Patents

Literature

169 results about "Deceleration time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Deceleration time is a term used to describe the amount of time it takes for a hard drive head to slowdown after it moves to a portion of the disk to retrieve information.

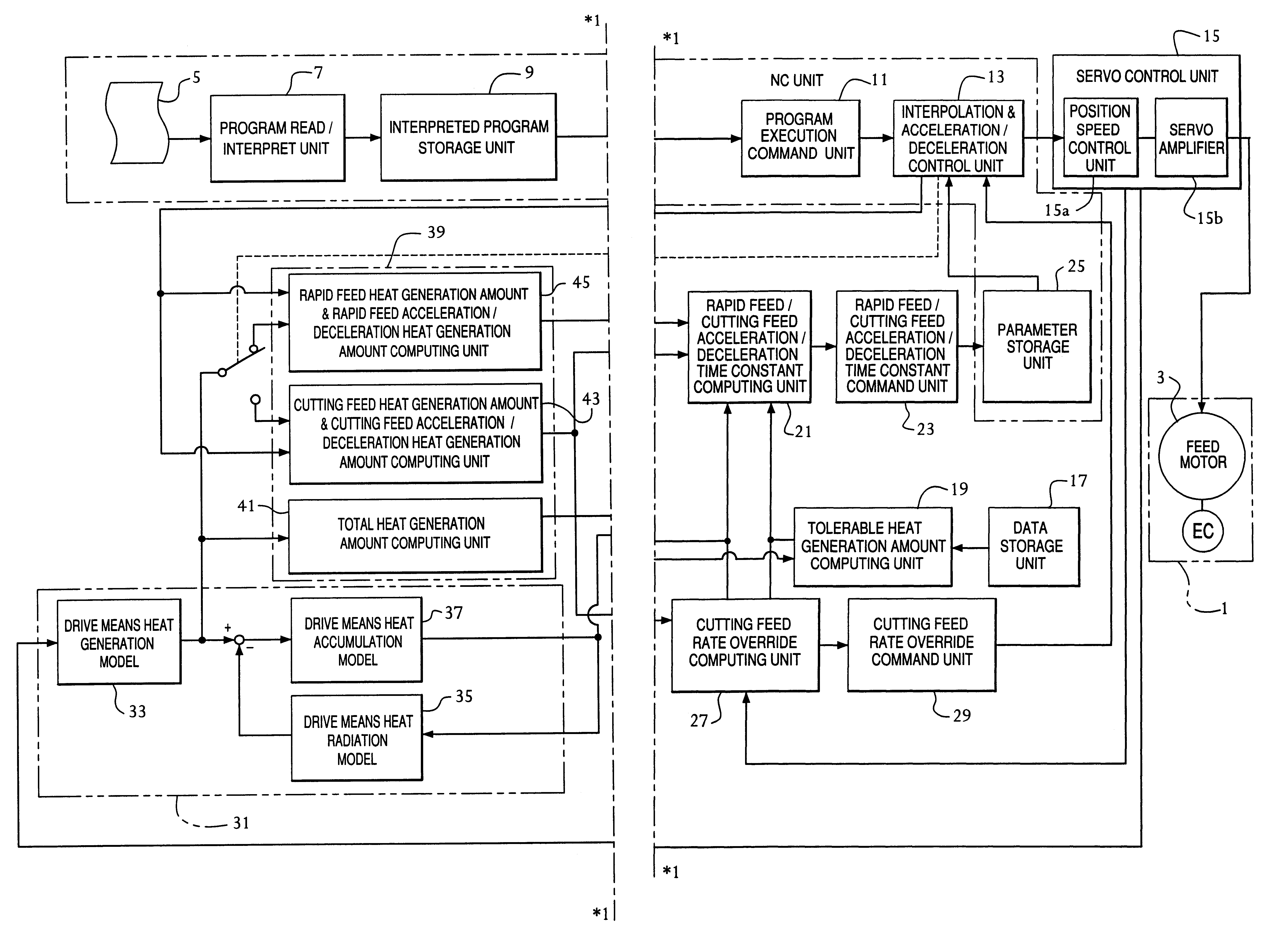

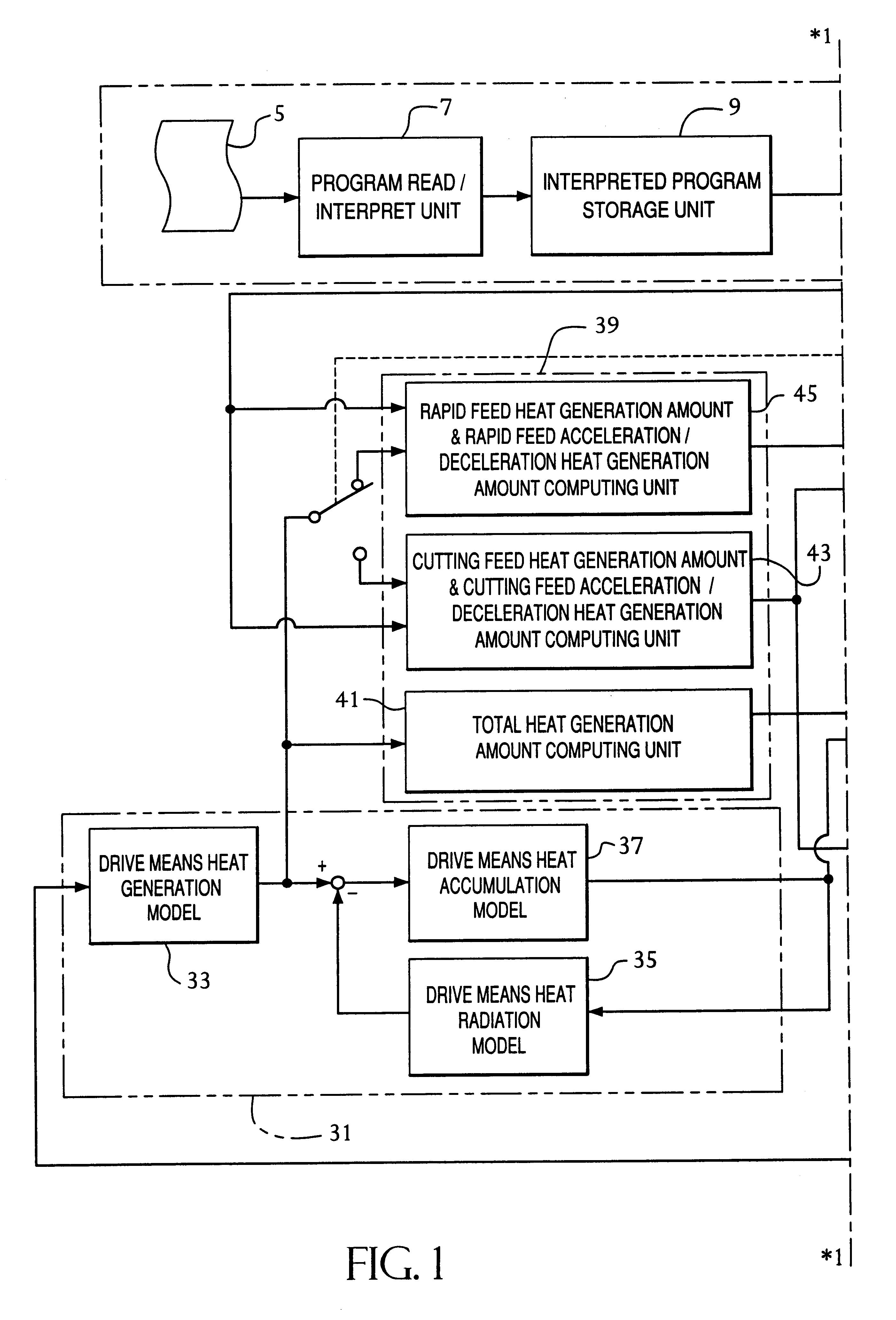

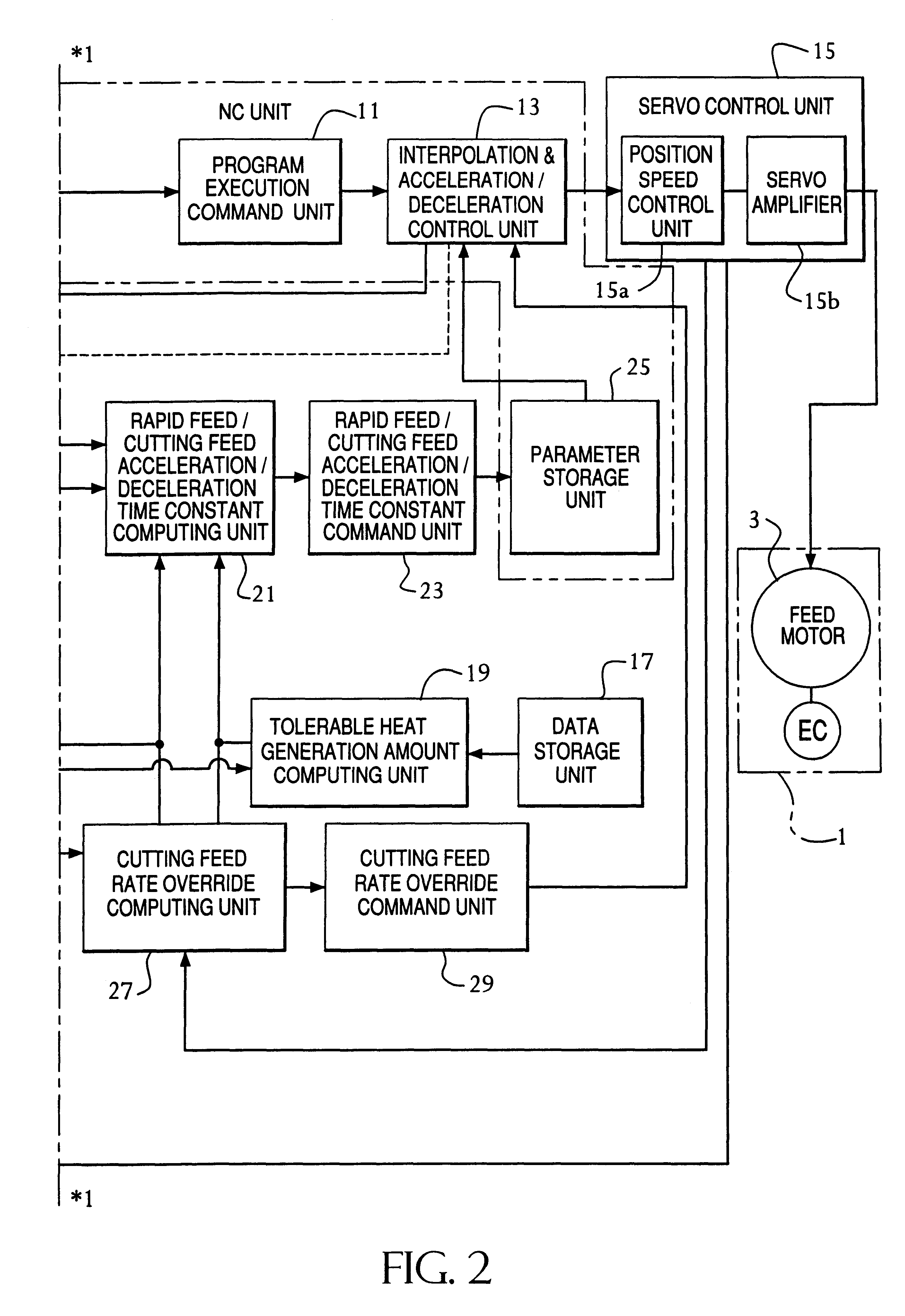

Method and apparatus for controlling numerically controlled machine tool

InactiveUS6291959B1Programme-controlled manipulatorAutomatic control devicesNumerical controlProcess engineering

A method and an apparatus for controlling a numerically controlled machine tool, wherein the heat generation amount and the temperature of a drive unit including a servo amplifier 15b and a feed shaft motor 3 are computed by a drive unit heat generation amount computing unit 31 by simulation, and from the computed heat generation amount and the computed temperature, the total heat generation amount of the drive unit, the cutting feed heat generation amount, the cutting load heat generation amount, etc. are computed by a feed heat generation amount computing unit 39, so that the cutting feed rate override value of the numerically controlled machine tool 1 is computed by a cutting feed rate override computing unit 27 and effectuated by being output to a NC unit. Further, based on the temperature of the drive unit computed by a computing unit 31 or the temperature computed by a temperature data computing unit 47 or the temperature detected by a temperature detection sensor 49, etc., the proper values of the feed acceleration / deceleration time constants τ<SMALLCAPS>r < / SMALLCAPS>and τ<SMALLCAPS>c < / SMALLCAPS>are computed and output as a ratio with respect to the set and stored initial values τ<SMALLCAPS>r0 < / SMALLCAPS>and τ<SMALLCAPS>C0 < / SMALLCAPS>thereby to control the NC commanded rate. The overheating of the feed axis drive unit is prevented while at the same time improving the machining efficiency.

Owner:MAKINO MILLING MASCH CO LTD

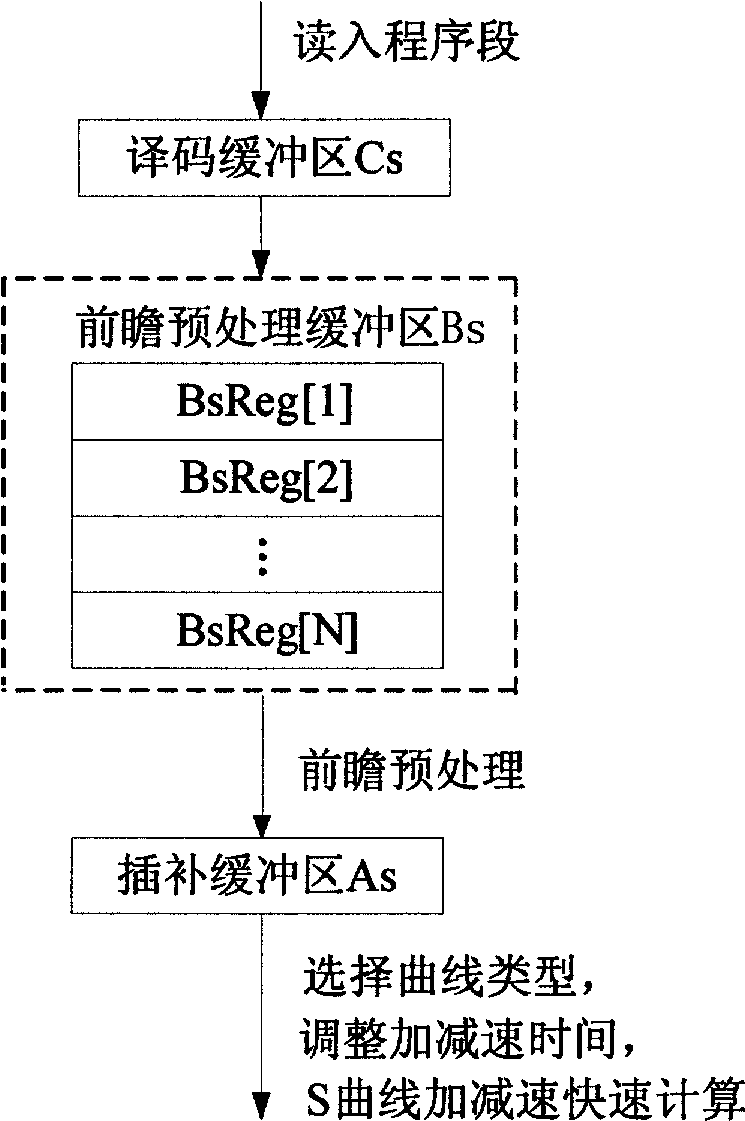

Forward looking self-adapting speed controlling method for high-speed processing tiny line segment

InactiveCN101510087AImprove practicalityMeet the requirements of high precision CNC systemNumerical controlProgram segmentSelf adaptive

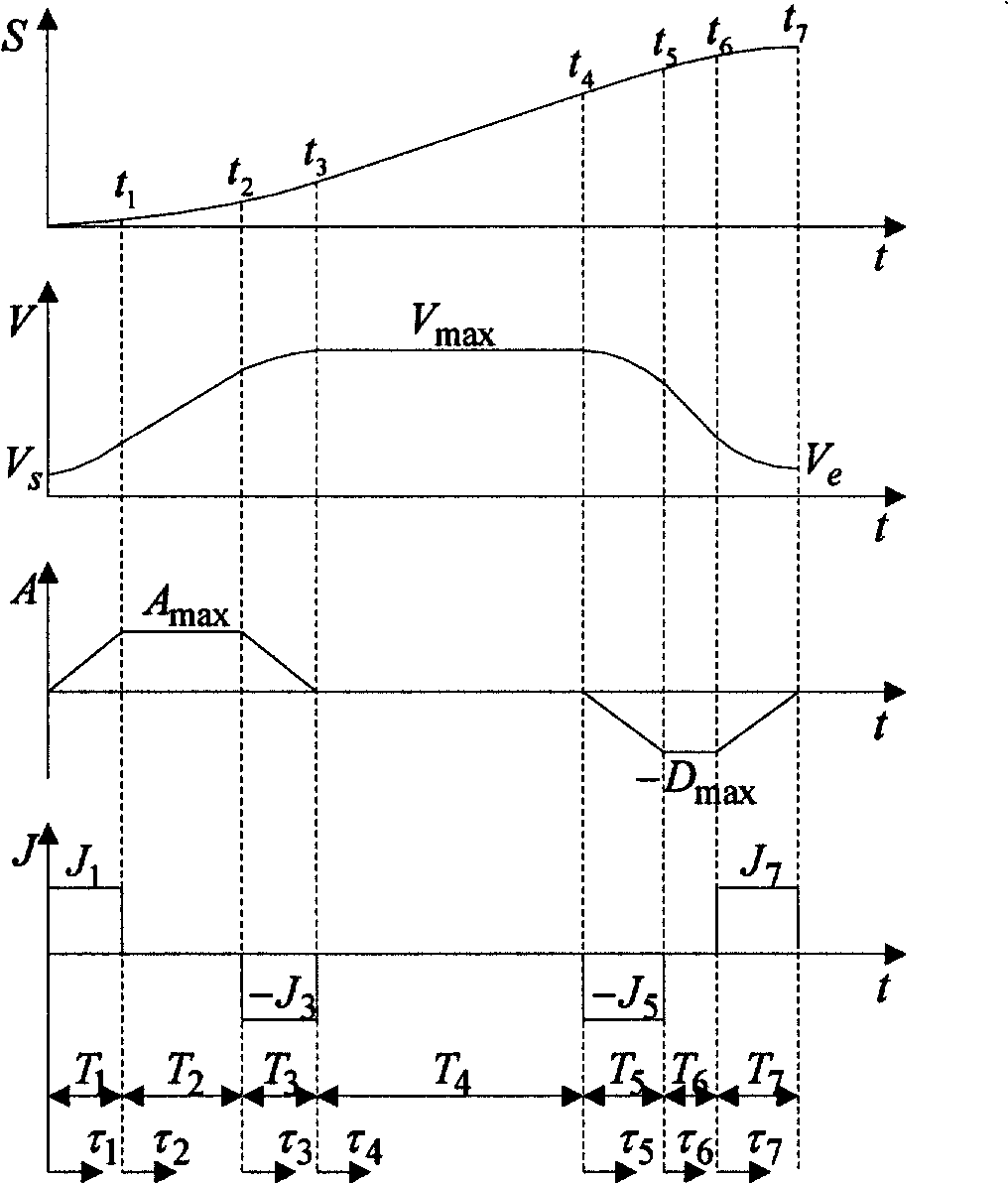

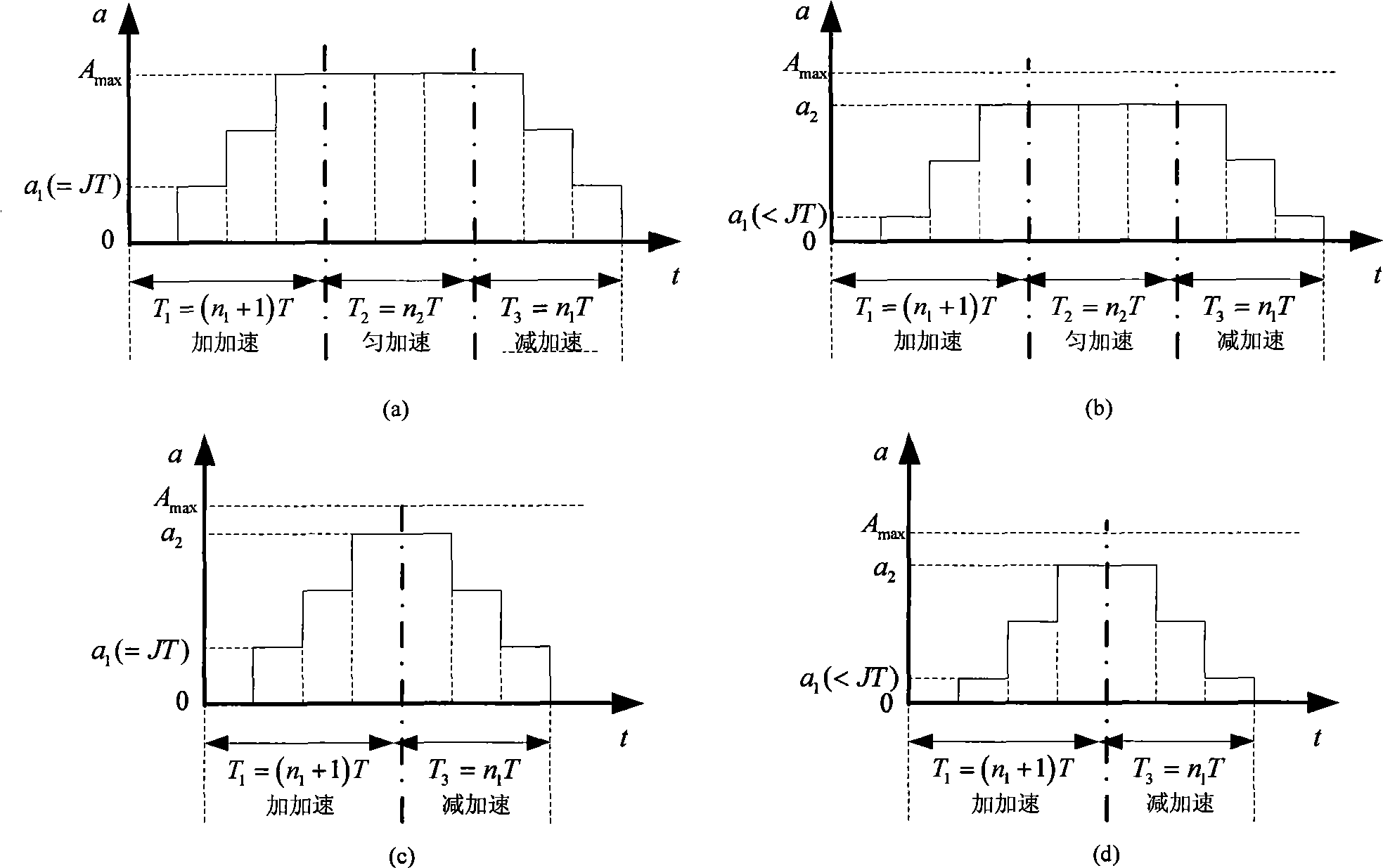

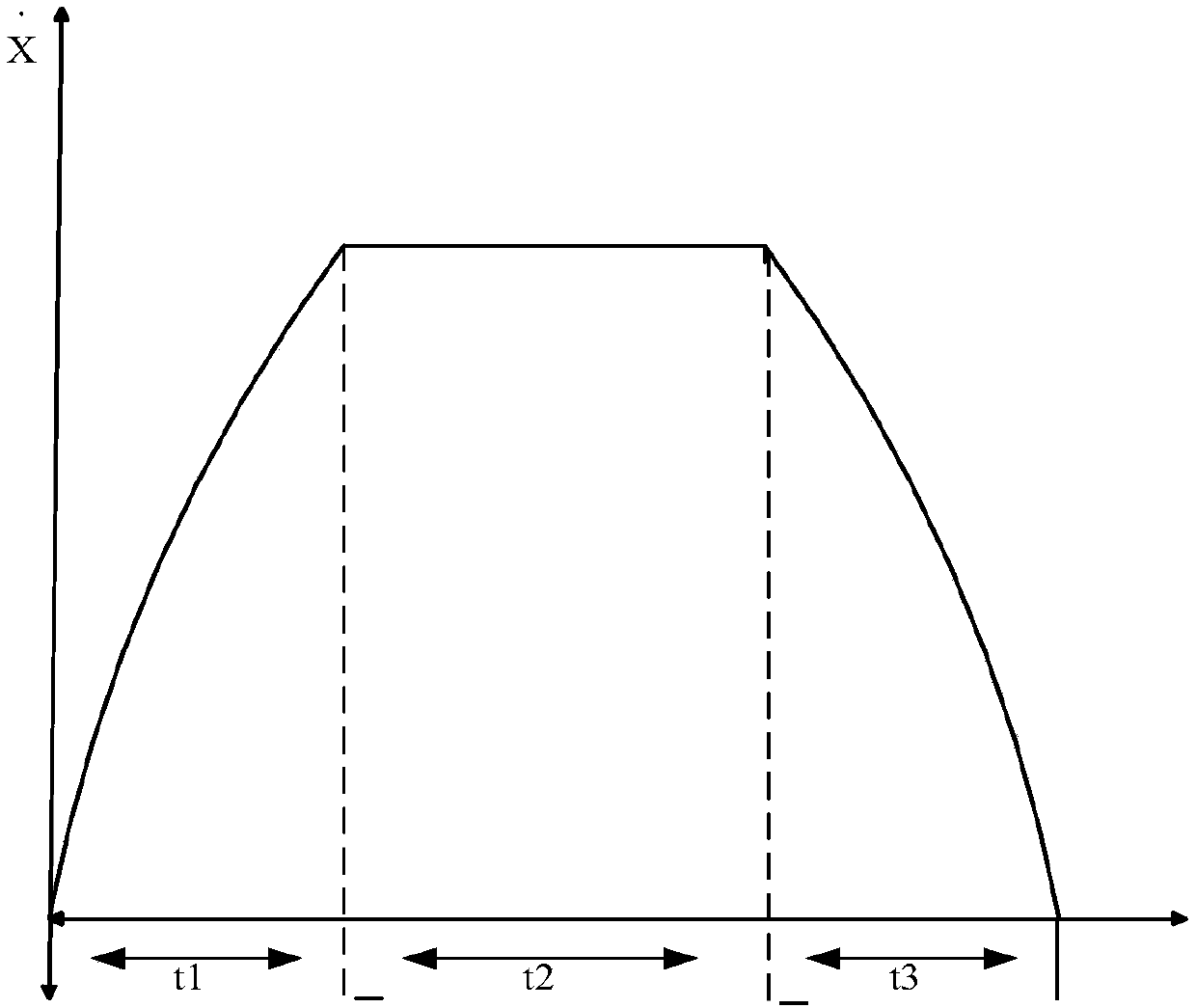

The invention discloses a forward-looking self-adaptive speed control method of high-speed numerical control equipment. The numerical control system of the method conducts a plurality of layers of pre-reading decoding processing, uses pre-reading program segment information for pre-calculation to the terminal speed of a segment to be processed, adjusts a speed acceleration and deceleration time constant according to the calculation result, selects a speed acceleration and deceleration curve type, and then conducts a fast speed acceleration and deceleration calculation to an S curve so as to lead the numerical control equipment to process the micro-segments with high speed and smooth operation. The forward-looking self-adaptive speed control method comprises the following steps of: the pre-calculation of the terminal speed of the segment to be processed, the self-adaptive selecting strategy of the speed acceleration and deceleration time constant, and the speed acceleration and deceleration curve type; and the fast speed acceleration and deceleration calculation of the S curve. The invention provides a self-adaptive speed acceleration and deceleration control method for the high-speed numerical control equipment, leads the numerical control equipment to have the capacity of processing the micro-segments with high speed and smooth operation, and satisfies the speed control requirements of high-speed high-precision numerical control equipment.

Owner:XI AN JIAOTONG UNIV

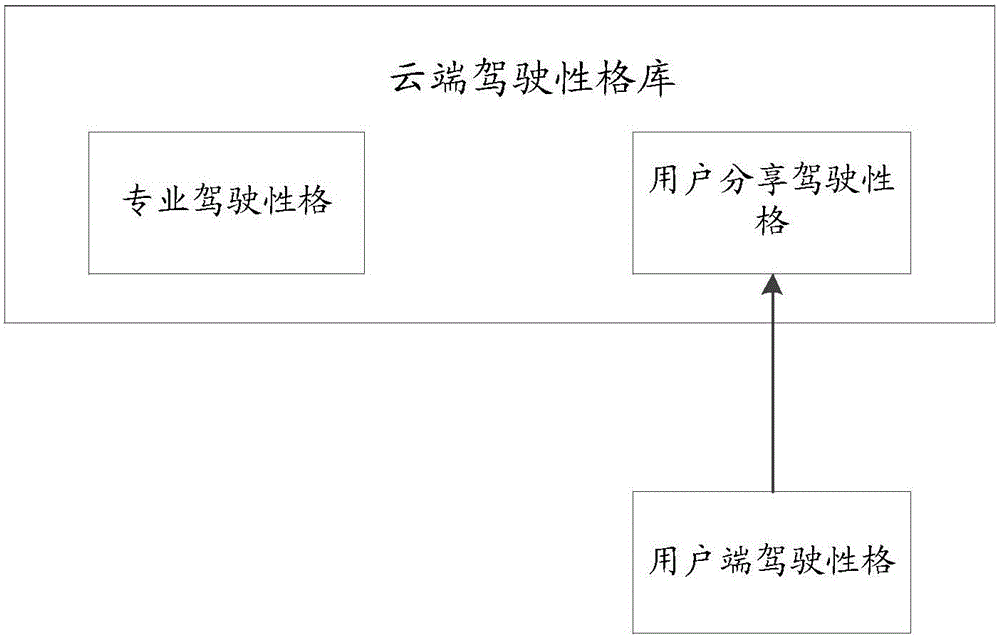

Control method and intelligent device applied to pilotless automobile

ActiveCN105818810AImprove stabilityImprove securityTransmission systemsDriver input parametersAutomatic controlBraking distance

The invention discloses a control method and an intelligent device applied to a pilotless automobile. The specific embodiment of the method comprises the steps of receiving a driving habit selection instruction input by a user; obtaining driving habit information corresponding to the driving habit selection instruction, wherein the driving habit information comprises a driving route, a driving speed, acceleration time, deceleration time and a braking distance; and controlling the pilotless automobile on the basis of the driving habit information. On one hand, the automobile is automatically controlled to drive by the collected driving habit information of the user, the operation in the driving process is simplified, and the driving habit information can be shared with other users; on the other hand, the pilotless automobile can be controlled by the obtained driving habit information of a professional driver, while the driving stability and safety of the automobile are improved, and the optimization cost of operation and control of the pilotless automobile is reduced.

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

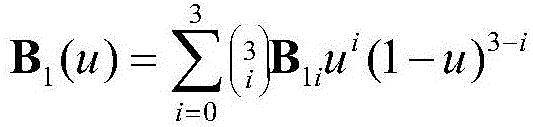

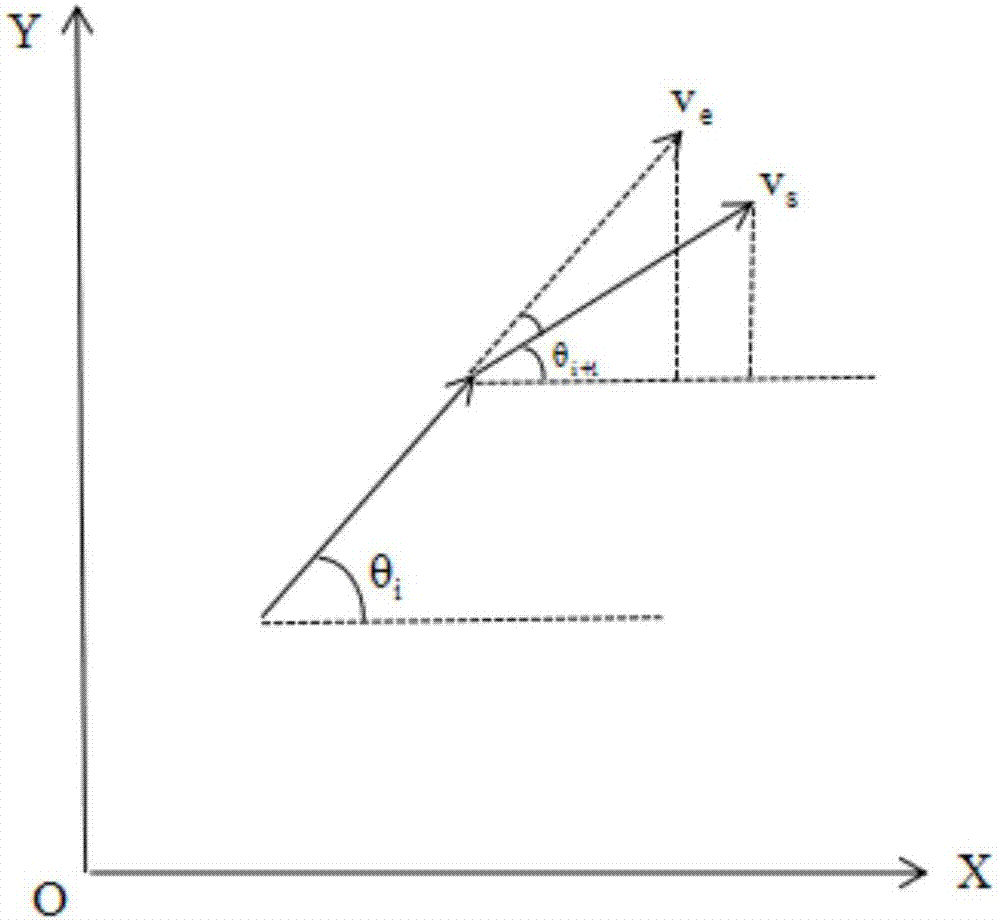

Unmanned aerial vehicle trajectory smoothing method based on Bessel curve transition

ActiveCN106325294AGuaranteed flight performanceImprove flight performanceForecastingPosition/course control in three dimensionsKinematicsTransition function

The invention provides an unmanned aerial vehicle (UAV) trajectory smoothing method based on Bessel curve transition, comprising the following steps: constructing a Bessel transition function according to known linear route segments, and quickly establishing flight trajectory geometrical characteristics satisfying curvature continuity; with the length of the linear route segments and the allowed maximum trajectory smoothing error as constraints, establishing and solving an optimization problem of the smoothing transition length of each Bessel curve; determining maximum speed, acceleration and jerk constraints, and determining the maximum flight speed of transition segments based on the nature of the Bessel function; performing S-shaped motion planning for all linear segments, and determining the acceleration and deceleration time of each linear segment; iteratively searching and planning the flight speed of each segment to ensure the kinematic compatibility; and performing real-time interpolation to complete flight path generation. The flight performance of UAV can be improved greatly under the premise of guaranteeing the calculation efficiency.

