Quick laser scanning and cutting method

A fast scanning and laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of long time, low cutting efficiency, etc., to increase the average speed, reduce lifting and empty movement, and shorten the length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

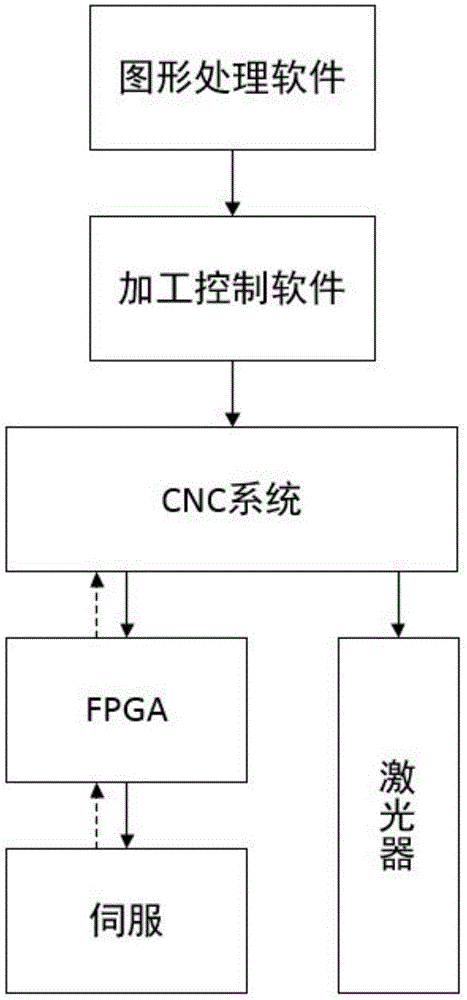

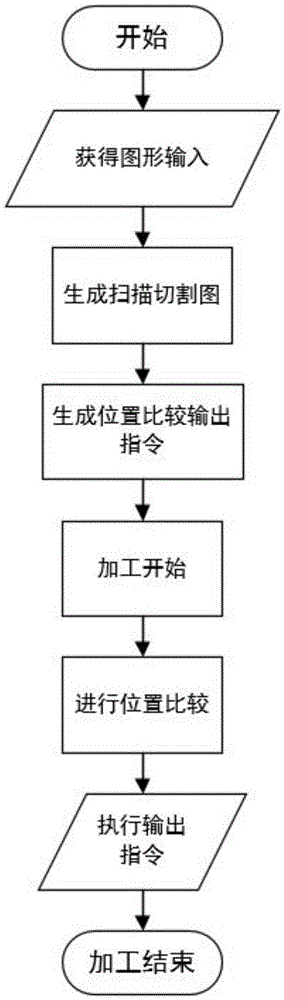

Method used

Image

Examples

Embodiment

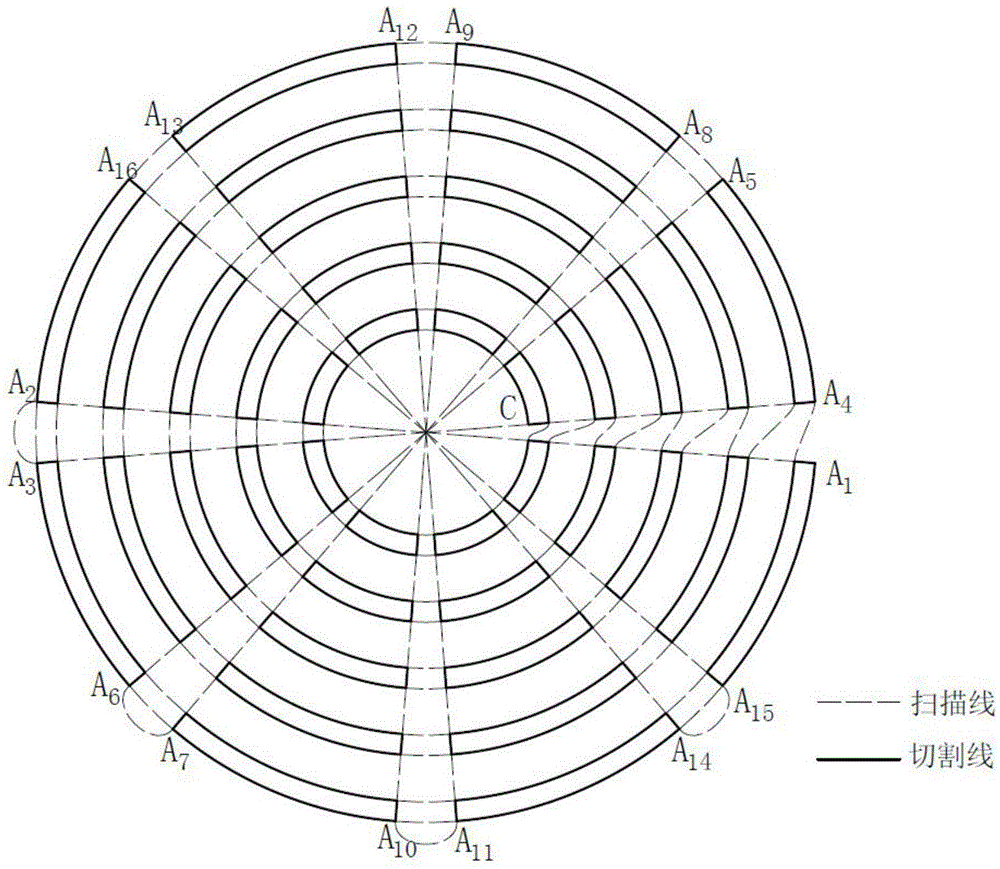

[0030] Such as image 3 As shown, the existing cutting method is: take a single fan graphic as a unit, and cut one fan at a time. First, the cutting head moves to the starting point of a fan graphic, and then follows the cutting. After cutting a fan, the cutting head lifts up. , move to the starting point of the next fan graphic, and then follow the cutting, and then repeat the above actions until all the graphics are cut. This cutting method spends more time on the moving and following actions of the cutting head, and the cutting efficiency lower.

[0031] In the present invention, cutting such as image 3 The graphical approach shown below combines the image 3 Example progress description: Step 1: First input in the graphics processing software image 3 The solid line graph in; the second step: the solid line graph is processed by the graphics processing software to obtain the following image 3 The scanning cutting diagram shown, in which the solid line is the cutting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com