Solar cell back silver slurry and preparing device thereof

A technology of solar cells and back silver paste, which is applied in the direction of cable/conductor manufacturing, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., and can solve the problem of poor adhesion of silver layer solderability and solder resistance to silicon substrates , can not reduce the production cost of back silver paste, increase the cost of back silver paste, etc., to achieve the effect of reducing the amount of silver powder used, alleviating the rise of silver price, and reducing the size of solder joints for series welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

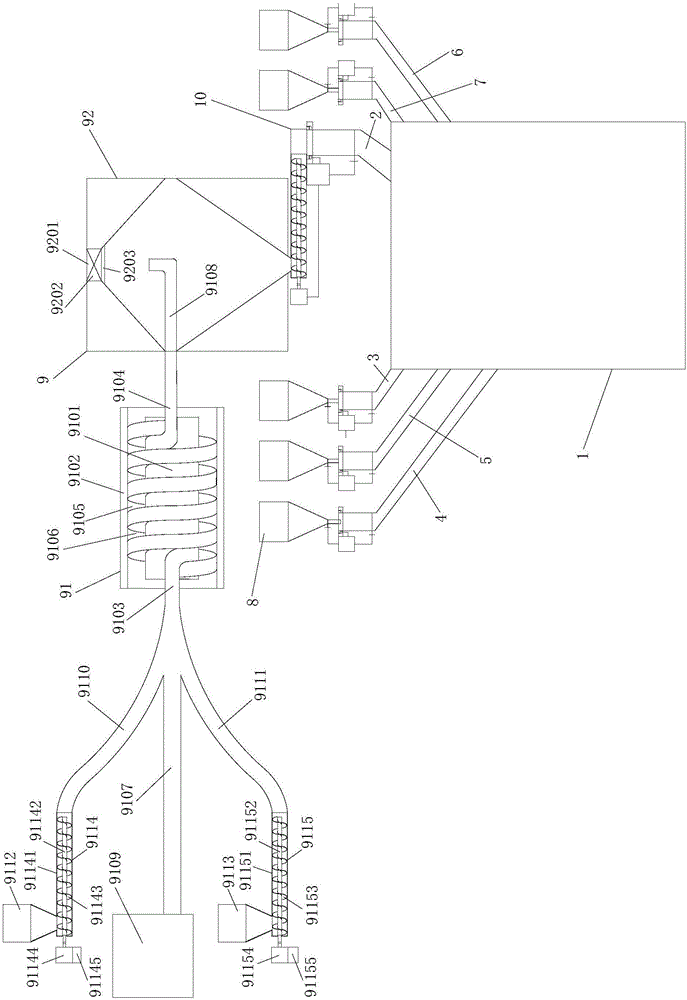

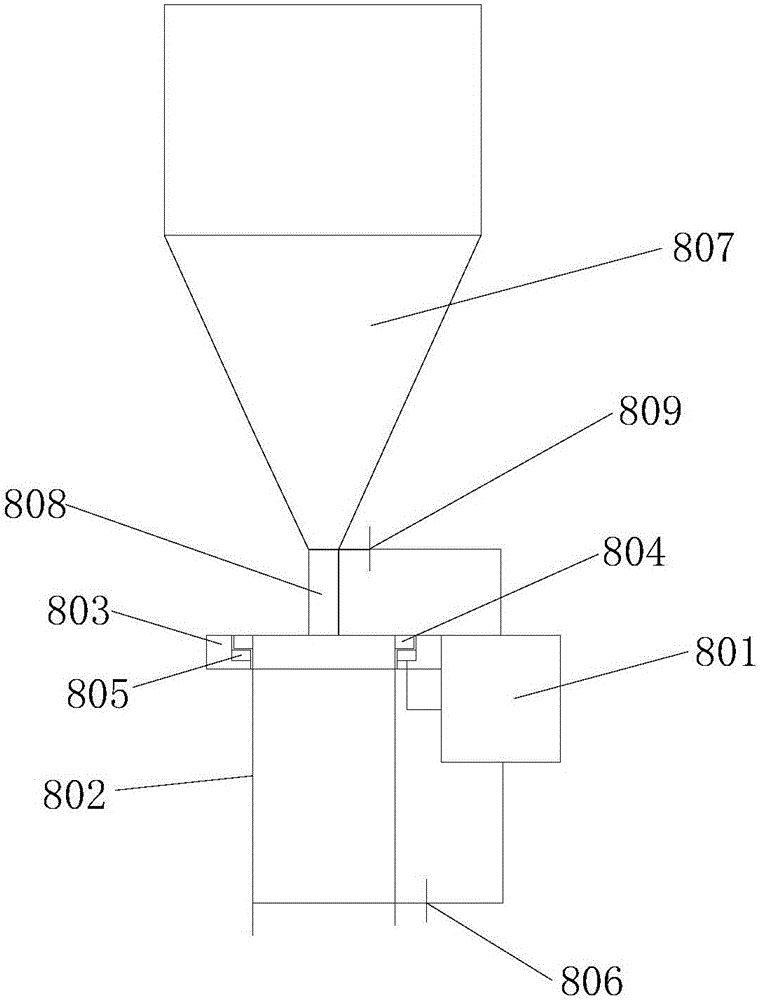

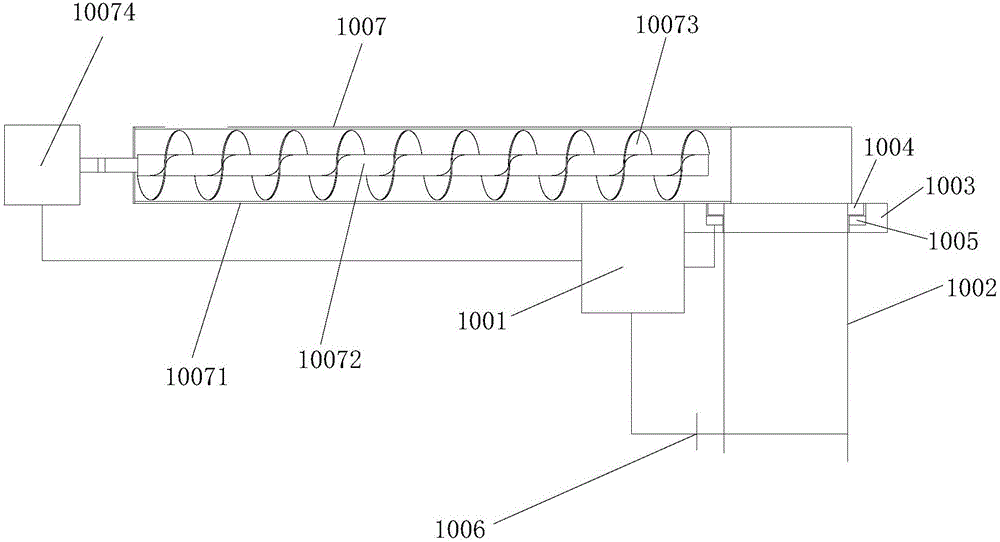

[0024] If the silver layer made of the existing solar cell back silver paste has good electrical conductivity, the adhesion to the silicon substrate is weak and the adhesion is poor. If the adhesion between the silver layer and the silicon substrate is strong, the silver layer The poor conductivity of the solar cell cannot guarantee the efficiency of the battery. After in-depth research, the present invention provides a solar cell back silver paste that can reduce the cost and ensure that the silver layer has good conductivity and strong adhesion to the silicon substrate. material. The present invention achieves the above-mentioned object in the following manner: the solar cell back silver paste is made up of the following components by weight: 65%-75% of powdery mixture, 8%-10% of ethyl cellulose, butyl 8%-10% carbitol, 5%-8% terpineol, 2%-4% thixotropic agent, and the balance is additives. The powdery mixture is a mixture of silver-coated copper powder and glass powder. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com