Patents

Literature

2902 results about "Electric properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electrical properties. Properties of a substance which determine its response to an electric field, such as its dielectric constant or conductivity.

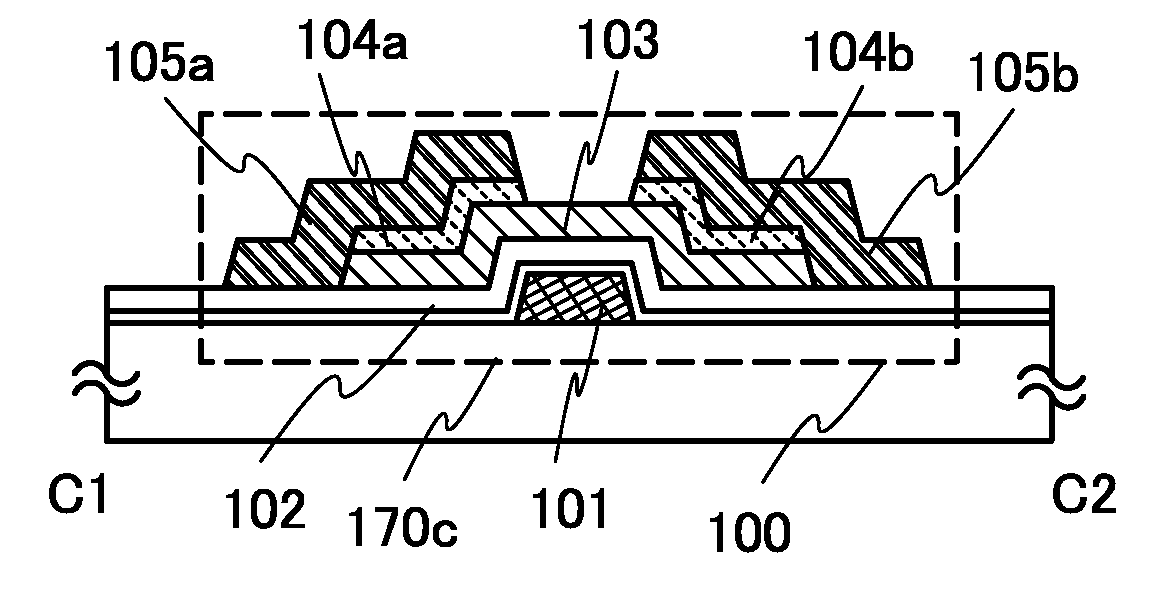

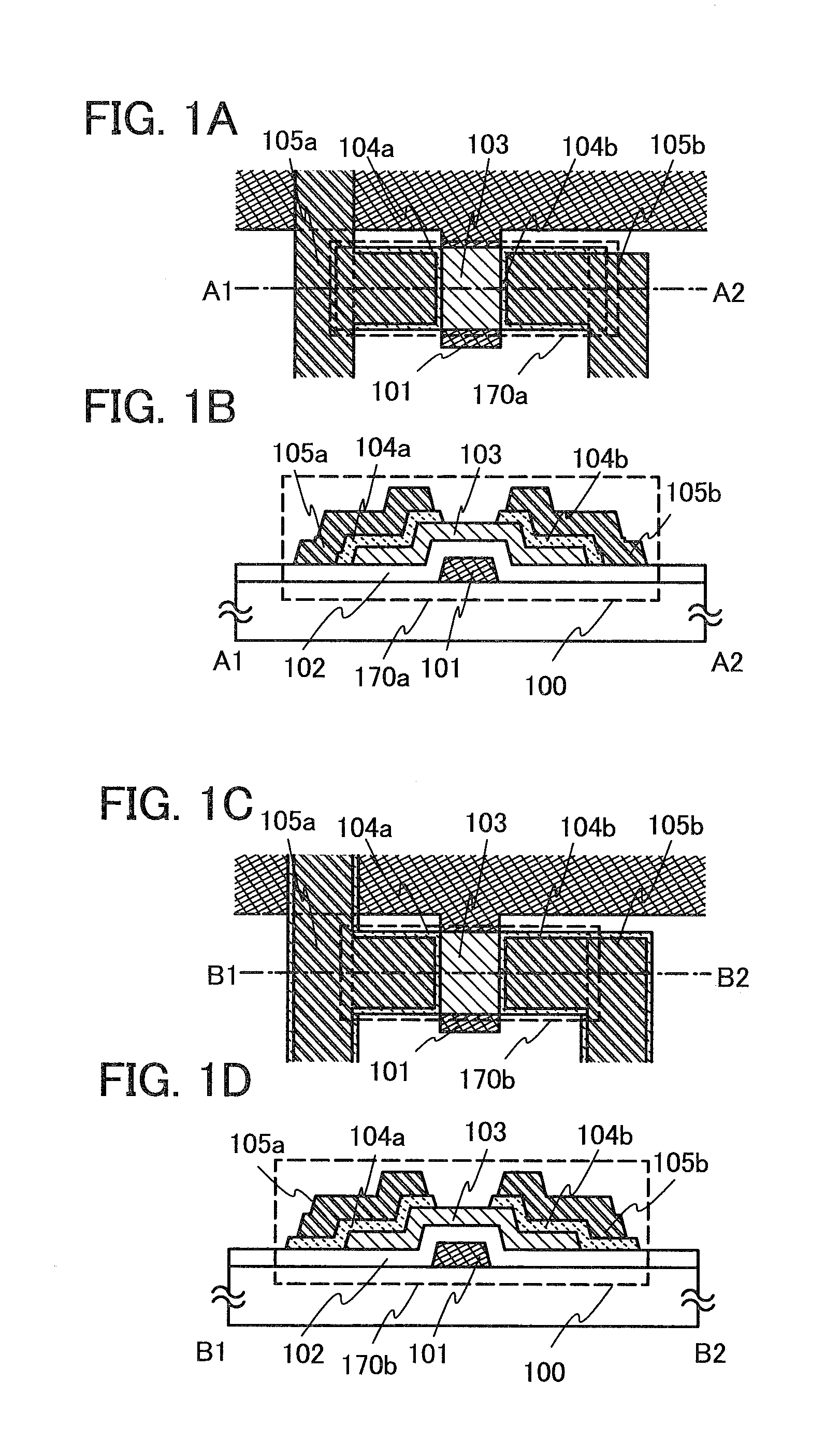

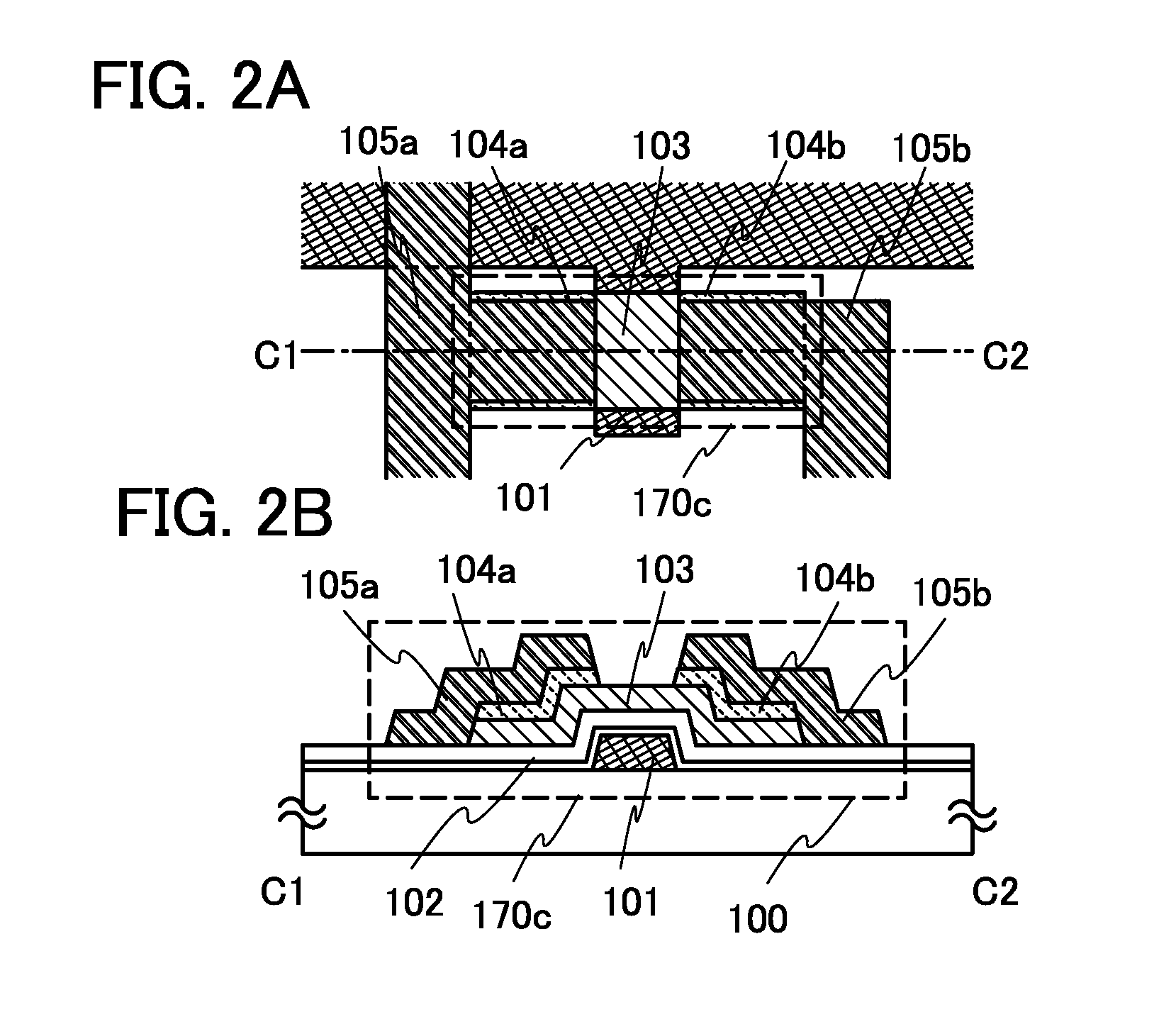

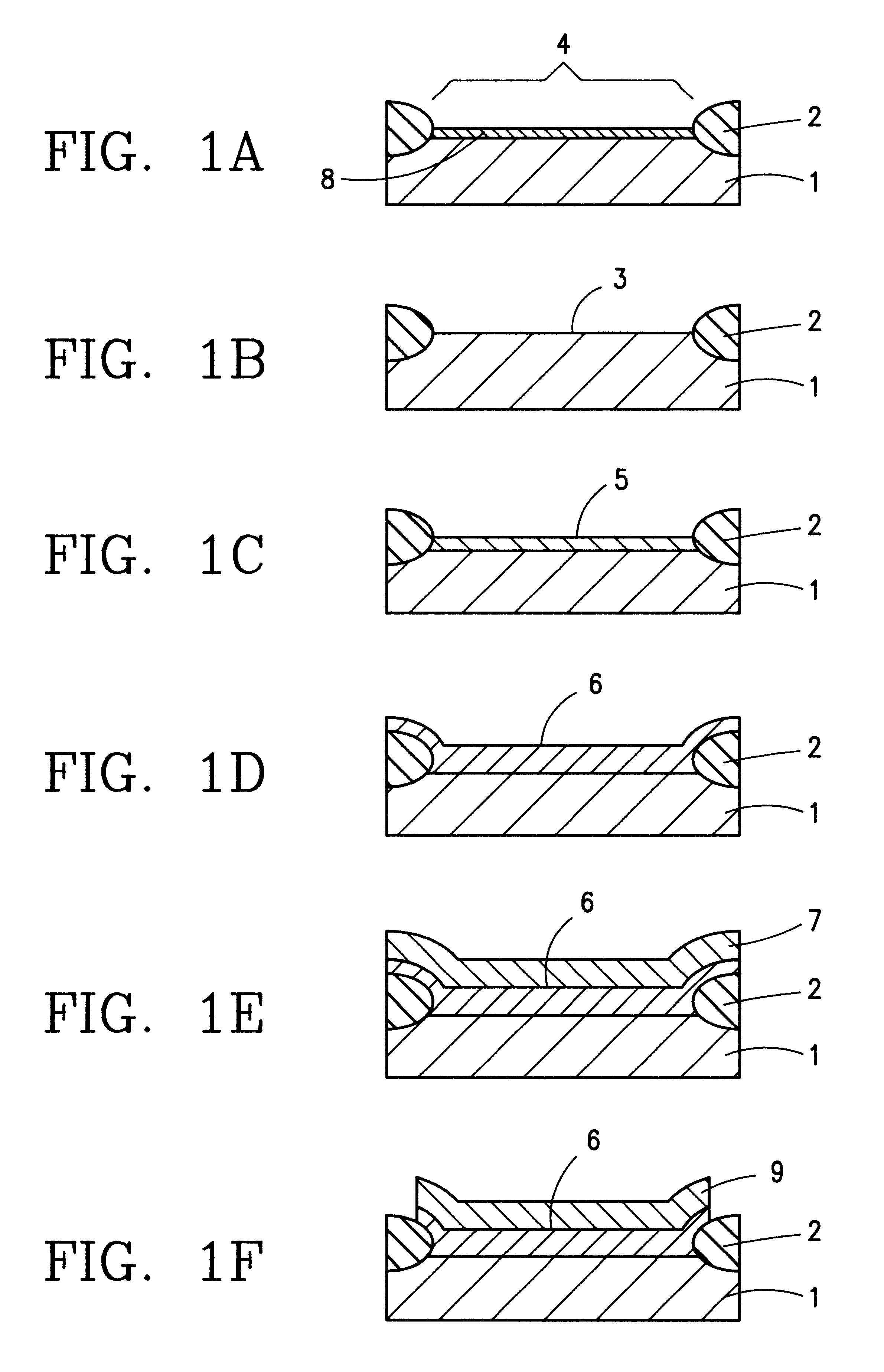

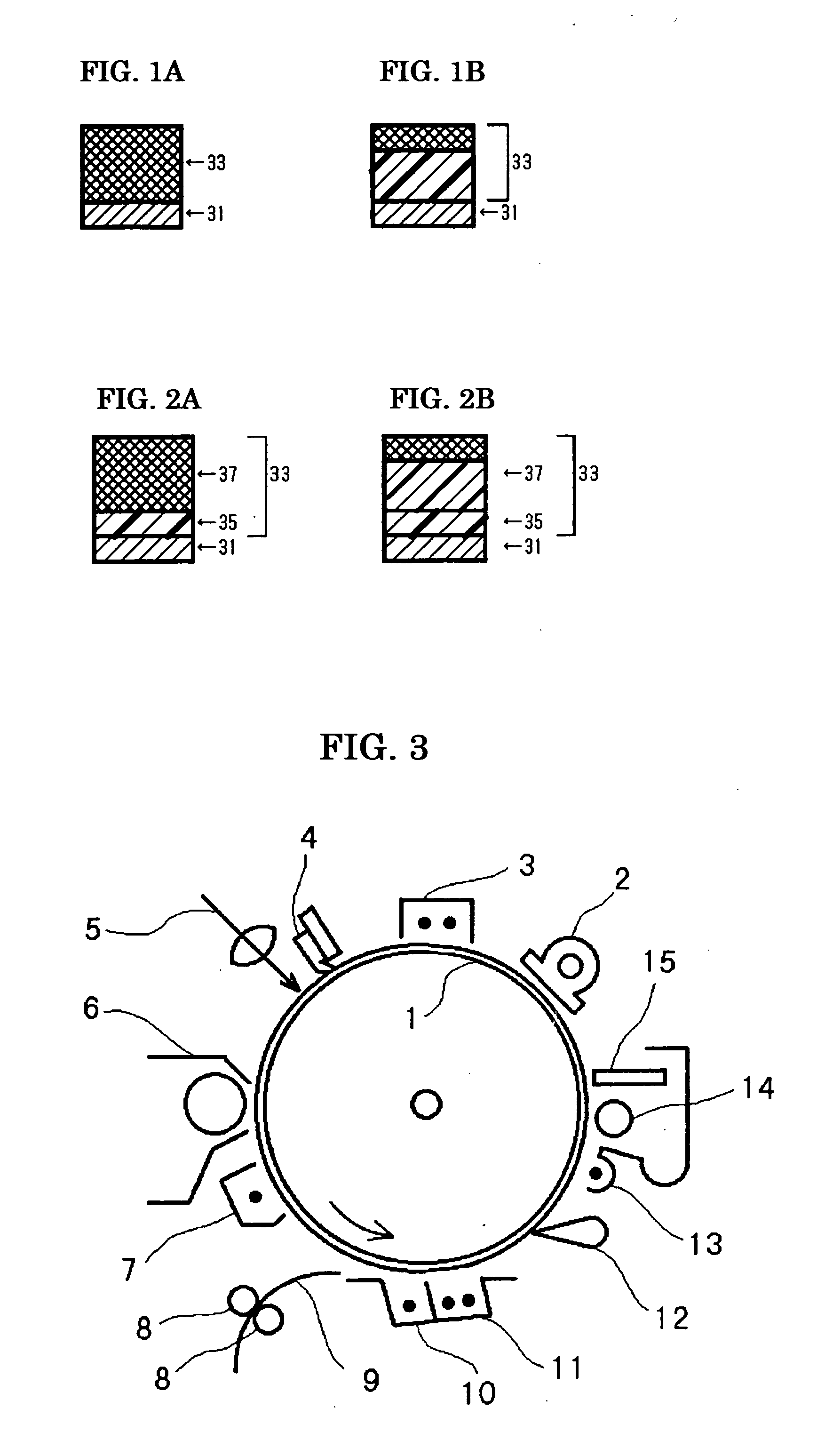

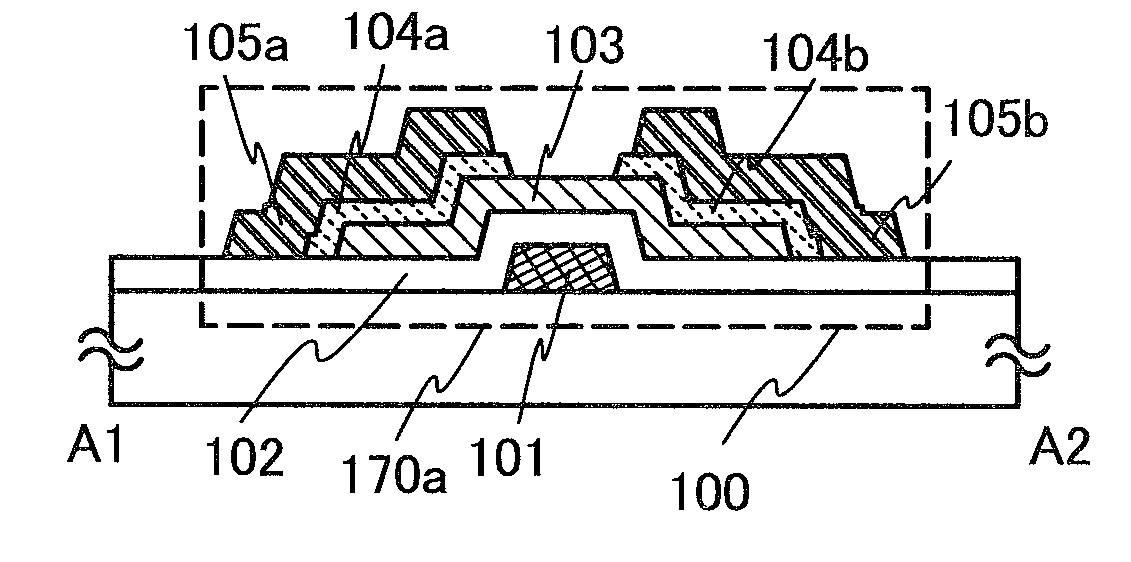

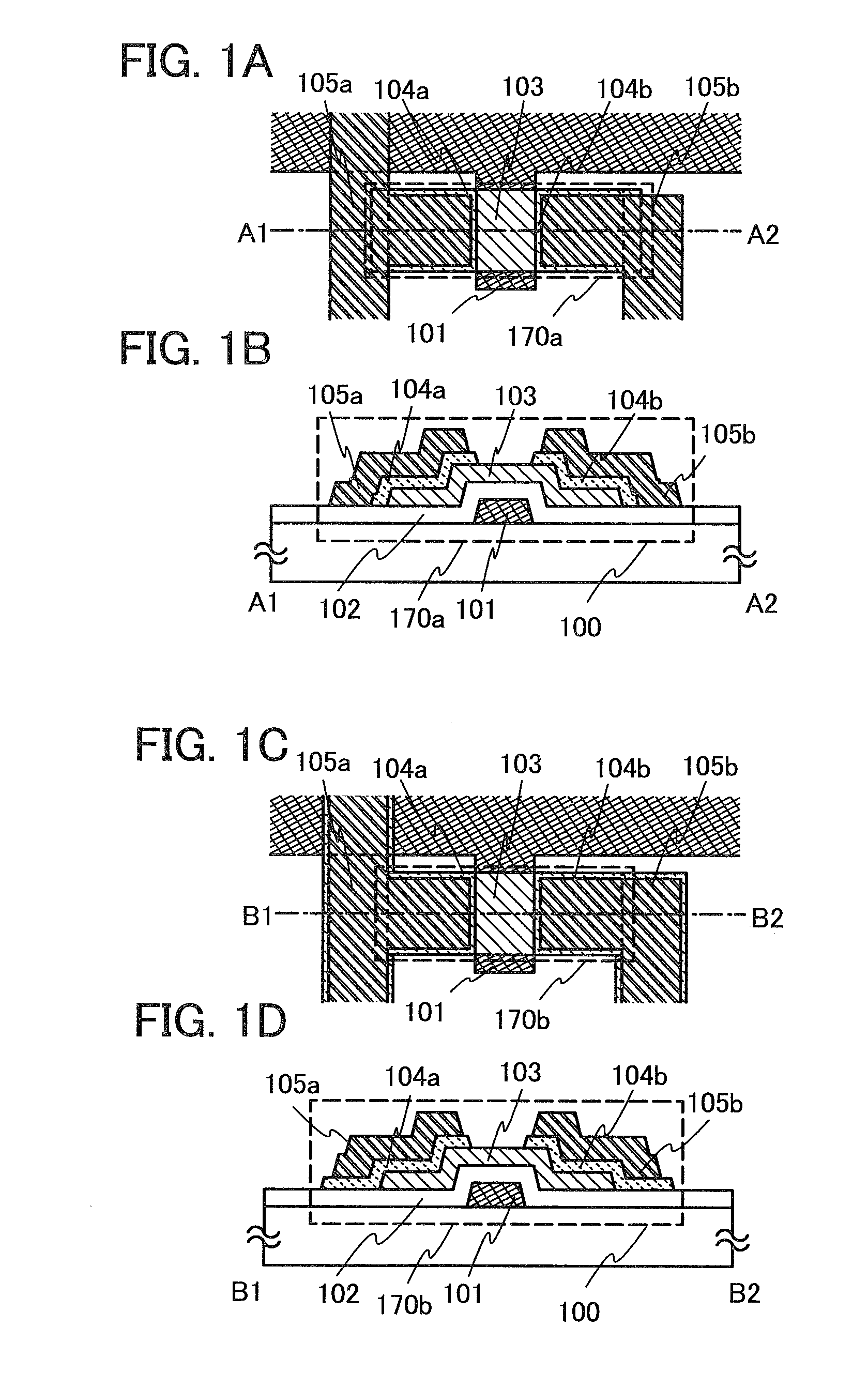

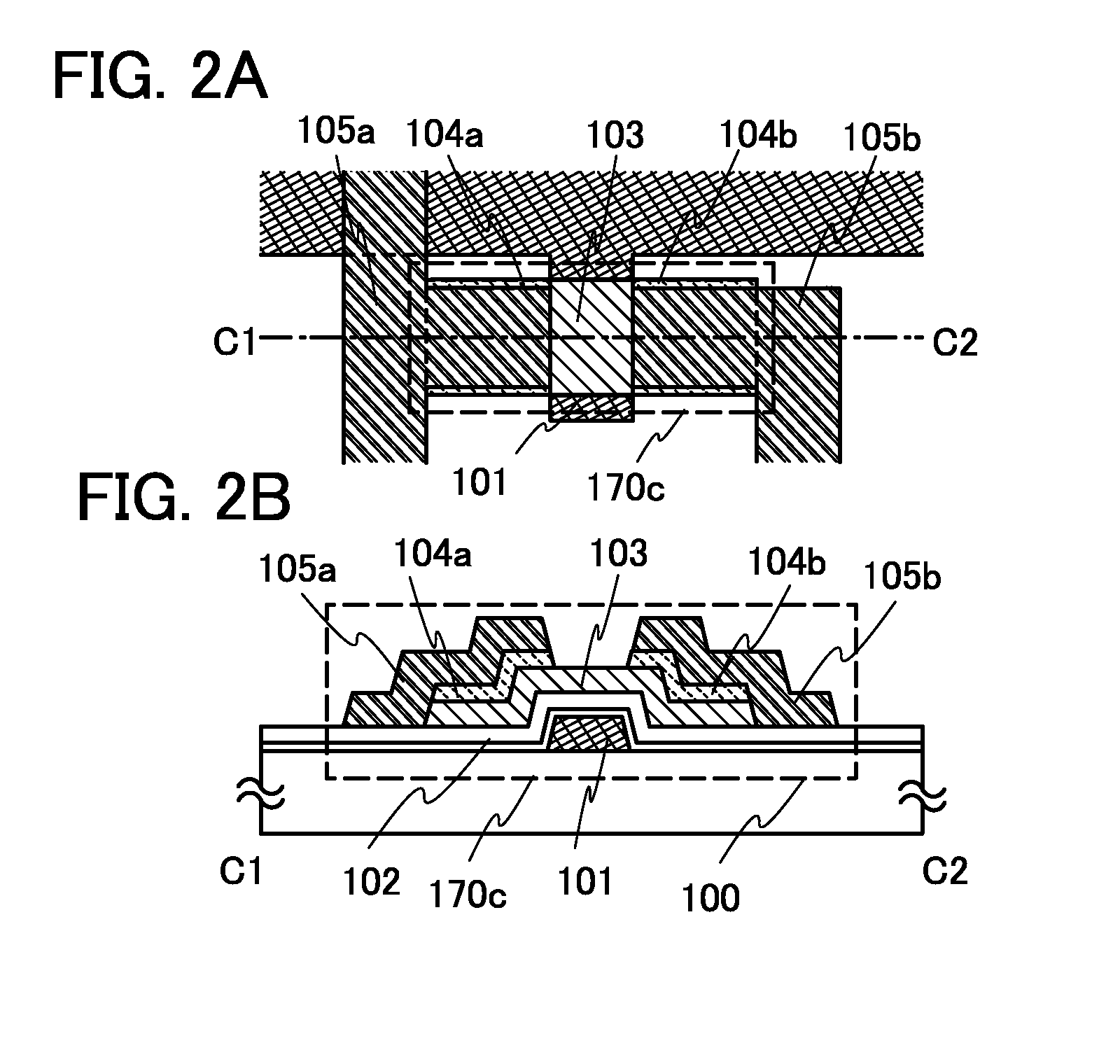

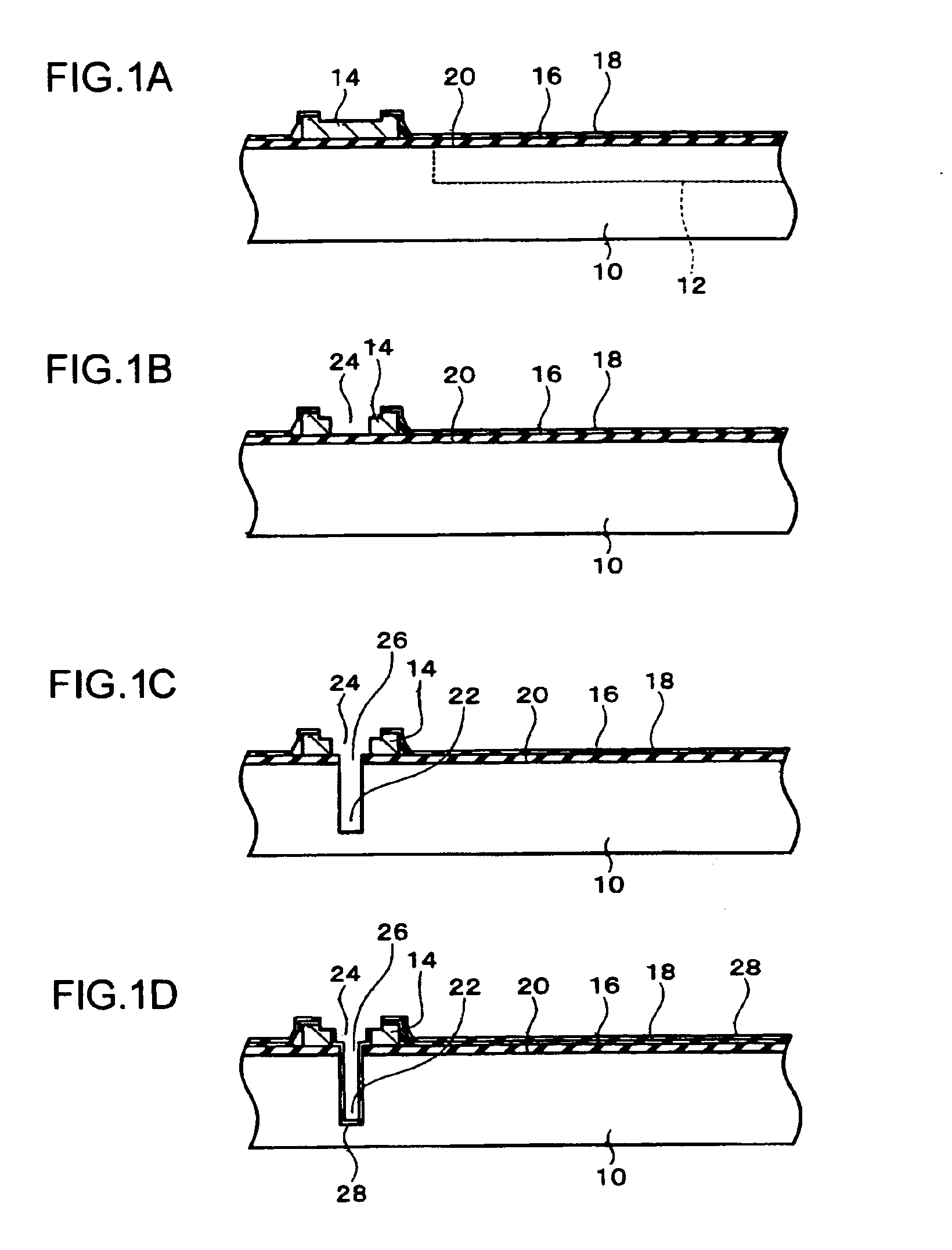

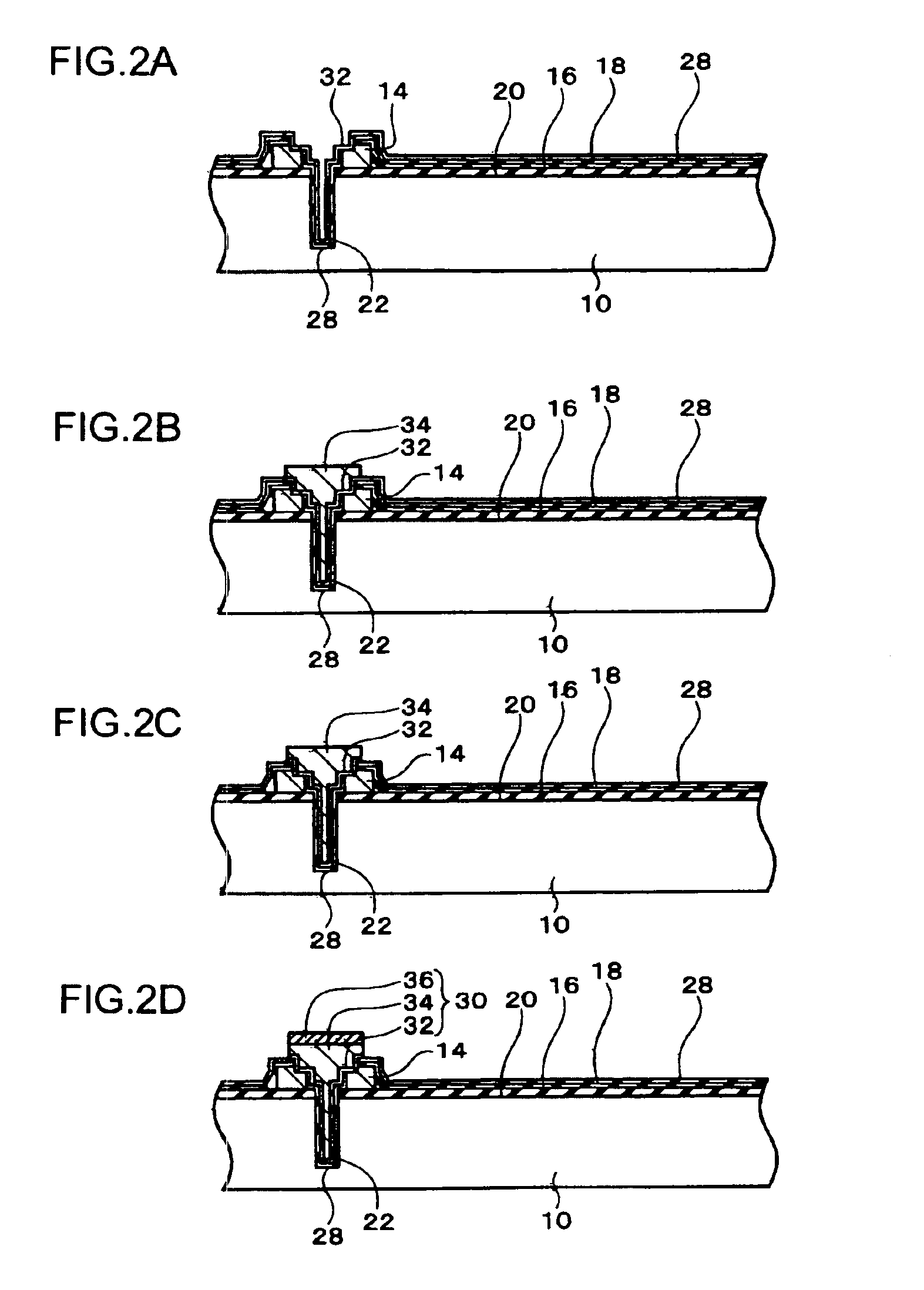

Semiconductor device and method for manufacturing the same

ActiveUS20100025678A1Comparatively-easy manufacturing processRun at high speedTransistorSolid-state devicesProduction rateOhmic contact

It is an object to provide a semiconductor device including a thin film transistor with favorable electric properties and high reliability, and a method for manufacturing the semiconductor device with high productivity. In an inverted staggered (bottom gate) thin film transistor, an oxide semiconductor film containing In, Ga, and Zn is used as a semiconductor layer, and a buffer layer formed using a metal oxide layer is provided between the semiconductor layer and a source and drain electrode layers. The metal oxide layer is intentionally provided as the buffer layer between the semiconductor layer and the source and drain electrode layers, whereby ohmic contact is obtained.

