Patents

Literature

1675 results about "Electronic materials" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

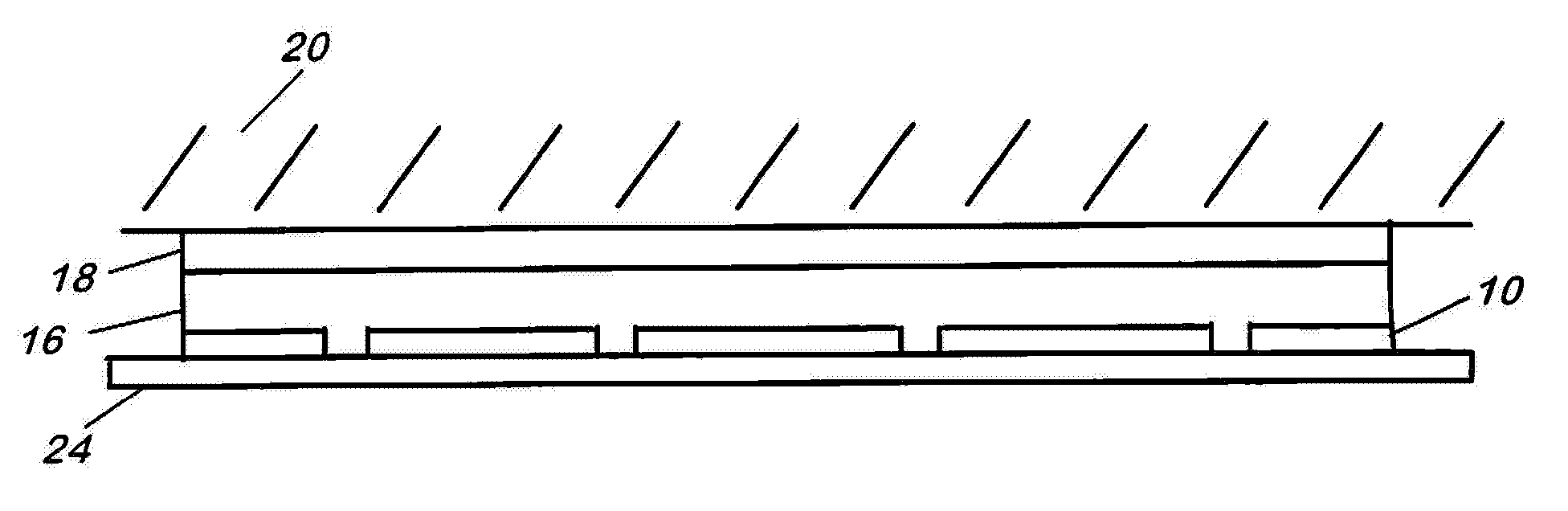

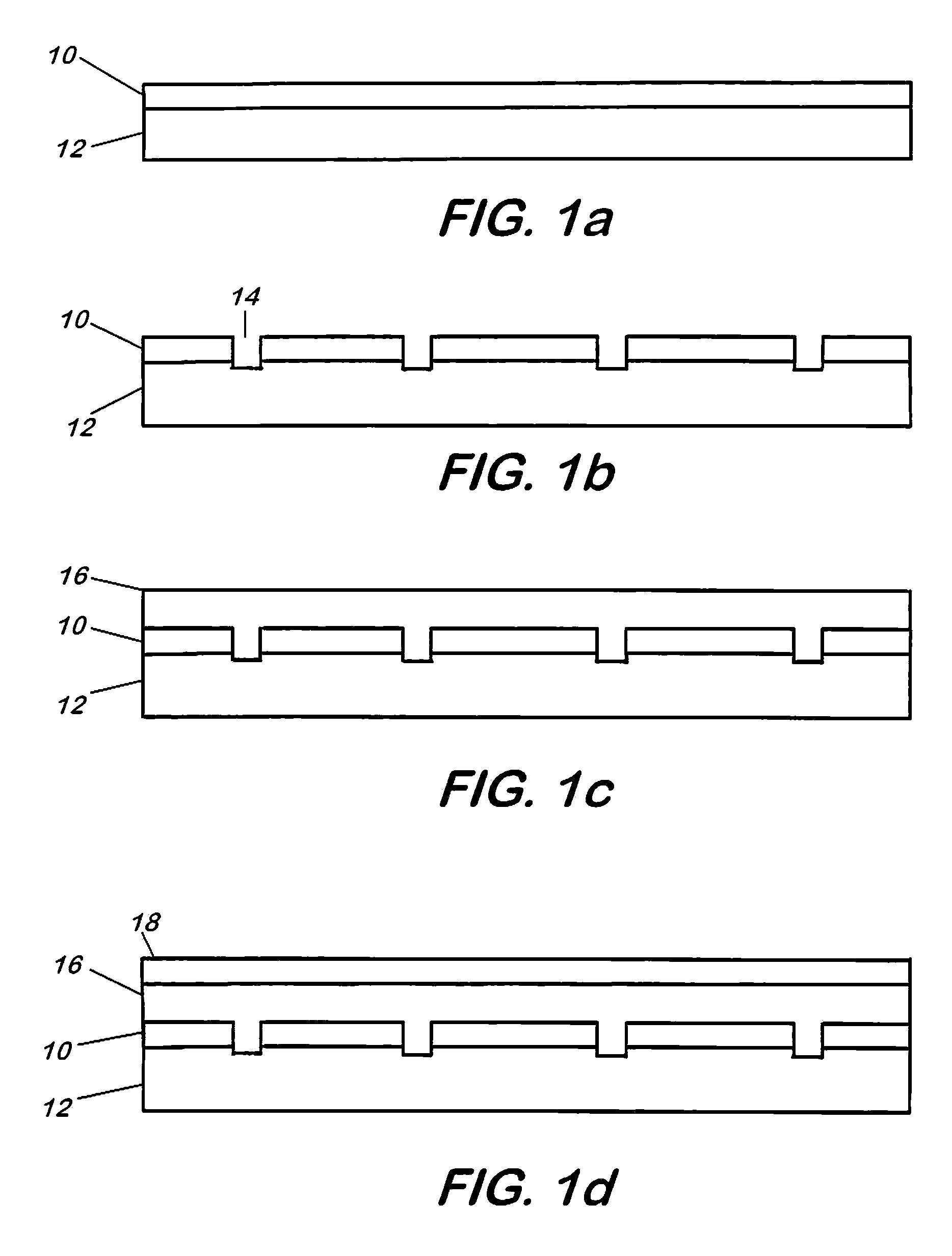

Wafer bonding of thinned electronic materials and circuits to high performance substrates

InactiveUS20040009649A1Material nanotechnologySemiconductor/solid-state device detailsWafer dicingEngineering

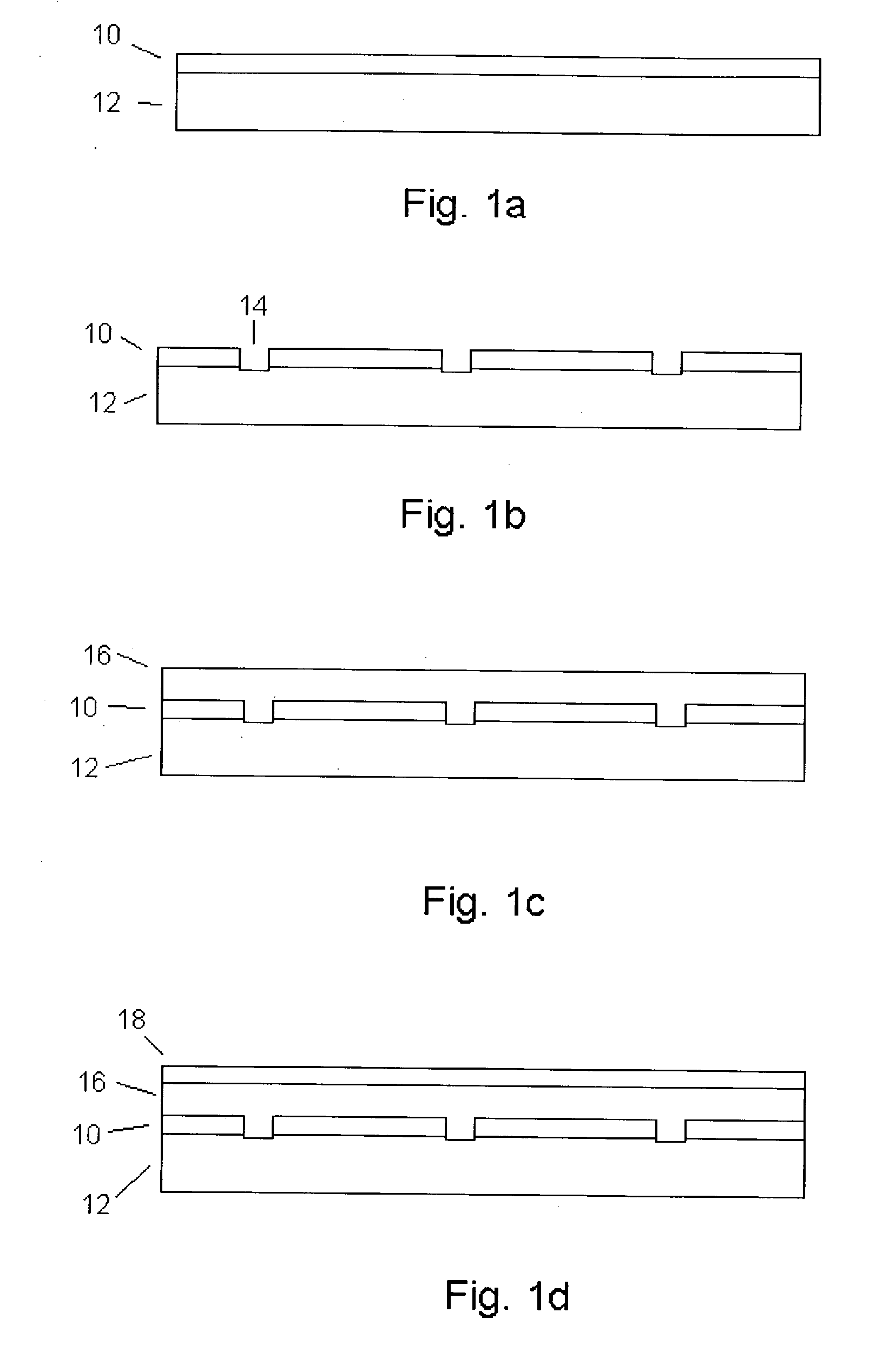

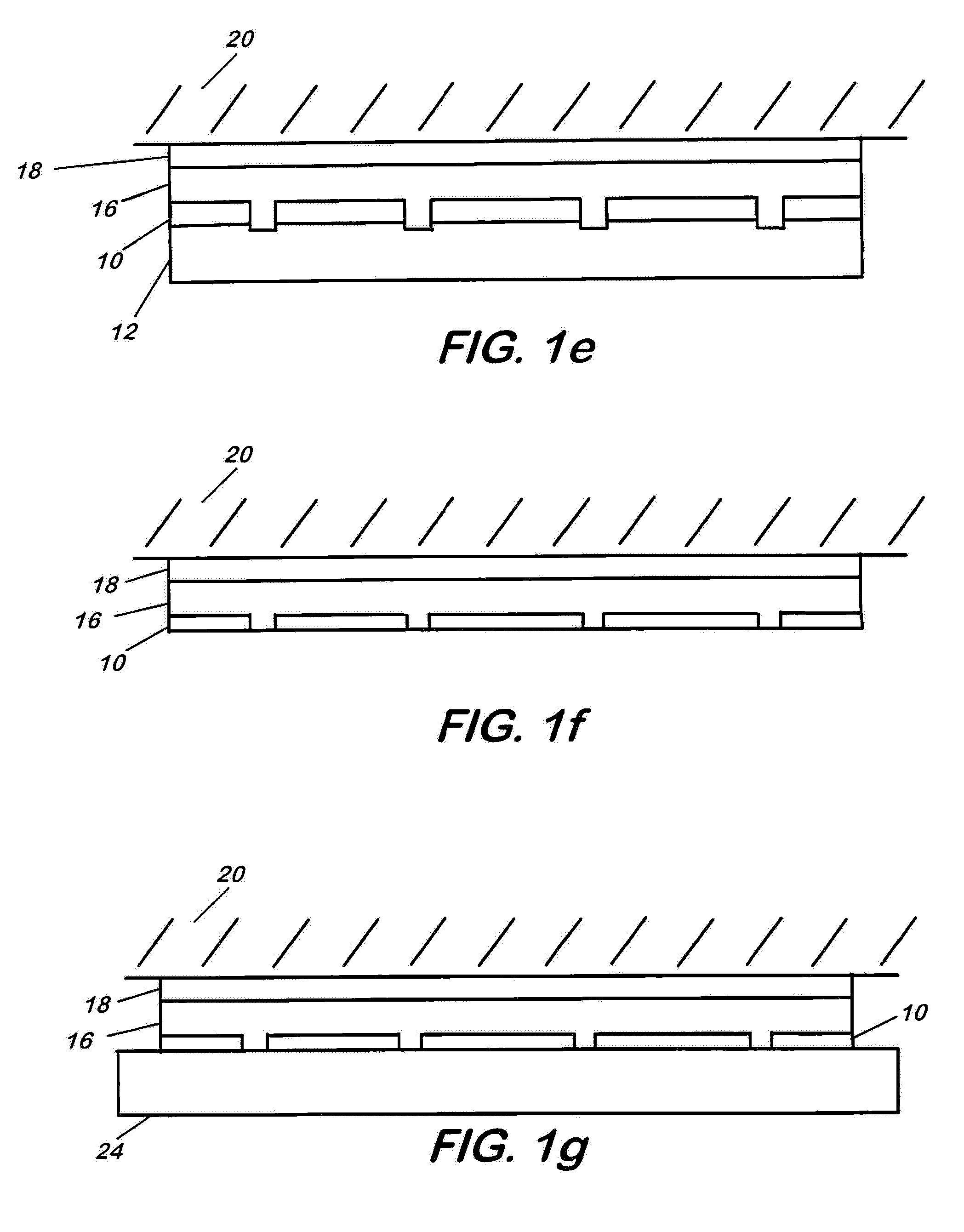

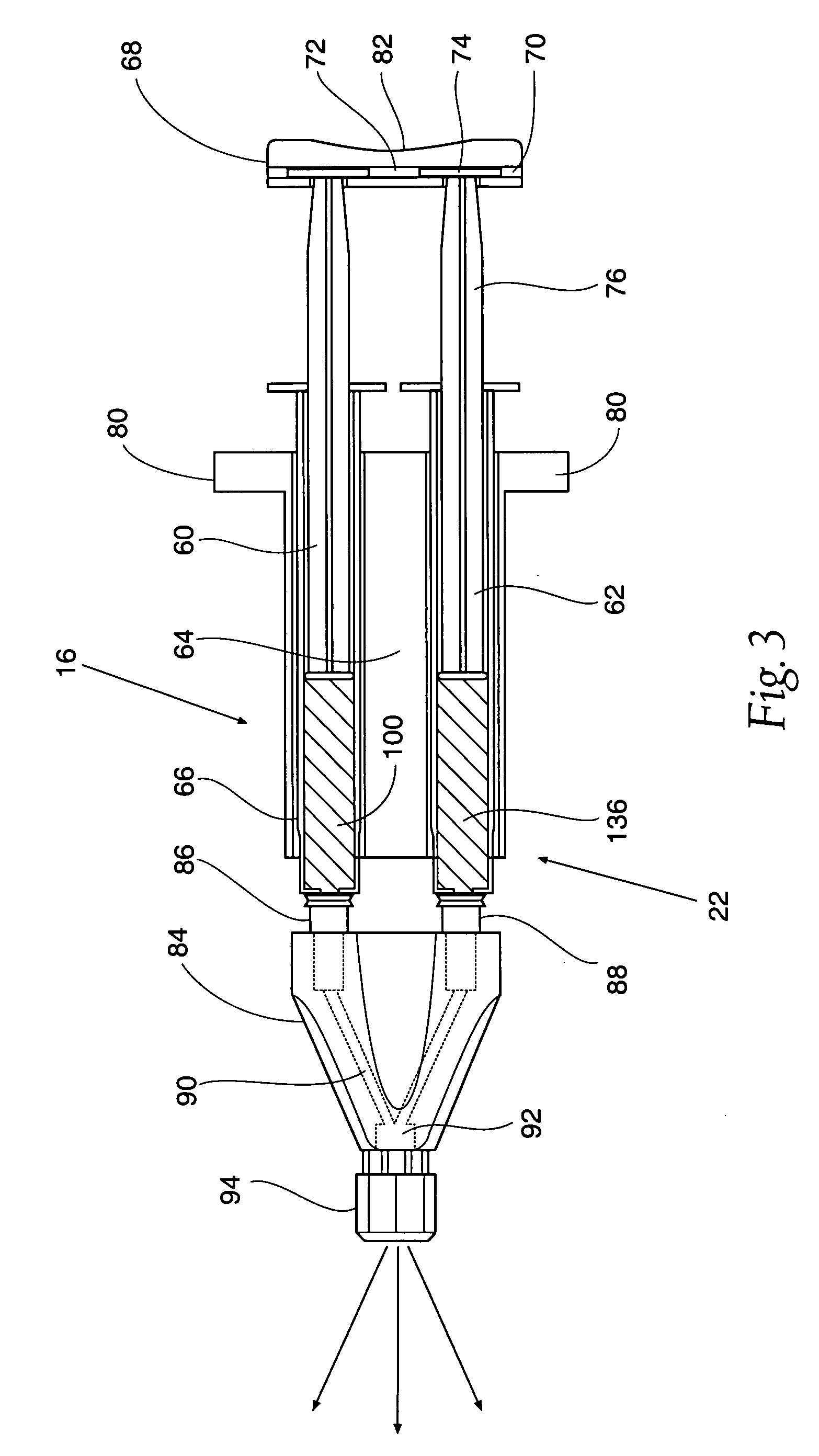

A method of bonding a wafer to a substrate comprising the steps of: providing a wafer having a front surface and a back surface; attaching the front surface of the wafer to a support; thinning the wafer from the back surface; bonding the back surface of the wafer to a substrate using a thin bonding technique; and removing the support from the front surface of the wafer. A circuit comprising: a substrate; and a wafer; wherein the wafer is at most about 50 microns thick; wherein the wafer has a front surface comprising features; and wherein the wafer has a back surface bonded to the substrate using a thin bonding technique.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

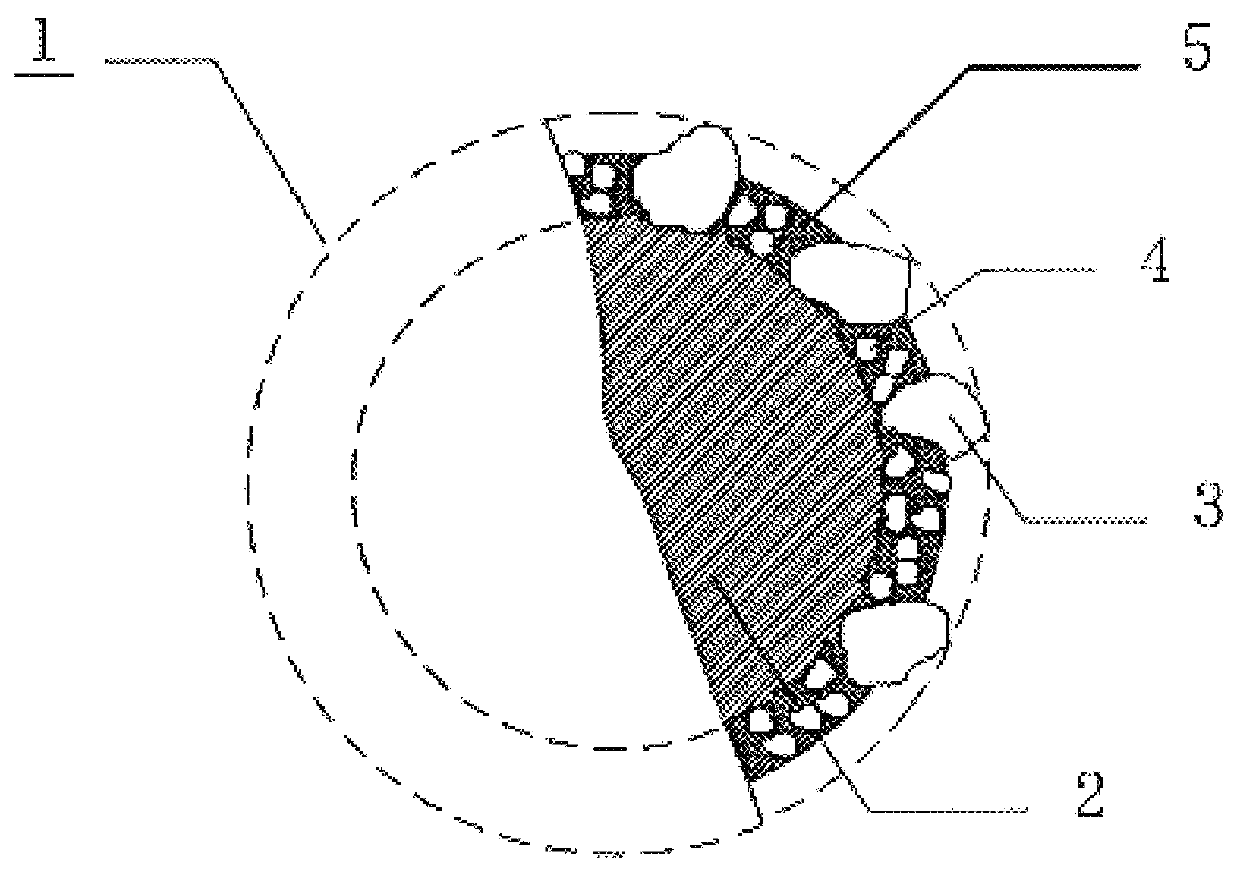

Wire-saw and its manufacturing method

InactiveUS6070570AReadily worked and finishedImprove homogeneityMetal sawing toolsGrinding devicesEngineeringElectronic materials

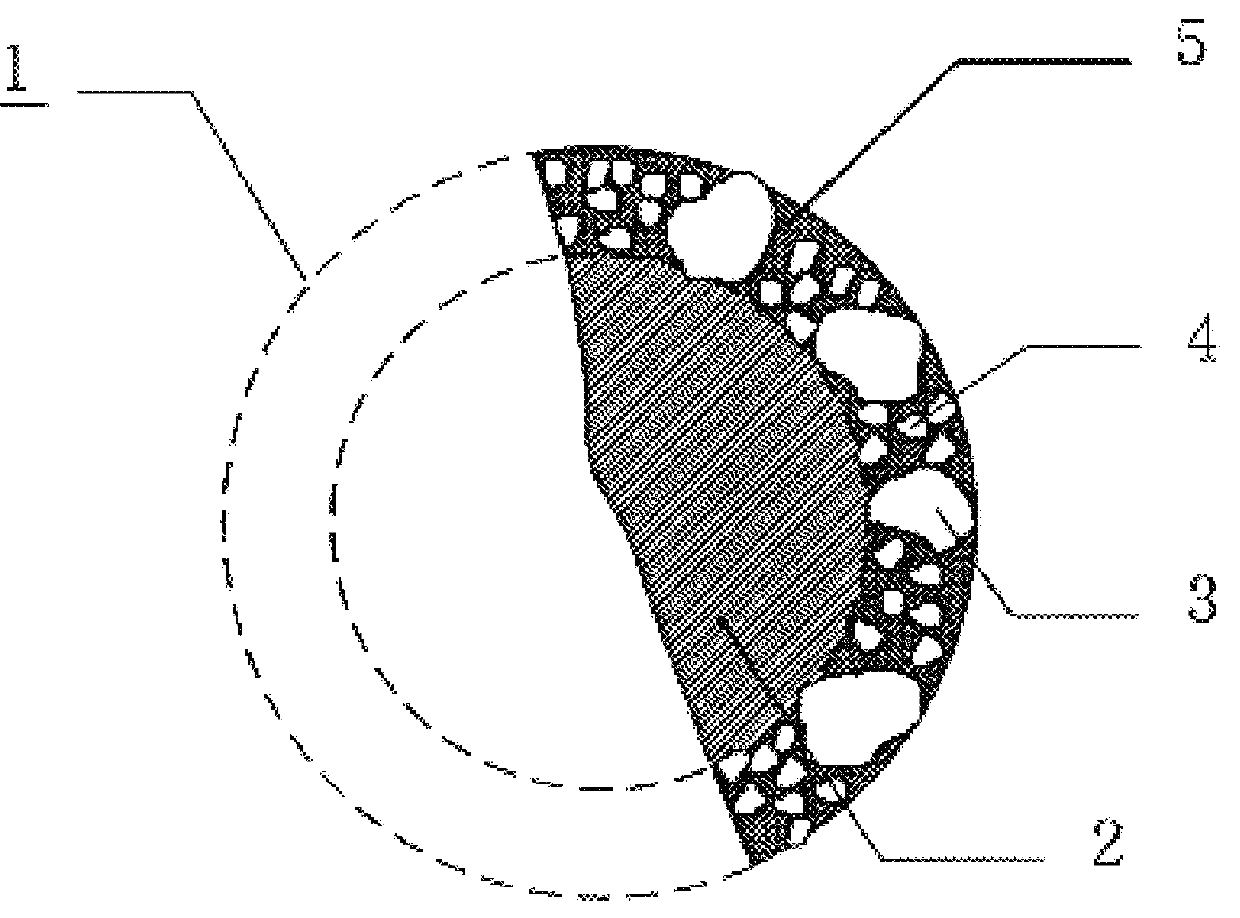

PCT No. PCT / JP98 / 00532 Sec. 371 Date Mar. 9, 1999 Sec. 102(e) Date Mar. 9, 1999 PCT Filed Feb. 9, 1998 PCT Pub. No. WO98 / 35784 PCT Pub. Date Aug. 20, 1998The present invention provides a wire saw for use in cutting works of electronics materials or optical materials and a method for manufacturing the same, said wire saw having the following characteristic features. Namely, onto a high-strength core wire 2, abrasive grains 3 having a grain size not smaller than two-thirds the thickness of a layer of resin bond 4 on said core wire 2 but not exceeding a half the diameter of said core wire are fixed with said resin bond, said resin bond containing a filler having a grain size smaller than two-thirds the thickness of said resin bond layer. The thus structured and arranged wire saw has an improved efficiency and precision in cutting. The wire saw can be manufactured readily by using an enamelling oven.

Owner:ALLIED MATERIAL +1

Wafer bonding of thinned electronic materials and circuits to high performance substrate

InactiveUS20060199353A1Material nanotechnologySemiconductor/solid-state device detailsEngineeringWafer bonding

A method of bonding a wafer to a substrate comprising the steps of: providing a wafer having a front surface and a back surface; attaching the front surface of the wafer to a support; thinning the wafer from the back surface; bonding the back surface of the wafer to a substrate using a thin bonding technique; and removing the support from the front surface of the wafer. A circuit comprising: a substrate; and a wafer; wherein the wafer is at most about 50 microns thick; wherein the wafer has a front surface comprising features; and wherein the wafer has a back surface bonded to the substrate using a thin bonding technique.

