Patents

Literature

484 results about "Wire tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

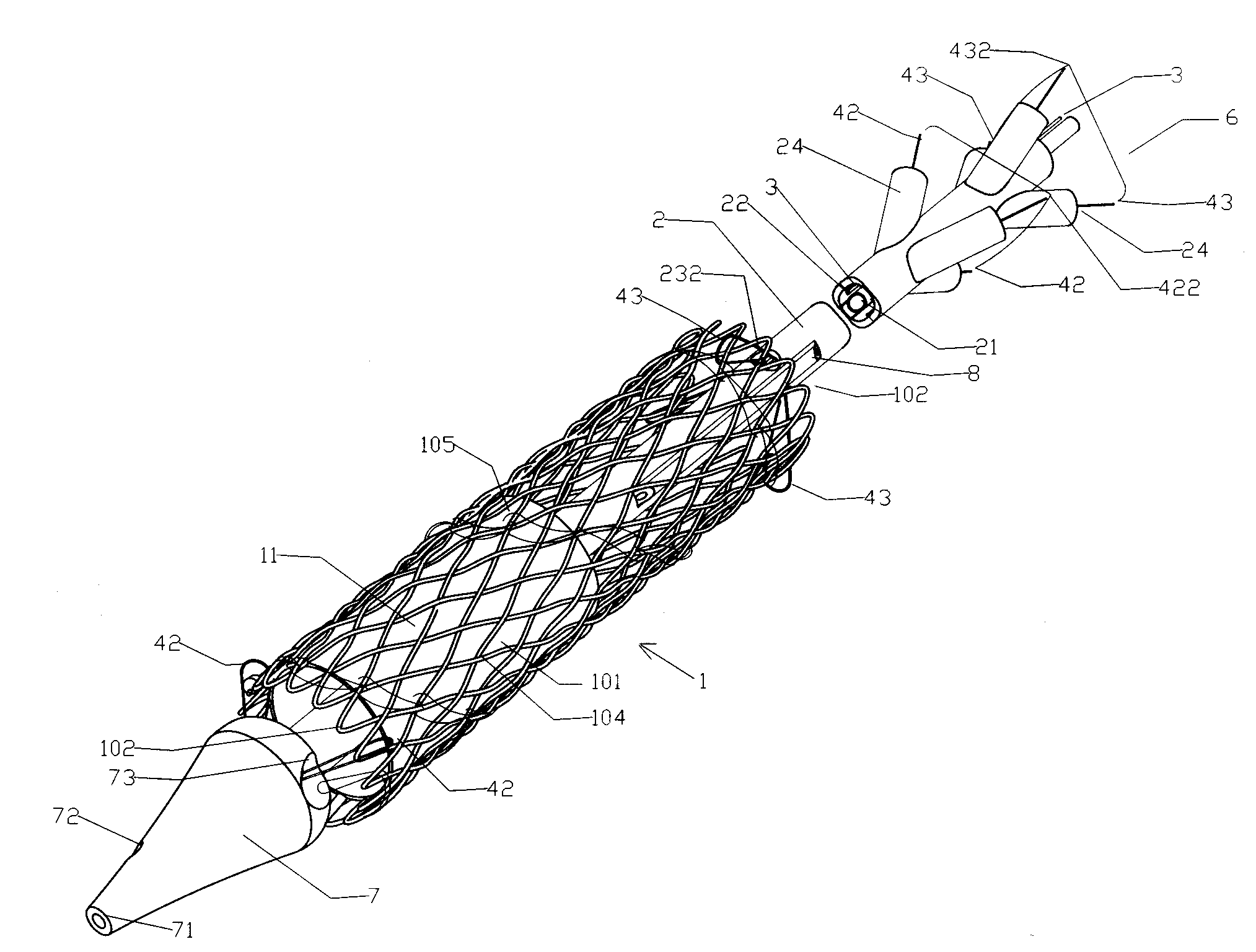

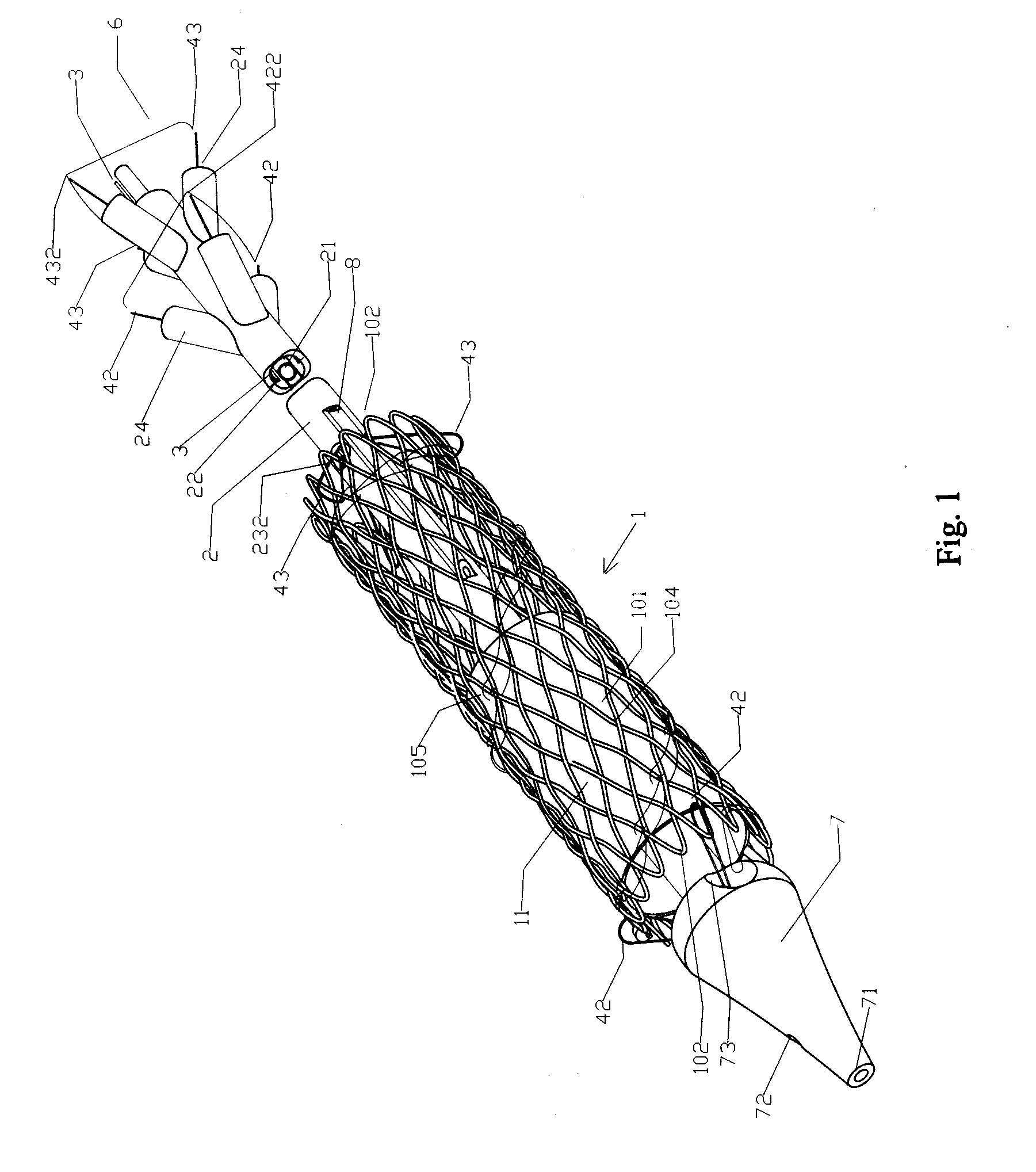

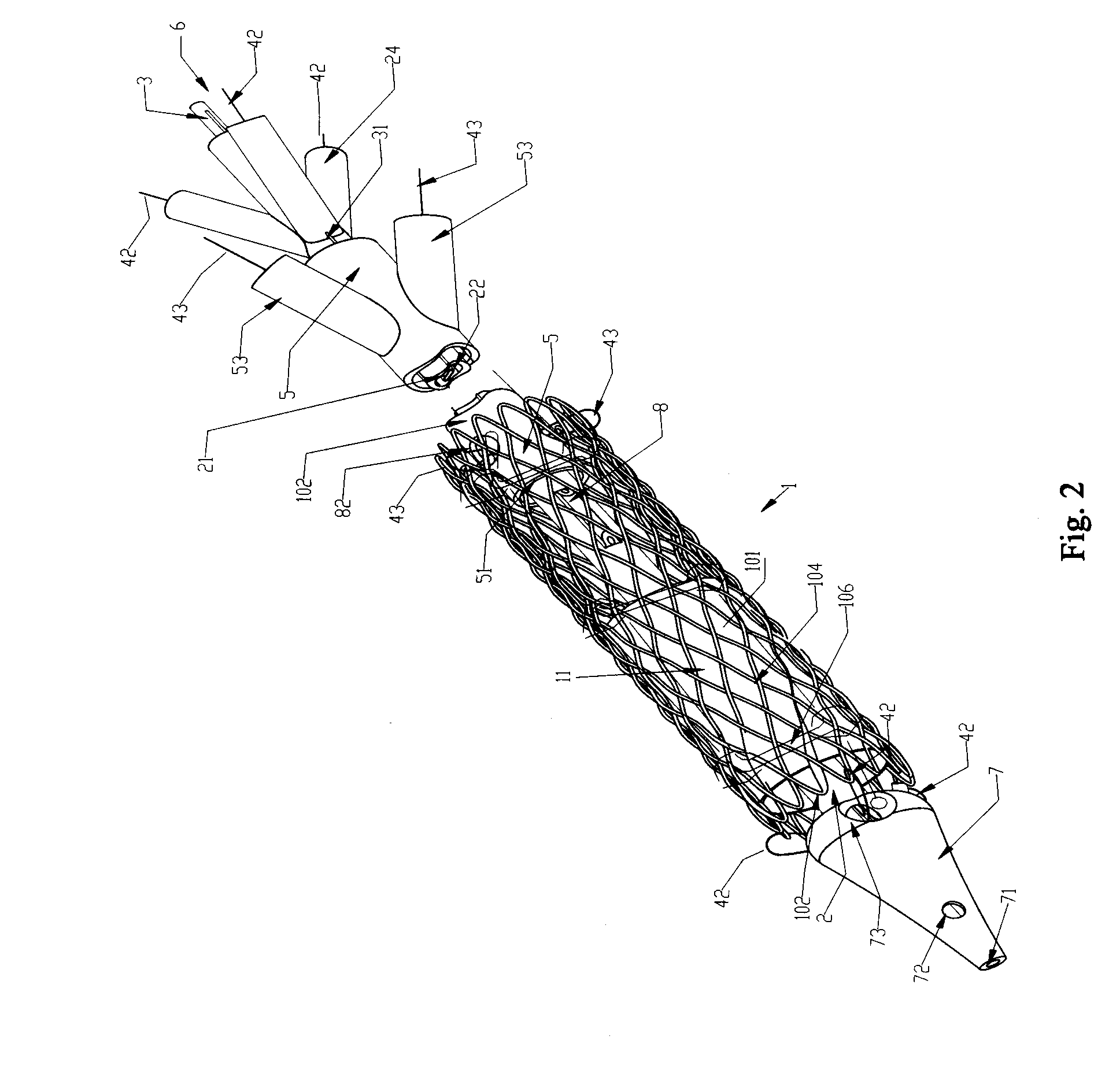

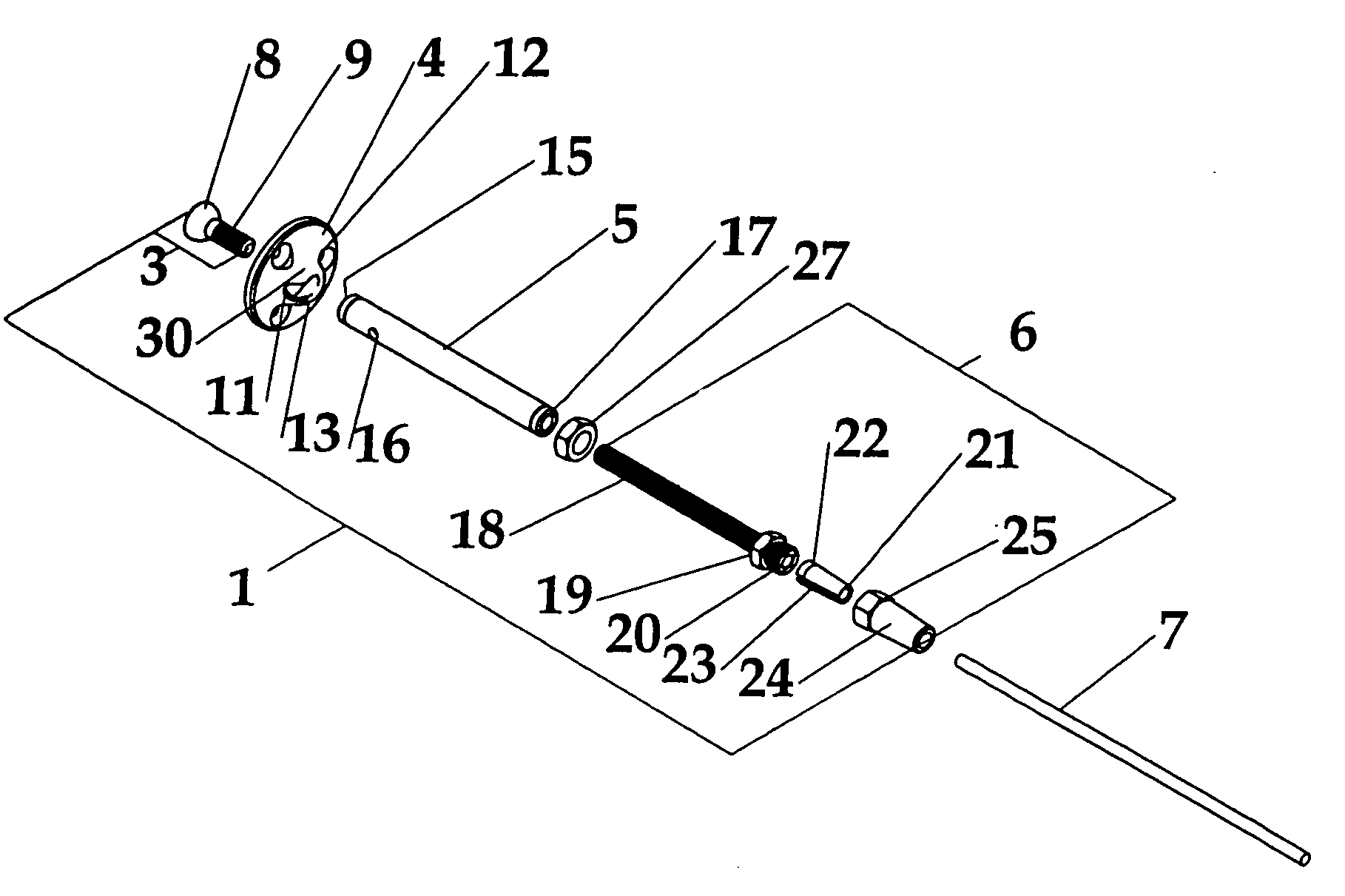

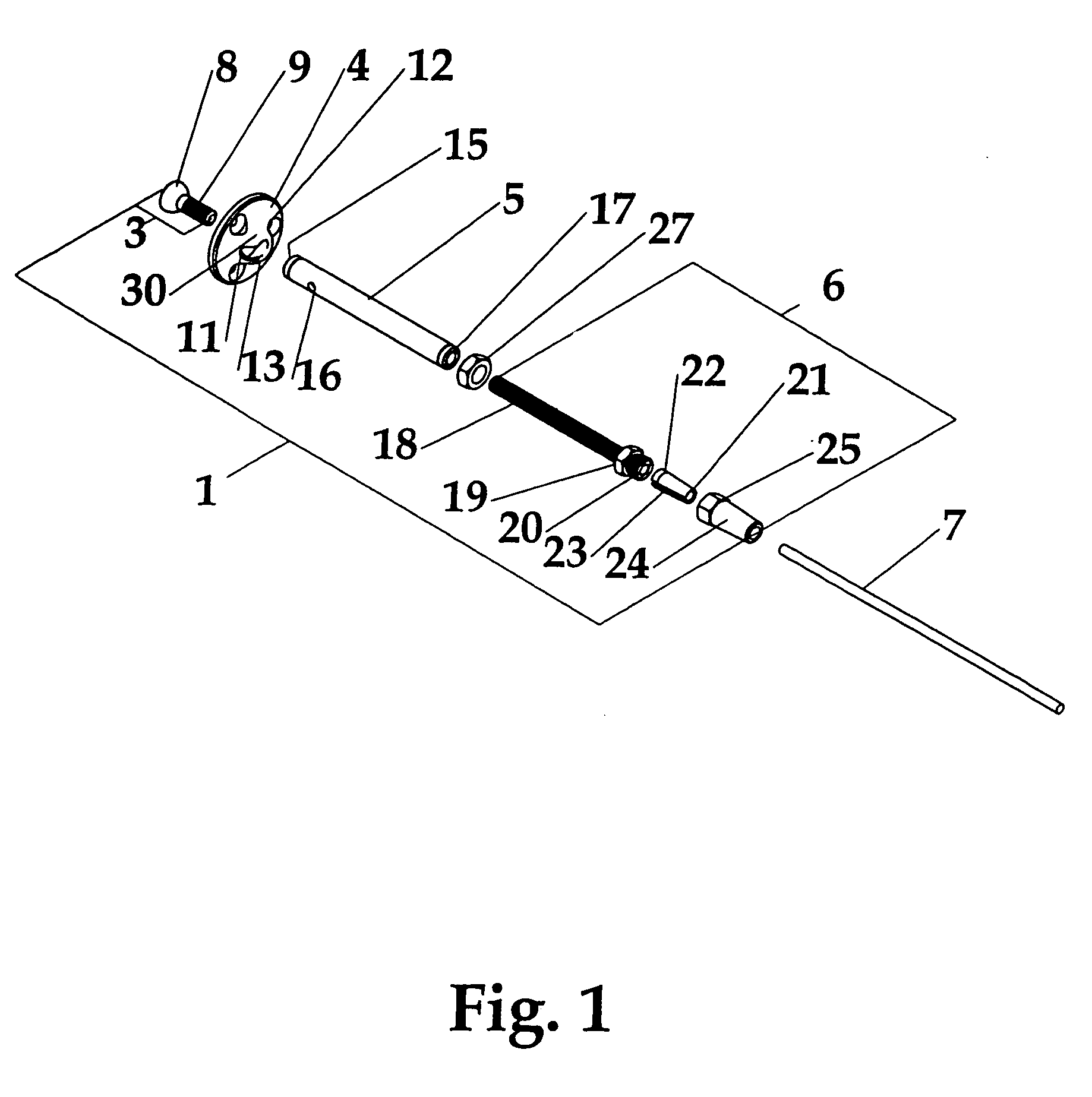

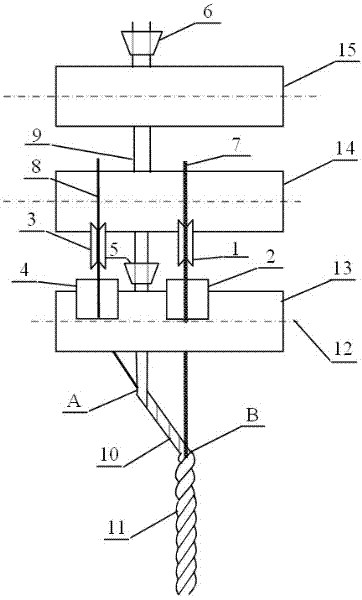

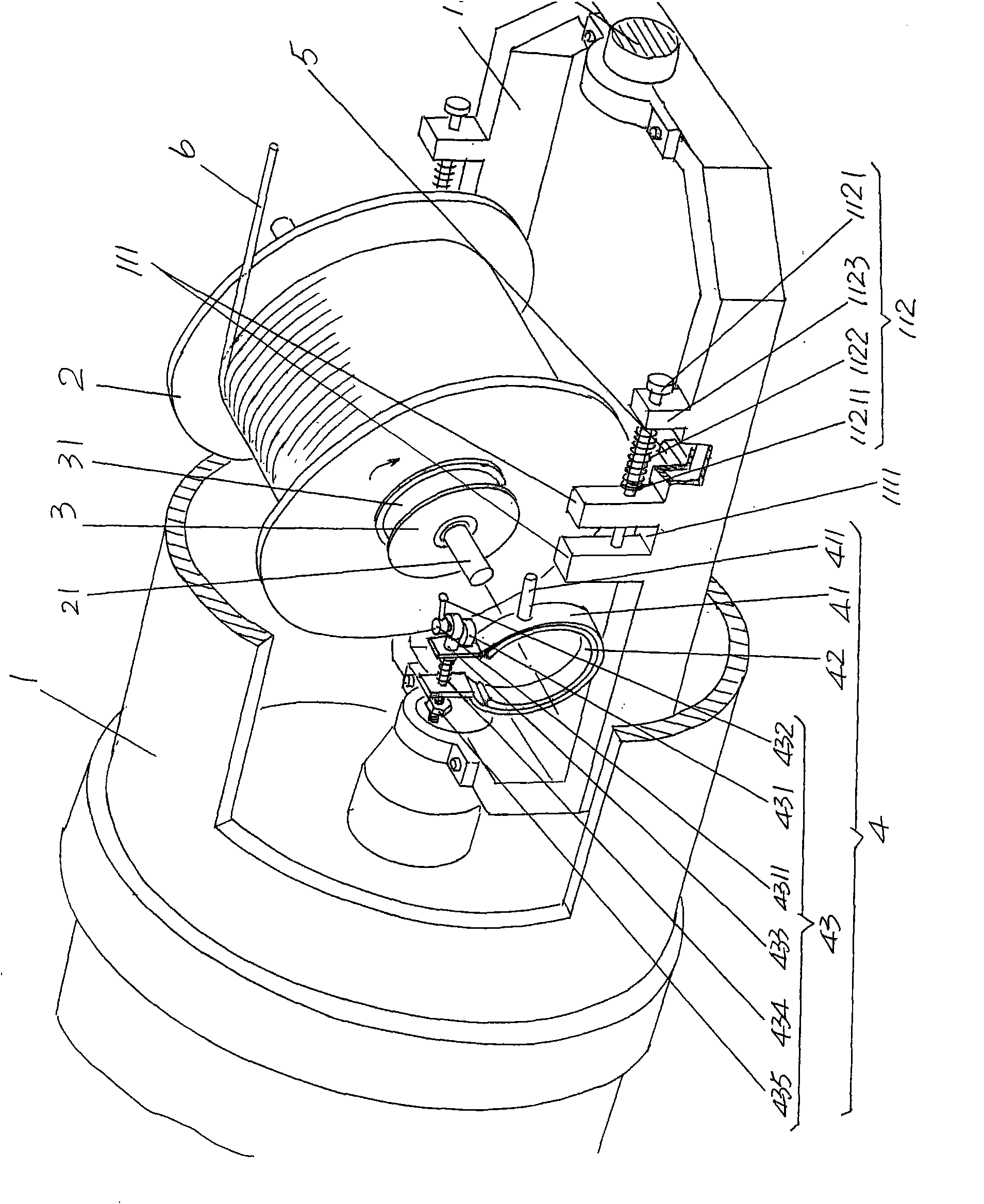

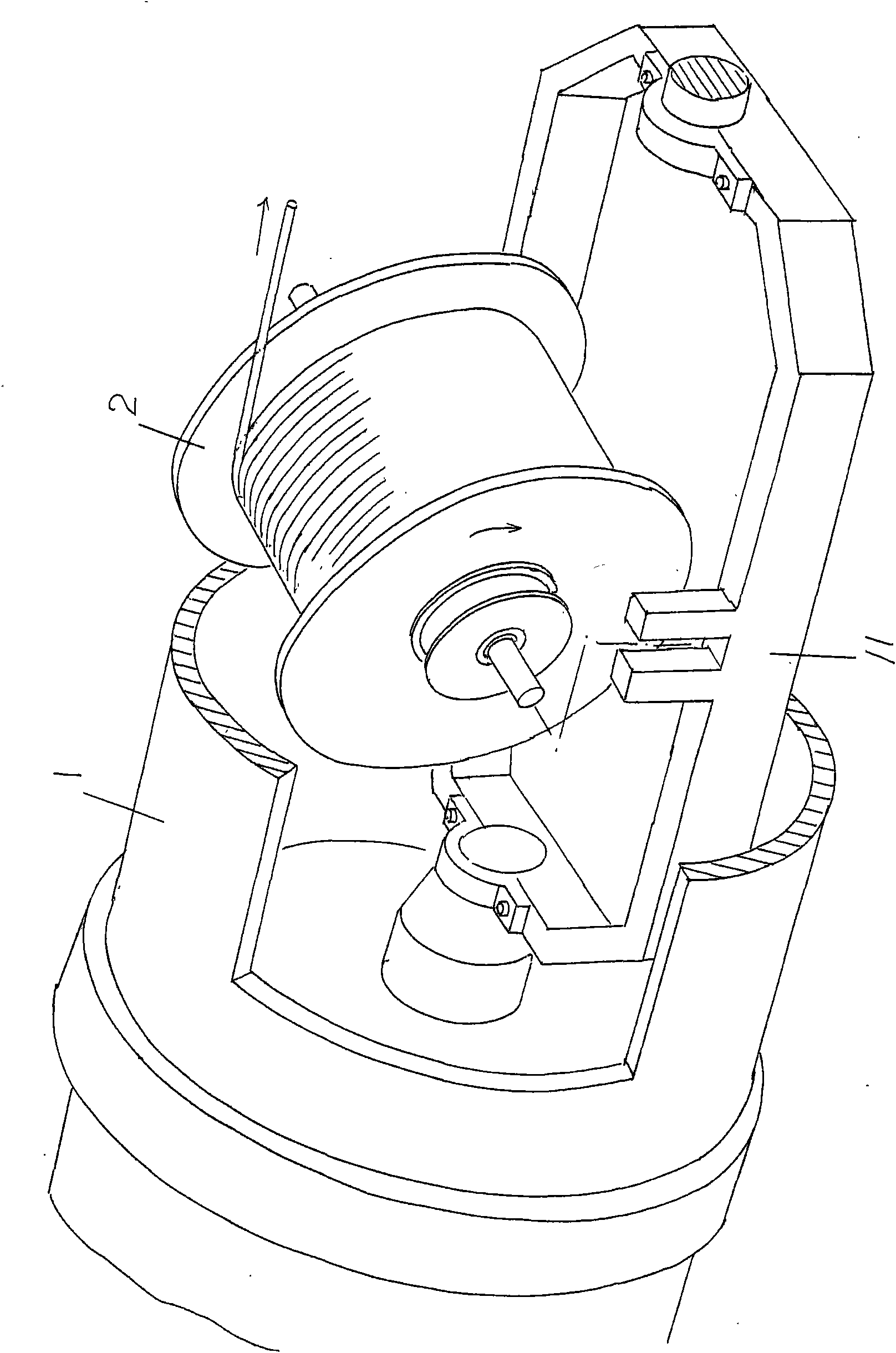

Axial Pullwire Tension Mechanism for Self-Expanding Stent

An axial pull wire tension mechanism for a self expanding stent includes a delivery system composed of an inner tube (2), a middle tube (5) and a lock wire (3), open wire knees (102) and / or close wire eyelets (103) at the both ends of the stent, and pull wires (4) for tensioning the stent. The pull wires (4) include at least one distal pull wire (42) and at least one proximal pull wire (43). A pull wire ring (421, 431) is provided at the distal end of each of the pull wires. Each pull wire passes through an opening of the inner tubing head (7) or the inner tube (2) or the middle tube (S) after the pull wire ring at its distal end is threaded through and locked temporarily by the lock wire, and travels between the open wire knees (102) or the close wire eyelets (103) at one end of the stent to constitute a temporary stent connection, thus forming the pull wire tension mechanism that can axially tension the stent. The present invention can locate the self-expanding stent in terms of its axial and rotational positions with great precision when in collaboration with the delivery system and the radially compression mechanism during the process of delivering the self-expanding stent into the patient's body, and is capable of either further adjustment should the position prove to be less ideal, or recycling should the stent prove to be incongruous after the expansion of the stent.

Owner:WENG NING

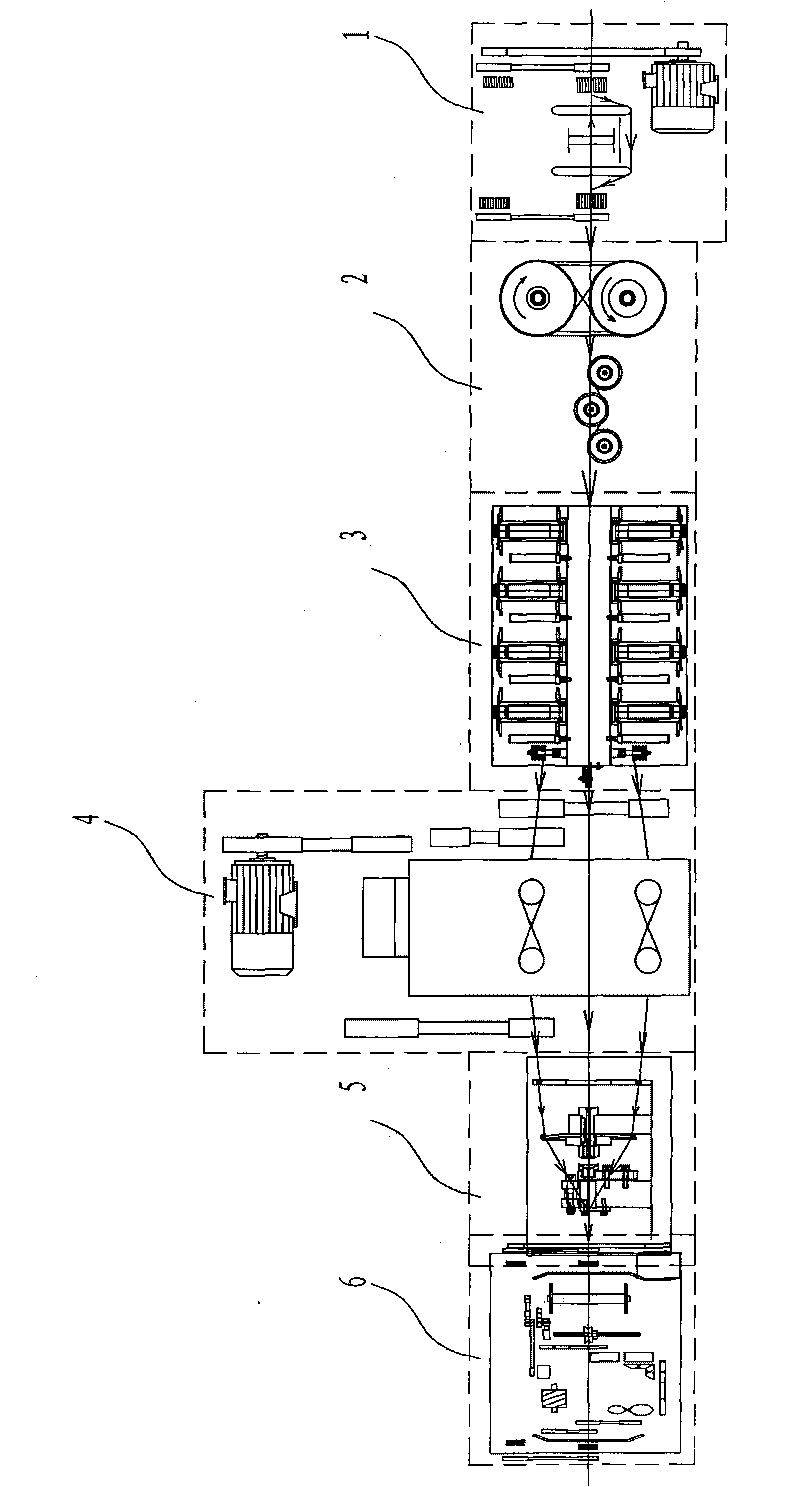

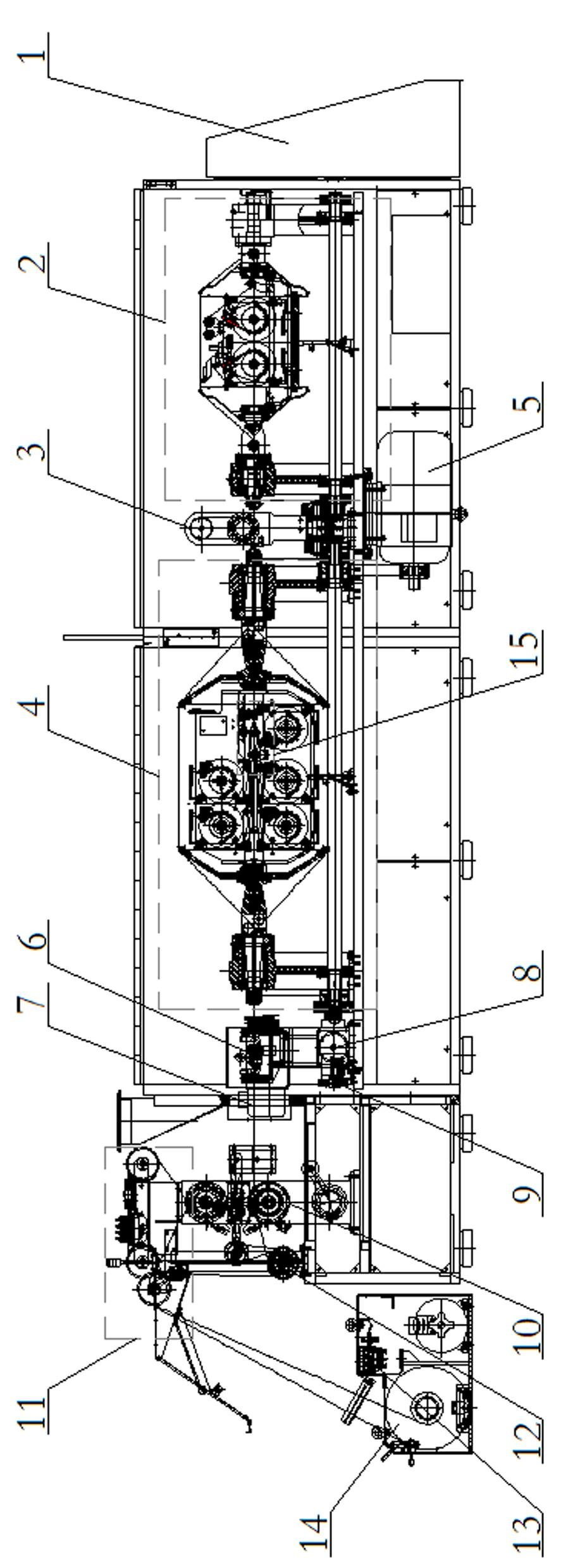

Double twisting rope laying machine

The invention discloses a double twisting rope laying machine which comprises a core wire laying machine, a core wire tension mechanism, a surface wire laying mechanism, a single wire pre-twisting machine, a wire collecting mechanism and a wire-rewinding machine arranged sequentially, wherein the core wire tension mechanism comprises a broken wire detecting device, a wire roller, a tension control device and a tension detecting device; the core wire output tension is detected by the tension detecting device, and if the tension exceeds a set tension range, the core wire output tension is adjusted by the tension control device to realize accurate control of the core wire laying tension; and the single wire pre-twisting machine comprises a motor, a transmission component and a plurality of groups of rotor components which are arranged at the front surface and the back surface of a stand. Through the rotation of each group of rotor components, the single wire pre-twisting process is realized and the single wire stress is eliminated, thereby being favorable to twisting and forming, and finally, the twisted cords have good straightness, stable residual torsion and high product quality and is difficult to loose; and the specifications of the producible cords are 3+9+15*0.22, 3+9+15*0.175 and 0.25+(6+12)*0.22.

