Patents

Literature

1027 results about "Solderability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The solderability of a substrate is a measure of the ease with which a soldered joint can be made to that material. Good solderability requires wetting (low contact angle) of the substrate by the solder.

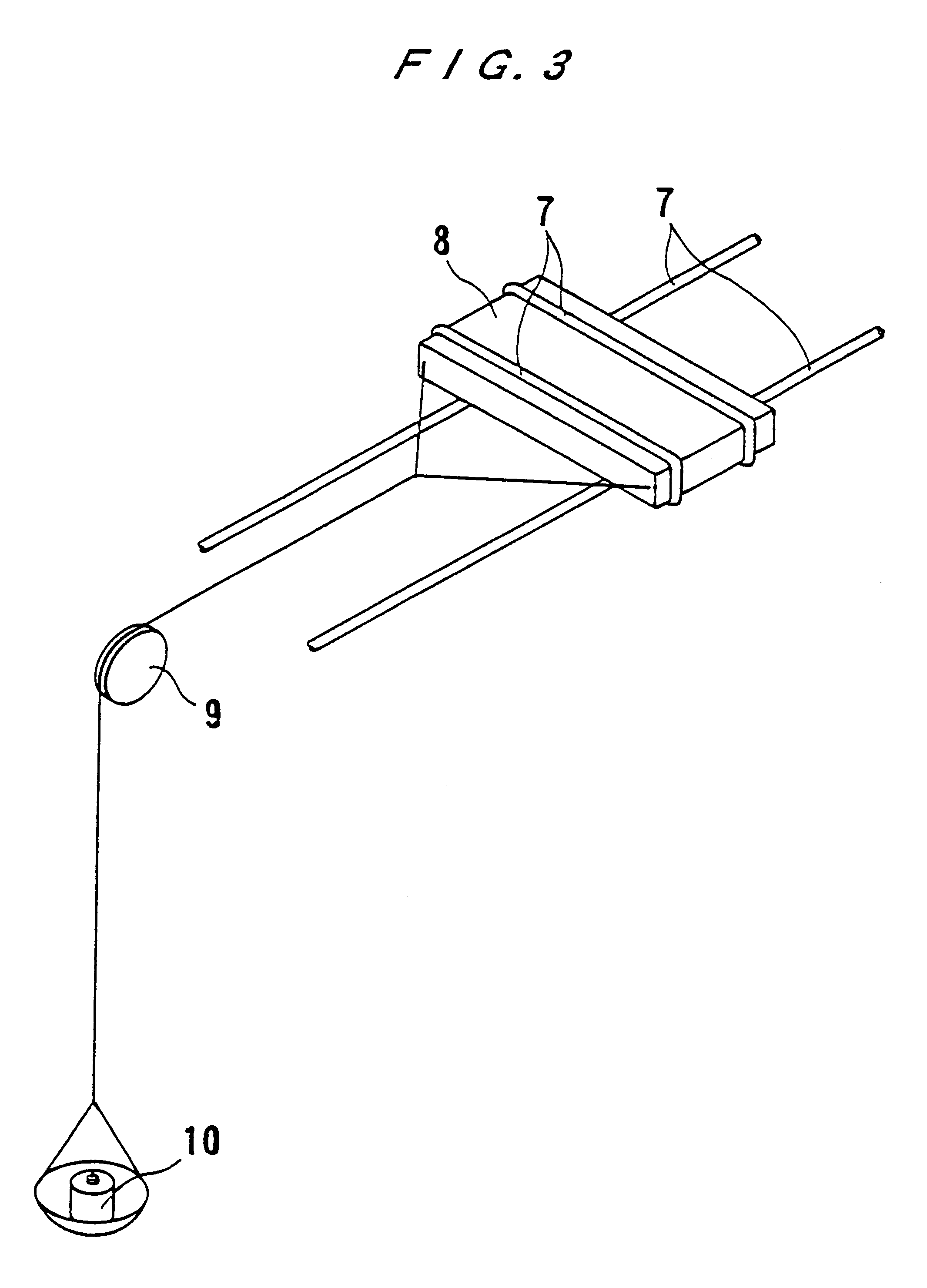

Method and apparatus for shaping spring elements

InactiveUS6836962B2Easy to disassembleEasy to manufactureElectrically conductive connectionsContact member assembly/disassemblyProbe cardCopper wire

