Independent control electrohydraulic system of oil inlet and outlet with pump valve composite flux matched

A flow matching, oil inlet and outlet technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems of difficult to guarantee control performance, applicable to a single actuator, low energy efficiency, etc., to reduce energy Low consumption, low throttling loss, and the effect of flow matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

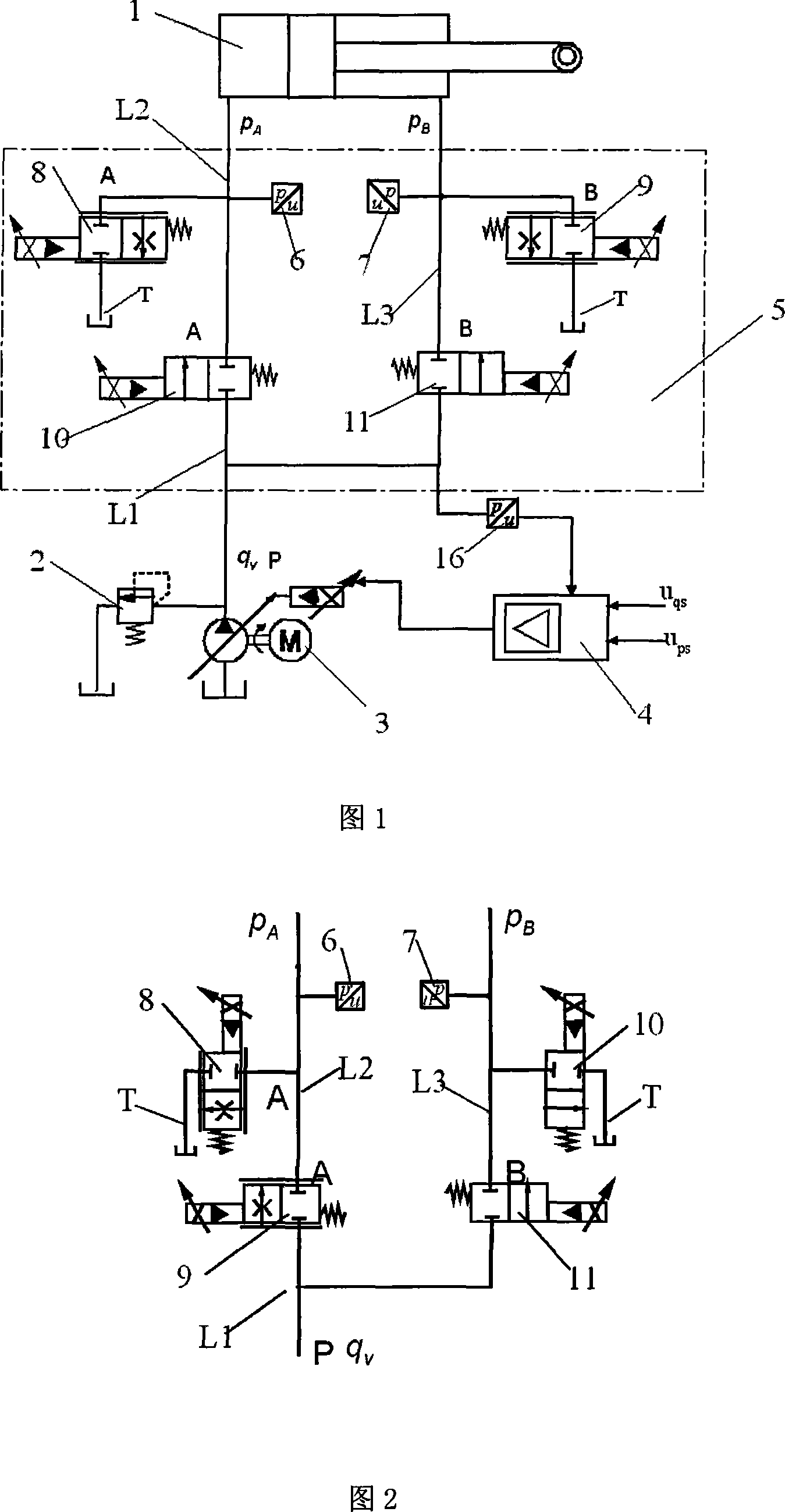

[0026] In Fig. 1, the electro-hydraulic system implementing the compound flow matching of the pump and valve of the present invention to independently control the inlet and outlet ports includes a hydraulic actuator 1, a safety valve 2, a hydraulic power source 3, a flow matching controller 4, and an independent control valve group for the inlet and outlet ports 5. Its pump valve electro-hydraulic system is composed of hydraulic power source 3. The output flow rate can be continuously adjusted by electronic signal control. A flow matching controller 4 is added. The oil inlet and outlet independent control valve group 5 is composed of pressure sensor I6, pressure sensor II7, 2-position 2-way proportional throttle valve I8, 2-position 2-way proportional throttle valve II9, 2-position 2-way electromagnetic directional valve I10 and 2-position 2-way electromagnetic directional valve II11.

[0027] Among them: the inlet of the two-position two-way proportional throttle valve I8 pass...

