Patents

Literature

256 results about "Dip soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dip soldering is a small-scale soldering process by which electronic components are soldered to a printed circuit board (PCB) to form an electronic assembly. The solder wets to the exposed metallic areas of the board (those not protected with solder mask), creating a reliable mechanical and electrical connection.

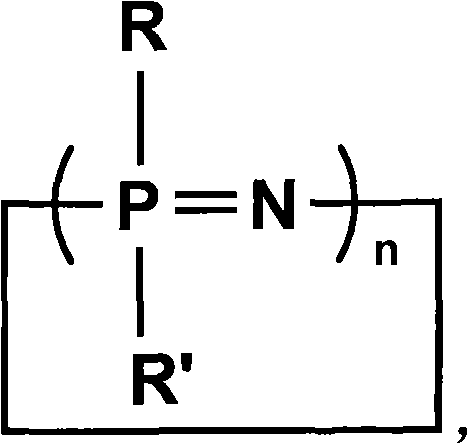

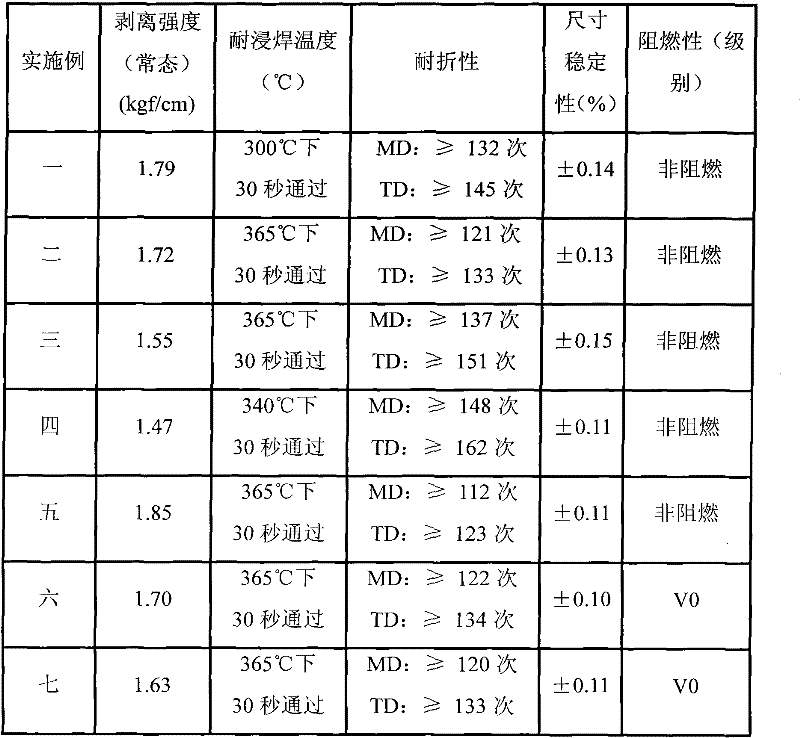

Compound base copper-clad laminate and manufacturing method thereof

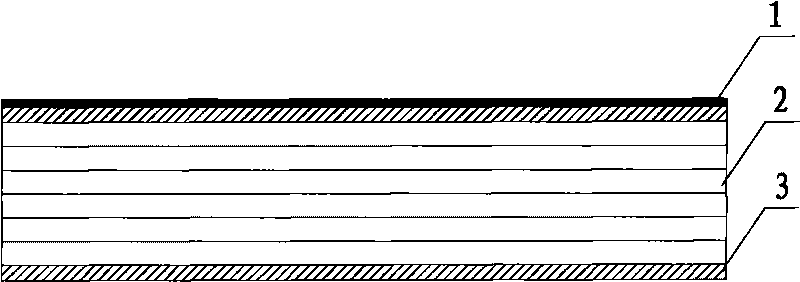

ActiveCN101746102ASmall water absorptionGood solder dip resistanceLamination ancillary operationsLaminationEpoxyGlass fiber

The invention discloses a method for manufacturing a compound base copper-clad laminate, which comprises the following steps of: rubberizing a glass fiber cloth through a first maceration extract, and drying prepregs to manufacture surface prepregs; rubberizing wood pulp paper through a second maceration extract, and drying core prepregs; and cutting more than two of the core prepregs to superpose the core prepregs together, superposing the surface prepregs on two sides respectively, then superposing a copper foil on a single surface or two surfaces, and performing hot press molding to obtain the compound base copper-clad laminate. The method for manufacturing the compound base copper-clad laminate can reduce the water absorbability of the laminate and prevent plate explosion by using the first maceration extract and the second maceration extract to perform optimization and using a phosphazene compound flame retardant to replace part of phosphorus-containing epoxy resin or phosphate, and the prepared compound base copper-clad laminate has the advantages of small content of chlorine and bromine, low water absorption, good dip soldering resistance, improved electrical property, high flame retardance capable of reaching the level of UL94V-0, and increased tenacity.

Owner:建滔积层板(昆山)有限公司

Low solid content halogenide-free water-based type cleaning-free scaling powder

InactiveCN101327552AHigh activitySolve the defect of insufficient wettabilityWelding/cutting media/materialsSoldering mediaWater basedAviation

The present invention relates to a medium-and-high-activity, low-solid-content halideless water-based type wash-free soldering flux which is applicable to the spraying process, the foaming process and the dipping process. The soldering flux is composed of the following weight proportions of substances: 1 percent to 4 percent of promoting agent, 0.5 percent to 1.5 percent of filmerformer, 20 percent to 40 percent of latent solvent, 0.1 percent to 2 percent of wetting agent and 0.01 percent to 0.1 percent of corrosion inhibitor, and the rest is deionized water. The soldering flux of the present invention does not contain halogen and colophony; soldering material can have good spreadability; a PCB board can have good solder permeability; soldering spots are plump and shiny; the surface of the soldered PCB board has no visible residues and is not eroded, and the surface insulation resistance is high; under the normal temperature, the soldering flux does not absorb moisture and cannot be decomposed, and a washing process can be omitted. Since the deionized water is used as solvent, the soldering flux does not contain any volatile organic substance, so the soldering flux cannot be ignited and does not explode, and therefore the soldering flux is environment-friendly. The soldering flux is applicable to the wave-soldering or dip-soldering production line of various printed boards in the fields of communication, aviation, computers, etc.

Owner:DONGGUAN YONGAN TECH

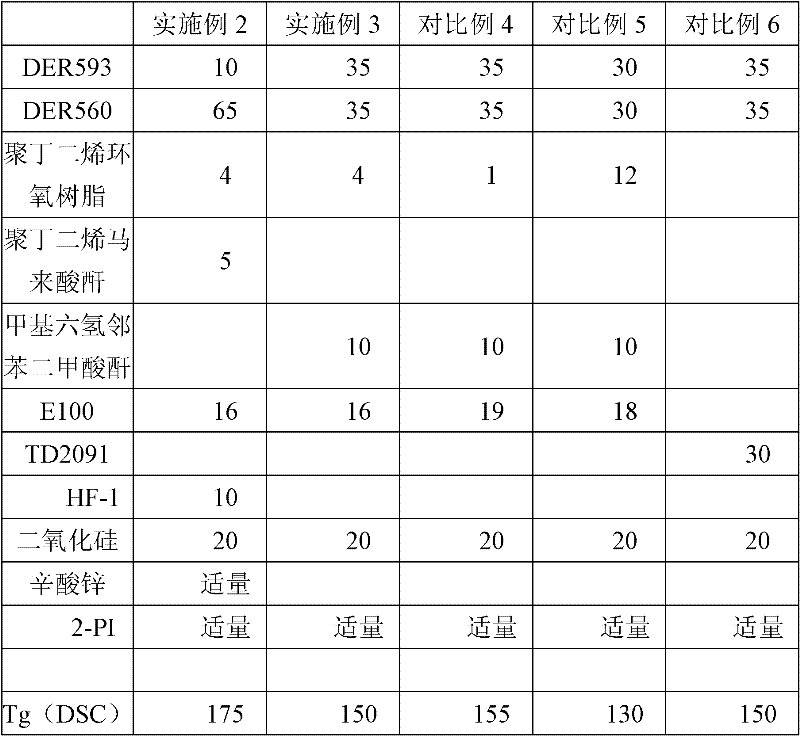

Epoxy resin composition as well as prepreg and metal-foil-clad laminated board manufactured by using same

InactiveCN102226033AImprove toughnessImproved Via ReliabilitySynthetic resin layered productsCircuit susbtrate materialsDip solderingMetal foil

The invention relates to an epoxy resin composition as well as a prepreg and a metal-foil-clad laminated board manufactured by using the same. The epoxy resin composition comprises the following components: epoxy resins, which are bisphenol A epoxy resins or isocyanate-modified epoxy resins or a mixture thereof; polybutadiene resins of which the epoxy equivalent is 200-1000 and the number average molecular weight is 500-5000; a curing agent, which is a mixed curing agent of amine and anhydride curing agents; and silicon micropowder. The prepreg using the epoxy resin composition includes a base material and the epoxy resin composition attached to the base material by impregnating and drying. The metal-foil-clad laminated board manufactured by using the epoxy resin composition includes a plurality of laminated prepregs and metal foils formed on one or two surfaces of the laminated prepregs. The epoxy resin composition provided by the invention has the advantages of heat resistance, dip soldering resistance, moisture resistance, moisture heat resistance, good toughness and high processing efficiency, and is adaptable to the lead-free printing performance requirements on the laminated board.

Owner:GUANGDONG SHENGYI SCI TECH

Low silver hypoeutectic Sn-Cu-Ag lead-free solder for electronic micro connection

InactiveCN101214591ALow costImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaDip solderingWave crest

The invention provides a low-Ag hypo eutectic Sn-Cu-Ag lead-free solder the components of which are 0.5 to 0.65wt percent of Cu, 0.1 to 0.45wt percent of Ag, 0.001 to 0.1wt percent of Ni, 0.001 to 0.3wt percent of Sb, 0.001 to 0.2wt percent of Bi and / or In, 0 to 0.01wt percent of P, 0 to 0.03wt percent of Ge and the rest is Sn. The solder is further characterized in that (1) the content of Ag in the solder of Cu plus Ag is less than 1wt percent is not more than 0.45wt percent; (2) the gross of the microelements like Ni, Sb, Bi, In, P, and Ge, etc., that are added is not more than 0.5wt percent. The solder has the advantages of low cost and excellent oxidation, wettability and overflow resistances, can remarkably reduce the waste of the solder, improve the forming of the welding point, remarkably reduce the connecting defects of braze welding. The solder can replace a Sn-Cu-Ag hypo eutectic material and is suitable for the wave crest welding, dip soldering as well as manual welding and reflow soldering for electric products.

Owner:重庆工学院

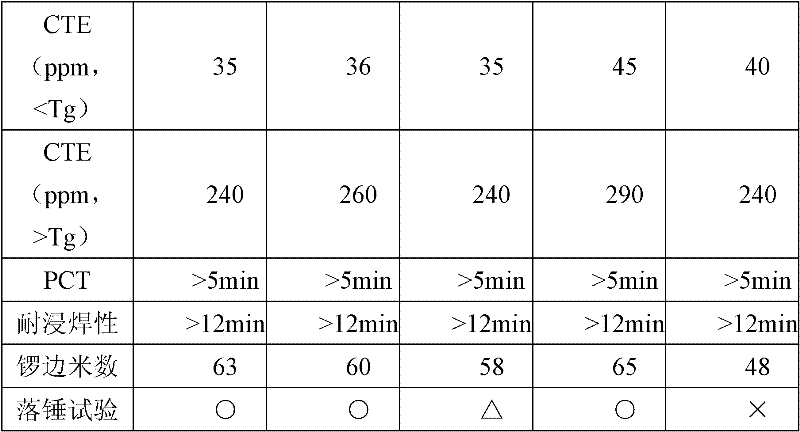

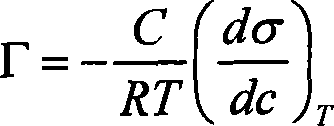

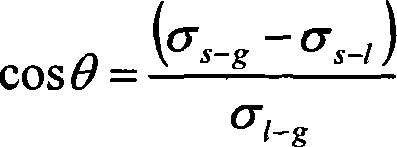

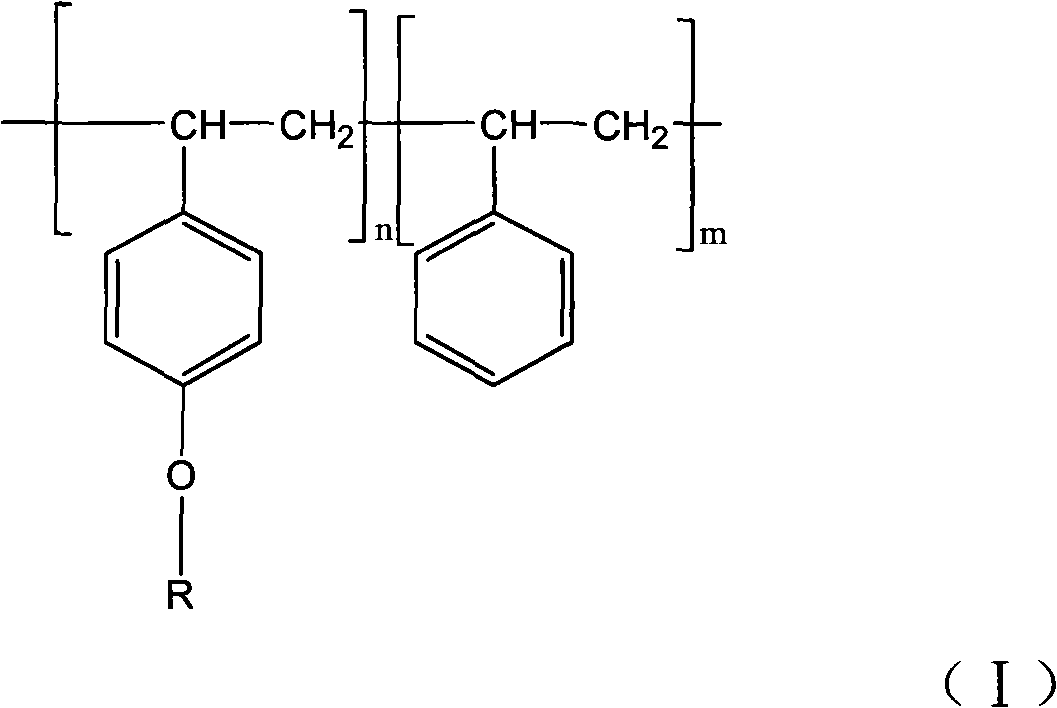

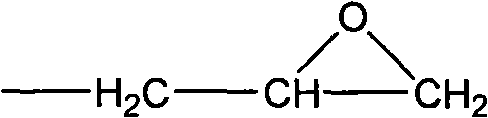

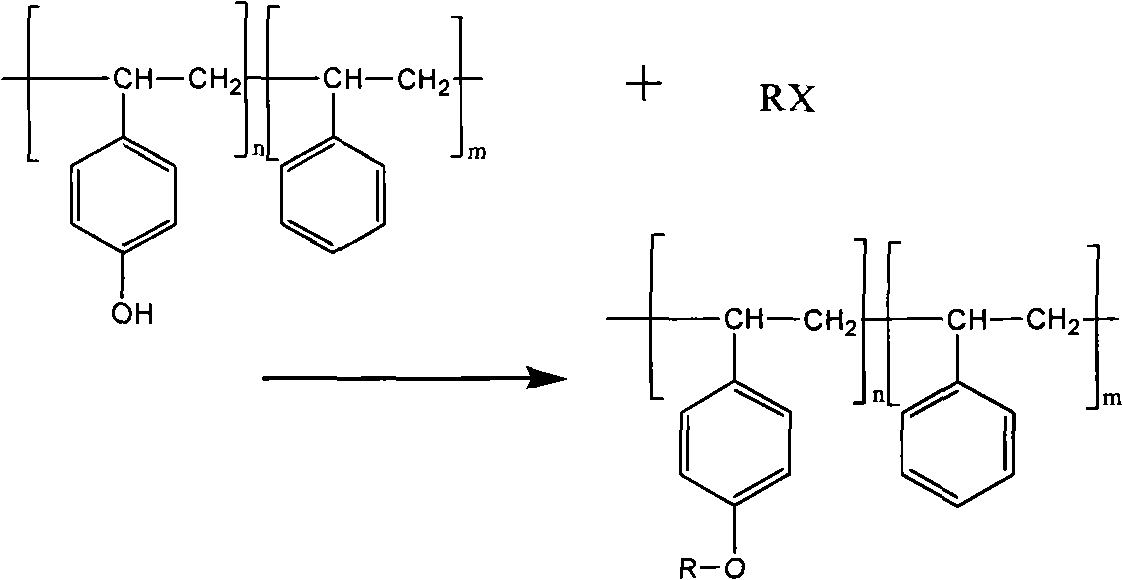

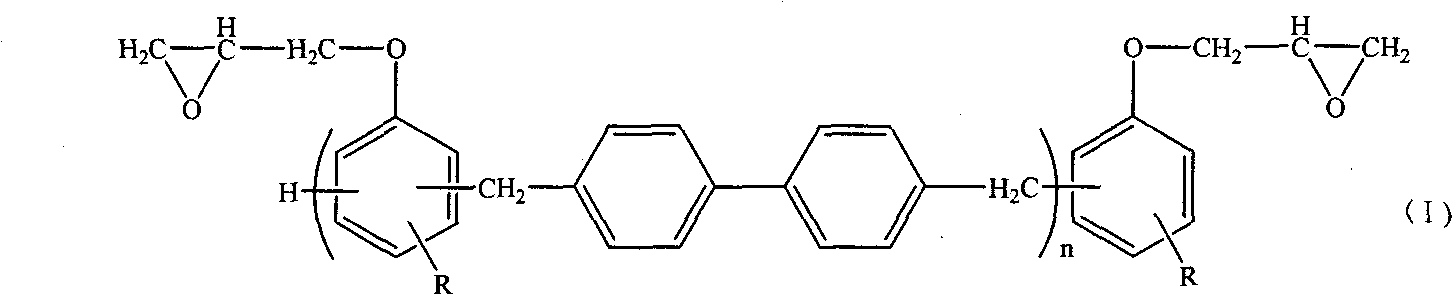

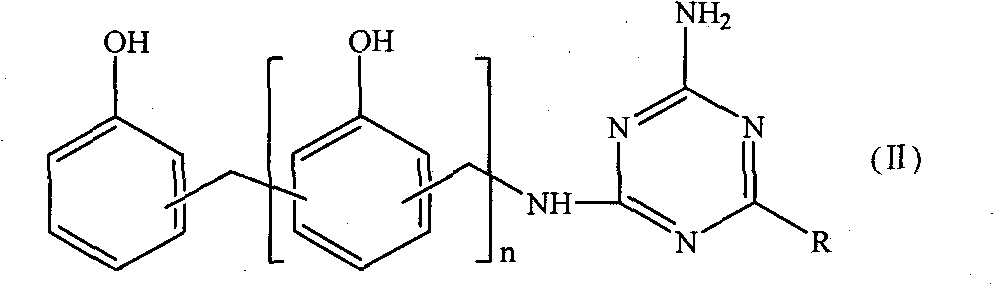

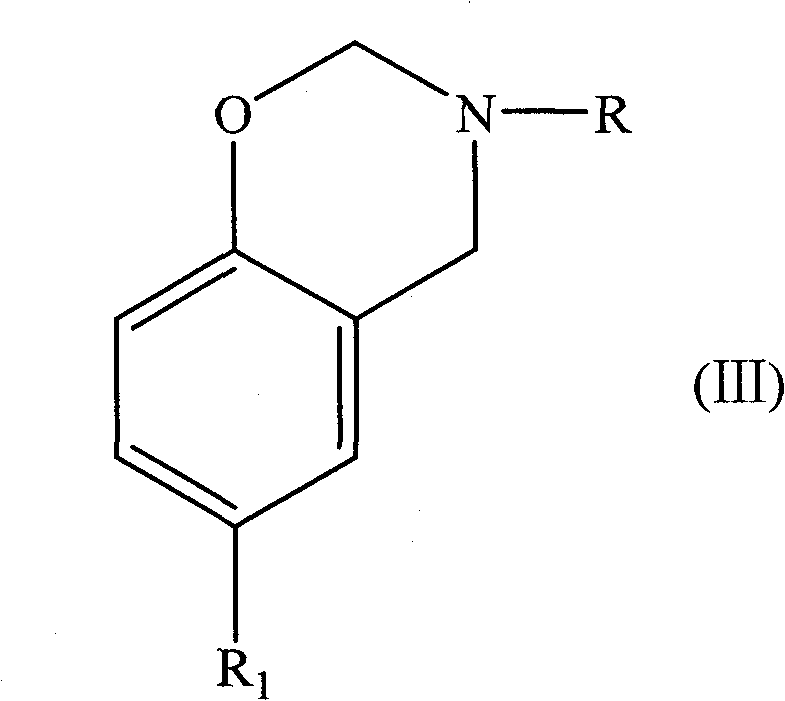

Thermosetting resin composition and prepreg and laminate for printed circuits thereby

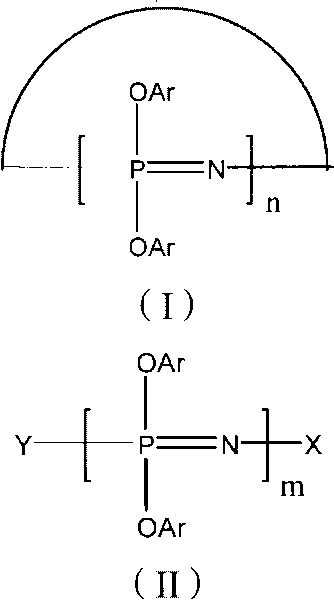

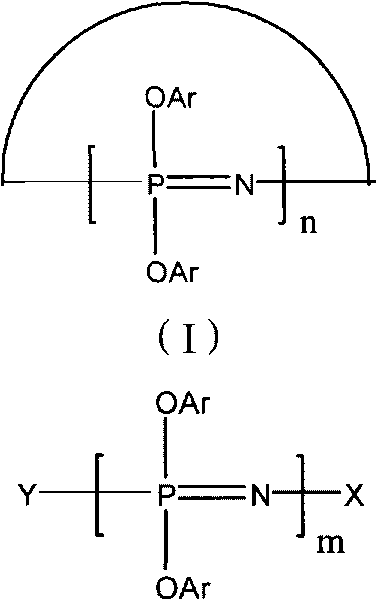

InactiveCN101643571AExcellent dielectric propertiesImprove thermal stabilityCircuit susbtrate materialsMetal layered productsEpoxyDip soldering

The invention relates to a thermosetting resin composition and a prepreg and a laminate for printed circuits thereby. The thermosetting resin composition comprises at least an epoxy resin with a component being the structural formula (I) and a curing agent. The molecular structure of the epoxy resin composition of the invention contains the low-polarity styrene structure, therefore, the dielectricproperty of the resin is optimized. The dielectric constant and the dielectric loss angle tangent are reduced compared with those of the common epoxy resins. The prepreg obtained by coating the resincomposition on the substrates and the laminate manufactured by laminating the prepreg simultaneously have the characteristics of low dielectric constant, low dielectric dissipation factors, good heatresistance, good dip soldering resistance, good moisture resistance, good humidity resistance and good cohesiveness with copper foils. The resin composition of the invention can be also used for manufacturing the resin sheets, resin composition copper foils, the laminate and the printed circuit boards. R is (a), and n and m are natural numbers.

