Patents

Literature

3412 results about "Oil intake" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

It is normal for there to be some oil in your intake manifold due to the PCV valve. This allows pressure to be released from the top of your heads to the intake manifold (its an emissions thing). The byproduct is an oily mist that travels from the top of your head to the inside of your intake manifold.

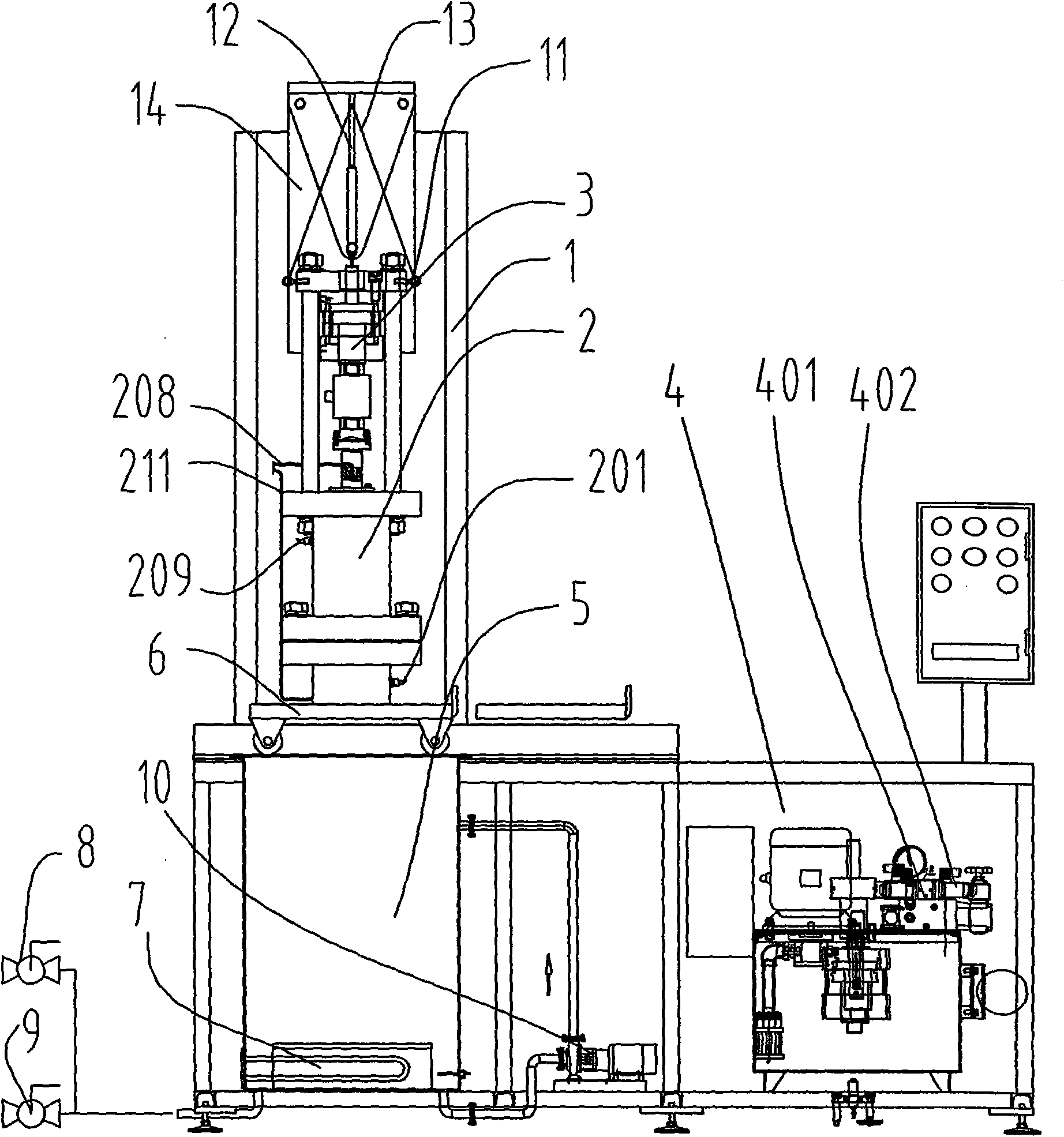

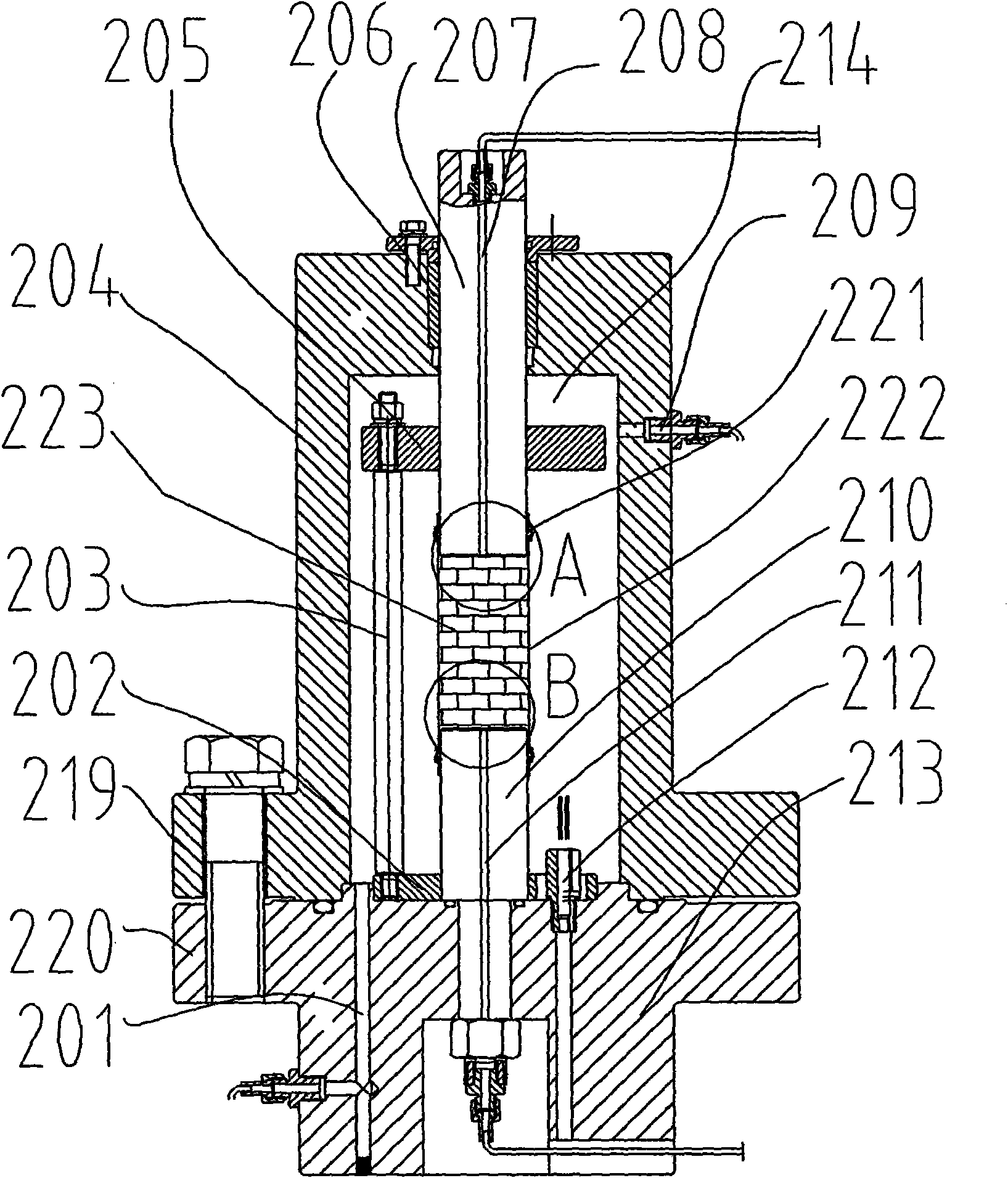

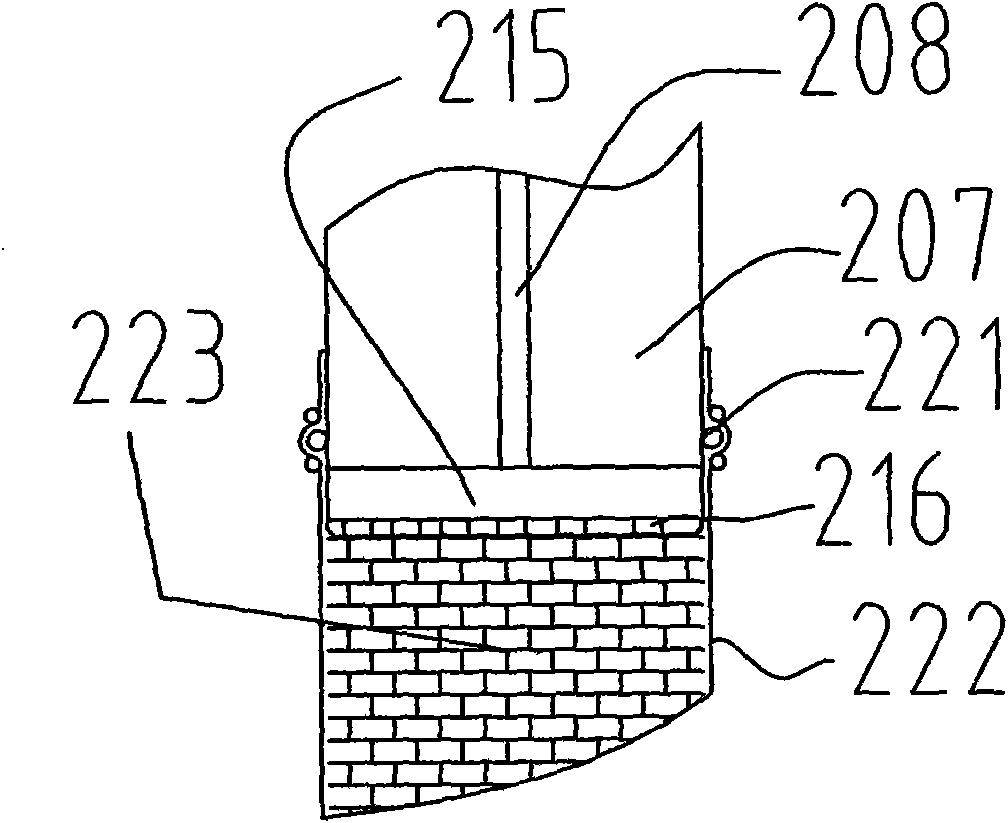

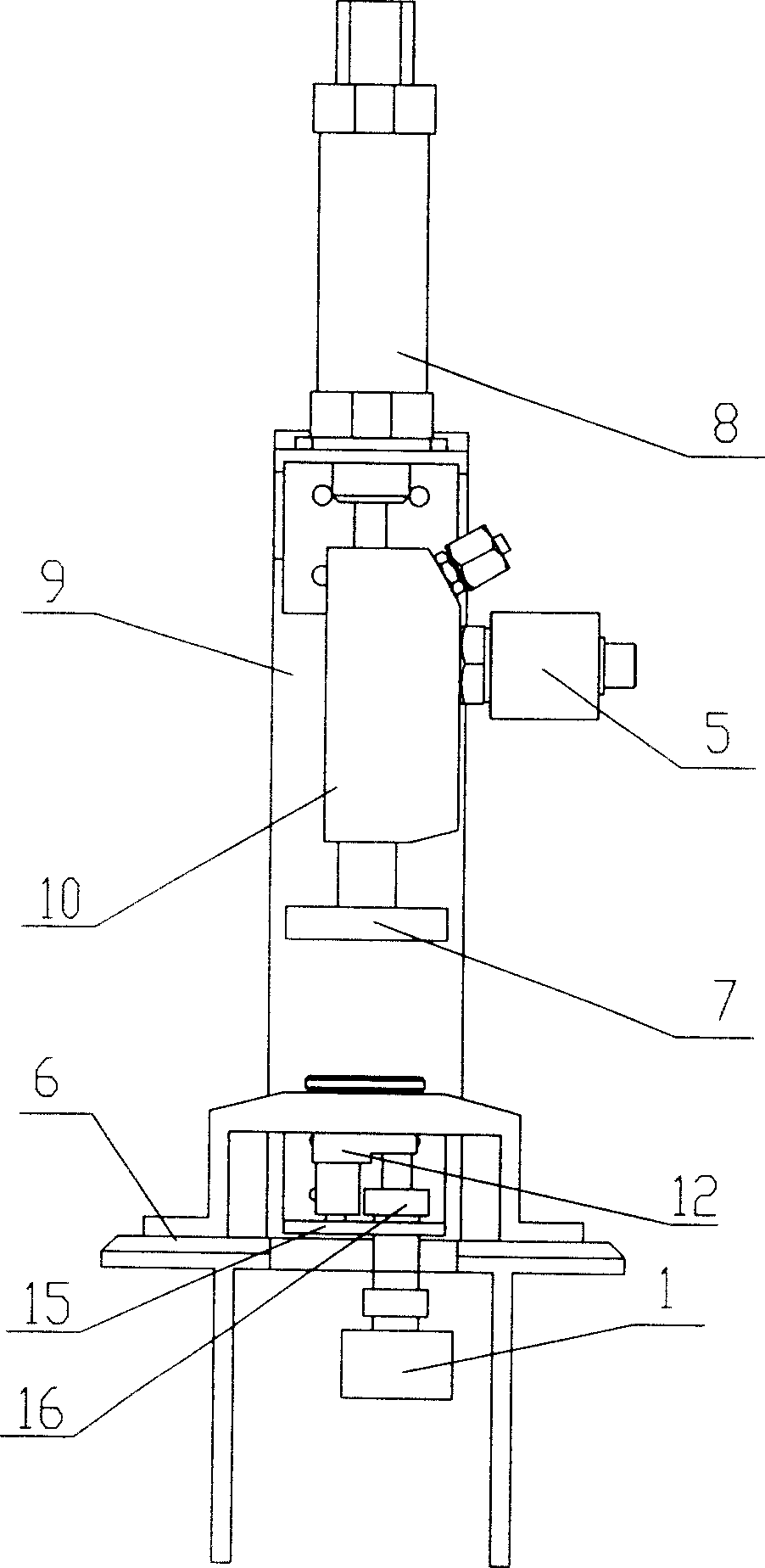

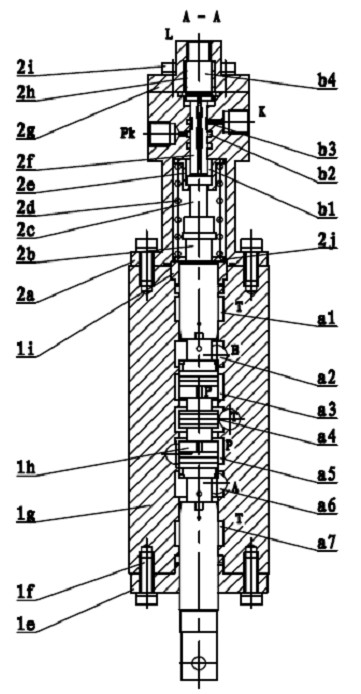

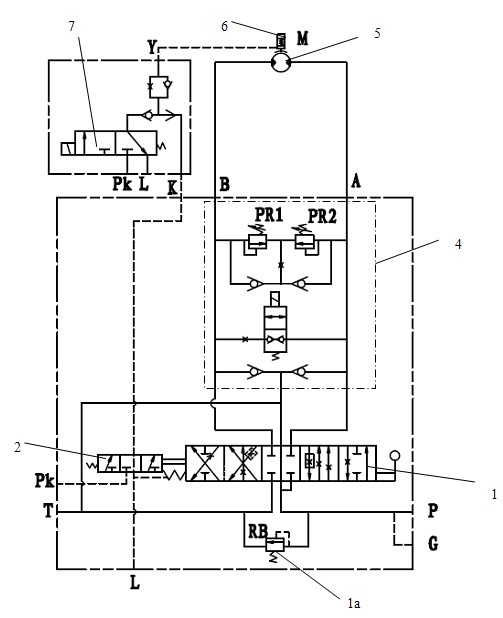

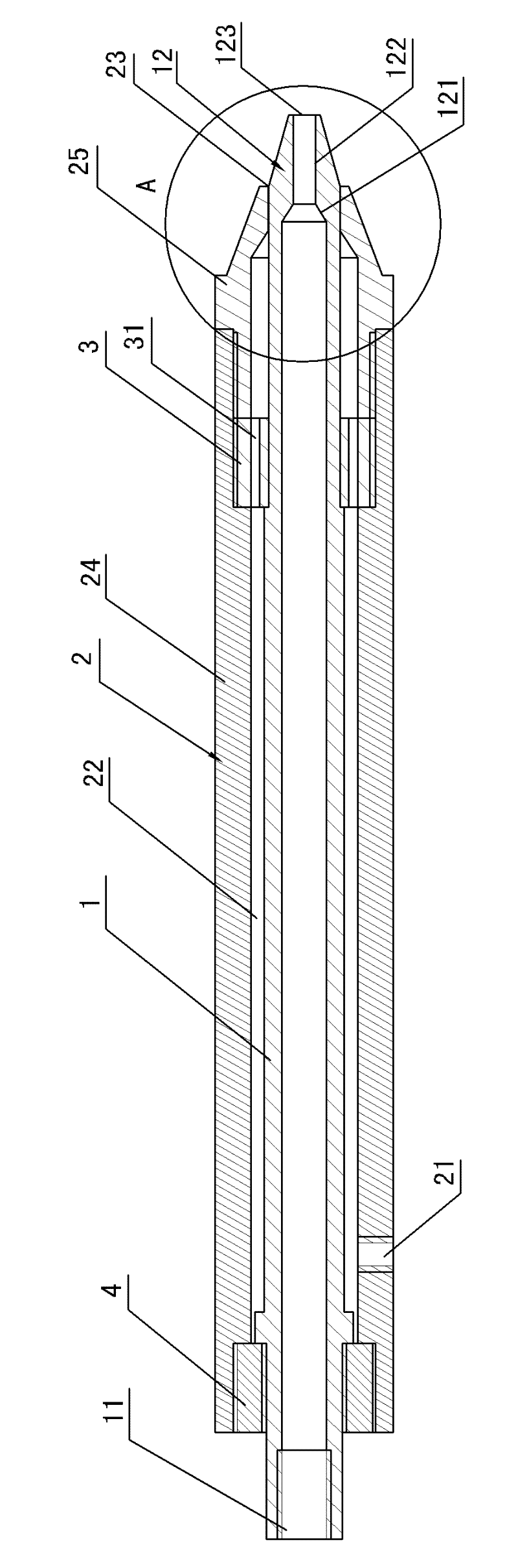

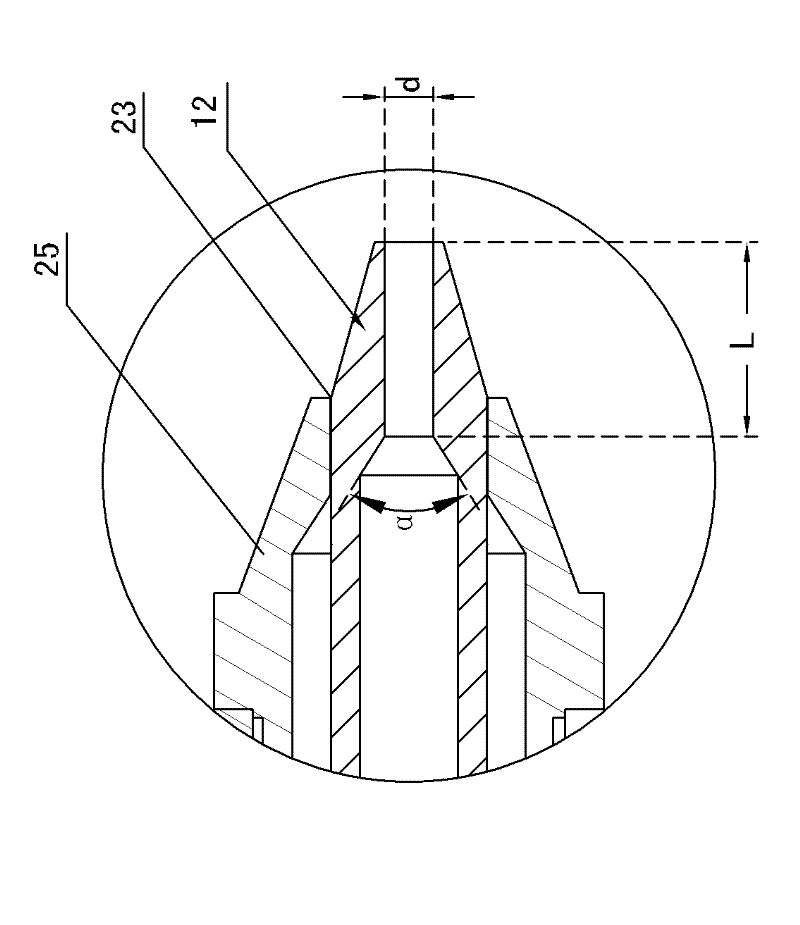

Fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal

InactiveCN101634621APrecise permeability measurementImprove breathabilitySurface/boundary effectMaterial strength using tensile/compressive forcesWater bathsAxial compression

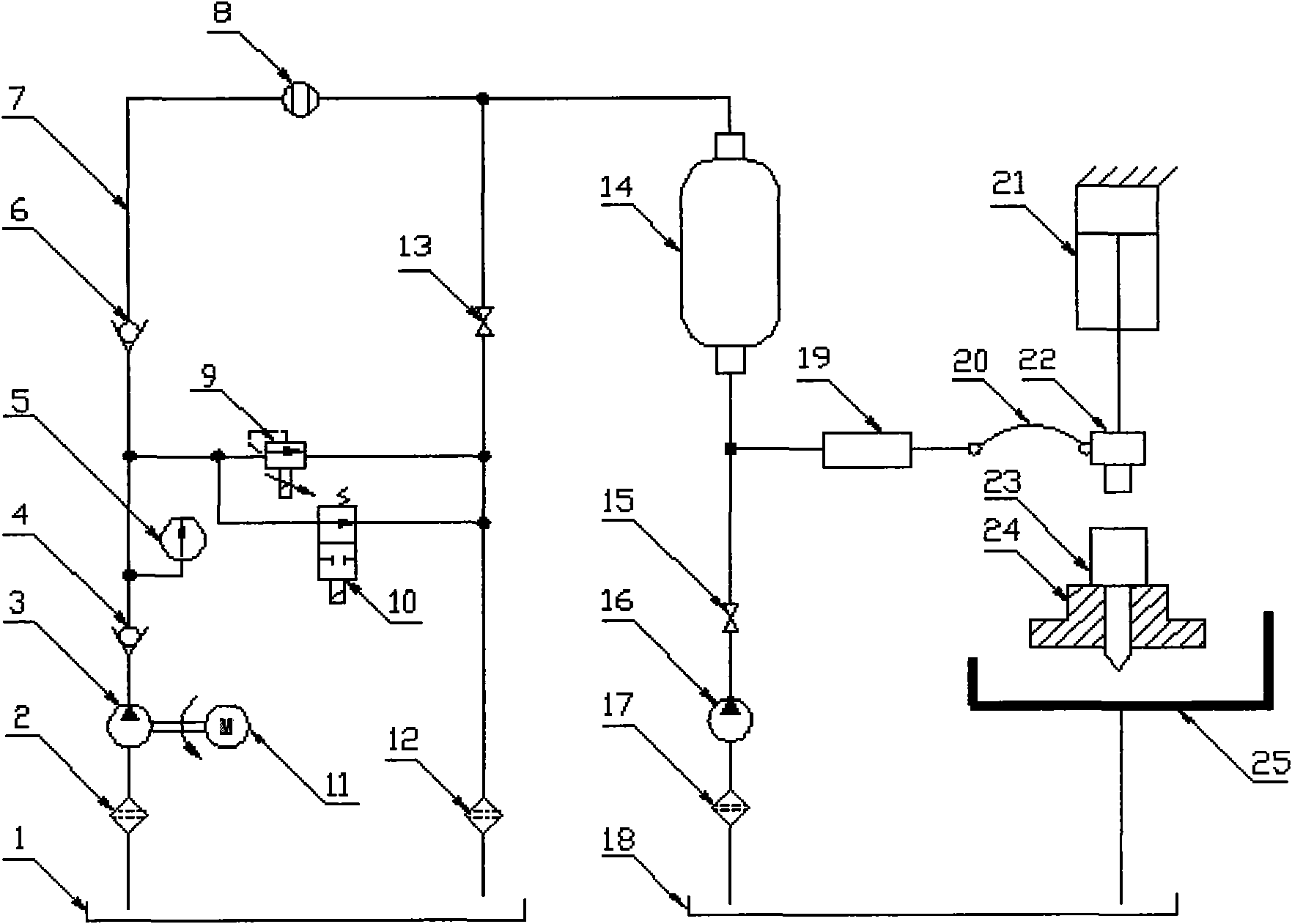

The invention discloses a fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal, comprising a lifting stand, a hydraulic servo control system, an axial loading device mounted at the top of the lifting stand and a triaxial pressure chamber connected with the lower end of the axial loading device. A thermostatic water tank is arranged below the triaxial pressure chamber; a movable worktable is arranged above the thermostatic water tank; the lower end of the triaxial pressure chamber is arranged on the movable worktable; heating tubes are arranged in the thermostatic water tank; and a water inlet valve, a water drain valve and a water-bath circulating water pump are arranged outside the thermostatic water tank and are communicated with the thermostatic water tank. In the hydraulic servo control system, an axial compression loading oil pump is communicated with an oil inlet and an oil outlet by a pipeline, and a peripheral compression loading oil pump is communicated with an oil intake / drain hole by a pipeline. The fluid-solid-heat coupling triaxial servo percolation device for gas-contained coal can carry out the research of gas-contained coal percolation tests in states, such as different terrestrial stresses, different gas pressures, different temperatures, and the like and the distortion and failure characteristics of the gas-contained coal in a percolation process.

