Surface treating method for magnesium lithium alloy

A magnesium-lithium alloy, surface treatment technology, applied in anodizing and other directions, to achieve the effect of high efficiency, optimized effect and excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

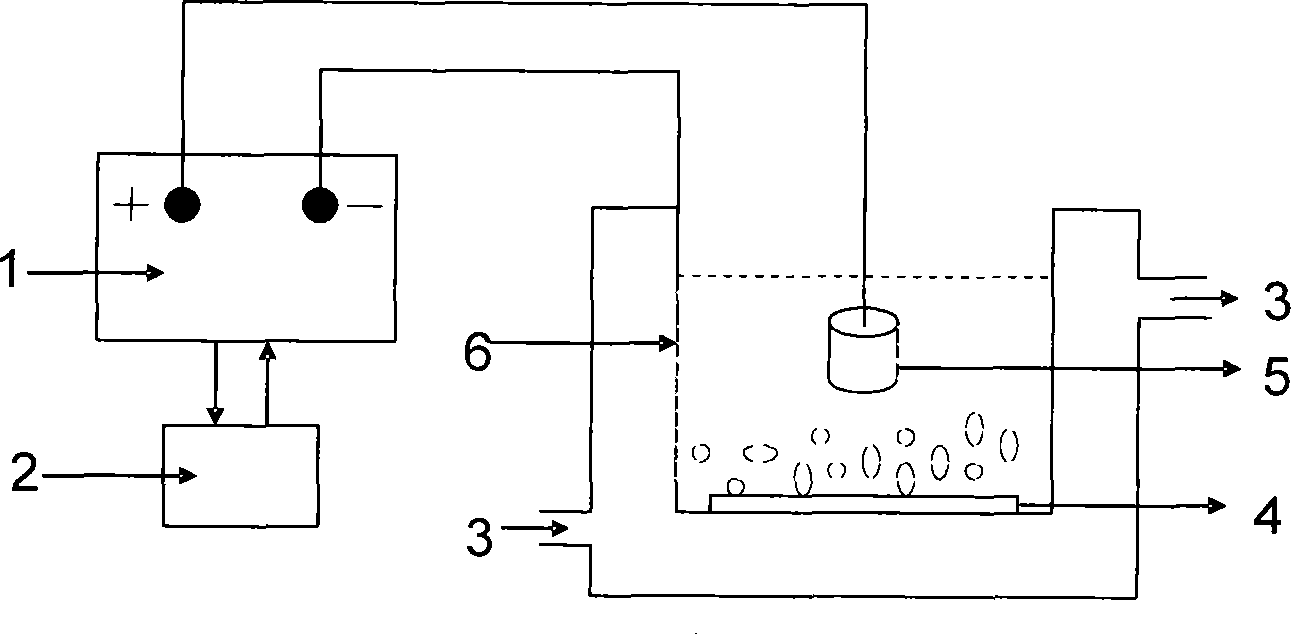

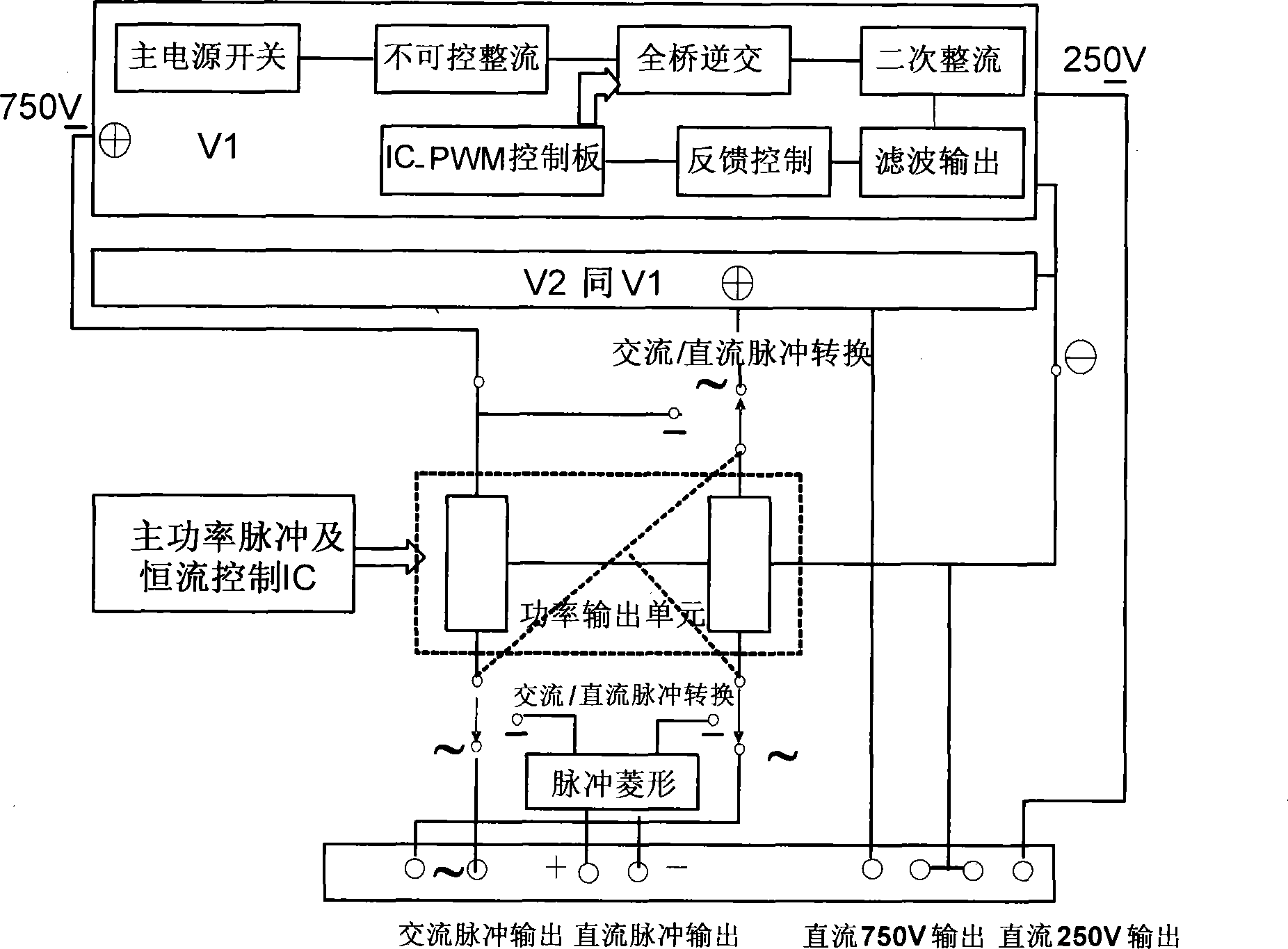

Method used

Image

Examples

Embodiment 1

[0040] The applied alloy is Mg-5.6%Li-3.5%Al-1%Zn-1.2%Ce-1.5%Mn alloy, the sample is cylindrical, the bottom surface is 16cm in diameter, 15cm in height, and the bottom surface is helical.

[0041] Table 1 Composition of electrolytes in different examples of micro-arc oxidation

[0042] Example 1

Example 2

Example 3

Sodium polyphosphate g / L

4

8

10

Sodium hexametaphosphate g / L

0.5

2

5

3

4

3

Triethanolamine mL / L

10

10

0

Ethylenediamine mL / L

0

0

10

[0043] Glycerol mL / L

0

5

10

Silica nano powder g / L

0

0

5

Titanium dioxide nanopowder g / L

0

5

0

Aluminum oxide nanopowder g / L

0

0

5

[0044] (a) Pretreatment

[0045] The sample was degreased in 60g / L sodium hydroxide solution at 80°C for 7 minutes, ...

Embodiment 2

[0054] The applied alloy is Mg-11.2%Li-3%Al-1.4%Zn-1.5%Ce-1.8%Mn alloy, and the sample is cylindrical, with a bottom diameter of 16cm, a height of 15cm, and a spiral thread at the bottom.

[0055] Corrosion voltage and corrosion current comparison of magnesium-lithium alloy before and after micro-arc oxidation treatment in example 2 of table 3

Corrosion current density (A / cm 2 )

