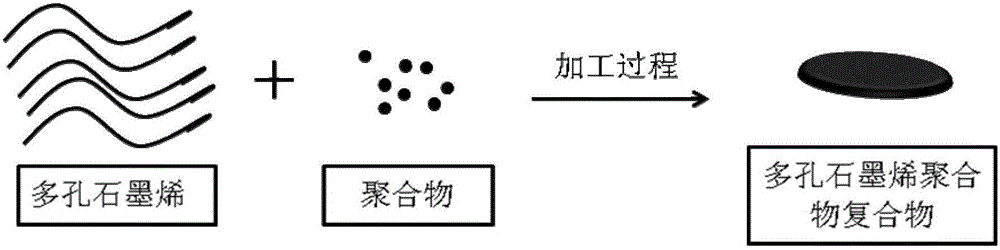

Porous graphene/polymer composite structure and preparation method and application thereof

A porous graphene and composite structure technology, applied in the field of nanomaterials, can solve the problems of high price, low thermal conductivity, large amount of addition, etc., and achieve the effect of low cost, wide source of raw materials, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

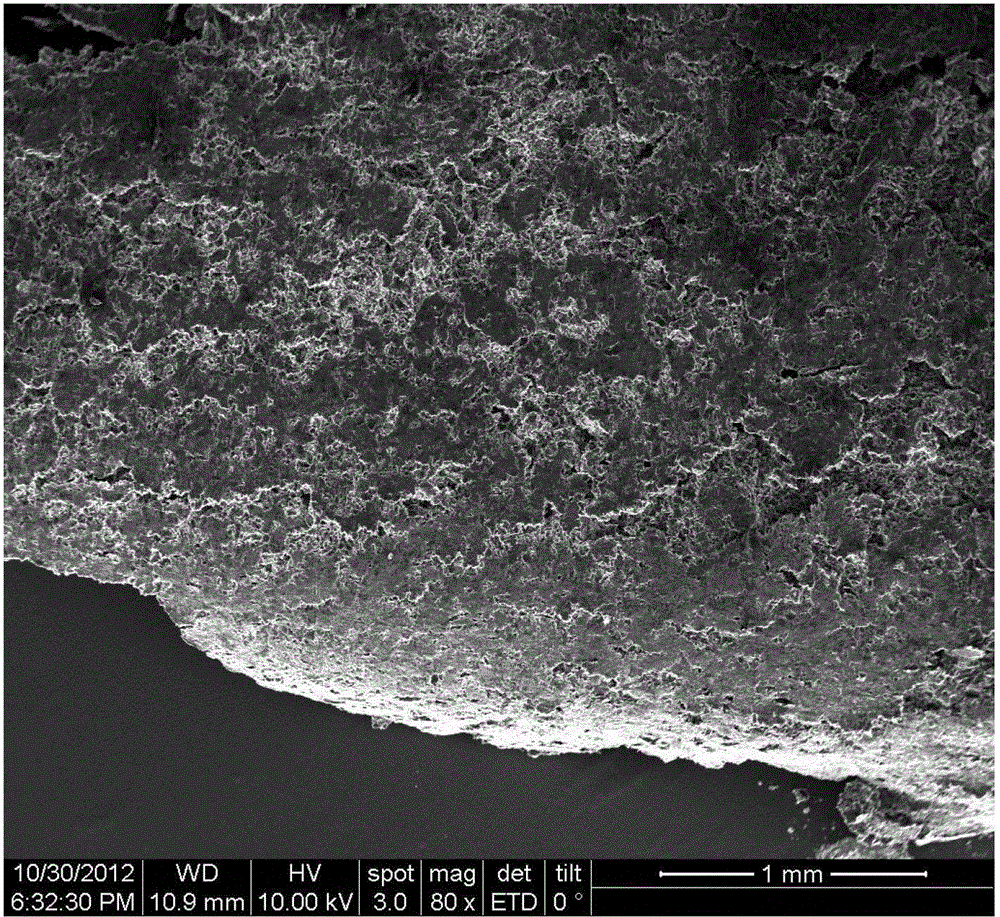

Examples

Embodiment 1

[0027] The preparation method of this high thermal conductivity porous graphene / polymer composite material of embodiment 1 comprises:

[0028] Take 0.5 g of high-quality porous graphene, ultrasonically disperse it in ethanol for 1 h, add 4.5 g of high-density polyethylene powder and stir at high speed for 1 h, filter it with suction, dry it, and mold it to obtain a graphene / high-density polyethylene composite material.

Embodiment 2

[0029] The preparation method of embodiment 2 this high thermal conductivity porous graphene / polymer composite material comprises:

[0030] Take 2kg of high-quality porous graphene and 20kg of high-density polyethylene and put them into a twin-screw extruder at 200°C to stir and extrude, cool and granulate to obtain a black compound.

Embodiment 3

[0031] Embodiment 3 The preparation method of this high thermal conductivity porous graphene / polymer composite material comprises:

[0032] Take 10 g of high-quality porous graphene and disperse it in 2000 ml of xylene, add 100 g of high-density polyethylene powder and stir at 120 ° C, and distill under reduced pressure to obtain a composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com