Patents

Literature

165results about How to "Reduce exhaust back pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

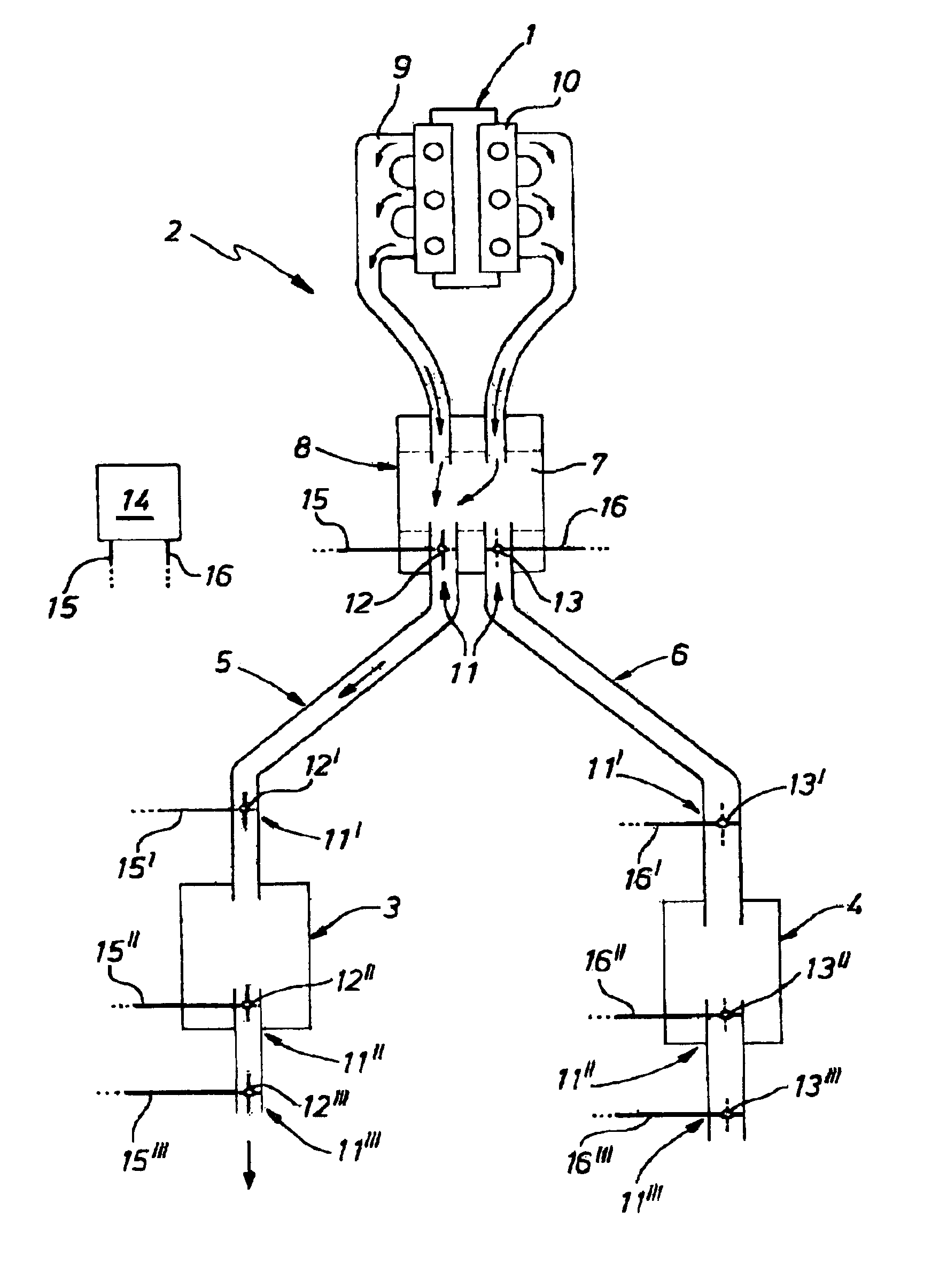

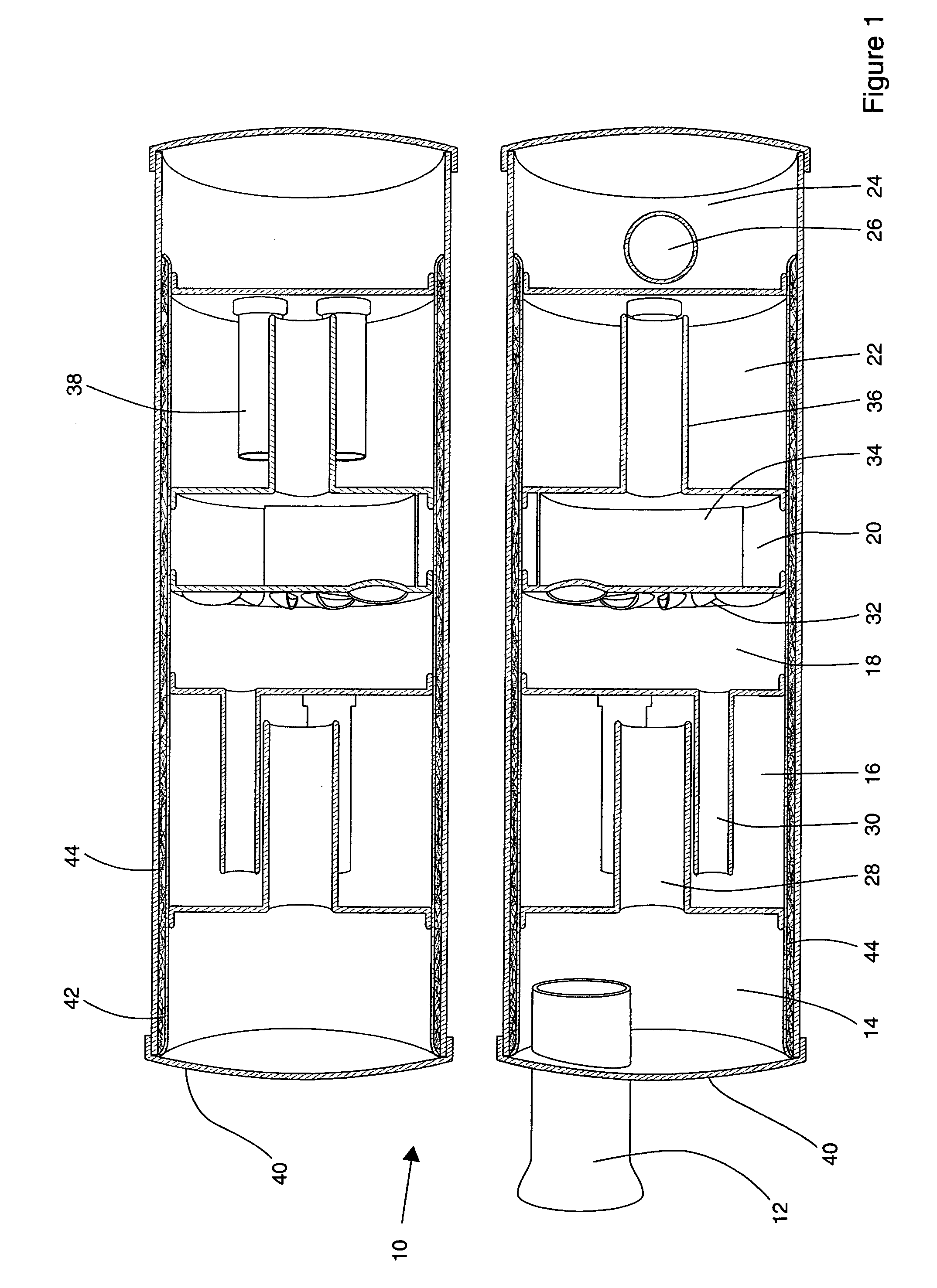

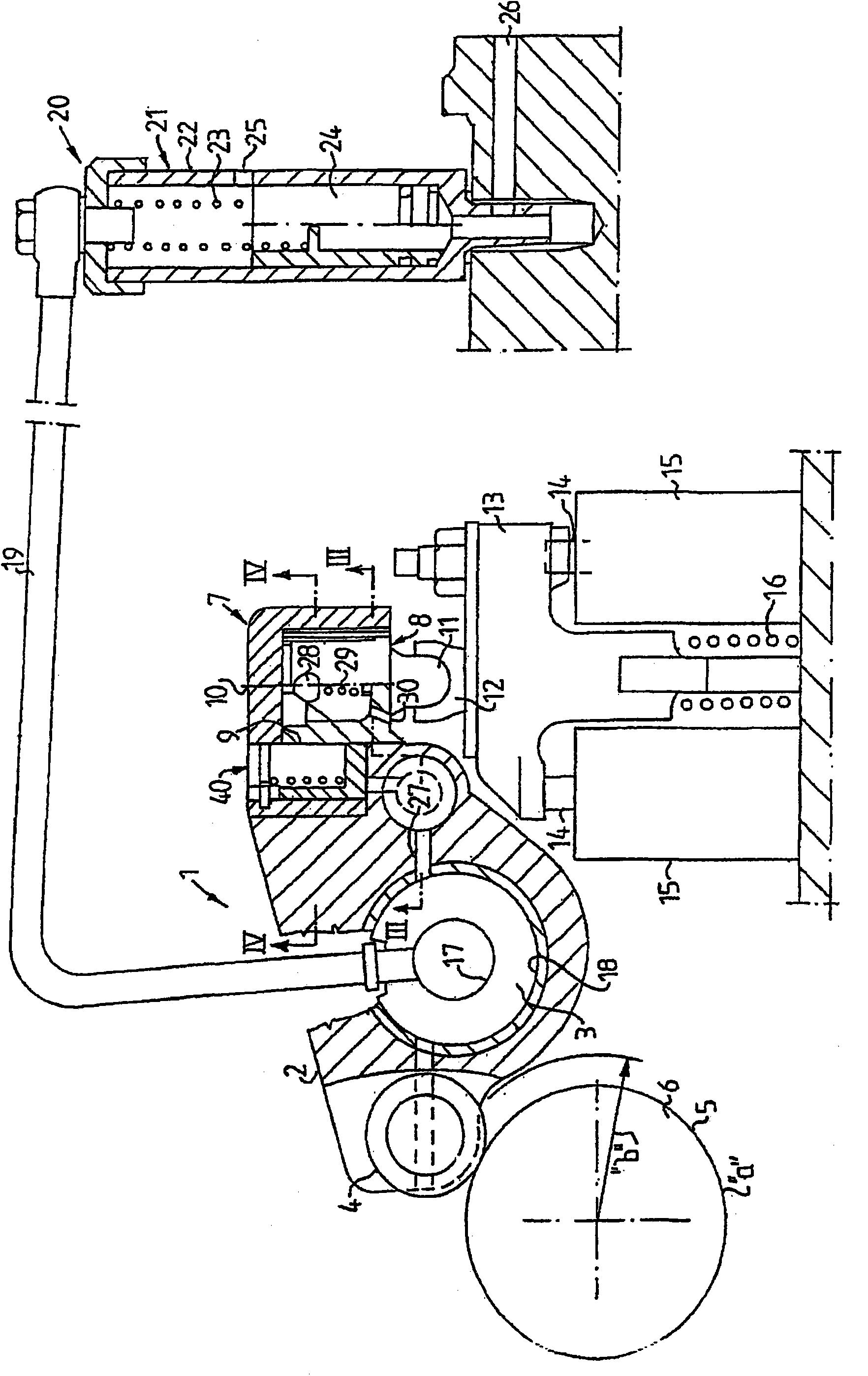

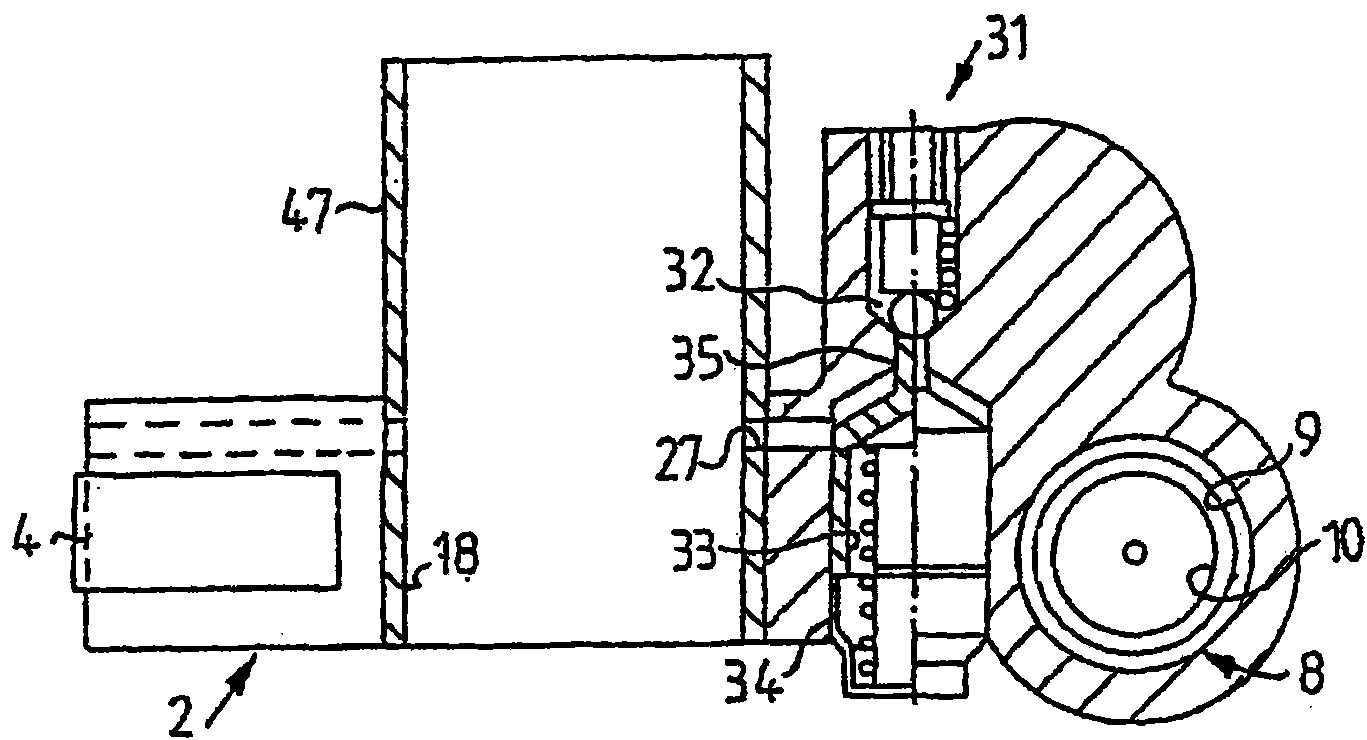

Exhaust gas system

InactiveUS6938729B2Sufficient effectIncrease powerExhaust apparatusSilencing apparatusExternal combustion engineExhaust fumes

An exhaust gas system for an internal combustion engine, in particular, of a motor vehicle has two mufflers through which the exhaust gas is able to flow in a parallel fashion. A switching unit makes it possible to selectively convey the exhaust gas flow of the internal combustion engine only or almost exclusively through the first muffler, or only or almost exclusively through the second muffler, or through both mufflers in a parallel fashion. The two mufflers are realized differently with respect to their muffling effect and / or flow resistance.

Owner:EBERSPACHER EXHAUST TECH GMBH & CO KG

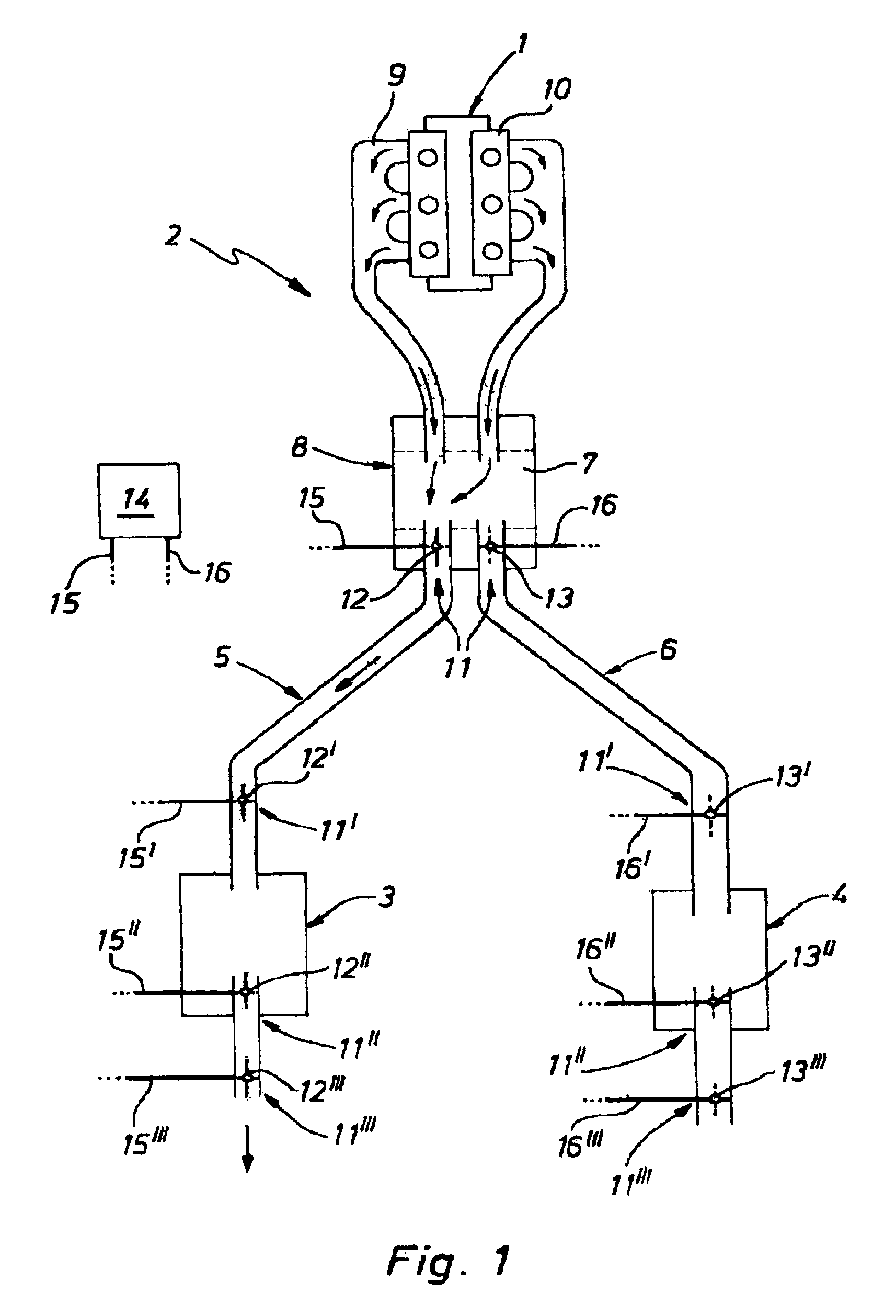

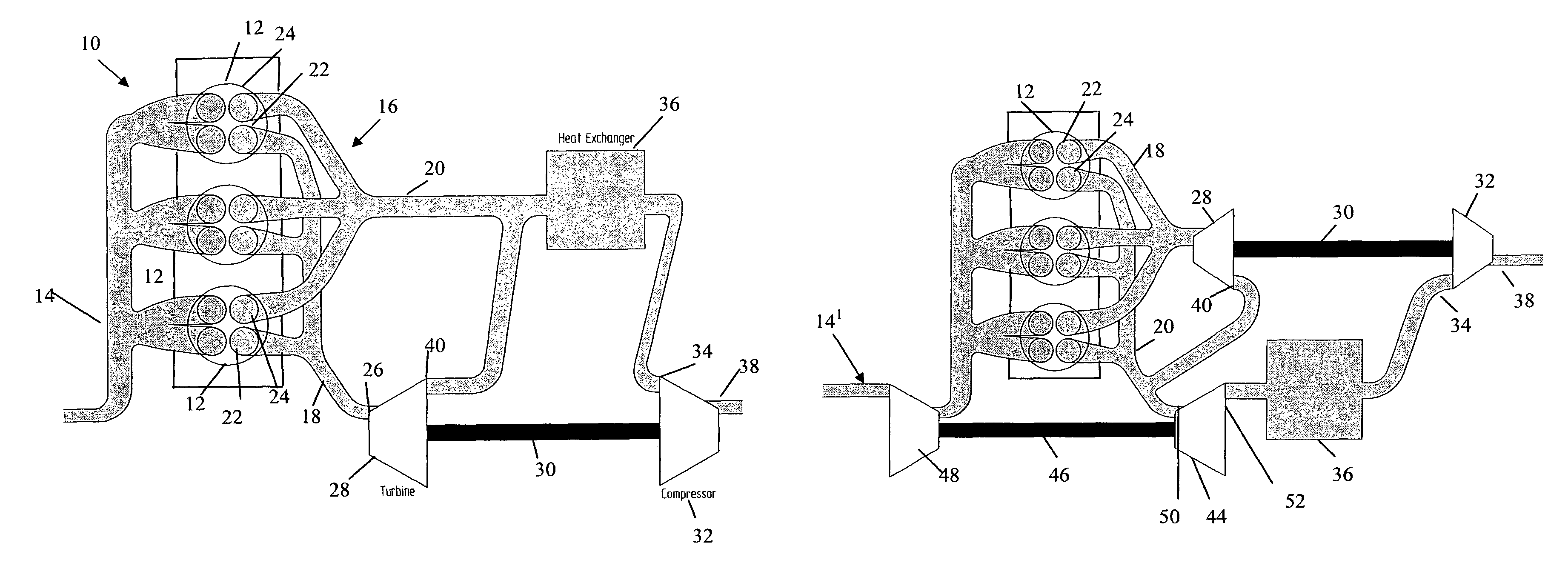

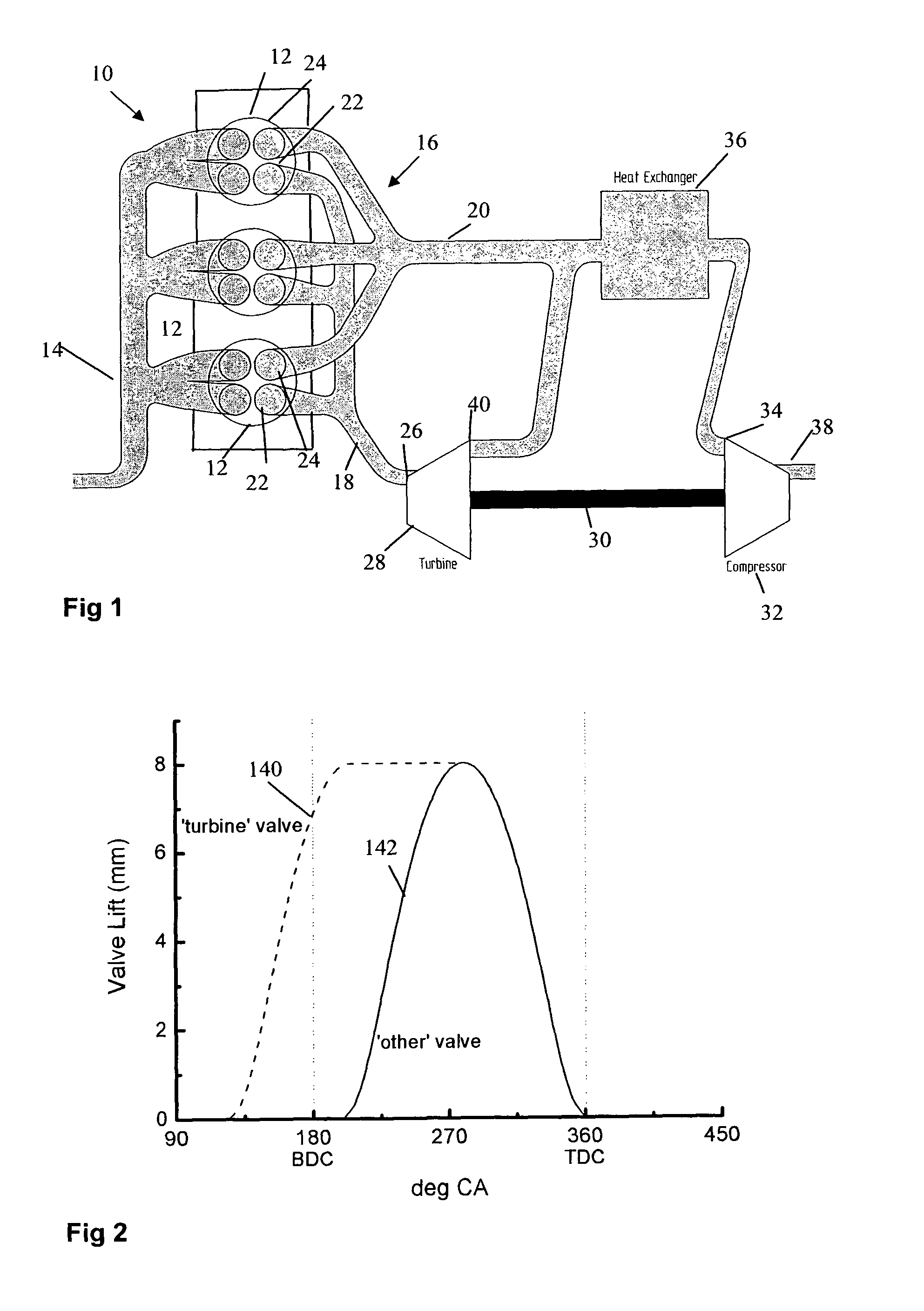

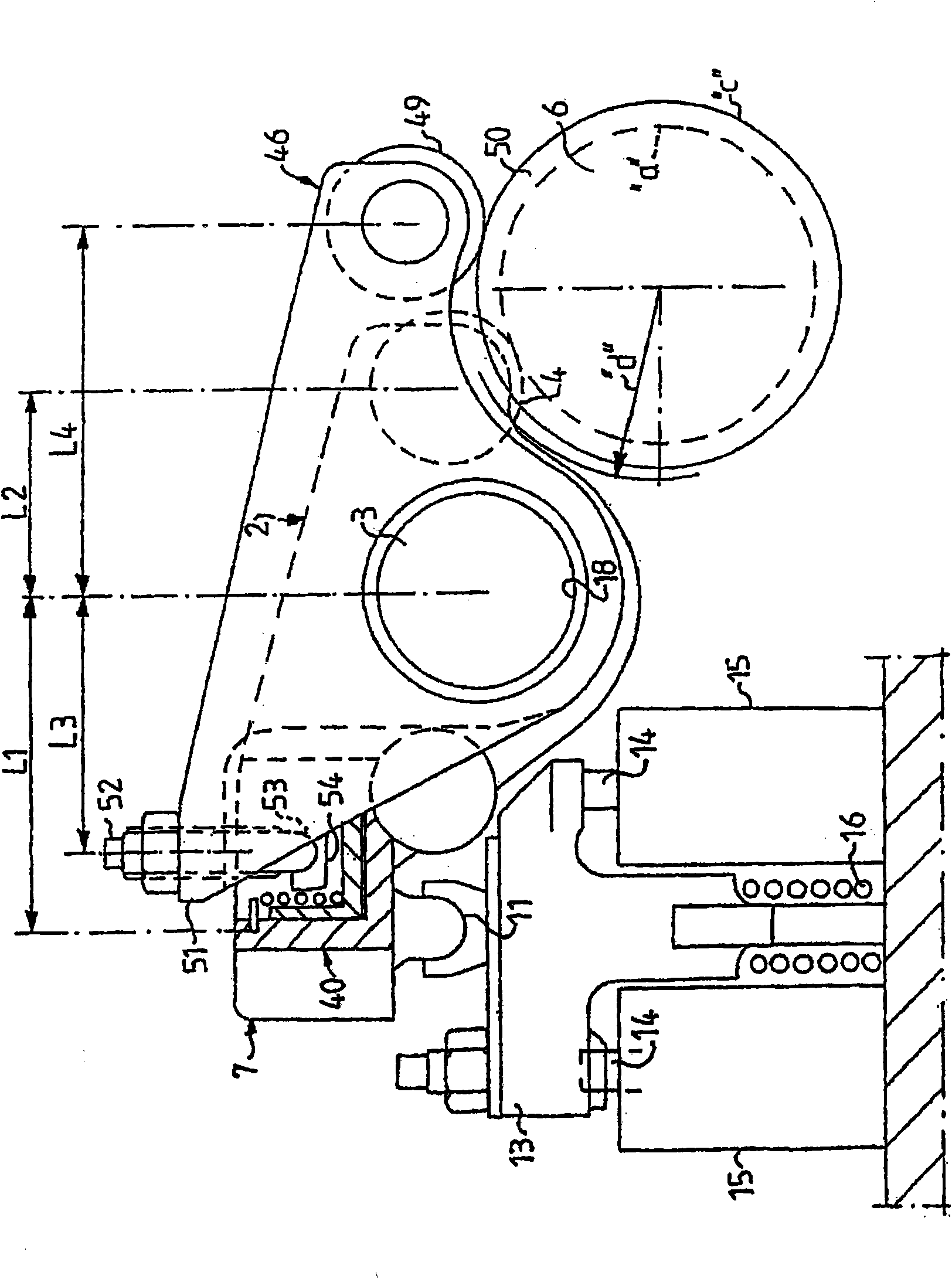

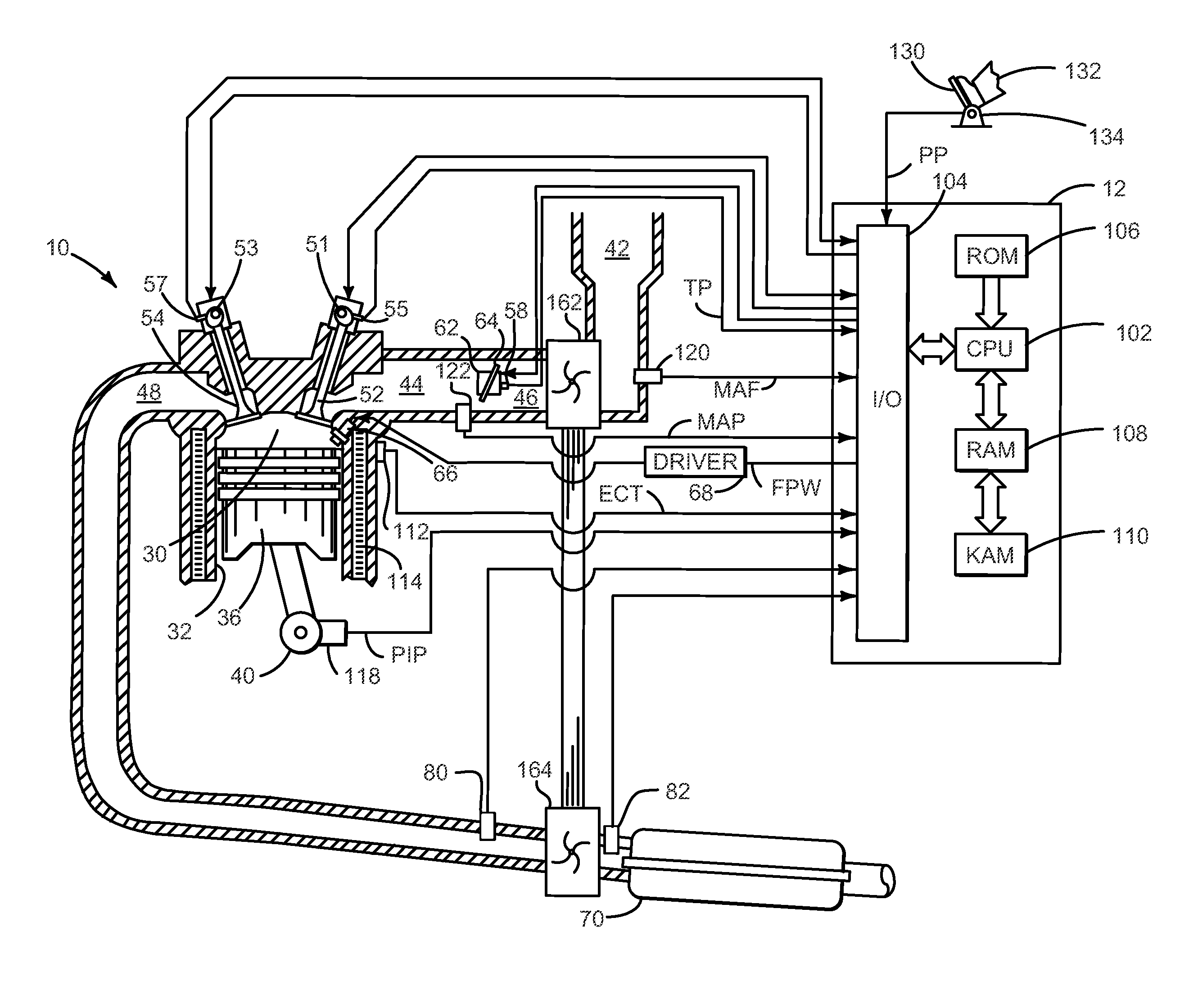

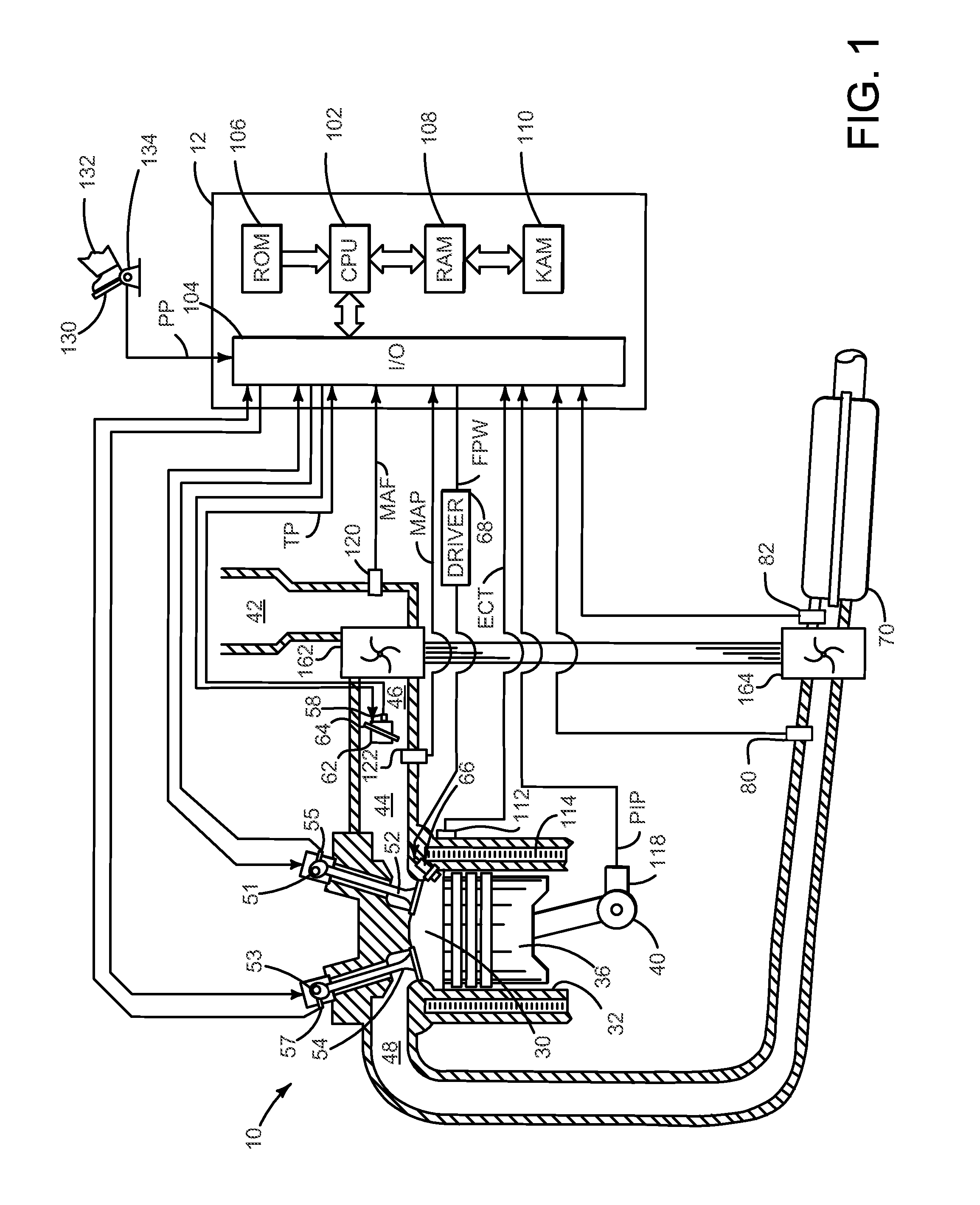

Exhaust arrangement for an internal combustion engine

ActiveUS8539770B2Not increase exhaust back pressure and exhaust pumping lossReduce back pressureInternal combustion piston enginesNon-fuel substance addition to fuelExhaust valveExternal combustion engine

An internal combustion engine including an exhaust arrangement comprises a first exhaust duct and a second exhaust duct. A valve arrangement preferably comprising separate first and second exhaust valves associated with each cylinder, to selectively direct exhaust from engine to the first exhaust duct during a first exhaust period, and to the second exhaust duct during a subsequent second exhaust period. A turbine having an inlet is connected to the first exhaust duct; and a compressor drivingly connected to and driven by the turbine, has an inlet connected to second duct. The compressor, driven by the turbine extracting energy from the exhaust, reduces the back pressure in the exhaust system reducing pumping losses, with the second duct bypassing the turbine in the second exhaust period such that the turbine also does not increase the exhaust back pressure at least during the main second exhaust phase.

