Patents

Literature

348 results about "Corrosion current density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

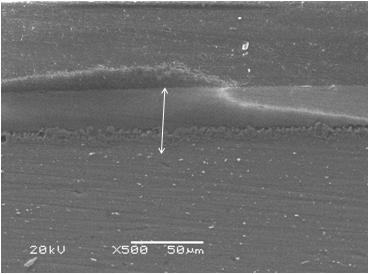

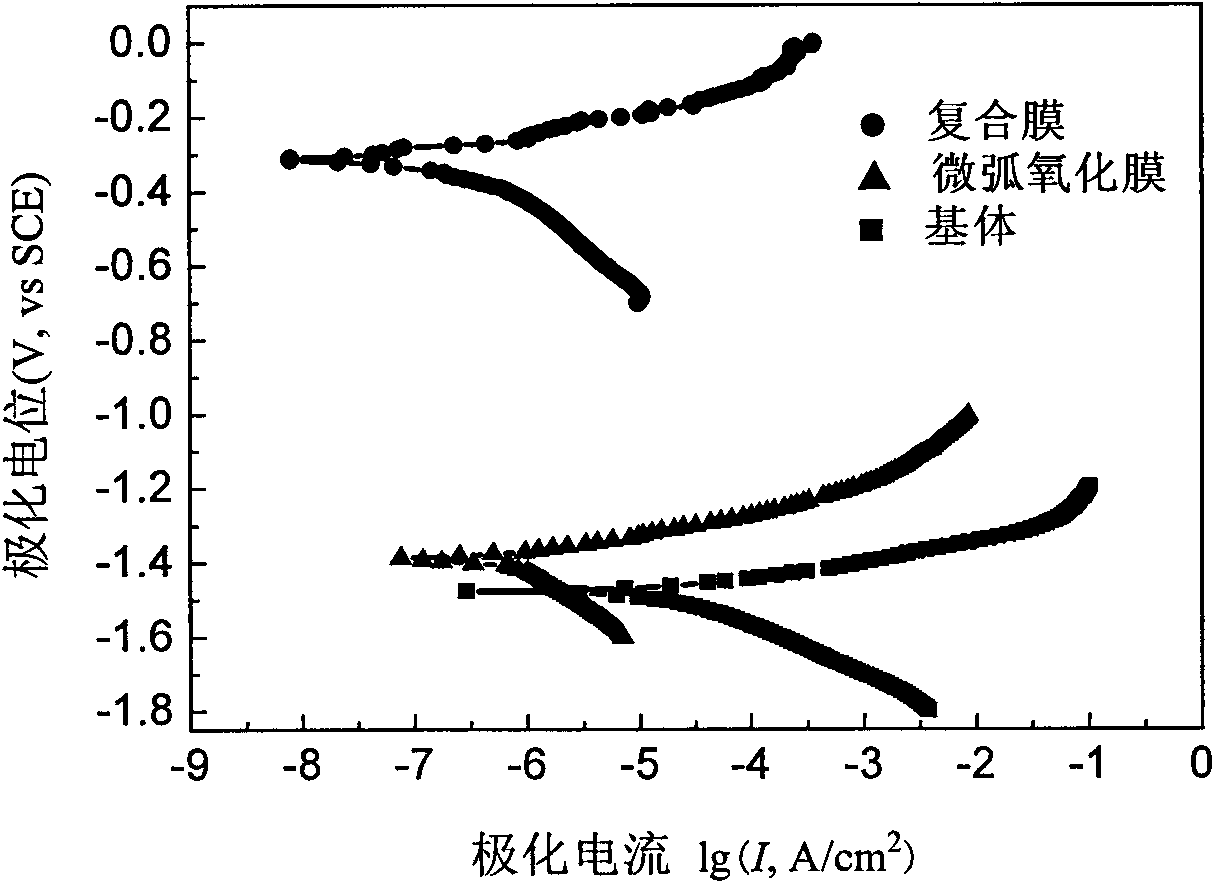

Preparation method of magnesium alloy surface micro-arc oxidation/spray coating compound film

ActiveCN101871119AHigh bonding strengthImprove corrosion resistanceAnodisationLiquid surface applicatorsMicro arc oxidationPlasma electrolytic oxidation

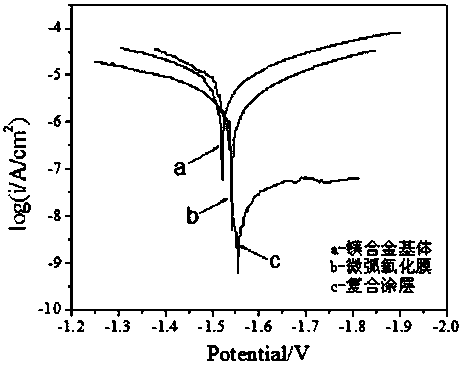

The invention provides a preparation method of a magnesium alloy surface micro-arc oxidation / spray coating compound film, which relates to a preparation method of a magnesium alloy surface compound film. The invention solves the problems that film layers obtained by chemical composition coating, anodic oxidation and vapor deposition in the existing magnesium alloy surface treatment method are thin and have poor corrosion resistance performance, the ion injection has high cost and is difficult to realize large-area processing, the combining force between coating layers and the magnesium alloy is poor, and organic coating layers has the defect of easy aging. The preparation method has the following steps: firstly, using micro-arc oxidation for preparing ceramic films on the surface of the magnesium alloy; then, adopting air spray coating for spraying and coating inorganic paint onto the ceramic films; and then, carrying out heat treatment to obtain the micro-arc oxidation / spray coating compound film. The method is simple, and the cost is low. The air spray coating uses porous structures of the micro-arc oxidation ceramic films, so the combination of the inorganic coating layers and the ceramic films is firm, the thickness of the compound films is between 20 and 40 mum, the self corrosion electric potential is positively moved to -1.02 V, the corrosion current density is lowered by 5 orders through being compared with that of the magnesium alloy, the magnesium alloy surface micro-arc oxidation / spray coating compound film has no damage after 72 to 144h of salt spray tests, and the corrosion resistance performance is good.

Owner:HARBIN INST OF TECH

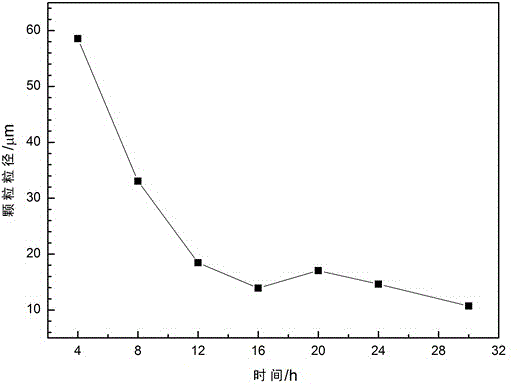

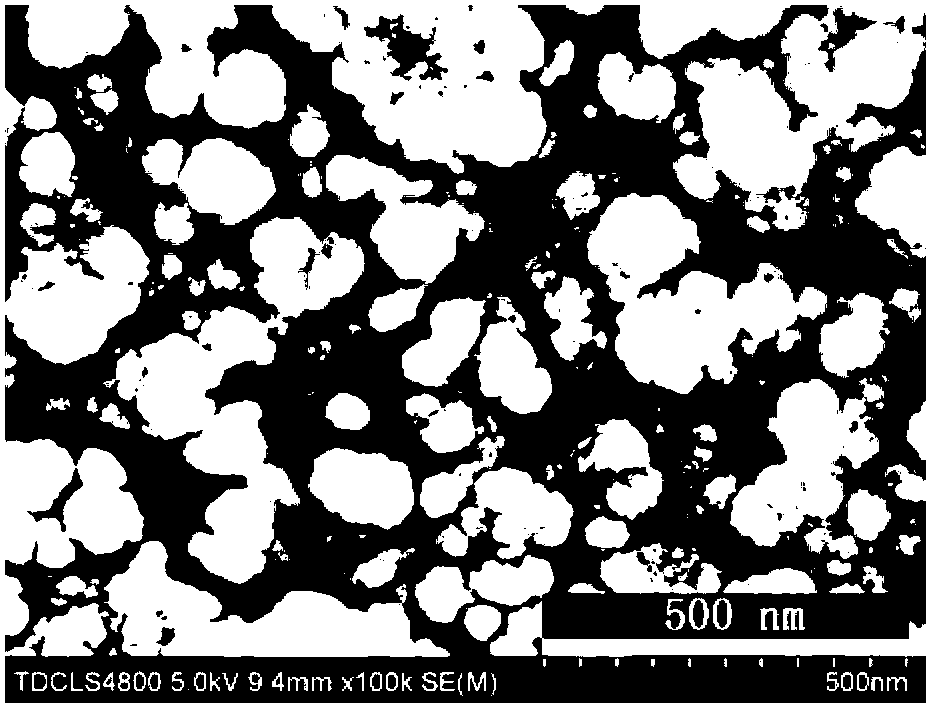

Method for preparing silicon-based nano-scale ordered porous silicon

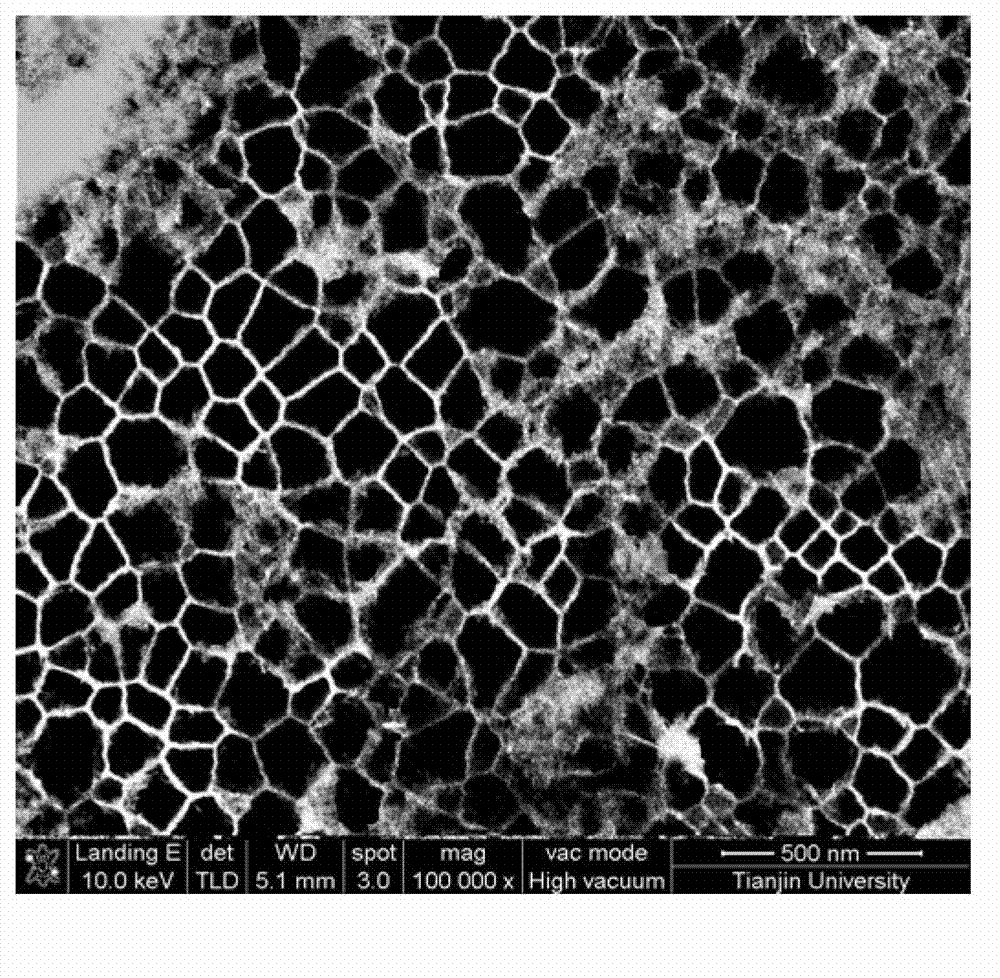

InactiveCN102953113ALarge specific surface areaInsufficient improvementVolumetric Mass DensitySolvent

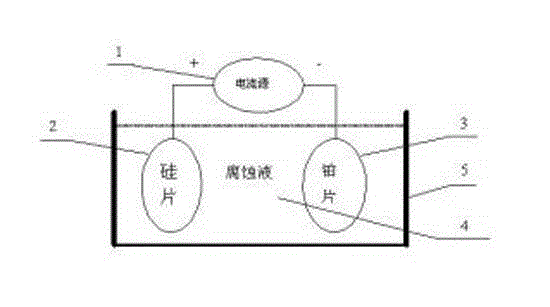

The invention discloses a method for preparing silicon-based nano-scale ordered porous silicon, comprising the following steps of: (1) ultrasonically washing an n-shaped one-side polished monocrystalline silicon piece in an acetone solvent, absolute ethyl alcohol and de-ionized water sequentially; and (2) preparing a porous silicon layer on the polished surface of the silicon piece by a double-tank electrochemical corrosion method, taking the aqueous solution of hydrofluoric acid having the mass fraction of 5-9% as corrosive liquid, and applying corrosion current, wherein the density of the corrosion current is 75-155 mA / cm<2>, and the corrosion time is 5-30 min; and the process is performed at the room temperature without illumination. The method disclosed by the invention is simple, quick, effective and practicable, and high in operability; and the bore diameter of the obtained porous silicon is at hundred-nanometer scale, and has the characteristics of high porosity and highly ordered pore canals. The method is capable of achieving the purpose of the silicon-based nano-scale ordered porous silicon by controlling the concentration of the hydrofluoric acid, the corrosion current density and the corrosion time; and the silicon-based nano-scale ordered porous silicon is an ideal material for preparing biological and chemical sensor elements.

Owner:TIANJIN UNIV

Superconducting and super corrosion resistant functional coating for fuel cell metal bipolar plate and preparation method thereof

ActiveCN107302094AExtended service lifeReduce processing costsCell electrodesVacuum evaporation coatingSelf-healingFuel cells

The invention relates to the technical field of fuel cell functional coating, in particular to a superconducting and super corrosion resistant functional coating of a fuel cell metal bipolar plate and a preparation method thereof. The superconducting and super corrosion resistant functional coating of the fuel cell metal bipolar plate comprises a self-healing layer, a super corrosion resistant layer and a selectively deposited superconducting layer. The premise of the superconducting and super corrosion resistant functional coating of the fuel cell metal bipolar plate is enhancing the service life of the fuel cell metal polar plate. The superconducting and super corrosion resistant functional coating material of the fuel cell metal bipolar plate disclosed by the invention has the capability of filling the pinholes automatically during use, therefore, a recycle multilayer structure to avoid the pinholes is not required to design; meanwhile, the coating has the super corrosion resistant and the superconducting compositions, therefore, the lower contact resistance and corrosion current density compared with the prior art can be achieved without adding noble metals, and the processing cost of the metal plate is greatly reduced.

Owner:常州翊迈新材料科技有限公司

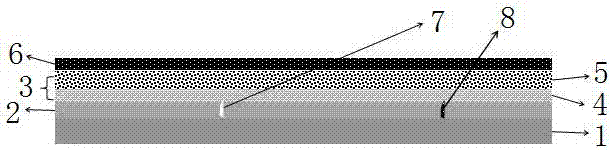

Graphene-doping conductive polymer modified metal bipolar plate of proton exchange membrane fuel cell and preparation method of metal bipolar plate

ActiveCN105552399ADoes not affect other performanceLow corrosion current densityFinal product manufactureCollectors/separatorsConductive polymerPre treatment

The invention relates to a graphene-doping conductive polymer modified metal bipolar plate of a proton exchange membrane fuel cell and a preparation method of the metal bipolar plate, belonging to the technical field of a fuel cell. The bipolar plate comprises a metal plate, a polarity oxide film layer and a graphene-doping conductive polymer film layer, wherein the polarity oxide film layer covers the surface of the metal plate, the graphene-doping conductive polymer film layer covers the surface of the polarity oxide film layer, and the thickness of the graphene-doping conductive polymer film layer is 0.005-0.3 millimeter, the thickness of the polarity oxide film layer is 5-30 nanometers, and the thickness of the metal plate is 0.1-2 millimeters. A graphene-doping conductive polymer film is deposited on the surface of a stainless steel plate after preprocessing by an electrochemical synthesis method, the metal bipolar plate prepared according to the invention has the advantages of relatively low contact resistance, low corrosion current density and high bonding firmness of the metal substrate and the conductive polymer film, moreover, the method is simple, the processing cost is low, and mass production can be achieved.

Owner:HUBEI UNIV +1

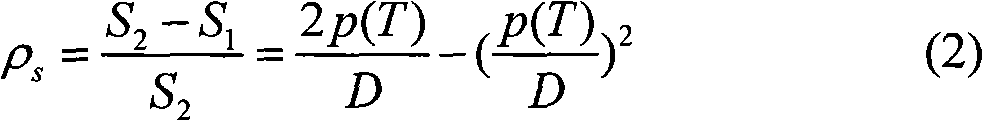

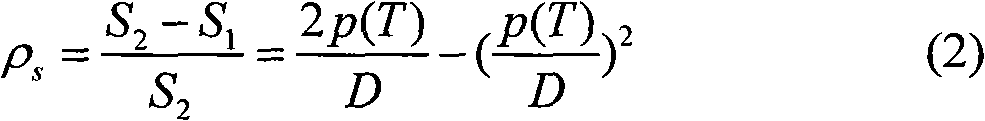

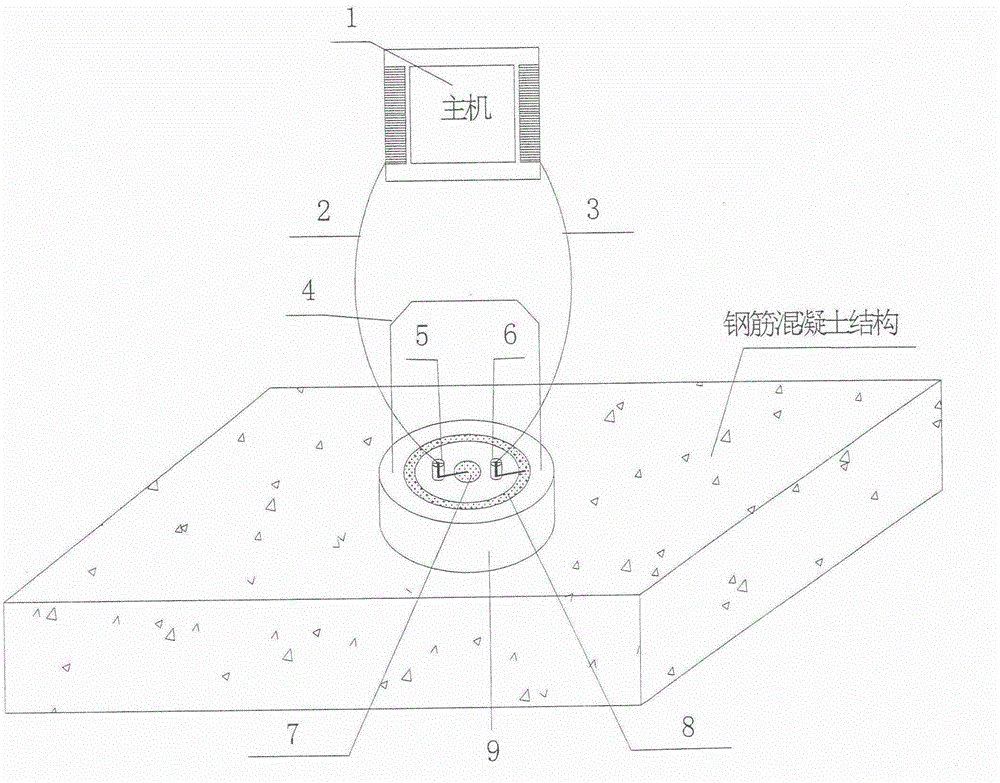

Electrochemical detection method for corrosion degree of steel reinforcing bar in concrete

InactiveCN102706933AReduce disturbanceEasy and fast testingMaterial electrochemical variablesEquilibrium potentialPower flow

The invention discloses an electrochemical detection method for the corrosion degree of a steel reinforcing bar in concrete. The electrochemical detection method comprises the following steps of: (1) respectively and correspondingly connecting the steel reinforcing bar, a counter electrode and a reference electrode which are arranged in a concrete sample with an electrochemical workstation to form a three-electrode testing system; (2) opening the electrochemical workstation for carrying out polarization test and recording anodic polarization current at the ending moment of the polarization; (3) calculating the corrosion current density icorr of the steel reinforcing bar; and (4) comparing the corrosion current density icorr of the steel reinforcing bar, which is calculated in the third step, with an internal standard value to judge whether the steel reinforcing bar is corroded or not. According to the method for determining the corrosion current density of the steel reinforcing bar in the concrete, an equilibrium potential is used as an initial polarization potential; according to the polarization mode, the distorsion of the measured polarization curve is avoided; an polarization potential amplitude is reasonable, so that the disturbance on the steel reinforcing bar is smaller; subsequent fitting processing for test data is avoided; the simplicity, convenience and quickness in test are realized; and the electrochemical detection method is suitable for engineering application.