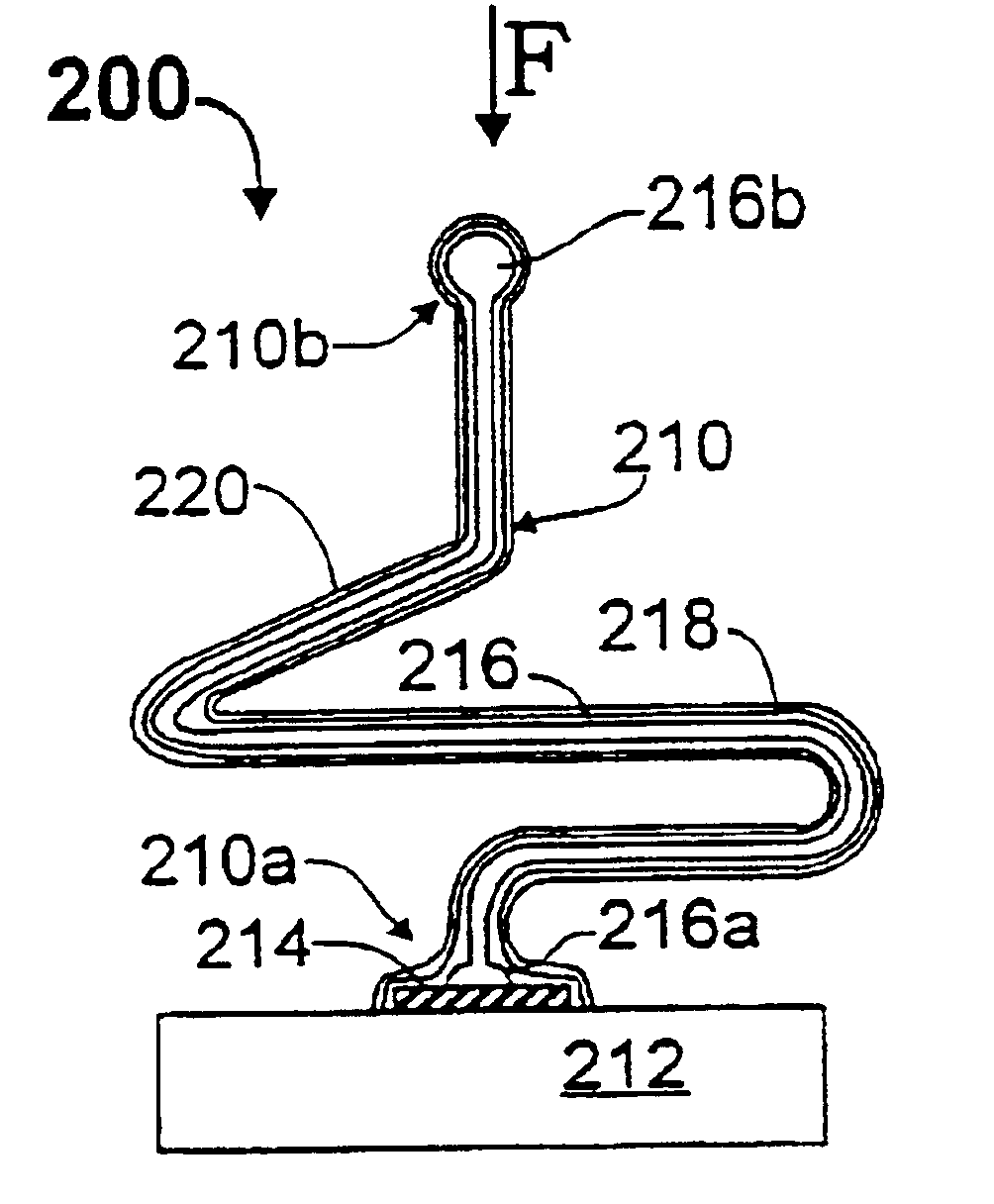

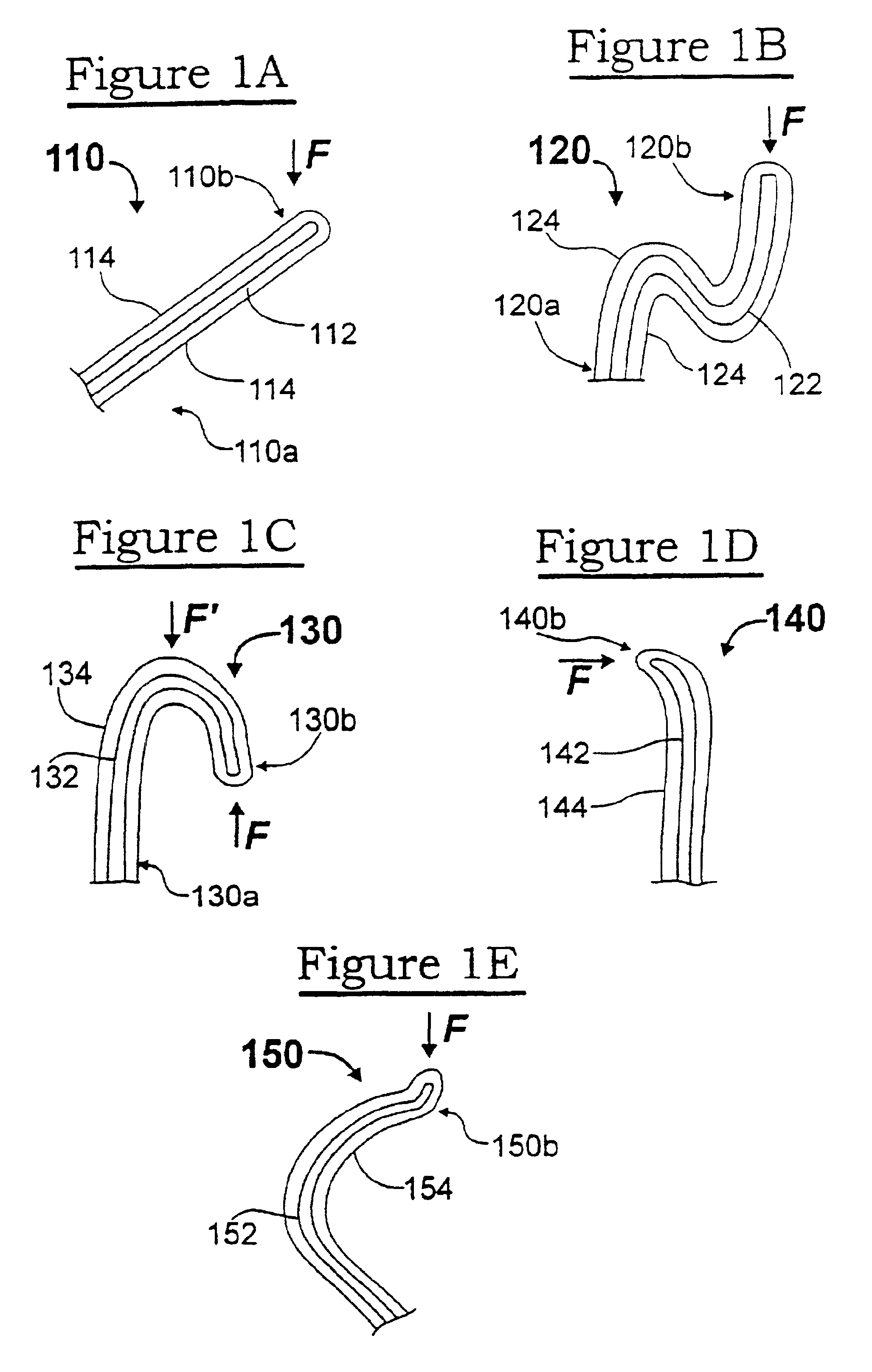

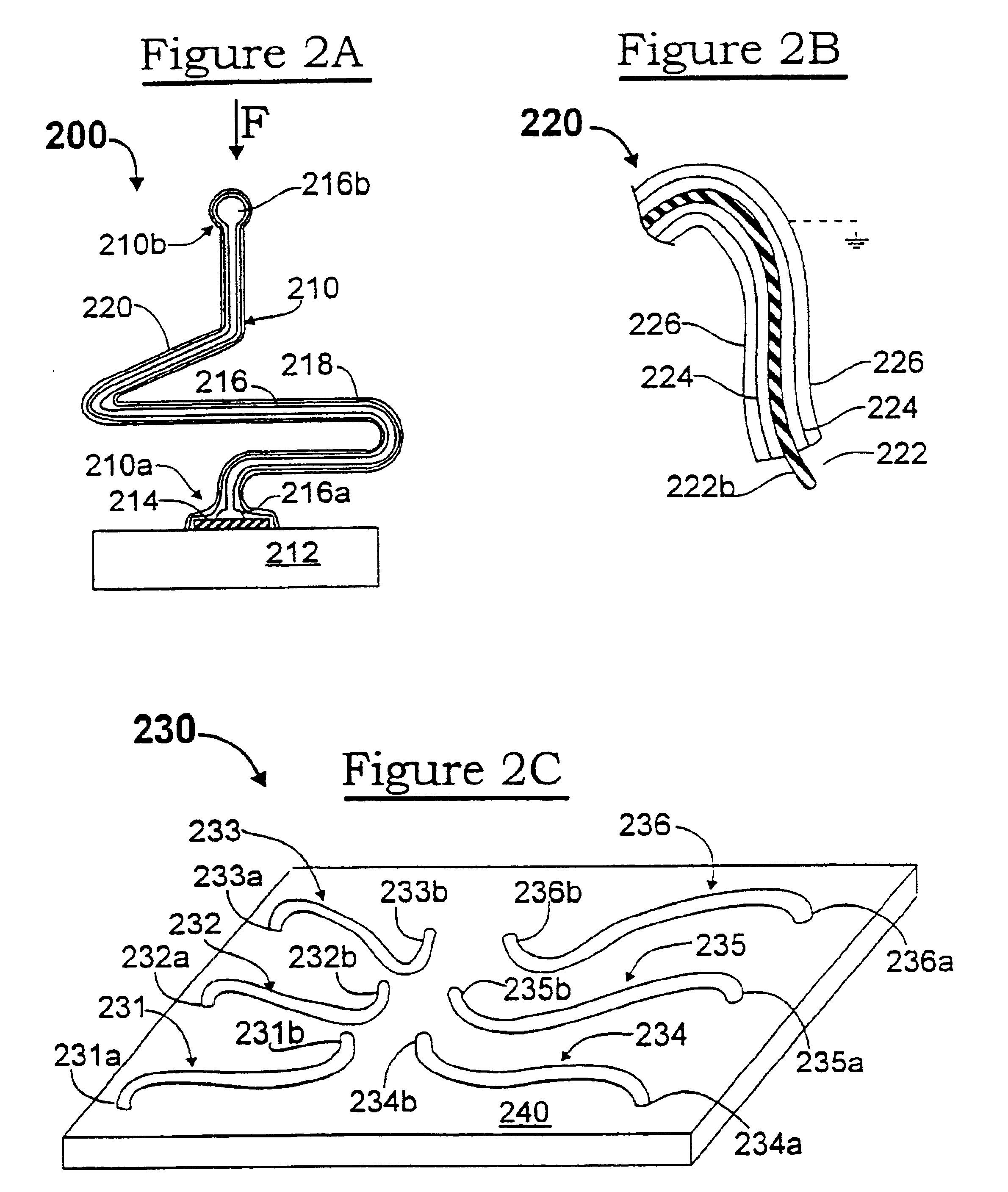

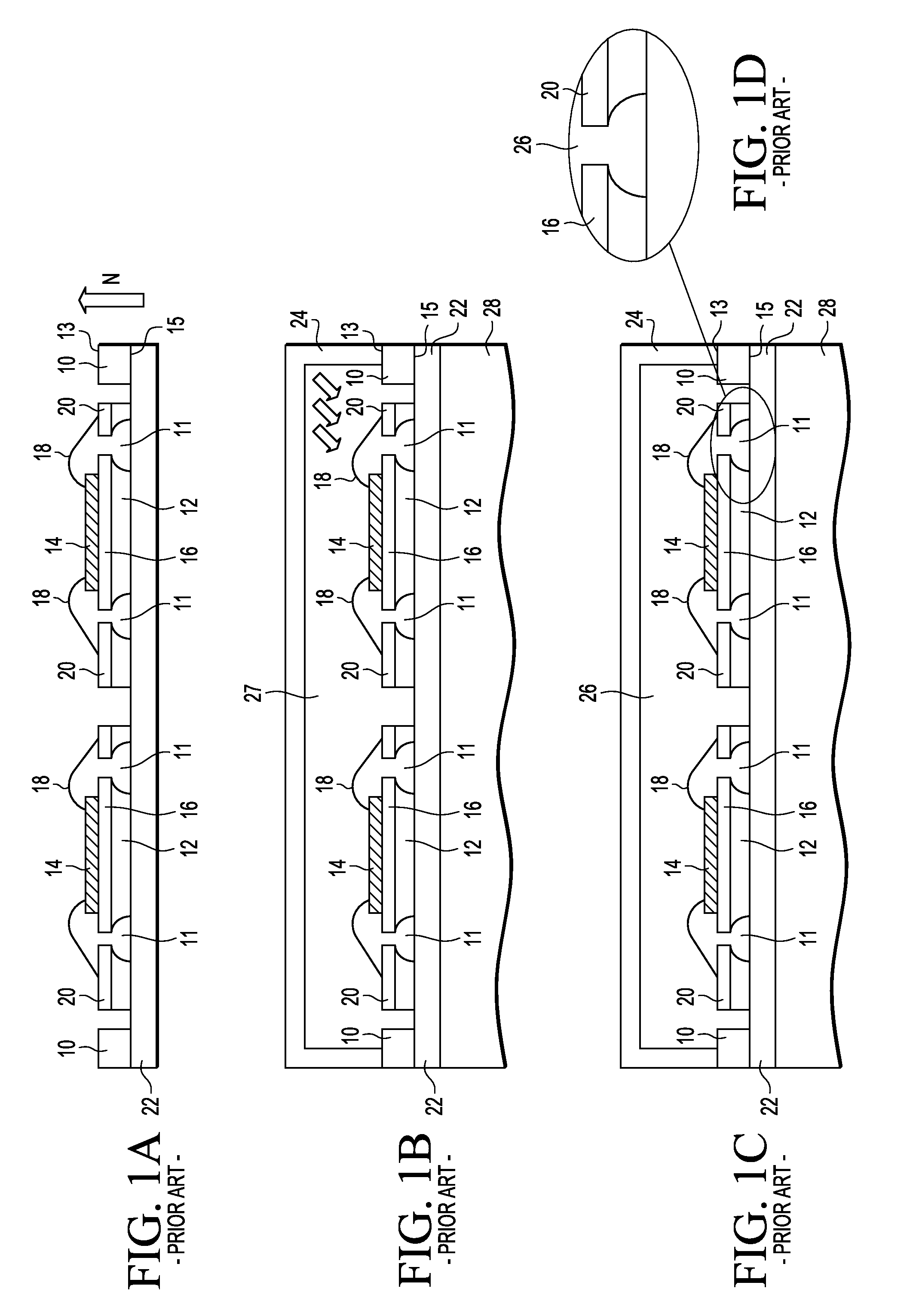

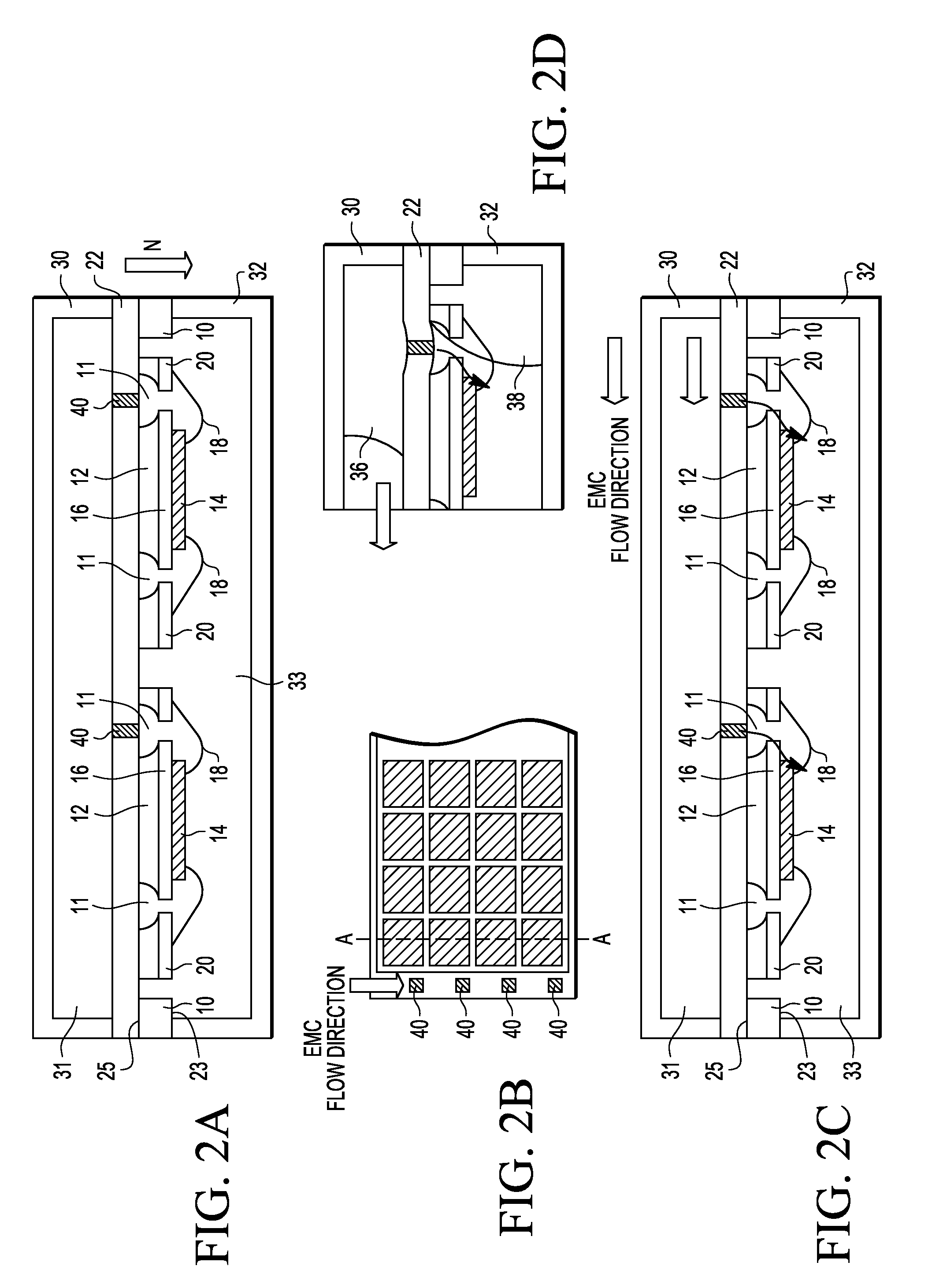

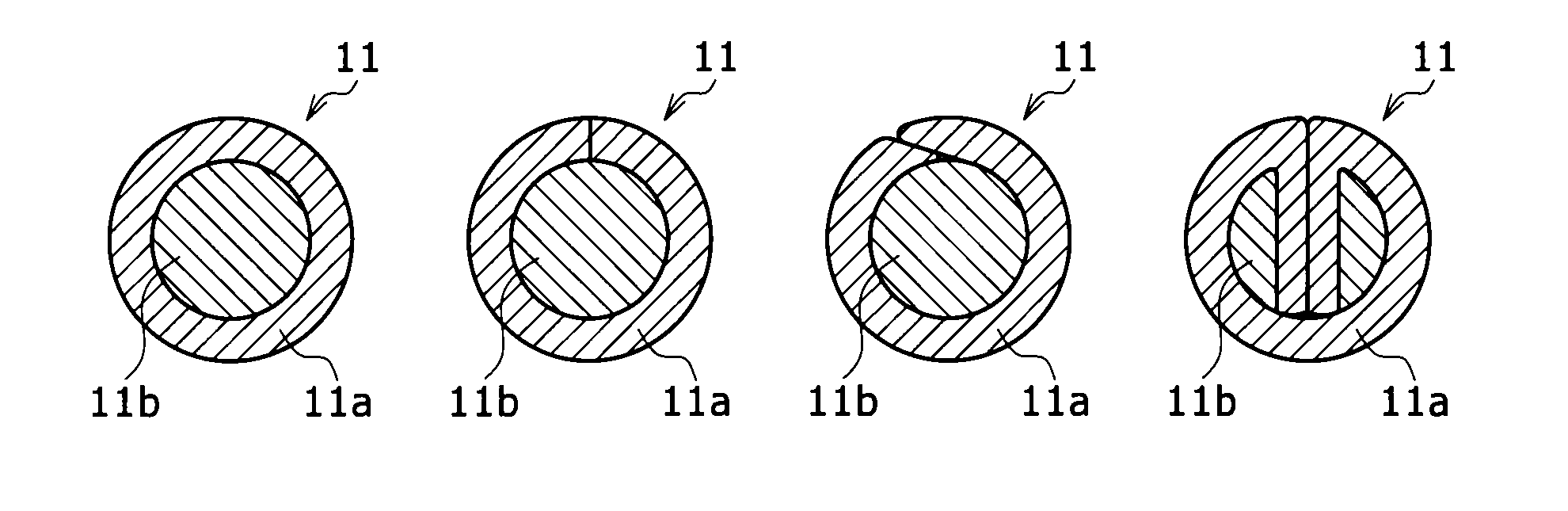

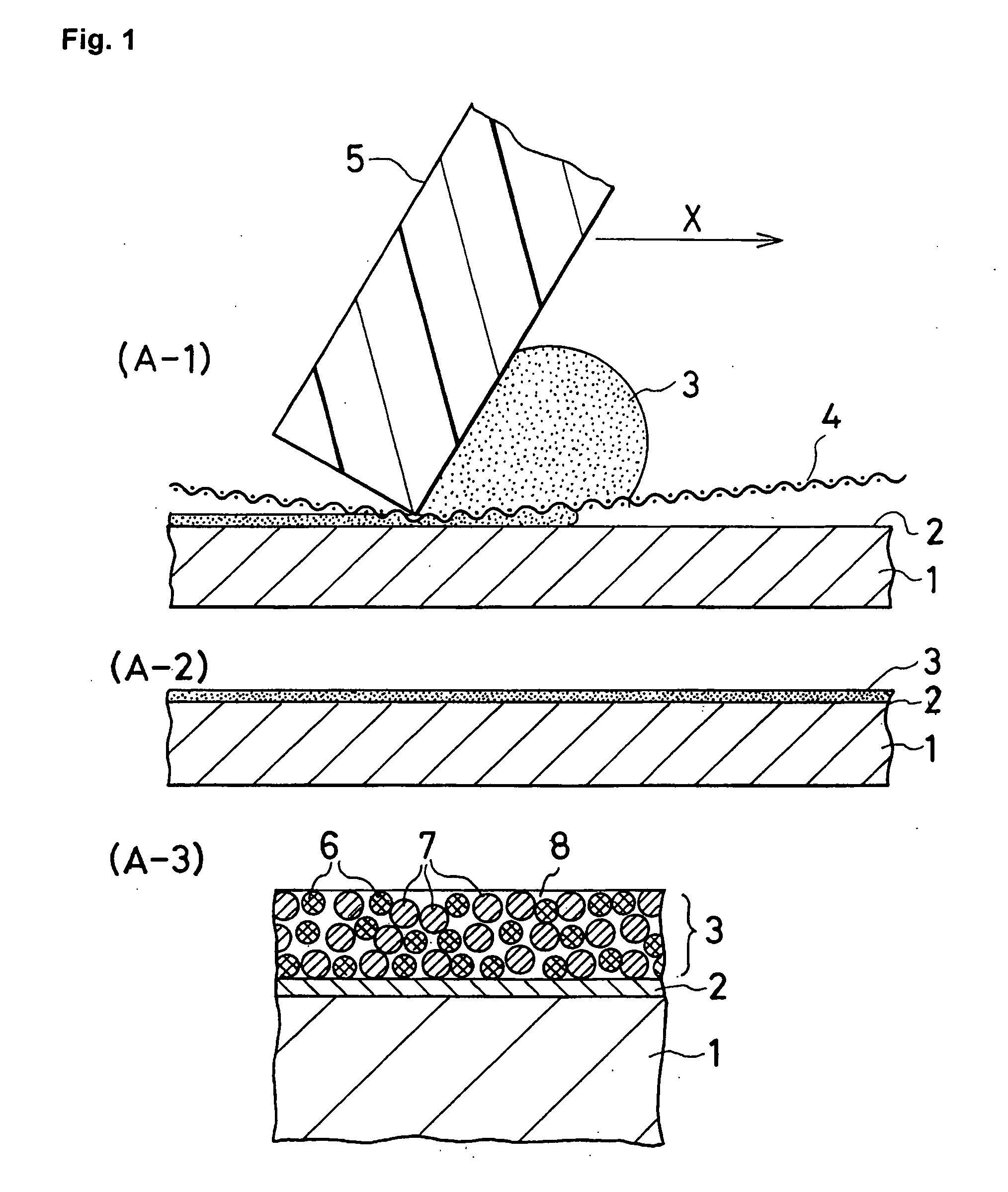

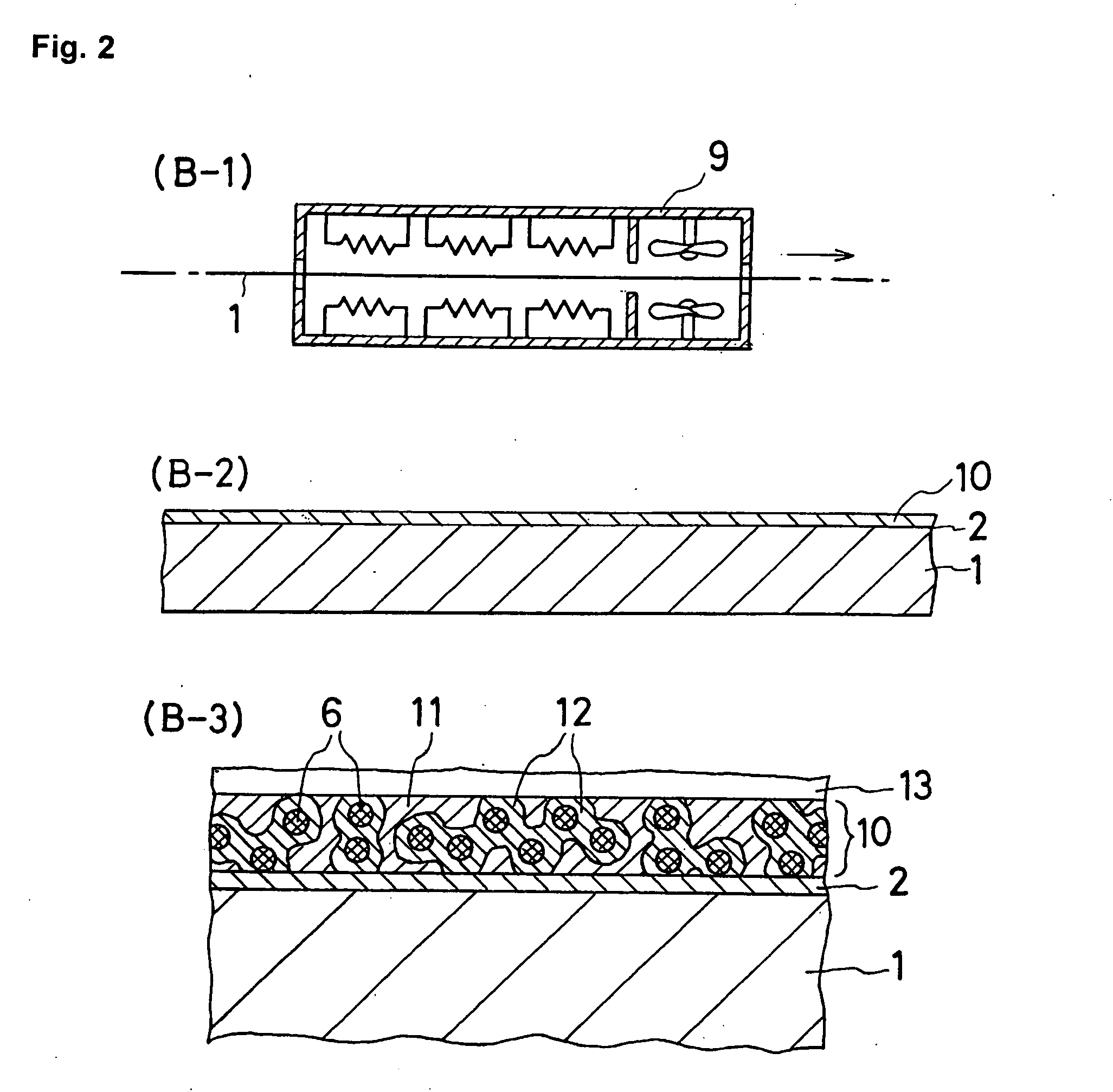

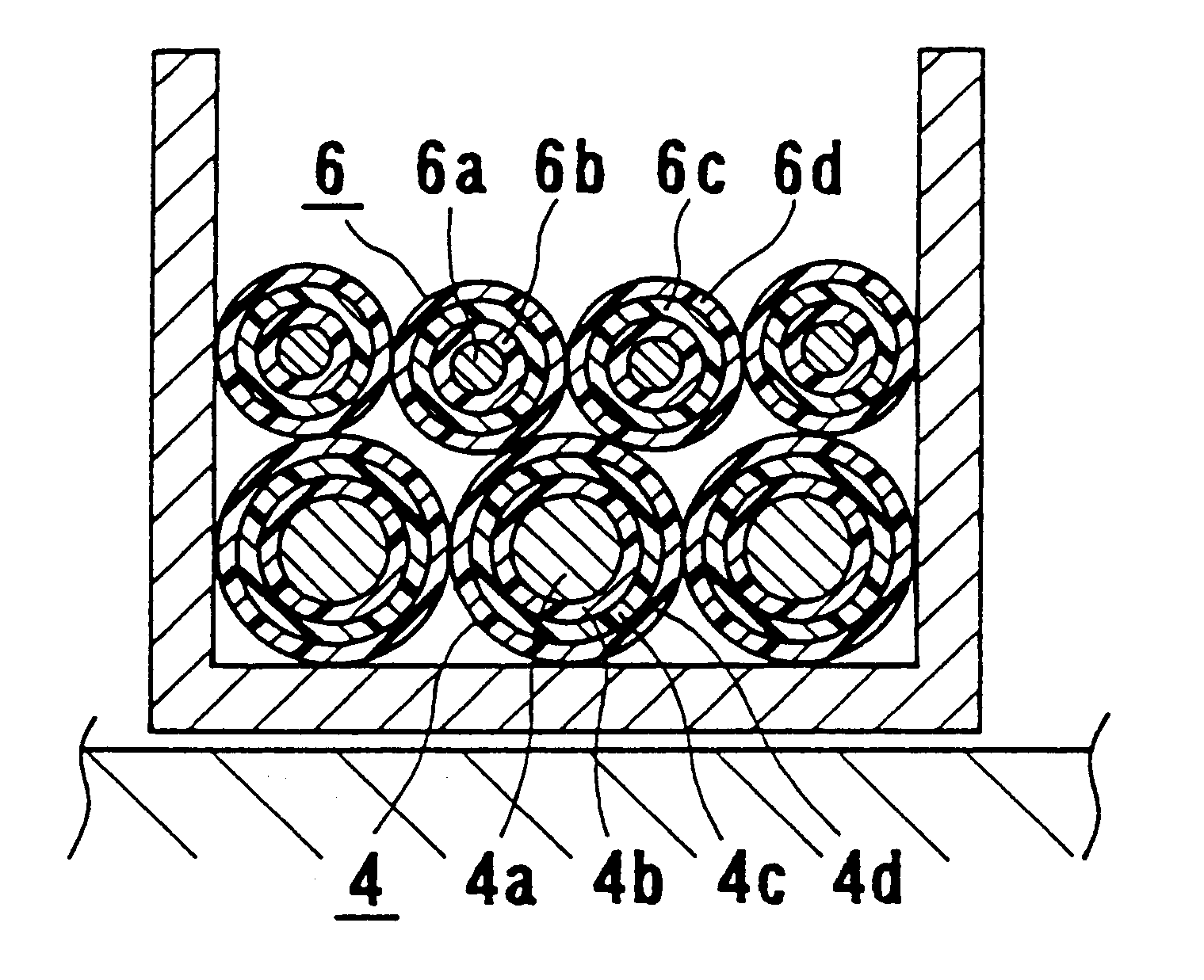

Interconnection elements for electronic components, exhibiting desirable mechanical characteristic (such as resiliency, for making pressure contacts) are formed by using a shaping tool (512) to shape an elongate core element (502) of a soft material (such as gold or soft copper wire) to have a springable shape (including cantilever beam, S-shape, U-shape), and overcoating the shaped core element with a hard material (such as nickel and its alloys), to impart to desired spring (resilient) characteristic to the resulting composite interconnection element. A final overcoat of a material having superior electrical qualities (e.g., electrical conductivity and / or solderability) may be applied to the composite interconnection element. The resulting interconnection elements may be mounted to a variety of electronic components, including directly to semiconductor dies and wafers (in which case the overcoat material anchors the composite interconnection element to a terminal (or the like) on the electronic component), may be mounted to support substrates for use as interposers and may be mounted to substrates for use as probe cards or probe card inserts. The shaping tool may be an anvil (622) and a die (624), and may nick or sever successive shaped portions of the elongate elements, and the elongate element may be of an inherently hard (springy) material. Methods of fabricating interconnection elements on sacrificial substrates are described. Methods of fabricating tip structures (258) and contact tips at the end of interconnection elements are also described.

Owner:FORMFACTOR INC

1000MPa grade cold rolling hot dip galvanizing two-phase steel and manufacturing method thereof

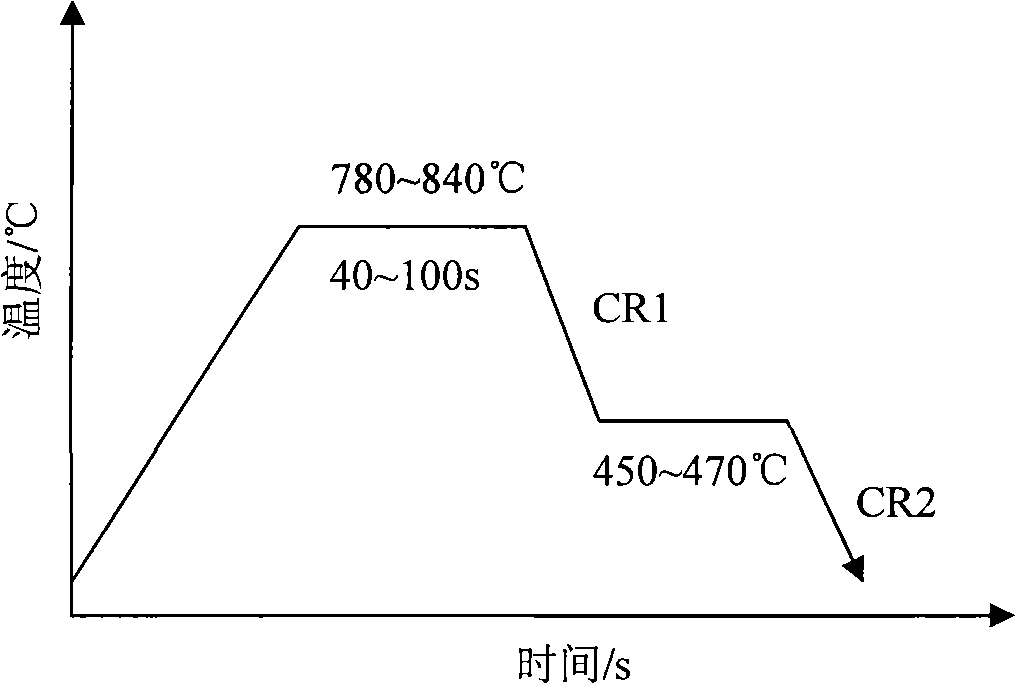

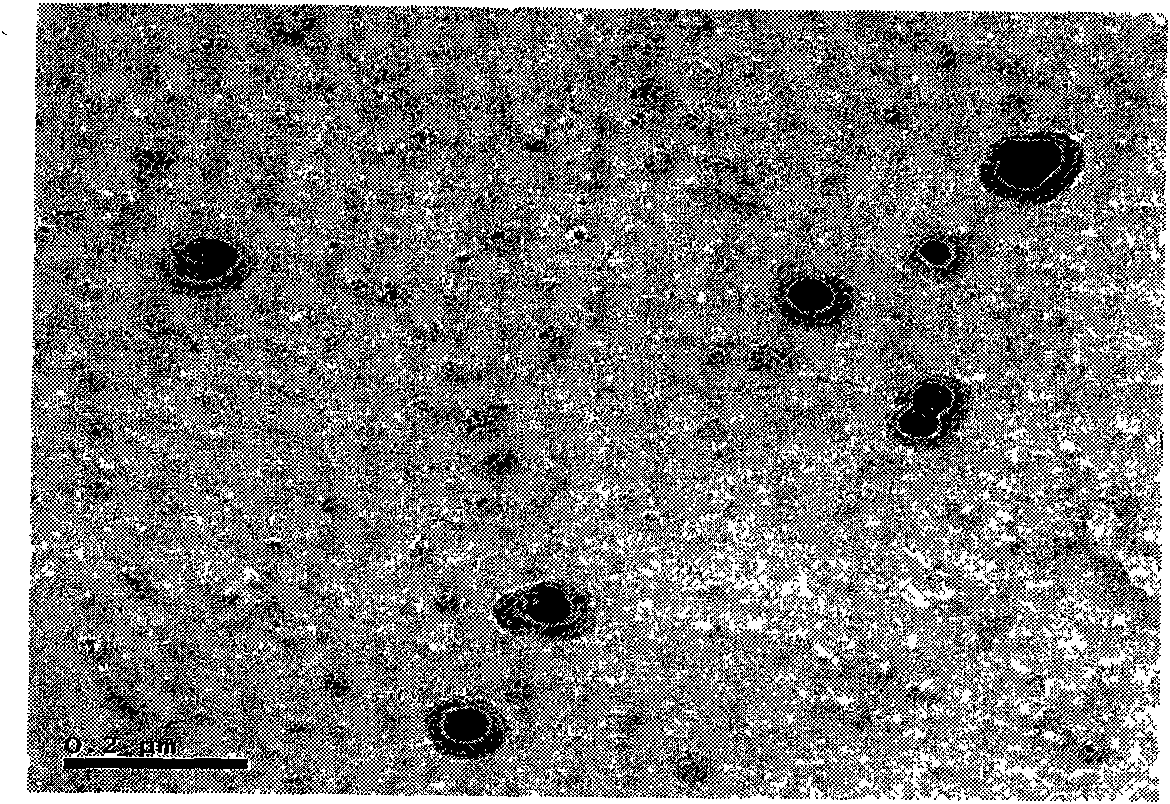

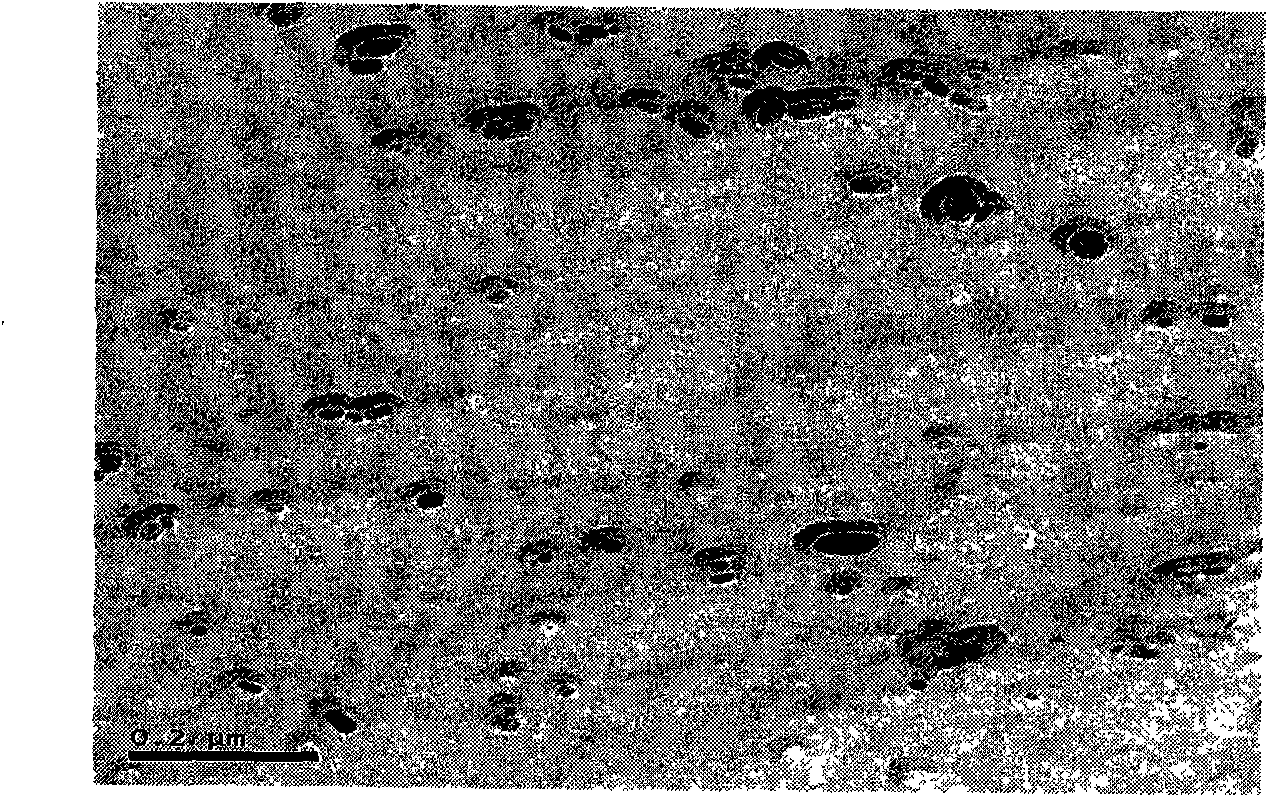

The invention provides 1,000 MPa cold-rolled hot-dip galvanized dual-phase steel and a manufacturing method thereof, belonging to the technical field of cold-rolled hot-dip galvanized high-strength steel plates. The chemical components in mass percentage of the cold-rolled hot-dip galvanized dual-phase steel are: 0.06 to 0.18 percent of C, less than or equal to 0.1 percent of Si, 1.2 to 2.5 percent of Mn,0.05 to 0.5 percent of Mo, 0.05 to 0.6 percent of Cr, 0.005 to 0.05 percent of Al, 0.01 to 0.06 percent of Nb, 0.01 to 0.05 percent of Ti, less than or equal to 0.02 percent of P, less than or equal to 0.01 percent of S, less than or equal to 0.005 percent of N, the balance being Fe and inevitable impurities. The manufacturing method adopts Cr or Mo to replace Si, so as to enlarge an austenitic and ferritic two-phase region and improve the hardenability of the dual-phase steel, and meanwhile, the manufacturing method improves the strength of toughness of the steel by adding Nb or Ti refined grains, so as to ensure that the steel has good weldability and usability, and the strength grade of the steel can reach over 1,000 Mpa.

Owner:UNIV OF SCI & TECH BEIJING +1

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

Halogen-free tin-bismuth-copper soldering paste and preparation method thereof

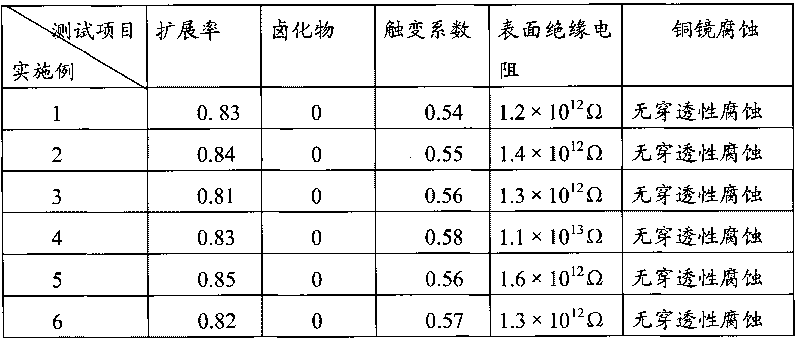

InactiveCN101695794AExtended shelf lifeExtended service lifeWelding/cutting media/materialsSoldering mediaAntioxidantExpansion rate

The invention relates to the technical field of soldering pastes, in particular to a halogen-free tin-bismuth-copper soldering paste and a preparation method thereof. A soldering flux of the halogen-free tin-bismuth-copper soldering paste consists of the following components in percentage by weight: 20 to 40 percent of polymerized rosin, 1 to 6 percent of rosin amine, 4 to 8 percent of thixotropic agent, 5 to 10 percent of organic acid, 5 to 10 percent of organic amine, 1 to 5 percent of antioxidant, 0.5 to 3 percent of surfactant and an organic solvent. The halogen-free tin-bismuth-copper soldering paste is mainly characterized by adopting the organic acid and the organic amine serving as activating agents and comprising no halogens at all, so not only the solderability is not reduced, but also the expansion rate and the insulation resistance value of the soldering paste are improved, and simultaneously the corrosivity of residues after soldering to a base material is reduced and the service life of the soldering paste is prolonged; and particularly, the peak temperature of the soldering paste during soldering is lower in favor of reducing the thermal damages to electronic components.

