Patents

Literature

785results about "Adjusting/maintaining mechanical tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

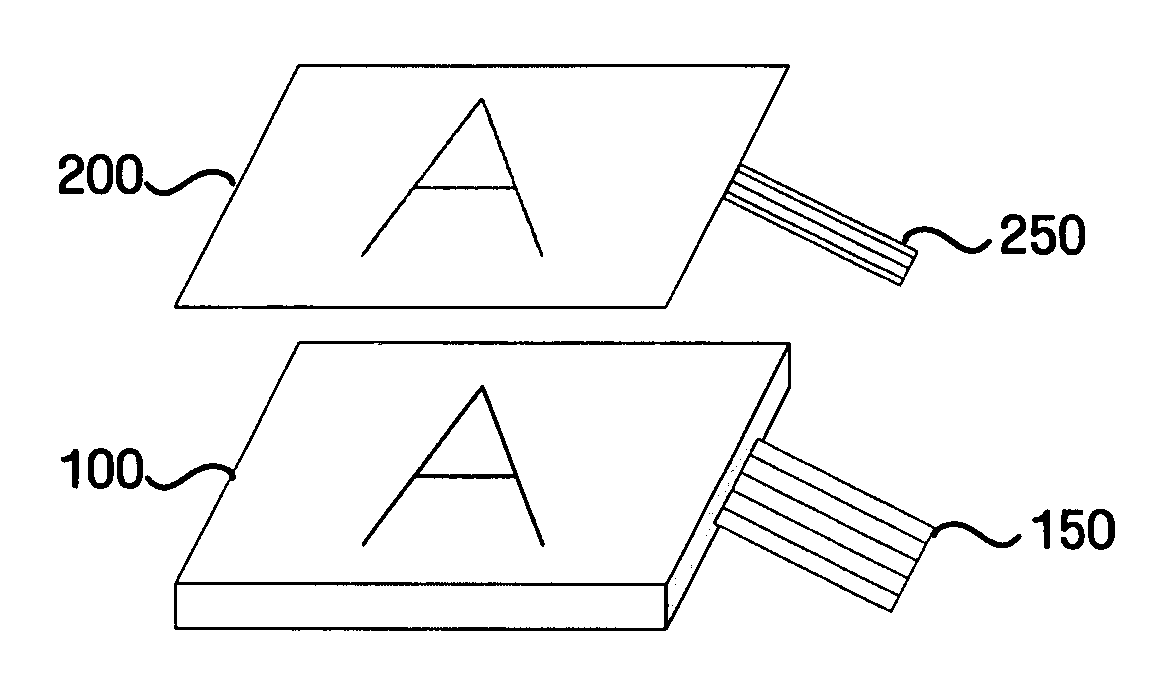

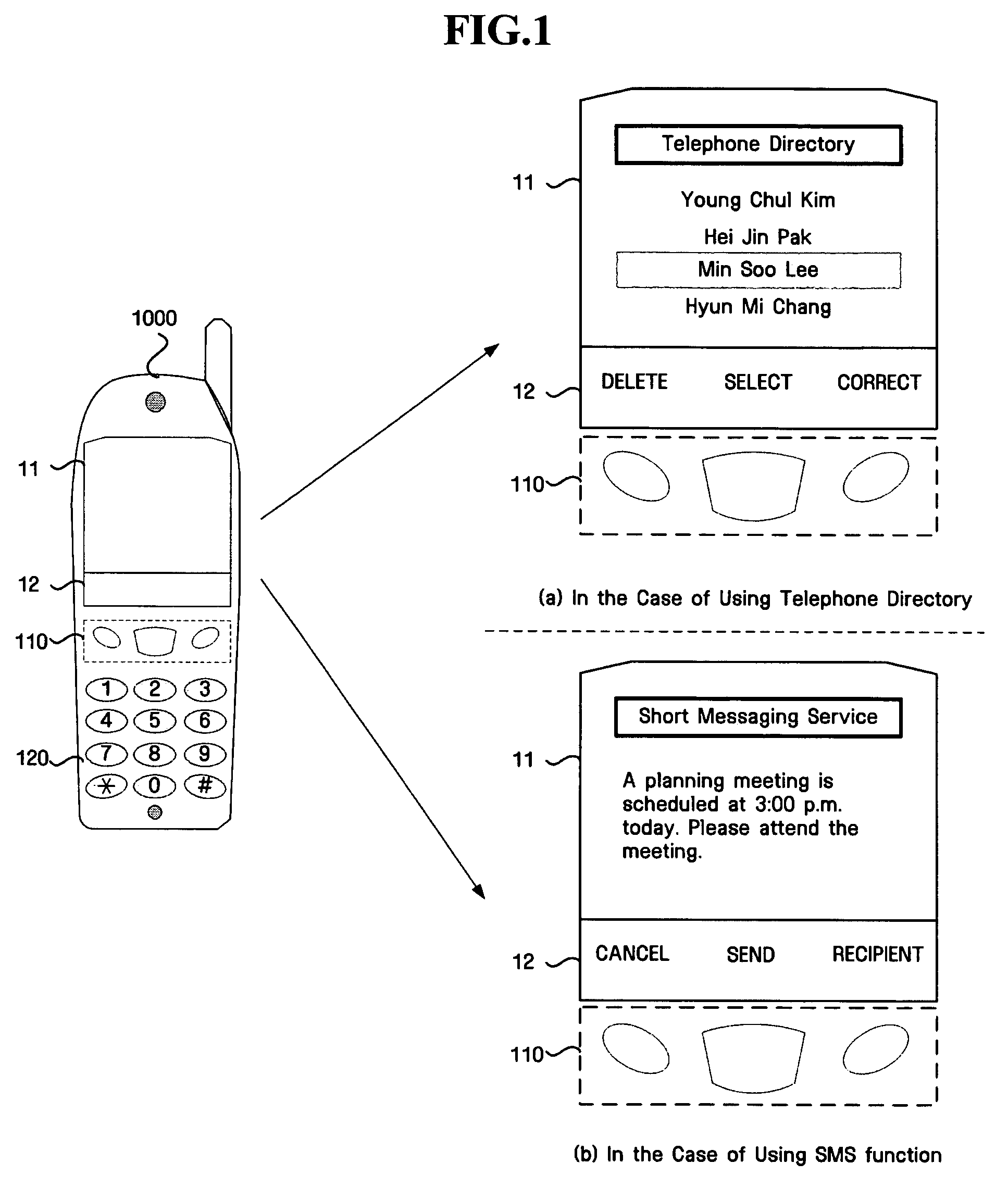

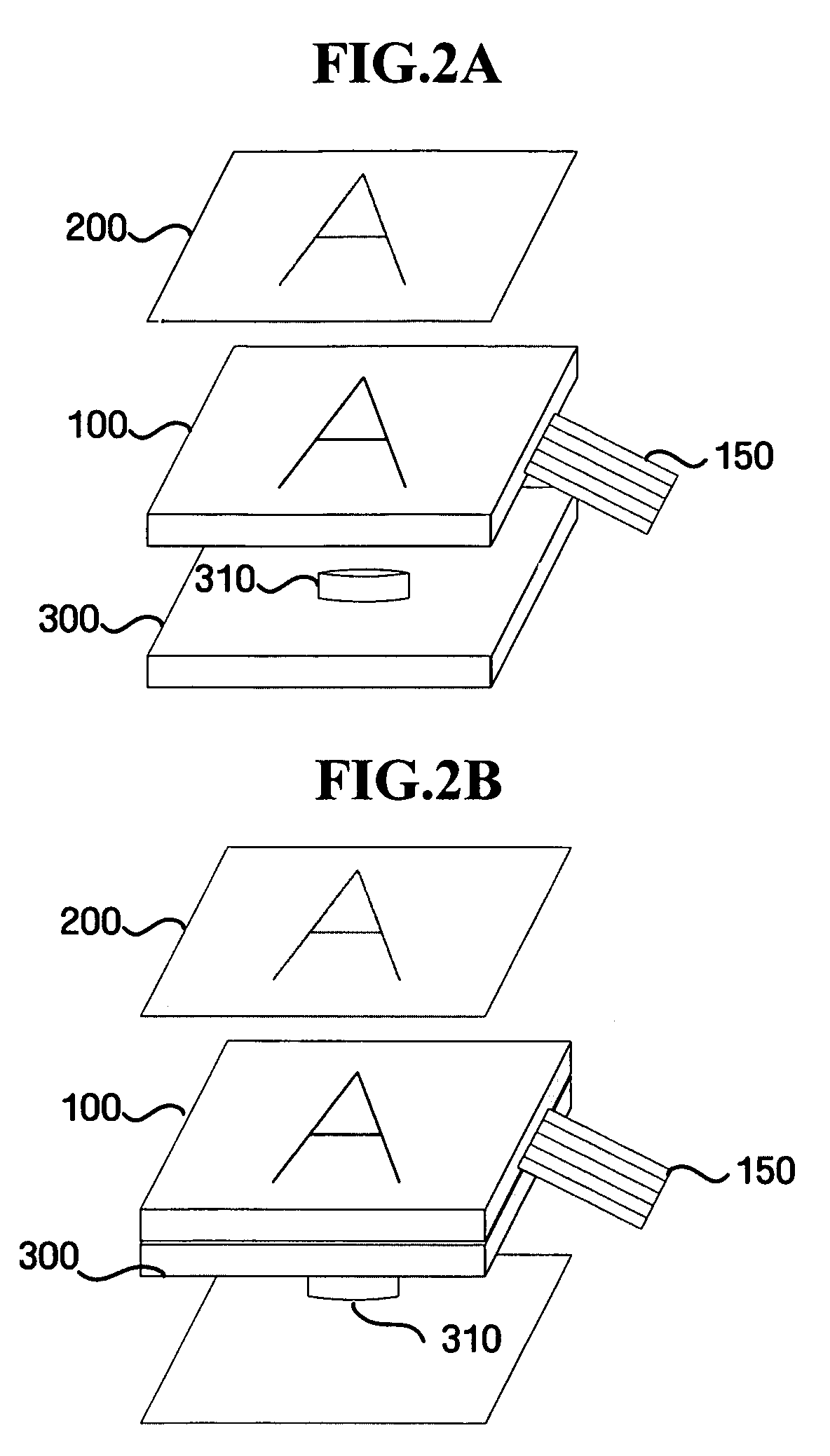

Key input device combined with key display unit and digital appliance having the same

InactiveUS7423557B2Input/output for user-computer interactionInterconnection arrangementsKey pressingTouch Senses

A key input device combined with a key display unit and a digital appliance having the same are disclosed. The key input device includes a key display unit for displaying a character or an image that identifies a key, a touch sensing unit that moves down and up by a pressure applied to this key, and a signal generation unit for generating an electric signal in accordance with the pressure applied to the key, wherein the character or the image displayed on the key display unit can be changed.

Owner:SAMSUNG ELECTRONICS CO LTD

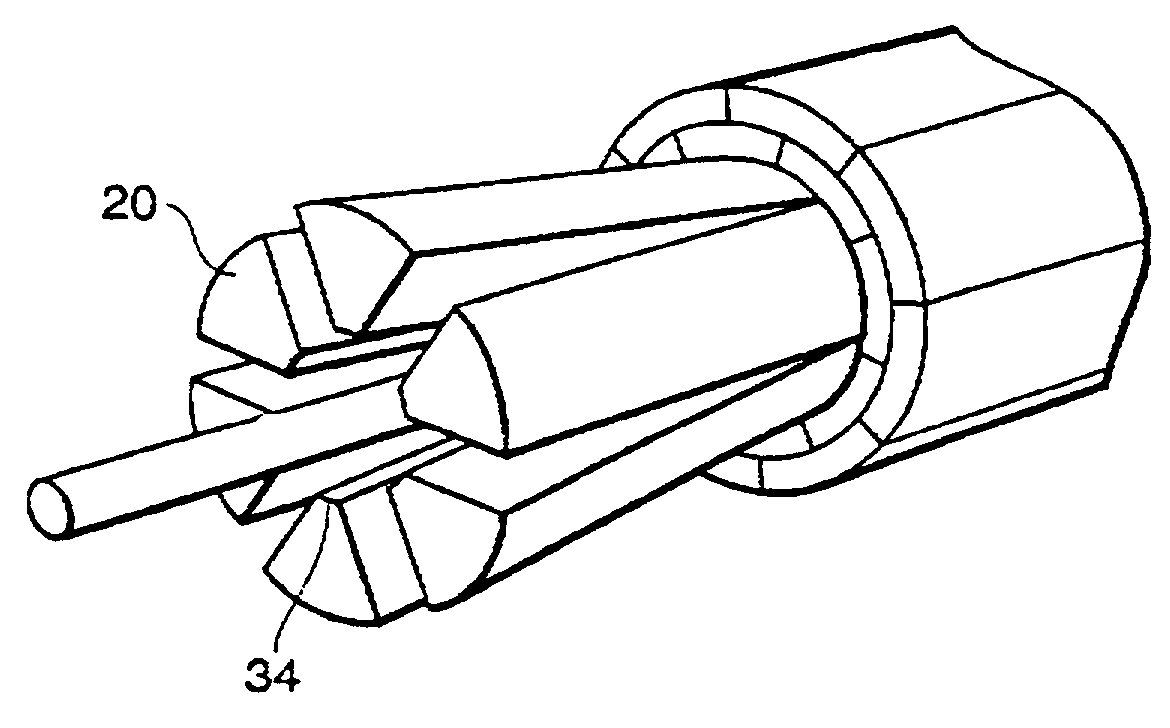

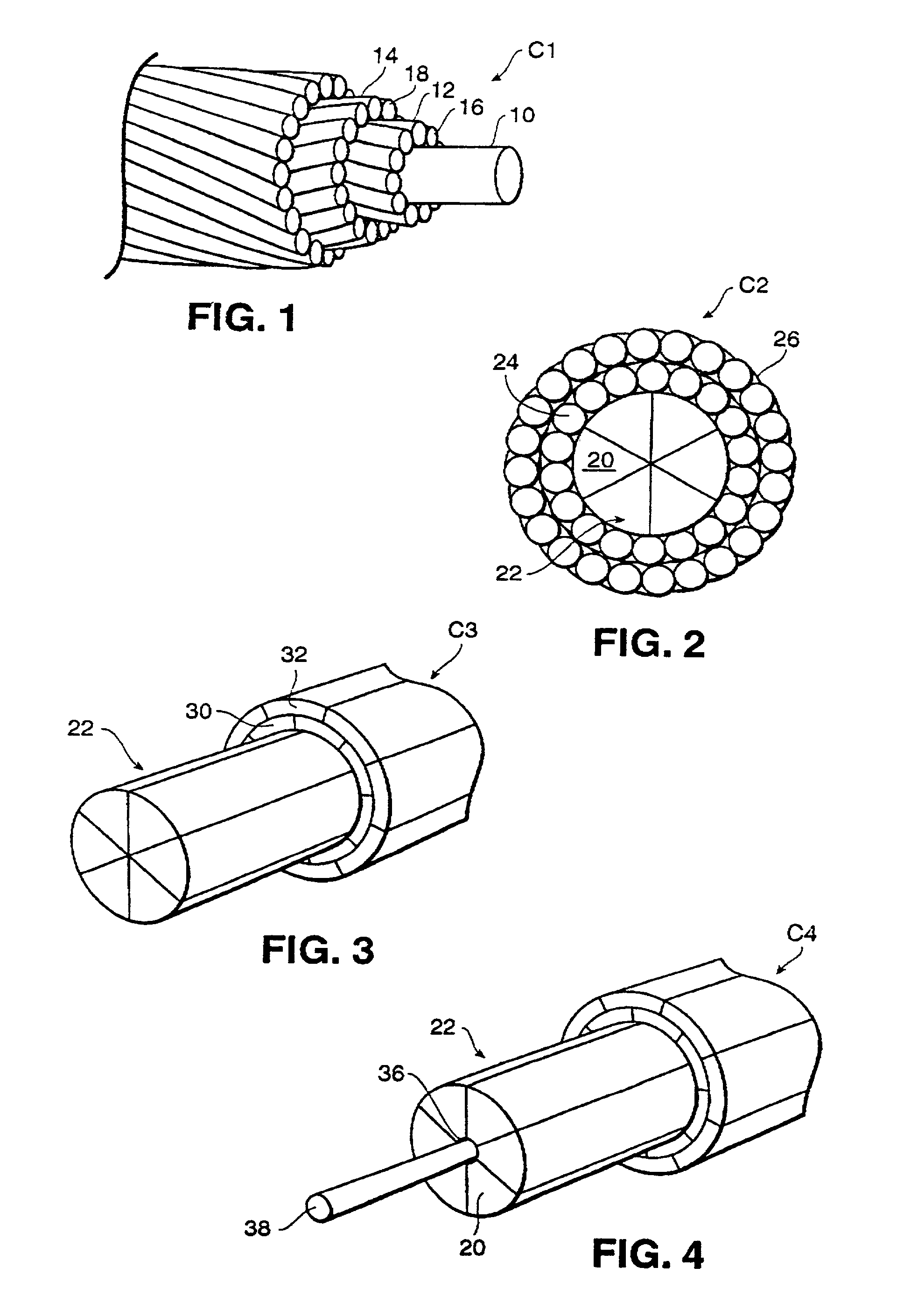

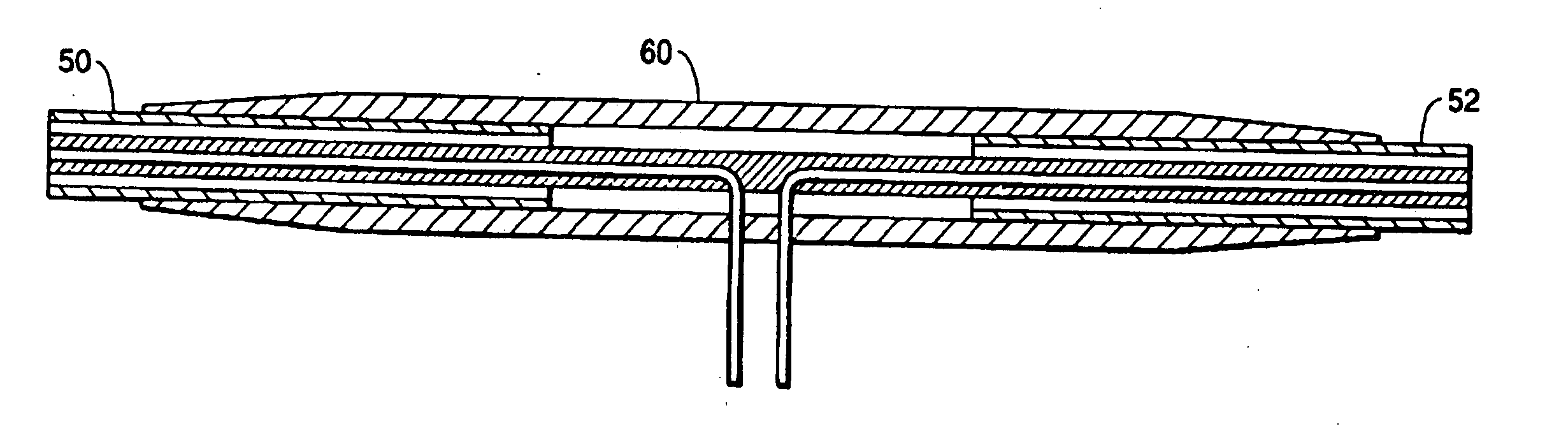

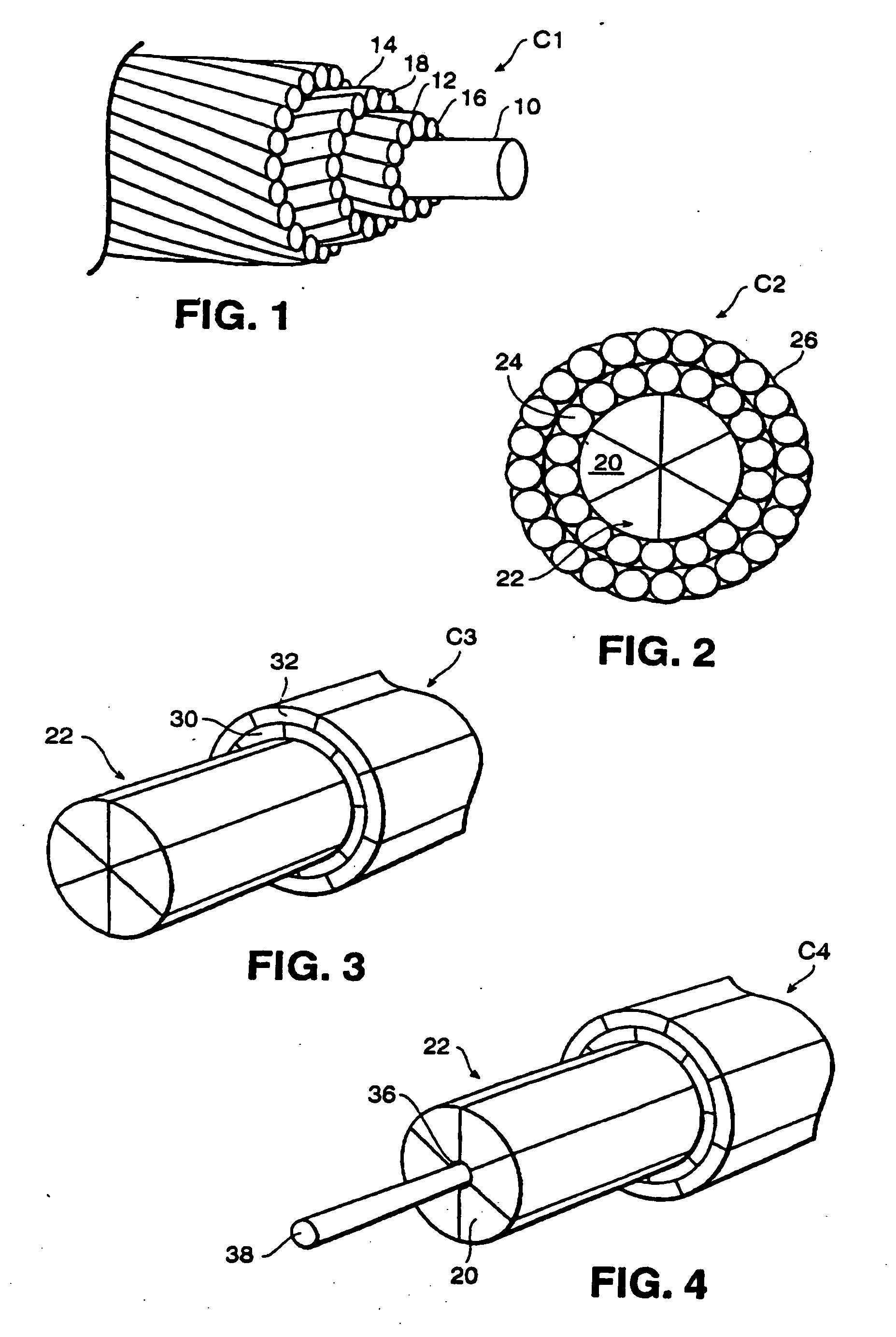

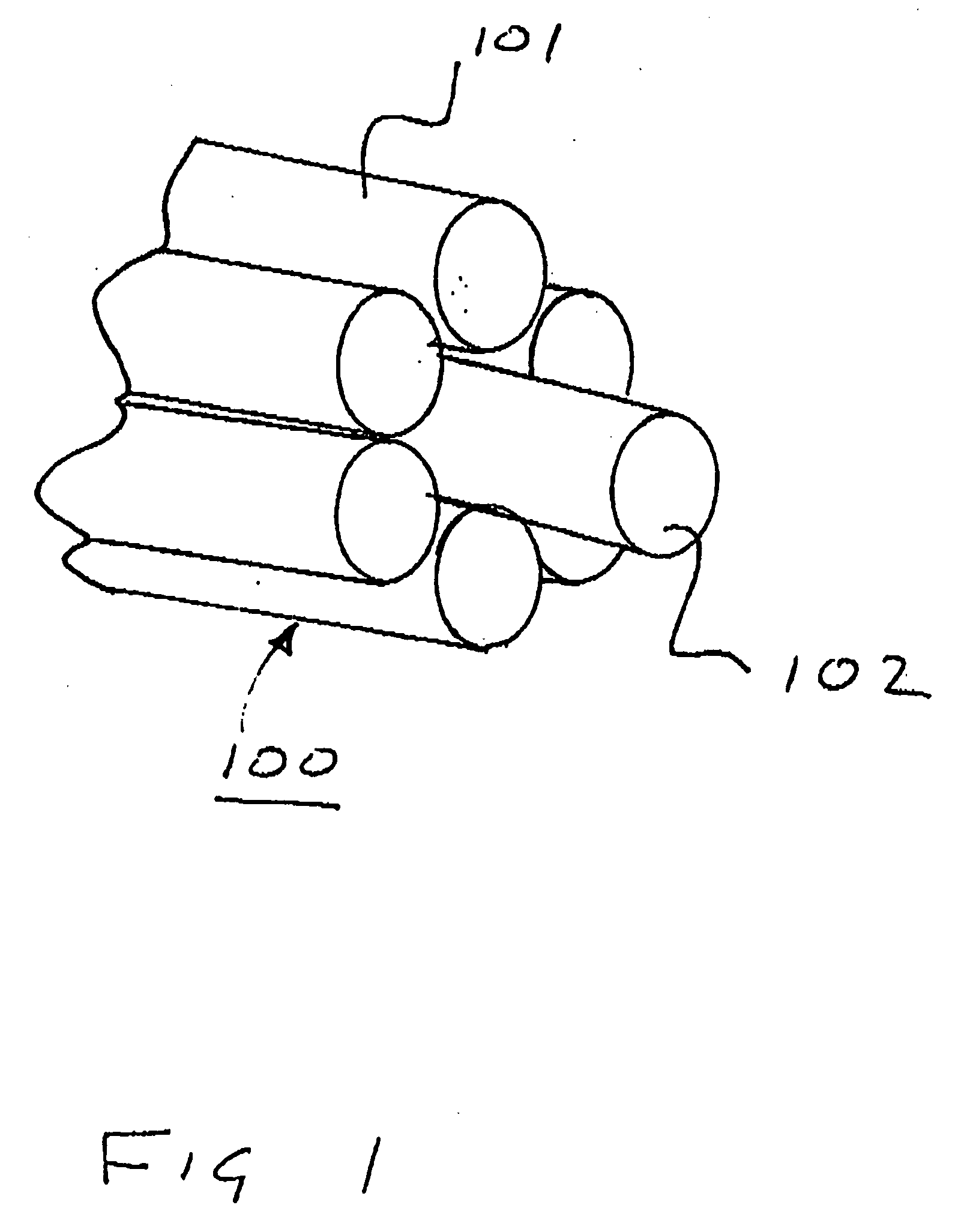

Composite reinforced electrical transmission conductor

InactiveUS7015395B2Avoid excessive labor intensityLow costNon-insulated conductorsPower cables with screens/conductive layersFiberElectrical conductor

A composite reinforced electrical transmission conductor primarily designed for transmission of electrical signals. The conductor is comprised of a reinforced plastic composite inner core along with an outer highly electrically conductive sheath therearound. In this way, the inner core provides the necessary strength and the outer sheath provides for transmission of the electrical signals. In a preferred embodiment, the reinforced composite core is comprised of individual sections which cooperate together to provide the necessary loading capabilities. Further, a fiber optic cable may also be carried by the composite reinforced core. A splicing arrangement for securing ends of the cable together is also provided.

