Natural gas engine waste gas bypass type booster control system and method

A supercharger control and engine technology, which is applied in combustion engines, machines/engines, internal combustion piston engines, etc., can solve the problems of reduced engine charging efficiency, reduced engine air intake, and reduced fuel economy, so as to improve the charging efficiency. , The effect of reducing exhaust back pressure and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

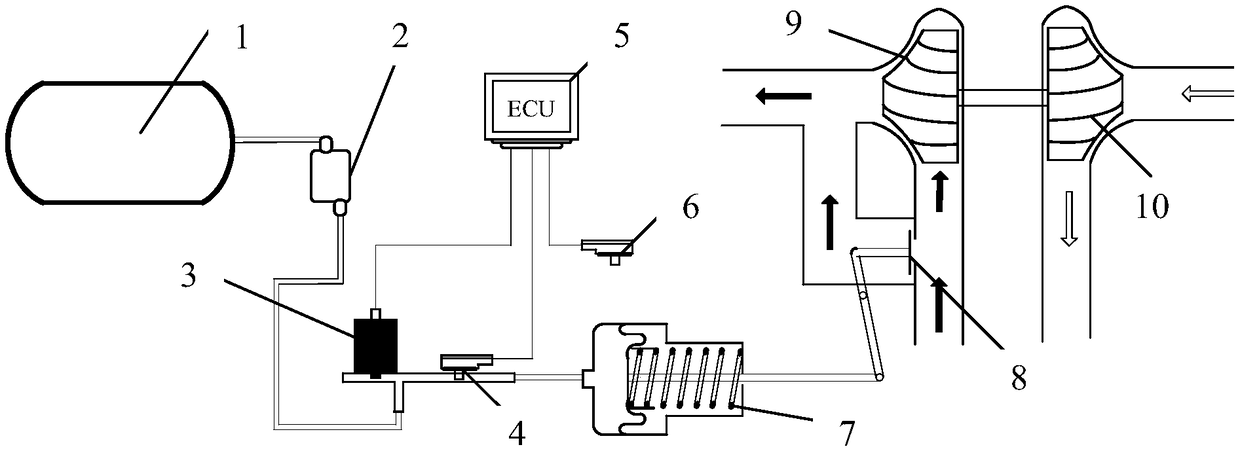

[0045] figure 1 A schematic structural diagram of a wastegate supercharger control system for a natural gas engine provided by an embodiment of the present invention. Such as figure 1 As shown, the natural gas engine wastegate supercharger control system provided by the embodiment of the present invention includes: a compressed air storage bottle 1, a pressure reducer 2, a supercharger control valve 3, a wastegate pressure sensor 4, an engine control Unit 5, boost pressure sensor 6, supercharger wastegate control diaphragm valve 7 and supercharger 11, said supercharger 11 includes supercharger wastegate valve 8, supercharger turbine 9 and supercharger Air compressor 10; the compressed air cylinder 1 stores high-pressure gas, used as a power source; one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com