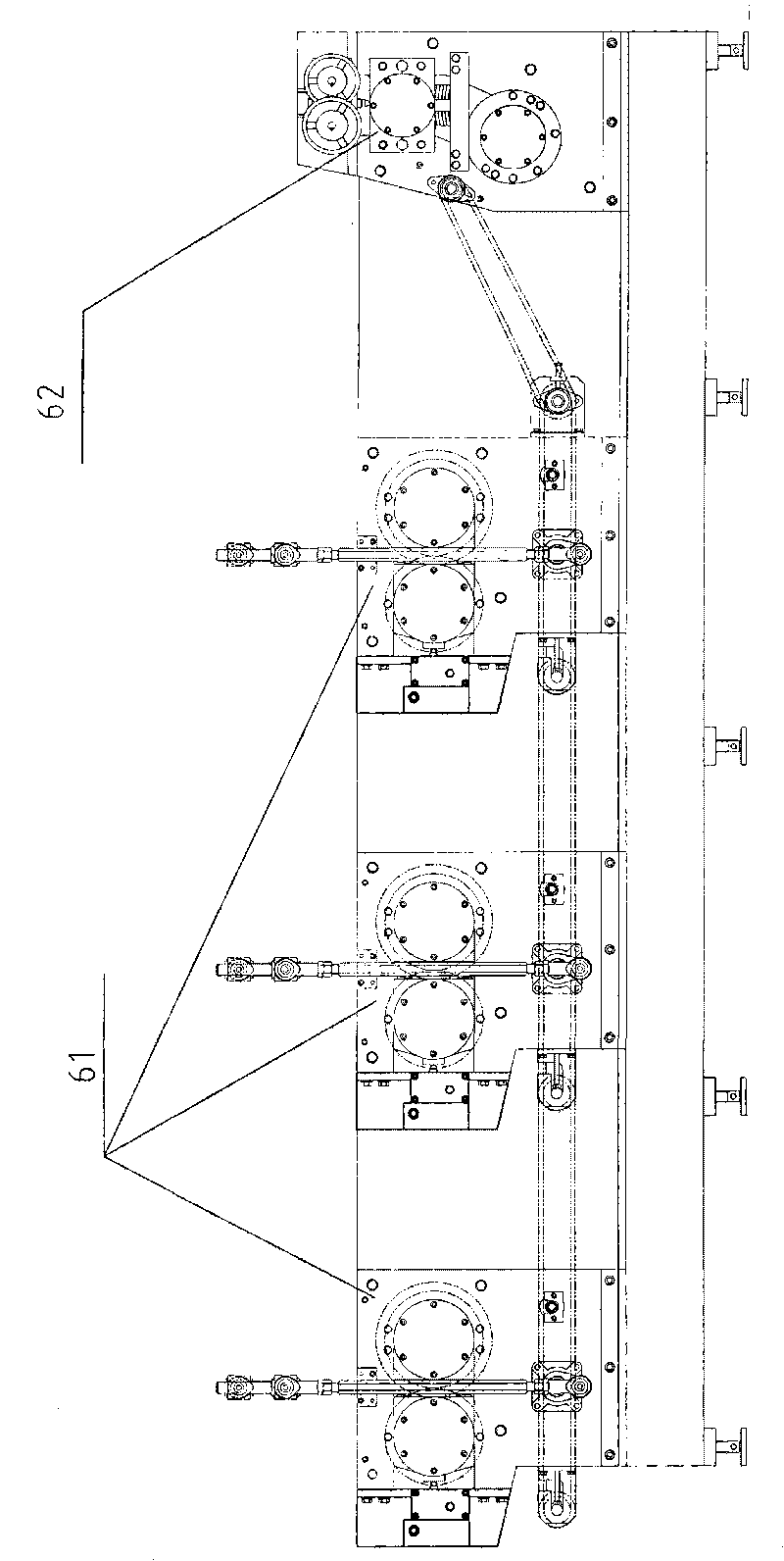

Oil spraying instant noodle production line and production technology thereof

InactiveCN101720890AFragrant and delicious tasteReduce oil contentFood preparationDough processingAlkaline waterHigh volume manufacturing

The invention relates to oil spraying instant noodle production line and production technology thereof. The production line is sequentially provided with an alkaline water bucket, a quantitative water adding bucket, a vibrating screen, a double shaft flour-mixing machine, a curing feeder, a composite tablet machine, a continuous tablet machine, a three-layer vaporizer, a cutting folder, a spraying flavouring machine, an oil spraying noodle frying machine, a microwave drying machine, an air cooling machine and an output packaging device. The equipment is full automatic, production efficiency is high, thus being applicable to mass production; in the production equipment, oil spraying device is adopted to carry out oil spraying treatment on noodle block, the noodle block has the flavour of common instant noodles while the oil content thereof is only about 5%, thus the noodle block is a good low oil content healthy food.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

Method for processing green tea

The invention discloses a method for processing green tea. The method comprises the following steps of: fixing, namely, selecting 2 to 3 leaves from each bud of a medium and small-leaf variety; spreading, namely, spreading tea leaves until the water content of the spread tea leaves is lowered to be between 70 and 75 percent; dampening and fixing; slowly twisting, namely, filling dampened tea leaves into a twisting bucket of a twisting machine, wherein the rotating speed of the twisting machine is between 30 and 40 r / min, total twisting time is between 22 and 28 minutes and the tea leaves are pressed lightly for 1 to 5 minutes in the midway; dewatering until water content is between 38 and 46 percent; shaping for three times; drying; spreading dried tea leaves with the thickness of between3 and 5 centimeters for 24 to 32 hours; and performing aroma extracting on the spread tea leaves at the high temperature of between 120 and 140 DEG C for 6 to 8 minutes. A product obtained by the method has attractive appearance and is soaking resistant and the quality of the green tea can be improved greatly.

Owner:GUIYANG CHUNQIU INDAL

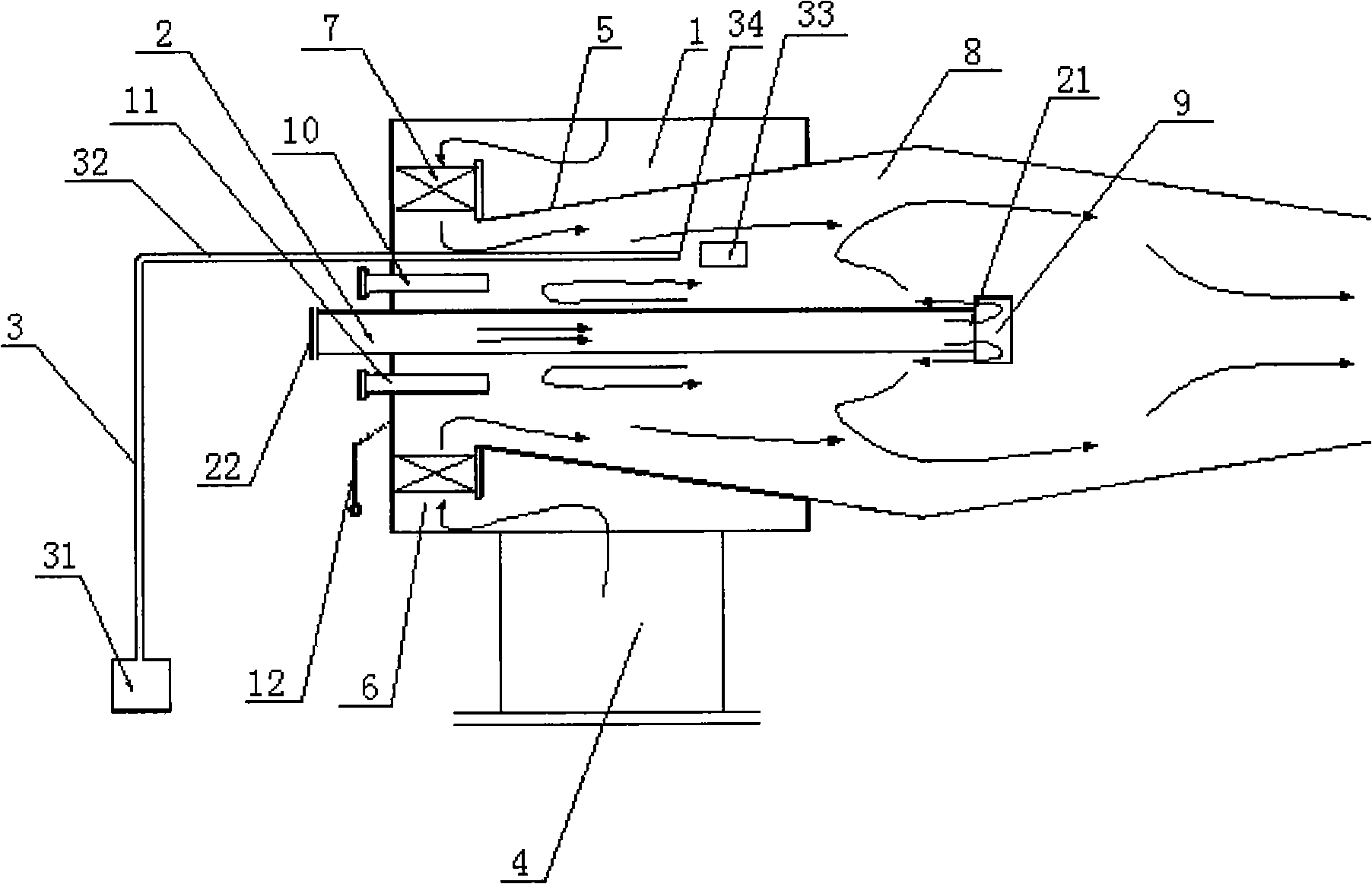

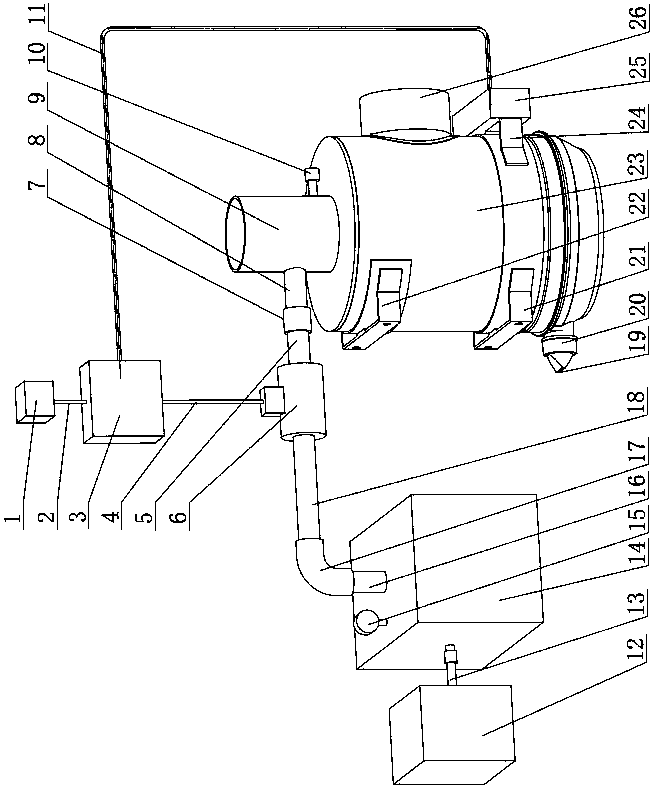

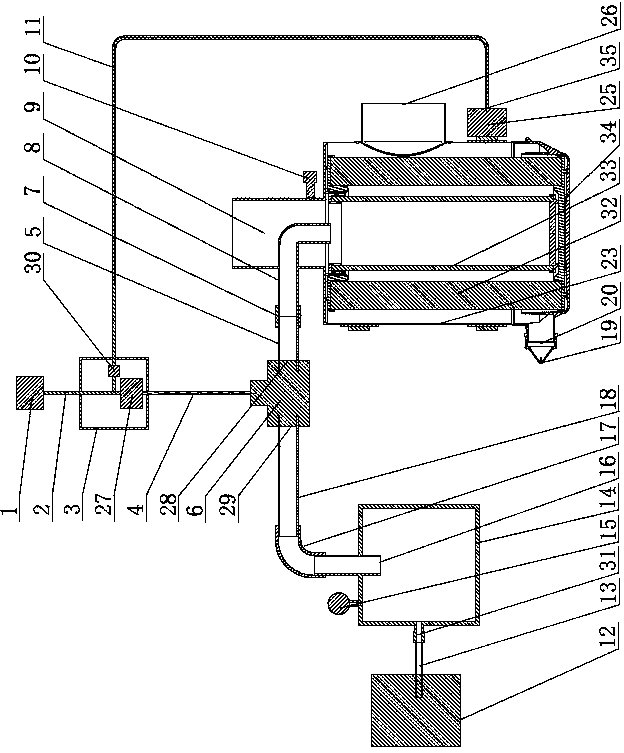

Pulverized coal burner

InactiveCN101576255AHas a burning effectUniform burning effectPulverulent fuel combustion burnersFuel tankEngineering

The invention relates to a pulverized coal burner which is characterized by comprising an air box, a powder feeding pipe, an ignition device and a blast pipe; a cylindrical fixed baffle plate with a conical cross section is axially arranged in the air box, an annular gap is left between one end of the fixed baffle plate and the air box, and a plurality of swirl vanes are circumferentially arranged in the annular gap; a precombustion chamber is arranged inside the fixed baffle plate; the outlet end of the powder feeding pipe penetrates the center of the air box to enter in the precombustion chamber, the inlet end of the powder feeding pipe is arranged outside the air box and connected with a feeder device, and the powder feeding pipe is fixedly connected with the air box; a return flow cap is arranged at the tail end of the outlet end of the powder feeding pipe and a special gap is left between the return flow cap and the outlet end of the powder feeding pipe; the ignition device comprises a fuel tank, a conduct pipe and an ignition electrode, wherein the fuel tank is arranged outside the air box; one end of the conduct pipe is connected with the fuel tank and the other end of the conduct pipe penetrates the air box to enter in the precombustion chamber to form a spouting vent; the ignition electrode is arranged at one side adjacent to the spouting vent; and one end of the blast pipe is connected with the air box and the other end of the blast pipe is connected with an air blower. The invention can be widely used in various small and medium-sized industrial coal powder boilers.

Owner:CHINA COAL RES INST

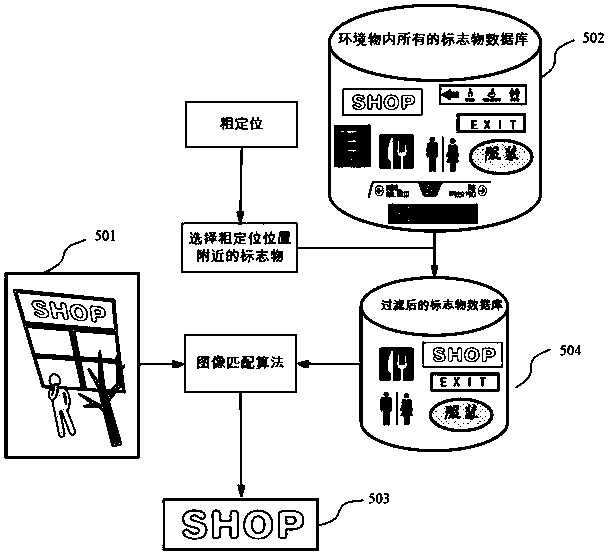

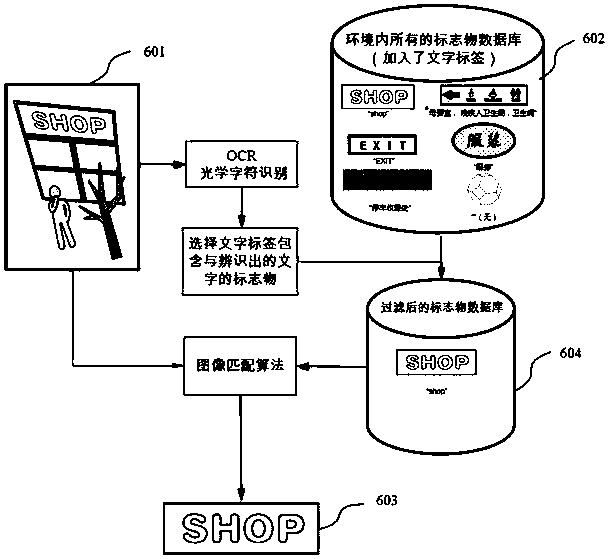

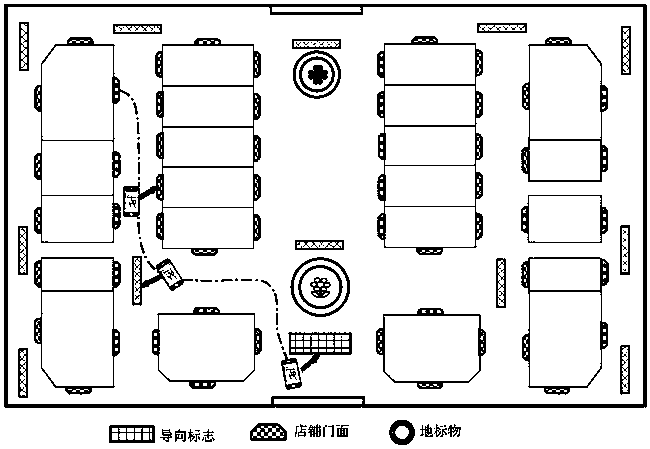

Visual positioning method and navigation method

InactiveCN110017841ASolve choice problemsFully distributedNavigational calculation instrumentsElectronic mapMarine navigation

The invention provides a visual positioning method. The visual positioning method includes the following steps that S1, images of markers in an environment to be positioned are acquired in advance, and an marker database containing the images of the markers is established; S2, images to be identified of the markers in the environment to be positioned are collected by intelligent equipment, then the images to be identified are matched with the images in the marker database, and then a current position is calculated according to known geometric features of the matched images; and S3, the currentposition is marked at the corresponding position of an electronic map or the current position is output to preset application. The invention provides a visual positioning navigation method. Through the visual positioning method, positioning is carried out for navigation.

Owner:大有智能科技(嘉兴)有限公司

Method for preparing supported iron oxide series desulfurizing agent

ActiveCN102049179AImprove desulfurization efficiencyGuaranteed desulfurization activityDispersed particle separationSulfur preparation/purificationChemical industrySulfur

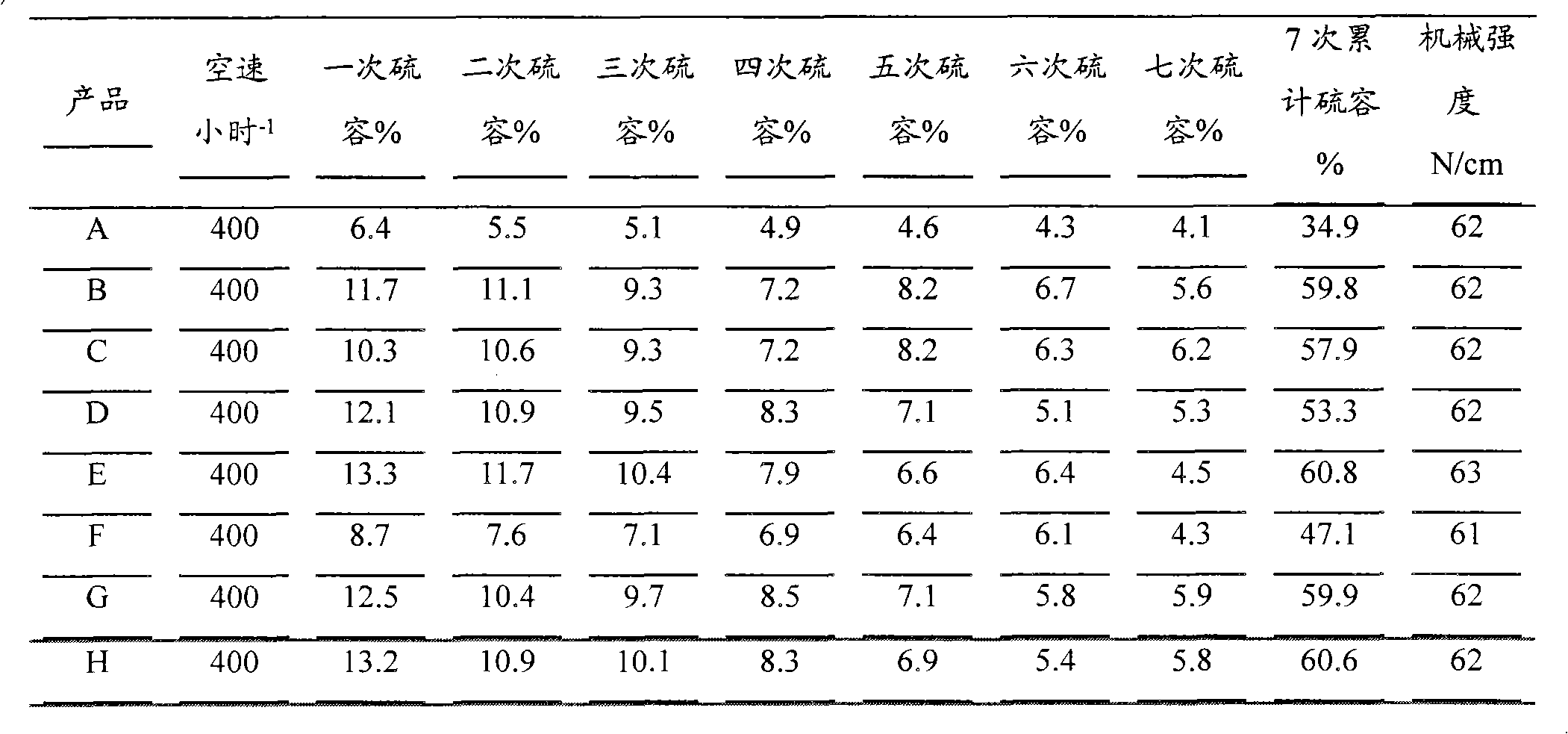

The invention discloses a method for preparing a supported iron oxide series desulfurizing agent. The preparation method comprises the following steps: a) preparing soluble iron salt solution and alkali solution; b) putting a porous material serving as a carrier into the soluble iron salt solution prepared in the step a), and soaking under the condition that the pressure is less than 3MPa and not equal to normal pressure; c) drying the carrier soaked in the step b) at the temperature of between 30 and 85 DEG C for 1 to 24 hours; d) putting the dried carrier obtained in the step c) into the alkali solution, and soaking under the condition that the pressure is less than 3MPa and not equal to normal pressure; e) drying or draining the carrier obtained in the step c), and eluting the carrier by using water of 20 to 80 DEG C till the eluted water has no negative ions; and f) drying the carrier obtained in the step e) for 1 to 24 hours at the temperature of between 30 and 85 DEG C to obtain the desulfurizing agent. The desulfurizing agent prepared by adopting the method has the advantages of high accumulative sulfur capacity, high mechanical strength, abrasion resistance and the like, is easy to regenerate, and is widely applied in the fine desulfuration process of petroleum industry, chemical industry and the like.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Plaster for treating retention of food and dysmenorrhea

InactiveCN101077403AFully distributedStrong penetrating powerHeavy metal active ingredientsHydroxy compound active ingredientsMedicinePoultice

The plaster for treating food retention and dysmenorrhea is prepared with over 70 kinds of Chinese medicinal materials, including pubescent angelica root, dahurian angelica root, peach twig, frankincense, aucklandia root, camphor, etc in certain weight proportion.