Owner:SEMICON ENERGY LAB CO LTD

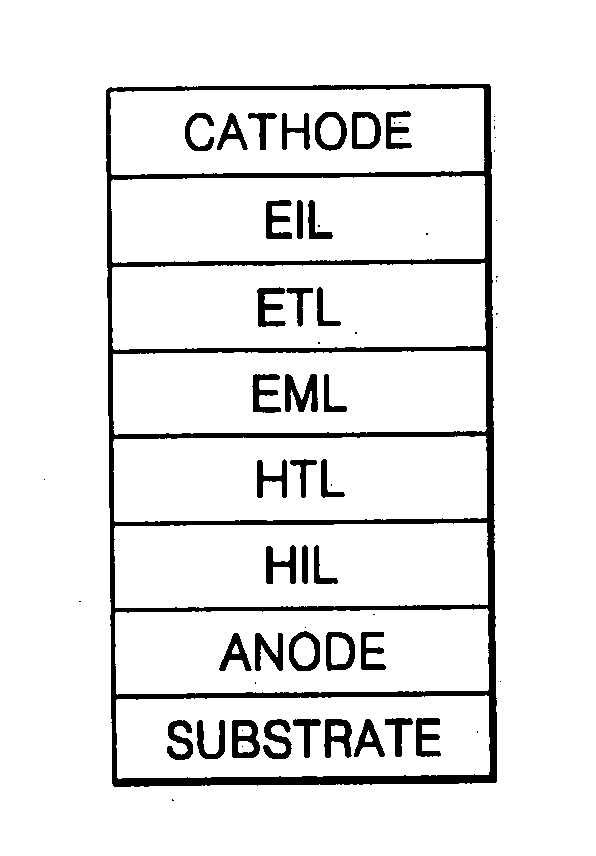

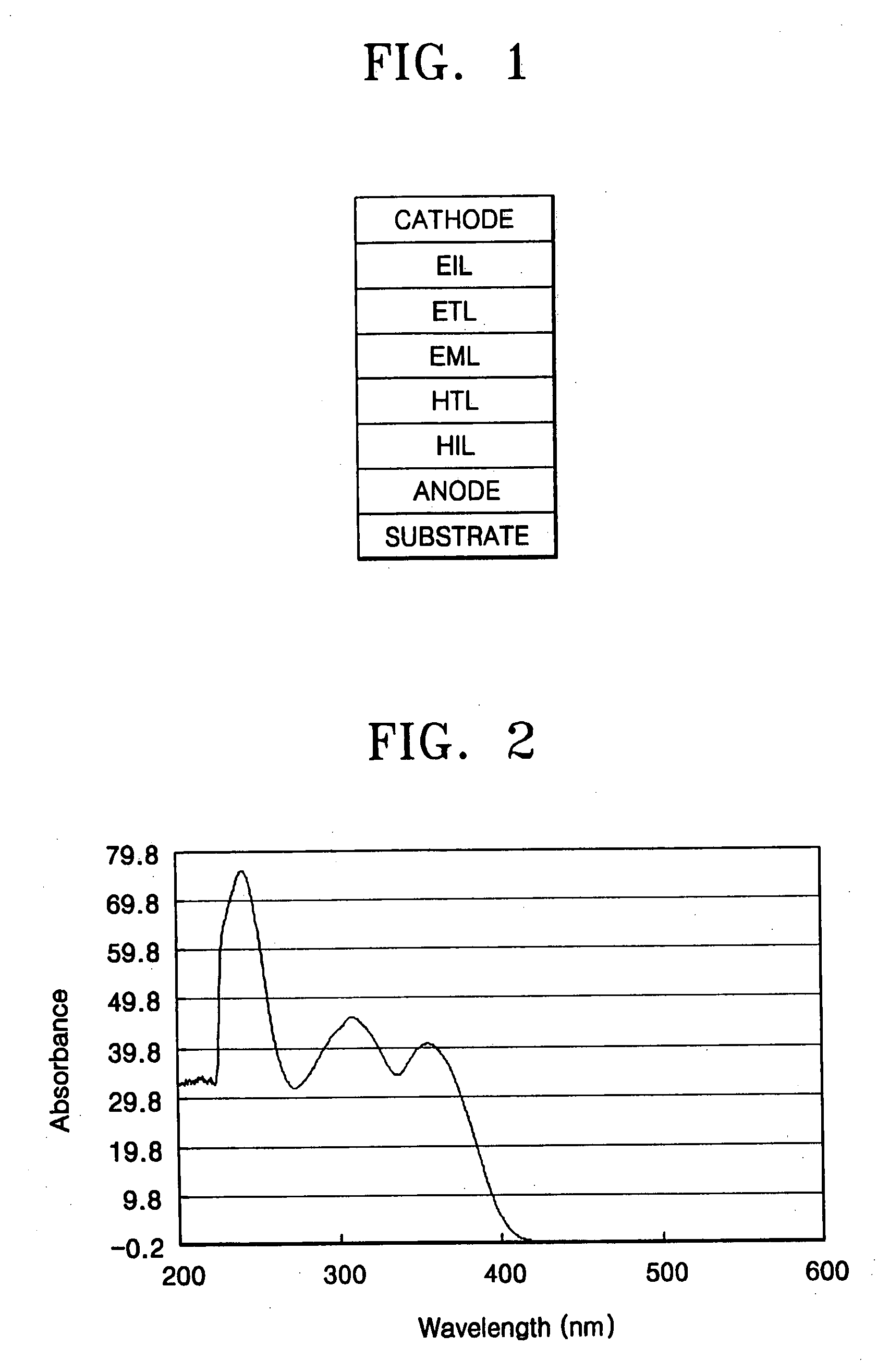

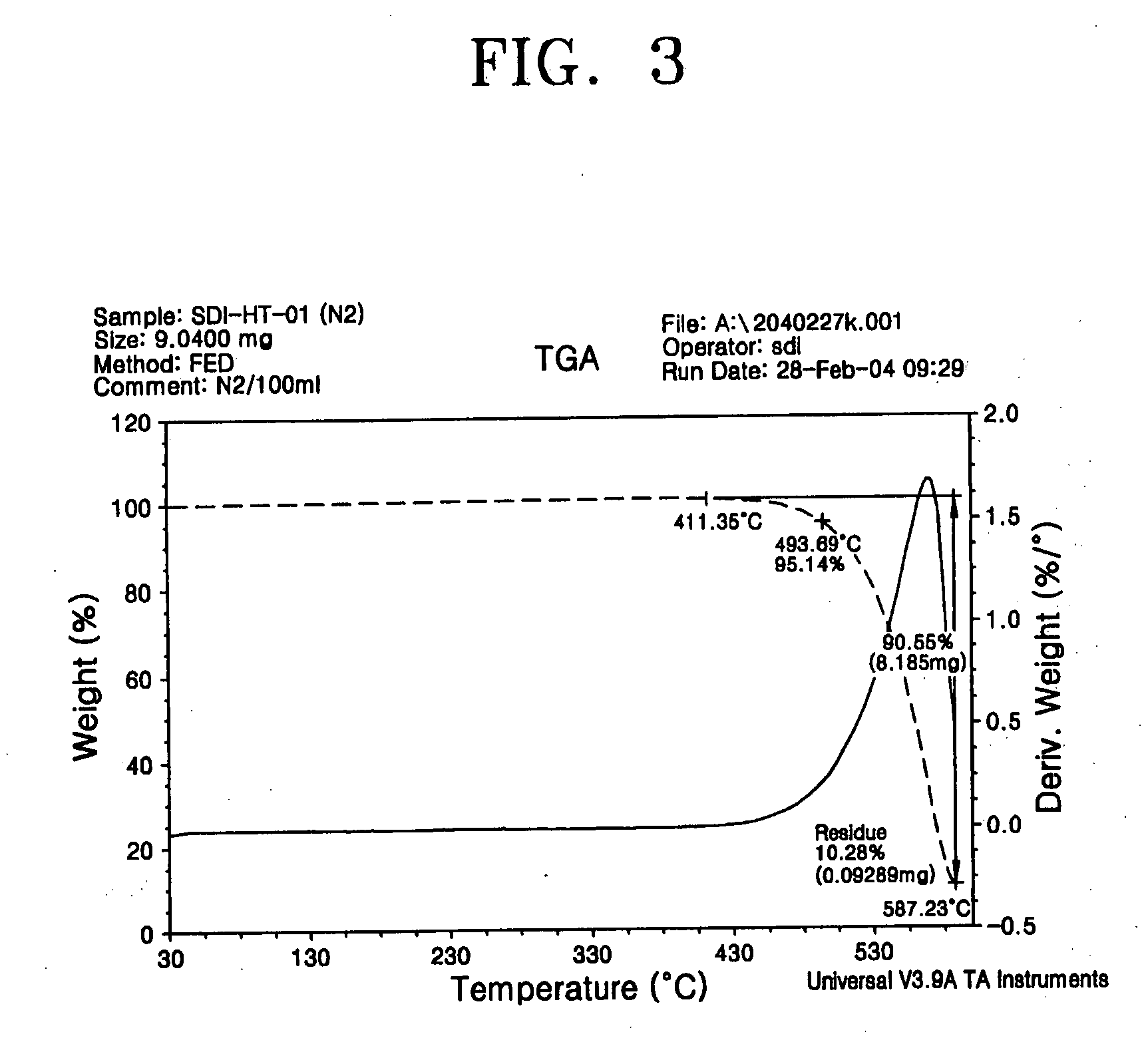

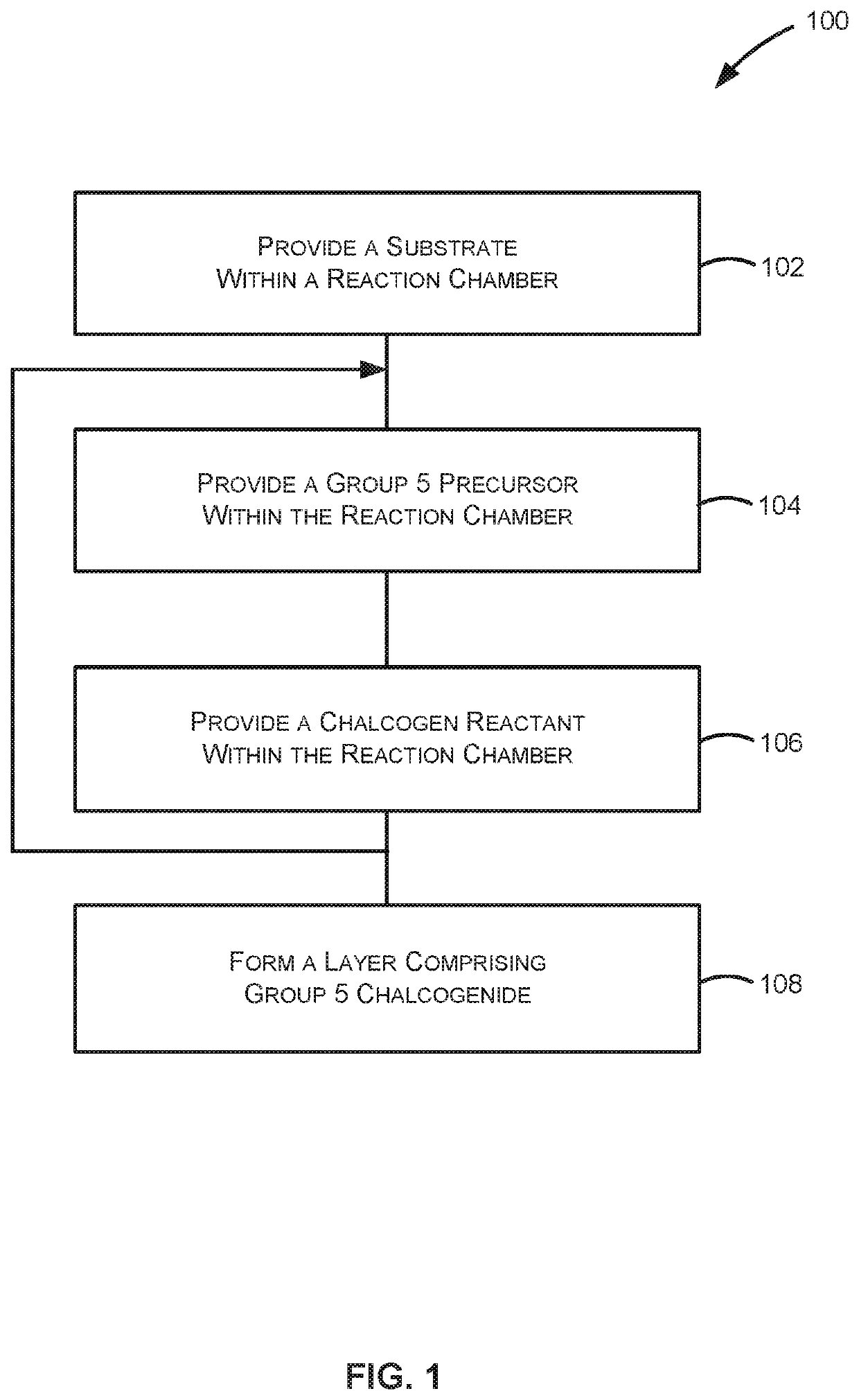

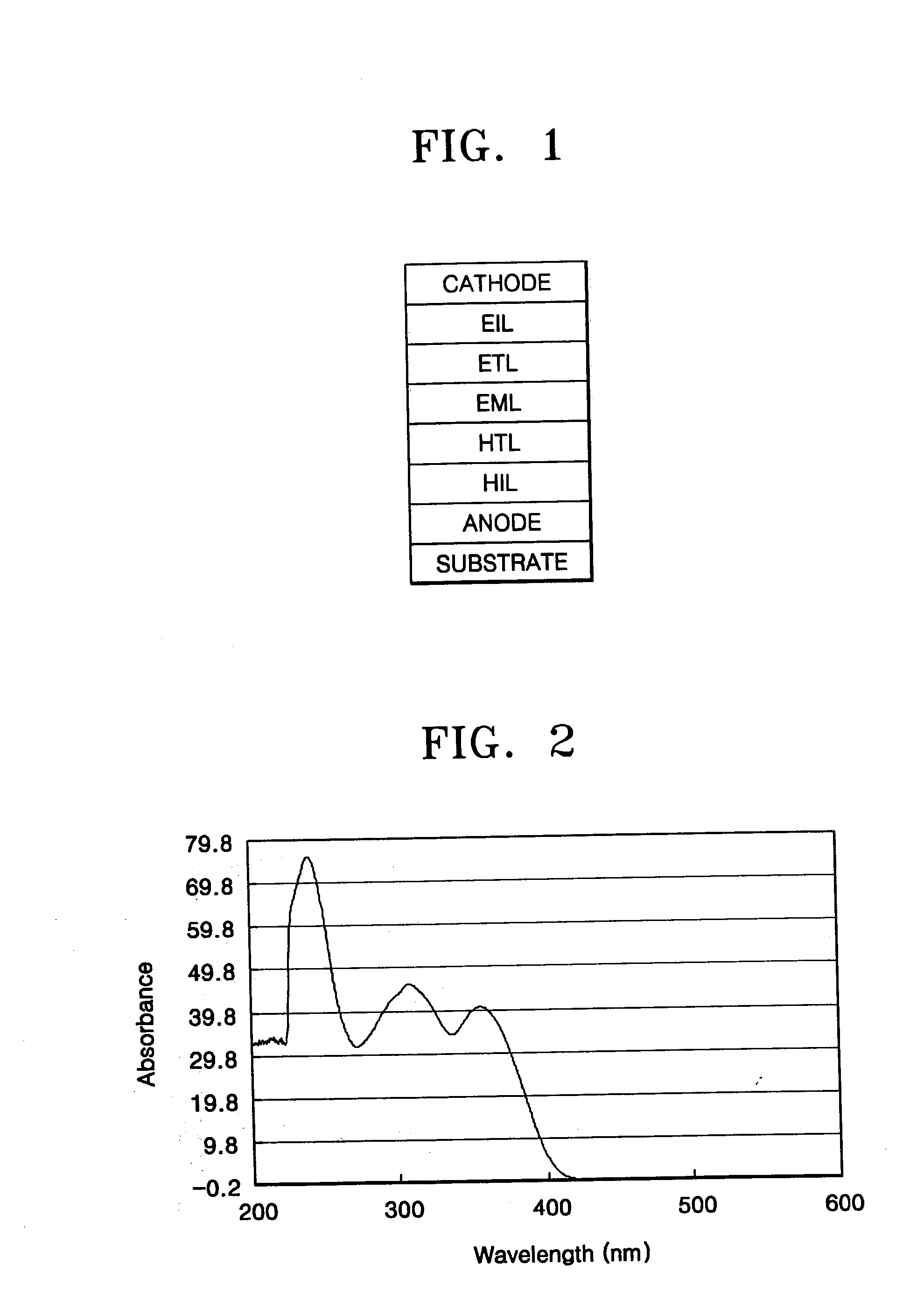

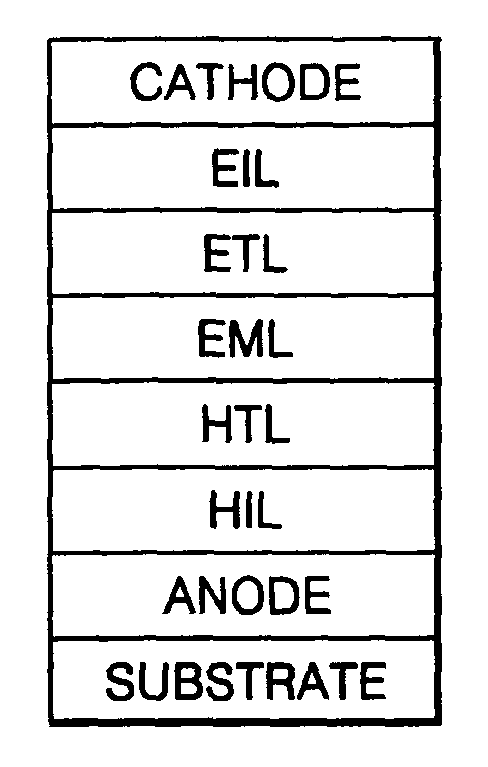

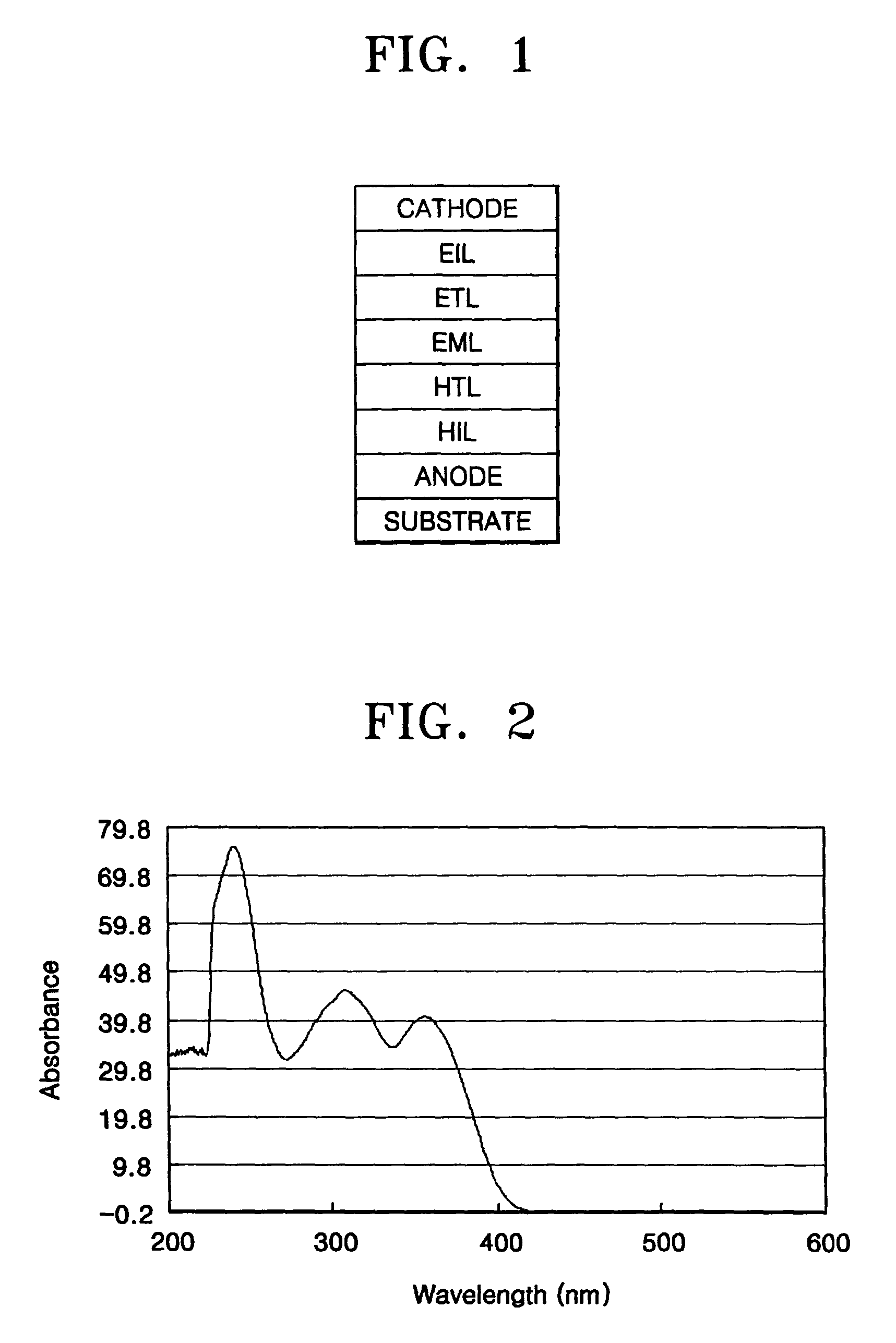

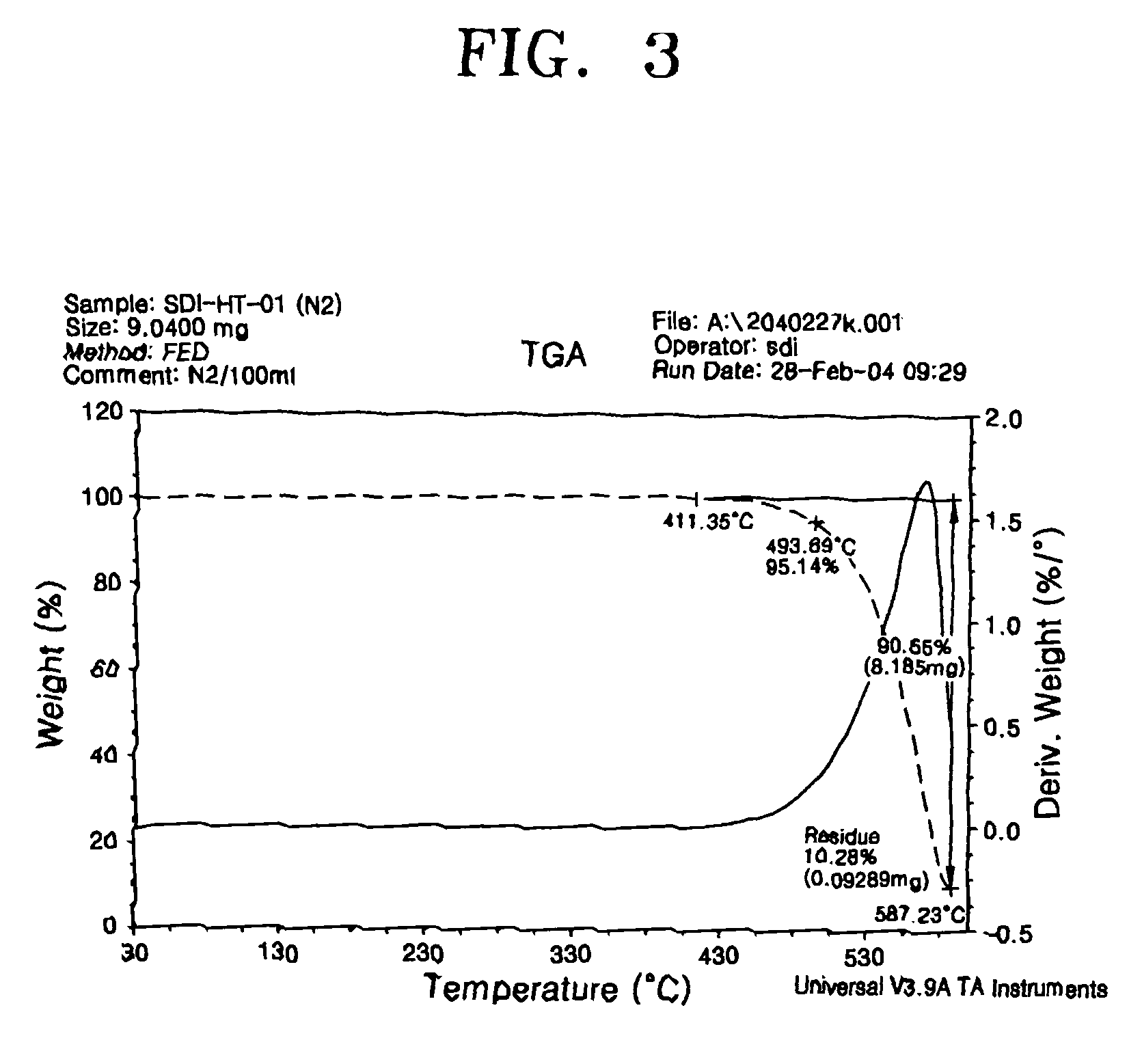

Phenylcarbazole-based compound and organic electroluminescent device employing the same

ActiveUS20080107919A1High glass transition temperatureElectric stabilityOrganic chemistryDischarge tube luminescnet screensCarbazoleLow voltage

A phenylcarbazole-based compound is represented by Formula 1, and has superior electric properties and charge transport abilities, and thus is useful as a hole injection material, a hole transport material, and / or an emitting material which is suitable for fluorescent and phosphorescent devices of all colors, including red, green, blue, and white colors. The phenylcarbazole-based compound is synthesized by reacting carbazole with diamine. The organic electroluminescent device manufactured using the phenylcarbazole-based compound has high efficiency, low voltage, high luminance, and a long lifespan.

Owner:SAMSUNG DISPLAY CO LTD

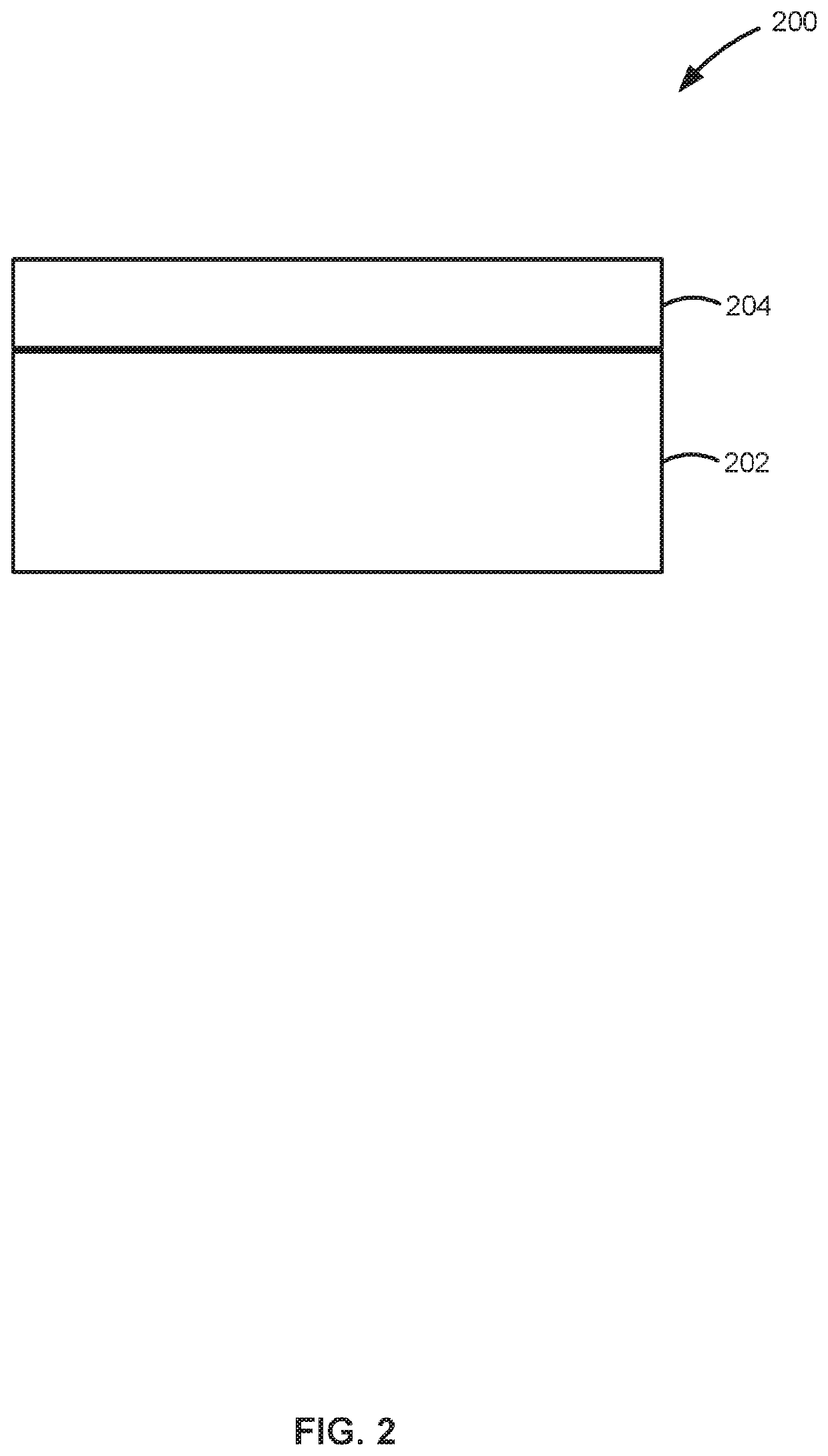

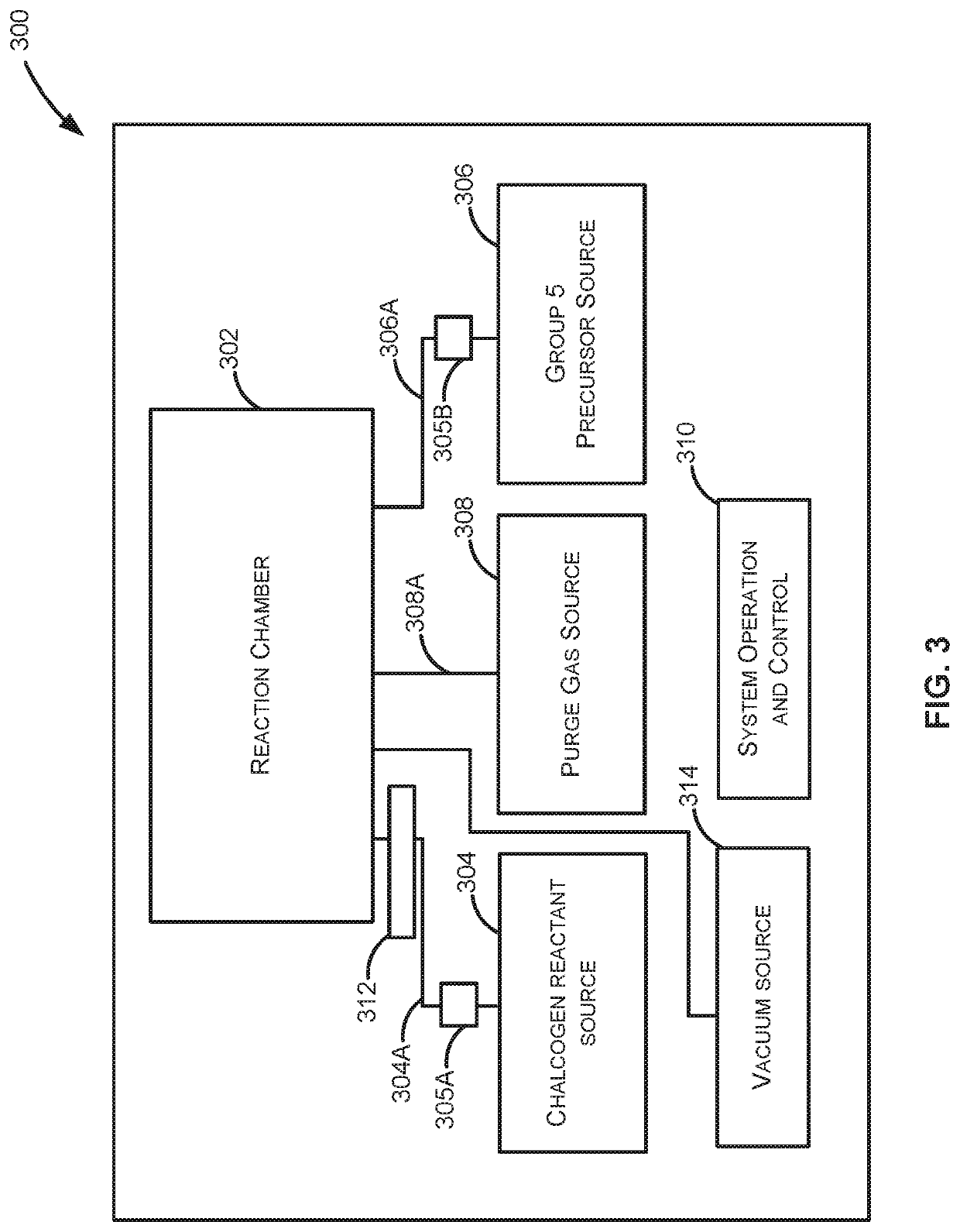

Methods and apparatus for depositing a chalcogenide film and structures including the film

PendingUS20210066080A1Readily apparentSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChalcogenChalcoides

Methods for depositing group 5 chalcogenides on a substrate are disclosed. The methods include cyclical deposition techniques, such as atomic layer deposition. The group 5 chalcogenides can be two-dimensional films having desirable electrical properties.

