Patents

Literature

33results about How to "Small atomic radius" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

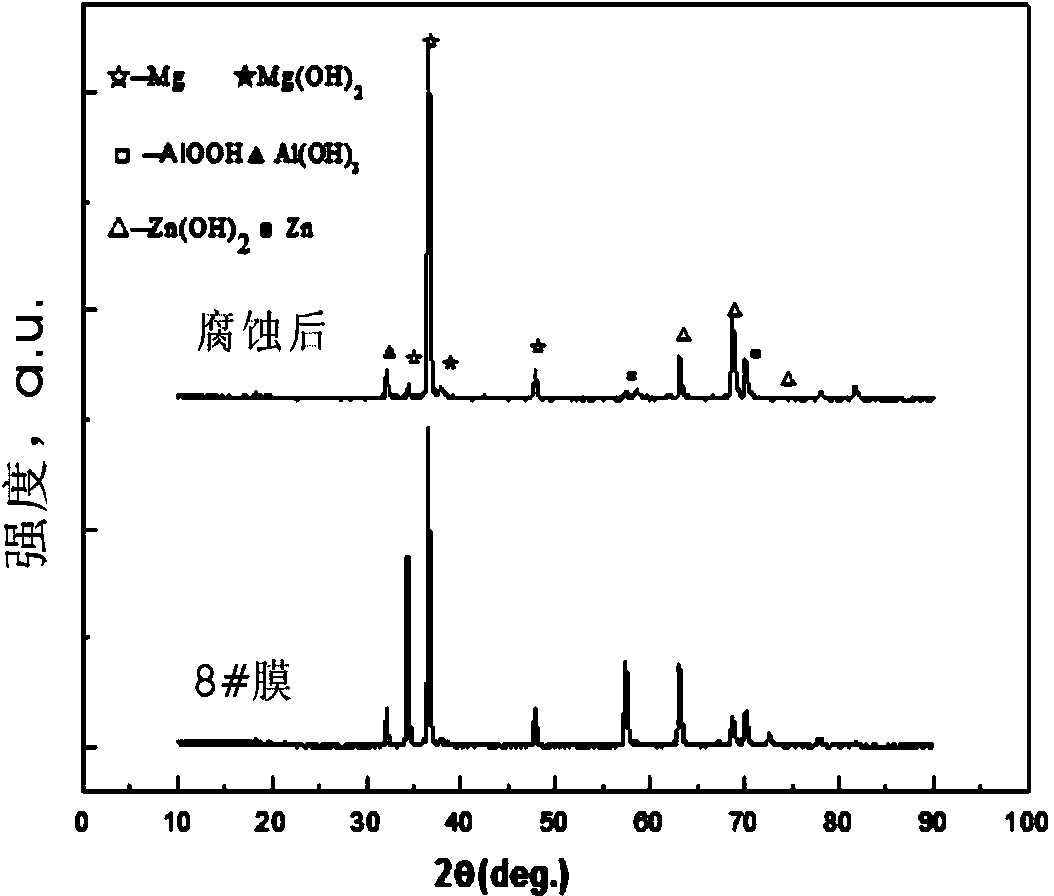

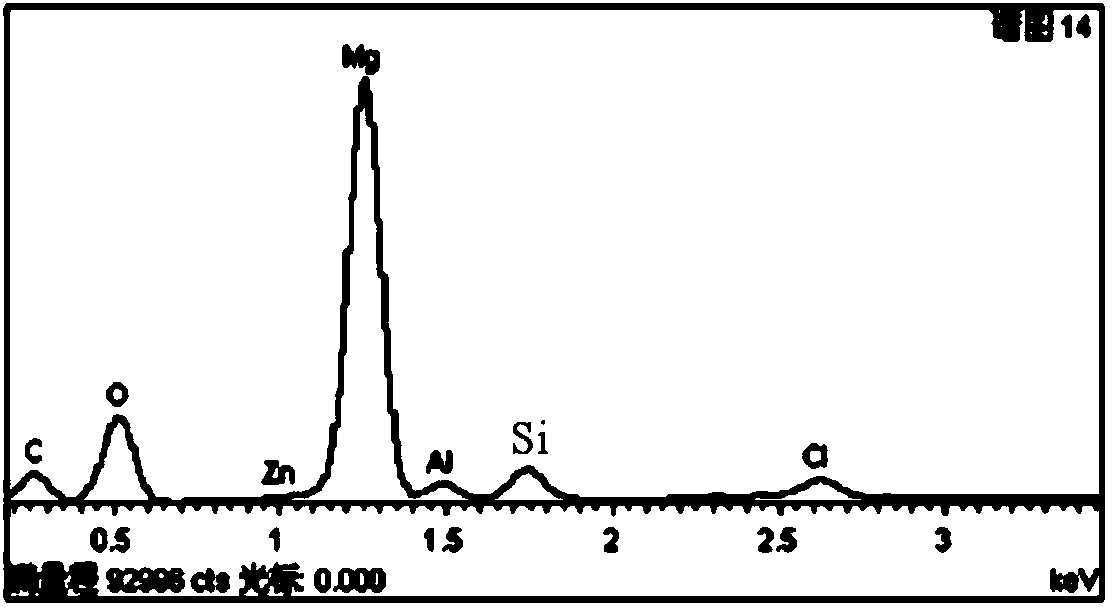

Corrosion resistant film prepared by magnesium alloy surface hydrothermal method and preparation technology thereof

ActiveCN103614717ASmall atomic radiusImprove polarization performanceMetallic material coating processesSolubilityLithium

The invention discloses a corrosion resistant film prepared by a magnesium alloy surface hydrothermal method and a preparation technology thereof, belongs to the technical field of magnesium surface processing, and solves the problem of bad corrosion resistant property of magnesium alloy in the prior art. The technology provided by the invention comprises the following steps: placing a processed magnesium alloy sample into a hydrothermal reactor, then injecting a treating fluid into the reactor according to a certain filling degree, and putting the reactor into a thermotank to maintain the temperature. The treating liquid comprises sodium hydroxide and lithium salt, sodium hydroxide provides a proper alkaline environment for film forming, lithium salt has a large solubility in water, Li+ can hydrolyze in water with a great amount at a certain temperature, so the pH value of the solution is improved so as to promote the film forming reactions on the magnesium alloy surface to move in the positive direction, the obtained film in situ grows on the magnesium alloy surface; the force between the film and the substrate body is excellent, the film is uniform, compact and ultra-thin, and has an excellent corrosion resistant property; the corrosion current density of the conversion film is increased by five magnitude orders compared to that of the substrate body, and reaches 10<-9> A / cm<2> magnitude grade.