Owner:赵启坤

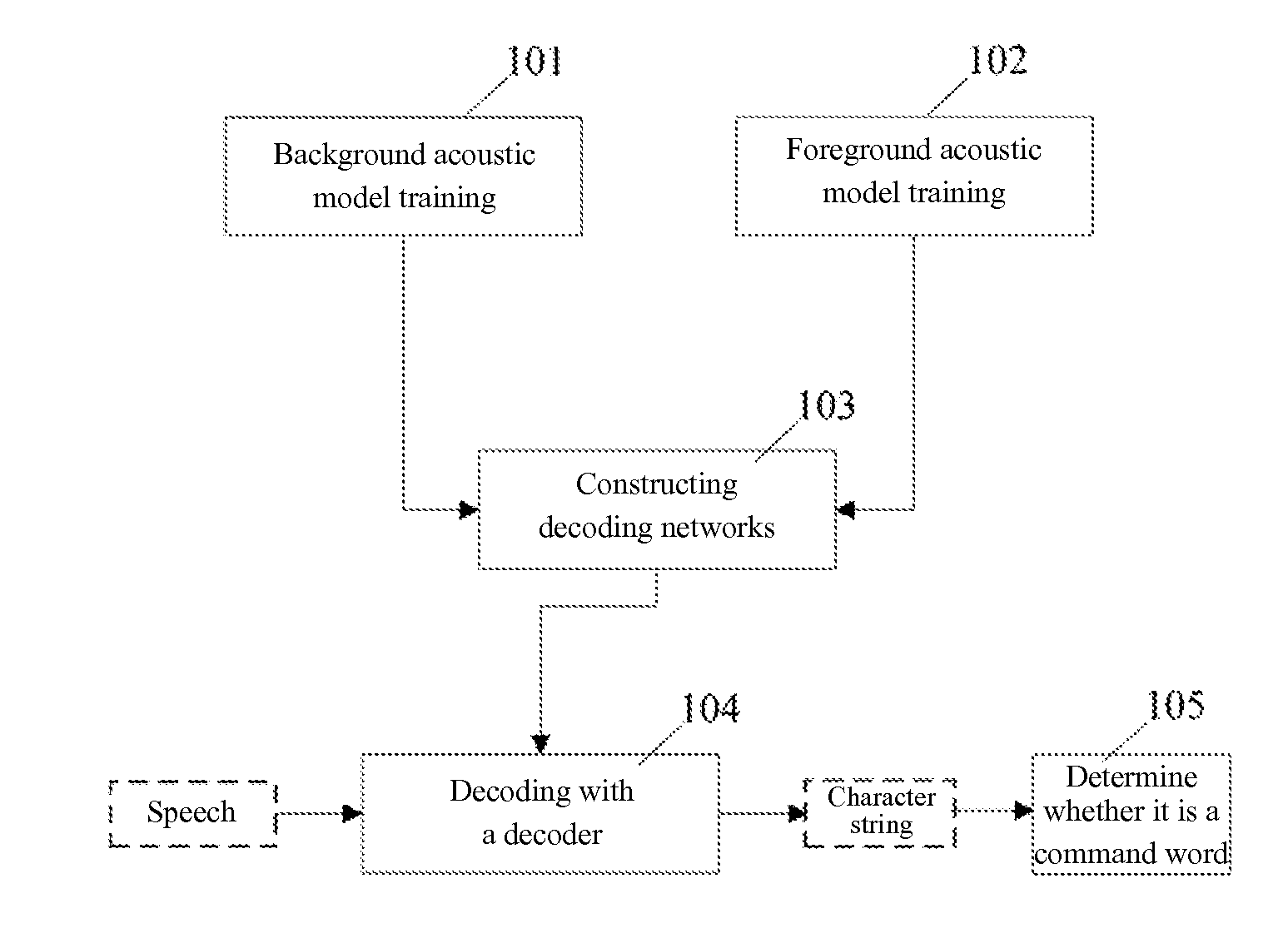

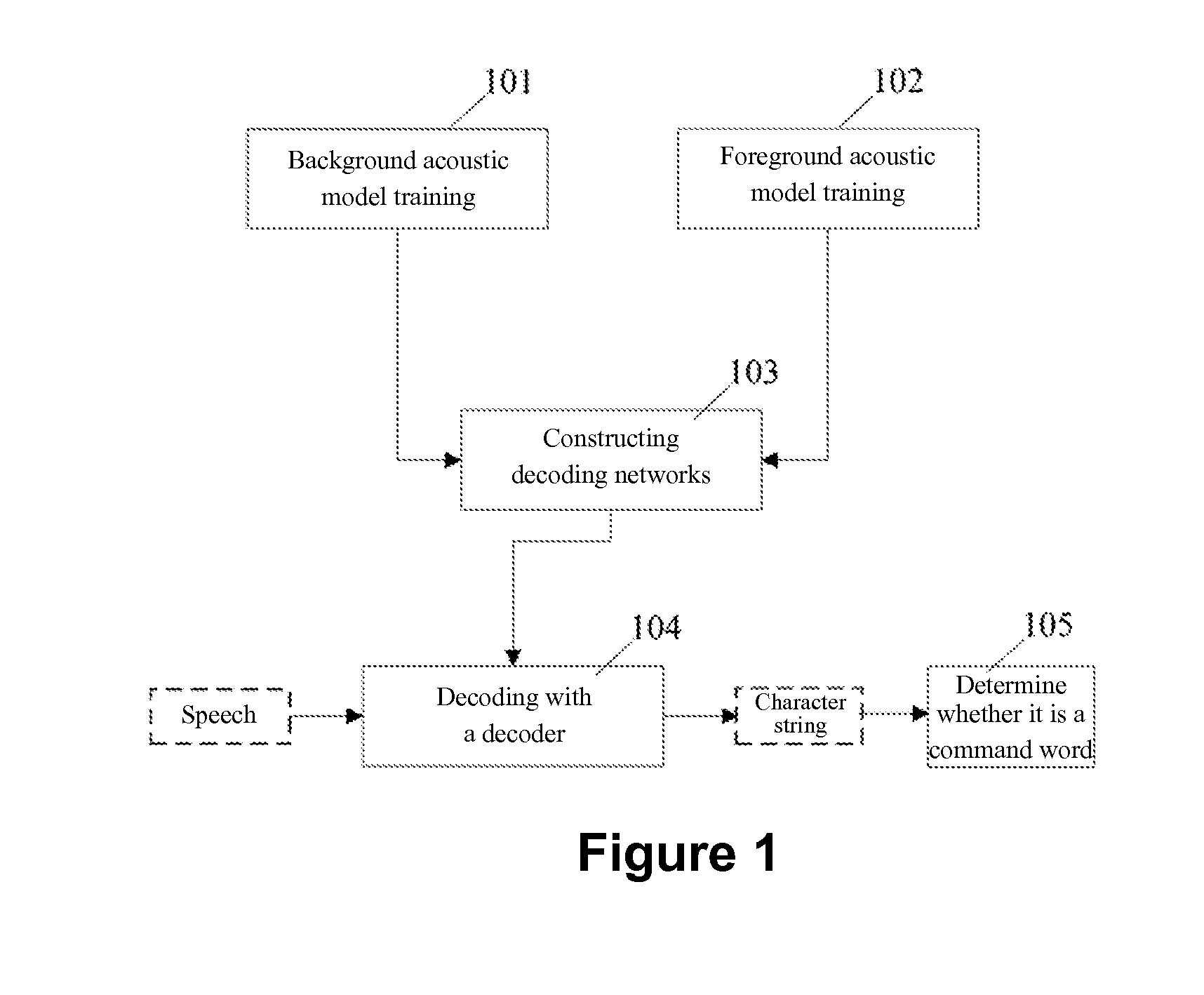

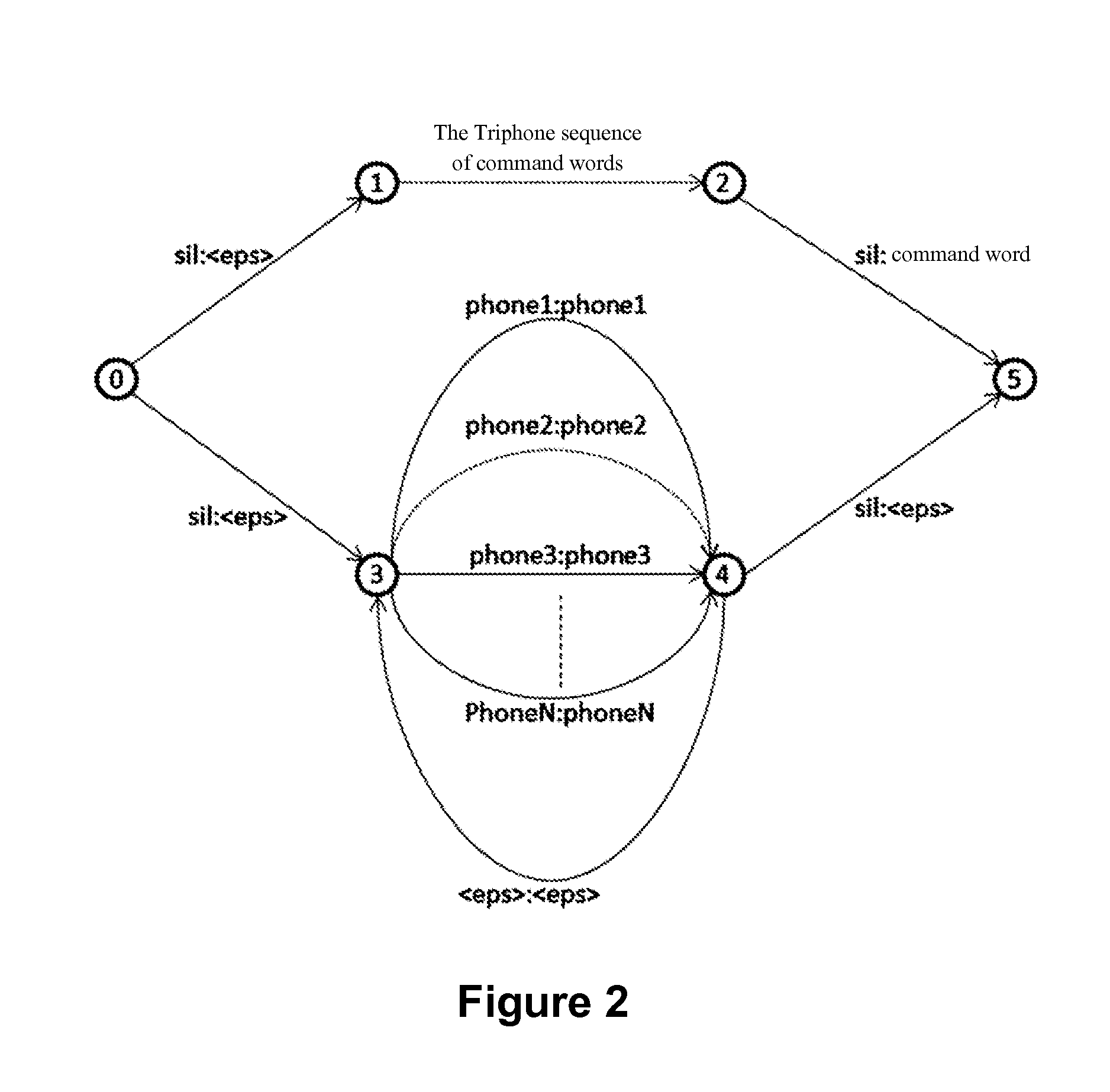

Method and system for recognizing speech commands

ActiveUS20140214416A1Efficient extractionFully distributedSpeech recognitionAcoustic modelSpeech sound

A method of recognizing speech commands includes generating a background acoustic model for a sound using a first sound sample, the background acoustic model characterized by a first precision metric. A foreground acoustic model is generated for the sound using a second sound sample, the foreground acoustic model characterized by a second precision metric. A third sound sample is received and decoded by assigning a weight to the third sound sample corresponding to a probability that the sound sample originated in a foreground using the foreground acoustic model and the background acoustic model. The method further includes determining if the weight meets predefined criteria for assigning the third sound sample to the foreground and, when the weight meets the predefined criteria, interpreting the third sound sample as a portion of a speech command. Otherwise, recognition of the third sound sample as a portion of a speech command is forgone.

Owner:TENCENT TECH (SHENZHEN) CO LTD

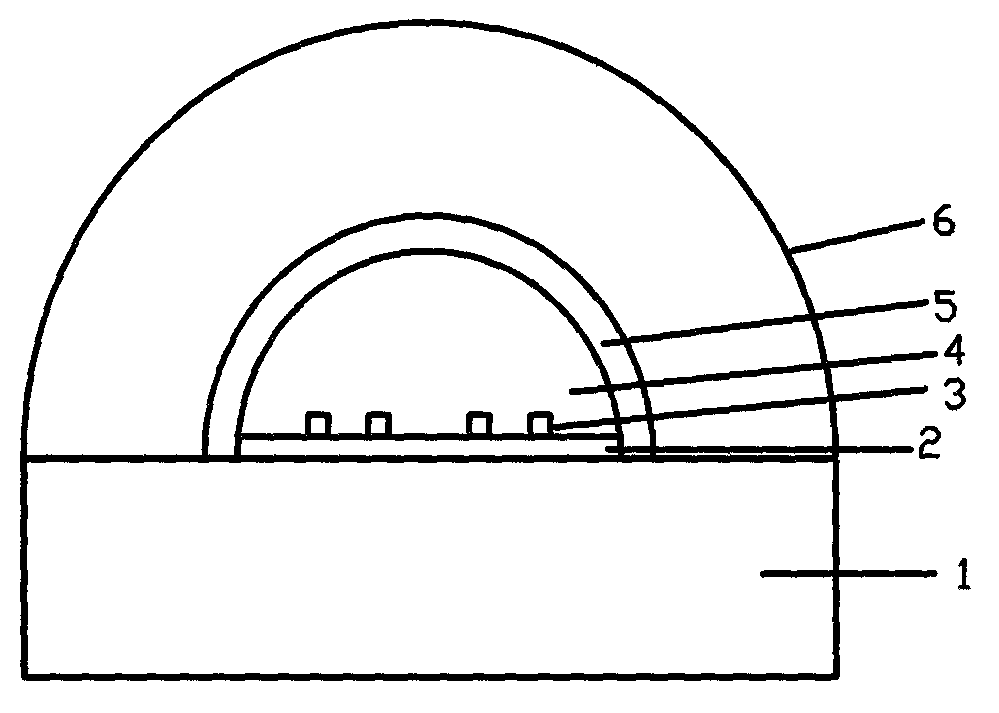

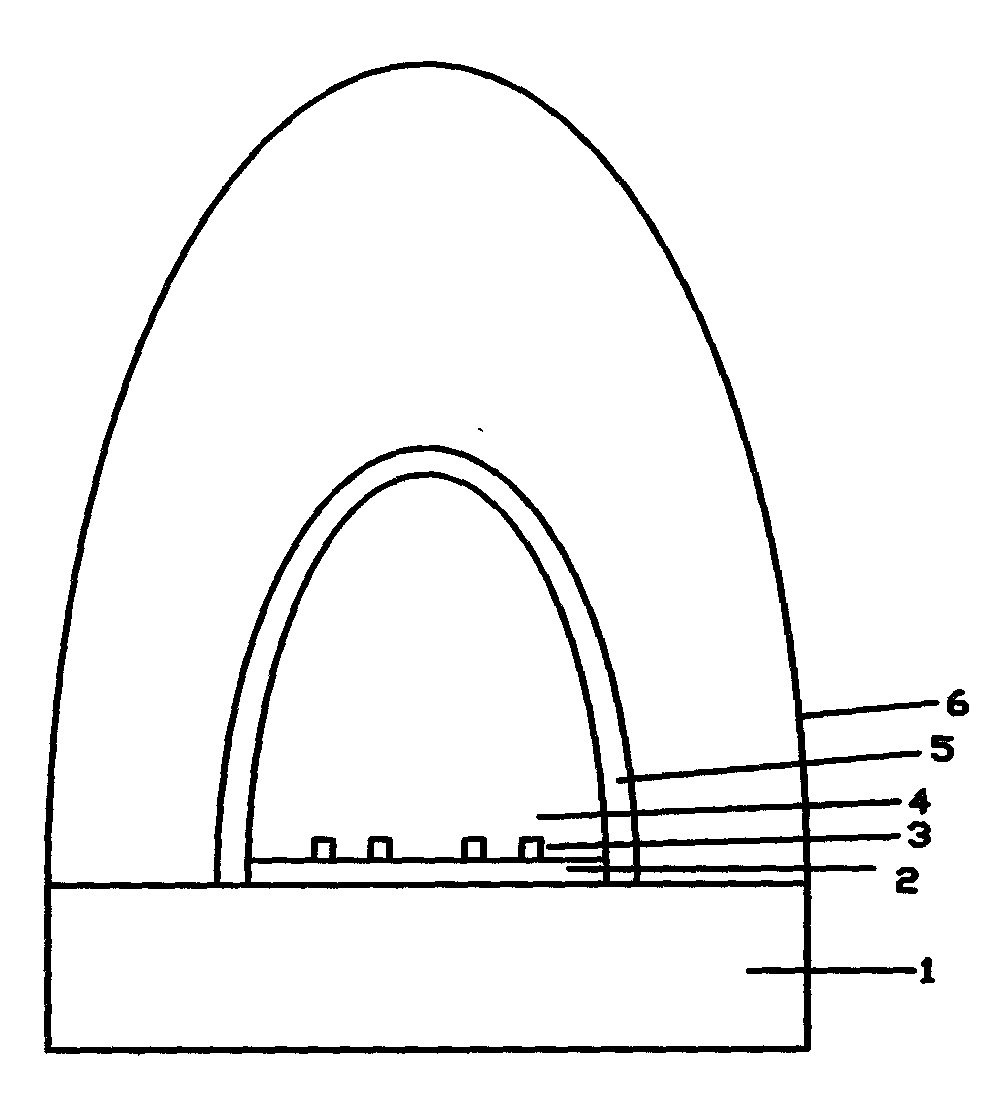

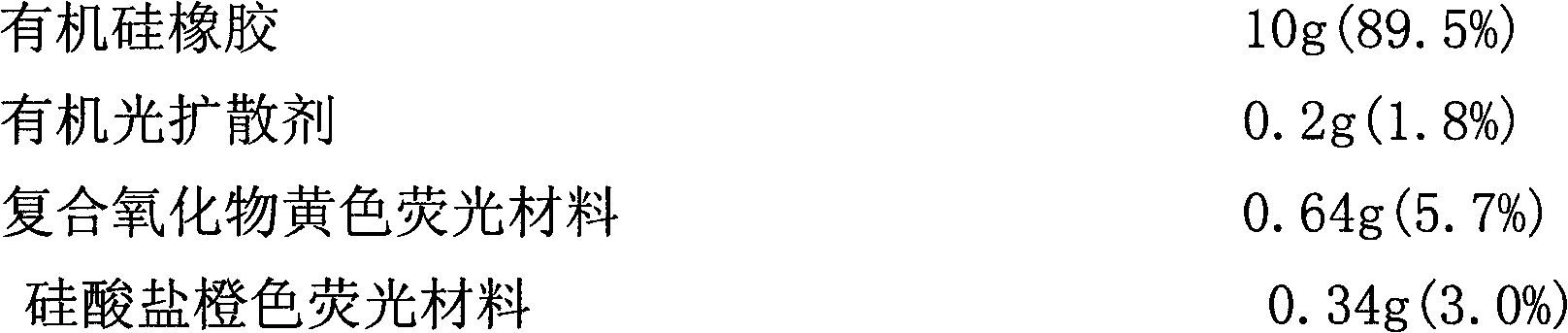

Light conversion module

InactiveCN102368496AIncrease the light output angleWell mixedSolid-state devicesSemiconductor devicesPhosphorScattering effect

The invention relates to a module possessing a light conversion function. An organic silicone rubber is taken as a carrier. An LED phosphor and an organic light diffuser agent are added to form the light conversion module. The module is soft and elastic. A preparation method is characterized by: mixing organic silicon glue, the LED phosphor and the organic light diffuser agent uniformity; injecting into a mould, heating, curing and molding. The module can be used in a blue ray LED light source. The LED phosphor can be excited to glow by the blue ray emitted by the blue ray LED light source, and through reflection, refraction and scattering effects of the organic light diffuser agent, the light of the LED phosphor and the blue ray which is not be absorbed are composited into the white light or the light with other colors. The light color and intensity of the obtained compound light distribute uniformly, and are soft without glare. The compound light can realize the wide-angle light and can be applied in LEC illumination and decorative lamps.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