Owner:LOUGHBOROUGH UNIV

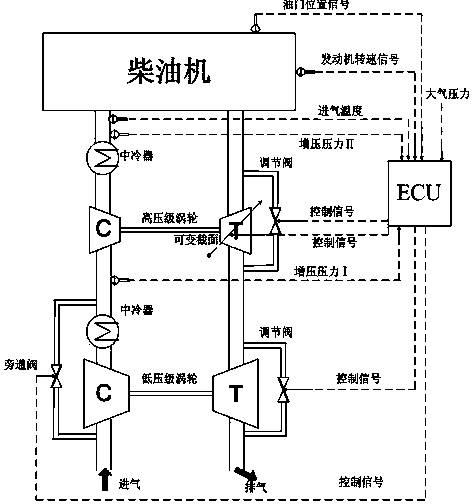

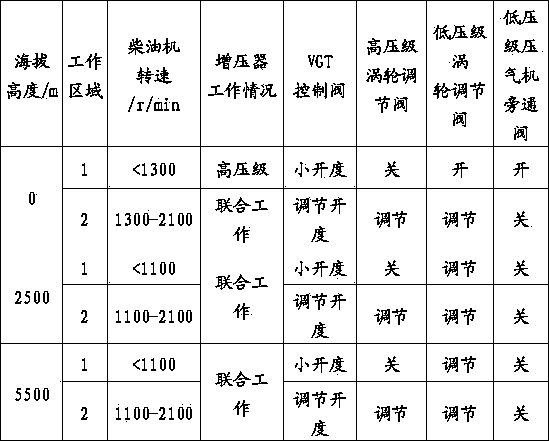

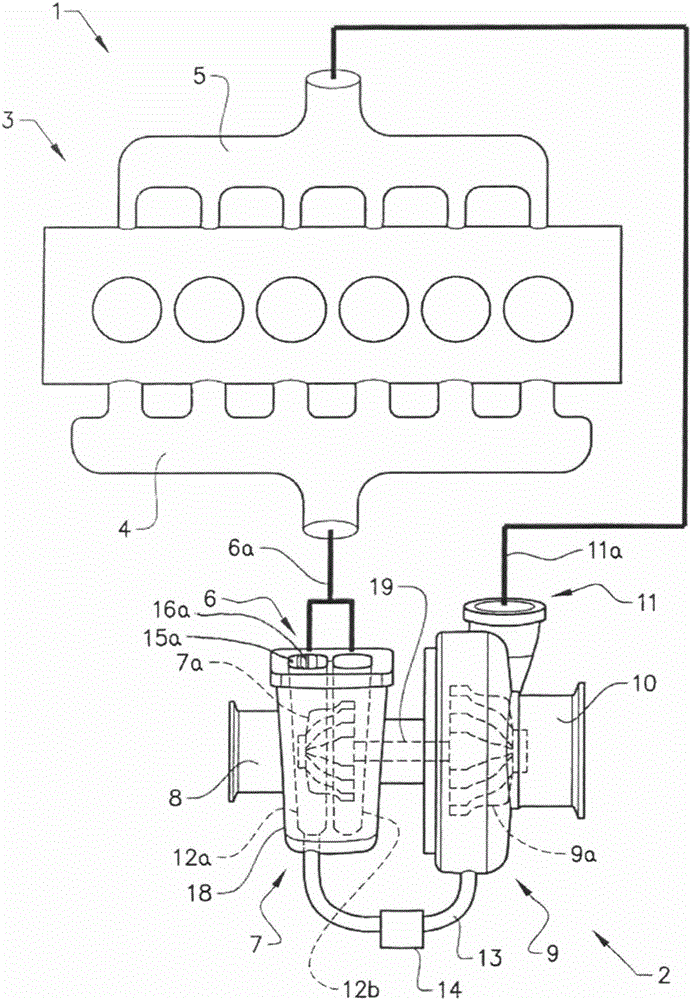

Vehicular diesel engine highland second-stage adjustable pressurization system and control method thereof

InactiveCN103362636ALow densityReduce work of expansionInternal combustion piston enginesAxial compressorTurbine blade

The invention discloses a vehicular diesel engine highland second-stage adjustable pressurization system and method. The system comprises a high-pressure stage supercharger, a low-pressure stage supercharger and an electronic control unit; a middle cooler is arranged between a high-pressure stage gas compressor and a low-pressure stage gas compressor; a middle cooler is arranged behind the high-pressure stage gas compressor; the high-pressure stage gas compressor is connected with the high-pressure stage supercharger; the low-pressure stage gas compressor is connected with the low-pressure stage supercharger; the high-pressure stage supercharger and the low-pressure stage supercharger are connected in series; the turbine side of the high-pressure stage supercharger is provided with a containment high-pressure regulating valve; the turbine side of the low-pressure stage supercharger is provided with a low-pressure regulating valve; the gas compressor side of the low-pressure stage supercharger is provided with a gas compressor by-pass valve; the high-pressure regulating valve, the low-pressure regulating valve, the by-pass valve and a turbine blade regulating mechanism of the high-pressure stage supercharger are controlled by an electronic control unit. a secondary middle cooling technology (the middle cooler is arranged between the high-pressure stage gas compressor and the lower-pressure stage gas compressor and the middle cooler is arranged behind the high-pressure stage gas compressor) is adopted, so that the air temperature after pressurization is reduced, the air input is improved, and the power performance and economical efficiency of an diesel engine are ensured.

Owner:MILITARY TRANSPORTATION UNIV PLA

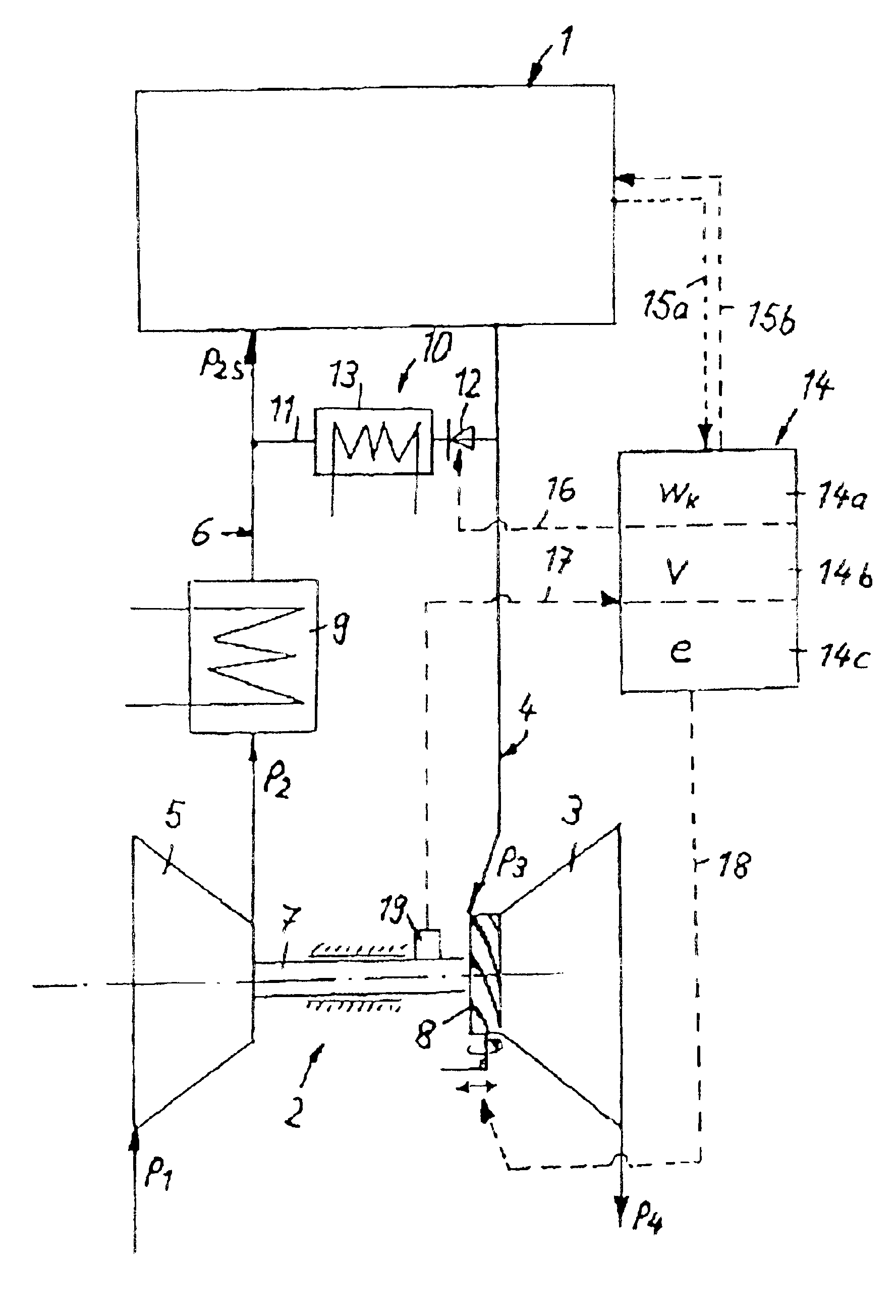

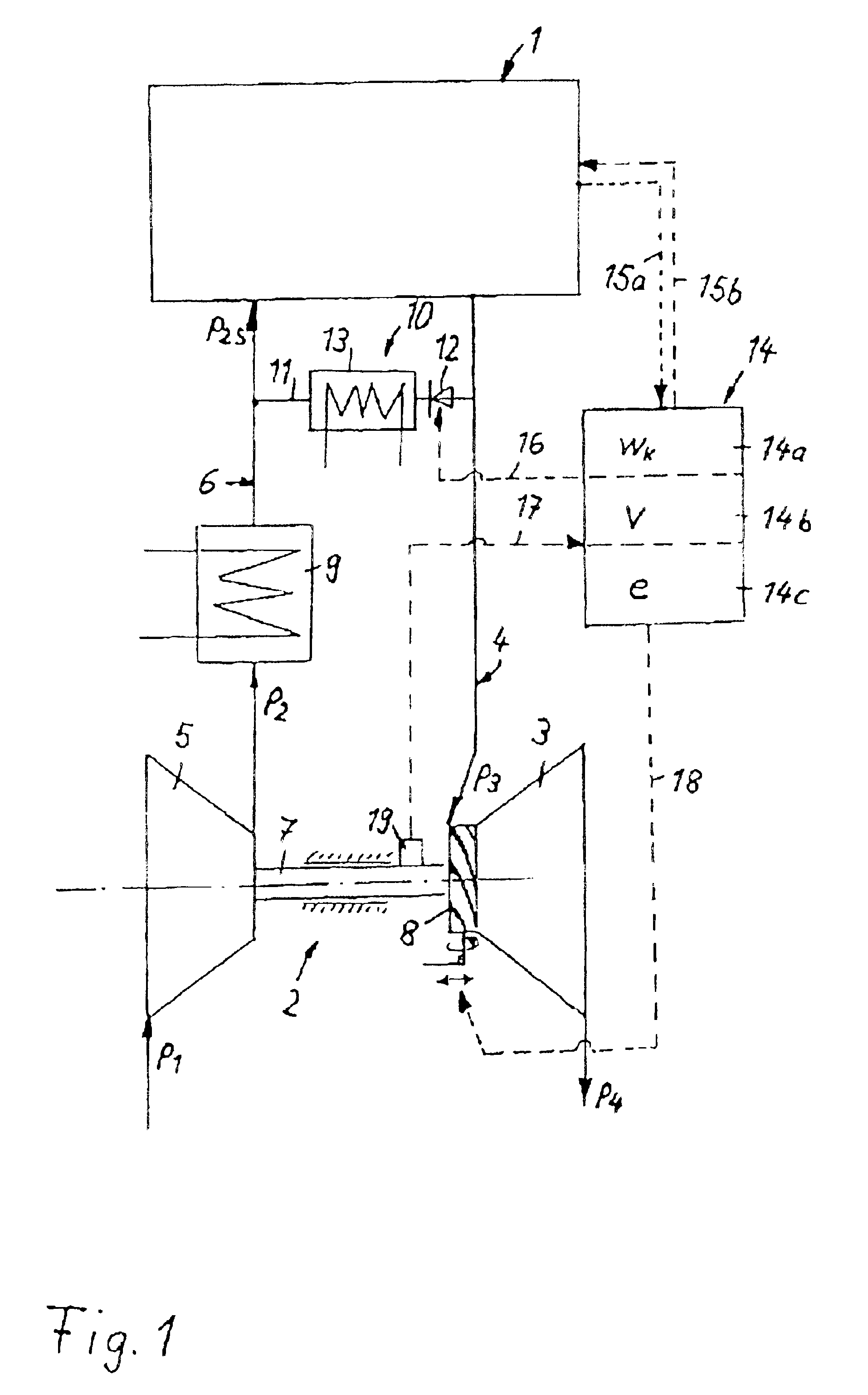

Method for operating an auto-ignition internal combustion engine

ActiveUS20130213363A1Eliminate riskReduce nitrogen oxide emissionsElectrical controlInternal combustion piston enginesSingle substanceLiquid fuel

A method for operating an auto-ignition internal combustion engine that is operable in a single substance mode in which the internal combustion engine is supplied with self-igniting liquid fuel, and a dual substance mode in which the internal combustion engine is supplied with the liquid fuel as an ignition agent and gaseous or liquid alternative fuel, includes operating the internal combustion engine in the dual-substance mode at an increased exhaust gas recirculation rate relative to the single-substance mode, and throttling an air supply in an intake system of the internal combustion engine such that a lambda value in an exhaust gas of the internal combustion engine is in a range greater than 1 up to 1.3.

Owner:MAN NUTZFAHRZEUGE AG

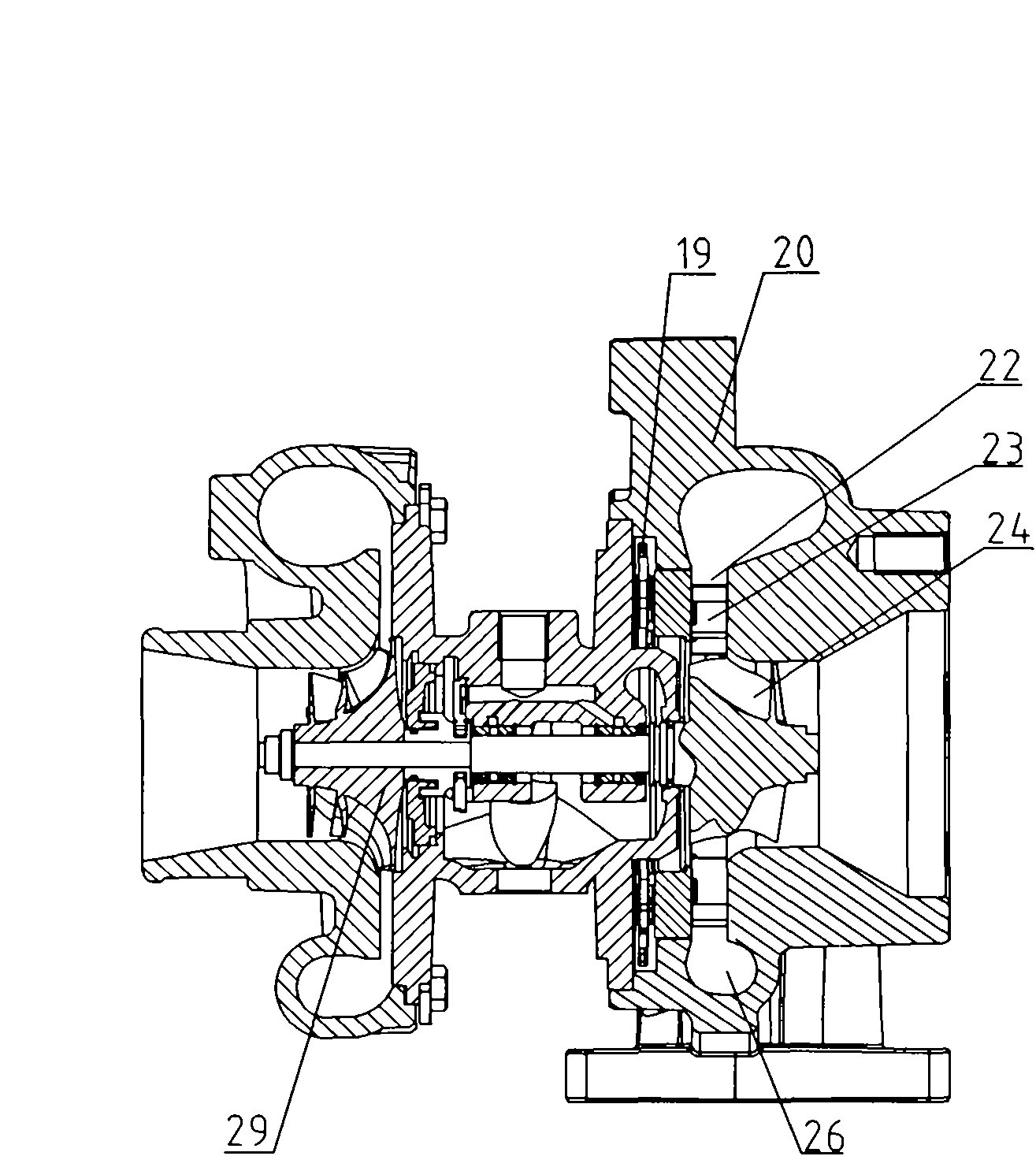

Complex turbine device with variable section

InactiveCN101985897AGuaranteed inflowAvoid enteringInternal combustion piston enginesBlade accessoriesImpellerLow speed

The invention discloses a complex turbine device with a variable section, comprising a double flow channel turbine volute, wherein the double flow channel turbine volute is provided with two air flow passageways; the double flow channel turbine volute is provided with a volute air outlet and a volute air inlet which are communicated with the air flow passageways; a complex turbine impeller is arranged in the double flow channel turbine volute; and the complex turbine impeller is formed by compounding two turbine impellers which correspond to the two air flow passageways one by one. In the invention, the variable section function can be achieved by design and development of the turbine of a turbocharger and by using the complex turbine device, thereby effectively solving the defects of poor reliability and high cost of a vane type turbocharger with the variable section, effectively improving the efficiency of the turbine of an engine in low speed and increasing the torque output of the turbine.