Owner:UNITED STATES OF AMERICA

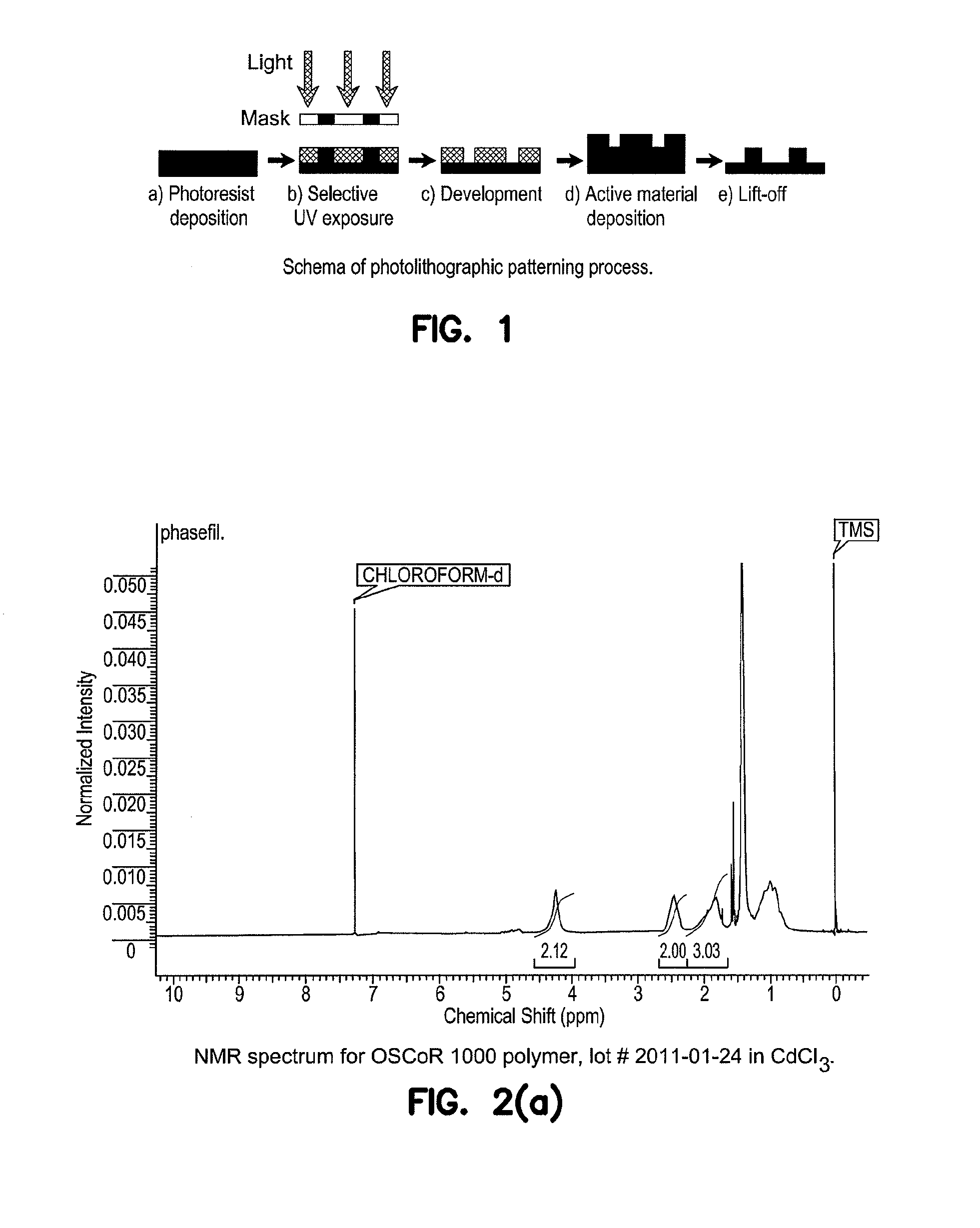

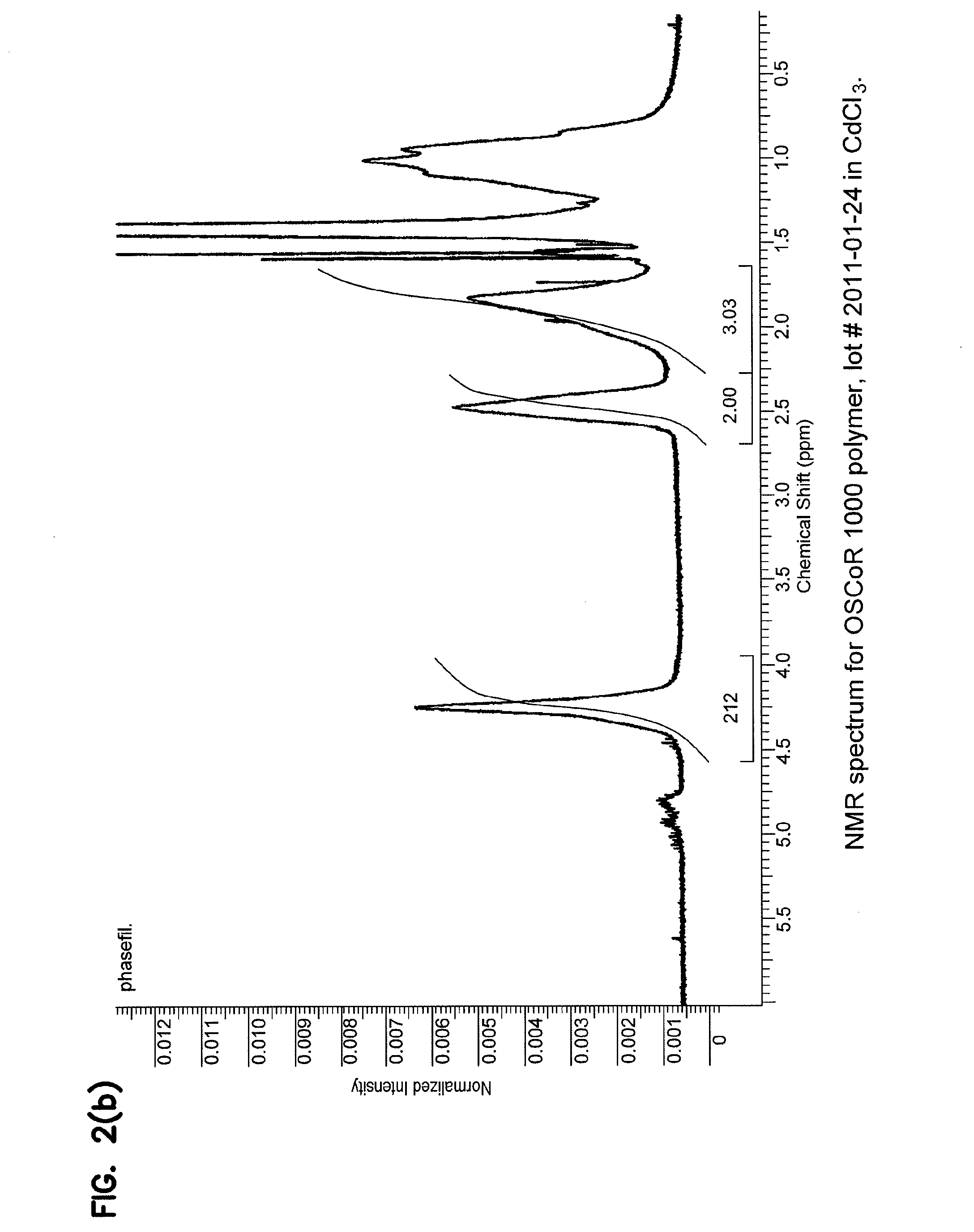

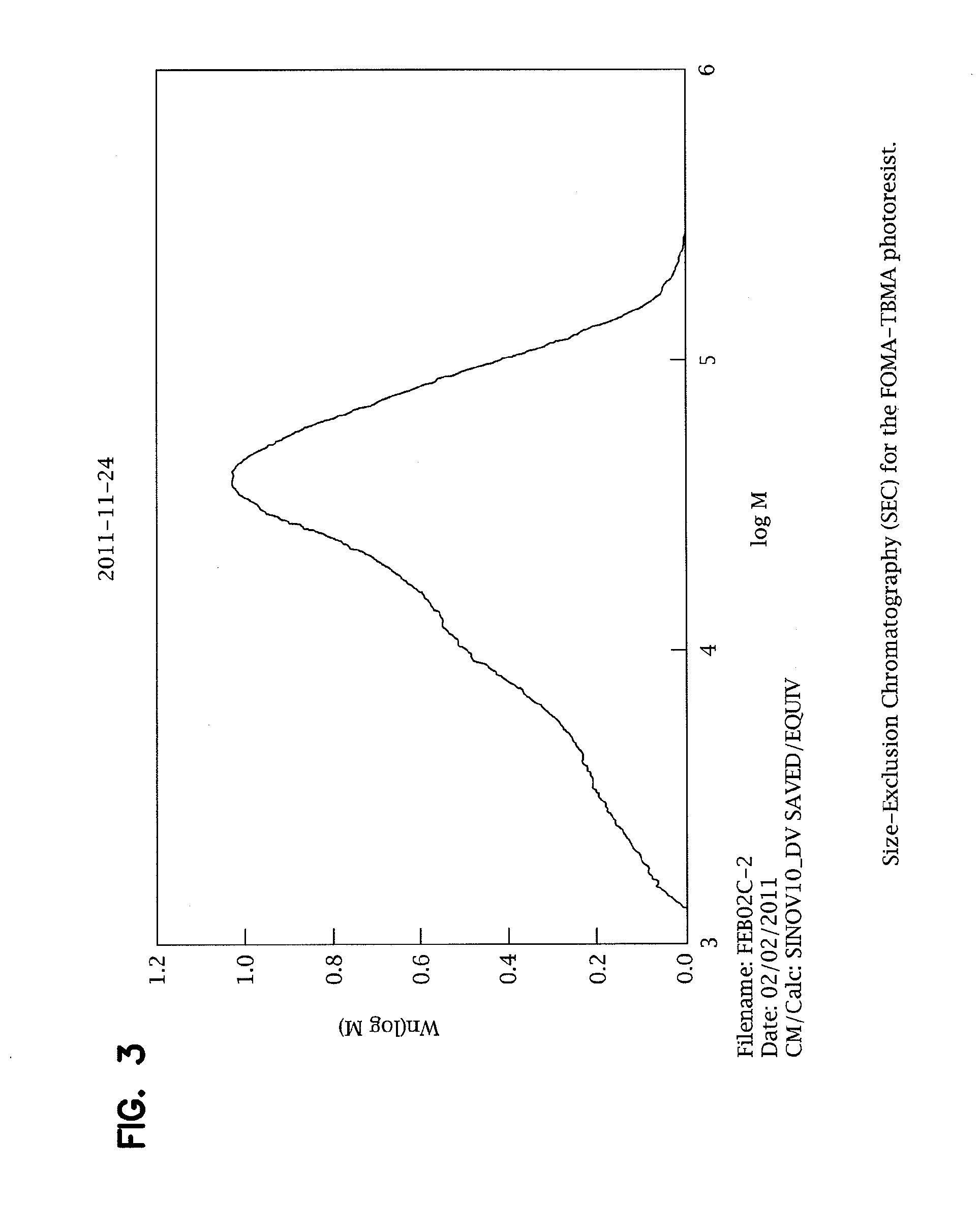

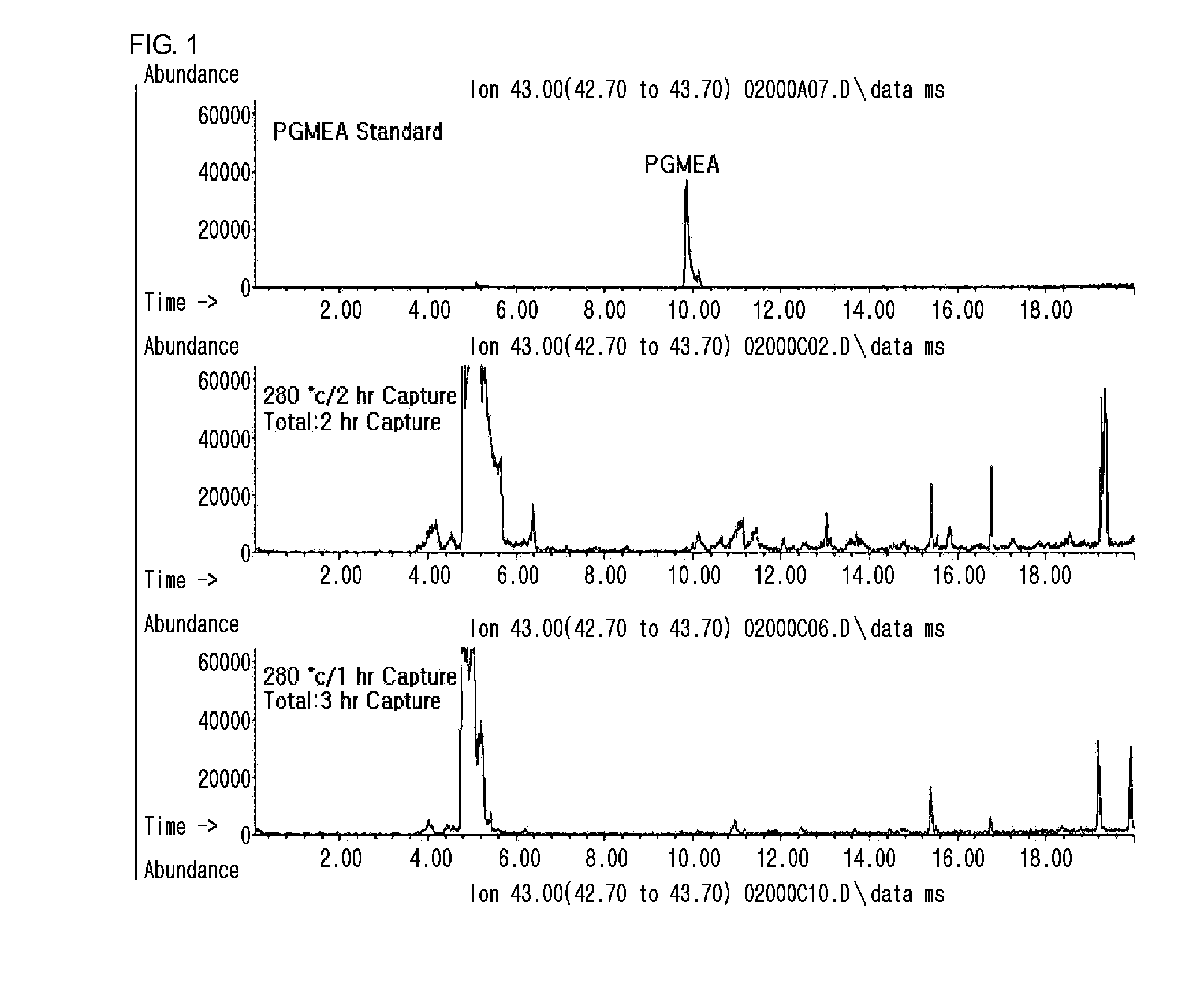

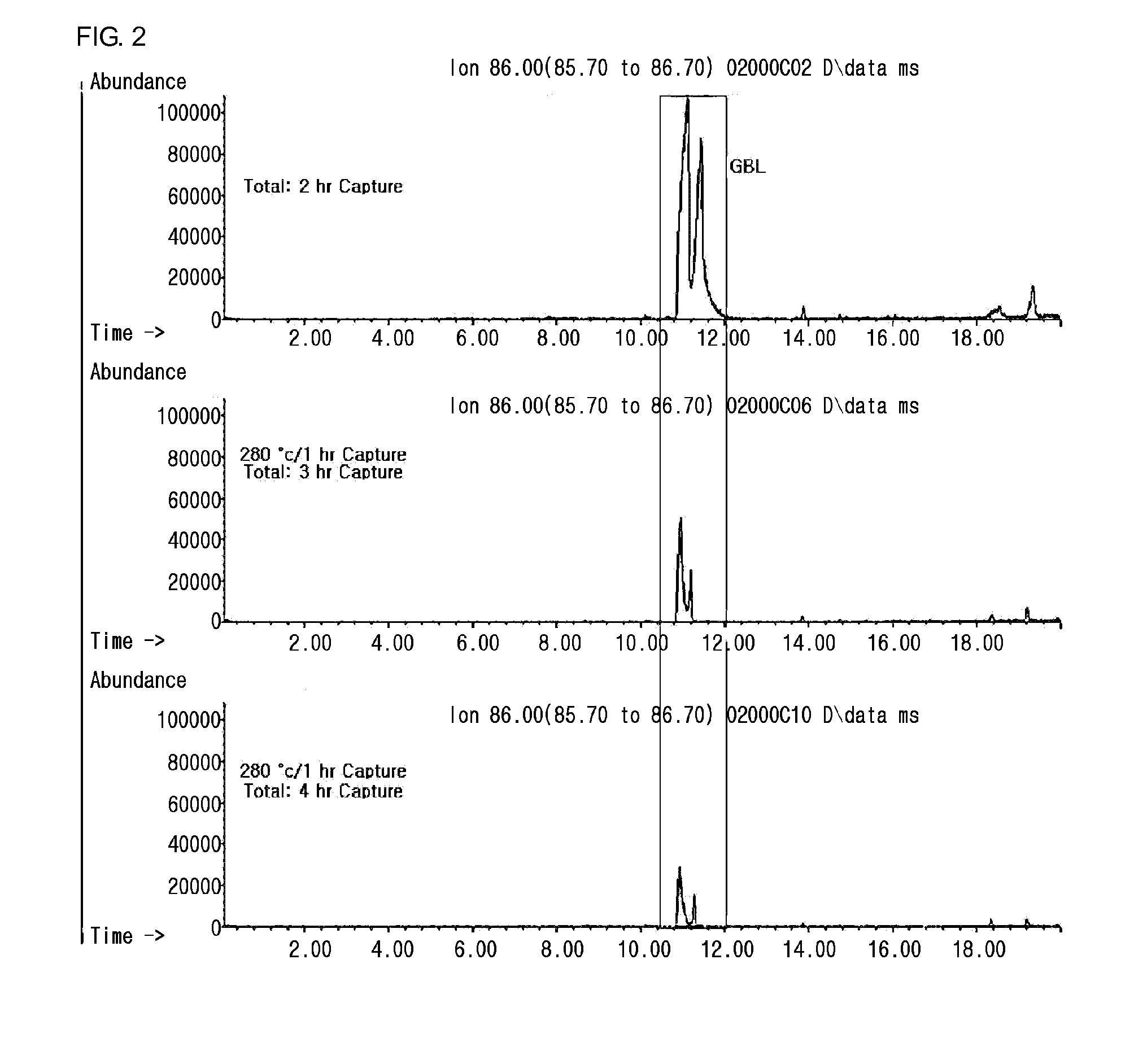

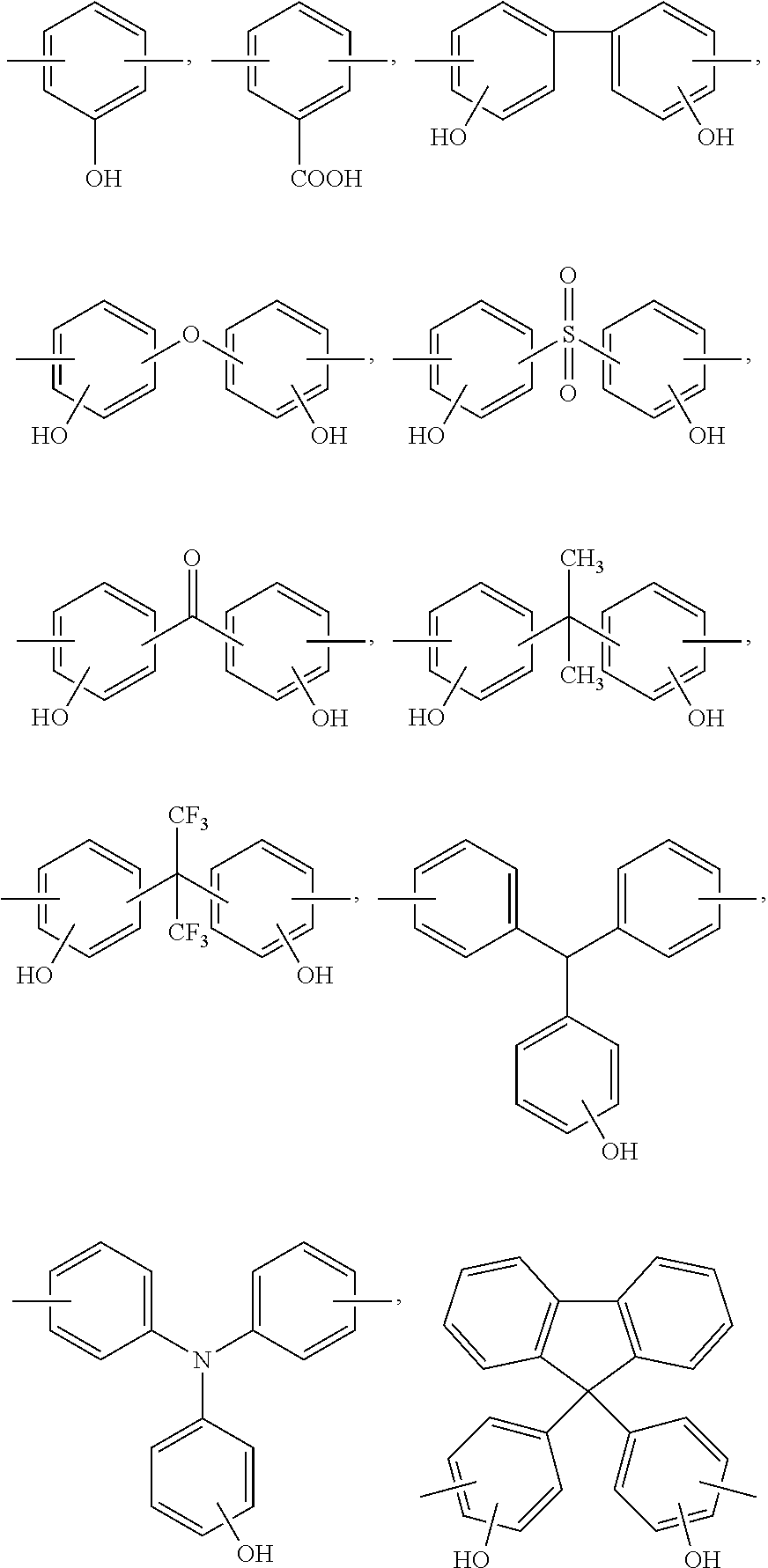

Orthogonal solvents and compatible photoresists for the photolithographic patterning of organic electronic devices

InactiveUS20140127625A1Photosensitive materialsOriginals for photomechanical treatmentSolventPhotoresist

The present invention provides improved solvents and photoresists for the photolithographic patterning of organic electronic devices, systems comprising combinations of these solvents and photoresists, and methods for using these systems of solvents and photoresists to pattern various organic electronic materials.

Owner:ORTHOGONAL

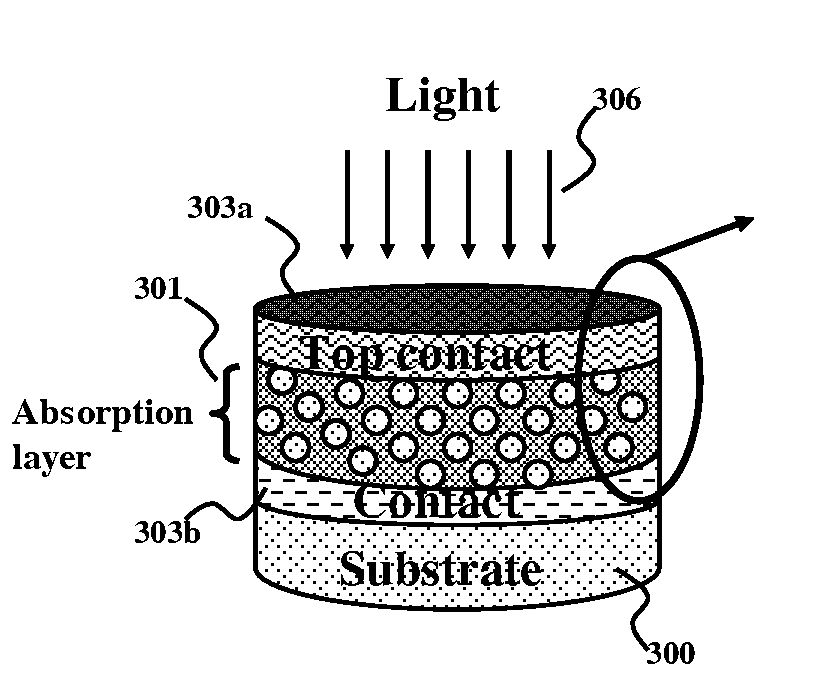

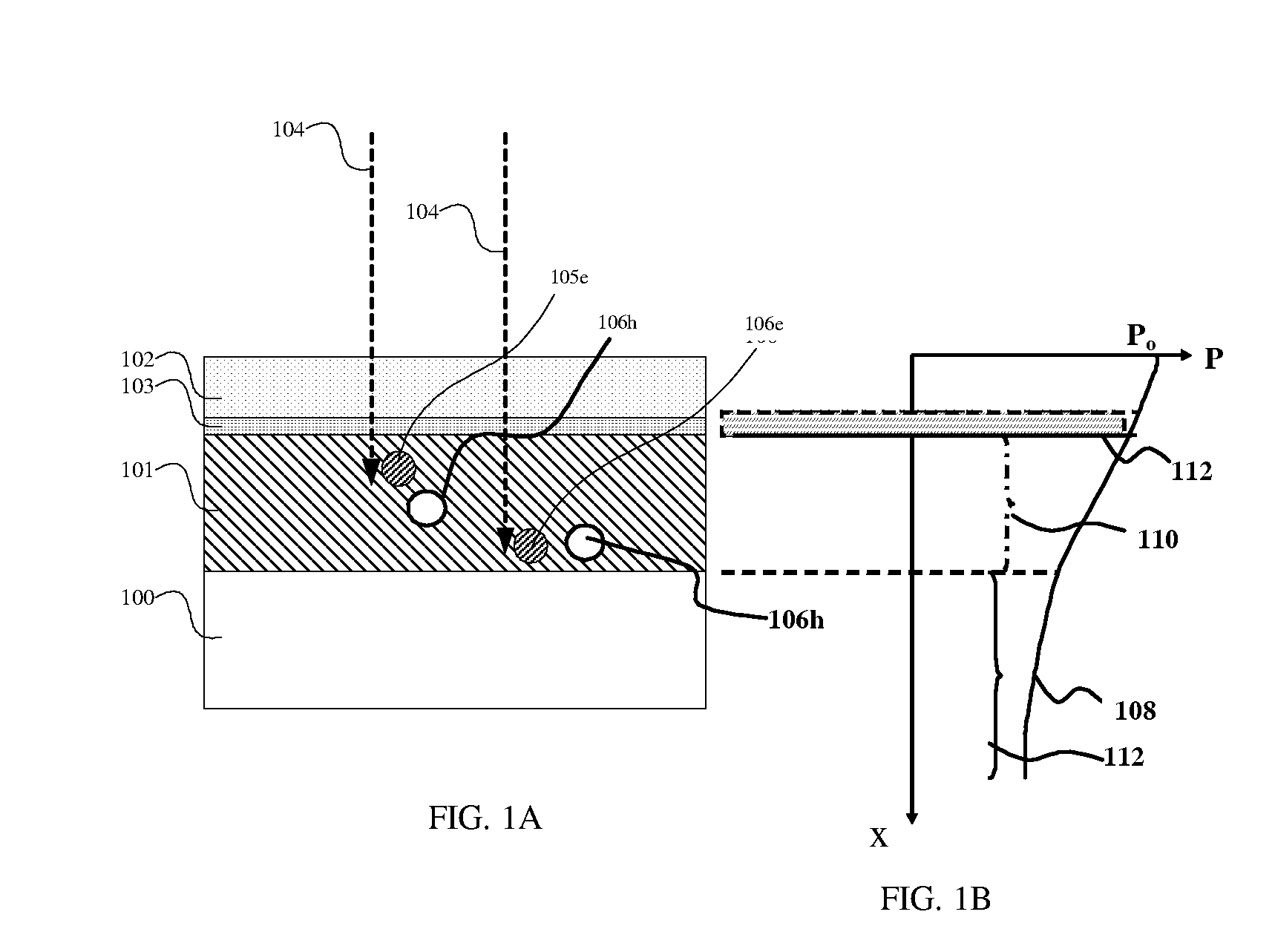

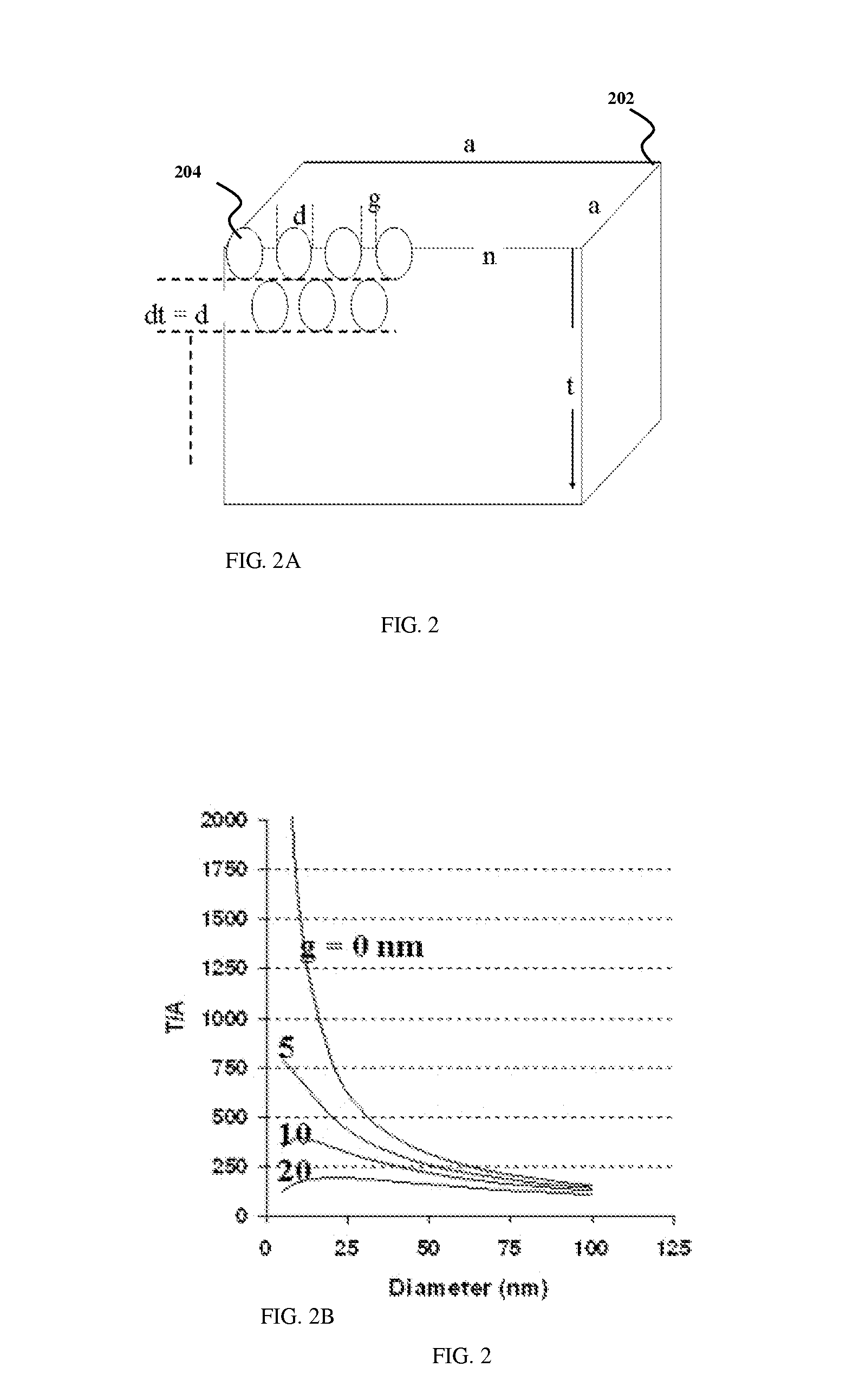

High efficiency photovoltaic cells and manufacturing thereof

ActiveUS20070204902A1Low costElectric power generatedElectrolytic capacitorsFinal product manufactureMicrometerEngineering