Owner:ZHEJIANG UNIV

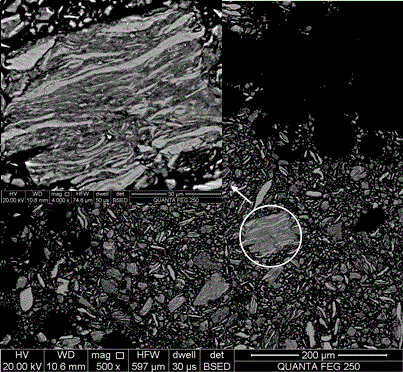

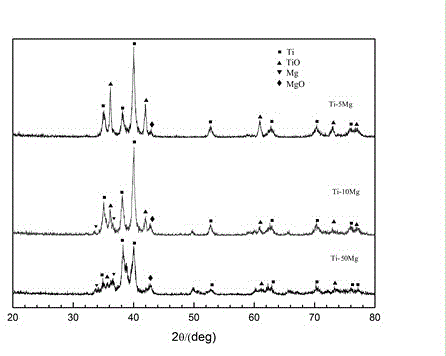

A Ti-Mg alloy material, a preparing method thereof and applications of the alloy material

The invention discloses a Ti-Mg alloy material applied as human tissue bone repair materials and a preparing method thereof. Phase composition of the alloy comprises Ti, Mg, TiO and MgO. The alloy comprises 70-80% of the Ti, 0-10% of the Mg, 8-20% of the TiO and 2-5% of the MgO. The Ti-Mg alloy is prepared by utilization of mechanical alloying and spark plasma sintering. The porosity of the alloy is smaller than 1%, the Vickers hardness of the alloy is HV400-HV500, the compressive strength of the alloy is 1600-1700 MPa, the elasticity modulus of the alloy is 12-13 GPa, the self-corrosion potential of the alloy ranges from -900 mV to -800 mV, the self-corrosion current density is 50-90 [mu]A / cm<2>. The alloy has characteristics of uniform structure, high compactness, good mechanical compatibility, capability of being biodegradable, and good corrosion resistance.

Owner:CENT SOUTH UNIV

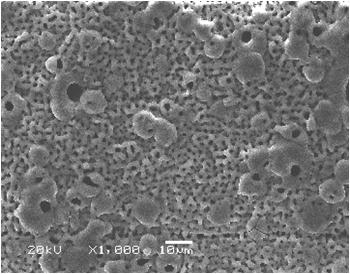

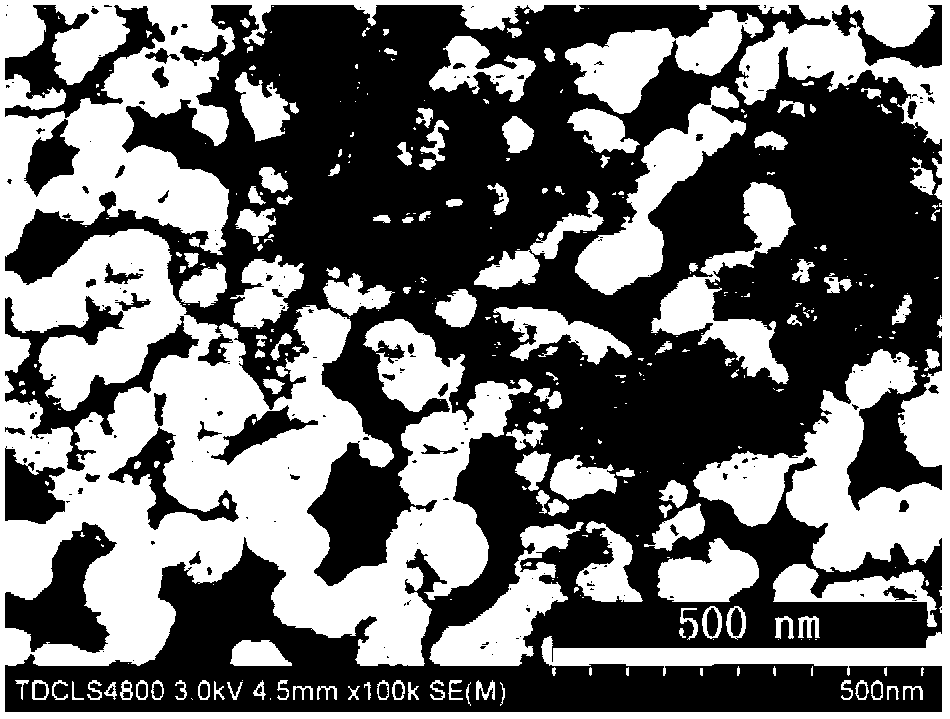

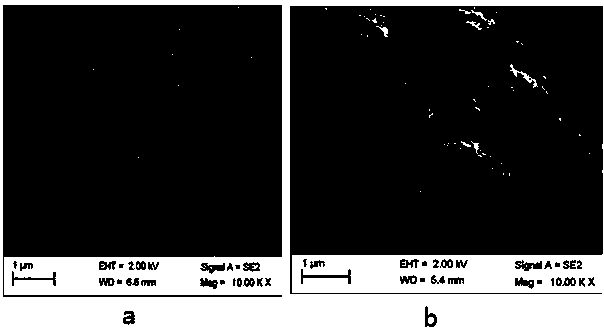

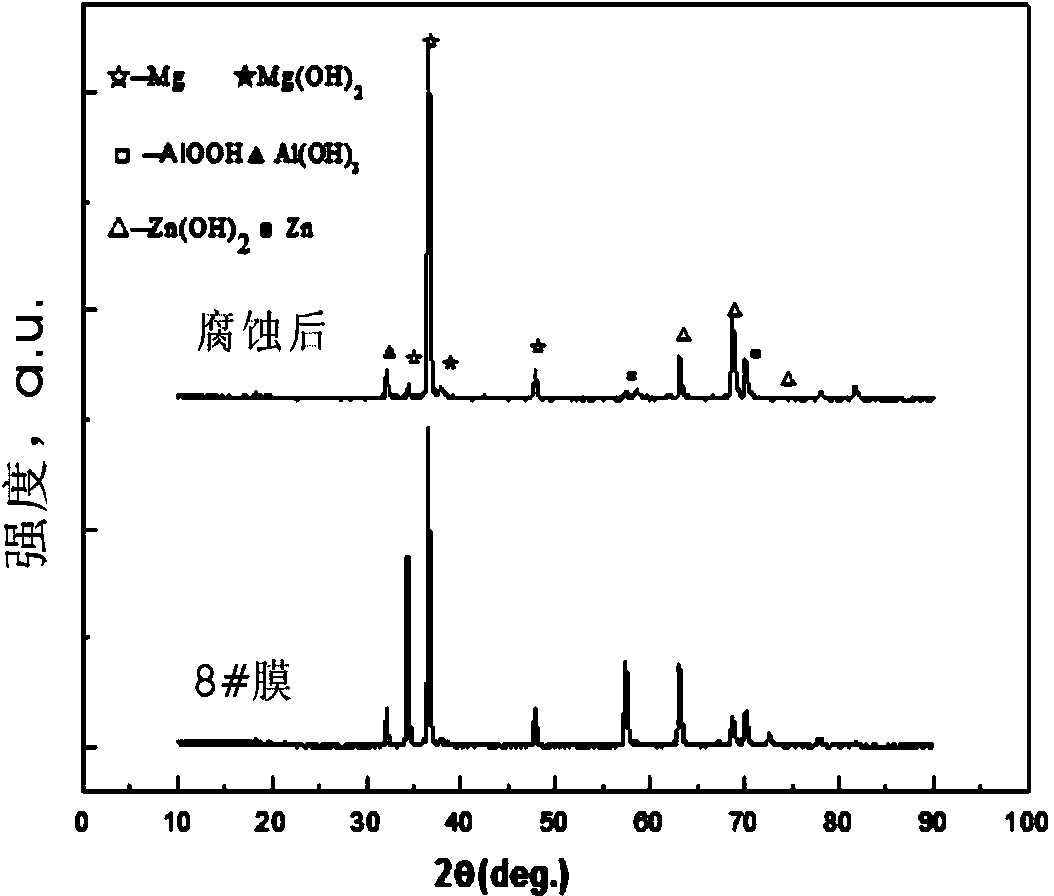

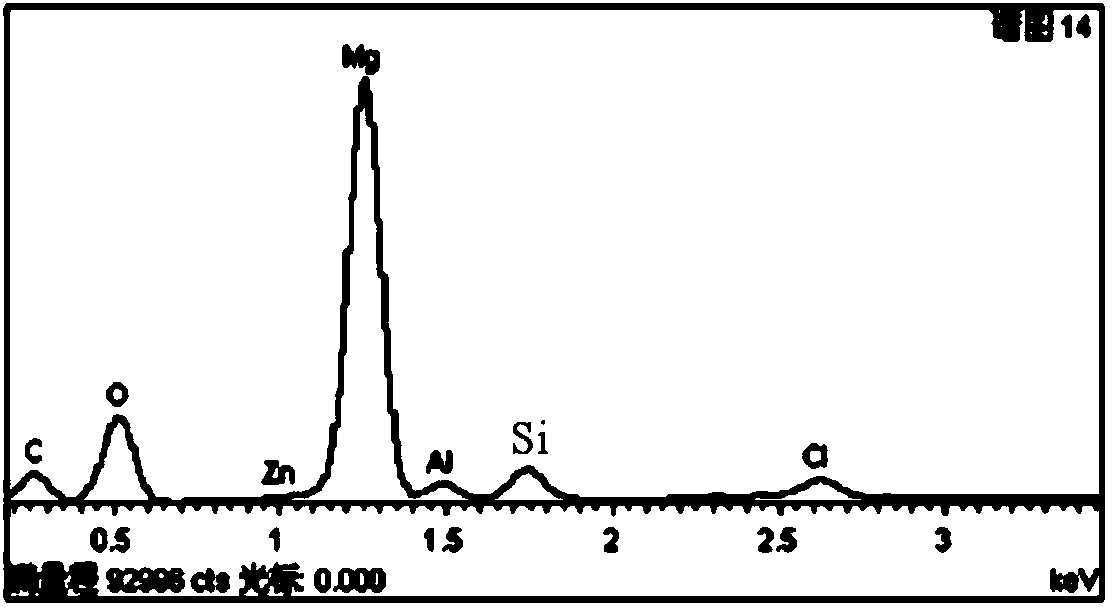

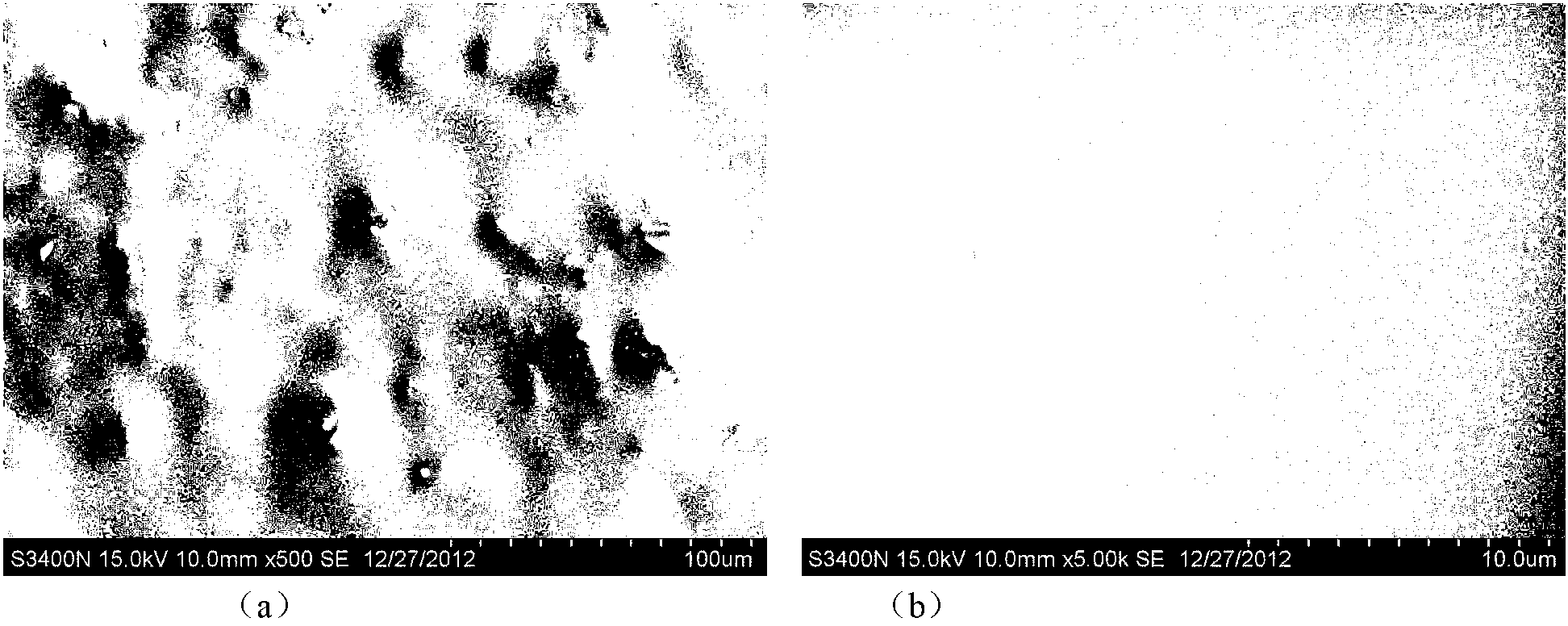

Method for preparing graphene oxide and micro-arc oxidized ceramic composite coating on surface of magnesium alloy

InactiveCN104878377AImprove corrosion resistanceReduce porosityAnodisationMetallic material coating processesPlasma electrolytic oxidationCeramic composite

The invention provides a method for preparing a graphene oxide and micro-arc oxidized ceramic composite coating on the surface of a magnesium alloy and relates to a method of preparing a coating on the surface of the magnesium alloy. The method is used for solving the problem of poor corrosion resistance of the micro-arc oxidized ceramic coating of a porous structure due to large contact area of the coating with a corrosive medium in the corrosion process. The method comprises the following steps: 1, magnesium alloy pre-processing; 2, ultrasonic processing; 3, oil removal; 4, micro-arc oxidization; 5, graphene oxide preparation; 6, application of the graphene oxide solution to the micro-arc oxidized ceramic coating on the magnesium alloy, thereby obtaining the magnesium alloy coated with the graphene oxide and micro-arc oxidized ceramic composite coating. According to the method, the corrosion current density of the graphene oxide and micro-arc oxidized ceramic composite coating is reduced to 14.5nA / cm<2>, which is 1 / 7240 of the corrosion current of the matrix magnesium alloy. The invention relates to the method for preparing the graphene oxide and micro-arc oxidized ceramic composite coating on the surface of the magnesium alloy.

Owner:HARBIN INST OF TECH

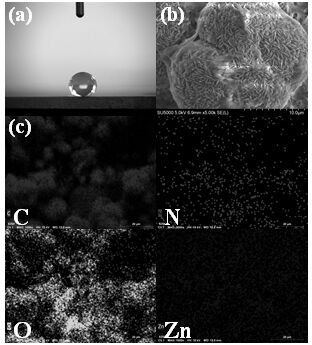

Corrosion-resistant self-assembled doped film layer on aluminum alloy surface and preparation method of corrosion-resistant self-assembled doped film layer

InactiveCN104630749ALow corrosion current densityHigh impedanceLiquid/solution decomposition chemical coatingAlloy substrateCorrosion current density

The invention discloses a corrosion-resistant self-assembled doped film layer on an aluminum alloy surface and a preparation method of the corrosion-resistant self-assembled doped film layer. The corrosion-resistant self-assembled doped film layer is composed of a self-assembled film and particles. The preparation method comprises the steps of firstly, carrying out pretreatment, namely grinding, washing, oil removal and the like on an aluminum alloy substrate; then, preparing a self-assembled doped solution; self-assembling the pretreated aluminum alloy to form a film; and taking out the film, drying and curing to obtain the corrosion-resistant self-assembled doped film layer on the aluminum alloy surface. The preparation method is low in cost, simple in preparation process and short in film formation time; the prepared self-assembled doped film is high in resistance and low in corrosion current density; and the film layer is uniform and level in surface, good in binding force on the aluminum alloy substrate, capable of favorably improving the corrosion resistance of the aluminum alloy surface and incapable of polluting the environment and equipment.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Preparation method for gas-sensitive material with composite structure

InactiveCN103063707AIncrease the areaGiant gas diffusion channelNanosensorsMaterial impedanceOxygen vacancySolvent

The invention discloses a preparation method for a gas-sensitive material with a composite structure. The preparation method comprises the following steps: (1) successively placing an n-type single-side polished monocrystalline silicon chip into an acetone solvent, absolute ethyl alcohol and deionized water for ultrasonic cleaning, then soaking the monocrystalline silicon chip in 5% of an aqueous hydrofluoric acid solution, flushing the monocrystalline silicon chip with ionized water and standing the monocrystalline silicon chip for subsequent usage; (2) preparing a porous silicon layer on the polished surface of the cleaned silicon chip by using a double-tank electrochemical corrosion process, wherein corrosion current density is 115 to 135 mA / cm<2> and corrosion time is 20 to 25 min; and (3) with metal tungsten as a target material, sputtering and depositing a nanometer tungsten oxide film on the surface of silicon-based porous silicon and carrying out heat treatment at a temperature of 450 to 500 DEG C for 3 to 4 h so as to prepare the gas-sensitive material with the composite structure. The invention provides a method for preparing the nanometer tungsten oxide film with a loose porous surface and containing considerable oxygen vacancies, the method has the advantages of simple equipment, convenient operation, easily controllable technological parameters and low cost, and the nanometer tungsten oxide film is fairly applicable to the gas-sensitive material.