Owner:东莞市特尔佳电子有限公司

Enamel steel for cold rolling water heater and manufacturing method thereof

InactiveCN101684532AGood explosivenessGood formabilityTemperature control deviceMetal rolling arrangementsEconomic benefitsSurface roughness

The invention discloses enamel steel for a cold rolling water heater and a manufacturing process thereof. The enamel steel for cold rolling water heater comprises components as follows in percentage by weight: C: 0.01%-0.08%. Si: less than or equal to 0.03%, Mn: 0.10%-0.60%, P: less than or equal to 0.02%, S: 0.003%-0.02%, N: 0.001%-0.006%, AIs: less than or equal to 0.04%, Ti: 0.02%-0.12%, and the balance of ferrum and unavoidable impurities, wherein excess Ti content in steel is equal to Ti-(4*C+3.43*N=1.5S) which is less than or equal to 0. The manufacturing process is characterized in that the heating temperature of billet steel is 1160-1300 DEG C; the hot rolling finish rolling temperature is 850-950 DEG C; the coiling temperature of steel plates is 660-760 DEG C; the cold rolling draft is 60%-80%; the annealing temperature is 760-880 DEG C; the temperature preservation time is 60-200s; rapid cooling speed rate is 15-45 DEG C / s, planishing elongation is 0.7%-1.8%; and surface roughness is 0.7-1.9 micrometres. The invention has the advantages of excellent formability, enamel-spreadable property, pressing resistance, weldability and fish-scaling resistance, stable yield strength after enamelfiring, less cost increase, stable effect and significant economic benefits.

Owner:ANGANG STEEL CO LTD

Silver plating in electronics manufacture

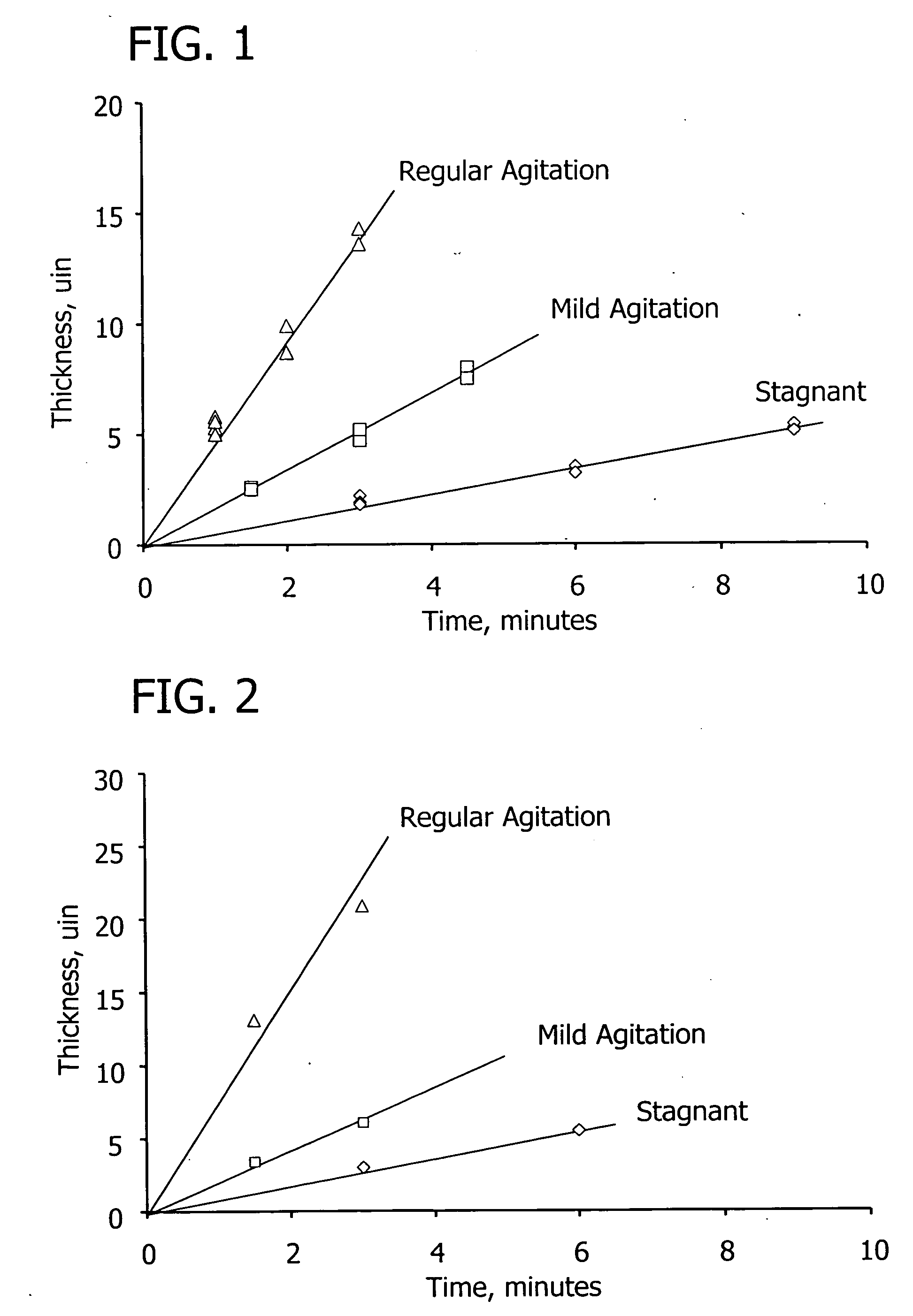

Compositions and methods for silver plating onto metal surfaces such as PWBs in electronics manufacture to produce a silver plating which is greater than 80 atomic % silver, tarnish resistant, and has good solderability.

Owner:MACDERMID ENTHONE INC

Semiconductor integrated circuit package and method of packaging semiconductor integrated circuit

InactiveUS20090236713A1Reduce the possibilityEasy to flow outTailstocks/centresSemiconductor/solid-state device detailsShell moldingSurface mounting

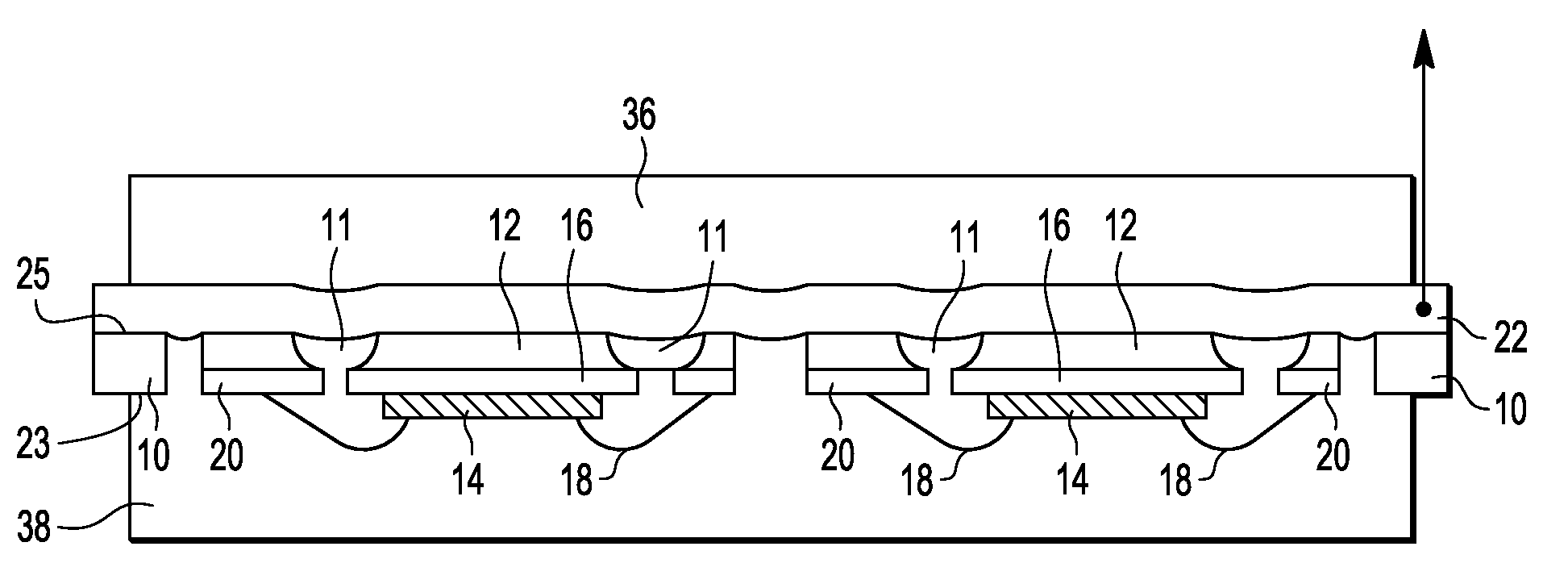

In a method of packaging a semiconductor IC, a tape is attached to a back surface of a lead frame array, and the lead frame array is held between an upper mold chase and a lower mold chase of a mold, with the back surface of the lead frame array upward. The upper and lower mold chases form an upper cavity and a lower cavity with respect to the lead frame array respectively. A mold compound is injected into the upper and lower cavities respectively. With respect to clearances between leads, between die pads and / or between the leads and the die pads, the mold compound injected into the upper cavity covers the portion of the tape over the clearances before the mold compound injected into the lower cavity fills the clearances, so that the tape is depressed. After curing the mold compound, removing the mold and de-taping, the mold compound filled in the clearances is recessed inward from the back surface, which increases the solderability in the subsequent surface mount process and decreases the possibility of the occurrence of lead short-circuits.

Owner:NXP USA INC

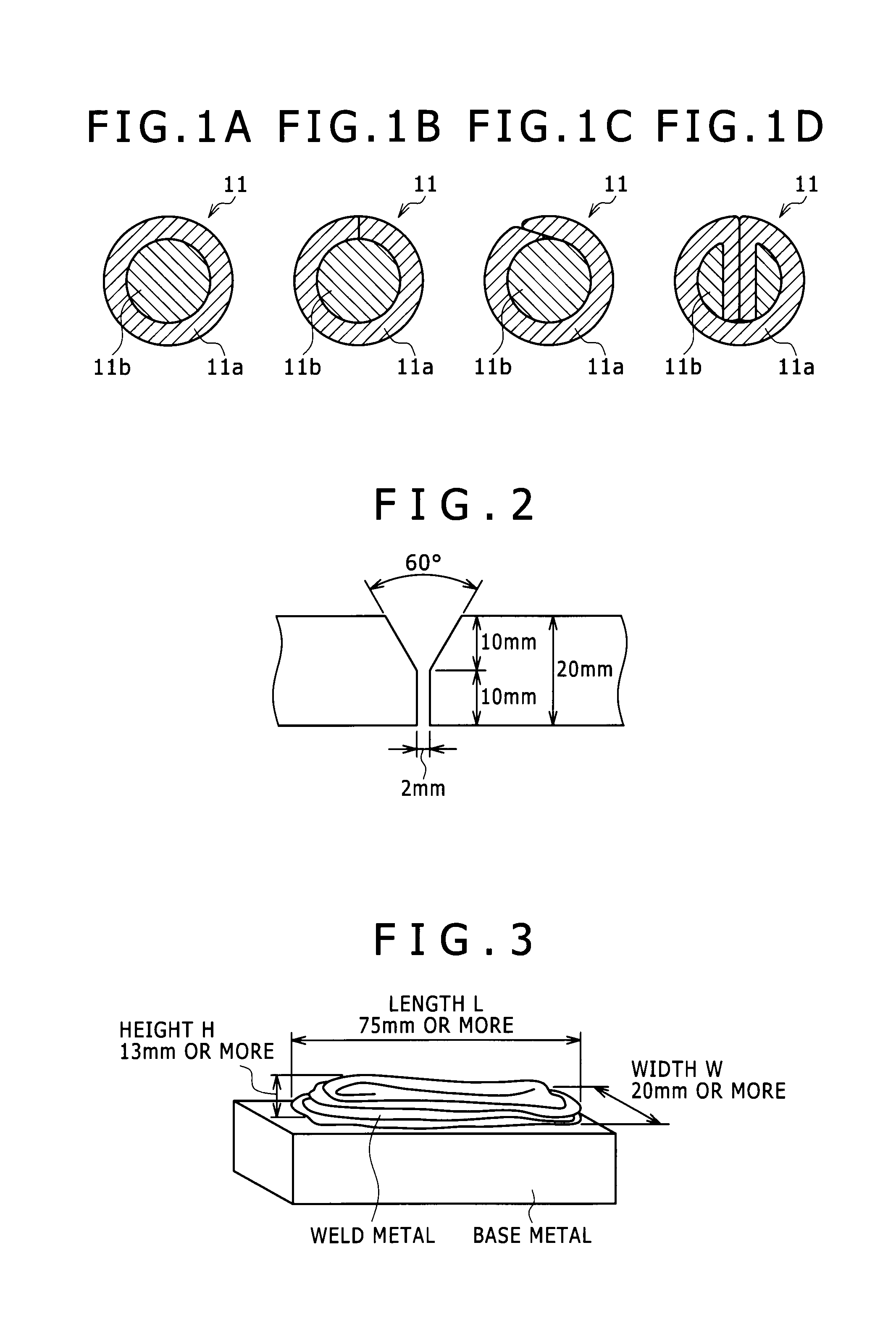

Flux-cored nickel-based alloy wire

InactiveUS20110171485A1Improve solderabilityImprove pitting resistanceWelding/cutting media/materialsThin material handlingPotassiumLithium compound

A flux-cored nickel-based alloy wire contains, based on the total mass of the wire, 3 to 11 percent by mass of TiO2, 0.2 to 1.3 percent by mass of SiO2, 1 to 3 percent by mass of ZrO2, and 0.3 to 1.0 percent by mass of manganese oxides in terms of MnO2, contains of a total of 0.2 to 1.0 percent by mass in terms of Na, K and Li of sodium compounds, potassium compounds, and lithium compounds. The flux has a ratio (([TiO2]+[ZrO2]) / [SiO2]) of the total of the TiO2 and ZrO2 contents to the SiO2 content of 5.0 to 14.5, in which [TiO2], [SiO2] and [ZrO2] represent TiO2, SiO2 and ZrO2 contents. The wire shows excellent weldability in welding of all positions typically on 9% nickel steels and nickel-based alloy steels and gives a weld metal having good pitting resistance, bead appearance, and resistance to hot cracking.

Owner:KOBE STEEL LTD

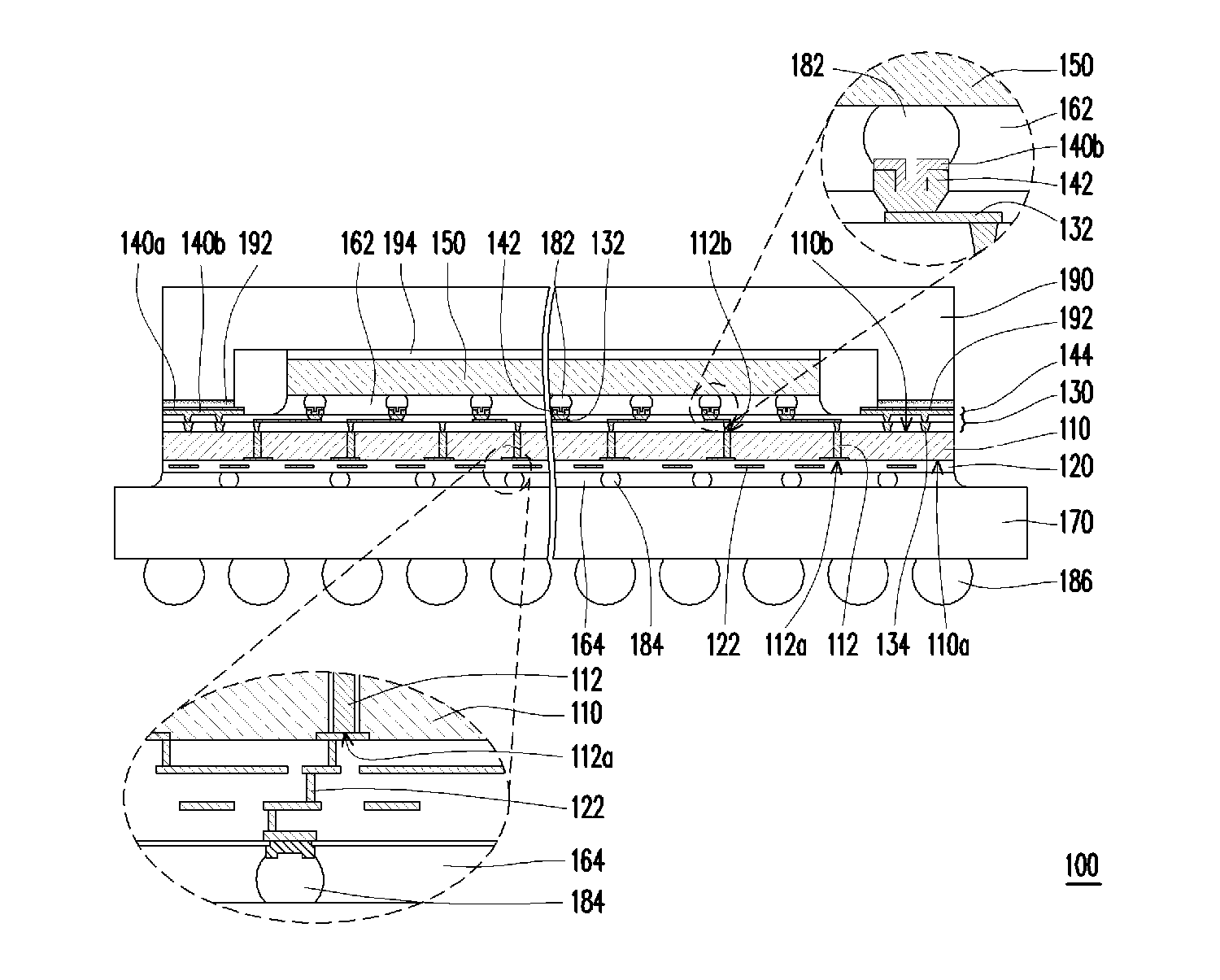

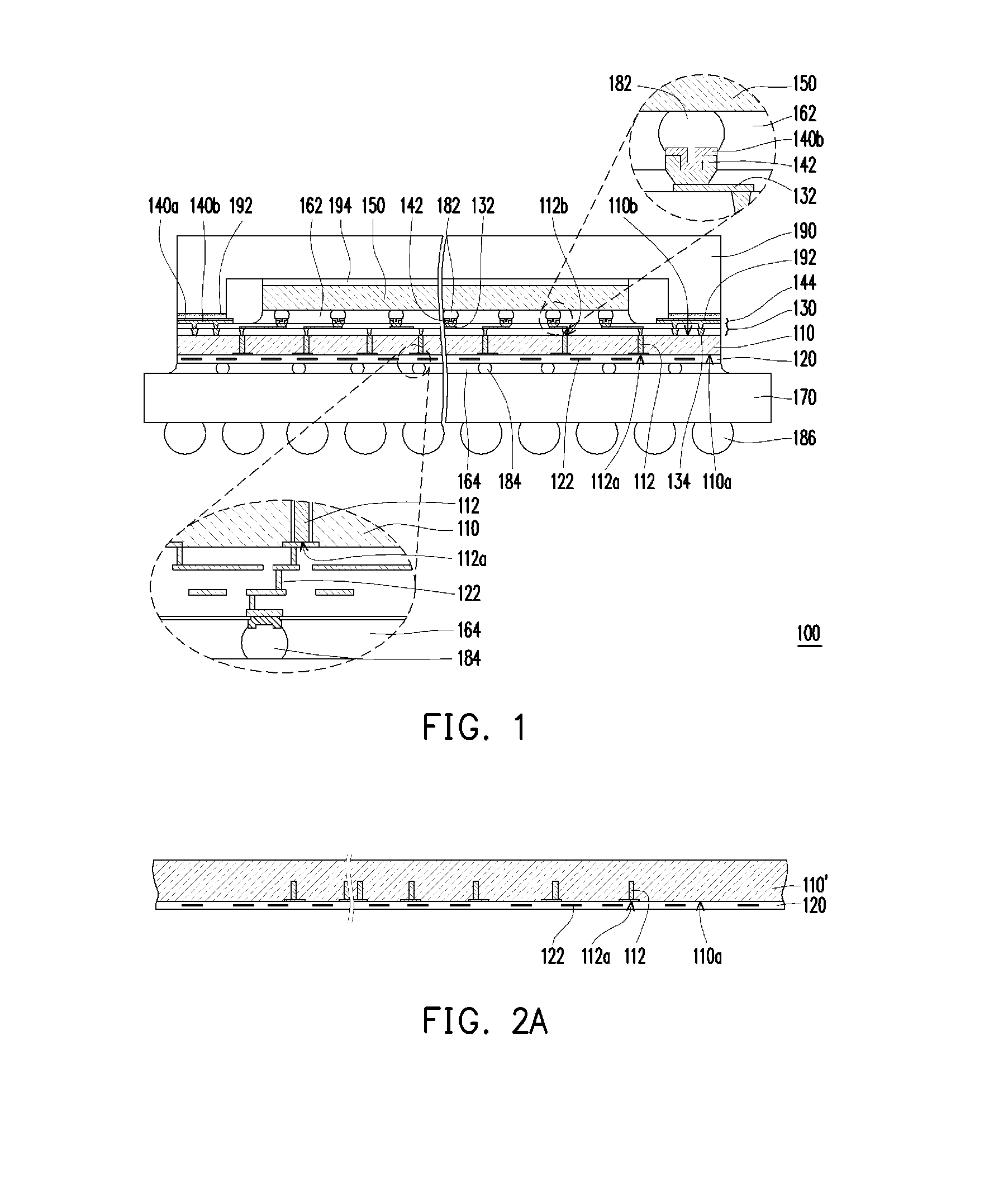

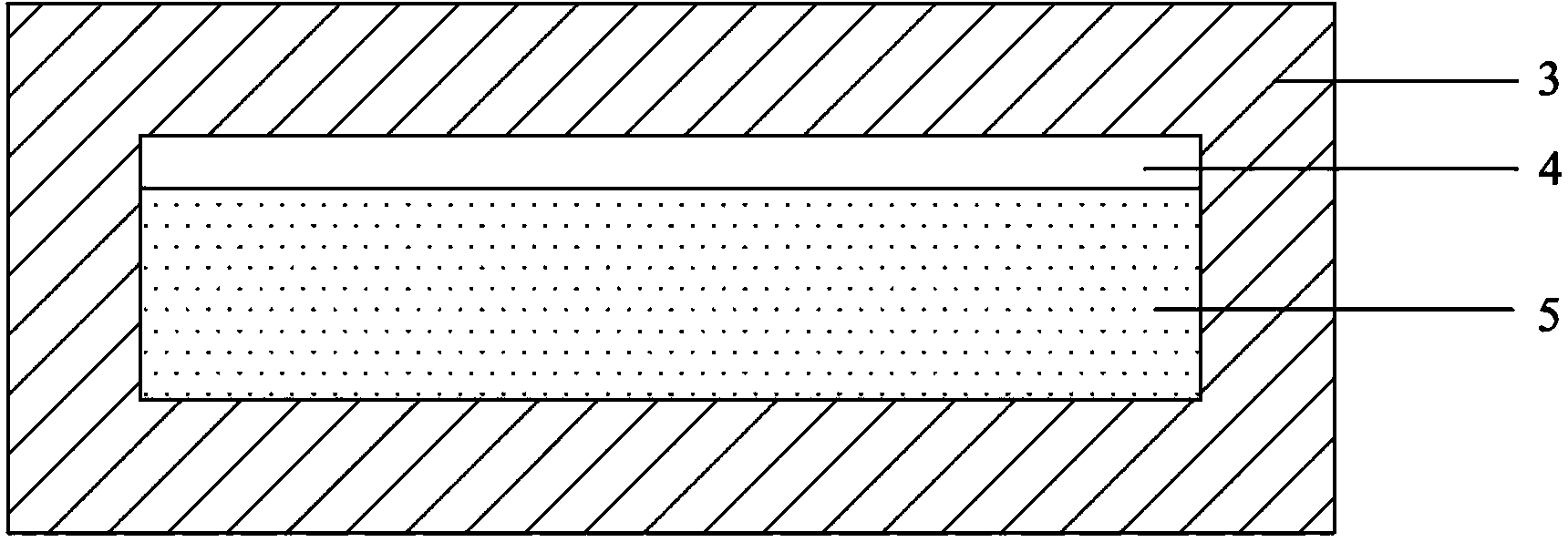

Semiconductor structure having conductive vias and method for manufacturing the same

ActiveUS20120049347A1Semiconductor/solid-state device detailsSolid-state devicesSemiconductor structureSolderability

A semiconductor structure includes a plurality of thermal vias and a heat dissipation layer disposed at a periphery of a back surface of a lower chip in a stacked-chip package. This arrangement improves solderability of a subsequently-bonded heat sink. Additionally, the thermal vias and the heat dissipation layer provide an improved thermal conduction path for enhancing heat dissipation efficiency of the semiconductor structure. A method for manufacturing the semiconductor structure is also provided.