Owner:江苏泰隆机电科技有限公司

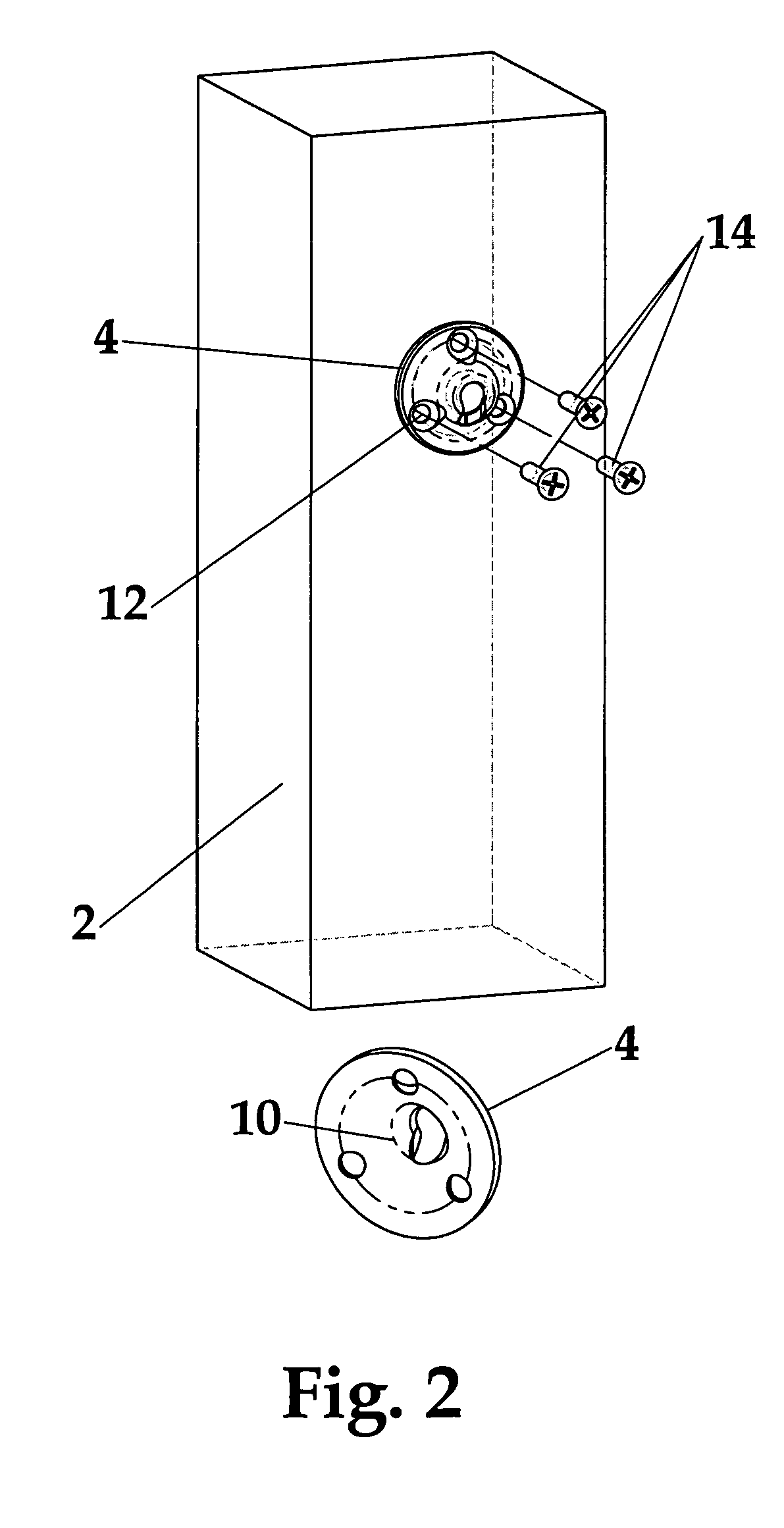

Wire rope connectors and tensioners for deck railing systems

ActiveUS7198253B2Good adhesionReduce wasteBalustradesRopes and cables for vehicles/pulleyWire tensionWire rope

