Patents

Literature

430results about How to "Reduce throttling loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

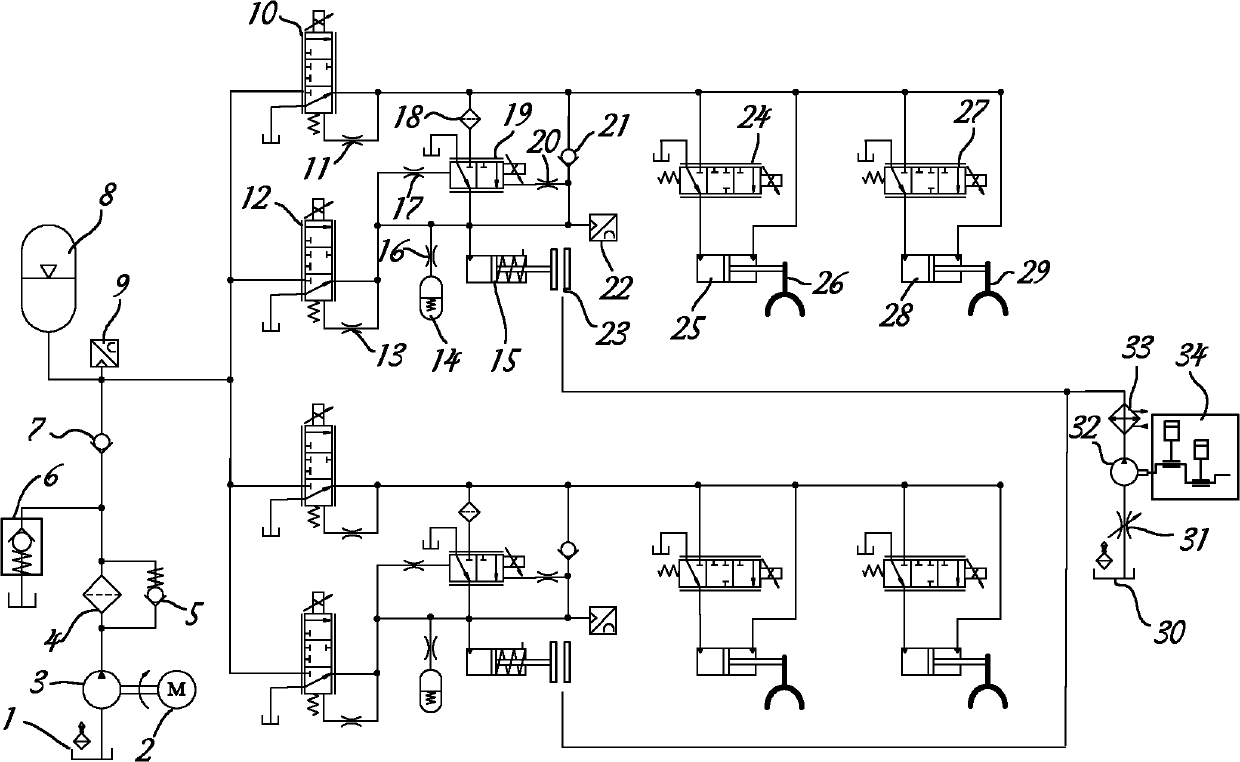

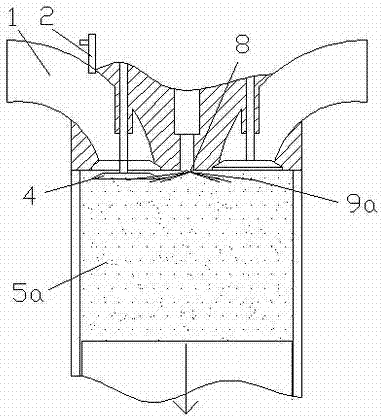

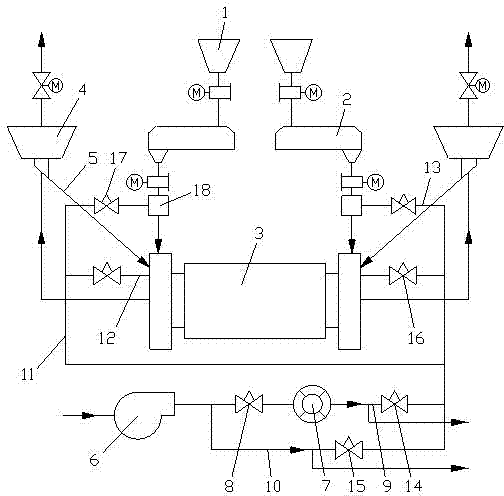

Hydraulic control system for wet-type double-clutch automatic transmission

ActiveCN102168754AReduce displacementLow powerClutchesGear lubrication/coolingAutomatic transmissionControl signal

The invention belongs to automobile transmissions, in particular to a hydraulic control system for a wet-type double-clutch automatic transmission. The hydraulic control system consists of two separate subsystems, wherein one subsystem is a clutch and gearshift mechanism hydraulic control subsystem which is mainly used for operating an odd number gear clutch and an even number gear clutch to separate and combine according to a control signal transmitted by an electronic control unit as well as operating a gear-shift mechanism control oil cylinder to finish switching of each gear synchronizer; and the other subsystem is a clutch cooling and lubricating subsystem. By adopting a more scientific and reasonable hydraulic control system, the efficiency of the hydraulic control system for the wet-type double-clutch automatic transmission is improved, the fuel consumption is reduced, the effects of saving energy and reducing emission are achieved, and the reliability of the system work and the compactness of the structure are enhanced.

Owner:ZHEJIANG WANGLIYANG TRANMISSION CO LTD

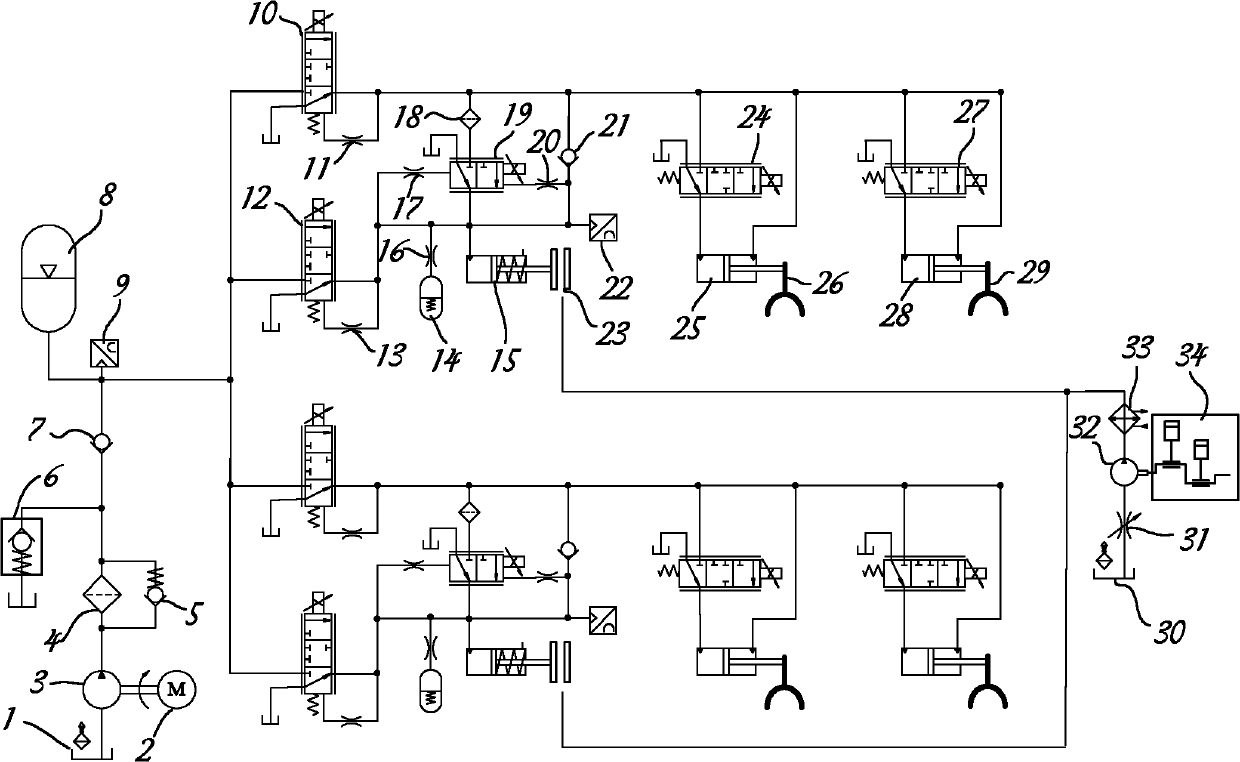

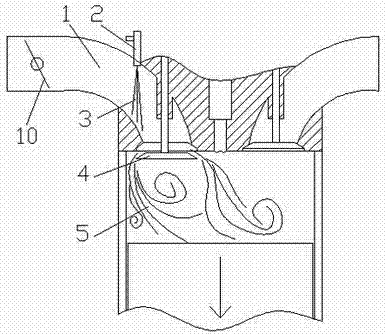

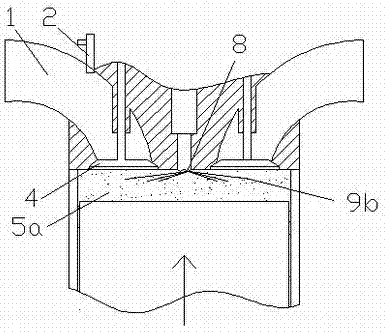

Fuel injection method for dual-fuel engine

InactiveCN106870186ANot easy to knockIncrease concentrationElectrical controlMachines/enginesExhaust valveCombustion

Owner:DALIAN UNIV OF TECH

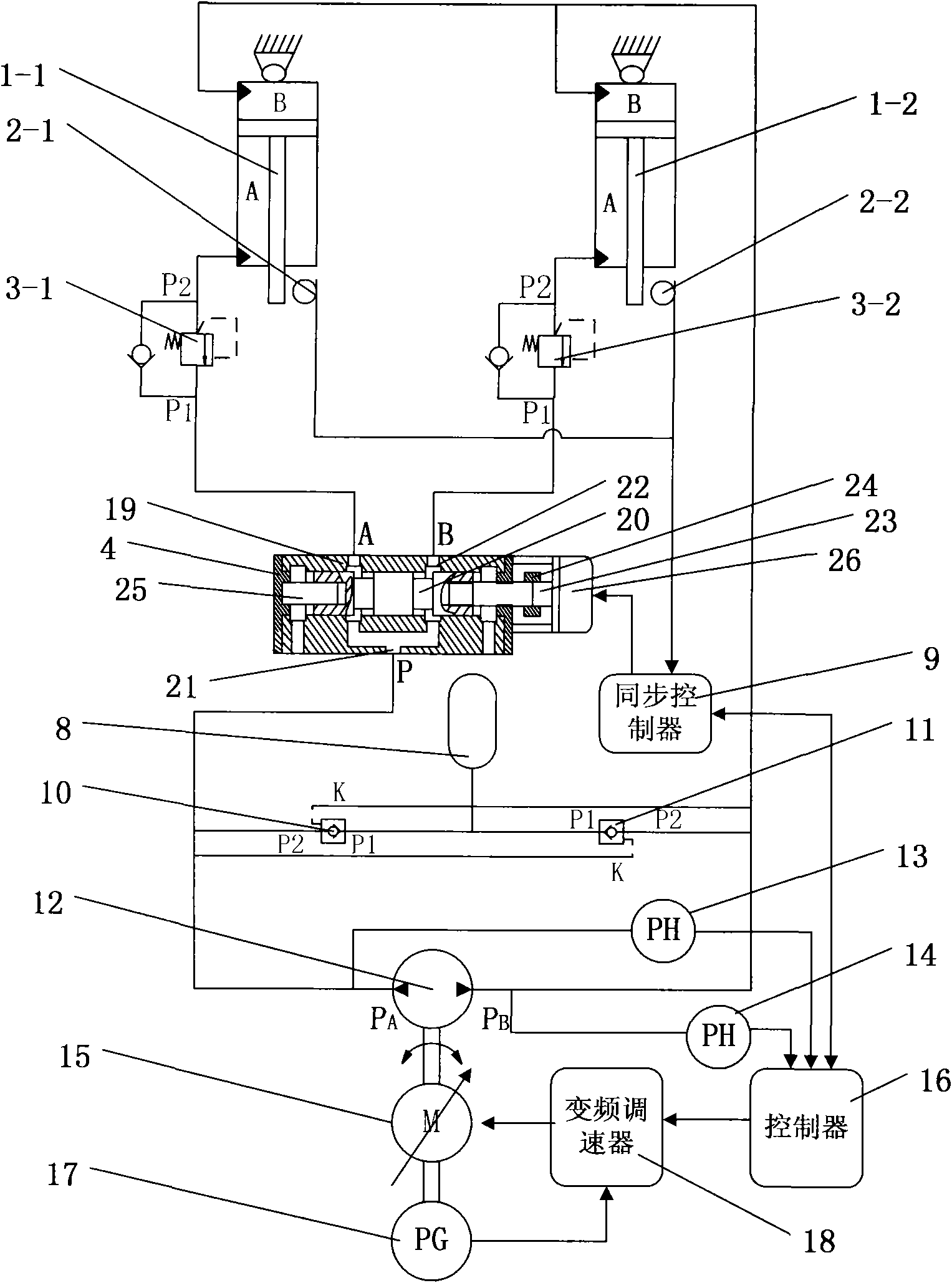

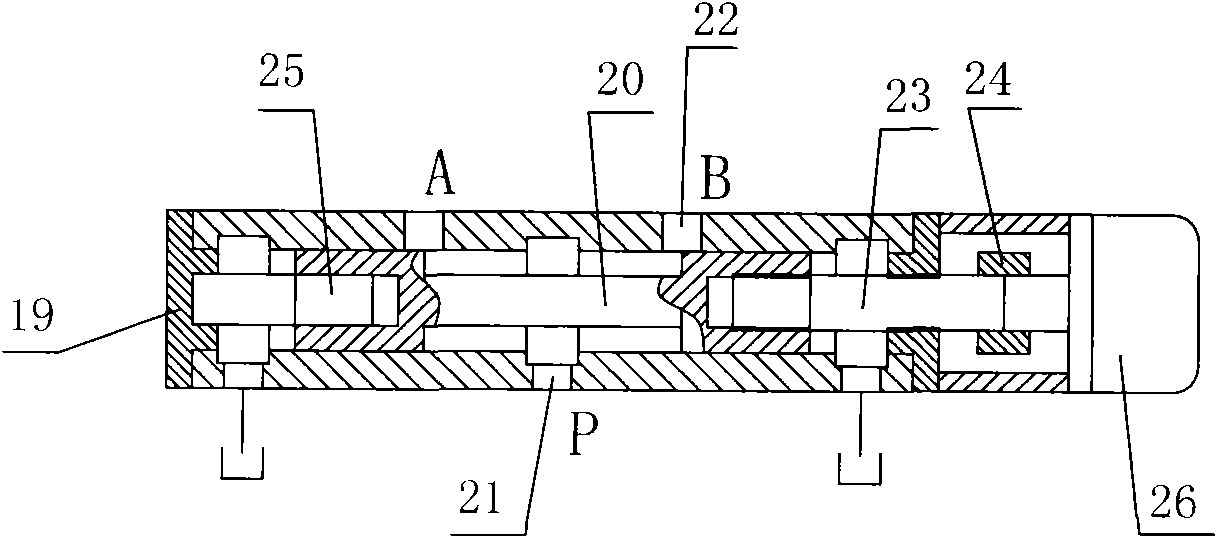

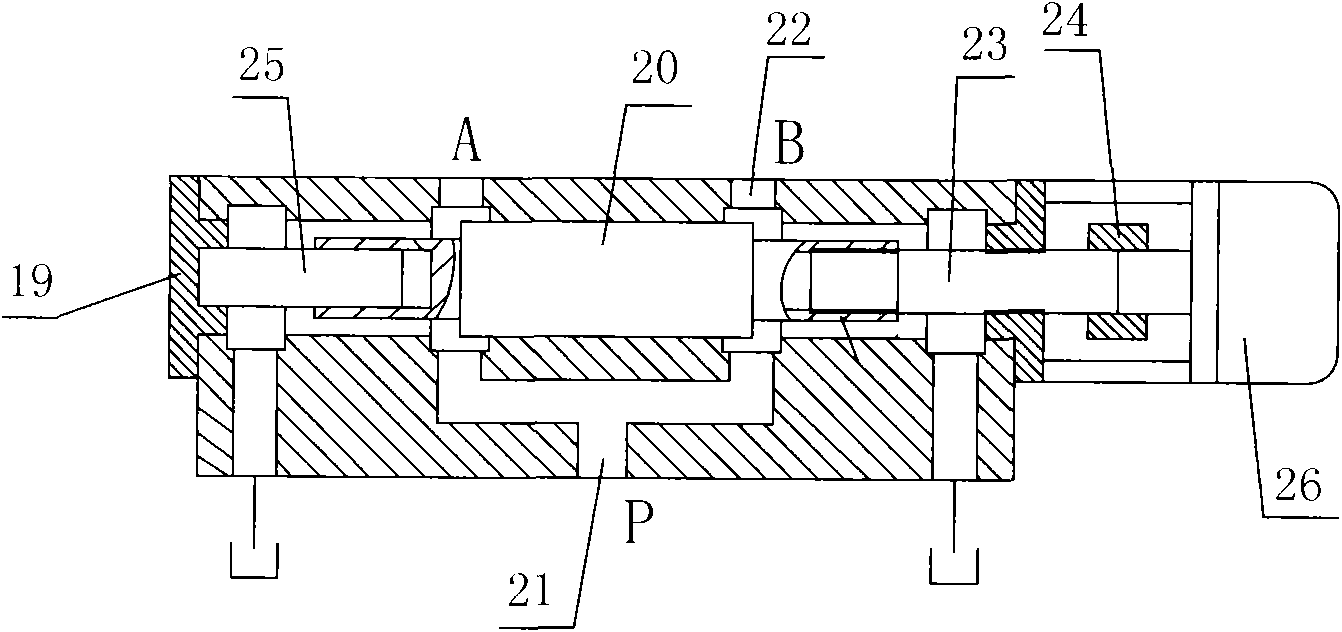

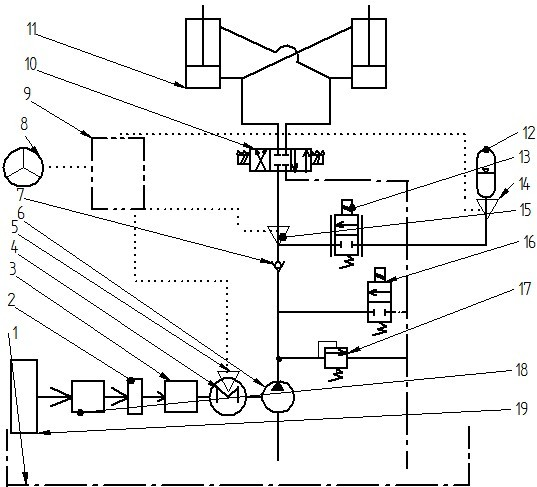

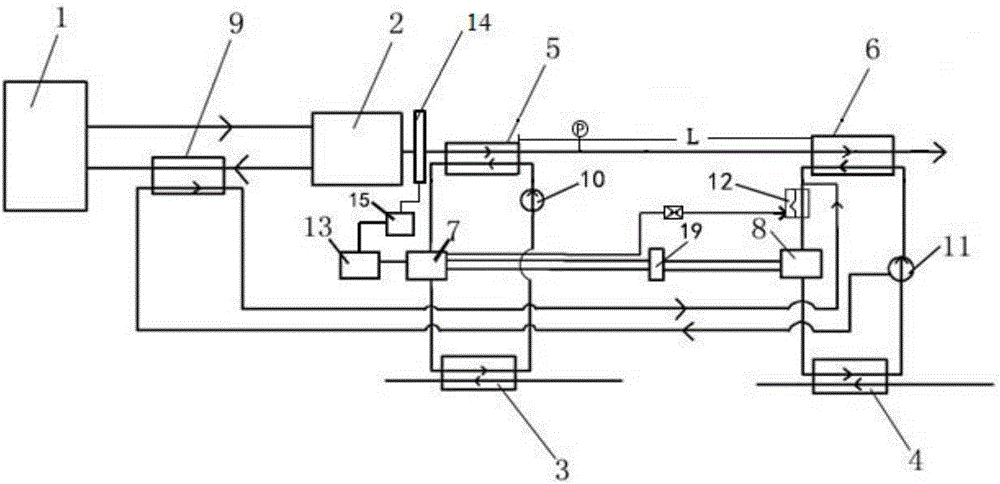

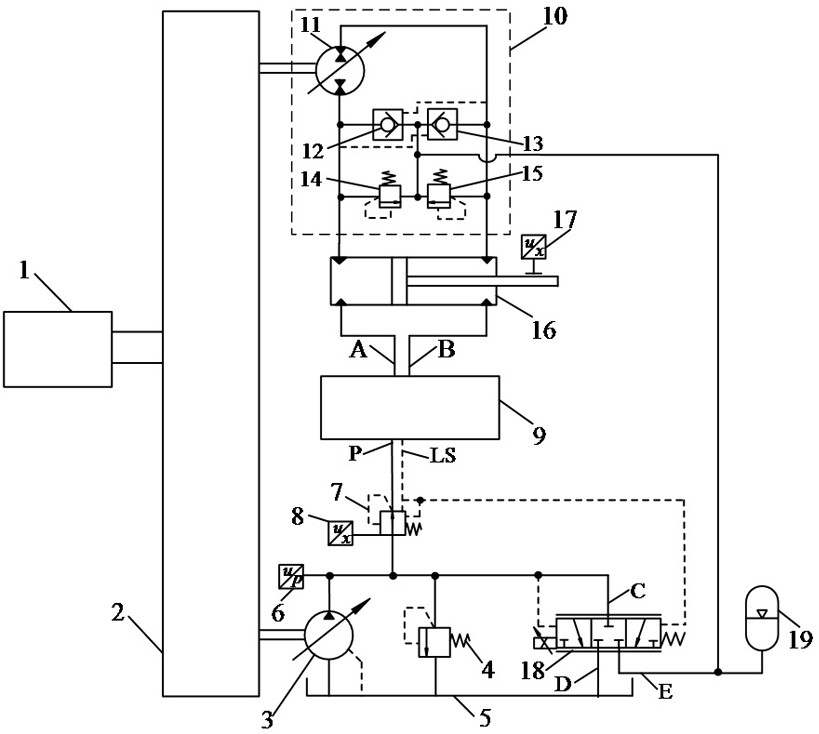

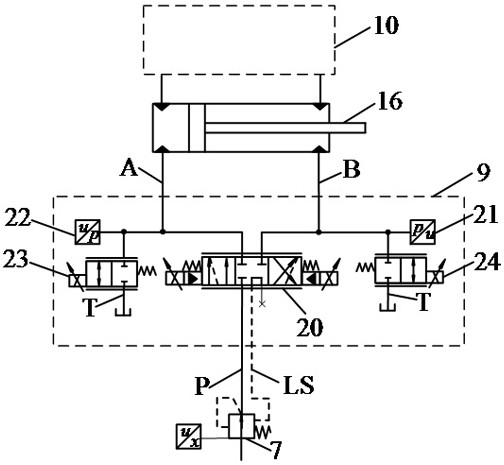

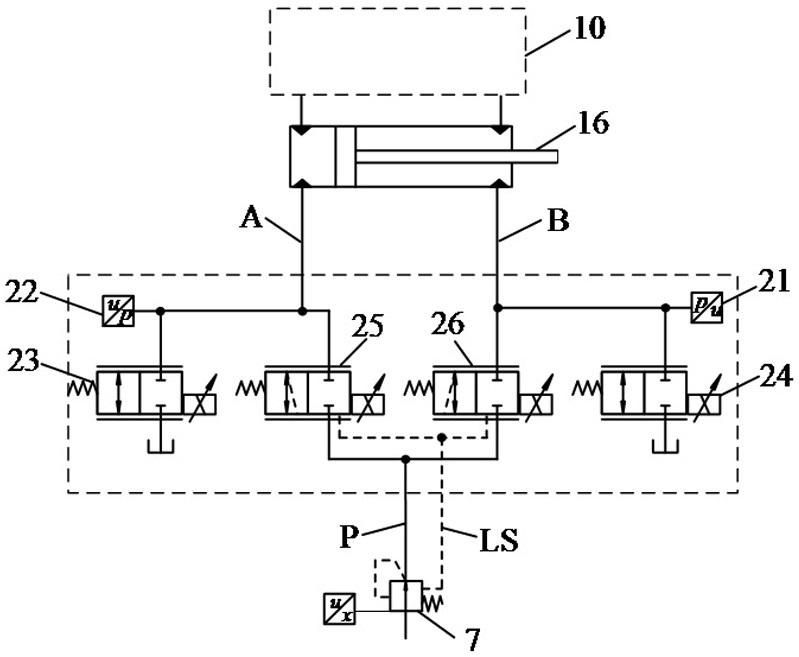

Digital electric-hydraulic synchronous control system

InactiveCN101571155AThrottle control responds quicklyIntelligentFluid-pressure actuator componentsHydraulic pumpFuel tank

The invention discloses a digital electric-hydraulic synchronous control system, which comprises a hydraulic actuating mechanism, a digital synchronous control mechanism for performing synchronous control on the hydraulic actuating mechanism, an electric-hydraulic power source for providing power oil for the hydraulic actuating mechanism and the digital synchronous control mechanism, and an electric-hydraulic control system for controlling the power source and the synchronous control mechanism. The hydraulic actuating mechanism is a hydrocylinder; the electric-hydraulic power source comprises an oil storage tank, a double-acting hydraulic oil pump and a driving motor; the electric-hydraulic control system comprises a detector for detecting the oil pressure of the hydraulic oil pump and the rotating speed of the motor respectively and a variable frequency speed regulator and a controller for controlling the motor; and the digital synchronous control mechanism comprises a digital synchronization valve, a digital synchronization controller and a displacement transducer for detecting the displacement of an output shaft of the hydrocylinder. The digital electric-hydraulic synchronous control system has the advantages of simple structure, simple and convenient use and operation, good use effect, energy conservation and no oil leakage, and can achieve the aims of stepless speed regulation and high-precision synchronization according to operating characteristic requirements of different types of controlled objects.