Owner:SHANGHAI JIAO TONG UNIV

S-type acceleration and deceleration control method of numerical control machine tool

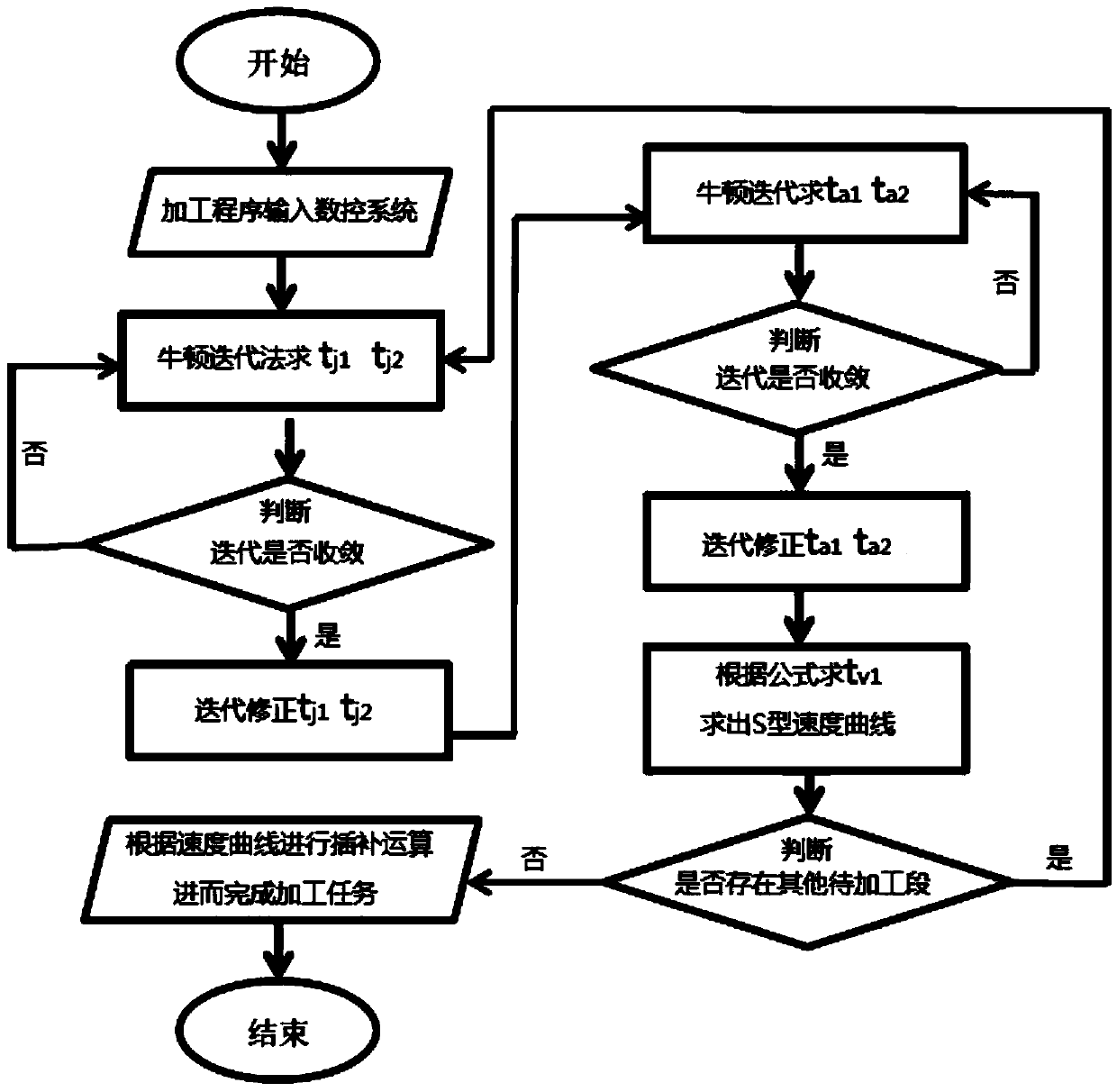

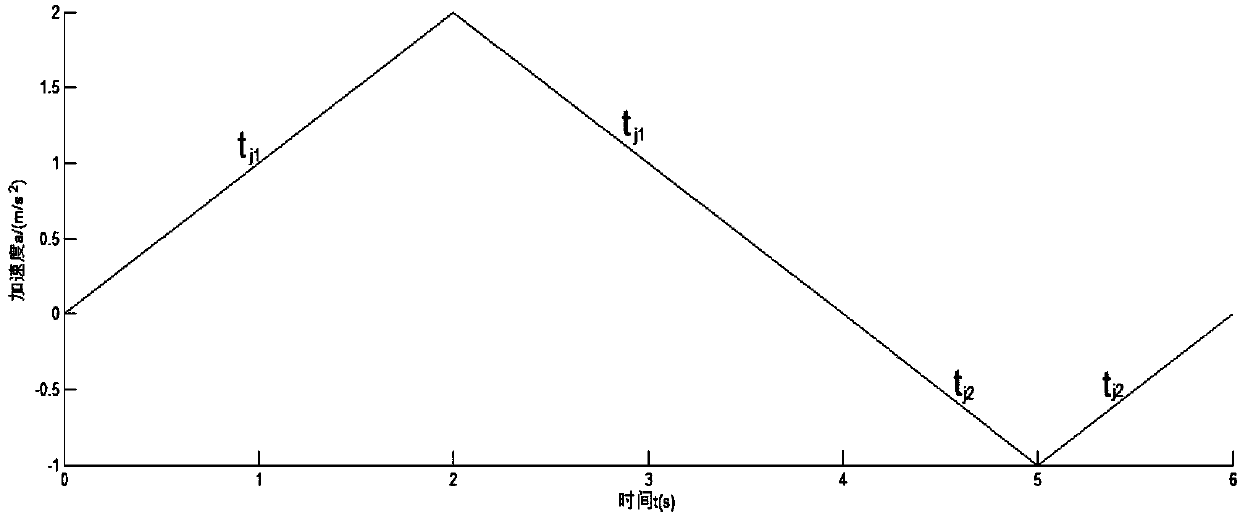

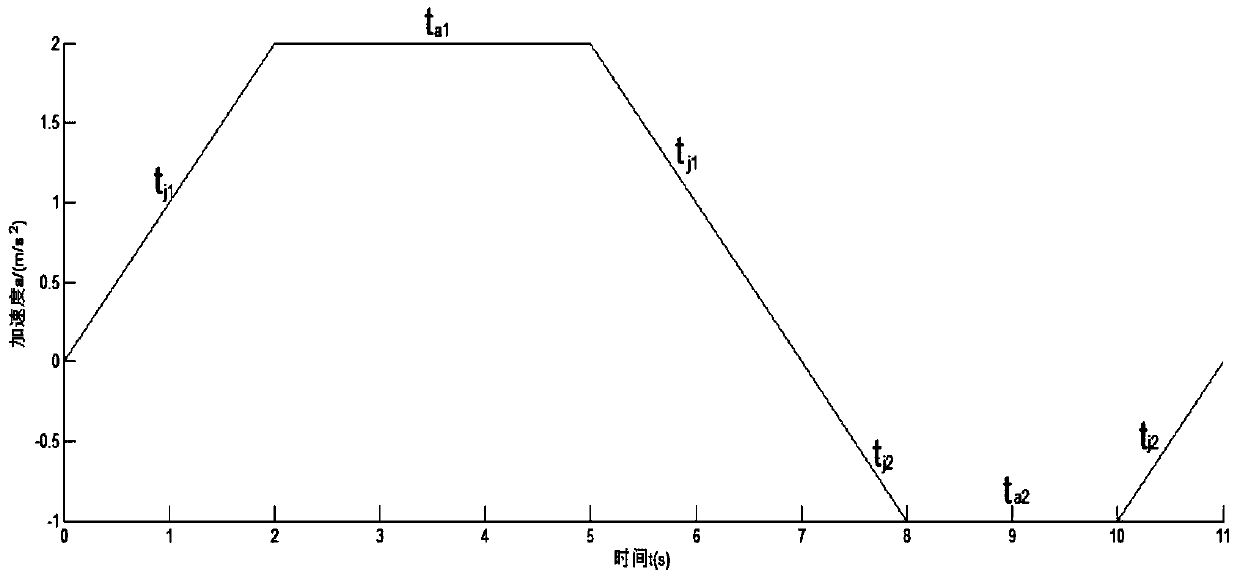

InactiveCN104181860AHigh precisionReduce shockNumerical controlNonlinear systems of equationsEngineering

Provided is an S-type acceleration and deceleration control method of a numerical control machine tool. Firstly, a machining program is input into a numerical control system, a numerical control device obtains necessary data, then a pentabasic nonlinear equation set referred to in S-type acceleration and deceleration control is factorized into two binary nonlinear equation sets and one unitary linear equation according to the shortest time rule and the limiting conditions of speed and accelerated speed, acceleration time and deceleration time meeting requirements are gradually solved through the Newton iteration method and the iteration correction method, then a speed curve is solved, interpolation operation is carried out finally, pulses are output, and the machining tasks of workpieces are completed. According to the method, the complex and tedious operation of existing S-type acceleration and deceleration control can be effectively avoided, and the acceleration and deceleration control method is high in precision, short in solving time, easy to understand and convenient to implement.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

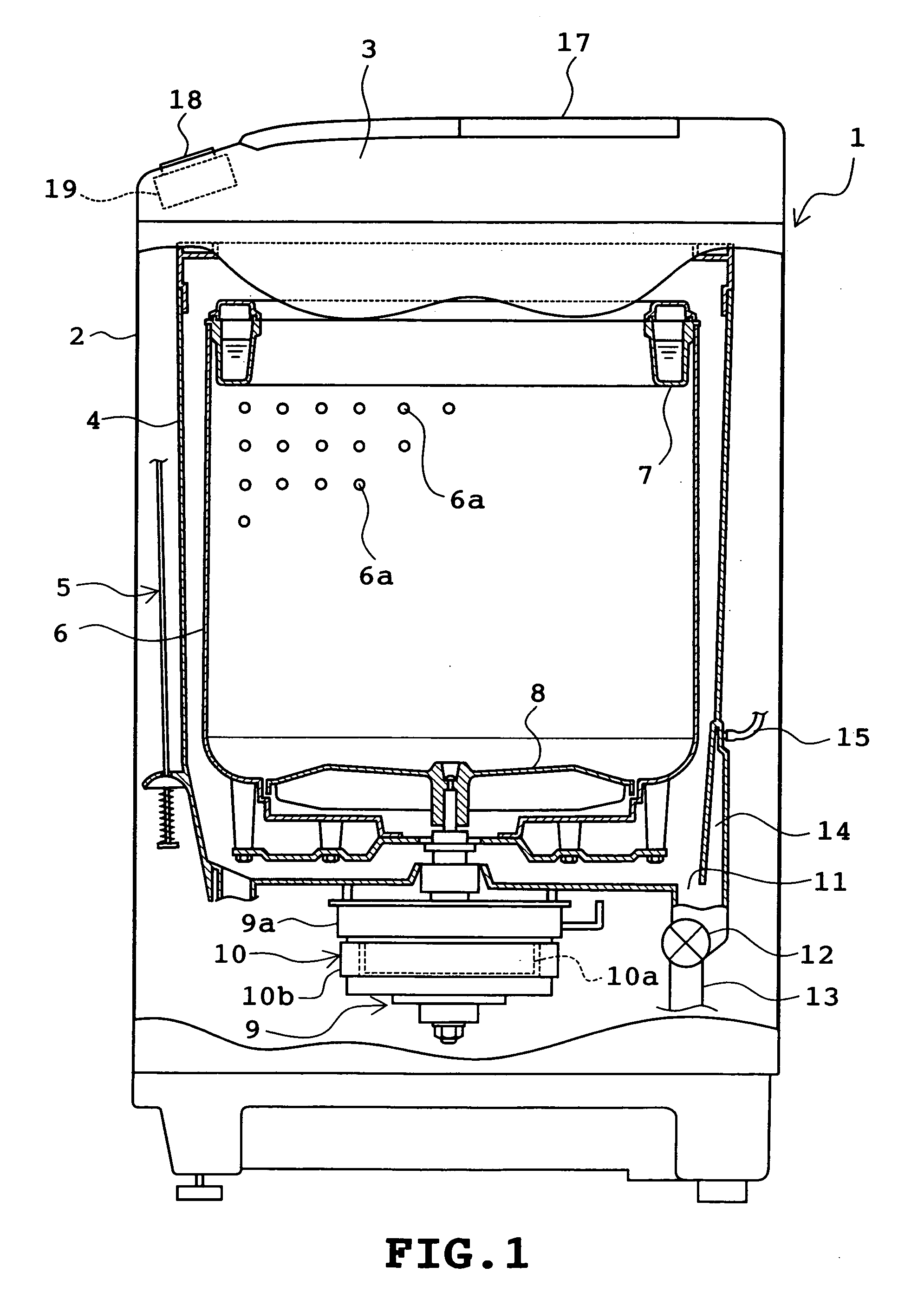

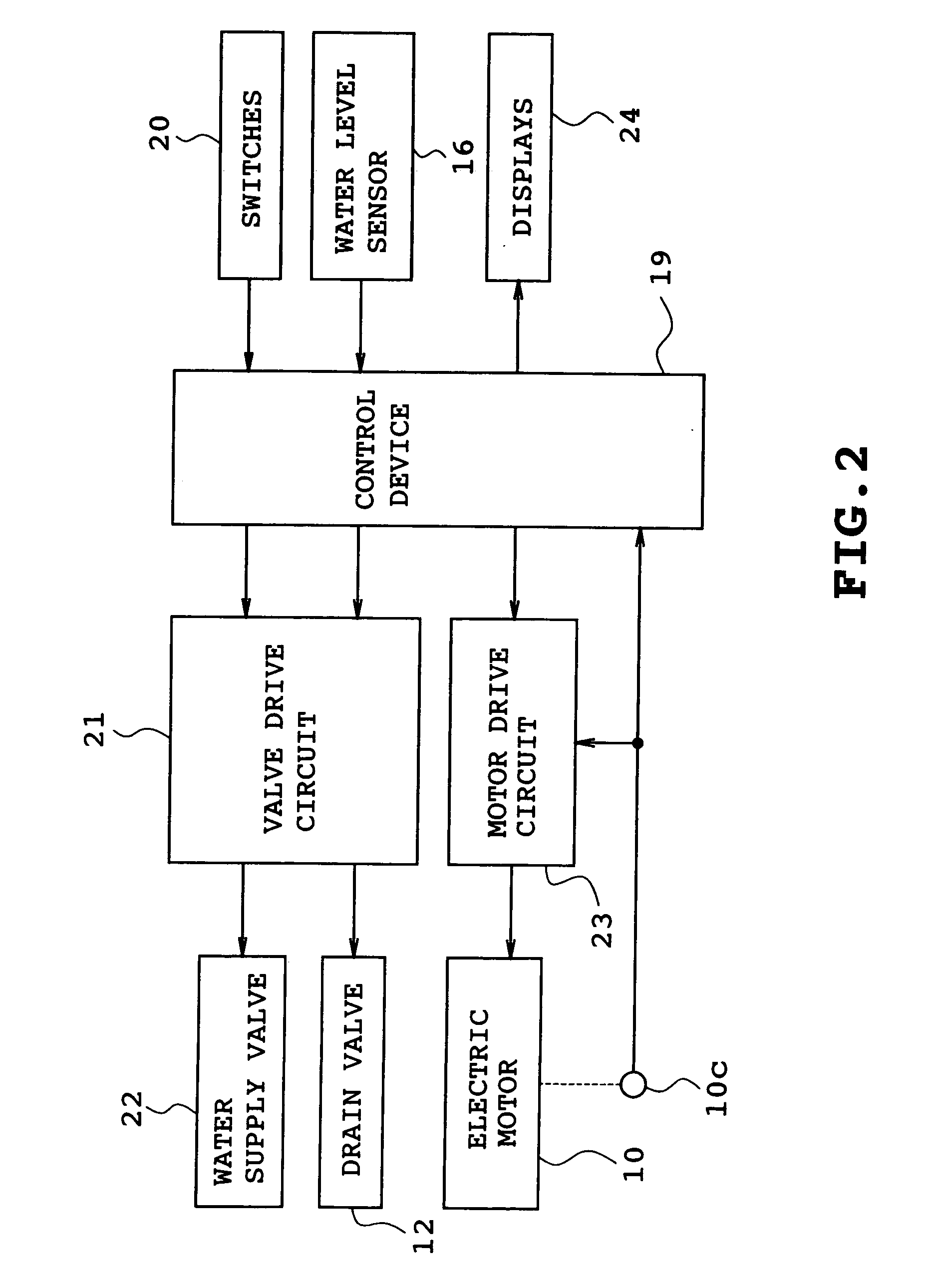

Washing machine

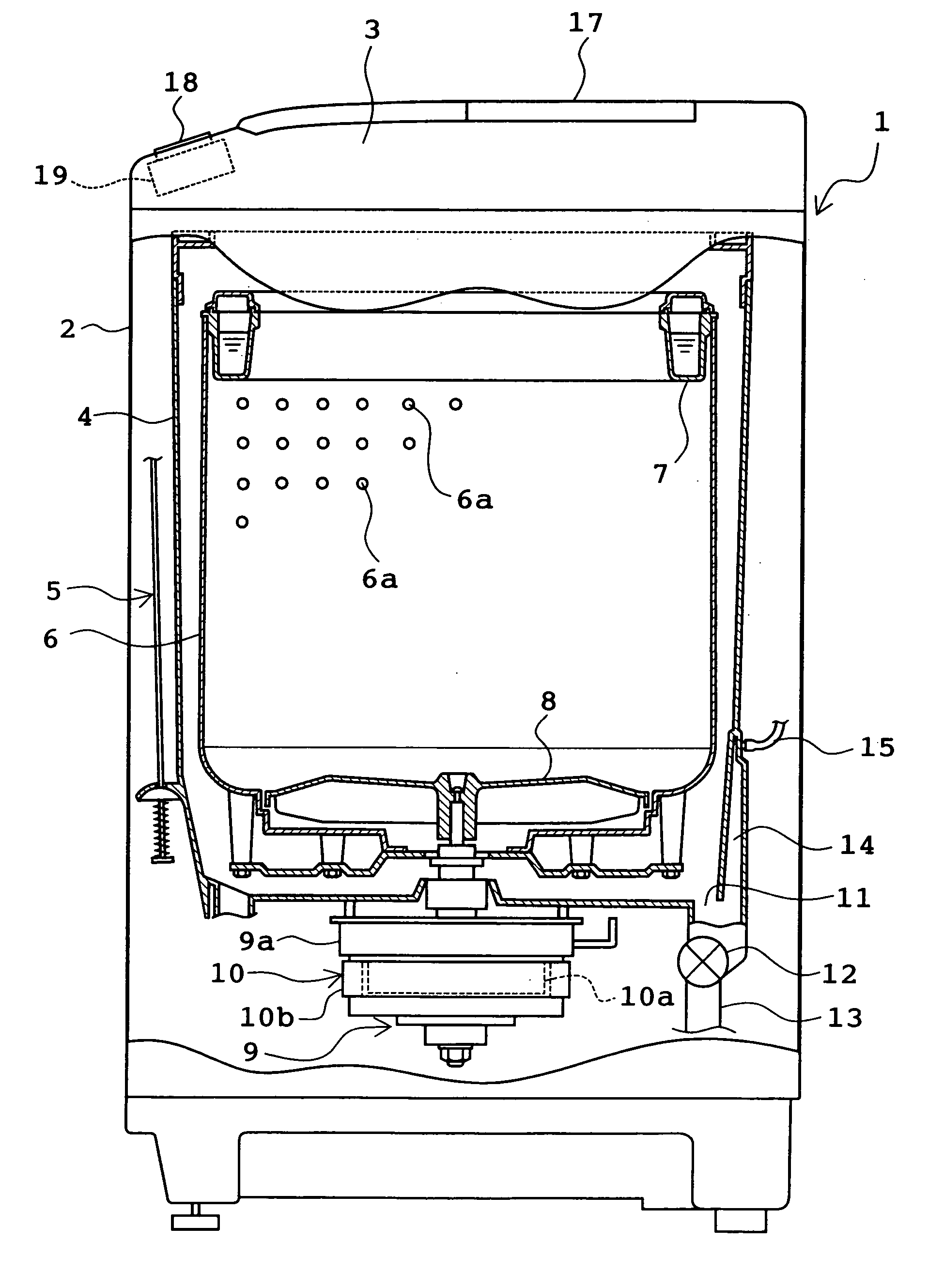

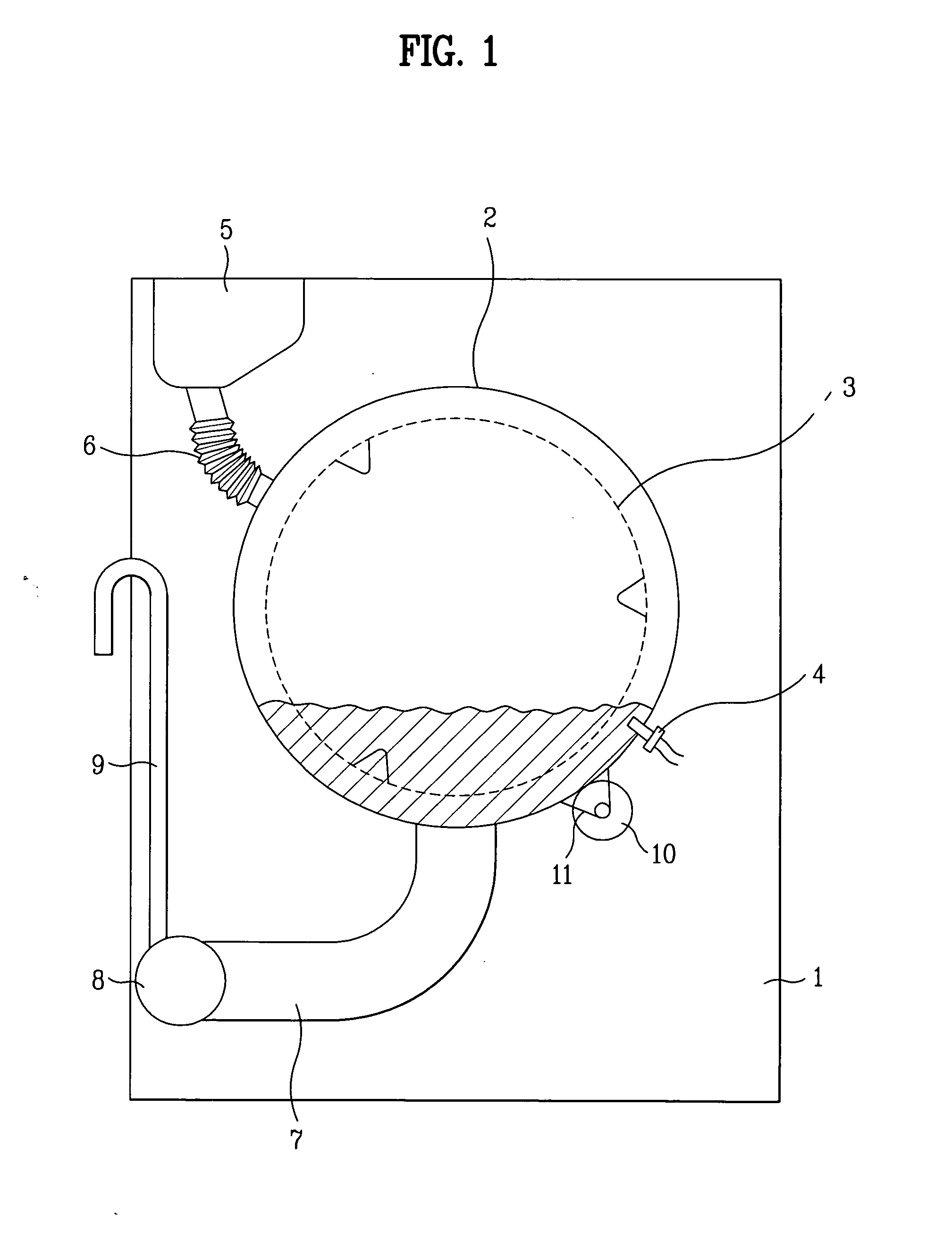

InactiveUS20050016226A1Big vibrationSignificant valueOther washing machinesControl devices for washing apparatusMechanical energyEngineering

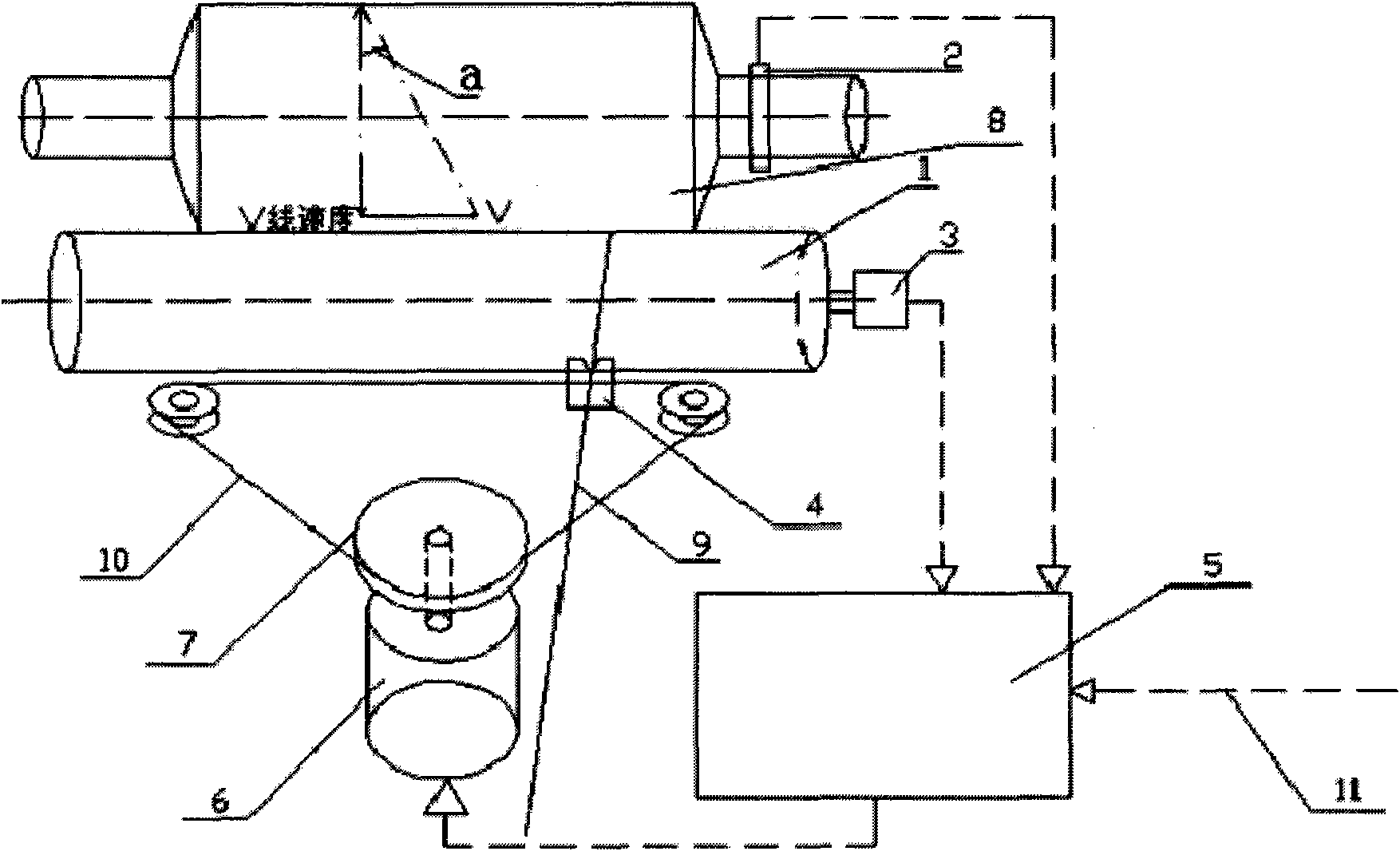

A direct drive washing machine is disclosed which is capable of performing a washing operation by efficiently converting electric energy supplied into an electric motor (10) into mechanical energy or with less vibration and noise. When a washing operation is carried out with efficient energy conversion, an acceleration time and a deceleration time of an agitator (8) rotated by the motor (10) are controlled on the basis of a measured value of a vibration sensor (25) or a measured value of clothes weight so that vibration of a water-receiving tub (4) becomes maximum. On the other hand, when a quiet washing operation with less vibration is carried out, the acceleration time and the deceleration time of an agitator (8) rotated by the motor (10) are controlled on the basis of the measured value of the vibration sensor (25) or the measured value of clothes weight so that vibration of the water-receiving tub (4) becomes minimum.