Owner:CHONGQING UNIV

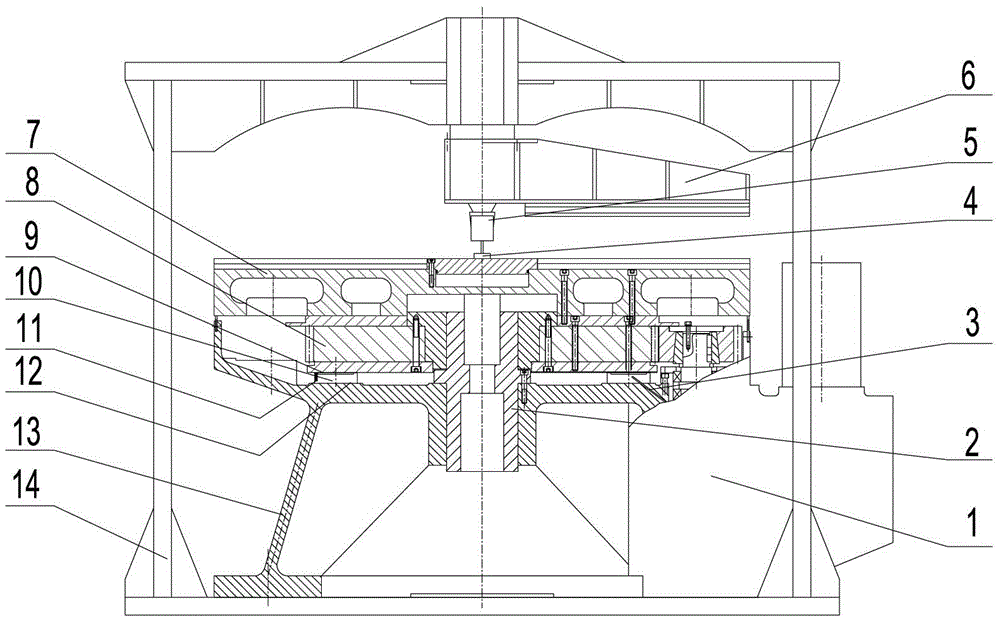

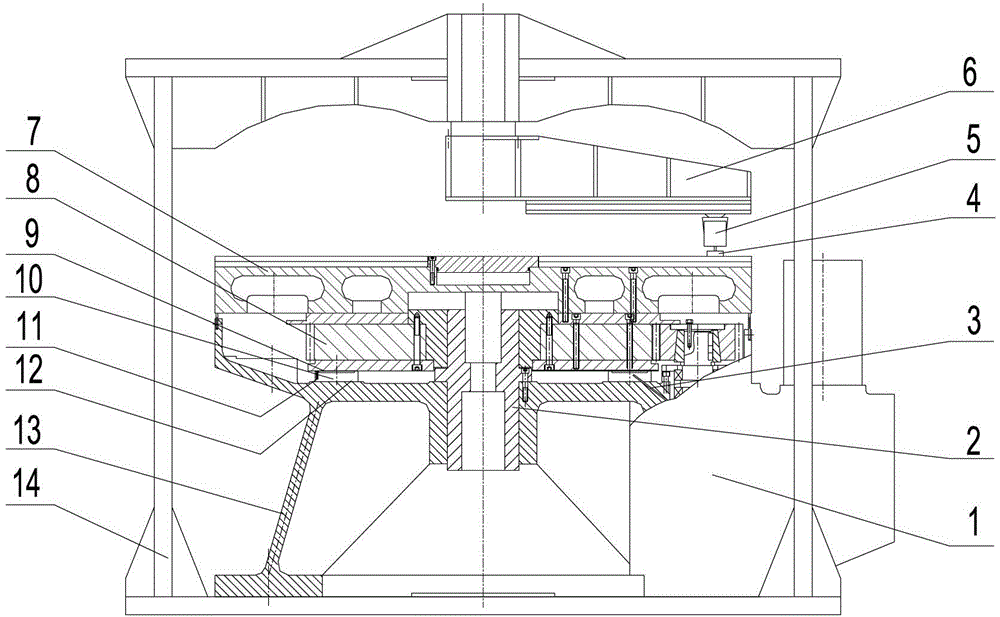

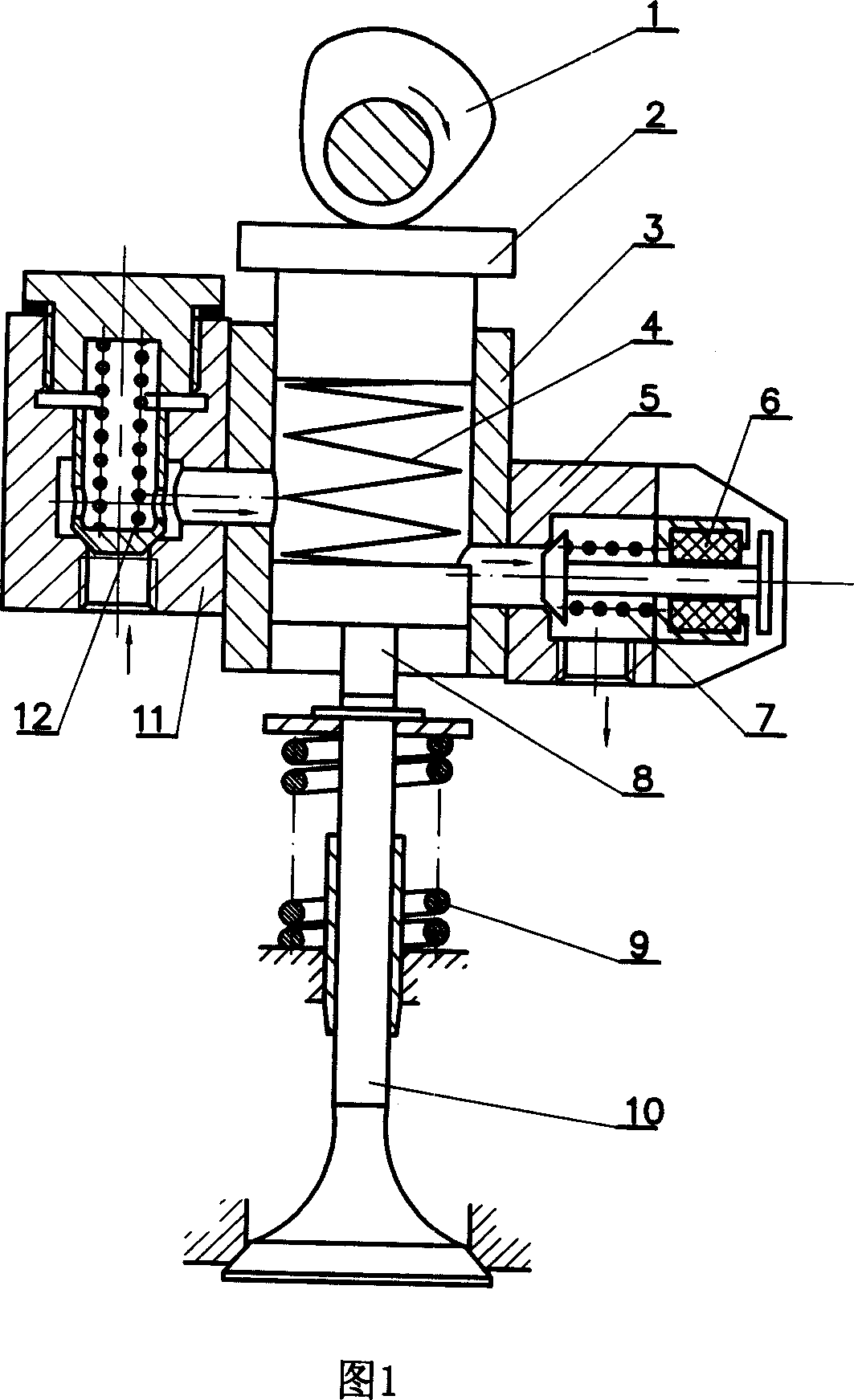

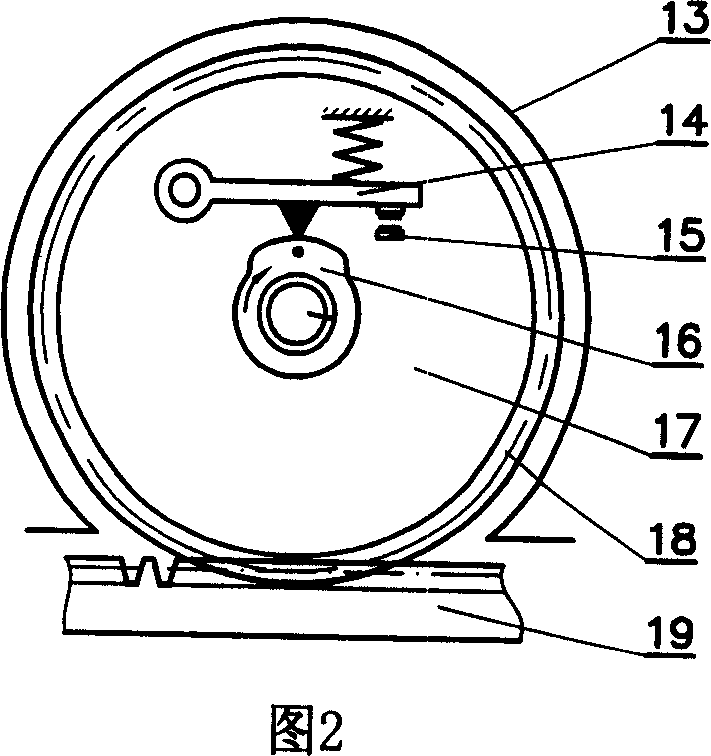

Quantitive type experimental device for dynamic and static performances of static-pressure rotary table

ActiveCN102980755AStructural parameter optimizationImprove machining accuracyMachine part testingElectricityEddy current

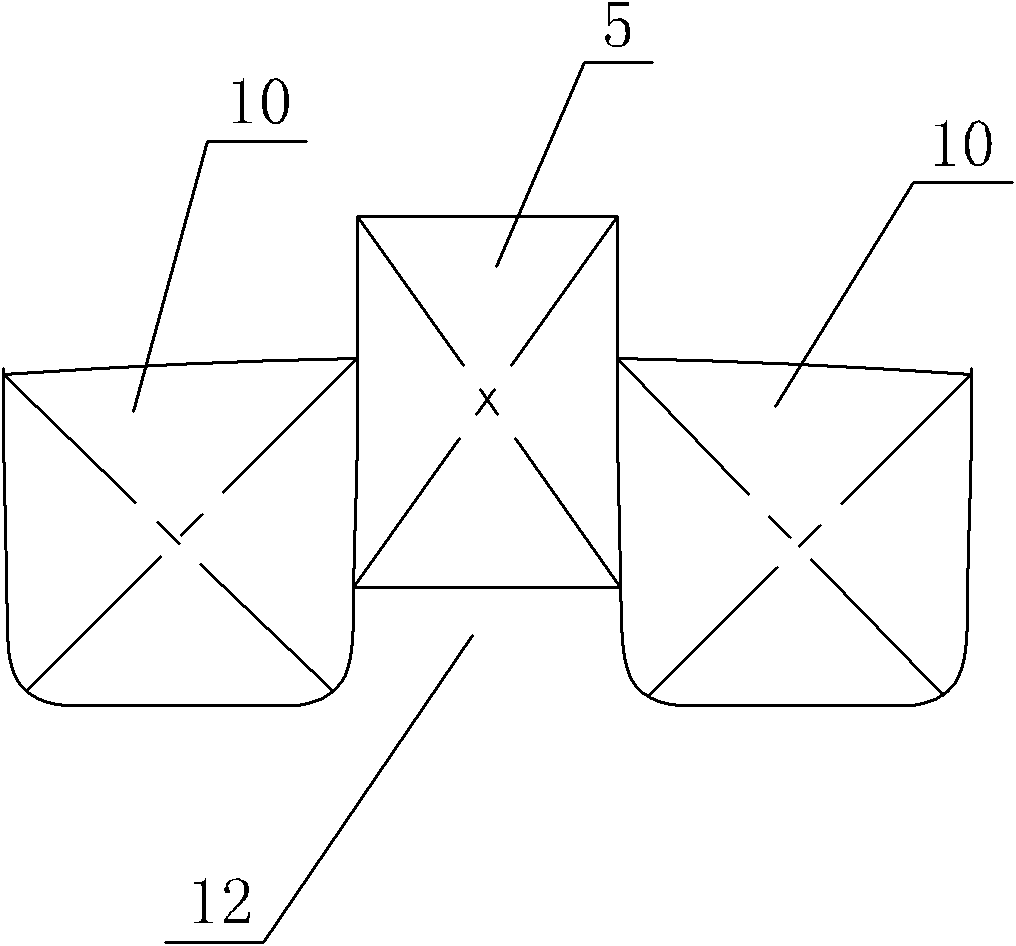

The invention provides a quantitive type experimental device for dynamic and static performances of a static-pressure rotary table, and belongs to the field of machinery design and manufacture. According to the experimental device, a loading device (5) and a loading arm (6) are used for changing magnitude of loads or changing oil supply pressure to control the distance between a static-pressure oil cushion (10) and a rotary table disc chuck (7), a pressure sensor (12) is used for measuring pressure in an oil cavity, an eddy current displacement sensor (11) is used for measuring the thickness of an oil film, a thermocouple temperature sensor (3) is used for measuring oil temperature, a force sensor (4) is used for obtaining magnitude of loading force, a pressure gauge a (15) on a multi-head pump at an oil inlet in the oil cavity is used for measuring pressure of the oil inlet of the oil cavity, and a pressure gauge b (16) arranged between an oil pump and the multi-head pump is used for measuring the oil supply pressure of the static-pressure rotary table. By means of the experimental device, a test of the dynamic and static performances of the static-pressure rotary table is carried out under the condition that temperature is between minus 10 DEG C and 60 DEG C and pressure is not more than 100 MPa, and the experimental device provides guarantee for solving problems in engineering, optimizing structural parameters of the rotary table, and improving machining precision of the rotary table.

Owner:BEIJING UNIV OF TECH

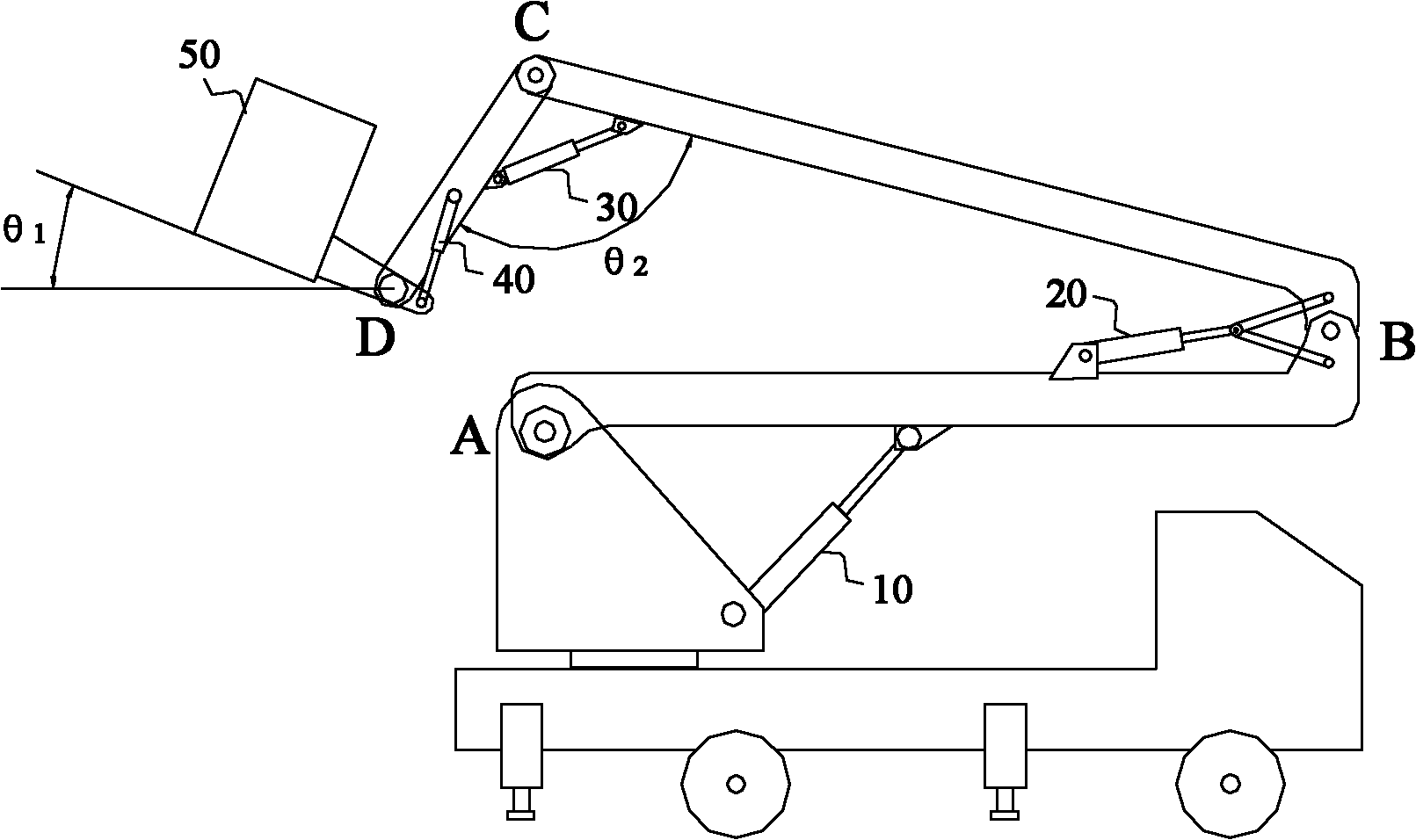

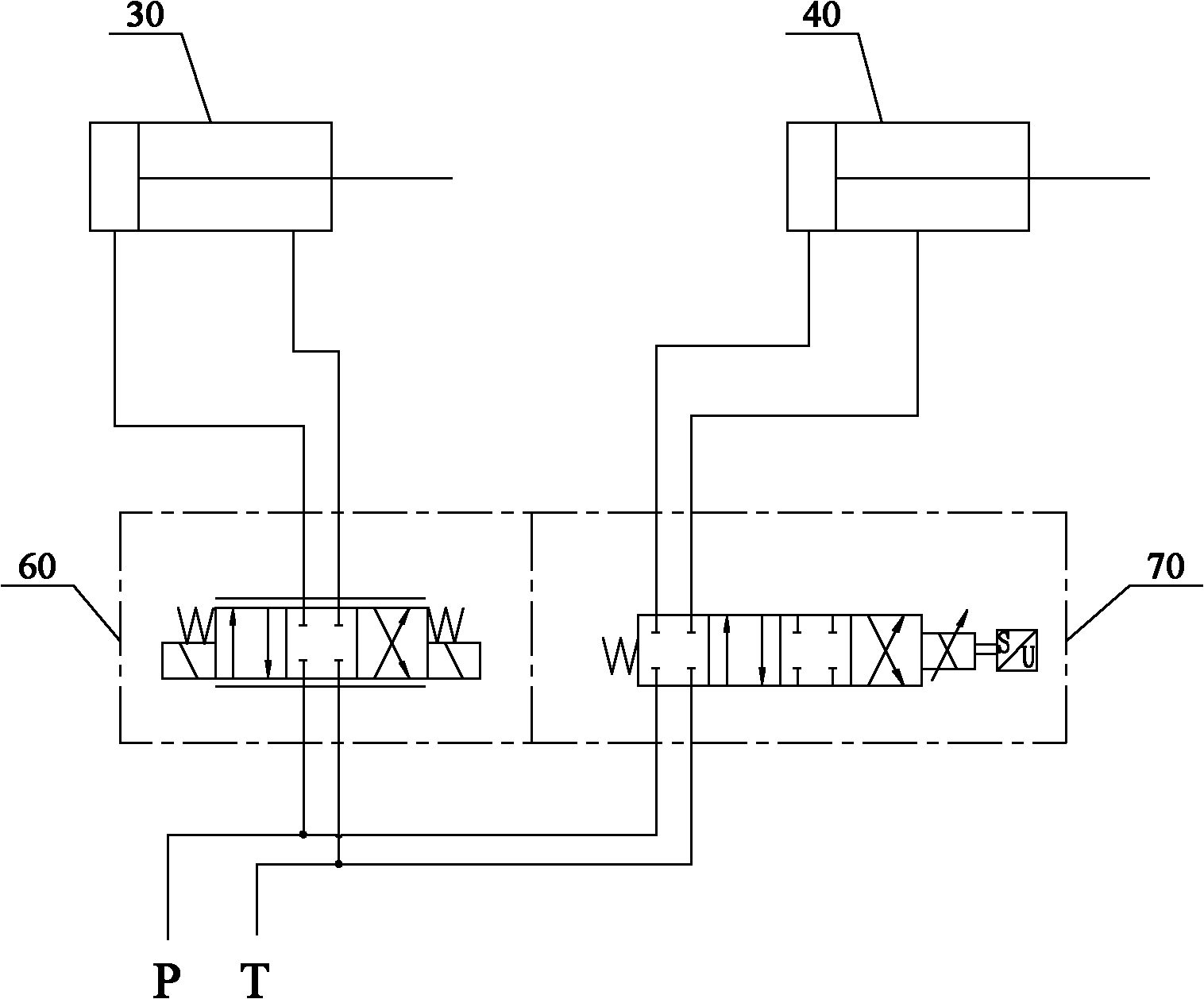

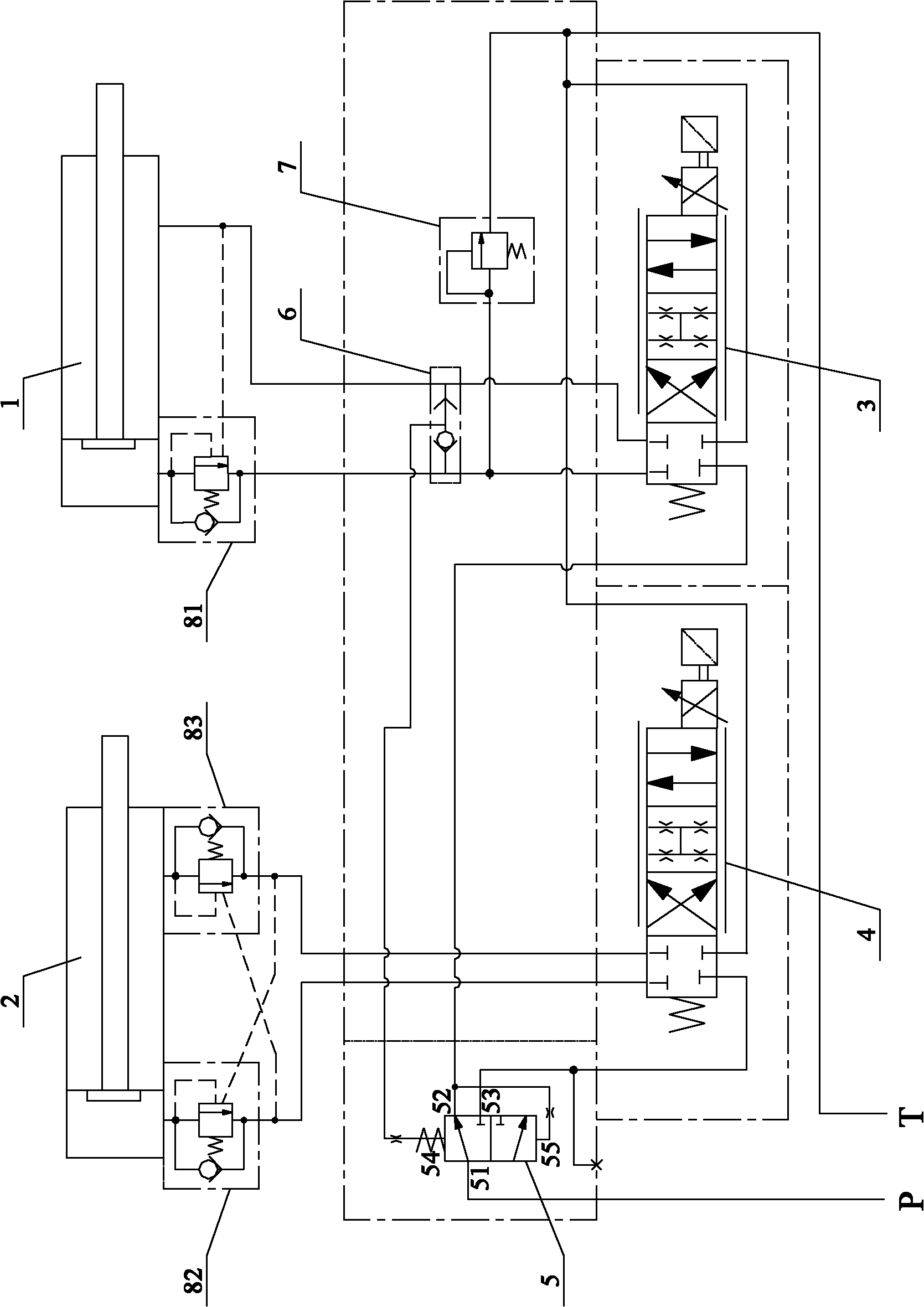

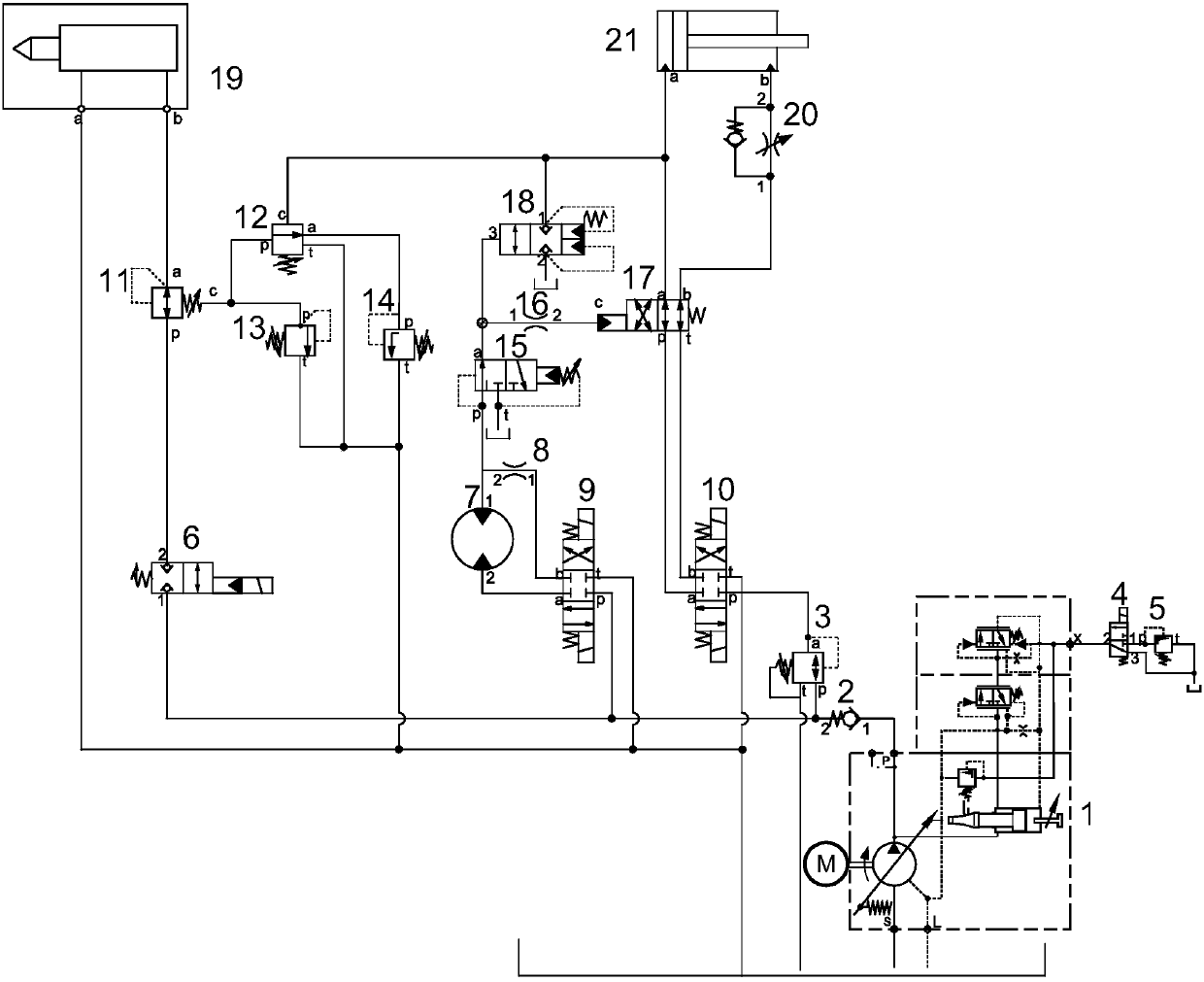

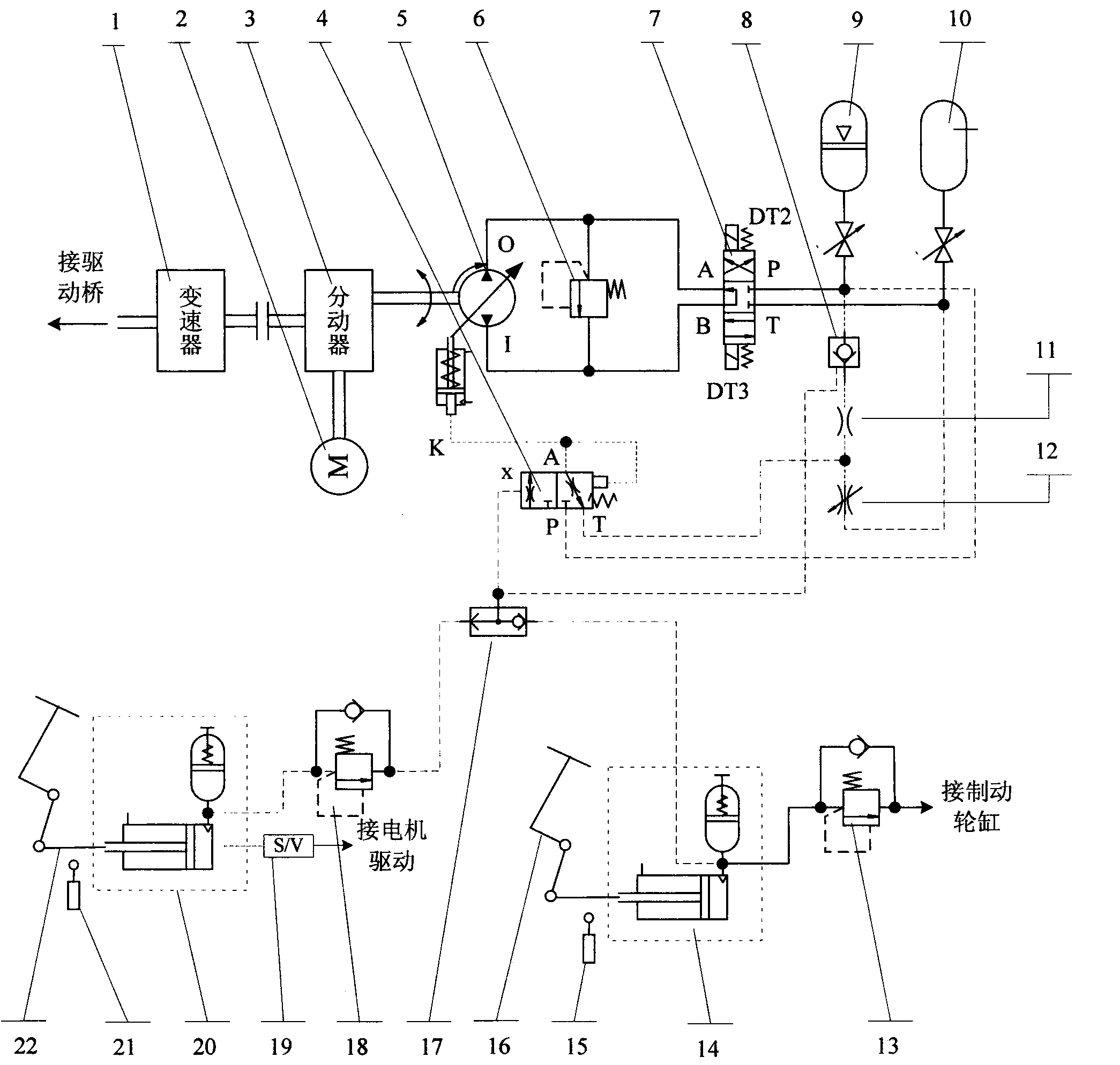

Elevated operation vehicle and platform leveling hydraulic system thereof

ActiveCN102030293AAvoidance of leveling aheadAvoid hysteresisServomotorsLifting devicesSystem pressureControl valves