Before MAO

-1.536

1.59×10 -3

After micro-arc oxidation

-1.360

2.42×10 -6

[0057] (a) Pretreatment

[0058] The sample was degreased in 80g / L sodium hydroxide solution at 90°C for 10 minutes, rinsed and dried, polished with 500# metallographic sandpaper, rinsed with acetone, ethanol, and dried with cold air.

[0059] (b) Micro arc oxidation

[0060] The sample is completely immersed in the micro-arc oxidation electrolyte, the power supply is adjusted to the AC pulse gear, and the constant voltage micro-arc ox...

Embodiment 3

[0065] The applied alloy is a Mg-14.2%Li-3.1%Al-1.1%Zn-1.5%Ce alloy, and the sample is cylindrical, with a bottom diameter of 16cm, a height of 15cm, and a spiral thread at the center of the bottom surface.

[0066] Corrosion voltage and corrosion current comparison of magnesium-lithium alloy before and after micro-arc oxidation treatment in table 4 example 3

[0067] Corrosion voltage (V)

Corrosion current density (A / cm 2 )

Before MAO

-1.540

2.28×10 -3

After micro-arc oxidation

-1.340

4.12×10 -6

[0068] (a) Pretreatment

[0069] The sample was degreased in 80g / L sodium hydroxide solution at 90°C for 10 minutes, rinsed and dried, polished with 500# metallographic sandpaper, rinsed with acetone, ethanol, and dried with cold air.

[0070] (b) Micro arc oxidation

[0071] The sample is completely immersed in the micro-arc oxidation electrolyte, the power supply is adjusted to the AC pulse gear, and the step-up micro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com