Owner:ASM IP HLDG BV

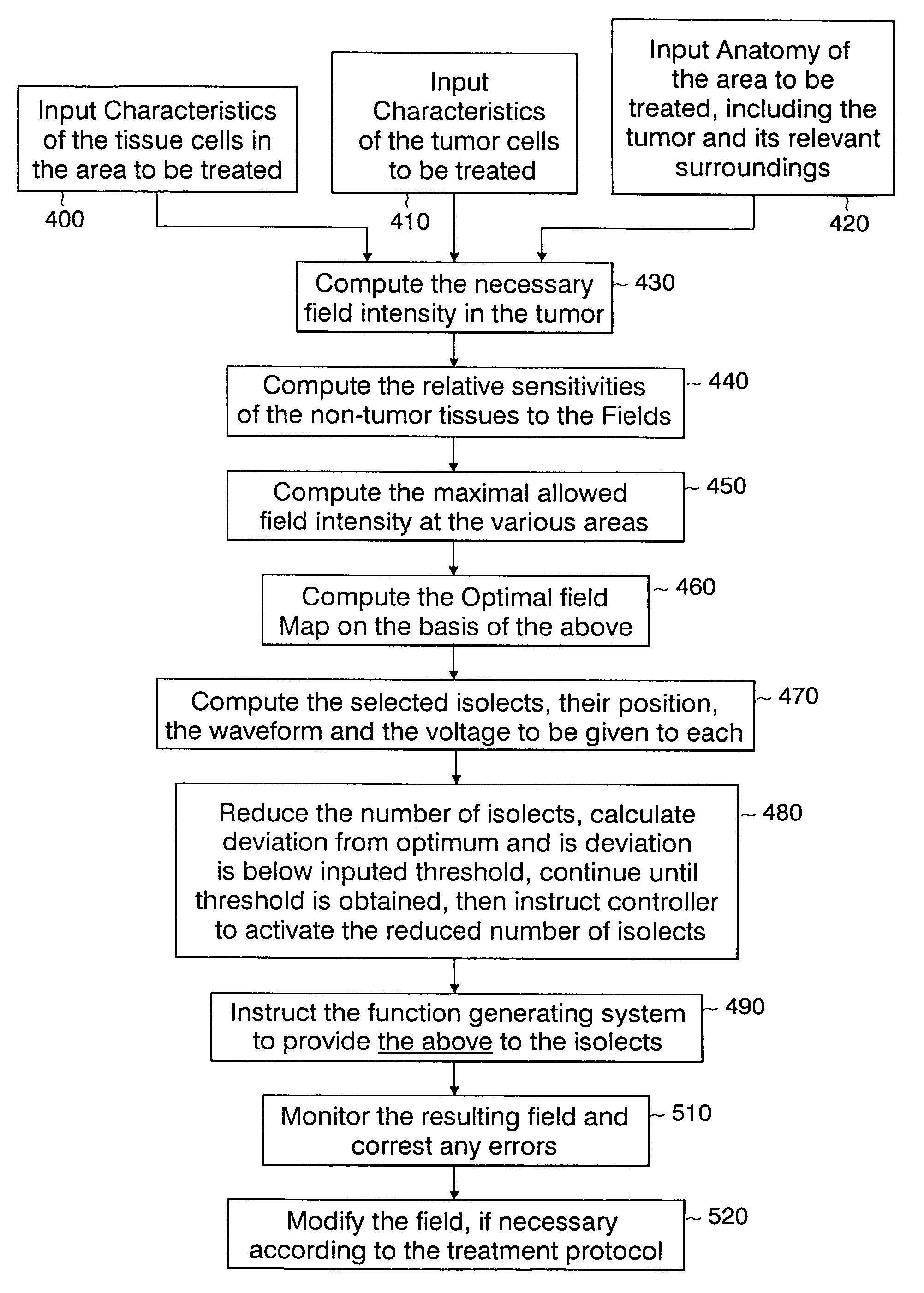

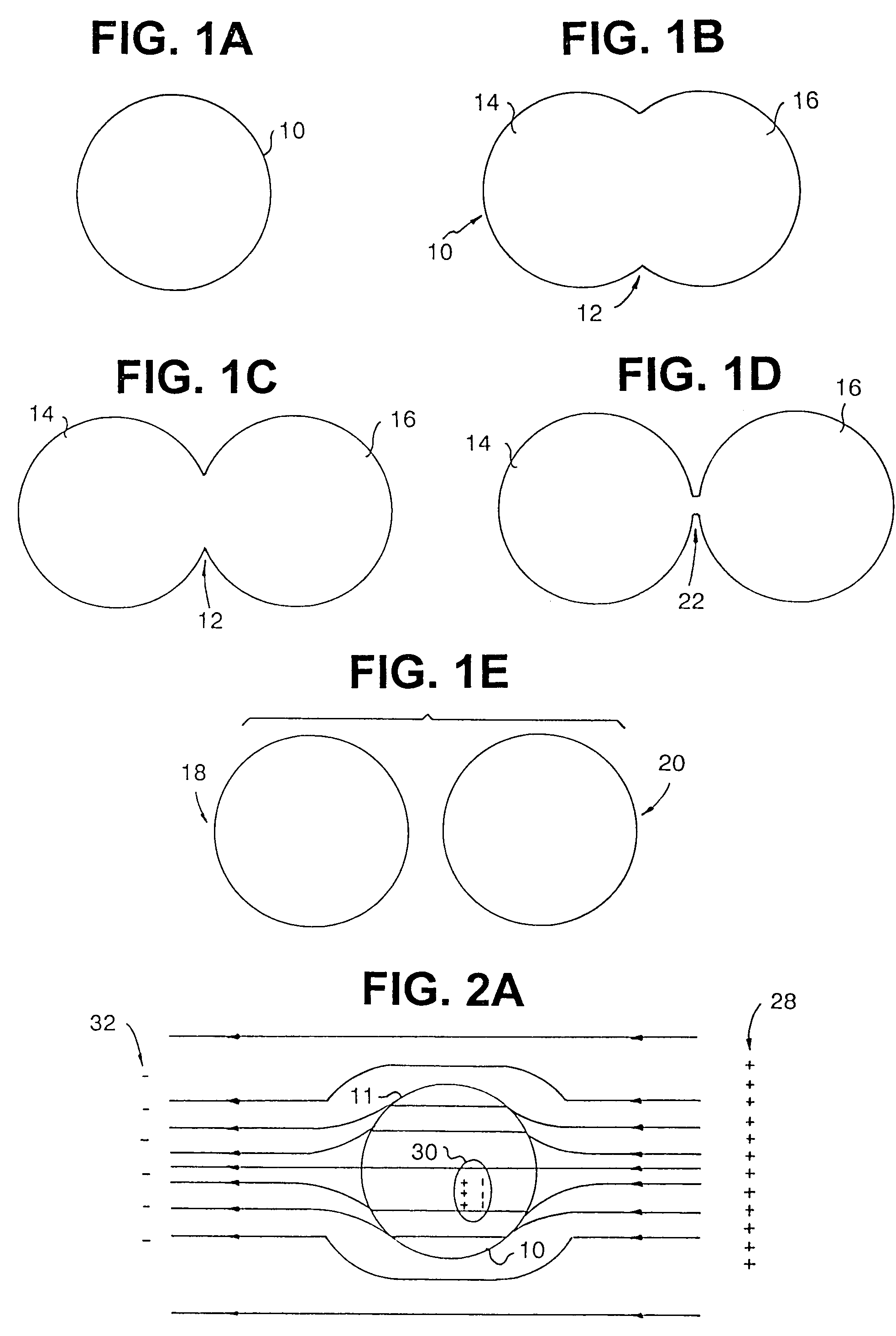

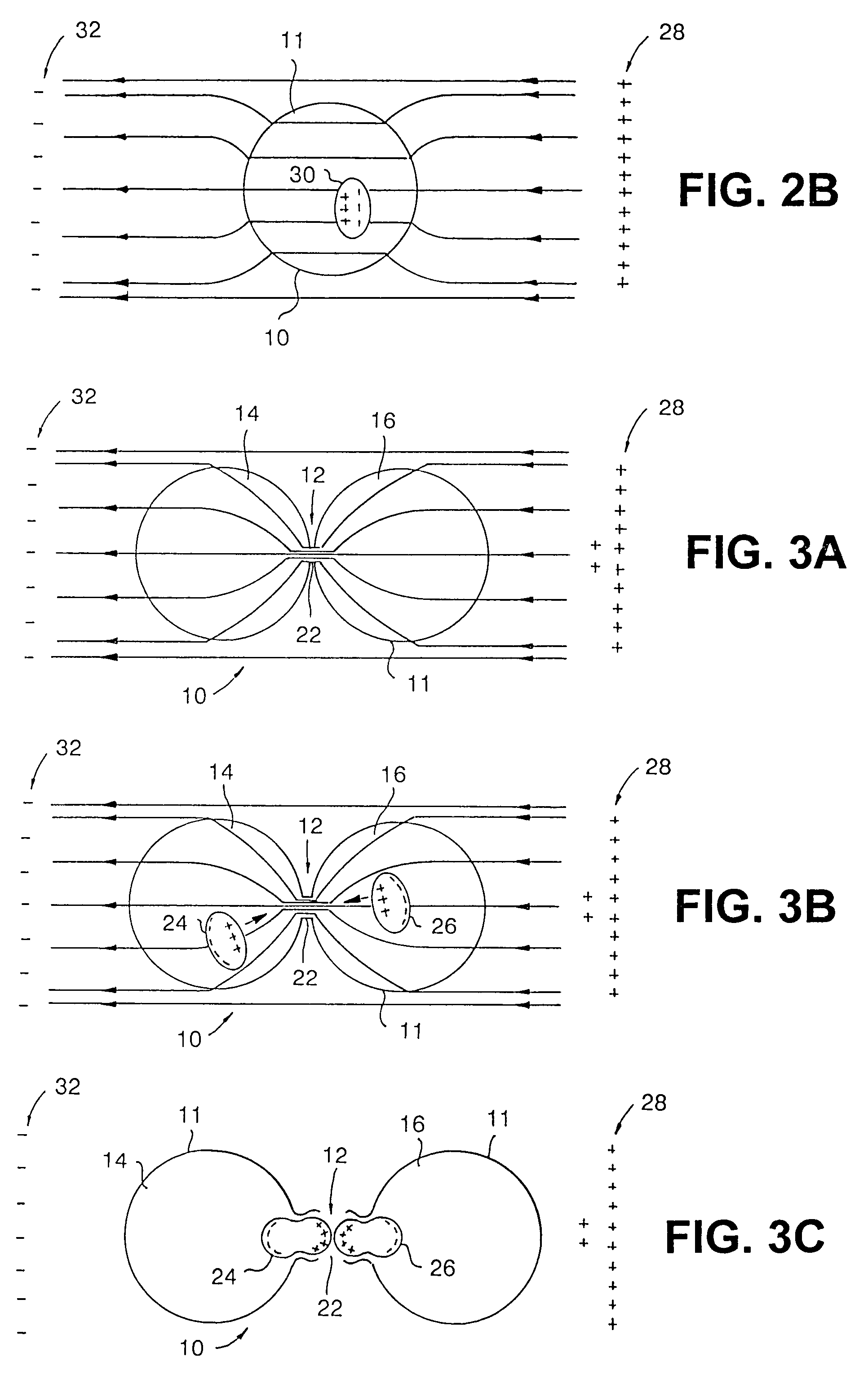

Apparatus and method for optimizing tumor treatment efficiency by electric fields

InactiveUS7146210B2Optimize spaceOptimal temporal characteristicSurgical instruments for heatingExternal electrodesElectricityCompanion animal

The apparatus and method are designed to compute the optimal spatial and temporal characteristics for combating tumor growth within a body on the basis of cytological (as provided by biopsies, etc.) and anatomical data (as provided by CT, MRI, PET, etc.), as well as the electric properties of the different elements. On the basis of this computation, the apparatus applies the fields that have maximal effect on the tumor and minimal effect on all other tissues by adjusting both the field generator output characteristics and by optimal positioning of the insulated electrodes or isolects on the patient's body.

Owner:NOVOCURE GMBH

Nanodiamond PCD and methods of forming

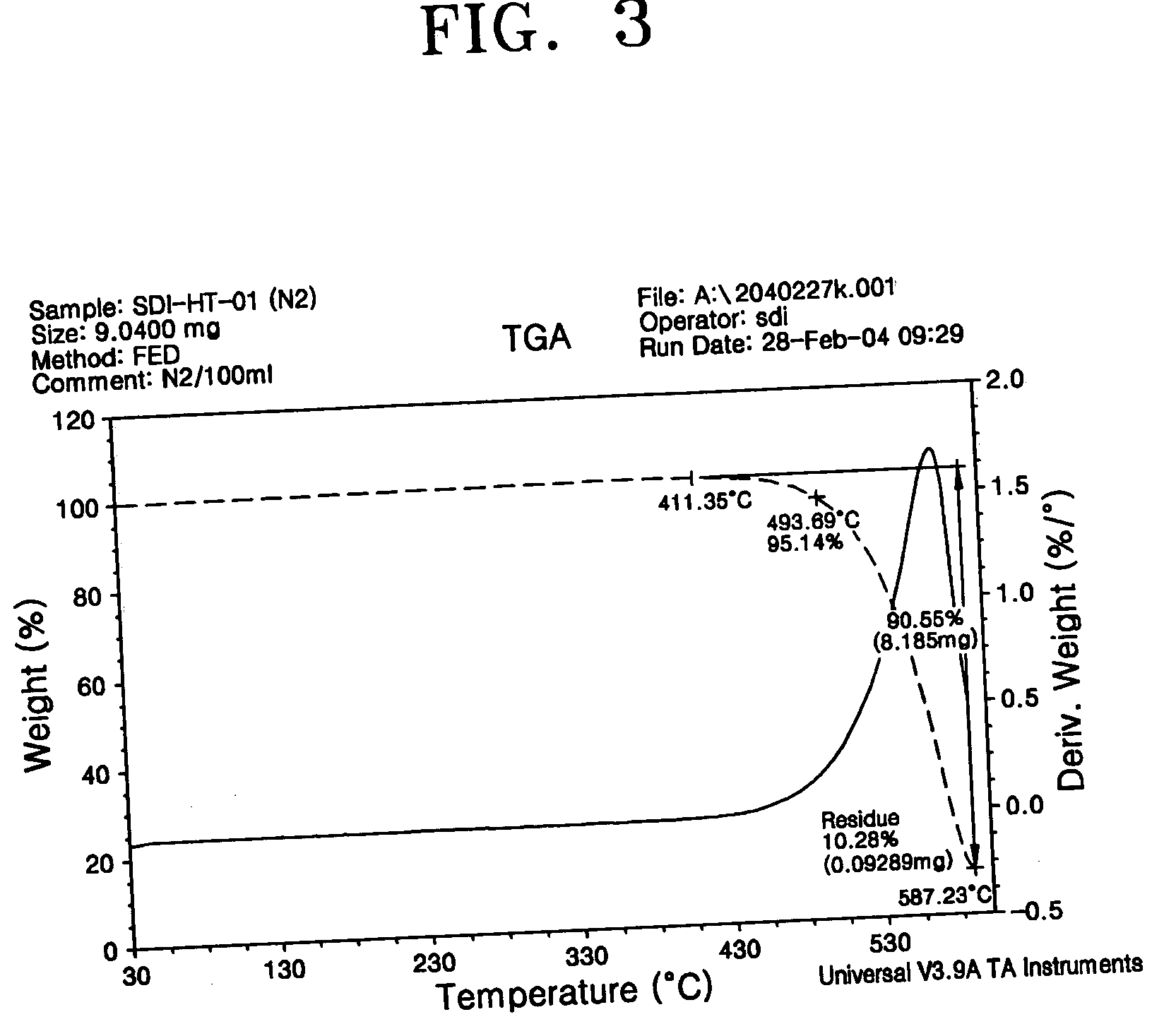

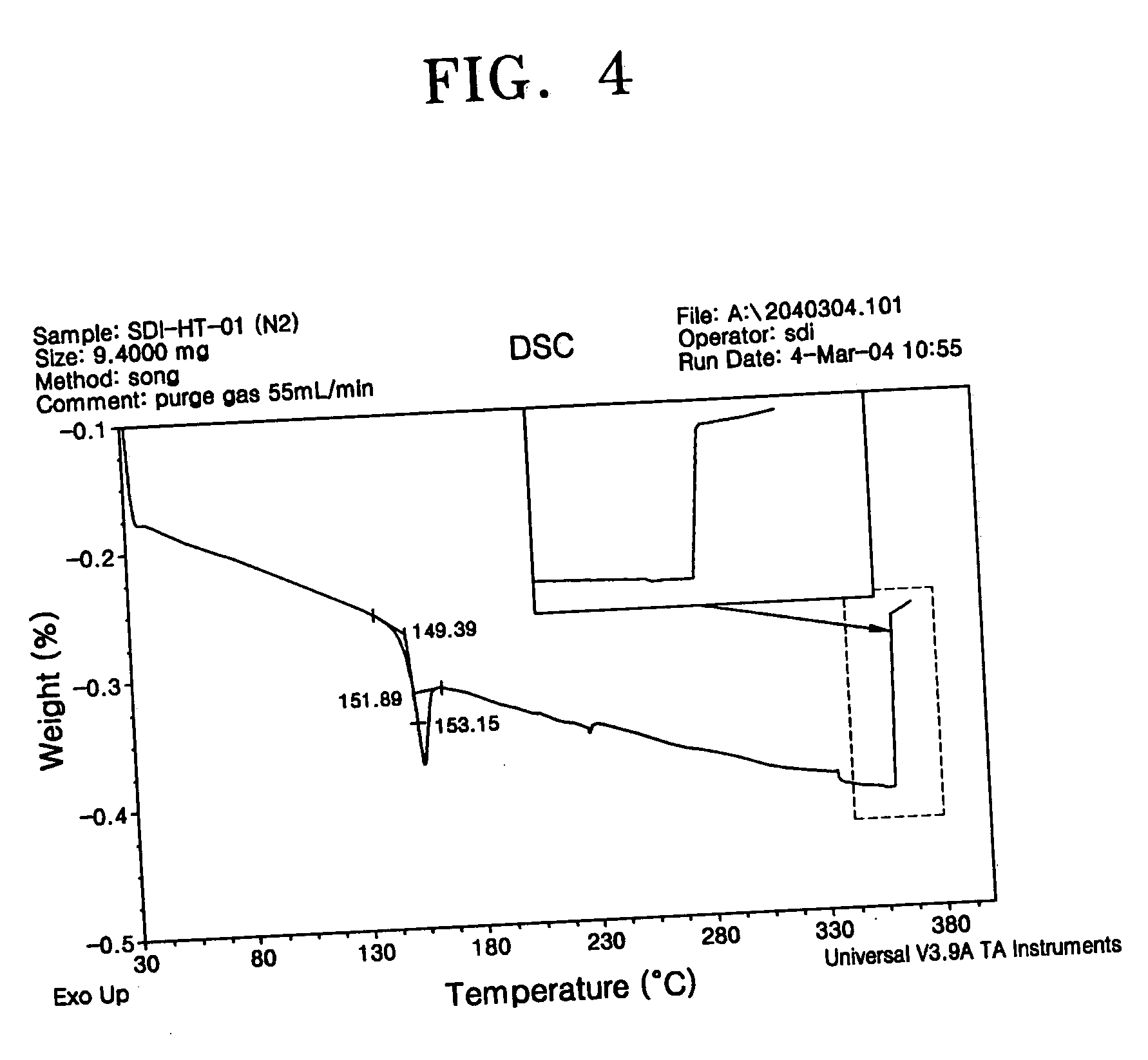

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

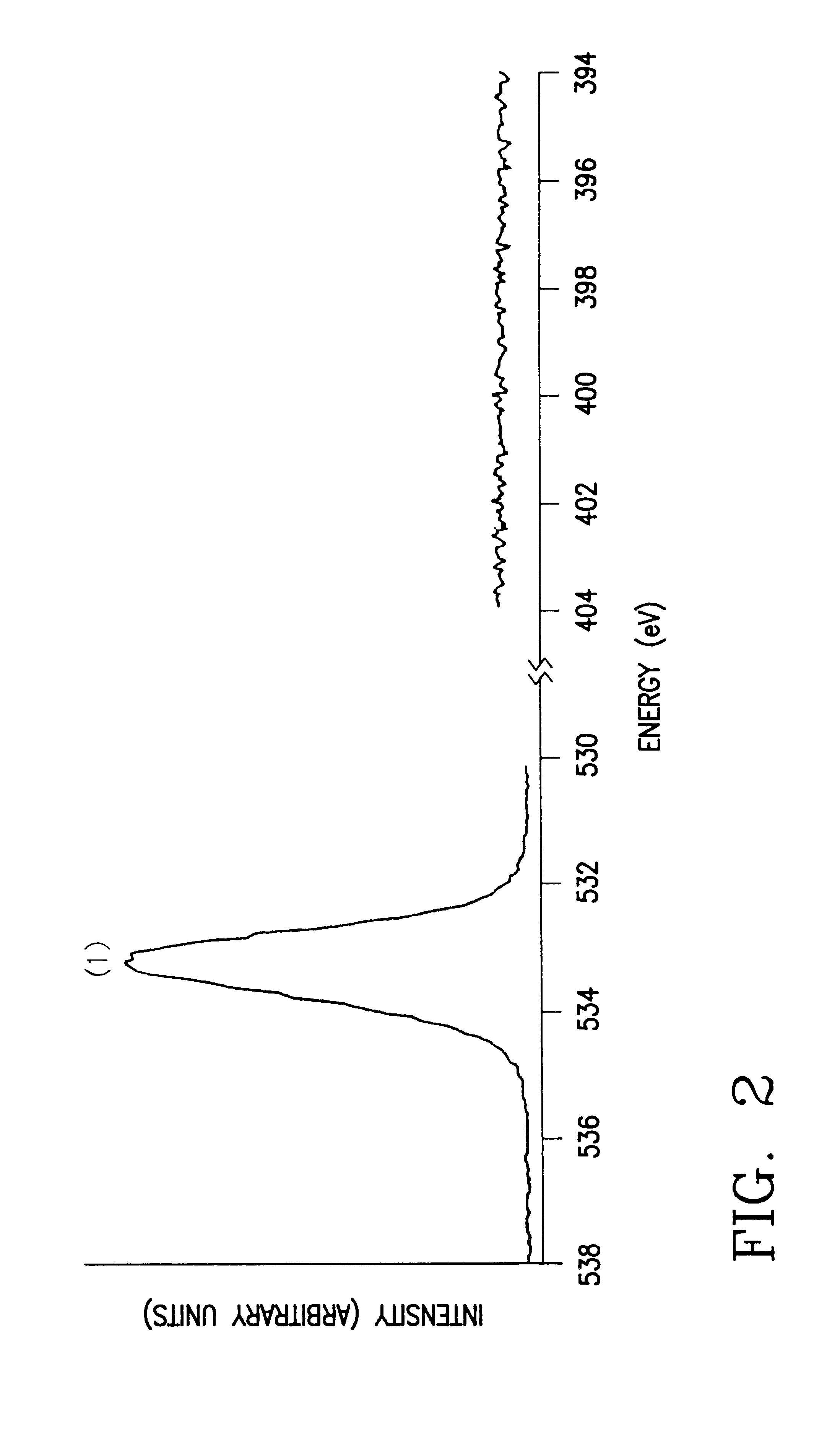

Method for forming an insulating film on semiconductor substrate surface and apparatus for carrying out the method

InactiveUS6265327B1Improve controllabilityQuality improvementElectric discharge tubesSemiconductor/solid-state device manufacturingNitrogenControllability

Disclosed are a method and apparatus for forming an insulating film on the surface of a semiconductor substrate capable of improving the quality and electrical properties of the insulating film with no employment of high-temperature heating and with good controllability. After the surface of a silicon substrate is cleaned, a silicon dioxide film having a thickness of 1-20 nm is formed on the substrate surface. The silicon substrate is exposed to plasma generated by electron impact, while the silicon substrate is maintained at a temperature of 0° C. to 700° C. Thus, nitrogen atoms are incorporated into the silicon dioxide film, obtaining a modified insulating film having good electrical properties.

Owner:JAPAN SCI & TECH CORP +1

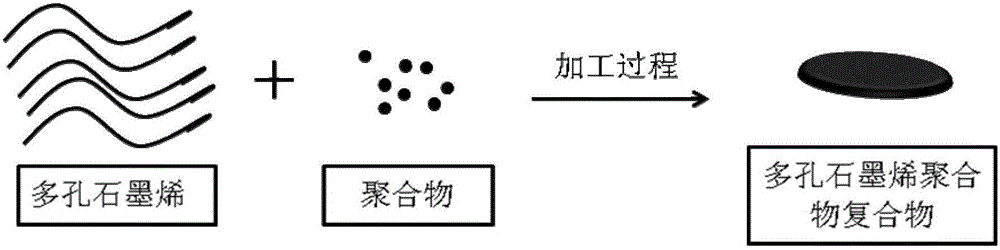

Porous graphene/polymer composite structure and preparation method and application thereof

The invention discloses a porous graphene / polymer composite structure, and a preparation method and application thereof. The composite structure mainly comprises a compound formed by porous graphene and more than one polymer and / or polymer monomer. The preparation method comprises the following steps of: compounding polymers and / or polymer monomers with porous graphene to form a target product, wherein the compounding manner comprises single-screw / double-screw fusing processing, injection molding, blow molding, melt spinning, solution spinning, electrostatic spinning, electrostatic spraying, powder metallurgy, liquid mixing or high speed mechanical stirring dispersion. The invention is simple in process, wide in source of raw materials, easy to implement in large scale, low in cost, safe, environment-friendly and free from toxic and harmful wastes, and the product obtained is excellent in thermal and electric properties, and has wide application prospect in the fields of heat conduction, radiation, electric conduction, anti-static electricity, electromagnetic shielding and the like.