Owner:薛国光

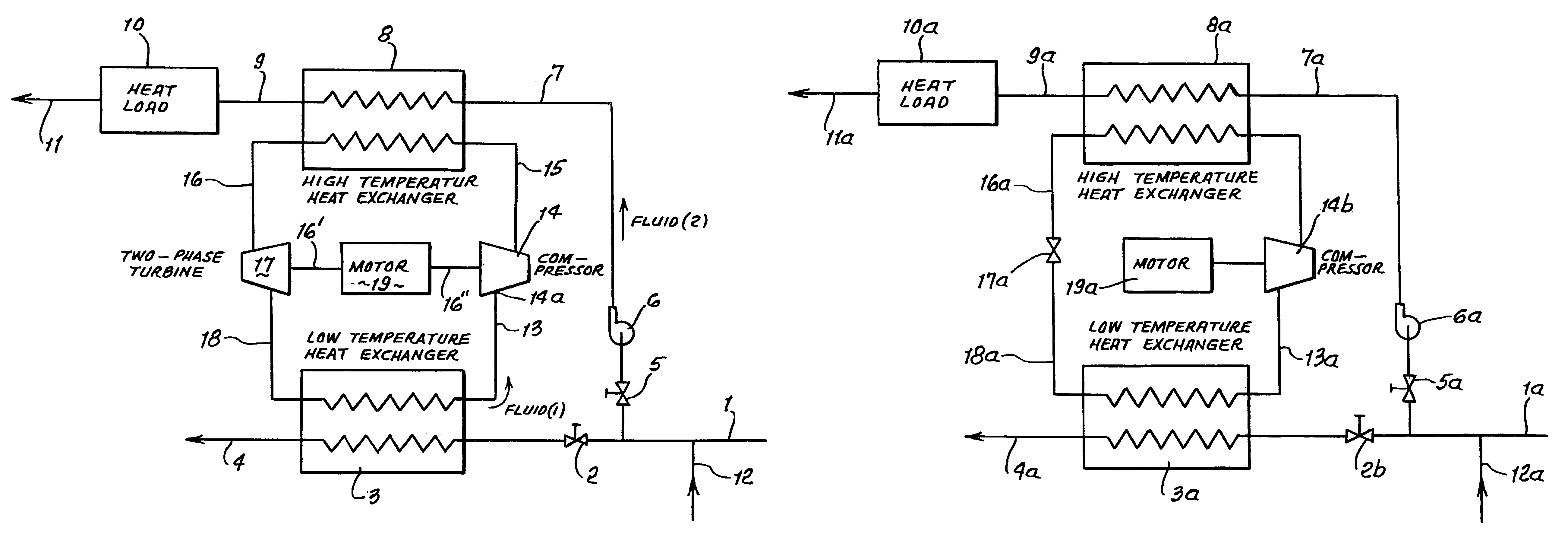

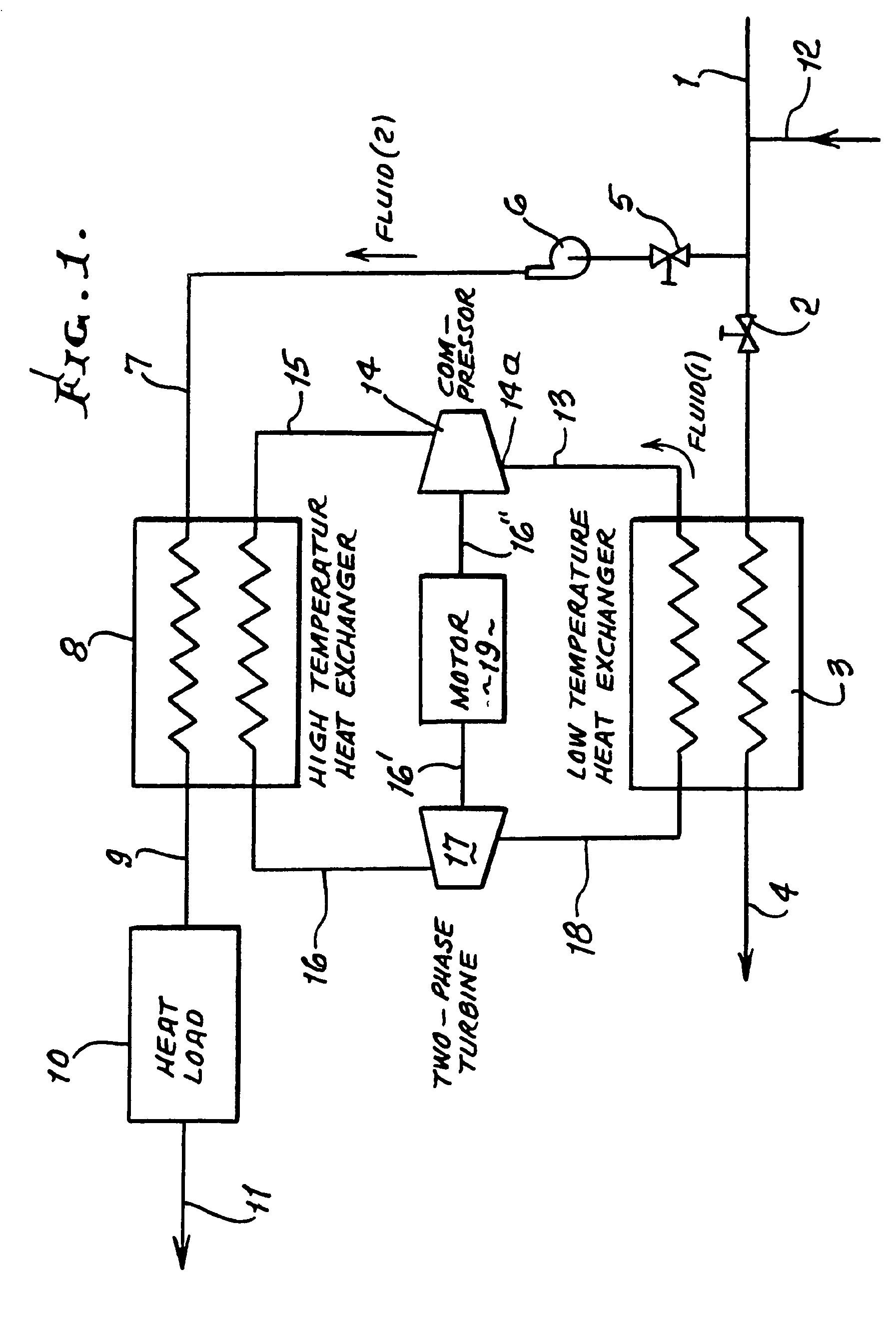

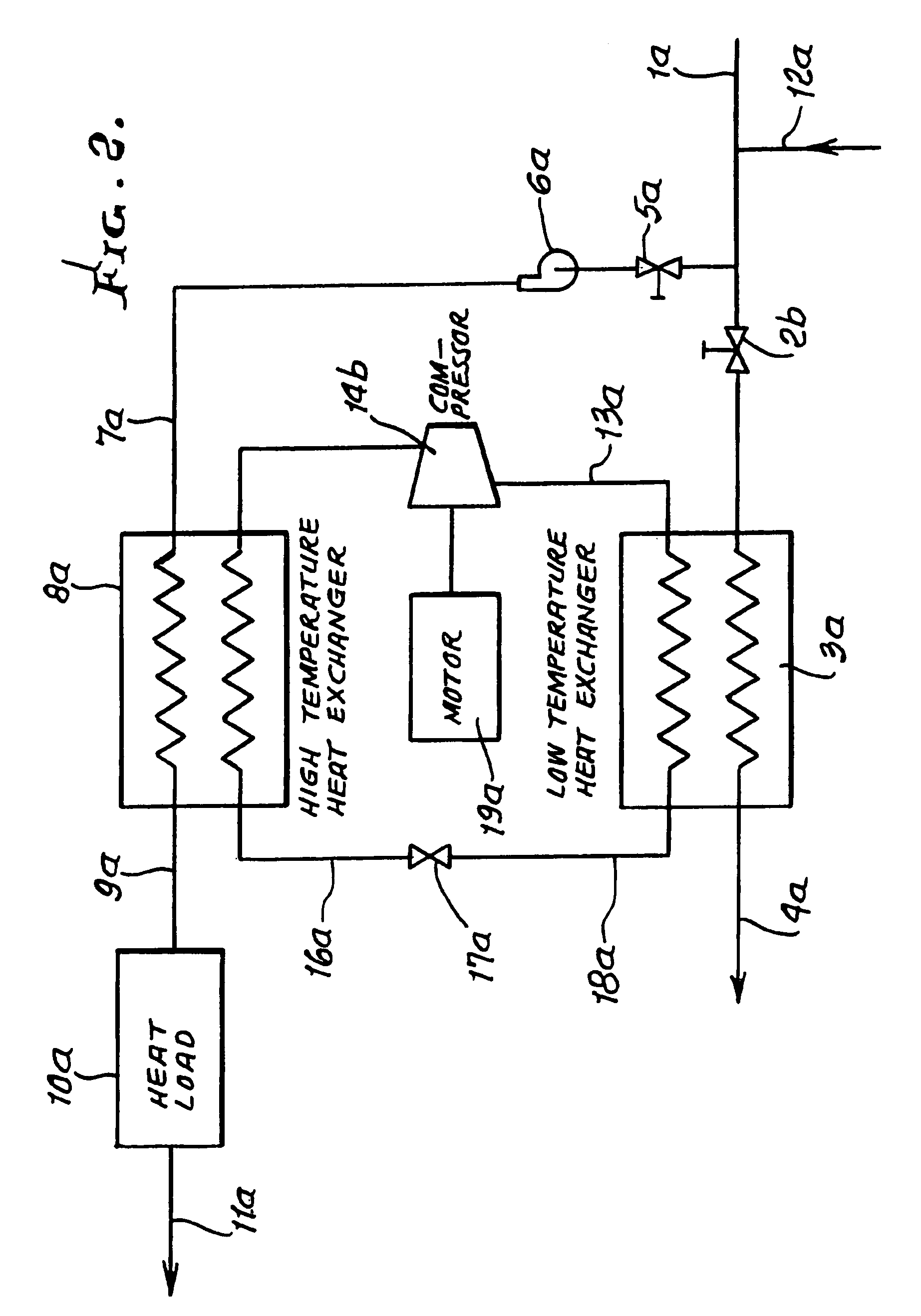

High temperature heat pump

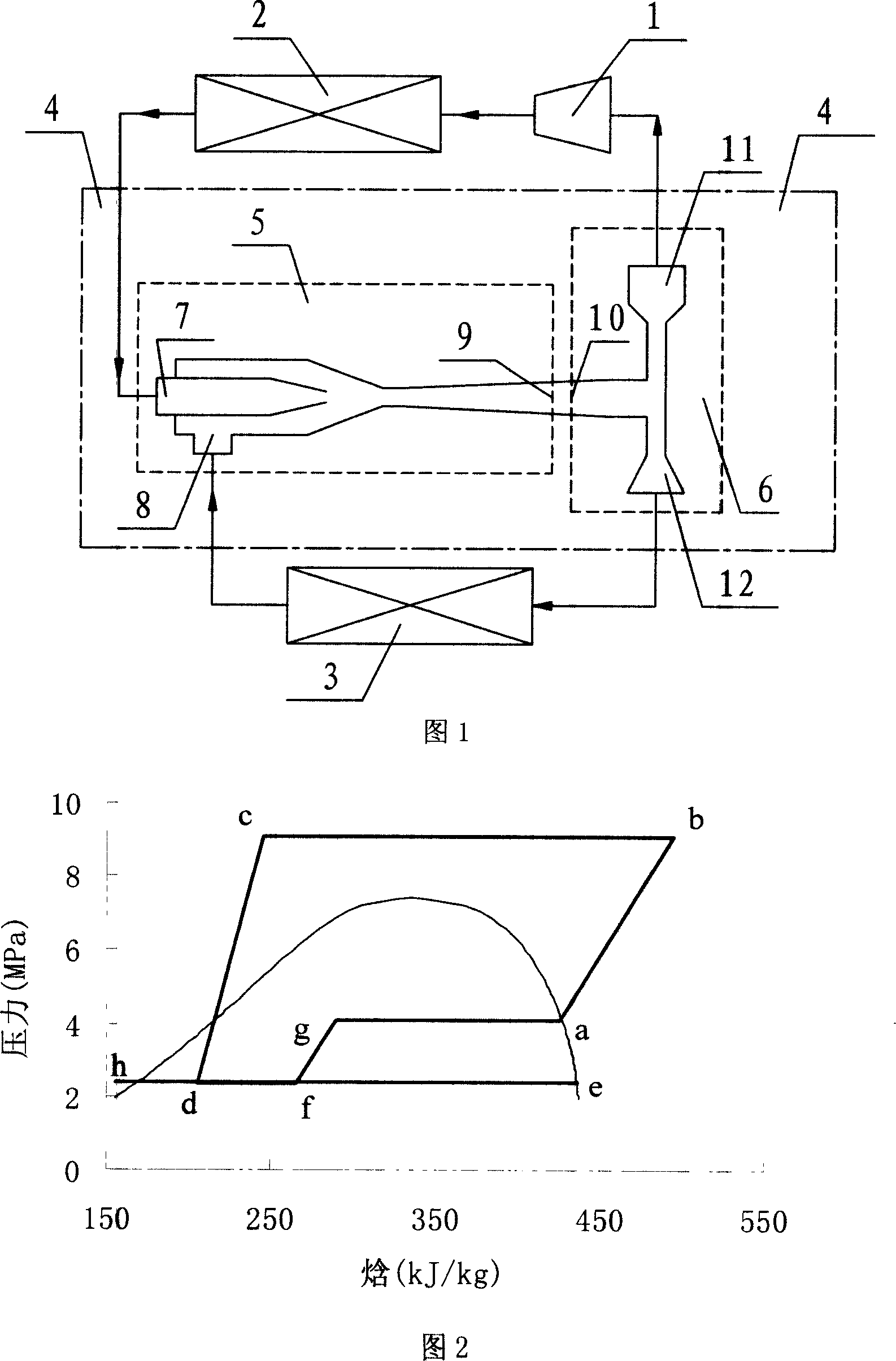

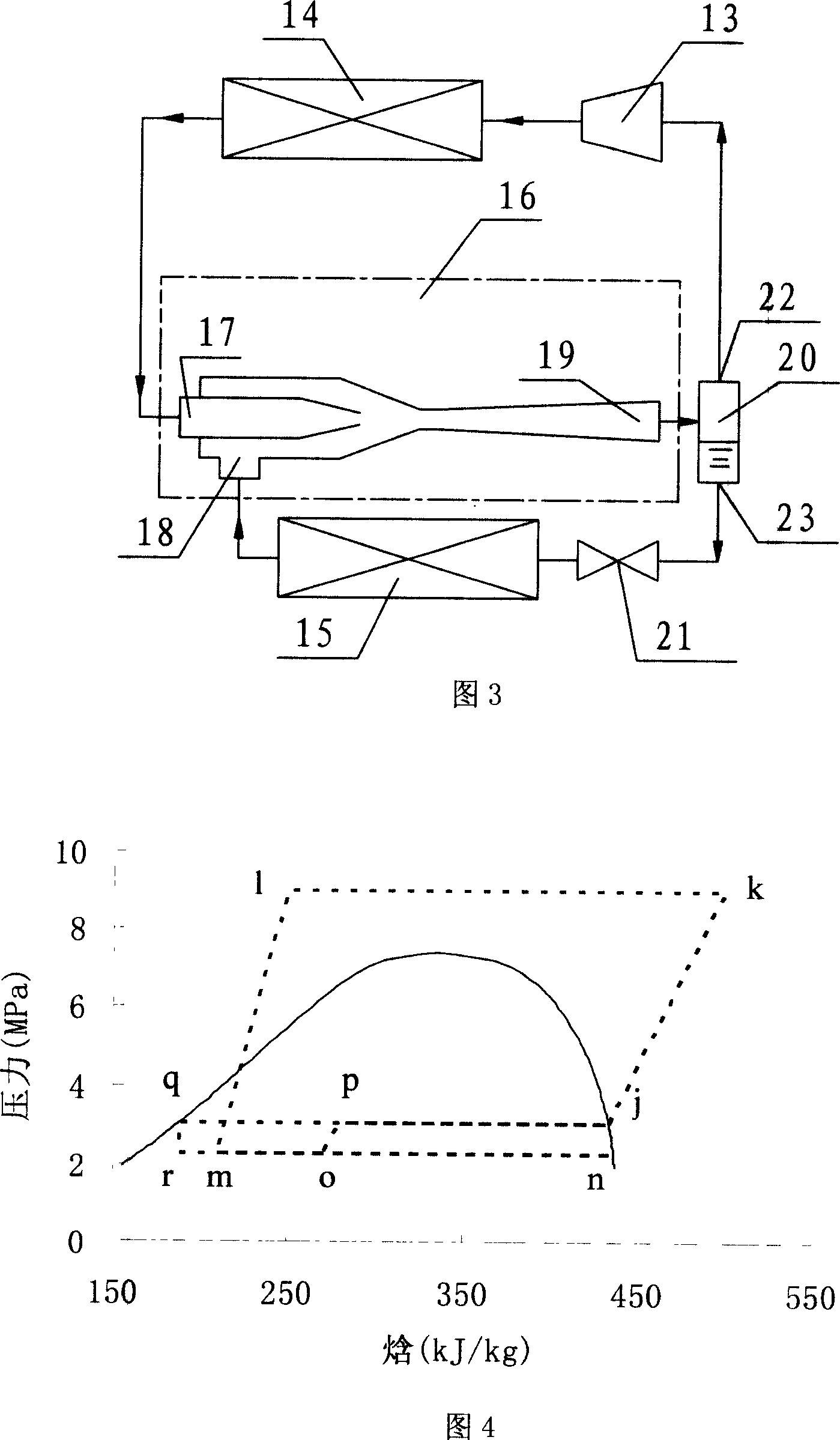

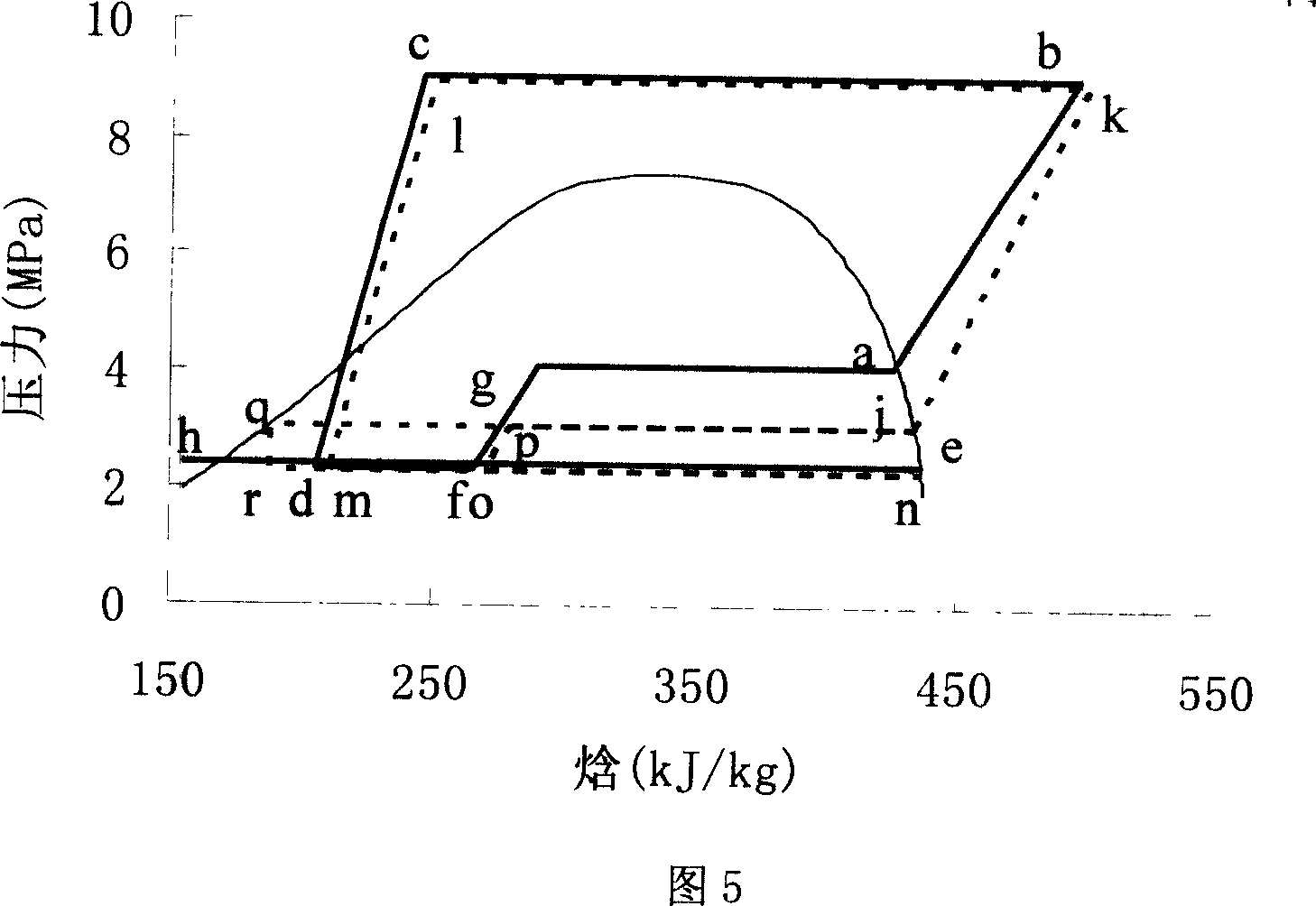

InactiveUS6913076B1Reduce throttling lossImprove efficiencyHeat pumpsCompression machines using turbinesEngineeringHeat pump

A high temperature heat pump comprising a low temperature heat exchanger to produce vapor of a first fluid from heat transferred from a second fluid to a mixture of liquid and vapor of the first fluid; a compressor to increase the pressure and temperature of the produced vapor; a high temperature heat exchanger to heat the second fluid to useful, high temperatures from the condensation of the first fluid; and an expander to lower the pressure and temperature of the first fluid producing a mixture of vapor and liquid.

Owner:ENERGENT CORP

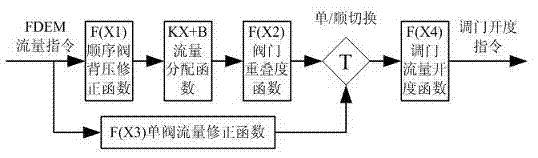

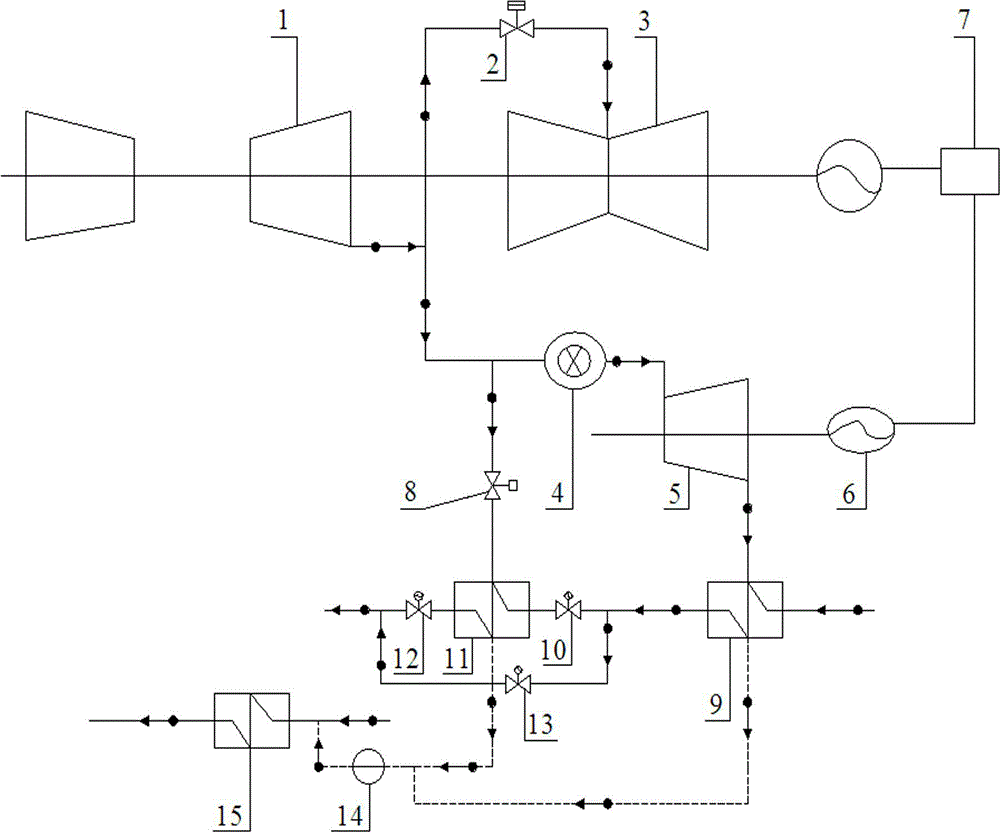

Nozzle governing steam turbine flow characteristic test method

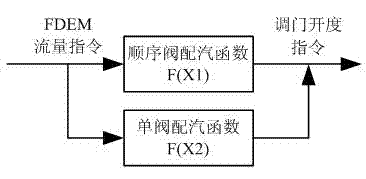

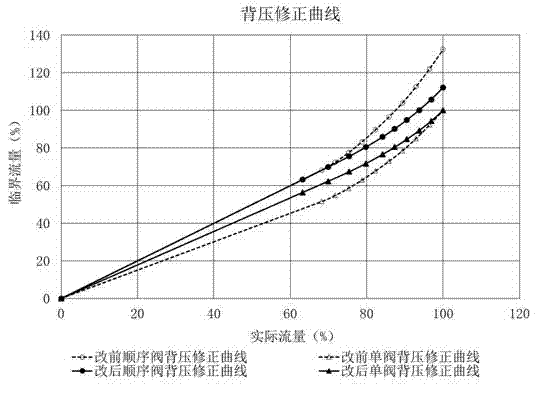

ActiveCN104849052AMeet FM requirementsReduce throttling lossEngine testingSpray nozzleOperation mode

Provided is a nozzle governing steam turbine flow characteristic test method. According to the method, the steam distribution end of a steam turbine is assumed as an equivalent nozzle, the forward pressure, backward pressure and pressure ratio of the equivalent nozzle are taken as variables to perform indirect numerical mapping (direct mapping when the intermediate conversion link 'flow ratio' is removed) on 'actual flow-flow ratio-regulating valve position instruction' of the steam turbine by two different mapping methods, namely, an 'indirect method' and a 'direct method', and regulating valve overlap is finely adjusted by double means of setting 'the regulating valve opening amplitude limit under inlet air flow increase per unit' and numerically quantizing 'the degree of influence of regulating valve throttling loss to the heat consumption of the steam turbine', thereby obtaining a steam distribution function conforming to the actual flow characteristic of the steam turbine and realizing precise control on the inlet air flow of the steam turbine under different valve control modes. The nozzle governing steam turbine flow characteristic test method of the invention is suitable for nozzle governing steam turbine flow characteristic setting and steam turbine steam distribution end operation mode integrated optimizing control research.

Owner:STATE GRID JIANGXI ELECTRIC POWER CO LTD RES INST +1

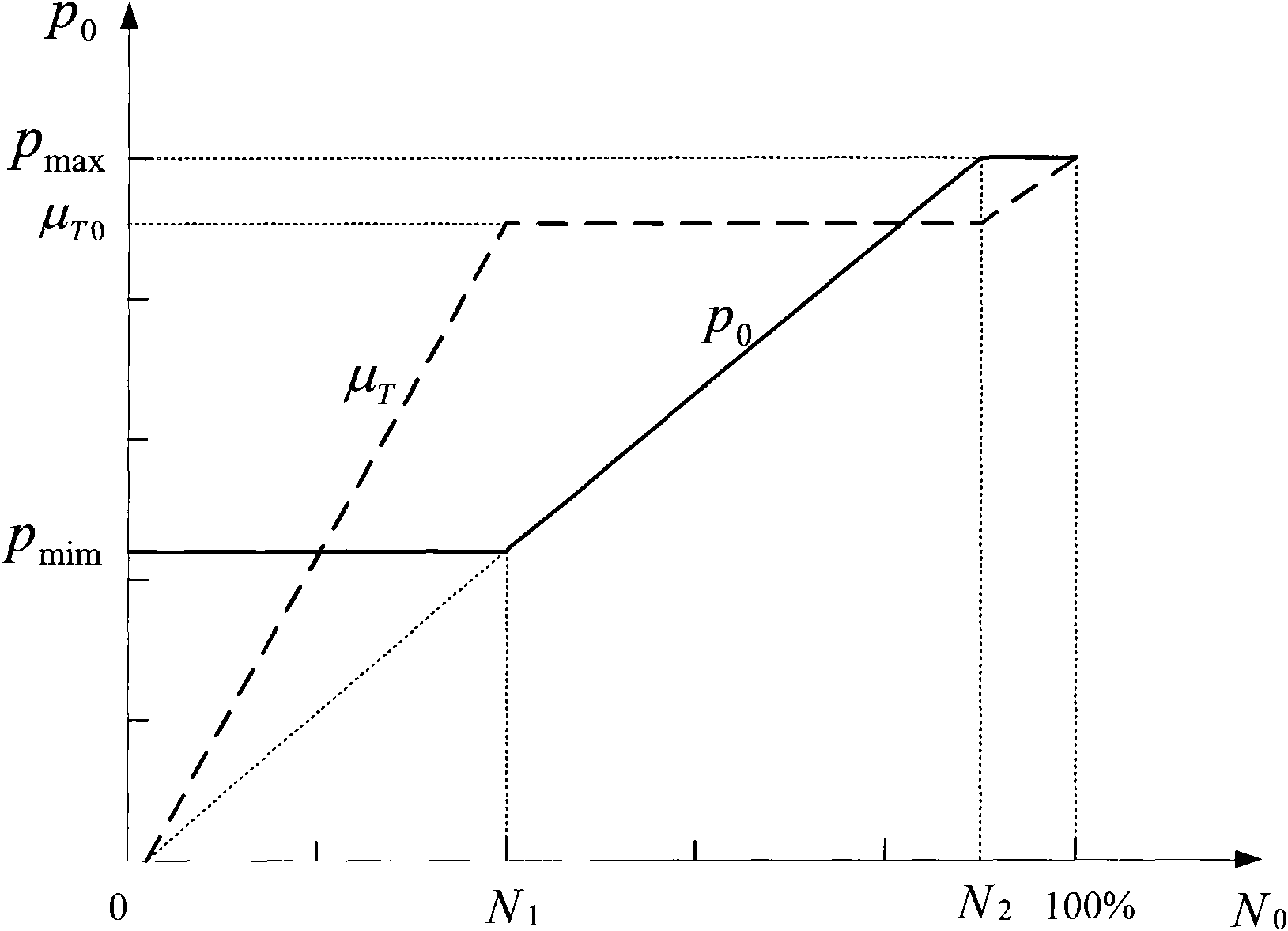

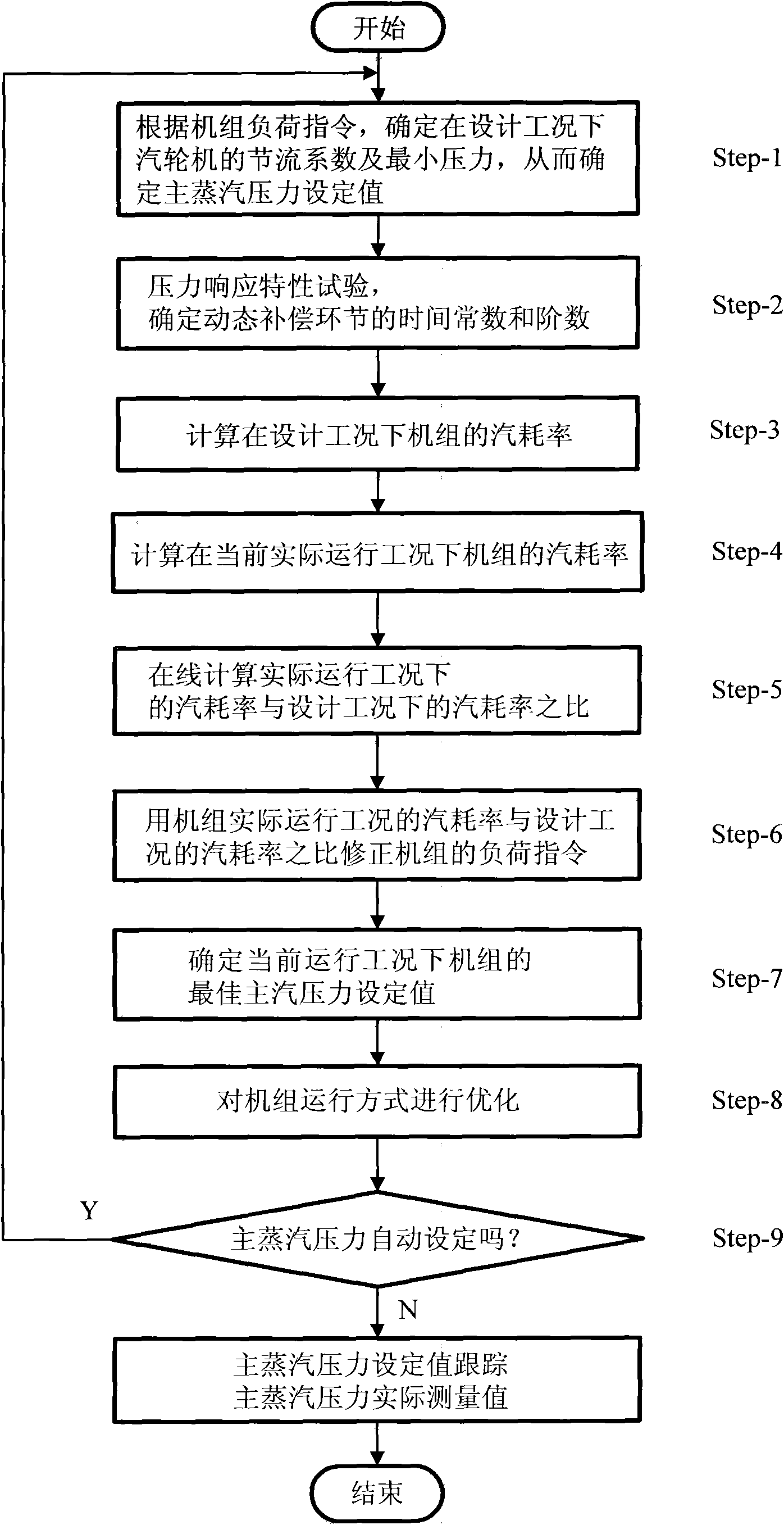

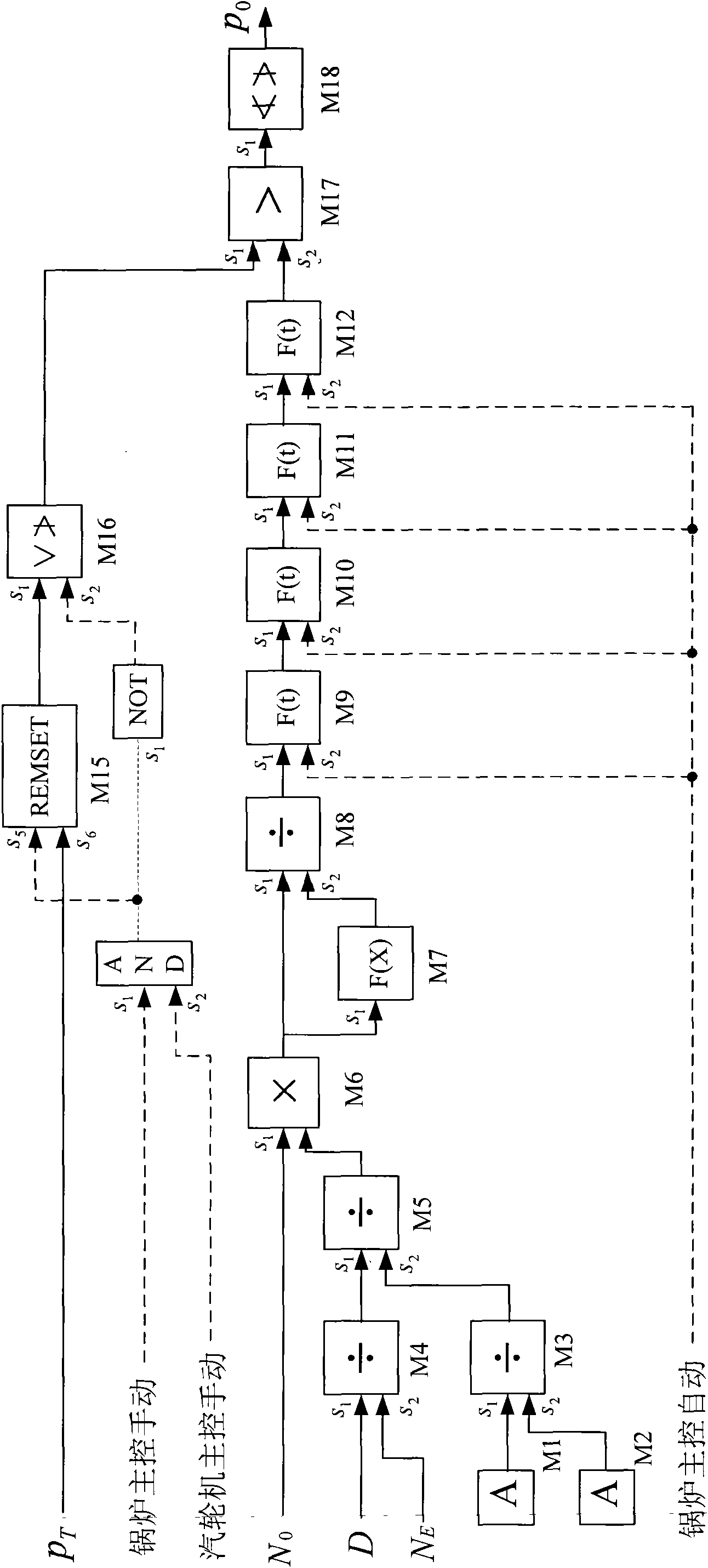

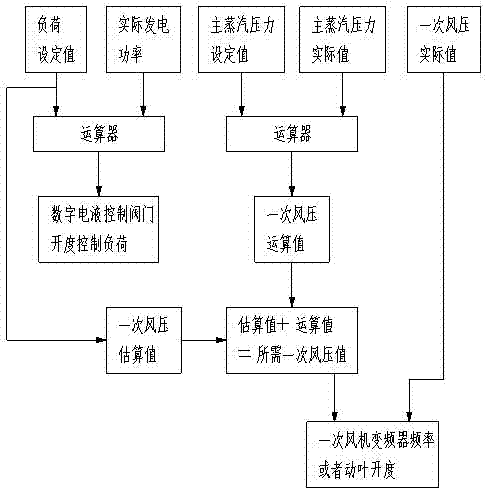

Generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate

ActiveCN101609312AImprove cycle efficiencyBest working pointProgramme control in sequence/logic controllersSteam pressureControl system

The invention discloses a generating set optimization control method for correcting sliding pressure operation curve by adopting steam consumption rate, which comprises the detailed steps of: confirming the throttling coefficients and minimum pressure of a steam turbine under a designed working condition according to the load command of the generating set and confirming the main steam pressure set value; confirming the parameters of dynamic compensation section according to the main steam pressure response characteristics; respectively calculating the steam consumption rate of the generating set under the designed working condition and the actual working condition, working out the steam consumption rate correction coefficients, and implementing online correction on the load command of the generating set; using the corrected load command to divide the throttling coefficients of the steam turbine, then implementing calculation on the dynamic compensation procedure and minimum pressure limitation, and finally obtaining the best main steam pressure set value of the generating set under the current operation condition. The best main steam pressure set value is applied in a cooperation control system of a unit set so as to realize the best cooperation relation between the inlet steam pressure and inlet steam flow of the generating set, thus reducing the throttling loss of the steam turbine and guaranteeing the best thermoeconomic performance of the generating set.

