Oil spraying instant noodle production line and production technology thereof

A technology for instant noodles and production lines, which is applied in the fields of dough processing, baking, food preparation, etc., can solve the problems of no aroma and taste of fried instant noodles, harmful to human health, and low production efficiency, and achieves good puffing effect and low oil content. , the effect of reducing oil content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0043] Such as figure 1 As shown, an oil-sprayed instant noodle production line is provided with an alkali water tank 1, a quantitative water adding tank 2, a vibrating screen 3, a double-axis dough mixing machine 4, a ripening feeder 5, a compound tablet press machine 6, and a continuous Tablet press machine 7, multi-layer steamed noodle machine 8, cutting and folding machine 9, spray flavoring machine 10, oil spray fried noodle machine 11, microwave dryer 12, air cooler 13, diverting conveyor 14, packaging conveyor 15. Packing machine 16, finished product conveyor 17.

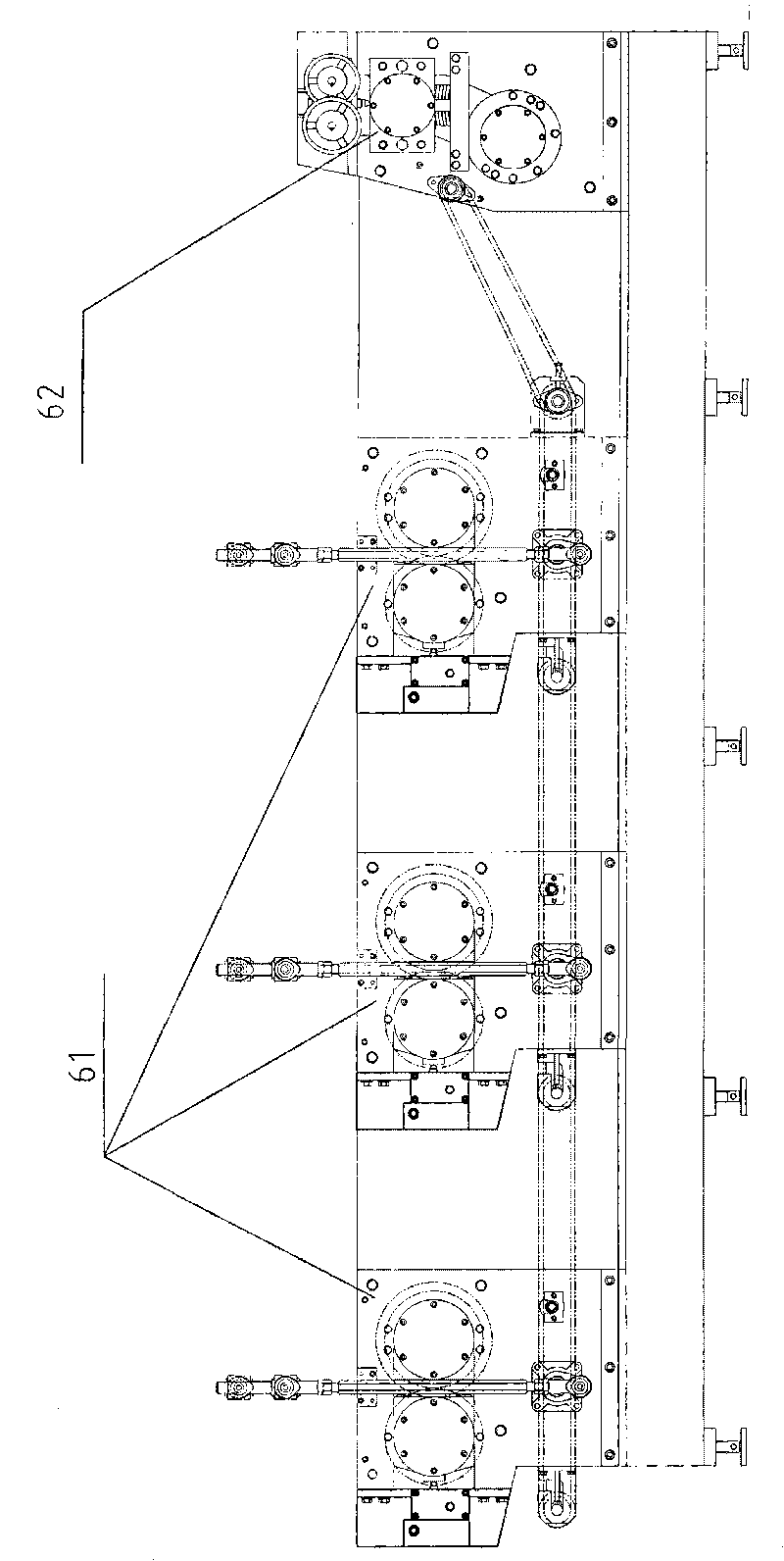

[0044] Such as figure 2 As shown, the composite tablet press 6 includes three sets of single-sheet pressing roller devices 61 and one set of composite pressing roller devices 62 , and each single-sheet pressing roller device 61 corresponds to one ripening feeder 5 . After the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com