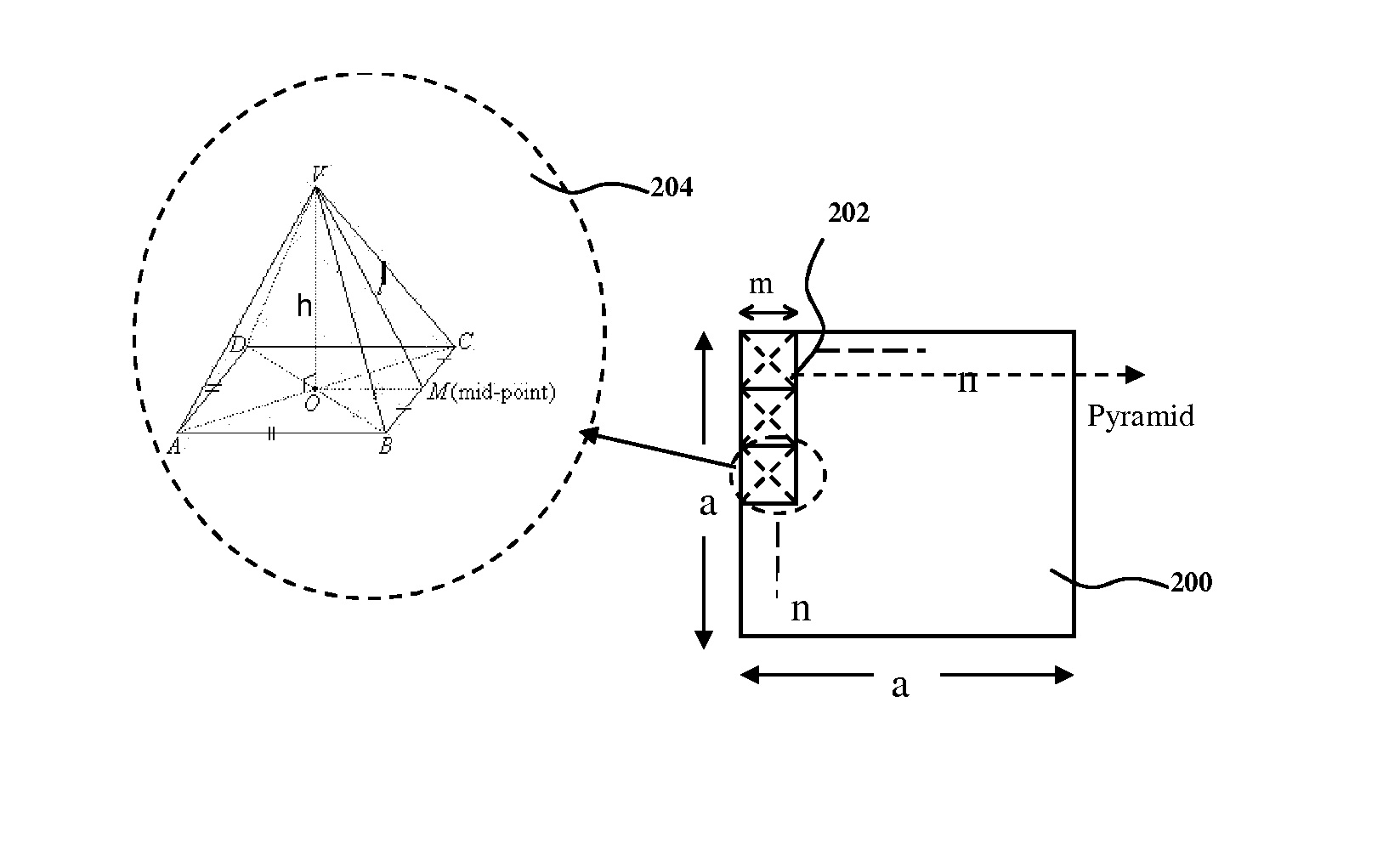

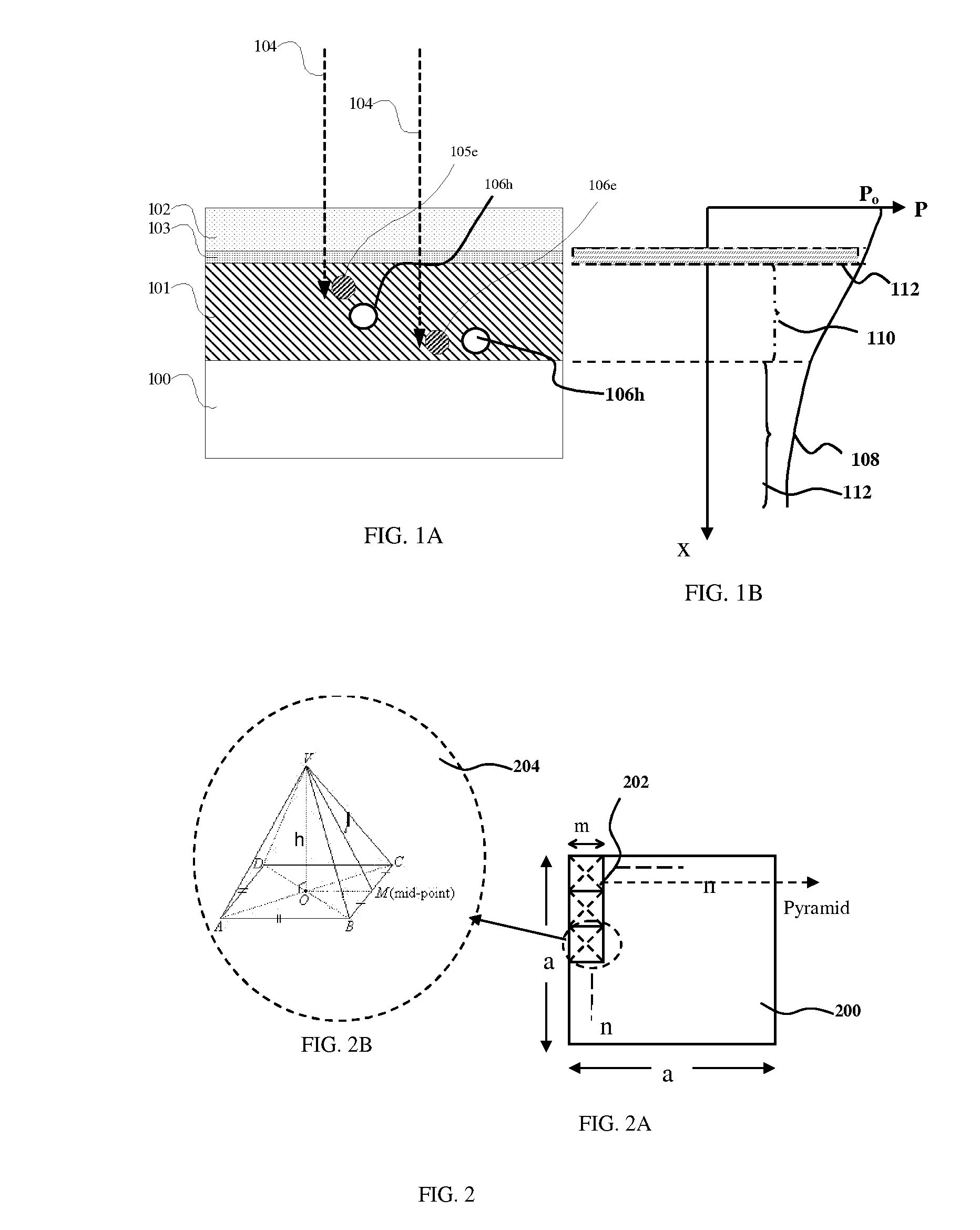

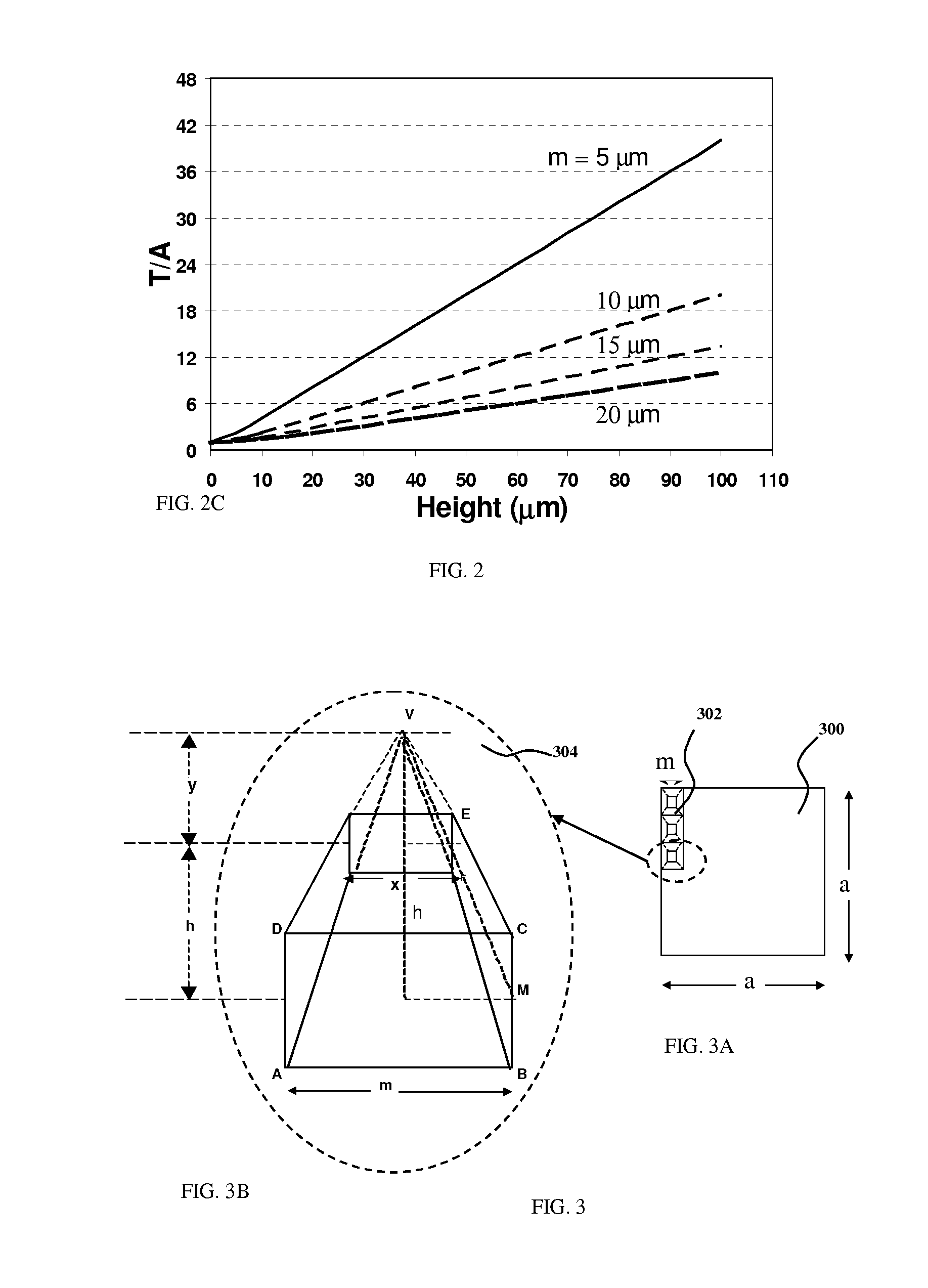

Novel structures of photovoltaic cells (also treated as solar cells) are provided. The cells are based on nanometer or micrometer-scaled wires, tubes, and / or rods, which are made of electronic materials covering semiconductors, insulators, and may be metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications such as in space, commercial, residential and industrial applications.

Owner:BANPIL PHOTONICS

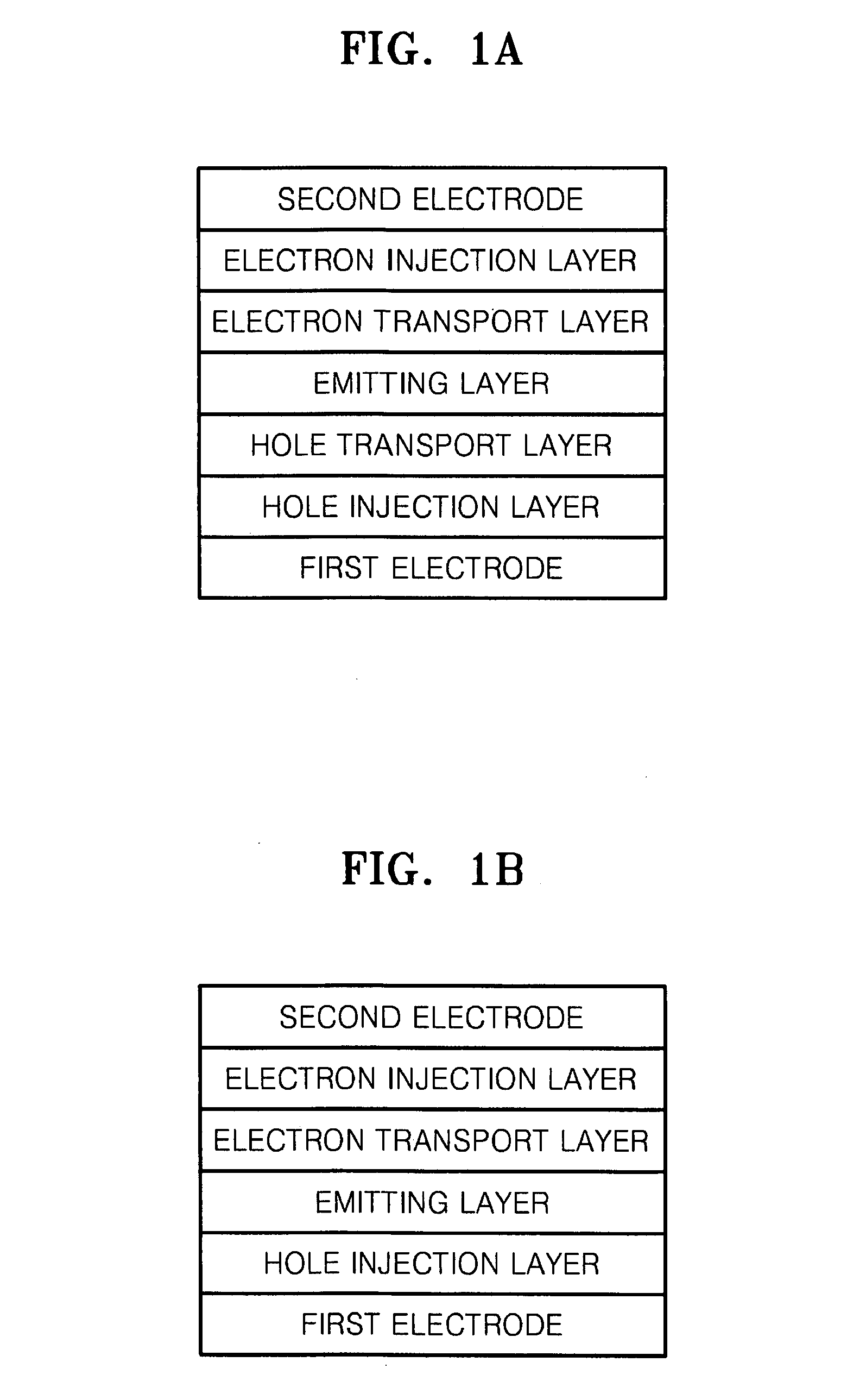

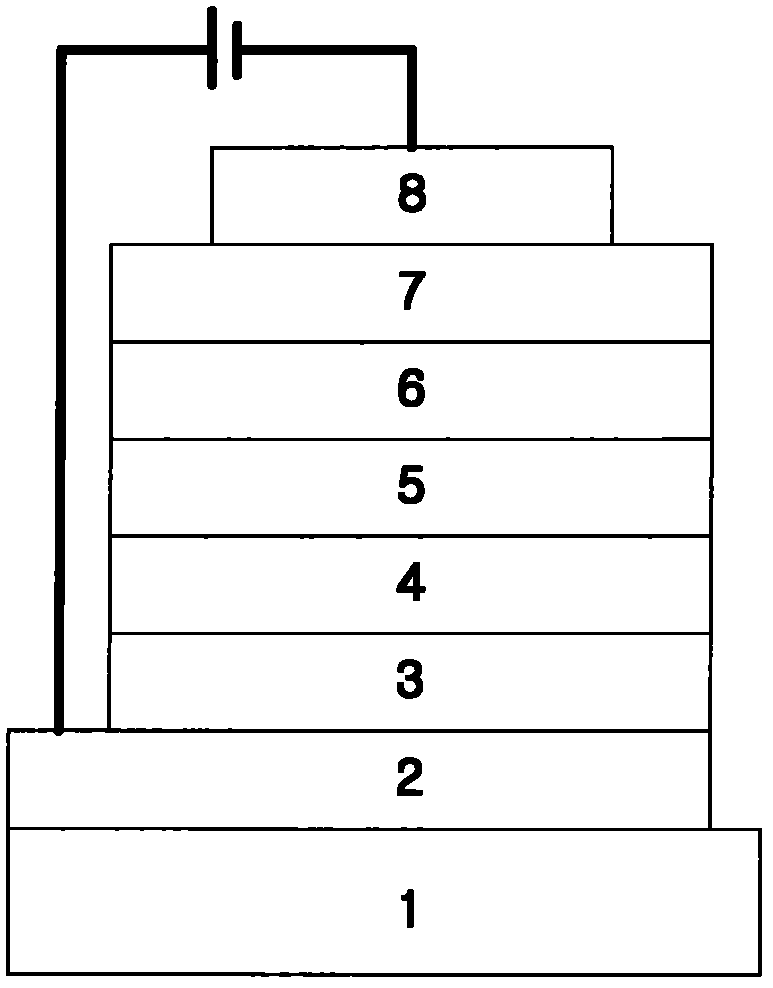

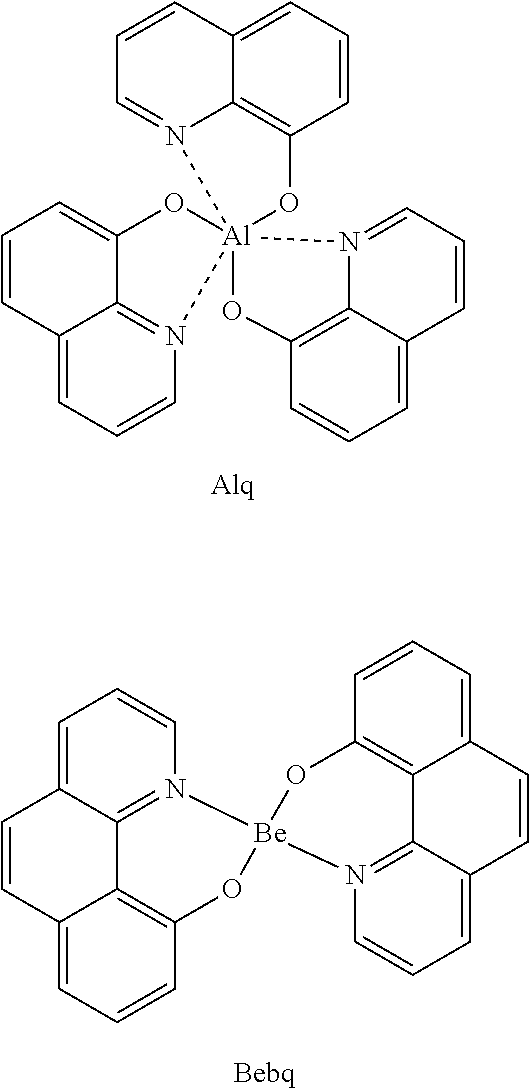

Organoelectroluminescent compound and organoelectroluminescent device employing the same

ActiveUS20080100207A1Stable film formationImprove solubilityDischarge tube luminescnet screensElectroluminescent light sourcesSolubilityOrganic dye

Provided are a cyclopentaphenanthrene-based compound and an organoelectroluminescent device employing the same. The cyclopentaphenanthrene-based compound is easy to prepare and excellent in solubility, color purity, color stability, and thermal stability. The cyclopentaphenanthrene-based compound is useful as a material for forming an organic layer, in particular, an emitting layer, in an organoelectroluminescent device, and as an organic dye or an electronic material such as a nonlinear optical material.

Owner:SAMSUNG DISPLAY CO LTD

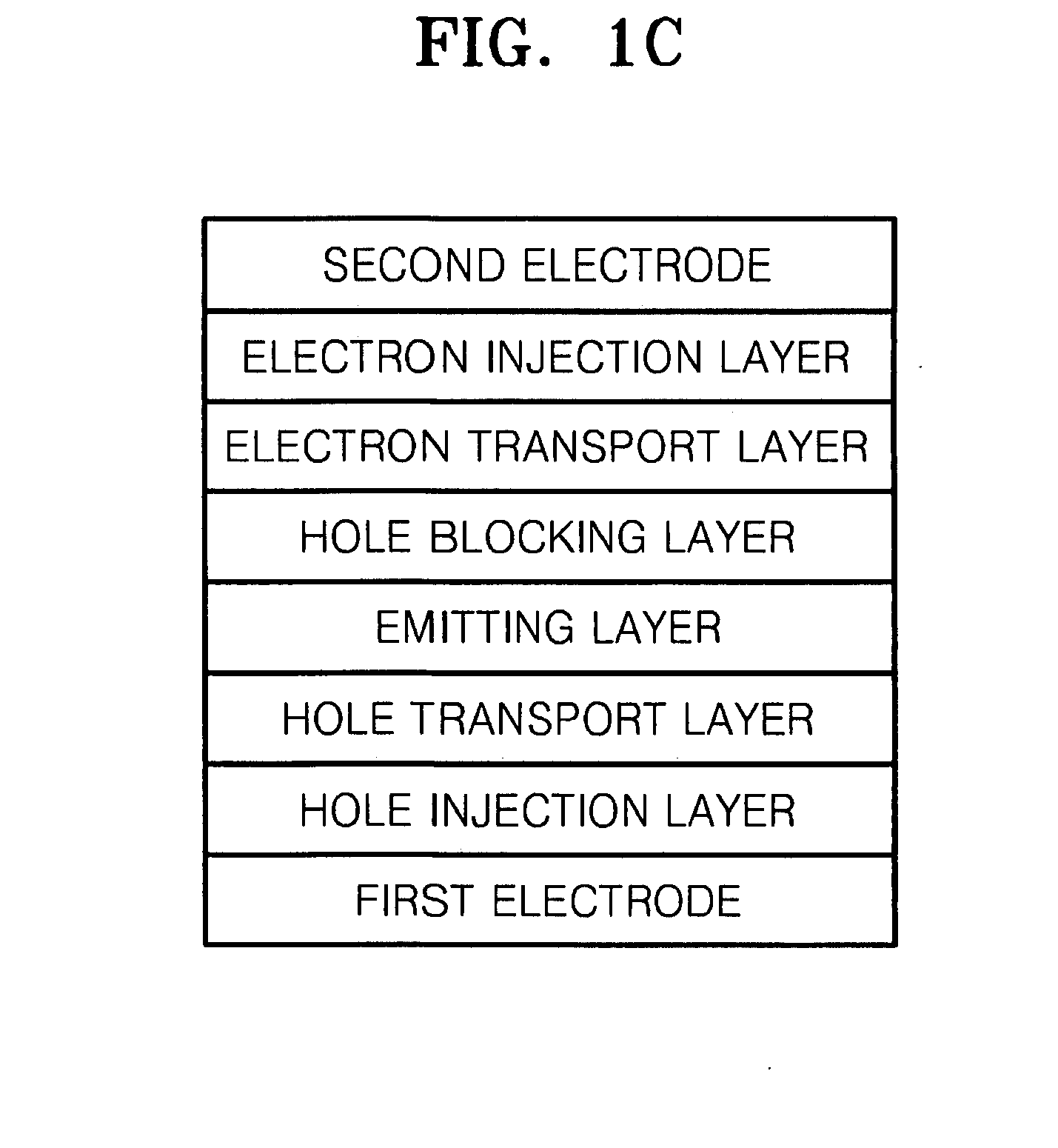

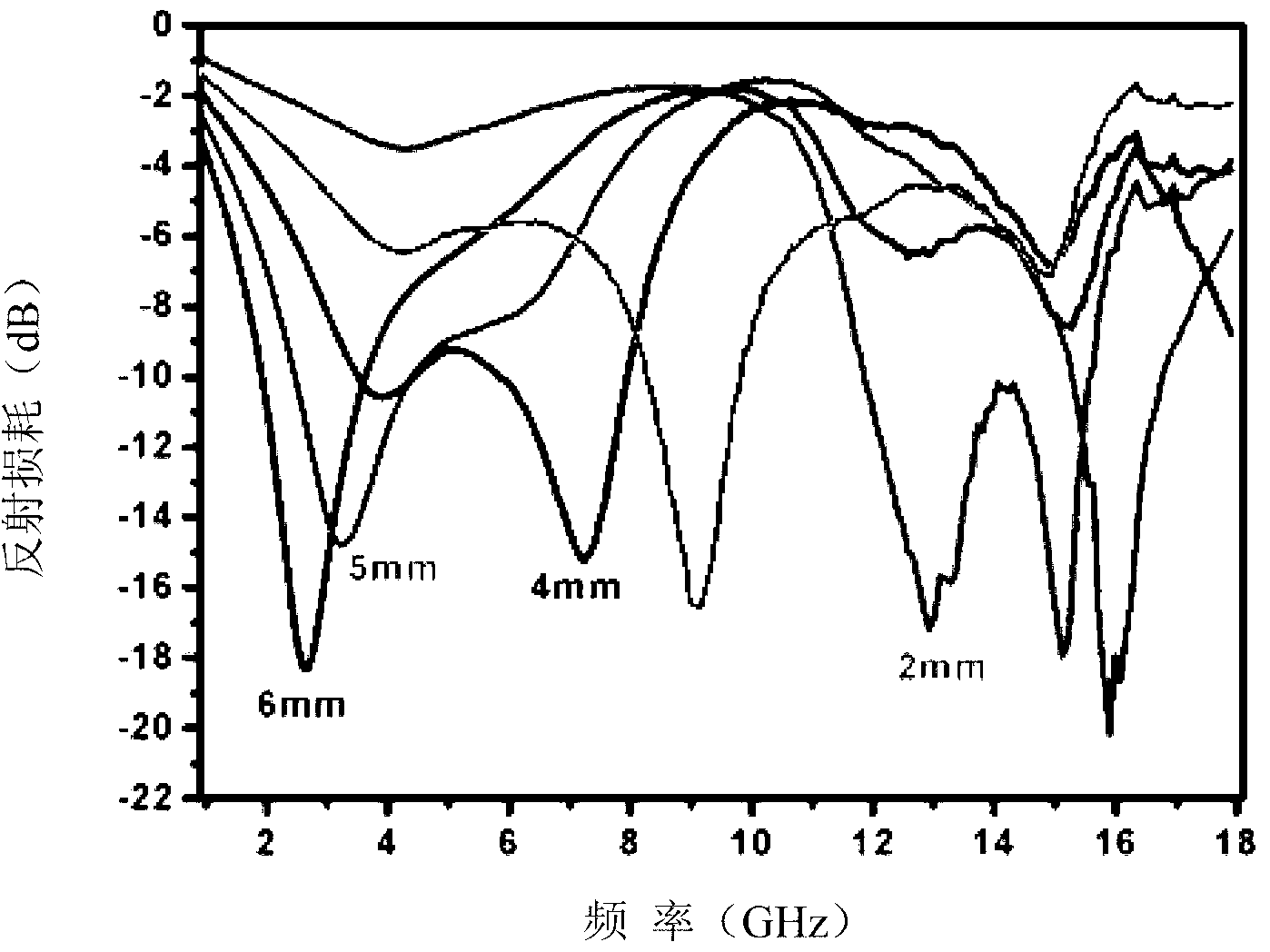

Preparation method of grapheme and ferriferrous oxide composite nanometer material

InactiveCN103274396ASolve the lack of interface binding forceResolving Particle MorphologyMaterial nanotechnologyGrapheneMicrosphereSolvent

A preparation method of a grapheme and ferriferrous oxide composite nanometer material belongs to the technical field of functional materials. The preparation method comprises the following steps: at first, oxidized grapheme is prepared by an improved chemical method; and then oxidized grapheme and ferric ions are adopted as raw materials, and are compounded through adopting a solvothermal technology to carry out one-step in-situ reduction to obtain the grapheme and ferriferrous oxide composite nanometer material. The preparation method solves the problems in the prior art that the interface binding force of grapheme and a magnetic material is insufficient, the appearances, the sizes and the magnetism of magnetic material particles are uncontrollable, and the magnetic material particles cannot be dispersed in water; the prepared composite nanometer material shows a microspheric appearance, has a loose surface and is high in specific surface area; through the change of the ratio of grapheme to the ferric ions, final magnetic property and electrical property of the composite material can be adjusted; and the controllable growth of the grapheme and ferriferrous oxide composite material is realized. The prepared grapheme and ferriferrous oxide nanometer microsheric material with magnetic and electric properties can be used in fields such as biological medicine, energy, invisibility and electronic materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

High efficiency photovoltaic cells

ActiveUS20070175507A1Low costReduce carrier recombinationPhotovoltaic energy generationSemiconductor devicesNanoparticleEngineering

Novel structures of photovoltaic cells (also called as solar cells) are provided. The cells are based on nanoparticles or nanometer-scaled wires, tubes, and / or rods, which are made of electronic materials covering semiconductors, insulators, and may be metallic in structure. These photovoltaic cells have large power generation capability per unit physical area over the conventional cells. These cells will have enormous applications such as in space, commercial, residential and industrial applications.