Owner:GIFT TECH LP

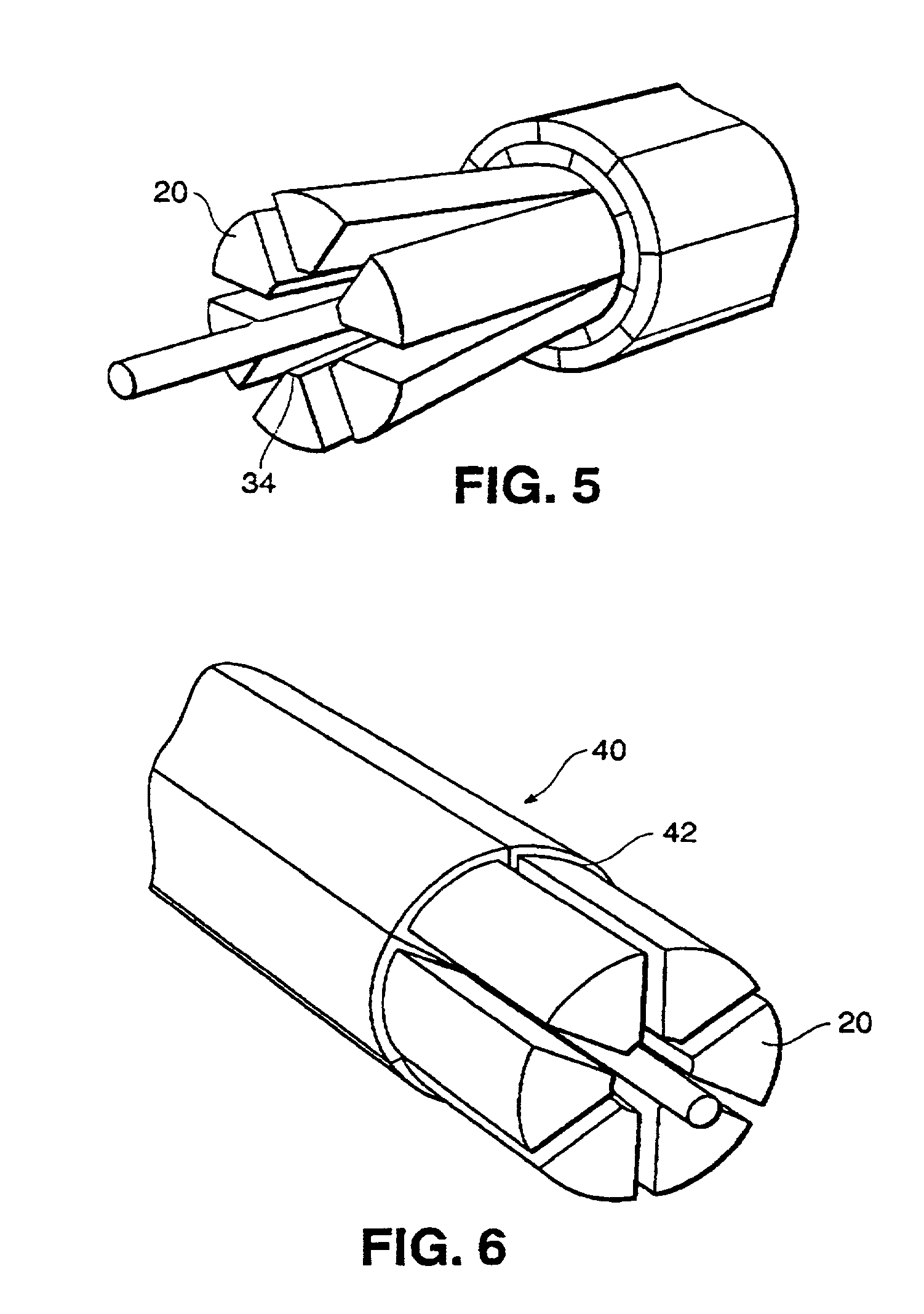

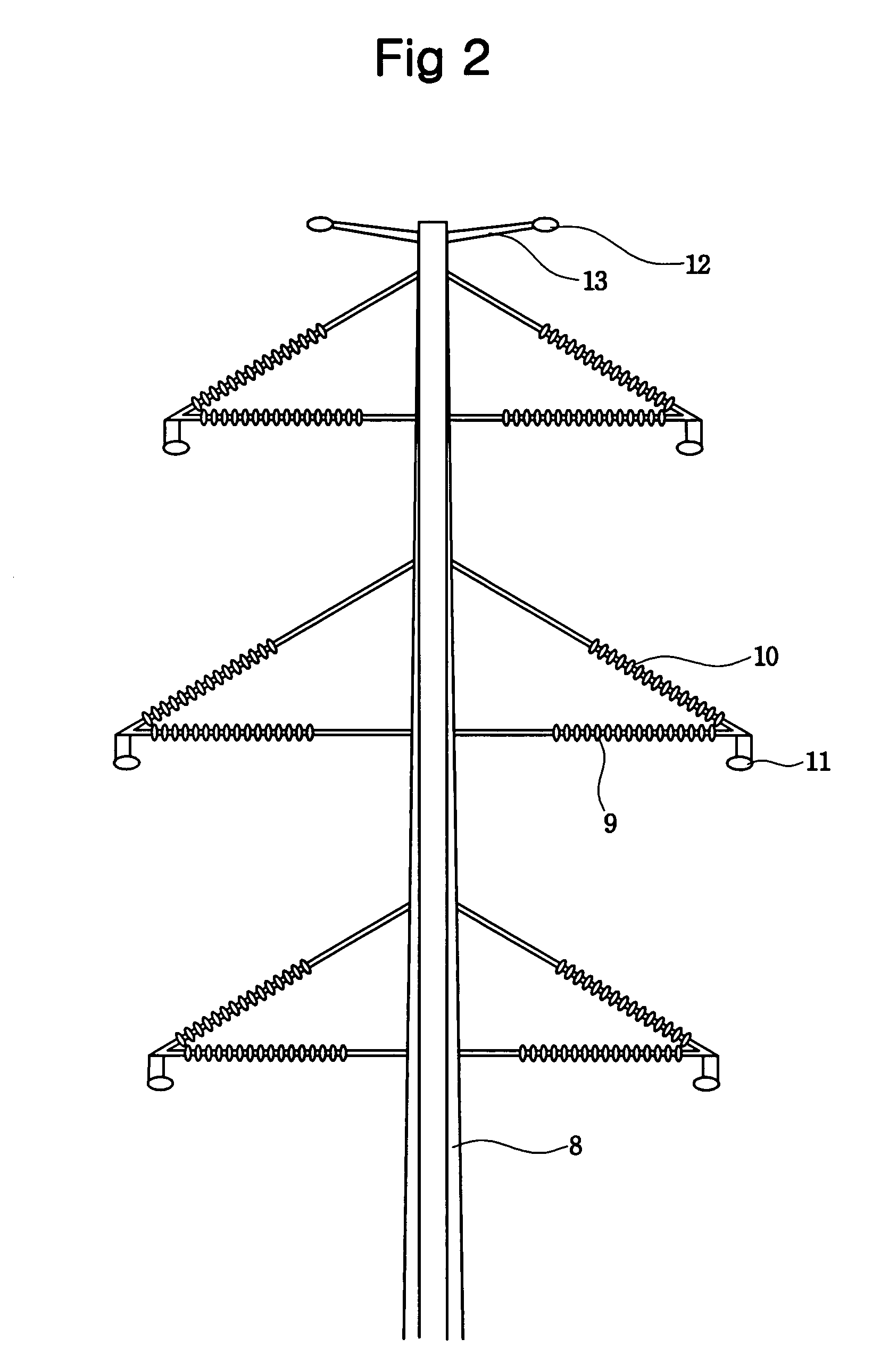

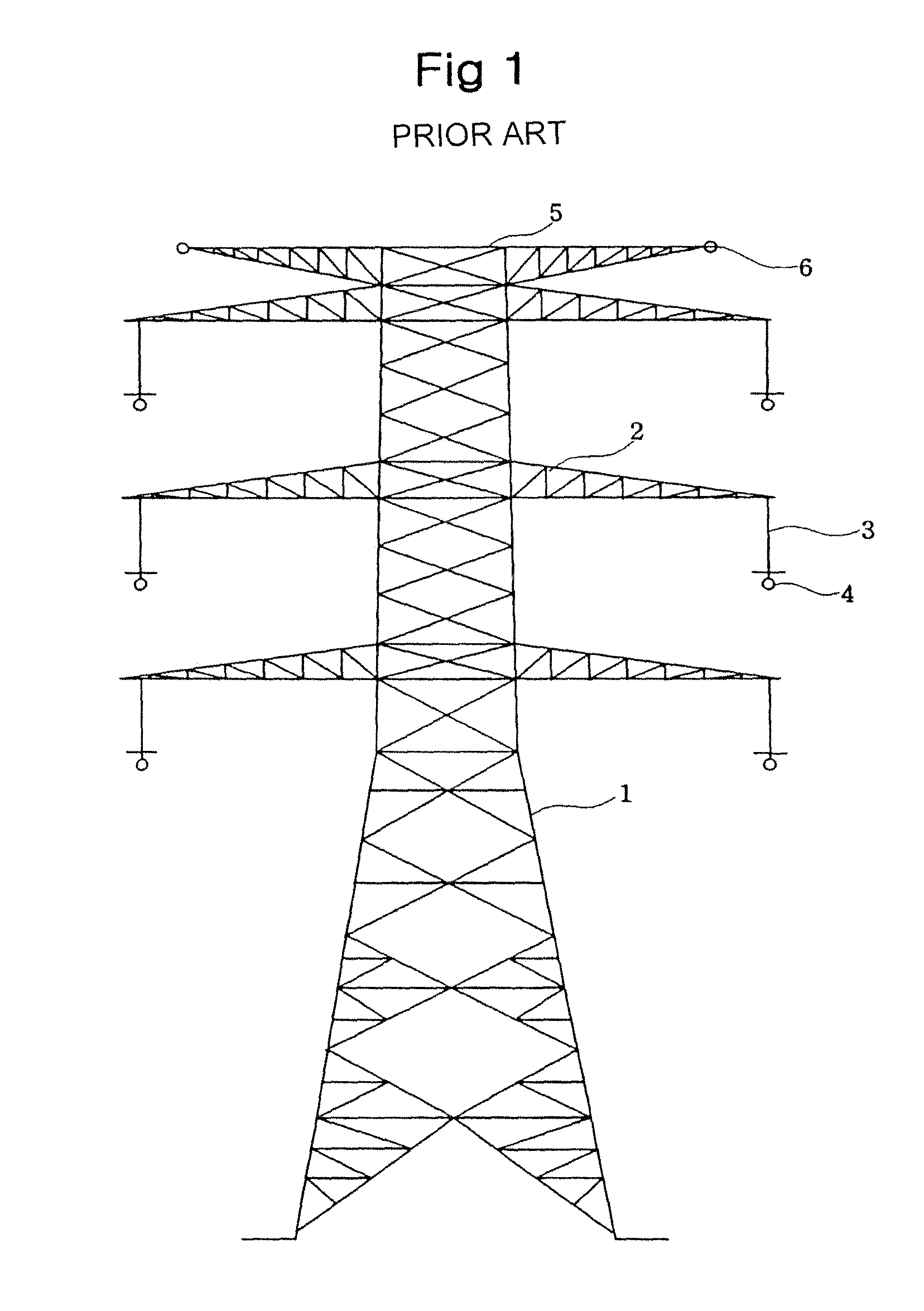

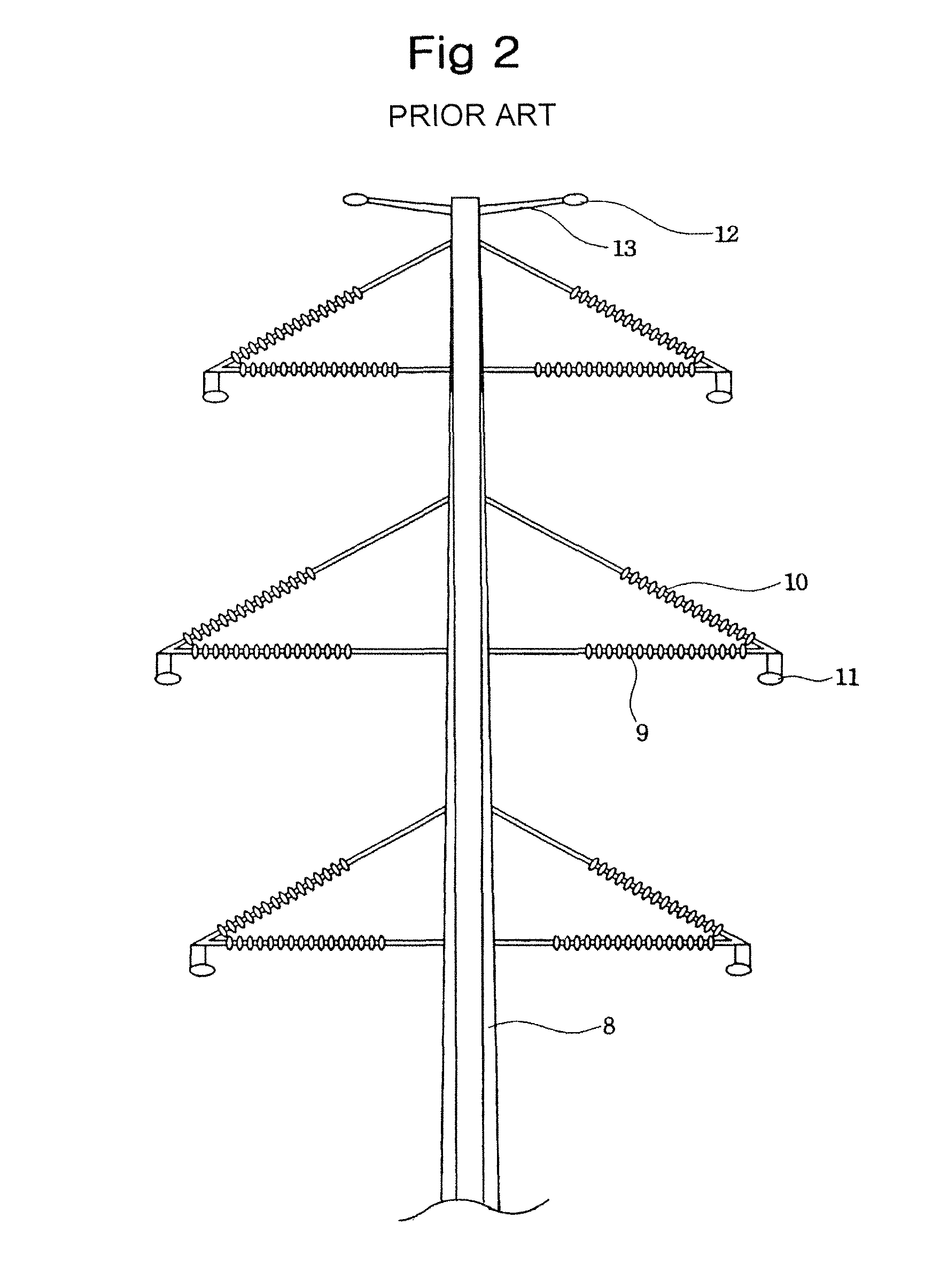

Power transmission tower

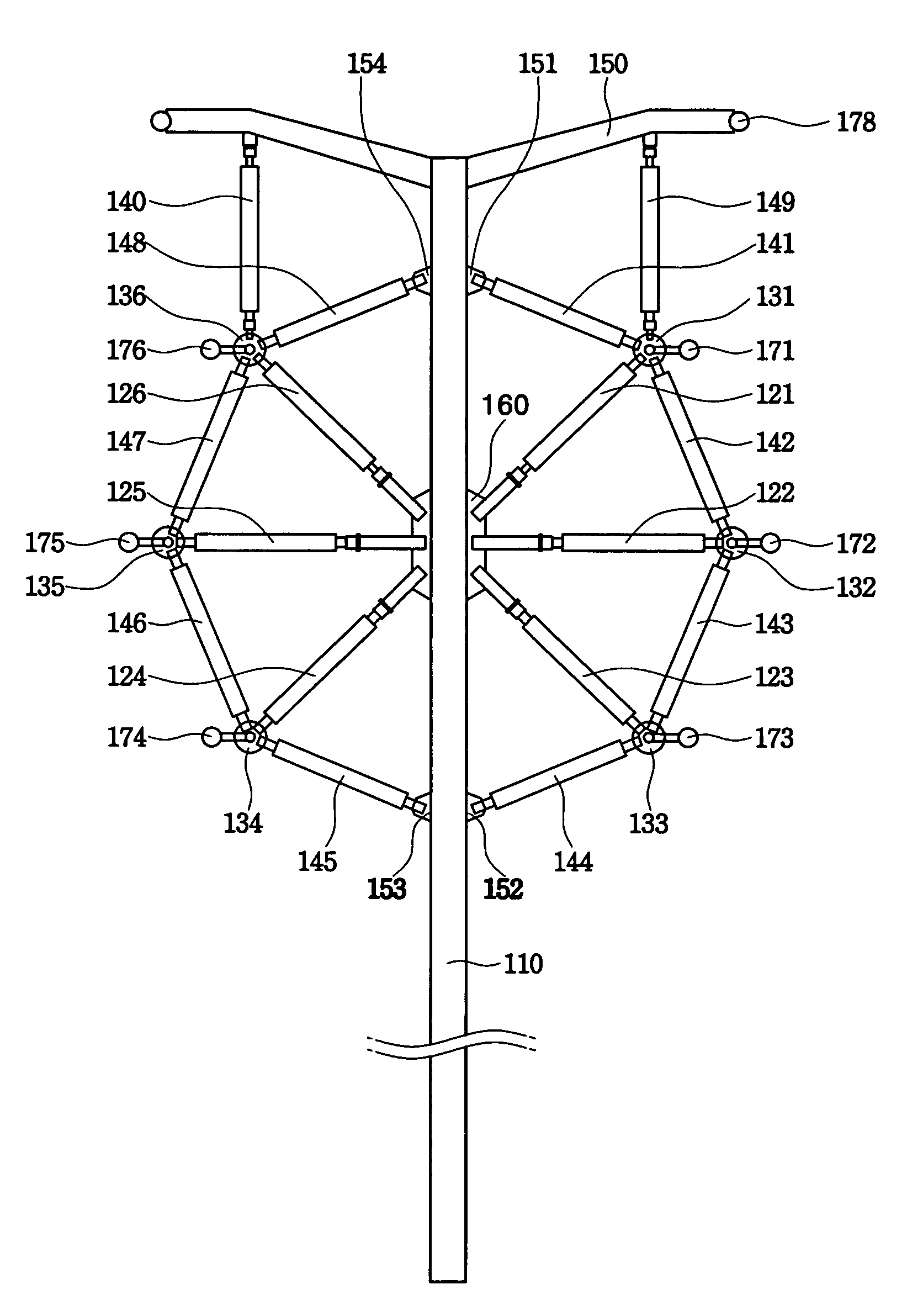

ActiveUS20100064598A1Miniaturization and light weightReduce areaAdjusting/maintaining mechanical tensionTowersElectricityTransmission tower

Disclosed is a power transmission tower, which includes a tower body; first through sixth main insulation arms connected by one end thereof to the tower body with an angle with the tower body, respectively, and arranged radially and symmetrically about the tower body in a longitudinal direction; and first through eighth auxiliary insulation arms for selectively connecting the other end of the first through sixth main insulation arms and the tower body so that each of the auxiliary insulation arms constitutes each side of an octagon.Since the insulation arms are octagonally arranged, it is possible to reinforce a mechanical strength and enhance electric properties of the tower.

Owner:KOREA ELECTRIC POWER CORP

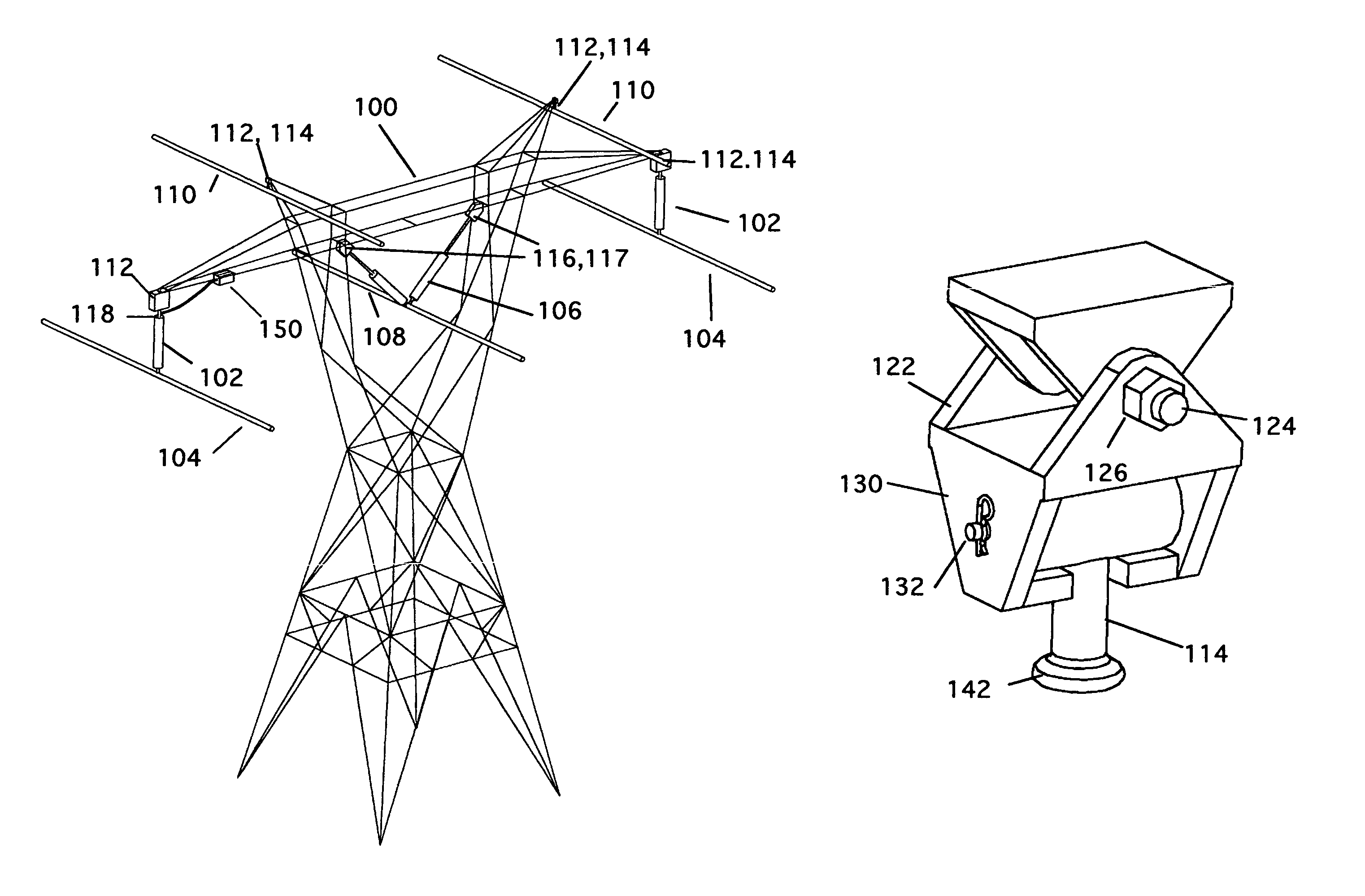

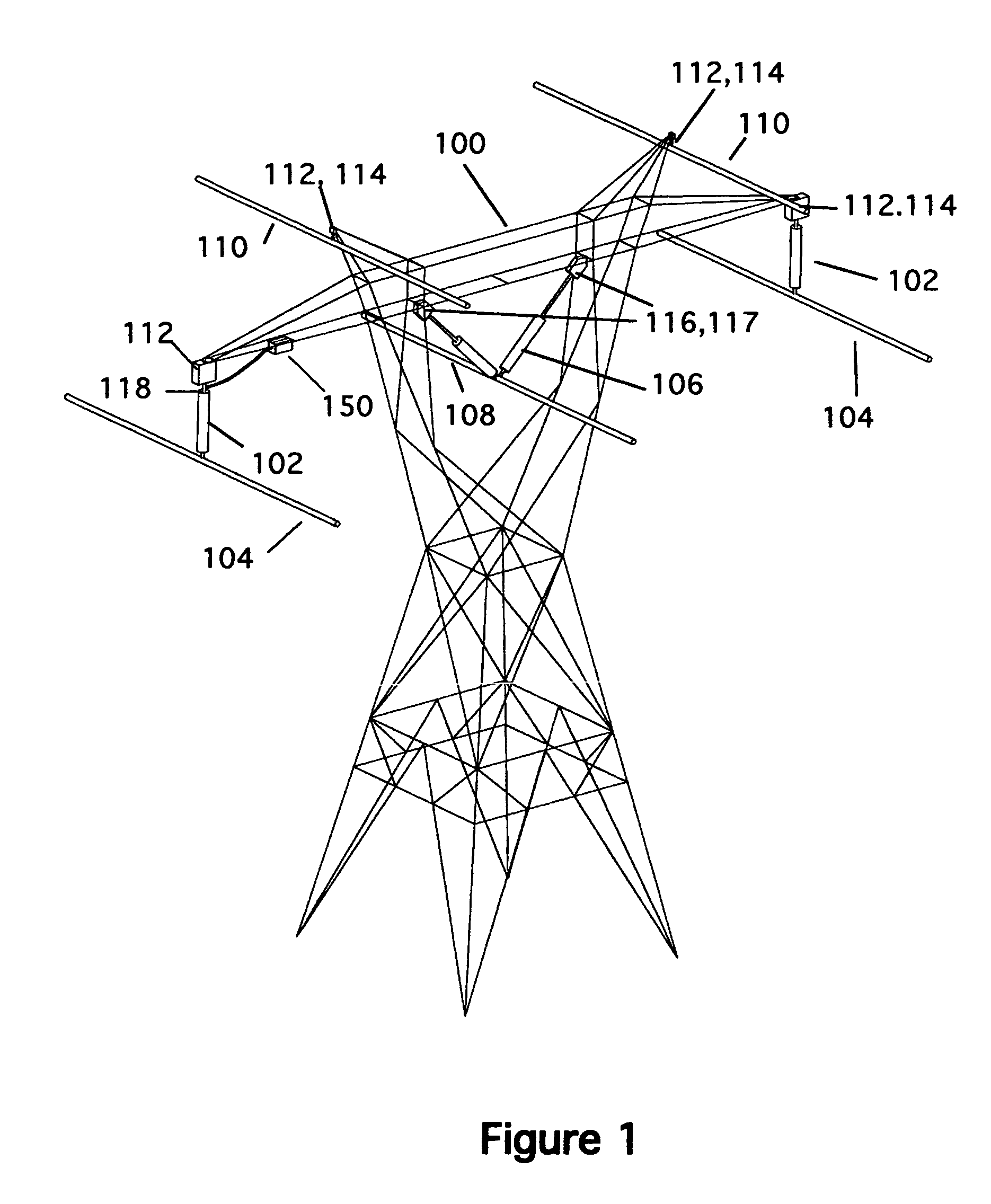

Robotic Bypass System and Method

InactiveUS20090095522A1Adjusting/maintaining mechanical tensionSuspension arrangements for electric cablesElectricityElectrical conductor

A system and method, and robotic equipment for mechanical and / or electrical bypassing of short sections of energized high voltage line conductors by gripping the conductor at two close-by points, making good electrical and mechanical connection, then drawing the two points towards one another so as to relieve both mechanical and current-carrying duty of the bypassed conductor section. Doing so can provide slack on the bypassed conductor section for maintenance or repair while simultaneously providing an alternative path for electric current, or increase tension on the adjacent conductor sections by essentially shortening the conductor in the region where the invention is applied. The invention may then reverse direction, placing (stretch) tension on the bypassed conductor section and the point of repair to assure its mechanical integrity. Mechanical bypassing only to temporarily shorten specific conductor spans may be achieved by the same device. Electrical bypassing only may be achieved in a similar manner by gripping and bridging two separate high voltage conductors, thus providing a means to connect and / or disconnect them with the aid of switching equipment incorporated into the invention. The invention allows all of the foregoing to be accomplished at line potential and in close line proximity by virtue of its being mounted on an insulated boom or suspended from a hovering helicopter or suspended from the line itself.

Owner:BARTHOLD LIONEL O

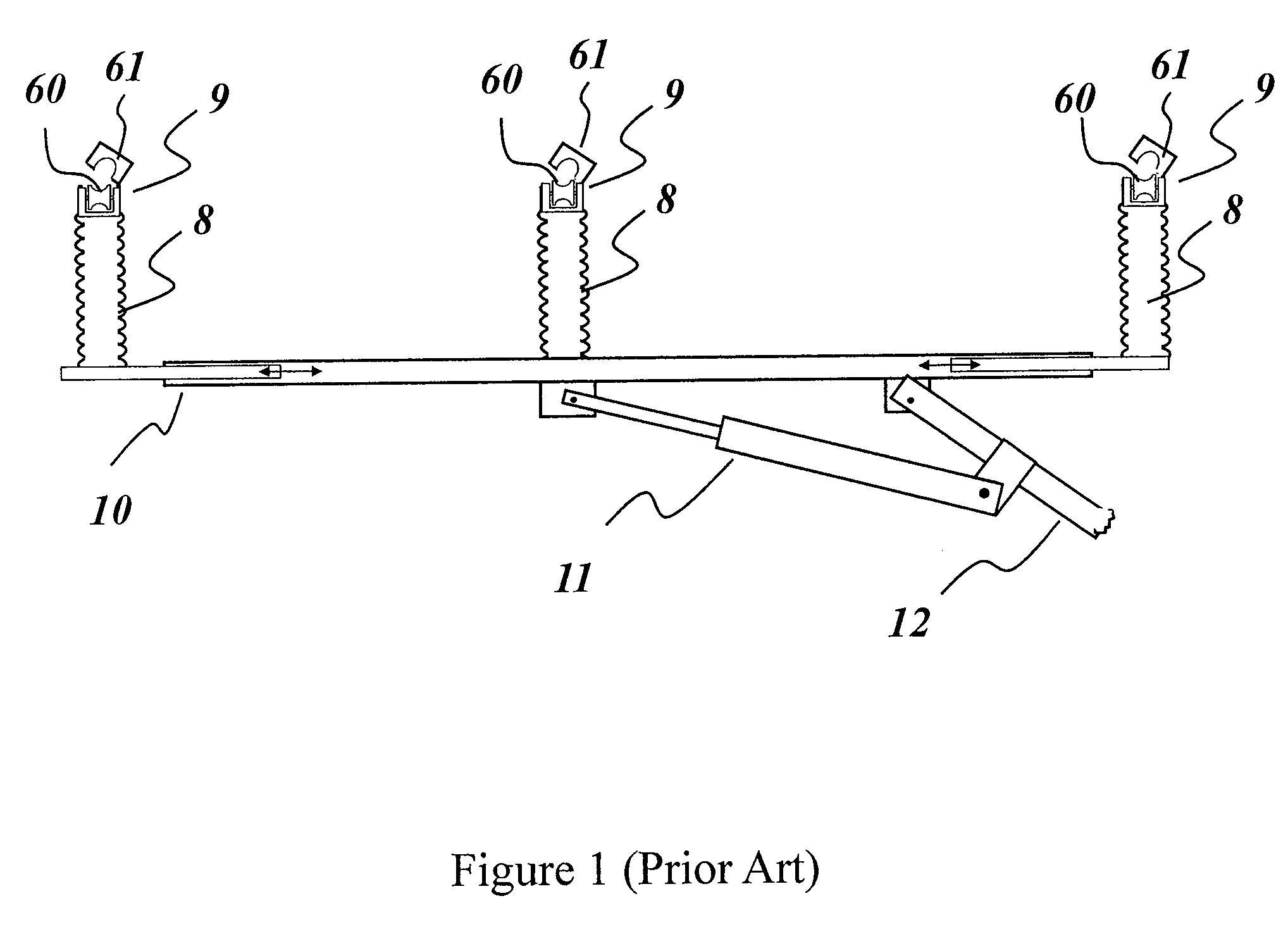

Transmission tower devices for reducing longitudinal shock loads

InactiveUS7057103B1Reduce shock loadEfficient reductionMaintaining distance between parallel conductorsDevices for damping mechanical oscillationsTransmission towerEngineering

A device for reducing a shock load having a longitudinal direction along a power line coupled through an insulator to a crossarm of a transmission tower, comprising: a rotary damper coupled between the insulator and the crossarm for rotating by the insulator in the longitudinal direction in response to the shock load, the damper having an axle to which the insulator is rotatably coupled; and, a torsion bar coupled at a first end to the axle and at a second end to the crossarm for resisting rotation of the insulator, whereby at least a portion of the shock load is absorbed.

Owner:PEABODY ALAN B

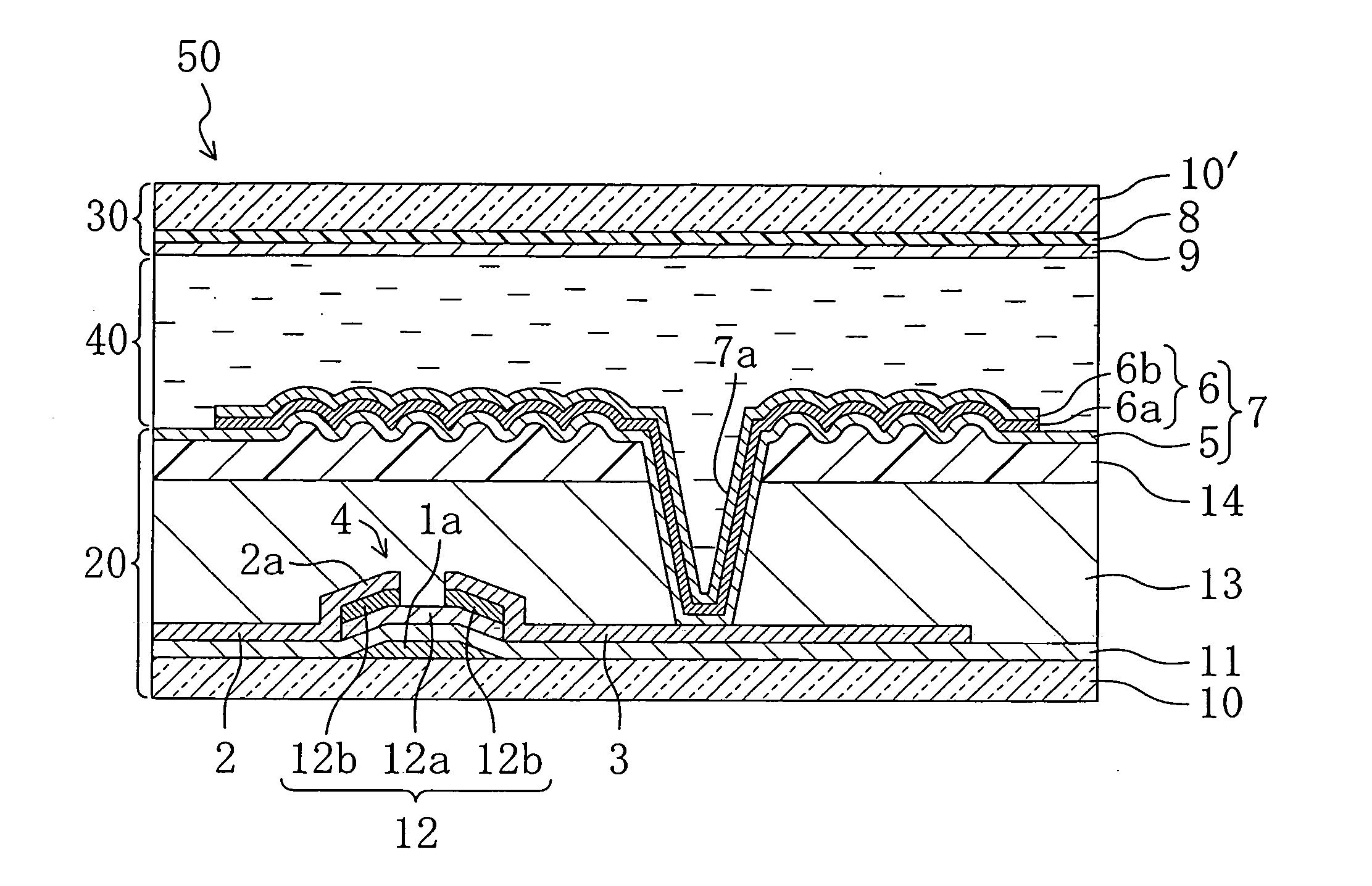

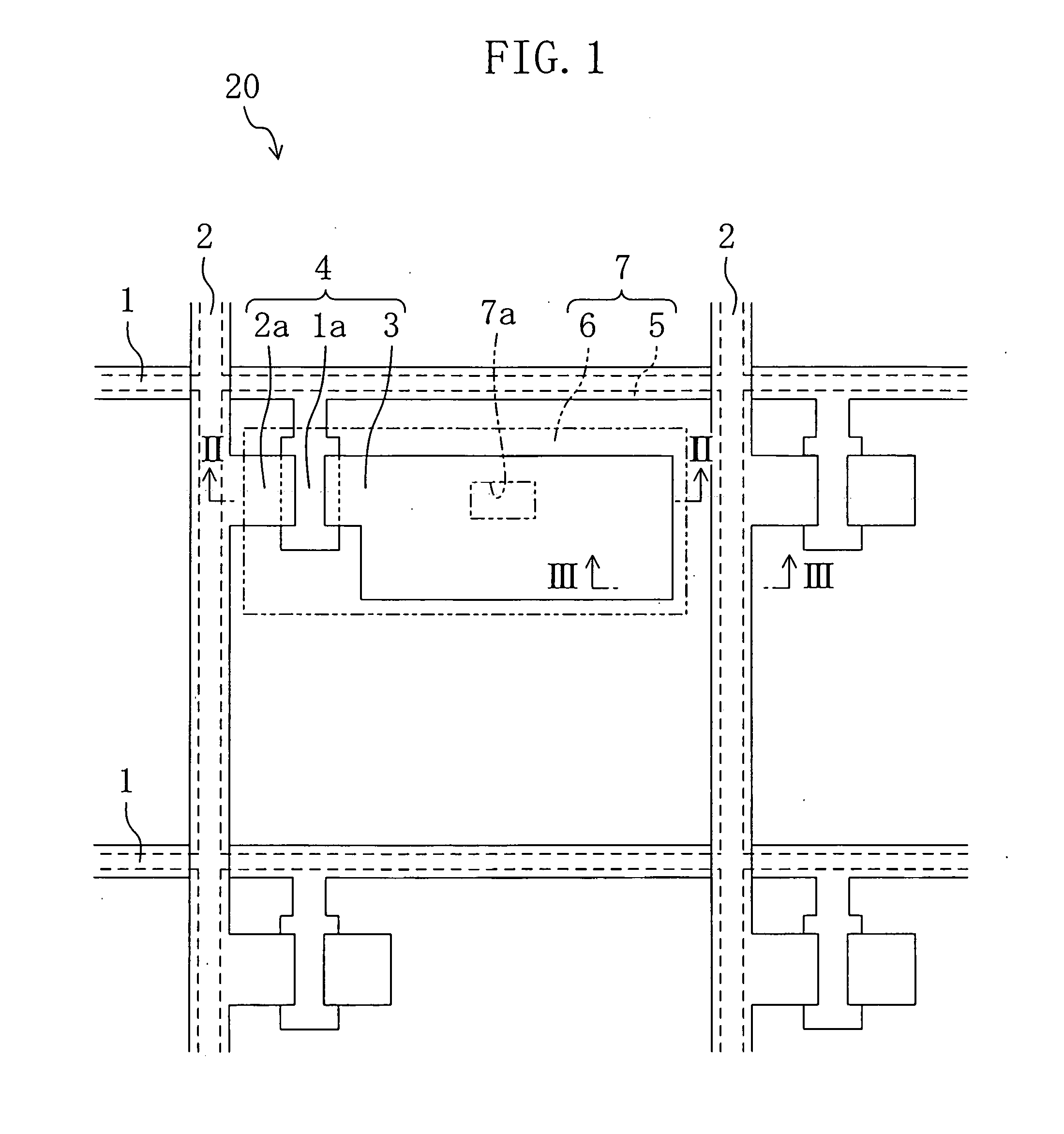

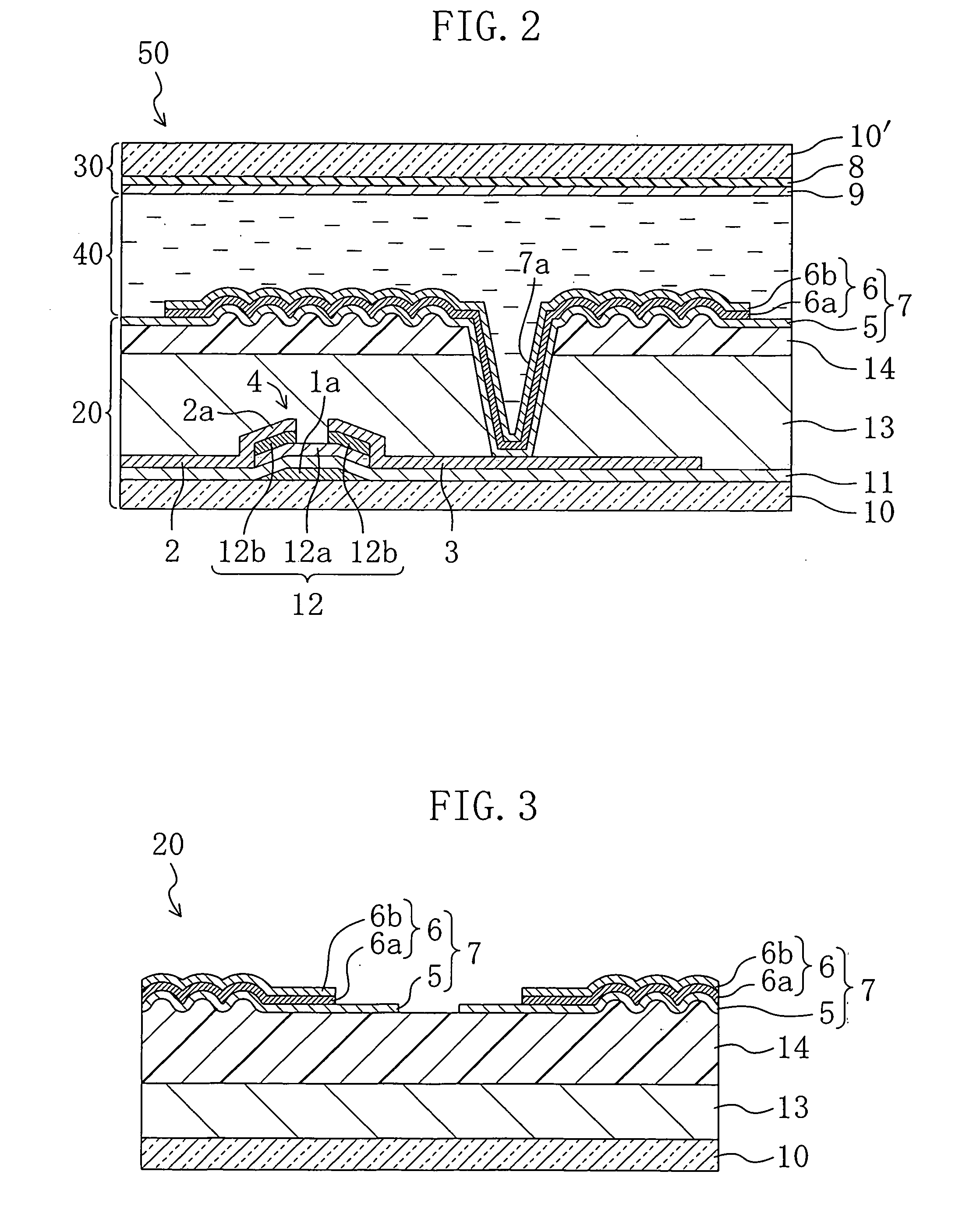

Method for manufacturing conductive element substrate, conductive element substrate, method for manufacturing liquid crystal display, liquid crystal display and electronic information equipment

InactiveUS20050186359A1High film strengthReduce etch rateLiquid crystal compositionsAdjusting/maintaining mechanical tensionLiquid-crystal displayActive matrix

A method for manufacturing a liquid crystal display which employs an active matrix substrate including a plurality of pixels arranged in matrix on a substrate and reflecting electrodes formed in the pixels, respectively. The method comprises (a) a laminated conductive film formation step of sequentially forming a conductive metal film and an amorphous transparent conductive film on a substrate to form a laminated conductive film and (b) a reflecting electrode formation step of patterning the laminated conductive film into a reflecting electrode, wherein the step (b) includes a first etching step of etching the conductive metal film and the amorphous transparent conductive film simultaneously and a second etching step of etching the amorphous transparent conductive film only.

Owner:SHARP KK

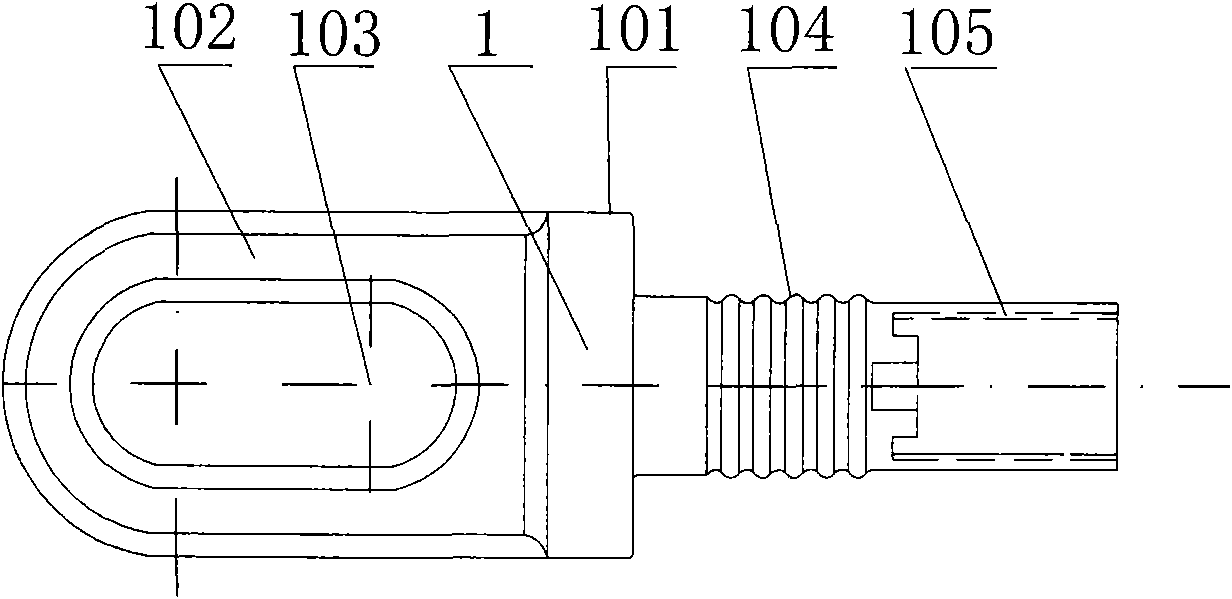

Strain clamp of aluminum alloy core aluminum stranded wire

InactiveCN102237660AGuaranteed uniformityImprove grip strengthAdjusting/maintaining mechanical tensionMaterials scienceAluminium alloy

The invention discloses a strain clamp of an aluminum alloy core aluminum stranded wire. The strain clamp comprises a steel anchor and a jumper clamp which is connected with the steel anchor, wherein an anchor head is connected with the rear end of the steel anchor; an external surface of the anchor head, from inside to outside, is sequentially sleeved with an inner-layer pressing connection pipe and an outer-layer sleeve; and a cavity into which an inner core of the aluminum alloy core aluminum stranded wire to be connected is embedded is formed in the inner-layer pressing connection pipe. By adding the inner-layer pressing connection pipe and the outer-layer sleeve which sleeves the inner-layer pressing connection pipe, when the aluminum alloy core aluminum stranded wire presses the strain clamp, a pressing force can be applied to a lead through two pipe walls, so the pressing force is dispersed to the forced steel anchor, the aluminum stranded wire can be forced uniformly, and the grip strength of the strain clamp on the aluminum stranded wire is improved. The strain clamp of the aluminum alloy core aluminum stranded wire is simple and reasonable in structure, convenient and reliable to anchor, reasonably stressed, and widely applicable to erection of a power transmission line of the aluminum alloy core aluminum stranded wire.