Owner:KK TOSHIBA +2

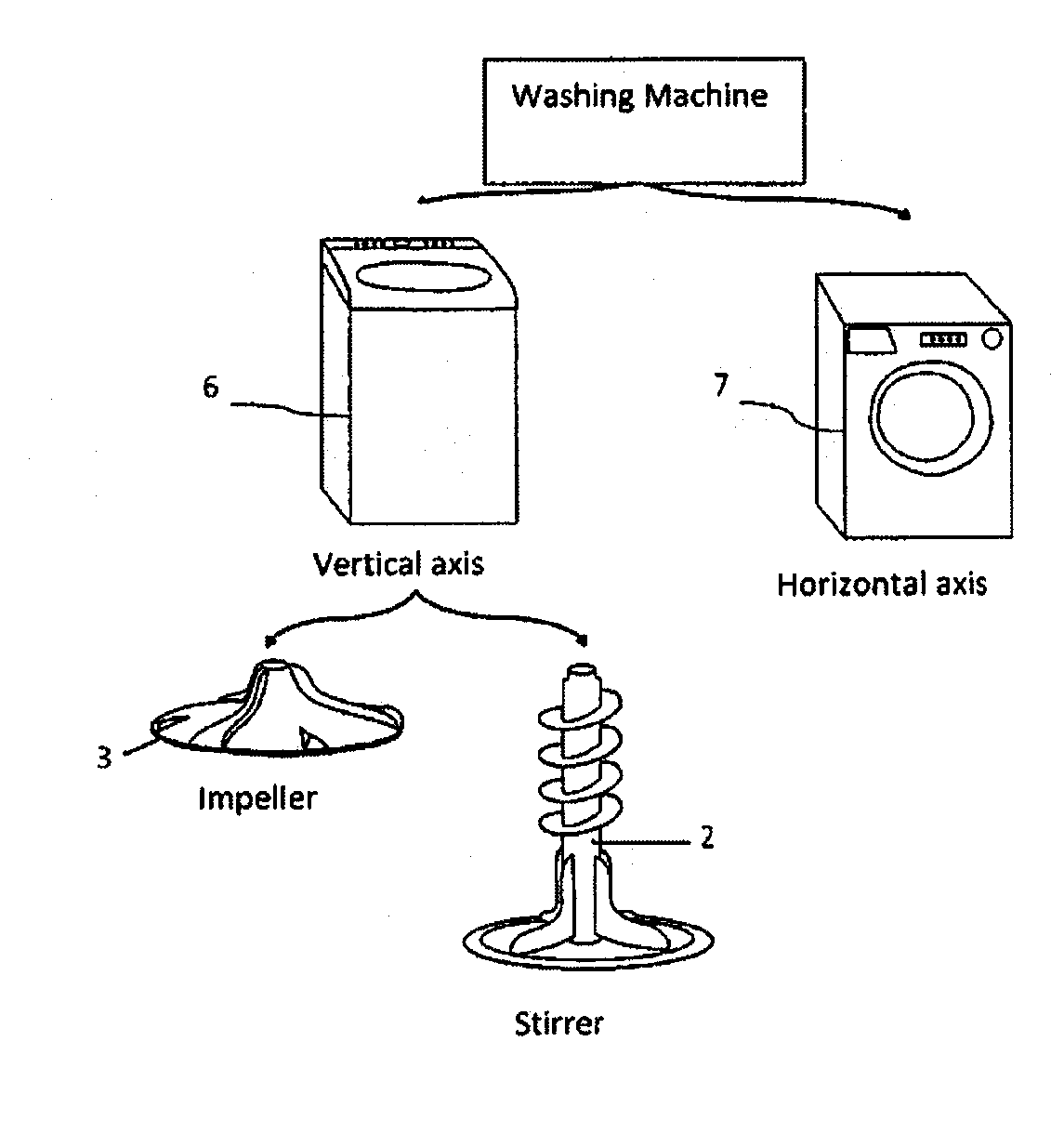

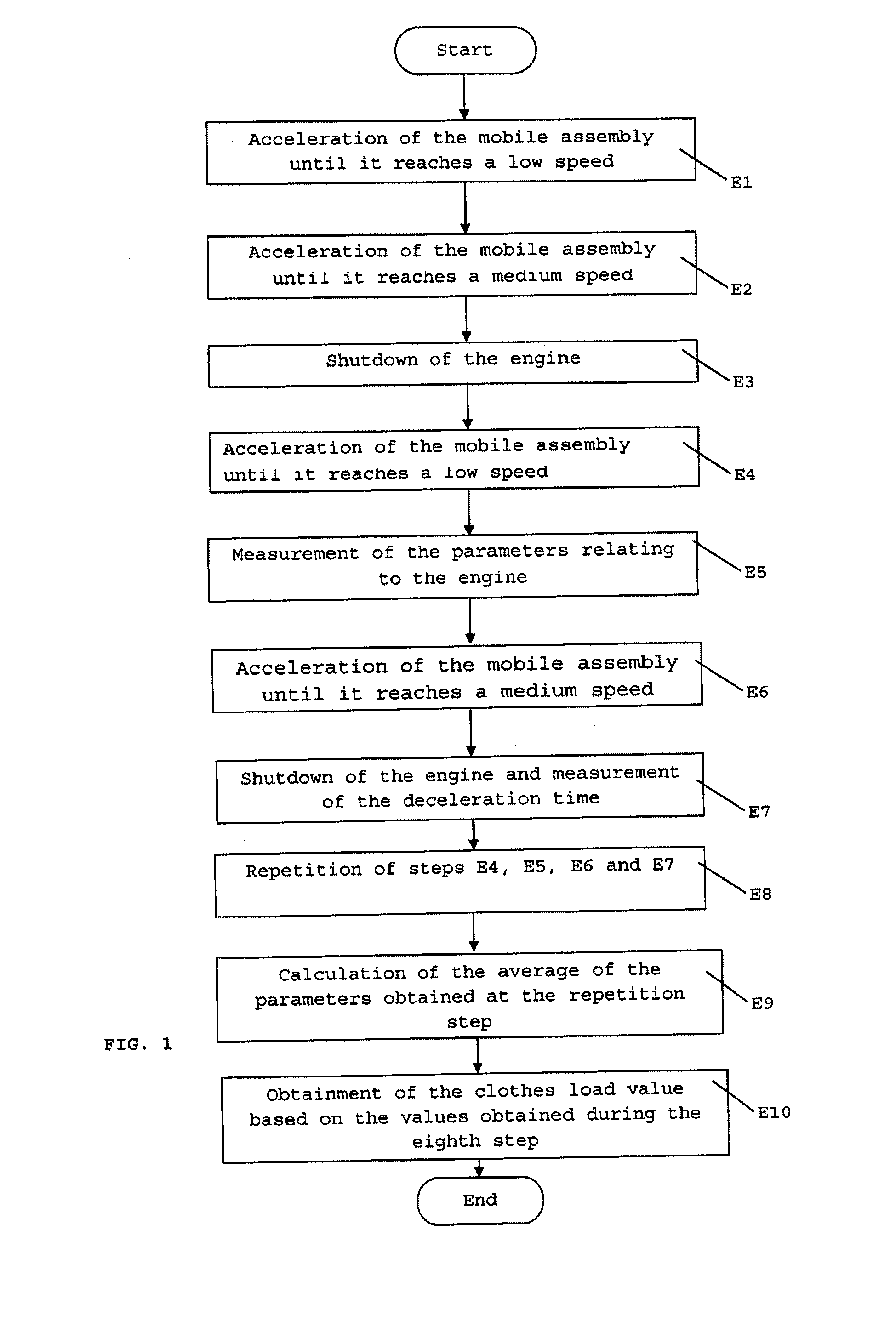

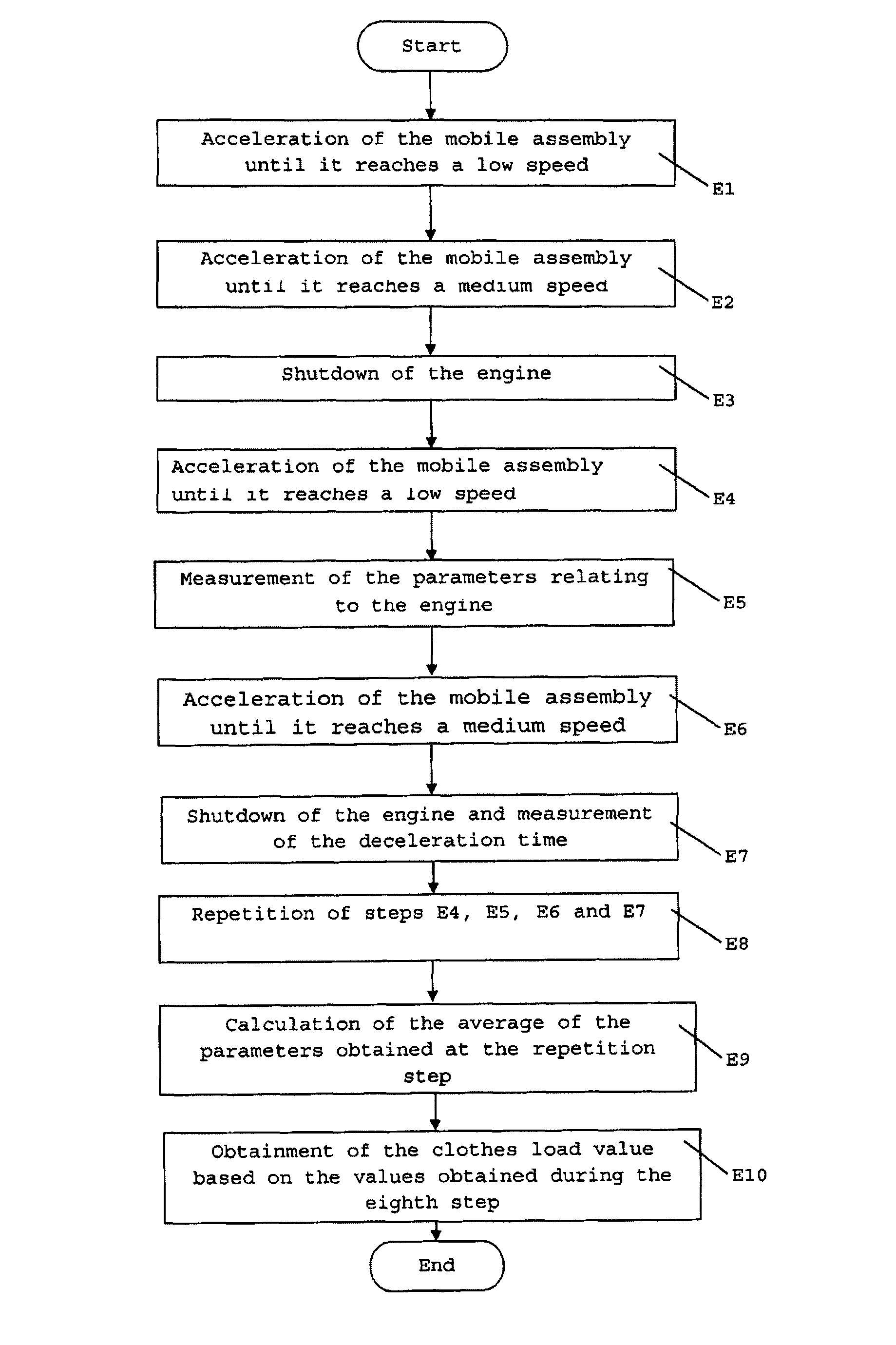

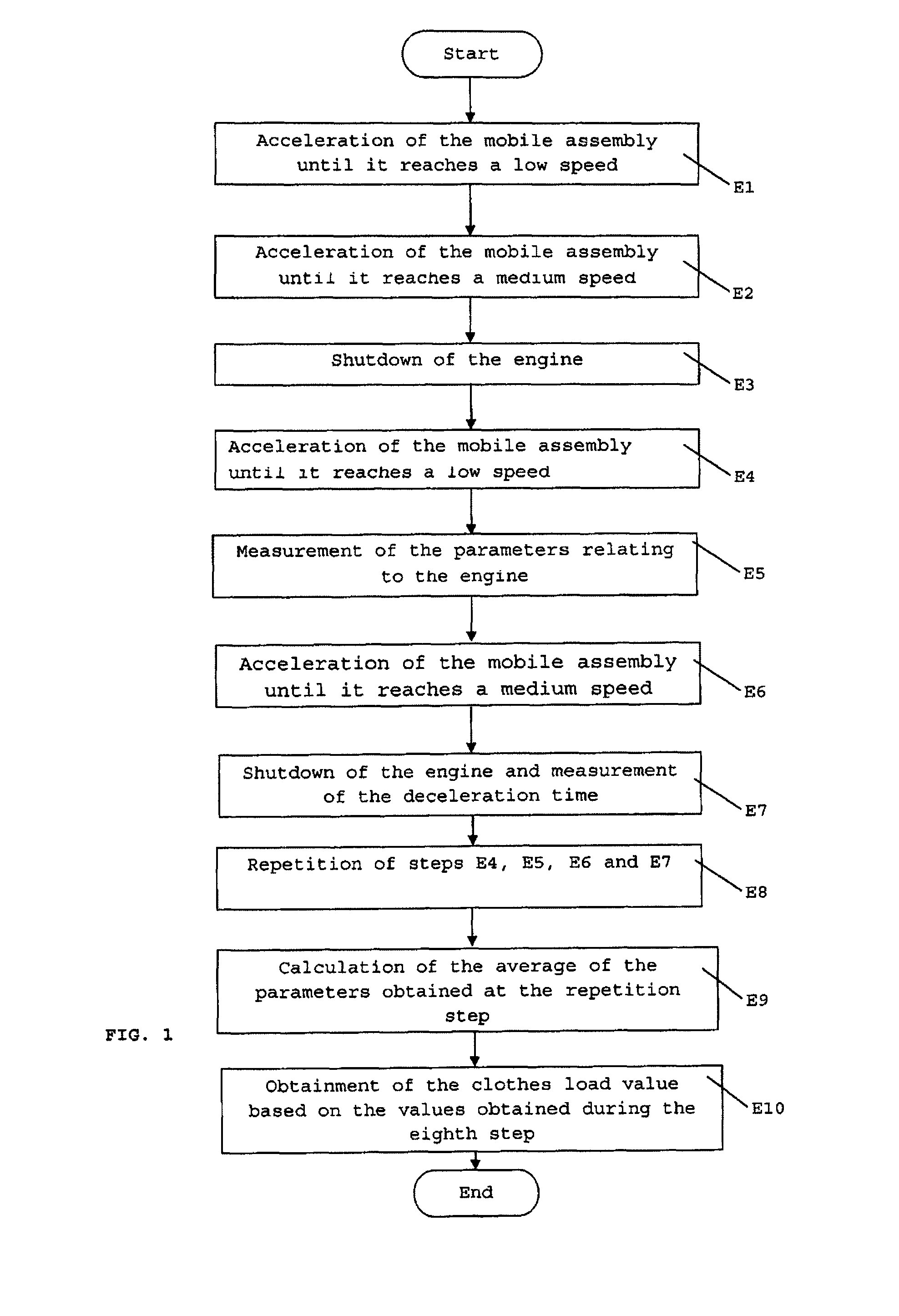

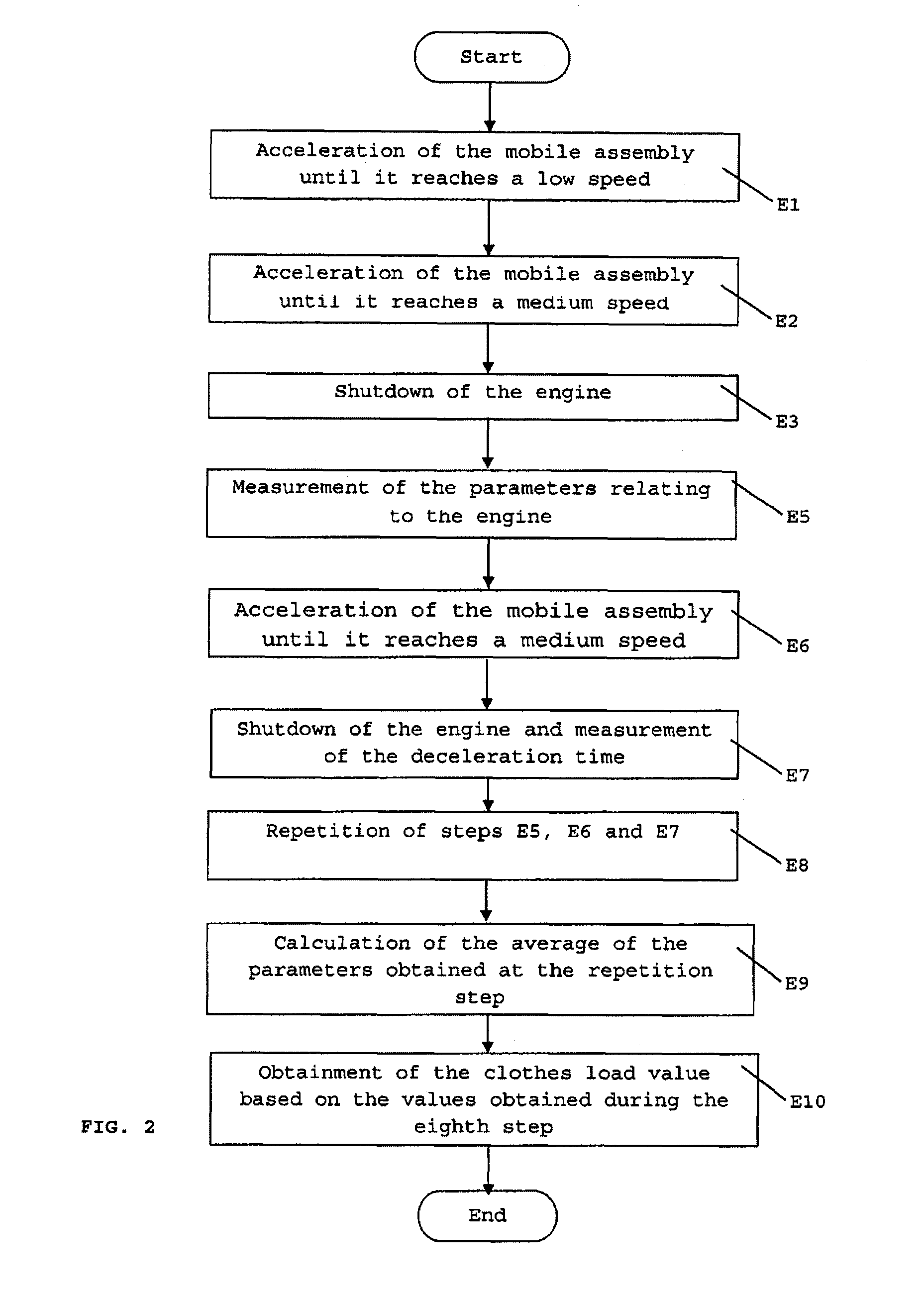

Method for determining loads in clothes washing machines

ActiveUS20110202303A1Low costEfficient and reliable and robustOther washing machinesDigital computer detailsEngineeringMechanical engineering

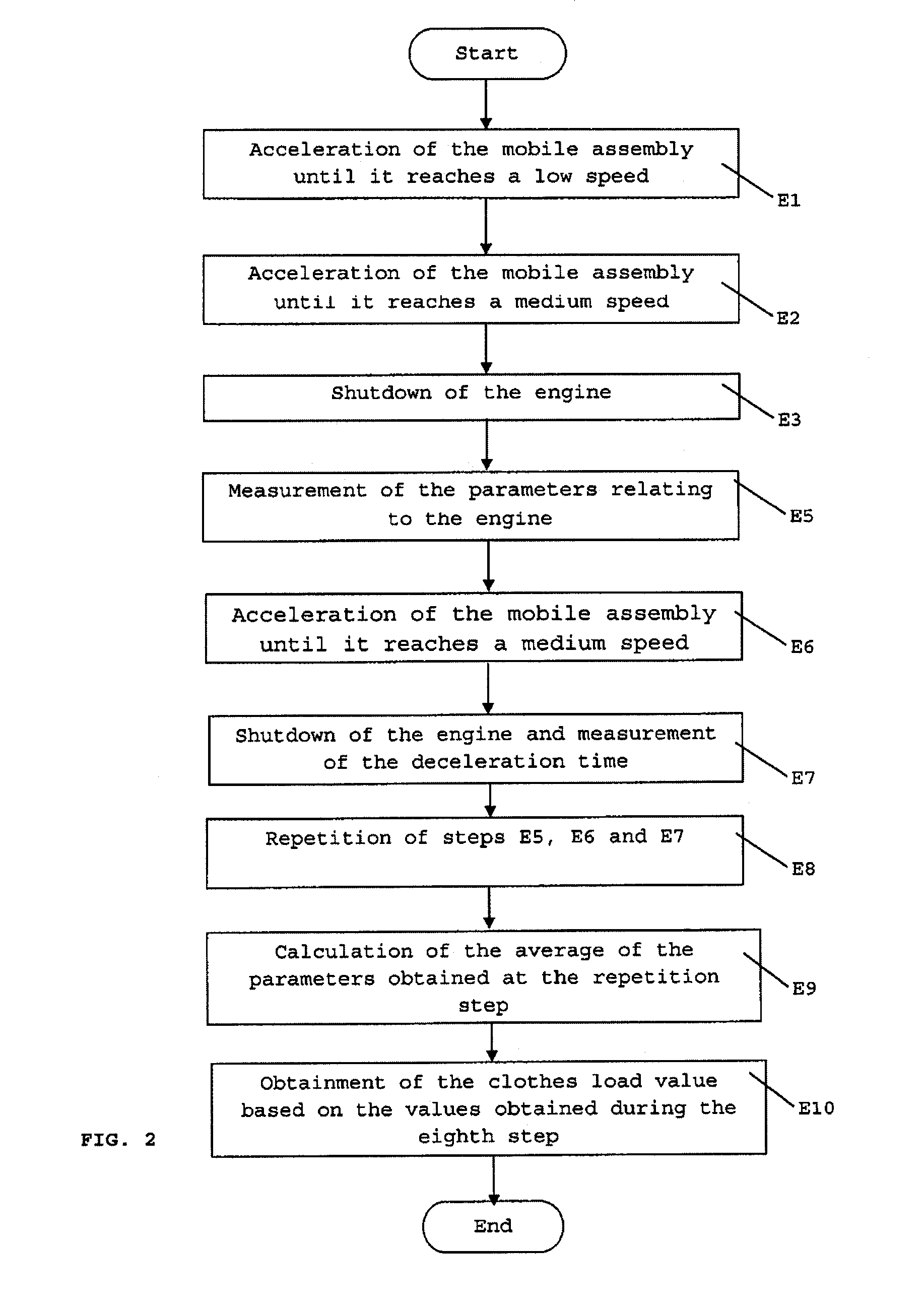

The present invention refers to a method for determining loads in clothes washing machines which comprises the following steps: method for measuring loads in clothes washing machines, characterized by comprising the following steps: (E1) Acceleration of the mobile assembly of the washing machine until the mobile assembly reaches a low rotation speed; (E2) Acceleration of the mobile assembly until the mobile assembly reaches a medium rotation speed faster than the speed in the first step (E1); (E3) Deceleration, whereby the engine which turns the mobile assembly is shutdown; (E4) Acceleration of the mobile assembly and measurement of the engine current, whereby the speed of the engine which turns the mobile assembly is increased up to a pre-determined rotation speed limit; (E5) Measurement, whereby parameters regarding the engine are measured; (E6) Shutdown of the engine and measurement of the deceleration time, whereby the said engine is turned off and turns via inertia, with the time spent from the shutdown until a pre-determined minimum speed limit is reached, being measured; (E7) Repetition, whereby the forth (E4), fifth (E5) and sixth (E6) steps are repeated at least once before the performance of the eighth step (E8); (E8) Calculation of the average of each one of the parameters measured in the fourth, fifth, sixth and seventh steps; and (E9); Obtainment of clothes load value based on the values obtained by the eighth step (E8) through the application of a neural network or from an empirical equation.

Owner:PETRONILHO ANDRE +1

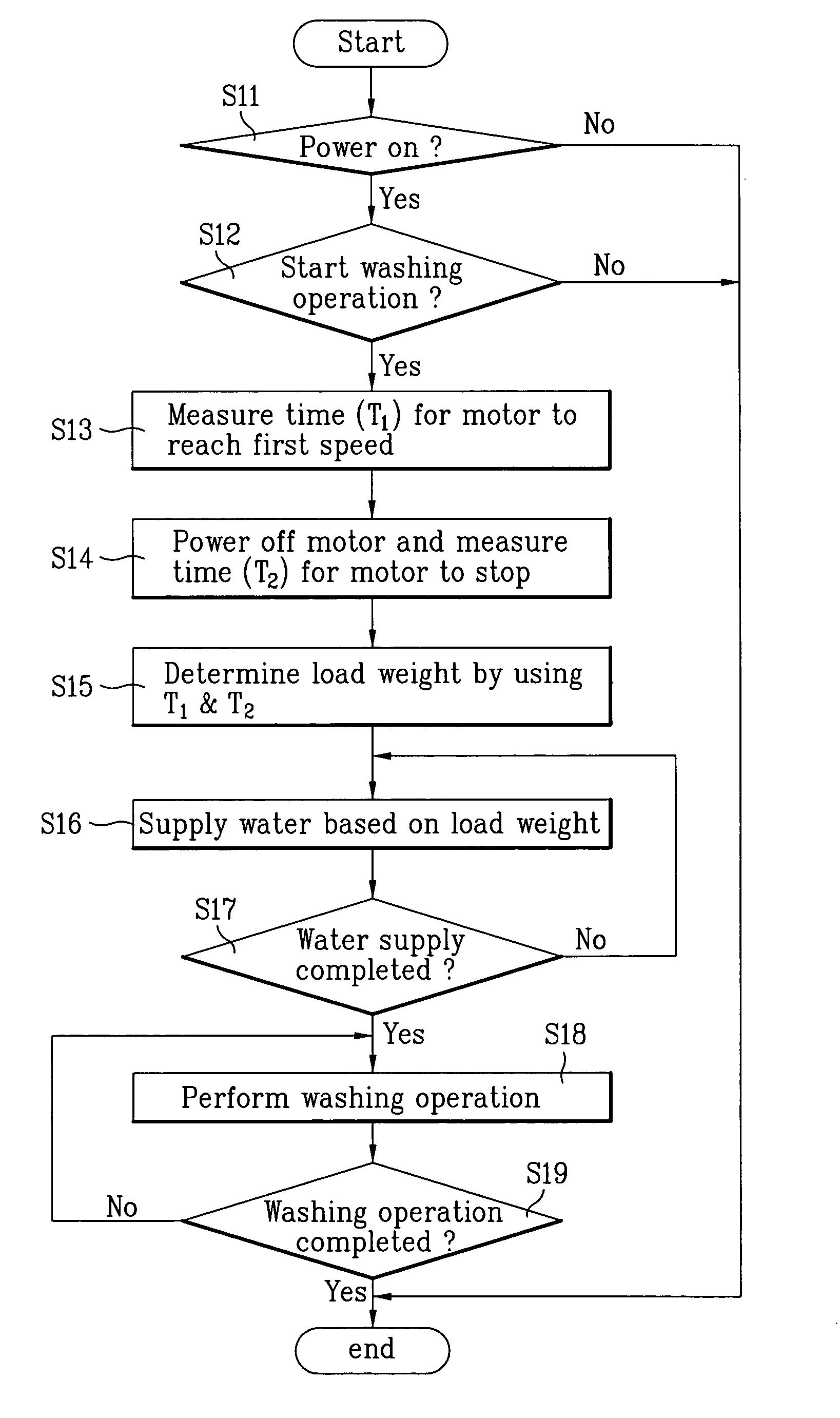

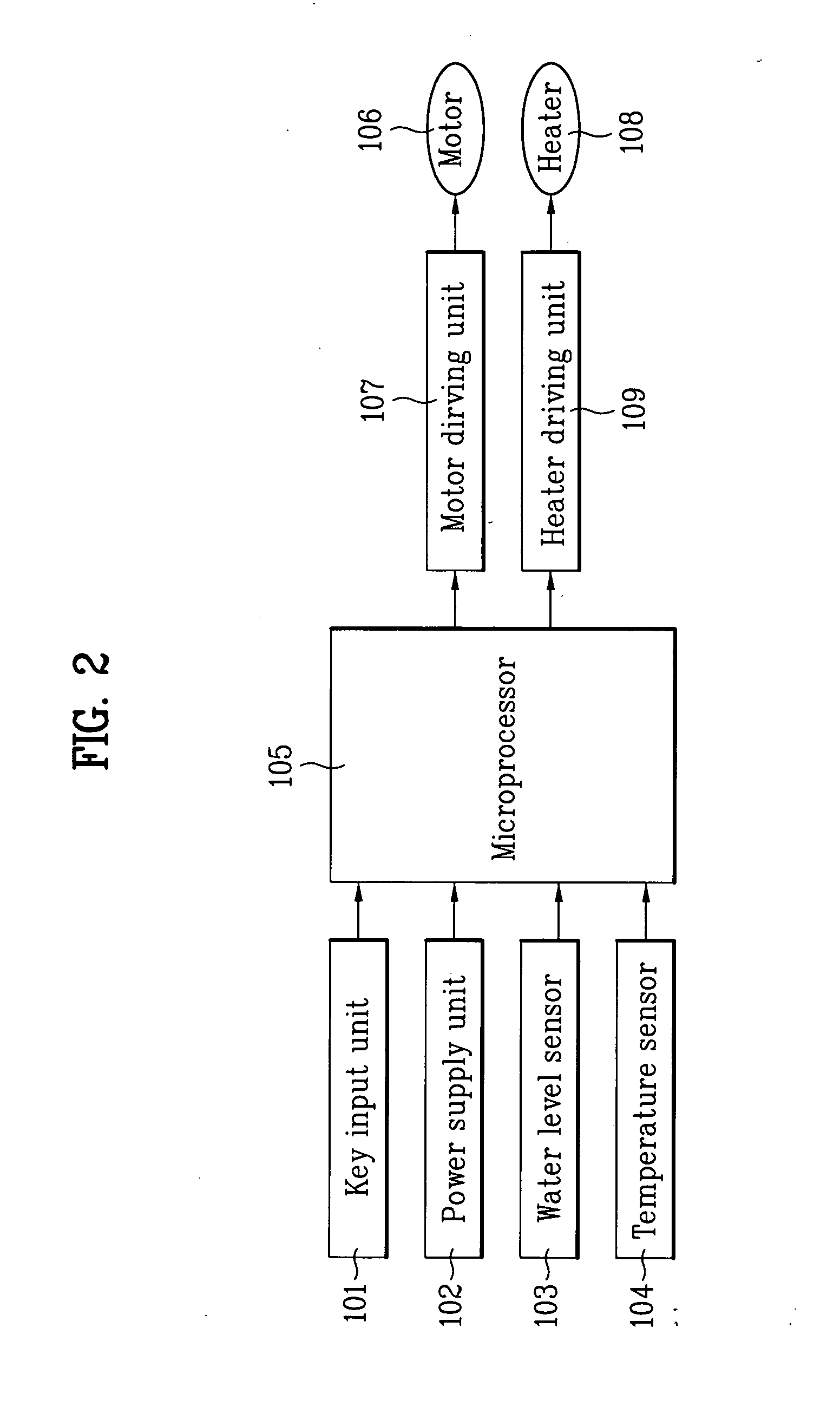

Washer and method of determining load weight for same

InactiveUS20050044641A1Accurate amount of waterImprove performanceOther washing machinesControl devices for washing apparatusEngineeringDeceleration time

A washer and a method of determining a load weight are disclosed. The washer includes a tub which stores clothes to be washed, and a motor which rotates the tub. It further includes a microprocessor which measures an acceleration time during which the motor rotates up to a certain speed, and a deceleration time during which the motor comes from another certain speed to a full stop. Then, the microprocessor determines the load weight by using at least one of the acceleration and the deceleration times.

Owner:LG ELECTRONICS INC

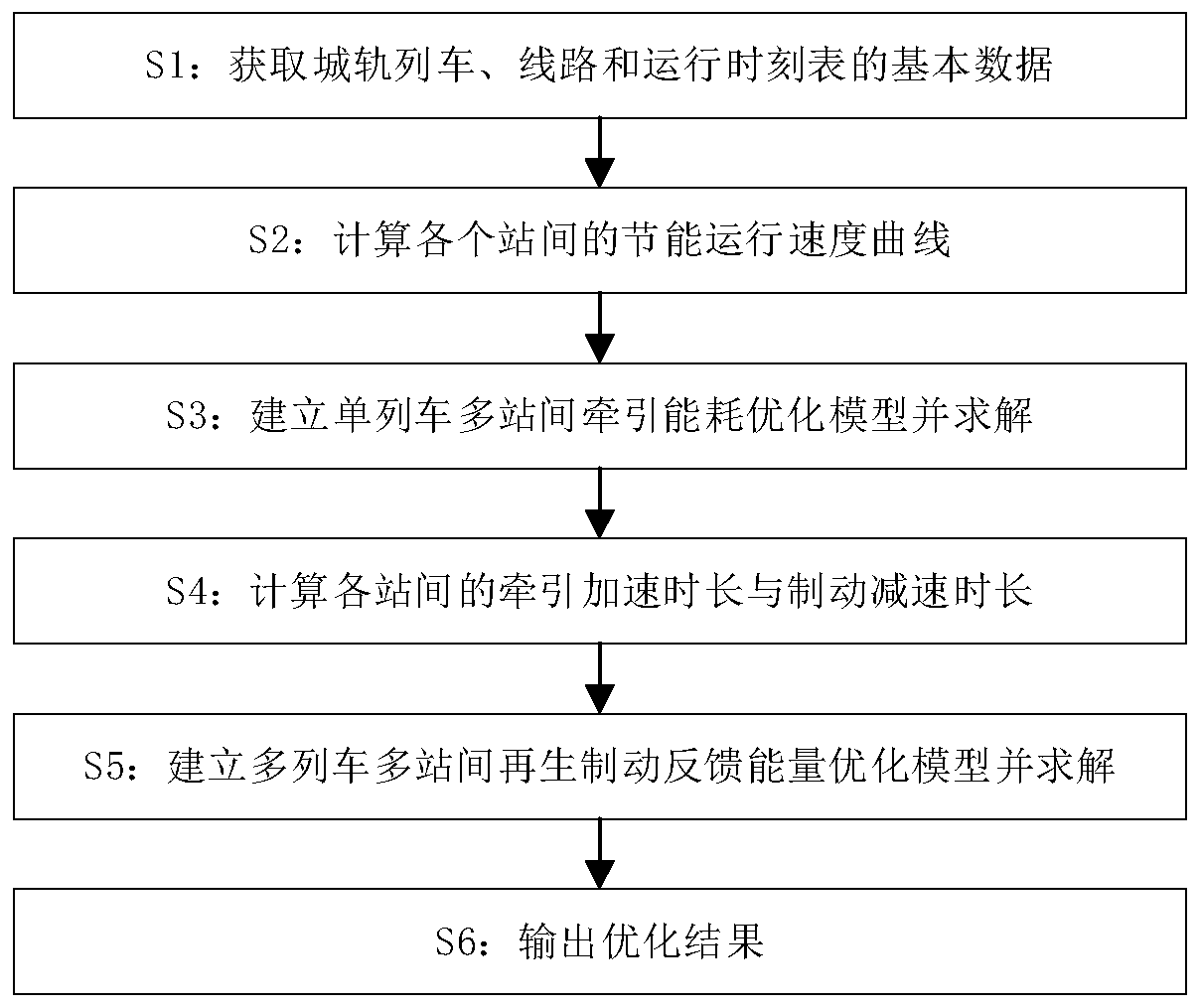

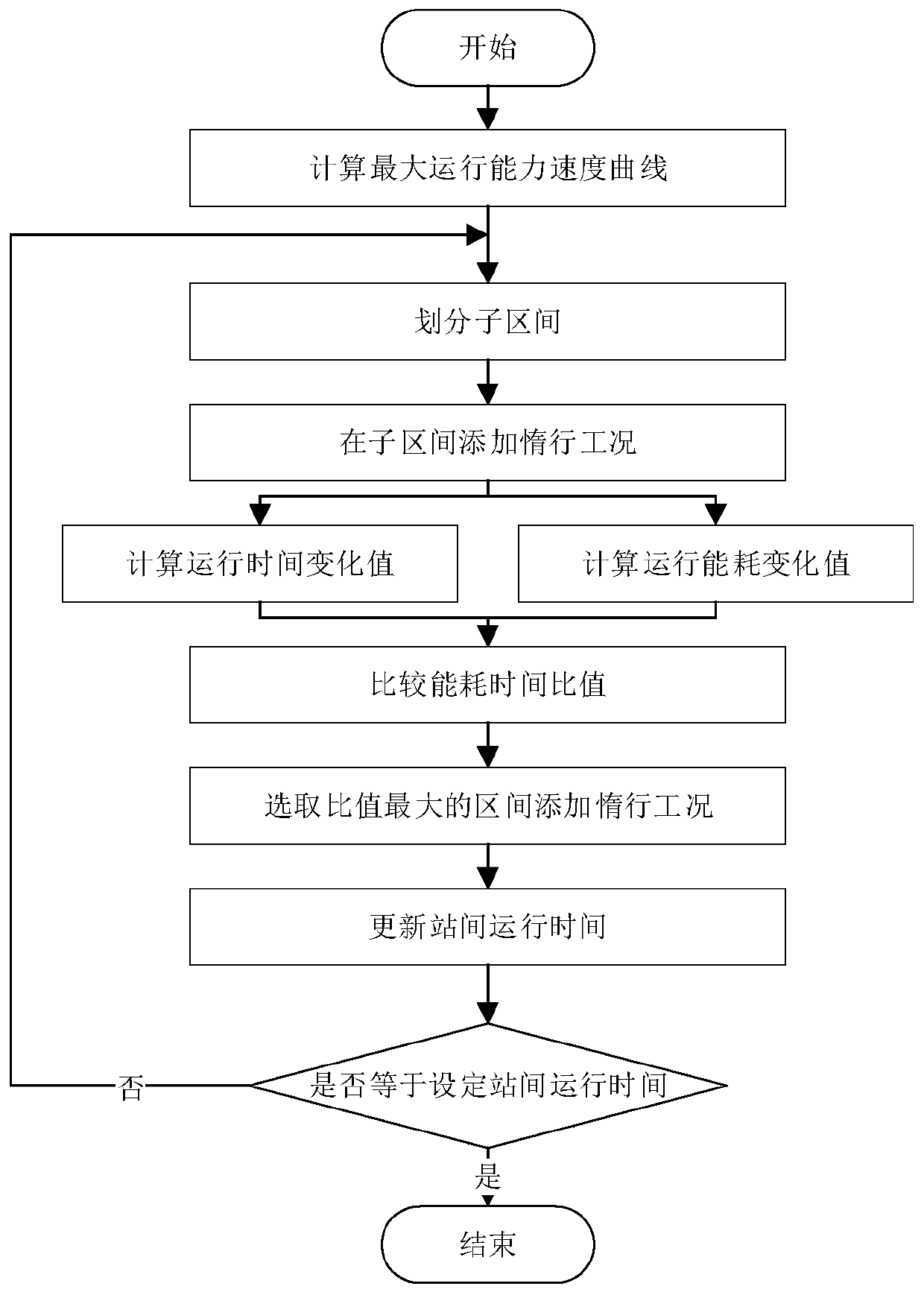

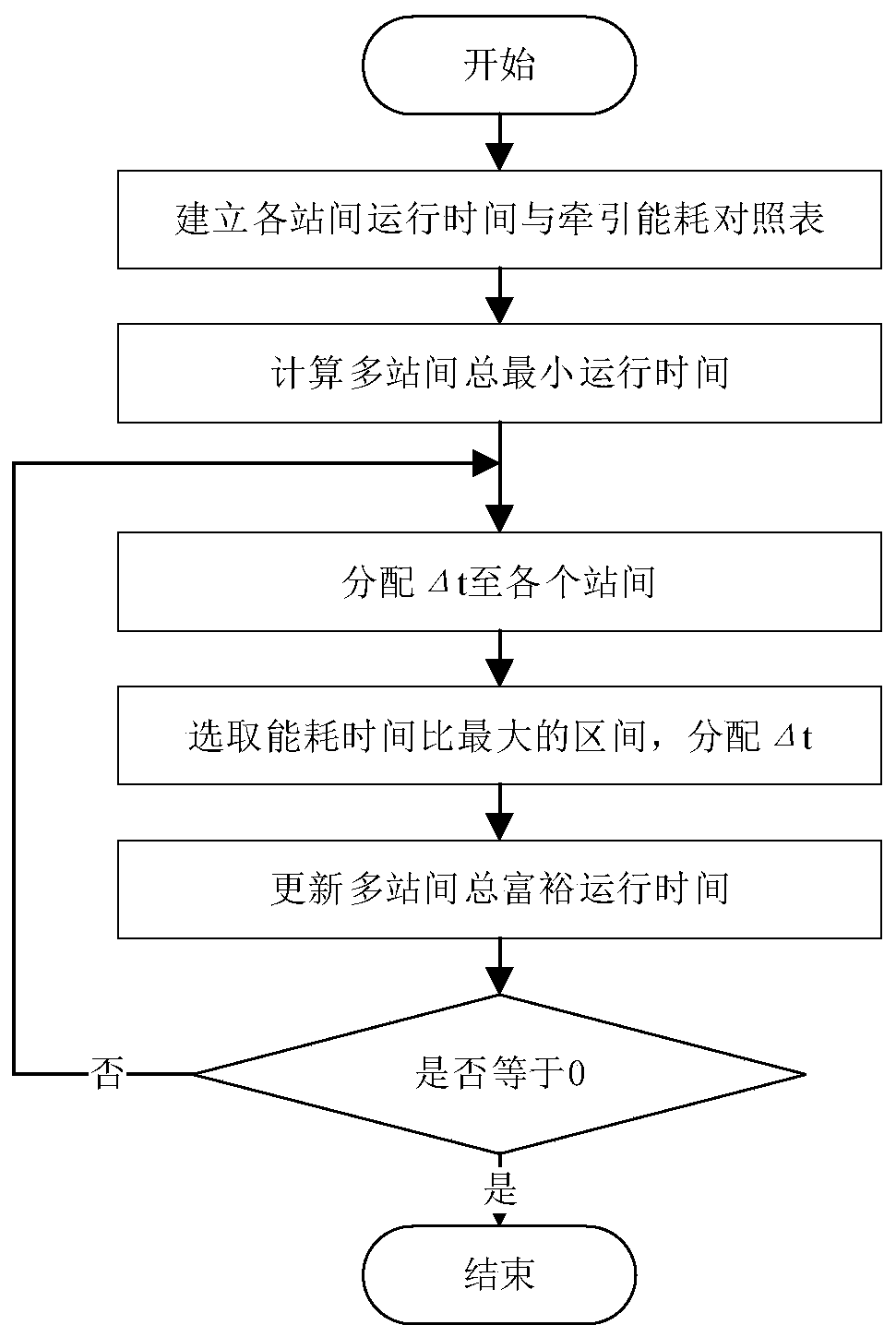

An urban rail transit energy-saving time table and an operation curve optimization method

ActiveCN109815536AShort calculation timeReduce mistakesSpecial data processing applicationsSimulationTraffic optimization

The invention relates to the technical field of urban traffic optimization, in particular to an urban rail transit energy-saving time table and an operation curve optimization method, and the method comprises the steps: S1, obtaining the basic data of an urban rail train, an urban rail line and an urban rail operation time table; S2, aiming at the operation process of a single train between singlestations, obtaining energy-saving operation speed curves of the single train between the stations at different operation times; S3, aiming at the operation process of the single train among a plurality of stations, obtaining an energy-saving interval operation time distribution scheme and a corresponding speed curve; S4, calculating the traction acceleration time length and the braking deceleration time length of each inter-station speed curve obtained in the step S3; S5, aiming at the operation process of multiple trains among multiple stations, obtaining an energy-saving departure intervaland stop time; S6, outputting an optimization result. The energy-saving operation speed curve is short in calculation time and small in error; traction energy consumption among multiple stations is reduced, and the regenerative braking feedback energy utilization rate is increased.

Owner:SOUTHWEST JIAOTONG UNIV

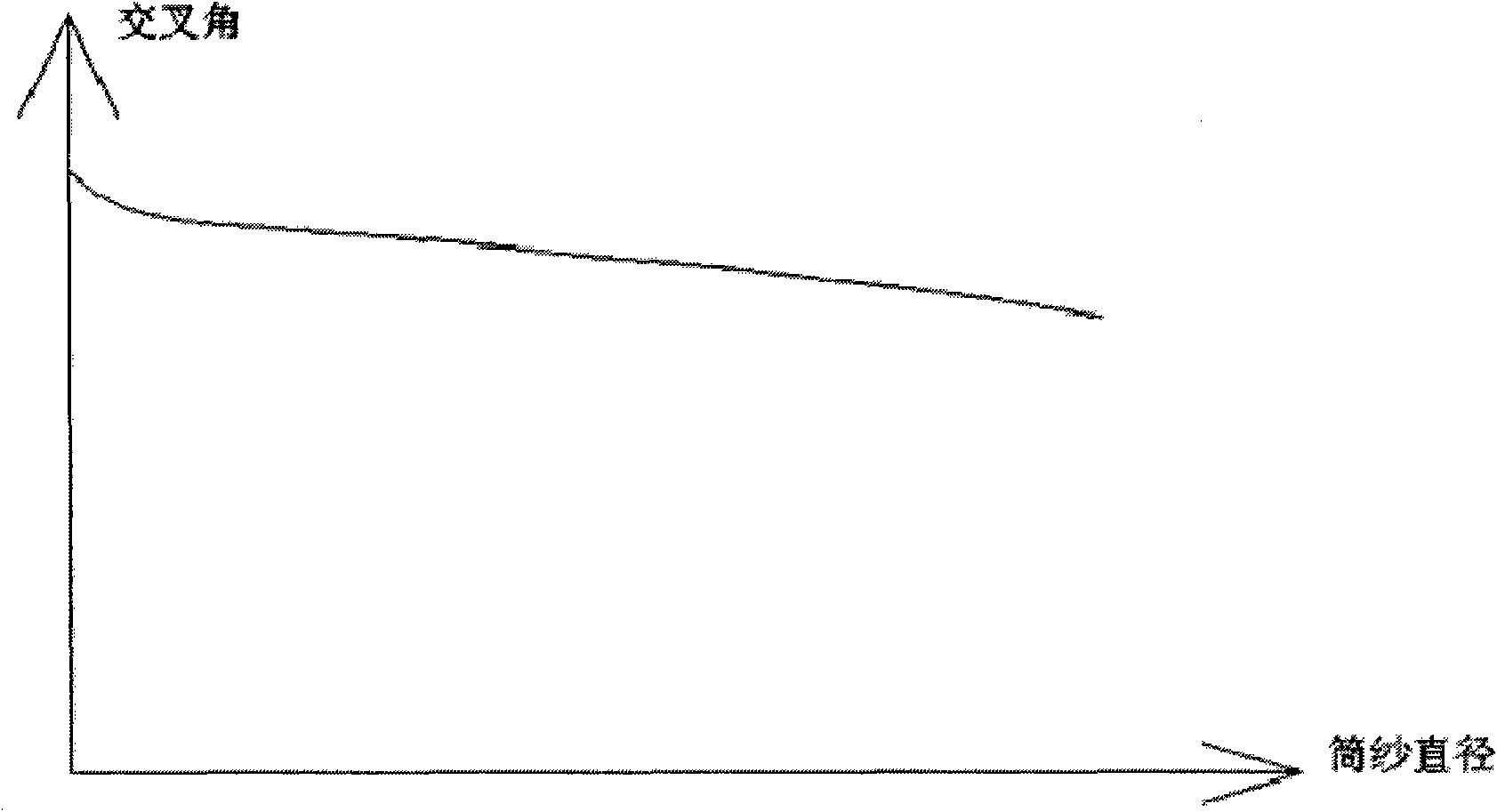

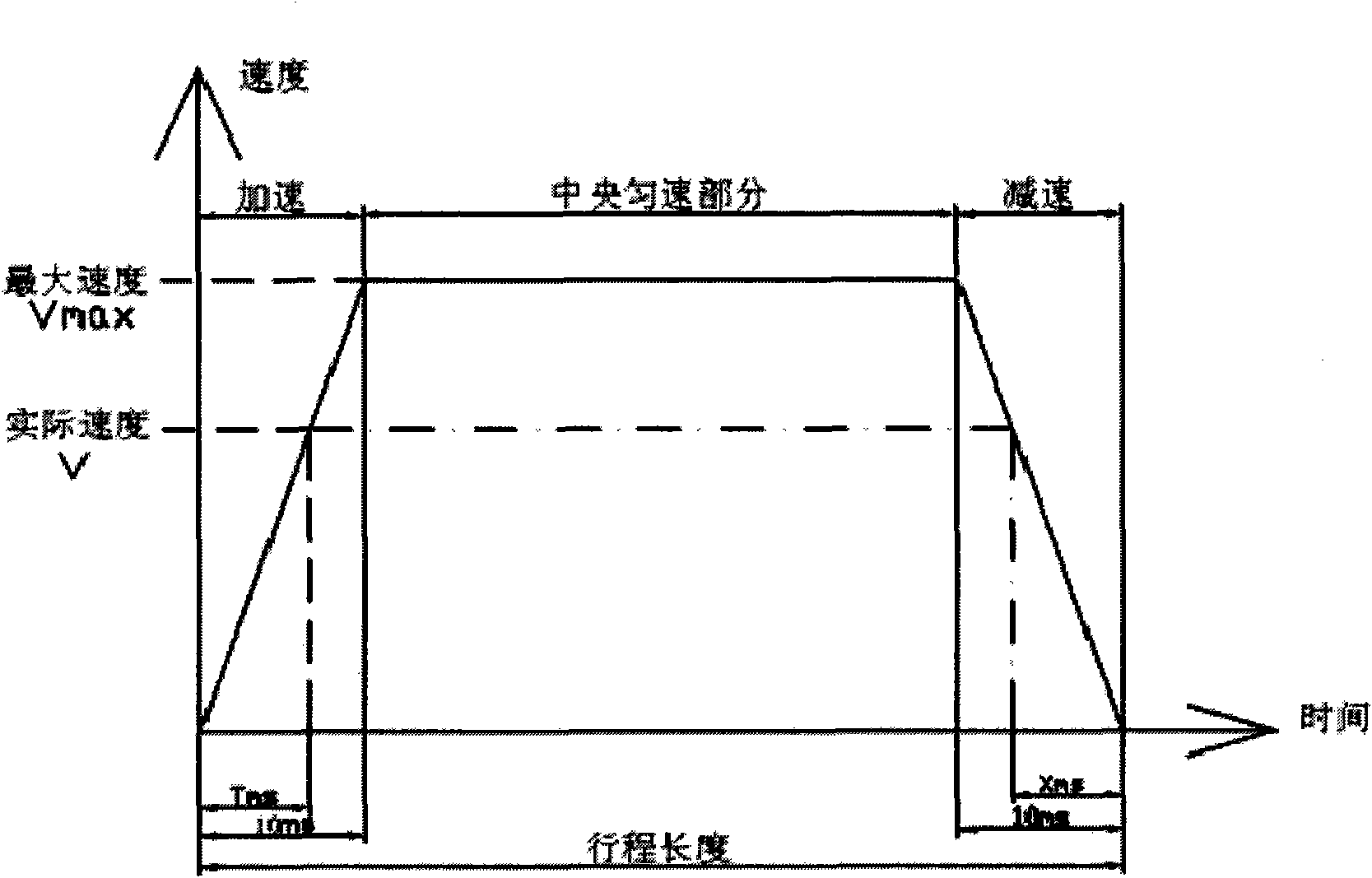

Method for winding yarns

The invention relates to a method for winding yarns. The method is implemented by a winding device, wherein the winding device drives a synchronous belt and a yarn guide connected with the synchronous belt to do transverse high-speed reciprocating motion through a control motor and drives a yarn roll to do longitudinal rotation through a winding motor; through the composition of the two motions, the yarn is wound on the surface of the yarn roll in a shape of spiral line; an acceleration time and a deceleration time of the control motor moving on the end part are set according to the diameter of the yarn roll at the end part of the yarn roll; and according to the acceleration time and the deceleration time, the speed of the yarn guide is controlled on the end part of the yarn roll so as to make the acceleration of the yarn guide constant and effectively avoid doffing.