Owner:KANGYUE TECH

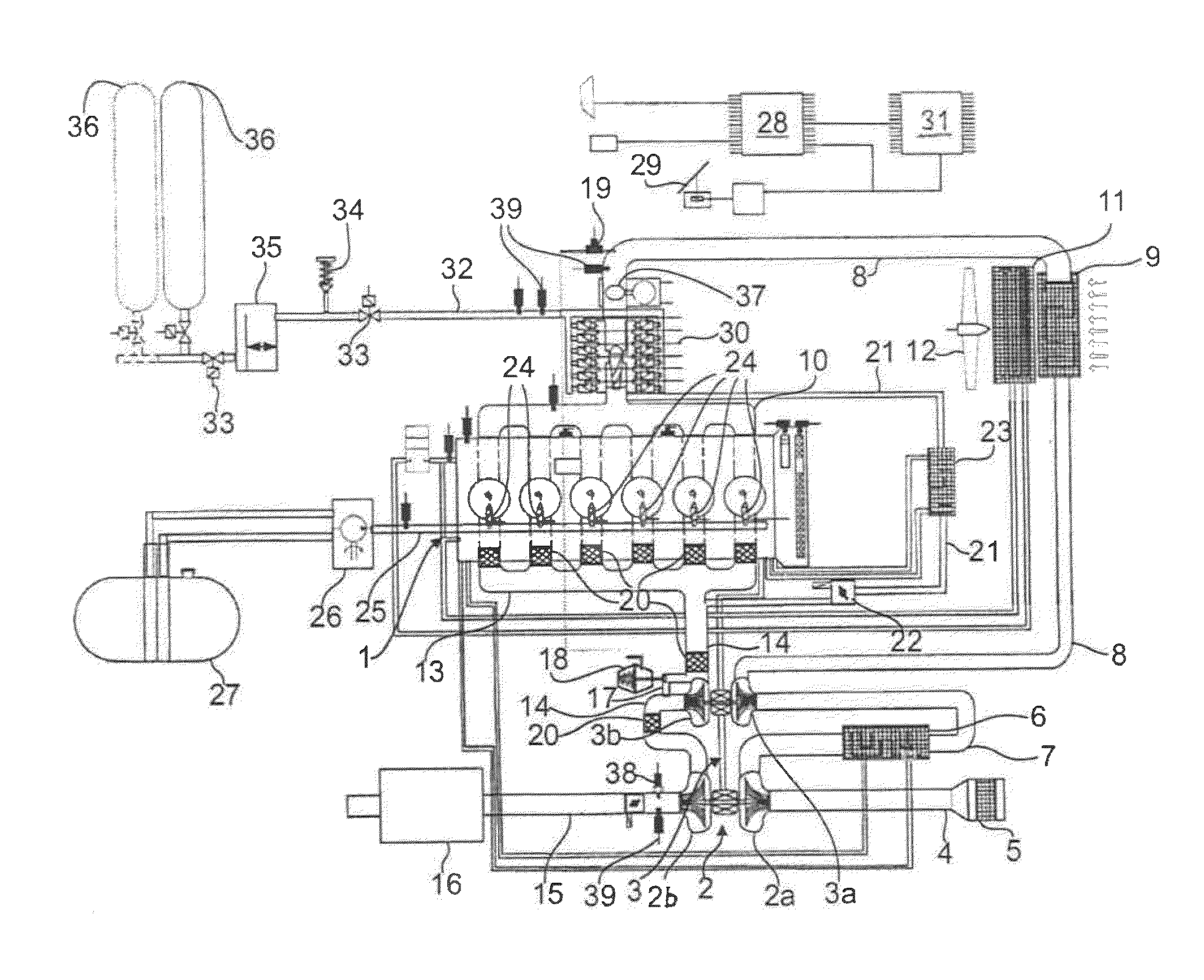

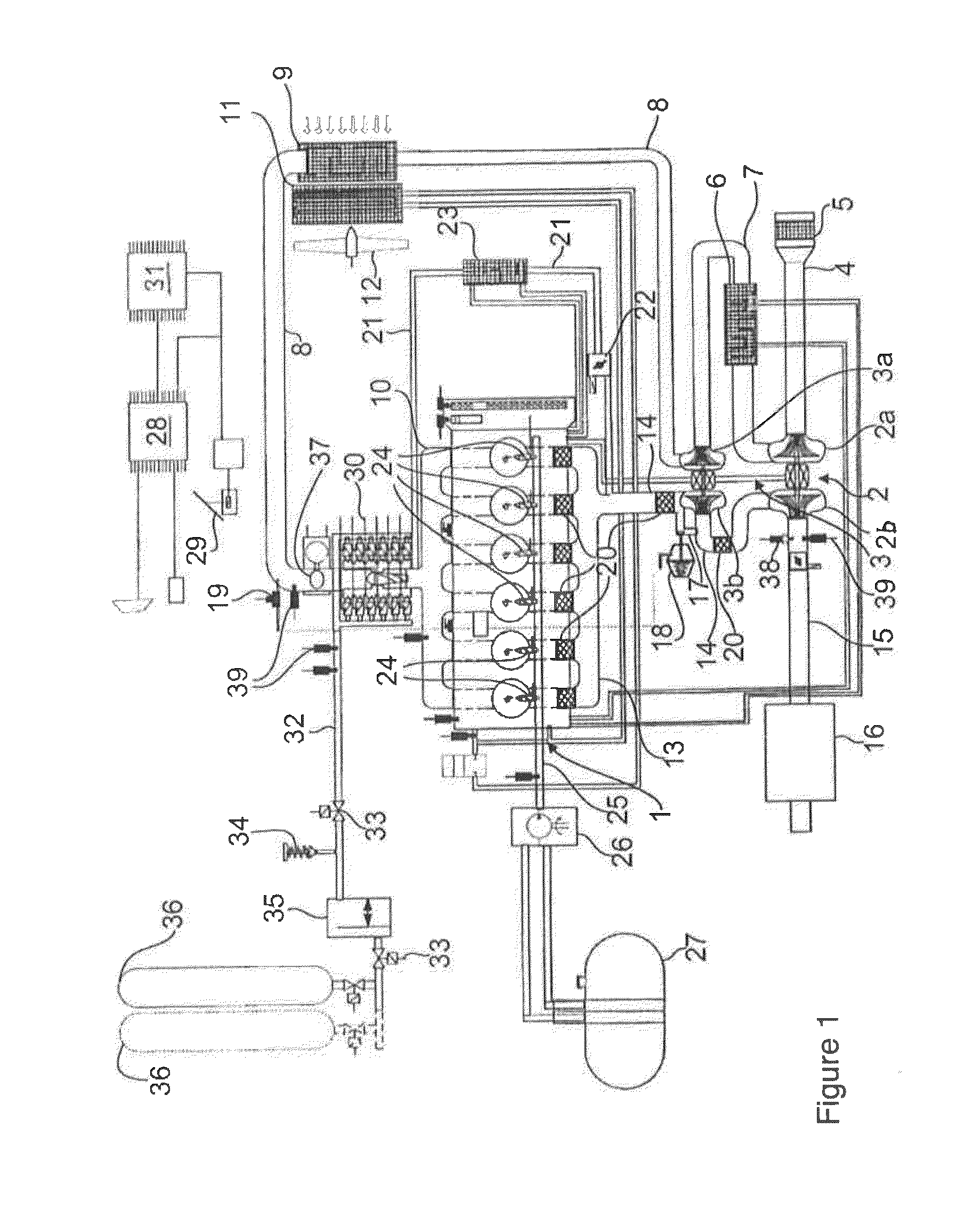

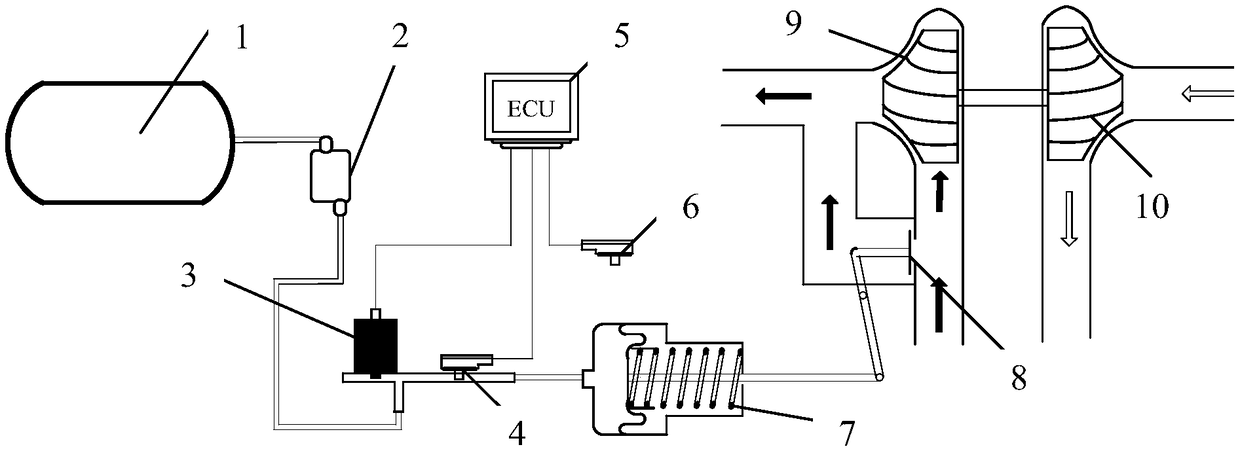

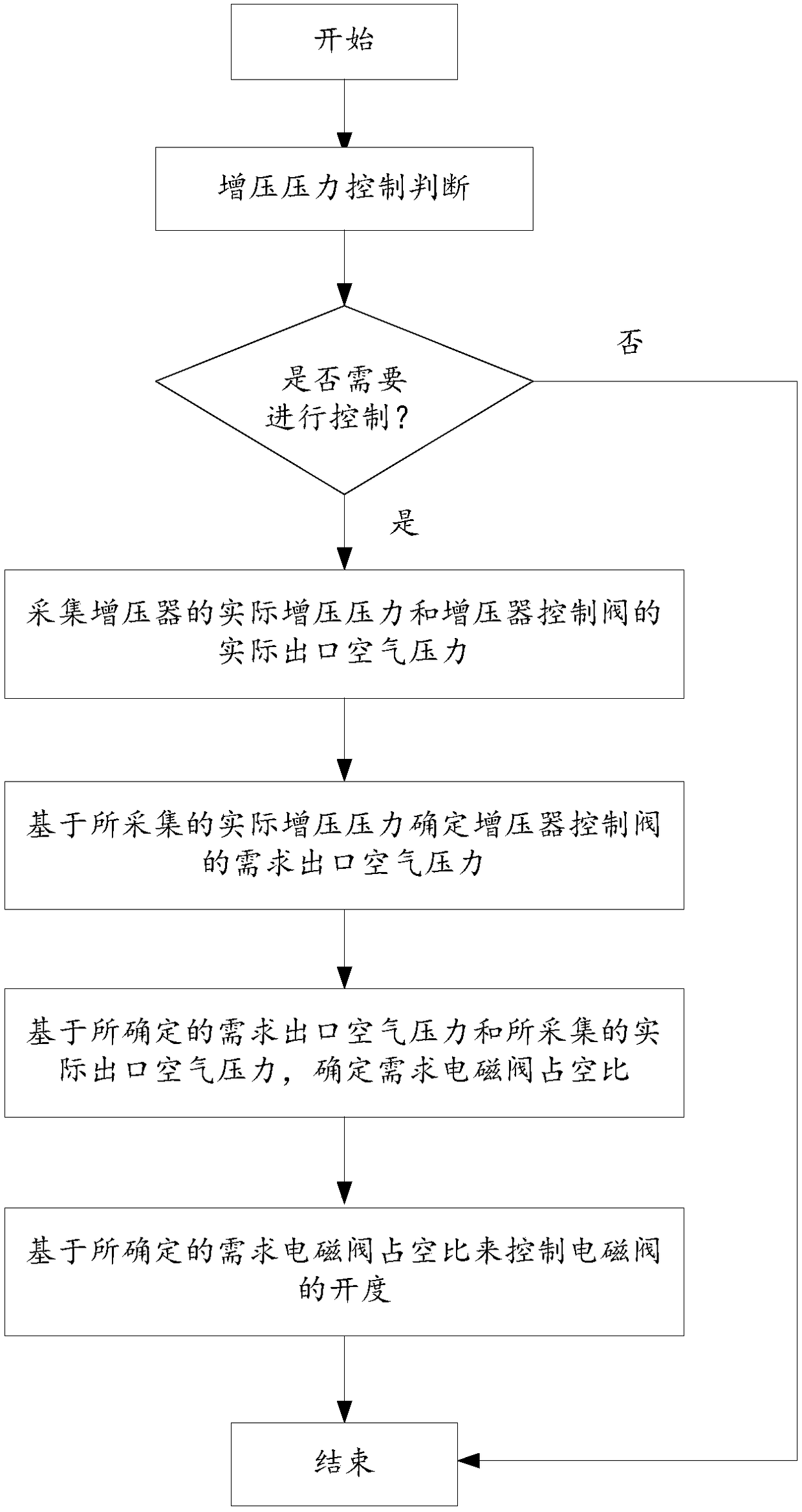

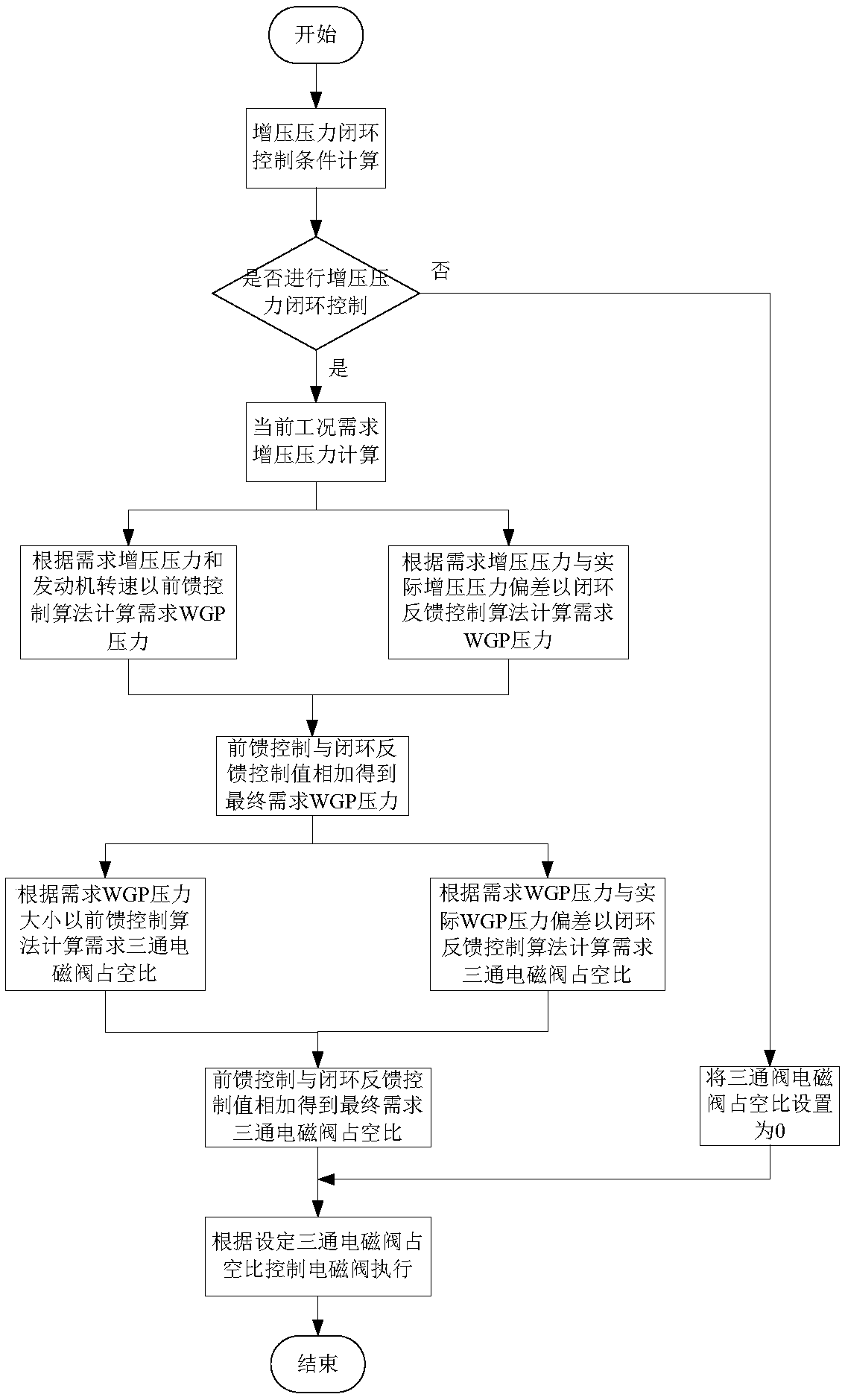

Natural gas engine waste gas bypass type booster control system and method

ActiveCN108087108AReduce fuel consumptionStable controlInternal combustion piston enginesBottlePressure data

The invention provides a natural gas engine waste gas bypass type booster control system which comprises a compressed air storage bottle, a pressure reducer, a booster control valve, a waste gas bypass pressure sensor, an engine control unit, a boosting pressure sensor, a booster waste gas bypass control membrane valve and a booster. The booster comprises a booster waste gas bypass valve, a booster turbine and a booster compressor. The engine control unit controls opening of an electromagnetic valve on the basis of pressure data collected by the boosting pressure sensor and the waste gas bypass pressure sensor, therefore, outlet air pressure of the booster control valve is controlled, and opening of the booster waste gas bypass valve is controlled. The invention further provides a naturalgas engine waste gas bypass type booster control method. An air inlet throttle loss can be reduced, exhaust back pressure can also be reduced, the charging efficiency is improved, and finally fuel economy is improved.

Owner:CHINA FIRST AUTOMOBILE

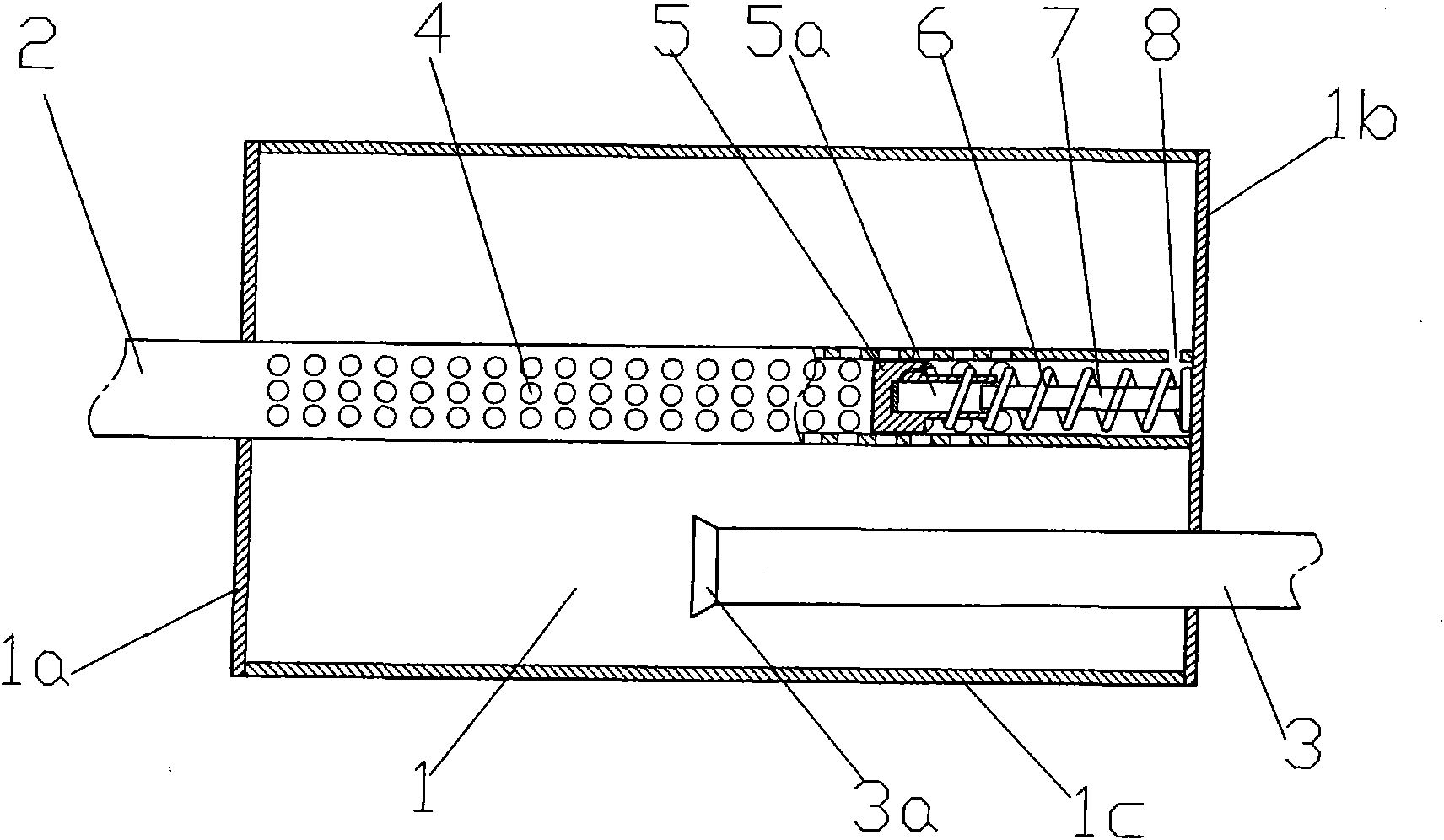

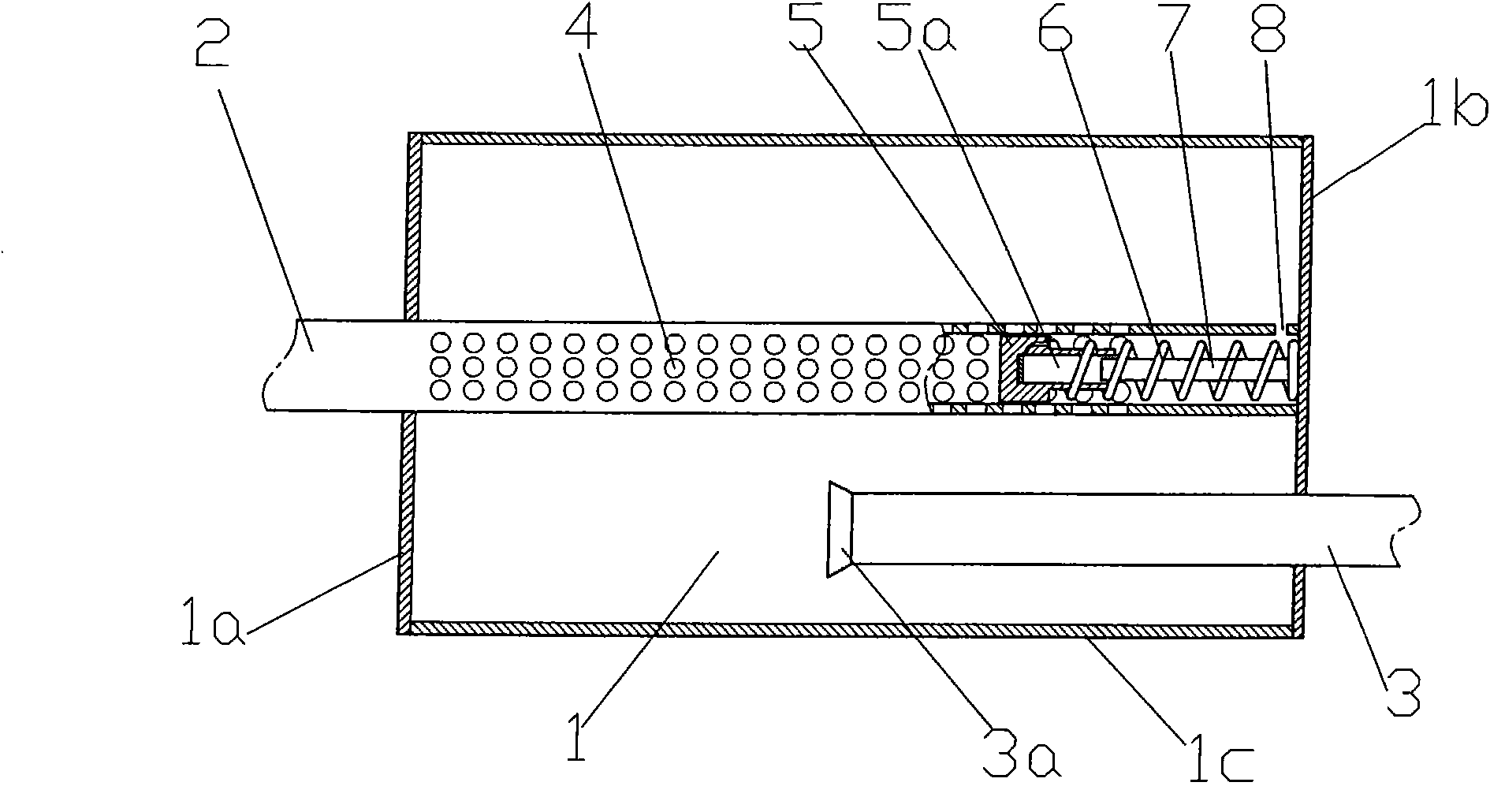

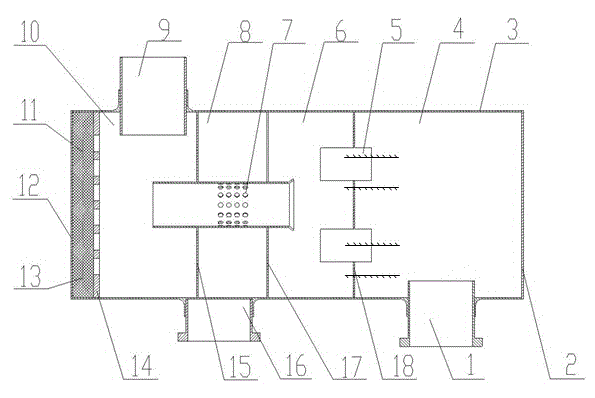

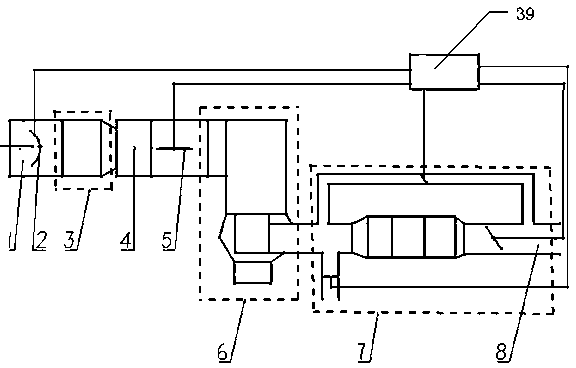

Exhaust muffler capable of automatically adjusting overflow area

InactiveCN101813017AImprove the noise reduction effectUniform flow rateExhaust apparatusSilencing apparatusEngineeringExpansion chamber

The invention discloses an exhaust muffler capable of automatically adjusting the overflow area, which comprises an air inlet pipe, an expansion chamber and an air outlet pipe, wherein the inner circle of the section (provided with radial through-holes) of the air inlet pipe is provided with a piston which can slide to and fro along the inner wall of the pipe, and the front end of the piston faces the air inlet direction, while the rear end is provided with a pressure spring which can apply pressure (with a direction opposite to the air inlet direction) to the rear end. The invention adopts a structure that the exhaust pipe section of the air inlet pipe is provided with the piston which divides the exhaust pipe section into an exhaust part and a closed part, the position of the piston can be automatically adjusted according to the exhaust pressure and the piston can reset under the action of the spring when the exhaust pressure is low; therefore, the exhaust muffler has the advantages of adjusting the area of the airflow ventilating section according to the exhaust gas flow of an engine under different working conditions, keeping the exhaust airflow in an even flow velocity, effectively lowering the exhaust backpressure, reducing the regenerated noise of the airflow, improving the erasure effect of the muffler, and having a positive significance for reducing the fuel consumption and carbon dioxide emission of an automobile.

Owner:CHONGQING UNIV

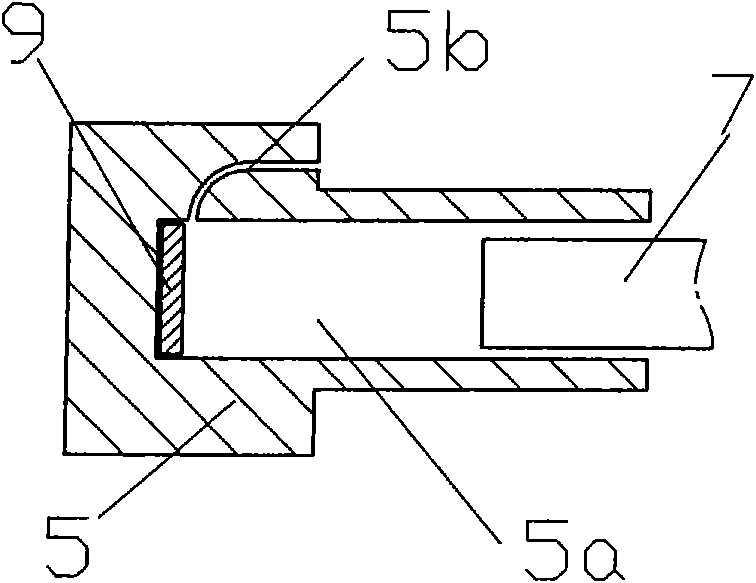

Exhaust muffler

InactiveUS7287622B2Reduce complexityReduce noiseExhaust apparatusSilencing apparatusExhaust fumesInternal combustion engine

The present specification discloses a muffler for attenuating exhaust noise from an internal combustion engine. The muffler includes a main chamber, an intermediate pipe, a diffuser chamber, a spark arrester, and an exhaust pipe. Exhaust gases from the engine enter the main chamber after which they flow through the intermediate pipe. The intermediate pipe extends back through the main chamber to the diffuser chamber. The spark arrester is a screen held within the exhaust muffler and removably coupled to the exhaust pipe. Gases flow through the screen to separate hot particles. The exhaust pipe extends within the main chamber, completing a 180° bend within the chamber before exiting the main chamber and the muffler. An outer enclosure may surround the muffler. A method of attenuating exhaust gas noise is also disclosed.

Owner:ARCTIC CAT

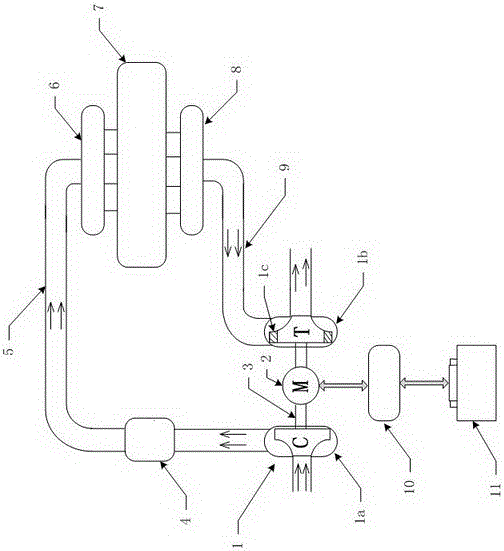

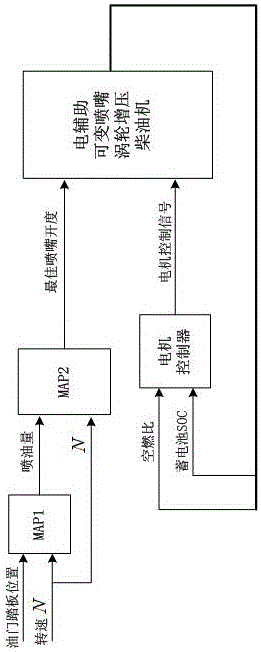

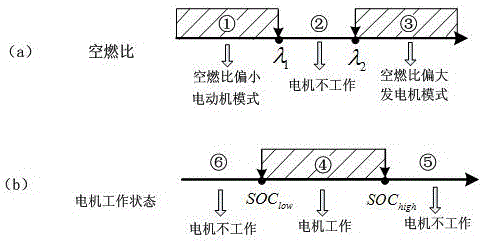

Electric-assistance variable nozzle turbocharging system and control method thereof

ActiveCN105781716AImprove transient response characteristicsMeet the performance requirements of working conditionsInternal combustion piston enginesElectricityTurbocharger

The invention provides an electric-assistance variable nozzle turbocharging system, and belongs to the technical field of turbochargers. The electric-assistance variable nozzle turbocharging system and the control method thereof aim at enabling a motor and a turbine variable nozzle ring to be coordinated through the influences of the motor and the turbine variable nozzle ring on performance of an engine. A diesel engine cylinder is directly connected between a gas inlet branch pipe and an exhaust branch pipe of the system. A gas inlet pipe is connected to the gas inlet branch pipe. An exhaust pipe is connected to the exhaust branch pipe. An intercooler is installed on the gas inlet pipe. An electric-assistance variable nozzle turbocharger is installed at an inlet of the gas inlet pipe and an outlet of the exhaust pipe. According to the electric-assistance variable nozzle turbocharging system and the control method, the high-speed motor is controlled on the basis of the air-fuel ratio of a diesel engine and the state of a storage battery, the gas inflow amount of the cylinder can be effectively and rapidly regulated so as to be matched with the changes of the oil spray amount, coordinated synchronization of oil and gas is achieved, it is ensured that the diesel engine keeps an appropriate air-fuel ratio value under various working conditions, and meanwhile it is ensured that the battery works in a high-efficiency area.

Owner:JILIN UNIV

Engine brake detection

InactiveCN101835967AMinimize the effect of large valve forceHigh accelerationElectrical controlInternal combustion piston enginesExhaust valvePiston

The present invention relates to a method for reducing engine vibrations during engine braking with a malfunctioning engine brake, where said engine brake comprising means for altering a timing of at least one exhaust valve and means for varying an exhaust gas back pressure, comprising the steps of: detecting piston acceleration for each cylinder in the engine during the use of said engine brake,comparing said detected piston acceleration with a predetermined reference value, decreasing exhaust gas back pressure during engine braking if at least one piston is detected with a piston acceleration deviating more than a predefined amount from said predetermined reference value so that said piston acceleration will be falling within said predefined amount from said predetermined reference value.