Owner:TIANJIN UNIV

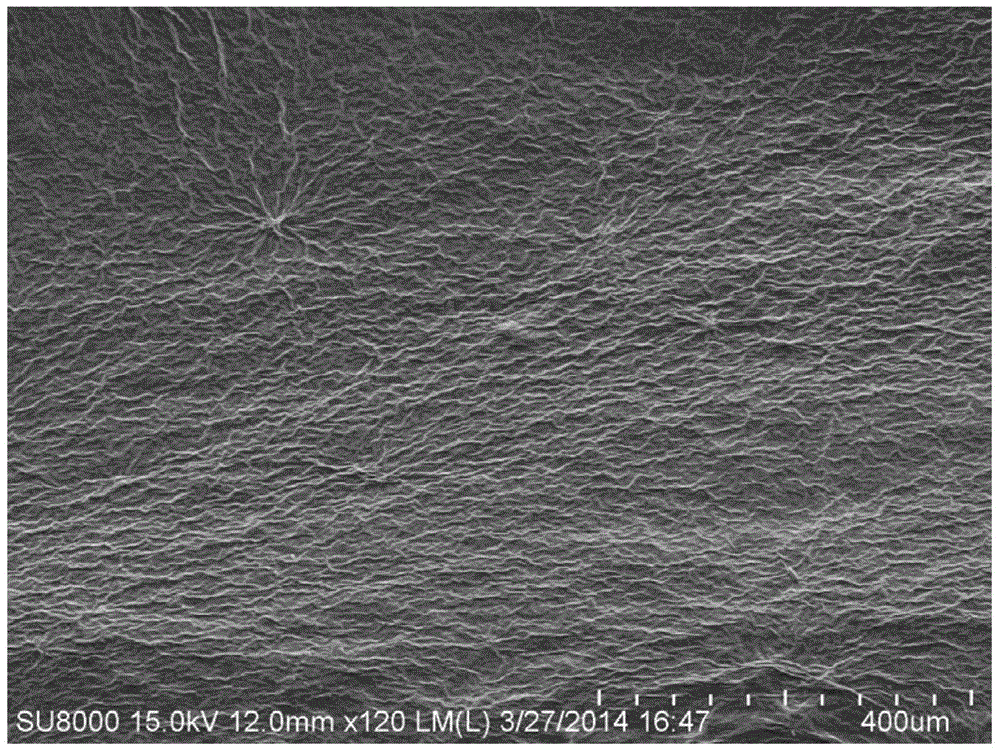

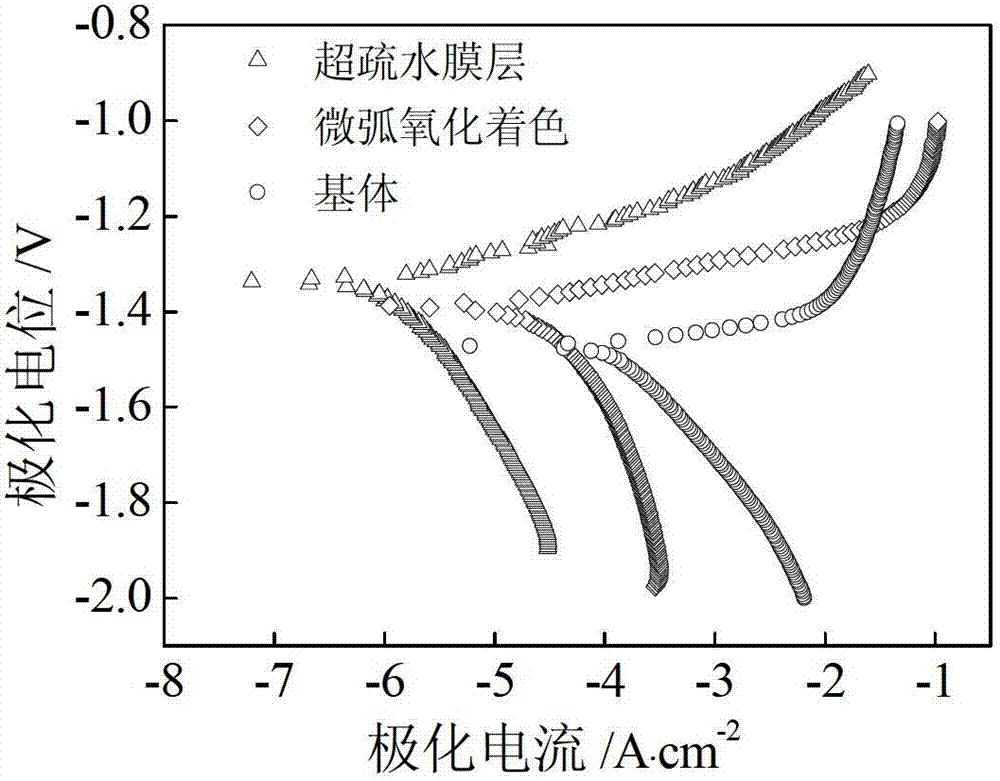

Magnesium alloy surface hydrophobization compound processing method

The invention discloses a magnesium alloy surface hydrophobization compound processing method combining micro-arc oxidation with an organic film coating technology and comprising the following steps:preparing a micro-nano porous super-hydrophilic surface by the micro-arc oxidation; and carrying out hydrophobization processing of an organic coating film. The invention prepares a micro-nano porouscompound structural film with hydrophobic and super-hydrophobic functions and excellent corrosion resistance; according to actual demand, a static contact angle of the compound structural film and distilled water is controllable within the range from 110 to174 degrees and the thickness of the compound structural film is controllable within the range from 2 to 30 micrometers, the electrokinetic potential polar characteristic, the electrical potential shuffle the corrosion current density of the compound structural film in a 3.5% NaCl solution or 0.1m / LNaCl solution are all reduced by 3 magnitude orders. The invention is suitable for the corrosion, pollution and water prevention of a magnesium alloy workpiece with large area and also suitable for the shell of a light precise magnesium alloyproduct to widen the application field of magnesium alloys and has simple and convenient technology, short period, low cost and easy industrialized production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method for light green superhydrophobic corrosion-resistant film on surface of magnesium-lithium alloy

InactiveCN102817063AEasy to operateImprove efficiencyAnodisationElectrolytic organic material coatingOrganic filmMicro nano

The invention discloses a preparation method for a light green superhydrophobic corrosion-resistant film on the surface of magnesium-lithium alloy. The method comprises the following steps: preparing a light green corrosion-resistant ceramic film on the surface of the magnesium-lithium alloy by using micro-arc oxidation coloring, wherein the ceramic film provides a micro-nano rough structure for preparation of the superhydrophobic film; and using triazine mercaptan organic compound salt containing fluorine substituent groups for organic film coating to realize hydrophobization which enables probability of contacting between a corrosion medium and a metal surface to be reduced and corrosion resistance of the film to be further improved. Potentiodynamic polarization corrosion current density of the light green superhydrophobic corrosion-resistant film on the surface of the magnesium-lithium alloy in an aqueous NaCl solution with a concentration of 0.1 mol / L is reduced by three orders of magnitude. The preparation method provided by the invention has simple operation and high efficiency and is easy for industrial production; and the prepared light green superhydrophobic corrosion-resistant film on the surface of the magnesium-lithium alloy has the characteristics of low cost and a wide application scope.

Owner:SOUTH CHINA UNIV OF TECH

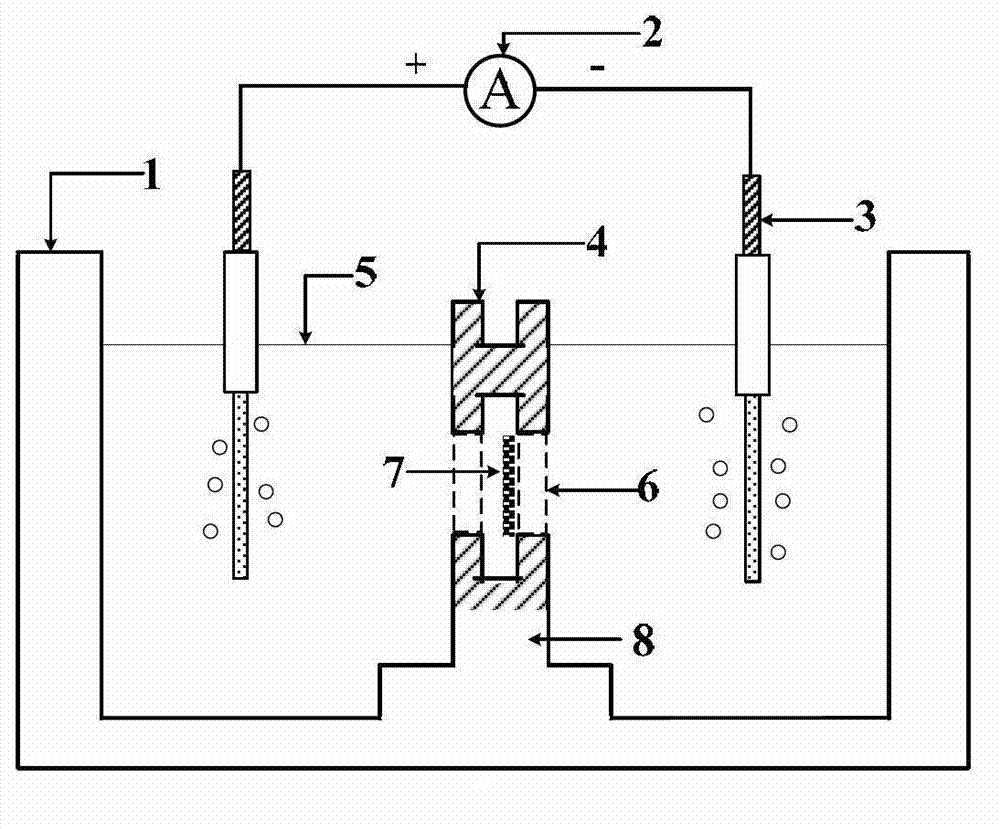

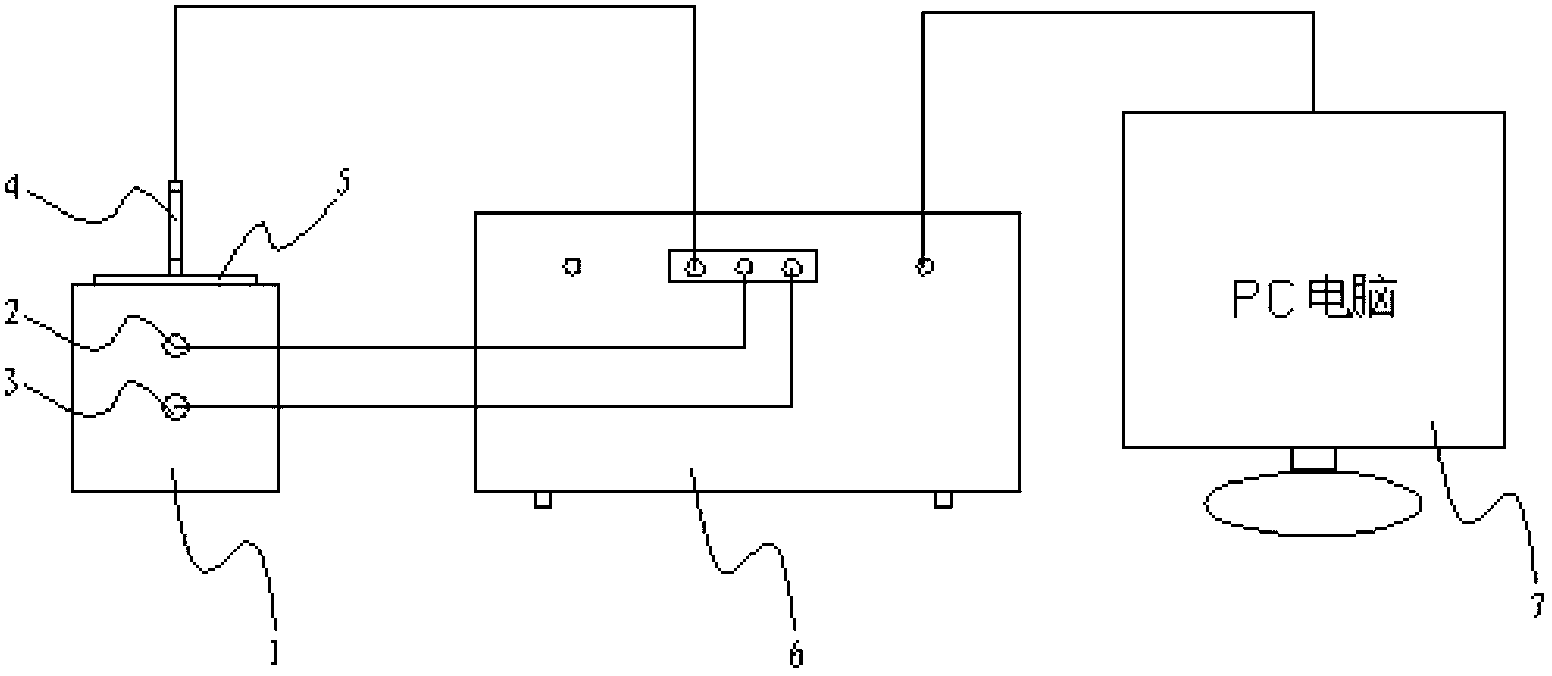

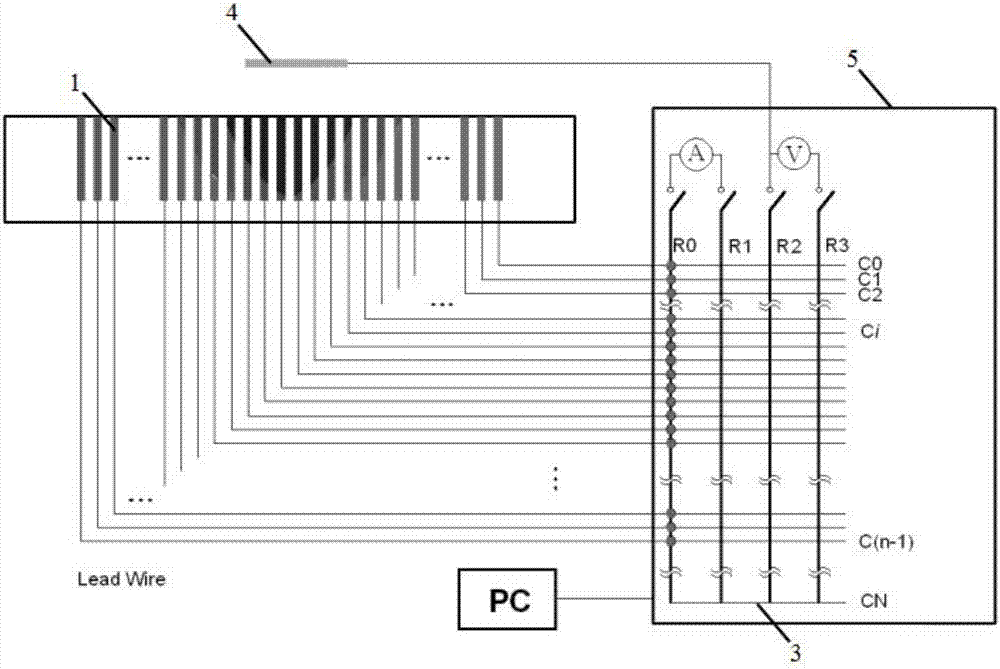

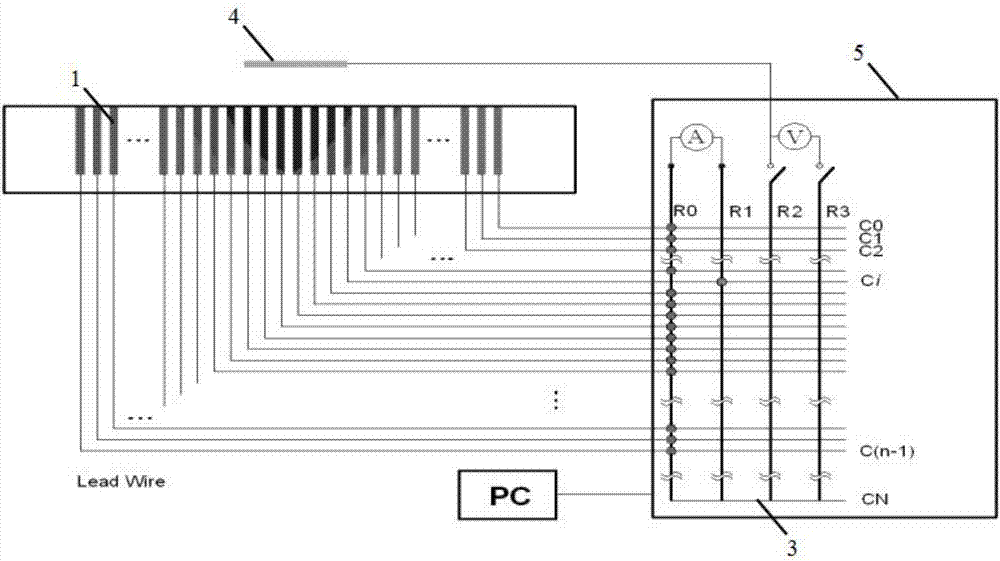

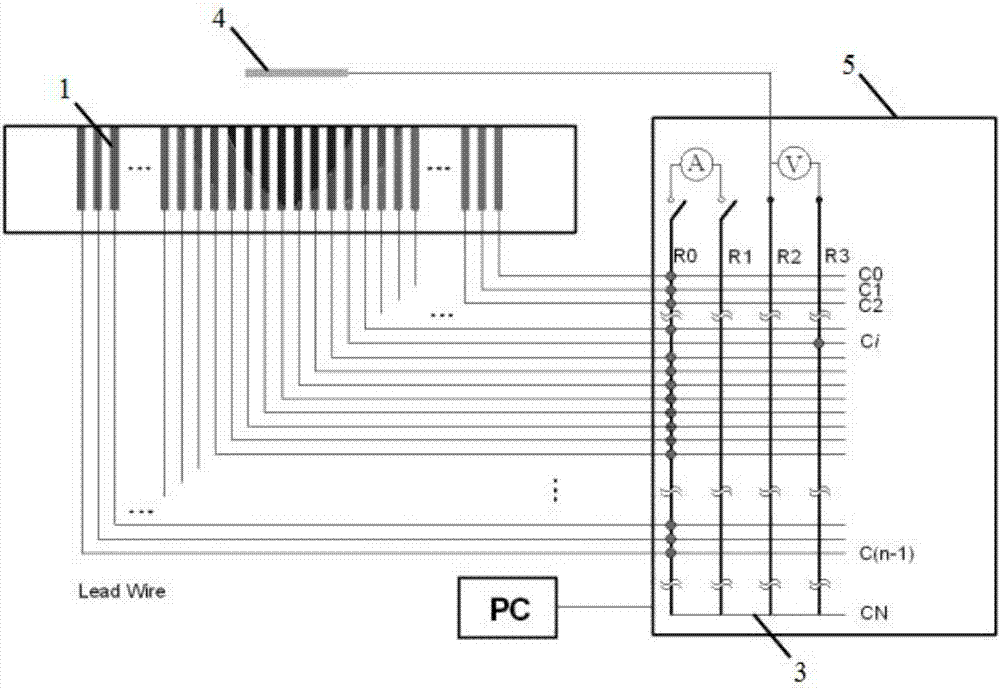

System and method for testing local corrosion of multi-electrode coupled inhomogeneous structure