Owner:GUANGZHOU XYHY ELECTRIC POWER LINE EQUIP

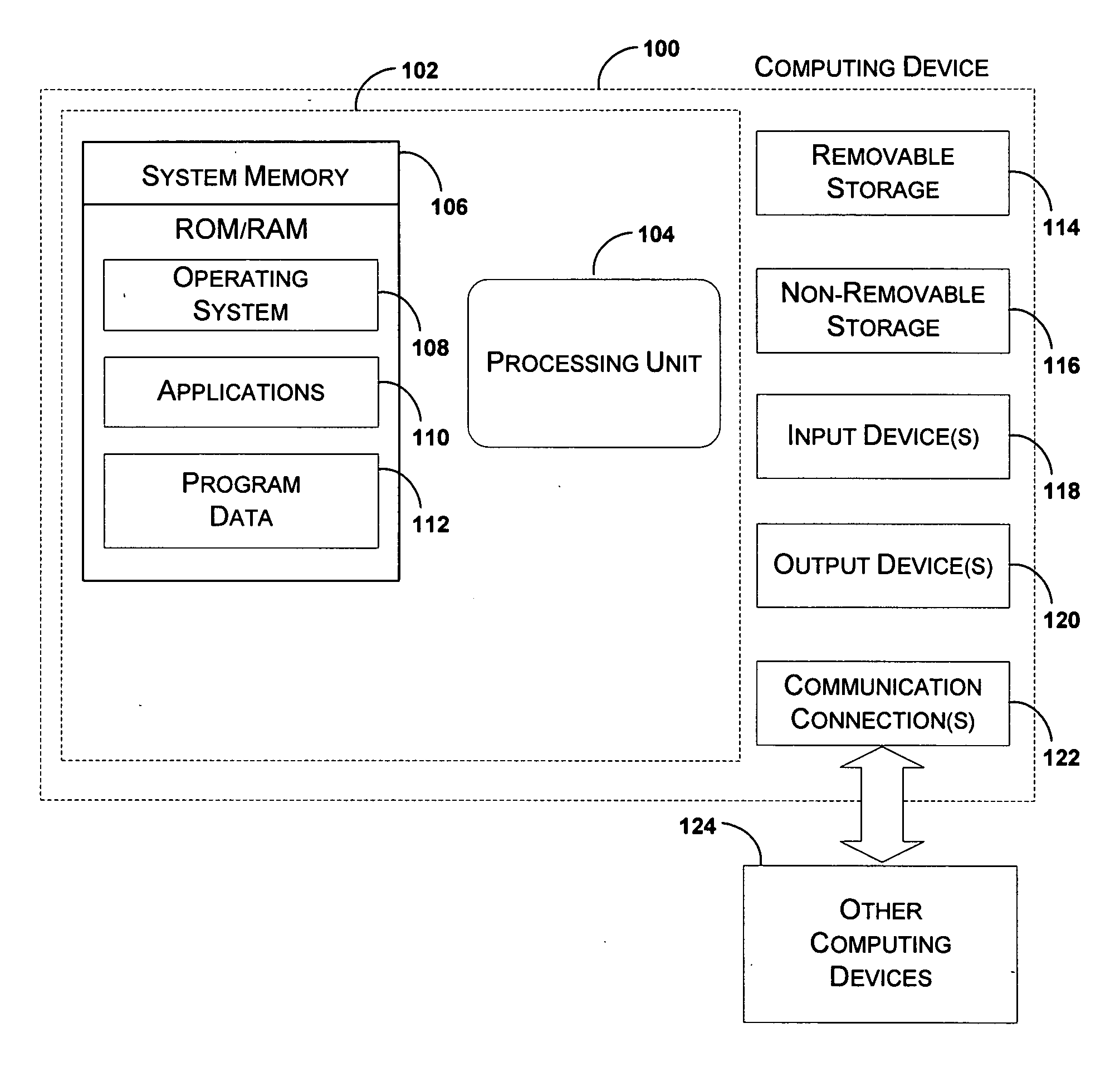

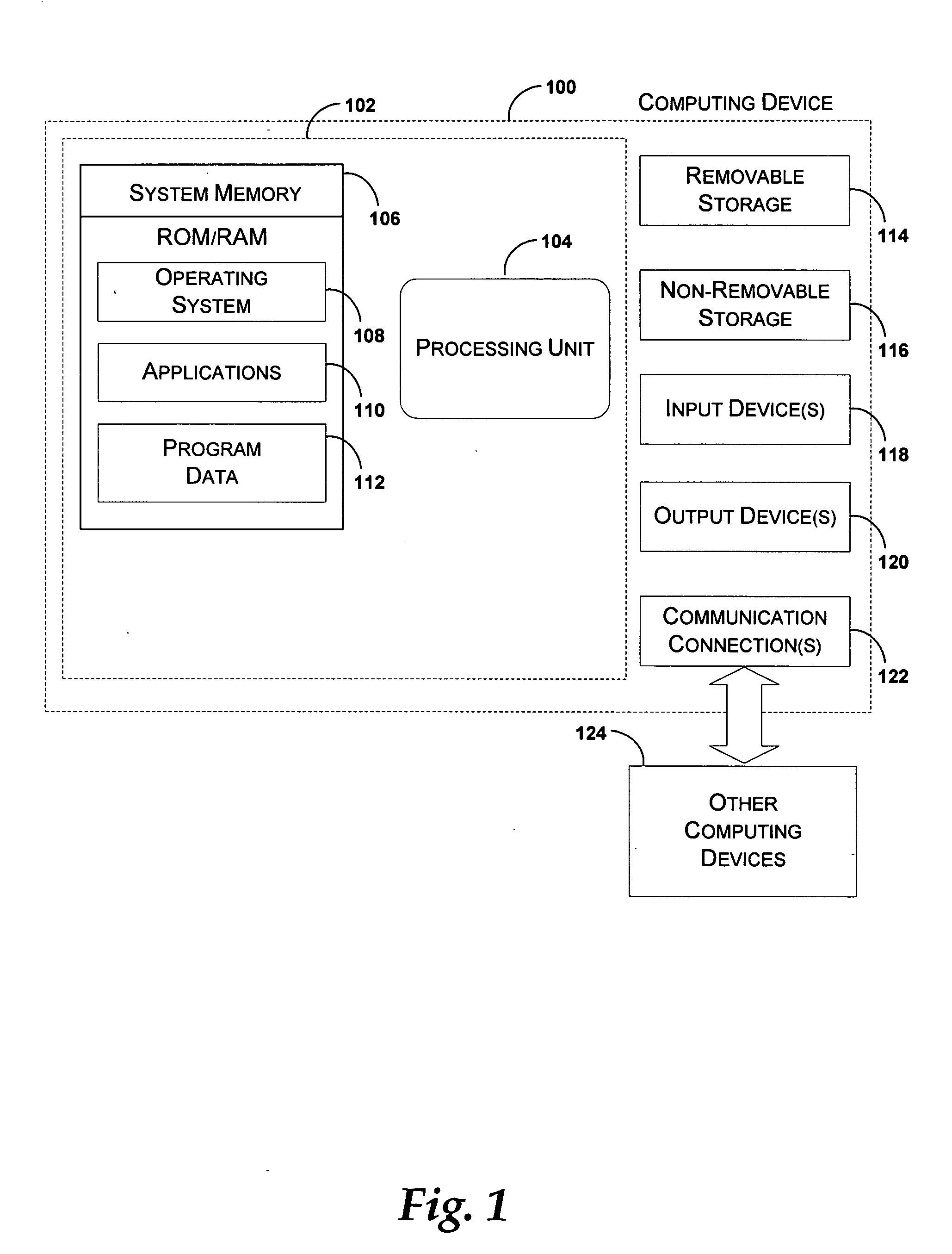

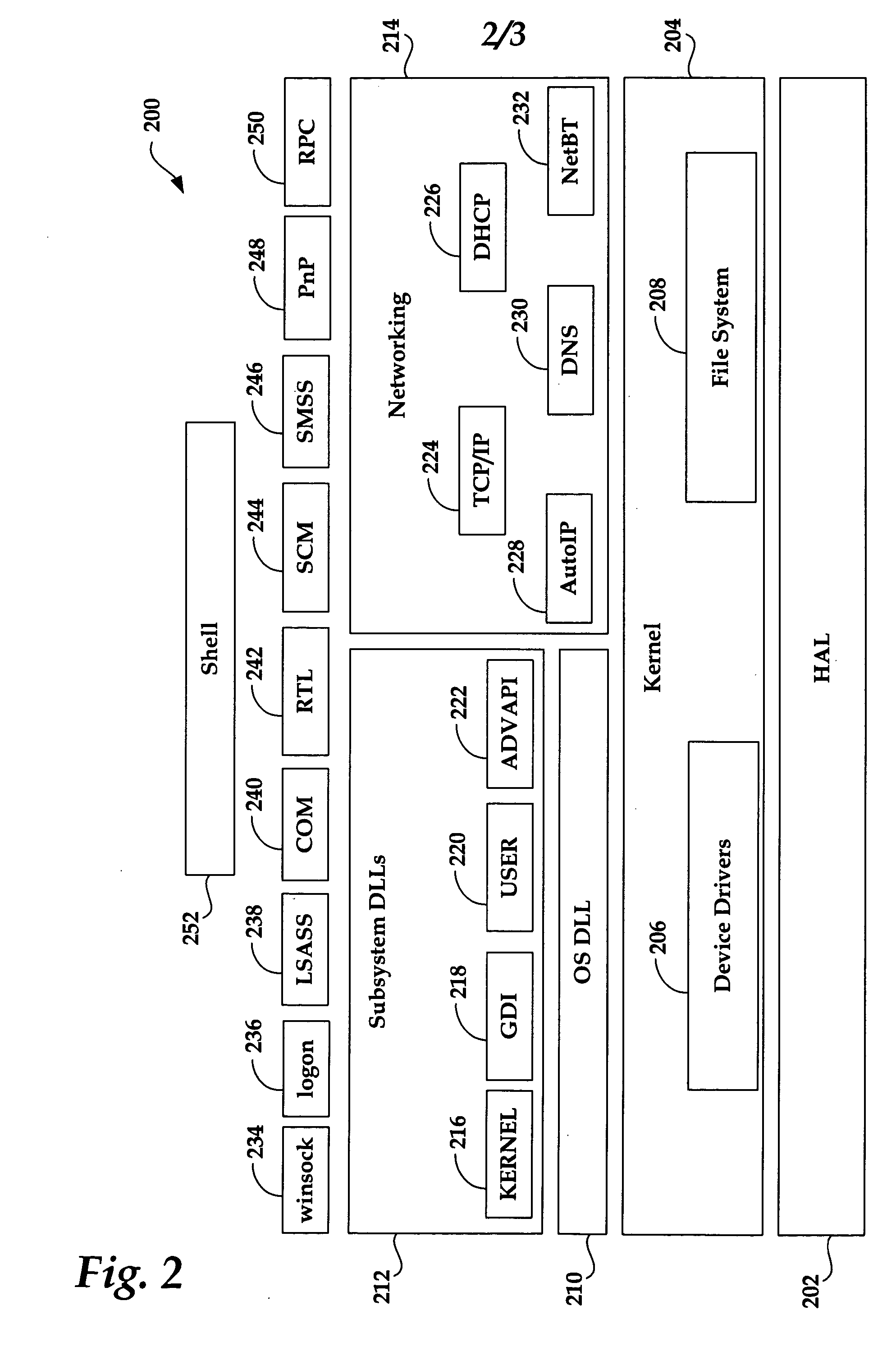

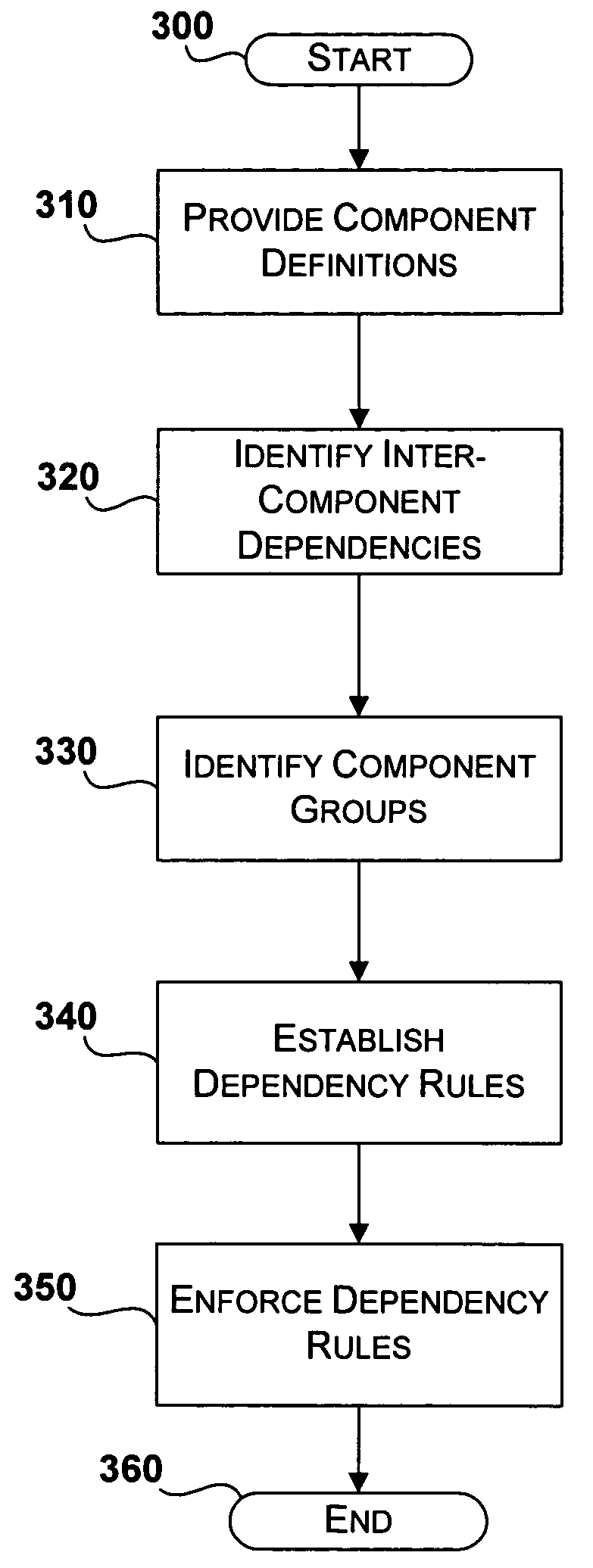

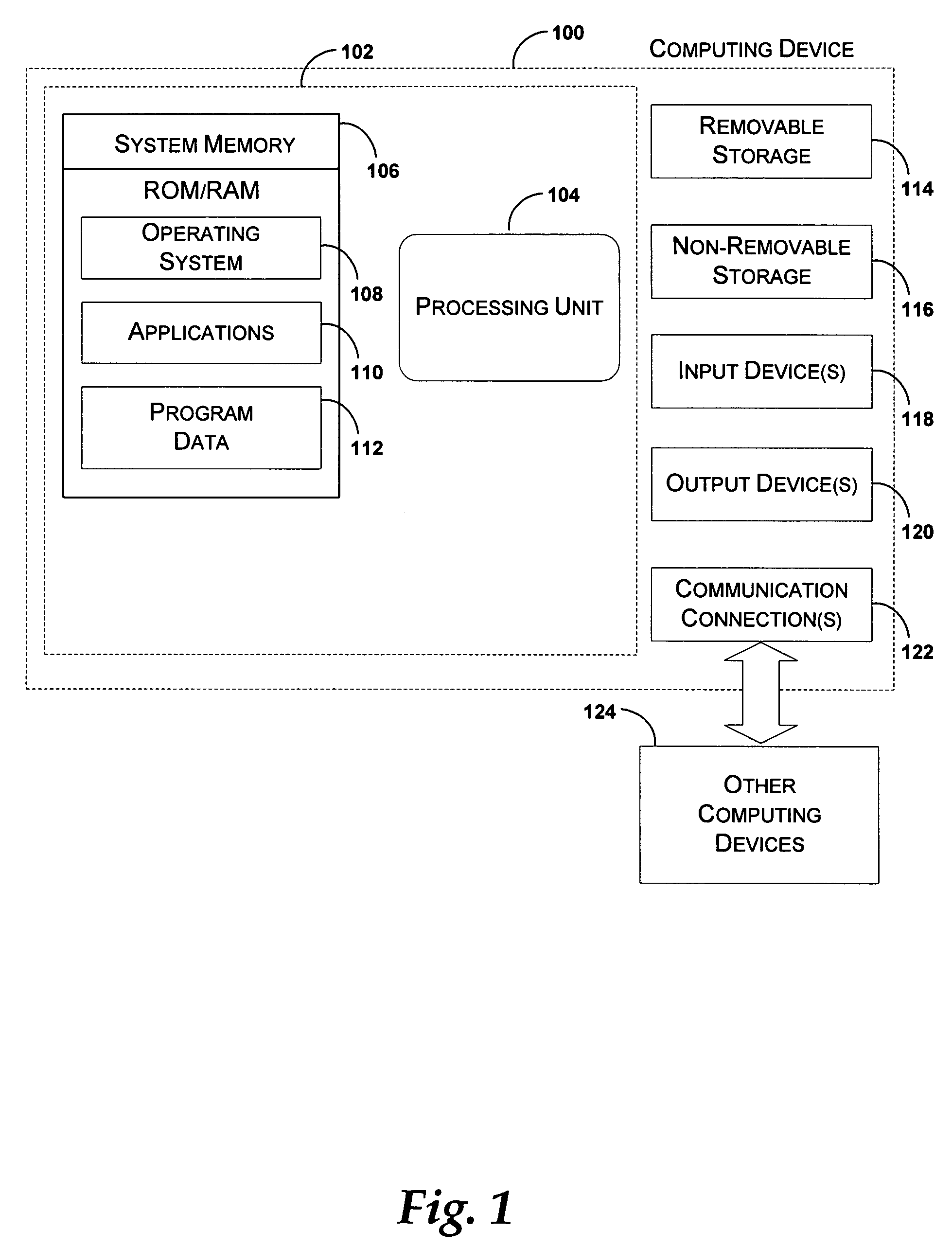

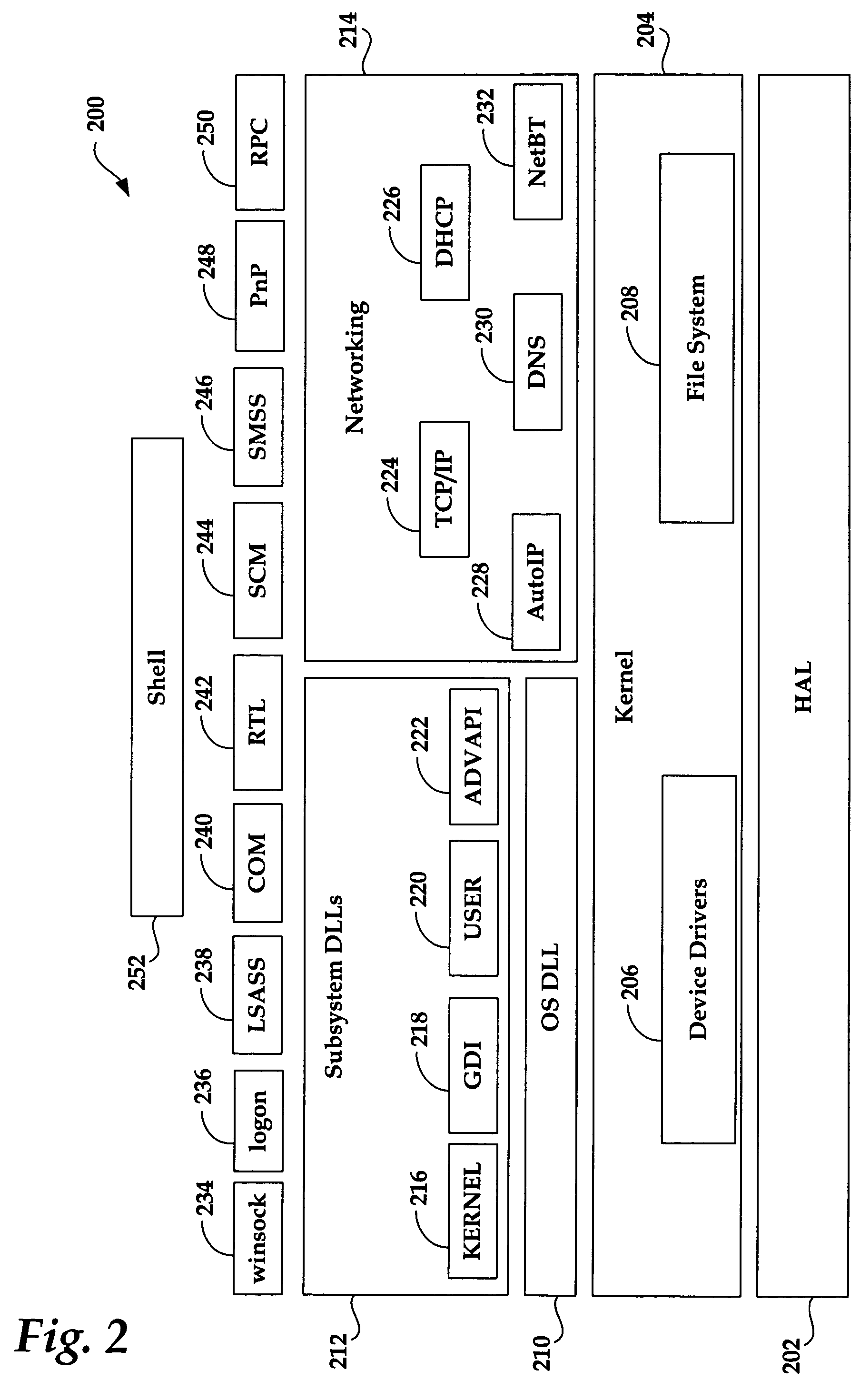

Method and system for providing a common operating system

ActiveUS20050187894A1Adjusting/maintaining mechanical tensionDigital data processing detailsFeature setOperational system

A method and system for providing a common operating system feature set for supporting a variety of operating system configurations is described. The common operating system feature set is organized to provide a minimal memory footprint applicable to a number of devices and methods of deployment. The common operating system includes dependencies among operating system components that provide a selection of integrated components that are validated for reliability. The common operating system includes an application program interface set that provides functionality for a variety of operating system scenarios.

Owner:MICROSOFT TECH LICENSING LLC

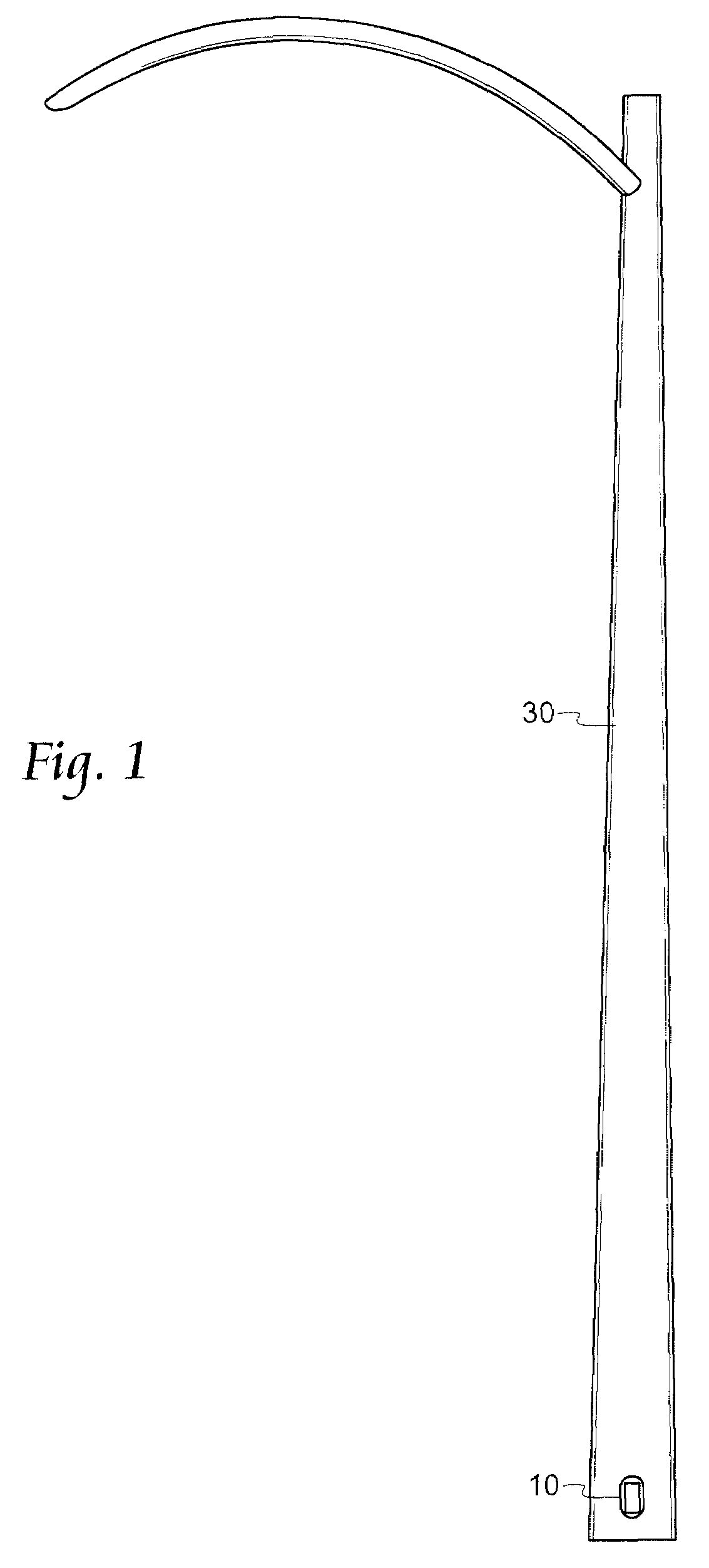

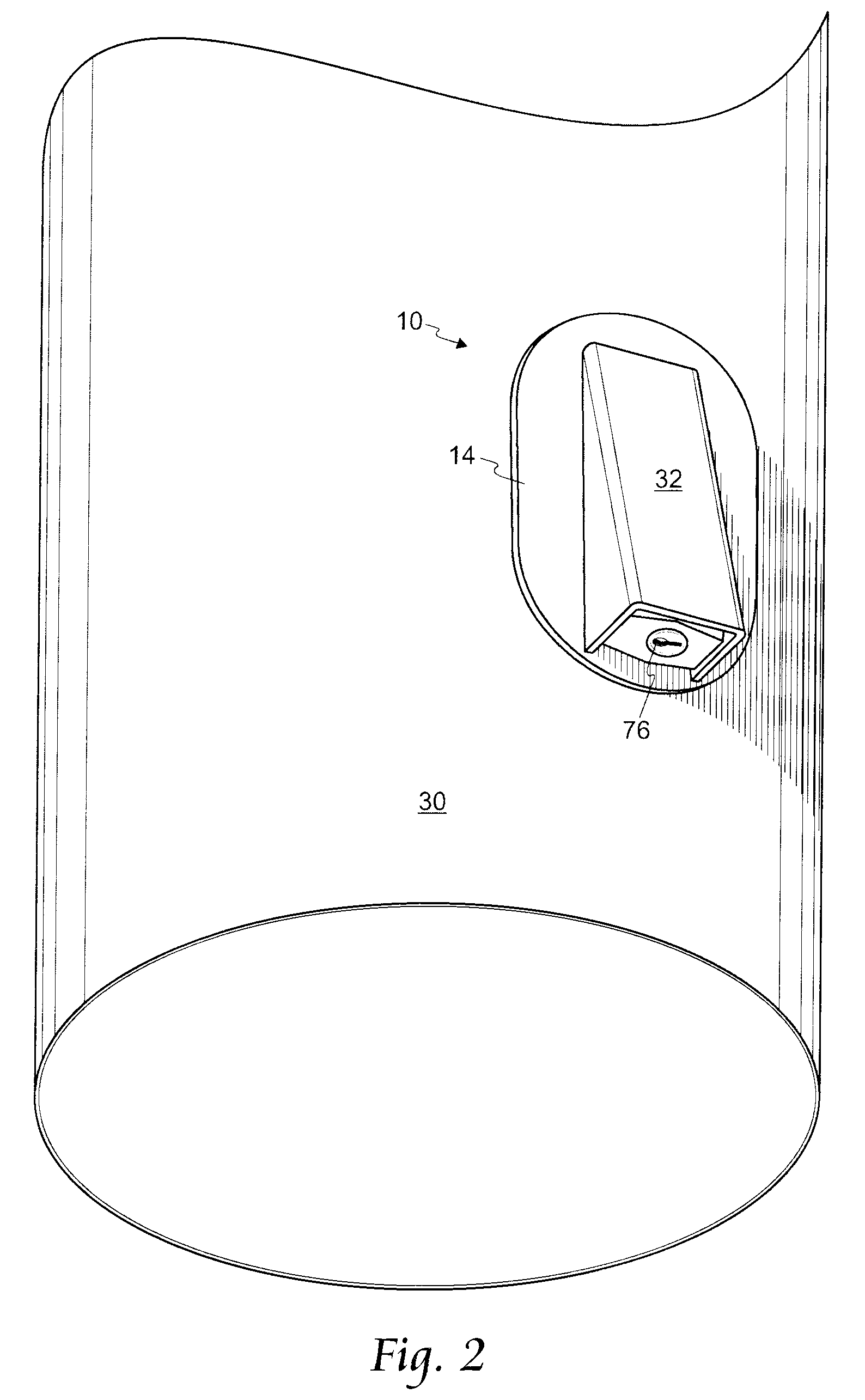

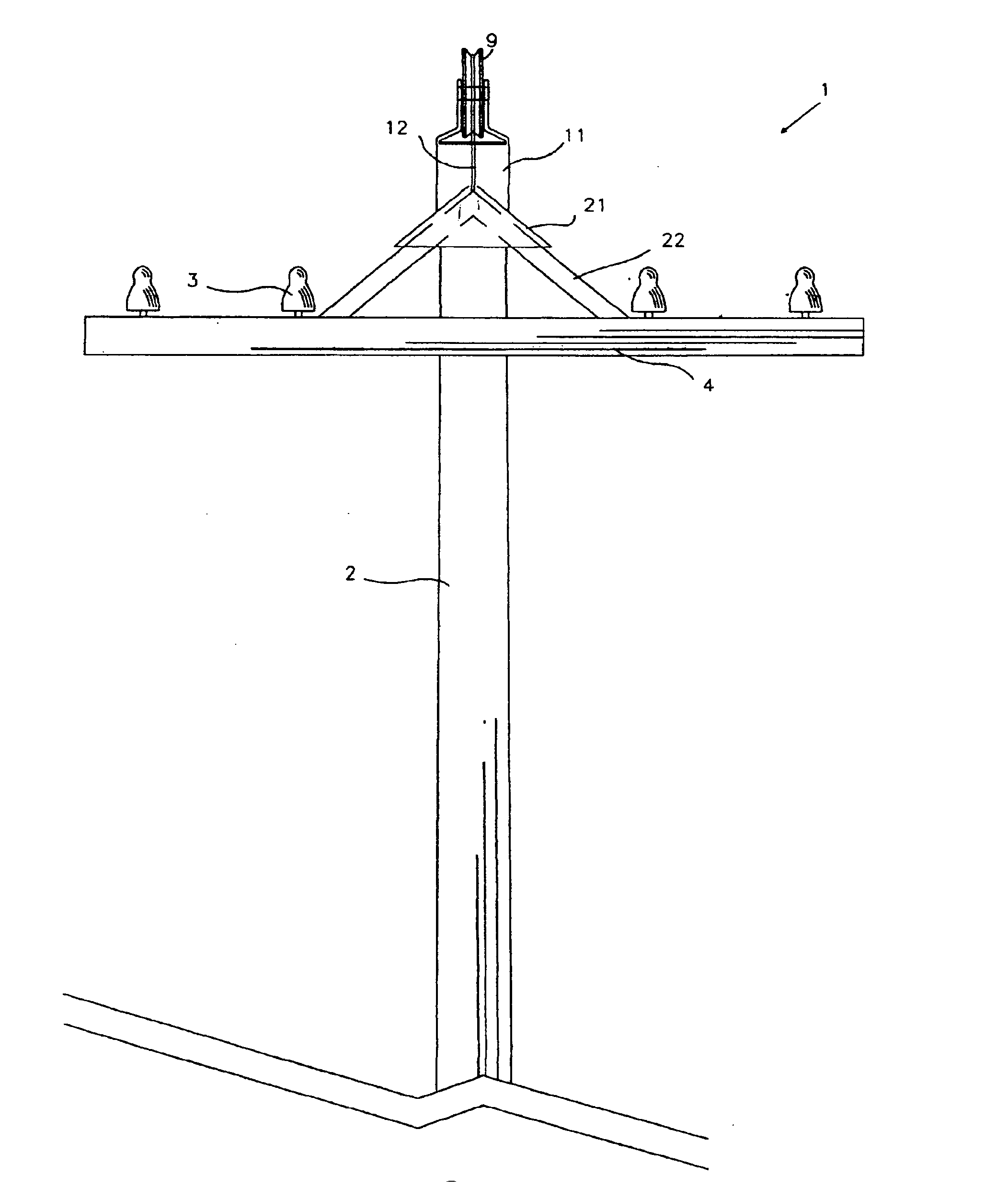

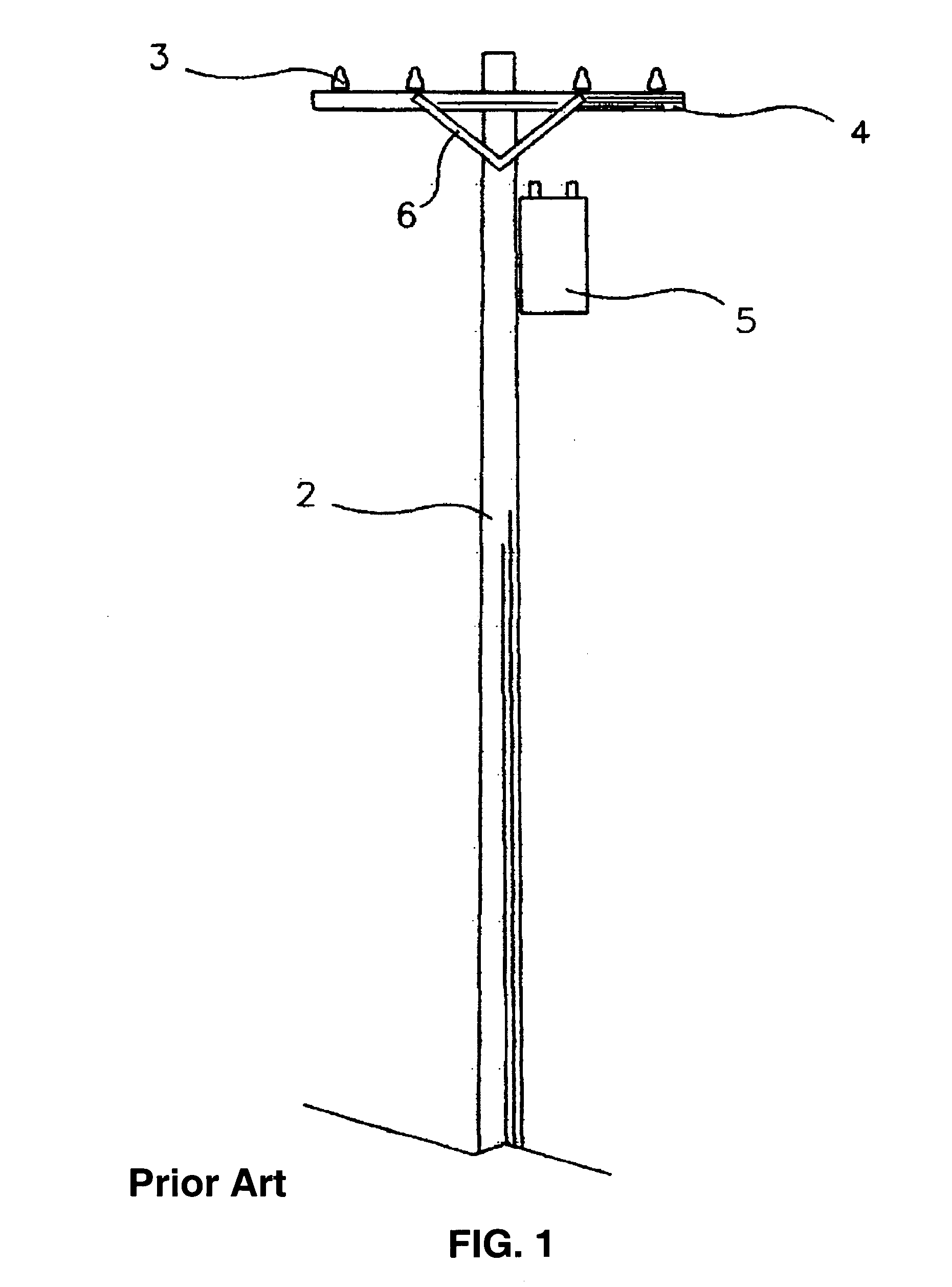

Tamper resistant locking cap for utility poles and method

InactiveUS7560642B2Improve securityPrevent tamperingPasturing equipmentTowersEngineeringUtility pole

A locking cap for a utility pole is provided to safeguard the metal wiring therein. The locking cap prevents access to the metal wiring through the access opening in the utility pole. The locking cap has a base that detachably mounts with one or more fasteners to a utility pole into and over the access opening and a locking shield that slidably engages with the base in a position overlying the one or more fasteners.