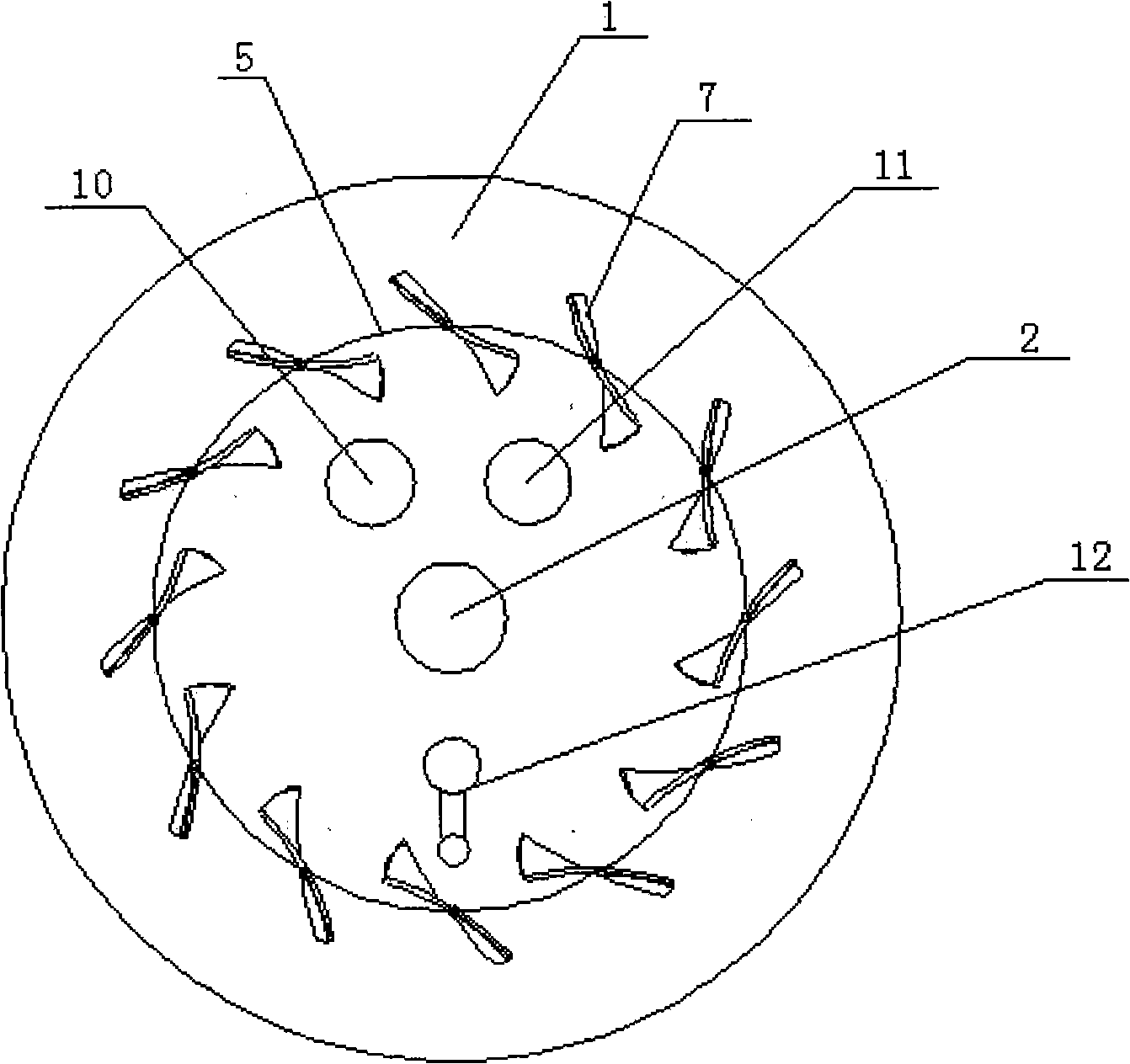

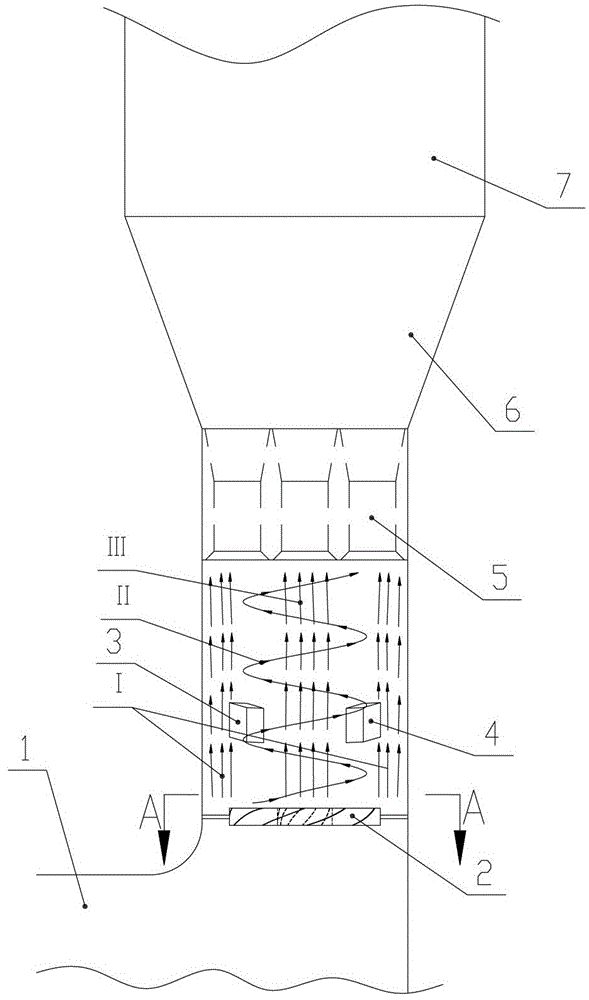

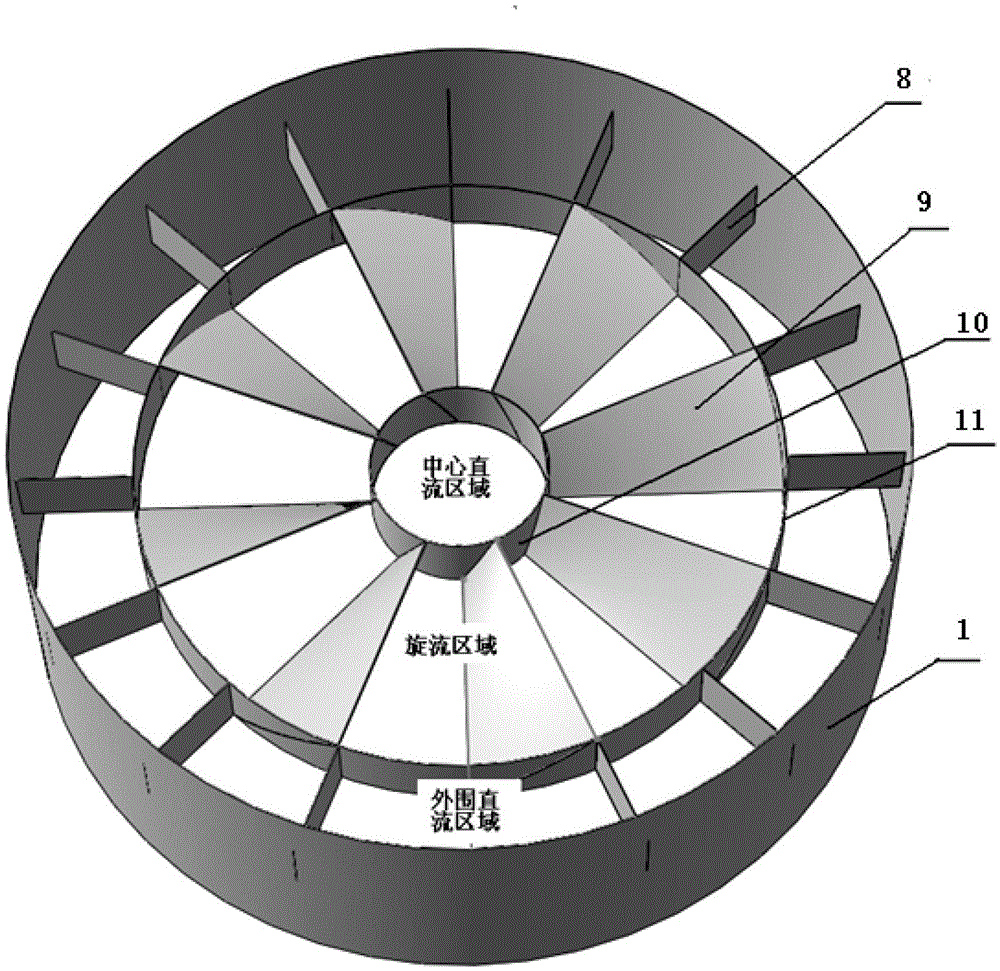

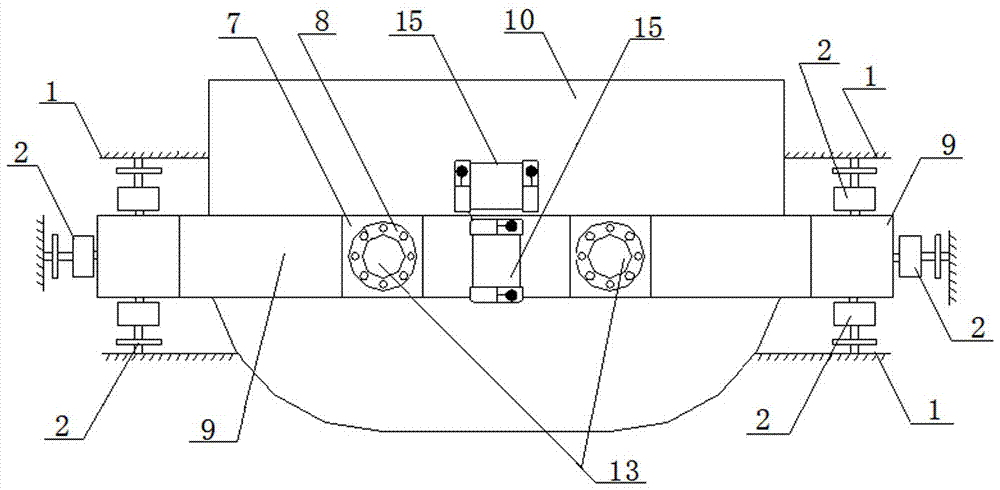

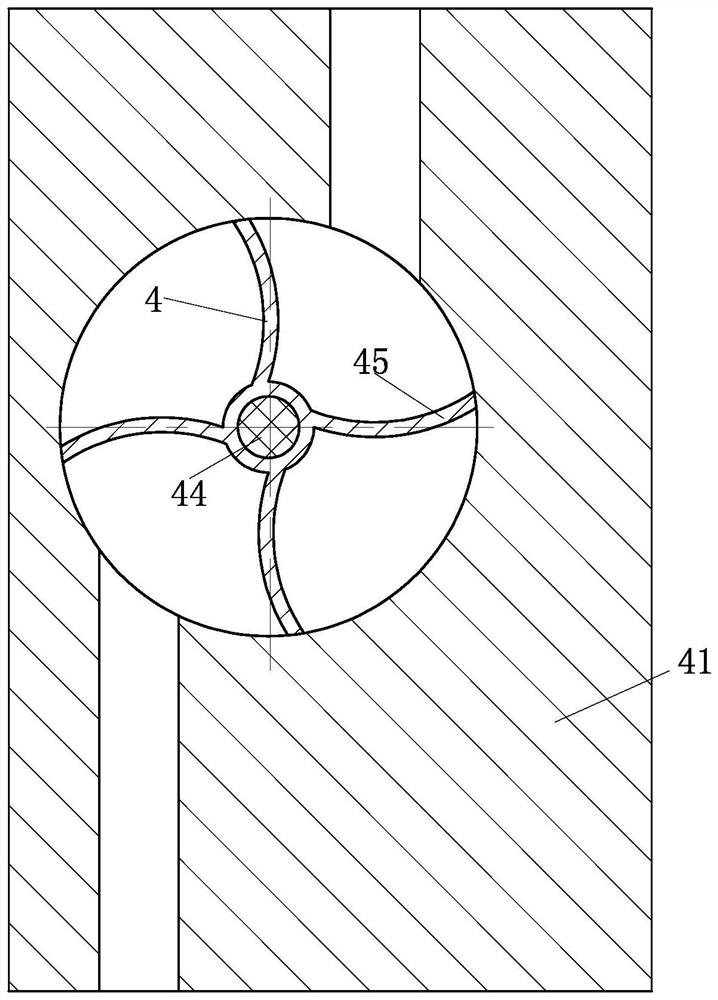

Compound airflow generator, circulating fluidized bed tower-front two-phase premixing device and method

ActiveCN103143254ADisperse fastReduce concentrationDispersed particle separationChemical/physical processesFluidized bedEngineering

The invention provides a compound airflow generator which comprises a plurality of fixing plate supports, a plurality of rotational flow guide vanes, an inner sleeve and an outer sleeve, wherein two ends of each rotational flow guide vane are respectively arranged on the external wall of the inner sleeve and the inner wall of the outer sleeve, the included angle between the plane of each rotational flow guide vane and the horizontal plane is 30-70 degree, the fixing plate supports are used for fixing the structure formed by the outer sleeve, the inner sleeve and the rotational flow guide vanes, one end of each fixing plate support is arranged on the external wall of the outer sleeve, the other end of the fixing plate support is arranged on the inner wall of a tower front flue, and the fixing plate support is vertically arranged. After passing by the compound airflow generator, smoke forms a direct current airflow in the inner sleeve, forms rotational flow between the inner sleeve and the outer sleeve, and forms a direct current airflow outside the outer sleeve, thus forming a direct-rotational-direct airflow flow field, under the disturbance of the direct-rotational-direct airflow flow field, particle granules and the smoke are premixed and homogenized, so that the smoke thoroughly reacts in a purification tower, and the purification efficiency of the smoke is improved.

Owner:FUJIAN LONGKING DSDN ENGINEERING CO LTD +1

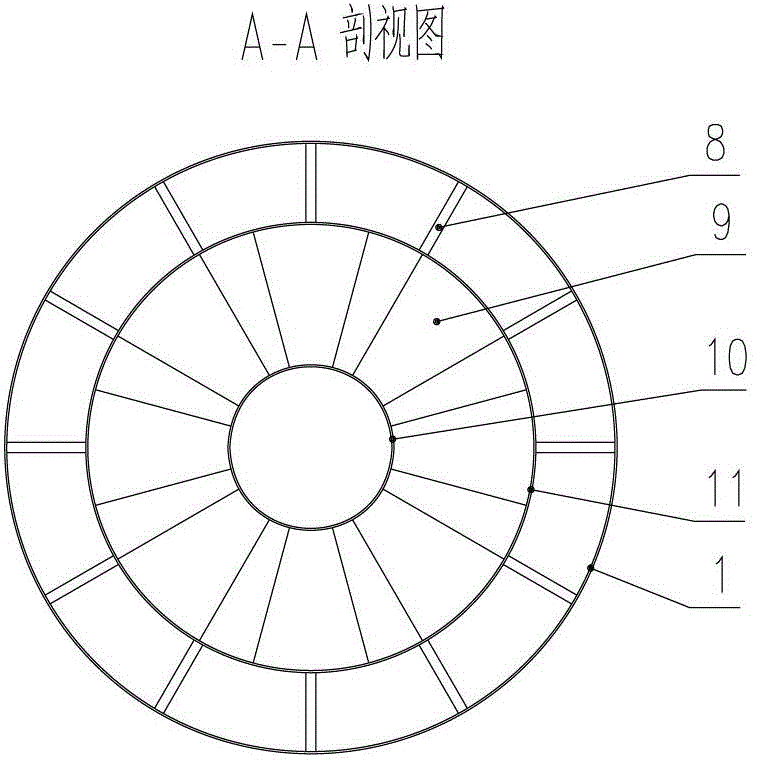

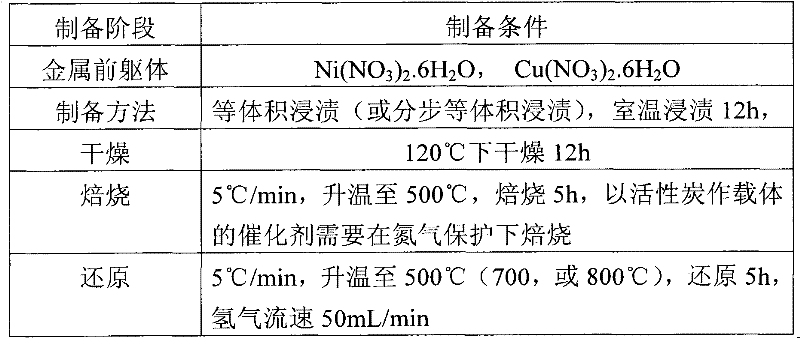

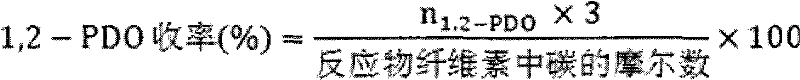

Method for directly preparing glycols from biological cellulosan

InactiveCN102442886AWide variety of sourcesWidely distributedOrganic compound preparationHydroxy compound preparationCelluloseAlcohol sugars

The invention discloses a method for directly preparing glycols from biological cellulosan, comprising the following steps: using cellulose cellulose as a raw material and a polar solvent as a reaction solvent, adding a catalyst in the raw material solution, and reacting for 0.5-72 h at a temperature of 150-300 DEG C under the condition of hydrogenation to obtain a mixture of glycols and sugar alcohol, wherein, the catalyst is a supported nickel-based catalyst, copper-based catalyst, nickel-copper, copper-zinc, nickel-copper-zinc dual metal of poly metal catalyst. According to the invention, various glycols can be obtained simultaneously; the product can be used individually by separation, and can be directly used for producing unsaturated polyester resin, polyurethane, fuel additive, surfactant, emulsifier, motor vehicle antifreeze fluid and the like without deep separation.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Black tea withering method

The invention discloses a black tea withering method. The black tea withering method comprises the following steps: spreading and withering, withering with hot air, and withering with cold air. Firstly, shrivelled leaf opexes caused by excessively fast withering can be effectively prevented due to spreading and withering, and then water in tea leaves can be rapidly evaporated through withering with hot air, the tension of tea cells is reduced, the toughness of buds is increased, the rolling of the tea is facilitated, the processing time is greatly reduced, the water in the tea can be enabled to be fully and uniformly distributed through the withering with cold air, and the foundation is laid for forming the high-quality black tea.