InactiveCN107192665ANon-uniform stateNon-uniform densityWeather/light/corrosion resistanceSpectroscopyEngineering

The invention relates to a system and a method for testing local corrosion of a multi-electrode coupled inhomogeneous structure. Three testing systems including a classic electrochemical comprehensive testing system, a micro-area electrochemical testing system and a micro-electrode array testing system are arranged in the system; the three testing systems can be used for testing separately and any two testing systems also can be combined together; by using a micro-electrode array as a bridge and a bond, the three testing systems are coupled and combined, three tests of a classic electrochemistry test, a micro-electrode array test and a micro-area electrochemistry test can be carried out, and overall average information such as self-corrosion potential, self-corrosion current density, polarization property and electrochemical impedance spectroscopy, local distribution information such as galvanic potential and galvanic current having certain statistical characteristics, and micro-area distribution information of local cathode and anode areas in a local corrosion process of an inhomogeneous structure can be acquired and effectively associated on aspects of large scale, middle scale and small scale.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

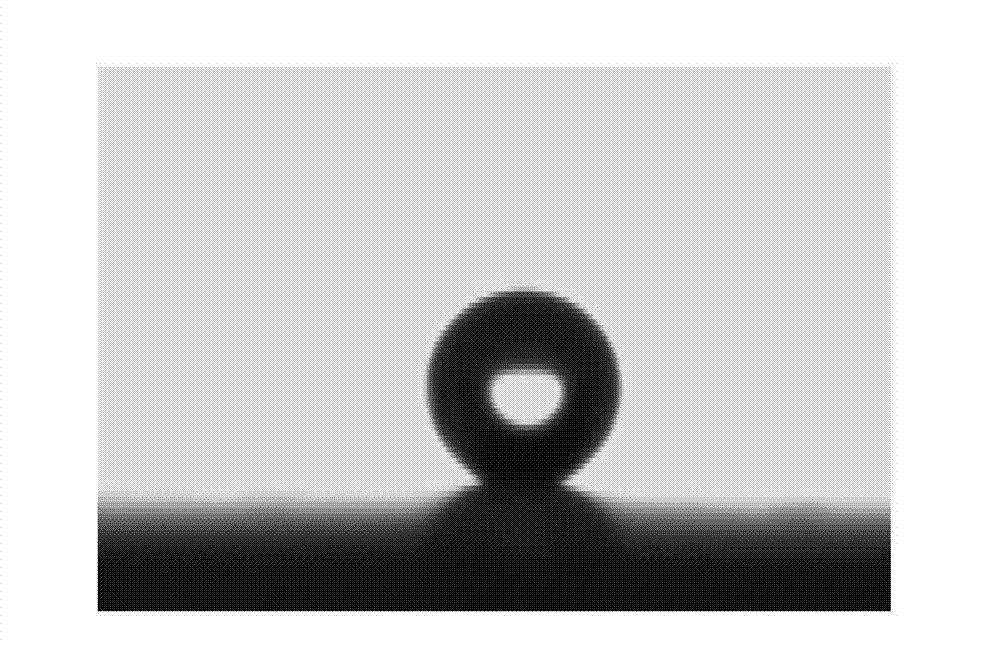

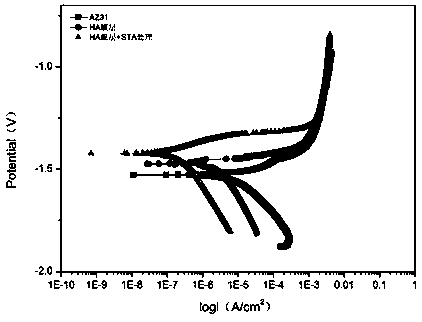

Preparation method of superhydrophobic hydroxyapatite film layer on surface of magnesium alloy

InactiveCN107789665AReduce corrosionCorrosive water environment contact, isolation and corrosion delayPharmaceutical delivery mechanismLiquid/solution decomposition chemical coatingMicron scaleStearic acid

The invention provides a preparation method of a superhydrophobic hydroxyapatite film layer on the surface of magnesium alloy. The preparation method comprises the following steps: performing surfacepretreatment, preparing a nano-structured hydroxyapatite layer by a hydrothermal method and performing hydrophobization treatment to the hydroxyapatite layer. The hydrothermal method is designed, andby the hydrothermal method, a rod-shaped hydroxyapatite crystal layer adopting micron-scale length and nano-scale diameter is prepared on the surface of the magnesium alloy, then a stearic acid film is prepared on the surface of the nano-structured hydroxyapatite film layer to form a superhydrophobic film layer with the contact angle of 153 degrees under a static droplet, the film layer can reducethe corrosion current density of the magnesium alloy by 2 orders of magnitude and the impedance modulus of coating is increased from 2029 Omega.cm2 to 117674 Omega.cm2. The preparation method of thenano-structured hydrophobic coating is simple, equipment is simple and easy to control, the cost is low, and the controllability is good; the preparation method is suitable for large-scale production.

Owner:CHONGQING UNIV OF TECH

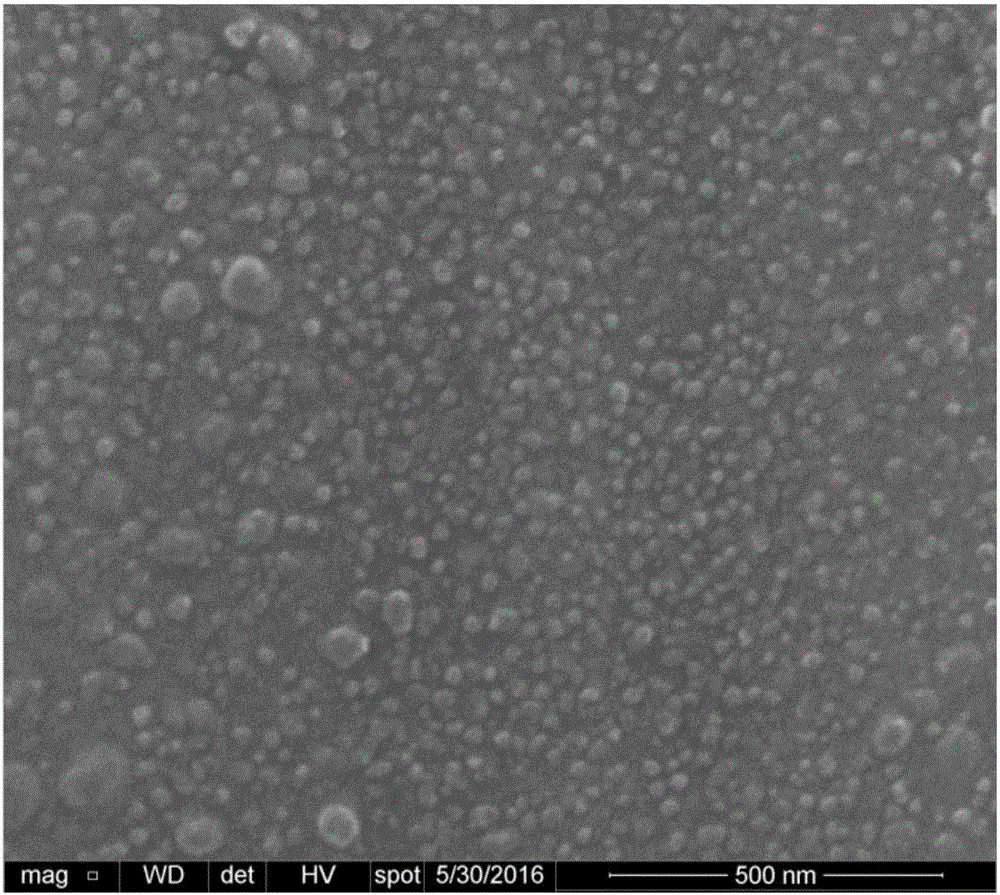

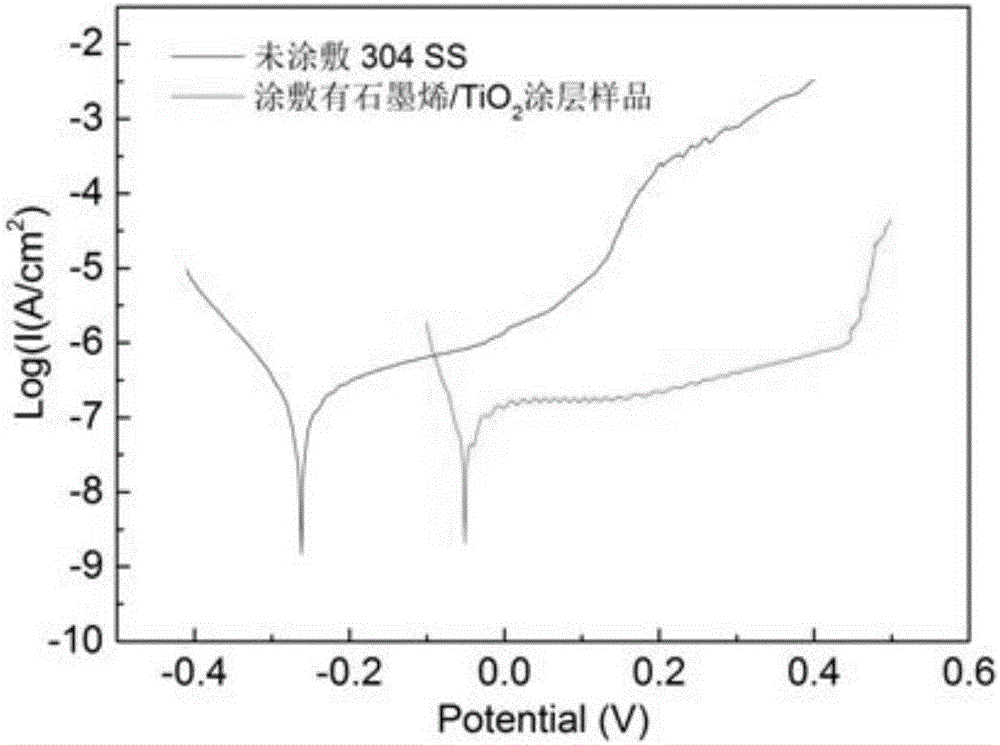

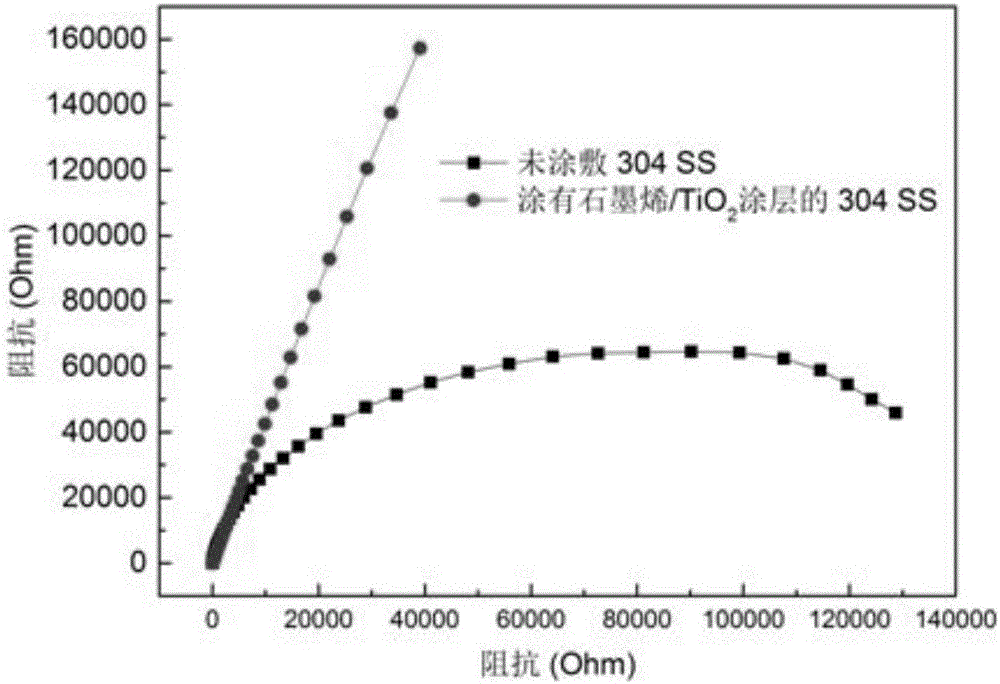

Preparation method of graphene/titanium dioxide transparent anticorrosive coating

InactiveCN106317976AOvercome porosityOvercome crackingLiquid surface applicatorsAnti-corrosive paintsElectrical resistance and conductanceSpray coating

The invention relates to a preparation method of graphene / titanium dioxide transparent anticorrosive coating. The preparation method includes: preparing graphene oxide dispersing liquid; preparing titanium oxide dispersing liquid; preprocessing a stainless steel sample; coating the stainless steel sample with graphene oxide / titanium oxide coating, to be more specific, using a suspension coating or ultrasonic spray coating manner to coat the stainless steel sample with the graphene oxide dispersing liquid, performing blow drying, using a suspension coating or ultrasonic spray coating manner to coat the stainless steel sample with the titanium oxide dispersing liquid, and performing blow drying; or using a suspension coating or ultrasonic spray coating manner to coat the stainless steel sample with the mixed solution of the graphene oxide dispersing liquid and the titanium oxide dispersing liquid; annealing the coated sample at 100-500 DEG C under N2 protective atmosphere for 20-120 minutes to obtain the graphene / titanium oxide anticorrosive coating. Tests show that compared with uncoated stainless steel, the corrosion current density of the polarization curve of the coated stainless steel sample in a sodium chloride solution is lowered by about one magnitude order, the passivation range of the coated stainless steel sample is increased by 2.5 times, and the polarization resistance of the coated stainless steel sample is increased by 8-17 times.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

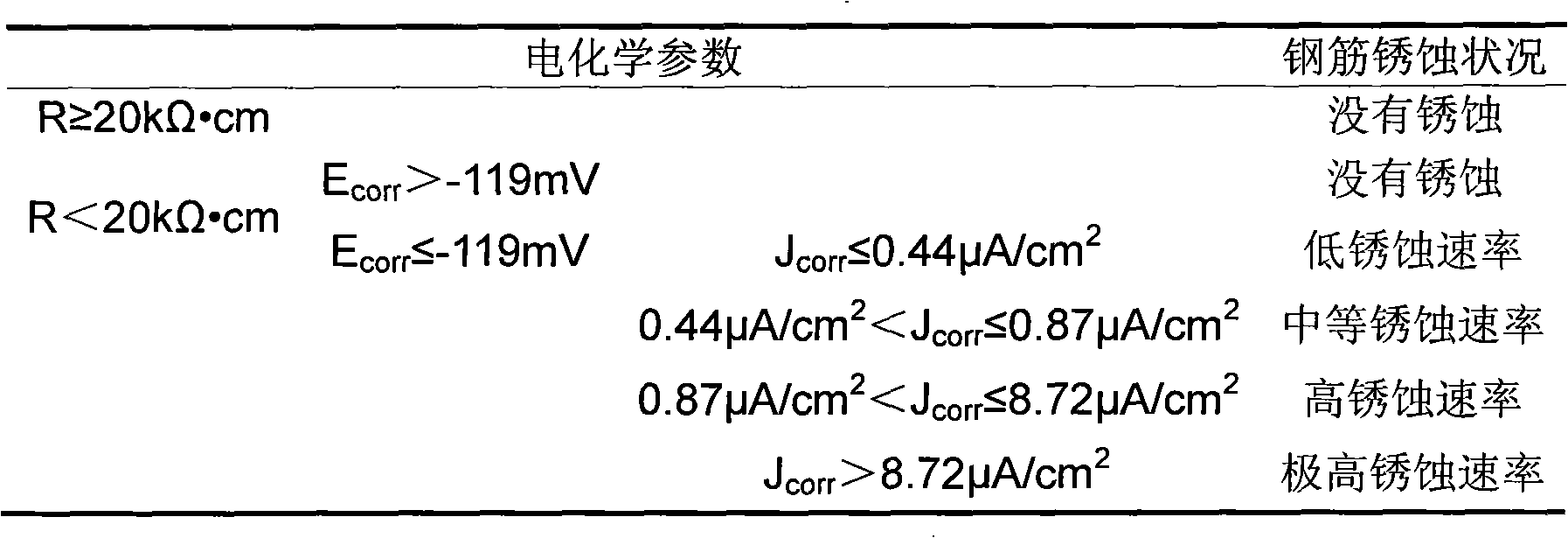

Coastal area concrete reinforcement erosion situation electrochemical test method

InactiveCN101339119AThe criteria are comprehensive and accurateWeather/light/corrosion resistanceMaterial testing goodsRebar corrosionLoss rate

The invention discloses an electrochemical test method of steel bar corrosion in the concrete of coastal area. The test method comprises the following steps: (1) under the concrete condition of the temperature of 0 to 50 DEG C and the relative humidity of 50 percent to 85 percent, the resistance rate R of the concrete is detected; if the estimated value of R is more than or equal to 20kilo-ohm, the passive film of the steel bar in the concrete is not damaged; if the estimated value of R is less than 20kilo-ohm, the second step is adopted; (2) a silver-silver chloride electrode is used for further determining the corrosion potential of the steel bar; if the estimated value of the corrosion potential of the steel bar is more than or equal to minus 119mV, the passive film of the steel bar in the concrete is not damaged; if the estimated value is less than 119mV, the passive film of the steel bar in the concrete is not damaged. The corrosion current density Jcorr of the steel bar in the concrete is further determined; the average corrosion depth and the average section loss rate of the steel bar are calculated. The guarantee rate of the estimated values is 95 percent. The electrochemical test method has the targeted characteristic and comprehensive criteria, and is in particular suitable for estimating the corrosion of the steel bar in the concrete structure without obvious cracking and rust on the surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

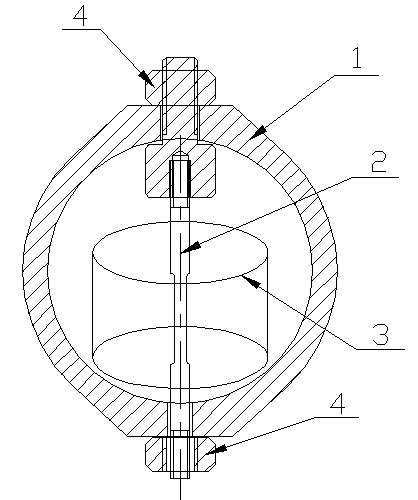

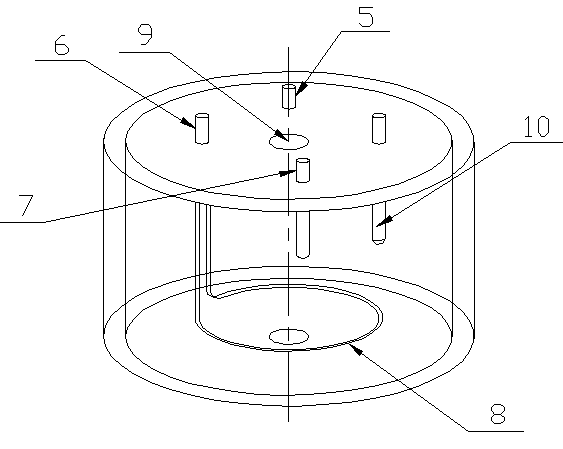

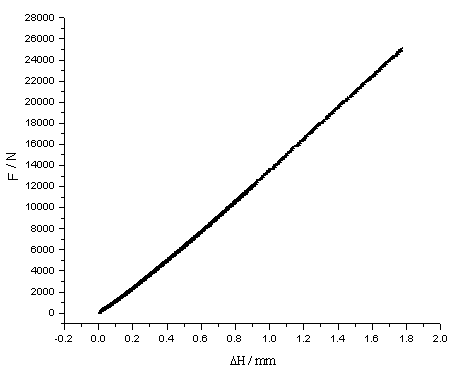

High-strength bolt delayed fracture test method and apparatus thereof

InactiveCN104251798AWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesEngineeringHigh intensity

The invention relates to the field of bolt quality control, and especially relates to a method for examining a bolt under simulated actual use conditions, and an apparatus thereof. A high-strength bolt delayed fracture test method comprises the following steps: applying a constant tensile force F to a tested bolt according to the service environment of the tested bolt, simulating the service environment of the tested bolt, and determining the corrosion current density iS under the service environment; and changing the medium solution, the atmosphere and the temperature in an environment container, carrying out acceleration test, determining the corrosion current density iA, calculating to obtain a speed-up ratio, and carrying out acceleration test by using changed parameters to obtain the delay fracture resistance. A high-strength bolt delayed fracture test apparatus comprises a pressure ring and the environment container, the tested bolt is arranged in the environment container, and two ends of the tested bolt are fixedly connected with the pressure ring. The high-strength method and the apparatus thereof can be used for evaluating the delayed fracture resistance of the bolt under the stimulated actual service conditions of the bolt, and predicting the actual service life of the bolt in an acceleration test medium.