Owner:ELECTRIC POWER RES INST STATE GRID SHANXI ELECTRIC POWER +1

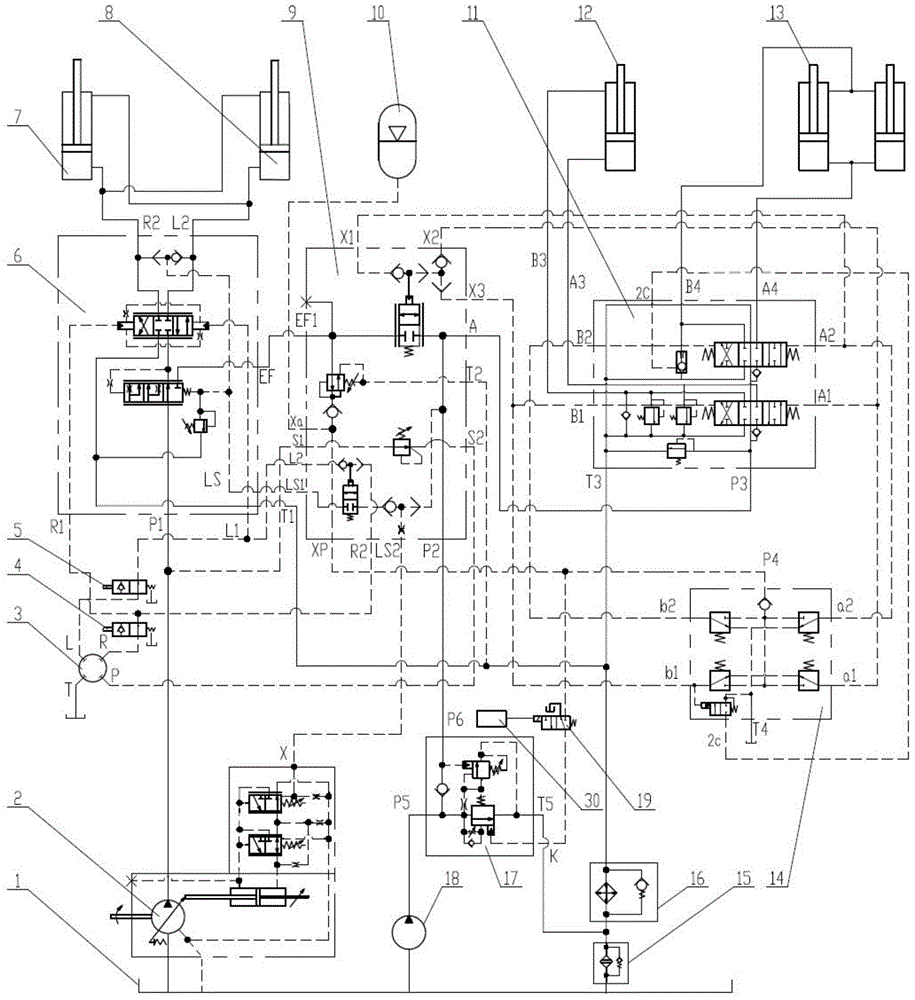

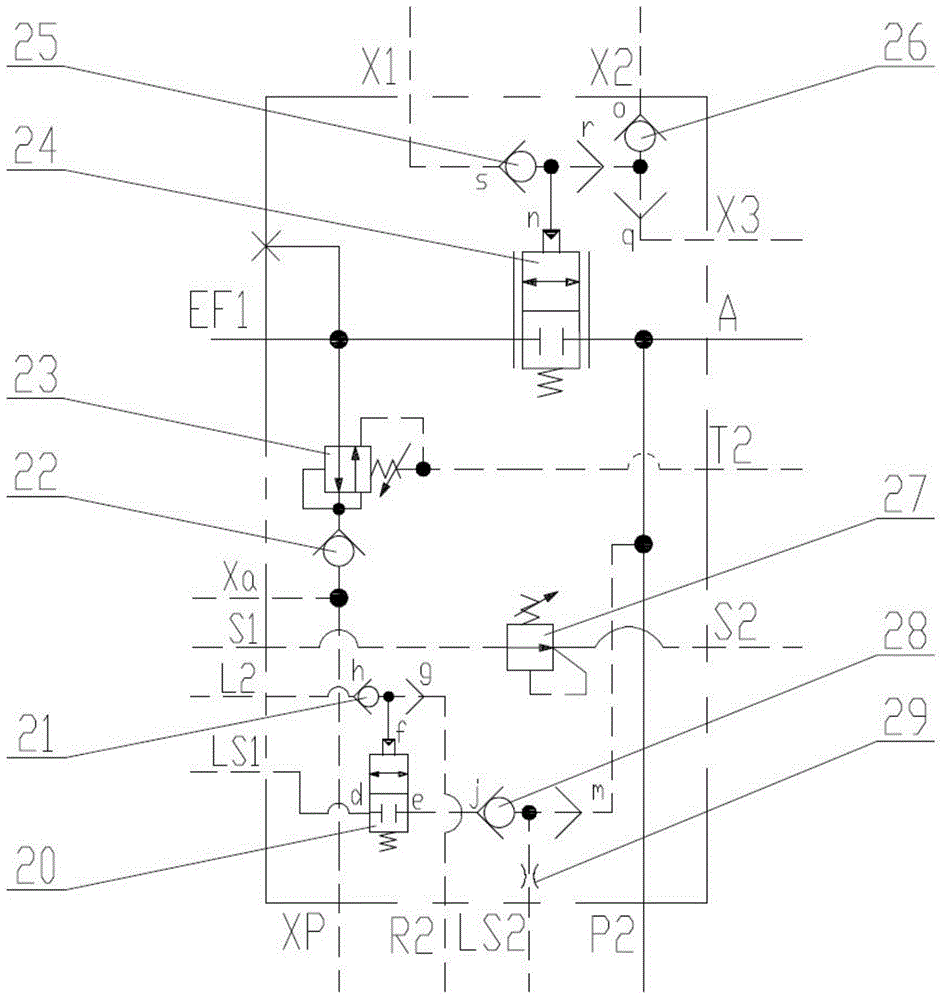

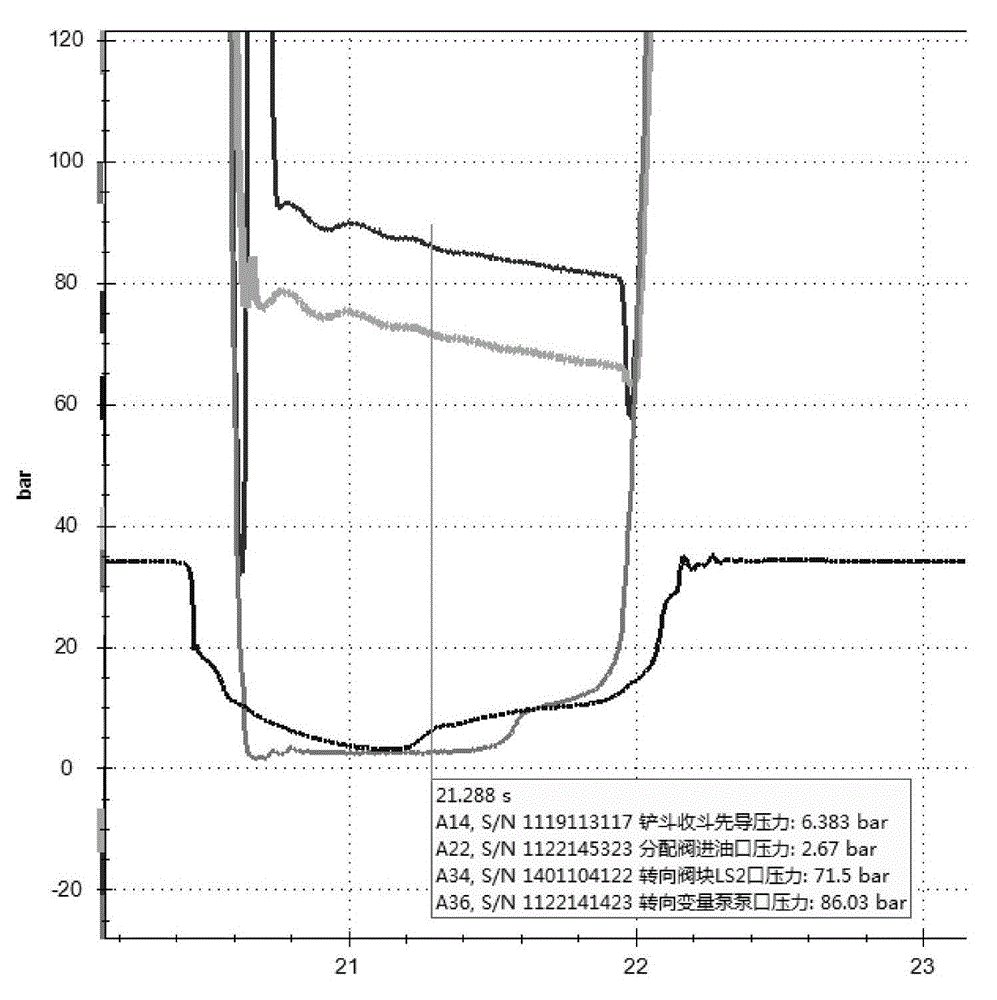

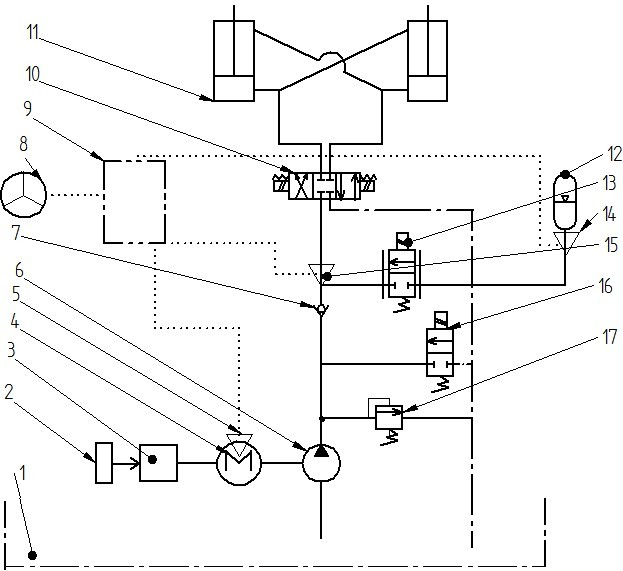

Loader constant and variable hydraulic system based on flow amplifying steering

ActiveCN104929183ALow powerProtect against high pressure shocksSoil-shifting machines/dredgersSolenoid valveEngineering

The invention discloses a loader constant and variable hydraulic system based on flow amplifying steering. The loader constant and variable hydraulic system comprises a hydraulic oil tank, a variable pump, a steering gear, a right limiting valve, a left limiting valve, a flow amplifying valve, a left steering cylinder, a right steering cylinder, a flow control valve block, an energy accumulator, a distribution valve, a tipping bucket cylinder, a movable arm cylinder, a pilot valve, an unloading valve block, a constant flow pump, a working mode switching electromagnetic valve and a working mode selector switch. The small-displacement steering gear is adopted to serve as a hydraulic pilot stage of the flow amplifying valve, throttling losses inside a coaxial flow amplifying steering gear in the rapid steering process can be removed, and fuel consumption is reduced; a low-cost home-made element is adopted to replace an inlet element, and steering stability of a variable system is achieved; a feedback signal of the flow amplifying valve is controlled in a time-shared manner, stability of a steering system is improved, and energy consumption is reduced; and meanwhile, the energy-saving effect and good control characteristics of the variable pump can be played out well, and the energy-saving effect and the control precision of a working system are improved.

Owner:XCMG CONSTR MACHINERY

Refrigerating system using swirling flow ejector

InactiveCN101017036AReduce throttling lossReduce power consumptionCompression machinesInjectorRefrigerant

A refrigerator with turbulence injector comprises a compressor, a condenser, an evaporator, and a turbulence injector, wherein the compressor outlet is connected with the inlet of the condenser whose outlet is connected with the nozzle of the turbulence injector, the high-temperature outlet of turbulence tube of the injector is connected with the inlet of the compressor, while the low-temperature outlet is connected with the inlet of the evaporator whose outlet is connected with the fluid inlet of the injector. The invention can recycle expansion energy of coolant, to improve 20% of energy / effect ratio, with simple structure and low cost.

Owner:SHANGHAI JIAO TONG UNIV

Direct blowing type double-inlet and double-outlet steel ball grinding energy conservation optimization system and method thereof

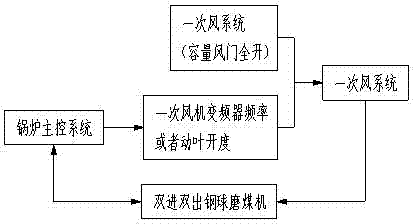

InactiveCN103047670AHigh frequency conversion adjustment accuracyReduce throttling lossAir supply regulationIndirect carbon-dioxide mitigationAir volumeFrequency changer

The invention relates to a direct blowing type double-inlet and double-outlet steel ball grinding energy conservation optimization system and a method thereof. The direct blowing type double-inlet and double-outlet steel ball grinding energy conservation optimization system comprises a direct blowing type double-inlet and double-outlet steel ball coal mill, a primary air system and a main boiler control system, wherein the primary air system is mainly formed by a primary air fan provided with a movable vane, an air preheating device, a control damper, an air pipe and the like. According to the method, the volume air control damper is manually adjusted to be entirely open in the normal state, the opening degree of the volume air control damper is manually adjusted during the upward and downward loading, the pressure of a main pipe of the volume air control damper is not adjusted by the primary air fan, and the frequency of a frequency converter of the primary air fan or the opening degree of the movable vane is directly controlled by the main boiler control system so as to adjust the volume of the air entering into a hearth. According to the method provided by the invention, the volume air control damper is entirely opened, and proper pressure of the main pipe of the primary air fan, namely the force directly acting on the primary air fan by the main boiler control system, is directly calculated by the main boiler control system according to the required hearth power, so that the throttling loss of the volume air control damper is greatly reduced. Moreover, the direct blowing type double-inlet and double-outlet steel ball grinding energy conservation optimization system is rapid in response time, thereby enhancing the adjustment quality of a machine set.

Owner:福州福大自动化科技有限公司

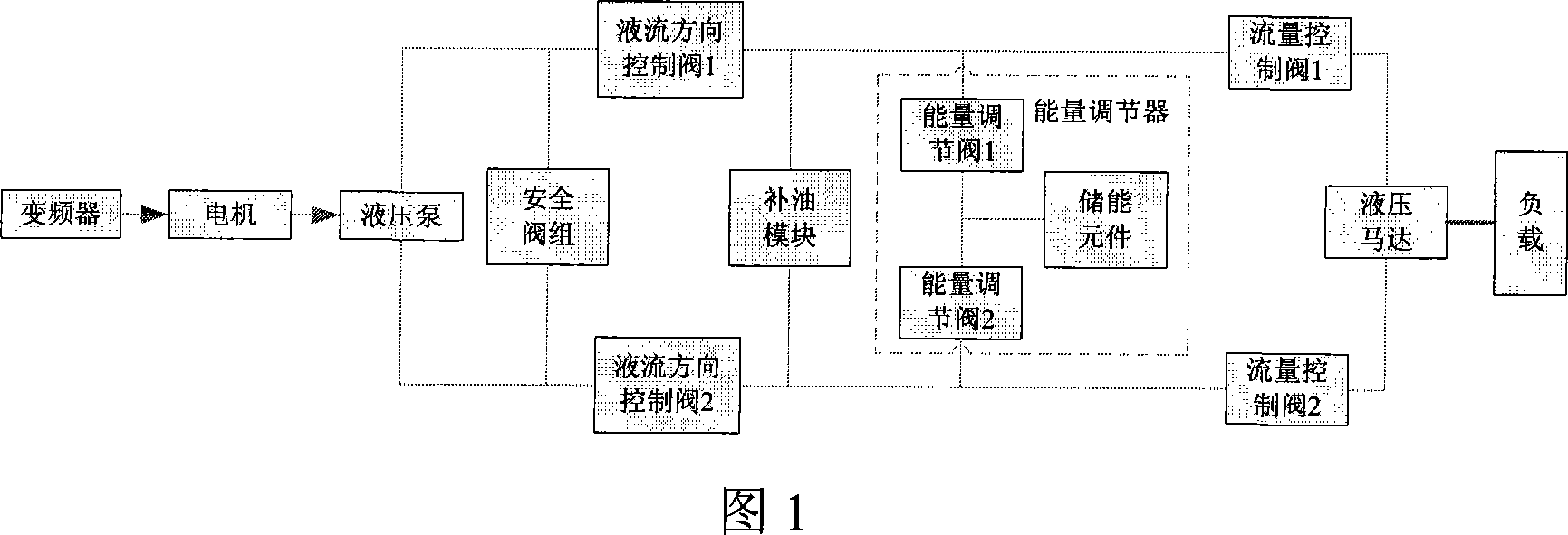

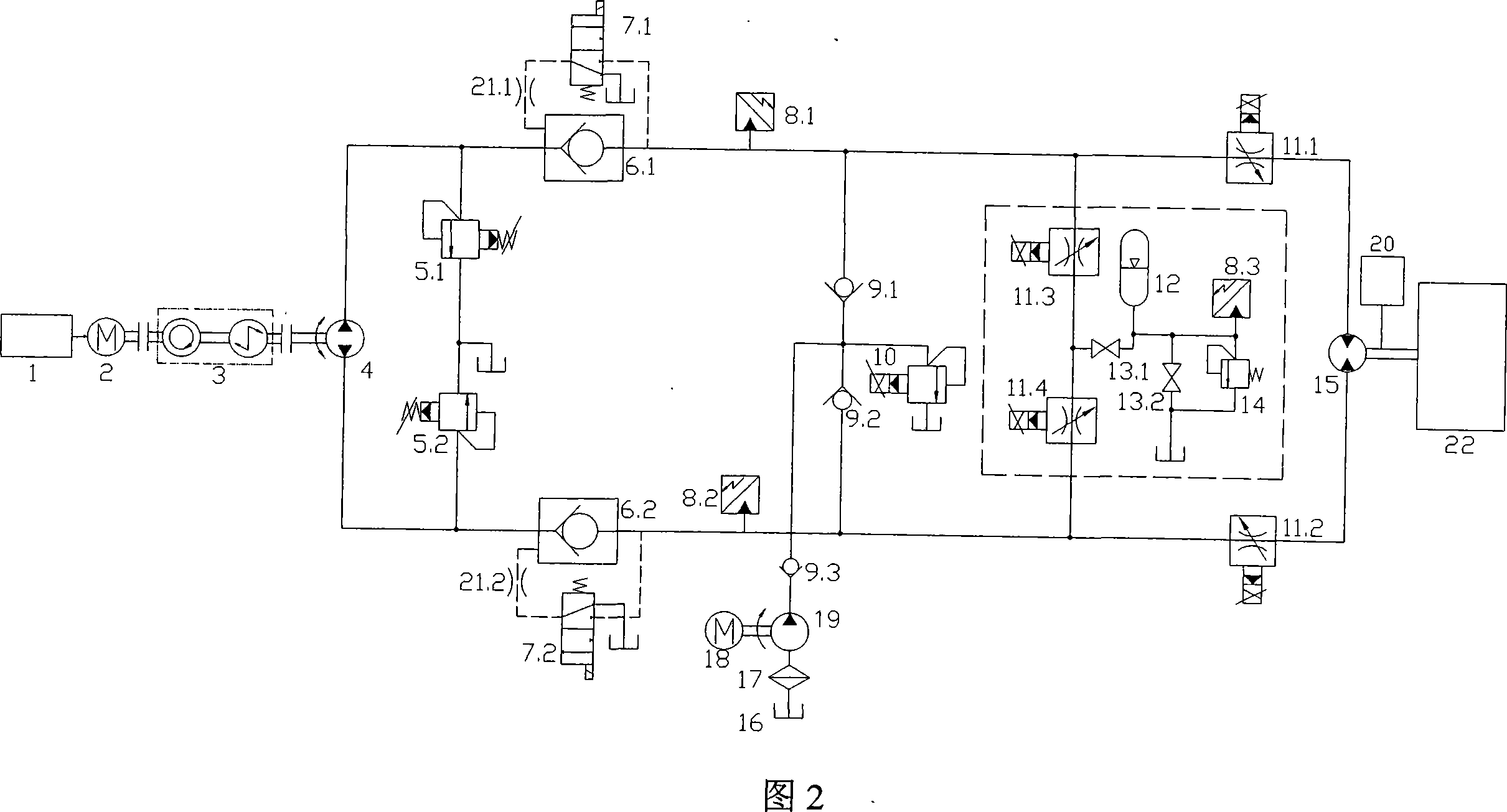

Variable frequency pump-control-motor closed circuit based on energy regulation

InactiveCN101201069AReduce lossQuick responseServomotor componentsServomotorsFrequency changerThrottle control

The invention discloses a closed loop of a variable frequency pump-control motor, which is based on the energy regulating. The invention includes an inverter, a motor, a hydraulic pump, a safety valve group, an oil supplementing module and a hydraulic motor. The inverter drives the motor which drives the hydraulic pump. The safety valve group, the oil supplementing module and the hydraulic motor are connected astride in the closed circuit. An energy regulator is connected astride in the main circuit between the oil supplementing module and the hydraulic motor. A flow direction control valve is respectively arranged in the upper main circuit and the lower main circuit between the safety valve bank and the oil supplementing module. A flow control valve is respectively arranged in the upper main circuit and the lower main circuit between the energy regulator and the hydraulic motor. Based on the energy regulating, the energy regulator and throttle control are added to the traditional closed circuit of the pump-control motor, which speeds up the booster response of the system greatly. The invention has good energy saving effect.

