Patents

Literature

2118 results about "Micro arc oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

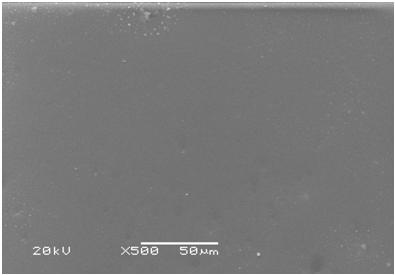

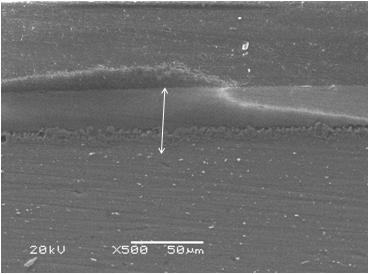

Micro arc oxidation (Microarc oxidation, MAO, Micro arc anodizing), also known as micro-plasma oxidation (Microplasma oxidation, MPO), which through a combination of electrolyte and corresponding electrical parameters, depended on impact of instantaneous high temperature & pressure generated by arc discharge,...

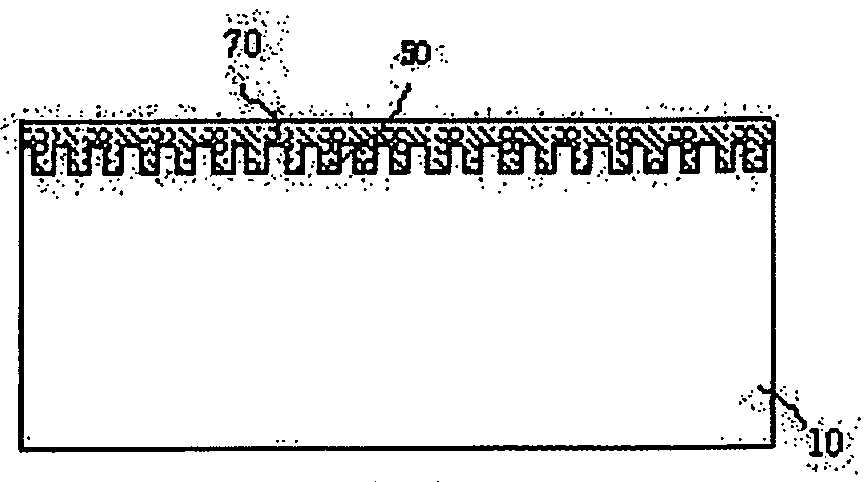

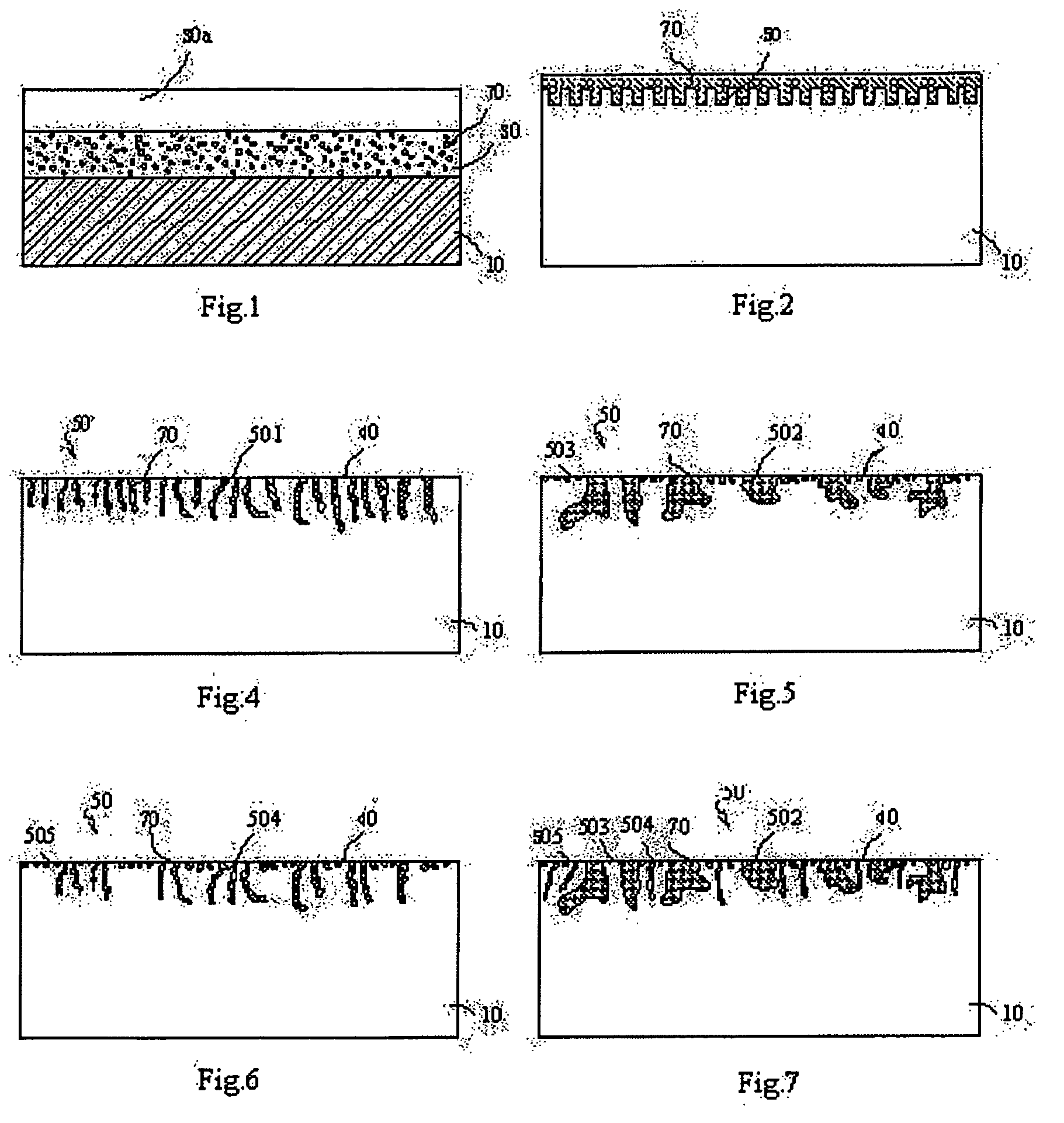

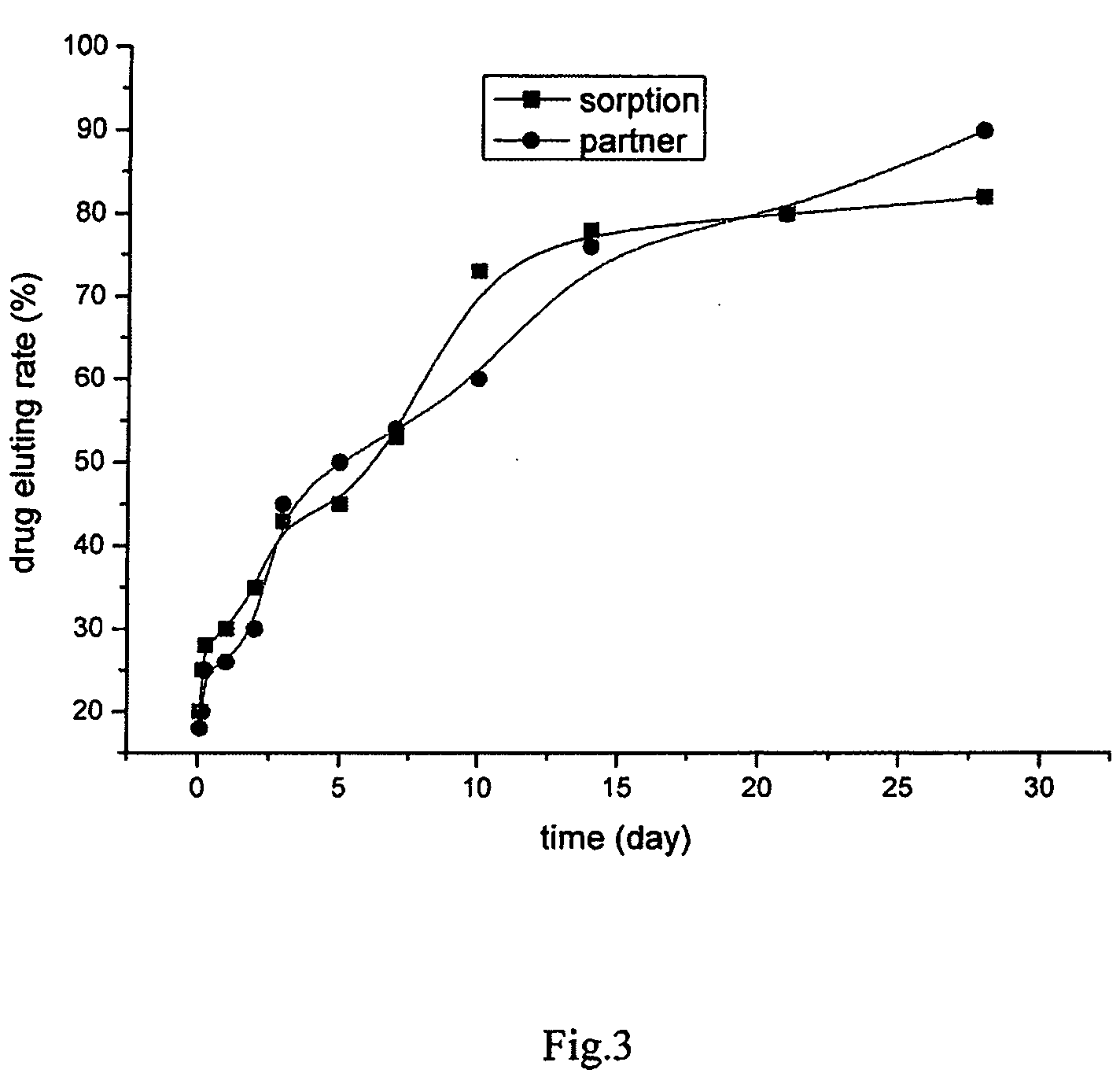

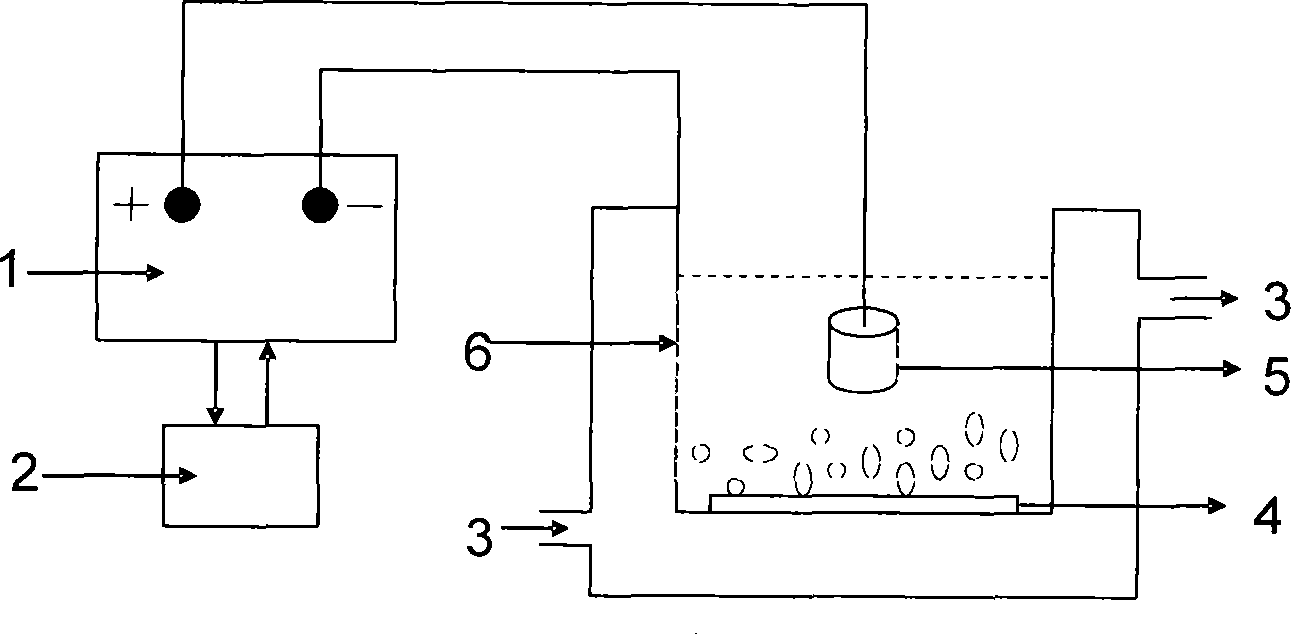

Nanoporous Drug Release Structure for Drug Elute Instruments and the Preparation Method Thereof