Owner:ADVANCED SEMICON ENG INC

Step circuit board with gold-masking copper-plating hybrid surface process and manufacture method thereof

InactiveCN102946693ASolve the problem of burning boardThe plated area is stablePrinted circuit detailsPrinted circuit manufactureElectricityScreen printing

The invention discloses a manufacture method for a step circuit board with a gold-masking copper-plating hybrid surface process. The manufacture method comprises the steps of cutting materials, transferring an inner pattern, browning and pressing a plate, drilling, plating copper, electroplating the whole plate, adhering a thick gold dry film, achieving pattern transfer for the first time through exposing and developing, exposing a local electrical thick gold part, plating copper, nickel gold and electrical thick gold on the electrical thick gold part, removing the film, adhering a dry film, achieving pattern transfer for the second time through exposing and developing, exposing a part needing plating copper, plating copper, removing the film, silk-screen printing a wet film, achieving pattern transfer for the third time through exposing and developing, exposing a needed outer circuit, adhering a dry film to completely cover a PTH (Plated Through Hole) through exposing and developing, etching an outer circuit, removing the film, carrying out AOI (Automated Optical Inspection) to the outer layer, silk-screen printing and resistance-welding, lettering, forming, electrically testing, carrying out an OSP (Organic Solderability Preservatives) surface process, carrying out final inspection, packaging and shipping. The gold-masked copper-plated step circuit board manufactured by the method disclosed by the invention can achieve more compact assembling needs and a better adhering effect.

Owner:GUILIN UNIV OF ELECTRONIC TECH

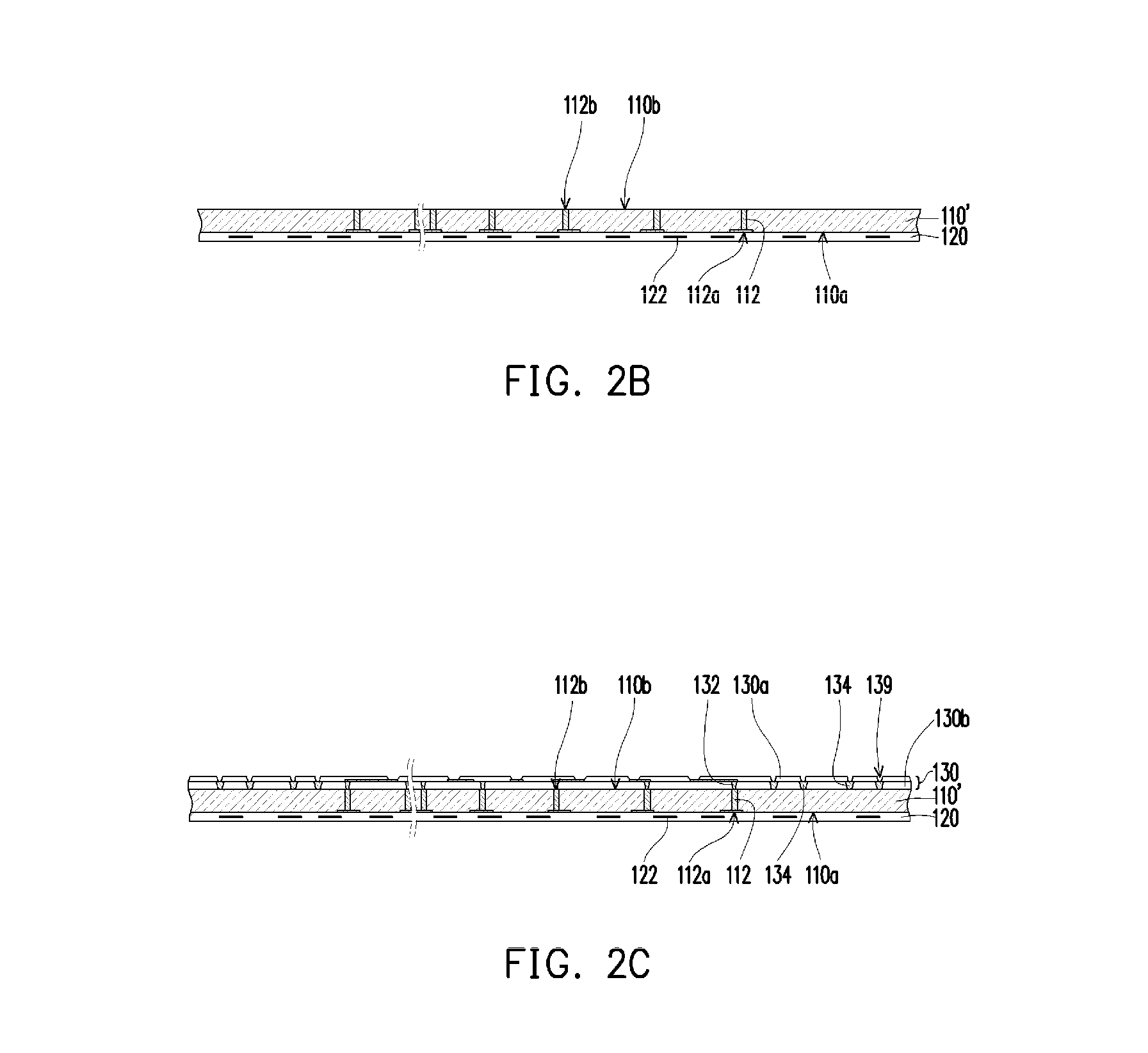

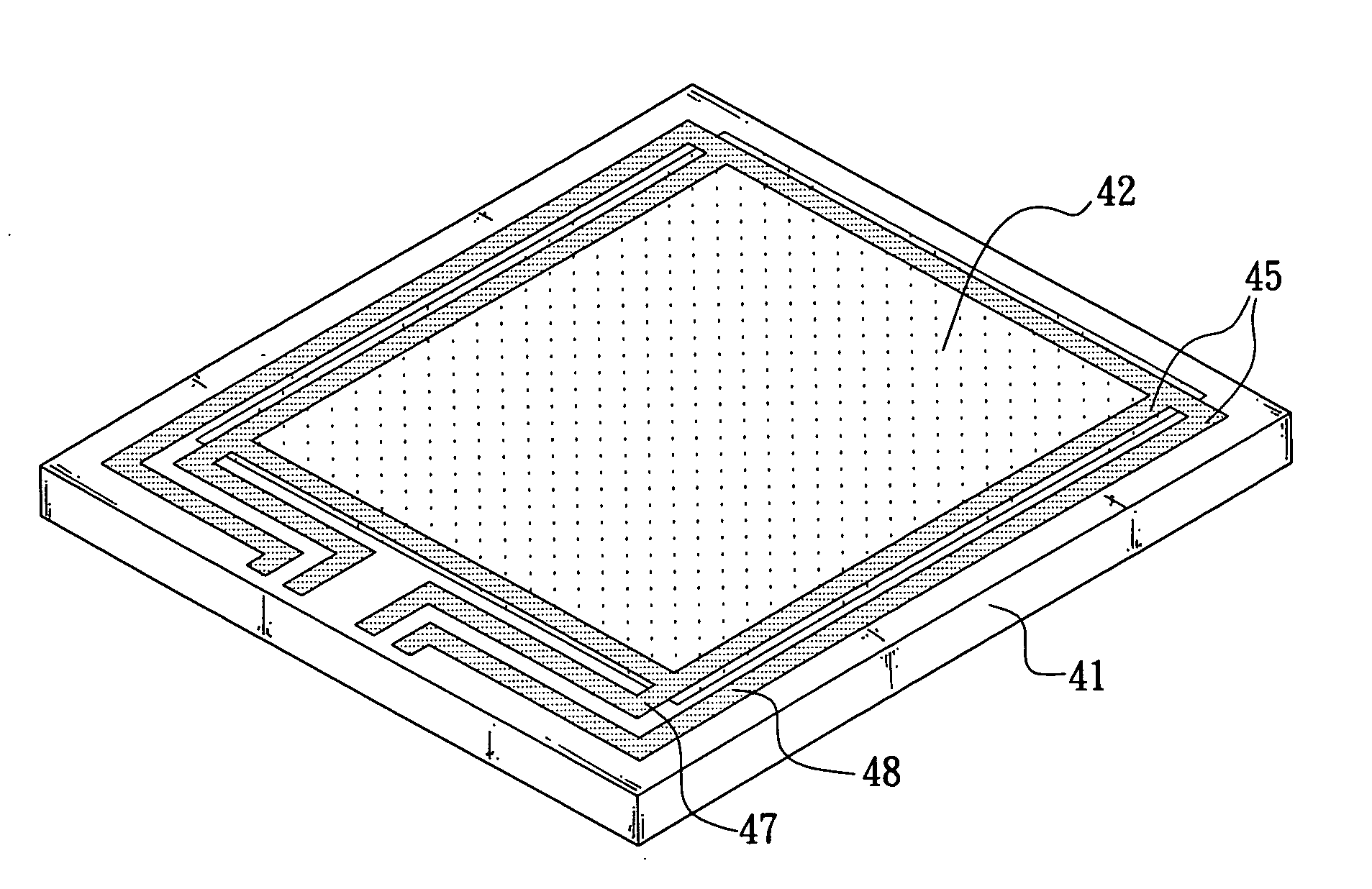

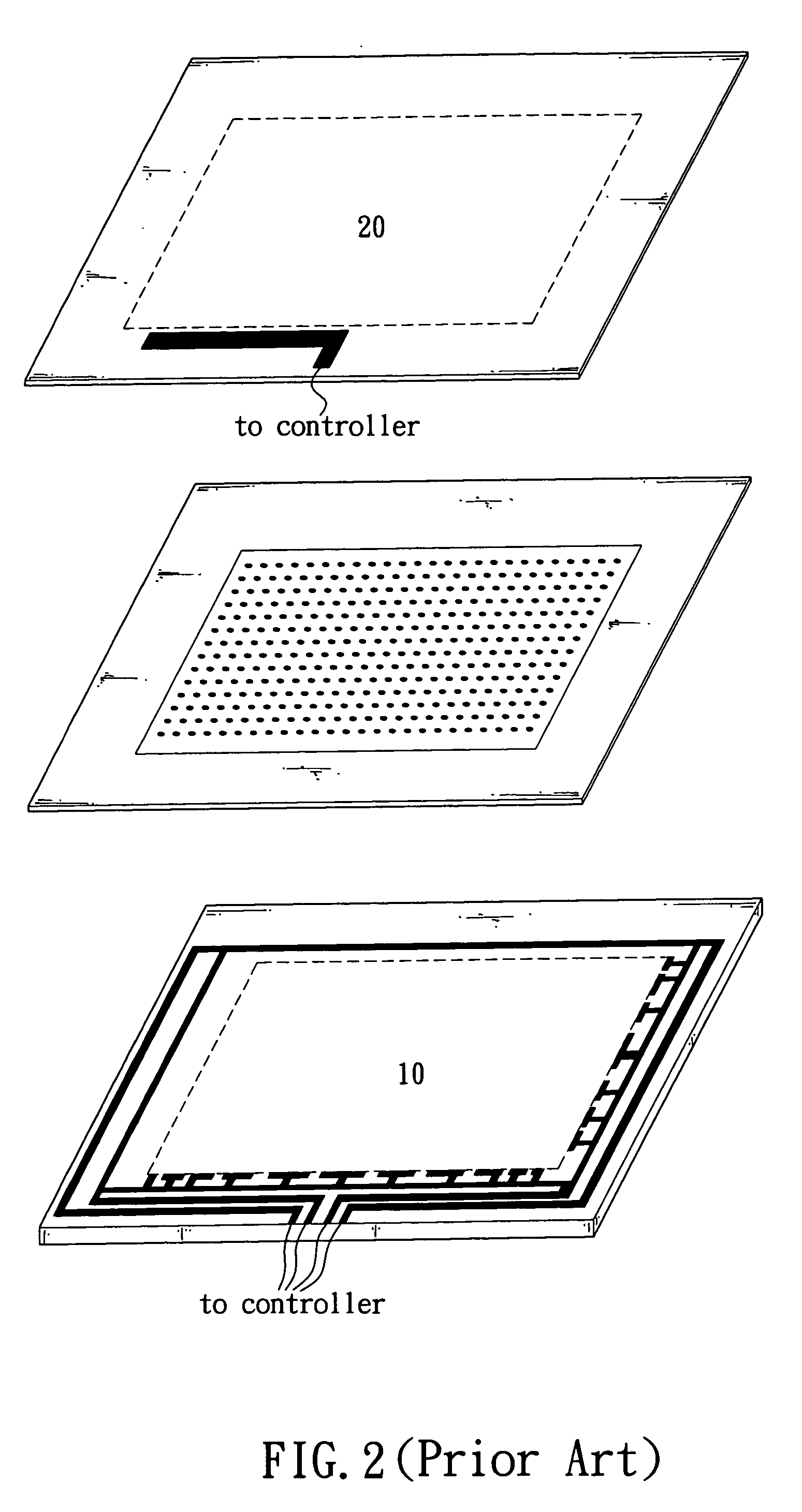

Method of manufacturing circuit layout on touch panel by utilizing metal plating technology

InactiveUS20050260338A1Uniform thicknessImprove adhesionPrinted circuit aspectsLiquid/solution decomposition chemical coatingSolderabilityEngineering

The present invention is to provide a method of manufacturing a circuit layout on a touch panel by utilizing metal plating technology, comprising uniformly coating a conductive metal or conductive oxidized metal on predetermined areas proximate edges of a transparent conductive layer on a transparent glass substrate for forming a circuit by utilizing metal plating technology, which has the advantages of uniform thickness of circuit, higher hardness, better adhesion of the plated material to the underlying substrate, whether it is a resistive film or bare glass, improved weathering and chemical properties, and solderability.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

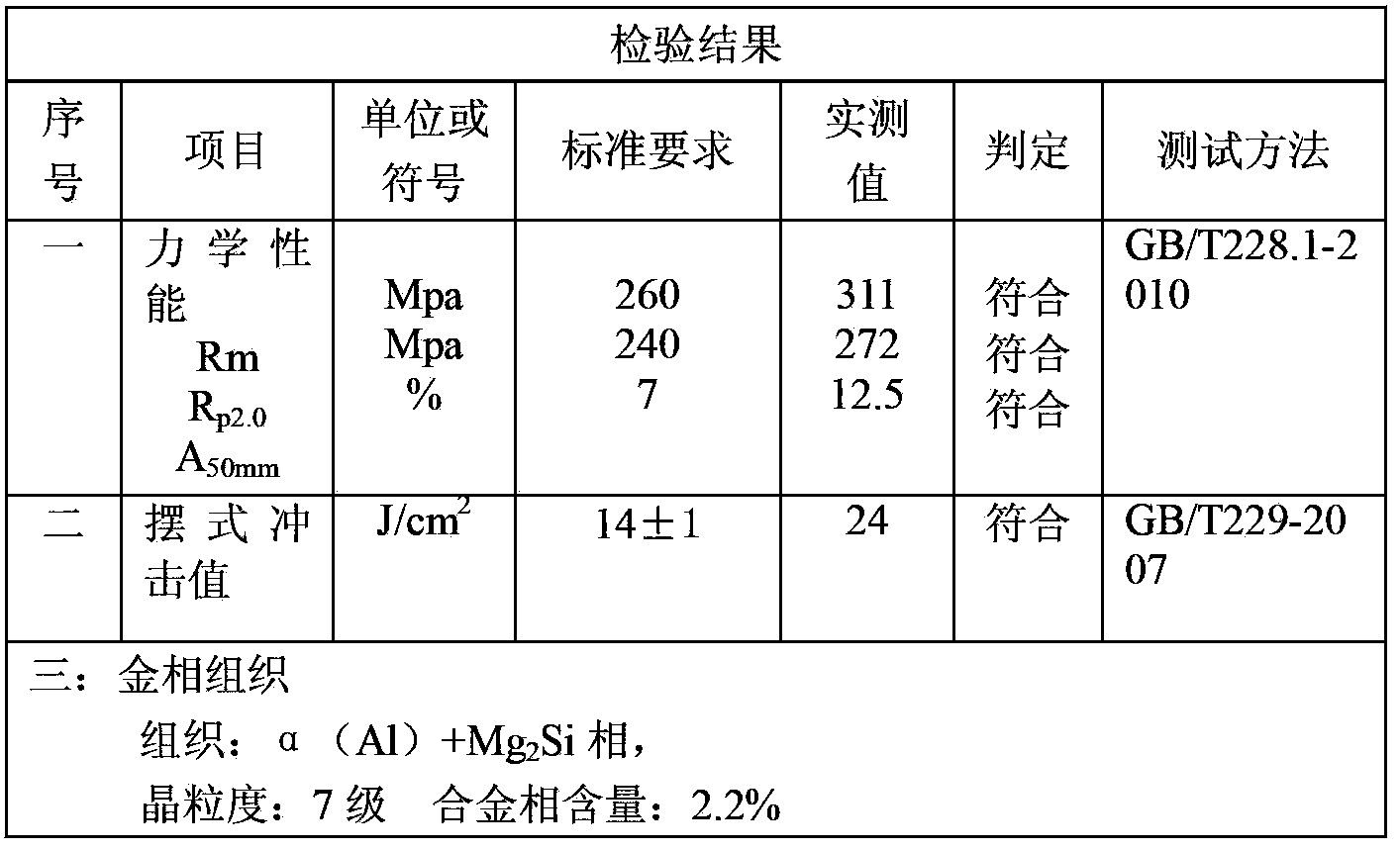

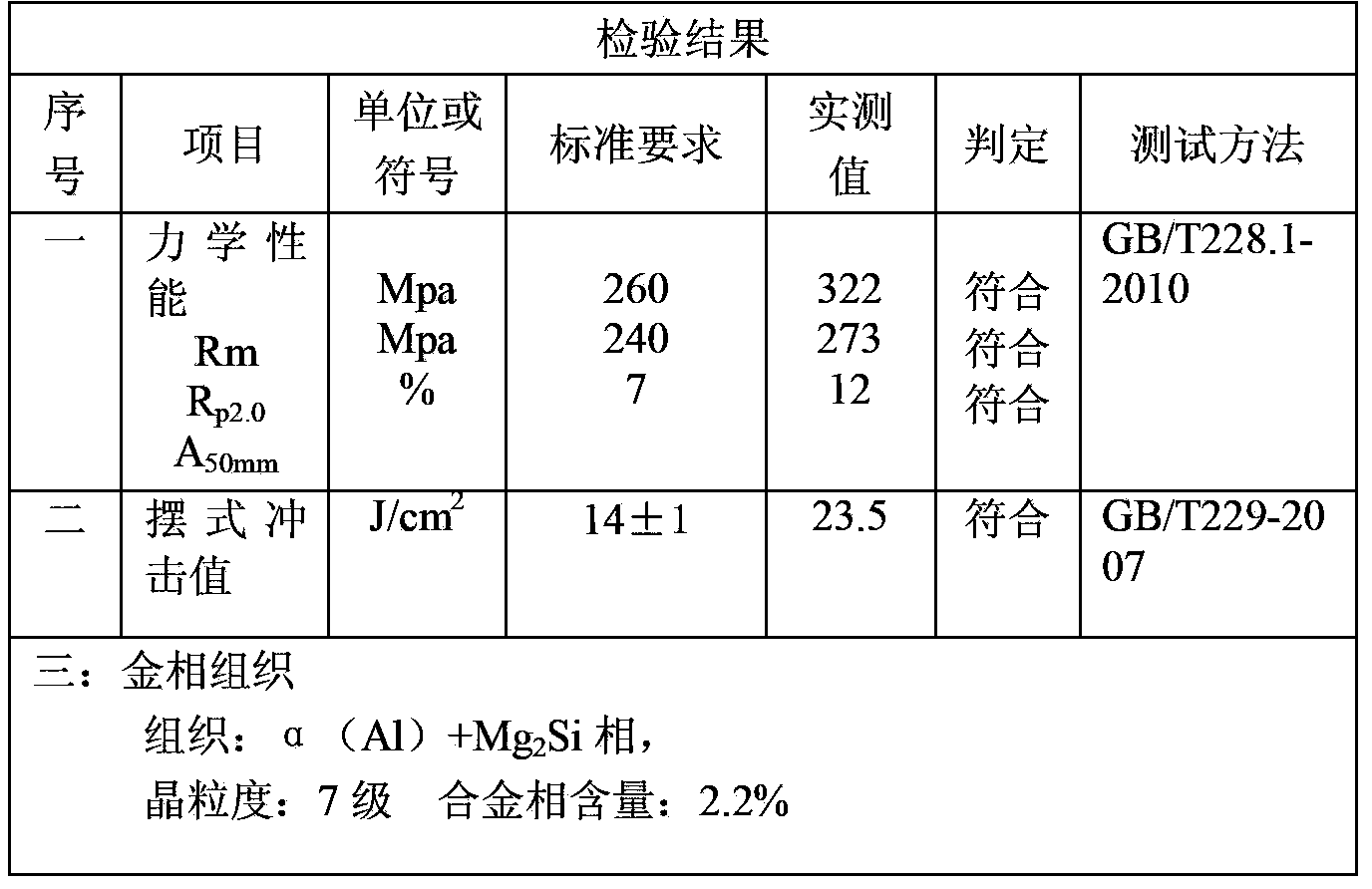

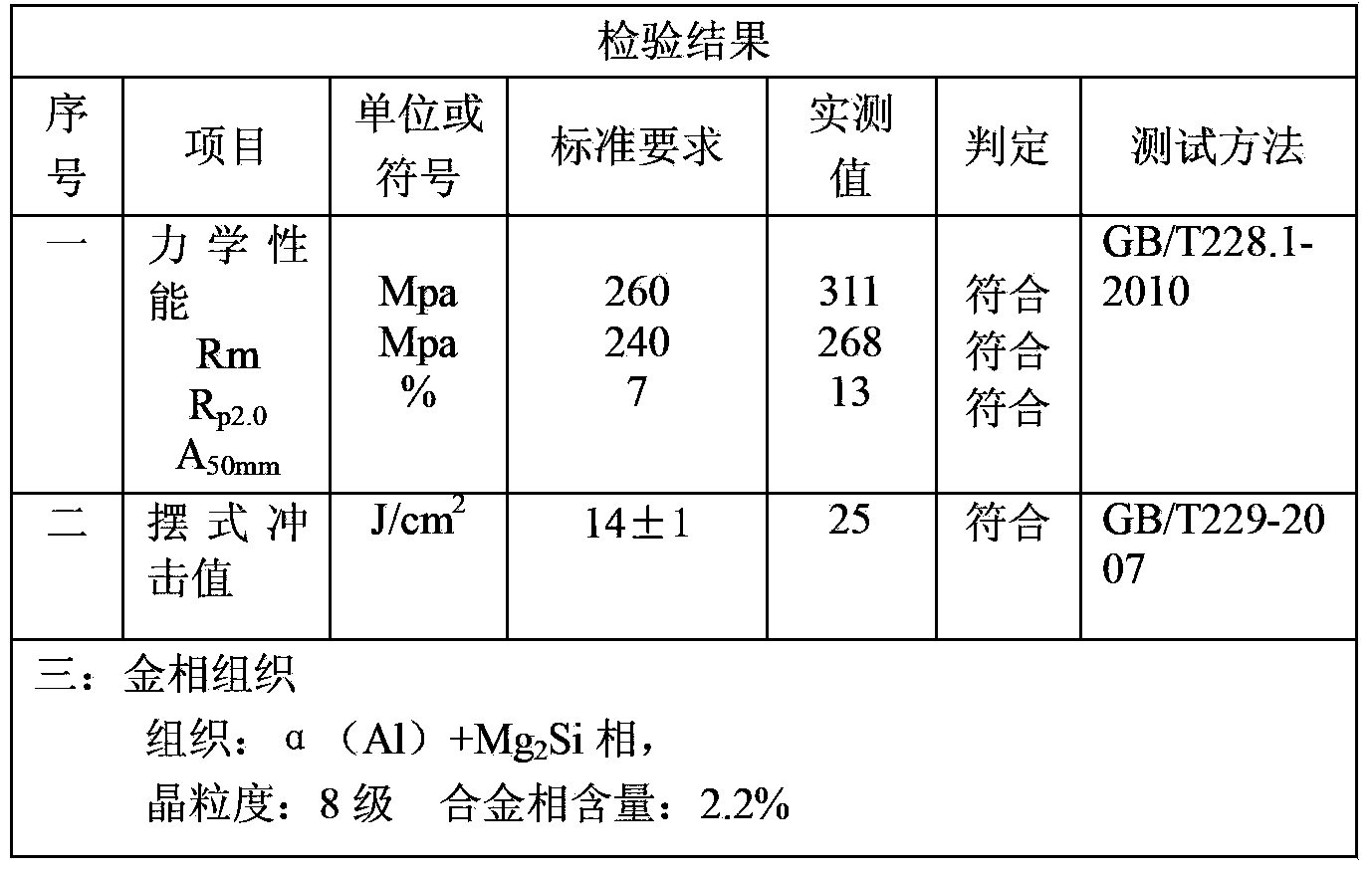

Aluminium alloy profile for building template, and preparation method thereof

The invention discloses an aluminium alloy profile for a building template, and a preparation method thereof. The aluminium alloy profile comprises the following components in percentage by weight: 0.85-0.95 percent of magnesium, 0.06-0.65 percent of silicone, 0.15-0.20 percent of copper, 0.05-0.08 percent of manganese, 0.03-0.05 percent of zirconium, 0.04-0.06 percent of chromium, 0.008-0.012 percent of titanium, 0-0.2 percent of iron, 0-0.10 percent of zinc and the balance of aluminium. The aluminium alloy profile provided by the invention has the advantages that the tensile strength is more than 300 MPa, the yield strength is more than 260 MPa, the breakage elongation percentage is more than 12 percent, the tenacity, the weldability and the corrosion resistance are obviously improved compared with that of an original 6061 alloy, the pendulum impact value is more than 20 J / cm<2>, the welding coefficient is not less than 0.6, smaller quench sensitivity is provided, and critical quenching speed is dropped from 10 DEG C / S of the original alloy to 7 DEG C / S; during the processing of the aluminium alloy profile, air cooling is adopted to process an extrusion outlet with the temperature of 450 DEG C in a high-temperature segment as well as an extrusion outlet with the temperature of being smaller than or equal to 25 DEG C in a low-temperature segment, while a moderate-temperature segment, namely a quench sensitive area with the temperature of 450-250 DEG C utilizes water mist to replace direct water-cooling, so that the difficulty for controlling cross section deformation of the profile in the production field is greatly reduced.