Owner:VOLVO TRUCK CORP

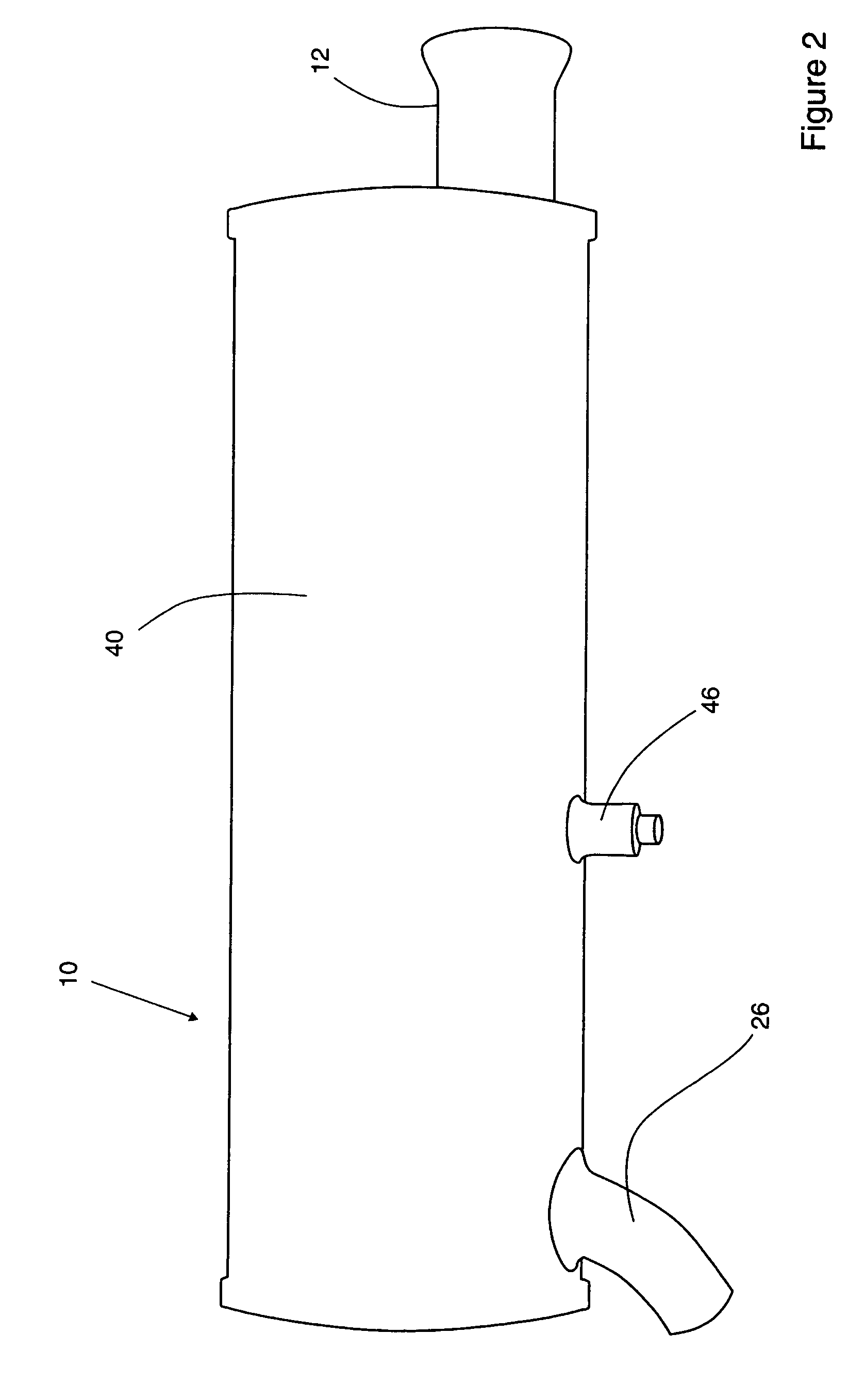

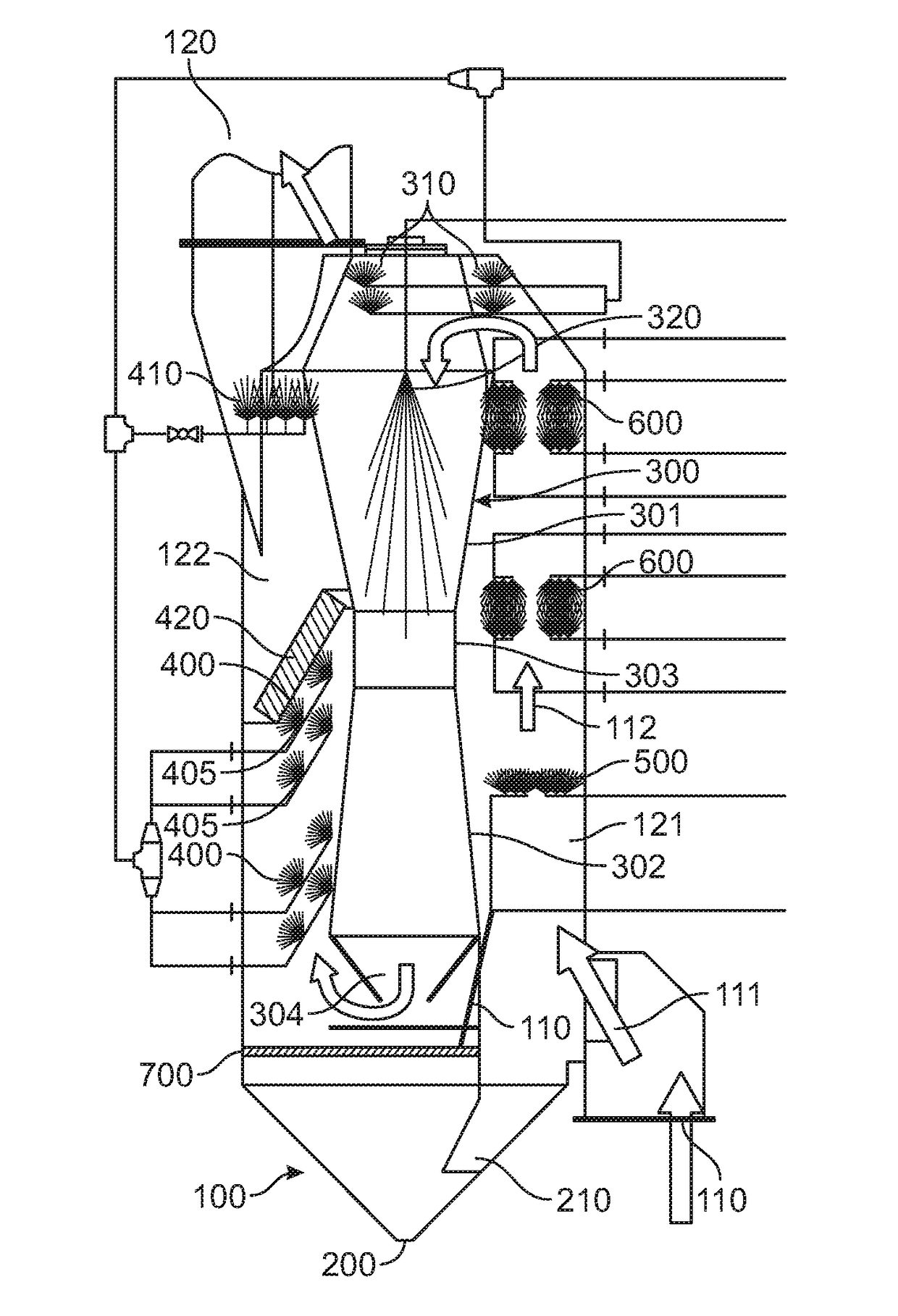

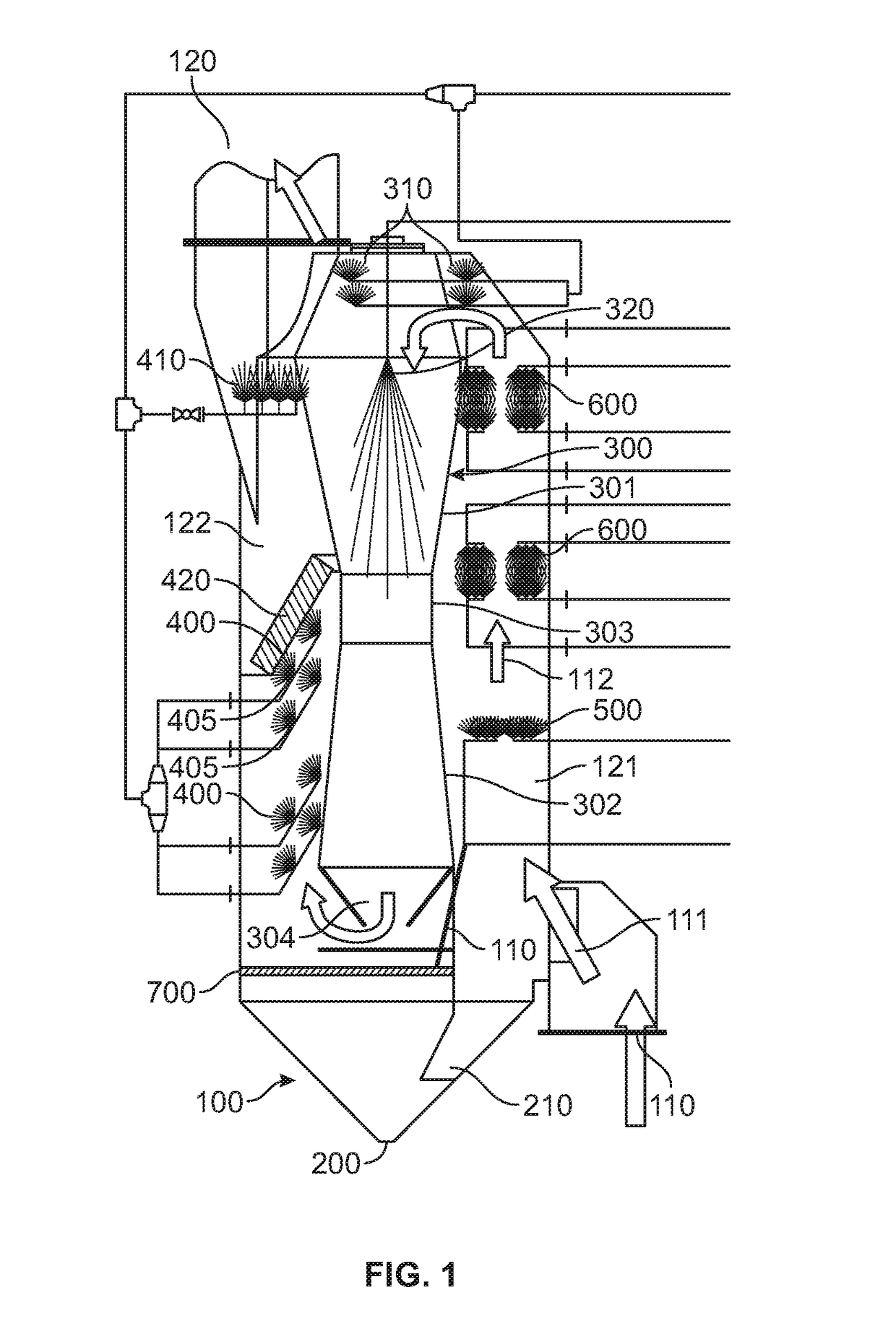

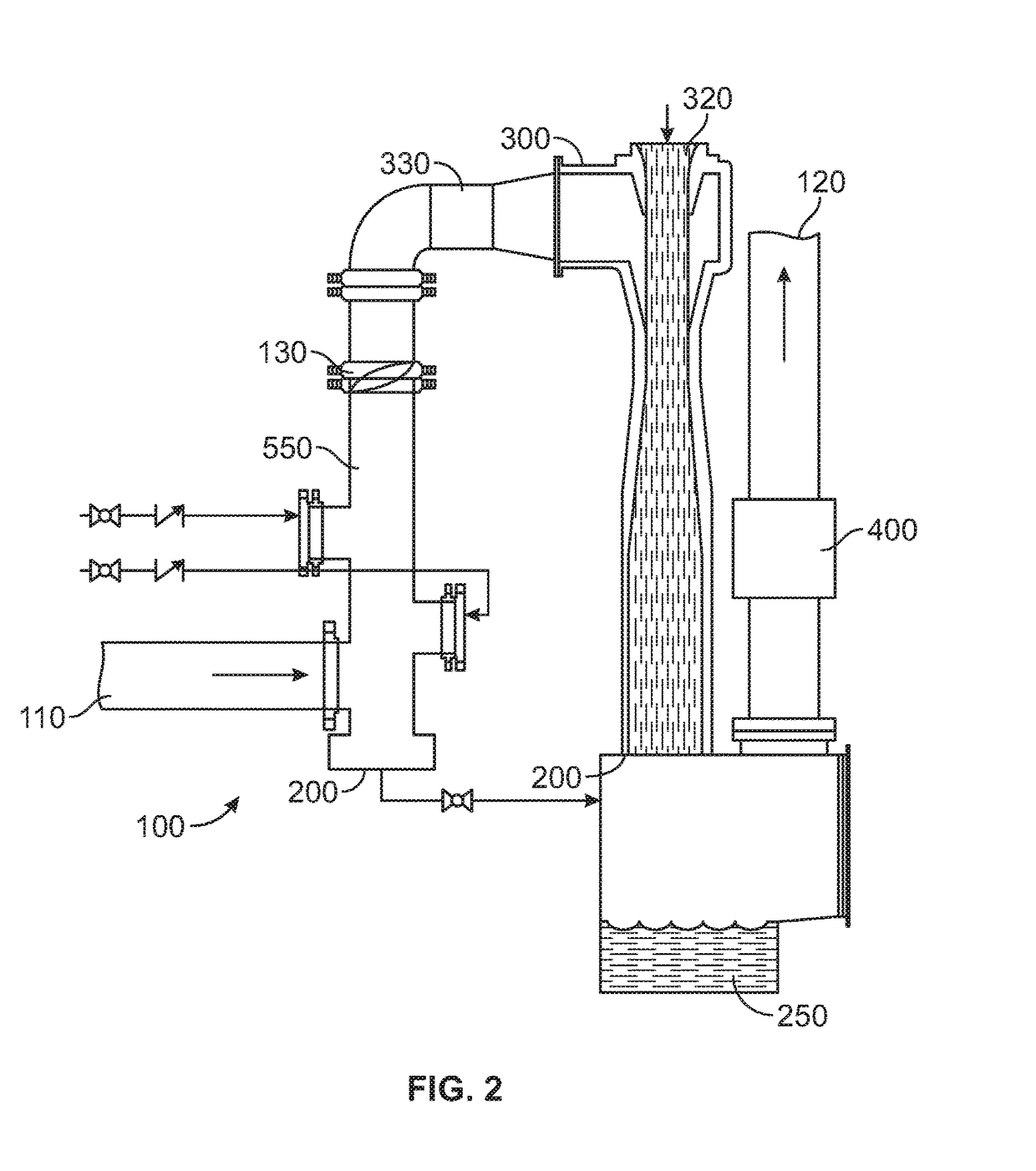

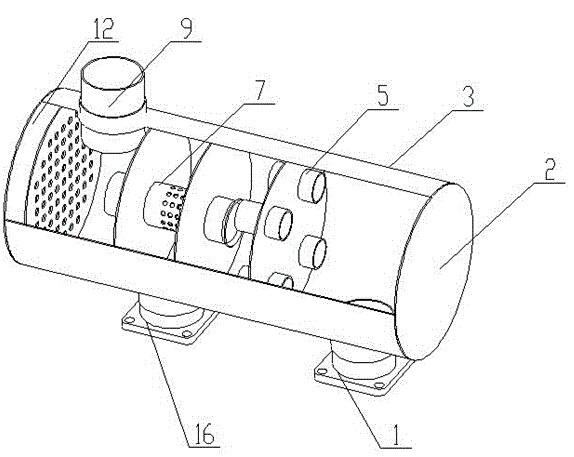

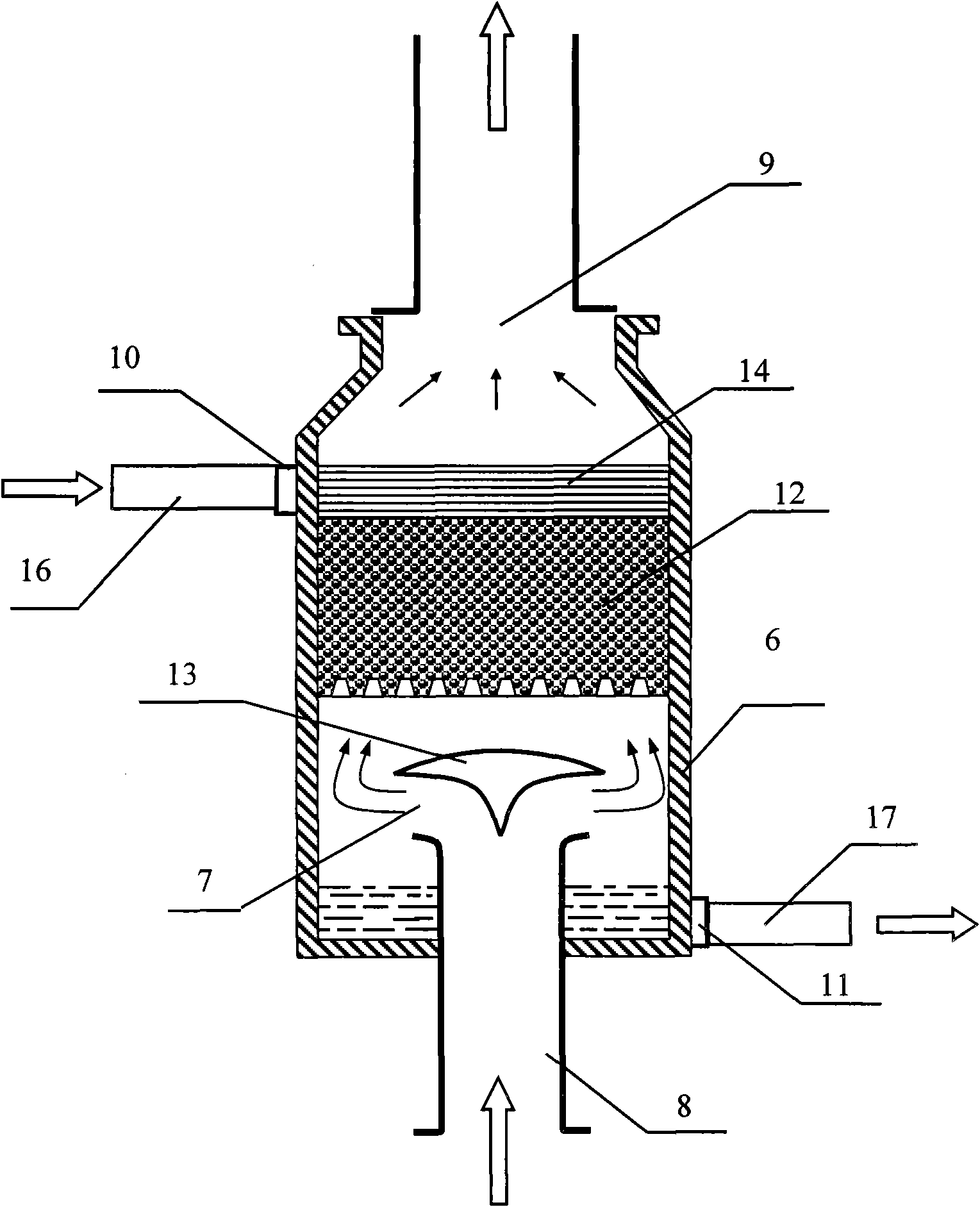

Marine exhaust gas cleaning system

InactiveUS9914094B2Increase pressureReduce stressGas treatmentUsing liquid separation agentExhaust fumesEngineering

A marine exhaust gas scrubbing device including an enclosure having a first end and a second end, an exhaust gas inlet, at least one quencher, at least one pre-treater, at least one venturi component including a venturi inlet and a venturi outlet, an impingement basket, at least one demister, an exhaust gas outlet, and a receiver, and a process for scrubbing a marine exhaust gas including cooling the exhaust gas, pre-treating the exhaust gas, washing the exhaust gas, mixing the exhaust gas and exhausting the scrubbed exhaust gas.

Owner:MARINE EXHAUST SOLUTIONS

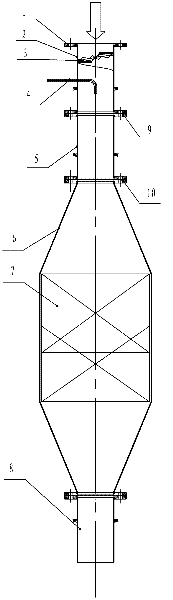

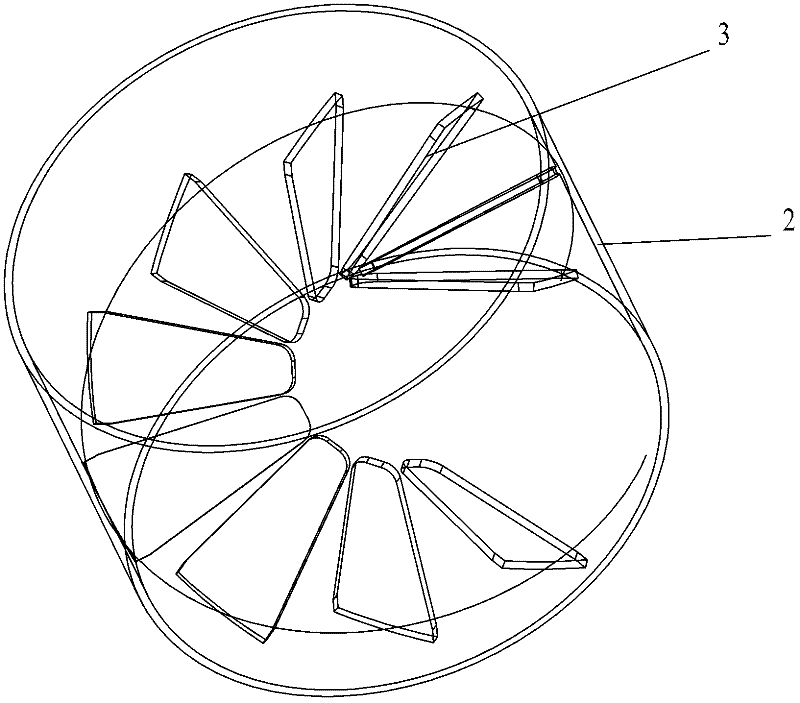

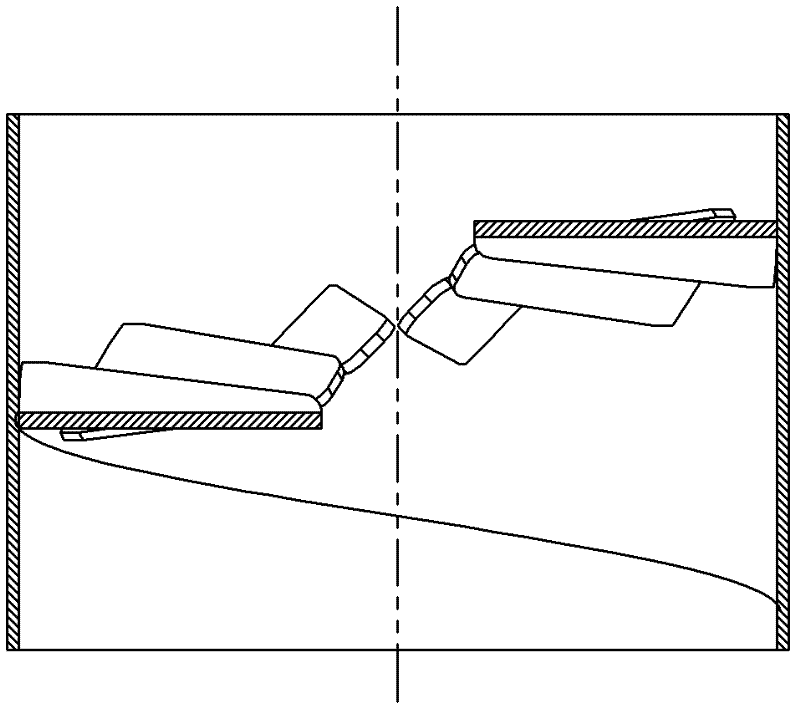

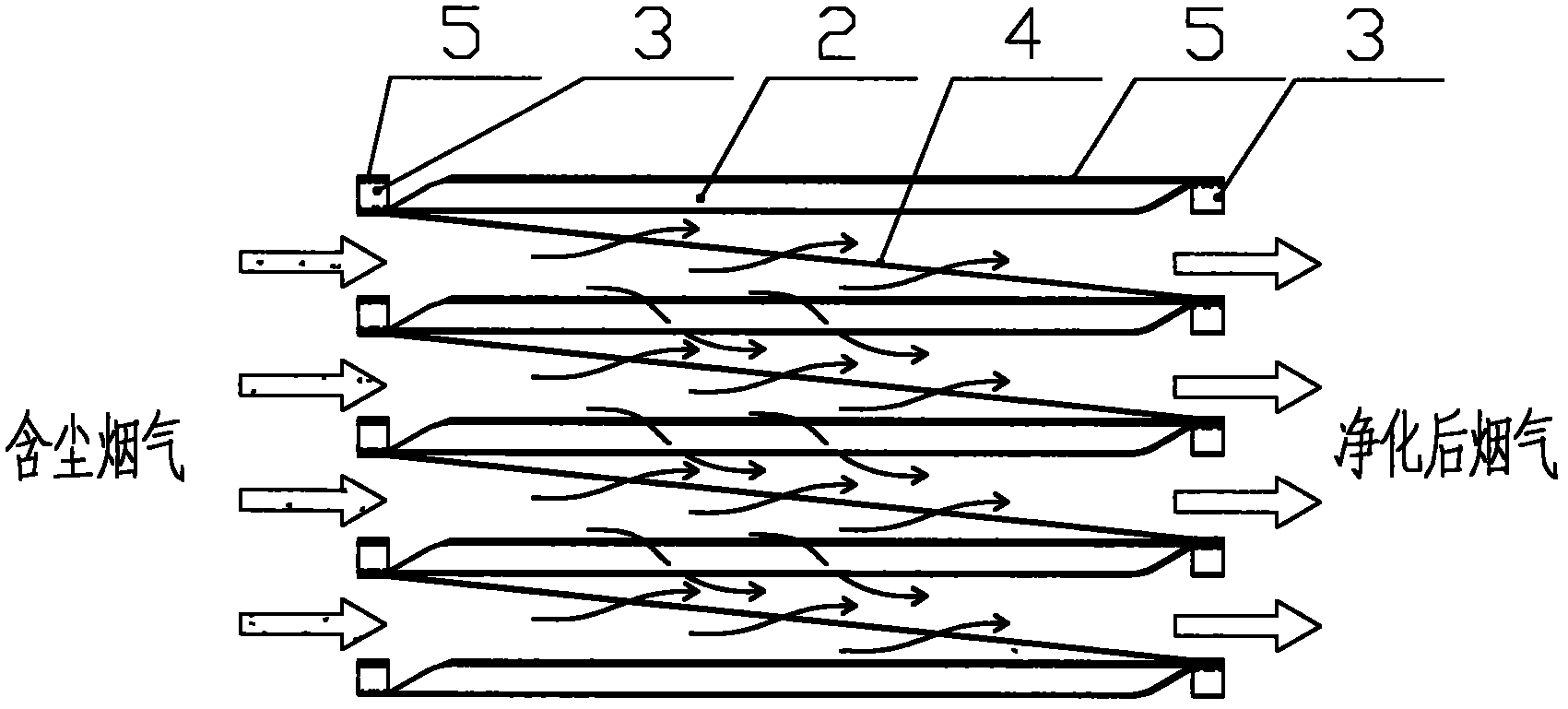

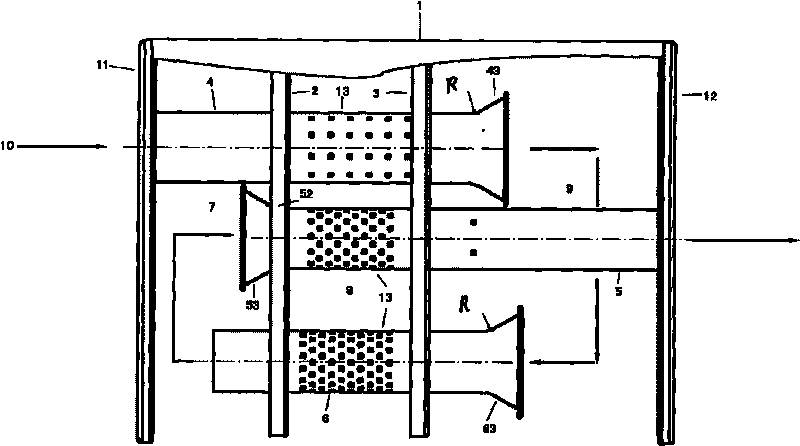

Vehicle urea SCR (Selective Catalyctic Reduction) system and static mixer thereof

ActiveCN102337950AImprove the mixing effectReduce exhaust back pressureInternal combustion piston enginesExhaust apparatusStatic mixerMixing effect

The invention discloses a static mixer of a vehicle urea SCR (Selective Catalyctic Reduction) system, which is characterized in that one group of fins is arranged in an exhaust pipe in a helical step manner, and the fins and the cross section of a pipe body are arranged at a certain included angle. Through calculation and analysis of special CFD (Computational Fluid Dynamics) software, the staticmixer can effectively increase gas disturbance to ensure that engine waste gas and urea drops are fully mixed through the mixer, obtain better distribution uniformity before entering an SCR catalyticconverter and fully react to reduce the content of NOx in the tail gas of a vehicle. The static mixer has a better mixing effect, small exhaust backpressure and a compact structure, is convenient forinstallation, and can be widely applied to a diesel engine exhaust pipeline with the urea SCR system.

Owner:HANGZHOU YINLUN TECH CO LTD +1

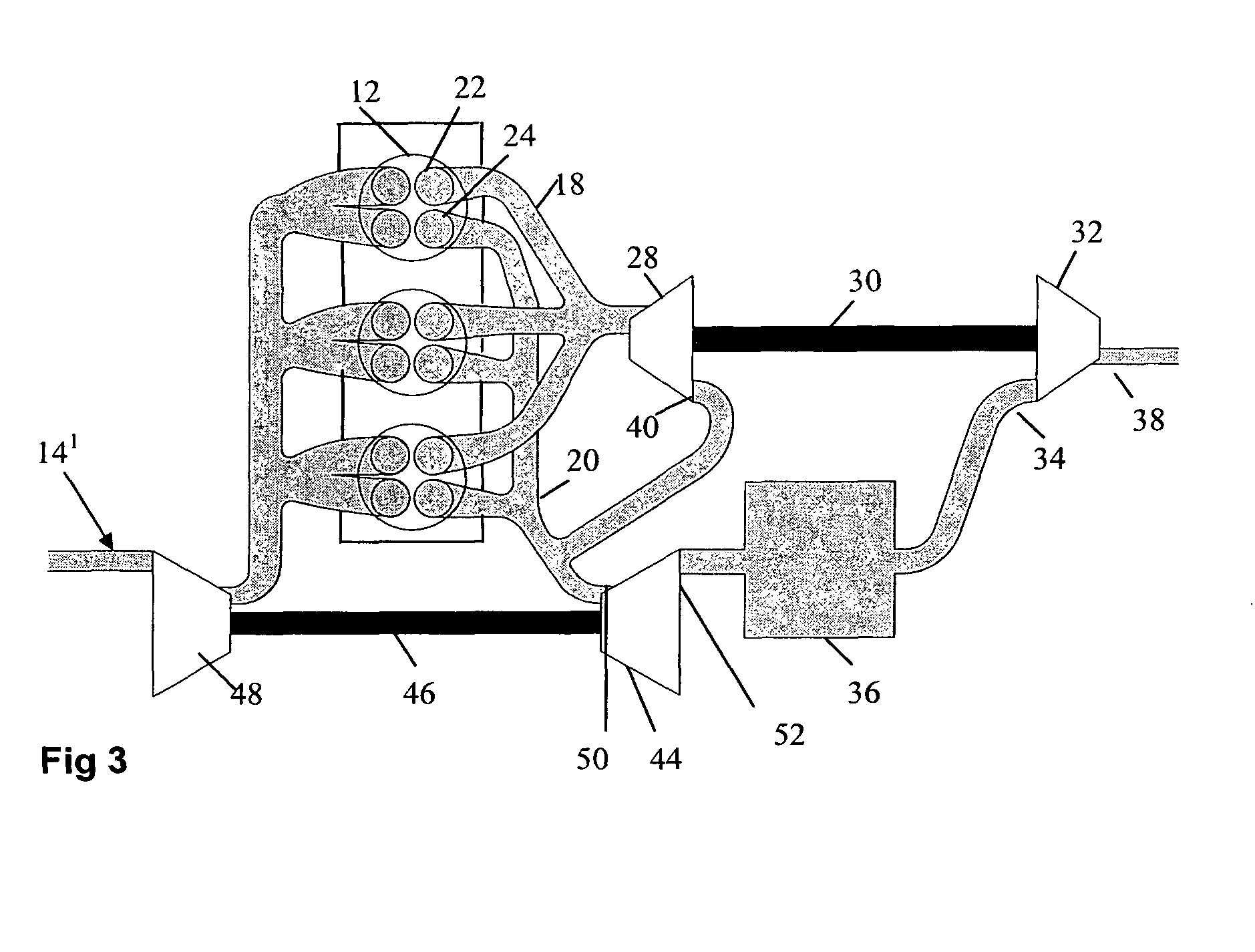

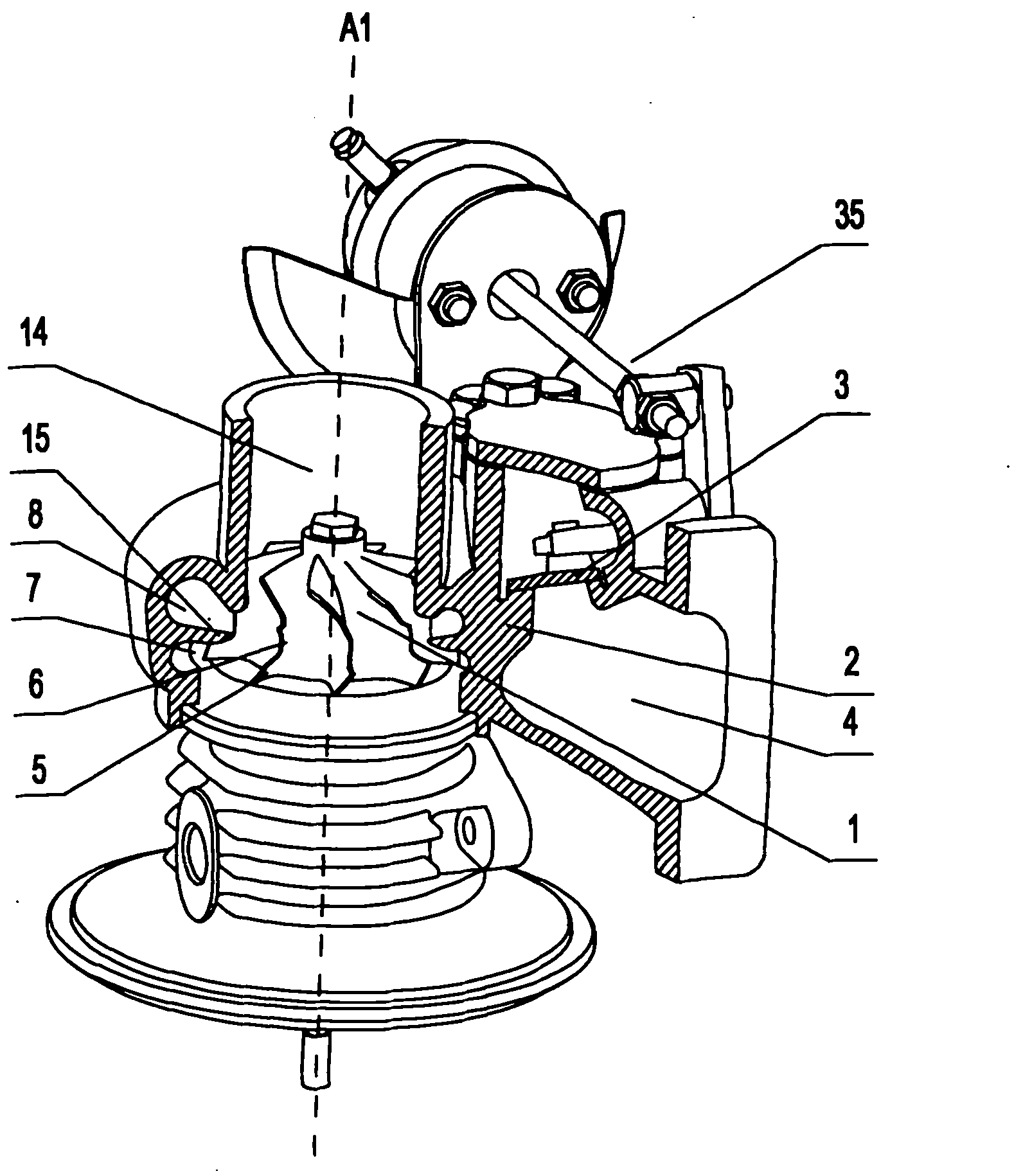

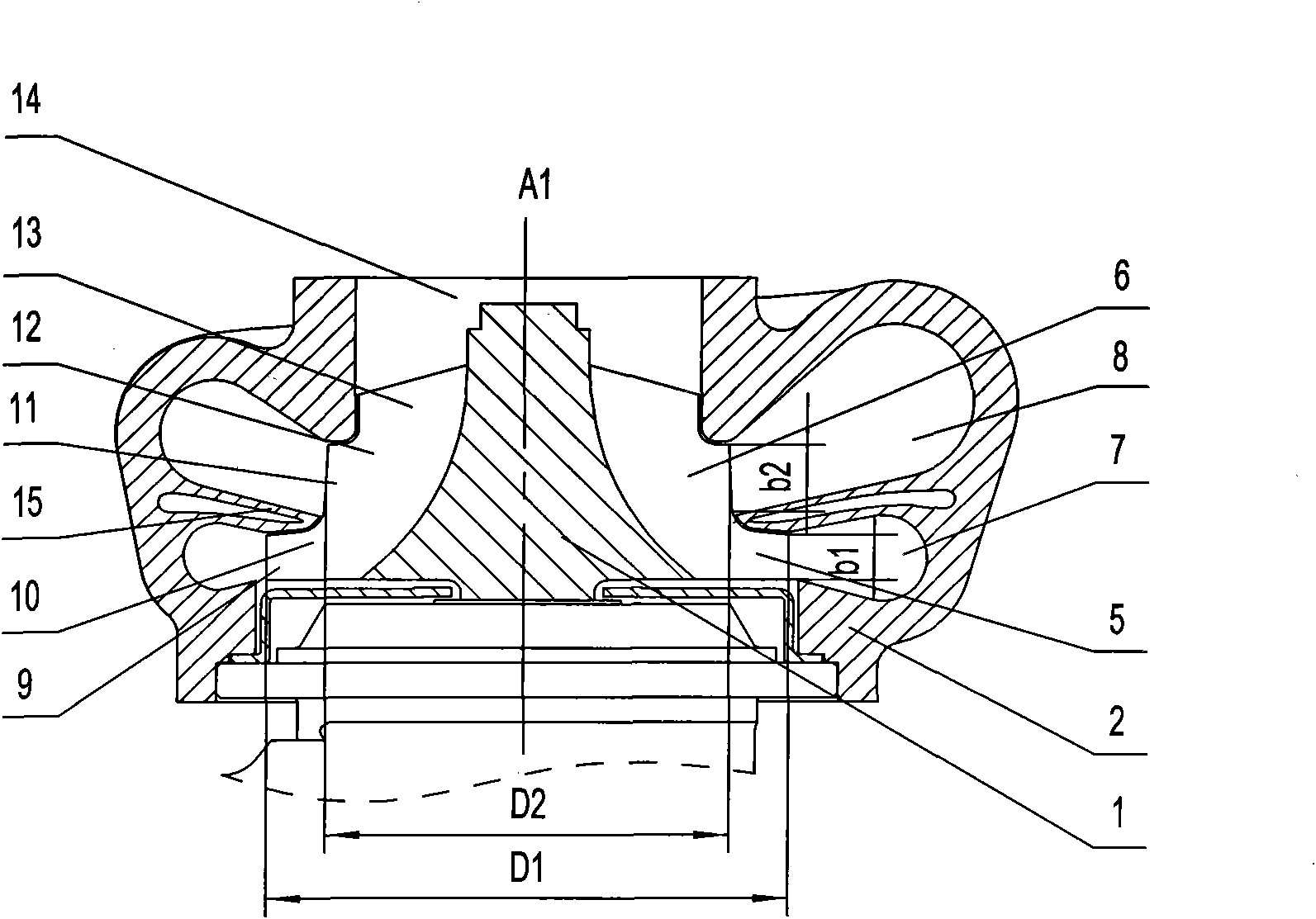

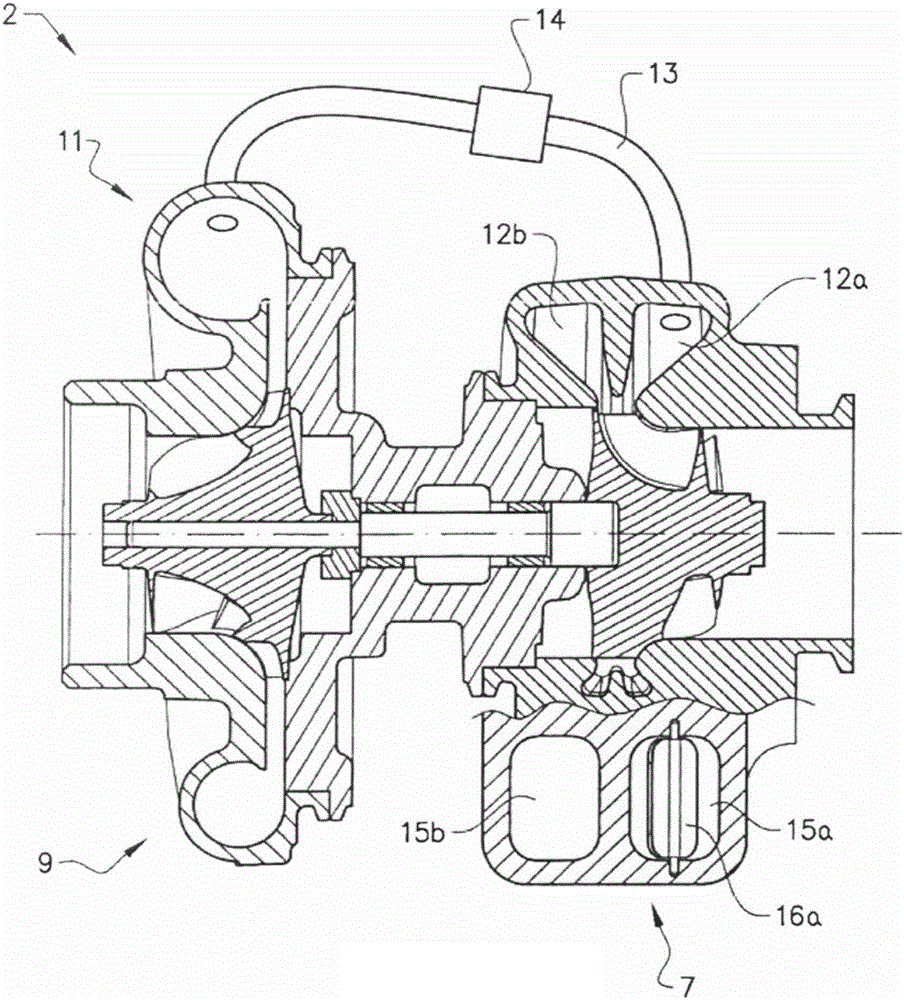

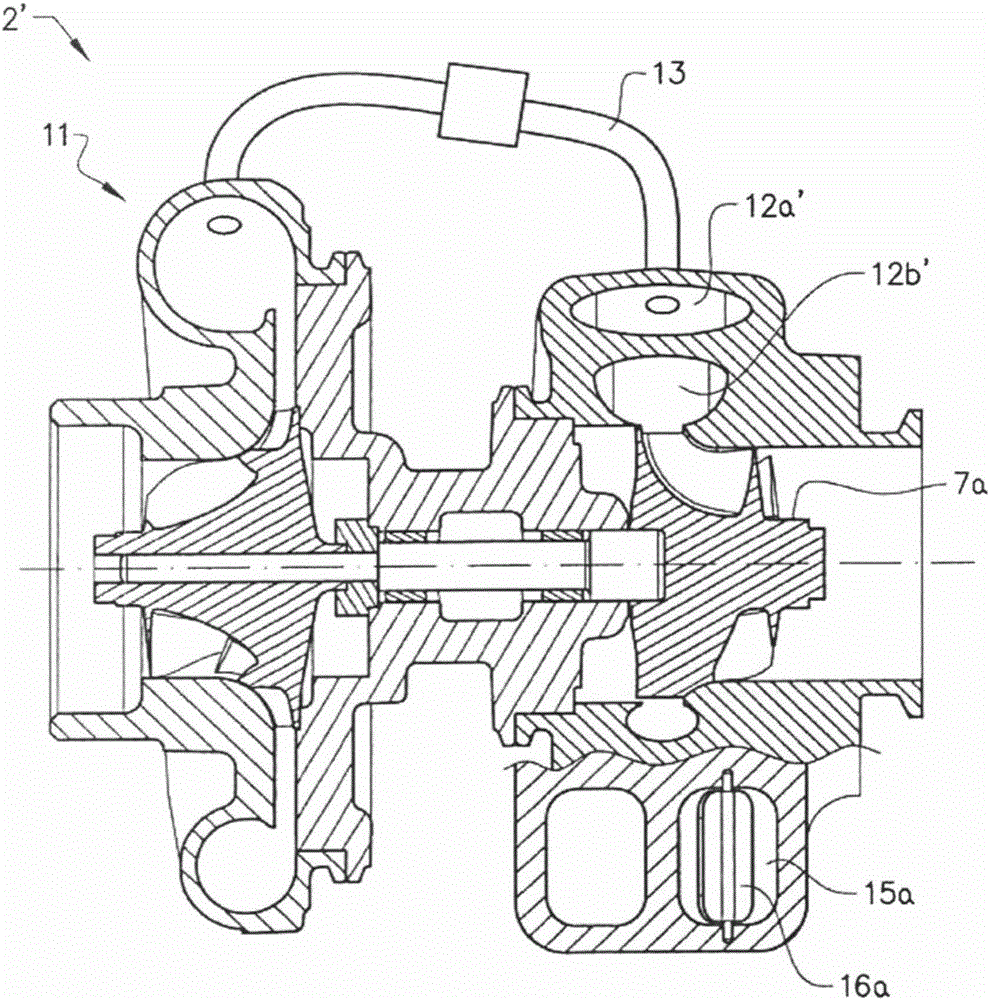

Twin scroll turbocharger device with bypass

ActiveCN105464789ALength minimizationMinimized pressure lossInternal combustion piston enginesStatorsTurbochargerInlet valve