Owner:SUNCOR STAINLESS

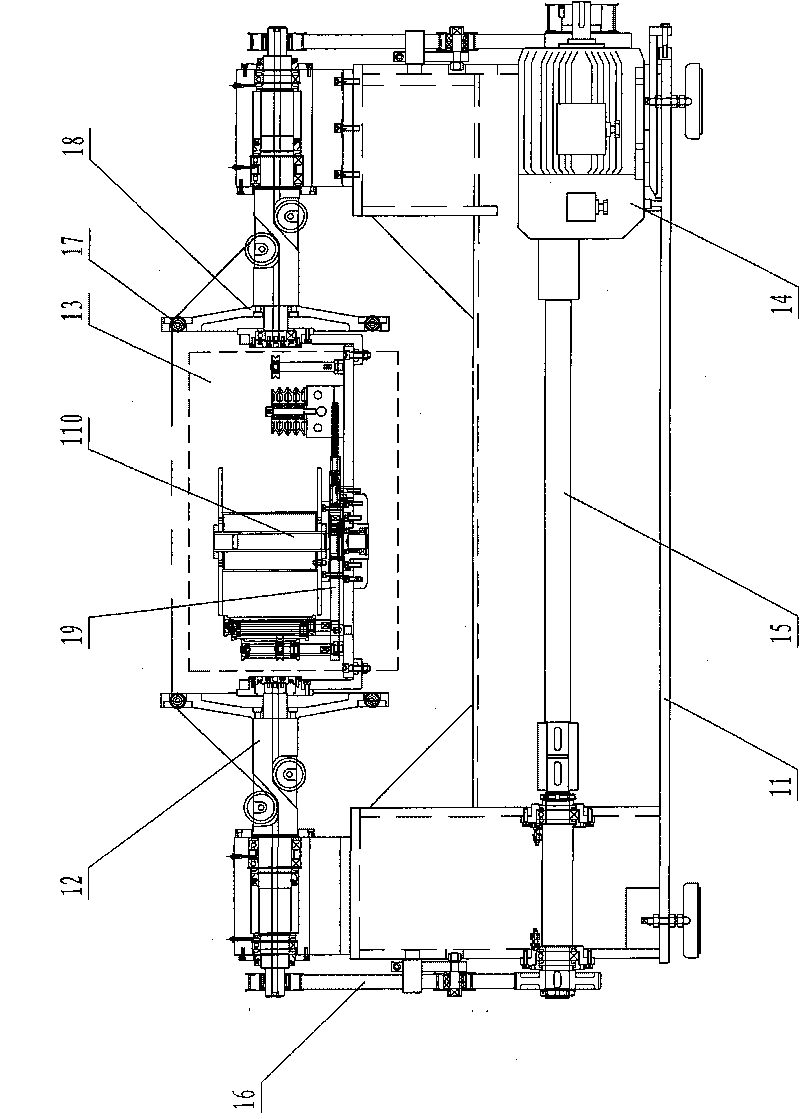

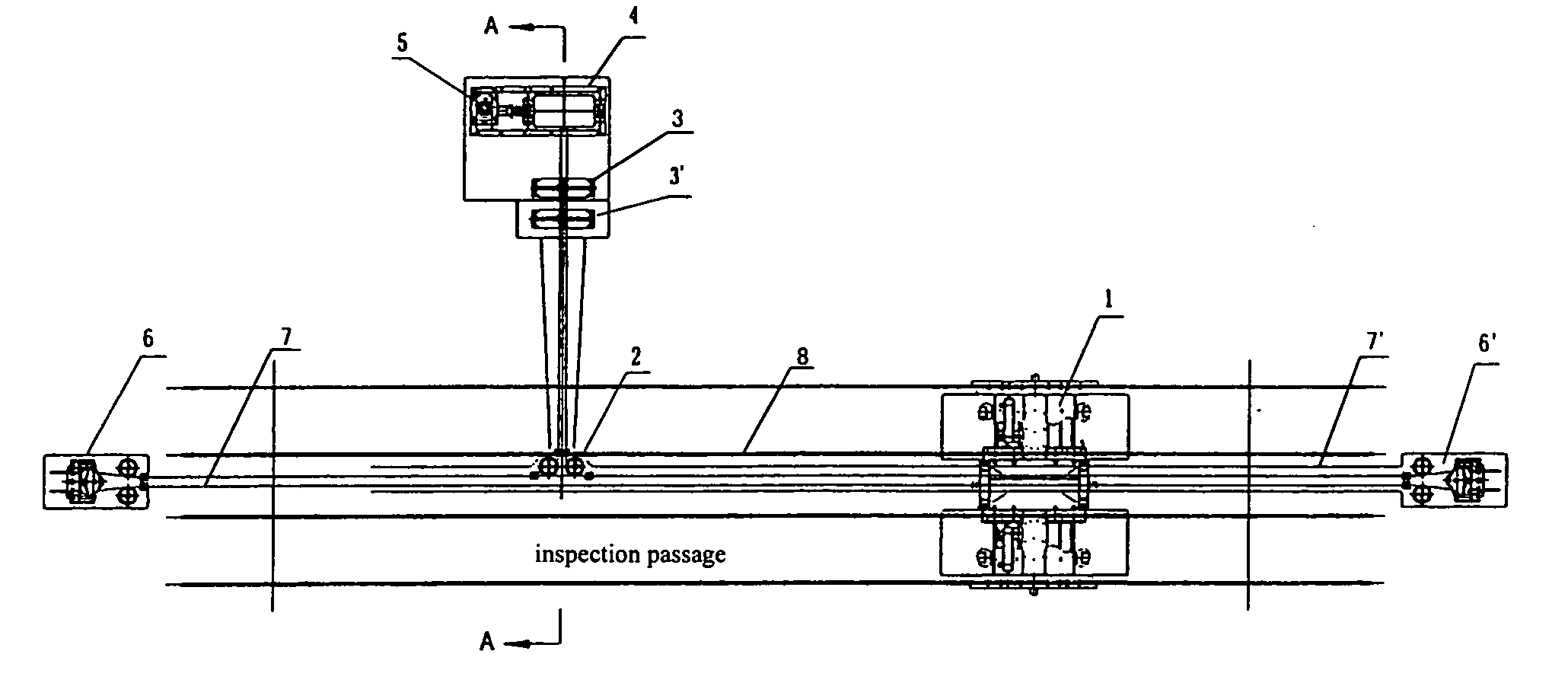

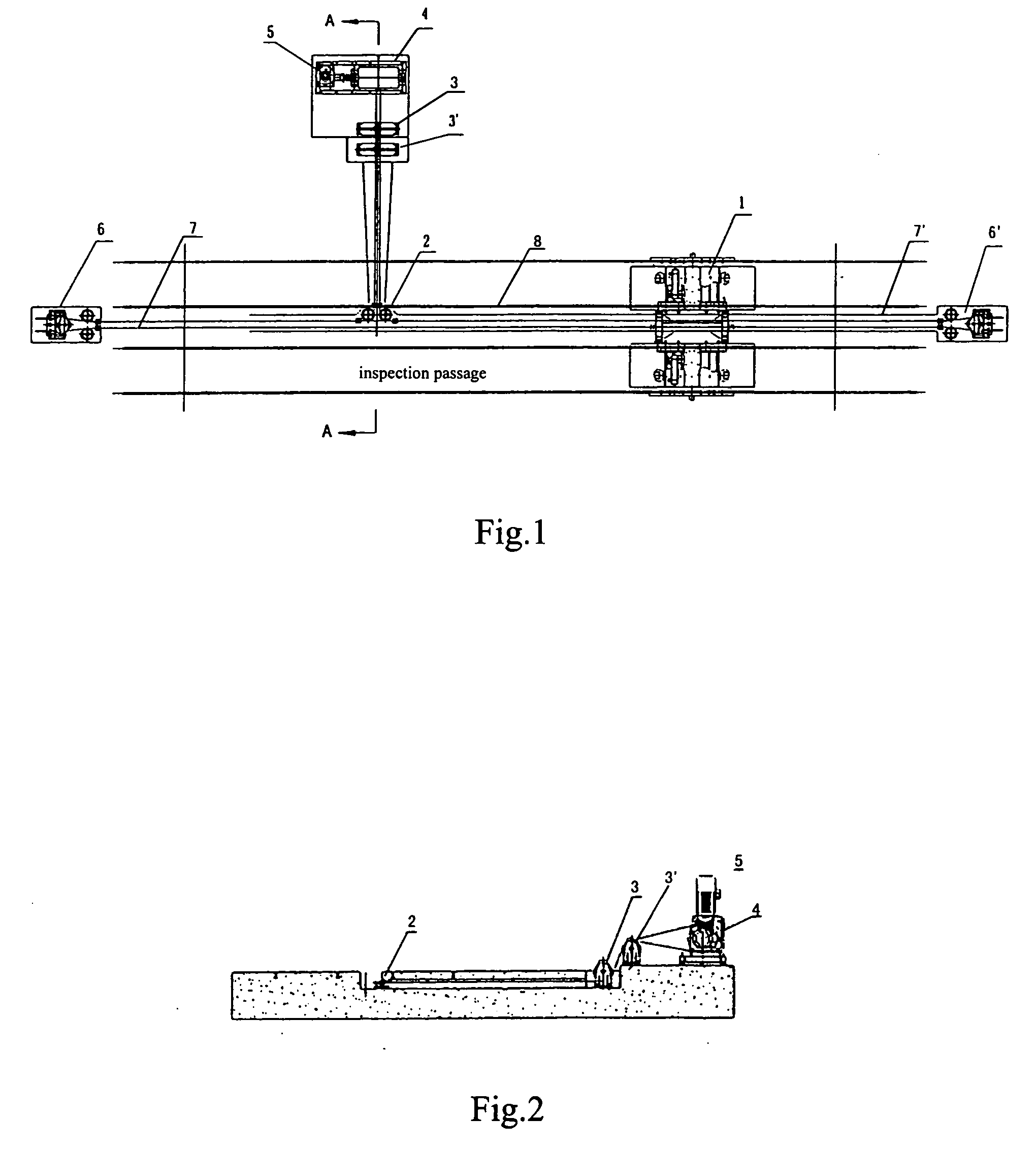

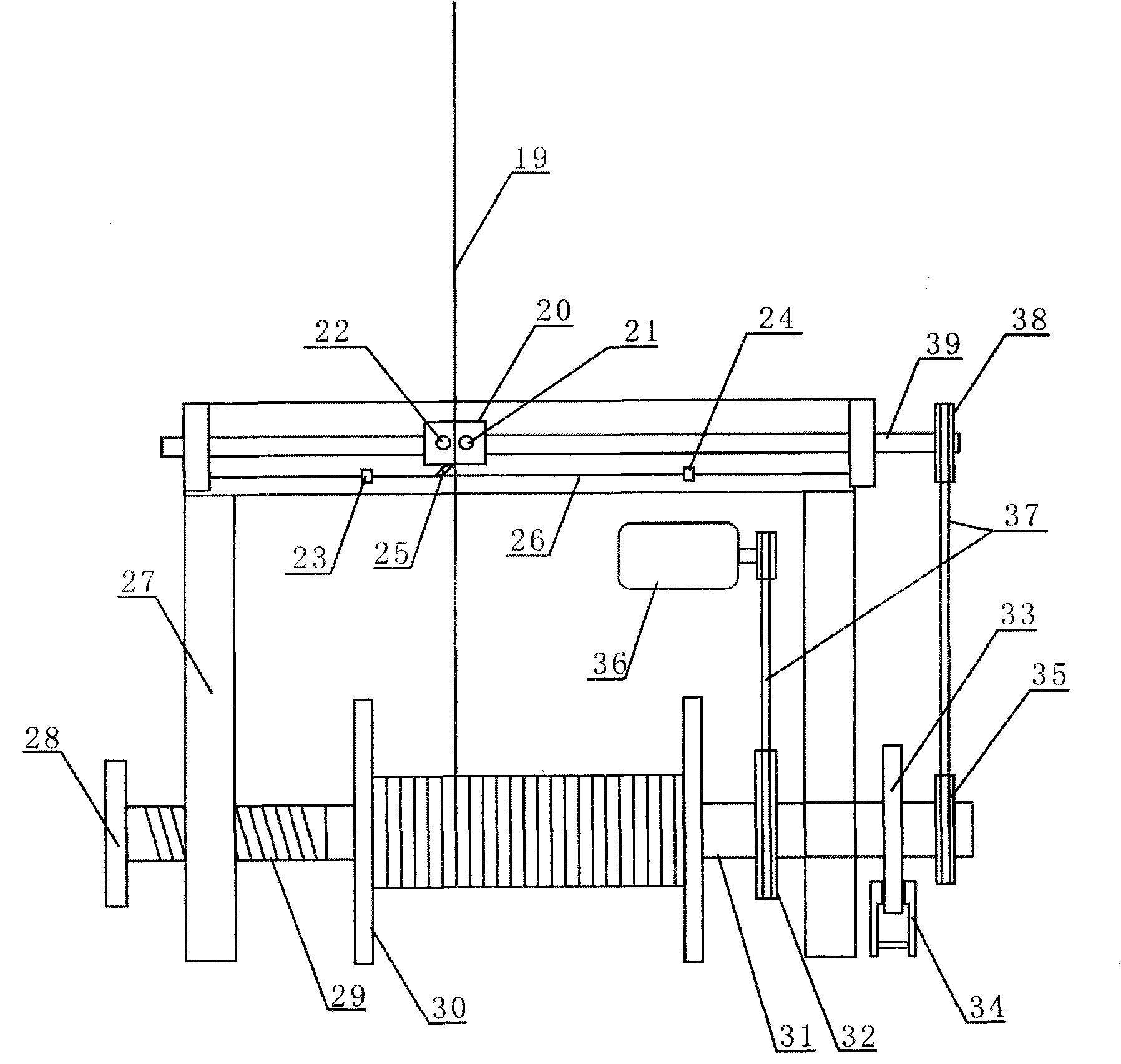

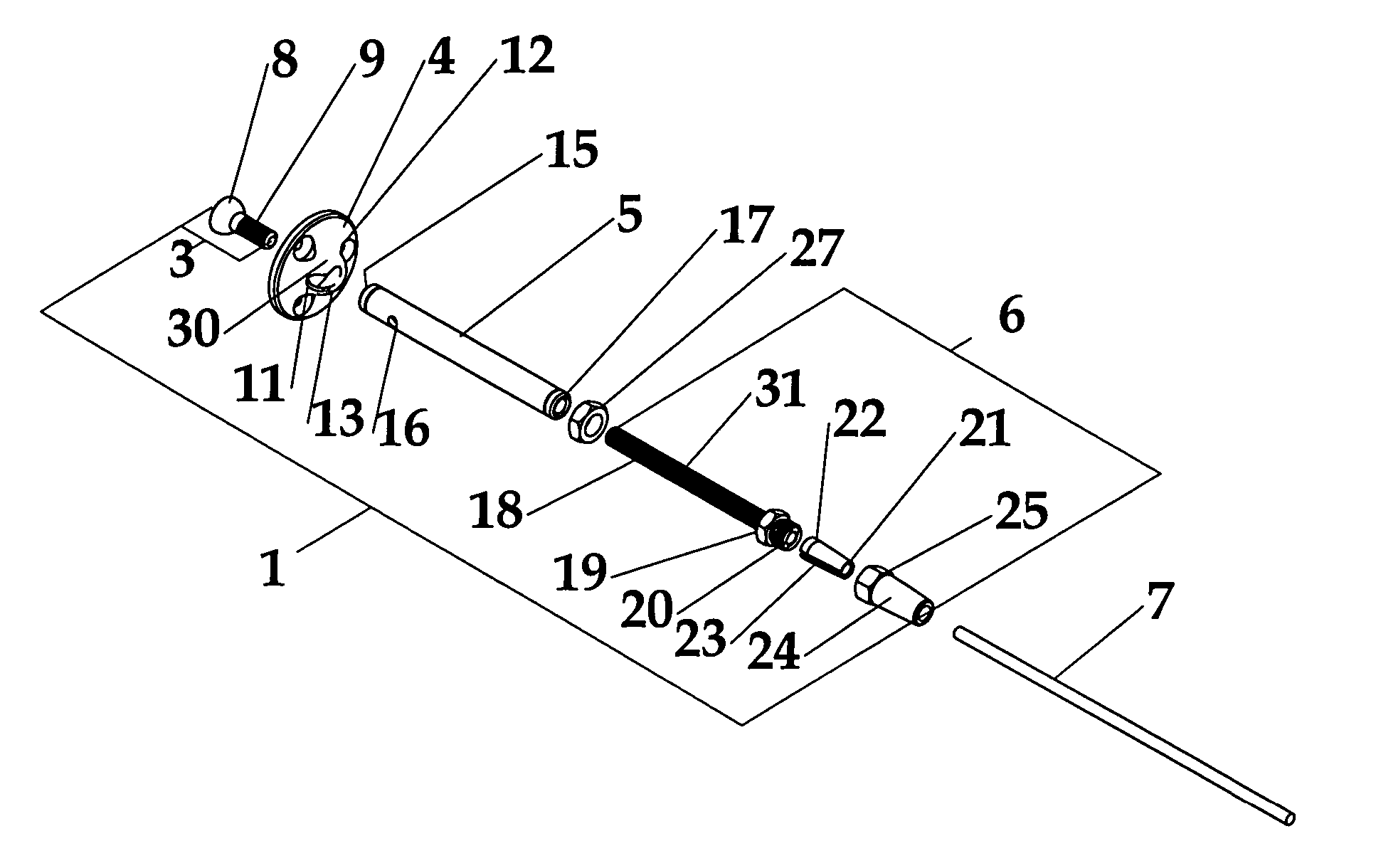

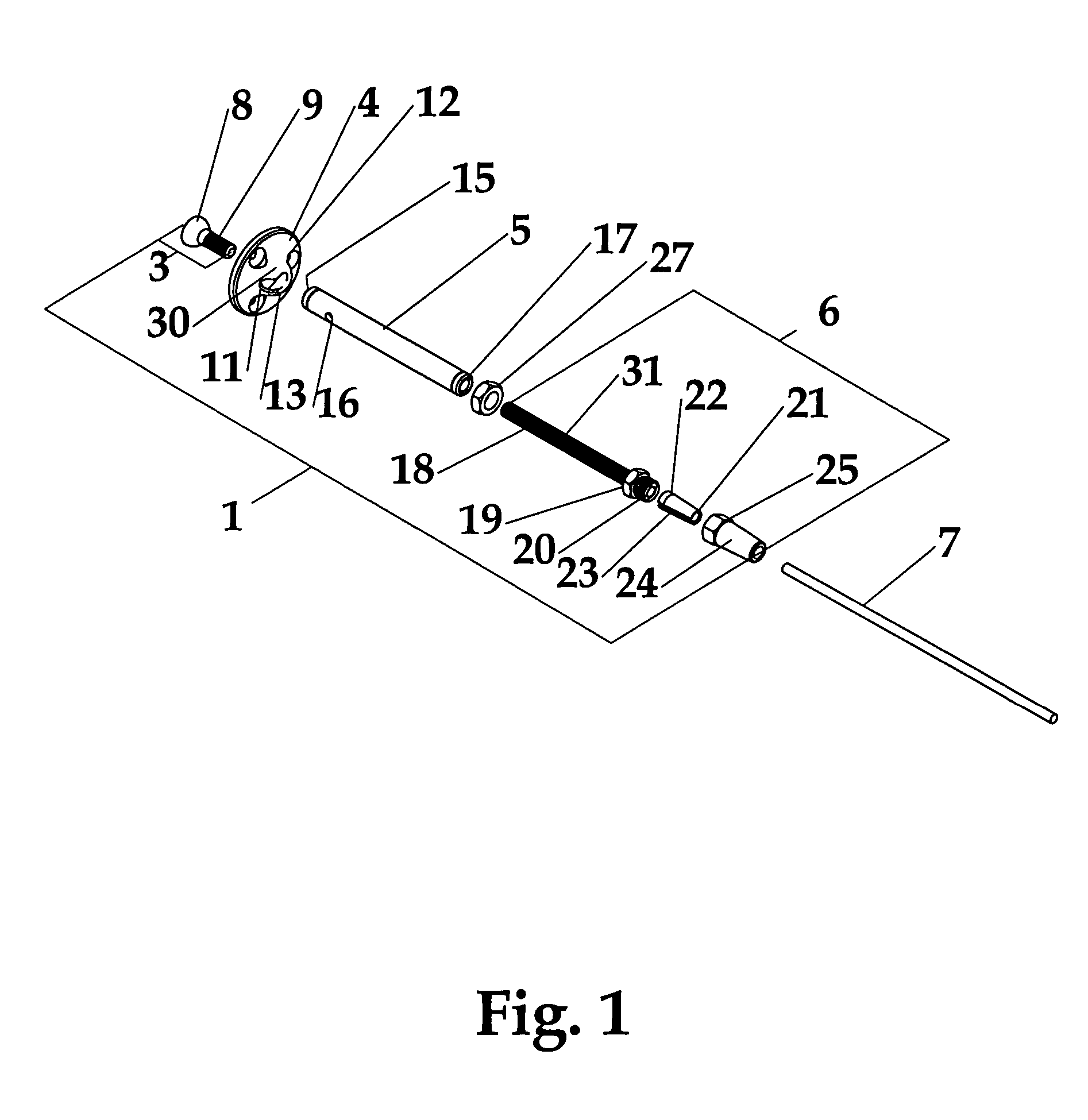

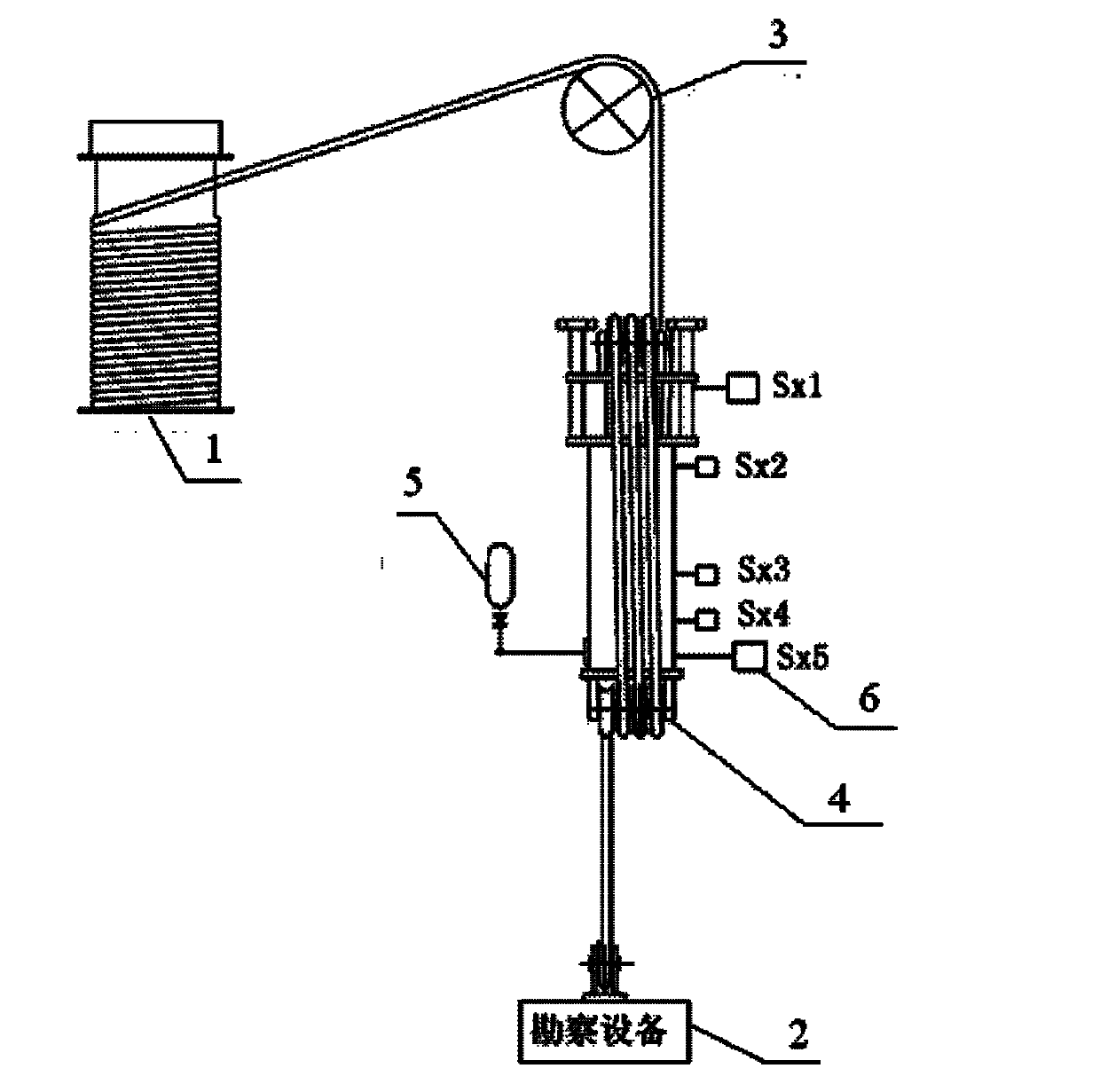

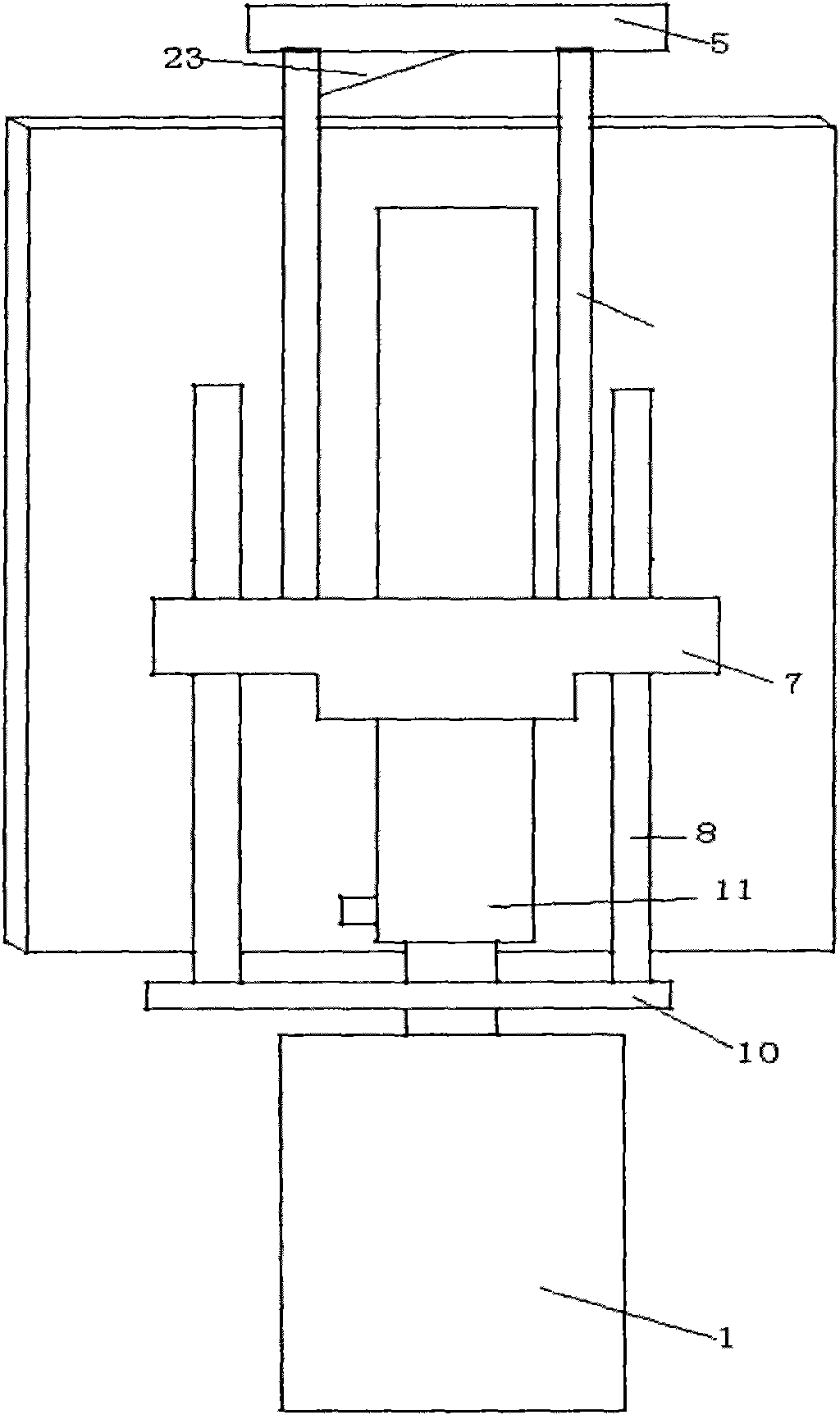

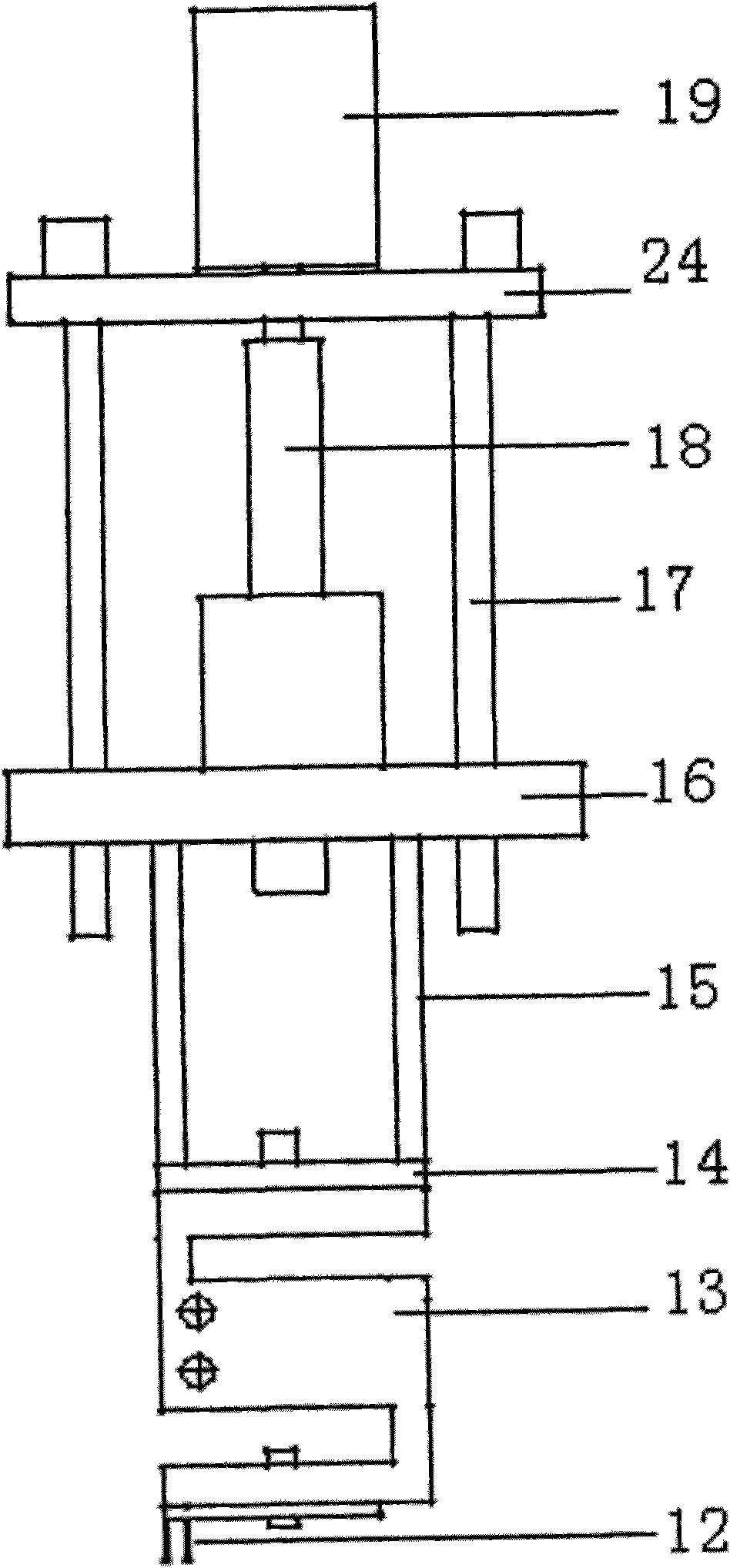

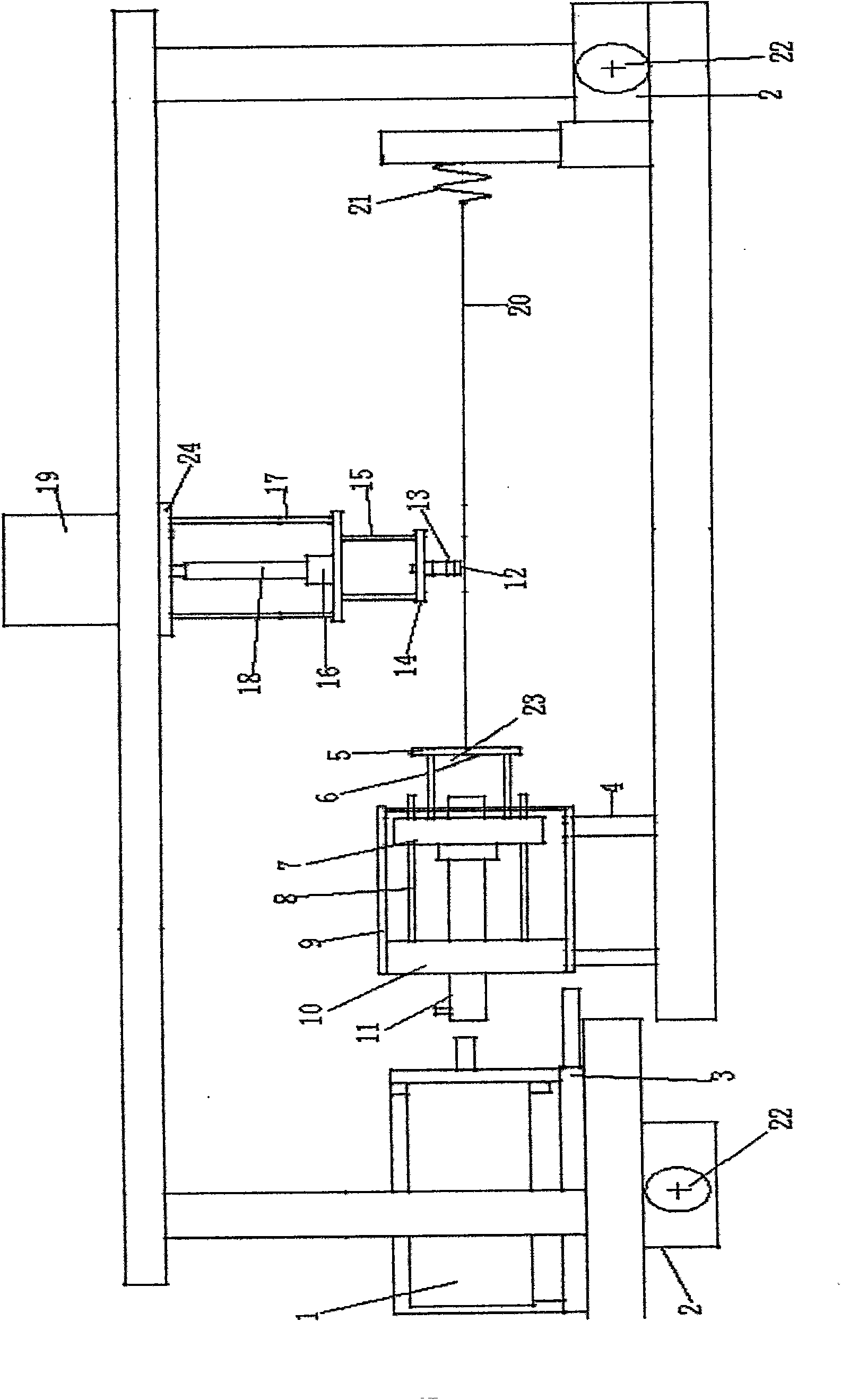

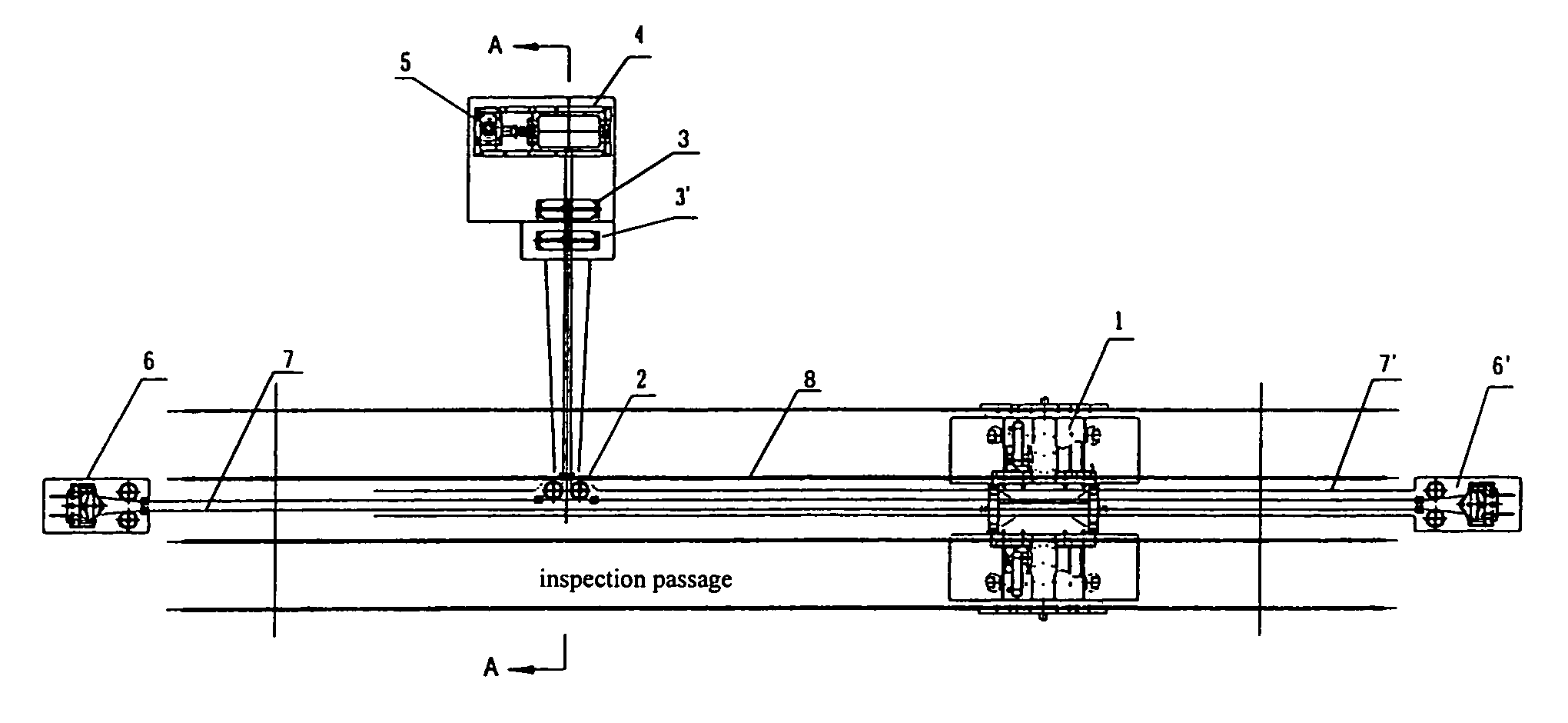

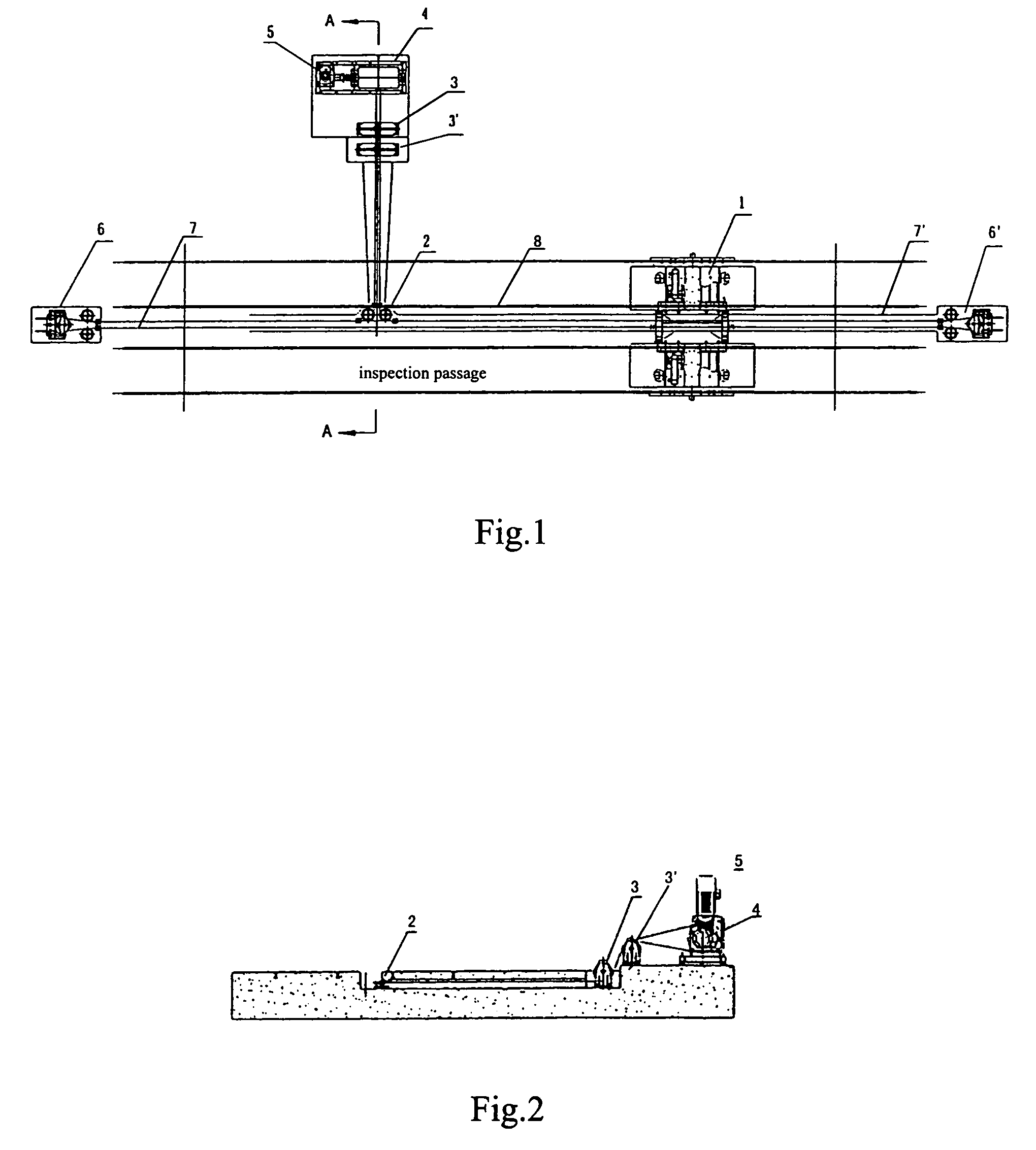

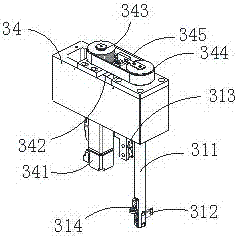

Pulling device for container inspection system

InactiveUS20060113163A1Reduce investmentReduced footprintMetal sawing devicesFeeding devicesWire tensionEngineering

The present invention discloses a pulling device for a container inspection system including a pulling vehicle (1) arranged inside an inspection passage, a winch (5) and wire tension mechanisms (6,6′). Front and rear ends of the pulling vehicle are connected to a wire rope so as to drive the pulling vehicle to move back and forth inside the inspection passage. The wire rope connected to front and rear ends of the pulling vehicle is wound around a wire tension mechanism arranged at front and rear ends of the inspection passage and is turned around by a swerving pulley (2) which is positioned at the same horizontal plane as that of the wire rope, the pulling vehicle, and the wire tension mechanisms, then the wire rope passes through the vertical pulley block, and finally it is connected to a single winding drum (4) of the winch (5) and wound around the single winding drum (4) respectively. Compared with the prior arts, the present invention is advantageous in reduction in equipment investment and decrease in area occupied by the pulling device. Further, the inspection operation can be carried out more reliably and safely.

Owner:NUCTECH CO LTD +1

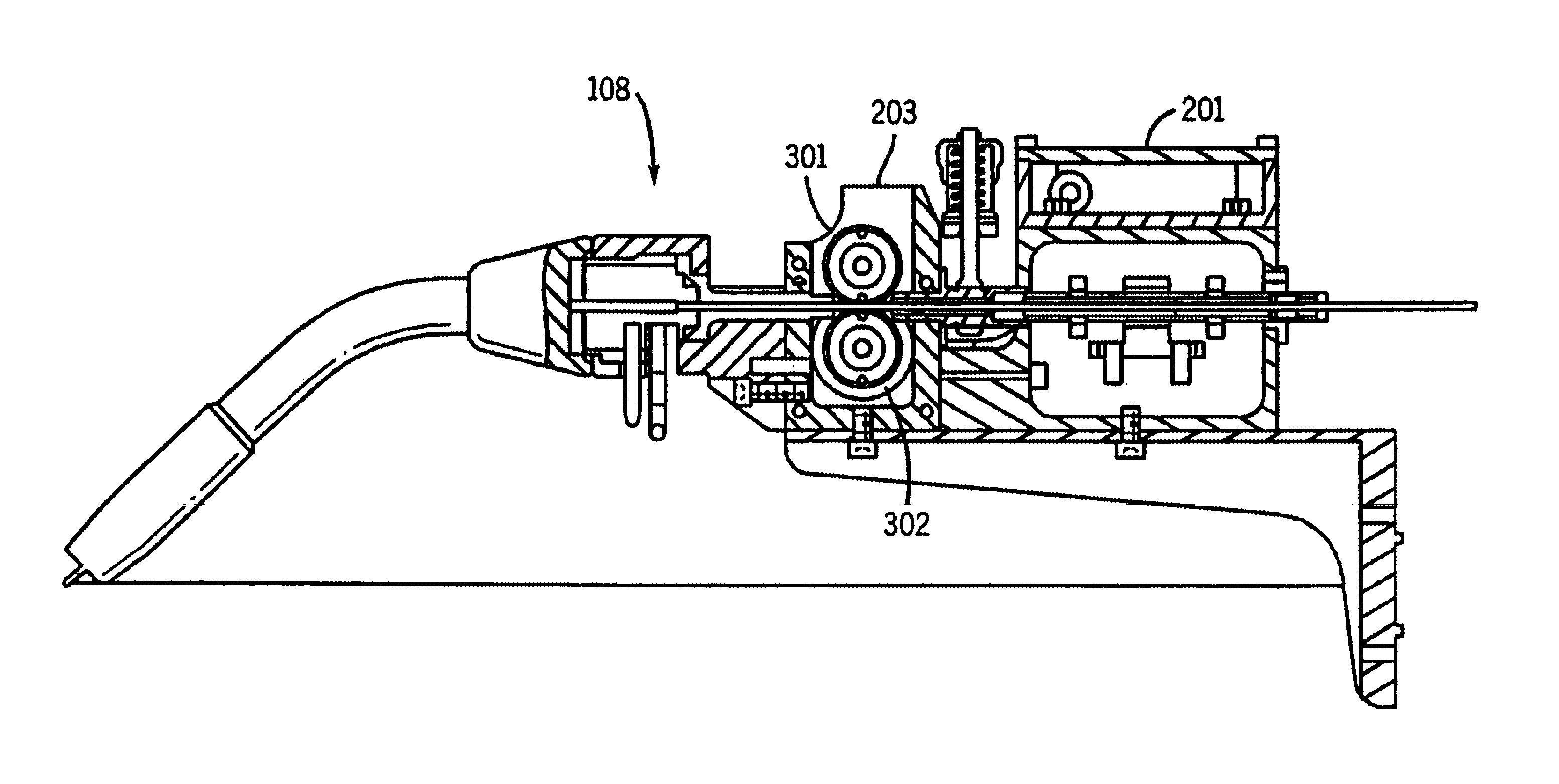

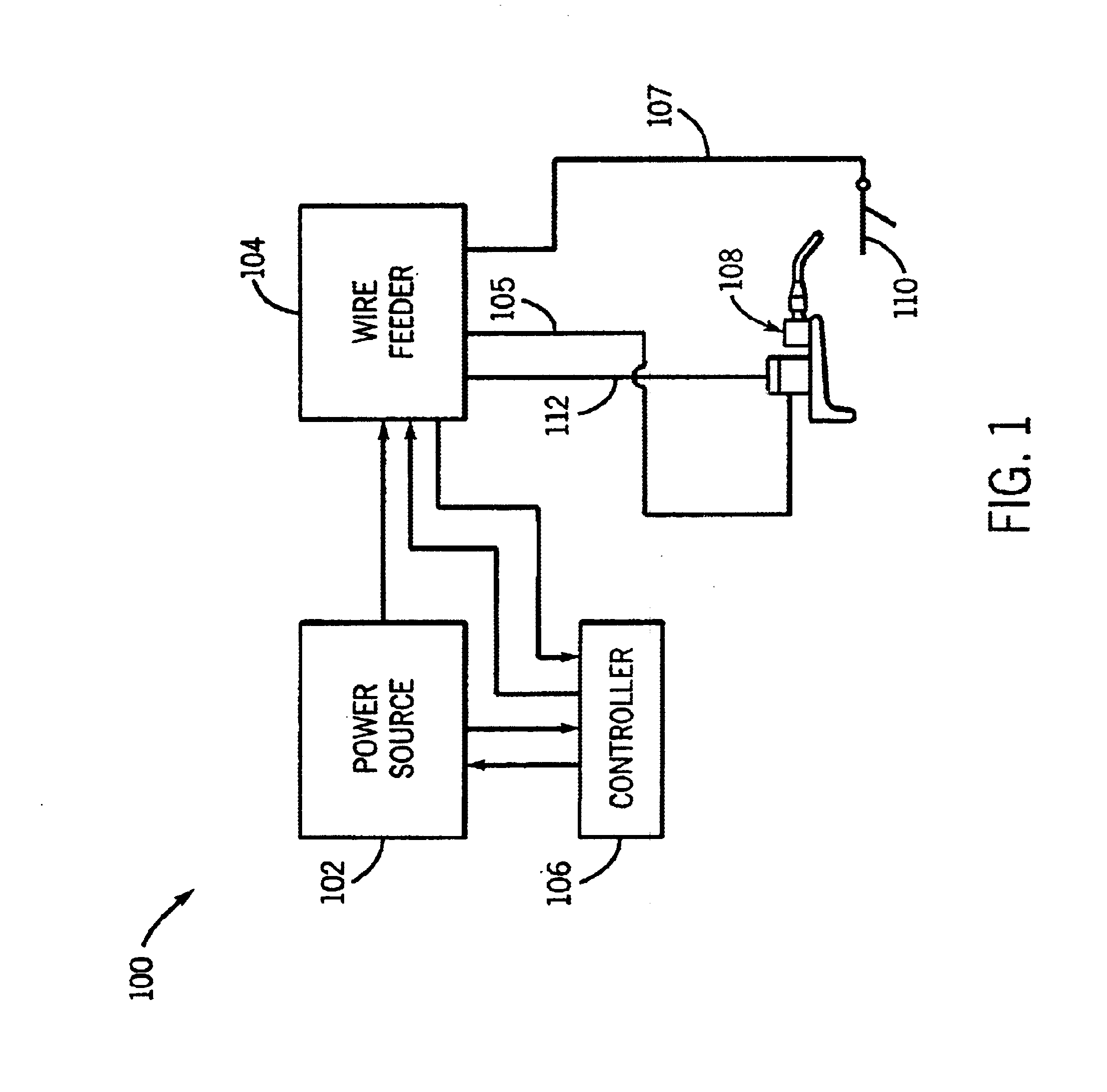

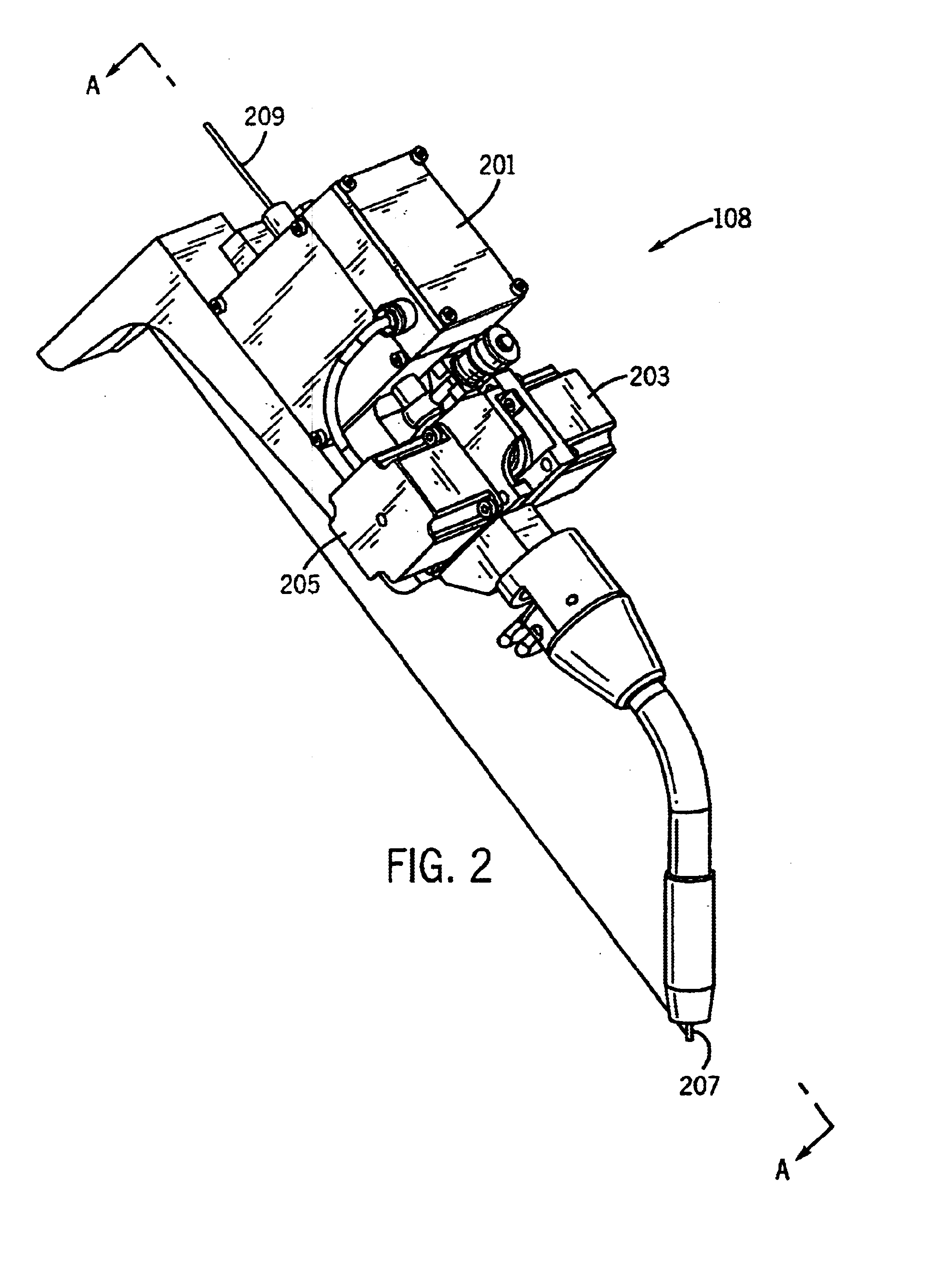

Method and apparatus for welding with mechanical arc control

InactiveUS6963048B2Support devices with shieldingWelding/cutting media/materialsPath lengthWire tension

A method and apparatus for feeding wire from a source of wire to a weld includes one or more motors disposed adjacent the wire to drive the wire to the weld. A buffer is disposed between the source and an arc end of the torch. Another motor may be disposed near the wire source.A wire tension controller may be provided. The one or more motors advance and retract the wire, and wire is stored, or the path length altered, when the wire is retracted.

Owner:ILLINOIS TOOL WORKS INC

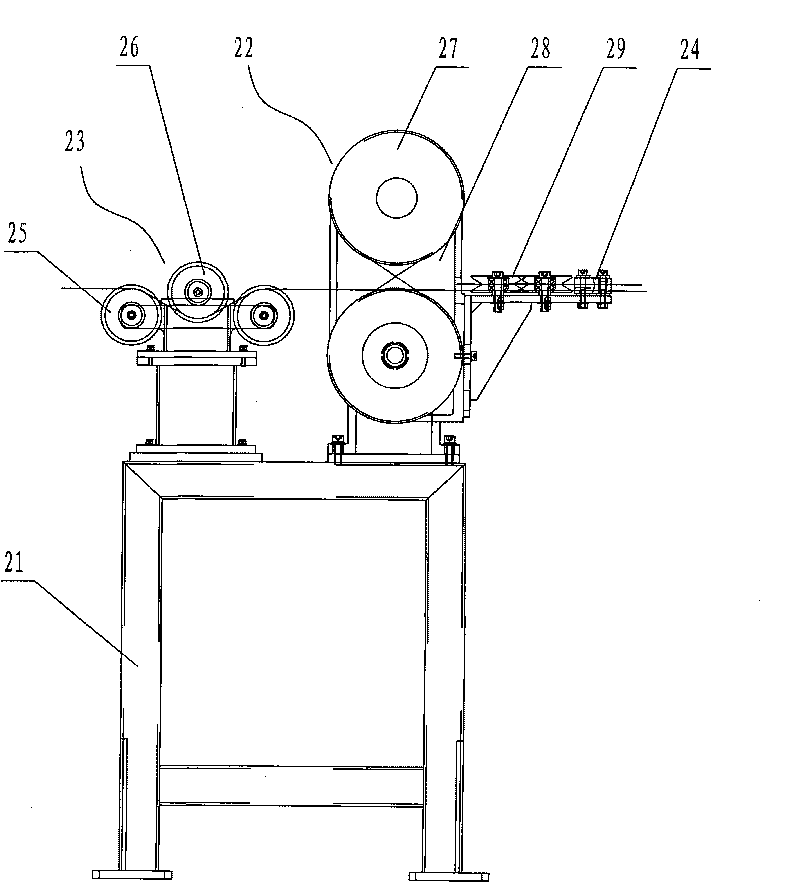

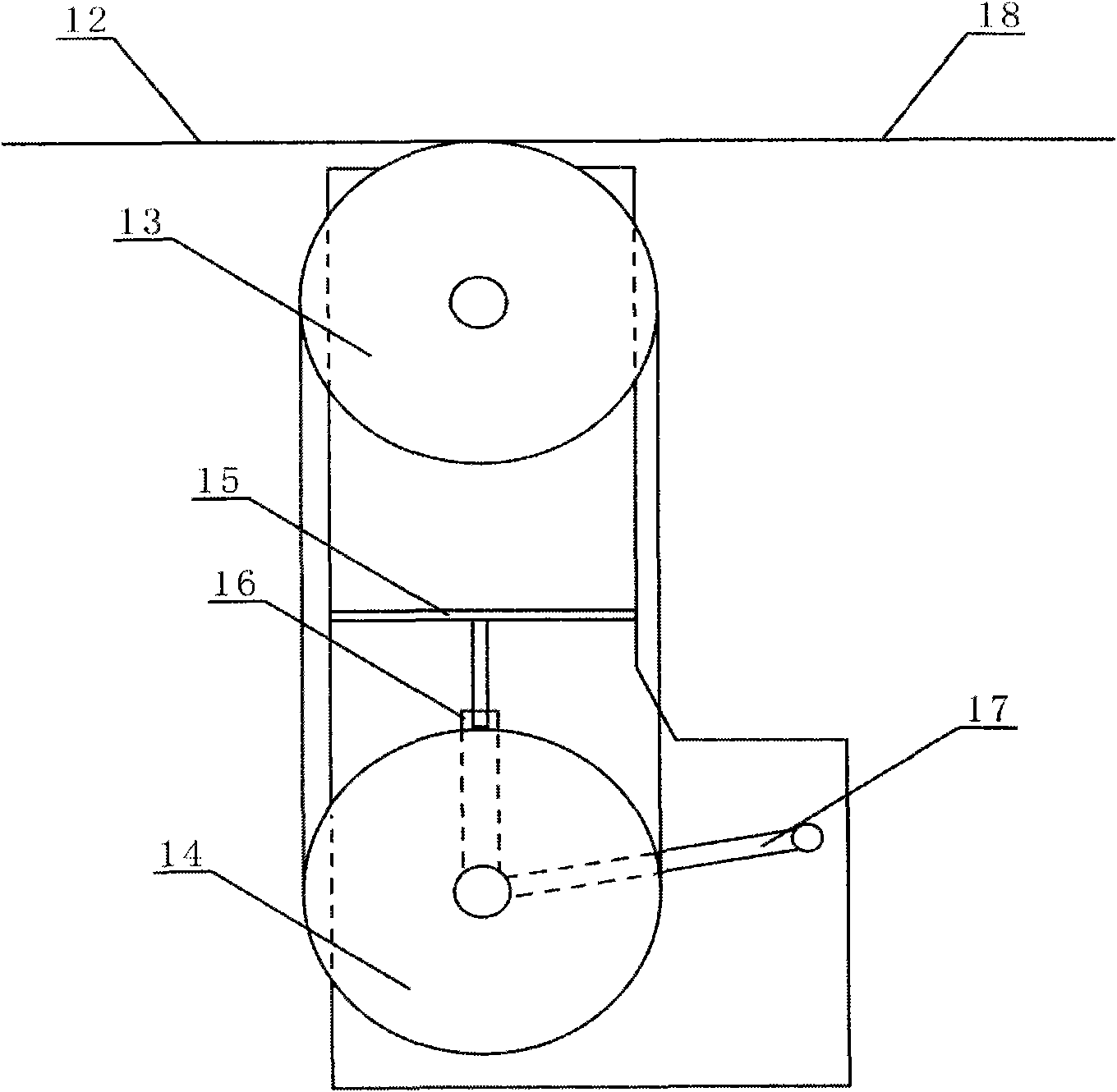

Active wire paying-off rewinder of aluminum clad steel wires

The invention discloses an active paying-off rewinder of aluminum clad steel wires. The rewinder is characterized by comprising an active paying-off mechanism, a tension mechanism and an automatic wire arranging and taking-up mechanism, wherein the aluminum clad steel wire grail tool of the active paying-off mechanism of the rewinder is driven by a motor to realize uniform wire paying-off; an upper tension pulley of the tension mechanism is fixed on a rack, and a lower tension pulley of the tension mechanism is jointly supported by a pneumatic cylinder and a lower tension pulley support; under the action of the pneumatic cylinder and aluminum clad steel wire tension, the tension pulley is used for adjusting the aluminum clad steel wire tension by vertical movement; and the automatic wire arranging and taking-up mechanism is characterized in that a wire arranging seat rotating shaft, a wire arranging seat guide rail, a movable mandril and a fixed mandril are arranged between two fixed supports; the wire arranging seat rotating shaft is provided with a wire arranging seat and a wire arranging seat driving wheel; the wire arranging seat guide rail is provided with two stop pins for playing a limit role; the movable mandril and the fixed mandril are respectively connected with the grail tool in a splicing mode; the fixed mandril is provided with a grail tool driving wheel, a brake pad and a driven wheel; and the driven wheel is connected with the wire arranging driving wheel which is arranged on the wire arranging seat rotating shaft by a driving belt. Therefore, the product quality is ensured, the production efficiency is improved and the labor intensity is reduced.