Owner:YGNELZI GIANNI +1

Extended length strand take up device

Owner:STEVENS JAMES A

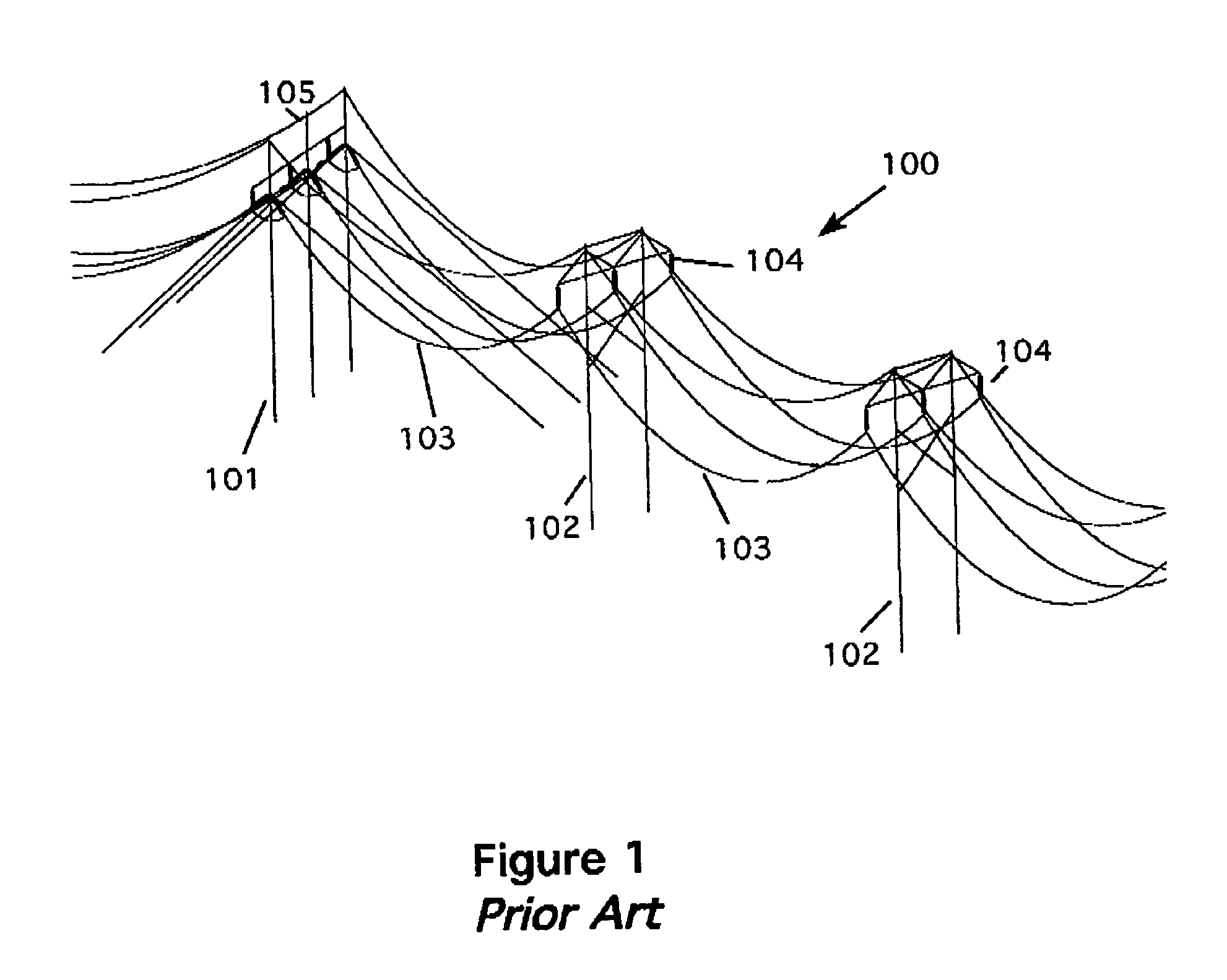

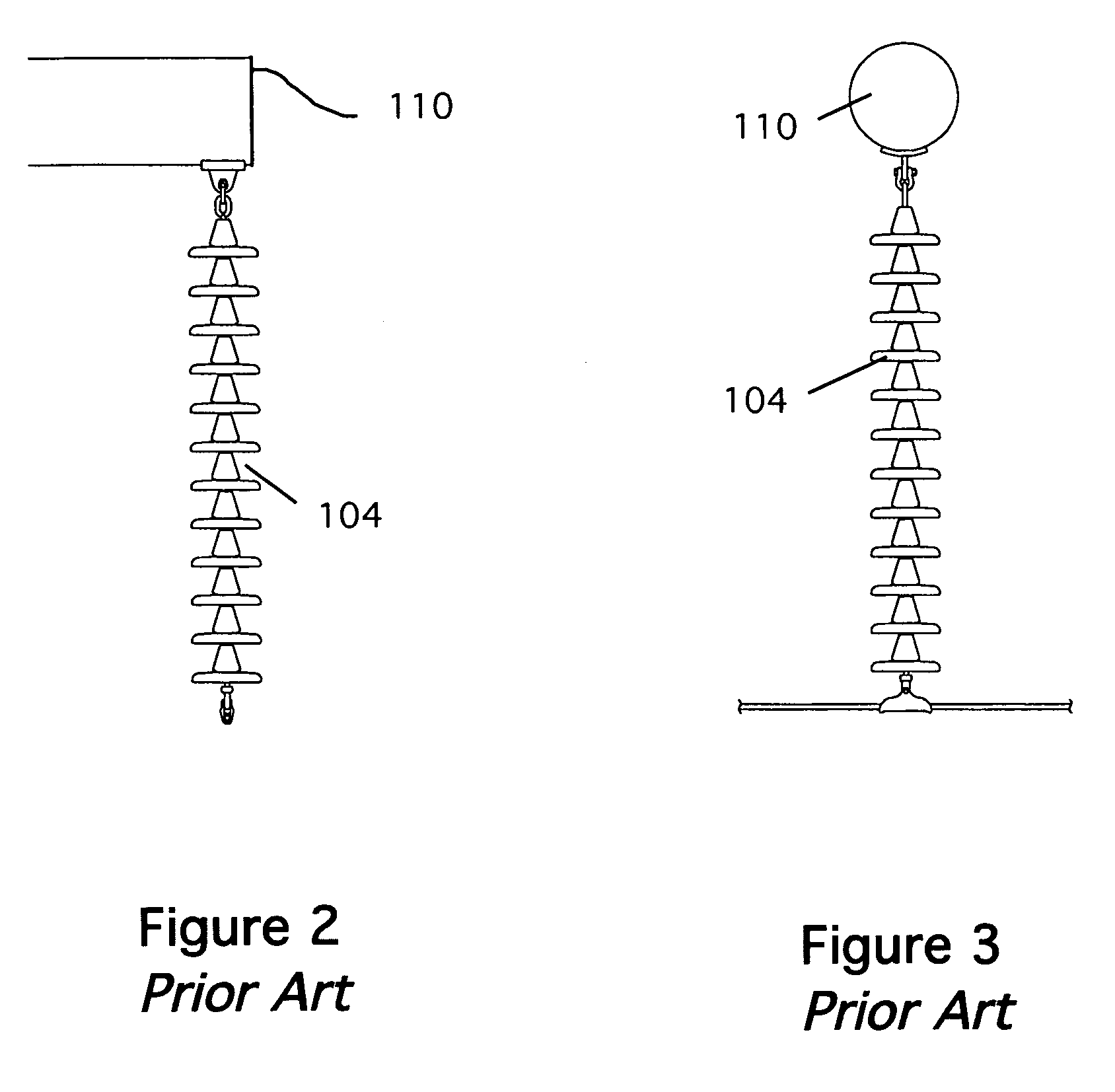

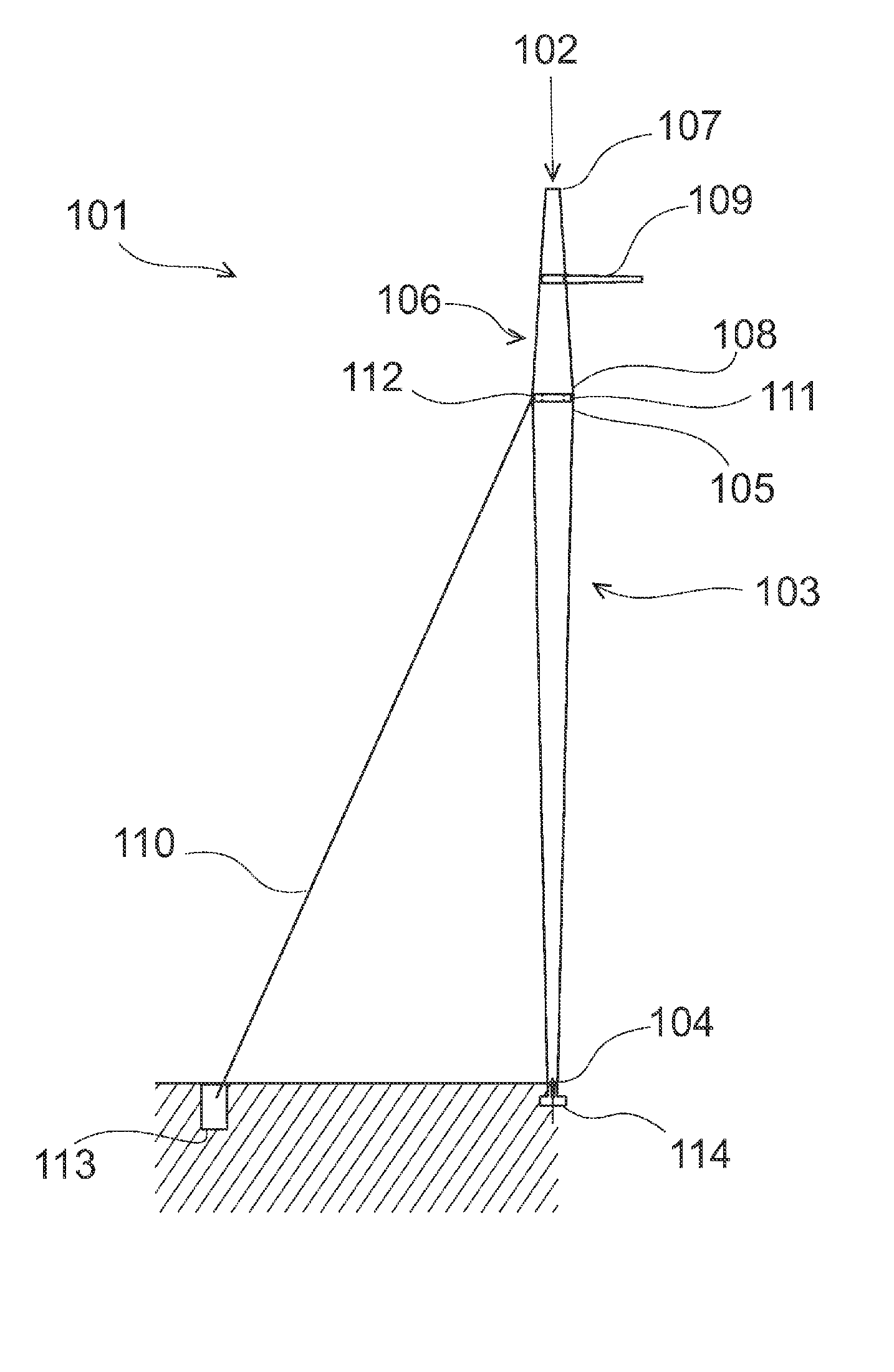

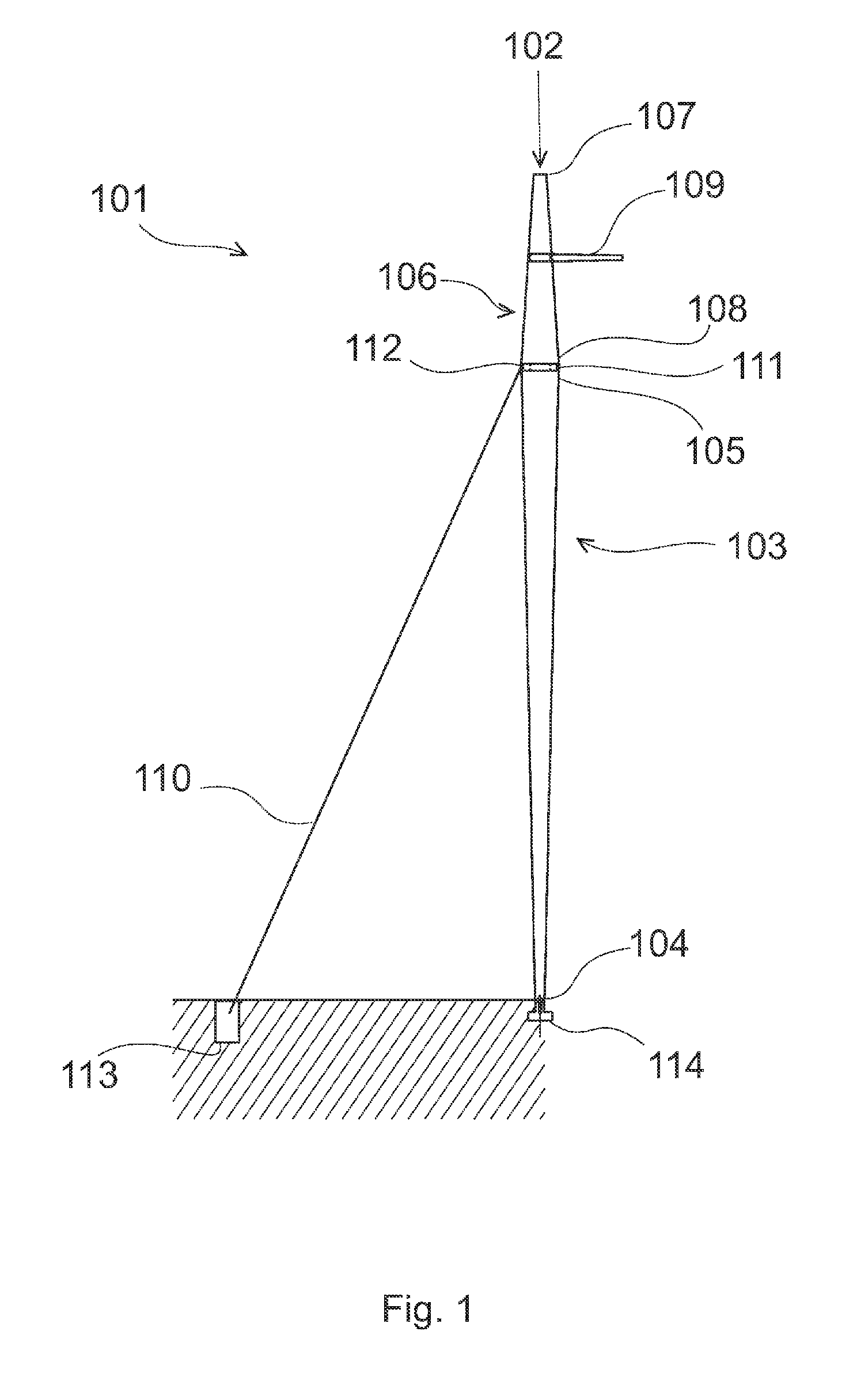

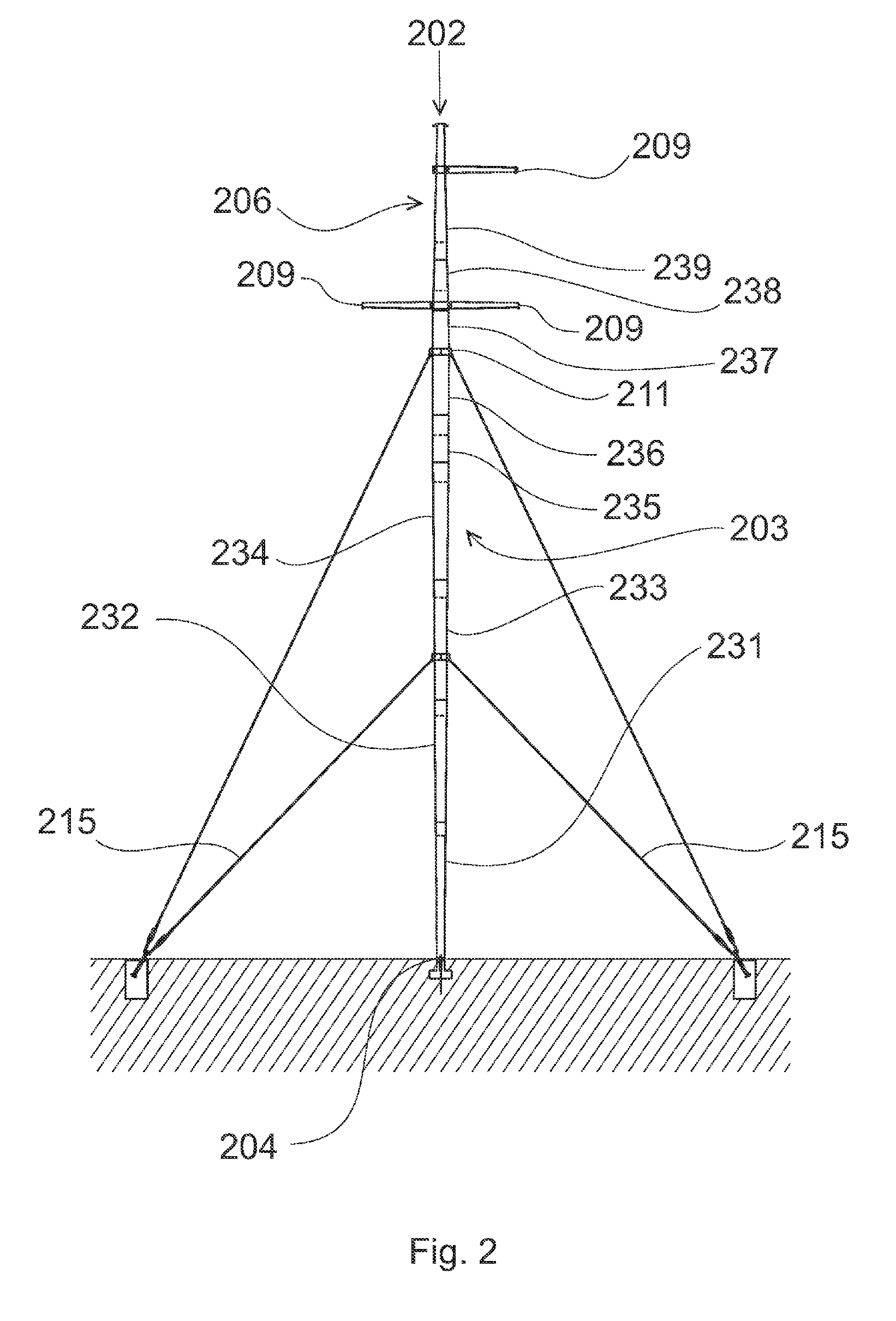

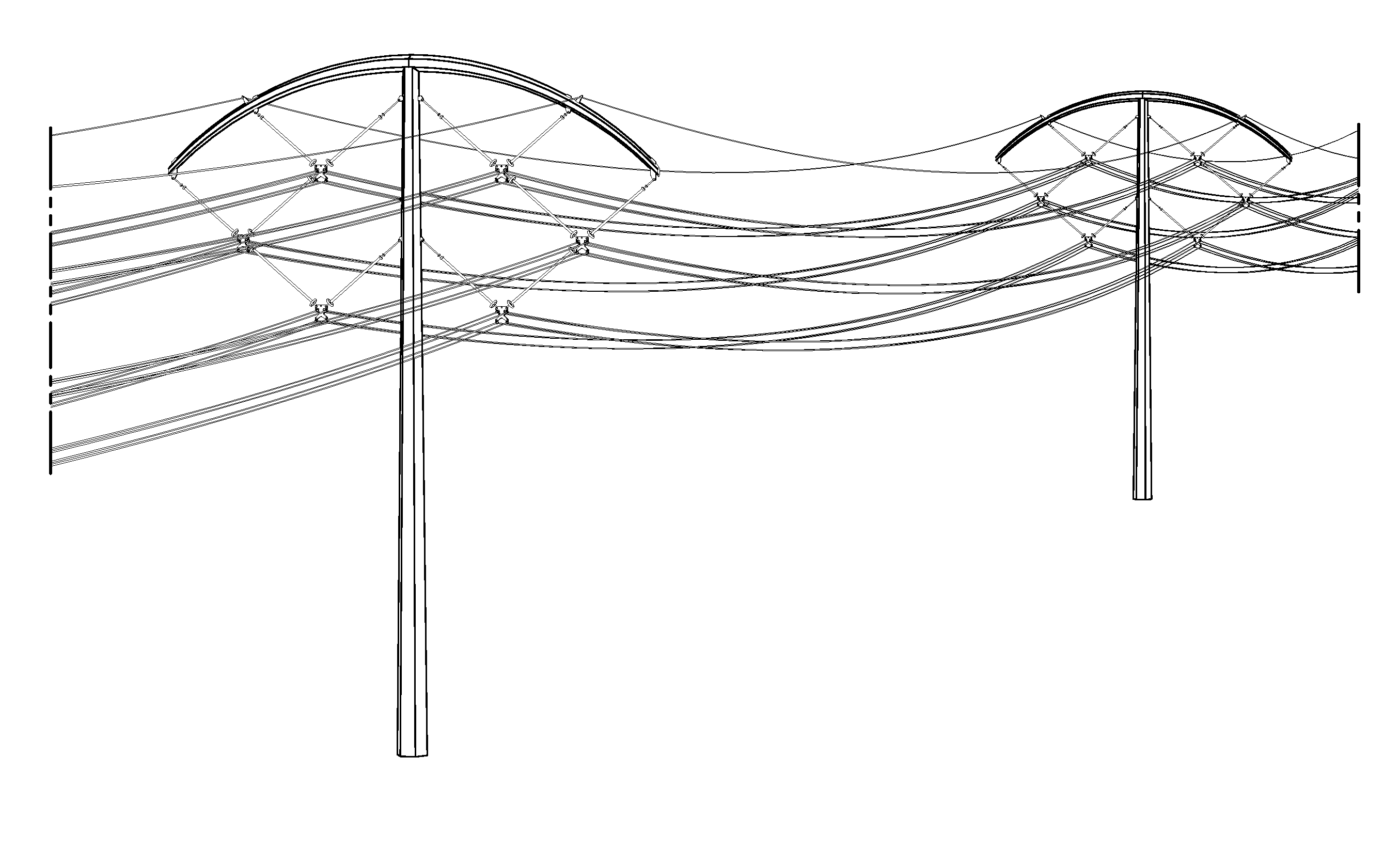

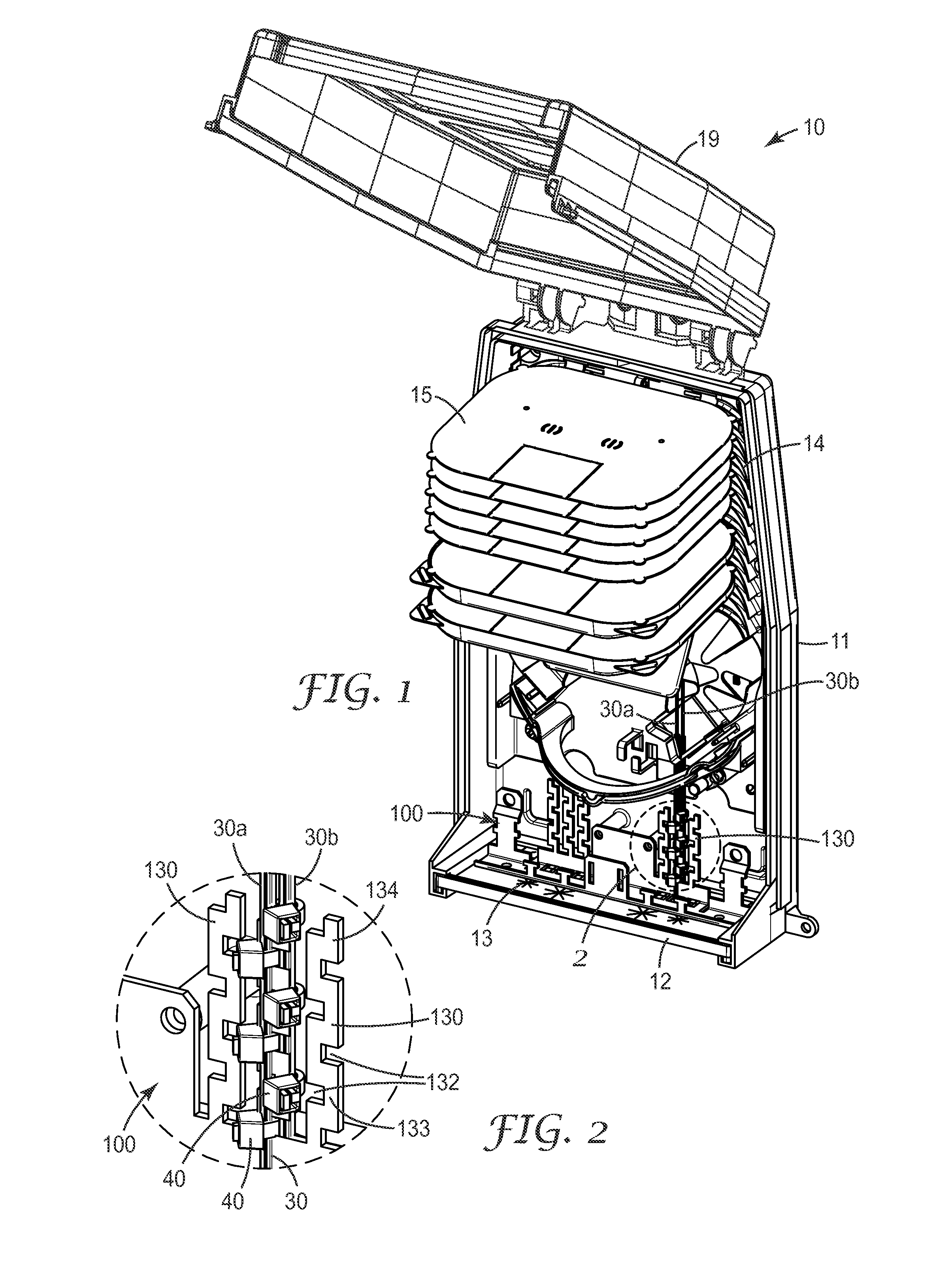

Structure for supporting electric power transmission lines

ActiveUS20100319983A1Improve stress conditionGood strain behaviourAdjusting/maintaining mechanical tensionTowersElectric power transmissionEngineering

A structure for supporting electric power transmission lines that aims to obtain a better stress and strain behaviour providing a higher ultimate economy. The preferred embodiment is directed to a structure that comprises a metallic vertical structure (101) having: a lower tubular frustum shape (103) with a smaller end (104) and a larger end (105), wherein the smaller end is on the bottom and the larger end on the top; an upper frustum shape (106) with a smaller end (107) and a larger end (108), wherein the smaller end is on the top and the larger end on the bottom; and wherein the larger end of the lower frustum is adjoined to the larger end of the upper frustum; line supporting members (109); side supporting elements (110) attached in the adjoining region (111) of the lower and upper frustums, and extending between the attachment and an anchoring base (113); and wherein the adjoining region is below the line supporting members.

Owner:SECCIONAL BRASIL SA

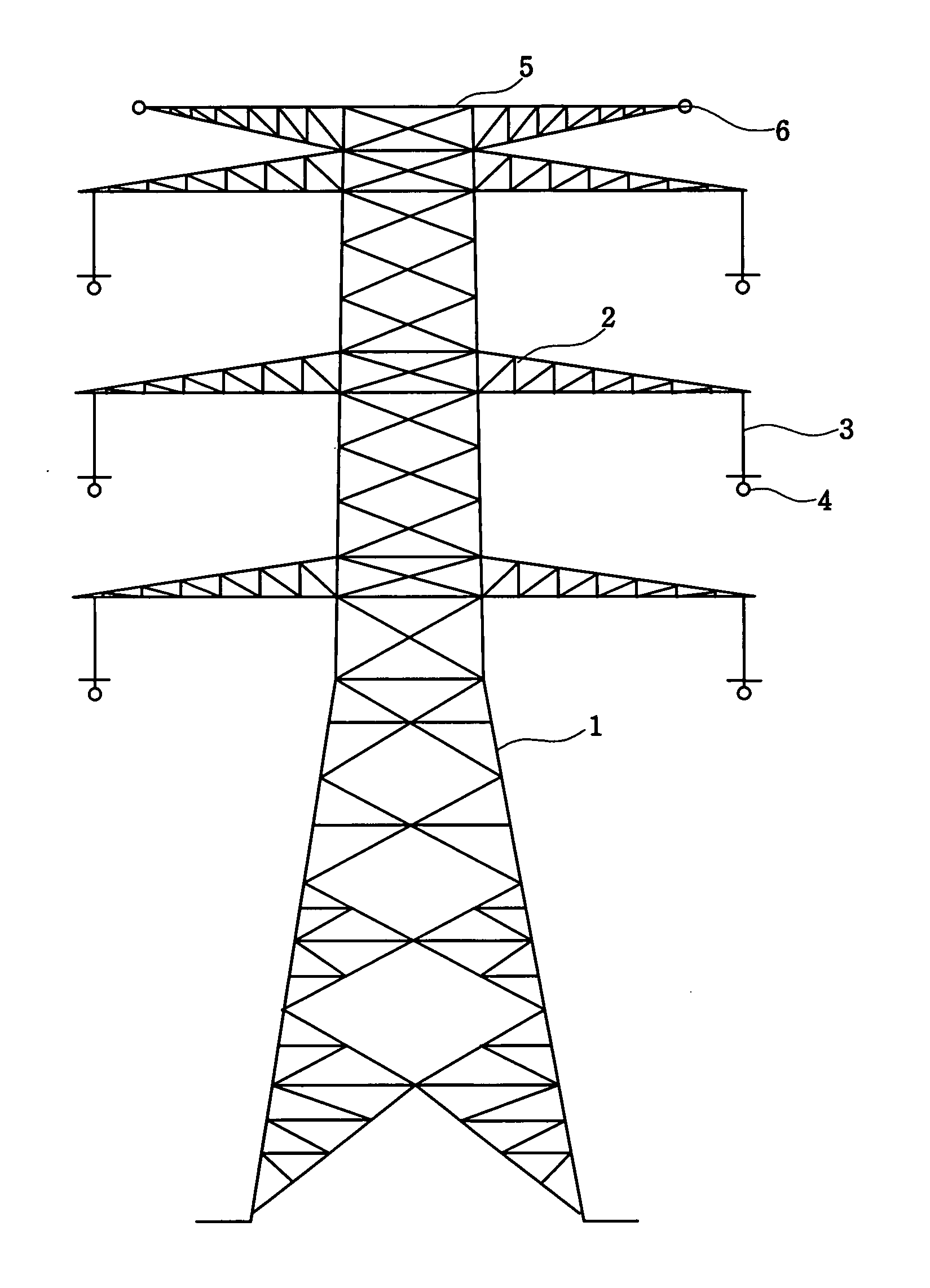

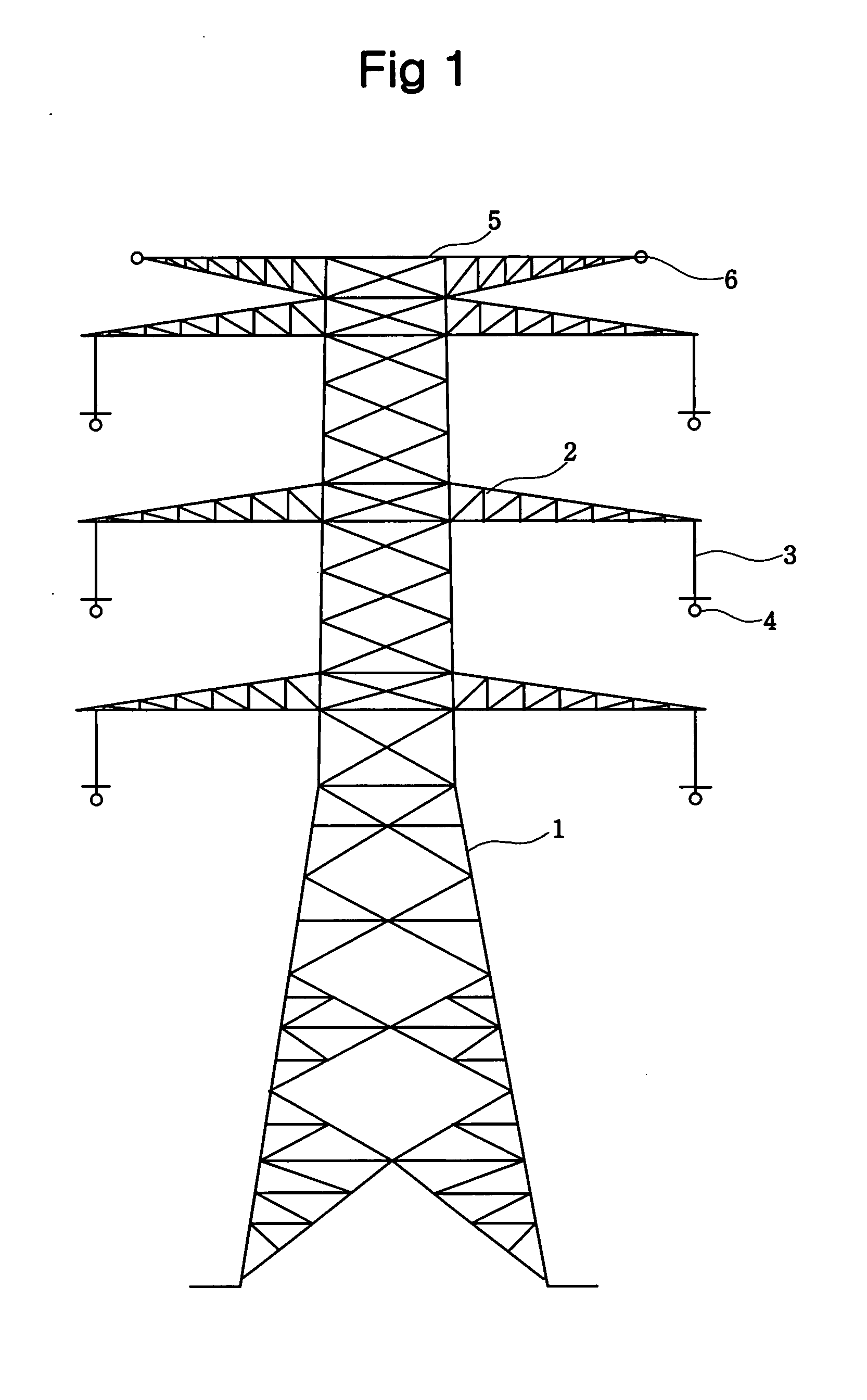

Power transmission tower

ActiveUS8122647B2Improve propertiesHigh strengthAdjusting/maintaining mechanical tensionTowersElectricityTransmission tower

Disclosed is a power transmission tower, which includes a tower body; first through sixth main insulation arms connected by one end thereof to the tower body with an angle with the tower body, respectively, and arranged radially and symmetrically about the tower body in a longitudinal direction; and first through eighth auxiliary insulation arms for selectively connecting the other end of the first through sixth main insulation arms and the tower body so that each of the auxiliary insulation arms constitutes each side of an octagon.Since the insulation arms are octagonally arranged, it is possible to reinforce a mechanical strength and enhance electric properties of the tower.

Owner:KOREA ELECTRIC POWER CORP

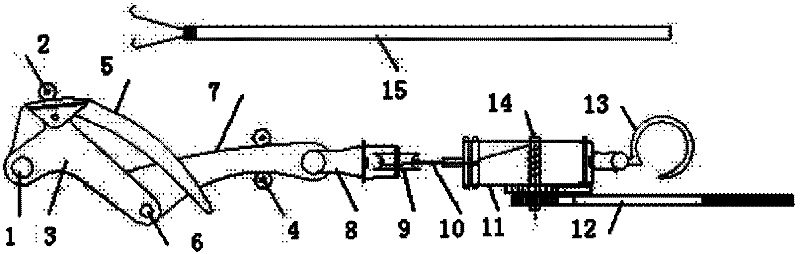

Electric stringing and tightening device

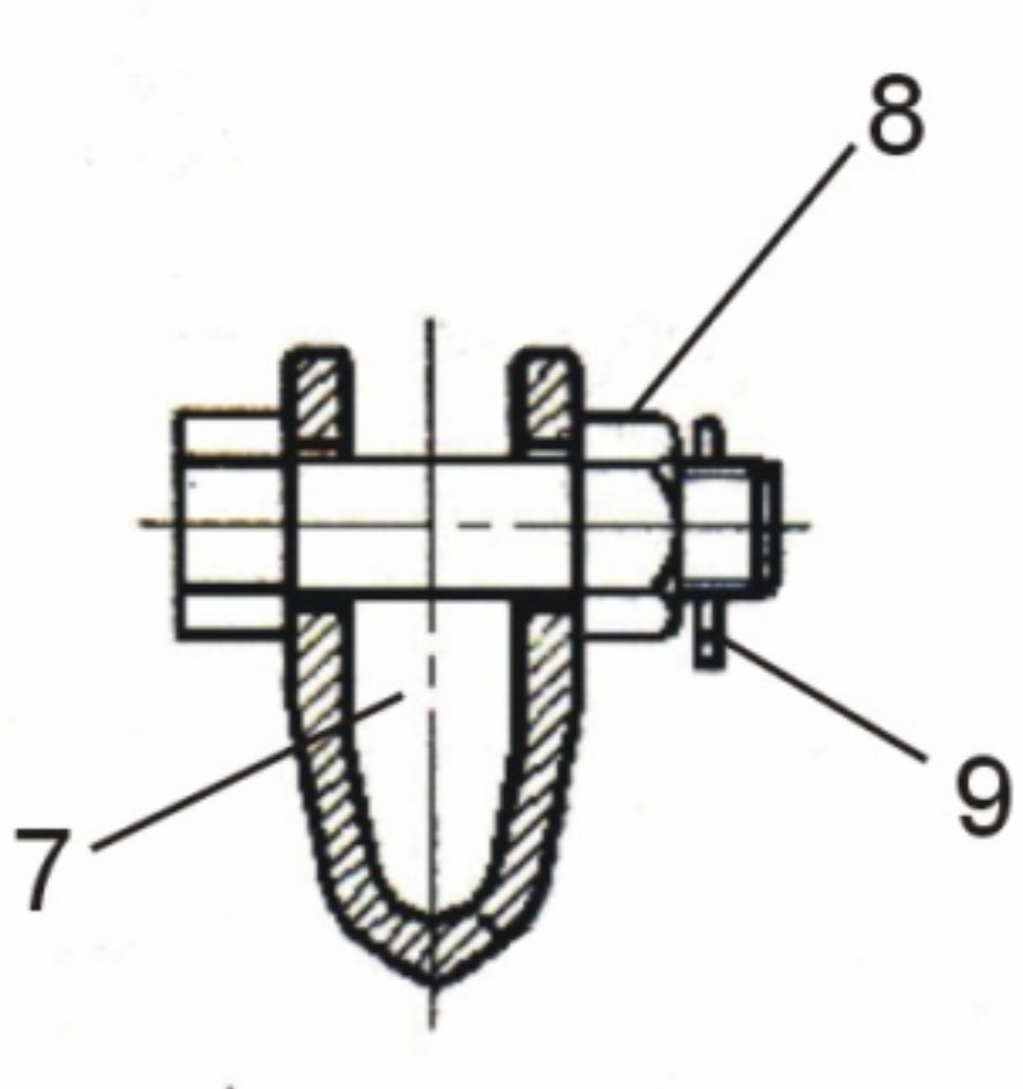

InactiveCN102361304AFlexible lengthSimple structureAdjusting/maintaining mechanical tensionApparatus for overhead lines/cablesEngineeringElectric power

The invention relates to an electric stringing and tightening device which comprises a front tightening arm (3), a rear tightening arm (7), a tightening rocking handle (5), a pulley base (8), a pulley (9) of the pulley base (8), a tightening rope (10) and a tightening mechanism, wherein the front tightening arm (3) is hinged with the rear tightening arm (7) by a hinge shaft (6); the tightening rocking handle (5) and the pulley base (8) are respectively hinged with the front end of the front tightening arm (3) and the rear end of the rear tightening arm (7); and the tightening mechanism is connected with the tightening rope (10). The electric stringing and tightening device is characterized in that a wire claming but (2) is arranged at the upper part in front of the front tightening arm (3); pay-off nuts (4) are respectively arranged at the upper part and the lower part at the back of the rear tightening arm (7); and a pay-off rod (15) with hooks, which are inserted and taken out by matching with the screw hole distances of the upper and lower pay-off nuts (4), is arranged at the positions of the upper and lower pay-off nuts (4). The invention adopting the technology has the characteristics of simple structure, easiness for processing and manufacturing, small size, light weight, simpleness for operation, one-time finishing for a tightening project, high efficiency and the like.