Owner:GUANGDONG SHENGYI SCI TECH

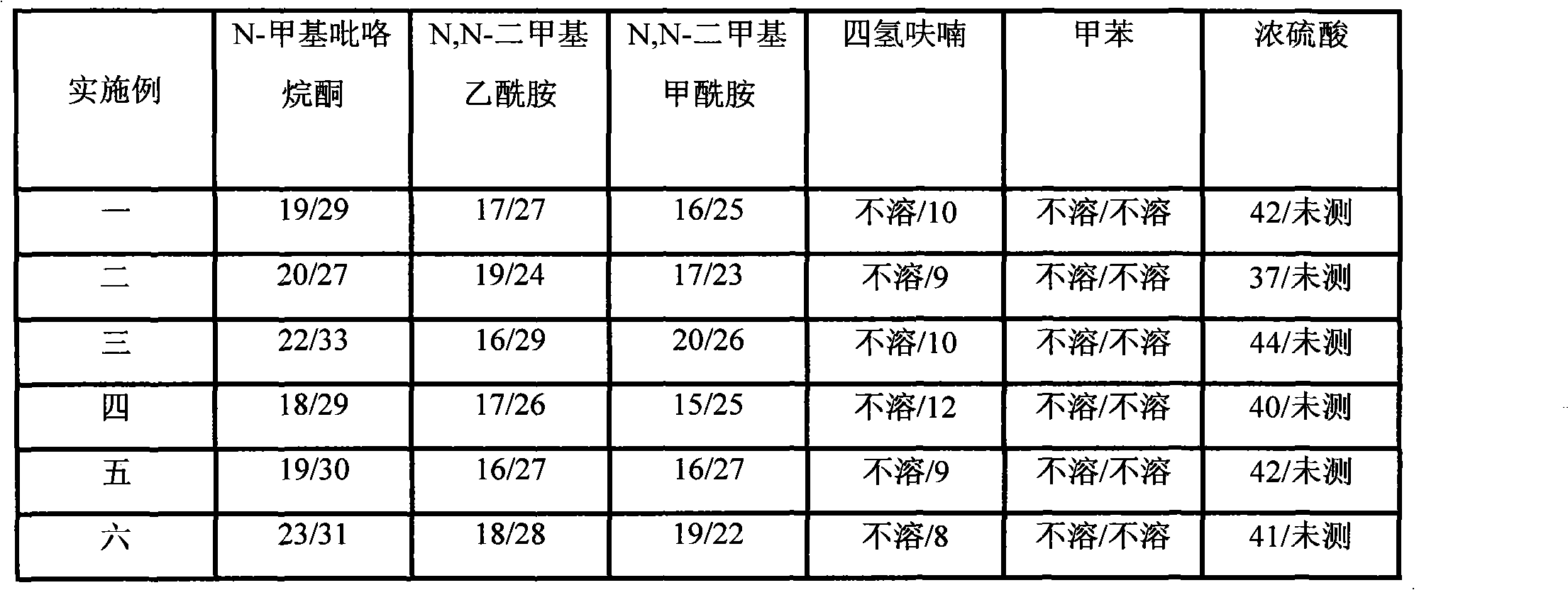

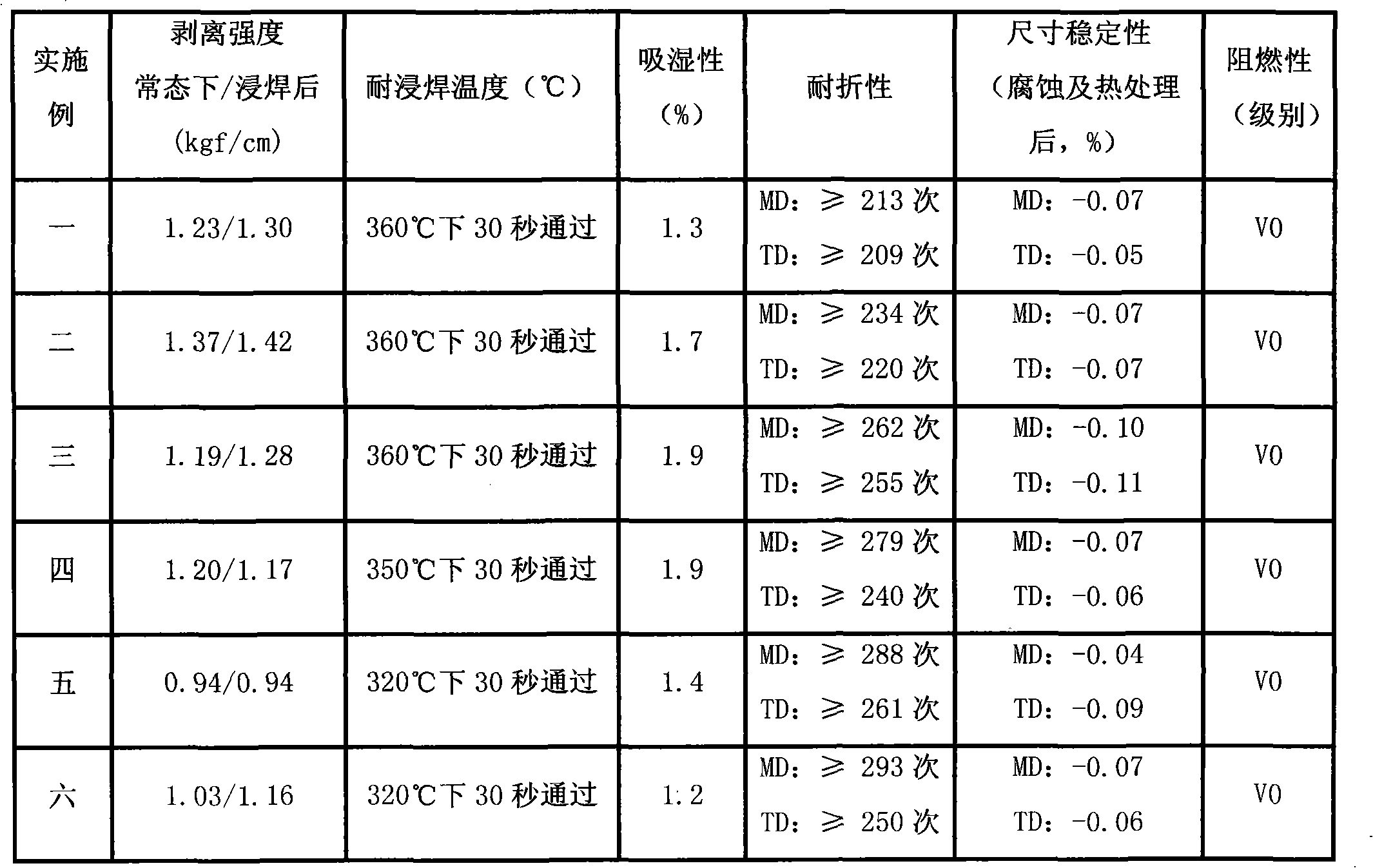

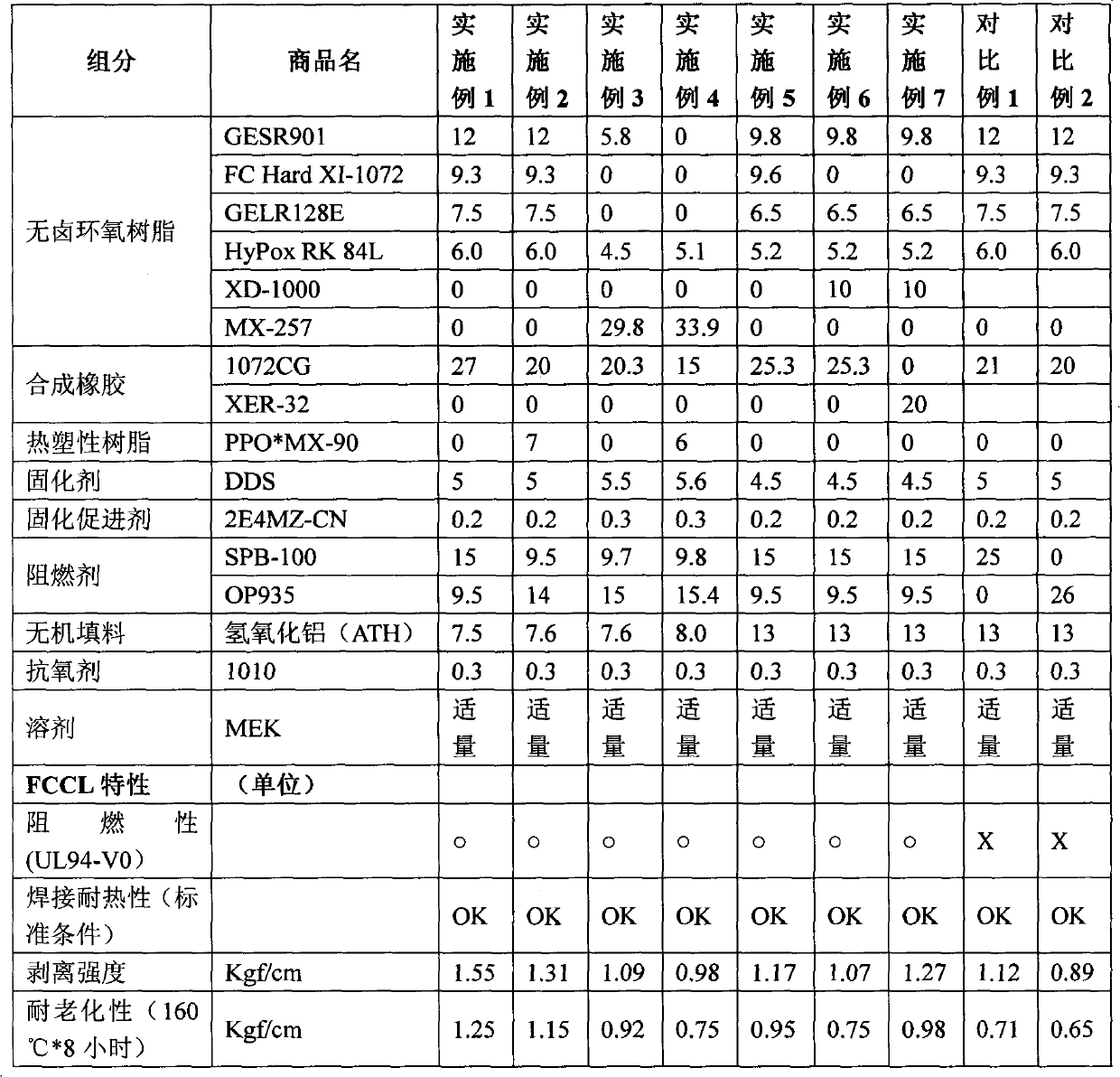

Halogen-free and phosphorous-free flame-retardant synthetic resin adhesive used for flexible copper clad laminate

InactiveCN101851480ANon-macromolecular adhesive additivesMacromolecular adhesive additivesElastomerEpoxy

The invention relates to a halogen-free and phosphorous-free flame-retardant synthetic resin adhesive used for a flexible copper clad laminate, in particular to the adhesive used for producing the flexible copper clad laminate. The adhesive comprises the following components: biphenyl epoxy resin, elastomer modified epoxy resin, a flexibilizer, a curing agent, a curing accelerator, an inorganic filler and an organic solvent. The halogen-free and phosphorous-free flame-retardant synthetic resin adhesive is halogen-free and phosphorous-free, is environmental-friendly and achieves fire retardance up to level UL94V-0; and the flexible copper clad laminate produced by using the adhesive has the characteristics of high folding endurance, high fire retardance, dip-soldering resistance, high peel strength, low water absorption and high dimensional stability.

Owner:HAISO TECH

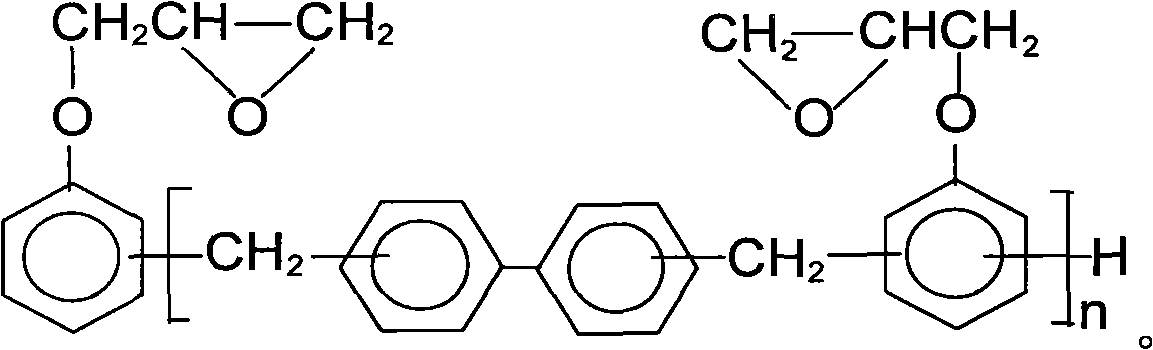

Low-halogen-content fire-retardant adhesive and flexible copper clad laminate prepared from same

InactiveCN101892027ALow halogen contentLow heat resistanceNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyDip soldering

The invention relates to a low-halogen-content fire-retardant adhesive and a flexible copper clad laminate prepared from the same. The low-halogen-content fire-retardant adhesive comprises synthetic rubber, brominated epoxy resin, biphenyl type epoxy resin, phosphonitrile compounds, an aromatic amine curing agent, an imidazole curing accelerator, inorganic filler, an ion exchanger, an oxidation inhibitor and a solvent. The flexible copper clad laminate prepared from the fire-retardant adhesive comprises a polyimide film, a low-halogen-content fire-retardant adhesive layer and copper foil, wherein the low-halogen-content fire-retardant adhesive layer is coated on the polyimide film, and the copper foil is pressed on the low-halogen-content fire-retardant adhesive layer. The fire-retardant adhesive has low halogen content, excellent flexibility, heat resistance, adhesion property and humidity resistance. The flexible copper clad laminate has excellent flexibility, folding resistance, deflection resistance, dip soldering resistance, ion mobility resistance and high peeling strength, the flame retardance reaches the UL94V-0 grade, and the flexible copper clad laminate is suitable for manufacturing a flexible printed circuit board.

Owner:GUANGDONG SHENGYI SCI TECH

Washing-free high temperature dip soldering flux

ActiveCN102029488AReduce physical impactDip soldering process is simpleWelding/cutting media/materialsSoldering mediaDip solderingBoiling point

The invention discloses a washing-free high temperature dip soldering flux, and belongs to the technical field of fluxes. The invention aims to solve the problems in the prior art, and provides a flux which has better depainting property and welding assistance property and wider operating temperature window and meets the requirement of environmental protection. The washing-free high temperature dip soldering flux comprises the following components in percentage by weight: 1.0 to 2.0 percent of active substance, 1.0 to 3.0 percent of resin, 0.05 to 0.10 percent of surfactant, 0.2 to 1.0 percent of high boiling solvent and the balance of solvent. The flux is particularly suitable for a high temperature dip soldering process for coating tin on enameled wires with the diameter of less than 0.5mm. The dip soldering process is simple, and convenient to operate; the operating temperature window is as wide as 290-480 DEG C; the flux is clean in depainting and better in coating the tin, has little residue after welding and does not require cleaning; and during operation, the smog generated by the flux is small so as to influence the body of the operators little.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