Owner:BAOSHAN IRON & STEEL CO LTD

Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

ActiveCN103614717ASmall atomic radiusImprove polarization performanceMetallic material coating processesSolubilityLithium

The invention discloses a corrosion resistant film prepared by a magnesium alloy surface hydrothermal method and a preparation technology thereof, belongs to the technical field of magnesium surface processing, and solves the problem of bad corrosion resistant property of magnesium alloy in the prior art. The technology provided by the invention comprises the following steps: placing a processed magnesium alloy sample into a hydrothermal reactor, then injecting a treating fluid into the reactor according to a certain filling degree, and putting the reactor into a thermotank to maintain the temperature. The treating liquid comprises sodium hydroxide and lithium salt, sodium hydroxide provides a proper alkaline environment for film forming, lithium salt has a large solubility in water, Li+ can hydrolyze in water with a great amount at a certain temperature, so the pH value of the solution is improved so as to promote the film forming reactions on the magnesium alloy surface to move in the positive direction, the obtained film in situ grows on the magnesium alloy surface; the force between the film and the substrate body is excellent, the film is uniform, compact and ultra-thin, and has an excellent corrosion resistant property; the corrosion current density of the conversion film is increased by five magnitude orders compared to that of the substrate body, and reaches 10<-9> A / cm<2> magnitude grade.

Owner:曾荣昌

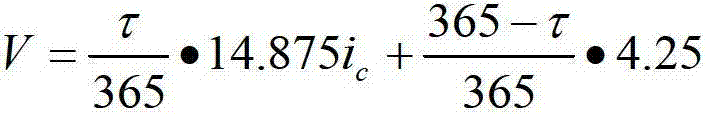

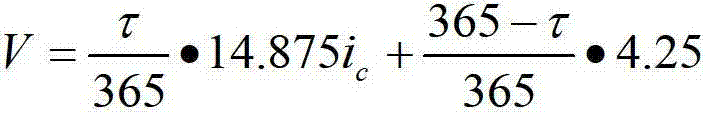

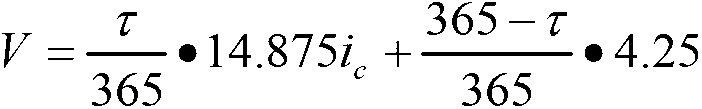

Method for predicting corrosion life of transmission line hardware in coastal regions

ActiveCN103091241ARapid Corrosion Life PredictionCorrosion Life PredictionWeather/light/corrosion resistanceEpoxyCopper wire

The invention discloses a method for predicting corrosion life of transmission line hardware in coastal regions. The method comprises the following steps: (1) sampling hardware replaced from a transmission line; (2) connecting a copper wire, and packaging an epoxy resin; (3) cleaning the outer surface of the sample; (4) calculating the annual average value of chlorine ion content in local rainwater; (5) preparing a simulated salt fog solution; (6) testing the sample in a three-electrode system electrolytic cell; (7) drawing a potentiodynamic polarization curve; (8) testing to obtain the simulated salt fog corrosion current density; (9) acquiring the annual average rainfall days; (10) calculating the medium / long-term annual average corrosion depth rate; (11) measuring a thickness average value of a galvanizing layer; and (12) acquiring the residual corrosion life of the galvanizing layer. According to the method, the traditional restriction is broken, and the galvanizing thickness on the surface of the hardware is measured, so that the corrosion rate and life of the transmission line hardware in coastal regions is evaluated, and rapidness and accuracy are realized and the practicality is high.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

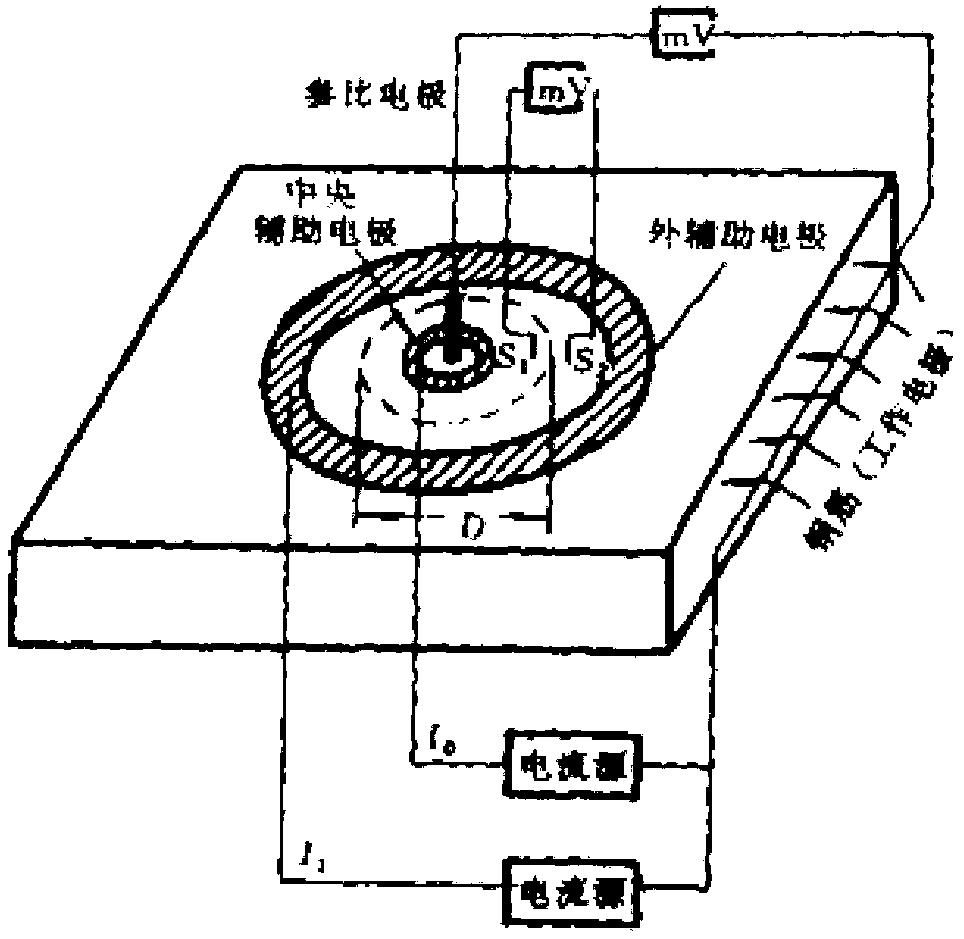

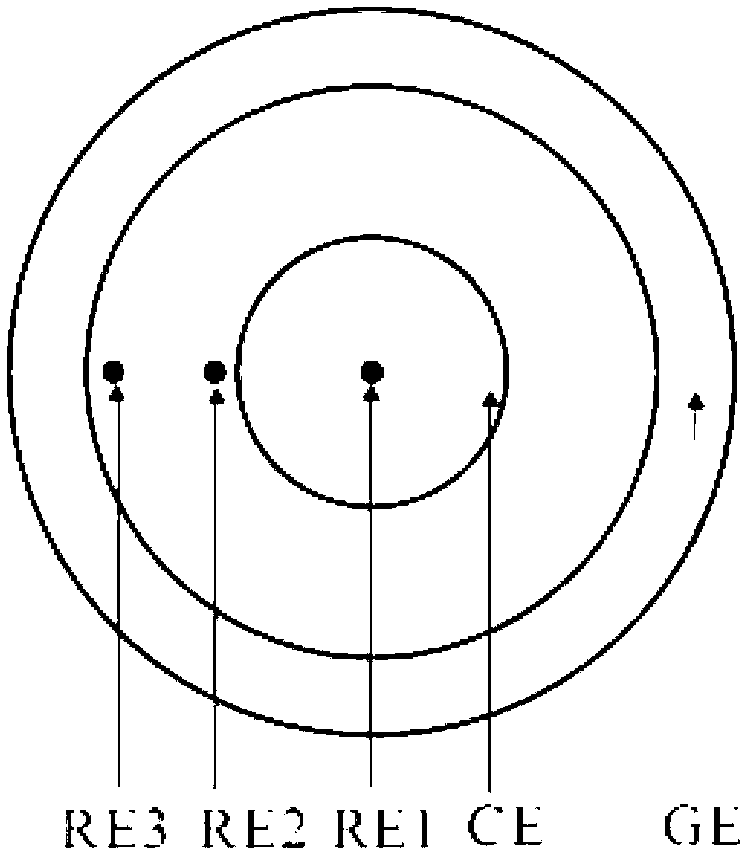

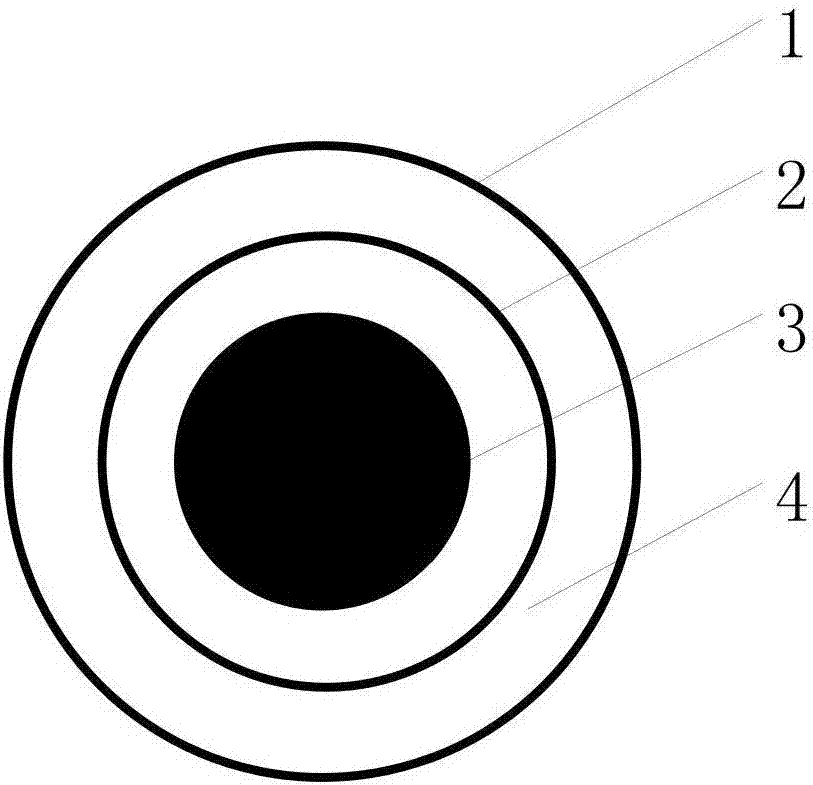

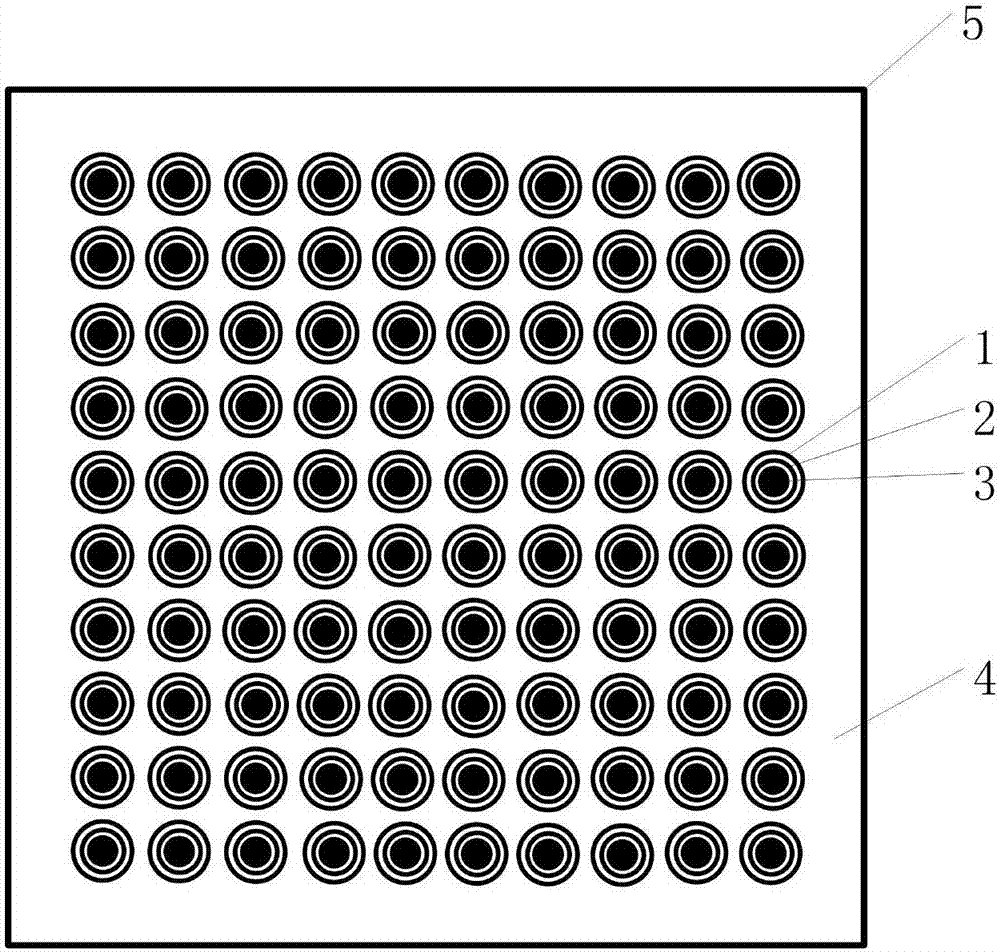

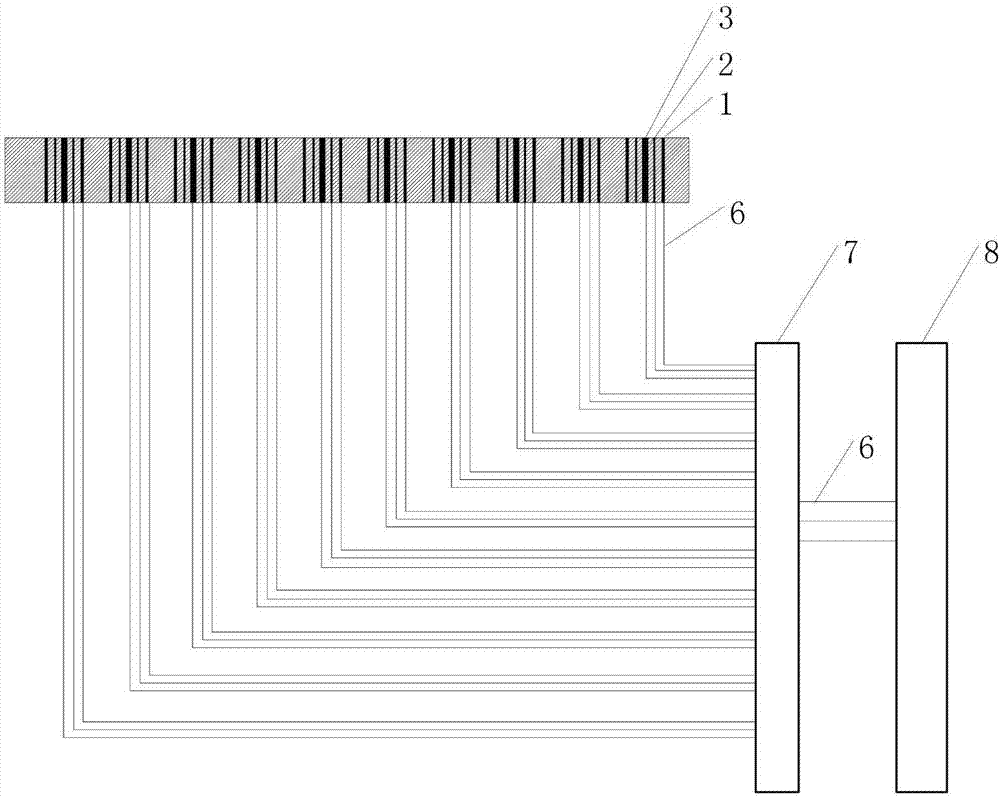

Local electrochemical information testing system and method for three-electrode array

ActiveCN107144613AComprehensive Test InformationRich test informationWeather/light/corrosion resistanceMaterial electrochemical variablesElectricityCoupling

The invention provides a local electrochemical information testing system for a three-electrode array. The system comprises a concentric circle three-electrode array, a high-speed diverter switch and an electrochemical working station which are sequentially and electrically connected, wherein the concentric circle three-electrode array comprises a plurality of concentric circle three-electrode units, and each two adjacent concentric circle three-electrode units are isolated from each other through an insulation material; and each concentric circle three-electrode unit comprises an annular auxiliary electrode, a solid-state reference electrode and a wire working electrode, the annular auxiliary electrode and the solid-state reference electrode form an annulus, the wire working electrode is located in the solid-state reference electrode, the wire working electrode and the solid-state reference electrode are isolated from each other through an insulation material, and the solid-state reference electrode is located in the annular auxiliary electrode. By utilizing the system, interface electrochemical information such as couple current, corrosion potential, corrosion current density and electrochemical impedance spectra under a coupling / non-coupling state of an electrode can be conveniently and comprehensively acquired. Meanwhile, the invention further provides a testing method of the system.