Owner:GUIZHOU FENGGANG COUNTY QIANYUZHI ECO TEA IND

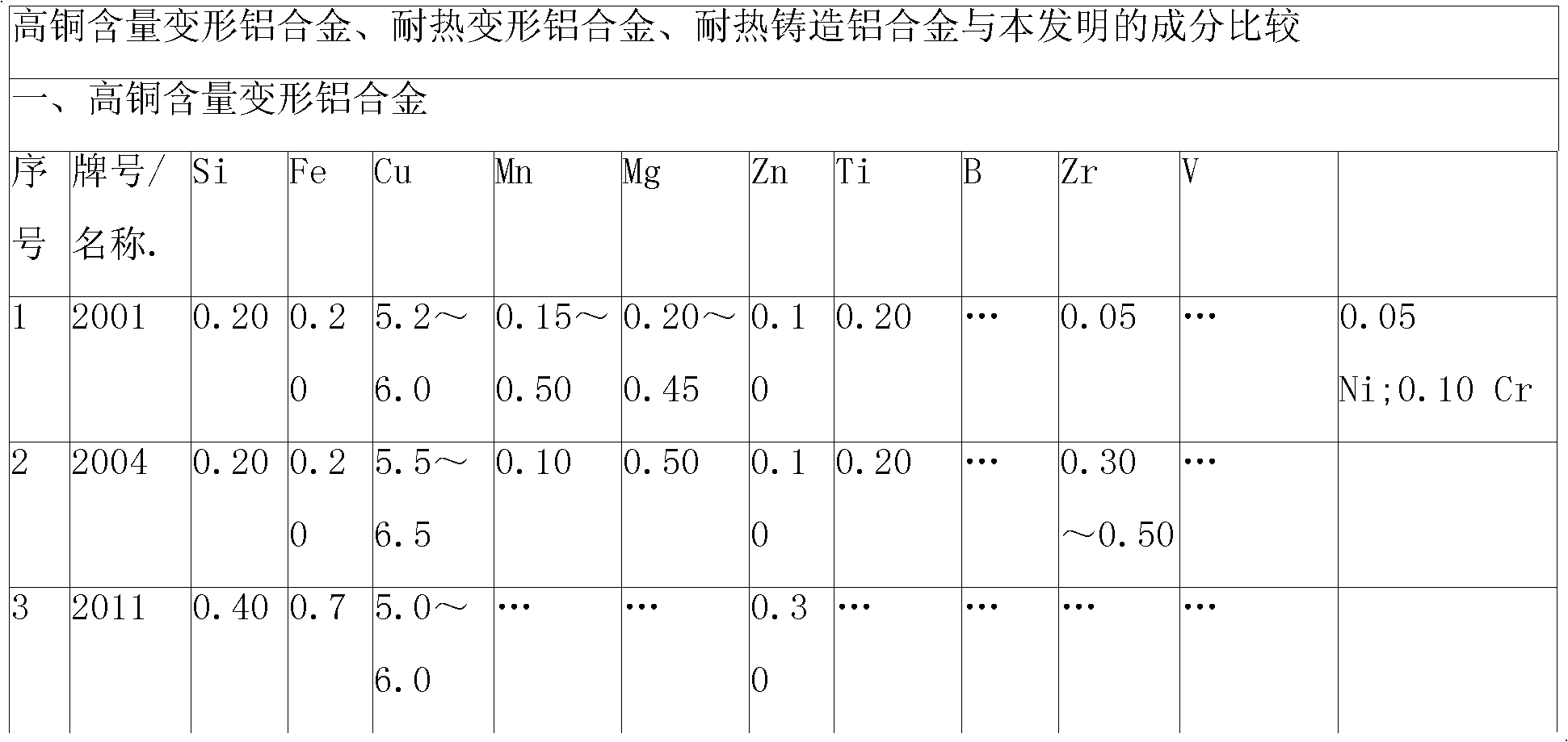

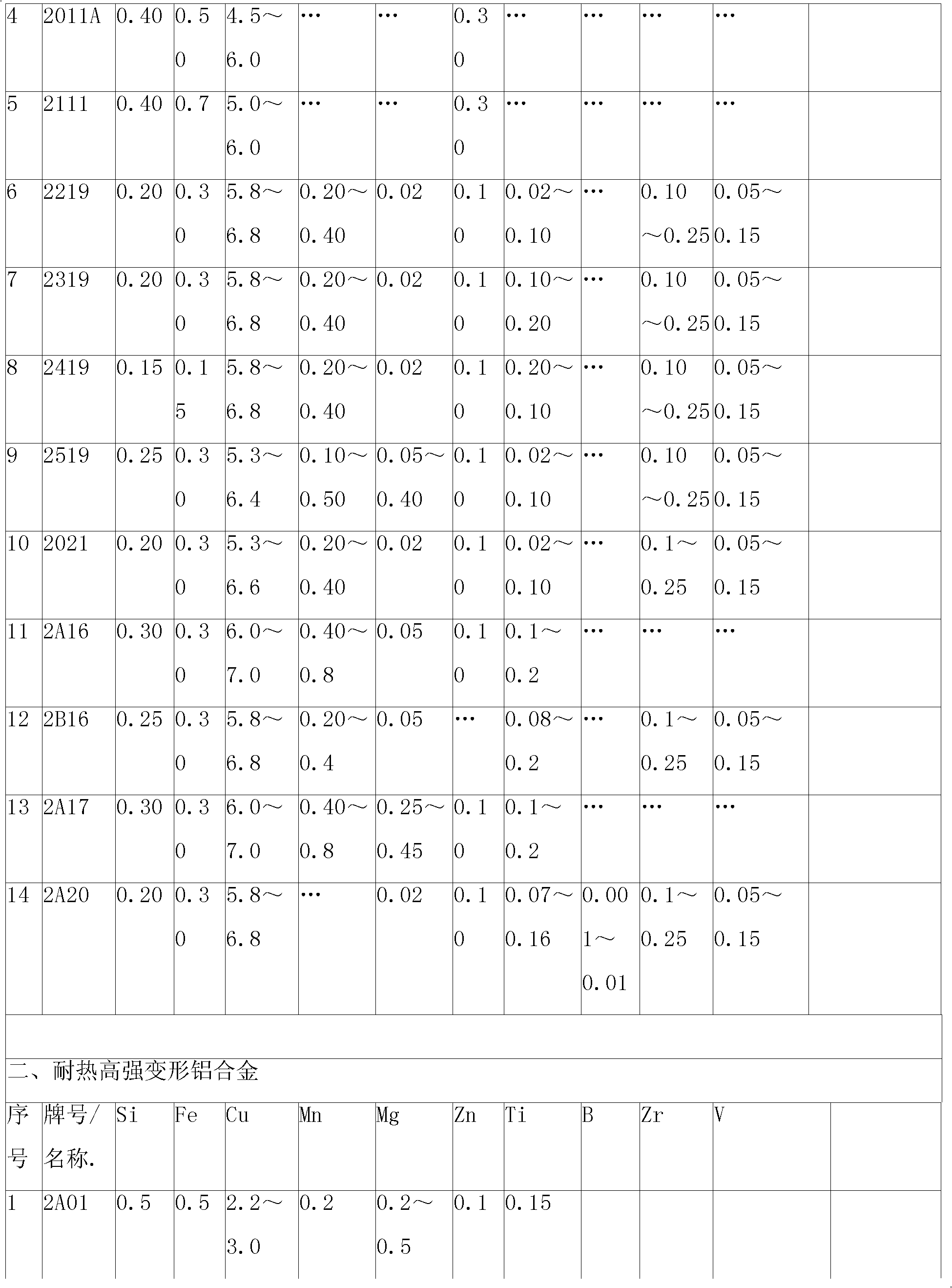

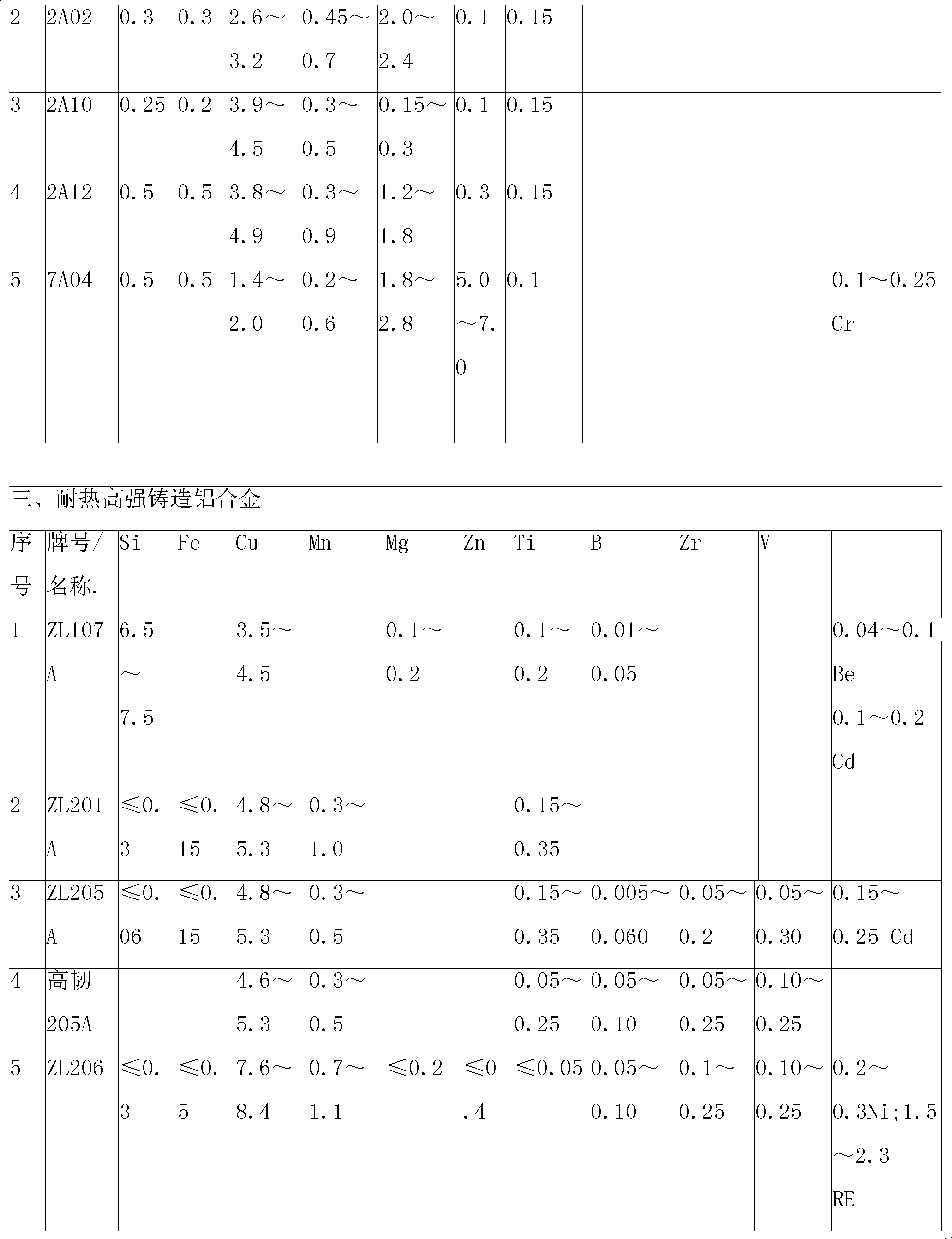

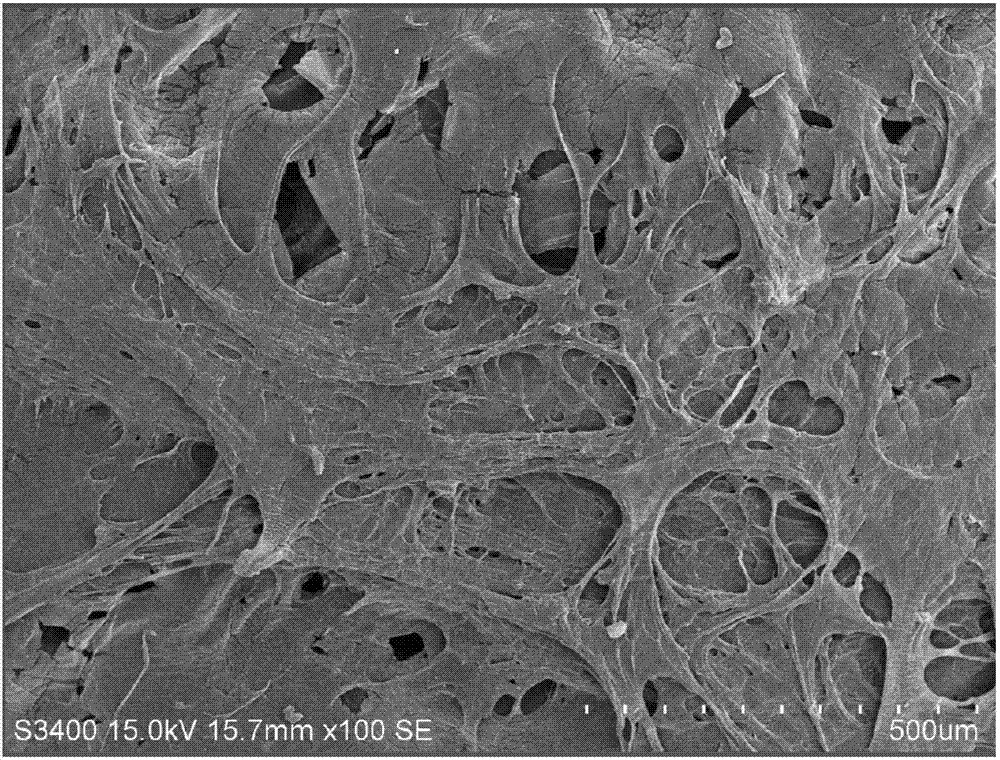

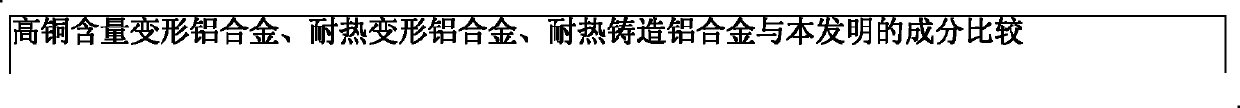

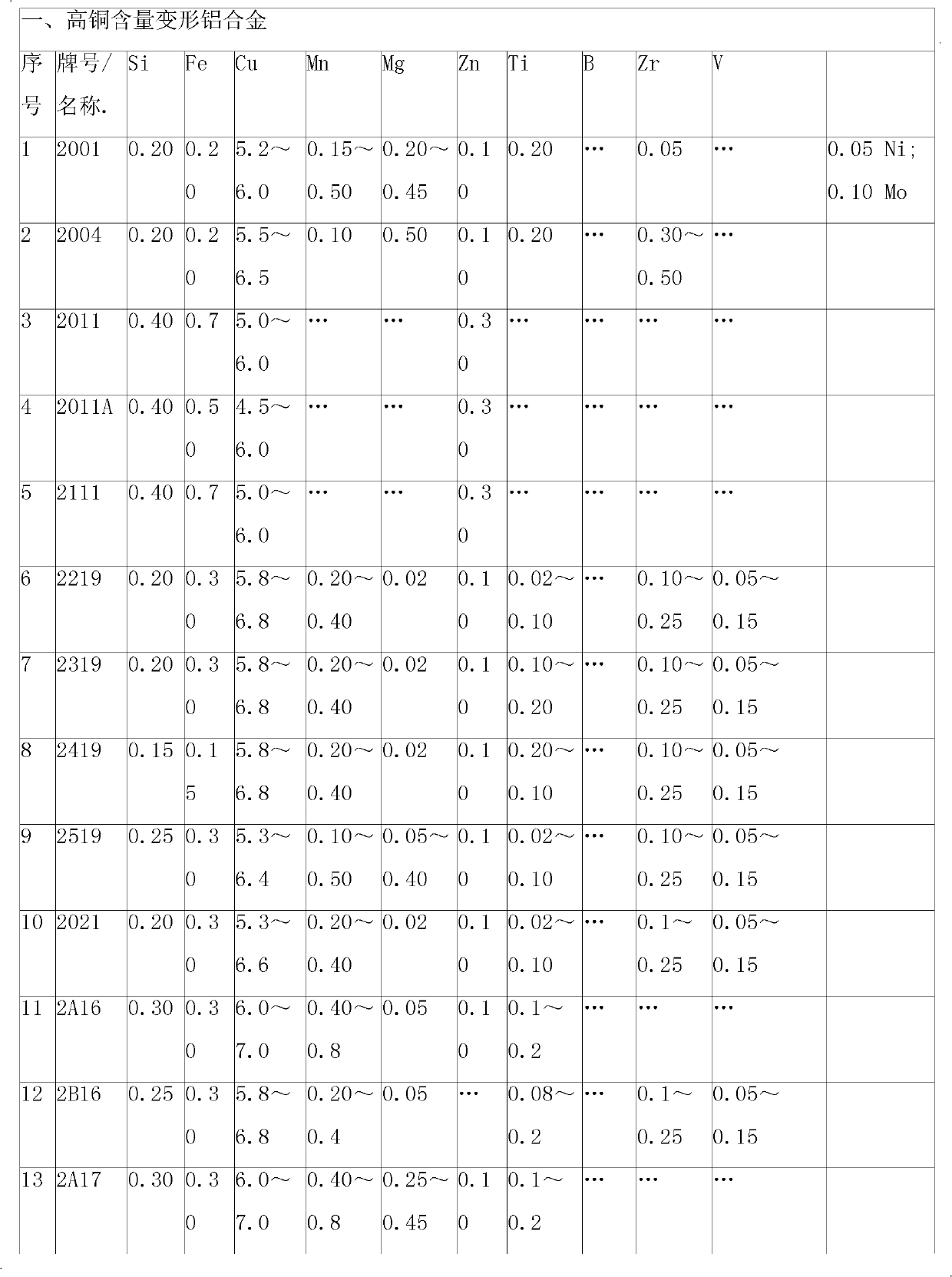

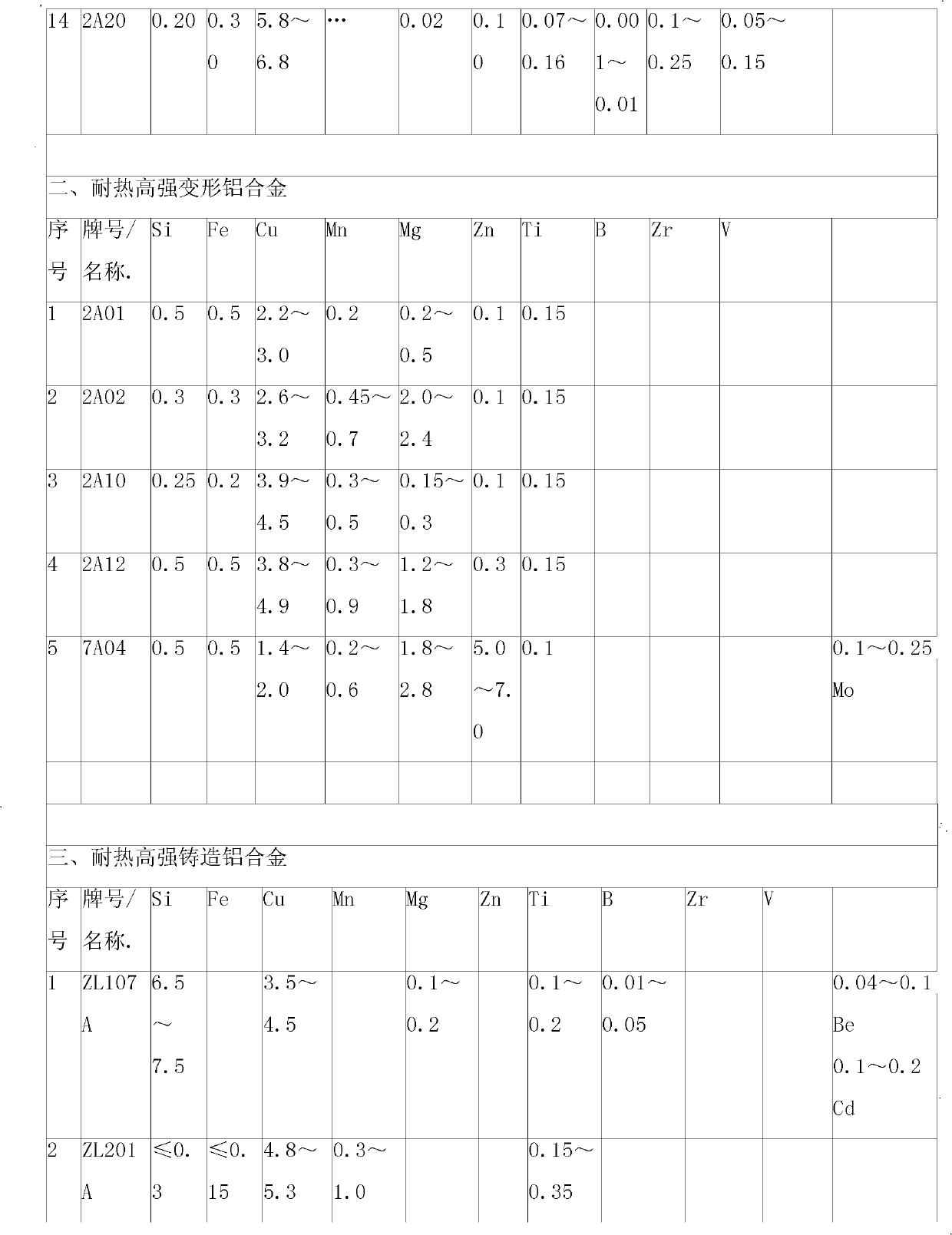

Li-W-RE high-strength heat resistant aluminum alloy material modified with C and preparation method thereof

The invention discloses a Li-W-RE high-strength heat resistant aluminum alloy material modified with C. The alloy comprises the following components by weight percent: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.0001 to 0.15 percent of C, 0.01 to 1.0 percent of Zr, 0.1 to 3.0 percent of Li, 0.01 to 1.0 percent of W, and 0.05 to 5 percent of rare earth element and the rest is Al. Through optimally choosing alloy host element Cu, Mn and RE prescription, the invention reduces alloy quasi-solid phase temperature range and solves the problems of large hot tear tend and low product high temperature strength in the casting process, guided by high quality melt, solid solution and phase diagram theory and taking a C element as modificator. The low cost multiple microalloyed element prescription is optimally choosen. Finally, a high-strength heat resistant aluminum alloy material is developed.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Electronic carrier board

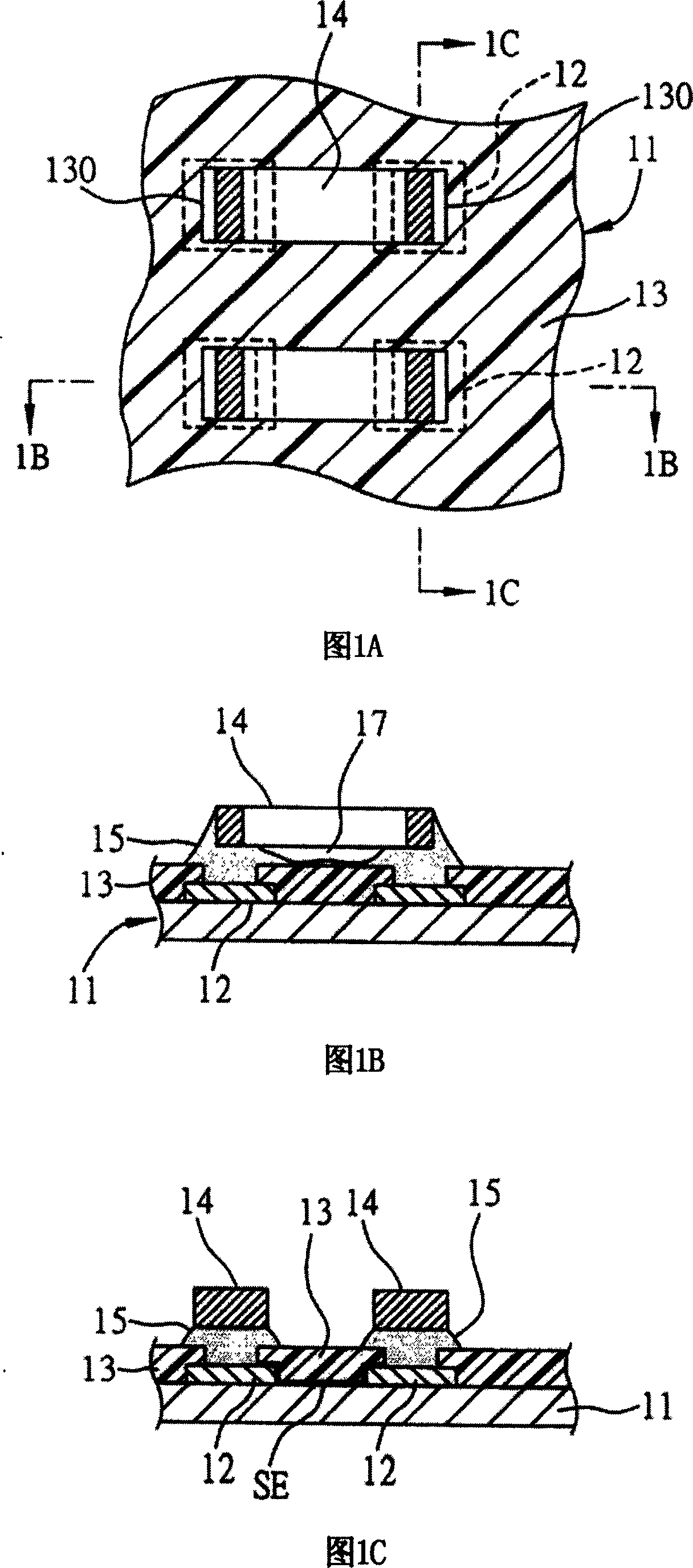

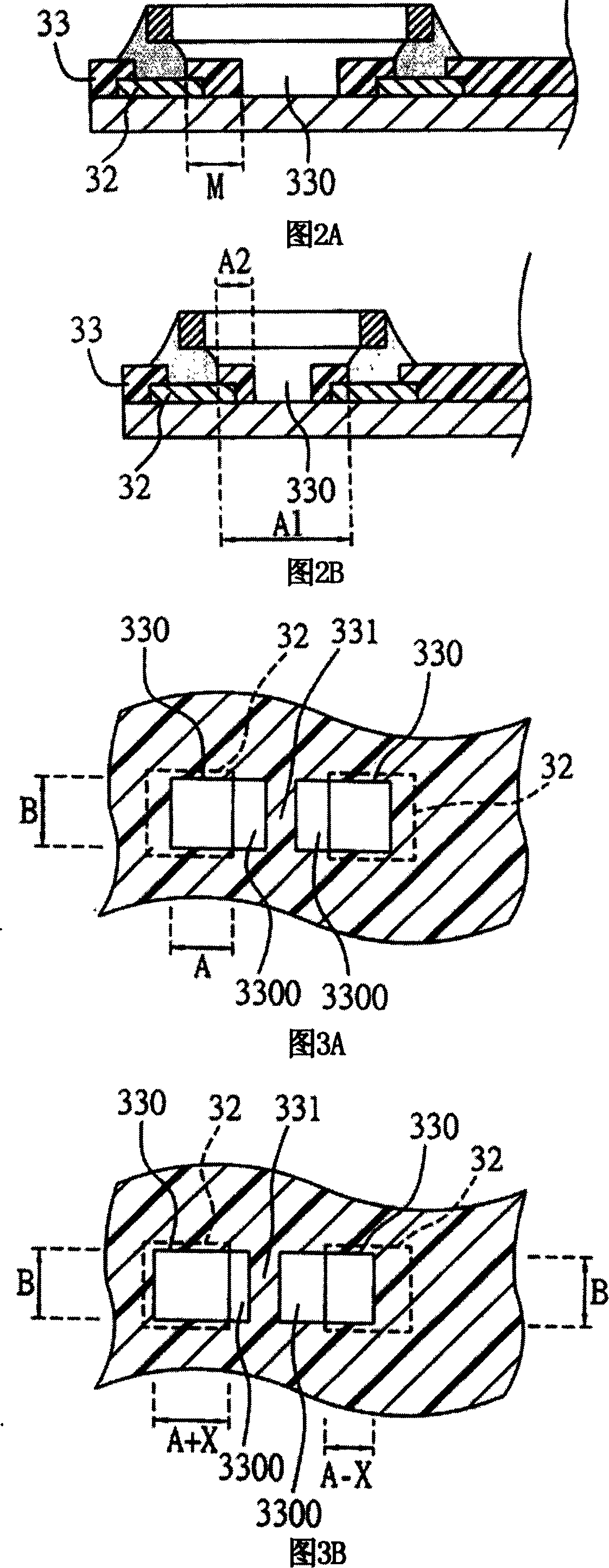

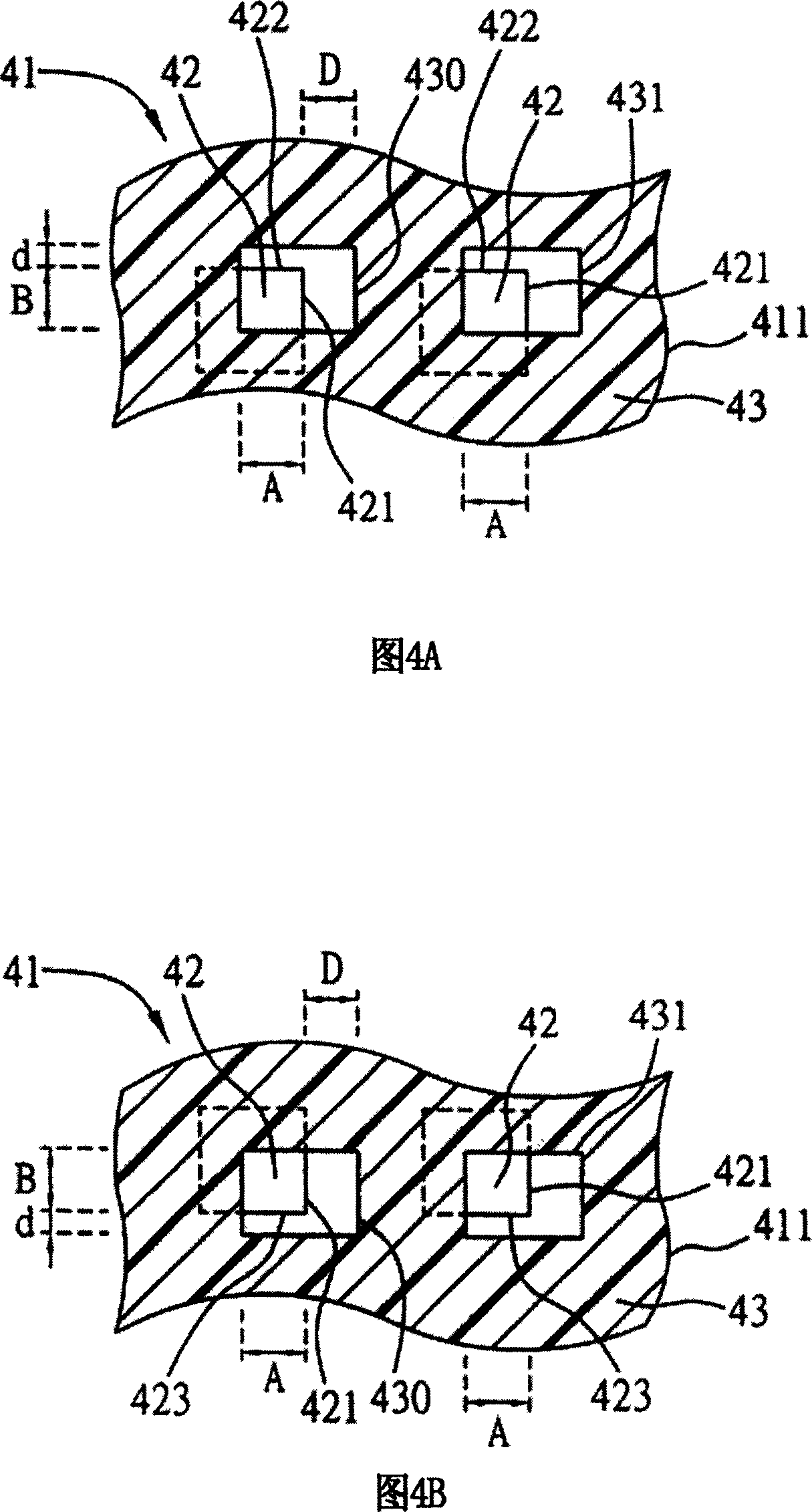

InactiveCN101009968AAvoid different pad areasAvoid different areasPrinted circuitsElectrical componentsEngineeringElectronic board

The disclosed electric carrier plate comprises: a main body, at least two welding mats set on body surface in pairs, a protective layer covering body surface and forming an opening opposite to the mat position, wherein there are at least two same side walls on the opening to expose the mats, the first one is set vertically to the mat arrangement direction, while the second one is parallel. This invention can avoid different area of exposed mats, prevents electric element standing on the plate, fills insulation material between element and plate efficiently, and overcomes problem that it cannot form flow-in groove for package resin on small-size passive element bottom.

