Preparation method of grapheme and ferriferrous oxide composite nanometer material

A composite nanomaterial, ferric oxide technology, applied in the direction of graphene, iron oxide/iron hydroxide, nanotechnology for materials and surface science, etc., can solve the problem of poor repeatability of magnetic materials, limited application, and limited use and other problems, to achieve the effects of good stability, high specific surface area and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

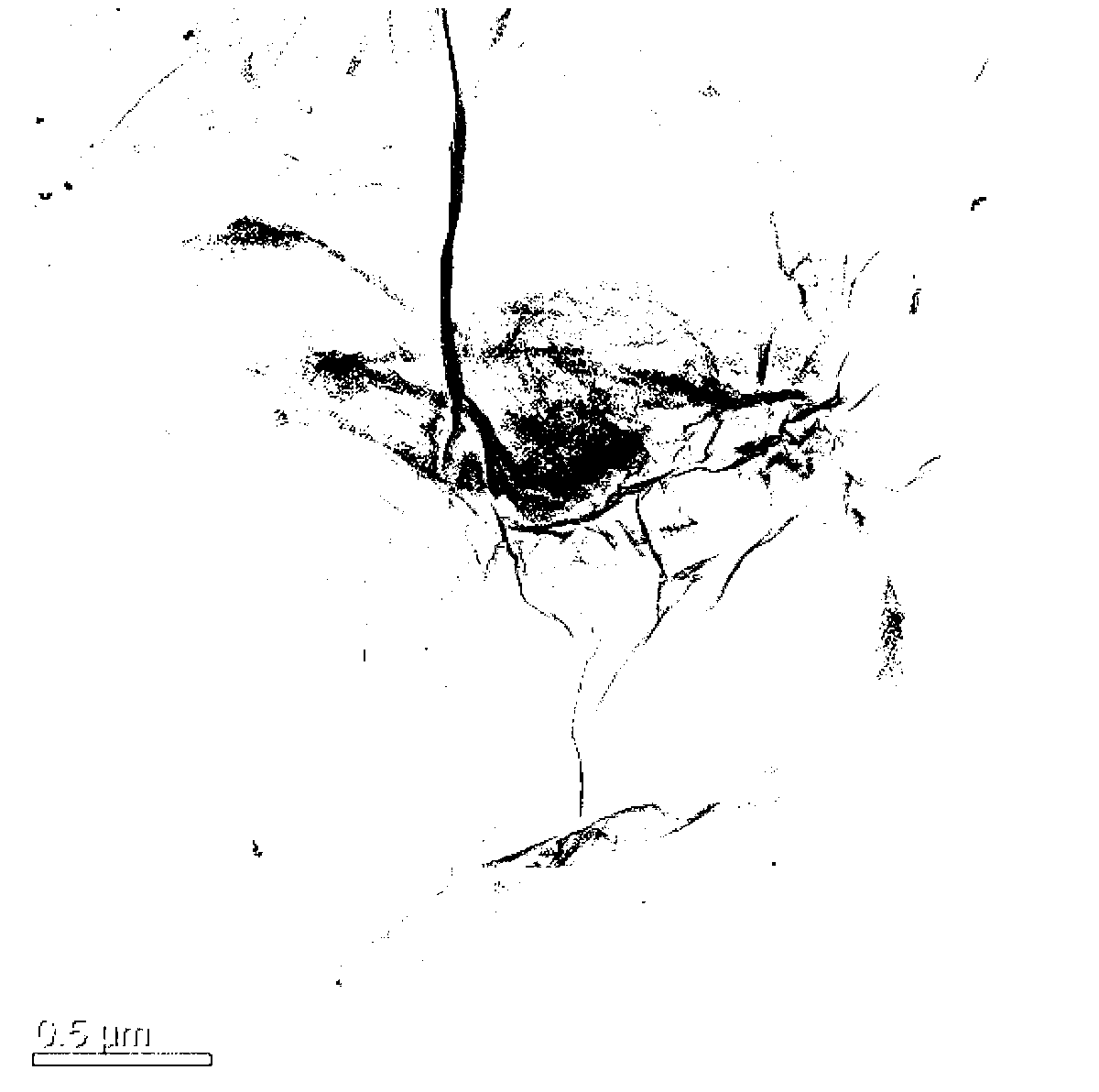

[0028] Step 1: Prepare graphene oxide. The preparation process of described graphene oxide comprises the following steps:

[0029] Step 1-1: Raw material preparation. With flake graphite powder, concentrated sulfuric acid, concentrated phosphoric acid and potassium permanganate as the main reaction raw materials for preparing graphene oxide, the ratio of each raw material component is controlled to be: flake graphite powder: concentrated sulfuric acid: concentrated phosphoric acid: potassium permanganate=1g :120mL:15mL:6g.