Owner:曾荣昌

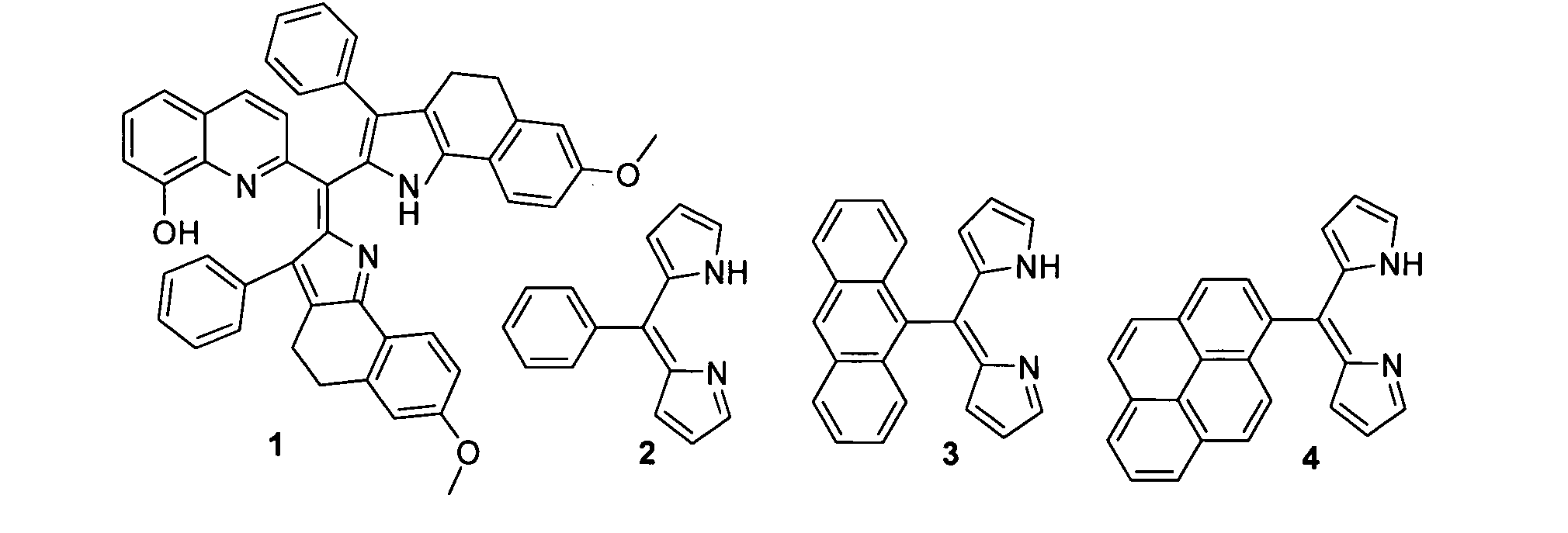

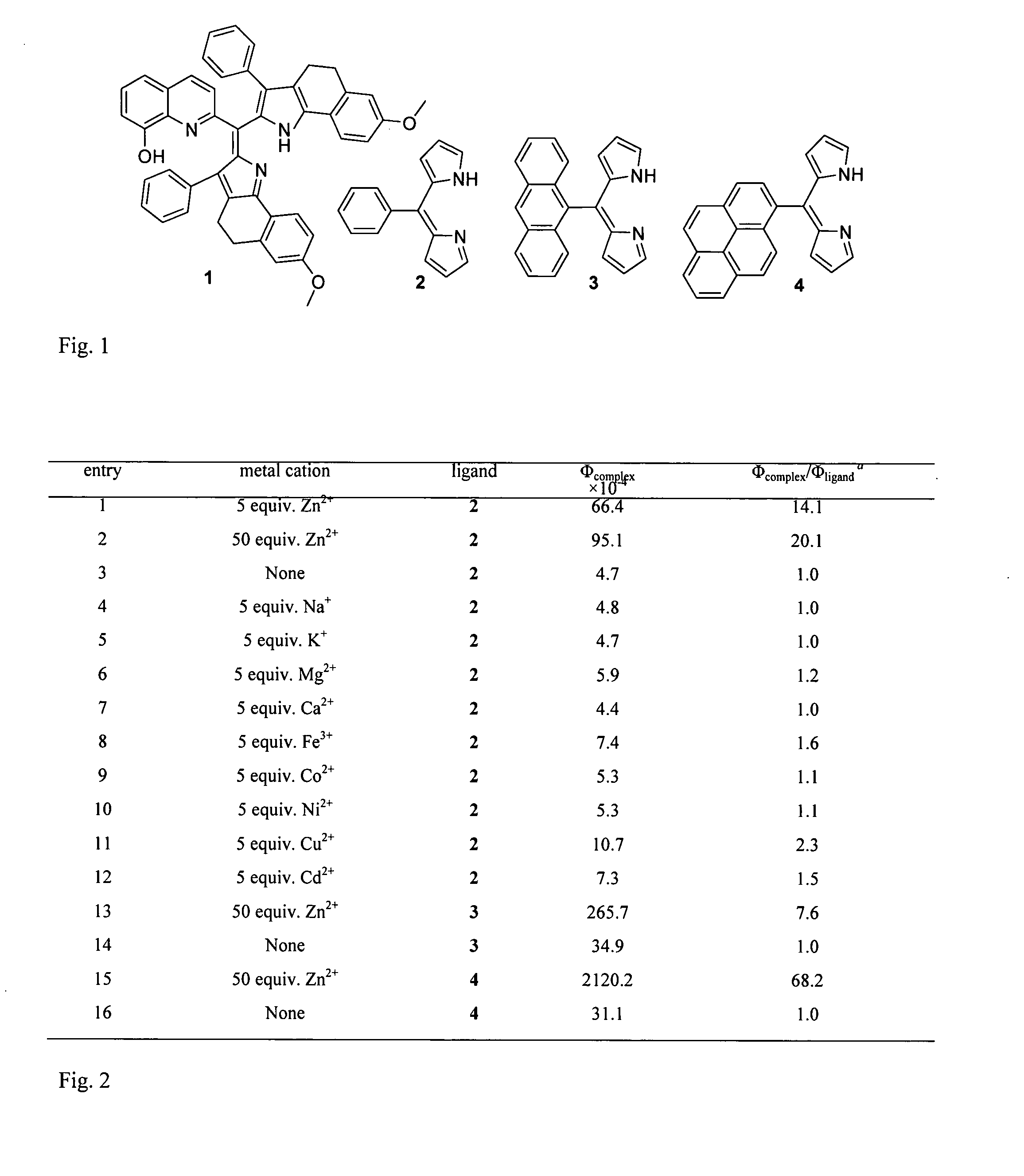

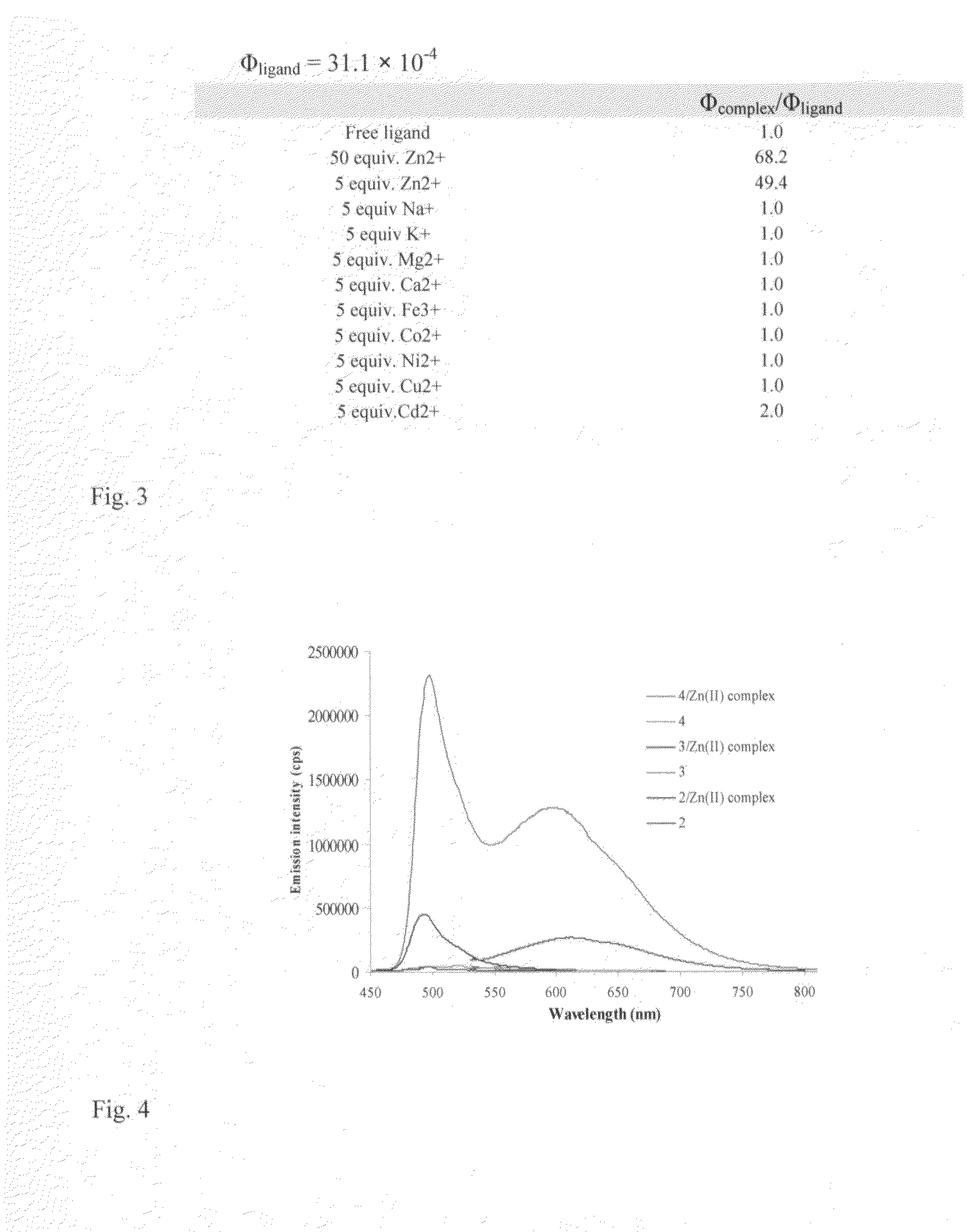

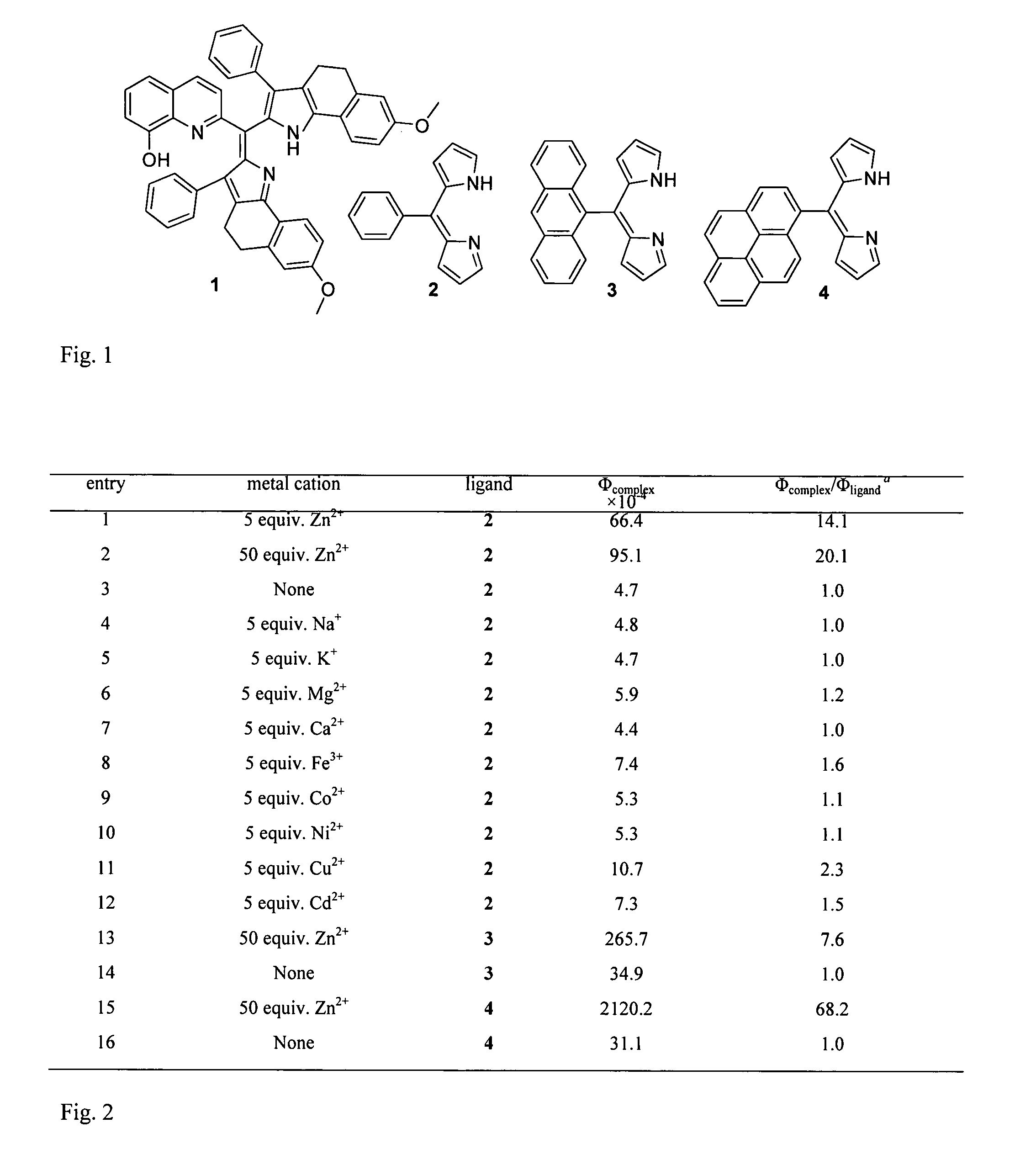

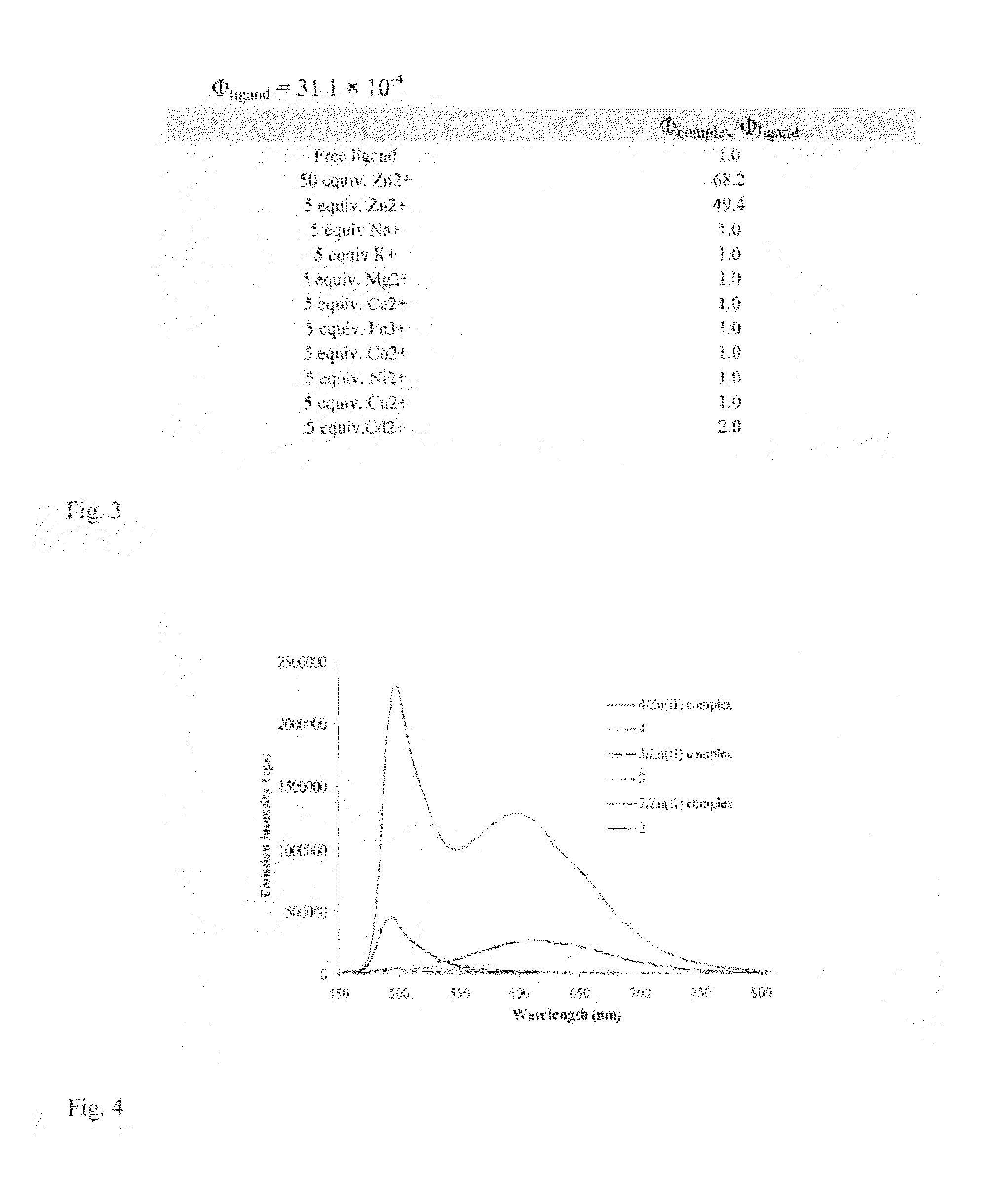

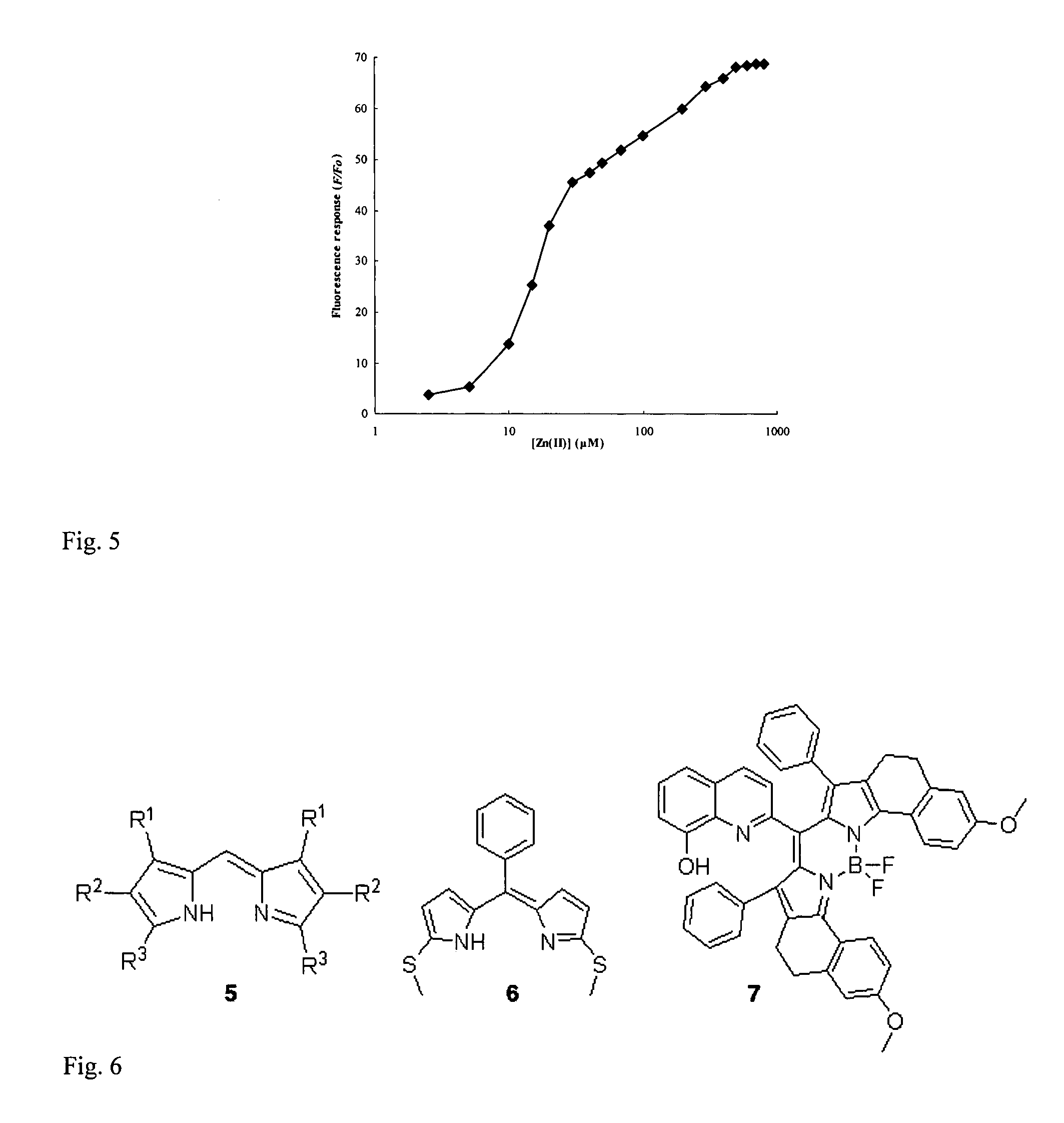

Fluorescent chemosensors for metals based on dipyrrins

InactiveUS20080182333A1Sharp absorptionConvenient bindingAnalysis using chemical indicatorsNanosensorsTransfer mechanismCopper

The present invention is a new class of fluorescent sensor with unprecedented sensitivity, selectivity and synthetic efficiency for the identification and qualitative and quantitative detection of transition metal ions. The chemosensing properties are based on an internal charge transfer mechanism or photo-induced electron transfer and are effective in vitro. The chemosensor comprises one or more electron donating dipyrrin functionalities linked to an electron withdrawing functionality. The chemosensor forms a stable transition metal complex through internal charge transfer between the electron donating functionality and the target transition metal, which results in measurable fluorescence. Specific examples for sensing zinc and copper ions are described.

Owner:STC UNM

Phase separation self cleaning acrylate stone-like paint emulsion and preparation method thereof

InactiveCN108383941AAvoid stayingHigh electronegativityAntifouling/underwater paintsPaints with biocidesFunctional monomerLatex particle

The invention discloses phase separation self cleaning acrylate stone-like paint emulsion and a preparation method thereof, and belongs to the field of stone-like paint emulsion. The phase separationself cleaning acrylate stone-like paint emulsion is prepared from the following raw materials in parts by weight: 160 to 240 parts of deionized water, 30 to 60 parts of styrene, 30 to 80 parts of methyl methacrylate, 40 to 80 parts of butyl methacrylate, 40 to 80 parts of acrylic acid-2-ethylhexyl acrylate, 10 to 40 parts of functional monomers, 4 to 25 parts of emulsifying agents, 2 to 20 parts of initiators and 1 to 10 parts of pH regulators. The self cleaning acrylate stone-like paint emulsion provided by the invention has the advantages that a copolymerization and shell-core technology composite process is used; a special synthesis processing method is used; special latex particles with two phases in one emulsion are finally obtained; latex particles in the film forming process are mutually interlinked and wound; the formed film is compact and hydrophobic; the pollution particle dwell can be effectively prevented.

Owner:佛山市顺德区巴德富实业有限公司

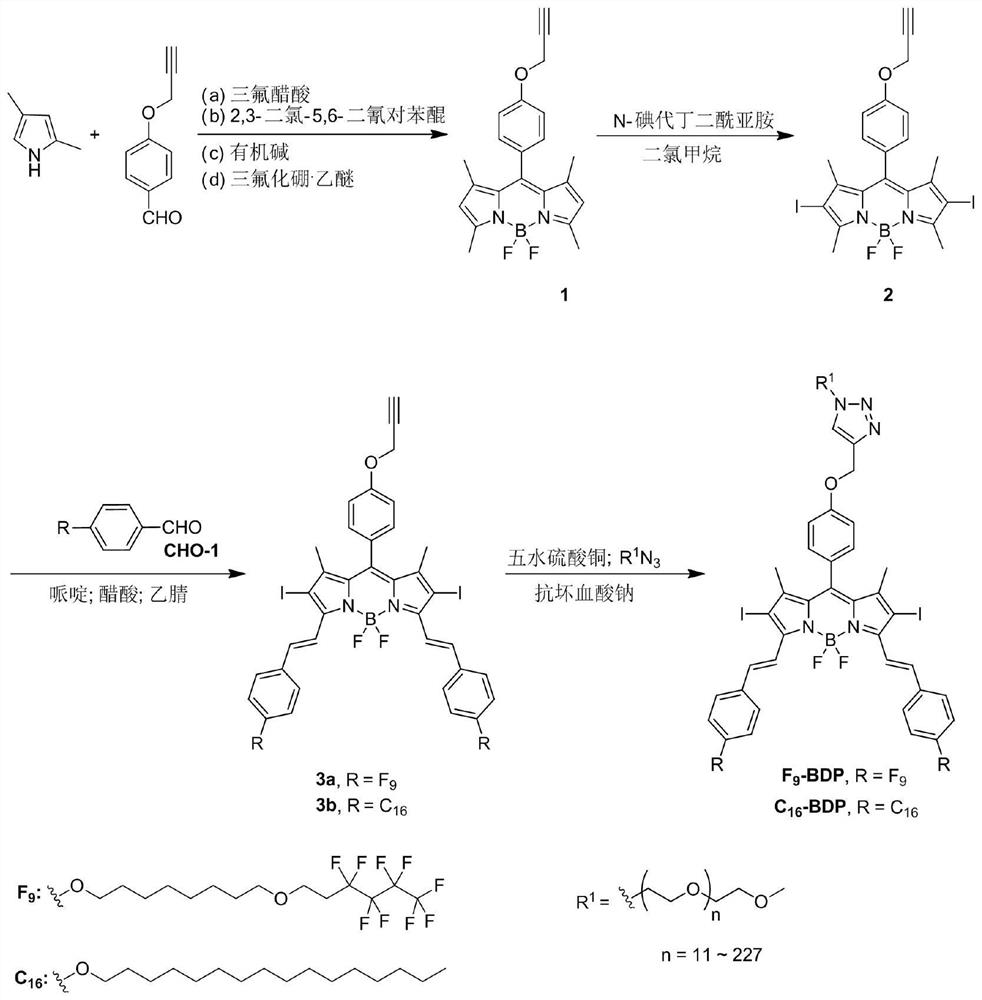

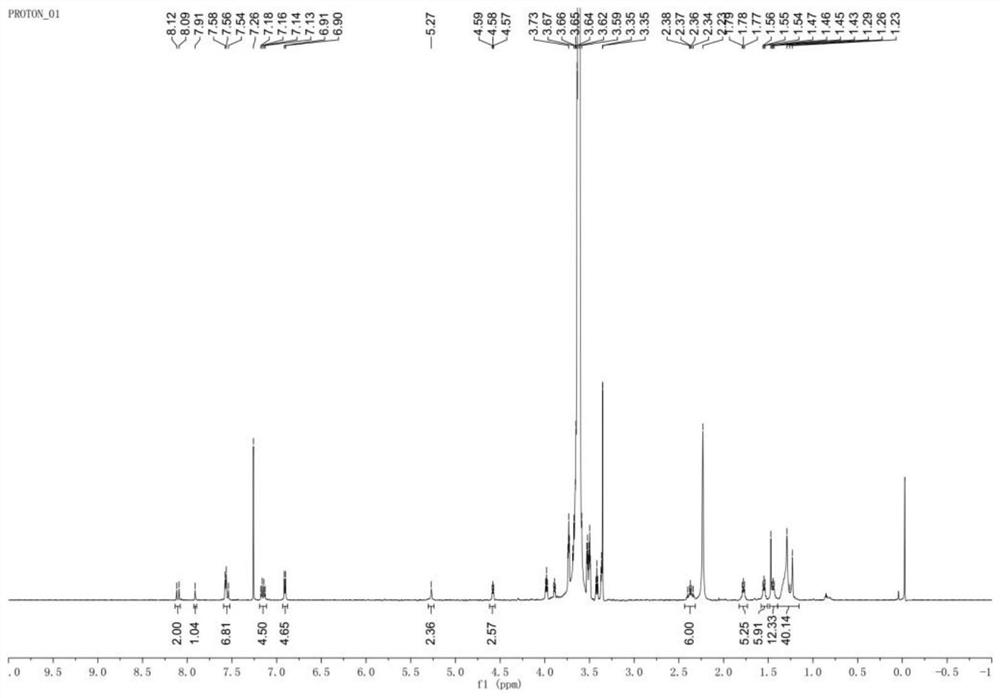

Near-infrared nano photosensitizer as well as preparation method and application thereof

ActiveCN114262432ASmall atomic radiusSmall polarizabilityEnergy modified materialsEmulsion deliveryAlkanePolyethylene glycol

The invention relates to a near-infrared nano photosensitizer as well as a preparation method and application thereof, and relates to the technical field of photosensitizers. According to the near-infrared nano photosensitizer disclosed by the invention, the absorption and emission spectrum of the near-infrared nano photosensitizer is close to a near-infrared light region by performing conjugate extension modification on a BODIPY parent nucleus; introducing a polyfluoroalkane group and a polyethylene glycol group into the BODIPY structure to obtain the amphiphilic photosensitizer; the nano photosensitive micelle with an ultralow CMC (Carboxymethyl Cellulose) value is finally constructed by utilizing the strong fluorine-fluorine action between the polyfluoroalkane groups and the hydrophilic action of the polyethylene glycol groups; j-aggregation of the BODIPY is induced by utilizing a fluorine-fluorine effect, so that the maximum absorption peak of the BODIPY is red-shifted to a near-infrared region, and deep phototherapy of tumors is facilitated.

Owner:SUZHOU UNIV

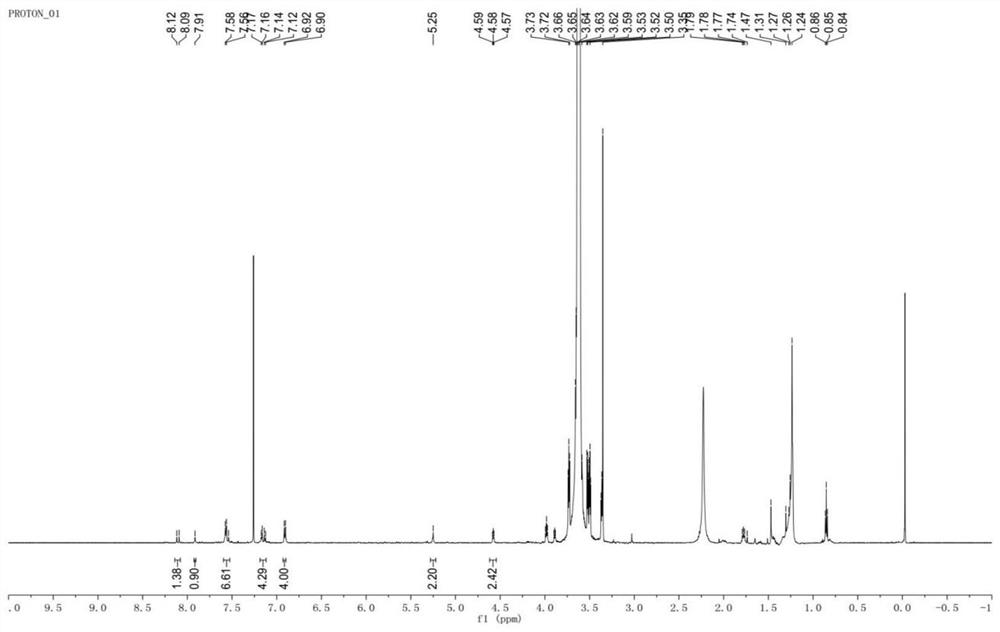

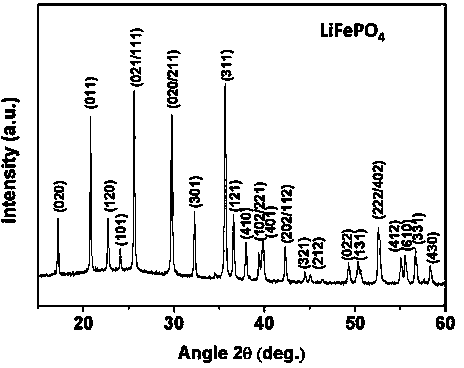

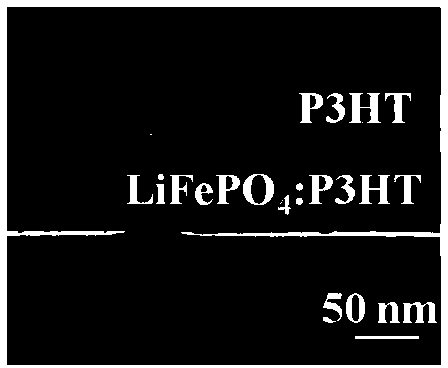

Organic-inorganic composite resistive random access memory and preparation method for same

InactiveCN104201281AFlat surfaceGood dispersionElectrical apparatusDigital storageLithiumNanoparticle

The invention relates to the technical field of electronic devices, in particular to an organic-inorganic composite resistive random access memory and a preparation method for the same. The organic-inorganic composite resistive random access memory comprises a substrate, as well as a bottom electrode deposited on the substrate, an organic-inorganic composite dielectric layer inlaid with lithium ion compound particles, and a top electrode which are sequentially arranged on the substrate. The organic-inorganic composite resistive random access memory disclosed by the invention has the following advantages that: metal lithium ions forming resistive random fine wires are provided by virtue of the lithium ion compound particles inlaid in an organic dielectric; the metal lithium ions have the characteristics of high redox reaction activity, small atomic radius and the like, and are capable of reducing a fine wire formation energy and increasing a resistive random access speed; the electric field formed by nano-particles is concentrated, thus reducing the randomness formed by the resistive random fine wires, and improving the uniformity and reliability of the memory device; the device has the characteristic of being flexibly printable.