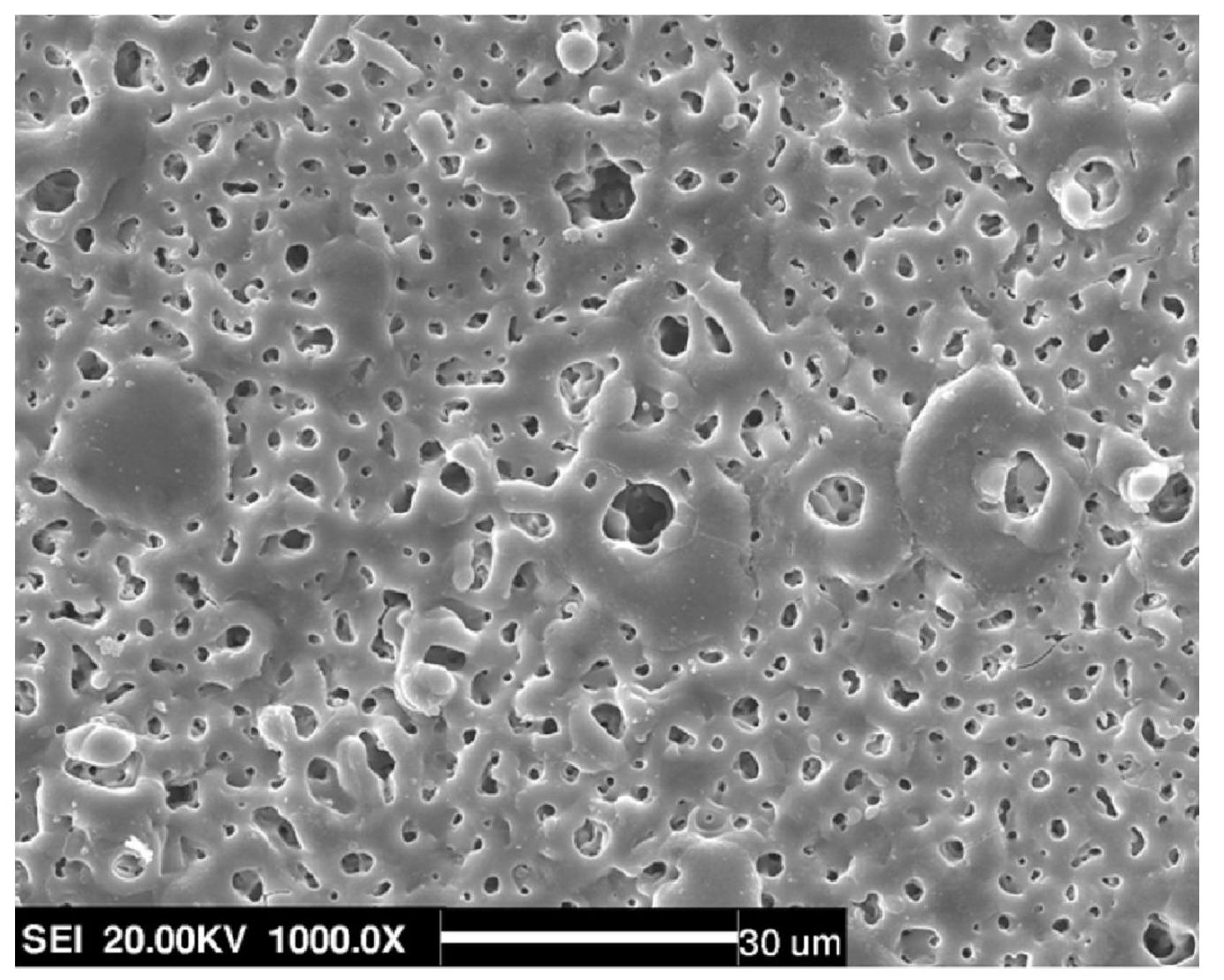

InactiveUS20090112310A1Reduce riskNo effect on mechanical propertySurgeryPharmaceutical delivery mechanismMicro arc oxidationPercent Diameter Stenosis

The present invention relates to a nanoporous configuration for drug release used in a drug-eluting device and its preparation, employing acid corrosion or anode oxidation to prepare pores, or employing acid corrosion to prepare pores firstly, then employing anode oxidation or micro-arc oxidation combined with micro-arc nitridation to prepare single sized or two sized or multiple sized nanopores, as well as a uniform size distributed or two or more nonuniform size distributed in pore diameter or pore depth h nanopores on the raw material of device body directly. The preparation process includes: ① Pre-treating the surface of the device body, ② Preparing pore, ③ Post-treating the surface of the device body, ④preparing drug, ⑤ Spraying drug etc. The nanoporous configuration lowers the risk of forming thrombus after the drug-delivery device with polymer carrier is implanted into the tissue. The device also controls the release rate of drug efficiently and lowers the incidence of restenosis significantly.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Ceramic membrane layer on metal surface and preparation method thereof

InactiveCN103014706AIncreasing the thicknessSolving problems in applications requiring high wear resistanceAnodisationSuperimposed coating processMicro arc oxidationPlasma electrolytic oxidation

Owner:柯全

Surface treating method for magnesium lithium alloy

InactiveCN101245485AGood effectImprove corrosion resistanceAnodisationMicro arc oxidationPlasma electrolytic oxidation

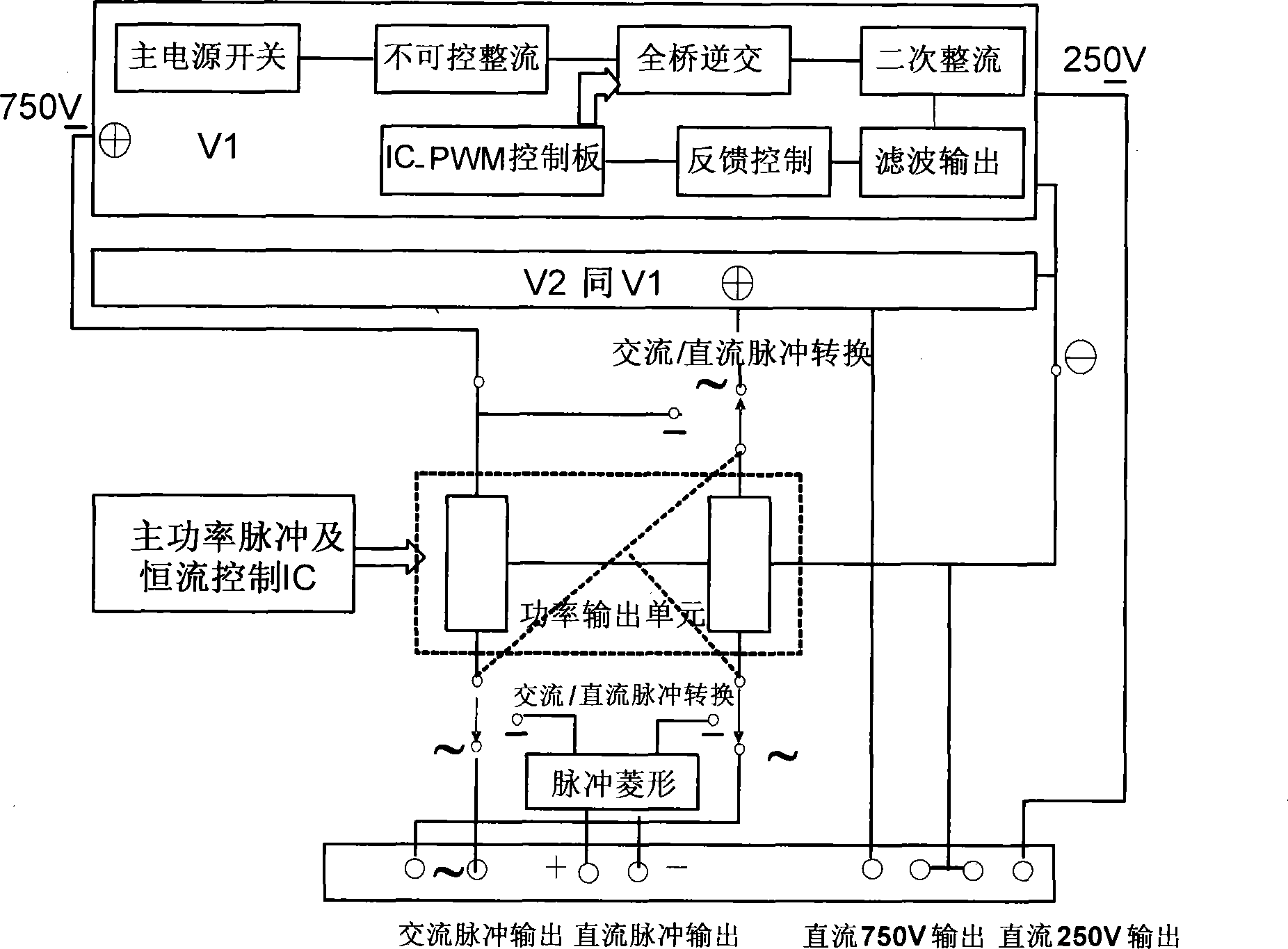

The invention provides a method for processing the surface of magnesium-lithium alloy. The technique of micro-arc oxidation is successfully applied to processing the surface of the magnesium-lithium alloy. Direct current / DC pulse / alternating current pulse multiplex power supply is used and the magnesium-lithium alloy with different lithium contents in a compound electrolyte system of sodium polyphosphate, sodium silicate, calgon and sodium hydroxide is carried out by micro-arc oxidation for 2-120min. A ceramic oxide film of 10-100Mum with a rigidity higher than 200Hv is formed in situ on the surface of the magnesium-lithium alloy, thus remarkably improving corrosion resistant property compared with an alloy matrix, solving the problem known at home and abroad concerning processing the surface of the magnesium-lithium alloy and broadening the application in the fields of aviation, aerospace, car, electronic, etc.

Owner:HARBIN ENG UNIV

Method for preparing environment-friendly micro-arc oxidation black ceramic film on aluminum alloy surface

ActiveCN102154673AUniform colorImprove corrosion resistanceAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an environment-friendly micro-arc oxidation black ceramic film on an aluminum alloy surface, and the method comprises the following steps: firstly, pouring deionized water into an oxidation tank, weighing 1-10g / L of sodium hexametaphosphate, 1-3g / L of sodium silicate, 0.5-2g / L of potassium hydroxide, 0.2-2g / L of sodium fluoride and 0.5-20g / L of ferric ammonium oxalate in terms of the volume of the added deionized water, and uniformly stirring and mixing the sodium hexametaphosphate, the sodium silicate, the potassium hydroxide and the sodium fluoride to obtain a micro-arc oxidation base electrolyte; adding the weighed ferric ammonium oxalate into the base electrolyte, and stirring and mixing uniformly to obtain an aluminum alloy micro-arc oxidant solution; and then, sequentially carrying out surface deoiling and cleaning, water washing, aluminum alloy micro-arc oxidation, sealing and drying on the aluminum alloy to prepare the environment-friendly micro-arc oxidation black ceramic film on the aluminum alloy surface. By means of the preparation method disclosed by the invention, the problems of single color, limited application range, and environment pollution caused by a vanadate electrolyte, of the existing aluminum alloy ceramic film layer, are solved.

Owner:CSIC NO 12 RES INST

Method for preparing corrosion protection abrasion resistant ceramic coating with alloy surface differential arc oxidization

InactiveCN101270495ALow power density per unitFast film formationAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing an antisepsis and antiwear ceramics coating layer on the surface of alloy through microarc oxidation. The method includes three steps of collocating electrolyte, arranging power electric parameters and microarc oxidation treatment; wherein, the component concentrations of the electrolyte are sodium silicate of 20 to 100g / L, sodium hydroxide of 5 to 10g / L and organic amine additive of 5 to 15ml / L; the current density of unit area is 50 to 100A / centiare; the pulse frequency is 100 to 700Hz; the pulse dutyfactor is 20 to 90 percent; the temperature of the electrolyte in the microarc oxidation treatment is not higher than 45 DEG C. The method needs lower unit power density and has fast film forming speed to prepare the ceramics coating layer on the surface of aluminum and magnesium alloys; the method adopts 100KVA power which can treat at least 2 centiares of the surface area of the aluminum alloy for one time; the growing speed of the ceramics coating layer can reach 1 to 1.5 micron / min. The formed ceramics coating layer is uniform and compact; the rigidity of the aluminum alloy can reach 1200 to 1300Hv.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing biomedical titanium and titanium alloy surface antibacterial coatings

ActiveCN102758202AImprove antibacterial propertiesReduce or avoid infectionSurface reaction electrolytic coatingLiquid/solution decomposition chemical coatingMicro arc oxidationPlasma electrolytic oxidation