Owner:SILICONWARE PRECISION IND CO LTD

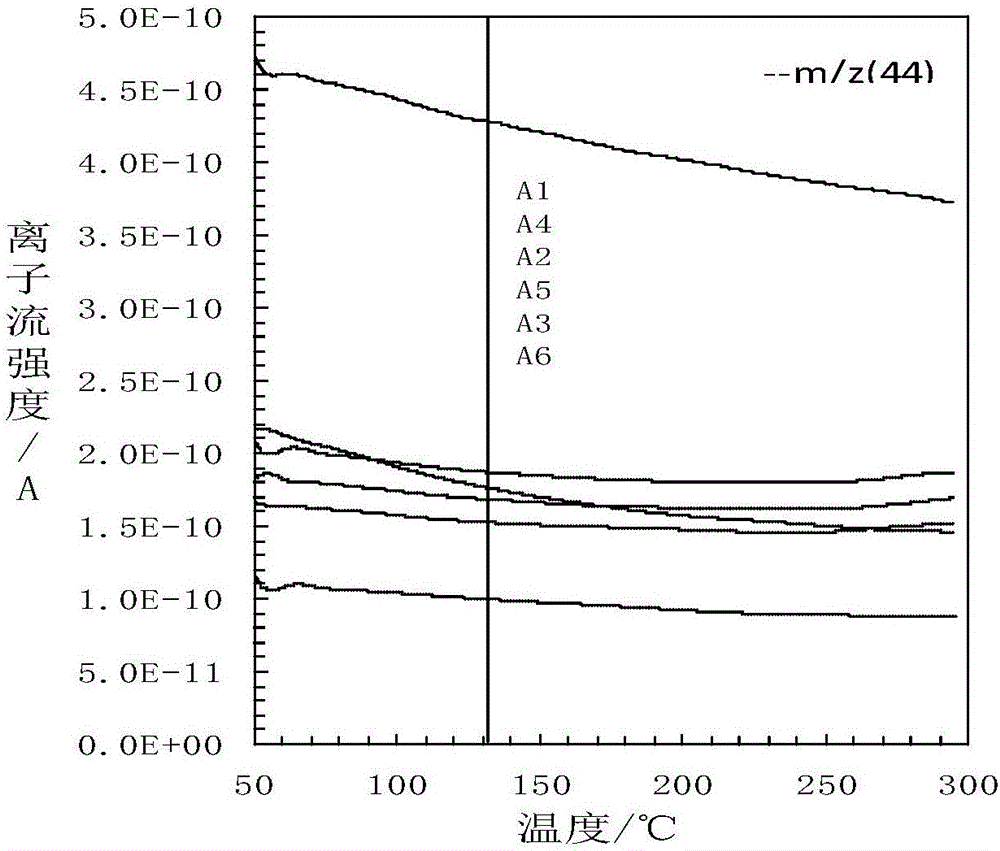

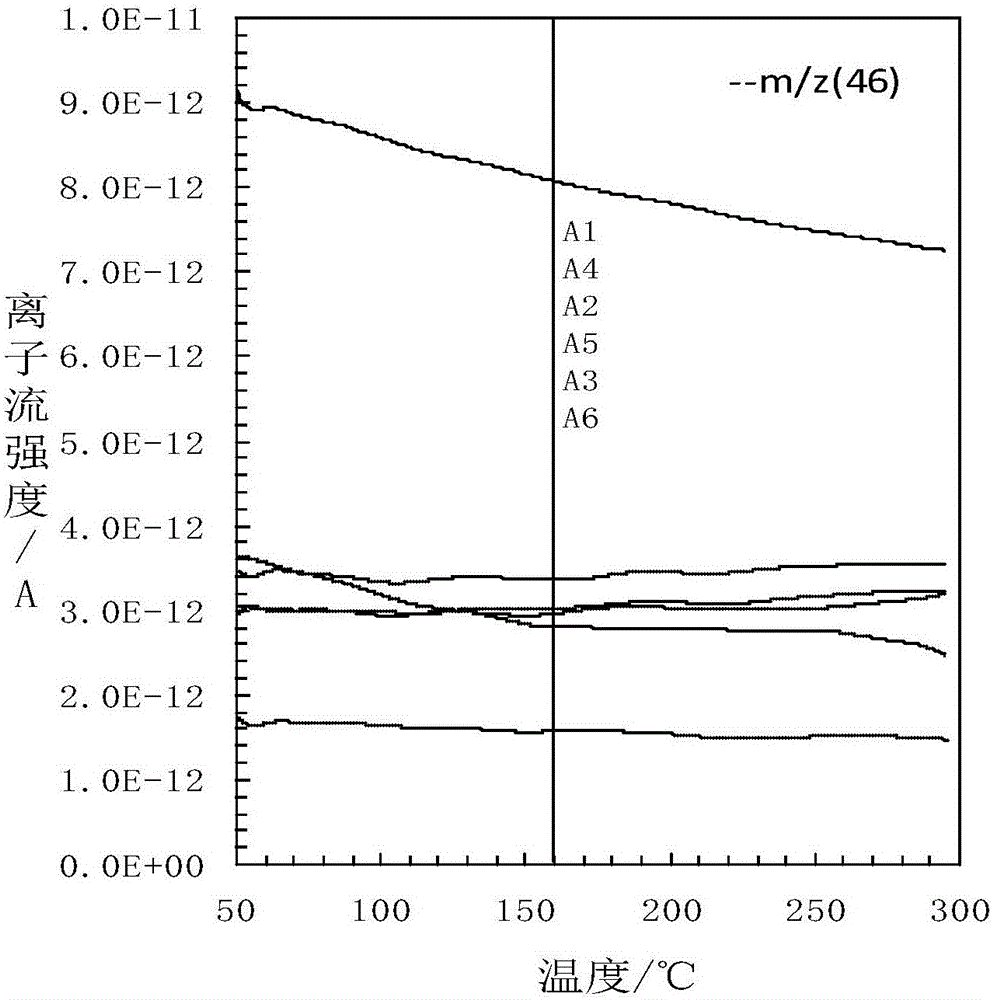

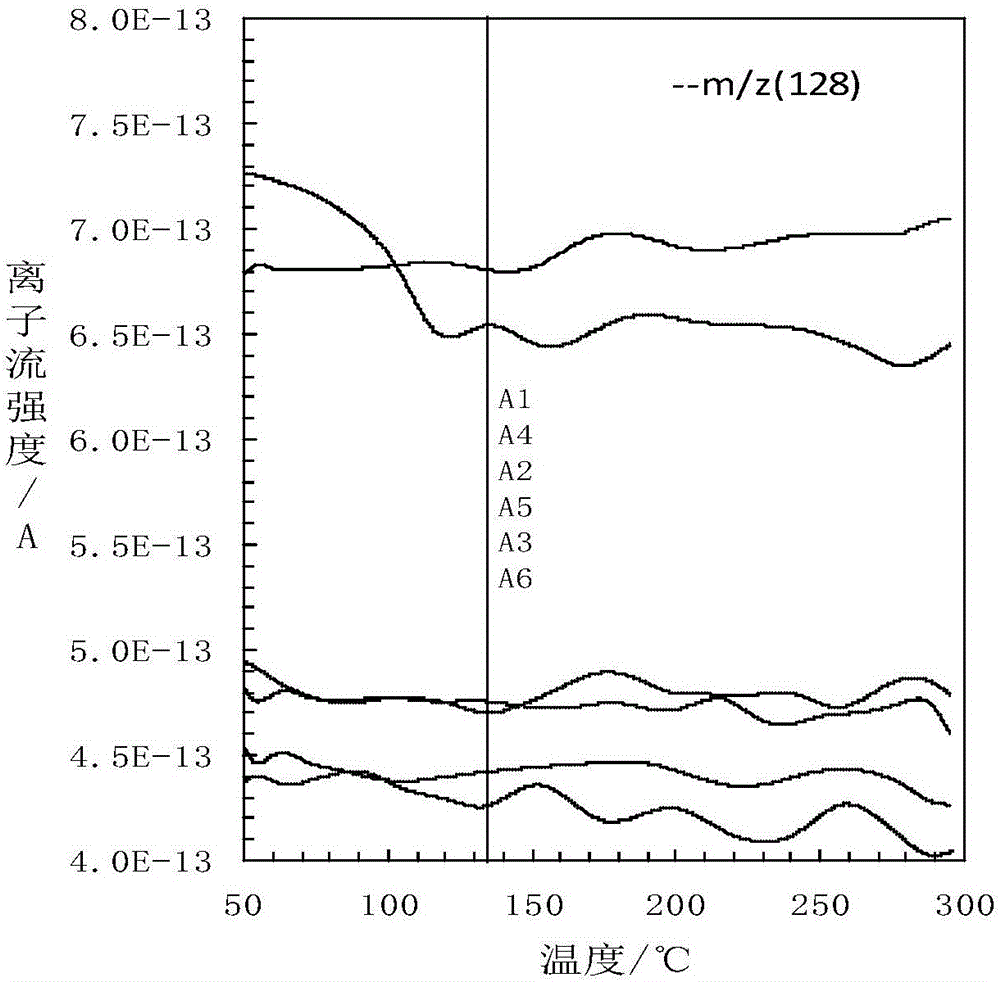

Asphalt volatile organic compound composite inhibitor, smoke-restraining asphalt, manufacturing method of asphalt volatile organic compound composite inhibitor and manufacturing method of smoke-restraining asphalt

InactiveCN105778531AReduce releasePrevent volatilizationBuilding insulationsActivated carbonGas release

The invention relates to the technical field of restraining of an asphalt volatile organic compound, in particular to an asphalt volatile organic compound composite inhibitor, smoke-restraining asphalt, a manufacturing method of the asphalt volatile organic compound composite inhibitor and a manufacturing method of the smoke-restraining asphalt. The composite inhibitor is prepared from the following components in parts by weight: 3-7 parts of an SBS modifying agent, 1.5-5 parts of activated carbon, and 1.5-6 parts of magnalium-based layered double-hydroxyl composite metal hydroxide. The smoke-restraining asphalt is prepared from the following components in parts by weight: 87-90 parts of substrate asphalt, 4-5 parts of an SBS modifying agent, 2-4 parts of activated carbon, and 2-4 parts of magnalium-based layered double-hydroxyl composite metal hydroxide. The manufacturing method of the smoke-restraining asphalt comprises the following steps: heating the substrate asphalt to 150-170 DEG C and performing stirring in a heat insulating manner; in the stirring process, sequentially adding the SBS modifying agent, the activated carbon and the magnalium-based layered double-hydroxyl composite metal hydroxide to the substrate asphalt; after performing stirring, performing cutting. The asphalt in which the composite inhibitor is added is better in gas released effect than the smoke-retraining asphalt modified by other inhibitors, so that VOC release amount of the asphalt is greatly reduced.

Owner:CHINA GEZHOUBA GROUP CO LTD

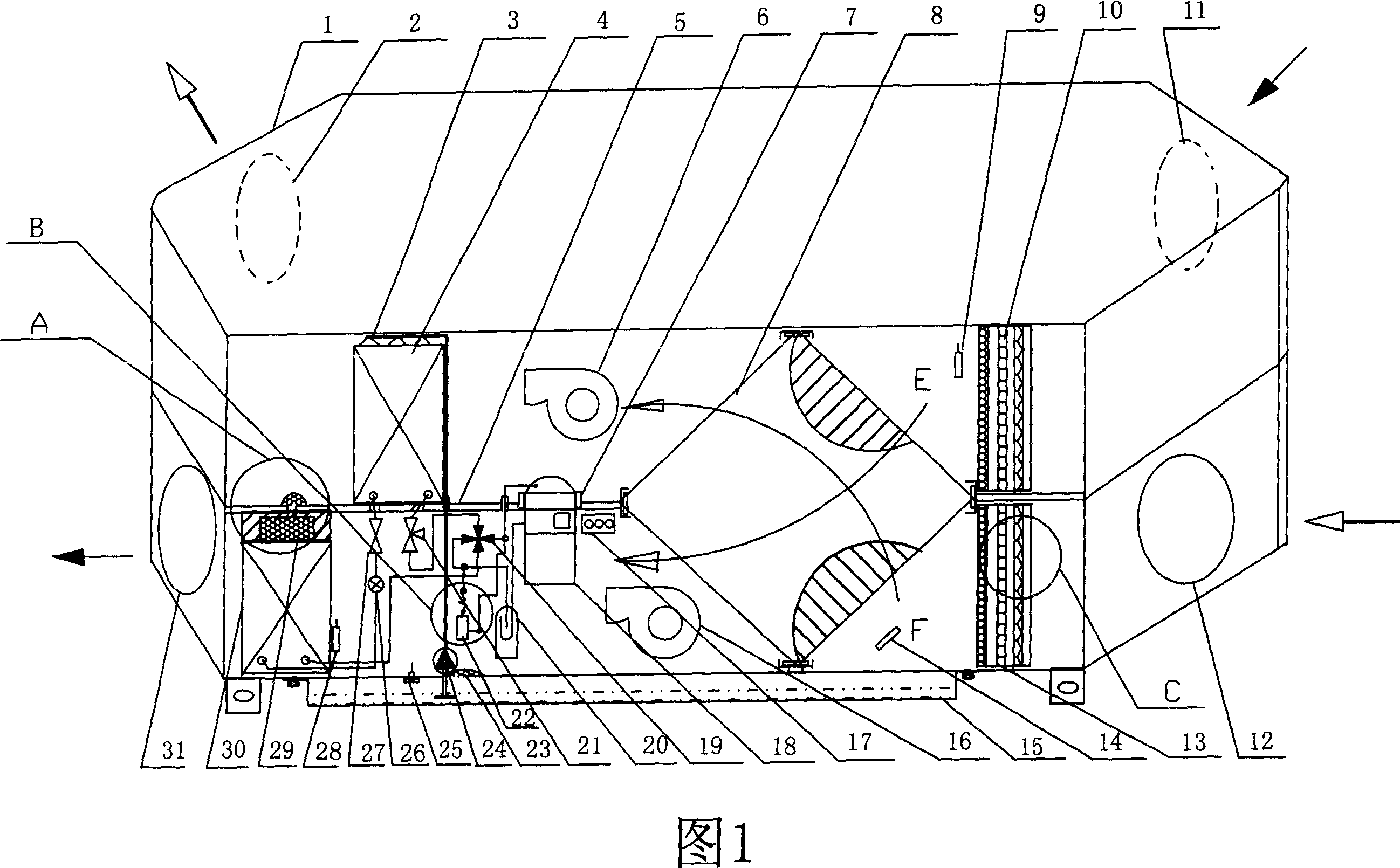

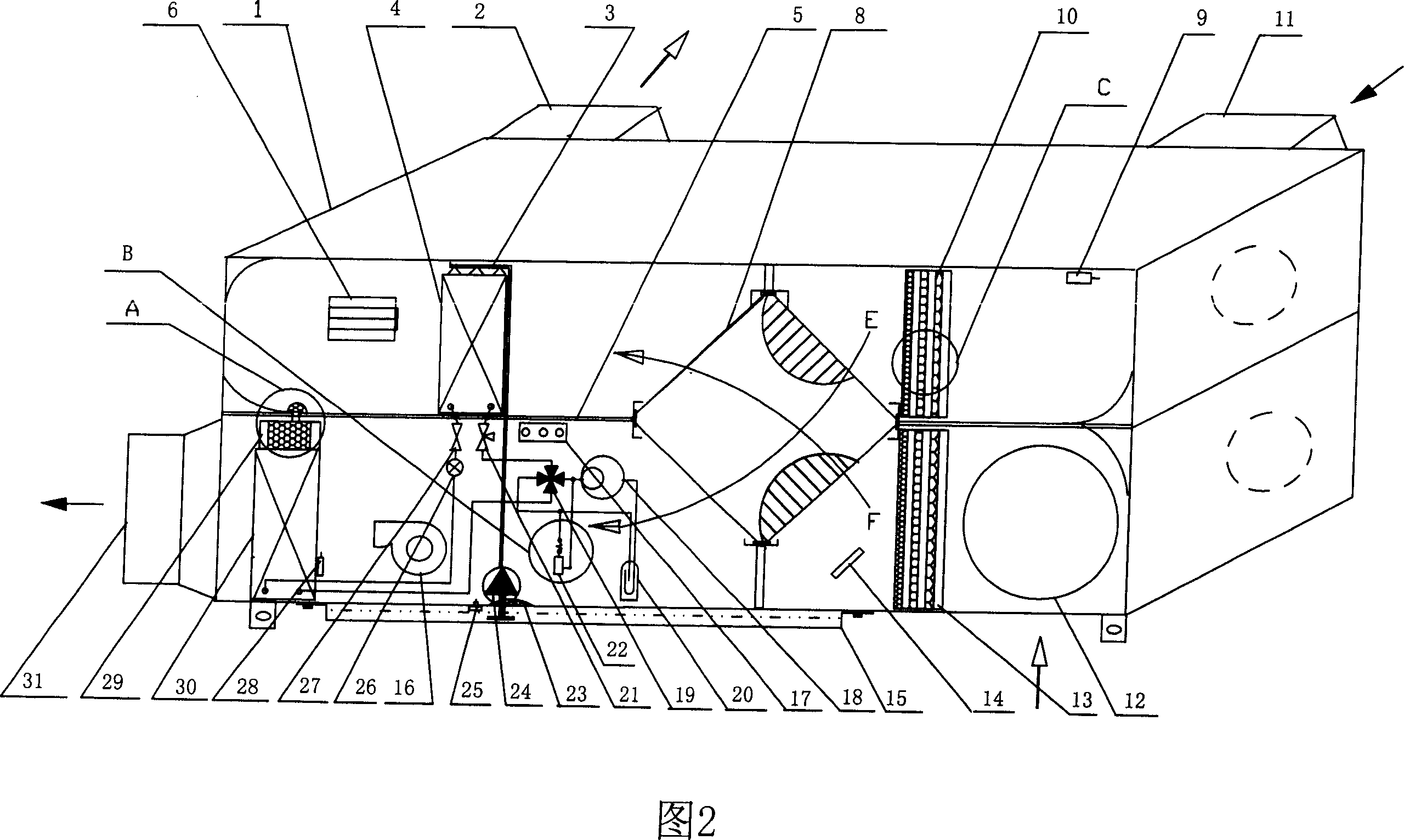

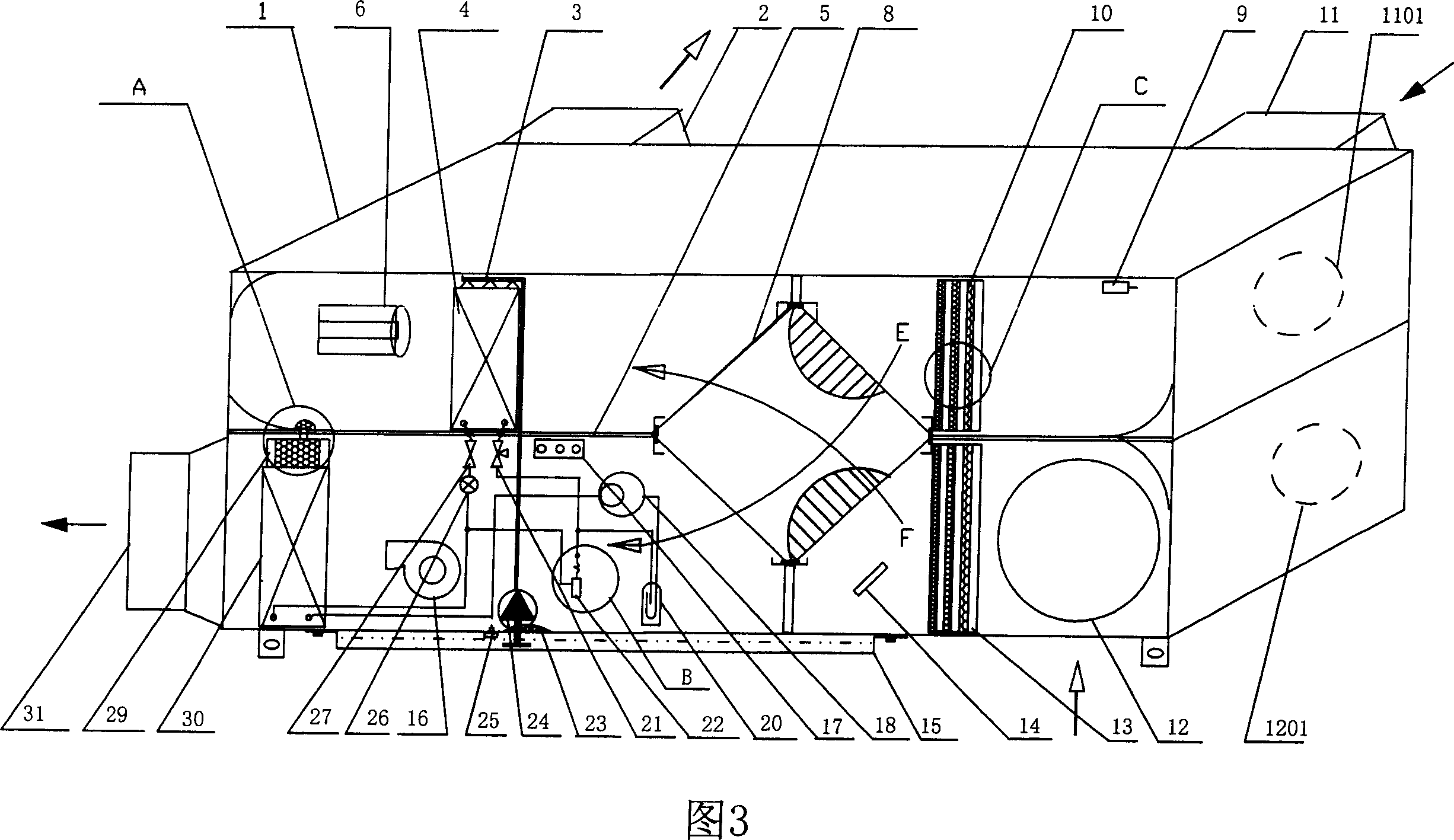

Energy-saving environment-friendly air-conditioner without condensed water

InactiveCN101101141ATake advantage ofFully distributedCondensate preventionLighting and heating apparatusWater channelEngineering

The invention relates to an energy conservation environmental protection air-conditioning without condensed water, which relates to the ventilation and air-conditioning electric appliance area of technology. It has the metal box body 1 which interior divides into up and down two floors with the partition board, the middle is partitioned by heat interchanger core body 8, composes the E and the F air flue; its characteristic is in the air flue includes: the condensed water energy reclamation plant which is composed of water channel and filtrate device and the wet-add circulatory system, automatic unloading gear which has the conventional air conditioning structure and protects compressor, the filtrate device and light accelerant heat change implement core body which may sterilize automatically and the nanometer light catalyst sterilization, the disinfection installment; specially it may conserves energy above 45%, and guarantees that the air quality achieves the environmental protection and the safety requirements. The invention together the waste gas energy recycling, the condensed water energy recycling, the energy conservation, no condensed water, no outdoor machine, the entire new atmosphere and the air purification, the sterilization, the disinfection function in a body, and has the huge environmental protection effect and the economic efficiency.