The invention discloses a platform leveling hydraulic system comprising a leveling cylinder, an arm-joint amplitude cylinder, a priority valve, a first flow control valve and a second flow control valve, wherein the first flow control valve is used for controlling the liquid feeding quantity of two cavities of the leveling cylinder; the second flow control valve is used for controlling the liquid feeding quantity of two cavities of the arm-joint amplitude cylinder; an oil inlet of the priority valve is communicated with a system pressure oil channel, a main oil port of the priority valve is communicated with an oil inlet of the first flow control valve, and a secondary oil port of the priority valve is communicated with an oil inlet of the second flow control valve; and a first control oil port for controlling the opening of the main oil port to change in an increasing trend is communicated with an oil outlet of the first flow control valve, and a second control oil port for controlling the opening of the secondary oil port to change in an increasing trend is communicated with the oil inlet of the first flow control valve. System pressure oil firstly satisfies the flow requirement of the leveling cylinder and can effectively avoid platform leveling advance or lag phenomena. On the basis, the invention also provides an elevated operation vehicle with the platform leveling hydraulic system.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

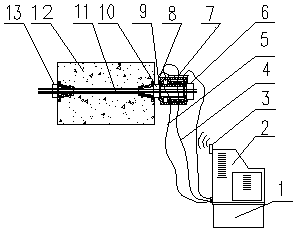

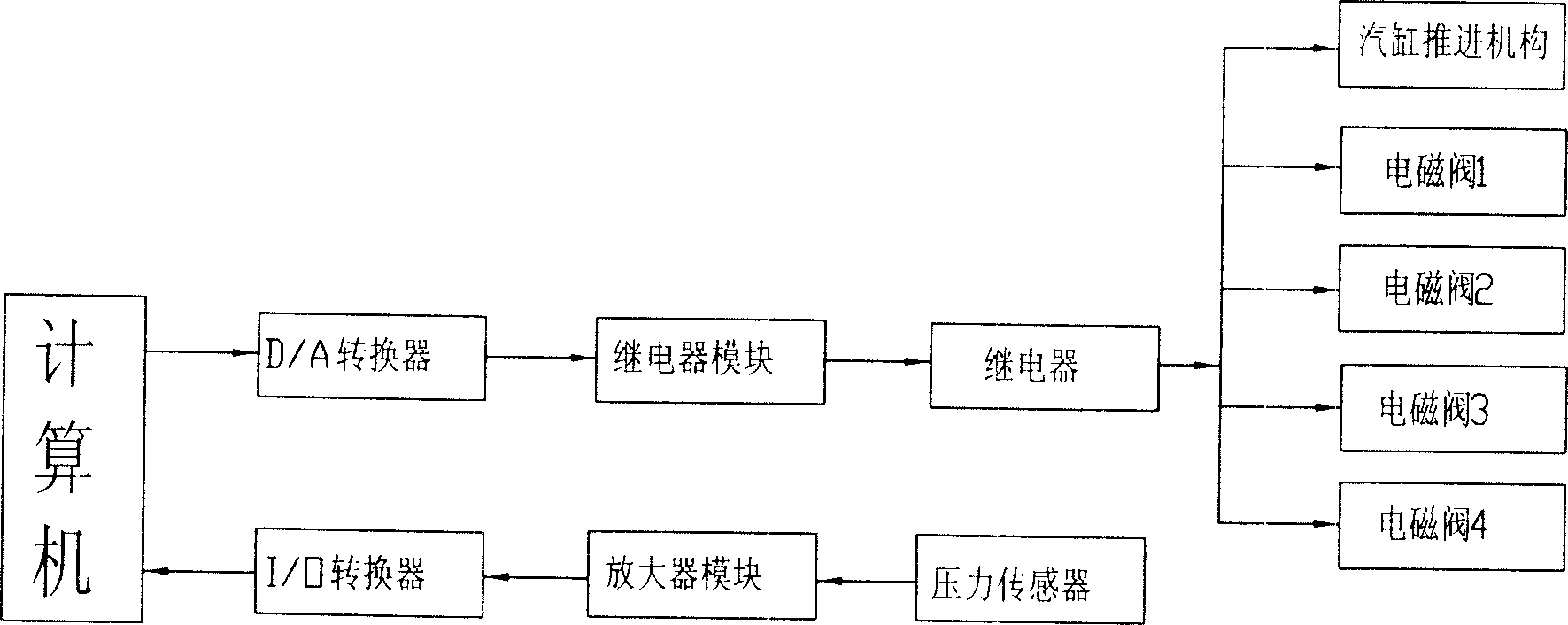

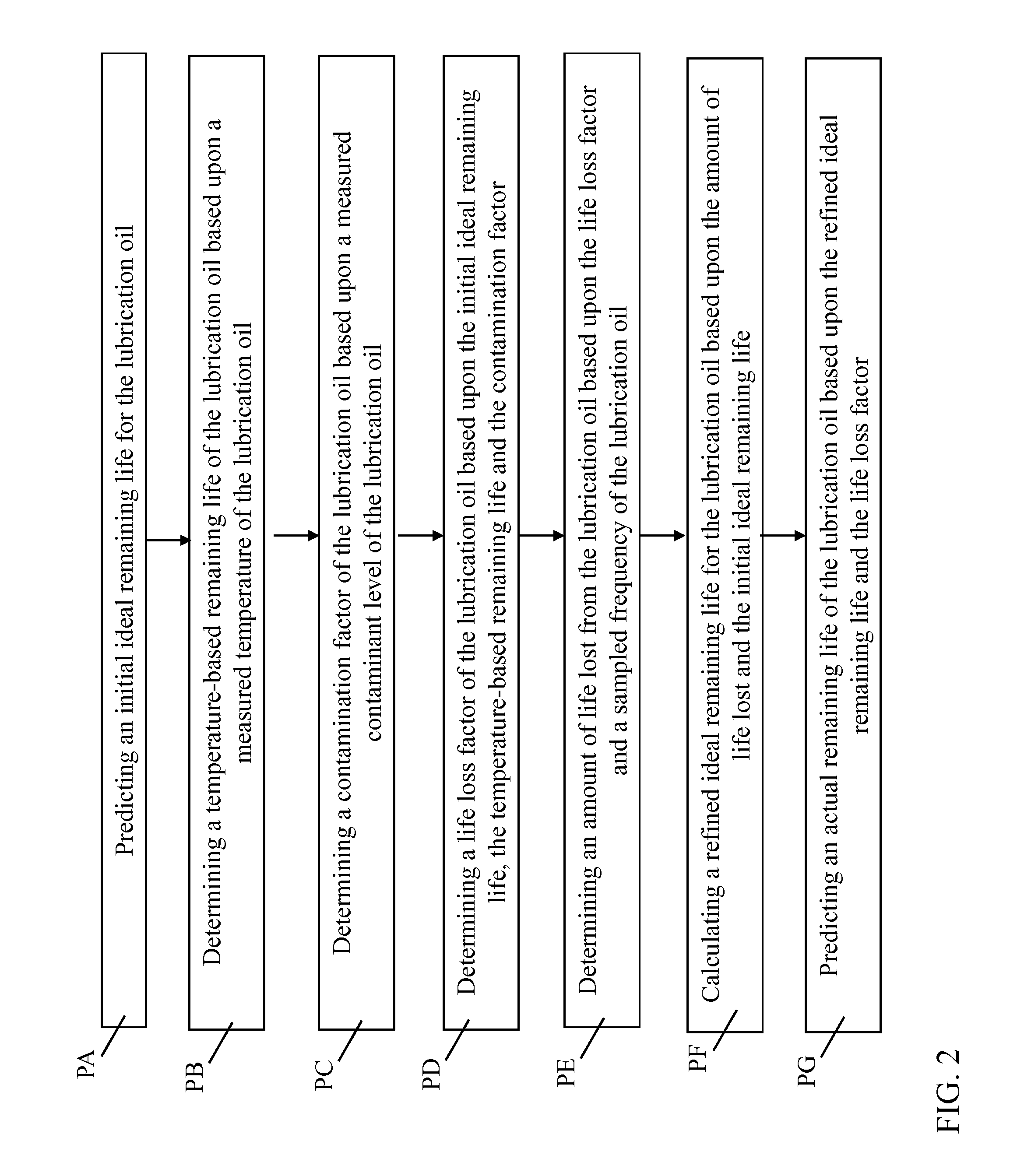

Control method of intelligent tension system and intelligent tension system

ActiveCN103526948AHigh measurement accuracyImprove construction efficiencyBuilding material handlingFrequency changerControl signal

The invention provides a control method of an intelligent tension system and the intelligent tension system. The method is characterized by including the steps that a loading speed control unit is built and used for detecting pressure of an oil inlet, and the pressure, monitored in real time, of the oil inlet is compared with preset pretightening force of each stage; a prestressing tendon extending amount control unit is built and used for detecting the displacement value of a prestressed steel bar in real time in the tensioning process and the displacement value of the prestressed steel bar in set holdup time after the prestressed steel bar reaches set tension force of each stage; tensioning values of different jacks are compared after first-stage tension; control signals of different stage conditions in the tensioning process are converted into electromagnetic motions and frequency converter rotation speed control requirements; according to signals fed back by a pressure sensor and a displacement sensor in the tensioning process, the related control commands undergo fuzzy conditioning. The control method and the system have the advantages of improving data measuring precision and construction efficiency, reducing labor intensity of construction workers, reducing cost, improving labor efficiency, eliminating safety hidden risks of the construction workers, and enabling the whole tensioning process to be finished at a time.

Owner:LIUZHOU QIAN BRIDGE ENG MATERIALS

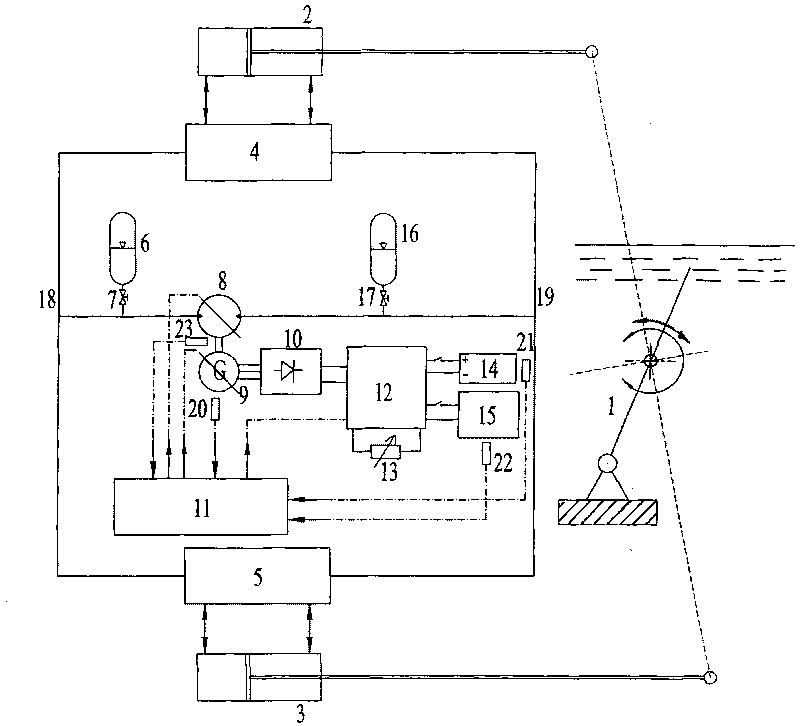

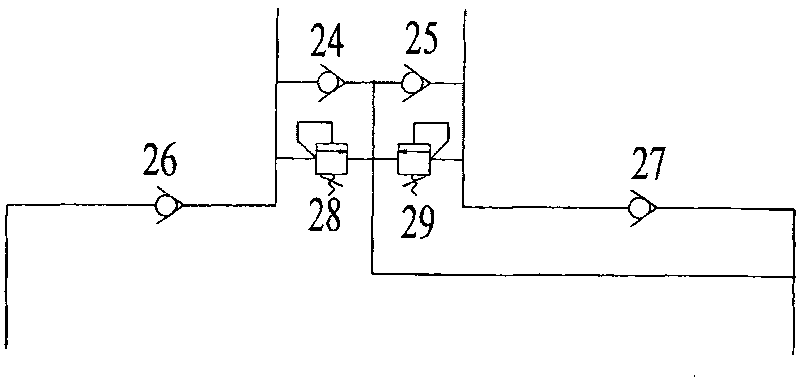

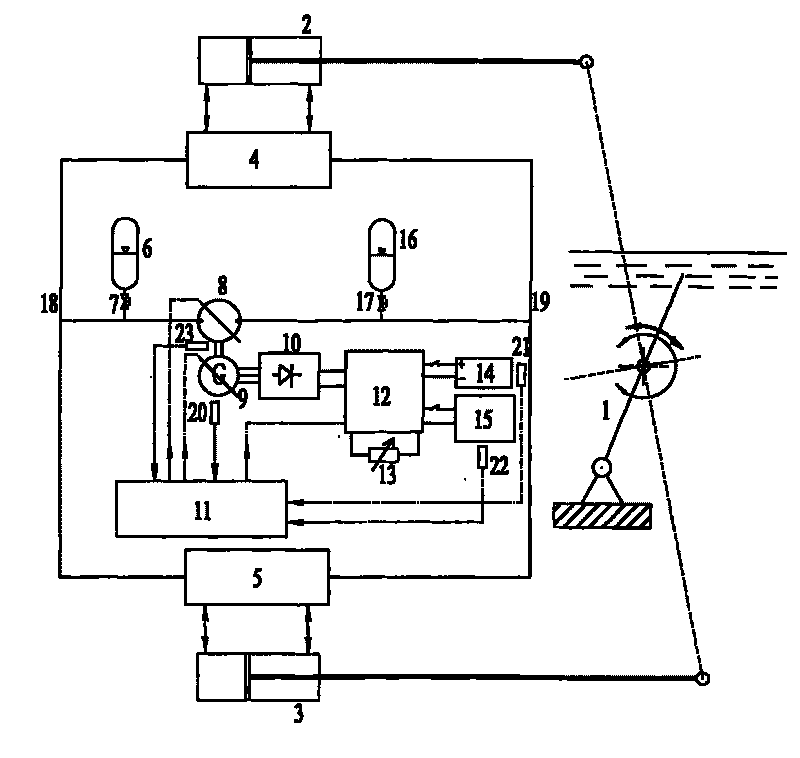

Hydraulic transmission-based method and device for storing energy and realizing stabilized voltage and constant frequency in wave power generation

InactiveCN101737241AThe overall structure is simple and reliableOutput delivery is smoothMachines/enginesEngine componentsPressure stabilizationConstant frequency

The invention discloses a hydraulic transmission-based method and a hydraulic transmission-based device for storing energy and realizing stabilized voltage and constant frequency in wave power generation. In the device, a floating pendulum is connected with a hydraulic cylinder, high pressure oil outputted by a non-rod cavity of the hydraulic cylinder enters a high pressure energy storing device and an oil inlet of a variable motor through a control integrated valve and through a high pressure oil tube, low pressure oil outputted by an oil outlet of the variable motor enters a low pressure big-capacity energy storing device and returns to the rod cavity of the hydraulic cylinder through the control integrated valve, the main shaft of the variable motor is connected with a permanent magnet synchronous generator, and the permanent magnet synchronous generator is connected to a rectifying module and a direct-current electric energy charging-discharging control module and then connected to a stepless unload adjustable load and a storage battery. The high pressure energy storing device and the low pressure big-capacity energy storing device realize the energy storage by absorbing the fluctuation, caused by the change of transient waves, of pressure and flow rate. A controller realizes the pressure stabilization constant frequency by the stepless unload adjustable load and the displacement of the hydraulic motor respectively. The device has the advantage of making the wave power generating device output more smoothly, more free from influence of the wave impact and have higher efficiency.

Owner:ZHEJIANG UNIV

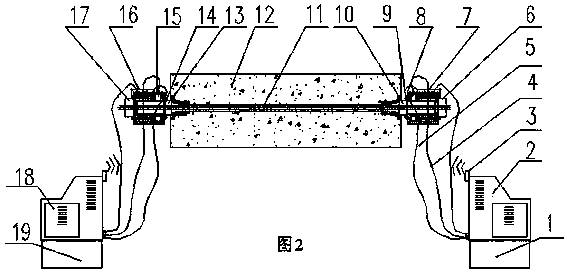

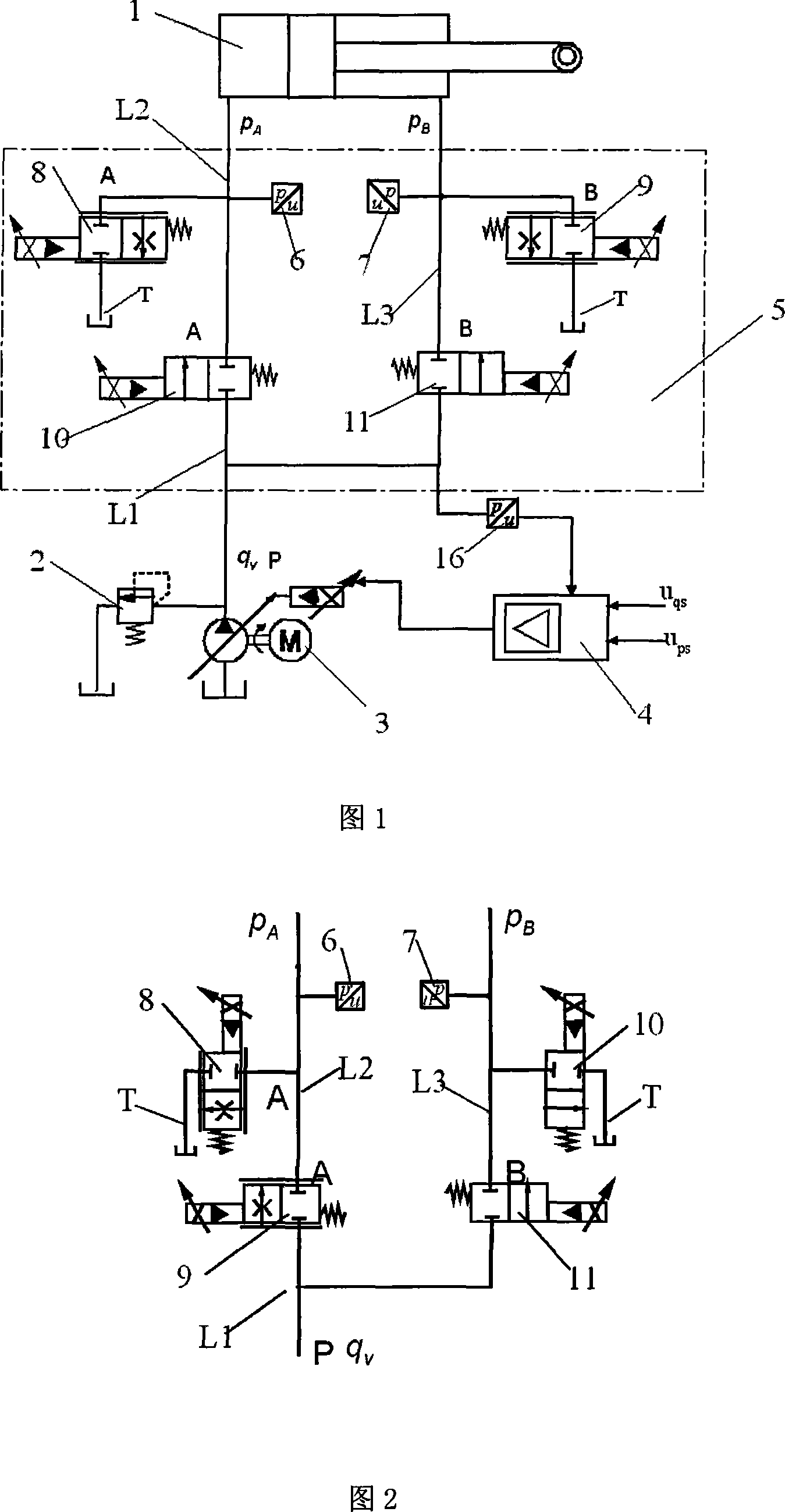

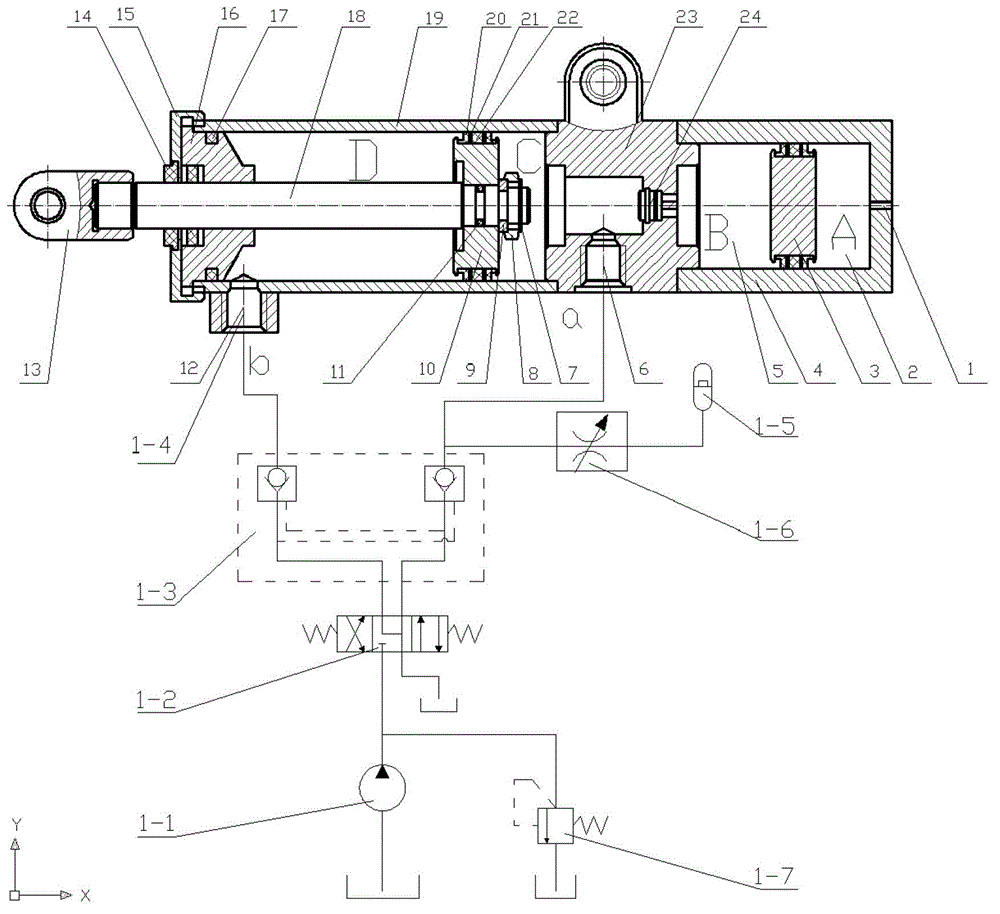

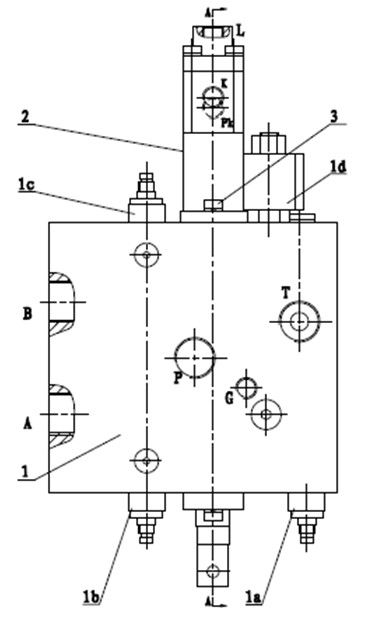

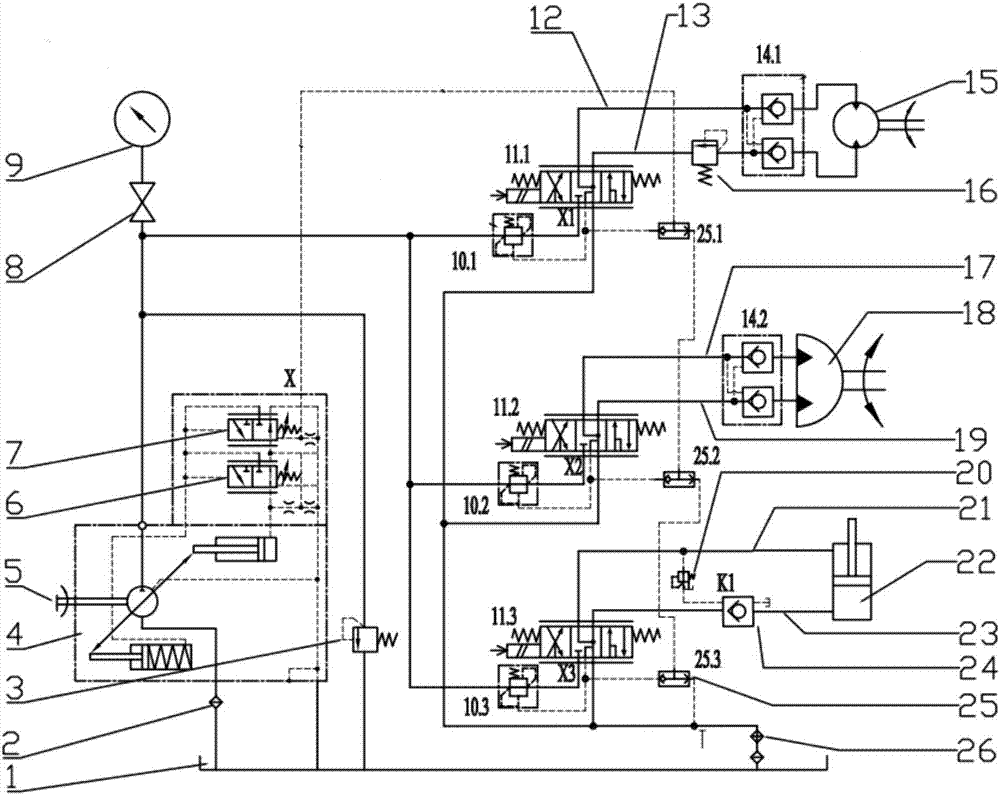

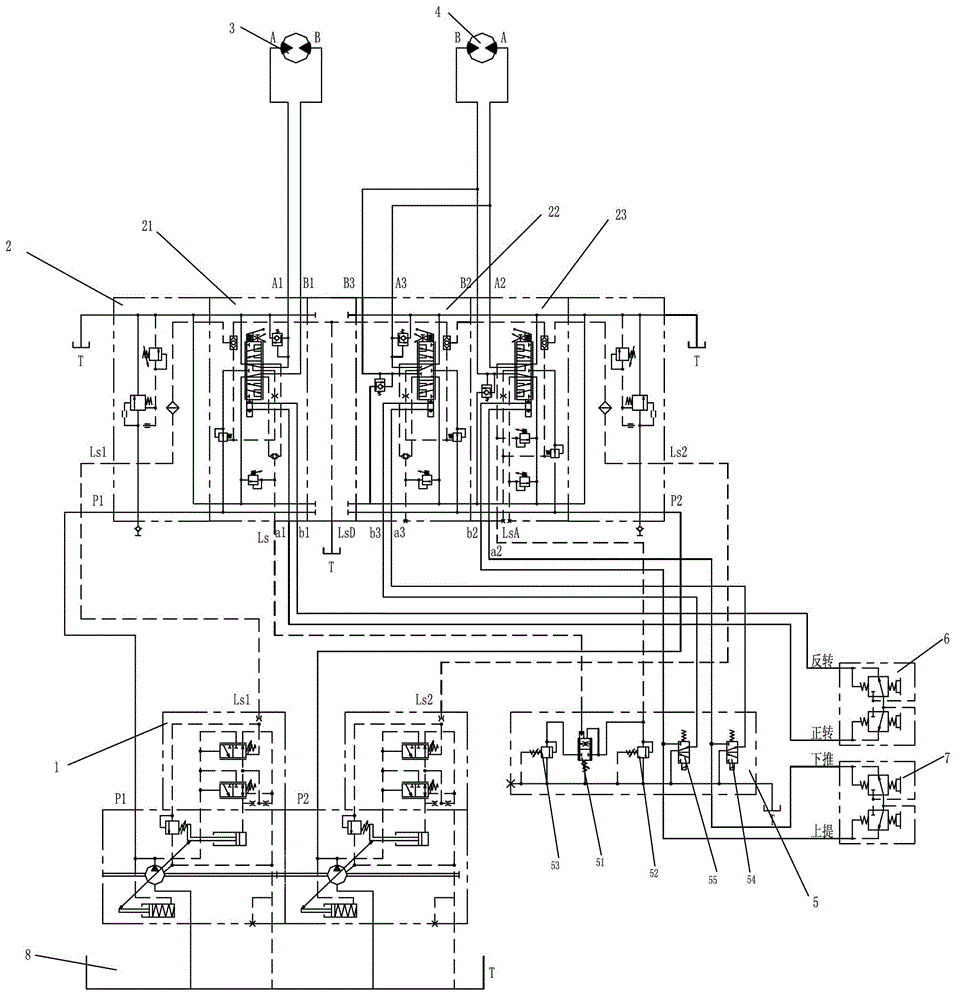

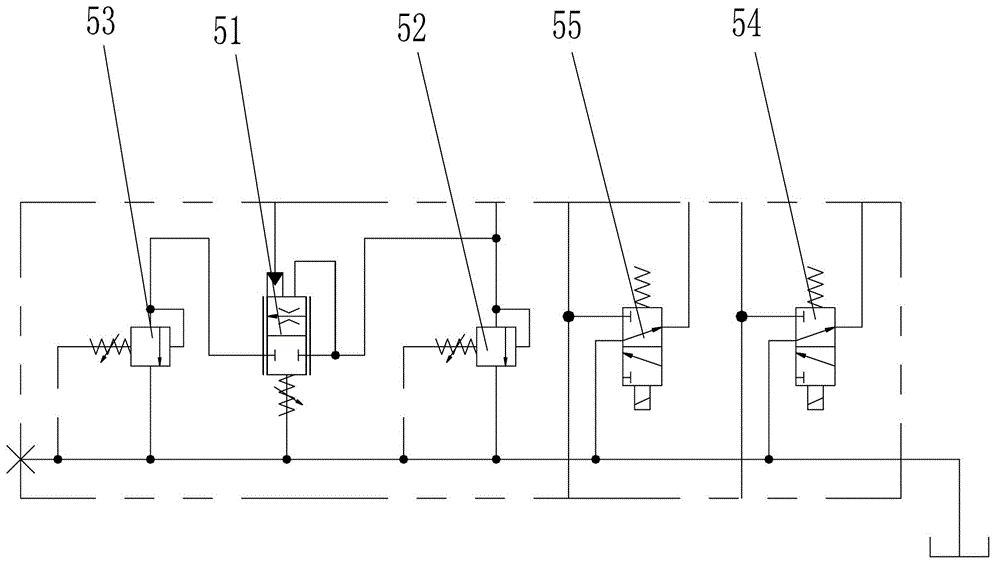

Independent control electrohydraulic system of oil inlet and outlet with pump valve composite flux matched