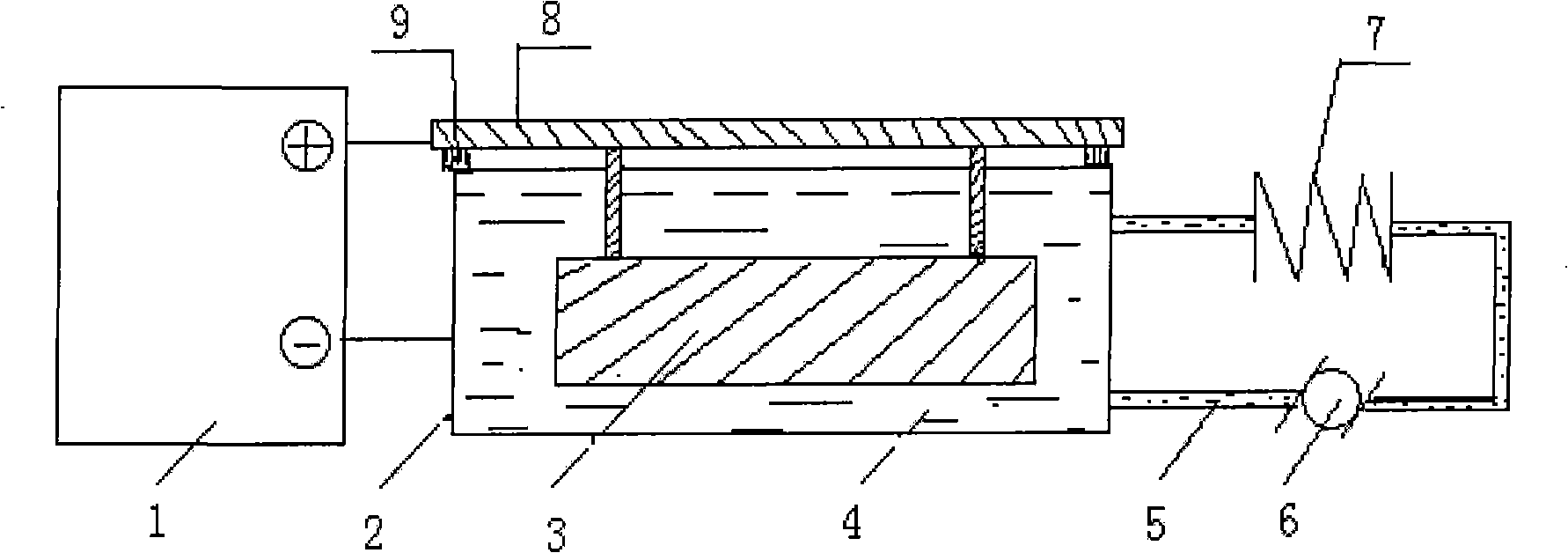

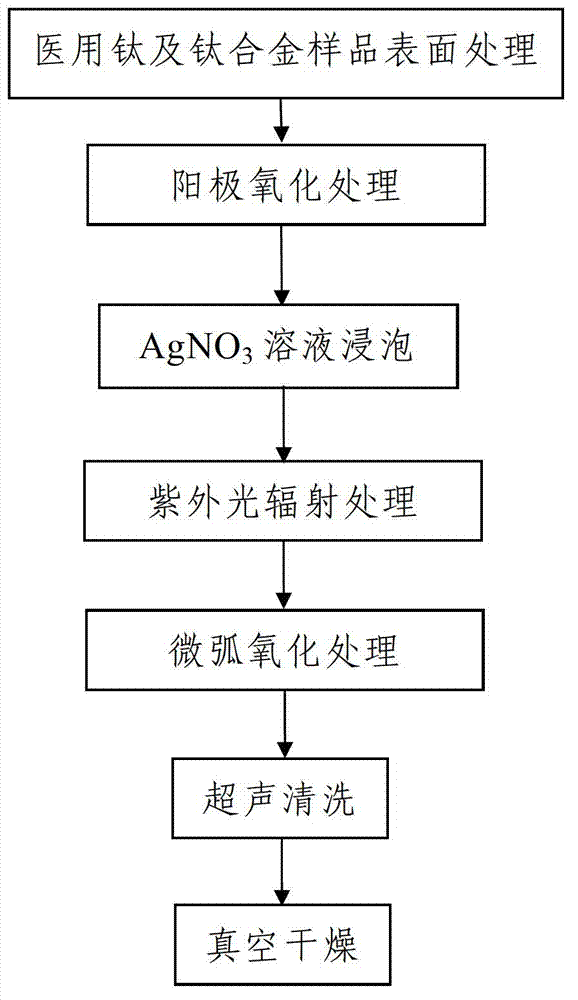

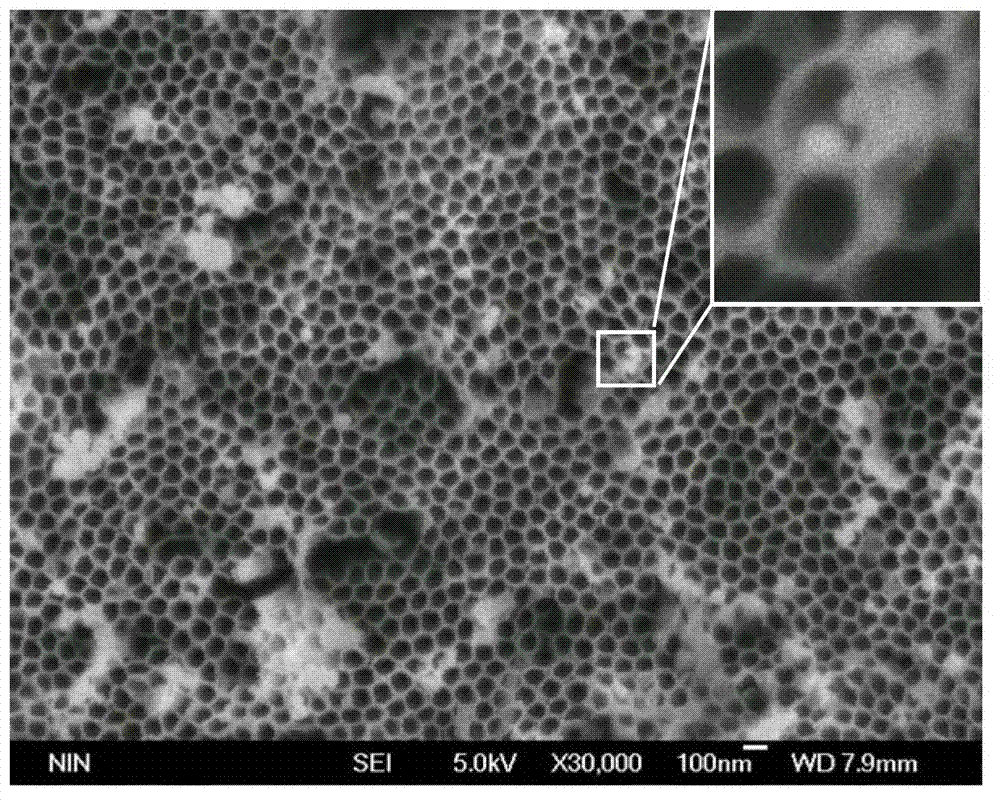

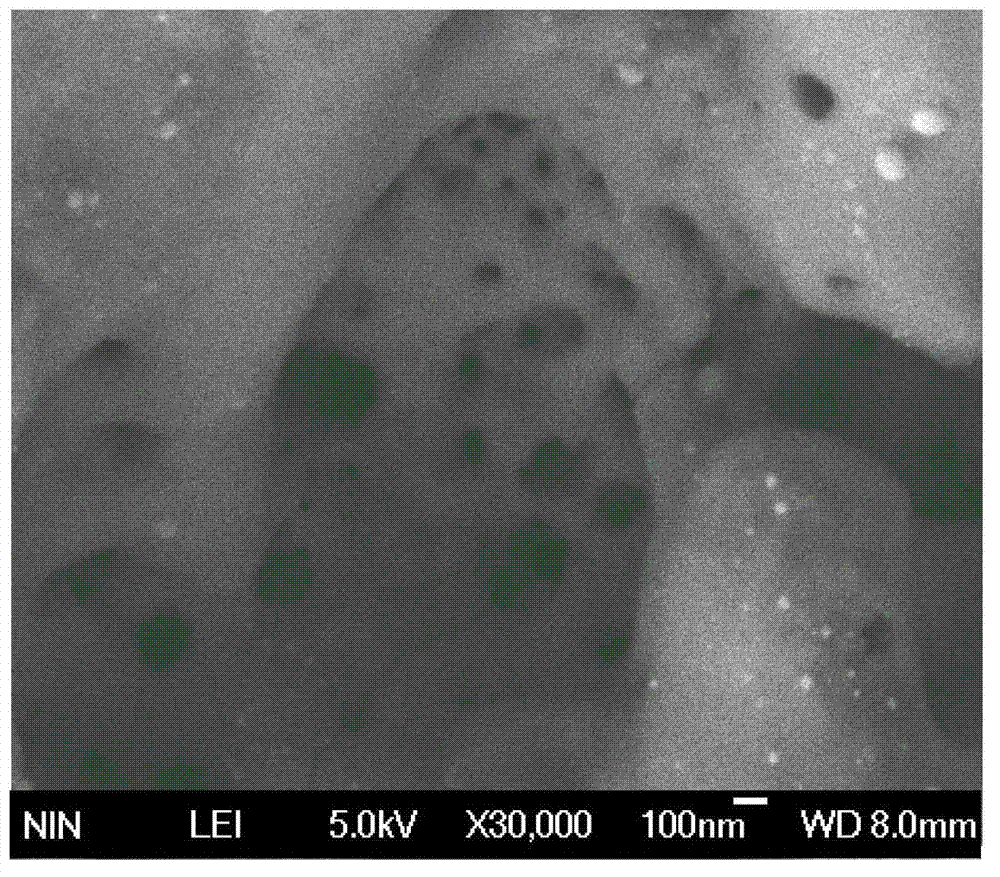

The invention discloses a method for preparing biomedical titanium and titanium alloy surface antibacterial coatings. The method comprises steps of firstly, processing the surface of a biomedical titanium or titanium alloy sample to be processed, immersing the biomedical titanium or titanium alloy sample in a glycol aqueous solution containing soluble fluoride and performing an anode oxidation treatment; secondly, immersing the biomedical titanium or titanium alloy sample after being subjected to the anode oxidation treatment in a silver nitrate solution, taking out the biomedical titanium or titanium alloy sample, using ultraviolet light radiation to process the biomedical titanium or titanium alloy sample and obtaining the silver-carrying biomedical titanium or titanium alloy sample; and performing a micro-arc oxidation treatment for the silver-carrying biomedical titanium or titanium alloy sample, performing ultrasonic cleaning and vacuum drying and obtaining the antibacterial coatings. The nano precoating layer preparation, the silver-carrying treatment and a micro-arc oxidation technology are combined, then a large amount of silver can be fixed on the biomedical titanium and titanium alloy sample surfaces and can be released slowly for a long time, the antibacterial performance of titanium and titanium alloys is greatly improved, the antibacterial effect can be kept for a long time, and the bacterial infection caused by the fact that a titanium and titanium alloy apparatus is embedded in a human body is greatly reduced or avoided.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Preparation method of ultrasonic microarc oxidation silver-carrying antibiotic bioactive coating on magnesium and titanium surface

InactiveCN101899700AImprove corrosion resistanceGood resistance to friction and wear in human environmentAnodisationProsthesisPorosityPlasma electrolytic oxidation