Owner:BANPIL PHOTONICS

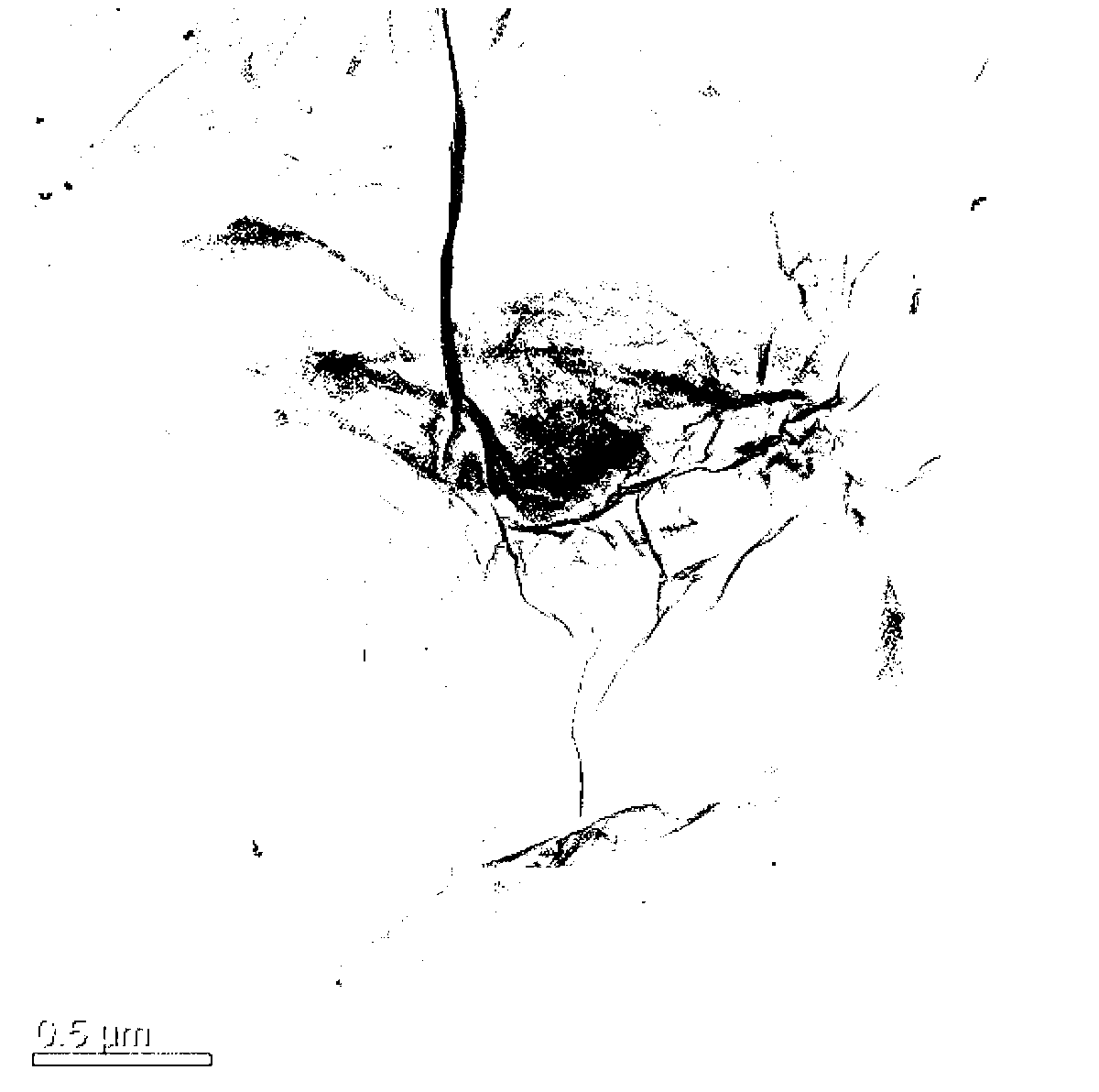

Preparation method of carbon-coated metallic nano-particles

InactiveCN102500295AEasy to operateHigh degree of graphitizationMicroballoon preparationMicrocapsule preparationTube furnaceCarbon coated

The invention discloses a preparation method of carbon-coated metallic nano-particles, which comprises the steps that: NaCl serves as dispersant and a carrier, and is fully mixed with a metal source and a solid carbon source; the mixed solution is dried under a vacuum condition, and mixture is obtained; the mixture is put into a tubular furnace and calcinated in the inertial / reduction atmosphere, and a calcinated product is obtained; and the calcinated product is washed and ground, and the carbon-coated metallic nano-particles are obtained. The method is safe, non-toxic, environmental-friendly and simple to operate, so that the grain sizes of the prepared carbon-coated nano-particles are controlled to be 0nm to 100nm, the graphitization degree of a carbon layer is high, the dispersion of the particles is good, and the yield is high. The carbon-coated metallic nano-particles which are prepared through the preparation method have better magnetism and larger specific surface areas, can be used for electronic and magnetic materials, and can be used for magnetic resonance imaging, targeted drug transportation and other fields through functionalization treatment and other steps.

Owner:TIANJIN UNIV

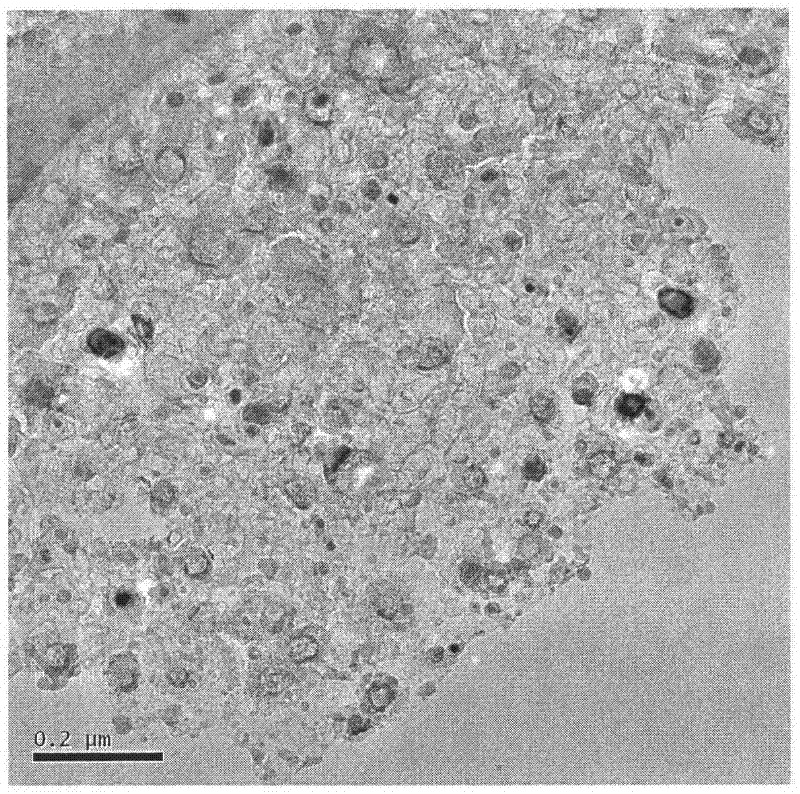

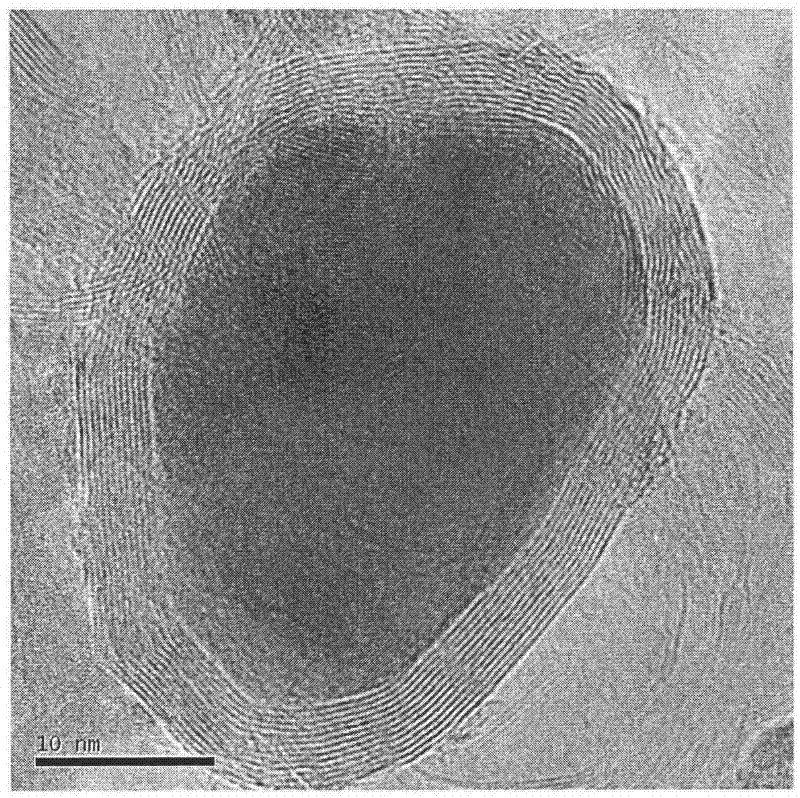

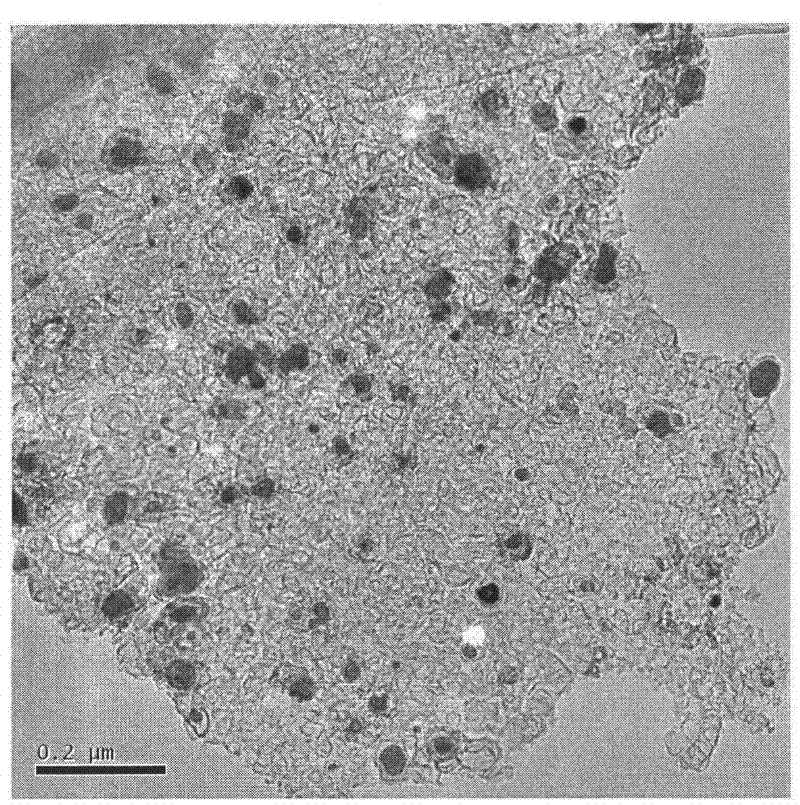

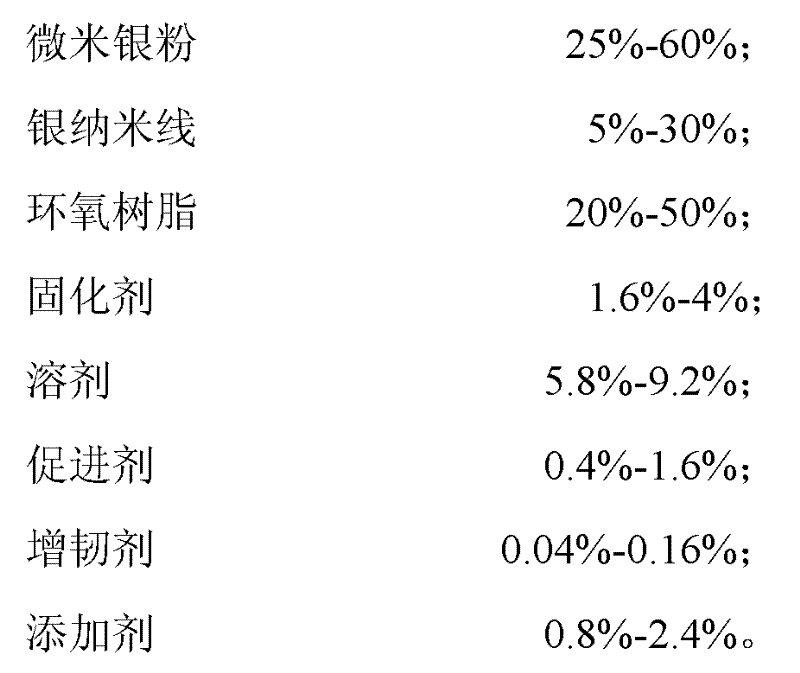

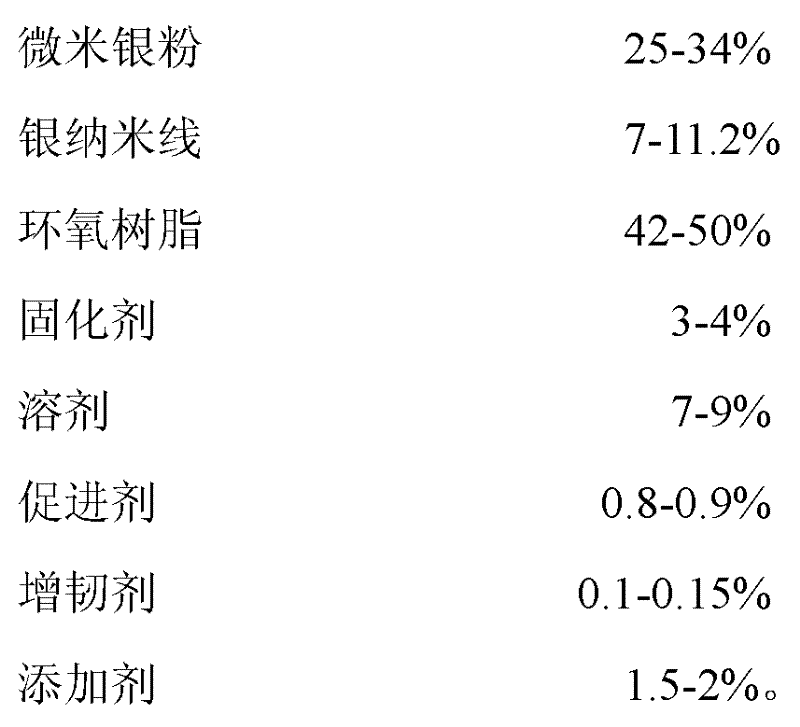

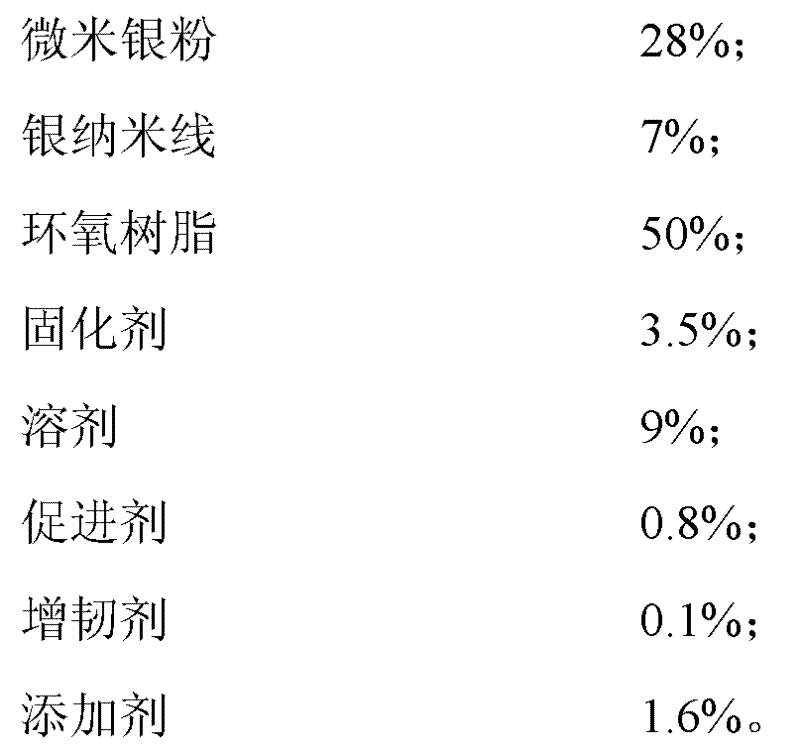

Silver nanowire doped conductive silver colloid and preparation method thereof

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

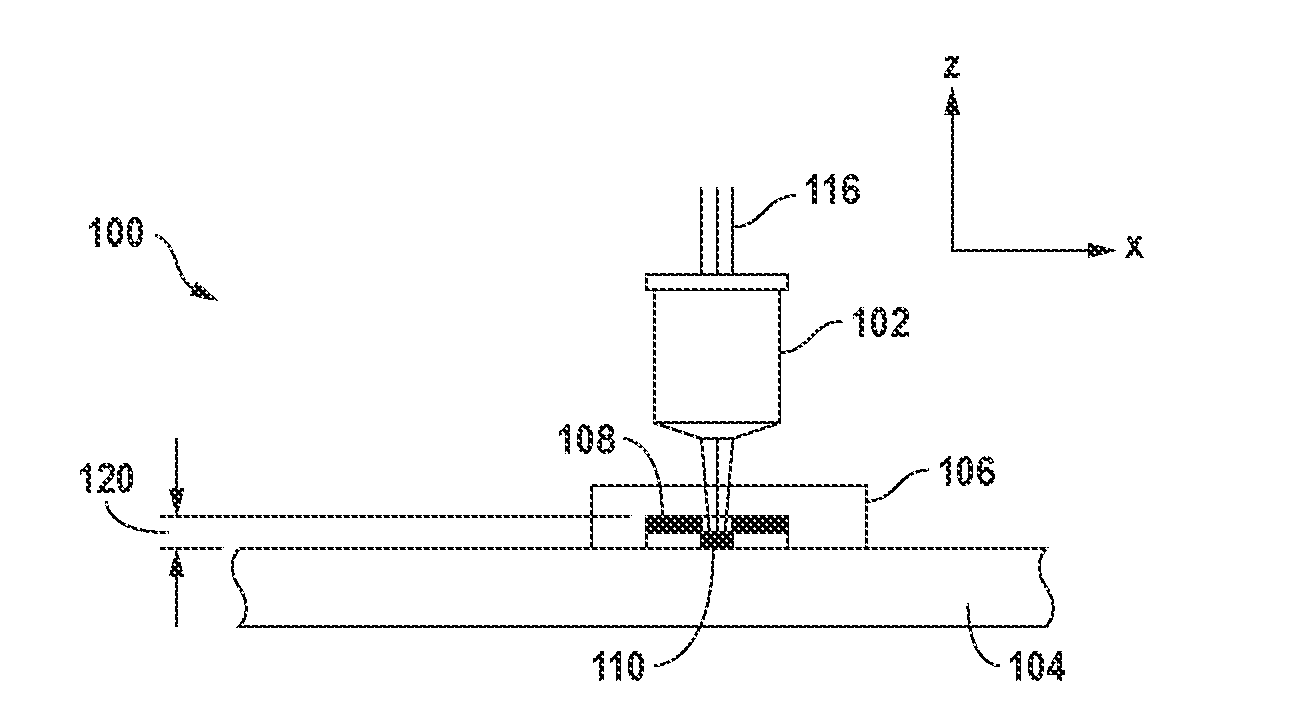

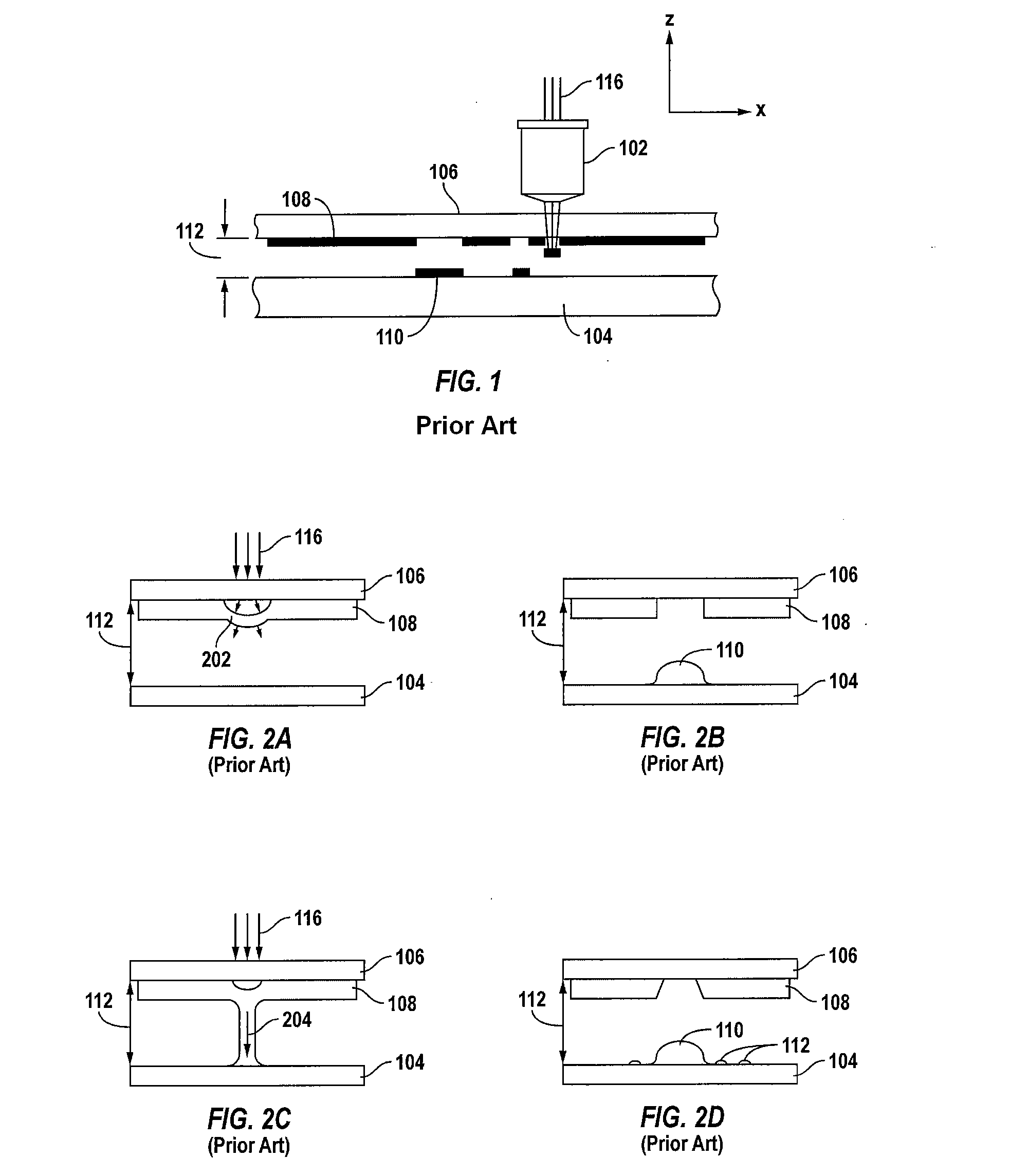

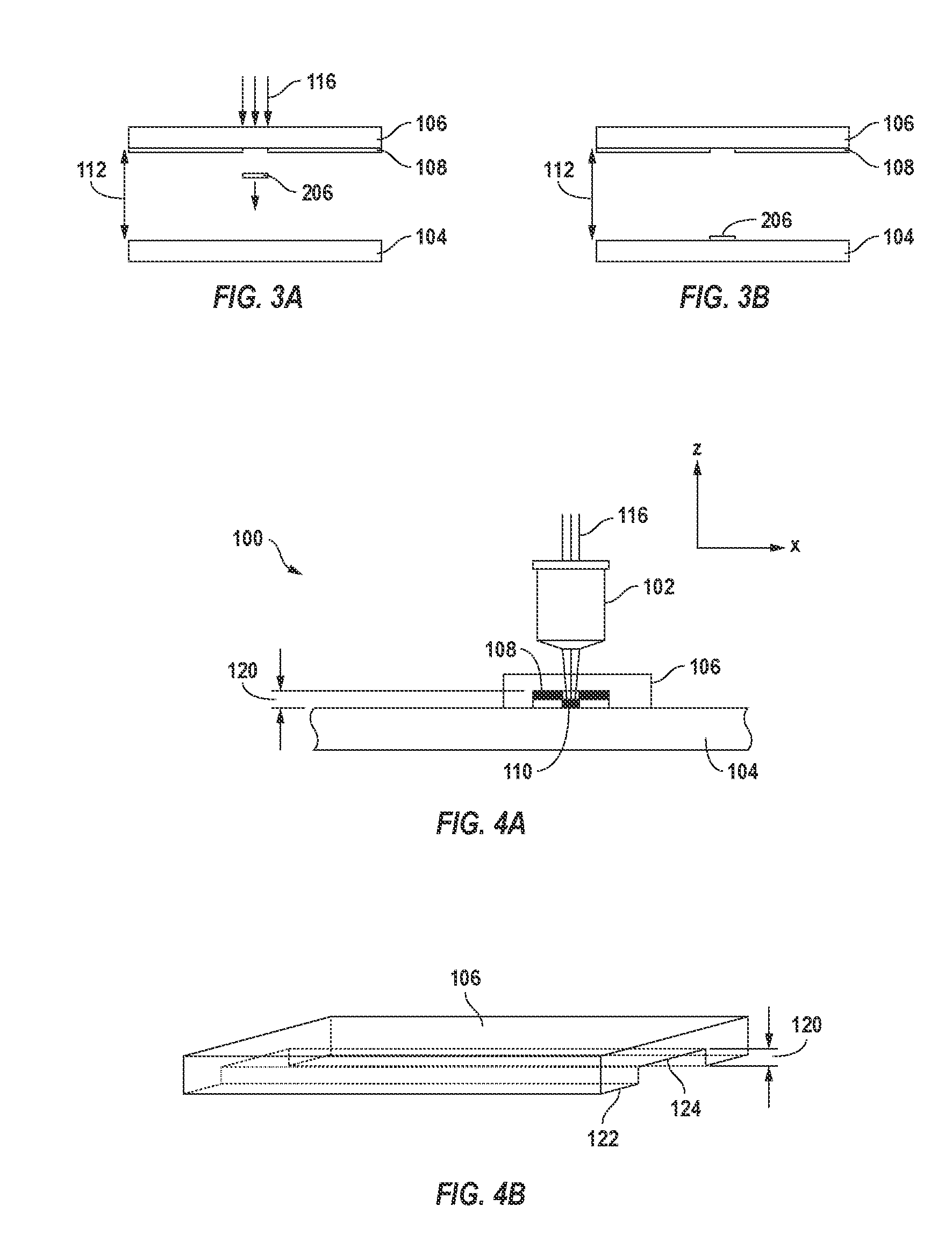

Laser decal transfer of electronic materials

ActiveUS20090074987A1Dampening any shear forceHigh viscosityElectric discharge heatingTransfer patterningThin layerOptoelectronics

A laser decal transfer is used to generate thin film features by directing laser pulses of very low energy at the back of a target substrate illuminating an area of a thin layer of a high viscosity rheological fluid coating the front surface of the target. The illuminated area is shaped and defined by an aperture centered about the laser beam. The decal transfer process allows for the release and transfer from the target substrate to the receiving substrate a uniform and continuous layer identical in shape and size of the laser irradiated area. The released layer is transferred across the gap with almost no changes to its initial size and shape. The resulting patterns transferred onto the receiving substrate are highly uniform in thickness and morphology, have sharp edge features and exhibit high adhesion, independent of the surface energy, wetting or phobicity of the receiving substrate.