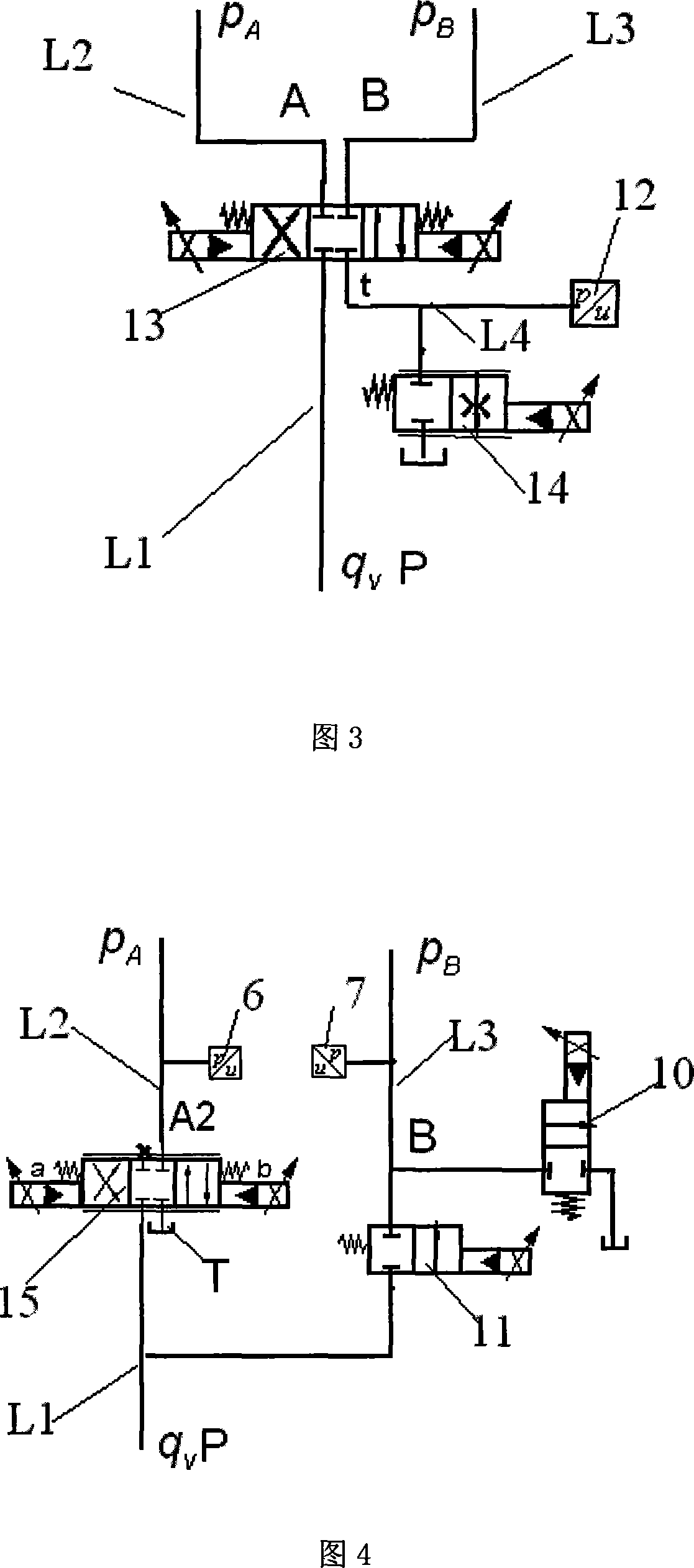

ActiveCN101109398AReduce consumptionImprove efficiencyServomotor componentsServomotorsAutomatic controlElectro hydraulic

The invention discloses an electro-hydraulic system with matched pump-valve compound flow and independent controlling at oil inlet / outlet, which is characterized in that the output flow of the hydraulic supply is continuously adjusted under control of electronic signals, the flow-matching controller is arranged between a pressure sensor and the oil pipe of the hydraulic supply; an independent oil inlet and outlet controlling valve set comprises two pressure sensor I, II, two 2-position 2-way proportion throttle valve I, II, and two 2-position 2-way electromagnetic directional valve I, II. The invention allows the output flow from the power supply to be always matched with the flow desired by all actuators, so that the oil-intake valve controlling the max. load actuator is fully open, this not only allows each actuator be controlled by the oil inlet and outlet independently, but also can minimize the loss of the system. The innovation in the invention also includes that the flow of the inlet and outlet are detected respectively depending upon the moving direction of the load, flow matching is realized for the system, moving steadiness of the actuators in each direction is guaranteed, and condition for automatic control for industrial control technology especially equipment manufacturing is provided.

Owner:TAIYUAN UNIV OF TECH

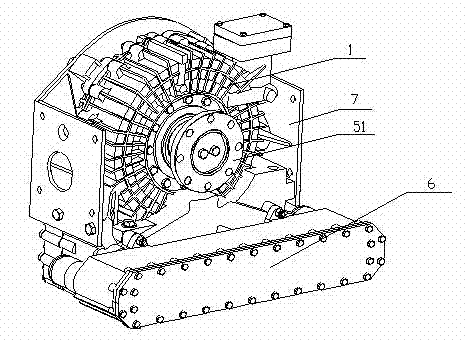

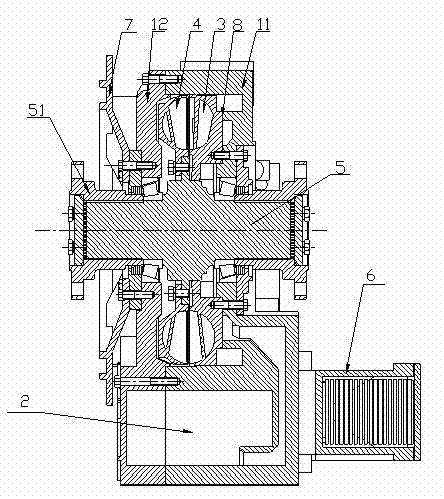

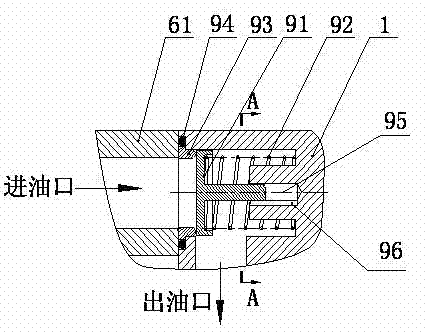

Non-oil-immersed air gap type hydraulic motor vane pump

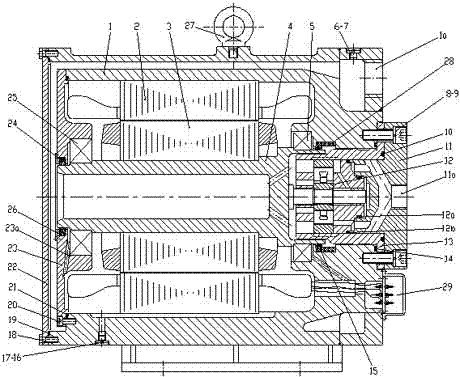

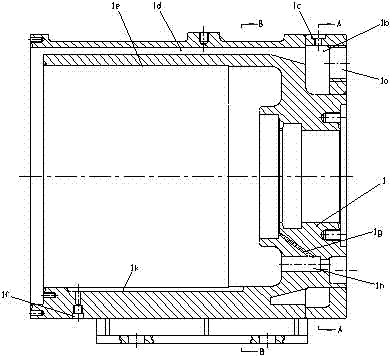

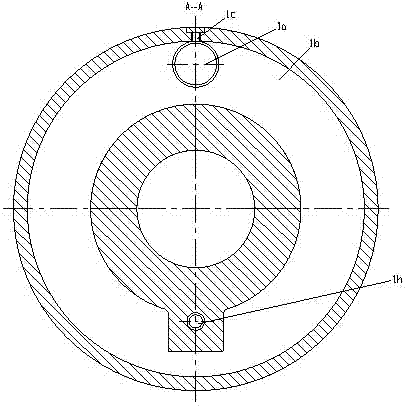

ActiveCN103047134AReduce weightImprove efficiencyMachines/enginesRotary/oscillating piston pump componentsHydraulic motorElectric machinery

The invention relates to a non-oil-immersed air gap type hydraulic motor vane pump. A motor rotor (3) and a main shaft (4) are compressed together, and are supported on a shell (1) and an inner end cover (23) by a first bearing (5) and a second bearing (25), a pump core (12) of the vane pump is connected with the main shaft (4) by a spline (4c), the pump core (12) of the vane pump is arranged in a pump core holder (13), a motor stator (2) is pressed in an inner hole (1e) of a shell (1), the shell (1) is provided with an oil inlet (1a), an annular flow channel (1b) and a cooling flow channel (1d), and the main shaft (4) is provided with a central hole (4a) of the main shaft and a pore plate centrifugal pump (4c). The heat generated by a motor and the like is taken away by oil flowing in a motor pump, the fan in the motor is saved, and meanwhile, the hydraulic motor vane pump can absorb oil and enhance the pressure by the central hole of the main shaft and the pore plate centrifugal pump. The aerodynamic noise and the cavitation noise are eliminated, so that the entire hydraulic motor vane pump has a favorable silencing performance.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

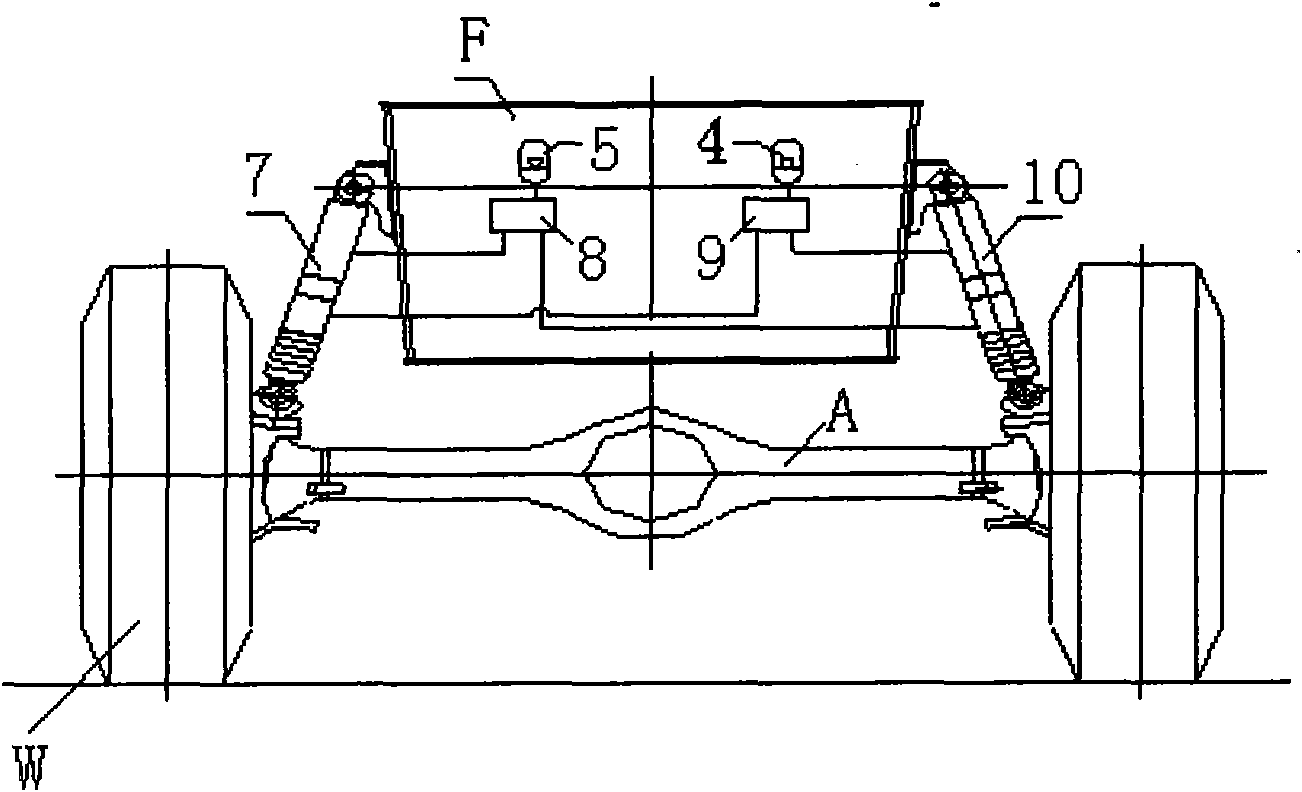

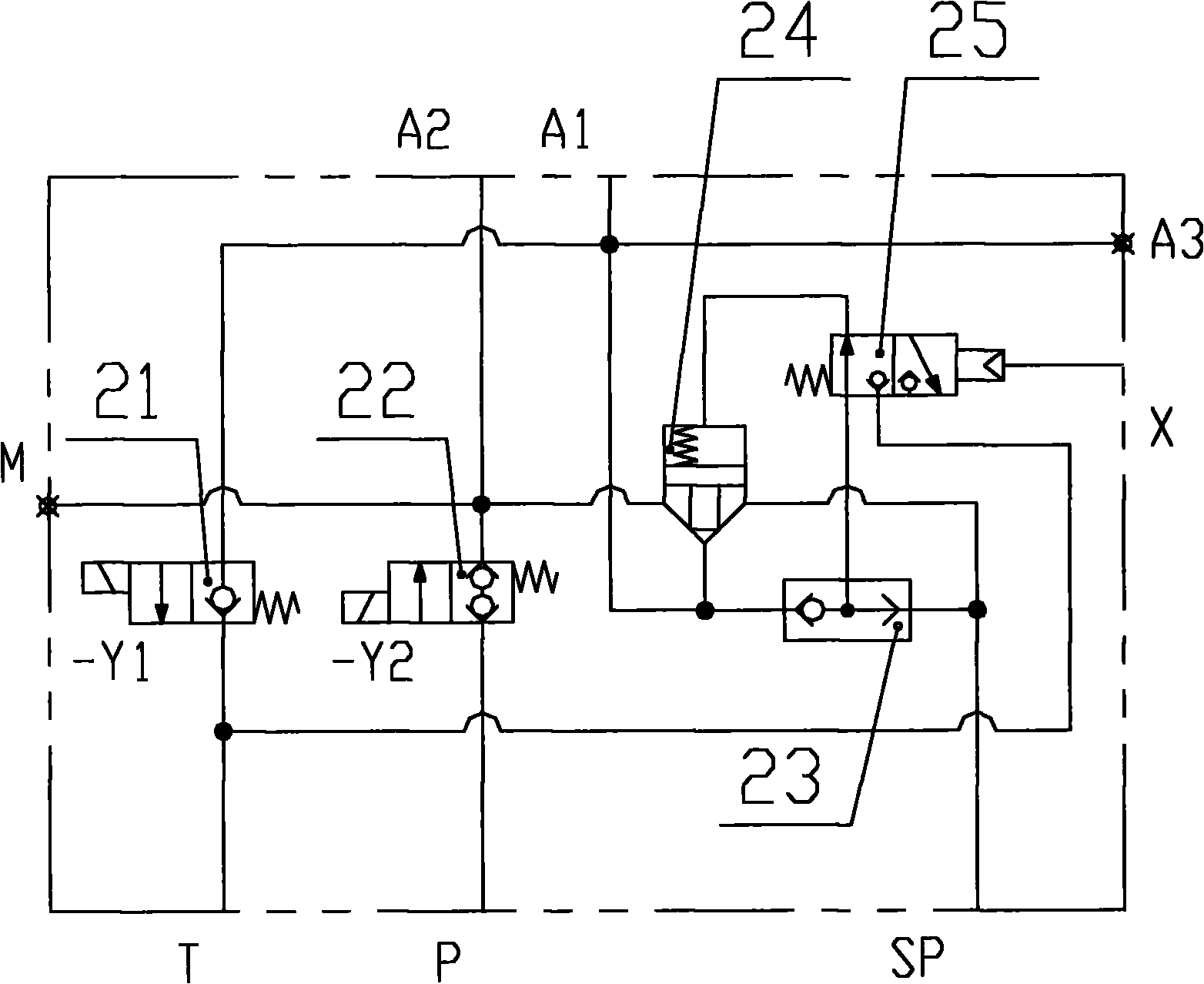

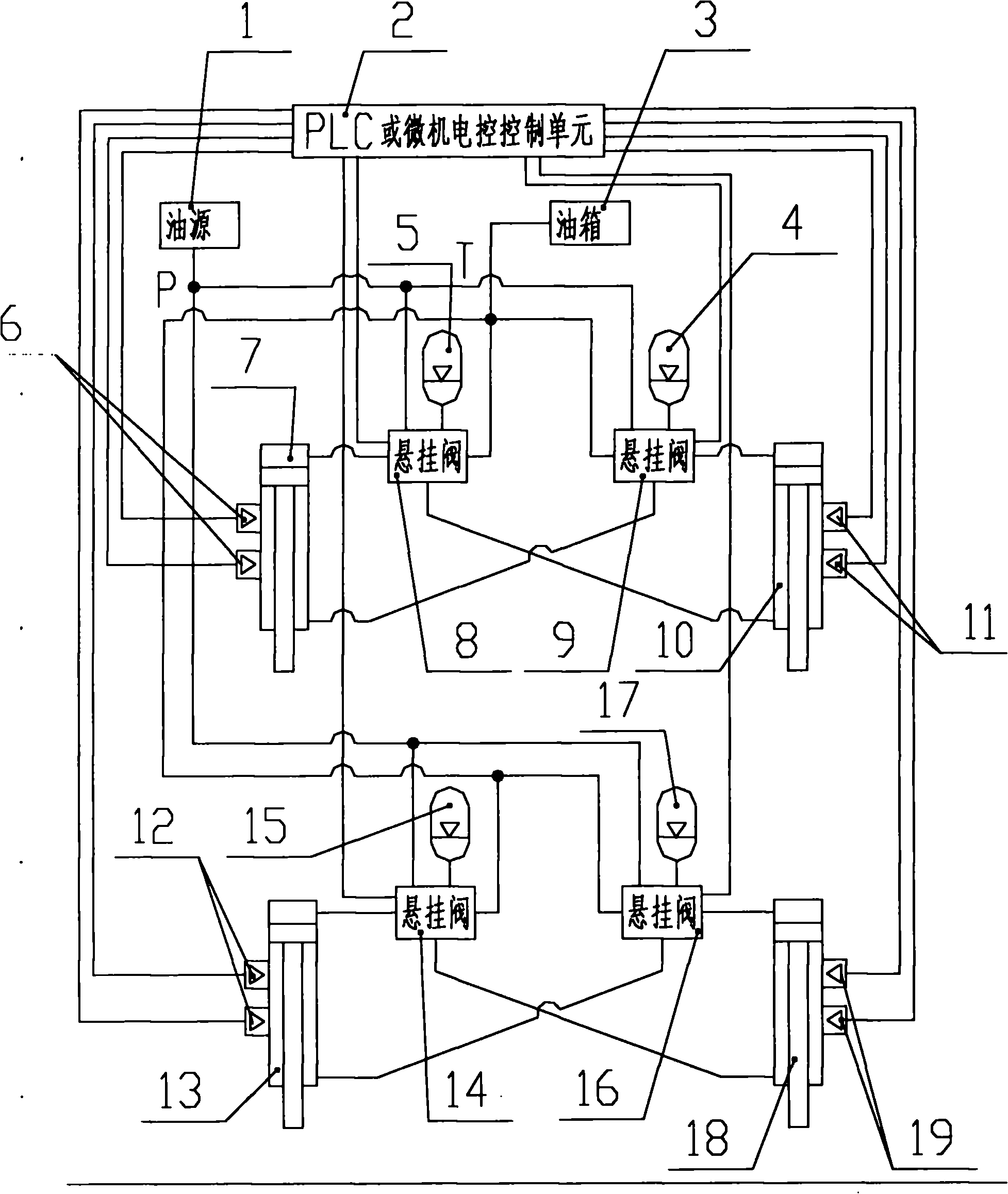

Suspension valve, oil gas suspension system and engineering vehicle

ActiveCN102039792APrioritize enhancementsImprove simplicityInterconnection systemsResilient suspensionsHydropneumatic suspensionDifferential pressure

The invention relates to a suspension valve comprising an oil intake switch lockup valve (22), an oil return switch lockup valve (21) and a differential-pressure sensing logic control element group. The differential-pressure sensing logic control element group comprises a logic shutter valve (23), a differential-pressure sensing lockup valve (24) and a pilot control valve (25), wherein the oil return switch lockup valve realizes the start and lockup functions of return oil; the oil intake switch lockup valve realizes the start and lockup functions of intake oil; the logic shutter valve realizes the logic comparison of pressures of a rod cavity and a rodless cavity of a suspension oil cylinder; and the differential-pressure sensing lockup valve realizes the differential-pressure sensing and the communication lockup of the pressures of the rod cavity and the rodless cavity of the suspension oil cylinder. In addition, the invention also provides an oil gas suspension system adopting the suspension valve and an engineering vehicle thereof. By applying the differential-pressure sensing logical control element group, the durable maintenance and the reliable and rapid conversion of rigidand flexible working conditions of the suspension system are realized more reliably, elements of the suspension valve of an axle suspension system are effectively reduced, and the control is simple and convenient.

Owner:ZOOMLION HEAVY IND CO LTD

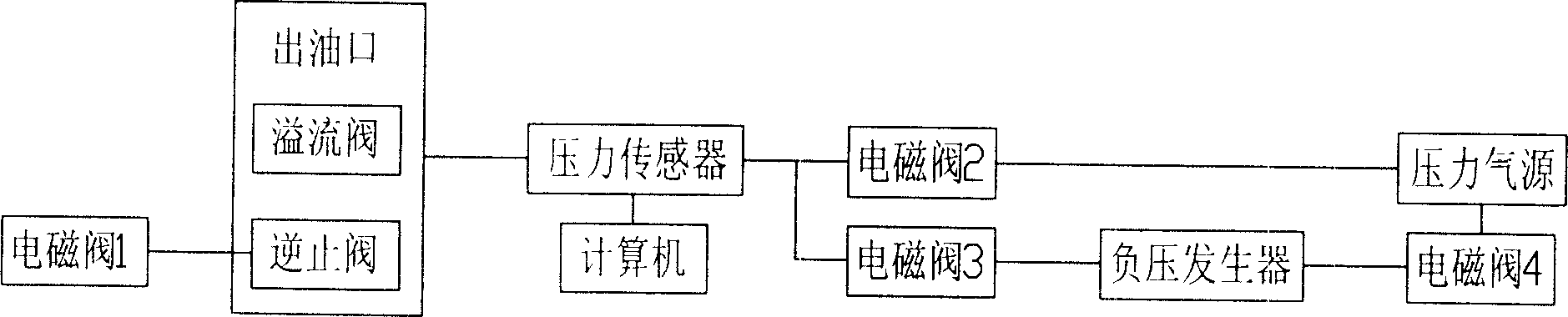

Equipment for testing valve performance of oil fuel pump

InactiveCN1687731AHigh precisionReduce mistakesMachine part testingMeasurement of fluid loss/gain rateSolenoid valvePositive pressure

The invention relates to the fuel pump valve performance testing equipment, which comprises the pipeline part, the pressure sensor testing the oil outtake pressure of the fuel pump, the electromagnetic valve on the outtake pipe of the reversing valve. The pipeline part comprises the pressure air source connecting the oil intake end of the output nozzle of the pump, the negative pressure producer connecting the intake end of the output nozzle of the fuel pump; the electromagnetic valves are between the intake end of the output nozzle of the pump and the pressure air source, and between the intake end of the output nozzle of the pump and the negative pressure producer; the output end of the pressure sensor connects the computer. The invention provides the positive pressure gas to the output nozzle through the pressure air source, vacuums through the negative pressure producer and makes the output nozzle produce the negative pressure, tests the starting pressure, the sealing performance of the overflow valve through the pressure sensor.

Owner:WUHAN UNIV OF TECH

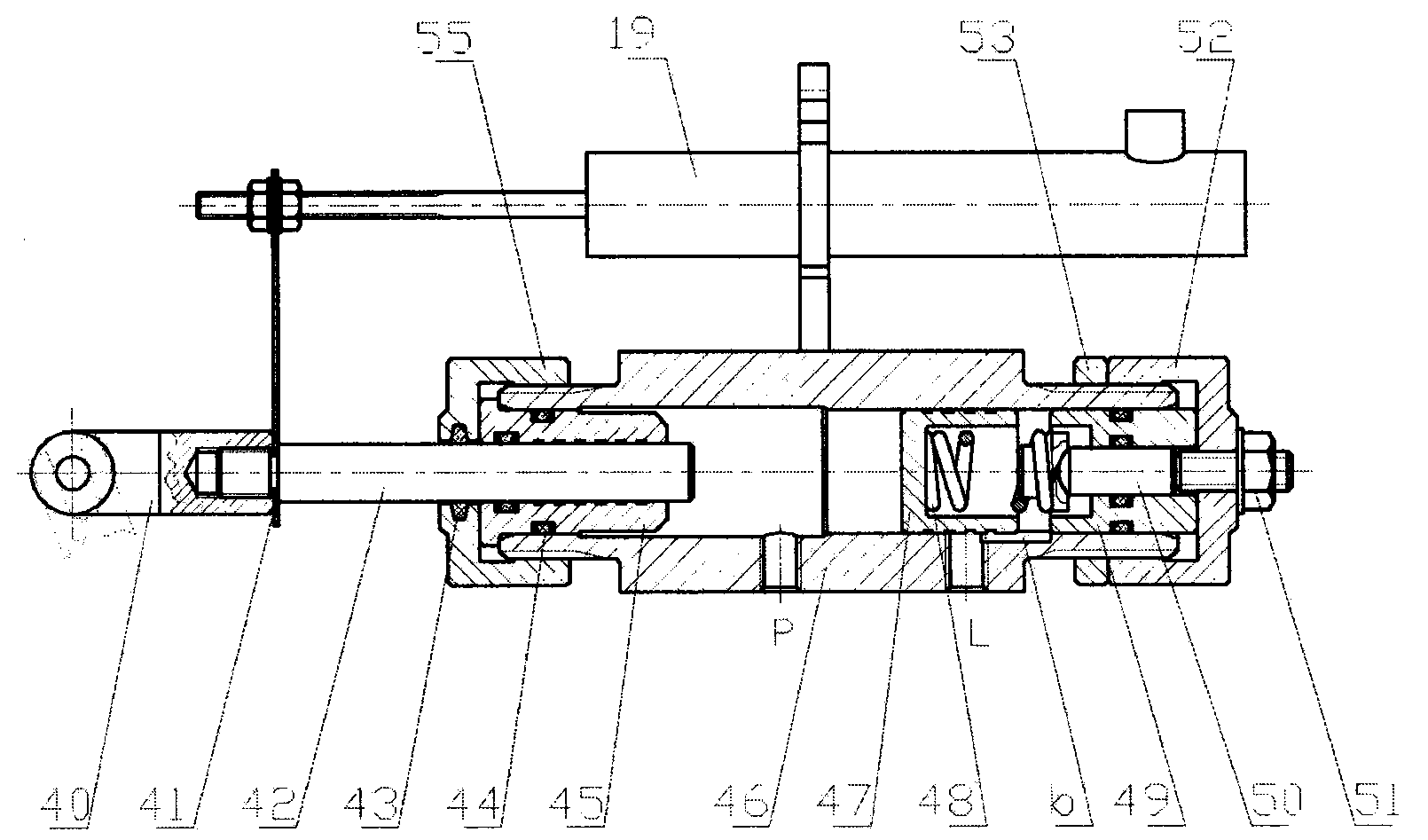

Electrohydraulic controlled continuously variable gas distribution timing system in internal-combustion engine

InactiveCN1959072AMeet the needs of high speedImprove powerMachines/enginesNon-mechanical valveHydraulic cylinderSolenoid valve

A continuous variable valve actuating-timing system controlled by electrohydraulic control and set on internal combustion engine is prepared as using entrance one-way valve to control oil intake of hydraulic cylinder and using one-way solenoid valve to control oil exhaust of hydraulic cylinder, using rise-up section of valve actuating cam to control open and rise-up of air door and controlling close and drop-down of air door by depending upon exhausting time of liquid in hydraulic cylinder.