Owner:陈国宝

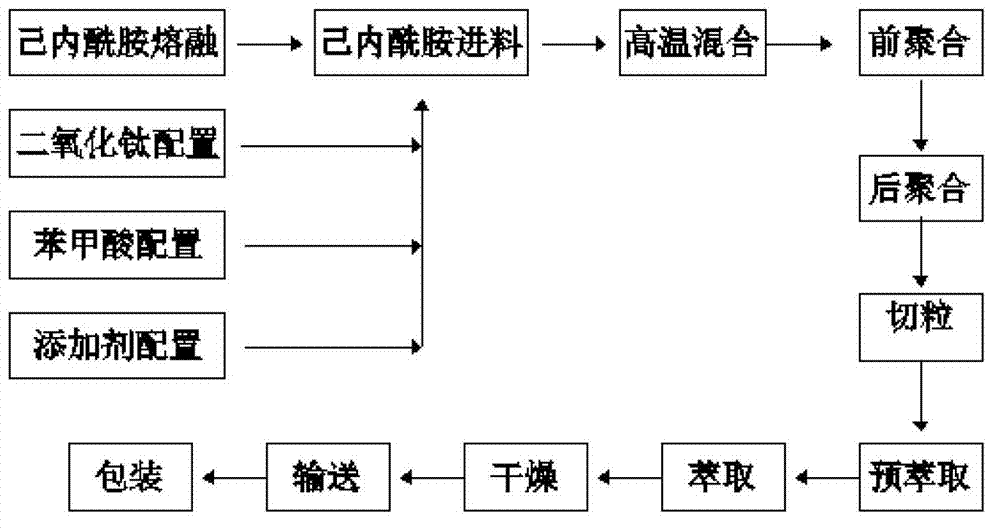

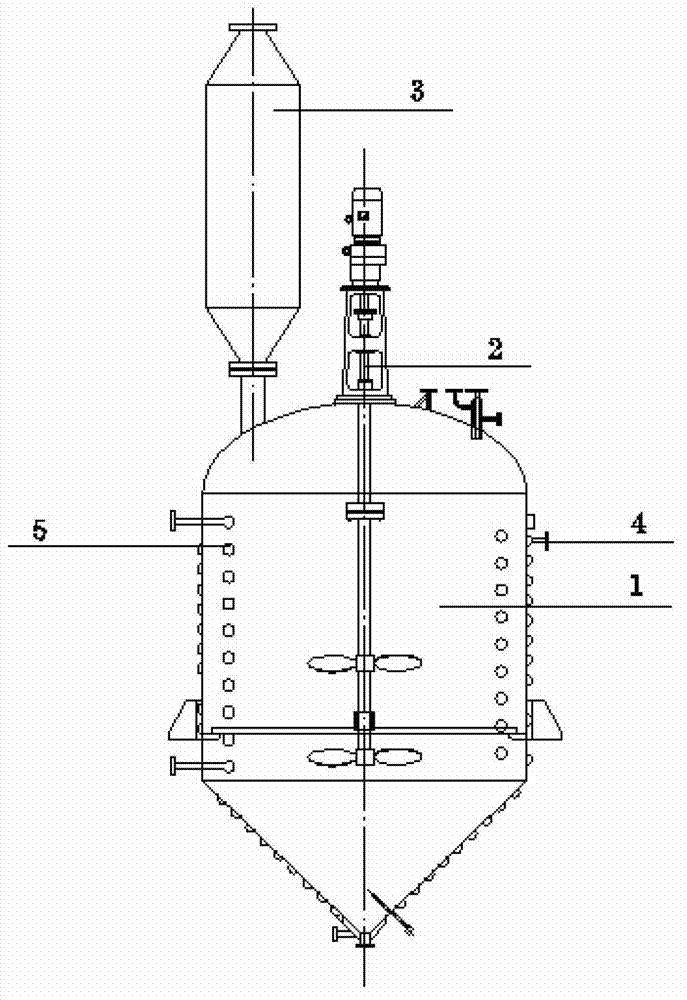

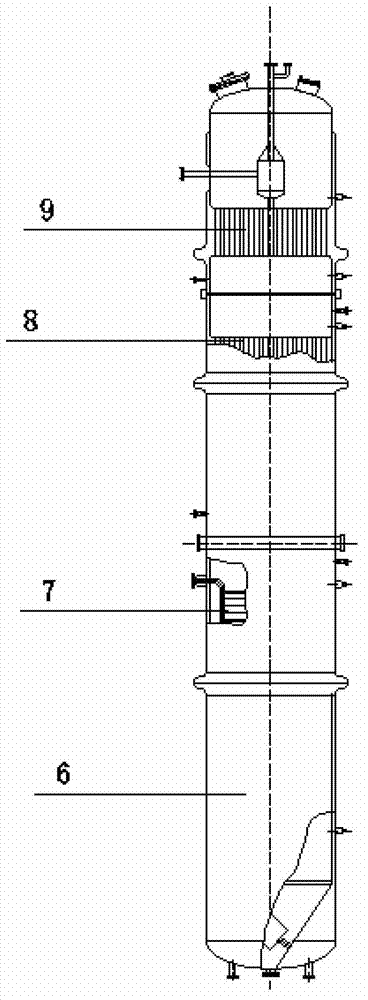

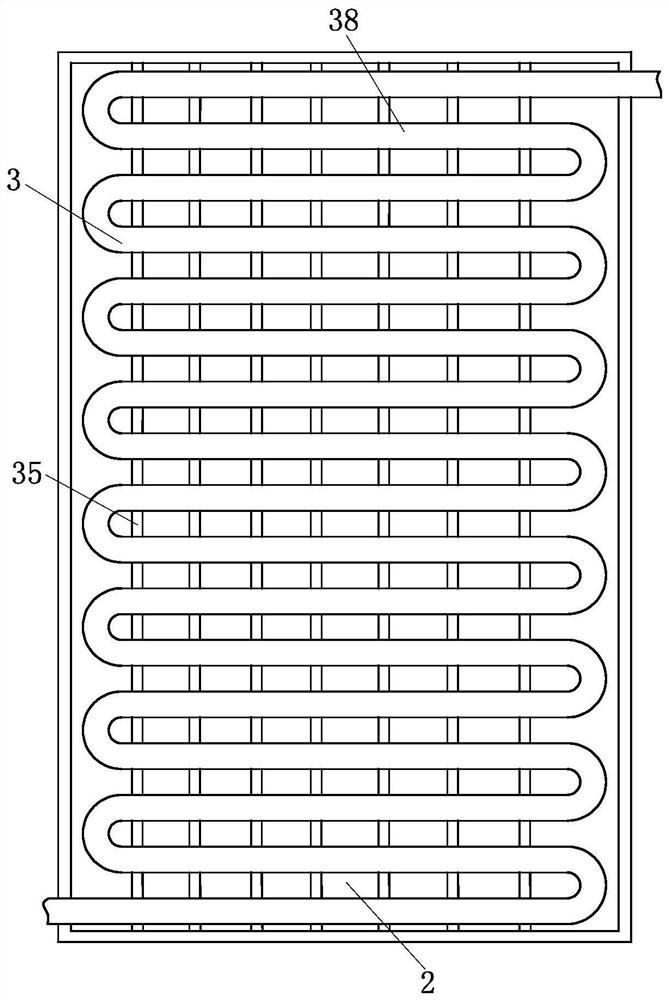

Polymerization manufacturing technique and device for polyamide

The invention relates to a polymerization manufacturing technique and device for polyamide. The manufacturing technique comprises the steps of feeding molten caprolactam, titanium dioxide, benzoic acid and an additive, dynamically mixing at a high temperature for prepolymerization and postpolymerization, granulating, pre-extracting, extracting and drying to obtain the final product. The device comprises a melting system, a feed system, a high-temperature dynamic mixing system, prepolymerization and postpolymerization towers, a pre-extraction column, an extraction column, a recycling system and a drying tower. According to the invention, a high-temperature dynamic mixing tank is set additionally. The mixing of the raw materials and hydrolysis for ring opening and dehydration of polyamide are performed at a state of dynamically mixing to achieve a more sufficient and stable pre-addition polymerization and a more uniform and stable molecular distribution of post-polycondensation. A slice and a water separator of the extraction column are used for mainly extracting oligomers through the pre-extraction column and extracting a caprolactam monomer through the extraction column with a stable concentration. A slice cooler of the drying tower is used for cooling the slices rapidly. An extraction water recycling system is used for recycling the oligomers in the pre-extraction water and the caprolactam monomer in the extraction water.

Owner:武汉森大科技研究发展中心

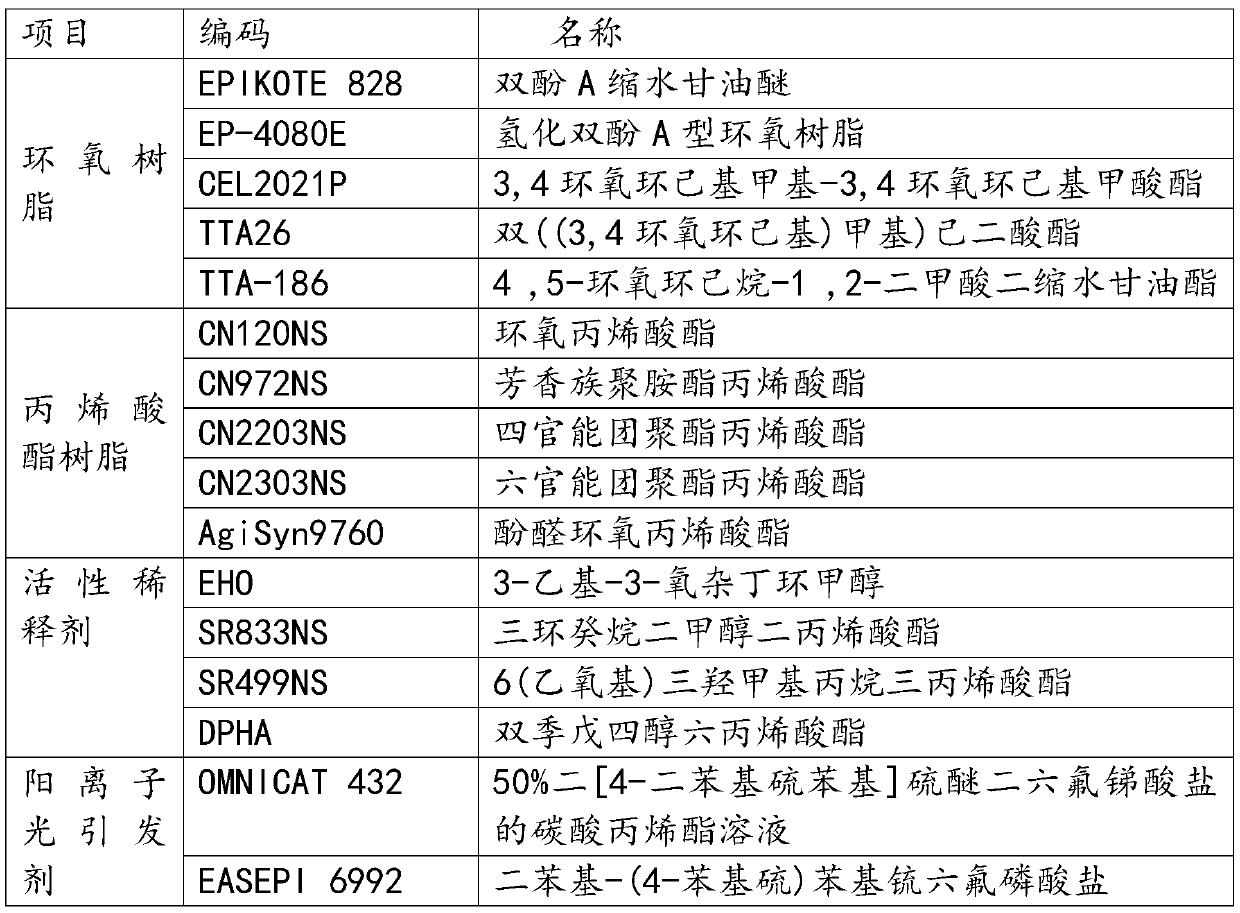

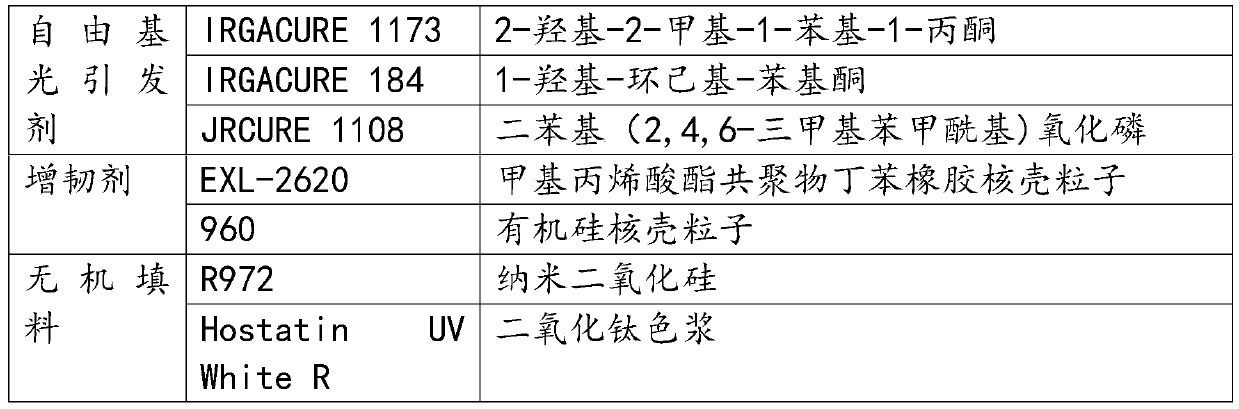

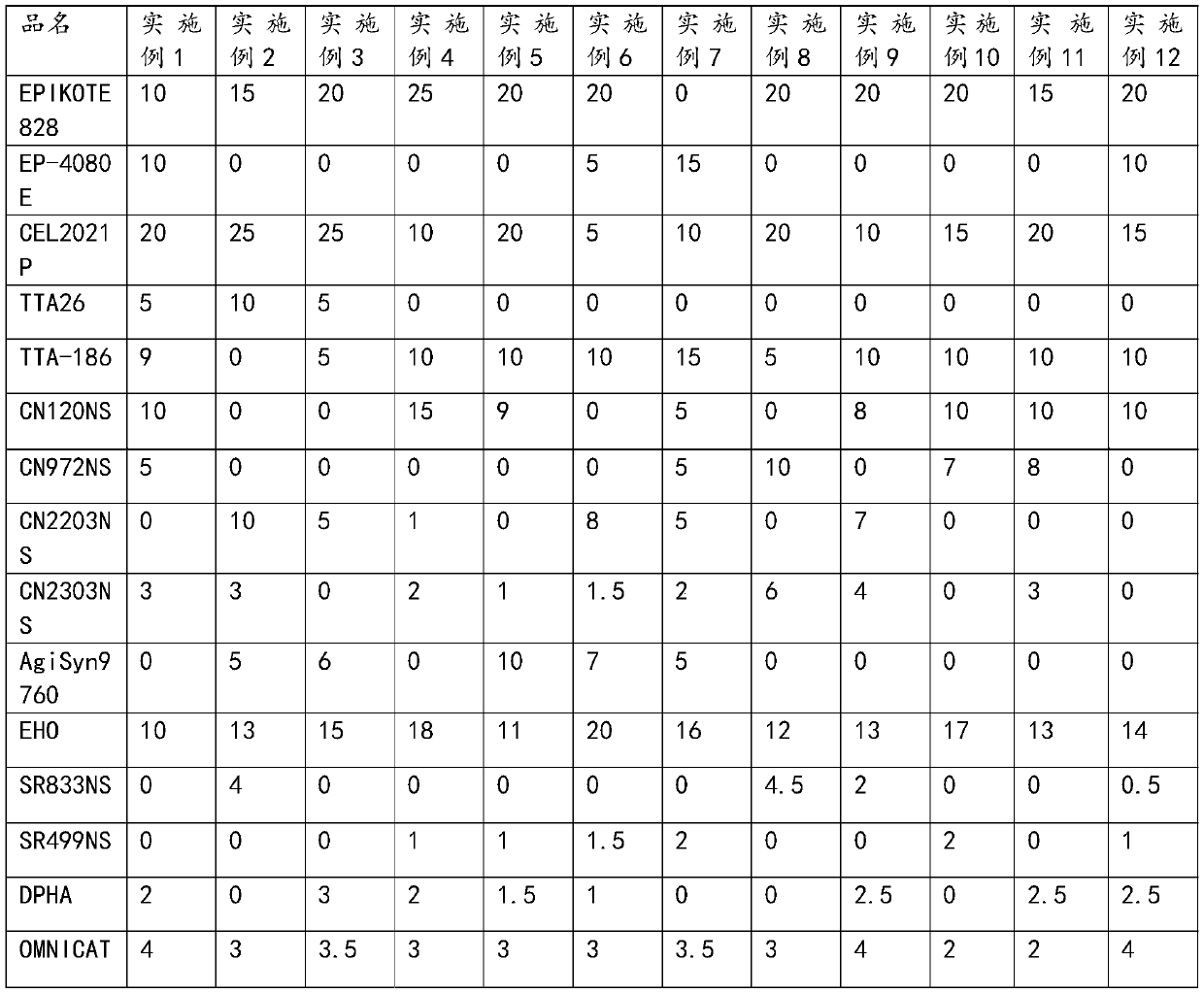

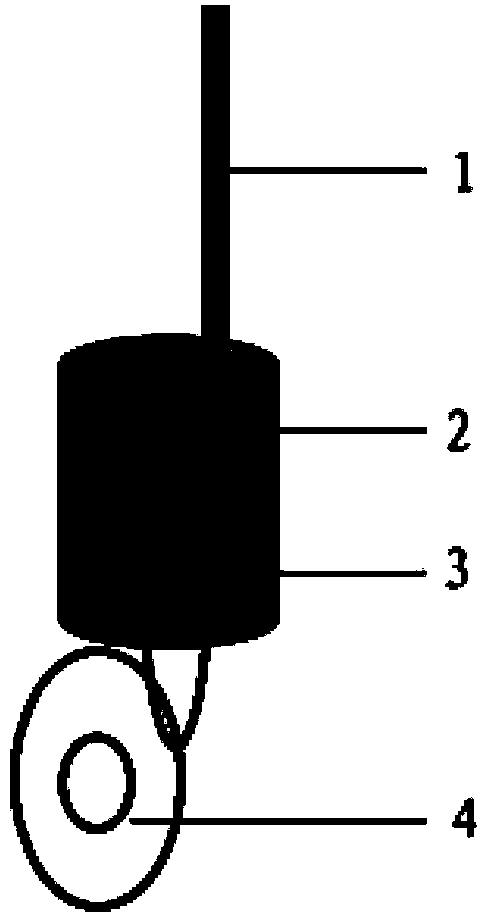

High-temperature-resistant light-cured resin and preparation method thereof

InactiveCN110724236APlay a synergistic roleLight curing reaction speed is fastAdditive manufacturing apparatusEpoxyPolymer science

The invention provides high-temperature-resistant light-cured resin and a preparation method thereof. The light-cured resin comprises the following components in percentage by mass: 40%-70% of epoxy resin, 5%-20% of acrylic resin, 10%-20% of an active diluent, 3%-6% of a cationic photoinitiator, 1%-3% of a free-radical photoinitiator, 5%-20% of a flexibilizer and 0.1%-3% of an inorganic filler. The high-temperature-resistant light-cured resin is high in curing reaction rate and has both toughness and strength.

Owner:威斯坦(厦门)实业有限公司

Preparation method of titanium alloy surface passivation film transmission observation sample

InactiveCN103364243AEvenly distributedFully distributedPreparing sample for investigationSand-paperTitanium

The invention relates to the field of preparation of a transmission sample, and in particular to a preparation method of a titanium alloy surface passivation film transmission observation sample. The method comprises the following steps of: (1) performing double-spray thinning treatment on a transmission sample with diameter of 3mm and thickness of 40-50 microns polished by sand paper in acid liquor at -20to -30 DEG C to prepare a transmission sample with thin region thickness of about 30nm-100nm and uniform distribution; (2) performing cathodic polarization on the transmission sample subjected to the double spray in electrolyte under the condition of -0.5V to -1.5V for about 1-10 min so as to remove an oxide film spontaneously formed on the surface of the sample in air; and (3) performing anodic passivation treatment on the alloy sample under the condition of 0 to 2V for 0.5-5 hours to fully oxidize the alloy surface so as to form a passivation film uniformly distributed at the thin region of the transmission sample. The fully passivated thin region is completely made from metal oxide and can be free from the influence of an alloy phase of a matrix, and thus the phase composition and the element distribution of the passivation film are easily observed. The preparation method is suitable for preparing of the transmission observation sample of the passivation film of titanium, titanium alloy and the like with thickness of only several nanometers.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Shaft-vibration forced mixer

PendingCN107116696AImprove performanceImprove adhesionCement mixing apparatusElectric machineryFixed frame

The invention discloses a shaft-vibration forced mixer. The shaft-vibration forced mixer comprises a mixing barrel, mixing shafts, a fixed frame, a speed reducer and a mixing motor. The shaft-vibration forced mixer is characterized by further comprising vibration frames horizontally arranged around the outer side of the mixing barrel, and two vibrators horizontally and vertically arranged on the vibration frames between bearing seats at the two ends of each of the two mixing shafts separately, wherein the two ends of each mixing shaft are fixedly connected with the corresponding vibration frame through the bearing seats and bearings thereof. The mixing shafts and mixing blades of the mixer rotate under the driving of the speed reducer and the mixing motor, and vibration is generated under the driving of the vibrators. A mixture can be adequately dispersed and uniformly fused, so that the mixture realizes macroscopic uniformity and microcosmic uniformity in a real sense; and repeated collision is carried out in the mixture to form high-quality cementing materials, and the cementing materials are uniformly distributed in the mixture and in better firm bonding with aggregates, so that a mixture with higher performance is formed. The shaft-vibration forced mixer is applicable to cement stabilized soil, cement concrete, cement mortar and asphalt mixture.

Owner:归立发

Additive resin carrier for cigarette filters and its preparation method

The invention provides an additive resin carrier for cigarette filters. The additive resin carrier is prepared by: subjecting 1-8% by mass of an essence microcapsule, 20-60% by mass of modified starch, 30-70% by mass of resin, 1-3% by mass of a plasticizer and 0.01-0.05% by mass of toner to an extrusion molding process. The additive resin carrier for cigarette filters provided in the invention reserves the advantages of easy shaping and rapid as well as convenient preparation of various shapes of resin, and can fully release the additive fragrance during cigarette smoking.

Owner:HUBEI CHINA TOBACCO IND +1

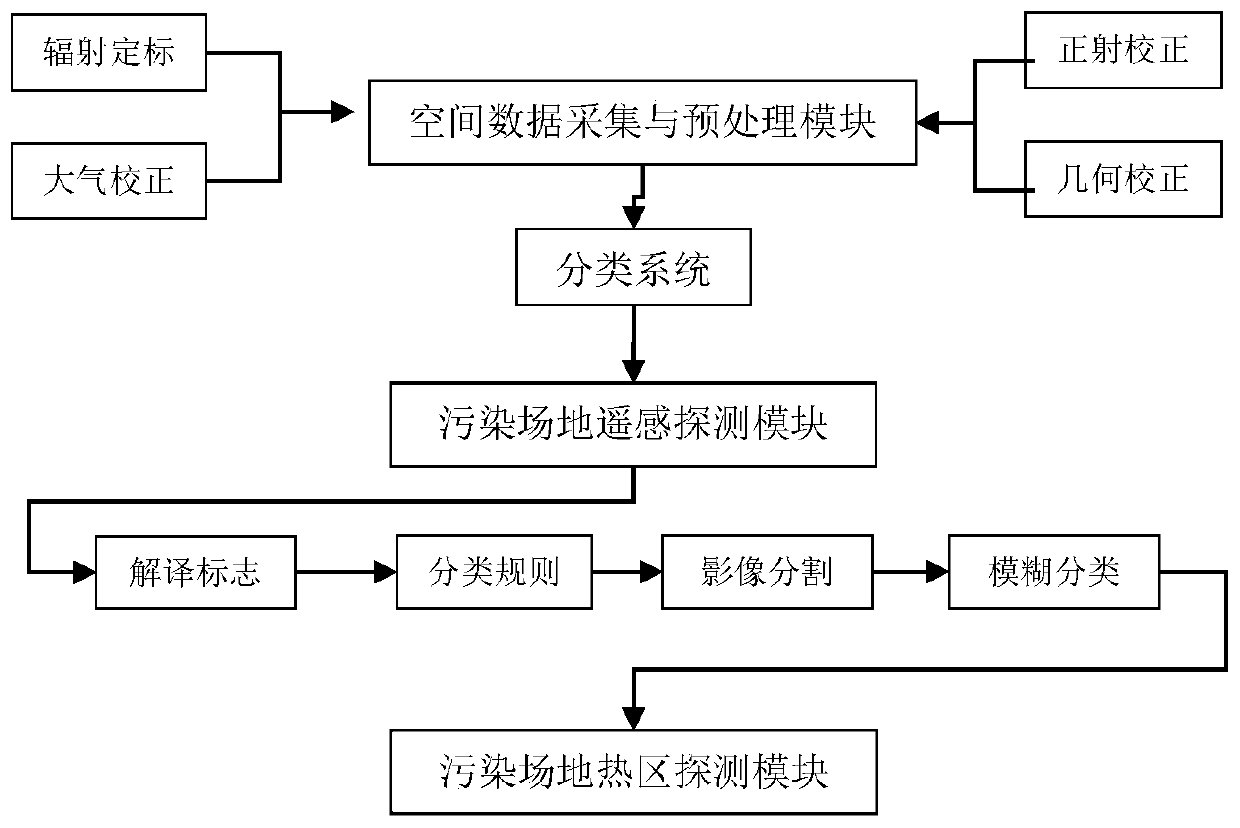

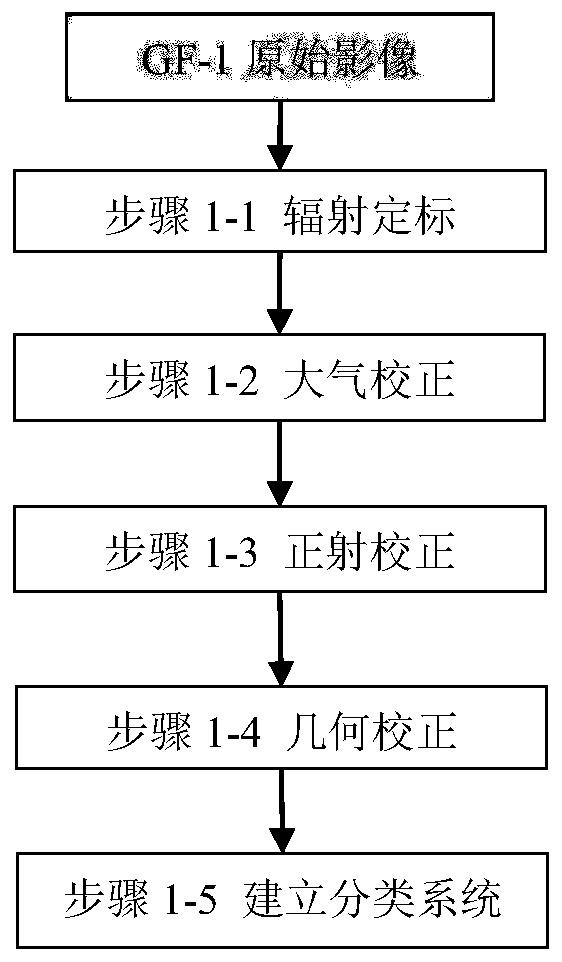

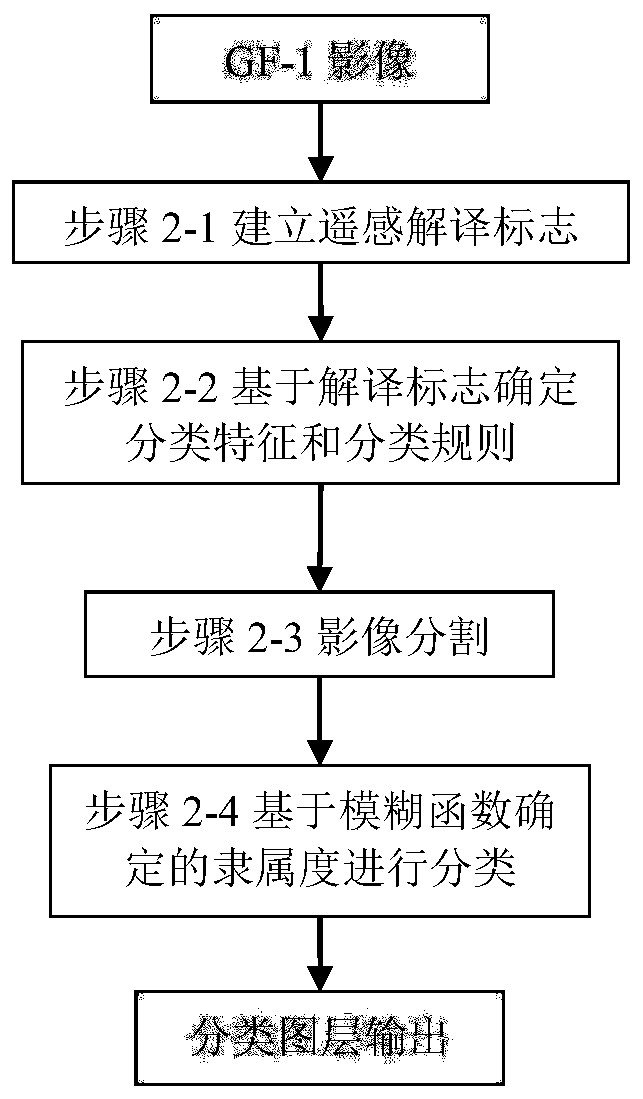

Remote sensing detection and spatial hot area identification system and method for contaminated site