Owner:SUN YAT SEN UNIV

Green high-strength and low-temperature composite brazing filler material and preparation method thereof

ActiveCN106271191AImprove wettabilityHigh strengthWelding/cutting media/materialsSoldering mediaIndiumComposite electrode

The invention relates to a green high-strength and low-temperature composite brazing filler material and a preparation method thereof. The green high-strength and low-temperature composite brazing filler material is prepared from 80-90% of Zn, 1-10% of Al, 0.5-5% of Cu, 0.5-1% of Li, 3-10% of In, 0.3-1% of Ti and 0.02-0.2% of B. The preparation method comprises the following steps: preparing metal Al into an Al wire for standby; respectively preparing intermediate alloys A and B from elements B and Ti having relatively high melting points together with Zn, wherein the intermediate alloy A is composed of B and Zn at weight ratio of 5:95, and the intermediate alloy B is composed of Ti and Zn at weight ratio of 5:95; melting the residual Zn, adding thin Cu pieces, and adding the intermediate alloys A and B after fusion; covering with a compound salt of cesium fluoroaluminate and potassium fluoroaluminate; cooling molten metal to 450-480 DEG C, adding metals In and Li, standing for 30-60 min after fusion, casting into ingot C having diameter of 60 mm; extruding and rolling the ingot C into a thin strip having thickness of 0.2 mm; preparing the 0.2 mm thin strip and aluminum wire into a finished electrode having required diameter through a composite electrode unit.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

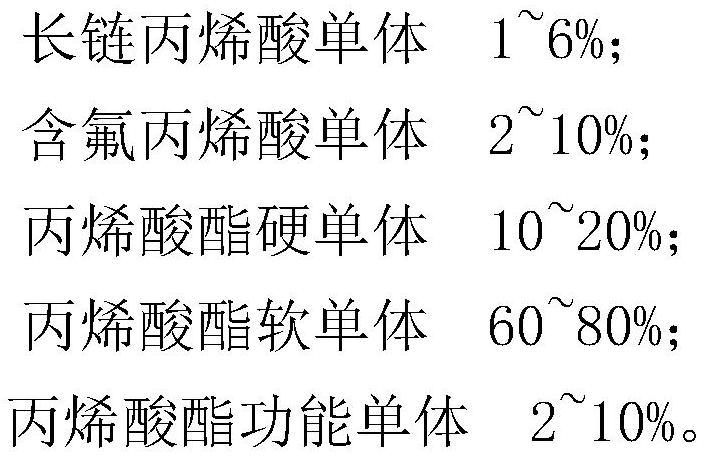

Polyester film protective film

PendingCN112280488AImprove flexibilityLower surface energyEster polymer adhesivesPressure sensitive film/foil adhesivesFunctional monomerPolyester

The invention belongs to the field of protective films, and relates to a polyester film protective film, which comprises a polyester film and a pressure-sensitive adhesive layer coated on the surfaceof the polyester film, the resistance of the pressure-sensitive adhesive layer is less than 10<10> ohm / square; the pressure-sensitive adhesive layer contains acrylate resin; the acrylate resin is prepared from a long-chain acrylic monomer, a fluorine-containing acrylic monomer, an acrylate hard monomer, an acrylate soft monomer and an acrylate functional monomer through free radical polymerization. According to the technical scheme, wettability and optical performance of the surface of the optical component can be considered at the same time.

Owner:HEFEI LUCKY SCI & TECH IND

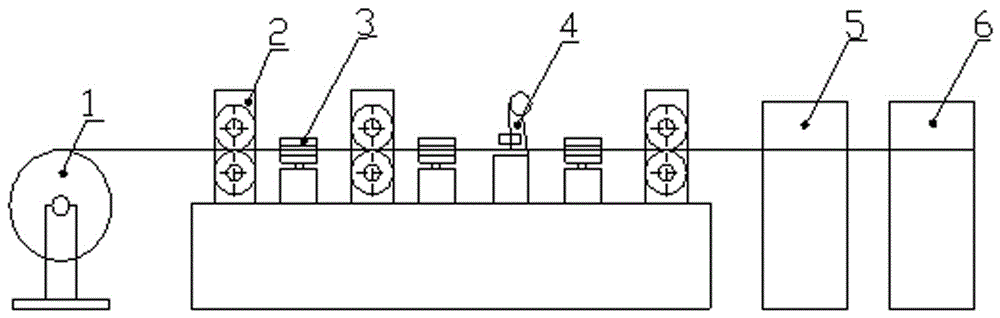

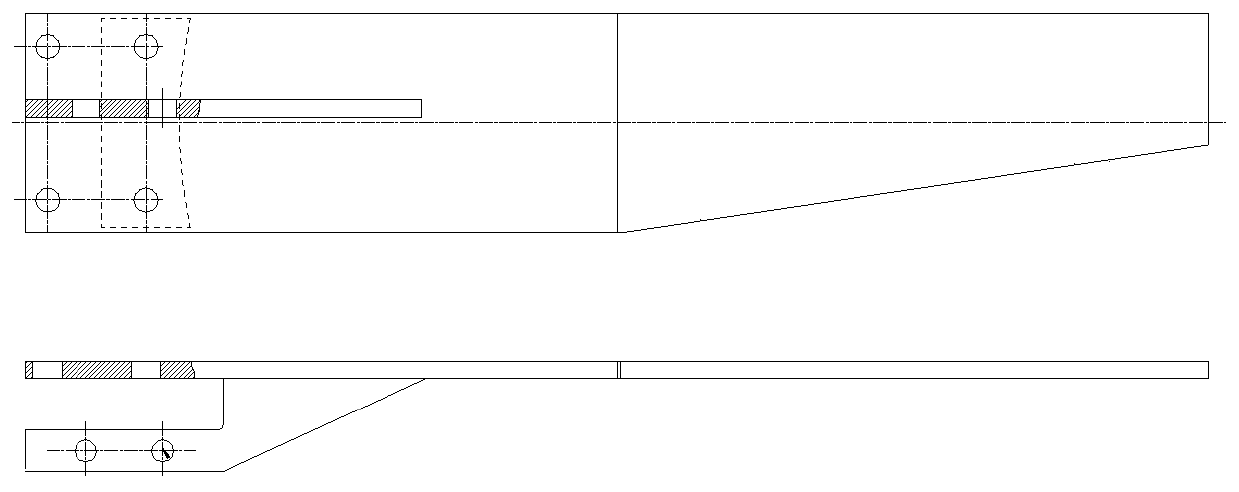

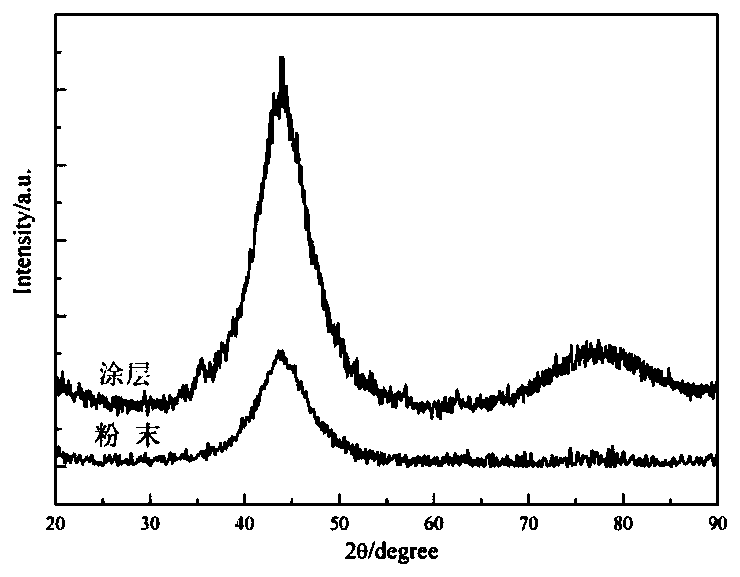

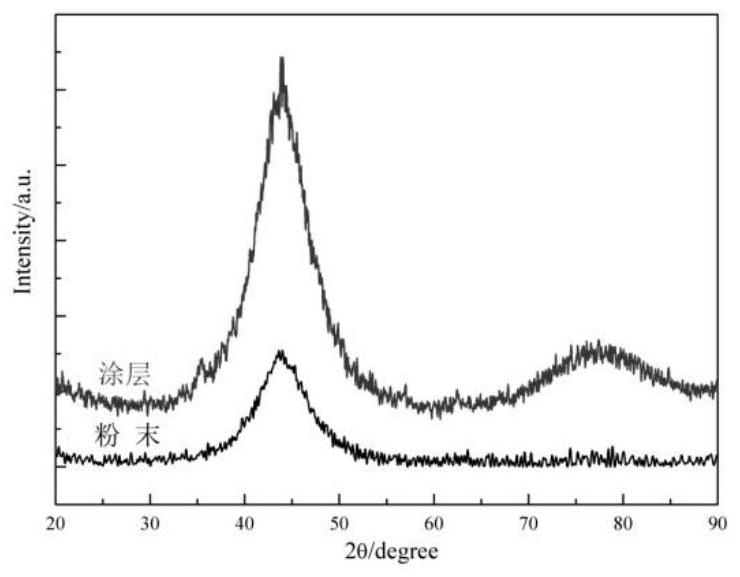

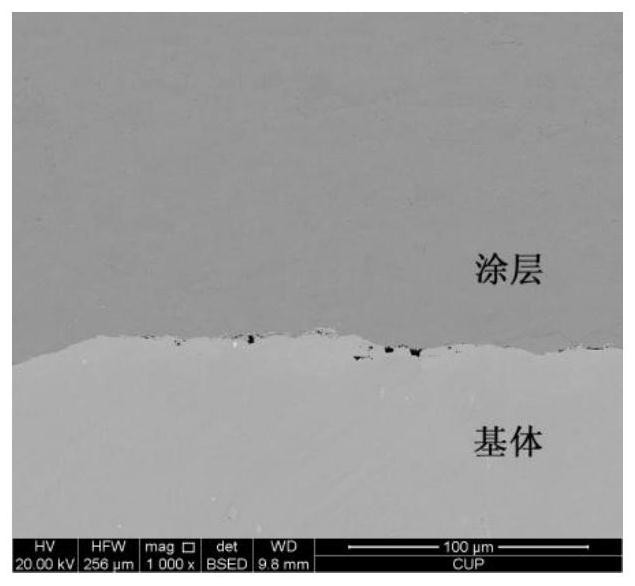

Composite manufacturing method of acid leaching stirrer

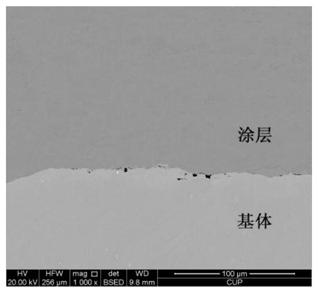

ActiveCN110029300AStrong ability to form amorphous stateEnhanced Amorphous Formation AbilityMolten spray coatingRare-earth elementTungsten

The invention relates to a composite manufacturing method of an acid leaching stirrer. Iron-based amorphous powder is taken as a spraying material, the supersonic flame spraying technology is adoptedto accelerate the heating of the powder, and an iron-based amorphous coating with the thickness of 150-250 [mu]m is prepared on the surface of a stirring shaft or a paddle. The iron-based amorphous powder is prepared from the following components in percentage by mass: 0-25% of chromium, 0-10% of molybdenum, 0-5% of tungsten, 0-12% of niobium, 0-4% of lutetium, 0-7% of manganese, 0-5% of boron, 0-4% of carbon, 0-3% of silicon, 0-2% of rare earth element and the balance of iron. The service life of the prepared composite material stirring shaft and paddle is several times longer than that of traditional stainless steel products.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Preparation method of stain-resistant real stone paint

InactiveCN110128862AImprove stain resistanceGood anti-ultraviolet aging performanceAntifouling/underwater paintsPaints with biocidesBond energyUltraviolet

The invention belongs to the technical field of coatings, and particularly relates to a preparation method of stain-resistant real stone paint. The carbon nano tubes and the argil are coated, so thatthe pigment in the color sand is not radiated by light rays; titanium dioxide also has the function of absorbing and converting ultraviolet rays, so that the stone-like paint has good ultraviolet aging resistance; a layer of fluorosilane molecules is formed on the surface of the titanium dioxide nanoparticles in the real stone paint coating; fluorine atoms in fluorosilane molecules of the coatinglayer are high in electronegativity, so that the bond energy of a single bond formed by the fluorosilane molecules and other elements is larger than that of a single bond formed by carbon atoms and other elements, and due to the fact that the carbon chains in the fluorosilane molecules are protected by the original space barrier effect, fluorosilane has good chemical stability and low surface freeenergy. The fluorosilane surface coating layer reduces the Van Der Waals' force of titanium dioxide nanoparticles on water and the effect of hydrogen bonds and greatly increases the contact angle ofthe surface of a paint film, so that the product shows super-hydrophobicity. The preparation method can obviously improve the stain resistance of the real stone paint, and has a wide application prospect.

Owner:梁荣付

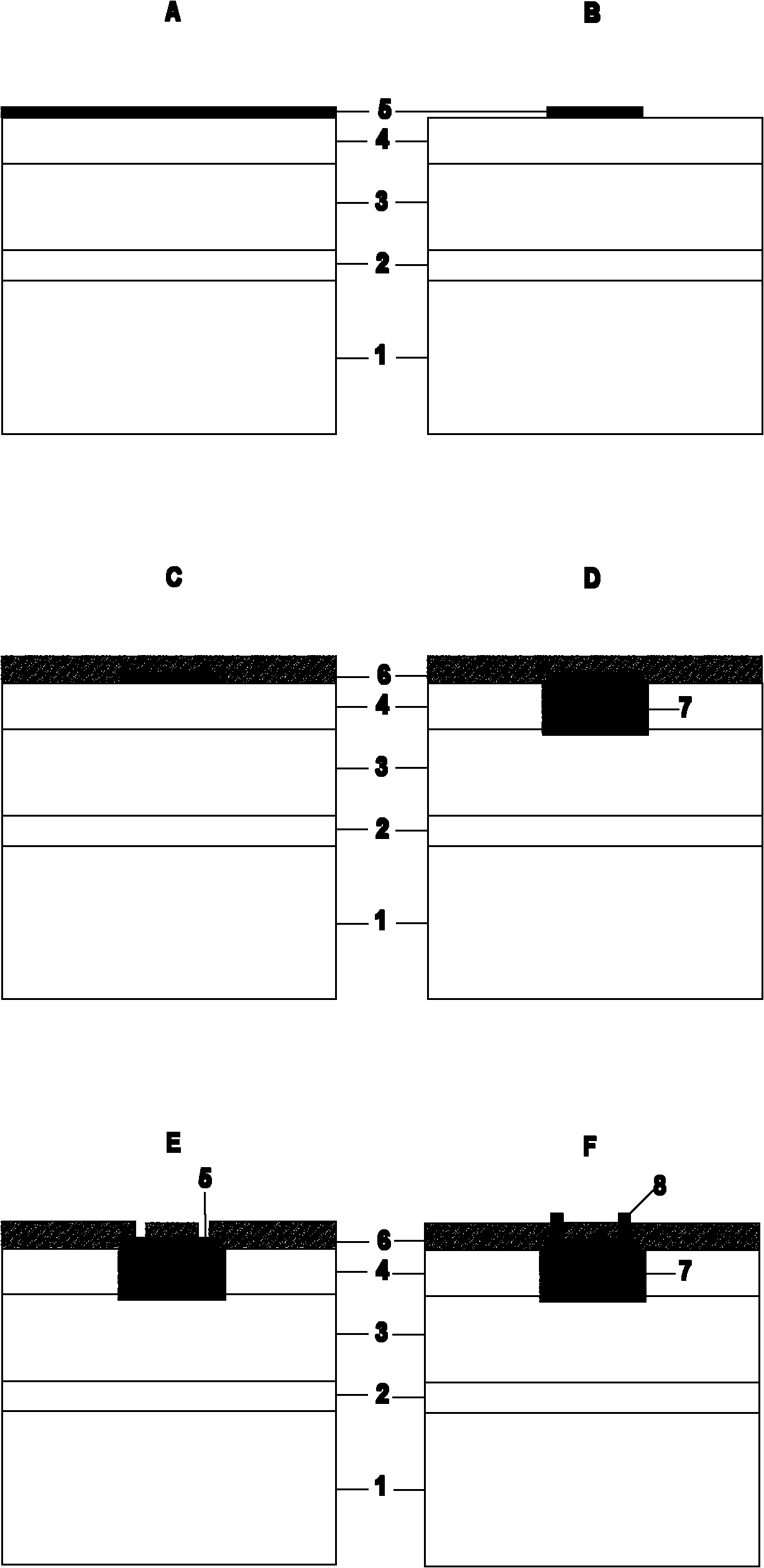

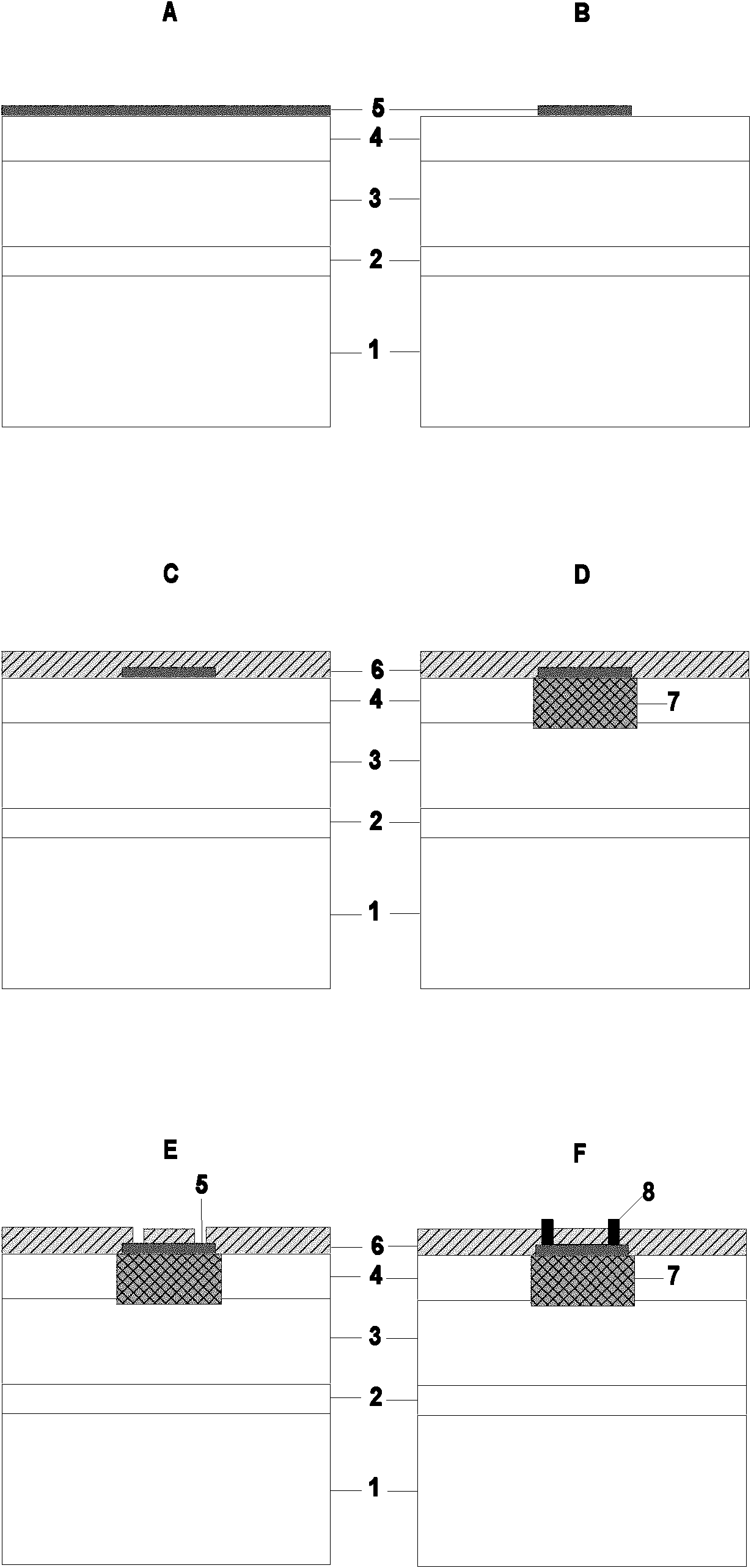

Method for manufacturing photoelectric detection unit or focal plane device by using molecular beam epitaxy method