Owner:济南轻骑摩托车有限公司 +1

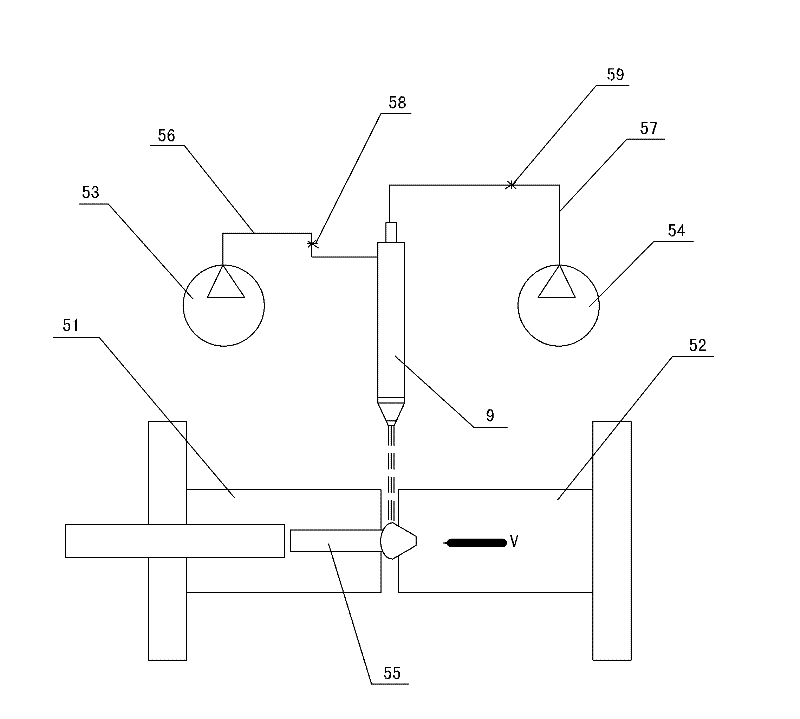

Equipment for processing abrasive slurry water-jet microporous nozzle internal runner and method for detecting and controlling real-time flux

InactiveCN101564831AIncrease the flow rate coefficientTraffic real-time detectionAbrasive feedersRelative volume flow measurementsControl signalFuel tank

The invention relates to an equipment for processing abrasive slurry water-jet microporous nozzle internal runner and a method for detecting and controlling real-time flux. The equipment comprises an oil tank, a slurry box and a high-pressure material tank; a high-pressure pipeline and an oil returning pipeline are communicated with the oil inlet of the high-pressure material tank and the oil tank; a material inlet pipe and a material supply pipe are communicated with the material inlet of the high-pressure material tank and the slurry box; the oil inlet of the high-pressure material tank is provided with a high-precision flowmeter; a processed microporous nozzle is communicated with a material supply interface; the inlet of the material supply joint is provided with a check valve; the material supply joint is arranged on a clamping device; the real-time oil inlet quantity of the high-pressure material tank, namely the real-time flux of the processing microporous nozzle, is measured by the high-precision flowmeter; the real-time slurry flux detection data is input to a controller; when the slurry flux reaches a given value, the controller outputs a control signal to close the check valve, thus stop processing. The equipment has high grinding efficiency and high precision.

Owner:SHANGHAI UNIV +2

Load-sensitive hydraulic system and power matching control method, device and system

ActiveCN103671336AImproved handling and reliabilityImprove Control ConsistencyServomotor componentsThrottleControl valves

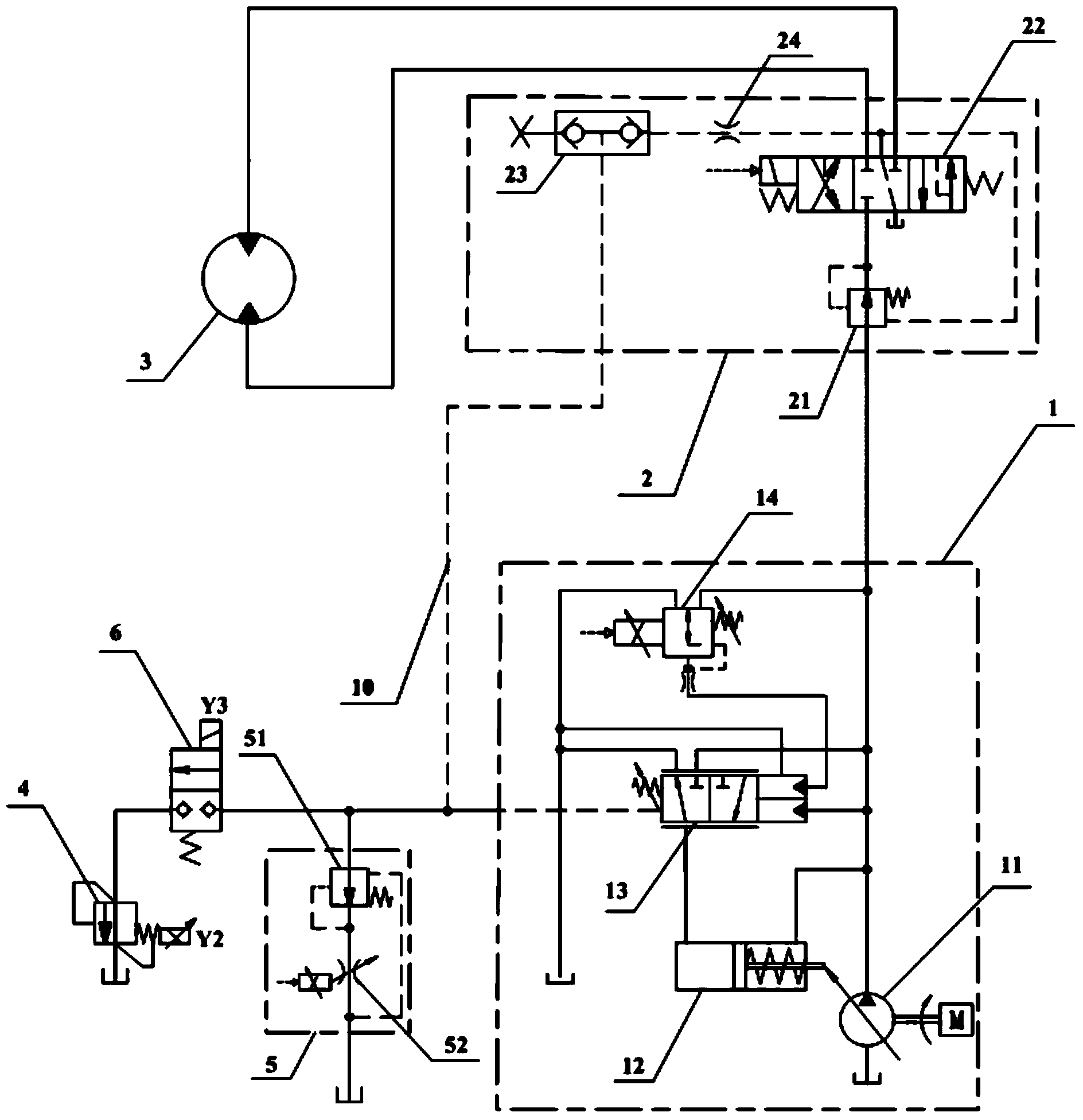

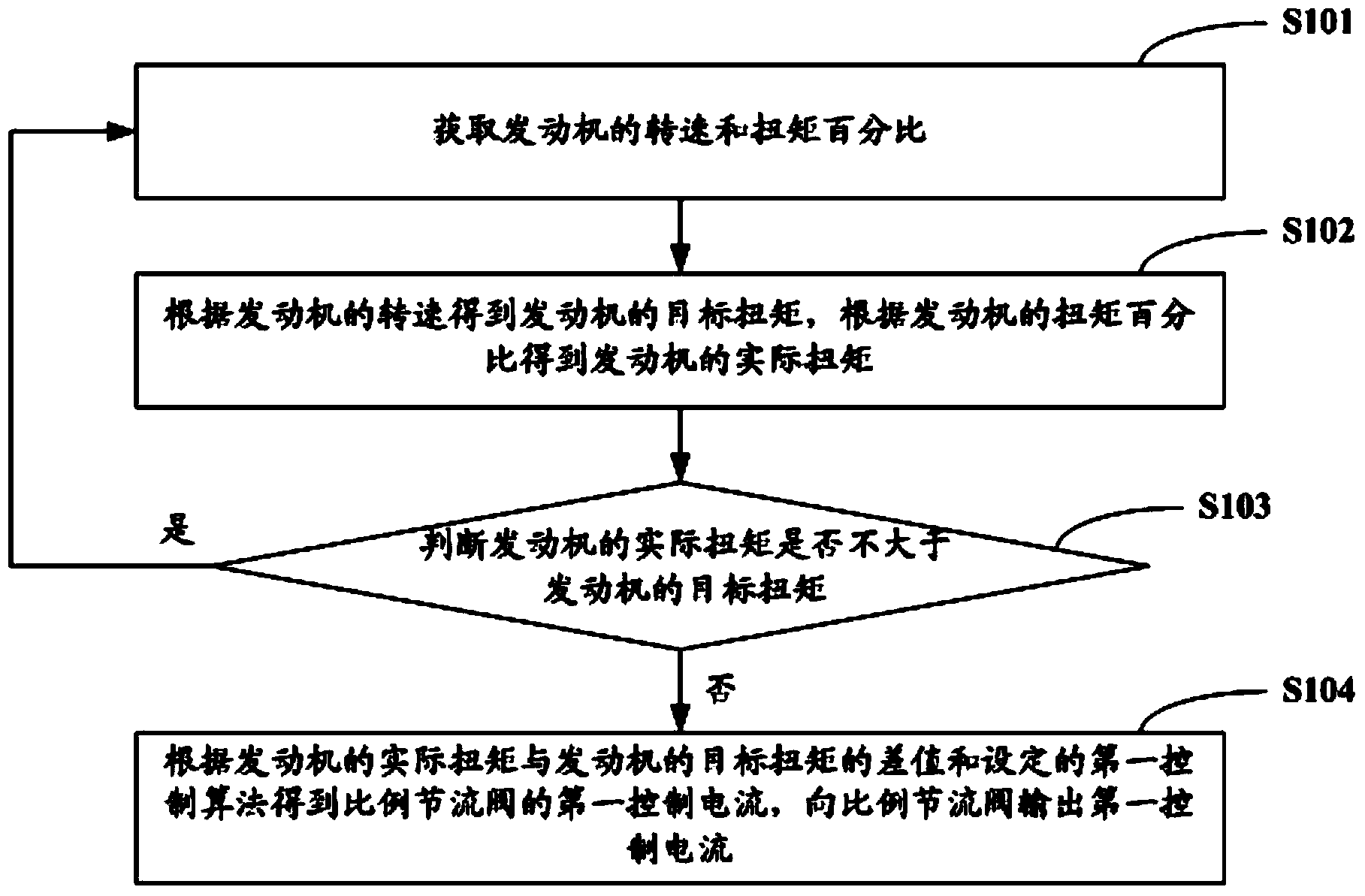

The invention relates to the technical field of engineering machinery, and discloses a load-sensitive hydraulic system, a power matching control method, device and system and an engineering machine. The load-sensitive hydraulic system, the power matching control method, device and system and the engineering machine are used for improving the control conformance, the dynamic responsiveness and the stability of the load-sensitive hydraulic system and the control performance of power matching. The load-sensitive hydraulic system comprises a variable pump assembly, a main control valve set, an actuator, an overflow valve and a flow control valve set. An oil inlet of the main control valve set is communicated with an oil outlet of the variable pump assembly, and a load-sensitive feedback oil path is arranged between a control oil port of the main control valve set and a control oil port of the variable pump assembly. Two oil ports of the actuator are communicated with two working oil ports of the main control valve set respectively. An inlet oil path of the overflow valve is communicated with the load-sensitive feedback oil path, and a switch valve is arranged on the inlet oil path of the overflow valve. An inlet oil path of the flow control valve is communicated with the load-sensitive feedback oil path, and the flow control valve comprises a proportional throttle valve and a first pressure-compensated valve arranged on an inlet oil path of the proportional throttle valve.