[0030] Step 1-2: Oxidative exfoliation of flake graphite powder. At room temperature, add the concentrated sulfuric acid and concentrated phosphoric acid prepared in step 1 into a three-necked flask with a condenser and mix them until the temperature of the mixed acid returns to room temperature; then slowly add the flake graphite powder prepared in step 1, and stir for 2 hours at room temperature; Slowly add the potassium permanganate prepared in step ...

Embodiment 2

[0035] Step 1: Prepare graphene oxide. The preparation of graphene oxide is the same as in Example 1.

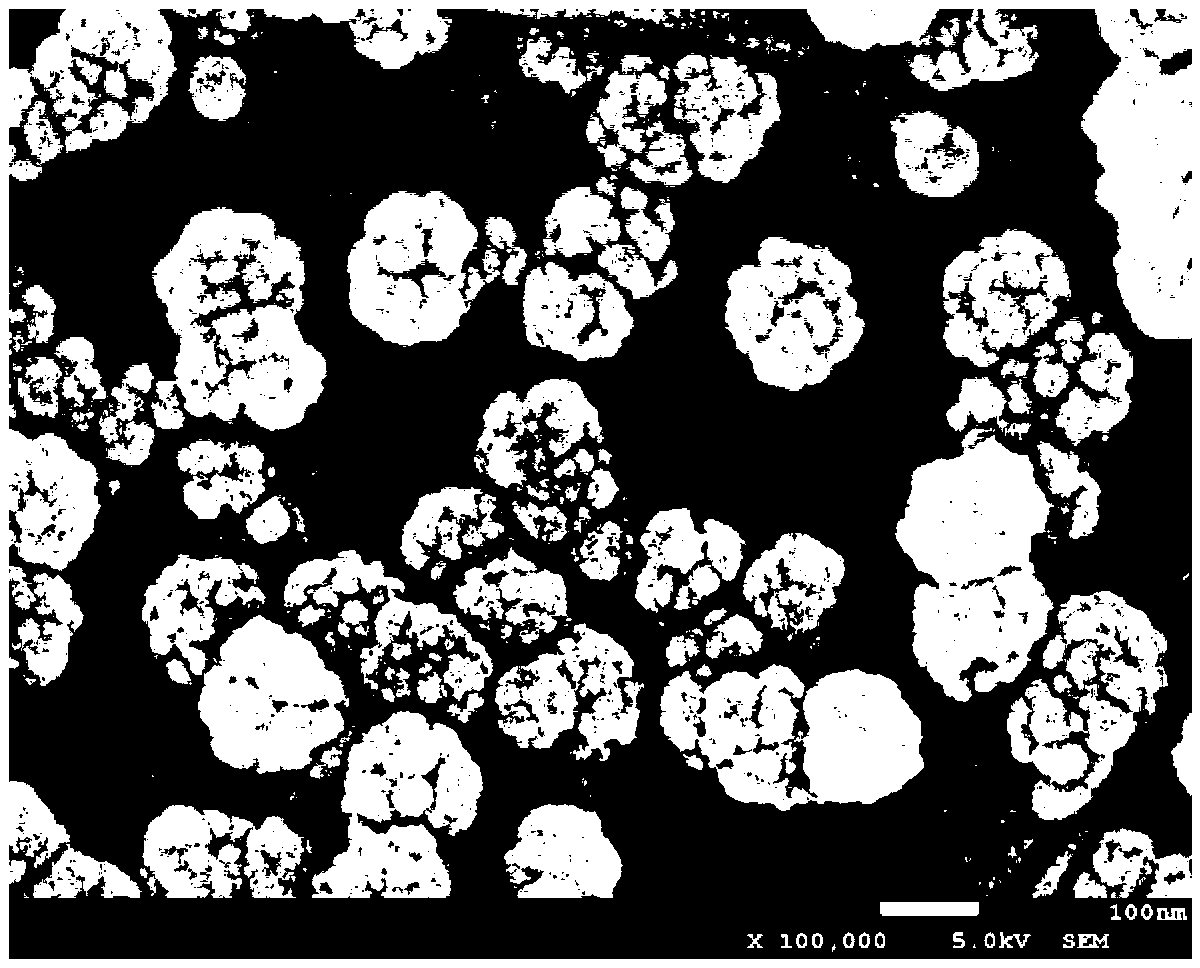

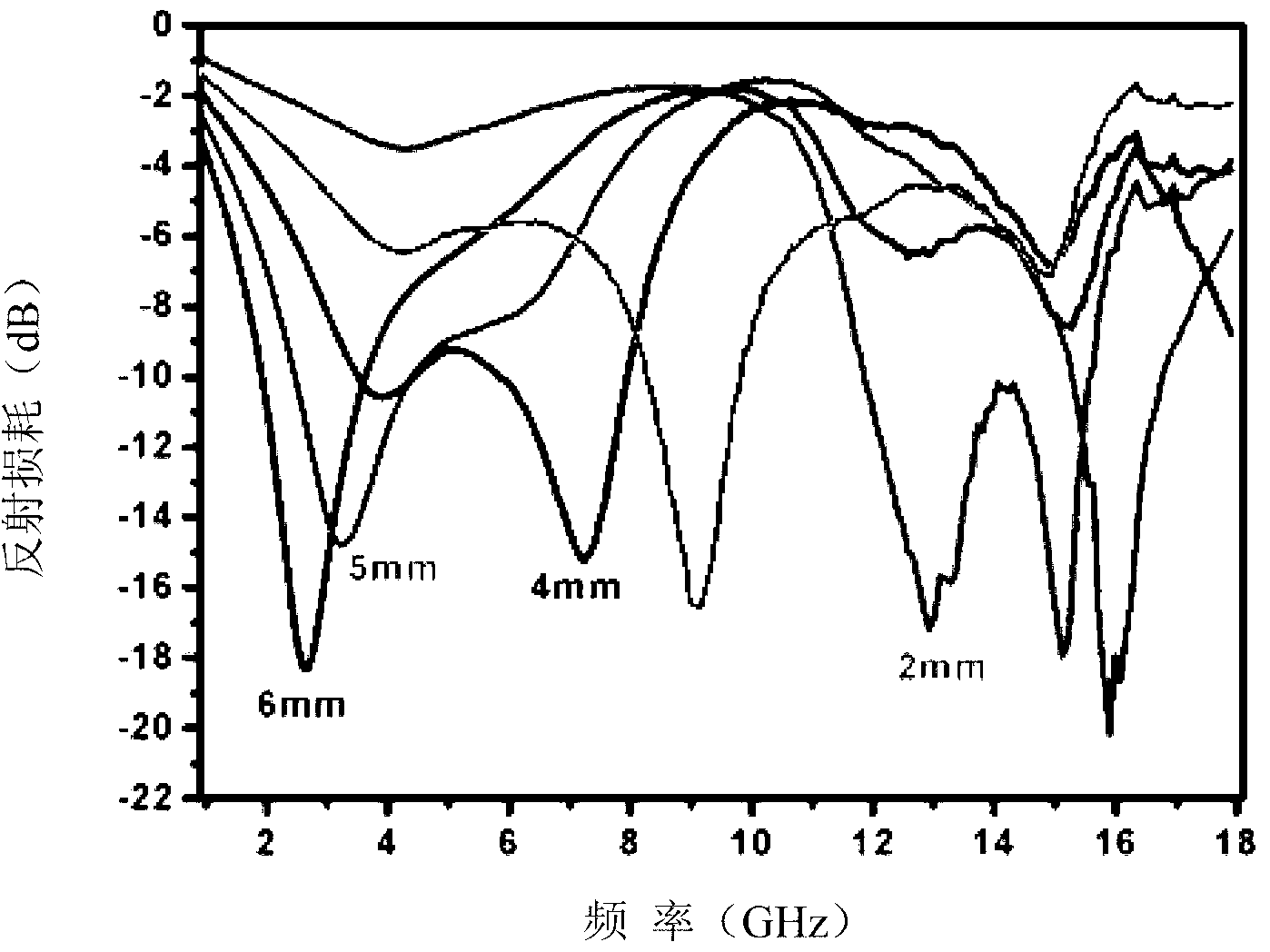

[0036] Step 2: using a solvothermal method to synthesize graphene and ferroferric oxide composite nanomaterials in one step. The specific process is: Dissolve 5g of polyethylene glycol 20000 in 100ml of ethylene glycol solution with mechanical stirring at a water bath temperature not exceeding 80°C. After the system becomes a uniform and transparent solution, add the graphene oxide prepared in step 1 and stir ultrasonically. Until the graphene is completely dispersed, the whole system is a uniform black solution; according to FeCl 3 ·6H 2 The ratio of O to graphene oxide is 1g:6.7mg, add ferric chloride hexahydrate, continue to stir for half an hour, add 9g of sodium acetate, continue ultrasonic stirring for 2 hours, and then transfer the mother liquor to the stainless steel high-pressure crystal glass lined with polytetrafluoroethylene. Crystallization at 200°C for 24 ho...

Embodiment 3

[0038] Step 1: Prepare graphene oxide. The preparation of graphene oxide is the same as in Example 1.

[0039] Step 2: using a solvothermal method to synthesize graphene and ferroferric oxide composite nanomaterials in one step. The specific process is: Dissolve 5g of polyethylene glycol 20000 in 100ml of ethylene glycol solution with mechanical stirring at a water bath temperature not exceeding 80°C. After the system becomes a uniform and transparent solution, add the graphene oxide prepared in step 1 and stir ultrasonically. Until the graphene is completely dispersed, the whole system is a uniform black solution; according to FeCl 3 ·6H 2 The ratio of O to graphene oxide is 1g:10.2mg, add ferric chloride hexahydrate, continue to stir for half an hour, add 9g of sodium acetate, continue ultrasonic stirring for 2 hours, and then transfer the mother liquor to a stainless steel high-pressure crystal glass lined with polytetrafluoroethylene. Crystallization at 200°C for 24 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com