InactiveCN102130208ASmall atomic radiusEasy to manufacturePolycrystalline material growthFinal product manufacturePhotovoltaic detectorsDelta doping

The invention relates to a method for manufacturing a photoelectric detection unit or a focal plane device by using a molecular beam epitaxy method, comprising the steps of: growing a buffer layer, a light absorption layer and an epitaxial structure of a wide bandgap cap layer on a conductive substrate by applying a molecular beam epitaxial growth technology, and then continuously growing a high-Be-doped or delta-doped heterogeneous narrow bandgap lamella to serve as a diffusion source layer; and (2) etching the diffusion source layer by using a conventional graph processing technology to form a locally doped source graph, forming a pn (positive negative) junction under the protection of a passivated dielectric film by applying a diffusion technology at the diffusion temperature of 450-600 DEG C, and then, manufacturing an electrode to form the photoelectric detection unit or the focal plane device. The method provided by the invention has the advantages of universality and simplicity, a doping junction-forming process is combined with the advantages of junction-forming convenience of a table-board type in-situ doping junction-forming process and good passivation effect of a planer type diffusion junction-forming process in the manufacturing of the photoelectric detection unit, the device process is simplified and the device property is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Magnalium alloy cutting fluid with excellent wear and extreme pressure resistance

The invention discloses magnalium alloy cutting fluid with excellent wear and extreme pressure resistance. The aluminum alloy cutting fluid is prepared from the following raw materials in parts by weight: 8 to 16 parts of boric acid ester, 5 to 15 parts of lubricating additives, 3 to 6 parts of water-soluble imidazoline corrosion inhibitors, 1 to 4 parts of carborane superacid, 2 to 5 parts of alkylphenol polyoxyethylene, 1 to 3 parts of triethanolamine oleate, 2 to 4 parts of alpha-sodium olefin sulfonate, 1 to 4 parts of alkylolamides, 2 to 5 parts of diethanol amine sebacate, 3 to 5 parts of dodecenylsuccinic acid, 1 to 5 parts of borax, 2 to 6 parts of triethanolamine, 1 to 3 parts of sodium benzoate, 2 to 8 parts of absolute ethyl alcohol and 4 to 12 parts of simethicone. The aluminum alloy cutting fluid provided by the invention has the excellent wear and extreme pressure resistance; the lubrication and anti-rust performance is excellent.

Owner:TIANCHANG RUNDA METAL ANTIRUST AUX

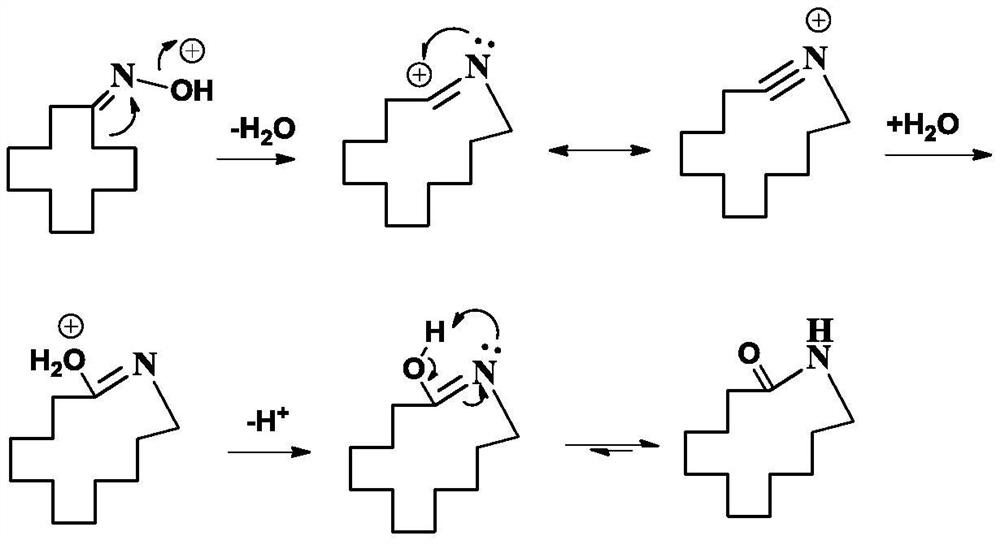

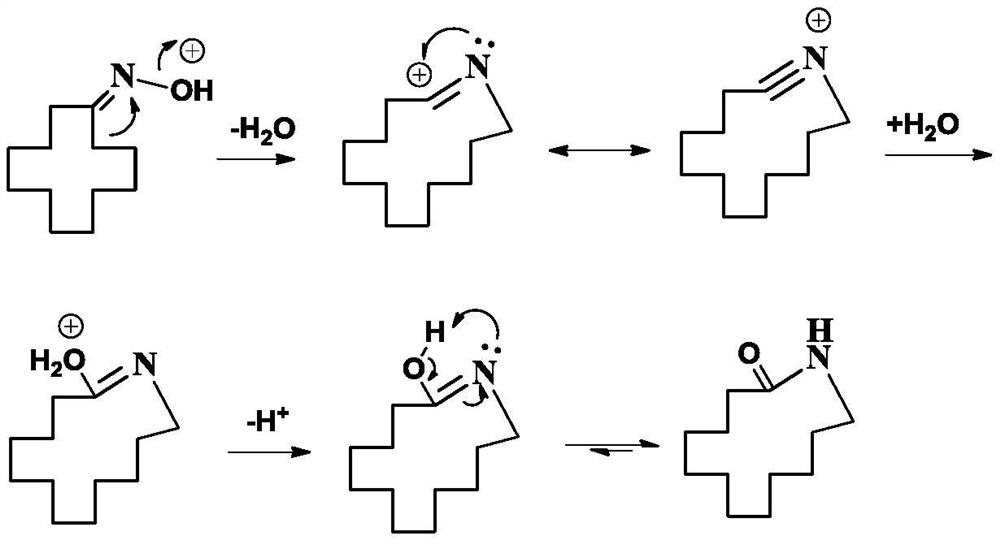

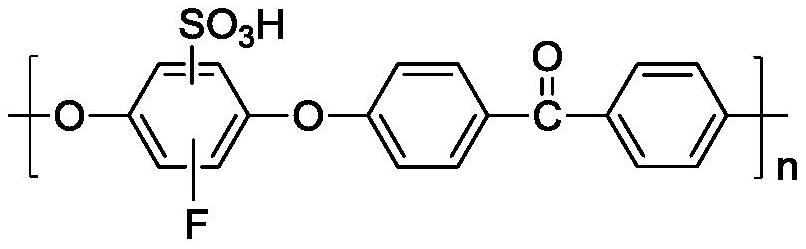

Catalyst and preparation method thereof, and method for preparing laurolactam through gas phase rearrangement reaction

ActiveCN112619673AHigh mechanical strengthImprove bindingLactams preparationPhysical/chemical process catalystsLaurolactamPtru catalyst

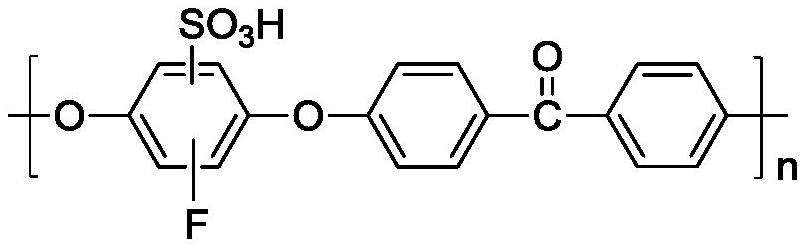

The invention discloses a catalyst and a preparation method thereof, and a method for preparing laurolactam through a gas phase rearrangement reaction. The catalyst comprises fluoride modified rare earth doped Al2O3-SiO2-ZrO2 and fluorine-containing sulfonated polyetheretherketone, and the loading capacity of the fluorine-containing sulfonated polyetheretherketone in the catalyst is 20-50wt%, preferably 30-45wt%. When the catalyst is used for catalyzing gas-phase rearrangement of cyclododecanone oxime, the conversion rate of cyclododecanone oxime reaches 99% or above, the selectivity of laurolactam reaches 99.5% or above, the service life of the catalyst reaches 3000h or above, no ammonium sulfate byproduct is produced in the reaction, the mechanical strength of the catalyst is high, and the problems of equipment corrosion and environmental pollution of a traditional liquid-phase rearrangement process are solved.