Owner:哈尔滨电业局 +1

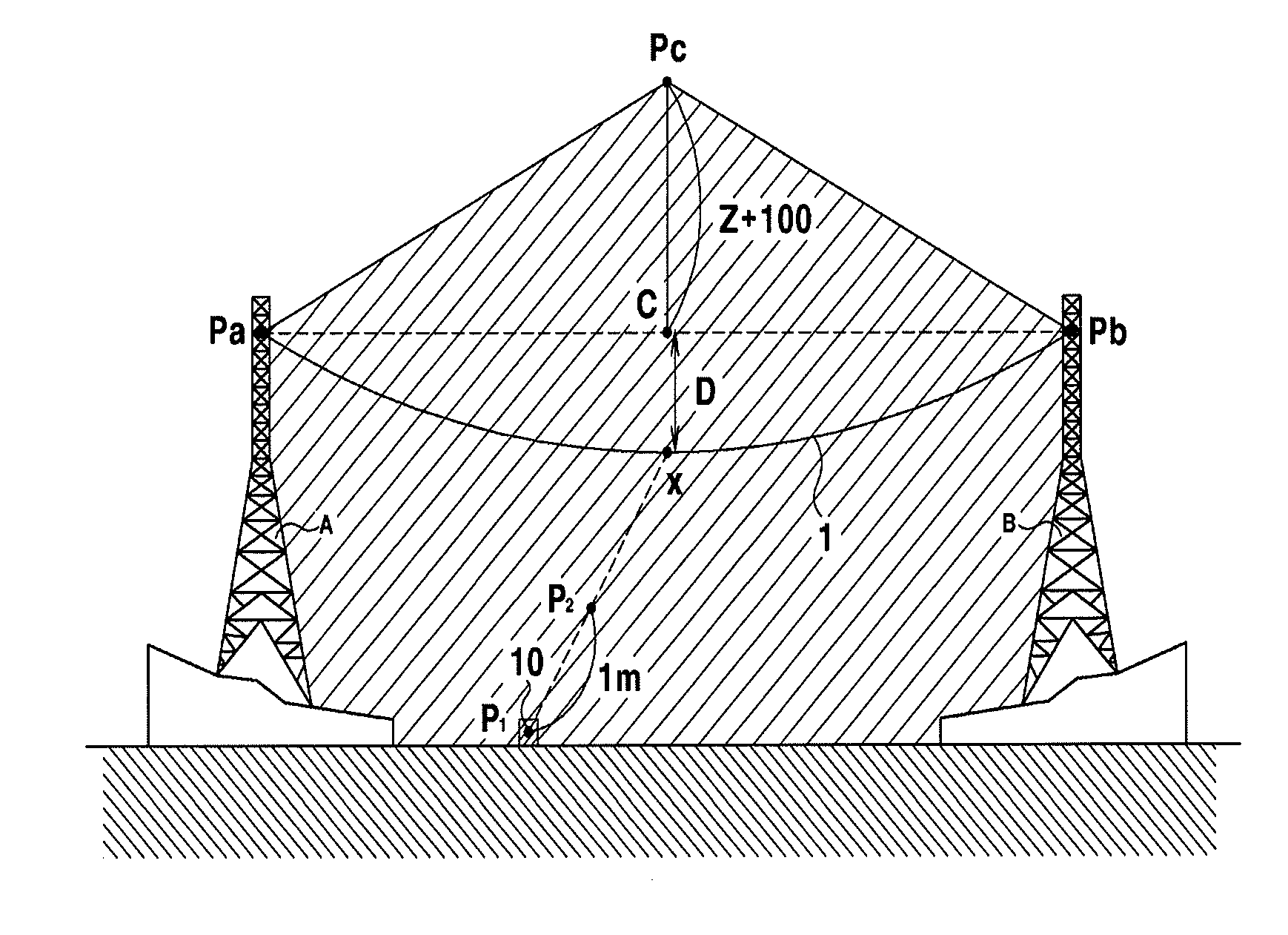

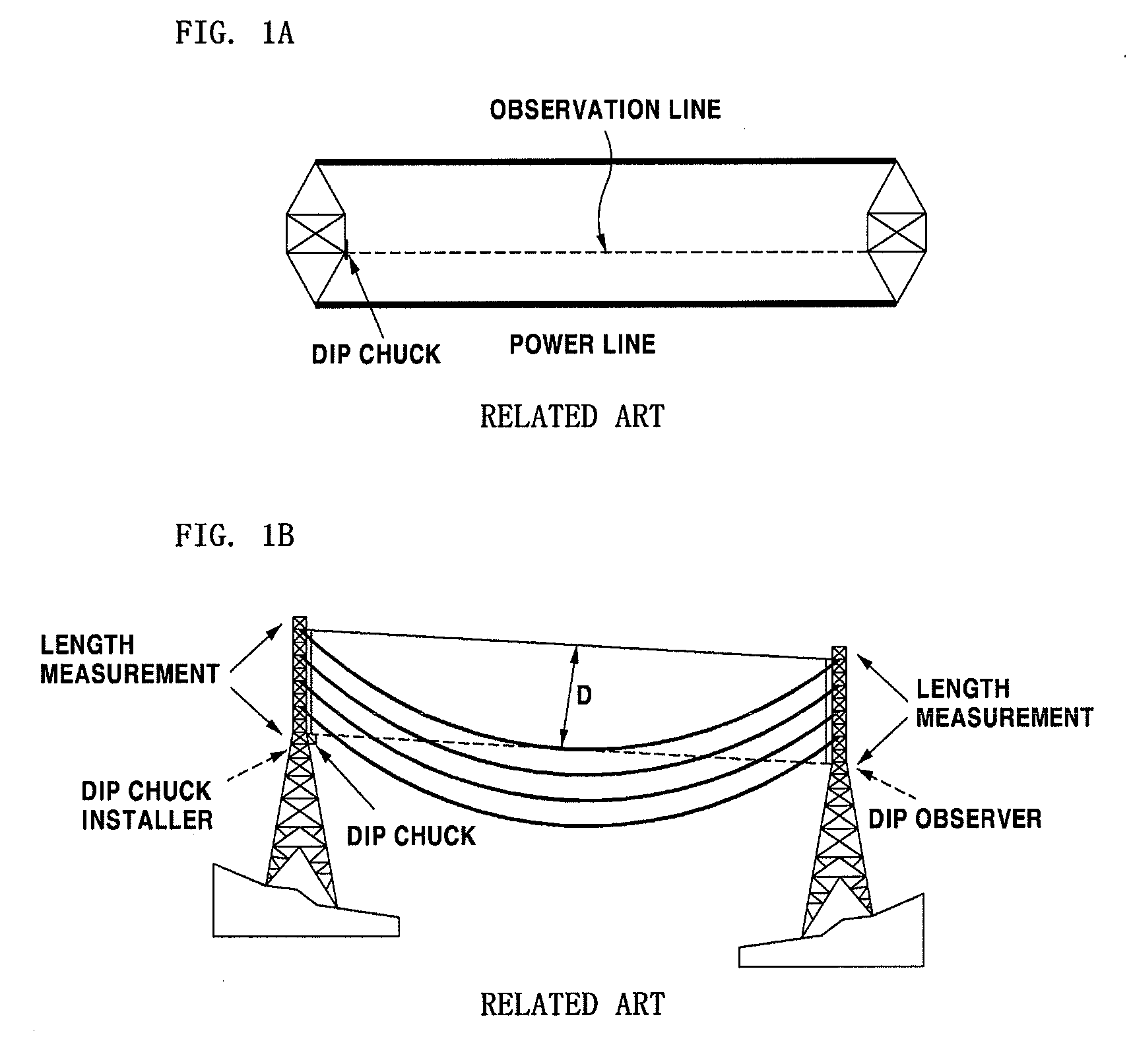

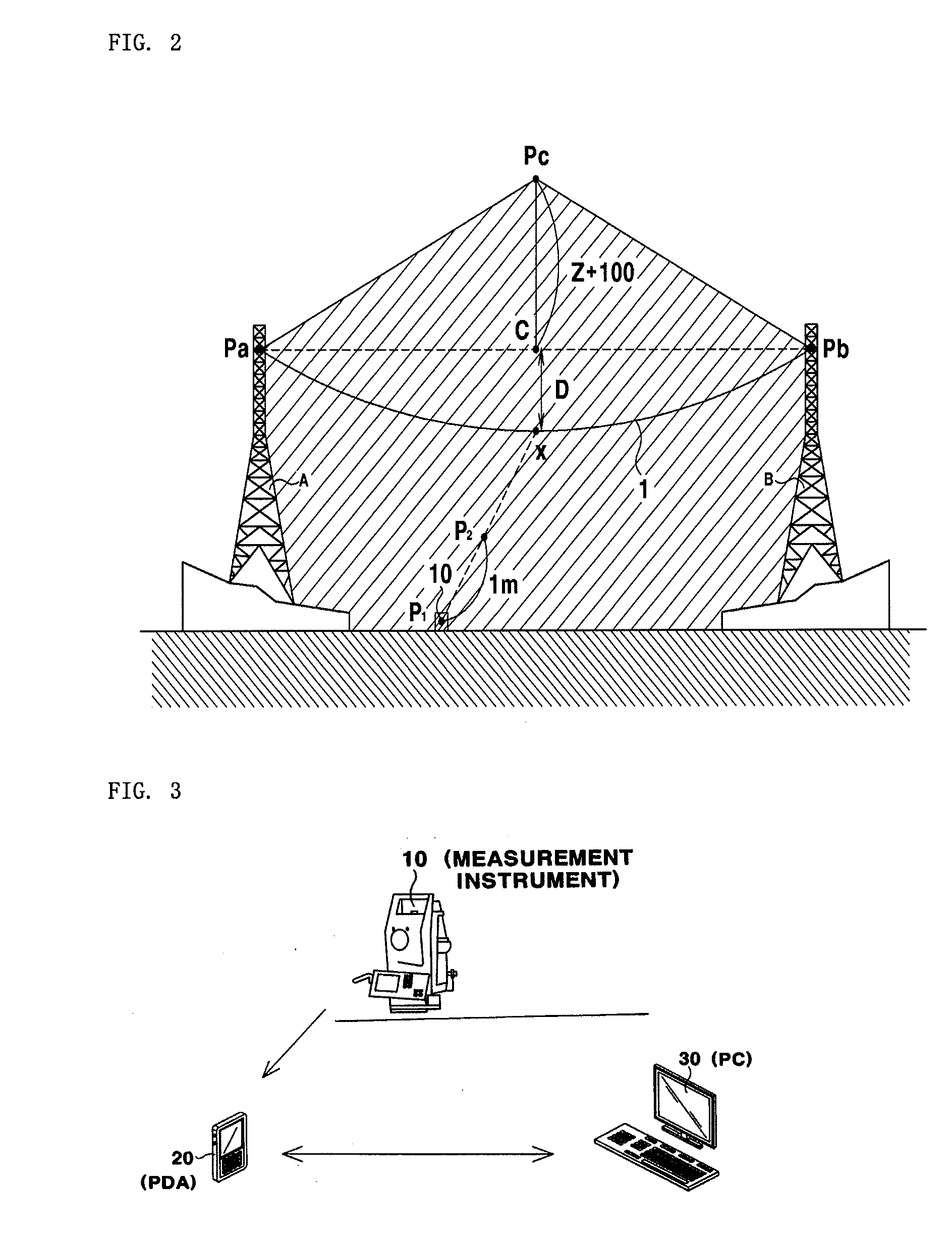

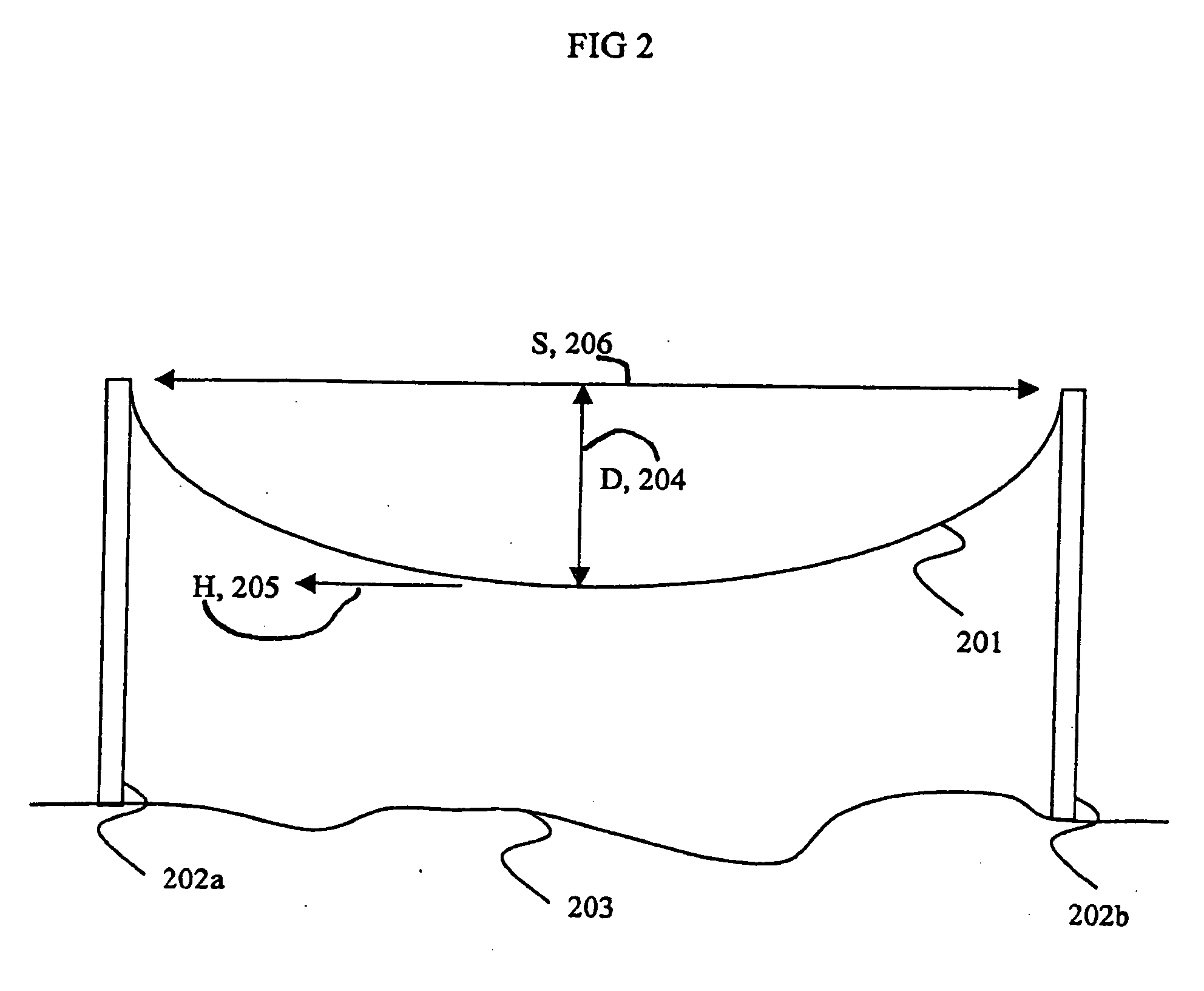

Power transmission line dip measurement method

ActiveUS20100138186A1Minimize measurement errorImprove efficiencyMechanical depth measurementsDigital computer detailsMeasuring instrumentTower

A power transmission line dip measurement method is disclosed. The dip measurement method includes installing a measurement instrument at a place where power line support points of steel towers can be seen from the ground, collimating the measurement instrument at the power line support point of one of the steel towers, transmitting a collimated value to a PDA in a wired or wireless manner, collimating the measurement instrument at the power line support point of the other steel tower, transmitting a collimated value to the PDA, calculating the collimated values to display a horizontal angle position of a dip base line, and adjusting an angle of the measurement instrument based on the horizontal angle displayed on a screen of the PDA by a worker, collimating the measurement instrument at a power line dip point as a dip base point, and displaying a dip value on the screen of the PDA.

Owner:KPS CO LTD

Method and system for providing a common operating system

ActiveUS7444621B2Adjusting/maintaining mechanical tensionDigital data processing detailsOperational systemFeature set

A method and system for providing a common operating system feature set for supporting a variety of operating system configurations is described. The common operating system feature set is organized to provide a minimal memory footprint applicable to a number of devices and methods of deployment. The common operating system includes dependencies among operating system components that provide a selection of integrated components that are validated for reliability. The common operating system includes an application program interface set that provides functionality for a variety of operating system scenarios.

Owner:MICROSOFT TECH LICENSING LLC

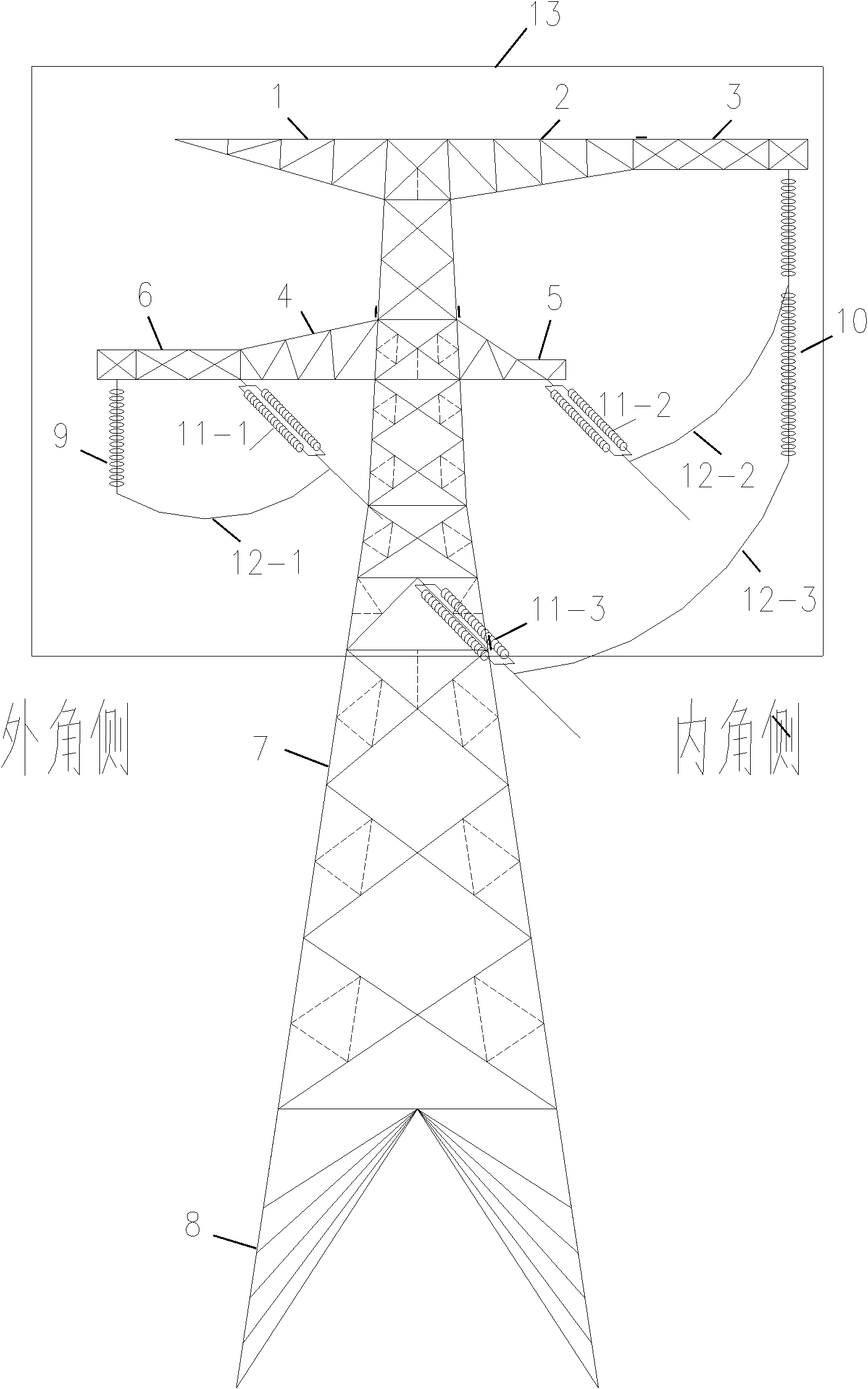

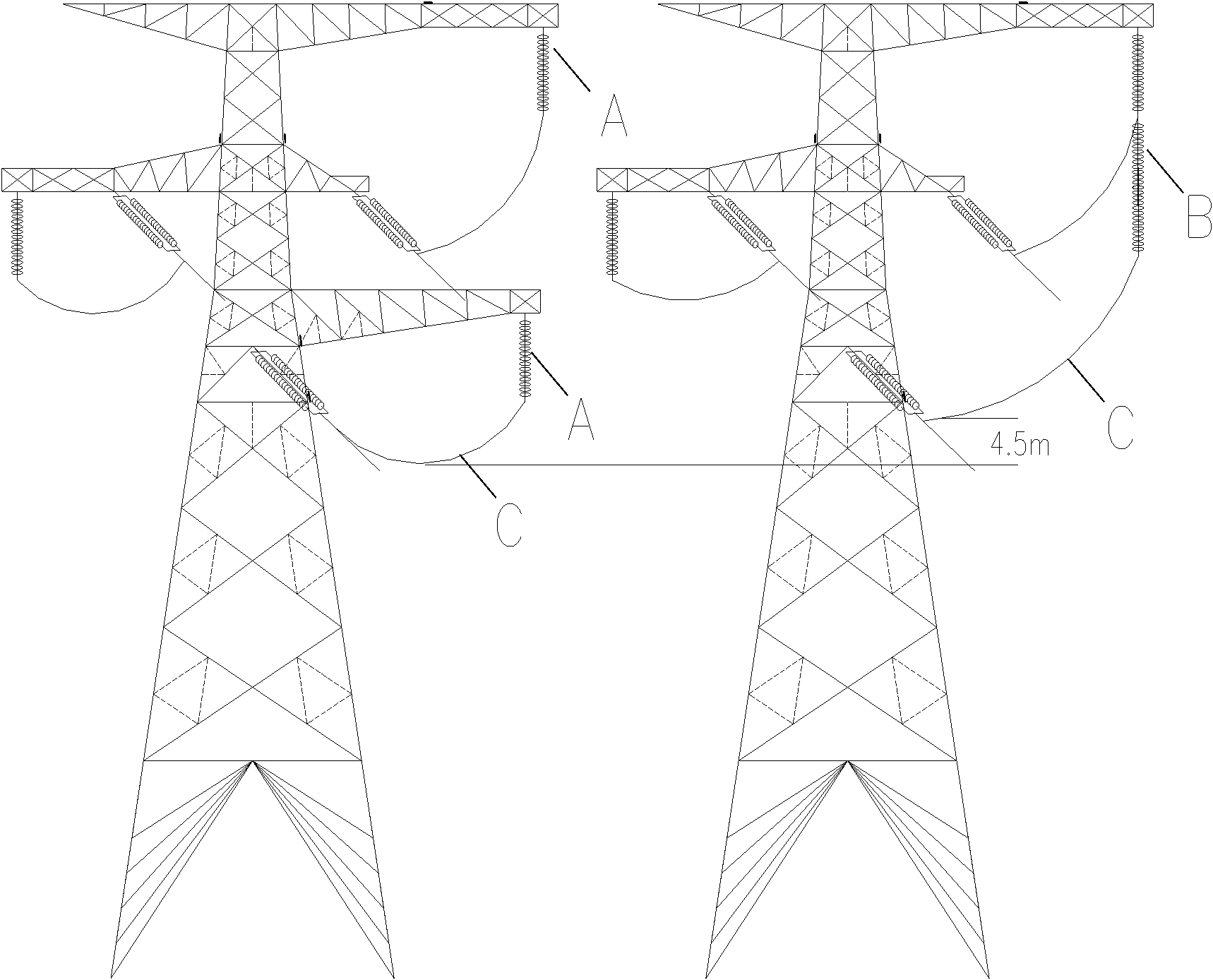

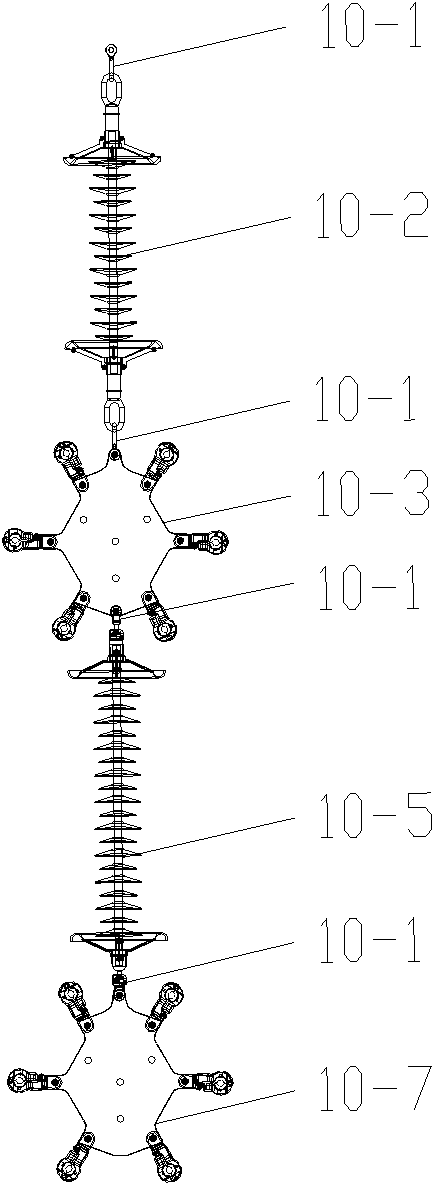

Strain tower with shape like Chinese character 'gan' of compact transmission line

ActiveCN101964505AStructural solutionAddressing Structural ComplexityAdjusting/maintaining mechanical tensionTowersChinese charactersUltra high voltage

The invention relates to a strain tower with a shape like a Chinese character 'gan' of a compact transmission line, comprising tower legs (8), a tower body (7), a tower head (13), a conducting wire strain string (11), a common jumper suspension string (9) and a united jumper suspension string (10), wherein a second conducting wire strain string (11-2) is connected with an upper-phase jumper suspension wire clamp (10-3) of the interphase united jumper string (10) by a second jumper (12-2), and a third conducting wire strain string (11-3) is connected with a lower-phase jumper suspension wire clamp (10-7) of the interphase united jumper string (10) by a third jumper (12-3). The invention has simple structure, increases the earth height of the lower-phase jumper, solves the detects of higher calling height, complicated structure and high self cost of the traditional compact type strain tower structure and reduces tree felling and earth and rock extraction. The compact ultra-high-voltage transmission line has more advanced technology, is more reasonable in economy and more environment-friendly in ecology.

Owner:CENT SOUTHERN CHINA ELECTRIC POWER DESIGN INST CHINA POWER ENG CONSULTING GROUP CORP

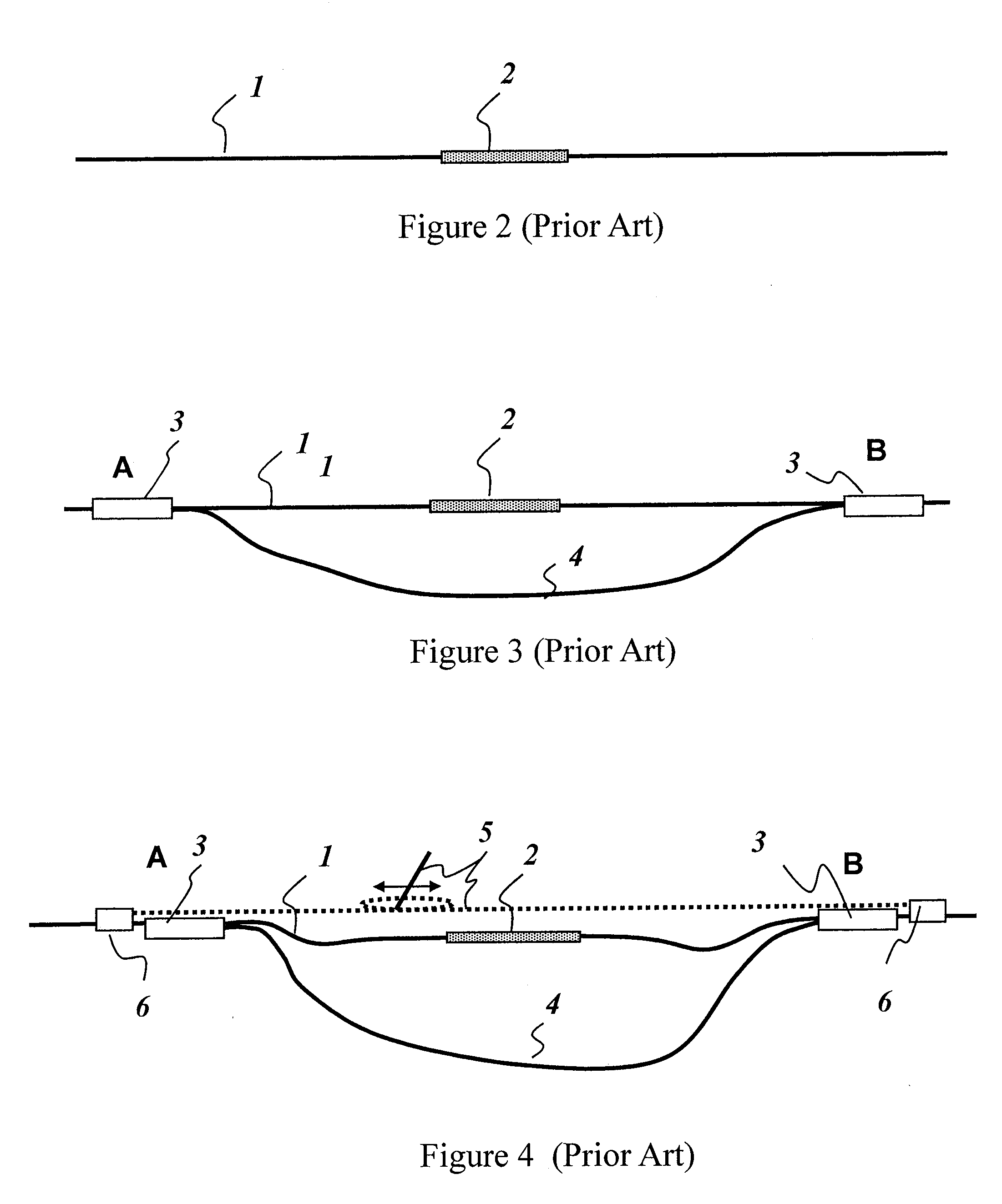

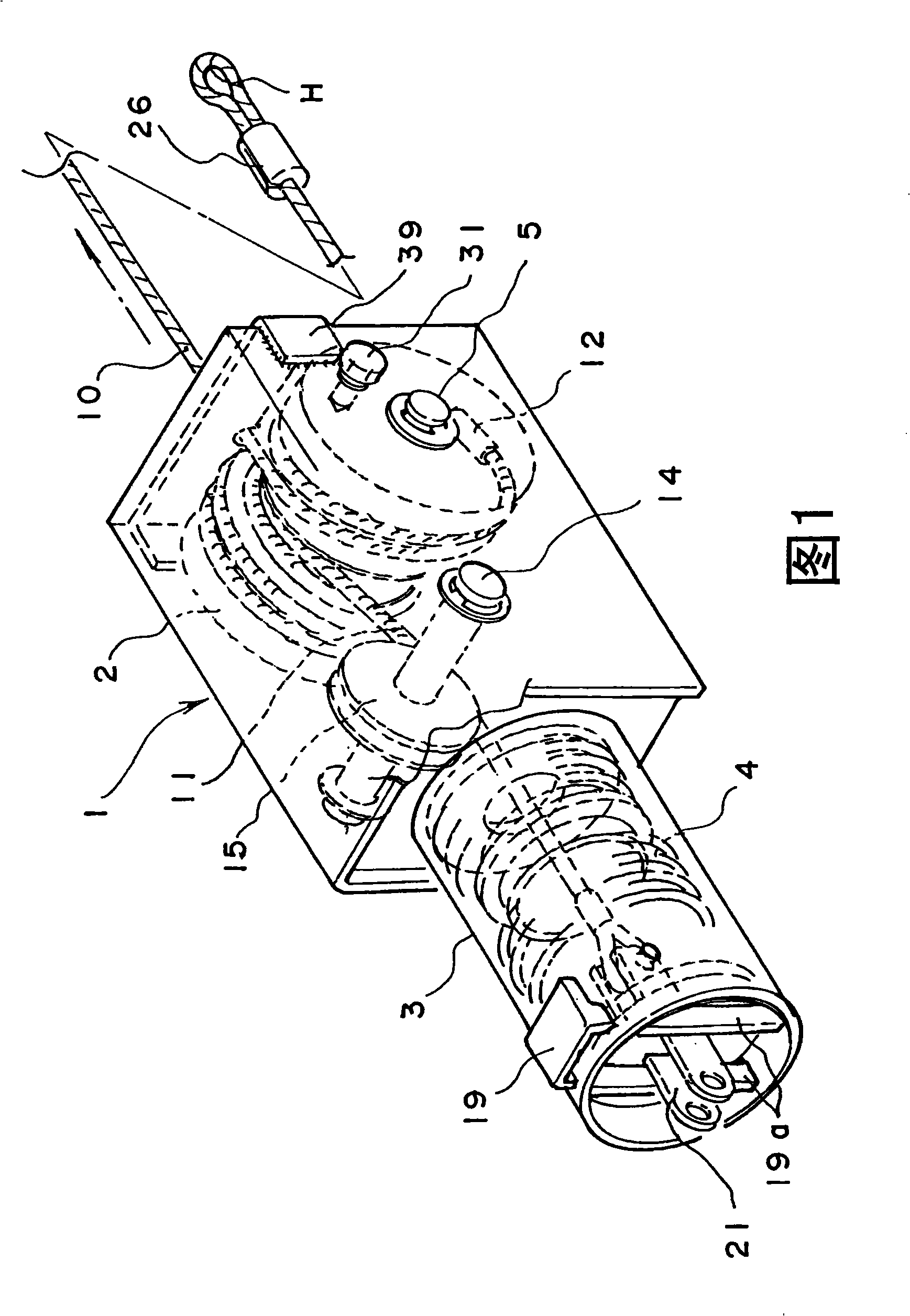

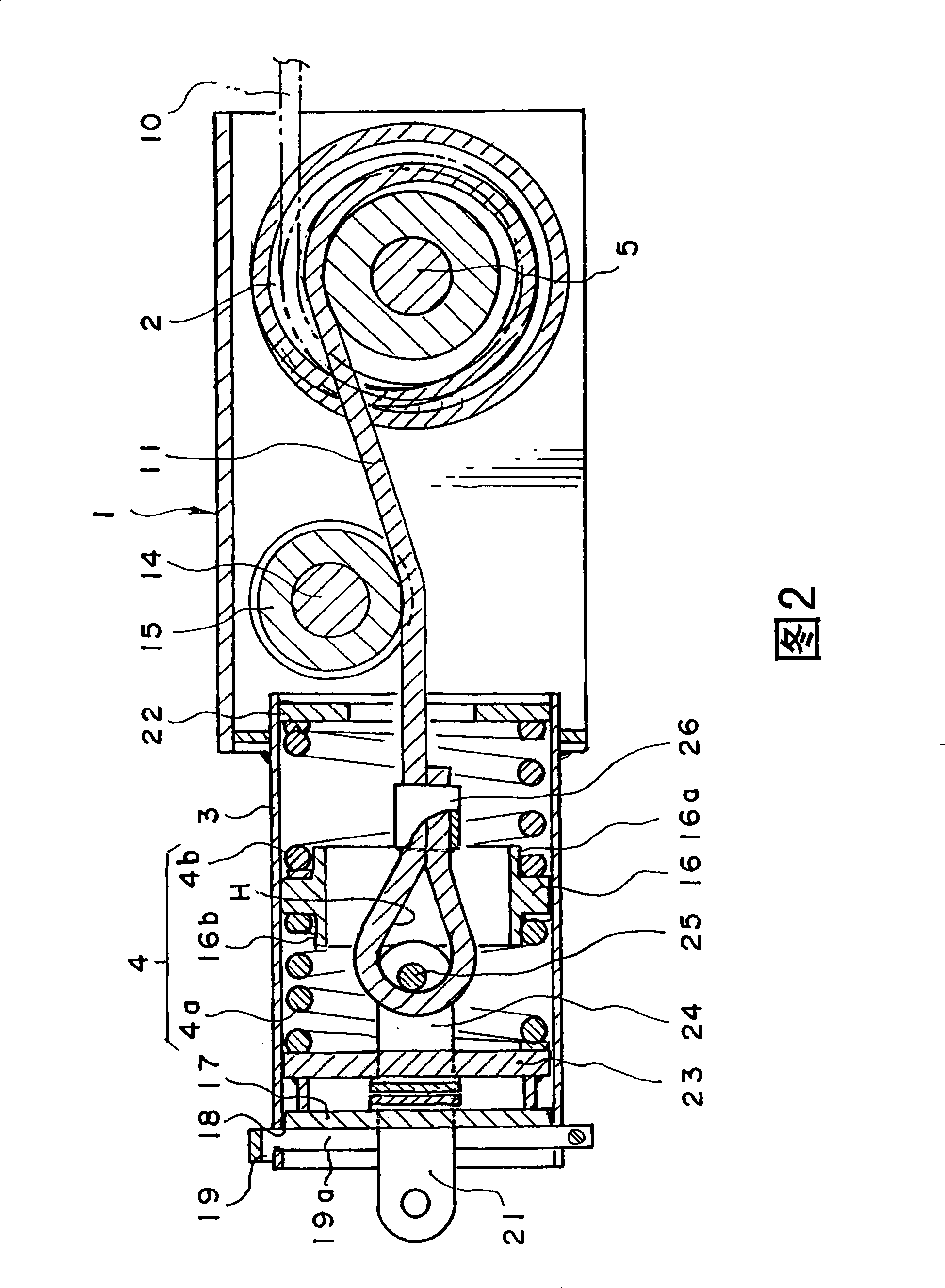

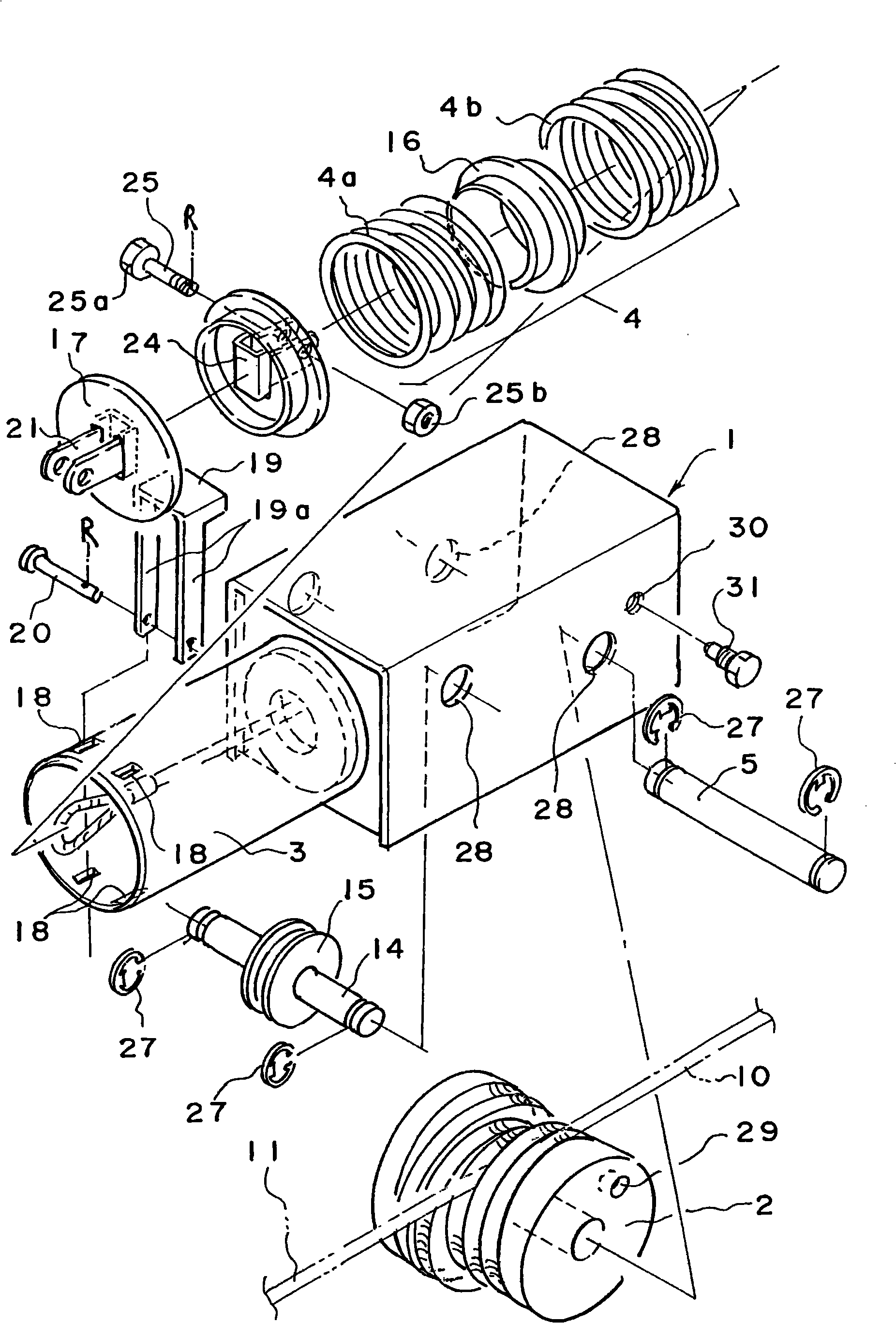

Tension balancer for overhead line

InactiveCN101330199AEasy to combineChange the tensionAdjusting/maintaining mechanical tensionTrolley linesAxial displacementCoil spring

The present invention provides a tensioning balancer for overhead wire, which can absorb the expansion of a overhead wire and hold the tensioning of the overhead wire to a certainty, can be realized only by maintaining timely, has good permanent stability, and can avoid generating tension force from unbalance caused by external causes. The tensioning balancer for overhead wire comprises: a tension force transformation pulley (2) forming with a first cable leading trough (6) and a second cable leading trough (7) with changeable diameter, a first cable (10) coiled in the first cable leading trough (6), a second cable (11) coiled in the second cable leading trough (7), and a coil spring (4) applying force on a axial displacement component to the opposite side of one end of the second cable (11), expansion amount of the overhead wire is absorbed by the expending action of the coil spring (4) with the rotation of the tension force transformation pulley (2).