Owner:HENAN TONG CABLE

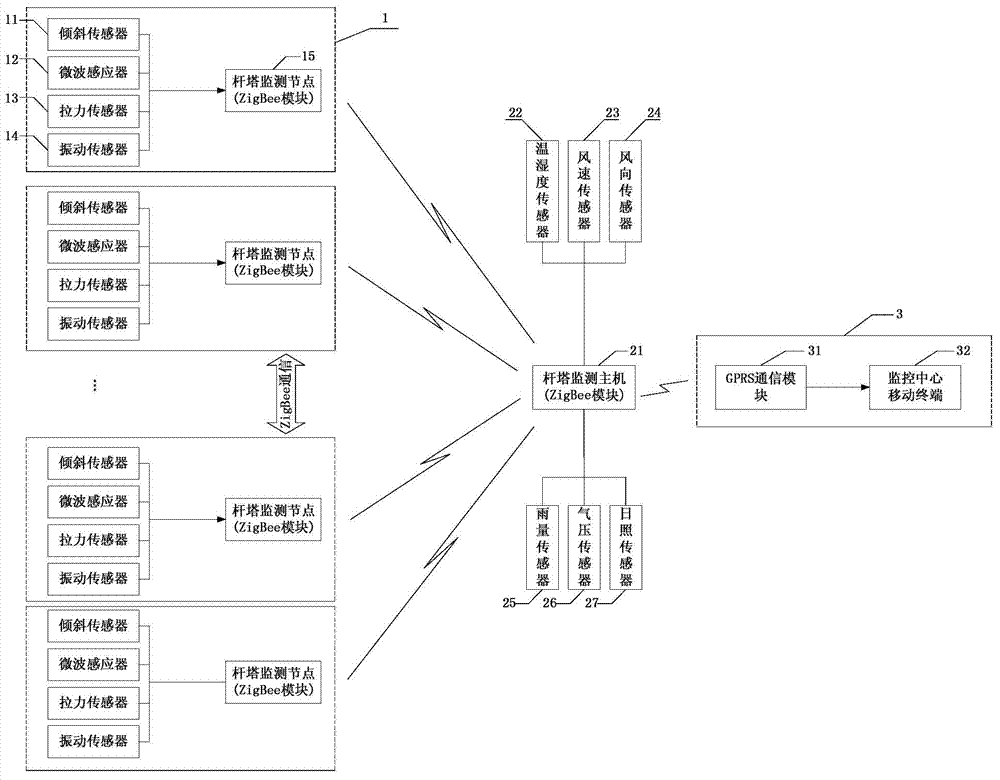

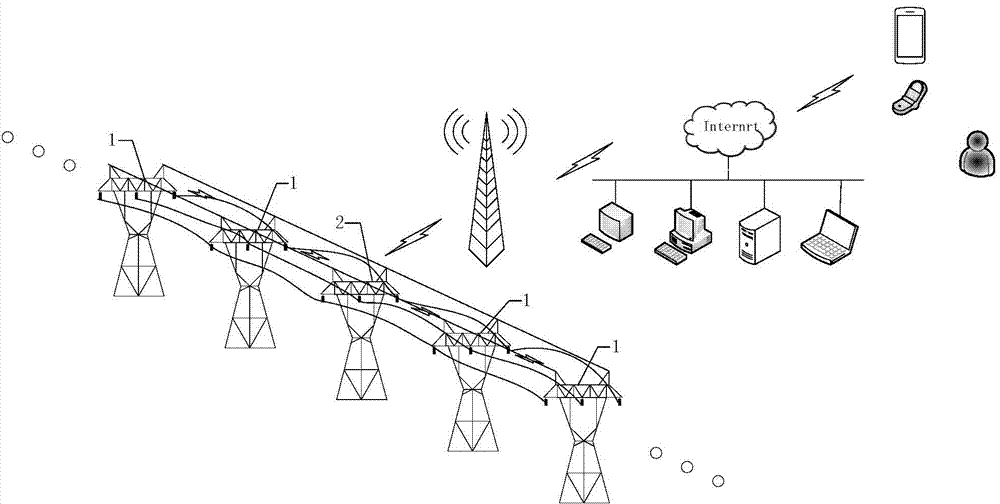

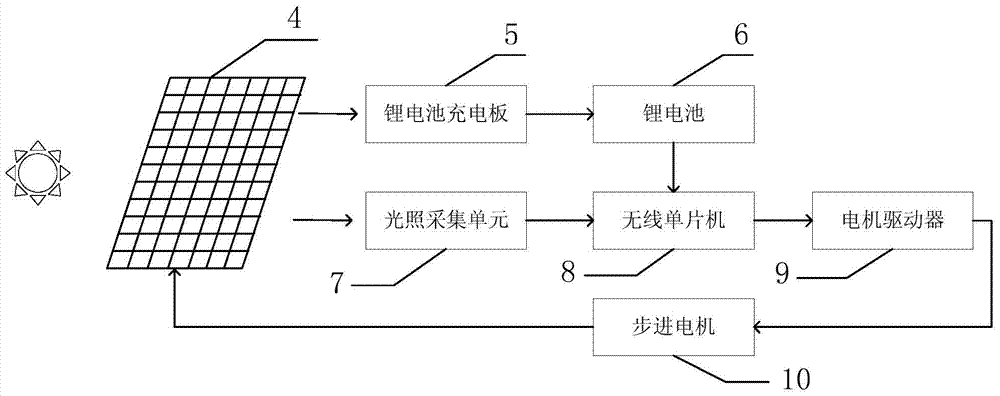

Transmission tower on-line monitoring system

InactiveCN103575335AImprove anti-interference abilityTransmission systemsIndication of weather conditions using multiple variablesTransmission towerSignal on

The invention provides a transmission tower on-line monitoring system and relates to the field of transmission tower on-line monitoring. The transmission tower on-line monitoring system solves the problems that an existing wired transmission tower on-line monitoring device is prone to being interfered by strong current signals on transmission lines and low in intellectualization degree. The transmission tower on-line monitoring system carries out multipoint data acquisition through N transmission tower monitoring units. Data comprise the tilt values, the microwave values, the wire tension values and the vibration values of transmission tower monitoring nodes. The tilt values, the microwave values, the wire tension values and the vibration values of the transmission tower monitoring nodes are transmitted to a transmission tower monitoring main unit in a wireless mode. The transmission tower monitoring main unit is used for monitoring the N transmission tower monitoring units, monitoring the temperature, the humidity, the wind speed, the wind direction, the rainfall, the air pressure and the sunlight illumination in the area where the transmission tower monitoring main unit is located, synthetically carrying out data processing and finally transmitting the processed data in a GPRS wireless communication mode to a monitoring center and mobile terminals capable of communicating with the monitoring center. The transmission tower on-line monitoring system is applicable to transmission tower on-line monitoring.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Monitoring system for wire rope tension balancing cylinder and lifting load

InactiveCN101279688ASolve monitoring problemsSolving Monitoring ChallengesElevatorsMine liftsWire tensionMonitoring system

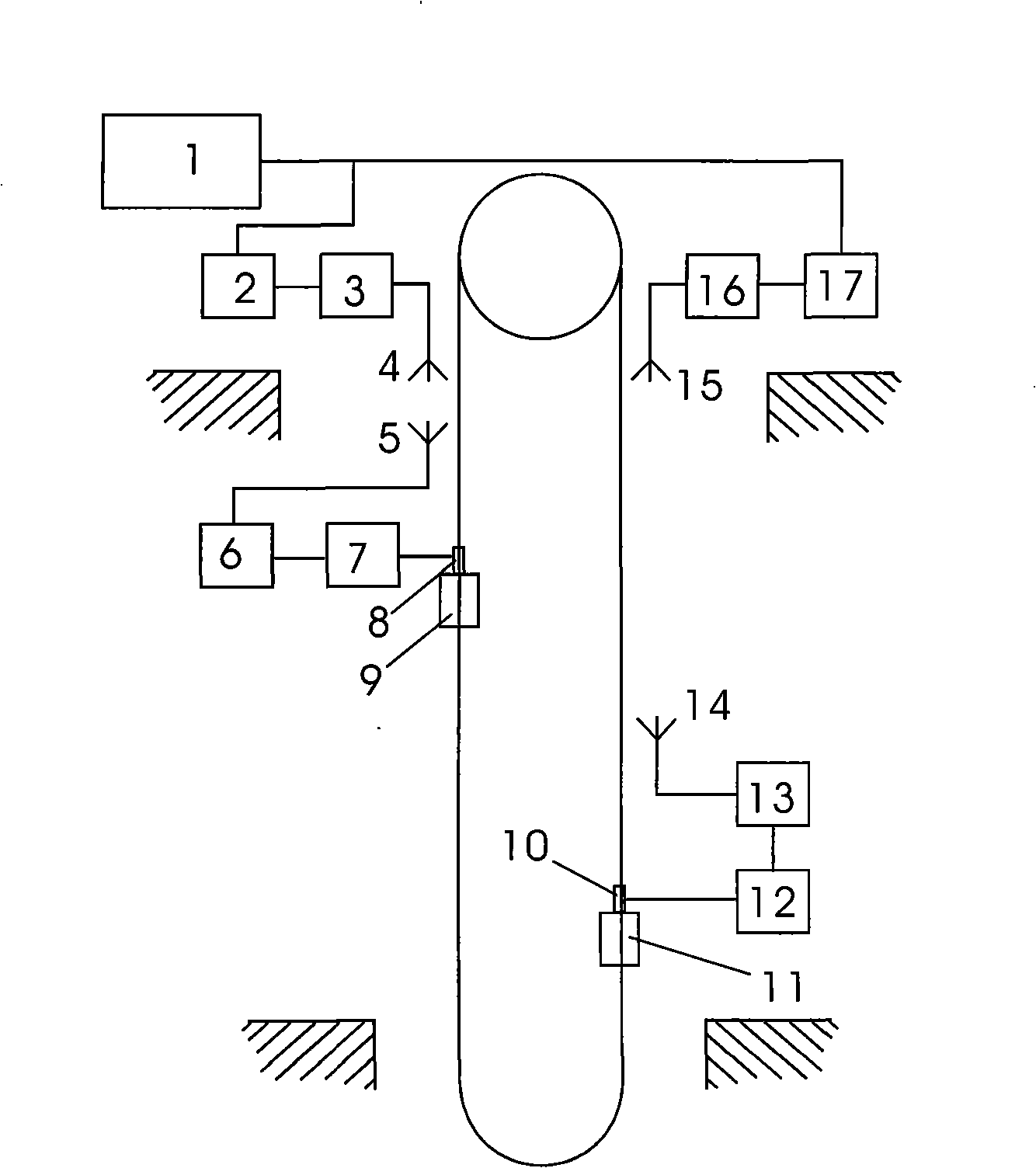

The invention relates to a system for monitoring the position of an oil cylinder for balancing tension of a steel wire and hoisting load, which consists of a monitor master computer, a master controller, a wireless signal receiver, a signal receiving antenna, a signal transmitting antenna, a wireless signal emitter, a signal processor, a displacement hydraulic sensor and a hoisting vessel. The monitor master computer is connected with two master controllers. The master controller is connected with the wireless signal receiver. The wireless signal receiver is connected with the signal receiving antenna. The steel wire is connected with two hoisting vessels at the same time. The hoisting vessel is provided with the displacement hydraulic sensor. The displacement hydraulic sensor is connected with the signal processor. The signal processor is connected with the wireless signal emitter. The wireless signal emitter is connected with the signal transmitting antenna. The system solves the problem of monitoring the position of the oil cylinder for balancing tension of the steel wire and hoisting load and effectively prevents the steel wire of the hoister from being broken and the occurrence of overload. The safety of hoisting is ensured. The monitor system is easy to be installed and convenient to be maintained.

Owner:董传德

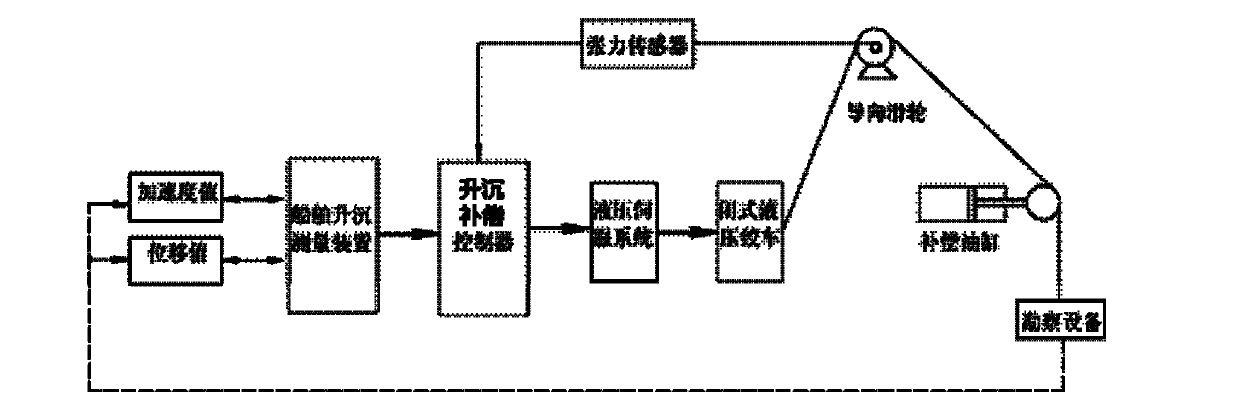

Apparatus and method for heave compensation

InactiveUS7731157B2Reduce tensionStrong loadArtificial islandsWaterborne vesselsMeasurement deviceWire tension

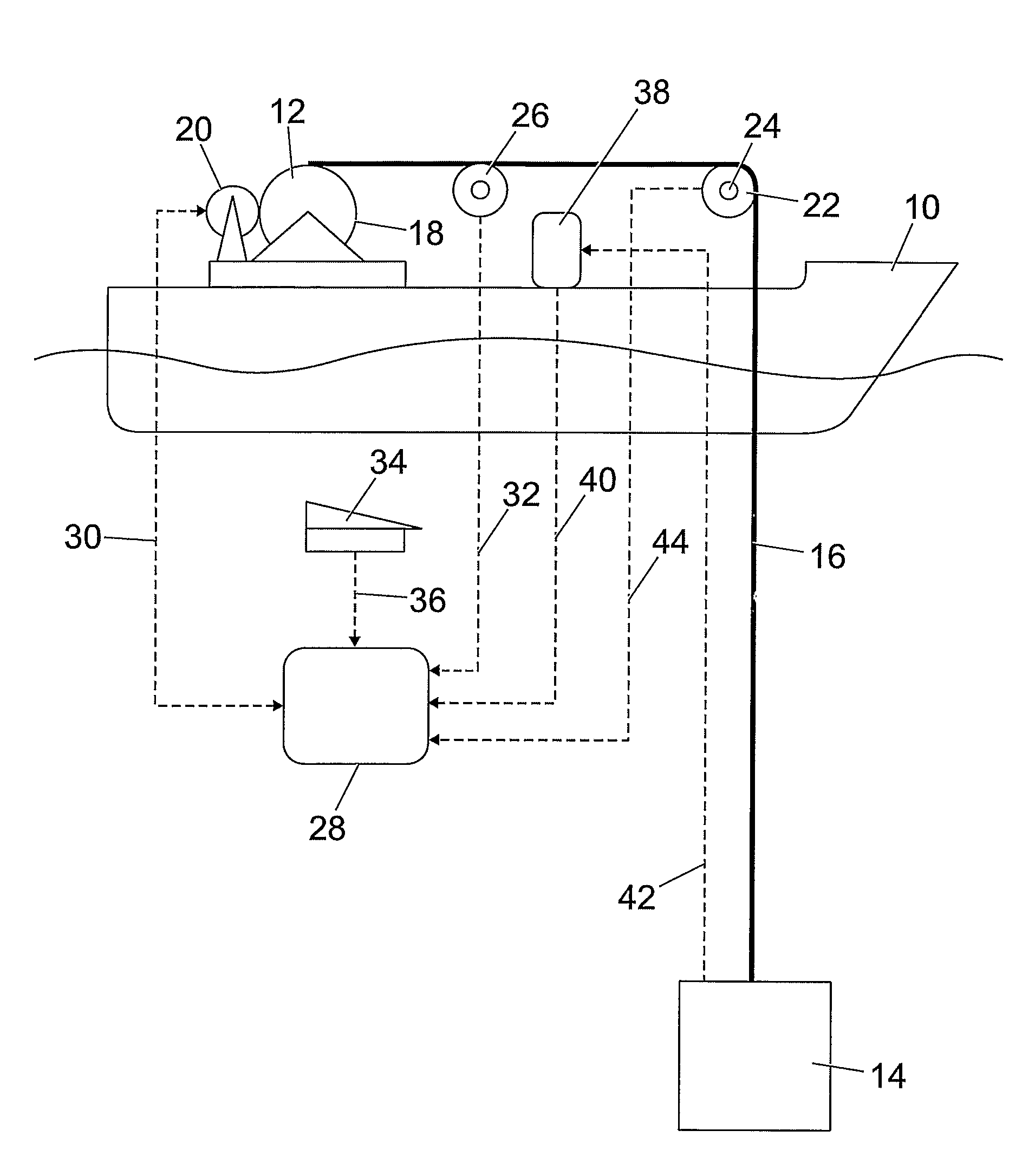

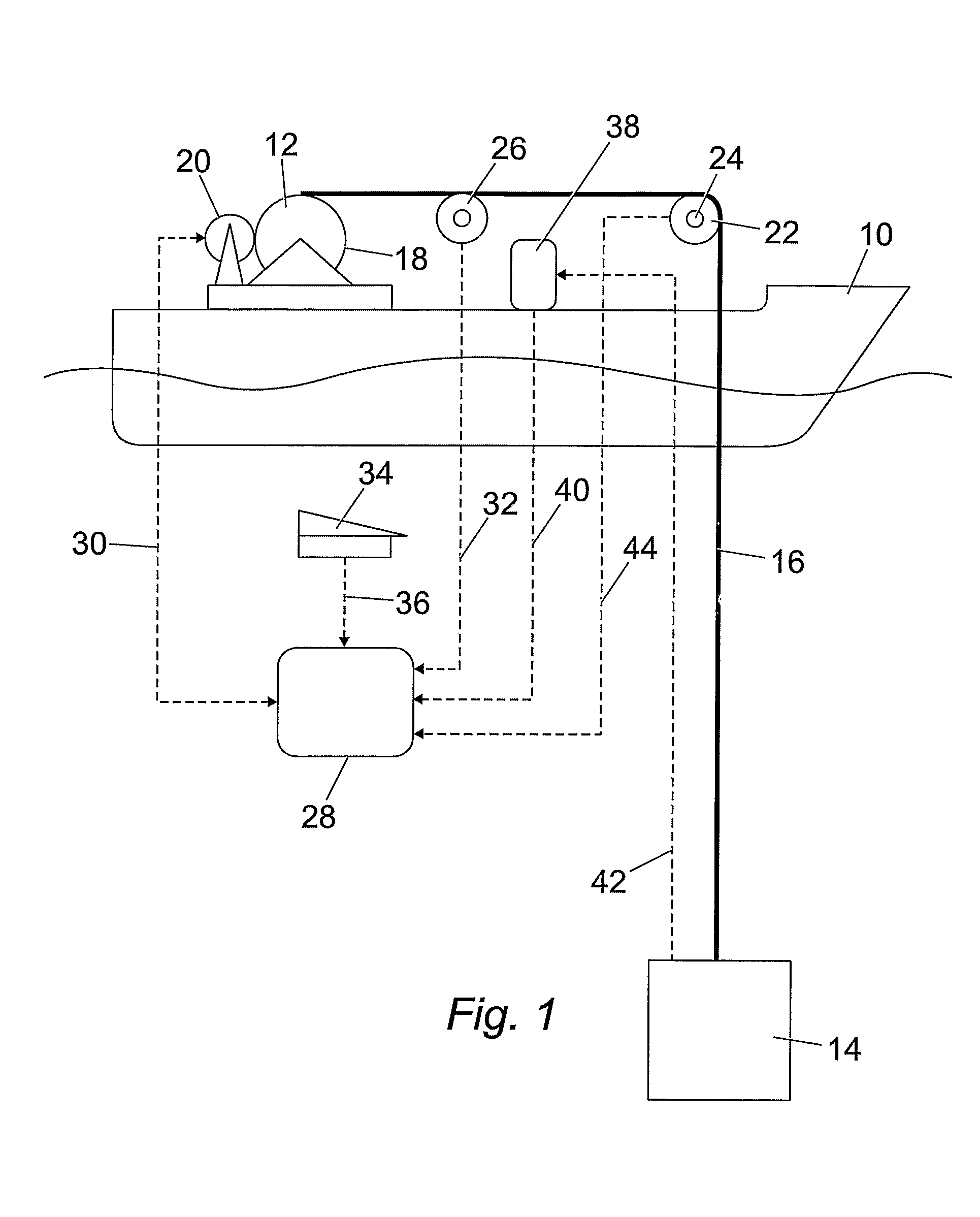

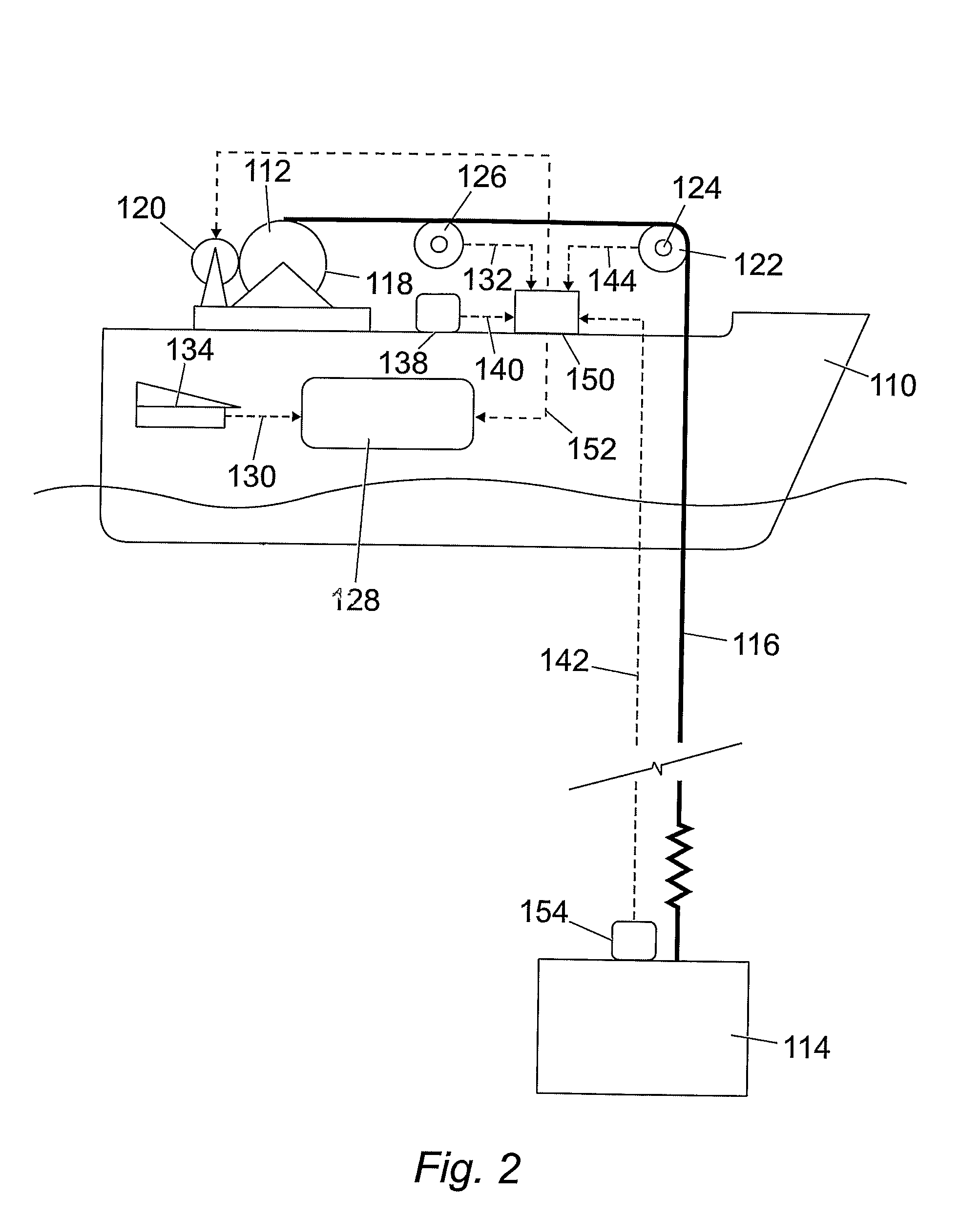

A heave compensation apparatus and method for a winch or crane system, the winch or crane system preferably for a vessel and including a lift wire for attachment to a load. The apparatus includes a vessel motion measurement device which may be in the form of a motion reference unit for measuring the motion of the vessel, and a control device or computer capable of receiving an output from the vessel motion measurement device and controlling the winch or crane system according to the movement of the vessel, so as to stabilise the load. The apparatus may further optionally include one or more of a lift wire tension measuring device for measuring the tension in the lift wire; a lift wire distance measurement device which measures the length of lift wire that has been paid out; and a load motion measurement device for measuring the motion of the load.