Owner:ZHEJIANG UNIV

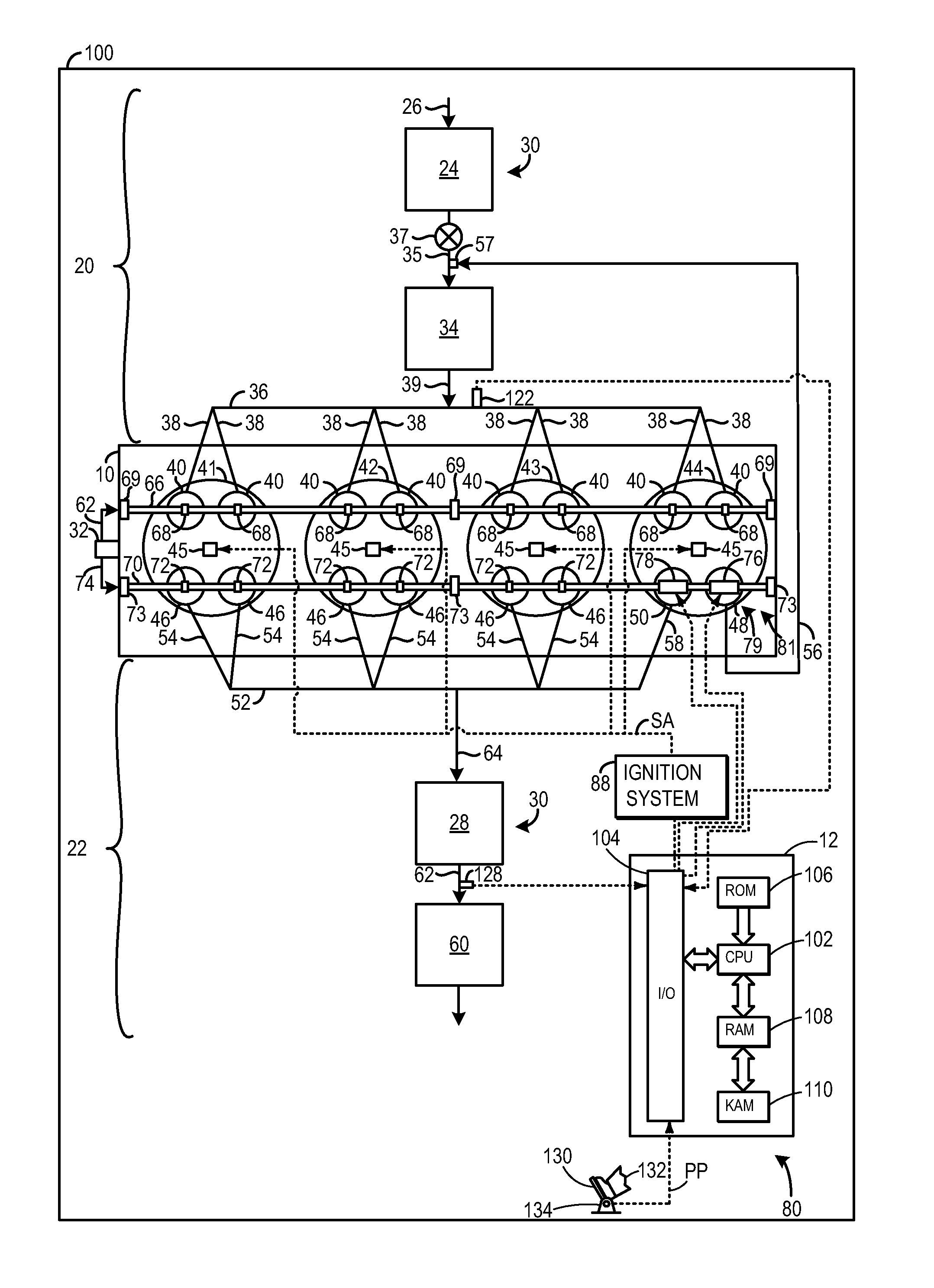

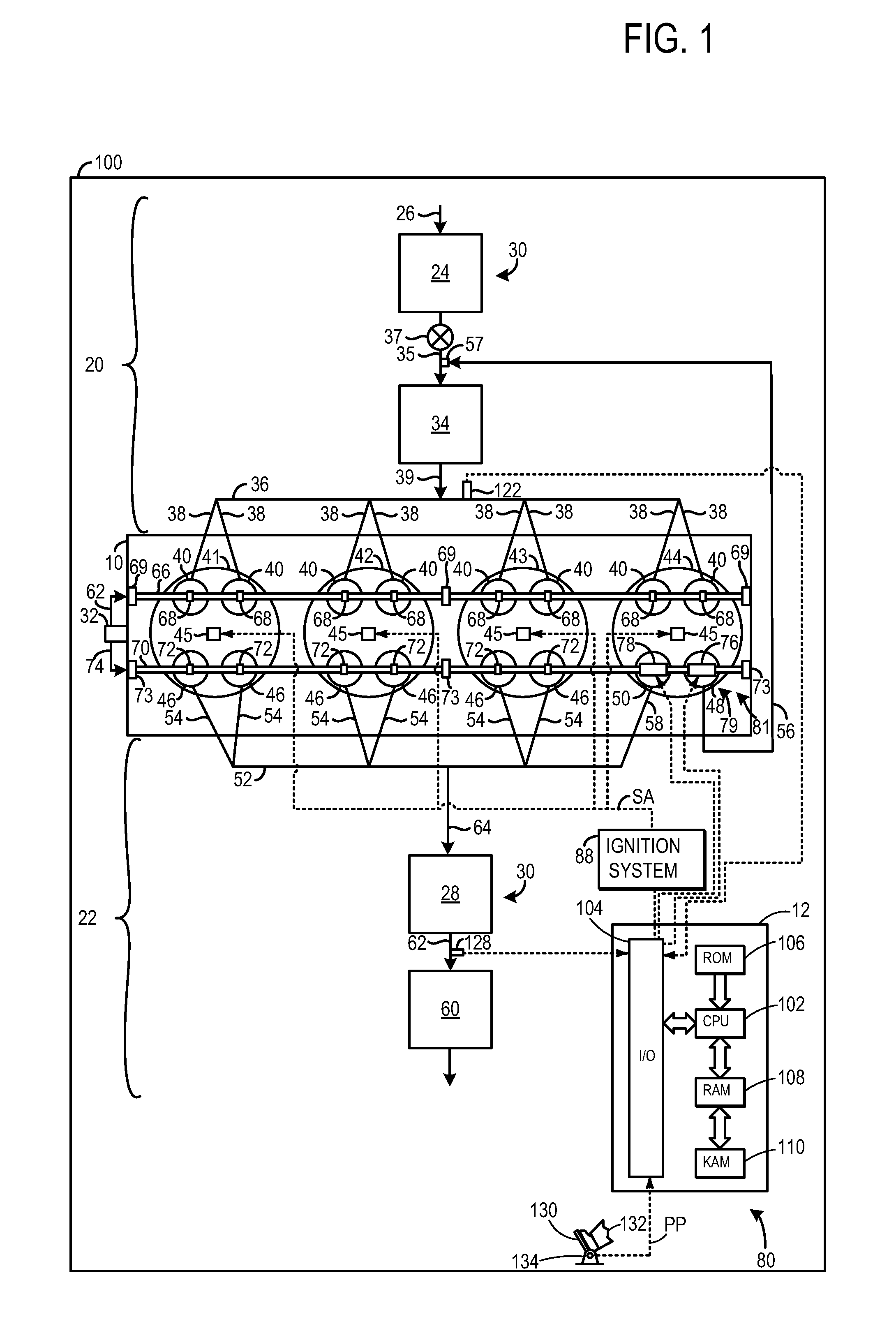

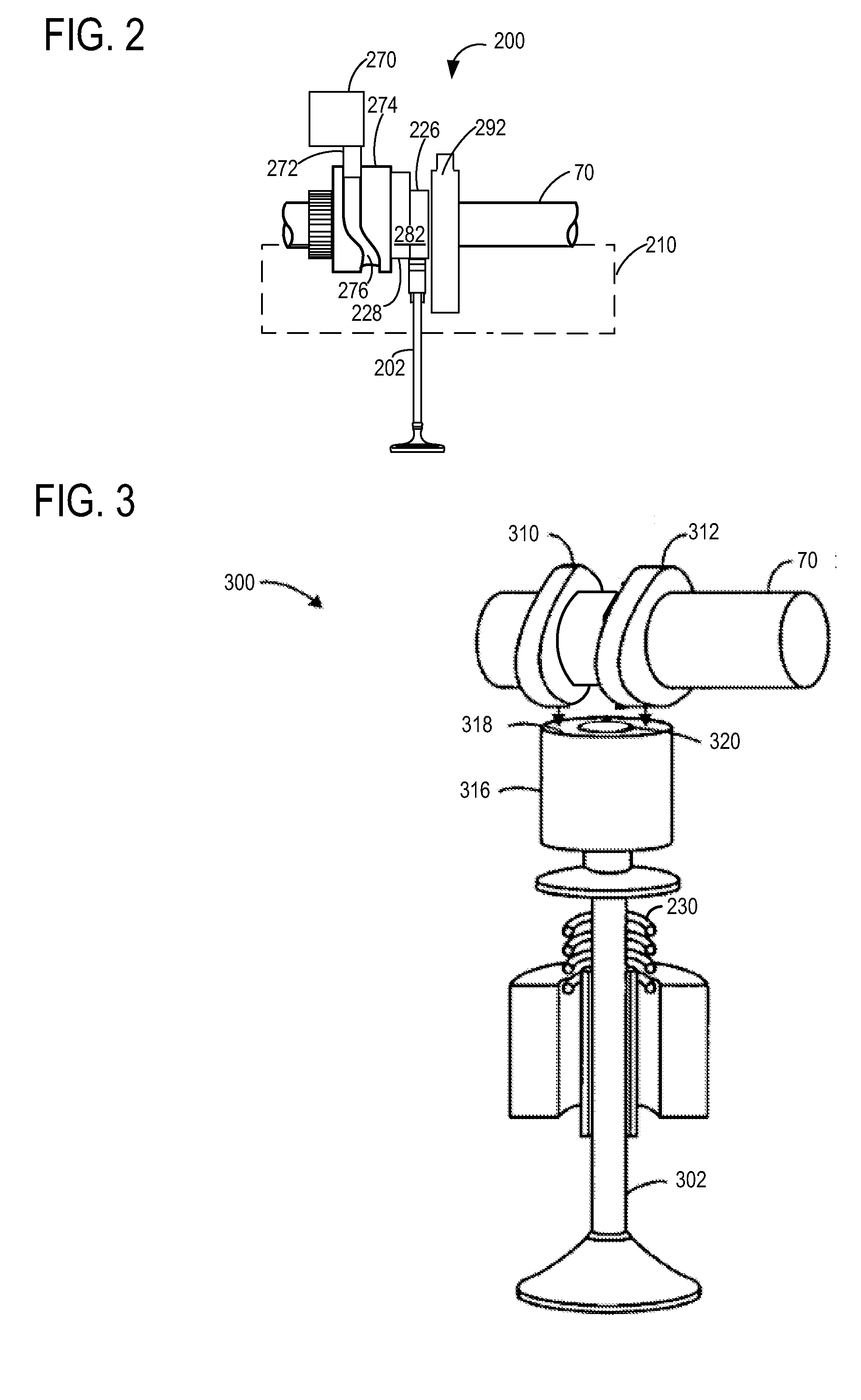

Devices and methods for exhaust gas recirculation operation of an engine

ActiveUS20140196703A1Emission reductionImprove combustion efficiencyValve arrangementsElectrical controlExhaust valveExhaust fumes

An engine is provided that includes an exhaust gas recirculation (EGR) conduit in fluidic communication with a first exhaust valve in a cylinder and an intake system, an exhaust conduit in fluidic communication with a second exhaust valve in the cylinder and an emission control device. During operation with the first valve active and the second valve deactivated, a fixed EGR level can be provided. However, during operation with the first valve deactivated and the second valve active, increased engine output can be achieved with reduced EGR without requiring additional exhaust throttling or switching valves.

Owner:CMR TECH +1

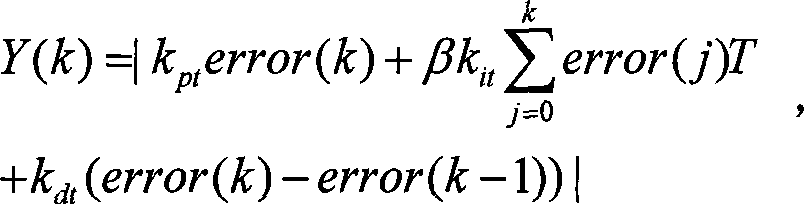

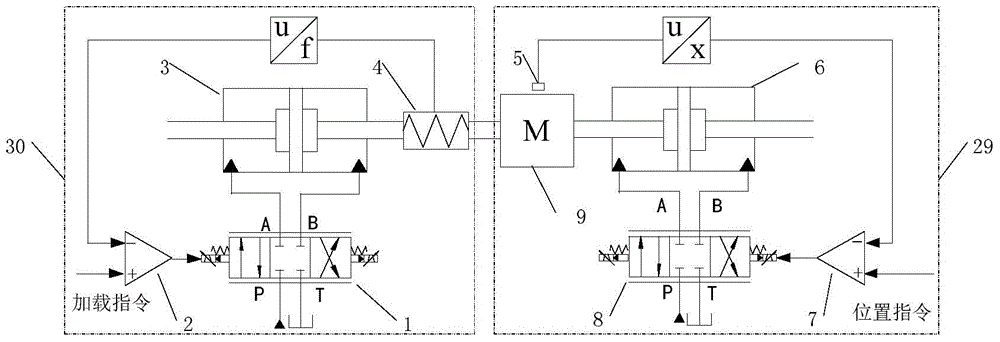

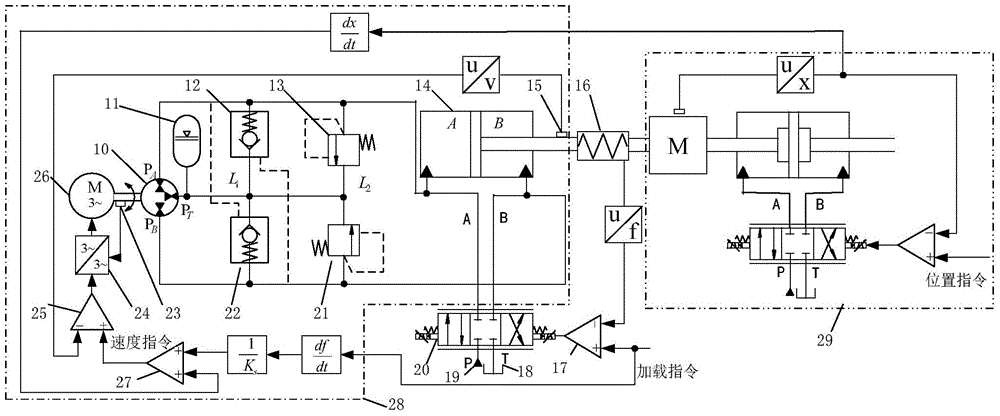

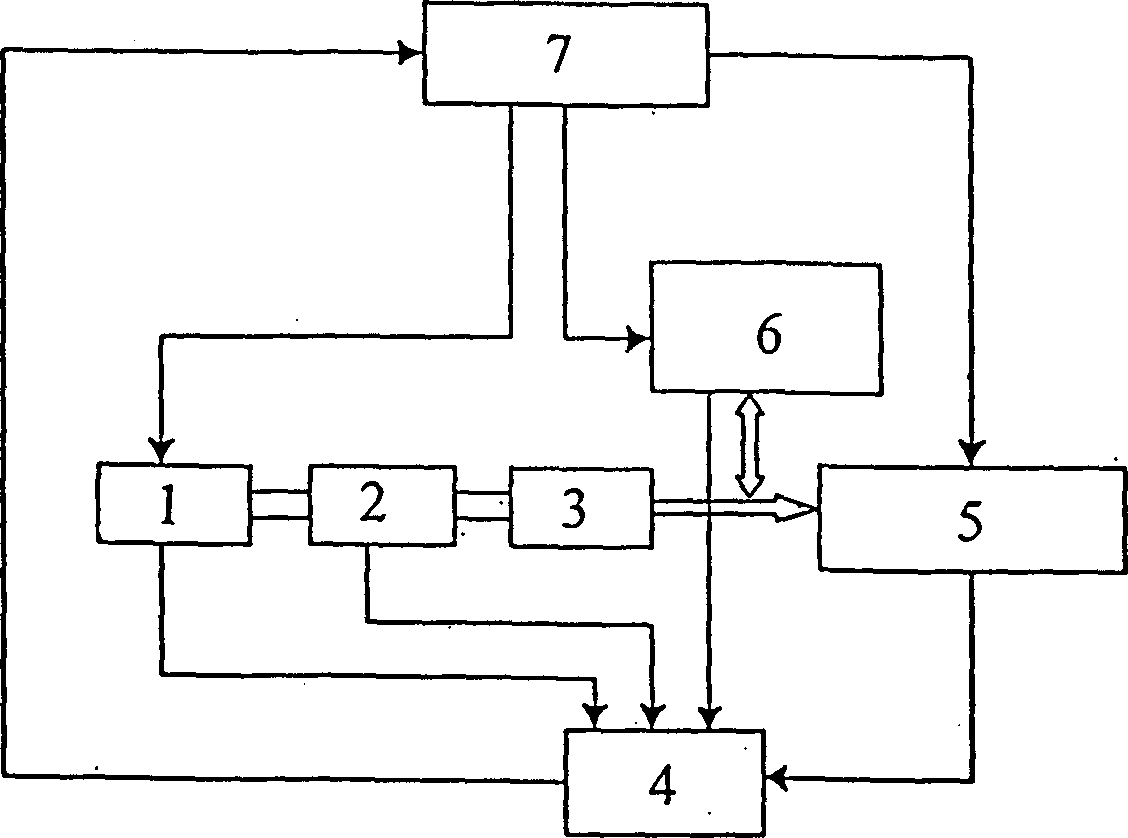

Pump-valve composite two-degree-of-freedom electro-hydraulic motion loading control method

ActiveCN104564915ASolve the problem of excess force interferenceSolve the real problemServometer circuitsSoftware simulation/interpretation/emulationLoad instructionElectro hydraulic

The invention discloses a pump-valve composite two-degree-of-freedom electro-hydraulic motion loading control method. According to the method, a pump-valve composite two-degree-of-freedom electro-hydraulic motion loading system is subjected to loading control, a speed servo subsystem and a pressure servo subsystem are subjected to independent coordination by a speed command planner to achieve two-degree-of-freedom servo control of speed and output force of a loading actuator, a speed controller controls rotating speed of a motor according to speed reference commands generated by the speed command planner, control of pressure of a chamber A and a chamber B of the loading actuator is achieved by adjusting displacement of a valve core of a loading valve, and further, the output force of the loading actuator is controlled to equal loading commands. The pump-valve composite two-degree-of-freedom electro-hydraulic motion loading control method achieves physical decoupling of steering engine motion interference, is high in loading precision and energy efficiency and is particularly applicable to high-power loading occasions.

Owner:山西亿鑫法兰股份有限公司

Electro-hydraulic control system and method based on frequency-conversion speed regulation

InactiveCN1391146AIncrease lossReduce lossFluid pressure controlFlow controlFrequency changerEnergy regulation

An electro-hydraulic control system based on frequency conversion type speed regulation is composed of frequency converter used to change rotation speed of pump, motor hydraulic pump, feedback unit for detection, hydraulic control system, energy regualting unit, and controller. The motor and hydraulic control valve are controlled by frequency converter. The electro-hydraulic control valve, energy regualting unit and frequency converter are controlled by controller. Its advantages are high efficiency, saving energy and high response speed.

Owner:ZHEJIANG UNIV

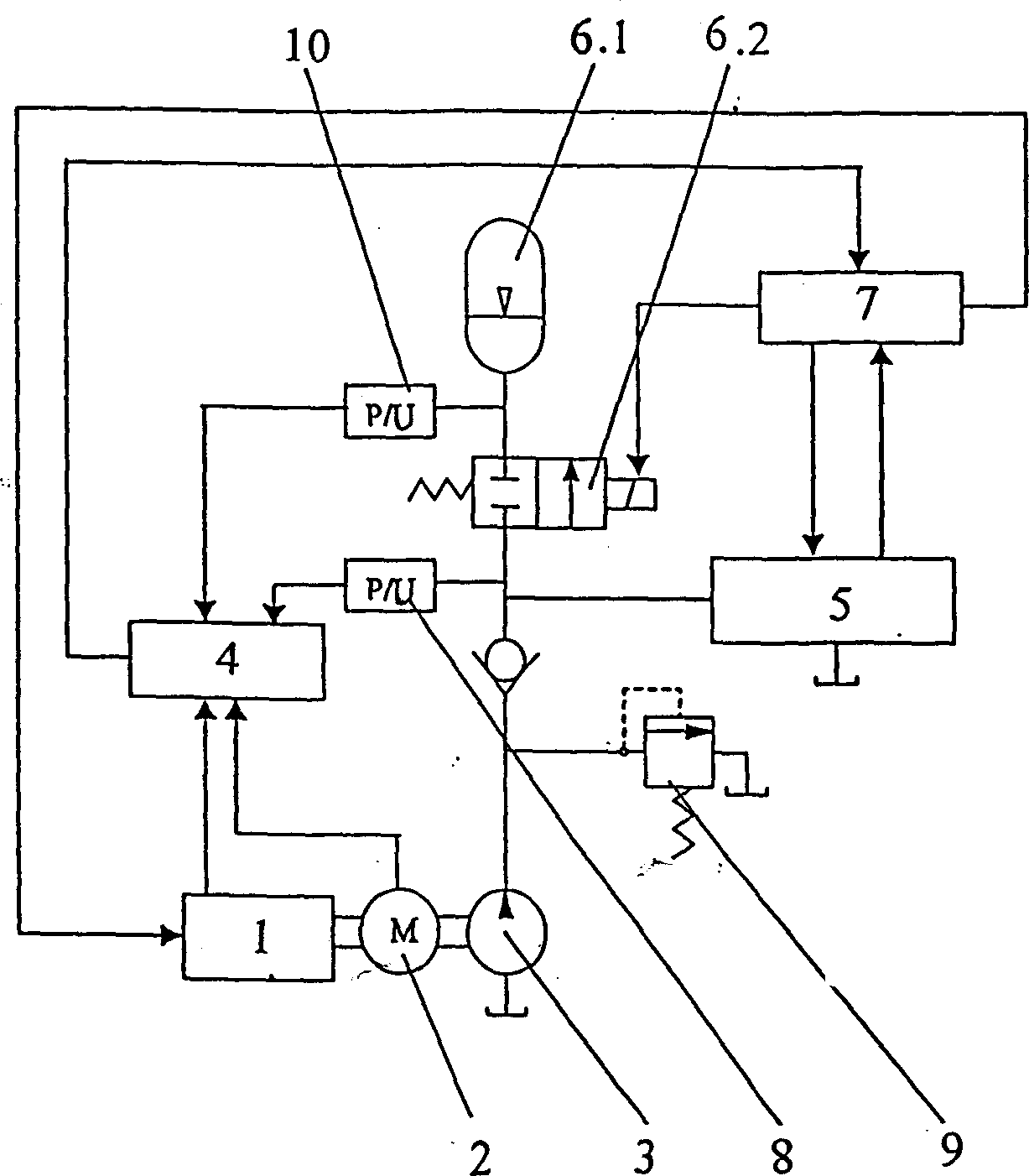

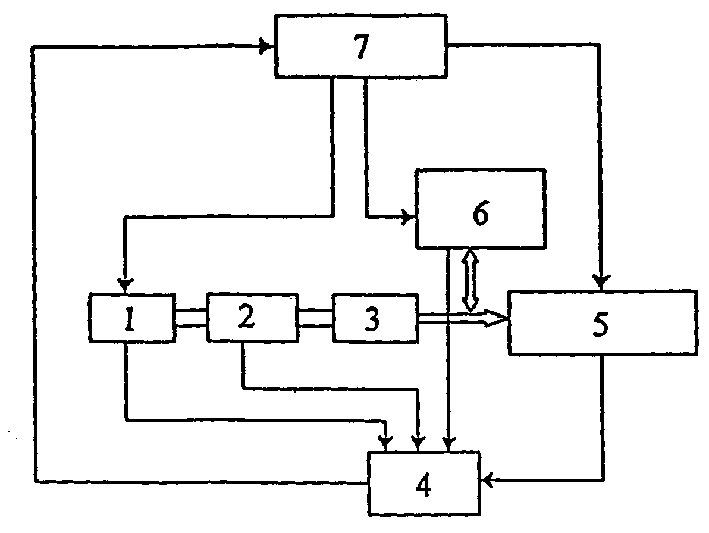

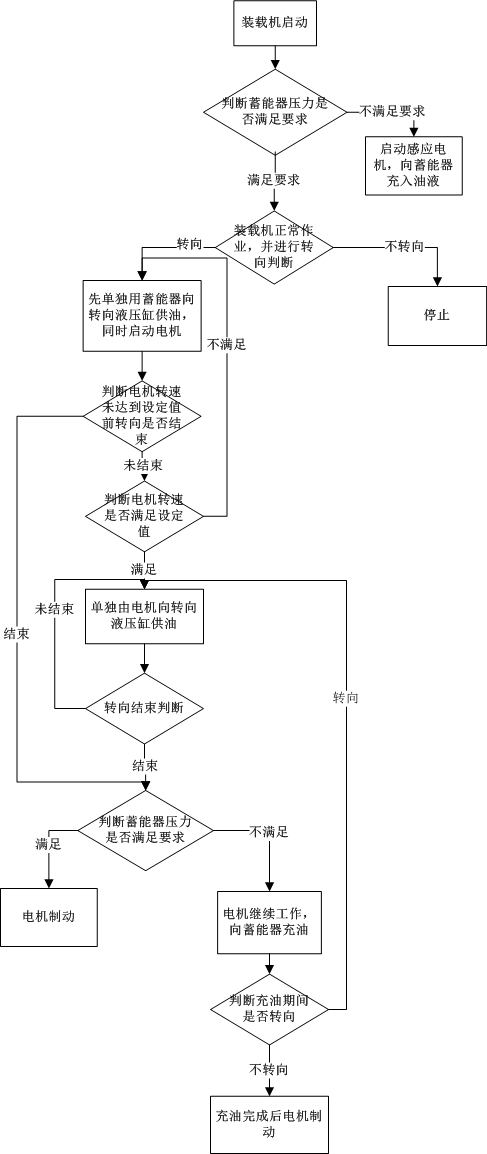

Frequency-conversion pump controlled steering hydraulic system for loader

InactiveCN102434502AImprove startup performanceHigh start-up performance requirementsAccumulator installationsFluid-pressure actuator componentsHydraulic cylinderMotor drive

The invention relates to a frequency-conversion pump controlled steering hydraulic system for a loader, wherein an alternating-current motor driven constant delivery pump is used as a main oil supply source, an energy accumulator is used as an auxiliary oil supply source. At the initial steering stage of the loader, the energy accumulator supplies oil to a steering hydraulic cylinder independently; after an alternating-current motor is started, the alternating-current motor driven constant delivery pump supplies oil to the steering hydraulic cylinder independently; through the mode, the response speed of a steering system is increased, and the energy consumption is saved at the same time; and after the loader is started, if the pressure in the energy accumulator is lower, the alternating-current motor driven constant delivery pump is used for injecting high-pressure oil liquid to the energy accumulator. The hydraulic system disclosed by the invention has the main advantage of high efficiency.

Owner:SICHUAN UNIV

Valve body external-open air distribution engine

InactiveCN101571068ASimple structureReduce volumeInternal combustion piston enginesLift valveInlet channelCombustion chamber

The invention discloses a valve body external-open air distribution engine which comprises an air inlet channel, an exhaust passage, a combustion chamber outer wall and a combustion chamber; the combustion chamber outer wall is provided with one or a plurality of external-open air distribution seat openings which cause the air inlet channel and the exhaust passage to be respectively or simultaneously communicated with the combustion chamber; each external-open air distribution seat opening is correspondingly provided with an external-open air distribution valve body; the external-open air distribution valve body is directly controlled or through a connecting piece by a valve body timing control device. The external-open air distribution seat opening corresponding to the external-open air distribution valve body is opened or closed according to the timing requirement of the engine. The engine can reduce the loss of air distribution and flow restriction and causes the degree of air current flowing and flue gas mixing in an air cylinder to be increased, thus increasing the efficiency of the engine.

Owner:靳宇男

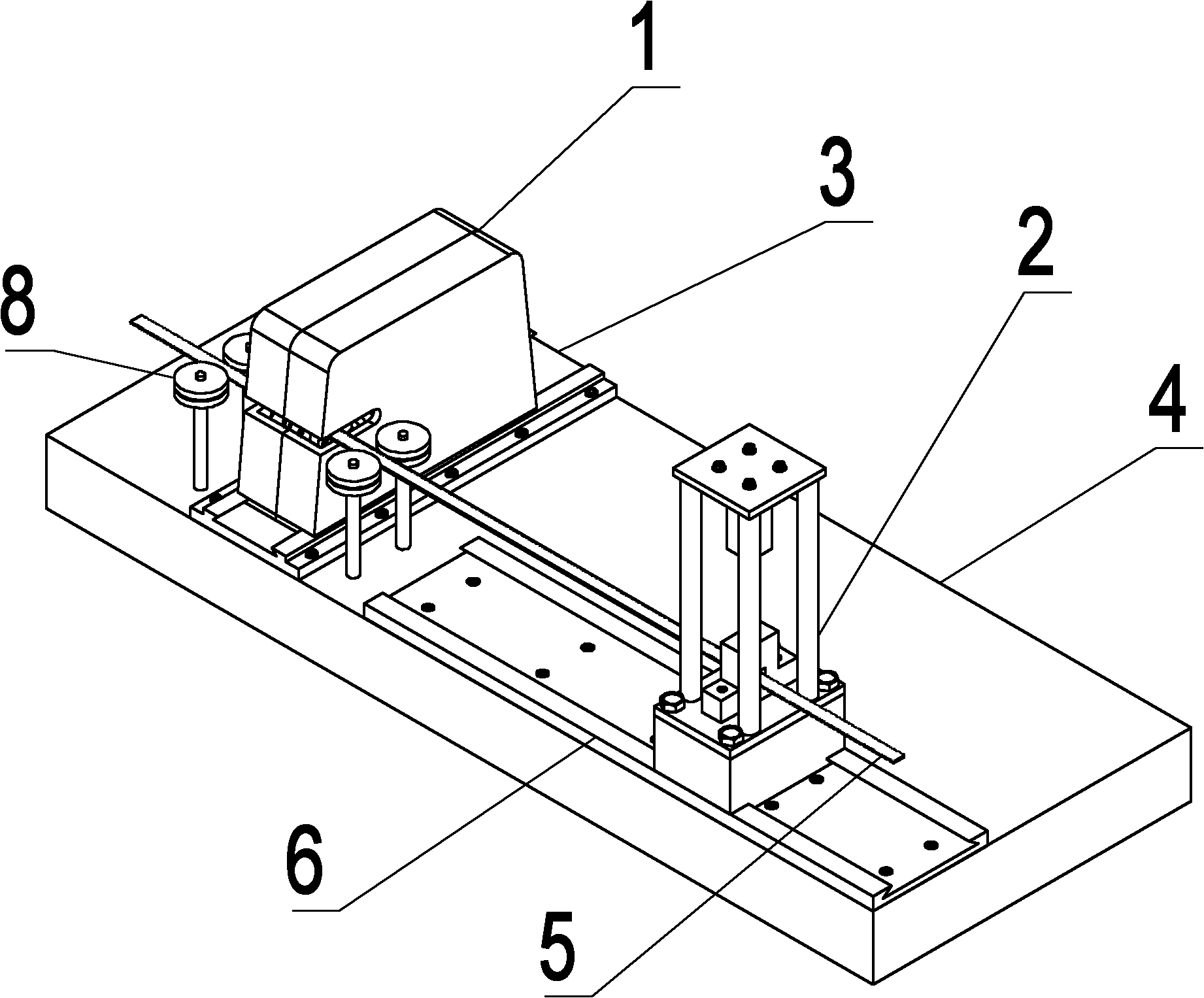

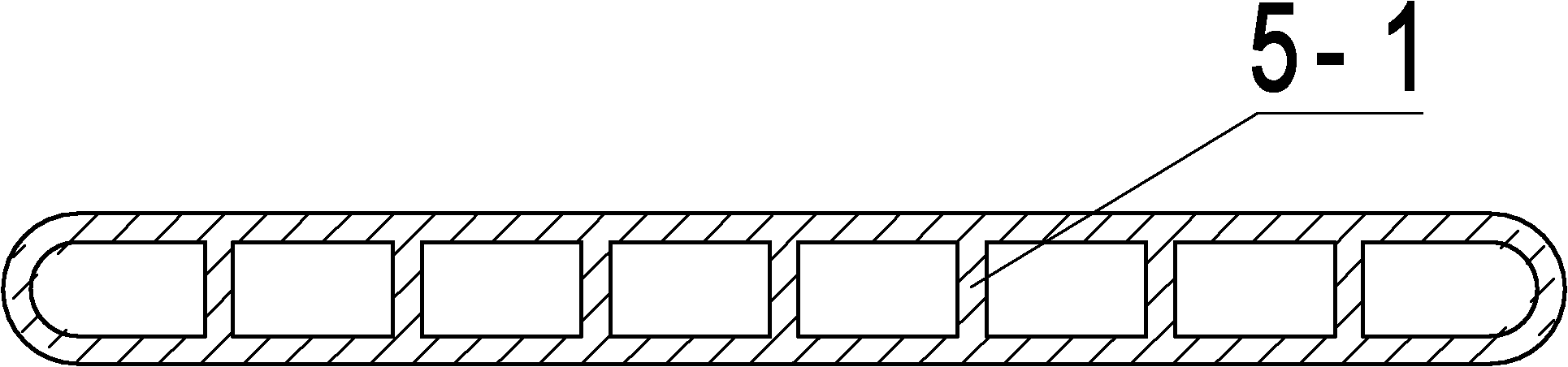

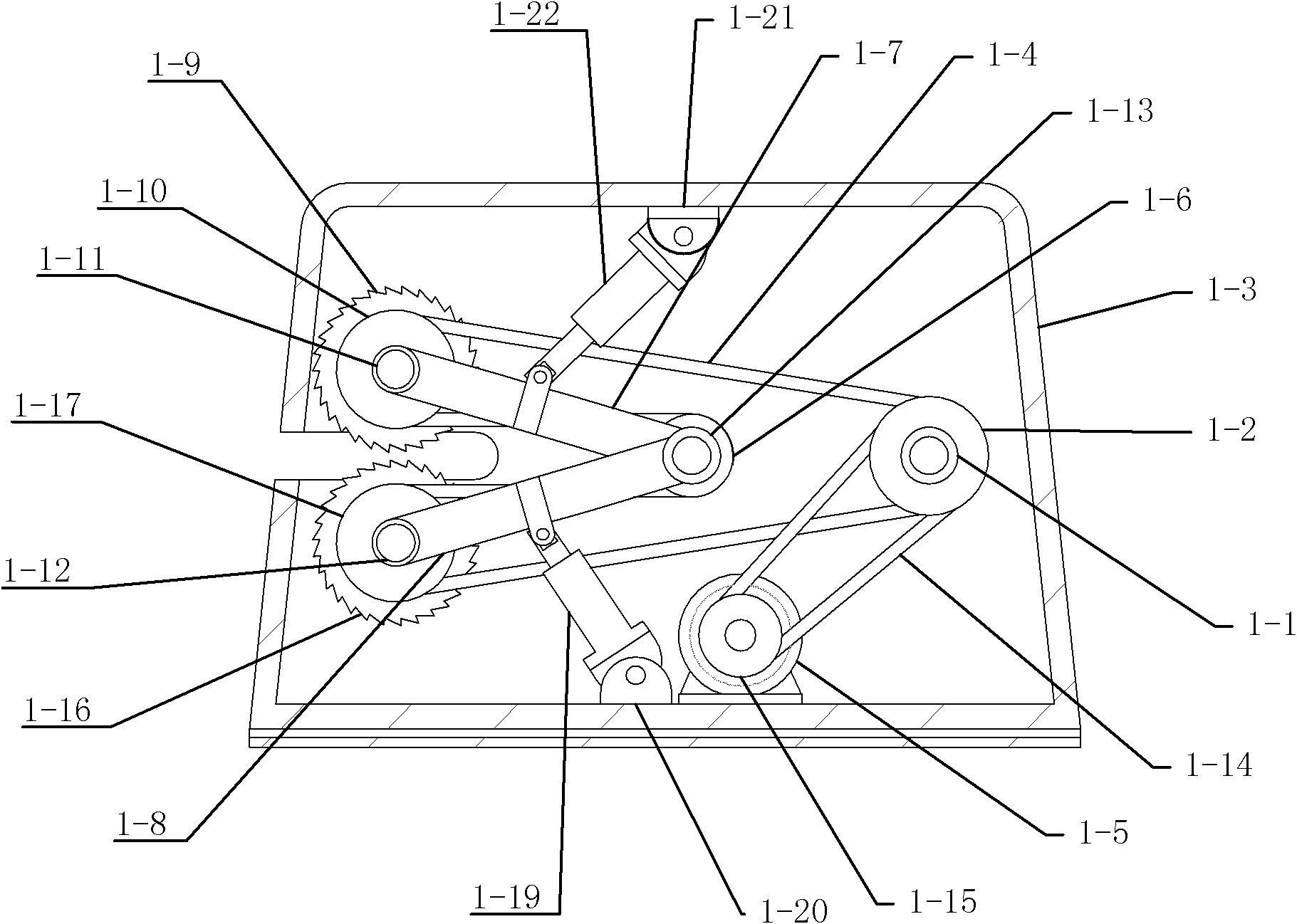

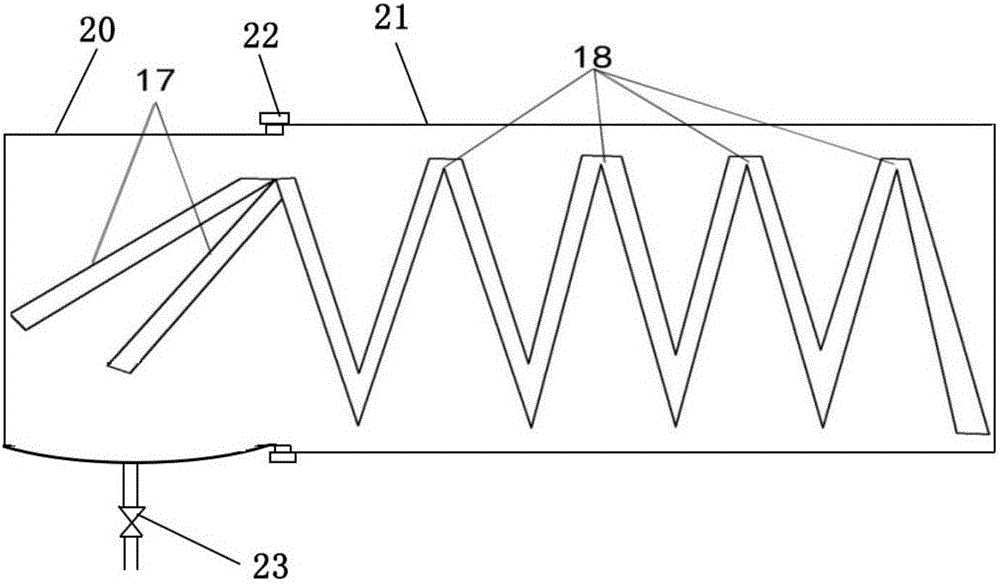

Device for cutting off flat tube of heat exchanger

ActiveCN102009349AReduce throttling lossIncrease productivityOther manufacturing equipments/toolsPlate heat exchangerMilling cutter

The invention provides a device for cutting off a flat tube of a heat exchanger, which comprises a machine base, a milling mechanism capable of transversely sliding along the machine base and a die-cutting mechanism capable of longitudinally sliding along the machine base, wherein the flat tube which is longitudinally conveyed along the machine base is arranged in the milling mechanism and the die-cutting mechanism by penetration, a milling cutter for milling the flat tube and forming a milling cut is arranged on the milling mechanism, and a die cutter which can detect the position of the milling cut and perform die-cutting is arranged on the die-cutting mechanism. The device has the advantages that the device for cutting off the flat tube of the heat exchanger can avoid the deformation and the shrinkage of the cut-off end surfaces of the flat tube, lead the flow of refrigerant to be smooth and improve the heat exchange efficiency of the heat exchanger.