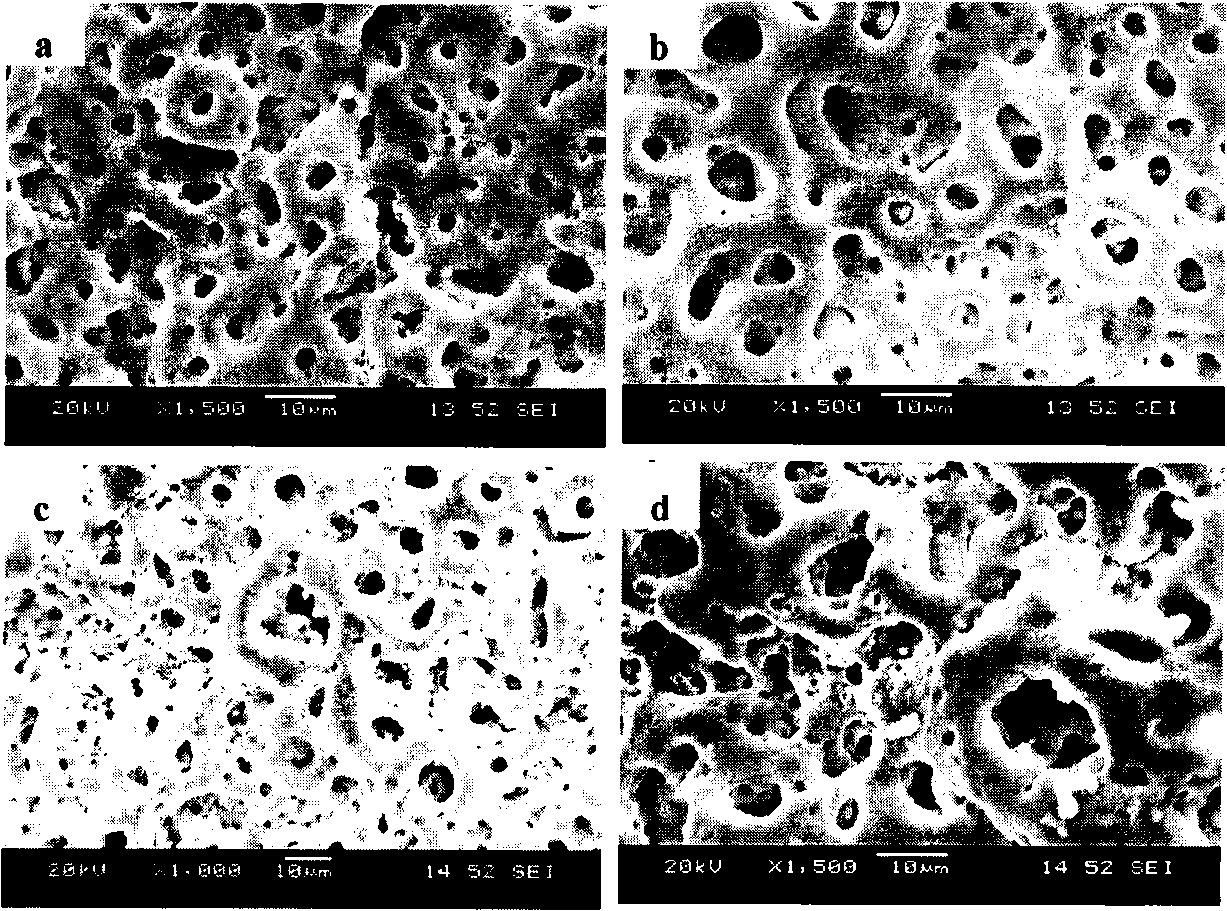

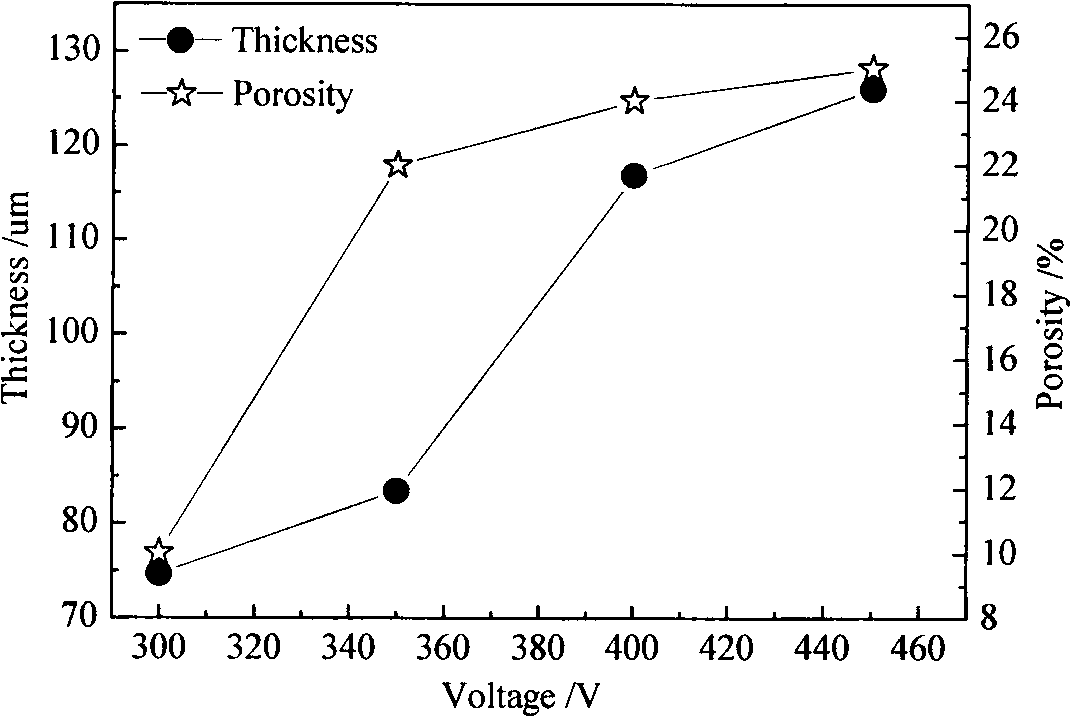

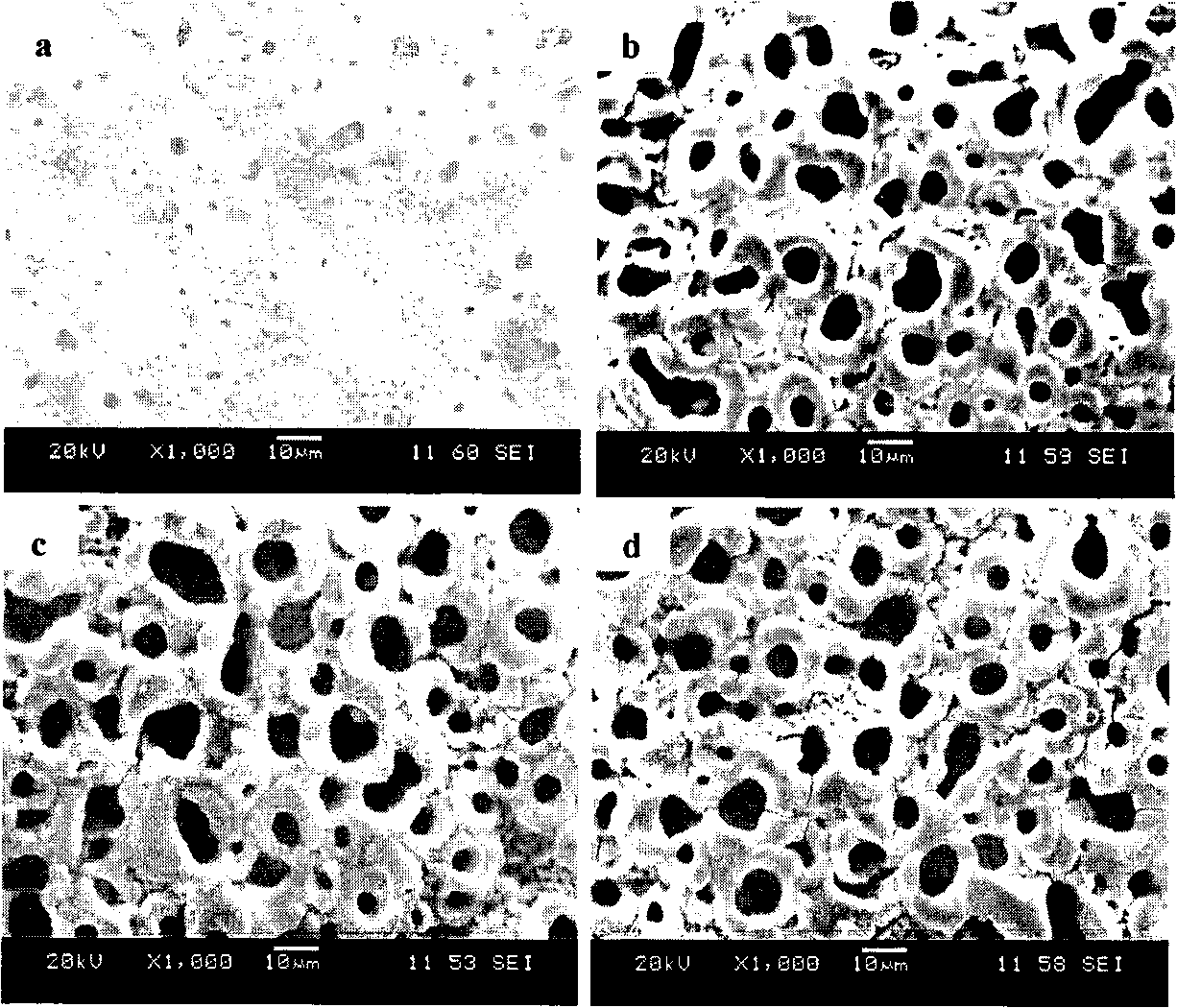

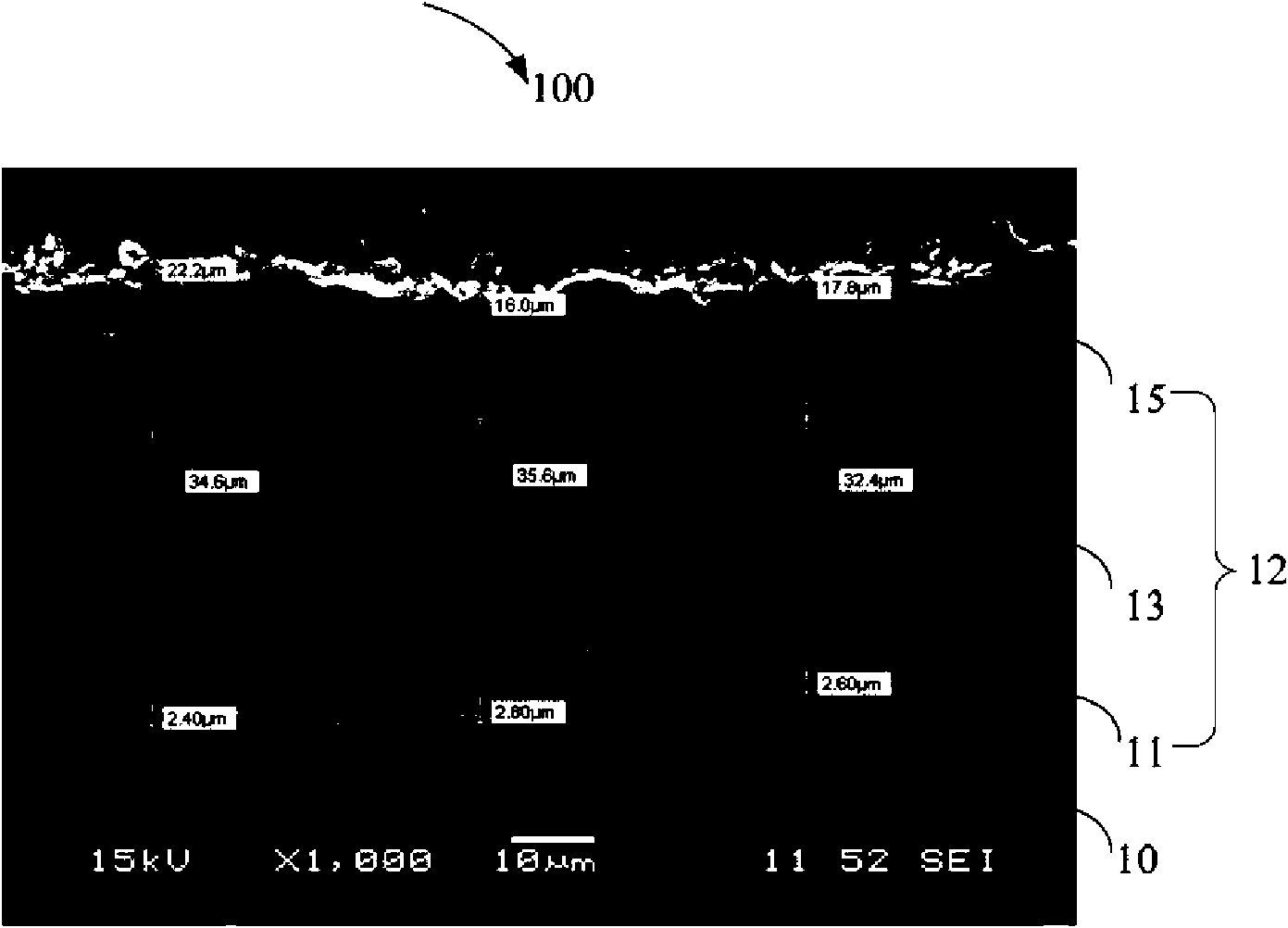

The invention relates to a new method for preparing an antibiotic bioactive coating material on the surface of titanium alloy and magnesium alloy by ultrasonic-microarc oxidation composite technology, which can be used for obtaining a biological coating material which is compact at the bottom layer and is porous at the surface layer, wherein Ca, P and Ag contained in the coating can improve the bioactivity and the corrosion resistance of magnesium and titanium, and reduce bacterial infection caused by implantation. The invention can meet the requirements of bearing bones of human beings for mechanical properties of implanted materials, and can overcome disadvantages of the traditional surface modification method for biologic materials. In the coating composite material, the coating thickness of titanium alloy is 50-85 mu m, the surface hole diameter is 4-25 mu m, the porosity is 20-30%, and the bonding strength between the coating and the matrix is 23-40 MPa. The coating thickness of magnesium alloy is 16-22 mu m, the surface hole diameter is 5-28 mu m, the porosity is 21-30%, and the bonding strength between the coating and the matrix is 8-20 MPa.

Owner:JIAMUSI UNIVERSITY

Aluminum alloy with micro-arc oxide ceramic membrane on surface and preparation method thereof

ActiveCN101608332AAvoid process problemsIncrease productivityAnodisationThin material handlingOxide ceramicPlasma electrolytic oxidation

The invention relates to an aluminum alloy which comprises an aluminum alloy matrix and a micro-arc oxide ceramic membrane formed on the surface of the matrix, wherein the ceramic membrane comprises a bottom transition layer, a middle compact layer and a surface compact layer. The preparation method of the aluminum alloy, which is used for forming the micro-arc oxide ceramic membrane without a loose layer on the surface of the aluminum alloy, comprises the following steps: putting the aluminum alloy matrix in an oxidation tank containing electrolyte; carrying out initial oxidation treatment for the aluminum alloy matrix by adopting constant current; and continuously applying oxidation treatment to the aluminum alloy matrix by adopting positive and negative bidirectional pulse voltage, wherein positive and negative voltage keeps constant after rising to the maximum value, wherein the maximum constant positive voltage is 450V-650V, the maximum constant negative voltage is 30V-200V, the width of positive and negative pulse is 1000-10000mus, the pulse interval is 300-2000mus, the continuous oxidation treatment time is 30-180min, and the treatment temperature is between 20 DEG C and 50DEG C.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Method for processing surface of magnesium alloy

InactiveCN101092694AReduced insulationPrevent breakdownAnodisationLiquid/solution decomposition chemical coatingMicro arc oxidationChemical plating

This invention discloses a surface treatment method for Mg-based material. The method comprises: (1) performing micro-arc oxidation treatment on Mg or Mg alloy work piece as the anode in a Cl--free alkaline micro-arc oxidation electrolyte; (2) activating; (3) performing preliminary chemical plating of Ni; (4) performing chemical plating of Ni; (5) performing thermal treatment. The micro-arc oxidation treatment comprises: (1) applying a positive pulse with an average current density of 5-20 A / dm2 until the voltage is automatically elevated to a critical value, and applying a constant working voltage of 50-80 V (total time = 5-30 min); (2) applying a positive pulse of 30-300 V and a negative pulse of 0-200 V with an average current density of 0.5-15 A / dm2 (total time = 10-60 min). The activation comprises: (1) performing anode alkaline coarsening treatment for 3-10 min; (2) performing surface activation treatment; (3) performing cathode alkaline electrification reduction activation treatment; (4) performing cathode acidic electrification dispergation activation treatment. The treated Mg alloy work piece has high corrosion resistance of ceramic materials and the properties and touch sense of metal materials.

Owner:李克清 +1

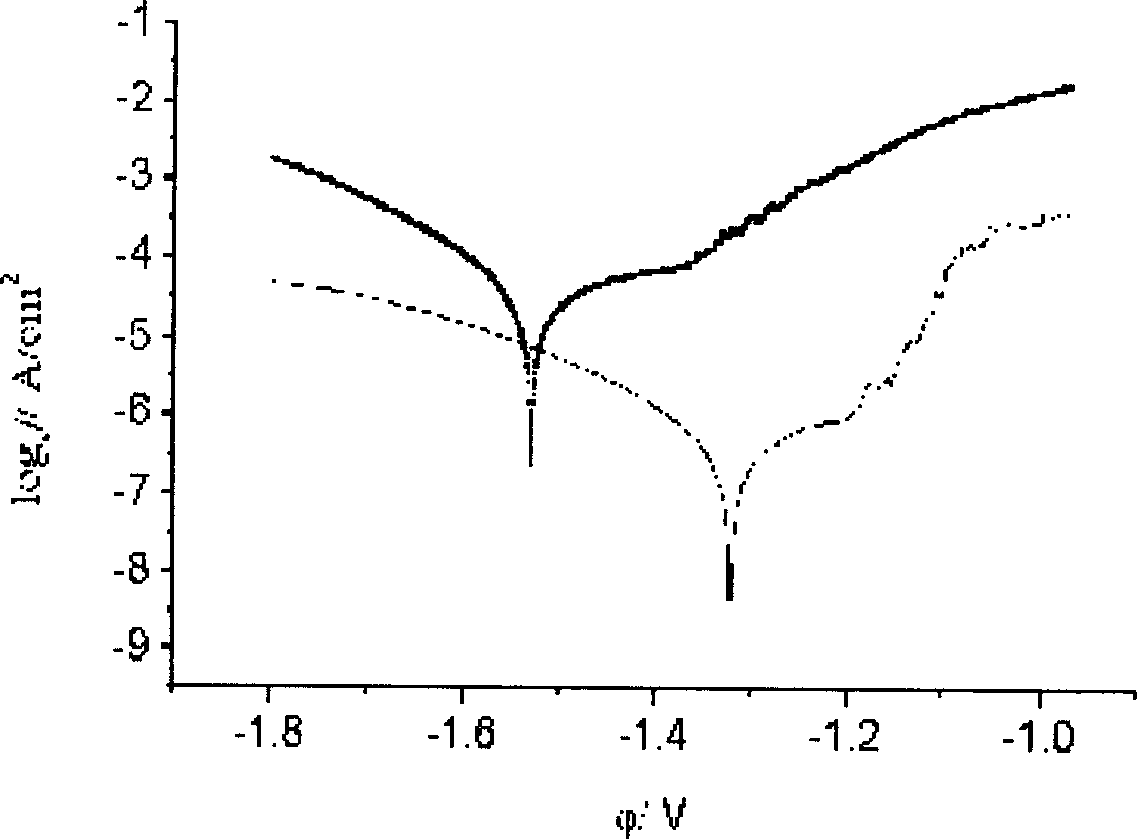

Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

ActiveCN101871119AHigh bonding strengthImprove corrosion resistanceAnodisationLiquid surface applicatorsMicro arc oxidationPlasma electrolytic oxidation

The invention provides a preparation method of a magnesium alloy surface micro-arc oxidation / spray coating compound film, which relates to a preparation method of a magnesium alloy surface compound film. The invention solves the problems that film layers obtained by chemical composition coating, anodic oxidation and vapor deposition in the existing magnesium alloy surface treatment method are thin and have poor corrosion resistance performance, the ion injection has high cost and is difficult to realize large-area processing, the combining force between coating layers and the magnesium alloy is poor, and organic coating layers has the defect of easy aging. The preparation method has the following steps: firstly, using micro-arc oxidation for preparing ceramic films on the surface of the magnesium alloy; then, adopting air spray coating for spraying and coating inorganic paint onto the ceramic films; and then, carrying out heat treatment to obtain the micro-arc oxidation / spray coating compound film. The method is simple, and the cost is low. The air spray coating uses porous structures of the micro-arc oxidation ceramic films, so the combination of the inorganic coating layers and the ceramic films is firm, the thickness of the compound films is between 20 and 40 mum, the self corrosion electric potential is positively moved to -1.02 V, the corrosion current density is lowered by 5 orders through being compared with that of the magnesium alloy, the magnesium alloy surface micro-arc oxidation / spray coating compound film has no damage after 72 to 144h of salt spray tests, and the corrosion resistance performance is good.