Owner:SUBSEA 7 BV

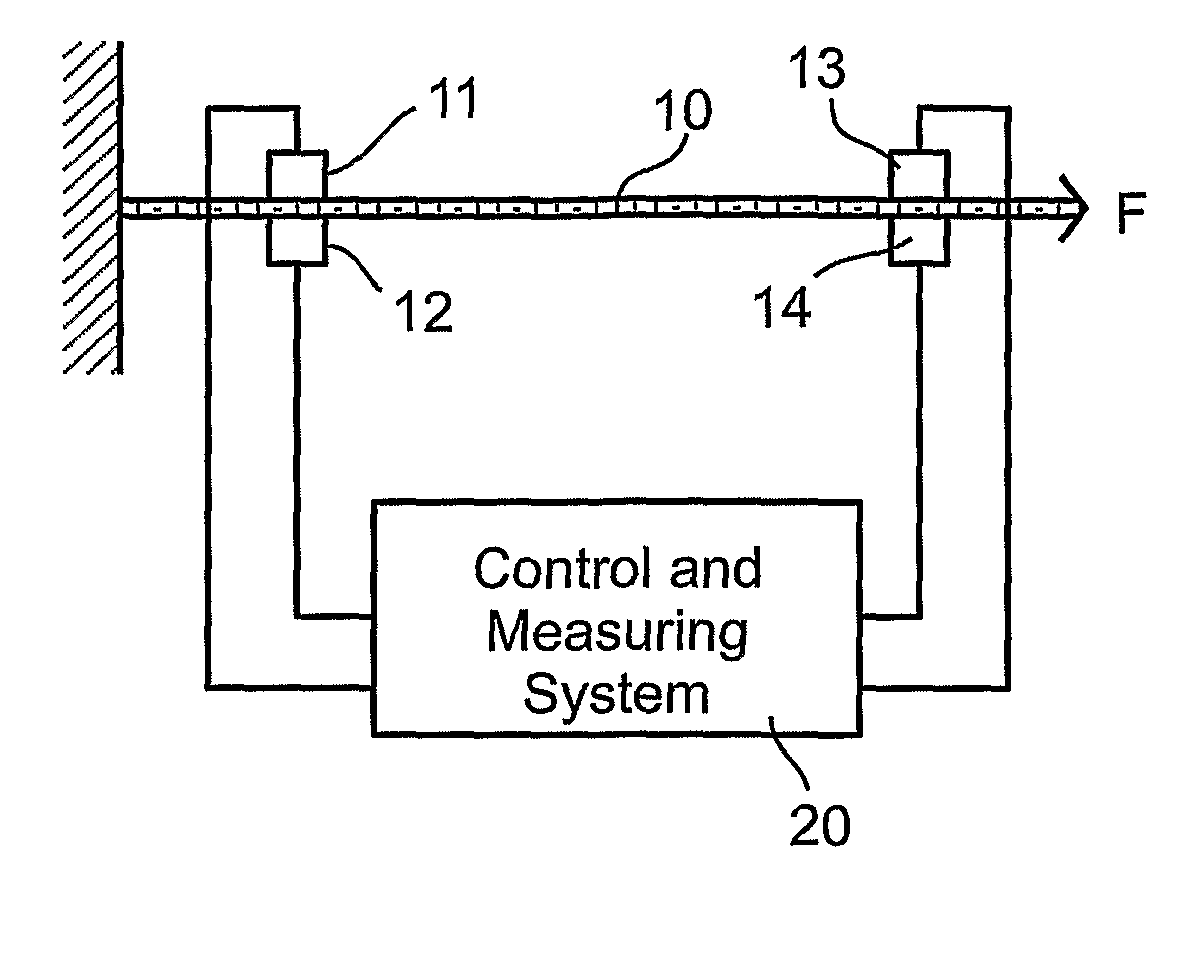

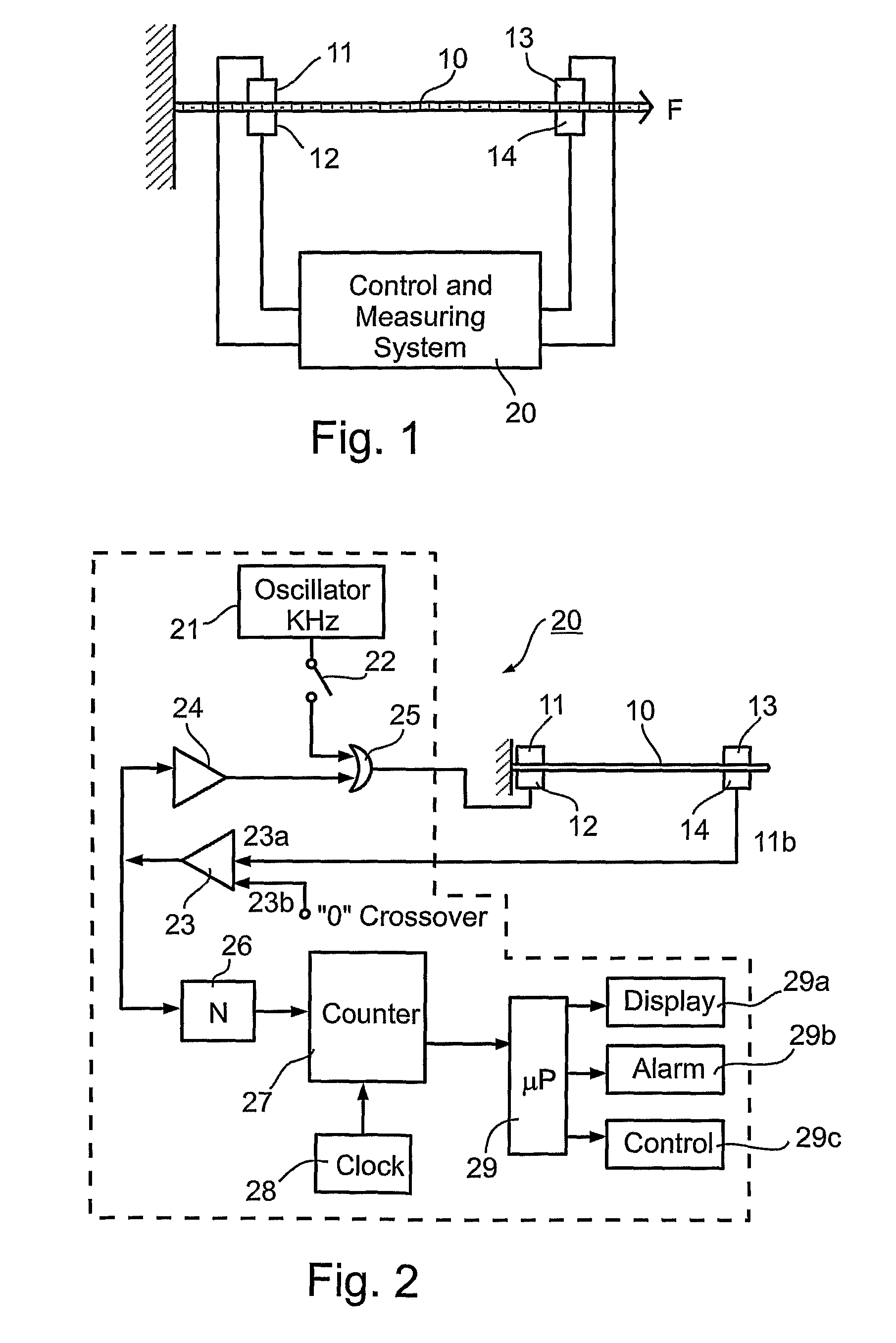

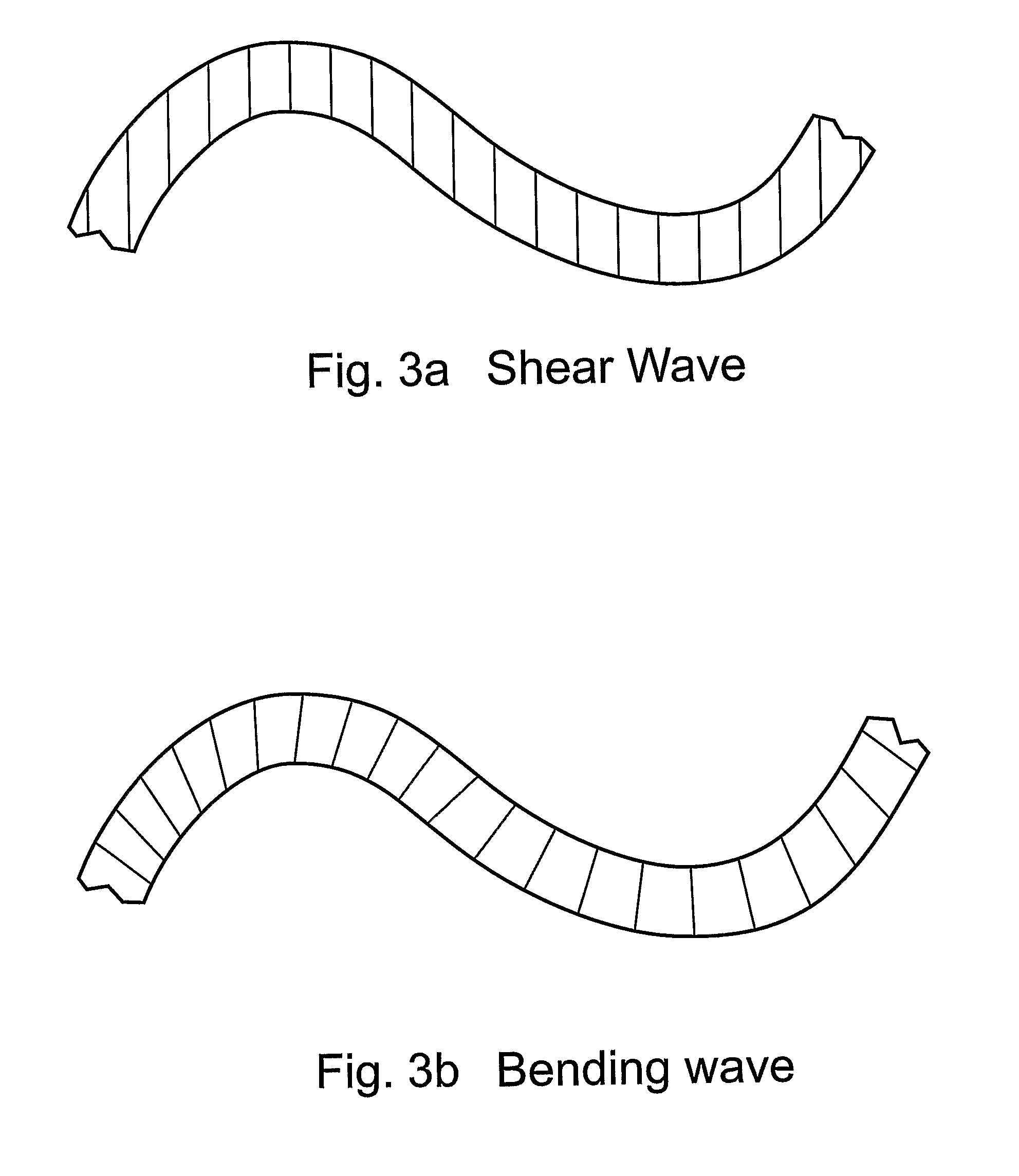

Method and Apparatus for Precisely Measuring Wire Tension and Other Conditions, and High-Sensitivity Vibration Sensor Constructed in Accordance Therewith

InactiveUS20080307885A1High sensitivityHigh precisionAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesContinuous measurementTransport time

A method and apparatus for monitoring a predetermined condition of a medium by; transmitting acoustical waves through the medium, continuously measuring changes in the transit time of the acoustical waves resulting from changes in the monitored condition; and utilizing the changes in transit time to provide a continuous measurement of the changes in the monitored condition. The acoustical waves are bending waves wherein cross-sections of the medium have a rotational movement orthogonally to the axis of propagation of the waves through the acoustical channel. Several examples of such method and apparatus are described, including a highly sensitive pressure sensor for sensing changes in pressure applied to a displaceable membrane, and a highly-sensitive vibration sensor for sensing earth or other vibrations.

Owner:NEXENSE

Wave-absorbing high-elasticity yarn and production equipment and production method thereof

The invention relates to a wave-absorbing high-elasticity yarn and production equipment and a production method thereof. The wave-absorbing high-elasticity yarn is characterized in that the wave-absorbing high-elasticity yarn comprises an elastic yarn, a core-spun structural yarn section is wound on the external side of the elastic yarn, and the core-spun structural yarn section comprises a metal wire and a staple strand which is wound on the external side of the metal wire. The production equipment of the wave-absorbing high-elasticity yarn comprises a ring spinning machine and is characterized in that the equipment additionally comprises an elastic yarn tension disc, an elastic yarn holding roll, a metal wire tension disc, a metal wire holding roll, a staple strand front bell mouth and a staple strand rear bell mouth. Only by adding a pair of tension plates, two holding rolls and two bell mouths on a common spinning machine, the high-elasticity composite spinning of the non-elastic metal wire can be realized. Therefore, the method is simple and practical.

Owner:DONGHUA UNIV

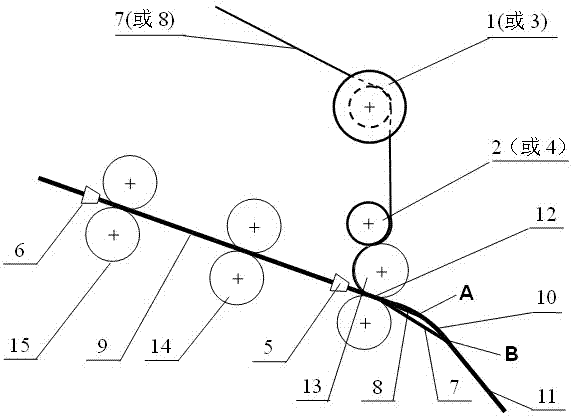

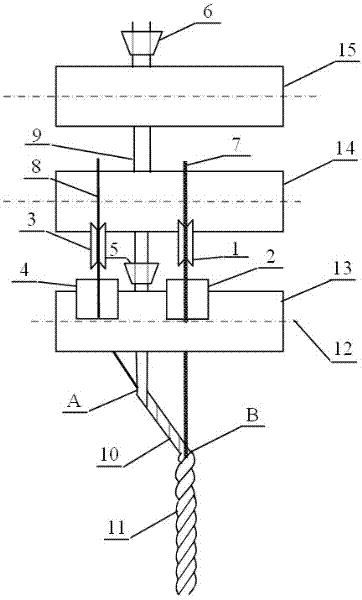

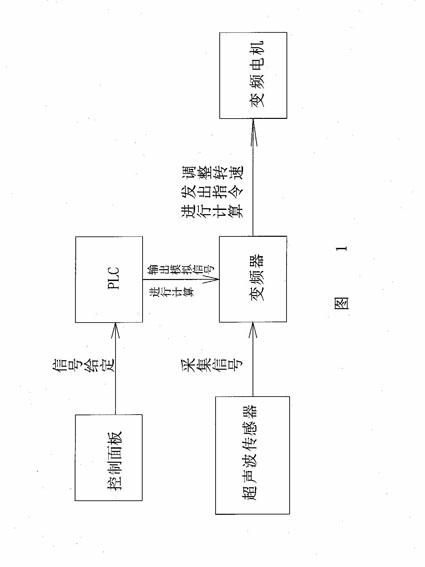

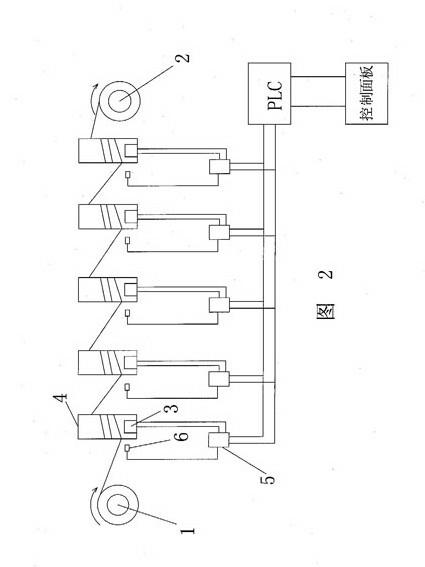

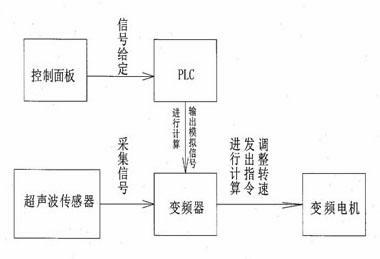

Metal wire tension detection and control device in straight line wire drawing machine

The invention provides a device for conveniently detecting and controlling tension of a metal wire in the wire drawing process, which is used for solving the problem of higher failure rate due to a severe working environment in the conventional tension detection and control device. The technical scheme is that: the front end of the wire drawing machine is provided with a wire unreeling wheel (1), and the tail end of the wire drawing machine is provided with a wire reeling wheel (2) using a variable frequency motor; variable frequency motors (3) are used by wire drawing units and wire reeling units; each wire drawing unit comprises a revolving drum (4), a frequency converter (5), a mechanical braking device and the like; an analog signal of a set speed is connected to a programmable logic controller (PLC) control unit and is output to the input end of the frequency converter (5) by the PLC control unit; meanwhile, an ultrasonic sensor (6) is arranged between every two wire drawing units; and the ultrasonic sensors (6) are used for transmitting corresponding data signals to serve as feedback signals for control according to variation in distances from transmitting ends and receiving ends of the ultrasonic sensors (6) to an object to be measured so as to adjust the rotation speeds of the variable frequency motors (3).

Owner:YUXI YUBEI METALWORK

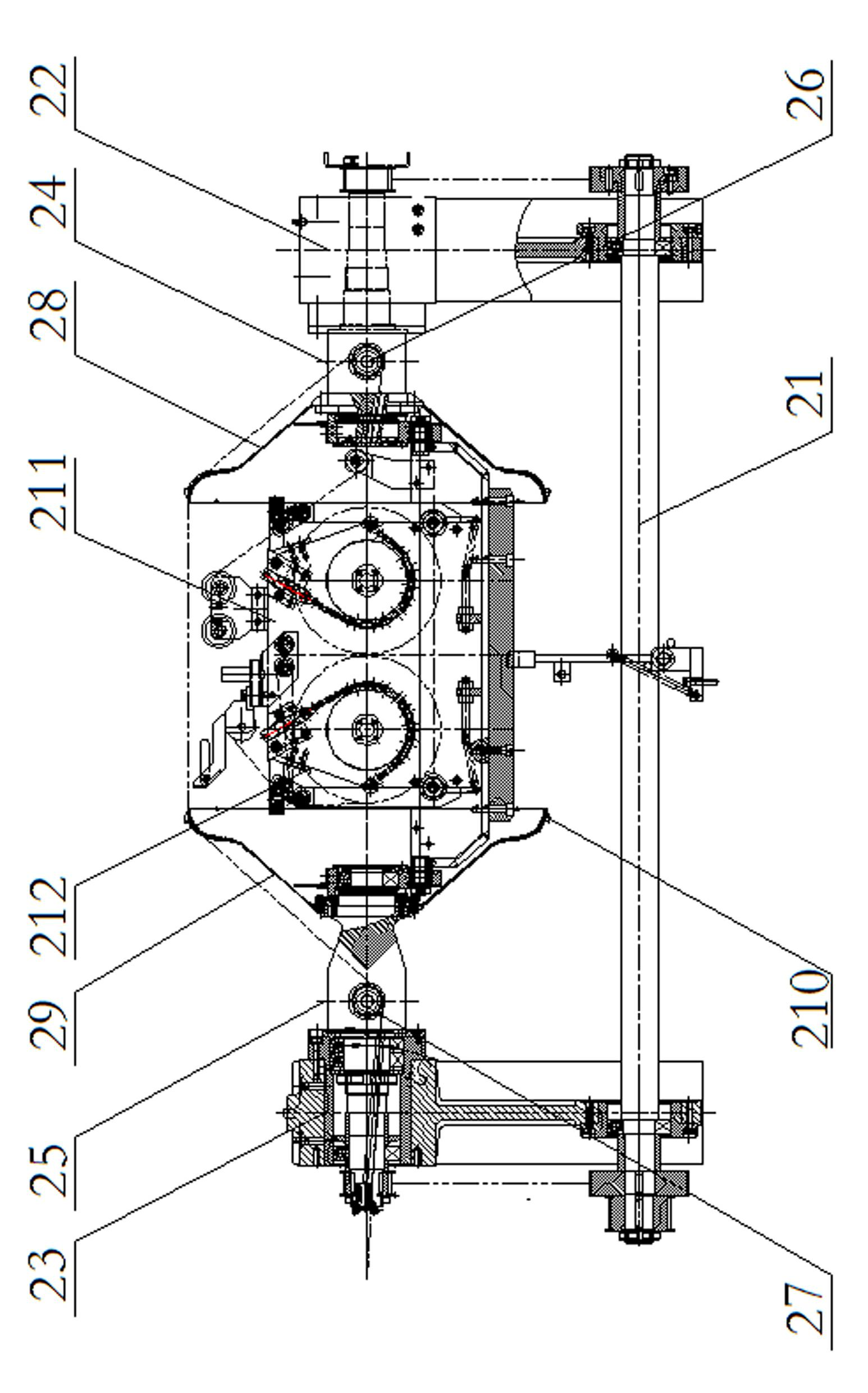

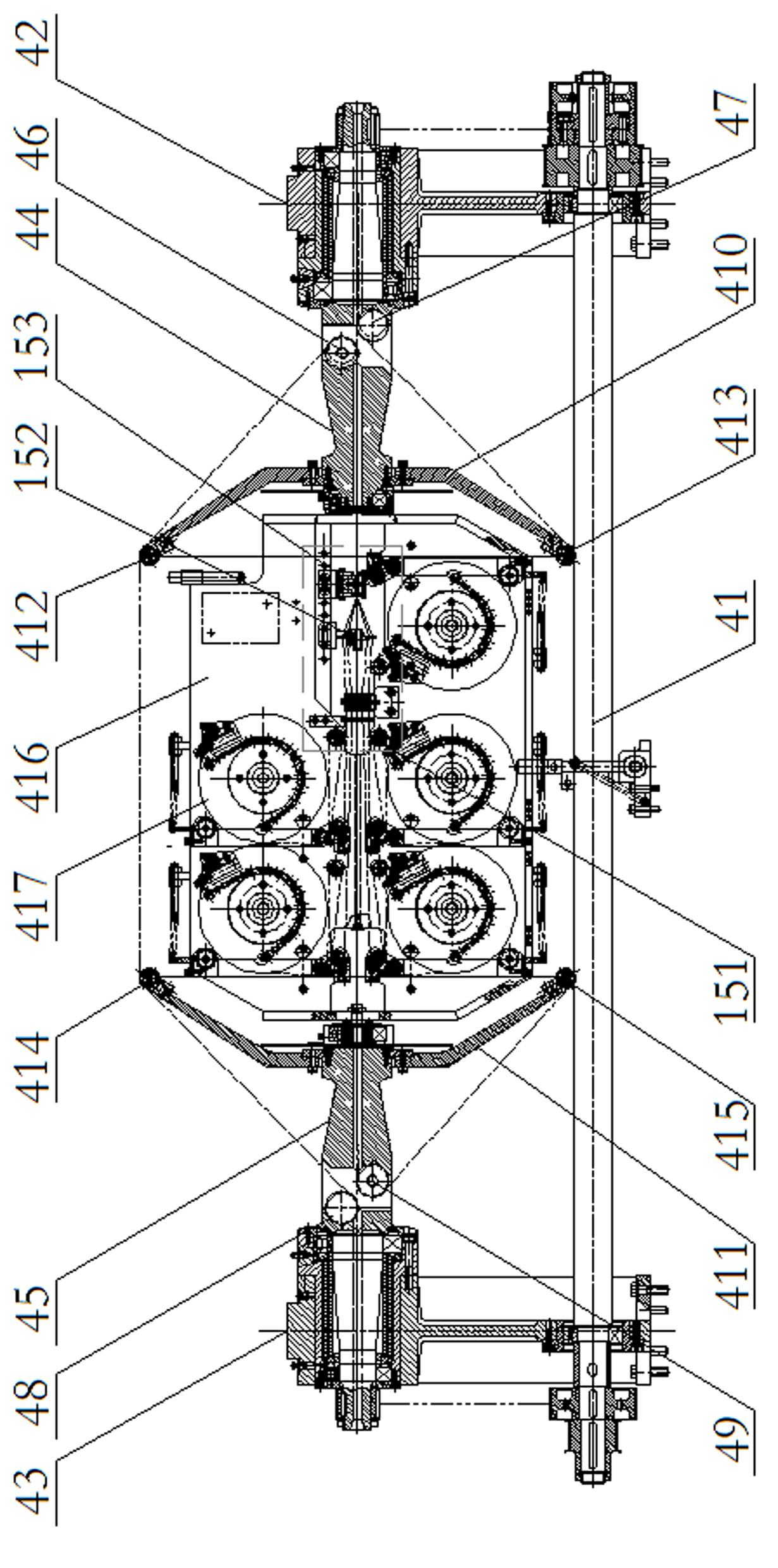

Special metal wire twisting machine

InactiveCN102493239ASave installation spaceReduce running noiseRope making machinesLow noiseWire tension

The invention relates to a special metal wire twisting machine which mainly consists of a core wire and a surface wire pay-off rack, a core wire cradle K30, a core wire transmission assembly, a core wire tension and bridge assembly, a surface wire cradle K90, a surface wire transmission assembly, an over-twisting mechanism, a speed reducer, a speedometer, a traction mechanism, a meter counter, a straightening device, a wire arranging and take-up mechanism, a main motor and an electric control cabinet. The twisting mechanism has a compact structure, causes low noise, is stable in operation, is convenient to install and maintain, ensures table product quality, and can produce cores of 3+9*0.175, 3+9*0.22 and 3+8*0.22HTHC.

Owner:江苏金泰隆机电设备制造厂

Wire rope connectors and tensioners for deck railing systems

ActiveUS20050207838A1Reduce wasteTurn easilyBalustradesRopes and cables for vehicles/pulleyWire tensionEngineering

Wire attachment and / or tensioning assemblies are described. The ends of wires may be fitted with mateable collar and wedge components to allow the wire to be securely attached to a supporting structure such as, for example, the surface of a railing post. The wire attachment assembly may be rotatably attached to a tensioning device that enables wire tension adjustments without rotating the wire itself, thereby avoiding the need to adjust the opposing end of the wire.

Owner:SUNCOR STAINLESS

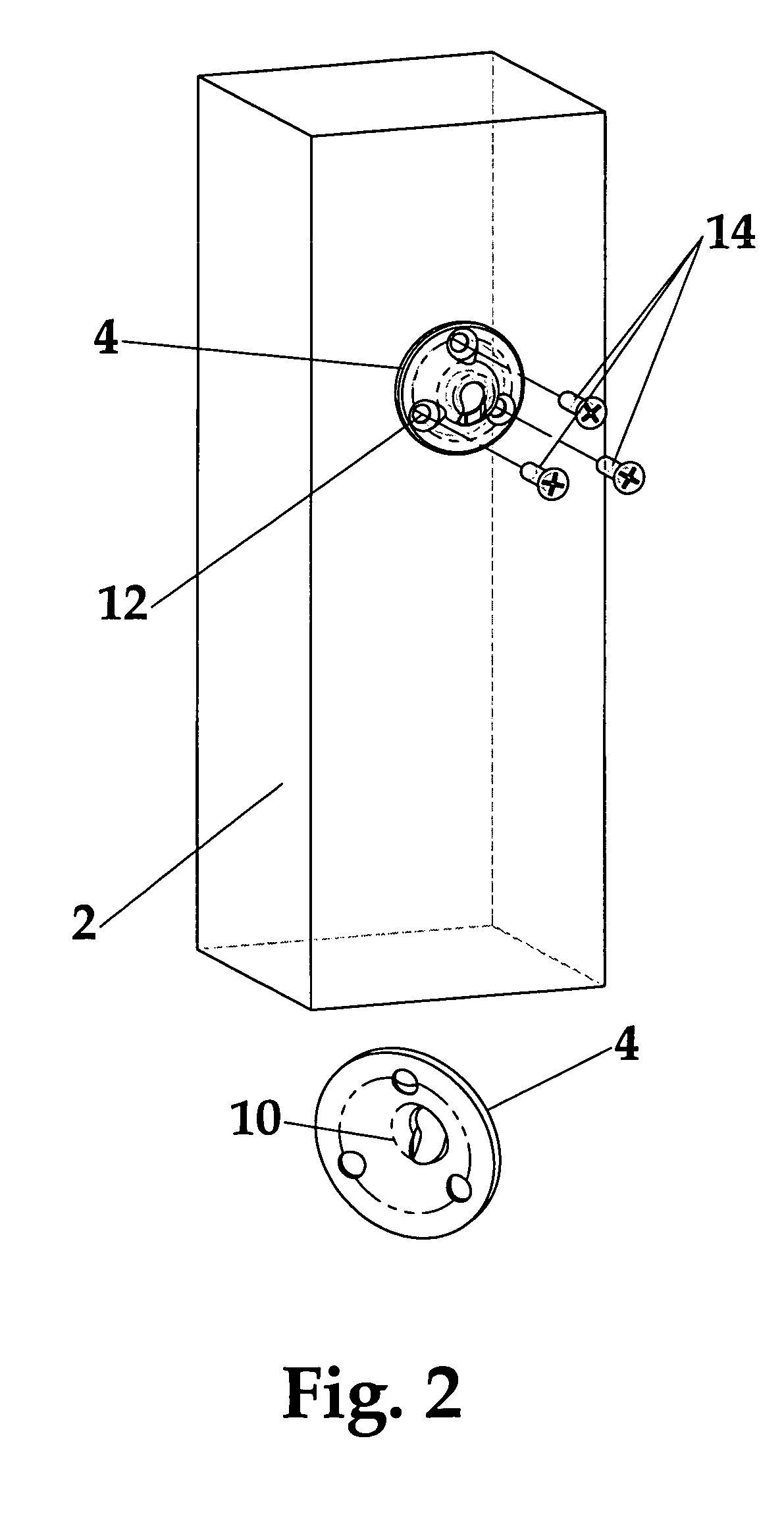

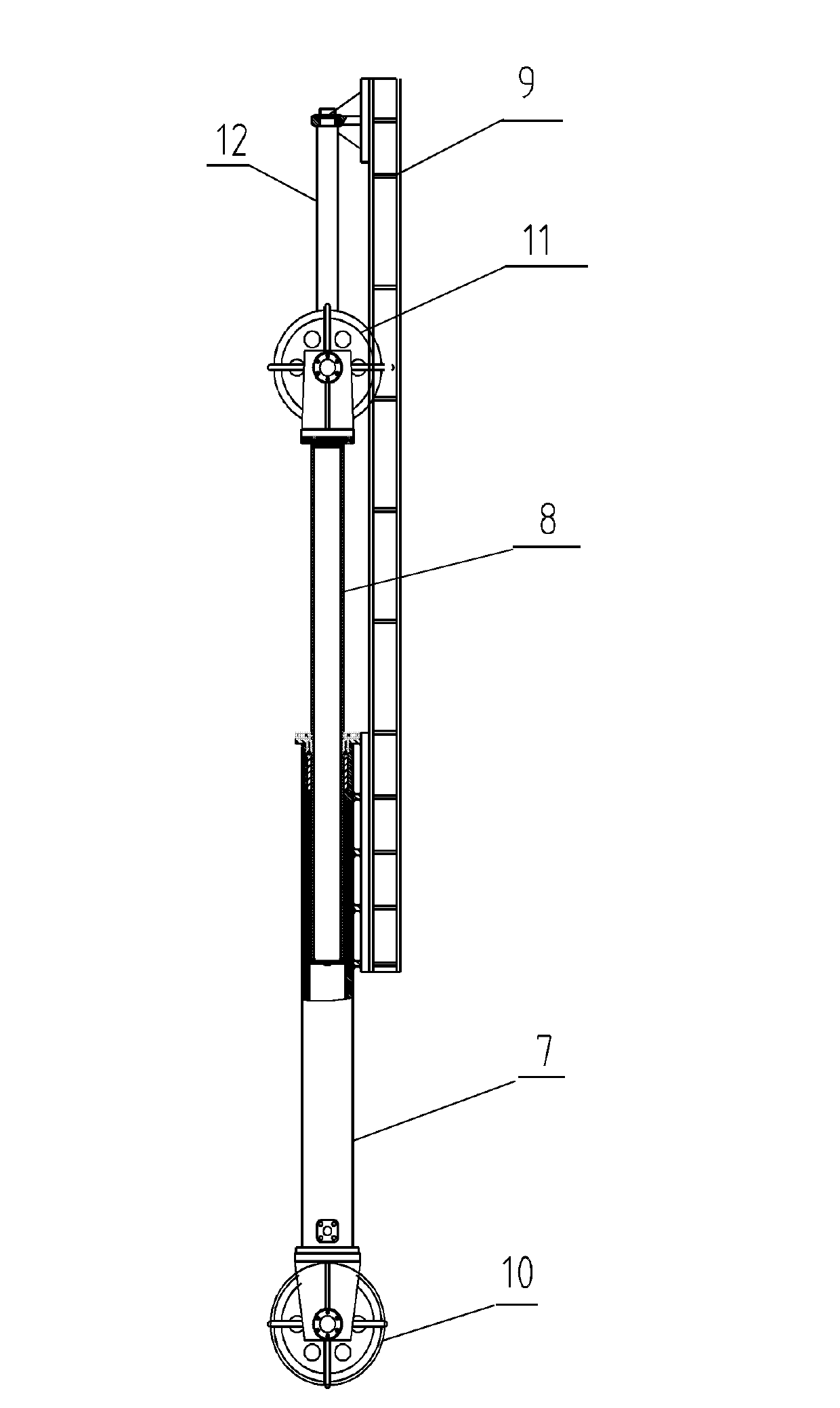

Heave compensating control system of ocean exploration equipment and control method

The invention relates to ocean exploration equipment, which belongs to the field of ocean exploration. A heave compensating control system of the ocean exploration equipment comprises exploration equipment, a lifting truck, a guide pulley and a compensating oil cylinder, wherein the lifting truck and the exploration equipment are connected by steel wires, and the guide pulley and the compensating oil cylinder are arranged between the exploration equipment and the lifting truck, the steel wires connecting the exploration equipment and the lifting truck lead out from the lifting truck and are wound on the guide pulley and connected with the exploration equipment after being wound on the compensating oil cylinder, a steel wire tension sensor is mounted on the guide pulley, the compensating oil cylinder is connected with an energy storage device, the steel wire tension sensor transmits signals to a heave compensating controller, the heave compensating controller is connected with the lifting truck and controls the lifting truck to adjust the exploration equipment. By combining the oil cylinder and tension compensation and combining active compensation and passive compensation, the heave compensating control system is applicable to various wave conditions, energy-saving and high in efficiency, can be closer to field conditions and high in control speed due to real-time feedback.