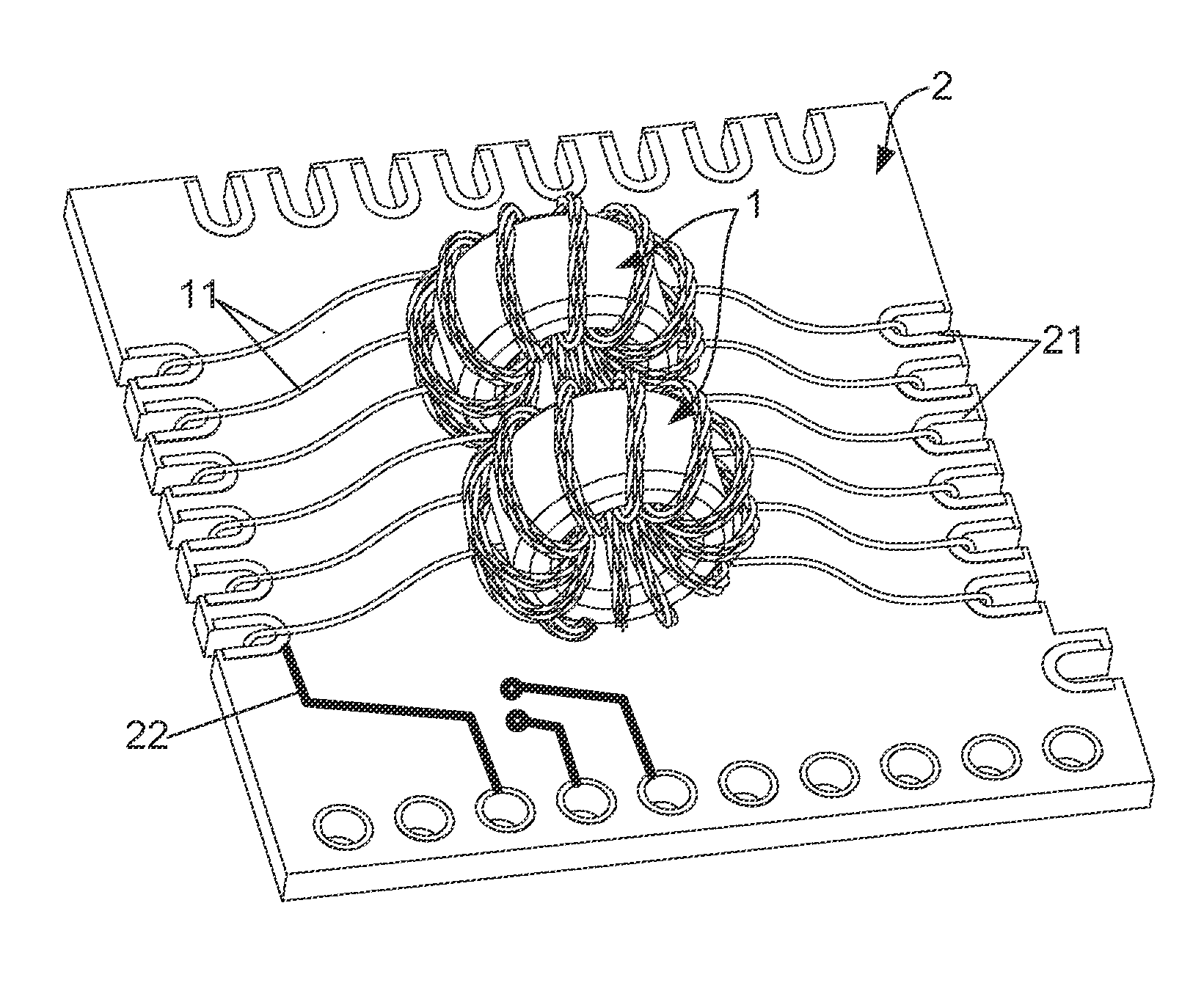

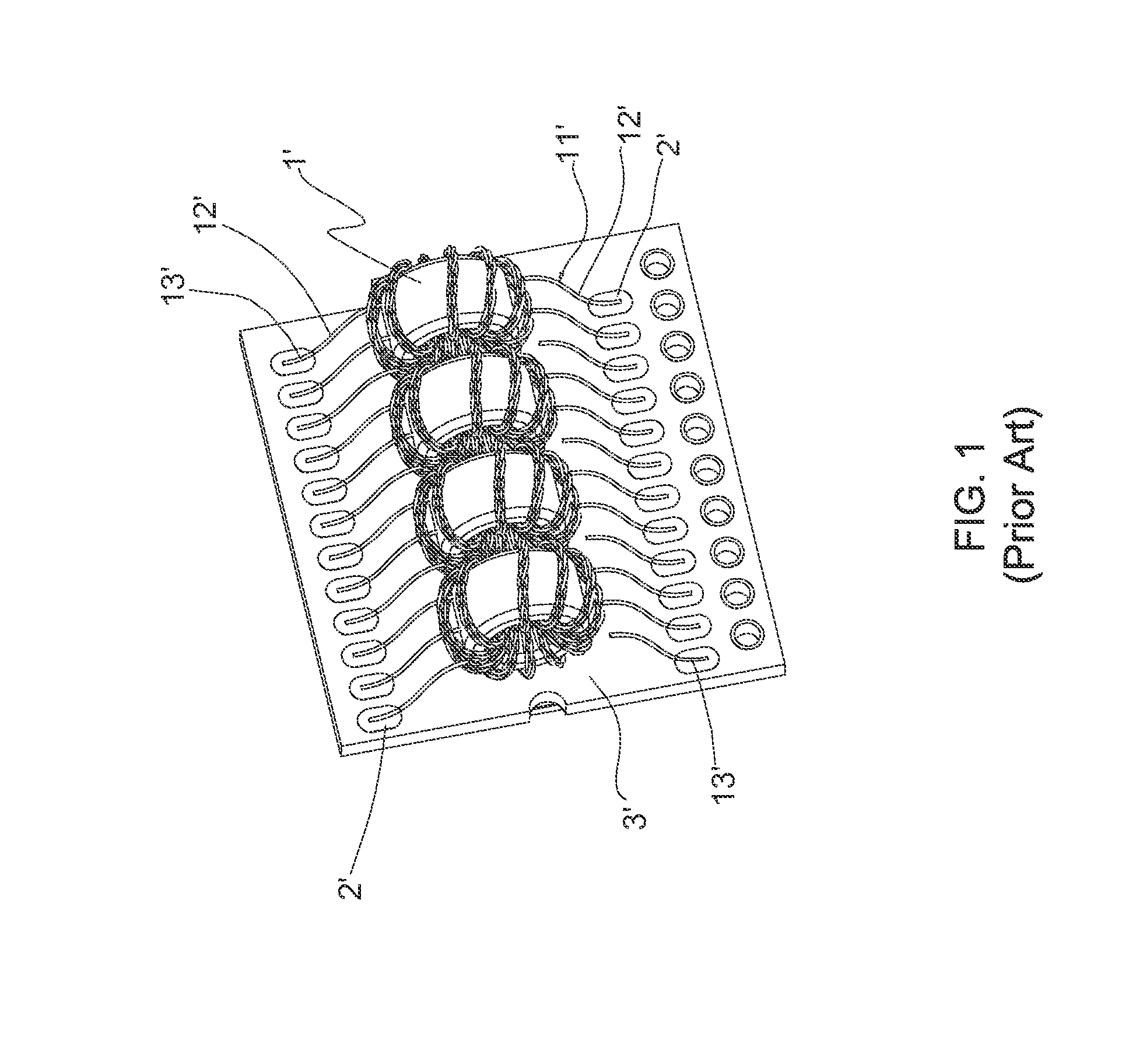

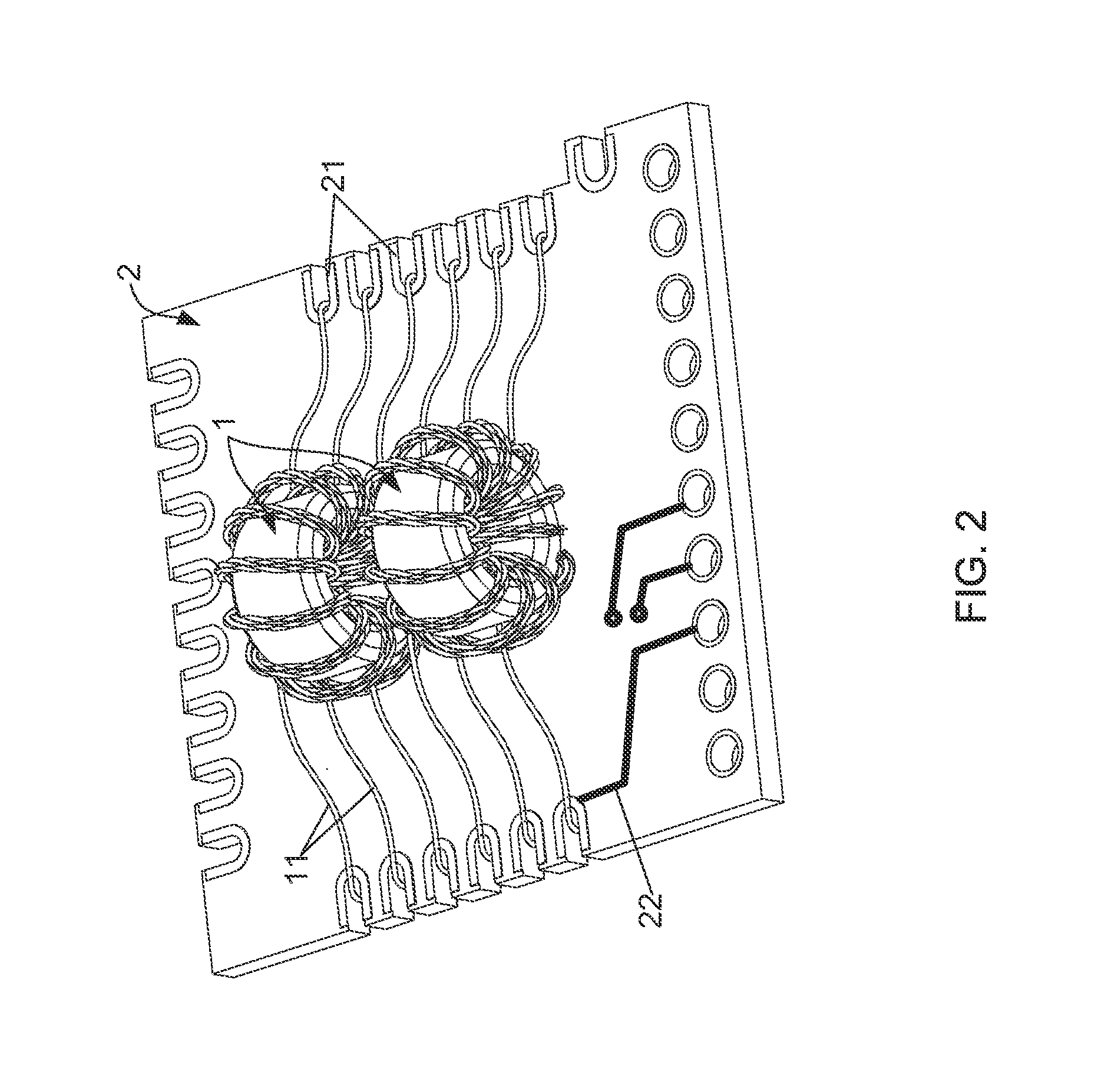

Assembly Structure with Filter Device and Printed Circuit Board and Welding Method for Making the Same

InactiveUS20140254094A1Easy to processFabrication yield can be improvedFinal product manufactureCross-talk/noise/interference reductionDip solderingInsulation layer

The present invention relates to an assembly structure with filter device and printed circuit board and a welding method for making the same. The welding method is firstly make the metal lines of at least one filter devices be disposed in the metal notches formed on at least one edges of the printed circuit board, and then respectively remove the insulation layers covering the metal lines; therefore, the welding metal lines can be respectively welded with the metal notches after the metal lines and the metal notches are treated with a dip soldering process. Thus, the welding process of the filter device and the printed circuit board can be carried out on the edges of the printed circuit board by simple process procedures; moreover, the fabrication yield of the assembly structure can be effectively increased, and the manufacturing time and cost of the assembly structure can be simultaneously reduced.