Owner:WANHUA CHEM GRP CO LTD

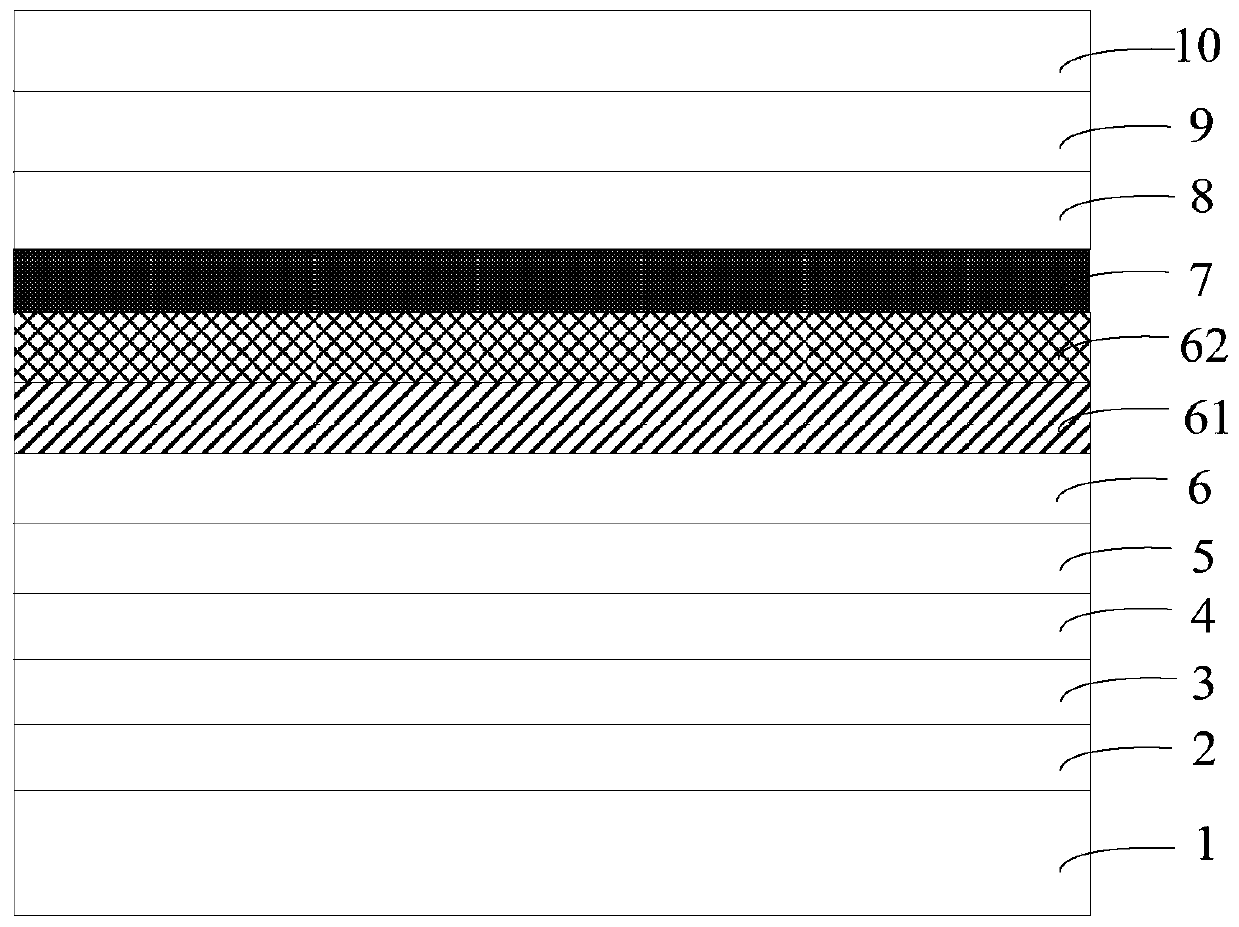

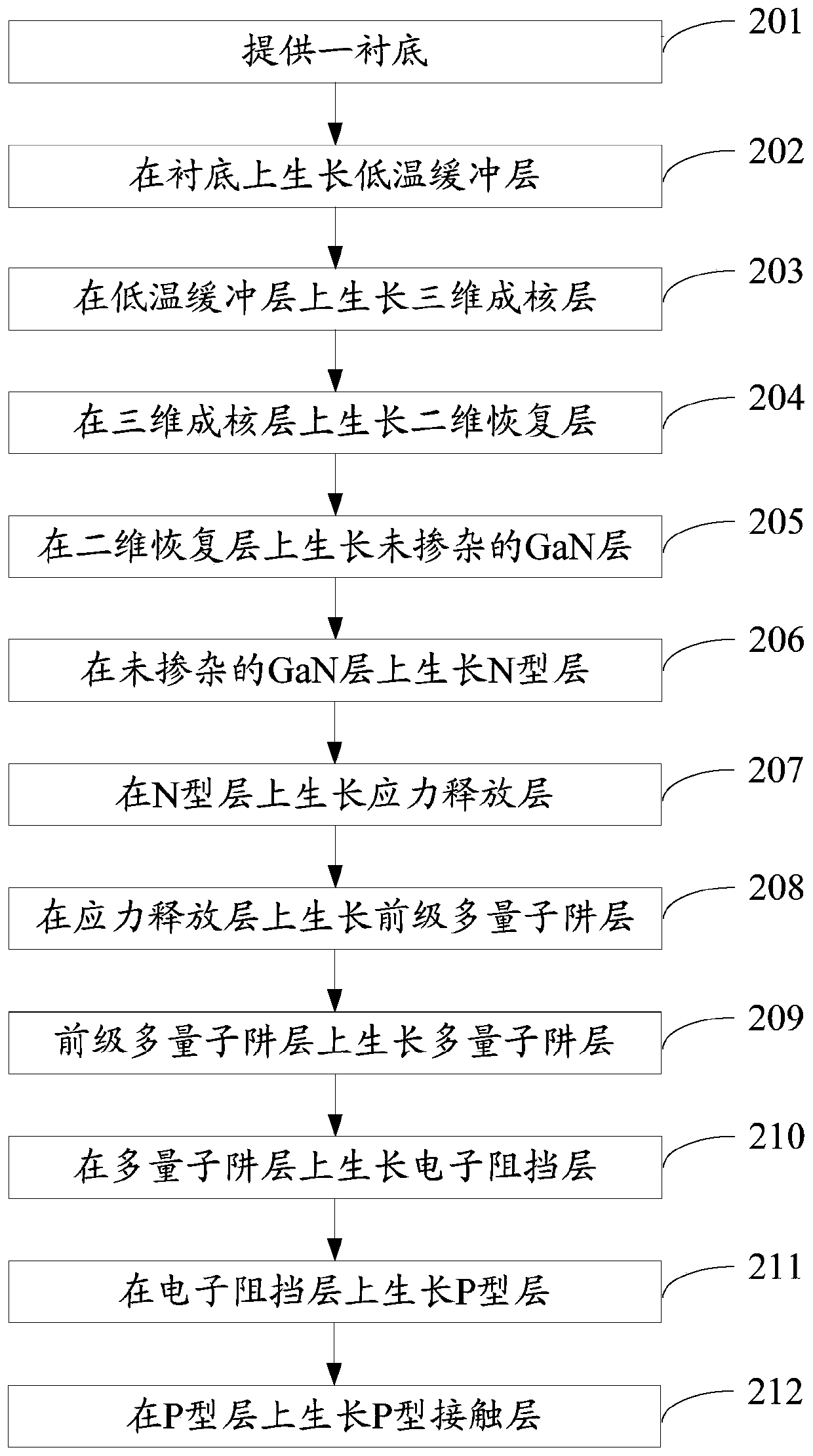

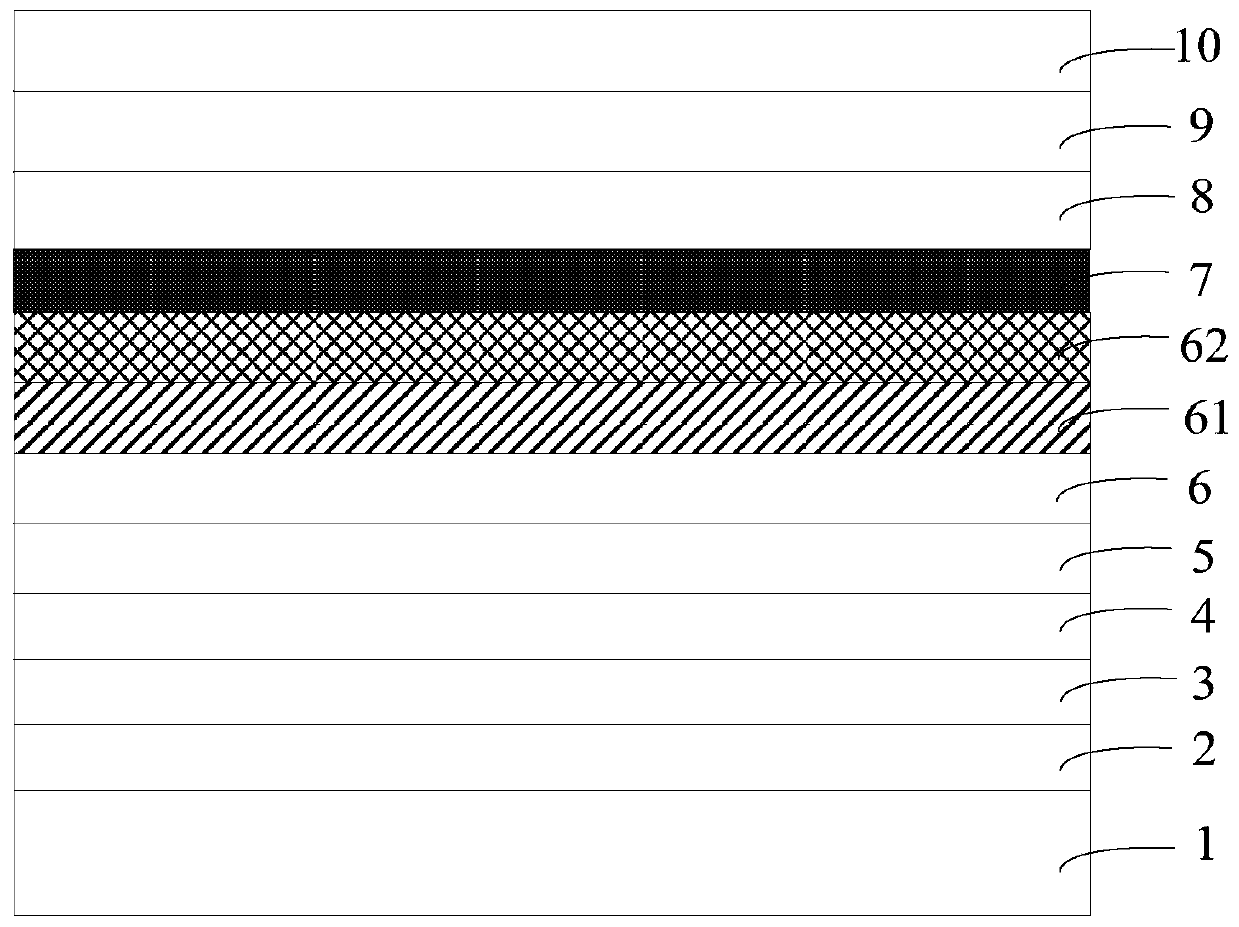

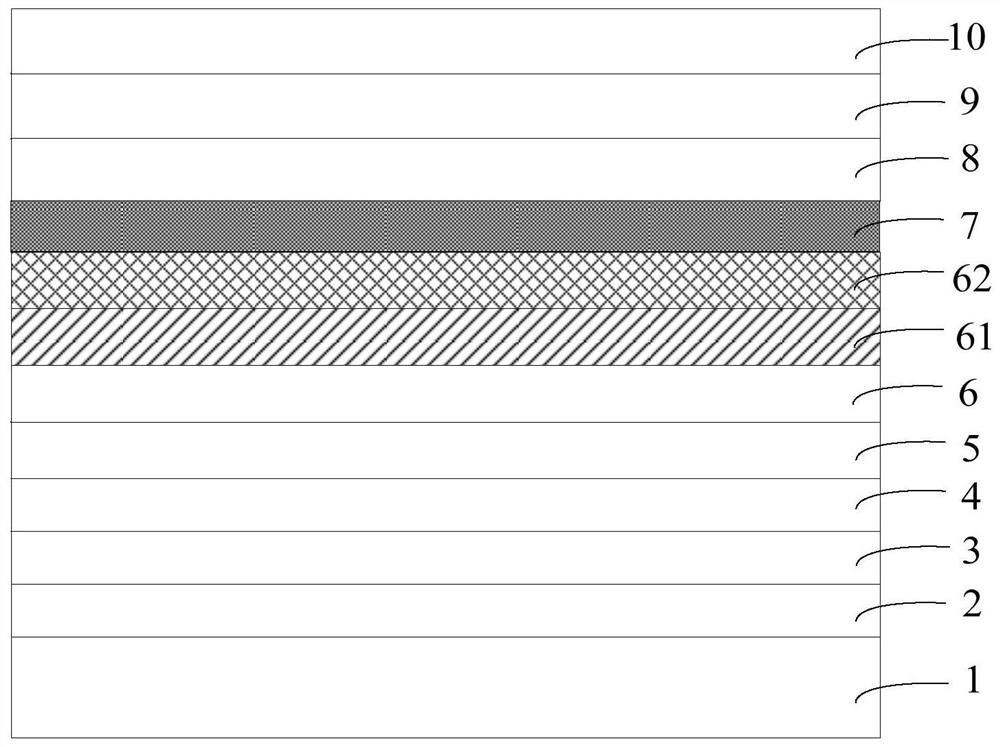

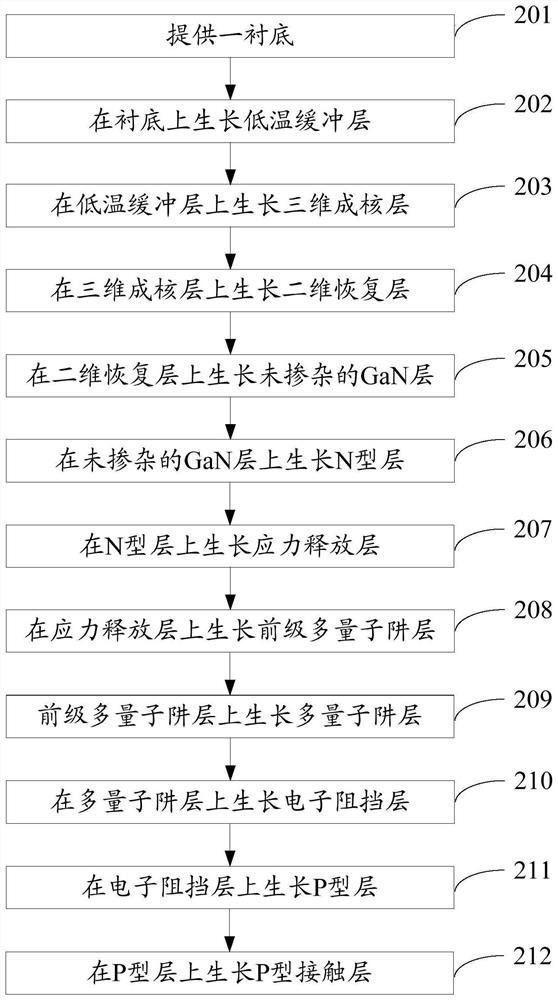

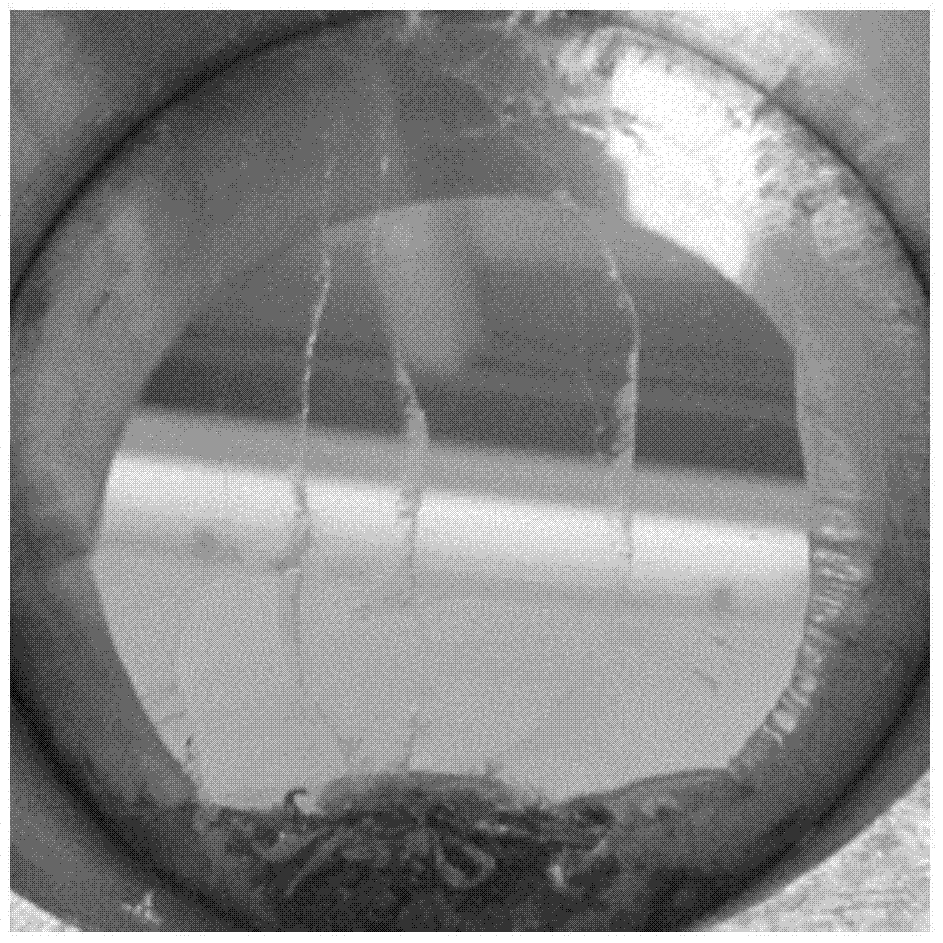

Gallium nitride-based light emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN109920883AImprove crystal qualityImprove luminous efficiencySemiconductor devicesQuantum wellGallium nitride

The invention discloses a gallium nitride-based light emitting diode epitaxial wafer and a manufacturing method thereof, and belongs to the technical field of semiconductors. The gallium nitride-basedlight emitting diode epitaxial wafer comprises a substrate, and a low-temperature buffer layer, a three-dimensional nucleating layer, a two-dimensional recovery layer, an undoped GaN layer, an N-typelayer, a multi-quantum well layer, an electron blocking layer and a P-type layer which grow on the substrate in sequence, wherein the low-temperature buffer layer and the three-dimensional nucleatinglayer are both beryllium-doped GaN layers, the doping concentration of beryllium in the low-temperature buffer layer is gradually increased in the stacking direction of the epitaxial wafer, and the doping concentration of beryllium in the three-dimensional nucleating layer is gradually reduced in the stacking direction of the epitaxial wafer. The gallium nitride-based light emitting diode epitaxial wafer provided by the invention can improve the bottom crystal quality of the epitaxial layer, thereby improving the crystal quality of the epitaxial layer.