Owner:WUXI HONGYUAN ELECTROMECHANICAL TECH

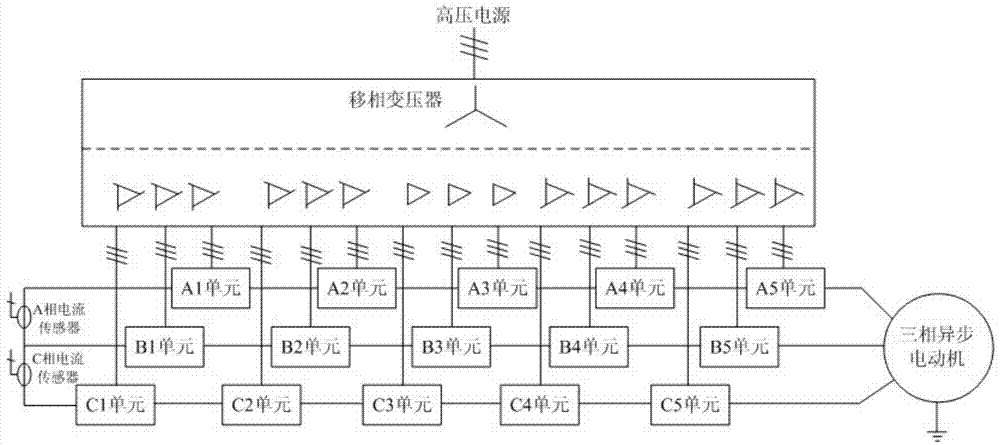

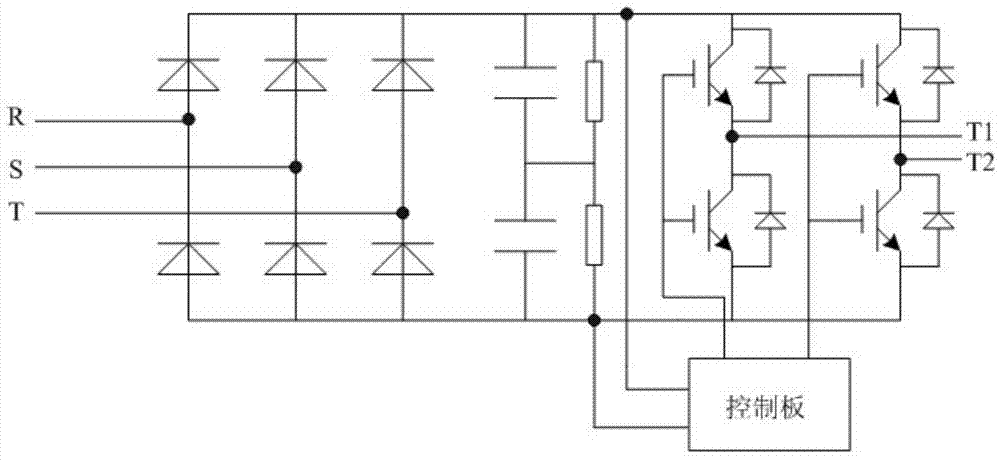

High-voltage frequency converter braking deceleration protection system and method

ActiveCN103501135ALow costPrevent overpressureMotor/generator/converter stoppersDynamo-electric converter controlConnection typeEngineering

The invention provides a high-voltage frequency converter braking deceleration protection system. A high-voltage frequency converter adopts a power unit serial connection type structure, and comprises a voltage sampling unit, a differential voltage calculation unit and a first self regulating controller, wherein the voltage sampling unit is used for sampling the direct current bus voltage of all power units of the high-voltage frequency converter, the differential voltage calculation unit is used for calculating the variation value of the direct current bus voltage, and the first self regulating controller is used for making the high-voltage frequency converter stop outputting braking voltage to an electric motor when the variation value of the direct current bus voltage exceeds the first threshold. The invention also provides a corresponding method. The deceleration time and / or the output torque upper limit of a speed regulator is automatically regulated according to the variation value of the direct current bus voltage change value of the power unit during the braking operation of the high-voltage frequency converter, the over voltage of the power unit can be avoided without the additional addition of circuits, and the cost of the high-voltage frequency converter is reduced.

Owner:SUZHOU INOVANCE CONTROL TECH CO LTD

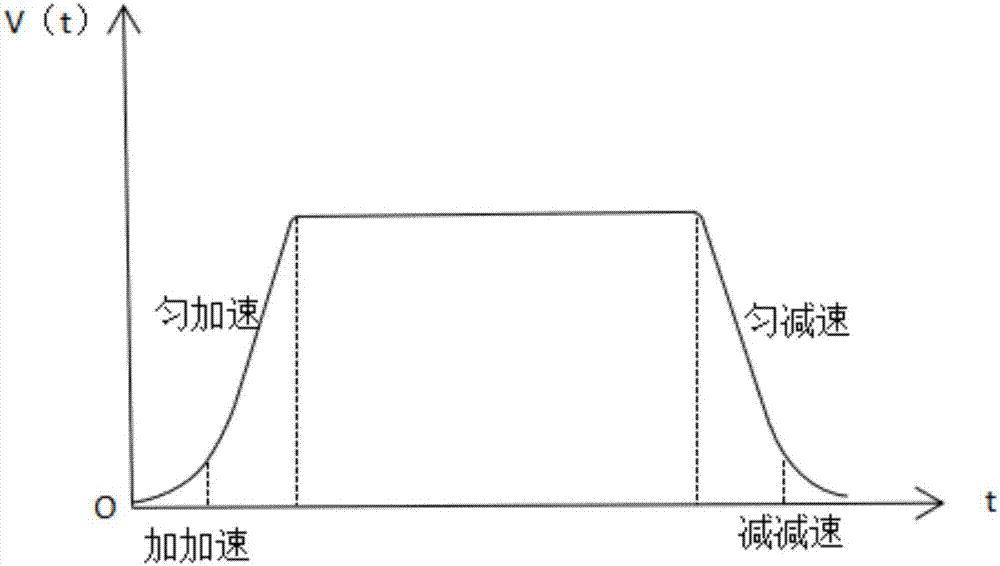

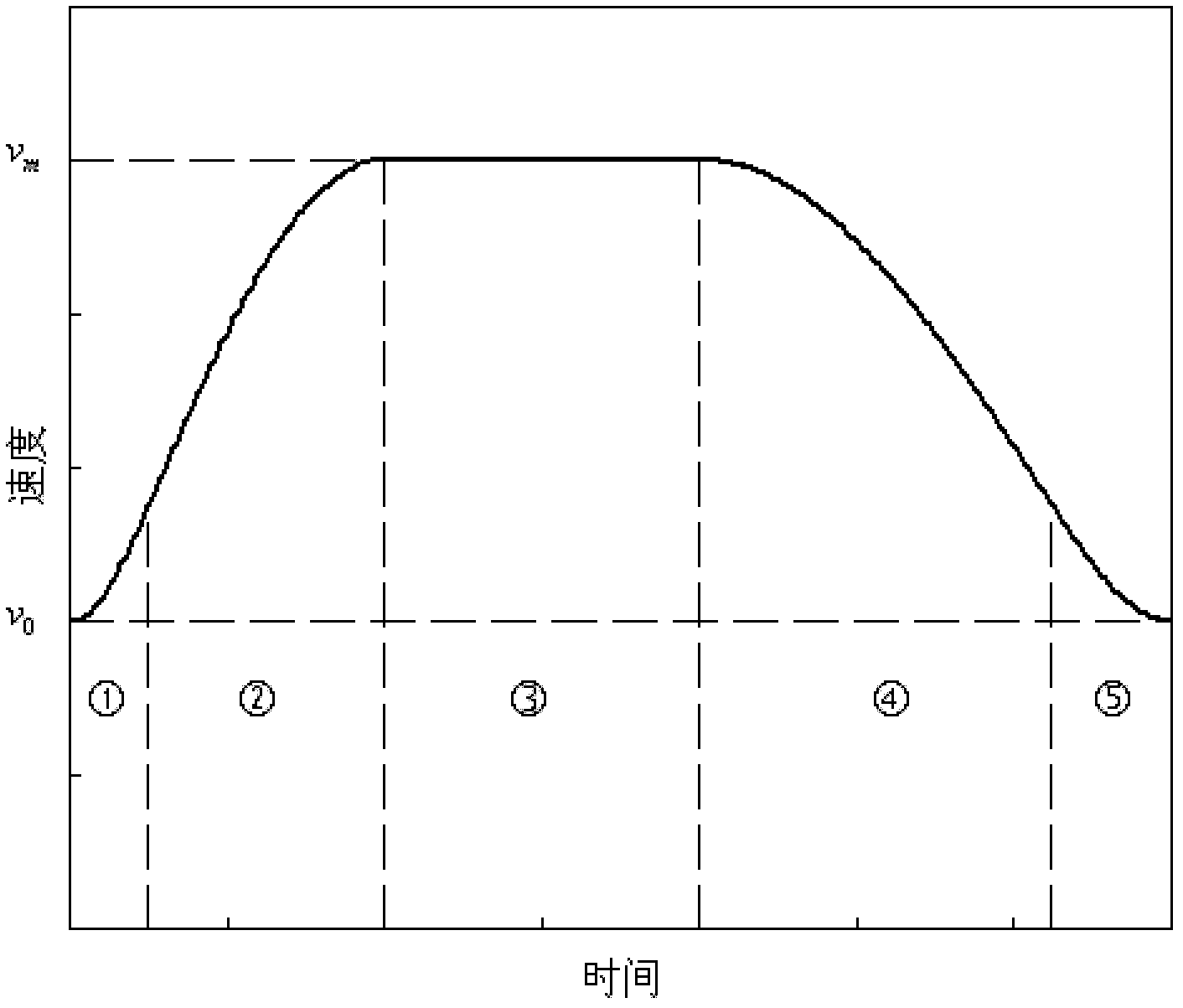

Speed planning method of cutting machine

ActiveCN107505918AAcceleration and deceleration time is shortGuaranteed uptimeNumerical controlAngular velocityEngineering

The invention discloses a speed planning method of a cutting machine. The speed planning method comprises the steps of: 1) determining a corresponding ladder step length table by adopting an S-like five-stage acceleration and deceleration control method; 2) implementing variable acceleration by determining relations among an inflection point speed, a corner size and an acceleration, and adjusting the acceleration according to a current real-time speed when passing through different corners of a track; 3) calculating a self-adaptive inflection point speed, and determining a final corner speed according to an angular velocity solution formula and a speed reverse derivation method. The speed planning method of the cutting machine provided by the invention effectively shortens the motion acceleration and deceleration time and increases the corner speed in the cutting process.

Owner:宁波永石精密工具有限公司

Method for determining loads in clothes washing machines

ActiveUS8489358B2Low costEfficient and reliable and robustAverage speed measurementOther washing machinesEngineeringMechanical engineering

The present invention refers to a method for determining loads in clothes washing machines which comprises the following steps: (E1) Acceleration of the mobile assembly of the washing machine until the mobile assembly reaches a low rotation speed; (E2) Acceleration of the mobile assembly until the mobile assembly reaches a medium rotation speed faster than the speed in the first step (E1); (E3) Deceleration; (E4) Acceleration of the mobile assembly and measurement of the engine current; (E5) Measurement, whereby parameters regarding the engine are measured; (E6) Shutdown of the engine and measurement of the deceleration time; (E7) Repetition, whereby the forth (E4), fifth (E5) and sixth (E6) steps are repeated at least once before the performance of the eighth step (E8); (E8) Calculation of the average of each one of the parameters measured in the fourth, fifth, sixth and seventh steps; and (E9) Obtainment of clothes load value.

Owner:PETRONILHO ANDRE +1

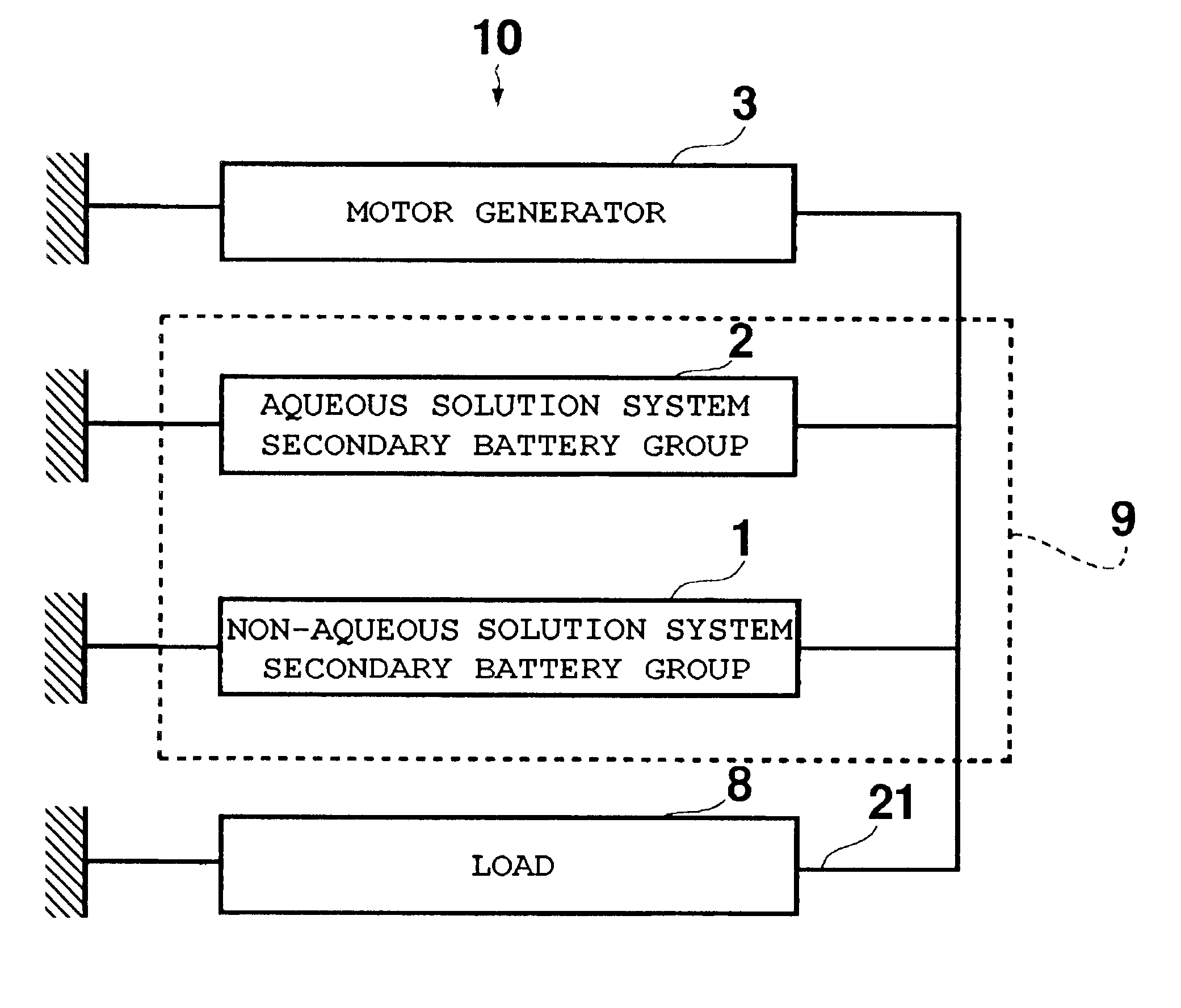

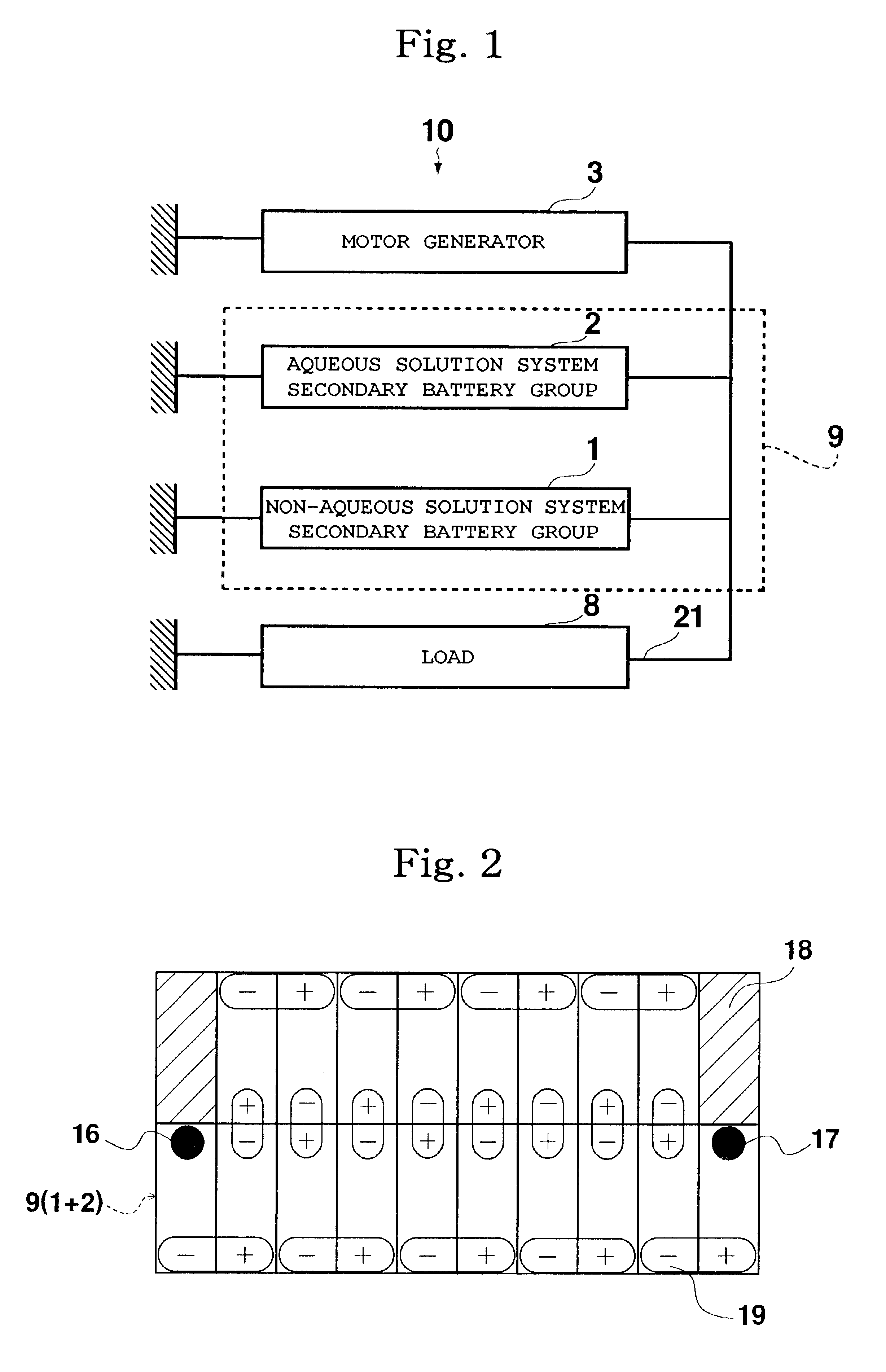

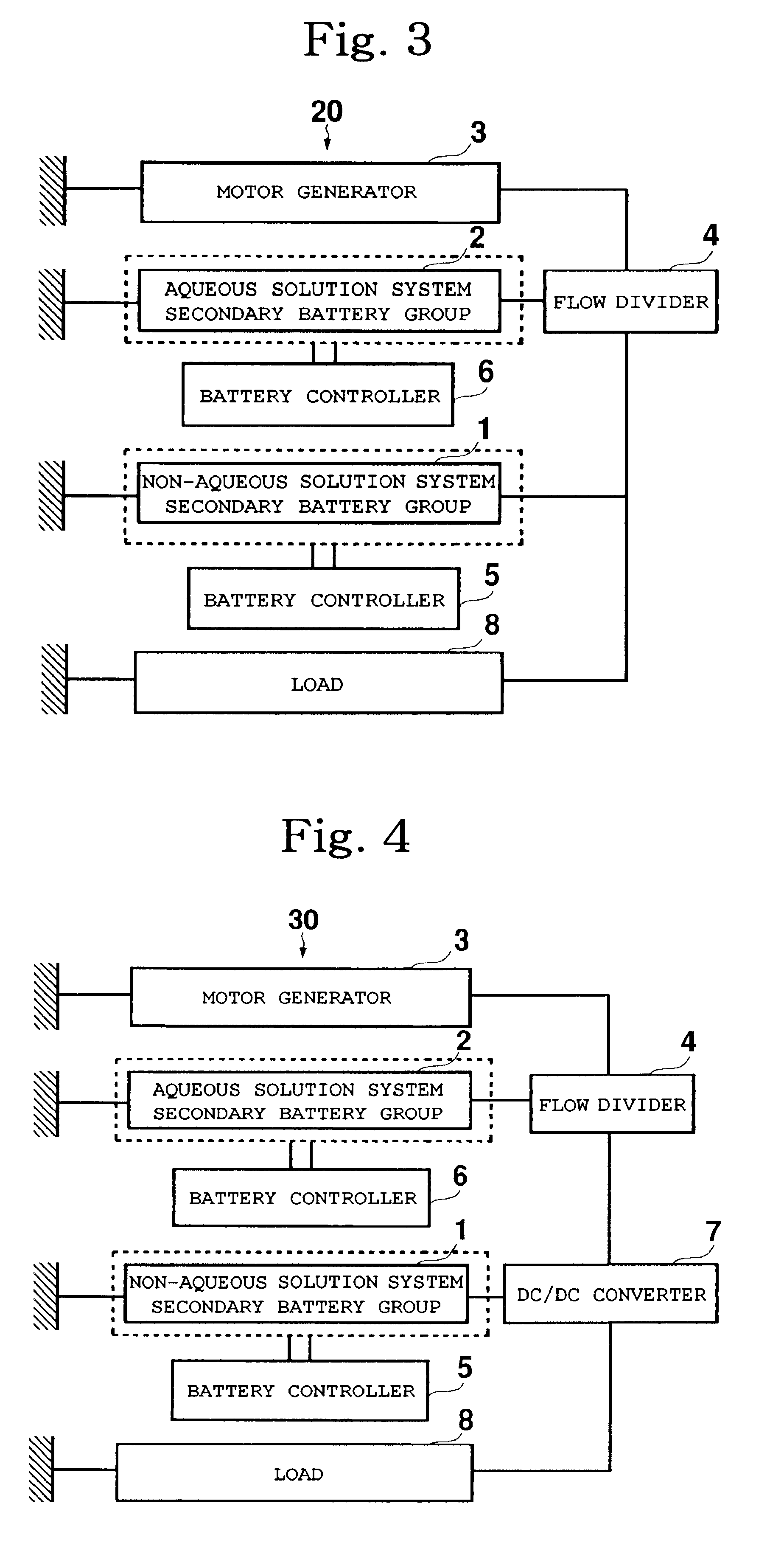

Power supply system and state of charge estimating method

InactiveUS6366055B1Batteries circuit arrangementsFinal product manufactureElectric power systemElectrical battery

A power system where energy generated at a deceleration time of a running vehicle such as an automobile can be accepted as regenerative energy sufficiently and safely is provided. In a power system 10, a non-aqueous solution system secondary battery group 1 where 10 to 11 lithium ion secondary battery cells are connected in series and an aqueous solution system secondary battery group 2 where 18 control valve type lead-acid battery cells are connected in series are connected in parallel. The battery capacity of the non-aqueous solution system secondary battery group 1 is smaller than that of the aqueous solution system secondary battery group 2. The non-aqueous solution system secondary battery group 1 and the aqueous solution system secondary battery group 2 are charged at a current value of 7C or less from a motor generator 3, and the ratio of the charged current value of the aqueous solution system secondary battery group 2 to the charged current value of the non-aqueous solution system secondary battery group 1 is 0.05 to 1.00.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

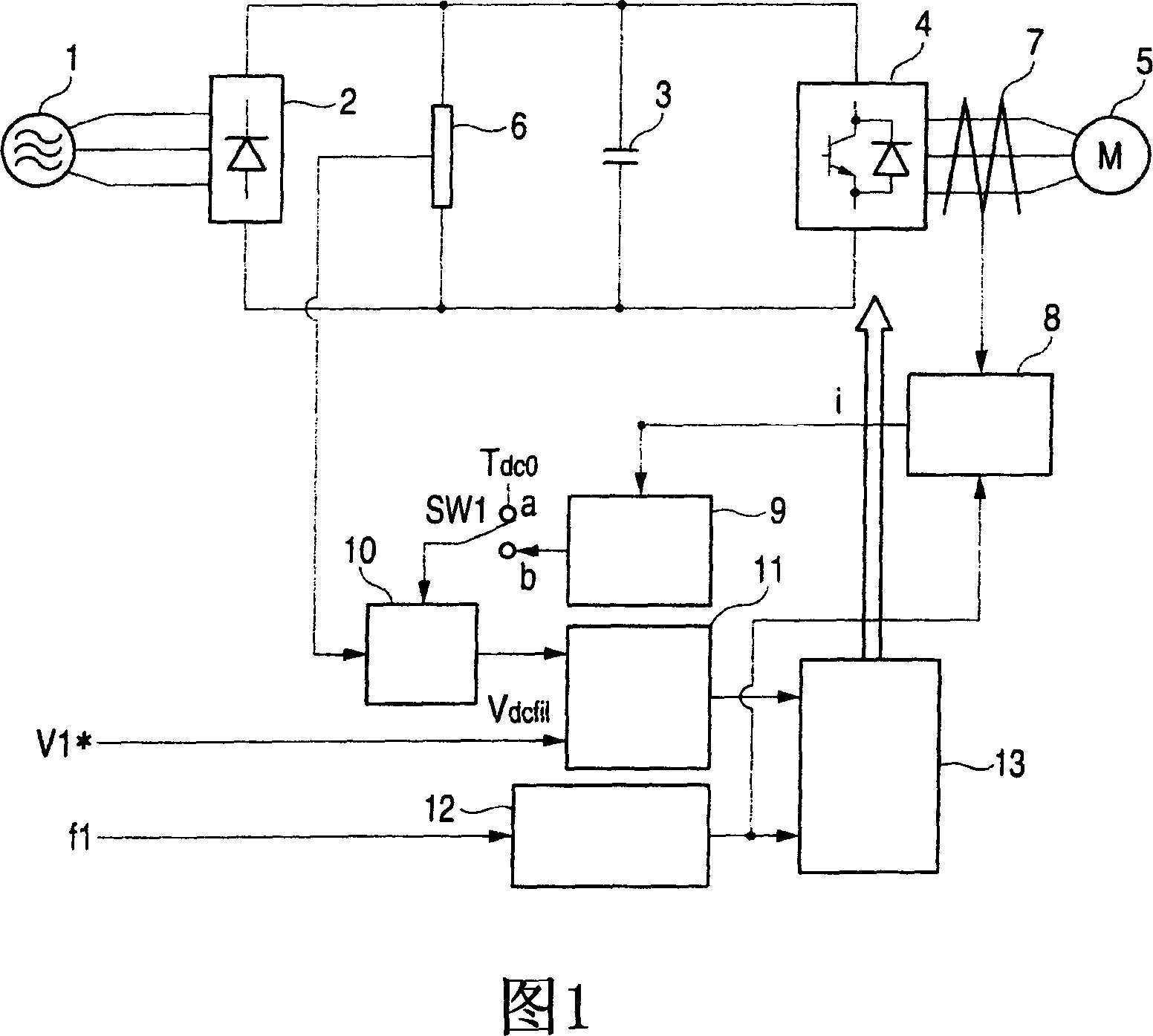

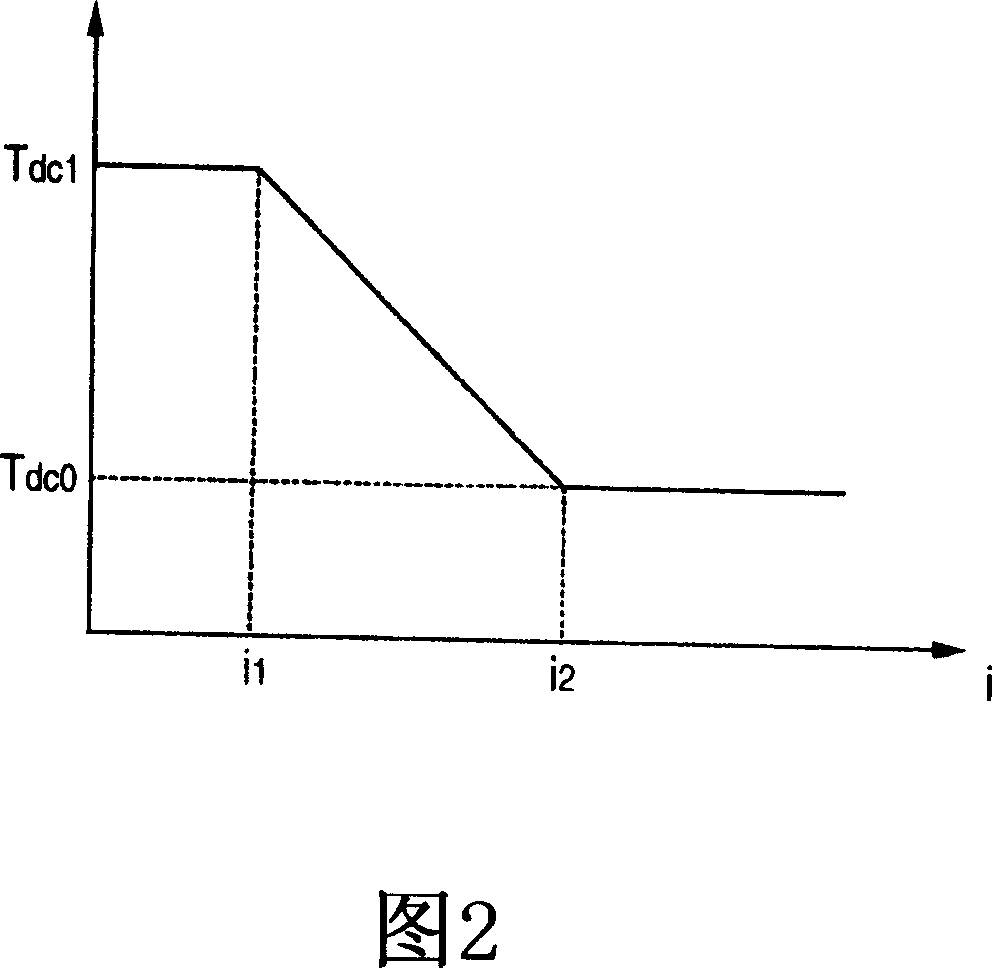

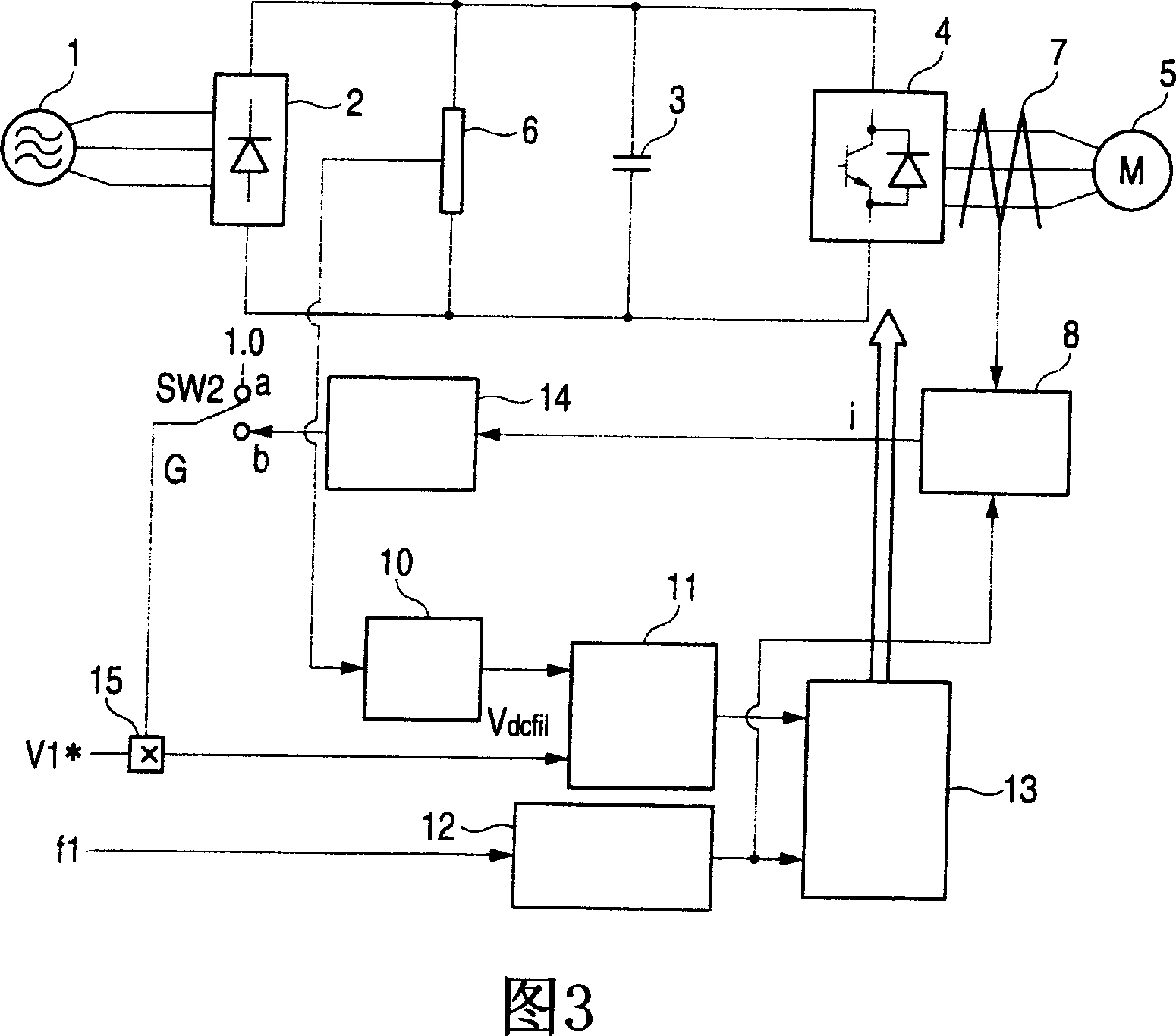

Ac motor decelerating method and inverter device

ActiveCN1961475ADecelerate fastElectronic commutation motor controlMotor/generator/converter stoppersVoltage inverterOvercurrent

An AC motor can be decelerated in as a short time as possible by means of an inverter and the current is controlled below a predetermined value so that the inverter does not stop because of an overcurrent or the AC motor does not fail due to burnout even if the AC motor is liable to be magnetically saturated. A method and device for driving an AC motor by means of a voltage inverter having therein a voltage correcting section for correcting a given voltage command by using the value obtained by passing a DC bus voltage detected value through a primary delay filter. The AC motor is decelerated in an overexcited state by increasing the time constant of the primary delay filter above the time constant in the normal control state. The current flowing through the AC motor is monitored and the time constant is adjusted according to the current flowing through the AC motor. Therefore, the AC motor is decelerated without causing a failure and the deceleration time can be shortened.