Owner:U D ELECTRONIC CORP +2

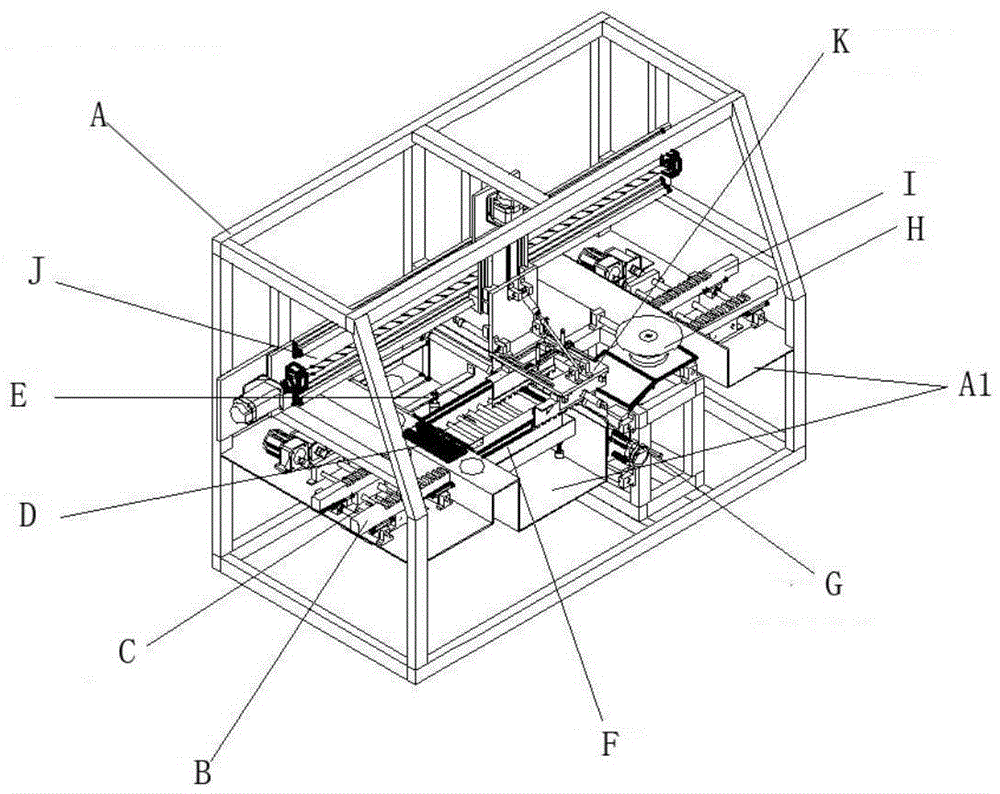

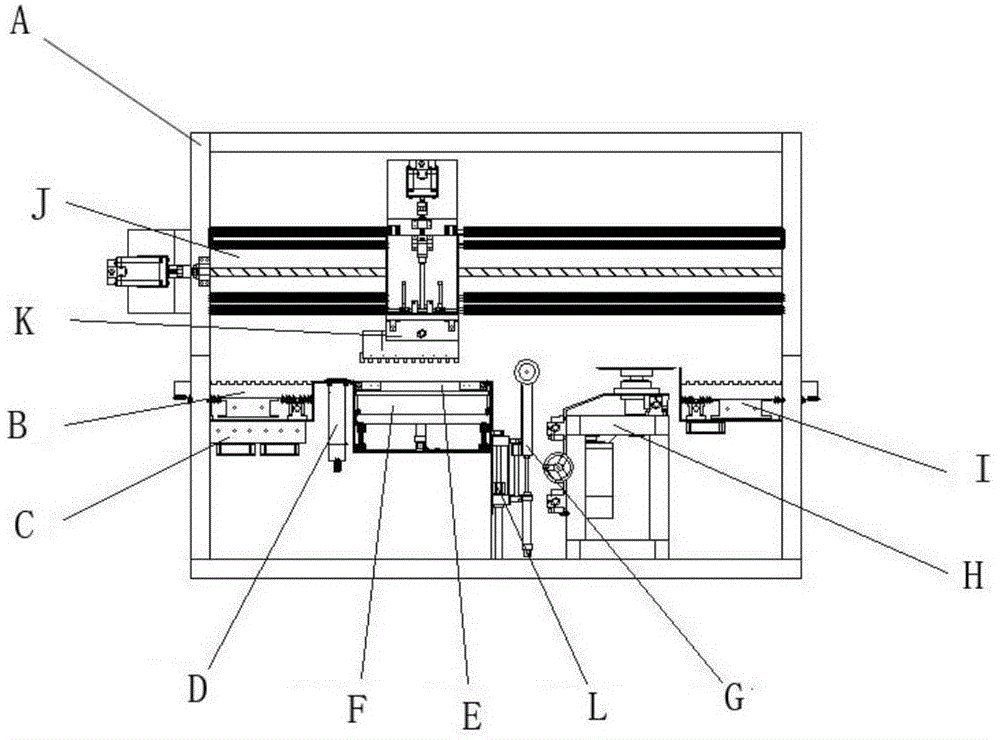

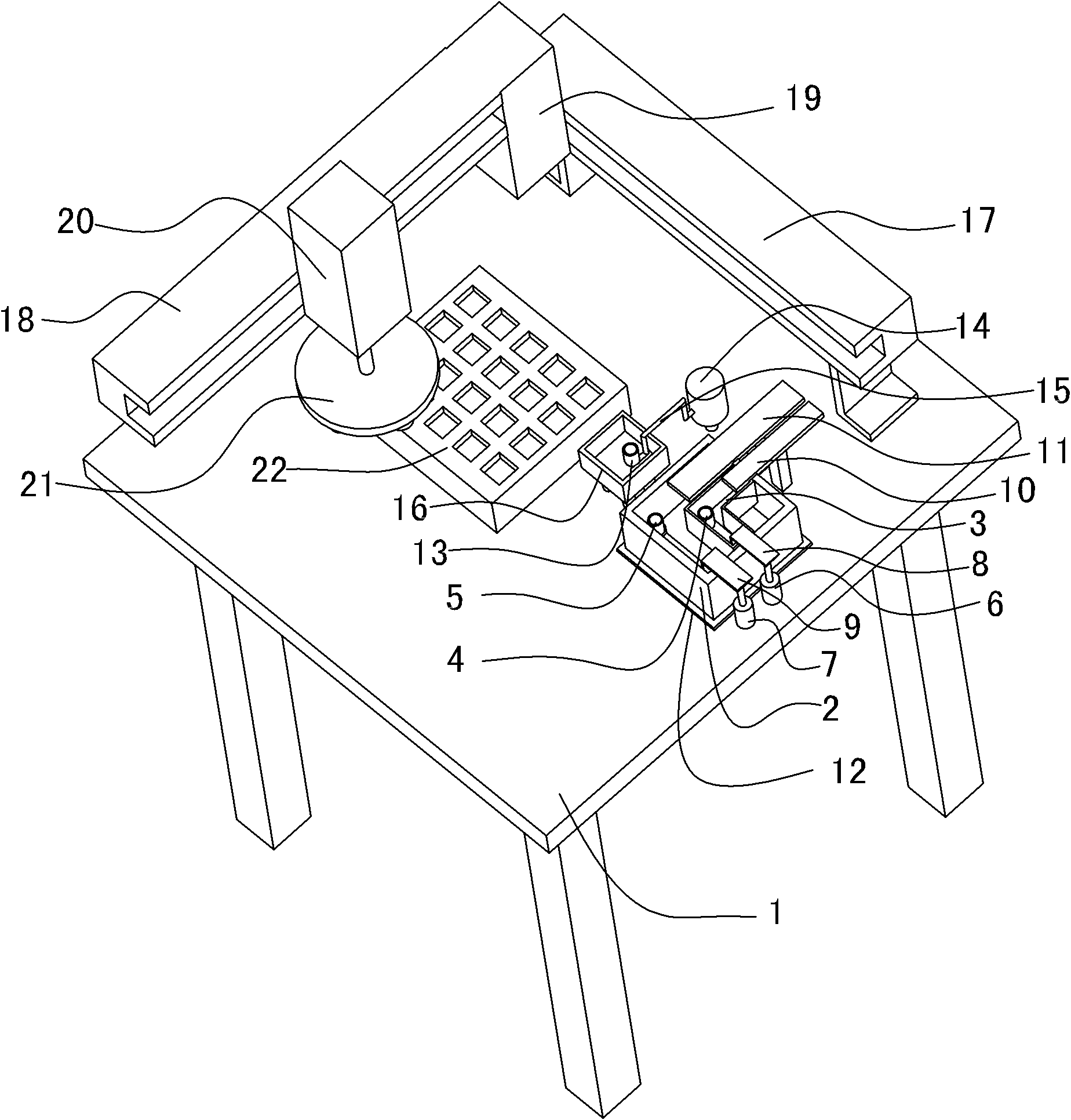

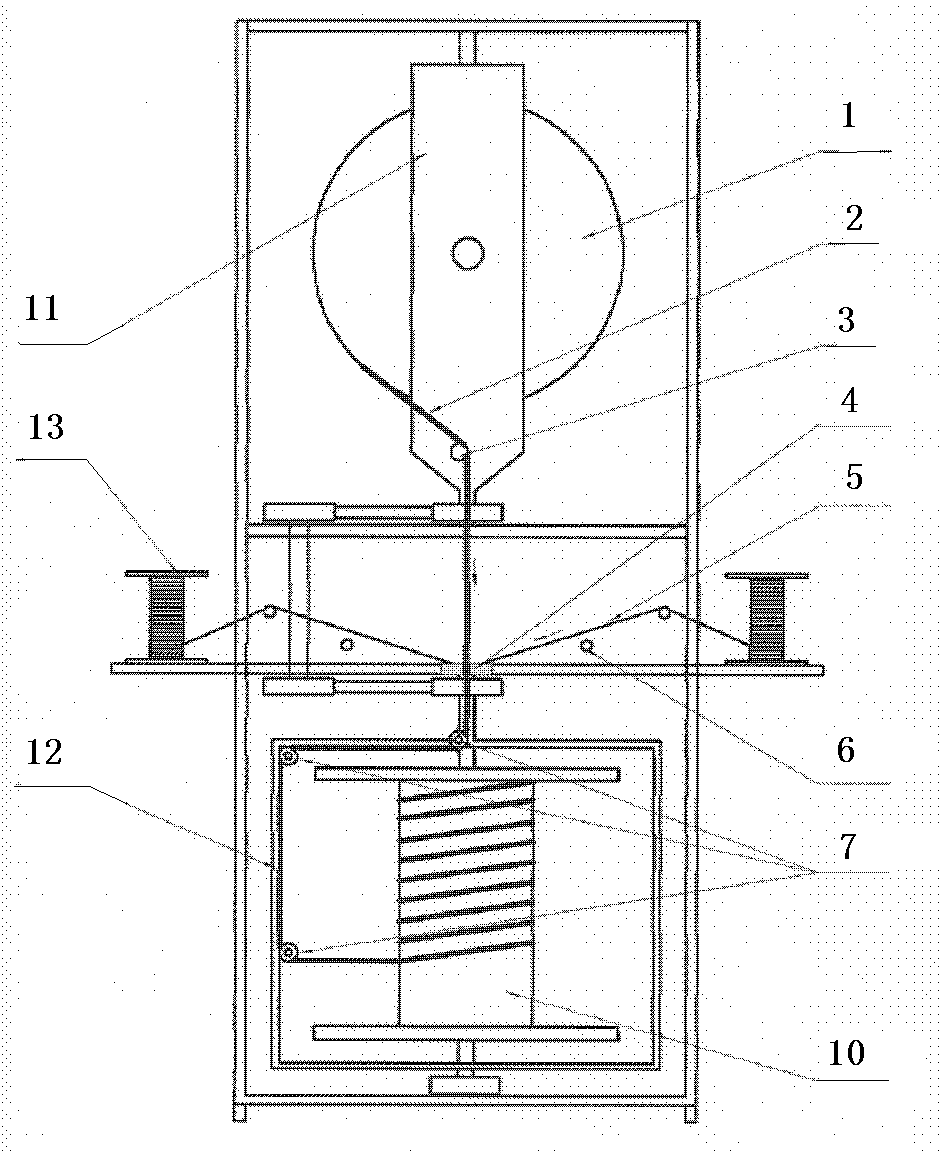

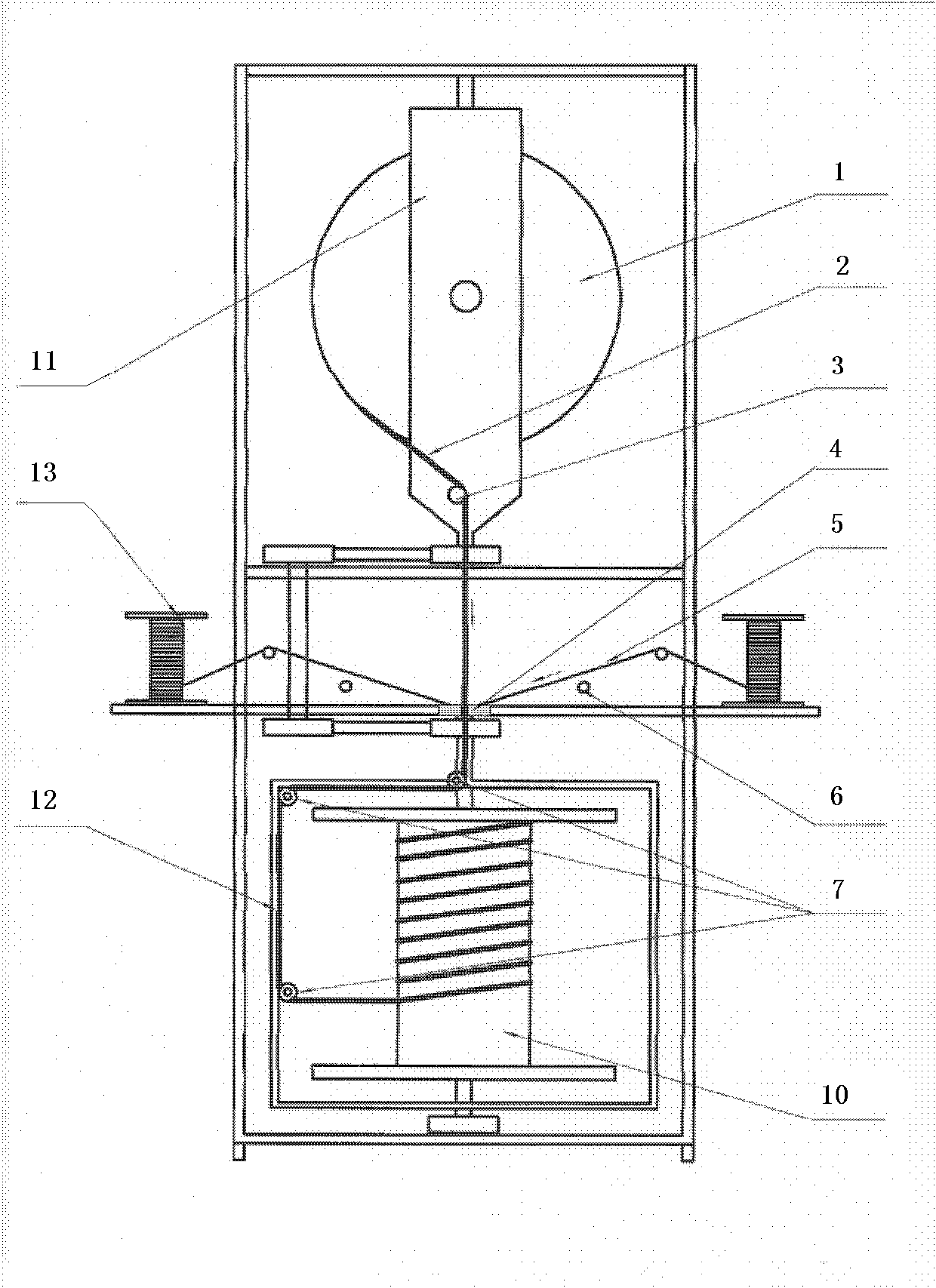

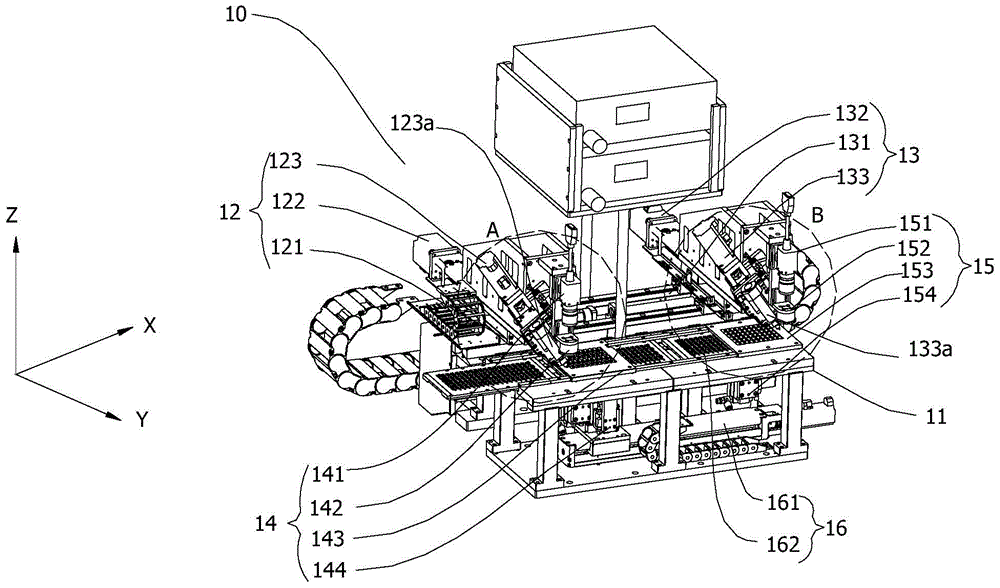

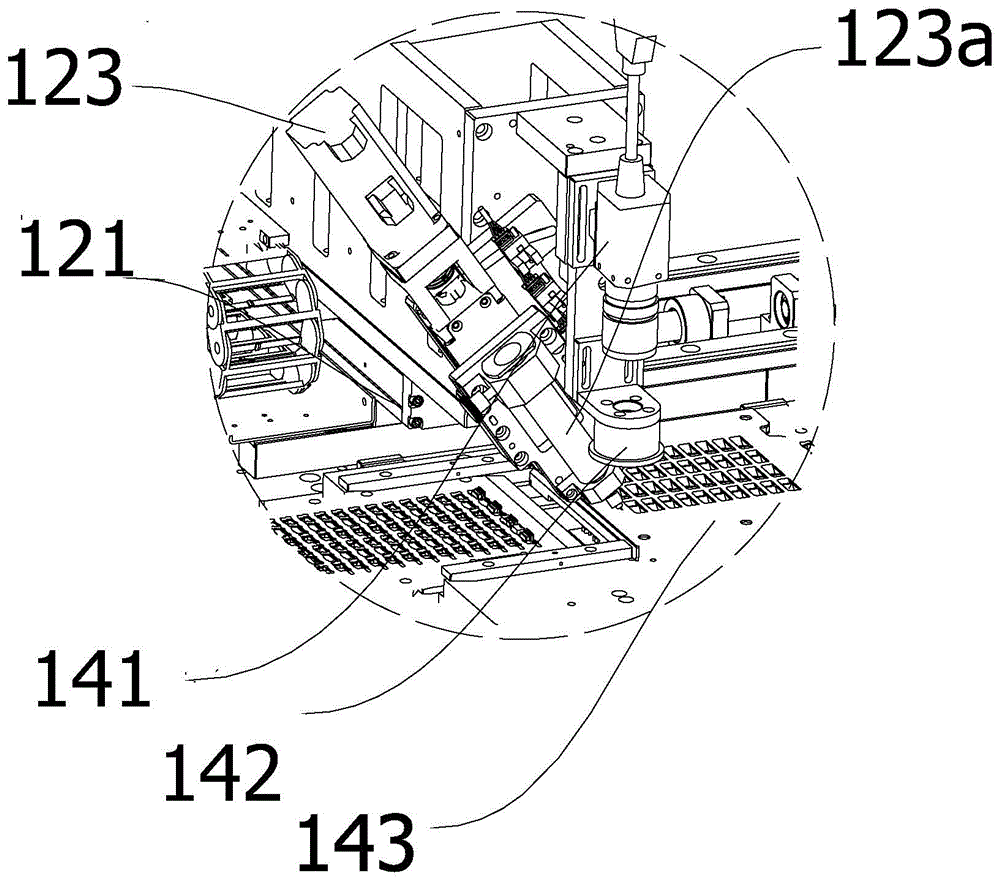

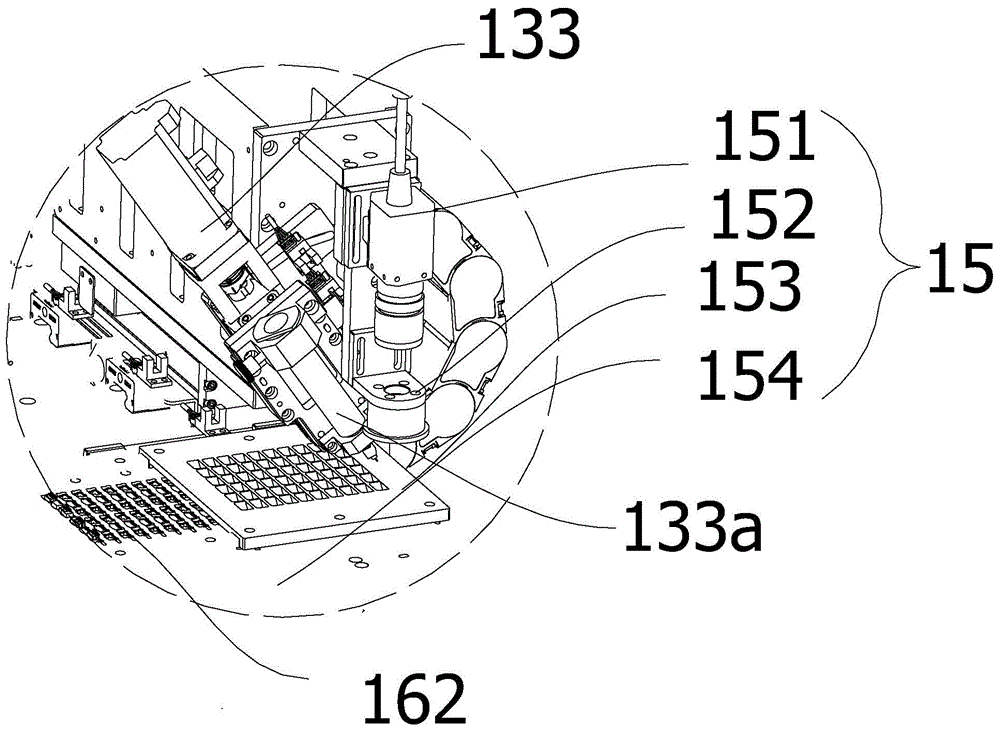

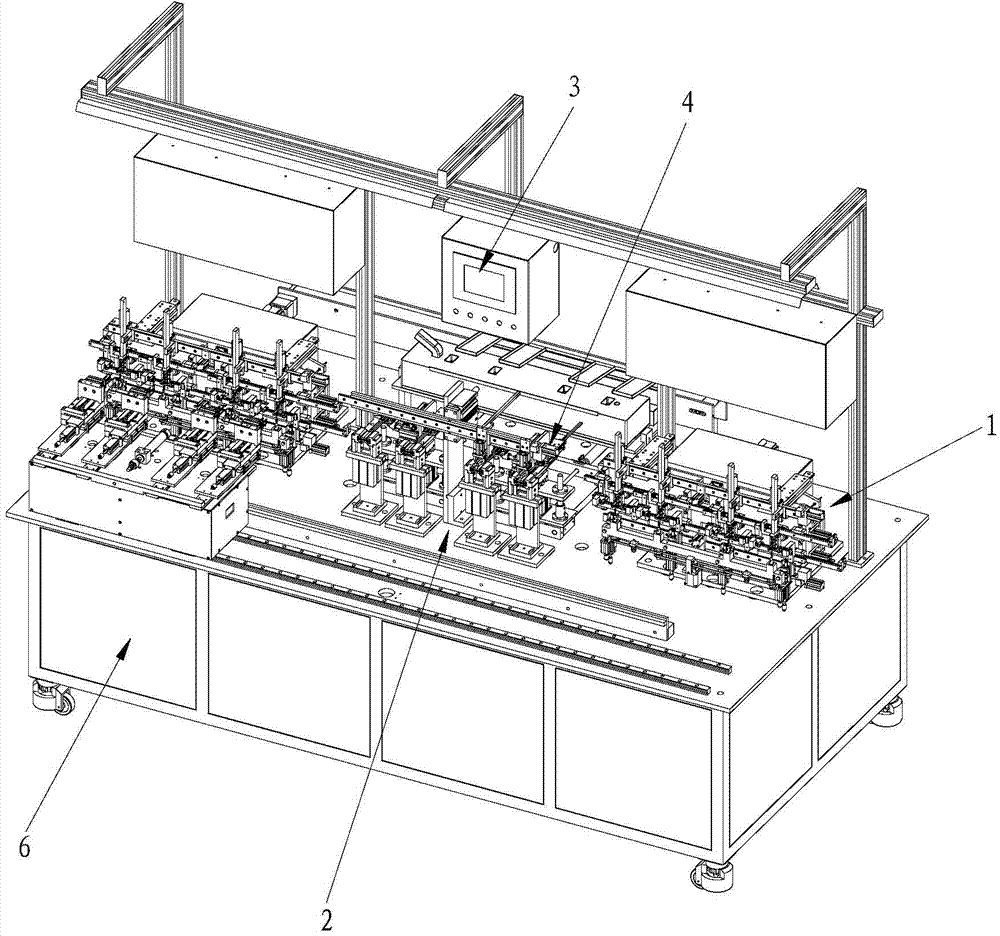

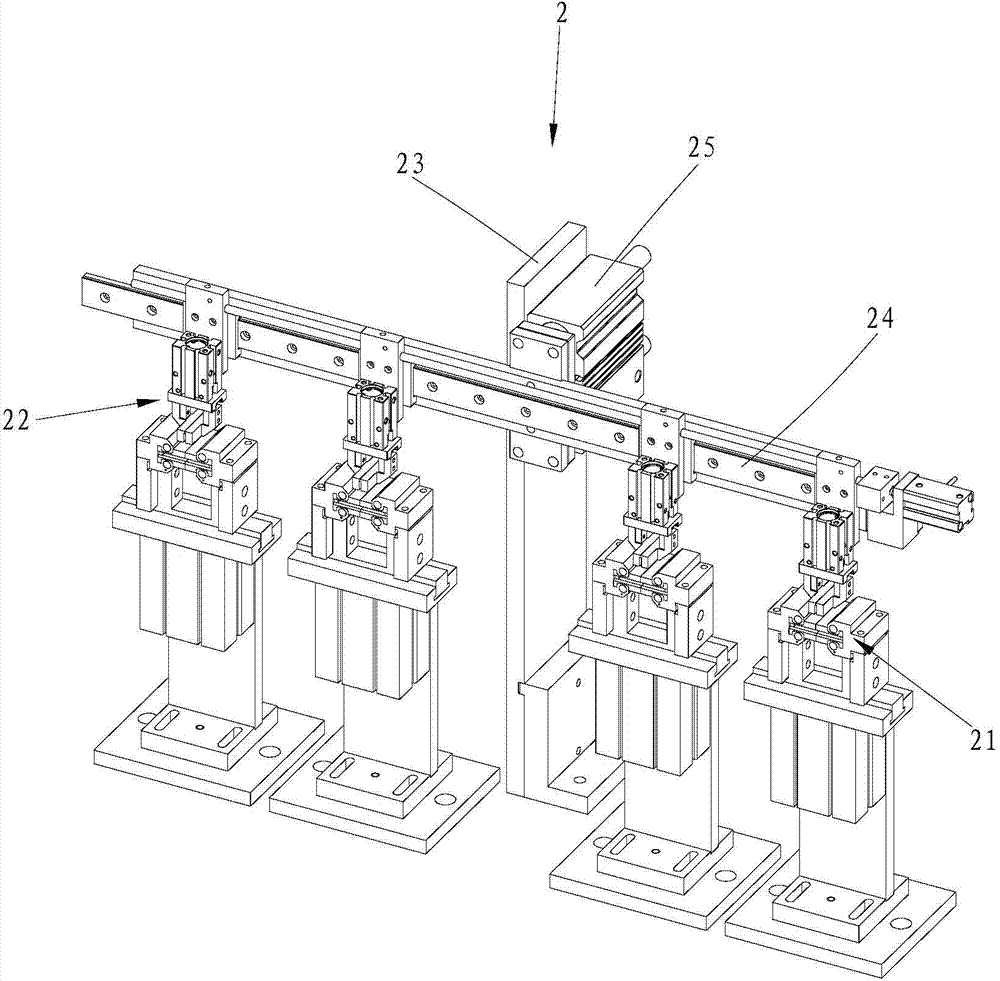

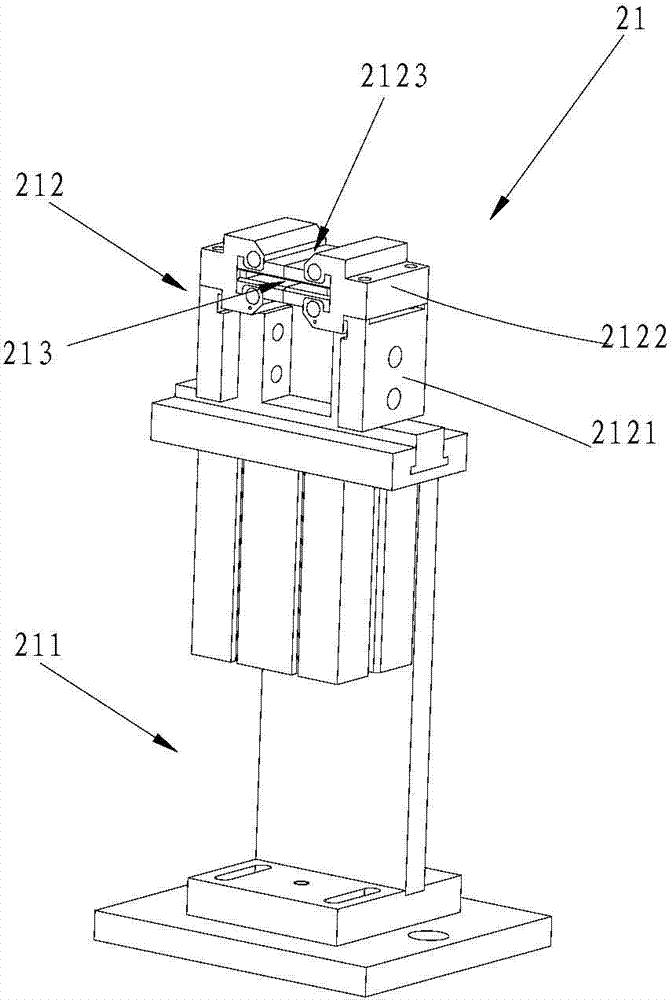

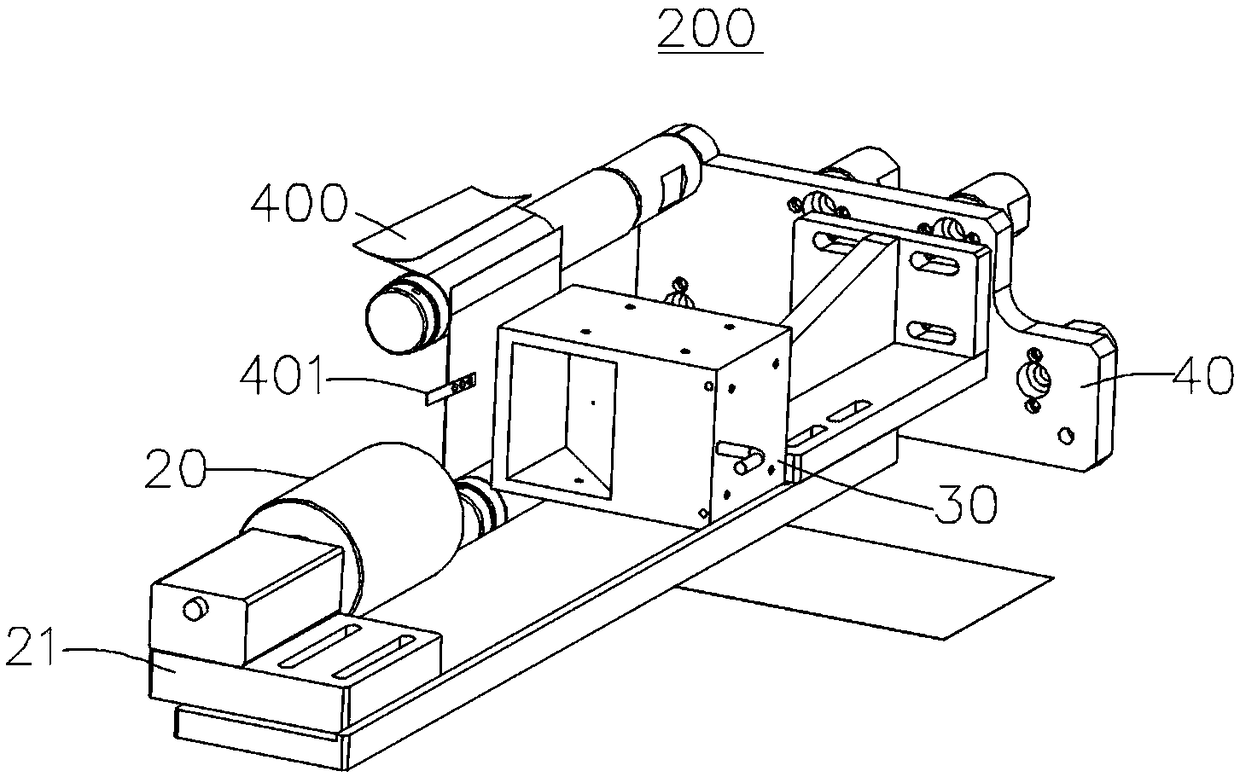

Automatic welding workpiece machine and dip soldering method

InactiveCN104439598ACompact structureHigh level of integrationPrinted circuit assemblingMetal working apparatusDip solderingSlag

The invention relates to an automatic welding workpiece machine. The automatic welding workpiece machine integrates a plate feeding mechanism, a preheating mechanism, a spraying mechanism, a solder machine mechanism, a tin scrapping mechanism, a conveying mechanism, a clamping dip soldering mechanism, a footing cutting mechanism, a slag blocking mechanism and a plate discharging mechanism, so that the automatic welding workpiece machine can accomplish a series operations of preheating, soldering flux spraying, tin soldering and foot cutting simultaneously, and conveys cut feet to the position of the preheating mechanism again through the conveying mechanism and to pass through the preheating mechanism, the spraying mechanism and the solder machine mechanism again, and performs a tin soldering operation again to realize secondary tin soldering on a PCB (printed circuit board). By being provided with the foot cutting mechanism, the problem that tin fluid is polluted because the feet cut material drops into a solder machine of the solder machine mechanism when the mechanisms are distributed in compact space and the foot cutting mechanism performs foot cutting on the PCB is solved. In addition, the invention further provides a dip soldering method utilizing the automatic welding workpiece machine.

Owner:乐清市浙佳电子科技有限公司

Thermoplastic polyimide material and method for preparing flexible copper clad laminate through using material

The invention relates to a thermoplastic polyimide (TPI) material used for preparing a two-layer flexible copper clad laminate (2L-FCCL). The excellent dissolvability TPI material is obtained through generating a polyamide acid copolymer by using main reaction components 4-ethoxydiphenol-3,5-diaminobenzoate and 2,2-bis(4-aminophenyl)hexafluoropropane according to a specific molar ratio, a corresponding diamine and a corresponding acid anhydride, and processing the copolymer by utilizing a chemical imidization process. The 2L-FCCL with good comprehensive performances of dimensional stability, dip soldering resistance, peeling performance and the like can be obtained through dissolving powder of the TPI material and compositing the TPI material with a thermosetting polyimide film and copper foil.

Owner:南通今朝机床有限公司

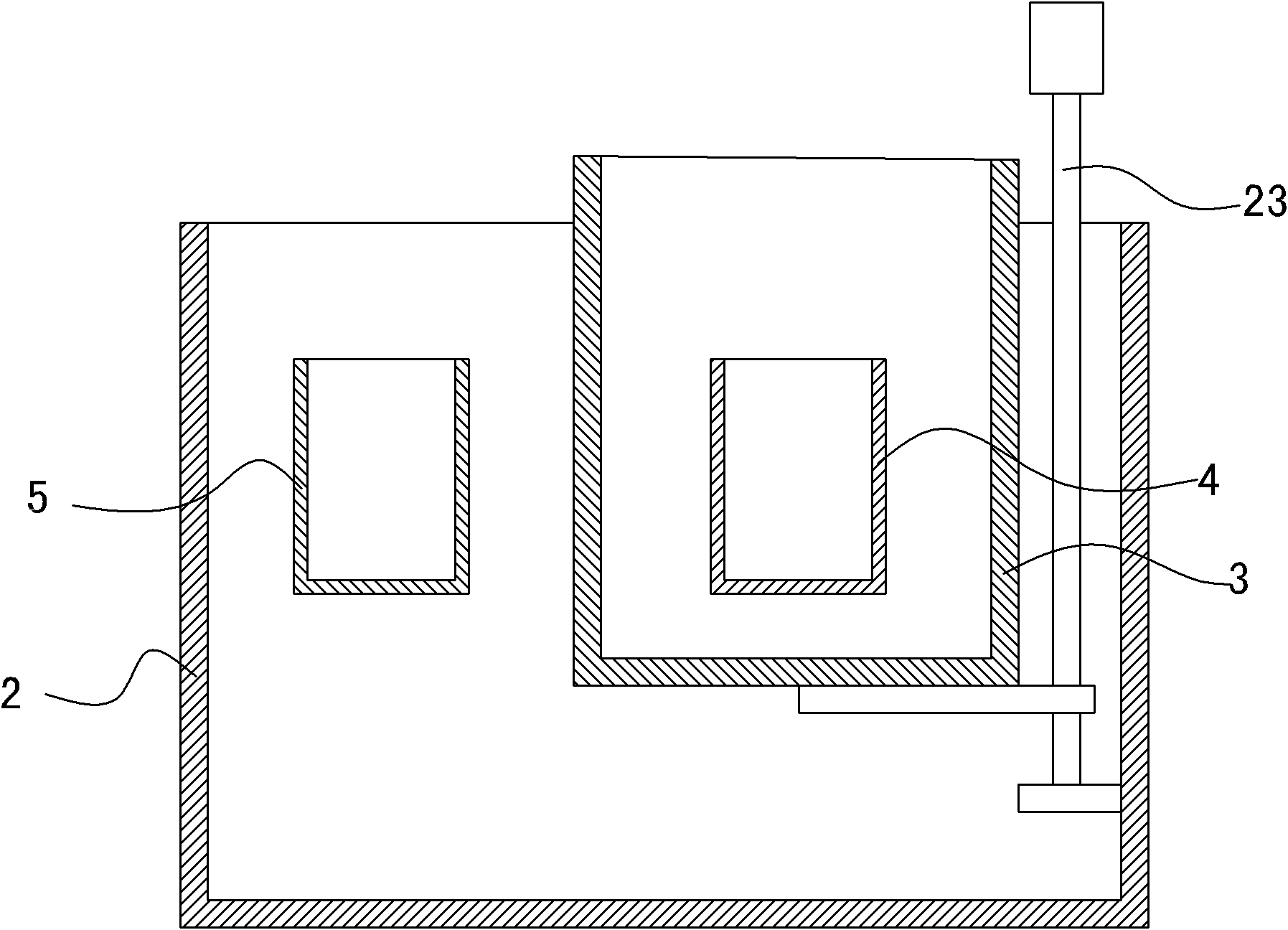

Fully-automatic tin soldering machine

ActiveCN102248244ASolve technical problems in welding operationsImprove reliabilityPrinted circuit assemblingMetal working apparatusDip solderingEngineering

The invention discloses a fully-automatic tin soldering machine capable of performing dip soldering on an electronic component on a printed circuit board (PCB). The tin soldering machine comprises a machine frame, an outer tin groove and an inner tin groove, wherein the outer tin groove is arranged on the machine frame; a heating device for heating tin in the outer tin groove is arranged at the position of the outer tin groove; the inner tin groove is arranged in the outer tin groove; tin in the inner tin groove is heated by the tin in the outer tin groove; a height adjusting device for adjusting the relative height of the inner tin groove and the outer tin groove is arranged between the inner tin groove and the outer tin groove; a first tin cup is arranged in the inner tin groove and is connected with a first lifting device; and the first lifting device can drive the first tin cup to ascend and descend, so that the first tin cup extends above the inner tin groove or is accommodated in the inner tin groove.