Owner:ZOOMLION HEAVY IND CO LTD

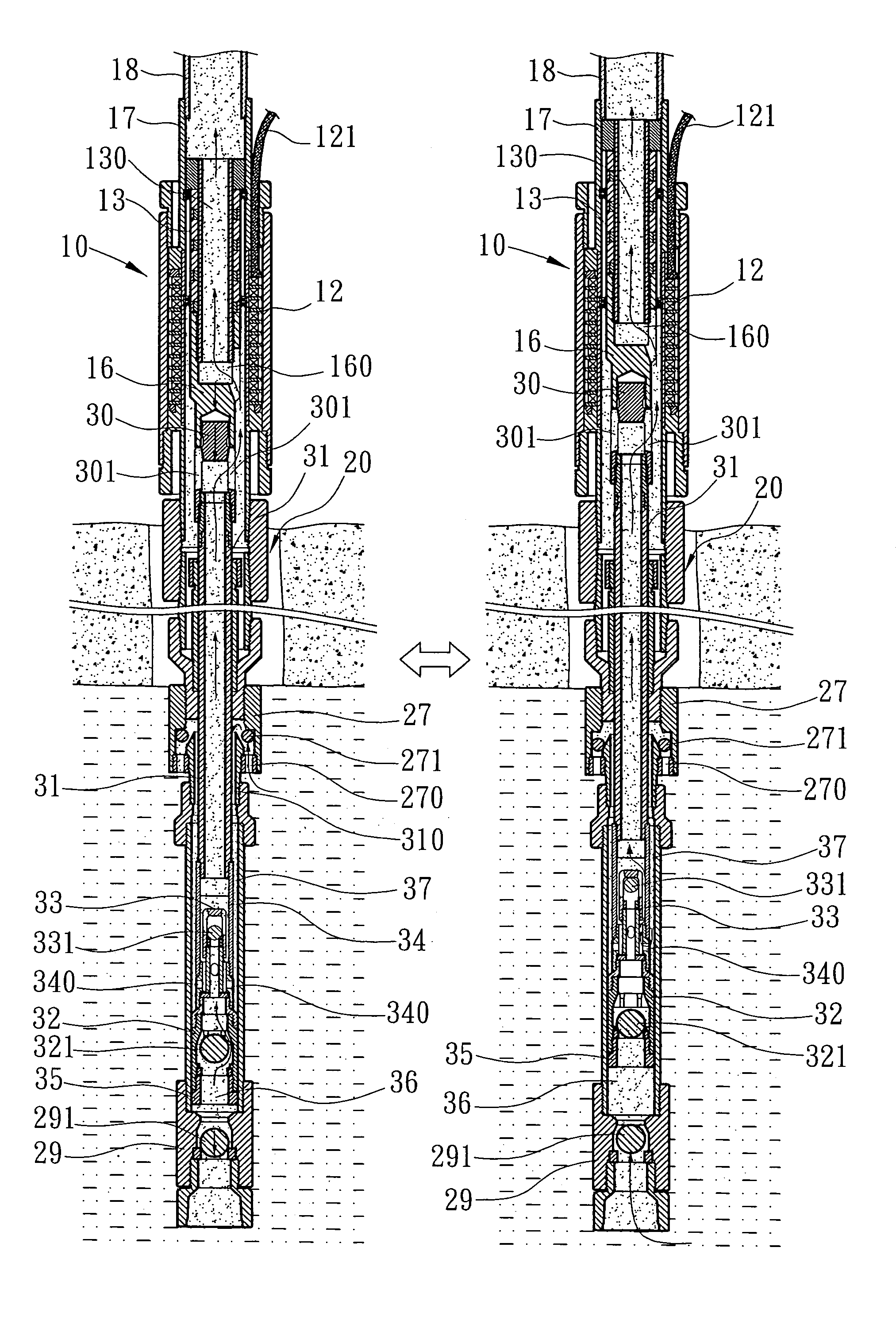

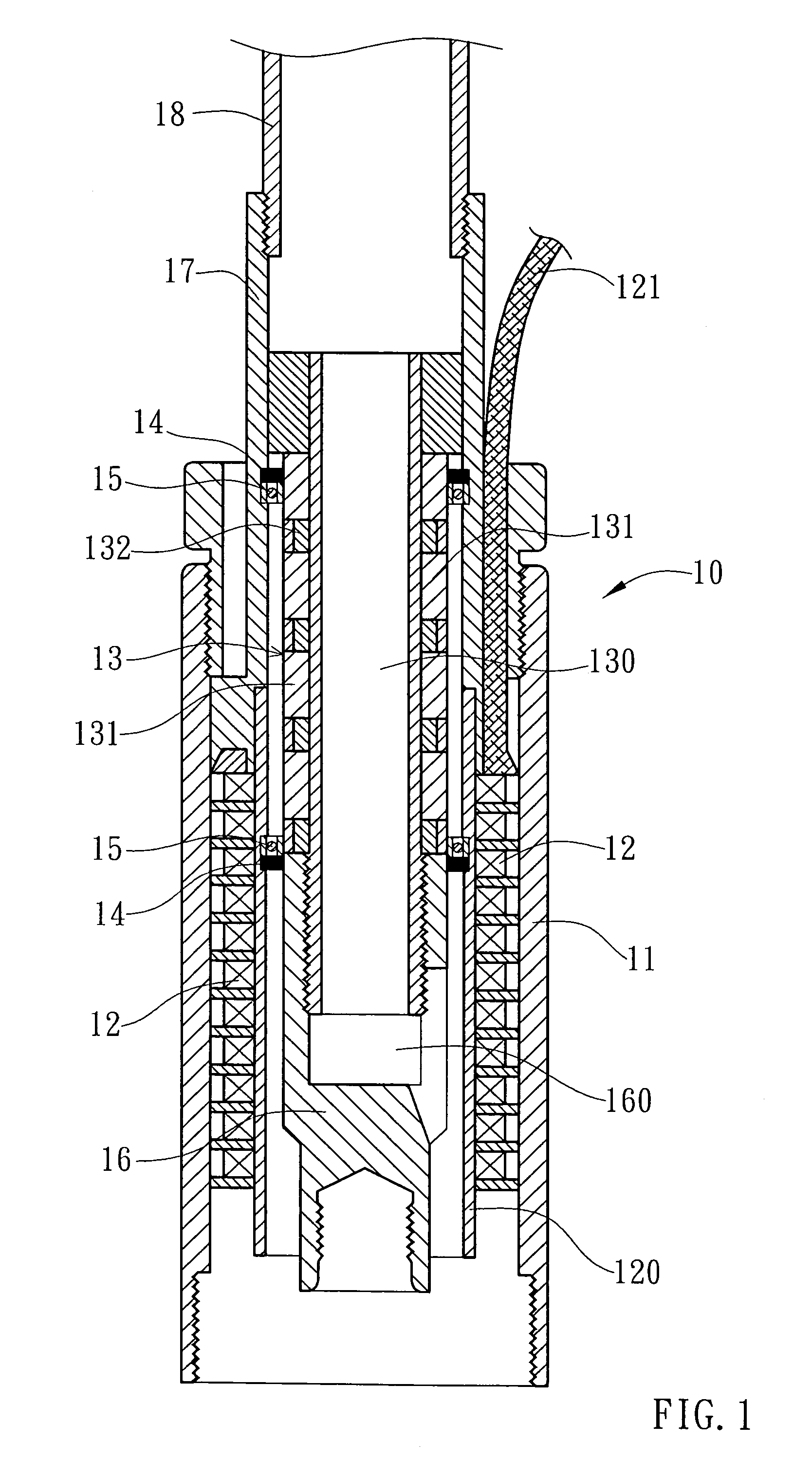

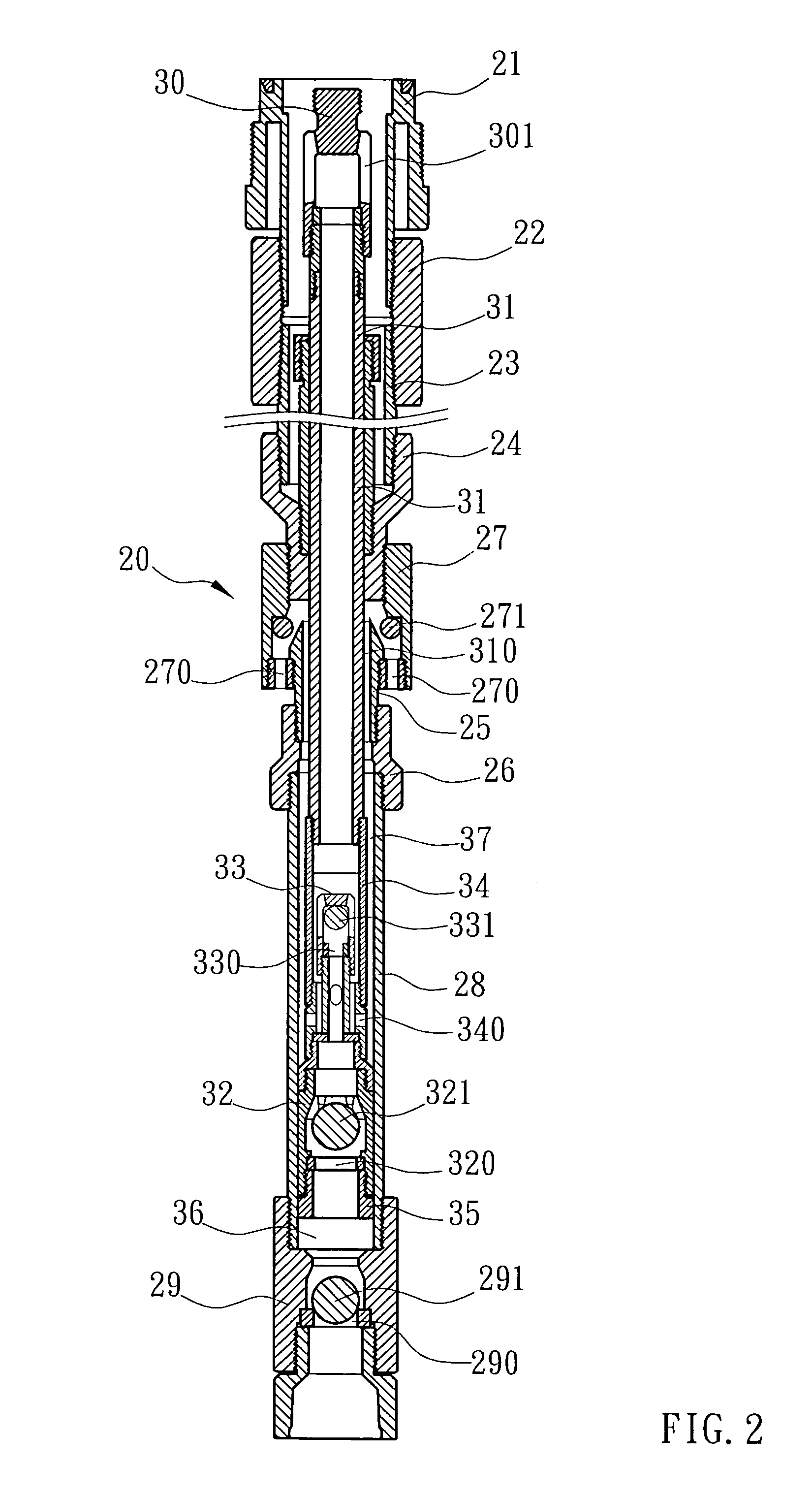

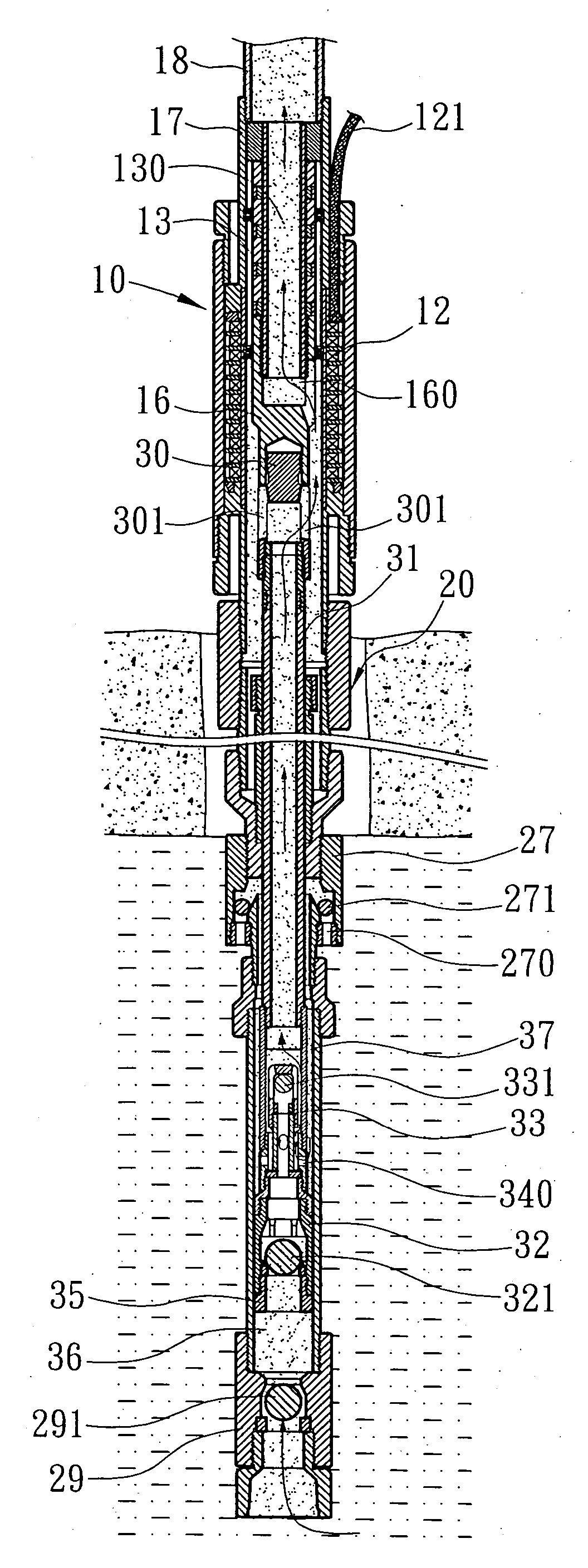

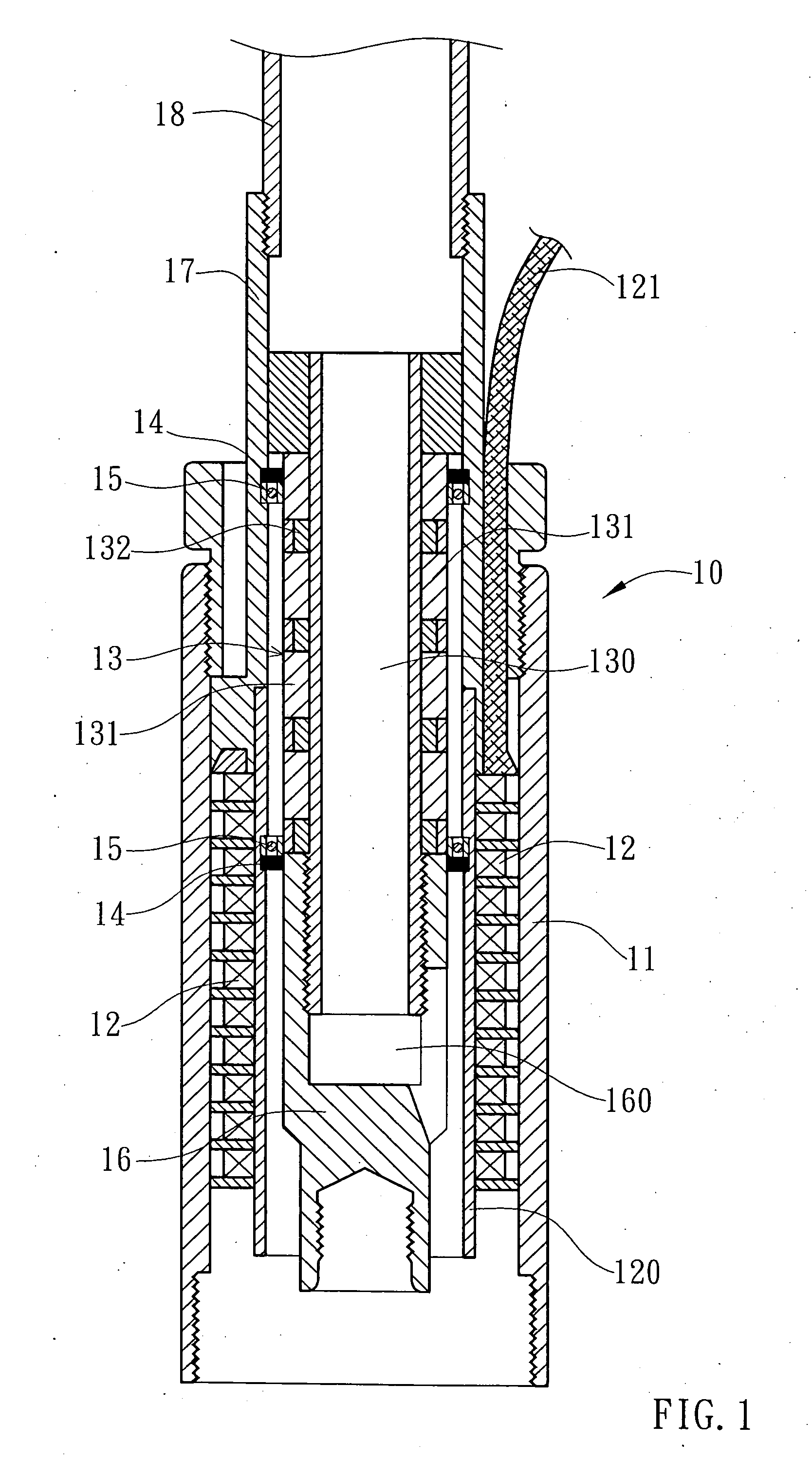

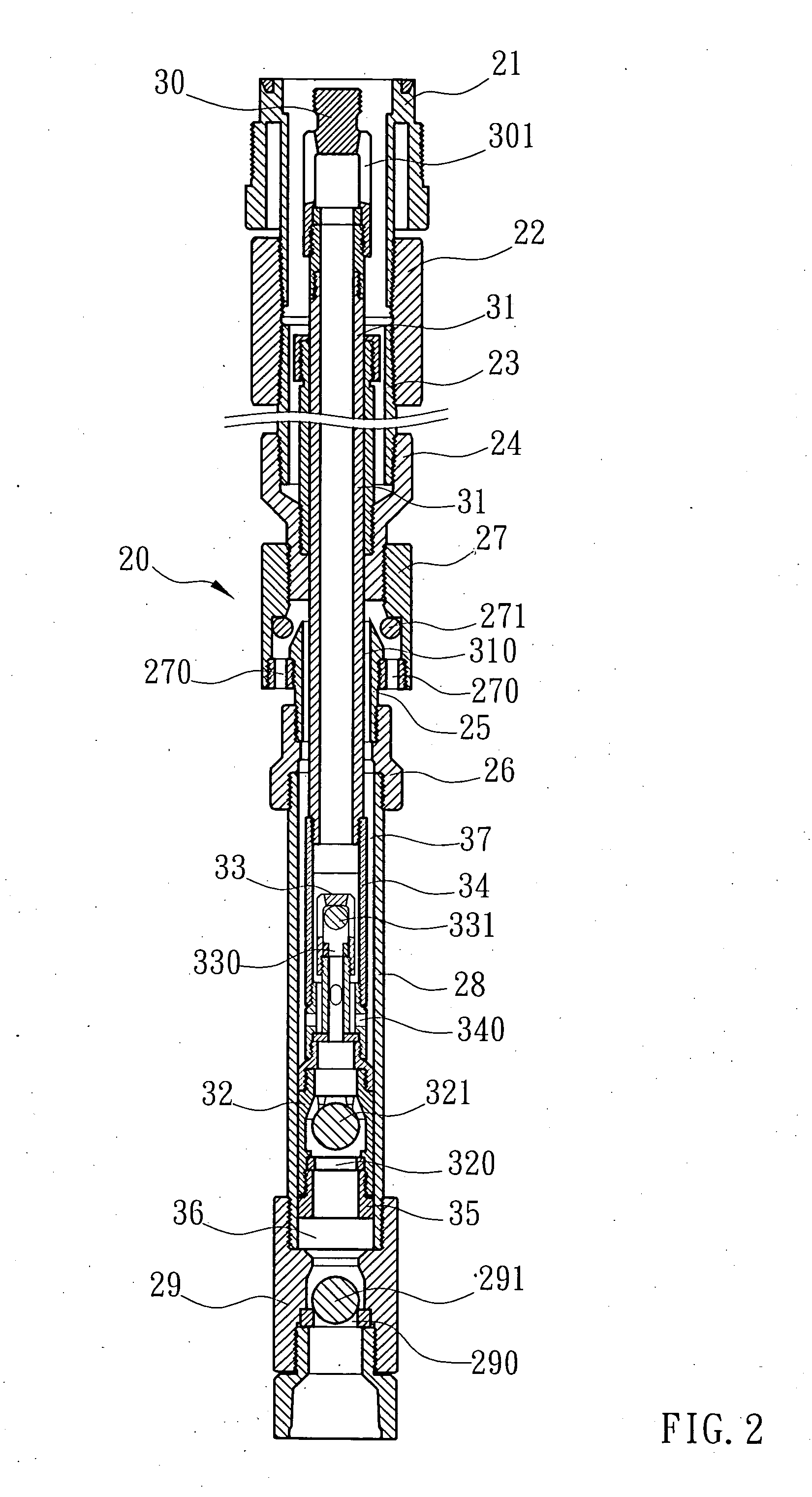

Oil pumping unit using an electrical submersible pump driven by a circular linear synchronous three-phase motor with rare earth permanent magnet

An oil pumping unit is disclosed to include a motor, which has a mover that moves alternately up and down when the motor is electrically connected, and a pump, which has a barrel, an oil suction pipe mounted in the barrel, an inner sleeve, which is connected to the suction pipe and has installed therein a mixing valve, a movable valve and a piston, a bottom one-way oil intake valve, and a one-way mixing flow intake valve respectively arranged in such a manner that when the mover is operated to reciprocate the oil suction pipe, crude oil is alternately pumped through the one-way bottom oil intake valve and the one-way mixing flow intake valve to alternately pass through the movable valve and the mixing valve to the ground.

Owner:WONG YEN HONG

Hydro-pneumatic spring for amphibious vehicles and hydraulic regulating device for hydro-pneumatic spring for amphibious vehicle

InactiveCN102720795ARealize the effect of foldingReduce stiffnessSpringsGas and liquid based dampersHydraulic cylinderGas spring

The invention discloses a hydro-pneumatic spring for amphibious vehicles and a hydraulic regulating device for the hydro-pneumatic spring for amphibious vehicles, and particularly relates to a hydro-pneumatic spring allowing for wheel release on land, wheel retracting in water, vehicle height control, and automatic change of pressure and supporting force for the vehicles. The hydro-pneumatic spring uses an inert gas as an elastic medium and oil as a force transfer medium and comprises a gas spring and a hydraulic cylinder servicing as a shock absorber. A hydro-pneumatic separate spring consists of a gas chamber, an oil chamber and a floating piston. Oil is sucked in from a piston rod and enters the oil chamber B through a damping valve to push a piston so that the gas is compressed or expanded, and elastic action is achieved. The shock absorber consists of a cylinder barrel, a piston and the damping valve. Under the action of the damping valve, energy can be attenuated effectively, the shock absorber is rebalanced, and shock absorption is achieved. In addition, oil intake of an oil inlet can be regulated to quickly and accurately change position of the piston, so that extension length of the piston rod is changed to change wheel state, and retracting and release of wheels and range adjustment of vehicle height are achieved.

Owner:JIANGSU UNIV OF SCI & TECH

Hydraulic retarder

InactiveCN103047322APrevent movementIncrease the oil inlet speedLiquid resistance brakesPiston GuideEngineering

The invention discloses a hydraulic retarder. The hydraulic retarder comprises a hydraulic retarder shell, an oil storage tank, a stator, a rotor and a heat exchanger, wherein the oil storage tank, the stator and the rotor are all arranged in the hydraulic retarder shell, and the heat exchanger is fixedly arranged outside the hydraulic retarder shell; oil inlet holes a and oil outlet holes are arranged on the stator and along the periphery of the stator; and a second oil inlet channel is internally provided with a check valve, the check valve comprises a piston, a spring, a piston guide hole and an oil discharge groove, one end of the piston is pressed at the end part of the heat exchanger shell to block an oil inlet, the other end of the piston extends into the piston guide hole to be matched with the piston guide hole in a sliding mode, the spring is sheathed on the piston, one end of the spring is pressed on the piston, the other end of the spring is pressed on the hydraulic retarder shell, and the piston guide hole is communicated with an oil outlet by the oil discharge groove. When oil in the piston guide hole is compressed by the piston, the oil is discharged by the oil discharge groove, so that the counter-acting force is not generated to the piston to block the movement of the piston, the oil feeding speed of the retarder is enhanced, and the response time of the retarder is improved.

Owner:韦健全

Rotary valve and rotary control loop using same

ActiveCN102022393AEasy to controlStart and stop running smoothlyServomotor componentsServomotorsRotary valveControl valves

The invention discloses a rotary valve and a rotary control loop using the same. The rotary valve comprises a master valve and a control valve, wherein the master valve comprises a master valve rod; the control valve comprises a control valve rod; the control valve is connected with a valve body on the master valve; and the master valve rod and the control valve rod push against each other through a connecting piece. The rotary control loop utilizes an oil pump for oil supply; an overflow valve is arranged between the oil pump and the rotary valve; a buffer valve is connected in parallel on an oil line between the master valve of the rotary valve and a motor; a control oil inlet of the control valve of the rotary valve is connected with an external oil source and depends on the external oil source for oil supply; and a control oil outlet is communicated with a brake cylinder to provide oil for the brake cylinder. The invention has the advantages that the oil control of the control cylinder is controlled by the control valve which is connected with the master valve into a whole, namely the movement of the master valve rod can drive the movement of the control valve rod synchronously so that the start of the brake cylinder is controlled well; and the rotary valve and the rotary control loop using the same are not disturbed by the load pressure oscillation, the stable start and stop operation can be realized under big and small flow rate and light and heavy load, and the impact under a dynamic working condition is weakened greatly.

Owner:CHANGDE ZHONGLIAN ZHONGKE HYDRAULIC

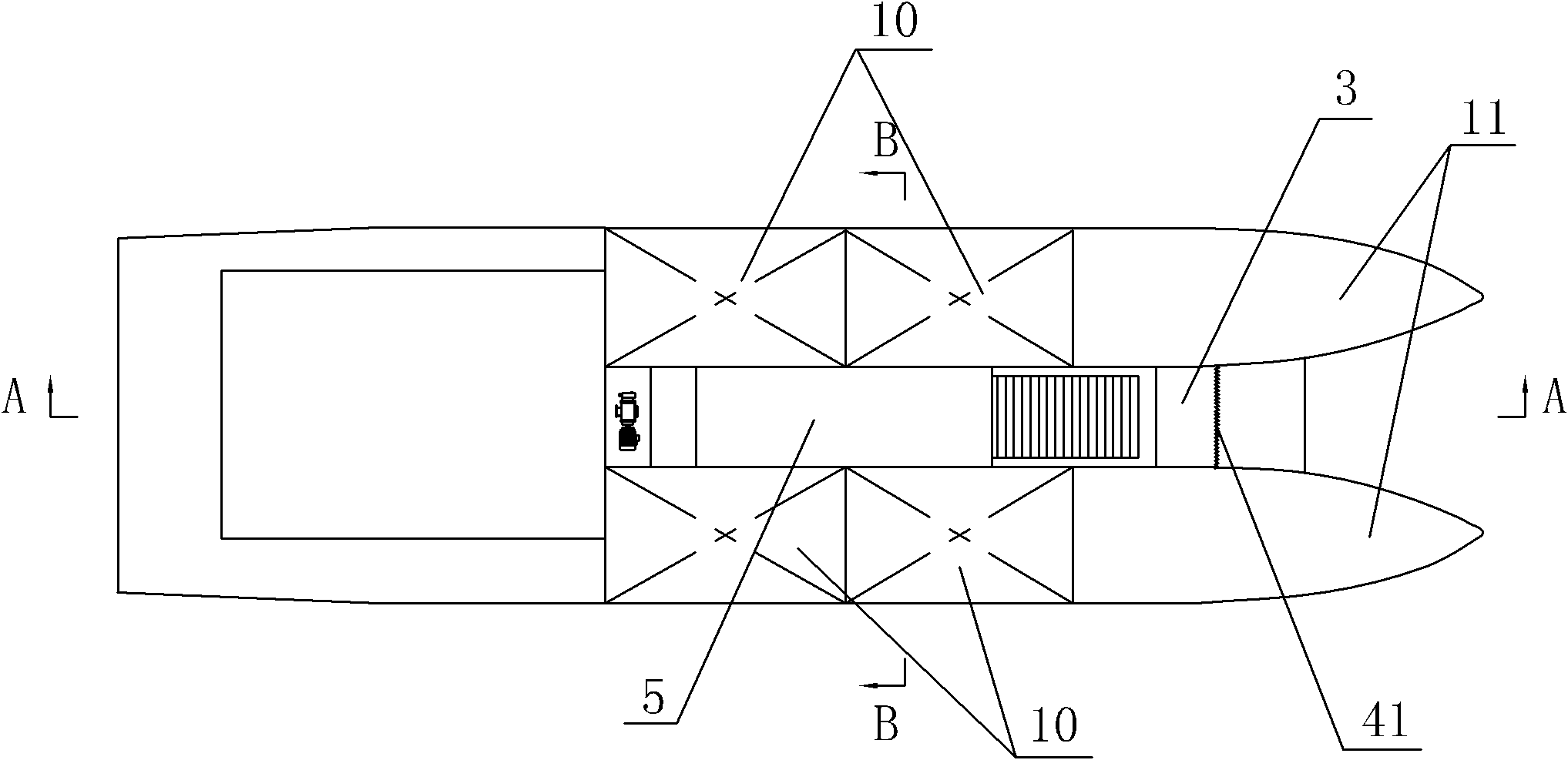

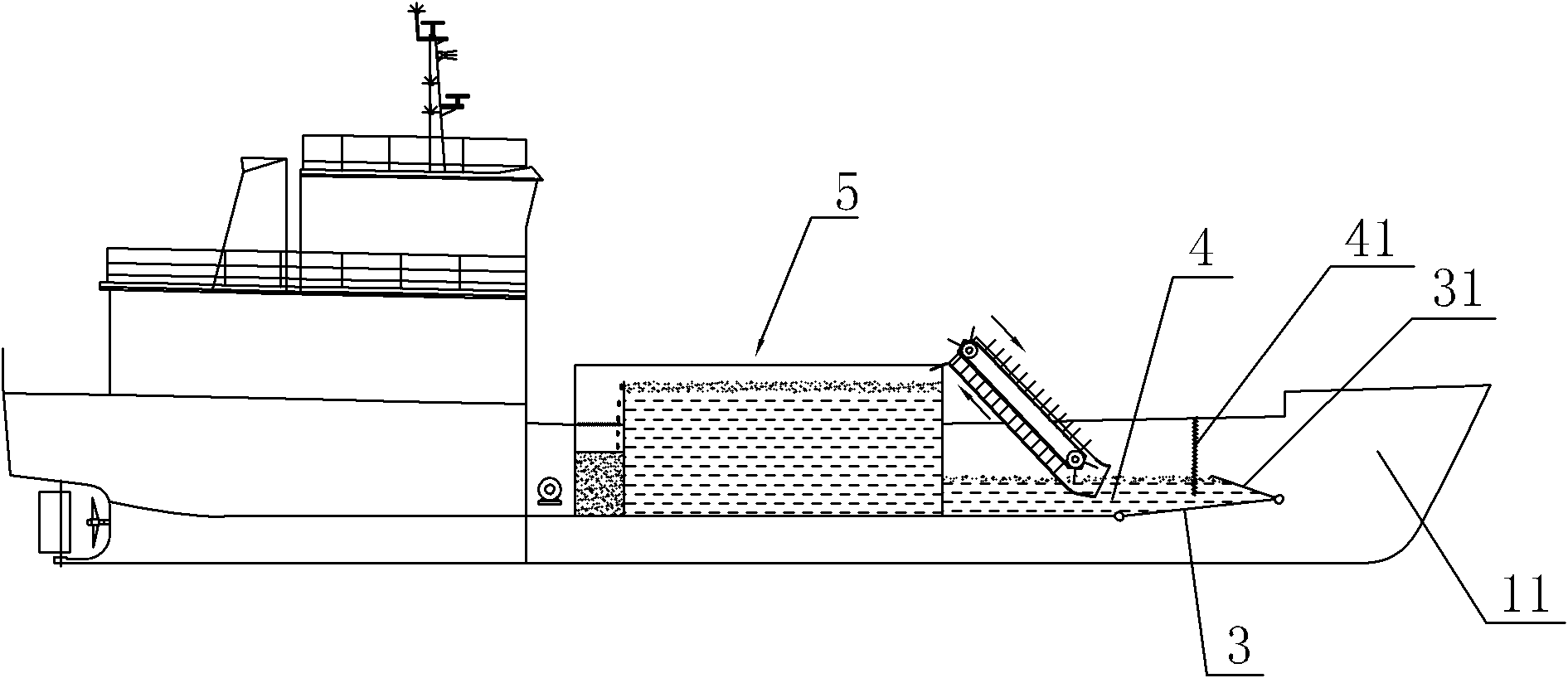

Water surface floating oil recovery ship

InactiveCN101962067AReduce oil inlet resistanceSmooth entryWaterborne vesselsSpecial purpose vesselsHull structureMarine engineering

The invention discloses a water surface floating oil recovery ship. The water surface floating oil recovery ship comprises a hull, a floating oil collecting device and an oil and water separating device, and is characterized in that: the stem of the hull has a catamaran structure and is in a pointed cone form; the middle part to the tail part of the hull has a single hull structure; and a flow guiding channel which is recessed inward and is through in the longitudinal direction is formed in the middle of the bottom of the part which has the single hull structure. The water surface floating oil recovery ship has the advantages that: because the stem of the hull has the catamaran structure, and the flow guiding channel which is recessed inward and is through in the longitudinal direction isformed in the middle of the bottom of the part which has the single hull structure, the oil intake resistance generated in the driving process of the ship can be greatly reduced, floating oil can smoothly enter an oil and water pool, and the oil sweeping area of the ship is increased; and due to a chain type floating oil lifting device, a floating oil heating device in an oil and water separatingcabin, and two garbage filtering grids which are additionally arranged, the overall floating oil recovery ship can be applied to the floating oil with any viscosity and any thickness and has low requirements on a water surface environment, and the applicable water area is wide.

Owner:宁波市科技园区海星船舶设计所

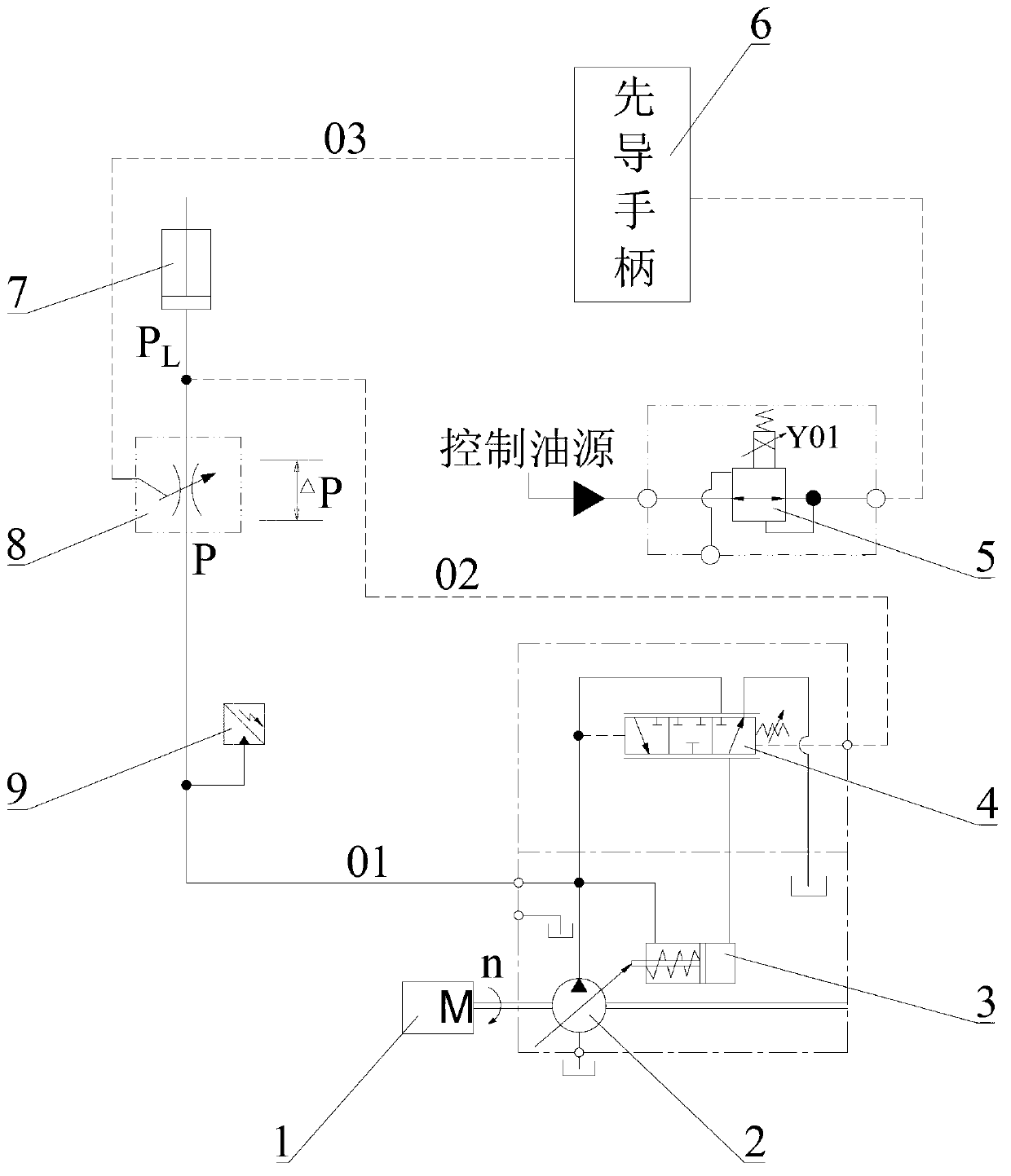

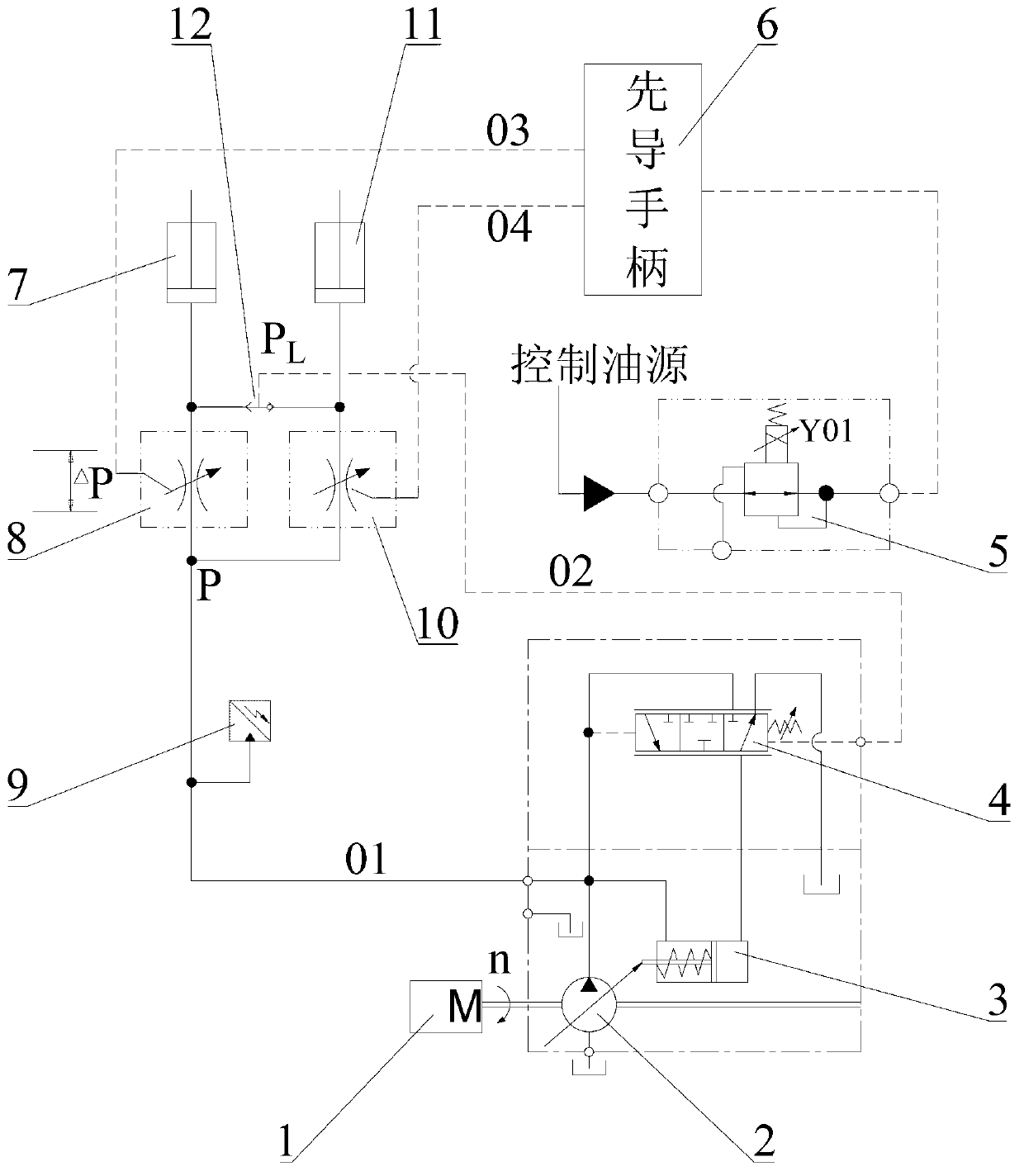

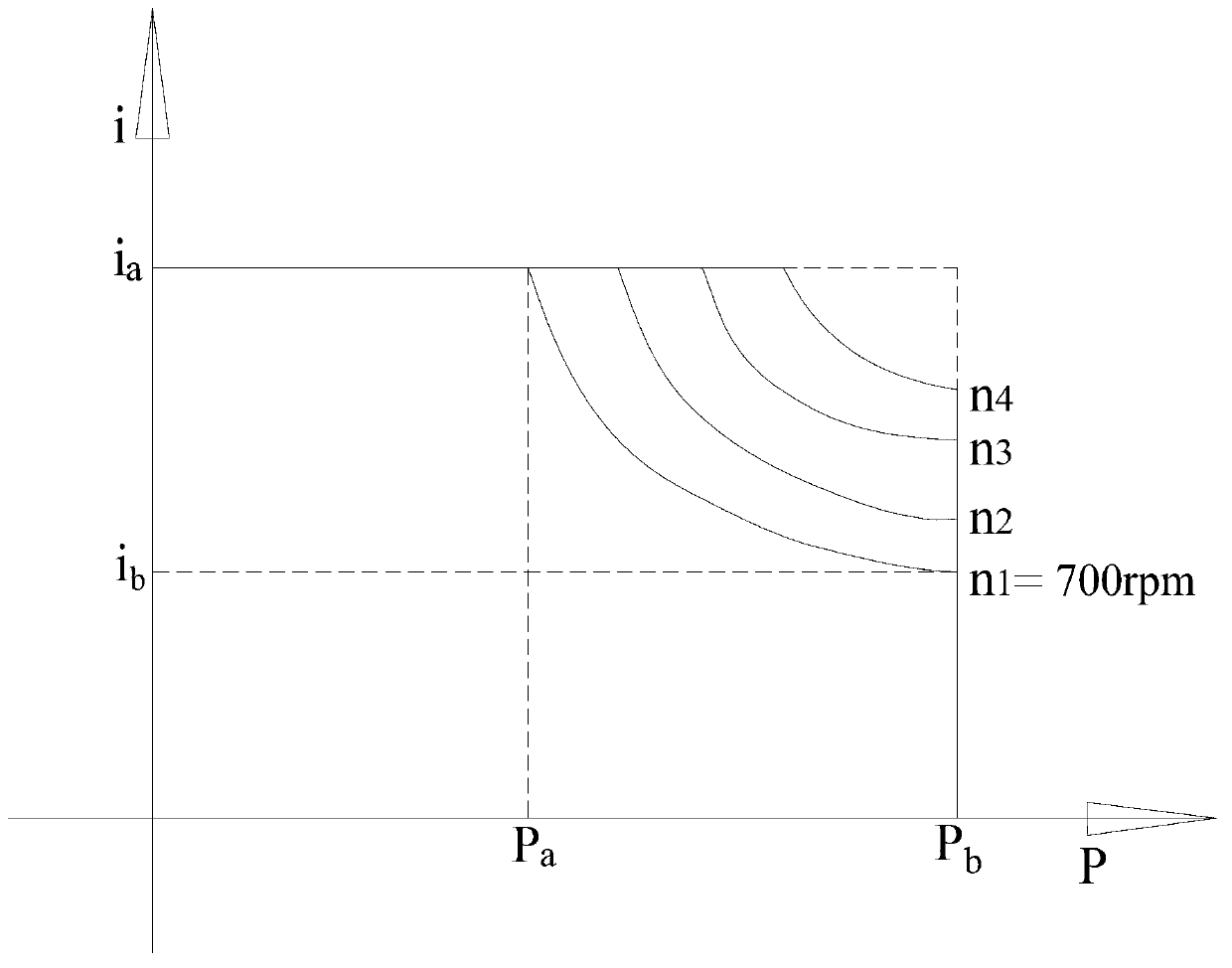

Load sensitive hydraulic system and power controller thereof as well as crane

InactiveCN102996536AIncrease powerReduce power consumptionServomotor componentsServomotorsPower controllerIdle speed

The invention discloses a load sensitive hydraulic system and a power controller thereof as well as a crane. The load sensitive hydraulic system comprises a proportional decompression valve, wherein the proportional decompression valve is arranged on an oil path between a control oil source and an oil inlet of a pilot-operated handle or is arranged on an oil path between a first oil outlet of the pilot-operated handle and a control end of a first main valve; and outlet pressure of the proportional decompression valve is preset so that when the pilot-operated handle is at the biggest opening degree, the output power of a load sensitive pump is matched with the output power of an engine. Compared with the prior art, the load sensitive hydraulic system has the advantages that the adaptability of the output power of the load sensitive pump and the output power of the engine can be improved, so that a lower engine idle speed can be selected and the power consumption is reduced; the great power can be output by an oil pump when the engine is operated at a high speed, and the energy efficiency is improved; and furthermore, the engine is effectively prevented from being stalled.