A twin scroll turbocharger device for an internal combustion engine comprising a turbine and a compressor wherein the turbine comprises a first turbine scroll and a second turbine scroll, and wherein at least said first turbine scrolls is provided with a turbine scroll inlet valve such that the exhaust gas flow through the first turbine scroll is controllable. The twin scroll turbocharger device is further characterized in that a bypass conduit is provided between a compressor and at least the first turbine scroll. The bypass conduit is provided with a bypass conduit valve such that a flow through said bypass conduit is controllable.

Owner:VOLVO CAR CORP

Impedance compound muffler

InactiveCN104948265ASpeed up the flowPrevent backflowSilencing apparatusMachines/enginesIntermediate frequencyEngineering

The invention discloses an impedance compound muffler. The impedance compound muffler comprises a cavity structure, the cavity structure is formed by a shell, a front end cover and a rear end cover and is separated into a first cavity body, a second cavity body, a third cavity body and a fourth cavity body by a first partition plate I, a second partition plate II and a third partition plate III, the first cavity body is provided with an inlet tube, the fourth cavity body is provided with an outlet tube, a plurality of insert tubes are arranged on the first partition plate I and communicate the first cavity body with the second cavity body, a perforation pipe is fixed on the first partition plate I and the second partition plate II, an inlet of the perforation pipe is positioned in the second cavity body, an outlet of the perforation pipe is positioned in the fourth cavity body, and small holes are uniformly distributed in the middle area of the part in the third cavity body. The impedance compound muffler has the advantages that by means of reasonably combining expansion and resonance, an effect of lowering noise of an air flow in low and intermediate frequencies and an effect of eliminating noise in high frequency are achieved, and a large noise elimination quantity and a wide noise elimination frequency band are acquired; the impedance compound muffler is low in pressure loss and power consumption, simple and easy to implement, convenient to machine and high in economic performance.

Owner:XCMG CONSTR MACHINERY

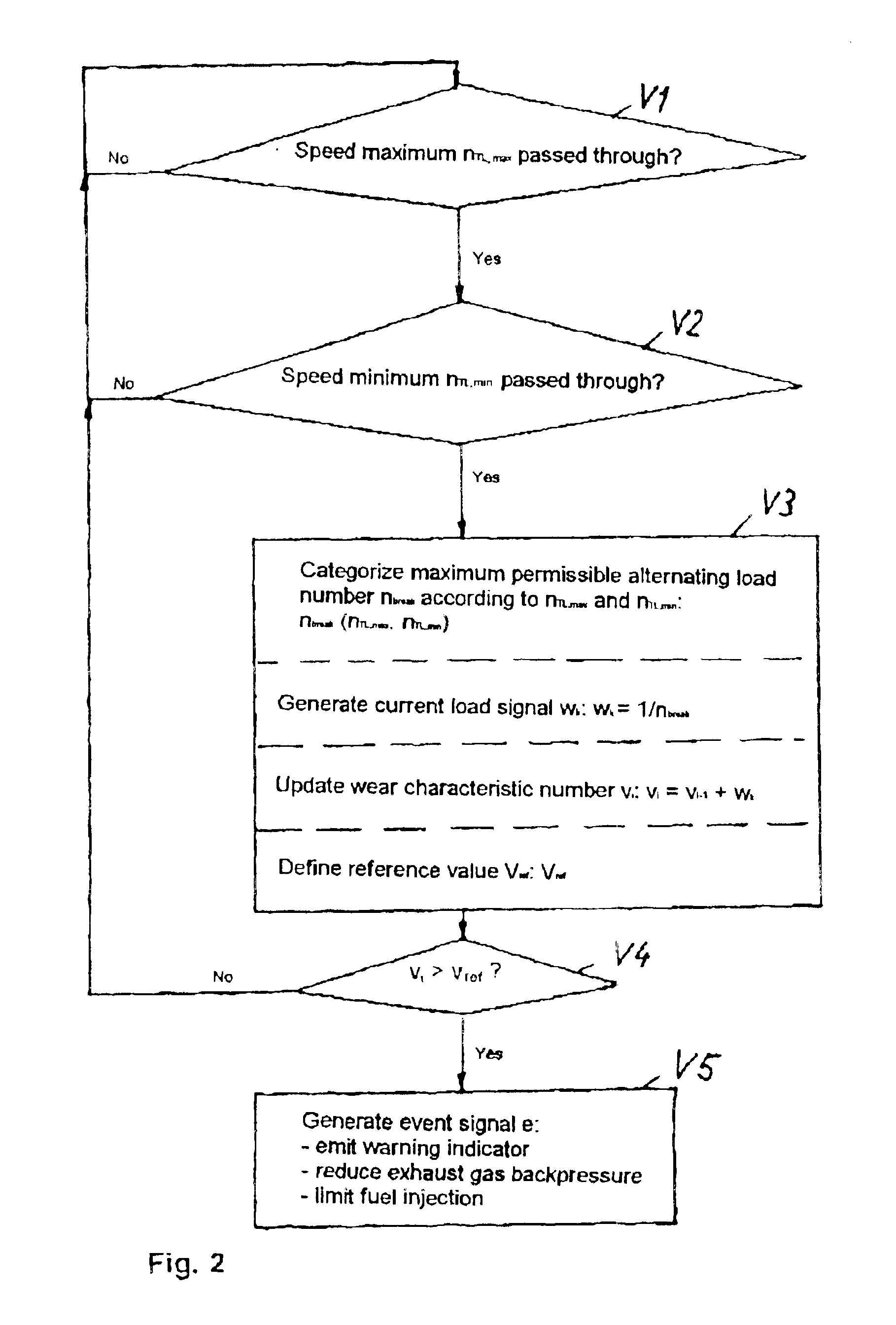

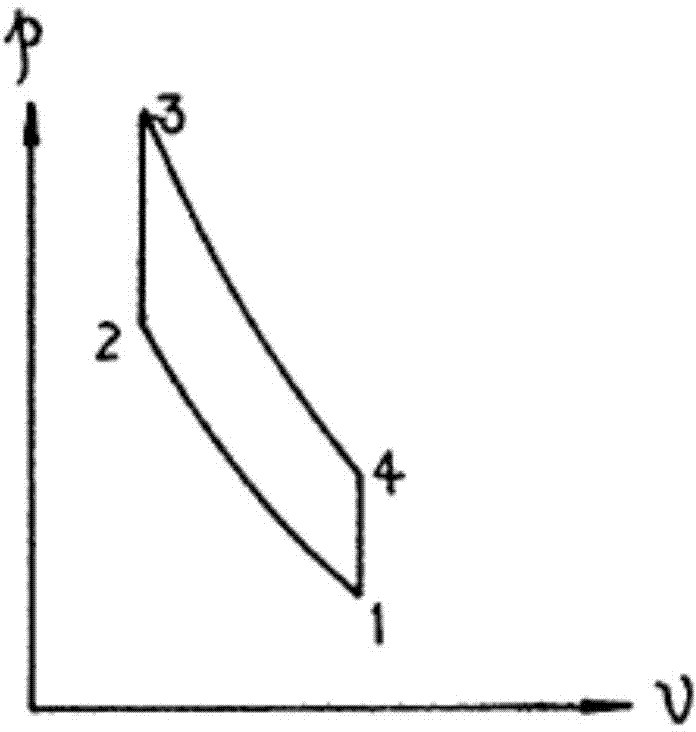

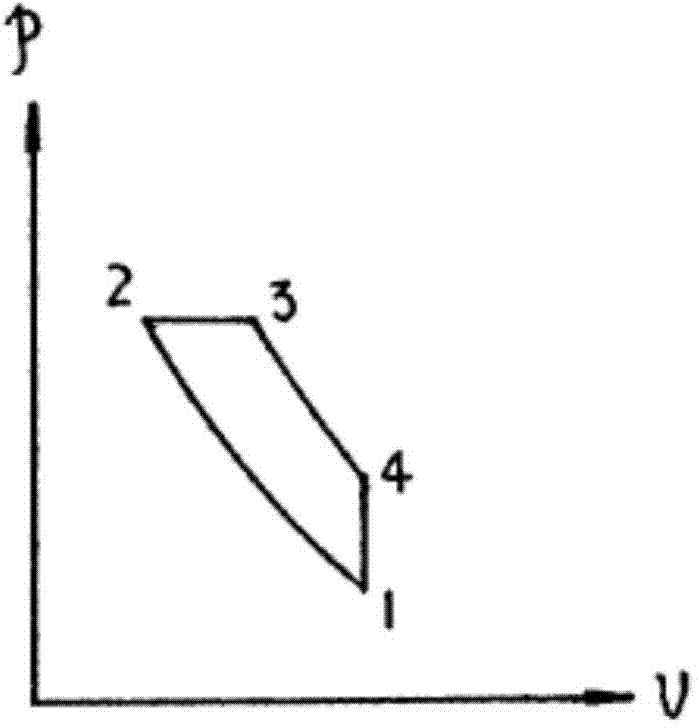

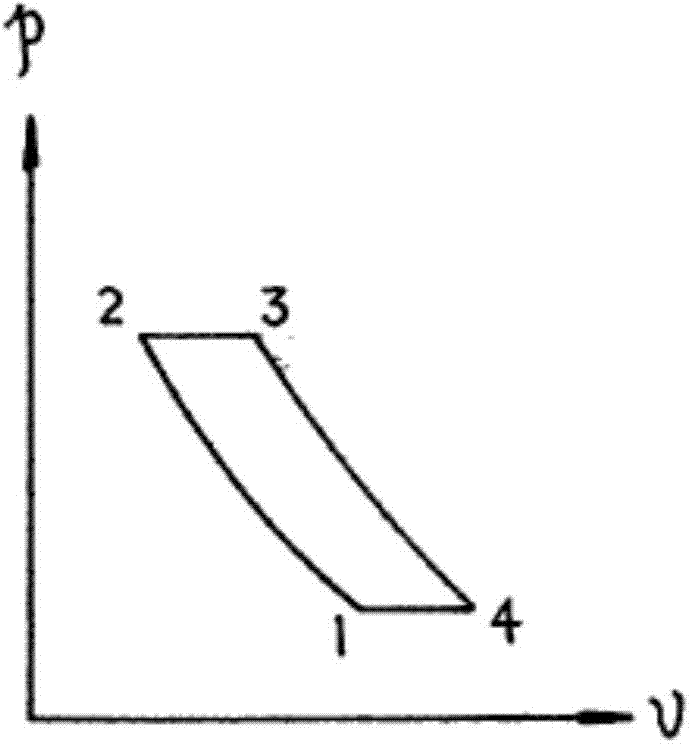

Method and appliance for diagnosis of an exhaust turbocharger for an internal combustion engine

InactiveUS6848300B2Reduce energyReduce speed and/or loadEngine testingCombustion enginesForced inductionEngineering

In a method for diagnosis of an exhaust turbocharger for an internal combustion engine, at least one value which characterizes the load on the exhaust turbocharger is determined and compared with a reference value, an event signal being generated in the event of the reference value being exceeded. A wear characteristic number which characterizes the alternating load on the exhaust turbocharger is formed by addition of load signals, in each case one change signal being generated whenever the charger speed of the exhaust turbocharger exceeds a maximum.

Owner:DAIMLER AG

Semi-closed type timing constant-volume thermodynamic circulation method and system of prime motor

ActiveCN103883399AReduced Compression Power ConsumptionReduce fresh working fluid temperatureInternal combustion piston enginesGas turbine plantsThermal dilatationPrime mover

The invention provides a semi-closed type timing constant-volume thermodynamic circulation method and a semi-closed type timing constant-volume thermodynamic circulation system of a prime motor. The thermodynamic circulation method comprises six processes, namely multi-compression-stage intercooling, countercurrent heat exchanging, timing constant-volume burning, adiabatic expansion, aftercooling, and carbon dioxide and water removal. Heat-power conversion is achieved in the thermodynamic circulation. In the process of multi-compression-stage intercooling, compression power consumption is lowered; in the process of countercurrent heat exchanging, the enthalpy of an expanded working medium is recovered to participate in thermodynamic circulation; the process of timing constant-volume burning effectively inhibits the generation of harmful pollutants such as HC, CO, PM and NOx; in the process of adiabatic expansion, complete expansion for working is achieved; in the process of aftercooling, the working medium is further cooled to the environment temperature and the expansion ratio in the process of adiabatic expansion is enhanced; in the process of carbon dioxide and water removal, the carbon dioxide and the water generated in the process of timing constant-volume burning are removed; the remaining work mediums participate in the next thermodynamic circulation. By the method and the system, the direction is defined for designing a high-efficiency low-pollutant-emission and high-performance prime motor in the future.

Owner:GREEN ENERGY HIGH TECH GRP +5

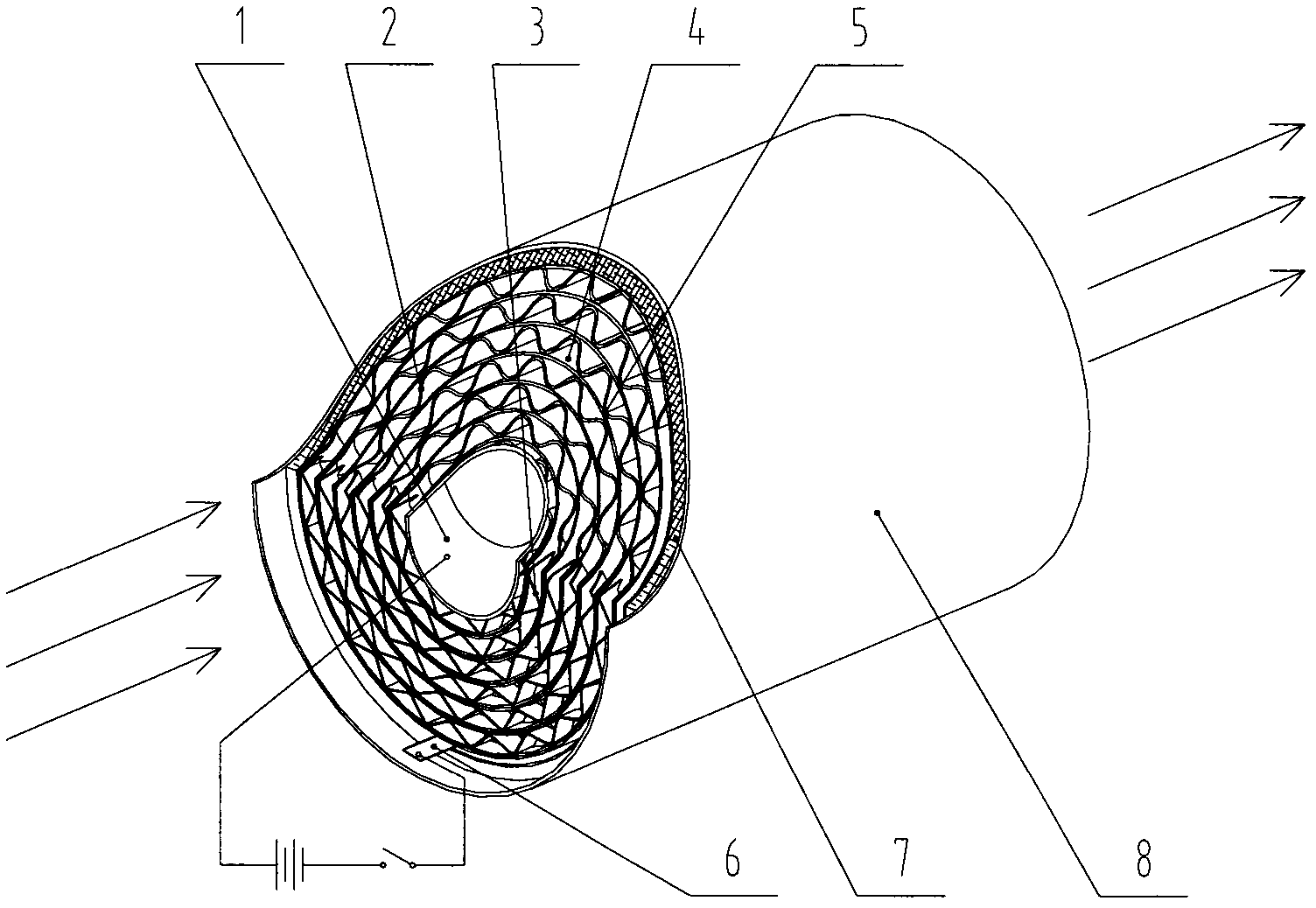

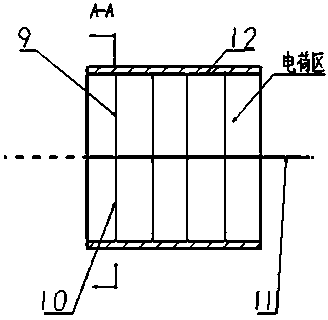

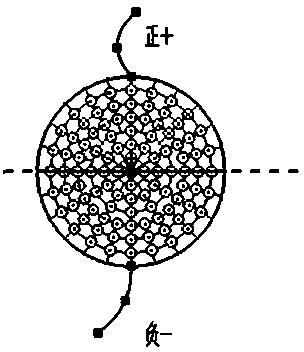

Electrothermic type diesel engine exhaust gas grain catcher

ActiveCN102071991AImprove filtration efficiencyReduce exhaust back pressureExhaust apparatusSilencing apparatusMetal stripsFiltration

The invention provides an electrothermic type diesel engine exhaust gas grain catcher, which comprises a conductive central tube, corrugated sheet filter elements, hold-down strips, flat plate filter elements, insulating coatings, a conductive metal strip, an outer ring insulating layer and a metal shell. The flat plate filter elements with the same width are superposed on a lower layer of the corrugated sheet filter elements to form a filter element, the head end of the filter element is flat and level, and is superposed and welded with a bus of the conductive central tube; the tail end of the filter element is closely welded together with the conductive metal strip; two hold-down strips coated with the insulating coatings are welded on straight edges of two ends of the corrugated sheet filter elements respectively; the filter element is wound into a cylindrical filter element by taking the conductive central tube as an axis, and outer layer of the filter element is bound up with the outer ring insulating layer and then is placed in the metal shell; and the height of the hold-down strips is the same as that of the wave crests of the corrugated sheet filter elements. The electrothermic type diesel engine exhaust gas grain catcher integrates the functions of filtering and heating, and has the characteristics of high filtration rate, low exhaust back pressure, direct and overall energization and heating, small power consumption, short regeneration time and simple and reliable control.

Owner:广东新力金属有限公司

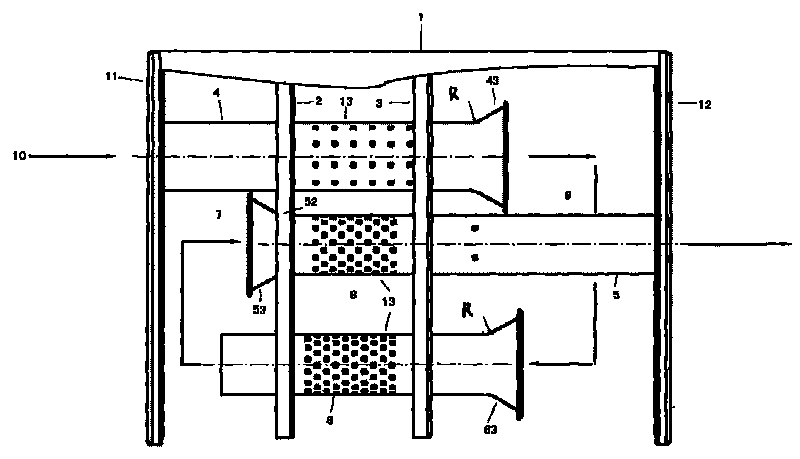

Motor vehicle and body floor structure thereof

InactiveCN102085883AReliable arrangementSave spaceElectric propulsion mountingPlural diverse prime-mover propulsion mountingMotor vehicle partHybrid vehicle

The present invention relates to a body floor structure (1, 21, 31, 41), which, within the center tunnel (2), comprises a first receiving clearance for receiving a first energy storage device (4, 34, 44) for the storage of energy for driving the vehicle and in the rear seat region (3) comprises a second receiving clearance for receiving a second energy storage device (5, 25) for the storage of energy for driving the vehicle and a motor vehicle, specifically a hybrid vehicle, which comprises this body floor structure (1, 21, 31, 41).

Owner:GM GLOBAL TECH OPERATIONS LLC

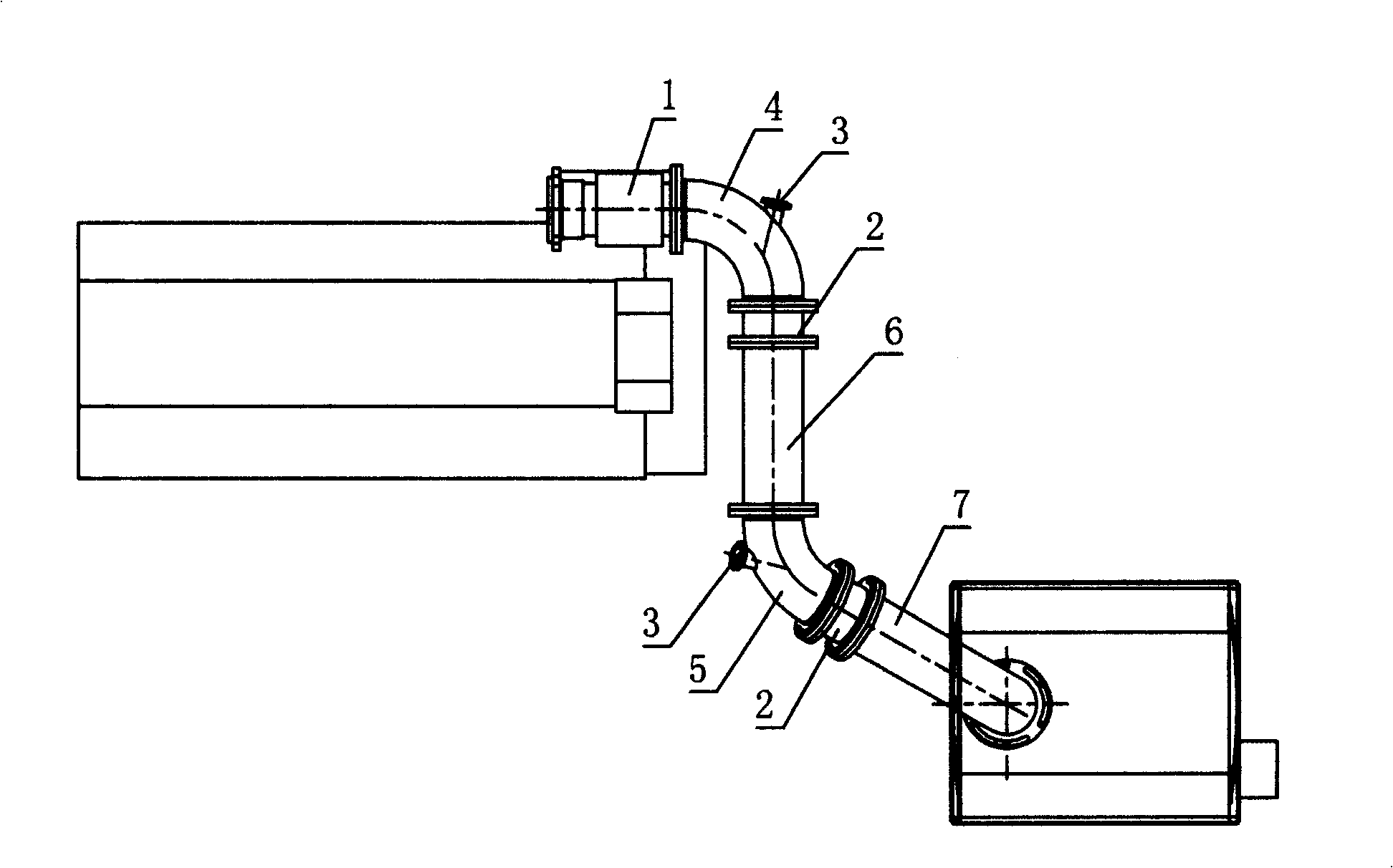

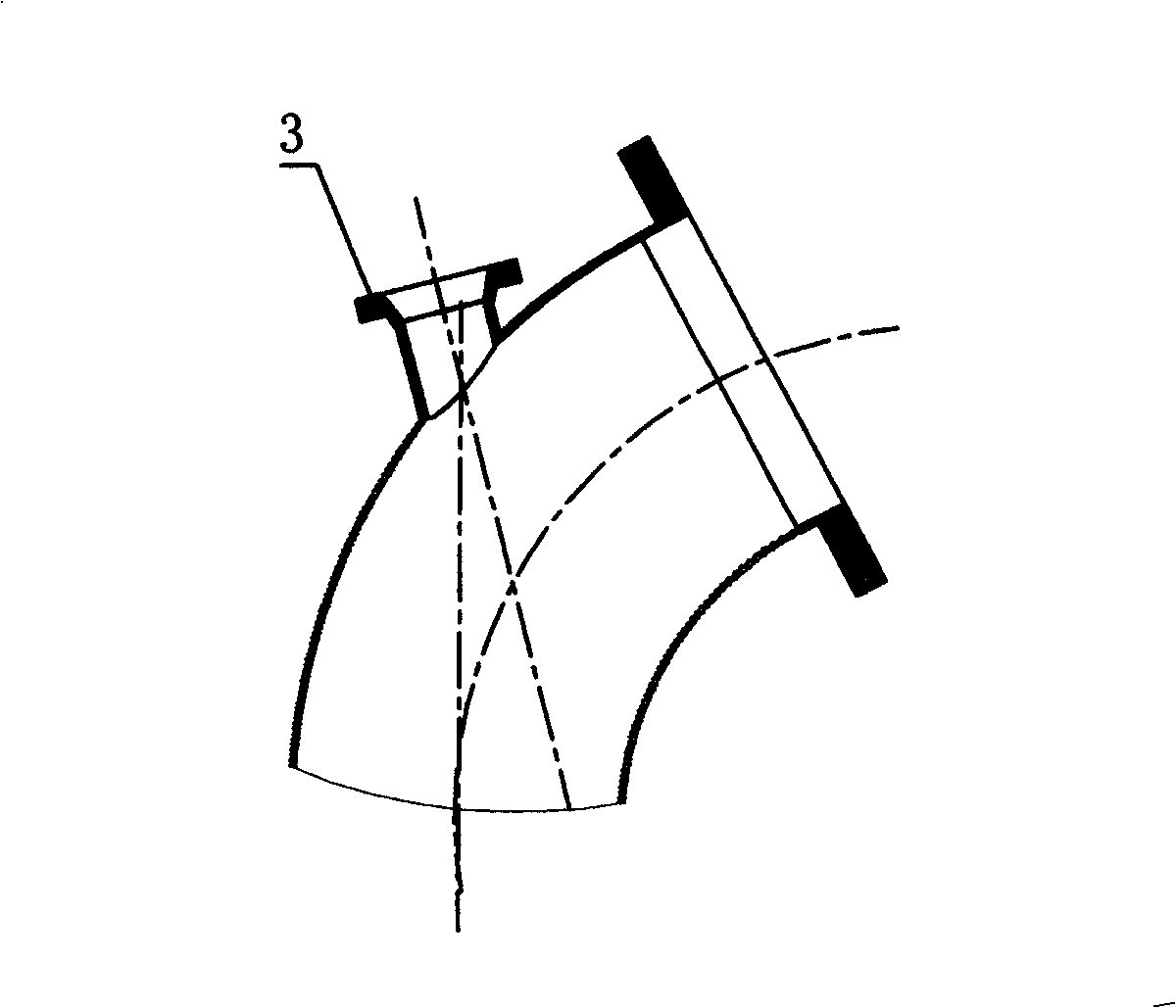

SCR reprocessing piping device of large-duty engine

ActiveCN101245726AImprove conversion rateReduce the impact of normal operationInternal combustion piston enginesExhaust apparatusExhaust fumesEngineering

The invention discloses an SCR post treatment pipeline device for a large displacement engine, which includes an ejection pipeline. The ejection pipeline is provided with at least one nozzle that can spray carbamide liquor in the ejection pipeline. The nozzle is mounted on the ejection pipeline in a mode that the spraying direction is along the flow direction of the smoke body in the ejection pipeline and the spraying axis of the nozzle forms an included angle together with the axis of the ejection pipeline positioned along the spraying direction of the nozzle. Mixers are respectively arranged along the spraying direction of the nozzle in the ejection pipeline. The device can lead the carbamide liquor to be fast hydrolyzed to release ammonia and uniformly mixed with waste gas. The hydrolyzing rate of the carbamide is higher, thus leading an NOx compound to have longer reaction time and to be fully reacted and leading the SCR system to have higher waste gas conversion rate.