Owner:GUANGDONG WEIYE ALUMINUM FACTORY GRP

Multilayer insulated wire and transformers made by using the same

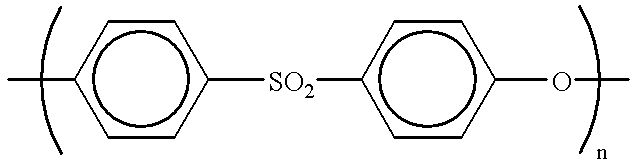

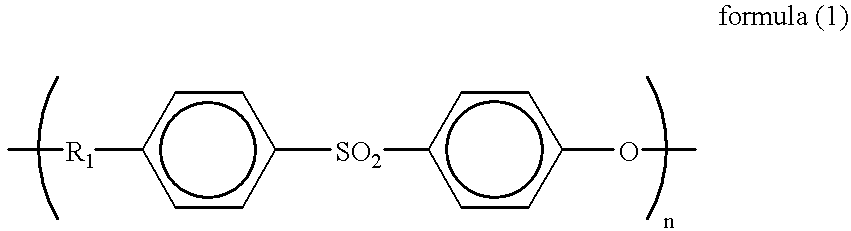

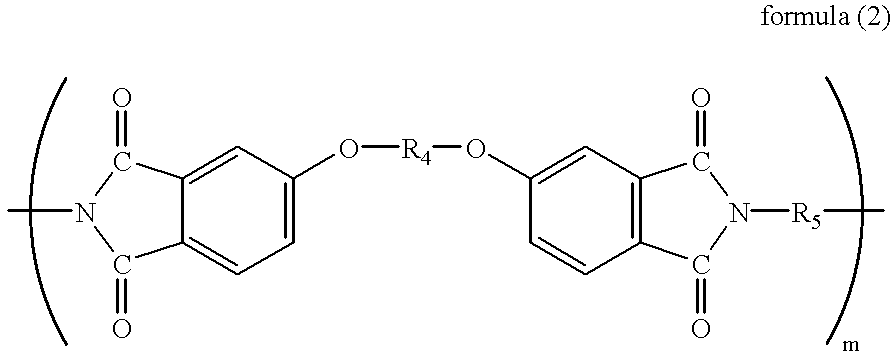

InactiveUS6329055B1Good effectLowered in electric propertyPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolymer sciencePolyetherimide

There is disclosed a multilayer insulated wire which comprises a conductor and solderable extrusion-insulating layers made up of two or more layers for covering the conductor, wherein at least one insulating layer is formed by a mixture comprising 100 parts by weight of a resin (A), of at least one selected from the group consisting of polyetherimide resins and polyethersulfone resins, 10 parts by weight or more of a resin (B), of at least one selected from the group consisting of polycarbonate resins, polyarylate resins, polyester resins, and polyamide resin, and 15 to 200 parts by weight of an inorganic filler (C). There is also disclosed a transformer which utilizes the multilayer insulted wire. The multilayer insulated wire is excellent in heat resistance, solderability, high-frequency characteristic, and coilability, and it is favorably suitable for industrial production. Further, the transformer utilizing the multilayer insulated wire is excellent in electrical properties and high in reliability, since when used at high frequencies, electric properties are not lowered and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

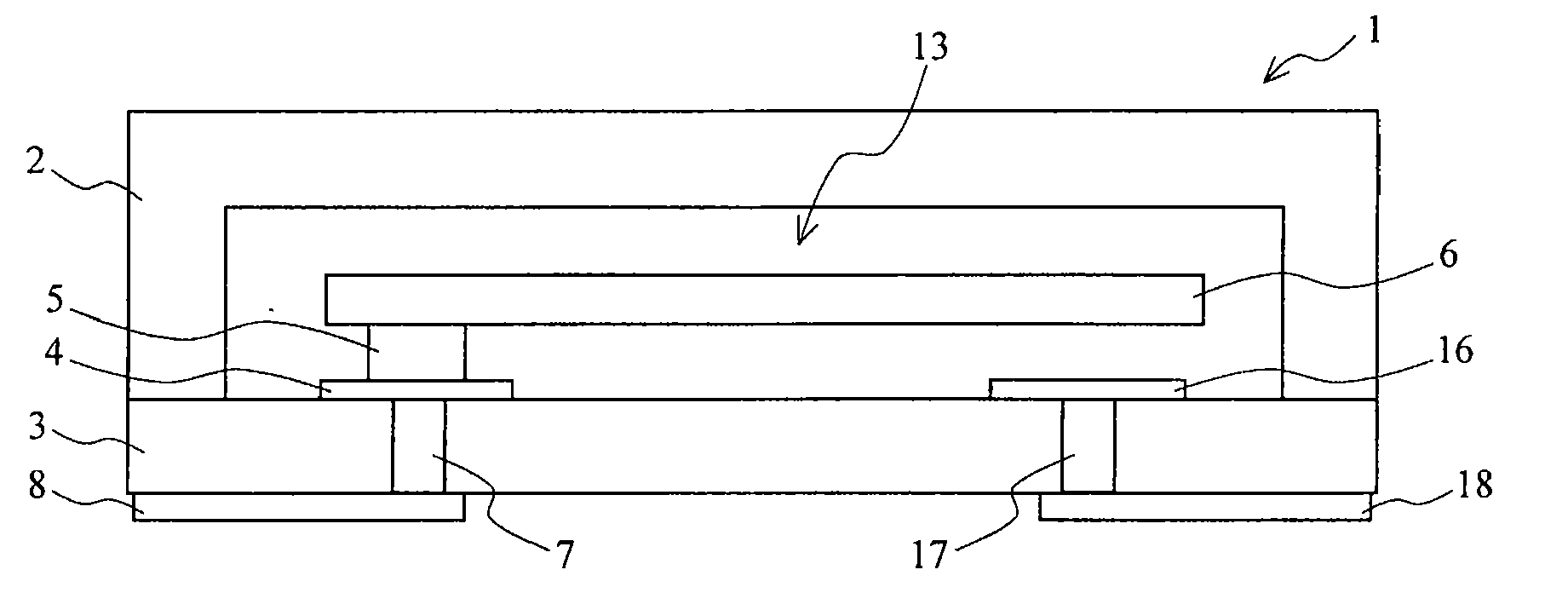

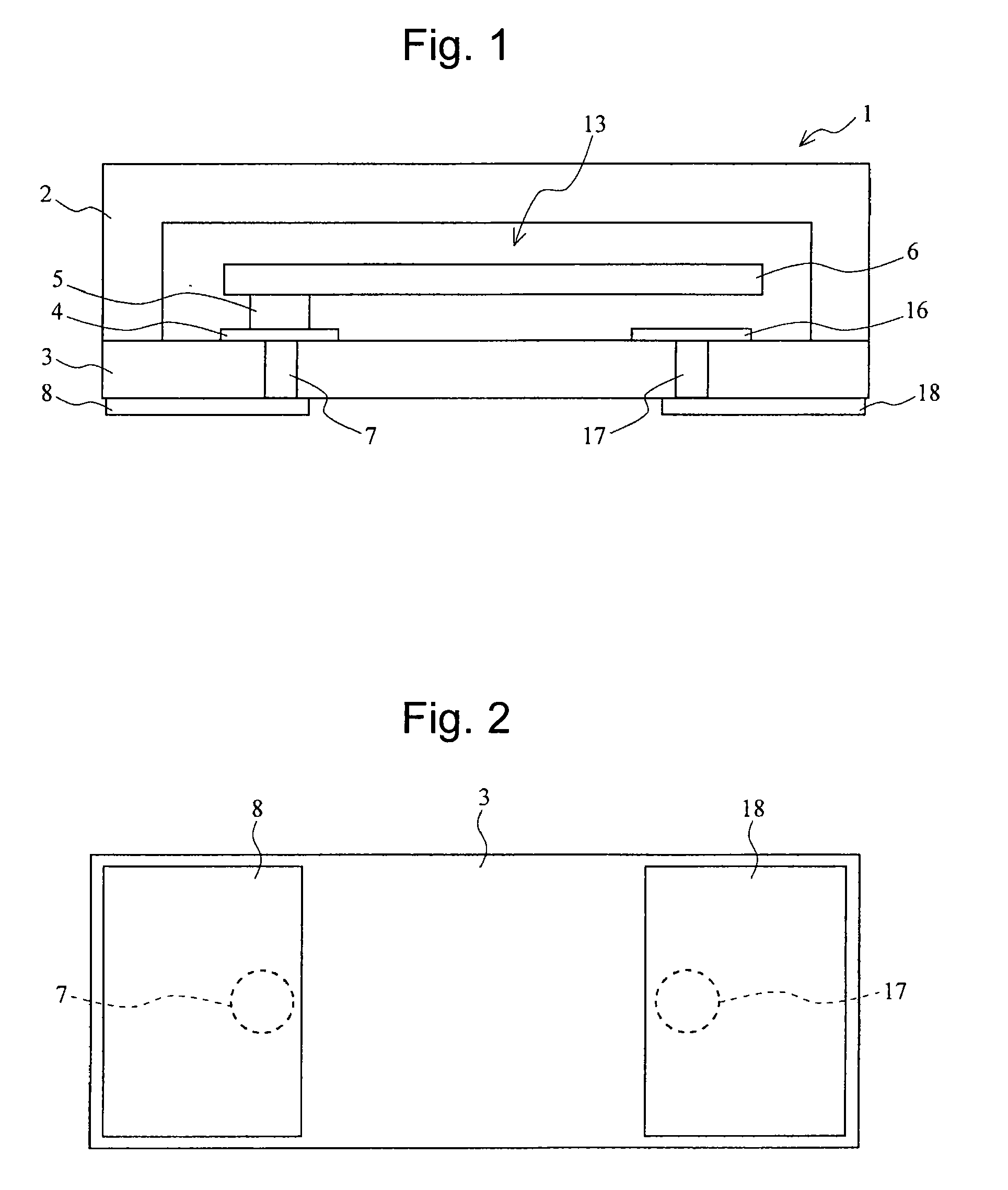

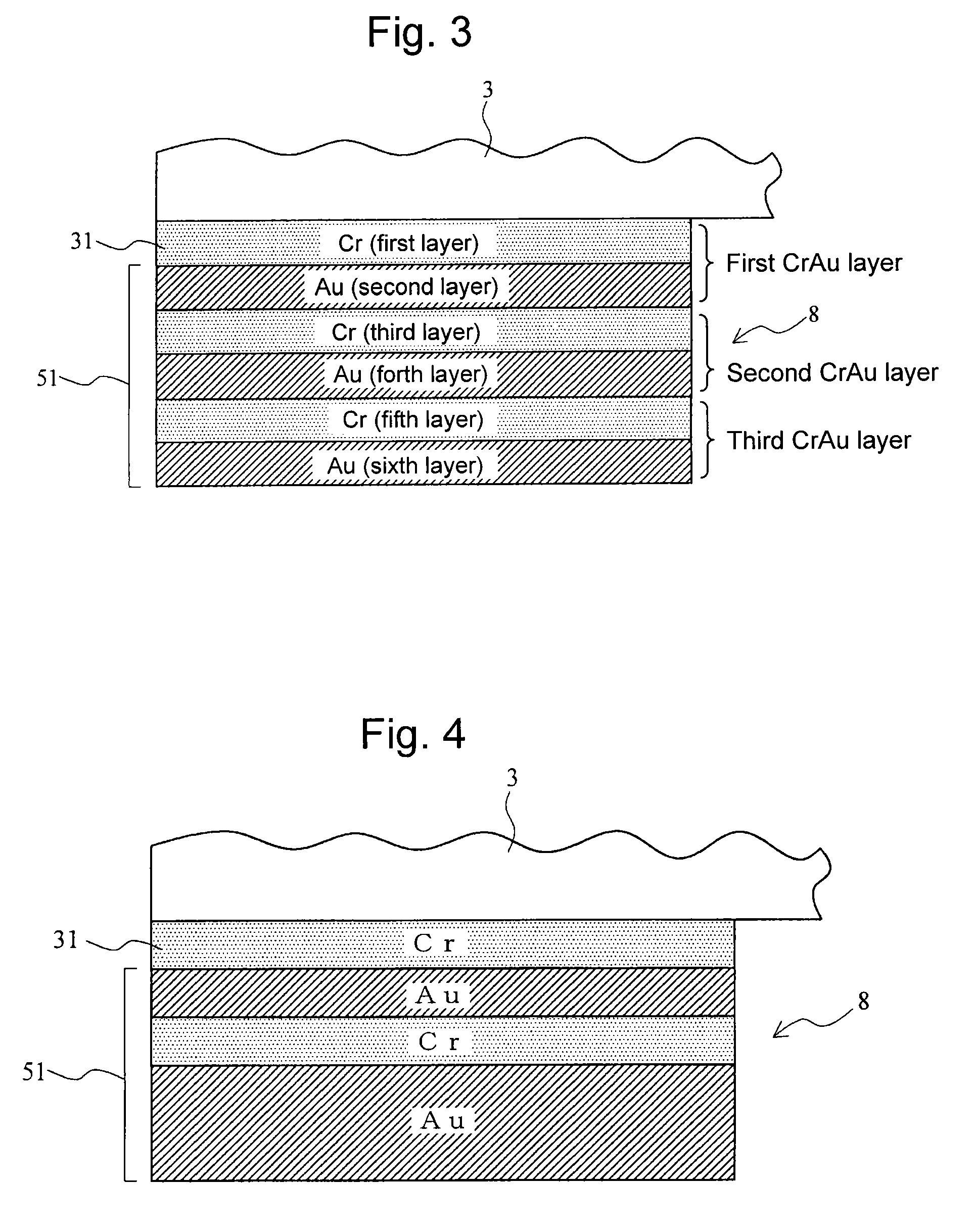

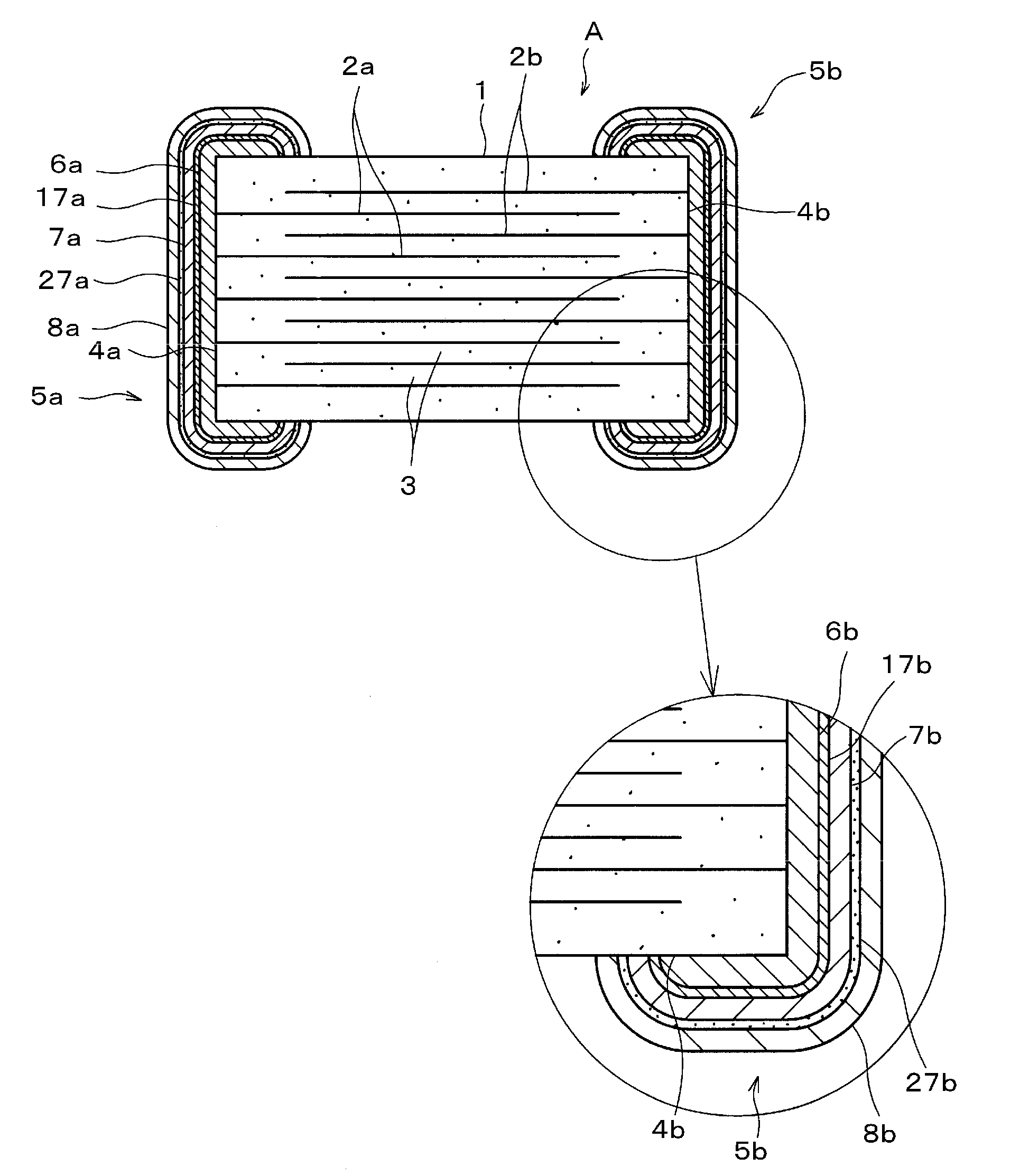

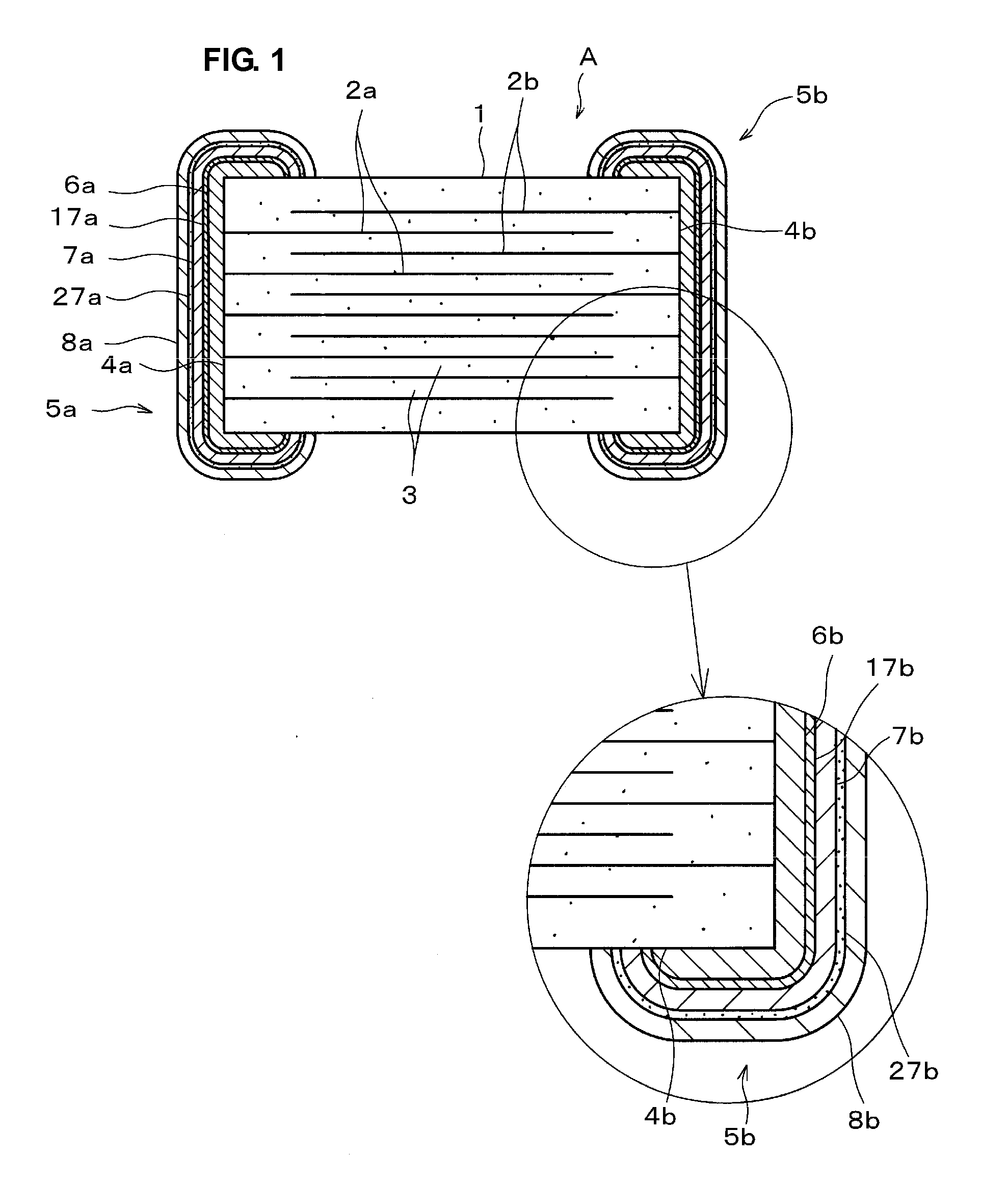

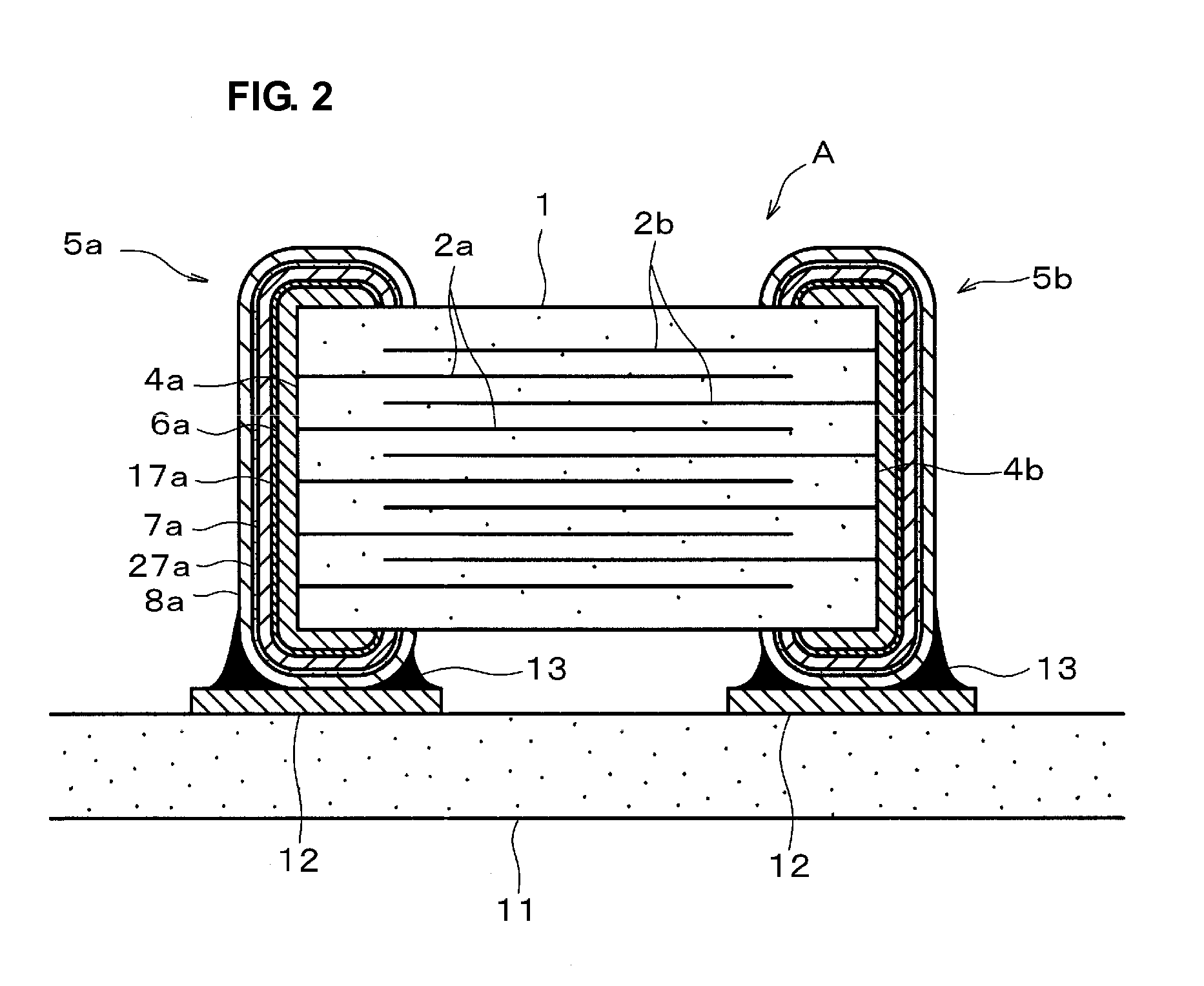

Electronic component, manufacturing method for electronic component, and electronic device