Owner:PHOTON DYNAMICS +1

Heat and flame resistant nylon composite

InactiveCN101735601AImprove flame retardant performanceImprove mechanical propertiesNylon materialNitrogen

The invention relates to heat and flame resistant nylon composite belonging to the filed of the electrical and electronic material. The heat and flame resistant nylon composite is characterized by comprising phosphorus flame retardant, nitrogen flame retardant, inorganic synergist, filler and auxiliary agent facilitating the processing and stabilizing. Due to the synergistic effect of the phosphorus flame retardant, the nitrogen flame retardant and the inorganic synergist, the nylon has the flame resistance, mains the mechanical performance, the thermal performance and the electrical insulating performance and can pass the test of the glow wire at 850 DEG C, and the problems that the defect of the nylon product is increased and the mechanical performance and the electrical insulating performance of the nylon produce are decreased due to the large consumption of the phosphorus flame retardant are solved. The heat and flame resistant nylon composite has good flame resistance, mechanical performance, thermal performance and electrical insulating performance and is mainly applied to the electrical and electronic industry.

Owner:SINOPLAST NEW MATERIAL

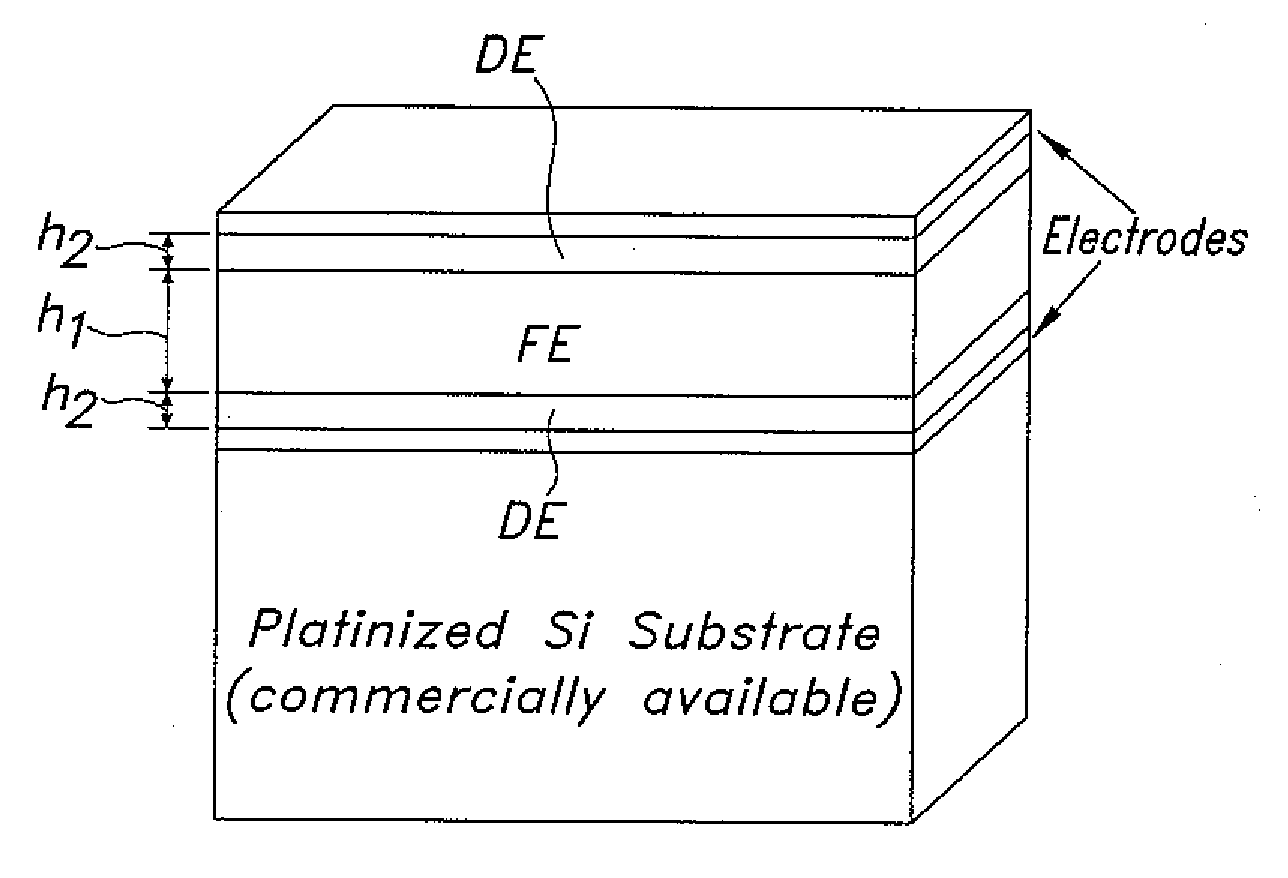

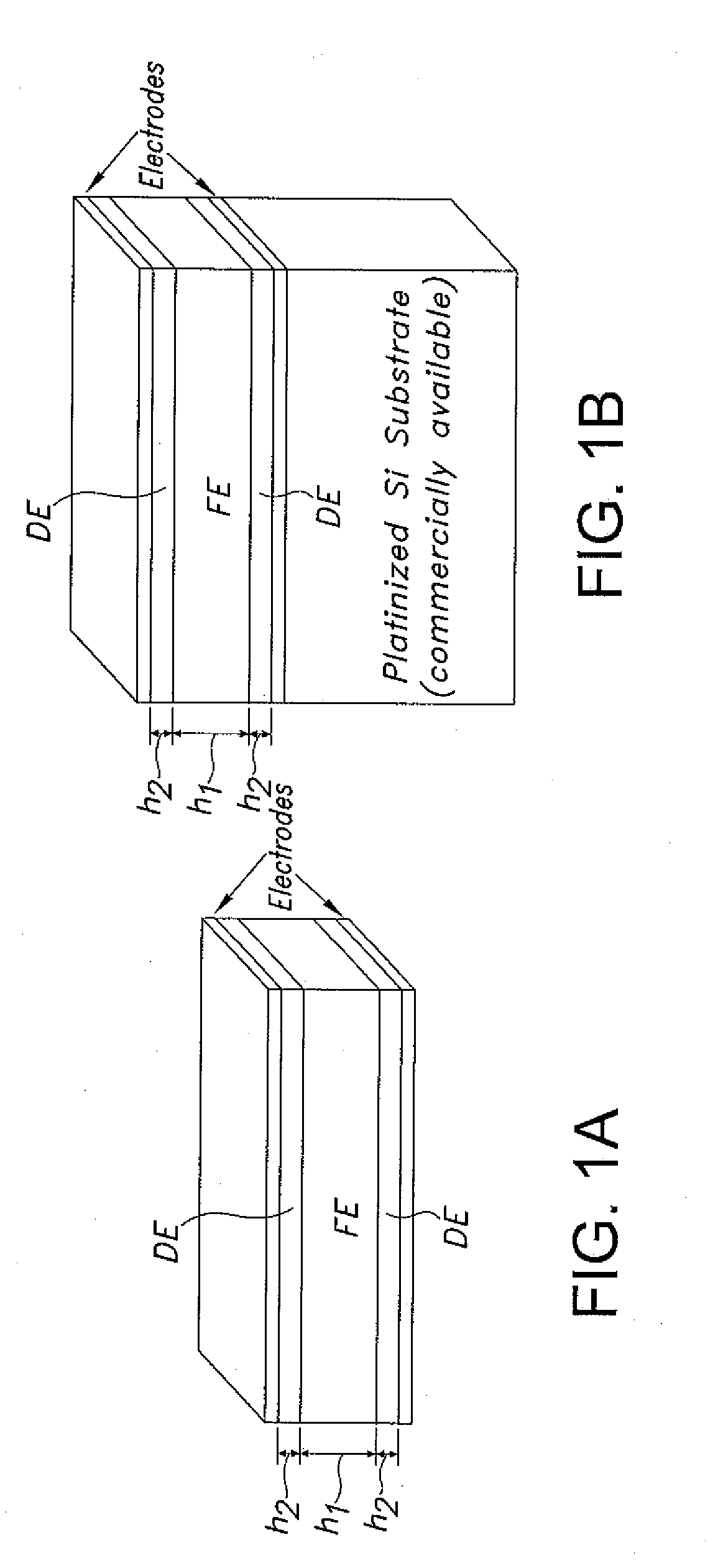

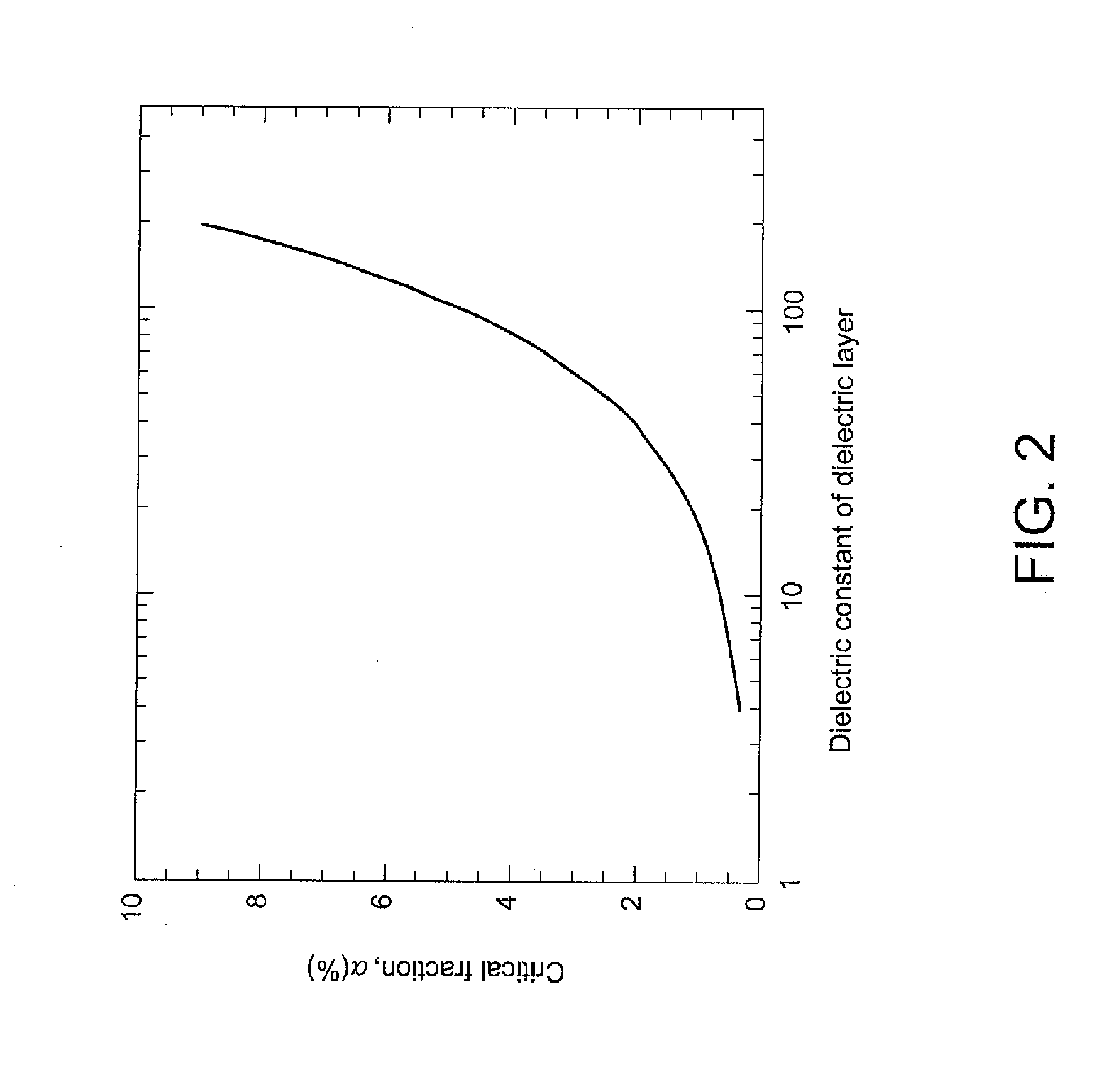

High-capacity, low-leakage multilayer dielectric stacks

InactiveUS20080107885A1Synthetic resin layered productsSemiconductor/solid-state device manufacturingDielectricElectricity

The present disclosure is directed to an exemplary method for designing, implementing, and making a high capacity low leakage multilayer stack for various electronic applications. In a particular embodiment, the multilayer stack is made up of a dielectric / ferroelectric / dielectric trilayer. This configuration has shown to have giant dielectric permittivity which is much higher than conventional gate dielectrics. The DE / FE interlayer exhibits strong interlayer coupling, yielding desired properties. In order to prevent leakage and loss while maintaining high capacity, certain parameters of each layer must exist. The present disclosure describes a method of quantitatively achieving these parameters through correlating critical fraction with dielectric constant. Moreover, this method can be used for scalability of electronic materials.

Owner:UNIV OF CONNECTICUT

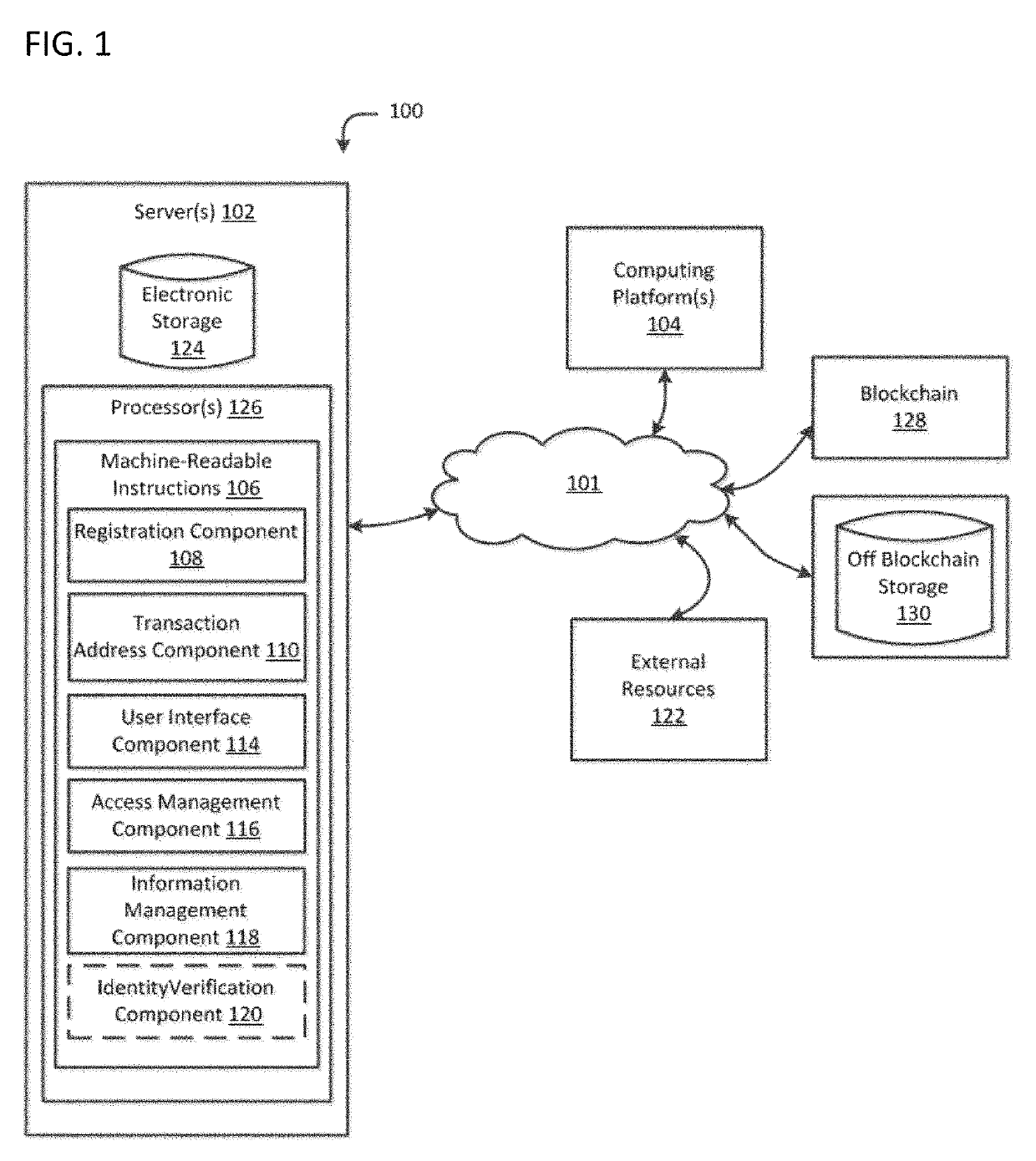

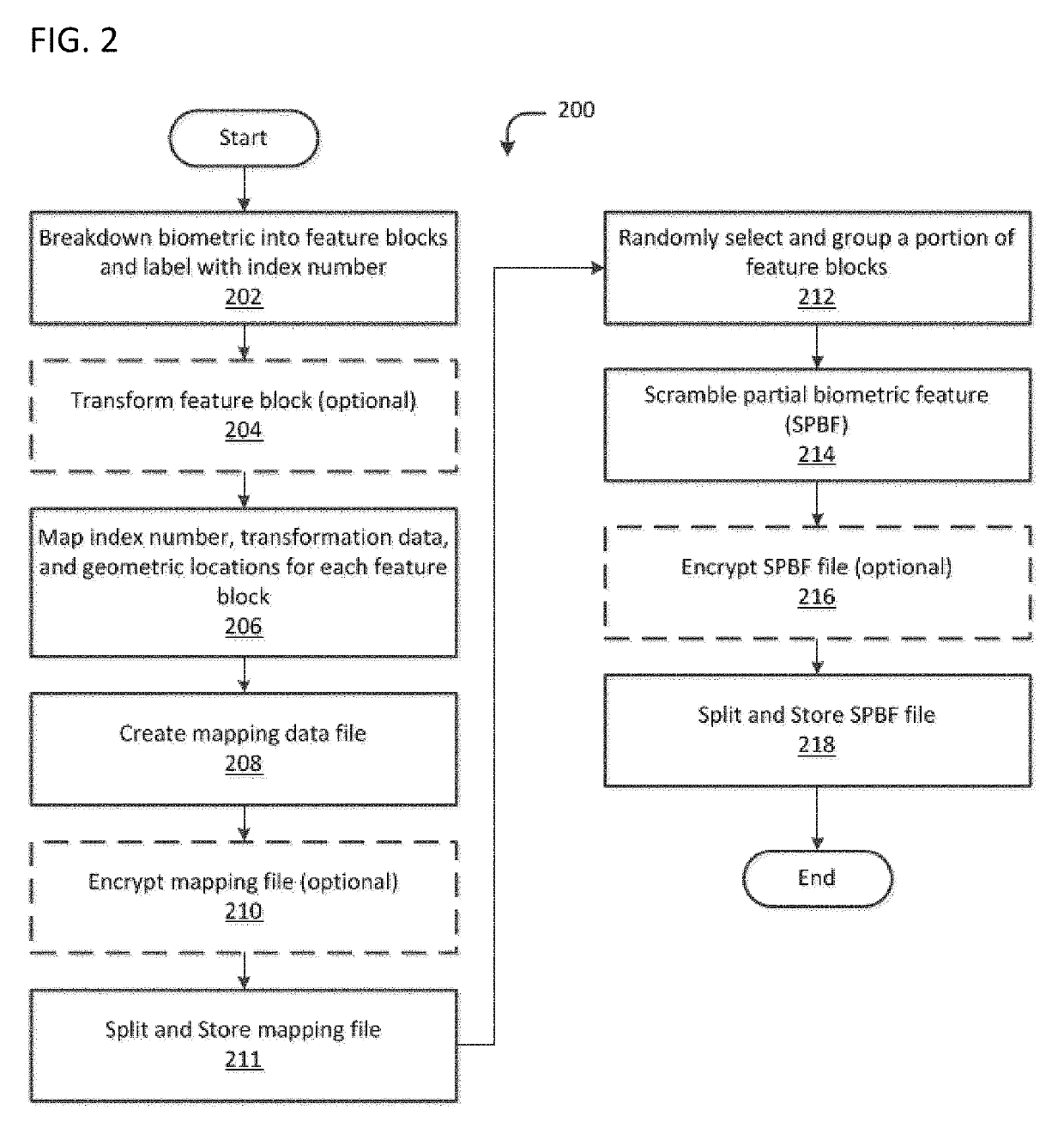

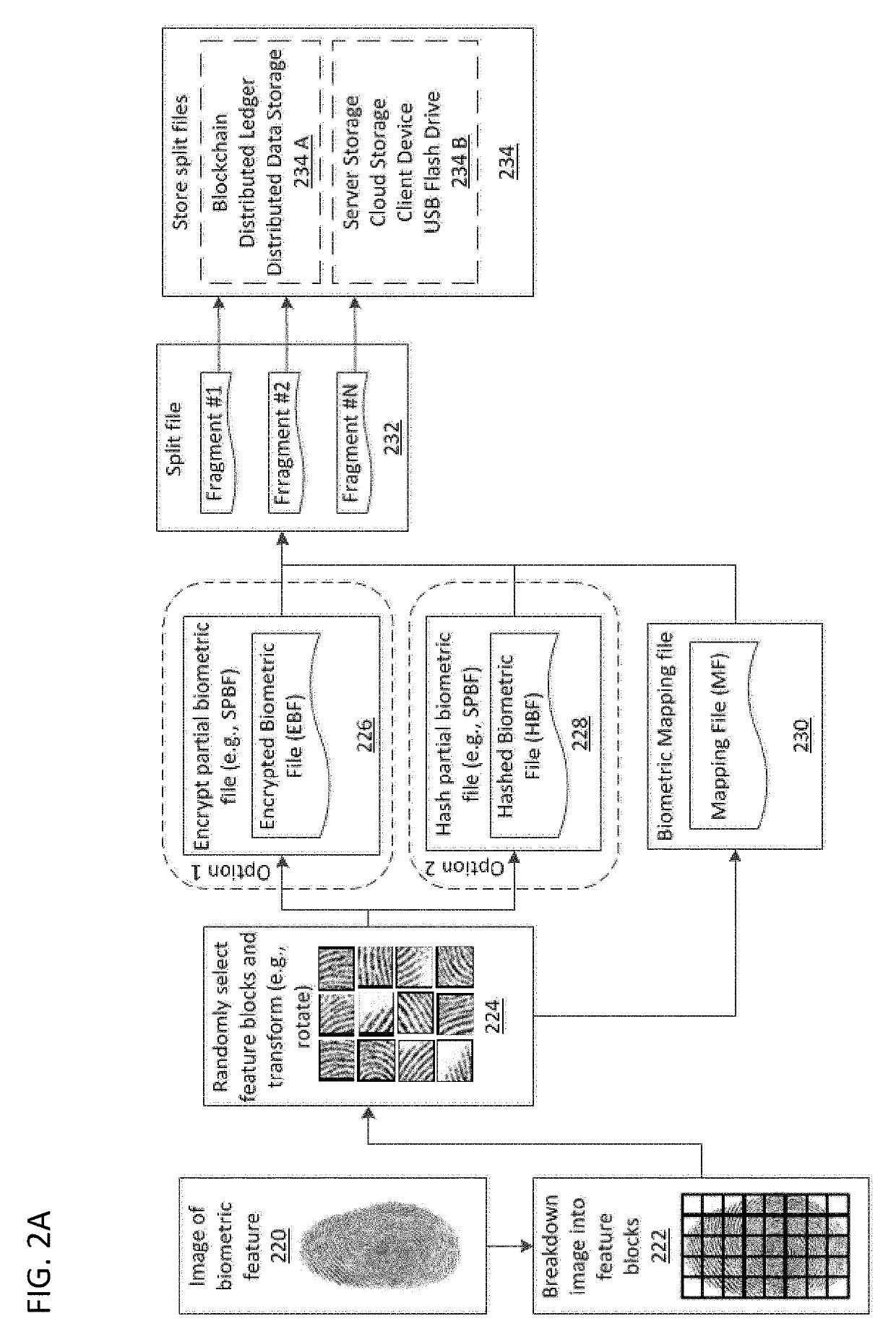

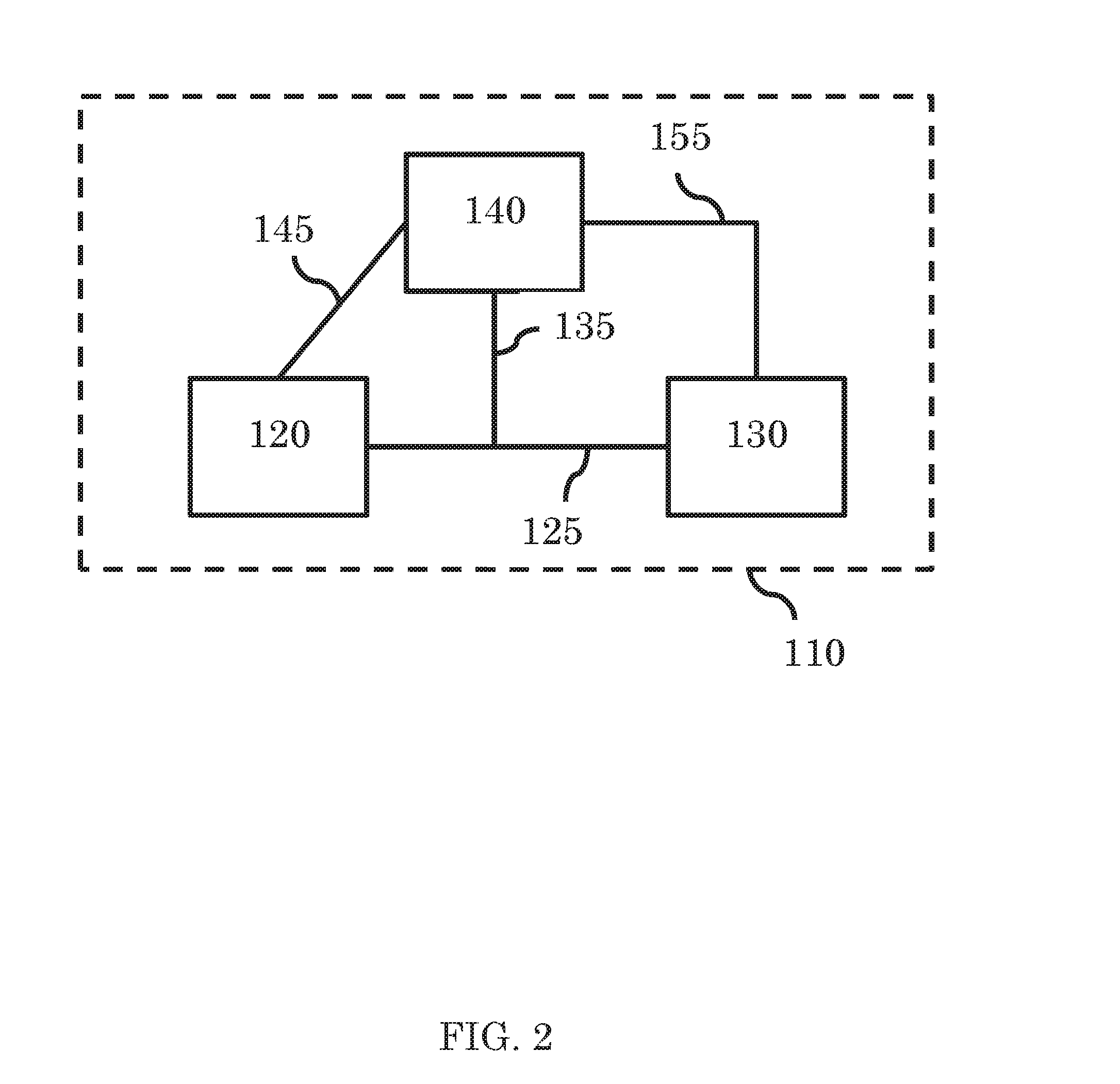

System and method for secure storage of electronic material

InactiveUS20190311148A1Encryption apparatus with shift registers/memoriesDigital data protectionUser deviceElectronic waste

A secure storage system and method for storing electronic material, e.g., digital files, is disclosed. In the system and method, a digital file is broken down into file fragments and one or more fragments are stored on a distributed ledger or distributed ledgers, and the remaining (one or more) fragments are stored off the distributed ledger, e.g., on a secure server or servers, and / or on a user device or devices. The files that are stored may be biometric or partial biometric files. The files may be encrypted or hashed. The file fragments are preferably unintelligible except when decrypted and fully assembled. For example, theft or copying or hacking of one file fragment will not be effective to steal or copy intelligible, useful information. In some embodiments, the benefits of storage on a distributed ledger or distributed ledgers are combined with the benefits of storage on a secure server or servers (and / or on a user's device or devices) or both.