Owner:YASKAWA DENKI KK

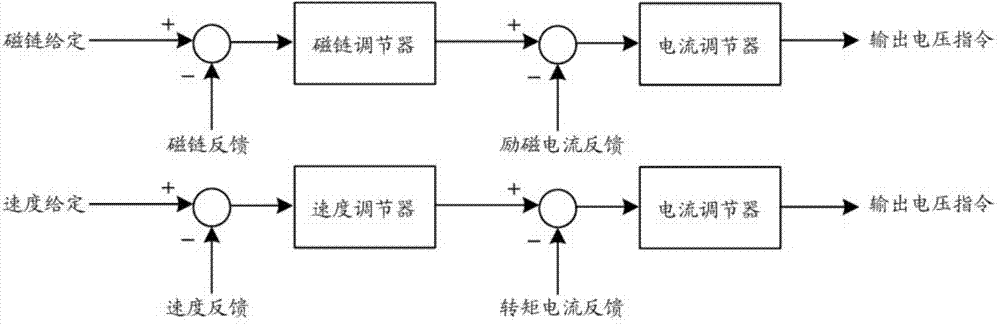

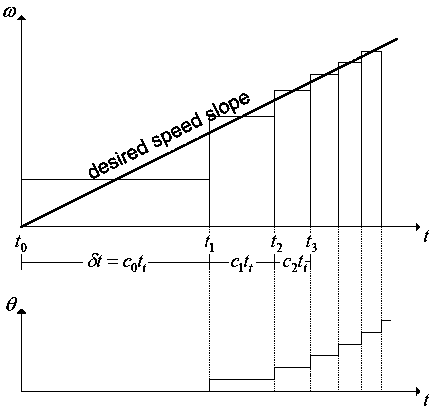

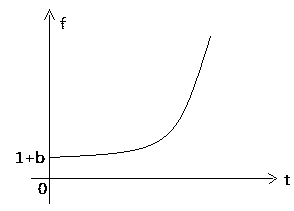

Servo-motor acceleration-deceleration control method for servo pressure machine

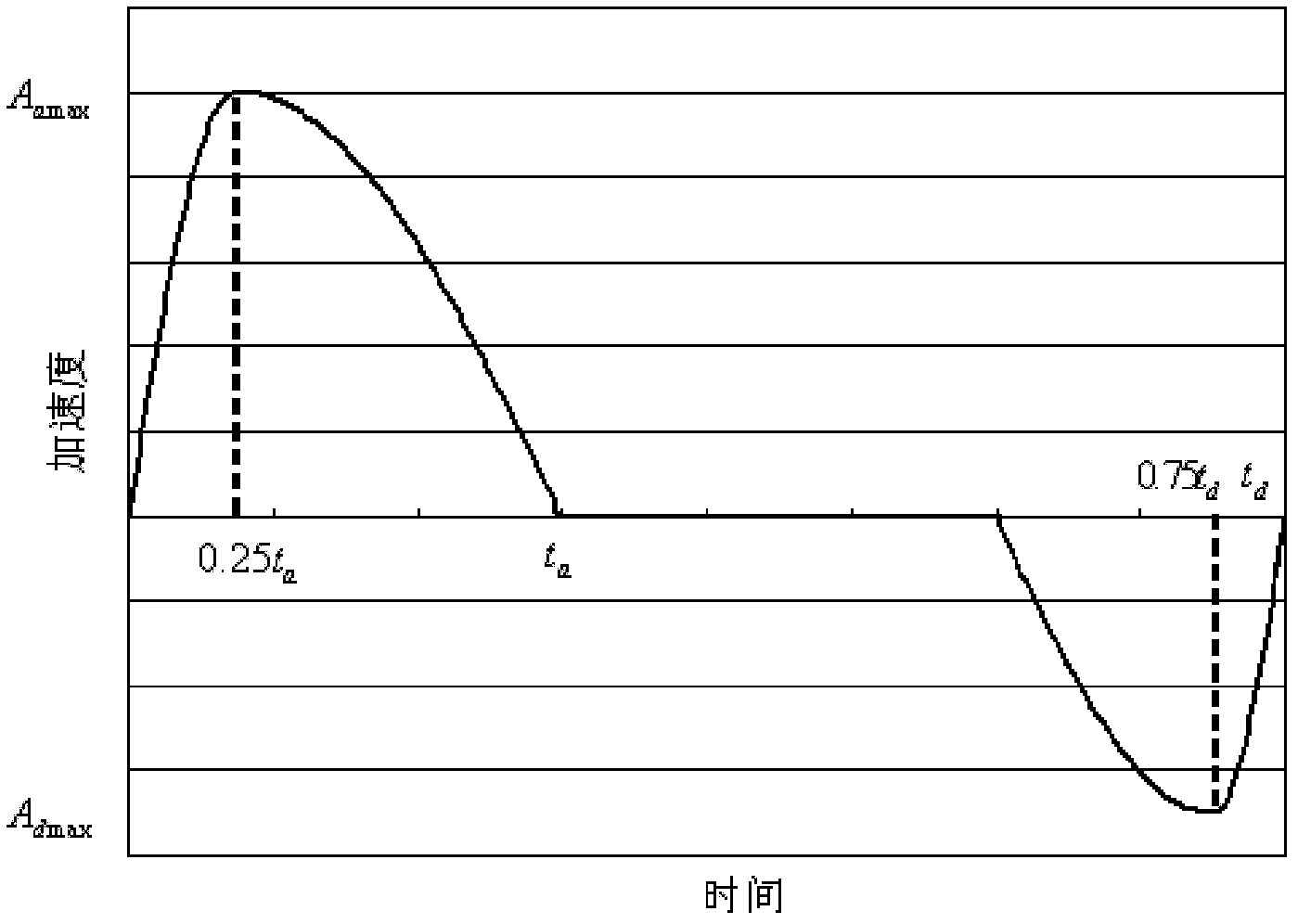

ActiveCN102522944AContinuous changeAvoid Flex ShockElectronic commutation motor controlElectric motor controlTriangular functionAcceleration deceleration

The invention discloses a servo-motor acceleration-deceleration control method for a servo pressure machine, comprising the following steps of: constructing an acceleration function of a servo motor at an acceleration stage; establishing a speed expression of the servo motor at the acceleration stage; establishing a rotary displacement expression of the servo motor at the acceleration stage; constructing an acceleration function of the servo motor at a deceleration stage; establishing a speed expression of the servo motor at the deceleration stage; establishing a rotary displacement expression of the servo motor at the deceleration stage; and determining total acceleration time and total deceleration time. According to the servo-motor acceleration-deceleration control method, two triangular functions with different periods are adopted as acceleration-deceleration constructed functions of the servo motor, so that the change of the speed, the acceleration and the accelerated acceleration is continuous, the soft shock of the acceleration-deceleration process on the machine body is avoided, the operation stability of the pressure machine is improved and the softness of acceleration-deceleration control of the pressure machine is higher; and by full utilization of the constant and maximum output torque of the server motor under the rated rotating speed, the operation period of the servo pressure machine can be shortened and the takt time of stamping production is improved.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

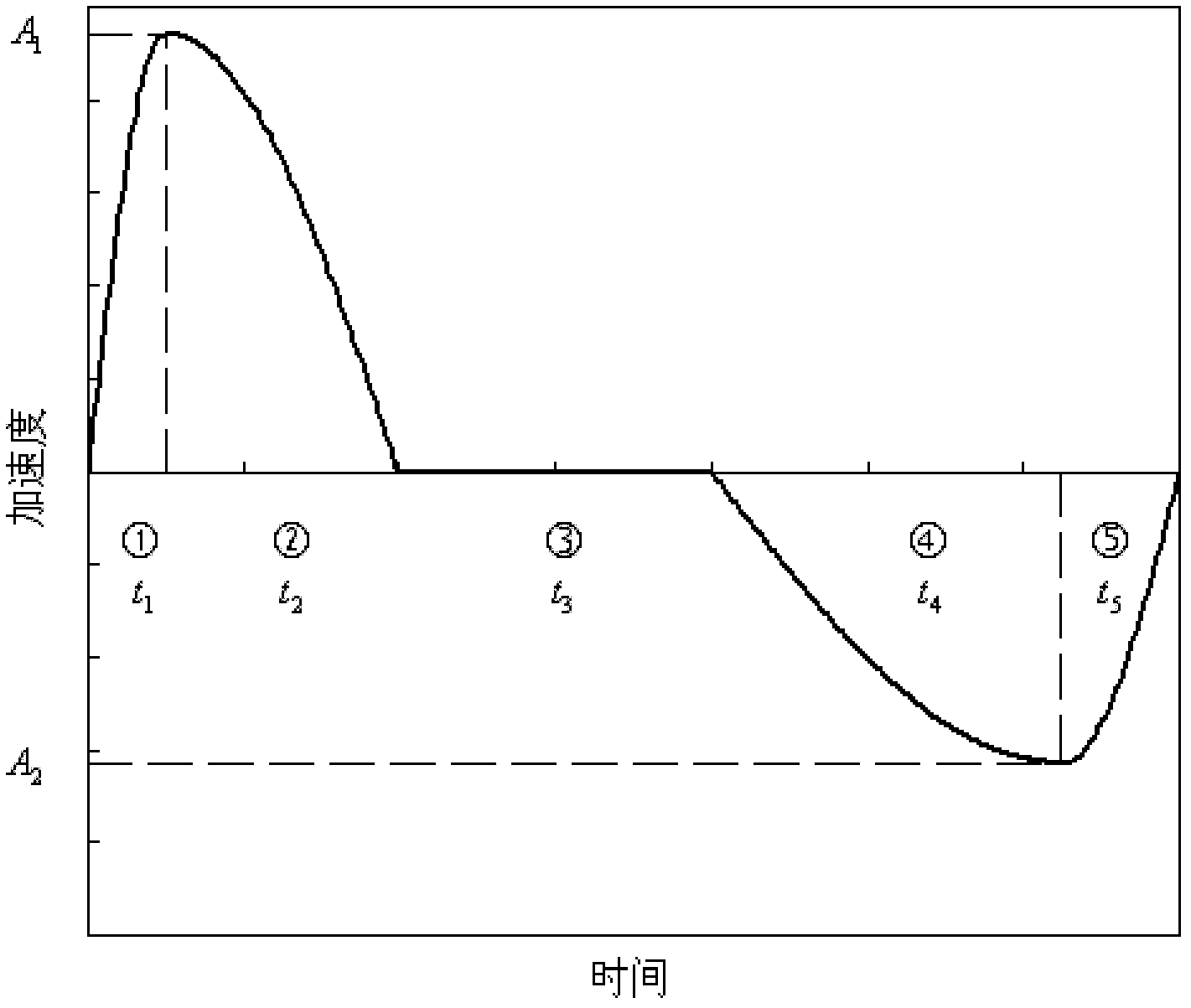

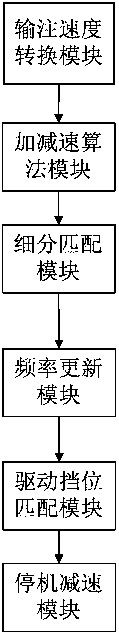

Infusion control method and device with stepping motor

ActiveCN109981008AReduce vibrationReduce noiseElectric motor controlDynamo-electric converter controlStep numberEngineering

The invention relates to an infusion control method with a stepping motor. The method comprises the following steps: the time, the step number and the smoothness required in a process of switching a current speed of the stepping motor to a target speed are assessed; then different acceleration and deceleration sections are divided according to an assessment result; and then acceleration and deceleration algorithms corresponding to the acceleration sections are selected to calculate out driving pulse frequencies corresponding to the acceleration sections. By dividing the different accelerationand deceleration sections, the balance of the acceleration and deceleration smoothness and the minimum acceleration and deceleration time / step number can be realized. For the same speed, the vibrationand noise of the motor can be effectively reduced by adopting an optimal subdivision ratio, so that the infusion precision is improved.