Owner:HARBIN INST OF TECH

Micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN101985768AImprove stain resistanceImprove compactnessAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the field of micro-arc oxidation, and relates to micro-arc oxidation electrolyte. The electrolyte comprises the aqueous solution of film former and toner, and has the pH value of 6.0 to 12, wherein the film former is phosphate and / or silicate; the toner is a titanium compound; and the film former content is 5 to 50 g / L, and the toner content is 5 to 30 g / L. When used for performing micro-arc oxidation on light metals, the micro-arc oxidation electrolyte provided by the invention can form blue ceramic films on the surfaces of the light metals so as to break the limitation of the conventional micro-arc oxidation technology to colors, expand grey-black and grey-white tones to colorful fields with uniform colors and achieve the decoration effect of a light-metallic product. Moreover, by the invention, the erosion resistance, the pollution resistance and the compactability of the micro-arc oxidized film are enhanced, and the surface of the micro-arc oxidized film has a ceramic texture. The invention further discloses a micro-arc oxidation method.

Owner:BYD CO LTD

Micro-arc oxidation electrolyte and micro-arc oxidation method

ActiveCN102560591ASimple compositionEasy to controlAnodisationPlasma electrolytic oxidationMicro arc oxidation

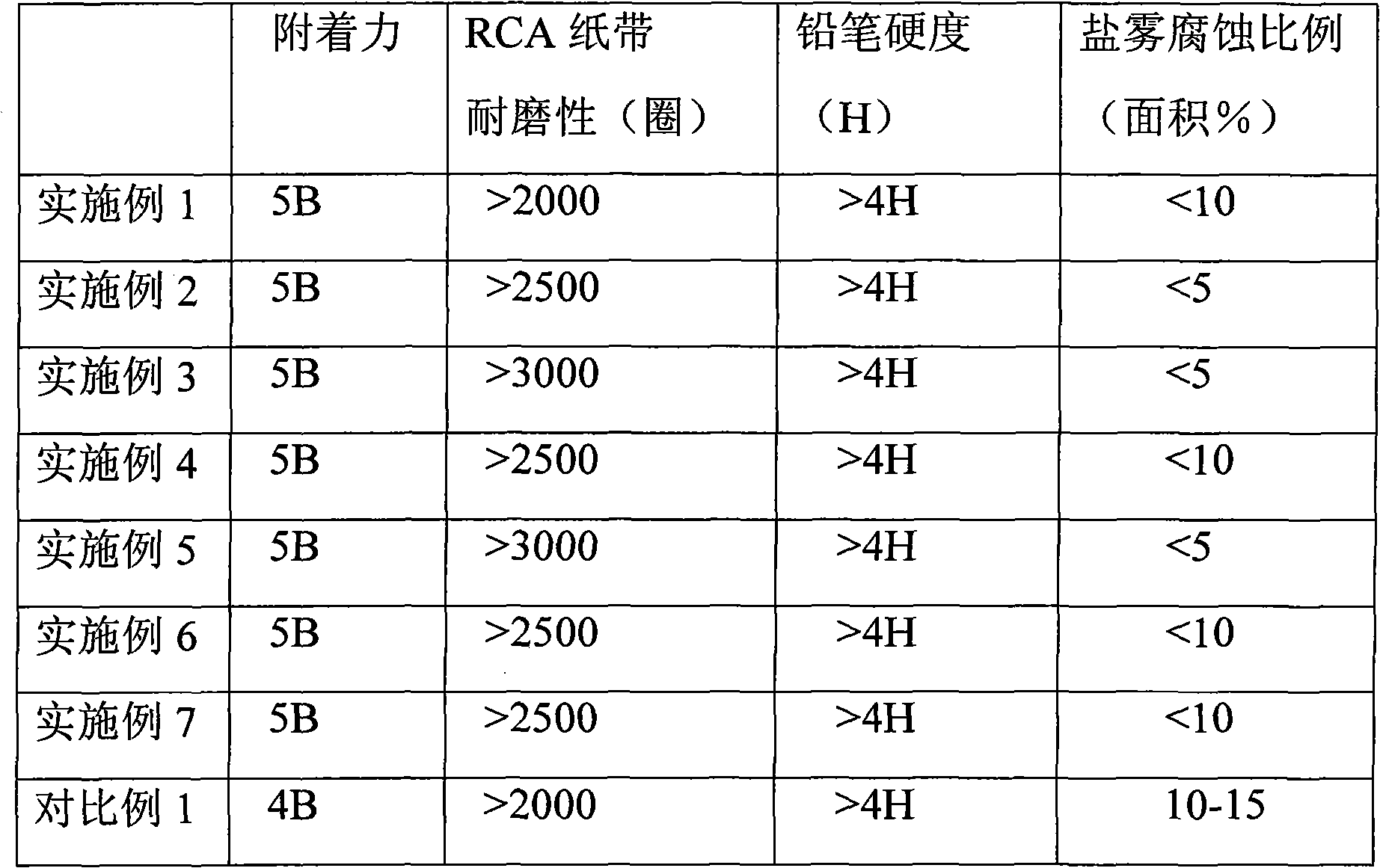

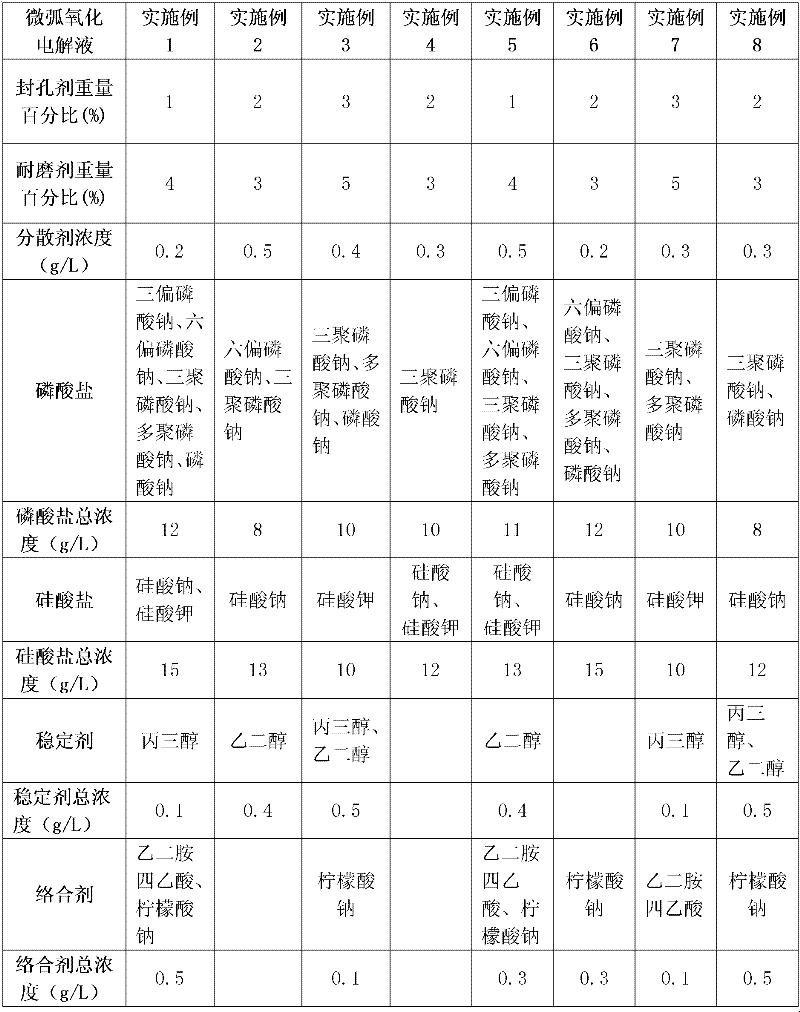

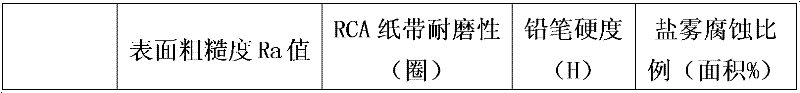

The invention discloses a micro-arc oxidation electrolyte and a micro-arc oxidation method. The micro-arc oxidation electrolyte comprises the following components: a basic solution, a wear-resisting agent, a pore sealing agent and a dispersing agent, wherein the basic solution is phosphate and silicate aqueous solution of pH 8-12, the wear-resisting agent is graphite powder, the pore sealing agent is silica powder or alumina powder, and the dispersing agent is polyoxyethylenealkylphenol ether. The micro-arc oxidation electrolyte of the invention is simple in composition, and easy in control. Light metal parts to be plated are subjected to micro-arc oxidation using the micro-arc oxidation electrolyte of the invention, and are directly subjected to pore sealing treatment in the micro-arc oxidation process without after-treatment. The process of the invention is simple, and obtained micro-arc oxide film layer is high in hardness, and is good in abrasion resistance and corrosion resistance.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Method of preparing hydroxyl apatite bioceramic film by plasma micro-arc oxidization method

InactiveCN101054708AComposition is stableStable structureSurface reaction electrolytic coatingPlasma electrolytic oxidationMicro arc oxidation

The present invention relates to a process for preparing hydroxylapatite bio-ceramic membranes at titanium or titanium alloy surfaces by utilizing differential arc oxidation process. Firstly, preparing electrolytic solution A by using calcium ion salts and phosphate radical ion-containing salts, or preparing electrolytic solution B by adding metal silver ions to the electrolytic solution A; or preparing electrolytic solution C by adding metal silicon ions to the electrolytic solution A; and then, selecting titanium or titanium alloy as anodes and putting them respectively into the electrolytic solution A, B and C, selecting the non-corrodible steel container for containing the electrolytic solutions as cathodes, controlling conditions such as impulse electrical source positive phase voltage, frequency for differential arc oxidation of titanium or titanium alloy, then hydroxylapatite bio-ceramic membrane layers possessing different performances are prepared. Said titanium based bio-ceramic compound material prepared according to said process possesses not only intensity and toughness of metals but also biological activity of hydroxylapatites, and is capable of being applied in the fields such as jackstraw chirurgery implantation body and tooth planting body.

Owner:QINGDAO UNIV OF SCI & TECH

Method for fabricating magnesium alloy super-hydrophobic surface

InactiveCN101469425AStrong process controllabilityEase of mass productionAnodisationPretreated surfacesMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing magnesium alloy super-hydrophobic surface. The method comprises: cleaning the magnesium alloy after conventional pretreatment, adopting the micro-arc oxidation technique to form a roughening micro / nano porous surface on the surface of a sample in a phosphate electrolyte, treating the surface in an acrylic acid solution, performing spin coating of ethylene dimethyl silicone polymer on the surface, and drying the processed sample to prepare the magnesium alloy super-hydrophobic surface.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Environmentally-friendly magnesium alloy chemical conversion film, microarc oxide film hole sealing solution and hole sealing method

InactiveCN101709497ANo pollution in the processSimple ingredientsAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention relates to an environmentally-friendly magnesium alloy chemical conversion film, microarc oxide film hole sealing solution and a hole sealing method. The hole sealing solution comprises phytate or phytic acid and one or more following substances of alkali metal hydroxide, silicate, phosphoric acid or phosphate. The hole sealing method is operated according to the following steps: preliminary treatment; chemical conversion or micro-arc oxidation; post treatment: in phytate, one of or several kinds of silicate, phosphoric acid or phosphate are added, the pH value of solution is adjusted by the alkali metal hydroxide or ammonia water, solution temperature is controlled at 30-100 DEG C, and hole sealing treatment is carried out. The hole sealing solution used by the invention does not contain Cr6 and F-, thus causing no pollution to environment. After sealing holes, the size of the crack or the micropore of the chemical conversion film or oxide film is obviously decreased, and corrosion resisting property is improved; meanwhile, the film layer and the organic coating obtained by next-step painting have favourable adhesive force.