Owner:BLACK GOLD COIN INC

3D printed active electronic materials and devices

Disclosed is a process whereby diverse classes of materials can be 3D printed and fully integrated into device components with active properties. An exemplary embodiment shows the seamless interweaving of five different materials, including (1) emissive semiconducting inorganic nanoparticles, (2) an elastomeric matrix, (3) organic polymers as charge transport layers, (4) solid and liquid metal leads, and (5) a UV-adhesive transparent substrate layer, demonstrating the integrated functionality of these materials. Further disclosed is a device for printing these fully integrated 3D devices.

Owner:THE TRUSTEES FOR PRINCETON UNIV

Microwave dielectric ceramic material and preparation method thereof

The invention provides a microwave dielectric ceramic material and a preparation method thereof, belonging to the technical field of electronic materials. The microwave dielectric ceramic material comprises the following components in percentage by mass: 25-35% of MgO, 60-68% of TiO2, 1-10% of CaO, 0-2% of SiO2, 0-2% of MnO2, 0-2% of Nb2O5 and 0-2% of CeO2; the microwave dielectric ceramic material is prepared by proportioning the MgO, TiO2, CaO, SiO2, MnO2, Nb2O5 and CeO2 according to the mass percentage of each component; performing ball milling and mixing; pre-calcining a mixture at a temperature in a range of 1050-1200 DEG C and sintering the mixture at the temperature in a range of 1250-1360 DEG C. In the invention, the microwave dielectric ceramic material is prepared by utilizing atraditional solid-phase sintering method, the process is simple and the cost is low; according to the prepared microwave dielectric ceramic material, the Q*f value is in a range of 63,000-83,000 GHz,the relative dielectric constant epsilon r is in a range of 20-22, and the temperature coefficient of resonance frequency is within + / -10 ppm / DEG C, so that the preparation requirements of a high-performance microwave device can be met.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

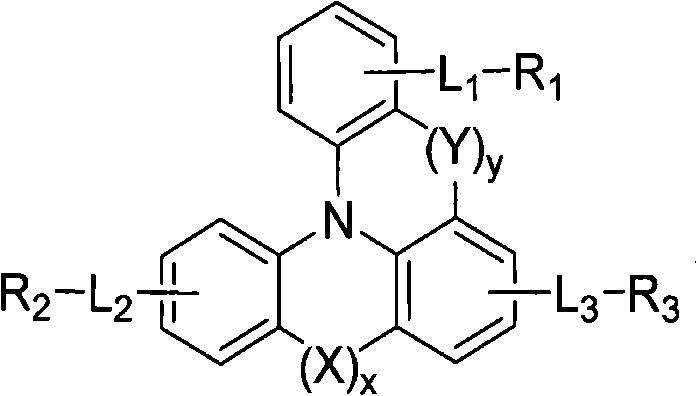

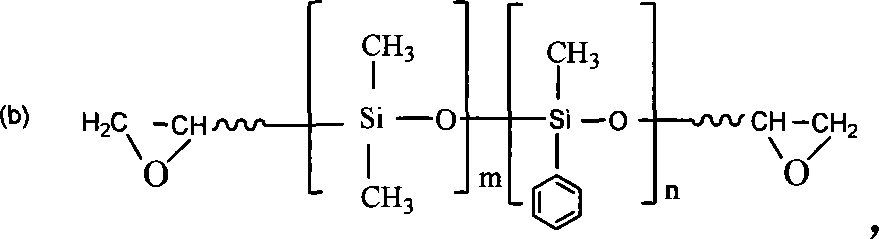

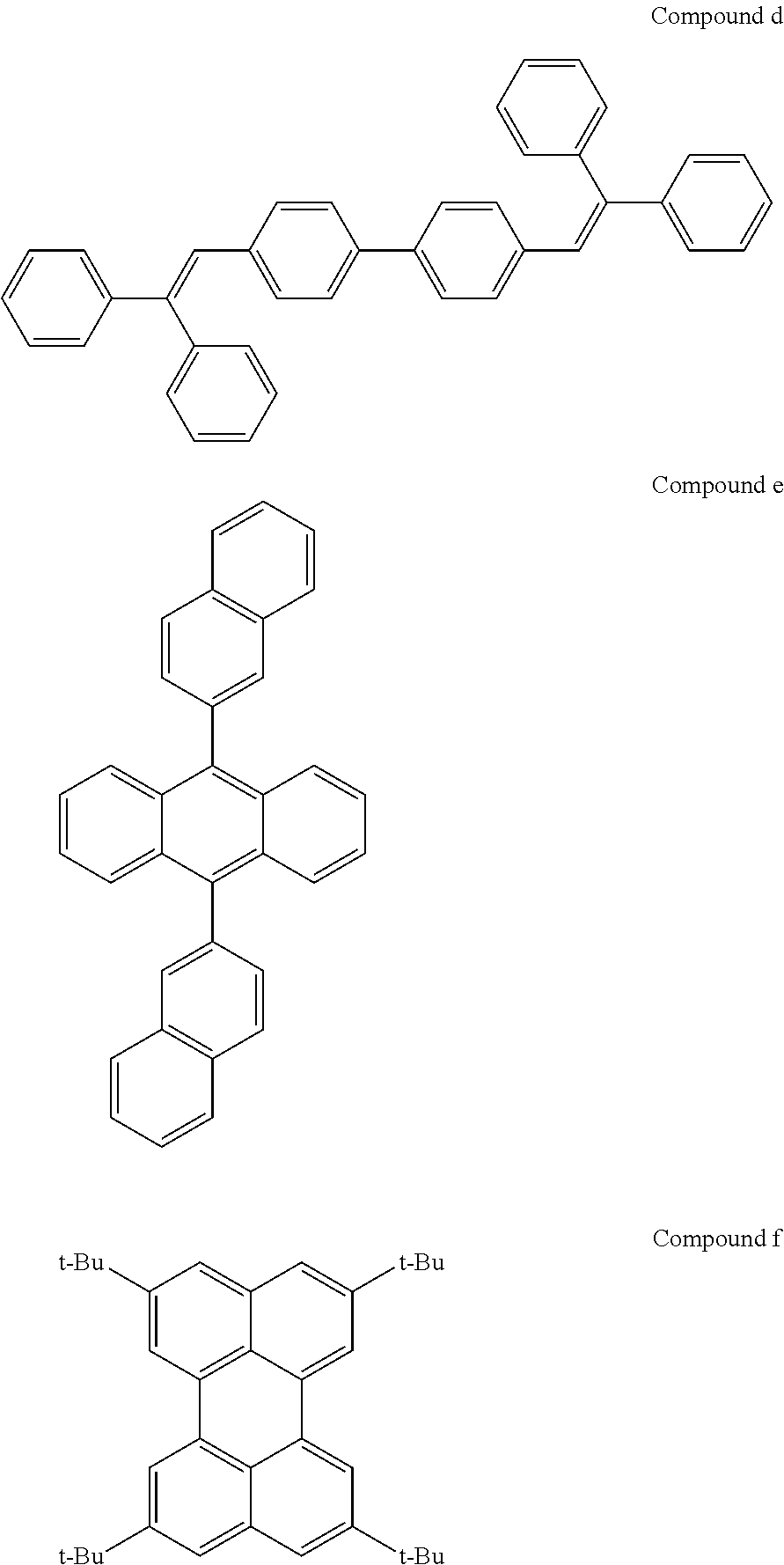

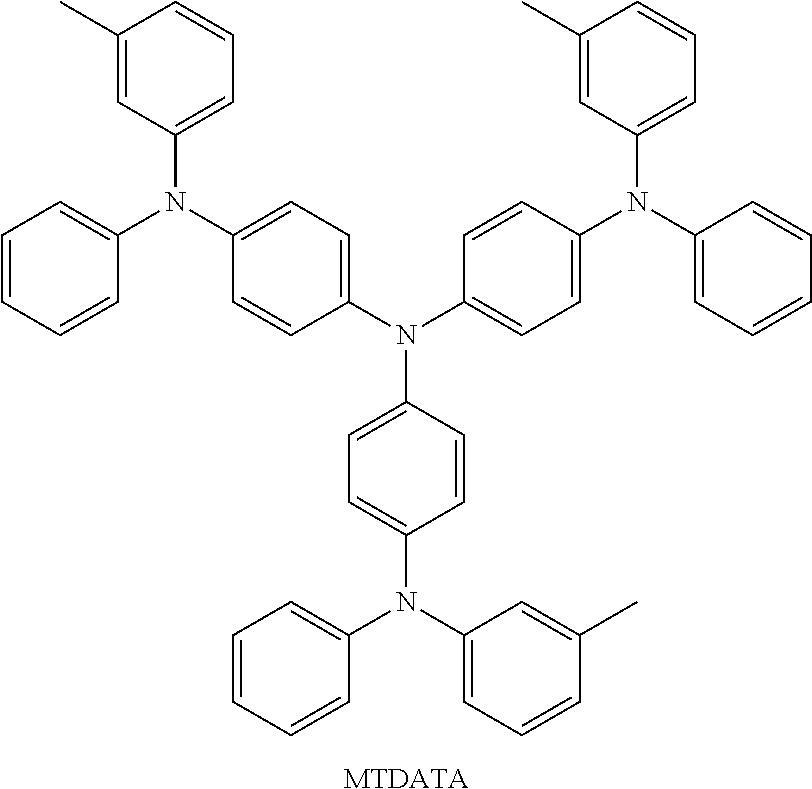

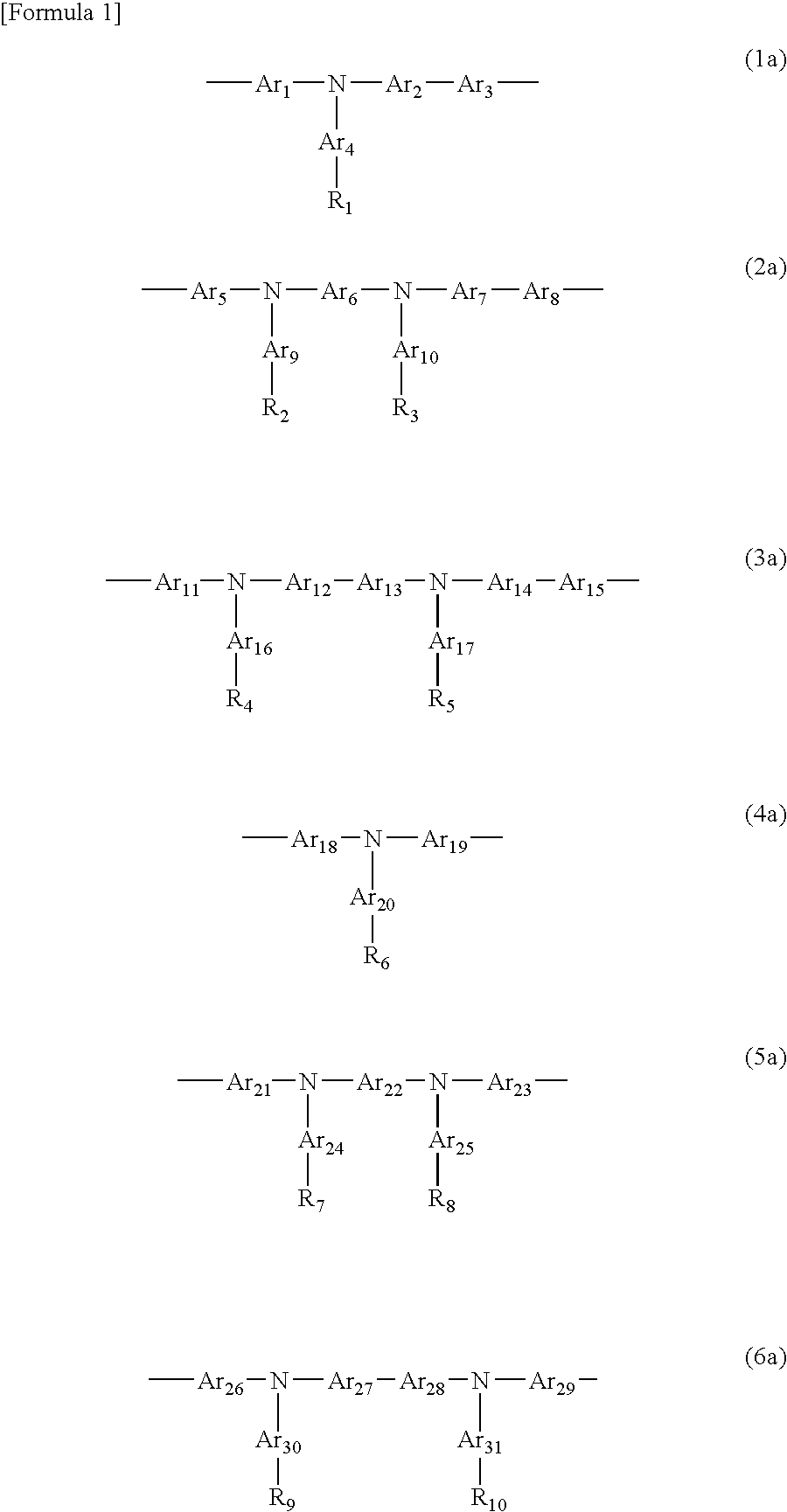

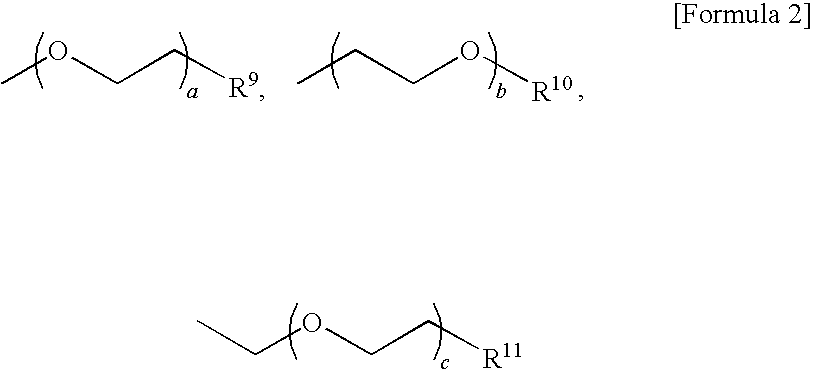

Novel compounds for organic electronic material and organic electronic device using the same

InactiveCN102203212AImprove luminous efficiencyExcellent operating lifeGroup 4/14 element organic compoundsGroup 5/15 element organic compoundsHydrogenChemical compound

Provided are novel compounds for organic electronic material, and organic electronic devices comprising the same. Specifically, the compounds for organic electronic material according to the invention are characterized in that they are represented by Chemical Formula (I) or Formula (II): wherein, R1, R2 and R3 cannot be hydrogen all at the same time; excluding the case wherein R1-L1-?, R2-L2 -?or R3-L3-?independently represents diphenylamino group(?-NPh2 ).

Owner:GRACEL DISPLAY INC

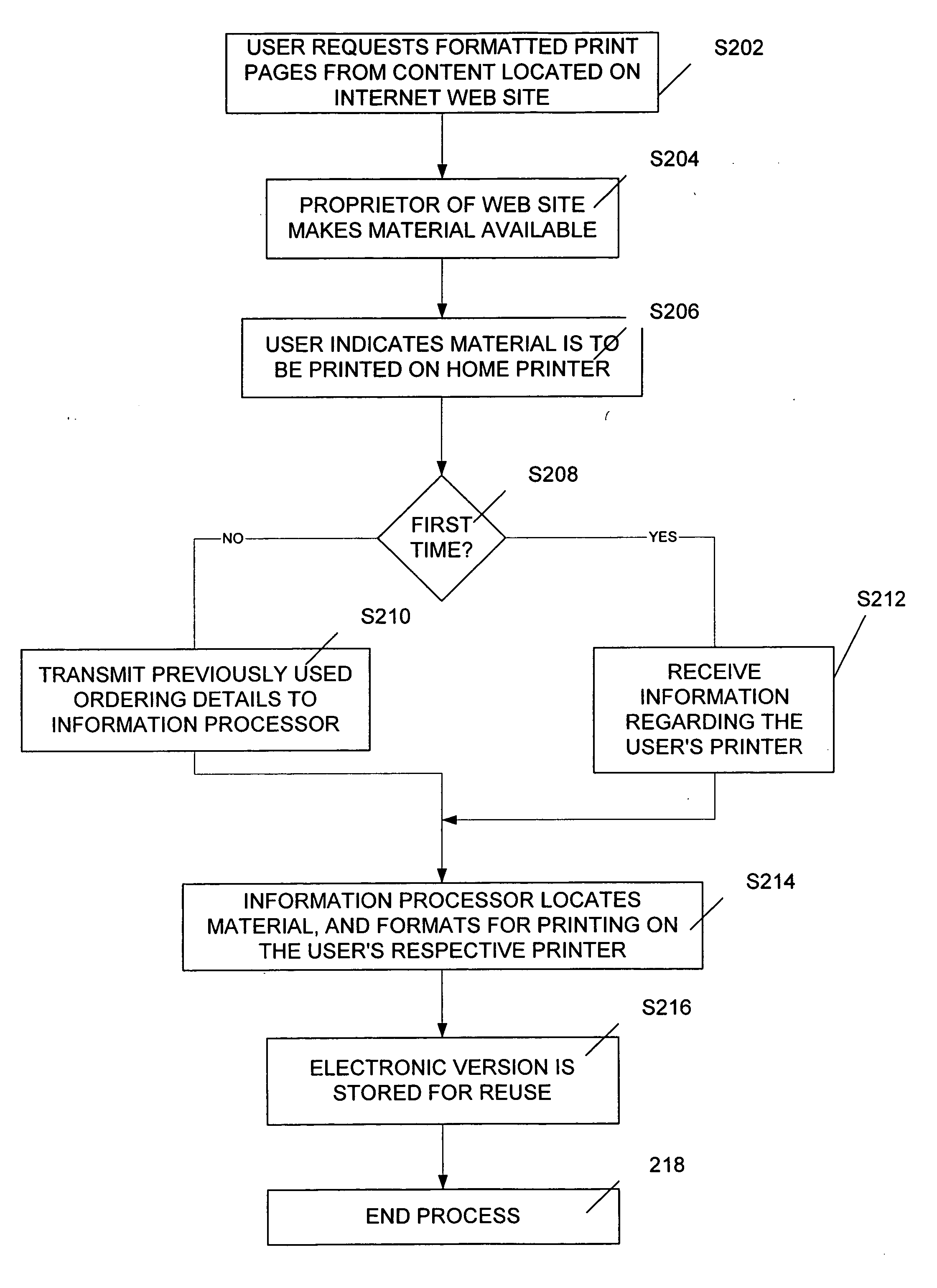

System and method for providing formatted print pages

InactiveUS20060041839A1Natural language data processingSpecial data processing applicationsElectronic materialsVirtual document

In one embodiment, the invention regards a method for providing formatted print pages of electronic material in response to a request initiated by a user. The method includes providing to the user a virtual document that includes at least one formatting instruction which affects the appearance of the virtual document. Further, an electronic request is received from the user for the formatted print pages, and the electronic request includes electronic order information, and the formatted print pages are based on the virtual document. The electronic order information is preferably processed to provide electronic production information that represents instructions for fulfilling the request. The electronic production information is preferably transmitted to a fulfillment facility, generating the formatted print pages by the fulfillment facility and providing the formatted print pages to the user from the fulfillment facility.

Owner:WINK INT

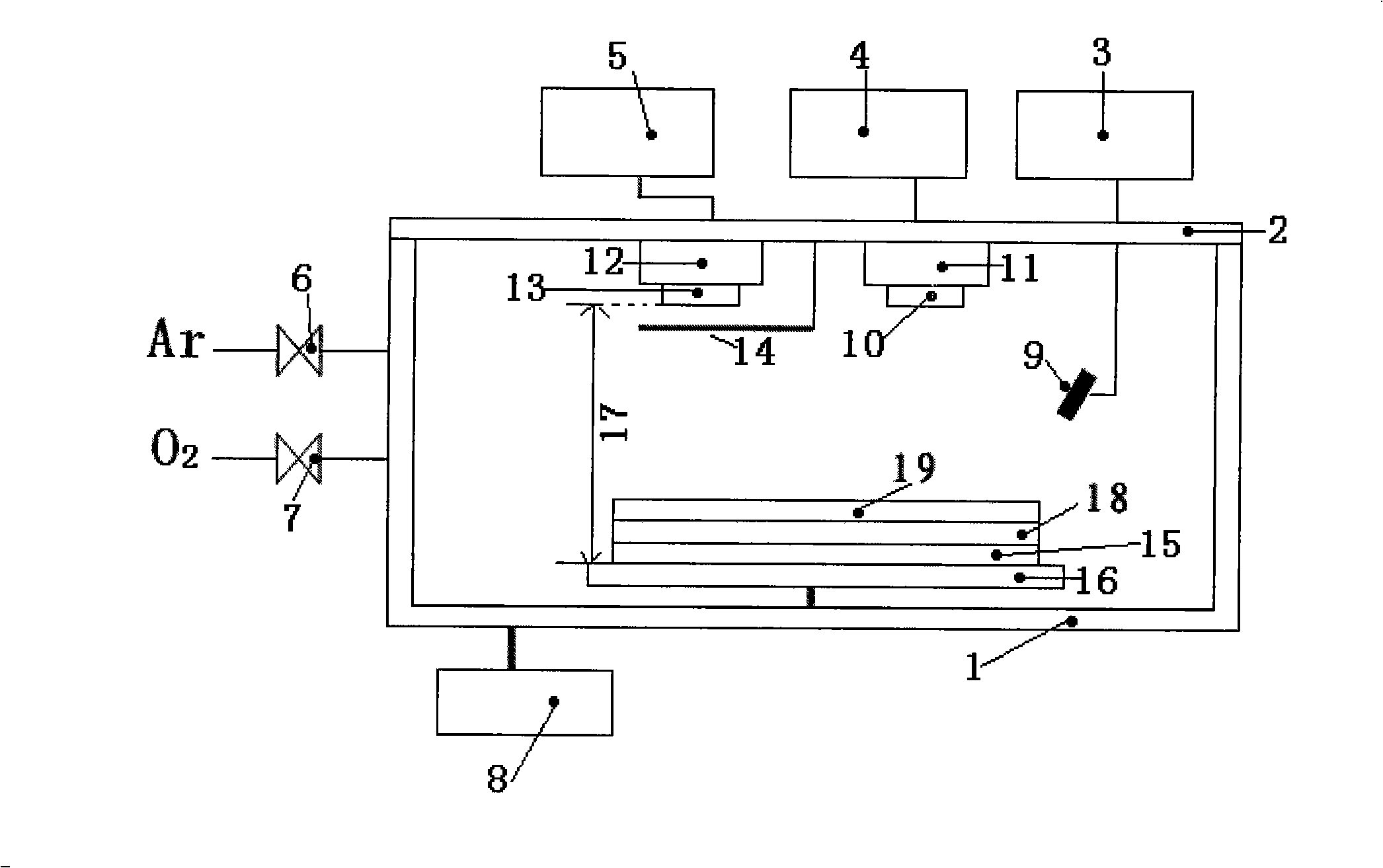

Method for sputtering and depositing tin indium oxide transparent electroconductive film on flexible substrate at room temperature

InactiveCN101294272ALow resistivityHigh light transmittanceVacuum evaporation coatingSputtering coatingIndiumUltraviolet

The invention relates to a method for preparing the transparent and conductive indium tin oxide thin film through sputtering flexible substrates at room temperature, which belongs to the technology field of electronic material; the method comprises the following steps: cleaning, charging working gas, ultraviolet irradiating, preparing a barrier layer and sputtering an indium tin oxide film; through the on-line ultraviolet irradiation, the argon oxygen ratio is (6.0 to 7.5):0.2, by adopting radio frequency sputtering or direct current sputtering, and at the room temperature, the indium tin oxide thin film can be prepared on the organic flexible substrate coated with a silicon dioxide layer in advance and taken as the diffusion barrier layer efficiently without damage. When the thickness of the indium tin oxide thin film is 700 nm, the electrical resistivity is 3.5*10-4 omega cm, the square resistance is 5 omega, the transmissibility of the visible light is 88 percent, and the film layer is even and smooth, and cannot be crimpled nor fall off. Compared with the preparation process of the traditional flexible indium tin oxide thin film, the method has the advantages that heating is not required, the process control is simple, and no damage is caused to the basal body; the method is suitable for large-area production and has good photoelectric characteristics.

Owner:ZHEJIANG UNIV

Thermoplastic powder electrically-conducting paint/printing ink and manufacture method thereof

ActiveCN101245201AMeet the requirements of environmental certification standardsImprove photoelectric conversion efficiencyWax coatingsRosin coatingsChemical industryElectronic communication

The invention relates to a chemical industry electronic material, in particular to a thermoplastic powder conductive coating / ink applied in solar field and electronic communication field. The chemical industry electronic material comprises the following components according to weight percentage: (1) conductive powder: 60 to 80 percent; (2) adhesive: 5 to 30 percent; (3) film-forming strengthening agent: 0.3 to 10 percent; (4) lubricant: 0.1 to 3 percent; (5) solidification regulator: 0.1 to 3 percent; (6) adhesion promoter: 0.5 to 10 percent; (7) antioxidant: 0.1 to 3 percent; (8) doping elements:0 to 5 percent.