Owner:苏州格瑞丰纳米科技有限公司

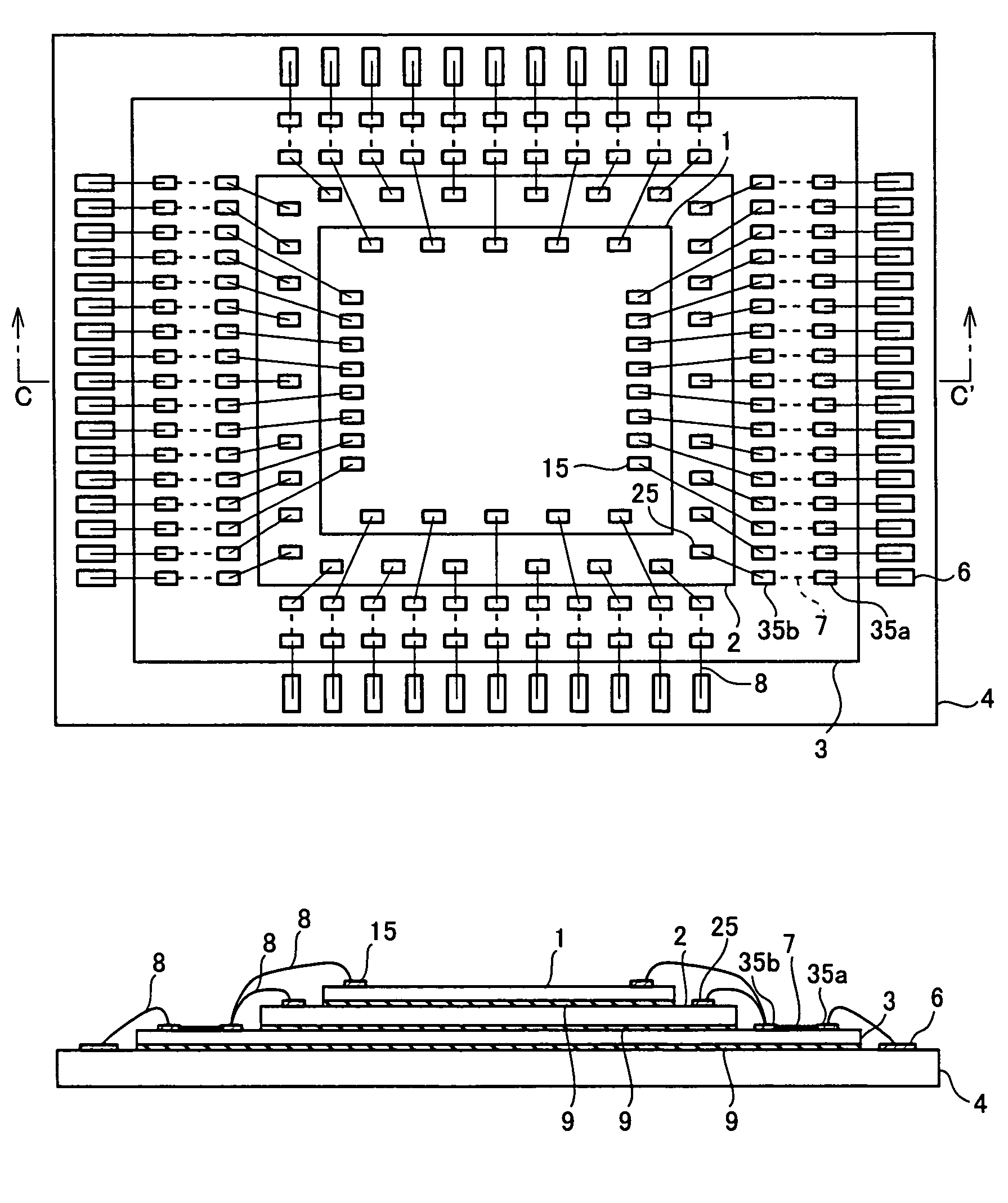

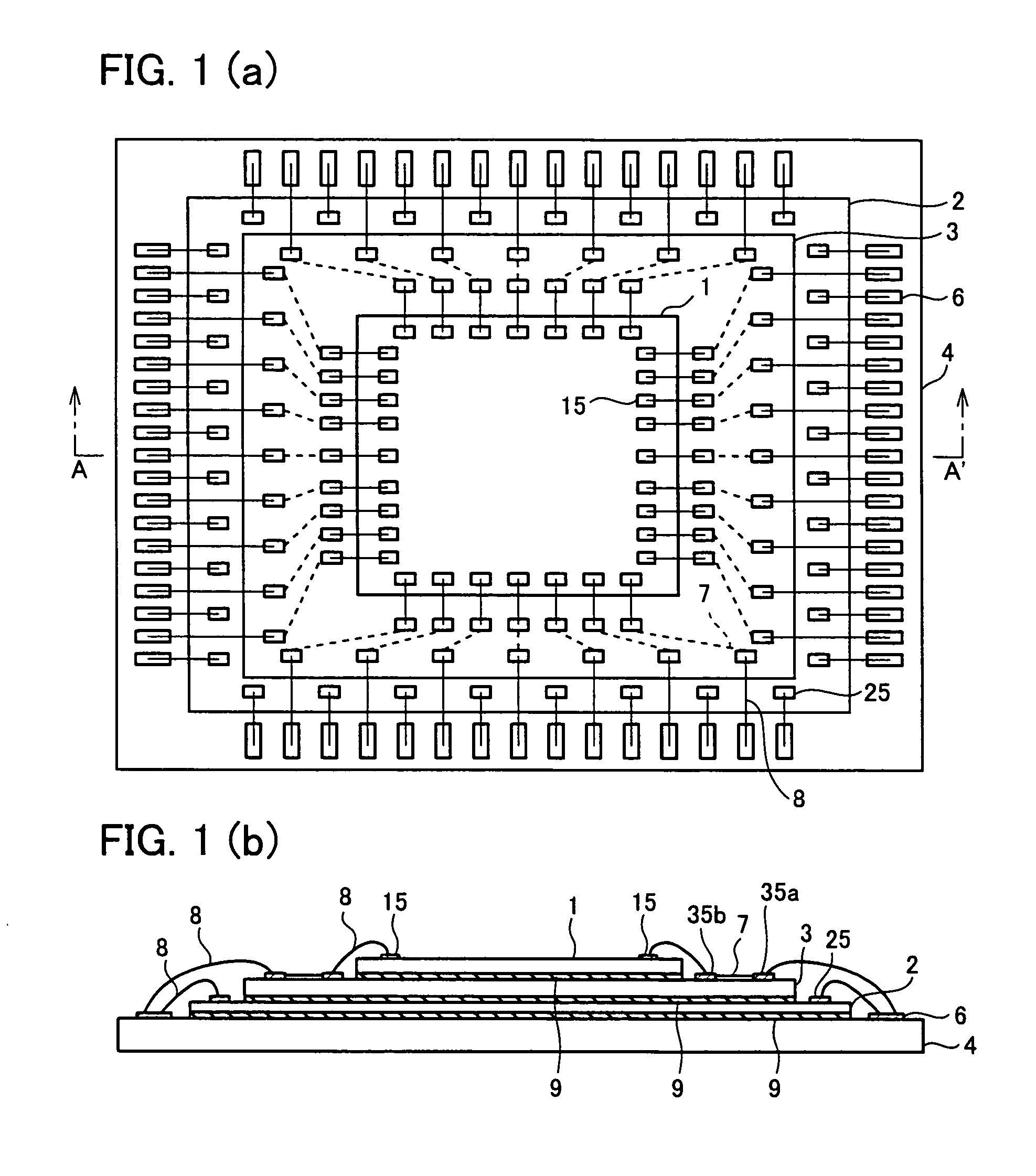

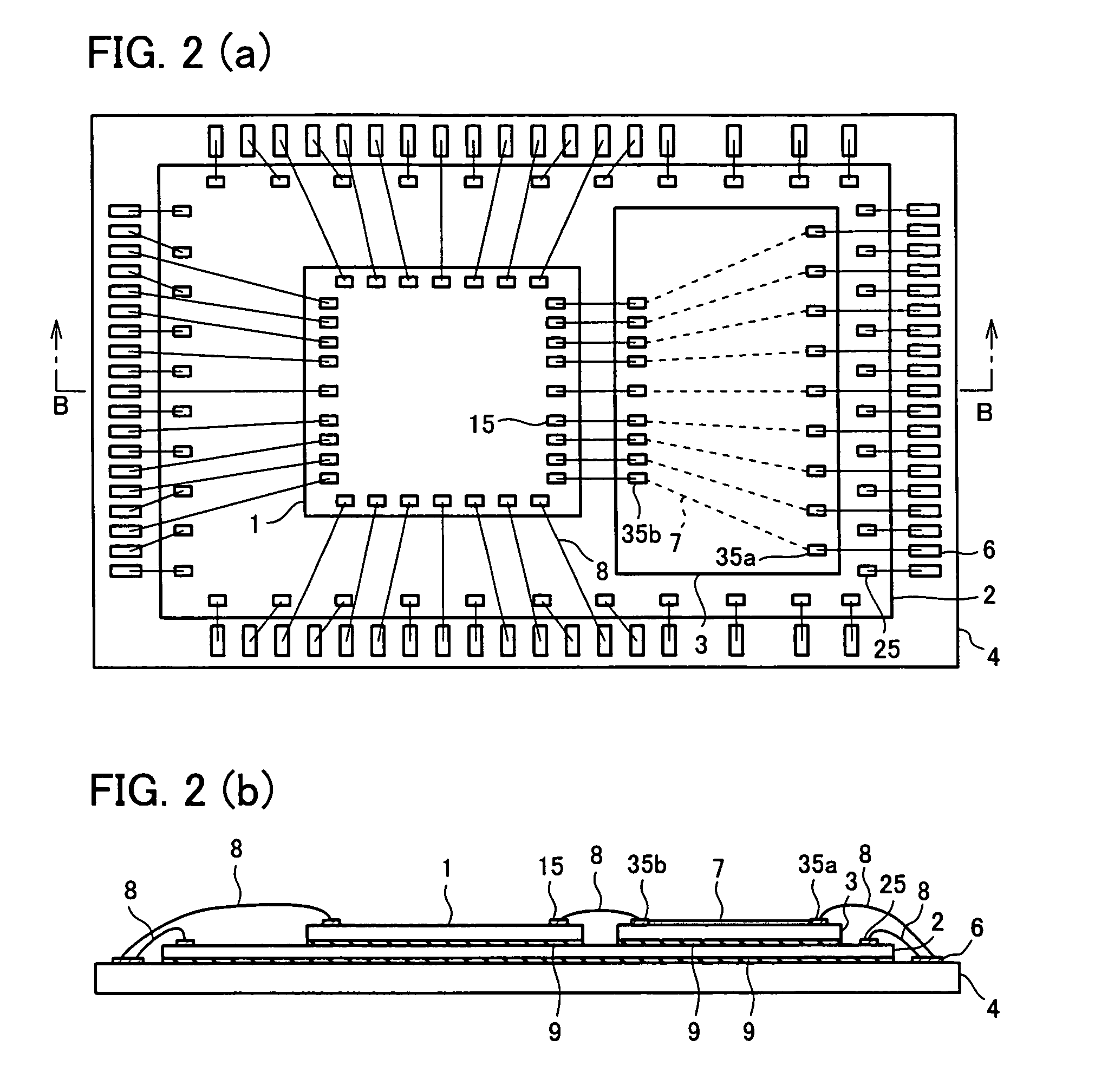

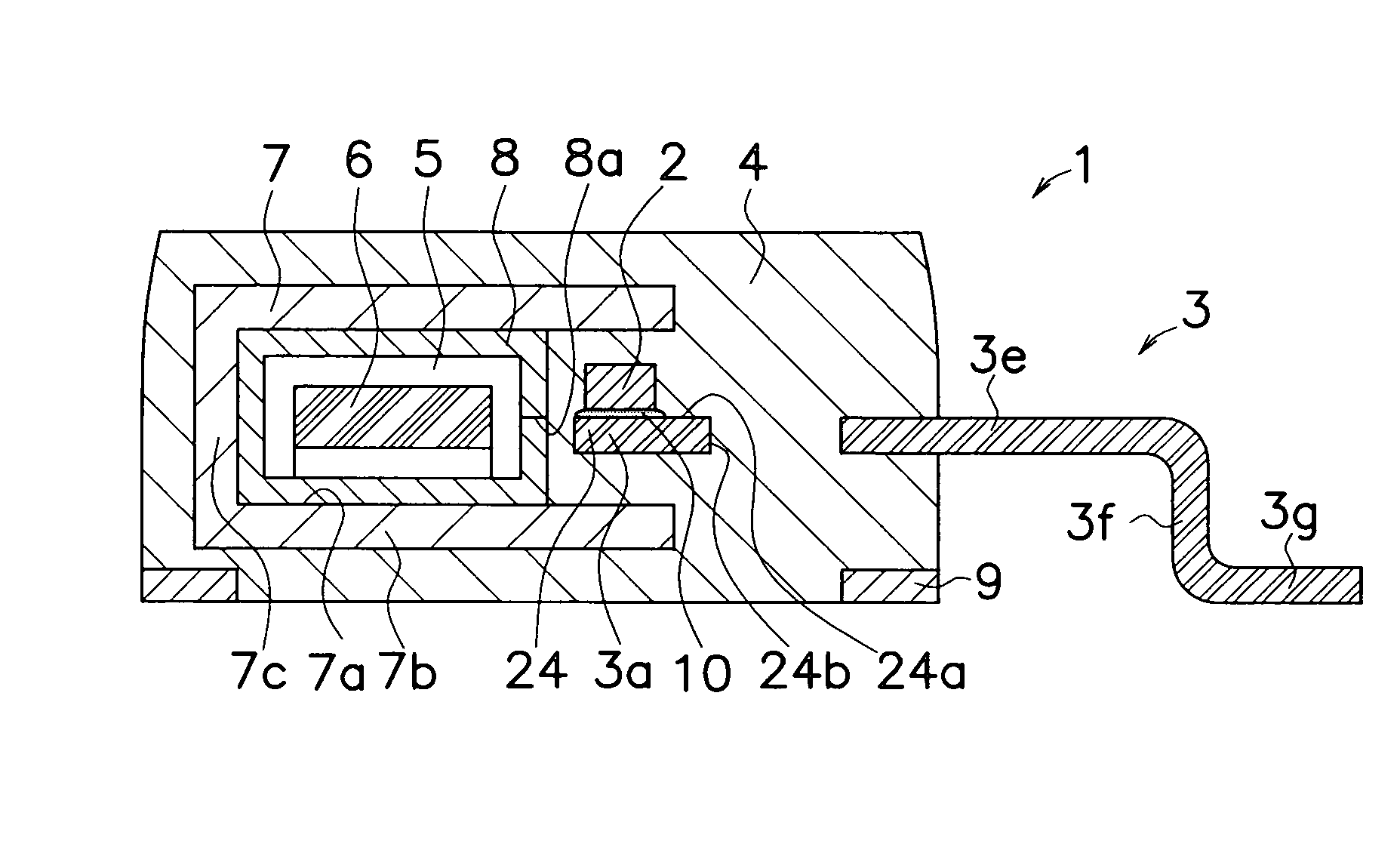

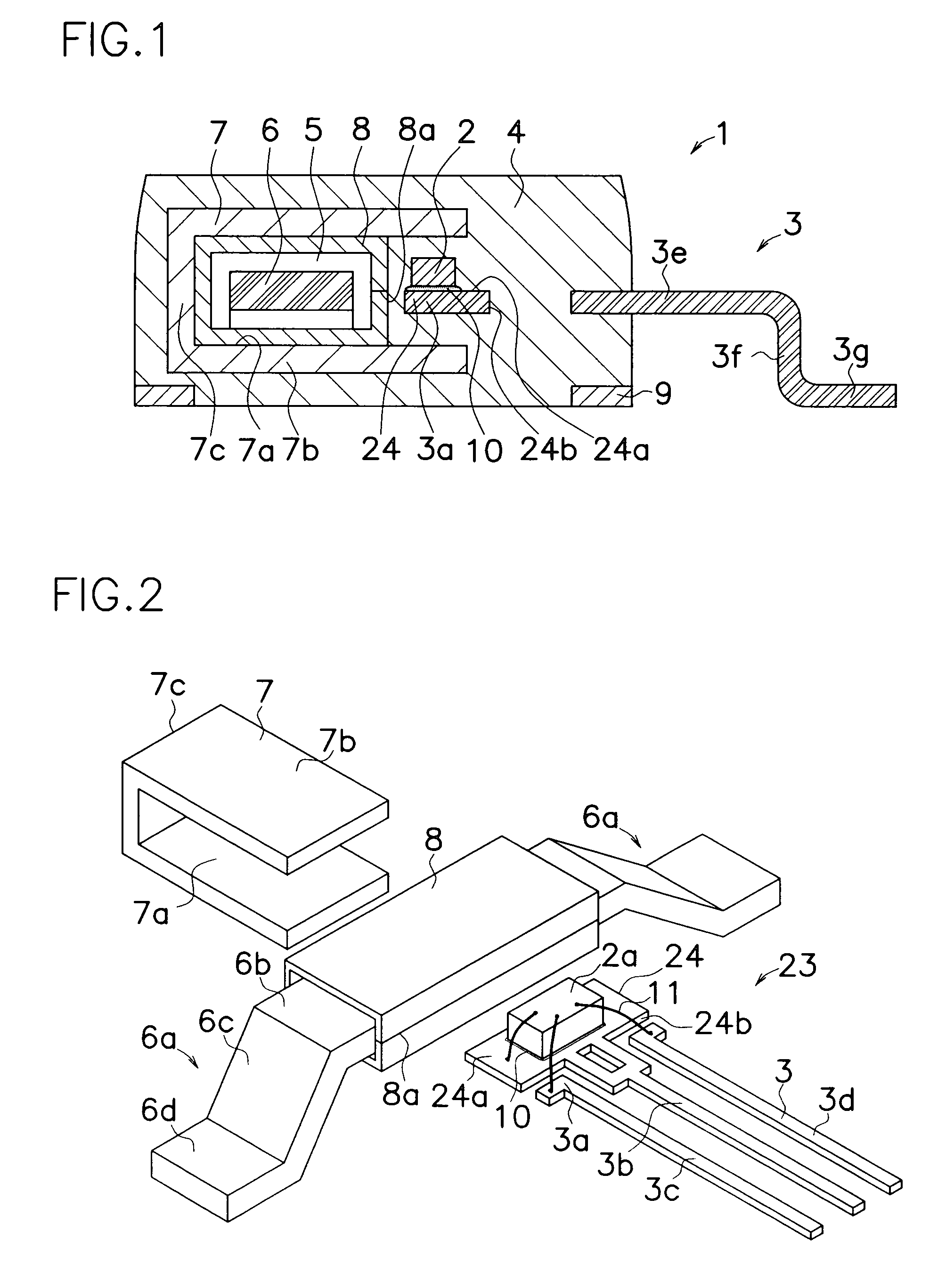

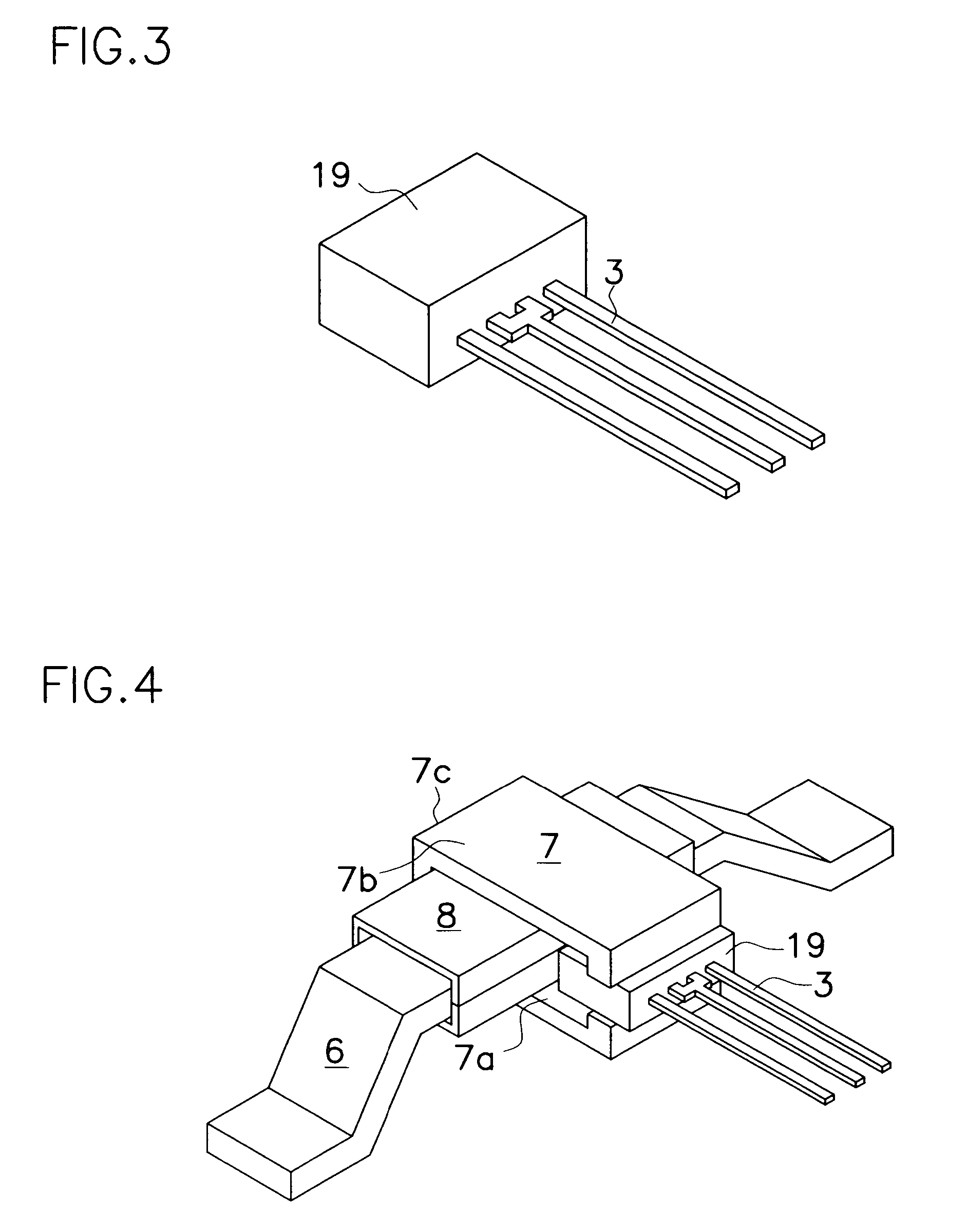

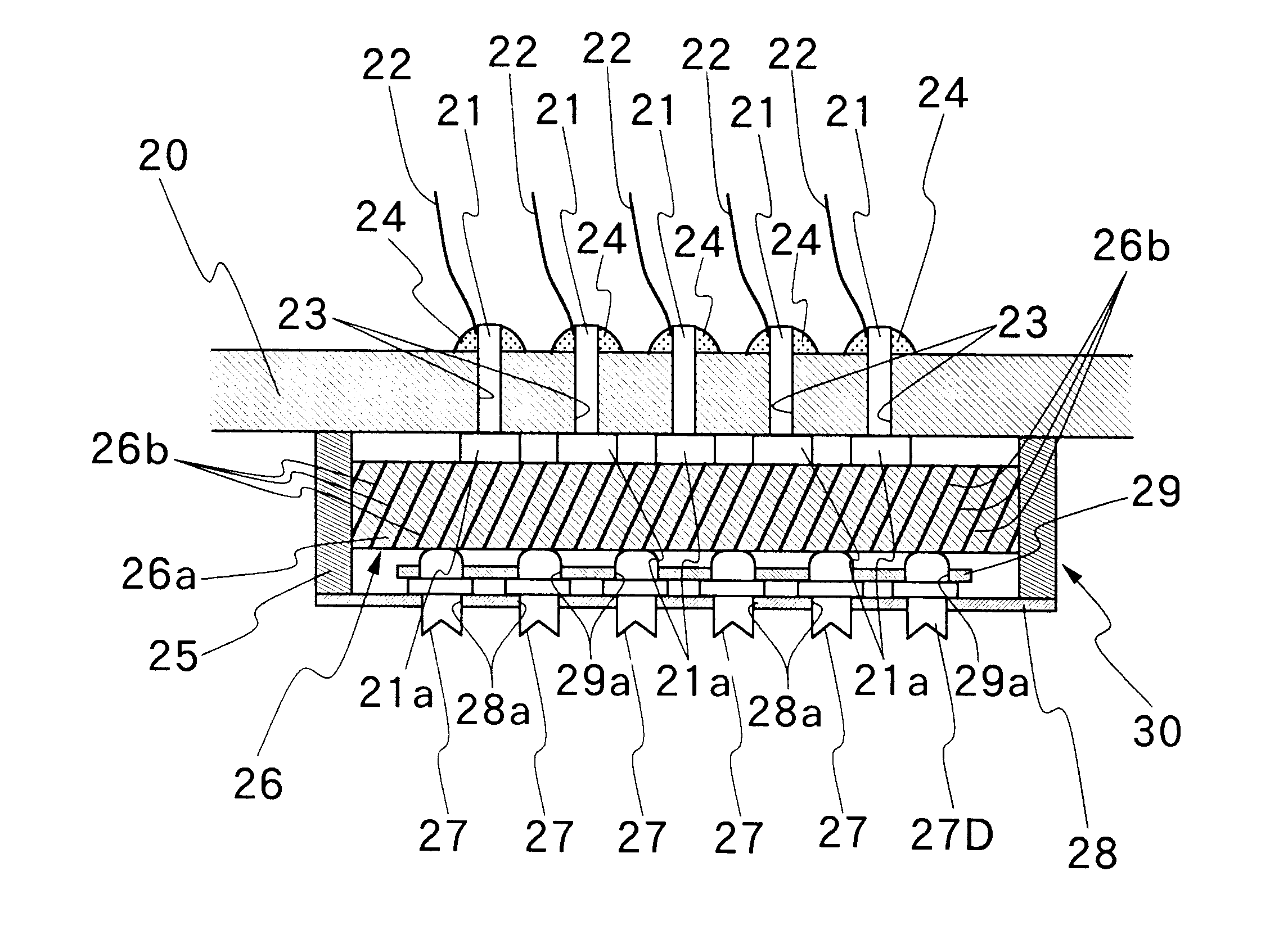

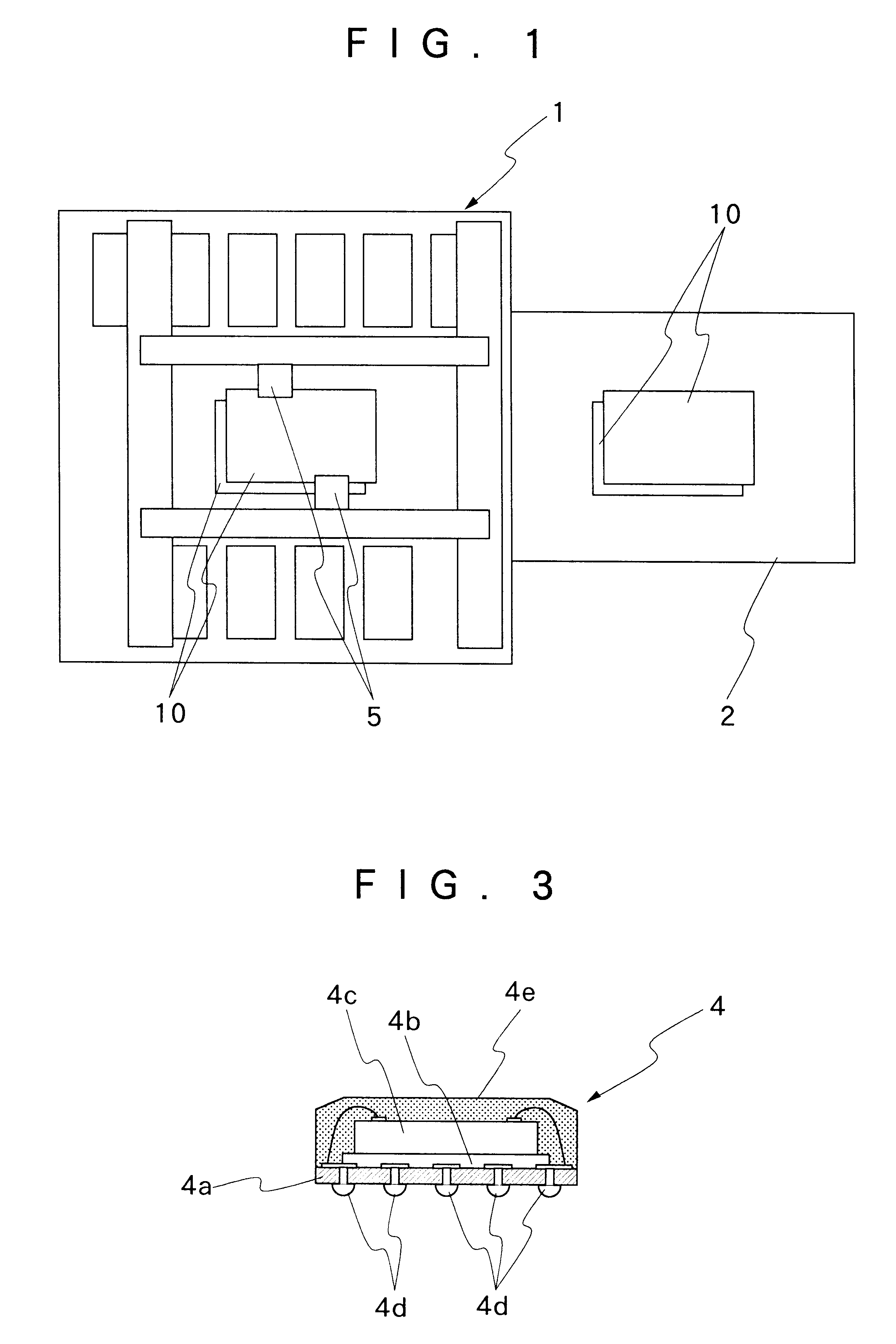

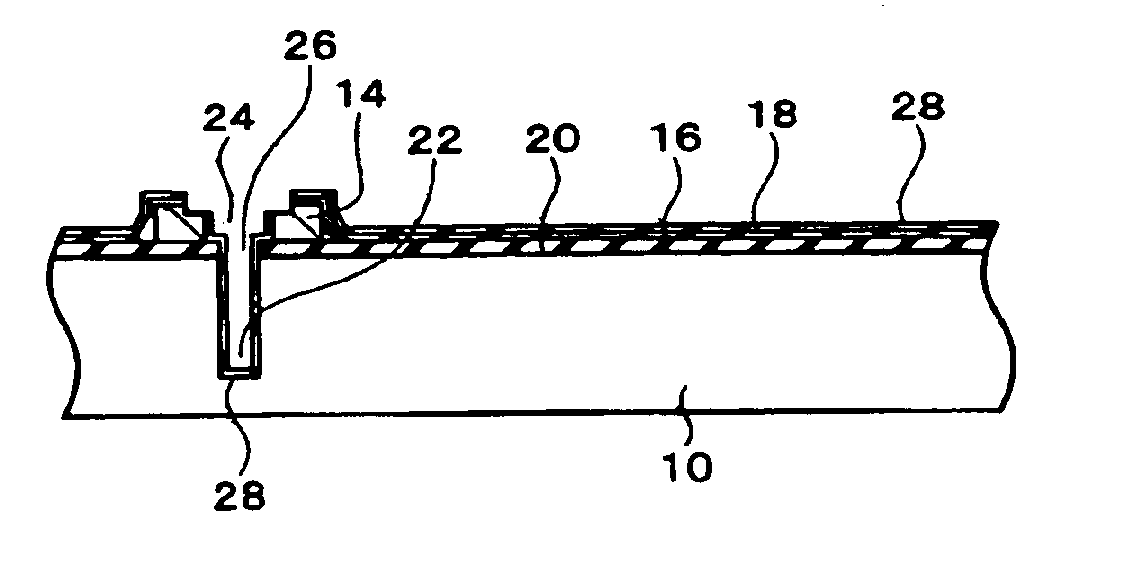

Semiconductor device

ActiveUS6979905B2Prevents wire bonding strengthInhibition strengthSemiconductor/solid-state device detailsSolid-state devicesElectric propertiesEngineering

In a semiconductor device in which a semiconductor chip is stacked on a substrate, an interposer chip having wirings is provided under the semiconductor chip. A bonding pad of the semiconductor chip is electrically connected to a bonding terminal provided on the substrate via the interposer chip by wire bonding. The interposer chip prevents a semiconductor element formed in the semiconductor chip from deteriorating in terms of an electric property and from being physically damaged. Further, the wire bonding strength does not drop. Moreover, it is possible to form a fine wiring pitch for relaying a wire-bonding wire.

Owner:SHARP KK

Phenylcarbazole-based compound and organic electroluminescent device employing the same

ActiveUS20060115680A1High glass transition temperaturePrevent crystallizationDischarge tube luminescnet screensOrganic compound preparationElectricityCarbazole

A phenylcarbazole-based compound is represented by Formula 1, and has superior electric properties and charge transport abilities, and thus is useful as a hole injection material, a hole transport material, and / or an emitting material which is suitable for fluorescent and phosphorescent devices of all colors, including red, green, blue, and white colors. The phenylcarbazole-based compound is synthesized by reacting carbazole with diamine. The organic electroluminescent device manufactured using the phenylcarbazole-based compound has high efficiency, low voltage, high luminance, and a long lifespan.

Owner:SAMSUNG DISPLAY CO LTD

Electric current detector with hall effect sensor

InactiveUS6989665B2Restrict and reduce deterioration of electric propertyGood adhesionMagnetic measurementsGalvano-magnetic device detailsElectrical conductorHeat stress

An electric current detector is provided wherein loose arrangement of conductor 6 in opening 5 provides an air gap between the conductor 6 and plastic package 4 in opening 5 to prevent close contact of conductor 6 to plastic package 4. When heat and heat stress are produced in conductor 6 by a large electric current flowing through conductor 6 during measurement, air gap surely prevents heat and heat stress from traveling to Hall effect sensor 2 and plastic package 4 while a part of heat in conductor 6 is radiated into air in opening 5. Thus, the loose arrangement of conductor 6 can restrict or reduce deterioration of electric property in Hall sensor 2 and degradation of mechanical property in plastic package 4 by heat and heat stress in conductor 6. Also, the loose arrangement ensures and facilitates attachment of the detector 1 in position on a surface of a substrate, and enables to maintain conductor 6 at the same level as lead terminals 3 of the detector.

Owner:SANKEN ELECTRIC CO LTD

Polypropylene film and capacitor using it as a dielectric

InactiveUS6094337AExcellent in heat resistance and long-term dielectric propertyFixed capacitor dielectricFolded capacitorsPolypropylenePolymer chemistry

PCT No. PCT / JP97 / 02791 Sec. 371 Date Mar. 6, 1998 Sec. 102(e) Date Mar. 6, 1998 PCT Filed Aug. 8, 1997 PCT Pub. No. WO98 / 06776 PCT Pub. Date Feb. 19, 1998Biaxially oriented polypropylene film excellent in heat resistance and long-term dielectric properties at high temperatures, reduced insulation defects, and excellent impregnation of insulating oil into the clearance between film layers and swelling resistance when immersed in the insulating oil; in a capacitor having excellent heat resistance, dielectric properties, corona resistance, long-term thermal durability and electric current resistance, with the polypropylene film serving as dielectric; the film is a biaxially oriented polypropylene film characterized by 98 to 99.5% isotacticity, 99% or more in isotactic pentad fraction, 30 ppm or less in ash content and 0.01 to 0.4 mu m in center line average surface roughnesses on both sides.

Owner:TORAY IND INC

Phenylcarbazole-based compound and organic electroluminescent device employing the same

ActiveUS8021764B2High glass transition temperatureElectric stabilityDischarge tube luminescnet screensOrganic compound preparationCarbazoleLow voltage

A phenylcarbazole-based compound is represented by Formula 1, and has superior electric properties and charge transport abilities, and thus is useful as a hole injection material, a hole transport material, and / or an emitting material which is suitable for fluorescent and phosphorescent devices of all colors, including red, green, blue, and white colors. The phenylcarbazole-based compound is synthesized by reacting carbazole with diamine. The organic electroluminescent device manufactured using the phenylcarbazole-based compound has high efficiency, low voltage, high luminance, and a long lifespan.