Owner:JIANGXI SCI & TECH NORMAL UNIV

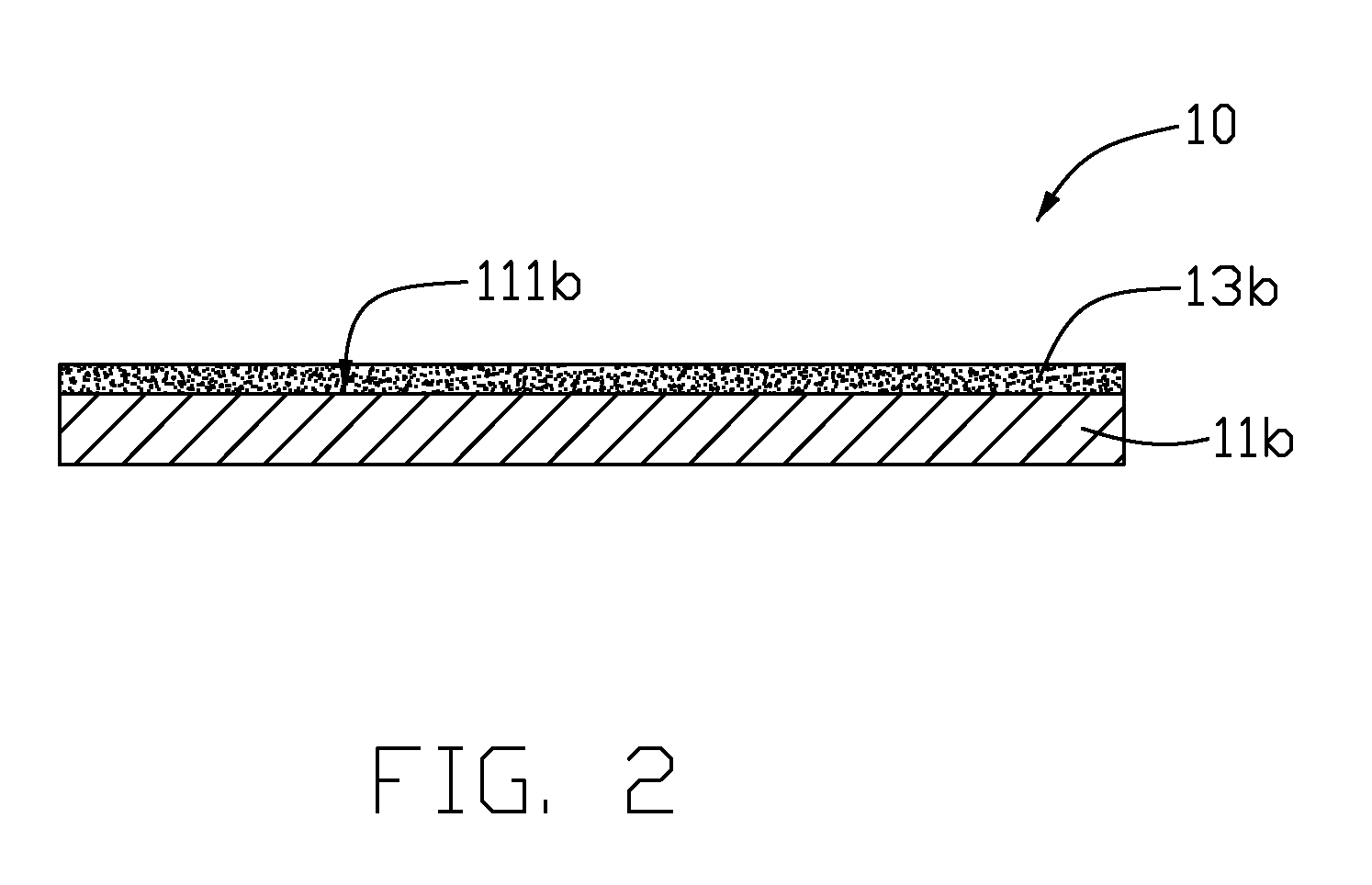

Housing for electronic device and method for making the same

An exemplary housing includes a light metal base and a ceramic film. The light metal base has an outer surface. The ceramic film is formed on the outer surface of the light metal base by micro-arc oxidation process. A method for making the present housing is also provided.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Strontium containing hydroxyapatite biologically active film and preparation method thereof

InactiveCN1927410ANo side effectsHigh bonding strengthProsthesisElectrolytic agentPlasma electrolytic oxidation

The invention relates to the means of active biological film, especially the titanium radicel porous nanometer Strontium hydroxyapatite active biological film and the Process for the manufacture. The differential arc oxidation technology is used in the method, the film is generated in the surface of titanium and titanium alloy, a electrolyte solution with phosphate radical ion, calcium ion and Strontium ion is supplied; the titanium and titanium alloy is the anode and the rustless steel or the titanium is the cathode, the direct current power supply or the direct current impulsing power source is applied to differential arc oxygenize the titanium and titanium alloy; the oxidate time is 3-60min; the temperature of electrolyte is not above 50DEG C. There is no interface between the porous hydroxyapatite containing Strontium film produced by the invention and the basal body, the modulus of elasticity is approximate with the sclerotin, the porous hydroxyapatite containing Strontium film produced by the invention which has perfect bioactivity can be the alternate material of several parts with heavy load, such as femur, hip joint and teeth root.

Owner:SOUTH CHINA UNIV OF TECH

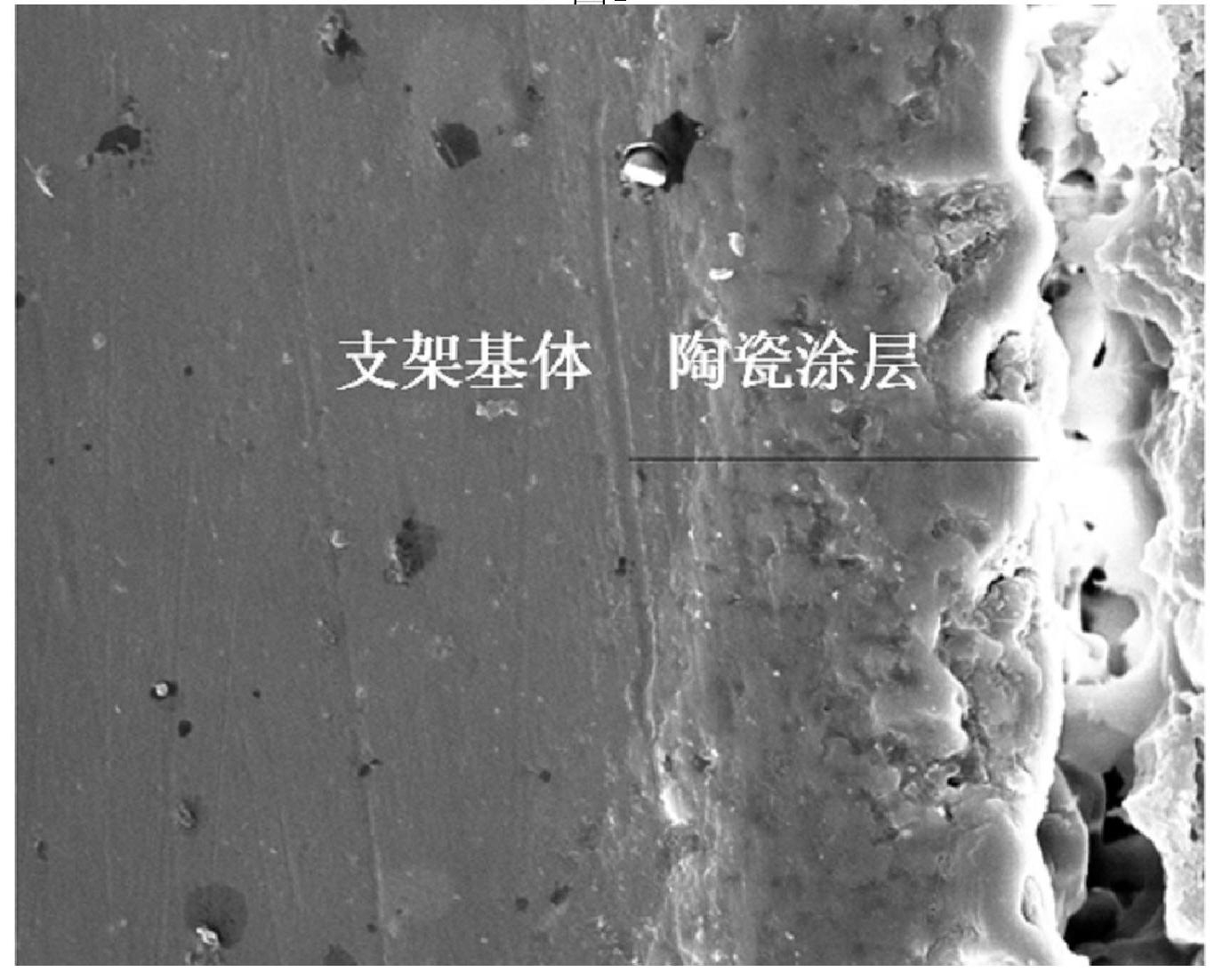

Corrosion-resistant magnesium alloy bracket and preparation method thereof

InactiveCN101797191AThe degradation rate can be adjustedUniform growthStentsAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a corrosion-resistant magnesium alloy bracket and a preparation method thereof, which relate to a magnesium alloy bracket with a corrosion-resistant coating and the preparation method thereof. The bracket and the method solve the problems of low bonding strength between the coating and a substrate, poor corrosion-resistant lasting stability, low mechanical bearing capacity and poor bracket coordination and deformation ability of the traditional magnesium alloy bracket. The corrosion-resistant magnesium alloy bracket is prepared by growing a ceramic coating in situ on the surface of the magnesium alloy by a micro-arc oxidation process. The method of the invention comprises the following steps: 1, processing the magnesium alloy to make a net-like bracket and removing oil to obtain the magnesium alloy bracket; 2, performing the micro-arc oxidation reaction; and 3, cleaning and drying the bracket to obtain the corrosion-resistant magnesium alloy bracket. The product of the invention is high in hardness and relatively high in tenacity and can coordinate with a substrate bracket to deform; and the ceramic coating is insusceptible to falling off and is high in body fluid corrosion resistance, so life cycle of the embedded bracket can be prolonged to a maximum extent. The method is simple and low in cost and can realize mass production. The product of the invention is suitable for implants with complex shapes, such as brackets, and is convenient to promote and use.

Owner:HARBIN INST OF TECH

Surface treatment method for light metal material

A surface treatment method of a light metal material comprises the following steps of forming a micro-arc oxide film on the surface of the light metal material, and sequentially subjecting the surface of the light metal material with the micro-arc oxide film to laser etching and anode oxidization. The light metal material obtained by the method in the invention has the advantages of very high hardness, abrasion resistance, corrosion resistance and electrical insulation, strong appearance decoration, bright and diversified color and three-dimensional pattern, thus greatly improving the additional value of the light metal material.

