Method, device and system for optimizing exhaust back pressure of internal combustion engine

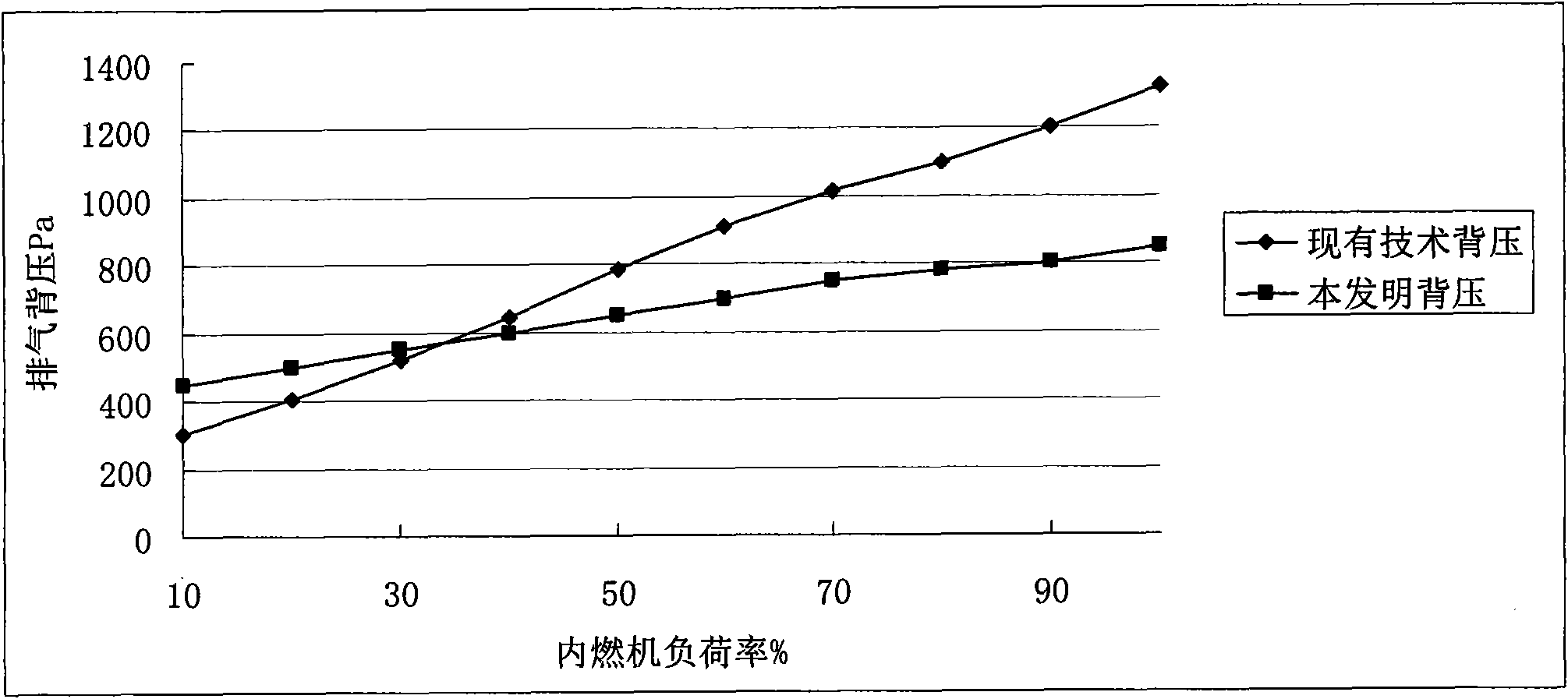

A technology of exhaust back pressure and internal combustion engine, which is applied in the direction of exhaust device, internal combustion piston engine, chemical instrument and method, etc. It can solve the problems of increasing exhaust back pressure of internal combustion engine, increasing energy consumption, reducing energy efficiency of internal combustion engine, etc., so as to reduce exhaust gas The effect of increasing the flow rate, increasing the density of the exhaust gas, and suppressing the excessive rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