Owner:恩迪检测技术(青岛)有限公司

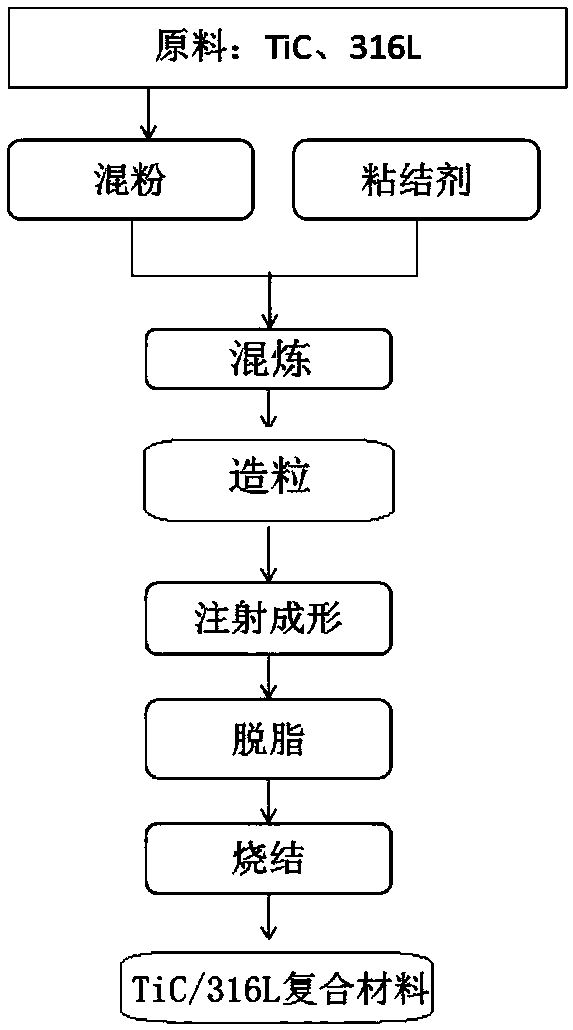

TiC/316L composite and preparing method thereof

ActiveCN108380889ATransportation and packagingMetal-working apparatusHardnessVolumetric Mass Density

The invention provides a TiC / 316L composite and a preparing method thereof, and belongs to the field of metal materials. The method comprises the following steps that TiC and 316L stainless steel powder are mixed and dried, and mixed powder is obtained; the mixed powder and a binding agent are mixed, and a mixed material is obtained; the mixed material is subject to granulation and injection forming in sequence, and a formed blank body is obtained; the formed blank body is subject to degreasing and sintering, and the TiC / 316L composite is obtained; the TiC / 316L composite has the good mechanical property, the hardness ranges from 238 to 288 HV, the tensile strength ranges from 502 to 508 MPa, the friction coefficient ranges from 0.55 to 0.70, the wear amount is reduced by 10 to 14% comparedwith the same-process pure 316 L stainless steel sintering test part, the corrosion current density ranges from 0.0079 to 0.0167mA / cm<2> in the 3.5% NaCl solution, and the corrosion potential is -0.706 to -0.676V.

Owner:HUAIHAI INST OF TECH

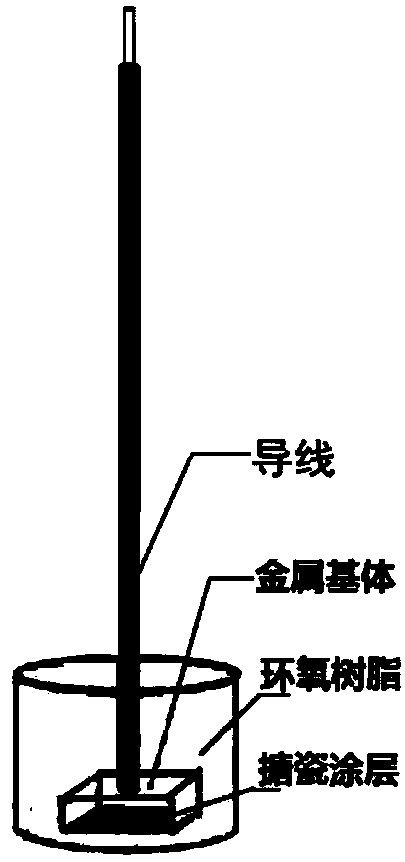

Enamel coating electrode as well as preparation method and corrosion resistance test method

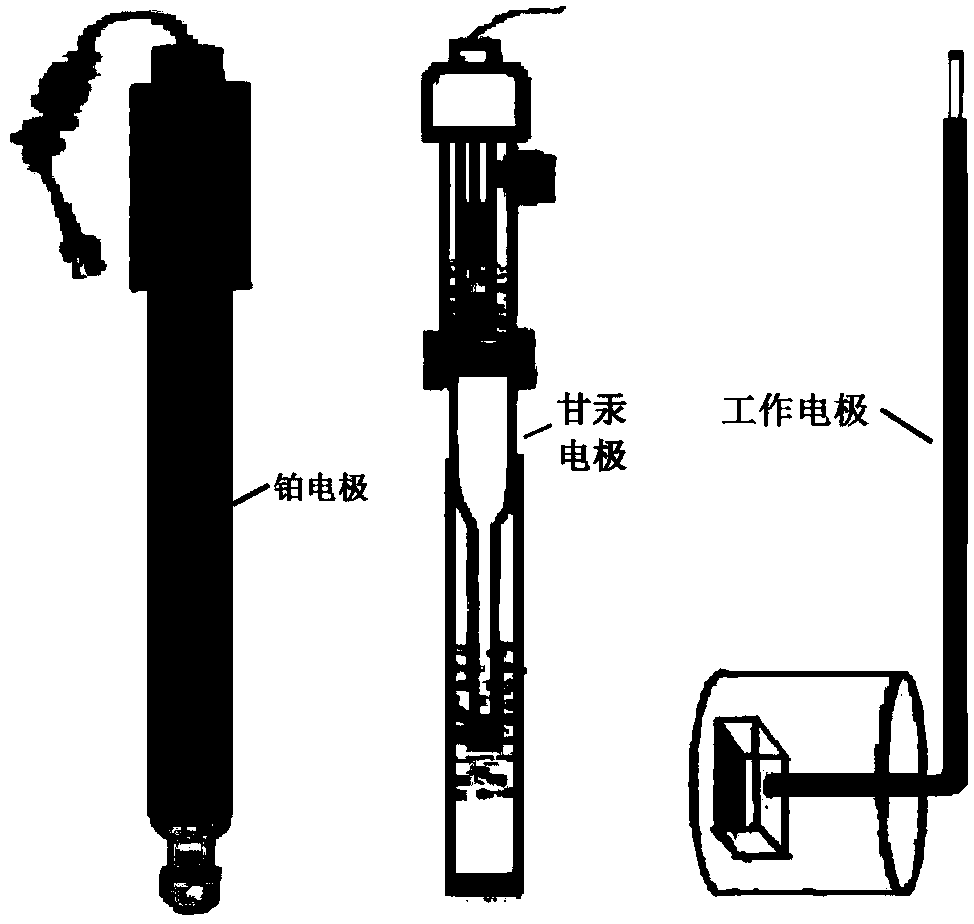

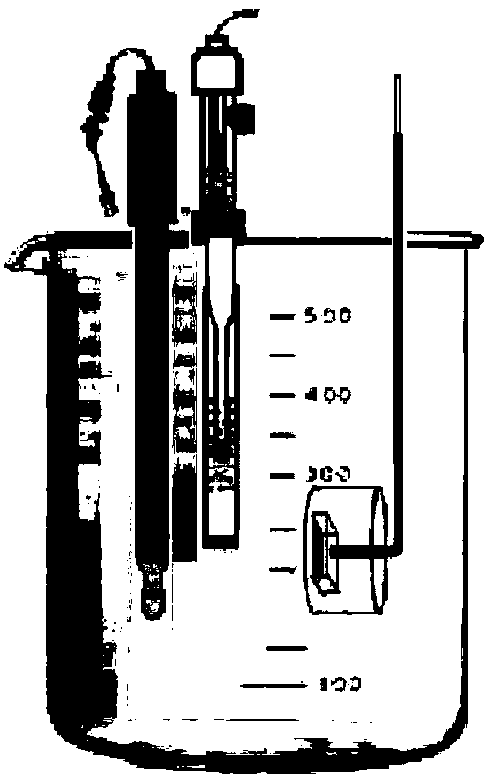

PendingCN108548775ANo crackingGuaranteed smoothWeather/light/corrosion resistancePlatinumAnalysis method

The invention belongs to the technical field of electrochemical materials, and particularly relates to an enamel coating electrode as well as a preparation method and a corrosion resistance test method. The technical problem solved by the invention is to detect the corrosion resistance of an enamel coating, and detection can be performed through an electrochemical analysis method. The test methodcomprises the following steps of preparing the enamel coating electrode firstly, then connecting and testing a polarization curve, which is in the corrosive solution system, of an enamel coating through the enamel coating electrode, an platinum electrode, a calomel reference electrode and an electrochemical analyzer, calculating the corrosion potential Ecorr and corrosion current density icorr ofthe enamel coating to obtain the corrosion rate V of the enamel coating finally. The method has the advantages of simple operation, less time consumption, more accurate result and the like.

Owner:PANZHIHUA UNIV

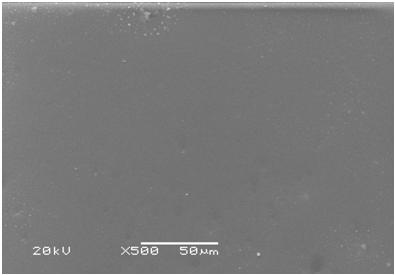

Preparation method for corrosion-resistant organic composite coating on surface of magnesium alloy

ActiveCN107855254AImprove corrosion resistanceEasy to operateAnodisationPretreated surfacesEpoxyMicro arc oxidation

The invention discloses a preparation method for a corrosion-resistant organic composite coating on the surface of magnesium alloy. The preparation method comprises the following steps: first, performing pre-treatment, such as grinding, polishing, water washing, oil removing and ultrasonic washing, on a magnesium alloy substrate in sequence; then, preparing micro-arc oxidizing electrolyte, and performing micro-arc oxidizing on the magnesium alloy which is subjected to the pre-treatment to form a micro-arc oxidation film; next, mixing epoxy resin and polyamide in proportion, dip-coating the surface of the micro-arc oxidation film with a mixture, and standing and drying at room temperature; and finally, dipping the micro-arc oxidation film in a polyacrylamide aqueous solution, taking out themicro-arc oxidation film, and frying for 1 to 12 hours at 80 to 150 DEG C to prepare the corrosion-resistant organic composite coating on the surface of the magnesium alloy. The method disclosed by the invention is easy to operate; the prepared organic composite coating on the surface of magnesium alloy can be bonded firmly with a substrate, has a smooth, uniform and dense surface, completely cover micro-pores of the micro-arc oxidation film, has high electrochemical impedance, low corrosion current density and hydrophobic property, and can improve the corrosion resistance of the magnesium alloy well.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

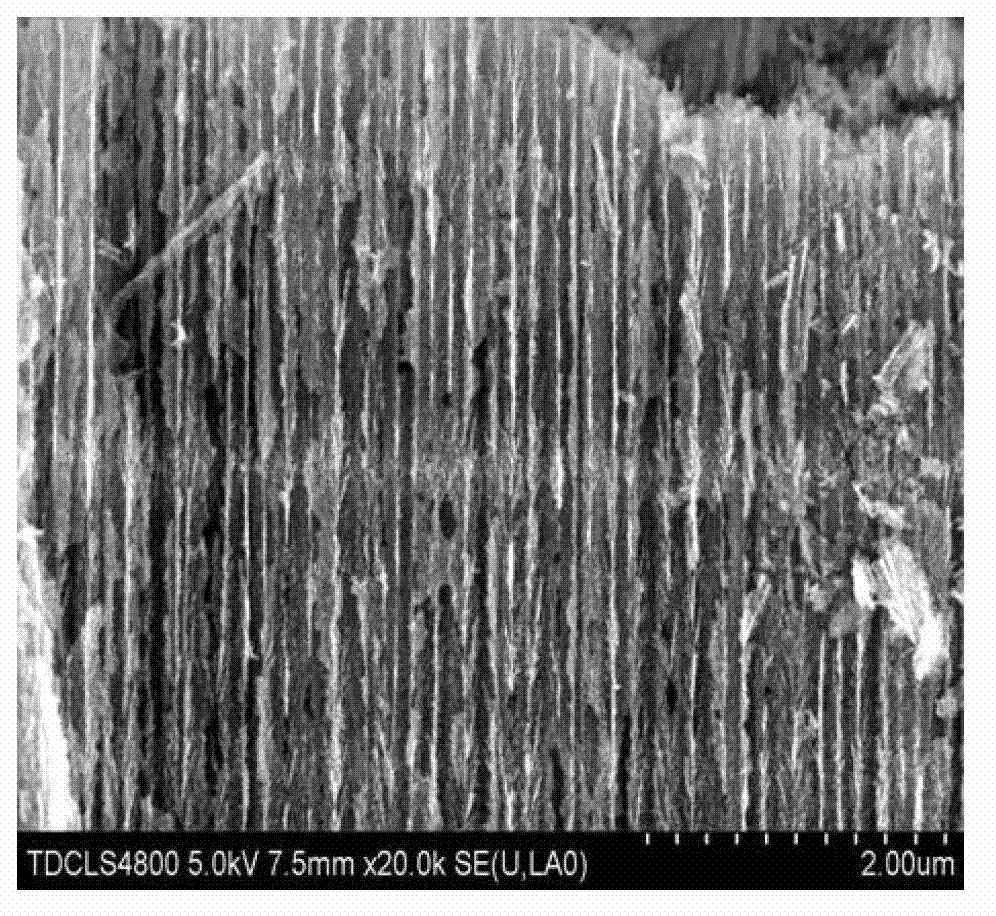

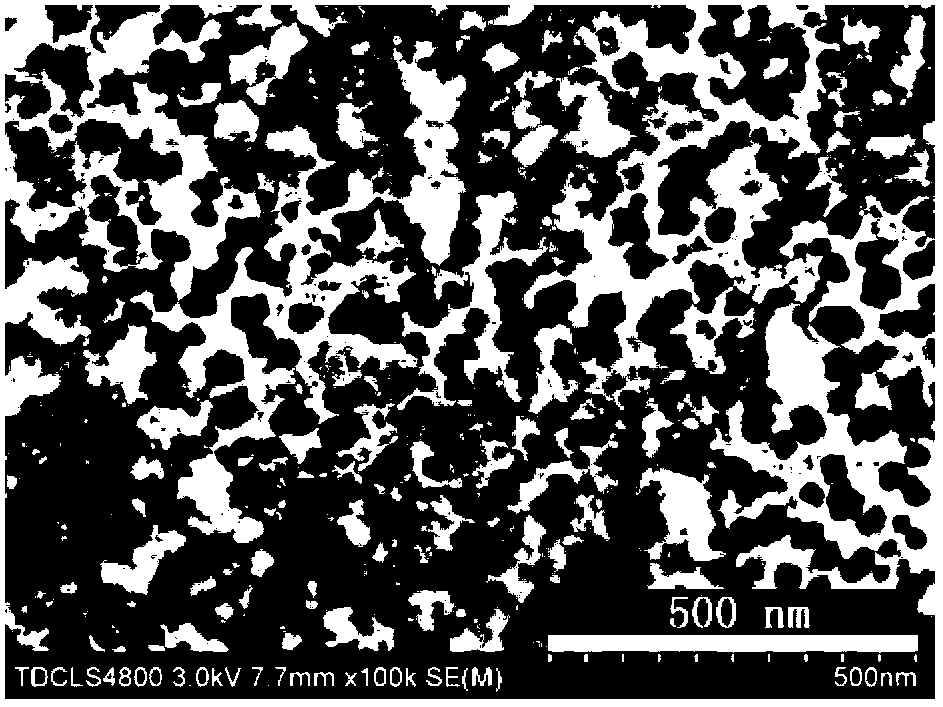

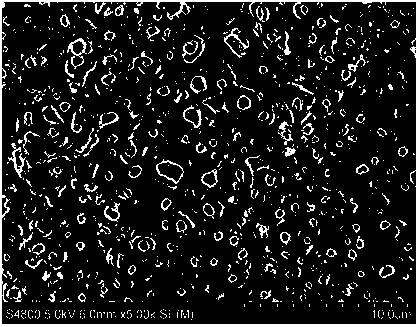

Method capable of improving uniformity of porous silicon film physical micro-structure and optical characteristics

InactiveCN102874746AImprove uniformityConducive to the establishment of flatnessDecorative surface effectsChemical vapor deposition coatingMicro structureDynamic balance

Provided is a method capable of improving uniformity of a porous silicon film physical micro-structure and optical characteristics. By reducing corrosion current density gradually, vesicularity in the longitudinal direction is reduced or refractive index is increased, increased vesicularity or reduced refractive index caused by increasing of corrosion depth is offset under the condition of constant corrosion current, so that a dynamic balancing state of the vesicularity and the refractive index is achieved, the uniformity of the physical micro-structure along the longitudinal direction of the porous silicon film and the optical characteristics is improved. The method has the advantages of improving the uniformity of the porous silicon film longitudinal physical micro-structure and the optical characteristics by reducing corrosion current density gradually so as to improve the uniformity of the physical micro-structure and the optical characteristics along the longitudinal direction; being favorable for building smooth level among multi-layer film interfaces of porous silicon; and being favorable for exploring an achieving scheme of a porous silicon multi-layer film with improved use uniformity and interface smooth level in photonic devices such as Prague reflectors and micro-cavities and achieving any wavelength hot shot of porous silicon micro-cavities possibly.

Owner:HUNAN UNIV OF ARTS & SCI

Multifunctional concrete structure steel bar corrosion ratio detector

InactiveCN104931409AEasy to operateEasy maintenanceWeather/light/corrosion resistanceHuman–machine interfaceRebar

The invention relates to a multifunctional concrete structure steel bar corrosion ratio detector. The multifunctional concrete structure steel bar corrosion ratio detector is characterized in that a host is composed of a human-computer interface operation module, a data collecting, processing and storing module, a temperature, humidity and carbon dioxide measuring and sensing module and a power module; according to a composite type signal collecting device, a plurality of half-cell electrodes of the same type are designed in a disc-shaped box at equal interval to form mutual compensation circuits so that non-destruction corrosion quantitative determination can be achieved; according to the detector, the faraday's law, a linear polarization method and potentiometry are comprehensively utilized for measuring the corrosion average cross section loss ratio, the corrosion current density and the position, range and degree of a corrosion pit, and therefore a corrosion average cross section loss ratio chart and a corrosion pit position, range and degree distribution diagram are drawn; meanwhile, the temperature, humidity and carbon dioxide concentration of the environment where a concrete structure is located are measured, and the corrosion condition and corrosion trend of the concrete structure are judged scientifically and quantitatively from many aspects. The multifunctional concrete structure steel bar corrosion ratio detector can provide important bases for safety and durability quantitative evaluation of the concrete structure.