Owner:SHENZHEN KEANDA ELECTRONICS TECH

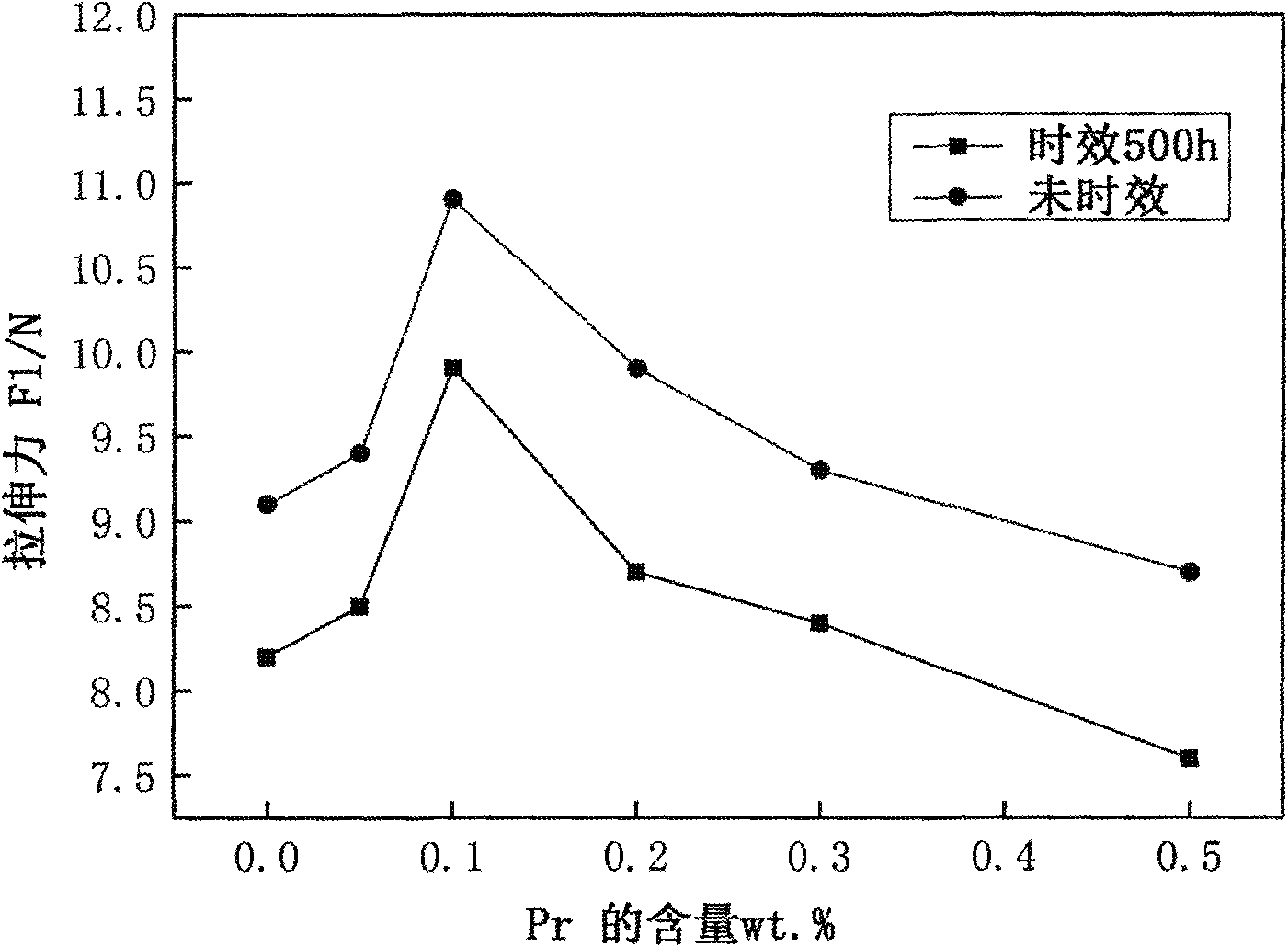

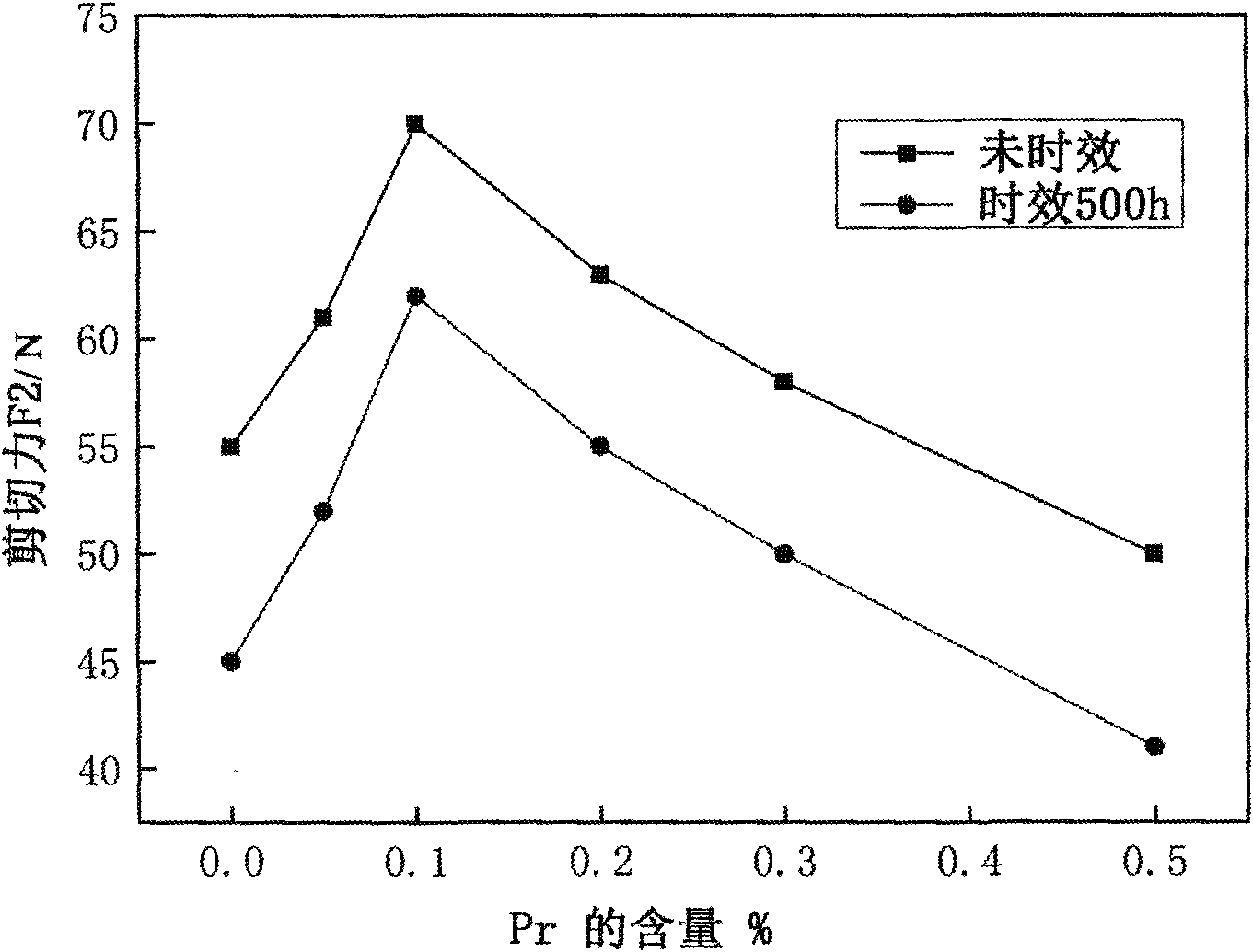

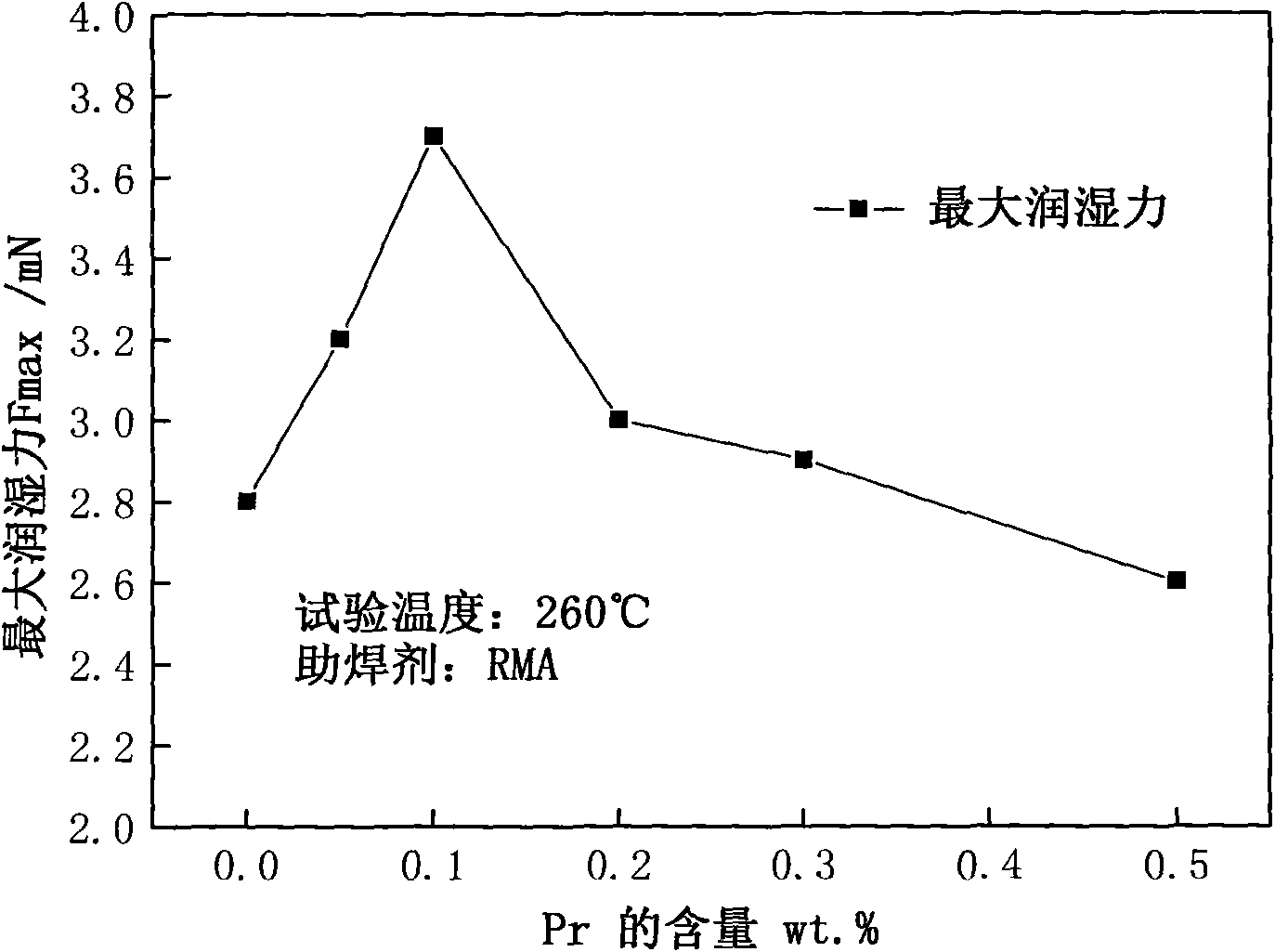

Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga

ActiveCN101862921AImprove wettabilityLow costWelding/cutting media/materialsSoldering mediaChemical compositionDip soldering

The invention relates to a Sn-Cu-Ni lead-free solder containing Pr, Sr and Ga, belonging to the metal material and the brazing material in the metallurgical field. The solder comprises the following chemical compositions by weight percent: 0.07-2.5% of Cu, 0.01-1.5% of Ni, 0.001-0.5% of Pr, 0.001-0.1% of Sr, 0.001-0.1% of Ga and the balance Sn. The solder has good wettability and soldering point (brazing seam) mechanical property and extremely good creep resistance, and is suitable for the welding methods such as wave-soldering, dip-soldering, manual welding and reflow soldering in the electronic industry.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

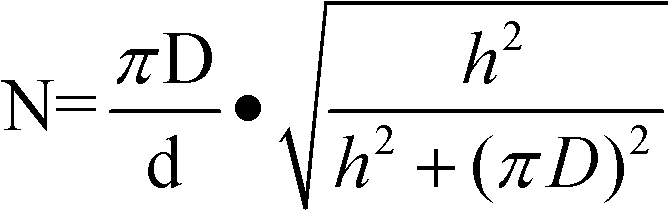

Manufacturing method of semi-flexible coaxial cable shielding layer

InactiveCN101853718AWon't fall offDip tin evenlyManufacturing co-axial cablesElectrical conductorCoaxial cable

The invention relates to a manufacturing method of a semi-flexible coaxial cable shielding layer. A semi-flexible coaxial cable comprises an inner conductor, an insulating layer, a shielding layer and a jacket layer, and the semi-flexible coaxial cable shielding layer is manufactured through unidirectionally winding a metal wire on an insulating ore and then carrying out dip soldering. The manufacturing method concretely comprises the following steps of: (1) setting winding parameters of the metal wire; (2) installing a pay-off spool on which the semi-flexible coaxial cable insulating core is wound, and arranging the insulating core; (3) installing a metal wire coil for winding, arranging the metal wire, and winding the metal wire on the insulating core; and (4) fluxing the wound shielding wire coil, drying, carrying out dip soldering, air cooling, and connecting with a second take-up spool assembled on a second take-up stand. The shielding layer is formed by unidirectionally winding the metal wire, the dip soldering is even, uniform and easy, and the tin layer can not fall off due to the relative sliding of interwoven metal wires in bending. The production efficiency is six times higher than the weaving efficiency, and the energy consumption of the manufacturing method only accounts for 1 / 24 of that of the weaving process. In addition, 100 percent of shielding can be realized.

Owner:杭州奥达线缆科技有限公司

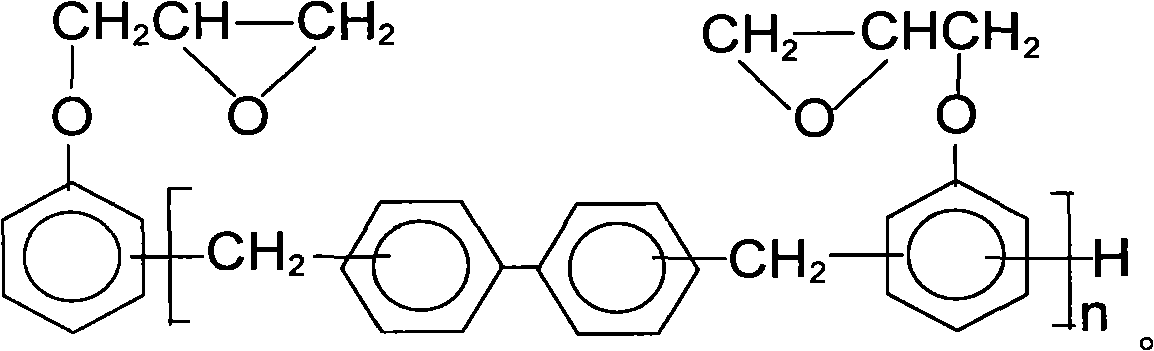

Halogen-free flame-retardant adhesive composition and flexible copper-clad plate using same

ActiveCN101921557AImprove heat resistanceHigh peel strengthNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyDip soldering

The invention discloses a halogen-free flame-retardant adhesive composition. The composition comprises the following components in part by weight: 15 to 45 parts of halogen-free epoxy resin, 15 to 60 parts of thermoplastic resin and / or synthetic rubber, 0.1 to 8 parts of curing agent and 5 to 60 parts of phosphorus-containing composite flame retardant. The invention also discloses a flexible copper-clad plate using the adhesive composition. The cured product of the adhesive composition provided by the invention shows high flame retardance, peeling strength, electric performance and welding heat resistance, does not comprise harmful substances or elements such as halogen, antimonide and the like and does not pollute environment; the flame retardant rating of the flexible copper-clad plate prepared from the composition of the invention reaches UL-94V0, and the flexible copper-clad plate also has the advantages of high heat resistance, high peeling strength, soldering resistance, no demixing after being subjected to dip soldering at the temperature of 300 DEG C for 1 minute and no bubbles; and because the halogen-free composition of the invention has high sticking performance, the speed of a production line can be increased and the production efficiency is improved.

Owner:ALLSTAE TECH ZHONGSHAN

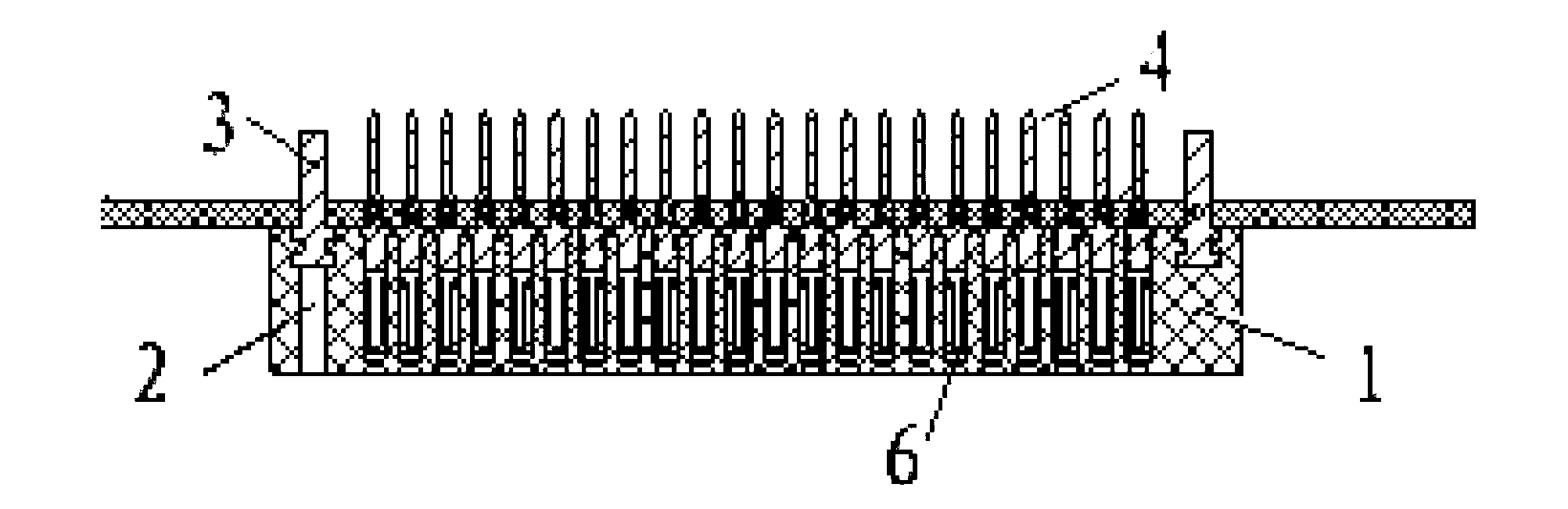

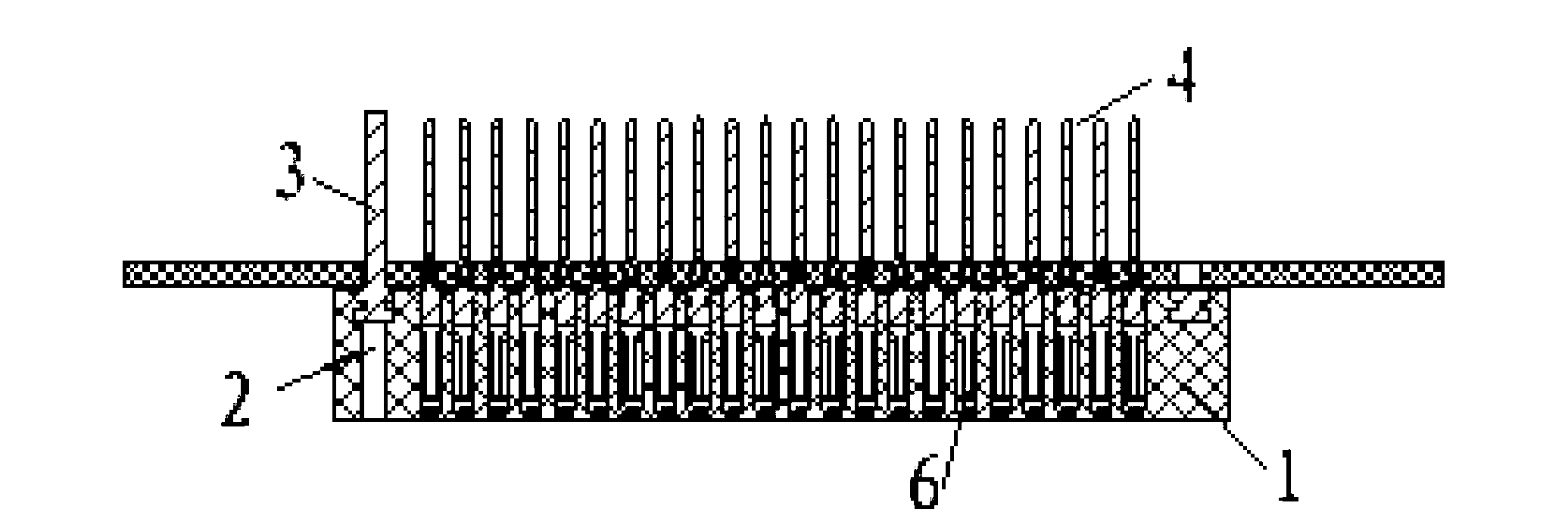

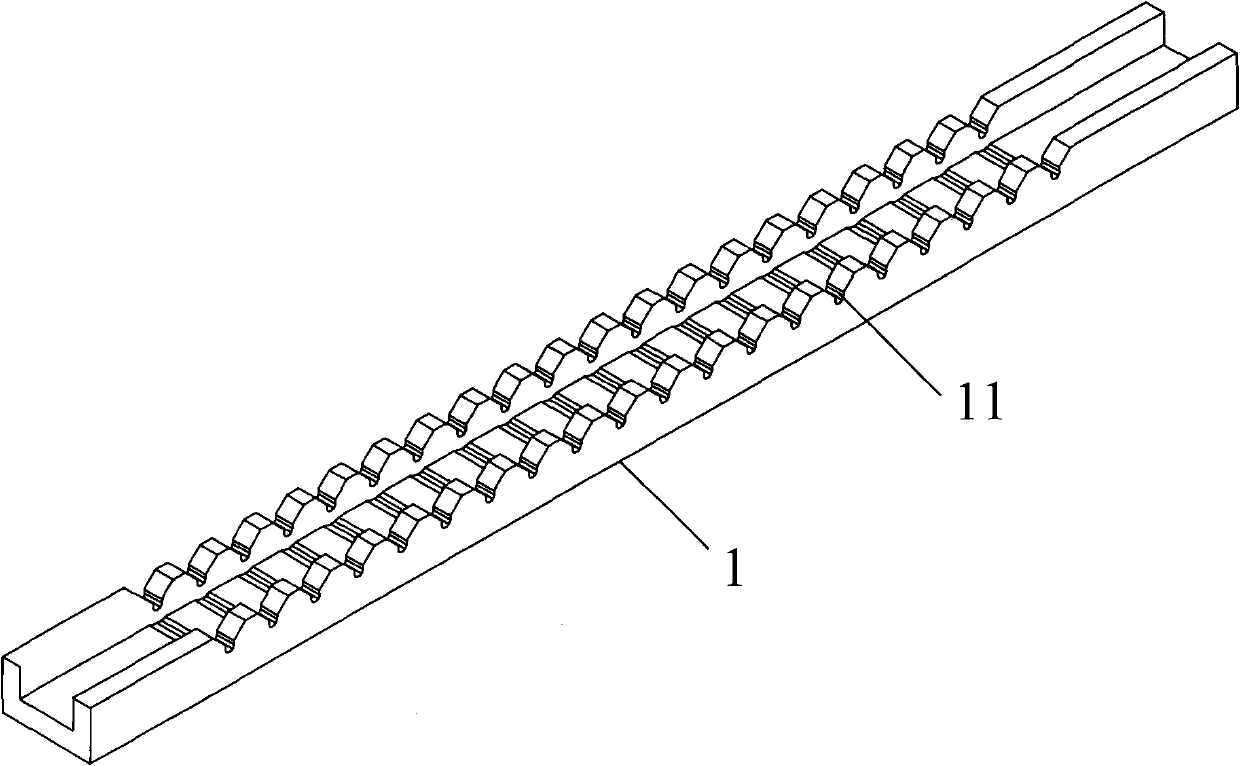

Printed circuit board press-in connection-type rectangular connector

InactiveCN103227372ASuitable for cascade installationAvoid cumbersome workmanshipCoupling device detailsFixed connectionsInterference fitConnection type

A printed circuit board press-in connection-type rectangular connector comprises an insulator (1), wherein guide sleeves (2) or guide pins (3) that are used for mutual connection in a positioning manner are arranged on the insulator (1); and in addition, one or a plurality of insertion holes (4), inserting needles (5) and slots (6) used for connecting a printed circuit board are also formed in the insulator (1). The printed circuit board press-in connection-type rectangular connector is characterized in that the insertion holes (4), the inserting needles (5) and the slots (6) are fixed in the insulator (1) in a barb interference fit fixing manner, and the connector and the printed circuit board are in interference fit in a press-in manner, so that the contact is reliable, the installation space is saved, the cumbersome dip soldering-type process of the common connector for the printed circuit board is also avoided, the printed circuit board press-in connection-type rectangular connector is very convenient to operate and is very suitable for stacking installation and use of the printed circuit boards, and signals among the printed circuit boards can be managed in a unified and integrated manner.