Owner:广州富瑞价值医疗健康产业有限公司

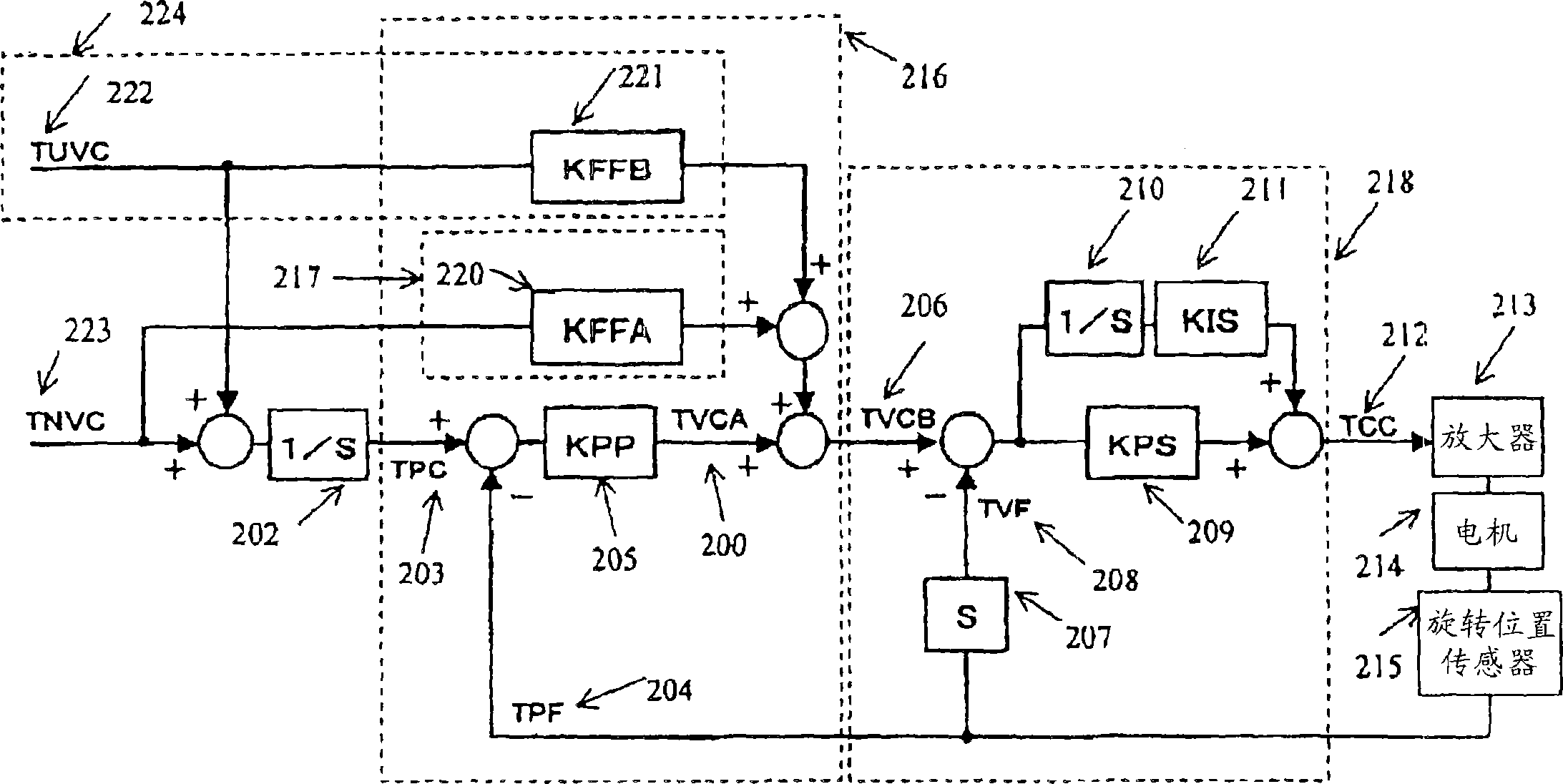

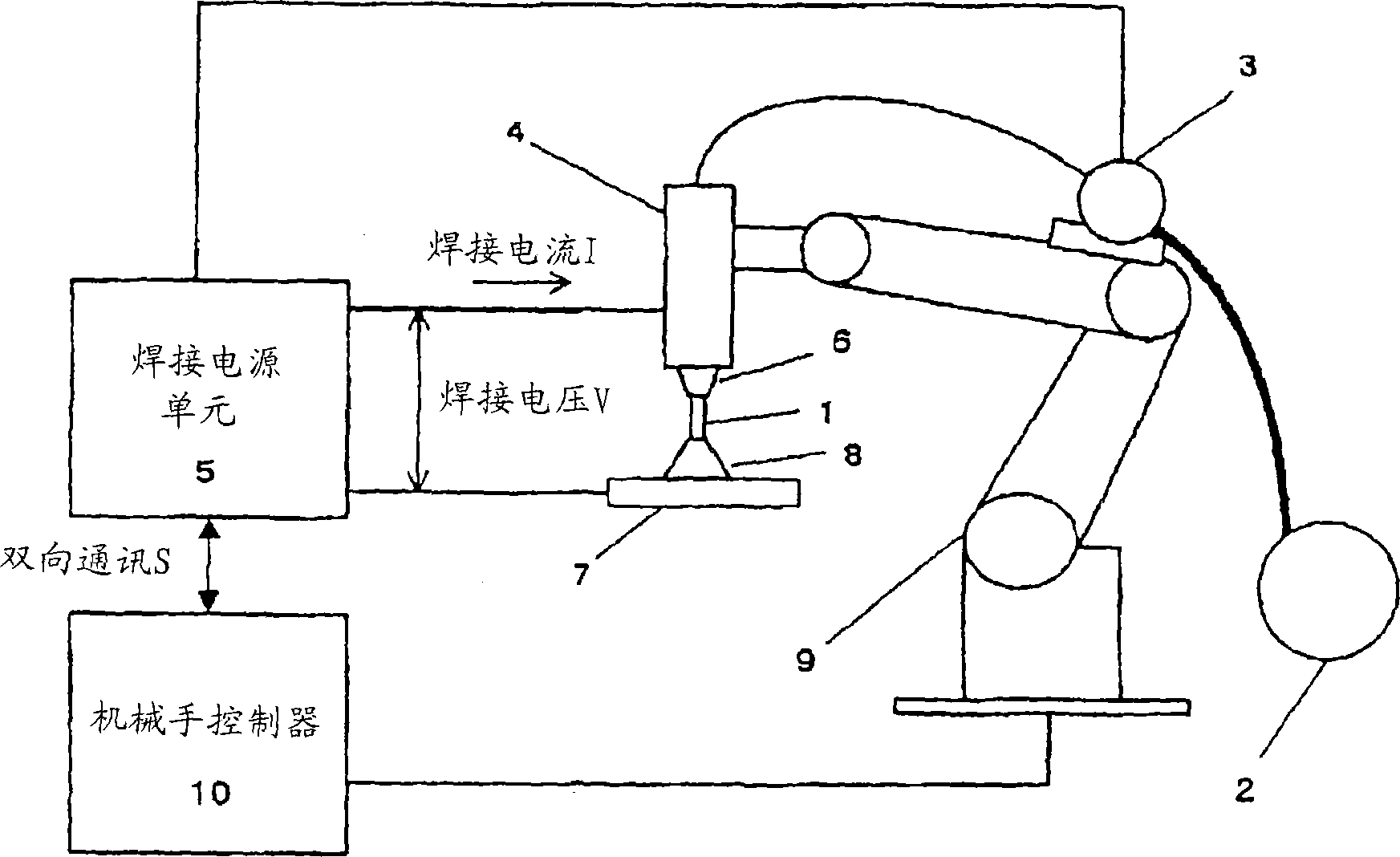

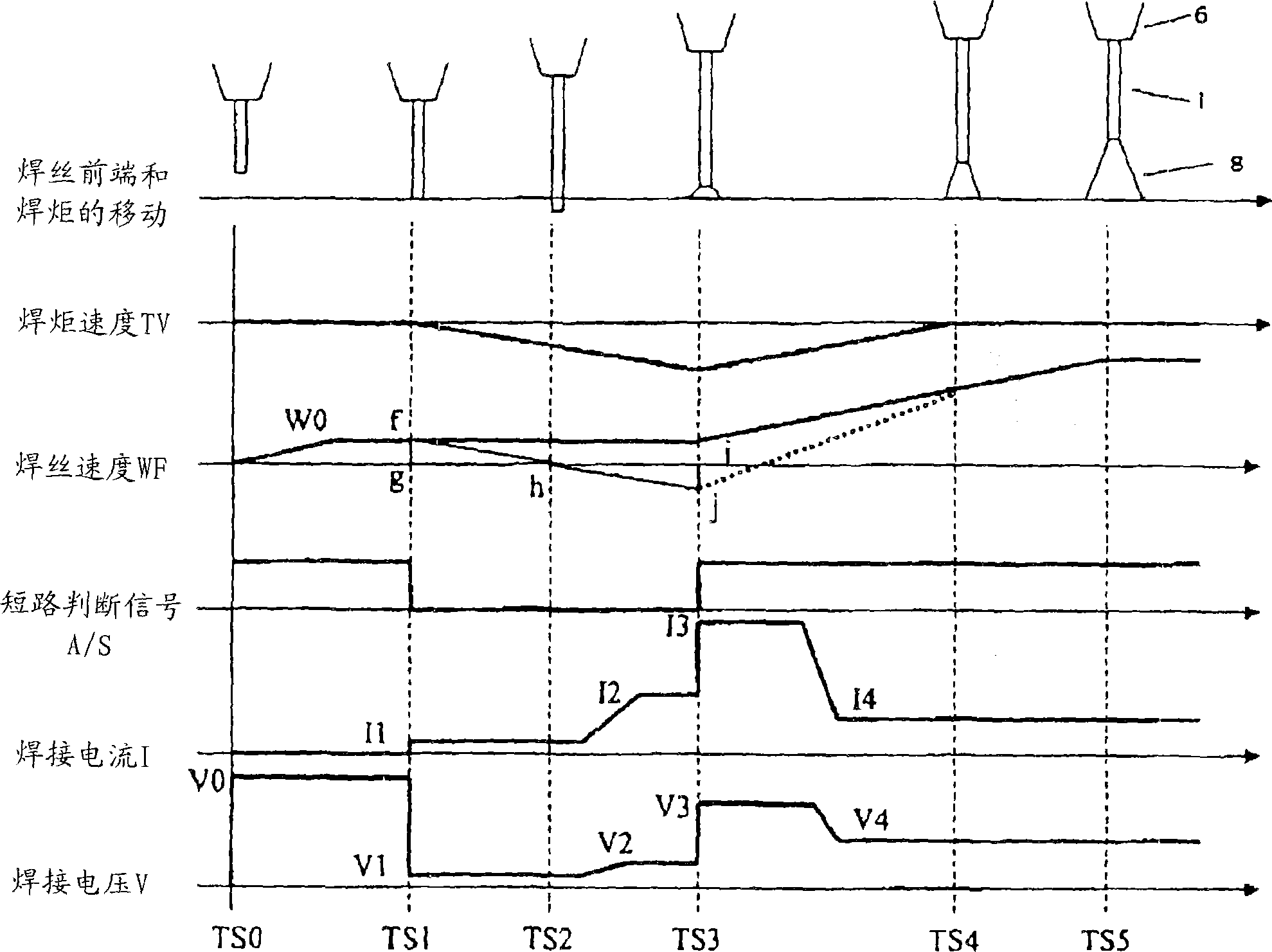

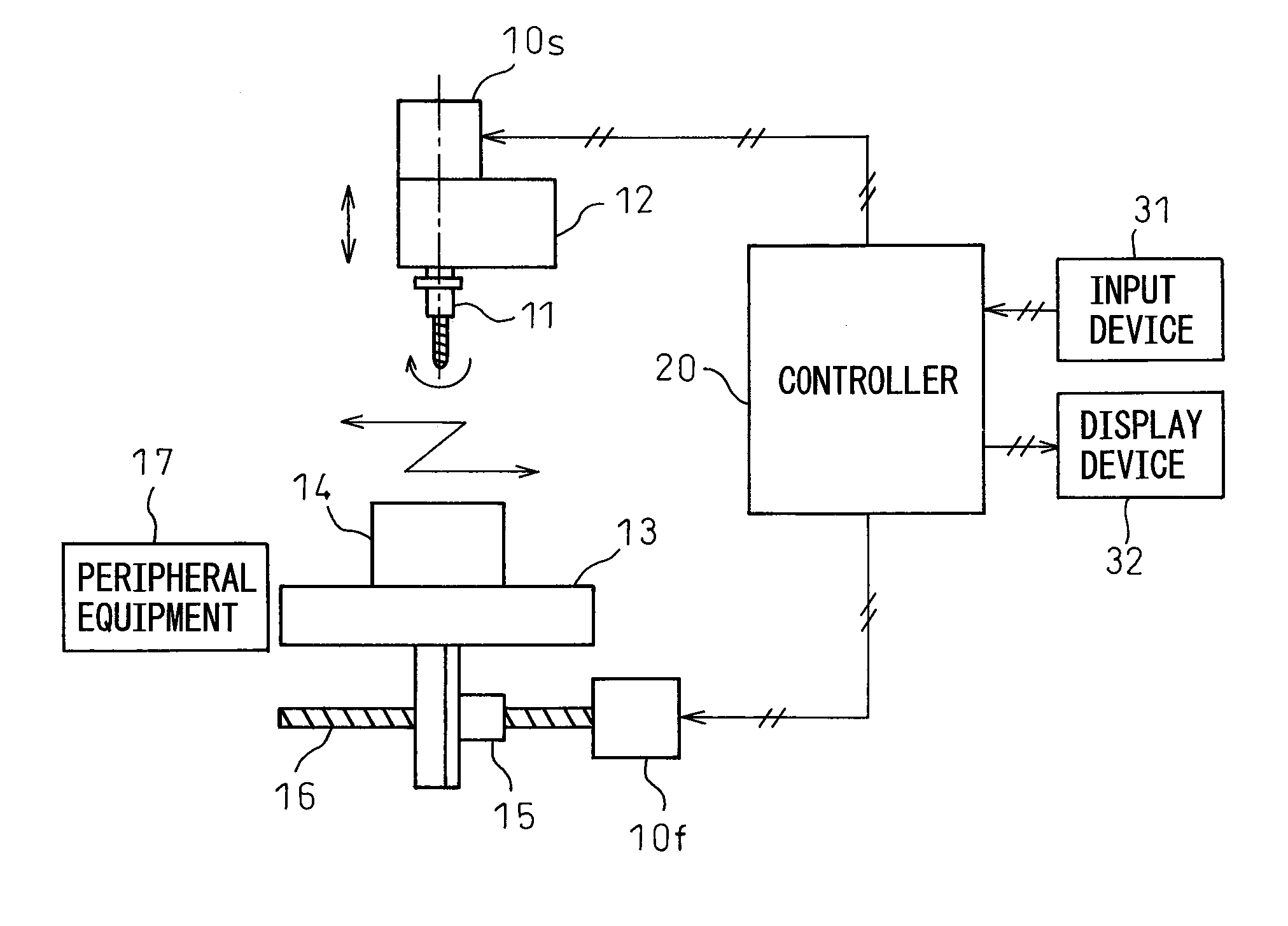

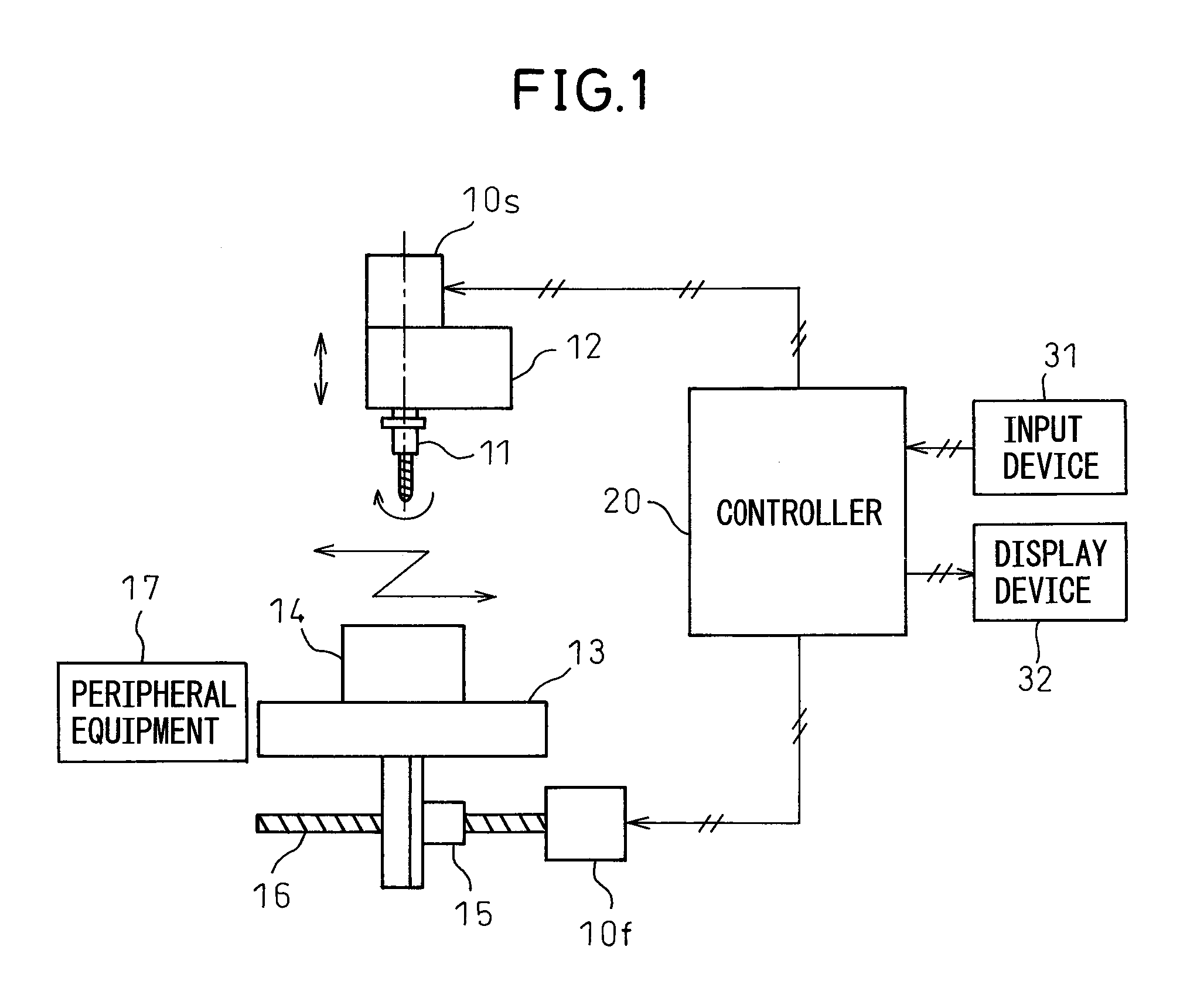

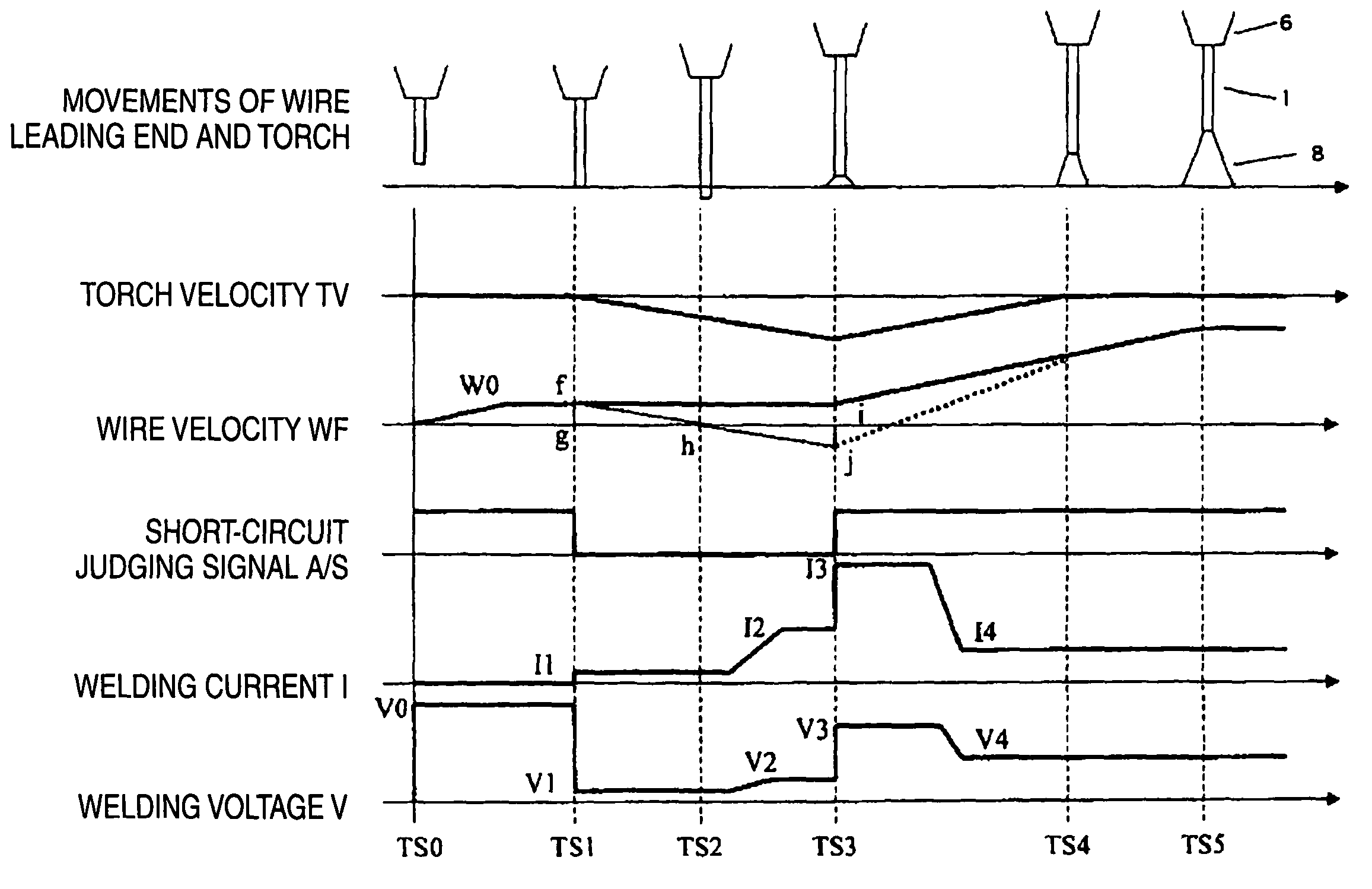

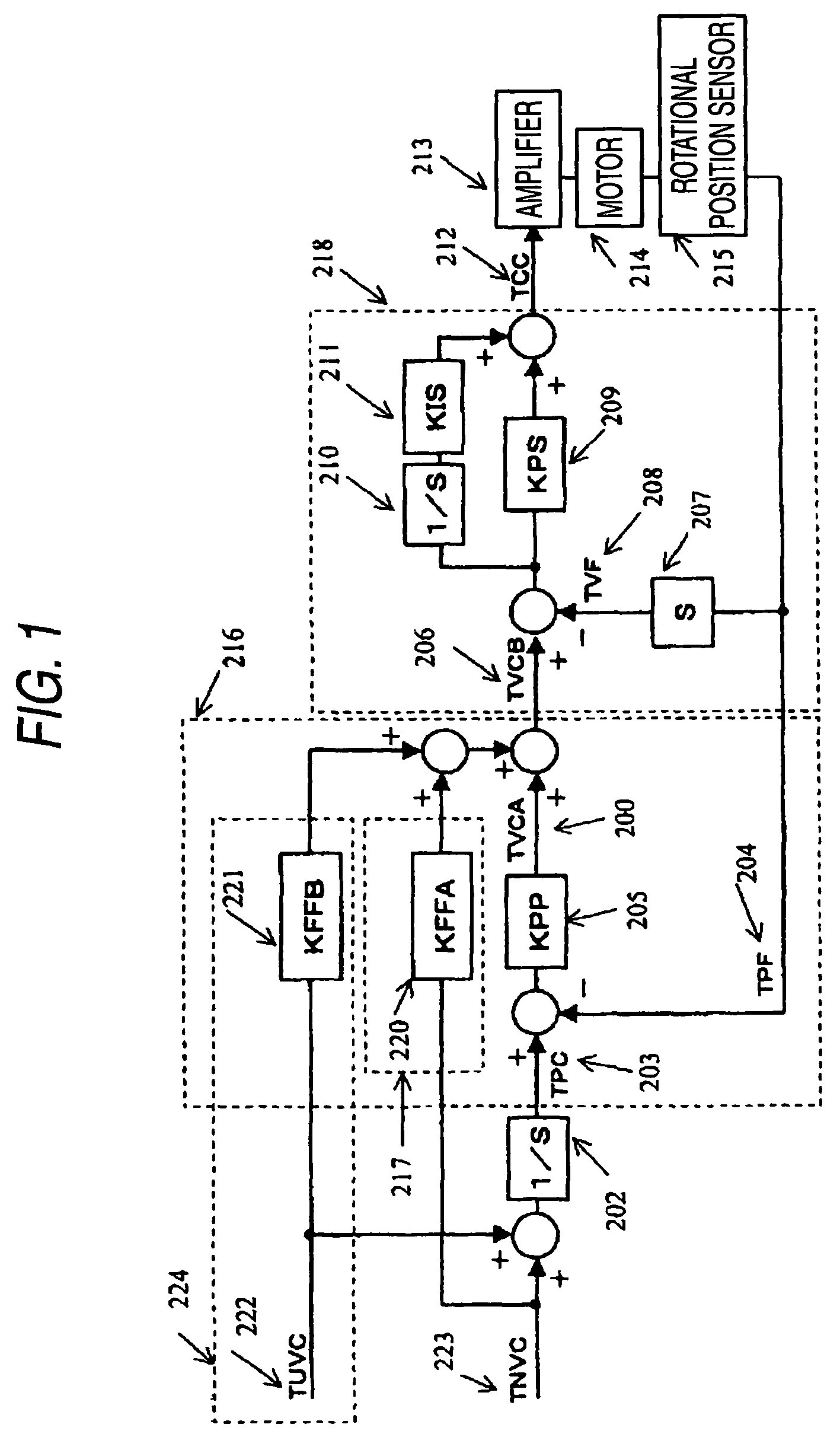

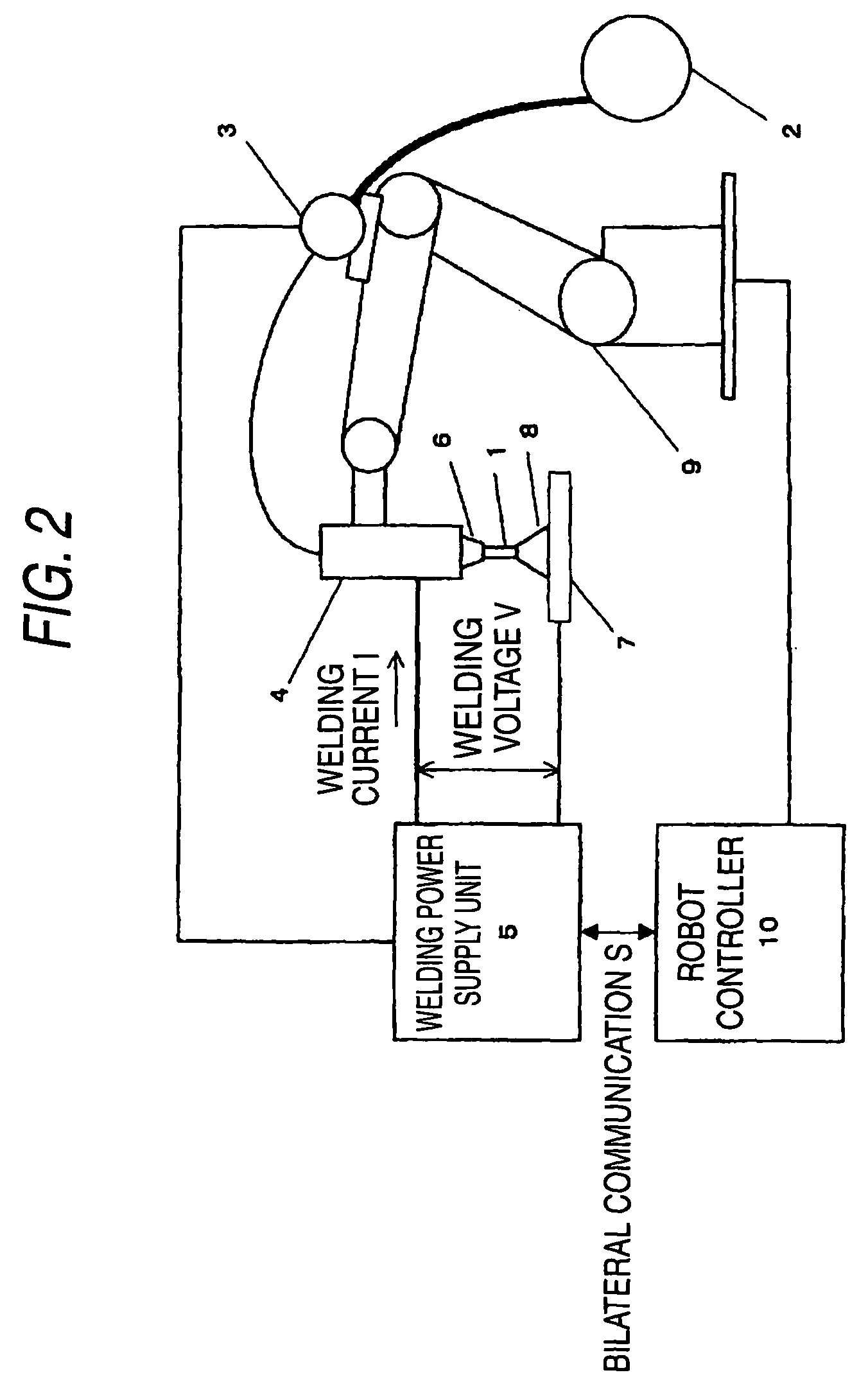

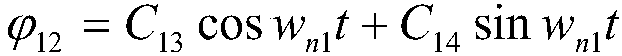

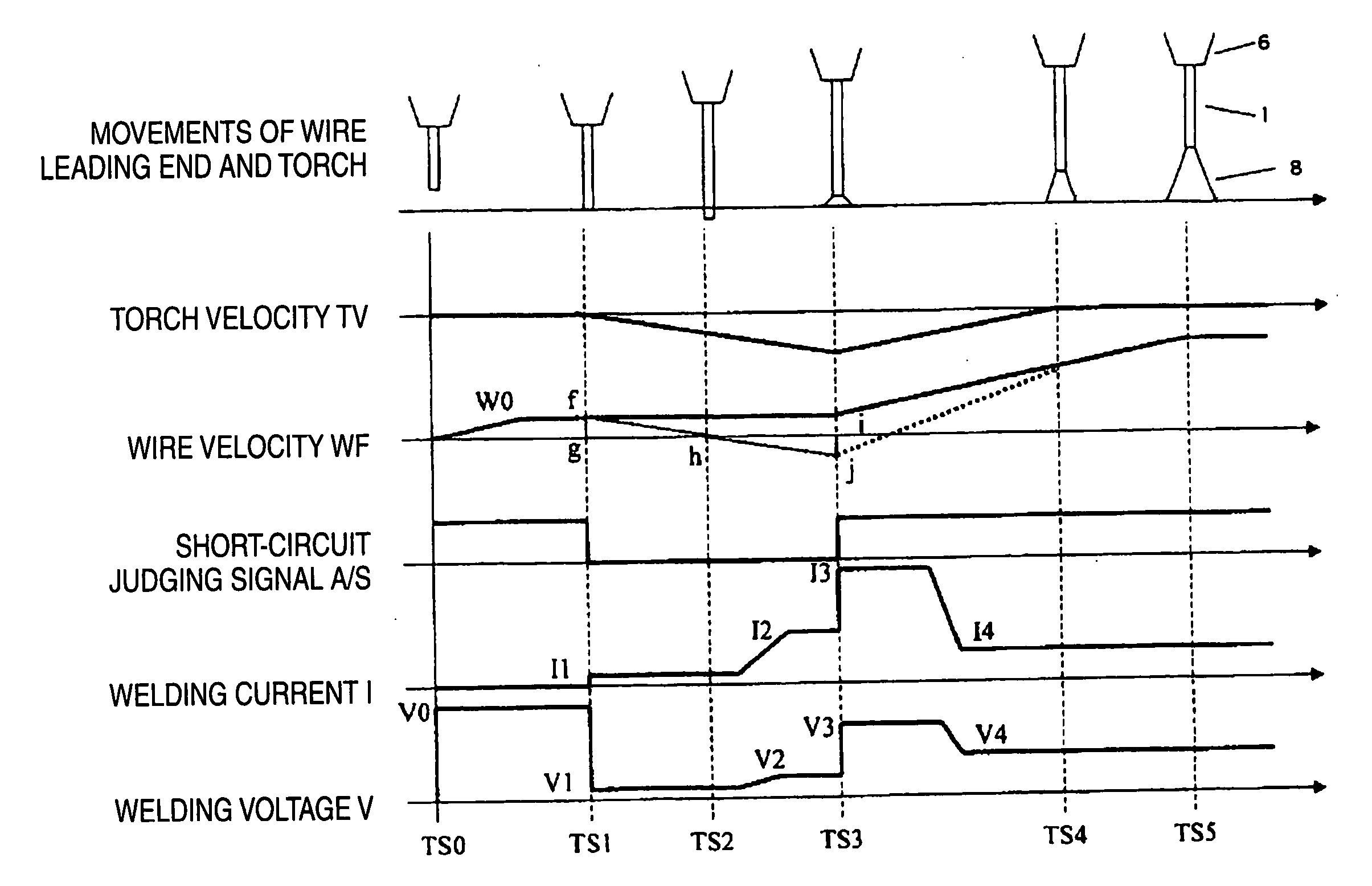

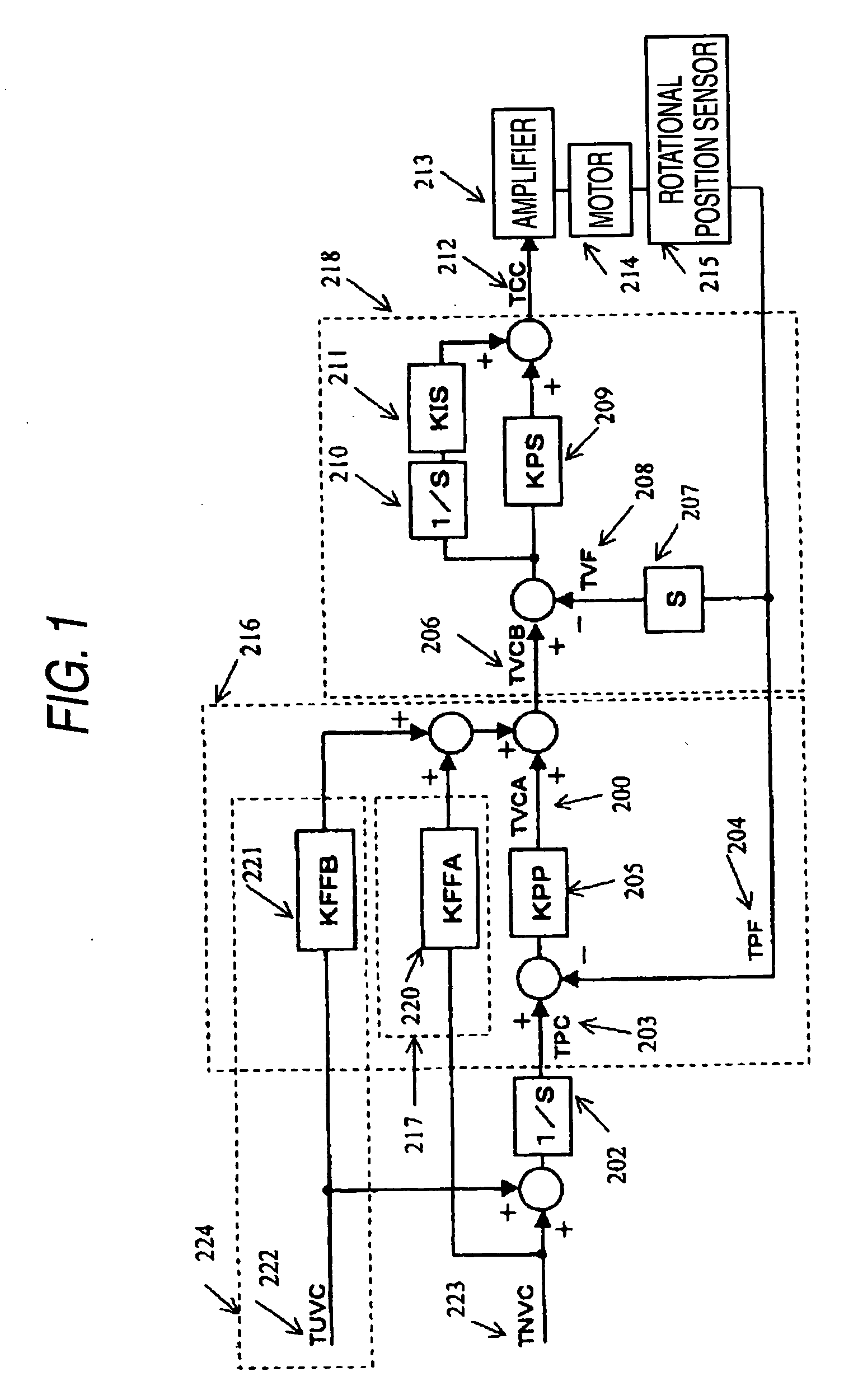

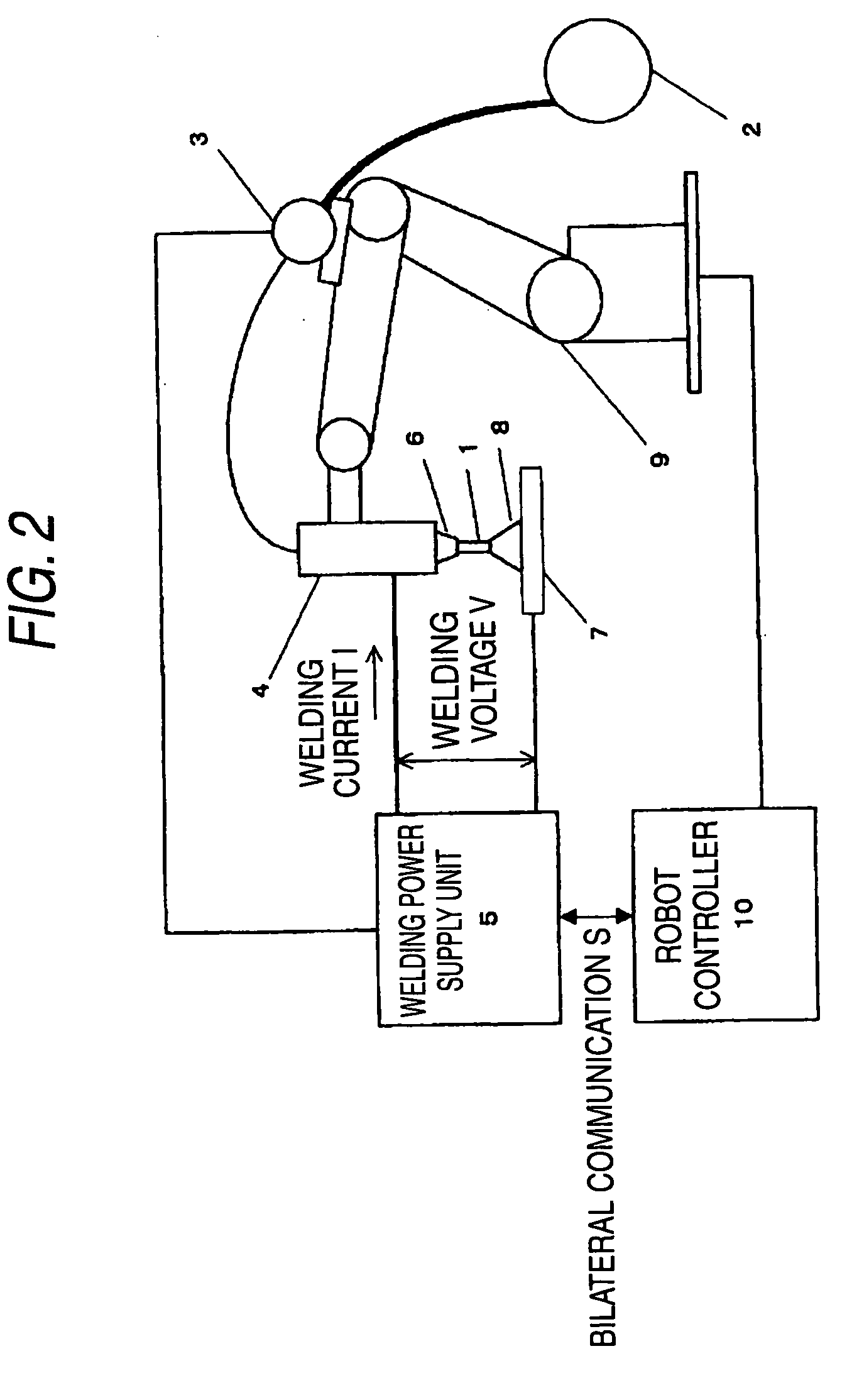

Welding system and consumable electrode welding method

Welding system and consumable electrode welding methodA torch is moved by a manipulator in a direction separating from a base material 7 while a wire is supplied, whereby an actuator driving the robot manipulator can control a velocity of the wire for a workpiece by a unidirectional operation of separating the torch, and vibration due to reverse of torch velocity is not generated. Further, by using a dedicated separation control system, velocity follow-up performance of the actuator moving the torch can be heightened without increasing overshoot in the usual operation time, and the acceleration and deceleration time of the manipulator can be reduced.

Owner:PANASONIC CORP

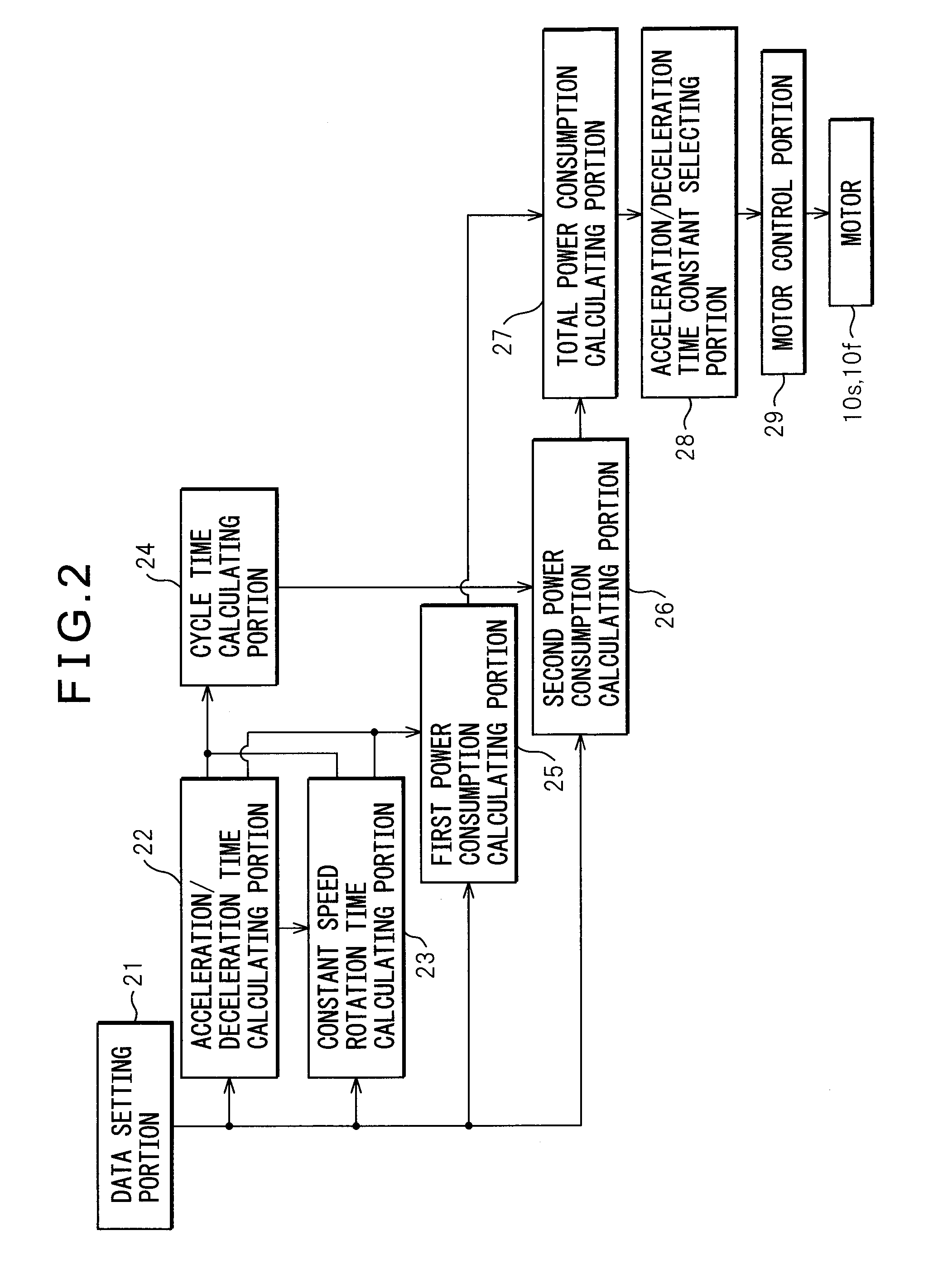

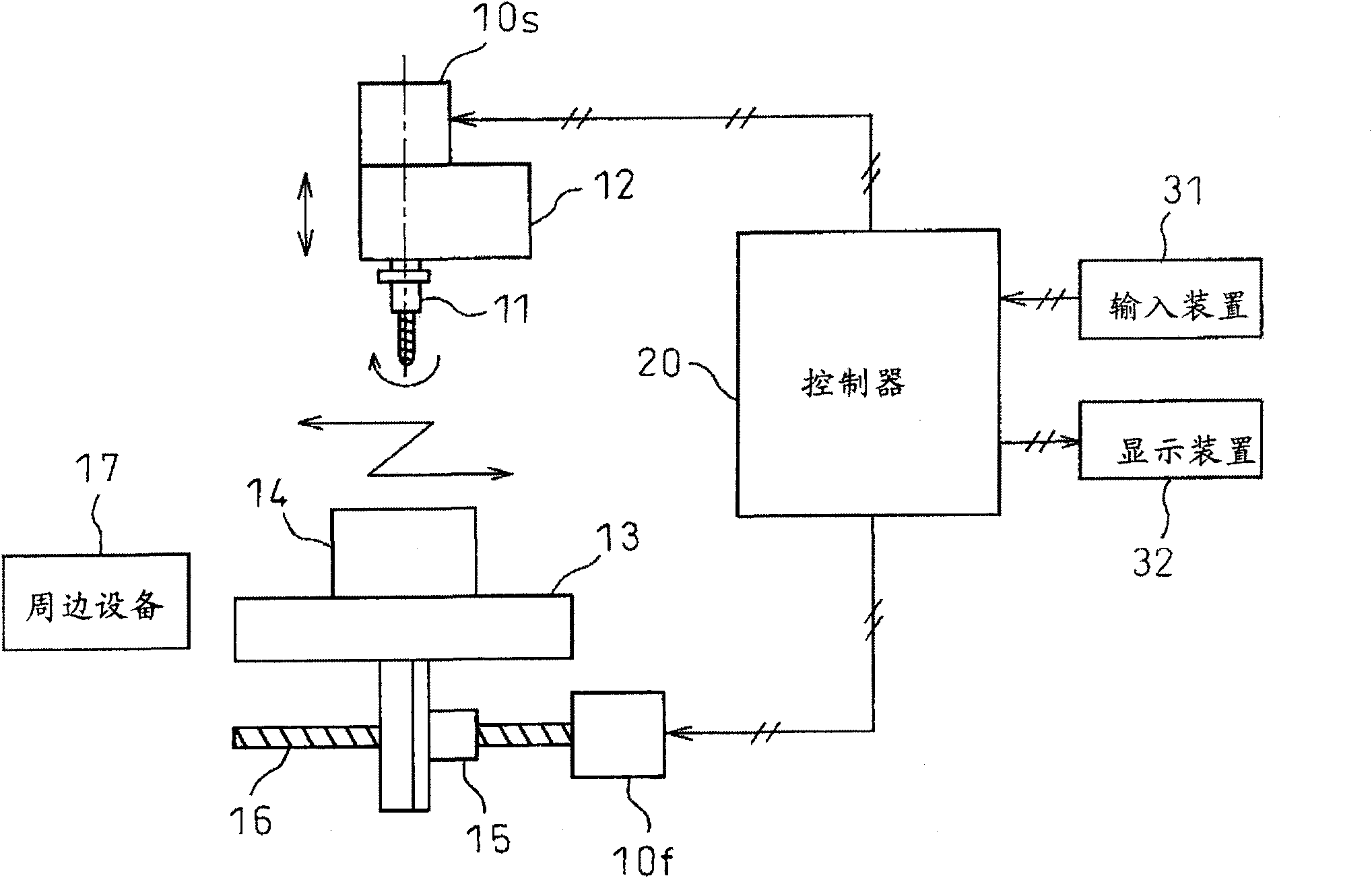

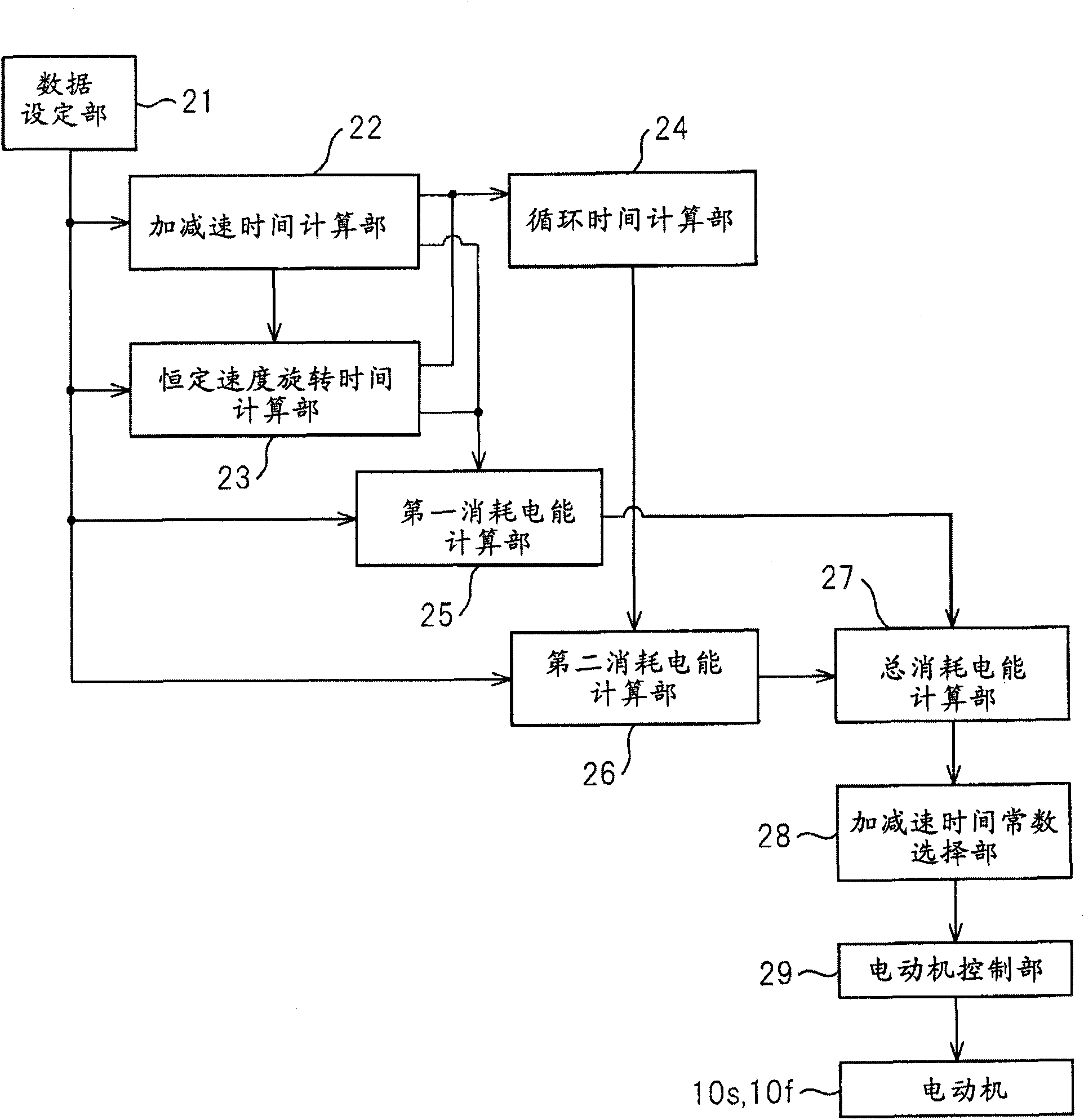

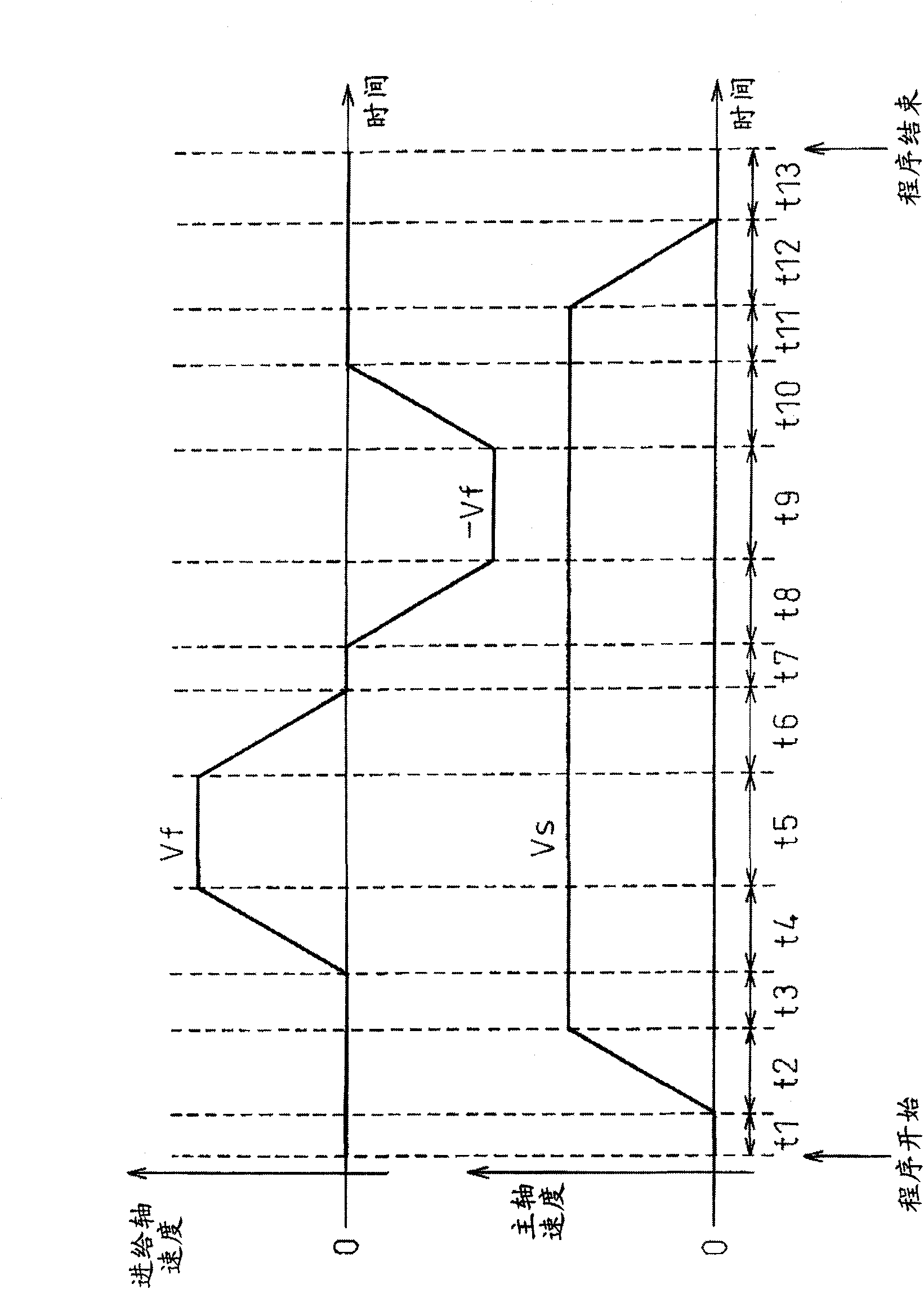

Control device for machine tool

A control device for a machine tool including a feed axis driving motor; a first power consumption calculating portion calculating power consumption of the feed axis driving motor; a second power consumption calculating portion calculating power consumption of equipment adapted to be operated by constant power; and a motor control portion determining a target time constant correlated with at least one of acceleration time and deceleration time of the feed axis driving motor, based on a summation of the power consumption calculated by the first power consumption calculating portion and the power consumption calculated by the second power consumption calculating portion, and controlling the feed axis driving motor based on the target time constant.

Owner:FANUC LTD

Welding system and consumable electrode welding method

Owner:PANASONIC CORP

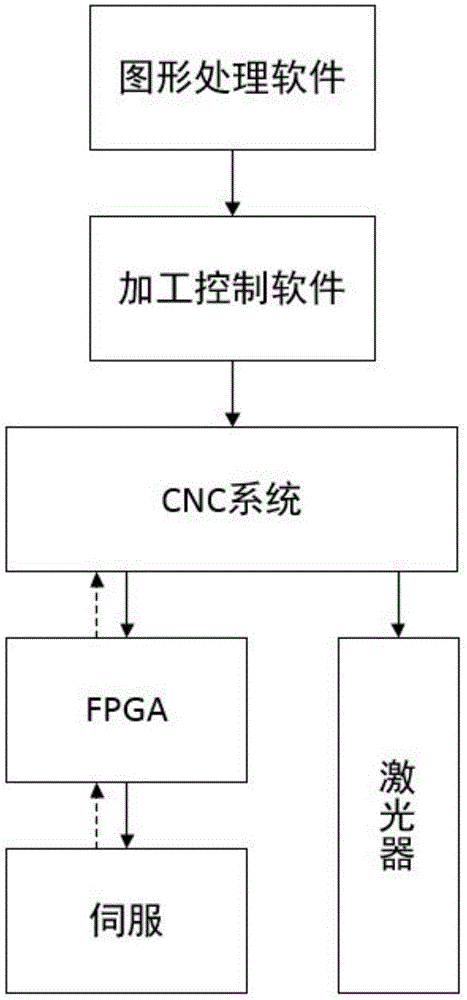

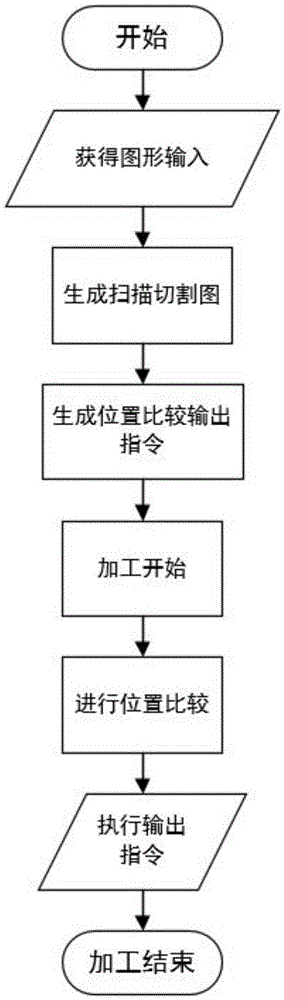

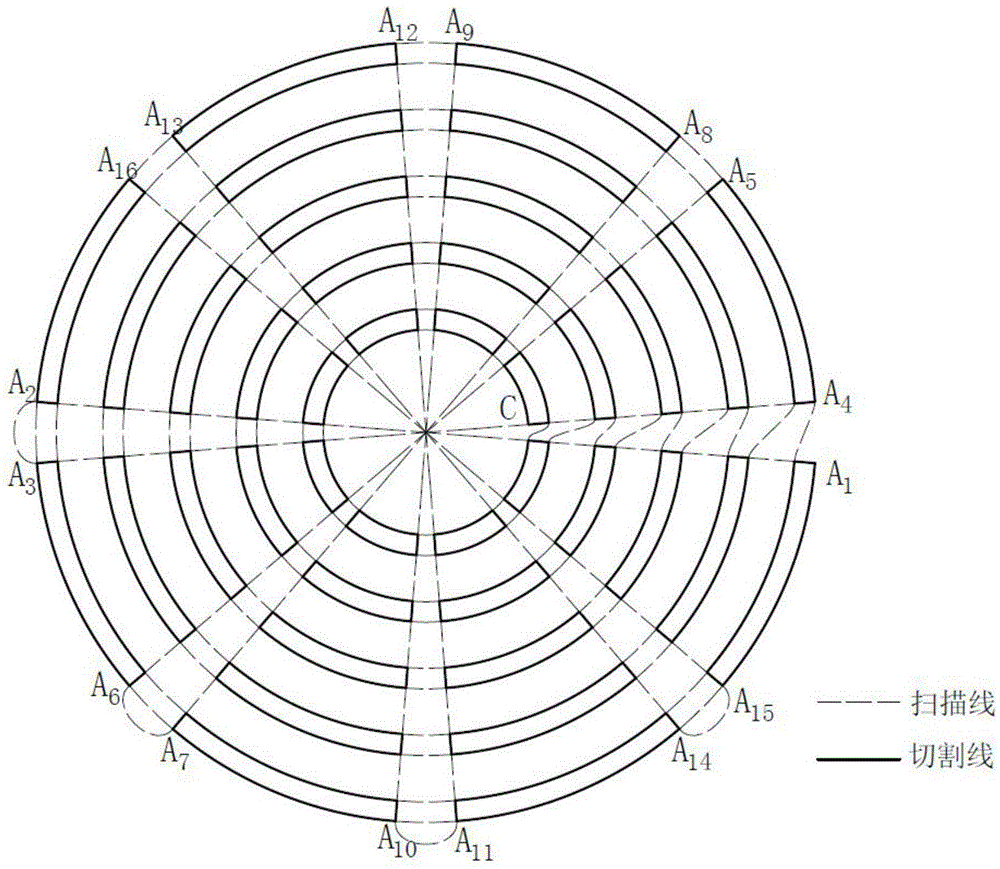

Quick laser scanning and cutting method

ActiveCN105522284AHigh speedShorten the lengthLaser beam welding apparatusNumerical controlLaser scanning

The invention relates to the field of laser cutting, in particular to a quick laser scanning and cutting method. The method comprises graphic processing software for acquiring graphic processing, machining control software for controlling a computer numerical control (CNC) system, the CNC system for controlling a machine tool servo and a laser device, a field programmable gate array (FPGA) system for processing and transferring signals, the servo for controlling a machine tool to move and the laser device which is used for producing lasers to carry out cutting and is provided with a pulse width modulation (PWM) switching system. The quick laser scanning and cutting method is characterized in that the method comprises the following steps that starting is carried out, a graph is input, a scanning and cutting pattern is generated, a position comparison and output instruction is generated, machining is started, position comparison is conducted, an output instruction is carried out, and stopping is conducted. Compared with the prior art, cutting and air moving paths of machining motion are optimized through a cutting line scanning mode, acceleration times and deceleration times in the motion process are decreased effectively, and the average speed of cutting and the average speed of air moving are increased; accordingly, the cutting motion time and the air moving motion time are shortened, and the purpose of quick cutting is achieved.