Owner:FISHERY MACHINERY & INSTR RES INST CHINESE ACADEMY OF FISHERY SCI

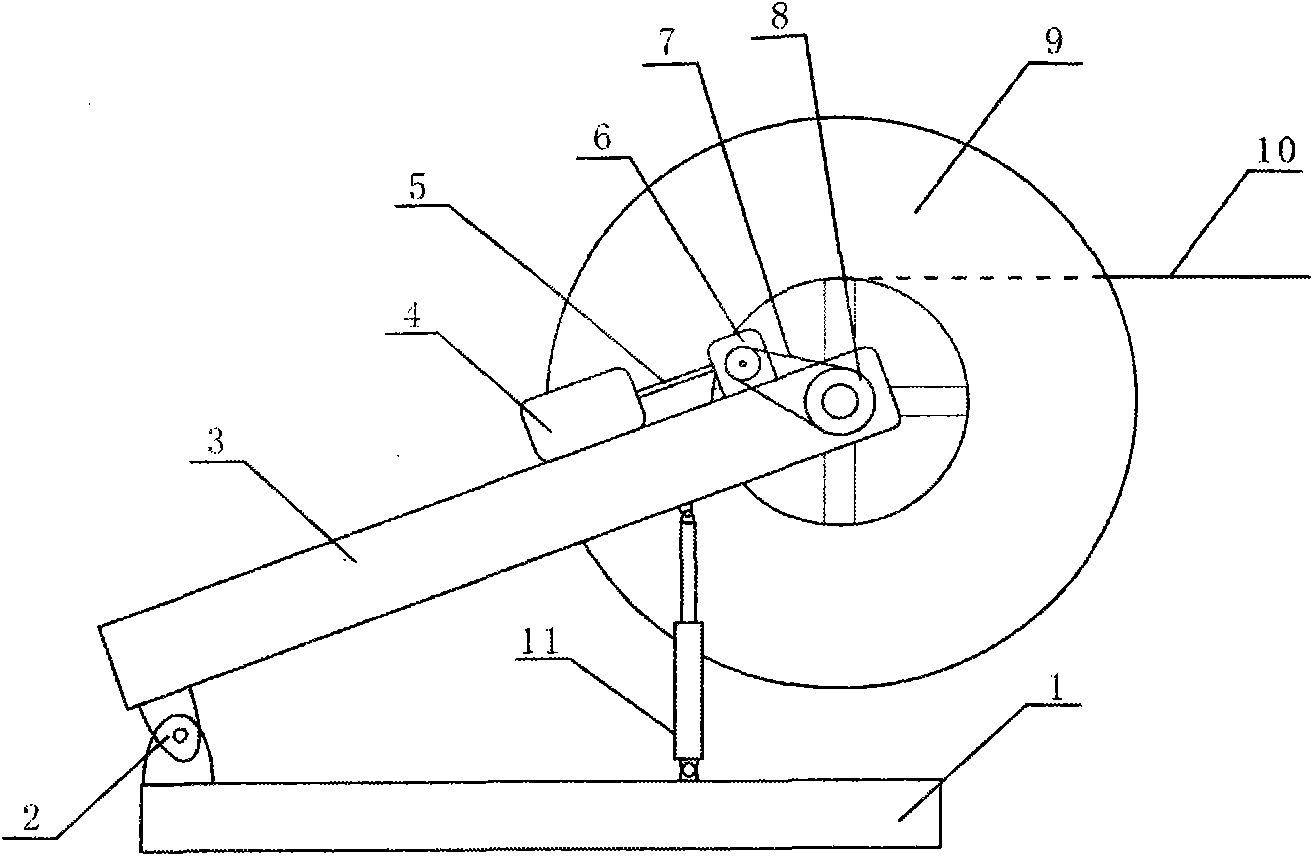

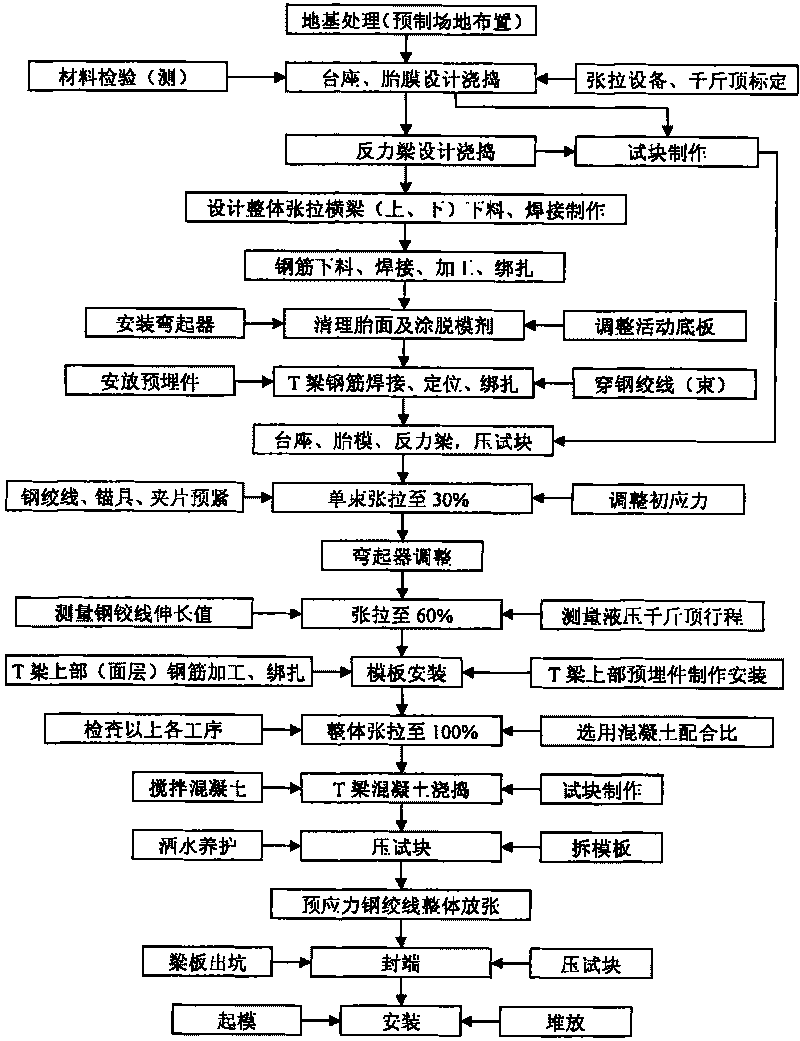

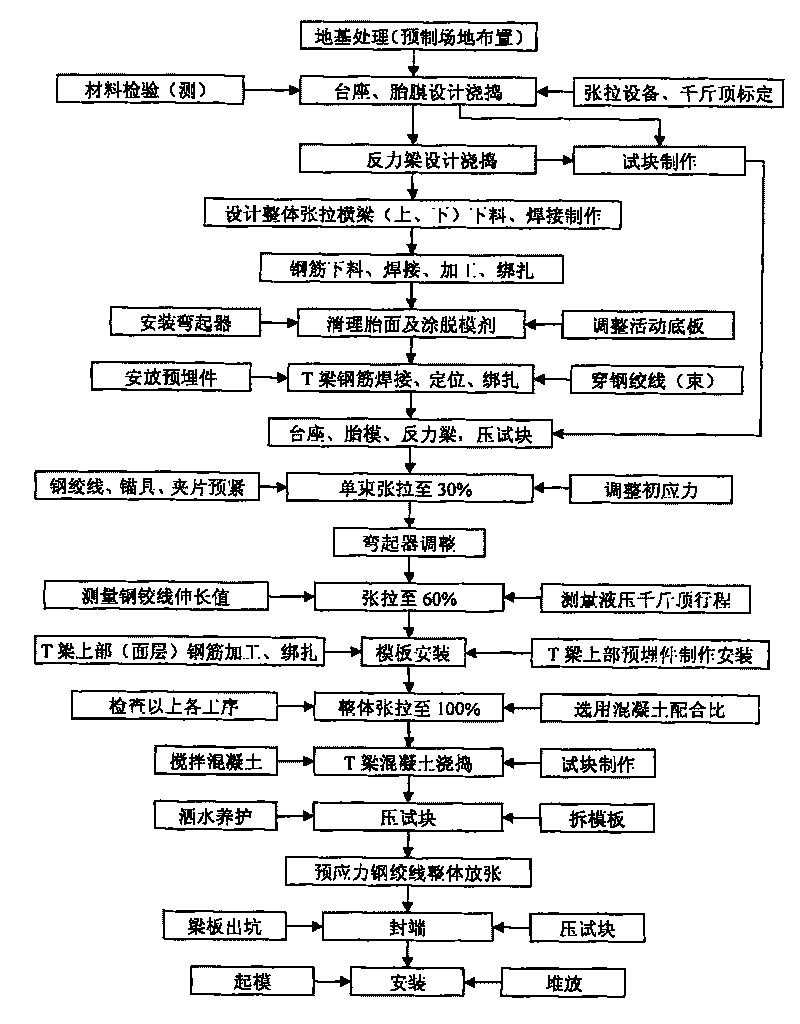

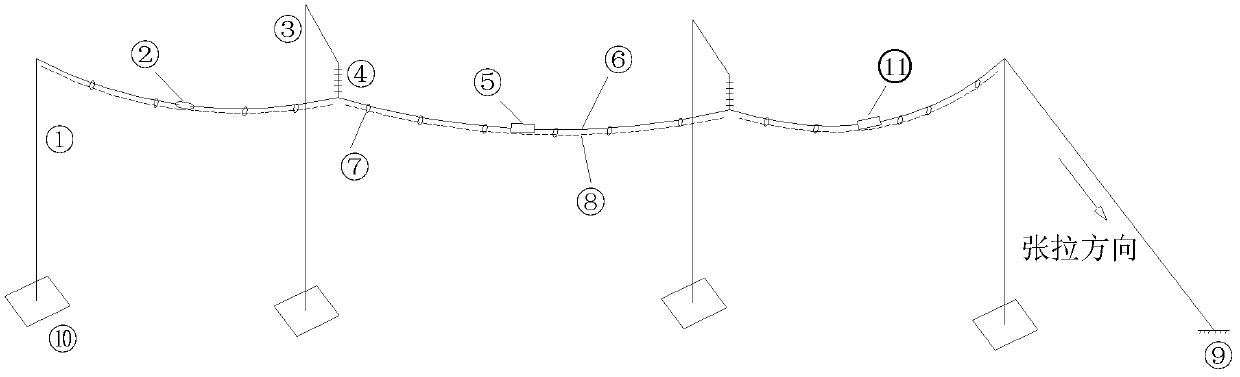

Pretensioning method construction technology of 50m broken line reinforced concrete T-shaped beam

ActiveCN101748681AImprove stabilityGood self-anchoring bonding effectBridge erection/assemblyBridge materialsShaped beamPolygonal line

The invention discloses a pretensioning method construction technology of 50m broken line reinforced concrete T-shaped beams, belonging to the technical field of bridge building constructions. The construction technology comprises the following steps of: foundation treatment; the design and fabrication of footstalls; the design and fabrication of reaction beams; the design and fabrication of tension beams; the design and fabrication of uplift piles; the fabrication and pre-embedment of a bent-up device; the design and fabrication of stranded steel wire tension connectors; the processing and colligation of reinforcing steel bars; the blanking and strand pricking of stranded steel wires; the tensioning of pre-stressed tendons; the fabrication and installation of templates; the pouring and maintenance of concrete; the relaxation of the pre-stressed tendons; and the pit-out and installation of T-shaped beams. The invention can solve various difficult problems in the prestress tensioning construction of high-span broken line reinforced concrete T-shaped beams and fills the gap of the technology of China, and the whole construction technology process and relevant control parameters has scientific and reasonable configuration, can meet the requirements of design and construction on quality, safety and the like, and have high operational instruction property. The invention can be widely applied to the stranded steel wire tensioning construction in structures similar to the high-span broken line pretensioning method T-shaped beams, the box girder and the like in engineering of large-scale buildings, bridges, wharfs and the like.

Owner:浙江省建投交通基础建设集团有限公司

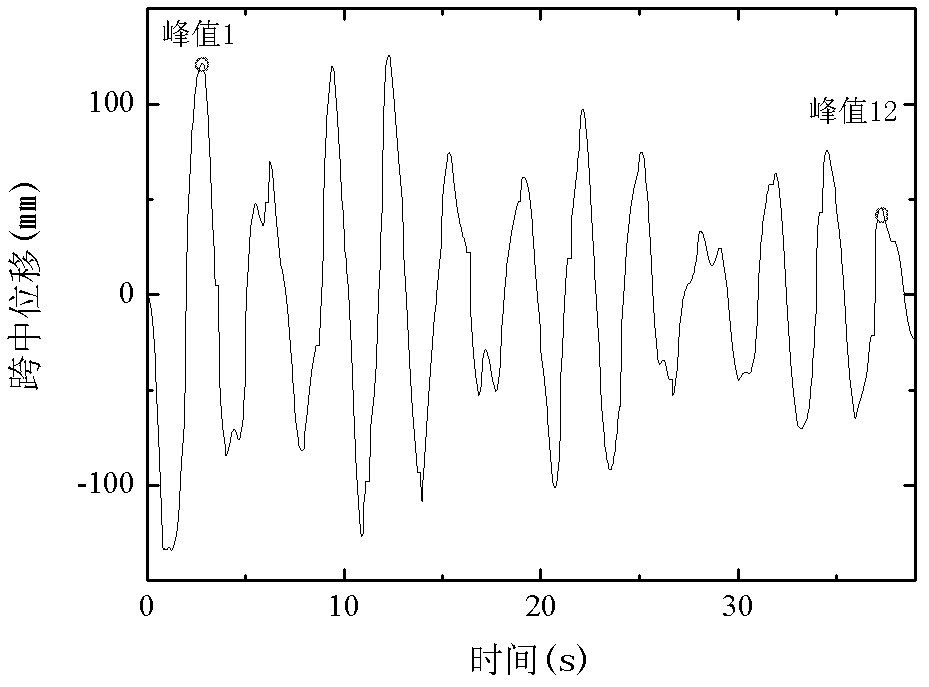

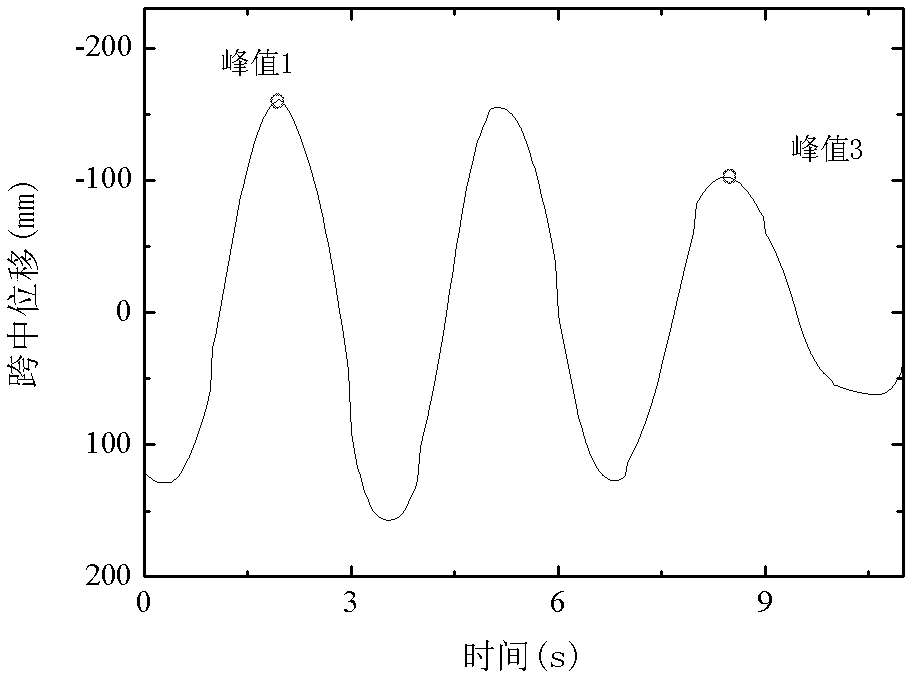

Test method used for transmission line ice coating disconnection

ActiveCN102507123AThe results of disconnection dynamic simulation analysis are accurateImprove applicabilityShock testingWire tensionDamping ratio

The invention provides a test method used for transmission line ice coating disconnection. In the method, the influences of the factors such as the wire model, the ice coating thickness and wire initial tension and the like are comprehensively considered, and the method has better adaptability and higher accuracy. The test method provided by the invention comprises the following steps of constructing a serial three-gear four-rod three-line model; simulating wire ice coating by using a method of a heavy steel wire rope adopting binding and ice coating and the like; installing a disconnection trip mechanism at a side gear midspan position; testing a transverse displacement decrement curve and a non-disconnection gear disconnection tension travel time curve of an intermediate gear midspan point in each working condition on the basis that test working conditions are designed in accordance with different wire models and ice coating thicknesses; and determining the ice coating wire damping ratio and a wire tension dynamic shock factor to finally provide a basis for the tower disconnection load value of an ice coating zone. The test method comprises the following steps: designing a disconnection test line section, calculating the weight of ice coating, carrying out damping identification on the ice coating wire and testing and analyzing the disconnection tension. The method provided by the invention has the advantages of simple theory, reliable computational result, and provides a basis for the construction of a transmission line.

Owner:CHINA ELECTRIC POWER RES INST +1

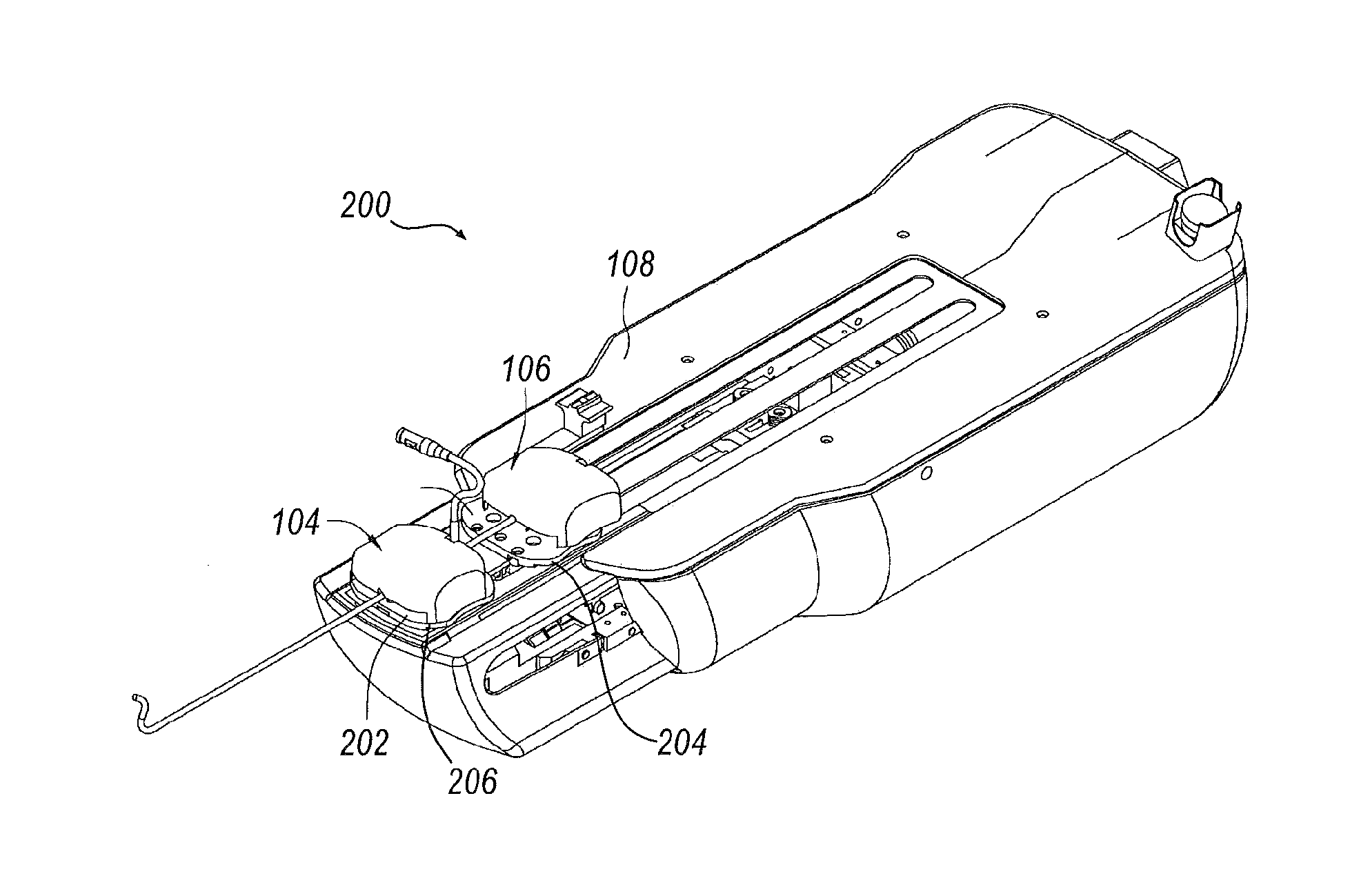

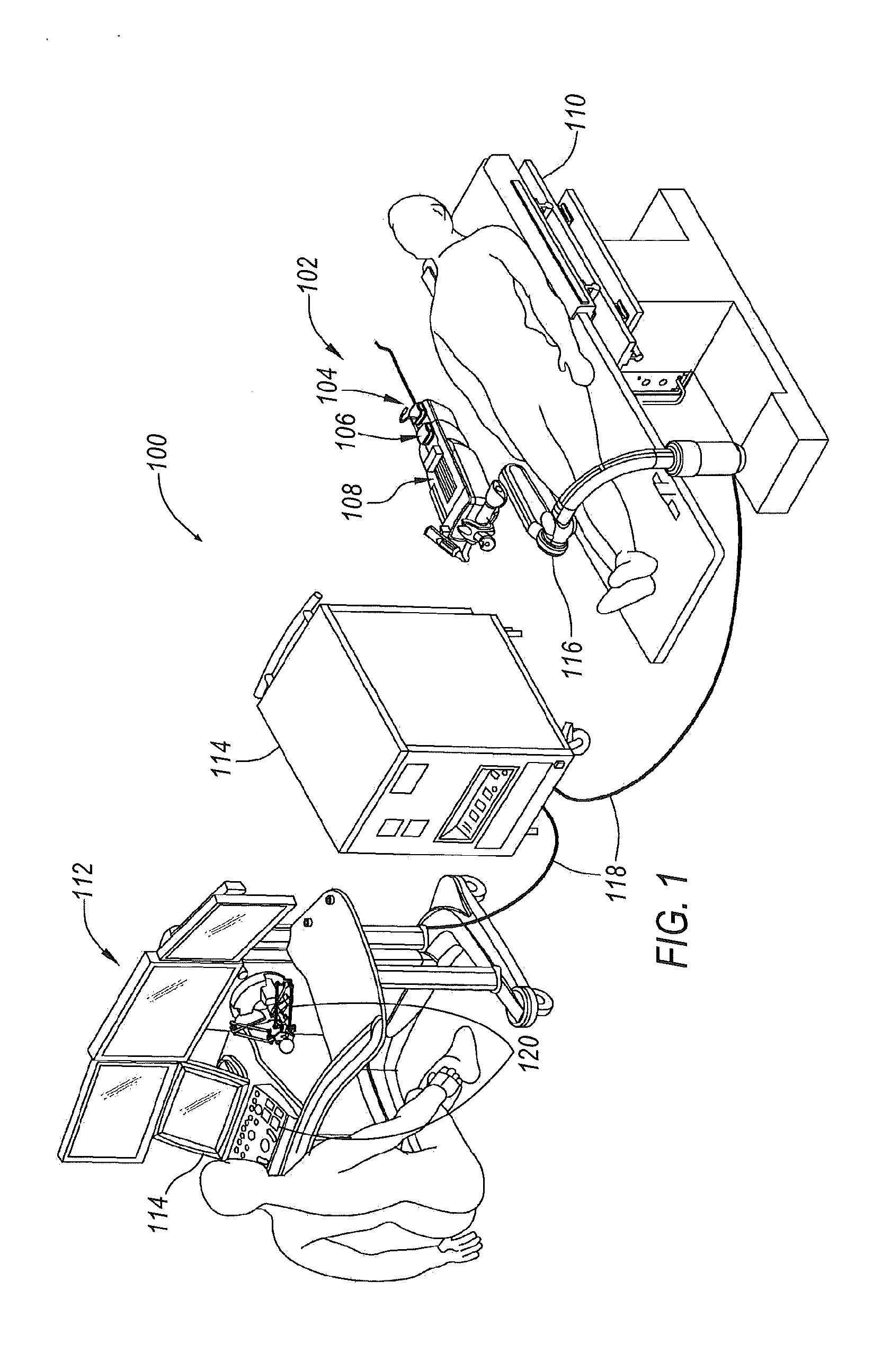

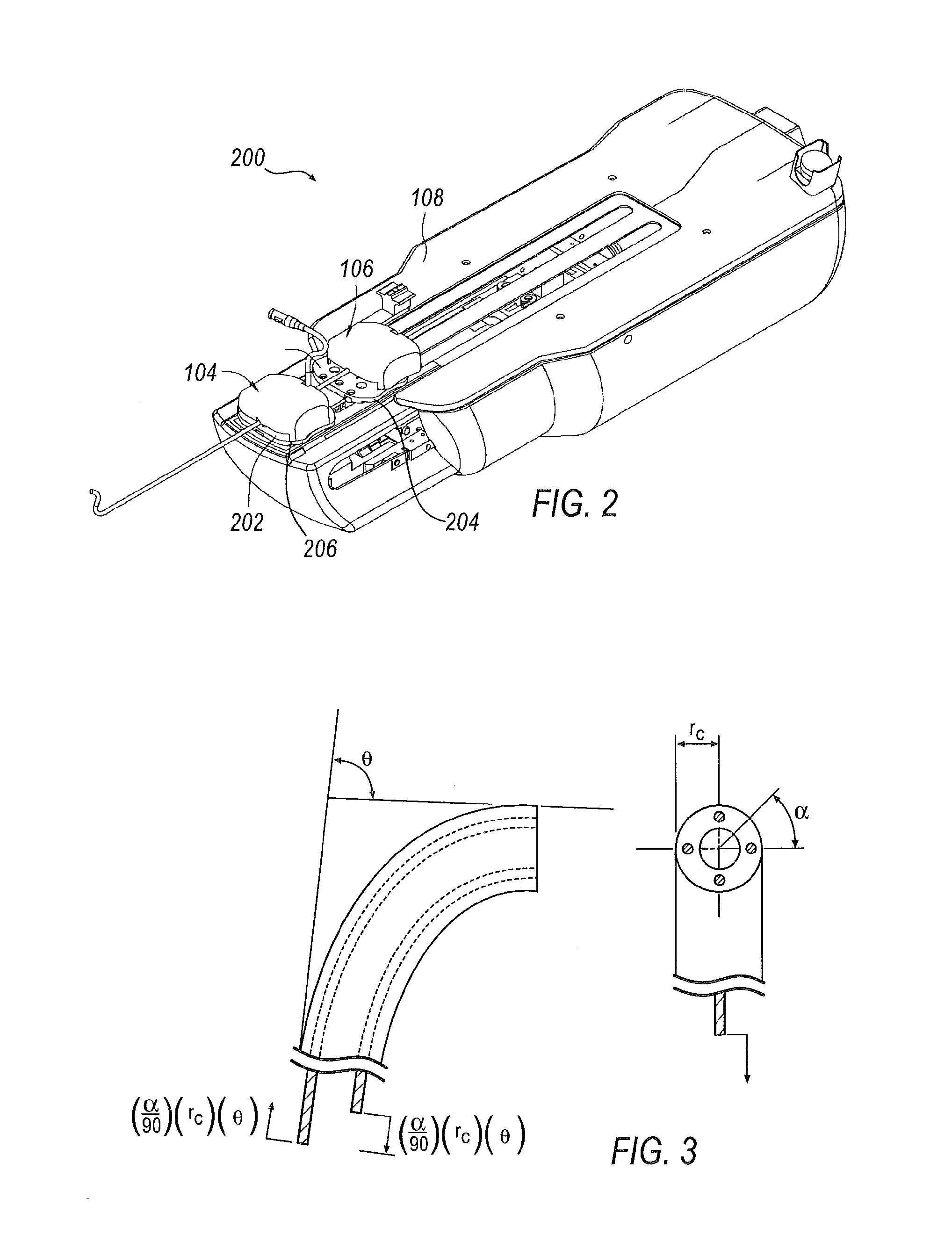

Torque-based catheter articulation

A robotic surgical system configured for the articulation of a catheter comprises an input device, a control computer, and an instrument driver having at least one motor for displacing the pull-wire of a steerable catheter wherein the control computer is configured to determine the desired motor torque or tension of the pull-wire of a catheter based on user manipulation of the input device. The control computer is configured to output the desired motor torque or tension of the pull-wire to the instrument driver, whereby at least one motor of the instrument driver implements the desired motor torque to cause the desired pull-wire tension to articulate the distal tip of the catheter. The present embodiment further contemplates a robotic surgical method for the articulation of a steerable catheter wherein an input device is manipulated to communicate a desired catheter position to a control computer and motor torque commands are outputted to an instrument driver. The robotic system may further comprise a torque sensor. The robotic system may also incorporate closed loop feedback in which data from the torque measuring device is used to ensure that the torque in the motor or tension in the pull-wire closely matches the motor torque command from the control computer.

Owner:AURIS HEALTH INC

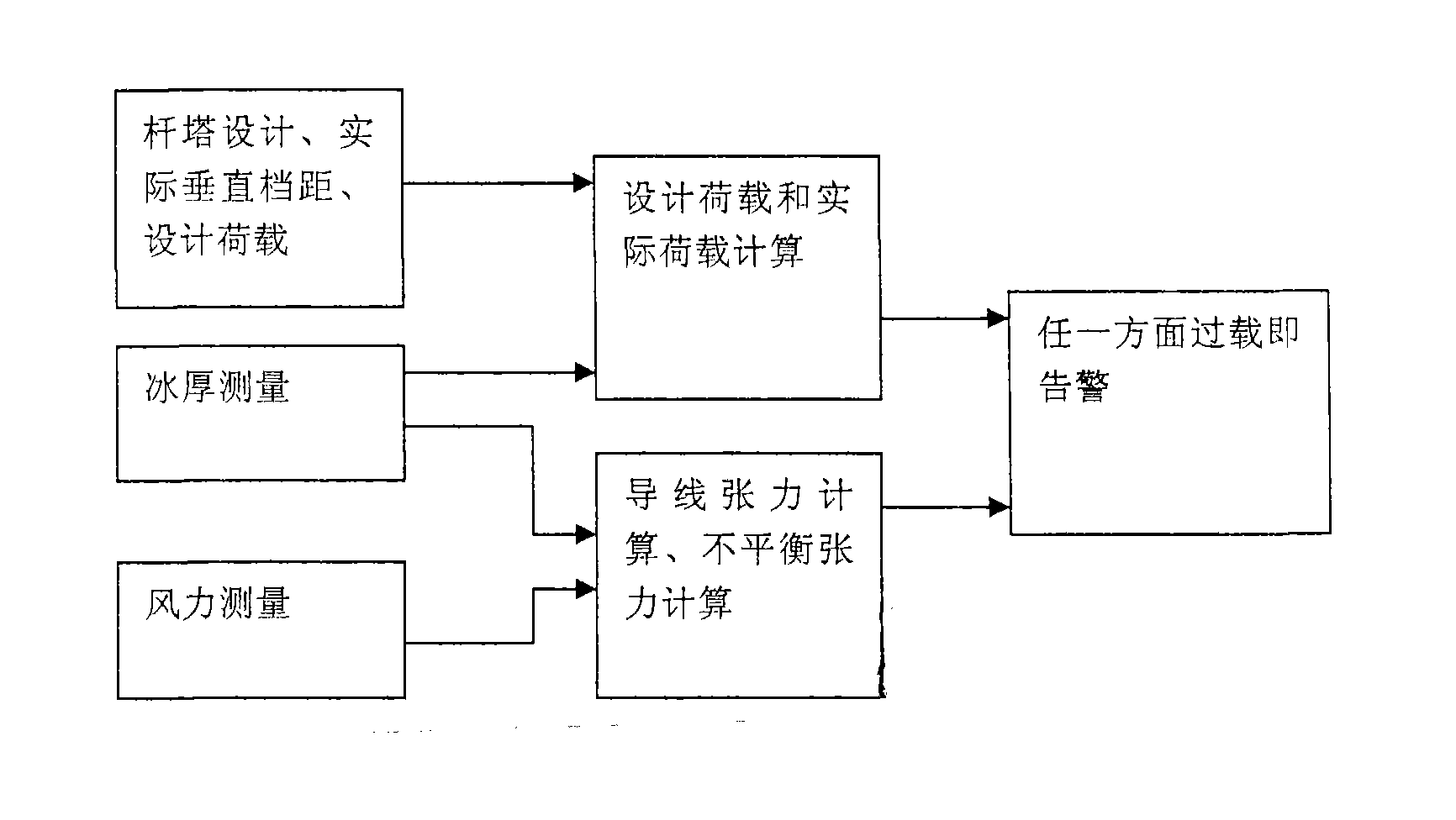

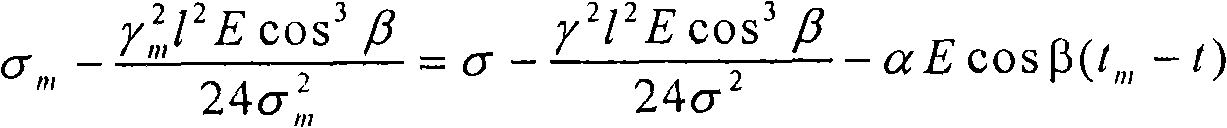

Method for giving wire damage alarm when lead wire is coated by ice

The invention relates to a method for giving a wire damage alarm when lead wire is coated by ice, which performs calculation and judgment on disconnection, vertical overload of a tower and longitudinal unbalanced tension of the lead wire. The method is implemented by the following work procedures: a, calculating design load and actual load according to tower design, actual vertical span, the design load and ice thickness measurement data; b, at the same time, calculating wire tension and unbalanced tension according to the ice thickness measurement data and wind measurement data; and c, sending early-warning information when any of the design load and the actual load calculation, the wire tension calculation and the unbalanced tension calculation is overloaded. When an icing on-line monitoring device monitors the icing condition of a power supply wire, the method performs calculation and analysis according to the monitored data to judge whether the wire icing condition threatens the safety operation, and send warning signals in time.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

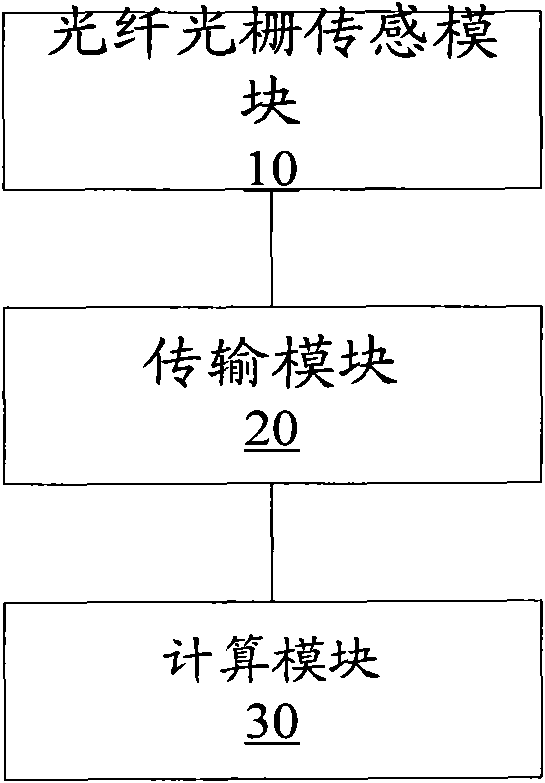

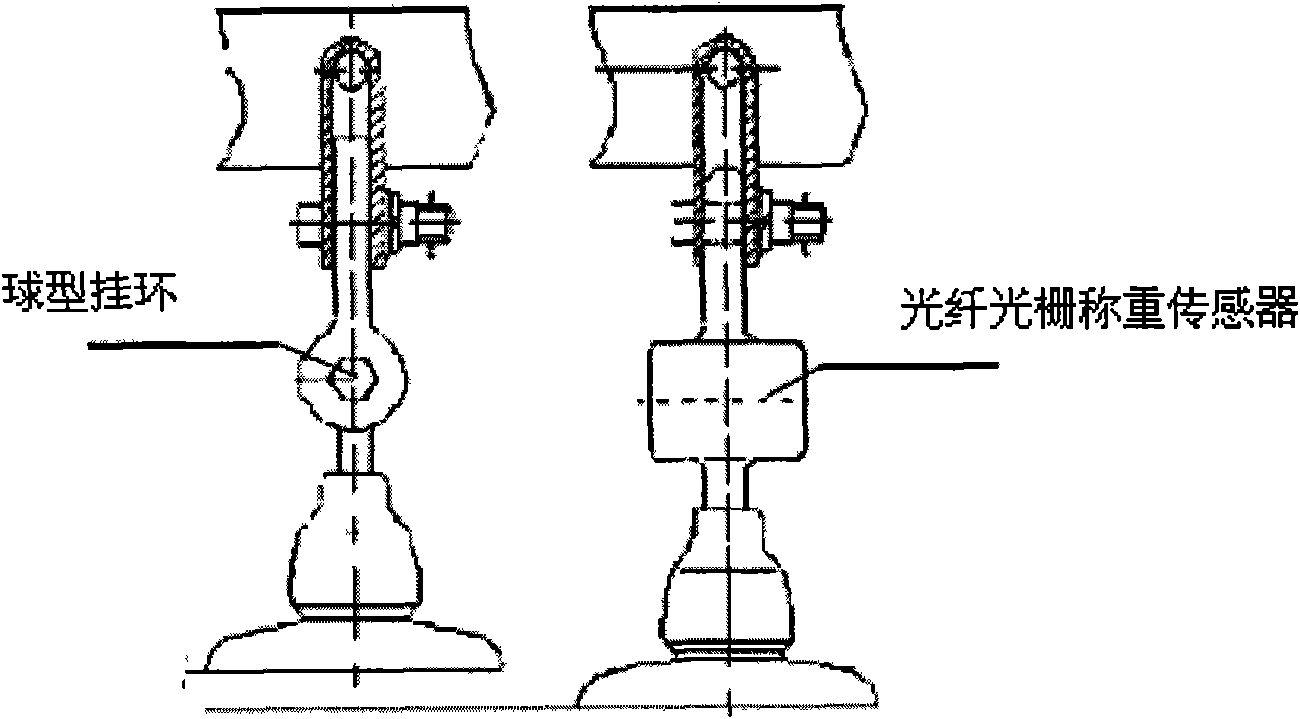

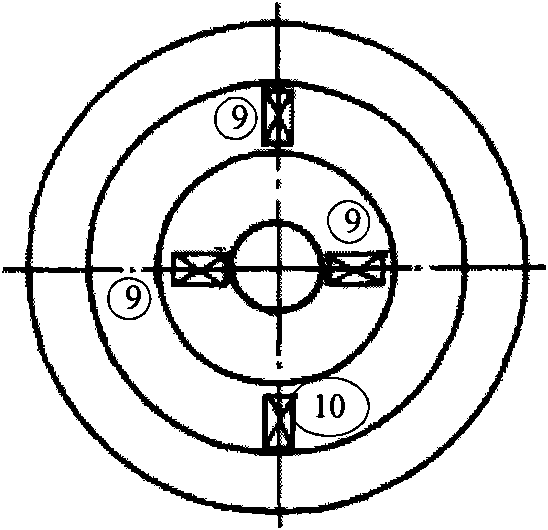

Sag on-line monitoring system of transmission line

The invention provides a sag on-line monitoring system of a transmission line, which comprises a fiber grating sensing module, a transmission module and a computation module, wherein the fiber grating sensing module is used for measuring a wire strain parameter and a temperature parameter of the transmission line and performs analog signal digitalization to the wire strain parameter and the temperature parameter; the transmission module is used for transmitting the digitized wire strain parameter and the digitized temperature parameter which are obtained through the fiber grating sensing module to the computation module; and the computation module is used for obtaining the wire sag of the transmission line by computing according to the digitized wire strain parameter and the digitized temperature parameter. The invention overcomes the problem that the accurate measurement to the wire sag is hard to sustain since the bridge balance of a resistance strain gauge is not easy because the weighing system for sag measurement in the prior art adopts the resistance strain gauge to measure the wire tension.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING) +1

Apparatus for automatically regulating tension of conductor

The invention relates to an automatic conducting wire tension adjusting device which pertains to the technical field of processing devices of electric wires and cables. The adjusting device comprises a chassis of a tension machine, a tension sensor, a tension display, a tension pulley arranged on the tension sensor, a guide pulley arranged on the chassis, an oscillating bar articulated with the chassis, an oscillating pulley arranged on the oscillating bar and a self-adjusting mechanism, wherein, the tension sensor and the tension display are arranged at the top of the chassis and electrically connected; the self-adjusting mechanism is arranged on the oscillating bar, used for changing the oscillating angle of the oscillating pulley and electrically connected with the controller of the tension machine. The adjusting device has the advantages that: due to the improvement, the oscillating angle of the oscillating pulley is changed by the movement of the self-adjusting mechanism, thereby timely and correctly obtaining the tension required by conducting wires.

