A kind of antioxidant suitable for snagcu or sncu solder and preparation method thereof

An antioxidant and solder technology, which is applied in the field of tin solder alloys, can solve the problems of alloy element burnout, hidden dangers of solder joint performance, etc., and achieve the effects of improved welding performance, good oxidation resistance and good fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the above-mentioned antioxidant suitable for SnAgCu or SnCu solder comprises the following steps: adding a certain amount of pure tin in the tin melting furnace, heating the tin melting furnace, when the temperature of the tin melting furnace is greater than 270 ° C, the weight of the pure tin 5.3% added CuBe foil strip 2 Master alloy (beryllium is 2% by weight), continue to heat the tin-melting furnace until the tin-melting furnace heats up to 400 ° C, start the mixer, and stir the mixed solution in the furnace (stir for 15 minutes), until the copper-beryllium master alloy in the furnace Completely melt, clean the scum on the surface of the molten liquid, and cast it, and cast it into a suitable weight according to the requirements of the follow-up process. At this time, the weight percentage of Be in the Sn-Be-Cu master alloy is 0.1%.

[0022] The preparation method of the above-mentioned antioxidant suitable for SnAgCu or SnCu solder compris...

Embodiment 1

[0024] Applications of the above antioxidants for SnAgCu or SnCu solders:

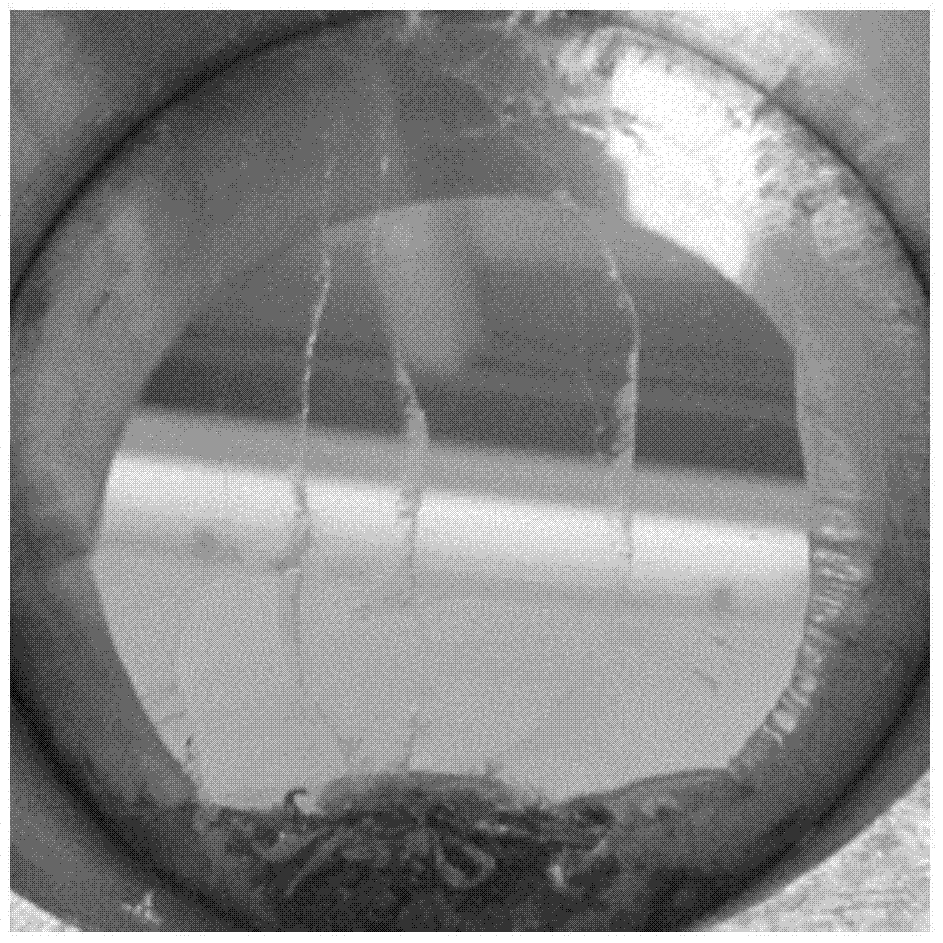

[0025] Add the antioxidant of the present invention (the weight percentage content of Be in this antioxidant is 0.1%) to Sn-3%Ag-0.5%Cu solder, according to wave soldering or immersion welding melting furnace melting tin weight, add this by 0.5% of soldering tin weight Antioxidants, put the antioxidants in a small colander, slowly immerse in the wave soldering or dip soldering molten tin, after 3-5 minutes, disturb the small colander to completely melt the antioxidants into the molten tin in the furnace, and clean the surface of the molten liquid A little scum, the weight percent content of Be in the molten tin is 0.0005%, and the Sn-3%Ag-0.5%Cu solder that has added the antioxidant of the present invention shows good oxidation resistance, such as image 3 Shown, add the solder surface oxidation 1h of antioxidant of the present invention and still keep better metallic luster.