Owner:SANY HEAVY IND CO LTD (CN)

Oil pumping unit using an electrical submersible pump driven by a circular linear synchronous three-phase motor with rare earth permananet magnet

An oil pumping unit is disclosed to include a motor, which has a mover that moves alternatively up and down when the motor is electrically connected, and a pump, which has a barrel, an oil suction pipe mounted in the barrel, an inner sleeve, which is connected to the suction pipe and has installed therein a mixing valve, a movable valve and a piston, a bottom one-way oil intake valve, and an one-way mixing flow intake valve respectively arranged in such a manner that when the mover is operated to reciprocate the oil suction pipe, cruel oil is alternatively pumped through the one-way bottom oil intake valve and the one-way mixing flow intake valve to alternatively pass through the movable valve and the mixing valve to the ground.

Owner:WONG YEN HONG

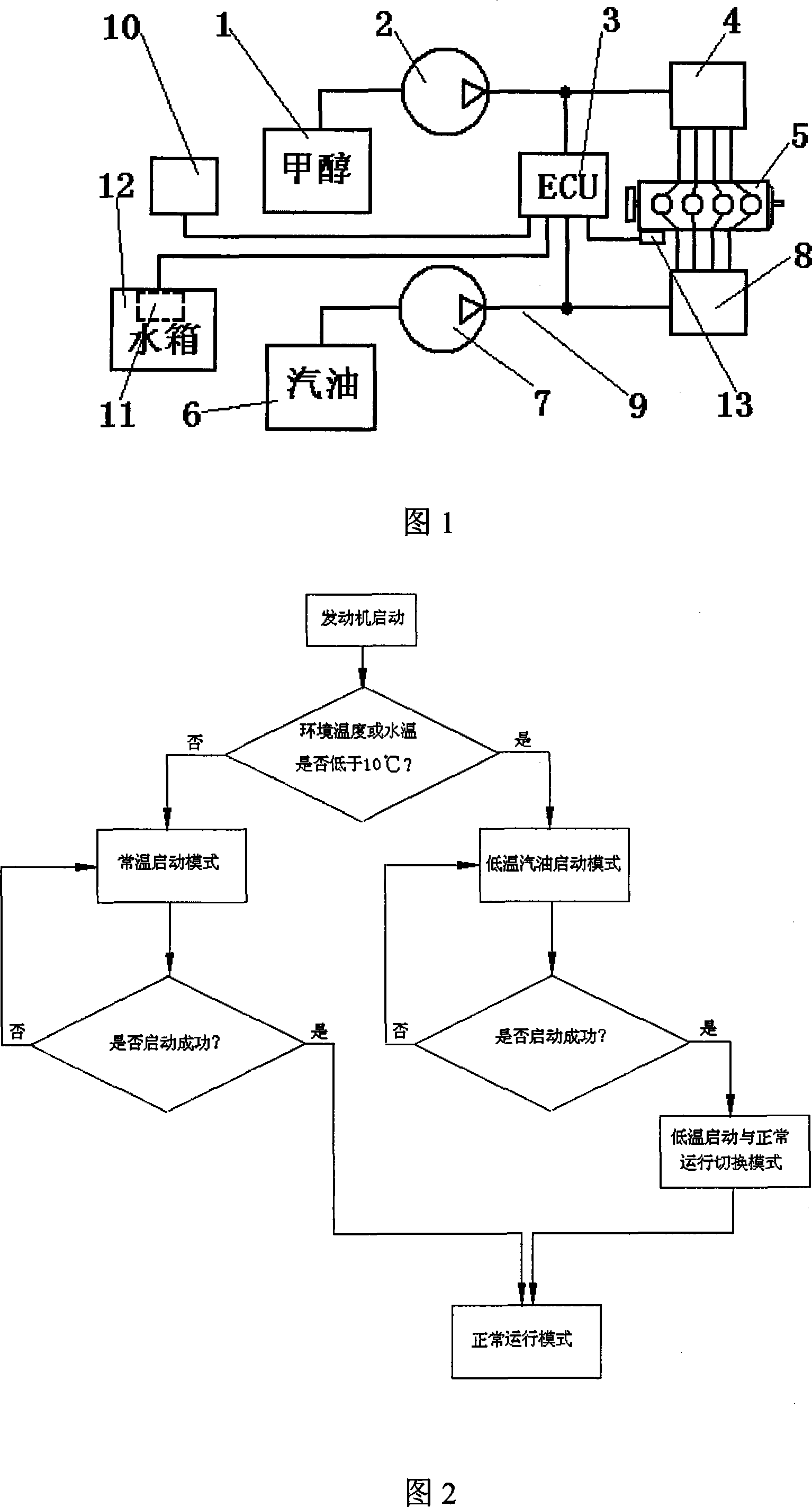

Methanol fuel engine low temperature start-up device and its control method

ActiveCN101086235ASolve the problem of difficult start at low temperatureReduce manufacturing costElectrical controlMachines/enginesMethanol fuelGasoline

The invention discloses a methanol fuel engine low tempreature start device, methanol fuel engine is also equipped with a petrol supply devices (9), including small petrol tank (6), gas pumps (7) and petrol injection (8), oil inlet of the gas pumps (7) connects with small gasoline tank (6), and its oil outlet connects with petrol injection(8), petrol injection (8) and the engine (5) cylinder connected. The invention also discloses a control method of cold start device, the control mode is divided into low-temperature petrol start model, low-temperature start with the normal operation of switching mode, room temperature start and normal operation mode. The invention ensure that the engine launch successful at a relatively low temperature, solution methanol engine difficult to start in cold, effect is remarkable, the control and processing are simple, operation is simple and easy to be realized, and the production cost is low.

Owner:CHERY AUTOMOBILE CO LTD

Lubricating and cooling jet nozzle for multi-station automatic cold header

ActiveCN102513481AReduce consumptionImprove permeabilityLiquid spraying apparatusHeating/cooling devicesJet flowCooling effect

The invention discloses a lubricating and cooling jet nozzle for a multi-station automatic cold header, comprising an oil fluid jet pipe and an airflow jet pipe coaxially sleeved out of the oil fluid jet pipe; wherein an oil inlet is arranged at the tail end of the oil fluid jet pipe; a shrinkable oil fluid nozzle is arranged at the front end of the oil fluid jet pipe; an air inlet is arranged at the tail part of the airflow jet pipe; an annular clearance between the inner peripheral wall of the airflow jet pipe and the outer peripheral wall of the oil fluid jet pipe forms an airflow channel; an annular air nozzle is arranged at the front end of the airflow jet pipe; the successive cylindrical oil jet jetted from the shrinkable oil fluid nozzle and the annular airflow jetted from the annular air nozzle form oil-air binary air-in-oil concentric jet flow, the oil and the air are not mixed, so that the low-pressure oil fluid under the holding of high-speed airflow is jetted to the surface of headed material and contact surface between the mold and the headed material during operation, the penetrability of the oil fluid molecule on the surface of the headed material and the contact surface between the mold and the headed material is higher, so that the lubricating and cooling effects are more sufficient, and the effects are maximized.

Owner:山东腾达紧固科技股份有限公司

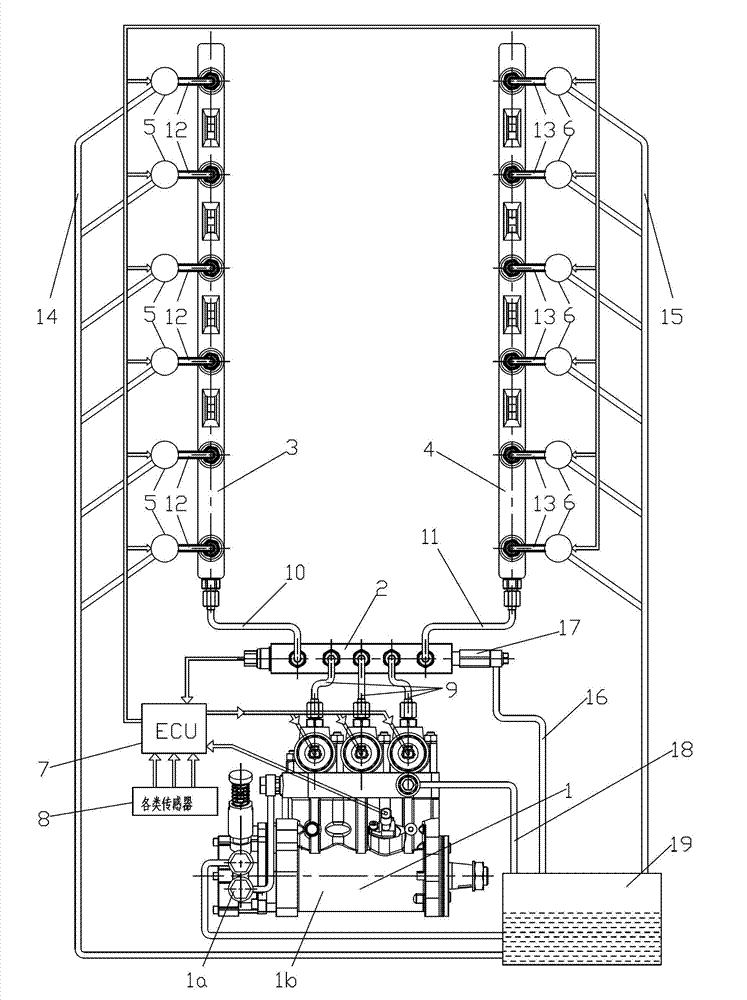

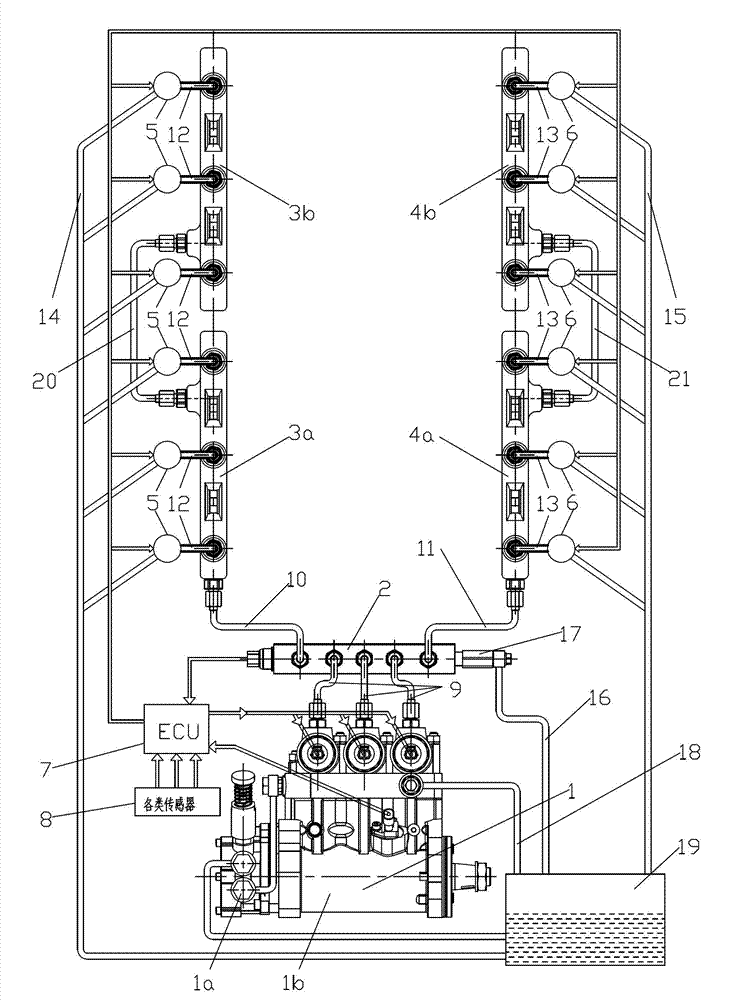

Electronic control high-pressure common-rail fuel injection system for V-shaped diesel engine

InactiveCN102734017AImprove reliabilityEmission reductionElectrical controlFuel injection apparatusCommon railFuel tank

The invention relates to an electronic control high-pressure common-rail fuel injection system for a V-shaped diesel engine. A fuel inlet of a common-rail pump is connected with a fuel tank; a fuel outlet of the common-rail pump is connected with a common-rail tube distributor through a high-pressure fuel tube; the common-rail tube distributor is respectively connected with a first common-rail tube and a second common-rail tube through a first high-pressure main fuel tube and a second high-pressure main fuel tube; the first common-rail tube is arranged on one side of a first line of cylinders of the V-shaped diesel engine; first fuel injectors on cylinders of the first line of cylinders are respectively connected with the first common-rail tube through first high-pressure branch fuel tubes; fuel return openings of the first fuel injectors are connected with the fuel tank through first fuel return tubes; the second common-rail tube is arranged on one side of a second line of cylinders of the V-shaped diesel engine; second oil injectors on cylinders of the second line of cylinders are respectively connected with the second common-rail tube through second high-pressure branch fuel tubes; and fuel return openings of the second fuel injectors are connected with the fuel tank through second fuel return tubes. By utilizing the V-shaped diesel engine, emission is reduced, economical efficiency is increased, operation control is automatic, and reliability is high.

Owner:WUXI KIPOR POWER CO LTD

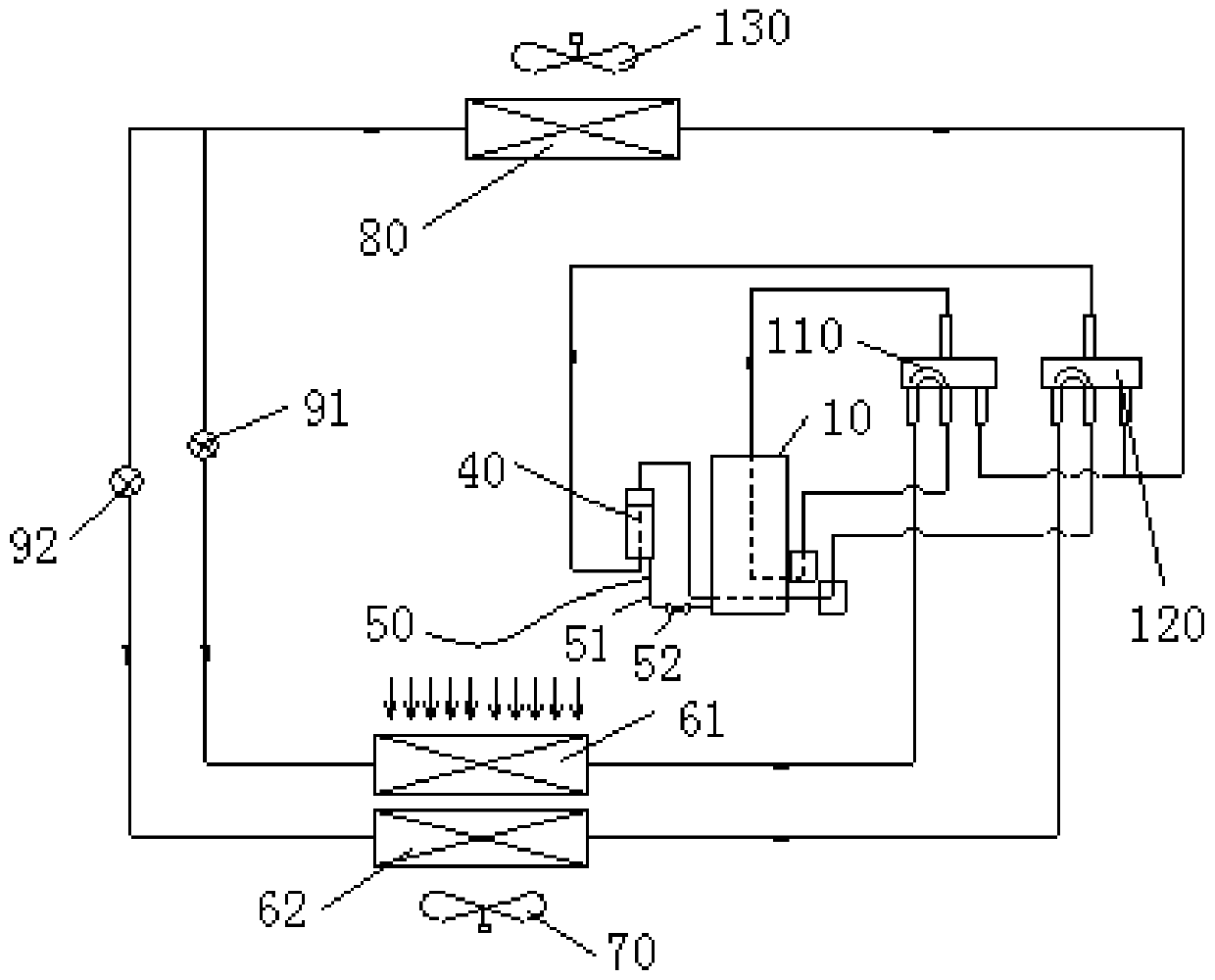

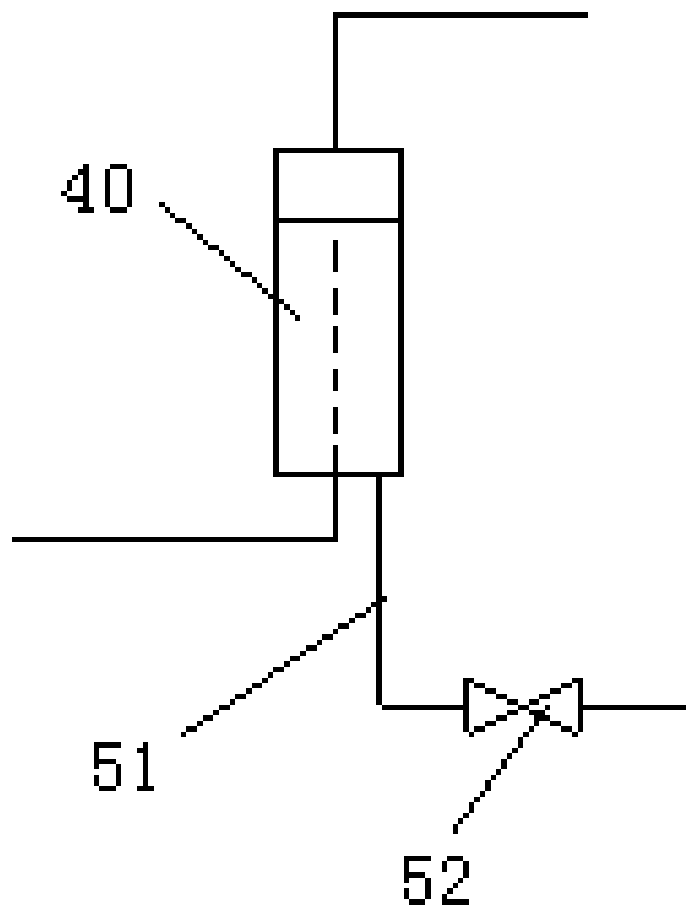

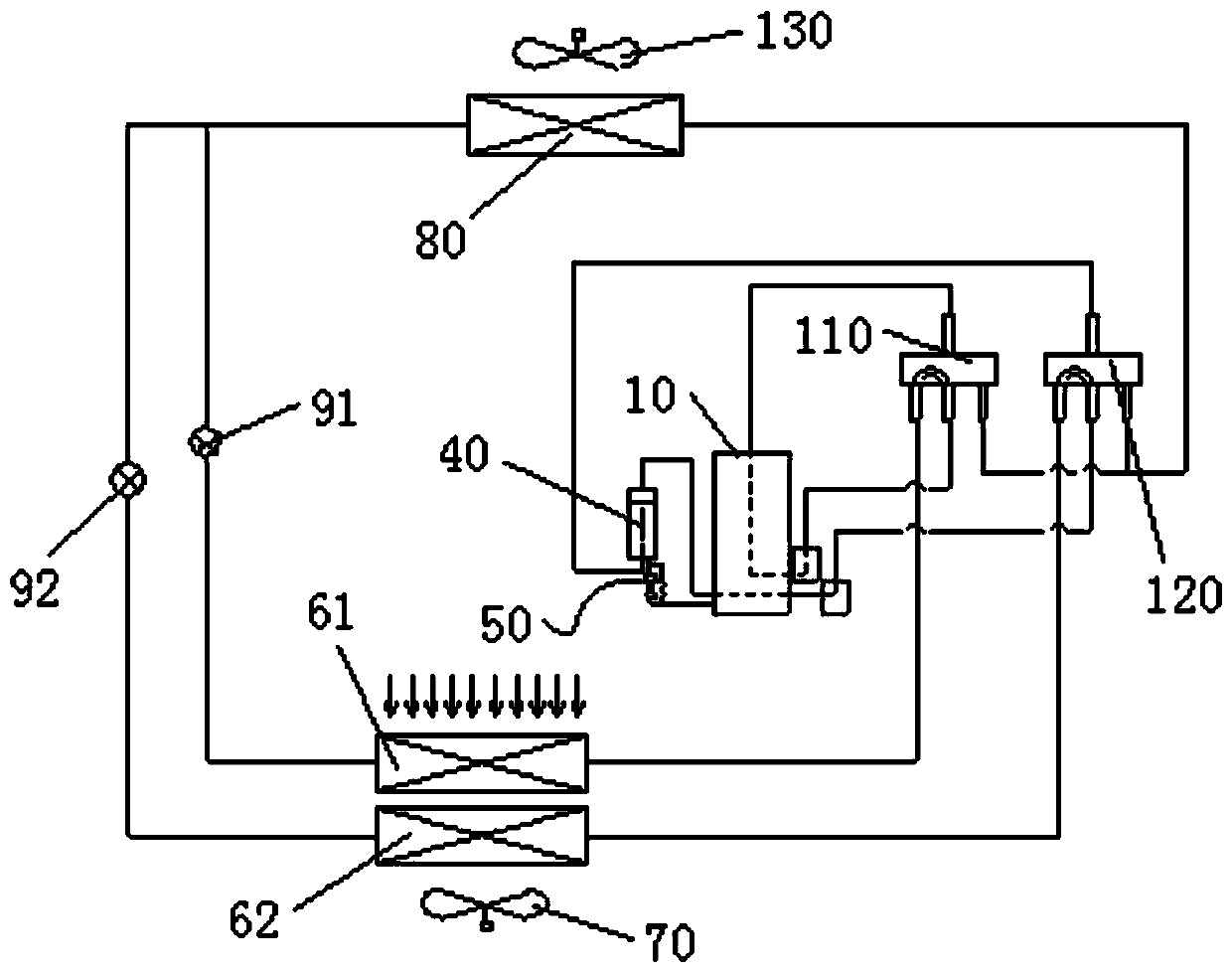

Compressor assembly and air conditioning system with same

InactiveCN110749126AAvoid oil starvation wearSolve the technical problems that are prone to oil shortage and wearCompressorMechanical apparatusEngineeringAir conditioning

The invention provides a compressor assembly and an air conditioning system with the same. The compressor assembly comprises a shell, a first compression cylinder, a second compression cylinder, a separation part and an oil return structure, wherein the shell is provided with an air outlet, the first compression cylinder is arranged in the shell, the first compression cylinder is provided with a first suction port and a first exhaust port, the first exhaust port communicates with the air outlet, the second compression cylinder is arranged in the shell, the second compression cylinder is arranged in parallel with the first compression cylinder, the second compression cylinder is provided with a second suction port and a second exhaust port, the separation part is arranged outside the shell,the separation part is provided with a separation cavity, the second exhaust port communicates with the separation cavity, the mixture discharged from the second exhaust port is separated through theseparation part, an oil inlet of the oil return structure communicates with an oil liquid outlet of the separation part, and the oil outlet of the oil return structure communicates with the oil return port of the shell so as to enable the oil liquid separated from the separation part to flow into the shell through the oil return opening under the action of the oil return structure. The technicalproblem that the double-suction double-row compressor in the prior art is prone to oil shortage and abrasion is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Bypass oil filter system and method of installing same