ActiveCN110726677AEasy to operateIncrease visibilityMaterial analysis by optical meansThermometers using physical/chemical changesSite monitoringSoil science

The invention discloses a remote sensing detection and spatial hot area identification system and method for a contaminated site. The system comprises a spatial data acquisition and preprocessing module, a contaminated site remote sensing detection module and a contaminated site hot area detection module. The system serves the work of contaminated site monitoring, hot area detection and the like.The system comprises a novel contaminated site remote sensing image detection method framework, and an identification method for a centralized distribution area of the contaminated site is realized. The system has the characteristic of high practicability, and has urgent application requirements in the related fields of current contaminated site situation monitoring, contaminated site planning, ecological environment restoration and the like.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

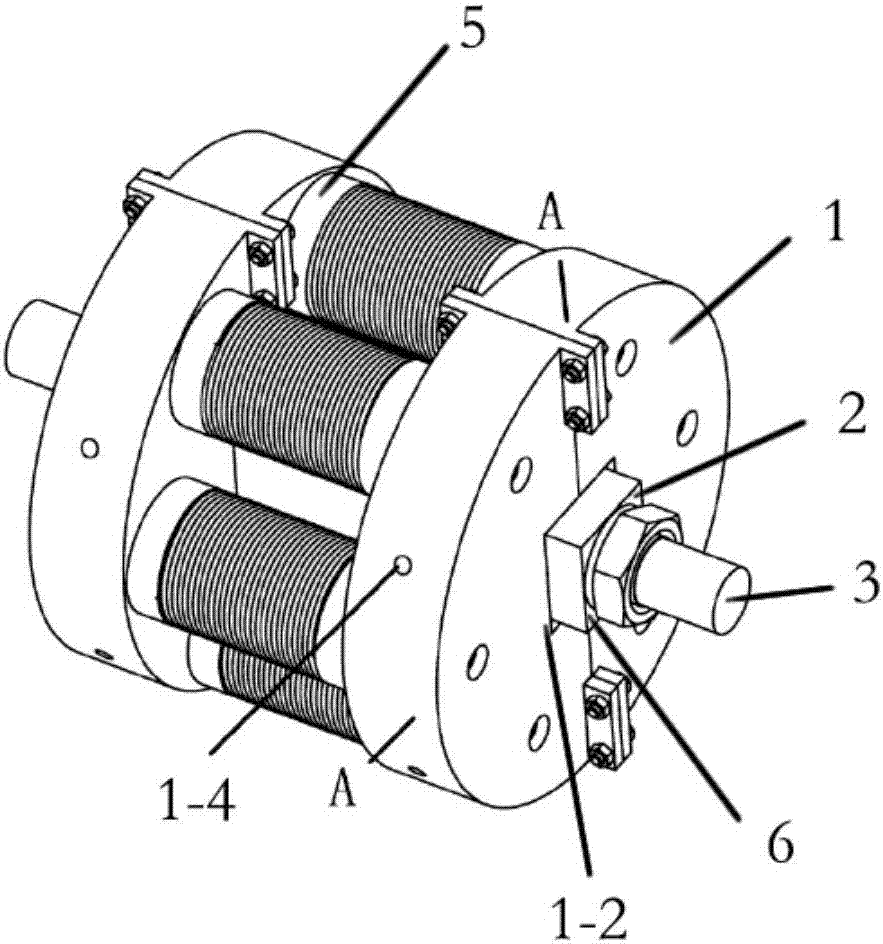

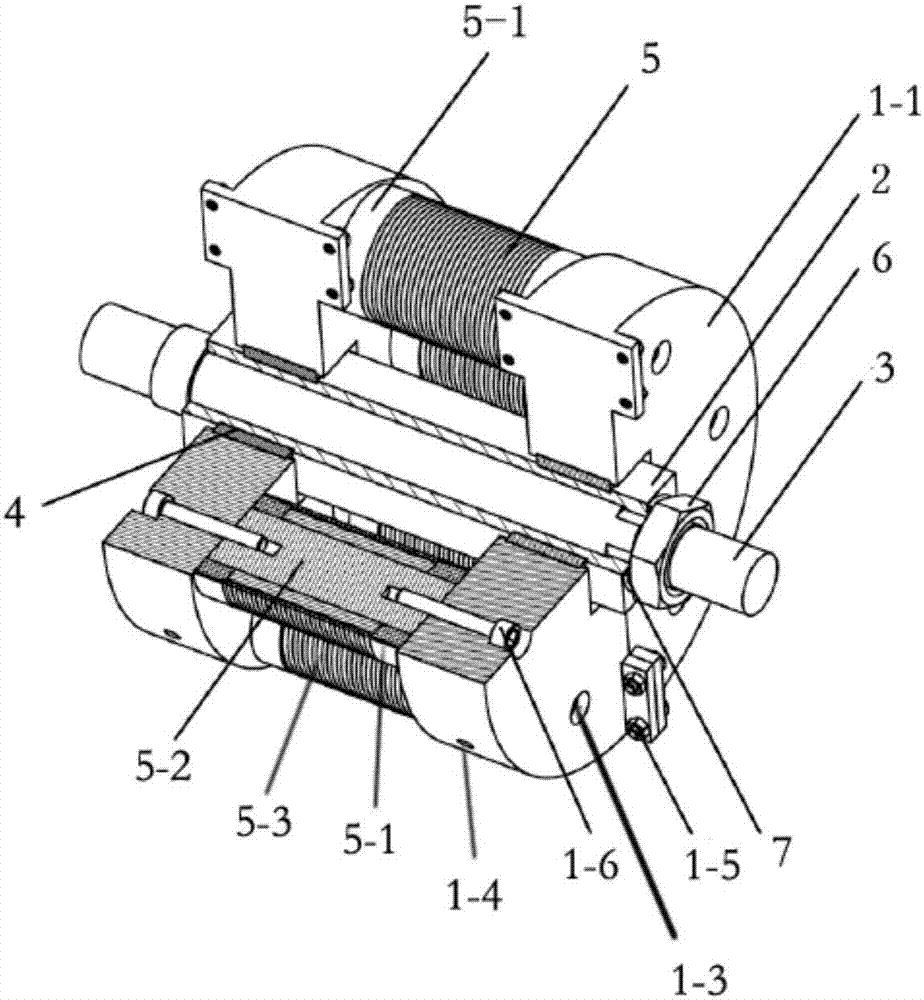

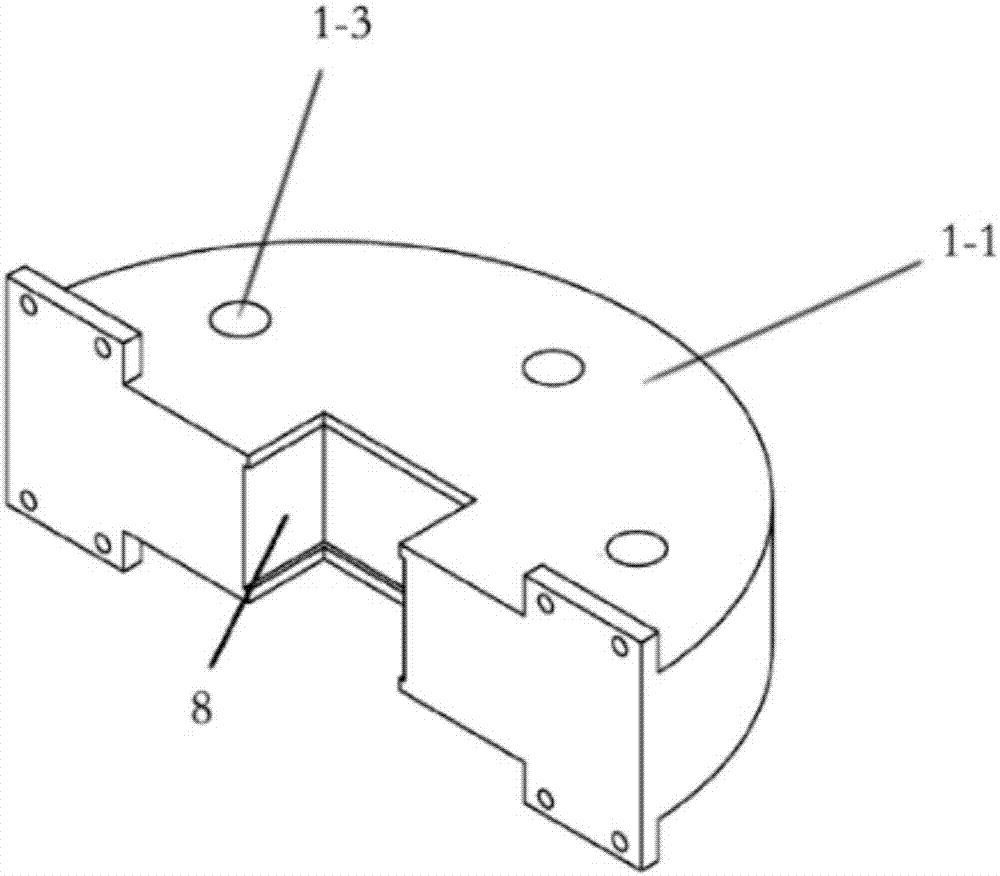

Magnetorheological elastomer thrust bearing base dynamic vibration absorber and use method

InactiveCN107191529ALongitudinal vibration controlReduce transmission rateSpringsNon-rotating vibration suppressionThrust bearingPropeller

The invention relates to the technical field of marine power, in particular to a magnetorheological elastomer thrust bearing base dynamic vibration absorber and a use method. The dynamic vibration absorber is arranged on a thrust bearing base and comprises magnet yoke sets, a magnetism isolating support shaft, a magnetic conductive shaft sleeve, magnetorheological elastomers and an electromagnetic assembly. The outer layer of the magnetism isolating support shaft is sleeved with the magnetic conductive shaft sleeve. The two ends of the magnetic conductive shaft sleeve are provided with the parallelly arranged magnet yoke sets correspondingly. The joints of the magnetic conductive shaft sleeve and the magnet yoke sets are provided with the magnetorheological elastomers. At least one electromagnetic assembly is arranged around the part, between the two magnet yoke sets, of the magnetic conductive shaft sleeve. According to the magnetorheological elastomer thrust bearing base dynamic vibration absorber and the use method, longitudinal vibration of the thrust bearing base is controlled effectively, then the transmitting ratio of pulsating force of a propeller through the bearing base to a boat body is lowered, and the purpose of reducing of radiation noise is achieved.

Owner:SHANGHAI JIAO TONG UNIV

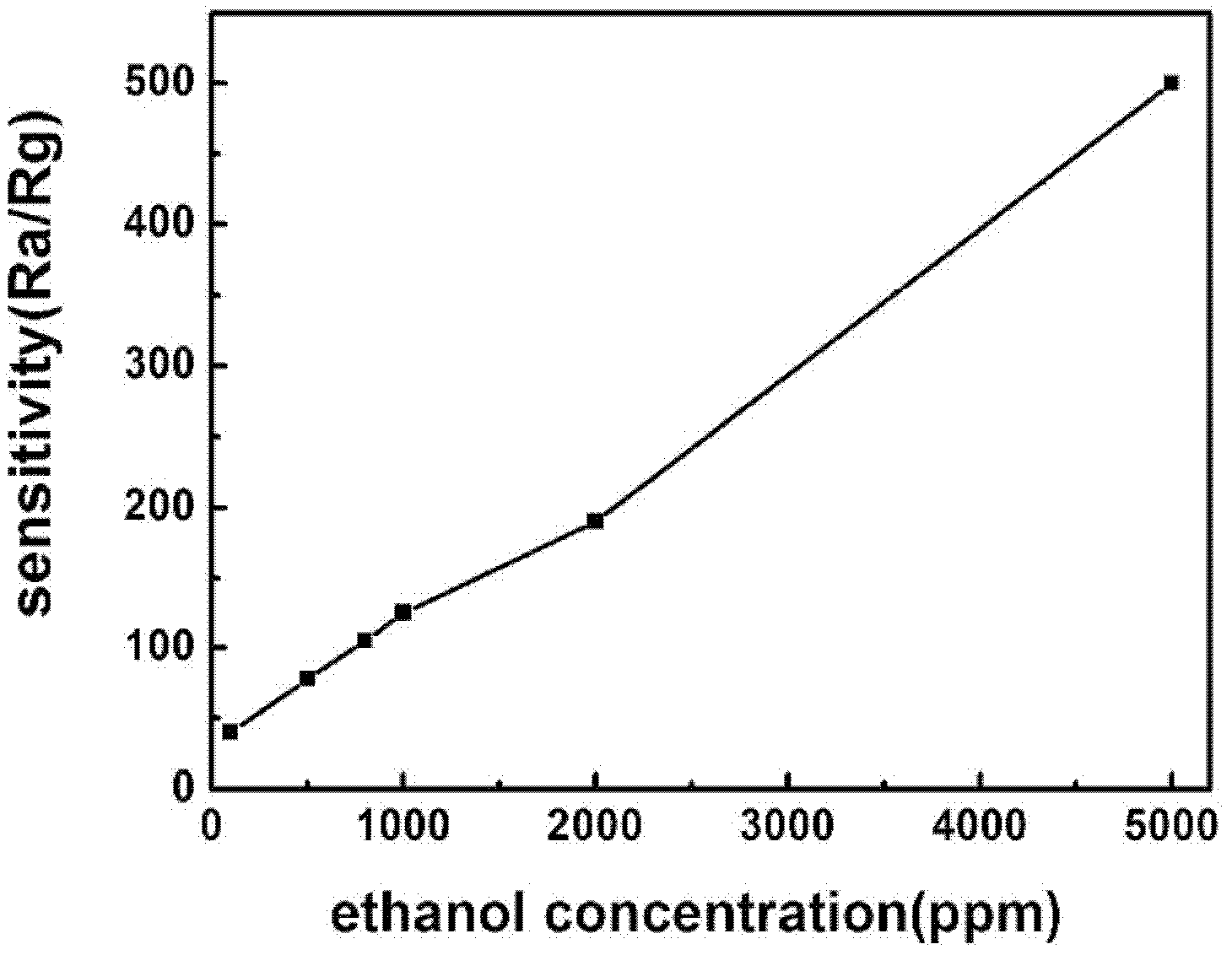

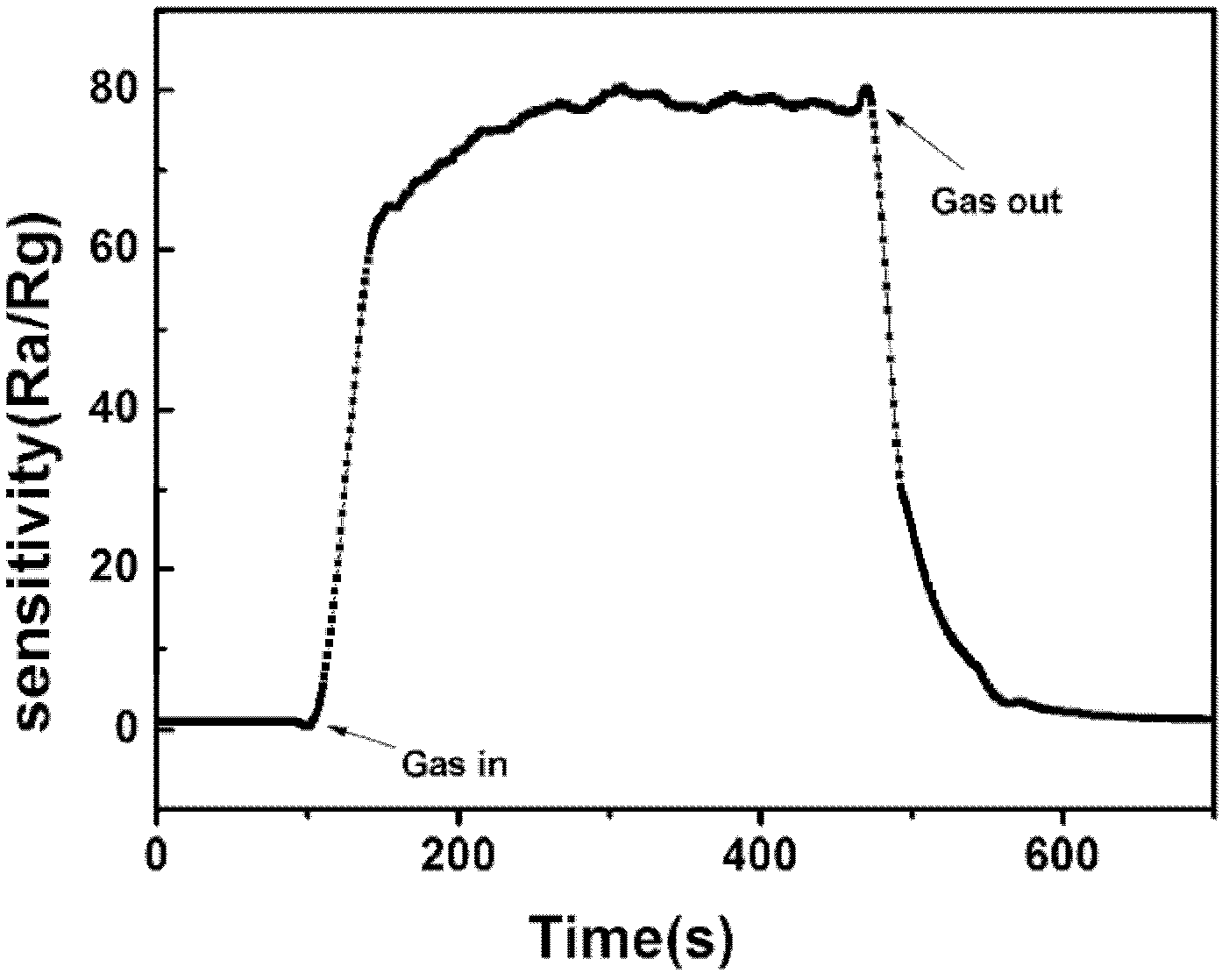

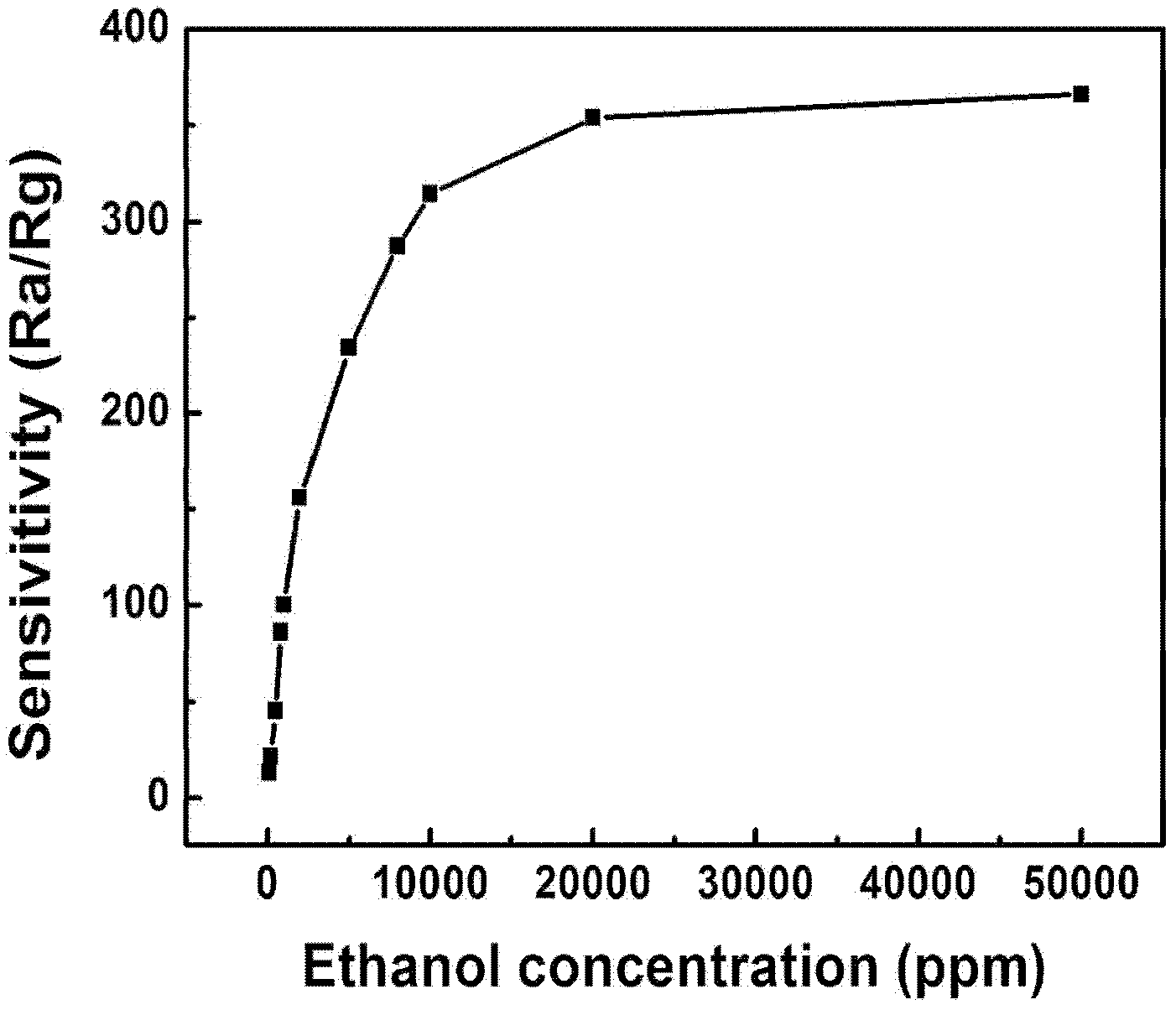

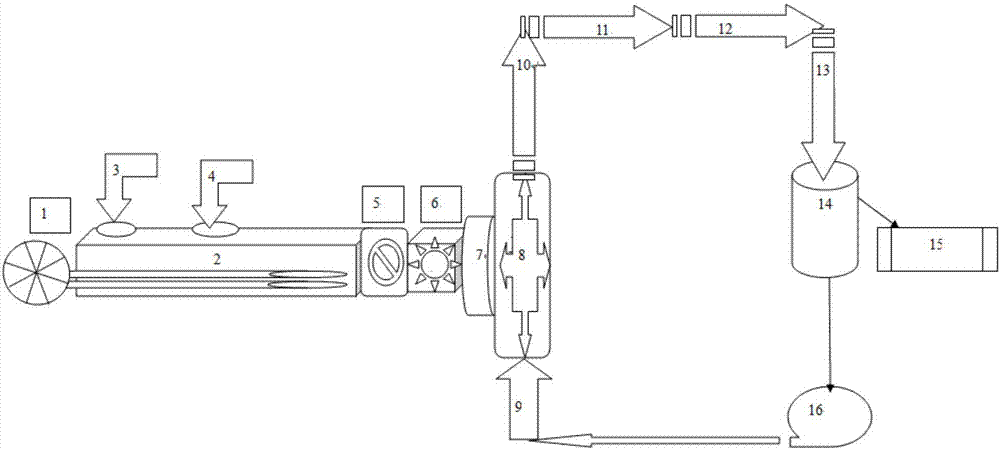

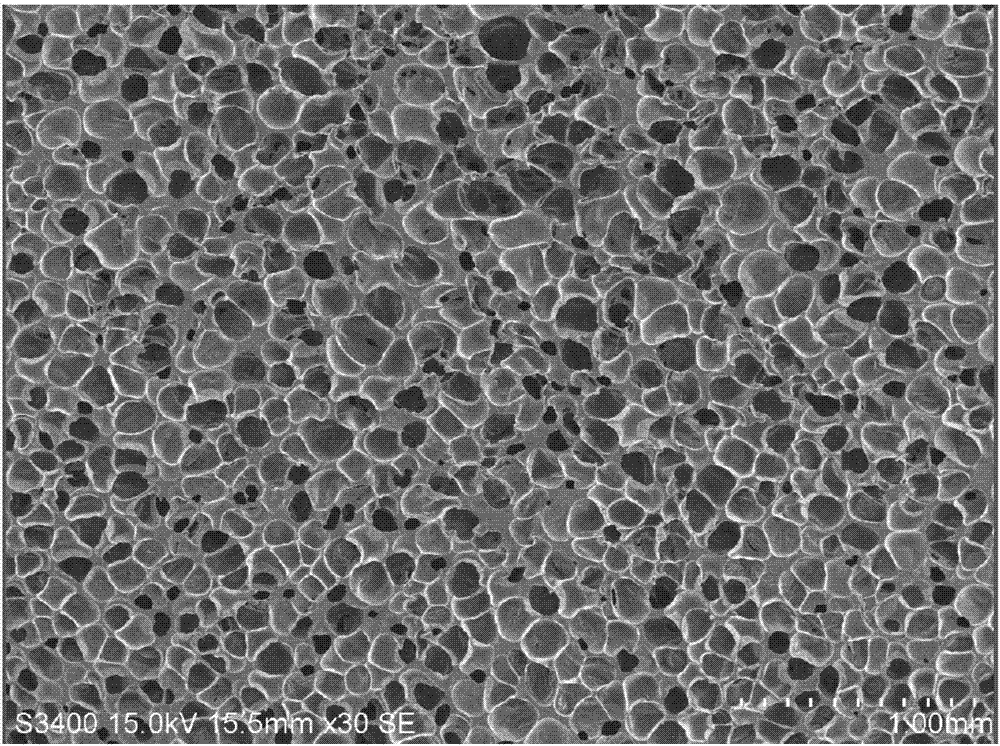

Gas sensitive element taking houghite as precursor and preparation method thereof

InactiveCN102628824ASimple preparation stepsLow costZinc oxides/hydroxidesMaterial resistanceElectrical resistance and conductanceGas detector

The invention discloses a method for preparing a gas sensitive element by taking houghite as a precursor, which belongs to the technical field of gas sensitive sensors. The method comprises the following steps of: preparing houghite by using a co-precipitation method; roasting the houghite at different temperatures to form a compound semiconductor metal oxide material; and preparing into a gas sensitive element, wherein the gas sensitive element can be used for detecting various gases by measuring the resistance values of the element in different gases. The gas sensitive element has the major advantages of simple preparation steps, low cost, diversified element compositions, and uniform distribution of elements of a compound oxide formed by roasting. The gas sensitive element prepared from the method has the advantages of high sensitivity, quick response and recovery, high stability, great developing potential and contribution to popularization.