Owner:西村生

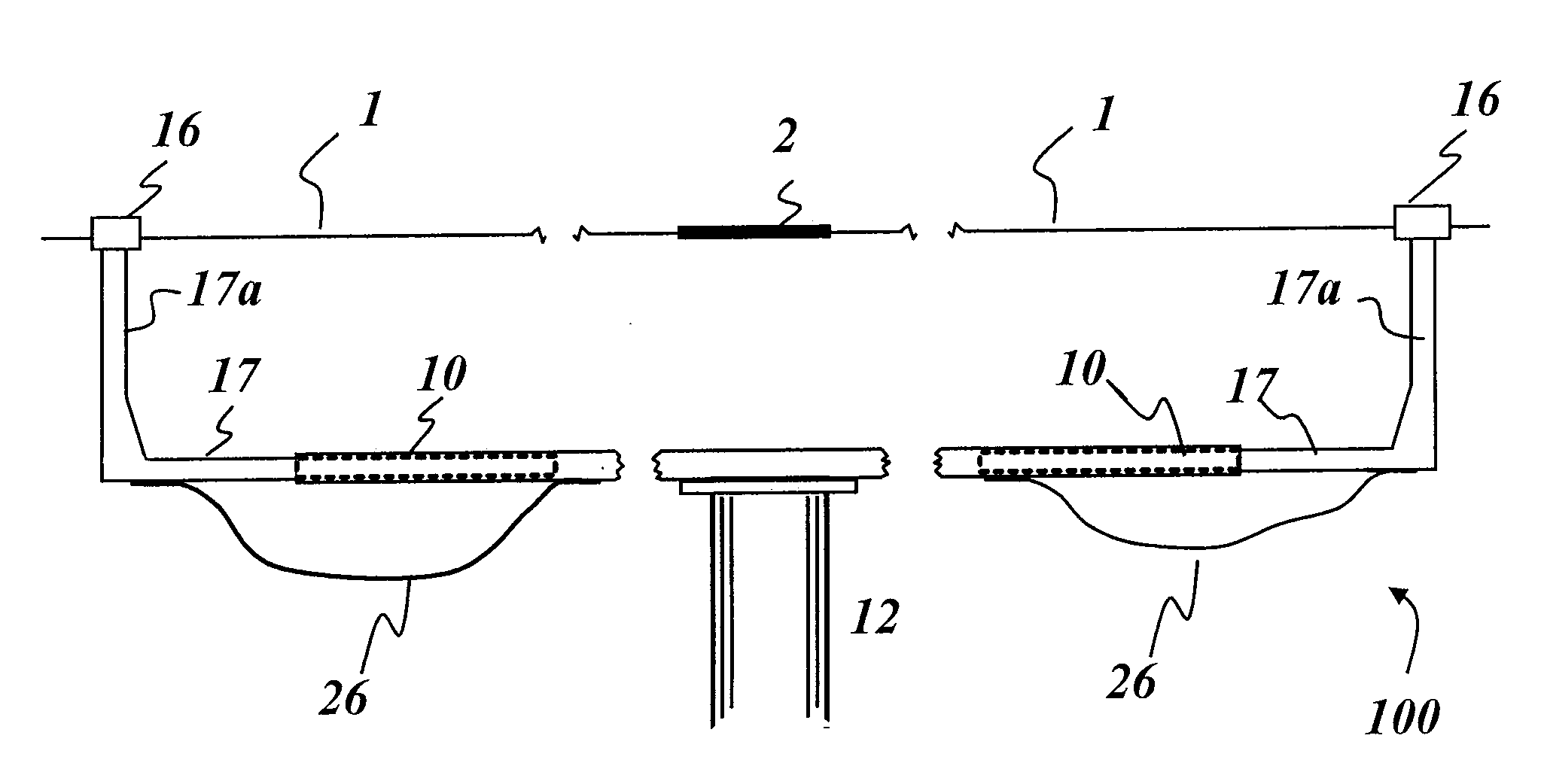

Method for increasing the current carried between two high voltage conductor support towers

InactiveUS20060016616A1Easily reheatedAvoid excessive labor intensityNon-insulated conductorsInsulated cablesElectrical conductorEngineering

A method for increasing the current carried between two high voltage conductor support powers is provided. The method includes removing a first high voltage carrying cable mounted between the towers and replacing it a composite core cable.

Owner:GOLDSWORTHY WILLIAM BRANDT +1

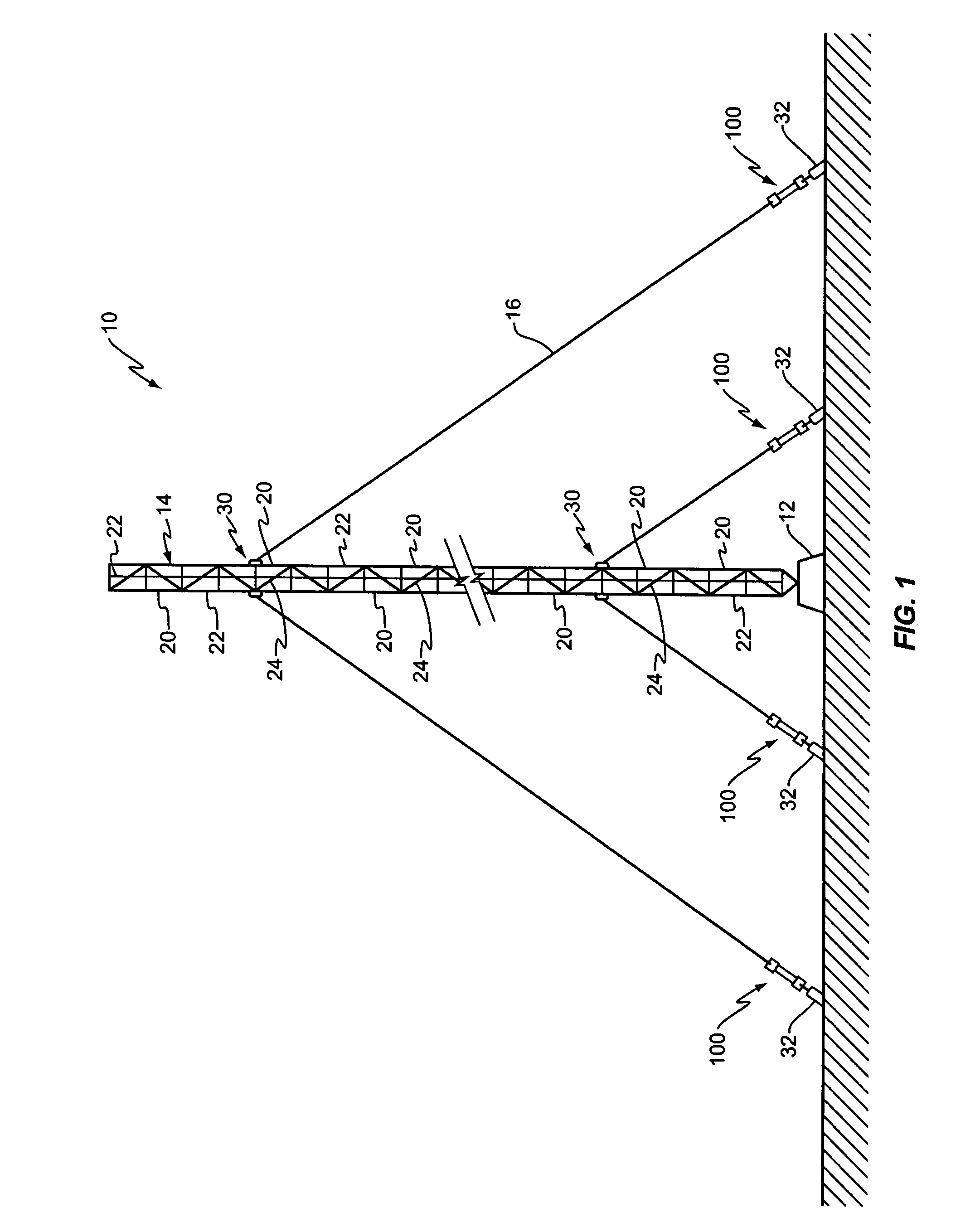

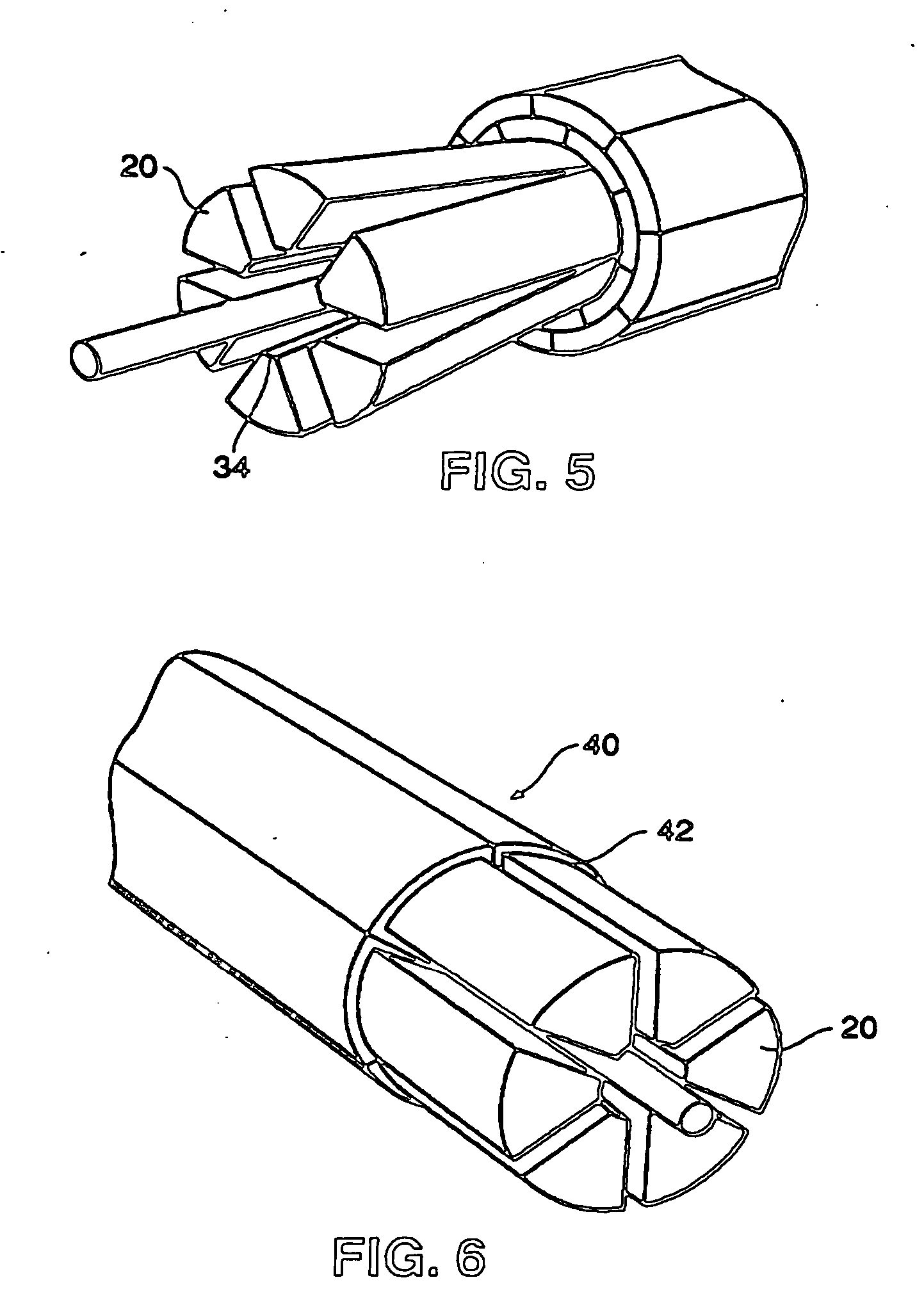

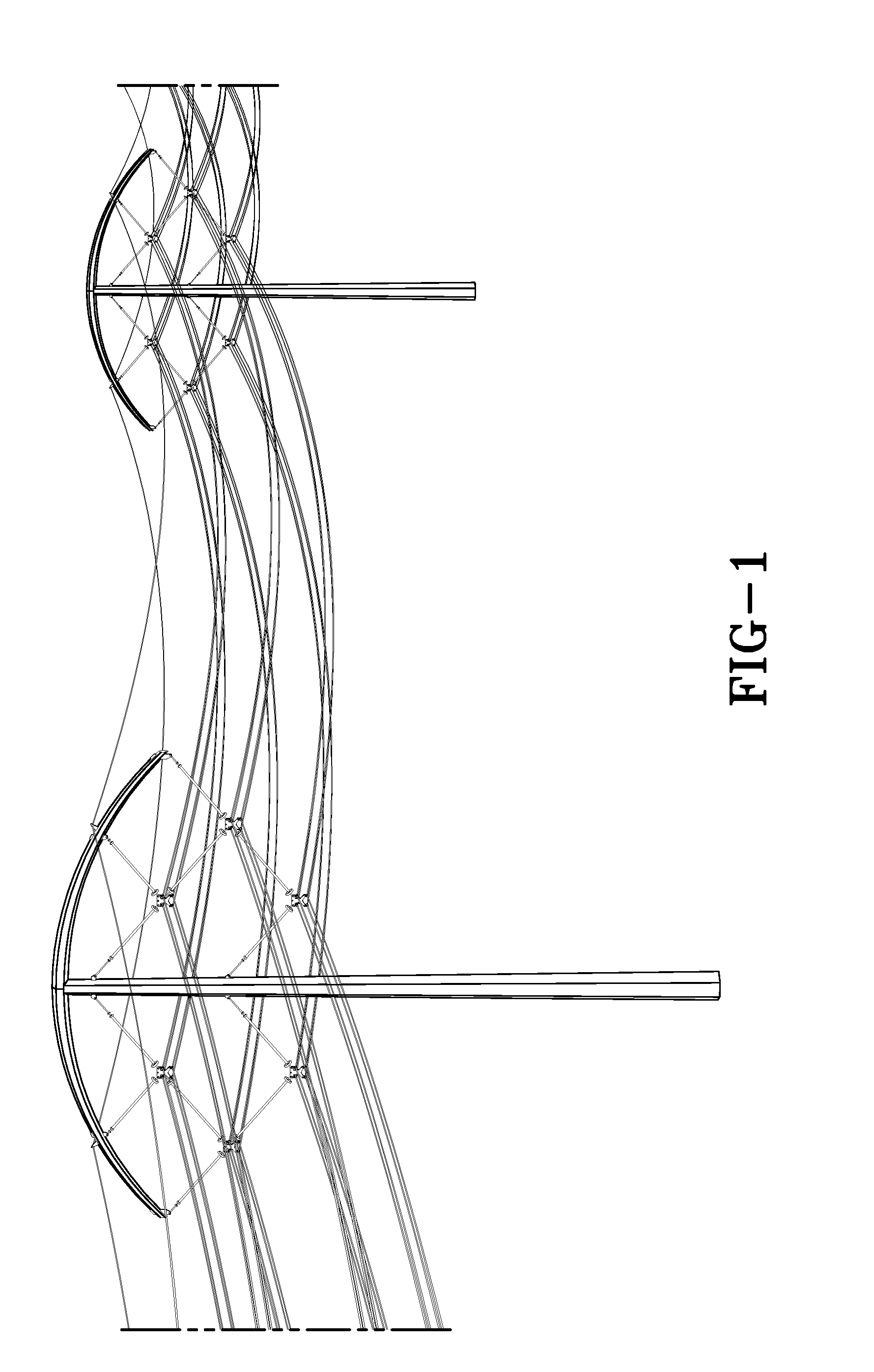

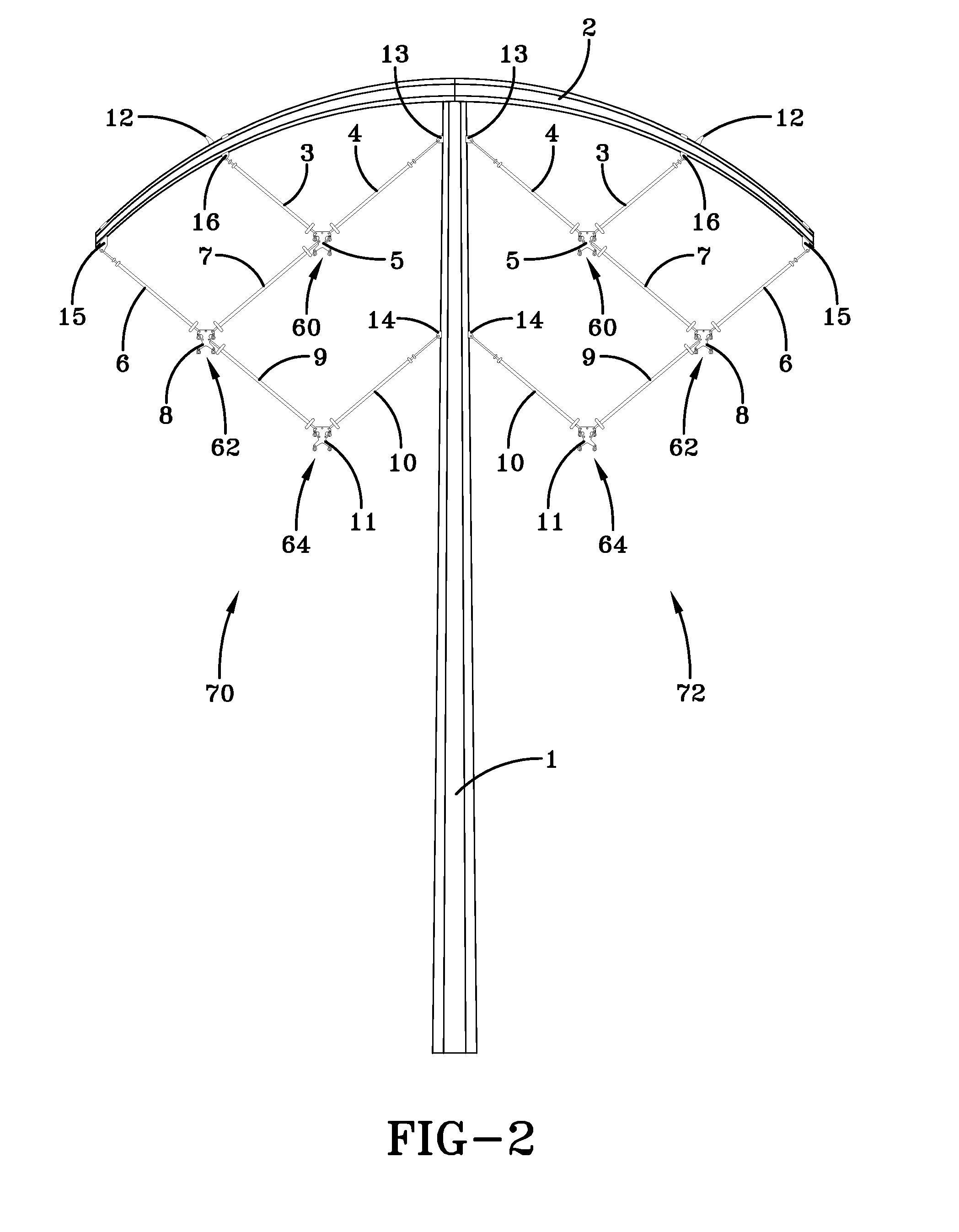

High-capacity/efficiency transmission line design

ActiveUS8952251B2Easy constructionLow costAdjusting/maintaining mechanical tensionSpatial arrangements/dispositions of cablesTransmission towerElectrical resistance and conductance

A transmission tower structure for suspending from an arched crossarm a three phased circuit arranged in a compact delta configuration that improves the surge impedance loading (SIL) of a transmission line, reduces its series impedance, lowers both resistive and corona losses, and moderates electromagnetic fields and audible noise effects at the ground level—all achieved in a cost effective manner. The structure further has a low overall height and aesthetic appearance enhancing the public acceptance of the embodiments.

Owner:BOLD TRANSMISSION LLC

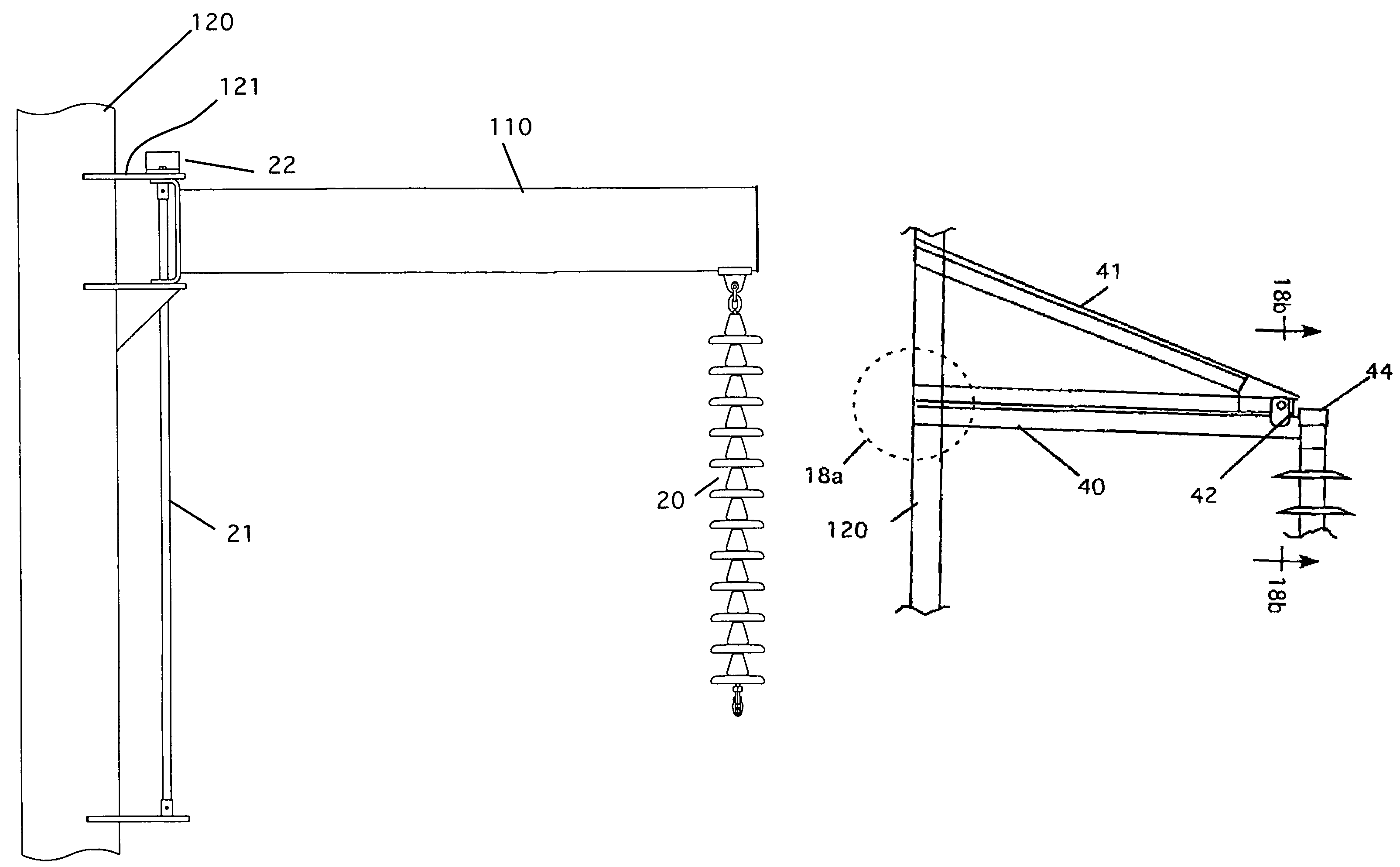

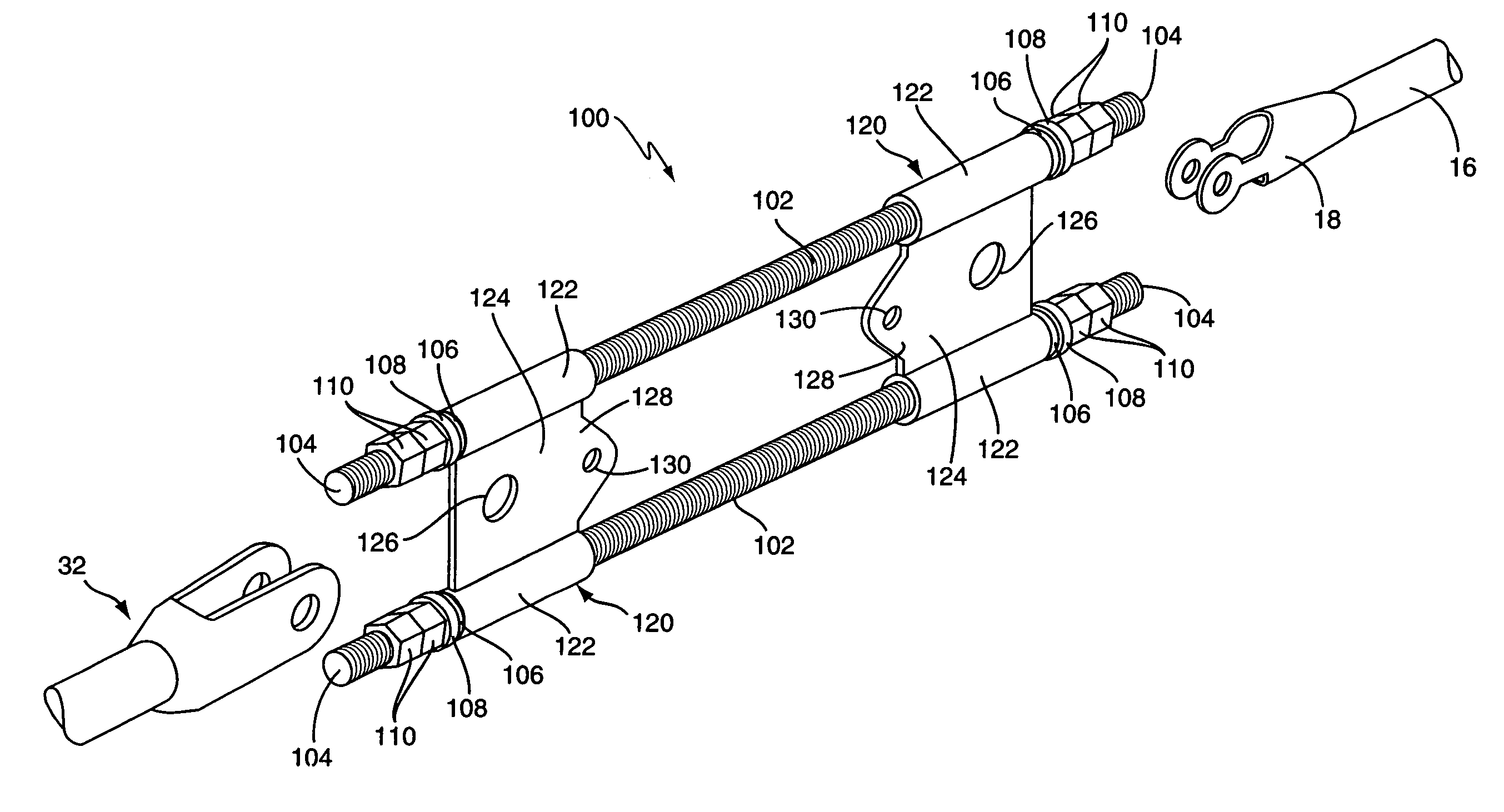

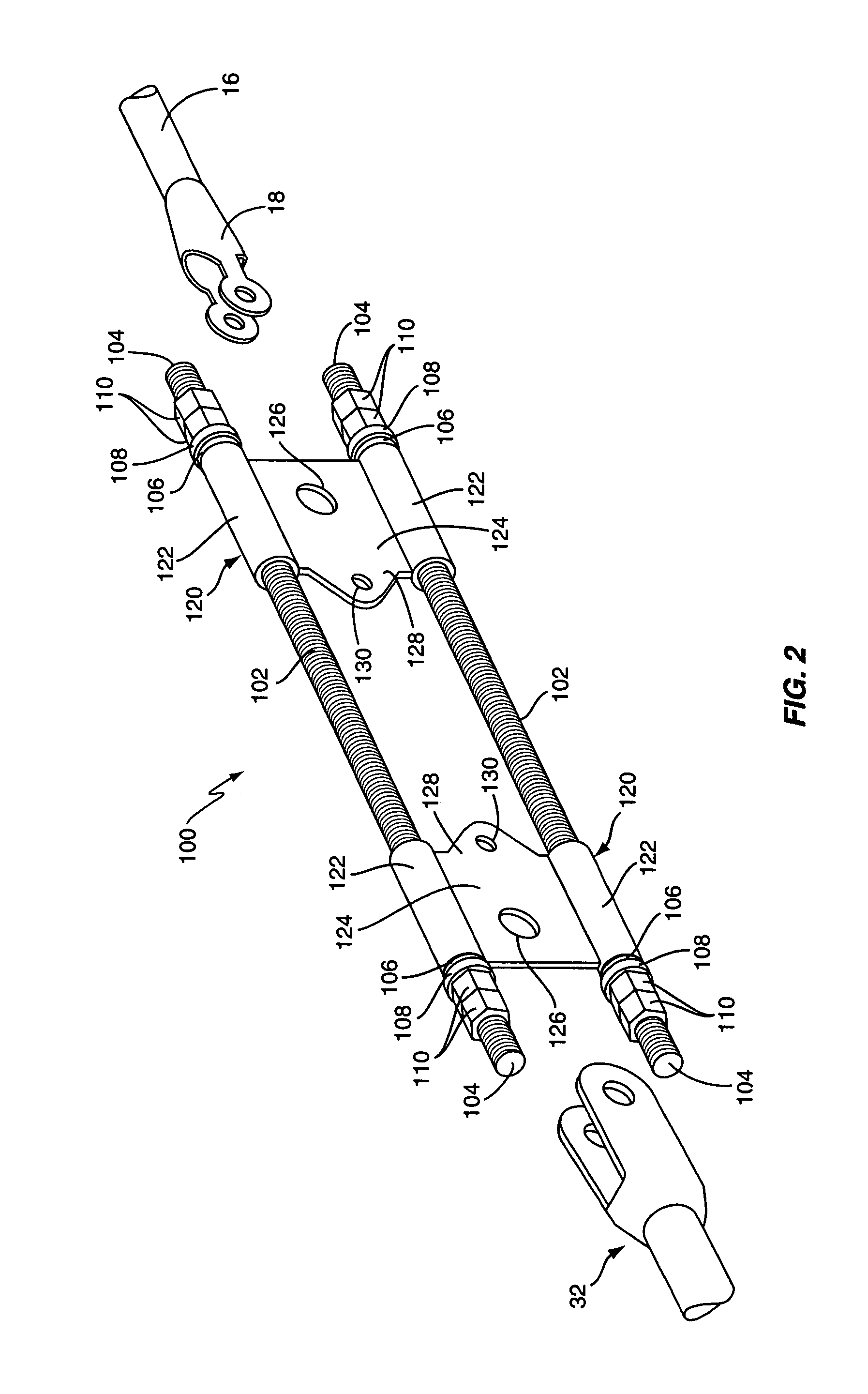

Longitudinal load limiting devices for transmission lines and the like

InactiveUS7732708B1Absorb energyPrevent freezingMaintaining distance between parallel conductorsPipe supportsEngineeringTower

A device for limiting loads on towers that limits loads only in the longitudinal direction and does not affect the manner in which vertical and transverse loads are resisted by the structure. The device incorporates a shield to prevent ice buildup that could affect its operation. It also has optional antifriction bearings to provide a consistent release force independent of the amount of ice that may accumulate on the wires. The device is of simple construction. The device includes an optional energy absorber, such as that used in U.S. Pat. No. 3,211,260 that can provide a resisting force that is within the longitudinal strength of the tower. The device includes both a mechanical fuse and an energy absorbing mechanism that is used to arrest the wire movement. The energy absorber can extend as much as 50 ft to safely absorb the energy released by broken wires with heavy ice coatings.