Owner:上海柏楚电子科技股份有限公司

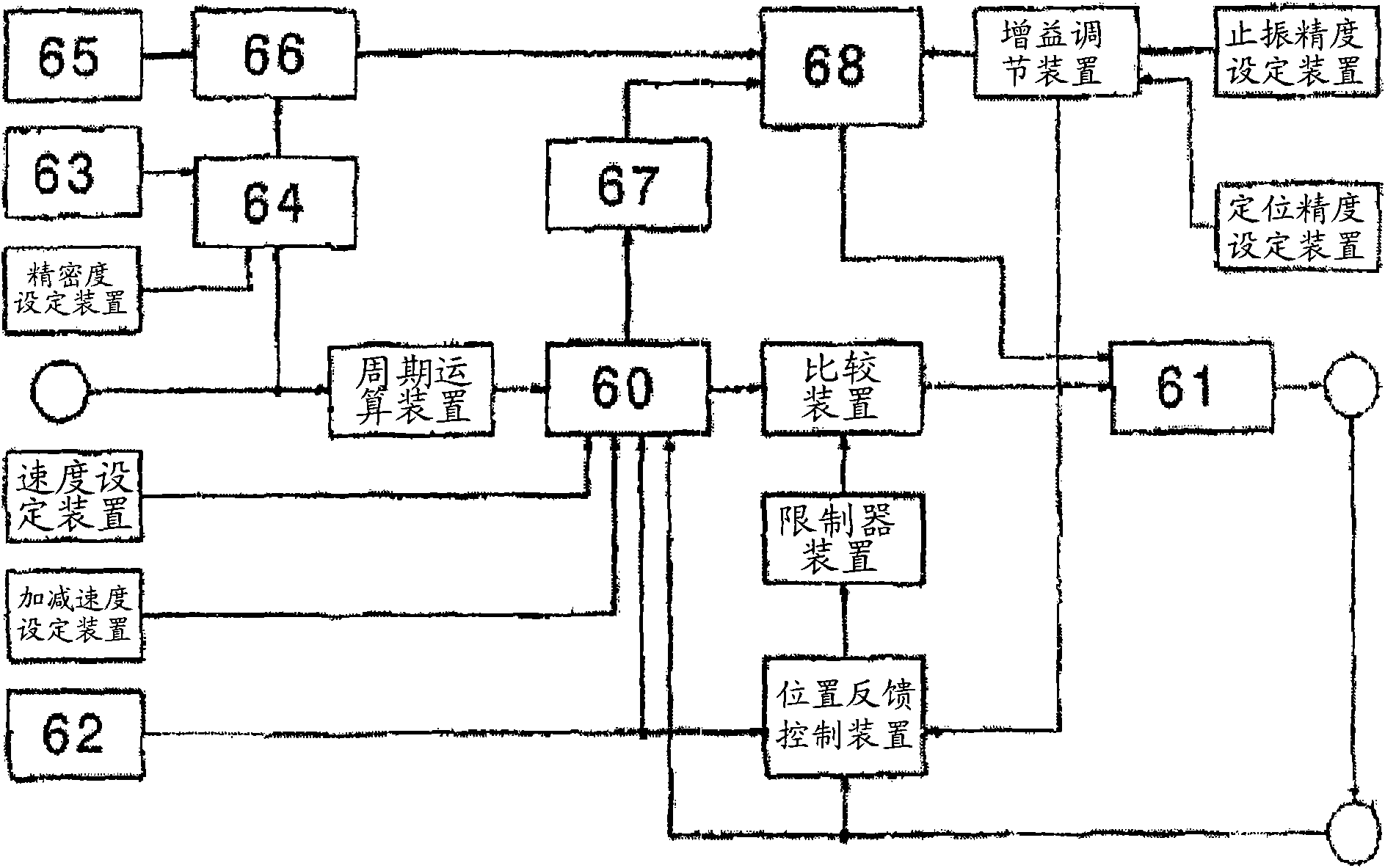

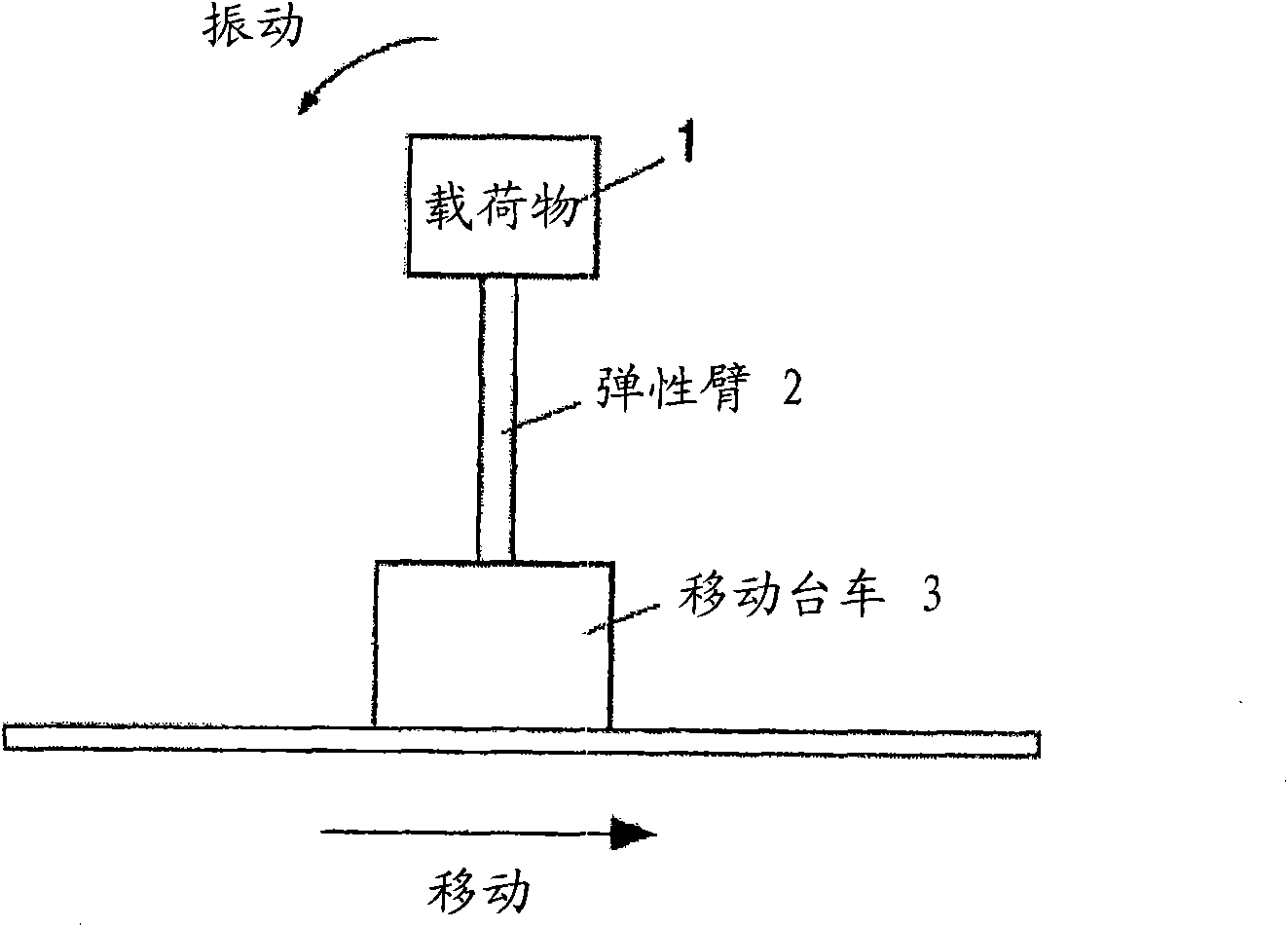

Position control method for vibration attenuation and apparatus thereof

ActiveCN101615039AReduce stressEasy to set upMechanical oscillations controlVibration attenuationState variable

A position control method for vibration attenuation and an apparatus thereof are provided. It is unnecessary to measure actual movement and parameter adjustment to reduce number of vibration during acceleration / deceleration period without generating vibration greater than static vibration generated by acceleration to reduce stress generation; it is unnecessary to set the number of vibration randomly by corresponding the acceleration / deceleration period with a natural period. The position control method for vibration attenuation and apparatus inhibit vibration of a mobile body with vibration or elastic deformation during acceleration / deceleration to position. Vibration of the mobile body is modeled by a spring-particle system with single-degree-of-freedom to solve the natural period of themodel so that the acceleration graph during acceleration / deceleration is trapeziform graph comprising constant speed increasing and decreasing of the acceleration and so that constant time of each acceleration is of integral multiple to the natural period to set the acceleration graph. The acceleration graph controls movement of the mobile body and detects state variables of the mobile body. The mobile body is feedback controlled according to a deviation of a target value of state variable generated by the acceleration graph and a current value of the state variable detected.

Owner:IHI CORP

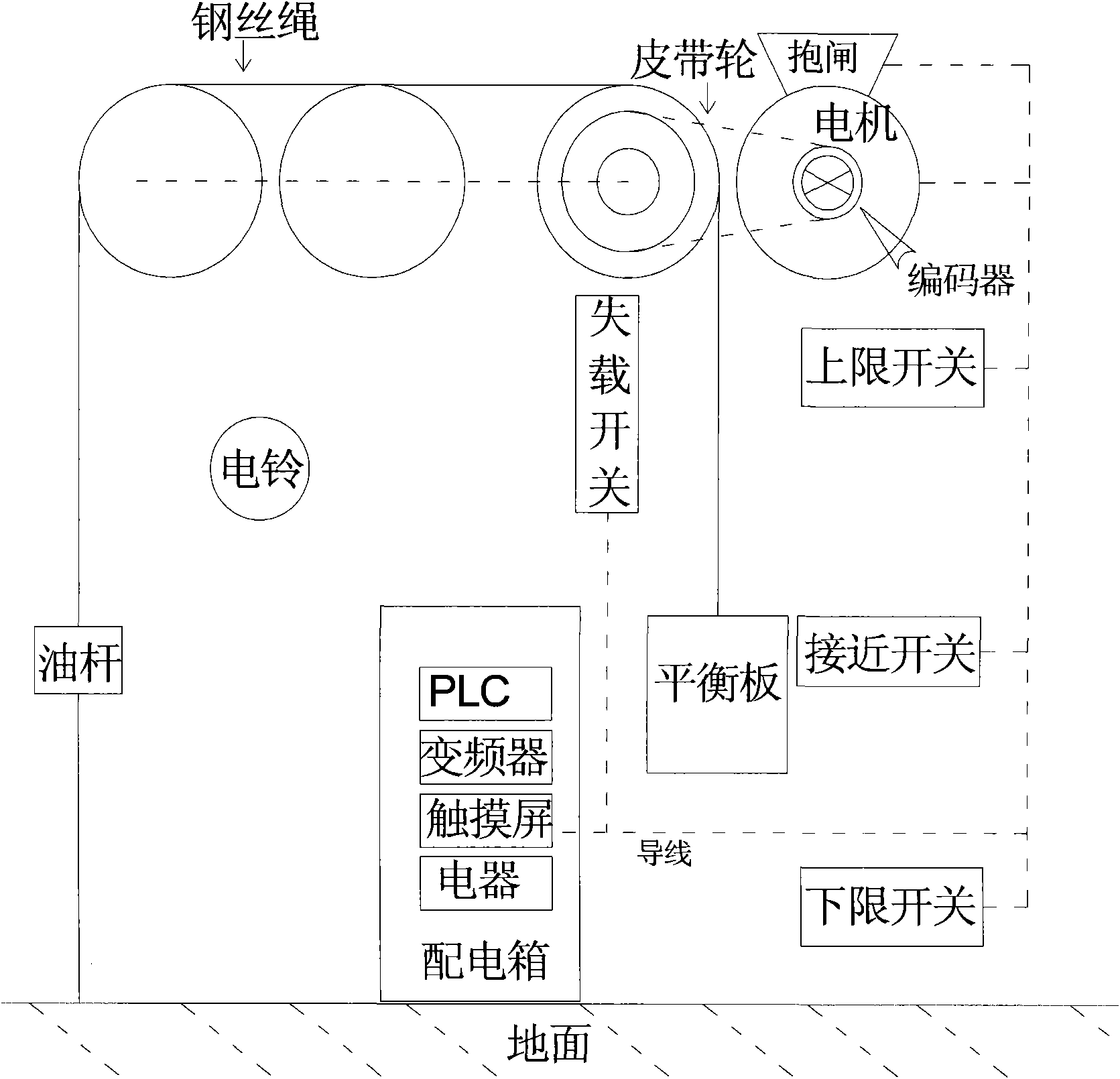

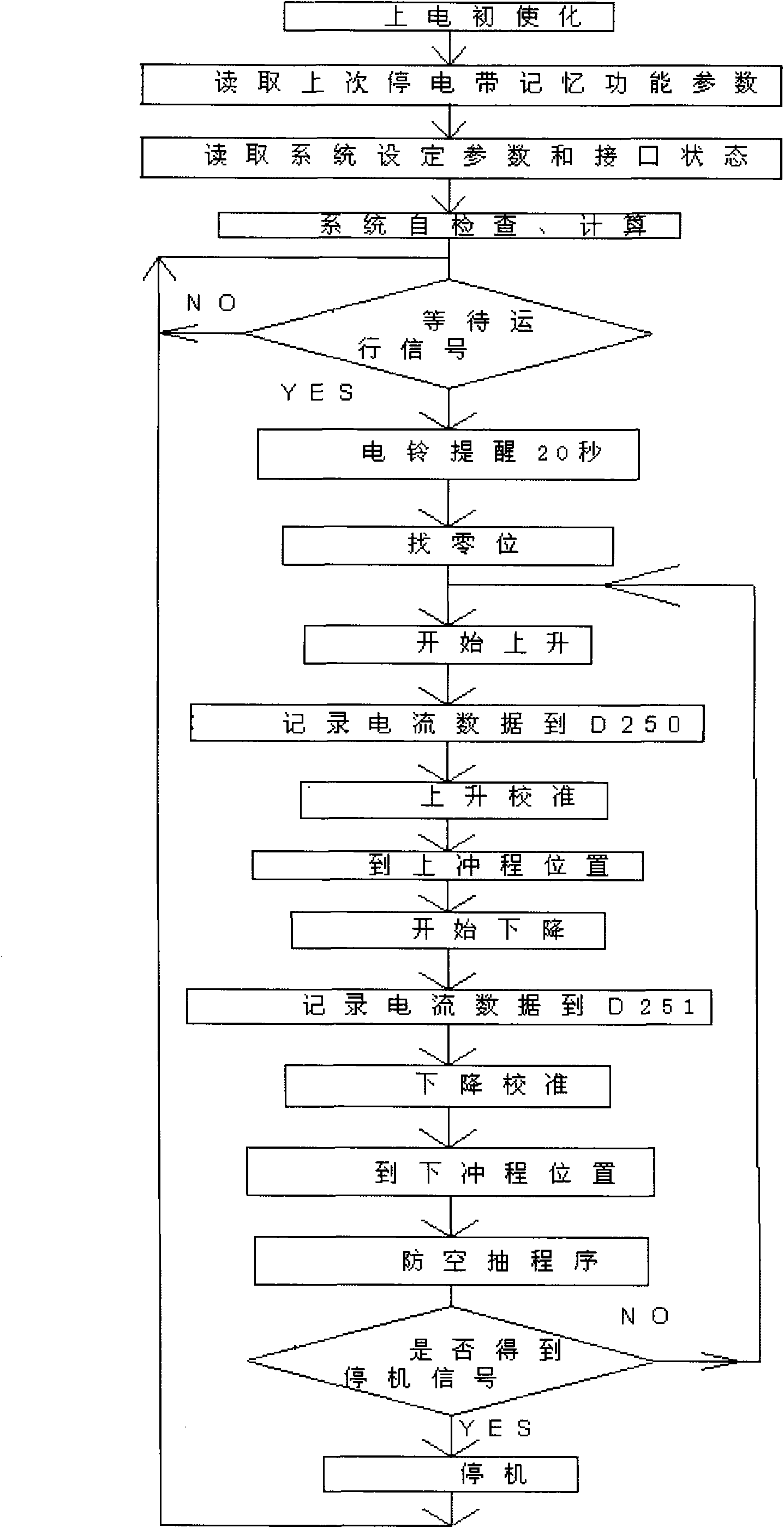

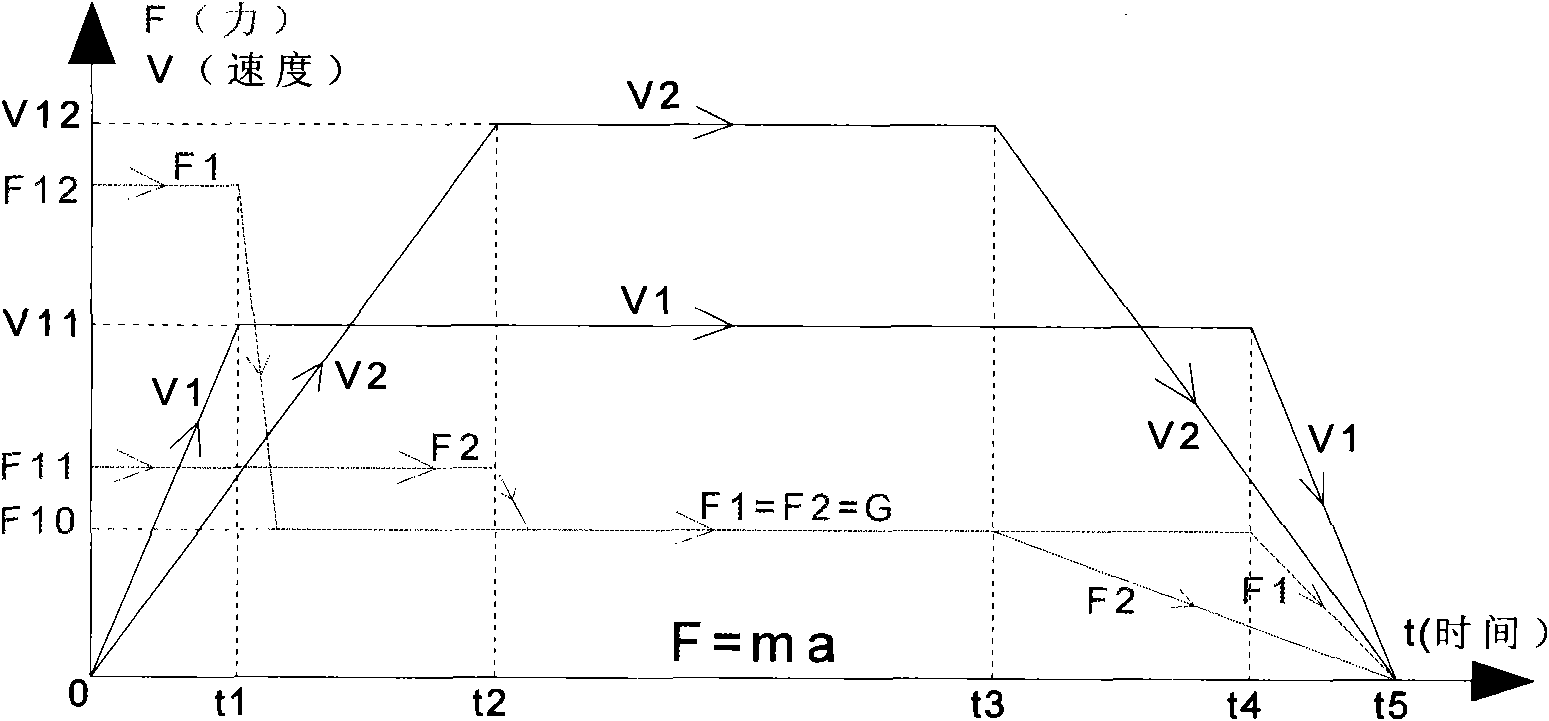

Method for controlling tower-type pumping unit

Owner:上海神源电气有限公司

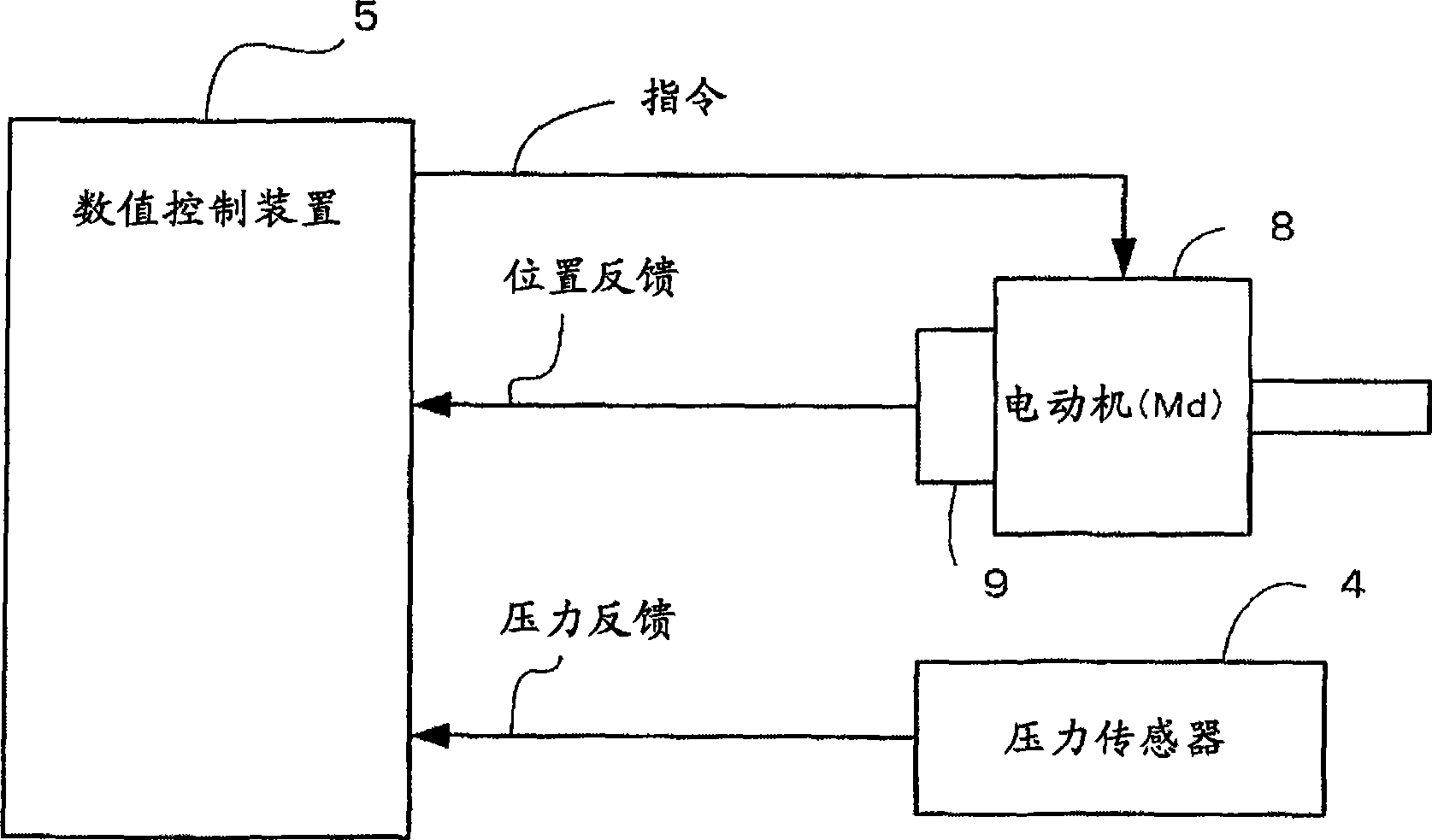

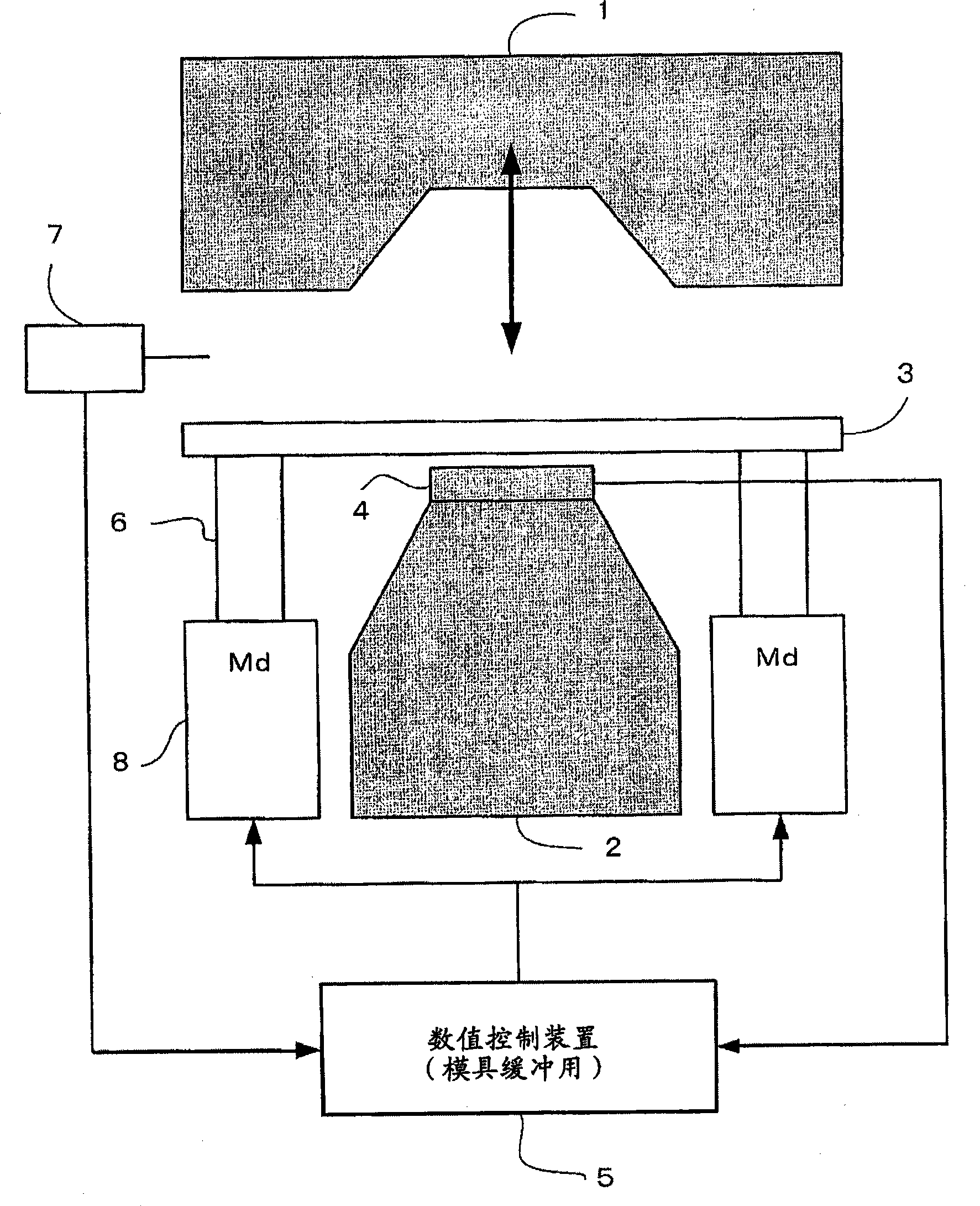

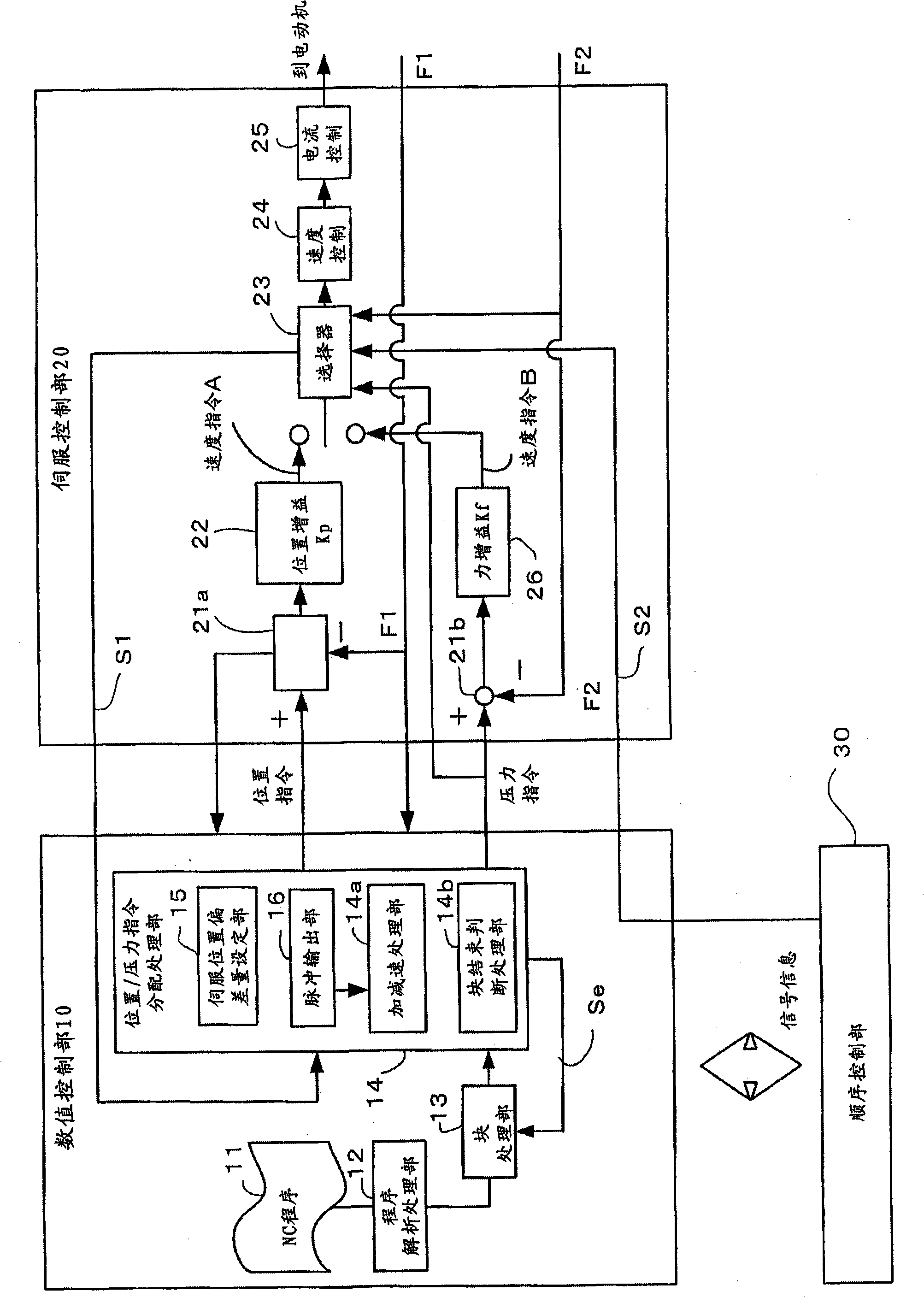

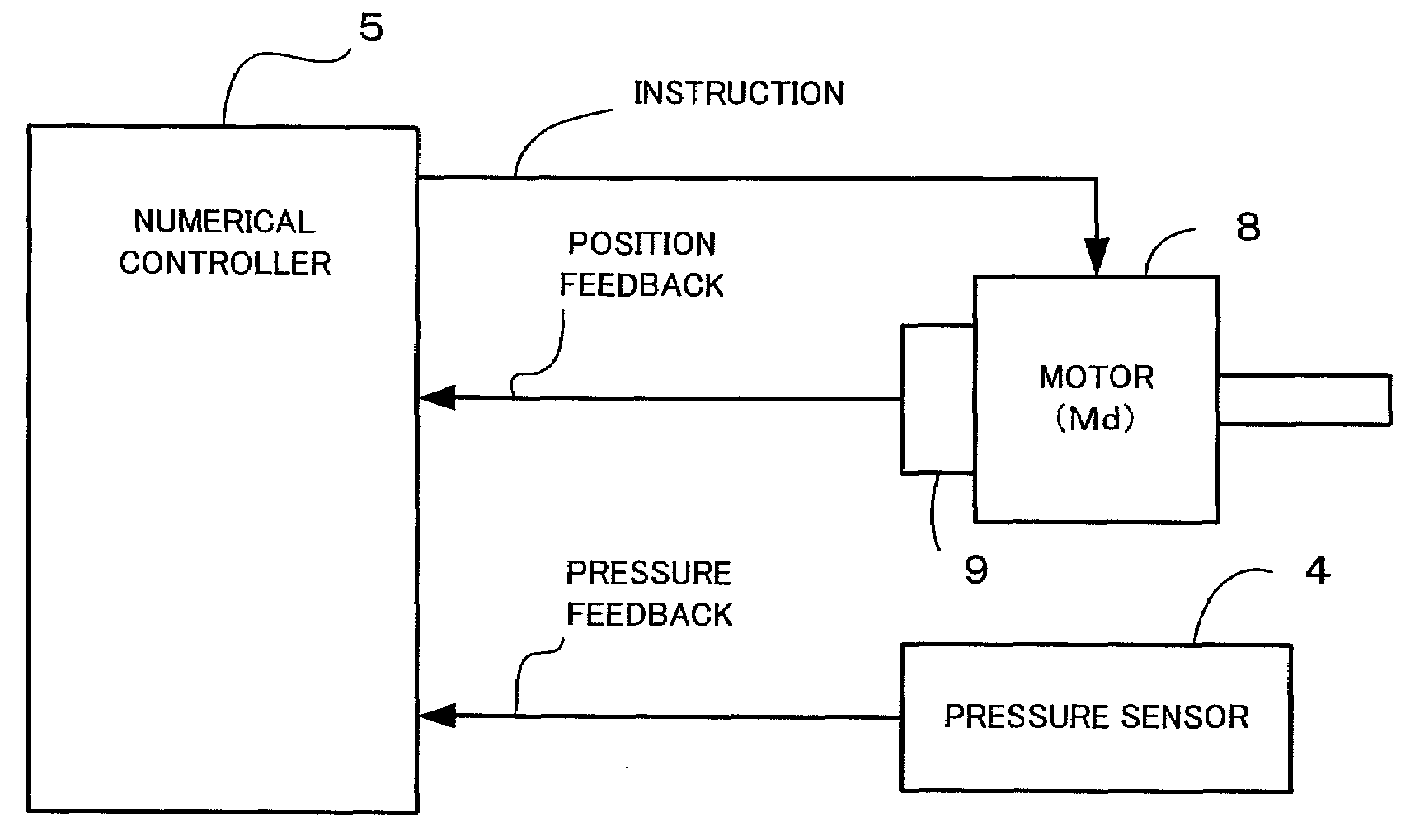

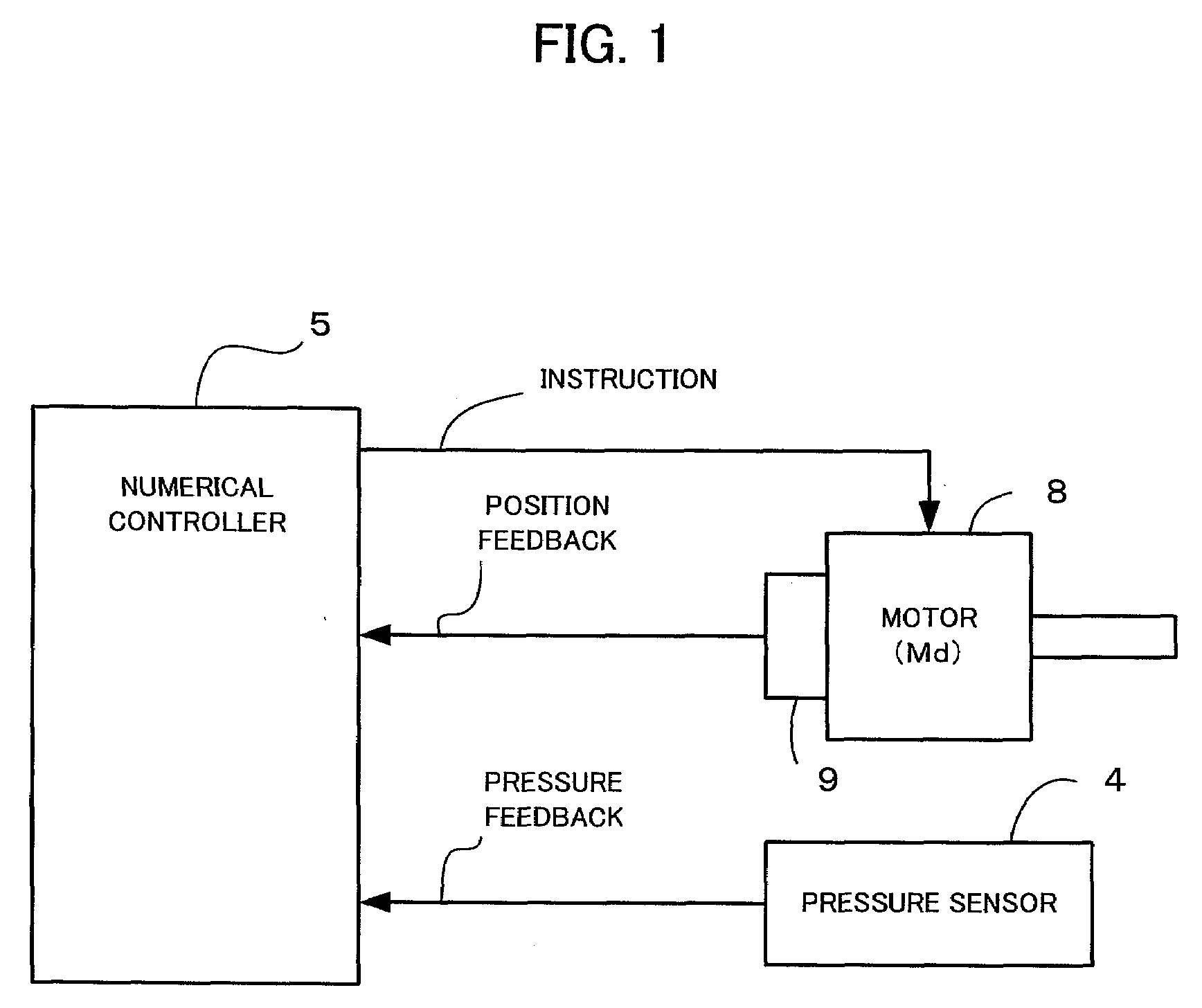

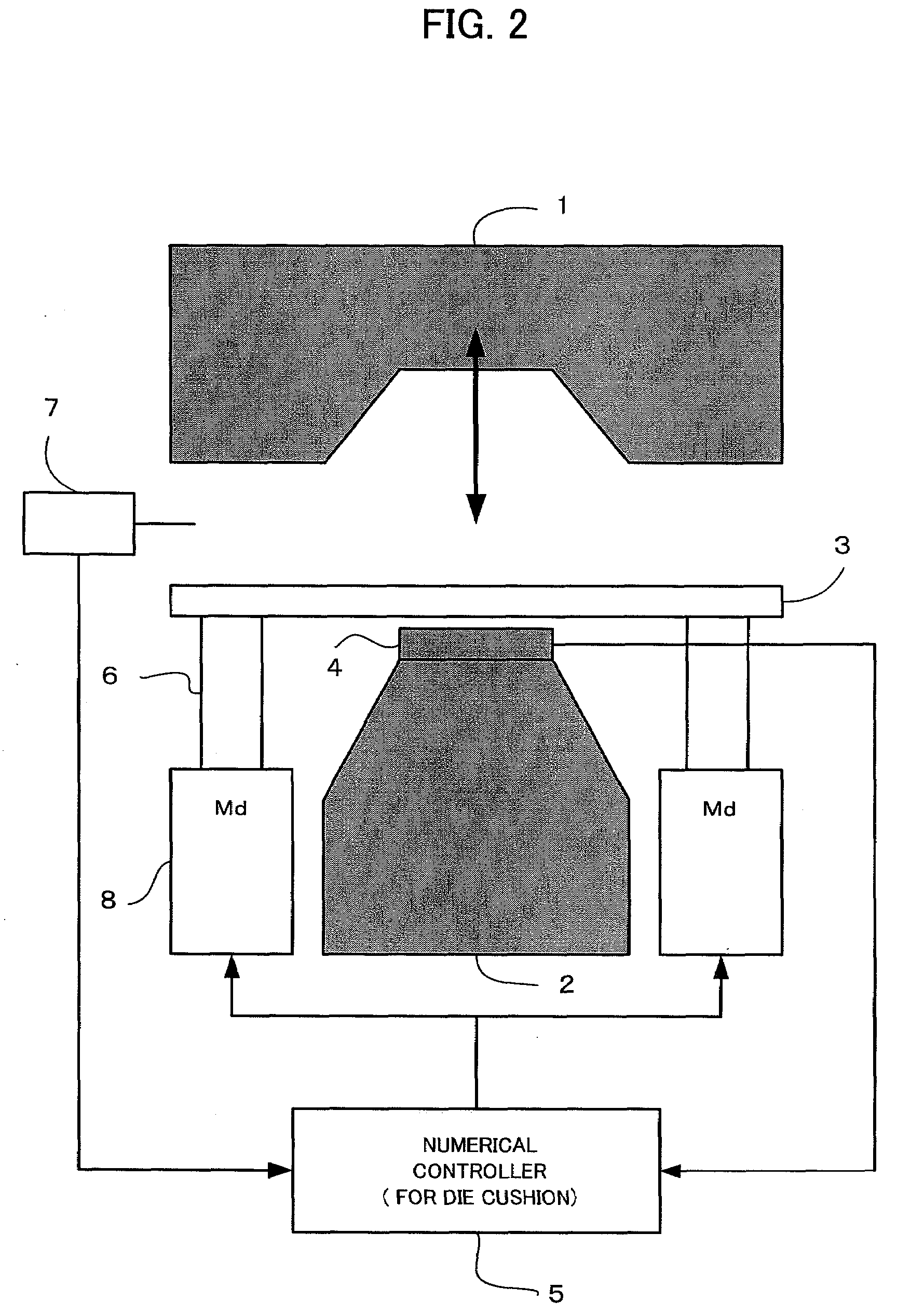

Numerical controller having function to switch between pressure control and position control

The inventio provides a numerical controller has function to switch between pressure control and position control, and comprises a numerical control unit and a servo control unit. While the servo control unit is controlling pressure, a servo position deviation amount corresponding to current actual speed of a control axis is set in the servo control unit. After the servo control unit switches to position control from pressure control, a number of pulses required for deceleration and stopping is output to an acceleration / deceleration processing unit of the numerical control unit according to an acceleration / deceleration time constant which is preset. The acceleration / deceleration processing unit outputs a moving amount for each distribution period to the servo control unit.