ActiveUS20100290201A1Improve solderabilityControl thicknessWave amplification devicesSemiconductor/solid-state device detailsSolderabilityEngineering

To provide an improved solderability for mounting an electronic component onto a circuit board, a package of an electronic component (1) is formed by bonding together a base (3) made of glass and a lid (2). Outer electrodes (8) and (18) are formed on a bottom surface of the base (3), and the outer electrodes (8) and (18) are respectively connected to through electrodes (7) and (17). The outer electrodes (8) and (18) each have a laminated structure of three CrAu layers, that is, from a Cr layer (first layer) to an Au layer (sixth layer). When the outer electrodes (8) and (18) are soldered onto a circuit board, the Au layers as the second, fourth, and sixth layers are dissolved into solder, whereas the Cr layers as the third and fifth layers, which hardly form an intermetallic compound with solder, are separated to remain in solder.

Owner:SEIKO INSTR INC

High ductility steel strip for J55 petroleum sleeve and manufacturing method thereof

InactiveCN101210299AImprove toughnessReduce contentManufacturing convertersMetal rolling arrangementsThin slabHigh pressure water

A steel strip for J55 petroleum casing with high strength and high toughness petroleum casing and a manufacture method thereof belong to the field of micro-alloyed steel production technology. The method comprises converter smelting, LF refining, medium-thin slab continuous slab, heating, high-pressure water descaling, hot rolling and laminar cooling, and reeling, wherein the chemical components of steel comprise (wt%) C 0.15 to 0.20, Si 0.15-0.30, Mn 1.00 to 1.45, P not larger than 0.020, S not larger than 0.010, Nb 0.020 to 0.040, Ti 0.015 to 0.040, Al 0.020 to 0.050, and allowance Fe and other in inevitable impurities. A J55 petroleum casing with a yield strength of 420 MPa can be produced by combining Nb and Ti, micro-alloying and reasonable production process, and the product has the advantages of high strength, high toughness and good solderability.

Owner:LAIWU IRON & STEEL GRP

Method for performing electroless nickel plating on surface of aluminum nitride ceramic

ActiveCN101962760AHigh bonding strengthImprove high temperature resistanceLiquid/solution decomposition chemical coatingElectroless nickelSodium acetate

The invention provides a method for performing electroless nickel plating on the surface of aluminum nitride ceramic, belonging to the ceramic thin-film metallization field. The method comprises the following specific steps: 1) polishing the surface of aluminum nitride with a machinery; coarsening the aluminum nitride substrate with mixed acid or alkali, completely cleaning away the residual acid or alkali; 3) sensitizing the coarsened substrate in stannous chloride solution, activating in palladium chloride solution or performing activation without palladium; 4) weighting a certain amount of nickel sulphate, sodium hypophosphite, sodium citrate, sodium acetate, lactic acid, thiourea and sodium dodecyl sulfate in sequence to prepare a chemical plating solution; and 5) adjusting the pH value of the solution to 4.0-6.0 with acid or alkali, heating the solution to 70-95 DEG C, and placing the prepared substrate in the solution to perform electroless nickel plating. The invention is characterized in that the electroless nickel plating can be performed on the surface of the aluminum nitride ceramic substrate which is difficult to plate; and a certain amount of surfactant is added so that the plating becomes denser and smoother, the binding force between the plating and the substrate is increased, and the solderability of the plating is better.

Owner:UNIV OF SCI & TECH BEIJING

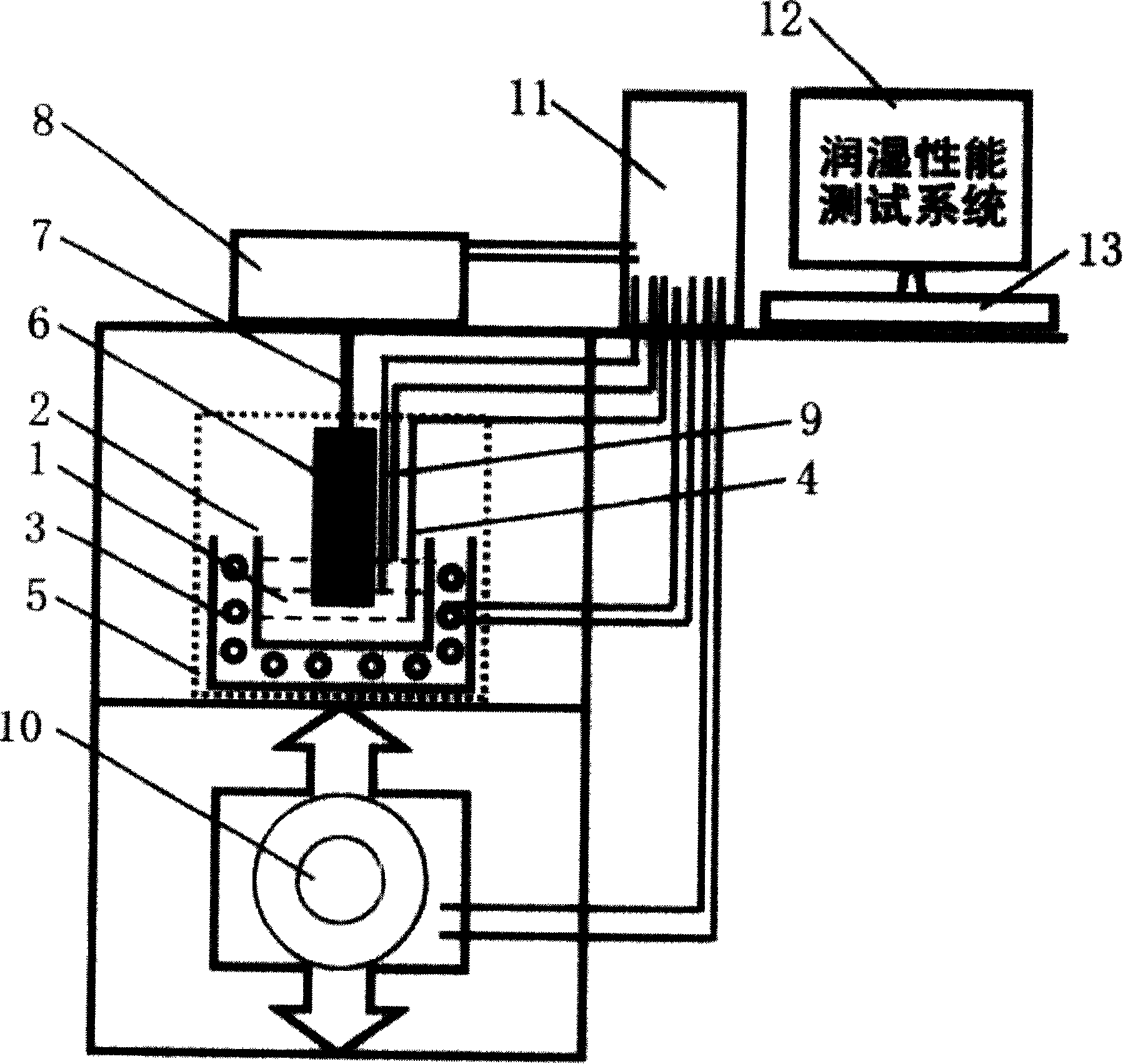

Dynamic testing method and system for wetting property

The invention provides a method for dynamically testing wettability and the testing system thereof, relates to a method for testing the wettablity of the solder, metal, ceramic, composite materials and fiber and the testing system thereof and belongs to the material performance detecting method and the detecting equipment thereof technical field, which comprises the wetability dynamic testing method, wetability dynamic testing software, an automatically controlled system (computer), a heating (cooling) system, a suspension system, a force testing balance system and a height adjusting hoist system. The method for dynamically testing wettability and the testing system thereof provided by the invention is capable of performing dynamic evaluation on the wetability of solder, the weldability of metals, ceramic and composite materials and the wetability of fiber to solution, and is capable of measuring the total wetting time.

Owner:廖树帜

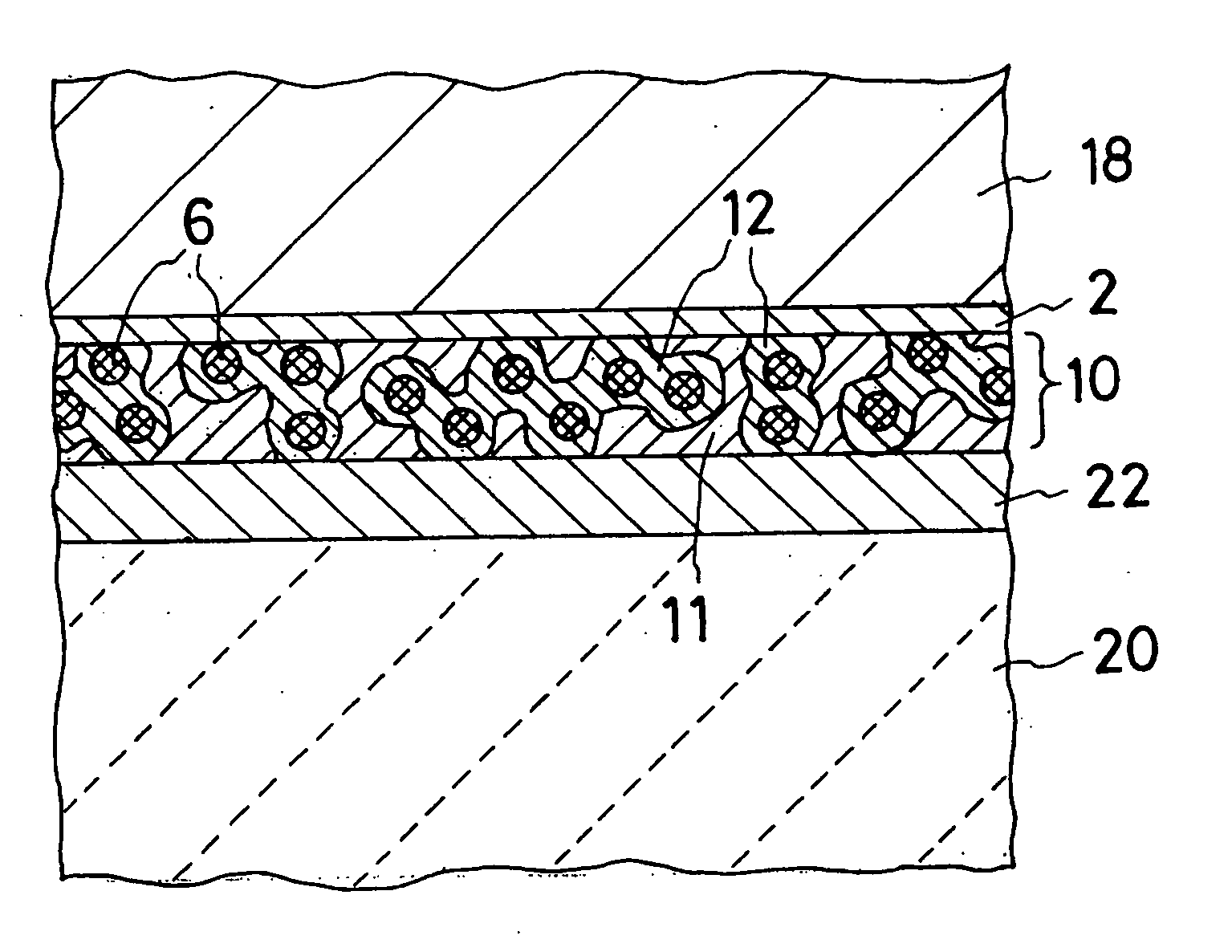

Lid for a functional part and a process for its manufacture

InactiveUS20100291399A1Easy to manufactureFunctionalHot-dipping/immersion processesSemiconductor/solid-state device detailsSolderabilitySolder paste

As a replacement for high-temperature solder having a solidus temperature of at least 250° C. for bonding a package and a lid of a functional part, a solder paste formed by mixing a Cu-based metal powder with a solidus temperature of at least 400° C. and an Sn-based solder powder is applied to a lid of a difficult to solder material which was previously subjected to plating having good solderability and heated to obtain a solder layer comprising the Cu-based metal powder, Cu6Sn5 intermetallic compounds, and lead-free solder on the plated surface. The intermetallic compounds are bonded to the difficult to solder material and the intermetallic compounds are connected to each other, so the solder layer functions as a high-temperature solder. The problem of poor solderability of high-temperature solders is avoided by the present invention.

Owner:SENJU METAL IND CO LTD

Leadless soft tin solder

InactiveCN101011782ACrystallizationLow melting pointWelding/cutting media/materialsSoldering mediaSolderabilityMaterials science

A lead free soft tin features in the composition of Cu 0.1-5.0%,Ni 0.01-2.0%,Ge 0.01-1.0%,In 0.01-1.5 %,Sb O005-2.0% and the rest being Sn with 0.05-1.0%Bi and or 0.001-1.0 %Ti to strengthen the anti oxidation to add 0.01-0.1%P and Ga, with good soldering effect, glaze on the surface, anti fatigue, anti oxidation, low soldering degree, good humidity, and fine crystallization.

Owner:太仓市南仓金属材料有限公司

Zinc-nickel seeping layer ferrous metal corrosion protection process

ActiveCN101319300AHigh hardnessImprove wear resistanceSolid state diffusion coatingAl powderRolling resistance

The invention discloses a process for resisting ferrous metal corrosion of a zinc nickel diffusion layer. The process comprises the steps of alkaline degreasing, shot blasting, heating diffusion layer, water washing dust removal and colorful closing according to the requirement of a customer, wherein in the heating diffusion layer step, the zinc nickel diffusion layer and a metal matrix are put in a sealed metallic container and heated; the zinc nickel diffusion layer is prepared by evenly mixing the following powders in mass proportion: 20 to 30 percent of Zn powder, 0.5 to 1.4 percent of Ni powder, 3 to 12 percent of Al powder, 2 to 6 percent of rare earth, 1 to 4 percent of NH4Cl ammonium chloride, the balance being Al2O3 powder. The diffusion layer has the advantages of high rigidity, good wear resistance, unchangeableness of original mechanical performances of products, high adhesion strength, bumping and rolling resistance, good solderability, moisture and heat resistance and acid and alkali resistance; the diffusion layer has uniform thickness and compactness, and appearances of finished products have good uniformity; and no three-waste emission occurs during the course of processing, so the process belongs to the clean production process and is environment-friendly.

Owner:CHONGQING DAYOU SURFACE TECH

Multilayer insulated wire and transformers using the same

InactiveUS6222132B1Prevent crystallizationSuppress the deterioration with lapse of time of the electrical propertiesPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsPolyesterPolymer science

A multilayer insulated wire has a conductor and solderable extrusion-insulating layer made up of two or more layers for covering the conductor. At least one insulating layer including the outermost layer is formed by a mixture of 100 parts by weight of resin components in which 100 parts by weight of a thermoplastic polyester-series resin (A) is blended with 5 to 40 parts by weight of an ethylene-series copolymer having a carboxylic acid component or a metal salt of the carboxylic acid component in its side chain, and 10 to 80 parts by weight of an inorganic filler (B). A transformer which utilizes the multilayer insulated wire has excellent solderability, high-frequency characteristics, peel resistance under high-voltage and high-frequency, and coilability, and it is favorably suitable for industrial production. A transformer utilizing the multilayer insulated wire has excellent electrical properties and high reliability, because when used at high frequencies, there arises no problem of lowering of electric properties and scraping-off from the wire by corona.