Owner:WEICHAI POWER CO LTD

Haze particle collection processing device

InactiveCN104963746AImprove collection efficiencyMake up for deficienciesExhaust apparatusSilencing apparatusFine particulateEngineering

The invention aims to provides a haze particle processing device; the device can effectively collect and process fine particles in waste gas, and can directly collect and process PM2.5 (fine particle with particle size less than or equal to 2.5 micrometers) massively existing in the atmosphere. A power device can pump the air containing haze particles into the haze particle collection processing device through an air inlet for purification, and the air flowing outside an air outlet complies with a national standard. The haze particle collection processing device is strong in versatility, can be applied to the industrial field, and can be applied to a waste gas exhaust port of a diesel engine device; the haze particle collection processing device is applied to the industrial production so as to greatly reduce waste gas particle and charcoal smog content without causing secondary airborne dust pollution; the haze particle collection processing device is applied to a diesel car so as to greatly improve particle collection and processing efficiency when compared with a conventional method, so the diesel car can be small in exhaust backpressure, small in pressure drop, high in particle collection efficiency, and complete in particle after-treatment.

Owner:SHENYANG LIGONG UNIV

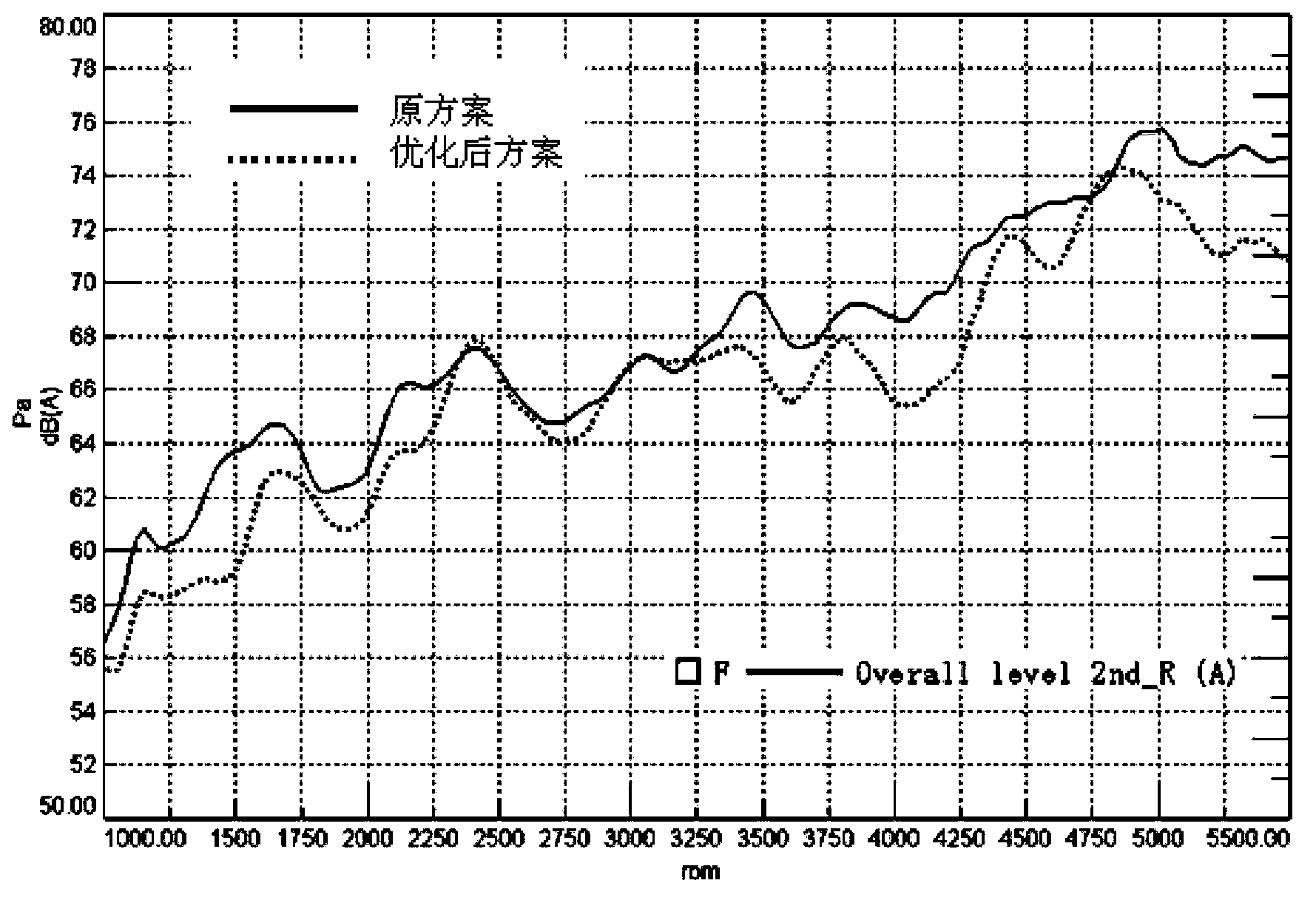

Automobile muffler for reducing exhaust back pressure

InactiveCN101694172AShorten speedReduce flow rateSilencing apparatusMachines/enginesEngineeringMuffler

The invention provides an automobile muffler for reducing exhaust back pressure. For the muffler, a shell is internally provided with a first baffle plate and a second baffle plate which divide the inner part of the shell into three chambers sequentially, including a first and a second expanding chamber and a resistive muffling chamber; from outside the shell, an air inlet pipe sequentially passes through a front end cover of the shell, the first baffle plate and the second baffle plate and then extends into the second expanding chamber; from the first expanding chamber, an air outlet pipe sequentially passes through the first baffle plate, the second baffle plate and the rear end cover of the shell and then passes out of the shell; a transition pipe passes through the first baffle plate and the second baffle plate from the first expanding chamber and then extends into the second expanding chamber; inside the resistive muffling chamber, parts of the air inlet pipe, the air outlet pipe and the transition pipe are all provided with micropores on pipe walls; and the outlet end of the air inlet pipe, the inlet end of the air outlet pipe and the inlet end of the transition pipe are all of the structure of expanded openings. The structure of the muffler can reduce the speed of exhaust air stream through smooth expansion and contraction, and expansion and contraction again, decrease the exhaust back pressure and improve the power and torque of a motor.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

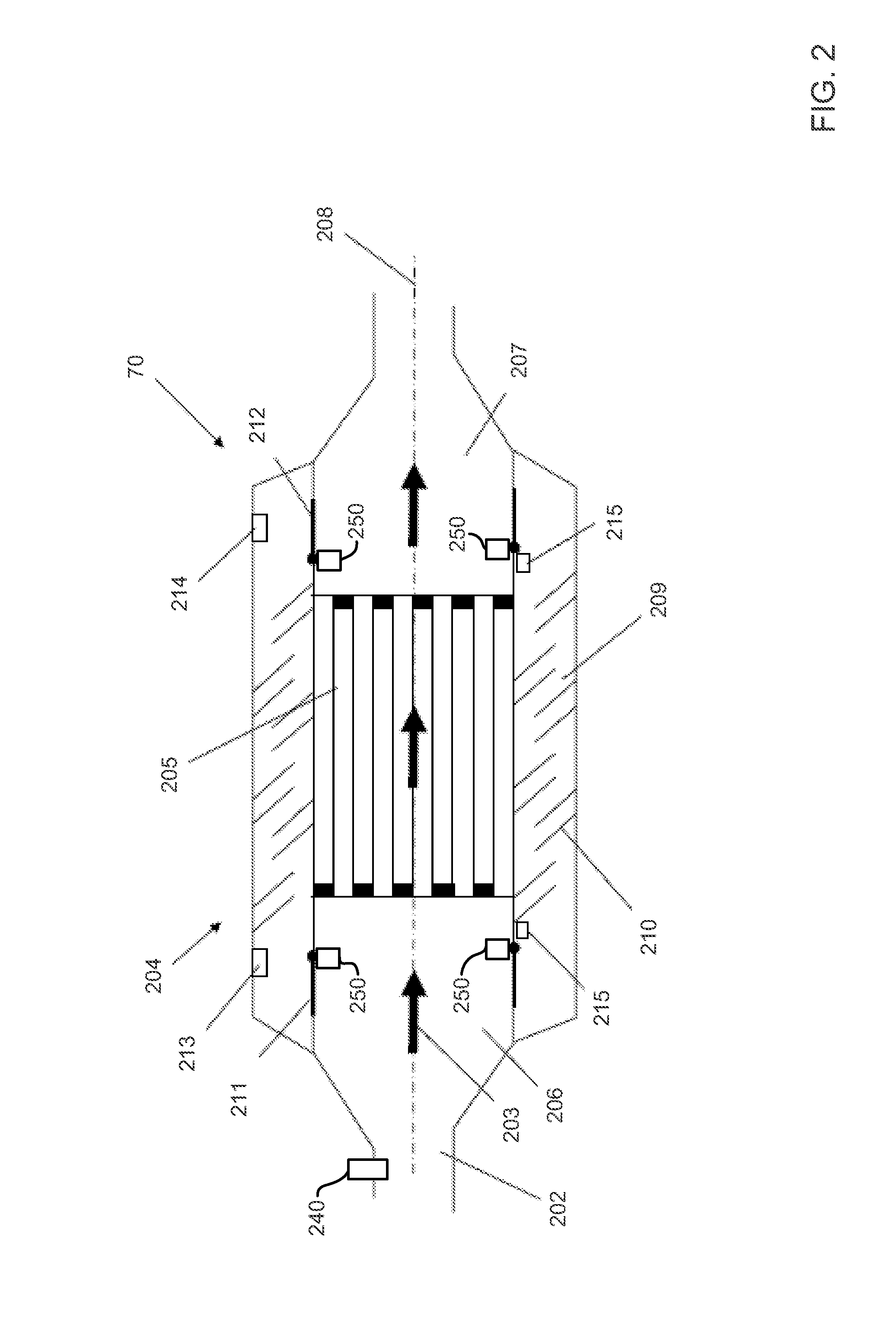

Particle filter and method for the purification of an exhaust-gas flow

InactiveUS20120186228A1Exhaust back pressure be reduceIncrease emissionInternal combustion piston enginesExhaust apparatusExhaust gasExhaust fumes

Particle filters and a method for the purification of an exhaust-gas flow are described. In one example, exhaust gas is directed solely to a first particulate filter until a predetermined condition. Then exhaust gas is directed to a second particulate filter. One particulate filter may surround the other of two particulate filters. The particulate filters may provide filtered exhaust gas even when one filter becomes at least partially loaded.

