Heterogeneous photovoltaic solder strip and manufacturing method thereof

A photovoltaic ribbon and heterogeneous technology, which is applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of overall electrical conductivity reduction of ribbon, waste of protective baseband 1, and increased fragmentation rate, etc., to achieve reduction Overall material cost, increase overall conductivity, and increase the effect of actual power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

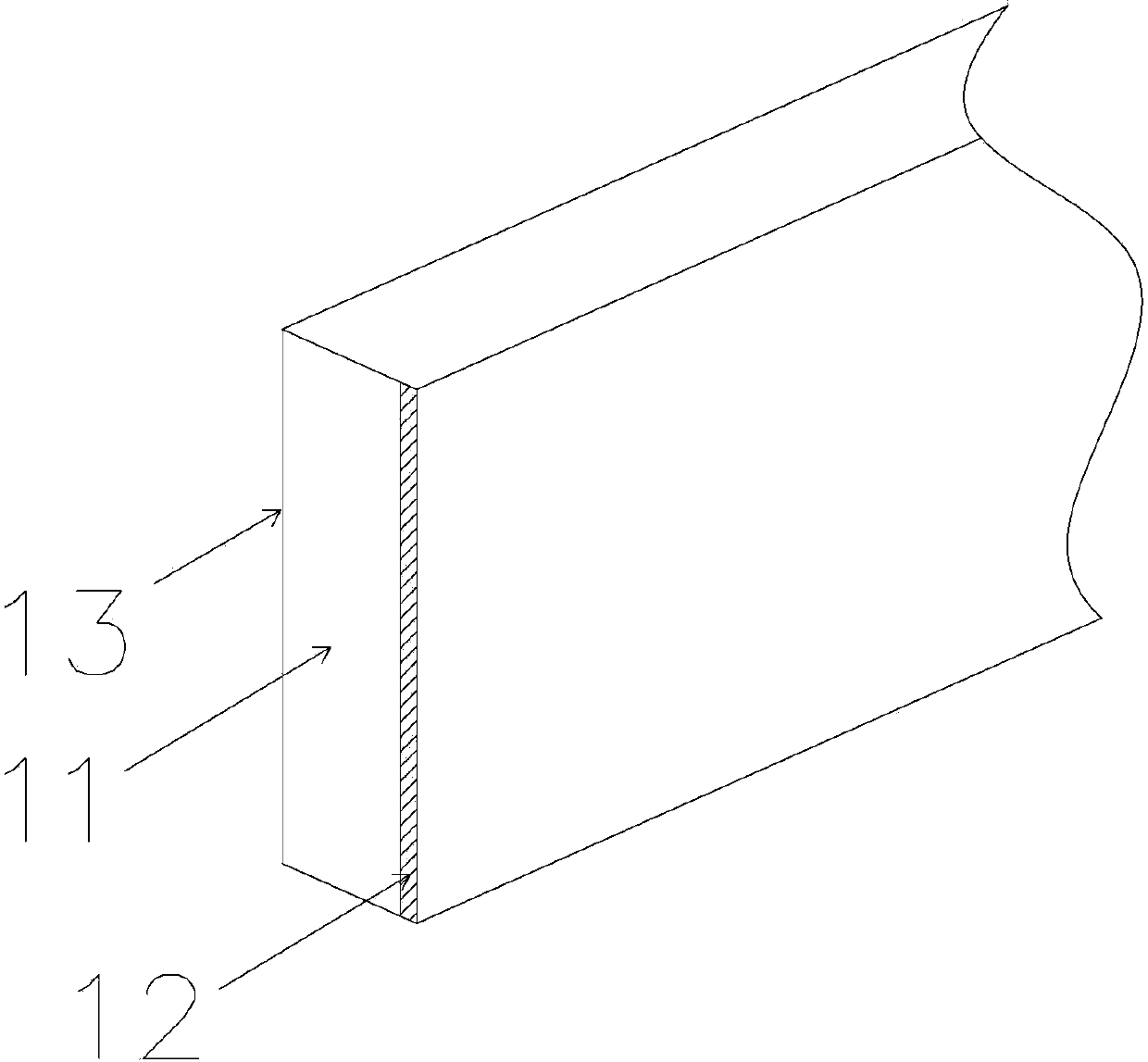

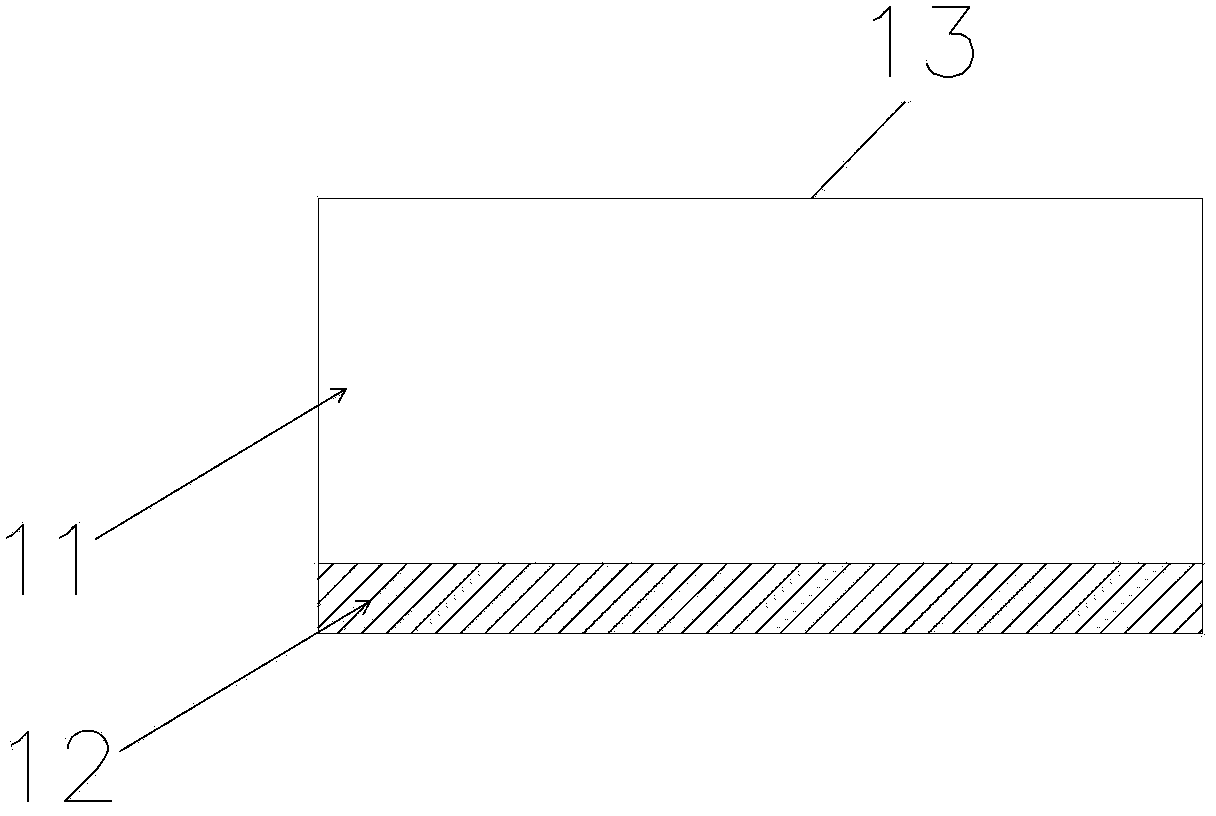

[0035] This embodiment uses a wide-width oxygen-free copper (a kind of pure copper) base belt. After tempering, firstly, a wide surface of the base belt 11 is covered with waterproof stickers, or other materials with certain strength and reasonable dimension stability can also be used. permanent waterproof protective film. Afterwards, the base belt 11 is electroplated through the electroplating tank by pulling the waterproof self-adhesive. The electroplating solution used in this embodiment is a pure tin plating solution. One side of the waterproof self-adhesive base tape is covered with a layer of about 8 μm pure tin solder layer, and then the waterproof self-adhesive is removed to obtain a wide-width heterogeneous photovoltaic ribbon. Then through the slitting machine, the wide-width heterogeneous photovoltaic ribbon is slit into the required size ribbon with a width of 1.5 mm, and the wide surface not covered with solder is passivated and protected by pure copper passivatio...

