Tension resisting clip for carbon fiber composite core conductive wire

A technology of tension-resistant wire clamp and composite core, which is applied in the direction of adjusting/maintaining mechanical tension, which can solve the problems of unsuitable carbon fiber composite core aluminum stranded wire, such as tension-resistant fixation, wire core damage, and fracture, etc., to achieve strong load-bearing grip , strong impact resistance and fatigue resistance, and broad development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

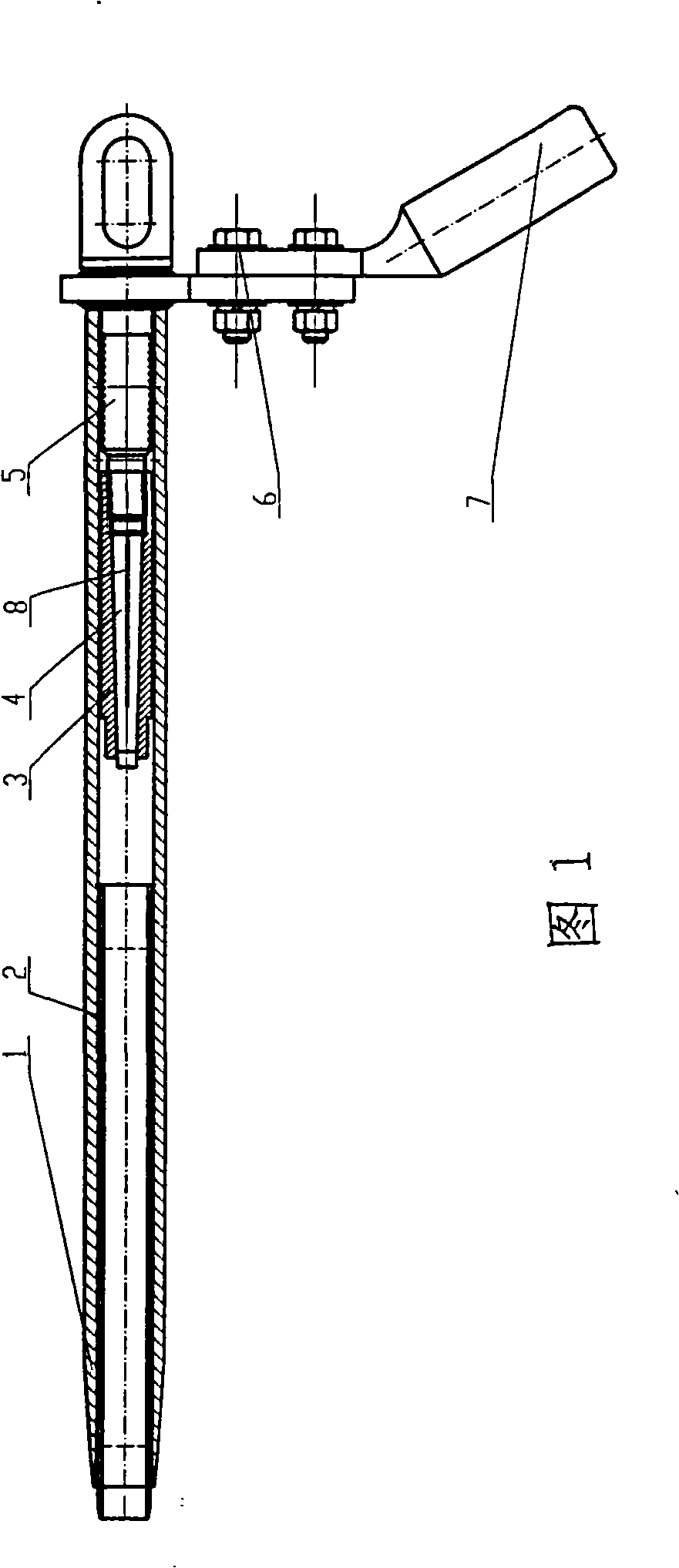

[0007] The outside of the tension clamp for carbon fiber composite core wire shown in Figure 1 is a clamp main body 1 composed of an aluminum tube and a connecting plate at one end of the aluminum tube. Inside the clamp main body 1, a liner tube 2 is provided for the corresponding crimping section. A wedge-shaped clamp seat 3 and a wedge-shaped clamp 4 in the wedge-shaped clamp seat 3 matching the shape of its inner hole are also arranged in the wire clamp main body 1 . The wedge-shaped clamp seat 3 is a cylindrical seat cover with a tapered through hole inside and one end protruding outside. The wedge-shaped clamp 4 is a truncated cone jacket with a through hole in it, and two groups of gaps 8 are axially symmetrically arranged on the cone of the jacket, and the two groups of gaps 8 are mutually 90°. The steel anchor 5 is screwed in from one end of the clamp main body 1 and is connected and fixed with the aluminum tube part of the clamp main body 1 and the wedge-shaped clamp ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com