Owner:FORD GLOBAL TECH LLC

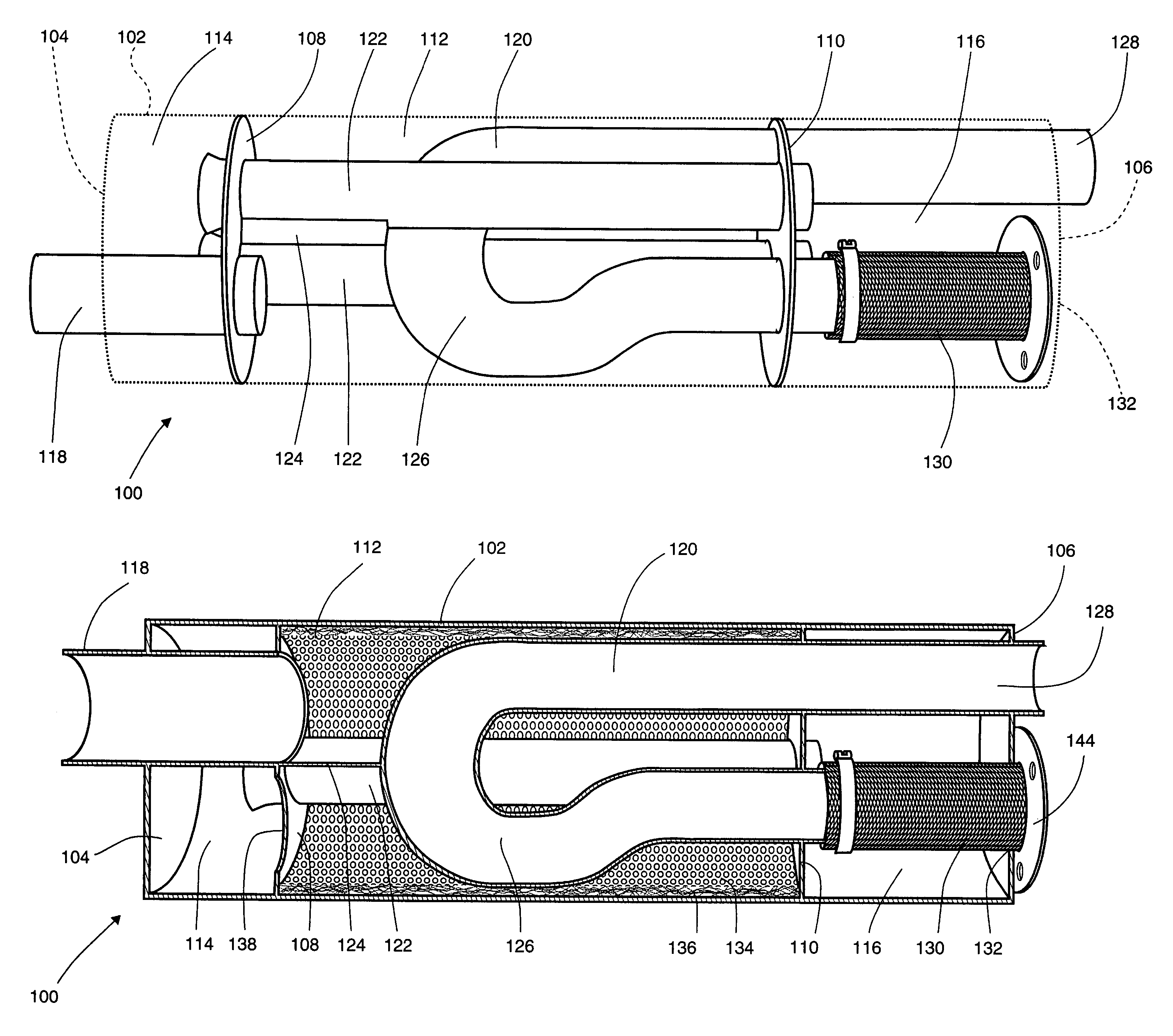

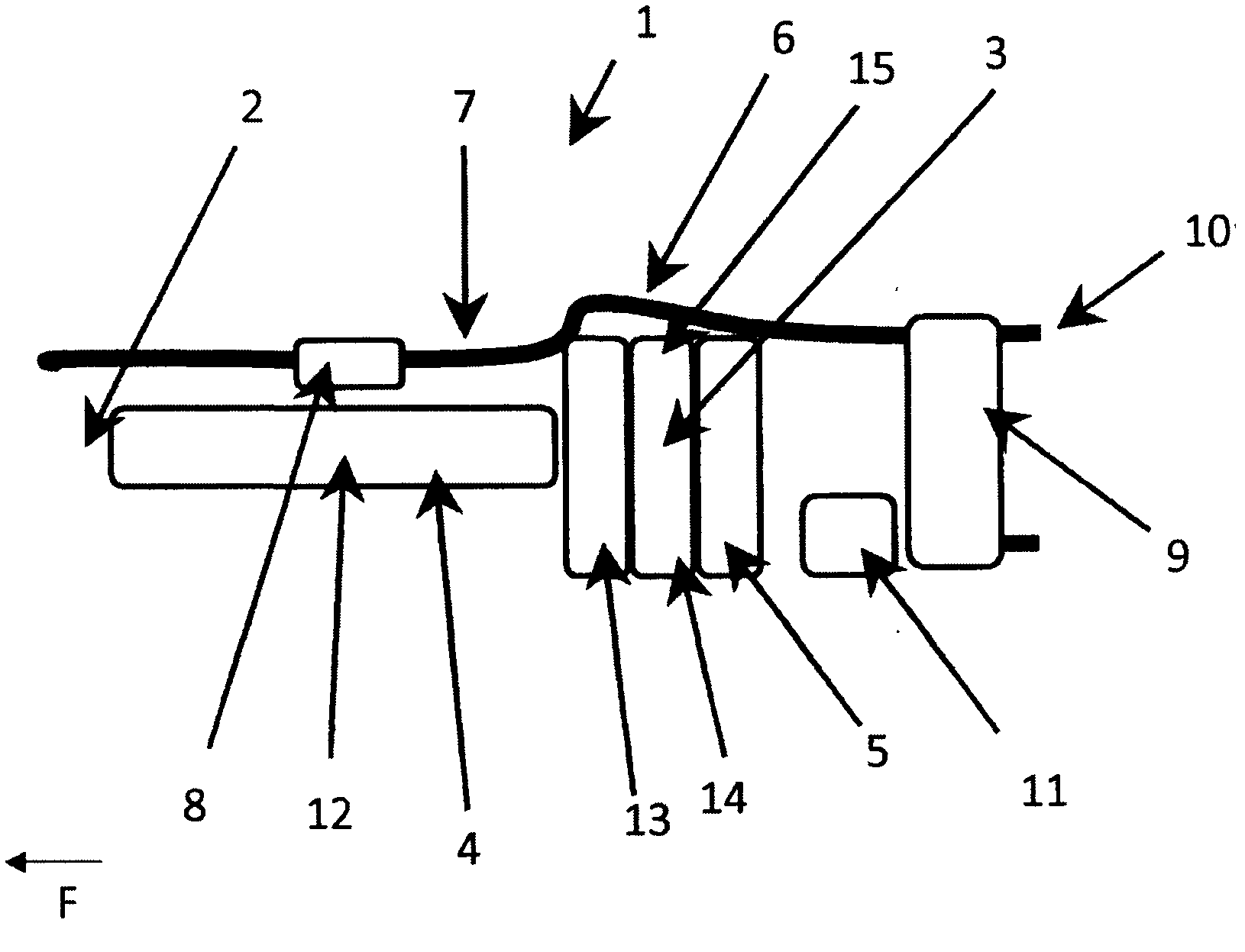

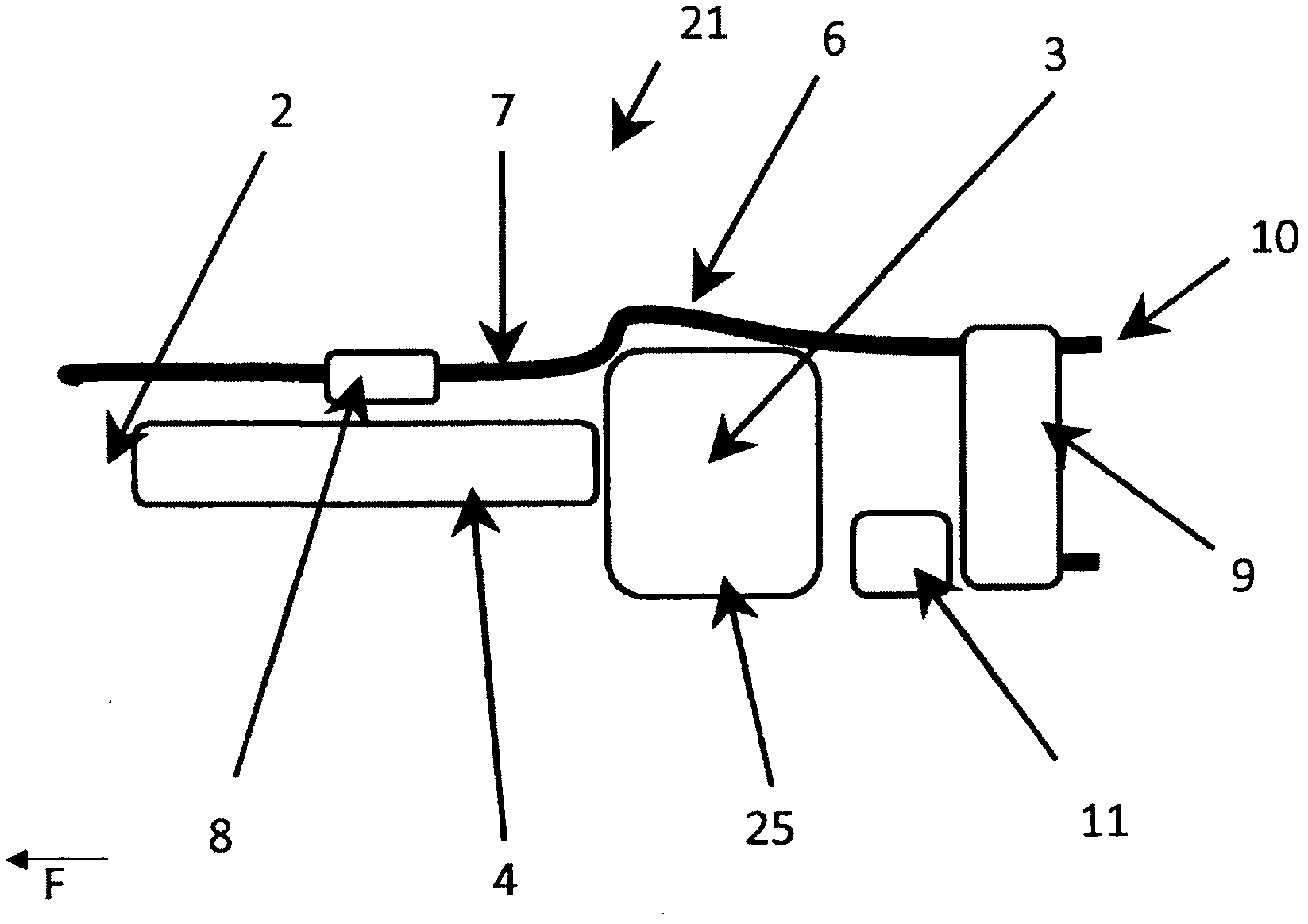

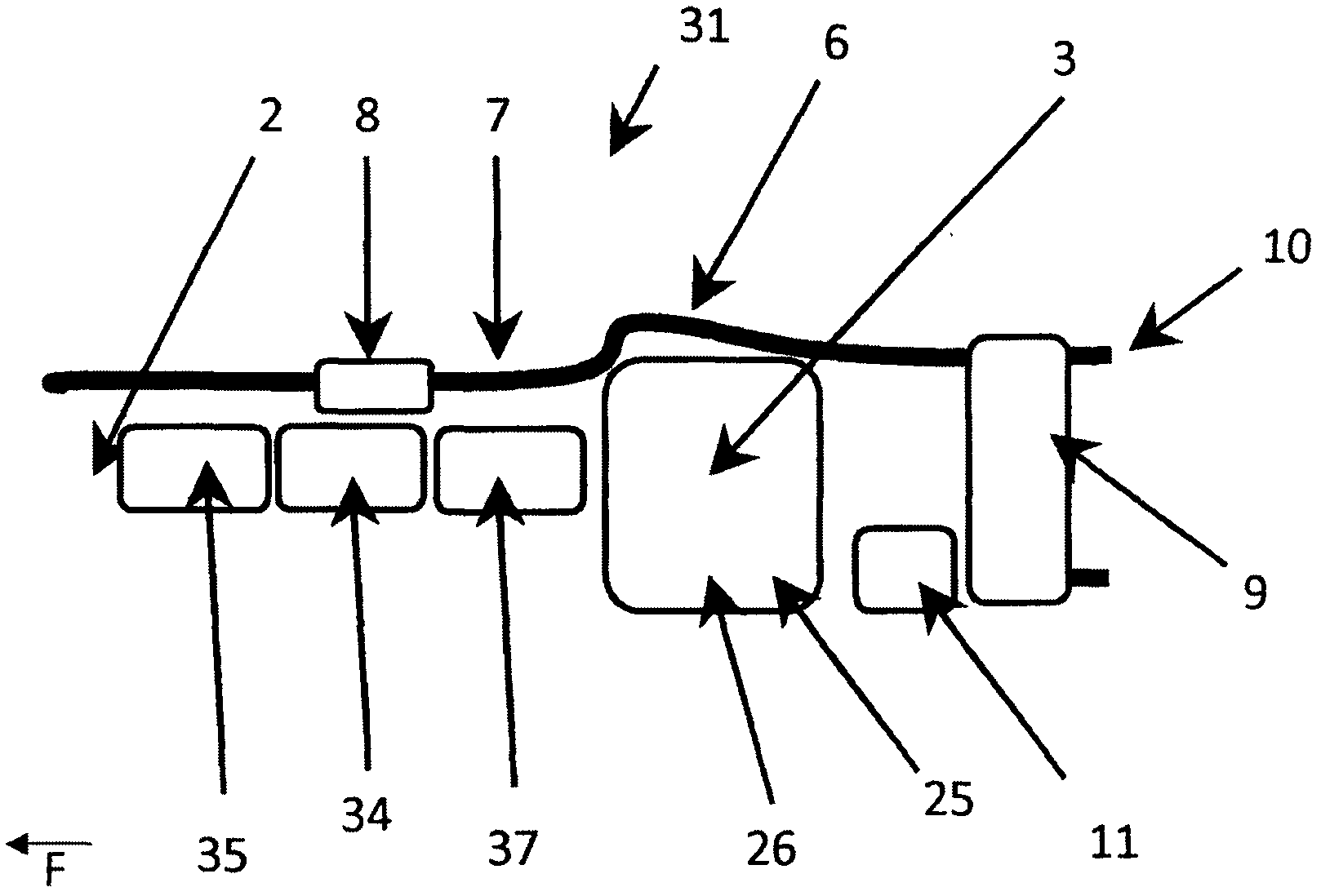

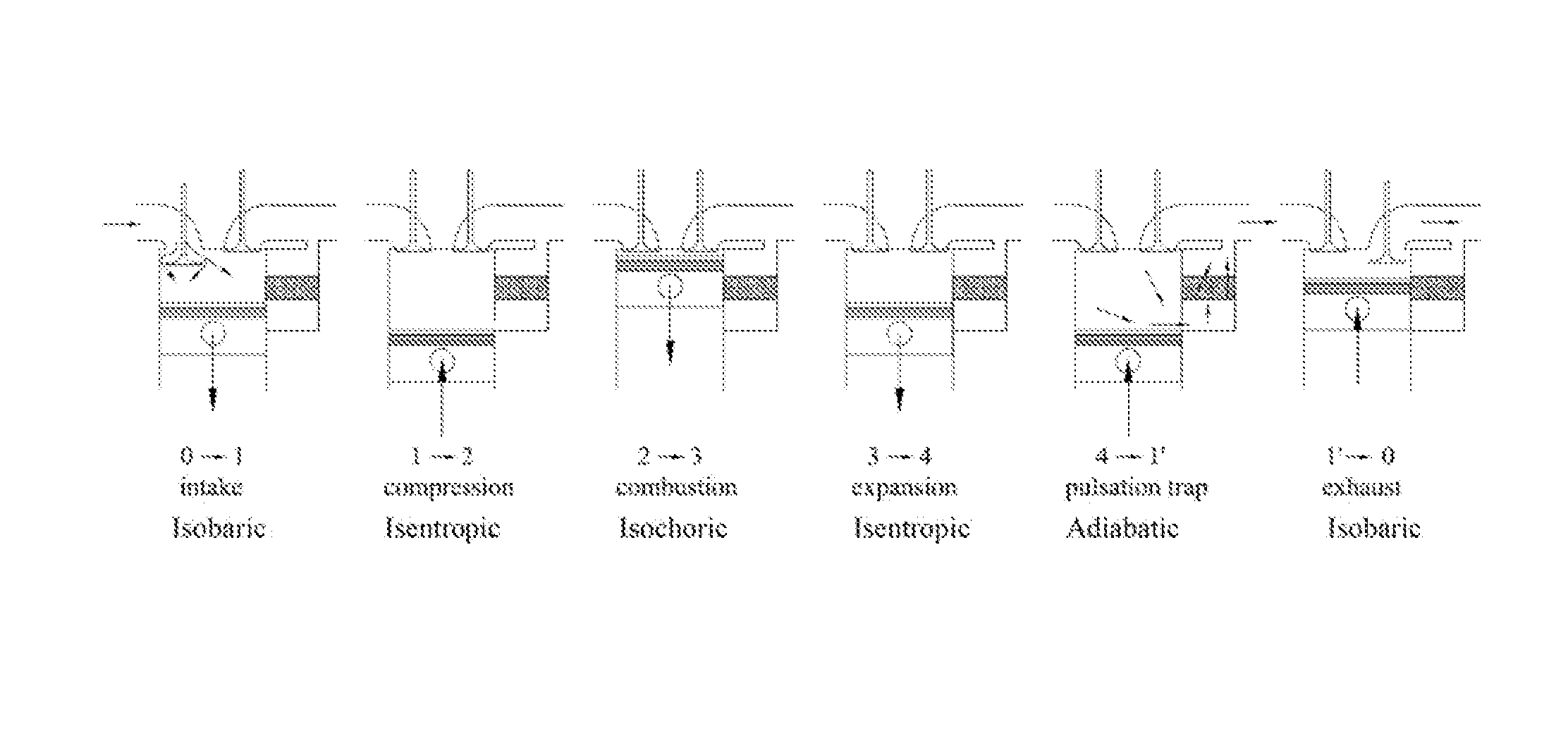

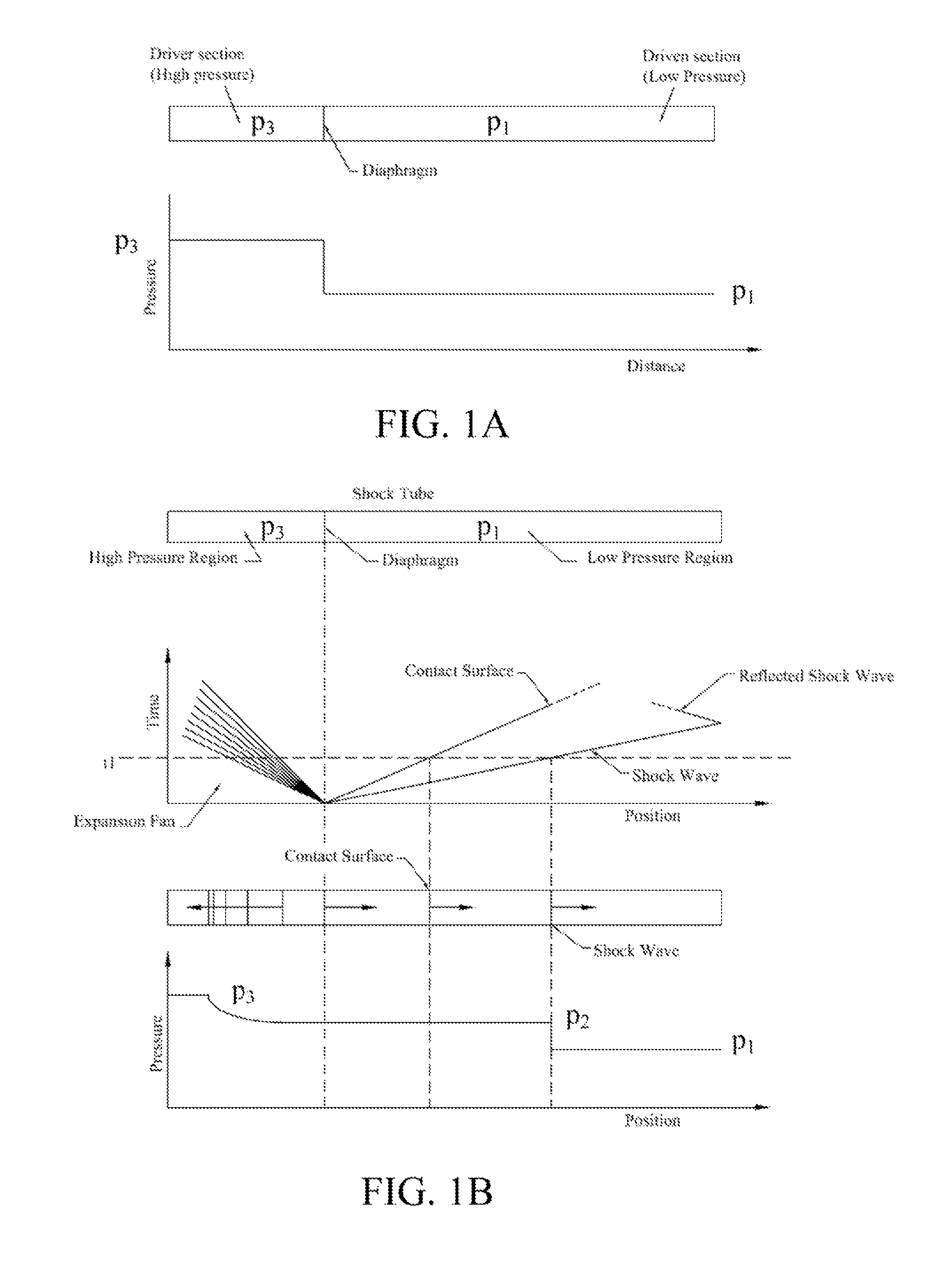

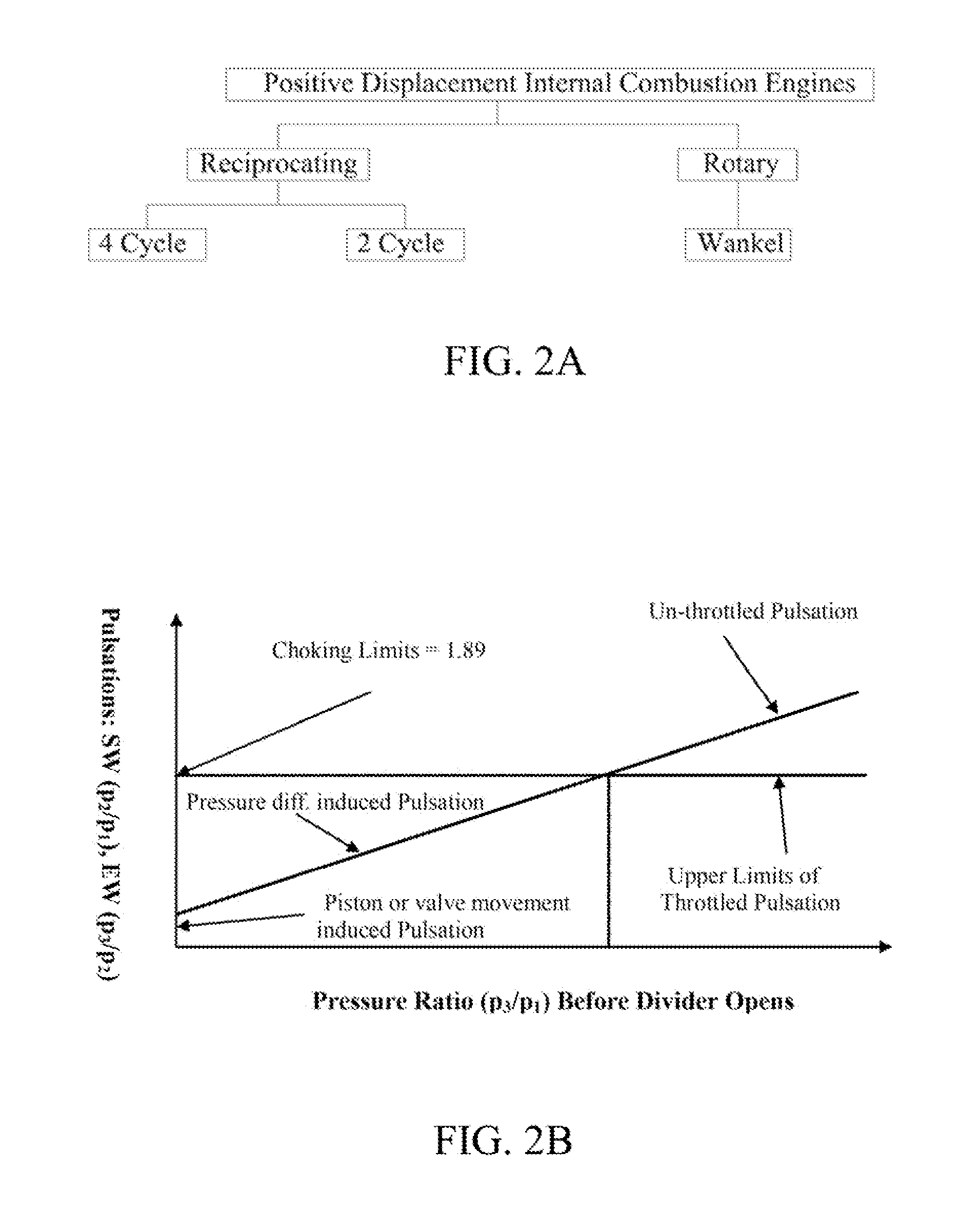

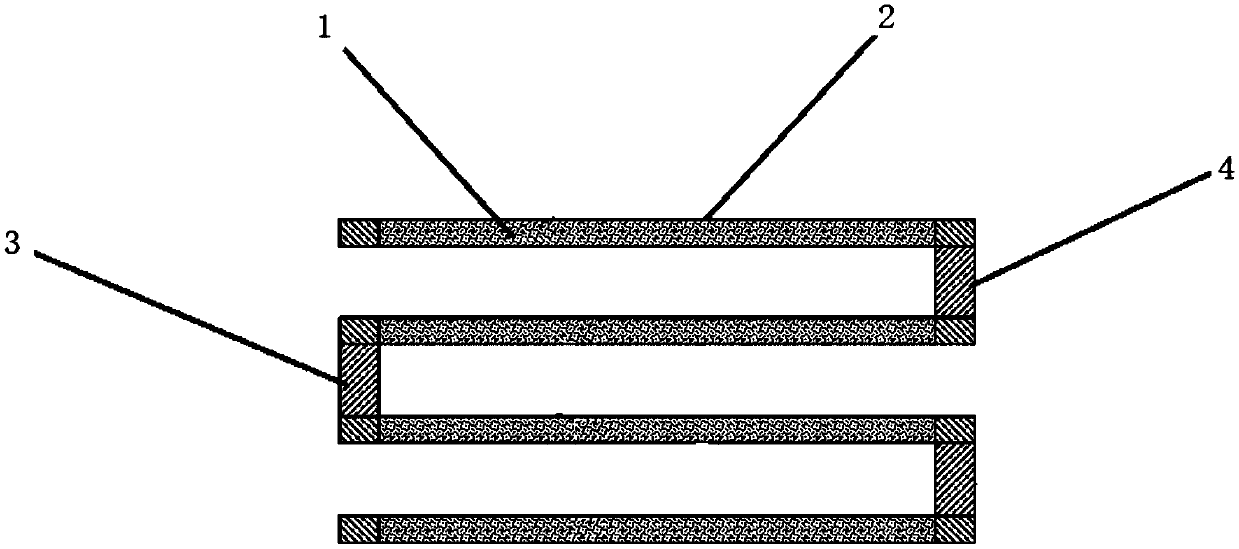

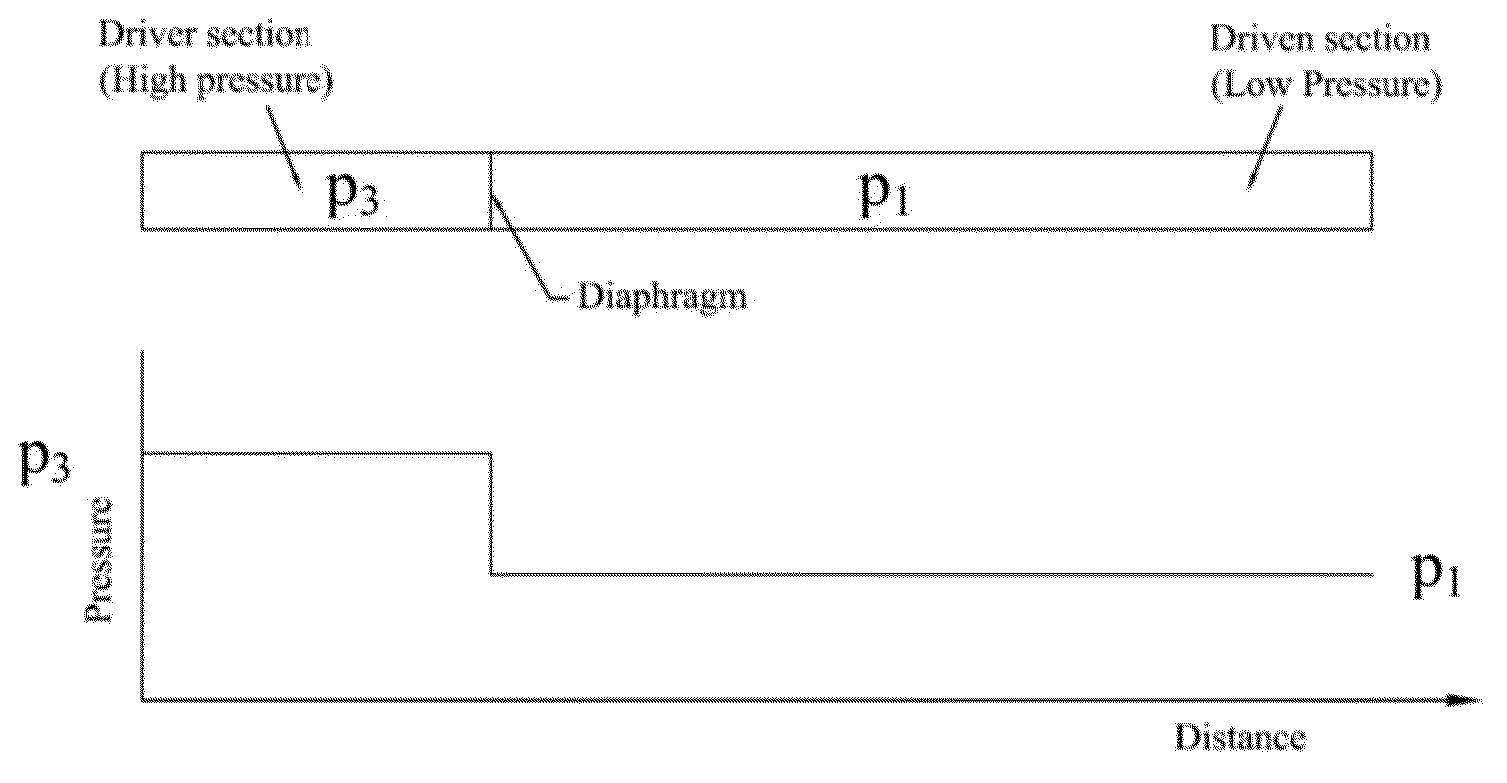

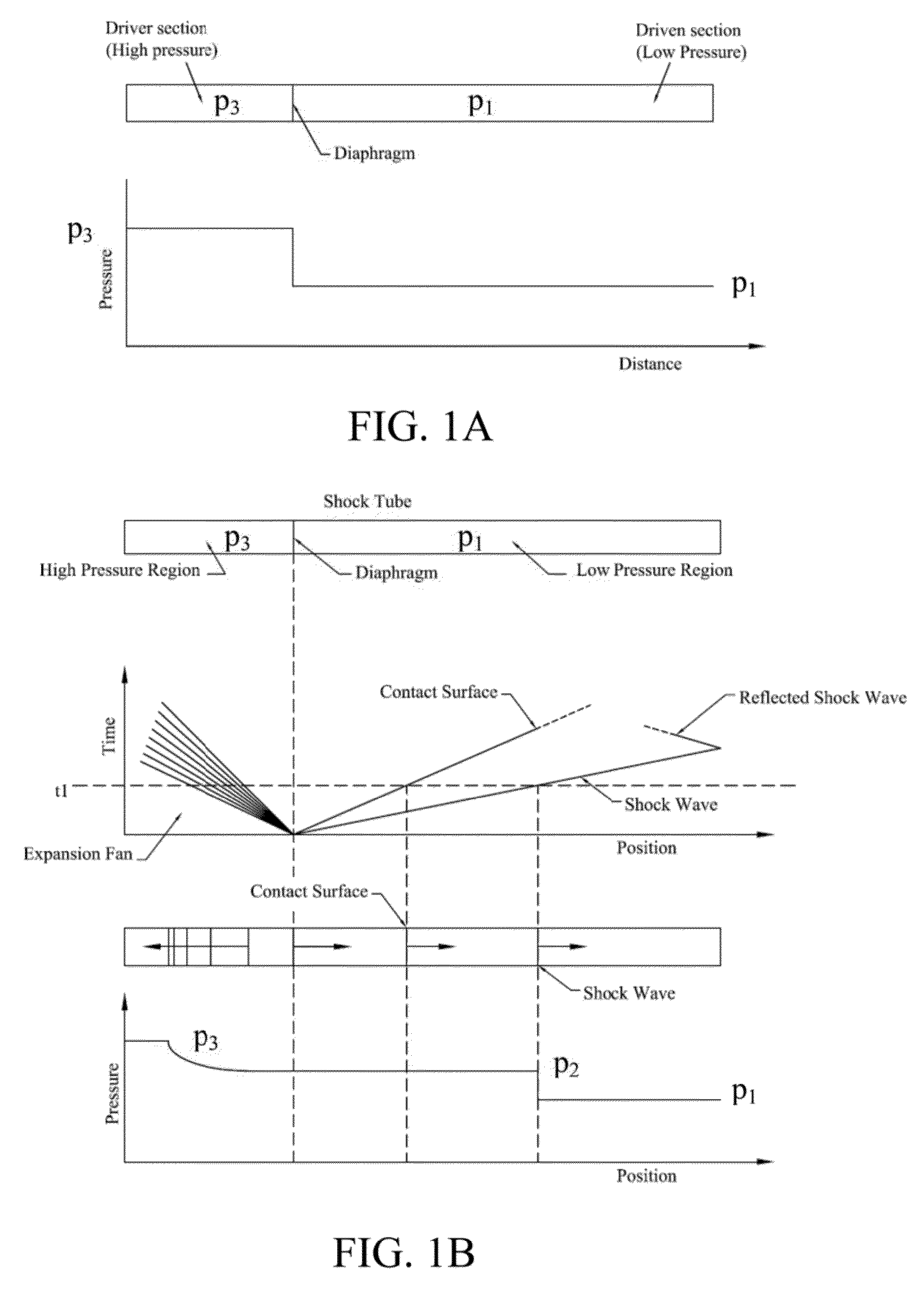

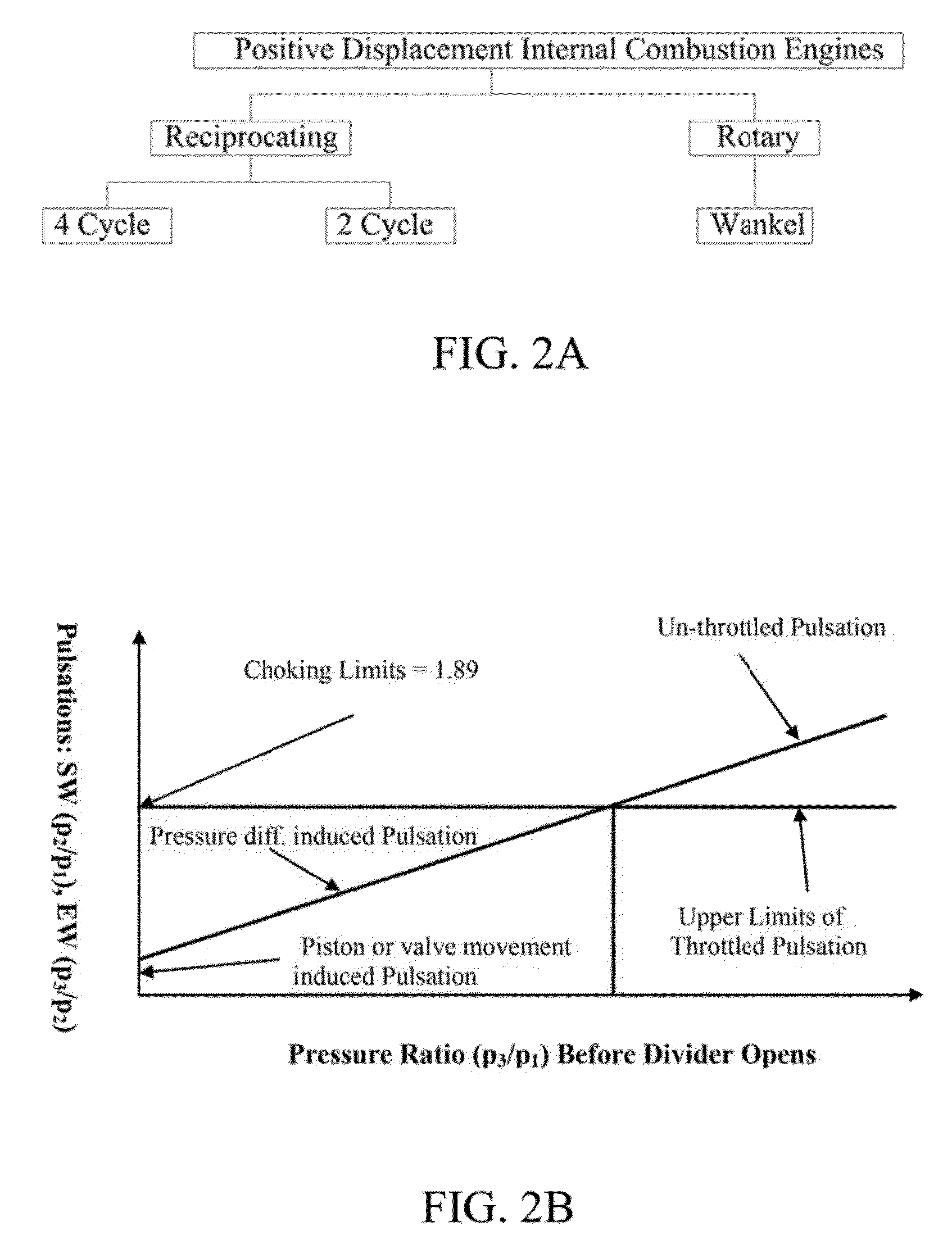

Shunt pulsation trap for positive displacement (PD) internal combustion engines (ICE)

ActiveUS9243557B2Reduce exhaust back pressureImprove fuel efficiencyValve arrangementsInternal combustion piston enginesCombustionExternal combustion engine

A shunt pulsation trap for a positive displacement (PD) internal combustion engine (ICE) reduces pulsation, as well as noise, vibration and harshness (NVH), and the overall size of the exhaust system, and also improves cycle (fuel) efficiency. A shunt pulsation trap for a PD-ICE is configured to trap and attenuate gas pulsations before discharge to engine outlet and includes a chamber (trap volume) adjacent to the PD-ICE cavity. The chamber houses at least one pulsation dampening device, at least one relief port (trap inlet) branching off from the PD-ICE cavity into the pulsation trap chamber and a feedback region (trap outlet) communicating with the PD-ICE outlet. The associated methods of reducing pulsations are included as another aspect of the invention.

Owner:HUANG PAUL XIUBAO +1

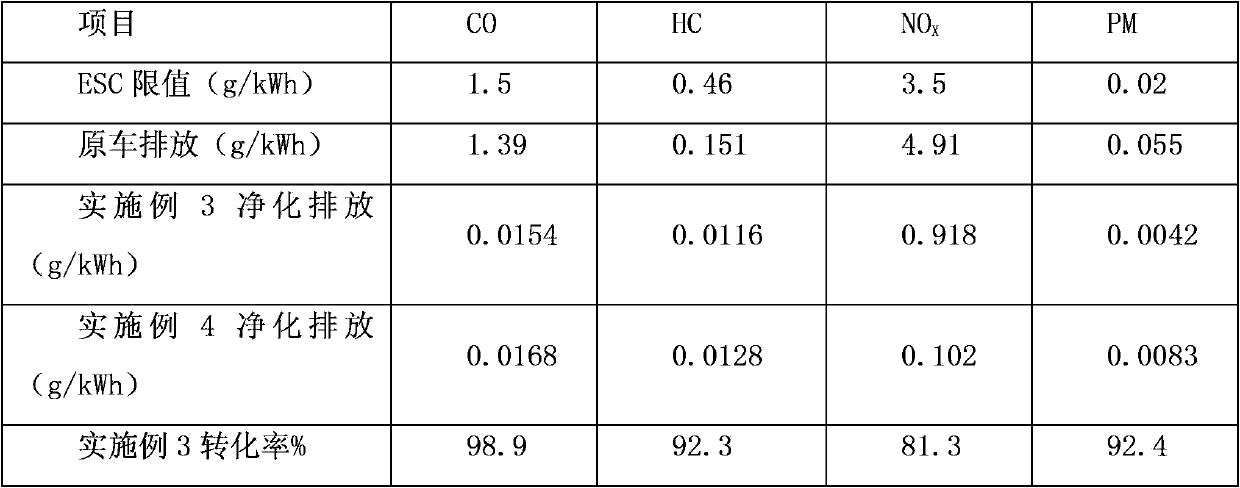

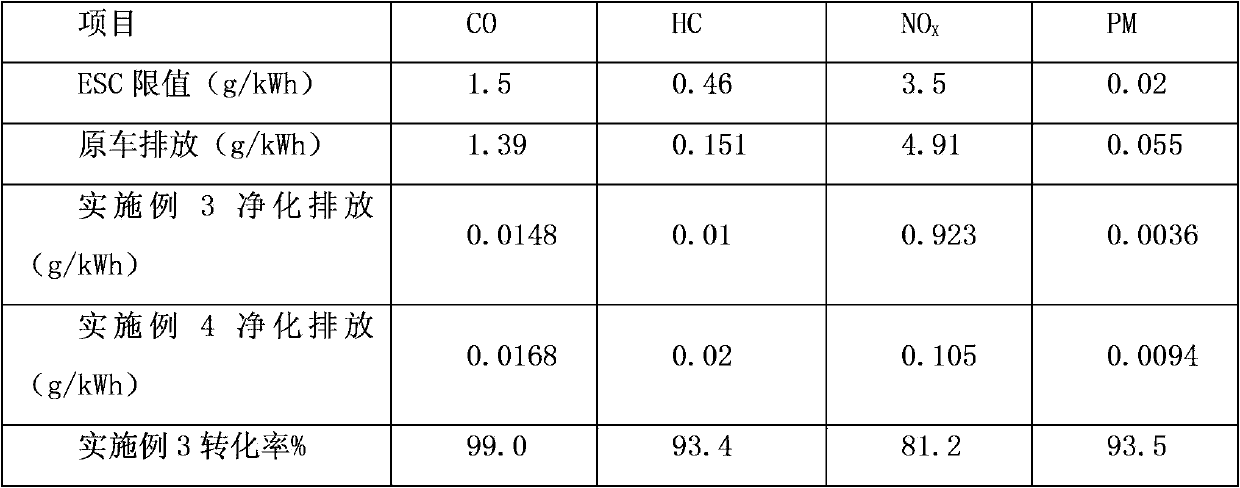

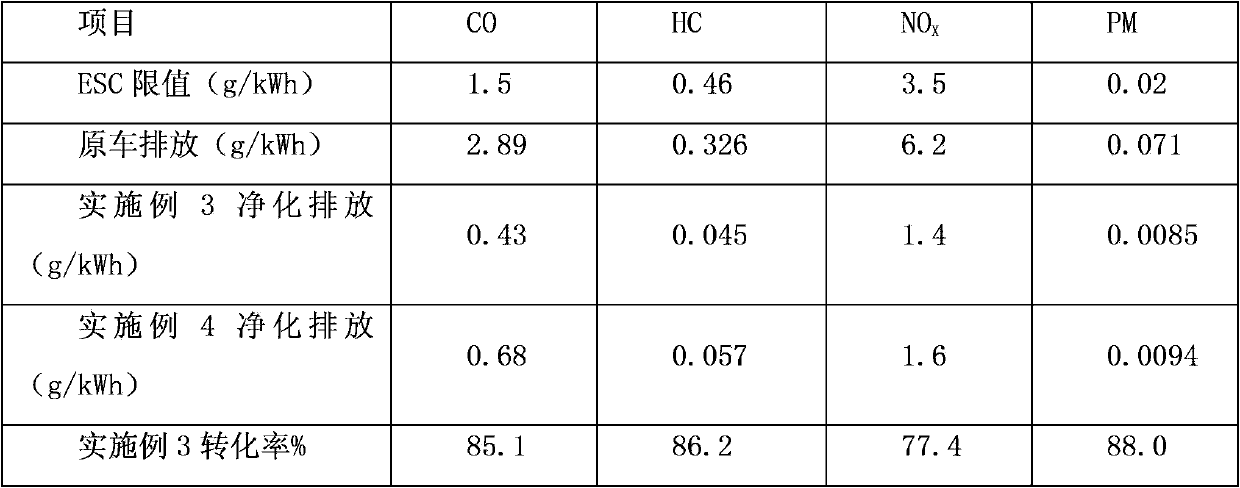

Gasoline engine tailing gas particle filtering device catalyst and preparation method thereof

ActiveCN109621952ADiffusion evenly distributedReduce exhaust back pressureDispersed particle separationCatalyst activation/preparationCeriumRare earth

The invention relates to a gasoline engine tailing gas particle filtering device catalyst and a preparation method thereof. The catalyst comprises a carrier, the inner wall of a hole of the carrier iscoated with a catalytic coating layer, the coating mount of the catalytic coating layer is 50-120 g / L, the height of the catalytic coating layer in the axial direction is 100% of the height f the carrier, the catalytic coating layer comprises cerium-zirconium rare-earth oxides, gamma-aluminum oxides and precious metal active components, the precious metal active components comprise Pd and Rh, wherein the loading amount of Pd is 0.1-1.5 g / L, and the loading amount of Rh is 0.05-0.5 g / h. the catalyst has the advantages that through the improvement of a catalytic coating layer coating technology, the uniform dispersing distribution on the inner wall structure of the hole of the catalytic coating layer is achieved to significantly reduce the gas discharging back pressure of a particle filtering device catalyst, the effects of intercepting particles and converting gaseous pollutants are well achieved by the uniformly distributed catalytic coating layer, and therefore gas discharging back pressure is reduced by the prepared filtering device catalyst while the particle capturing rate and catalytic performance are not impacted by negative influences.

Owner:WUXI WEIFU ENVIRONMENT PROTECTION CATALYST

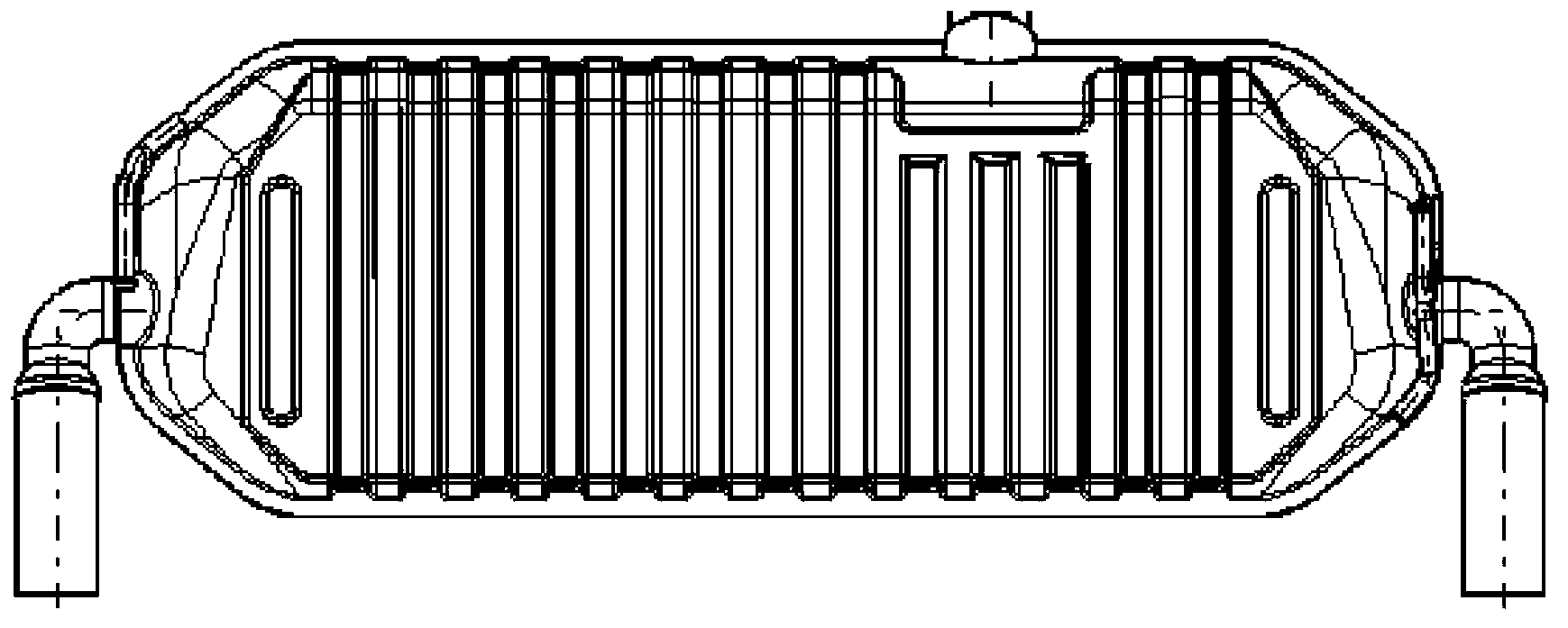

Multifunctional muffler structure

ActiveCN103410586AStationary Noise ReductionGood exhaust noiseExhaust apparatusSilencing apparatusSiphonEngineering

The invention relates to a multifunctional muffler structure. The multifunctional muffler structure comprises a barrel body, an inner partition plate A, an inner partition plate B, an inner partition plate C and an inner partition plate D are arranged in the barrel body, and an air inlet muffler pipe, a middle muffler pipe and two air outlet muffler pipes are fixed in the barrel body; the four inner partition plates divide the barrel body into five muffler cavities. The air outlet muffler pipes are arranged symmetrically, so that exhaust back pressure is favorable for being reduced, and then the work efficiency of an engine is ensured; because siphons are arranged on the air outlet muffler pipes, water accumulating in a muffler can be eliminated by the utilization of the pressure difference between an inlet and an outlet of the muffler and on the basis of the siphon principle, the muffler is prevented from rusting, and the service life and the using reliability of the muffler are ensured; due to the combination of the multiple muffler cavities and the muffler components, exhaust noise is reduced substantially, and the riding comfort of a whole vehicle is improved; the application of a stamped shell makes the muffler be more beautiful and more elegant and fully show the feel of modern science and technology.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Shunt pulsation trap for positive displacement (PD) internal combustion engines (ICE)

ActiveUS20130247849A1Reduce exhaust back pressureImprove fuel efficiencyValve arrangementsInternal combustion piston enginesCombustionExternal combustion engine

A shunt pulsation trap for a positive displacement (PD) internal combustion engine (ICE) reduces pulsation, noise, vibration and harshness (NVH), and overall size of the exhaust system and improves cycle (fuel) efficiency. Generally, a shunt pulsation trap for a PD-ICE is configured to trap and attenuate gas pulsations before discharge to engine outlet and comprises a chamber (trap volume) adjacent to the PD-ICE cavity, therein housed various pulsation dampening means or pulsation containment means, at least one relief port (trap inlet) branching off from the PD-ICE cavity into the pulsation trap chamber and a feedback region (trap outlet) communicating with the PD-ICE outlet. The associated principles, methods and embodiments are disclosed.

Owner:HUANG PAUL XIUBAO +1

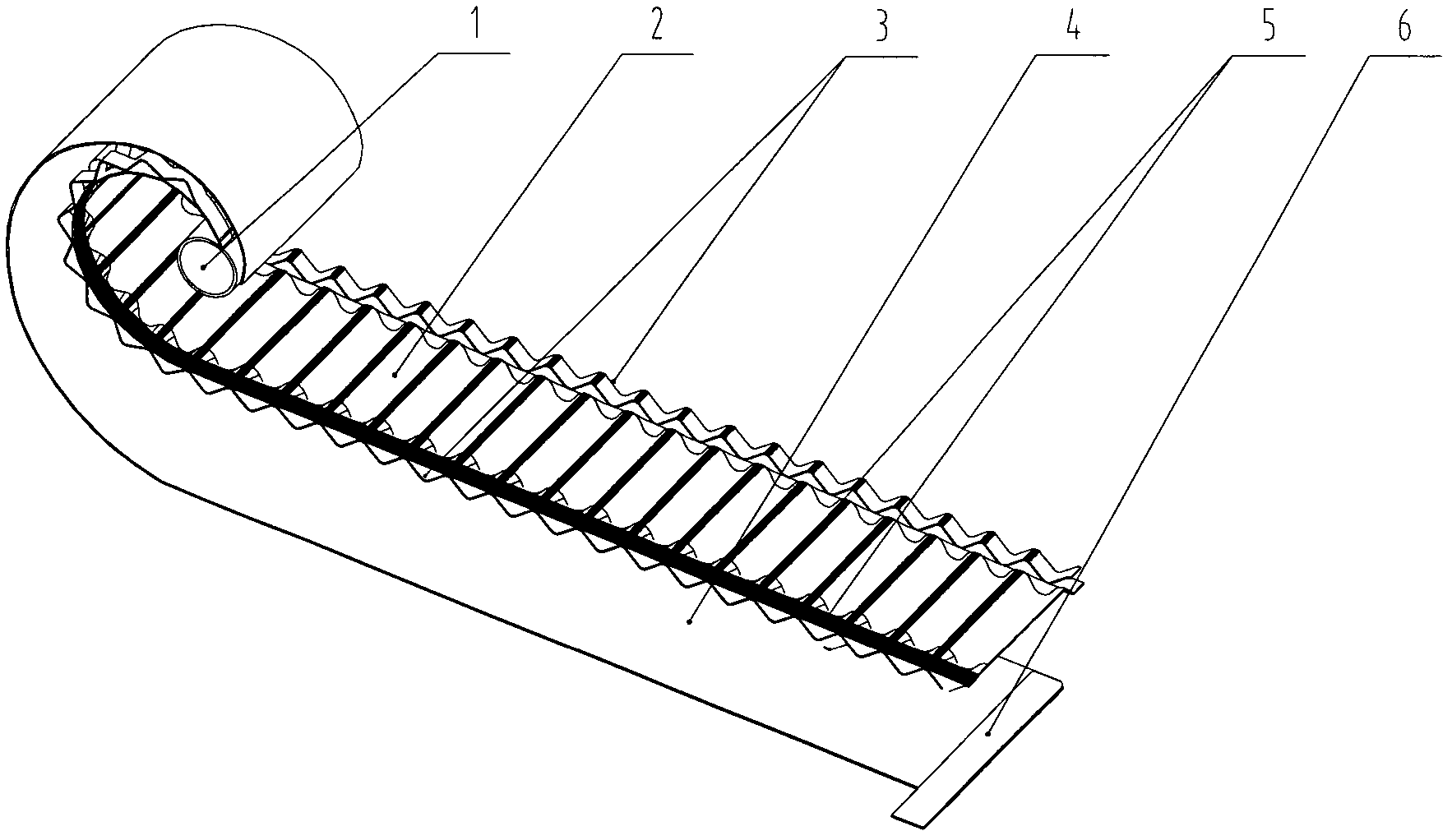

Catalyst used for diesel engine tail gas soot collection catalysis

InactiveCN103861612ALower combustion temperatureImprove purification efficiencyCatalyst carriersDispersed particle separationEngineeringSoot

The invention provides a catalyst used for diesel engine tail gas soot collection catalysis. The catalyst is prepared via following processing on stainless steel meshes: the stainless steel meshes are subjected to bluing liquid treatment, electroplating, and pressure wave treatment, are cut into strips, are rolled, and then are delivered into stainless steel pipes for encapsulation brazing. The catalyst can be used for diesel engine tail gas soot collection catalysis; pressure reduction is less; and catalysis performance is excellent.