Owner:沈阳兴华航空电器有限责任公司

Resin combination and method for producing environmental friendly highly-durable dip welding flame-resistant paper-based copper-coated board

ActiveCN101096442AMeet the requirements of reflow solderingNon-fibrous pulp additionLamination ancillary operationsRefluxDip soldering

The invention discloses an environment-protective resin composition and environment-protective high-dip-soldering proof flameproof paper backing copper covering board in the copper covering board manufacturing technical domain, which is characterized by the following: adding flameproof agent without halogen such as nitrate, phosphate and so on into modified phenol resin; making the environment-protective resin to form semi-solidifying piece through dipping paper of resin composition; overlapping several semi-solidifying piece to press under certain temperature and pressure to obtain the product to satisfy the request of European environment protection order and non-lead reflux welding need.

Owner:SHANDONG JINBAO ELECTRONICS

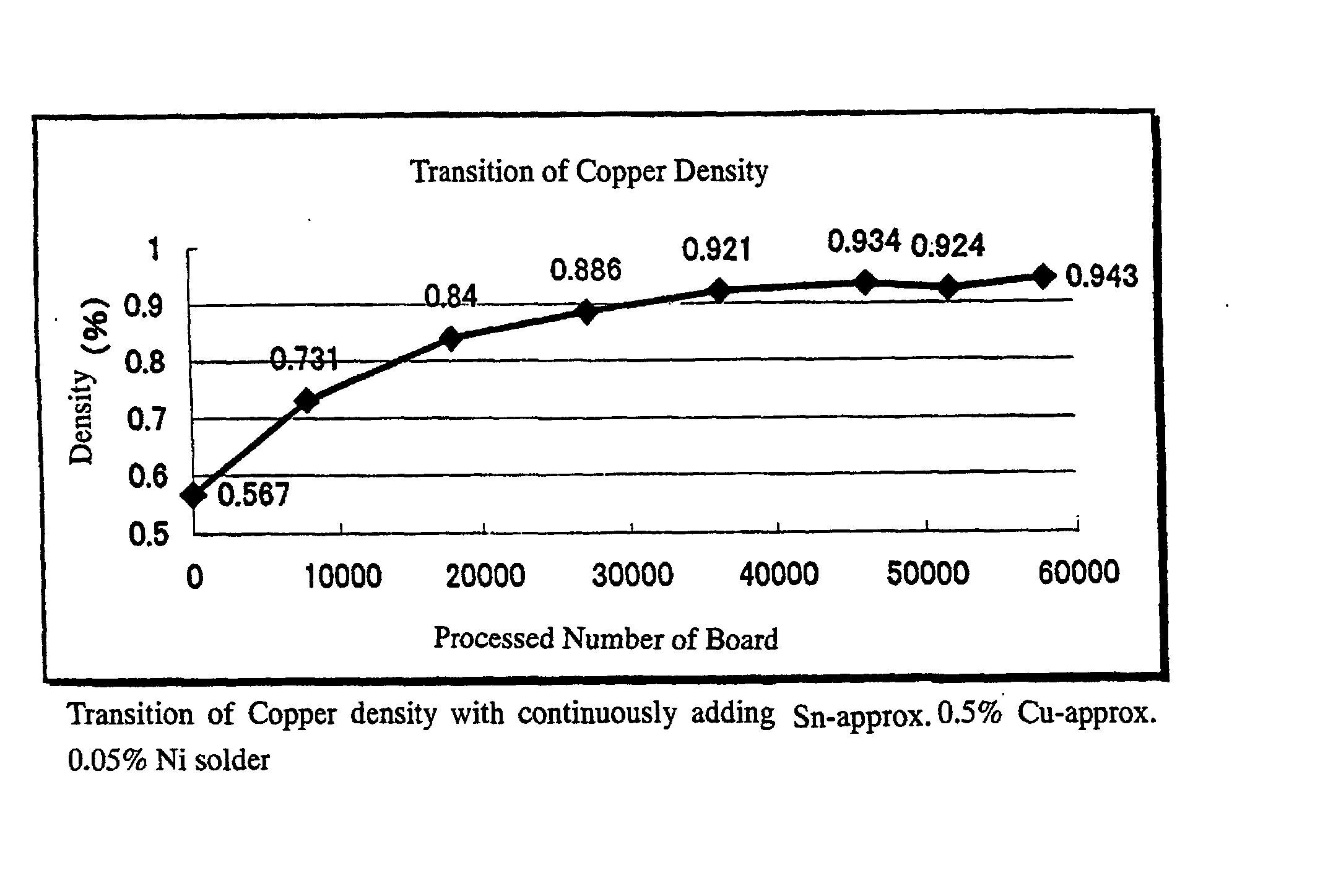

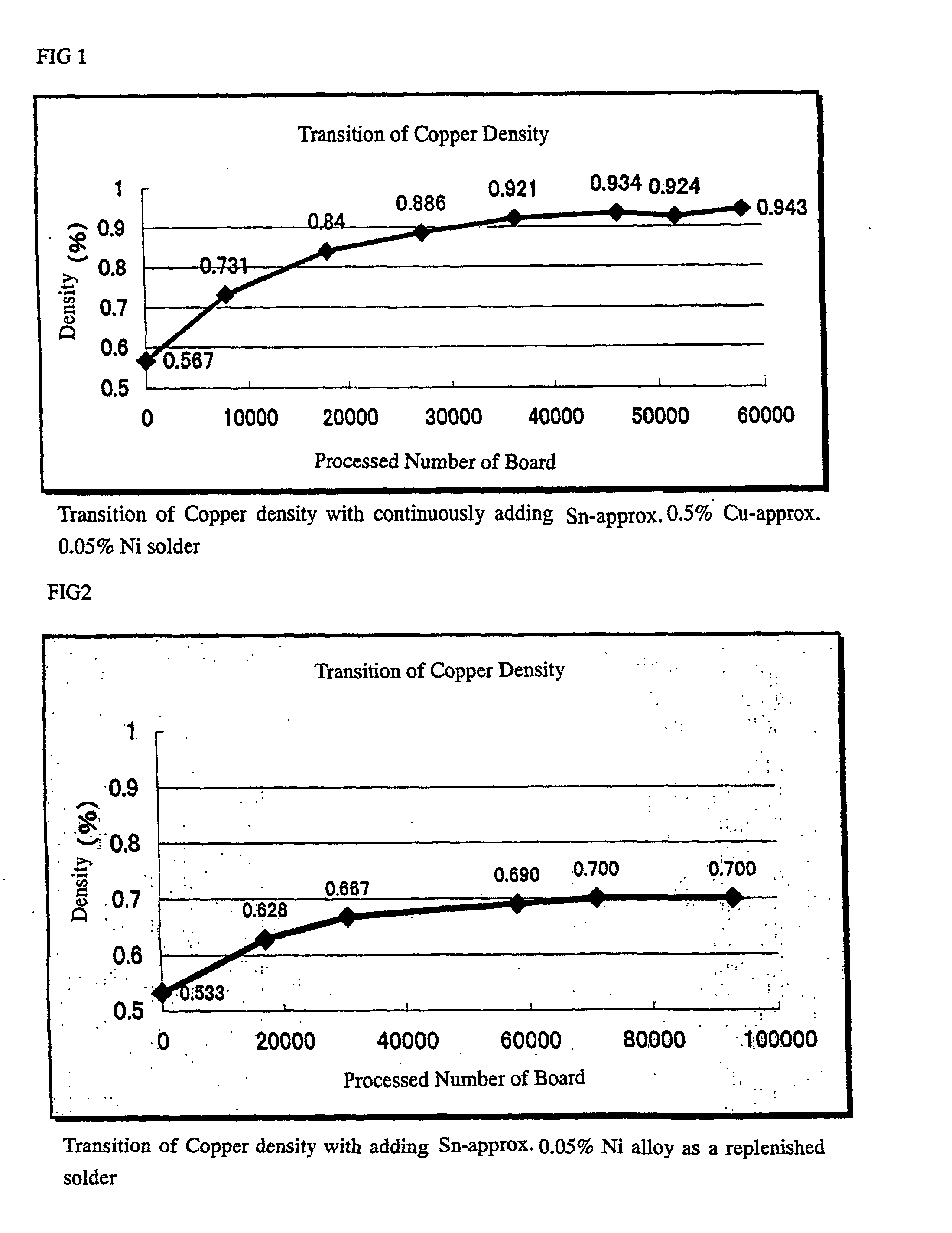

A control method for copper density in a solder dipping bath

InactiveUS20020134200A1Avoid introducingPrinted circuit assemblingAutomatic control devicesDip solderingVolumetric Mass Density

This method controls a copper density in a dip solder bath holding a molten solder alloy containing at least copper as an essential composition thereof during a dip soldering step of one of a printed circuit board with a surfaced copper foil and a component part having a copper lead attached thereto. The method includes a step of introducing a replenished solder containing no copper at all or a copper content having a density lower than that of the molten solder in the bath prior to the supply of the replenished solder to the bath so that the copper density in the bath is controlled to a predetermined constant density or lower The molten solder alloy in the bath contains tin, copper and nickel as the major compositions thereof, and the replenished solder contains nickel and balanced tin, for example. Alternatively, the molten solder alloy in the bath contains tin, copper, and silver as the major components thereof and the replenished solder contains silver and balanced tin. The copper density of the molten solder in the bath is controlled to less than 0.85 weight % at a solder temperature of about 255° C.

Owner:NIHON SUPERIOR CO LTD +1

Composition for dip molding and dip-molded article

A dip-molding composition of the present invention contains a latex (A) of a nitrile-group-containing highly saturated copolymer rubber (a). The nitrile-group-containing highly saturated copolymer rubber (a) contains an α,β-ethylenically unsaturated nitrile monomer unit and a conjugated diene monomer unit, and being obtained by hydrogenating at least part of the conjugated diene monomer unit. A dip-molded article of the present invention is produced by dip molding of the above dip-molding composition

Owner:ZEON CORP

Modified epoxy resin adhesive used for polyimide flexible copper-clad plate

InactiveCN102199413APlay a role in tougheningImprove heat resistanceEpoxynovolac adhesivesMetal layered productsEpoxyOrganic solvent

The invention relates to an epoxy resin adhesive modified by bismaleimide and liquid butadiene nitrile rubber, and a method for manufacturing a polyimide flexible copper-clad plate using the adhesive. The adhesive is composed of a bismaleimide copolymer, liquid rubber-modified epoxy resin, unmodified epoxy resin, filler, a curing agent and an organic solvent. The adhesive can be used for manufacturing a three-layer flexible copper-clad plate composed of a polyimide thin film, the adhesive and a copper foil, and the dip-soldering resisting temperature of the obtained copper-clad plate can reach 365 DEG C.

Owner:ZHOUSHAN WEITE NEW MATERIAL TECH

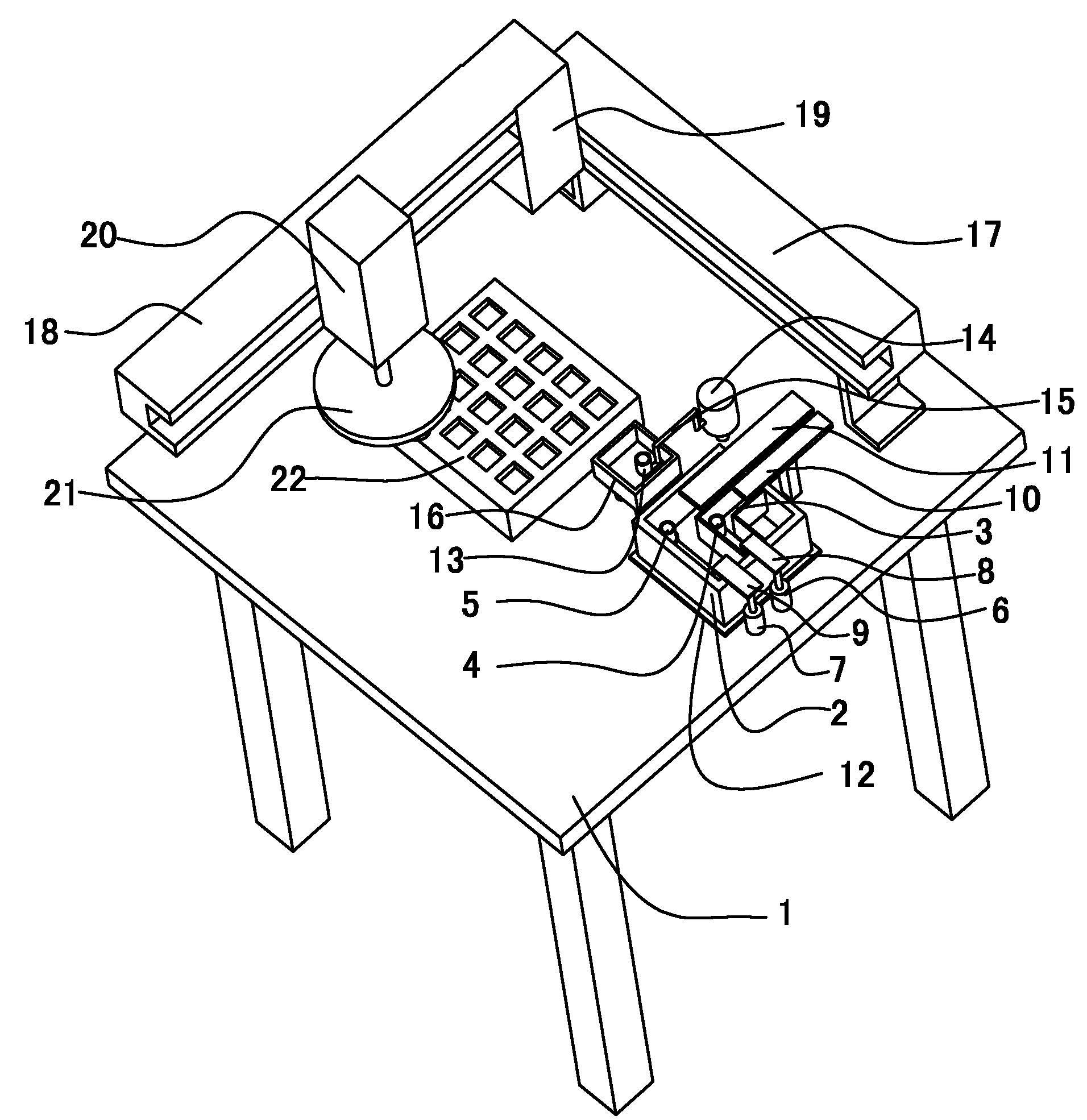

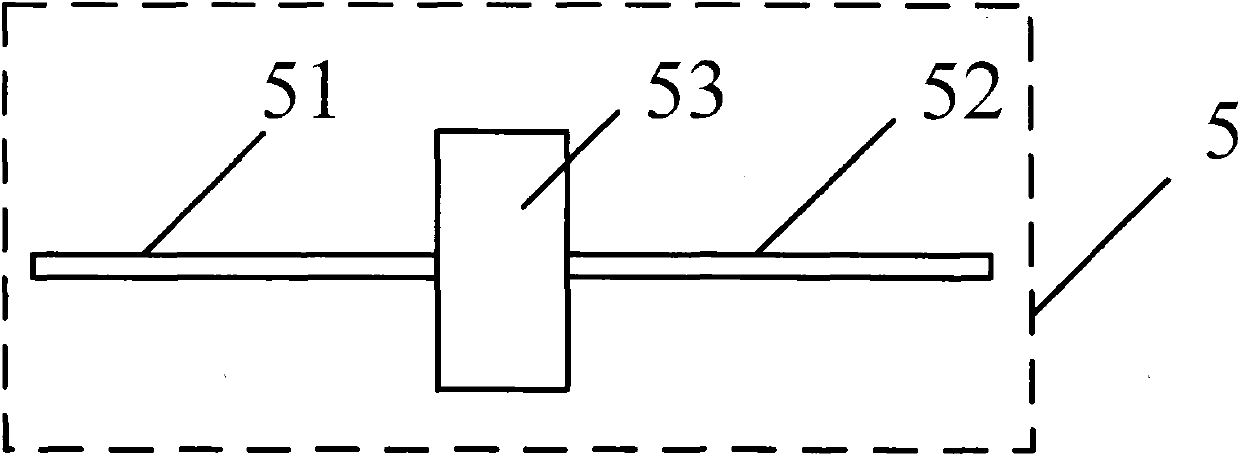

Novel probe-positioning tin soldering device and tin soldering method

ActiveCN105364252AImprove work efficiencyHigh precisionLaser beam welding apparatusSolder feeding devicesDip solderingEngineering

The invention discloses a novel probe-positioning tin soldering device. The novel probe-positioning tin soldering device comprises a device body, a control assembly, a first tin soldering structure assembly, a second tin soldering structure assembly, a first positioning mechanism, a second positioning mechanism and a tray mechanism. The first tin soldering structure assembly and the second tin soldering structure assembly can both move along the X axis, the Y axis and the Z axis relative to the device body. A sliding rail is arranged on the device body. The first tin soldering structure assembly comprises a first tin soldering needle, a second tin soldering needle, a first CCD camera and a plurality of first elastic positioning probes. The second positioning mechanism comprises a second CCD camera, a second tin soldering positioning reference panel and a plurality of second elastic positioning probes. The novel probe-positioning tin soldering device is high in work efficiency, capable of accurately regulating the height of a product to be subjected to tin soldering, high in accuracy, and capable of running in a full automatic manner, accurately positioning tin soldering positions of electronic products and meeting the requirement of laser welding. The invention further discloses a novel probe-positioning tin soldering method.