Owner:BEIJING UNIV OF CHEM TECH

Degradable antifouling thermoplastic micro-airbag polymer elastomer material and preparation thereof

The invention relates to a degradable antifouling thermoplastic micro-airbag polymer elastomer material which is prepared from the following ingredients in percentage by weight: 88 to 98% of polymer raw material, 0.05 to 0.5% of nucleating agent, 0.4 to 2% of foaming agent and 0.1 to 10% of environment-friendly degradable organic perfluorosebacamidine material. A preparation method specifically comprises the steps: (1) feeding the polymer raw material, the nucleating agent and the environment-friendly degradable organic perfluorosebacamidine material from a feeding opening in the front end of a twin-screw extruder, feeding the foaming agent from a feeding opening in a middle section of the twin-screw extruder, hot melting and fully mixing all the raw materials, then sending into a static mixer to be further homogenized and then controlling pressure and quantitatively conveying by a melt pump; (2) sending hot melt sent out by the melt pump into an underwater pelletizing chamber to be pelletized, bringing out by technological water to be separated and screening and drying the particles to obtain a target product. Compared with the prior art, the degradable antifouling thermoplastic micro-airbag polymer elastomer material disclosed by the invention effectively achieves performance of antifouling, soiling-resistant, oil-resistant, contamination-resistant, attractive and good touch and is especially suitable for being applied to the fields of shoe materials, food package and the like.

Owner:NANTONG DE NEW MATERIAL CO LTD

Ag-RE high-strength high-toughness aluminum alloy material and preparation method thereof

The invention discloses an Ag-RE high-strength high-toughness aluminum alloy material and a preparation method thereof. The alloy comprises the following components in percentage by weight: 1.0 to 10.0 percent of Cu, 0.05 to 1.5 percent of Mn, 0.01 to 0.5 percent of Cd, 0.01 to 0.5 percent of Ti, 0.01 to 0.2 percent of B, 0.01 to 1.0 percent of Zr, 0.01 to 1.0 percent of Ag, 0.05 to 5 percent of RE, and the balance of Al. High-quality melt, solid solution and a phase diagram theory are taken as guidance, and by using a preferable alloy main element formula of Cu, Mn and RE, the quasi solid temperature range of the alloy is reduced, and the problems of large hot tearing tendency in the casting process, low high-temperature strength of products and the like are solved; by using a preferable multielement microalloying element formula, material foundation conditions are created for the cultivation of a strengthening phase in the solid solution and grain refining effect; and the high-strength high-toughness aluminum alloy material is finally manufactured by optimizing smelting and thermal treatment process technology.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

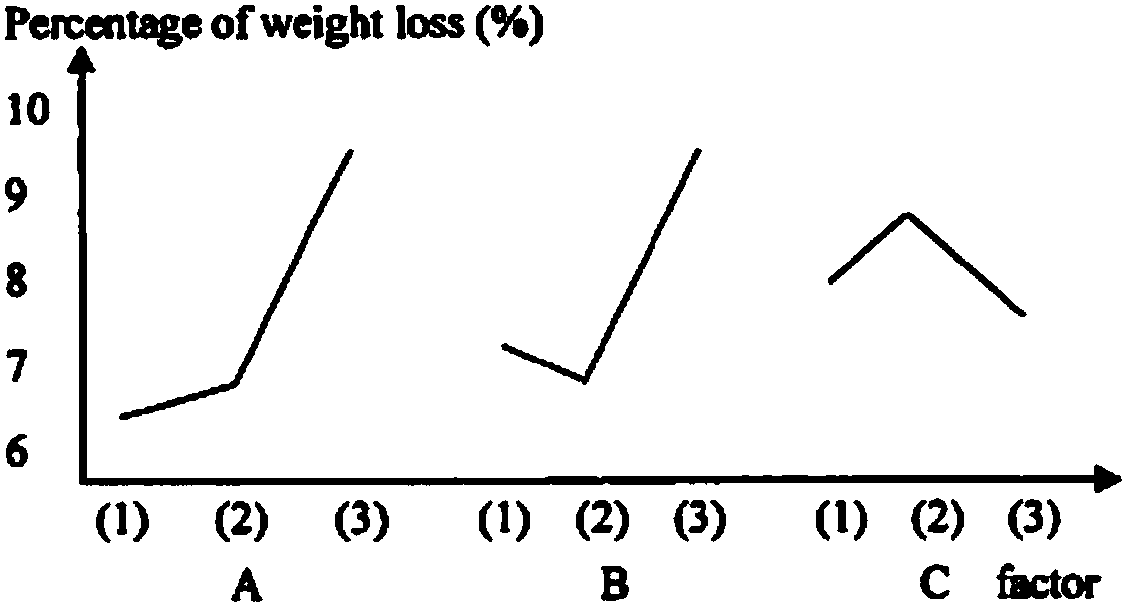

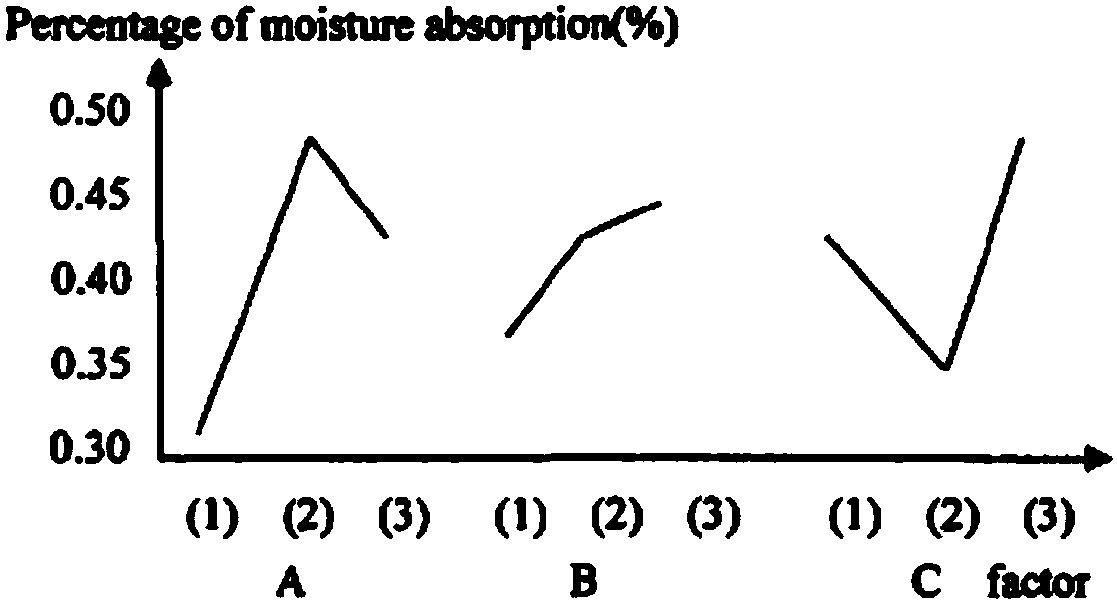

Modification method for polypropylene fibers

The invention discloses a modification method for polypropylene fibers and belongs to the technical field of chemical fiber materials. The modification method comprises the following steps: firstly, drying the polypropylene fibers to constant weight for later use; secondly, preparing a chromic acid solution, taking K2Cr2O7, H2O and H2SO4 for mixing and reacting to obtain chromic acid; thirdly, weighing the constant-weight polypropylene fibers, putting into the chromic acid solution, soaking at room temperature for 0.5 to 2.5 hours and then reacting; fourthly, washing the reacted polypropylenefibers, filtering and carrying out drying treatment to constant weight, thus obtaining modified polypropylene fibers; fifthly, measuring and calculating the weight loss ratio and moisture rate of themodified polypropylene fibers as well as the change of the contents of surface functional groups of the polypropylene fibers before and after modification. According to the modification method disclosed by the invention, the surfaces of the polypropylene fibers are oxidized and active groups are introduced while the adhesion between the polypropylene fibers and a base material is enhanced, so thatthe surfaces of the polypropylene fibers have certain hydrophilic ability and sufficient distribution of the modified polypropylene fibers in cement-based materials is more easily realized.

Owner:LIAONING TECHNICAL UNIVERSITY

Self-cleaning air filter and self-cleaning step thereof

PendingCN108970284AWon't breakAchieve reuseDispersed particle filtrationTransportation and packagingSolenoid valveAir filter

The invention discloses a self-cleaning air filter. A main filter element is arranged in an air filter shell body; an air inlet is formed in a side face of the shell body; an air outlet is formed in the upper end of the shell body; a pressure air source is connected to a solenoid valve through a pipeline; the solenoid valve is connected to a safety filter element through a pipeline; an ash discharging opening is formed in the bottom of the shell body. According to the self-cleaning air filter disclosed by the invention, the pressure air source is connected to the solenoid valve through a pipeline; the solenoid valve is connected to the interior of the safety filter element through a pipeline. According to the self-cleaning air filter disclosed by the invention, pressure airflow passes through the solenoid valve and then is blown back to the safety filter element; air fluid instantly generates strong pressure difference on inner and outer surfaces of the filter element and dust pollutant particles are enforced to be dispersed and stripped from the outer surface of the filter element and are discharged from an air inlet or an ash discharging opening under the action of an air flow field. A blowing-back acting force acts on the inner surface of the whole safety filter element and the acting force is more uniform and does not damage filter paper on the outer surface of the filter element; meanwhile, a main filter element is repeatedly utilized, the service life is prolonged and the maintenance cost of the air filter is reduced.

Owner:无锡亿利环保科技有限公司

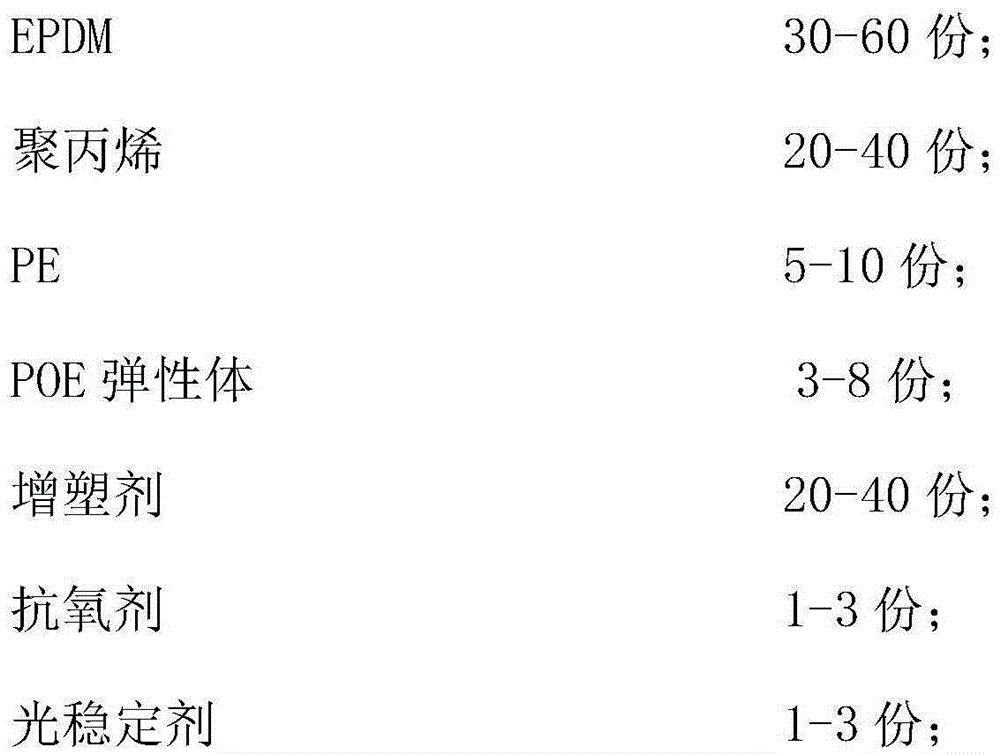

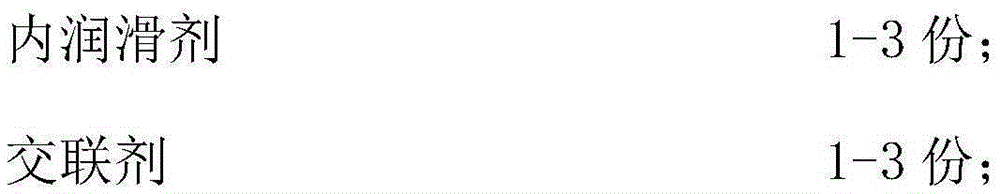

High-fluidity TPV material and preparing method thereof

The invention discloses a high-fluidity TPV material. The high-fluidity TPV material is prepared from, by weight, 30-60 parts of EPDM, 20-40 parts of polypropylene, 5-10 parts of PE, 3-8 parts of POE elastomer, 20-40 parts of plasticizer, 1-3 parts of antioxidant, 1-3 parts of light stabilizer, 1-3 parts of internal lubricating agents and 1-3 parts of cross-linking agents. The high-fluidity TPV material has high fluidity, low compressive deformation, and excellent shock resistance, chemical resistance and oil resistance.

Owner:安徽韧达高分子材料有限公司

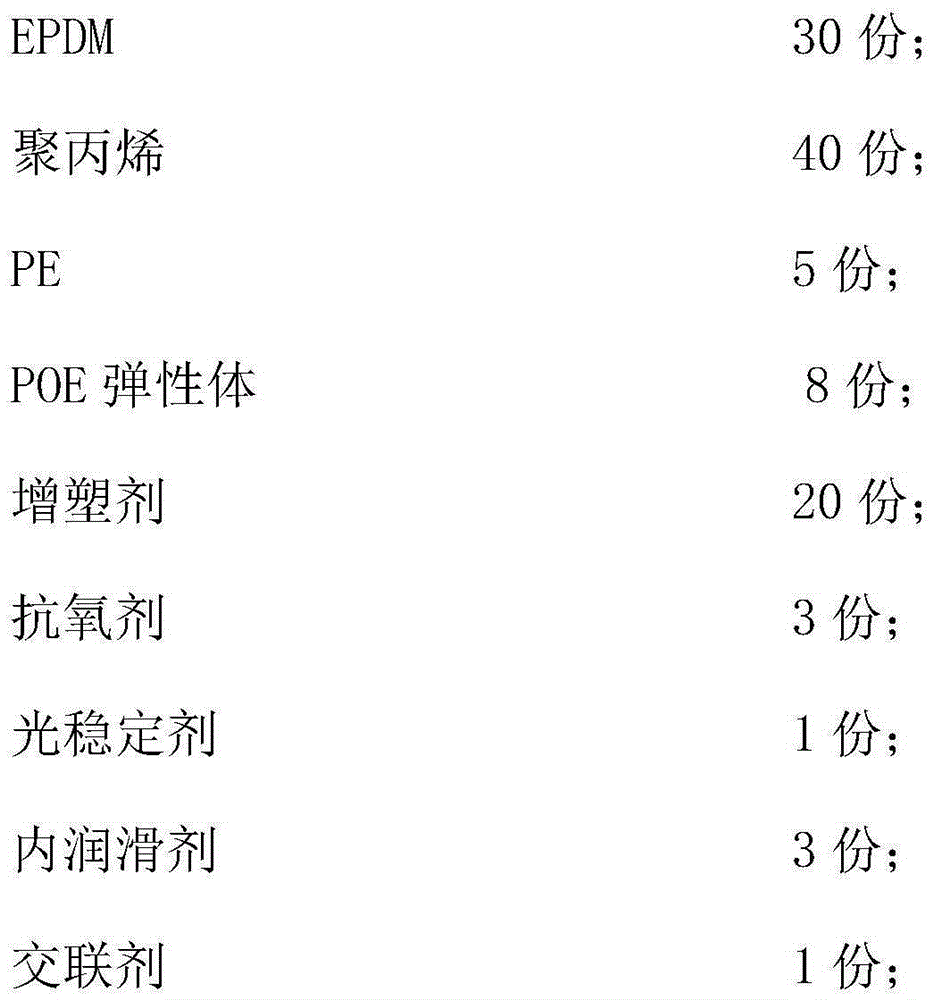

Protective shell of radio frequency repeater device with heat dissipation assembly

ActiveCN111836132AImprove cooling effectFull water coolingCasings/cabinets/drawers detailsCooling/ventilation/heating modificationsPhysicsRadio frequency

The invention relates to the field of radio frequency repeater devices, in particular to a protective shell of a radio frequency repeater device with a heat dissipation assembly, which comprises a base, a shell, a heat dissipation structure, an ash removal structure, a moving structure, a limiting structure, a protective structure and a fixed structure, through arrangement of the heat dissipationstructure, heat dissipation work can be fully carried out on electrical elements in the shell, electrical elements in the shell can be prevented from being damaged due to over-high temperature, whilethe heat dissipation structure works, the ash removal structure can be synchronously driven to work, the ash removal structure works, dust cleaning work can be carried out on the heat dissipation structure, the heat dissipation structure is prevented from being blocked by dust, through the arrangement of the moving structure, the moving assembly can be conveniently stretched out and stored, the moving structure can react to the fixing structure while working, through the arrangement of the fixing structure, the base and the ground can be stably fixed, and therefore the situation that the device slides in the working process can be avoided.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY TAIZHOU POWER SUPPLY

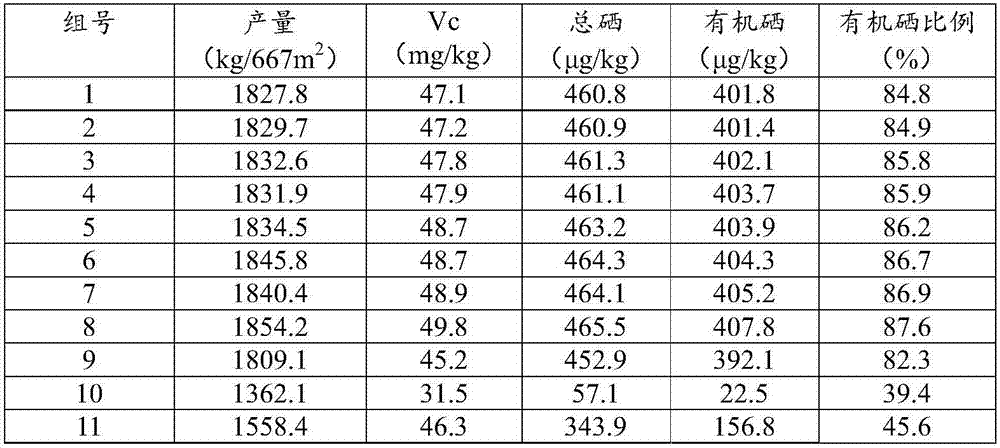

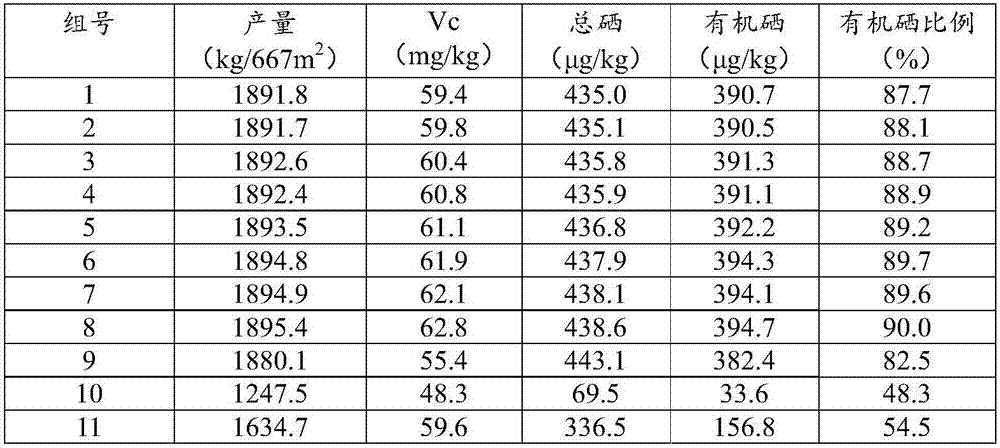

Rich-in-selenium liquid bacterial manure, preparation method and application

InactiveCN107151189AGuaranteed cleanlinessIncreased machinery costsBio-organic fraction processingExcrement fertilisersSlagSlurry

The invention provides rich-in-selenium liquid bacterial manure, a preparation method and application, and belongs to the technical field of agricultural biology. The raw materials of the rich-in-selenium liquid bacterial manure comprise biogas slurry, mushroom slag, EM bacteria solution, EM raw bacteria solution, CM bacteria, selenite and brown sugar. The rich-selenium liquid bacterial manure can provide various nutrition elements for vegetables for promoting the growth. The preparation method of the rich-in-selenium liquid bacterial manure comprises the following steps of adding partial EM bacteria solution, mushroom slag and partial CM bacteria solution into the biogas slurry; regulating the pH value; performing primary fermentation to obtain first fermentation solution; mixing the rest EM bacteria solution and the partial selenite solution with the first fermentation liquid; after 4 to 6 days, adding partial EM raw bacteria solution, the rest CM bacteria solution and the rest selenite solution; performing secondary fermentation to obtain the rich-in-selenium liquid bacterial manure. The preparation method has the advantages that the technology is simple; the selenium liquid bacterial manure with the excellent performance can be effectively prepared. The preparation method of the rich-in-selenium liquid bacterial manure can be applied to leaf fertilizers or root irrigation fertilizers.

Owner:WUHAN ACADEMY OF AGRI SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com