Owner:聂志虎

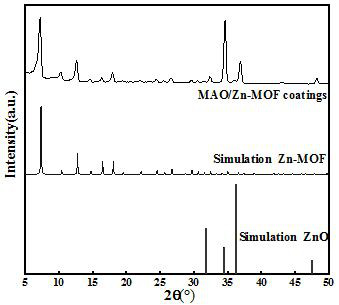

Fluorine-free super-hydrophobic Zn-MOF composite coating on surface of magnesium alloy and preparation method thereof

ActiveCN112522703AImprove bindingAchieve superhydrophobic effectAnodisationSuperimposed coating processMicro arc oxidationStearic acid

The invention discloses a fluorine-free super-hydrophobic Zn-MOF composite coating on the surface of a magnesium alloy and a preparation method thereof. The fluoride-free super-hydrophobic Zn-MOF composite coating on the surface of the magnesium alloy specifically comprises a micro-arc oxidation layer, a Zn-MOF layer and a stearic acid layer which are sequentially attached to the surface of the magnesium alloy. A magnesium alloy matrix is sequentially subjected to grinding and polishing, oil removal and ultrasonic cleaning, then micro-arc oxidation treatment is carried out, after a micro-arc oxidation film is formed on the surface of the magnesium alloy matrix, the micro-arc oxidation film is placed in a polytetrafluoroethylene reaction kettle for high-temperature and high-pressure reaction to form the Zn-MOF coating, and finally the Zn-MOF coating is treated with a low-surface-energy substance stearic acid, and the fluorine-free super-hydrophobic Zn-MOF composite coating on the surface of the magnesium alloy is obtained after drying. The method is simple in preparation process and free of fluorine, the composite coating and a magnesium alloy base material have good binding force,the composite coating can be evenly distributed on the surface of the magnesium alloy, the corrosion current density is low, the super-hydrophobic effect is achieved, and good corrosion resistance isshown.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

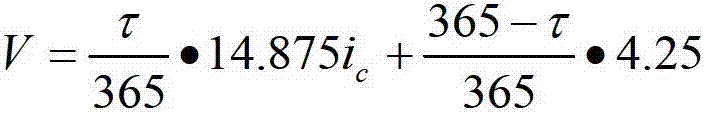

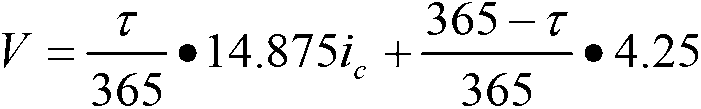

Method for predicting corrosion life of transmission line hardware in industrial area

ActiveCN103134748ARapid Corrosion Life PredictionCorrosion Life PredictionWeather/light/corrosion resistanceEpoxyCopper wire

The invention discloses a method for predicting the corrosion life of transmission line hardware in an industrial area. The method for predicting the corrosion life of the transmission line hardware in the industrial area comprises the following steps: (1) sampling from the hardware from the transmission line; (2) connecting a copper wire and packaging epoxy resin; (3) calculating the local annual average potential hydrogen (pH) value of acid rain; (4) configuring simulated acid rain solution; (5) putting the simulated acid rain solution into a three-electrode system electrolytic tank to test; (9) calculating annual average rate of the corrosion depth in a medium-long term; (10) measuring the average value of the thickness of the zinc coating of the hardware; and (11) obtaining the rest of corrosion life of the zinc coating. The method for predicting corrosion life of the transmission line hardware in the industrial area has the advantages that the traditional constraints is broken, the thickness of the zinc coating which is arranged on the surface can be measured, evaluations of the corrosion speed and the service life of the transmission line hardware in the industrial area wherein the pH value of the acid rain is <=5.2 can be achieved, the evaluation is fast and accurate, and the safe of power grids is guaranteed.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

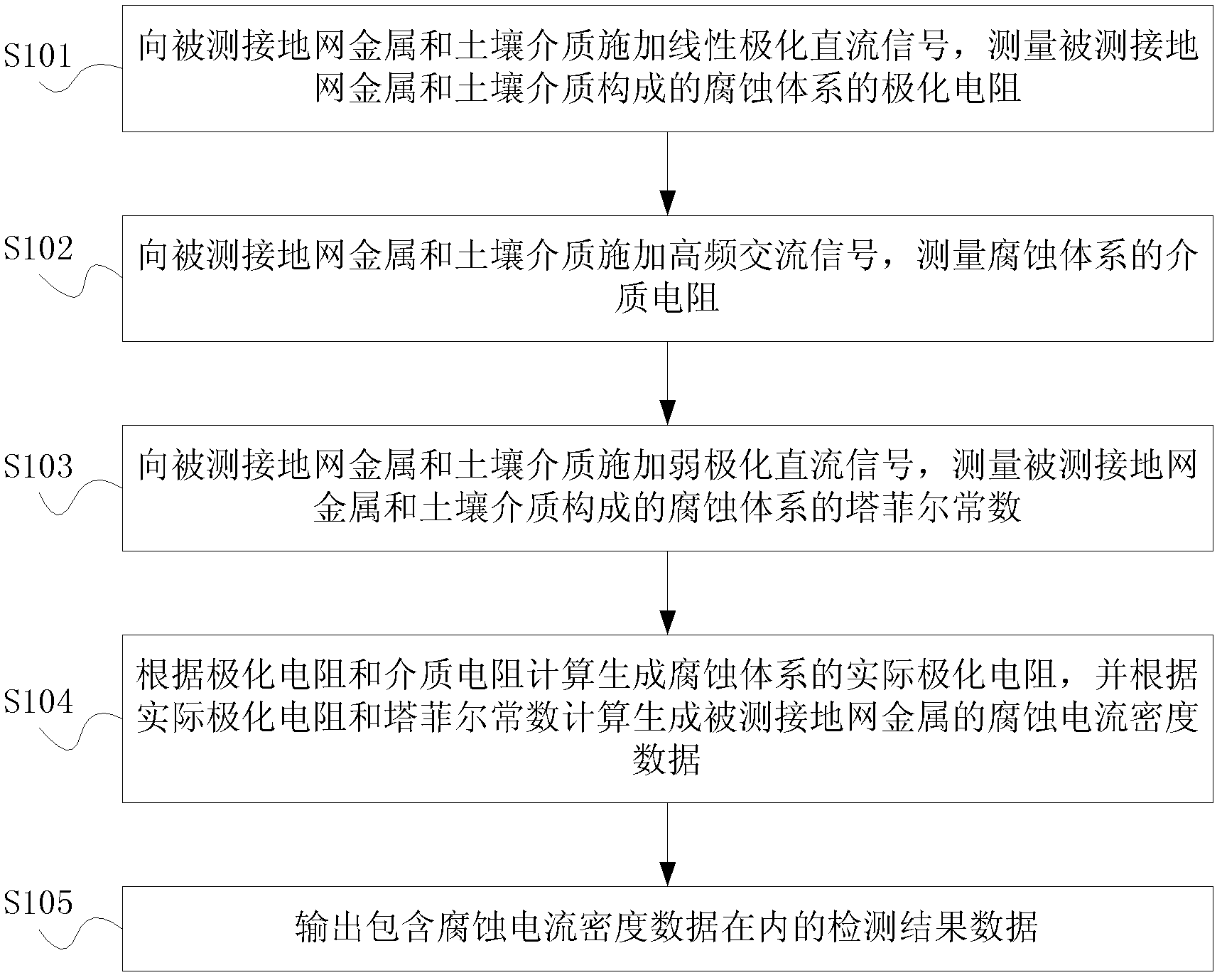

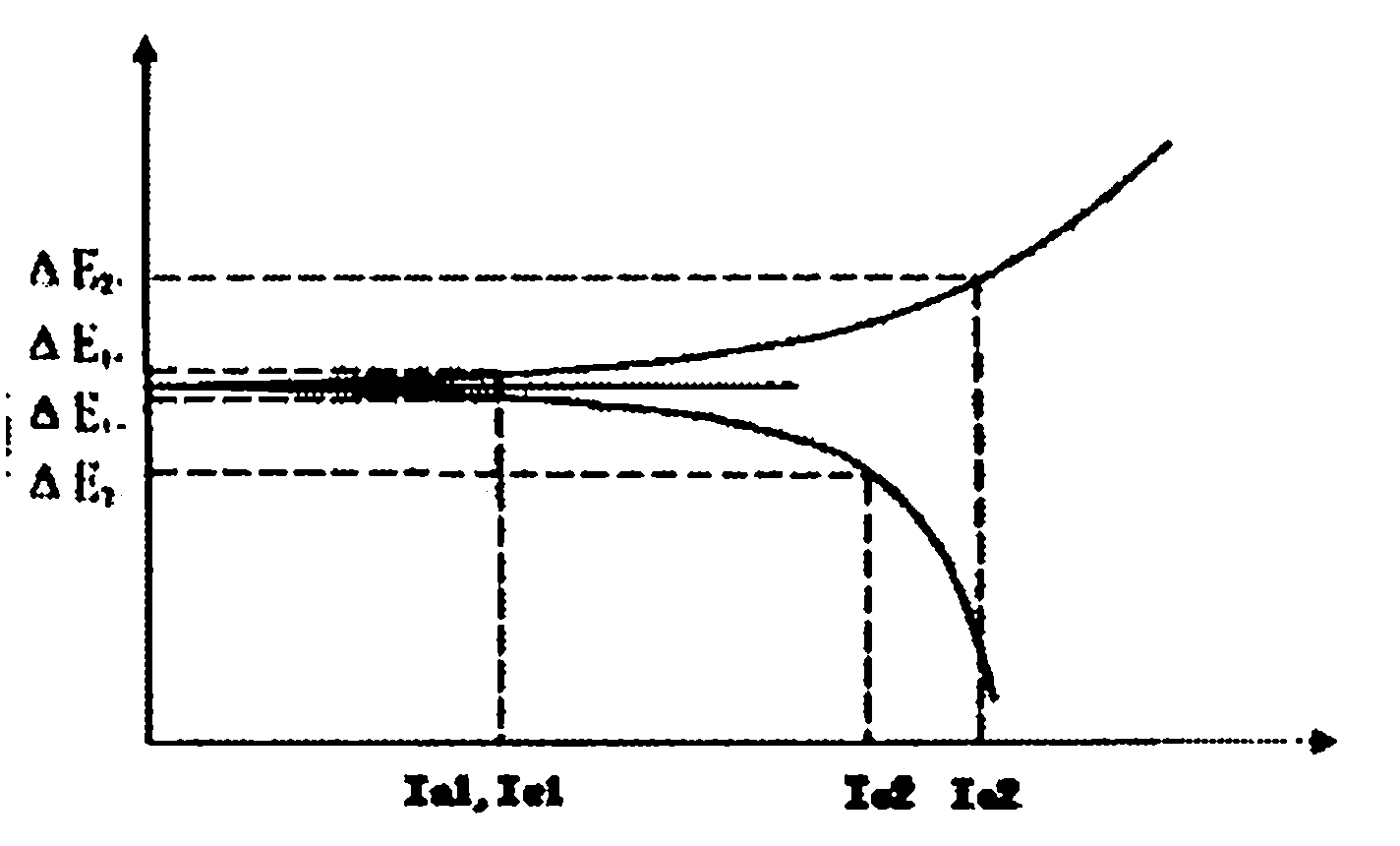

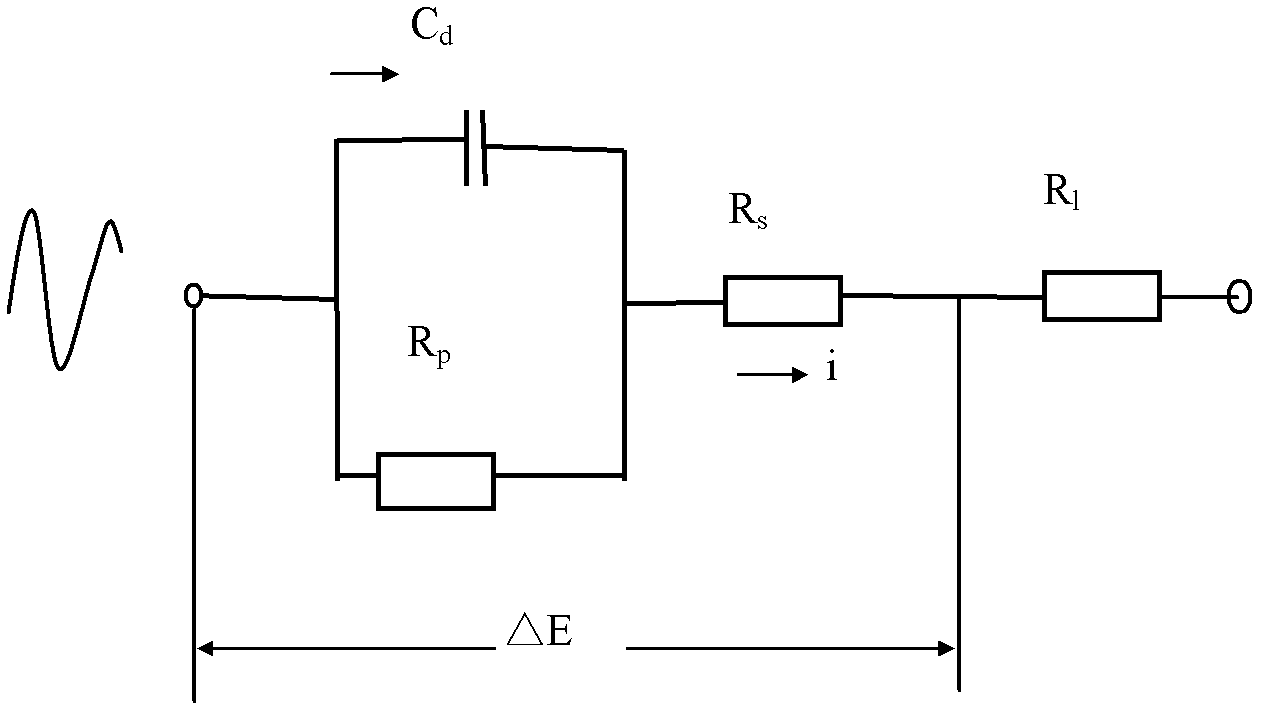

Method and device for detecting corrosion of grounding grid of electric transmission line iron tower

ActiveCN103105355ARealize on-site inspectionImprove accuracyWeather/light/corrosion resistanceDielectricEngineering

The invention discloses a method and a device for detecting the corrosion of a grounding grid of an electric transmission line iron tower. The device comprises a polarization resistance detection unit, a dielectric resistance detection unit, a Tafel constant detection unit, a detection result generating unit and a detection result output unit, wherein the polarization resistance detection unit is used for applying a linear polarization direct current signal to detected grounding grid metal and soil medium for measuring the polarization resistance of a corrosion system; the dielectric resistance detection unit is used for applying a high-frequency alternating current signal to the detected grounding grid metal and soil medium for measuring the dielectric resistance of the corrosion system; the Tafel constant detection unit is used for applying a weak polarization direct current signal to the detected grounding grid metal and soil medium for measuring the Tafel constant of the corrosion system; the detection result generating unit is used for calculating and generating the actual polarization resistance of the corrosion system according to the polarization resistance and the dielectric resistance and calculating and generating corrosion current detection data of the detected grounding grid metal according to the actual polarization resistance and the Tafel constant; and the detection result output unit is used for outputting detection result data including the corrosion current density data. The device is used for solving the problem of corrosion detection of the grounding grid of the electric transmission line iron tower.

Owner:NORTH CHINA ELECTRICAL POWER RES INST +1

Germanium-contained (Ge-contained) corrosion-resistant aluminum-based solder

InactiveCN103008908AThe process is simple and easy to controlLow content of Ge elementWelding/cutting media/materialsSoldering mediaCeriumCopper

The invention discloses germanium-contained (Ge-contained) corrosion-resistant aluminum-based solder. The solder comprises the following components in mass percent: 6.5 percent of silicon (Si), 15.0 percent of copper (Cu), 0.1-8.0 percent of Ge, 6.0 percent of stannum (Sn), 1.0 percent of cerium (Ce) and the balance aluminum (Al). The solder is prepared by adopting the rapid cooling technique. The melting point of the solder is lower than 520 DEG C, and the brazing temperature is 540-550 DEG C. The Ge-contained corrosion-resistant aluminum-based solder is suitable for brazing of aluminum alloy of which the solidus is higher than 550 DEG C, such as flame brazing, induction brazing, furnace brazing and gas shield brazing. The solder is matched with a QJ201 brazing aluminum plate 3003, so that the shear strength of a brazed joint is higher than 82MPa. When the percentage composition of the Ge is 2.5, the corrosion resistance of solder alloy is optimal, and the corrosion current density is 3.562muAcm<-2>.