Owner:HC SEMITEK ZHEJIANG CO LTD

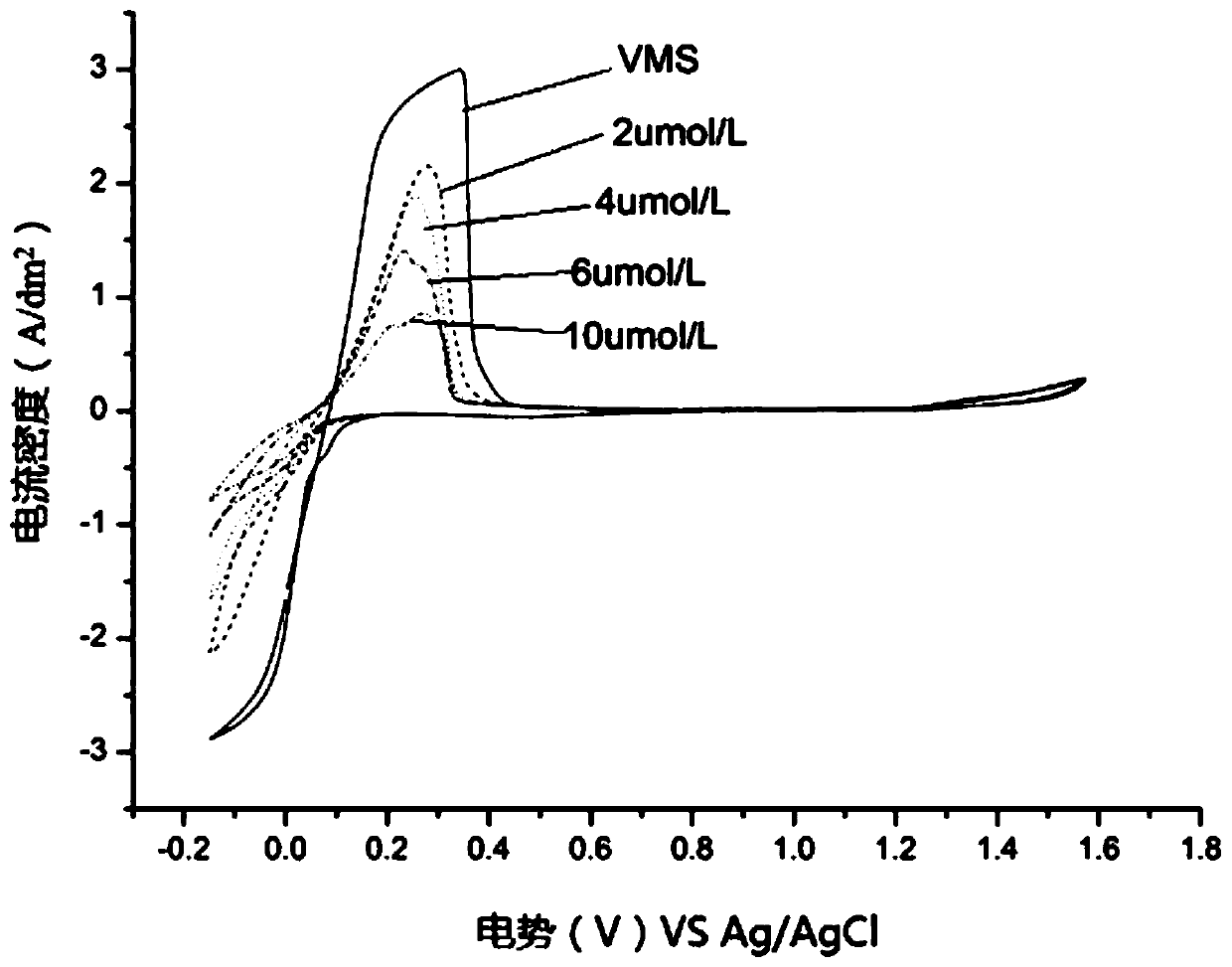

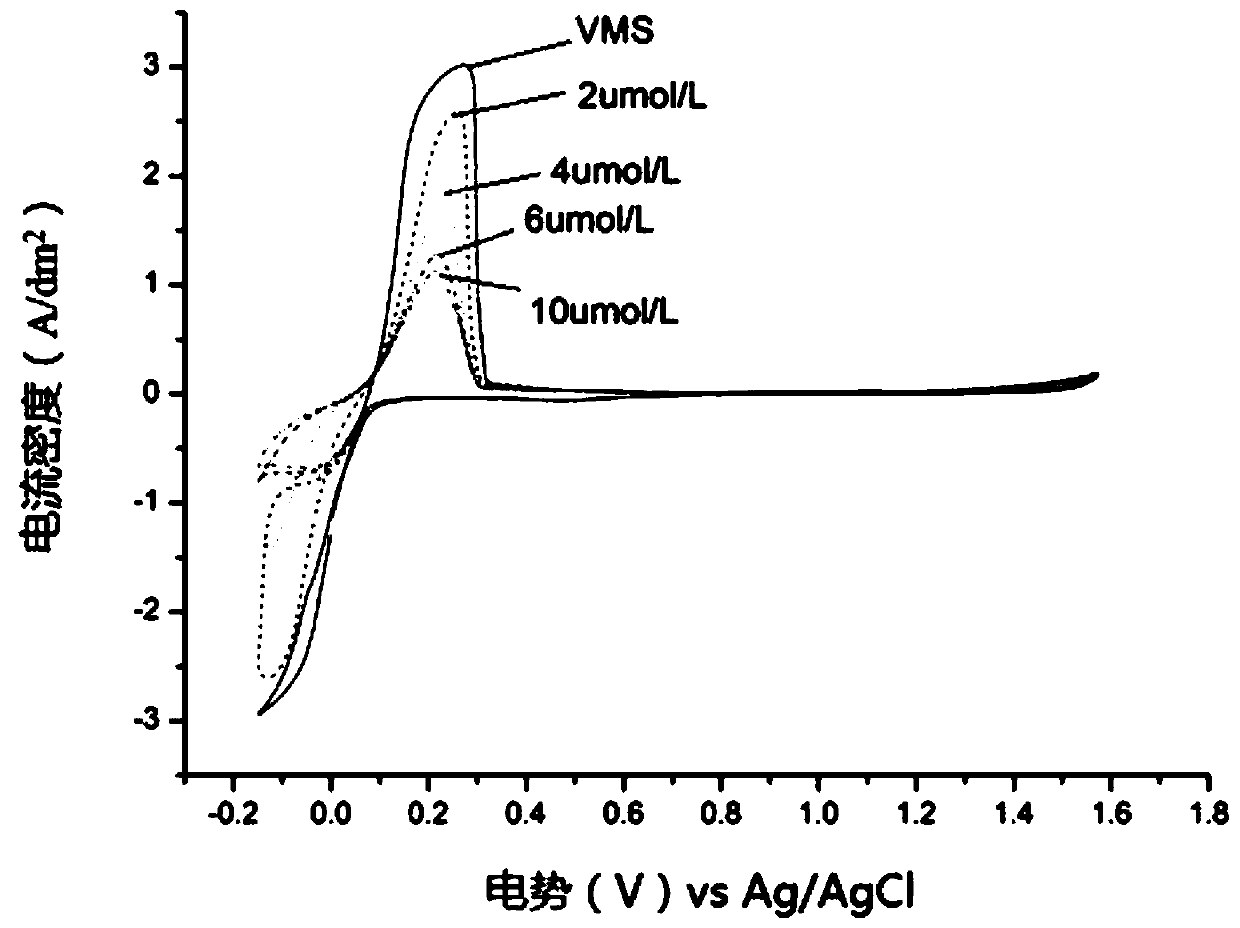

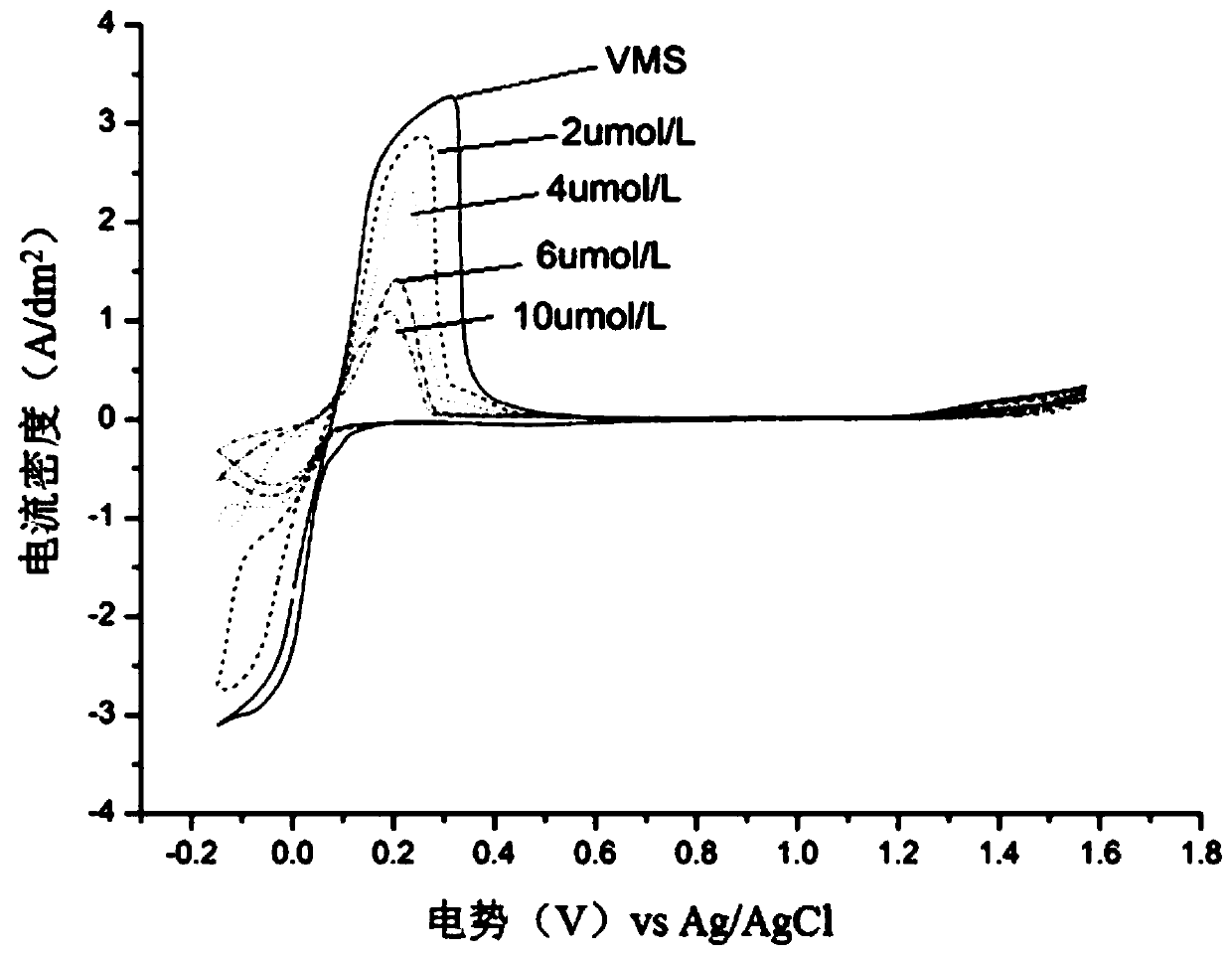

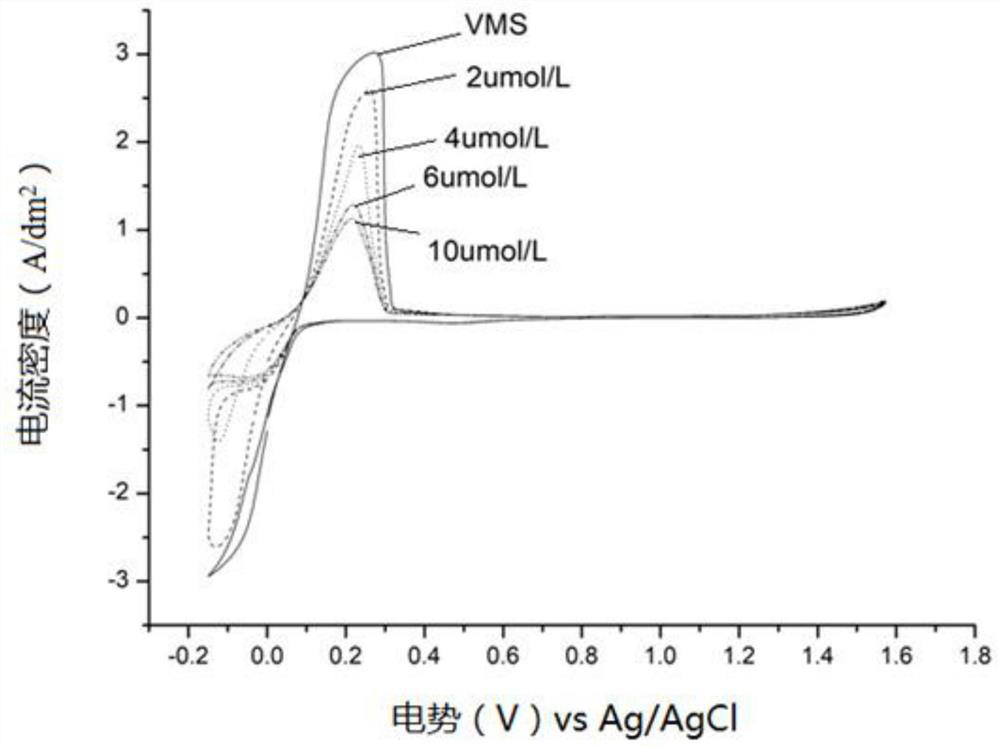

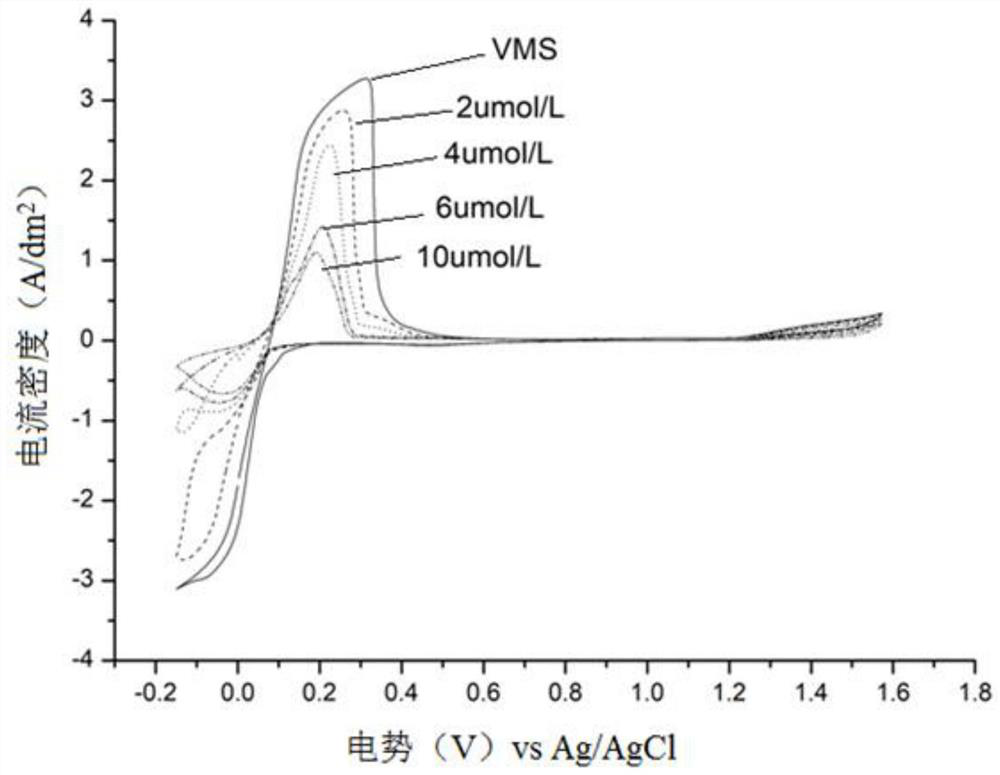

Fluorine-bearing diketopyrrolopyrrole quaternary ammonium salt compound and preparation method and application thereof

ActiveCN109897043AEnhanced inhibitory effectGood solvent resistanceOrganic chemistryBenzonitrileSuccinates

The invention discloses a fluorine-bearing diketopyrrolopyrrole quaternary ammonium salt compound, having a structure shown as the formula (I) which is shown in the description, wherein R1 is one of F, CH2F, CHF2, CF3, OCH2F, OCHF2, OCF3, SCH2F, SCHF2, SCF3, CF2(CF2)nCF3, n is an integer of 0-10, and X is F, Cl, Br or I. The fluorine-bearing diketopyrrolopyrrole quaternary ammonium salt compound is prepared from diisopropyl succinate and benzonitrile of different substituents and can act as a plating leveling agent.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Waste polystyrene foamed plastic modified coating and preparation method thereof

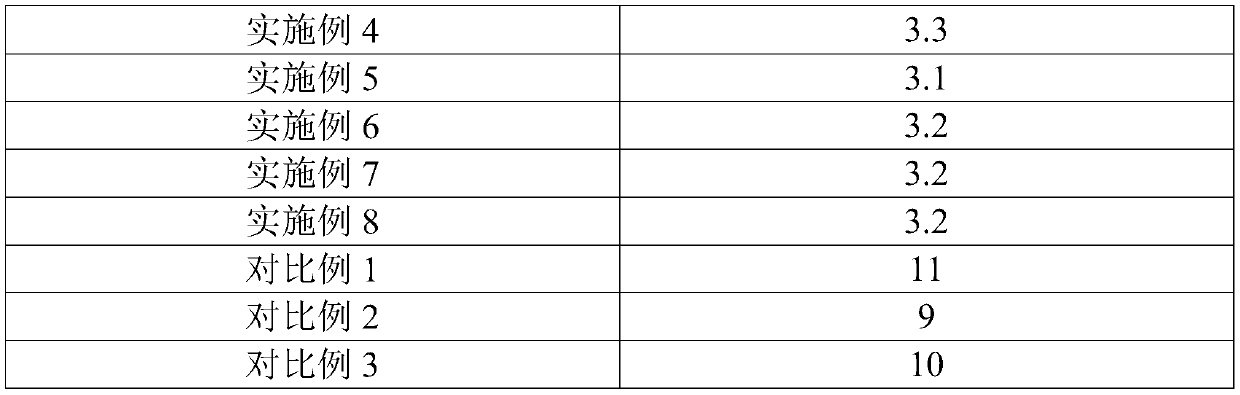

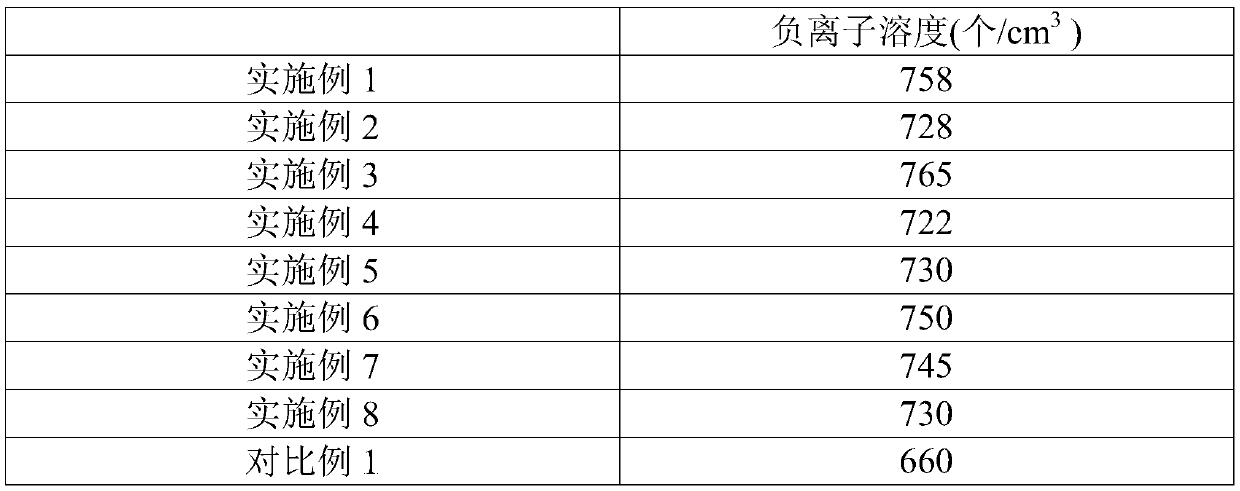

The invention discloses waste polystyrene foamed plastic modified coating which comprises the following ingredients in parts by weight: 100-150 parts of fluorosilicon resin, 50-60 parts of modified waste polystyrene foamed plastics, 50-60 parts of anion powder, 30-40 parts of light calcium carbonate, 30-40 parts of modified CNTs (carbon nano tubes), 30-40 parts of nano-silver, 30-40 parts of calcium hydroxide, 20-30 parts of titanium dioxide, 15-30 parts of coal ash, 15-25 parts of nano-SiO2, 3-5 parts of a surfactant, 1-2 parts of a silane coupling agent and 1-2 parts of a flatting agent. Dueto the application of the modified waste polystyrene foamed plastics in the coating, so that on one hand, the recycling of resources is achieved; on the other hand, the characteristics of the modified waste polystyrene foamed plastics of being hard in texture and good in transmission of light can be utilized, and the flexibility of the plastics is enhanced after the plastics are modified.

Owner:HENAN YUQIAN TECH TRANSFER CENT CO LTD

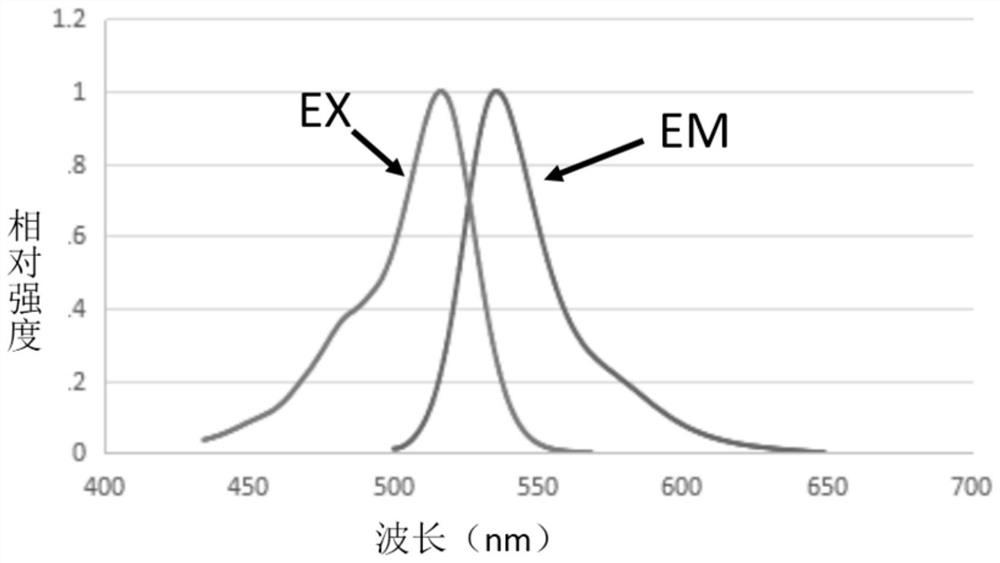

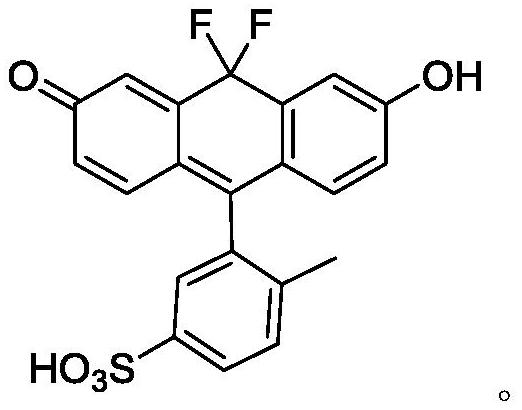

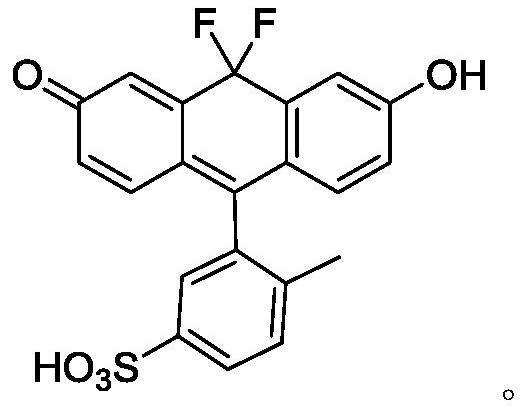

Hydrophilic anthracene fluorescent dye and synthesis method thereof

ActiveCN112300599AGood water solubilityImprove solubilityPreparing sample for investigationAnthracene dyesGrignard reagentBenzaldehyde

The invention provides a hydrophilic anthracene fluorescent dye and a synthesis method thereof. By introducing a sulfonic acid group and a difluoro substituent group, the hydrophilicity and stabilityof the anthracene fluorescent dye are improved. The synthesis method mainly comprises the following steps: reacting halogenated benzaldehyde with a phenyl Grignard reagent to generate a benzhydrol derivative; oxidizing an alcoholic hydroxyl group into a keto carbonyl group to obtain a benzophenone derivative with a phenolic hydroxyl group protecting group; converting the keto carbonyl group into dithioketal by using ethanedithiol for protection; carrying out fluorination by using a fluorine reagent to obtain an anthrone difluoride compound; conducting reacting by using a lithium reagent to achieve conversion into a lithium Grignard reagent; conducting oxidizing to obtain benzophenone; removing a protecting group from benzophenone, and carrying out cyclization reaction under an acidic condition; and carrying out sulfonation reaction on the obtained fluorinated fluorescent dye to obtain the fluorinated fluorescent dye.