Owner:FURUKAWA ELECTRIC CO LTD

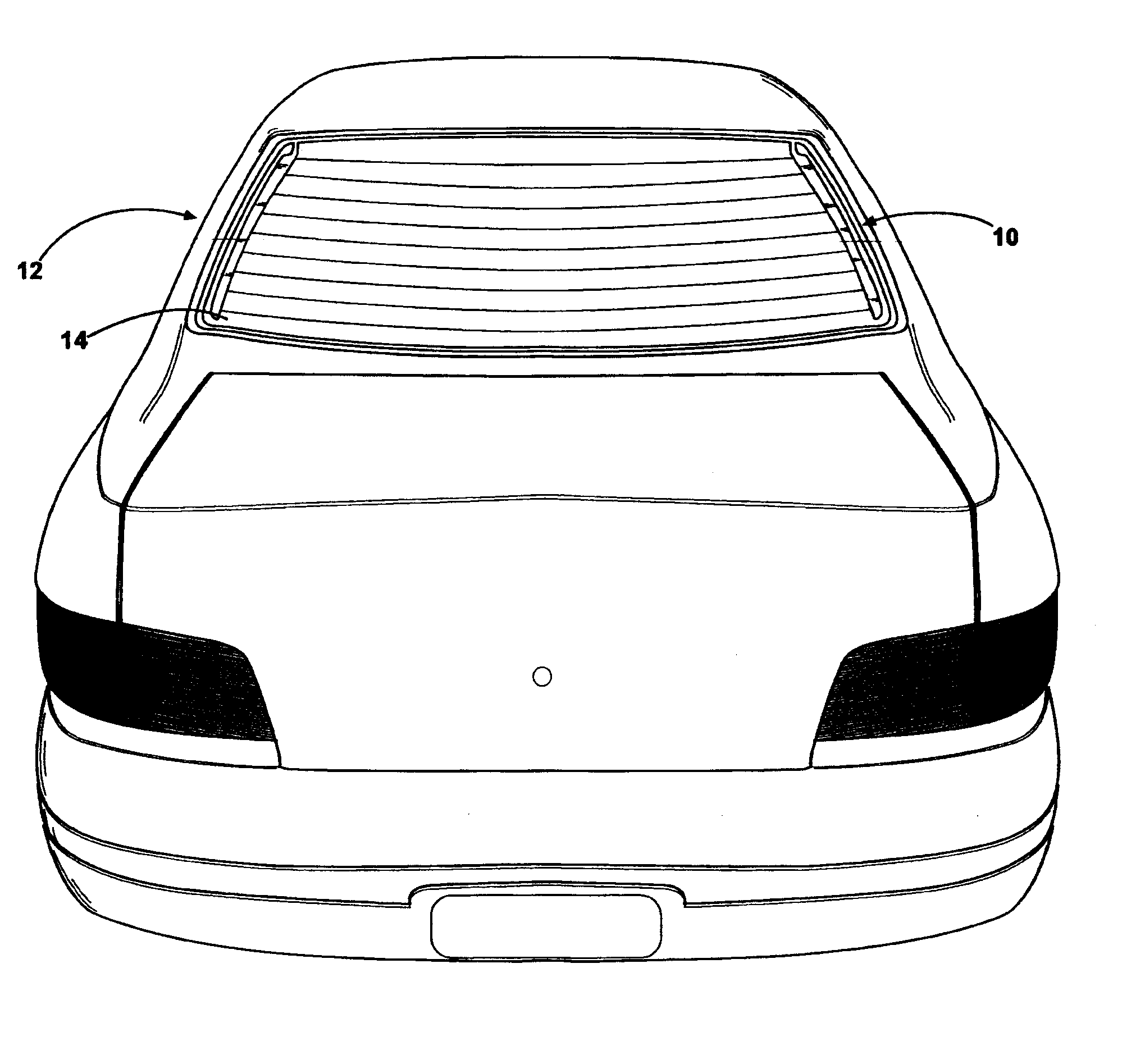

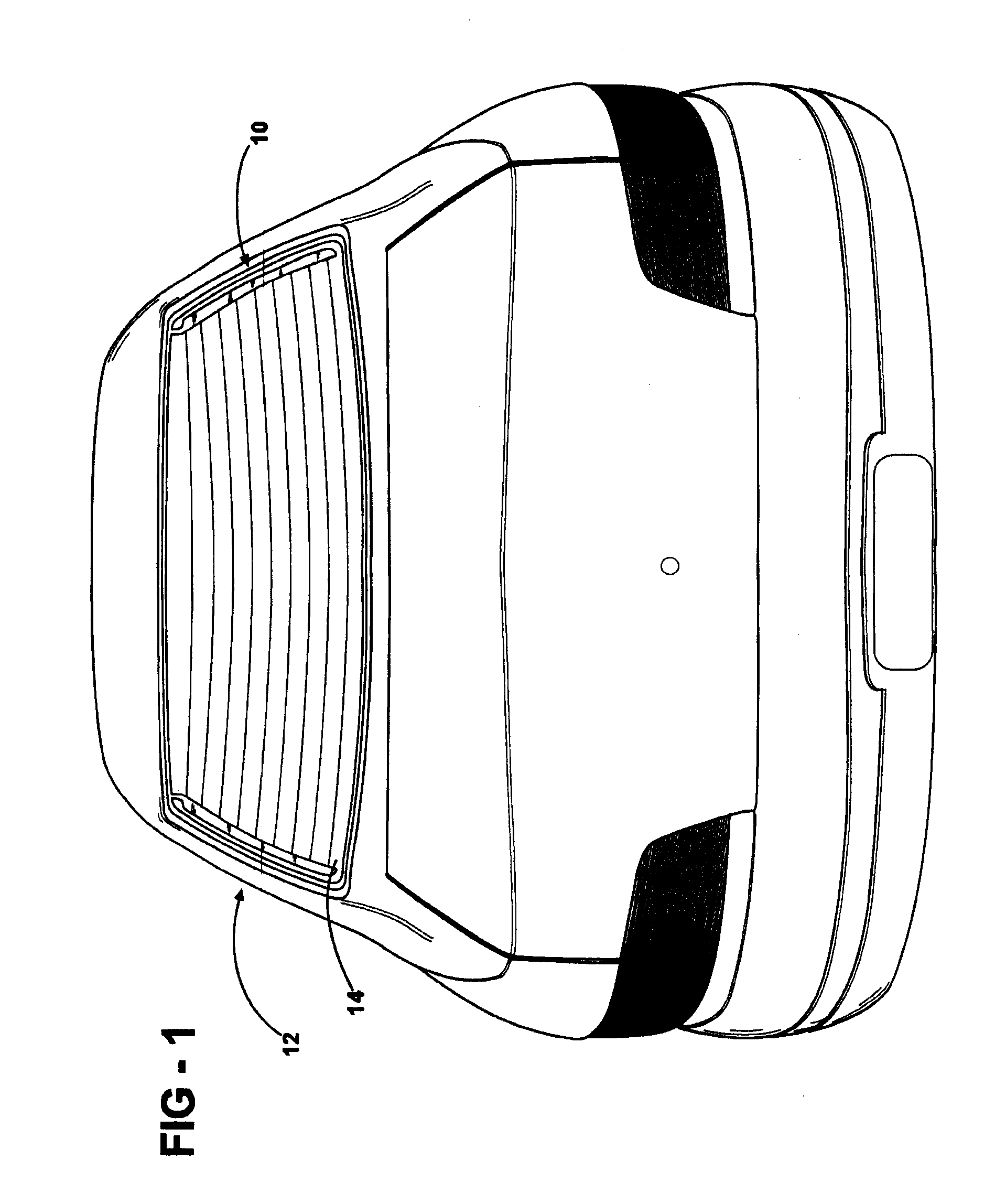

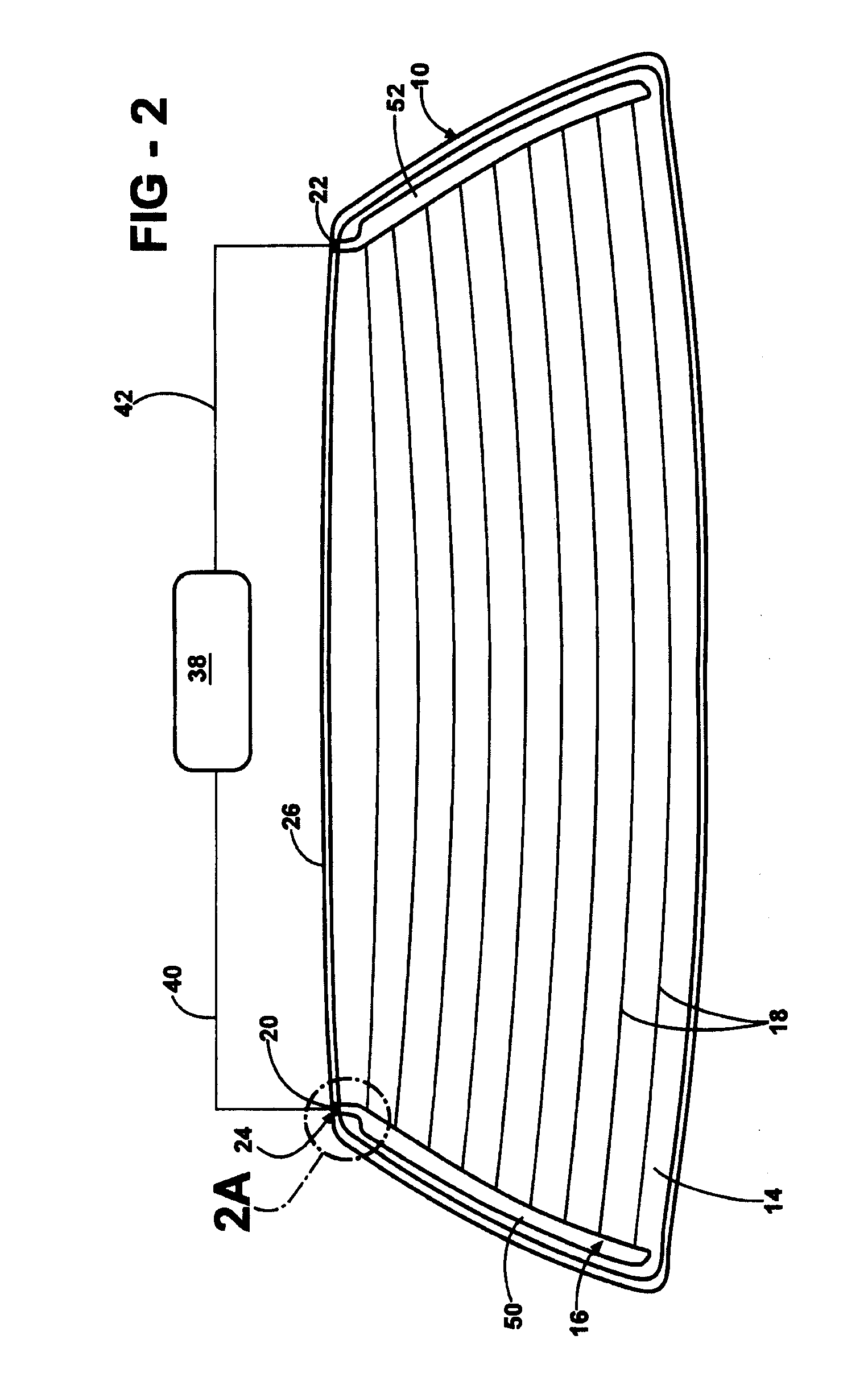

Electrical Connector For A Window Pane Of A Vehicle

InactiveUS20070105412A1Minimizes mechanical stressResists delaminationWindowsWindscreensElectrical conductorReaction rate

A window pane has a substrate formed from glass and includes an electrical device. The electrical device includes an electrical conductor and an electrical connector. A layer of solderable metal is bonded to the connector. A layer of solder is bonded to the layer of solderable metal and the conductor, with the connector and the conductor in electrical communication through the layer of solderable metal and the layer of solder. The substrate has a first coefficient of expansion and the connector has a second coefficient of thermal expansion. A difference between the first and second coefficients of thermal expansion is equal to or less than 5×10−6 / ° C. for minimizing mechanical stress between the connector and the substrate due to thermal expansion of the connector and the substrate resulting from changes in temperature. The solder is comprised of less than 70 parts by weight of Sn along with a greater than 30 parts by weight of a reaction rate modifier. The reaction rate modifier increases the solderability of the solder to the conductor.

Owner:AGC AUTOMOTIVE AMERICAS

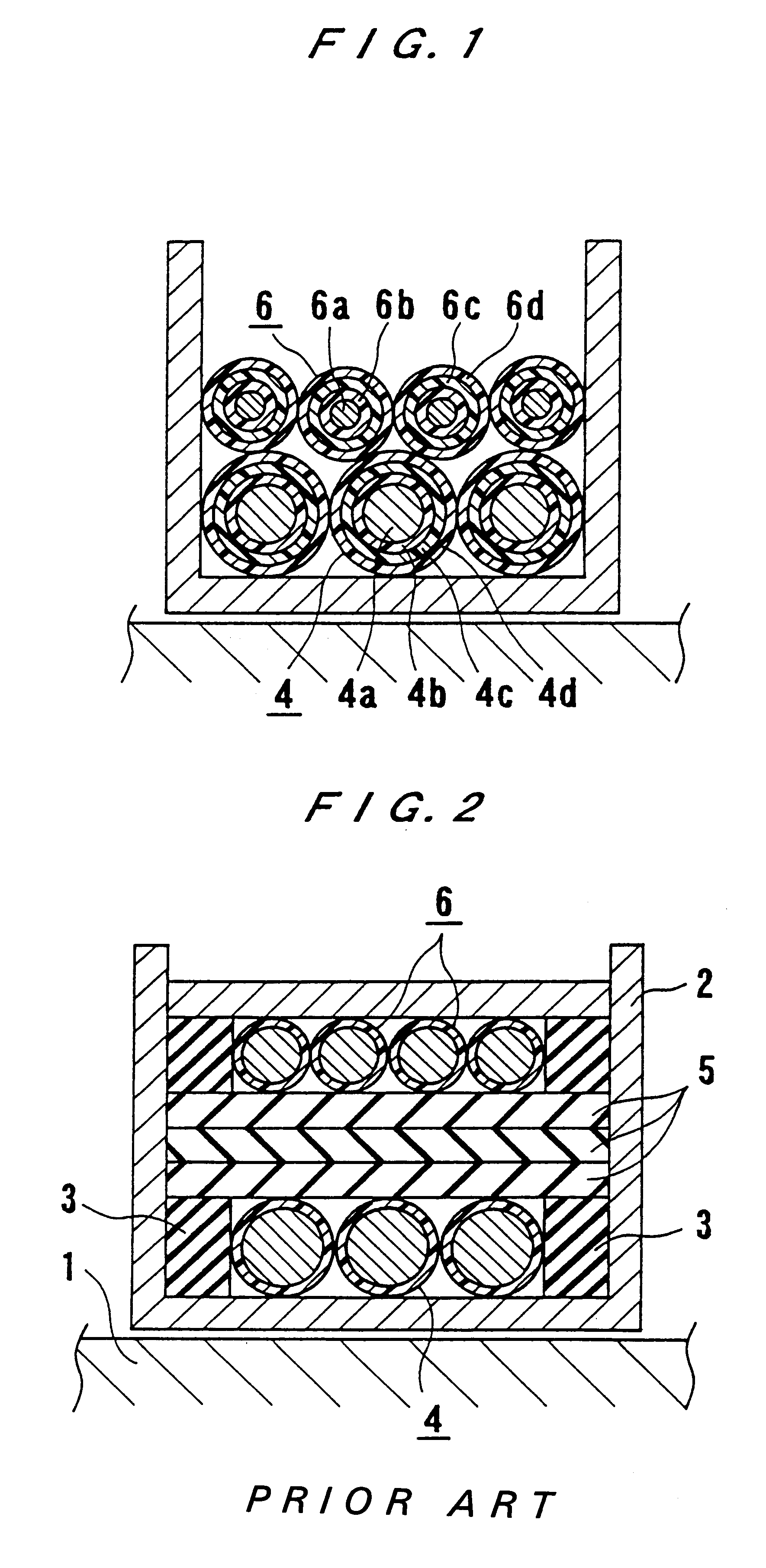

Hot press-formed article and a method for its manufacture

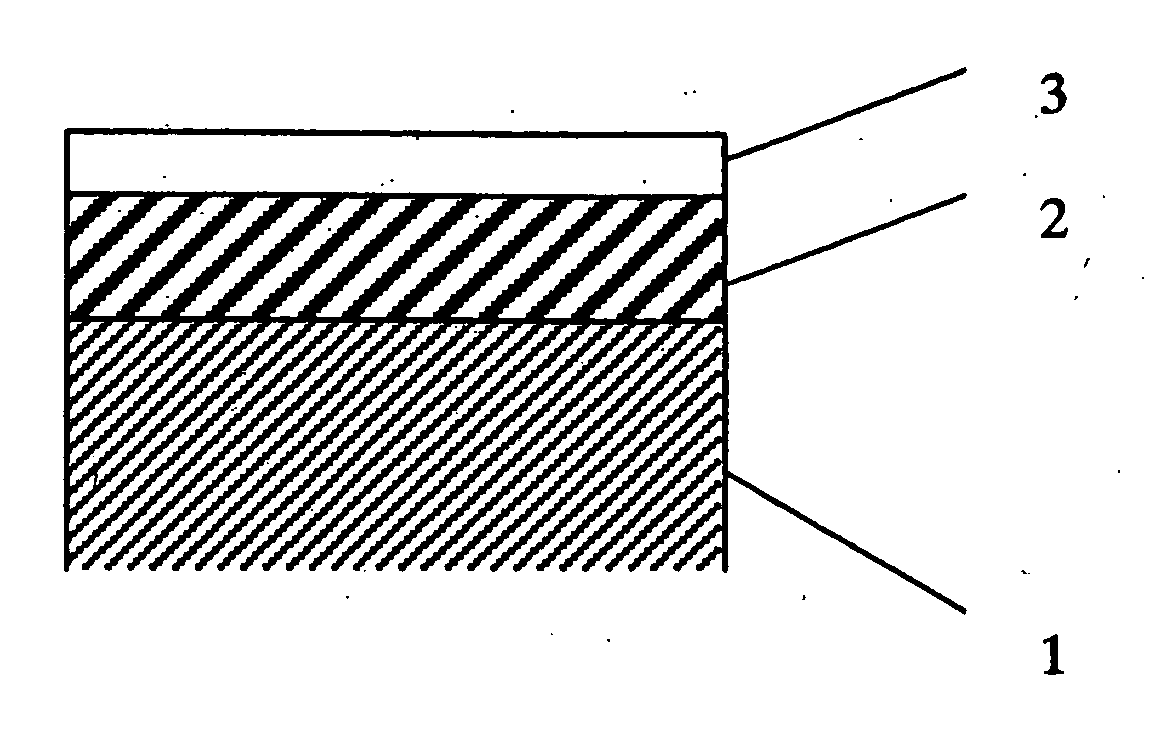

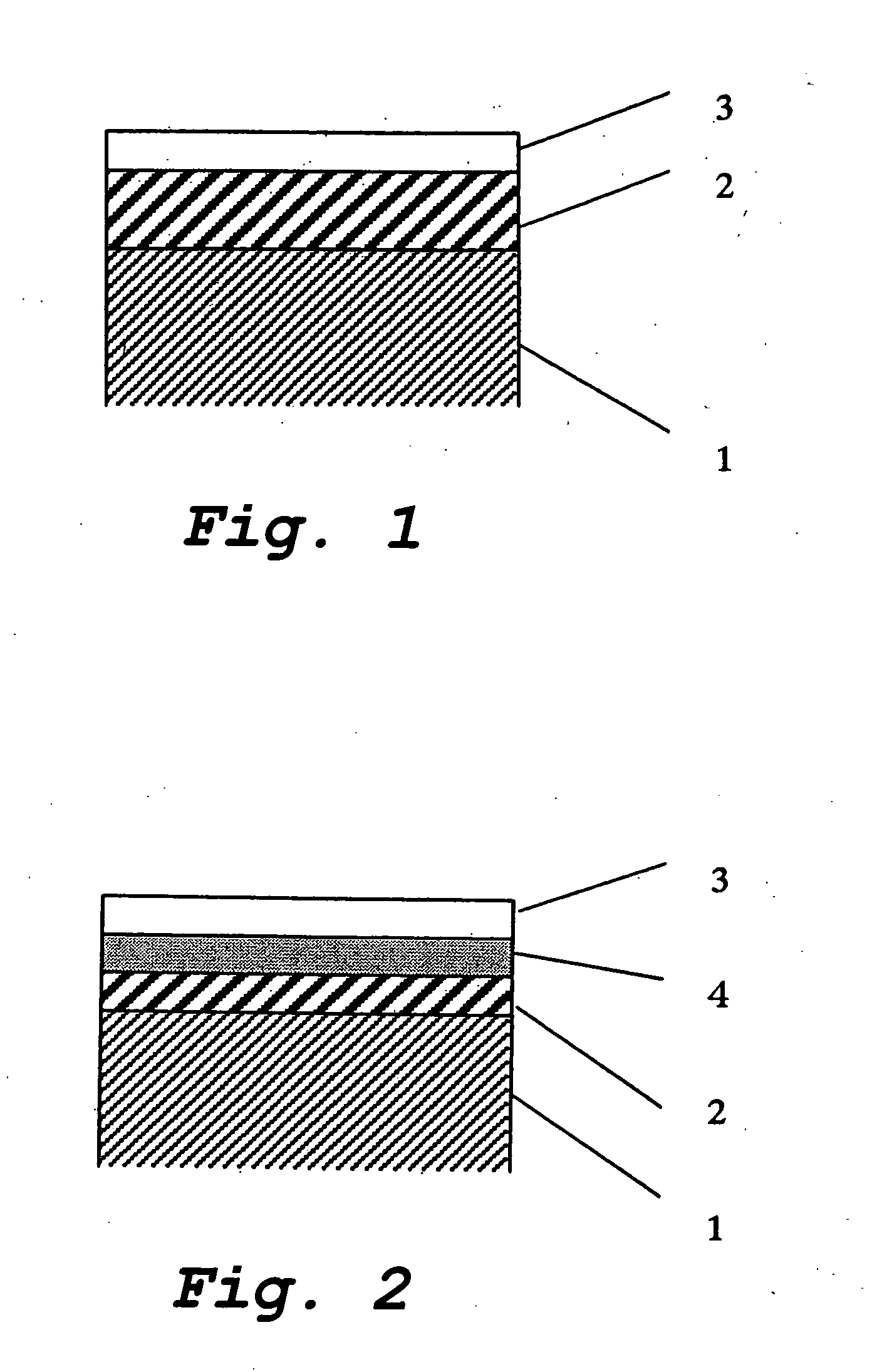

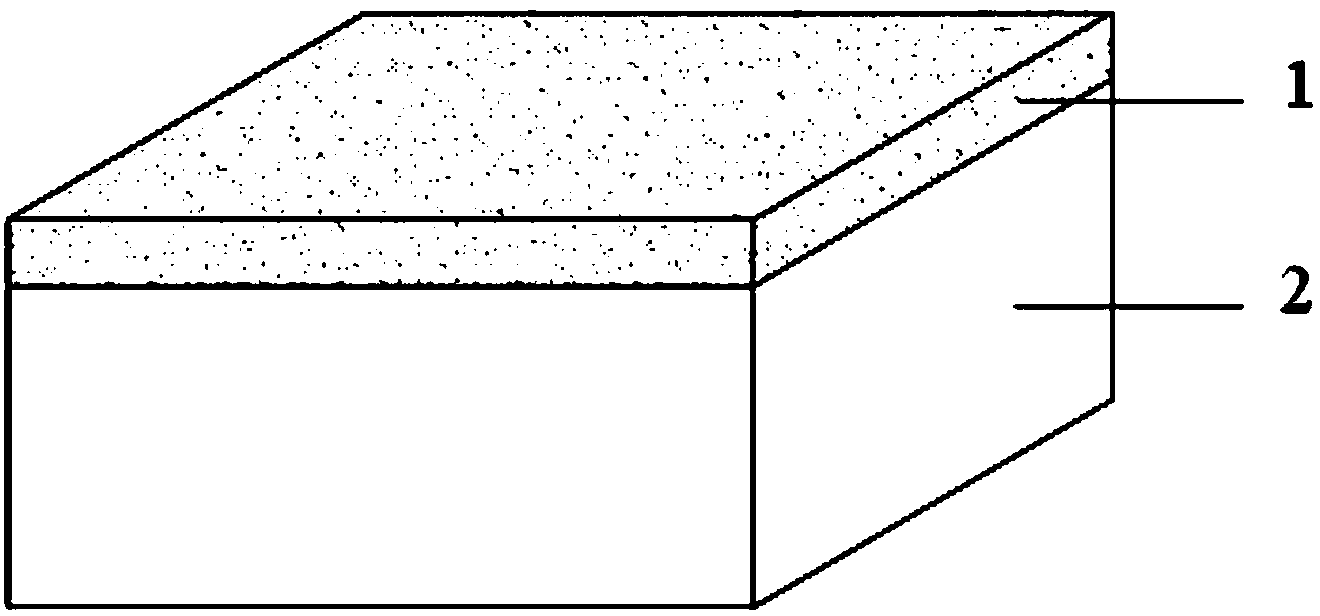

ActiveUS20060121305A1Improve corrosion resistanceNot readily peel offAnodisationHot-dipping/immersion processesSolderabilitySolid solution

A hot press-formed article having improved corrosion resistance and coating adhesion when coated is obtained by hot press forming of a zinc-based plated steel material. It has a zinc-based plating layer comprising an iron-zinc solid solution phase and atop it a zinc oxide layer. The average thickness of the zinc oxide layer which is the outermost layer is at most 2 μm. A hot press-formed article having a good appearance and excellent corrosion resistance, coating adhesion, post-coating corrosion resistance, and weldability has a layer (2) consisting essentially of an iron-zinc solid solution phase atop a base material steel sheet (1). It also has a zinc oxide layer (3) with an average thickness of at most 5 μm as an uppermost layer, but it does not have a substantial amount of an iron-zinc intermetallic compound phase. The total amount of Al contained in the iron-zinc solid solution layer (2) and the zinc oxide layer (3) is at most 0.5 g / m2, and / or the total amount of Al oxides contained in these layers is at most 5 mg / m2.

Owner:NIPPON STEEL CORP +2

Electronic component, mounting structure of electronic component, and process for producing electronic component

ActiveUS20080118721A1Satisfactory solderabilityFixed capacitor dielectricPrinted electric component incorporationHigh humiditySolderability

Owner:MURATA MFG CO LTD

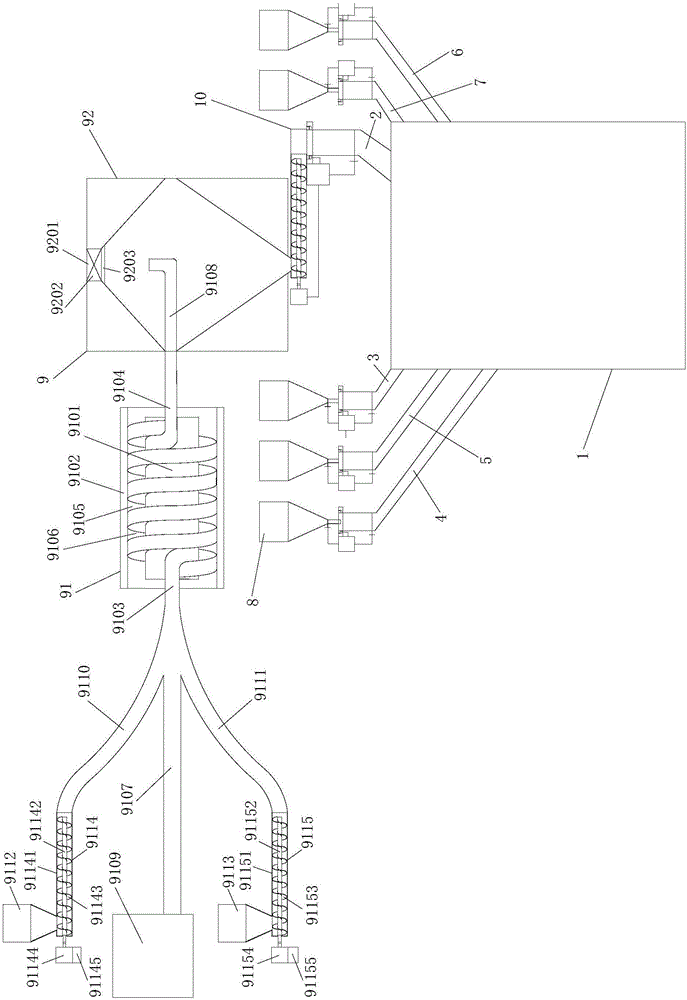

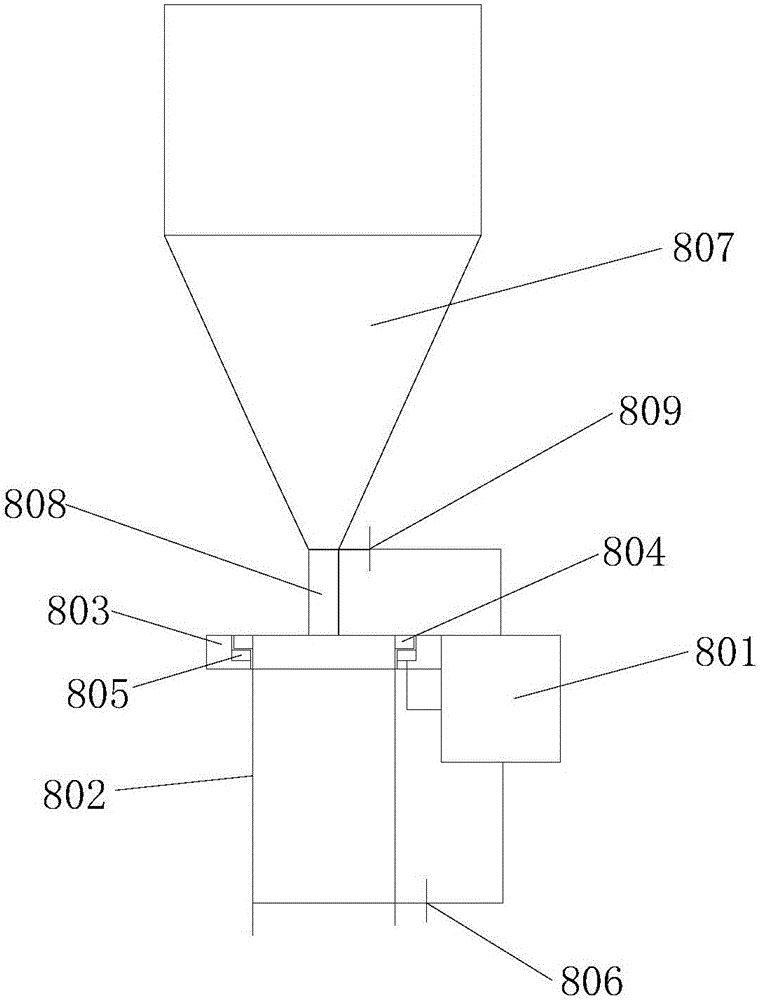

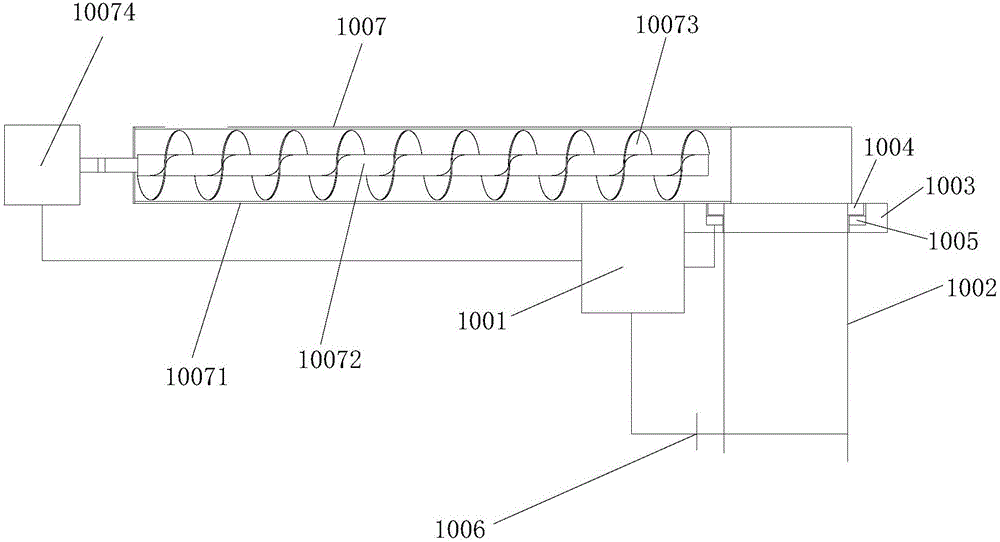

Solar cell back silver slurry and preparing device thereof

ActiveCN106128550ALow costStrong costFinal product manufactureNon-conductive material with dispersed conductive materialSolderabilityMixed materials

The invention provides a solar cell back silver slurry which can reduce the cost, and guarantee better conductivity of a silver layer and great adhesive force with a silicon substrate, and a preparing device thereof. The solar cell back silver slurry is composed of: 65%-75% of powdery mixed materials, 8%-10% of ethyecellulose, 8%-10% of butyl carbitol, 5%-8% of terpilenol, 2%-4% of thixotropic agents and remaining weight ratio of auxiliary agents, wherein the powdery mixed materials are the mixed materials of silver-coated copper powder and glass powder, and the weight ratio between the silver-coated copper powder and the glass powder is (7-12):1. The content of pure silver in the back silver slurry is only about 35%, which is much lower than the heavy silver content of present back silver slurry, so that the usage amount of silver powder is substantially reduced, the cost of the back silver slurry is greatly reduced, and the cost pressure caused by silver cost increase can be alleviated; in addition, greater adhesive force exists between a finally prepared silver layer and the silicon substrate, and the binding property, solderability and soldering resistance are greater. The solar cell back silver slurry and the preparing device thereof are suitable for popularization in the electronic material technical field.