Owner:CHANGSHU HONGLIN WIRE & CABLE CO LTD

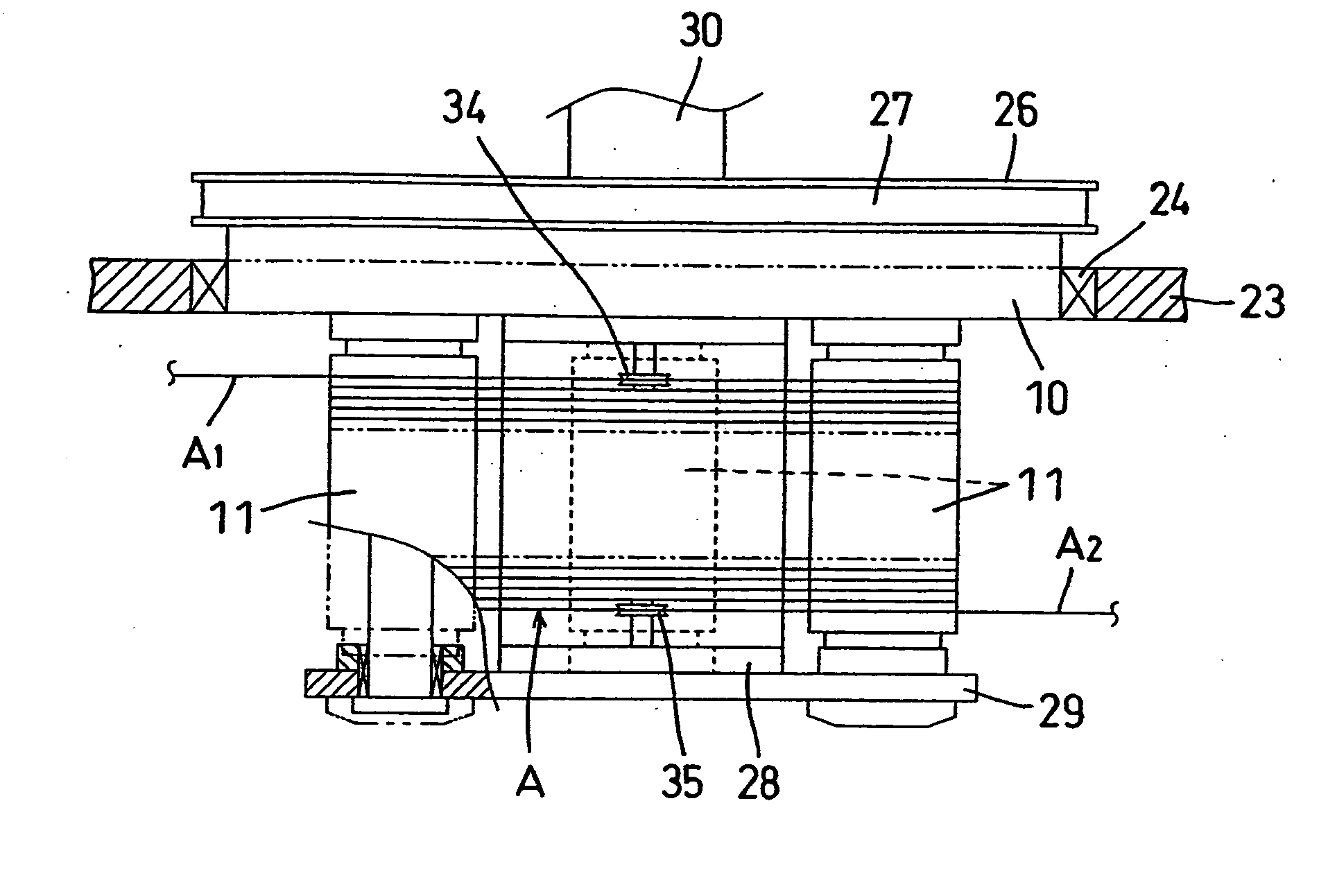

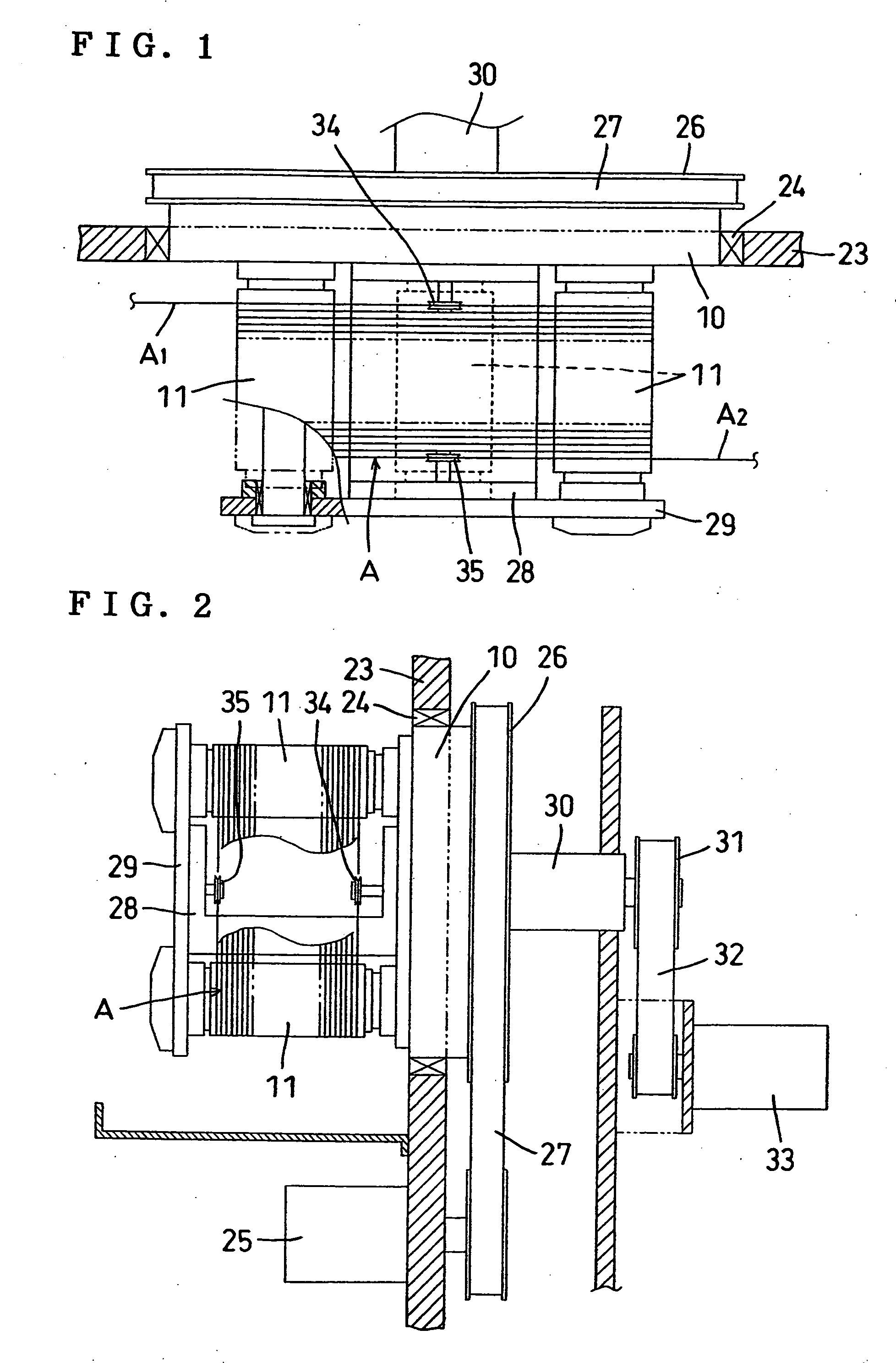

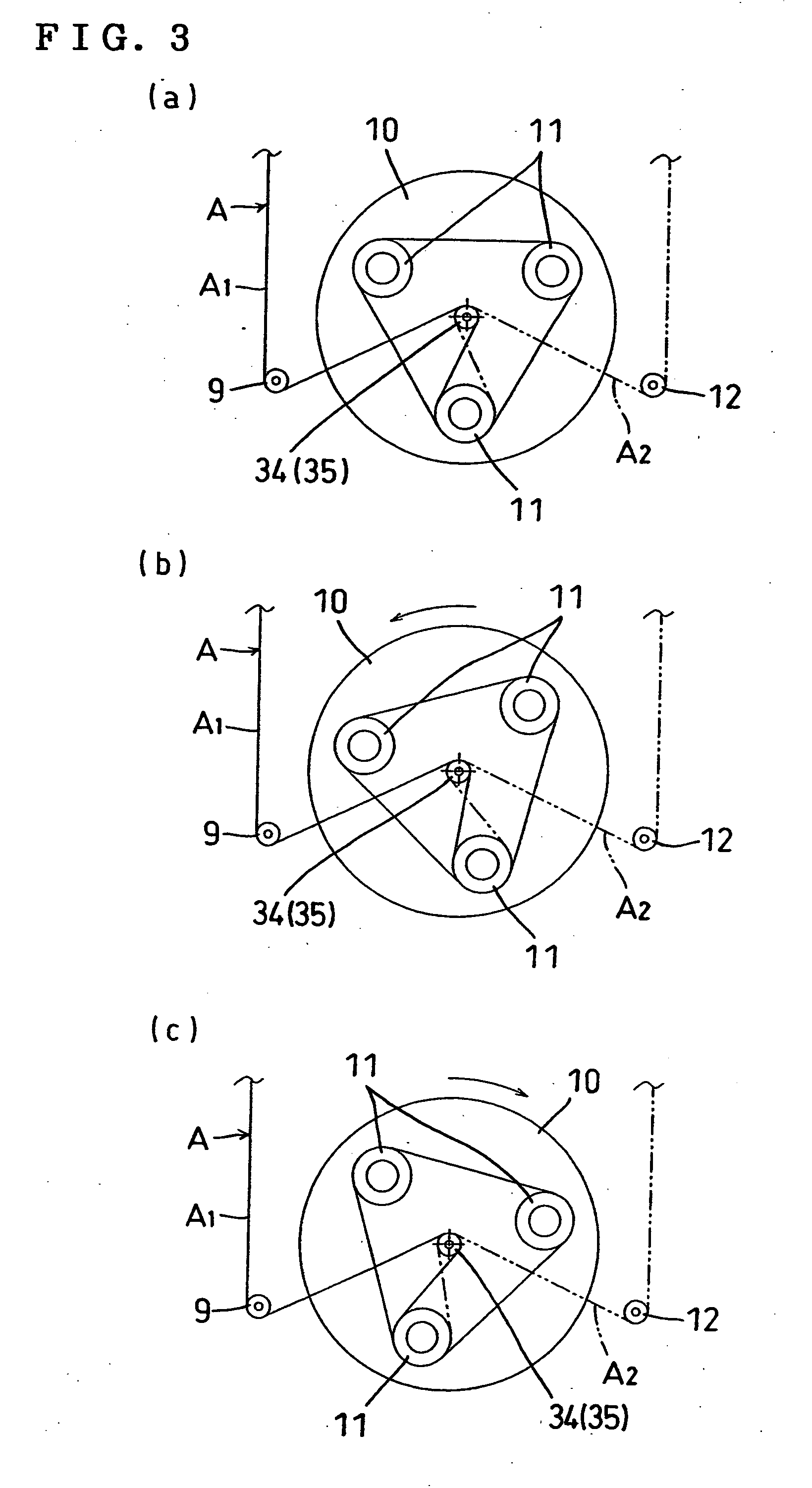

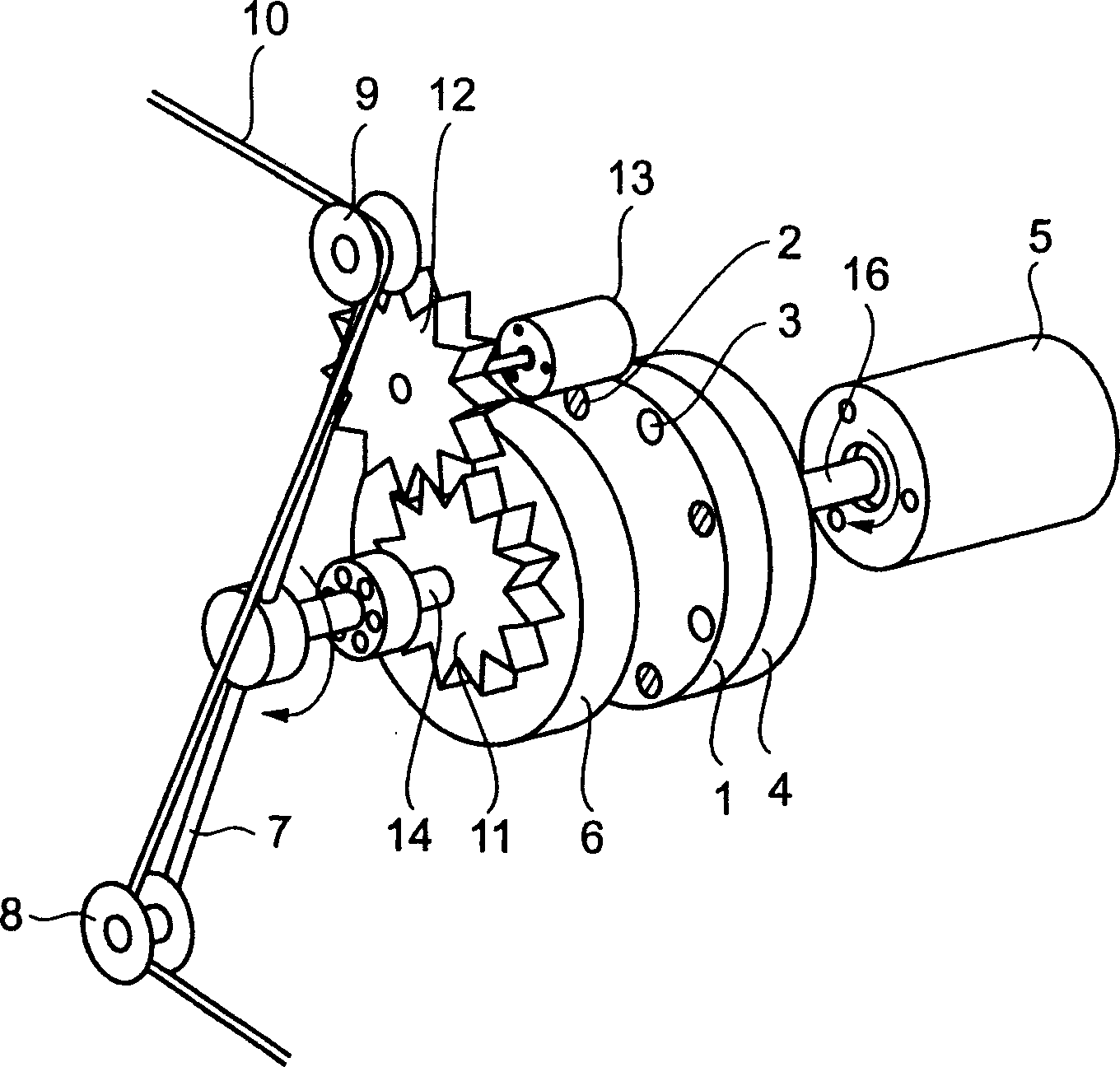

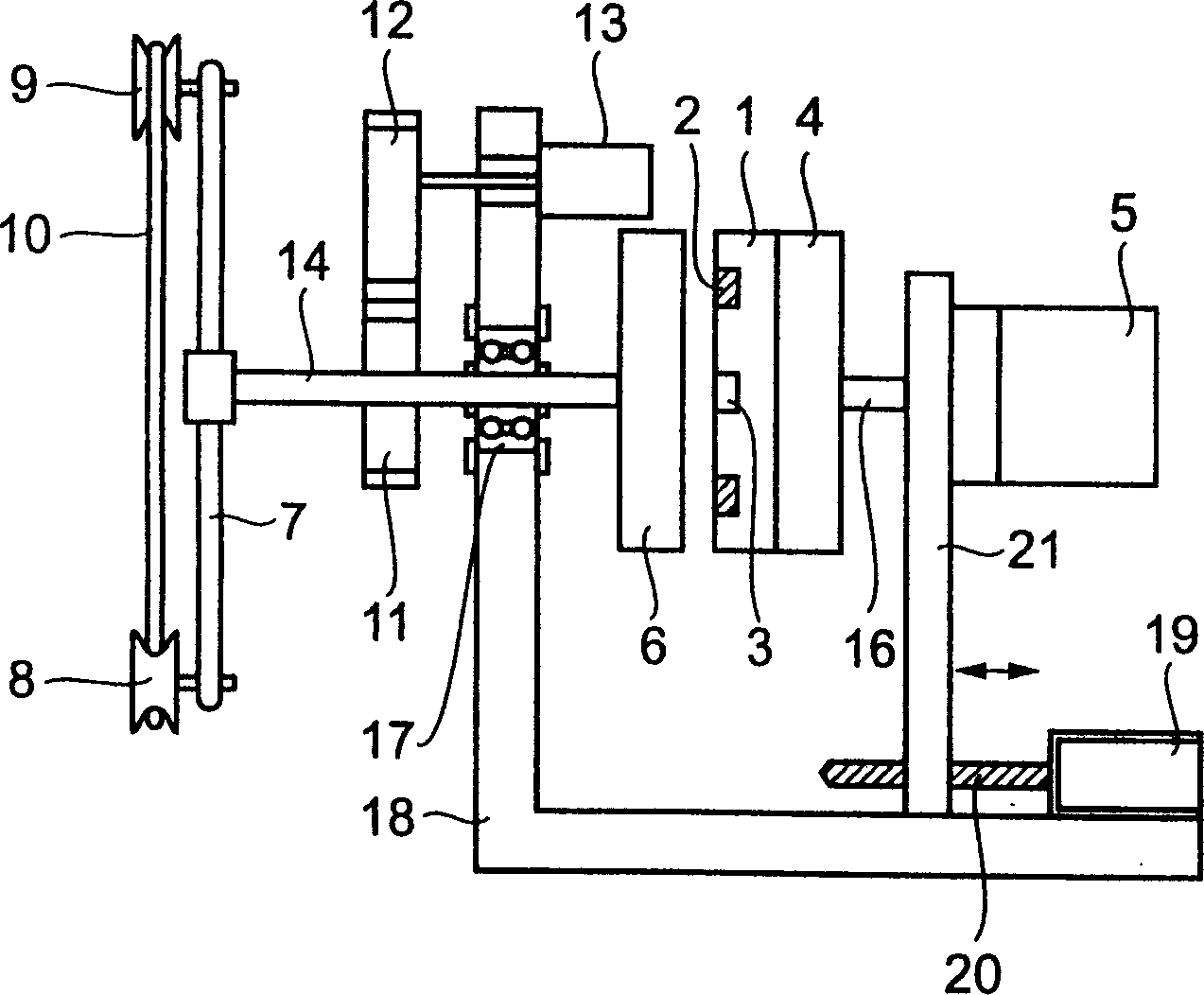

Wire saw

InactiveUS20070131214A1Low costAvoid it happening againMetal sawing devicesBelt grinding machinesWire tensionHigh velocity

The invention provides a wire saw in which wire tension fluctuations occurring in swinging of a row of wires can be accommodated to thereby increase a velocity of the wire and to carry out cutting with efficiency and precision by utilizing swinging of the row of wires even with thin wire. In the wire saw having the row of wires formed by winding the wire about a plurality of work rollers provided to a swinging disk many times, for pushing a workpiece against the row of wires caused to reciprocate or travel in one direction at high velocity to cut the workpiece into a plurality of pieces, and for swinging the row of wires in cutting of the workpiece, a feed side pulley for guiding feed side wire going into the work rollers to the work rollers and a retrieving side pulley for guiding retrieving side wire going out of the work rollers to an outside are disposed coaxially on an axial center of rotation of the swinging disk so that the tension fluctuations do not occur in the wire even if the row of wires swings.

Owner:TAKATORI

Cutting wire tensity and temperature measurement and control device for EPS (Expanded Poly Styrol) slab cutting machine

InactiveCN102366963AAchieve tensionImprove cut qualityMetal working apparatusTemperature controlOptical axis

The invention provides a cutting wire tensity and temperature measurement and control device for an EPS (Expanded Poly Styrol) slab cutting machine, belonging to the field of machining. The cutting wire tensity and temperature measurement and control device is used in non-manual installation regulation and temperature control of cutting wires for solving the problems of large installation error and human injury due to broken wires. The cutting wire tensity and temperature measurement and control device for the EPS slab cutting machine is composed of a cutting wire set tension automatic maintaining and adjusting mechanical traction mechanism, a cutting wire tension sensor, a cutting wire temperature sensor, a control traction mechanism and a cutting wire working temperature control circuit. The cutting wire set tension automatic maintaining and adjusting mechanical traction mechanism is composed of a step motor, a supporting plate, a lead screw, a movable disk, an optical axis and a wire hanging plate; and the tension sensor comprises a step motor, a lead screw, a movable disk, an optical axis, a pressure sensor, an F contactor and a PT100 temperature sensor installed at one side of a cutting wire of the traction mechanism. The invention has the advantages of automatically maintaining the cutting wire tension and the cutting wire working temperature and adjusting errors to maintain the cutting wire at the optimal working state, improving the cutting quality of EPS slabs and eliminating potential safety hazards caused by manual installation.

Owner:JILIN AGRICULTURAL UNIV

Conducting wire tension adjusting device of stranding machine

ActiveCN101599324AAvoid redundancyQuality assuranceCable/conductor manufactureWire tensionEngineering

The invention relates to a conducting wire tension adjusting device of a stranding machine, and belongs to the technical field of wire and cable processing devices. The stranding machine comprises a frame, wherein a group of swing frames are arranged in the length direction of the frame at intervals; and each swing frame is provided with a pay-off disk. The device is characterized in that: the conducting wire tension adjusting device comprises a friction disk with a brake shoe slot, a friction disc braking device and a baffle pin; the friction disk is arranged on a pay-off disk shaft of the pay-off disk; the friction disk braking device is arranged on the friction disk and contacts the baffle pin; the baffle pin is fixed on the swing frame; and the pay-off disk shaft is positioned in a seat cavity of a pay-off disk seat on the swing frame. The device has the advantages that: the tension of a conducting wire payed off from the pay-off disk can be controlled by braking the friction disk to avoid redundancy of the conducting wire so as to ensure the quality of the stranded conducting wire.

Owner:JIANGSU ZHONGLI GRP CO LTD +4

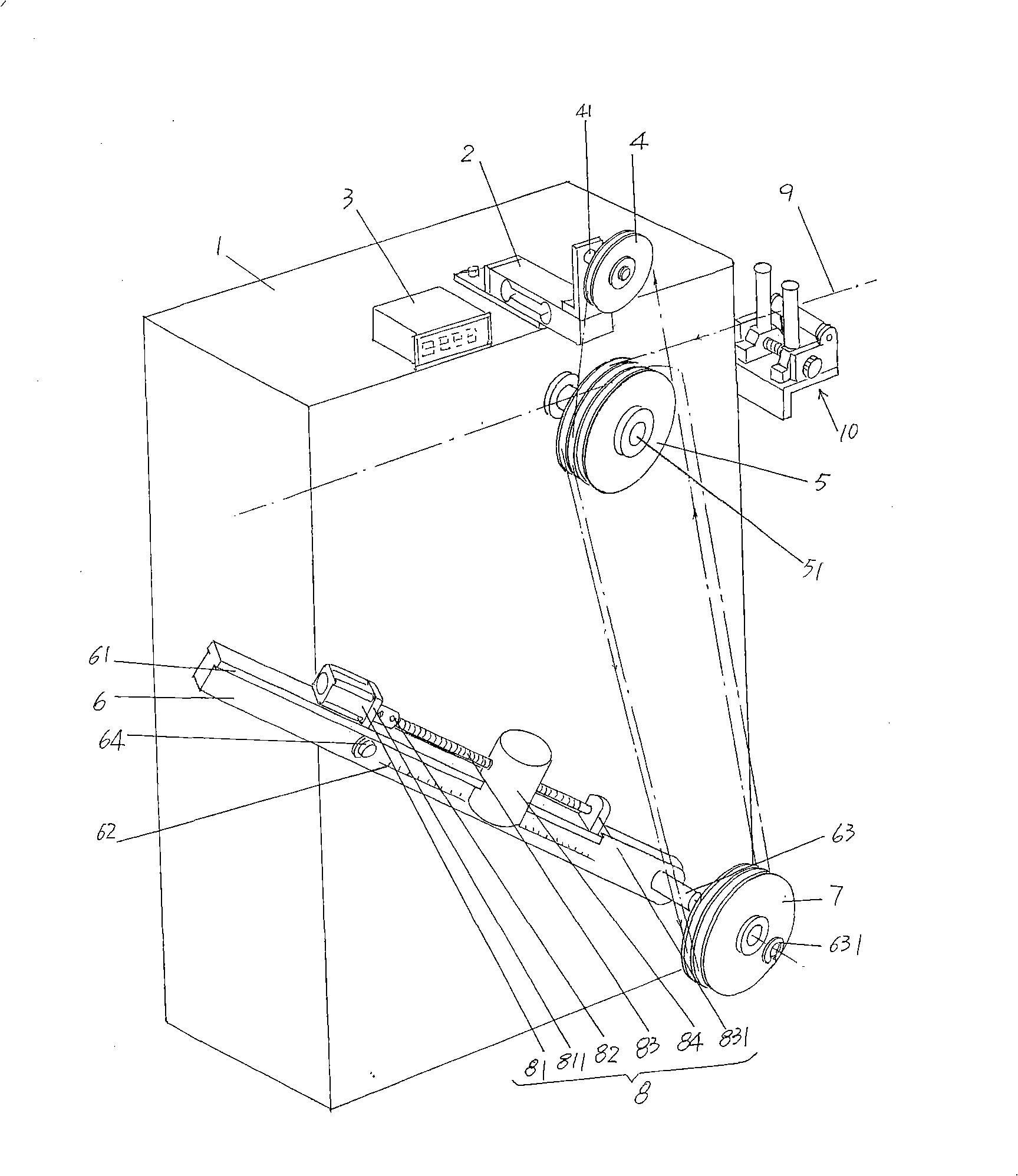

Pulling device for container inspection system

InactiveUS7475866B2Reduce investmentReduced footprintMetal sawing devicesFeeding devicesWire tensionConductor Coil

The present invention discloses a pulling device for a container inspection system including a pulling vehicle (1) arranged inside an inspection passage, a winch (5) and wire tension mechanisms (6,6′). Front and rear ends of the pulling vehicle are connected to a wire rope so as to drive the pulling vehicle to move back and forth inside the inspection passage. The wire rope connected to front and rear ends of the pulling vehicle is wound around a wire tension mechanism arranged at front and rear ends of the inspection passage and is turned around by a swerving pulley (2) which is positioned at the same horizontal plane as that of the wire rope, the pulling vehicle, and the wire tension mechanisms, then the wire rope passes through the vertical pulley block, and finally it is connected to a single winding drum (4) of the winch (5) and wound around the single winding drum (4) respectively. Compared with the prior arts, the present invention is advantageous in reduction in equipment investment and decrease in area occupied by the pulling device. Further, the inspection operation can be carried out more reliably and safely.

Owner:NUCTECH CO LTD +1

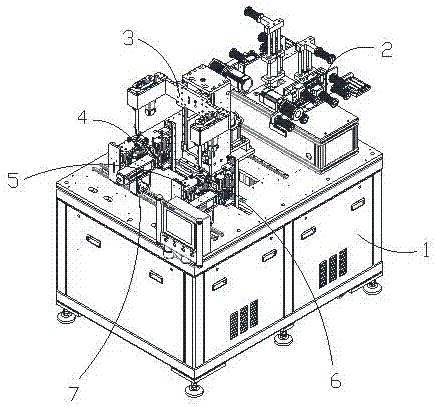

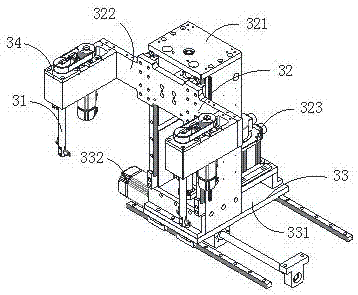

Vertical winding machine and winding method thereof

InactiveCN107546934AAvoid tanglesImprove stabilityManufacturing dynamo-electric machinesWinding machineWire tension

The invention discloses a vertical winding machine and a winding method of the vertical winding machine, which mainly include a frame and a tension control mechanism installed on the frame for controlling the tension of the enameled wire, and for embedding the enameled wire into the stator wire groove. The vertical winding mechanism, the product rotation mechanism used to fix the stator and drive the stator to rotate, the clamping and arranging mechanism used to limit the position of the enameled wire in the stator wire slot, and the cross-slot mechanism used to hook the enameled wire when the enameled wire crosses the slot And control components for controlling all power sources on the inner winding machine. The multi-strand wire vertical inner winding machine provided by the invention can automatically wind the inner winding stator in the whole process, and the winding is uniform, and the enameled wire will not be scratched during the winding process.