Owner:SHANGHAI TRANSCOM ELECTRONICS TECH

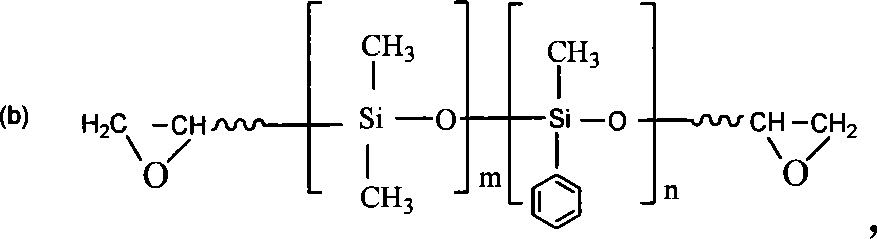

Method for preparing epoxy resin adhesive

InactiveCN101186796AGood compatibilityImprove toughness and strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyDecomposition

The invention discloses a process for preparing epoxy resin adhesive. epoxy phenyl silicone oil(PEPDMS) is employed as a toughening modifier of the epoxy-resin binder, the mixing compatibility of organosilicon resin and epoxide resin are improved by introducing phenyl group to the molecular structure of the naphthene-base silicone oil, simultaneously, the impact ductility and bending intensity of solidifying matters can be increased owing to the mutual function of the soft Si-O-Si chain and the rigid phenyl group, thereby the invention has the function of toughening and strengthening, and the invention has the advantages of sound fire-resisting property and electricity-air insulating property. The beginning heat decomposition temperature is more than 400 DEG C, volume resistivity is more than 10 17 omega, cm under indoor temperature, the consumption of medium is less than 2% under indoor temperature and in 155 DEG C, and the invention is in particular adaptable for casting and packaging of electronic materials and the manufacture of electrical resistant materials.

Owner:SHANGHAI JIAO TONG UNIV

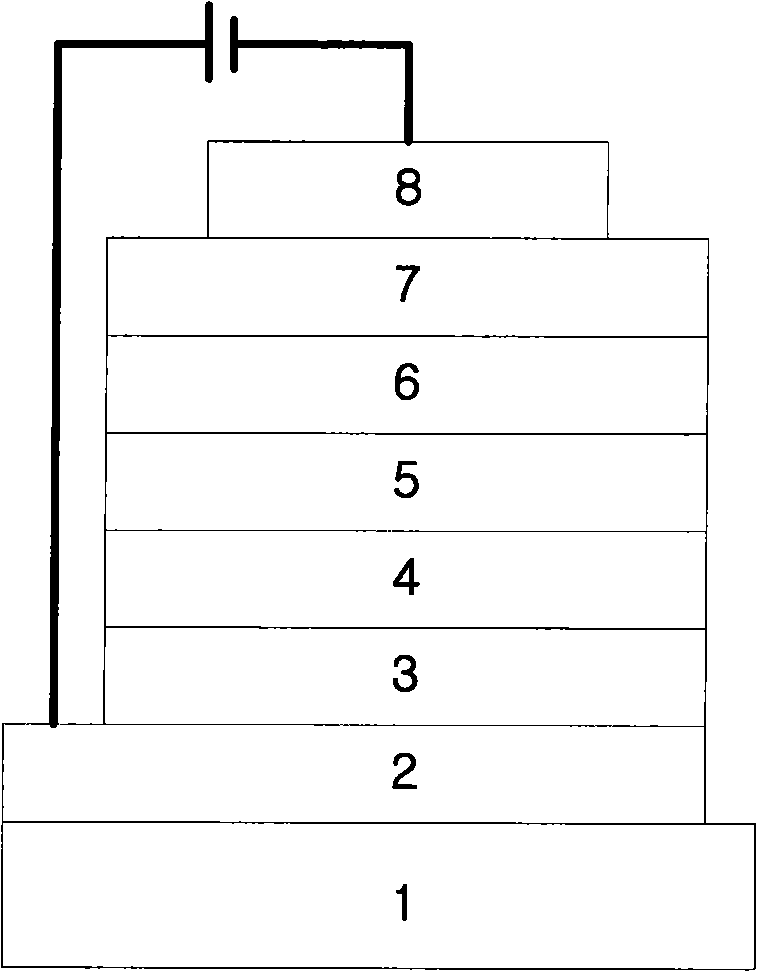

Novel compounds for organic electronic material and organic electronic device using the same

InactiveUS20120104940A1Extended service lifeMaintain good propertiesSilicon organic compoundsDischarge tube luminescnet screensDopantOrganic solar cell

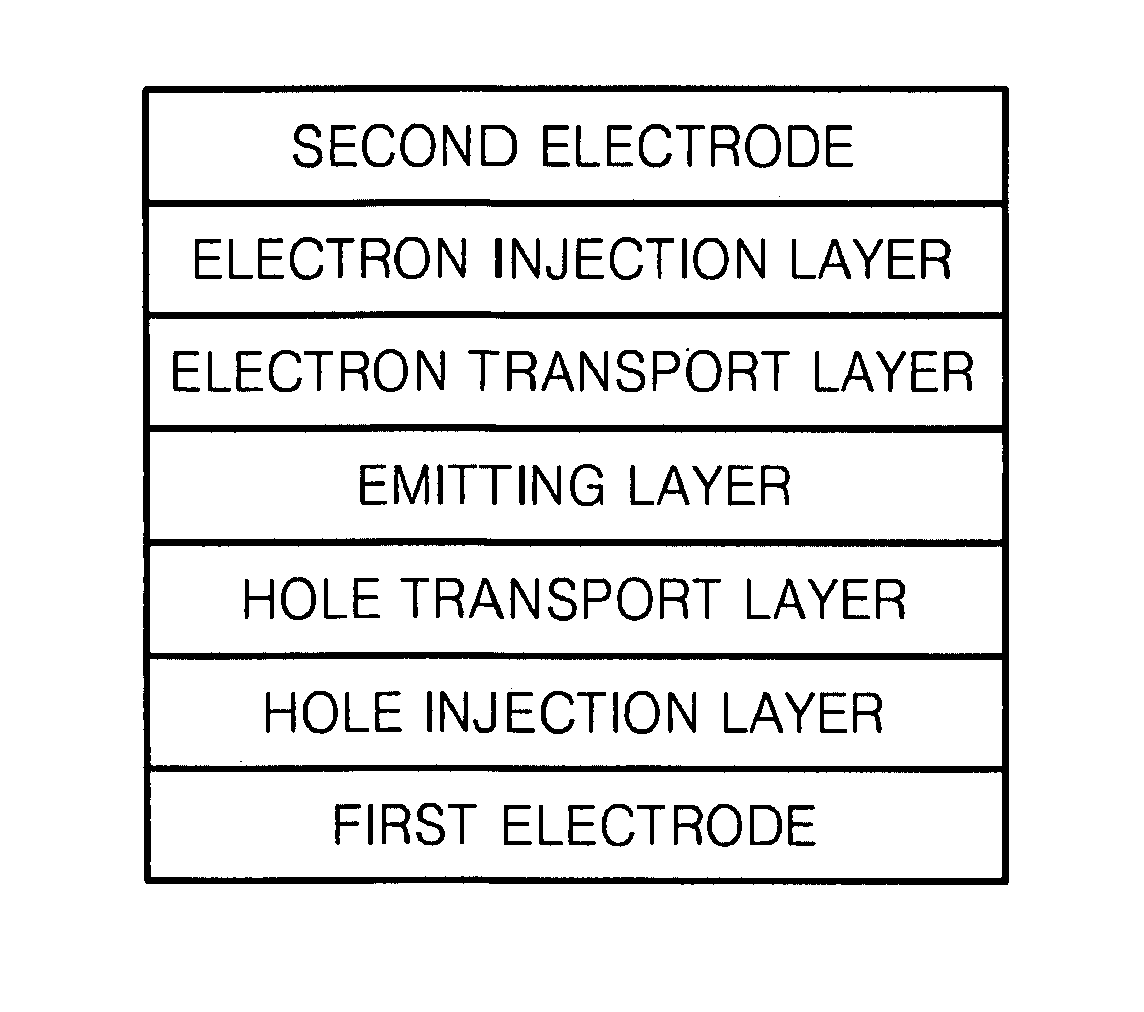

The present invention relates to novel compounds for organic electronic material, and organic electronic devices and organic solar cells using the same. The compounds for organic electronic material may be included in a hole transport layer, electron transport layer or hole injection layer, or may be used as host or dopant. With good luminous efficiency and excellent life property of the material, they may be used to manufacture OLEDs having very good operation life.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

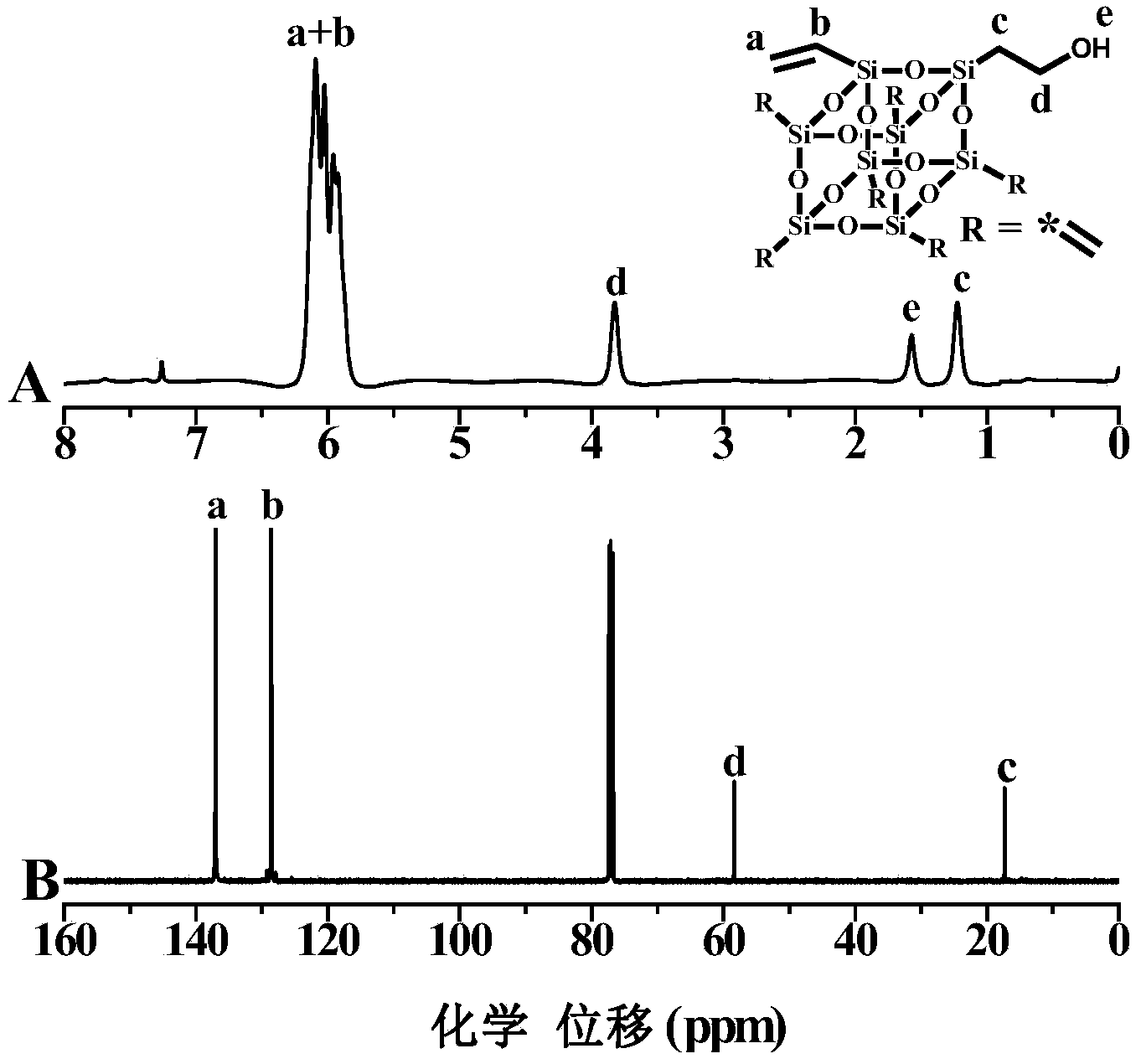

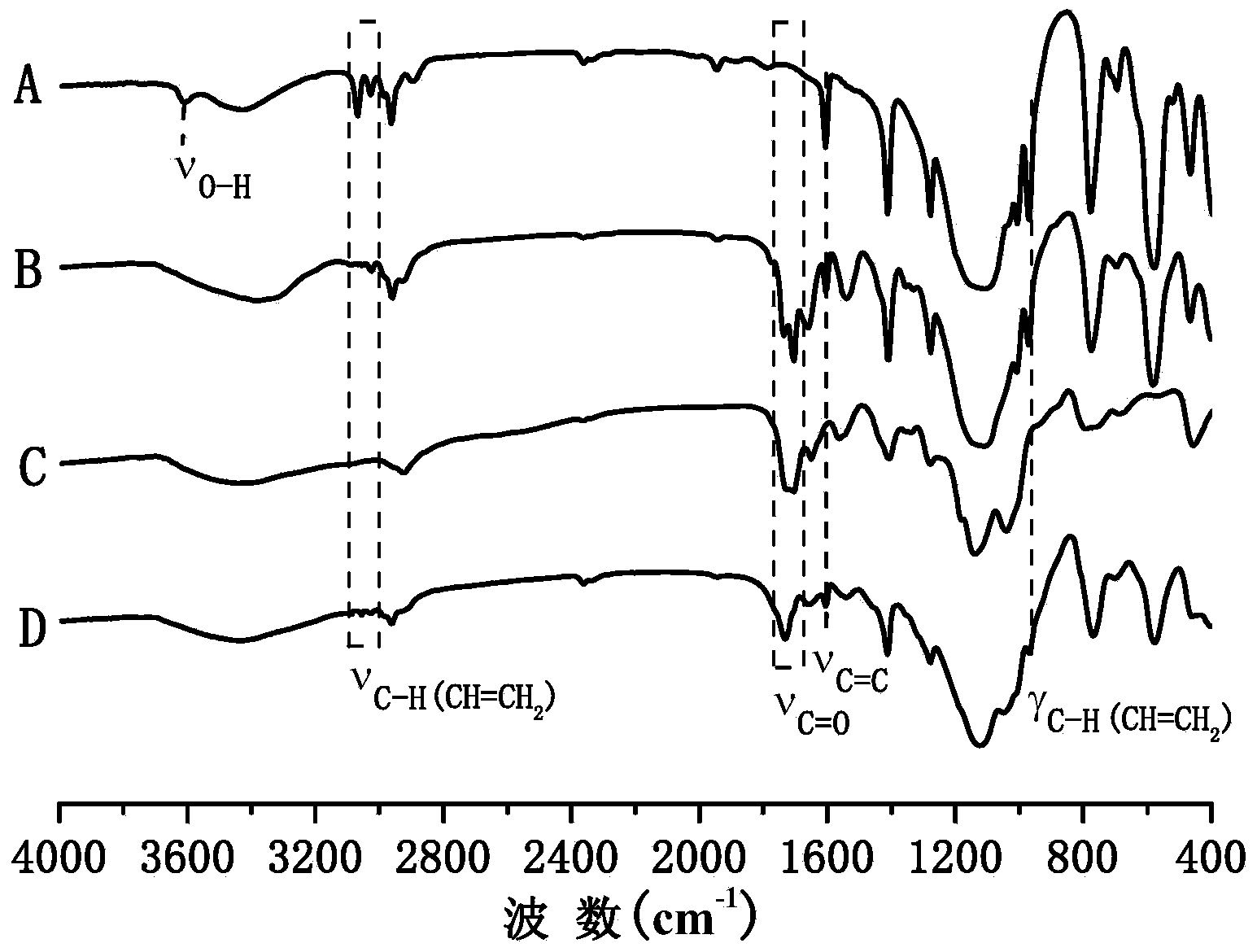

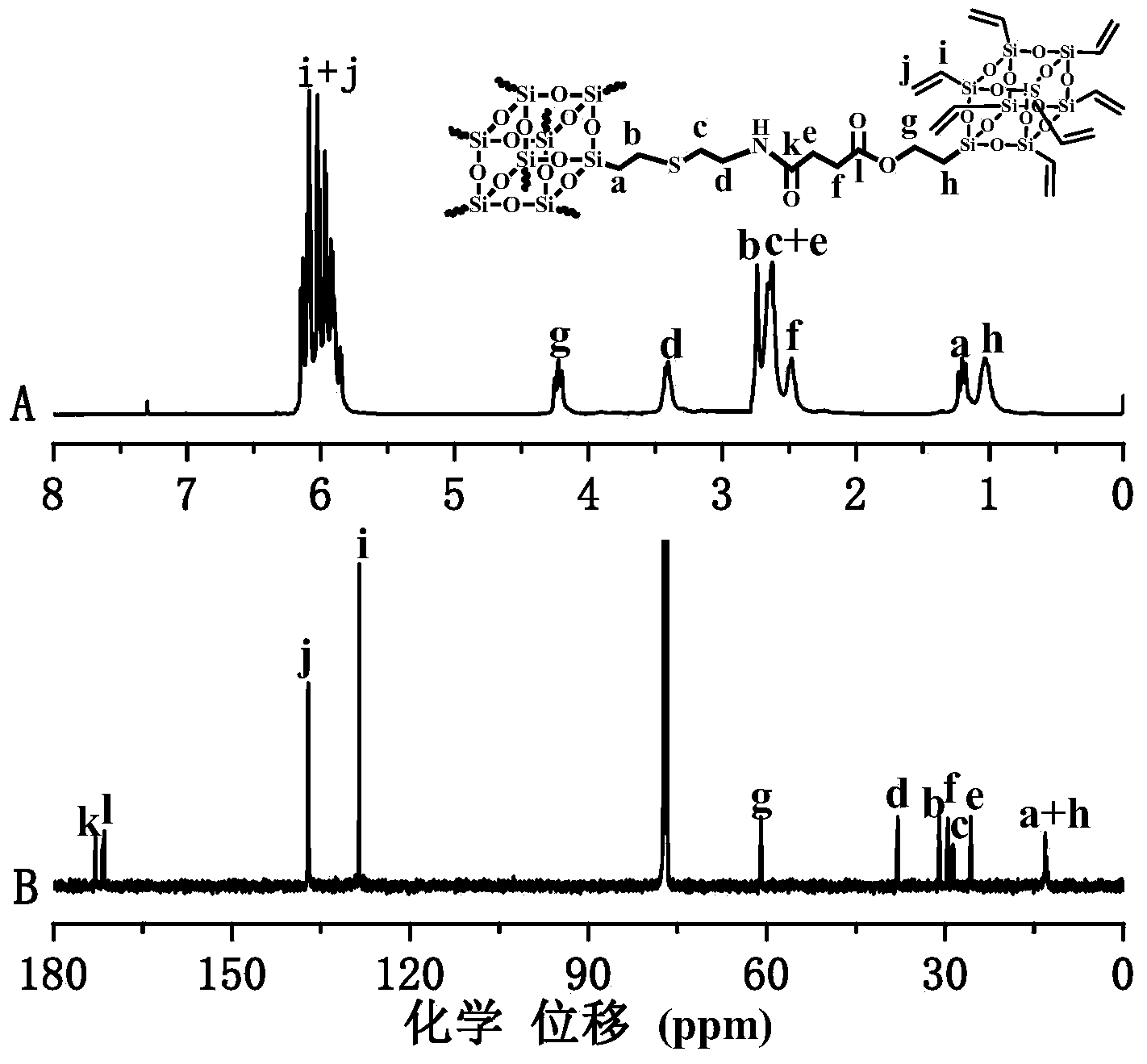

Dendritic polymer with POSS group and preparation method thereof

ActiveCN103642050AWide variety of sourcesRich varietySilicon organic compoundsChemical synthesisCrystallography

The invention relates to a dendritic polymer with POSS group and preparation method thereof. The preparation of the product comprises the following steps: designing a POSS group intermediate R2-POSS-(R1)n-1 (n=6, 8, 10, 12) with asymmetric structure, and then using a chemical synthetic method, and obtaining a dendritic polymer (containing derivatives thereof) containing POSS group and a lot of end functional groups. The product has the advantages of unique structure design and diversified selections, thereby the product has latent application prospects for the aspects of surfactant, biological medicine carrier, catalyst, photon crystallization, optical material, anti-corrosion material, electronic material, information recording material, printing material, battery material, magnetic material, electronic luminescent device, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

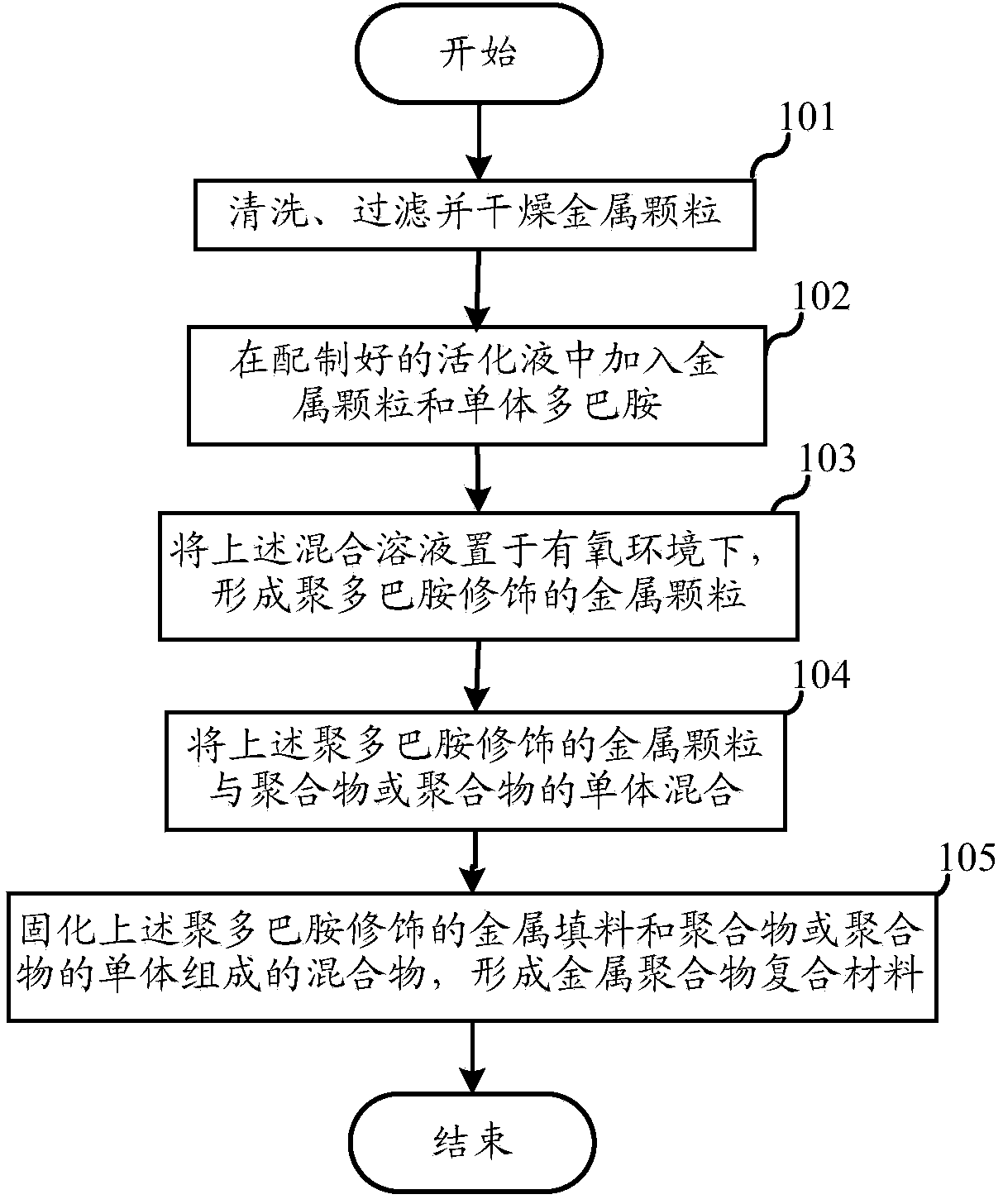

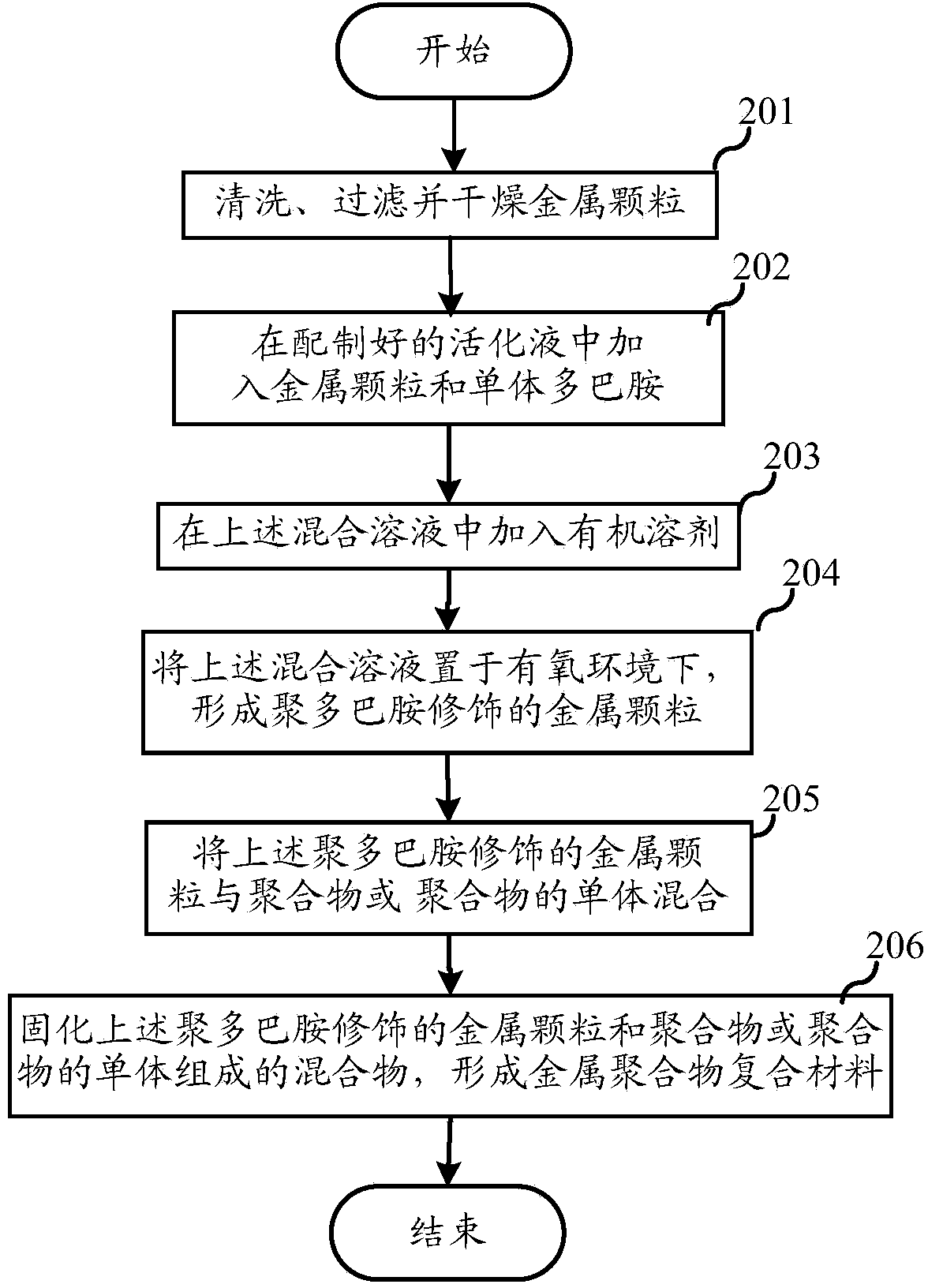

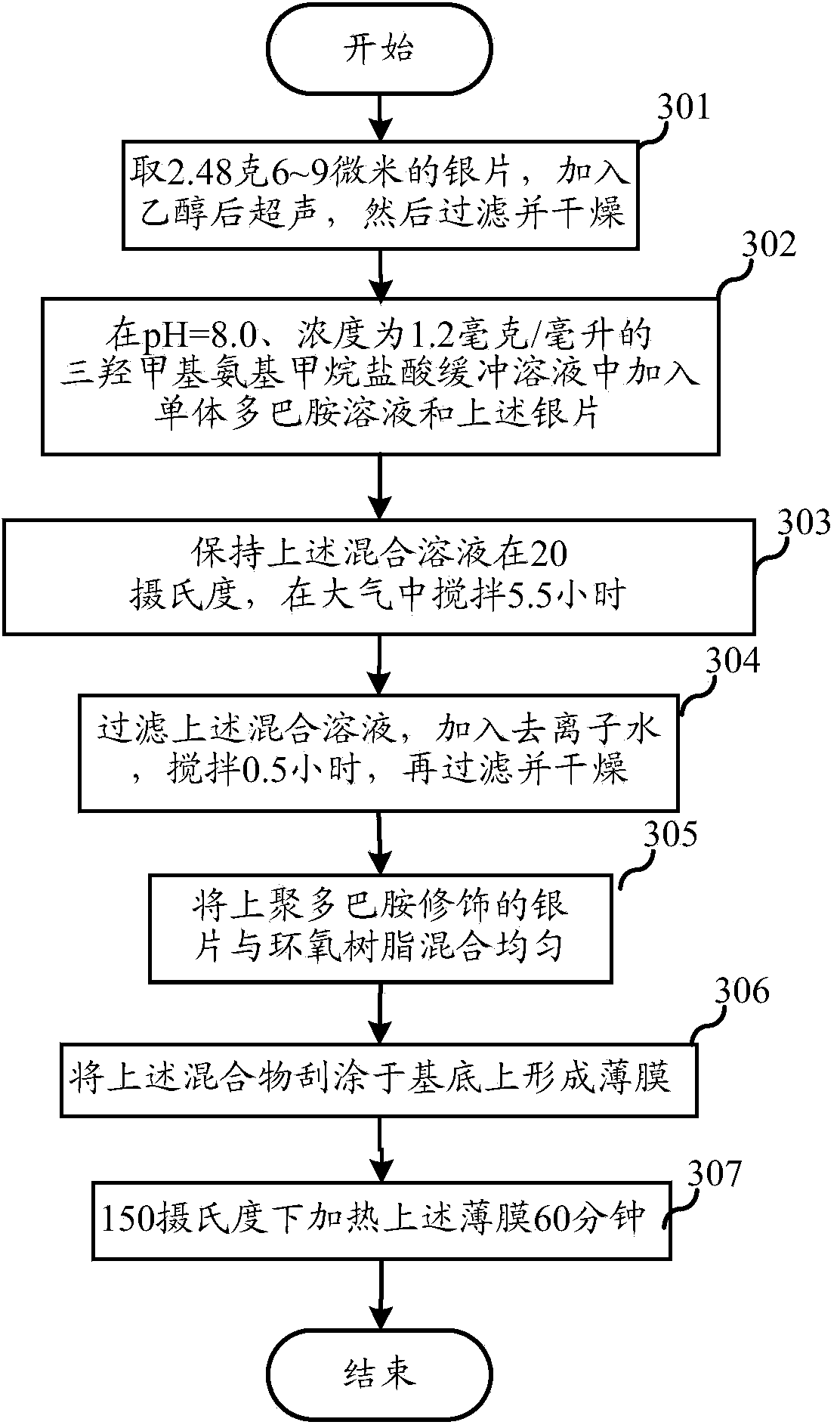

Preparation method of metal polymer composite material

The invention relates to the field of an electronic material, and discloses a preparation method of a metal polymer composite material. The method comprises the following steps: firstly, adding metal grains and monomer dopamine to a prepared activated solution, and then putting a mixed solution composed of the activated solution, the metal grains and monomer dopamine into an oxygen environment, so as to form polydopamine-modified metal grains; mixing the polydopamine-modified metal grains with a polymer or a monomer of the polymer; finally solidifying a mixture composed of the polydopamine-modified metal grains and the polymer or the monomer of the polymer, so as to form a metal polymer composite material. Compared with the prior art, by adopting the metal polymer composite material prepared by the method, the requirements of high dielectric constant, heat conduction and insulation can be simultaneously met, meanwhile, the binding power between the metal grains and a matrix is improved by the metal grain surface-modified polydopamine, and improvement of the shear strength of the composite material is facilitated.