Embodiment 2

[0027] Applications of the above antioxidants for SnAgCu or SnCu solders:

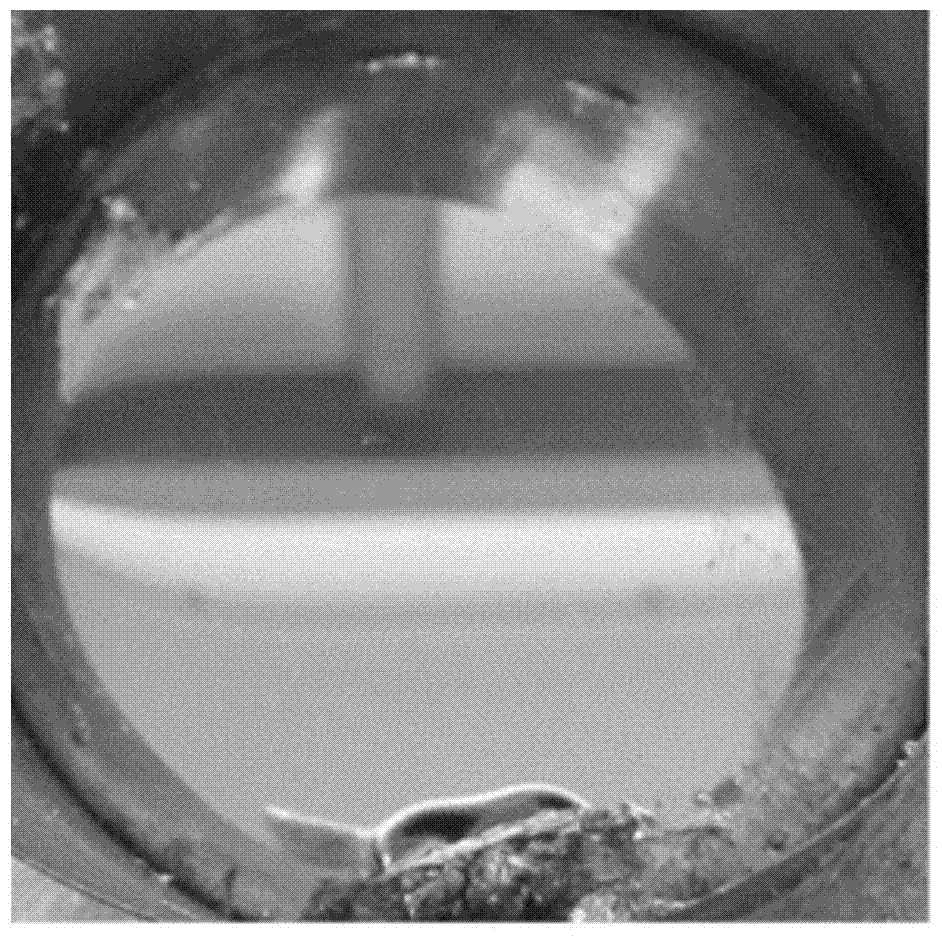

[0028] Add the antioxidant of the present invention (the weight percent content of Be in this antioxidant is 0.1%) to the Sn-0.3%Ag-0.7%Cu solder, according to the weight of the melting tin in the wave soldering or immersion soldering furnace, add this by 1% of the soldering tin weight Antioxidants, put the antioxidants in a small colander, slowly immerse in the wave soldering or dip soldering molten tin, after 3-5 minutes, disturb the small colander to completely melt the antioxidants into the molten tin in the furnace, and clean the surface of the molten liquid A little scum, the weight percent content of Be in the molten tin is 0.0010%, and the Sn-0.3%Ag-0.7%Cu solder that has added the antioxidant of the present invention shows good oxidation resistance, such as Figure 5 Shown, add the solder surface oxidation 1h of antioxidant of the present invention and still keep better metallic luster.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com