Owner:SHANGHAI LANGT AUTOCATALYST

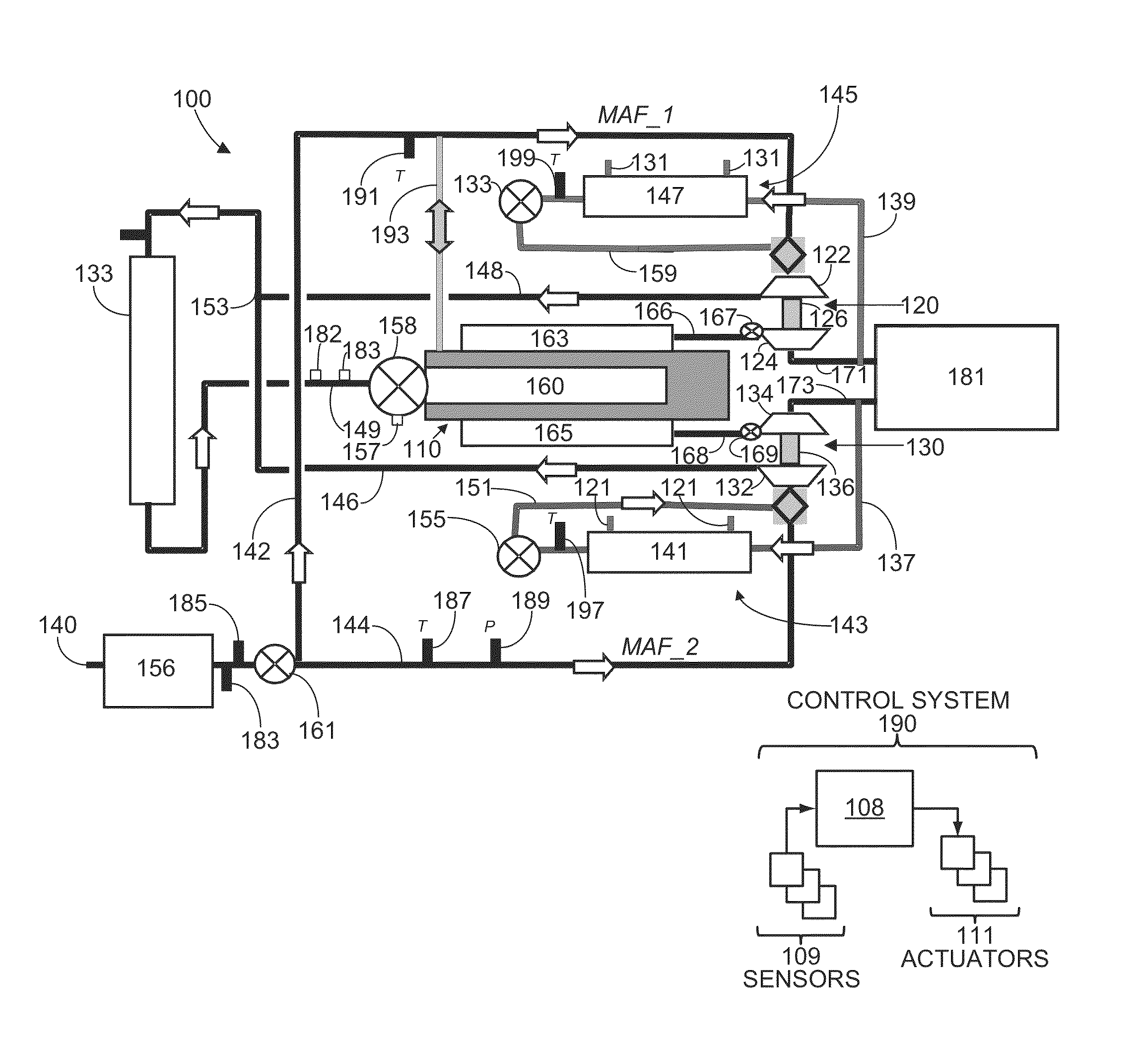

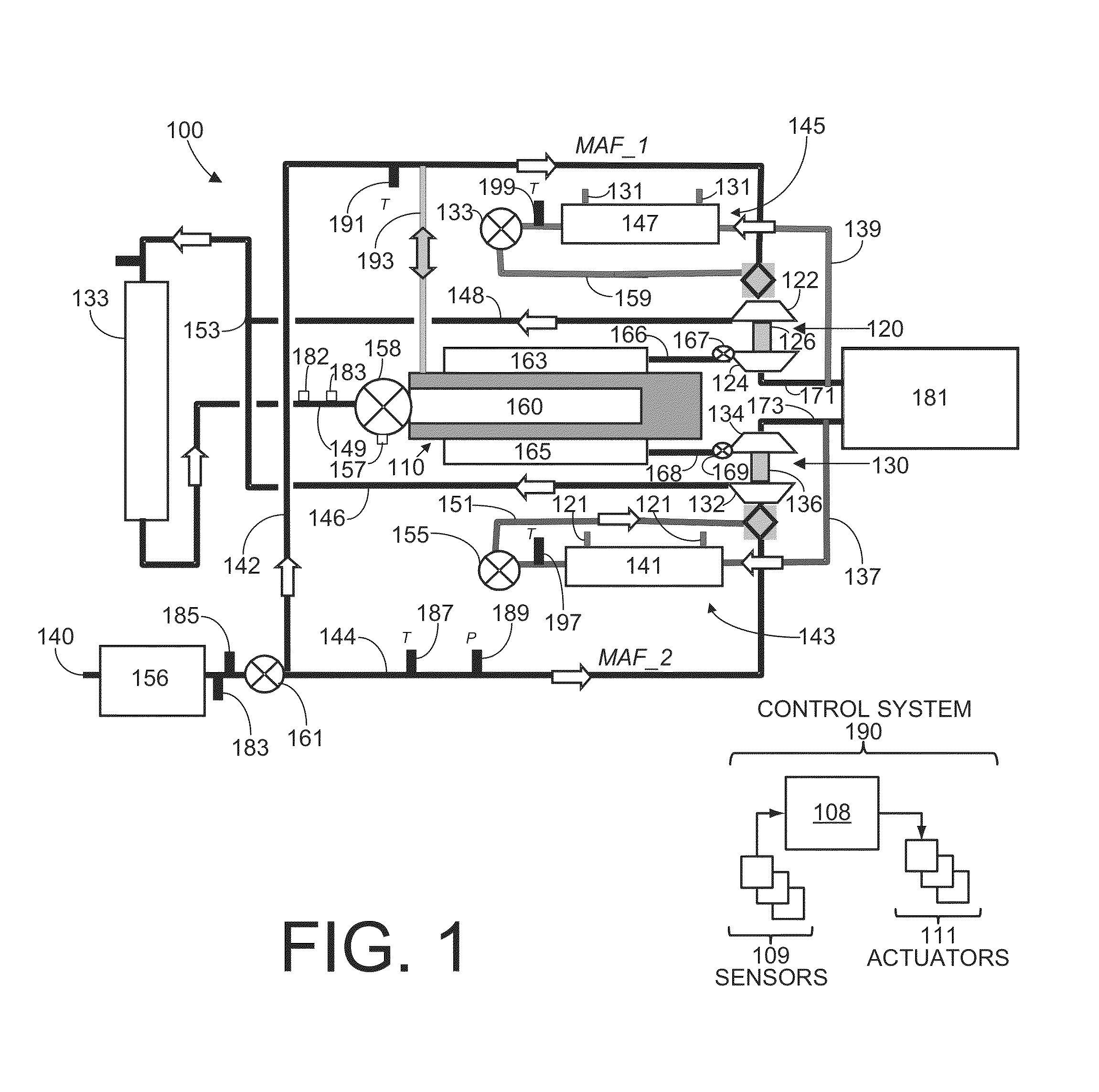

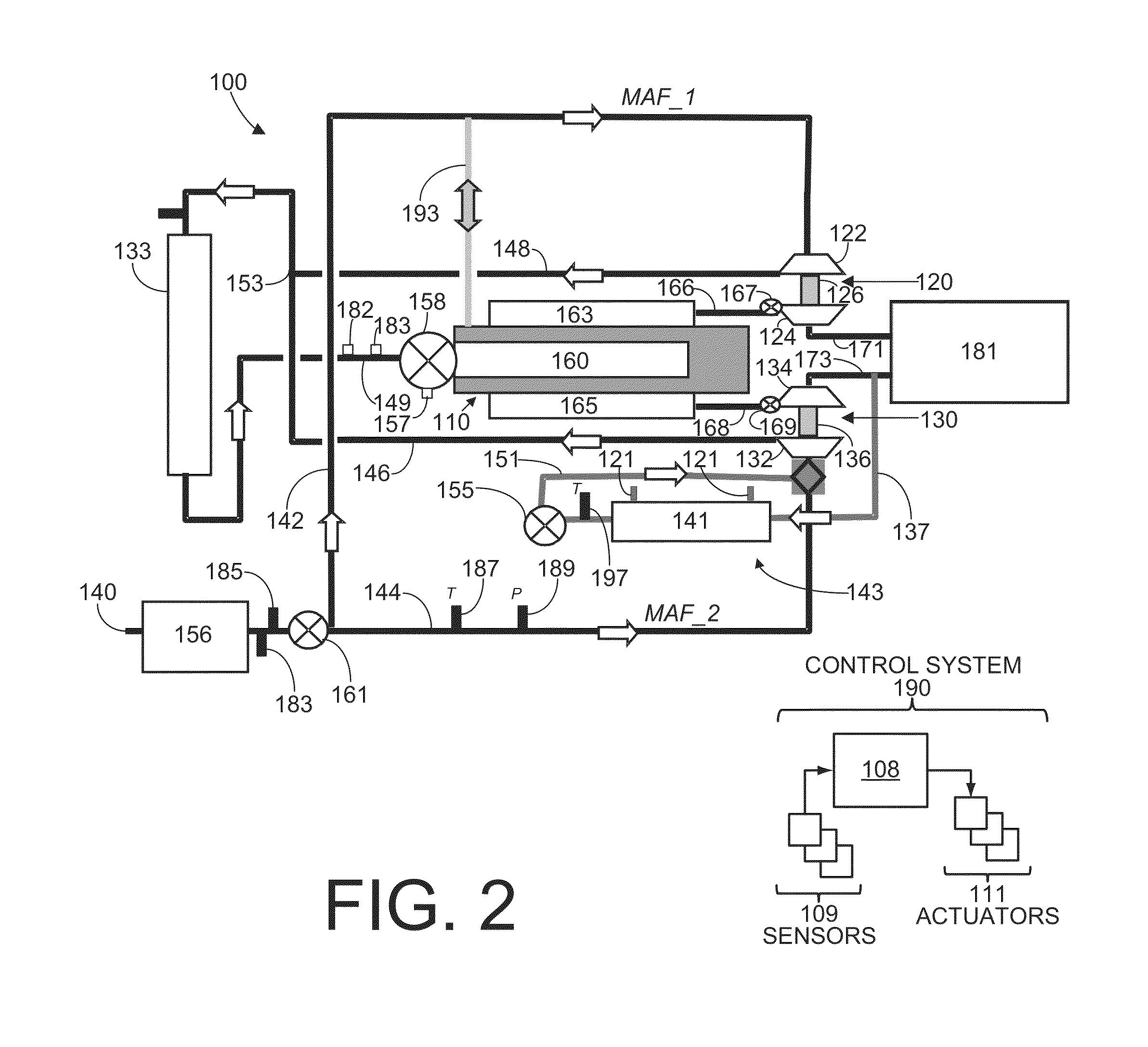

Asymmetric exhaust gas recirculation system

ActiveUS20130205774A1Low costGood flexibilityNon-fuel substance addition to fuelInternal combustion piston enginesTurbochargerExhaust fumes

Systems and methods for a twin turbocharged engine with a single exhaust gas recirculation (EGR) system are disclosed. In one example approach a system is provided comprising a first turbocharger in a first intake passage with a low-pressure EGR system fluidically coupling exhaust exiting the first turbocharger to intake air entering the first turbocharger, and a second turbocharger in a second intake passage without a low-pressure EGR system fluidically coupling exhaust exiting the second turbocharger to intake air entering the second turbocharger.

Owner:FORD GLOBAL TECH LLC

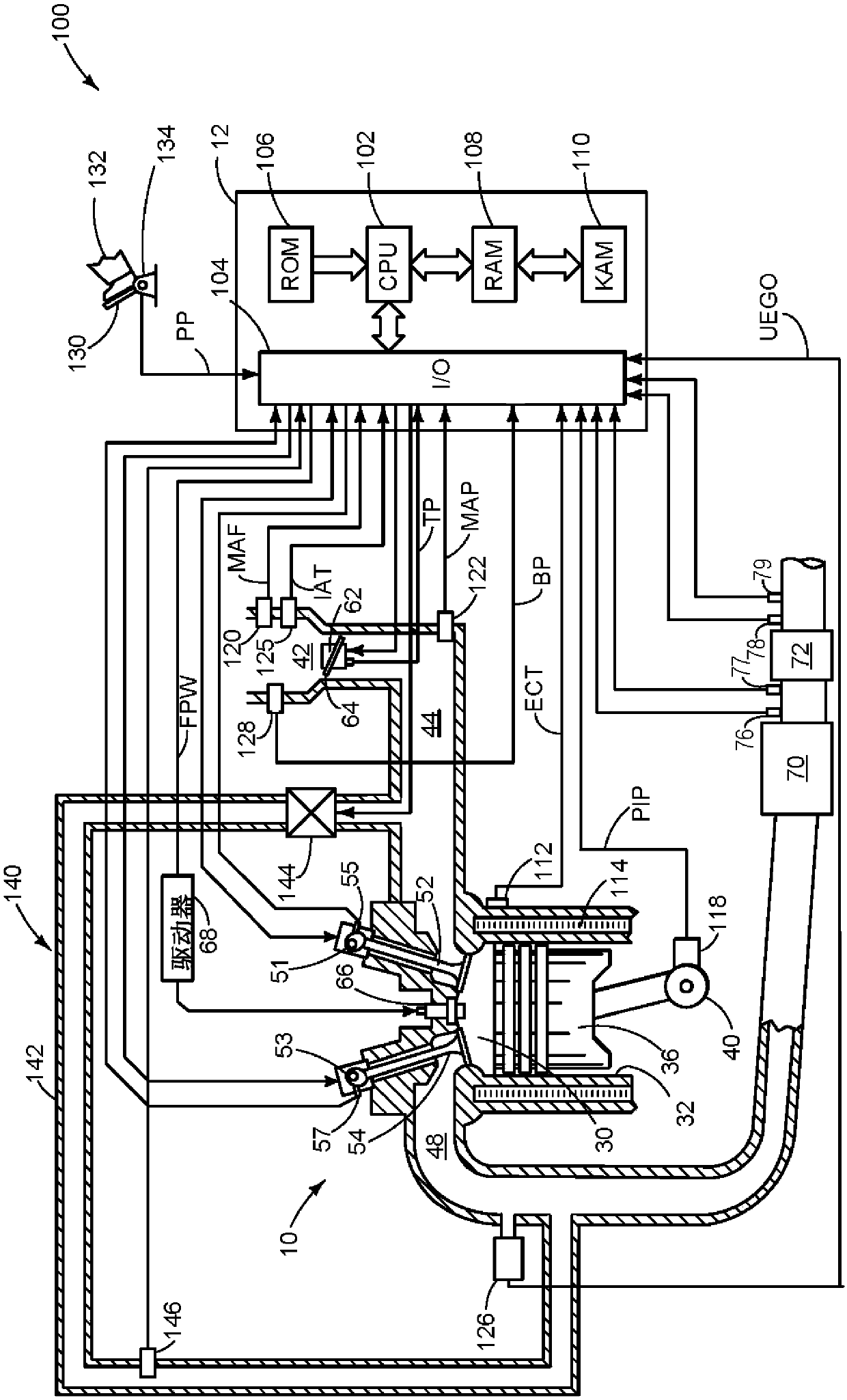

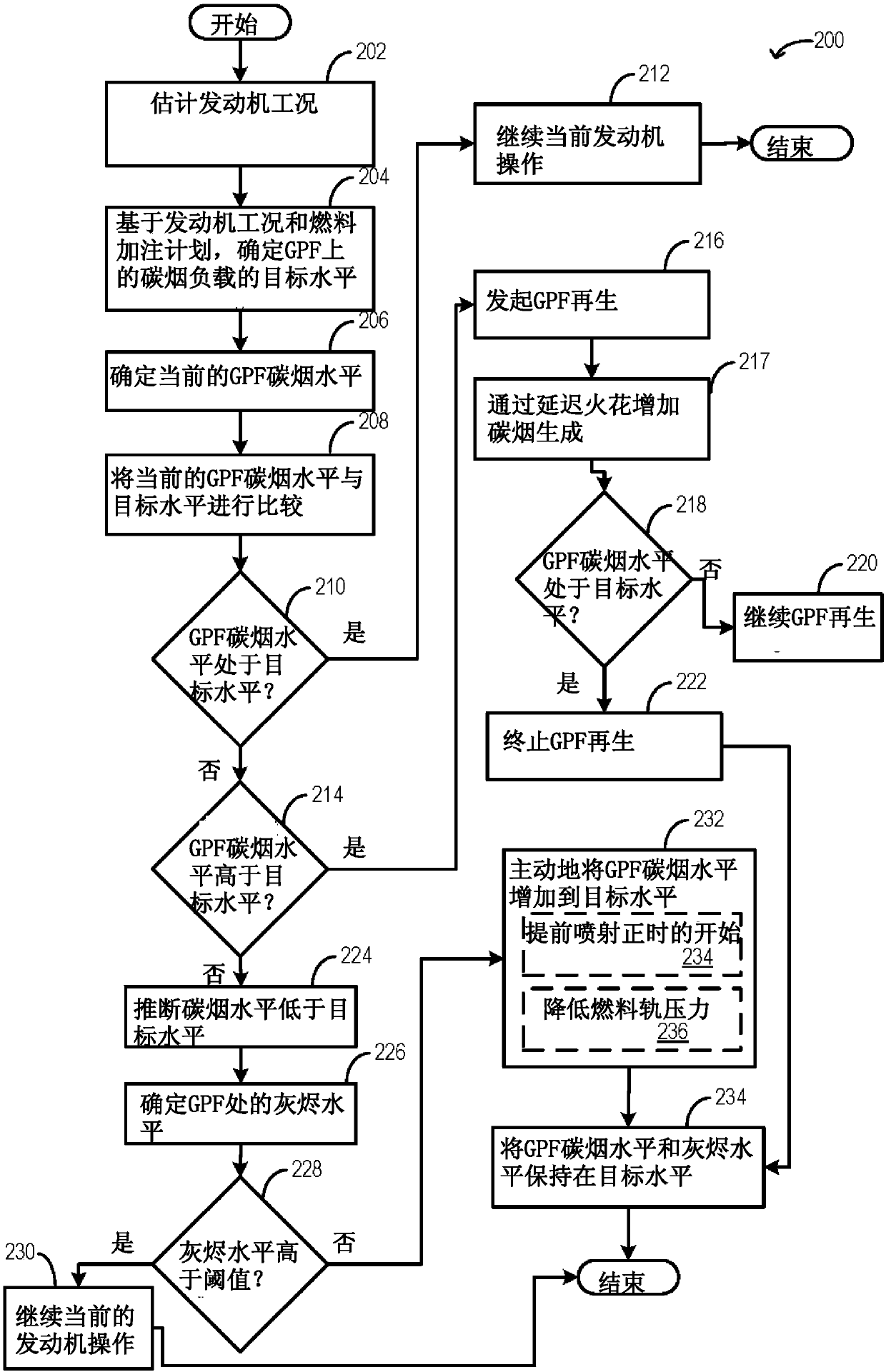

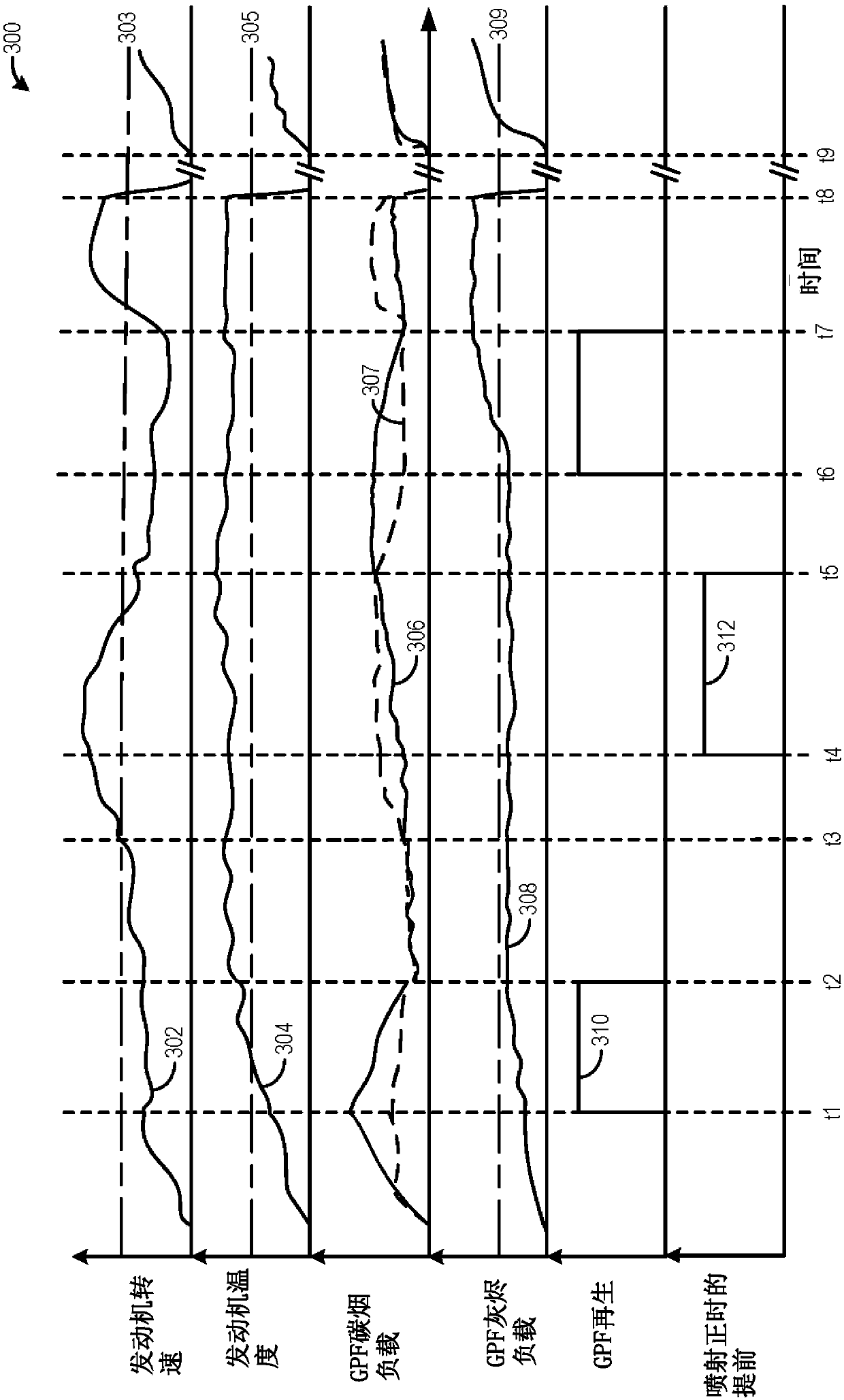

Method and system for gasoline particulate filter operations

ActiveCN107620618AIncrease capture rateImprove power efficiencyElectrical controlInternal combustion piston enginesParticulatesRail pressure

The present invention relates to a method and system for gasoline particulate filter operations. Methods and systems are provided for optimal operation of a gasoline particulate filter coupled to an engine exhaust system. Based on engine operating conditions, a target soot level on the GPF may be determined, and one or more engine operating parameters may be adjusted to maintain the actual GPF soot level at the target level. In one example, if the actual GPF soot level is lower than the target level, one or more of a fuel injection timing and a fuel rail pressure may be adjusted to increase soot generation, and if the actual GPF soot level is higher than the target level, the GPF may be regenerated until the actual soot level reaches the target level.

Owner:FORD GLOBAL TECH LLC

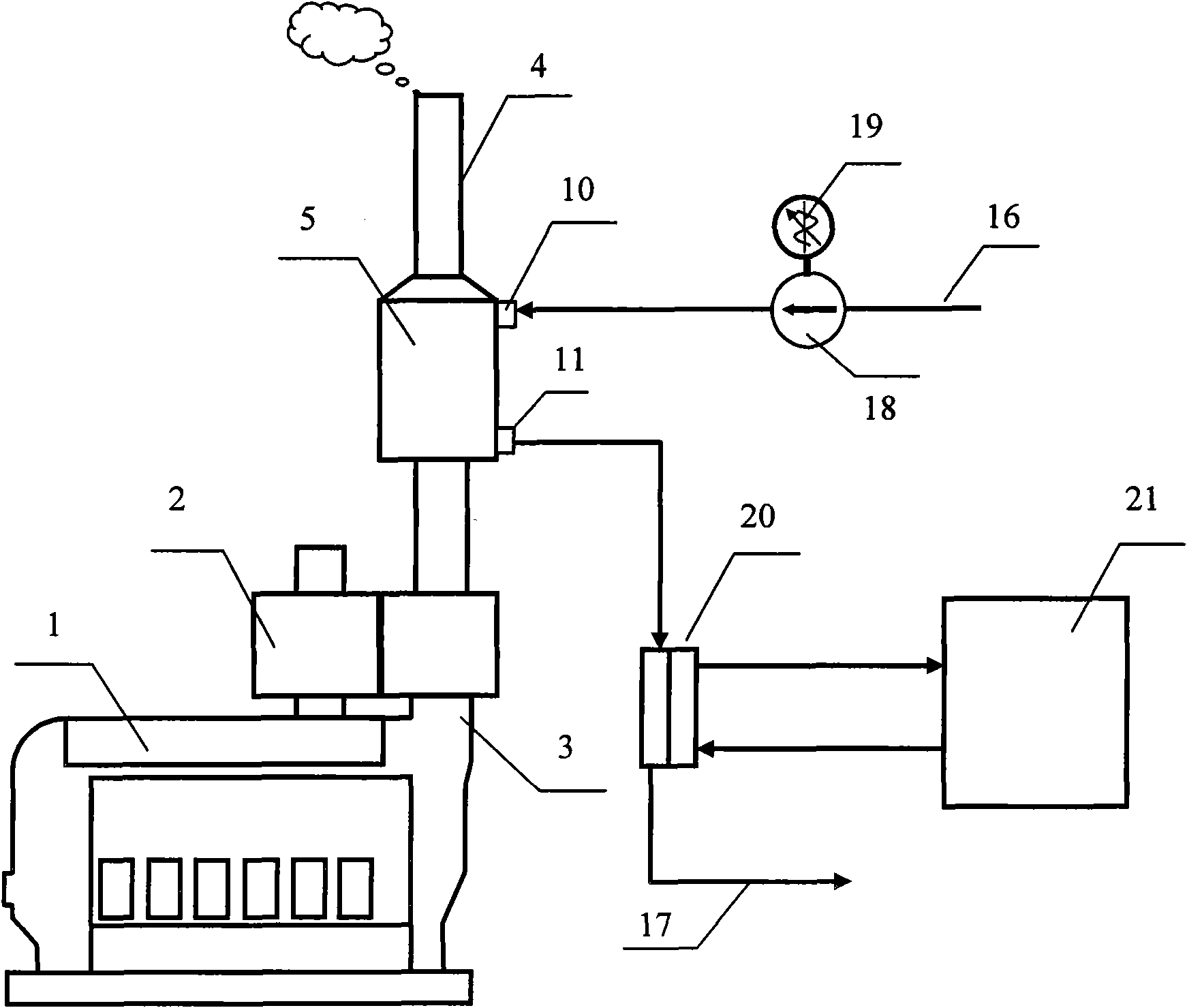

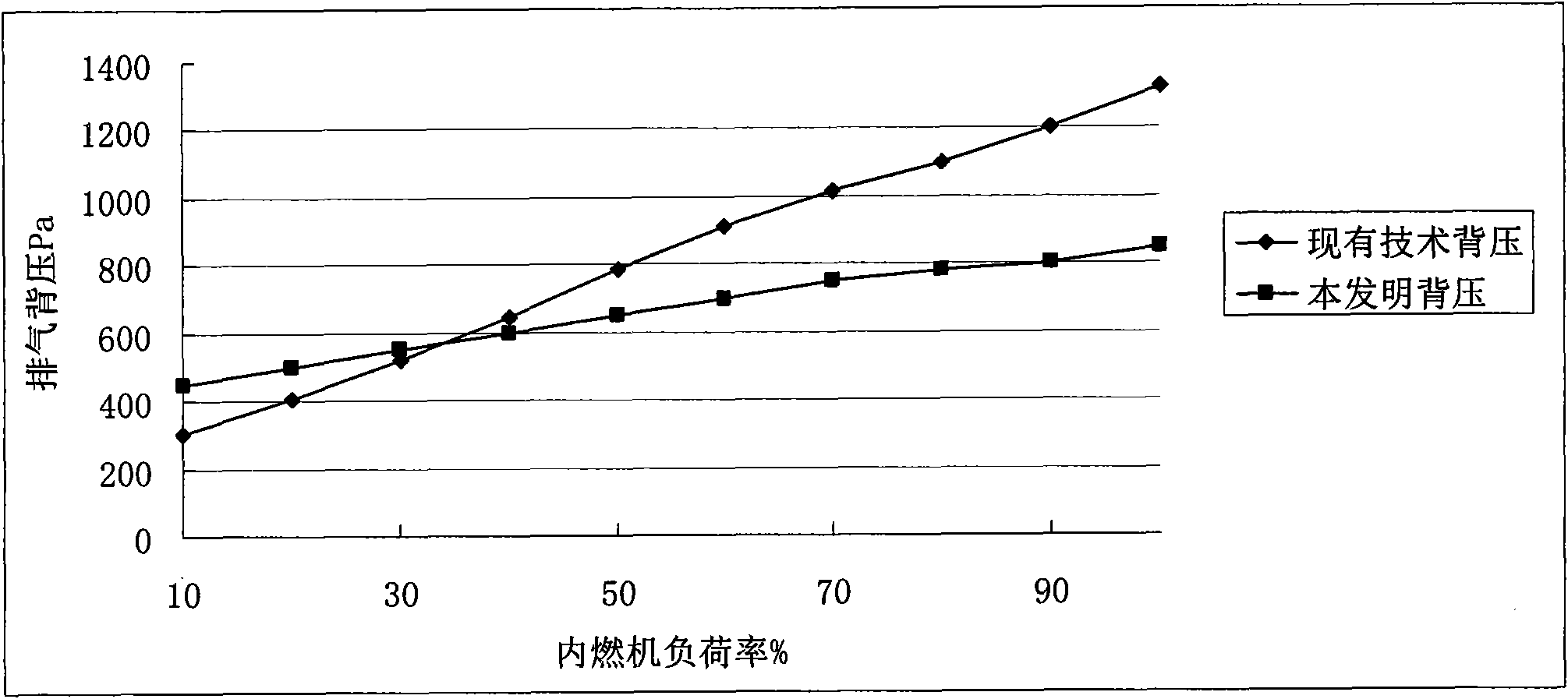

Method, device and system for optimizing exhaust back pressure of internal combustion engine

InactiveCN102852596AHigh expansion ratioIncrease resistanceGas treatmentInternal combustion piston enginesExternal combustion engineInternal combustion engine

The invention provides a method for optimizing exhaust back pressure of an internal combustion engine. The method comprises arranging a damping component in an exhaust passage of the internal combustion engine, and enabling tail gas exhausted out of the internal combustion engine to pass the damping component; and enabling the tail gas to be cooled before passing the damping component, or enabling the tail gas to be cooled while passing the damping component. Through the method, the internal combustion engine has the high exhaust back pressure when in a low load, and the exhaust back pressure does not rise too quickly when the internal combustion engine is in a high load. The invention further provides a device and system for optimizing the exhaust back pressure of the internal combustion engine.

Owner:彭斯干

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com