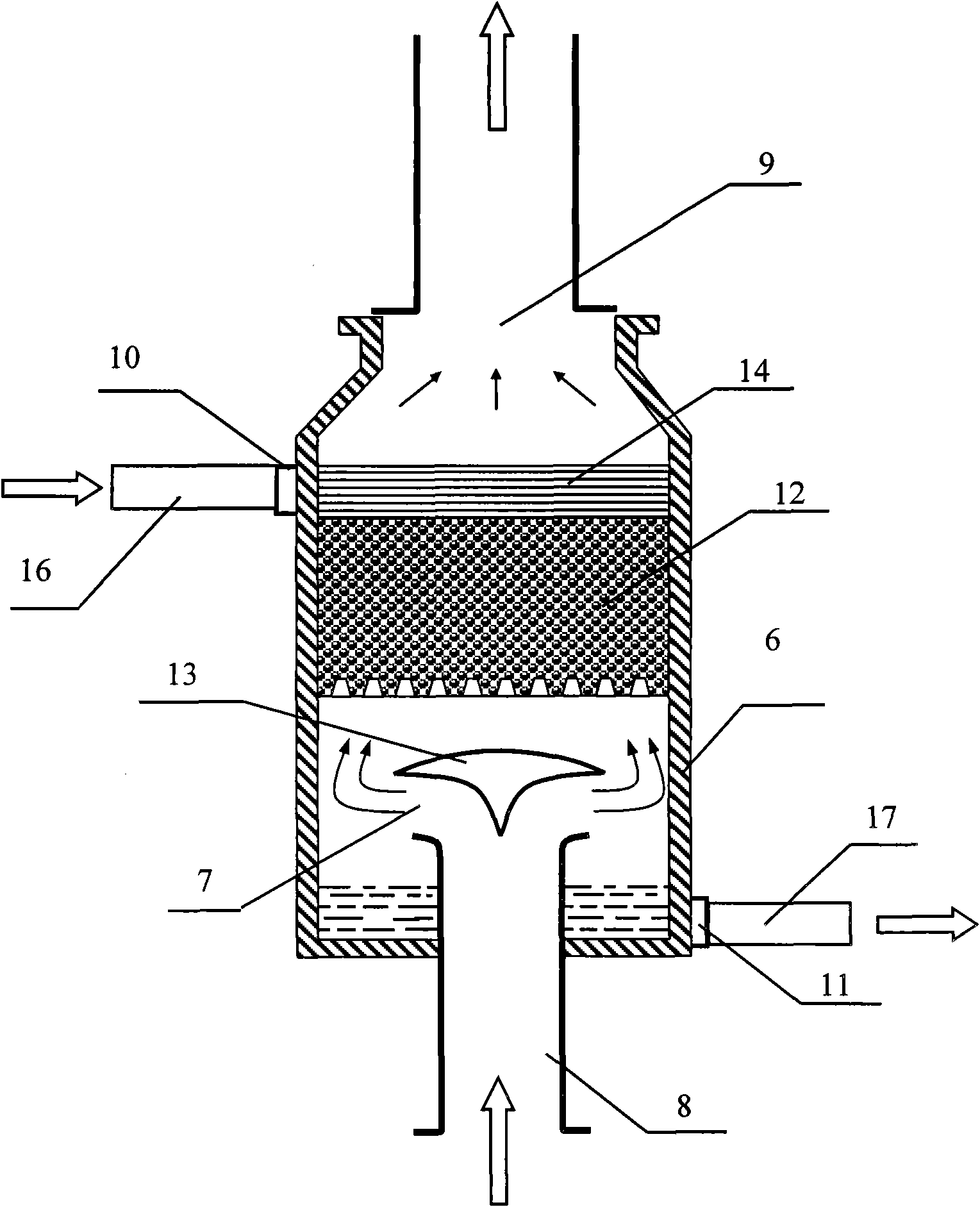

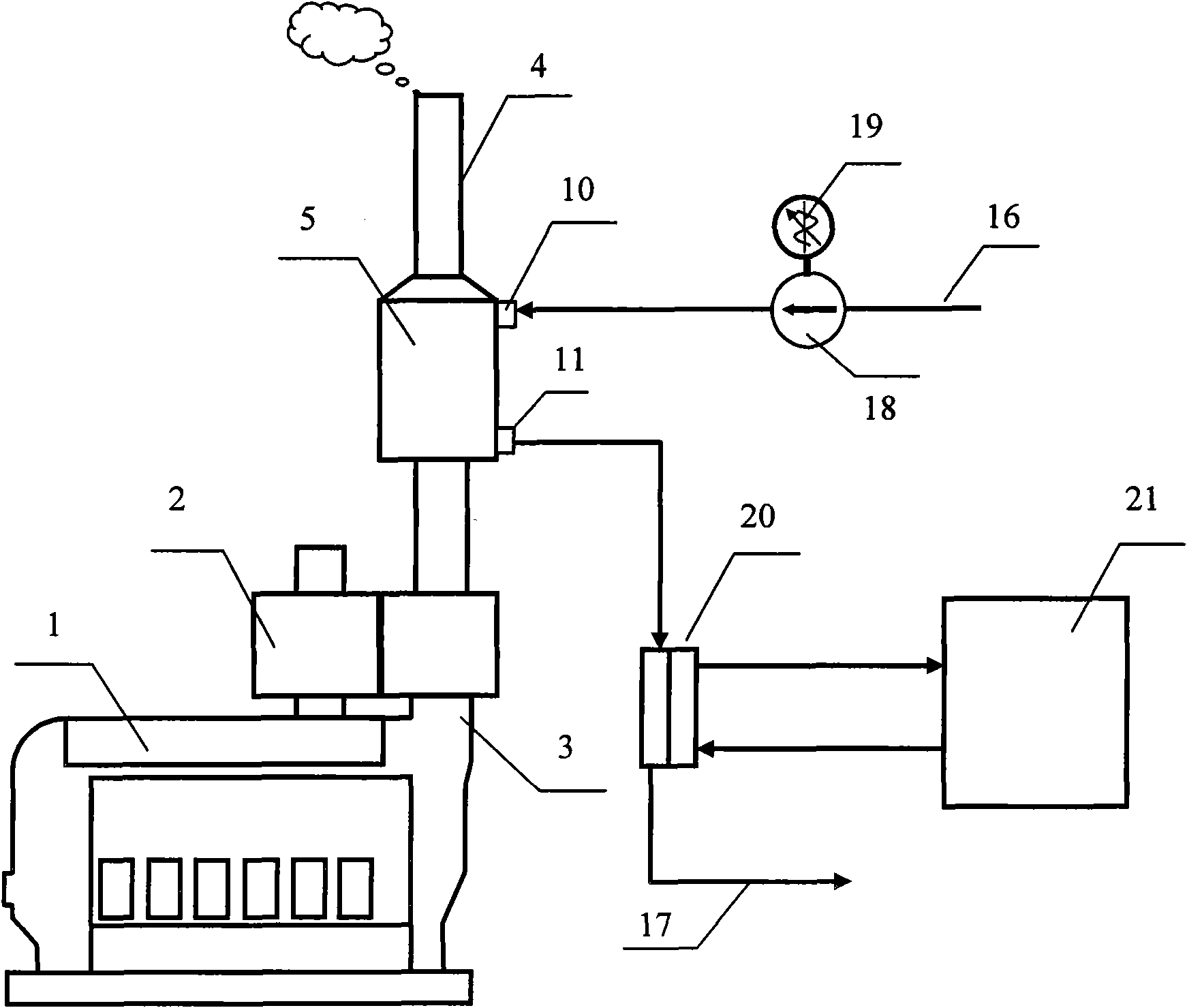

[0109] Figure 1 to Figure 4 A device and system for optimizing exhaust back pressure of an internal combustion engine according to a first embodiment of the present invention is shown.

[0110] like figure 1 As shown, in this embodiment, the device for optimizing exhaust gas of an internal combustion engine includes a housing 6 on which a cooling water inlet 10 and a cooling water outlet 11 are arranged. Wherein, the cooling water inlet 10 is located at the upper side of the housing, and the cooling water outlet 11 is located at the lower side of the housing. Under the action of gravity, the cooling water entering the casing from the cooling water inlet 10 passes from top to bottom, and is discharged through the cooling water outlet 11 .

[0111] The casing 6 is also provided with an exhaust gas inlet pipe 8 and an exhaust gas outlet 9 . Wherein, the exhaust gas inlet pipe 8 extends into the inside of the housing, and the pipe mouth extending into the housing inside is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com