Owner:SHENZHEN INTE LASER TECH

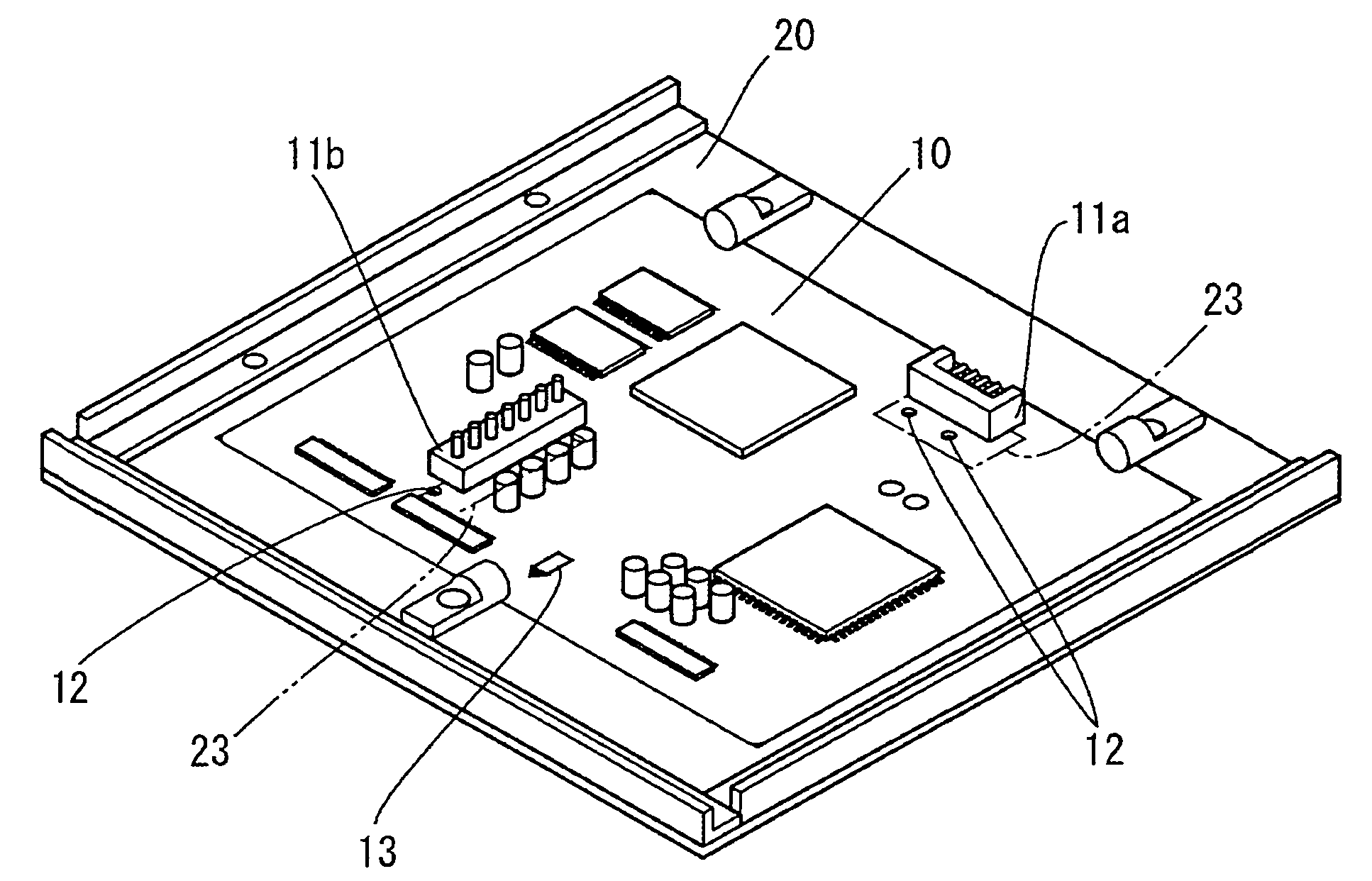

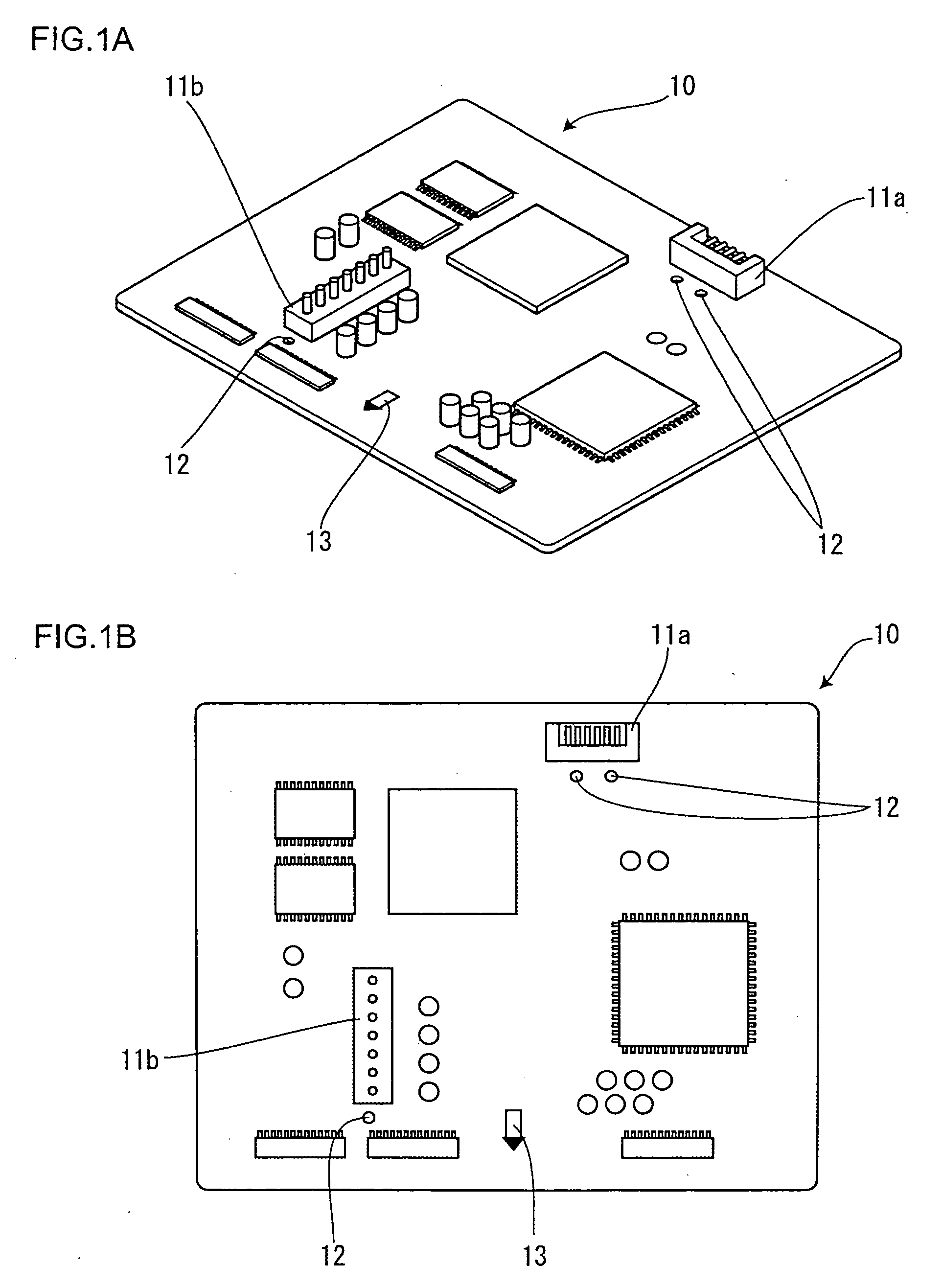

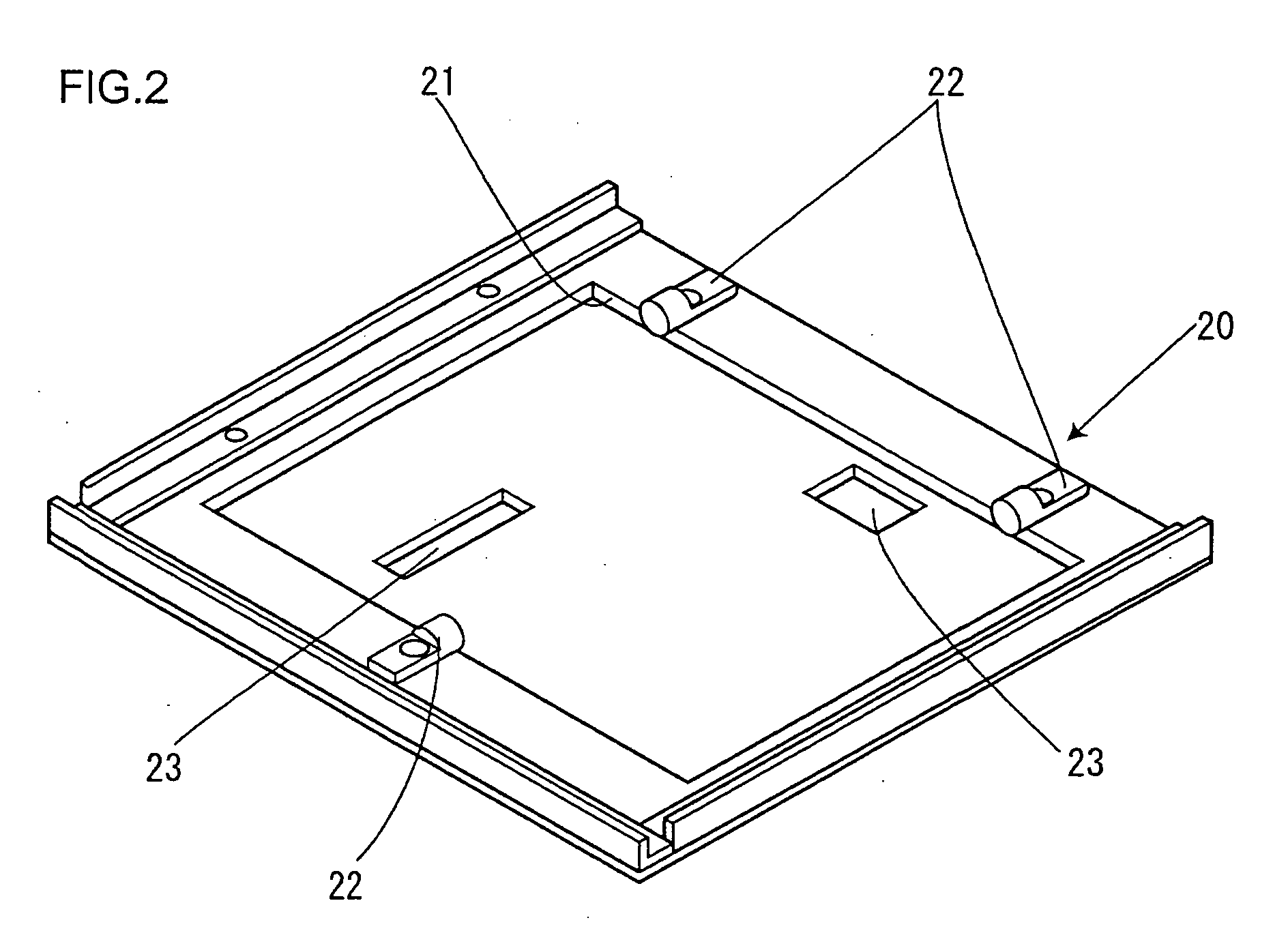

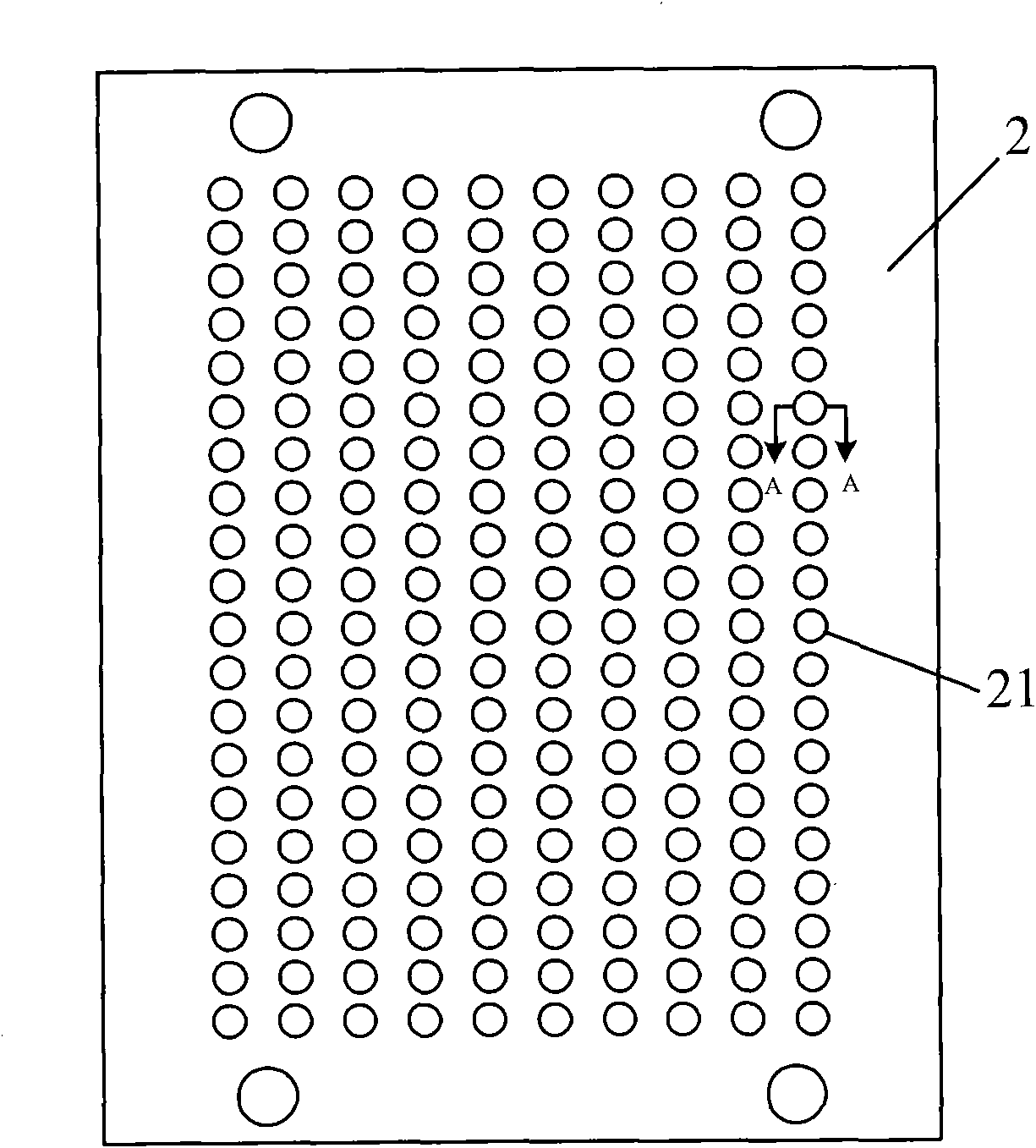

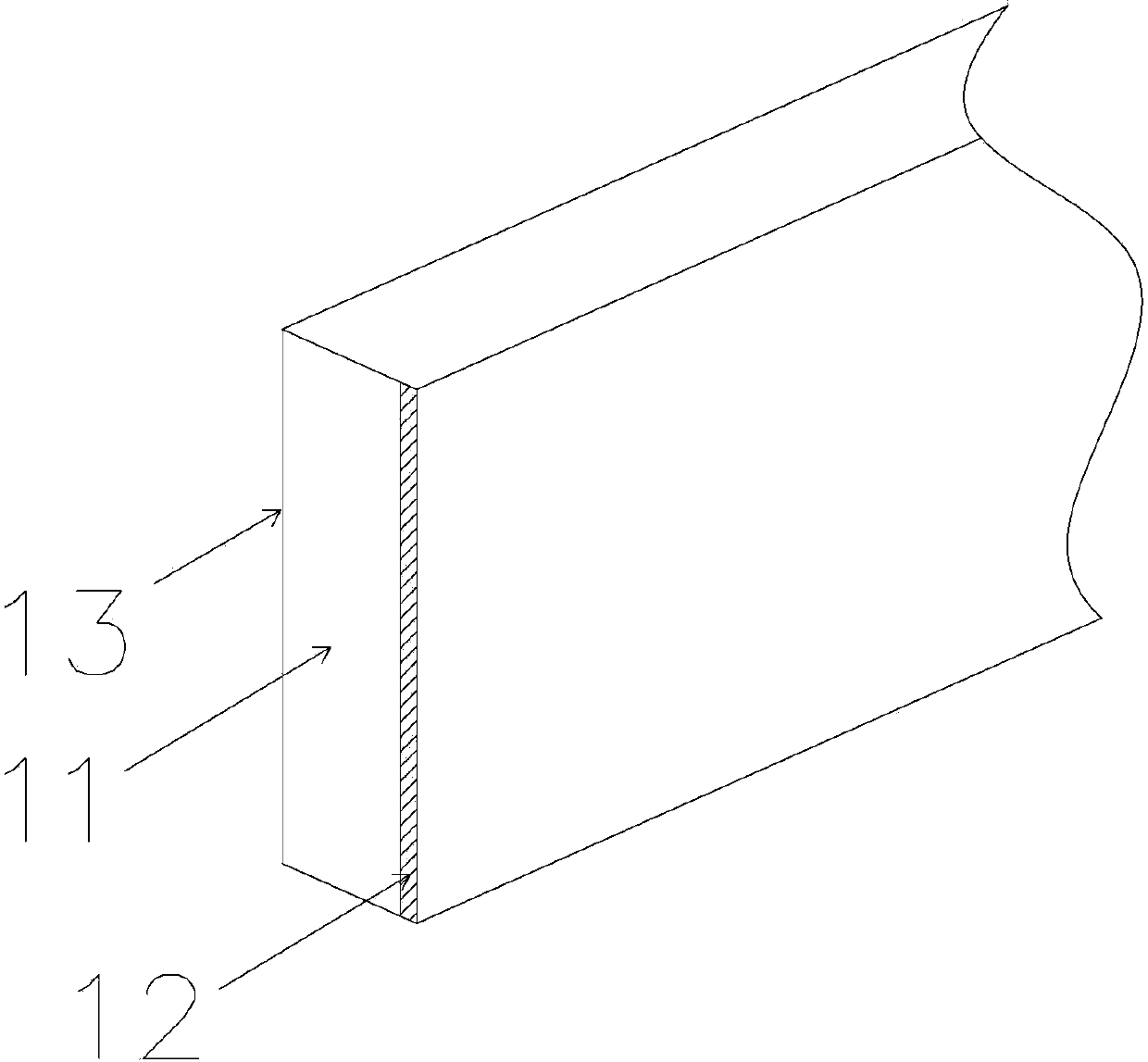

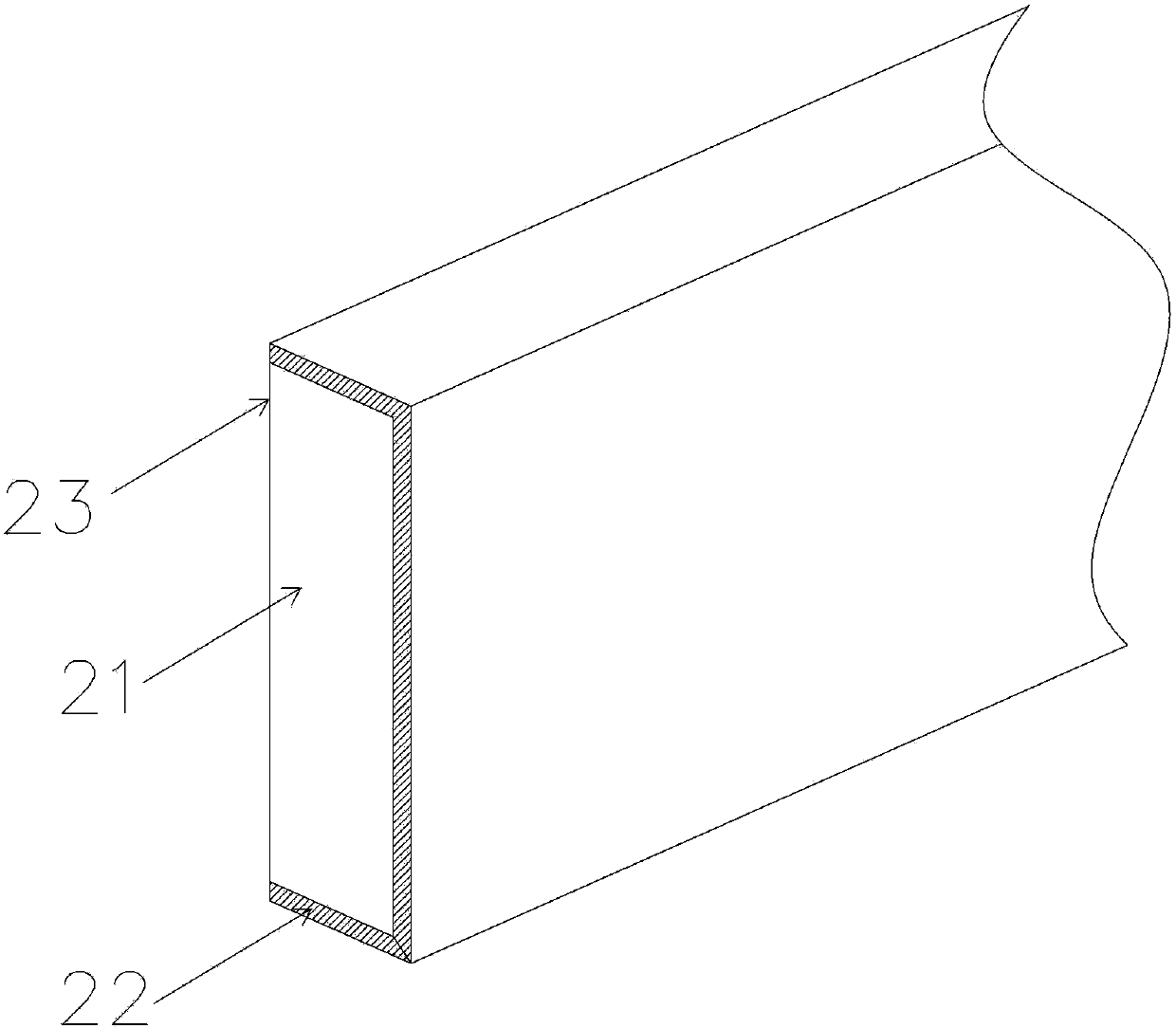

Method for manufacturing printed circuit board and printed circuit board with gas venting hole

InactiveUS20050284656A1Effective gas discharge performancePrevent leakagePrinted circuit assemblingPrinted circuit aspectsDip solderingEngineering

The invention provides a printed circuit board to be subjected to dip soldering process using a dip soldering jig, the board capable of discharging gases generated by the volatilization of flux thereby preventing solder defects, and a method for manufacturing the printed circuit board. Gas venting holes 12 are formed in areas adjacent to lead wire welding components 11 on the forward side of the feeding direction of the printed circuit board in the dip soldering process (board feeding direction 13) and within the area of an opening 23 formed to the dip soldering jig 20. Thereby, gases generated during the dip soldering process are discharged efficiently.

Owner:ORION ELECTRIC CO LTD

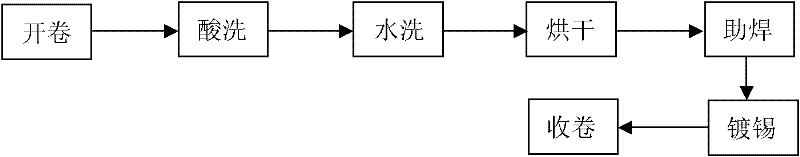

Preparation method for stannum, indium and stibium series lead-free solder tinning copper strip used for solar battery

InactiveCN102174676AHigh hardnessHigh tensile strengthFinal product manufactureSemiconductor devicesTinningDip soldering

The invention relates to a preparation method for a stannum, indium and stibium series lead-free solder tinning copper strip used for a solar battery. The preparation method comprises the following steps: pure stannum, indium and stibium, as well as bismuth, copper and silver are weighted according to the mass ratio of (83-99):(0.5-9):(0.1-8):(0-4):(0-1):(0-1); firstly, stibium, copper and silver are melted along with stannum in a smelting furnace in the proportion of 1:10 and then stirred to enable the stibium, copper and silver to be completely melted in stannum, and a stannum, stibium, silver and copper intermediate alloy is formed; secondly, the residual stannum and the other components are melted to form corresponding intermediate alloys; then two intermediate alloys are melted and stirred to be evenly mixed; and finally, the traditional hot dip-soldering process is used, and lead-free solder is dip-soldered on a copper wire or a copper strip. The Sn-In-Sb series lead-free solder has very low silver content, the solder cost is greatly lowered, the copper strip has better ductility and tensile strength, and the connection interface has high reliability. The high-performance solder alloy is taken as the object of study and is enabled to meet the industrial application requirements, so that the development prospect is good.