Owner:SAMSUNG DISPLAY CO LTD

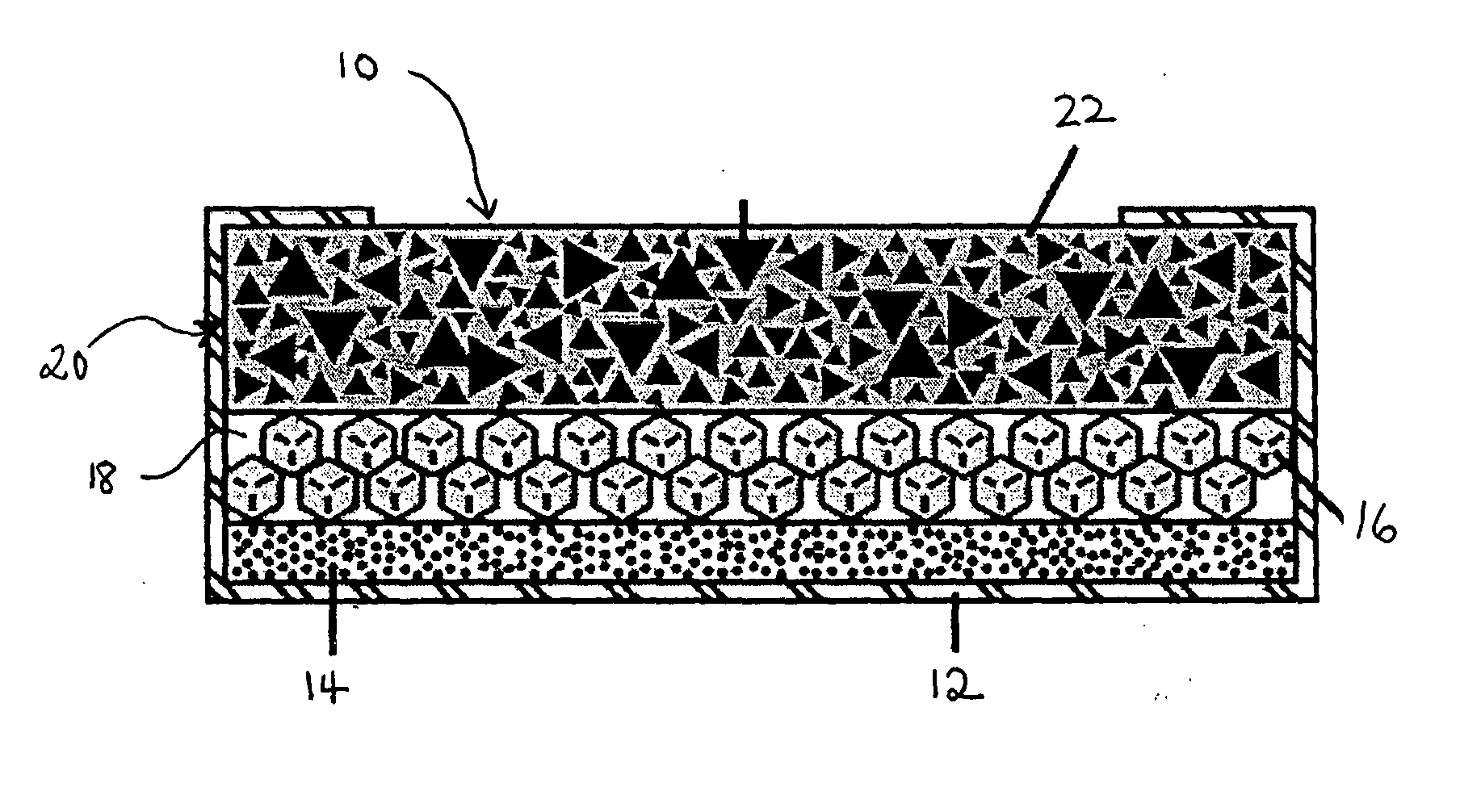

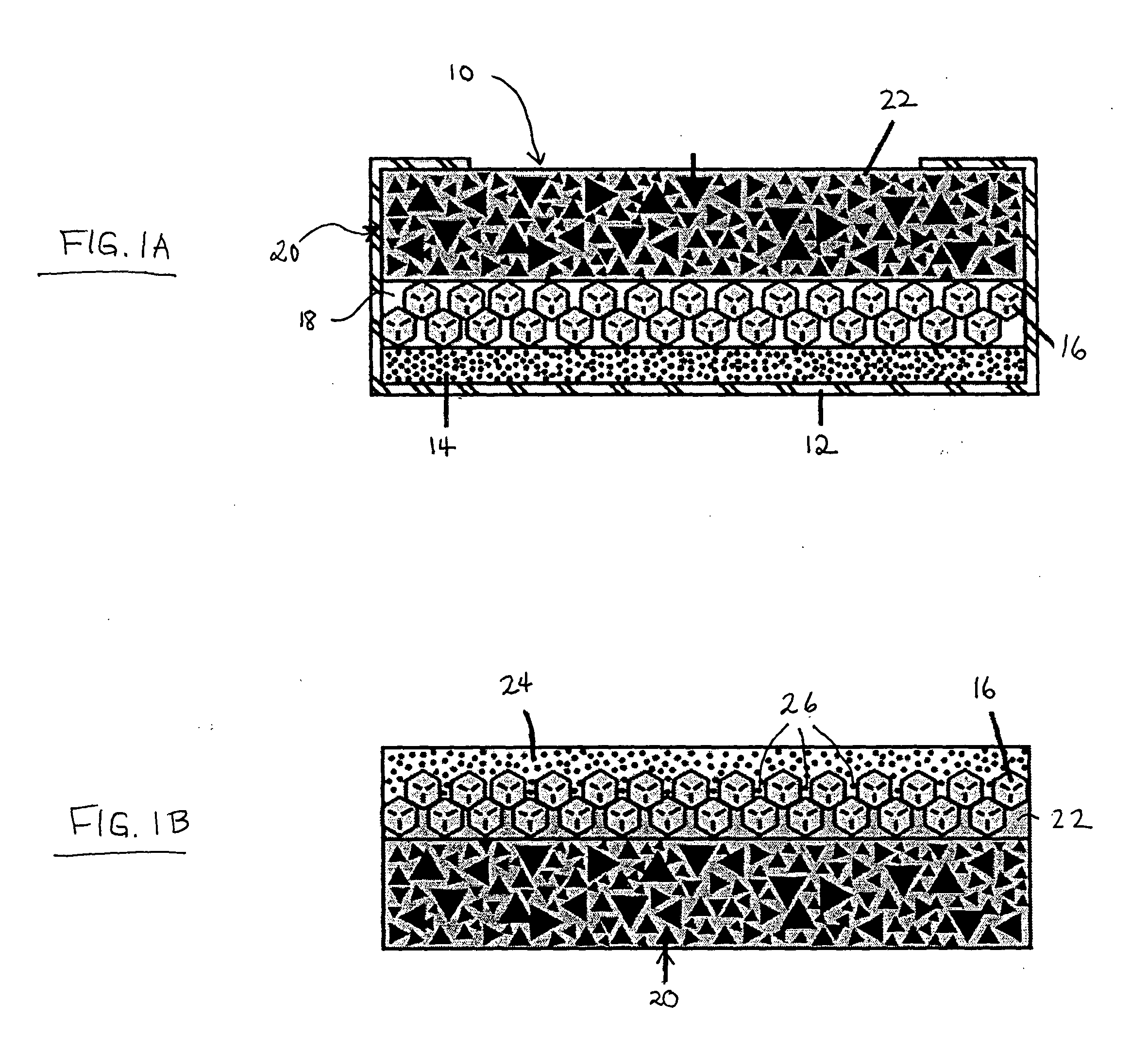

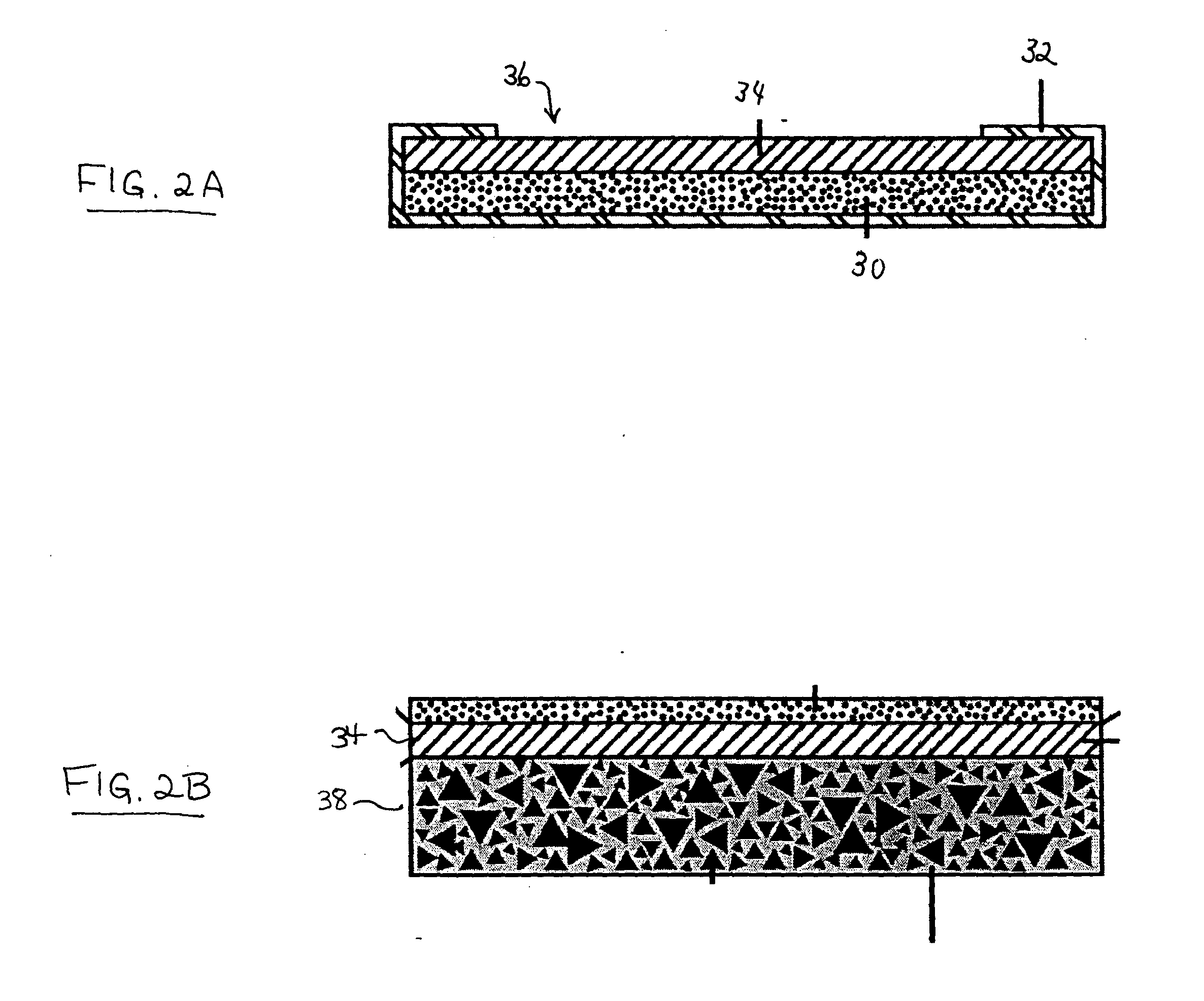

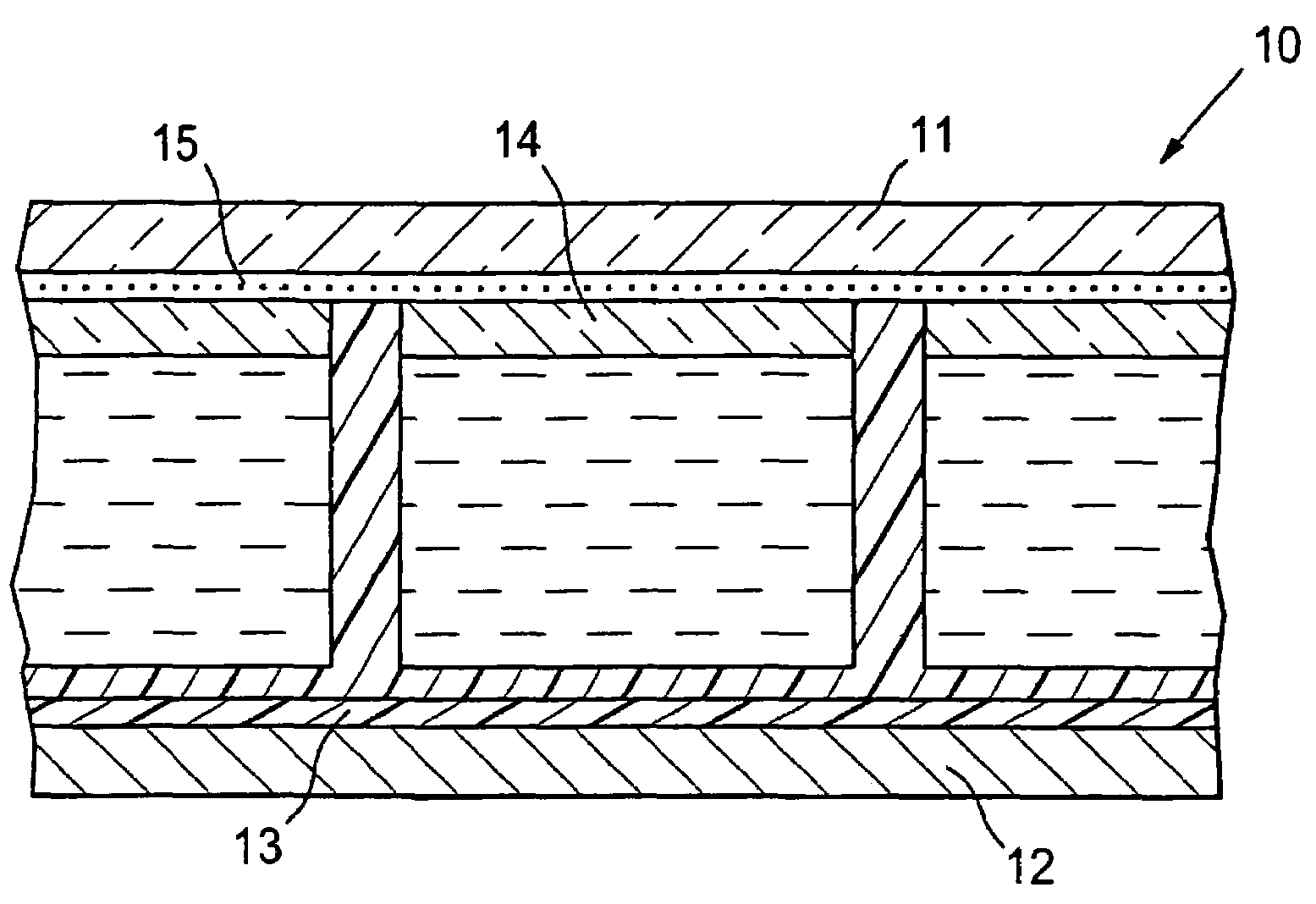

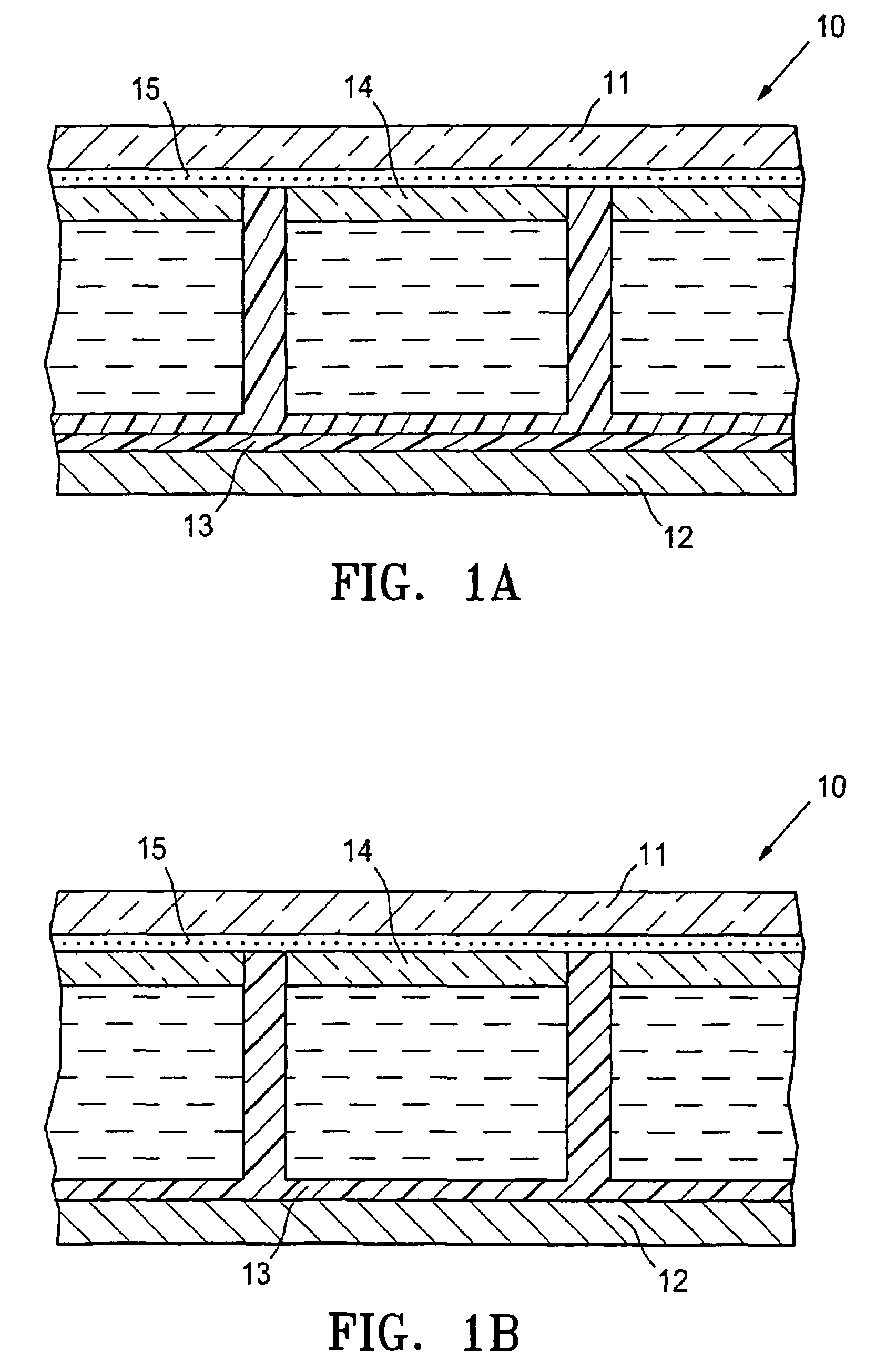

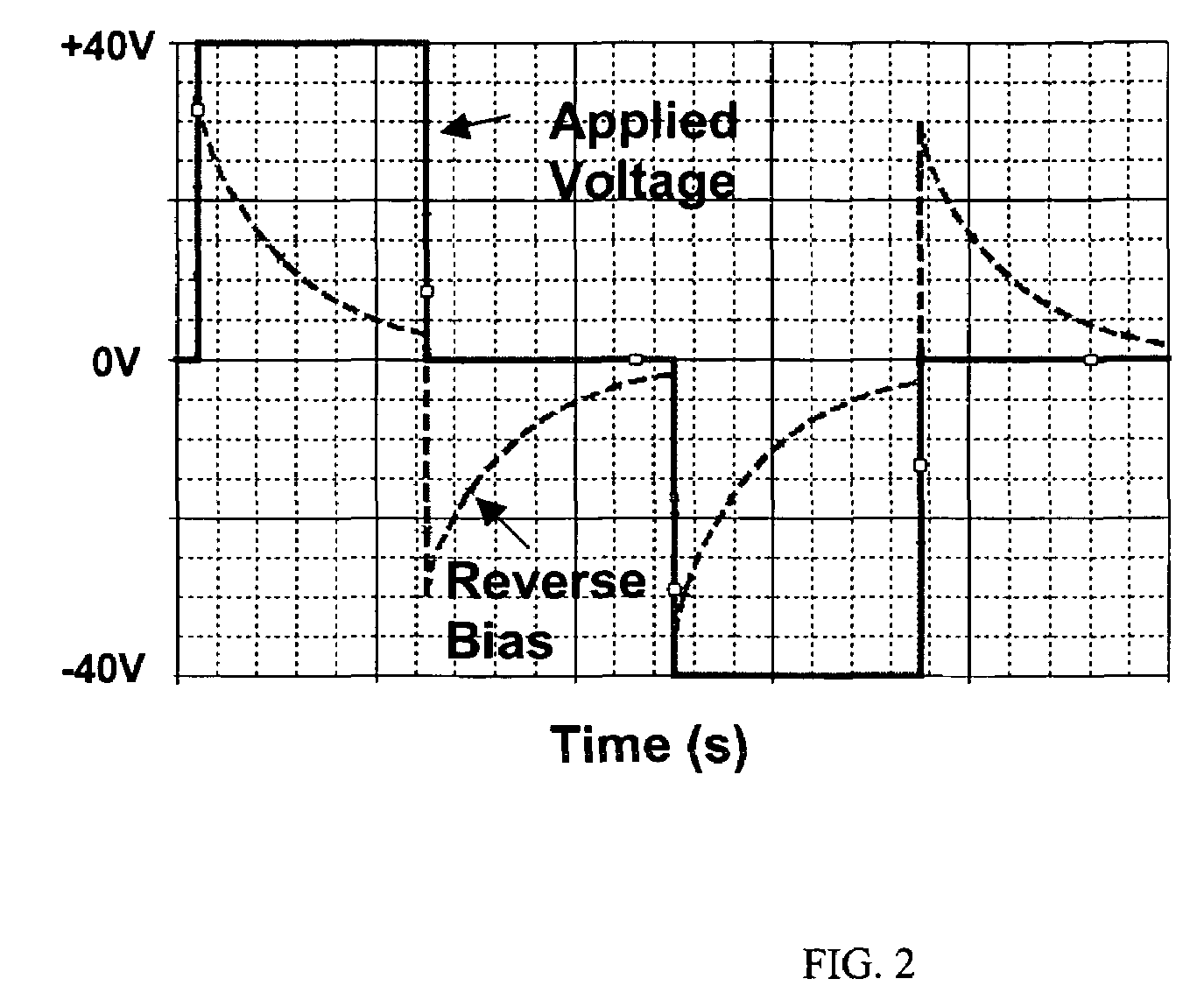

Modification of electrical properties of display cells for improving electrophoretic display performance

ActiveUS7504050B2Improve performanceIncreased process windowStatic indicating devicesConductive materialElectricityElectrophoresis

Owner:E INK CORPORATION

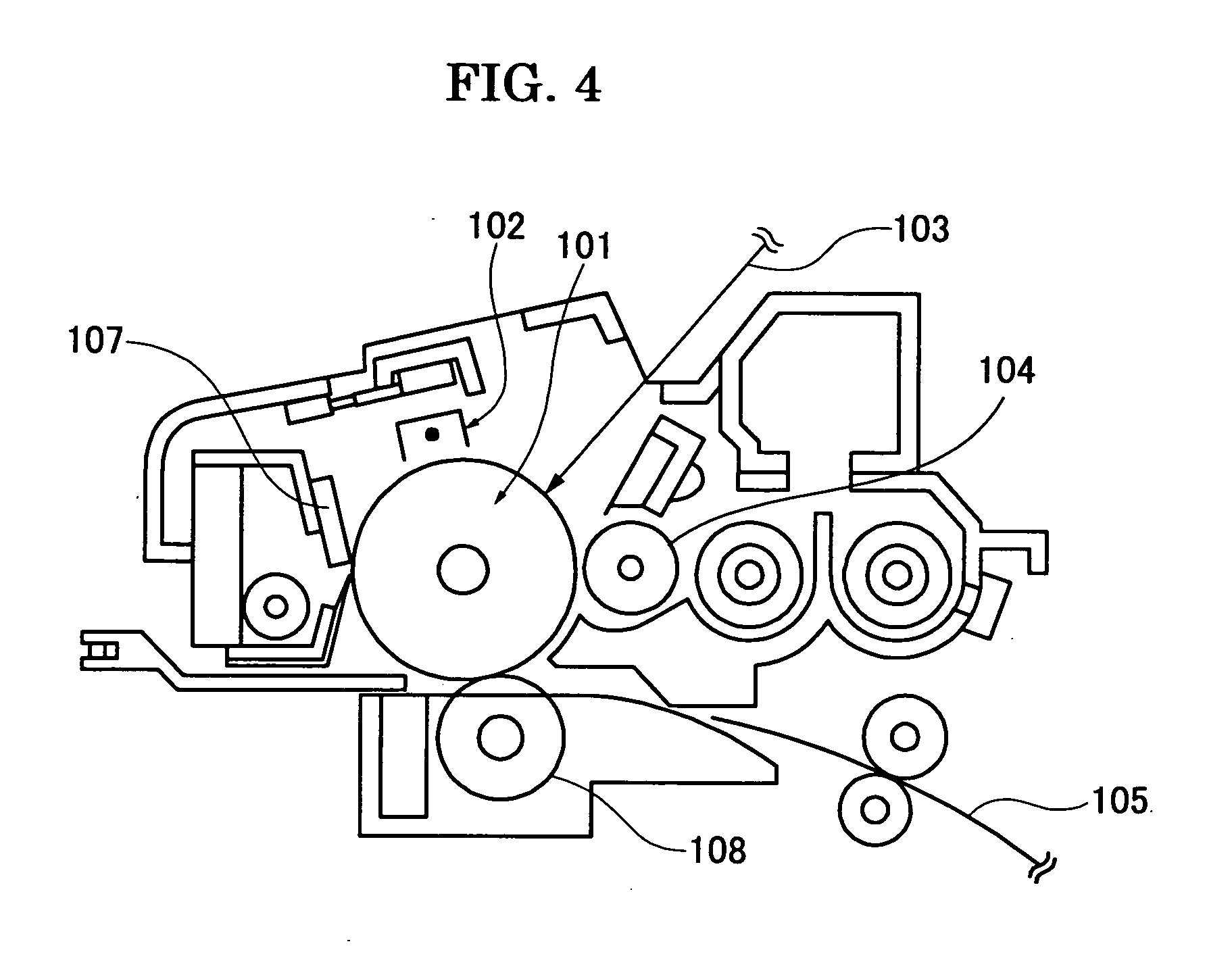

Photoconductor, image forming process, image forming apparatus, and process cartridge

InactiveUS20050287452A1Improve wear resistanceImprove crack resistanceElectrographic process apparatusElectrographic processes using charge patternElectrical conductorImage formation

A photoconductor is disclosed that exhibits superior wear resistance, excellent flaw resistance, and appropriate electric properties owing to a photosensitive layer having a crosslinked layer with superior smoothness and higher crosslink density, wherein the photoconductor comprises a support, and a photosensitive layer disposed on the support, the photosensitive layer comprises a crosslinked layer, the crosslinked layer comprises a radical polymerizable monomer having three or more functionalities and no charge transport structure and a radical polymerizable compound having one functionality and a charge transport structure, and the crosslinked layer is cured by way of photopolymerization and thermal polymerization.

Owner:RICOH KK

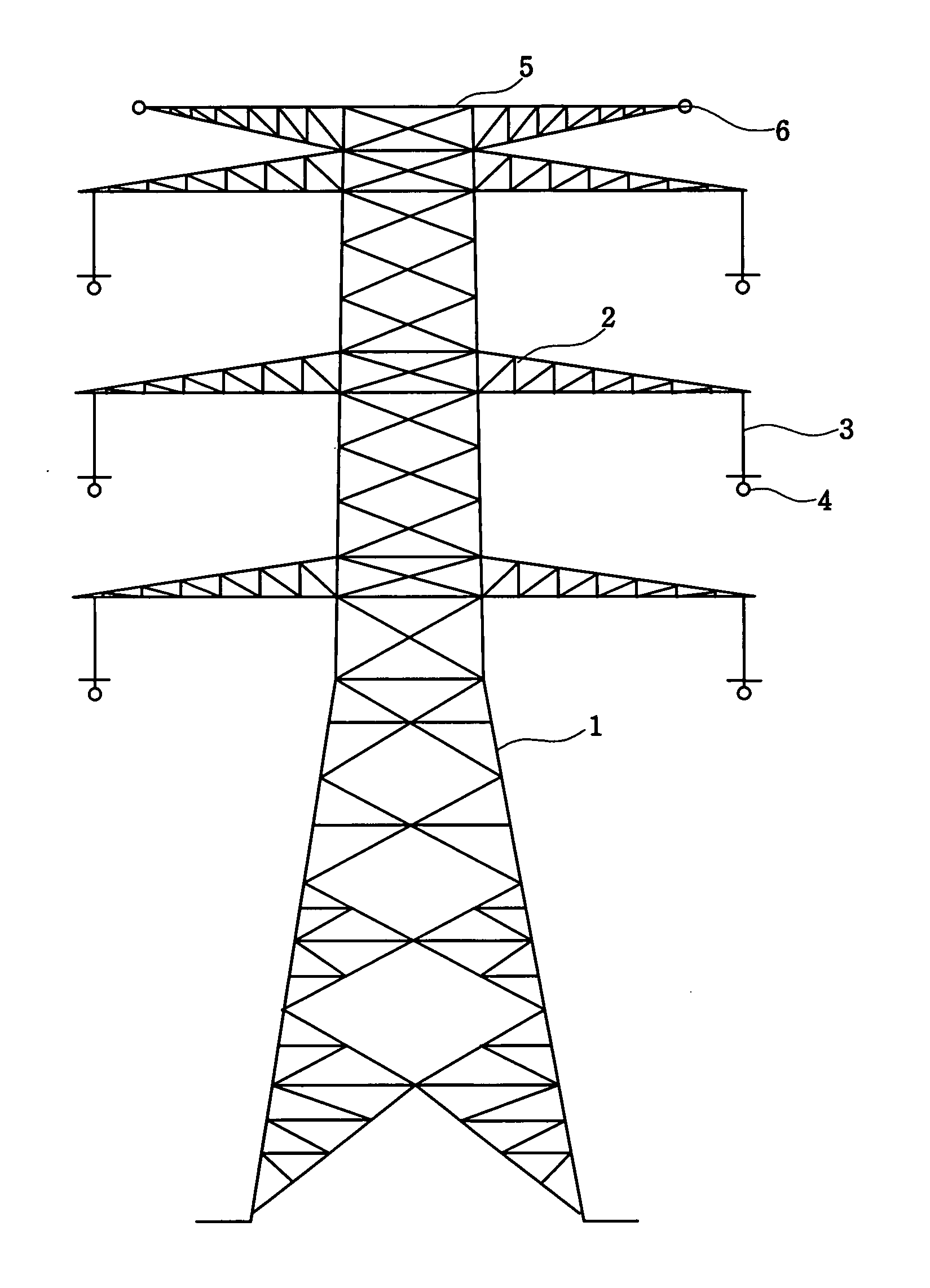

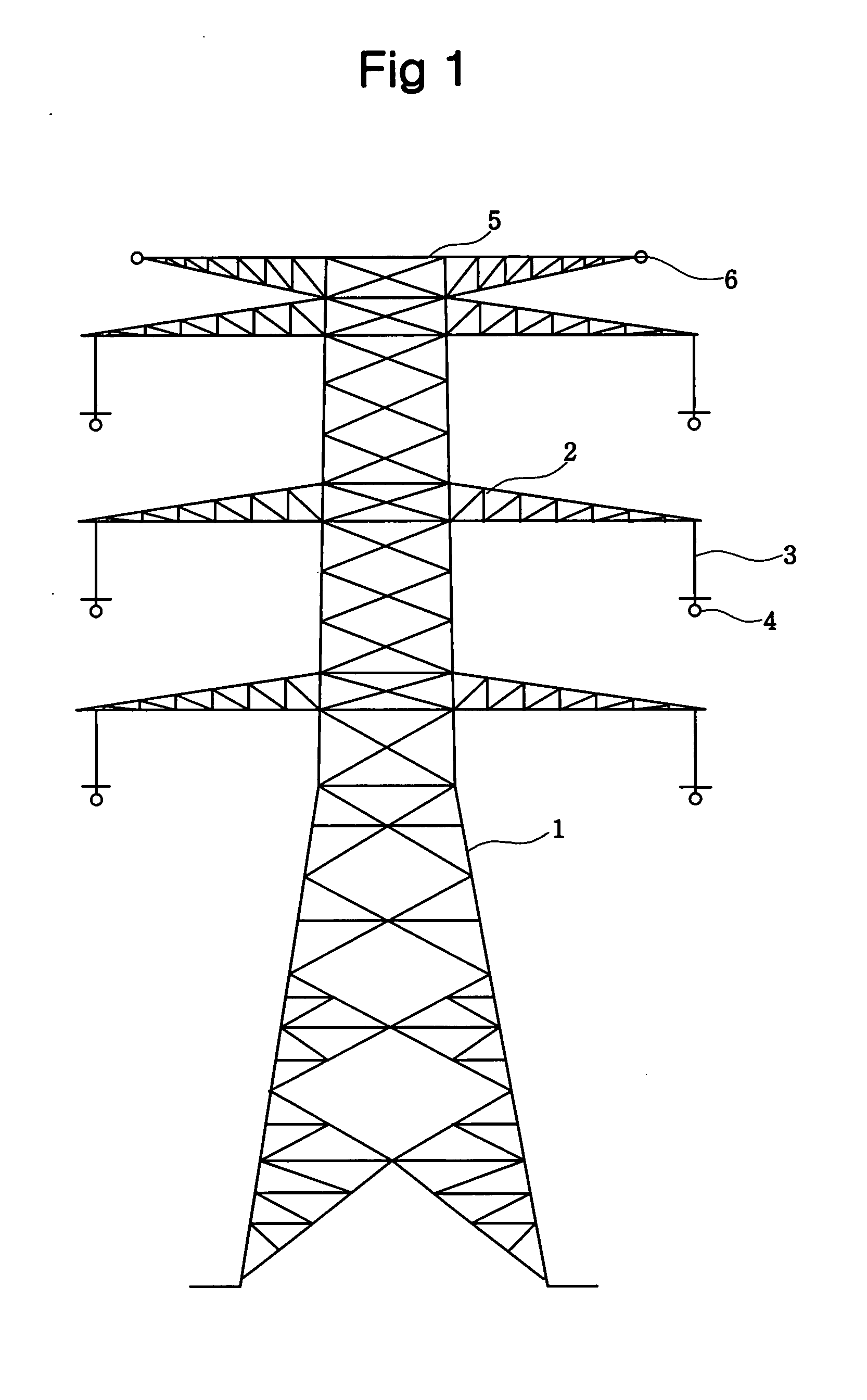

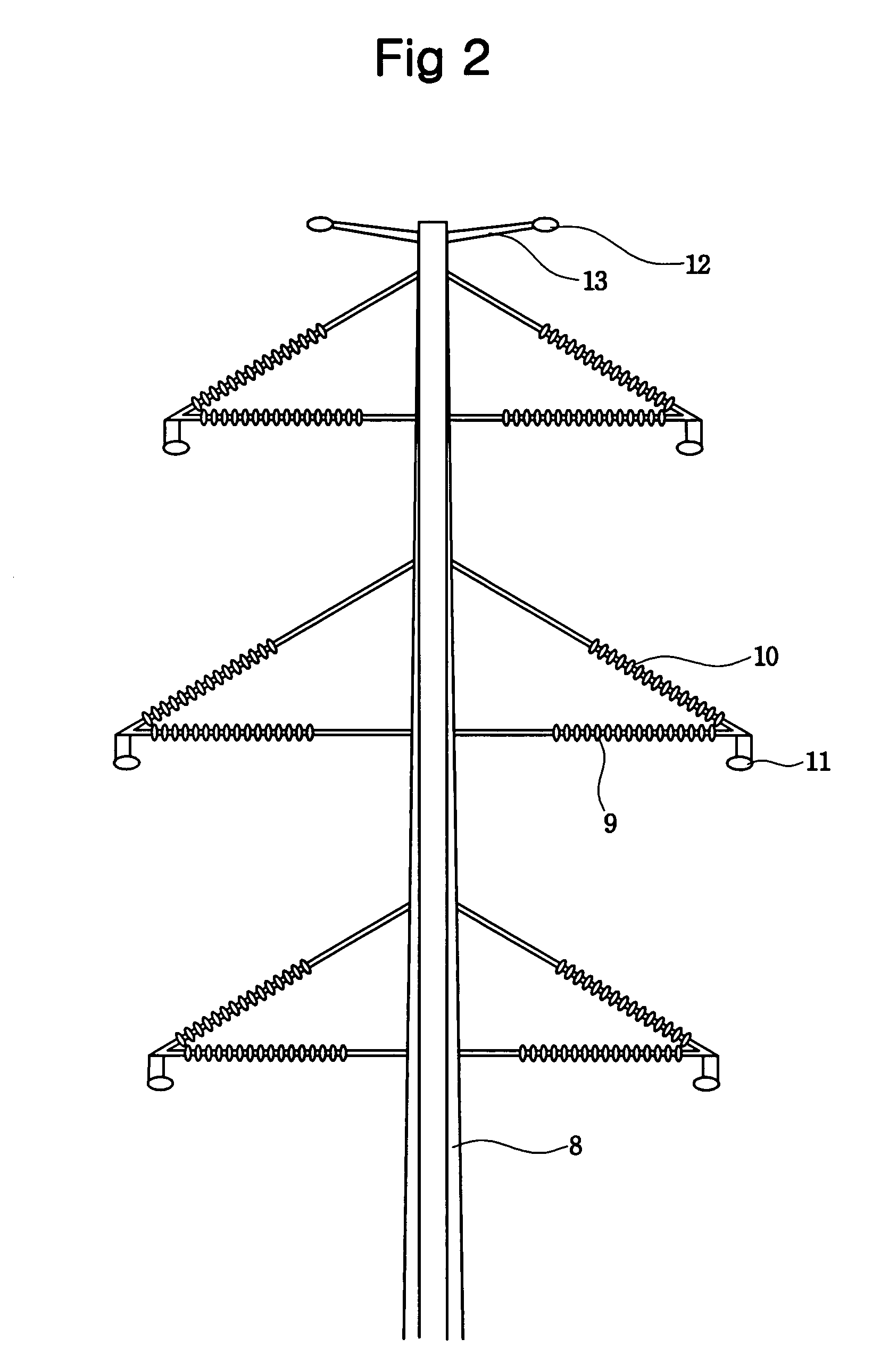

Power transmission tower

ActiveUS20100064598A1Miniaturization and light weightReduce areaAdjusting/maintaining mechanical tensionTowersElectricityTransmission tower

Disclosed is a power transmission tower, which includes a tower body; first through sixth main insulation arms connected by one end thereof to the tower body with an angle with the tower body, respectively, and arranged radially and symmetrically about the tower body in a longitudinal direction; and first through eighth auxiliary insulation arms for selectively connecting the other end of the first through sixth main insulation arms and the tower body so that each of the auxiliary insulation arms constitutes each side of an octagon.Since the insulation arms are octagonally arranged, it is possible to reinforce a mechanical strength and enhance electric properties of the tower.

Owner:KOREA ELECTRIC POWER CORP

Semiconductor device and method for manufacturing the same

ActiveUS20110115763A1Comparatively-easy manufacturing processRun at high speedTransistorSolid-state devicesProduction rateOhmic contact

It is an object to provide a semiconductor device including a thin film transistor with favorable electric properties and high reliability, and a method for manufacturing the semiconductor device with high productivity. In an inverted staggered (bottom gate) thin film transistor, an oxide semiconductor film containing In, Ga, and Zn is used as a semiconductor layer, and a buffer layer formed using a metal oxide layer is provided between the semiconductor layer and a source and drain electrode layers. The metal oxide layer is intentionally provided as the buffer layer between the semiconductor layer and the source and drain electrode layers, whereby ohmic contact is obtained.