Owner:FUDAN UNIV

Organic electronic material, organic electronic device, and organic electroluminescent device

InactiveUS20090321723A1Improve efficiencyProlong lifeOrganic chemistryElectroluminescent light sourcesOligomerOrganic electroluminescence

An object of the present invention is to provide an organic electronic material that can be easily formed into a multilayer structure. A further object of the present invention is to provide an organic electronic device and an organic EL device that exhibit a better emission efficiency and a better emission lifetime than heretofore achieved. In order to achieve these objects, an organic electronic material is provided, the material includes a polymer or oligomer that has at least one polymerizable substituent and a hole-transporting repeat unit.

Owner:HITACHI CHEM CO LTD

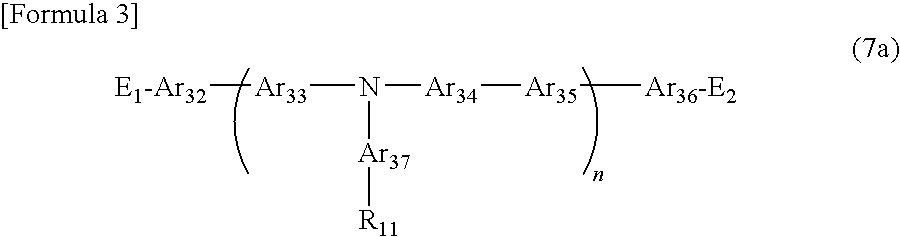

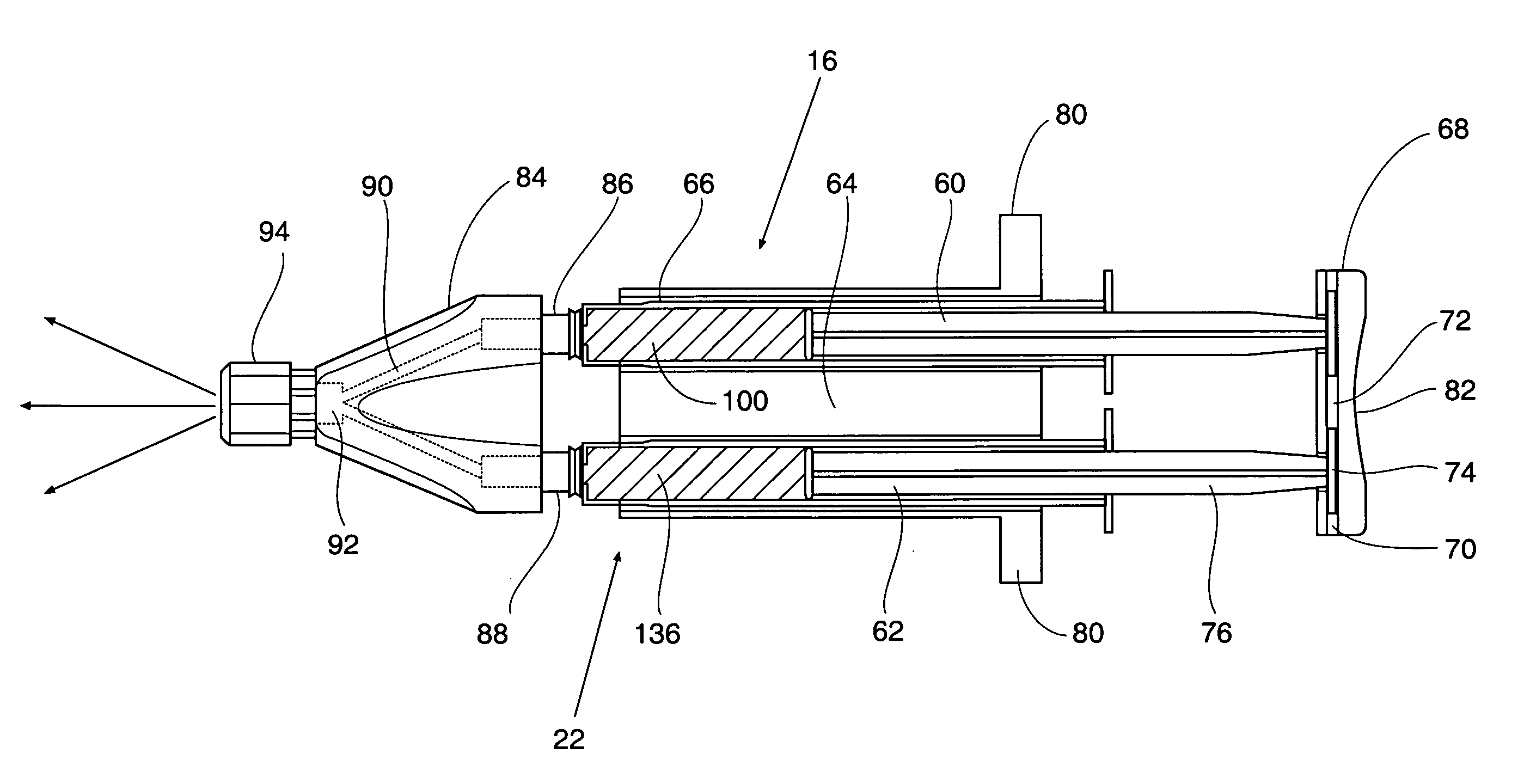

Systems, methods, and compositions for prevention of tissue adhesion

A blended electrophilic material with a first component having a functionality of at least three and a second component having a functionality of two is mixed with a nucleophilic material. The blended electrophilic material cross-links with the nucleophilic material to form a non-liquid, three dimensional structure which can applied, e.g., as an adhesion barrier.

Owner:NEOMEND INC

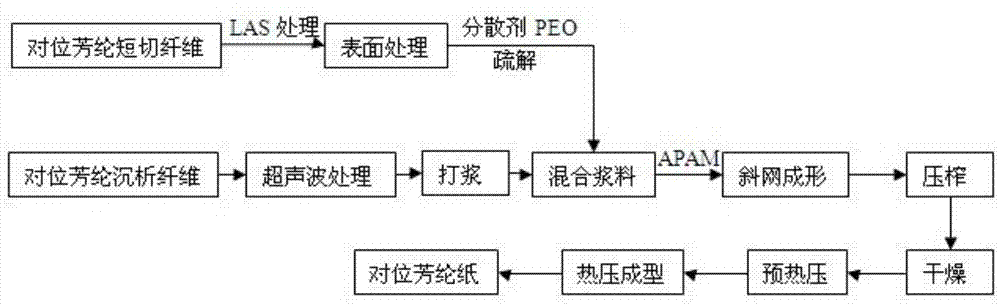

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

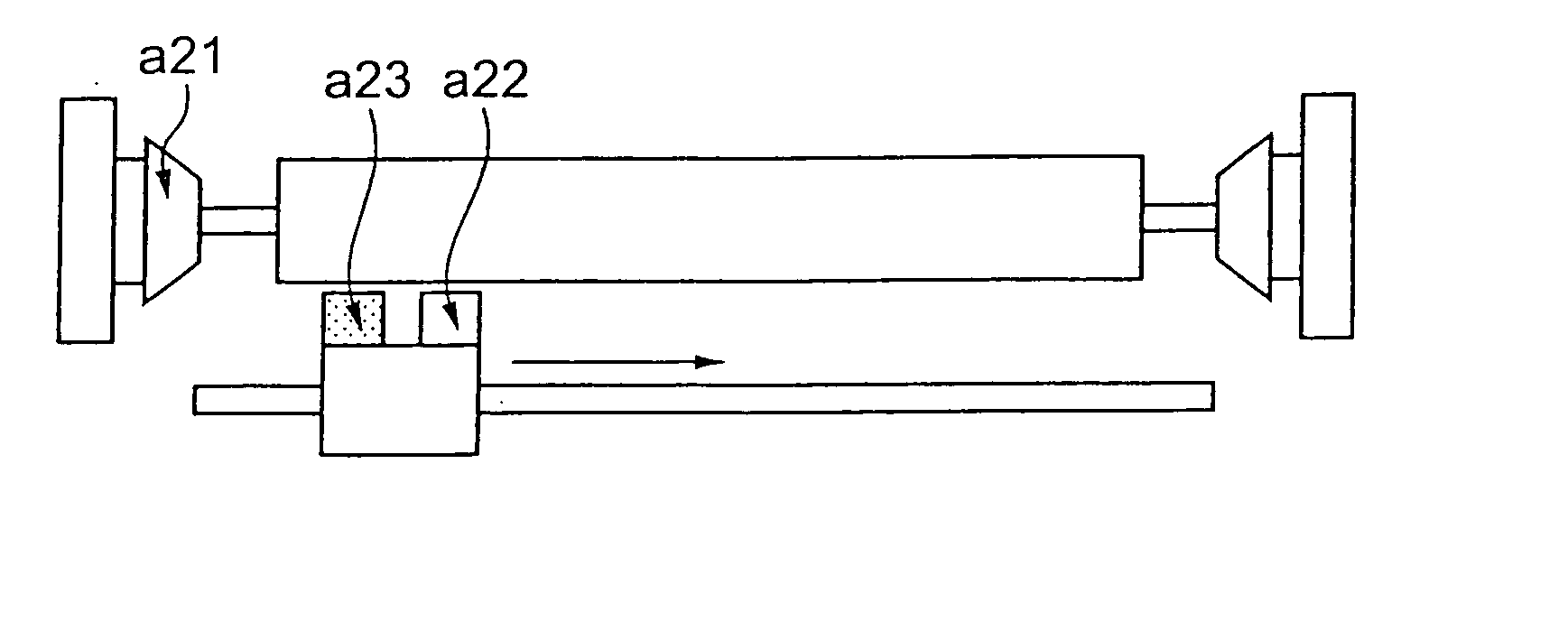

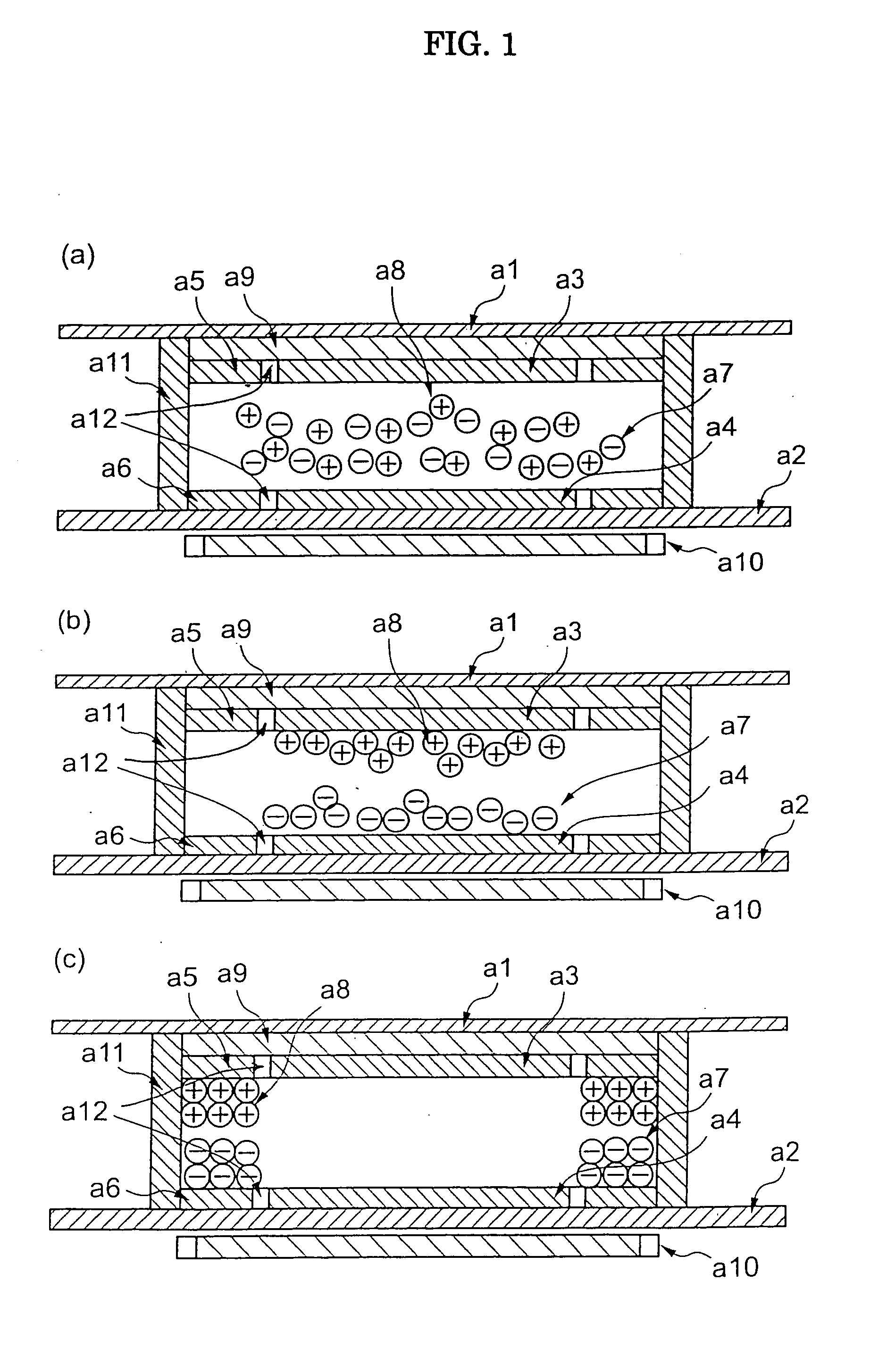

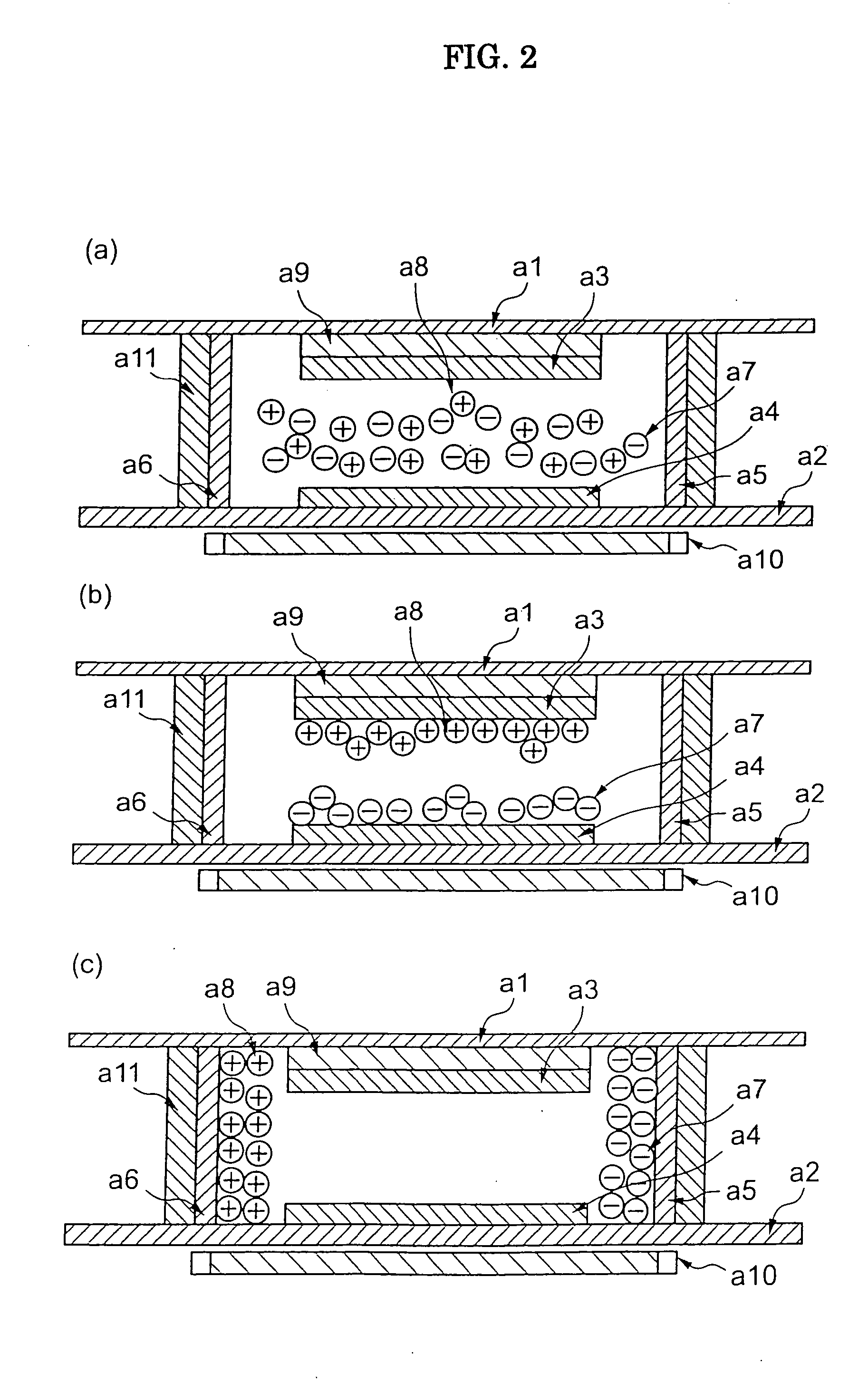

Reversible image display sheet and image display

InactiveUS20050052402A1Quick responseSimple structureStatic indicating devicesNon-linear opticsDisplay deviceColor charge

A reversible image display panel which comprises a pair of substrates one of which is transparent and a group of particles charged with single polarity, a group of particles with single color charged with single polarity, a group of particles having portions with different colors and different charge characteristics, or two groups of particles with different charge characteristics each enclosed between the substrates, characterized in applying an electric field across the substrates, and displaying images by flying and moving the particles. The reversible image display panel and the image display device in accordance with the invention have fast response speed and simple structure, being superior in stability and vividity. In an occasion of driving, generation of the strong electric field is unnecessary for them and accordingly, electric circuits can be assembled employing general purpose electronic materials.

Owner:BRIDGESTONE CORP

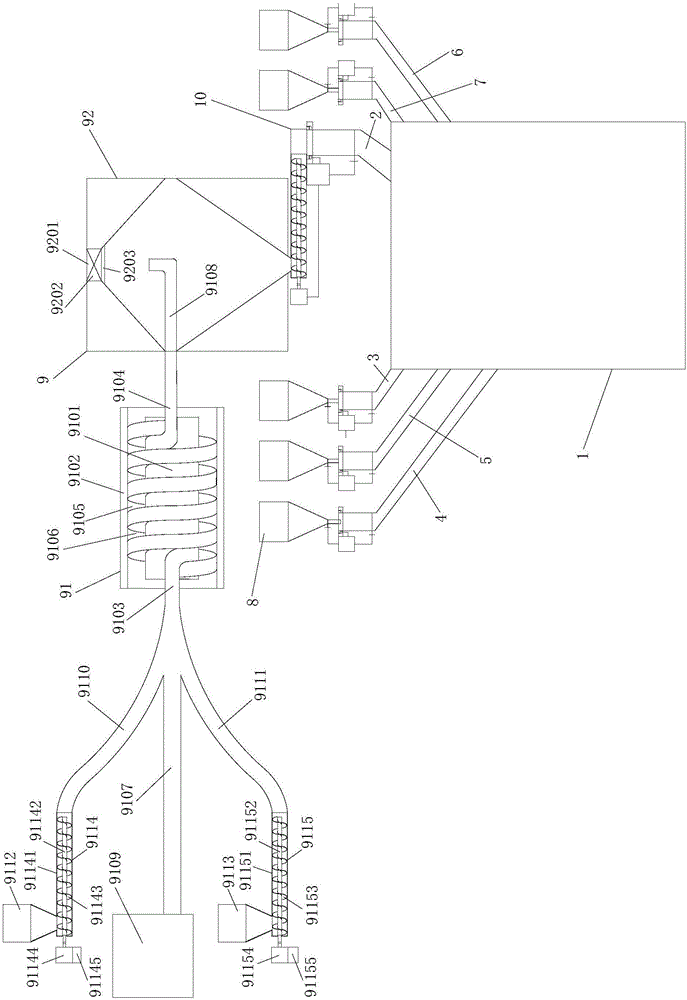

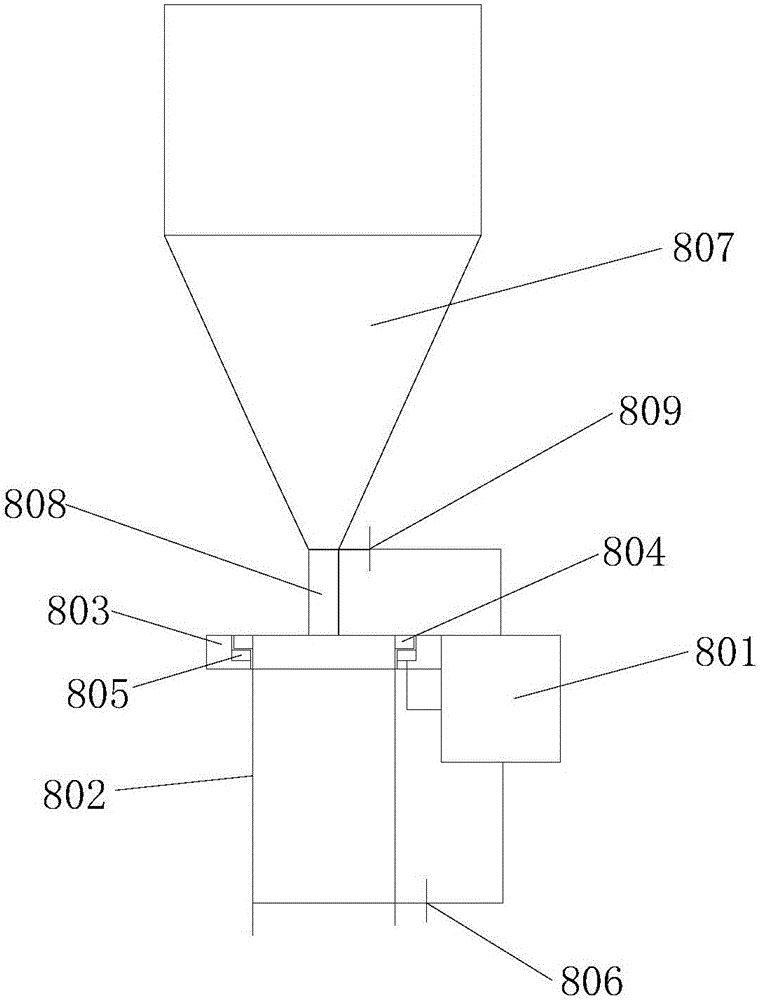

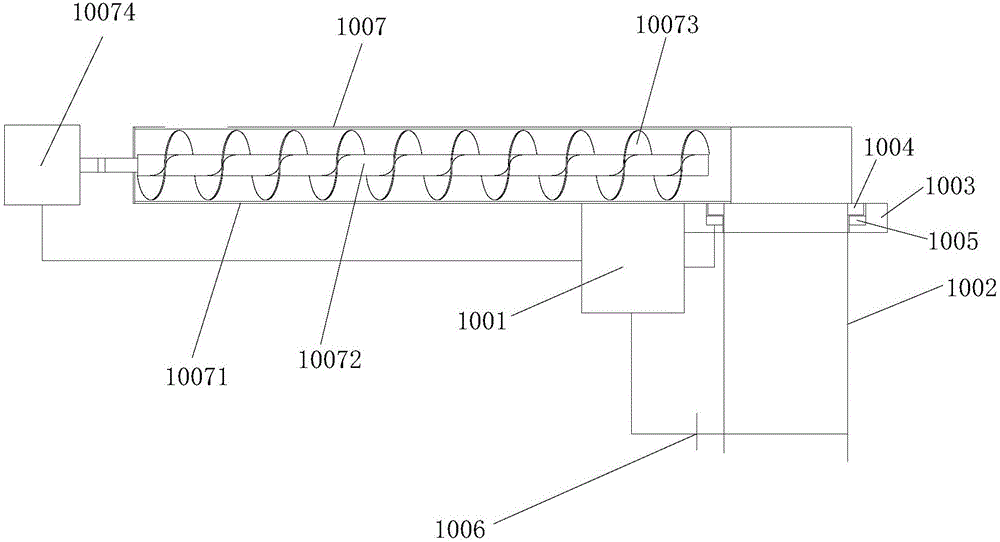

Solar cell back silver slurry and preparing device thereof

ActiveCN106128550ALow costStrong costFinal product manufactureNon-conductive material with dispersed conductive materialSolderabilityMixed materials

The invention provides a solar cell back silver slurry which can reduce the cost, and guarantee better conductivity of a silver layer and great adhesive force with a silicon substrate, and a preparing device thereof. The solar cell back silver slurry is composed of: 65%-75% of powdery mixed materials, 8%-10% of ethyecellulose, 8%-10% of butyl carbitol, 5%-8% of terpilenol, 2%-4% of thixotropic agents and remaining weight ratio of auxiliary agents, wherein the powdery mixed materials are the mixed materials of silver-coated copper powder and glass powder, and the weight ratio between the silver-coated copper powder and the glass powder is (7-12):1. The content of pure silver in the back silver slurry is only about 35%, which is much lower than the heavy silver content of present back silver slurry, so that the usage amount of silver powder is substantially reduced, the cost of the back silver slurry is greatly reduced, and the cost pressure caused by silver cost increase can be alleviated; in addition, greater adhesive force exists between a finally prepared silver layer and the silicon substrate, and the binding property, solderability and soldering resistance are greater. The solar cell back silver slurry and the preparing device thereof are suitable for popularization in the electronic material technical field.

Owner:LESHAN TOPRAYCELL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com