Owner:PEABODY ALAN B

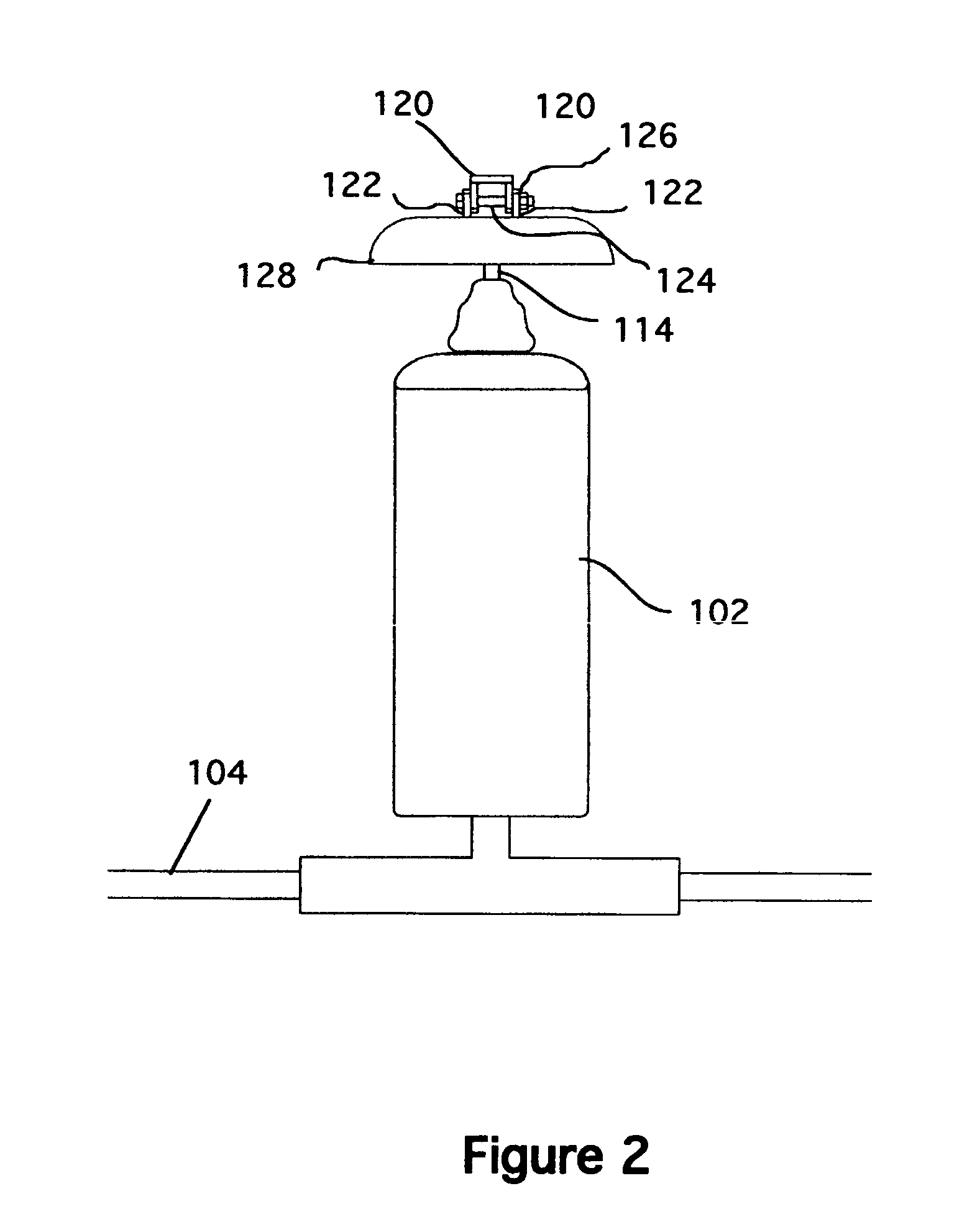

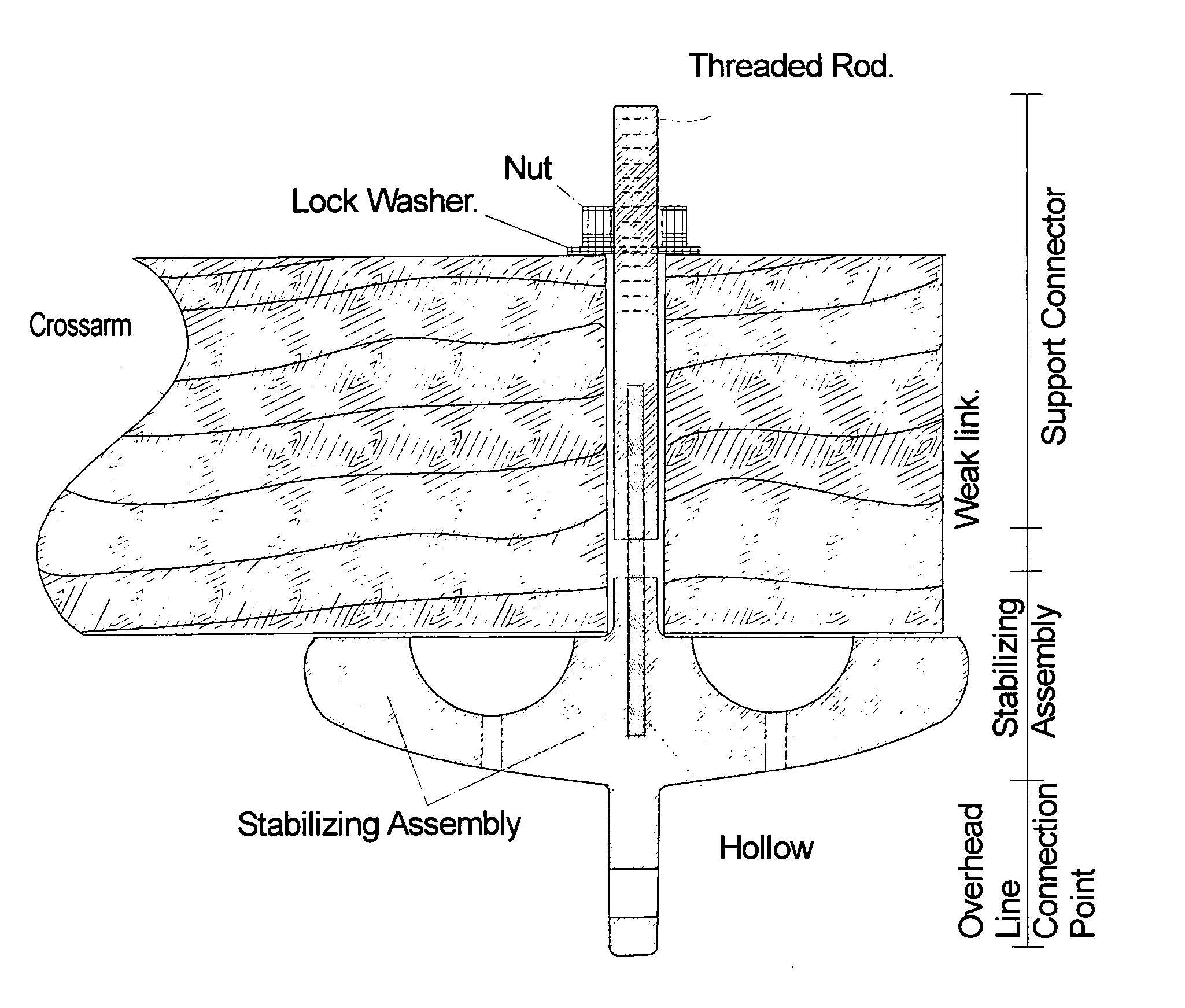

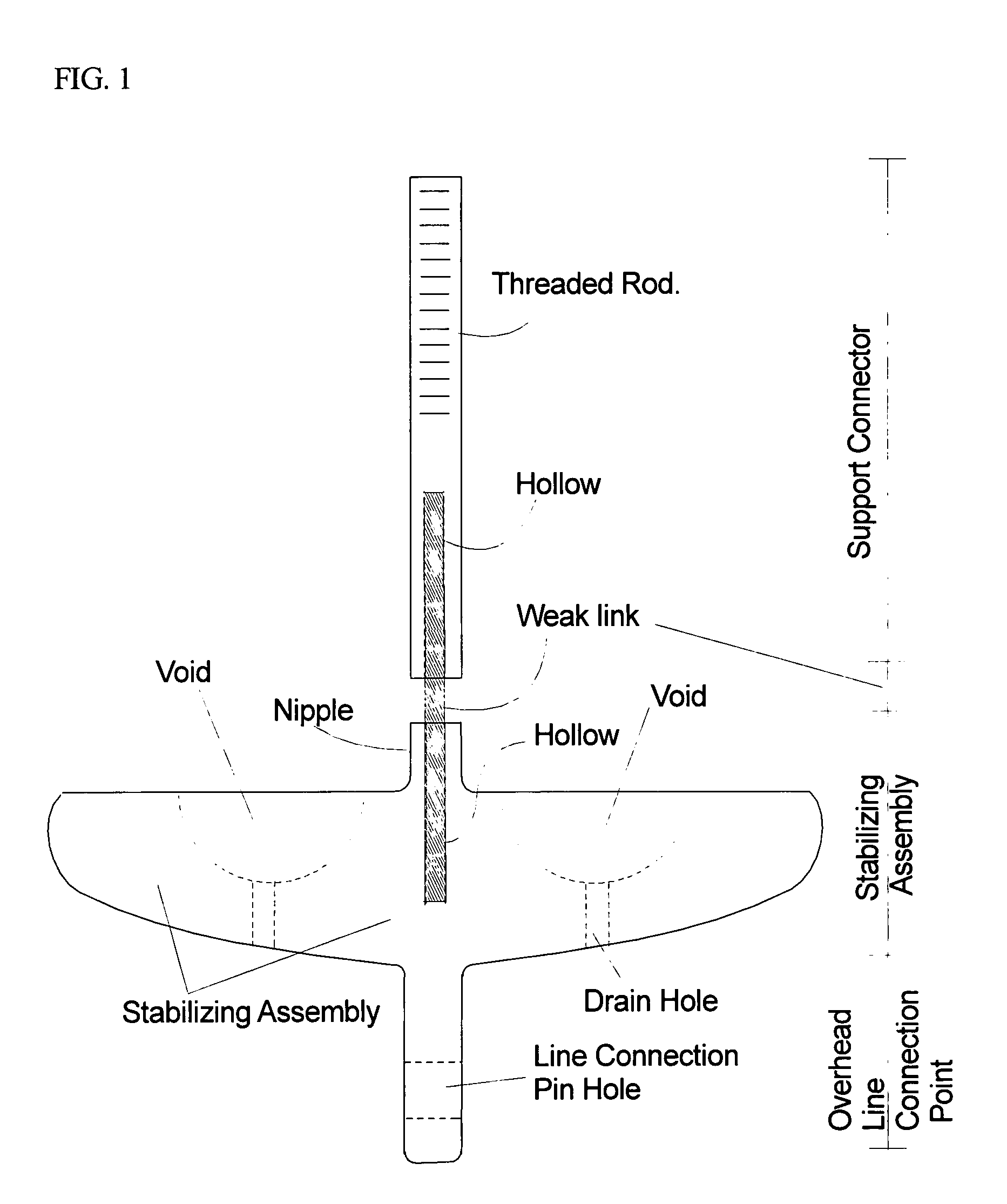

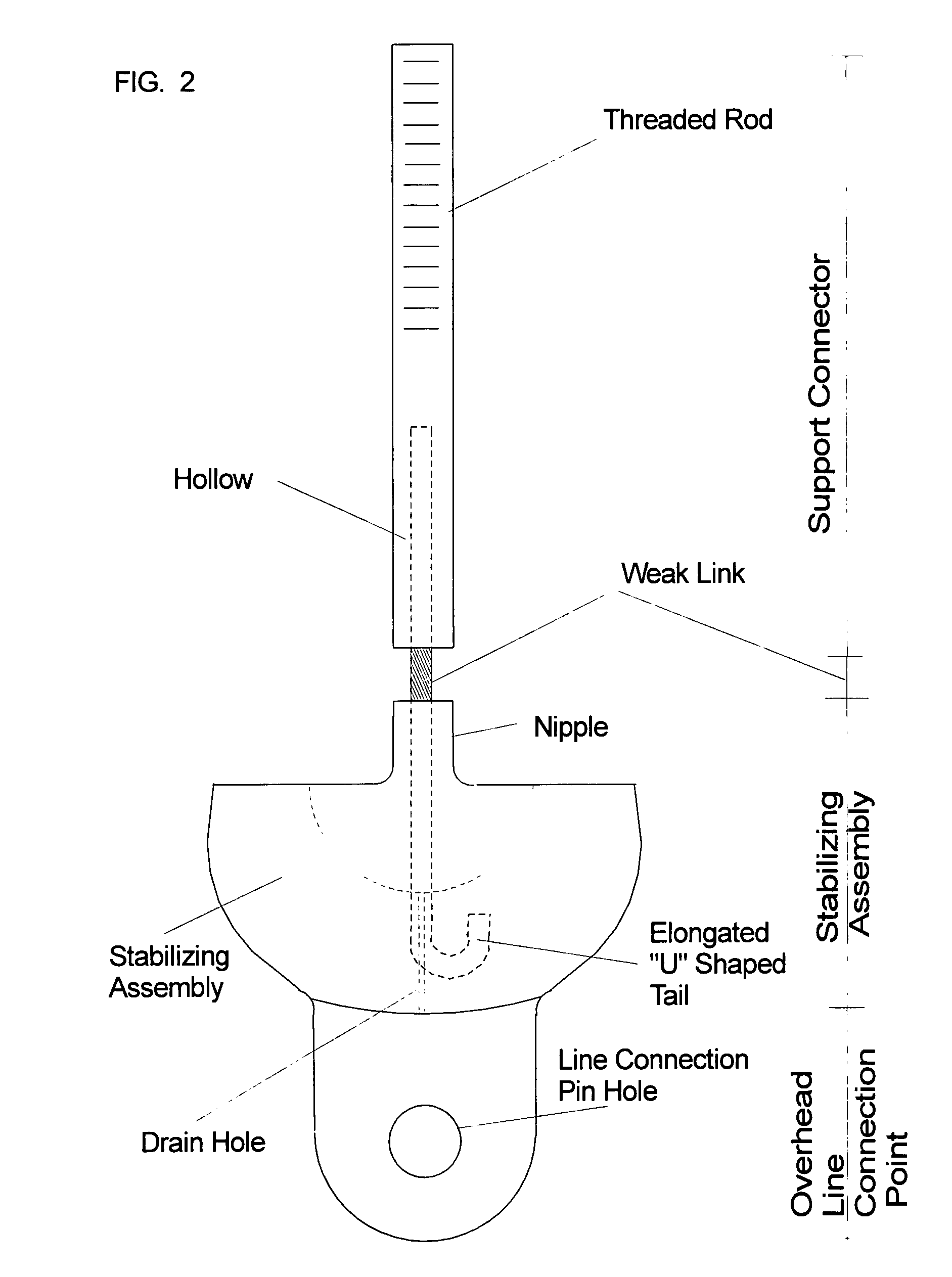

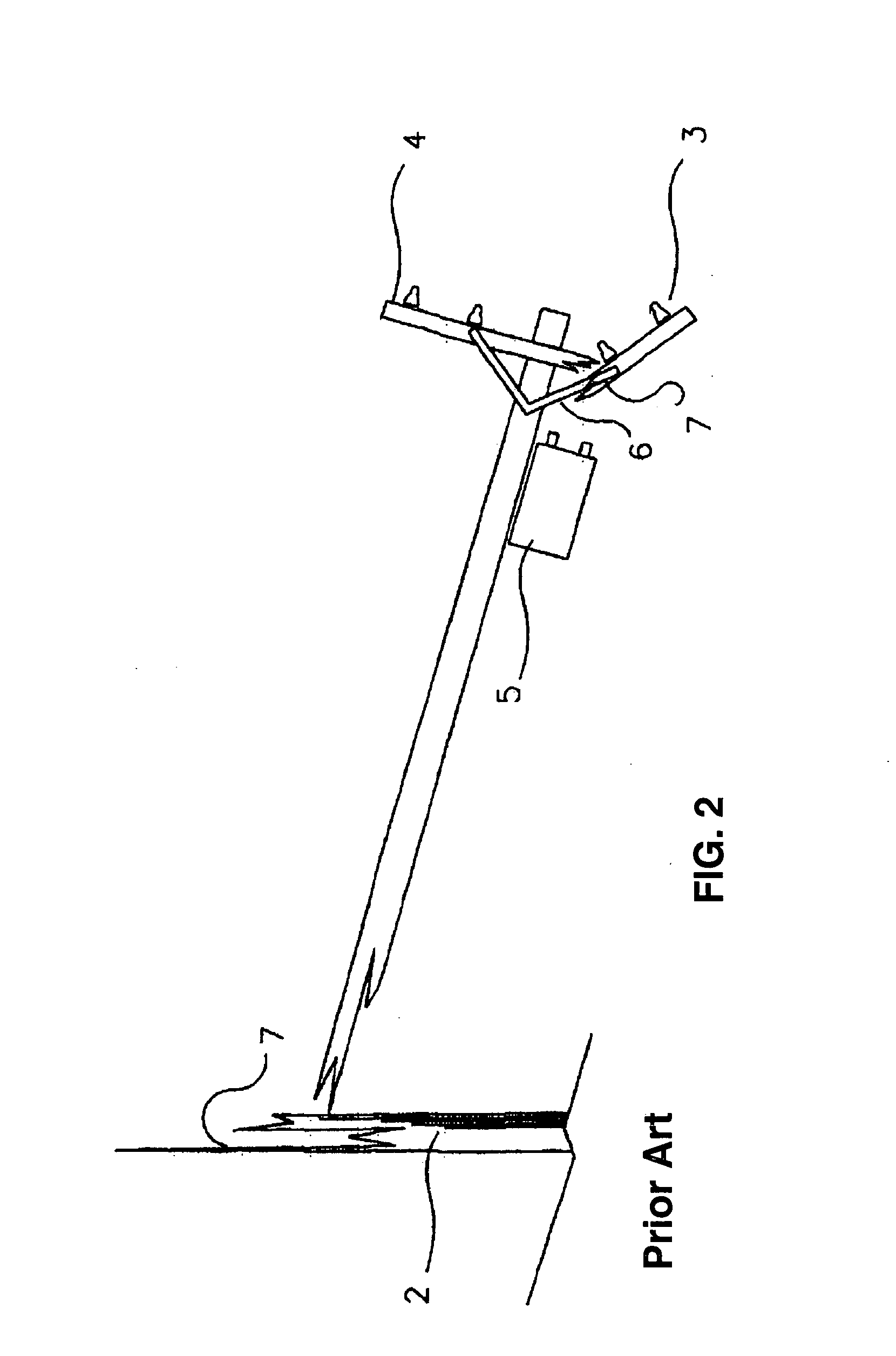

Breakaway support for overhead lines

InactiveUS20050081458A1Quicker and less-costly restorationAvoid damageAdjusting/maintaining mechanical tensionCouplings for rigid shaftsEngineeringOverhead line

The breakaway support for overhead lines is a coordinated failure control device. The breakaway support for overhead lines sacrifices itself to ensure that the supporting structure is not damaged. The device has an intentional weak link. The breakaway support for overhead lines will release when the overhead line it is supporting receives a stress that exceeds the tensile strength of the weak link in the breakaway support for overhead lines. The stress causes the weak link to fail. The structure is not damaged and a repair crew can quickly affect repairs. It is much cheaper and easier to reconnect an overhead line than it is to replace or repair a structure and then reconnect the overhead line.

Owner:MCDONALD RICHARD ALAN

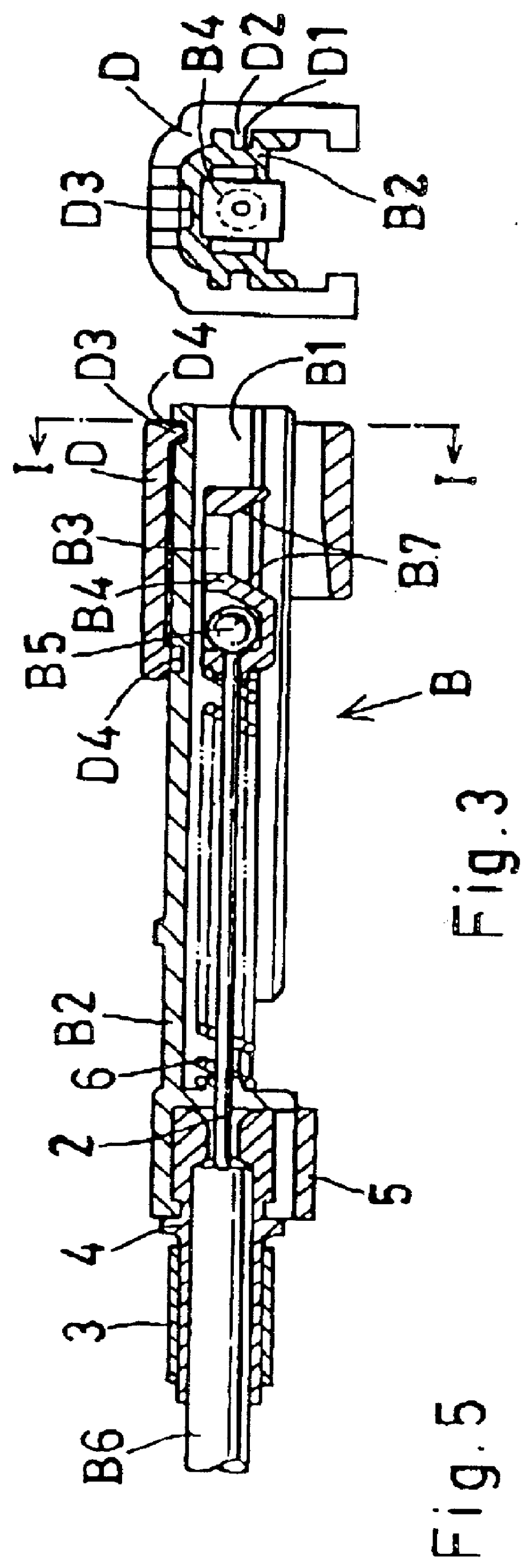

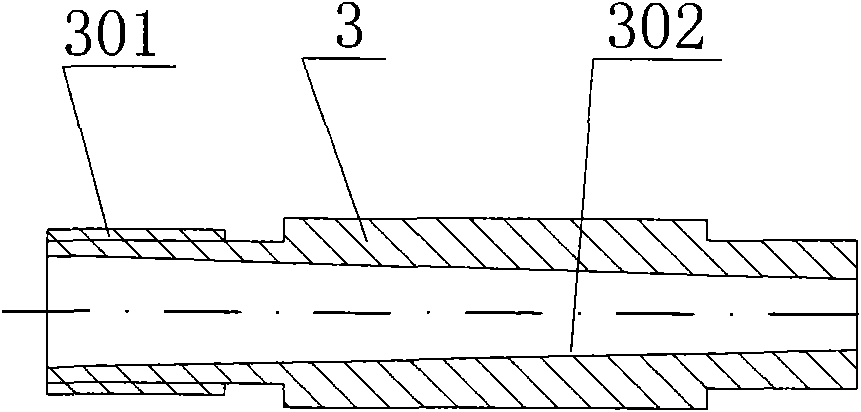

Cable joint structure

InactiveUS6102609AFast disconnectionEasy to handleAdjusting/maintaining mechanical tensionRopes and cables for vehicles/pulleyMechanical engineeringEngineering

Owner:CHUO SPRING

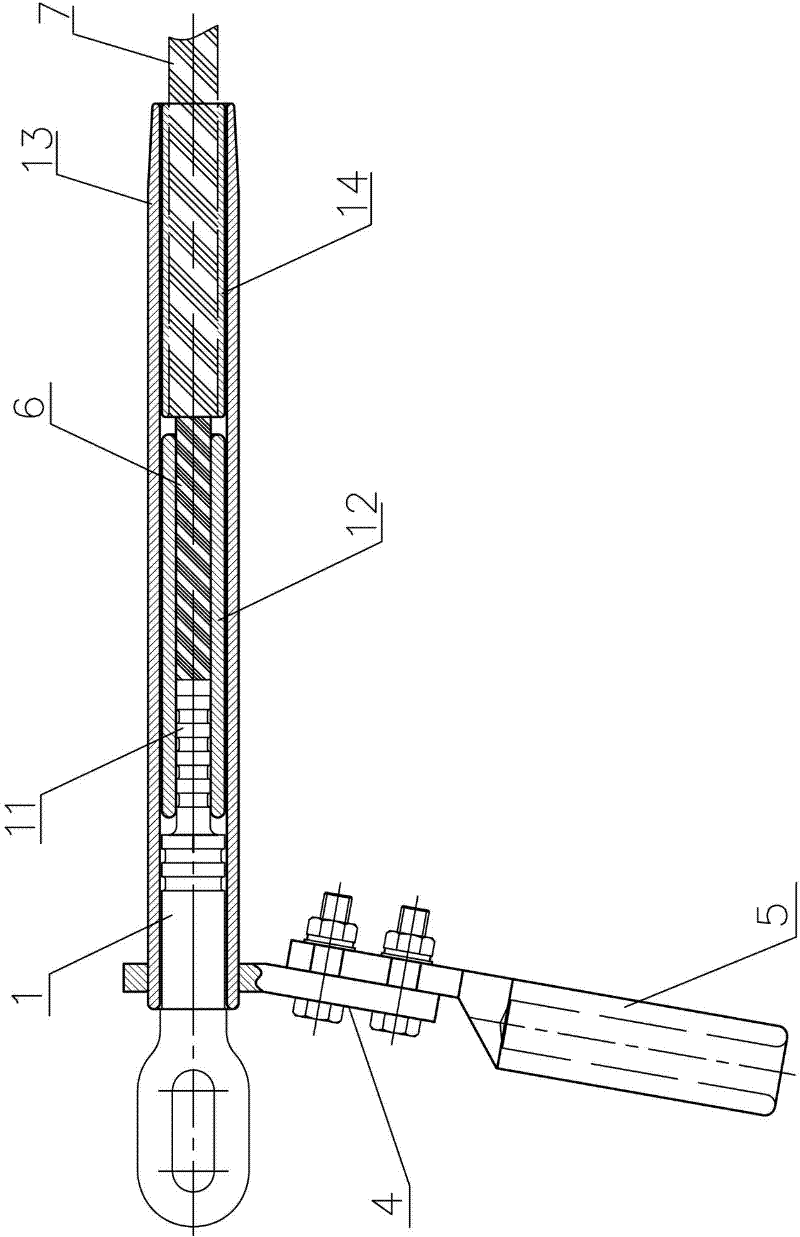

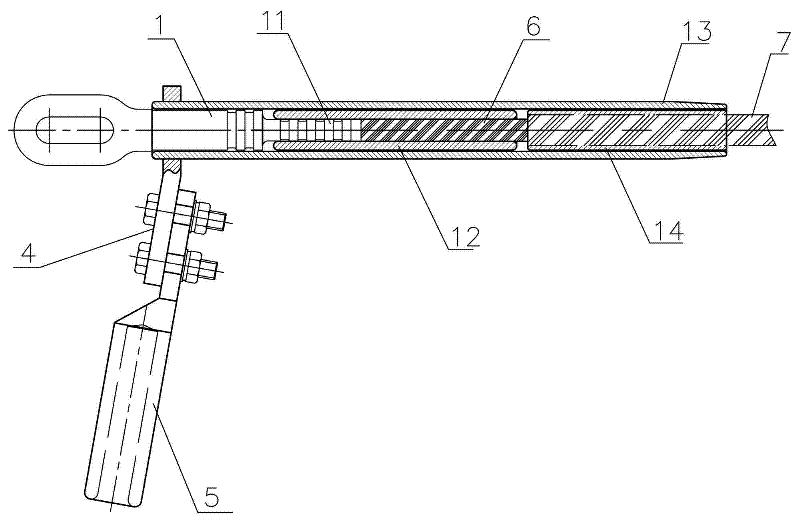

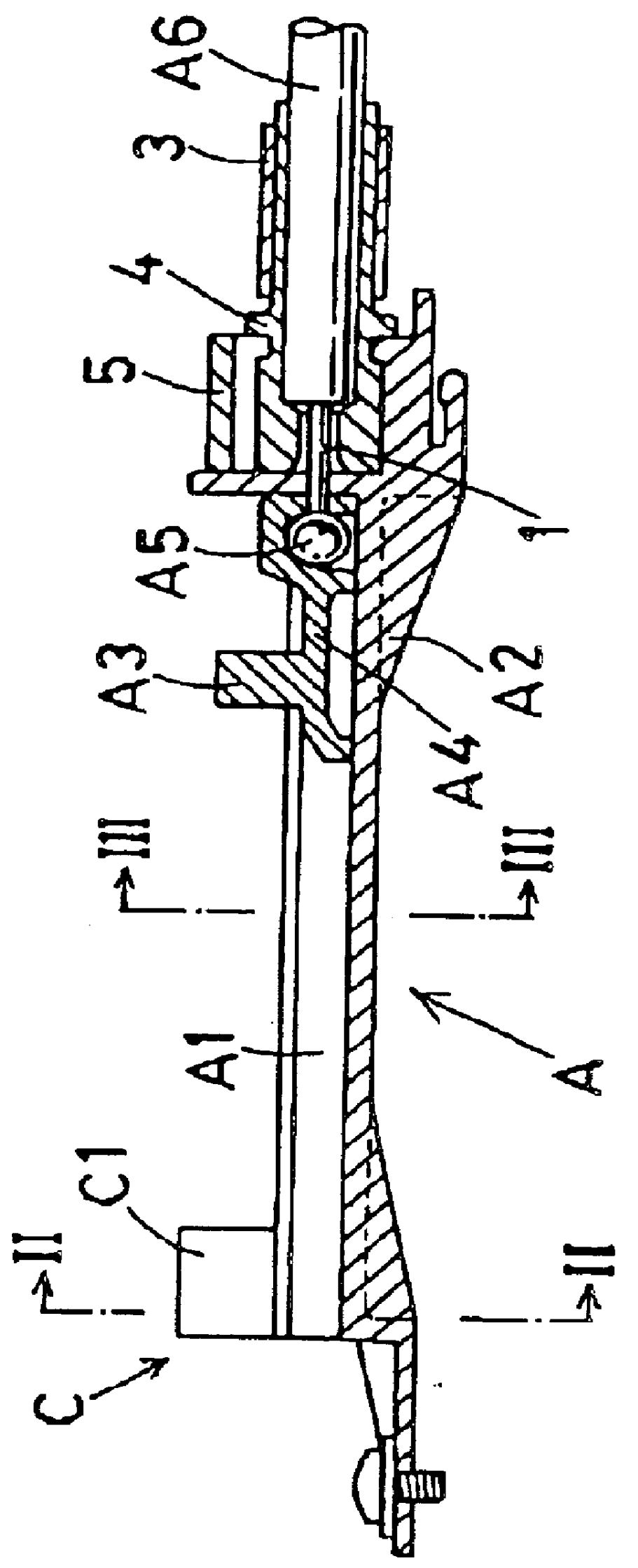

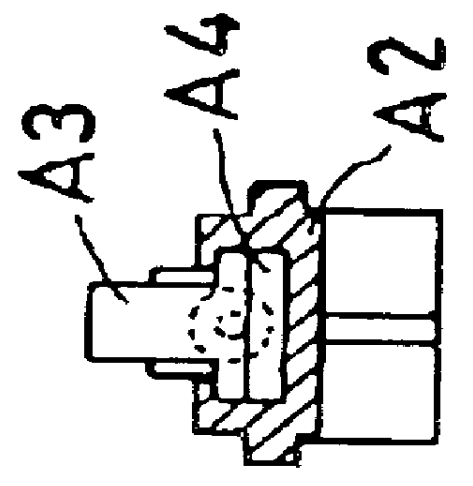

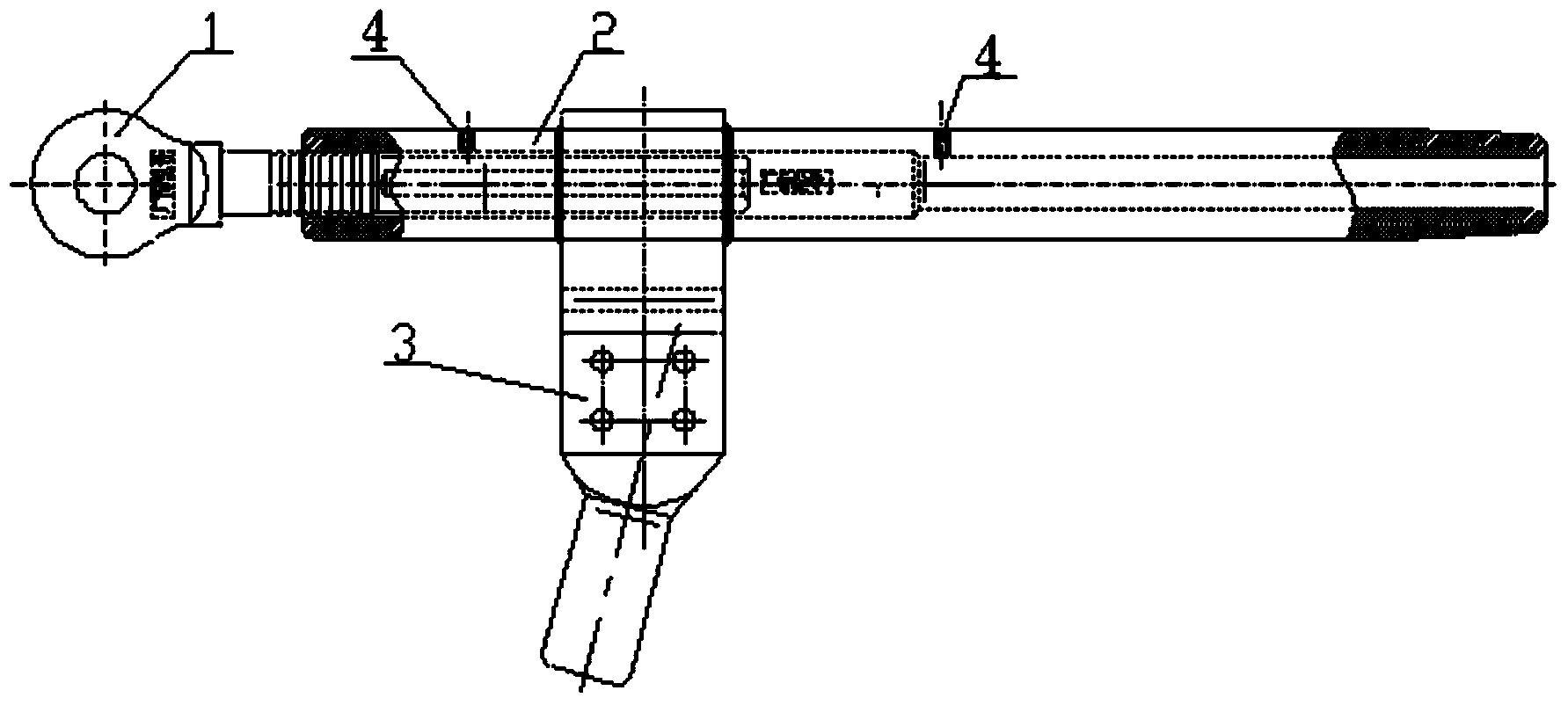

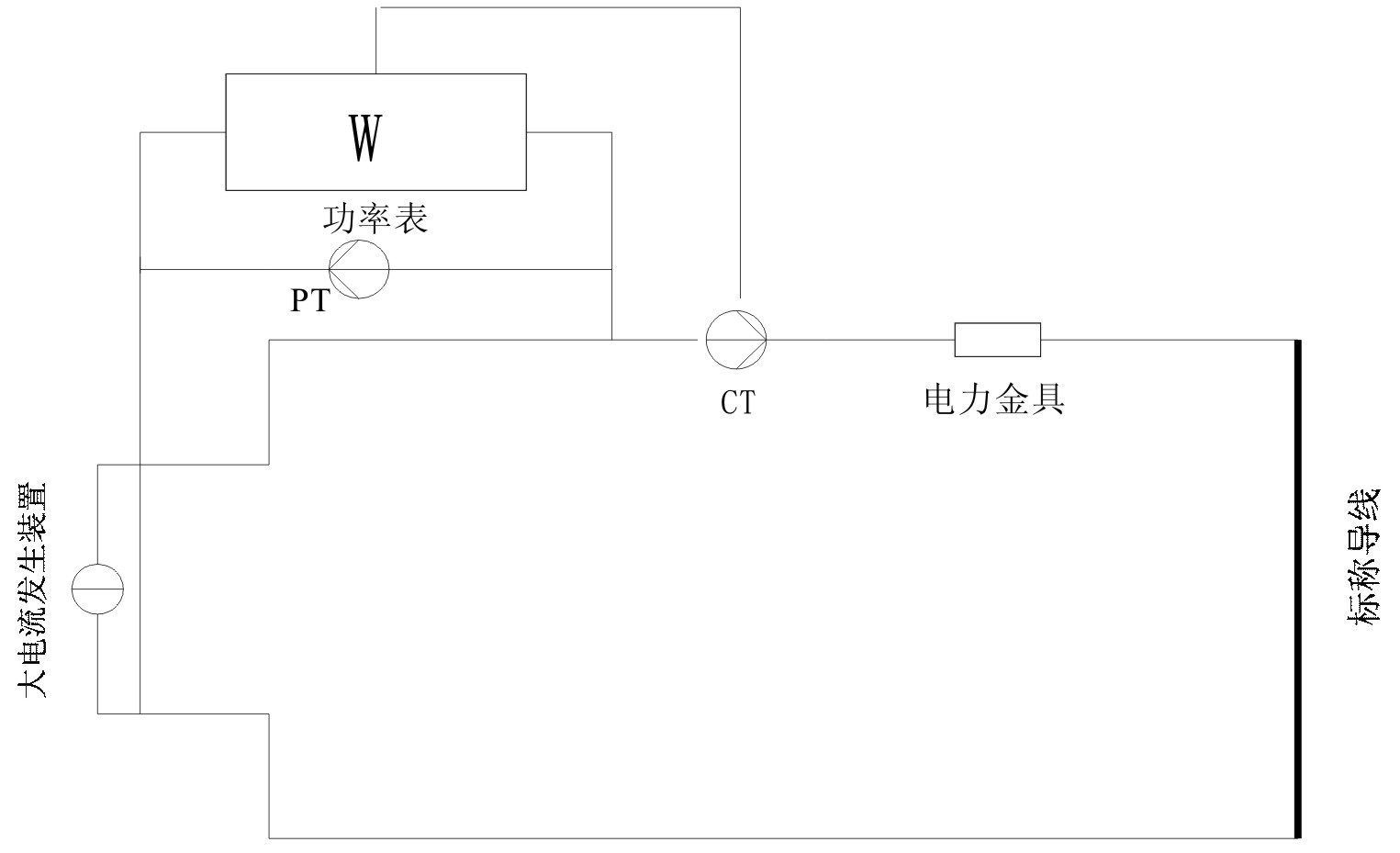

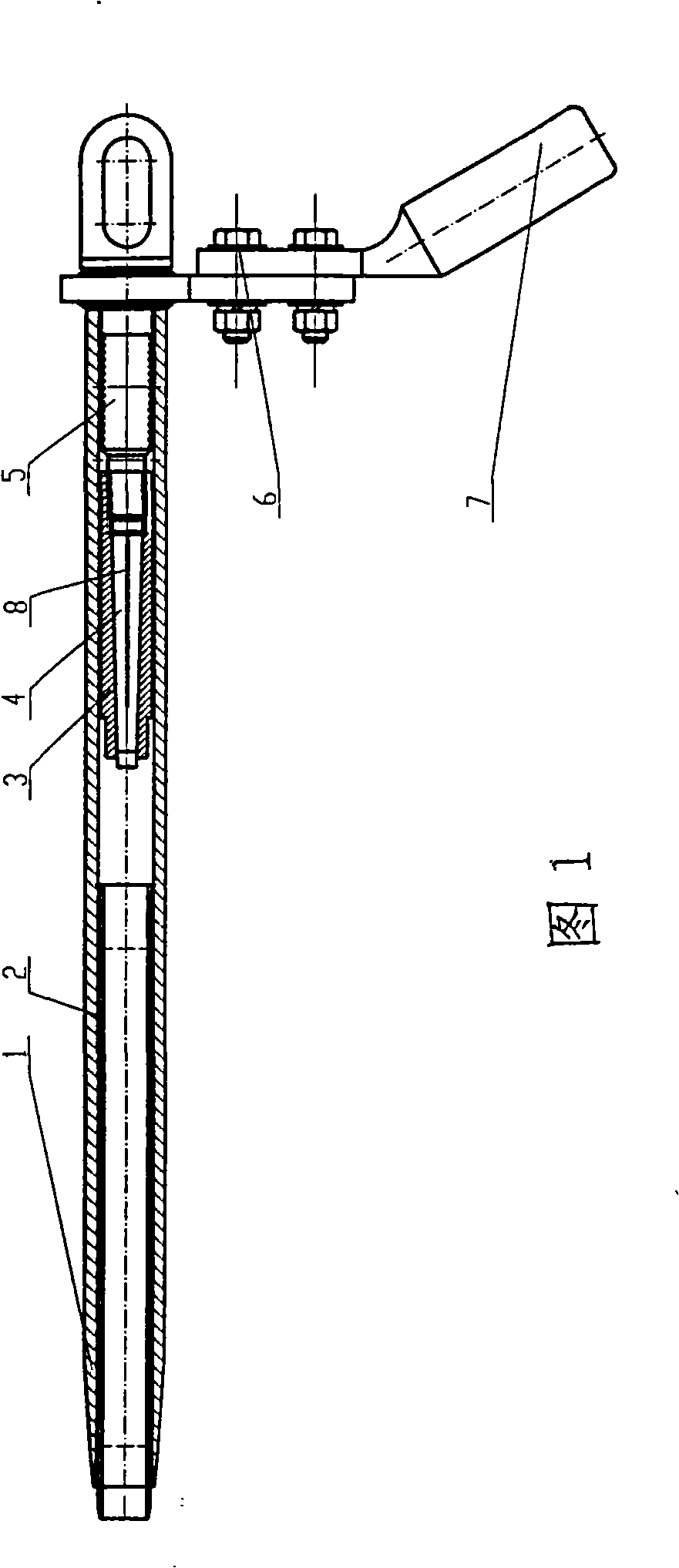

Strain clamp for JRLX/T carbon fiber leads

InactiveCN101567537ADesign scienceNovel structureAdjusting/maintaining mechanical tensionFiberCarbon fibers

The invention provides a strain clamp for JRLX / T carbon fiber leads, relates to a strain clamp for connecting, fixing and tensioning the JRLX / T (ACCC) carbon fiber leads on a pole tower in an overhead electric transmission and transformation circuit, is classified in H02G7 / 02, and relates to electric power fittings arranged in the electric transmission and transformation circuit, namely the technical field of devices for adjusting and keeping mechanical tension. The strain clamp comprises an internal thread pull anchor, a sleeve, an inner-cone external thread core sleeve, an outer-cone elastic clamp core, a bush, and the like. The strain clamp is mainly characterized in that the internal thread pull anchor is connected with the inner-cone external thread core sleeve the middle of which the outer-cone elastic clamp core passes through, a lead composite core passes through the interior of the outer-cone elastic clamp core, the outer-cone elastic clamp core is automatically clamped with the inner-cone external thread core sleeve through a radial acting force to lock the lead composite core, and the JRLX / T (ACCC) carbon fiber leads are connected and fixed on the pole tower through hydraulic pressure and the like. The strain clamp has the advantages of novel structure, good guide performance, strong stability, stable holding power, low cost, convenience for mounting and constructing, low labor intensity, and the like.