Owner:东莞拓蓝自动化科技有限公司

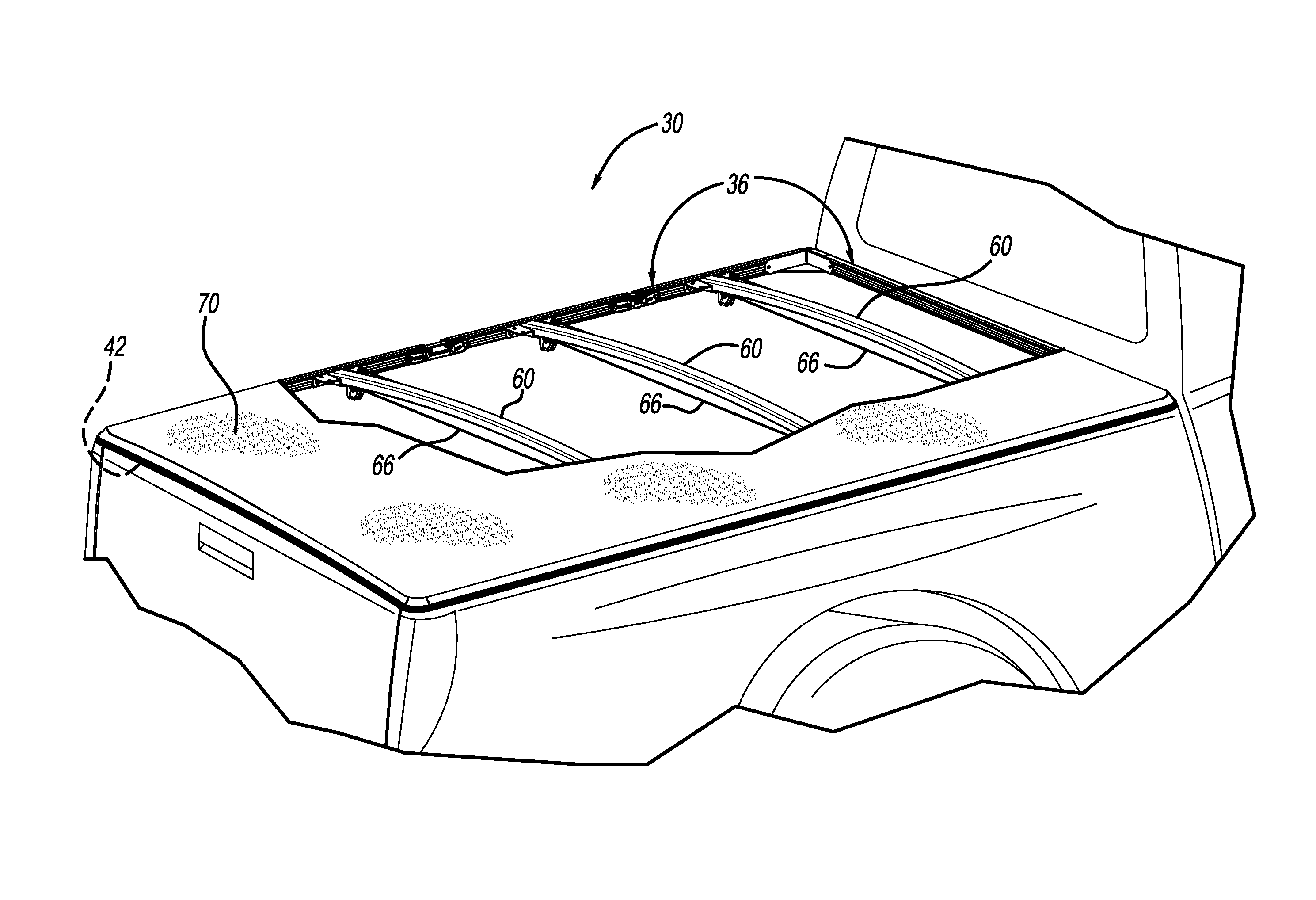

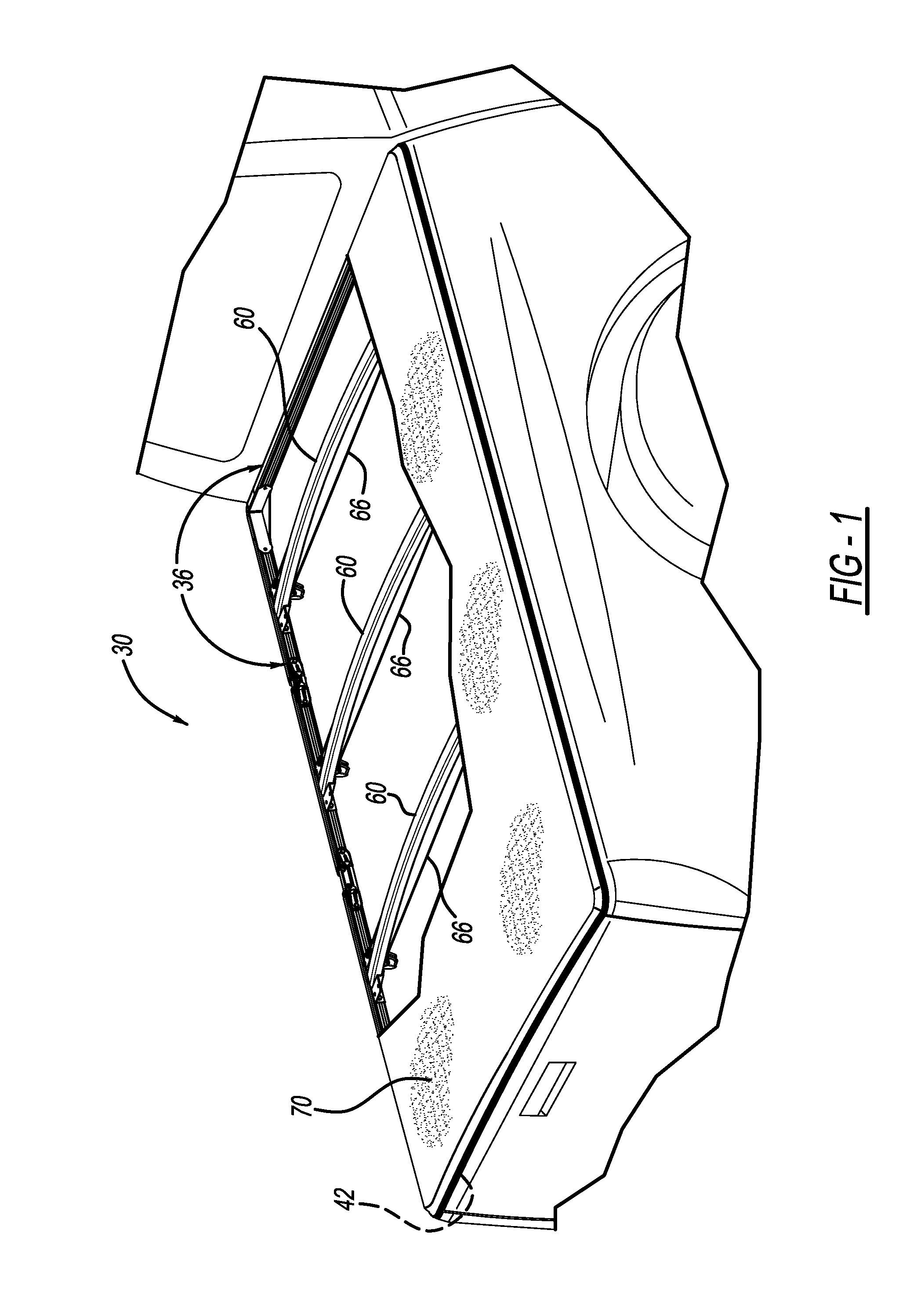

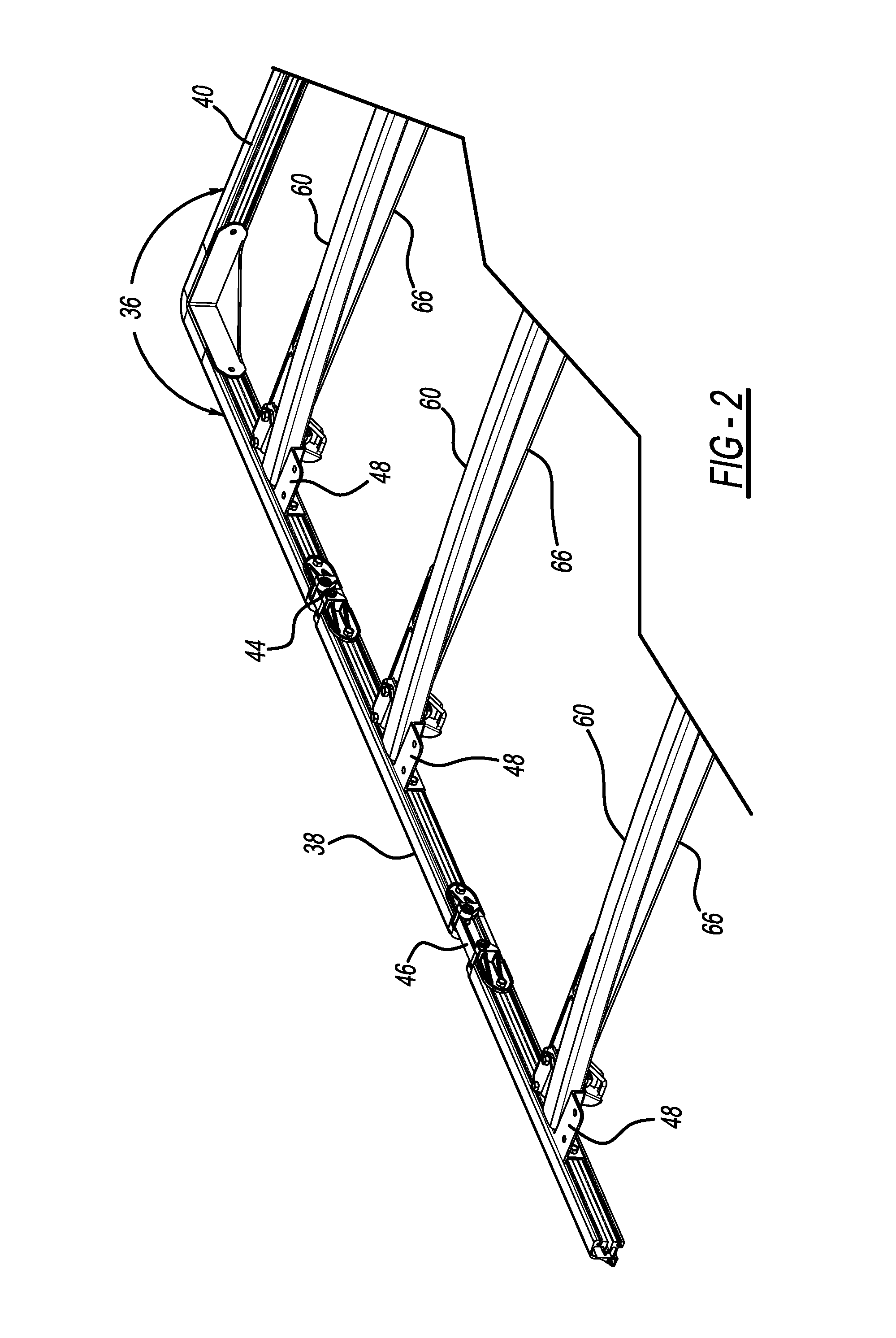

Pickup truck bed tonneau cover support structure and method

Owner:SPECIALTY VEHICLE ACQUISITION

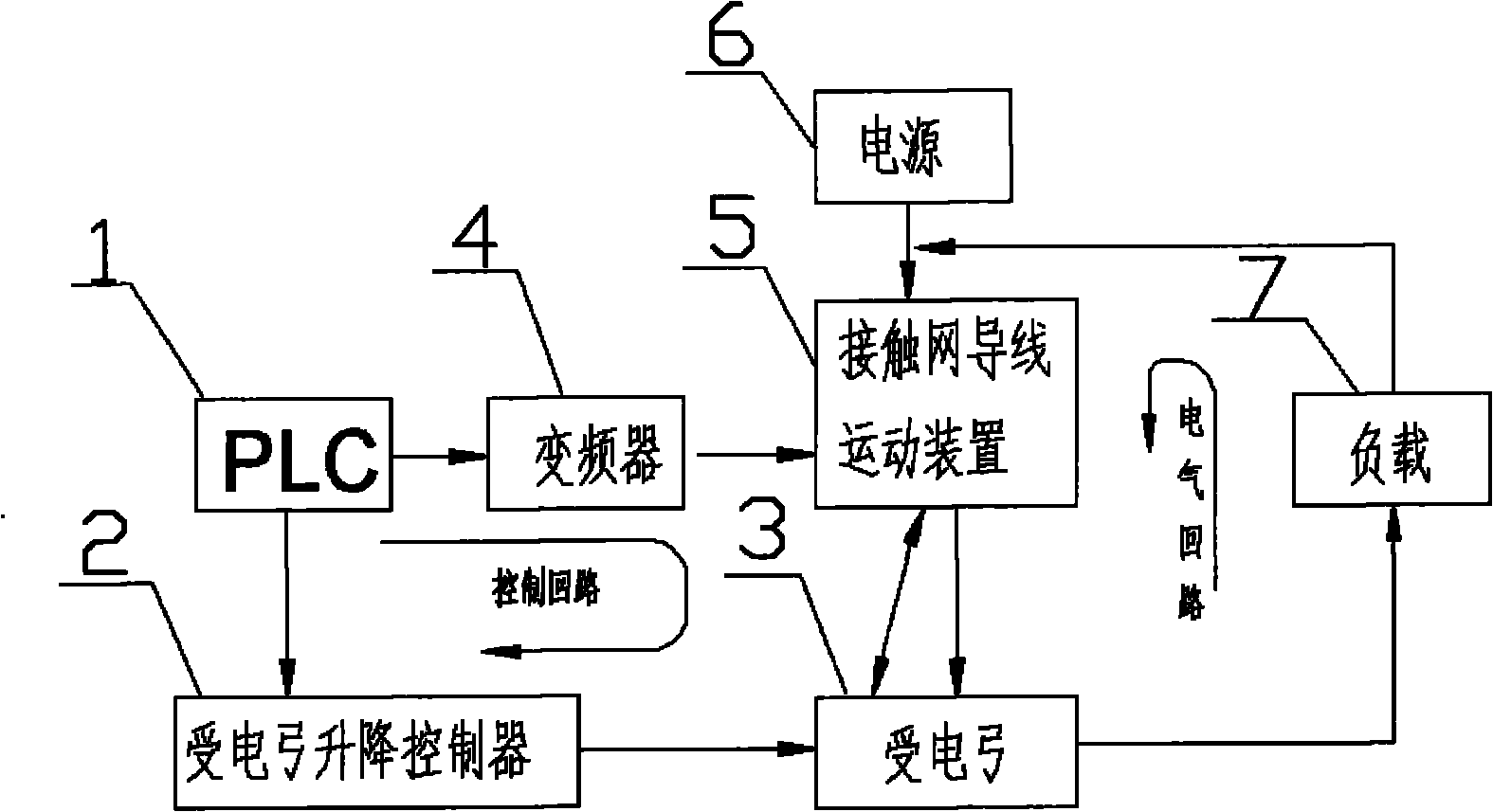

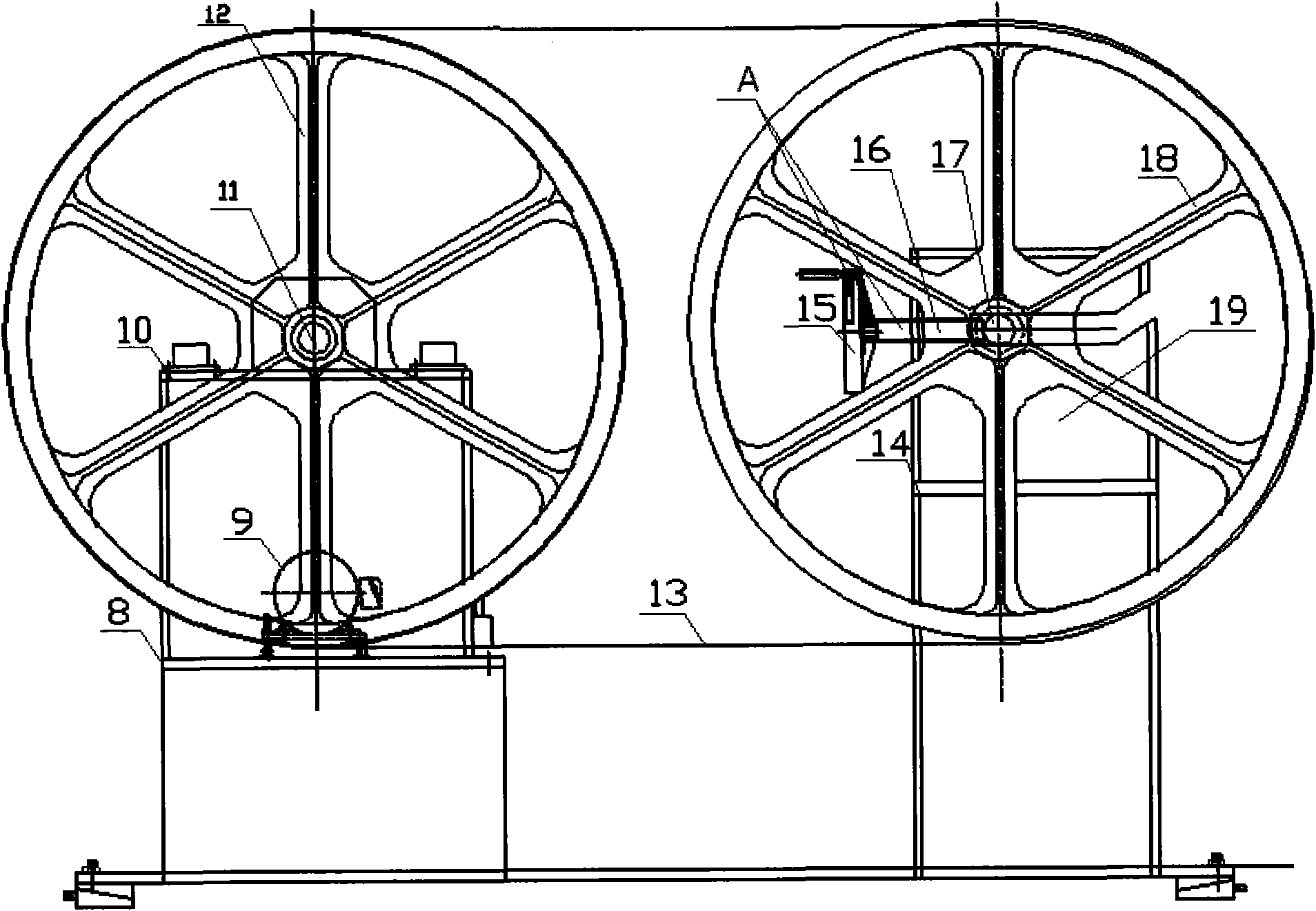

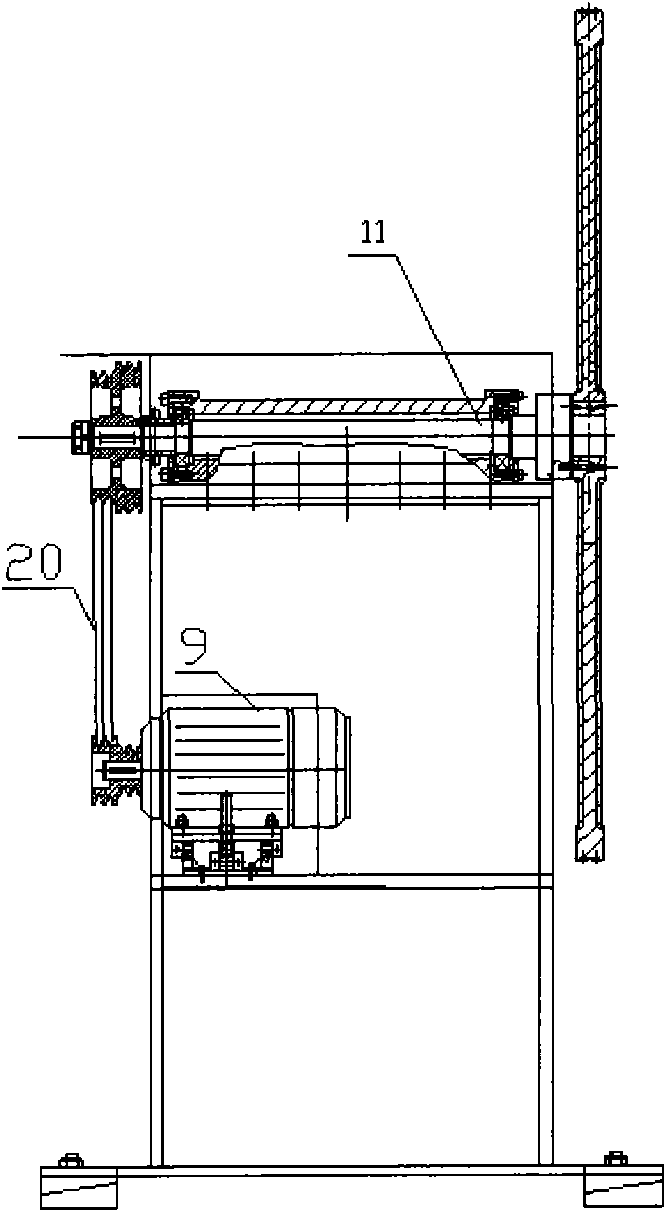

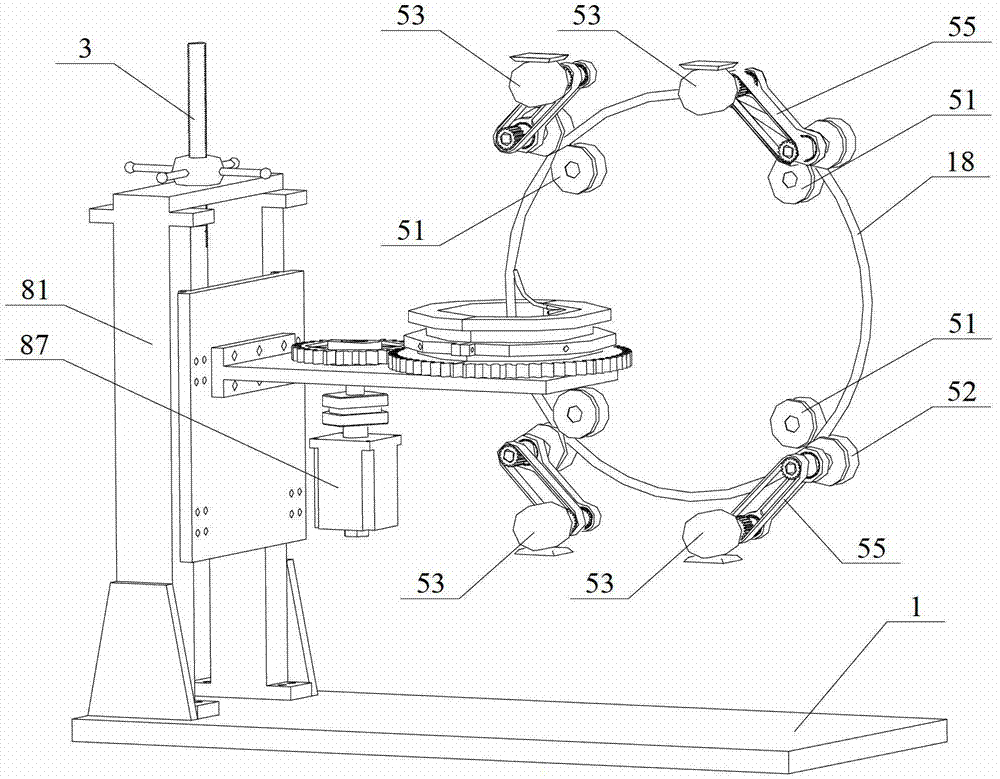

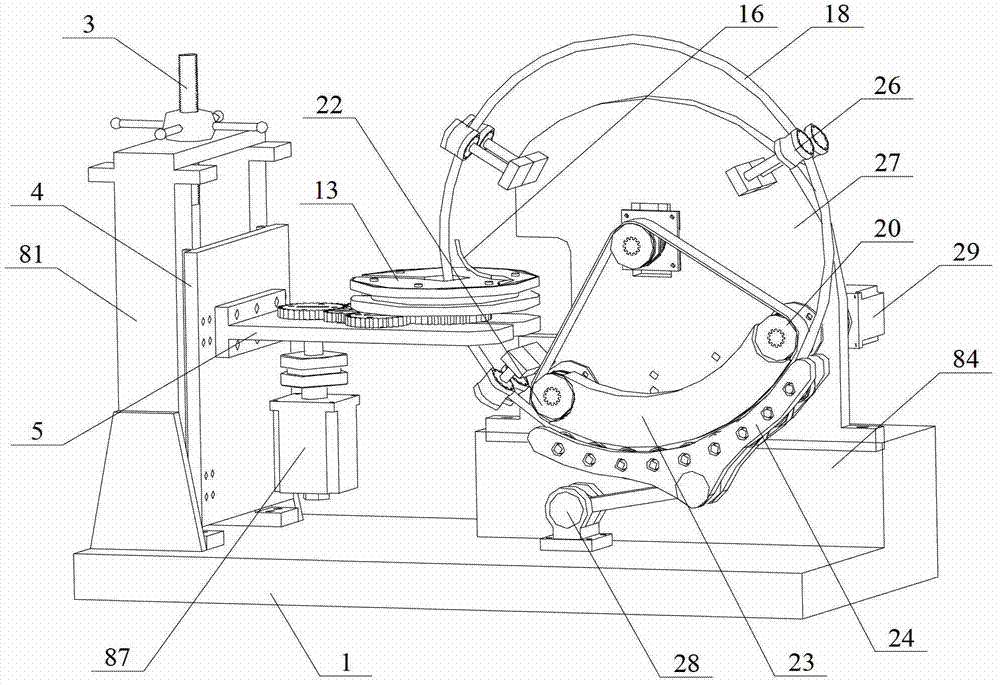

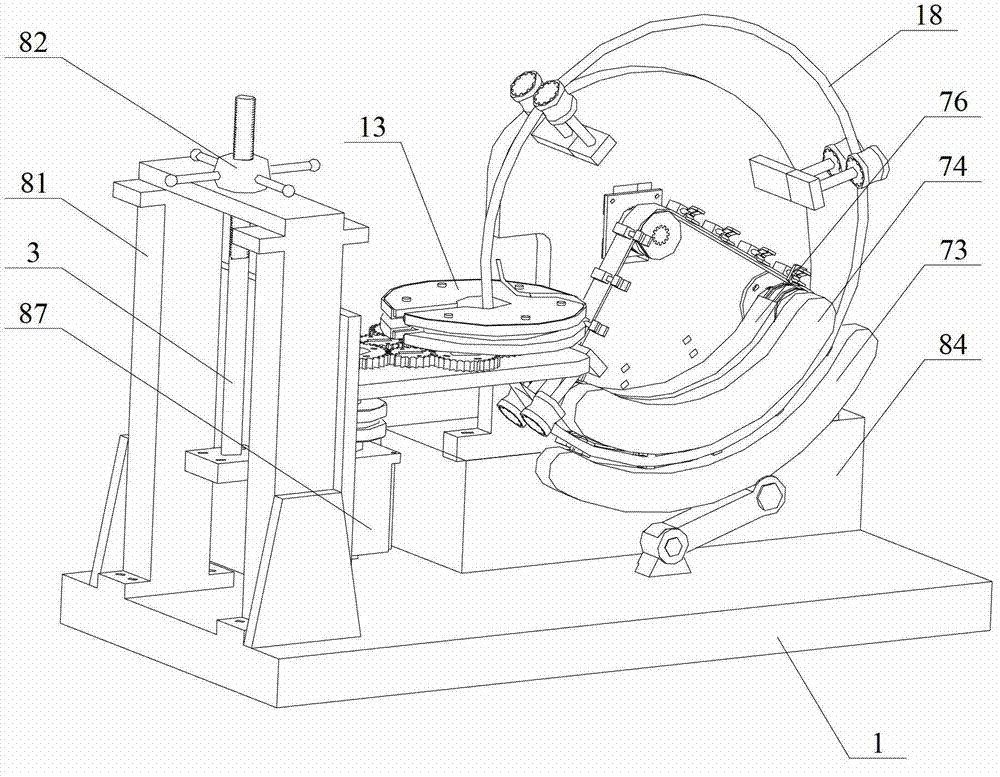

Bow net electric contact characteristic testing device

InactiveCN101963638ATrue reflection of contact morphologyElectrical testingTrolley linesElectricityDrive wheel

The invention discloses a bow net electric contact characteristic testing device which comprises a motor, a motor control system, a power transmission system, a drive wheel, a driven wheel, a contact net wire, a contact net wire tension adjuster, a pantograph type current collector and a pantograph type current collector lifting controller, wherein the drive wheel is connected with the driven wheel through the contact net wire in a transmission manner, the contact net wire between the drive wheel and the driven wheel is in a flat state, and the pantograph type current collector is in dynamic contact with the contact net wire under the control of the pantograph type current collector lifting controller. The invention has the advantages that the contact net wire in contact with a bow net contact section is in the flat state and is in flexible contact with the pantograph type current collector; and the tension of the contact net can be adjusted, thus the electric contact state of the bow net can be really reflected.

Owner:SOUTHWEST JIAOTONG UNIV

Steel wire ring winding machine

The invention discloses a steel wire ring winding machine, and belongs to the technical field of winding machines. A main transmission device is arranged on one side of a rack, a stored wire and steel wire tension controlling device is arranged on the upper portion of the main transmission device, and a steel wire positioning and clamping rotating device is arranged on the other side of the rack. The steel wire ring winding machine is simple in structure and easy to produce and manufacture. Rotating directions of an outer layer and an inner layer of the wound steel wires are opposite, the steel wire in one layer rotates leftwards, the steel wire in the other layer rotates rightwards, no rubber filling is required between the steel wires, and the steel wire ring winding machine can be directly used in manufacturing of tires. The tire produced by the steel wire rings manufactured by the steel sire ring winding machine is applicable to usage in high internal pressure, high load, large deformation and strong impact load. A tire bead portion of the tire is not easy to damage even if large yielding deformation is repeatedly generated, delaminating or cord thread breaking between the steel wire ring and a cord fabric surface is avoided, and durability of the tire is greatly improved.

Owner:哈尔滨工大宏图橡塑科技有限公司

Wire tension exerting device for coil winder exerting method thereof

InactiveCN1482630ASimple structureLow priceFilament handlingCoils manufactureElectrical conductorWire tension

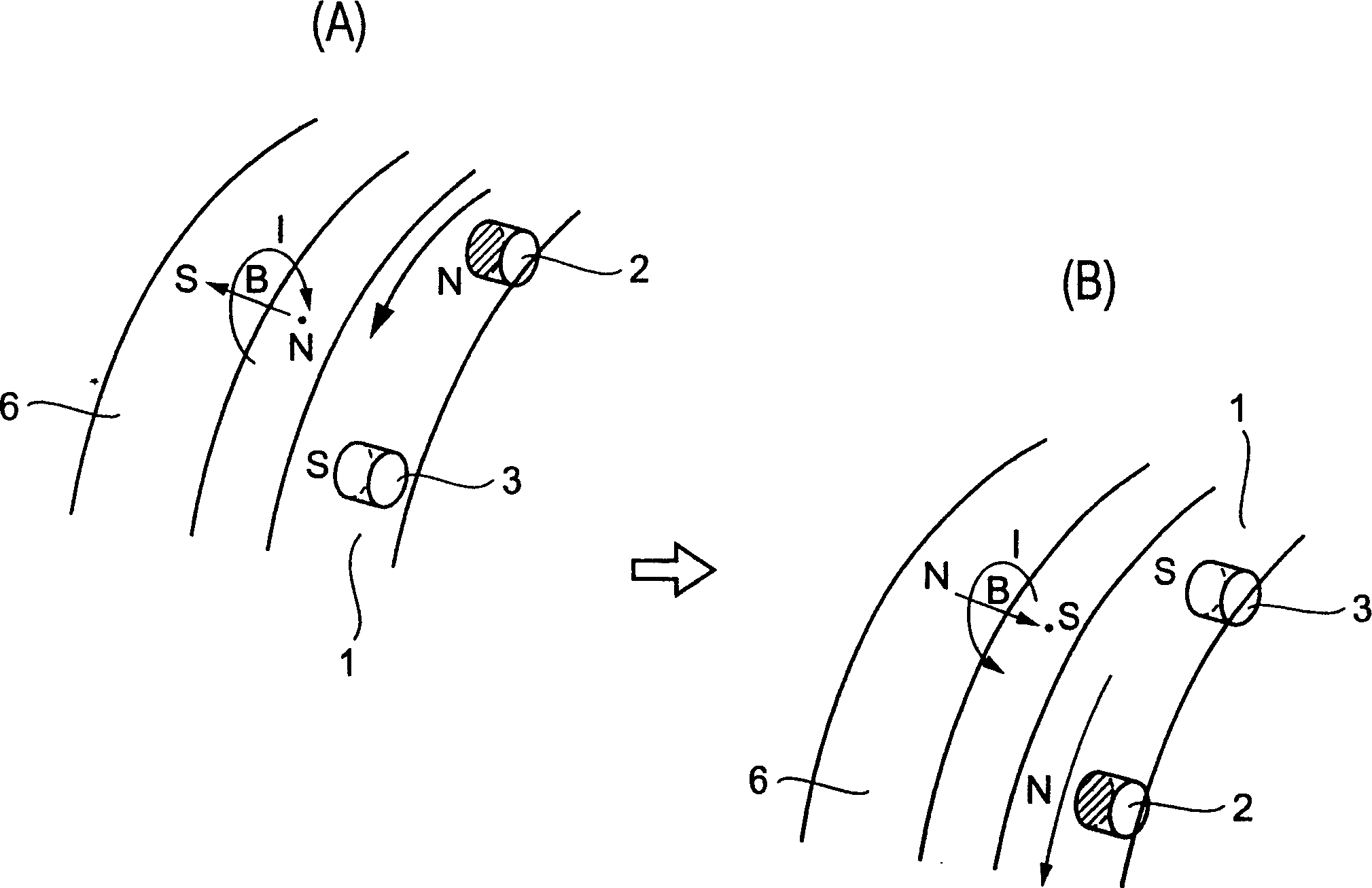

Disclosed is a device and method for providing tension to wires of a wire take-up machine by a simple and low-cost construction while capable of configuring the tension of the wire take-up machine within a wide range, characterized in including: a non-magnetic plate where NS poles of permanent magnets are provided in a circumferential direction in an alternate manner, being driven to rotate by a rotating means; a conductive plate, spaced from the non-magnetic plate by a specific distance in a rotatable manner, and including an integrally formed support having a wire guide at a front end thereof; and a magnetic field generated by the rotating means which drives rotation of the non-magnetic plate and acted on the conductive plate due to electromagnetic induction, such that a twisting effect is generated between the magnetic field and the permanent magnets for rotating the conductive plate and support thereby providing tension to wires.

Owner:NITTOKU ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com