Embodiment 2

[0029] In Fig. 2, the electro-hydraulic system implementing the compound flow matching of the pump and valve of the present invention to independently control the inlet and outlet ports includes a hydraulic actuator 1, a safety valve 2, a hydraulic power source 3, a flow matching controller 4, and an independent control valve group 5 for the inlet and outlet ports , the electro-hydraulic system of the pump valve is composed of the output flow of the hydraulic power source 3 can be continuously adjusted by electronic signal control, a flow matching controller 4 is added, and the independent control valve group 5 of the oil inlet and outlet is composed of a pressure sensor I6, a pressure sensor II7, two One-position two-way proportional throttle valve I8, two-position two-way proportional throttle valve II9, two-position two-way electromagnetic directional valve I10 and two-position two-way electromagnetic directional valve II11.

[0030] Among them, the oil inlet and outlet inde...

Embodiment 3

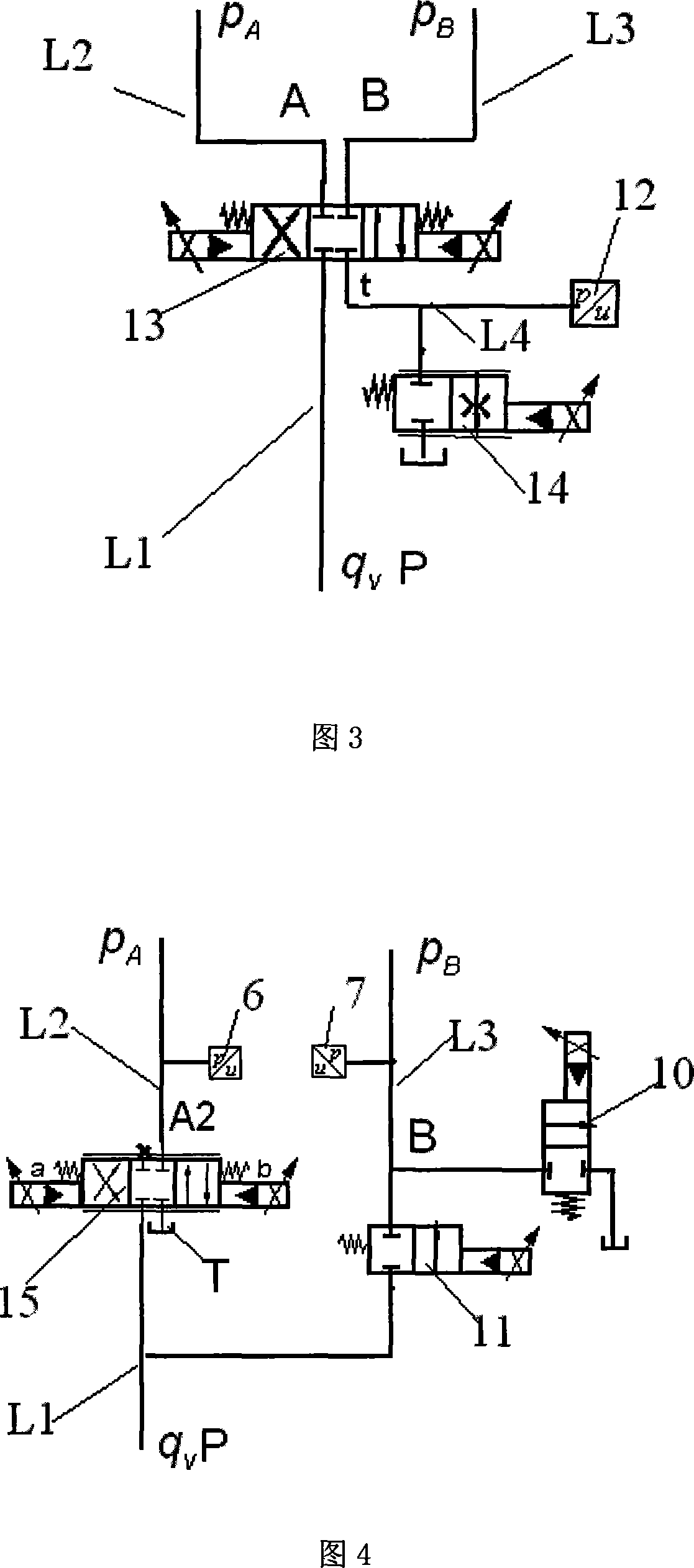

[0032] In Fig. 3, according to the method of embodiment 2, the oil inlet and outlet independent control valve group 5 is composed of a pressure sensor III12, a three-position four-way reversing valve 13, a two-position two-way proportional throttle valve III14, and a three-position four-way The oil inlet of the reversing valve 13 is connected to the outlet P of the hydraulic power source 3 through the oil pipe L1, and the oil outlet A is connected to the oil port P of the hydraulic actuator 1 through the oil pipe L2 A , the oil outlet B is connected to the oil port P of the hydraulic actuator 1 through the oil pipe L3 B , the oil return port t is connected to the outlet of the two-position two-way proportional throttle valve through the oil pipe L4 to communicate with the fuel tank T, the pressure sensor III12 is installed on the oil pipe L4, and its output signal is connected to the flow matching controller 4 through wires;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com