Owner:浙江兰通空调设备有限公司

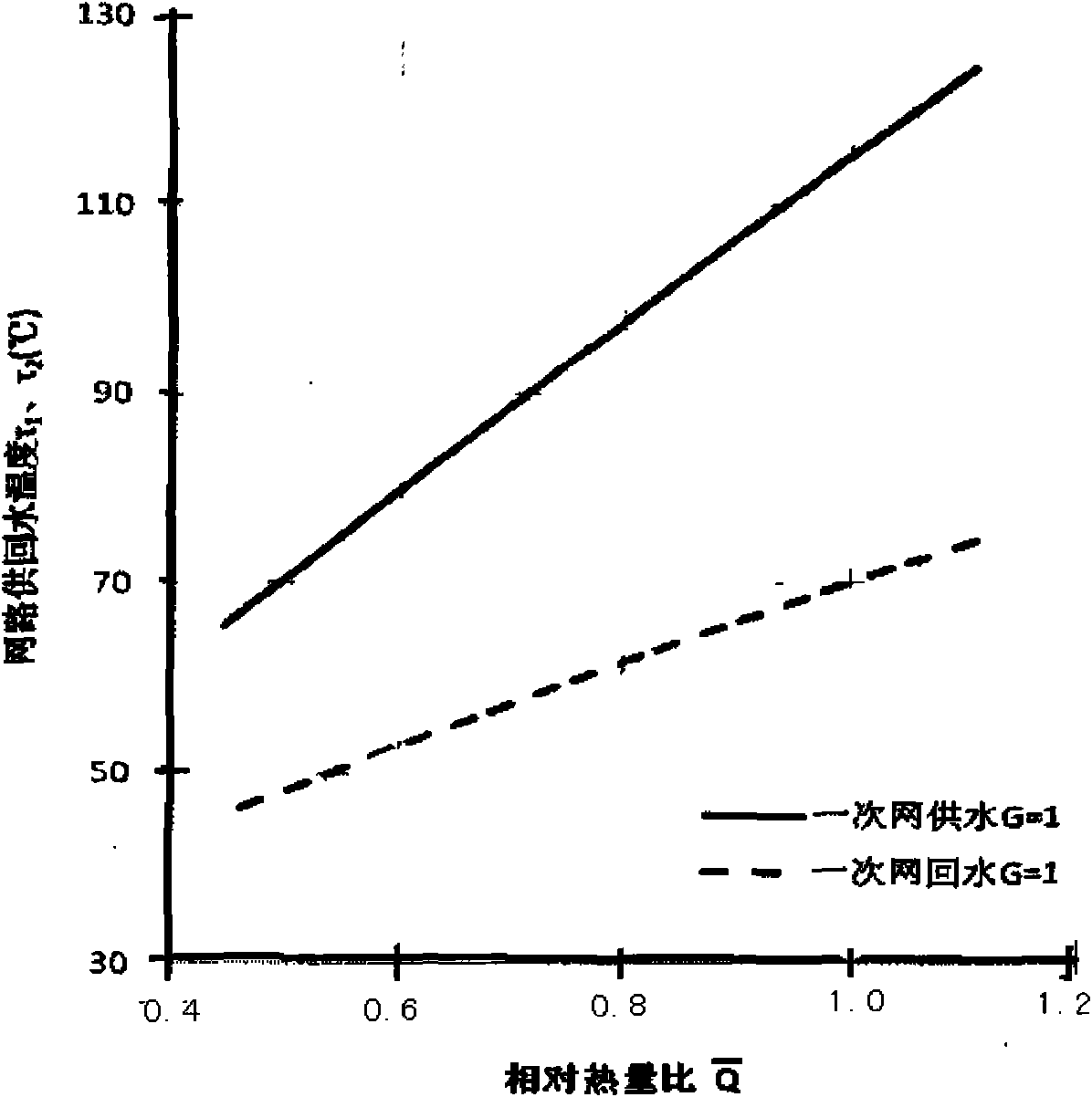

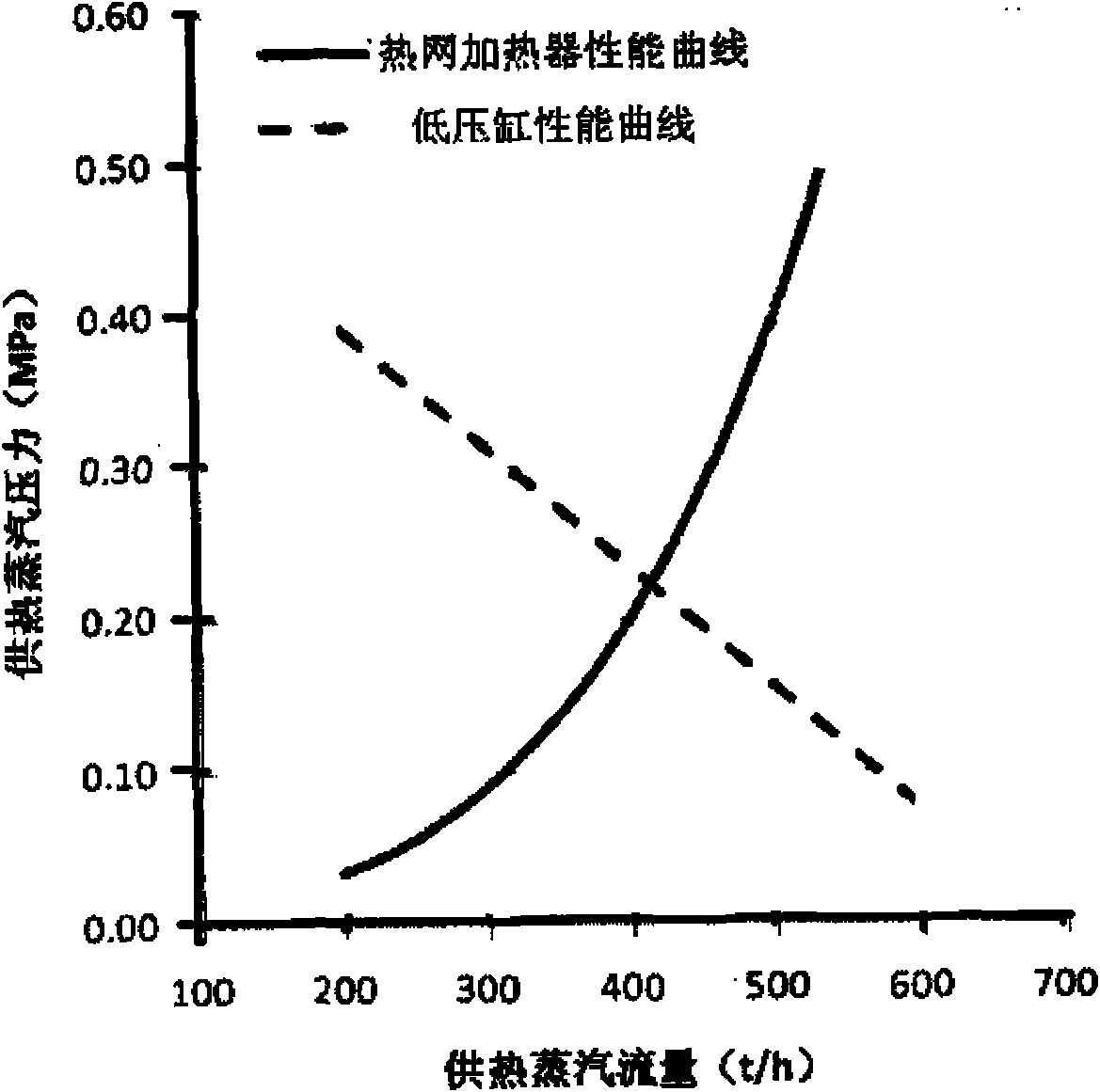

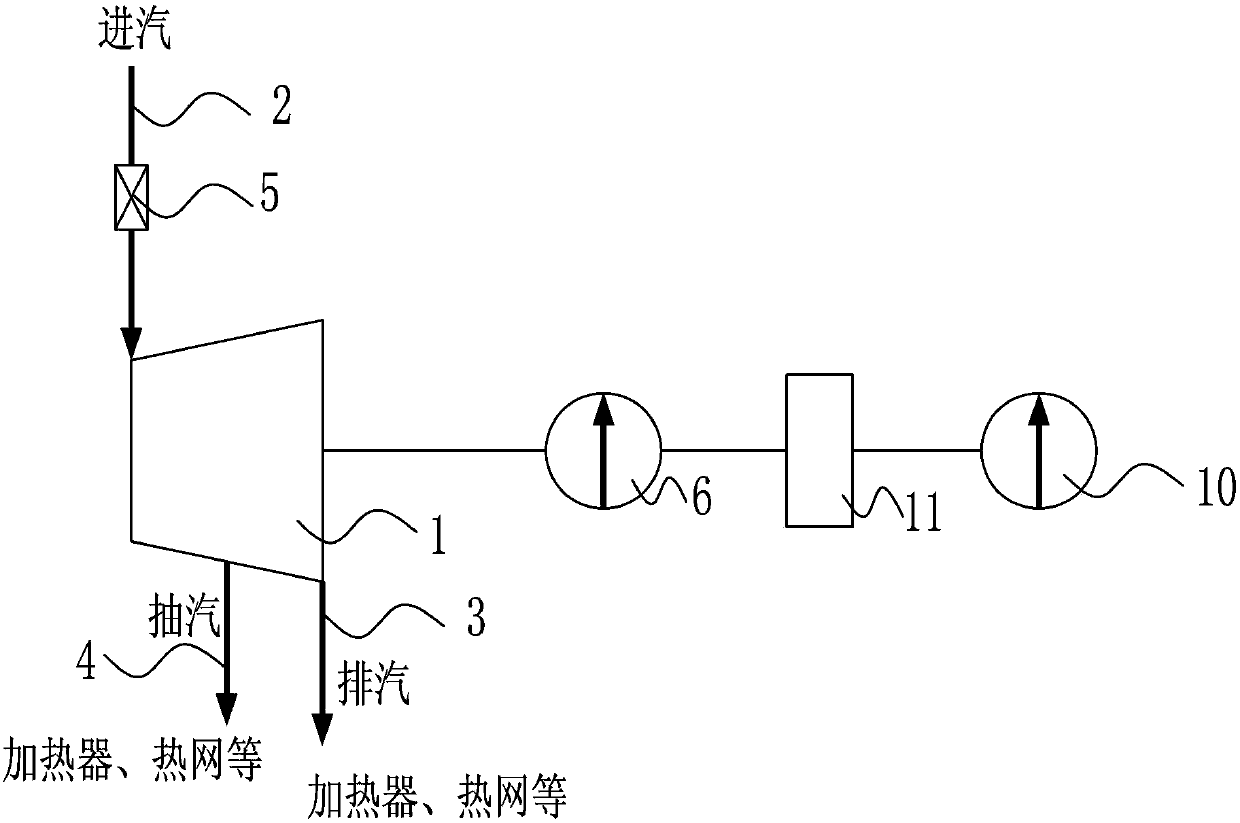

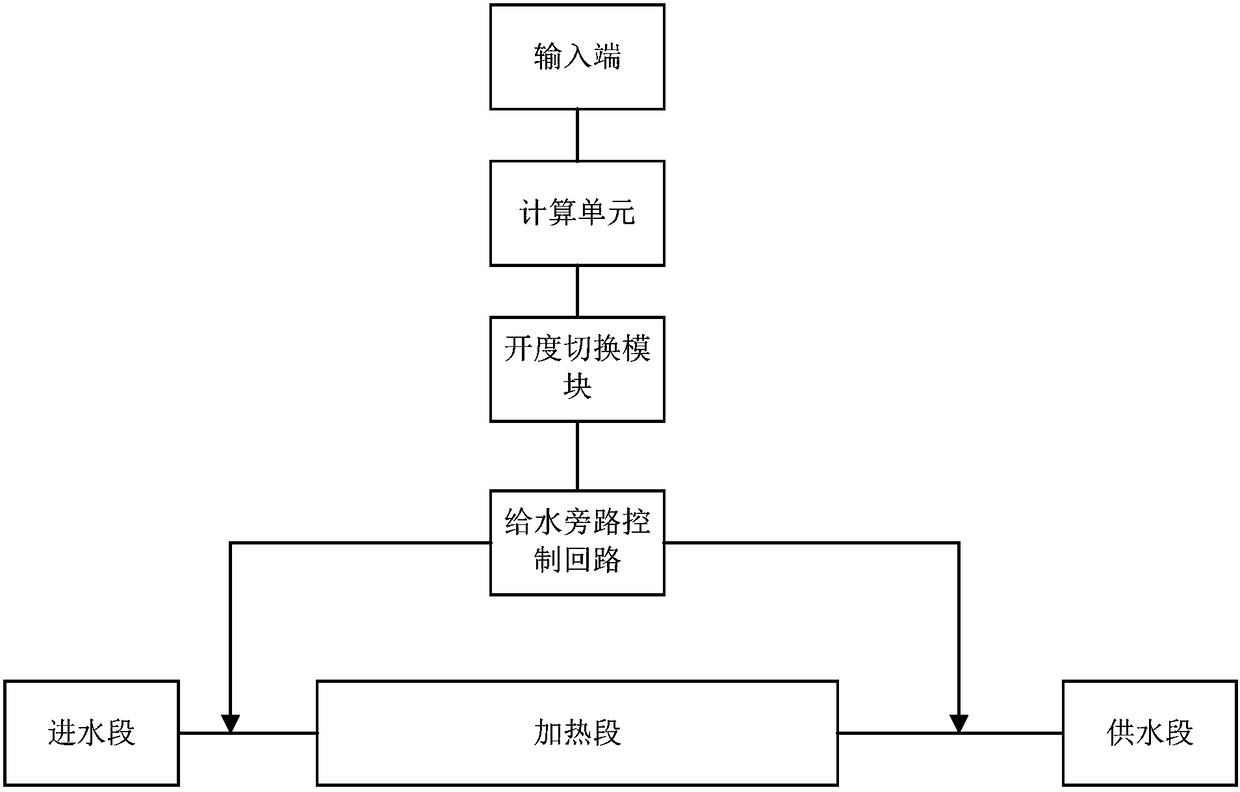

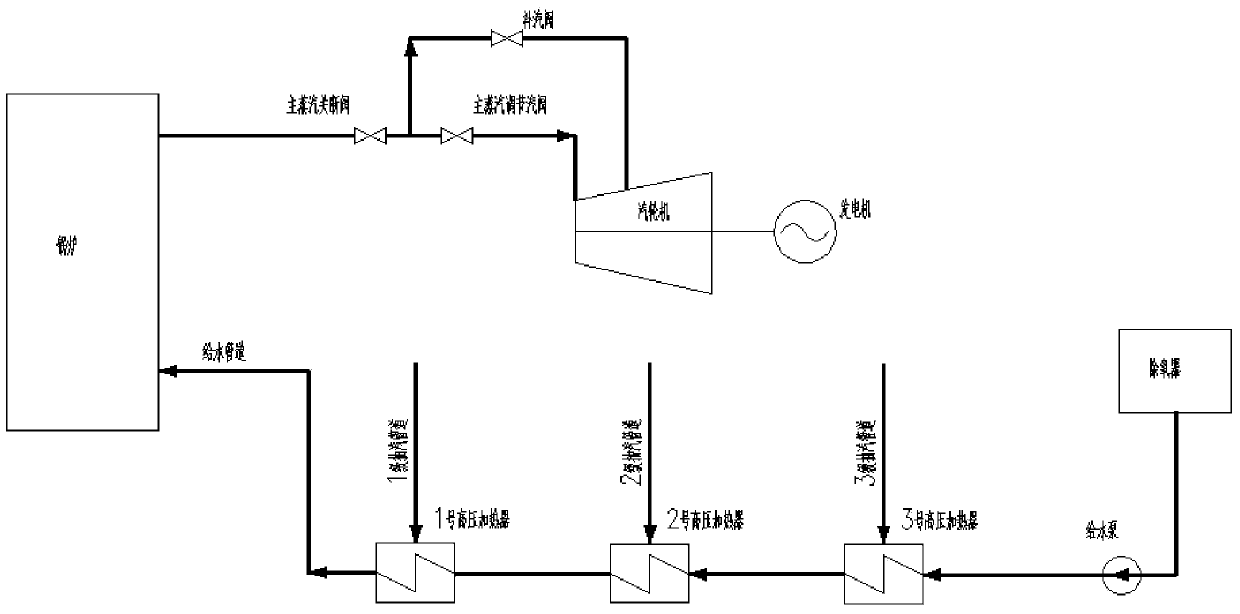

Adjusting method for heating steam of cogeneration system

InactiveCN101672203AReduce wasteReduce throttling lossSteam useEngine componentsCogenerationEngineering

The invention discloses an adjusting method for heating steam of a cogeneration system, which belongs to the energy technical field, can improve the heat efficiency of a central heating system greatlyand can improve the heating efficiency of a heating unit. In the method, based on the corresponding reasonable use of the temperature of the heating steam of the cogeneration system, a heat supply network, a heat supply network heater and the hating unit are considered as an integral system, so as to provide the heating steam extraction parameter accurately and reduce the throttle loss in the heating process; the heating load of a heat user changes along with the change of the outdoor temperature, namely, the return water supply temperature of the heat supply network is changed, so as to change the steam extraction parameter of the heating unit; due to the associated coordination of the heat supply network, the heat supply network heater and the hating unit, the heating steam extraction parameter is matched with the external heating load requirement, so as to produce heating water or domestic hot water that meets the heating requirement; thereby not only meeting the comfort requirement of the heat user, but also improving the generated energy of the heating unit and increasing the economic benefit of a heating power plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

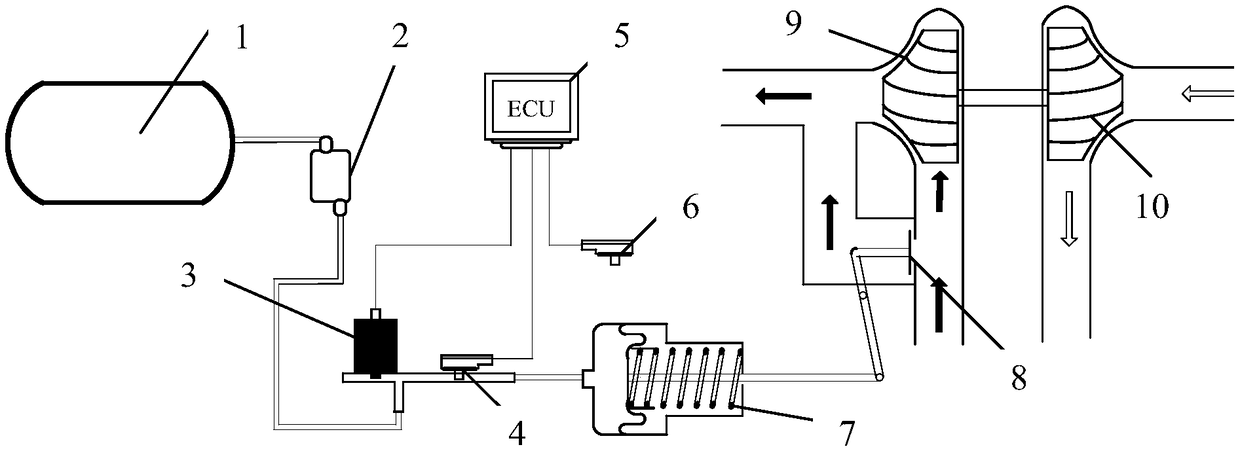

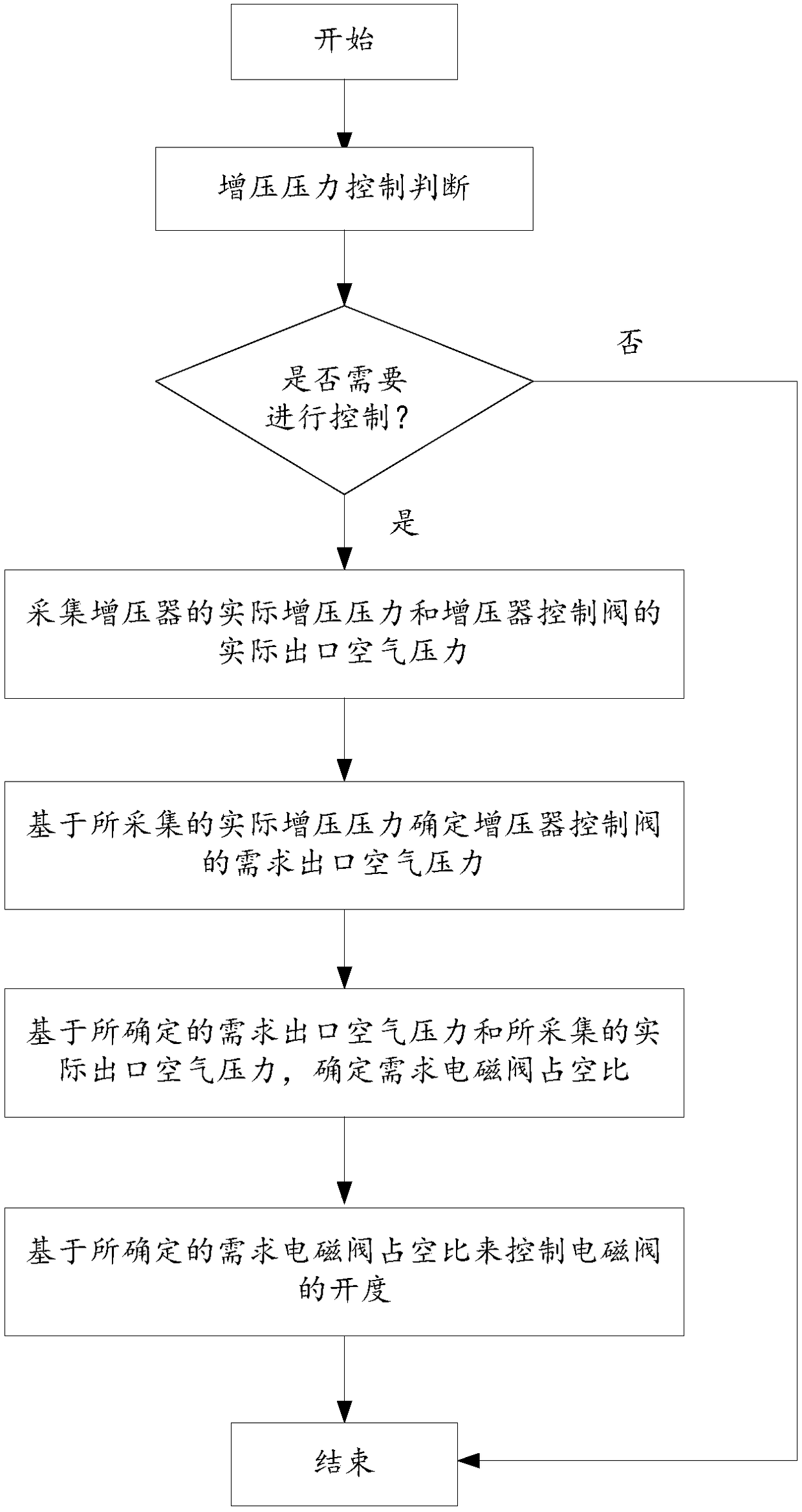

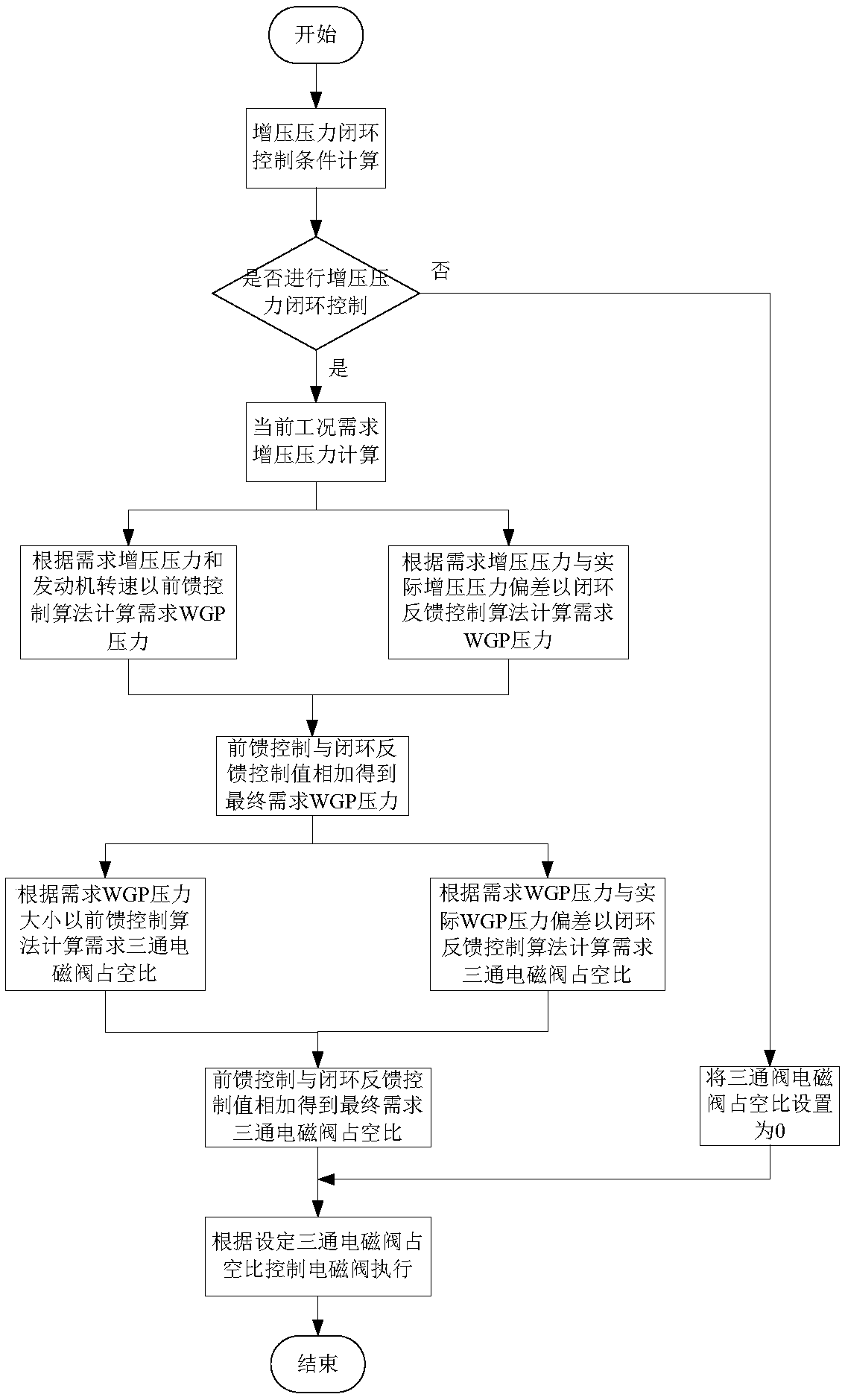

Natural gas engine waste gas bypass type booster control system and method

ActiveCN108087108AReduce fuel consumptionStable controlInternal combustion piston enginesBottlePressure data

The invention provides a natural gas engine waste gas bypass type booster control system which comprises a compressed air storage bottle, a pressure reducer, a booster control valve, a waste gas bypass pressure sensor, an engine control unit, a boosting pressure sensor, a booster waste gas bypass control membrane valve and a booster. The booster comprises a booster waste gas bypass valve, a booster turbine and a booster compressor. The engine control unit controls opening of an electromagnetic valve on the basis of pressure data collected by the boosting pressure sensor and the waste gas bypass pressure sensor, therefore, outlet air pressure of the booster control valve is controlled, and opening of the booster waste gas bypass valve is controlled. The invention further provides a naturalgas engine waste gas bypass type booster control method. An air inlet throttle loss can be reduced, exhaust back pressure can also be reduced, the charging efficiency is improved, and finally fuel economy is improved.