Owner:SEMICON ENERGY LAB CO LTD

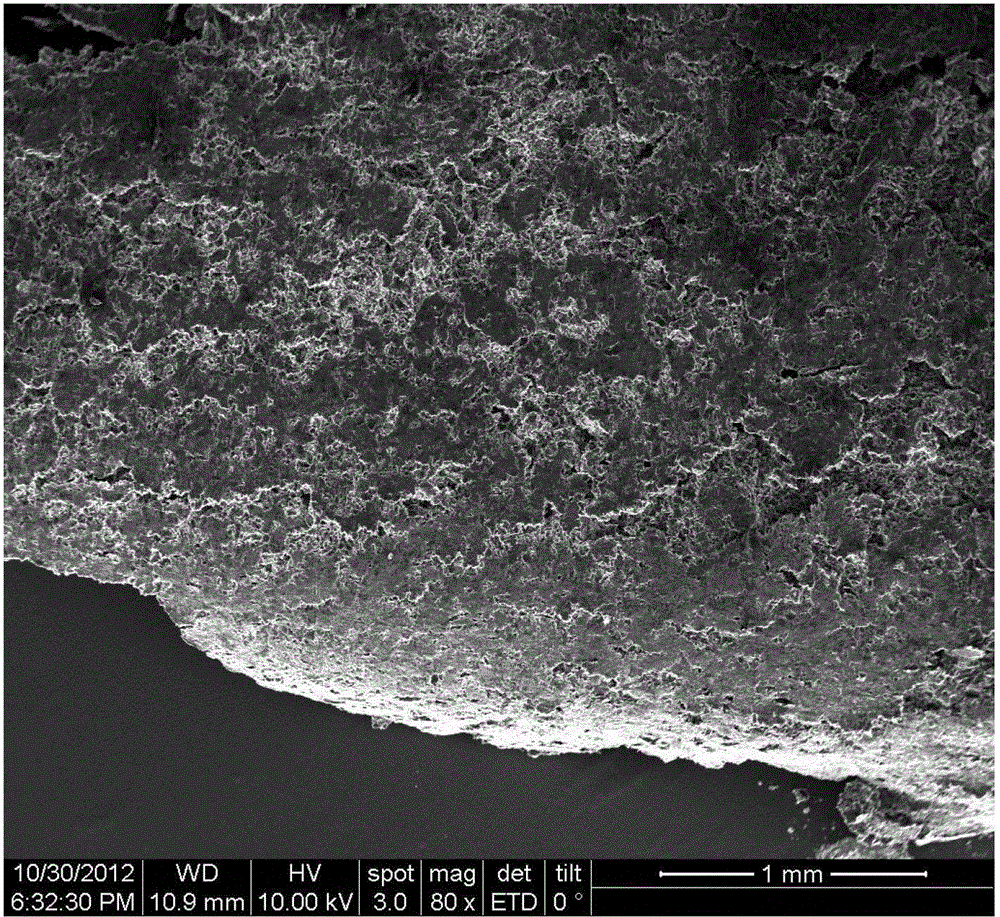

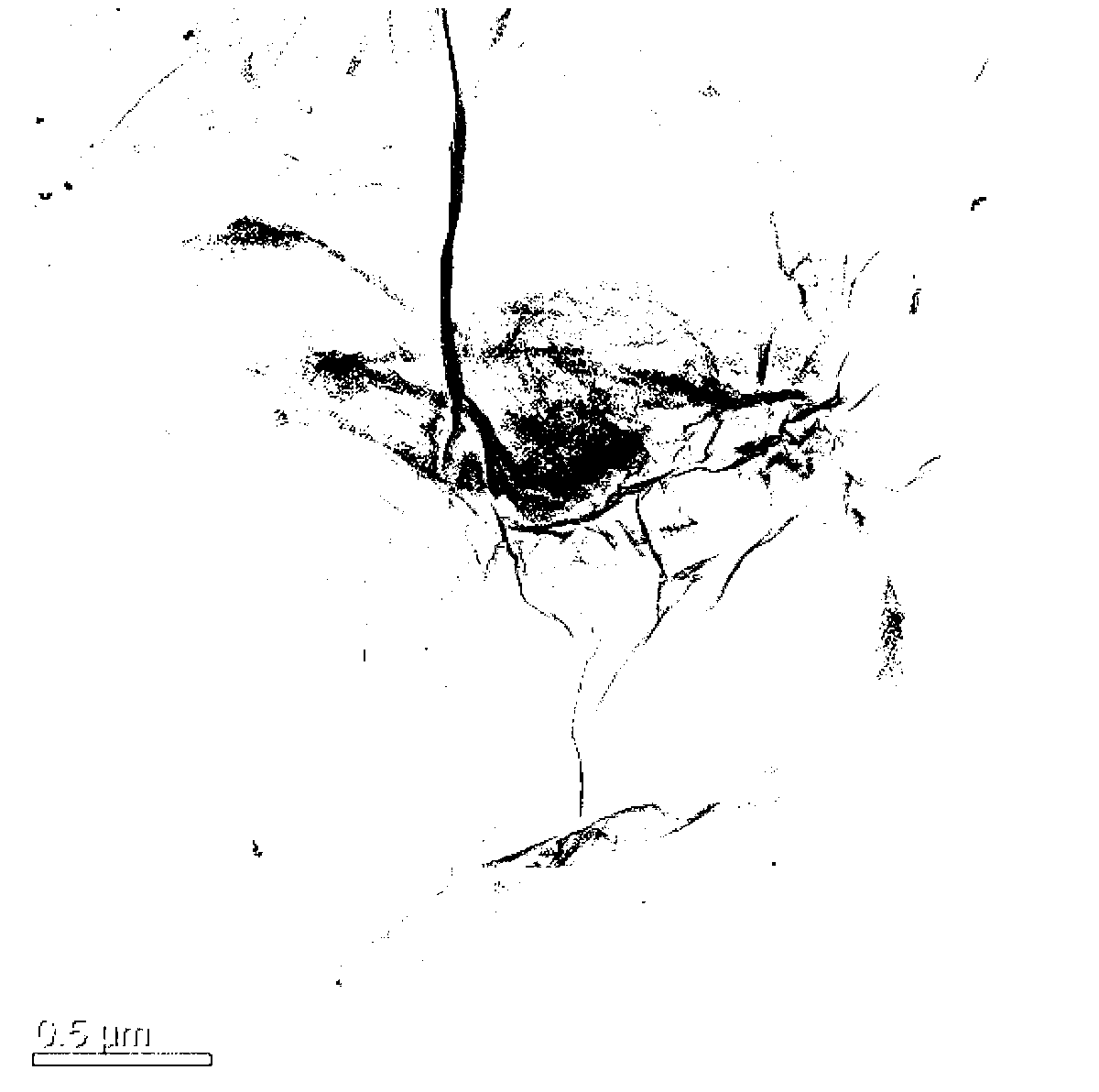

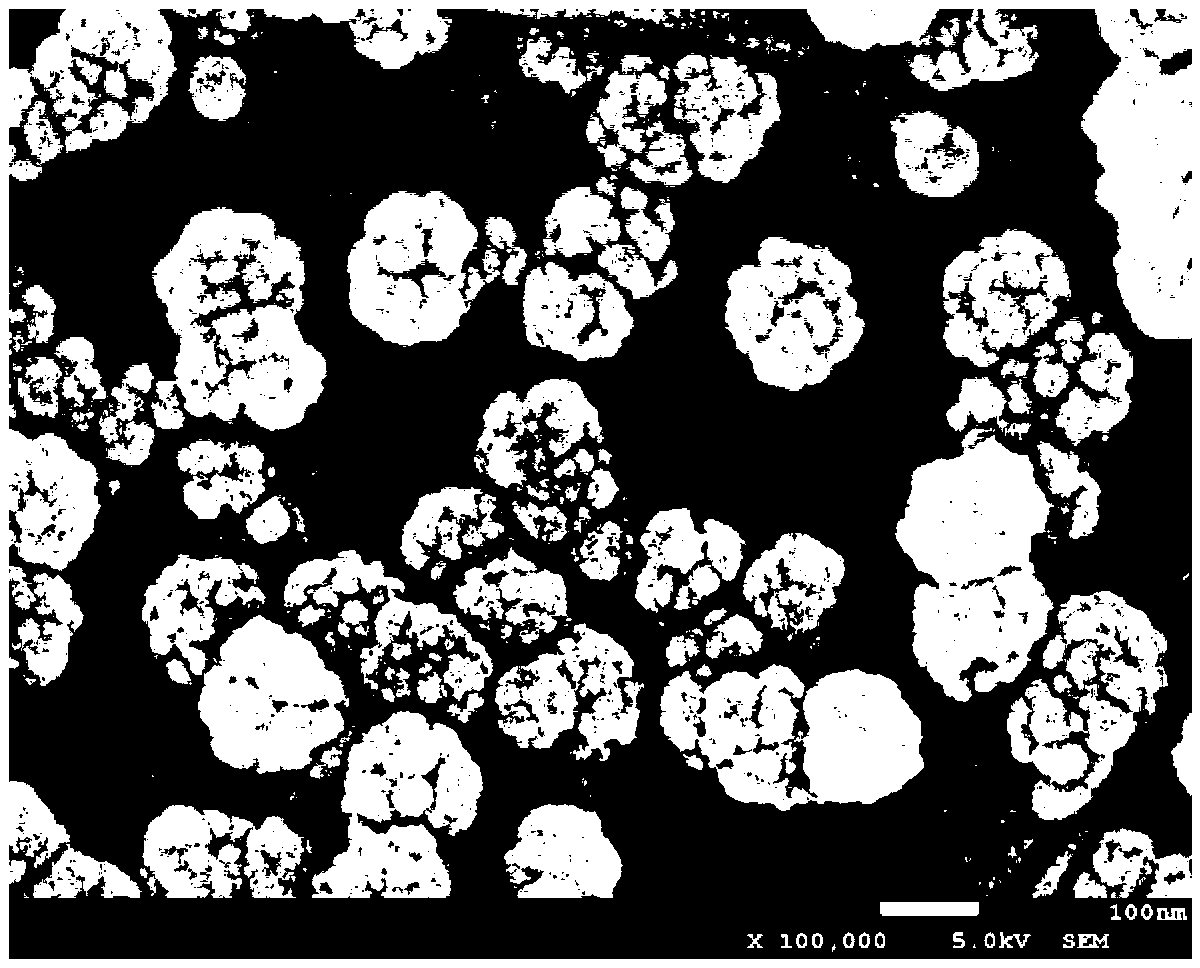

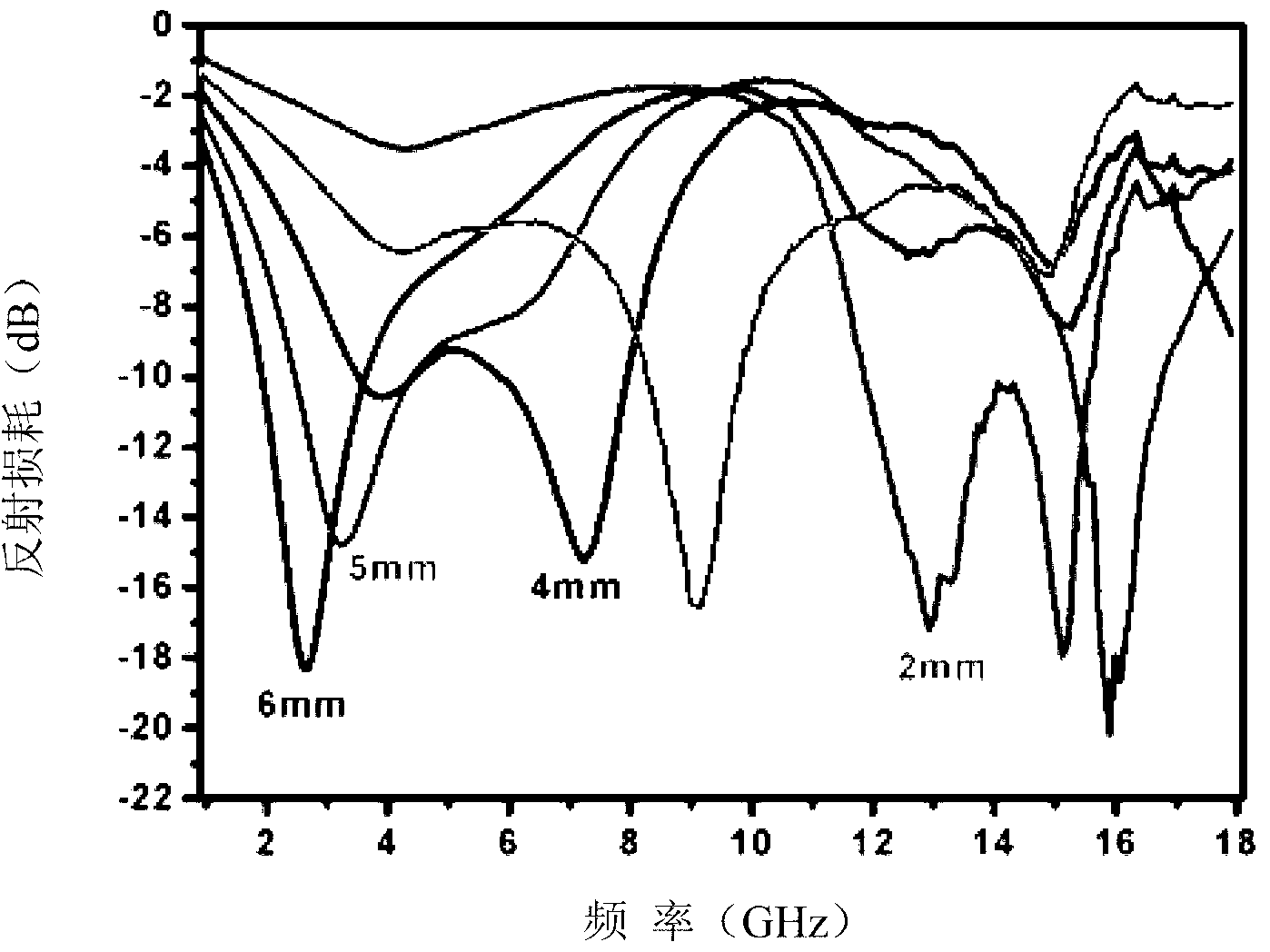

Preparation method of grapheme and ferriferrous oxide composite nanometer material

InactiveCN103274396ASolve the lack of interface binding forceResolving Particle MorphologyMaterial nanotechnologyGrapheneMicrosphereSolvent

A preparation method of a grapheme and ferriferrous oxide composite nanometer material belongs to the technical field of functional materials. The preparation method comprises the following steps: at first, oxidized grapheme is prepared by an improved chemical method; and then oxidized grapheme and ferric ions are adopted as raw materials, and are compounded through adopting a solvothermal technology to carry out one-step in-situ reduction to obtain the grapheme and ferriferrous oxide composite nanometer material. The preparation method solves the problems in the prior art that the interface binding force of grapheme and a magnetic material is insufficient, the appearances, the sizes and the magnetism of magnetic material particles are uncontrollable, and the magnetic material particles cannot be dispersed in water; the prepared composite nanometer material shows a microspheric appearance, has a loose surface and is high in specific surface area; through the change of the ratio of grapheme to the ferric ions, final magnetic property and electrical property of the composite material can be adjusted; and the controllable growth of the grapheme and ferriferrous oxide composite material is realized. The prepared grapheme and ferriferrous oxide nanometer microsheric material with magnetic and electric properties can be used in fields such as biological medicine, energy, invisibility and electronic materials.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

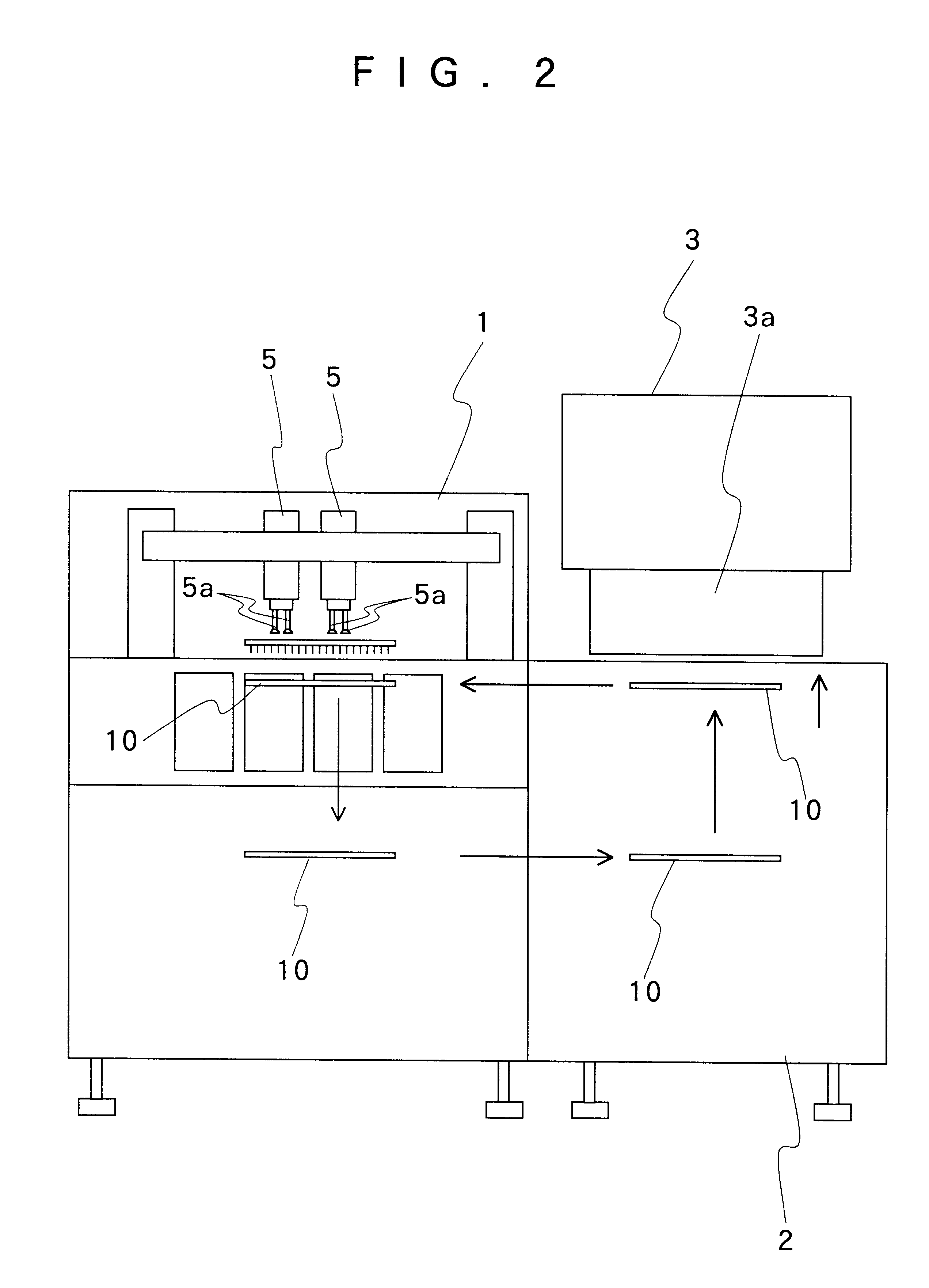

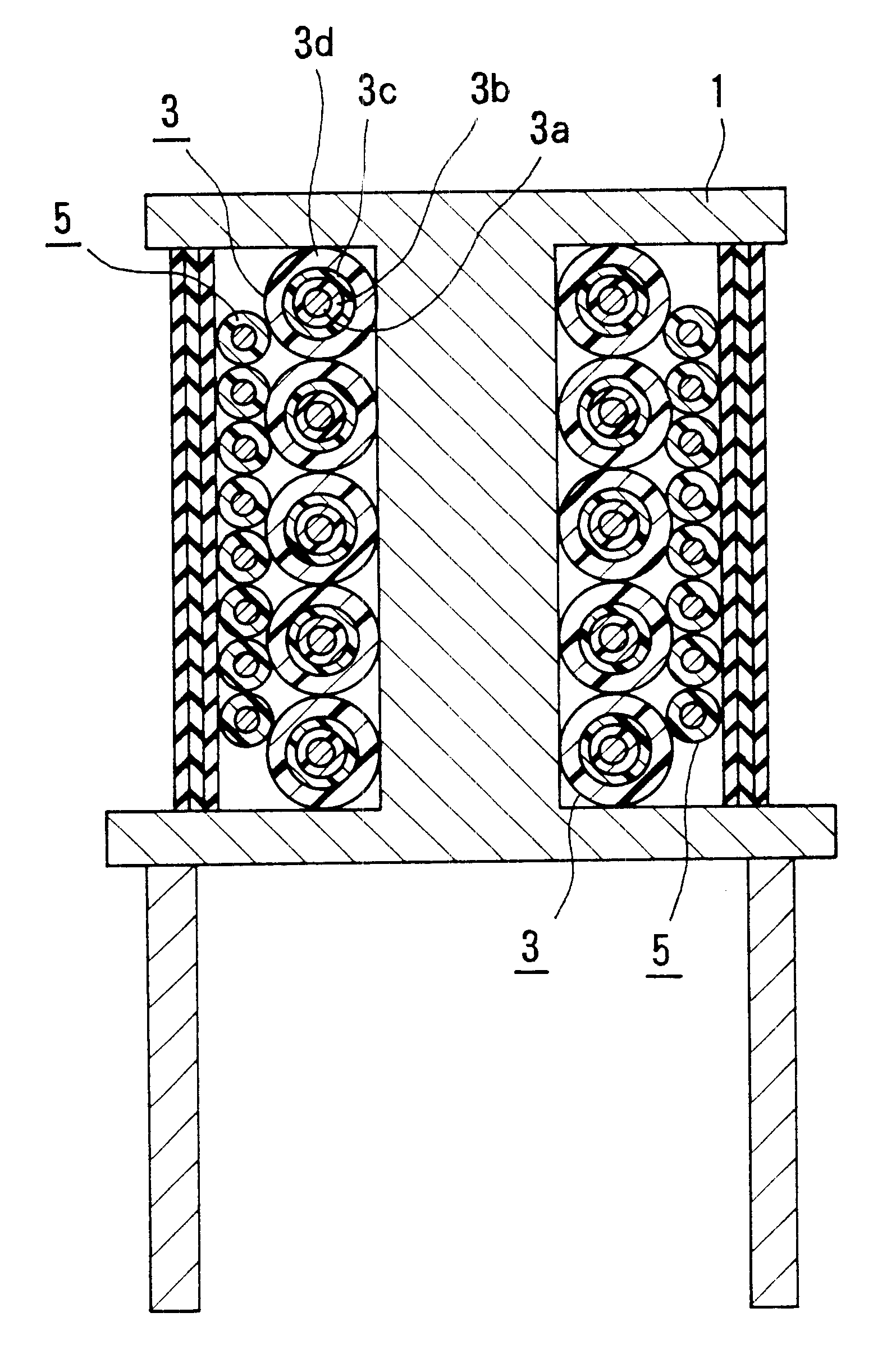

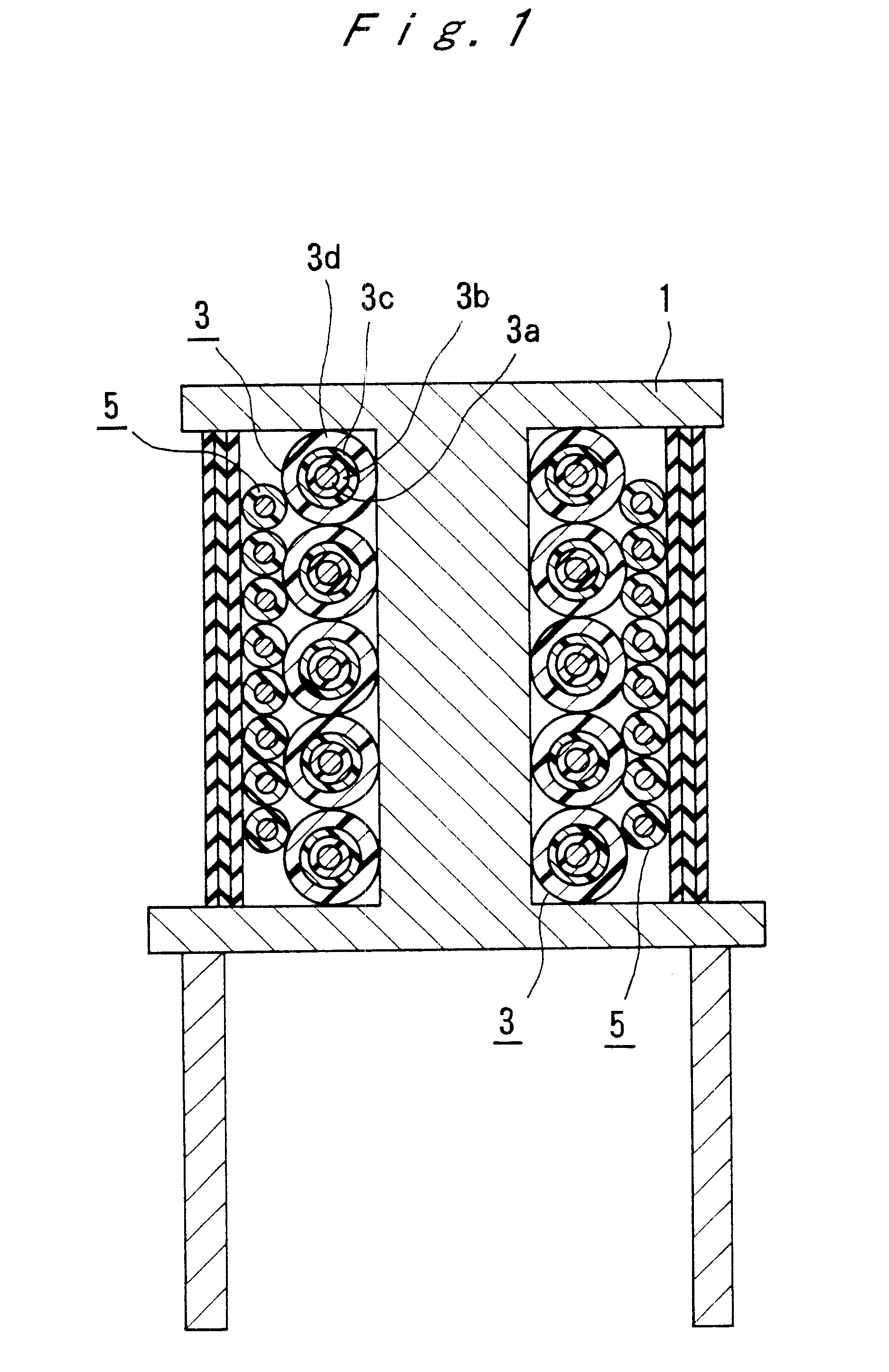

IC device contactor

InactiveUS6204681B1Increase the number ofProtection from damageCoupling device connectionsElectronic circuit testingElectricityEngineering

An IC device contactor for electrically connecting IC devices each having a large number of spherical electrodes on one side of a substrate to an IC tester head for a test of electrical properties or characteristics. The IC device contactor includes: a socket board having a predetermined number of contact points formed on a surface thereof; an anisotropic conductive sheet having a multitude of fine conductive wires embedded in the insulating sheet in an angularly oriented state; a tip holder perforated with a predetermined number of apertures; and a predetermined number of contact tips fitted in the apertures of the tip holder for contact with the spherical electrodes of the IC devices. The anisotropic conductive sheet is disposed with its side in engagement with the socket board and the other side in engagement with the contact tips to electrically connect the contact tips with the contact points on the socket board. The contact tips are assembled with the tip holder in such a way as to be securely retained in position within the respective aperture and are brought into pressed contact with the anisotropic conductive sheet at one end while the other end of the contact tips is projected out of the aperture by a predetermined length.

Owner:HITACHI ELECTRONICS ENG CO LTD

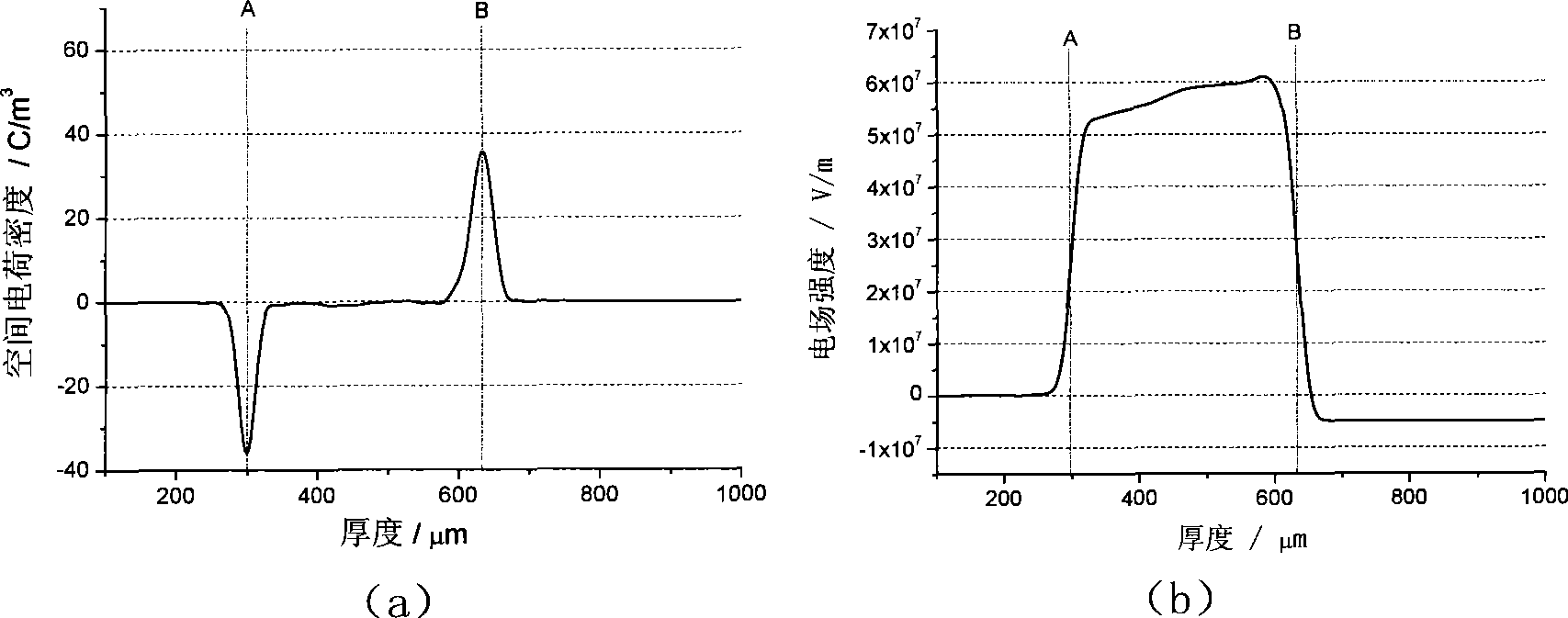

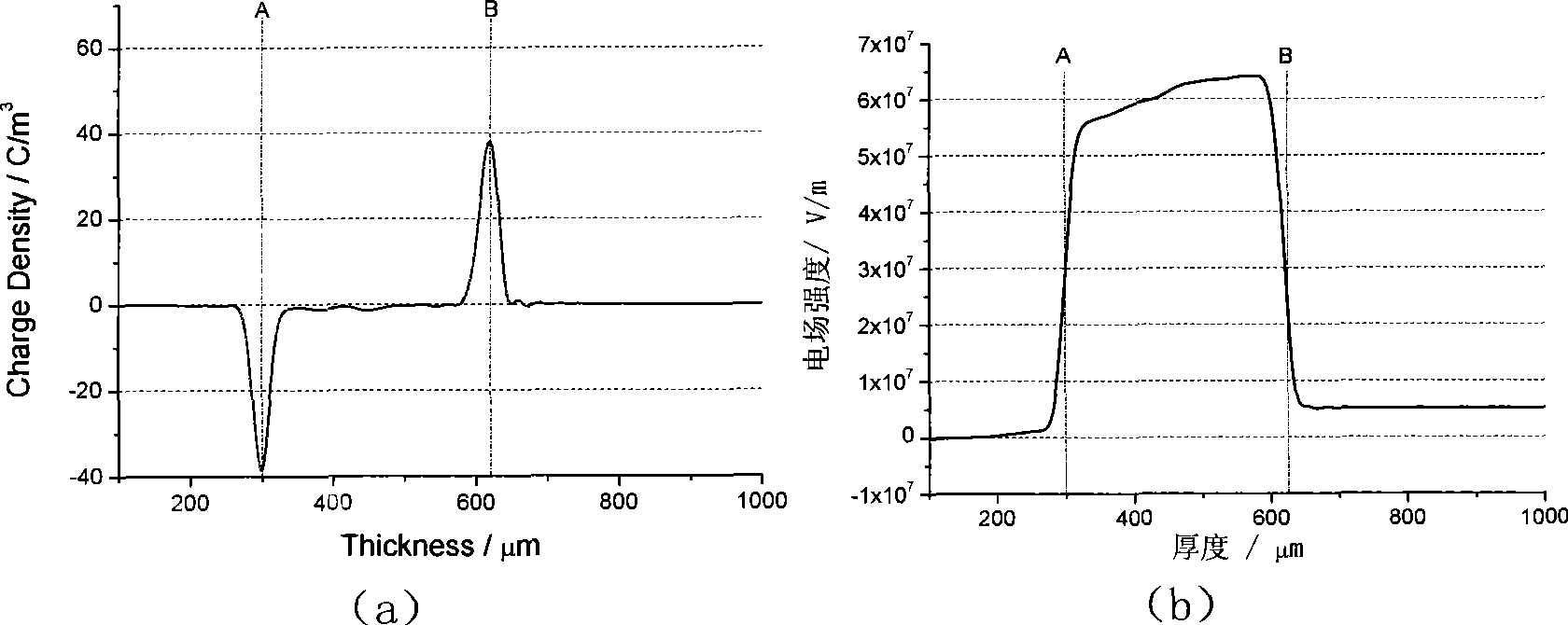

High-voltage DC cable insulating material and a preparation method thereof

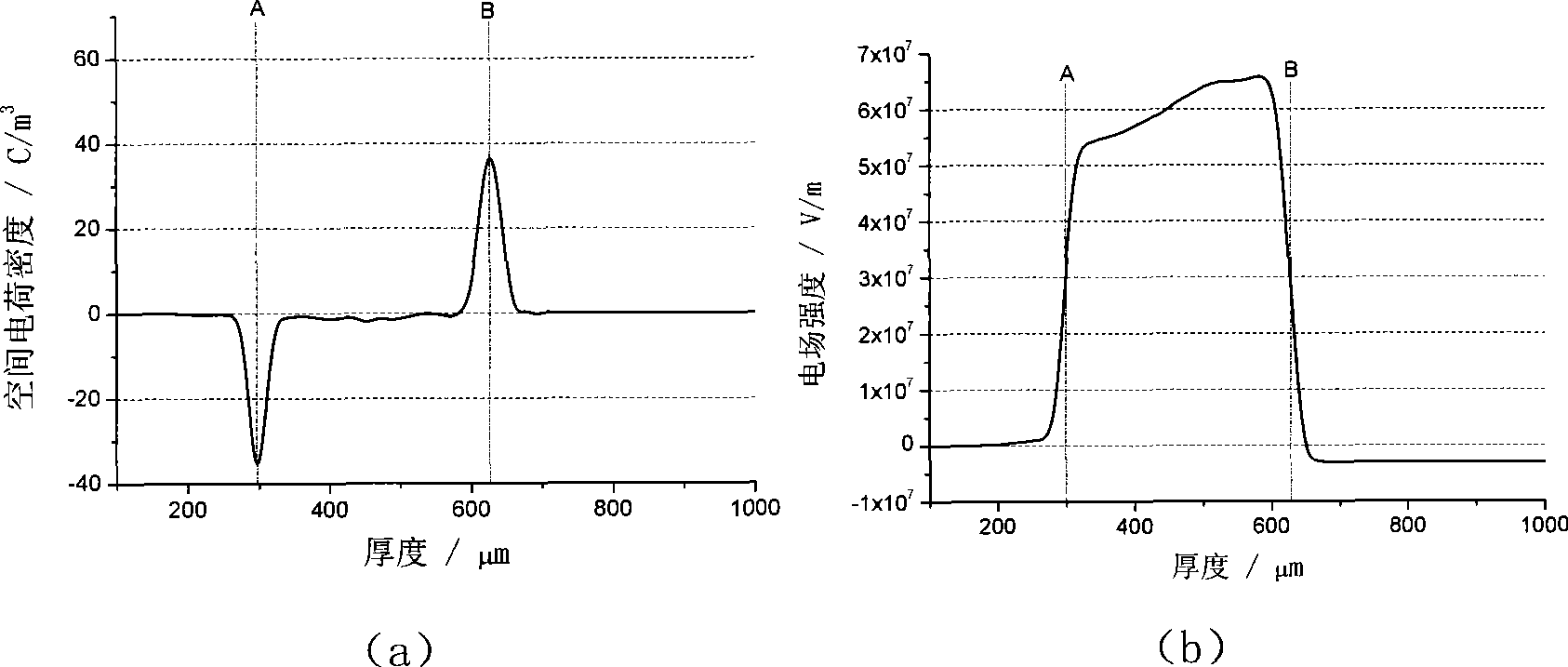

InactiveCN101445627AAvoid accumulationApparent space charge phenomenonPlastic/resin/waxes insulatorsLow-density polyethyleneHigh-voltage direct current

The invention relates to high-voltage DC cable insulating material and a preparation method thereof in the technical field of the insulating material. The preparation method is that: 100 weight portions of low-density polyethylene, 0.1-1 weight portion of anti-oxidizer, 0.5-5 weight portions of nano inorganic powder and 0.2-5 weight portions of maleic anhydride are placed into and mixed and compounded in a banbury mixer; the temperature of mixing and compounding is 373K to 378K and the mixing and compounding time is 10 to 15 minutes; 0.1-5 weight portions of cross-linking agent is added into the mixture and is mixed and compounded under the temperature of 373K to 378K for 10 to 15 minutes; then, the high-voltage DC cable insulating material is obtained; wherein, the density of the low-density polyethylene is less than 0.9g / cm<3>. The insulating material of the preparation method can effectively improve the mechanical and electric properties of the high-voltage DC cable, thus avoiding the disadvantage that the environment is polluted and damaged by an oilpaper insulating cable due to the leakage of the insulating oil.

