Metal wire tension detection and control device in straight line wire drawing machine

A straight wire drawing machine and tension detection technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high failure rate of regulating rollers, increase of production efficiency and production cost, harsh working environment of wire drawing machine, etc. Achieve the effects of improving cooling effect, improving output and quality, and stabilizing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

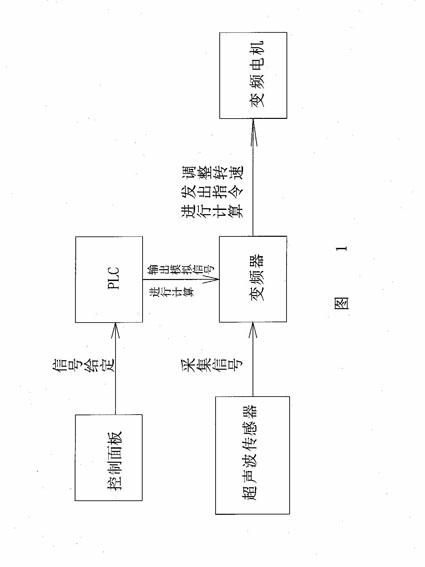

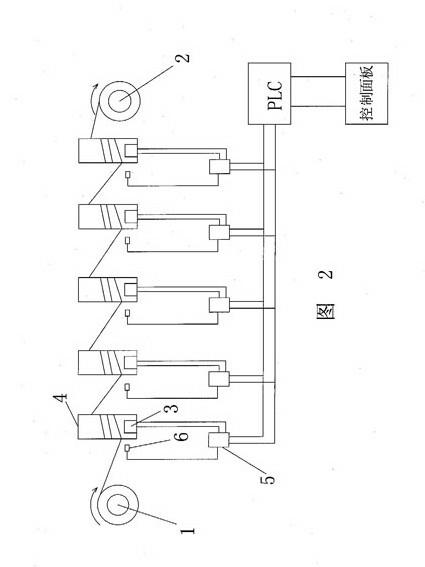

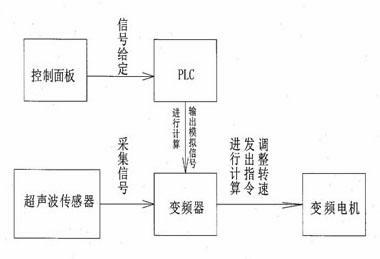

[0020] This embodiment is used to realize the drawing of high-quality carbon steel hard wire with a diameter of 6.5mm, and form a finished product with a diameter of 2.2mm after drawing, such as figure 1 , 2 As shown, the front end of the wire drawing machine is provided with a pay-off reel 1, and the end is provided with a take-up reel 2 using a frequency conversion motor. Both the wire drawing unit and the take-up unit use a frequency conversion motor 3. Braking devices, etc., and various linkages of the wire drawing system are realized by the PLC control unit, and the synchronous control is realized inside the frequency converter 5. According to the operating speed set on the control panel, the analog signal of the speed is connected to the PLC control unit , the PLC control unit considers the acceleration and deceleration time and then outputs the analog signal to the input terminals of all inverters 5 as the main given signal of the speed; at the same time at the nth and ...

Embodiment 2

[0026] This embodiment is used to realize that the high-quality carbon steel hard wire with a diameter of 3.8mm is drawn, and a finished product with a diameter of 1.6mm is formed after drawing, such as figure 1 , 2 As shown, the front end of the wire drawing machine is provided with a pay-off reel 1, and the end is provided with a take-up reel 2 using a frequency conversion motor. Both the wire drawing unit and the take-up unit use a frequency conversion motor 3. Braking devices, etc., and various linkages of the wire drawing system are realized by the PLC control unit, and the synchronous control is realized inside the frequency converter 5. According to the operating speed set on the control panel, the analog signal of the speed is connected to the PLC control unit , the PLC control unit considers the acceleration and deceleration time and then outputs the analog signal to the input terminals of all inverters 5 as the main given signal of the speed; at the same time at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com