Owner:FANUC LTD

Control device for machine tool

A control device for a machine tool including a feed axis driving motor; a first power consumption calculating portion calculating power consumption of the feed axis driving motor; a second power consumption calculating portion calculating power consumption of equipment adapted to be operated by constant power; and a motor control portion determining a target time constant correlated with at least one of acceleration time and deceleration time of the feed axis driving motor, based on a summation of the power consumption calculated by the first power consumption calculating portion and the power consumption calculated by the second power consumption calculating portion, and controlling the feed axis driving motor based on the target time constant.

Owner:FANUC LTD

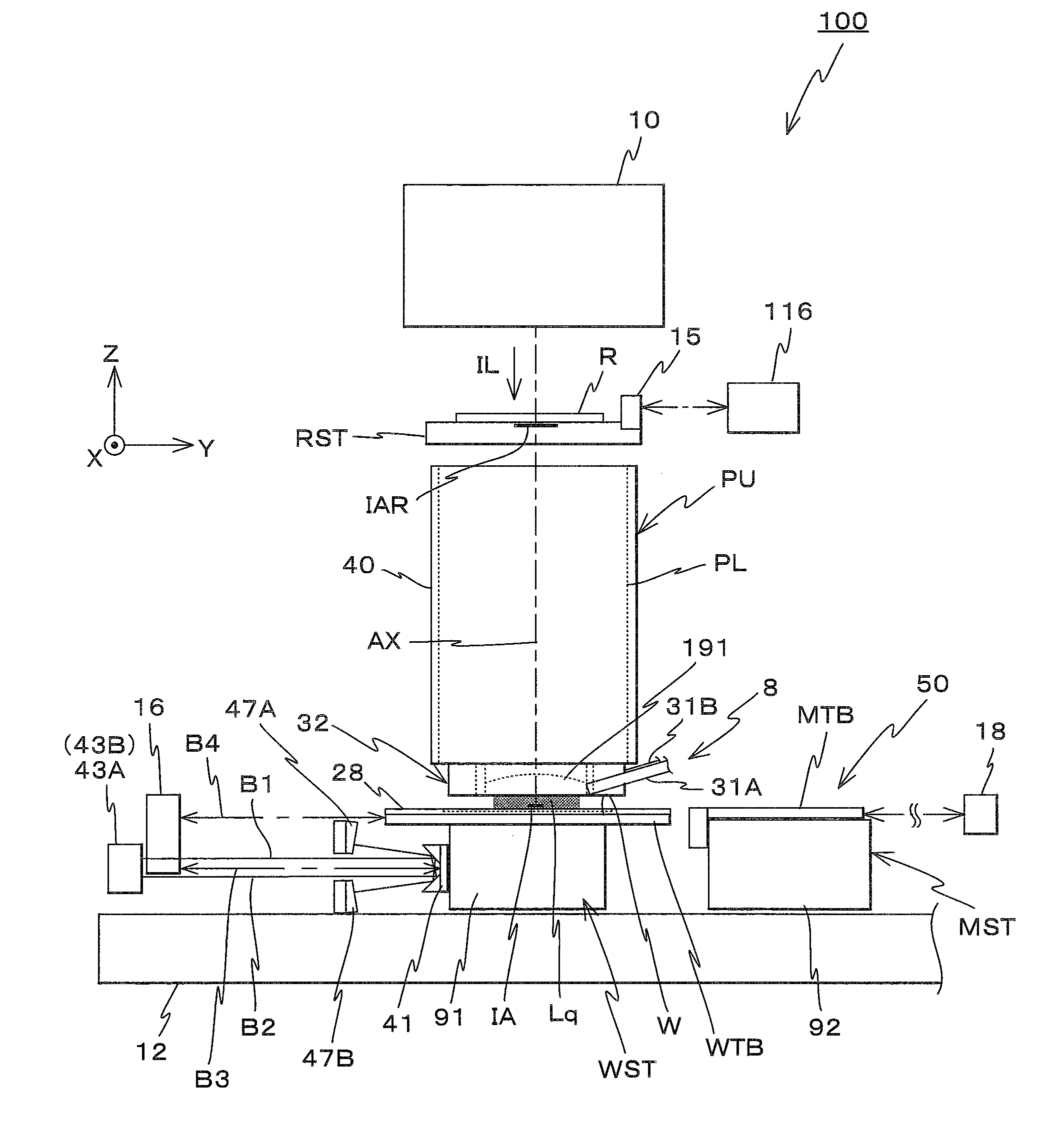

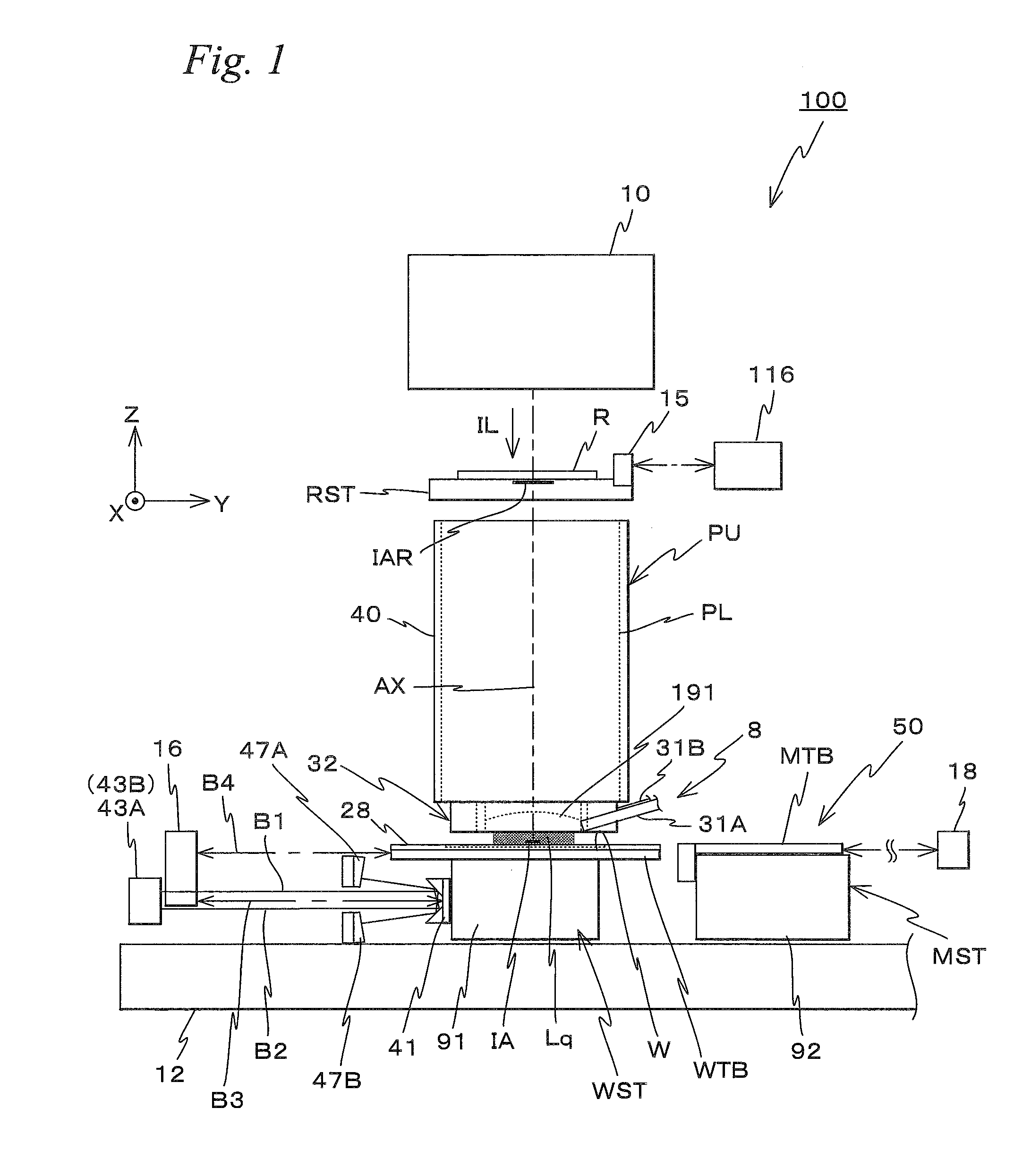

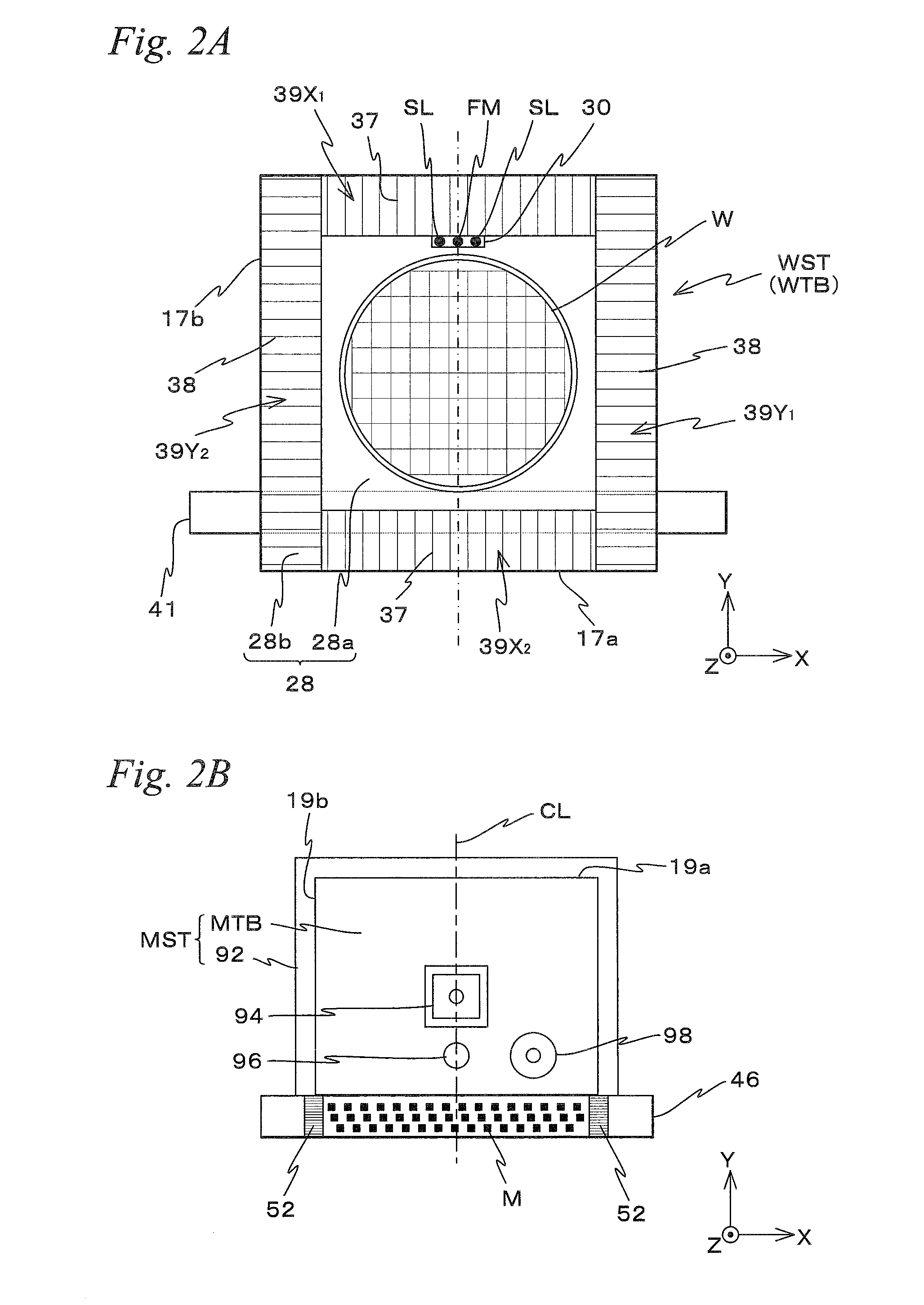

Exposure method, exposure apparatus, and device manufacturing method

ActiveUS20110051108A1Good precisionPrecise alignmentUsing optical meansPhotomechanical exposure apparatusMechanical stabilityEngineering

Positional information of a stage is obtained using an interferometer system only during an exposure time when a constant speed drive of the stage is performed to form a pattern. Therefore, the linear measurement of the positional information is secured enough, which makes it possible to linearly drive the stage with high accuracy. Meanwhile, between an acceleration time and a deceleration time in which a step drive is performed, the positional information of the stage is obtained using an encoder system and a surface position measurement system. Therefore, measurement reproducibility of the positional information is sufficiently secured by the mechanical stability of a diffraction grating, which makes it possible to drive the stage precisely to the starting position of the constant speed drive.

Owner:NIKON CORP

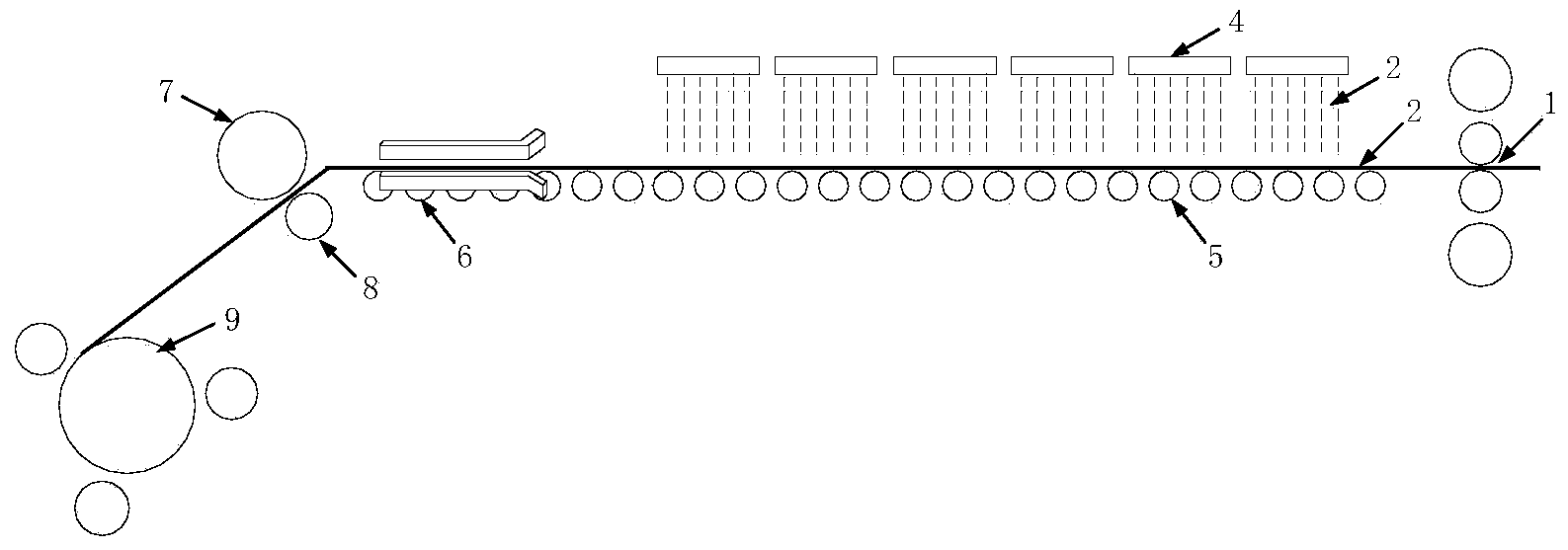

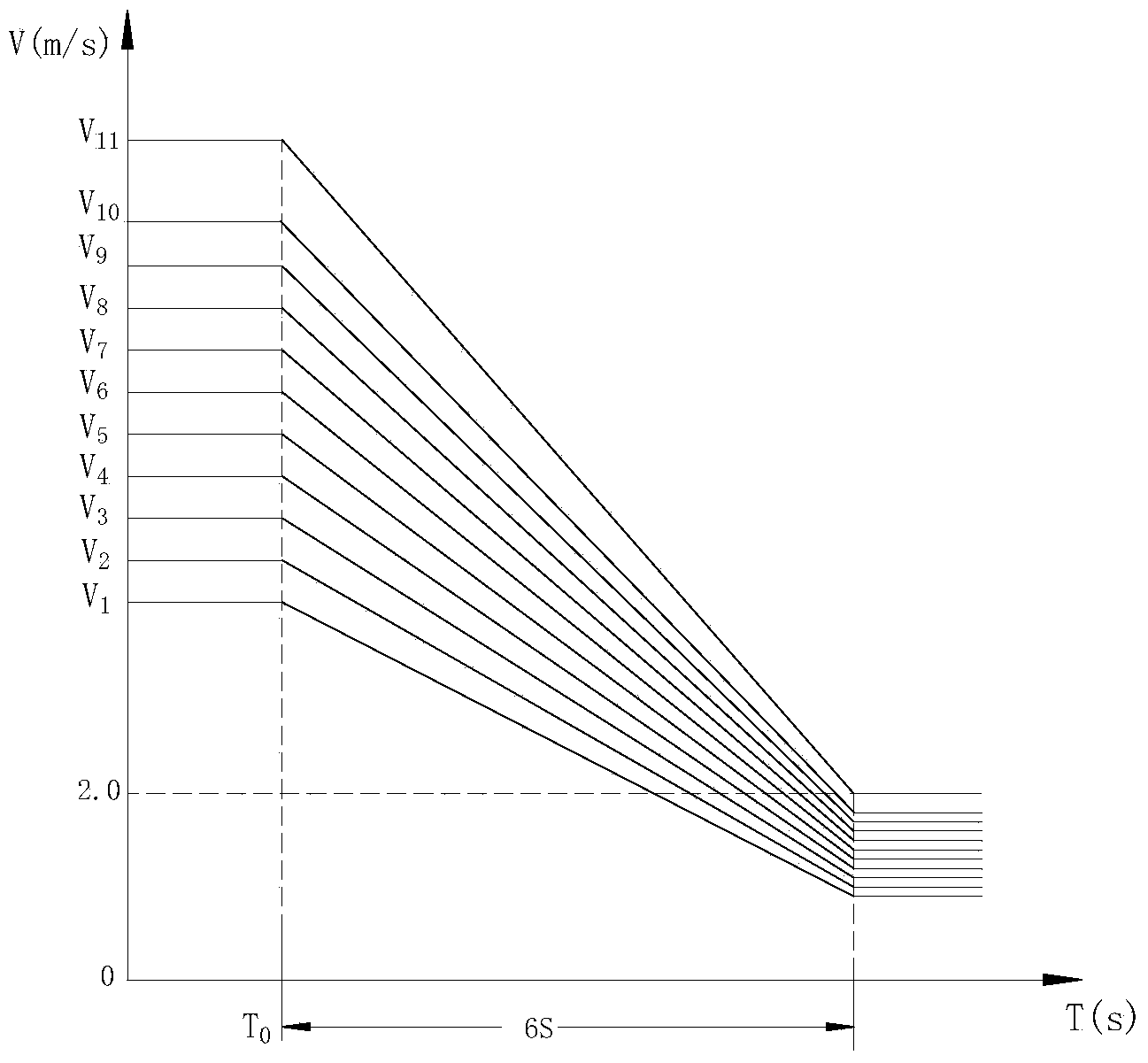

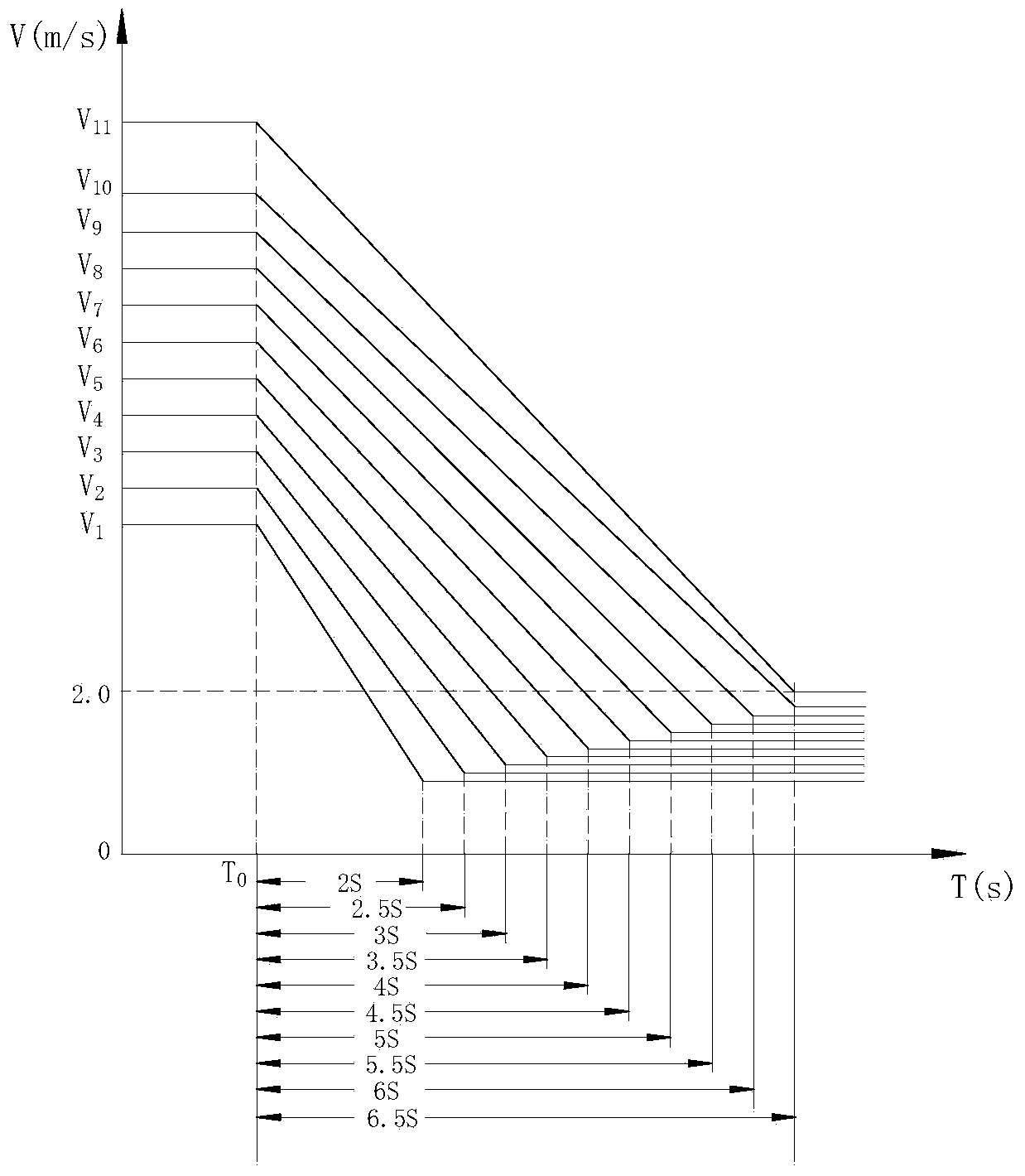

Method for preventing tail part of band steel from loop rising in front of coiling machine

ActiveCN103521554AAvoid the phenomenon of set-upQuality improvementDeceleration timeTransmission equipment

The invention discloses a method for preventing the tail part of band steel from loop rising in front of a coiling machine. The method is realized by the following manners: firstly, the water amount of a laminar cooling upper collection pipe is increased so that the temperature of the tail part of the band steel is reduced to 650 DEG C; when the temperature of the tail part of the band steel is reduced, a downward impact force of a water flow is used for enhancing the fitting degree of the band steel and a roller way so as to increase the friction force between the roller way and the band steel and enable the speeds of the band steel and the roller way to be synchronized; secondly, the speed of finish rolling and steel polishing is controlled to be lower than 10m / s; thirdly, deceleration time of each section of a hot conveying roller way, a coiling machine inlet roller way and a front clamping roller of the coiling machine is increased gradually and sequentially from a finish rolling outlet to a coiling machine inlet; the deceleration non-synchronization caused by the condition that the properties of roller way transmission equipment are different is avoided by increasing the speed difference of all the sections of the hot conveying roller ways; the method disclosed by the invention has the advantages that a phenomenon of the loop rising of the tail part of thin steel in front of the coiling machine can be avoided effectively so that the product quality and the yield are improved.

Owner:BEIJING ARITIME INTELLIGENT CONTROL

Numerical controller having function to switch between pressure control and position control

InactiveUS20090230910A1Avoid switchingAvoid it happening againIgnition automatic controlArrangements for smooth engagement/disengagementNumerical controlPosition control

The numerical controller has function to switch between pressure control and position control, and comprises a numerical control unit and a servo control unit. While the servo control unit is controlling pressure, a servo position deviation amount corresponding to current actual speed of a control axis is set in the servo control unit. After the servo control unit switches to position control from pressure control, a number of pulses required for deceleration and stopping is output to an acceleration / deceleration processing unit of the numerical control unit according to an acceleration / deceleration time constant which is preset. The acceleration / deceleration processing unit outputs a moving amount for each distribution period to the servo control unit.

Owner:FANUC LTD

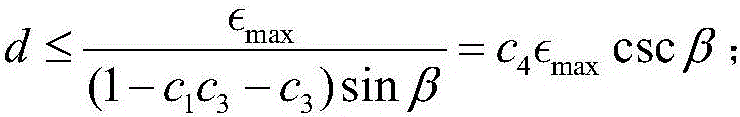

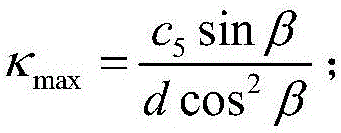

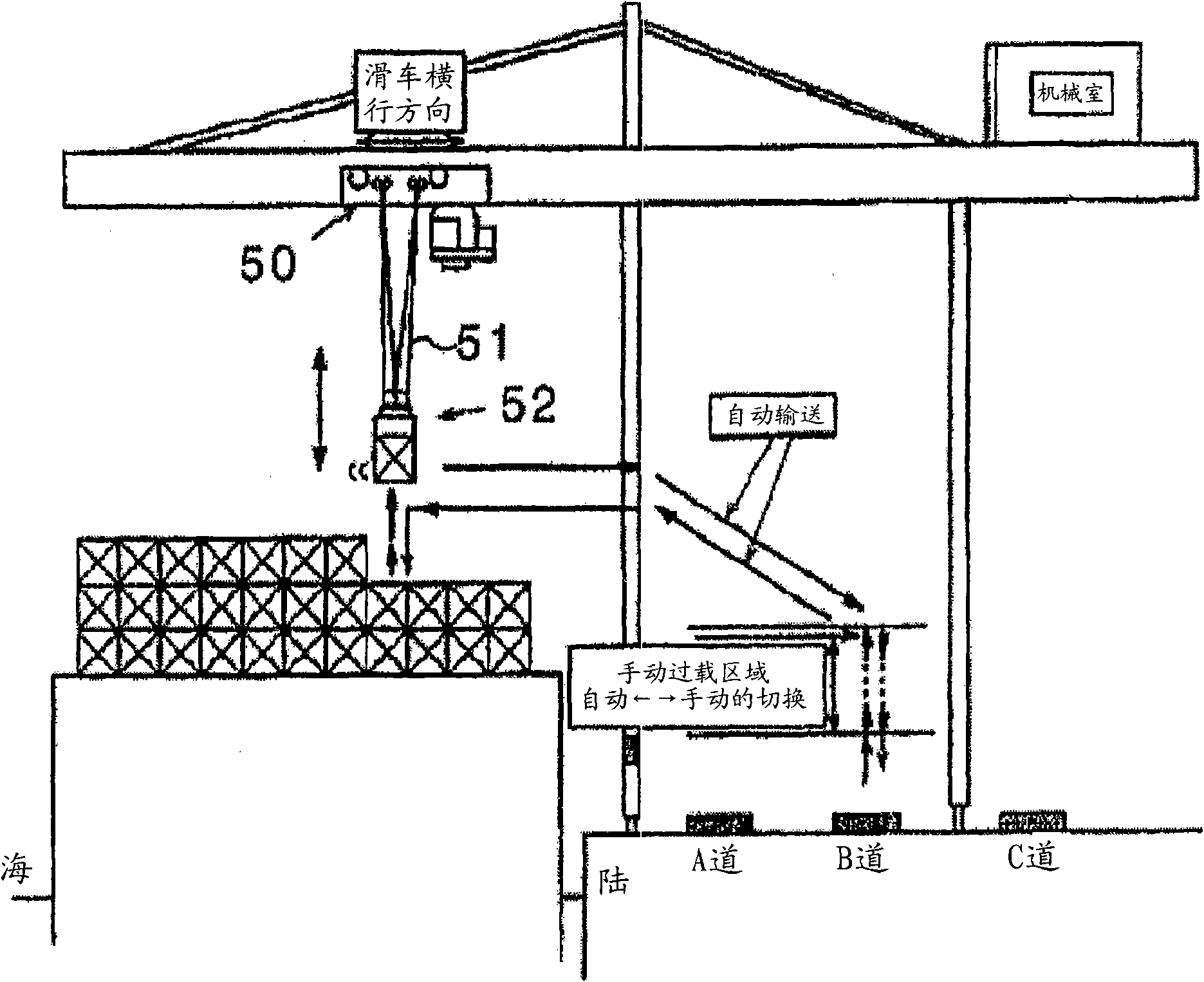

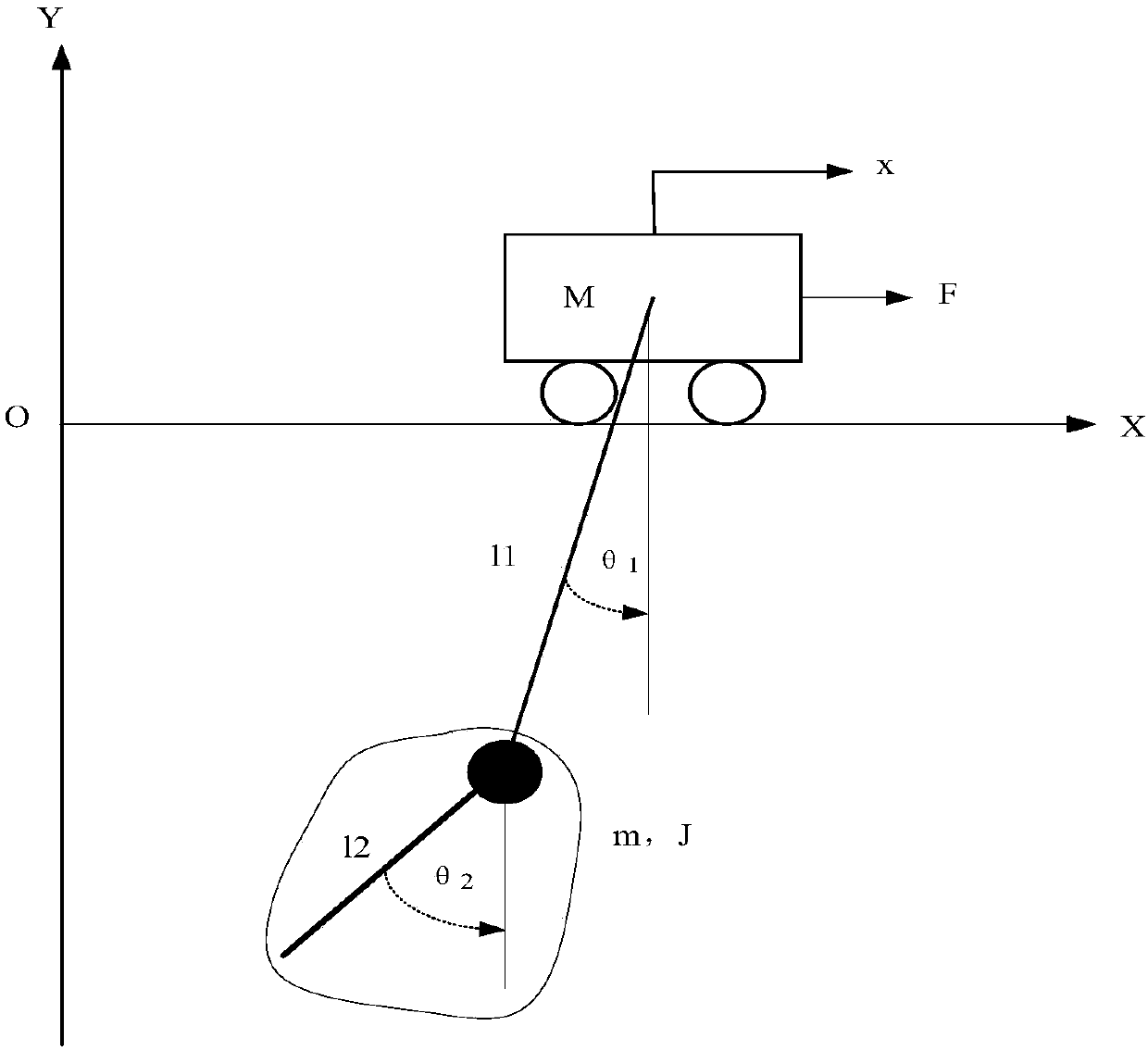

Speed trajectory planning anti-swing method of double-pendulum bridge crane

ActiveCN107826978AImprove transportation efficiencyGuaranteed operational safetyLoad-engaging elementsEngineeringTrajectory planning

The invention discloses a speed trajectory planning anti-swing method of a double-pendulum bridge crane; when a crane load is in an irregular shape (distributive mass), a crane model needs to be seenas a double-pendulum crane; and the double-pendulum crane model is nearer actual life. The main thought of the method is to build a double-pendulum crane linear model for combining with a set speed trajectory planning equation; time-optimal acceleration and deceleration time parameters are obtained by using boundary conditions; then, the car tracking speed trajectory operation is controlled to achieve swing elimination of the double-pendulum bridge crane under the condition of no sensor feedback; when the load is operated in an appointed position, and when swing of the load is zero, the time is optimal. The method considers inhibition of first-grade and second-grade swing angles at the same time, but the control method is simple and easy to realize, can greatly improve the working efficiency of the crane, can effectively prevent accidents caused by swing of goods, and achieves wide application value on future transportation industry.

Owner:南京黎创智能装备有限公司

Welding system and consumable electrode welding method

A torch is moved by a manipulator in a direction separating from a base material 7 while a wire is supplied, whereby an actuator driving the robot manipulator can control a velocity of the wire for a workpiece by a unidirectional operation of separating the torch, and vibration due to reverse of torch velocity is not generated. Further, by using a dedicated separation control system, velocity follow-up performance of the actuator moving the torch can be heightened without increasing overshoot in the usual operation time, and the acceleration and deceleration time of the manipulator can be reduced.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com