Owner:TIANJIN UNIV

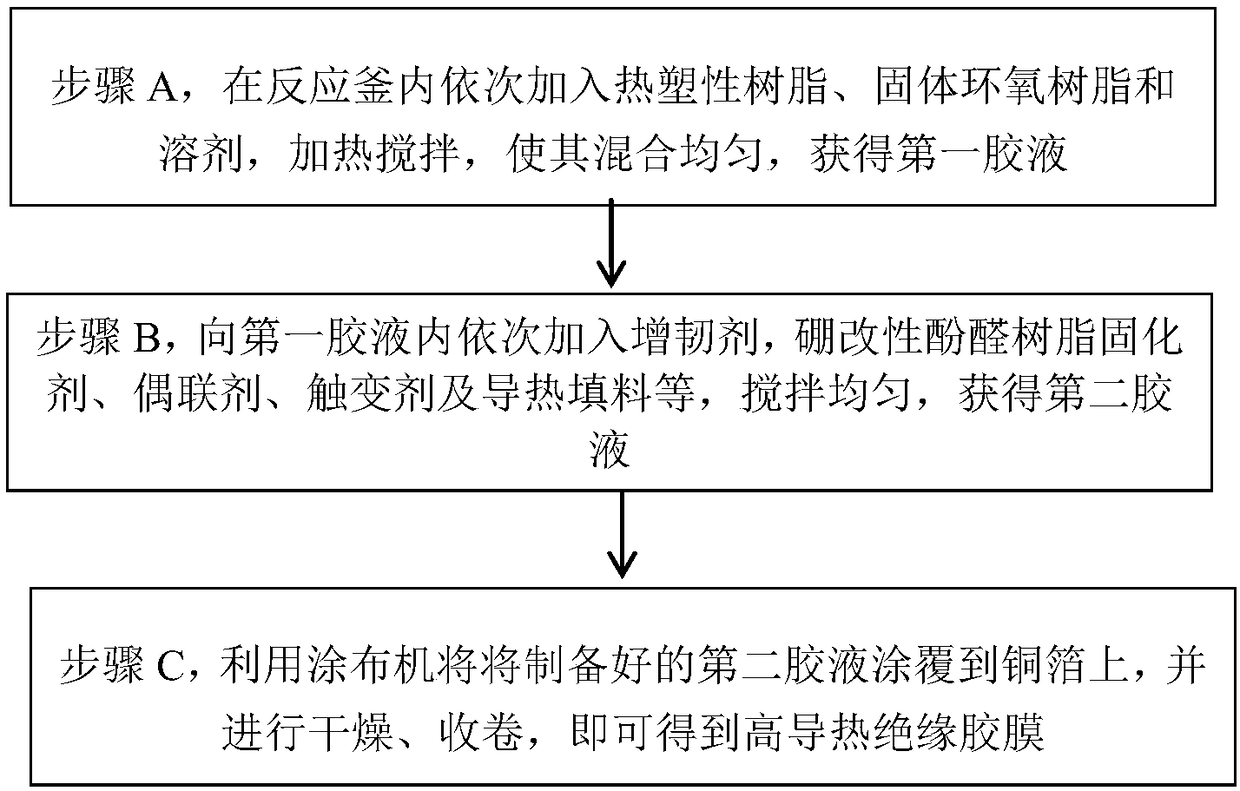

High-performance thermally-conductive and insulating film for aluminum-based copper-clad laminate, and preparation method thereof

InactiveCN108329847AImprove heat resistanceHigh peel strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesThermoplasticDip soldering

The invention relates to a high-performance thermally-conductive and insulating film for an aluminum-based copper-clad laminate, and a preparation method thereof. The high-performance thermally-conductive and insulating film for the aluminum-based copper-clad laminate comprises 5 to 30% of solid epoxy resin, 1 to 30% of a boron-modified phenolic resin curing agent, 1 to 20% of thermoplastic resin,1 to 10% of a flexibilizer, 0.01 to 3% of a coupling agent, 0.1 to 5% of a thixotropic agent, 20 to 40% of a solvent and 30 to 70% of a heat-conducting filling material. According to the invention, the boron-modified phenolic resin curing agent is employed, so the heat resistance and anti-stripping strength of the film are substantially improved, and the storage life and the operating period of the film are greatly prolonged; and the thermoplastic resin is used so as to effectively regulate the rheological performance of the film at high temperature and overcome the problem of glue flowing inthe preparation process of conventional aluminum substrates. The novel high-performance thermally-conductive and insulating film provided by the invention has the characteristics of good heat resistance, high heat conductivity, strong caking properties, dip soldering resistance, reflow soldering resistance, etc., is extensively applicable to solid-state relays, high-power transistors, pulse motordrivers, LEDs and other fields, and shows important value to improvement of the reliability of power devices and products.

Owner:SHENZHEN INST OF ADVANCED TECH

Method for preparing heat dipping tin of plastic sealed axial diode

ActiveCN101768710ASimple structureEasy to assemble and disassembleHot-dipping/immersion processesSemiconductor/solid-state device manufacturingProduction lineDip soldering

The invention discloses a method for preparing heat dipping tin of a plastic sealed axial diode, which comprises the following steps: placing the plastic sealed axial diode in an adapter plate; placing a first heat dipping tin positioning fixture below the adapter plate, ensuring that a lower substrate of the first heat dipping tin positioning fixture is tightly attached to a bottom plate of the adapter plate, and tightly clamping a first electrode of the diode by using the first heat dipping tin positioning fixture; removing the adapter plate, placing the first heat dipping tin positioning fixture in a guide rail of a tin dipping machine, and starting the tin dipping machine to perform dip soldering on a second electrode of the diode; tightly clamping the second electrode of the plastic sealed axial diode by a second heat dipping tin positioning fixture through the adapter plate; placing the second heat dipping tin positioning fixture in the guide rail of the tin dipping machine, and performing dip soldering on the first electrode of the diode; and finally, cleaning and drying the plastic sealed axial diode. The plastic sealed diode heat dipping tin positioning fixture with simple structure, convenient assembly and disassembly and reliable positioning is adopted, so that the processing speed of the heat dipping tin is improved, the material backlog of the procedure is reduced, and the production line is facilitated.

Owner:SIYANG GRANDE ELECTRONICS CO LTD

Lead-free welding flux alloy

InactiveCN101007373AImprove solderabilityImprove connection strengthWelding/cutting media/materialsSoldering mediaReflow solderingDip soldering

Lead-free solder alloy. The invention involves an alloy, particularly a lead-free solder alloy. The components weight percentages of the solder alloy are: Silver 0.1%~4.0%, copper 0.1% ~ 2%, Sb 0.002% ~ 0.2% and the rest is tin. The formula of said solder alloy in the invention is reasonable, has characteristics of unleaded, low prices, excellent weldability, it can prevent lead damage the human body when welding; it can replace the solder containing lead and can the prevent the welding silver plate eroded by silver; it is suitable to wave soldering, dip-soldering and reflow soldering,etc.

Owner:YUNNAN TIN GROUP HLDG

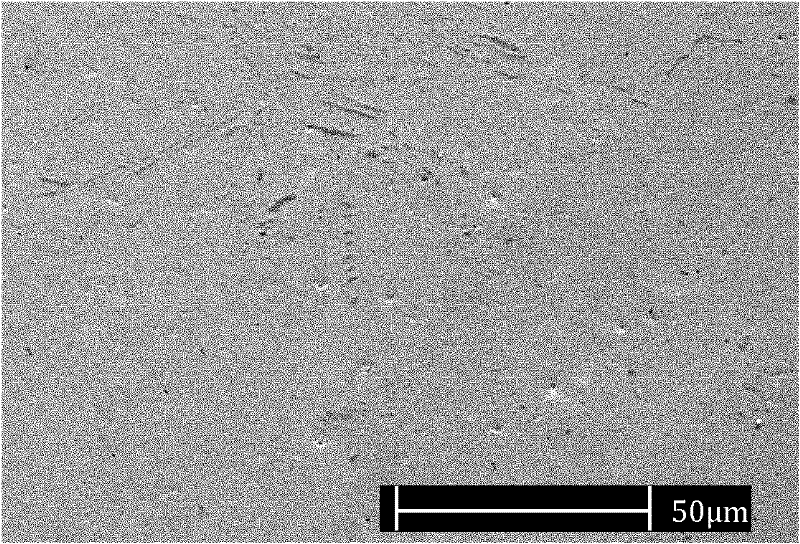

Heterogeneous photovoltaic solder strip and manufacturing method thereof

InactiveCN103794672AImprove conductivityReduce material costsFinal product manufacturePhotovoltaic energy generationDip solderingSolderability

The invention provides a heterogeneous photovoltaic solder strip and a manufacturing method thereof. Through an electroplating technology, electrotinning or tin alloy is performed on high conductive metal or an alloy base band. Under the condition that solderability is not reduced, a soldering tin layer on a non-soldering surface is removed. A thickness of the soldering tin layer of a soldering surface can be greatly reduced compared to the solder strip made through a traditional hot dip soldering mode. The non-soldering surface carries out base band surface passivation treatment or be served as an electroplating ultrathin protection film. Under an allowable solder-strip mechanical property, a thickness of a high conductivity matrix is maximized so that an overall conductivity of the solder strip is increased; battery pack power is increased because of an increase of solder strip conflux efficiency and simultaneously total material cost of the solder strip is reduced.

Owner:FUNDANT CHANGZHOU ADVANCED METAL TECH

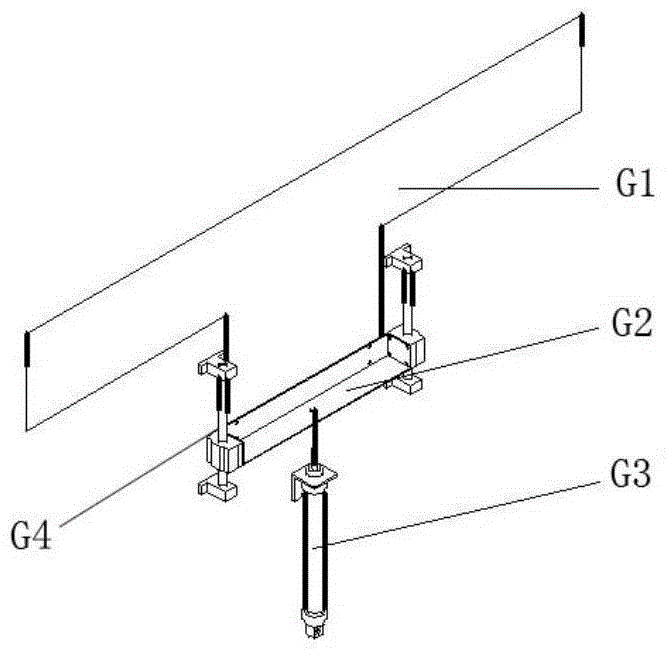

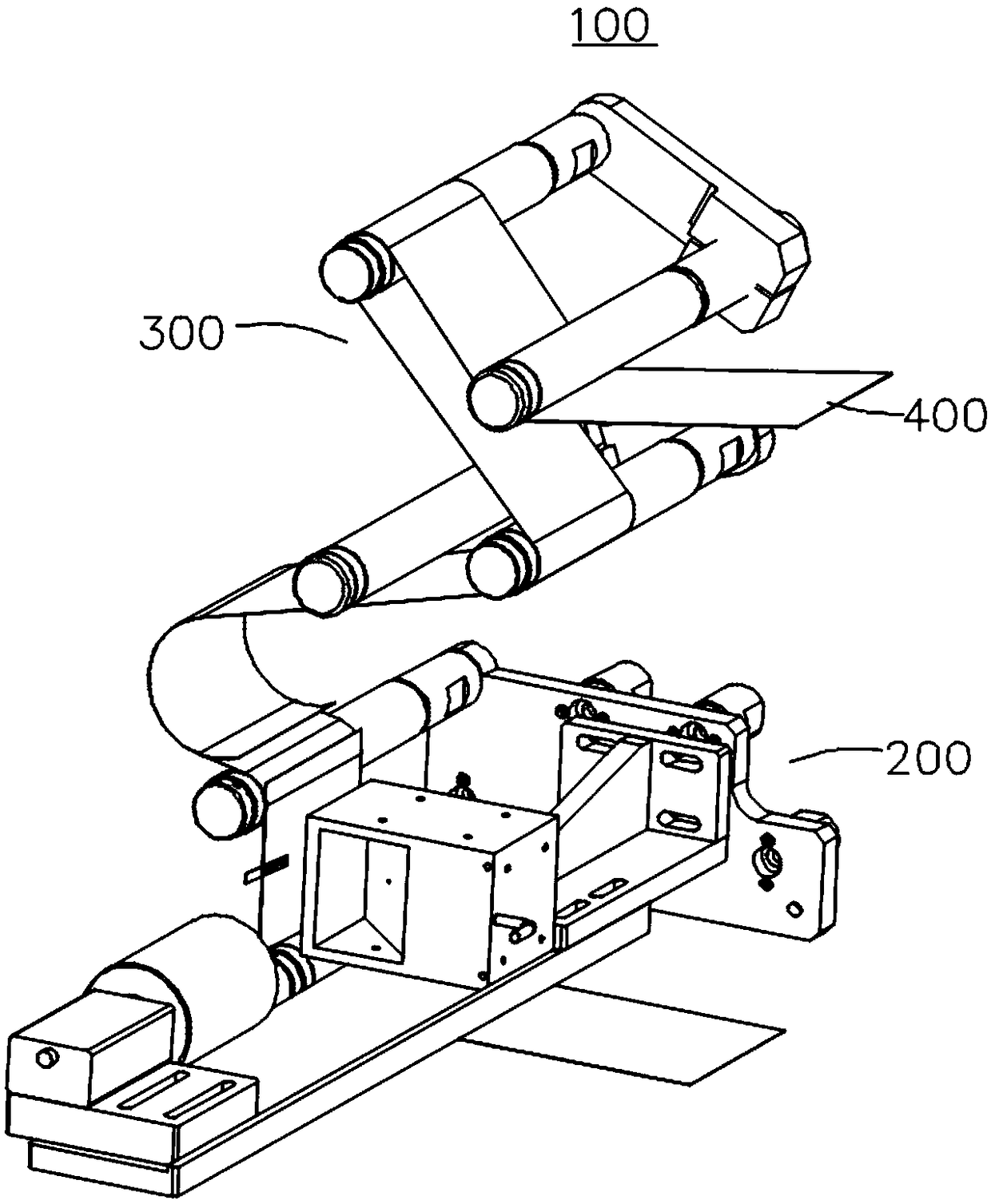

Coil winding machine of moving-coil motor

ActiveCN103683738AIncrease productivityEasy to operateManufacturing dynamo-electric machinesWinding machineDip soldering

The invention belongs to the technical field of a motor coil winding machine and particularly relates to a coil winding machine of a moving-coil motor. The coil winding machine comprises a winding mechanism capable of winding a varnished wire into a coil with two thread residues and a plurality of electrode tips, a thread residue removing mechanism for clamping a coil and removing the thread residues and a control mechanism arranged on a rack, wherein the control mechanism is used for controlling the movement of the winding mechanism and the thread residue removing mechanism; the coil winding machine comprises a dip soldering furnace and a dip soldering mechanism for clamping the coil arranged in the thread residue removing mechanism and carrying out a dip soldering process on the electrode tips; the dip soldering mechanism comprises a clamping part for clamping the coil, an overturning part for overturning the coil and a moving part for driving the clamp part to move and dipping the overturned electrode tips into the dip soldering furnace; the moving part is connected with the clamping part and the clamping part is mounted on the moving part; the control mechanism is used for controlling the movement of the clamping part, the overturning part and the moving part; the clamping part is used for automatically clamping the coil; the overturning part is used for overturning the coil; the moving part is used for placing the electrode tips into the dip soldering furnace to finish the dip soldering operation.

Owner:SHENZHEN SHUANGHUAN QX MOTOR

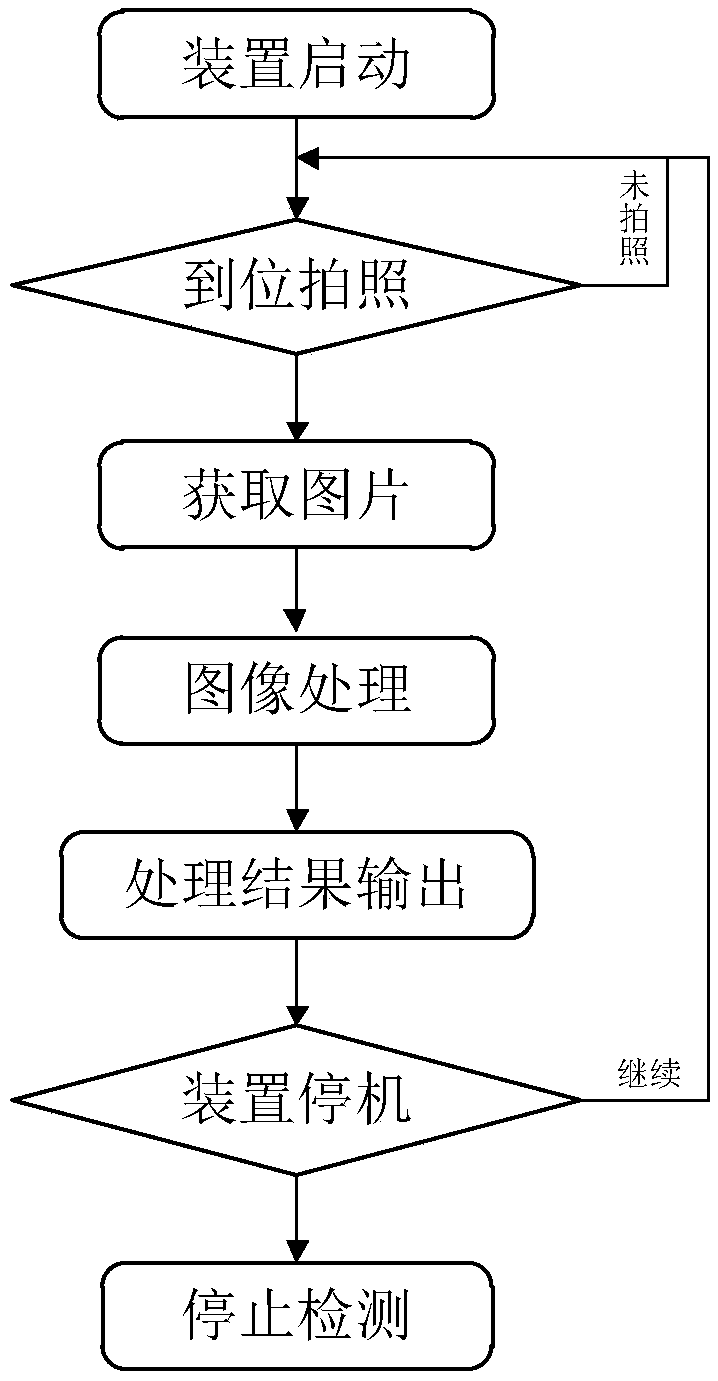

Method for detecting cold joints of leads of lithium battery and system for detecting soldering of leads

InactiveCN109142367AHigh degree of automationImprove detection efficiencyOptically investigating flaws/contaminationDip solderingSoldering

The invention discloses a method for detecting cold joints of leads of a lithium battery and a system for detecting soldering of the leads. A lead soldering detecting device is used for detecting theleads in real time, and a lead soldering database and a classifying model are established. The method includes the steps of data obtaining, basic data marking, generating of the classification model and outputting of a detection result, the leads to be detected are detected in real time, detection data is input into the classification model for comparison and analysis, whether or not the cold joints of the leads exist is judged, and the detection result is output. In the implementation of the method through the system, whether or not the cold joints occur on welding points of lead welding canbe rapidly detected, and therefore the automation and detection efficiency are improved.

Owner:GUANGZHOU SUPERSONIC AUTOMATION TECH CO LTD

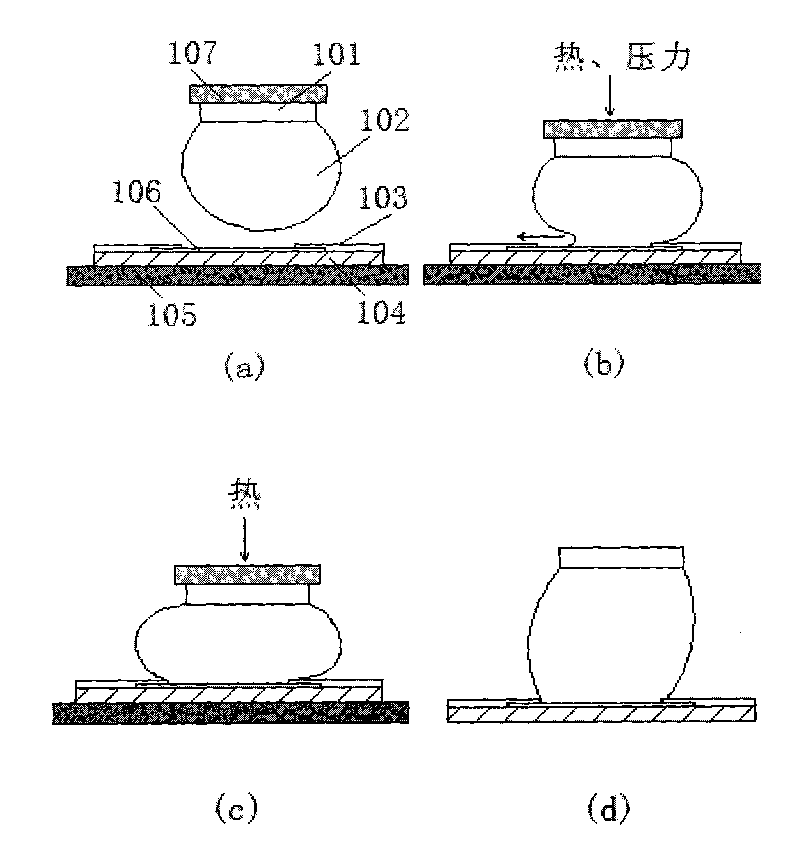

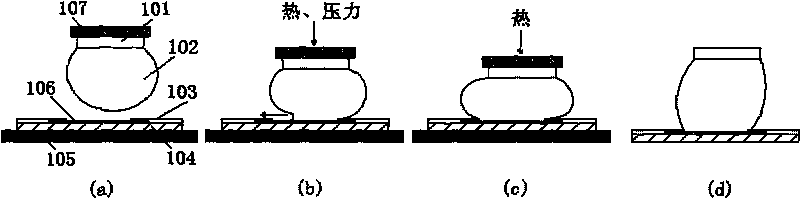

Flip chip bonding process for base plate

InactiveCN101740429AImprove interconnect yieldReliable interconnectionSolid-state devicesSemiconductor/solid-state device manufacturingDip solderingHigh density

The invention relates to a flip chip bonding process for a large-deformation pre-pressed base plate. The process is characterized in that: firstly, a soldering flux is printed on the base plate; after the soldering flux is coated and a chip is aligned with the base plate, certain pre-pressure is applied to one side of a suction head at a chip end, so that salient points undergo large deformation under the pre-pressure and is tightly connected with a Cu soldering-pan on a PCB in a more effective mode; and the height of a welding spot is recovered under the effect of surface tension in a subsequent refluxing process. The interconnection rate between a high-density welding spot and a PCB base plate is greatly enhanced, basically to 100 percent, and reliable interconnection between the welding spot and the PCB base plate can also be realized even under the condition of poor coplanarity of array salient points or severe alignment error between the welding spot and the Cu soldering-pan. The process solves the problem of low conduction rate between the high-density salient points and the soldering-pan, and has the advantages of high welding intensity, good technical stability and high repeatability.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com