Owner:JIANGSU YIDING POWER TECH

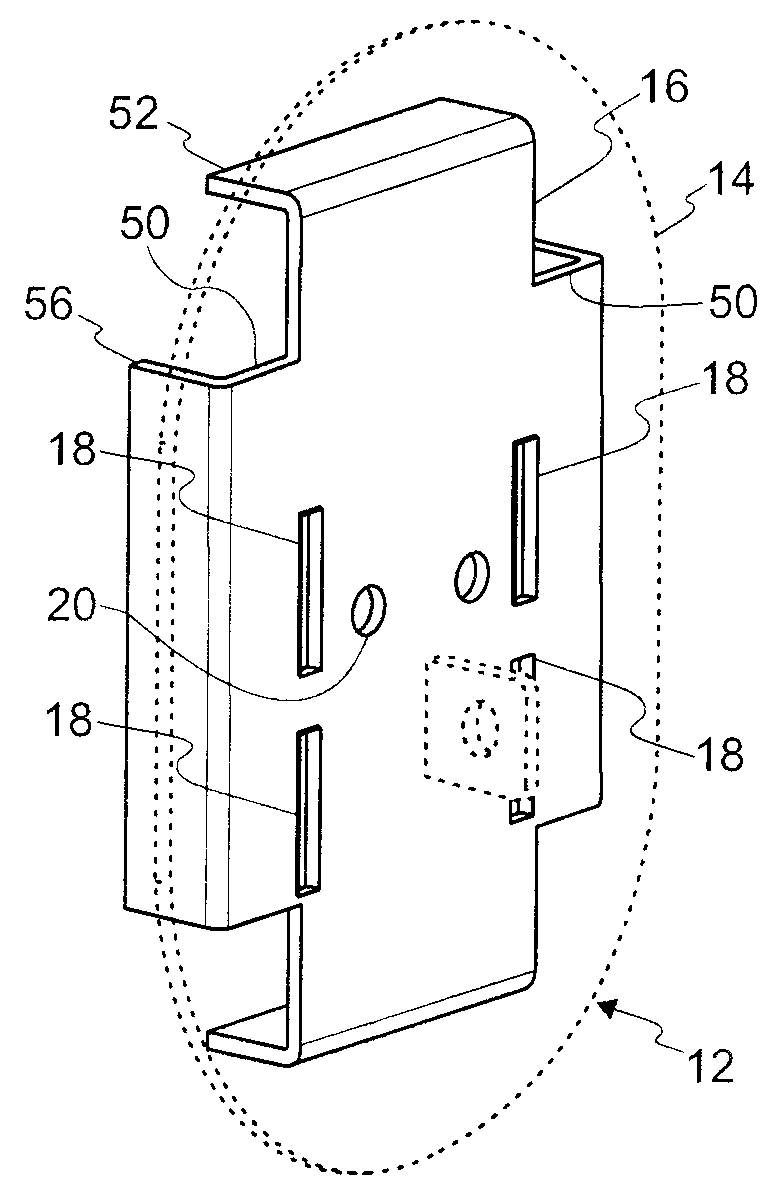

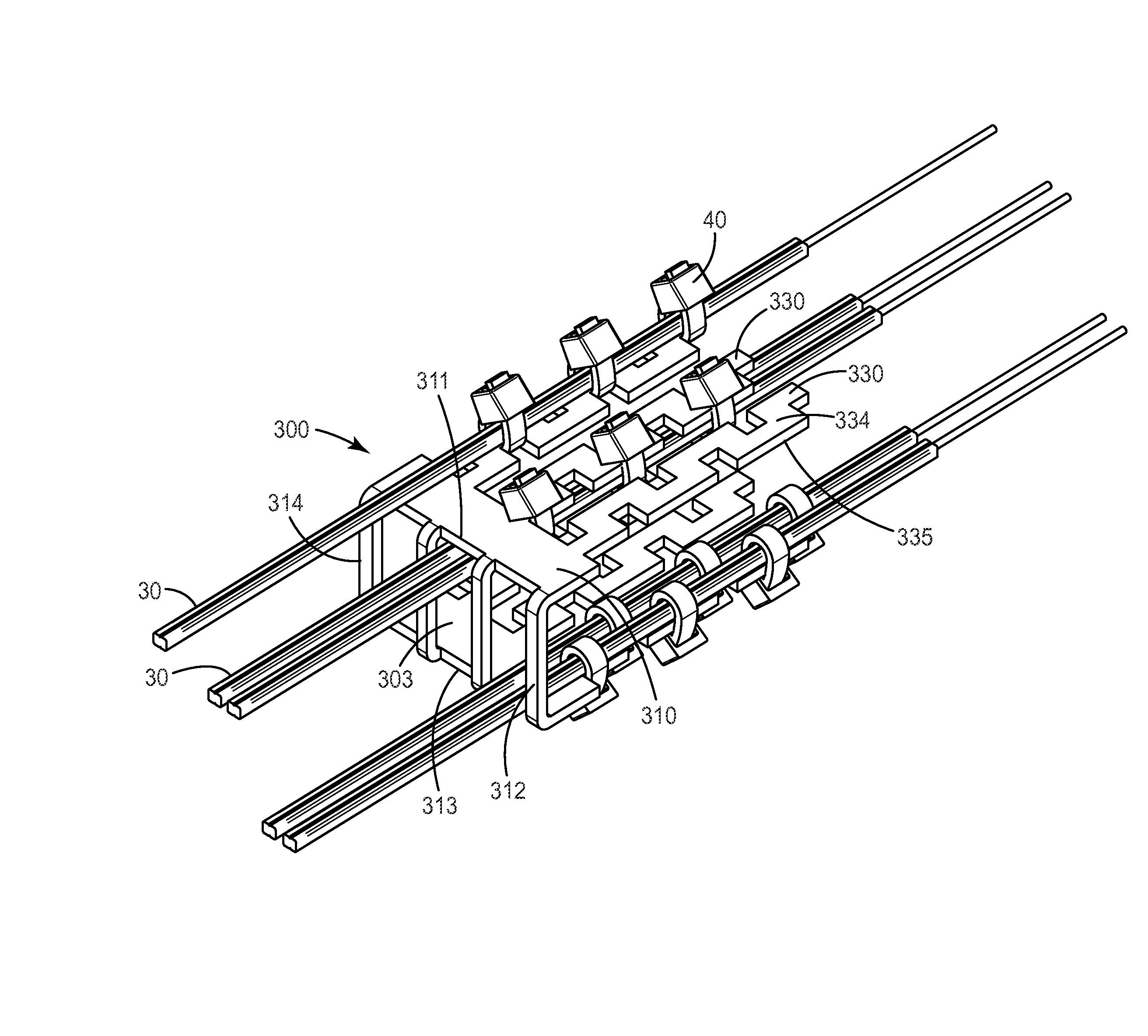

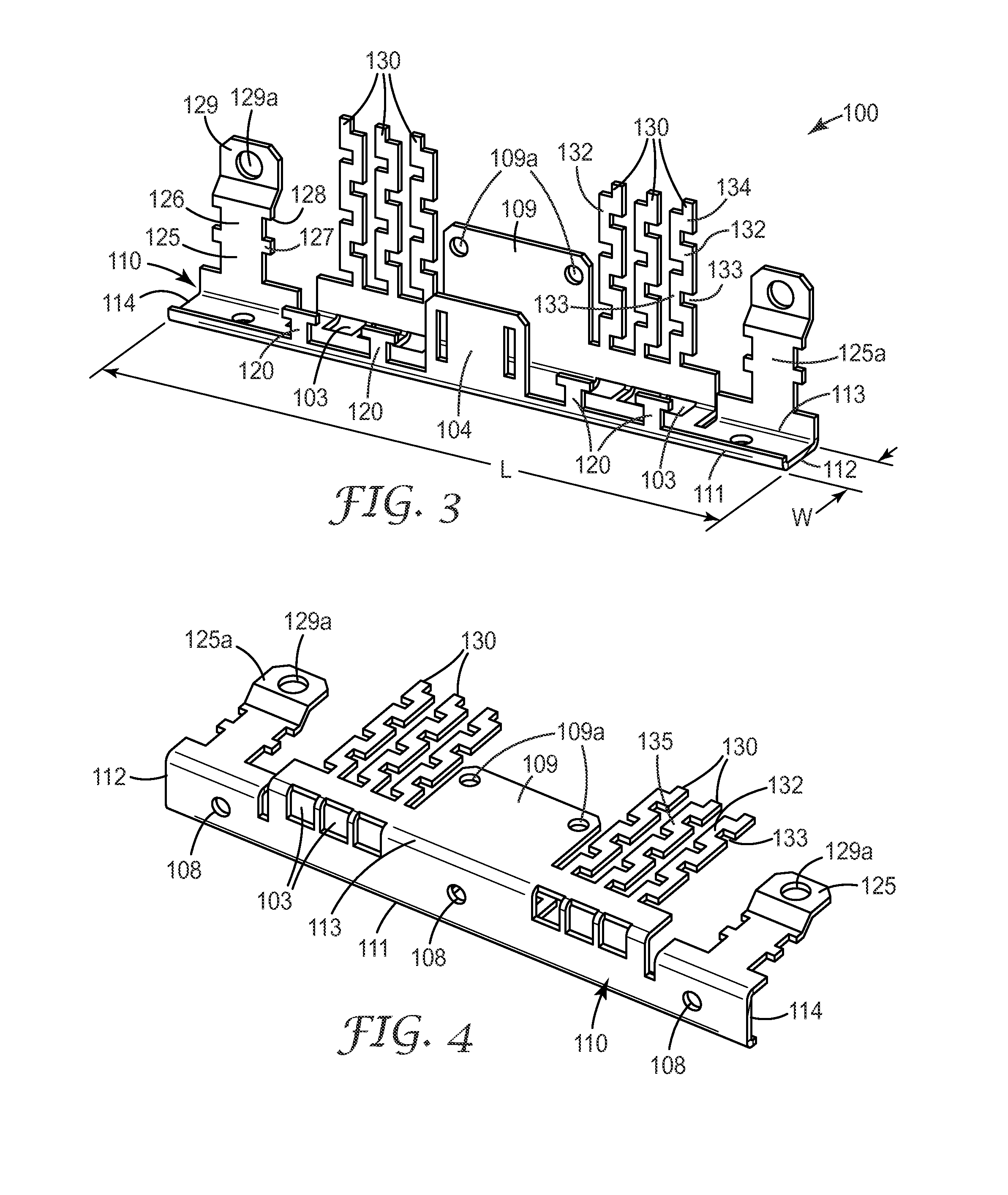

Strain relief device for low friction drop cable

InactiveUS20160134092A1Easy to handlePipe supportsAdjusting/maintaining mechanical tensionChicaneBiomedical engineering

The present invention relates to a strain relief device for use in a telecommunication enclosure. The exemplary strain relief device includes a bracket body base and a plurality of retention fingers extending from the bracket body base. Each of the plurality of retention fingers has a series of slots that define a plurality of tie down points for securing a drop cable at a plurality of points along one of the plurality of retention fingers. Each of the plurality of retention fingers has one of a chicane configuration, a serpentine configuration, comb configuration, and a rectangular configuration.

Owner:CORNING RES & DEV CORP

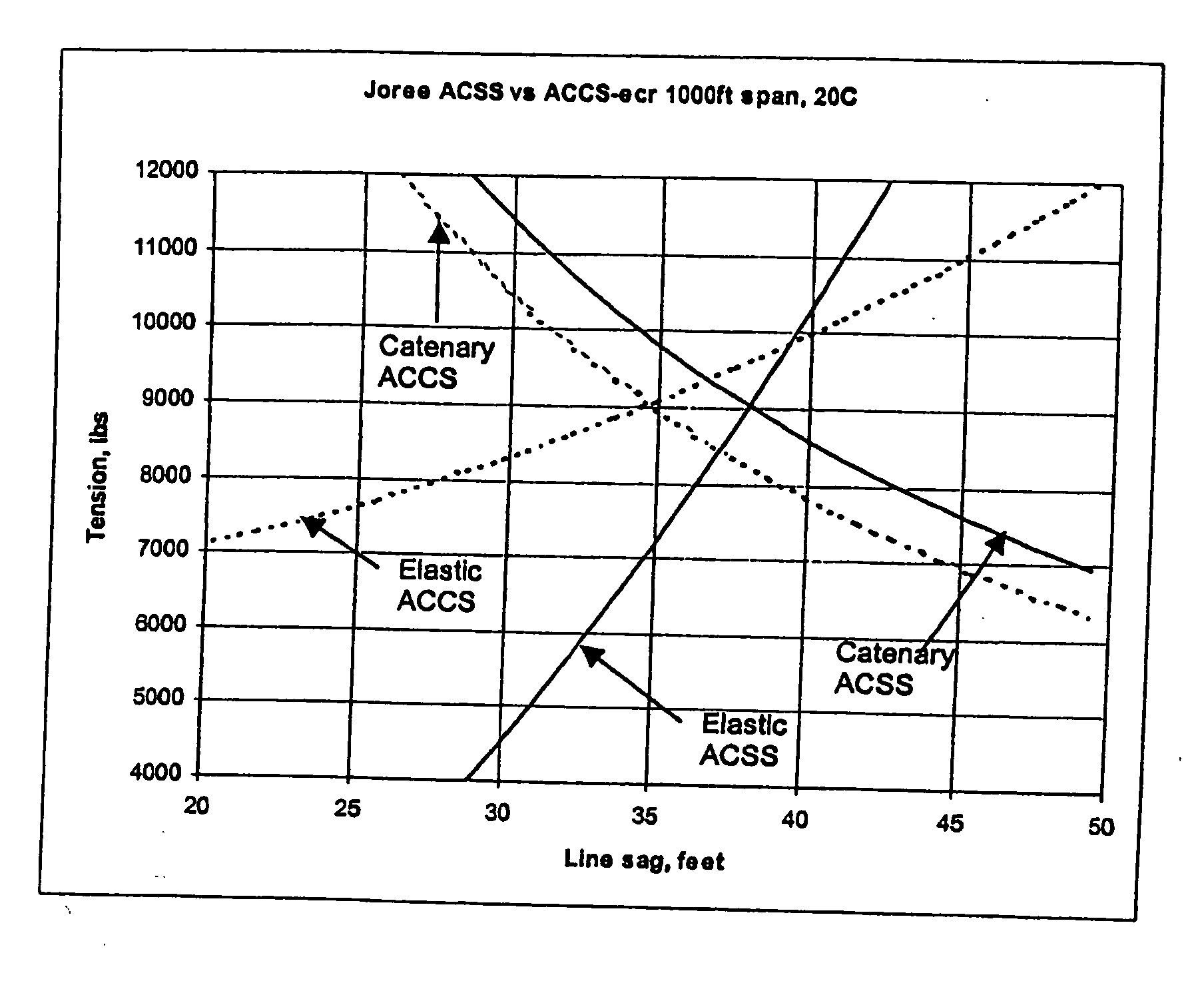

Method for controlling sagging of a power transmission cable

InactiveUS20070009224A1Low sag with temperatureLow costElectric devicesAdjusting/maintaining mechanical tensionElectric power transmissionEngineering

A method is provided for controlling the sagging of a power transmission cable hang between two towers. The cable has a first supporting portion and a second conductive portion. The method includes a first act of mounting the cable between the two towers, such that when mounted between the towers the cable has a cable load. The method further includes a second act of stretching the first portion to have a cable sag less than a desired sag, a third act of releasing at least some of the tension to obtain the desired sag, and a fourth act calculating a load magnitude carried by the first portion. If the load magnitude is less than a desired load magnitude the method includes repeating the second, third and fourth acts until the load magnitude is at the desired level.

Owner:GIFT TECH LLC

Anti-waterlogging strain clamp

ActiveCN103490359APrevent infiltrationSafe and stable operationAdjusting/maintaining mechanical tensionEngineeringFrost heaving

The invention provides an anti-waterlogging strain clamp which comprises a steel anchor, an aluminum pipe and a drainage plate, wherein the steel anchor is arranged at one end of the aluminum pipe and is connected with a wire arranged in the aluminum pipe. The anti-waterlogging strain clamp is characterized in that a grease injection hole is formed in the lateral wall of the aluminum pipe. Compared with the prior art, the anti-waterlogging strain clamp has the advantages that rain water is prevented from seeping into the strain clamp to cause waterlogging, frost heaving is avoided, safe and steady operation of an electric transmission line is guaranteed, the anti-waterlogging effect is good, the structure is simple, installation and operation are easy, economic performance is good, and large-scale popularization and usage can be realized easily.

Owner:STATE GRID CORP OF CHINA +1

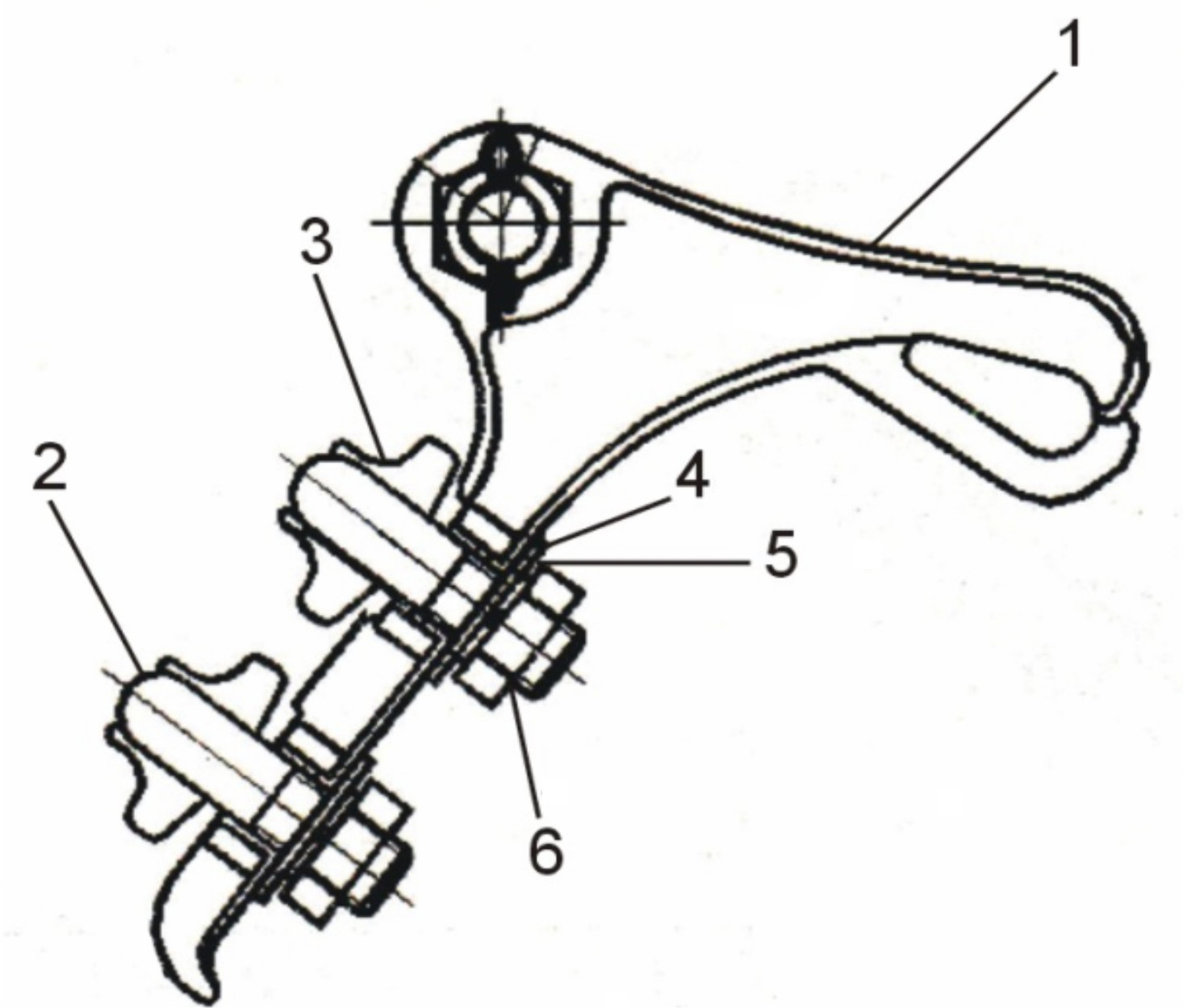

Energy-saving bolt-type strain clamp

InactiveCN102222873AReduce pollutionHigh precisionAdjusting/maintaining mechanical tensionManganeseCerium

The invention discloses an energy-saving bolt-type strain clamp, which comprises a clamp body, a U-shaped screw and a pressing block. The energy-saving bolt-type strain clamp is characterized in that: a wire slot is formed in the clamp body; a pressing slot along the clamp body penetrates through a lead; the pressing block is locked and fixed on the clamp body through the U-shaped screw above the lead; the clamp body is made of cast steel or cast iron; the U-shaped screw is made of austenitic steel; the pressing block is made of the austenitic steel or aluminum alloy; the U-shaped screw is made of the austenitic steel; and the austenitic steel comprises 21.5 to 25 weight percent of manganese, 3 to 5 weight percent of aluminum, 2 to 4 weight percent of chromium, 2 to 3 weight percent of vanadium, 0.14 to 0.2 weight percent of carbon, 0.2 to 0.3 weight percent of lanthanum and cerium composite rare earth, 0.5 to 0.8 weight percent of silicon, less than 0.05 weight percent of sulfur, less than 0.03 weight percent of nitrogen, less than 0.04 weight percent of phosphorus, and the balance of the cast steel. Each index of the strain clamp manufactured by the production mode meets related specifications of electrical power fittings GB / T2315-2000 'Nominal Failing Load Series Dimensions and Coupling Mode for Electric Power Fittings'. The strain clamp is low in energy consumption, which is only 10 to 20 percent of that of the conventional strain clamp; and the strain clamp is high in economical efficiency, and strong in popularization value.

Owner:LESHAN KEJIEFA ELECTRIC POWER EQUIP

Utility pole and tower safety and protection device

InactiveUS20060169470A1Eliminate lossImprove security featuresAdjusting/maintaining mechanical tensionSuspension arrangements for electric cablesAutomatic controlElectrical conductor

A Utility Pole and Tower Safety and Protection Device includes a utility pole with a crossbar to support utility conductors. The crossbar is attached to the pole with a release mechanism. A pressure transducer is attached to the release mechanism and automatically controls the release and descent of the crossbar at a predetermined load limit. A shear pin may also be used if a mechanical system is desired. An alarm system is attached to the pole and linked to a relay station announces when the system is activated. Power and continuity to the utility conductors is terminated when the system is activated, virtually eliminating the risks of a downed utility conductor. The device protects power and utility lines from breakage due to external forces, such as weather or trees. When the external force is removed, the device is reset by winching the crossbar into position and resetting the release mechanism.

Owner:MILLER MICHAEL L MR +7

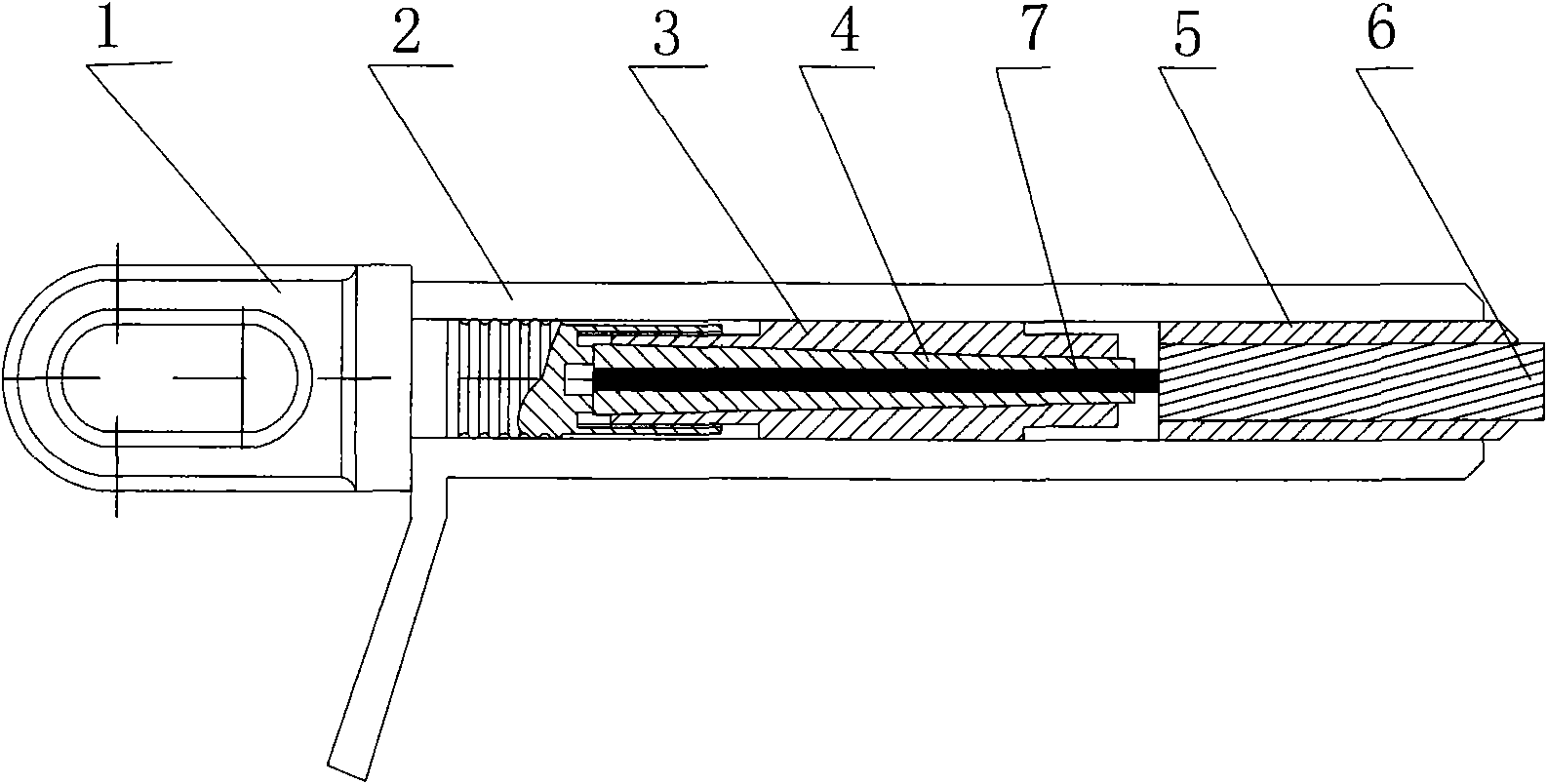

Tension resisting clip for carbon fiber composite core conductive wire

InactiveCN101335444ANo damagePlay a protective effectAdjusting/maintaining mechanical tensionFiberElectrical conductor

The invention discloses a strain clamp used by a carbon fiber composite core lead for fixing carbon fiber composite core aluminum strands on overhead power lines and strain poles and towers of a substation in the electric power system. The clamp of the invention is composed of a sphenoid clip holder provided in a wire clamp body, a sphenoid clip in the clip holder with a shape matching the shape of inner holes of the sphenoid clip holder and an internal liner pipe provided additionally. The wire clamp of the invention fully utilizes the feature that the sphenoid clip moves inside of the clip holder to clamp the carbon fiber composite core reliably under the change of temperature, forms a conductor by the crimp connection of the internal liner pipe with the wire clamp body and the aluminum strands, and imposes no damage to the carbon fiber composite core. The wire clamp of the invention has the advantages of compact and reasonable design, novel and ingenious construction, small impact from temperature, strong shock and endurance resistance, even grip distribution, strong bearing grip strength and effective avoidance of grip looseness. Furthermore, the wire clamp of the invention, in the situation that a system increases capacity, needs not to replace an iron tower, imposes no damage to green land and reduces economic loss, thus being economical and practical. The development prospect thereof is broad and an extensive application is available.

Owner:中国电建集团四平线路器材有限公司 +1

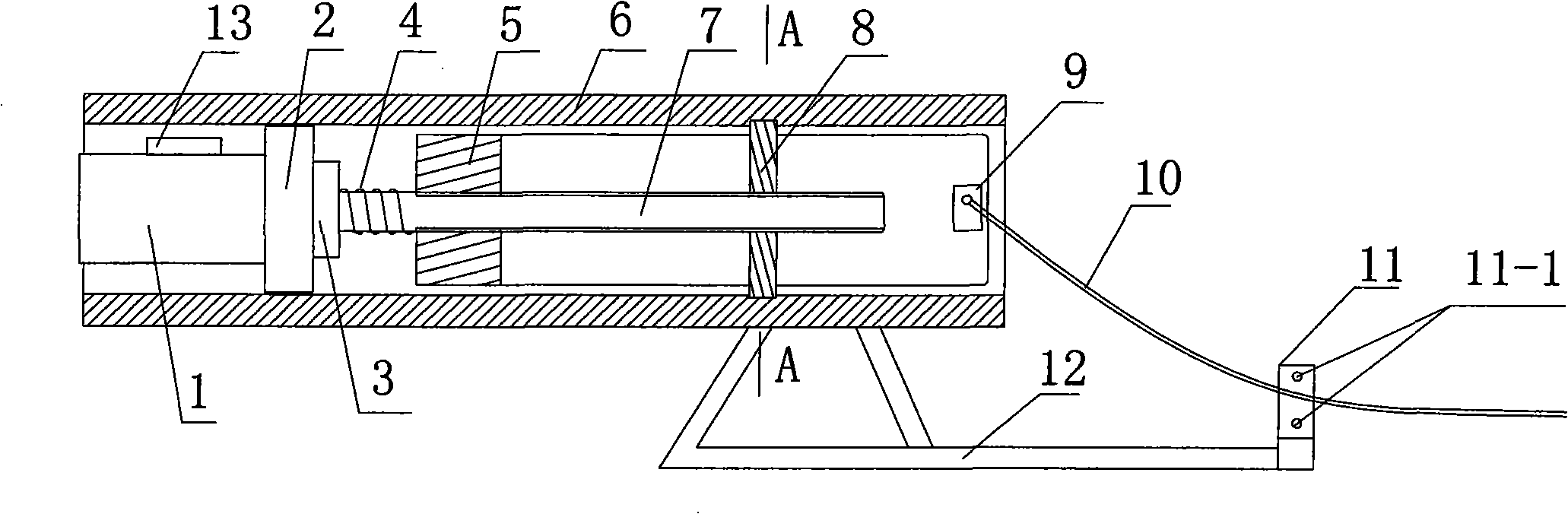

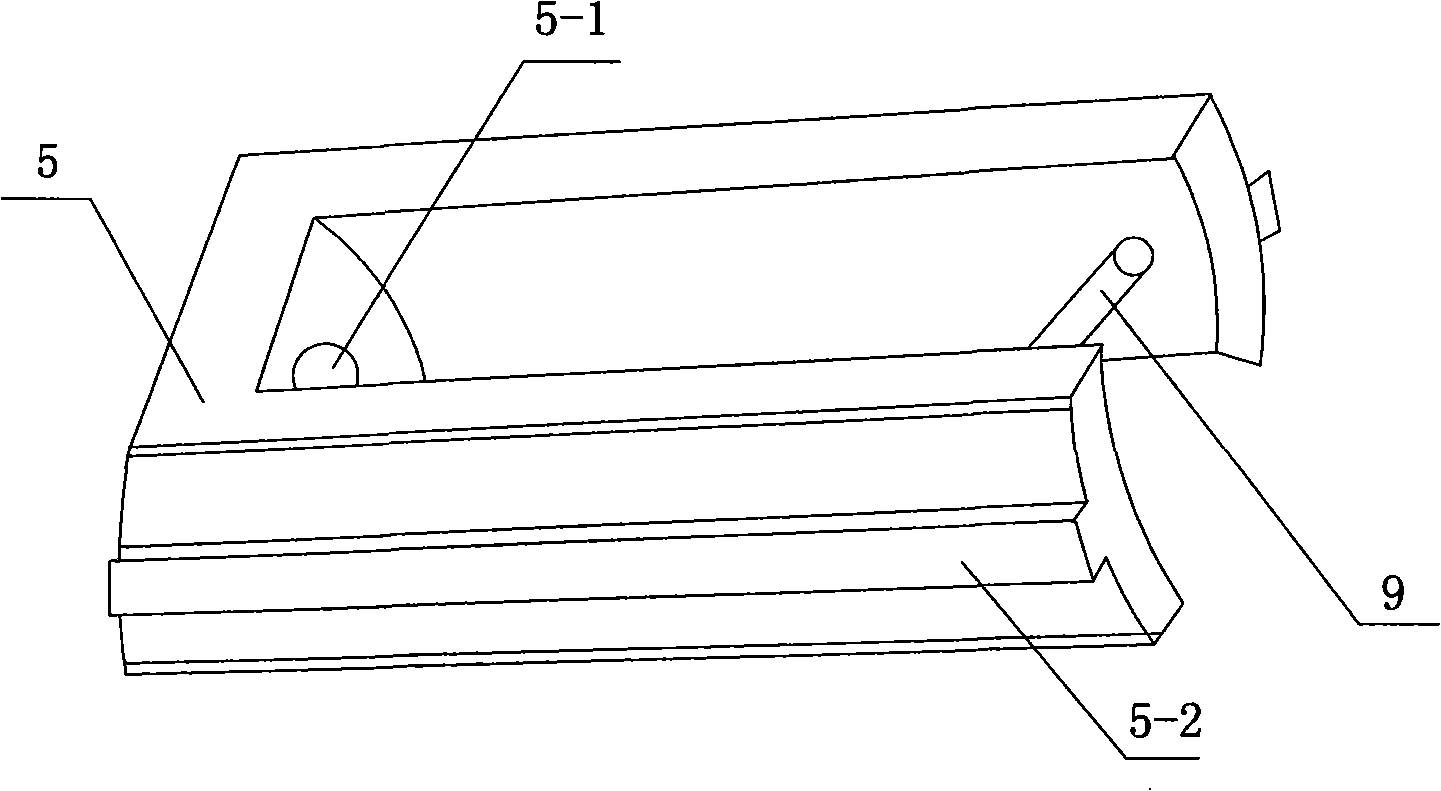

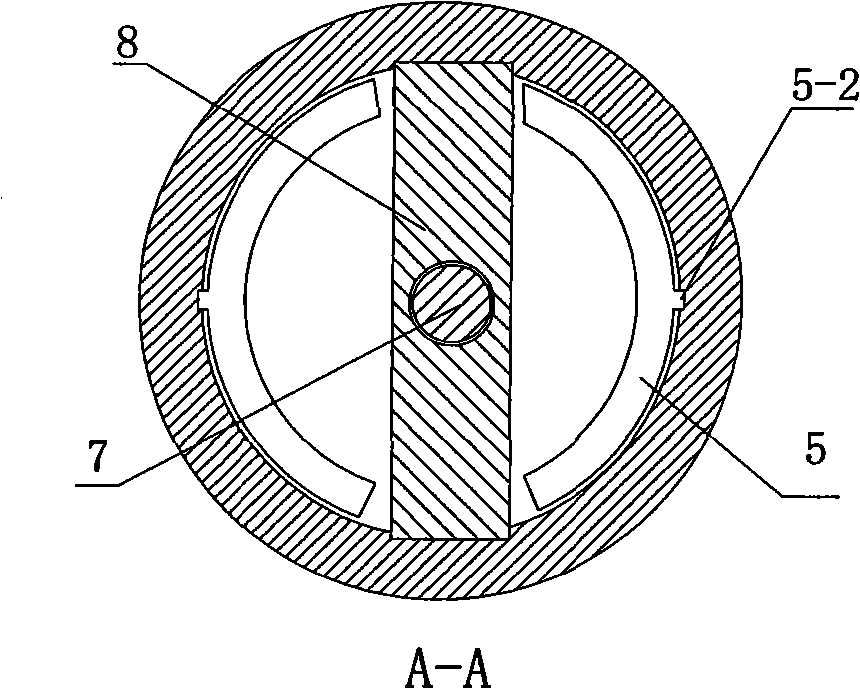

Automatic tensile-force compensator of soft part

InactiveCN101527439ARealize automatic compensationGuaranteed to workAdjusting/maintaining mechanical tensionTrolley linesReduction driveEngineering

The invention relates to an automatic tensile-force compensator of a soft part, which comprises an electric motor, a speed reducer, an axial positioning screw rod, a nut, a fixed sleeve and an infrared switch, wherein the electric motor is provided with a controller, the screw rod and the central thread hole of the nut form a spiral pair, the nut is provided with a connection member of a soft part and positioned in the fixed sleeve, the nut and the fixed sleeve are used cooperatively by tracks of mutual concave and convex close fit, and the nut slides along a fixed track. The invention changes the work mode of the passive adaptability compensation of the traditional potential-energy element compensator, and can timely and actively control the load change according to the using requirements.

Owner:CHANGZHOU MINGJIN SPRING +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com