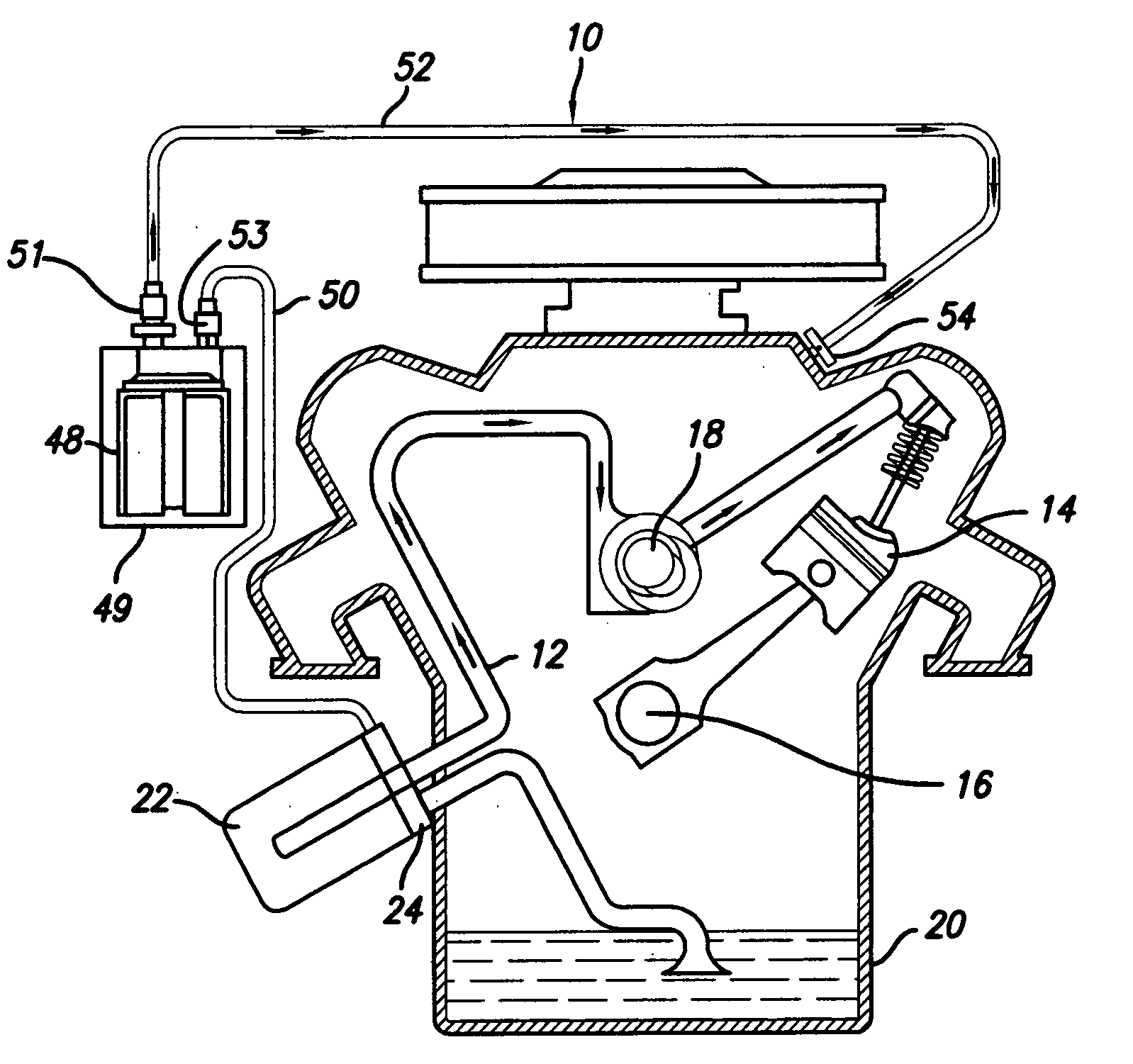

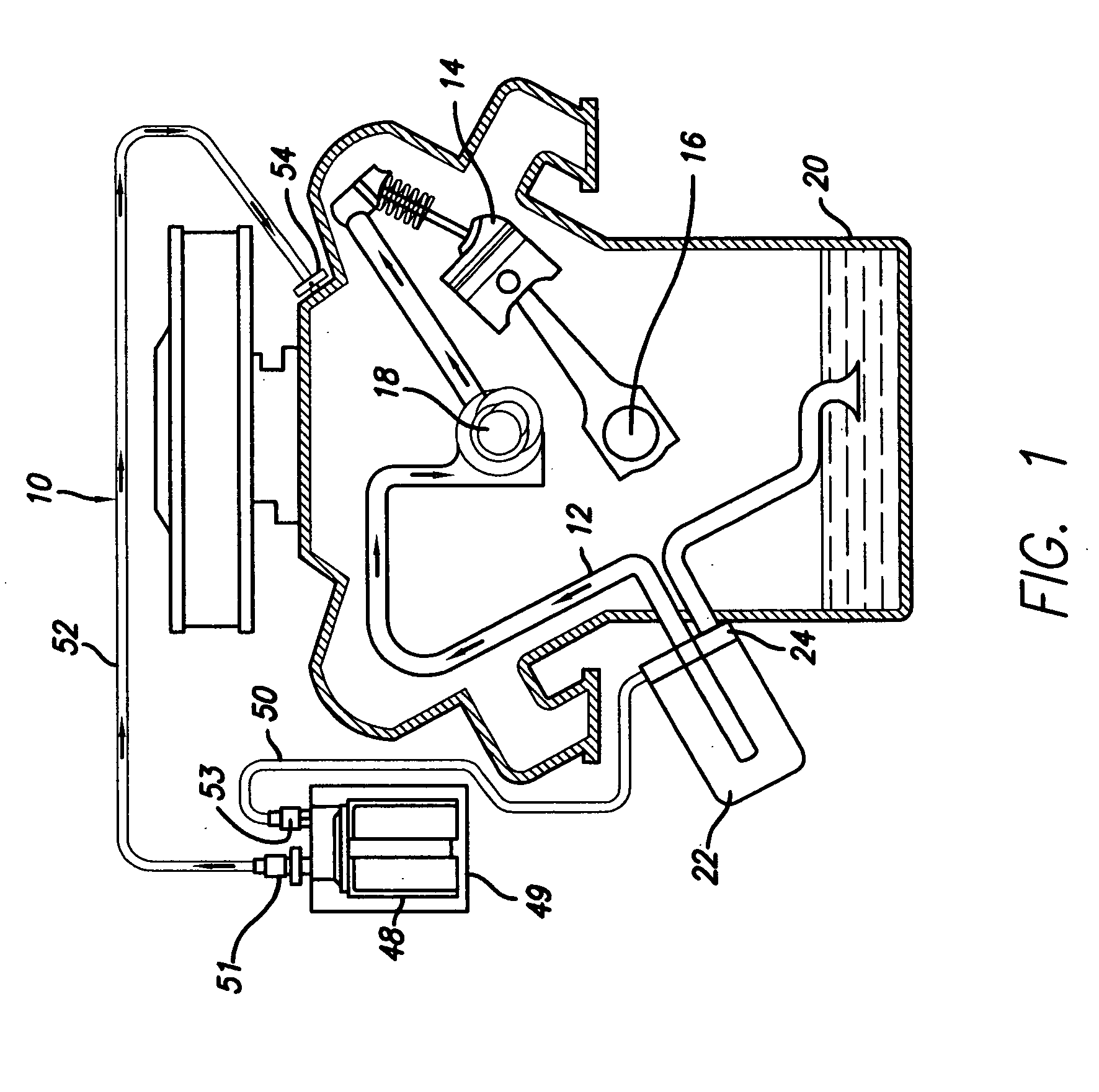

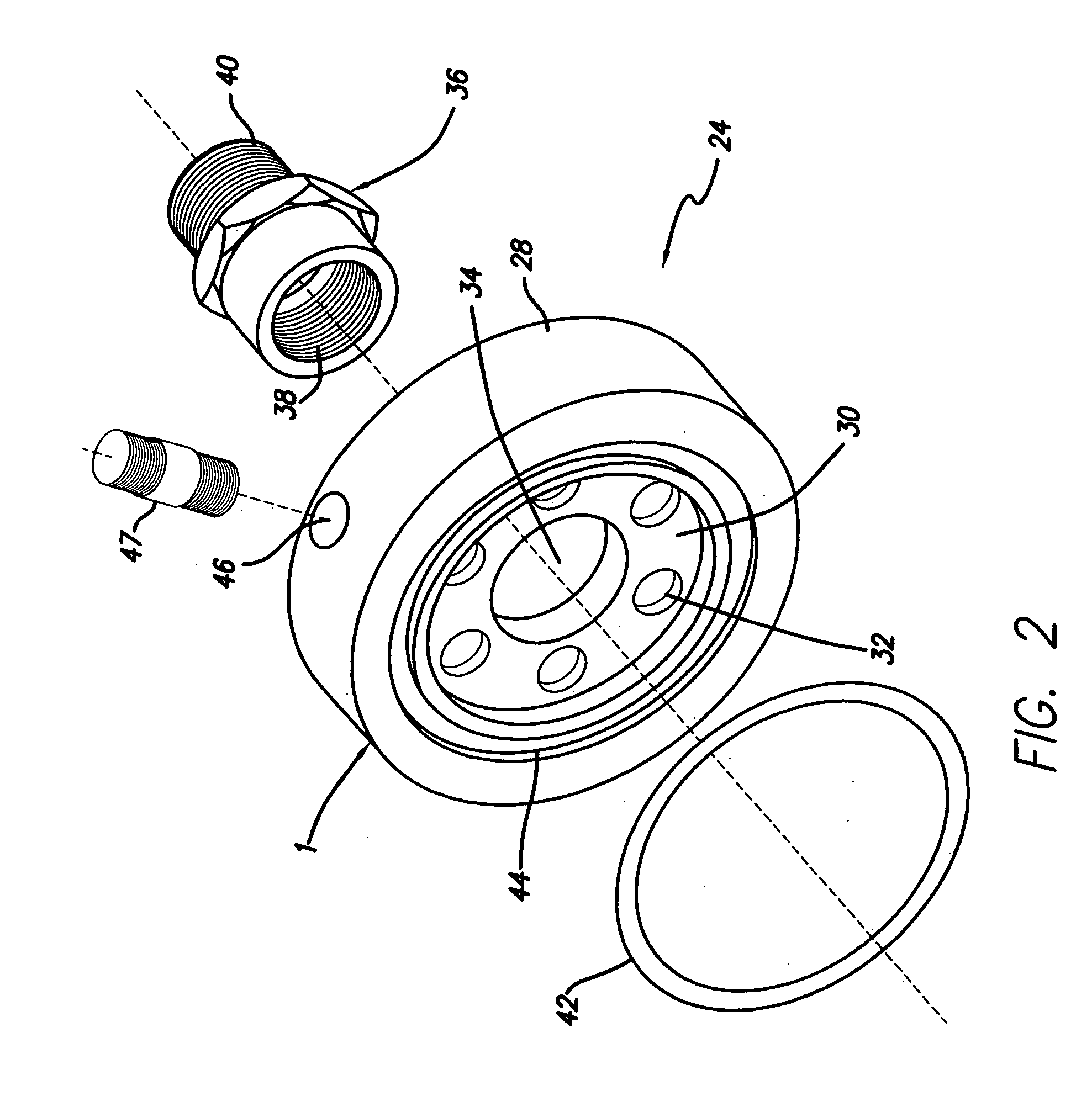

InactiveUS20080078716A1Easy and fast mannerProlong lifeSettling tanks feed/dischargeMachines/enginesOil intakeLubrication

A bypass oil filter system, and a method of installing same, for a vehicle having an engine compartment, an oil lubrication system having a full flow oil filter attached to a free flow oil filter mount and an oil intake line having an oil filler cap comprising, a bypass filter, means to mount the bypass filter in the engine compartment, a sandwich adaptor placed between the full flow oil filter and the full flow oil filter mount, hose means to direct a portion of the oil from the oil lubrication system to the bypass filter and hose means to pass the oil from the bypass filter through the oil filler cap to the oil intake line.

Owner:HEPO FILTERS

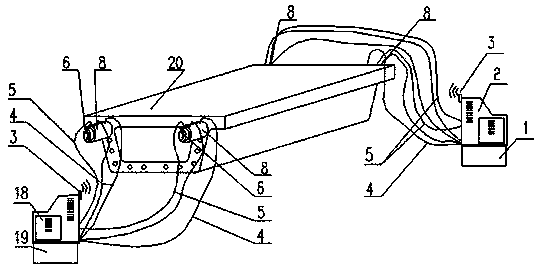

Hydraulic control loop of mechanical arm and action method

ActiveCN107061392APrevent overspeed instabilityOverspeed instability meetsFluid-pressure actuator safetyServomotor componentsLoop controlHydraulic pump

The invention discloses a hydraulic control loop of a mechanical arm and an action method, and belongs to the field of hydraulic loop control over the mechanical arms. The hydraulic control loop of the mechanical arm comprises a general hydraulic loop, a lifting hydraulic loop, a rotary hydraulic loop and a swinging hydraulic loop, wherein the general hydraulic loop comprises an oil tank, an oil filter, a motor, a load sensitive pump, a shuttle valve group, a safety valve, a pressure meter, a pressure meter switch and a cooler; the oil tank is connected with an oil inlet of the load sensitive pump through the oil filter; an oil outlet of the load sensitive pump is connected with the oil tank through the safety valve; hydraulic oil is pumped out of the oil tank through the load sensitive pump via the oil filter; and one path of the hydraulic oil is connected with the pressure meter and the pressure meter switch, and the other path of the hydraulic oil is connected with the lifting hydraulic loop, the rotary hydraulic loop and the swinging hydraulic loop respectively through a main oil pipe and finally is connected with the oil tank through the cooler and the oil filter. The hydraulic control loop of the mechanical arm is safe and low in system power loss and can meet the self-locking property of a hydraulic arm and prevent overspeed instability of an oil cylinder during retraction.

Owner:SHANDONG JIANZHU UNIV

Double-pump hydraulic control loop of key drilling action of cutting drill rig

ActiveCN102747948AAvoid stuck drillPrevent slippingServomotor componentsServomotorsFuel tankEngineering

A double-pump hydraulic control loop of a key drilling action of a cutting drill rig comprises a double linkage load-sensitive variable pump set, a double oil intake linkage load-sensitive multi-way valve, a rotary motor, a propulsion motor, a drilling logic control block, a rotation guide handle, a propulsion guide handle, and a hydraulic oil tank. An oil inlet of the double linkage load-sensitive variable pump set is connected with the hydraulic oil tank. An oil outlet and a load-sensitive opening are connected with an oil inlet and a load-sensitive opening of the double oil intake linkage load-sensitive multi-way valve respectively. Each valve pressure difference compensator of the load-sensitive multi-way valve is provided with an external control opening. The external control openings are connected with the drilling logic control block. The rotation guide handle and the propulsion guide handle are connected with the drilling logic control block or a guide control opening of the load-sensitive multi-way valve. The double-pump hydraulic control loop has the advantages that power head rotation-proportion-controlled propulsion is achieved, independent load-sensitive control of rotation and propulsion is achieved, propulsion speed is increased, and the like.

Owner:SUNWARD INTELLIGENT EQUIP CO LTD

Rock drill and hydraulic drilling control system thereof

PendingCN107906084AAvoid jammingQuick responseFluid-pressure actuator testingServomotor componentsFuel tankThrottle

The invention discloses a hydraulic drilling control system of a rock drill. The hydraulic drilling control system of the rock drill comprises a pumping device, an oil tank, a revolving motor, a pushing oil cylinder and an impact device; and a throttling valve is arranged between a working oil port of a revolving reversing valve and an oil port of the revolving motor. The hydraulic drilling control system of the rock drill further comprises a sequence valve, a hydraulic control reversing valve and a hydraulic control unbalanced cone valve; two working oil ports of the hydraulic control unbalanced cone valve respectively communicate with a rodless cavity of the pushing oil cylinder and the oil tank; the sequence valve can control the hydraulic control reversing valve to switch oil inlet directions of a rod cavity and the rodless cavity of the pushing oil cylinder according to the pressure change at an oil inlet thereof and meanwhile control an on-off state of the hydraulic control unbalanced cone valve to enable the rodless cavity of the pushing oil cylinder to directly communicate with the oil tank. The jamming of a drill bit can be stably and efficiently prevented; and the hydraulic control unbalanced cone valve with high circulating capacity is additionally arranged to reduce a back pressure value on the rodless cavity side in retreating of the pushing oil cylinder and to accelerate the system response speed. The invention further discloses the rock drill comprising the hydraulic drilling control system.

Owner:CHINA RAILWAY CONSTR HEAVY IND

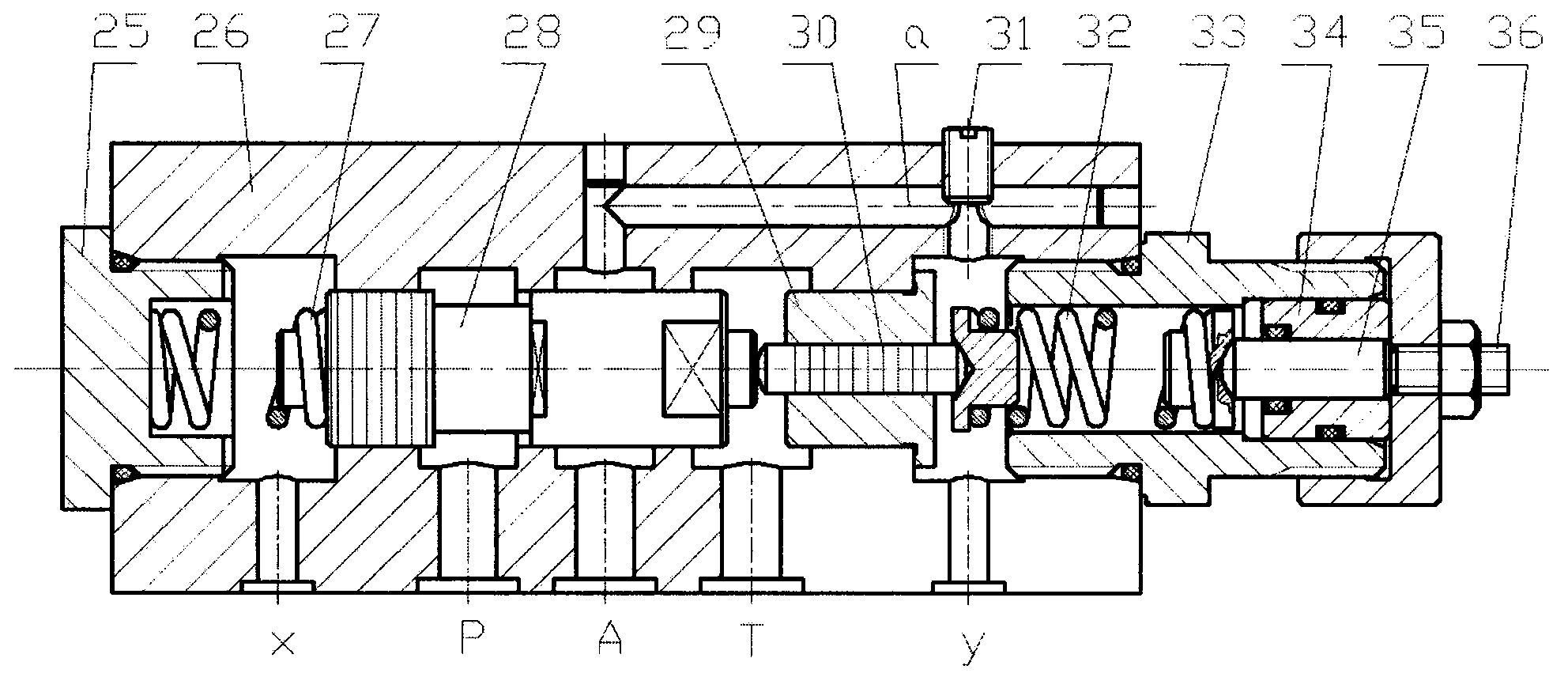

Hydraulically-controlled proportional valve

InactiveCN103727086AGuaranteed proportional relationshipSimple structureServomotor componentsEngineeringMechanical engineering

The invention discloses a hydraulically-controlled proportional valve for a hydraulic power-assisted system of an electric car, belonging to the technical field of a hydraulic element. The hydraulically-controlled proportional valve comprises a valve body, a centralizing spring, a valve core, a valve sleeve, a plunger, an adjusting spring, an adjusting screw and the like. Five undercutting grooves are formed in a valve hole and are respectively communicated with oil ports X, P, A, T and Y. The valve core is provided with two shoulders, two throttling edges are formed by the two end surfaces of the right shoulder and the undercutting grooves and are used for respectively controlling the damping from the oil inlet P to the oil outlet A and the damping from the oil outlet A to the oil return port T. When the oil port X has no pressure, the valve core is at zero position under the action of the spring, and the oil outlet A has no pressure. When the oil port X has input pressure, the valve core moves rightwards, the P-A throttling edge is opened, and the oil outlet A has pressure output. The spring is soft, therefore, the product of oil pressure of the oil port X multiplied the area of the left end of the valve core is controlled to be approximately equal to the product of the oil pressure of the oil outlet A multiplied by the end area of the plunger, namely, the ratio of output oil pressure to input oil pressure is approximately the ratio of the section area of the plunger to the section area of the valve core.

Owner:江苏阜华阀门有限公司

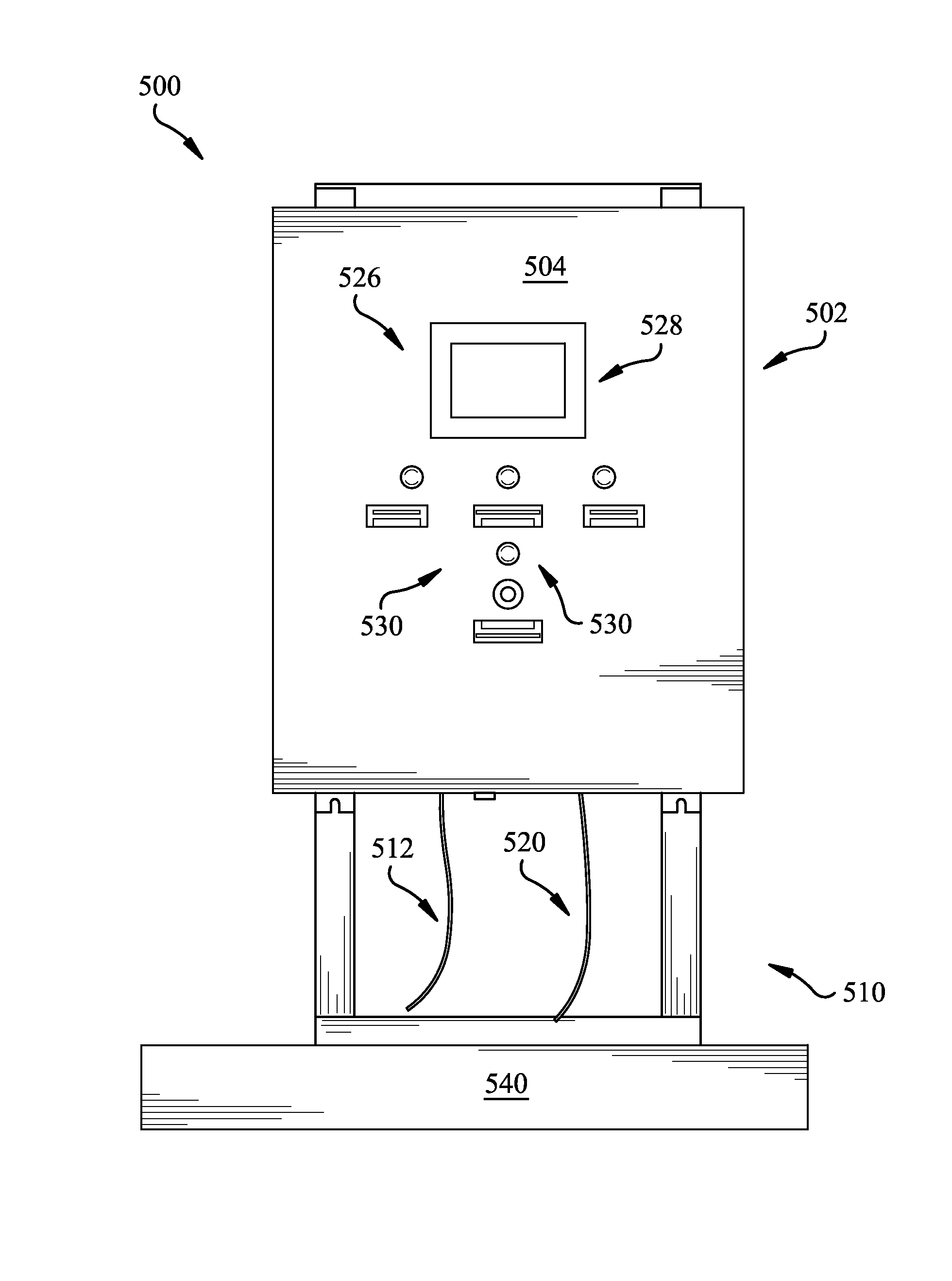

Turbomachine lubricating oil analyzer apparatus

Various embodiments of the invention include an apparatus for monitoring a lubrication oil in a turbomachine oil reservoir, the apparatus having: a housing section including: a casing; a base plate and a back support coupled with the casing; an oil intake conduit extending through the base plate, the oil intake conduit for fluidly connecting with the turbomachine oil reservoir; a pump fluidly connected with the oil intake conduit; an oil analyzer fluidly connected with the pump; and a drain conduit fluidly connected with the oil analyzer and extending through the base plate; and a mount coupled with the housing section, the mount for coupling with the turbomachine oil reservoir.

Owner:GENERAL ELECTRIC CO

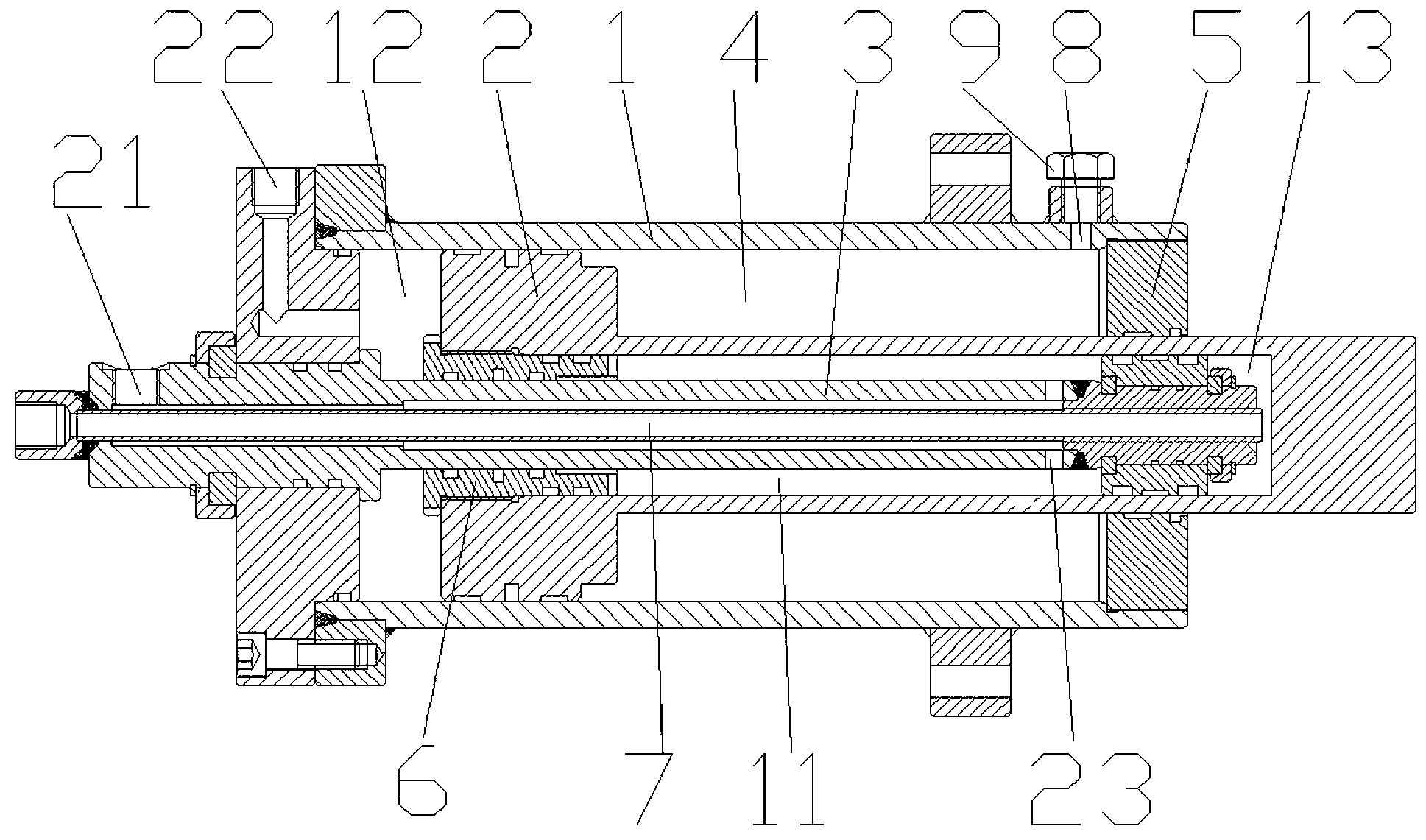

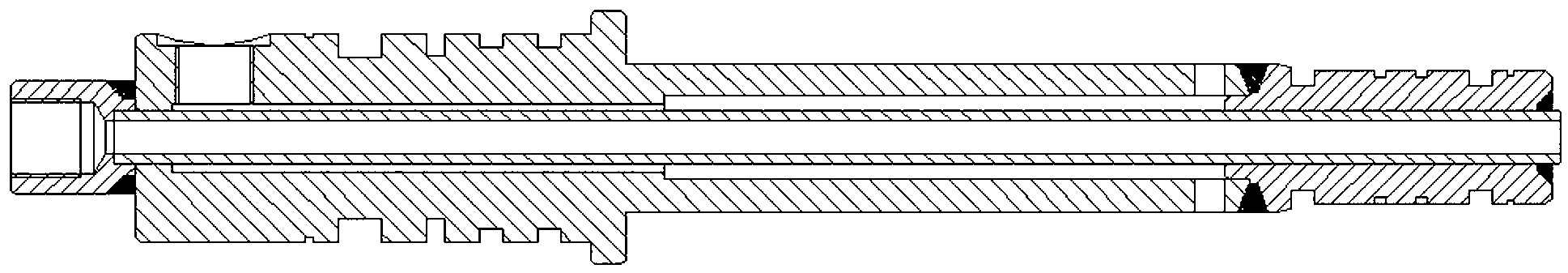

Quick double-acting hydraulic cylinder

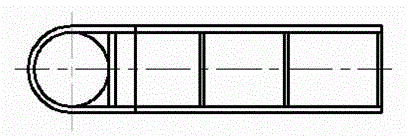

The invention discloses a quick double-acting hydraulic cylinder which comprises a cylinder barrel, a large piston rod and a small piston rod. The large piston rod is nested in the cylinder barrel, an oil-free cavity is formed between the large piston rod and the cylinder barrel, the tail end of the large piston rod is fixed on the cylinder barrel through a pressing ring, the small piston rod is nested in the large piston rod, a first oil cavity and a third oil cavity are formed between the small piston rod and the large piston rod, a guide sleeve is arranged among two ends of the small piston rod and the large piston rod, an oil conduit is arranged in the small piston rod, a second oil cavity is formed among the large piston rod, the small piston rod and the cylinder barrel, the small piston rod is provided with a first oil inlet and a second oil inlet, a third oil inlet is arranged at the front end of the cylinder barrel, the cylinder barrel is provided with an exhaust port communicated with the oil-free cavity, and a bleed screw is arranged in the exhaust port. Compared with a common oil cylinder, the quick double-acting hydraulic cylinder in the structure is more compact in integral structure, large in pushing force and high in feeding speed and return speed, and normal running rate of mechanical equipment is increased.

Owner:FUJIAN LONGYAN SHENGTONG HYDRAULIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com