Owner:CHINA FIRST AUTOMOBILE

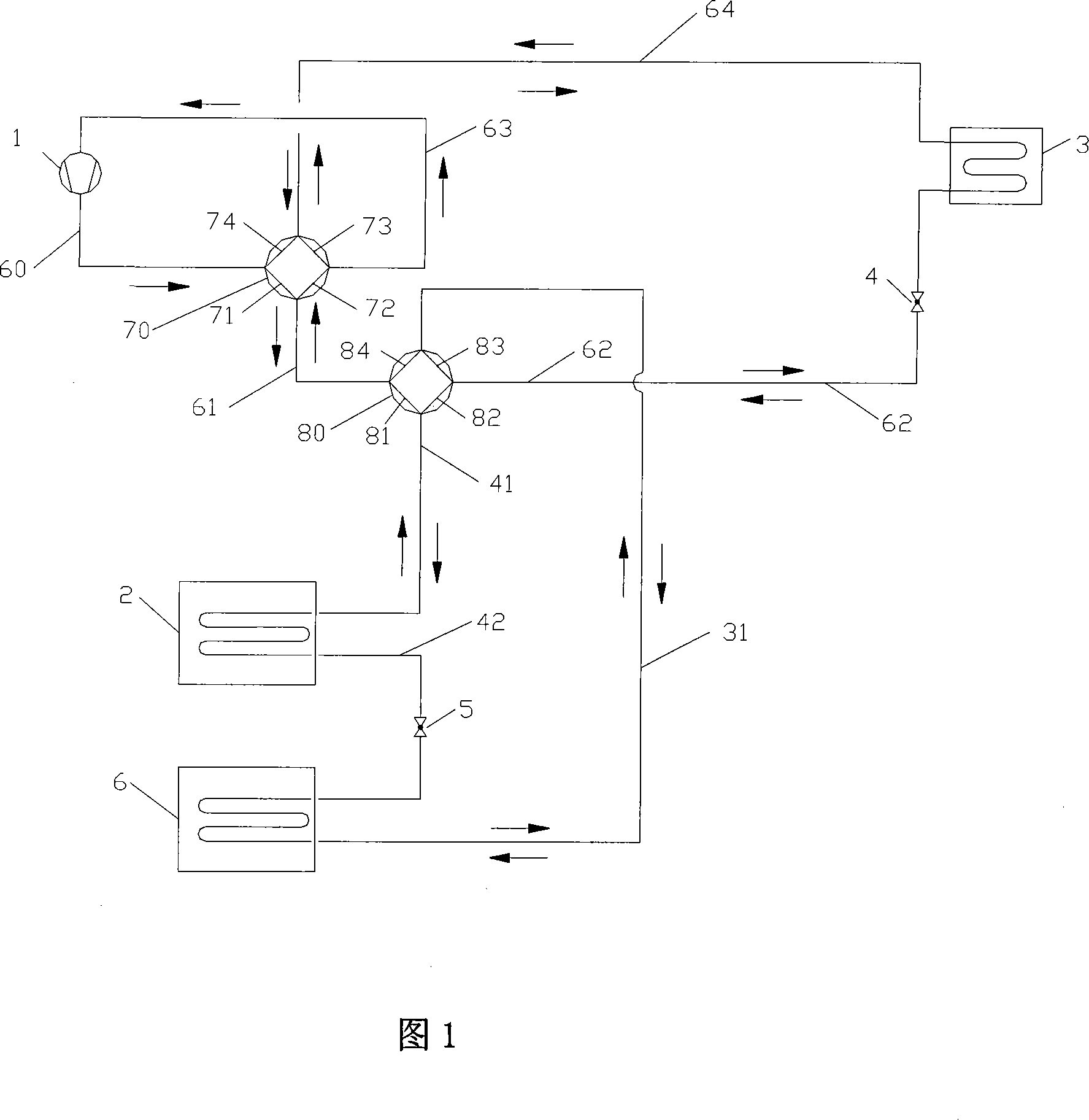

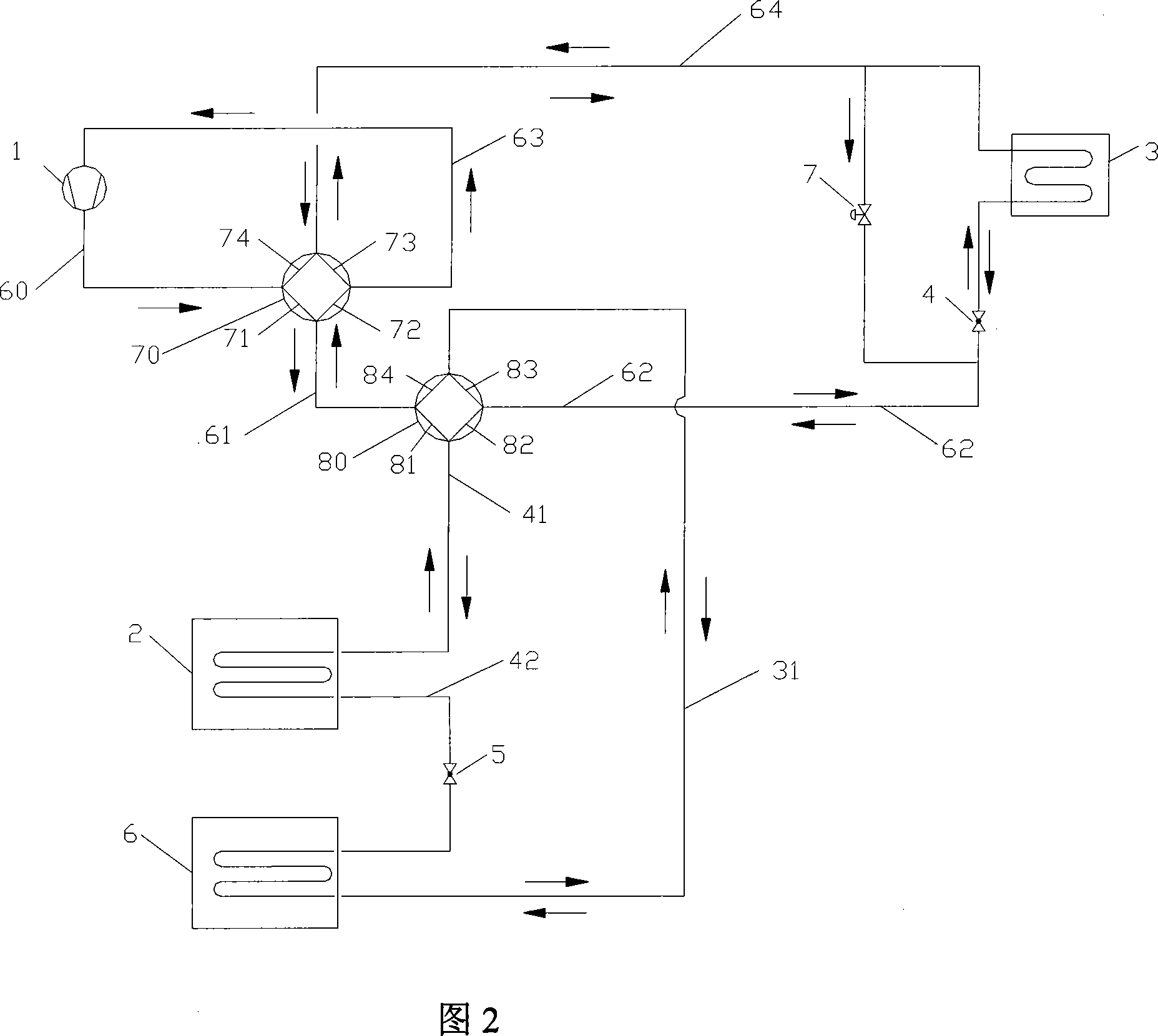

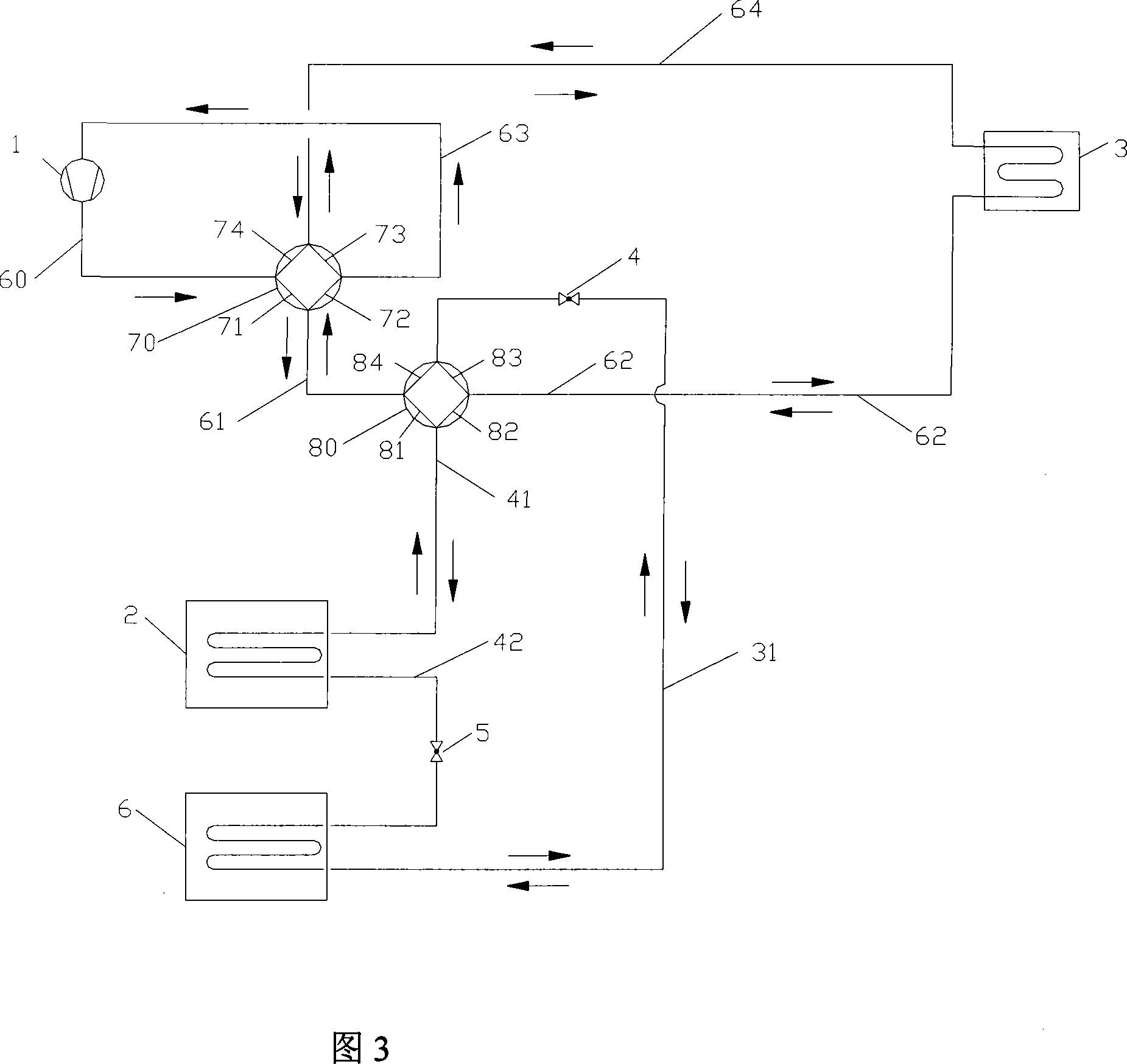

Winter, summer bi service heat pump apparatus of air source

InactiveCN101093117AAvoid canceling each other outReduce consumptionHeat pumpsCorrosion preventionSuper coolingFour-way valve

This invention discloses an air-source thermal pump device used in summer and winter including a compressor, an outdoor heat-exchanger, a user heat-exchanger, a throttle unit and a four-way valve. This invention adds an outer door second heat exchanger, a throttle unit and a four-way valve, which absorbs heat from outdoor air when defrosting in winter to realize defrosting to hot gas and avoid counteract of cold and hot volume and reduce energy cost in the process and increase performance of hot pump device, besides, this invention can realize super-cooling of cooling agent.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

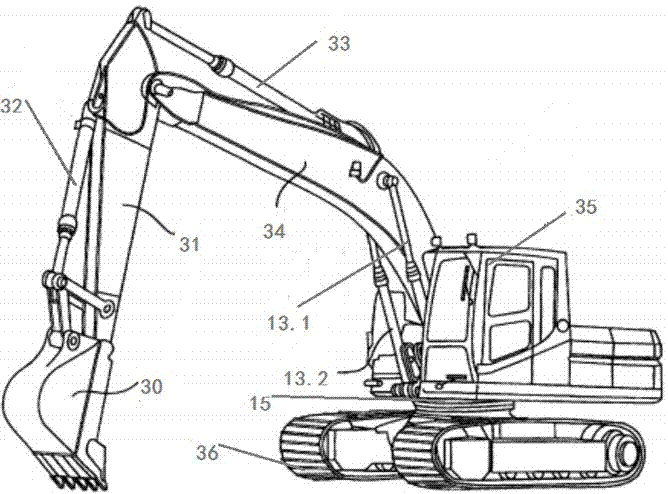

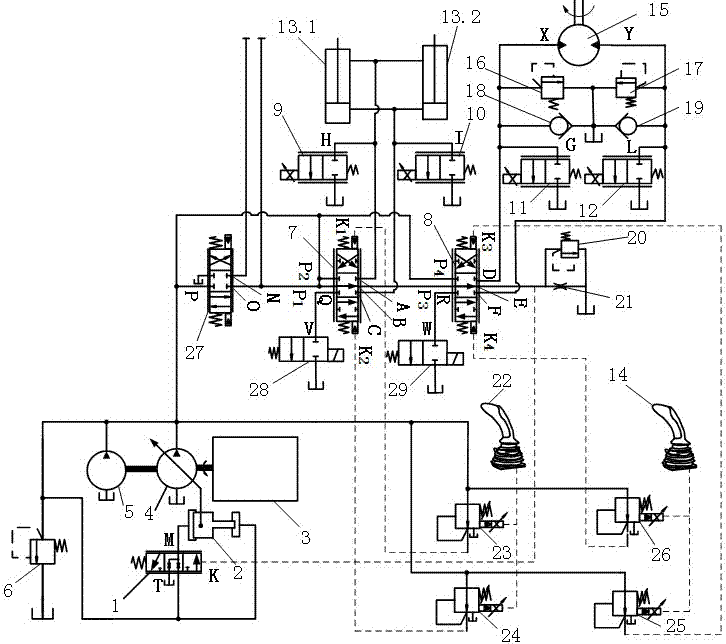

Negative flow inlet and outlet separated combined control hydraulic system

ActiveCN107059983AAchieve regenerationRun fastSoil-shifting machines/dredgersHydraulic cylinderHydraulic motor

A negative flow inlet and outlet separated combined control hydraulic system is additionally provided with four proportional throttle valves and two two-position two-way electromagnetic valves. The proportional throttle valves are additionally arranged in a movable arm hydraulic cylinder and a rotation hydraulic motor while displacement of a main pump is changed through negative flow control. When the main pump supplies oil to the movable arm hydraulic cylinder or the rotation hydraulic motor through a main control multi-path valve, the pressure or flow of the cavity to which the oil is supplied is controlled by the main control multi-path valve; the other of the movable arm hydraulic cylinder and the rotation hydraulic motor communicates with the proportional throttle valves, the pressure or flow thereof is controlled through movement of a valve element, and separated control over the pressure or flow of an oil inlet and an oil outlet is achieved. According to the negative flow inlet and outlet separated combined control hydraulic system, the throttling loss of a valve port is reduced, and the amount of system heating is reduced; and particularly under the overcharging situation, the throttling loss is remarkably reduced, the operation speed of a hydraulic actuator is improved, flow regeneration is achieved easily, and the effect is more remarkable.

Owner:TAIYUAN UNIV OF TECH

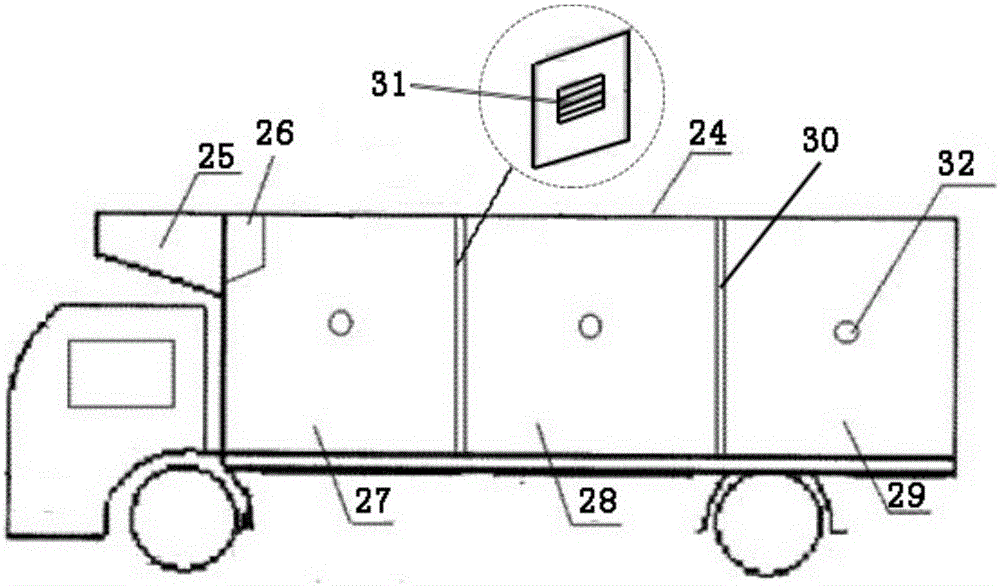

Multi-partition logistics apparatus

ActiveCN105857155ASimple structureMeet simultaneous transportationAir-treating devicesExhaust apparatusLogistics managementEnergy recovery

The invention discloses a multi-partition logistics apparatus which comprises a compartment, a refrigerating unit, an evaporator and an engine energy recovery device. The compartment is sequentially divided into a freezing chamber, a refrigeration chamber and an insulating chamber through insulation boards front left to right. The refrigerating unit is mounted at the front end of the freezing chamber and used for refrigeration. The evaporator of the refrigerating unit is arranged in the freezing chamber and used for exchanging heat with air in the freezing chamber. Each insulation board is provided with an electrically controlled louver and used for controlling the temperatures in the three chambers by being matched with a solar heat collecting plate on the roof. The freezing chamber, the refrigeration chamber and the insulating chamber are each provided with a temperature sensor. The logistics apparatus is driven by an engine, and the engine energy recovery device is used for recovering heat of engine exhaust. The multi-partition logistics apparatus is simple in structure and practical and can transport objects while freezing and refrigerating the objects and keeping the objects fresh, and transporting quality is guaranteed; engine exhaust gas energy of the logistics apparatus can be secondarily utilized, so that energy is saved and environment is protected.

Owner:江苏海涛新能源科技有限公司

Pump valve coordinated multi-actuator electro-hydraulic system and control method thereof

ActiveCN112648244AReduce installed powerAllocation is accurateFluid-pressure actuator testingServomotor componentsTransfer caseHydraulic pump

The invention relates to a pump valve coordinated multi-actuator electro-hydraulic control system. The pump valve coordinated multi-actuator electro-hydraulic control system comprises a prime motor, a transfer case, one or more hydraulic cylinders, distributed pump control units and a hydraulic cylinder displacement sensor, a centralized flow power compensation unit is additionally arranged for the distributed pump control units, and the centralized flow power compensation unit comprises a main hydraulic pump, a first overflow valve and an oil tank, a first pressure sensor, a pressure compensator, a control valve set, a bypass proportional valve and an oil supplementing energy accumulator. A valve core displacement sensor is additionally arranged on the pressure compensator. Each distributed pump control unit comprises a two-way variable pump / motor, a first oil supplementing one-way valve, a second oil supplementing one-way valve, a second overflow valve and a third overflow valve. By additionally arranging the centralized flow power compensation unit, the asymmetric flow of all the distributed pump control units is subjected to centralized compensation and power supplementation, various flow compensation auxiliary elements are not needed, a small-power pump control system drives and drags a high-power actuator, and the total installed power of the pump control multi-actuator system is remarkably reduced.

Owner:TAIYUAN UNIV OF TECH

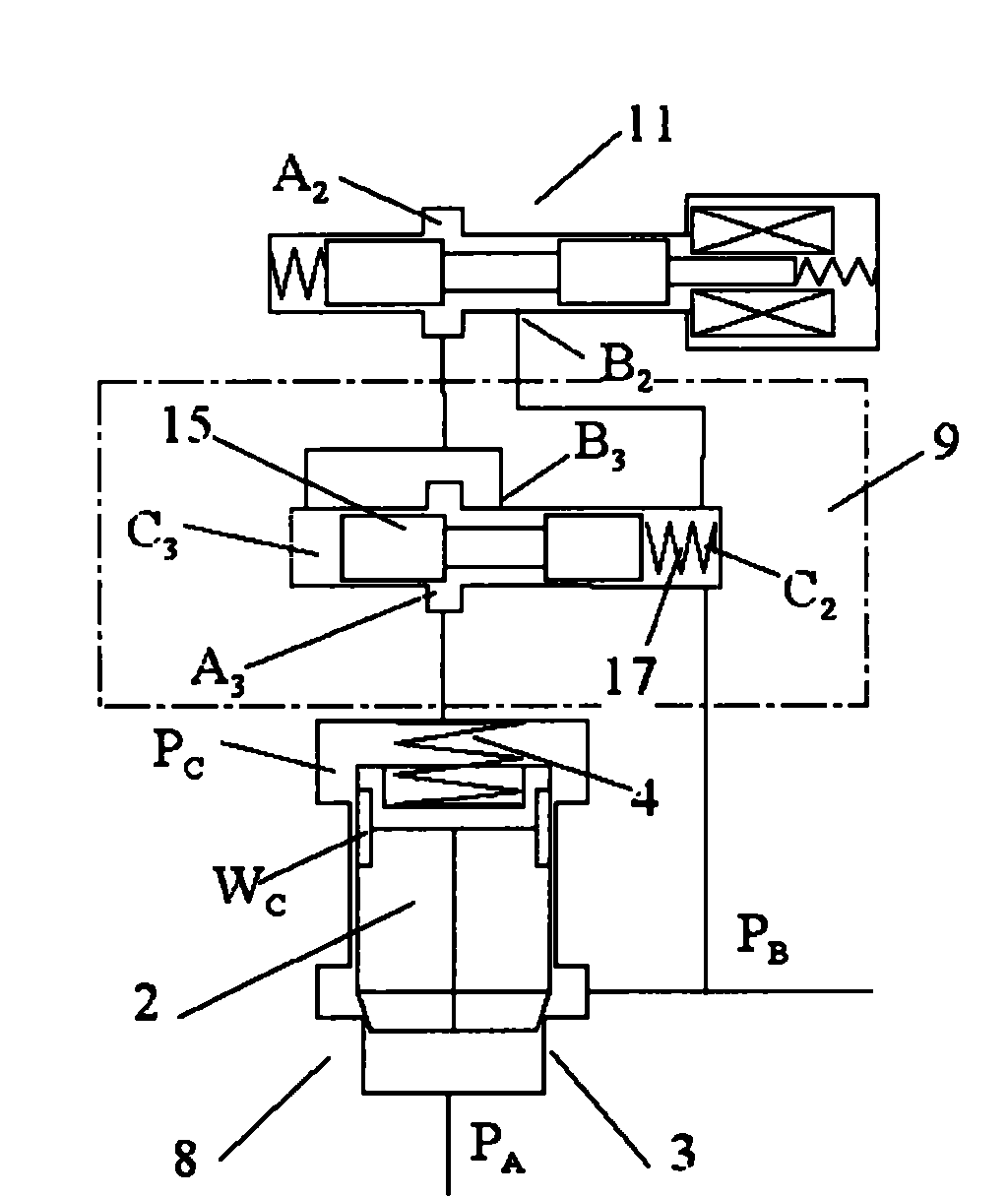

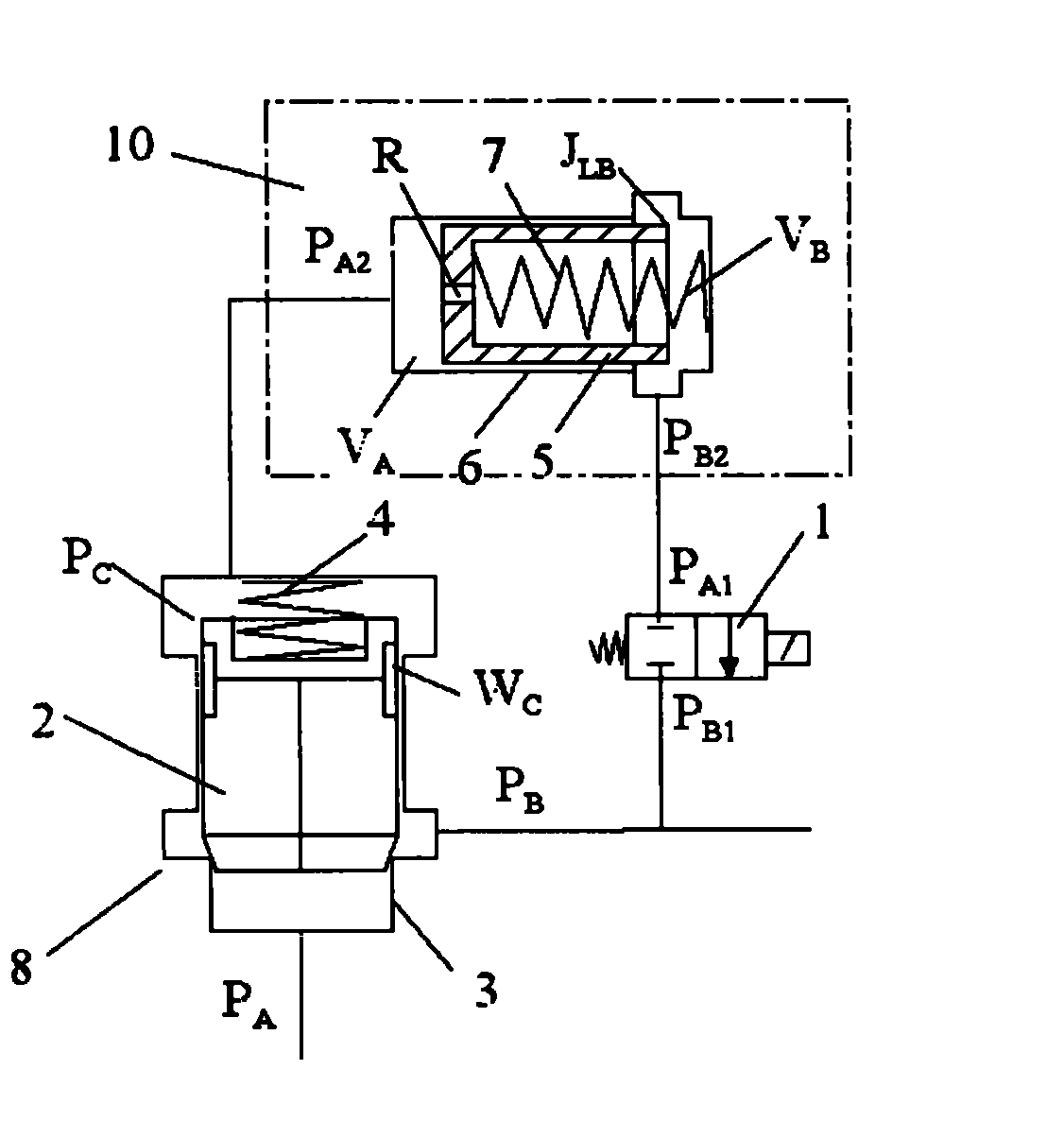

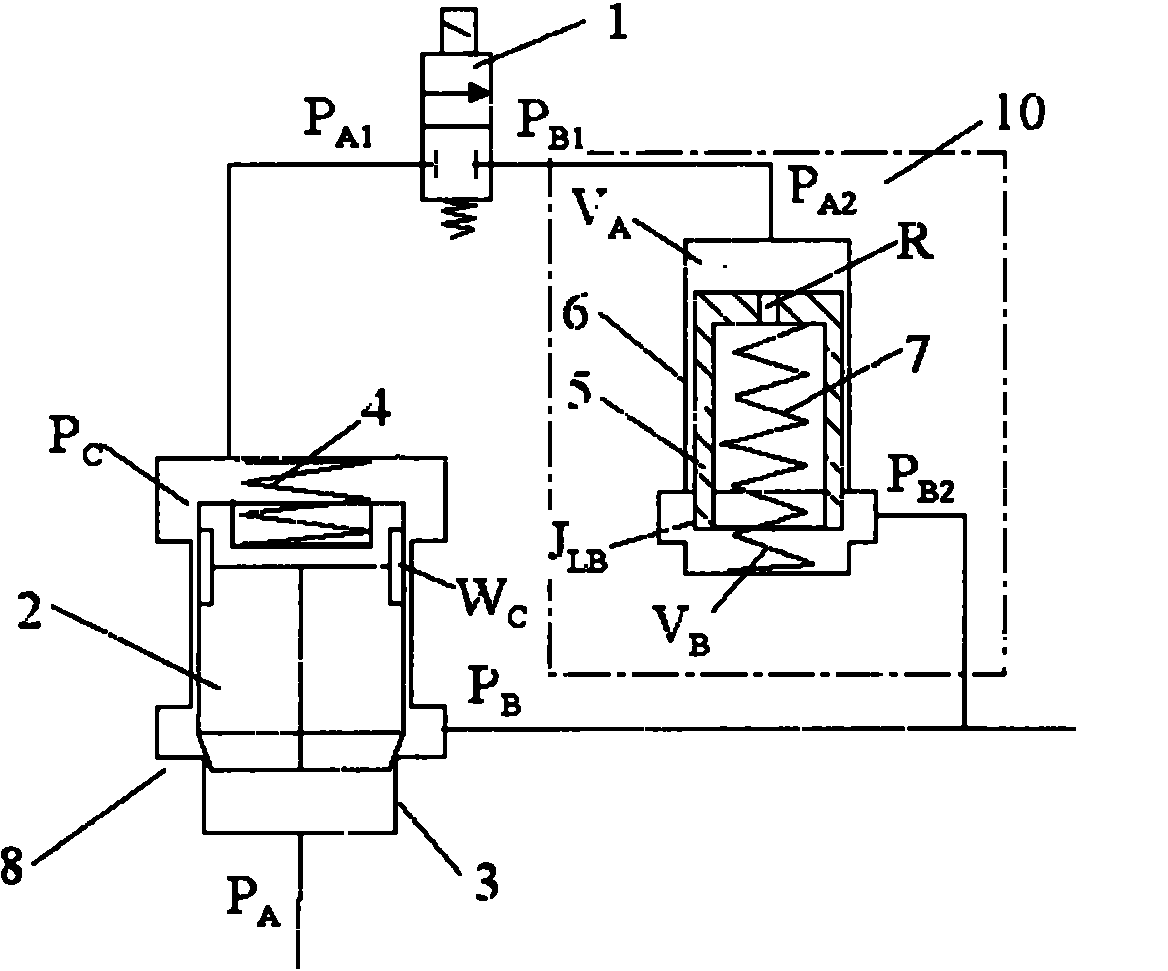

Digitally controlled leading type proportional flow valve

InactiveCN102155449ASimple structureStrong anti-pollutionServomotor componentsControl flowControl system

The invention relates to a digitally controlled leading type proportional flow valve belonging to a device which controls flow rate of a hydraulic actuator in an electric hydraulic control system. The digitally controlled leading type proportional flow valve mainly solves the technical problems that the existing control valve has high cost, poor oil pollution resisting capacity and low precision. In the technical scheme in the invention, the digitally controlled leading type proportional flow valve comprises a two-position two-way high-speed switch valve and a main valve which consists of a main valve element, a main valve jacket, a main valve spring, a main valve oil inlet PA, a main valve oil outlet PB, a main valve control cavity PC and a flow rate feedback throttling groove WC, further the digitally controlled leading type proportional flow valve also comprises a constant value flow device consisting of a valve element, a valve jacket, a fixed orifice R, a first control cavity VA, a second control cavity VB, a variable throttling side JLB, an oil inlet PA2 of a constant value flow device, and an oil outlet PB2 of the constant value flow device. The digitally controlled leading type proportional flow valve has the advantages of simple structure and strong contamination resistance, and works reliably.