Owner:CYGNUS BIOSCI BEIJING CO LTD

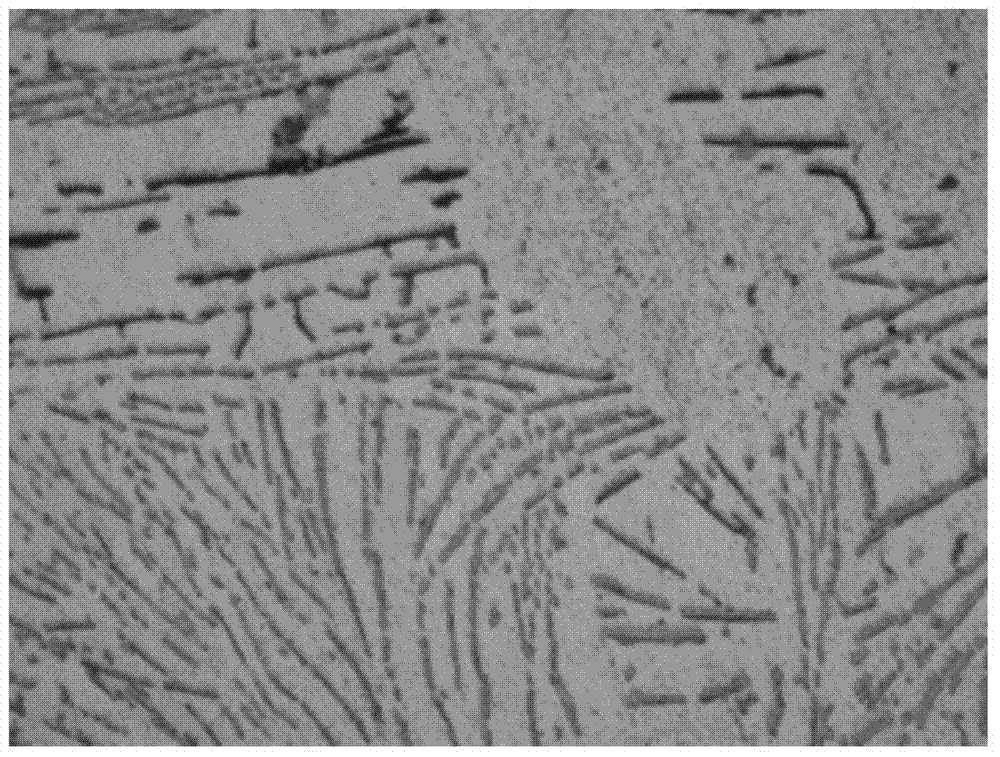

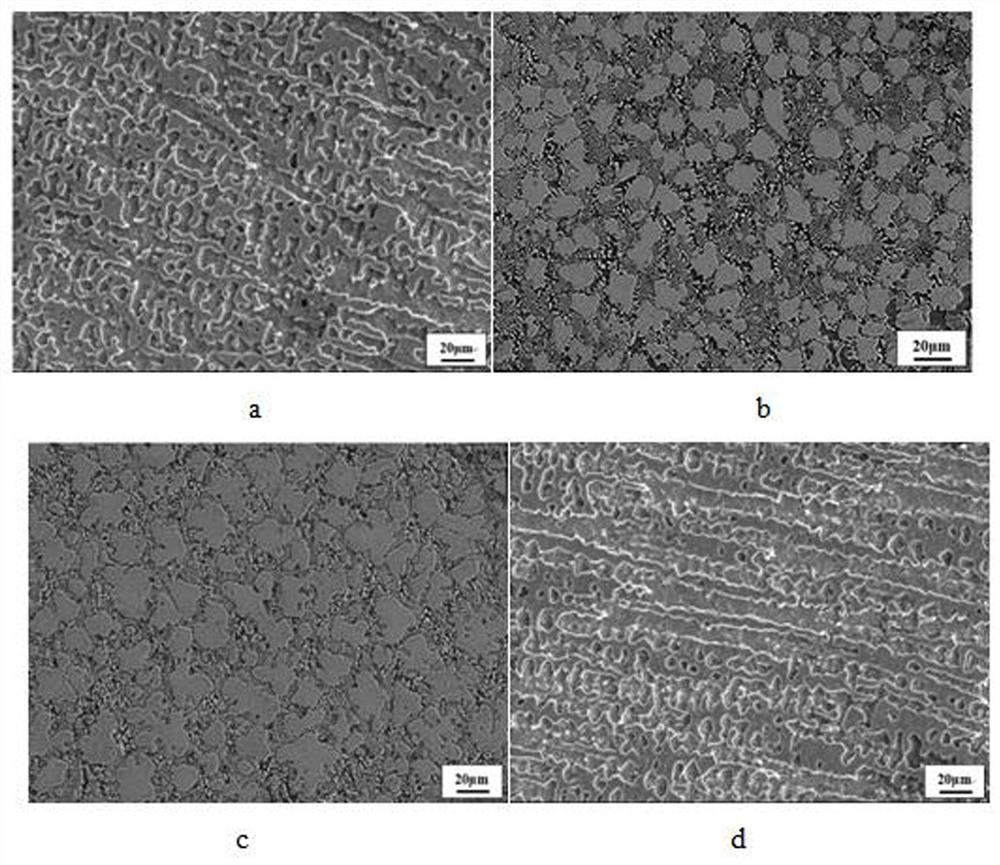

Aluminum-silicon-magnesium casting alloy mechanical property improving method

The invention discloses an aluminum-silicon-magnesium casting alloy mechanical property improving method. Light rare earth is adopted and cooperates with heavy rare earth to process alloy melt, and the iron content is 0.09-0.20 wt% of the alloy melt mass. According to the improving method, based on the difference, in the aspect of physicochemical property, between light rare earth elements and heavy rare earth elements as well as the influence on the alloy crystallization process, the method of utilizing the light rare earth and the heavy rare earth to be combined and modified to control the microstructure and mechanical property of alloy is provided, the light rare earth and the heavy rare earth give play to advantage separately, namely, the light rare earth is focused on enriching on thealpha-Al and Si crystal solidification front and being adsorbed on the surface of crystal, and achieves the effects of refining and modifying; and the heavy rare earth is focused on adsorbing or conducting solid solution on iron-rich Al-Fe and Al-Fe-Si group harmful compound, influencing the microstructure of the compound, impeding growth of crystal, and promoting the compound to be decomposed into short rod-like shape or granular shape at the high temperature; and the light rare earth and the heavy rare earth achieve mutual complementarity in the aspect of controlling the microstructure of the alloy, and substantially, the quite good modifying effect is achieved.

Owner:INNER MONGOLIA UNIV OF TECH

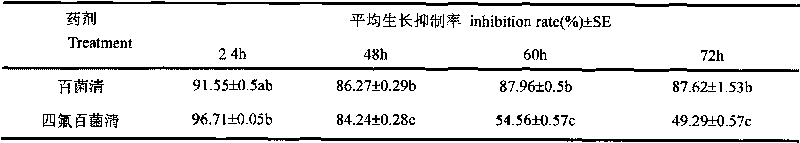

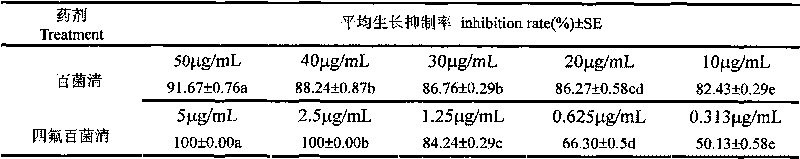

Preparation process and application of tetrafluoro chlorothalonil microemulsion

The invention belongs to the pesticide and fungicide fields, in particular relates to a preparation method and application of tetrafluoro chlorothalonil (2,4,5,6-tetrafluoro-1,3-dicyanobenzene) microemulsion. The tetrafluoro chlorothalonil microemulsion with good physical and chemical stability and high dispersibility can be prepared by screening from various emulsifiers, cosolvents, penetrants and stabilizers. The microemulsion is characterized in that the tetrafluoro chlorothalonil microemulsion comprises the following components: 5-50% of tetrafluoro chlorothalonil, 7-27% of emulsifier, 5-18% of penetrant, 5-26% of cosolvent and the balance water. The fungicide form of the invention is microemulsion using water as solvent so as to avoid the unsafety of production, operation and storage caused by largely used organic solvent and is characterized by wide anti-fungal spectrum, low dosage and environmental friend; and the microemulsion has obvious drug effect for controlling Pyriculariagrisea, Alternaria alternate, Pellicularia sasakii and Botrytis cintrea.

Owner:云天化集团有限责任公司 +1

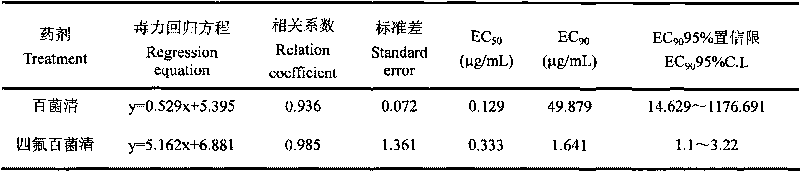

Fluorine-containing diketopyrrolopyrrole quaternary ammonium salt compound and its preparation method and application

The invention discloses a fluorine-containing diketopyrrolopyrrole quaternary ammonium salt compound, the structure of which is shown in formula I: R 1 for F, CH 2 F. CHF 2 、CF 3 , OCH 2 F. OCHF 2 、OCF 3 、SCH 2 F. SCHF 2 、SCF 3 、CF 2 (CF 2 ) n CF 3 A kind of, n is an integer from 0 to 10; X is F, Cl, Br, I. The present invention selects diisopropyl succinate and differently substituted benzonitriles as raw materials to prepare fluorine-containing pyrrolopyrrole diketone quaternary ammonium salt compounds, which can be used as electroplating leveling agents.

Owner:EAST CHINA UNIV OF SCI & TECH +1

A kind of compound manufacturing method of acid leaching stirrer

ActiveCN110029300BSmall atomic radiusAccelerated corrosionMolten spray coatingRare-earth elementLutetium

The invention relates to a compound manufacturing method of an acid leaching stirrer, which uses iron-based amorphous powder as a spraying material, adopts supersonic flame spraying technology to heat and accelerate the powder, and prepares a layer of 150-250 μm thick on the surface of the stirring shaft or blade Iron-based amorphous coating, the chemical ratio of iron-based amorphous powder by mass percentage: chromium 0-25%, molybdenum 0-10%, tungsten 0-5%, niobium 0-12%, lutetium 0-4%, 0-7% manganese, 0-5% boron, 0-4% carbon, 0-3% silicon, 0-2% rare earth elements, and the rest is iron; the service life of the prepared composite stirring shaft and blade is several times For traditional stainless steel products.

Owner:INST OF APPLIED PHYSICS JIANGXI ACADEMY OF SCI

Fluorescent chemosensors for metals based on dipyrrins

InactiveUS7994311B2High binding affinityReduce capacityAnalysis using chemical indicatorsNanosensorsTransfer mechanismCopper

The present invention is a new class of fluorescent sensor with unprecedented sensitivity, selectivity and synthetic efficiency for the identification and qualitative and quantitative detection of transition metal ions. The chemosensing properties are based on an internal charge transfer mechanism or photo-induced electron transfer and are effective in vitro. The chemosensor comprises one or more electron donating dipyrrin functionalities linked to an electron withdrawing functionality. The chemosensor forms a stable transition metal complex through internal charge transfer between the electron donating functionality and the target transition metal, which results in measurable fluorescence. Specific examples for sensing zinc and copper ions are described.

Owner:STC UNM

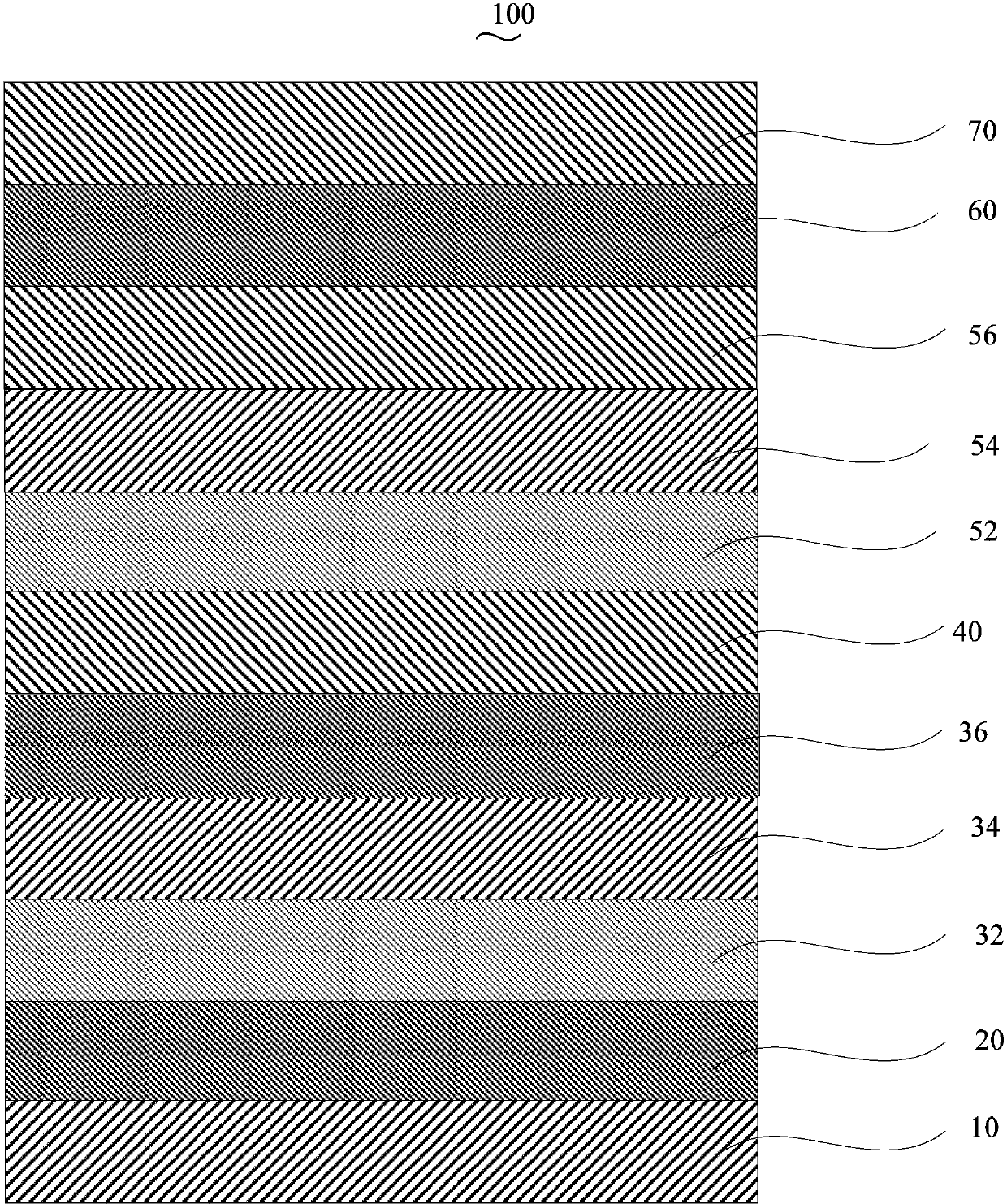

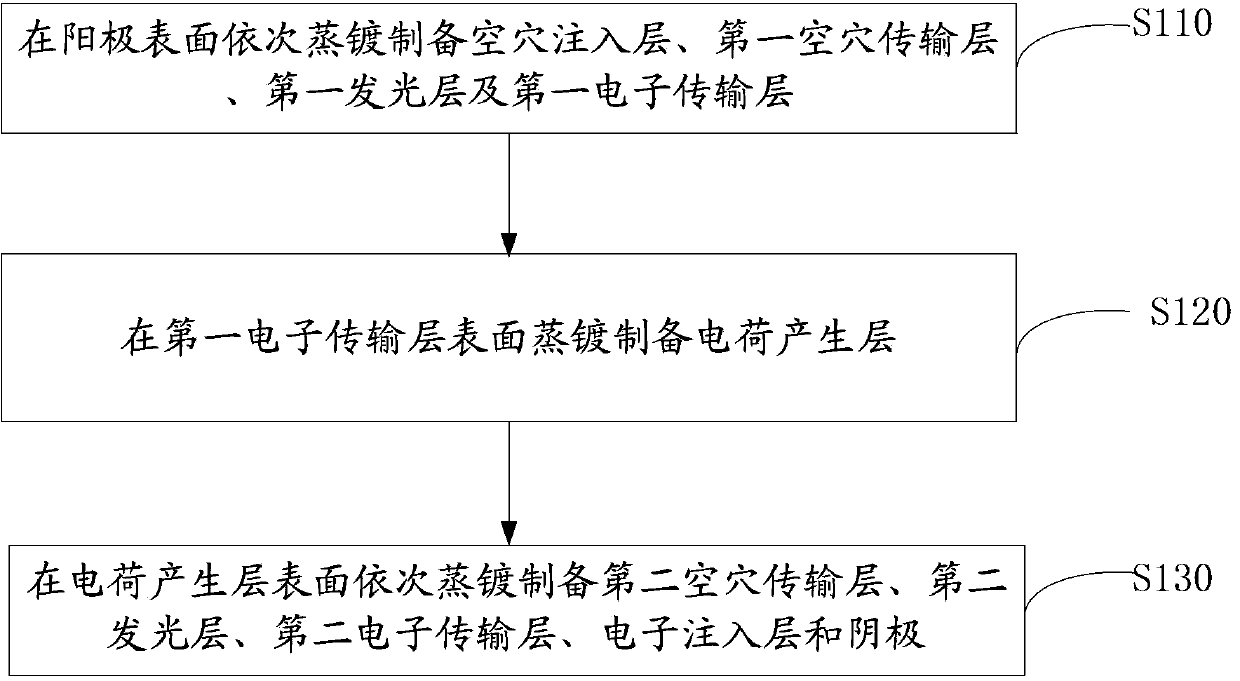

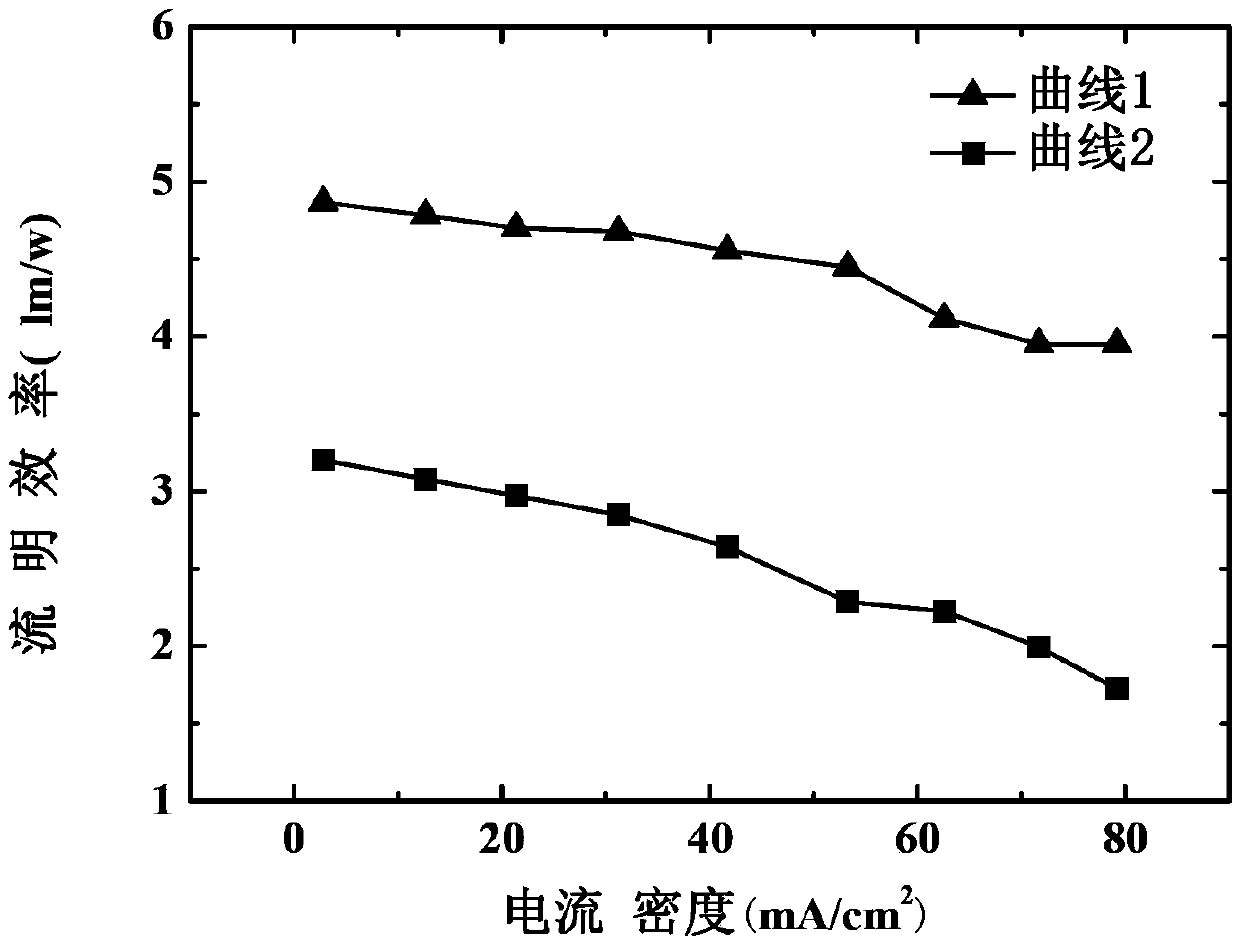

Organic electroluminescent device and preparation method thereof

InactiveCN104183741AImprove luminous efficiencySmall atomic radiusSolid-state devicesSemiconductor/solid-state device manufacturingLithiumHole injection layer

Provided is an organic electroluminescent device which comprises an anode, a hole injection layer, a first hole transmission layer, a first luminescent layer, a first electron transmission layer, a charge generation layer, a second hole transmission layer, a second luminescent layer, a second electron transmission layer, an electron injection layer and a cathode which are laminated in turn. Material of the charge generation layer comprises fullerene material, and lanthanide oxide and lithium salt which are doped in fullerene material, wherein mass ratio of lanthanide oxide to fullerene material is 1:100-1:10, and mass ratio of lithium salt to fullerene material is 1:5-3:5. The aforementioned organic electroluminescent device is relatively high in luminescence efficiency. The invention also provides a preparation method for the organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Gallium nitride-based light-emitting diode epitaxial wafer and manufacturing method thereof

ActiveCN109920883BImprove crystal qualityImprove luminous efficiencySemiconductor devicesPhysical chemistryGallium nitride

The invention discloses a gallium nitride-based light emitting diode epitaxial wafer and a manufacturing method thereof, and belongs to the technical field of semiconductors. The gallium nitride-basedlight emitting diode epitaxial wafer comprises a substrate, and a low-temperature buffer layer, a three-dimensional nucleating layer, a two-dimensional recovery layer, an undoped GaN layer, an N-typelayer, a multi-quantum well layer, an electron blocking layer and a P-type layer which grow on the substrate in sequence, wherein the low-temperature buffer layer and the three-dimensional nucleatinglayer are both beryllium-doped GaN layers, the doping concentration of beryllium in the low-temperature buffer layer is gradually increased in the stacking direction of the epitaxial wafer, and the doping concentration of beryllium in the three-dimensional nucleating layer is gradually reduced in the stacking direction of the epitaxial wafer. The gallium nitride-based light emitting diode epitaxial wafer provided by the invention can improve the bottom crystal quality of the epitaxial layer, thereby improving the crystal quality of the epitaxial layer.