Owner:SHANGHAI JIAO TONG UNIV

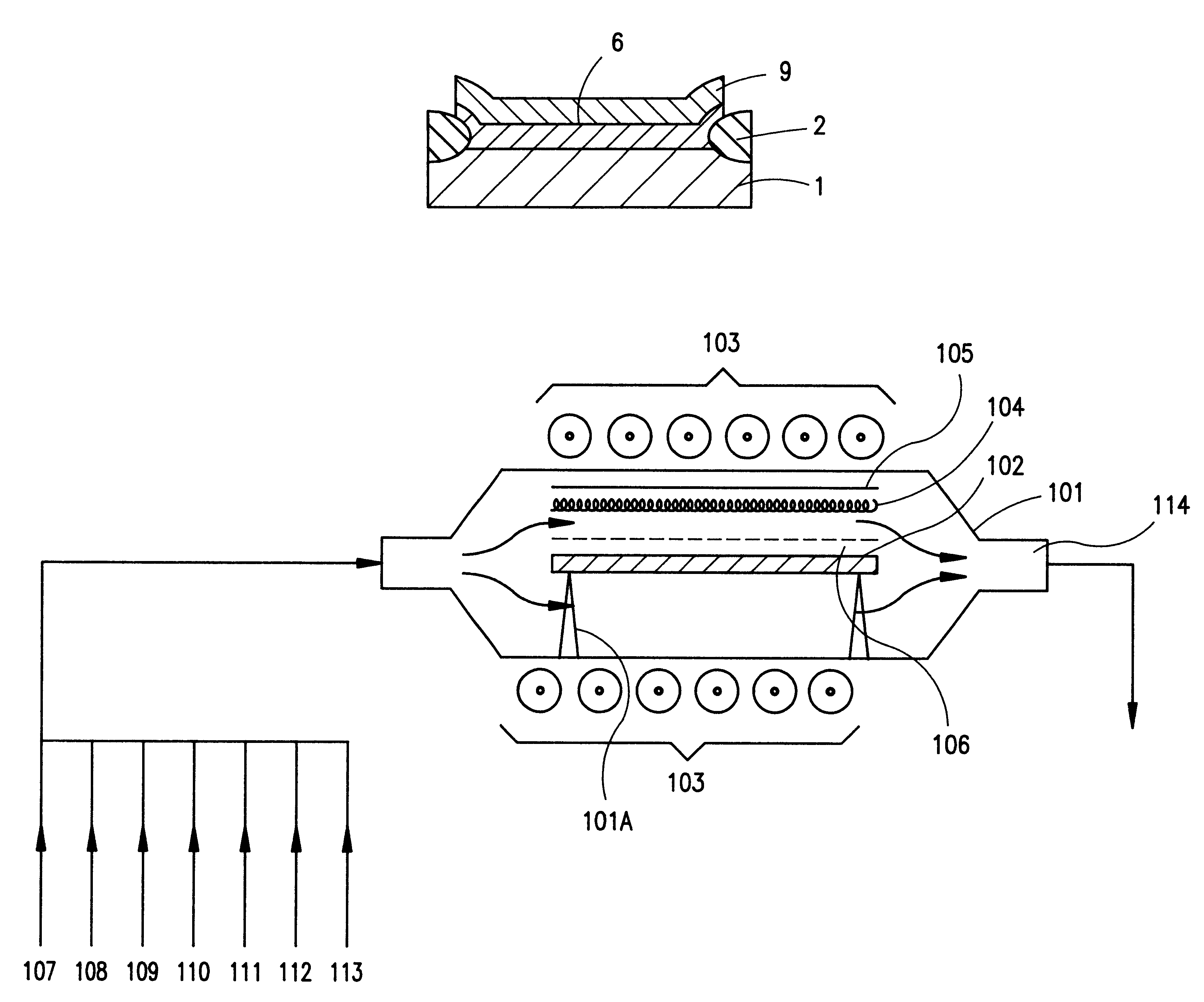

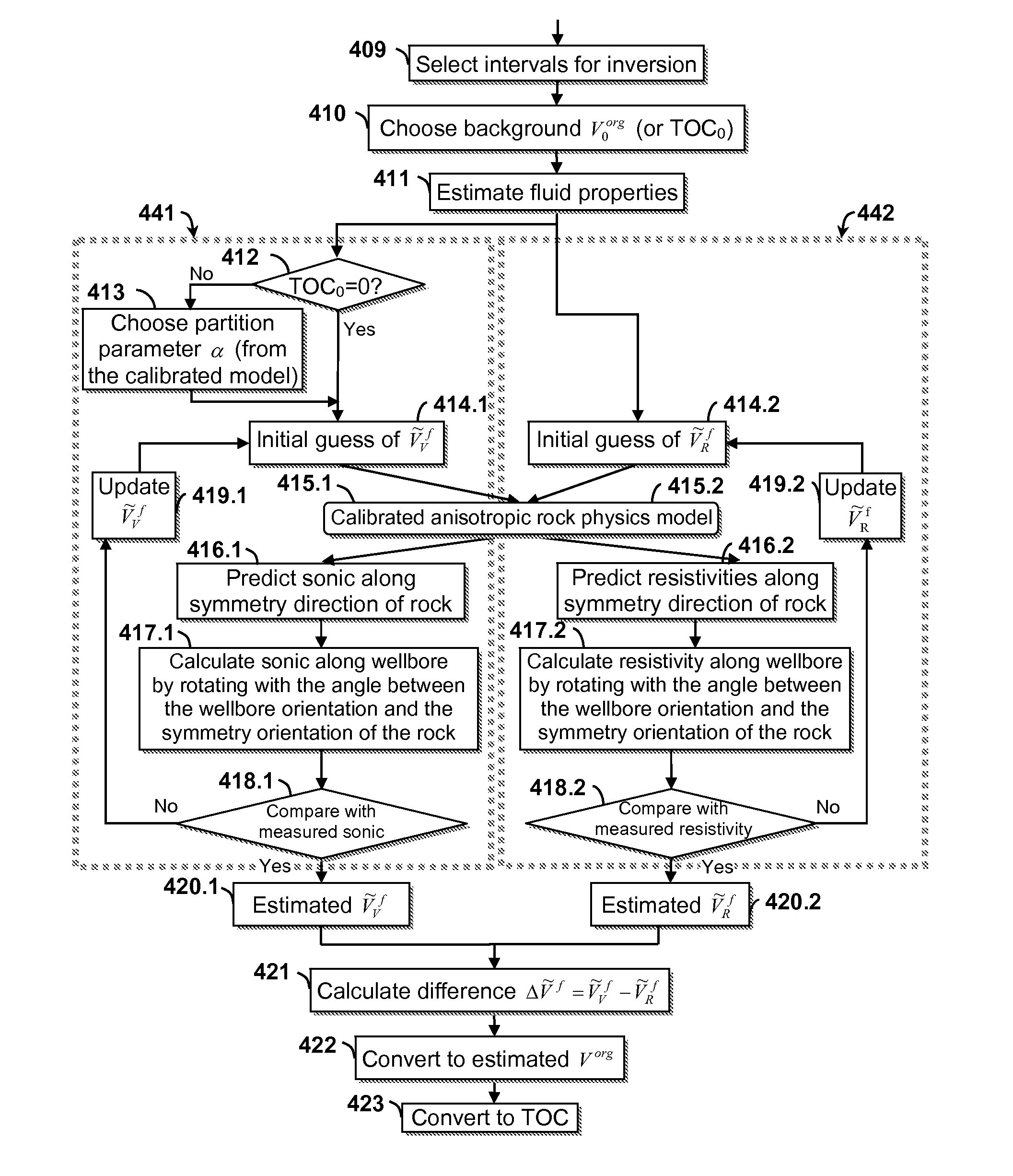

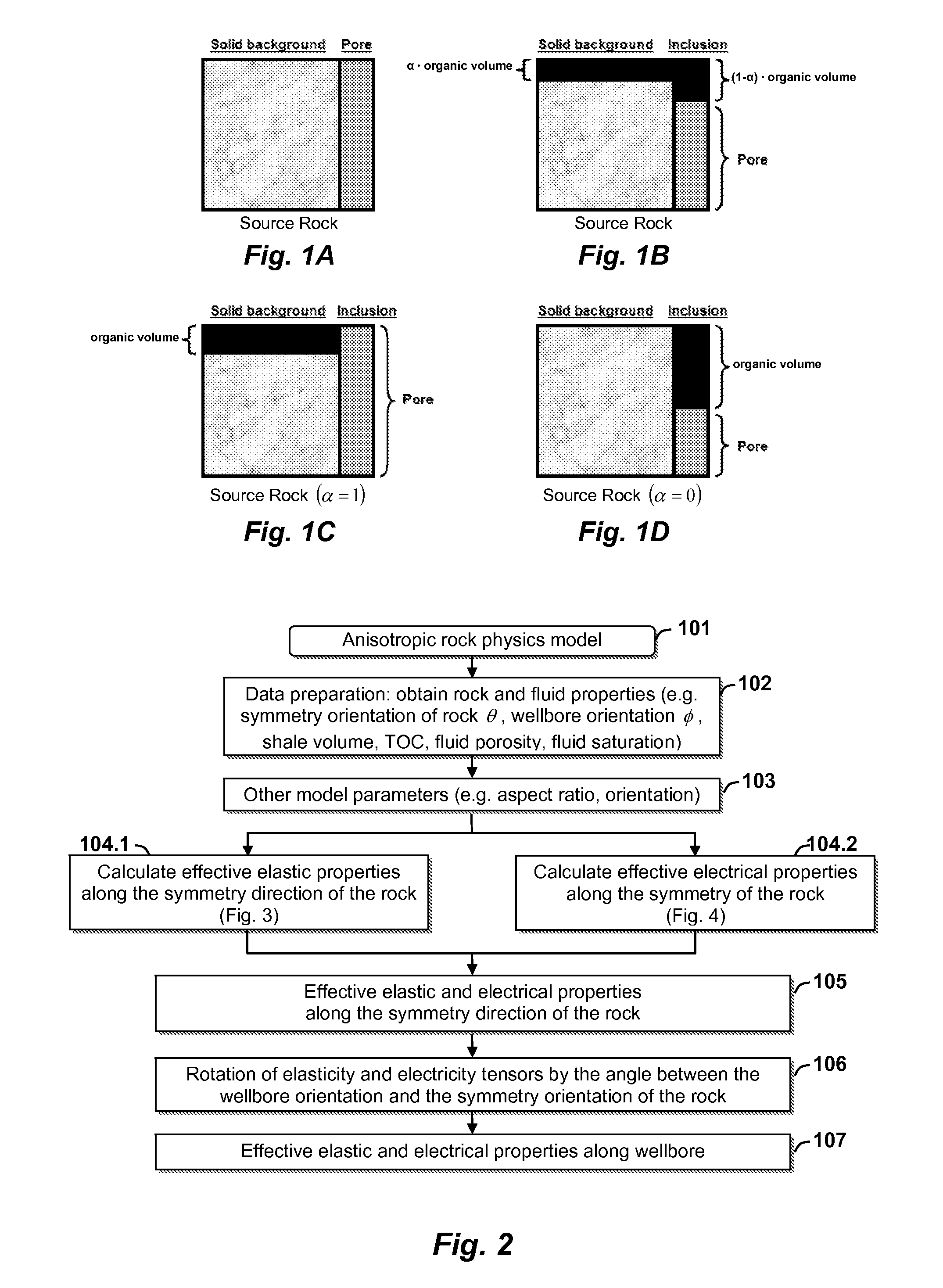

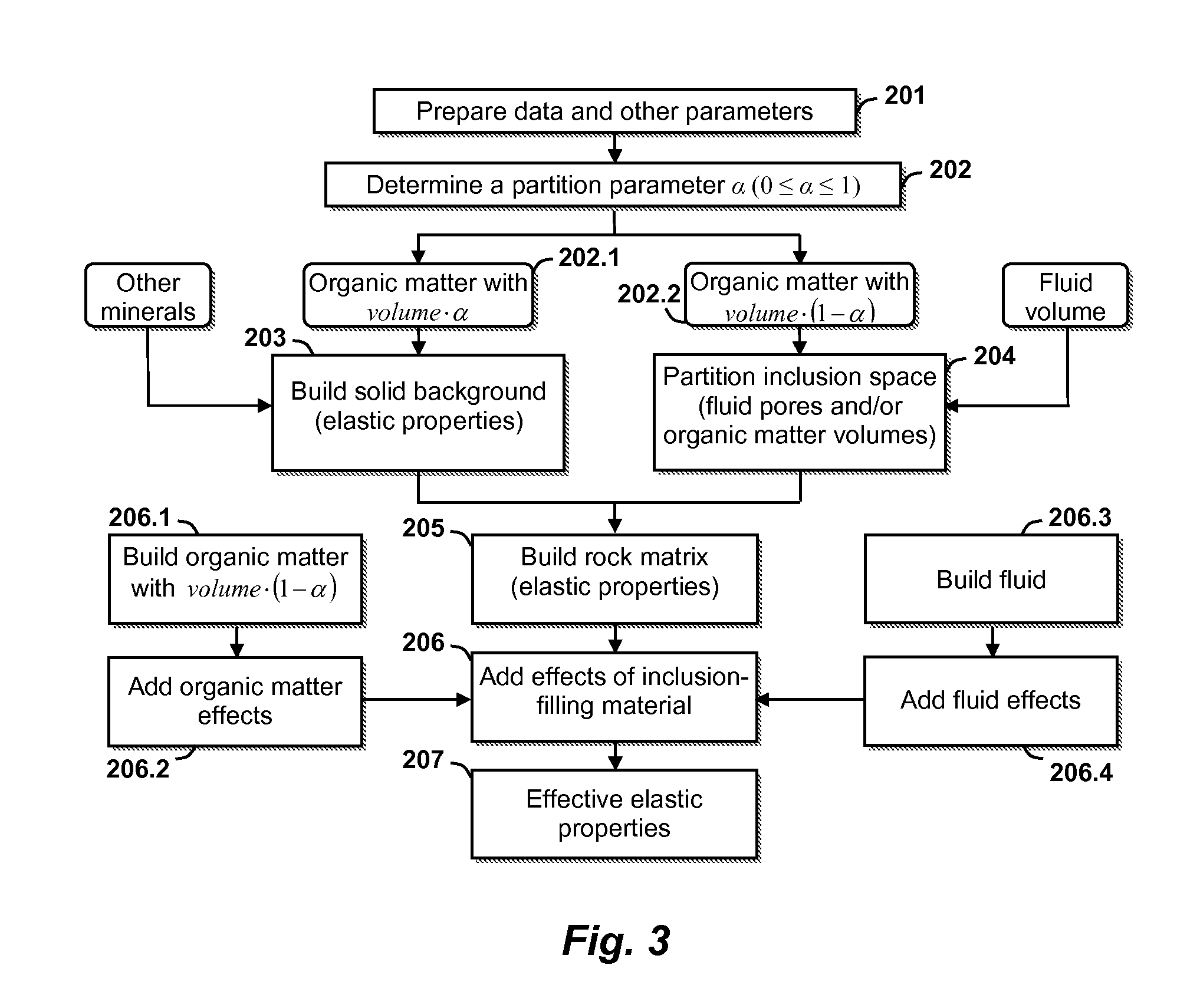

Predicting anisotropic source rock properties from well data

InactiveUS20130013209A1Electric/magnetic detection for well-loggingEarth material testingAcoustic waveOrganic matter

Method for predicting physical properties of a source rock formation wherein an inclusion-based (103) mathematical rock physics model (101) is constructed that treats organic matter as solid inclusions, solid background, or both, and relates anisotropic elastic and electric properties of source rock to in-situ rock and fluid properties (102). The model is calibrated with well log data and may be used to forward model calculate effective anisotropic elastic (104.1) and electrical (104.2) properties of the source rock formation, or by inversion (441-442) of sonic and resistivity log data to calculate total organic carbon (423) in terms of a difference (421) between elastic and electrical properties of the source rock.

Owner:ZHU YAPING +4

Method of manufacturing semiconductor device

ActiveUS6953748B2Improve reliabilityEasy to handleSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringElectric properties

To enhance and / or improve reliability in a method of forming a semiconductor device. An exemplary method of forming a semiconductor device forms a conductive part within a concave portion which is formed in a first surface of a semiconductor substrate. The semiconductor substrate includes an integrated circuit. The method also thins the substrate by removing a part of a second surface of the semiconductor substrate so as to make the conductive part penetrate from the first surface to the second surface, and cuts the semiconductor substrate into pieces. An electric property of the semiconductor substrate is inspected through the conductive part after the conductive part is formed.

Owner:ADVANCED INTERCONNECT SYST LTD

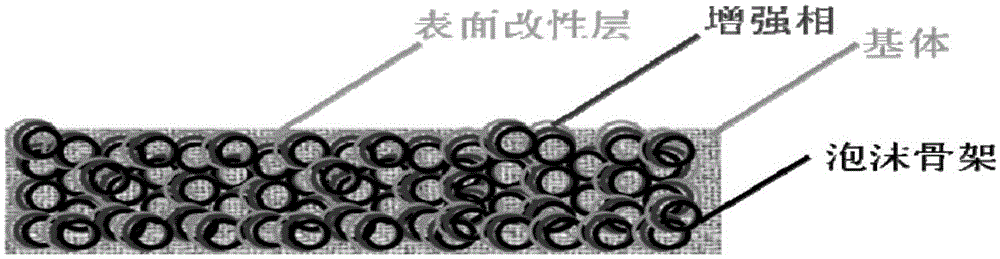

Foam graphene skeleton reinforced aluminum-base composite material and preparation method thereof

ActiveCN105603265ADoes not reduce ductilityReduce negative impactChemical vapor deposition coatingThree-dimensional spaceCarbon nanotube

The invention discloses a foam graphene skeleton reinforced aluminum-base composite material and a preparation method thereof. The composite material consists of a foam substrate, a graphene reinforcing layer and a base material or is added with reinforcing particles, wherein the foam substrate is foam metal, foam ceramic or foam carbon; the base material comprises aluminum and an aluminum base alloy; and the reinforcing particles are at least one of high-thermal conductivity diamond powder, graphene and carbon nanotubes or a combination of more or high-thermal conductivity low-expansion ceramic particles for improving the mechanical strength of the composite material and reducing the coefficient of thermal expansion. In the composite material disclosed by the invention, since graphene and aluminum are continuously distributed in a three-dimensional space to form a network interpenetrating structure, remarkable influence on the thermal and electric properties of the material caused by the compound interface is weakened, the reinforcing phase can form a whole without reducing the good plasticity and toughness of the metal base in the composite material, and the heat conduction efficiency and electric conduction efficiency of the reinforcing body are maximized, so that the thermal conductivity, electric conductivity and mechanical strength of the composite material are remarkably improved over traditional composite materials; and therefore, the foam graphene skeleton reinforced aluminum-base composite material is a novel multifunctional composite material with great potential.

Owner:CENT SOUTH UNIV

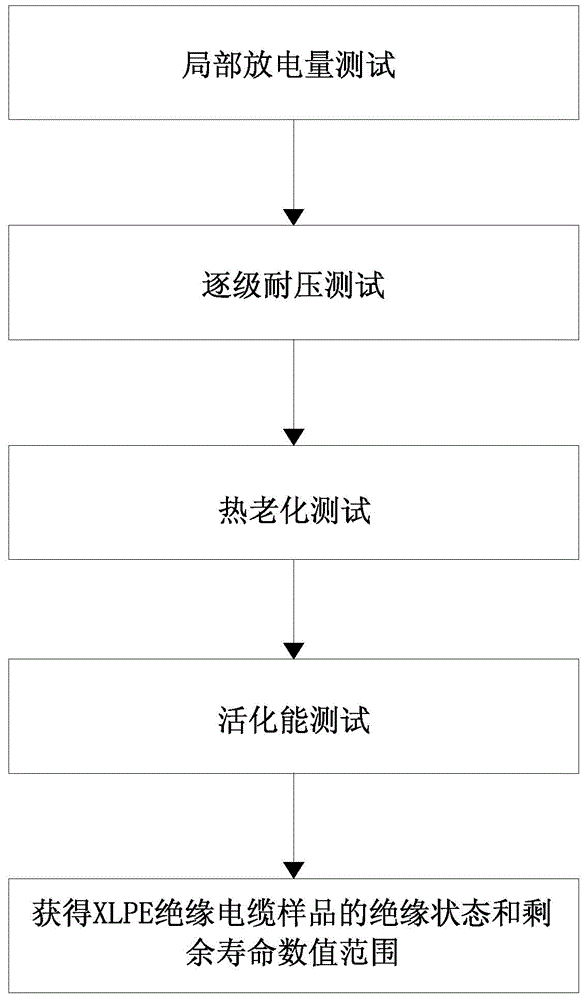

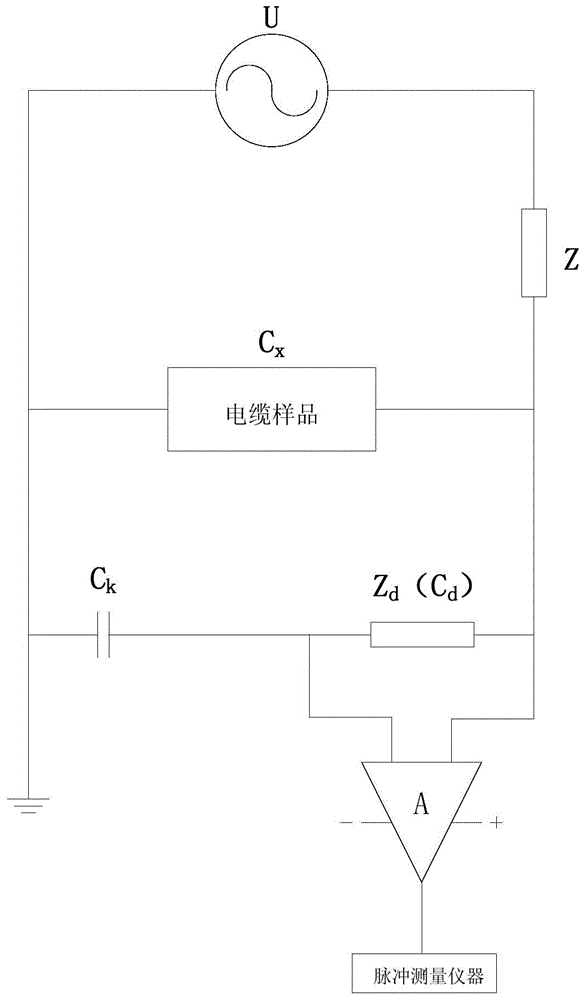

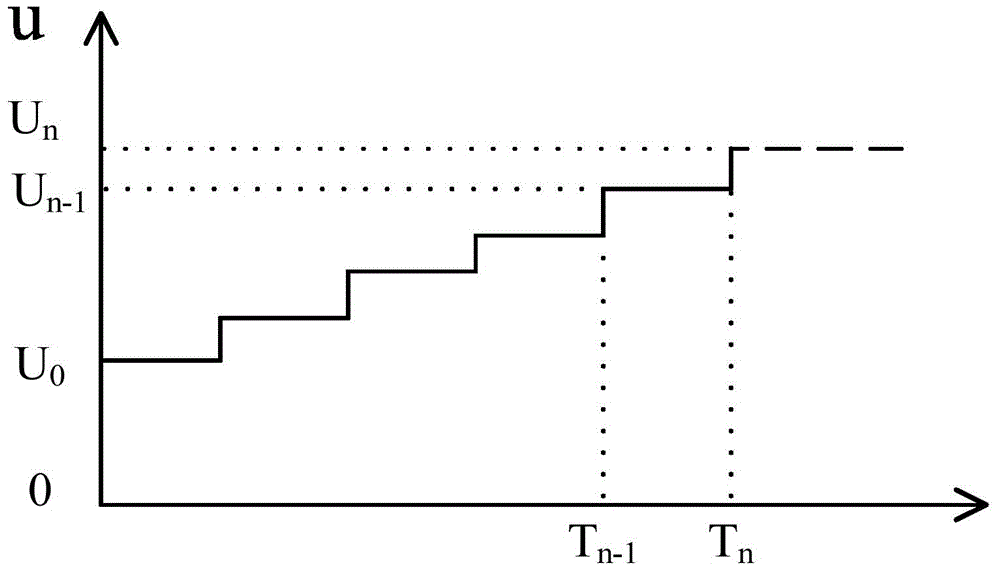

Insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties

The invention discloses an insulating cable residual service life comprehensive evaluation method based on physical, chemical and electric properties. An insulating cable is an XLPE (Cross Linked Polyethylene) insulating cable. The method comprises a partial discharging amount test, a gradual layer voltage-resisting test, a thermal aging test and an activating energy test; an insulating state of an XLPE insulating cable sample is obtained according to a partial discharging amount calculated by he partial discharging amount test; a residual service life numerical value range of the XLPE insulating cable sample is obtained according to testing results of the gradual layer voltage-resisting test, the thermal aging test and the activating energy test. The method can integrate a plurality of indexes of cable aging evaluation, and combines macroscopic and microscopic change conditions, so that the residual service life data of the cable is completely analyzed in the three aspects of physical performances, chemical performances and electric performances, and the method has important guiding meanings on line modification and power grid planning.