Owner:山西北山重工集团有限公司

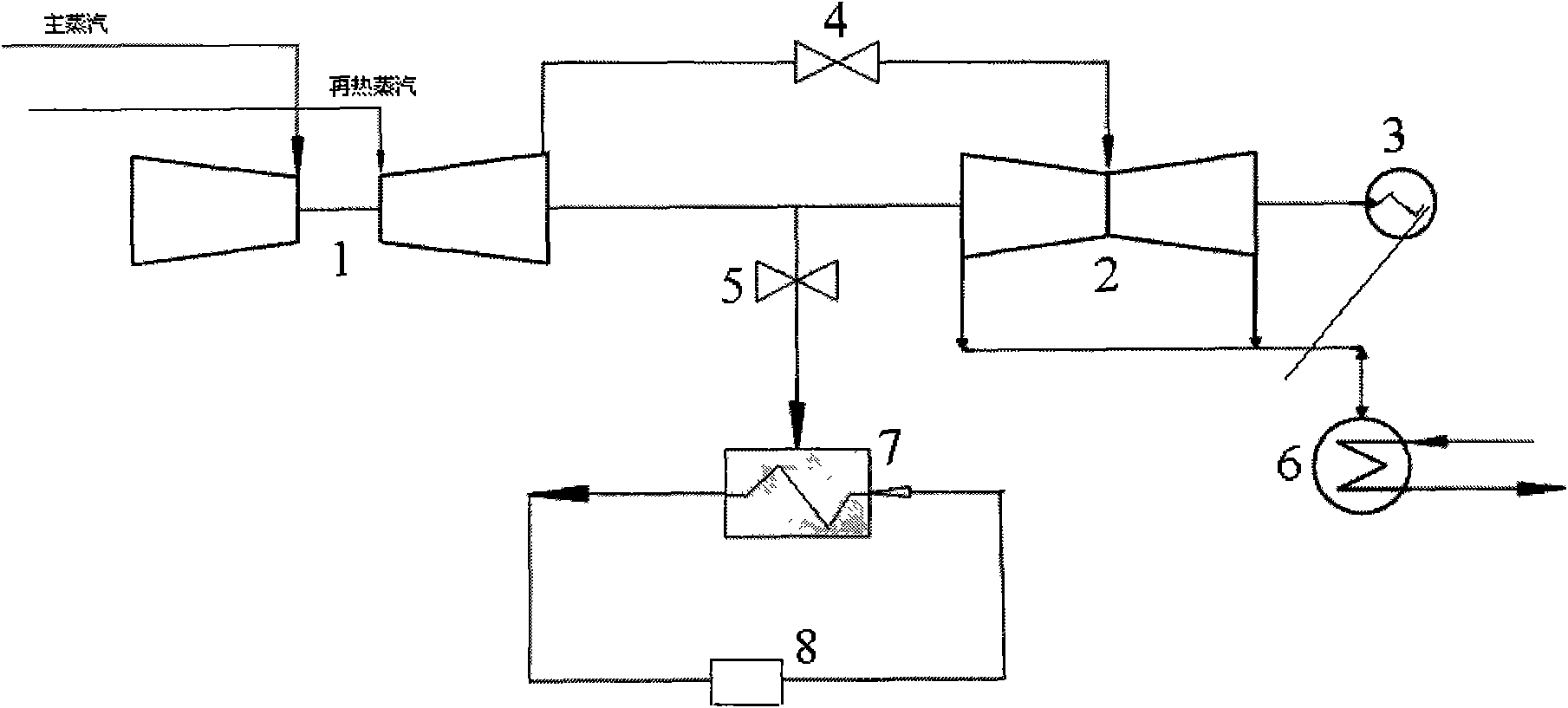

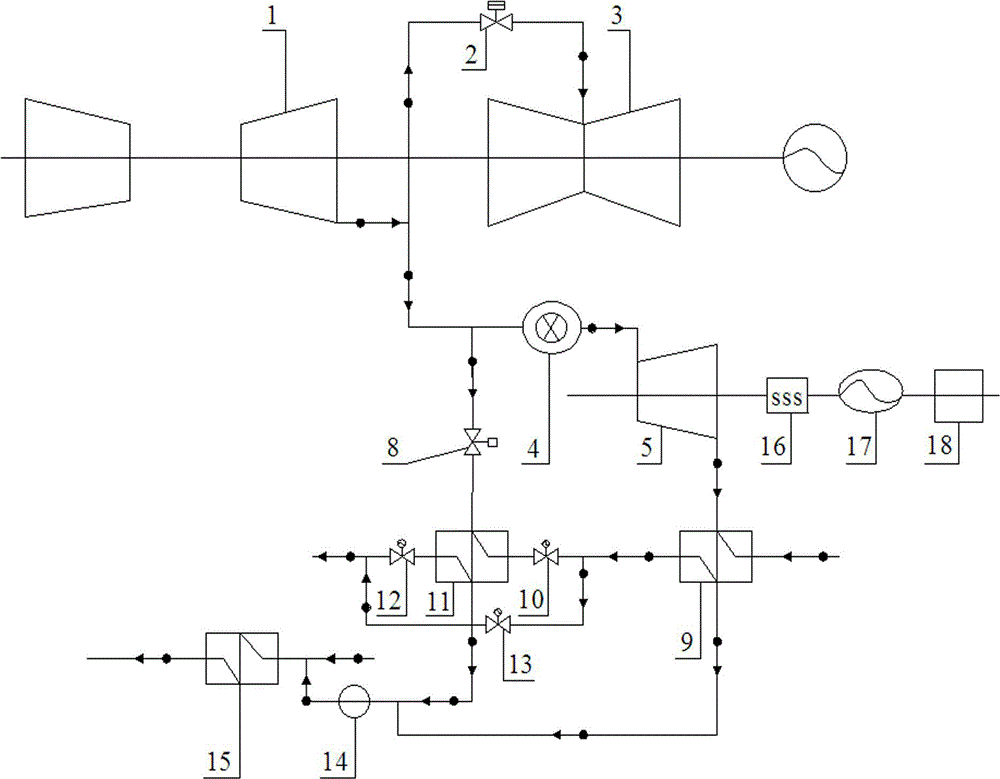

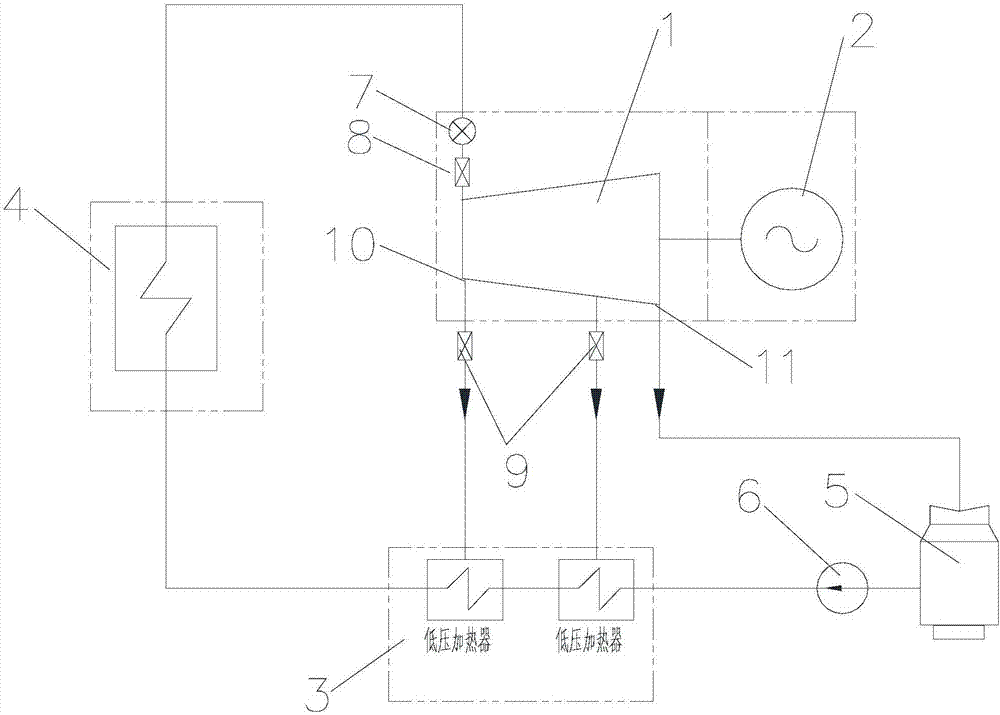

Backpressure machine acting and heat supply device for steam exhaust heat supply network of intermediate pressure cylinder of steam turbine

InactiveCN104405459AReduce throttling lossReduce electricity consumptionSteam useCombined combustion mitigationSynchroEngineering

The invention discloses a backpressure machine acting and heat supply device for a steam exhaust heat supply network of an intermediate pressure cylinder of a steam turbine. The backpressure machine acting and heat supply device comprises a backpressure machine and control equipment thereof, wherein an electric generator is arranged at a power output end of the backpressure machine to output electric energy, or an electric motor is arranged at the power output end of the backpressure machine to drive power equipment. The backpressure machine is additionally arranged on a pipeline between exhausted and extracted steam of the intermediate pressure cylinder and a first heater of a heat supply network so that the exhausted and extracted steam of the intermediate pressure cylinder drags the electric generator to generate electricity after being expanded by the backpressure machine and acting, or the power equipment is coaxially dragged by an SSS (Synchro-Self-Shifting) clutch and the electric motor; the steam exhausted after the backpressure machine acts is supplied to the first heater of the heat supply network. Compared with the prior art, the backpressure machine acting and heat supply device has the beneficial effects that the throttling loss of the exhausted steam of the intermediate pressure cylinder is reduced to the minimal without influencing a heat supply requirement by additionally arranging the backpressure machine, and part energy of the extracted steam is converted into high-grape power output which is used for generating the electricity or coaxially dragging the power equipment with the electric motor, so that the remarkable technical effects of energy conservation, consumption reduction and low-carbon environment protection are achieved.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

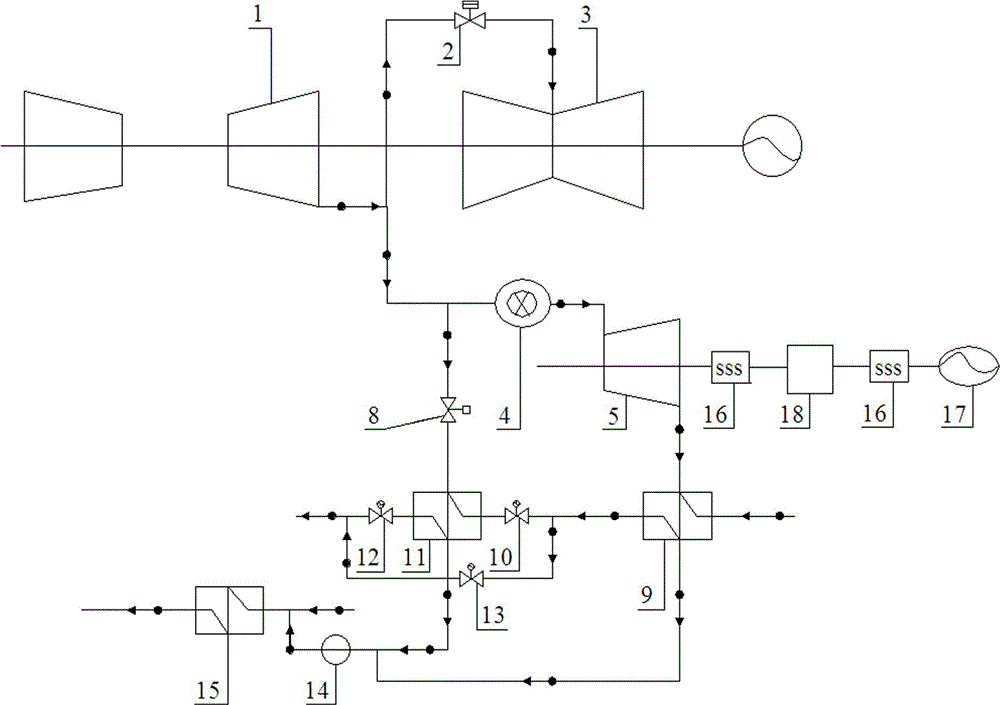

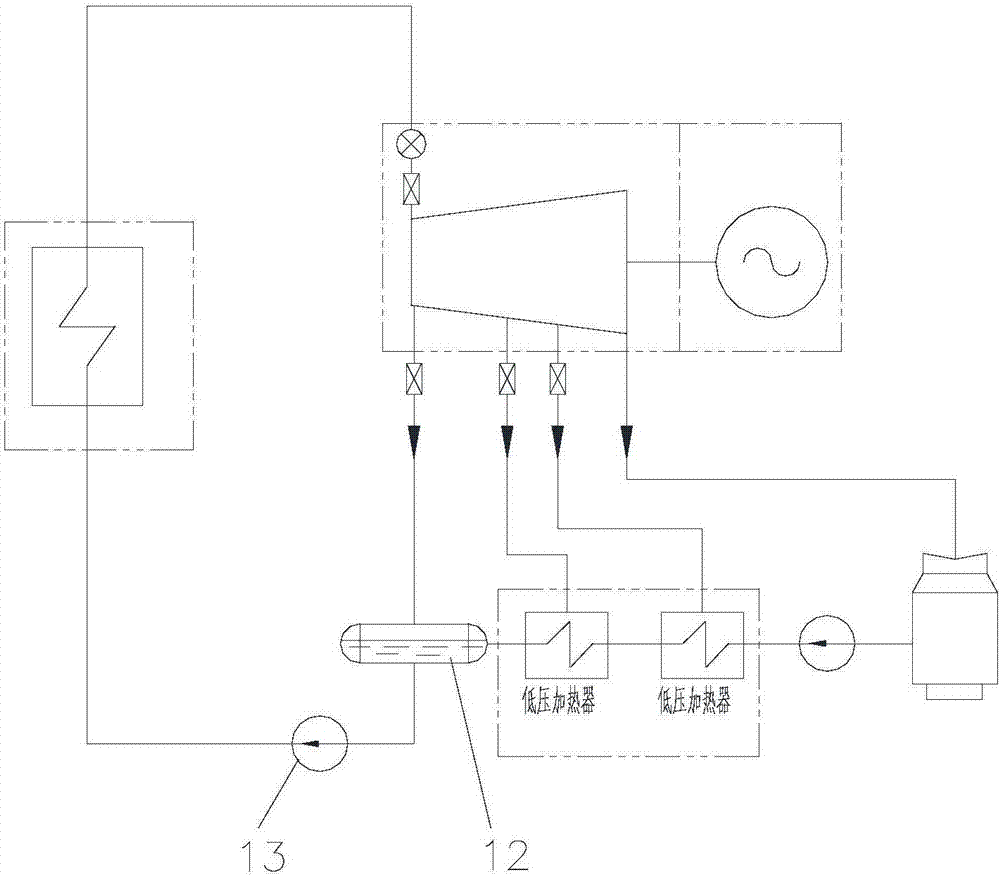

System and method of back pressure type small steam turbine driving water supply pump for power frequency electric generator speed adjustment

ActiveCN103362770AImprove operational efficiencyIncrease revenue from electricity salesPump controlPumpsFully developedPower capability

The invention discloses a system of a back pressure type small steam turbine driving water supply pump for power frequency electric generator speed adjustment. The system comprises a back pressure type small steam turbine, a water supply pump set, a power frequency electric generator and a speed adjustment gearbox. The back pressure type small steam turbine, the water supply pump set, the power frequency electric generator and the speed adjustment gearbox are coaxially connected. The speed adjustment gearbox is arranged between the back pressure type small steam turbine and the power frequency electric generator. After the speed is adjusted by the speed adjustment gearbox, the power frequency electric generator is driven to rotate. The rotating speed of the back pressure type small steam turbine is controlled through the control over the output of the power frequency electric generator, so that the rotating speed of the water supply pump set is controlled. According to the system of the back pressure type small steam turbine driving water supply pump for power frequency electric generator speed adjustment, the loss of steam inlet and throttling of the small steam turbine is greatly reduced, the operation efficiency is improved, the power capability of the small steam turbine is fully developed, and operation benefits are increased. The invention further discloses a steam electric generator set and a method for adjusting the rotating speed of the water supply pump.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

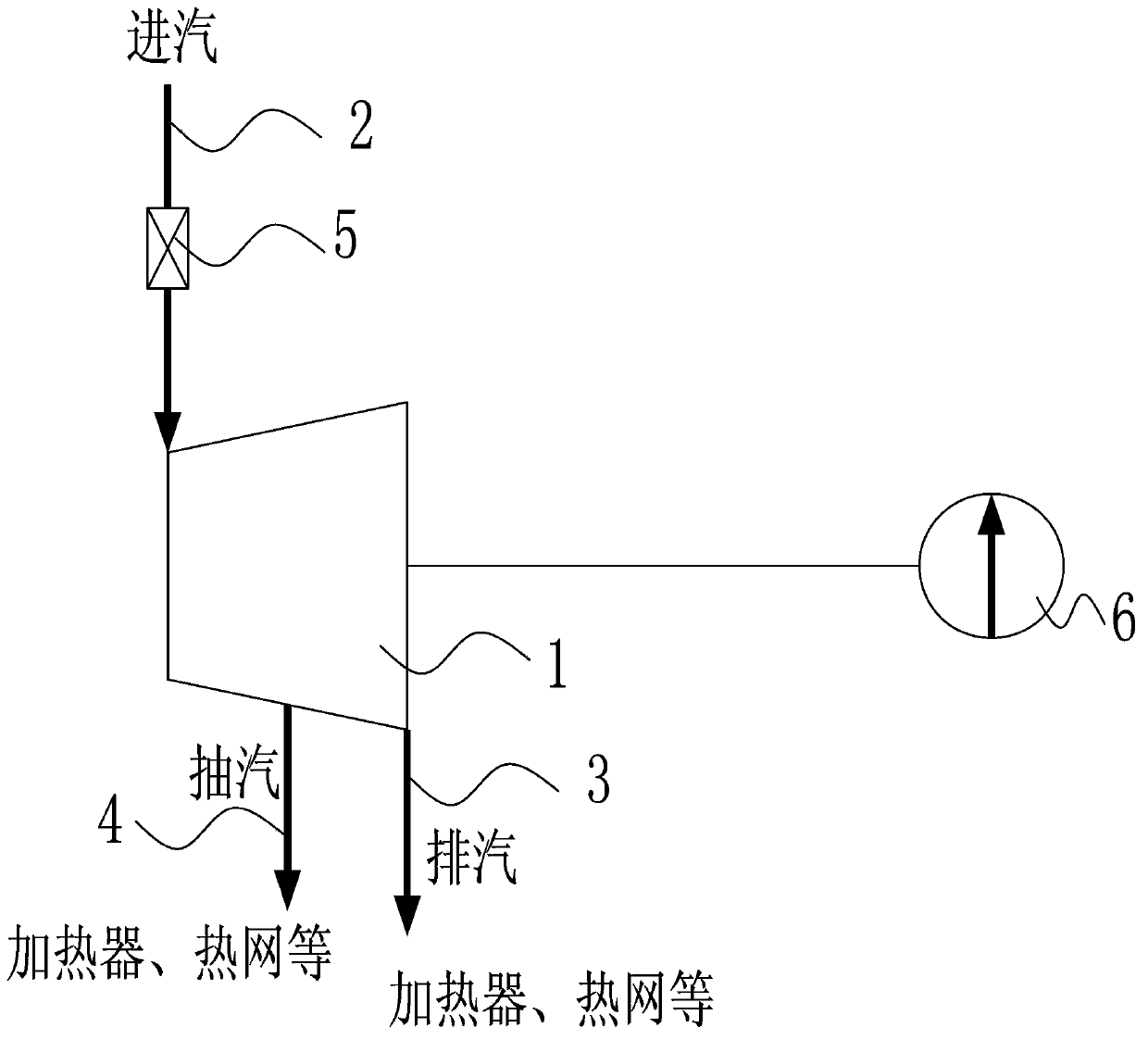

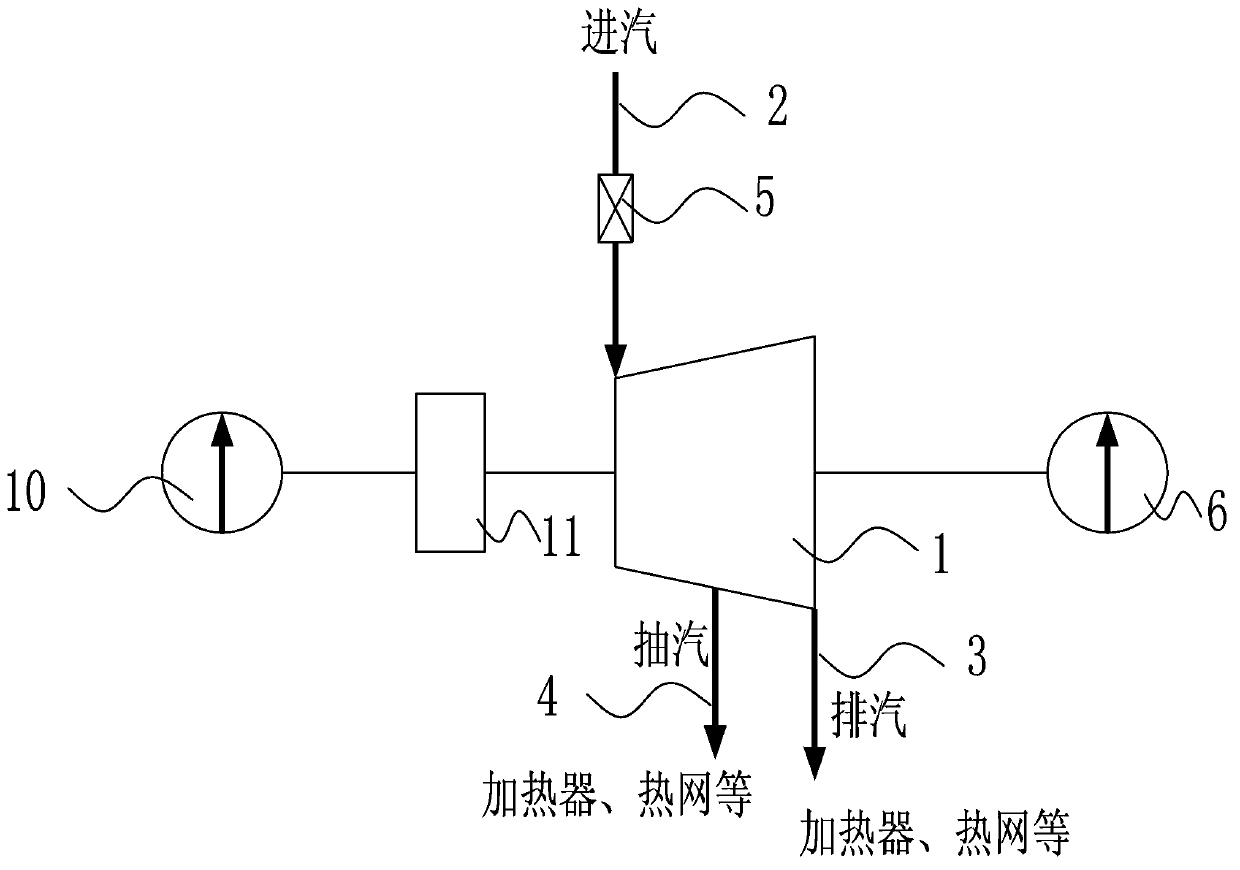

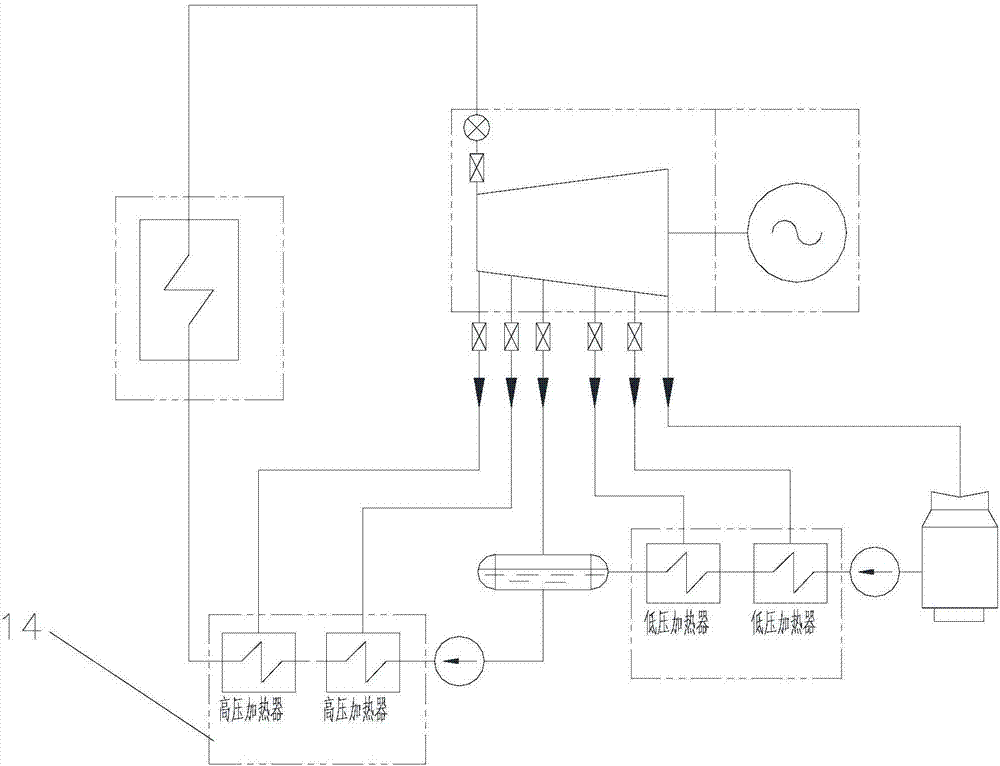

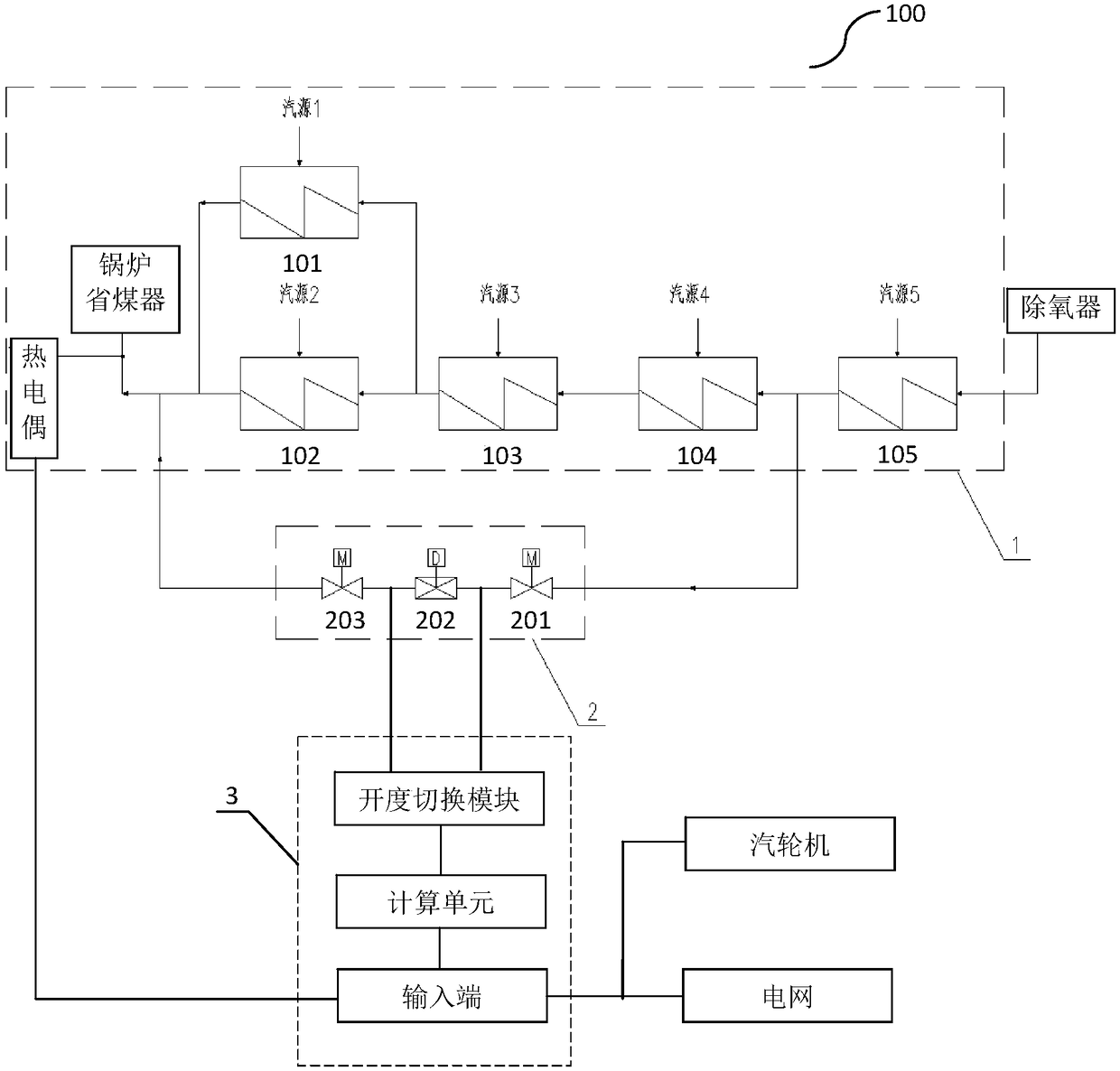

Extraction regulation type turbo generator unit, load control method and primary frequency regulation method