Owner:LESHAN TOPRAYCELL

Nano copper-tin alloy conductive ink and preparation method and usage of nano copper-tin alloy conductive ink

ActiveCN102675960ALower sintering temperatureImprove antioxidant capacityInksMetallic pattern materialsRare earthElectron scattering

The invention belongs to the technical field of material chemistry, relates to conductive ink, and particularly relates to nano copper-tin alloy conductive ink and a preparation method and usage of the nano copper-tin alloy conductive ink. Nano copper-silver alloy is replaced by nano copper-tin alloy to be used as conductive filler in the conductive ink, sintering temperature of the conductive ink is lowered, and when the nano copper-tin alloy conductive ink is compared with nano copper-silver alloy conductive ink, antioxidant capacity of the conductive ink during sintering is improved, mechanical property and solderability of a conductive circuit formed after sintering of the conductive ink are improved, and the problem of silver ion migration is avoided. Further, since rare earth metal elements are doped in the nano copper-tin alloy, grain boundary of the nano copper-tin alloy is increased, electron scattering power is increased, and conductivity is improved as compared with that of nano copper alloy. On the other hand, tin is much cheaper than silver, so that raw material cost of the nano copper-tin alloy conductive ink is reduced.

Owner:深圳市尊业纳米材料有限公司

Environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and preparation method of electrode silver slurry

ActiveCN104934103AGuaranteed normal transmissionReduce interface contact resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSlurryResistor

The invention discloses an environment-friendly electrode silver slurry of zinc oxide varistor suitable for two soldering technologies and a preparation method of the electrode silver slurry. The silver slurry is composed of 60-80% silver powder, 1-5% of metal oxide, 2-5% of leadless glass powder and 10-37% of organic carriers by weight. The preparation method comprises the steps that the leadless glass powder is prepared by that raw materials are mixed well, placed in a platinum crucible and melt, and the melt material is removed and dried to obtain the leadless glass powder; the organic carriers are prepared by adding an organic solvent into a stainless steel container, adding organic resin, carrying out heating, and carrying out cooling and adding a surfactant after the resin is completely dissolved; and the silver slurry is prepared by mixing the silver powder, the metal oxide, the leadless glass powder and the organic carriers, and stirring and grinding the mixture in a vacuum manner. The preparation method is simple and suitable for both the reflow soldering and immersed soldering technologies, the solderability and the soldering resistance are high, the silver slurry can be used to prepare common type as well as lightning protection type varistor, the adhesion force, the conductivity and the electrical performance are high, and the performance completely reach the using requirements.

Owner:GUIYAN DETECTION TECH YUNNAN CO LTD

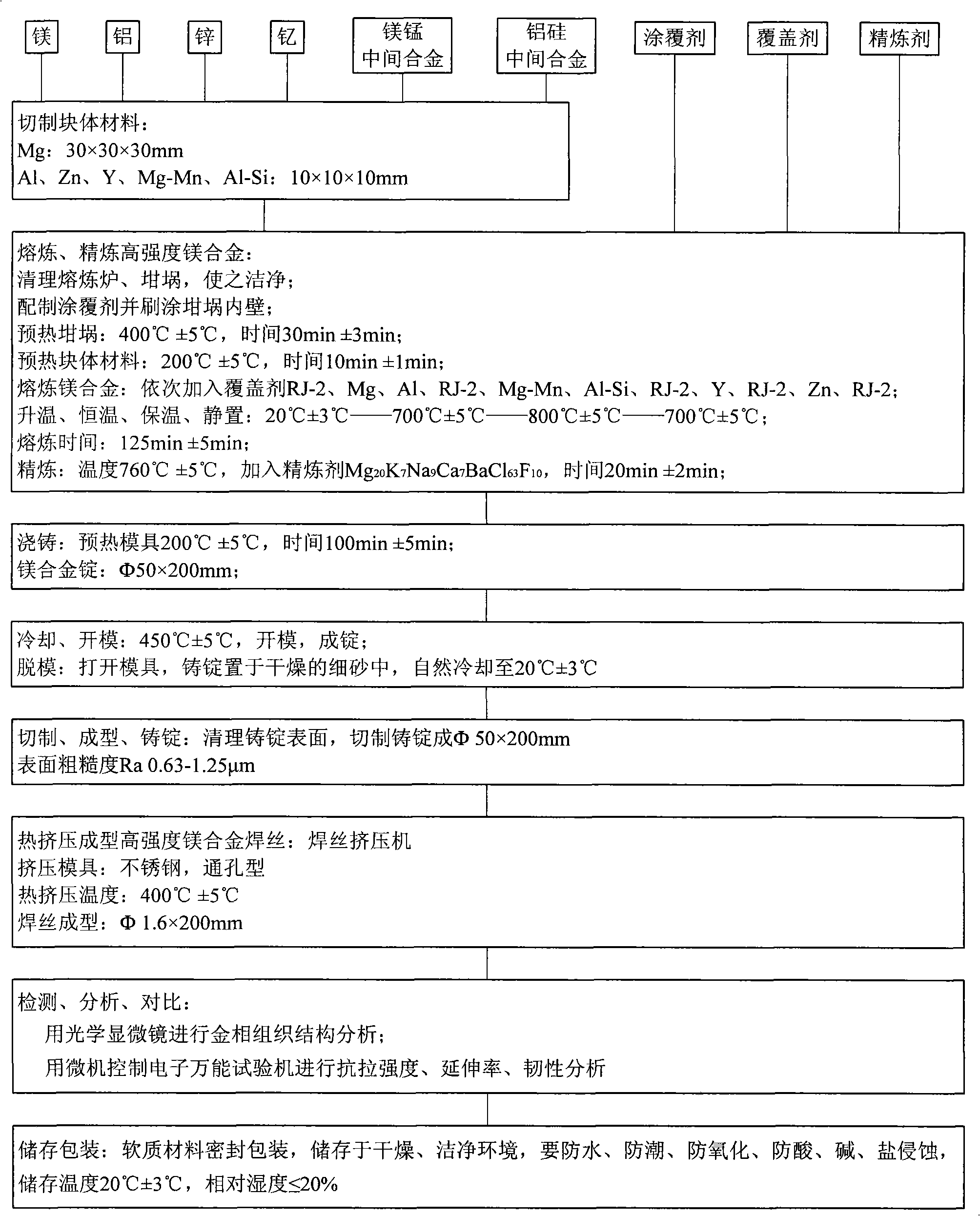

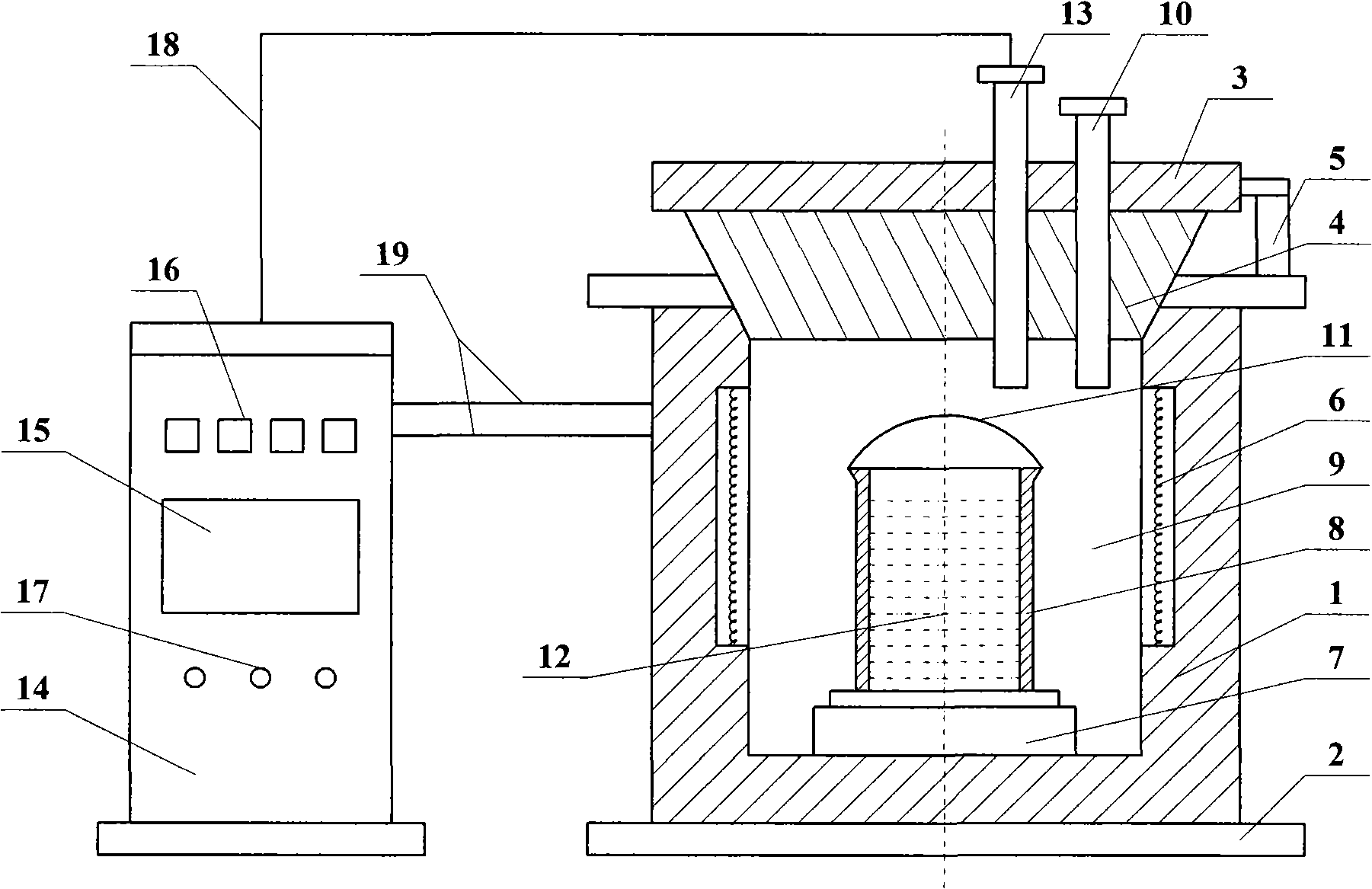

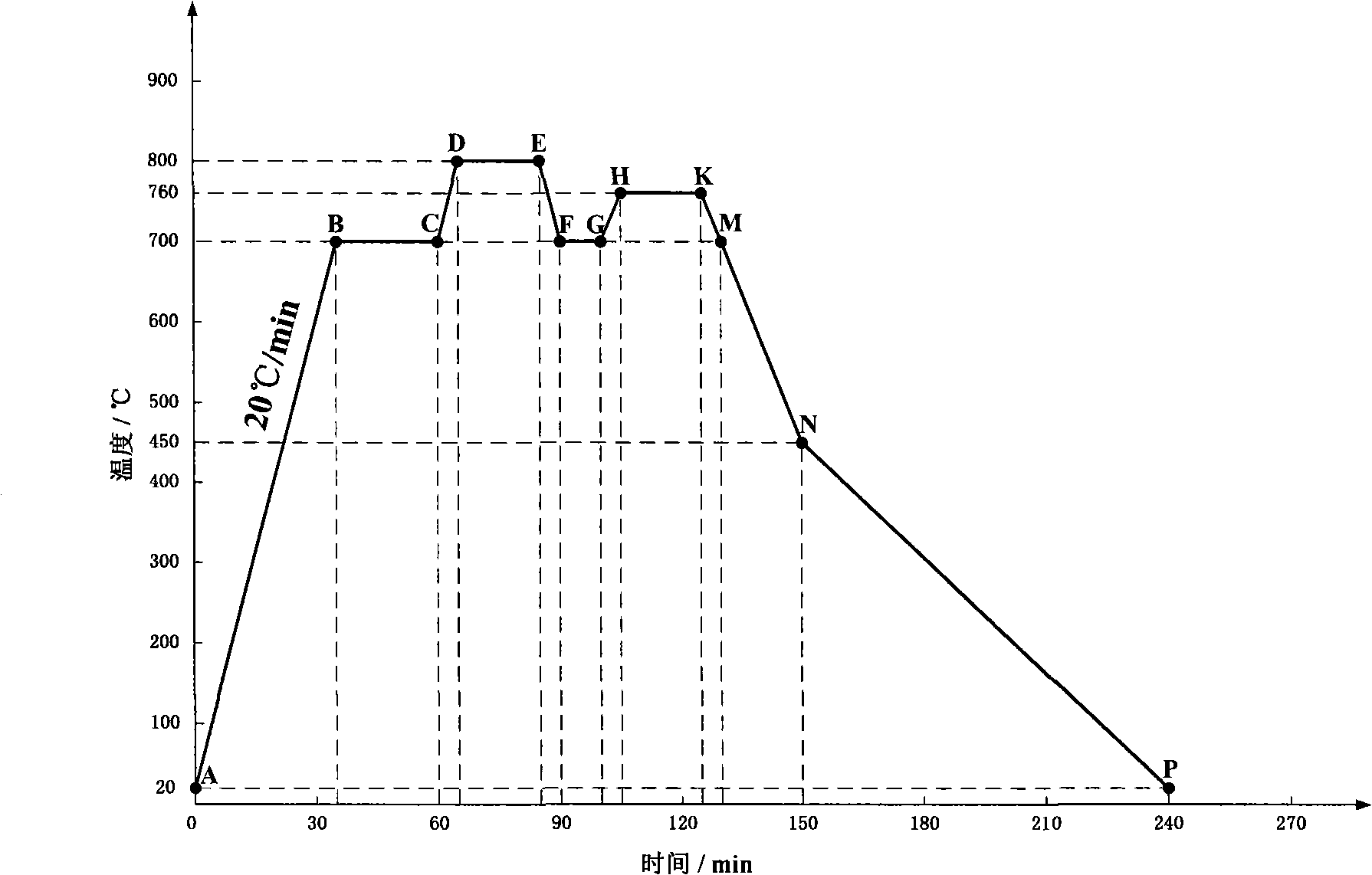

Method for manufacturing high-strength magnesium alloy solder wire

InactiveCN101269449AImprove toughnessImprove solderabilityWelding/cutting media/materialsSoldering mediaRare-earth elementManganese

The invention relates to a preparation method of a high-intensity magnesium alloy soldering wire, which adopts alloy agent magnesium, aluminum, zinc, yttrium, magnesium-manganese intermediate alloy and aluminium-silicon intermediate alloy as raw materials. In a vertical melting furnace, through being melted at 700 DEG C, rare-earth element yttrium is added at 800 DEG C and is refined at 760 DEG C, with a covering agent and a refine agent being added, through constant temperature, thermal retardation and stewing, then magnesium alloy molten liquid is made; through casting a mould, magnesium alloy ingot is made; through cooling, cutting and forming, and then thermoplastic extruding, in the end, the high-intensity magnesium alloy soldering wire is made; the yttrium element, the magnesium-manganese intermediate alloy and aluminium-silicon intermediate alloy can greatly improve the intensity, the malleability and the solderability of the magnesium alloy soldering wire; the preparation technology is refined, the mixture ratio is reasonable, the environment pollution does not exist; the outcome of a magnesium alloy soldering wire metallic phase has uniform structure and good compactability, the average grain size is 25microns, the tensile strength can reach 330MPa, the elongation percentage can reach 25 percent and can be improved by 18 to 28 percent compared with the prior art, and the solderability is good.

Owner:TAIYUAN UNIV OF TECH

Cleaning-free lead-free solder soldering fluid not containing halide

ActiveCN101367160AReduce surface tensionEnhance wetting powerWelding/cutting media/materialsSoldering mediaSolventCorrosion

The invention discloses halogen-free cleaning-free soldering flux for lead-free solder, which comprises the compositions in percentage by weight: 1.5 to 4.5 percent of organic acid activator, 0.5 to 8.5 percent of high-quality abietic resin, 0.3 to 1.5 percent of activated reinforcer, 0.2 to 0.8 percent of surfactant, 3.0 to 15.0 percent of wet strengthening agent, and the balance being solvent isopropanol, absolute ethyl alcohol or deionized water. The soldering flux fully meets various regulation requirements for limiting halogen. The soldering flux developed by using a novel material which does not contain the halogen can scientifically reduce the surface tension of the lead-free solder, strengthen the wetting power of the lead-free solder, improve the solderability, can be compatible with a plurality of welding materials, and has no corrosion effect on lead-free solder alloy; composing materials are volatilized by stages during the welding process, so after the welding, the surface of a PCB board has less residue, even spread, less ion residue, and reliable electrical insulating property, and does not need to be washed; and the soldering flux is a novel environment-friendly halogen-free cleaning-free soldering flux for the lead-free solder.

Owner:深圳市唯特偶新材料股份有限公司

Aluminum silicon carbide composite material with laser welding layer and preparing method of aluminum silicon carbide composite material

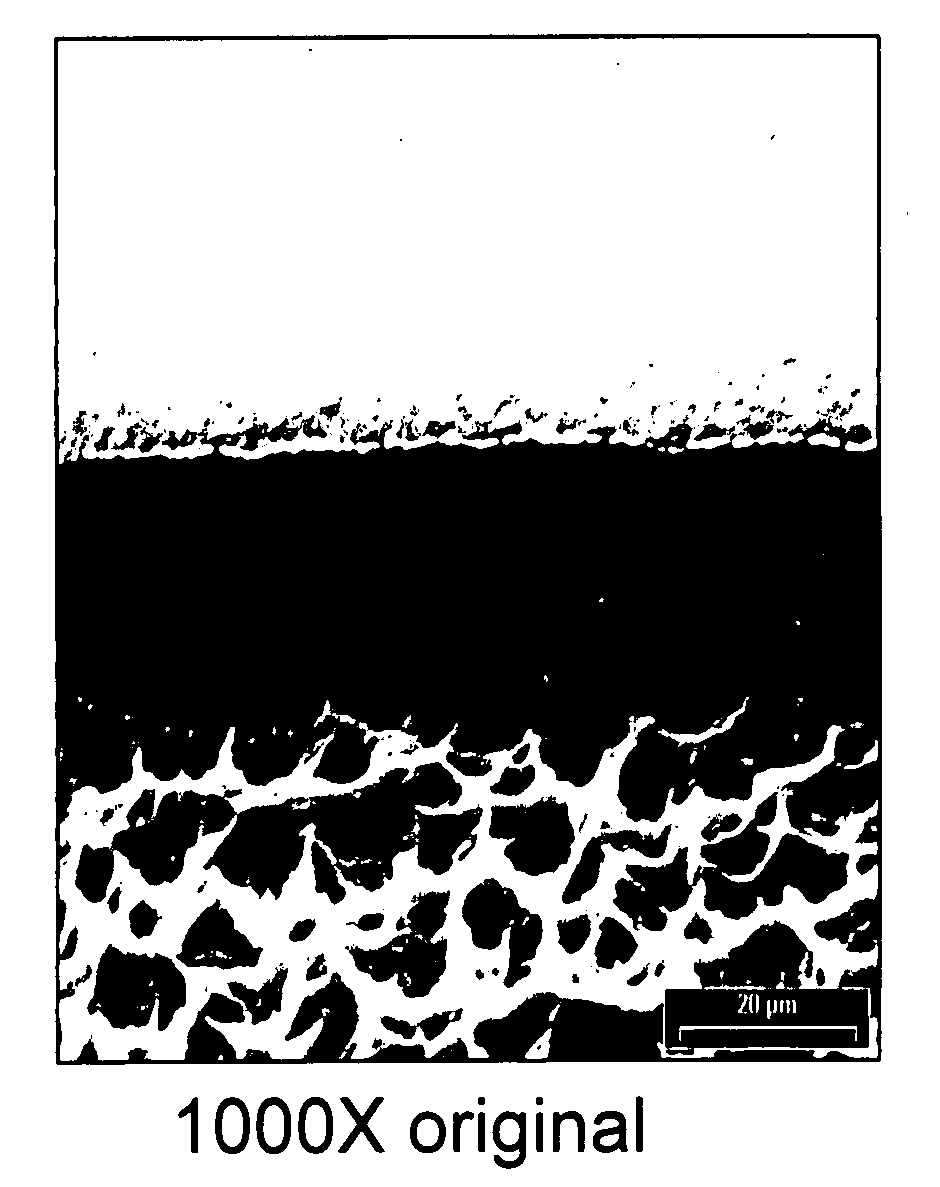

ActiveCN103367270AImprove thermal conductivityReduce bloatSemiconductor/solid-state device detailsSolid-state devicesThermal dilatationCarbide silicon

The invention discloses an aluminum silicon carbide composite material with a laser welding layer and a preparing method of the aluminum silicon carbide composite material. The composite material is composed of the laser welding layer and an aluminum silicon carbide layer, the laser welding layer is composed of pure aluminum or aluminum alloy comprising silicon and aluminum, the volume fraction of the silicon in the aluminum alloy is a, the volume fraction of the aluminum in the aluminum alloy is b, the a is greater than 0 and less than or equal to 30%, and the b is greater than or equal to 30% and less than 100%. The aluminum silicon carbide layer is composed of silicon carbide and pure aluminum or aluminum alloy, and the volume fraction of the silicon carbide ranges from 30% to 70%. The preparing method comprises the steps that silicon carbide pelleting powder is prepared firstly, then silicon carbide preformed parts are prepared, and the aluminum silicon carbide composite material with the laser welding layer is prepared in the vacuum pressure impregnation method finally. The aluminum silicon carbide composite material is good in weldability and gas tightness, high in heat conductivity, low in coefficient of thermal expansion, simple in preparing method, efficient and low in cost.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com