Owner:浙江博凡核工程技术有限公司

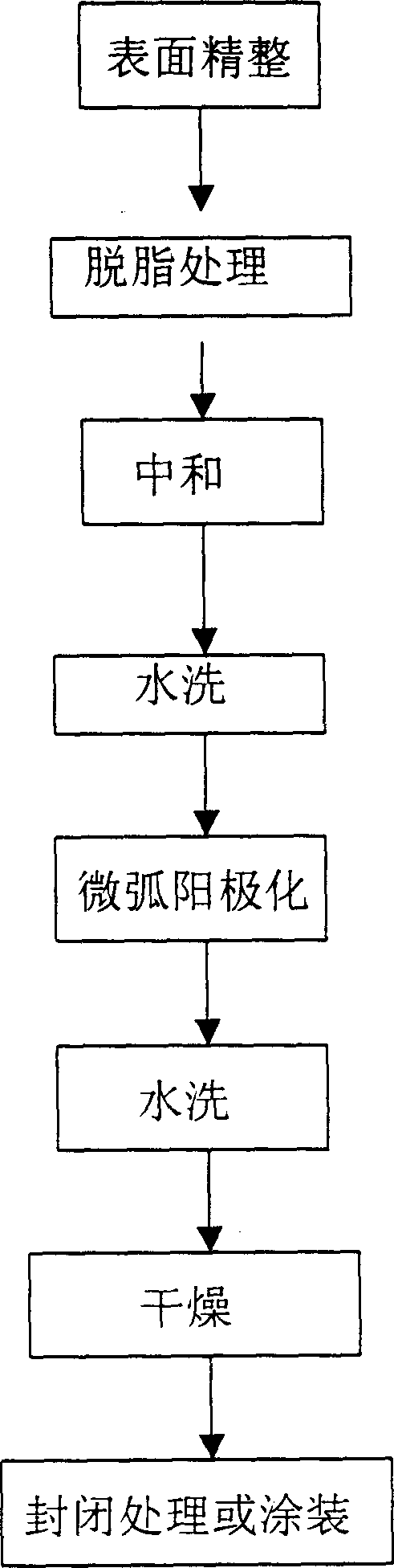

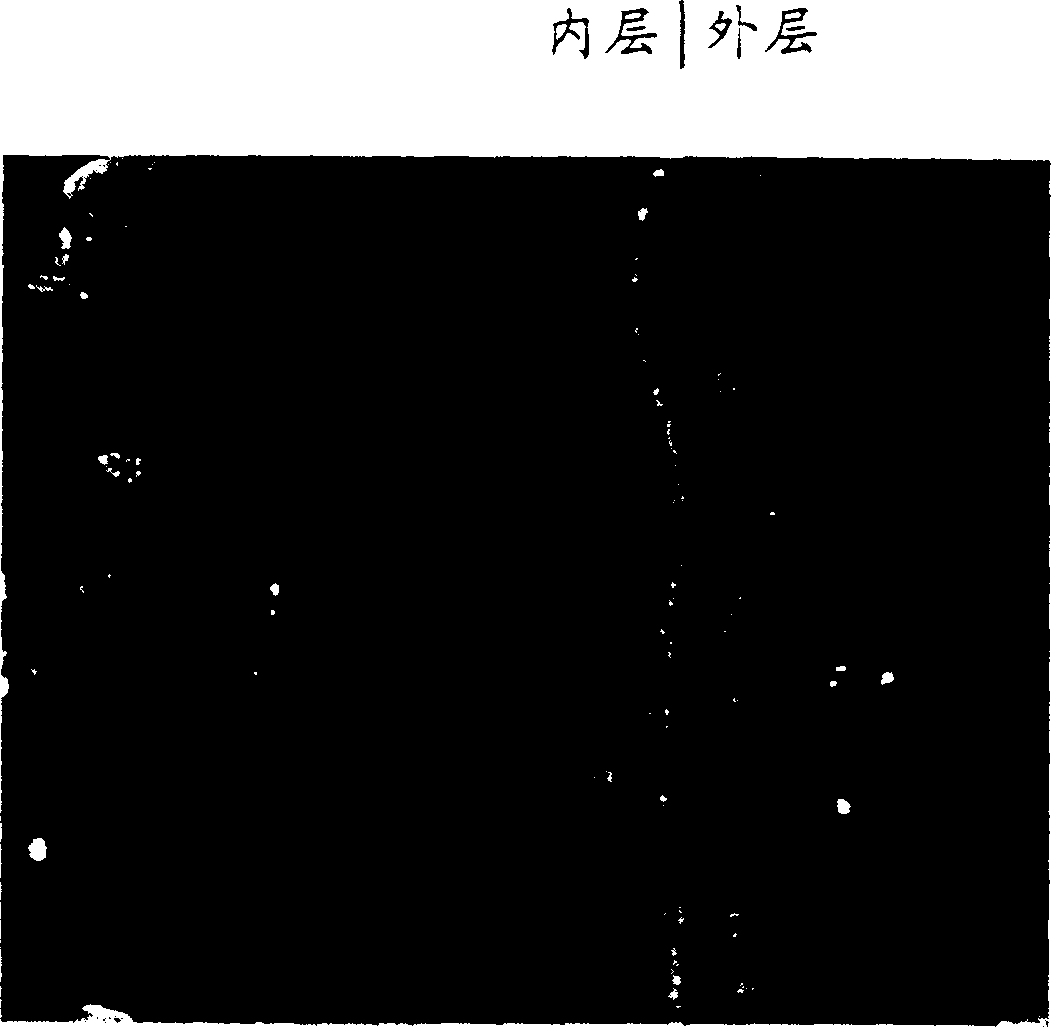

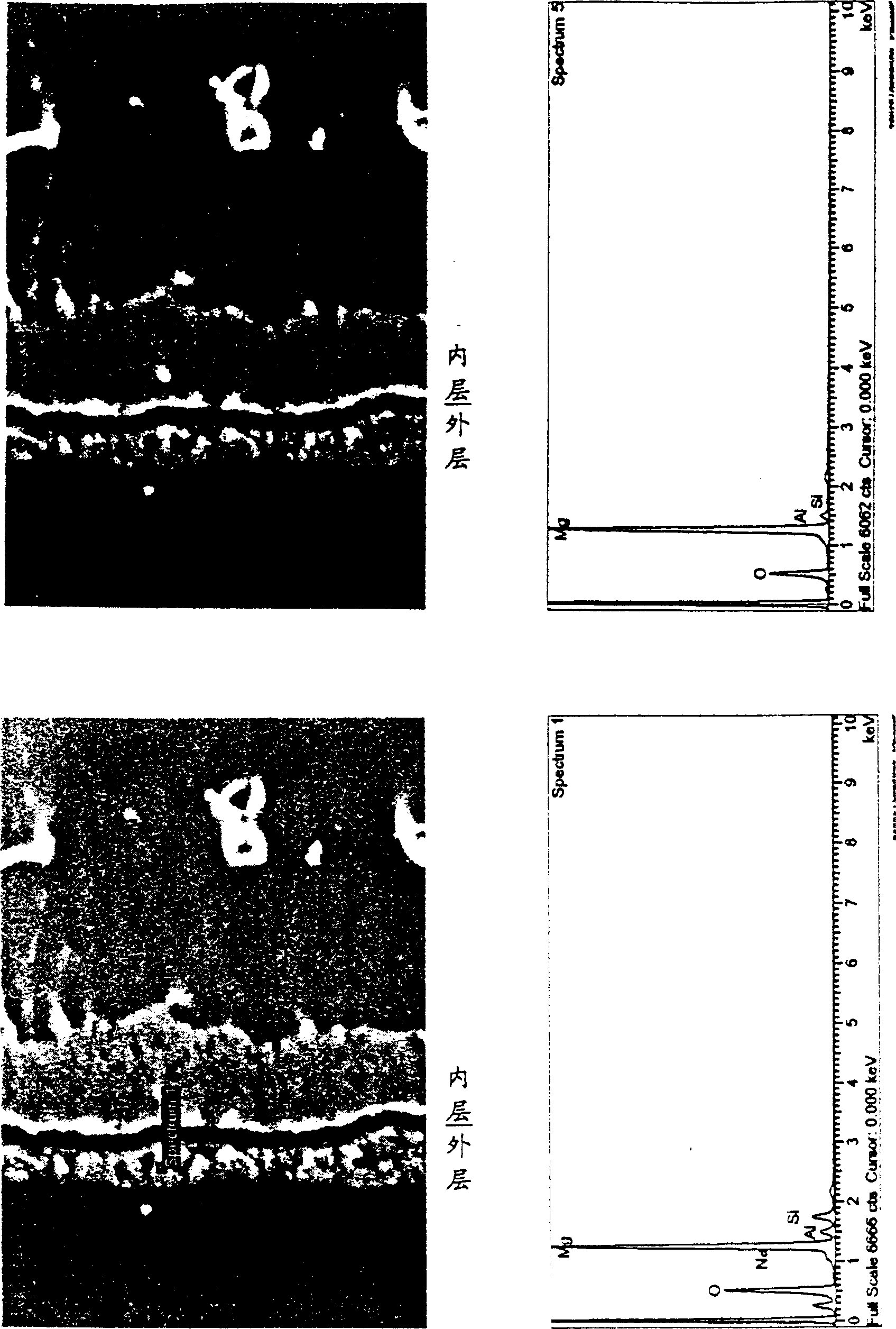

Composite ceramic film on surface of magnesium alloy and its forming process

InactiveCN1388272AOvercoming brittlenessOvercoming the formation of voids in the film layerAnodisationMicro arc oxidationPlasma electrolytic oxidation

The present invention features that the composite ceramic film consists of two layers, the inner layer film of silicon-containing composite Mg-Al oxide and the outer layer film of Mg-Al silico-oxide of 5-70 micron thickness each. The composite ceramic film is formed through surface treatment, degreasing, neutralizing, water washing, micro-arc anodizing, water washing, drying, closing treatment or painting. The composite ceramic film has no holes and cracks, high corrosion resistance, high wear resistance and smooth surface.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Process for magnesium alloy surface micro-arc oxidation

InactiveCN1772968ASmall coefficient of thermal expansionStrong corrosion resistanceAnodisationAluminateMicro arc oxidation

The present invention relates to a magnesium alloy surface microarc oxidation method. Said method includes the following steps: (1), pretreatment; (2), preparing alkaline silicate electrolyte or alkaline aluminate electrolyte; and (3), placing the pretreated magnesium alloy in the alkaline silicate electrolyte or alkaline aluminate electrolyte and making microarc oxidation; applying DC current, continuously rising voltage, constant current, current density is 1-15 A / sq.dm, galvanization time is 5-90 min and electrolyte temperature is less than 40 deg.C.

Owner:HARBIN INST OF TECH

Pure-titanium metal surface micro-arc oxidation treatment electrolyte and antimicrobial bioactive coating preparation method thereof

InactiveCN102146577AImprove antibacterial propertiesImprove biological activitySurface reaction electrolytic coatingProsthesisPlasma electrolytic oxidationMicro arc oxidation

The invention discloses pure-titanium metal surface micro-arc oxidation treatment electrolyte and an antimicrobial bioactive coating preparation method thereof, belongs to a medical titanium metal surface modification technology, and aims to provide a micro-arc oxidation treatment electrolyte which can remarkably improve pure-titanium metal surface bioactivity and coating bonding strength and a coating preparation method thereof. The electrolyte comprises a compound system including the components of calcium acetate, sodium phosphate and a zinc oxide precursor, wherein the phosphorous ion concentration is 0.5 to 1.0 M, the molar ratio of Ca to P is 0.2 to 1.0, and the designed Zn<2+> concentration accounts for 10 to 20 percent of the total concentration. A biological composite coating is directly generated on the surface of a titanium metal surface in-situ by adopting the electrolyte and a micro-arc oxidation technology. The coating has high bonding strength with a substrate, dense inner layer, coarse and porous outer layer, high bioactivity and high antibacterial property; moreover, the used raw materials are easy to obtain; the process is simple and easy to operate; and the electrolyte has stability, reusability, and low production cost and is suitable for industrial production.

Owner:JIAMUSI UNIVERSITY

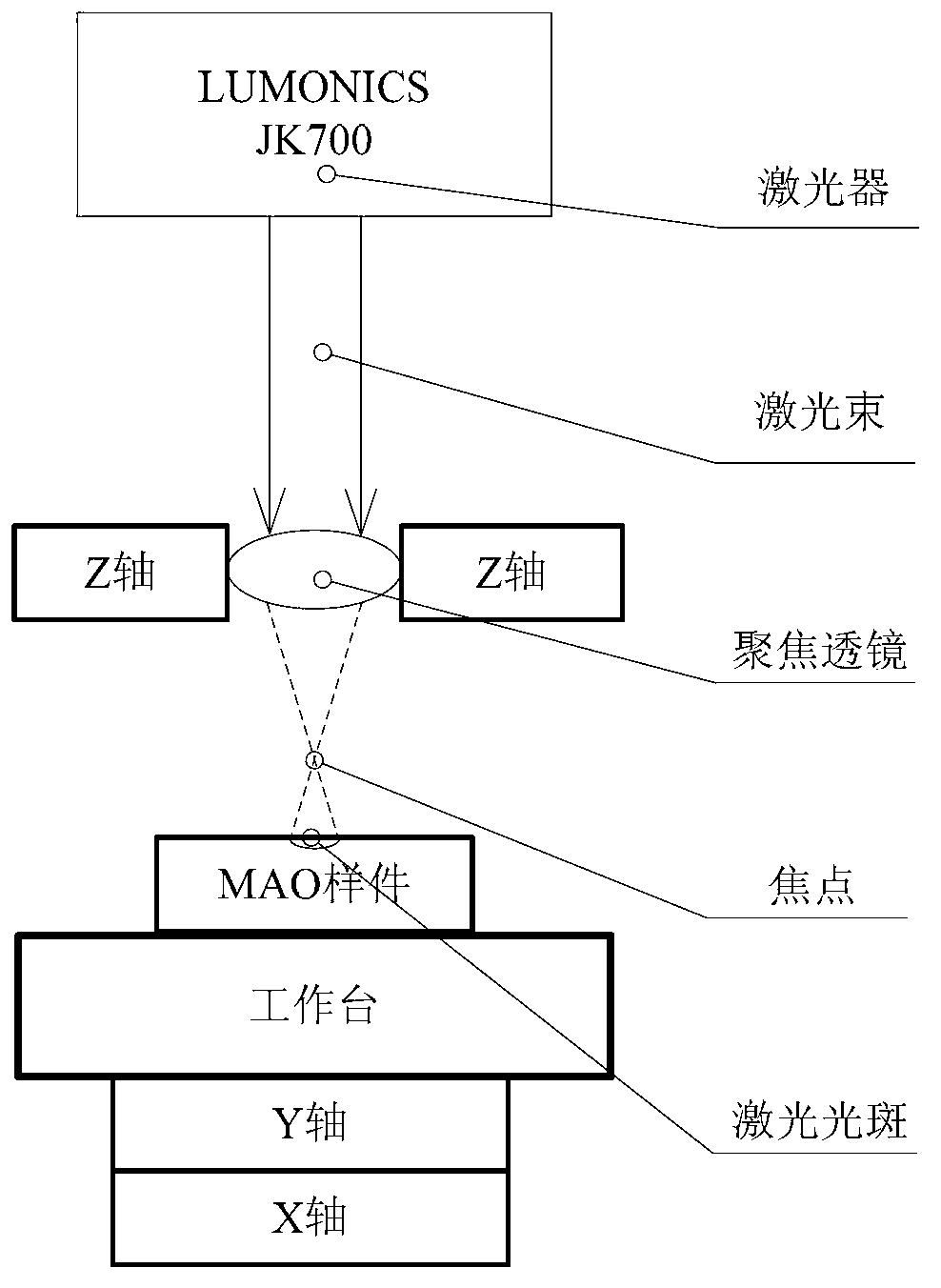

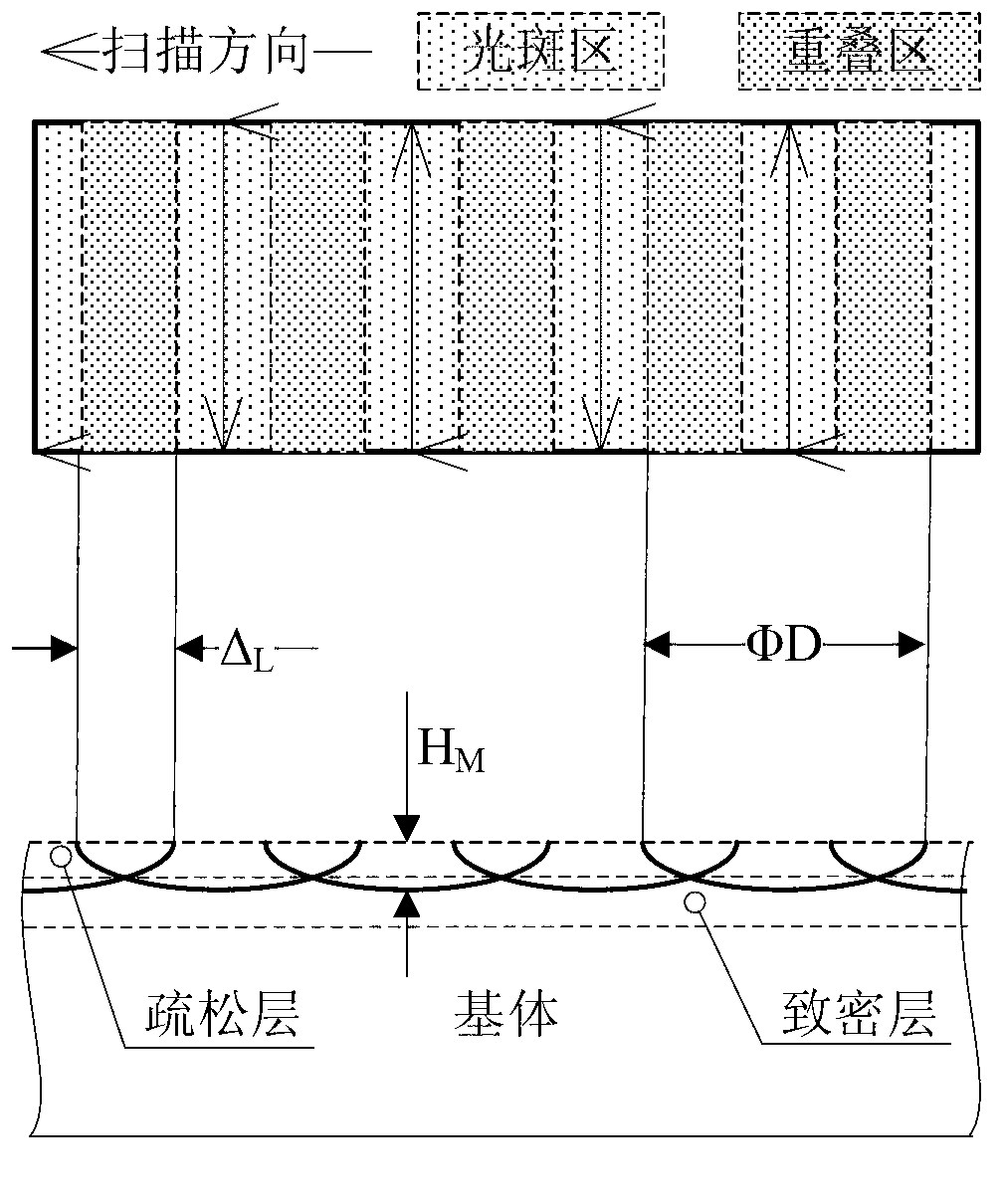

Method for preparing dense enhancement type ceramic membrane based on micro-arc oxidizing and laser remelting

The invention discloses a method for preparing a dense enhancement type ceramic membrane based on micro-arc oxidizing and laser remelting, and relates to a method for preparing a dense enhancement type ceramic membrane on the surfaces of light metals such as magnesium, aluminium and titanium and other alloys. The method is used for solving the problems that a micro-arc oxidizing surface treatment technology for preparing the dense enhancement type ceramic membrane on the surfaces of light metals such as magnesium, aluminium and titanium and other alloys cannot have low energy consumption and high membrane performance at the same time. The method comprises steps of: 1, pretreatment of basic materials; 2, working liquid preparation treatment; 3, micro-arc oxidation; and 4, laser remelting treatment of the micro-arc oxidation (MAO) membrane, and thus obtaining a sample piece of the dense enhancement type ceramic membrane. The prepared membrane has good binding force with a base body, dense tissues, low porosity, high hardness and good corrosion resistance and wear resistance; and the porosity of the membrane can be reduced to below 3%, the harness number can be improved by double times of the original MAO membrane which is not subjected to laser remelting treatment. The method can be used for preparing the dense enhancement type ceramic membrane on the surfaces of light metals such as magnesium, aluminium and titanium and other alloys.