ActiveCN106988807AReduce throttling lossReduce heat consumptionEngine componentsSteam engine plantsEngineeringLoad regulation

The invention discloses an extraction regulation type turbo generator unit, as well as a load control method and a primary frequency regulation method based on the turbo generator unit. The turbo generator unit comprises a steam turbine, an electric generator, a condenser, a steam heating system and a load regulation system; the electric generator is driven by the steam turbine; an extraction opening formed in the steam turbine is connected with the steam heating system through an extraction pipeline; an exhaust opening formed in the steam turbine is connected with the condenser; steam entering from the extraction pipeline and condensation water entering from a condensation water pipeline are subjected to heat exchange through the steam heating system and then conveyed into a boiler; the condensation water is heated by the boiler, and thus, steam with the appropriate parameter is produced; the output end of the boiler is in corresponding connection with the input end of the steam turbine through the steam pipeline; and the load regulation system is connected with a steam regulation device on an input end pipeline of the steam turbine, and an extraction flow regulation device on the extraction pipeline so as to control the opening degree of the steam regulation device and the opening degree of the extraction flow regulation device. According to the extraction regulation type turbo generator unit, as well as the load control method and the primary frequency regulation method based on the turbo generator unit, control over the load of the turbo generator unit and primary frequency regulation can be achieved, and the advantages that the throttling loss is small, and the response time is short are achieved.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

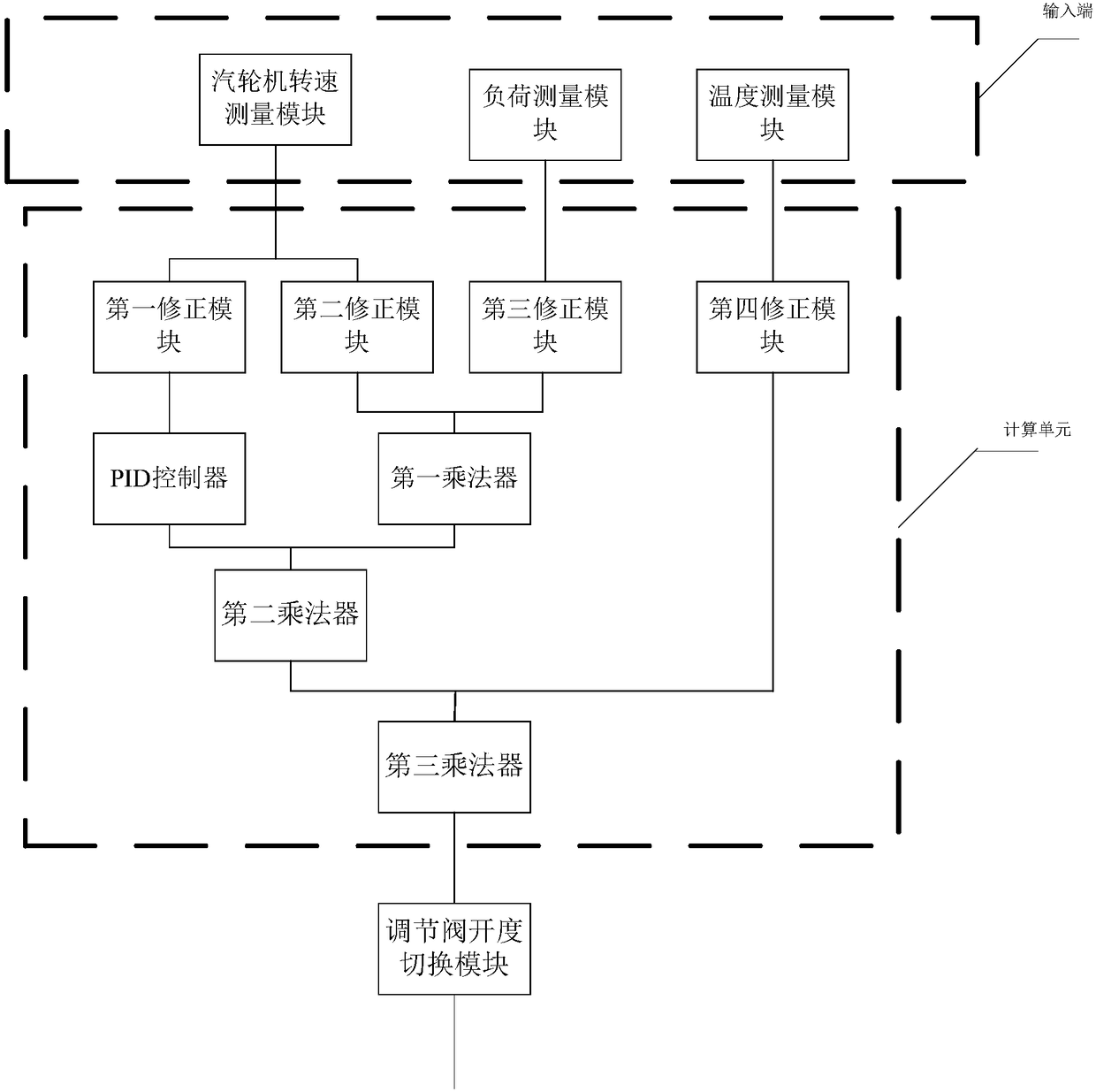

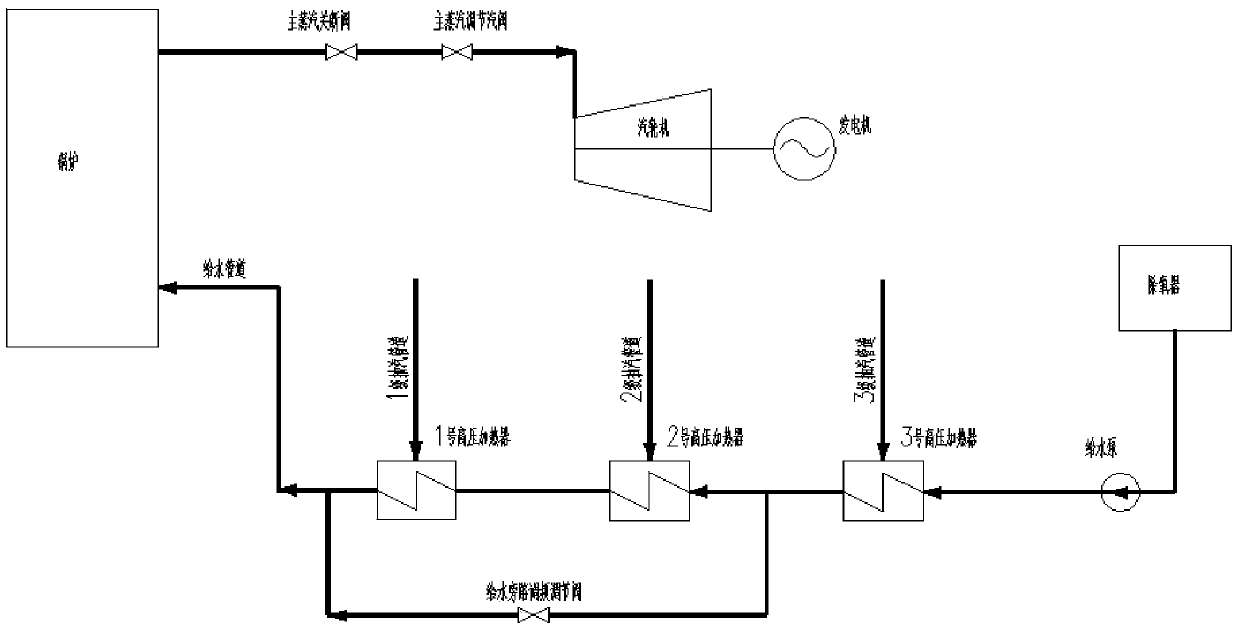

Primary frequency modulation control system adopting feed-water throttling and control method of primary frequency modulation control system

PendingCN108730954AQuick responseFast response to frequency changing requirementsMachines/enginesEngine componentsControl systemPower grid

The invention provides a primary frequency modulation control system adopting feed-water throttling and a control method of the primary frequency modulation control system. When the power grid frequency is reduced, the primary frequency modulation demand is rapidly responded to maintain power grid stability. The method comprises the steps that a, turbine rotating speed signals, unit load signals,economizer inlet feed-water temperature signals and power grid real-time frequency signals are collected; b, the deviation of a first turbine rotating speed and a second turbine rotating sped is calculated, the variation amount of the actual load of a unit is determined, and the frequency modulation load set value of the unit is determined; c, a frequency difference signal is calculated, when thefrequency difference signal is smaller than 0 and exceeds a primary frequency modulation dead zone, the opening degree theoretical value of an adjusting valve of a feed-water bypass control loop is calculated, a first modification value of the opening degree theoretical value is calculated, a second modification value of the opening degree theoretical value is calculated through a PID controller,and a third modification value of the opening degree theoretical value is calculated according to the economizer inlet feed-water temperature signals; d, the opening degree set value of the adjustingvalve is calculated; and e, the opening degree of the adjusting valve is adjusted according to the opening degree set value to control the feed-water quantity of a feed-water bypass.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST +1

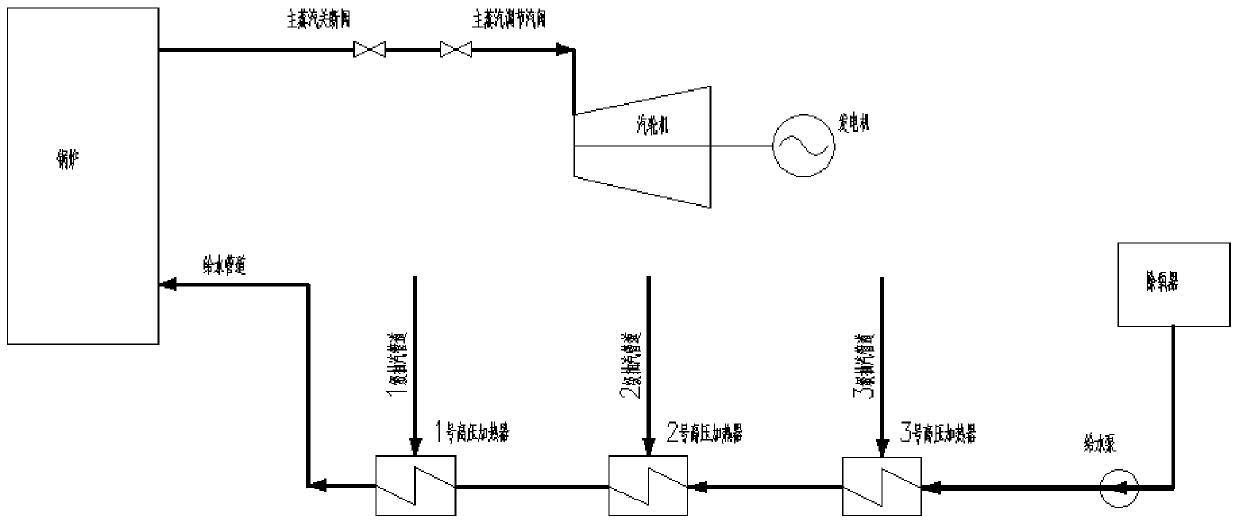

Full-arc admission generator set and water supply bypass regulation method thereof

InactiveCN104213946AChange outputImprove securityMachines/enginesEngine componentsDeaeratorEngineering

The invention discloses a full-arc admission generator set and a water supply bypass regulation method of the full-arc admission generator set. The full-arc admission generator set comprises a deaerator, n high-pressure heaters, a boiler, a turbine, a generator, a water supply bypass frequency adjustment regulating valve, a main steam shut-off valve and a main steam adjusting valve, wherein the n high-pressure heaters are respectively connected with the deaerator by a water feed pump, and n is more than or equal to 3; each high-pressure heater is connected with a steam extraction pipeline; the boiler is connected with the n high-pressure heaters by water feed pipes; one end of the water supply bypass frequency adjustment regulating valve is connected with a feed water outlet main pipe of the high-pressure heater closest to the deaerator in the n high-pressure heaters, and the other end of the water supply bypass frequency adjustment regulating valve is connected with a feed water outlet main pipe of the high-pressure heater closest to the boiler in the n high-pressure heaters; the main steam shut-off valve and the main steam adjusting valve are connected between the turbine and the boiler.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

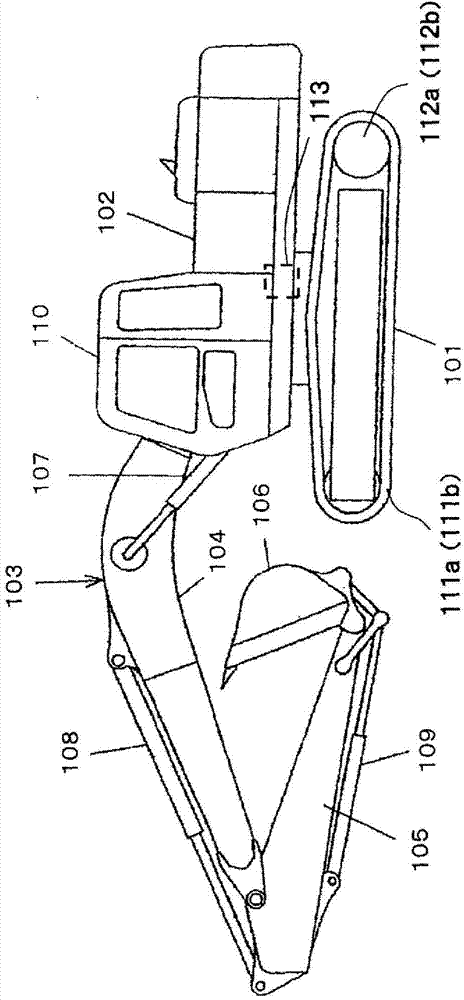

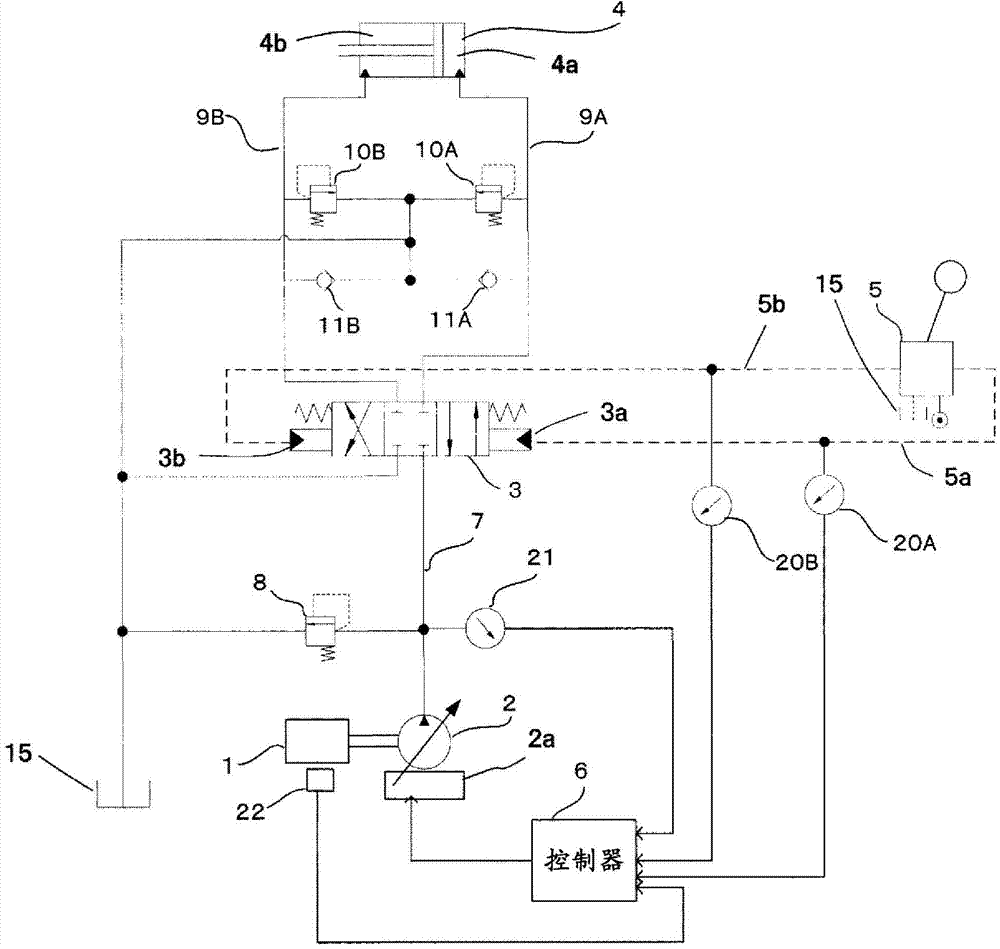

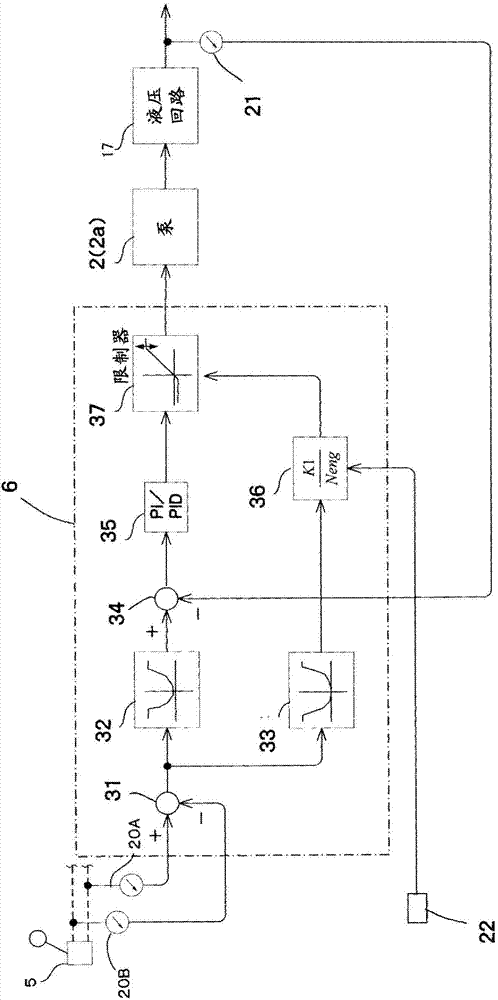

Hydraulic pressure control device for machinery

ActiveCN104736856AReduce throttling lossImprove energy efficiencyMechanical machines/dredgersServomotorsHydraulic pumpPump pressure

The present invention improves energy efficiency by reducing the throttling-off loss of the delivery flow rate of a hydraulic pump due to bleed-off control and improves operational performance by enabling control of hydraulic pump delivery pressure according to the control input of an operating lever device. A controller (6) comprises a target pump pressure-setting unit (32) for calculating, on the basis of control input signals from control input detectors (20A, 20B), a target pump delivery pressure, which increases as the control input signals increase, and a pump flow rate upper limit-setting unit (33) for calculating, on the basis of the control input signals, the pump flow rate upper limit, which increases as the control input signals increase. The amount of tilt of the hydraulic pump (2) is controlled on the basis of the target pump delivery pressure calculated by the target pump pressure-setting unit (32), the pump flow rate upper limit calculated by the pump flow rate upper limit-setting unit (33), and the delivery pressure of the hydraulic pump (2) detected by a pressure detector (21).

Owner:NIHON KENKI CO LTD

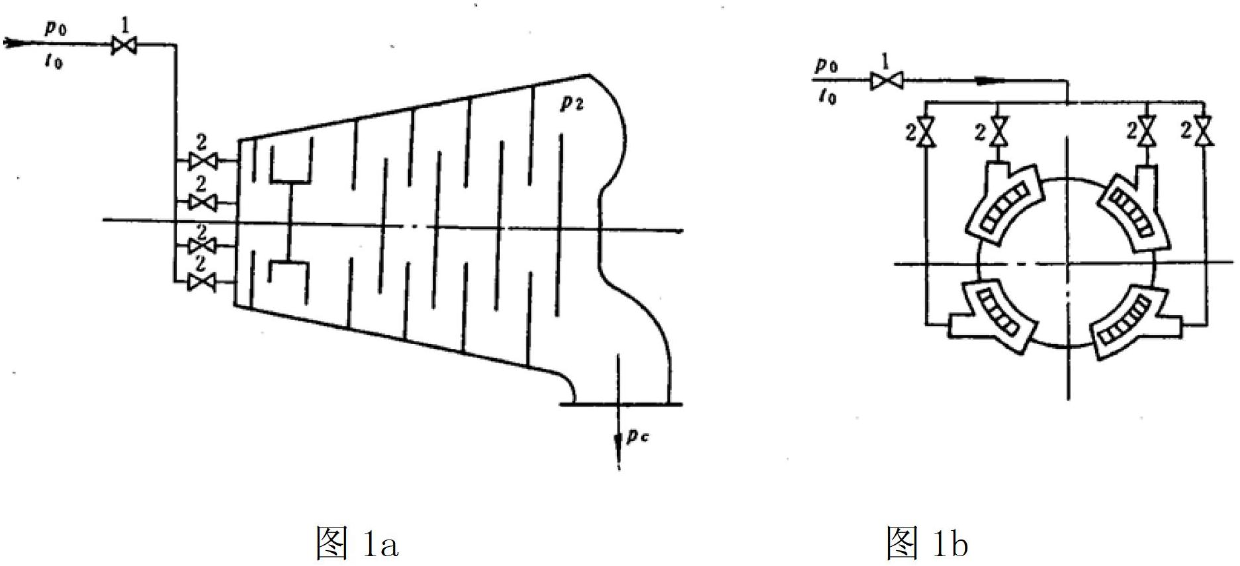

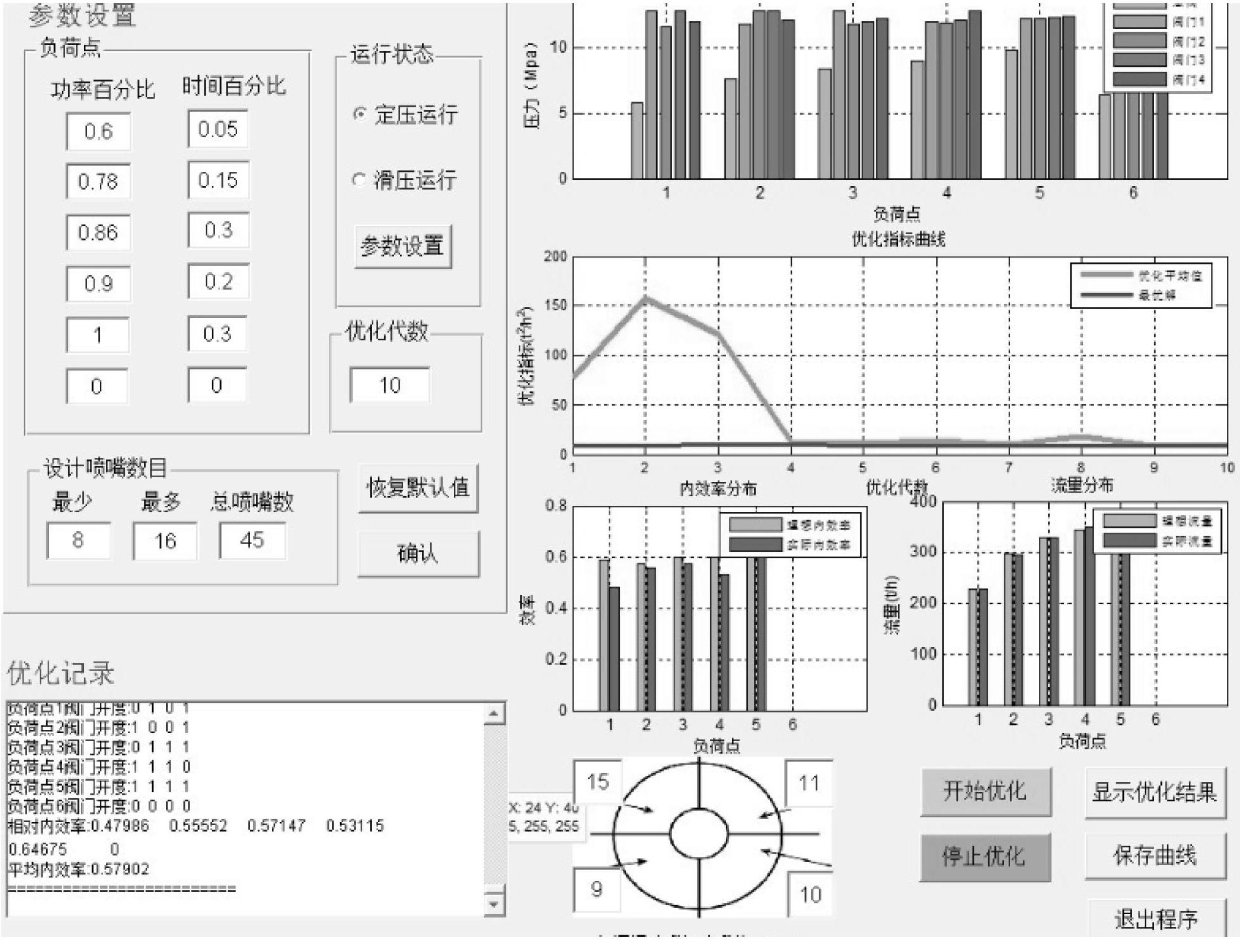

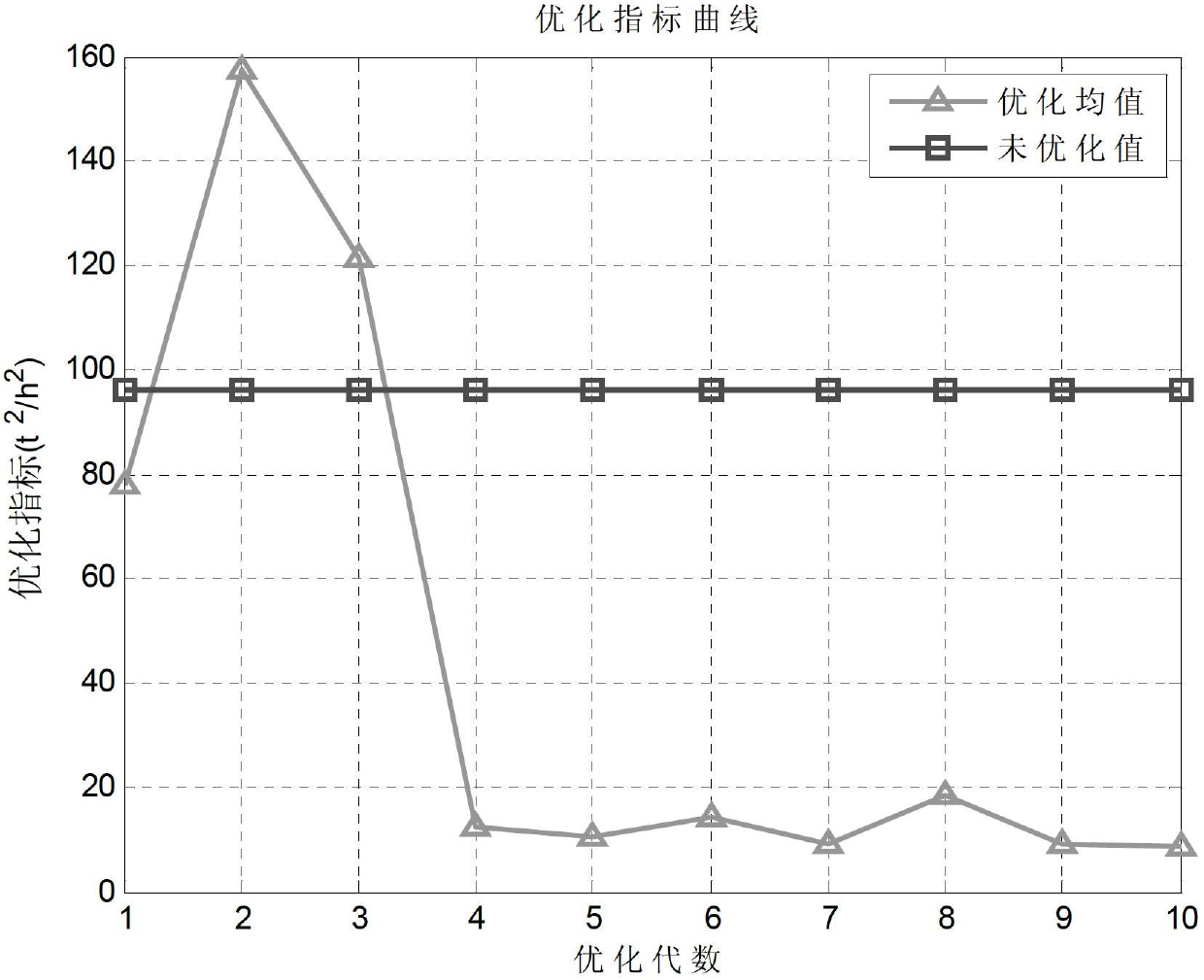

Optimized design method for nozzle number of nozzle sets considering turbine actual operation binding

ActiveCN102678192AImprove economyExcellent number combinationStatorsMachines/enginesTraffic capacityGenetic algorithm

The invention discloses an optimized design method for nozzle number of nozzle sets considering turbine actual operation binding and relates to an optimized design method for the nozzle number of a turbine. The optimized design method aims at solving the problem of large throttle loss and relative reduced inner efficiency caused by small valve opening degree of several working load points under the condition of a plurality of normally used working load points of the existing units. The method includes: constructing a nozzle number optimizing model; calculating actual flow of each load point; calculating theoretical flow of each designated load points; constructing constraint conditions of the nozzle number optimizing model; and obtaining a corresponding optimized nozzle number combination when the comprehensive deviation degree Y is minimum under the designated load point based on the genetic algorithm theory. The optimized design method ensures that when the unit reaches the load points, the adjusting-level valves can be in the full-opening or full-closing state, so that the maximum valve nozzle number combination can be optimized, and the unit has optimal economy under the condition that the throttling reduction of an adjusting level of the turbine is reduced maximumly.

Owner:NANJING POWER HORIZON INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com