Owner:ZHEJIANG UNIV +1

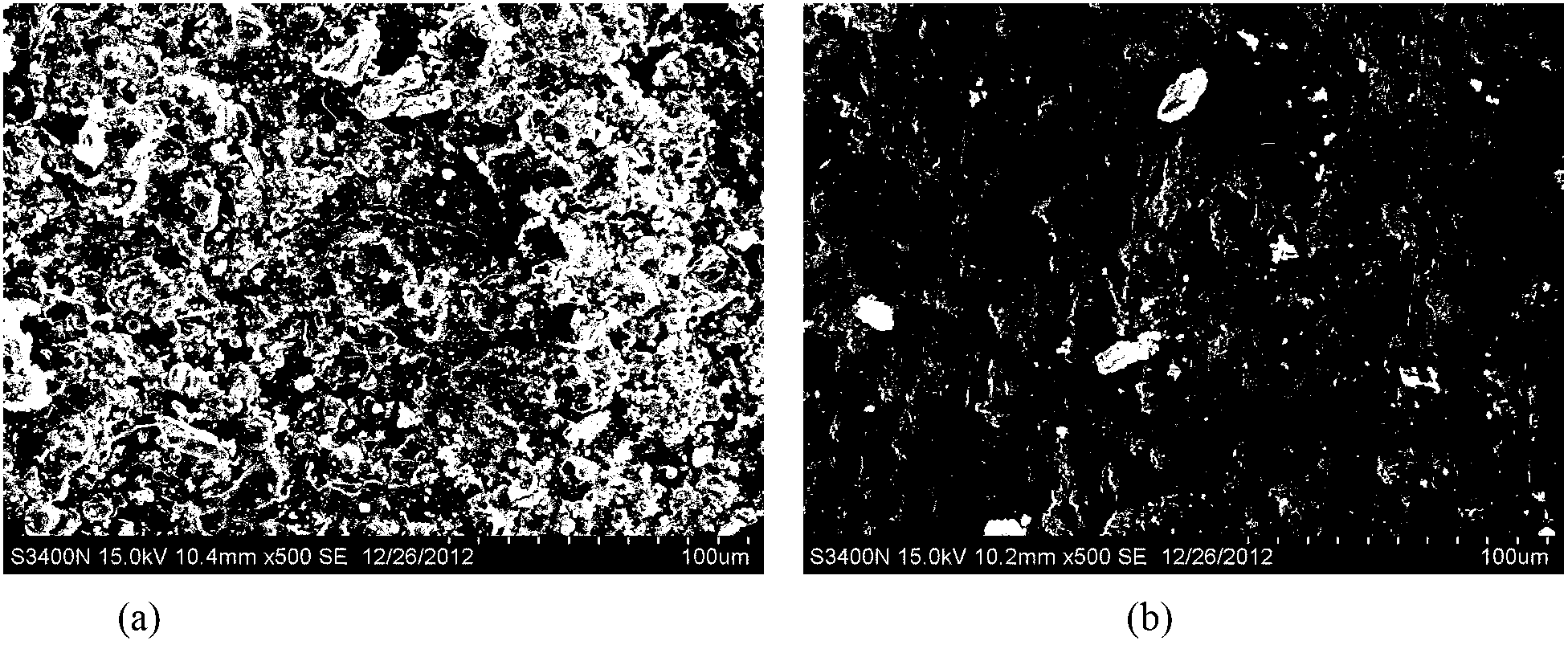

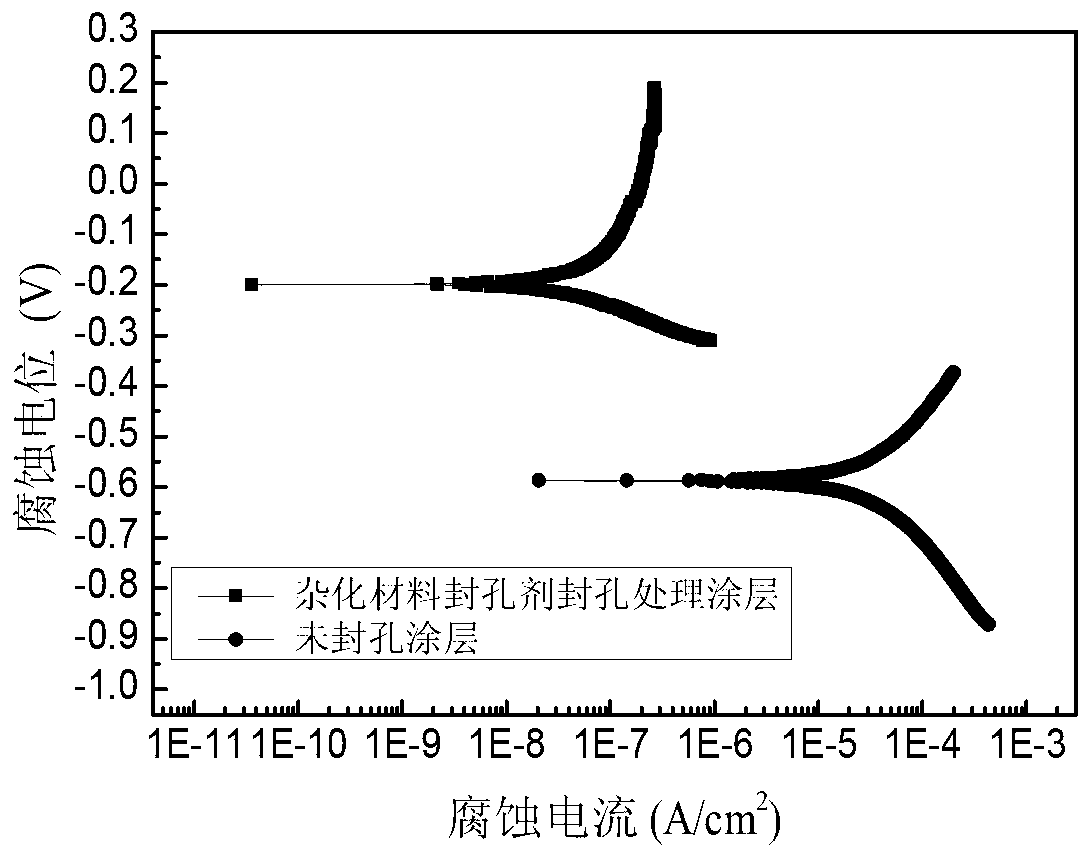

Hybrid material hole sealing agent for improving corrosion resistance of plasma spraying coating in acid environment

InactiveCN103184406AGood sealing effectStrong acid corrosion resistanceMolten spray coatingPorosityN dimethylformamide

A hybrid material hole sealing agent for improving corrosion resistance of a plasma spraying coating in acid environment is composed of the following components: ethyl orthosilicate, anhydrous ethanol, N,N-Dimethylformamide, Gama-methacryloxy propyl trimethoxyl silane, 25vol.% nitric acid, 25vol.% ammonia water and distilled water, wherein the proportion according to volume ration of ethyl orthosilicate to anhydrous ethanol to N,N-Dimethylformamide to distilled water to Gama-methacryloxy propyl trimethoxyl silane is equal to 4:3:1:(4-6), and the volume of N,N-Dimethylformamide is 20% to 30% of the total volume of ethyl orthosilicate, anhydrous ethanol, distilled water and Gama-methacryloxy propyl trimethoxyl silane; and the hybrid material hole sealing agent is prepared with a sol-gel method, wherein the 25vol.% nitric acid and 25vol.% ammonia water are used as pH regulators. The porosity factor of the plasma spraying coating processed by using the hybrid material hole sealing agent is reduced to 1 / 40 to 9 / 250 of that of a coating with unsealed holes, the electrochemical corrosion potential is increased by 65.2% to 65.8% of that of the coating with unsealed holes, and the corrosion current density is reduced to 1 / 370 to 1 / 500 of that of the coating with unsealed holes.

Owner:HOHAI UNIV

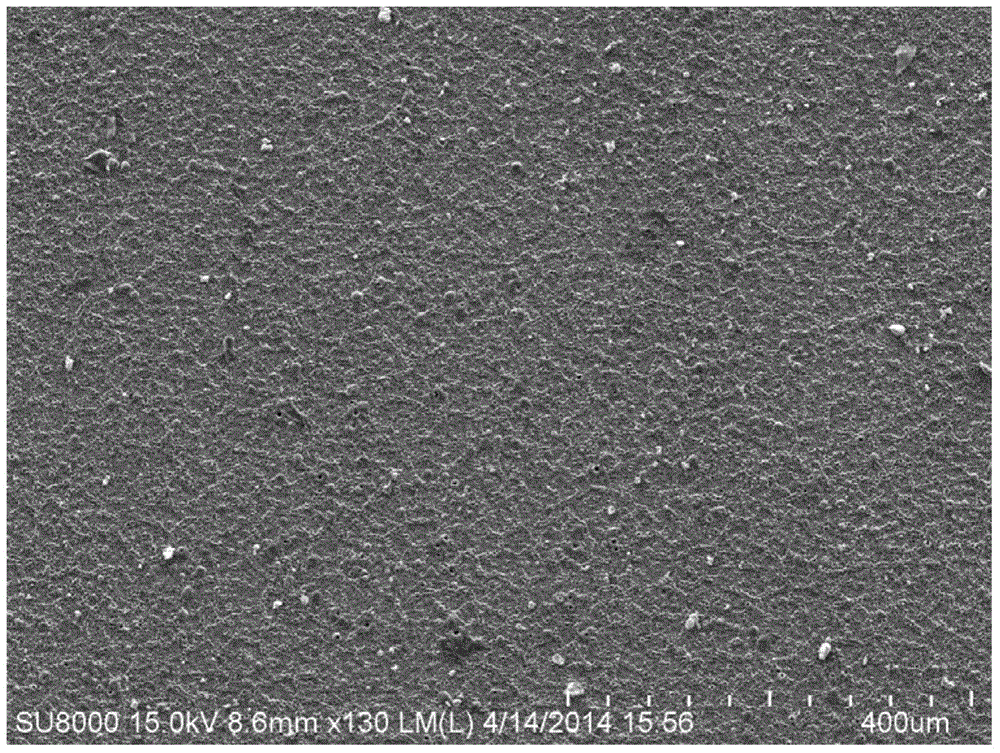

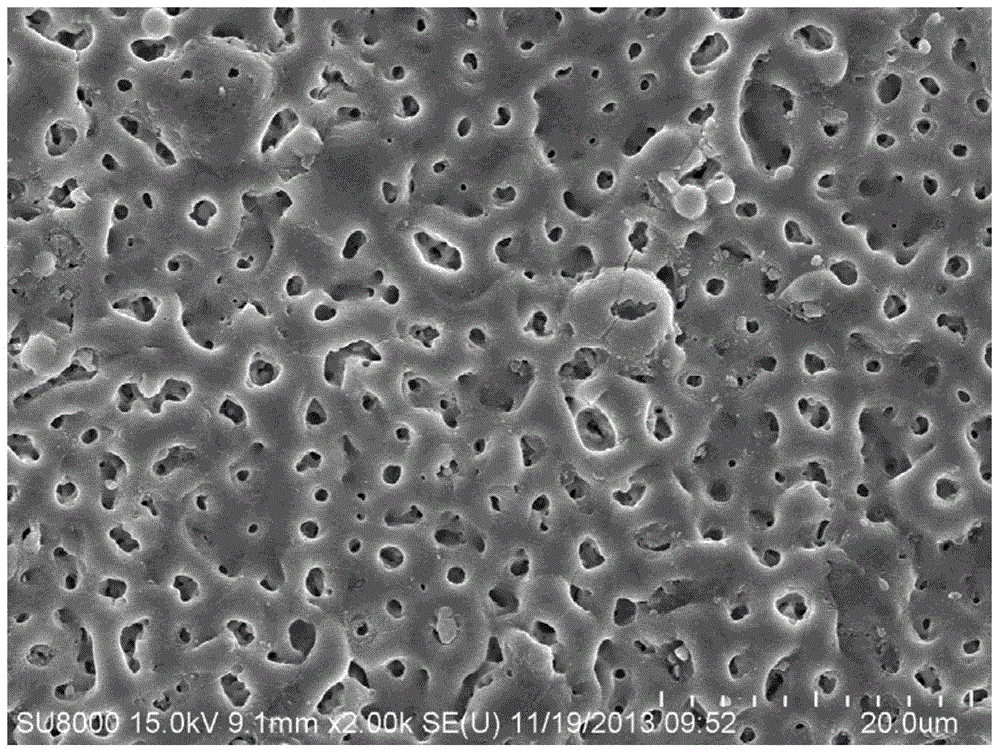

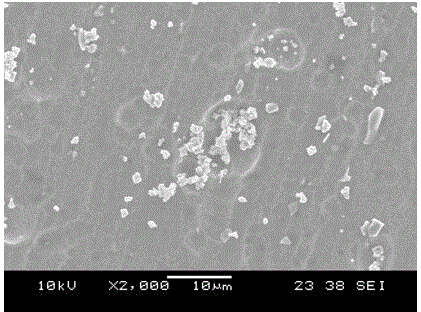

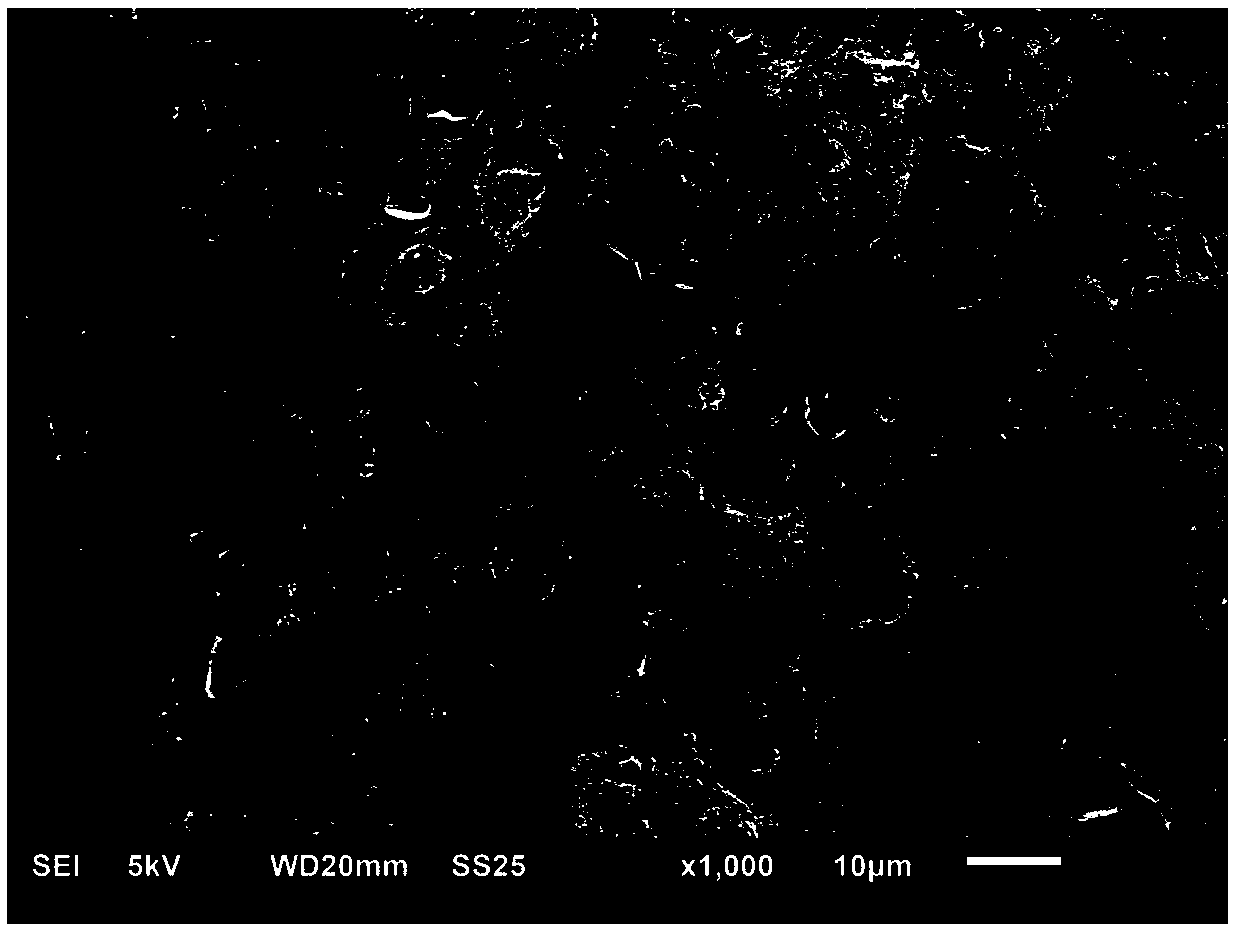

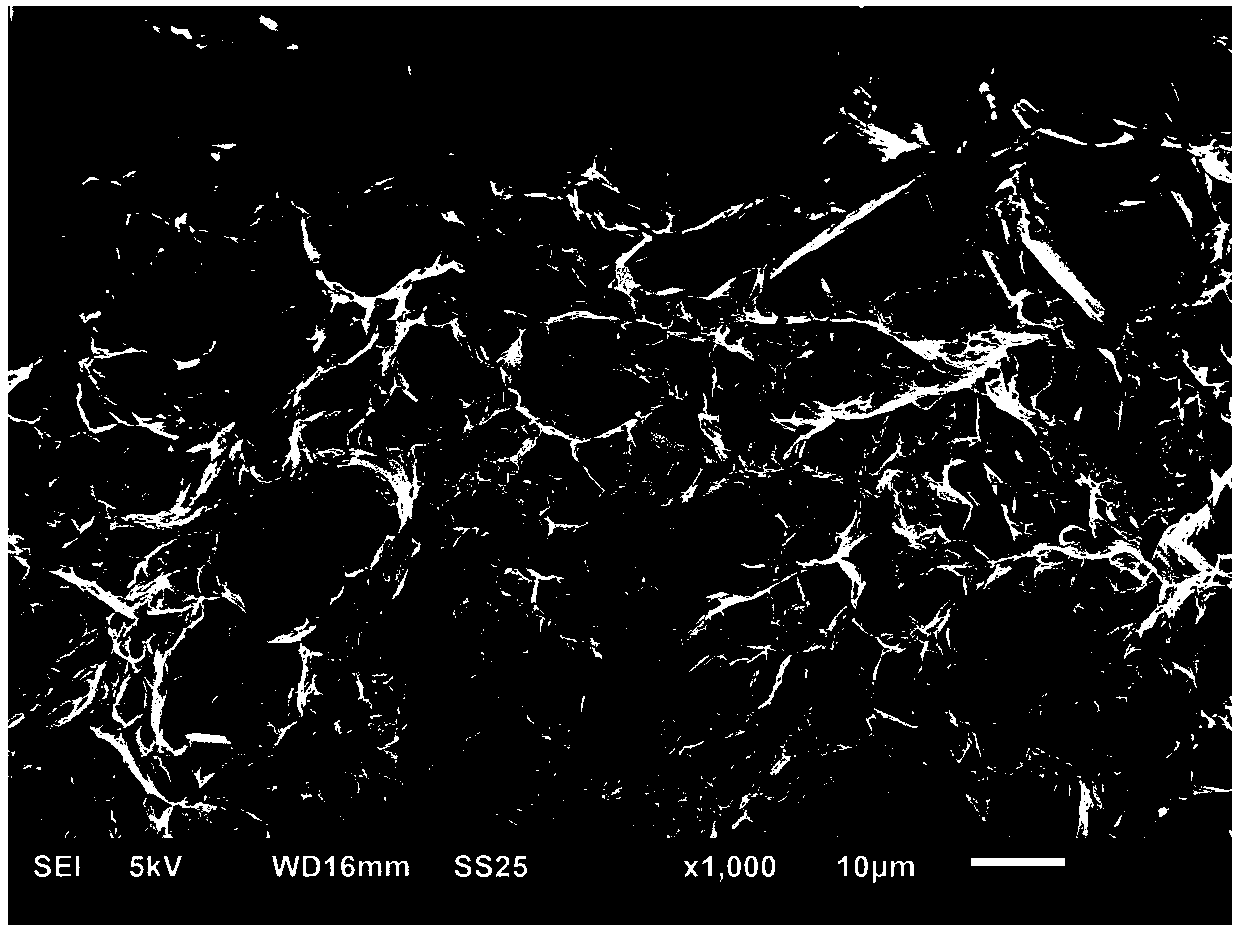

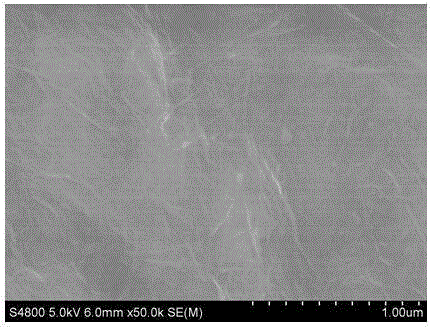

Preparing method for graphene oxide composite coating on surface of magnesium alloy

ActiveCN105350049AImprove corrosion resistanceEasy to operateElectrolytic coatingsElectrolytic agentOxide composite

The invention discloses a preparing method for a graphene oxide composite coating on the surface of a magnesium alloy. The preparing method includes the steps that firstly, a magnesium alloy matrix is preprocessed; then, graphene oxide is prepared and dissolved into a 1-5 ml / L triethanolamine water solution and is subjected to ultrasonic dispersing for 2 hours to serve as an electroplating electrolyte; afterwards, a CHI860D type electrochemical workstation is used for assembling a three-electrode system, the preprocessed magnesium alloy serves as a study electrode, a platinum electrode serves as an auxiliary electrode, a saturated calomel electrode serves as a reference electrode, and the chronoamperometry is selected for conducting electrochemical deposition on the magnesium alloy; and finally, the magnesium alloy is taken out to be dried for 1-2 hours at the temperature ranging from 60 DEG C to 70 DEG C, and the graphene oxide composite coating on the surface of the magnesium alloy is obtained. The method is easy to operate, the surface of the obtained composite coating is even and flat, a typical crumple structure of the graphene oxide exists, low corrosion current density and high electrochemical resistance are achieved, and corrosion resistance of the magnesium alloy can be well improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com