Owner:HARBIN INST OF TECH

Method for preparing titanium-alloy surface micro-arc oxidation antifriction compound film layer

InactiveCN102021629AGood anti-frictionReduce pollutionSurface reaction electrolytic coatingElectrolytic agentMicro arc oxidation

The invention relates to a method for preparing a titanium-alloy surface micro-arc oxidation antifriction compound film layer, which is characterized by comprising the following steps of: (1) micro-arc oxidation of an electrolyte; and (2) preparation of a compound film. The invention has the technical effects that: 1. the method provided by the invention is used for preparing the micro-arc oxidation compound film layer with an antifriction effect by introducing a solid lubricant and experimenting on a one-step method in the titanium-alloy micro-arc oxidation process on the premise of not destroying a micro-arc oxidation film layer, and the antifriction effect is remarkable; and 2. the composition raw materials of a sodium-silicate system electrolyte adopted by the invention are simply and easily obtained, a solution is neutral or weakly alkaline, the solution does not contain heavy metal ions, such as chromium ions and the like or environment-friendly constraint elements and does not contain substances harmful to human bodies and environments, the environmental pollution is small, and the requirements of high-quality clean production are satisfied.

Owner:NANCHANG HANGKONG UNIVERSITY

Method for preparing magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition

InactiveCN103194782ABiologically activeImprove corrosion resistanceAnodisationElectrophoretic coatingsPlasma electrolytic oxidationMicro arc oxidation

The invention discloses a method for preparing a magnesium-based ceramic coating by micro-arc oxidation-electrophoretic deposition. The method comprises the following steps of: immersing preheated magnesium alloy taken as an anode in an electrolyte, taking a micro-arc oxidation stainless steel electrolytic cell as a cathode, adopting a direct-current pulsed micro-arc oxidation device, carrying out micro-arc oxidation for 10-25 minutes under the conditions that the electric current is 10-20A / dm<2>, the duty ratio is 37.5-50%, and the temperature of the electrolyte is 20-30 DEG C, taking out the anode, naturally drying, thus obtaining magnesium alloy subjected to micro-arc oxidation; immersing the magnesium alloy subjected to micro-arc oxidation and taken as the anode in electrophoretic deposition liquid, taking the stainless steel electrolytic cell as the cathode, adopting a pulsed power supply, carrying out electrophoretic deposition treatment for 10-30 minutes under the conditions that the voltage is 250-350V, and the duty ratio is 37.5-50%, naturally cooling, thus obtaining the magnesium-based ceramic coating. The adhesive force of the biological nanometer coating is obviously enhanced, the toughness and the corrosion resistance of the coating are improved, and the coating has certain biological activity.

Owner:ZHEJIANG UNIV OF TECH

Micro-arc oxidation-electrodeposition preparation method of magnesium-based bioactive coating

InactiveCN101709496AMatch mechanical propertiesAvoid degradation difficultiesAnodisationElectrolytic inorganic material coatingMicro arc oxidationPlasma electrolytic oxidation

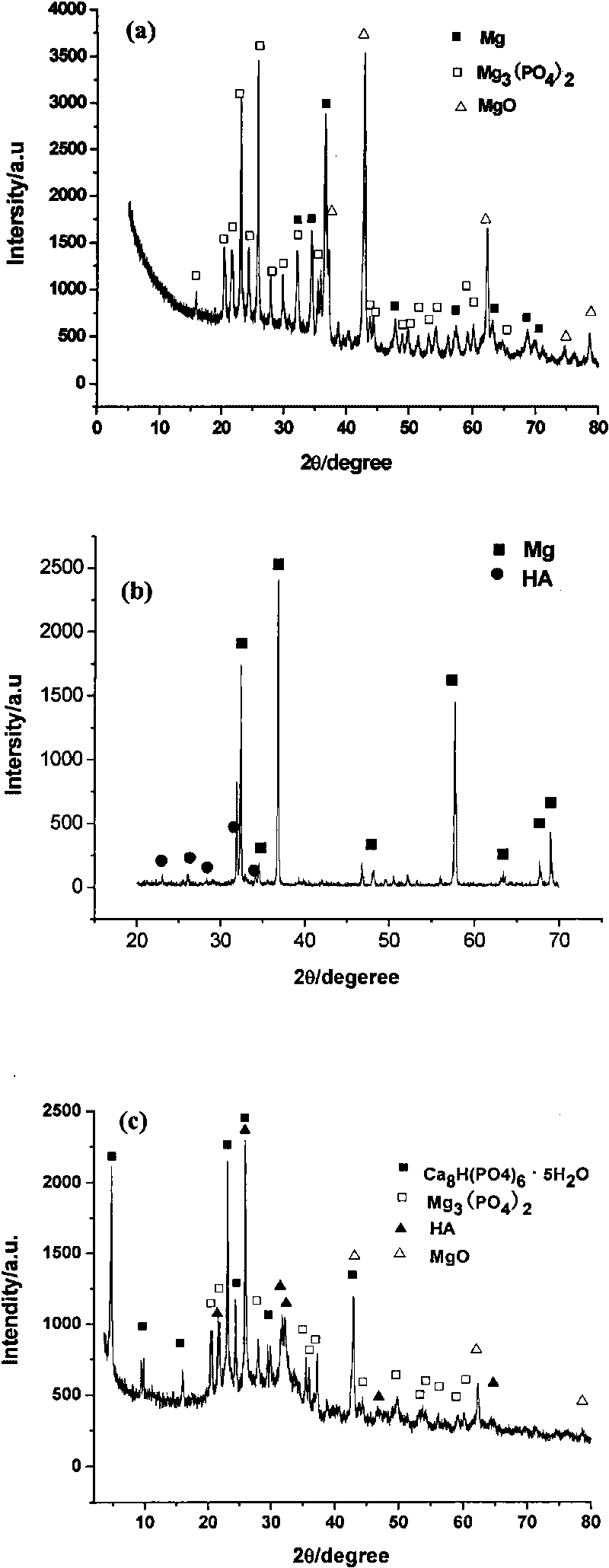

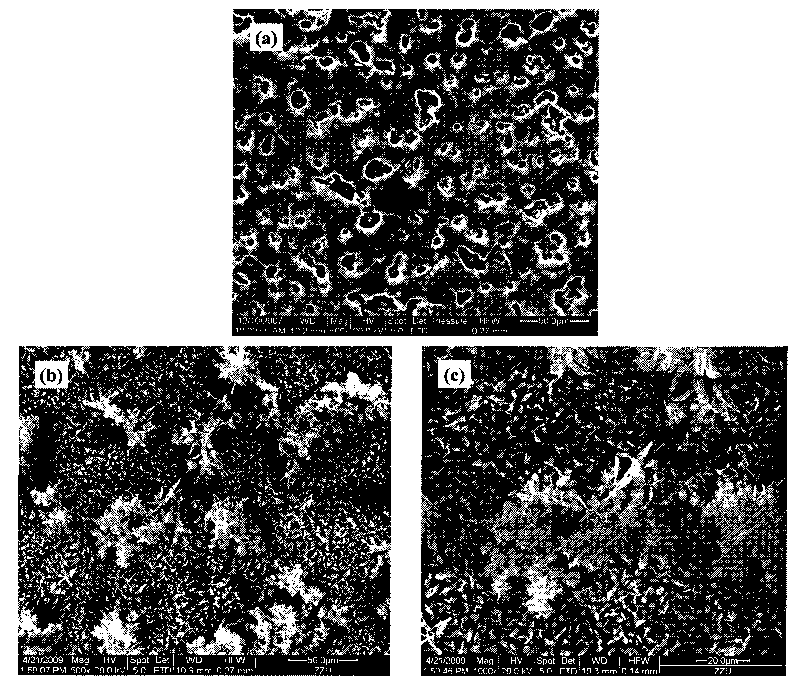

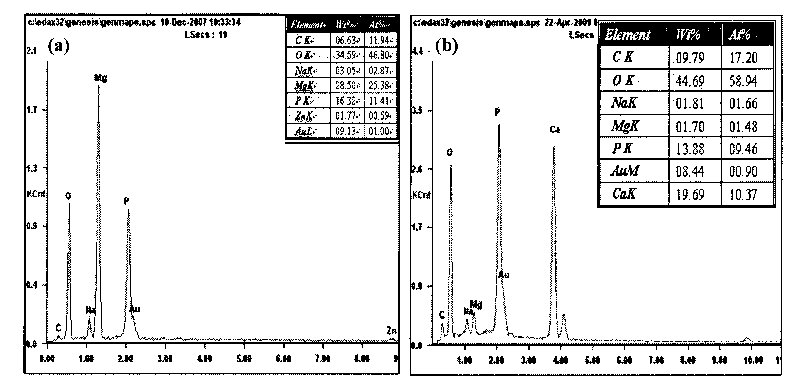

The invention discloses a micro-arc oxidation-electrodeposition preparation method of a magnesium-based bioactive coating. The preparation method comprises the following steps: putting a magnesium-based base material in micro-arc oxidation electrolyte after pretreatment to perform micro-arc oxidation reaction to obtain a micro-arc oxidation coating sample; then, putting the micro-arc oxidation coating sample in electrodeposition electrolyte to perform electrodeposition reaction; and after electrodeposition, taking the sample out, and washing and drying the sample. The micro-arc oxidation-electrodeposition preparation method has the advantages that a biologic coating prepared by the method has high binding property with a base material; and the entire biologic coating has excellent corrosion resistance, bioactivity and compatibility; moreover, the formed bioactive coating is a composite coating (comprising HA, OCP, Mg3(PO3)2 and MgO); and because the composite coating comprises OCP, problems that the degradation of pure HA is difficult are avoided and only an HA crust is left after the degradation of formed magnesium alloy can be avoided.

Owner:ZHENGZHOU UNIV

Magnesium alloy micro-arc oxidation electrolyte and micro-arc oxidation method

InactiveCN103173838ANo pollution in the processLess strong alkaliAnodisationElectrolytic agentAluminate

The invention relates to a magnesium alloy micro-arc oxidation electrolyte and a micro-arc oxidation method. The electrolyte comprises phytate (or phytic acid), a calcic electrolyte, and further one or more added electrolytes as follows: carbonate, silicate, boric acid or borate, and aluminate or aluminum hydroxide. The micro-arc oxidation method comprises the following steps of: pre-treatment; micro-arc oxidation; and post-treatment. The micro-arc oxidation electrolyte provided by the invention does not contain Cr<6+>, F<-> and PO4<3->, and even if strong base used is less, so that the environment is not polluted. The film obtained by the micro-arc oxidation method is smooth in surface, good in corrosion resistance and better in antibacterial performance and biological activity. According to the method, raw materials are easily available, and the method is suitable for industrialized production.

Owner:JIANGXI SCI & TECH NORMAL UNIV

Preparation method of ceramic film through chemical conversion and micro-arc oxidation of aluminum and aluminum alloy

ActiveCN102242364AImprove the decorative effectImprove corrosion resistanceAnodisationMetallic material coating processesPlasma electrolytic oxidationMicro arc oxidation

The invention belongs to the technical field of surface treatment, and relates to a preparation method of a ceramic film through chemical conversion and micro-arc oxidation of aluminum and aluminum alloy. The preparation method comprises: cleaning aluminum and aluminum alloy, and then carrying out chemical conversion treatment on the cleaned aluminum and aluminum alloy to generate chemical conversion film containing metal ions; and then placing the chemical conversion film in a micro-arc oxidation electrolyte and carrying out micro-arc oxidation treatment on the chemical conversion film to obtain dark micro-arc oxidized ceramic film. In the preparation method provided by the invention, different metal cations such as Mn<7+>, Mo<6+>, Ni<2+>, Ce<2+>, Co<2+> and Zr<2+> are introduced to formthe chemical conversion film containing the corresponding metal ion on the surfaces of the aluminum and aluminum alloy, then the chemical conversion film is placed in different micro-arc oxidation electrolytes, the micro-arc oxidized ceramic film with improved corrosion resistance is obtained by virtue of micro-arc oxidation treatment, and simultaneously the film is colored.

Owner:北京京磁电工科技有限公司

Micro arc oxidation electrolytic solution for light metals and micro arc oxidation method

ActiveCN101311326AIncrease added valueHigh hardnessAnodisationPlasma electrolytic oxidationMicro arc oxidation

The invention provides an electrolyte used for micro-arc oxidation of light metal. The electrolyte is aqueous solution containing sodium hexametahposphate and sodium silicate, wherein, the electrolyte also contains cobalt sulfate and ammonium metavanadate. The invention also provides a method of micro-arc oxidation by adopting the electrolyte. By adopting the electrolyte and the micro-arc oxidation method provided by the invention, light metal products with good pollution resistance, scrape resistance and compactness can be obtained.

Owner:BYD CO LTD

Preparation of magnesium alloy surface high corrosion resistance differential arc oxidation compound film

InactiveCN101469439ASimplify the sealing processProcess stabilityAnodisationComposite filmMicro arc oxidation

The invention discloses a method for preparing a microarc oxidation composite film with high corrosion resisting surface of magnesium alloy. The method utilizes the absorption and the mechanical capture effect of micropores of TiO2 sol particles in a microarc oxidation film and the instantaneous high temperature and high pressure produced by arc discharge in the microarc oxidation process to calcine and solidify the TiO2 sol particles to finally realize in-situ hole sealing effect and obtain the compact microarc oxidation composite film by introducing the prior process for preparing nano-particles, namely sol-gel into the microarc oxidation treatment on the surface of the magnesium alloy, and directly adding TiO2 sol into a microarc oxidation electrolyte.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com