Owner:HC SEMITEK ZHEJIANG CO LTD

A kind of antioxidant suitable for snagcu or sncu solder and preparation method thereof

ActiveCN105149809BImprove antioxidant capacityDoes not increase surface tensionWelding/cutting media/materialsSoldering mediaAntioxidantAlloy

The invention discloses an antioxidant suitable for SnAgCu or SnCu solder. The antioxidant is Sn-Be-Cu intermediate alloy, wherein the alloy is prepared from, by weight, 0.1-0.25% of Be, 2-5% of Cu and the balance Sn. The invention further discloses a preparation method of the antioxidant suitable for the SnAgCu or SnCu solder. The antioxidant contains Be with the specific gravity smaller than that of Sn, Be has a small atomic radius, then Be can gather on the surface of the Sn-based alloy solder and also can fill up gaps in the surface of the Sn-based alloy solder, the combining capacity of Sn and O can be effectively isolated or weakened, and accordingly the solder has excellent anti-oxidation performance when the antioxidant is added into the solder; besides, Be will not increase the surface tension of the solder, then the solder has better fluidity, and accordingly the soldering performance of the solder is improved.

Owner:NANJING TIN REFINING CO LTD

A novel high-temperature cl-corrosion-resistant nitrogen-containing low-nickel alloy and preparation method thereof

The invention belongs to the technical field of alloy materials, and in particular relates to a novel high temperature resistant Cl ‑ Corroded nitrogen-containing low-nickel alloy and preparation method. A new type of high temperature resistant Cl ‑ The corroded nitrogen-containing low-nickel alloy, measured by mass percentage, comprises the following components: Ni: 42.0-46.0wt%, Cr: 20.0-26.0wt%, Mn: 7.0-8.0wt%, Si: 1.6wt% and below, Mo: 6.0‑8.0wt%, Cu: 0.5wt% or less, Co: 0.8‑1.0wt%, N: 0.12‑0.21wt%, Ti+Al=2.8‑3.0wt%; Ti / Al=1.0‑1.3, Nb: 6-7%, W: 2.0-3.0wt%, V: 1.25-1.55wt%, and the rest are Fe and inevitable impurities. The optimization of the alloy composition of the present invention enables the nitrogen-containing low-nickel alloy to have excellent Cl resistance at high temperature ‑ Corrosive, can replace Inconel 625 alloy, used in high temperature, high pressure chemical, energy and marine engineering fields, such as facing 900 ℃, Cl ‑ Corrosion of the energy storage medium in the solar heat storage tube.

Owner:SHENYANG POLYTECHNIC UNIV

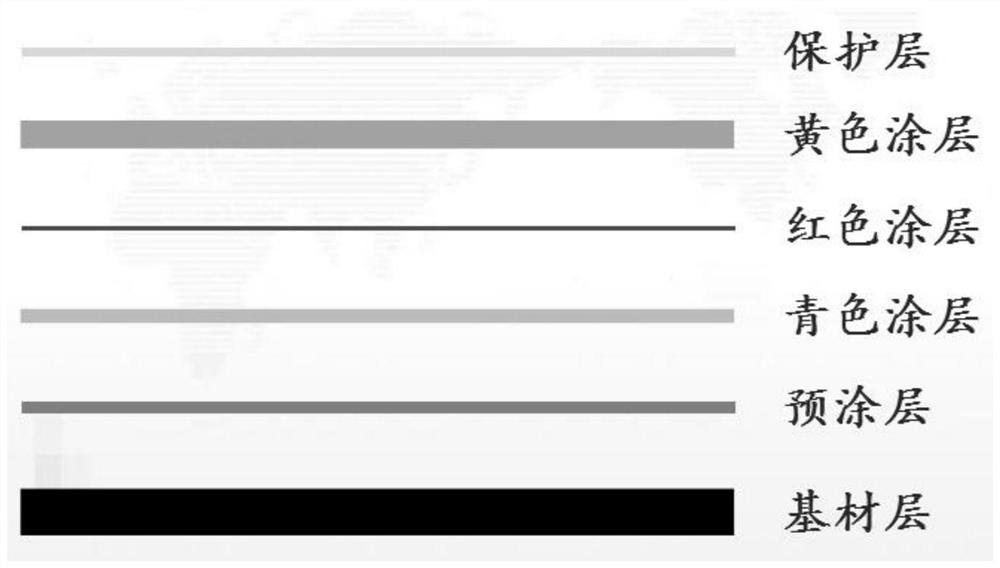

Colorful inkless printing paper

PendingCN114481689AHigh glossImprove aging resistanceNon-fibrous pulp additionPaper coatingVinyl etherProtection layer

The invention relates to colored inkless printing paper which comprises a base material layer, an inkless coating and a protective layer, and the protective layer comprises fluorocarbon resin, an adhesion promoter, a solvent and an auxiliary agent, the fluorocarbon resin is selected from one or more of polytetrafluoroethylene resin, polyvinylidene fluoride resin, polytrifluorochloroethylene resin, vinyl ether resin and polyvinyl fluoride resin and accounts for 5-30% by mass, the adhesion promoter is selected from one or more of tetraethyl titanate and tetrabutyl titanate and accounts for 0-2% by mass, and the solvent accounts for 1-5% by mass. The solvent is water and accounts for 60-85% by mass, and the auxiliary agent is selected from one or more of dibutyl phthalate, dimethyl phthalate, polyethylene wax and dimethyl silicone oil and accounts for 2-5% by mass. Based on the colored inkless printing paper, colored advertisement images and texts can be directly printed on a PET material through inkless printing.

Owner:湖南鼎一致远科技发展股份有限公司

A kind of catalyst and preparation method thereof, and a kind of method for preparing laurolactam by gas phase rearrangement reaction

ActiveCN112619673BHigh mechanical strengthImprove bindingLactams preparationPhysical/chemical process catalystsLaurolactamPoly ether ether ketone

The invention discloses a catalyst and a preparation method thereof, as well as a method for preparing laurolactam by gas-phase rearrangement reaction. The catalyst comprises fluoride modified rare earth doped Al 2 O 3 ‑SiO 2 ‑ZrO 2 and fluorine-containing sulfonated polyether ether ketone, wherein the loading amount of fluorine-containing sulfonated polyether ether ketone in the catalyst is 20-50wt%, preferably 30-45wt%. Using the catalyst to catalyze the gas-phase rearrangement of cyclododecanone oxime, the conversion rate of cyclododecanone oxime can reach more than 99%, the selectivity of laurolactam can reach more than 99.5%, the life of the catalyst can reach more than 3000h, and the reaction has no by-product of ammonium sulfate. , The catalyst has high mechanical strength and solves the equipment corrosion and environmental pollution problems of the traditional liquid phase rearrangement process.

Owner:WANHUA CHEM GRP CO LTD

Preparing method for Zr:LiNbO3 crystal

InactiveCN100480436CFast growthExcellent ferroelectricPolycrystalline material growthBy pulling from meltCzochralski methodLithium niobate crystal

The invention relates to a Zr:LiNbO3 crystal and the preparing method thereof, relating to a crystal and the preparing method. And the Zr:LiNbO3 crystal is made of ZrO2, Nb2O5 and LiCO3 with the same purity of 99.99%, where ZrO2 doping quantity is 4%-6% of total quantity of ZrO2, Nb2O5 and LiCO3, and the molar ratio of Li to Nb is 0.946; and the preparing method: (1) weighing and mixing ZrO2, Nb2O5 and LiCO3; (2) making crystal growth by Czochralski method; (3) polarizing; (4) cutting crystals and making surface optical quality polishing and obtaining Zr:LiNbO3 crystals. And it assures the original excellent performance of LiNbO3 crystal and has optical loss resistance higher than 5mol%Mg:LiNbO3,6.5%Zn:LiNbO3 and 4mol%Hf:LiNbO3 by 85%, 100% and 112%, respectively. And the preparing method has features of simple, convenient to operate and high crystal growing rate.

Owner:YIBIN UNIV

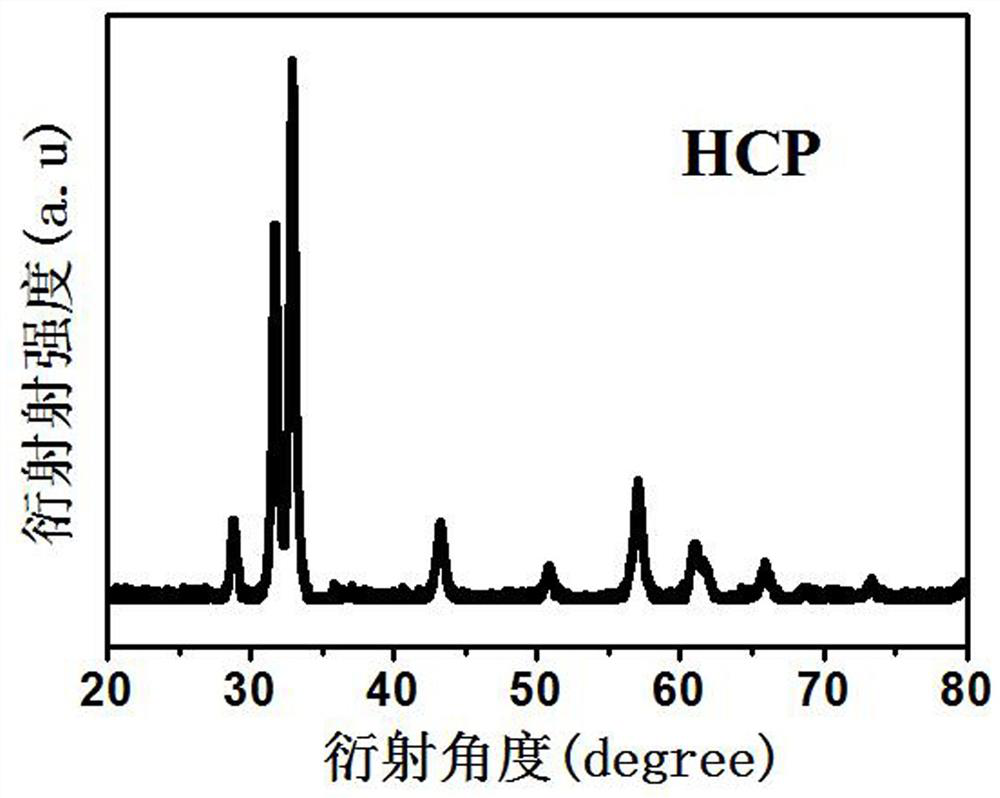

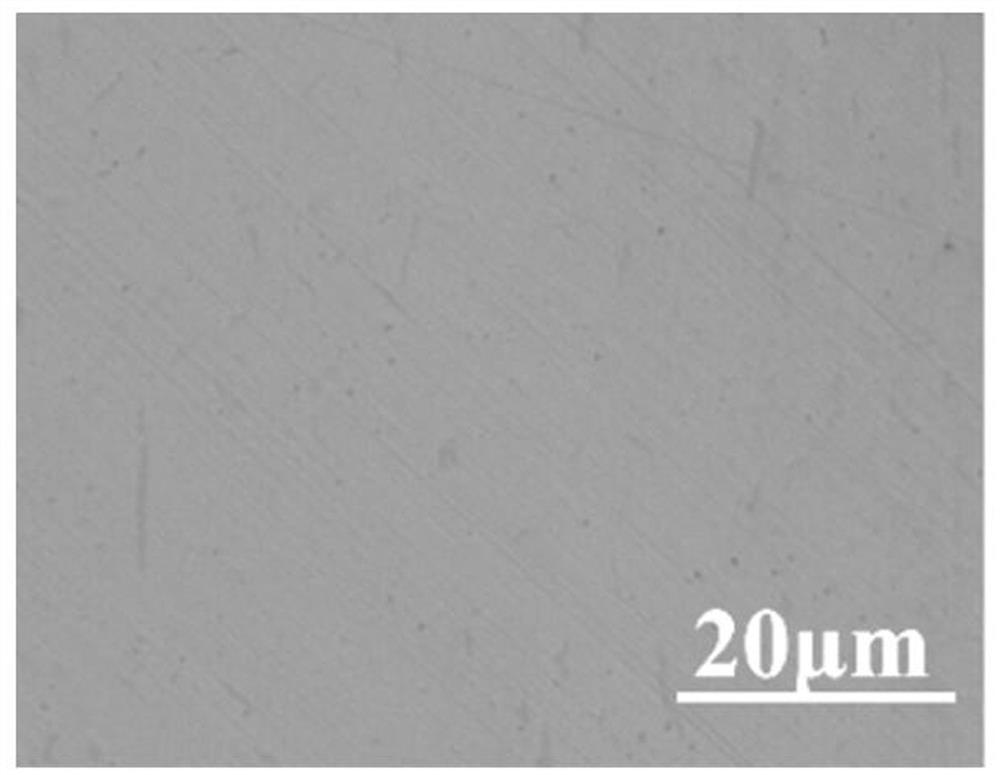

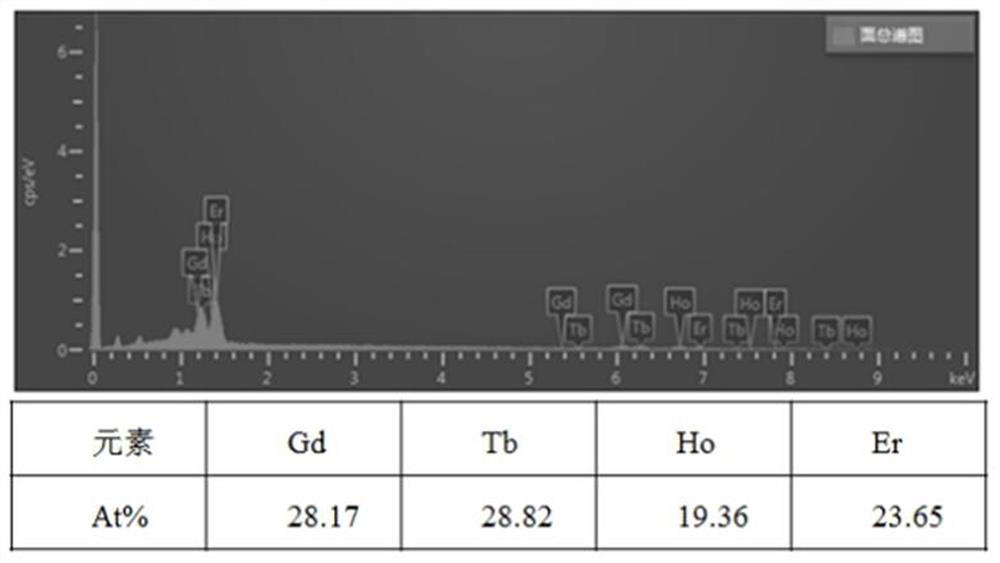

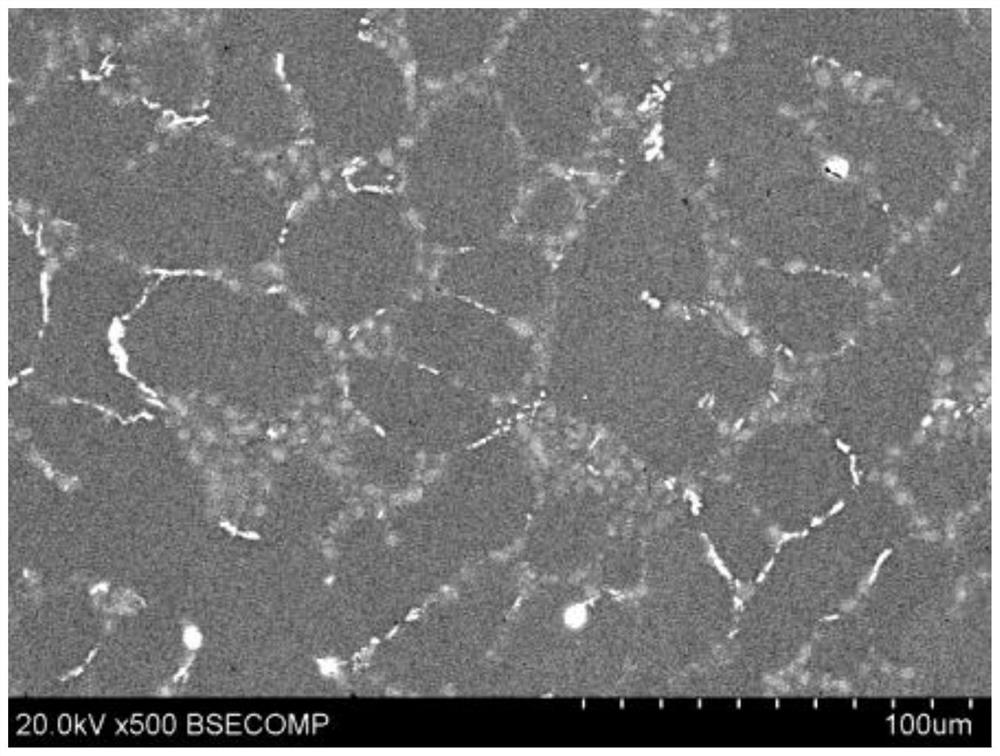

Rare earth high-entropy alloy material with high saturation magnetization and preparation method thereof

InactiveCN111719076ASmall atomic radiusSimple processMagnetic materialsMagnetic phaseHigh entropy alloys

The invention discloses a GdTbHoEr material with high saturation magnetization. The GdTbHoEr material is prepared by taking Gd, Tb, Ho and Er as raw material and carrying out electric arc melting, wherein the chemical formula of the material is GdTbHoEr, and the material with high saturation magnetization has a single close-packed hexagonal crystal structure; and the element components further comprise one or two of La and Y. When being used as a magnetic material, the material has the magnetic phase transformation characteristic, and the saturation magnetization reaches 290-300 emu / g when thetemperature is lower than the Neel temperature; the high-entropy alloy GdTbHoEr is used as a matrix, La and Y are added, the magnetic transition temperature of the alloy is regulated and controlled within the range of 190 K-120 K, and the coercive force of the alloy is regulated and controlled within the range of 600 Oe -1706 Oe. The high-saturation magnetization intensity material has the characteristics of high magnetization intensity, wide existing temperature range, adjustable components, adjustable Neel temperature, simple and diversified process and low overall preparation cost, and issuitable for industrial production.

Owner:GUILIN UNIV OF ELECTRONIC TECH

A method for improving the mechanical properties of aluminum-silicon-magnesium casting alloy

Owner:INNER MONGOLIA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com