Embodiment 2

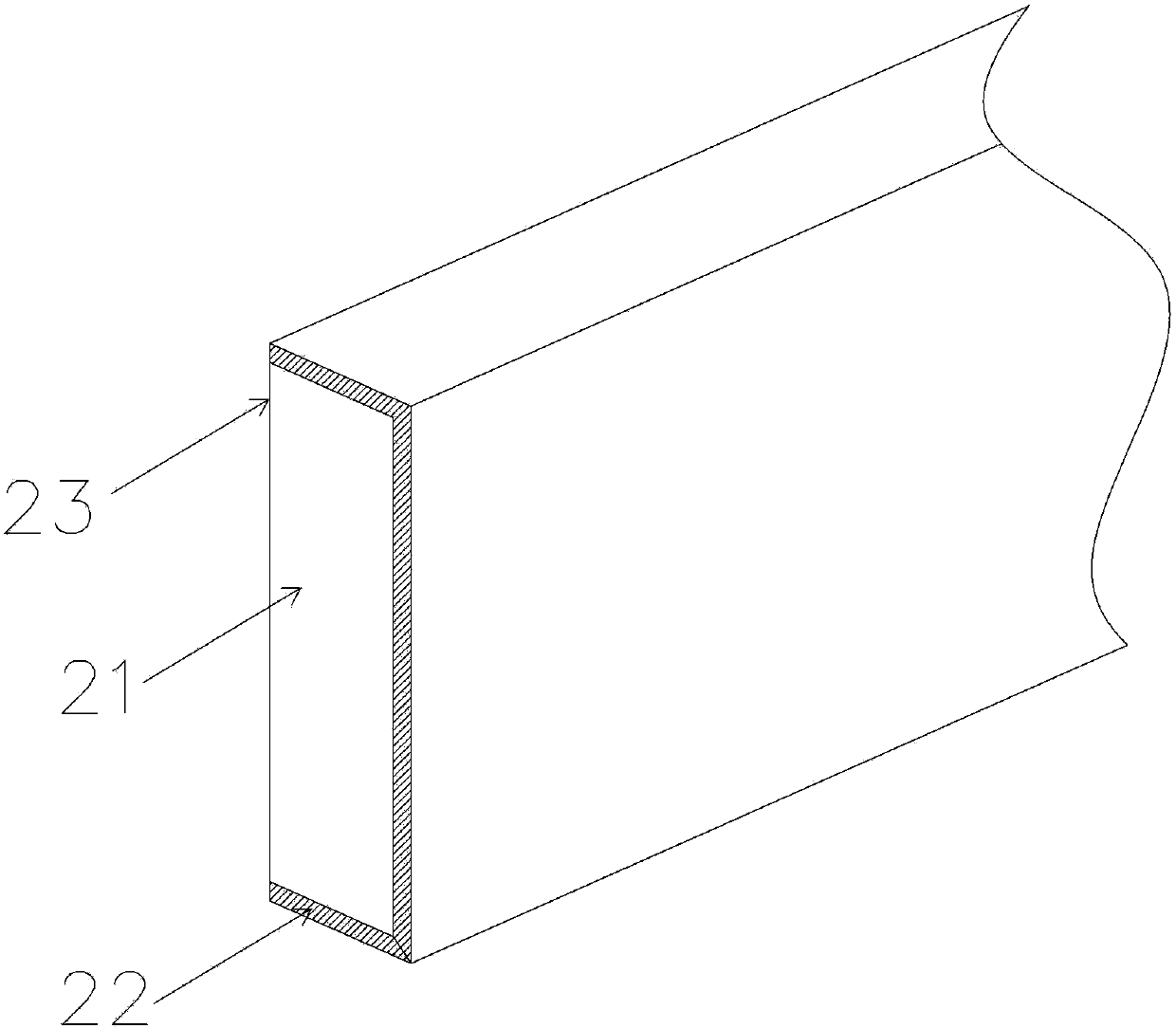

[0039] In this embodiment, high-purity raw copper containing a certain proportion of lanthanum is used as the wide-width baseband. After tempering, the wide-width baseband is slit (or rolled) into the required size of 1.48 mm wide, and the slitted baseband 21 is a wide surface. Adhered to waterproof stickers, or other waterproof protective films with certain strength and reasonable dimensional stability. Then by pulling the waterproof sticker, the base belt 21 is electroplated through the electroplating tank. The electroplating solution used in this embodiment is a tin-copper plating solution. One side of the self-adhesive base tape is covered with a 10μm tin-copper solder layer, and then the waterproof self-adhesive is removed, and the non-solder surface is passivated to obtain the required size of the heterogeneous photovoltaic ribbon. prepared in photovoltaic modules.

[0040] Using 72 pieces of 156*156 polysilicon wafers, using this ribbon to prepare a set of battery modu...

Embodiment 3

[0043] In this embodiment, copper-aluminum alloy is used as the wide-width base tape. After tempering, the wide-width base tape is cut (or rolled) into the required size of 1.60 mm wide, and then a layer of 0.5 μm nickel protective film is pre-coated. One wide side of the cut base tape 31 containing the ultra-thin protective film 32 is adhered to the waterproof sticker, or it can be other waterproof protective film with certain strength and reasonable dimensional stability. Then, the base belt 31 is electroplated through the electroplating tank by pulling the waterproof self-adhesive. The electroplating solution first used in this embodiment is a tin-bismuth alloy plating solution. One side of the base tape 31 without waterproof self-adhesive is covered with a layer of 6 μm tin-bismuth solder layer 33, and then a pure tin plating solution is used. The solder layer is covered with a layer of 4 μm pure tin solder layer 34 and then the waterproof adhesive is removed, so as to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com