Owner:SOUTH CHINA UNIV OF TECH

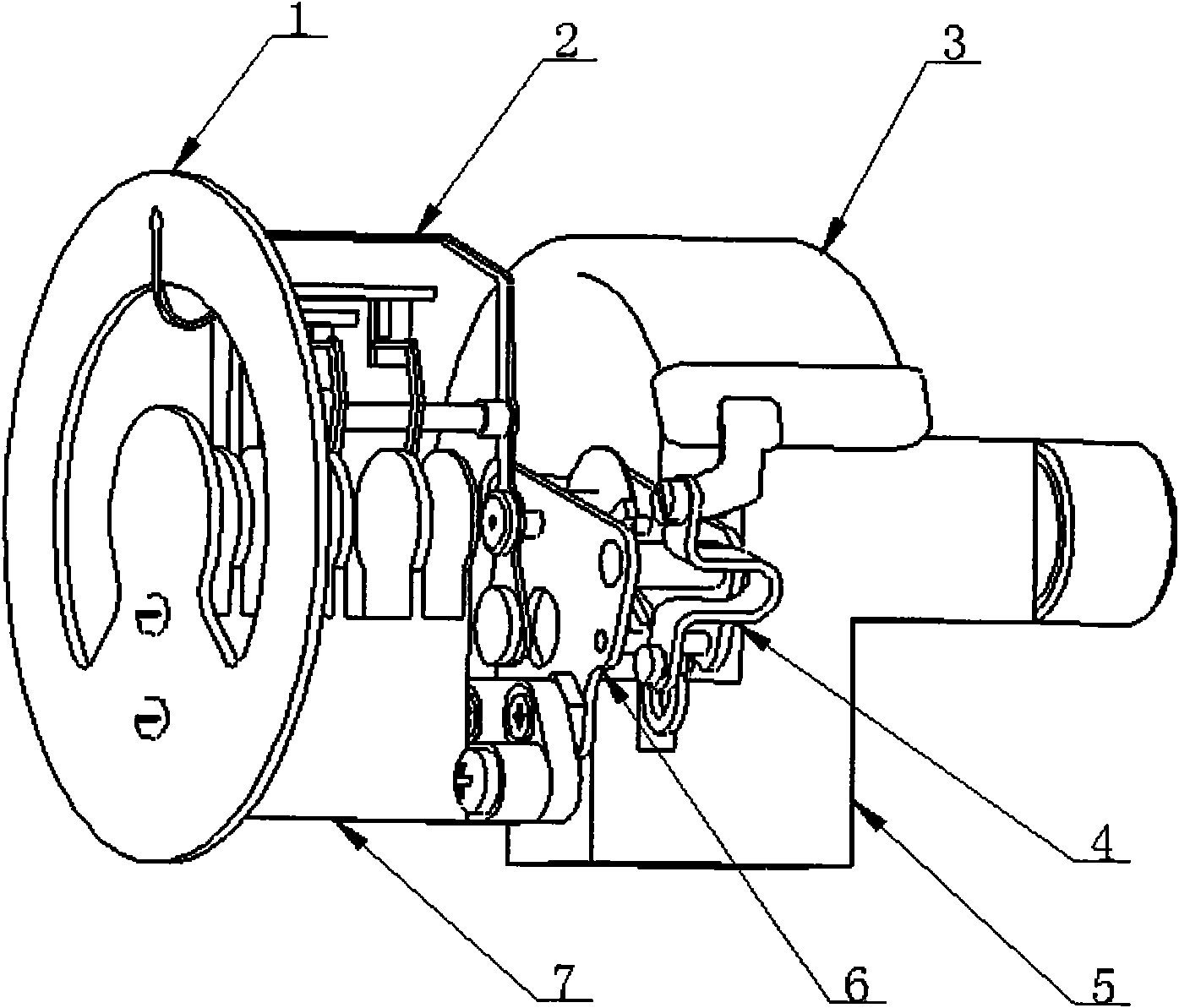

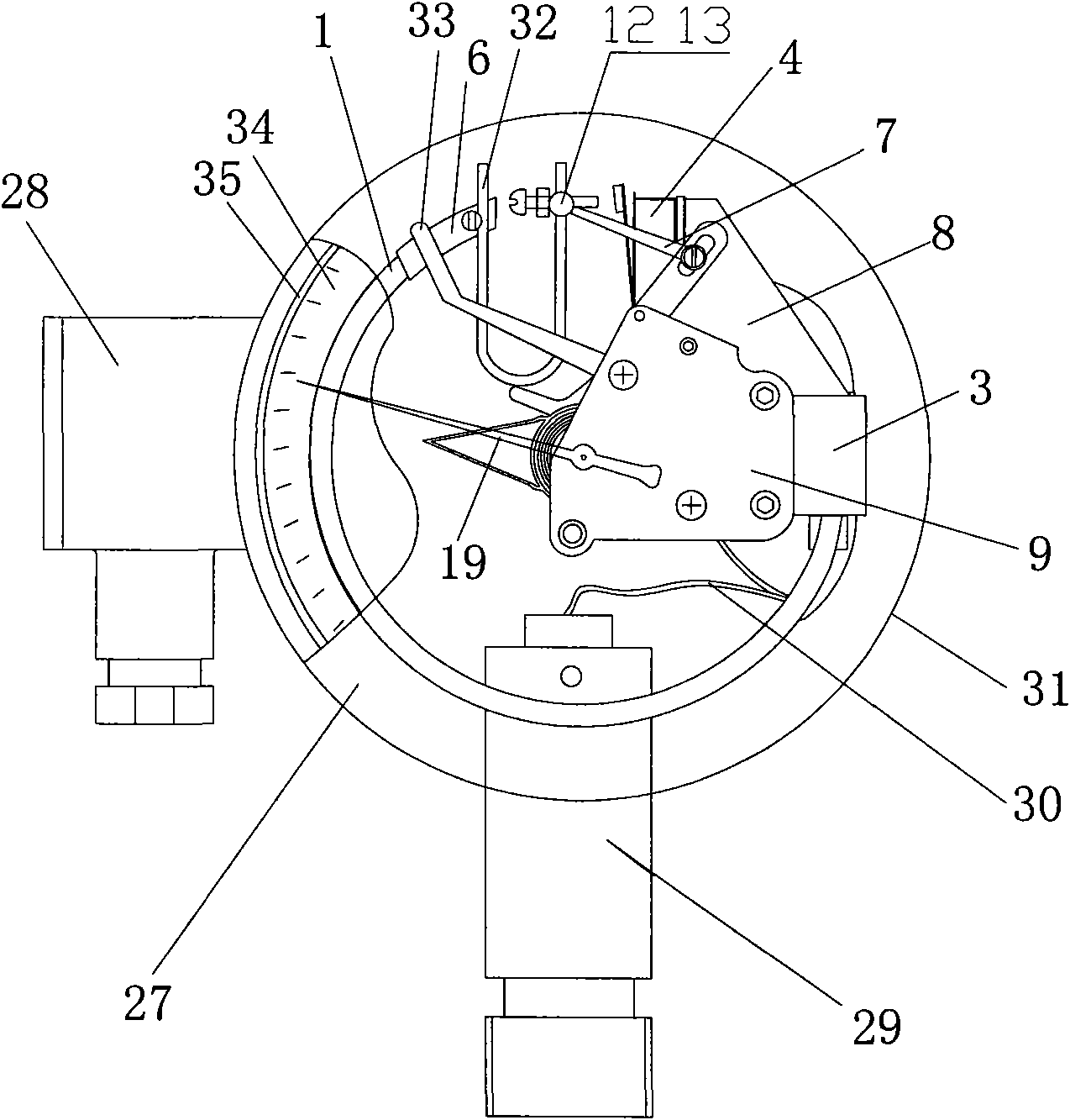

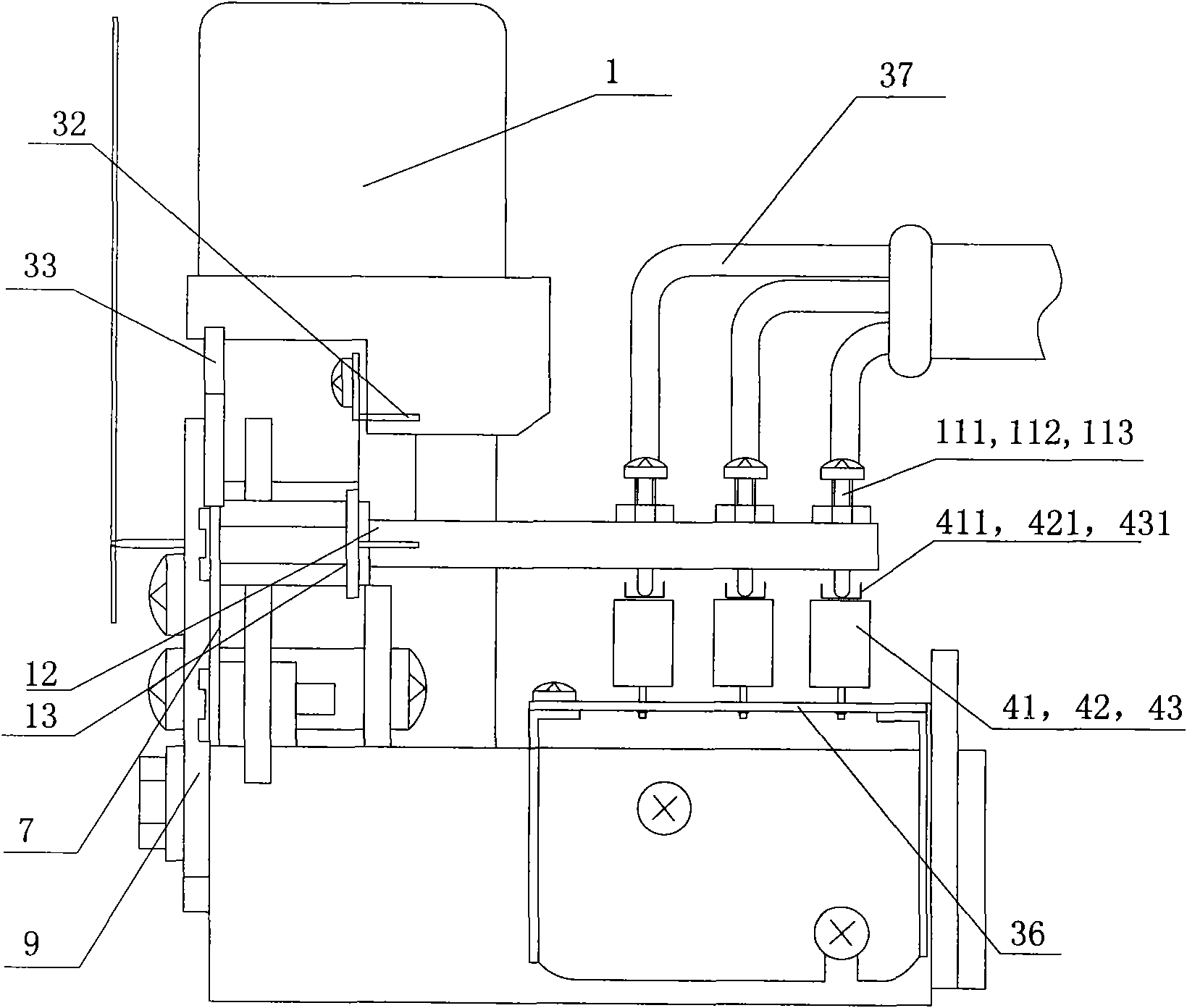

Sulfur hexafluoride gas density relay

InactiveCN102013357AImprove vibration resistanceImprove electrical performanceElectric switchesSulfur hexafluorideEngineering

The invention relates to a sulfur hexafluoride SF6 gas density relay with low pressure. In the structure of the density relay, a control part and a display part are separately designed, the control part comprises a Bourden tube, a temperature compensation element and a joint operating arm; the display part also comprises a Bourden tube and a temperature compensation element; the two Bourden tubes are welded on a base, the other ends of the Bourden tubes are connected with an end sea, the end seat is connected with one end of each temperature compensation element, and the other ends of the temperature compensation elements are connected with the joint operating arm or a clock mechanism. Therefore, the display part and the control part are not mutually influenced when working, and the display precision and the display range of the display part are not limited, and the electric property and the service life of the relay are greatly improved.

Owner:SHANGHAI ROYE ELECTRIC SCI & TECH

Porcelainized polyolefin composite material and preparation method thereof

InactiveCN104497404AImprove integritySimple processPlastic/resin/waxes insulatorsPolyolefinAntioxidant

The invention discloses a porcelainized polyolefin composite material, comprising the following raw materials in parts by weight: 50-100 parts of polyolefin resin, 10-200 parts of porcelainized powder, 0.1-50 parts of an accelerant, 0-100 parts of a fire retardant, 0.3-15 parts of a compatilizer, 0.2-10 parts of a coupling agent, 0.1-5 parts of a lubricant and 0.1-8 parts of an antioxidant. The porcelainized polyolefin composite material disclosed by the invention is simple in technological process, easy to operate, free of three wastes, and excellent in mechanical property and electric property, and can be sintered into ceramic at a temperature over 600 DEG C or in a flame within 5-10 minutes; and the formed shell is good in integrity, free of cracking or drippage, has excellent fireproof performance and heat-insulating property, and has high application value in the fields of fire-resistant wires and cables and indoor fire-resistant decoration.

Owner:常州市沃科科技有限公司

Quick high-flexibility manufacturing method for ceramic circuit board

ActiveCN103188877AImprove bindingImprove thermal conductivityPrinted circuit manufactureLaser beam welding apparatusChemical platingChemical reaction

A quick high-flexibility manufacturing method for a ceramic circuit board comprises the following steps: irradiating laser on the surface of a ceramic matrix, and controlling the energy density of the laser to reach above the fracture threshold of the chemical bond of the compound containing active ions, so that chemical reaction occurs on the surface of the ceramic matrix, an active substance is separated out to serve as a chemical plating catalytic source, and the active substrate generated by the reaction and the matrix form chemical metallurgical bonding, wherein different laser sources are selected aiming at different ceramic materials according to the chemical bond energy of the ceramic material components, and the laser energy is controlled to reach the ceramic modified threshold by controlling the average power of laser output, pulse repetition frequency, scanning speed, defocusing amount, space between scanning line and scanning times; and the ceramic matrix modified by the laser is placed into a chemical plating solution to perform plating to form a metal coating. The surface of the ceramic is modified by the laser, so that a metal conductive layer and the matrix form chemical metallurgical bonding, the bonding force of the circuit board is greatly increased, and the heat-conducting property and the electric property are improved.

Owner:SHENZHEN SUNSHINE LASER & ELECTRONICS TECH CO LTD

Silver coated copper conductor slurry for front electrode of solar battery and preparation method of silver coated copper conductor slurry

ActiveCN102610297ALow costImprove electrical performanceNon-conductive material with dispersed conductive materialCable/conductor manufactureCopper conductorMetallurgy

The invention provides silver coated copper conductor slurry for a front electrode of a solar battery and a preparation method of the silver coated copper conductor slurry for the front electrode of the solar battery. The silver coated copper conductor slurry for the front electrode of the solar battery comprises a conductive phase, glass powder and an organic carrier, wherein the conductive phase is silver coated copper powder and silver powder which account for 68-85% of the total weight of the slurry, the glass powder is Bi-B-Zn-Si-Ti-Ba-Al-O glass powder which accounts for 5-10% of the total weight of the slurry, and the organic carrier accounts for 10-22% of the total weight of the slurry. The preparation method comprises the steps: mixing the silver coated copper powder, the silver powder and the glass powder; weighing the organic carrier to agitate adequately; then mixing the silver coated copper powder, the silver powder and the glass powder with the organic carrier; and then rolling the mixture to obtain the silver coated copper conductor slurry for the front electrode of the solar battery. According to the silver coated copper conductor slurry for the front electrode of the solar battery, the electric properties of the electrode greatly is improved, and the photoelectric conversion rate of the battery is enhanced. The maximum fineness of the silver coated copper conductor slurry for the front electrode of the solar battery is 15 microns, the average fineness of the silver coated copper conductor slurry is less than 7 microns, the solid content is 80-87%, and the viscosity is 200-100keps. The solar battery printed and sintered by the silver coated copper slurry has higher photoelectric conversion rate and low cost.

Owner:昆明高聚科技有限公司

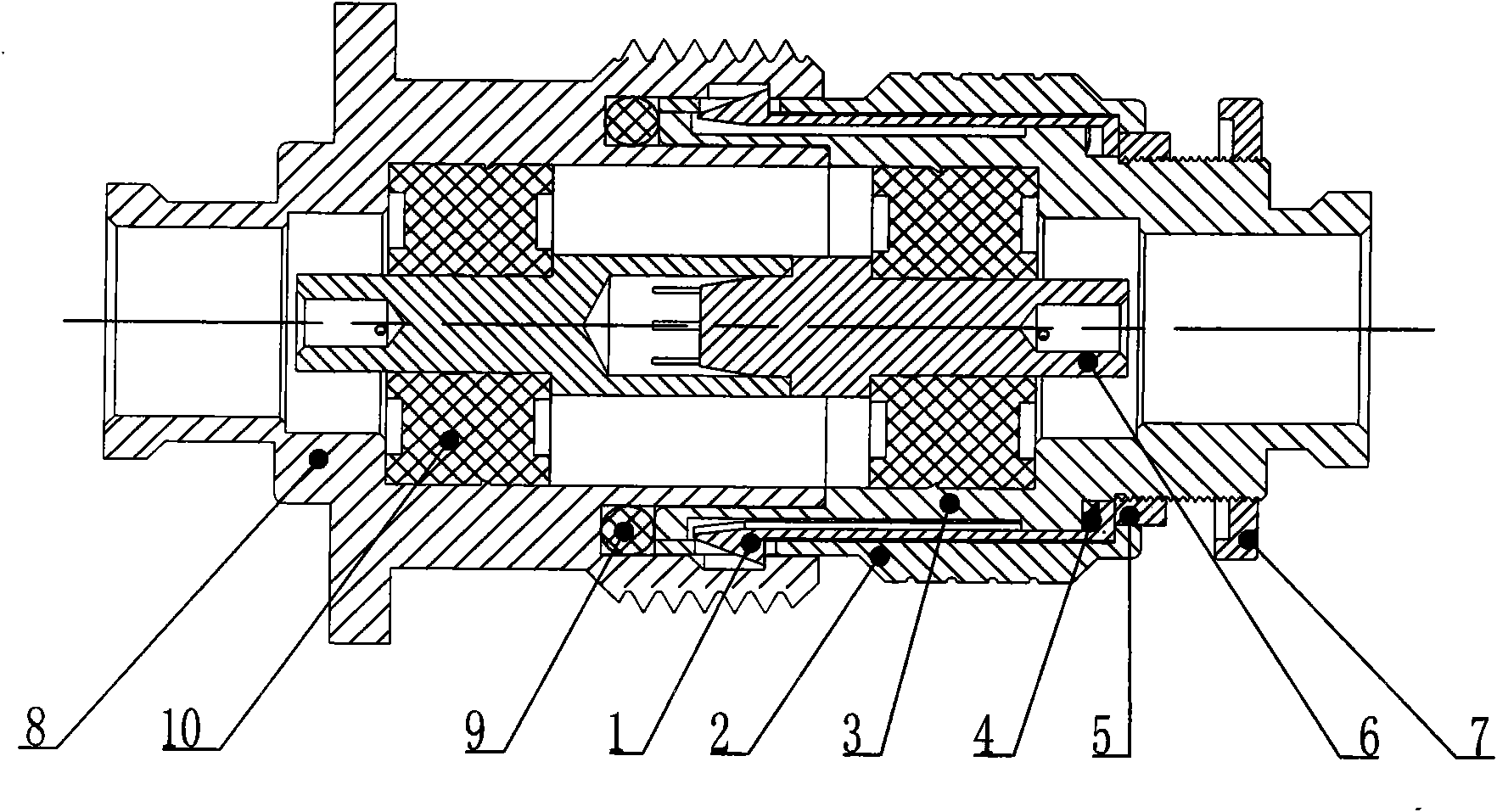

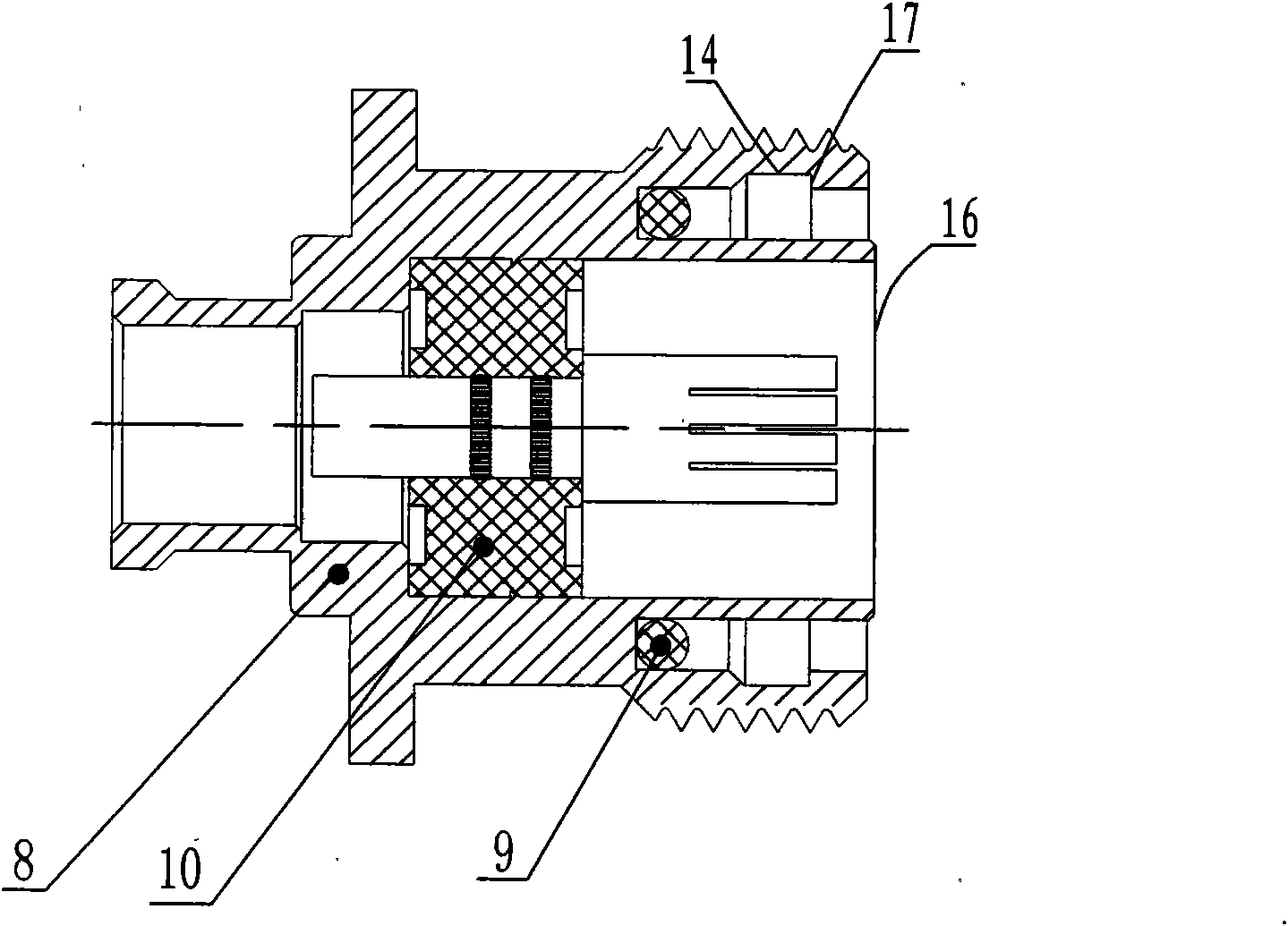

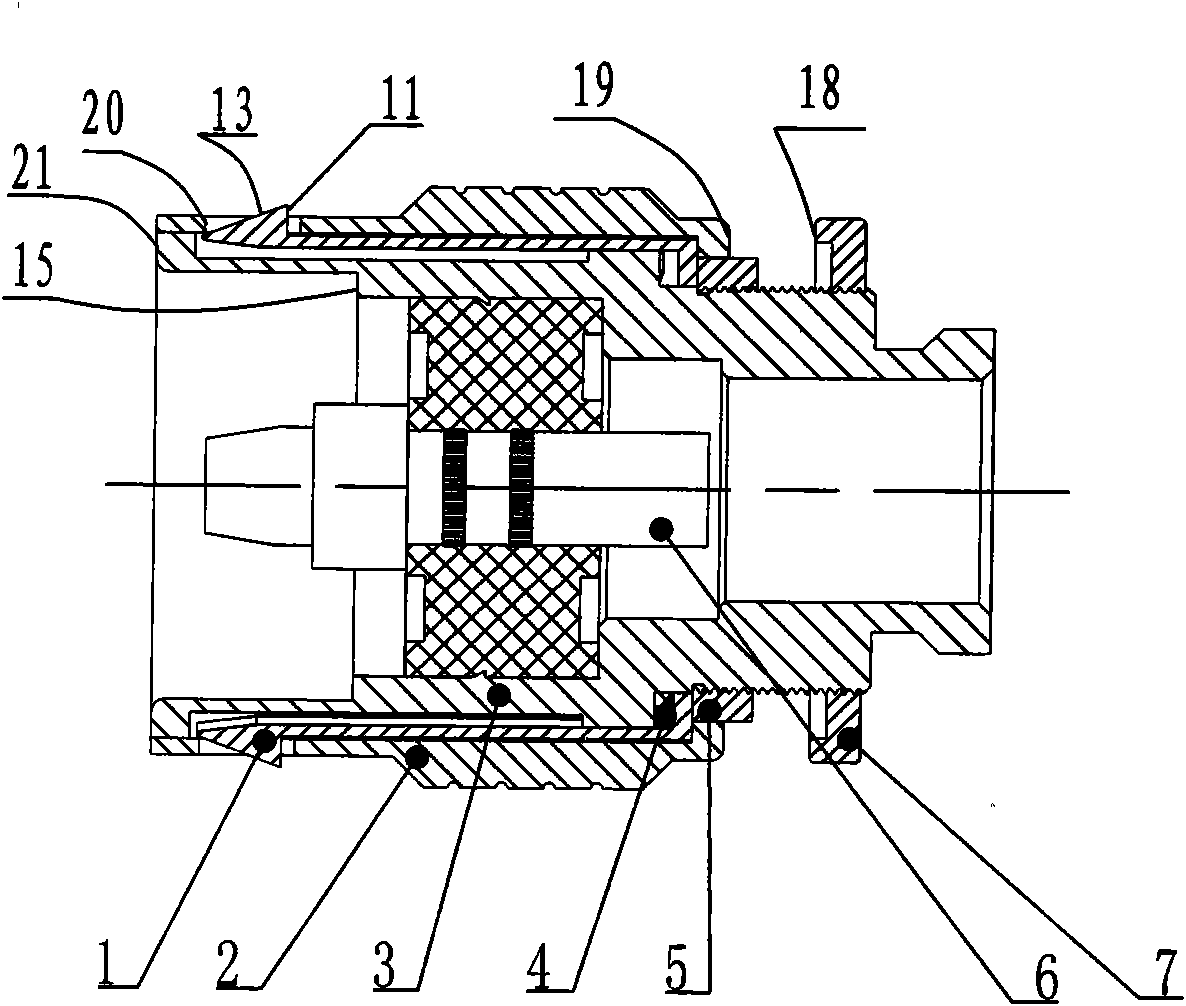

High-power radio frequency connector provided with fast locking and separation mechanism

ActiveCN101656380AReduce reflectionLow crosstalk indicatorCoupling device detailsTwo-part coupling devicesElectrical conductorElectrical performance

The invention relates to a high-power radio frequency connector provided with a fast locking and separation mechanism, which comprises a plug and a socket. The plug comprises an elastic claw, an unlocking sleeve, a plug external conductor, an elastic gasket, a positioning nut, a dielectric body and an auxiliary nut. The locking face of the elastic claw, after being arranged in the unlocking sleeve, extends out of the unlocking sleeve a certain distance through a corresponding positioning groove and is axially positioned on the plug external conductor together with the elastic gasket through the positioning nut. The front end of the unlocking face of the elastic claw is positioned below the unlocking sleeve and locks the locking face in the locking groove. The socket comprises a socket external conductor, a waterproof O-shaped ring and a dielectric body, and a locking groove is arranged on the socket external conductor. The high-power radio frequency connector is ensured to meet the indexes of low reflection and low intermodulation and is convenient to use, high in reliability and excellent in mechanical and electric properties.

Owner:SHANGHAI AEROSPACE SCI & IND ELECTRIC APPLIANCE RES INST

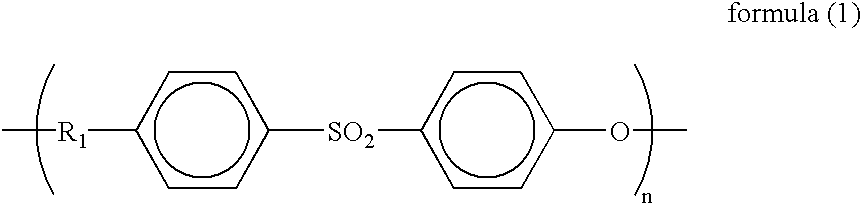

Multilayer insulated wire and transformer using the same

InactiveUS6437249B1High enough heat-resistanceGood effectPlastic/resin/waxes insulatorsTransformers/inductances coils/windings/connectionsElectricityElectrical conductor

A multilayer insulated wire has two or more extrusion-coating insulating layers provided on a conductor directly or via some other layer, or provided on the outside of a multicore wire composed of conductor cores or insulated cores that are collected together, wherein at least one of the insulating layers is made of a mixture prepared by mixing 100 parts by weight of a polyethersulfone resin and 10 to 100 parts by weight of an inorganic filler. A transformer utilizes the multilayer insulated wire. The multilayer insulated wire can realize such high heat resistance as heat resistance F class (155° C.), which satisfies IEC 950 standards, or higher heat resistance, in transformers; and can exhibit excellent electrical properties even at high frequencies. Further, when the transformer is used at high frequencies, the electric properties are not lowered, and influence by the generation of heat can be prevented.

Owner:FURUKAWA ELECTRIC CO LTD

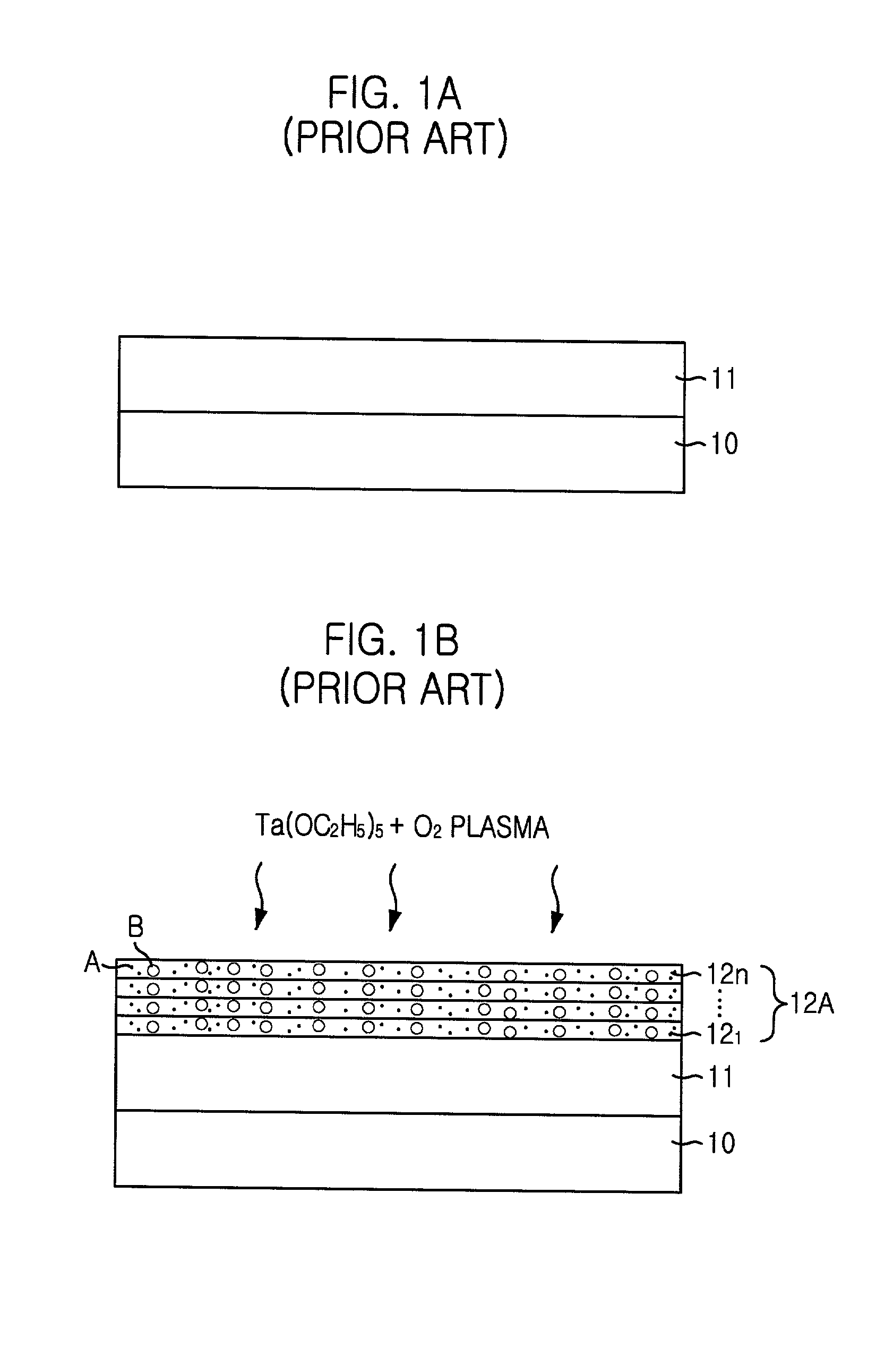

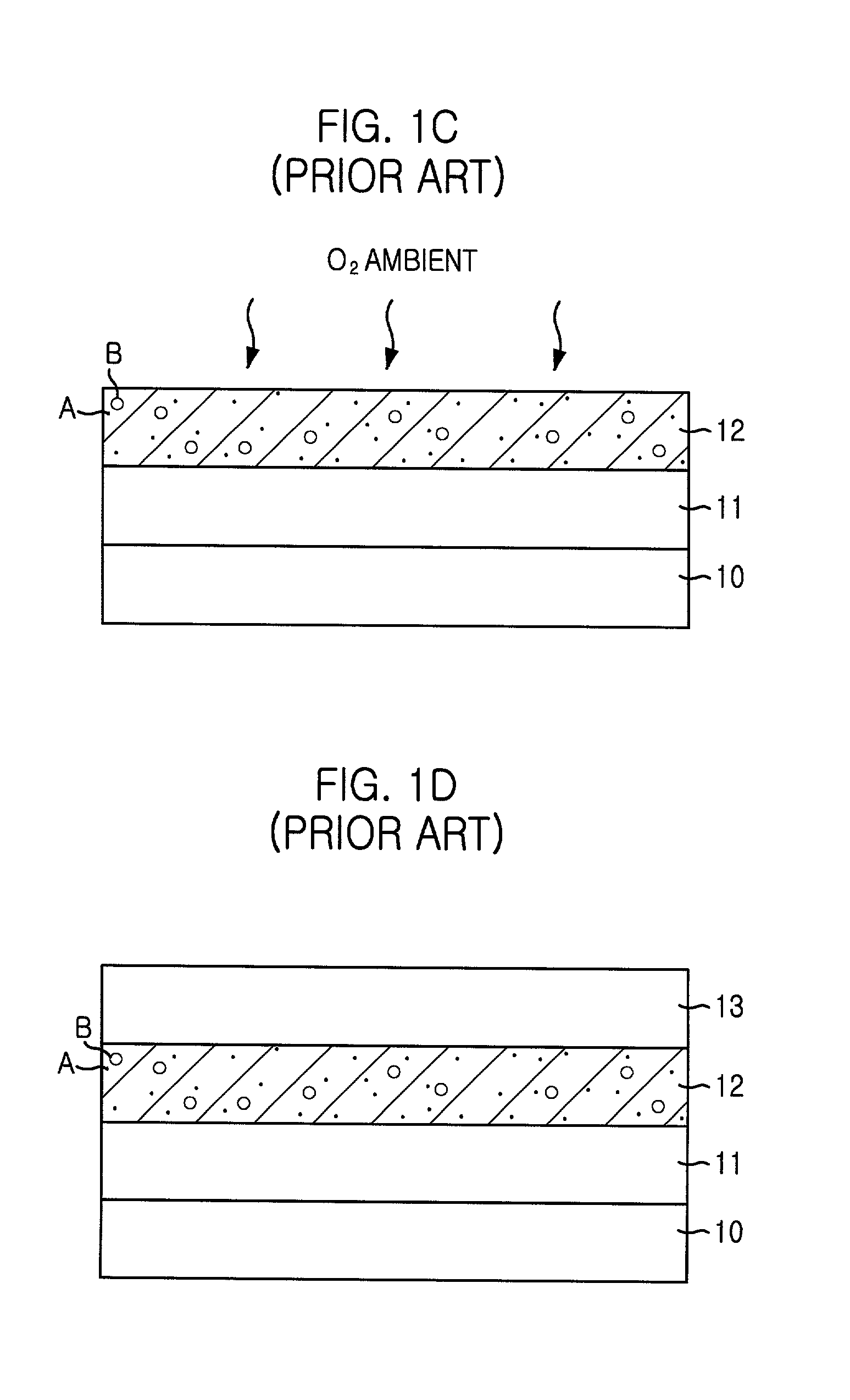

Method for forming Ta2O5 dielectric layer using plasma enhanced atomic layer deposition

InactiveUS20020086476A1Enhance layeringImprove propertiesTransistorSemiconductor/solid-state device manufacturingElectric propertiesAtomic layer deposition

A method for forming a Ta2O5 dielectric layer using plasma enhanced atomic layer deposition, which can improve the quality of a layer and its electric property by forming a Ta2O5 dielectric layer using a plasma enhanced atomic layer deposition. The method for forming a Ta2O5 dielectric layer using plasma enhanced atomic layer deposition, comprising the steps of: a) flowing Ta(OC2H5)5 source gas in a chamber and generating plasma; b) depositing a Ta2O5 layer by using the plasma; c) purging the chamber; d) repeatedly performing the steps a) to c) in order to form a Ta2O5 dielectric layer; e) thermally treating the surface of the Ta2O5 dielectric layer in an oxygen atmosphere; and f) crystallizing the Ta2O5 dielectric layer.

Owner:INTELLECTUAL DISCOVERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com